Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce bowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

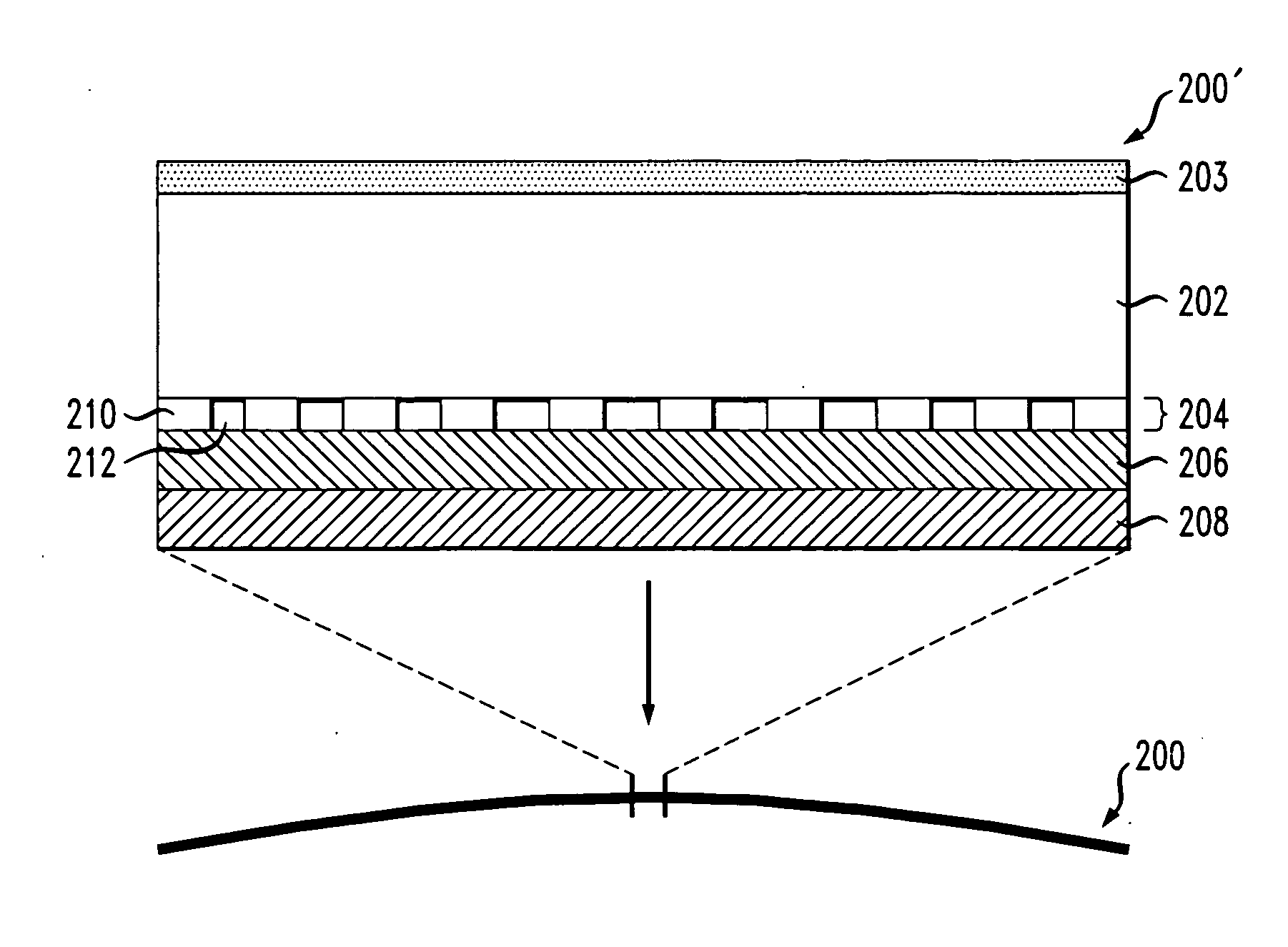

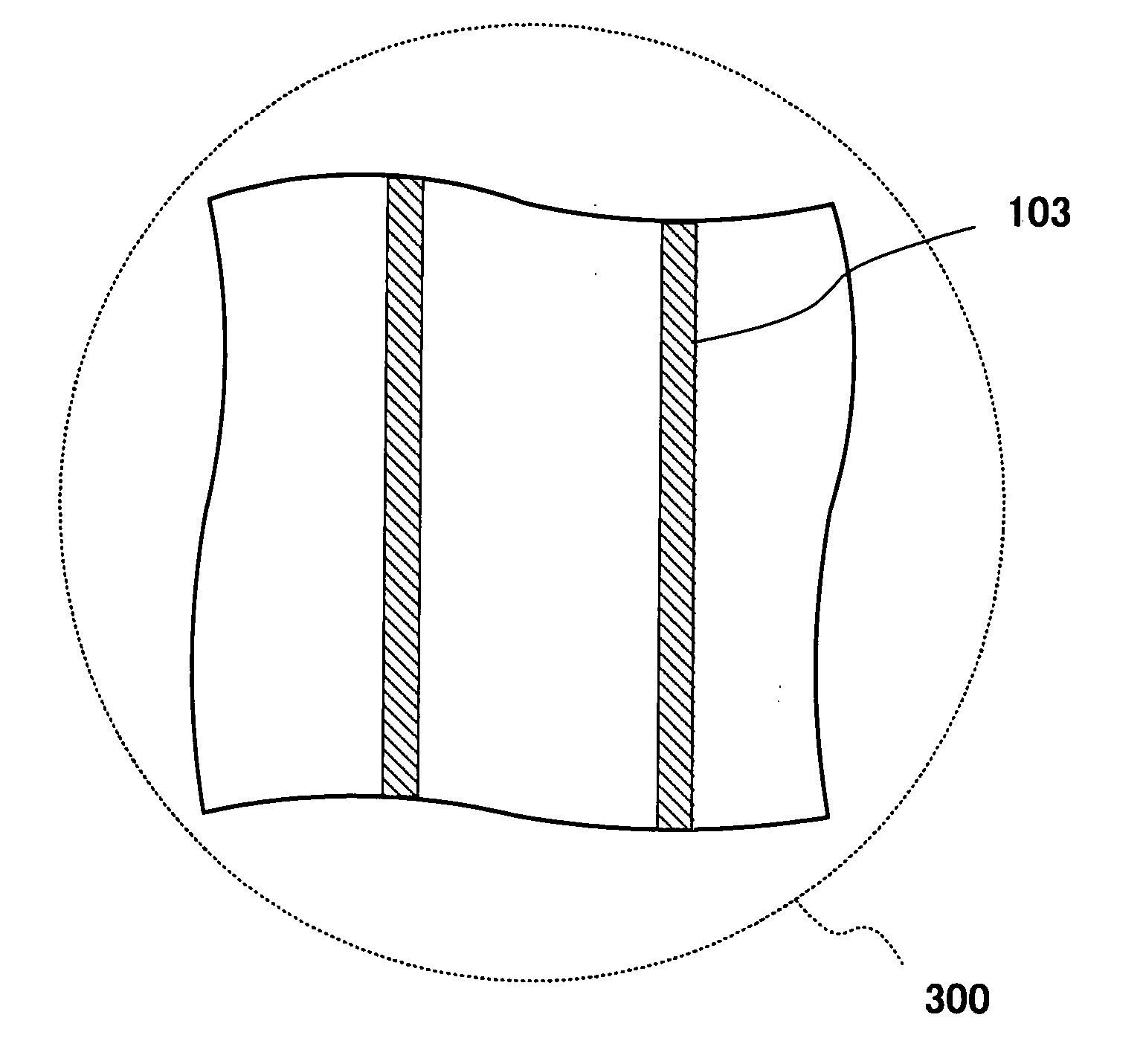

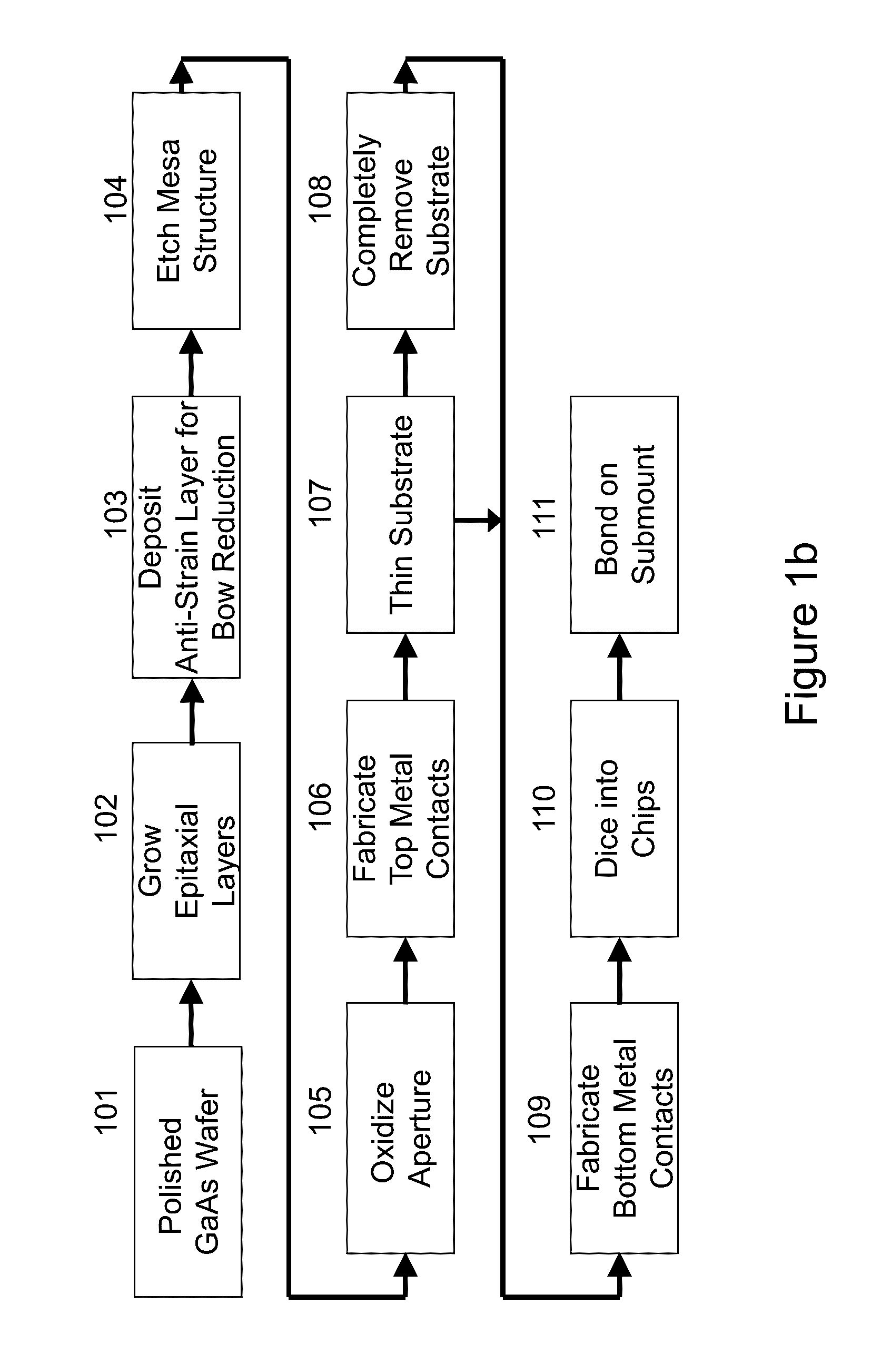

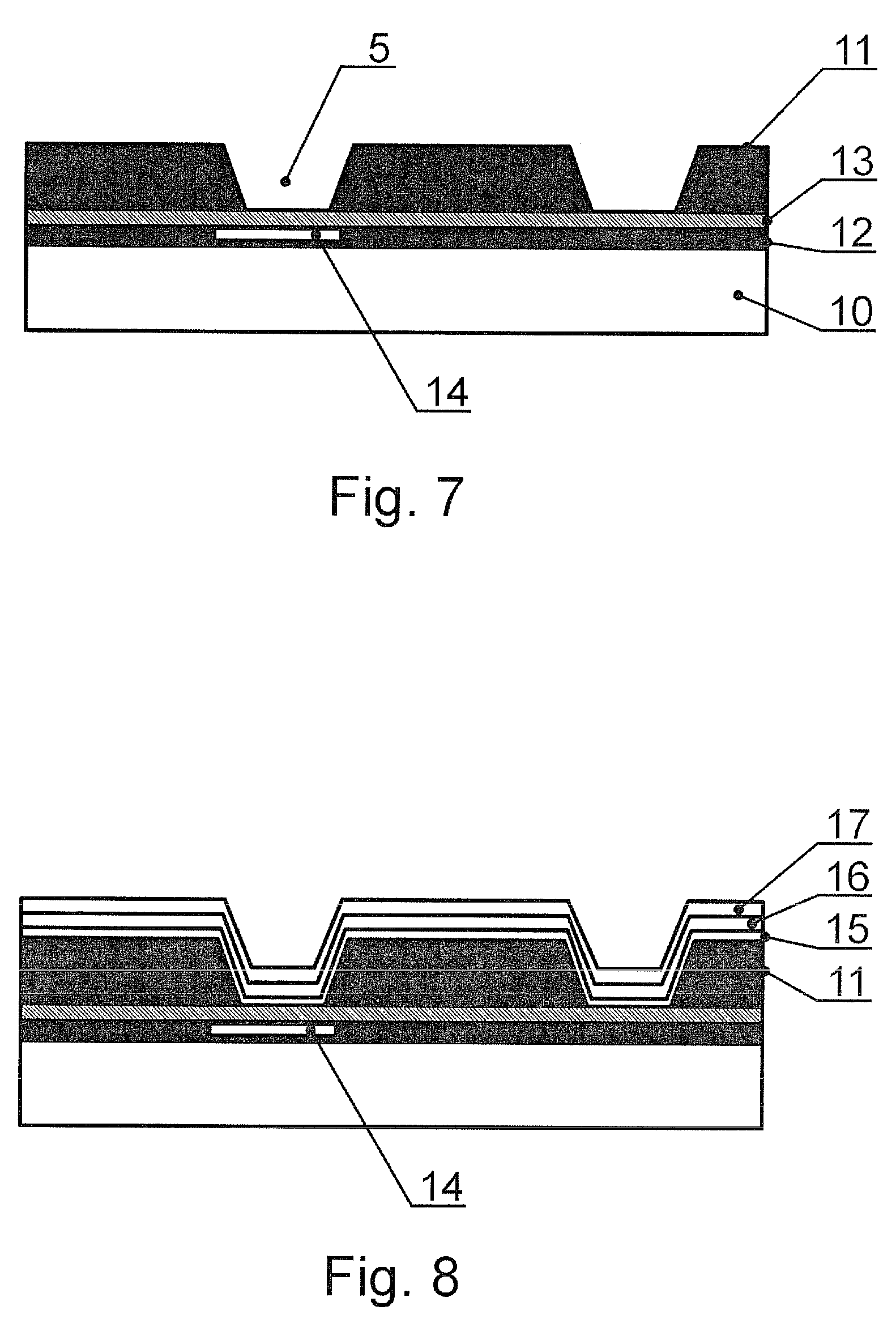

Processes for Making Reliable VCSEL Devices and VCSEL arrays

ActiveUS20150255955A1Easy to controlMinimized volumeLaser detailsSolid-state devicesWafer bowEngineering

A set of VCSEL fabrication methods has been invented which enhance the performance and long time reliability of VCSEL devices and arrays of devices. Wafer bow caused by growing a large number of epitaxial layers required to fabricate VCSEL device generates strain and results in bowing / warping of the device wafer. The stress so generated is eliminated by applying a stress compensation layer on the substrate to a surface opposite to the epitaxial layer surface. New oxidation equipment designs and process parameters are described which produce more precision apertures and reduce stress in the VCSEL device. An ultrathin fabrication procedure is described which enables high power VCSELs to be made for high power operation at many different wavelengths. A low temperature electrical contacting process improves VCSEL long term reliability.

Owner:PRINCETON OPTRONICS

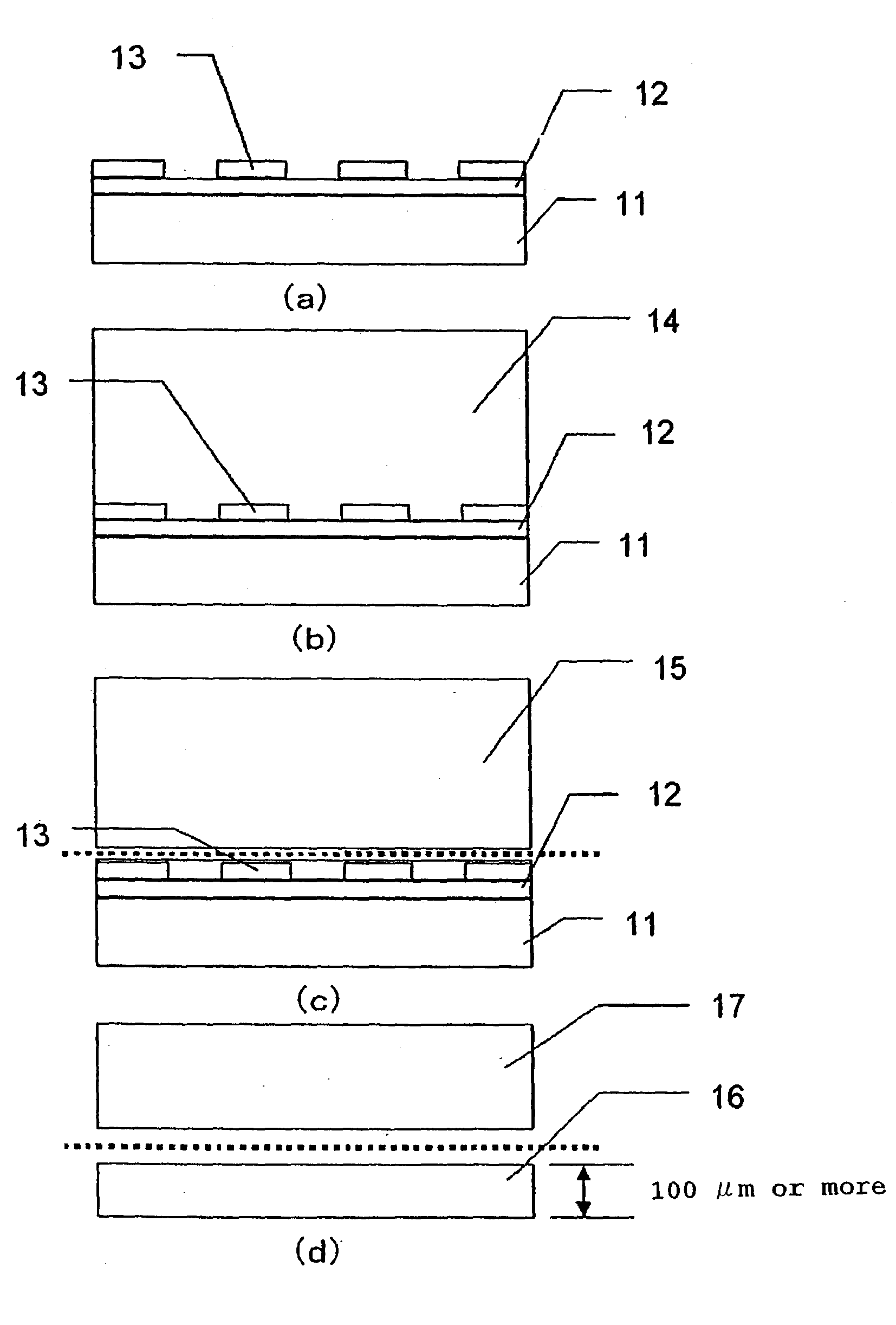

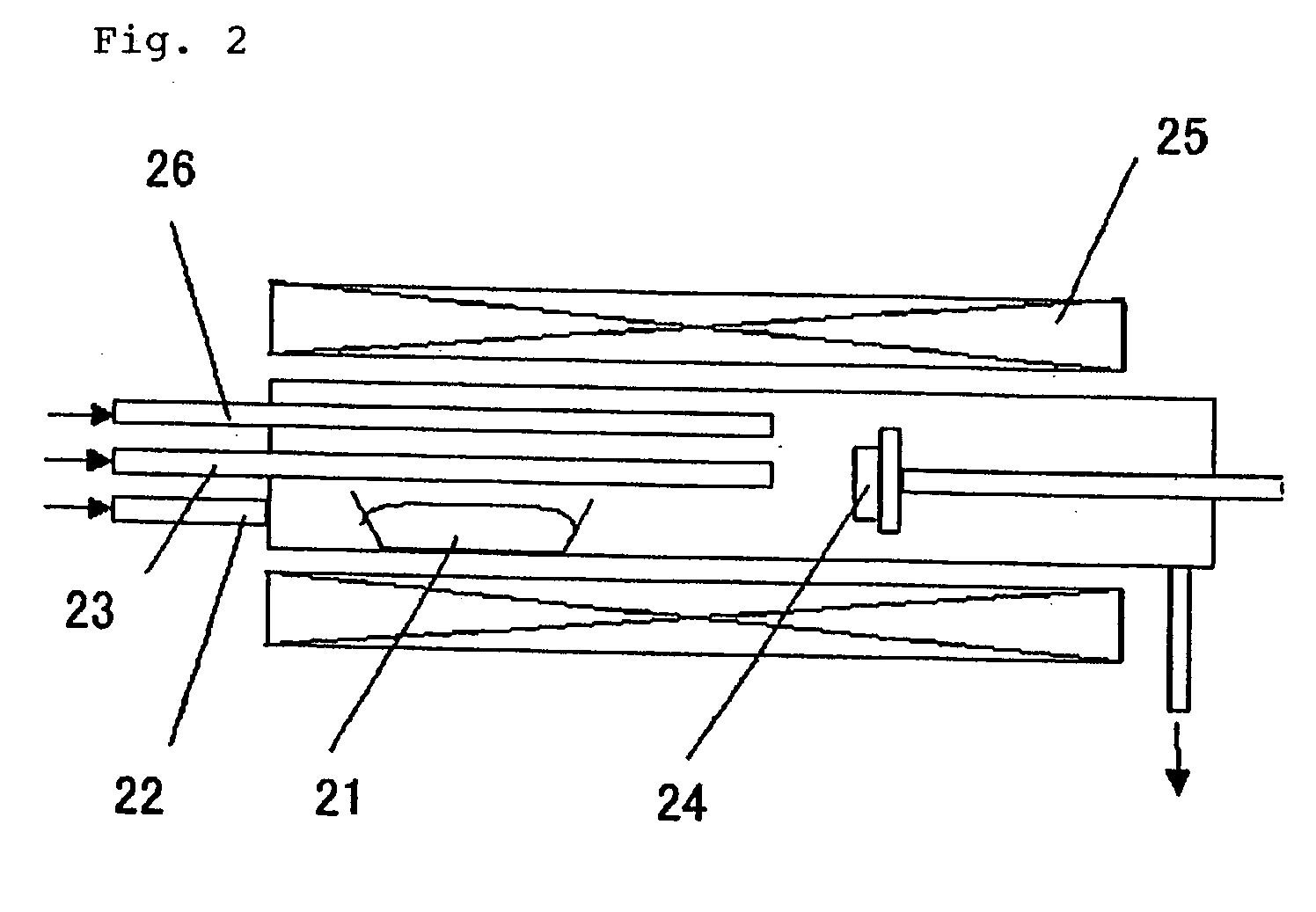

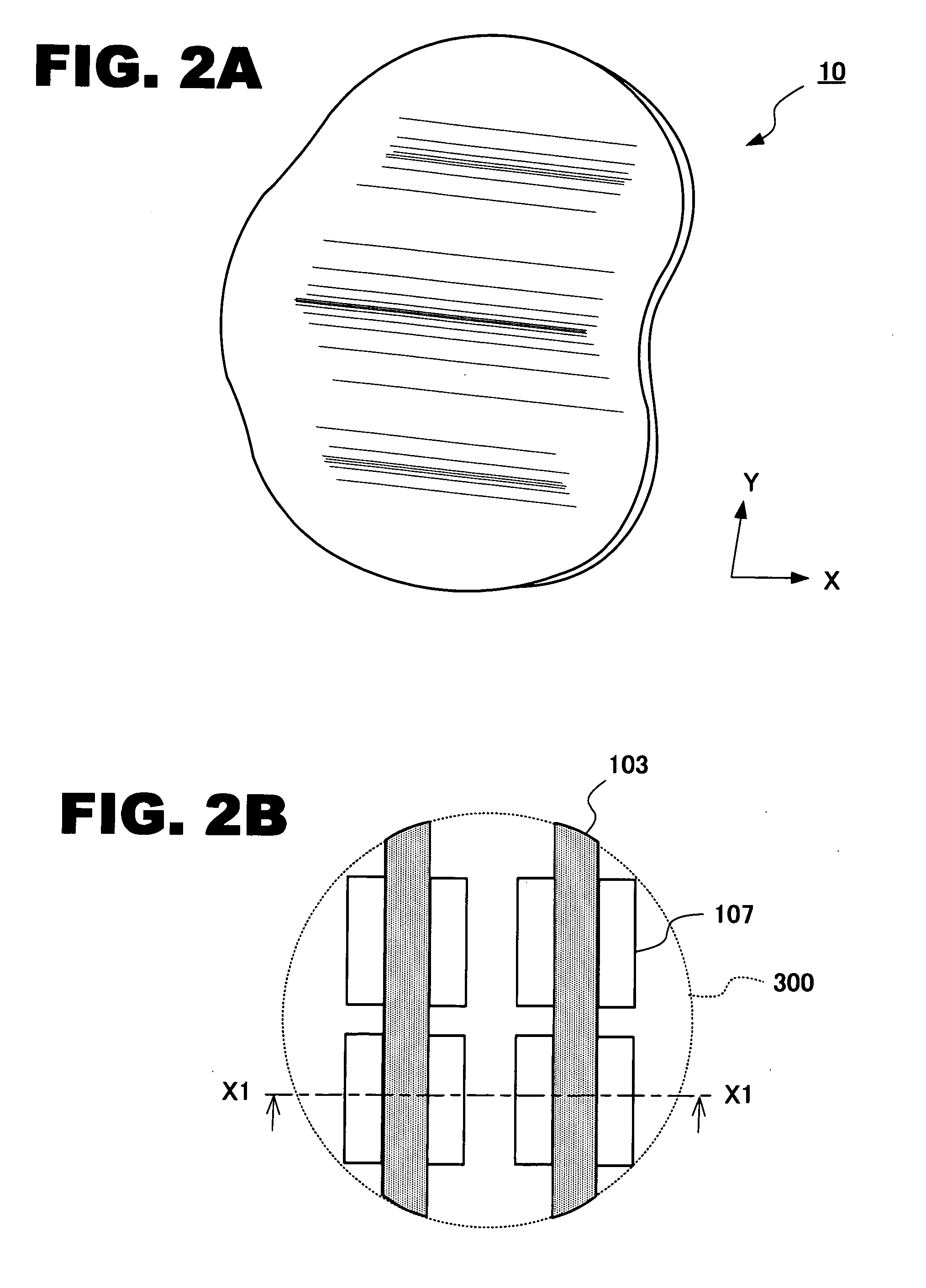

Group III nitride based semiconductor substrate and process for manufacture thereof

InactiveUS20030183157A1Quality improvementStable productionLaser detailsFrom solid stateDislocationNitride

To provide a semiconductor substrate of a group III nitride with a little warp, this invention provides a process comprising such steps of: epitaxial-growing a GaN layer 33 with a GaN low temperature grown buffer layer 32 upon a sapphire substrate 31; removing the sapphire substrate 31, the GaN buffer layer 32 and a small portion of the GaN layer 33 from the substrate taken out of a growth reactor to obtain a self-supporting GaN substrate 35; and after that, heat-treating the GaN substrate 35 by putting it into an electric furnace under the NH3 atmosphere at 1200° C. for 24 hours; which leads to a marked reduction of the warp of the self-supporting GaN substrate 35 such that dislocation densities of its obverse and reverse surface are 4x10<7 >cm<-2 >and 8x10<5 >cm<-2>, and thereby such a low ratio of dislocation densities of 50 is well-controlled.

Owner:SUMITOMO CHEM CO LTD

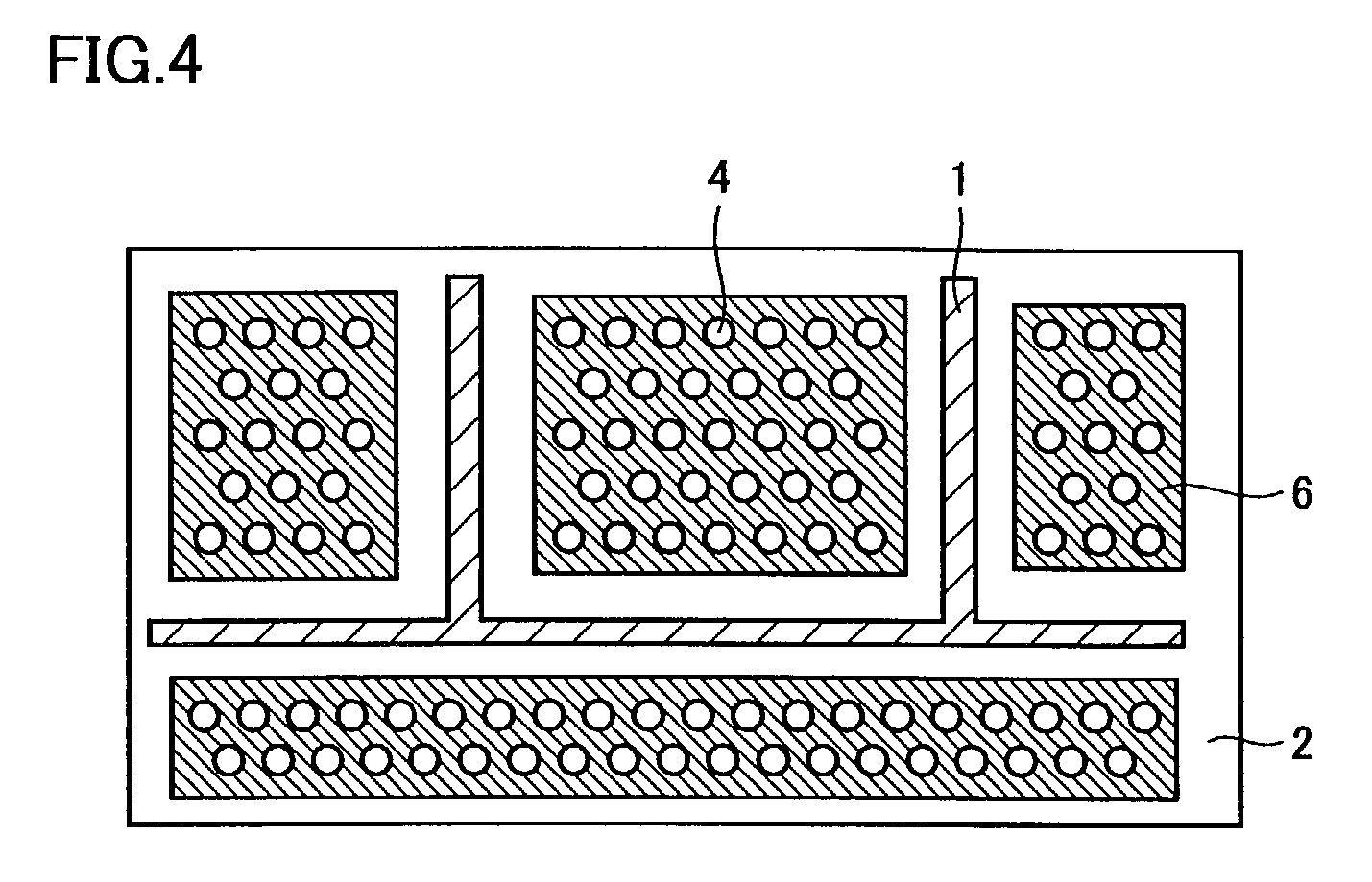

Adaptive chuck for planar bonding between substrates

InactiveUS20110083786A1Reduces bowingReduce warpingLamination ancillary operationsControlling laminationElectrical conductorEngineering

An electrostatic chuck includes an array of independently biased conductive chuck elements, an array of sensor-conductor assemblies, and / or a combination of an array of sensor-conductor assemblies and at least one motorized chuck. Conductive chuck elements, either standing alone or embedded in a sensor-conductor assembly, are independently biased electrostatically to compensate for bowing and / or warping of a substrate thereupon so that the substrate can be bonded with a planar surface. A single electrostatic chuck can be employed to reduce the bowing and warping of one of the two substrates to be bonded, or two electrostatic chucks can be employed to minimize the bowing and warping of two substrates to be bonded.

Owner:GLOBALFOUNDRIES INC

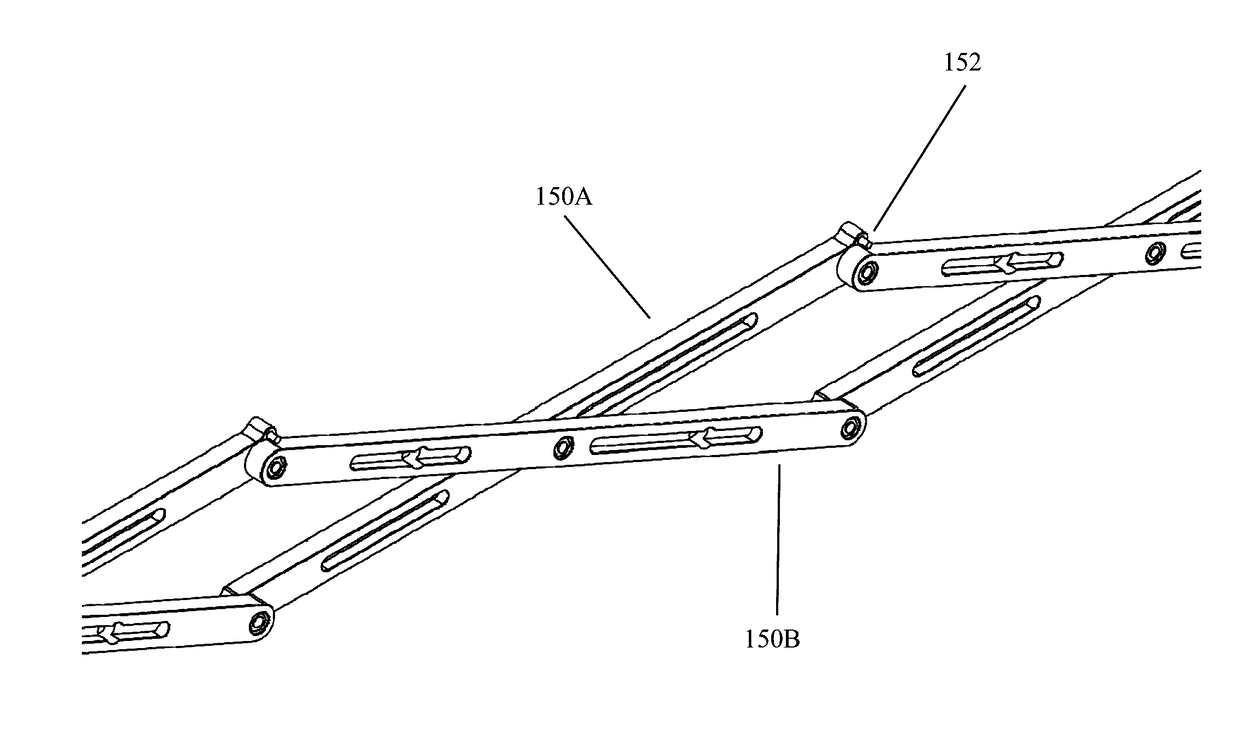

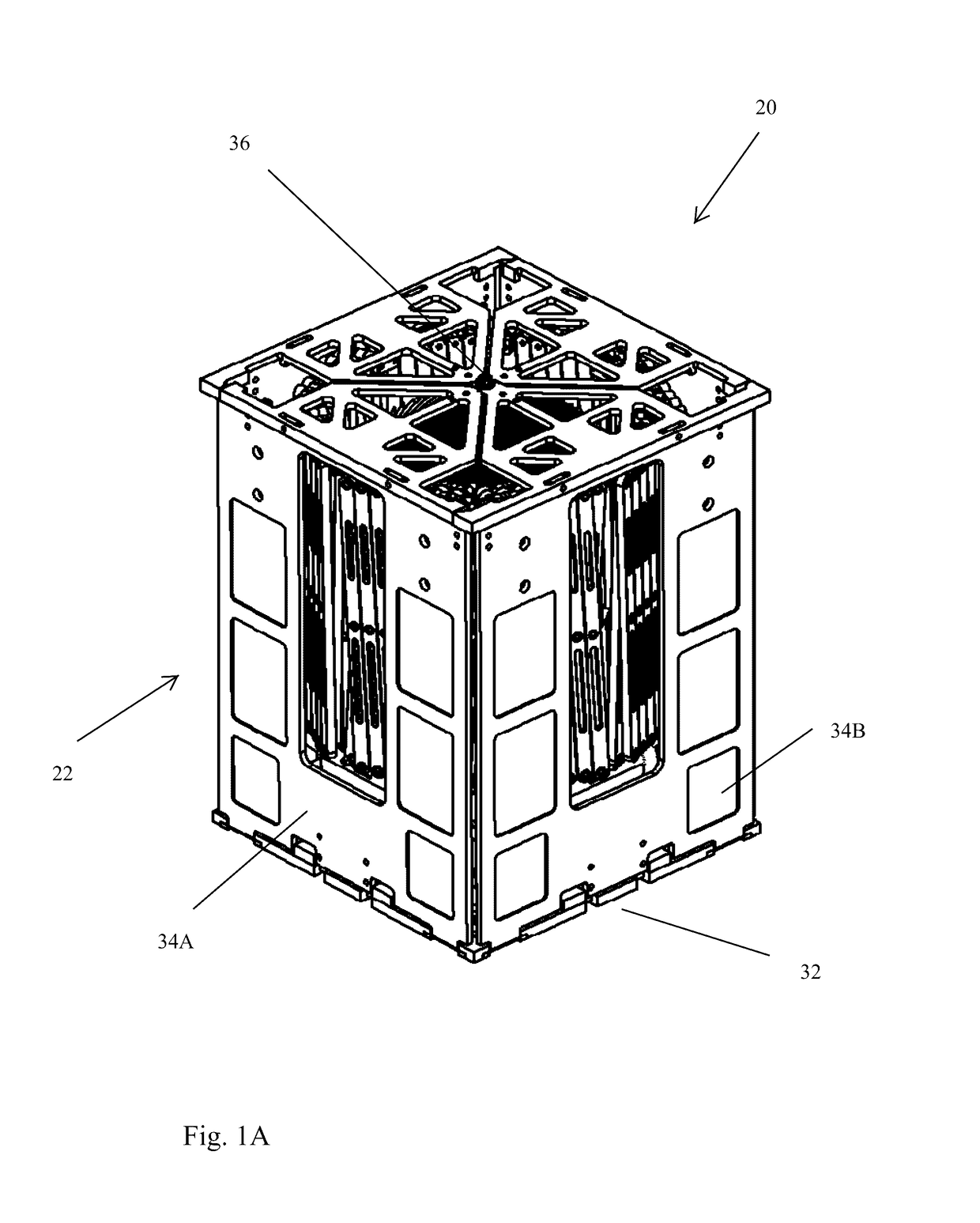

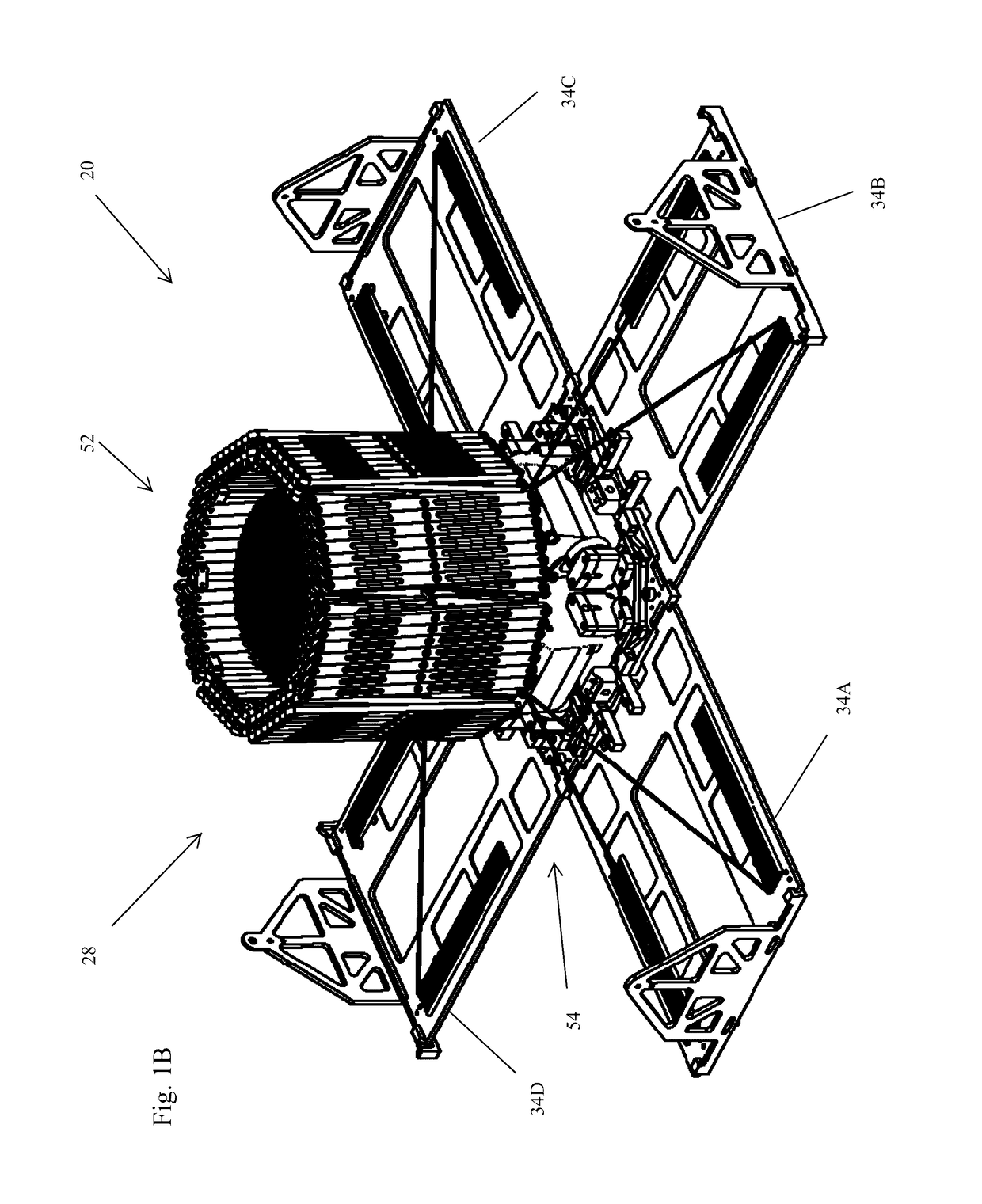

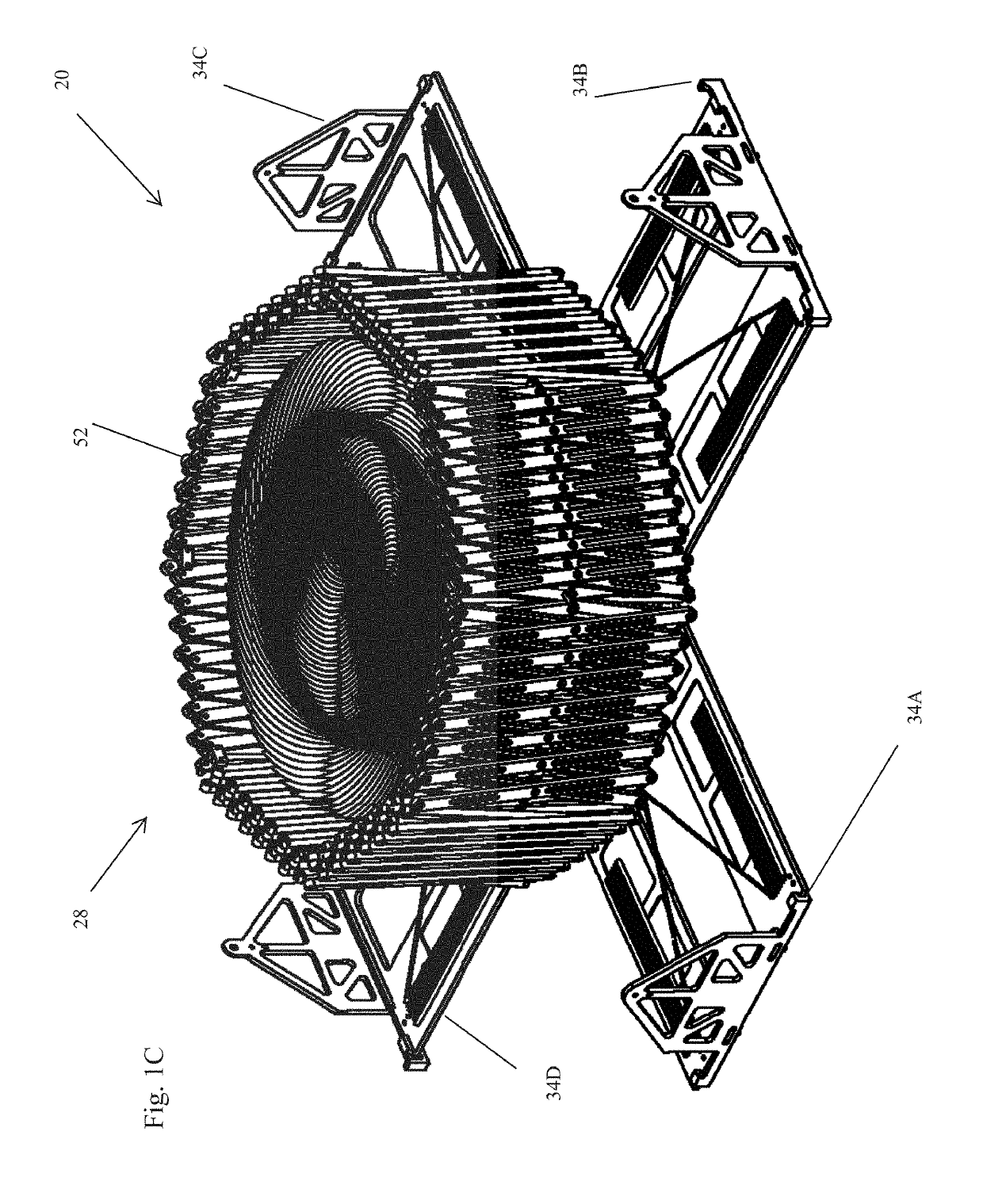

Deployable Structure for Use in Establishing a Reflectarray Antenna

ActiveUS20170093046A1Help positioningEasy to deployCollapsable antennas meansCosmonautic vehiclesPantographWaste management

A deployable structure for use in establishing a reflectarray antenna is provided that includes a flexible reflectarray and a deployment structure that includes an endless pantograph for deploying the flexible reflectarray from a folded, undeployed state towards a deployed state in which the flexible reflectarray is substantially planar. In a particular embodiment, the deployment structure includes a plurality of tapes that engage the endless pantograph and are used to establish a positional relationship between the deployed reflectarray and another component of the reflectarray antenna.

Owner:M M A DESIGN

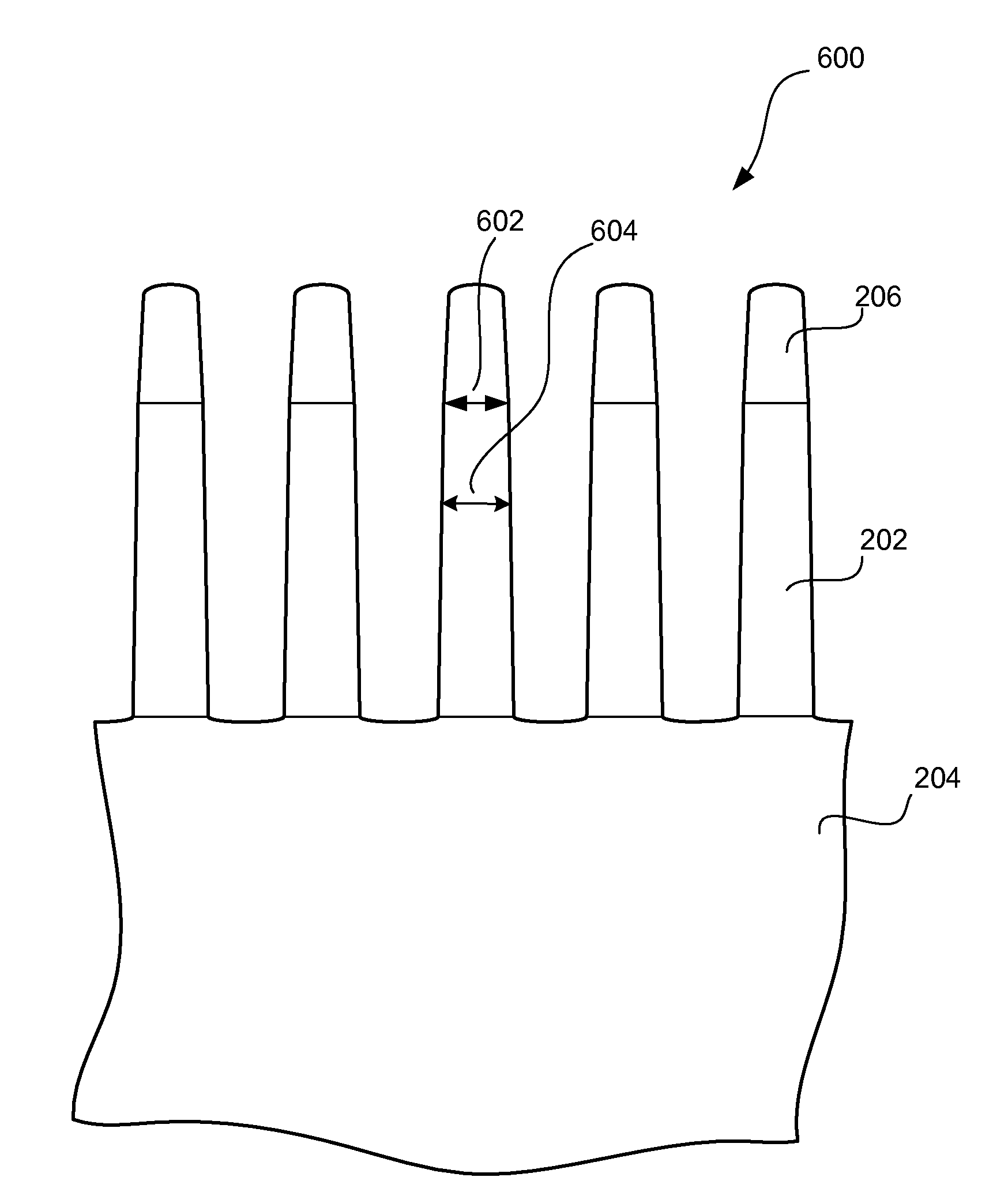

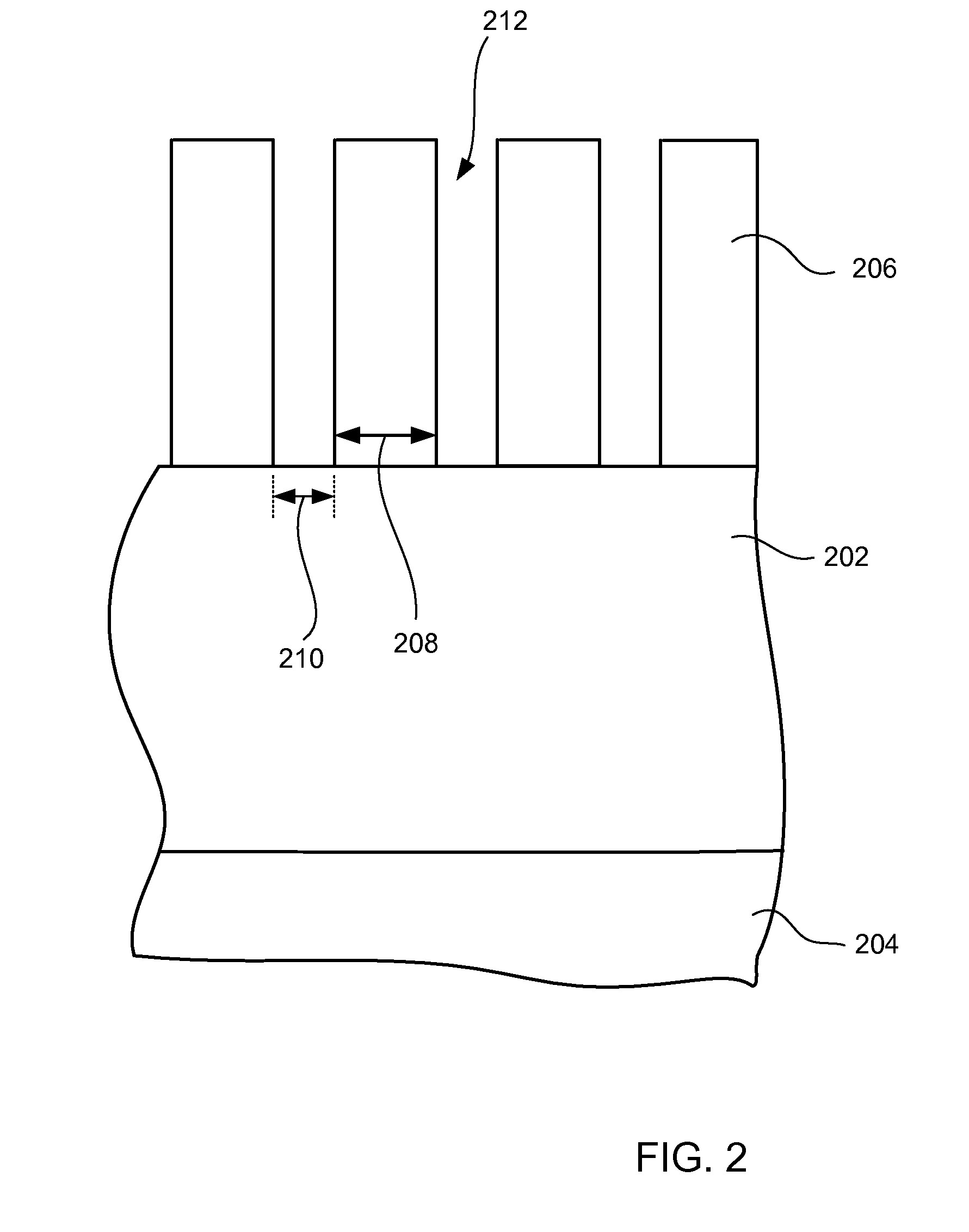

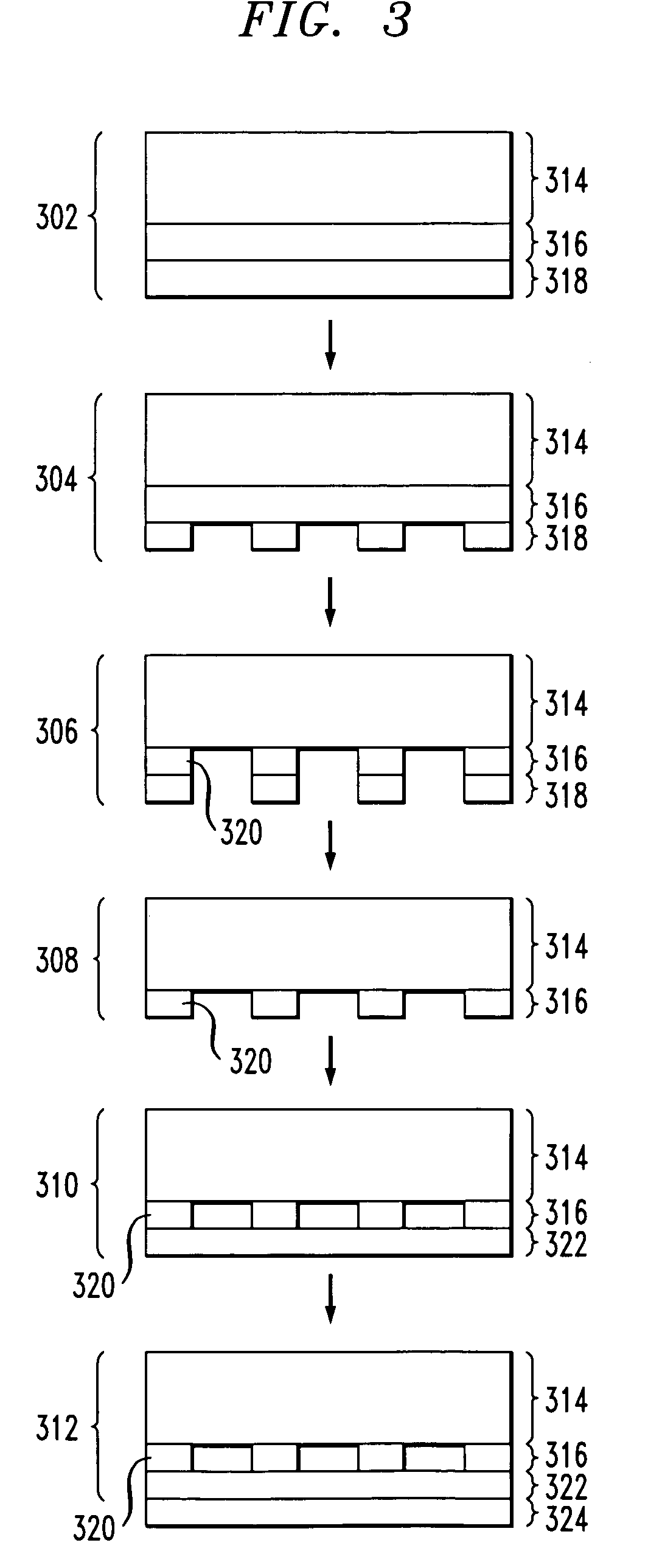

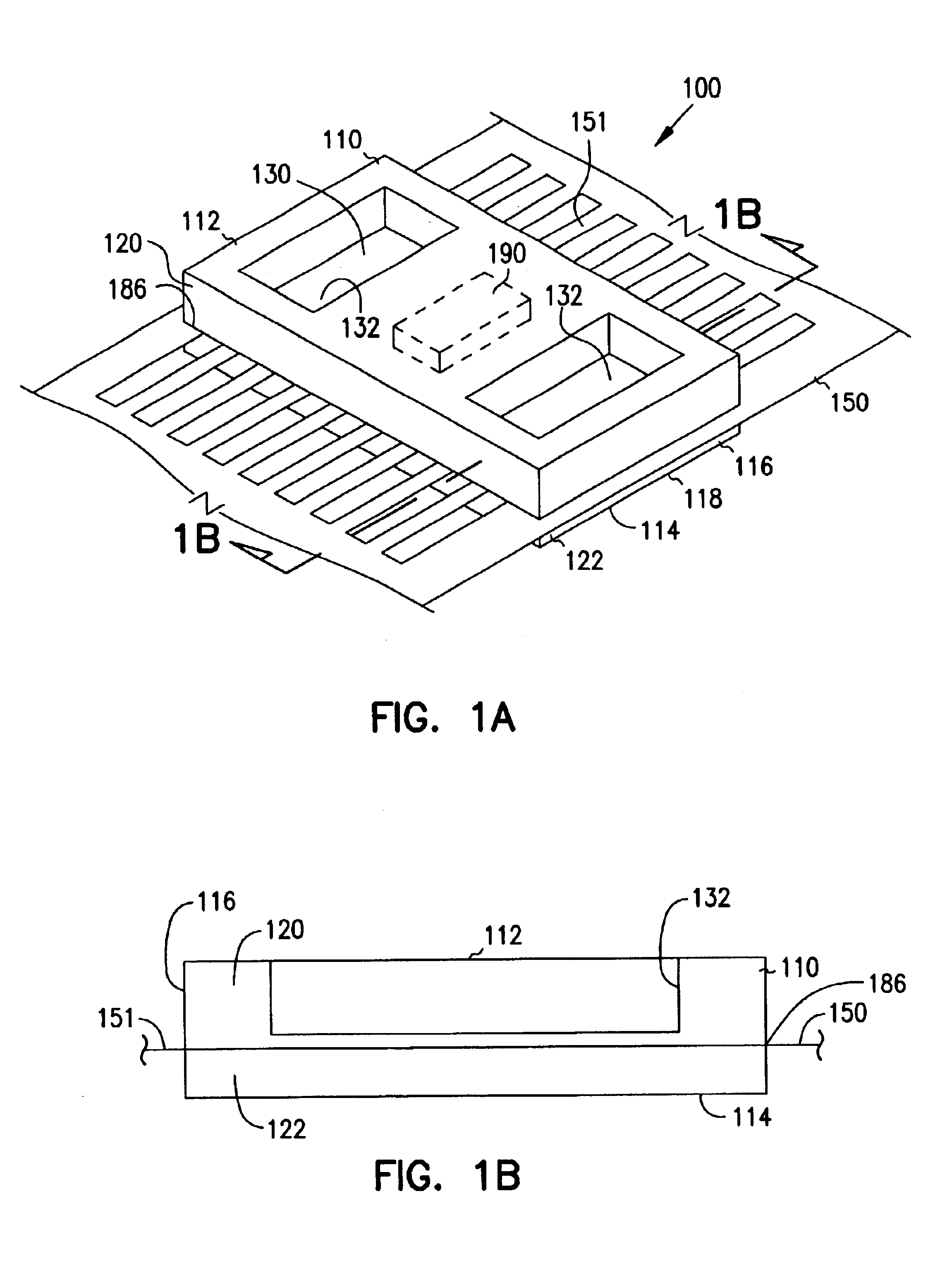

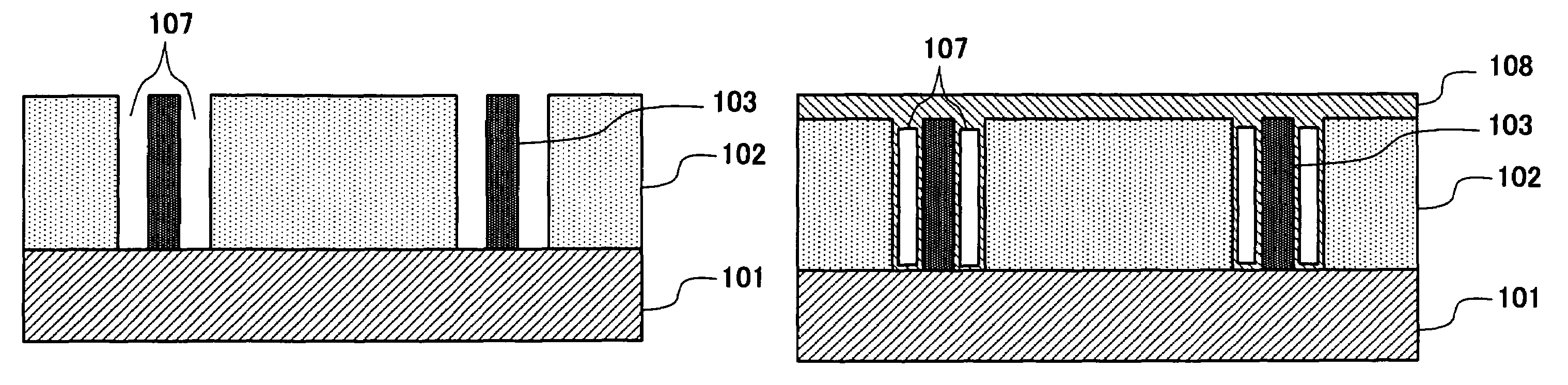

Techniques for reducing bowing in power transistor devices

ActiveUS20050189616A1Reduce bowingReduce the amount requiredSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitTransistor

Power transistor devices and techniques for reducing bowing in such devices are provided. In one aspect, a power transistor device is provided. The power transistor device comprises a substrate, a device film formed on the substrate and an adhesion layer formed on a side of the substrate opposite the device film, wherein at least a portion of the adhesion layer is at least partially segmented. The power transistor device thereby exhibits a reduced amount of bowing relative to an amount of bowing expected without the segmenting of the adhesion layer. The power transistor device may be part of an integrated circuit.

Owner:BELL SEMICON LLC

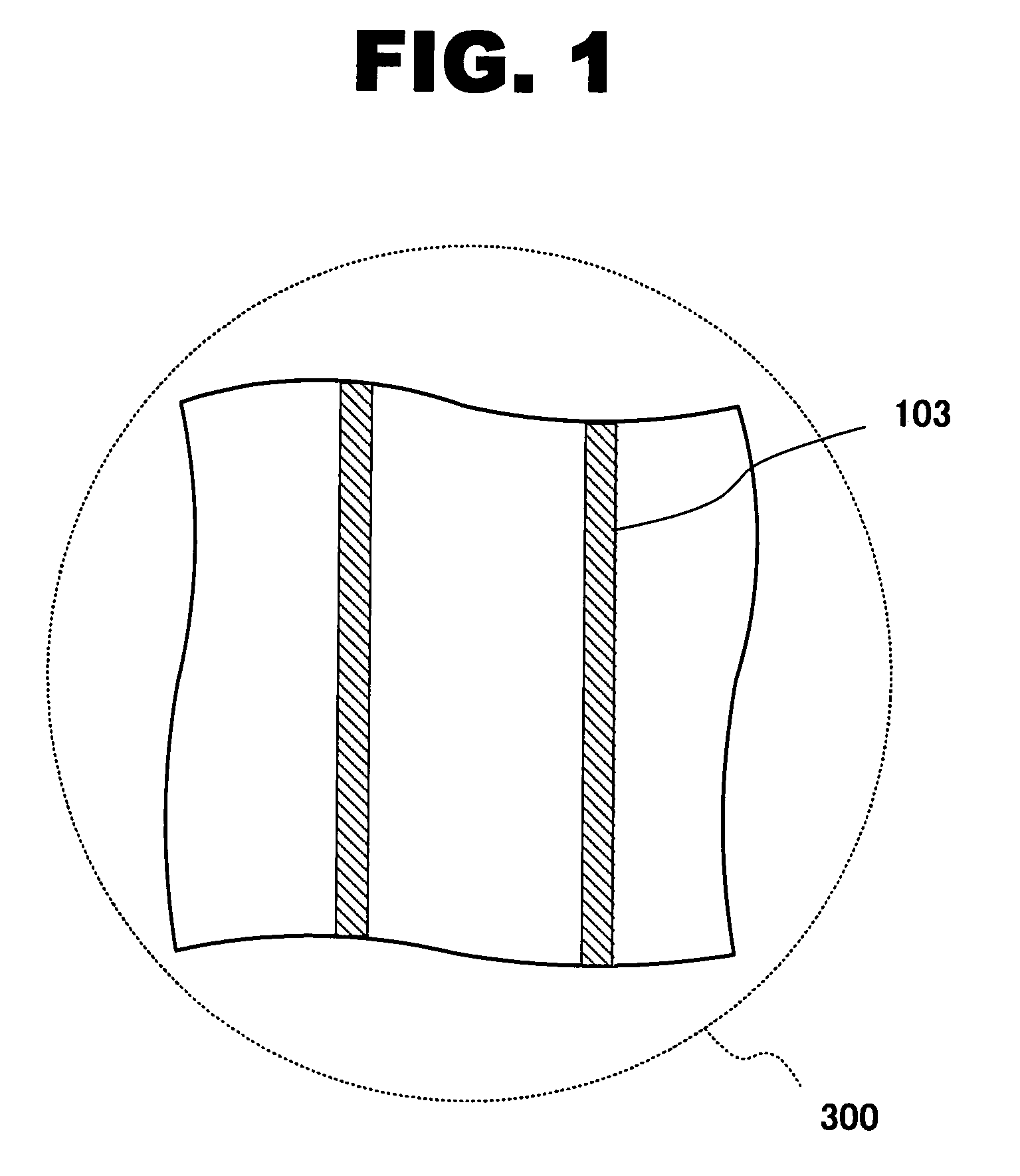

Method for fabricating semiconductor device

ActiveUS20080233716A1Good directionEasy to shapeSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSilicon carbide

The principal objects of the present invention are to provide structure of a semiconductor device capable of reducing a bowing of a wafer, and a method for fabricating the semiconductor device. The present invention is applied to a semiconductor device, which is fabricated with a semiconductor substrate having a silicon carbide (SiC) film. The method includes the steps of: forming the SiC film on a semiconductor wafer; discriminating a deformation condition of the semiconductor wafer; and forming grooves in the SiC film, the grooves having a shape determined in accordance with the deformation condition of the semiconductor wafer.

Owner:LAPIS SEMICON CO LTD

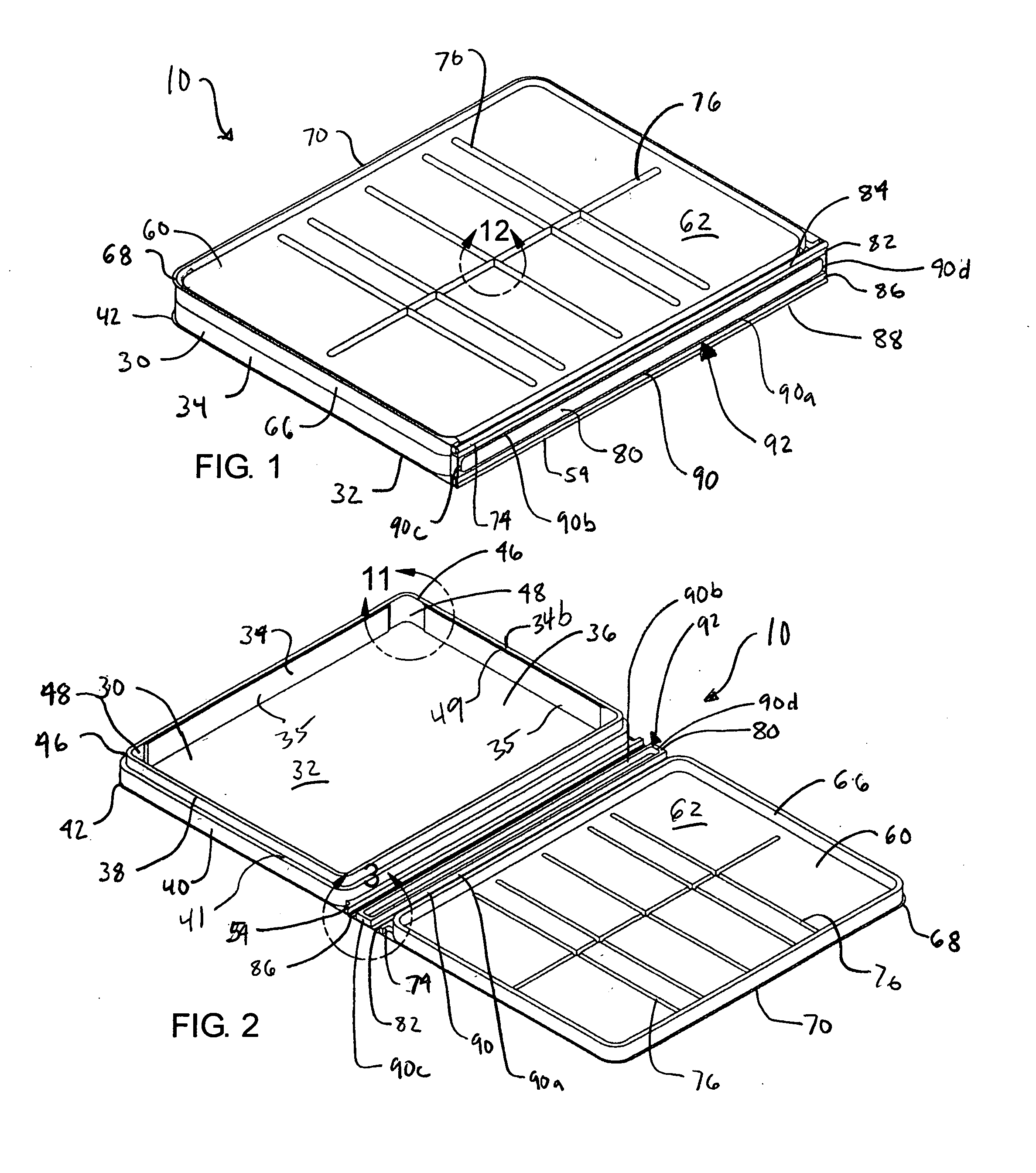

Sortables storage container

InactiveUS20080099485A1Restricts passageMinimize catch pointInternal framesBoxesBiomedical engineeringHolding room

A storage container includes a base with a storage compartment and a lid positionable to fit over an upwardly extending perimeter wall of the storage compartment. A spine is hinged between the base and the lid to allow articulated movement of the lid with respect to the base. The spine includes at least one stiffener ridge integrally formed in the spine and extending longitudinally along the spine. The stiffener ridge reduces bowing of the spine between a lid hinge and a base hinge. A removable tray is insertable into the storage compartment to divide the compartment into a plurality of smaller compartments. Partitions may be placed in the storage compartment to divide the storage compartment into smaller compartments. The partitions may extend into receiving grooves in the lid to block movement of sortables from one compartment to another.

Owner:HOLBROOK JIMMY E +1

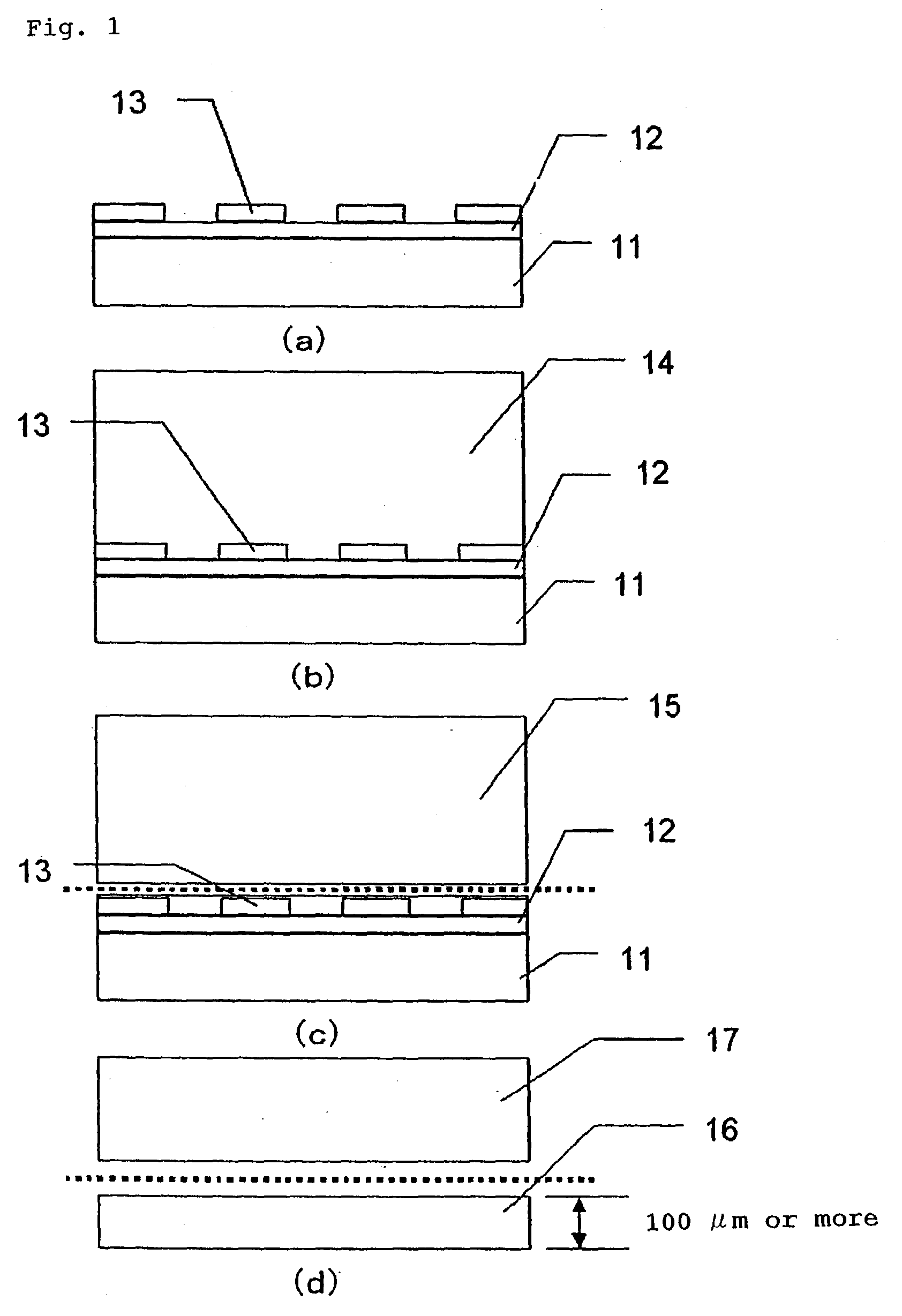

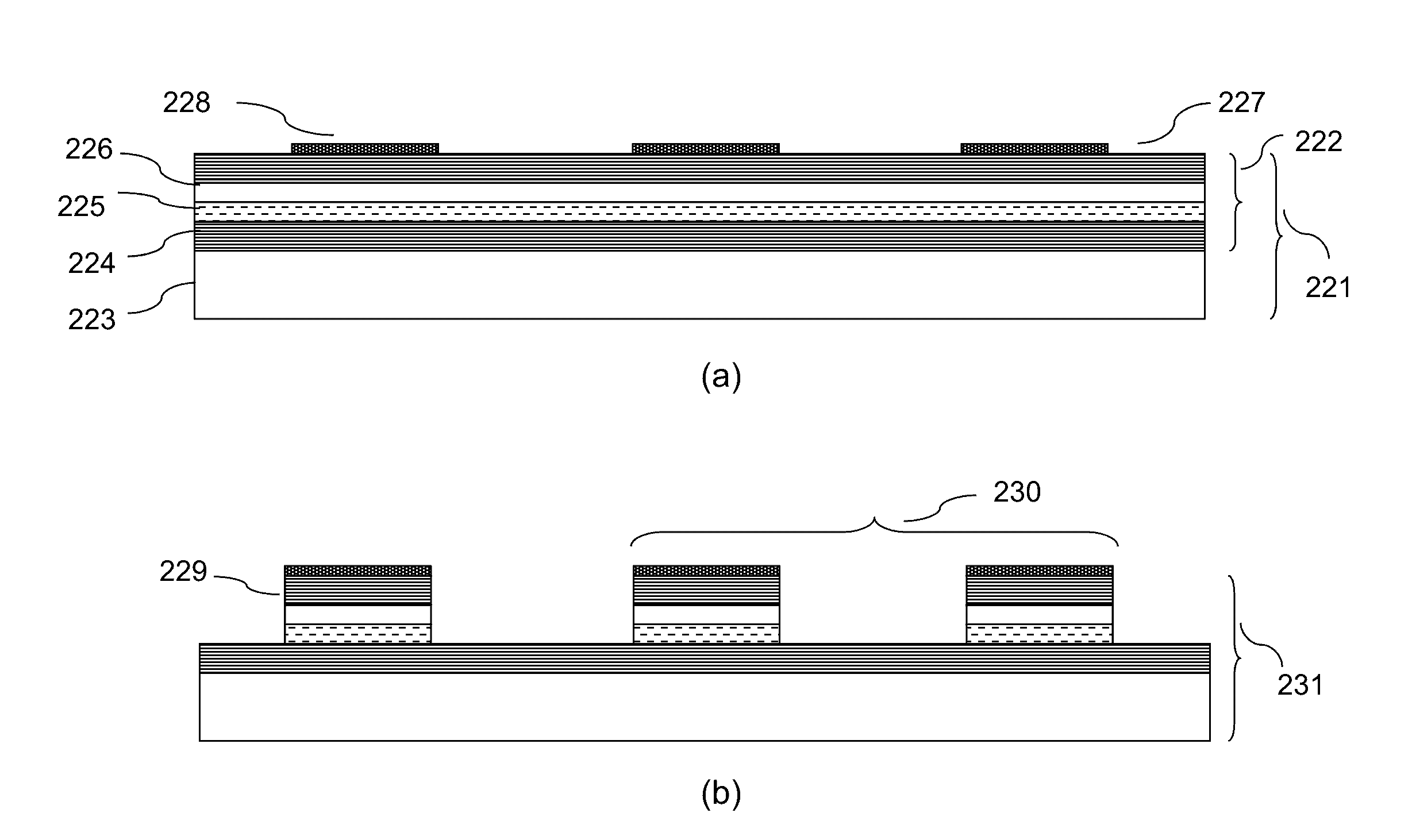

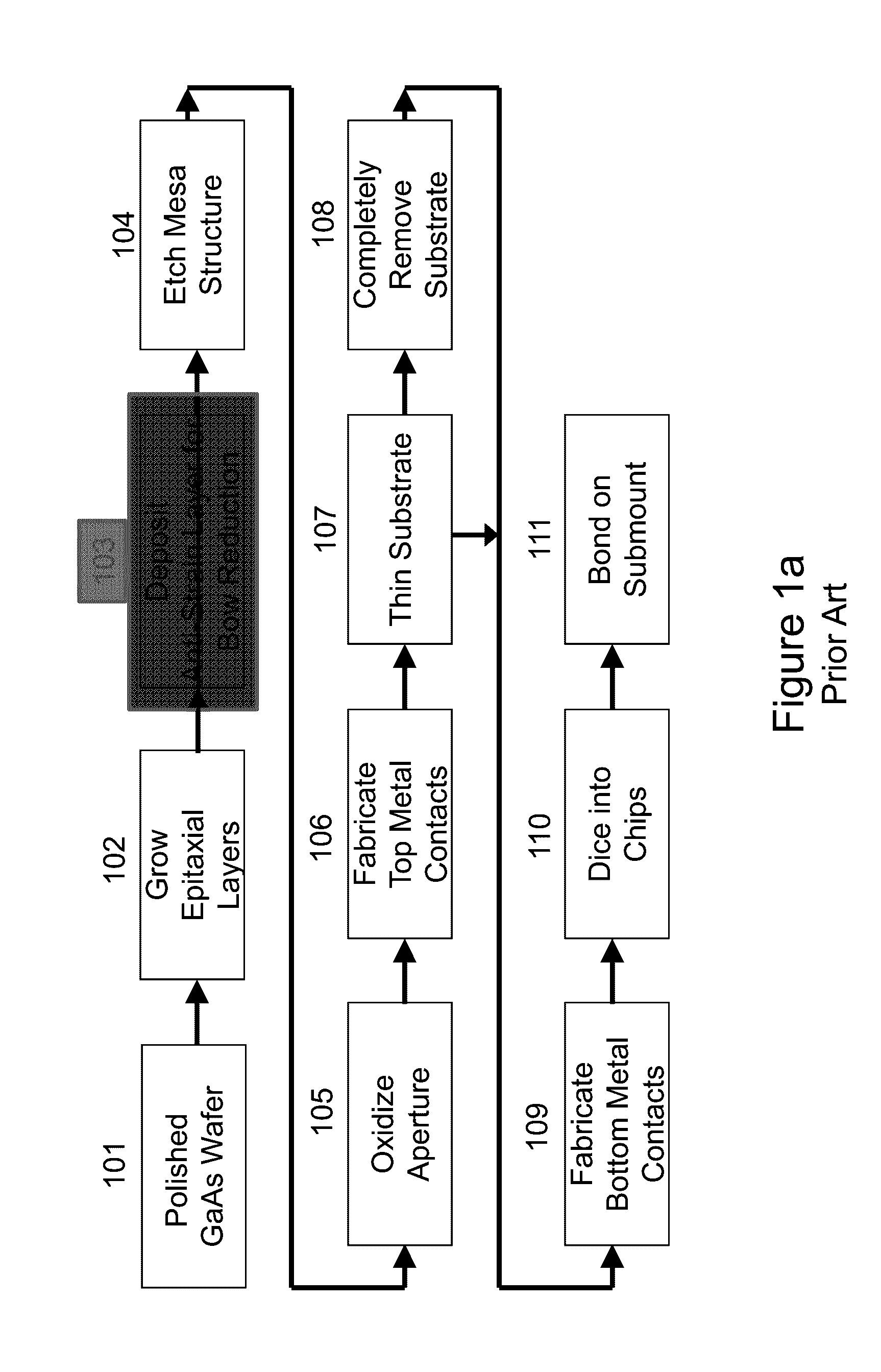

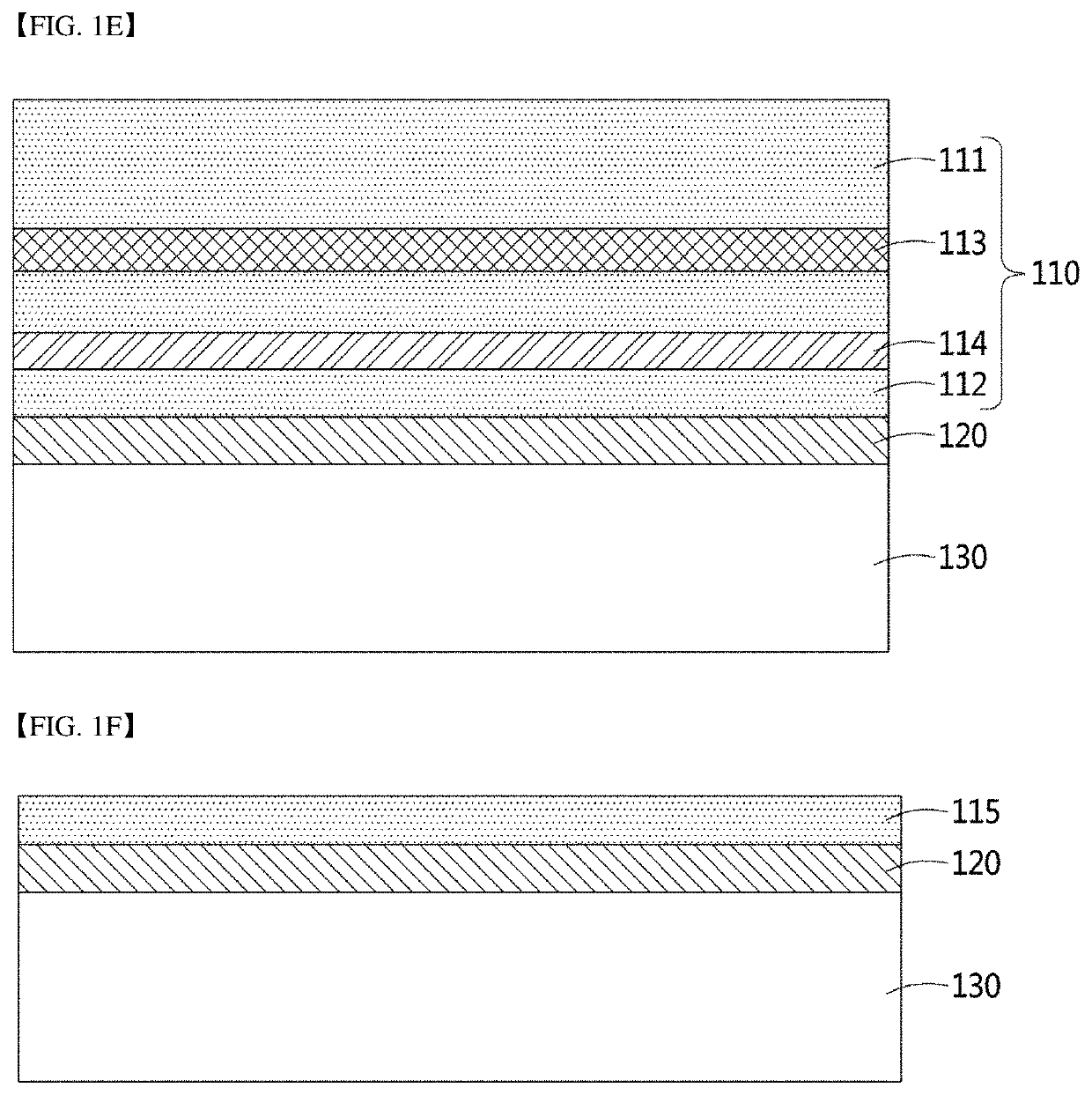

Processes for making reliable VCSEL devices and VCSEL arrays

ActiveUS9520696B2Improve reliabilityCounteract significant bowing and warpingLaser detailsSemiconductor laser structural detailsElectricityWafer bow

A set of VCSEL fabrication methods has been invented which enhance the performance and long time reliability of VCSEL devices and arrays of devices. Wafer bow caused by growing a large number of epitaxial layers required to fabricate VCSEL device generates strain and results in bowing / warping of the device wafer. The stress so generated is eliminated by applying a stress compensation layer on the substrate to a surface opposite to the epitaxial layer surface. New oxidation equipment designs and process parameters are described which produce more precision apertures and reduce stress in the VCSEL device. An ultrathin fabrication procedure is described which enables high power VCSELs to be made for high power operation at many different wavelengths. A low temperature electrical contacting process improves VCSEL long term reliability.

Owner:PRINCETON OPTRONICS

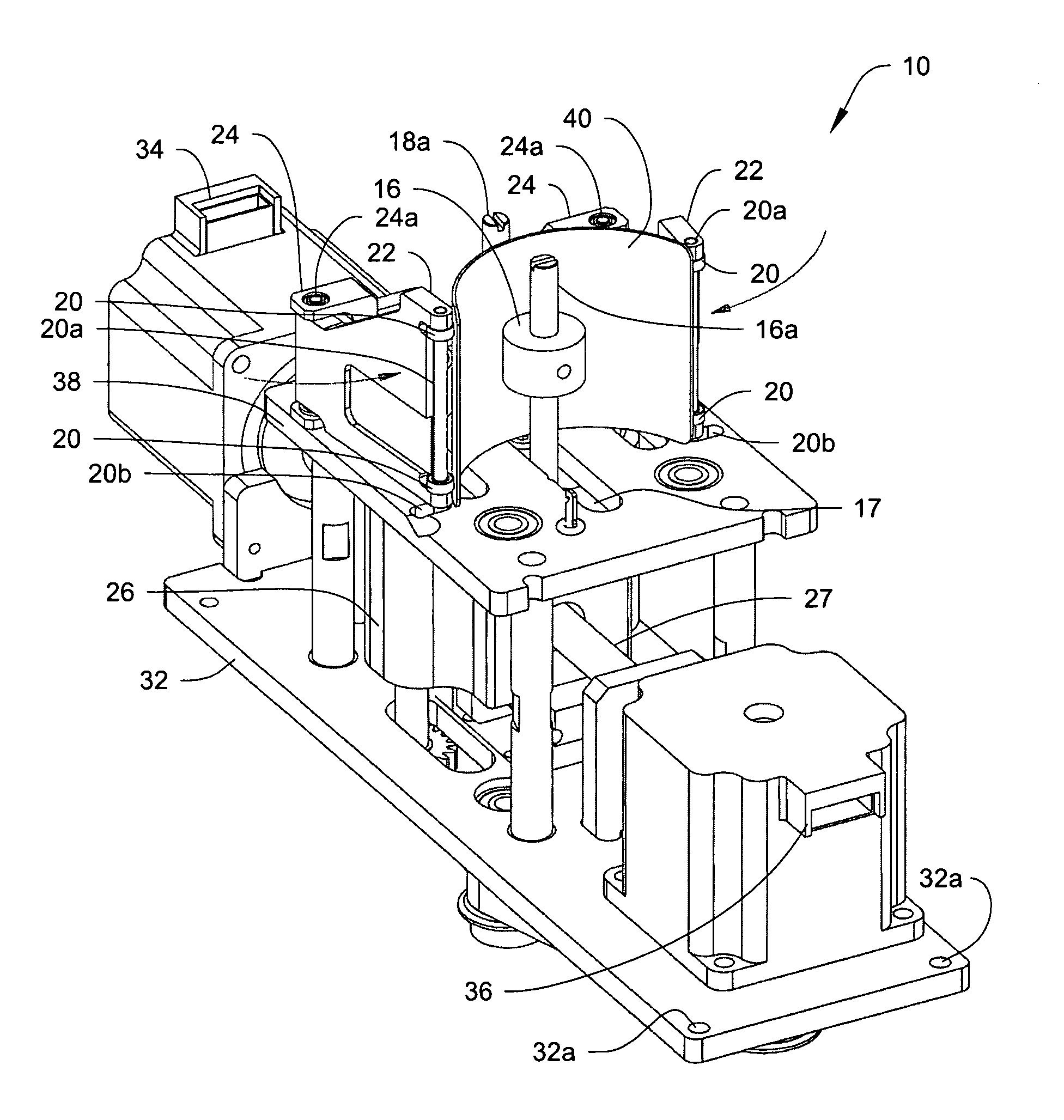

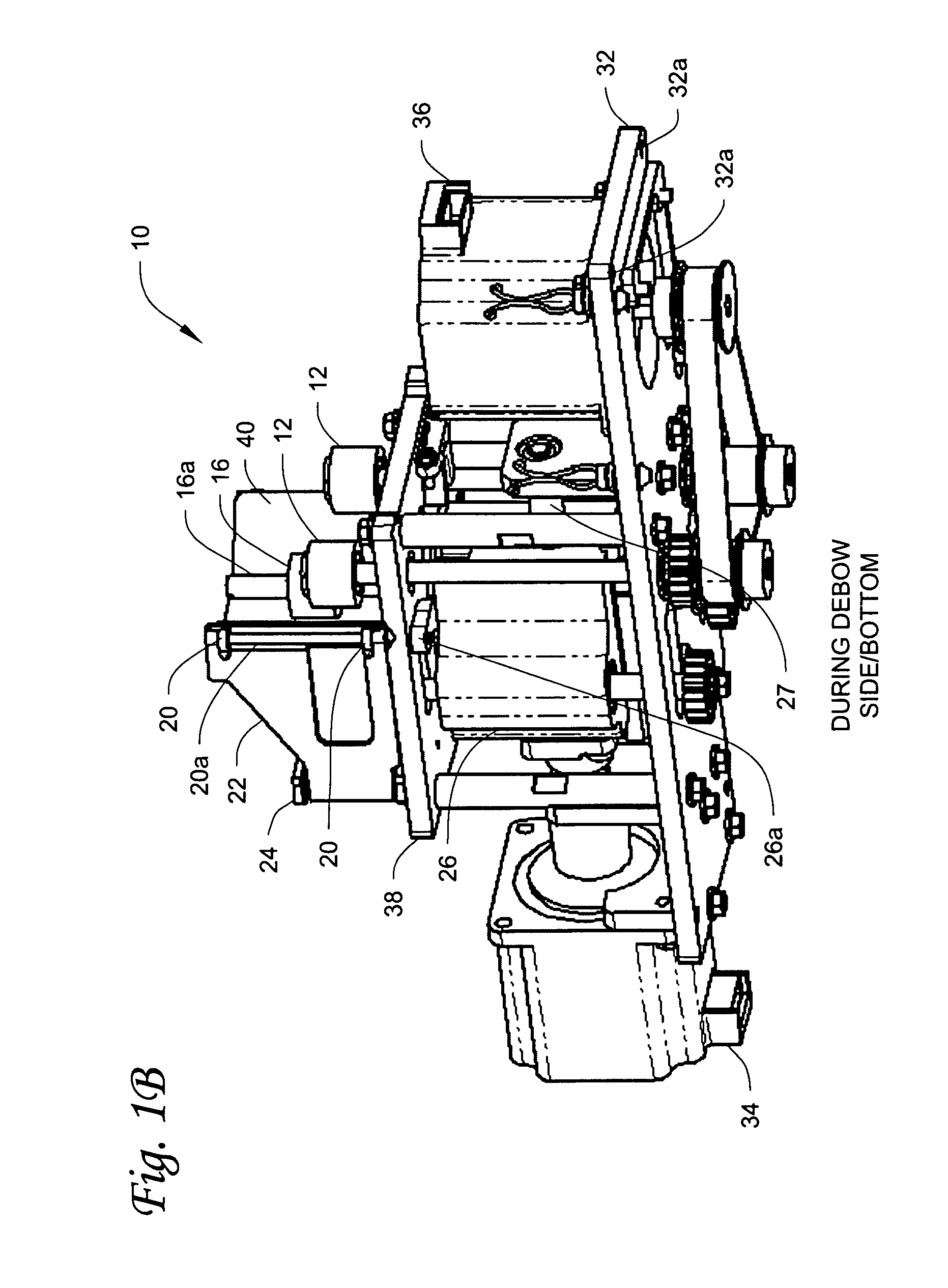

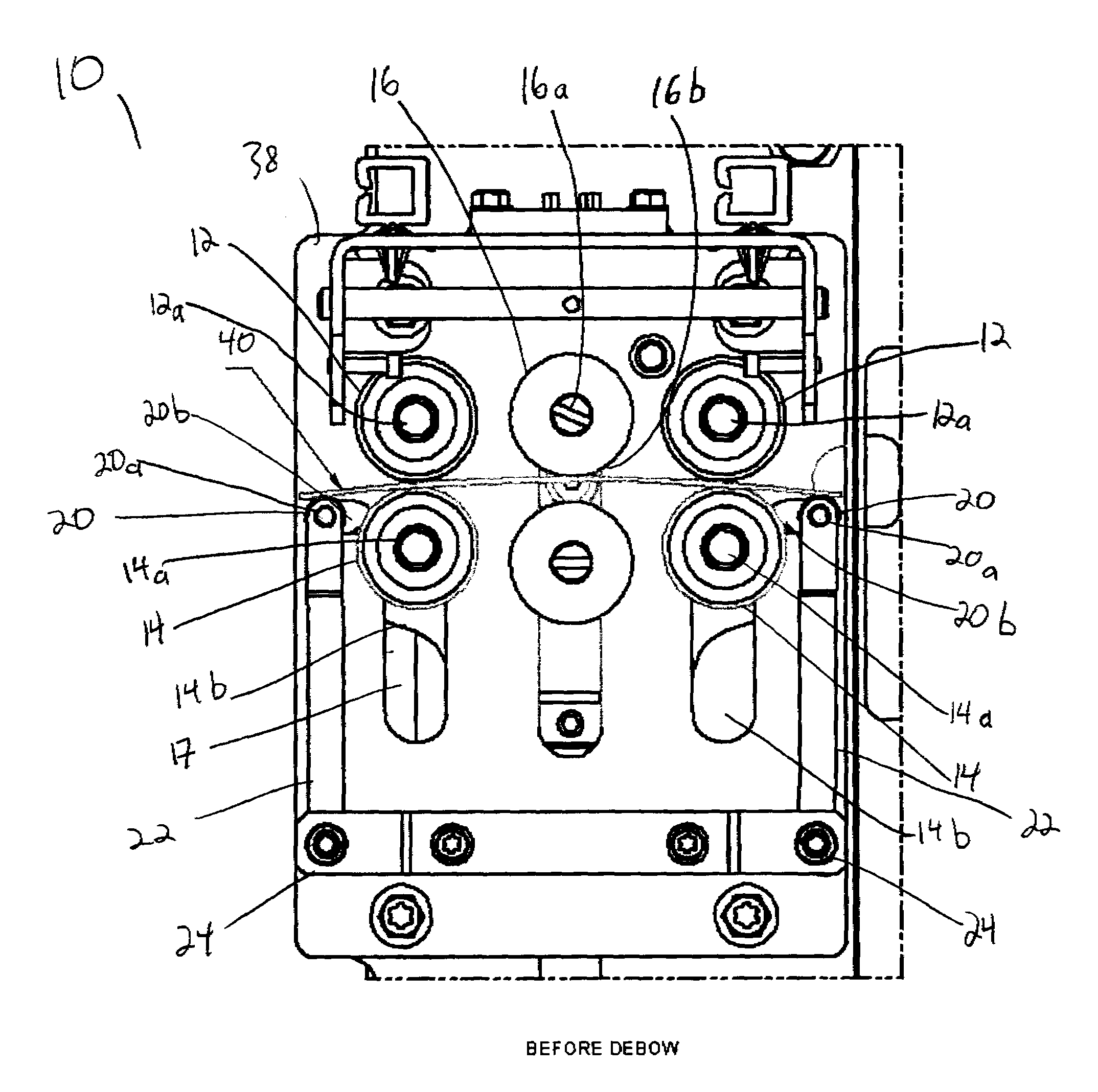

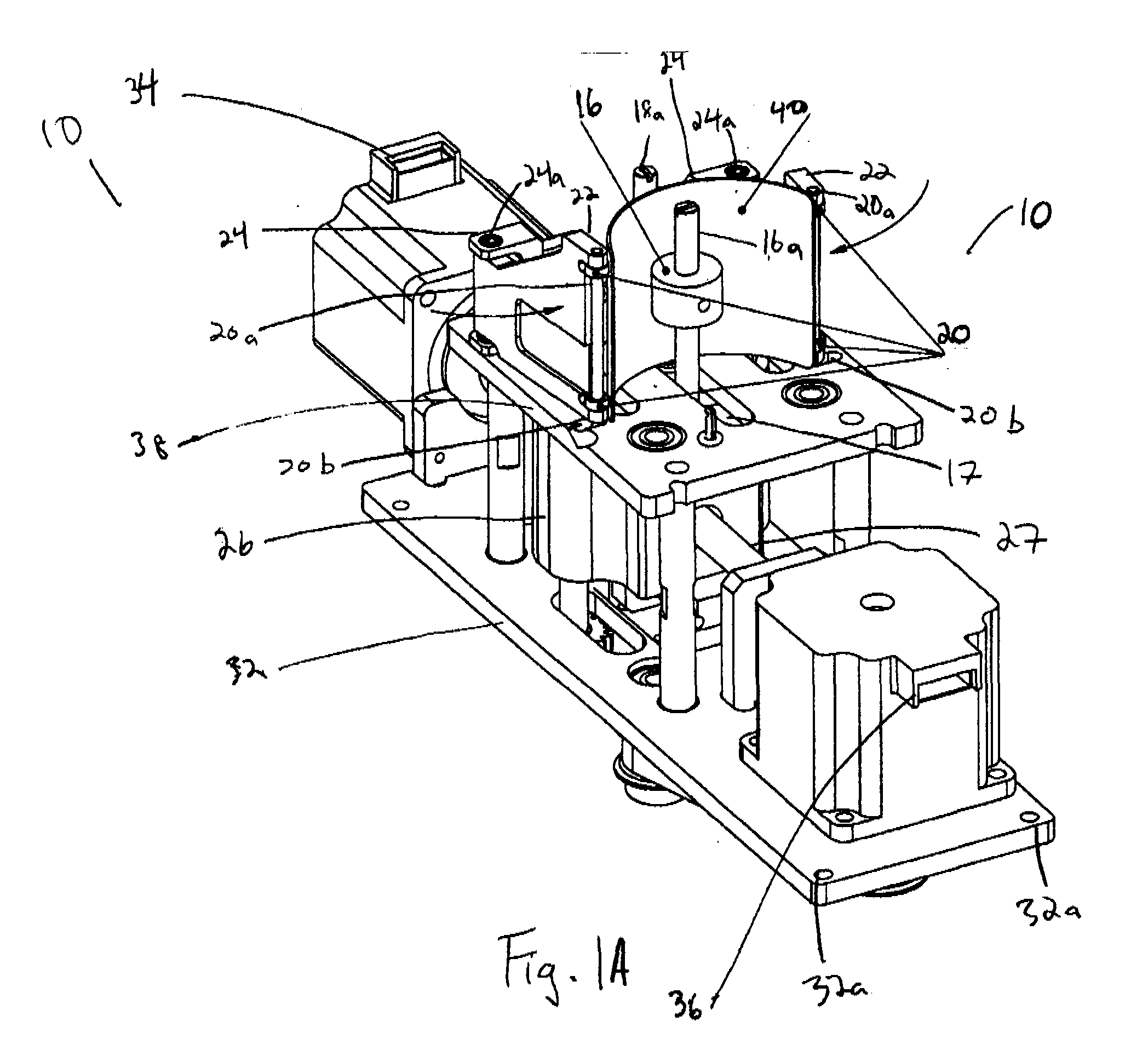

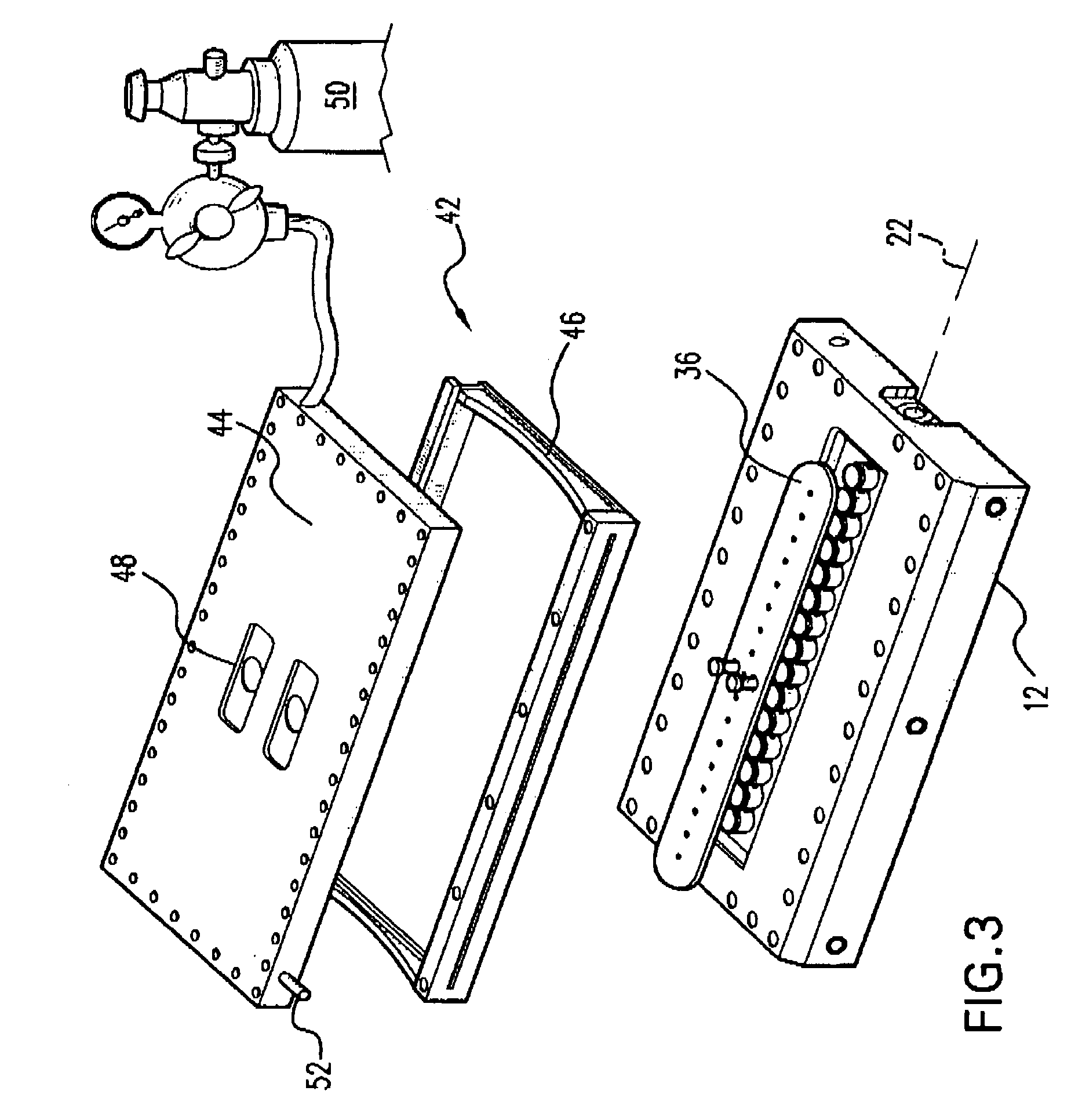

De-bowing personalized cards

ActiveUS7784700B2Reduce bowingImproved reliability and performanceRecord carriersConveying record carriersPersonalizationHorizontal and vertical

An apparatus and method for de-bowing personalized cards which includes a first contact member. The first contact member can be positioned for contacting a personalized card received by the apparatus and for displacing the personalized card against a bow occurring therein. The first contact member contacts and displaces a portion of the personalized card on one side of the personalized card and at an area that is generally centered horizontally and vertically. A second contact member can be supported by the frame for contacting the personalized card on a side opposite the first contact member. The second contact member being arranged and configured to contact an opposite side of the personalized card at a plurality of positions proximate the perimeter of the personalized card. In this manner, the first and second contact members cooperate to bend substantially the entire surface area of the personalized card against the occurring bow.

Owner:ENTRUST CORP

Plasma etching of tapered structures

InactiveUS20070108160A1Simple structureReduce bowingDecorative surface effectsSolid-state devicesOxygenPlasma etching

Owner:SCHOTT AG

De-bowing personalized cards

ActiveUS20070102518A1Reduce bowImprove reliability and performanceRecord carriersConveying record carriersPersonalizationEngineering

An apparatus and method for de-bowing personalized cards which includes a first contact member. The first contact member can be positioned for contacting a personalized card received by the apparatus and for displacing the personalized card against a bow occurring therein. The first contact member contacts and displaces a portion of the personalized card on one side of the personalized card and at an area that is generally centered horizontally and vertically. A second contact member can be supported by the frame for contacting the personalized card on a side opposite the first contact member. The second contact member being arranged and configured to contact an opposite side of the personalized card at a plurality of positions proximate the perimeter of the personalized card. In this manner, the first and second contact members cooperate to bend substantially the entire surface area of the personalized card against the occurring bow.

Owner:ENTRUST CORP

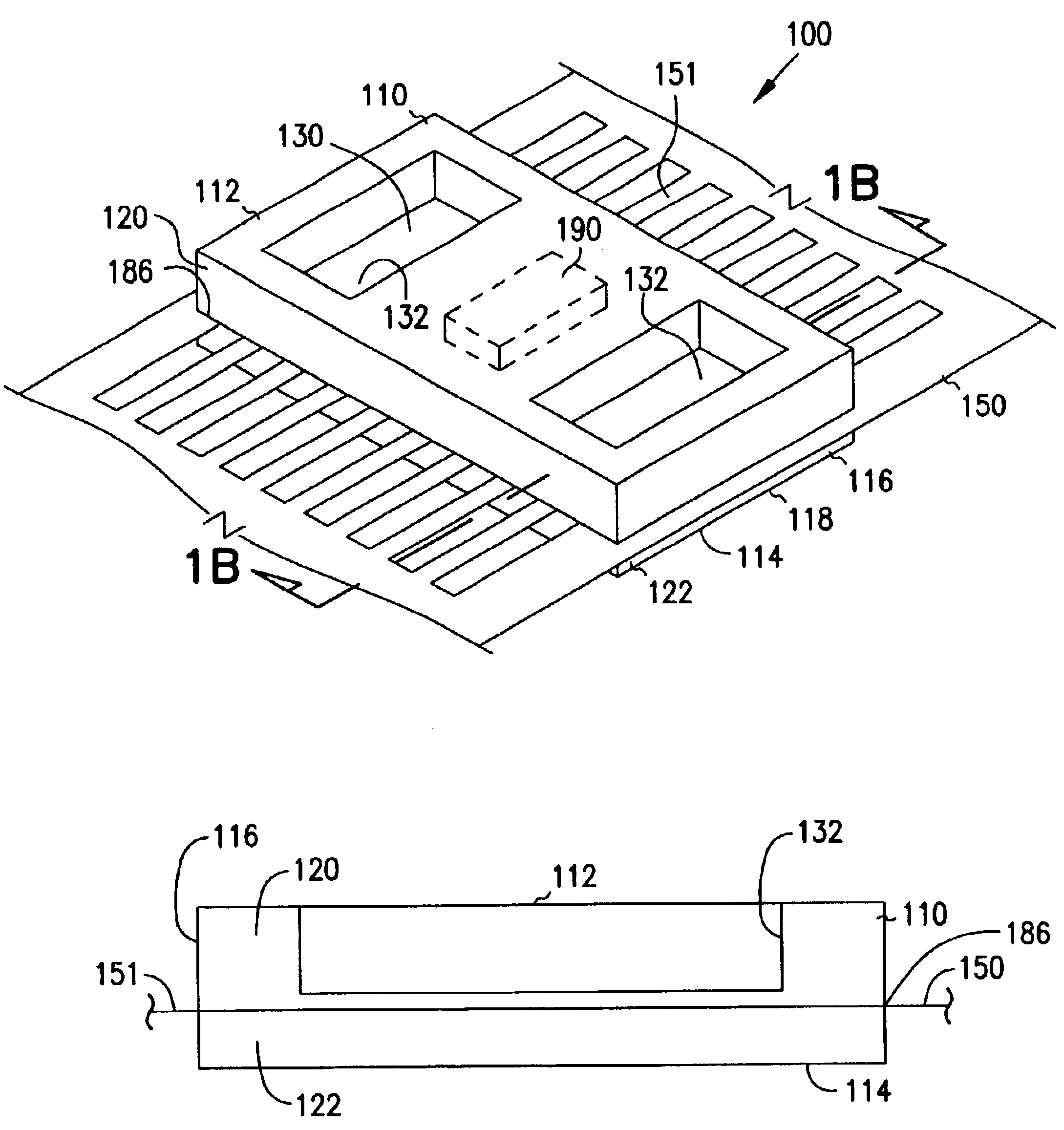

Printed circuit board, radio wave receiving converter, and antenna device

InactiveUS7378599B2Reduce bowingAvoid performance degradationAntenna supports/mountingsPrinted circuit aspectsPrinted circuit boardRadio wave

A printed circuit board has a substrate formed of an insulator, a strip line provided on a front surface of the substrate, and a ground metal layer provided on a rear surface of the substrate. An opening is provided in the ground metal layer to reach the substrate. A radio wave receiving converter and an antenna device each include the printed circuit board.

Owner:SHARP KK

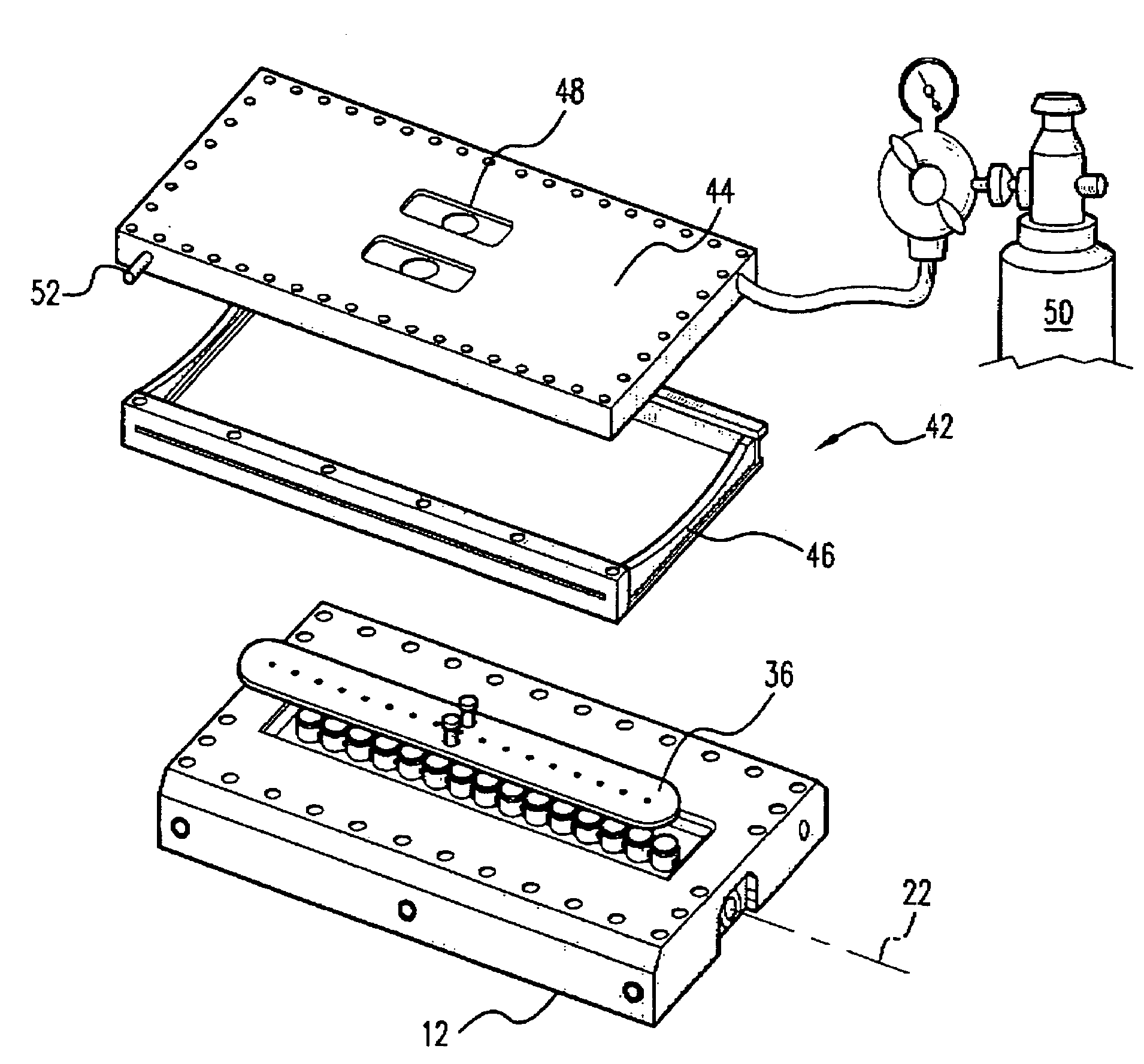

Chamber for a high energy excimer laser source

ActiveUS7369596B2Reduce bowingReduce distortionActive medium materialGas laser constructional detailsElectrical conductorHigh energy

A chamber for a gas discharge laser is disclosed and may include a chamber housing having a wall, the wall having an inside surface surrounding a chamber volume and an outside surface, the wall also being formed with an orifice. For the chamber, at least one electrical conductor may extend through the orifice to pass an electric current into the chamber volume. A member may be disposed between the conductor and the wall for preventing gas flow through the orifice to allow a chamber pressure to be maintained in the volume. The chamber may further comprise a pressurized compartment disposed adjacent to the orifice for maintaining a pressure on at least a portion of the outside surface of the wall to reduce bowing of the wall near the orifice due to chamber pressure.

Owner:CYMER INC

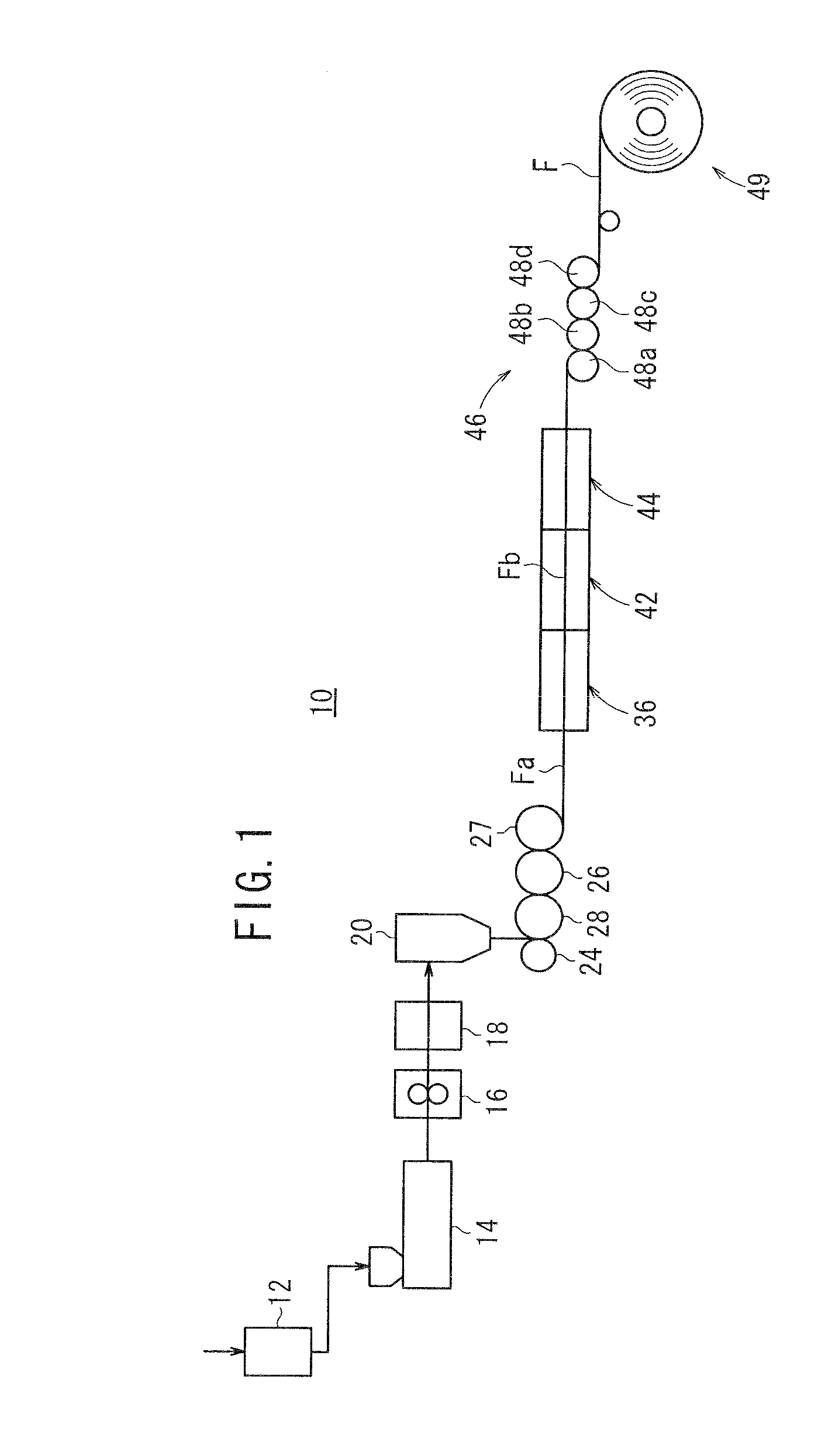

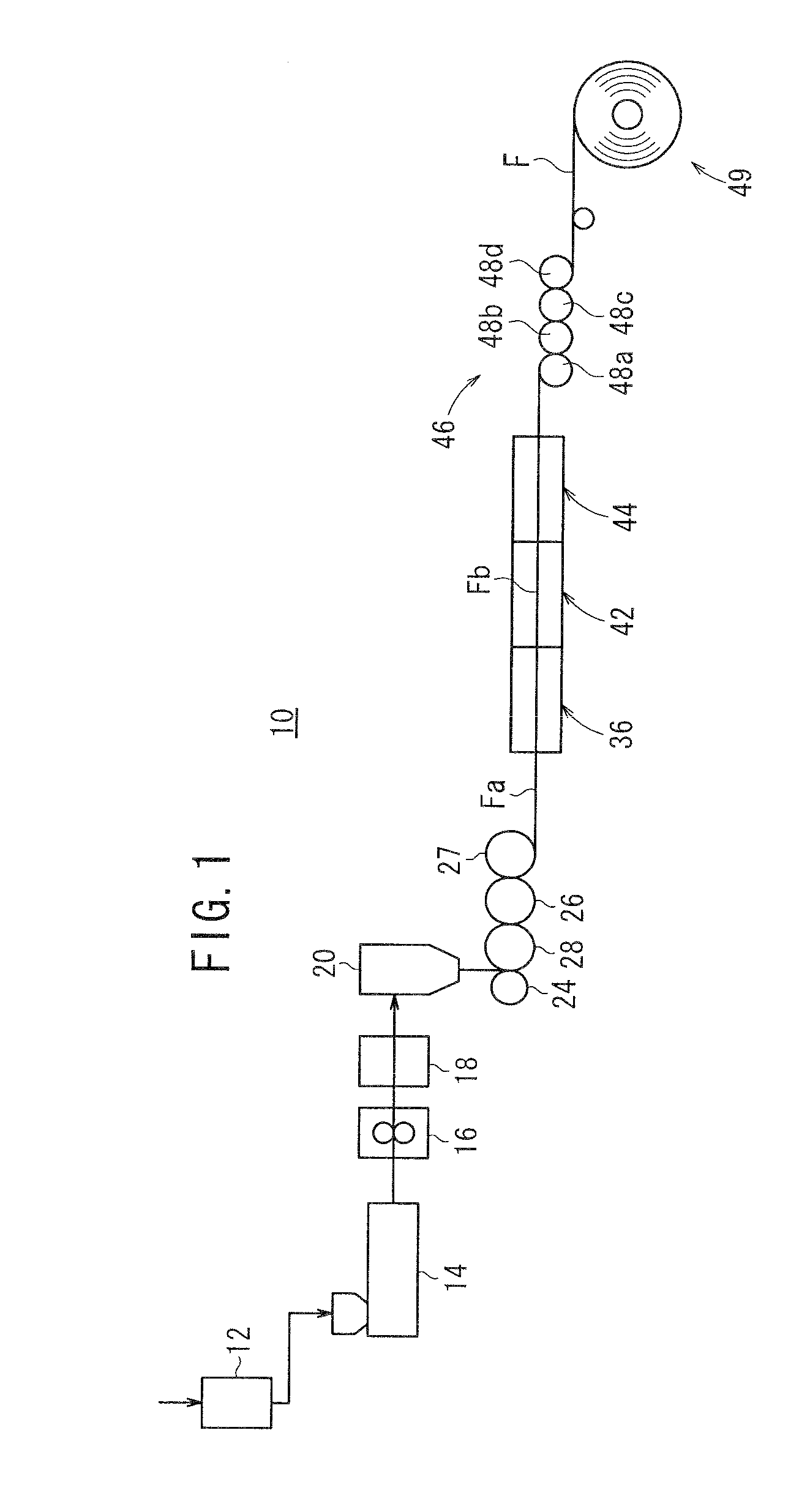

Heat treatment of thermoplastic film, and thermoplastic film and method for producing the same

InactiveUS20090042005A1Reduce bowingBowing can be reducedSynthetic resin layered productsOptical articlesVitrificationGlass transition

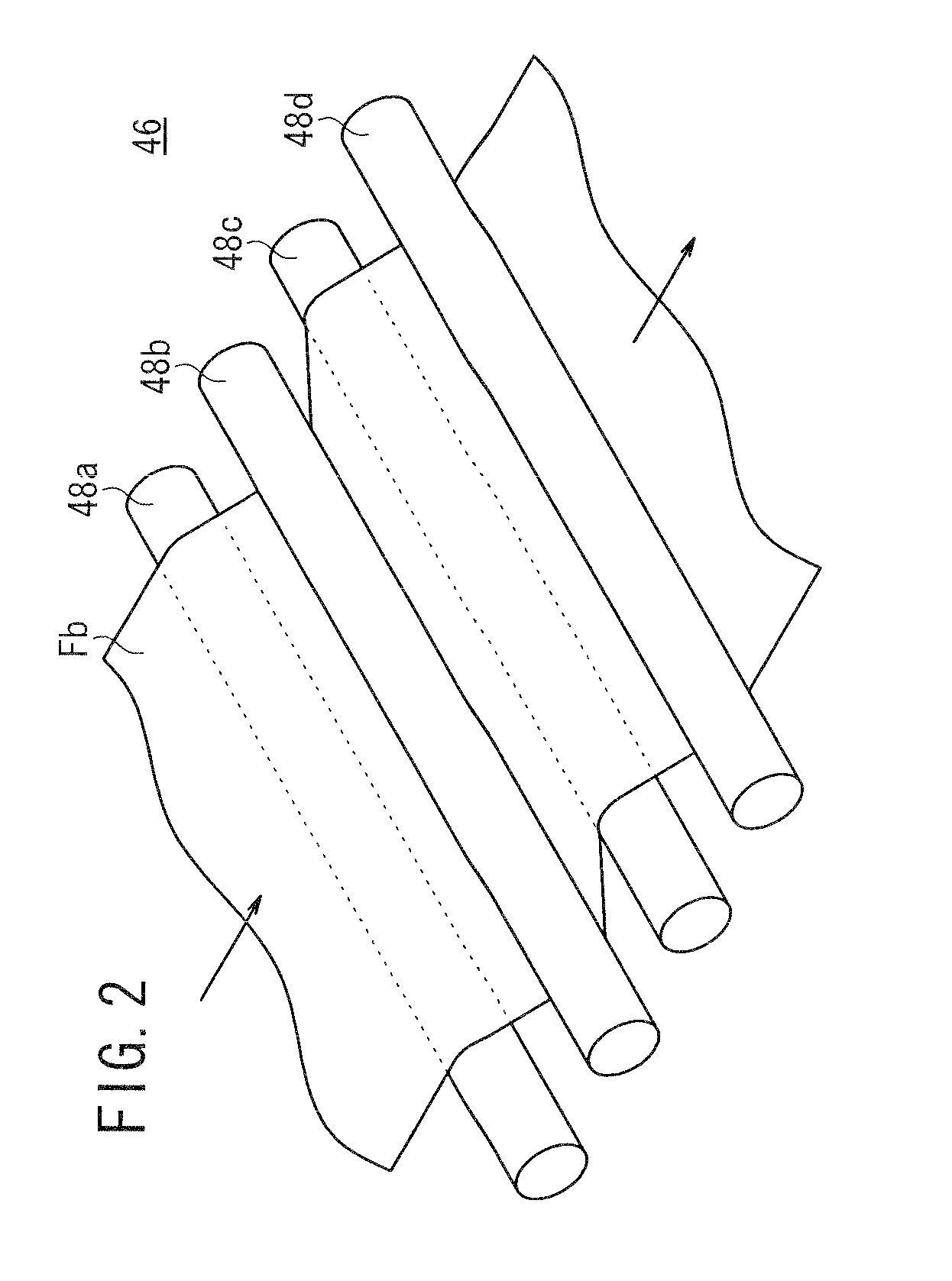

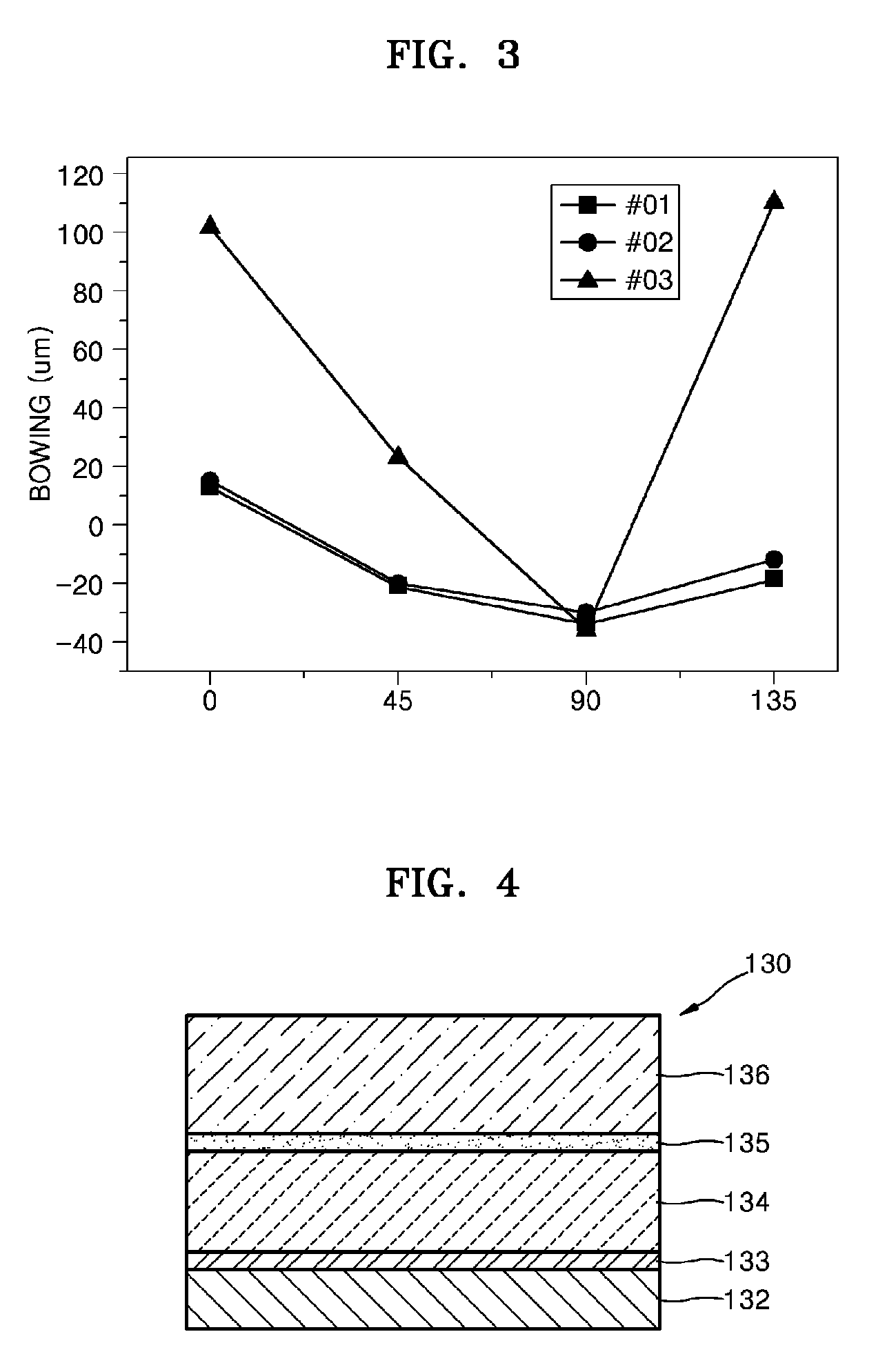

A thermoplastic film is transversely stretched, and then transported in a heat-treating zone (46) such that the ratio (GID) of an inter-roll distance (G) to a roll lap length (D) is 0.01 to 3, and the ratio (V2 / V1) of an exit-side transporting speed (V2) to an entry-side transporting speed (V1) is 0.6 to 0.999. The thermoplastic film is heat-treated in the heat-treating zone (46) at (Tg−20)° C. to (Tg+50)° C., in which Tg is the glass transition temperature of the film. The heat-treated thermoplastic film exhibits an Rth / Re ratio of at least 0.5 and less than 1, an Rth / Re ratio range of 0.01 to 0.1 in the width direction, and a thermal dimensional change of 0.001% to 0.3% under conditions of 80° C. and 200 hours.

Owner:FUJIFILM CORP

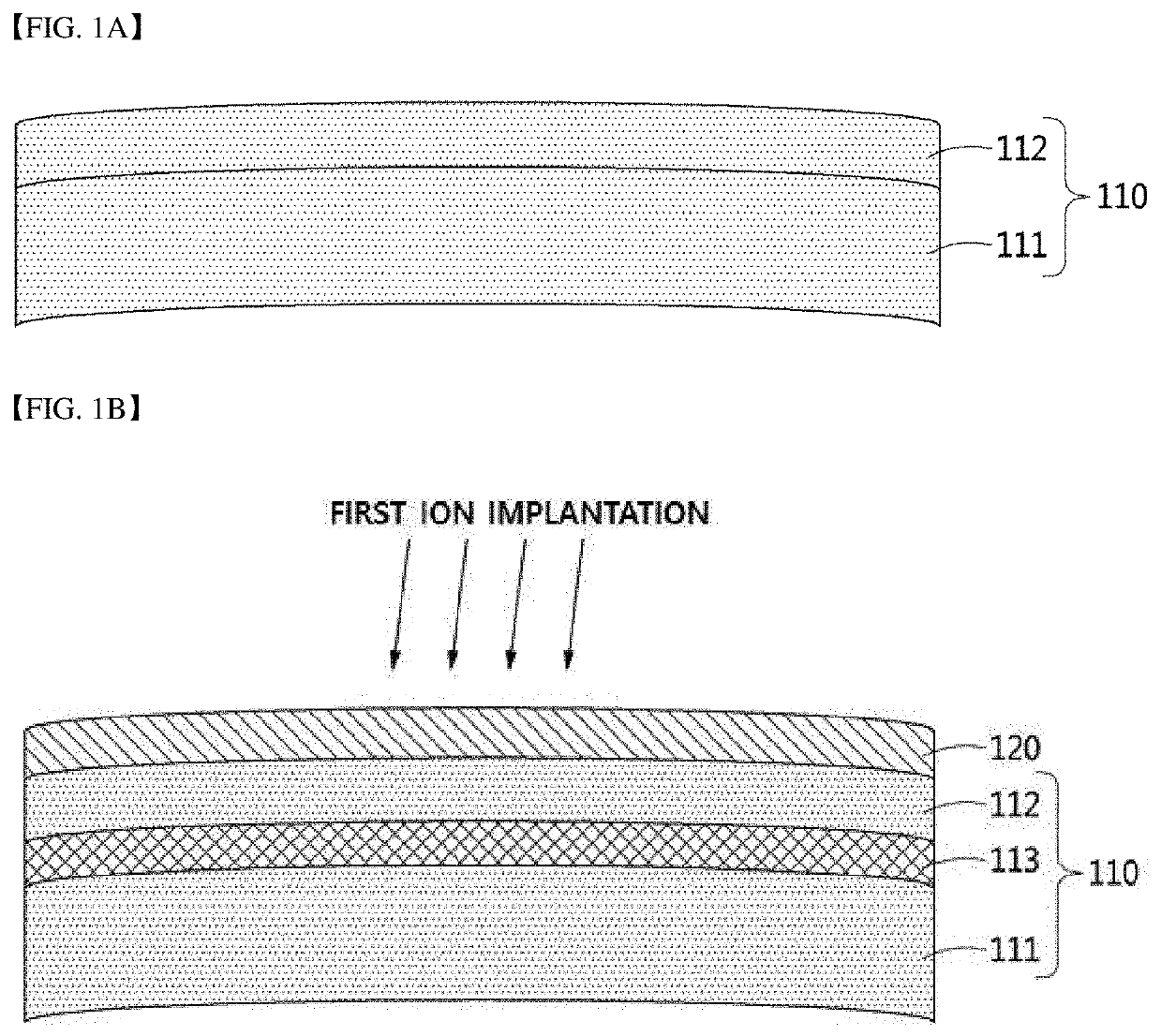

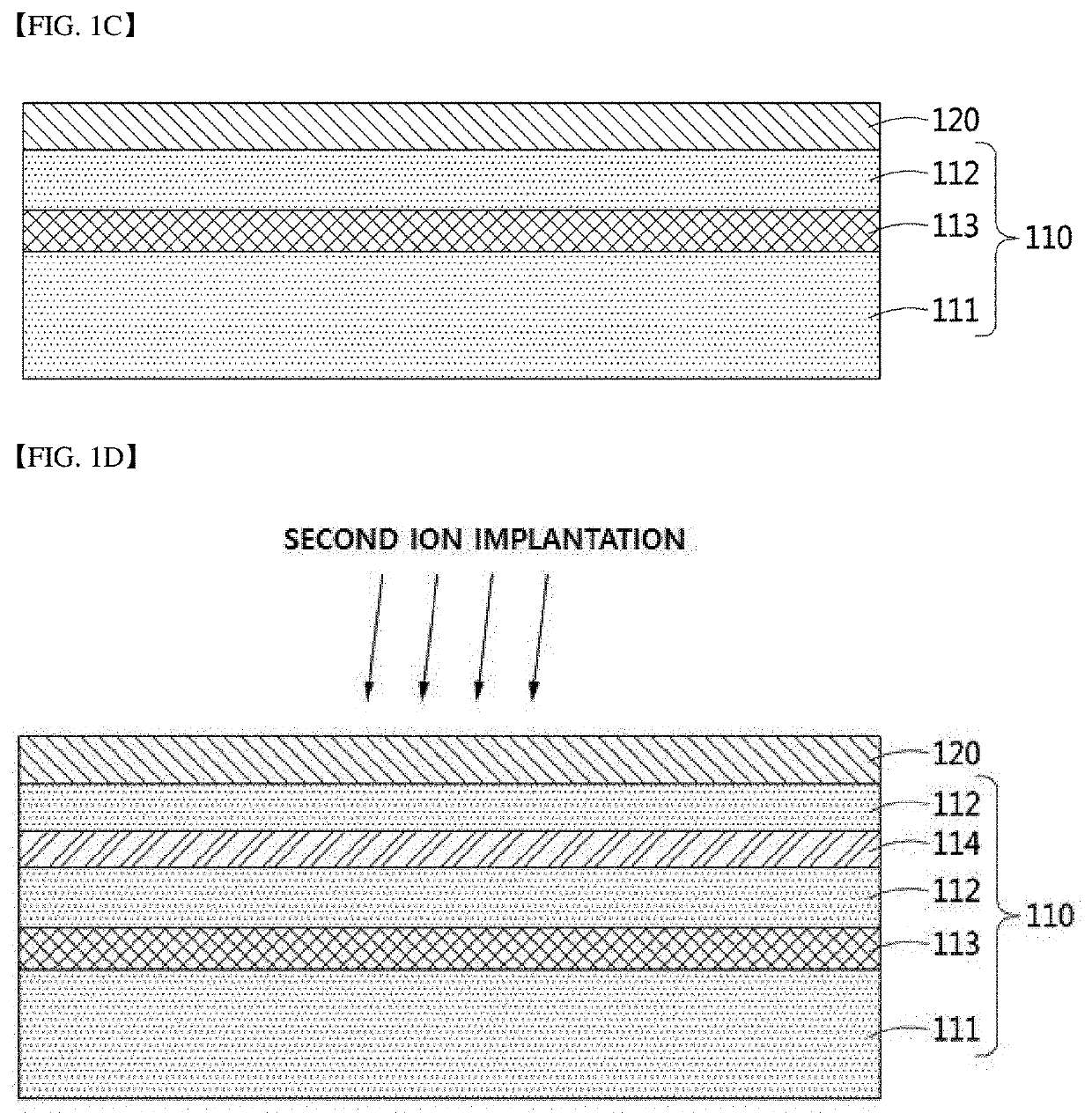

Method for manufacturing gallium nitride substrate using the multi ion implantation

ActiveUS20190371604A1Reduce bowingQuality improvementSemiconductor/solid-state device manufacturingGallium nitrideBlisters

Disclosed is a method of fabricating a gallium nitride substrate using a plurality of ion implantation processes. A method of fabricating a gallium nitride substrate using a plurality of ion implantation processes according to an embodiment of the present disclosure includes a step of forming a bonding oxide film on the first gallium nitride; a step of performing first ion implantation for a surface of the first gallium nitride, on which the bonding oxide film is formed, at least once to form a damaged layer, thereby releasing bowing of the first gallium nitride; a step of performing second ion implantation for the surface of the first gallium nitride, on which the bonding oxide film is formed, to form a blister layer; a step of bonding the bonding oxide film of the first gallium nitride to a temporary substrate; a step of separating the first gallium nitride using the blister layer to form a seed layer; and a step of allowing growth of the second gallium nitride using the seed layer to form bulk gallium nitride.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

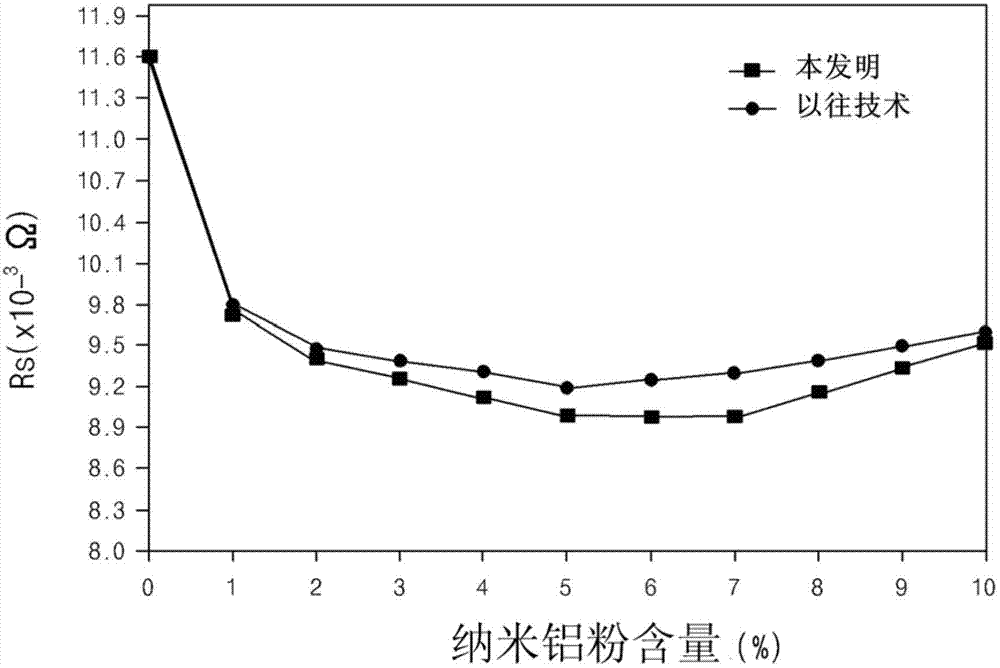

Composition for manufacturing a back contact for a crystalline solar cell

InactiveCN102714237AReduce bowingNon-conductive material with dispersed conductive materialPhotovoltaic energy generationPowder mixtureAluminium powder

The present invention relates to a composition for manufacturing a back contact for a crystalline solar cell. The back contact material used for manufacturing a crystalline solar cell, a front contact and back contact of which are formed on the front side and rear side of a wafer, respectively, comprises a mixture composition consisting of an acrylate- or cellulose-based resin, aluminum powder, an inorganic binder, and an additive for increasing adhesion to a wafer, wherein the aluminum powder is a powder mixture containing aluminum powder, the size of which is 30-100 nm, and aluminum powder, the size of which is 2-10 [mu]m. The composition of the present invention uses said types of aluminum powder, the sizes of which are smaller than those disclosed in prior art, thereby reducing Rs-contact resistance and thus enabling a solar cell to have excellent photoelectric conversion efficiency.

Owner:TAIYO INK MFG CO KOREALTD

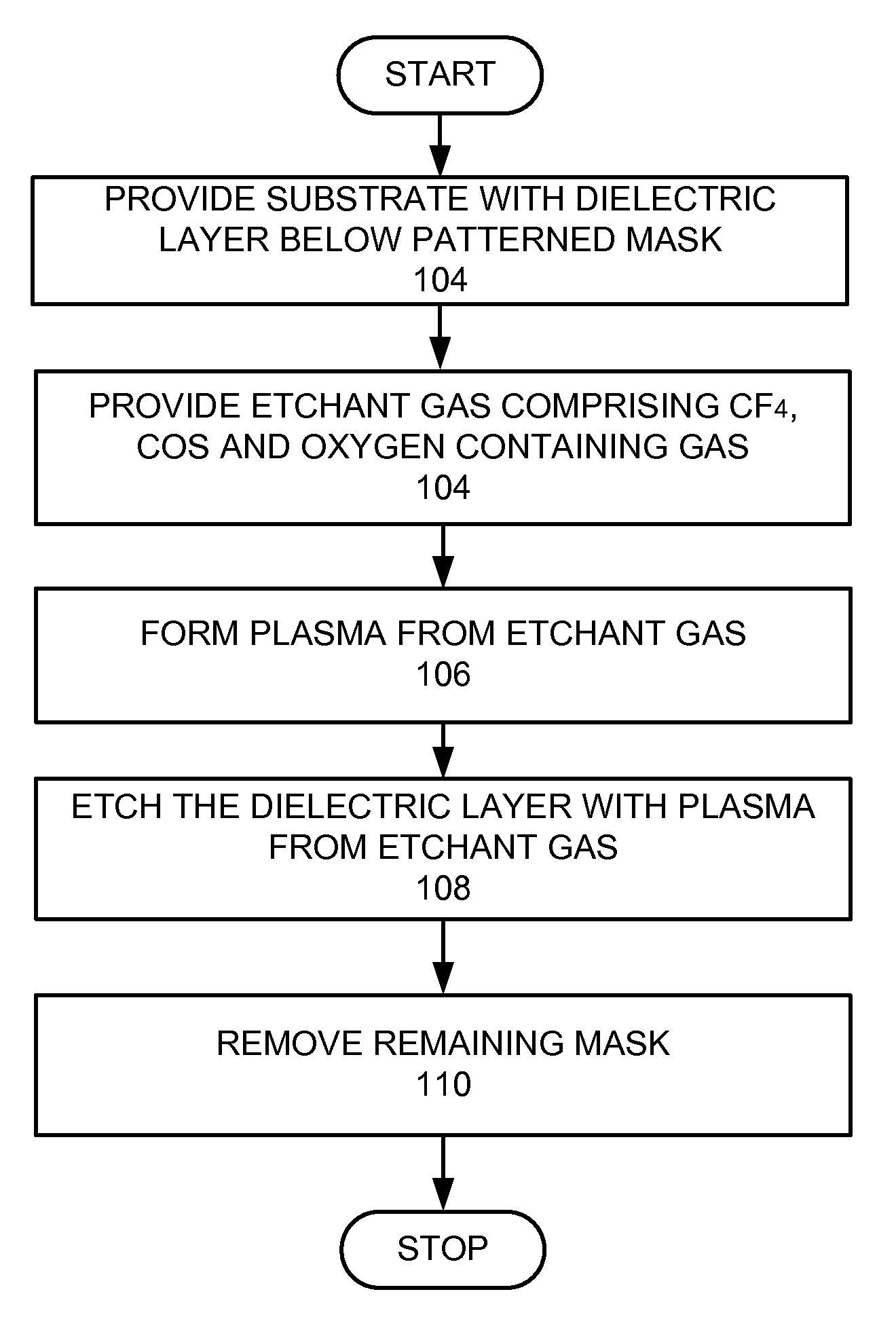

Profile control in dielectric etch

InactiveUS20110053379A1Reduce bowingDecorative surface effectsSemiconductor/solid-state device manufacturingElectricityReactive gas

A method for etching a dielectric layer is provided. The dielectric layer is disposed over a substrate and below a patterned mask having a line-space pattern. The method includes (a) providing an etchant gas comprising CF4, COS, and an oxygen containing gas, (b) forming a plasma from the etchant gas, and (c) etching the dielectric layer into the line-space pattern through the mask with the plasma from the etchant gas. The gas flow rate of CF4 may have a ratio greater than 50% of a total gas flow rate of all reactive gas components. The gas flow rate of COS may be between 1% and 50%. The method reduces bowing in etching of the dielectric layer by adding COS to the etchant gas.

Owner:LAM RES CORP

Techniques for reducing bowing in power transistor devices

ActiveUS7164200B2Reduce bowingReduce the amount requiredSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit

Power transistor devices and techniques for reducing bowing in such devices are provided. In one aspect, a power transistor device is provided. The power transistor device comprises a substrate, a device film formed on the substrate and an adhesion layer formed on a side of the substrate opposite the device film, wherein at least a portion of the adhesion layer is at least partially segmented. The power transistor device thereby exhibits a reduced amount of bowing relative to an amount of bowing expected without the segmenting of the adhesion layer. The power transistor device may be part of an integrated circuit.

Owner:BELL SEMICON LLC

Deployable structure for use in establishing a reflectarray antenna

ActiveUS10283835B2Increase stiffnessReduce bowingCollapsable antennas meansCosmonautic vehiclesPantographWaste management

A deployable structure for use in establishing a reflectarray antenna is provided that includes a flexible reflectarray and a deployment structure that includes an endless pantograph for deploying the flexible reflectarray from a folded, undeployed state towards a deployed state in which the flexible reflectarray is substantially planar. In a particular embodiment, the deployment structure includes a plurality of tapes that engage the endless pantograph and are used to establish a positional relationship between the deployed reflectarray and another component of the reflectarray antenna.

Owner:M M A DESIGN

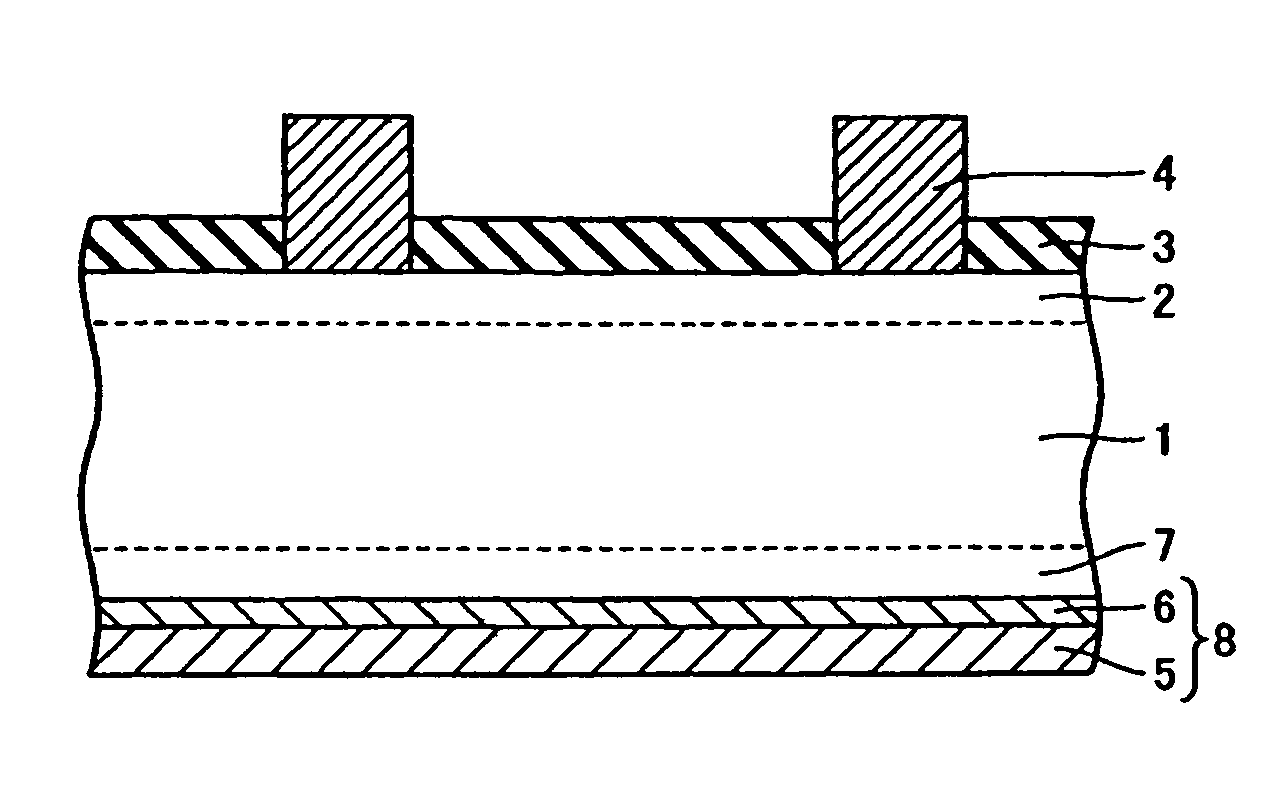

Aluminum paste composition and solar cell element using the same

InactiveUS7879262B2Bow of the silicon semiconductor substrate can be reducedImprove manufacturing yieldConductive materialNon-conductive material with dispersed conductive materialHigh energyPlasticizer

Provided are an aluminum paste composition capable of inhibiting formation of blisters and globules of aluminum in a back surface electrode layer, which is caused at the time of firing, of reducing bow of a silicon semiconductor substrate even when a thinner silicon semiconductor substrate is used, and of attaining a high BSF effect and a high energy conversion efficiency; and a solar cell element comprising an electrode formed by using the composition. The aluminum paste composition is a paste composition for forming an electrode (8) on a silicon semiconductor substrate (1), comprising: aluminum powder; an organic vehicle; and a plasticizer. The solar cell element comprises the electrode (8) formed by applying on the silicon semiconductor substrate (1) the paste composition having the above-mentioned features and thereafter, firing the paste composition.

Owner:TOYO ALUMINIUM KK

Method for making an integrated circuit package having reduced bow

InactiveUS6887740B2Low costLess materialSemiconductor/solid-state device detailsSolid-state devicesLead frameCircular segment

An integrated circuit device includes a semiconductor component coupled with a lead frame, and an integrated circuit package encompassing at least a portion of the semiconductor component. The package has a first surface and a second surface, and side surfaces, where the first surface is opposite the second surface. A parting line of the integrated circuit package is offset toward the second surface of the package, where the first surface optionally comprises the bottom surface of the package. The first surface of the package has one or more recessed areas.

Owner:MICRON TECH INC

Profile control in dielectric etch

InactiveUS8501627B2Reduce bowingDecorative surface effectsSemiconductor/solid-state device manufacturingReactive gasOxygen

A method for etching a dielectric layer is provided. The dielectric layer is disposed over a substrate and below a patterned mask having a line-space pattern. The method includes (a) providing an etchant gas comprising CF4, COS, and an oxygen containing gas, (b) forming a plasma from the etchant gas, and (c) etching the dielectric layer into the line-space pattern through the mask with the plasma from the etchant gas. The gas flow rate of CF4 may have a ratio greater than 50% of a total gas flow rate of all reactive gas components. The gas flow rate of COS may be between 1% and 50%. The method reduces bowing in etching of the dielectric layer by adding COS to the etchant gas.

Owner:LAM RES CORP

Biaxially stretched polyamide resin film

ActiveUS20150064485A1Does not affect appearanceHigh surface glossSynthetic resin layered productsDomestic containersIn planePolyamide

The invention provides a biaxially stretched multilayer polyamide resin film having 8 or more layers in total and using a same resin composition for 80% based on the ratio of the number of the layers. The film is stretched 2.5 to 5.0 times in the longitudinal direction of the film and has an in-plane orientation coefficient (ΔP) of 0.057 to 0.07 and a strain of 0.1 to 2.0% after boiling treatment.

Owner:TOYOBO CO LTD

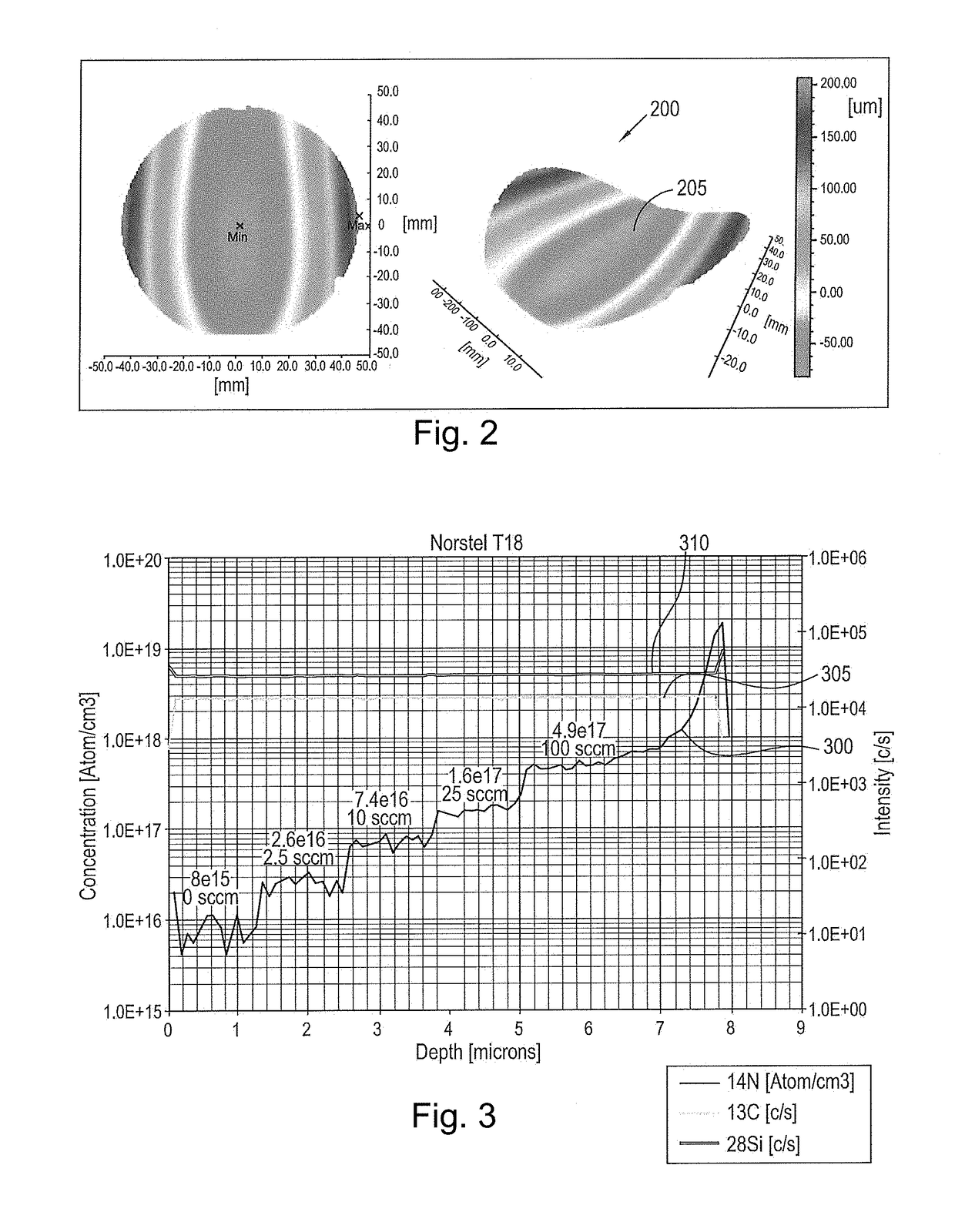

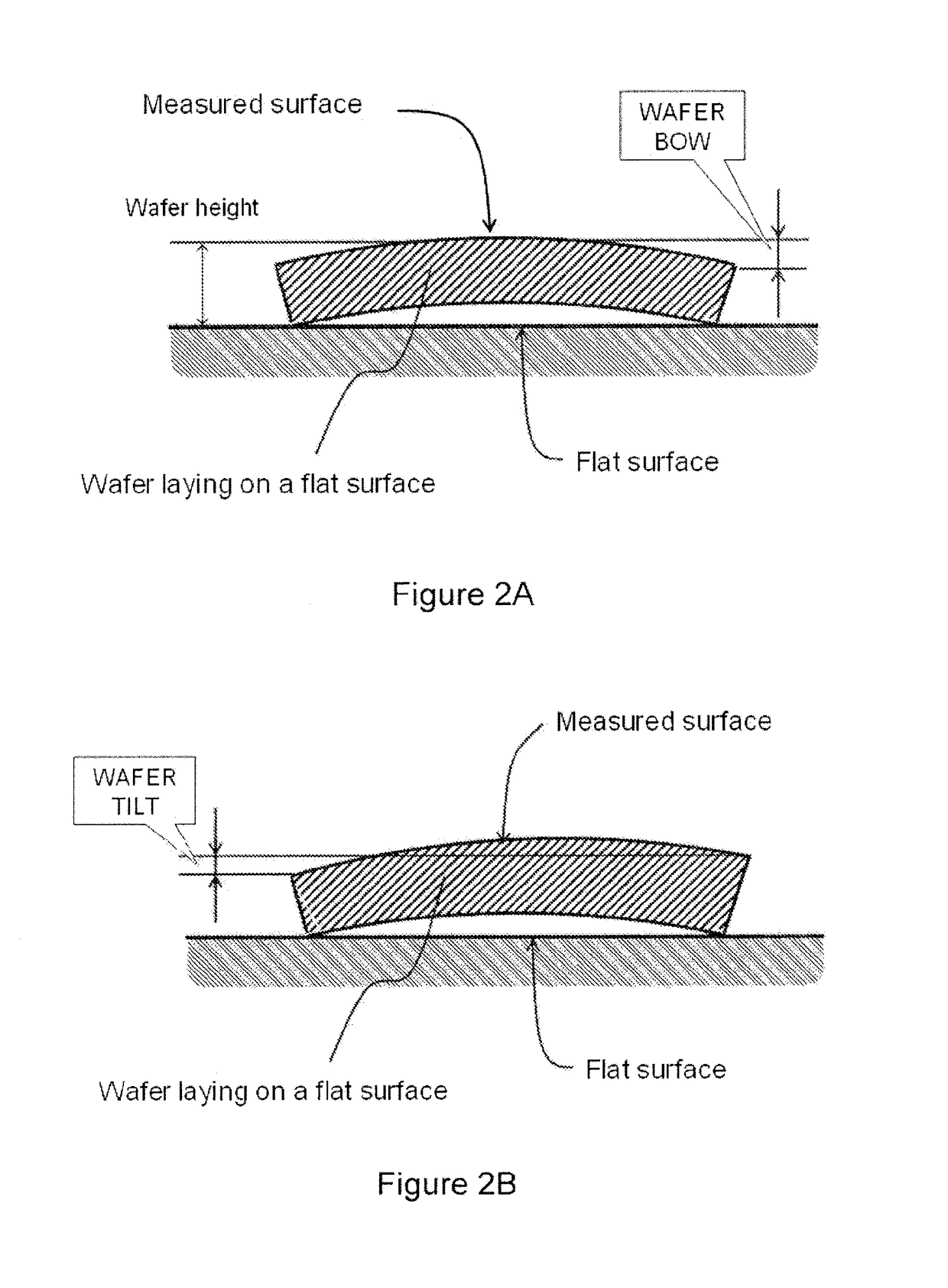

Wafer bow reduction

ActiveUS20170323790A1Reduces wafer bowImprove robustnessPolycrystalline material growthSemiconductor/solid-state device manufacturingWafer bowNitrogen

We describe a method for reducing bow in a composite wafer comprising a silicon wafer and a silicon carbide layer grown on the silicon wafer. The method includes applying nitrogen atoms during the growth process of the silicon carbide layer on the silicon wafer so as to generate a compressive stress within the composite wafer.

Owner:ANVIL SEMICON

Heat treatment of thermoplastic film, and thermoplastic film and method for producing the same

InactiveUS8153044B2Reduce bowingBowing can be reducedSynthetic resin layered productsPolarising elementsVitrificationGlass transition

Owner:FUJIFILM CORP

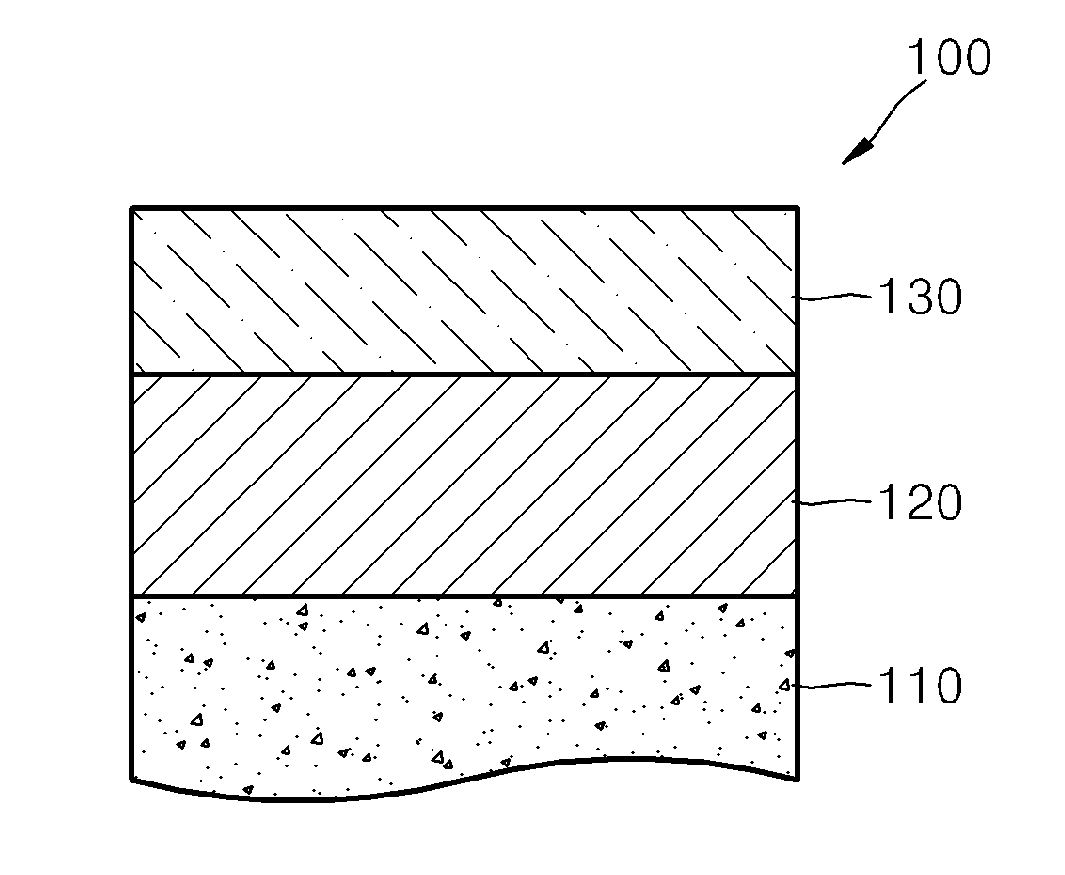

Gallium nitride based semiconductor device and method of manufacturing the same

ActiveUS9202878B2Avoid damageReduce deformationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationDevice material

A gallium nitride based semiconductor device includes a silicon-based layer doped simultaneously with boron (B) and germanium (Ge) at a relatively high concentration, a buffer layer on the silicon-based layer, and a nitride stack on the buffer layer. A doping concentration of boron (B) and germanium (Ge) may be higher than 1×1019 / cm3.

Owner:SAMSUNG ELECTRONICS CO LTD

Gallium nitride based semiconductor device and method of manufacturing the same

ActiveUS20130328054A1Avoid damageReduce deformationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationDevice material

A gallium nitride based semiconductor device includes a silicon-based layer doped simultaneously with boron (B) and germanium (Ge) at a relatively high concentration, a buffer layer on the silicon-based layer, and a nitride stack on the buffer layer. A doping concentration of boron (B) and germanium (Ge) may be higher than 1×1019 / cm3.

Owner:SAMSUNG ELECTRONICS CO LTD

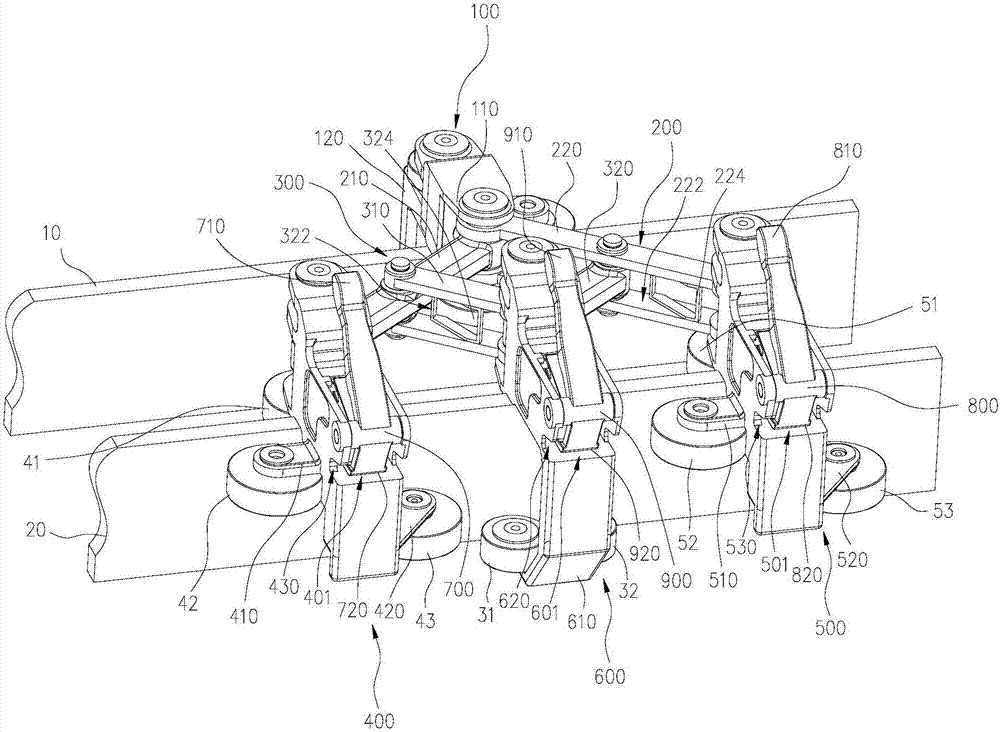

Linkage chain clamp mechanism and staggered combination device

ActiveCN106881854AGuaranteed uptimeMeet the needs of stretching productionFlat articlesEngineeringMechanical engineering

The invention relates to a linkage chain clamp mechanism and a staggered combination device. The linkage chain clamp mechanism comprises a first mounting base, a first connecting rod assembly, a second connecting rod assembly, a second mounting base, a third mounting base and a fourth mounting base, wherein the first mounting base can move along a first guide rail; a first connecting part is arranged on the first mounting base; the second mounting base is provided with a first clamping fixing part; the third mounting base is provided with a second clamping fixing part; the fourth mounting base is provided with a third clamping fixing part; and the first mounting base is matched with the second mounting base, the third mounting base and the fourth mounting base through the first connecting rod assembly and the second connecting rod assembly, so that the third clamping fixing part can move relative to the first clamping fixing part or / and the second clamping fixing part. The linkage chain clamp mechanism and the staggered combination device can meet the production demands of various products; and meanwhile, the film arch phenomenon can be reduced, side crops on the two side of a film are reduced, and the film stretching quality is improved.

Owner:MCE STRETCHING IND CO LTD

Method for fabricating semiconductor device

ActiveUS7718515B2Reduce bowingQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

The principal objects of the present invention are to provide structure of a semiconductor device capable of reducing a bowing of a wafer, and a method for fabricating the semiconductor device. The present invention is applied to a semiconductor device, which is fabricated with a semiconductor substrate having a silicon carbide (SiC) film. The method includes the steps of: forming the SiC film on a semiconductor wafer; discriminating a deformation condition of the semiconductor wafer; and forming grooves in the SiC film, the grooves having a shape determined in accordance with the deformation condition of the semiconductor wafer.

Owner:LAPIS SEMICON CO LTD

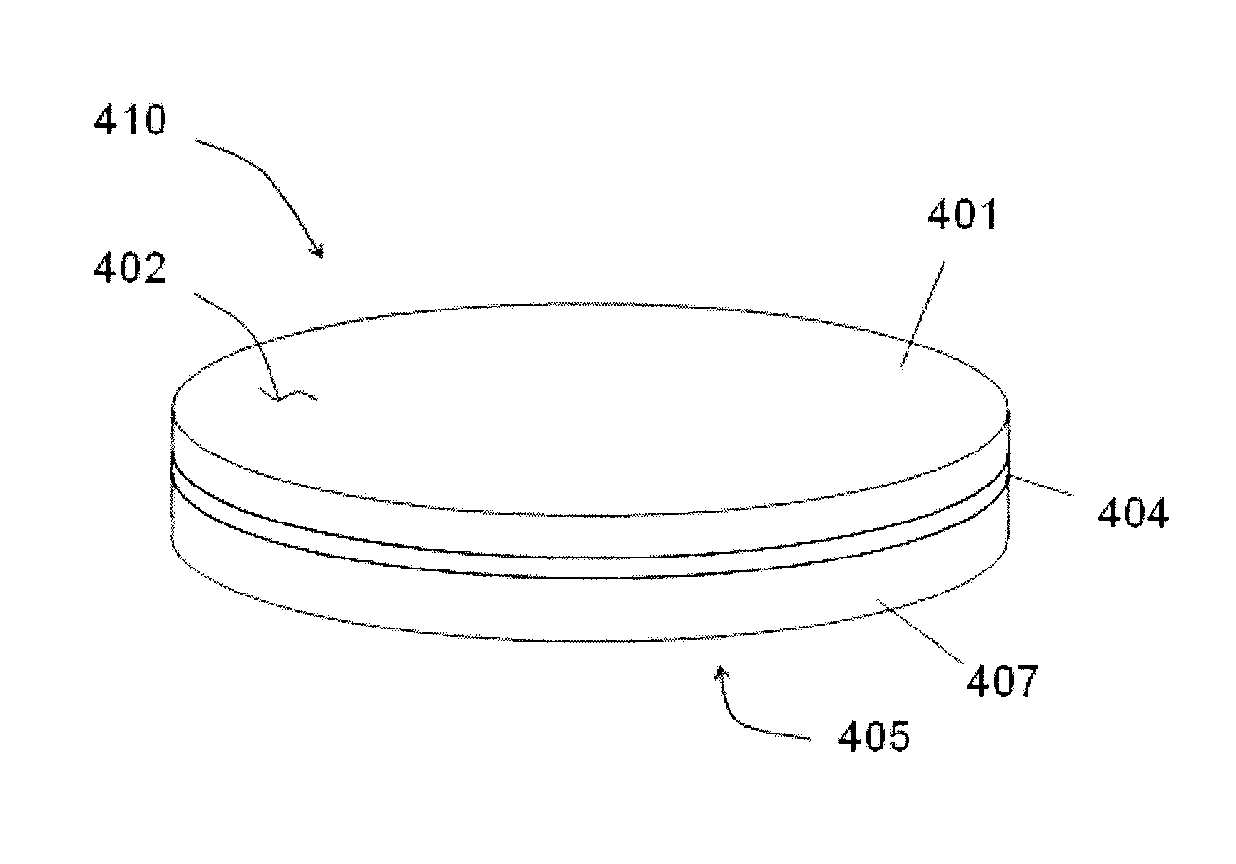

Handle for semiconductor-on-diamond wafers and method of manufacture

ActiveUS9882007B2Reduction factorMore commercially viableSemiconductor/solid-state device detailsSolid-state devicesWaferingEngineering

Methods for mounting and dismounting thin and / or bowed semiconductor-on-diamond wafers (401) to a carrier (407) are disclosed that flatten said wafers and provide mechanical support to enable efficient semiconductor device processing on said semiconductor-on-diamond wafers.

Owner:AKASH SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com