Electronic skin with irregular surface microspikes and preparation method of electronic skin

An electronic skin and irregular technology, applied in the field of sensors, can solve the problems of unsuitable large-area preparation process, high cost and manufacturing, and achieve the effect of high sensitivity, low cost and increased sensitive pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

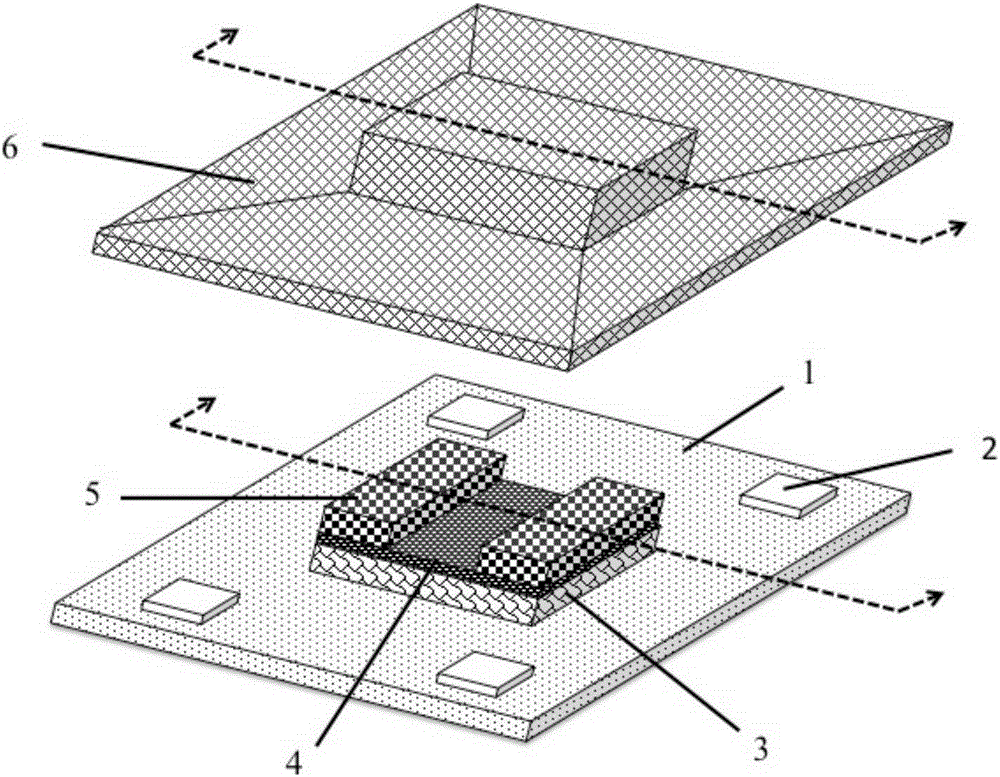

[0042] Example 1: Preparation of electronic skin based on #180 sandpaper.

[0043] Concrete preparation is carried out as follows:

[0044] 1. Use #180 sandpaper as a template, first clean the surface of the sandpaper with oxygen-plasma and then treat it with the release agent perfluorooctyltrichlorosilane;

[0045] 2. Then, mix the PDMS (polydimethylsiloxane) monomer and the crosslinking agent uniformly according to the mass ratio of 10:1 to obtain a PDMS mixed solution, which is used to prepare the support layer;

[0046] 3. After vacuumizing the PDMS mixed solution to remove air bubbles, prepare a wet film on the surface of the treated sandpaper by using the rotary homogenization method at a speed of 500 rpm;

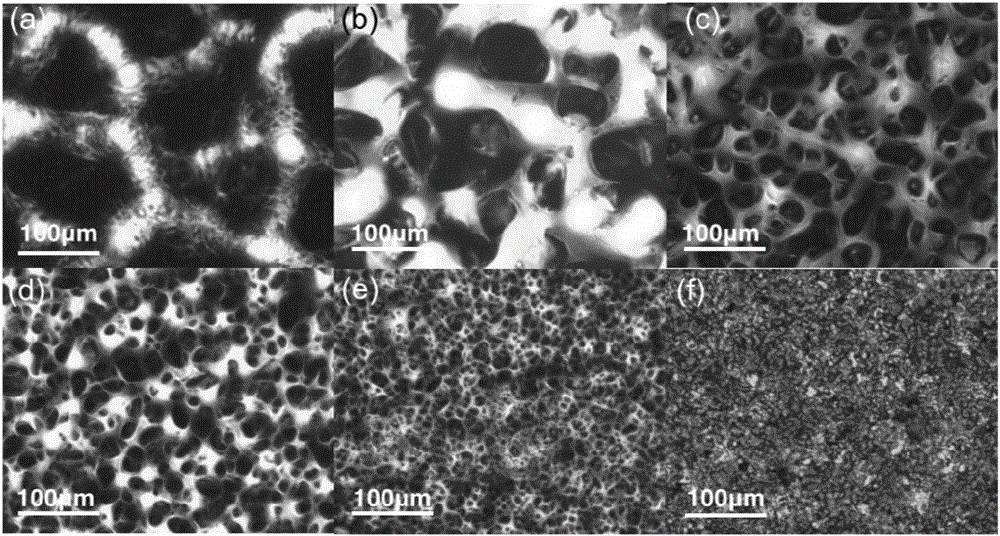

[0047] 4. Heat at 100°C for 30 minutes to solidify the wet film, and prepare a highly irregular PDMS support layer 3 with a thickness of about 150 μm; the surface of the support layer prepared with #180 sandpaper has an average height of 80 μm and an average diamete...

Embodiment 2

[0052] Example 2: Preparation of electronic skin based on #240 sandpaper.

[0053] Concrete preparation is carried out as follows:

[0054] 1. Use #240 sandpaper as a template, first clean the surface of the sandpaper with oxygen-plasma, and then use the release agent perfluorooctyltrichlorosilane for vacuum evaporation treatment;

[0055] 2. Then mix the PDMS monomer and crosslinking agent evenly according to the mass ratio of 10:1;

[0056] 3. After vacuumizing the PDMS mixed solution to remove air bubbles, prepare a wet film on the surface of the treated sandpaper by using the rotary homogenization method at a speed of 700 rpm;

[0057] 4. Heating at 100°C for 30 minutes to solidify the wet film, and prepare a highly irregular PDMS support layer 3 with a thickness of about 120 μm;

[0058] 5. After demoulding the PDMS, treat the undulating surface with oxygen plasma to make the surface hydrophilic;

[0059] 6. Prepare a wet film of PEDOT:PSS on the surface of the treated...

Embodiment 3

[0063] Example 3: Preparation of electronic skin based on #600 sandpaper.

[0064] Concrete preparation is carried out as follows:

[0065] 1. Use #600 sandpaper as a template, first clean the surface of the sandpaper with oxygen-plasma, and then use the release agent perfluorododecyltrichlorosilane for vacuum evaporation treatment;

[0066] 2. Then mix the PDMS monomer and crosslinking agent evenly according to the mass ratio of 10:1;

[0067]3. After vacuumizing the PDMS mixed solution to remove air bubbles, prepare a wet film on the surface of the treated sandpaper by using the rotary homogenization method at a speed of 2000 rpm;

[0068] 4. Heating at 100° C. for 30 minutes to solidify the wet film, and prepare a PDMS support layer 3 with a thickness of about 60 μm;

[0069] 5. After demoulding the PDMS, treat the undulating surface with oxygen plasma to make the surface hydrophilic;

[0070] 6. Prepare a wet film of PEDOT:PSS (CleviosPH1000) on the surface of the treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com