Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2074results about "Semiconductor laser structural details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of growing nitride semiconductors, nitride semiconductor substrate and nitride semiconductor device

InactiveUS6153010APolycrystalline material growthLaser detailsNitrogen sourceCrystallographic defect

PCT No. PCT / JP98 / 01640 Sec. 371 Date Dec. 9, 1998 Sec. 102(e) Date Dec. 9, 1998 PCT Filed Apr. 9, 1998 PCT Pub. No. WO98 / 47170 PCT Pub. Date Oct. 22, 1998A method of growing a nitride semiconductor crystal which has very few crystal defects and can be used as a substrate is disclosed. This invention includes the step of forming a first selective growth mask on a support member including a dissimilar substrate having a major surface and made of a material different from a nitride semiconductor, the first selective growth mask having a plurality of first windows for selectively exposing the upper surface of the support member, and the step of growing nitride semiconductor portions from the upper surface, of the support member, which is exposed from the windows, by using a gaseous Group 3 element source and a gaseous nitrogen source, until the nitride semiconductor portions grown in the adjacent windows combine with each other on the upper surface of the selective growth mask.

Owner:NICHIA CORP

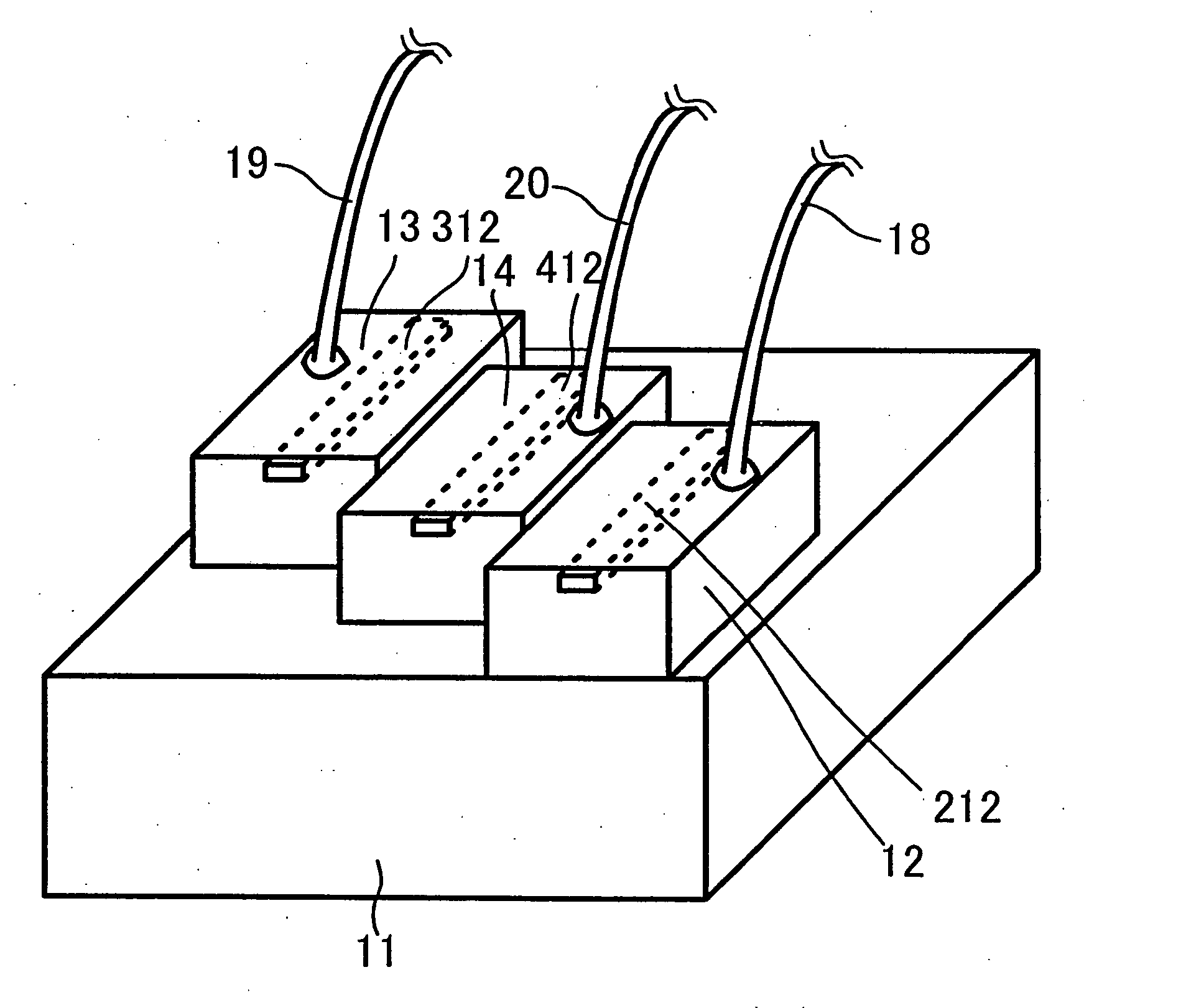

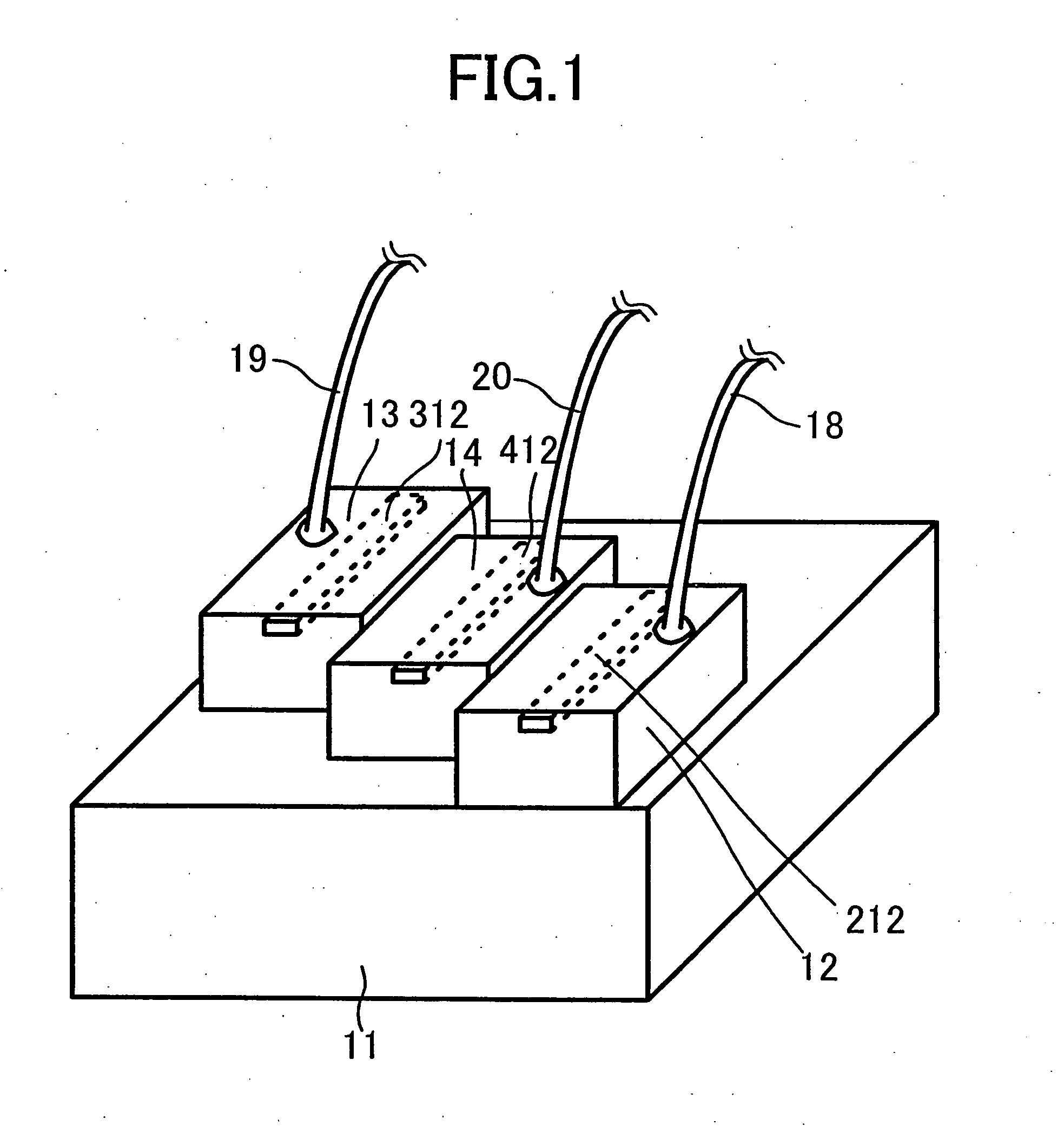

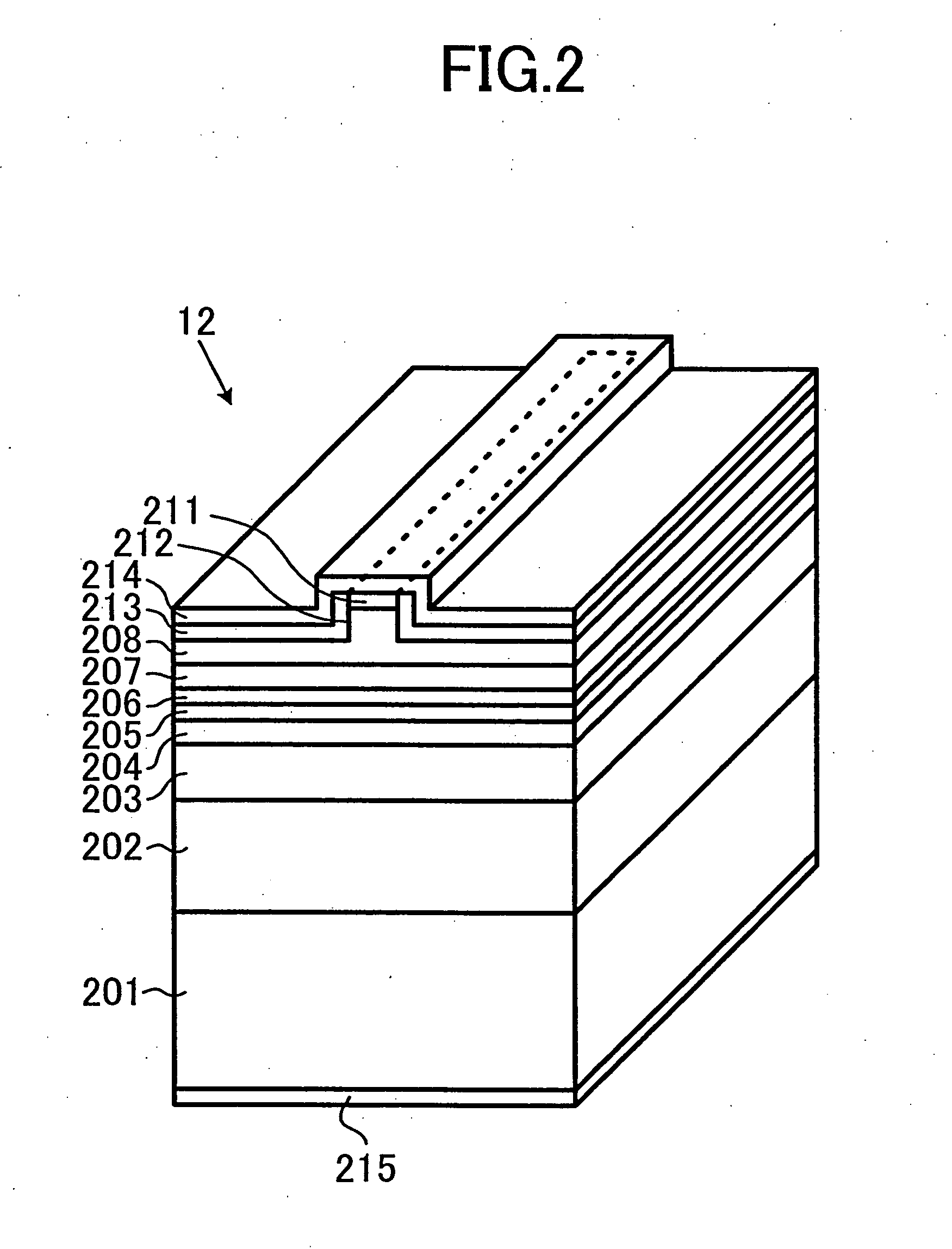

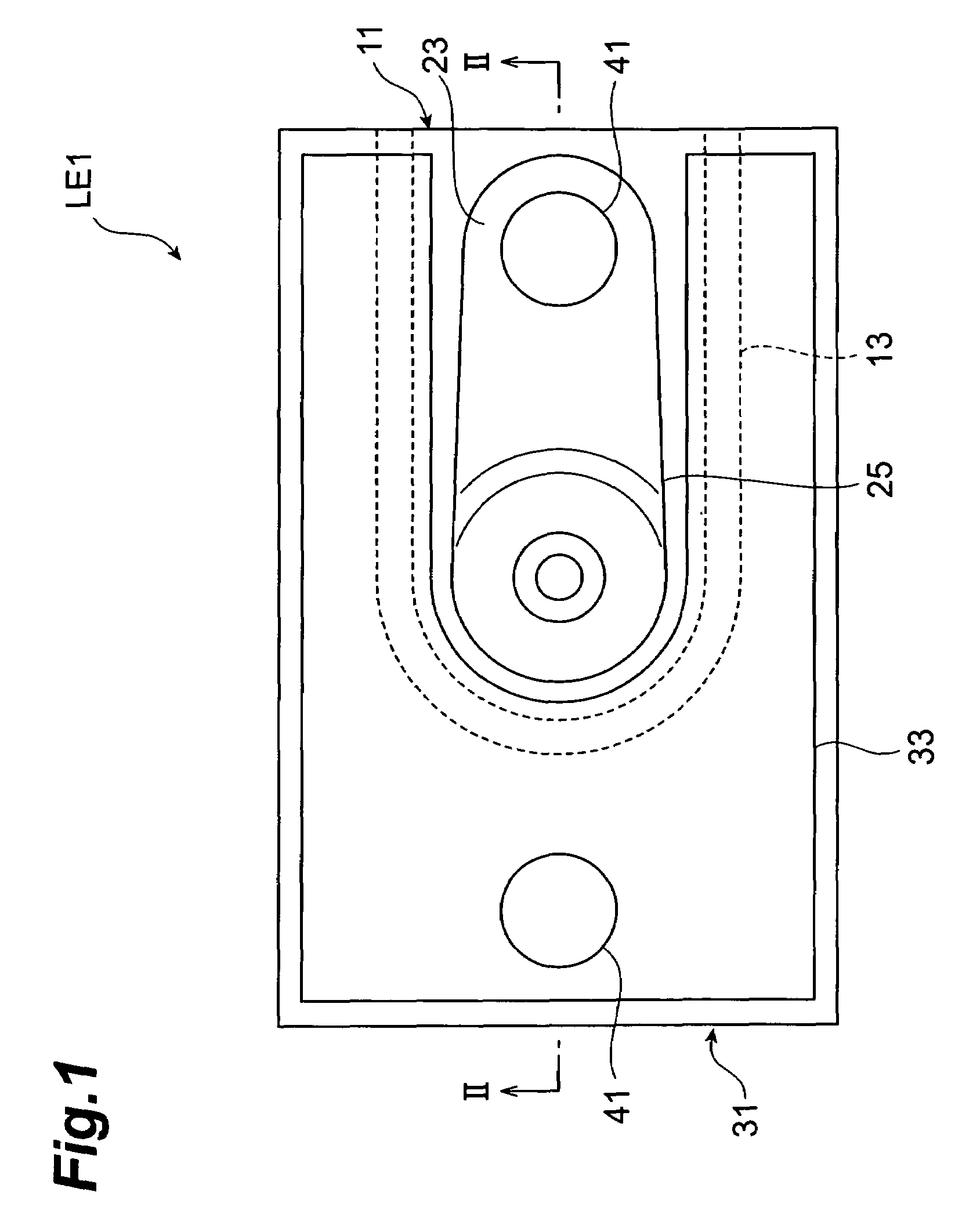

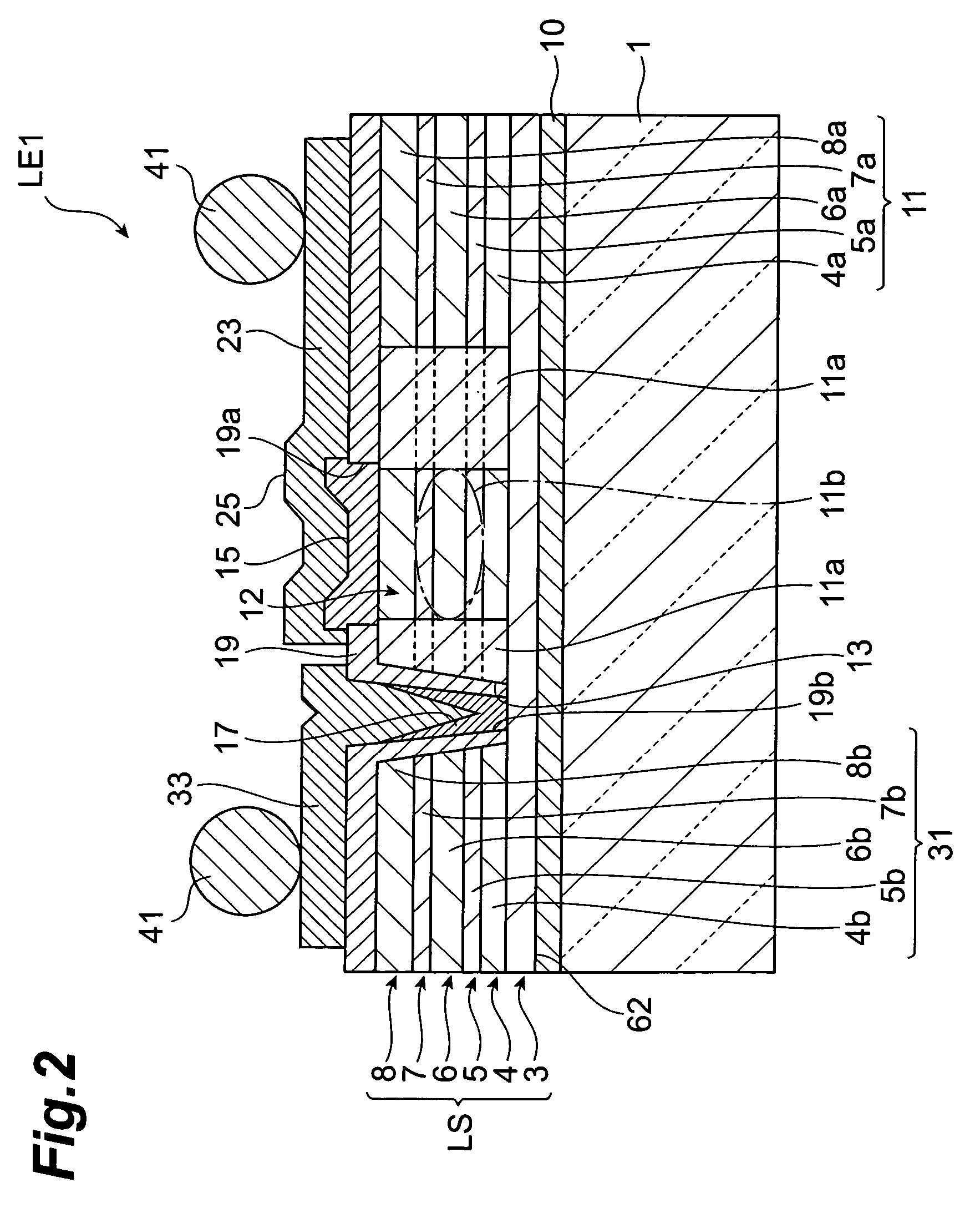

Multi-wavelength laser device

ActiveUS20040196877A1Semiconductor laser arrangementsSemiconductor laser structural detailsRed laserLaser light

A multi-wavelength laser device includes at least two of a blue laser diode, a red laser diode, and an infrared laser diode, which are arranged in the same direction on the same base. One laser light emission point is arranged behind another in increasing order of wavelengths of the laser diodes.

Owner:SHARP FUKUYAMA LASER CO LTD

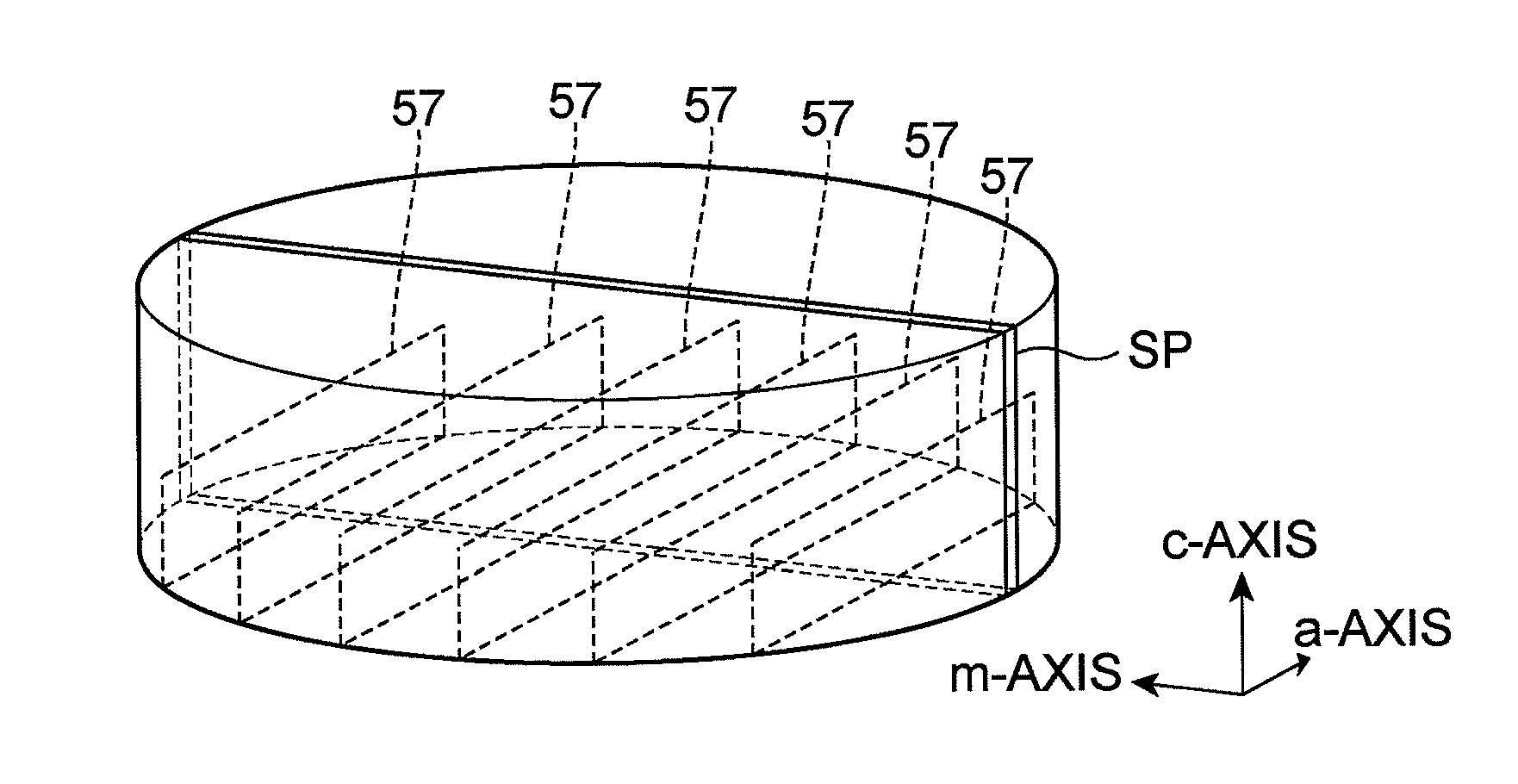

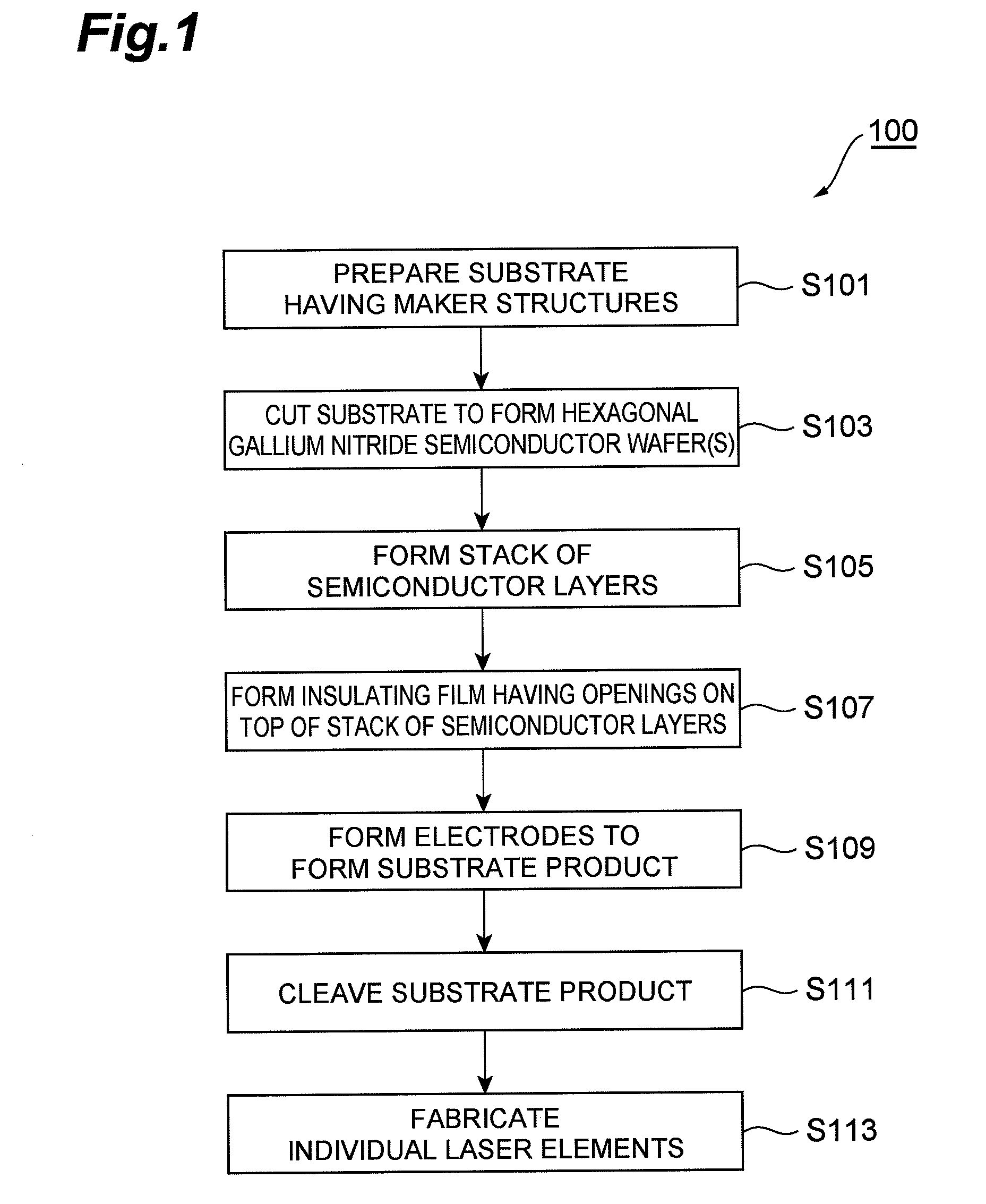

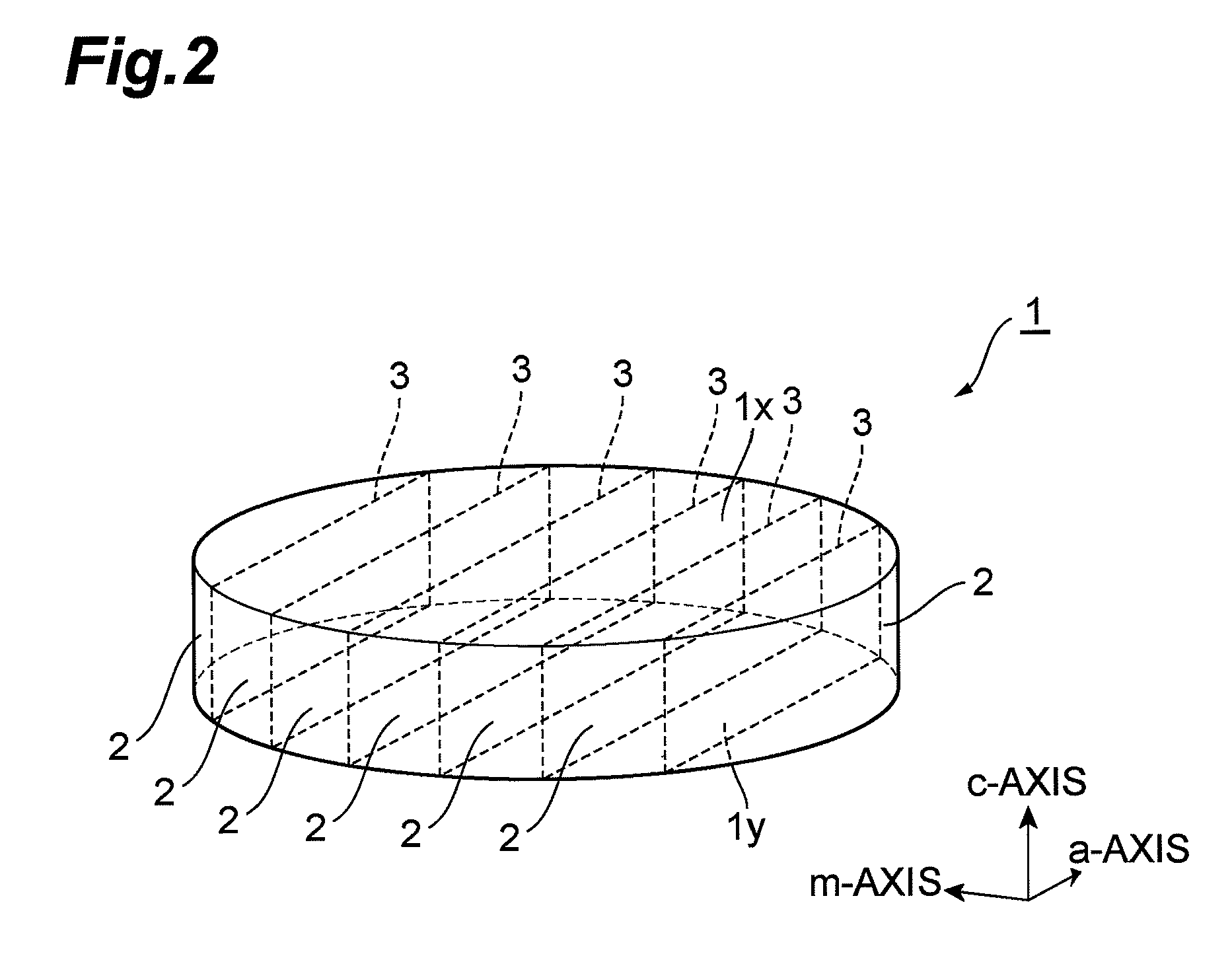

Method of fabricating nitride semiconductor laser

InactiveUS7939354B2Good orientationLarge caliberSemiconductor/solid-state device detailsSemiconductor laser structural detailsGallium nitrideNitride semiconductors

A method of fabricating a nitride semiconductor laser comprises preparing a substrate having a plurality of marker structures and a crystalline mass made of a hexagonal gallium nitride semiconductor. The primary and back surfaces of the substrate intersect with a predetermined axis extending in the direction of a c-axis of the hexagonal gallium nitride semiconductor. Each marker structure extends along a reference plane defined by the c-axis and an m-axis of the hexagonal gallium nitride semiconductor. The method comprises cutting the substrate along a cutting plane to form a wafer of hexagonal gallium nitride semiconductor, and the cutting plane intersects with the plurality of the marker structures. The wafer has a plurality of first markers, each of which extends from the primary surface to the back surface of the wafer, and each of the first markers comprises part of each of the marker structures. The primary surface of the wafer is semipolar or nonpolar. The method comprises growing a number of gallium nitride based semiconductor layers for a semiconductor laser. The method comprises cleaving the substrate product at a cleavage plane of the hexagonal gallium nitride semiconductor, after forming a substrate product in an electrode forming step.

Owner:SUMITOMO ELECTRIC IND LTD

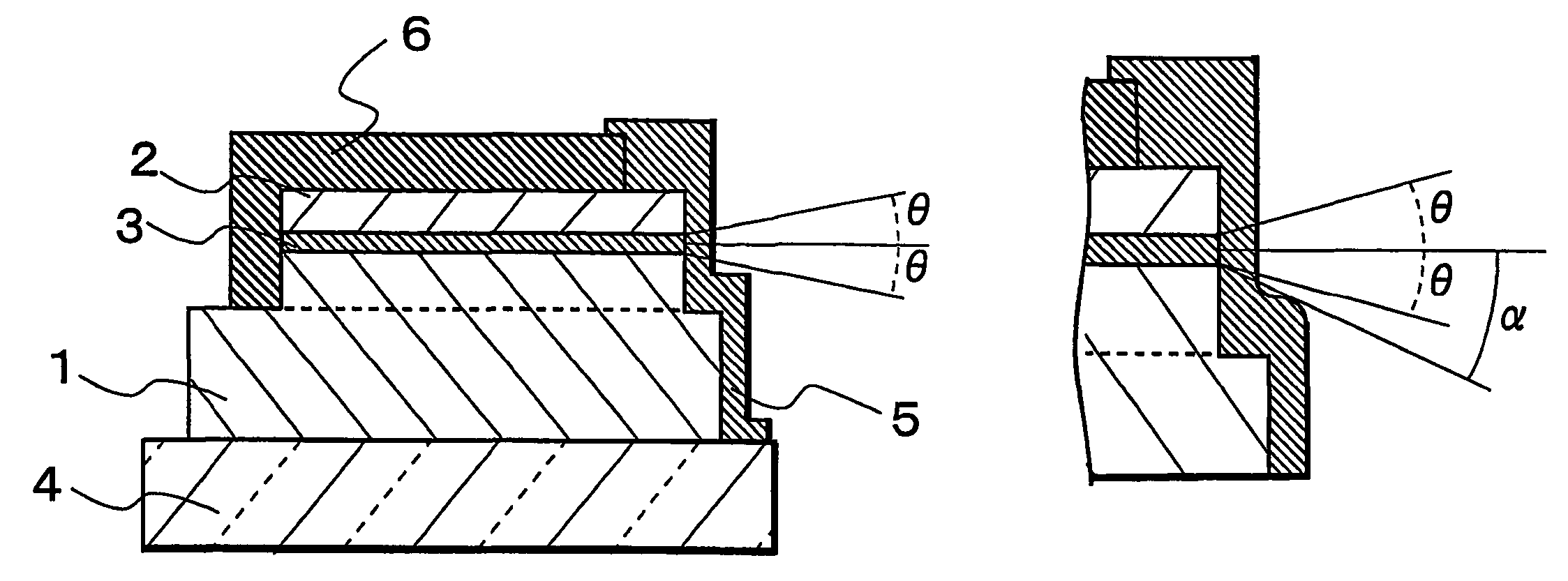

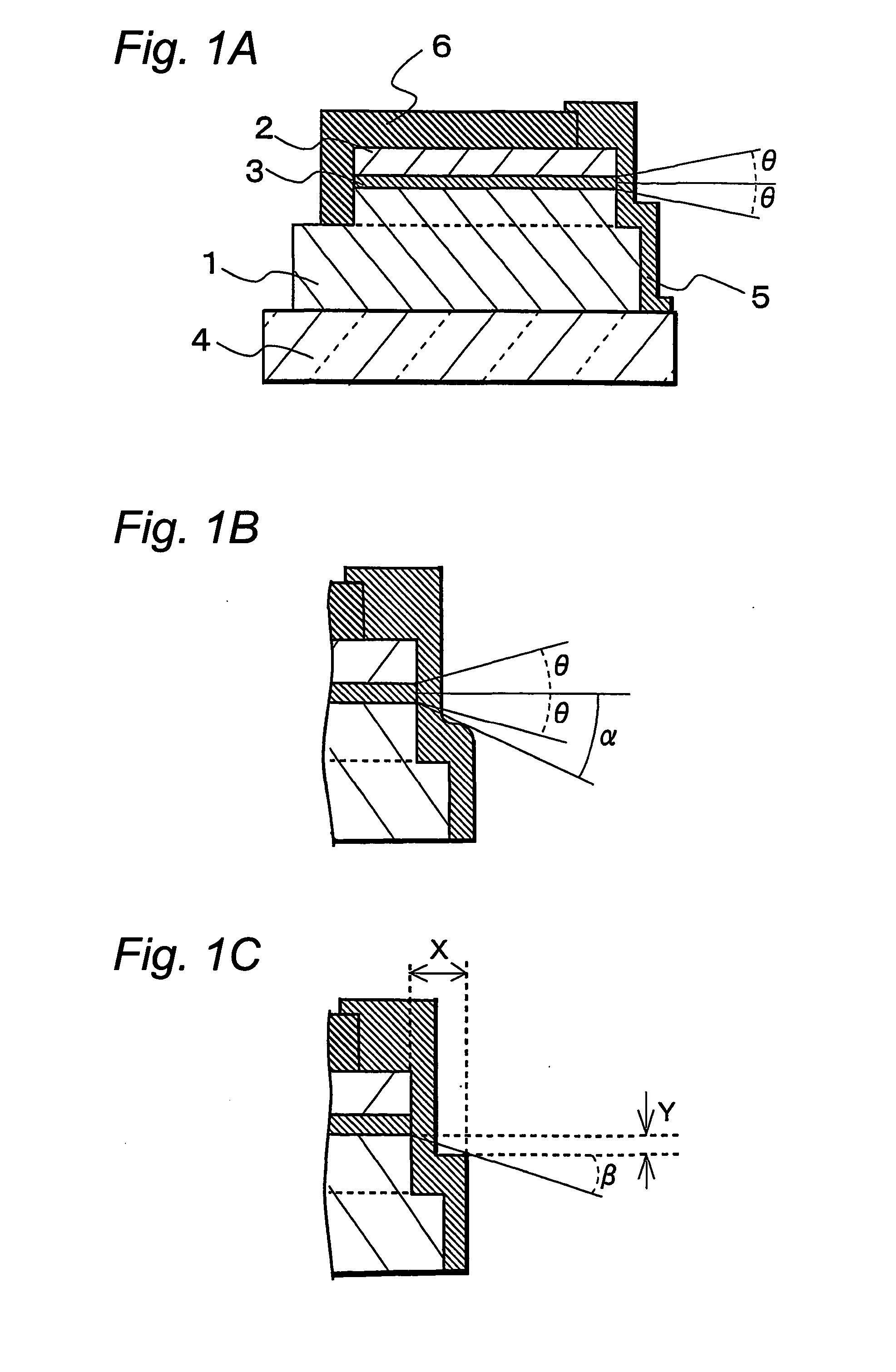

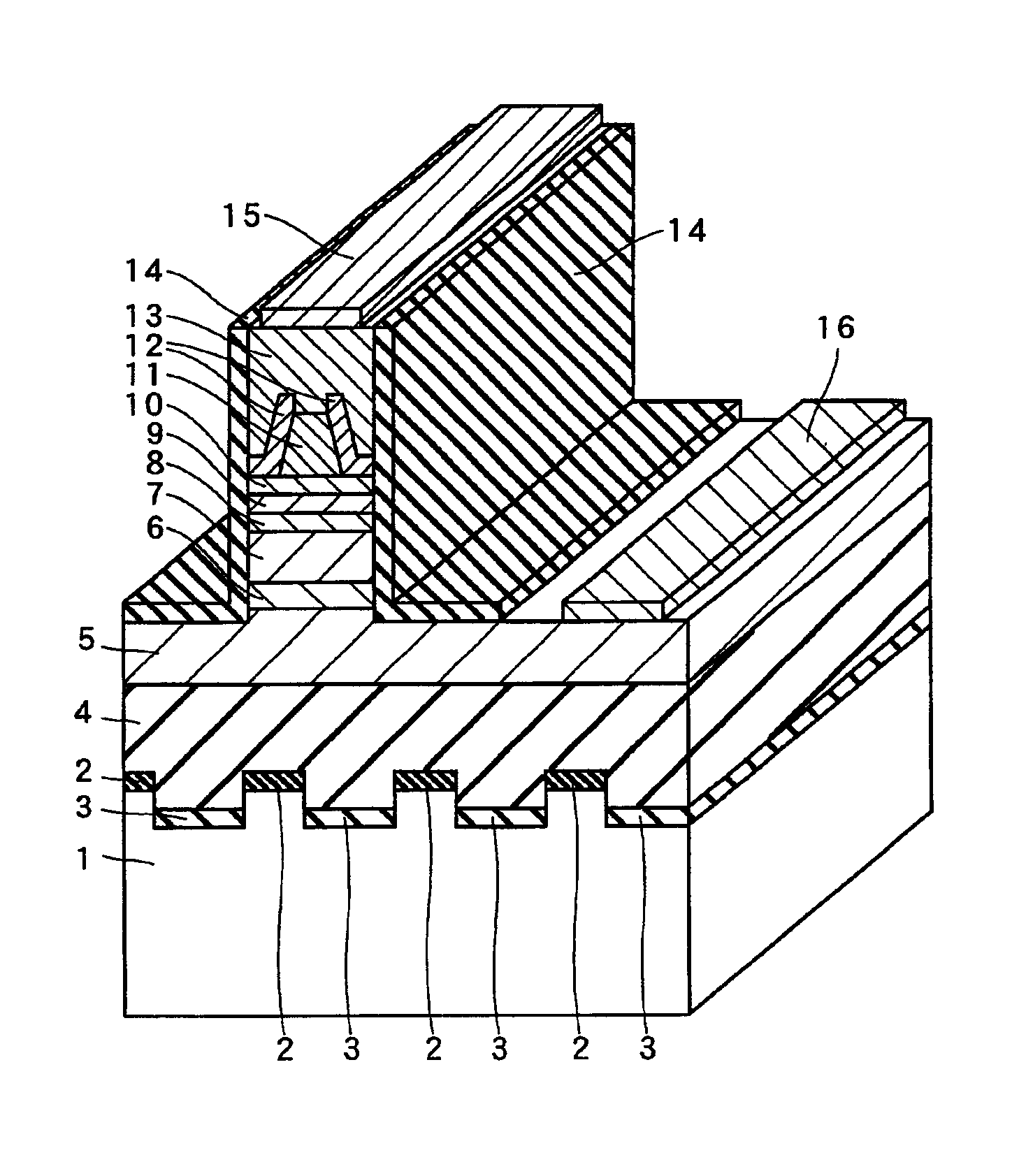

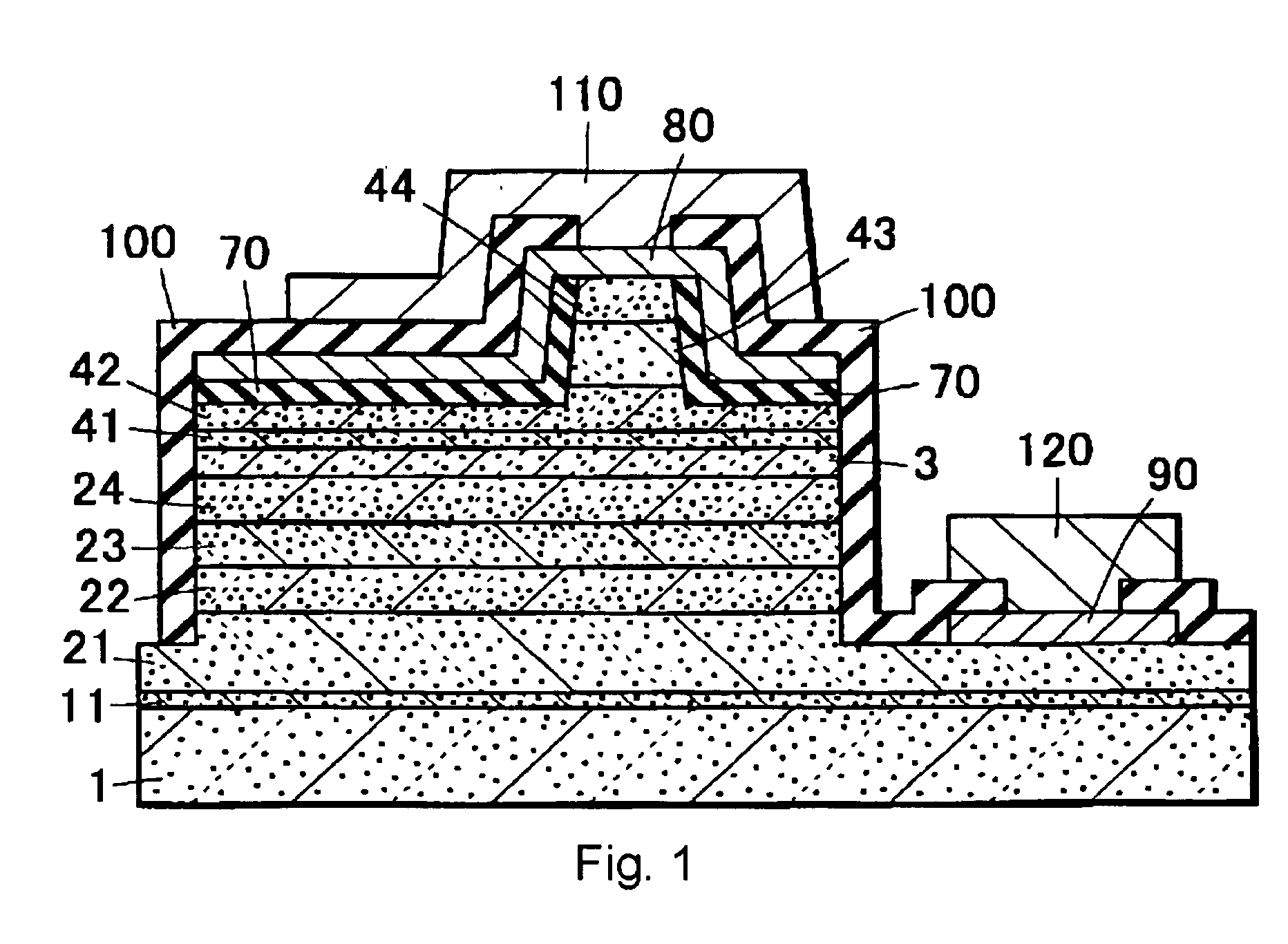

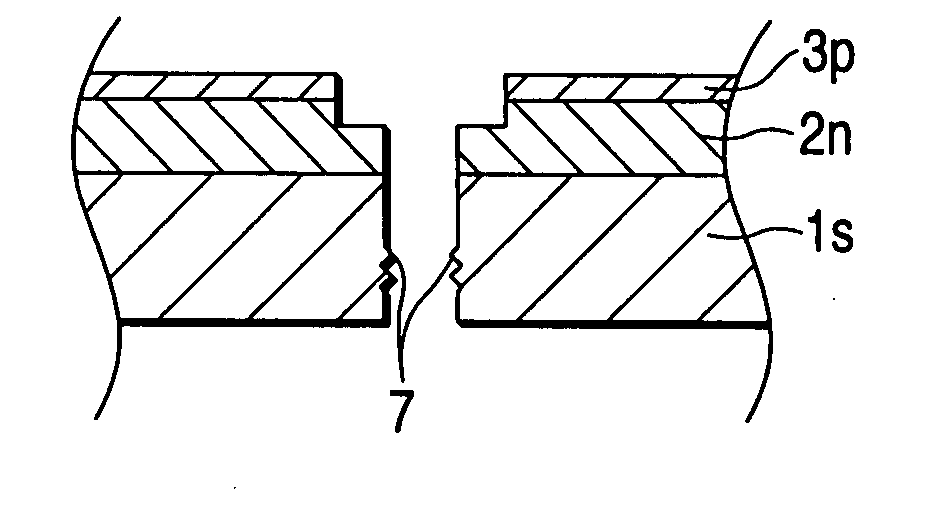

Semicondutor laser device and its manufacturing method

InactiveUS20040233950A1Efficient executionLaser optical resonator constructionSemiconductor laser structural detailsTectorial membraneSemiconductor package

A semiconductor laser device have, on a substrate, a semiconductor layer including an active layer sandwiched between an n-type layer and a p-type layer, the semiconductor layer having a sonator face formed by etching and a projection projecting out in an emission direction relatively to the resonator face, wherein a protective film is formed to extend from the resonator face to an end face of the projection, and, an emission critical angle, which is the largest angle at which light emitted from the resonator face can be radiated without being blocked by the projection and the protective film formed on the projection, is larger than an emission half-angle of an emission distribution in a vertical direction of a laser beam emitted from the resonator face.

Owner:NICHIA CORP

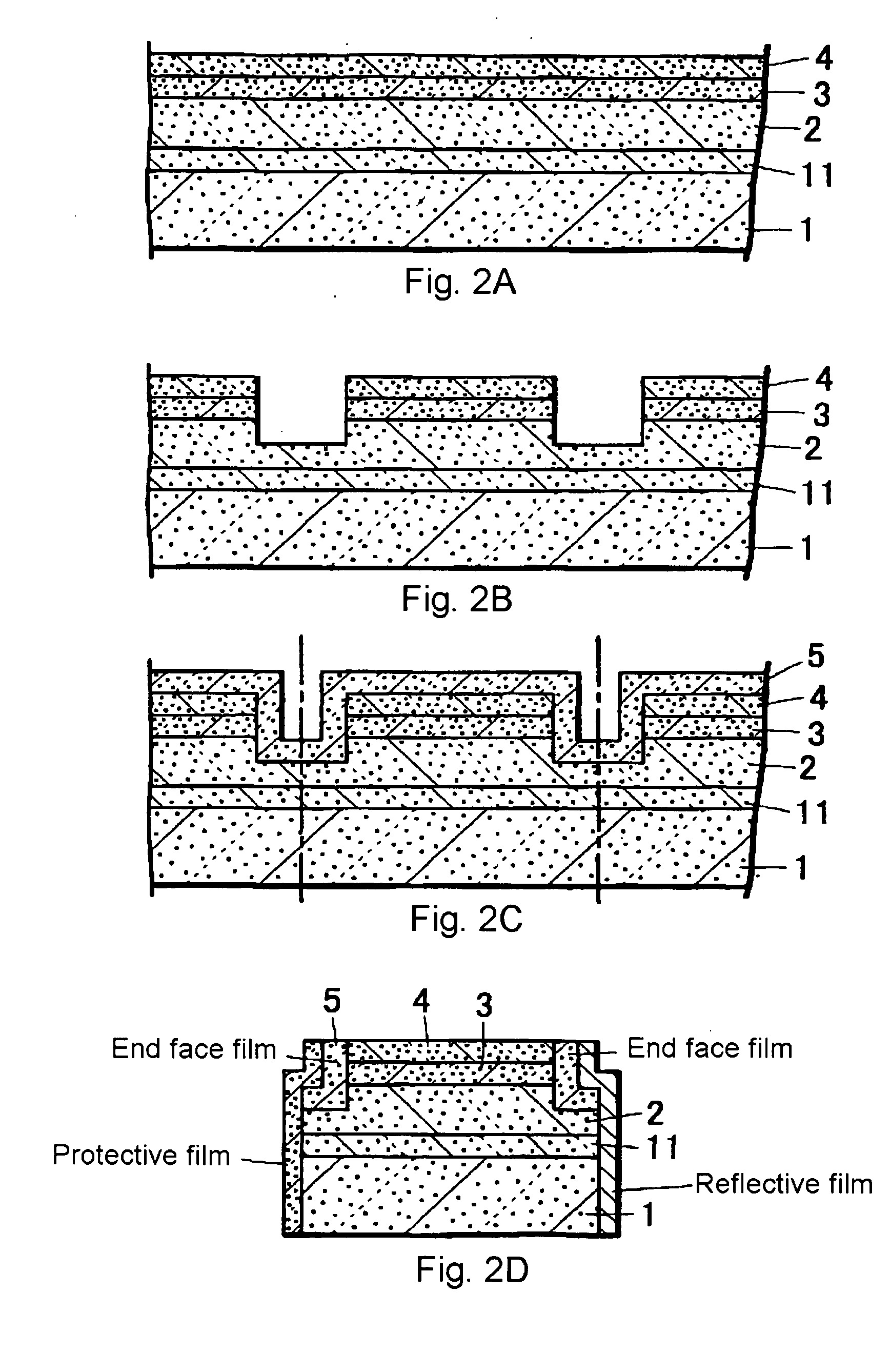

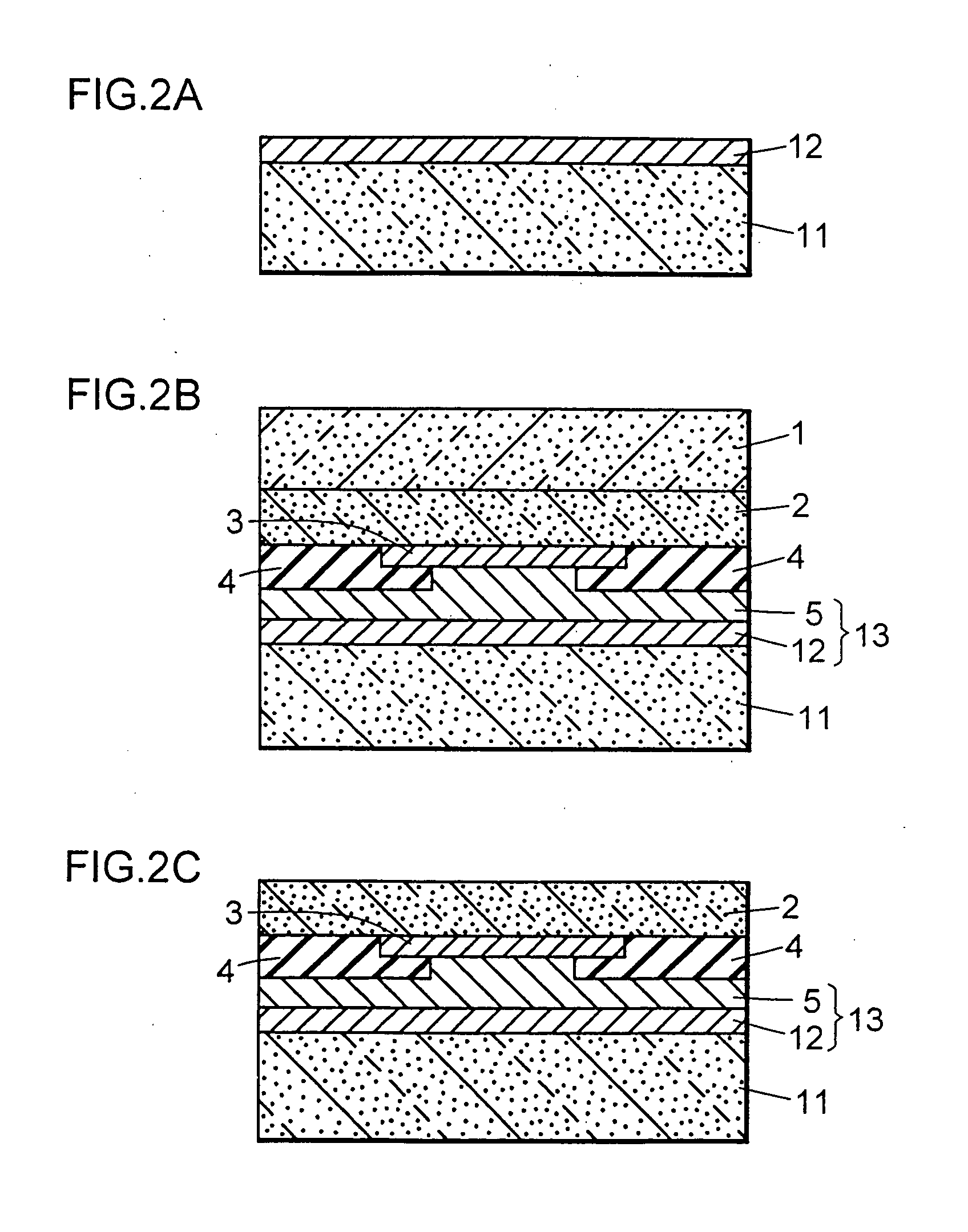

Light emitting element structure using nitride bulk single crystal layer

InactiveUS20040251471A1Improve crystal qualitySimple structureOptical wave guidancePolycrystalline material growthSingle crystalActive layer

The object of this invention is to provide a high-output type nitride light emitting device. The nitride light emitting device comprises an n-type nitride semiconductor layer or layers, a p-type nitride semiconductor layer or layers and an active layer therebetween, wherein a gallium-containing nitride substrate is obtained from a gallium-containing nitride bulk single crystal, provided with an epitaxial growth face with dislocation density of 10<5> / cm<2 >or less, and A-plane or M-plane which is parallel to C-axis of hexagonal structure for an epitaxial face, wherein the n-type semiconductor layer or layers are formed directly on the A-plane or M-plane. In case that the active layer comprises a nitride semiconductor containing In, an end face film of single crystal AlxGa1-xN (0<=x<=1) can be formed at a low temperature not causing damage to the active layer.

Owner:AMMONO SP Z O O (PL) +1

Semiconductor light-emitting device and method for manufacturing the same

InactiveUS7132691B1High crystallinityHigh light emitting efficiencyLaser detailsLaser active region structureCrystallinityActive layer

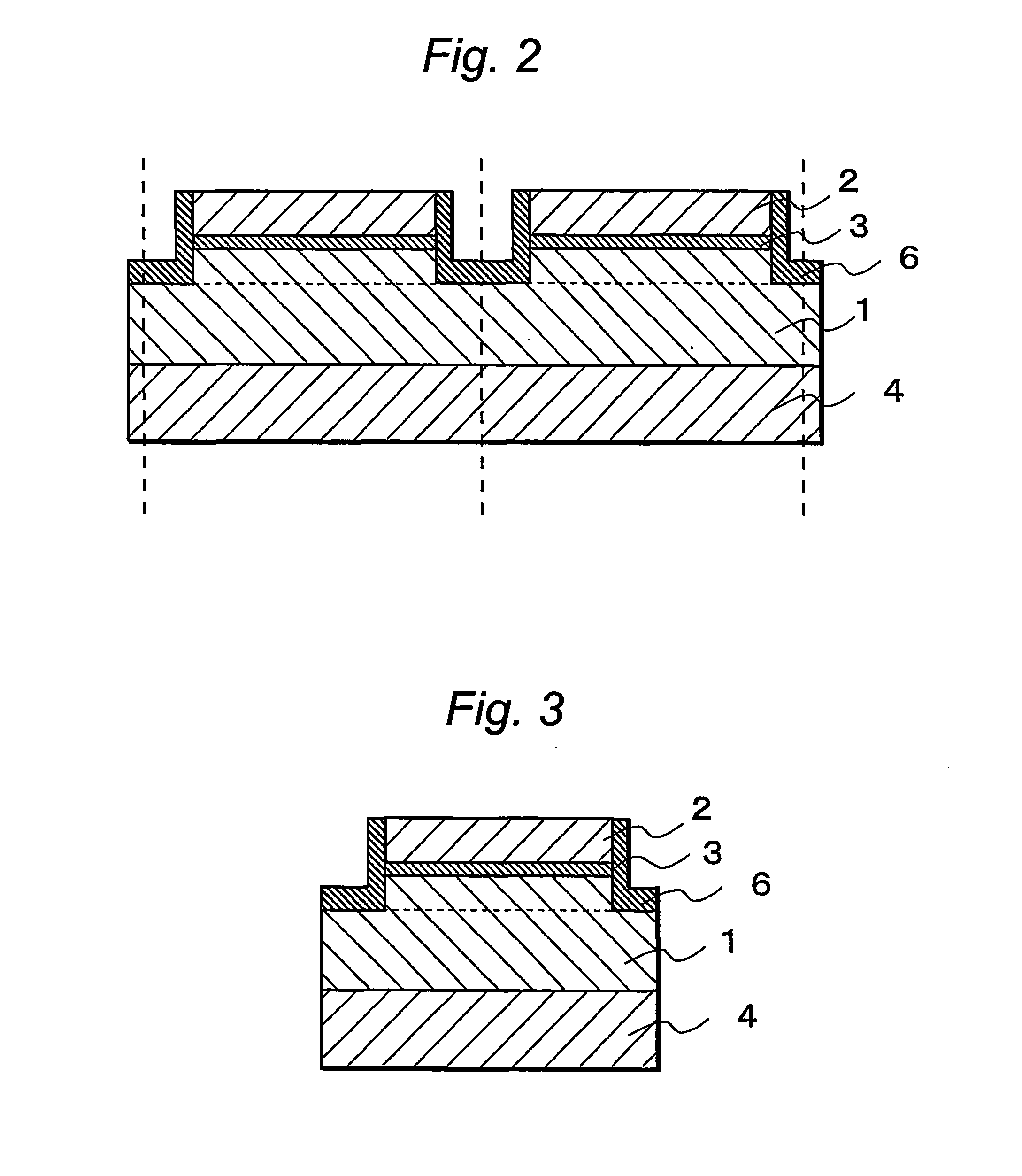

It has a structure in which an active layer (5) that emits light by electric current injection is sandwiched between an n-type cladding layer (4) and a p-type cladding layer (6) made of materials having a larger band gap than the active layer (5), wherein the active layer (5) is made, for example, of CdxZn1−xO (0≦x<1). It is further more preferable if the cladding layers (4), (6) are made, for example, of MgyZn1−yO (0≦y<1). This narrows the band gap of the ZnO materials, and an oxide semiconductor capable of being wet-etched, easy to handle with, and excellent in crystallinity can be used as a material for an active layer or a cladding layer of a semiconductor light emitting device such as a blue light emitting diode or a blue laser diode in which an active layer is sandwiched between cladding layers, so that a blue semiconductor light emitting device being excellent in light emission characteristics can be obtained.

Owner:ROHM CO LTD

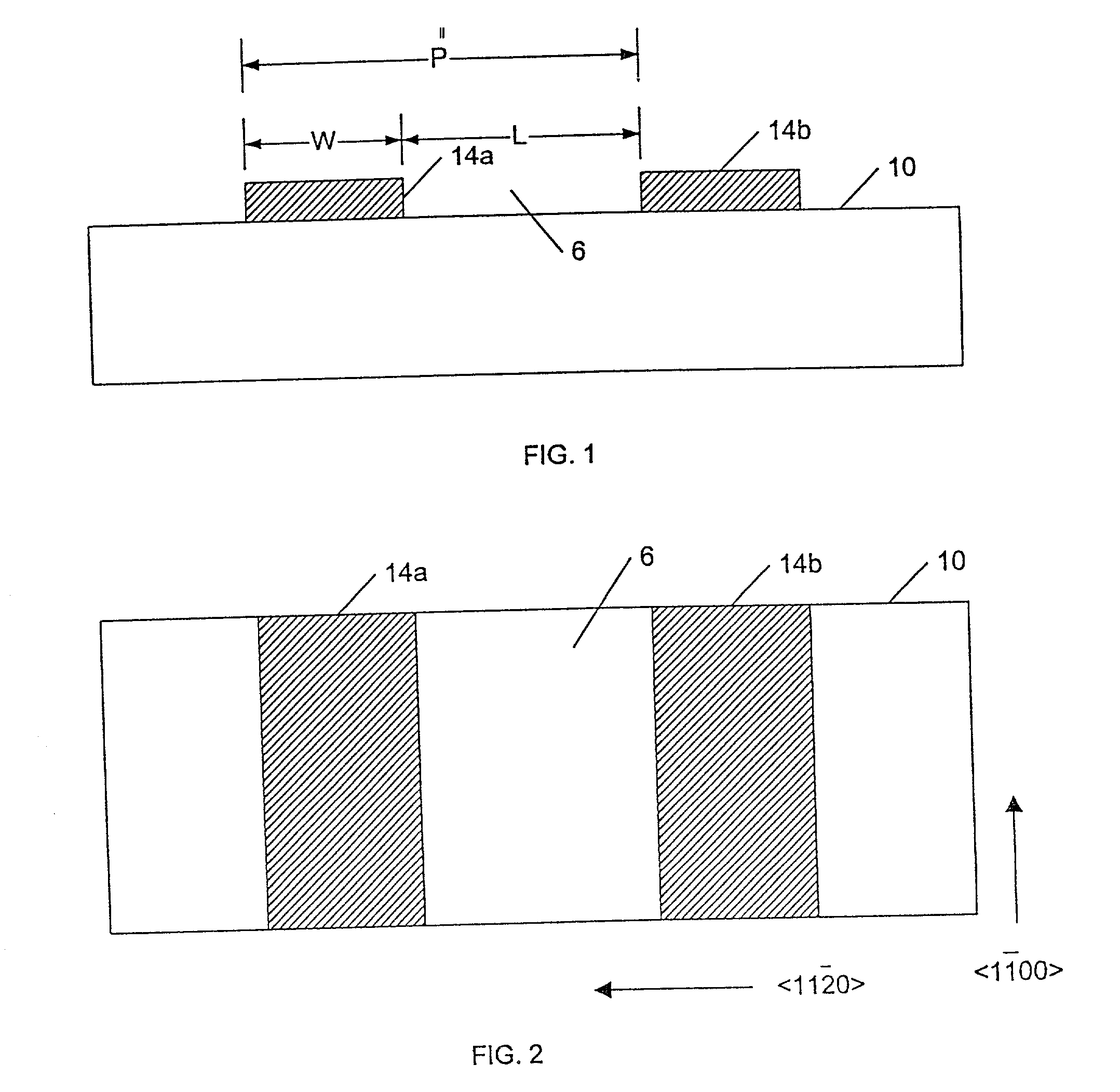

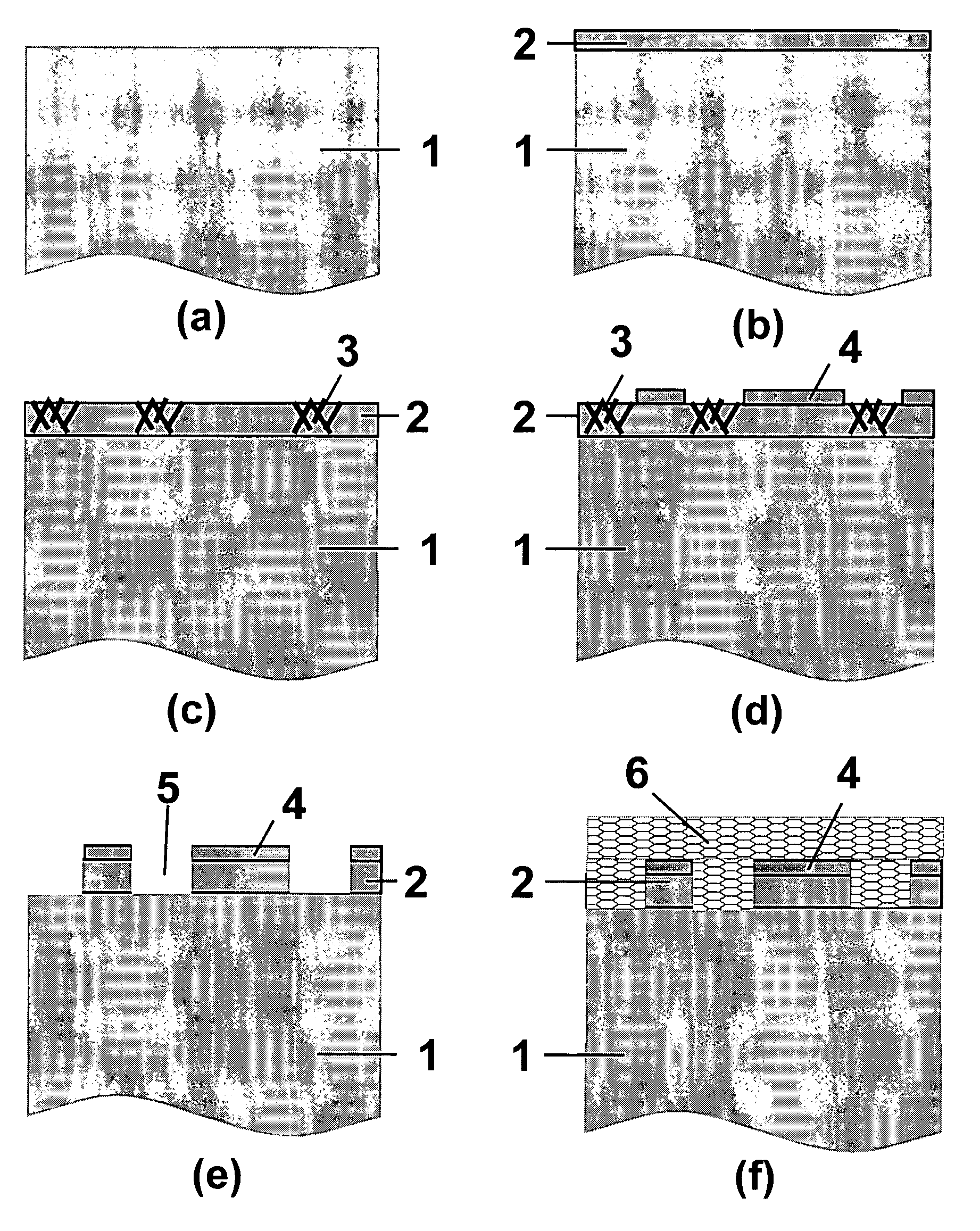

Single step pendeo-and lateral epitaxial overgrowth of group III-nitride epitaxial layers with group III-nitride buffer layer and resulting structures

InactiveUS20020022290A1Semiconductor laser structural detailsSemiconductor/solid-state device manufacturingSemiconductor structureGallium nitride

A method of fabricating a gallium nitride-based semiconductor structure on a substrate includes the steps of forming a mask having at least one opening therein directly on the substrate, growing a buffer layer through the opening, and growing a layer of gallium nitride upwardly from the buffer layer and laterally across the mask. During growth of the gallium nitride from the mask, the vertical and horizontal growth rates of the gallium nitride layer are maintained at rates sufficient to prevent polycrystalline material nucleating on said mask from interrupting the lateral growth of the gallium nitride layer. In an alternative embodiment, the method includes forming at least one raised portion defining adjacent trenches in the substrate and forming a mask on the substrate, the mask having at least one opening over the upper surface of the raised portion. A buffer layer may be grown from the upper surface of the raised portion. The gallium nitride layer is then grown laterally by pendeoepitaxy over the trenches.

Owner:CREE INC

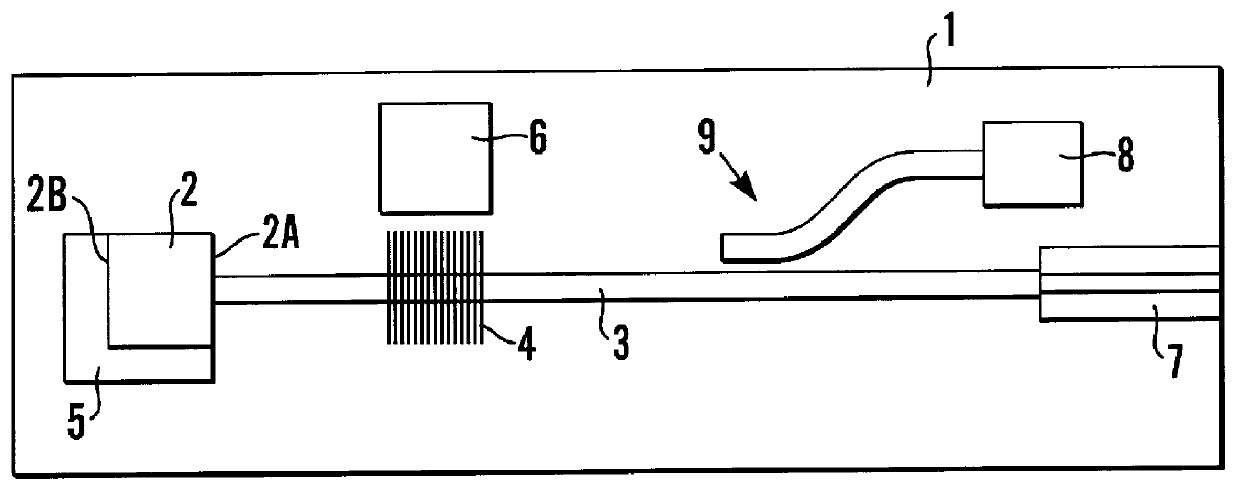

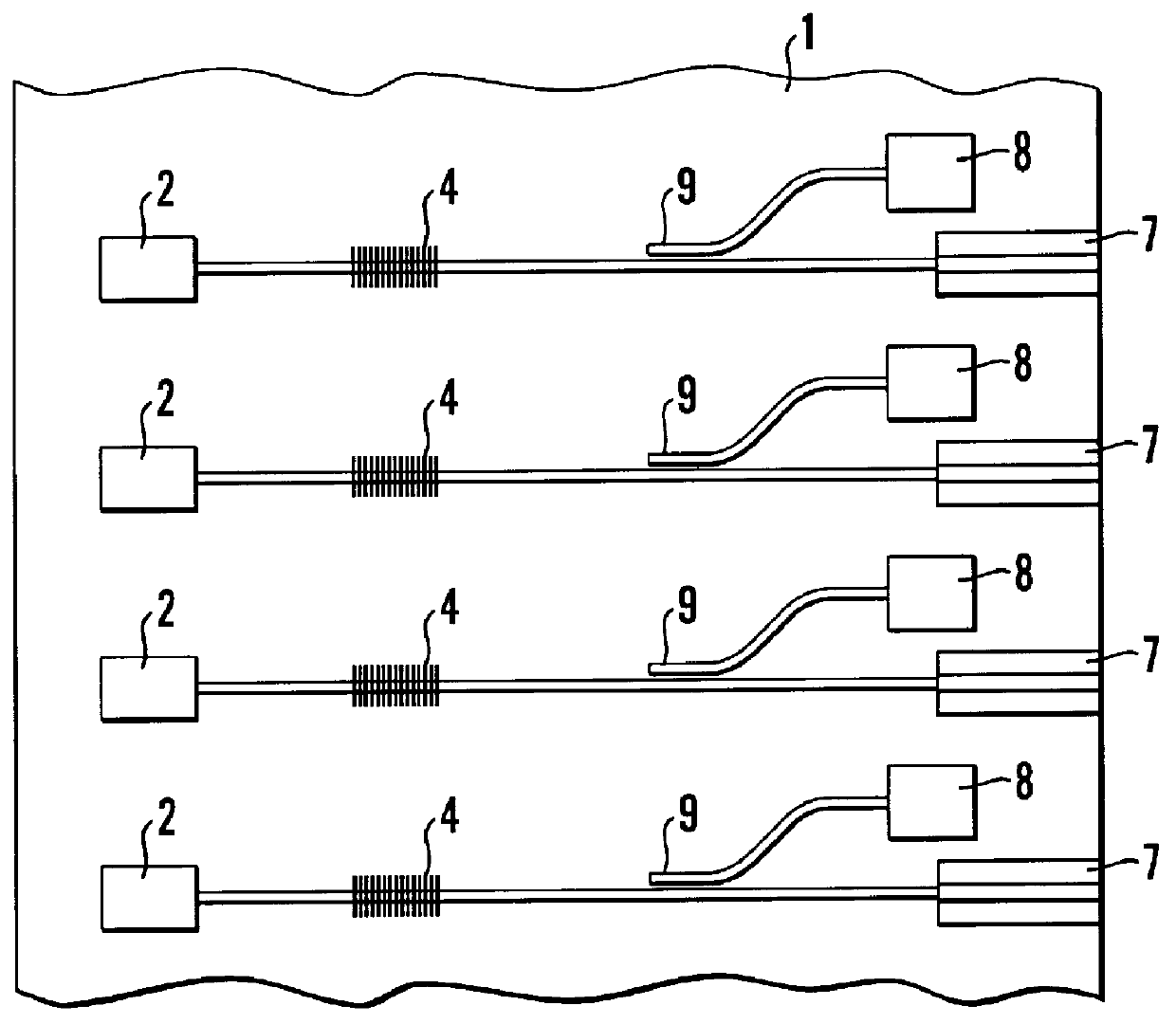

External cavity laser

InactiveUS6101210AAvoid disadvantagesEasy temperature controlLaser optical resonator constructionSemiconductor laser arrangementsTemperature controlGrating

External Cavity Laser An external cavity laser comprising first and second feedback means with an optical gain medium (2) therebetween, one of the feedback means is provided by a grating (4) formed in a silicon waveguide and the other feedback means is provided by a reflective back facet (2B) of the optical gain medium (2). The output wavelength of the laser, at a given temperature, can thus be determined during its manufacture and the laser can be made by mass production techniques. The grating (4) may be thermally isolated to obviate the need for temperature control means (6) to control the temperature of the grating (4). An array of lasers may be provided on a single chip.

Owner:KOTURA

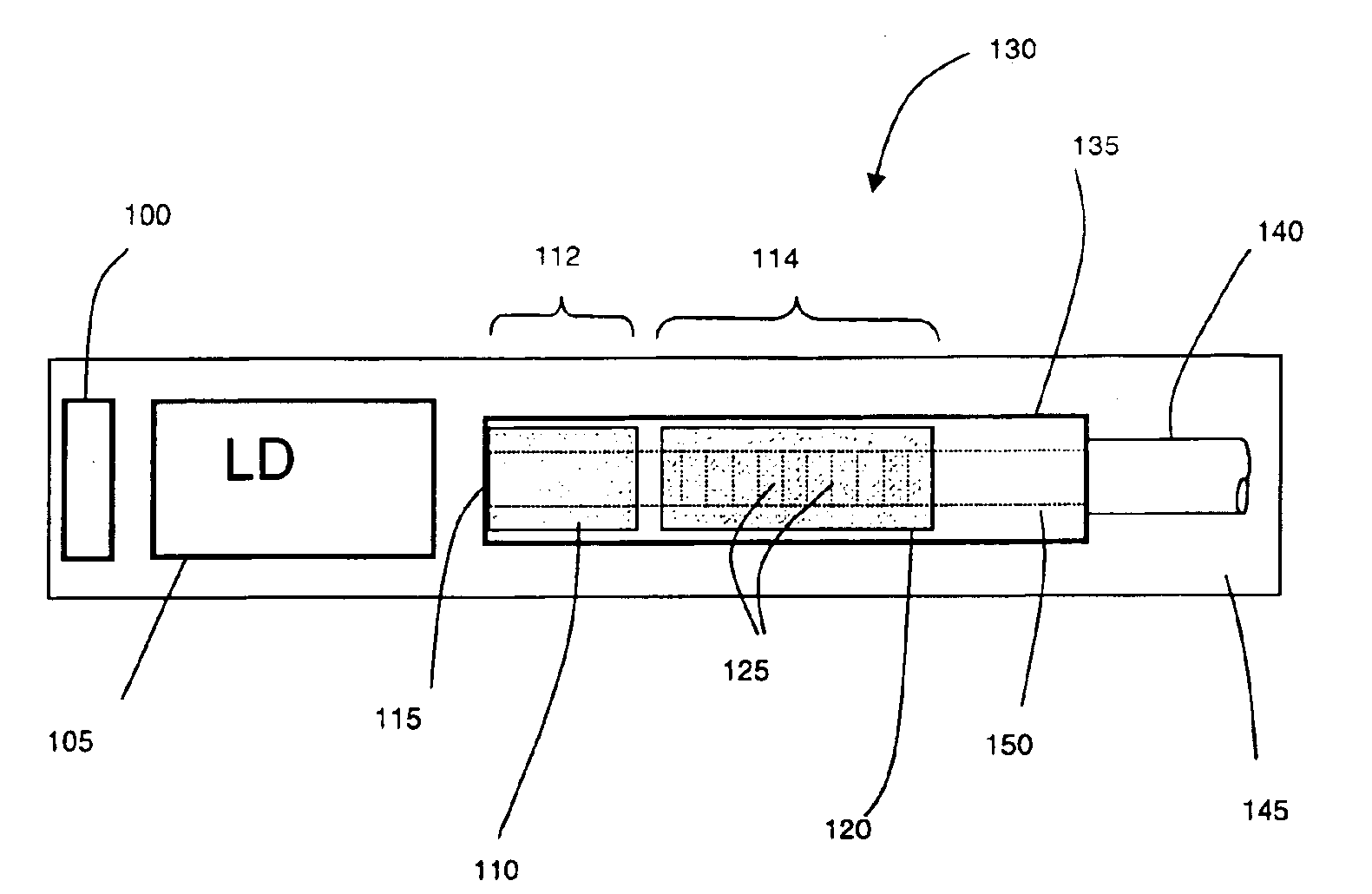

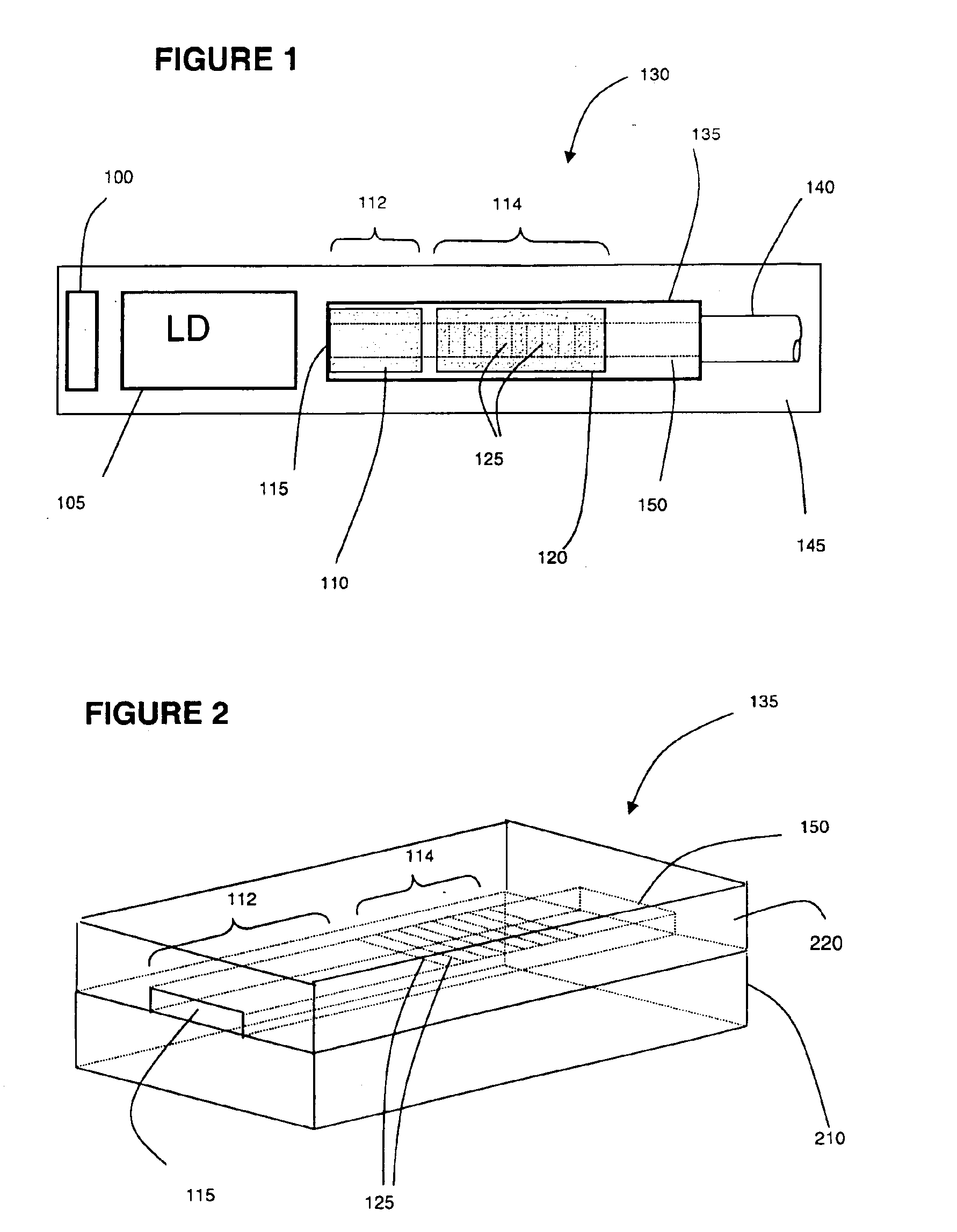

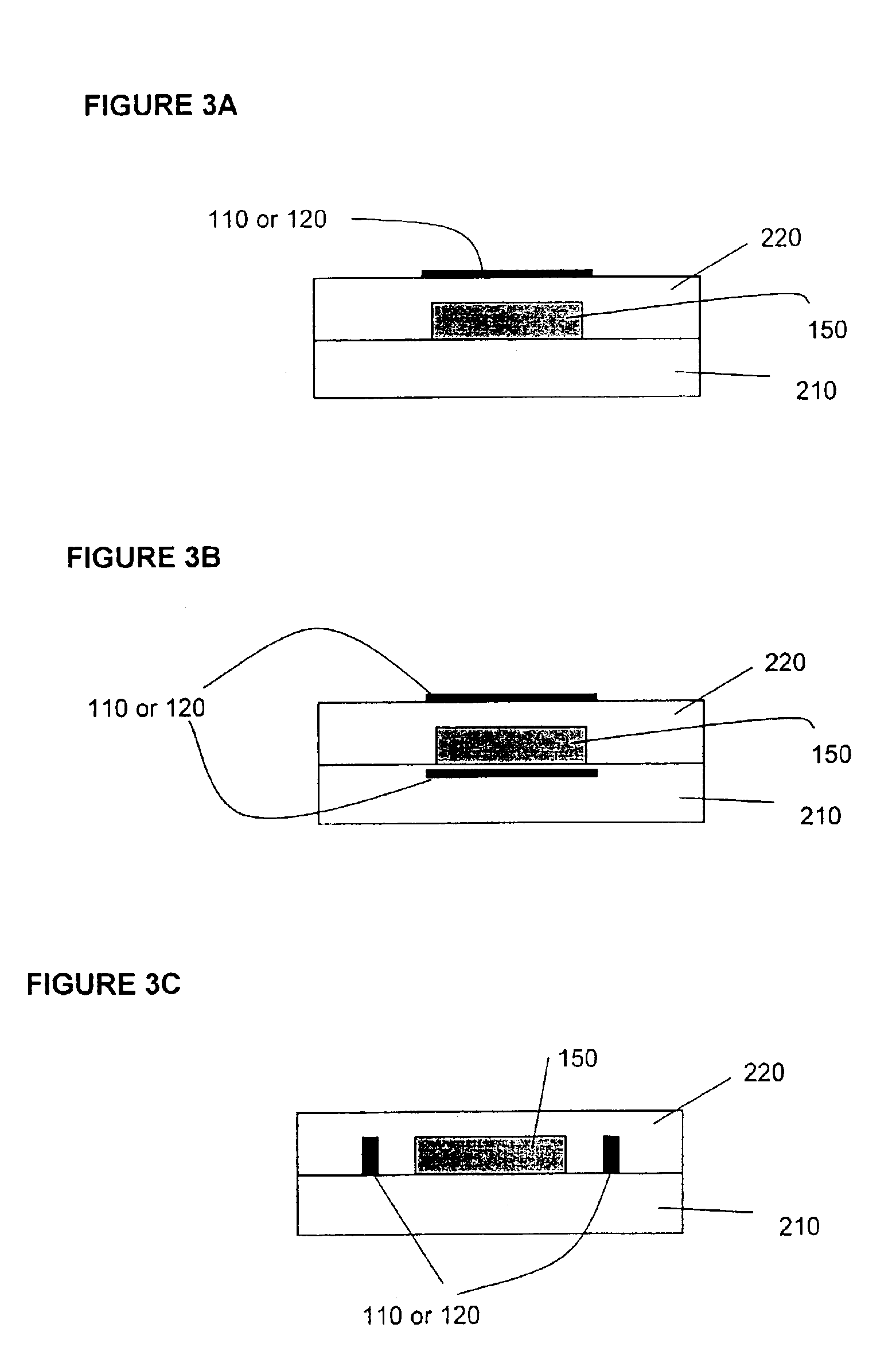

Tunable optical source

InactiveUS6920159B2Consider flexibilityControl of the refractive index of the glass materialSemiconductor laser structural detailsOptical resonator shape and constructionOptical radiationCoupling

A tunable optical source comprises a laser diode and an external optical feedback device. The feedback device has a waveguiding portion fabricated at least in part out of a glass material having both organic and inorganic components. A control device is provided for controlling the refractive index of the glass material so as to change the wavelength of feedback to the laser diode. The glass material may for example have thermo-optic properties and the control device might then be a heating device for heating the glass material. The feedback device can have more than one portion, a second portion for example having controllable coupling characteristics for coupling optical radiation into or out of the feedback device. It also preferably has a portion for controlling optical path length in the feedback device.

Owner:OPTITUNE

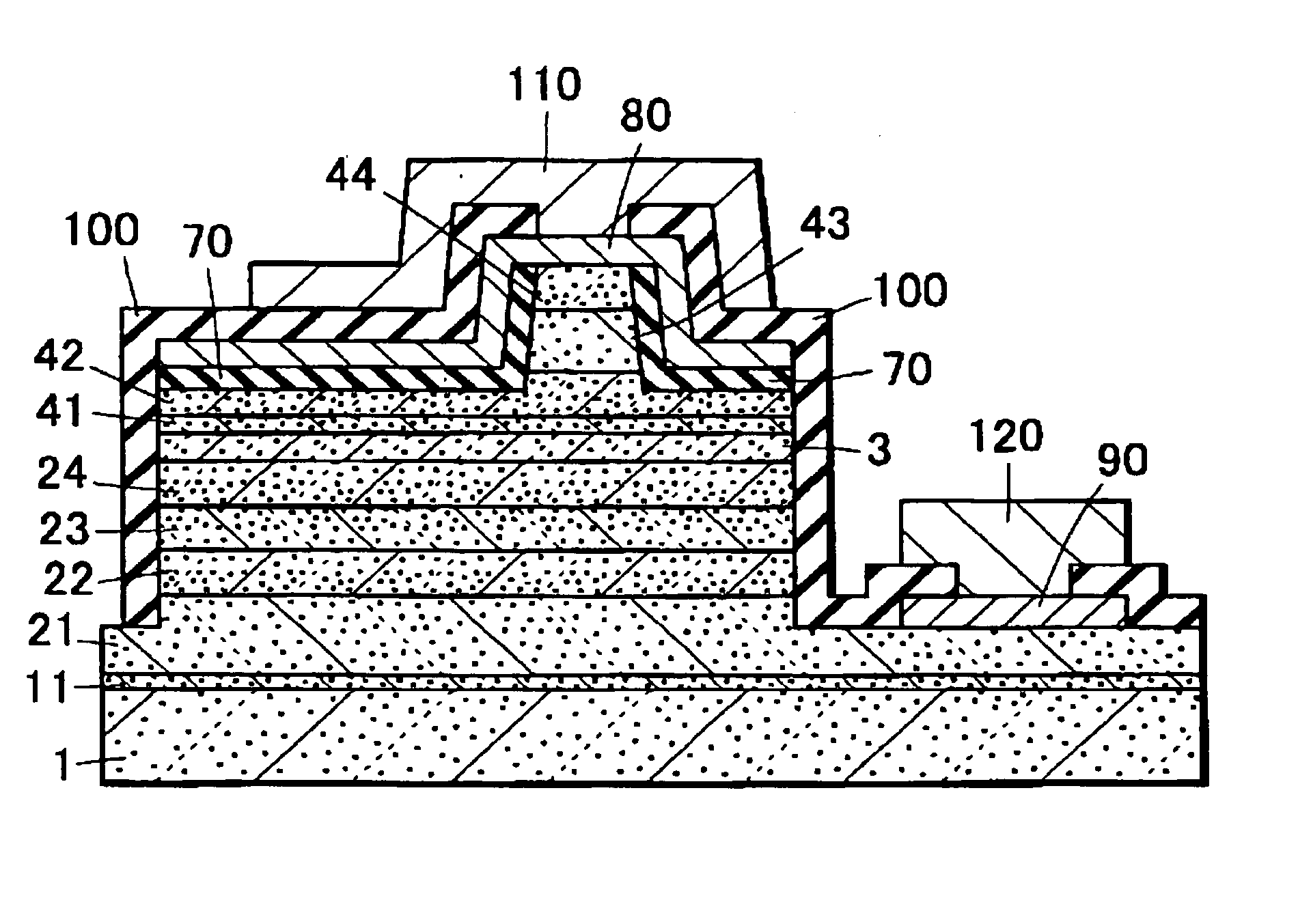

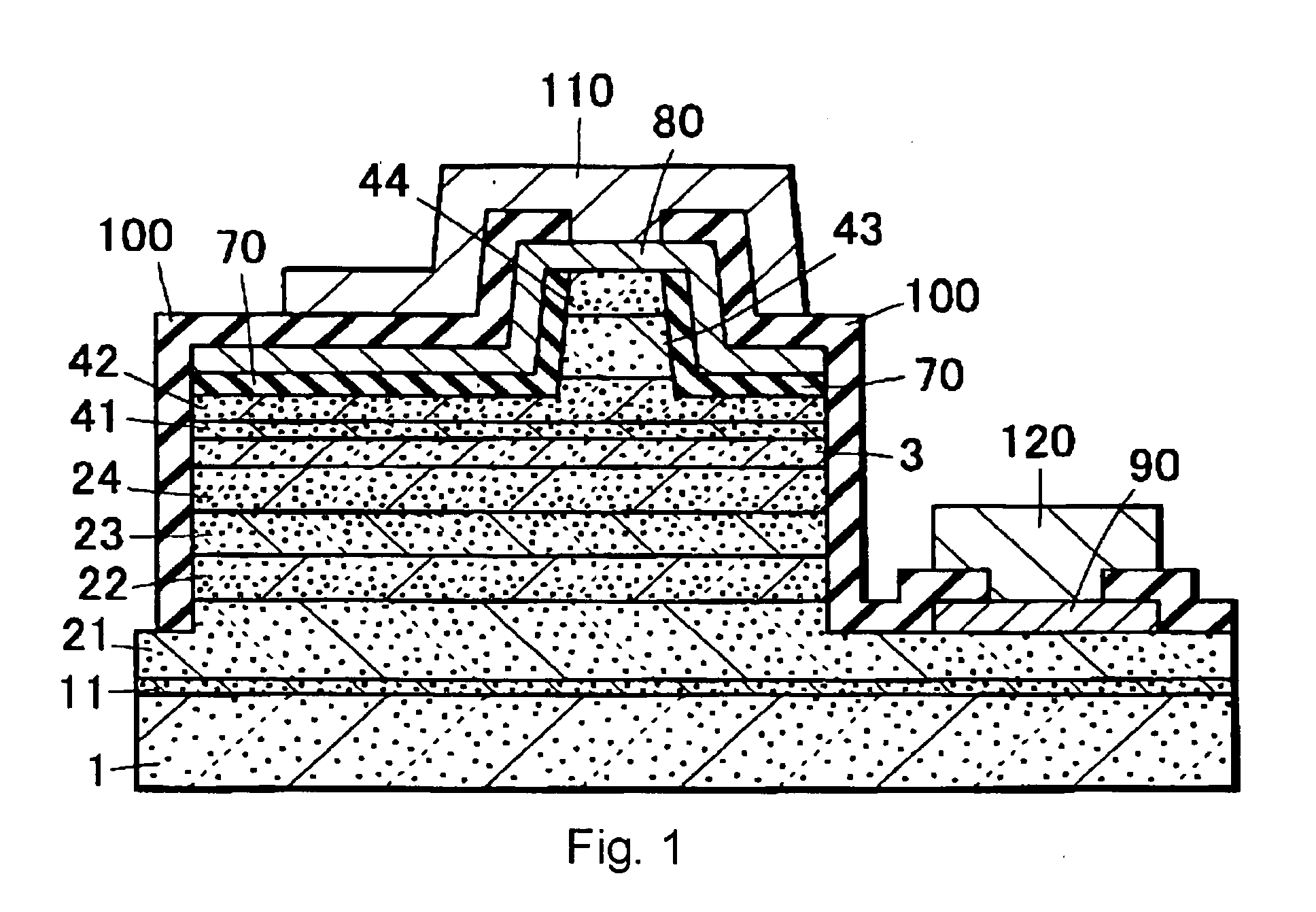

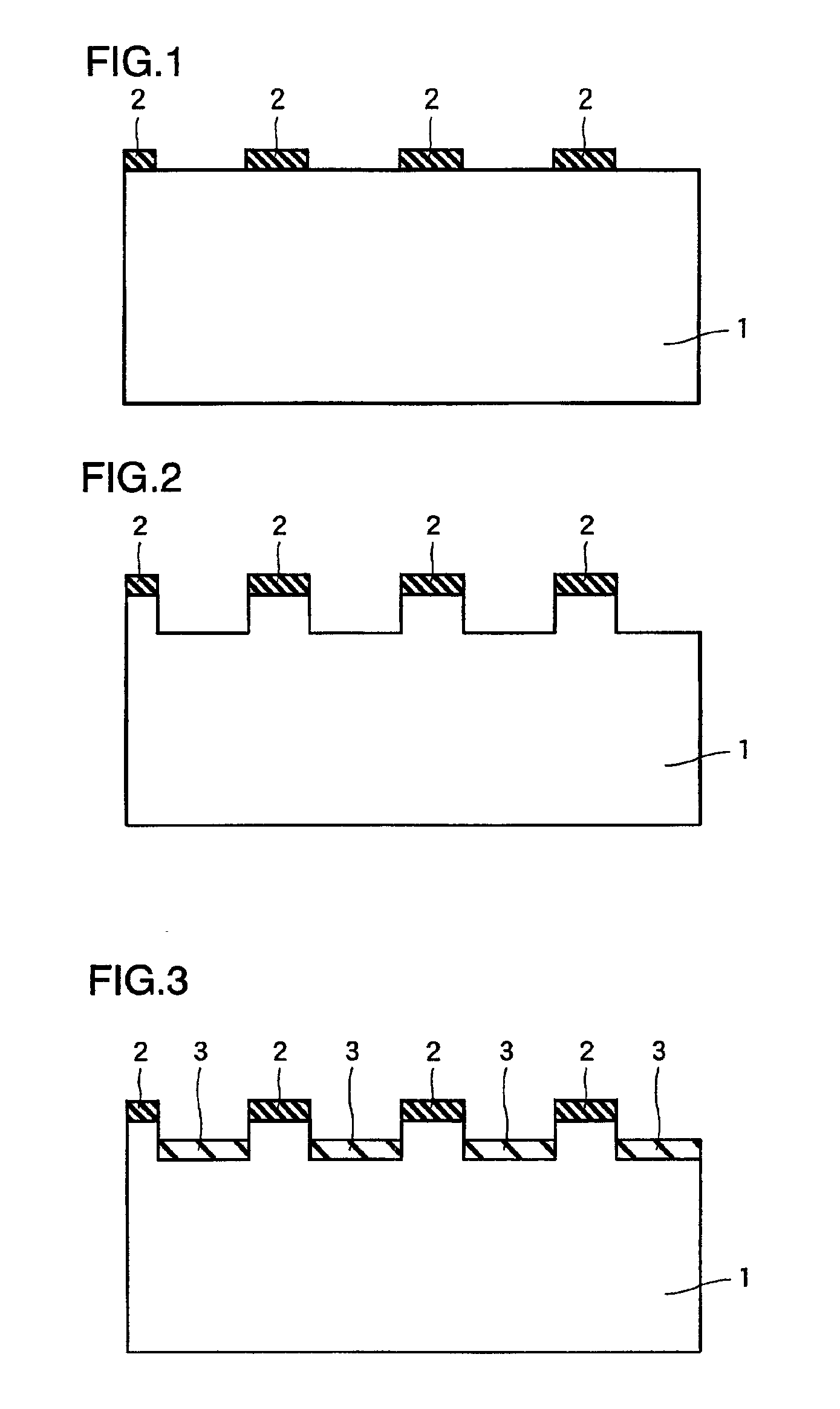

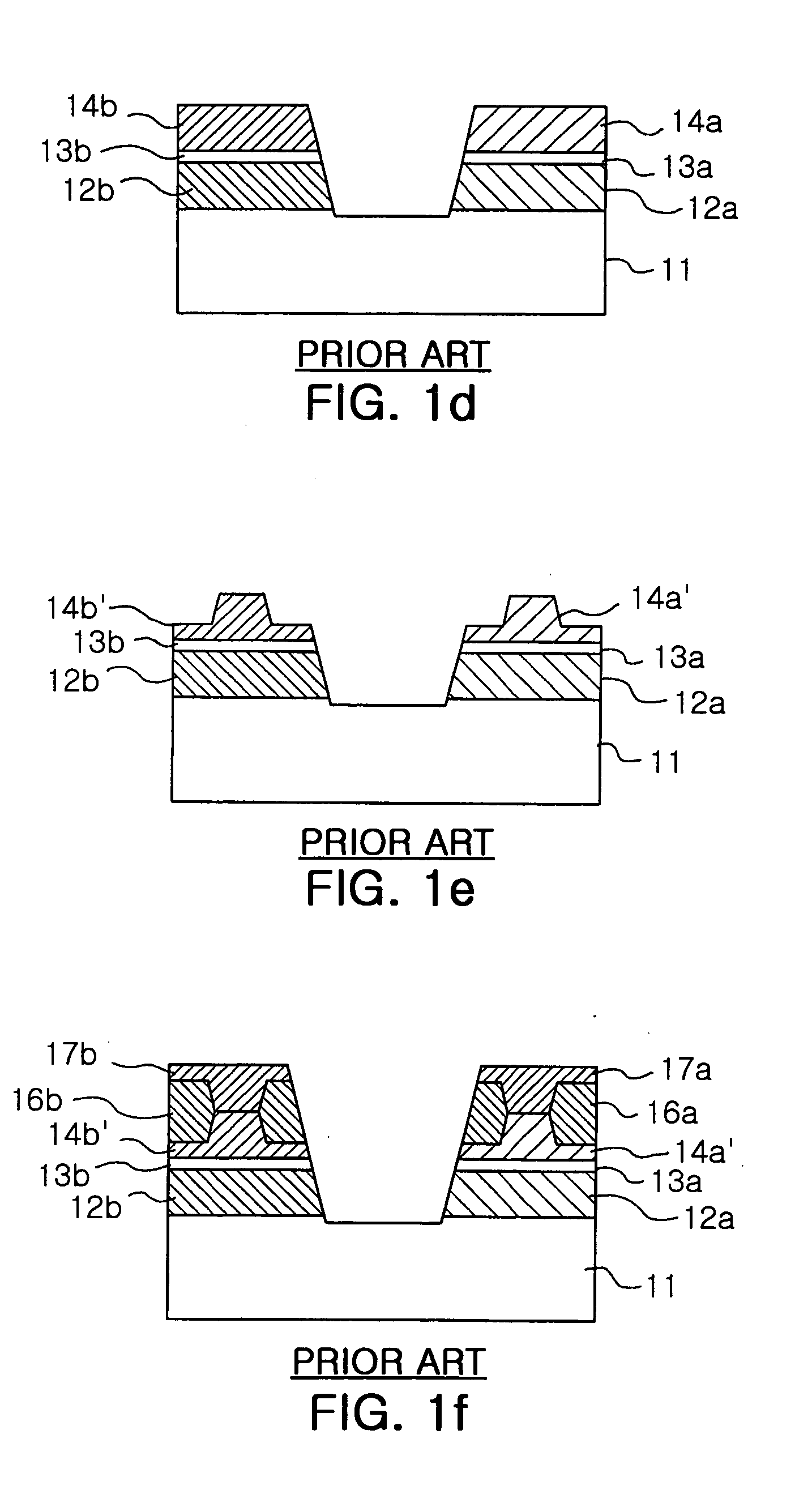

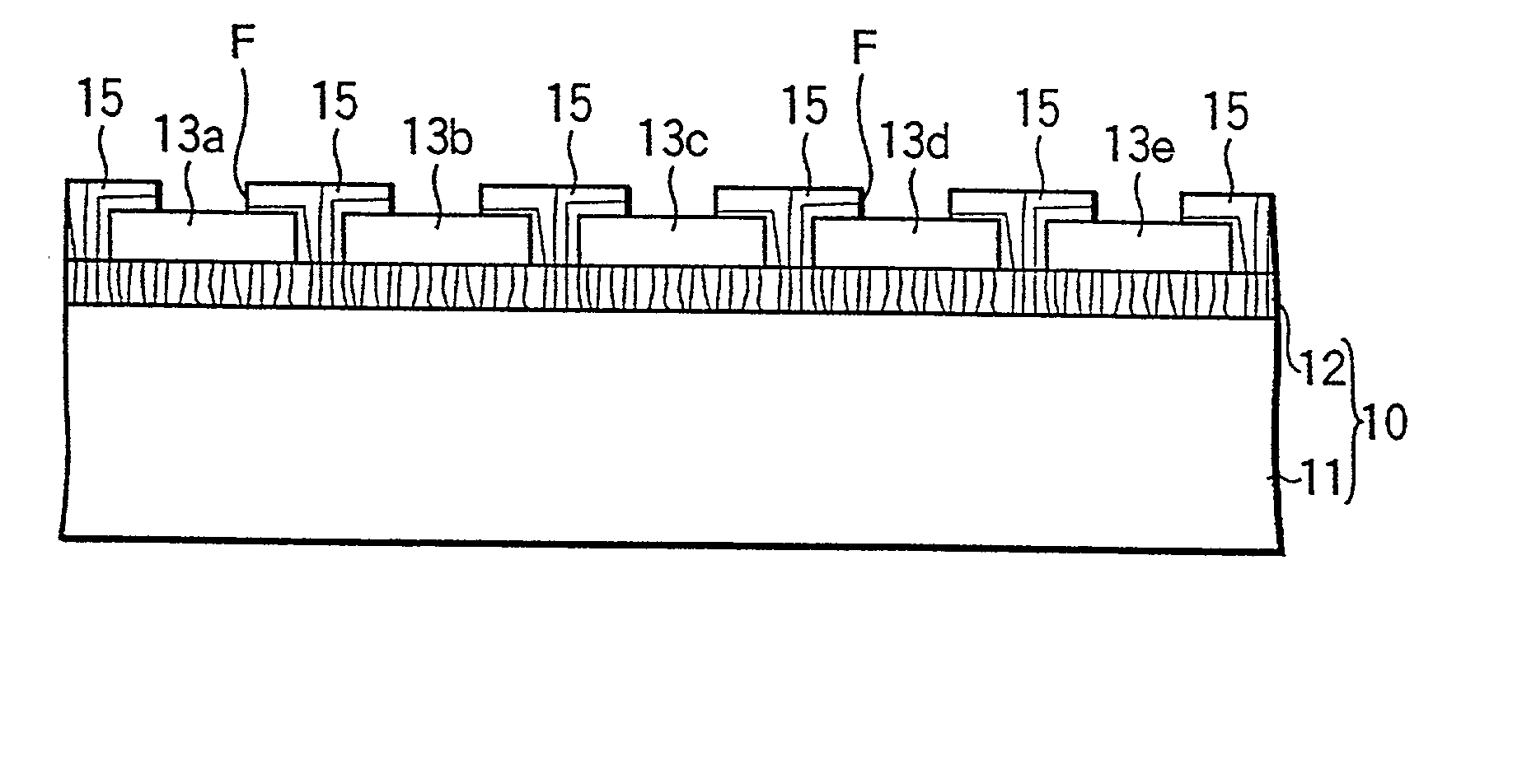

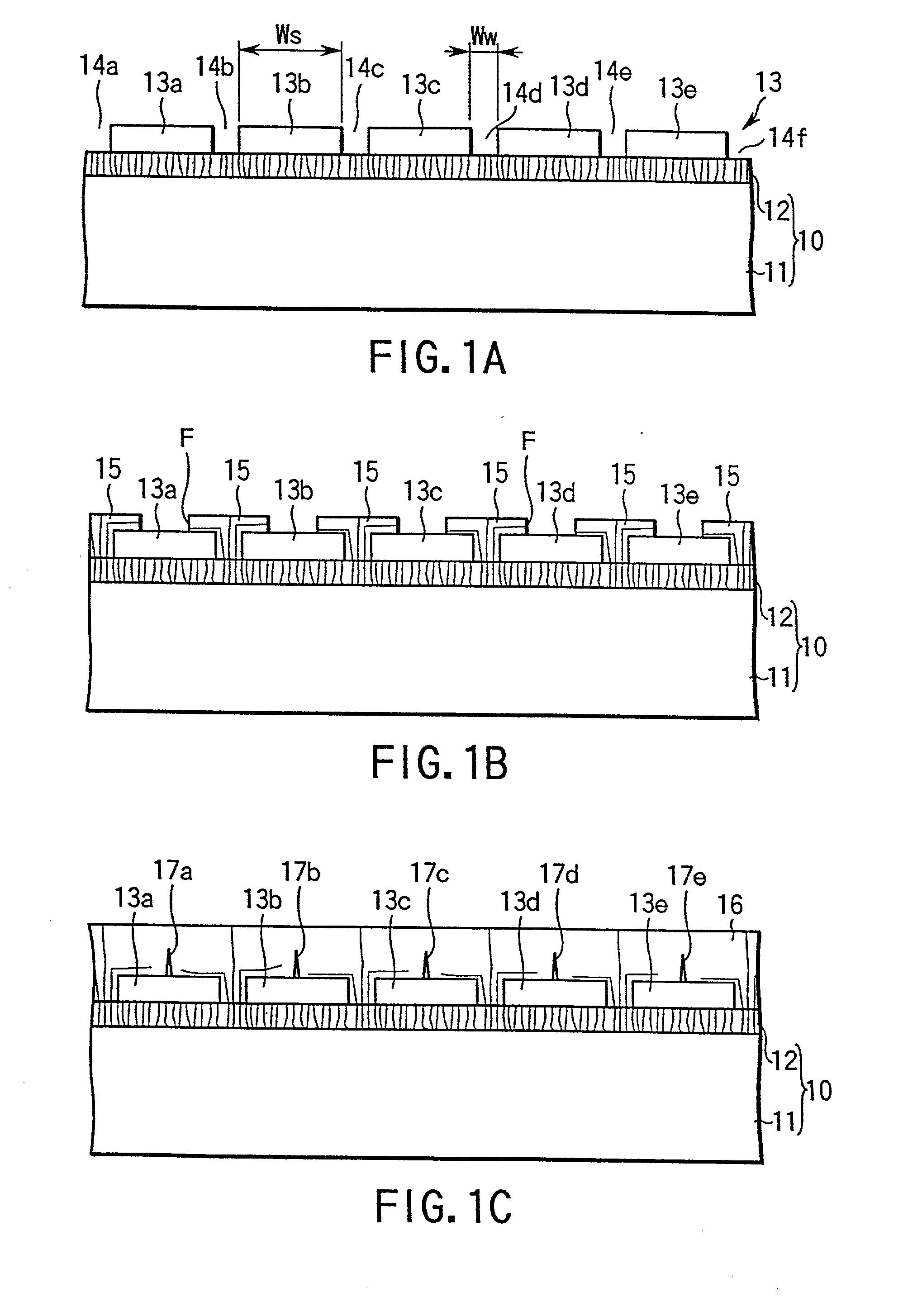

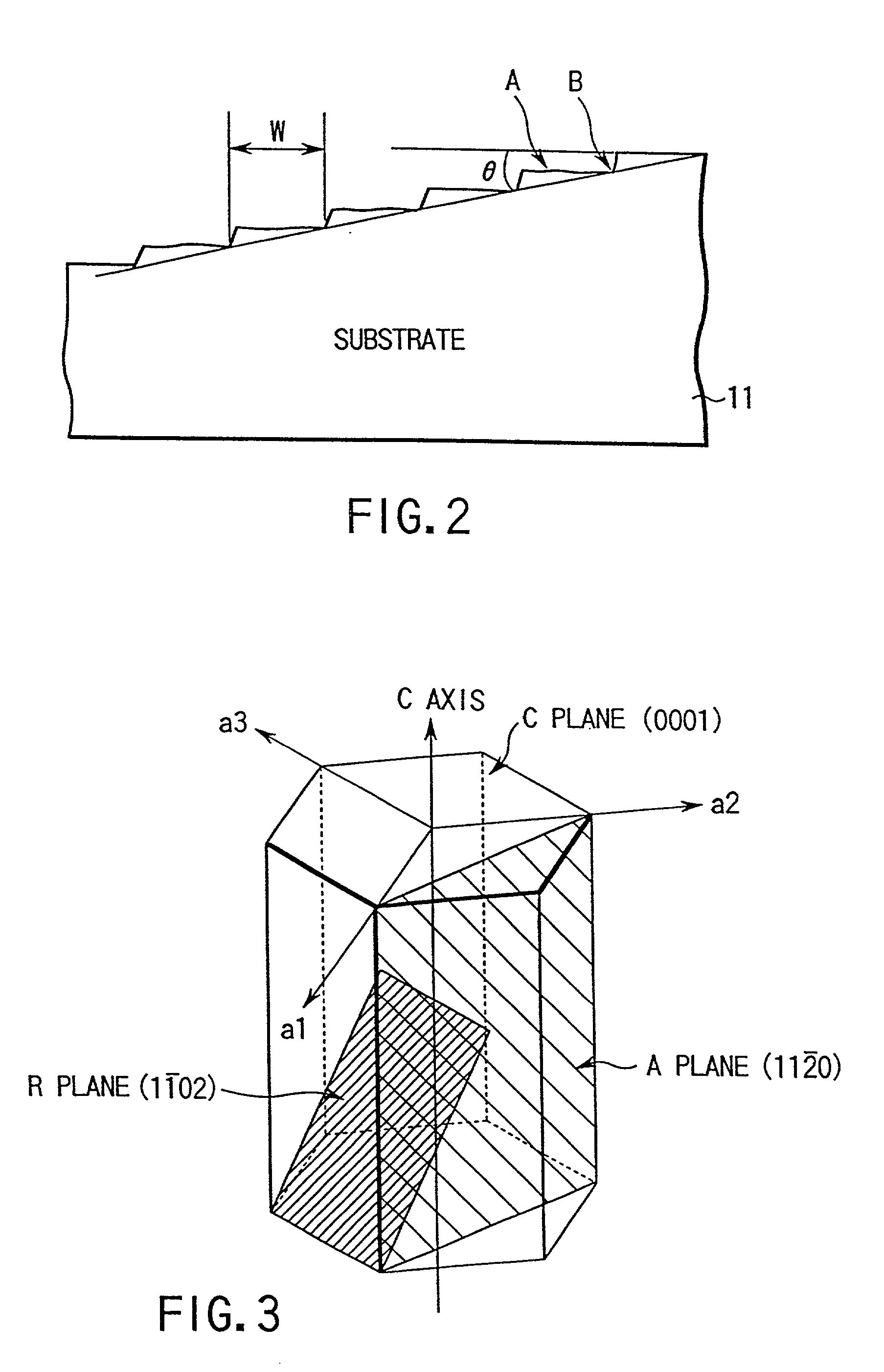

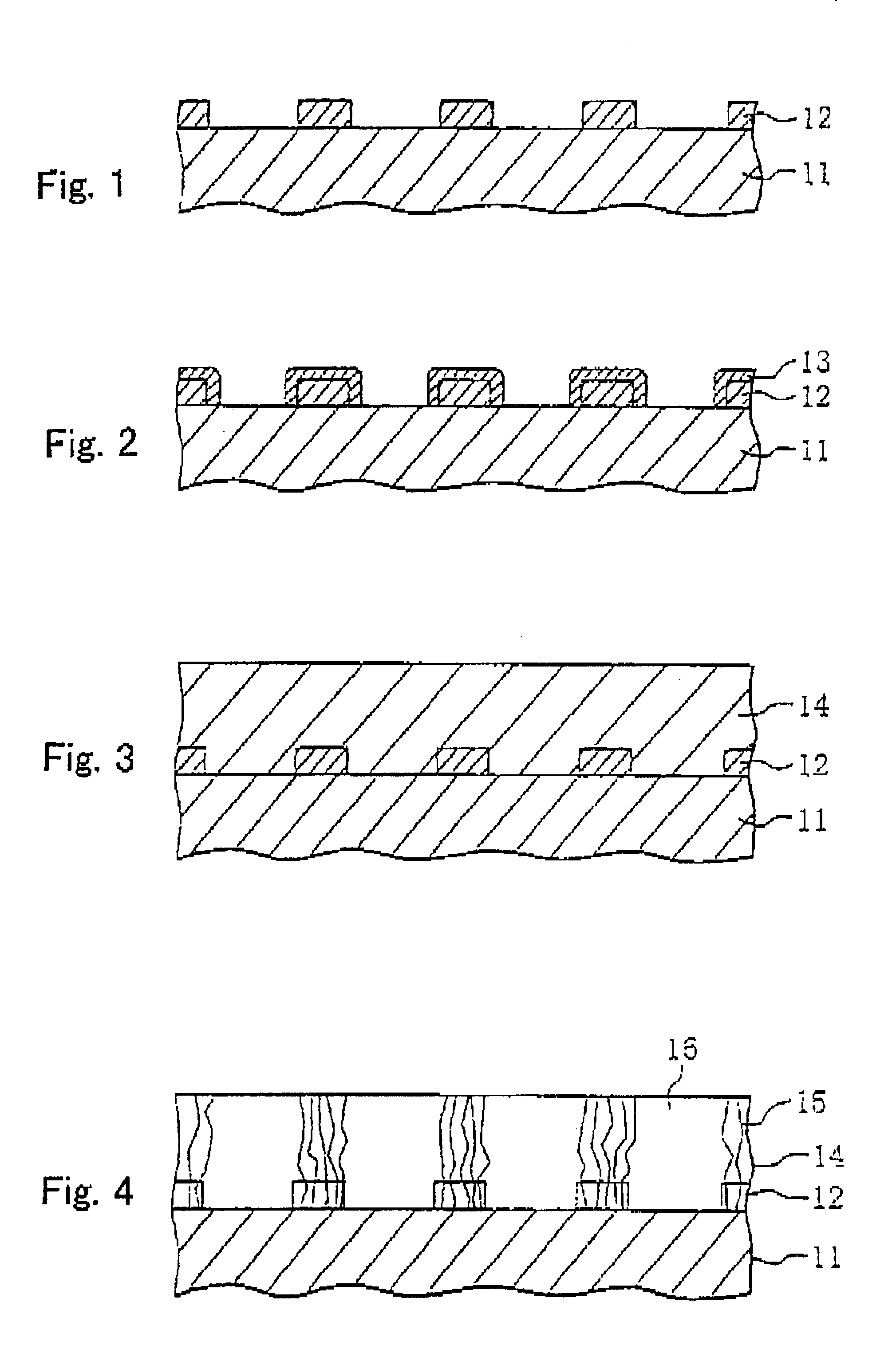

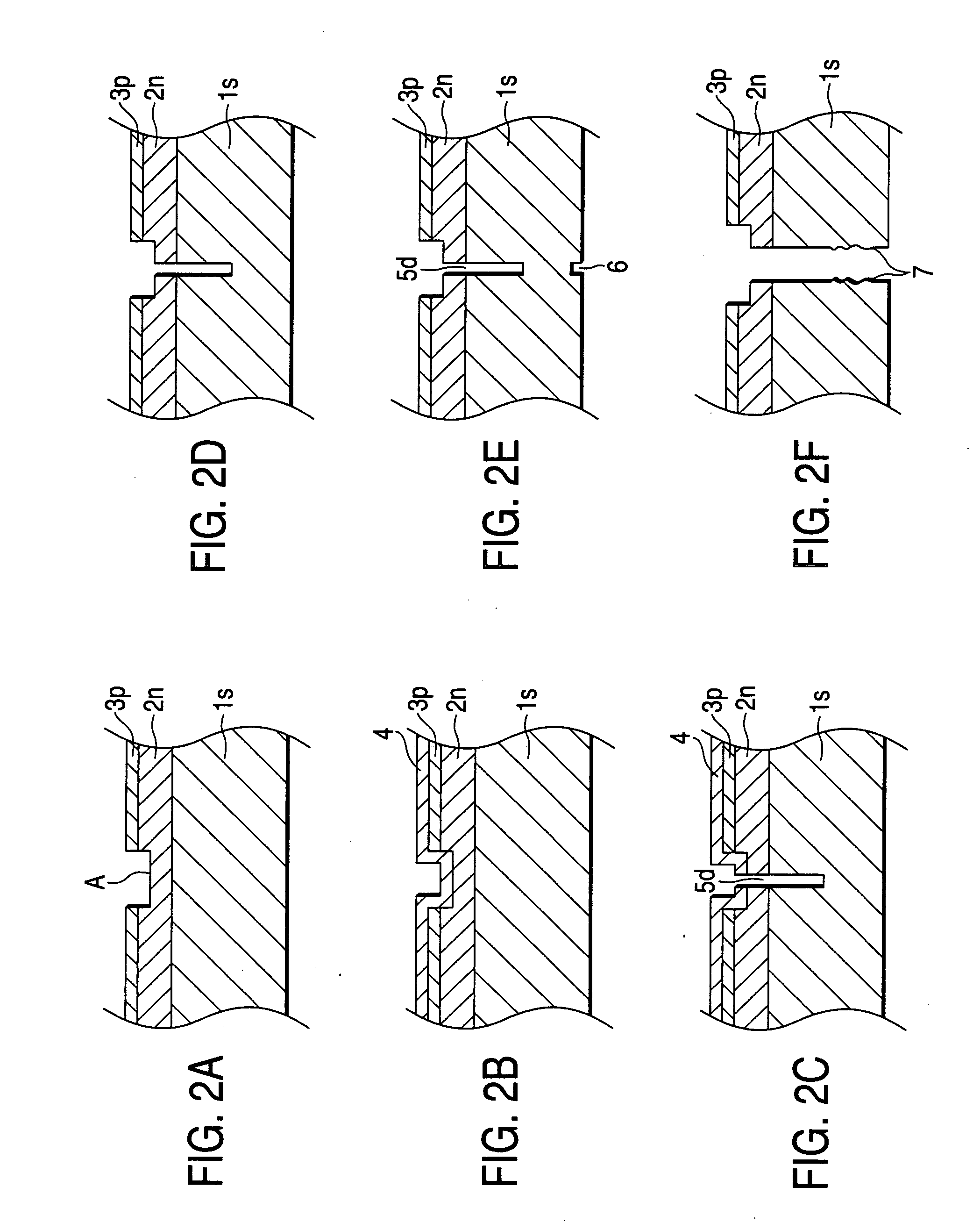

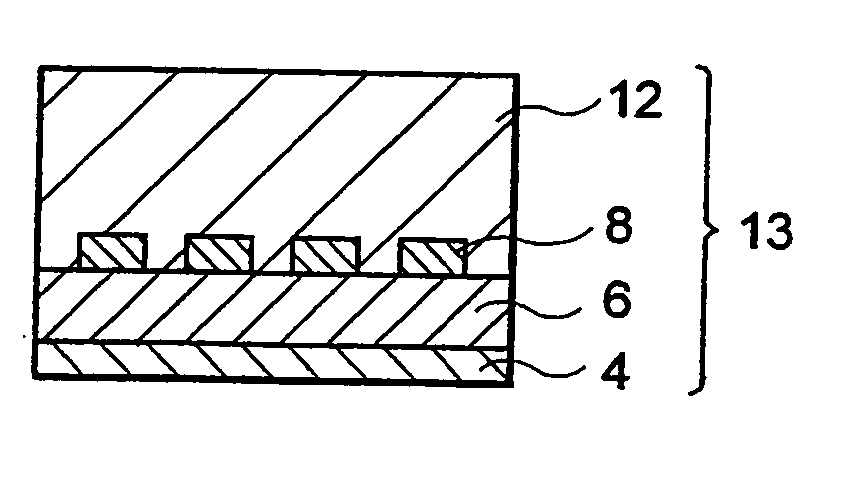

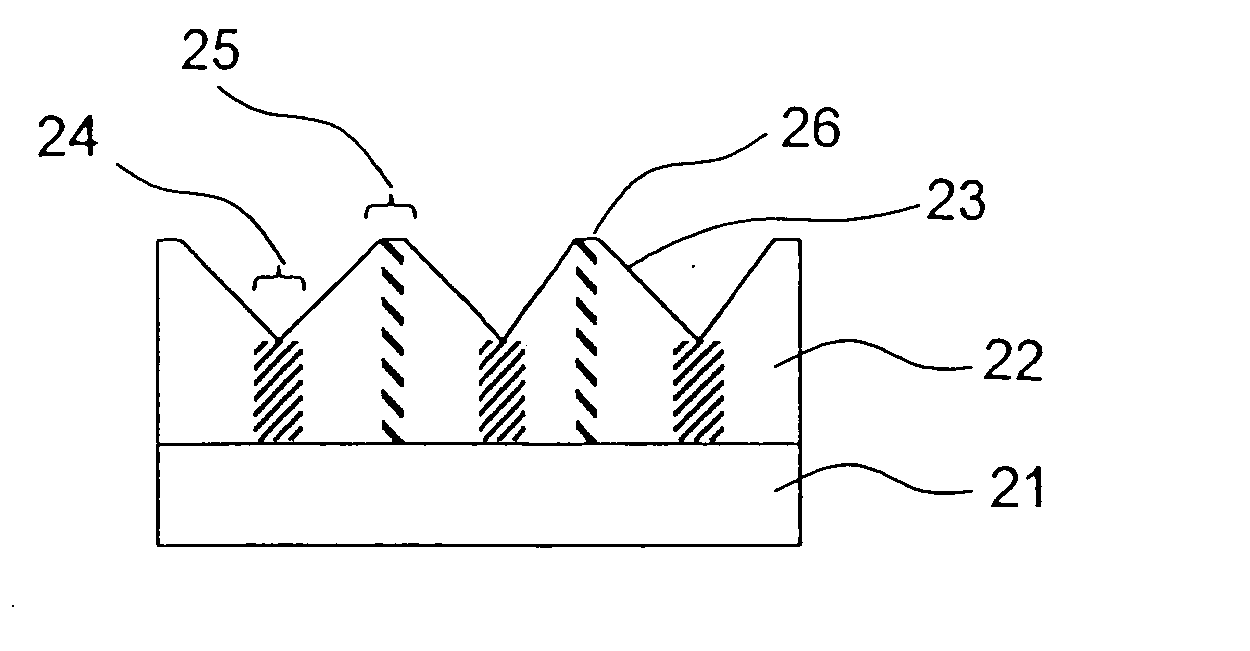

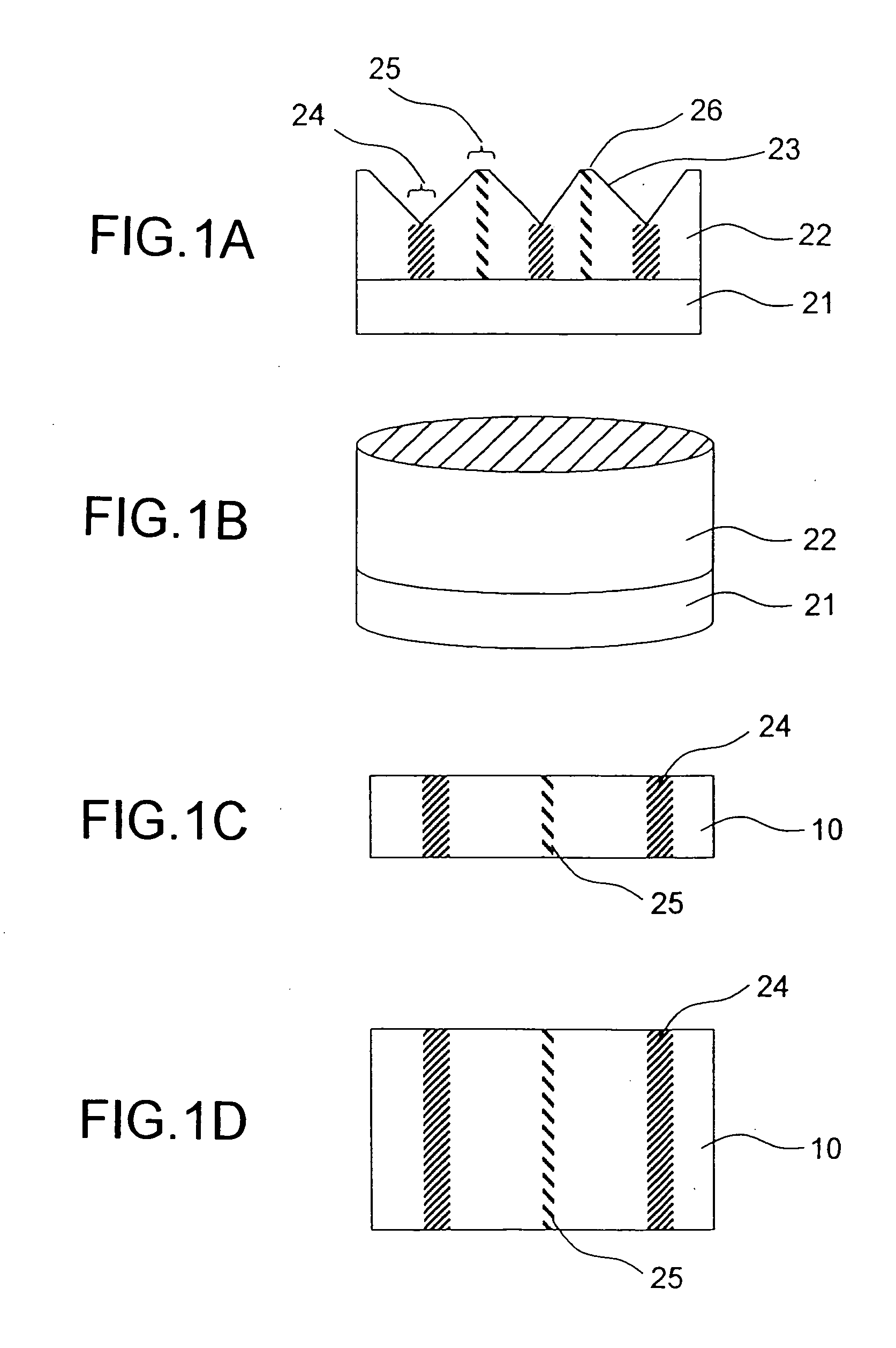

Nitride-based semiconductor element and method of forming nitride-based semiconductor

InactiveUS6994751B2Improve batch productivityExcellent element characteristicOptical wave guidancePolycrystalline material growthProduction rateDislocation

A nitride-based semiconductor element having superior mass productivity and excellent element characteristics is obtained. This nitride-based semiconductor element comprises a substrate comprising a surface having projection portions, a mask layer formed to be in contact with only the projection portions of the surface of the substrate, a first nitride-based semiconductor layer formed on recess portions of the substrate and the mask layer and a nitride-based semiconductor element layer, formed on the first nitride-based semiconductor layer, having an element region. Thus, the first nitride-based semiconductor layer having low dislocation density is readily formed on the projection portions of the substrate and the mask layer through the mask layer serving for selective growth. When the nitride-based semiconductor element layer having the element region is grown on the first nitride-based semiconductor layer having low dislocation density, a nitride-based semiconductor element having excellent element characteristics can be readily obtained. The first nitride-based semiconductor layer is formed through only single growth on the substrate, whereby a nitride-based semiconductor element having excellent mass productivity is obtained.

Owner:LEDVANCE GMBH

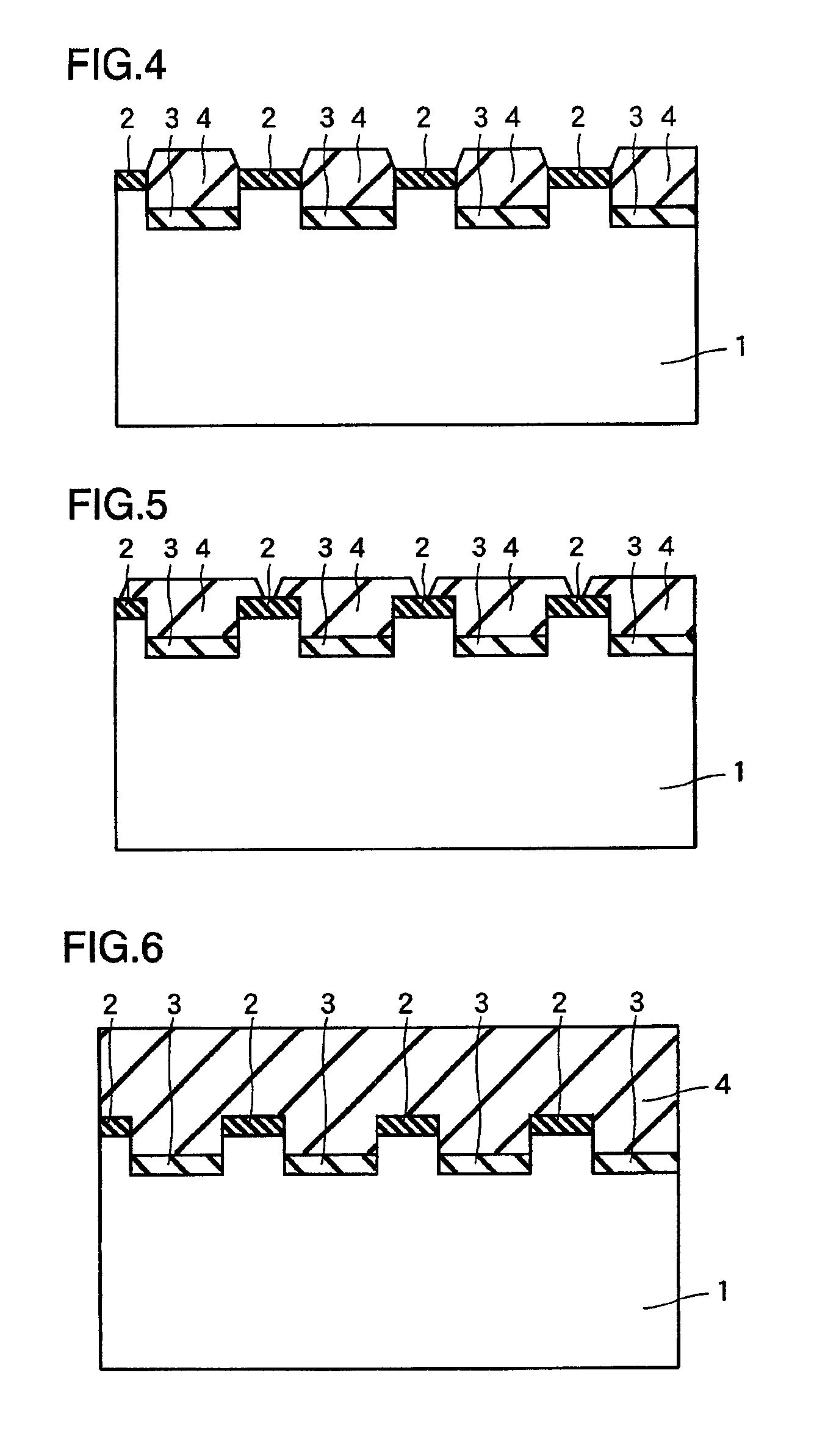

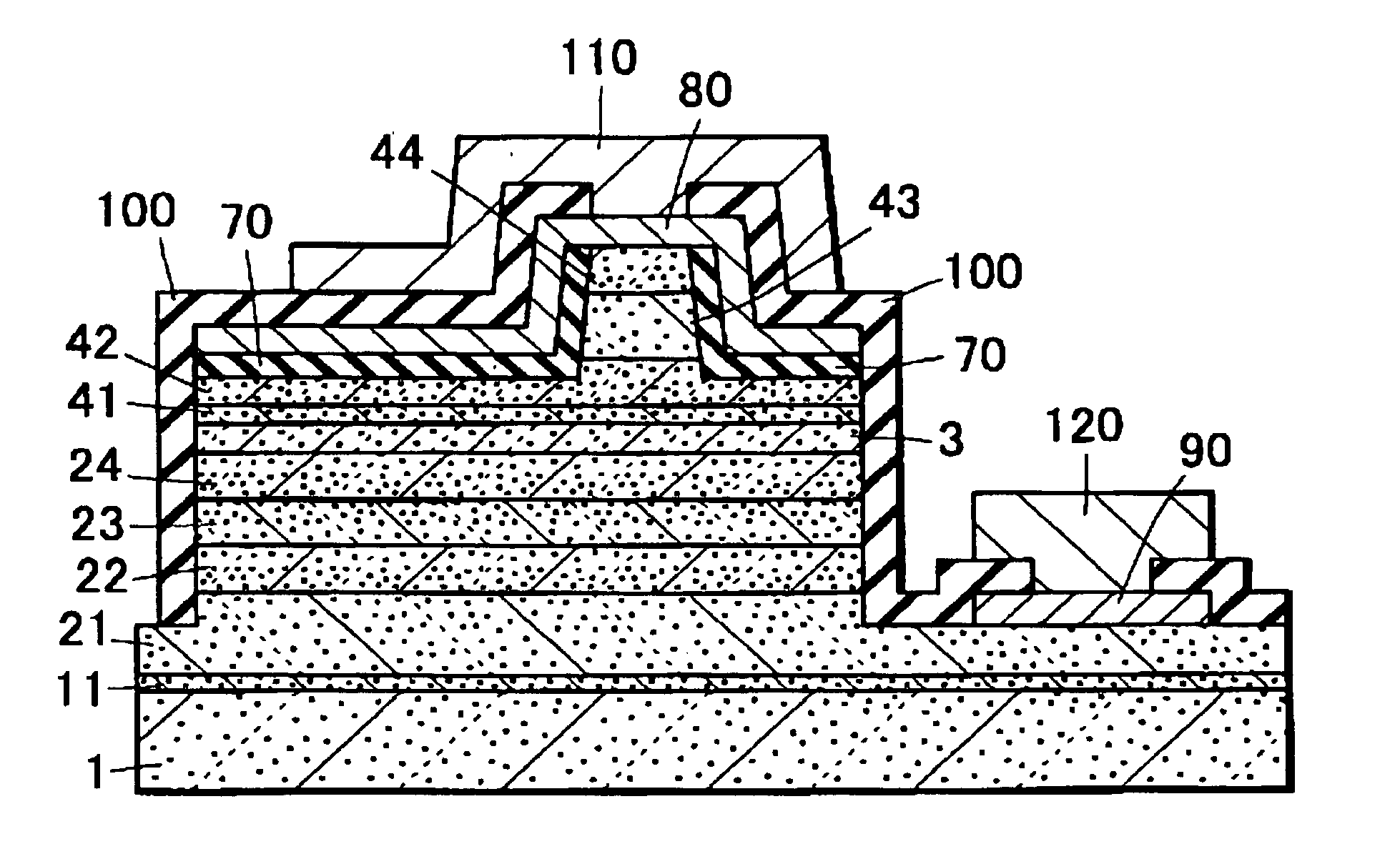

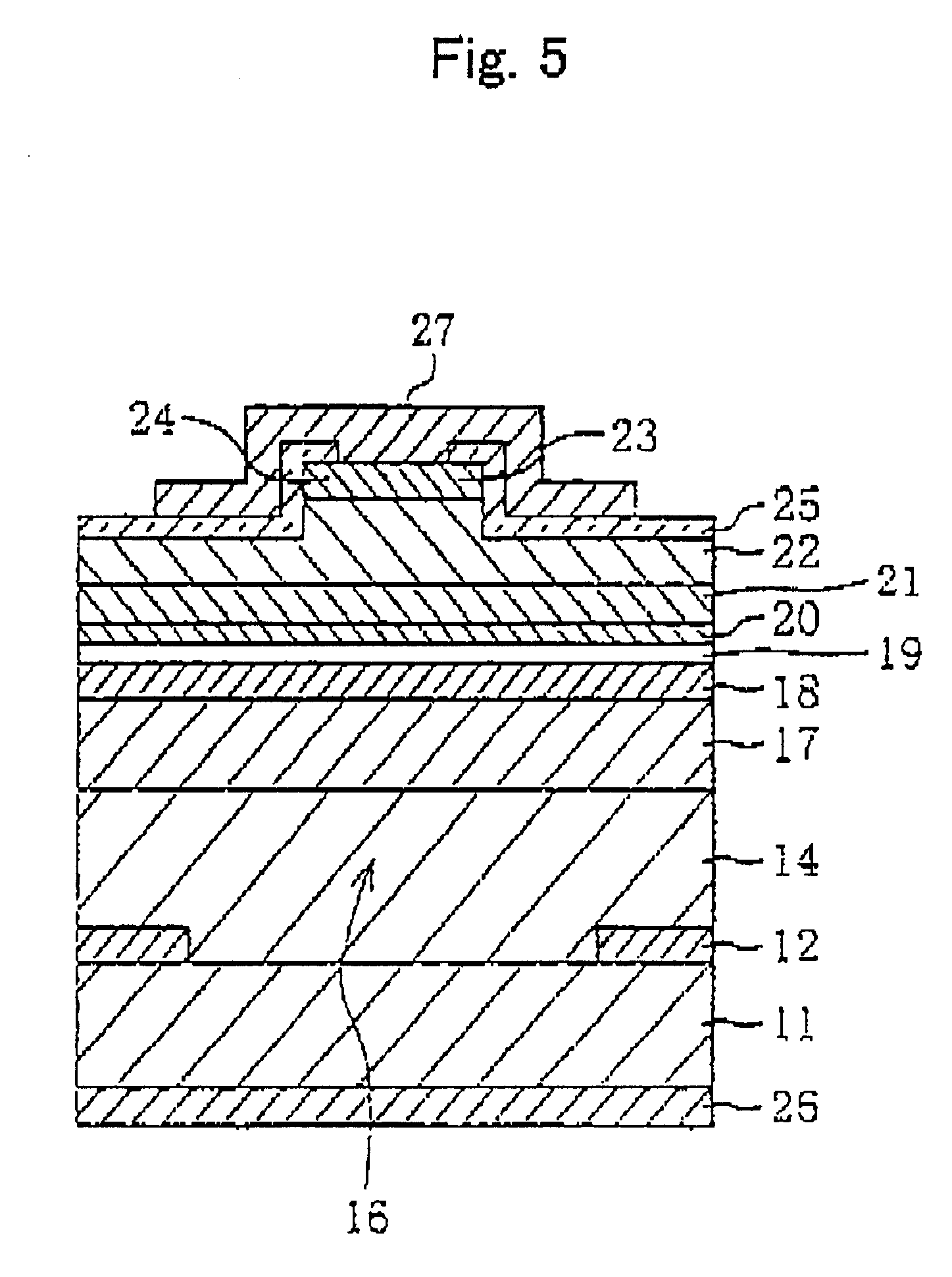

Method of producing multi-wavelength semiconductor laser device

InactiveUS20050286591A1Easy alignmentReduce thicknessOptical wave guidanceSemiconductor laser arrangementsSingle crystalMaterials science

Disclosed herein is a method for producing a multi-wavelength semiconductor laser device. The method comprises the steps of: forming first and second nitride epitaxial layers in parallel on a substrate for growth of a nitride single crystal; separating the first and second nitride epitaxial layers from the substrate; attaching the separated first and second nitride epitaxial layers to a first conductivity-type substrate; selectively removing the first and second nitride semiconductor epitaxial layers to expose a portion of the first conductivity-type substrate and to form first and second semiconductor laser structures, respectively; and forming a third semiconductor laser structure on the exposed portion of the first conductivity-type substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

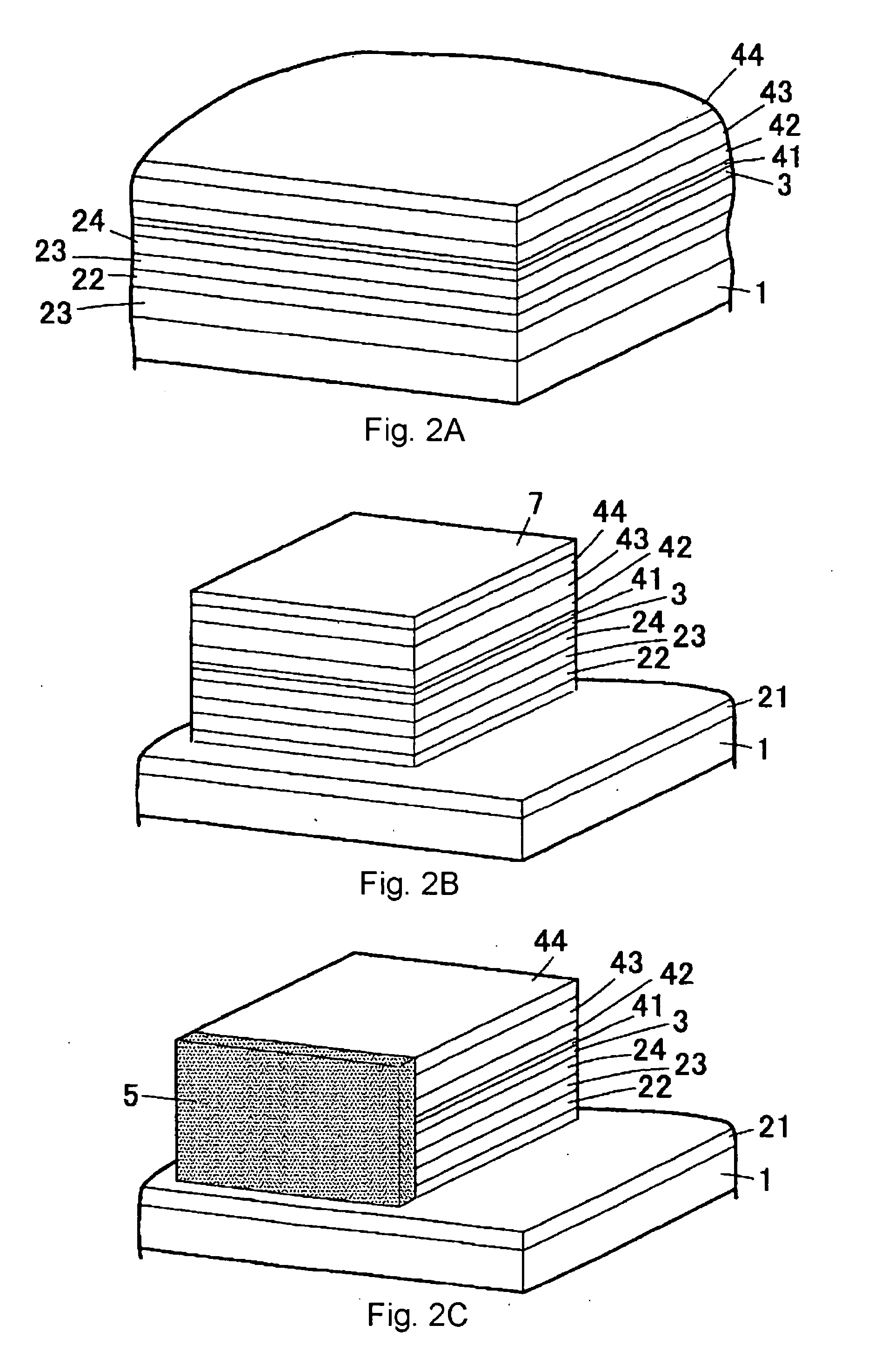

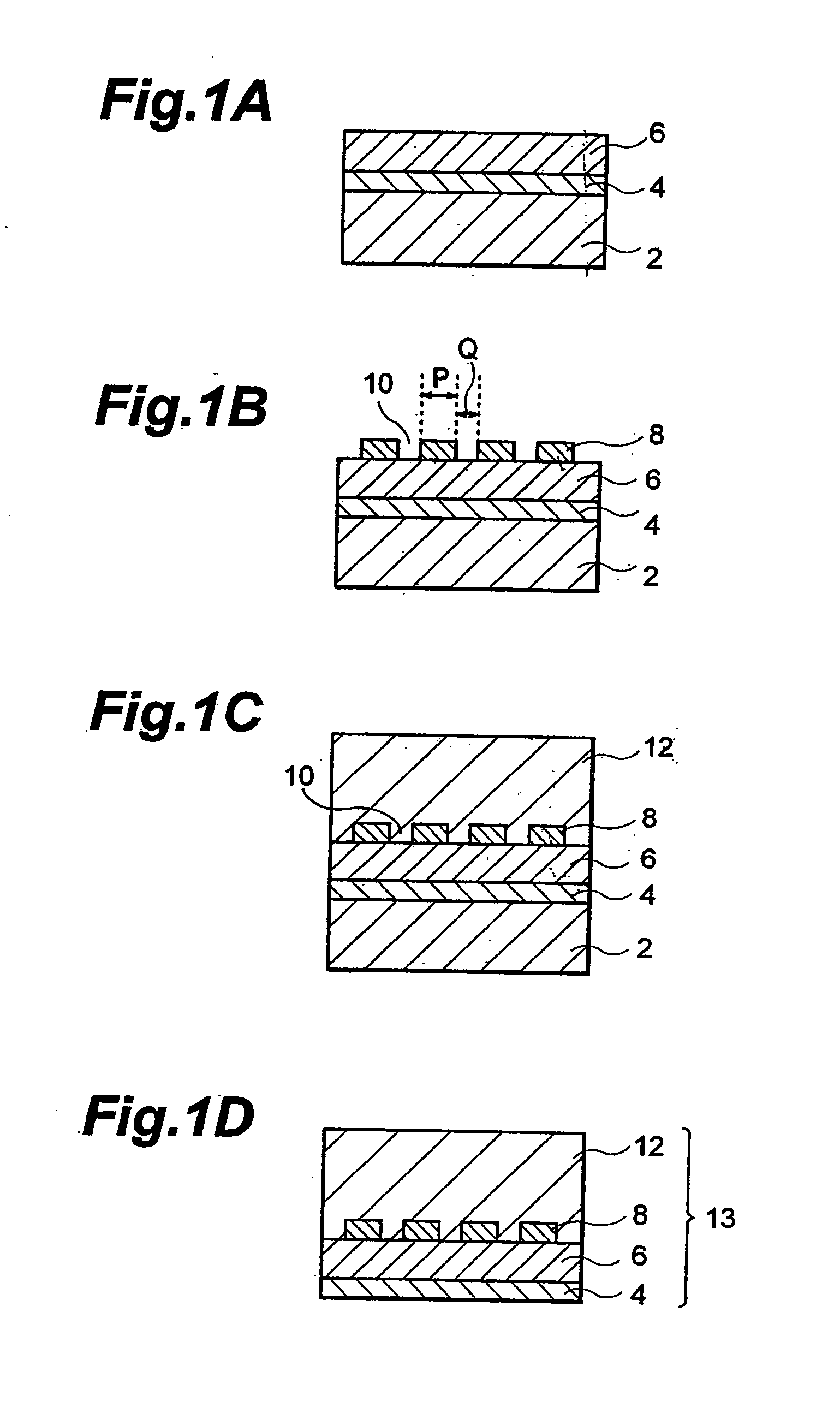

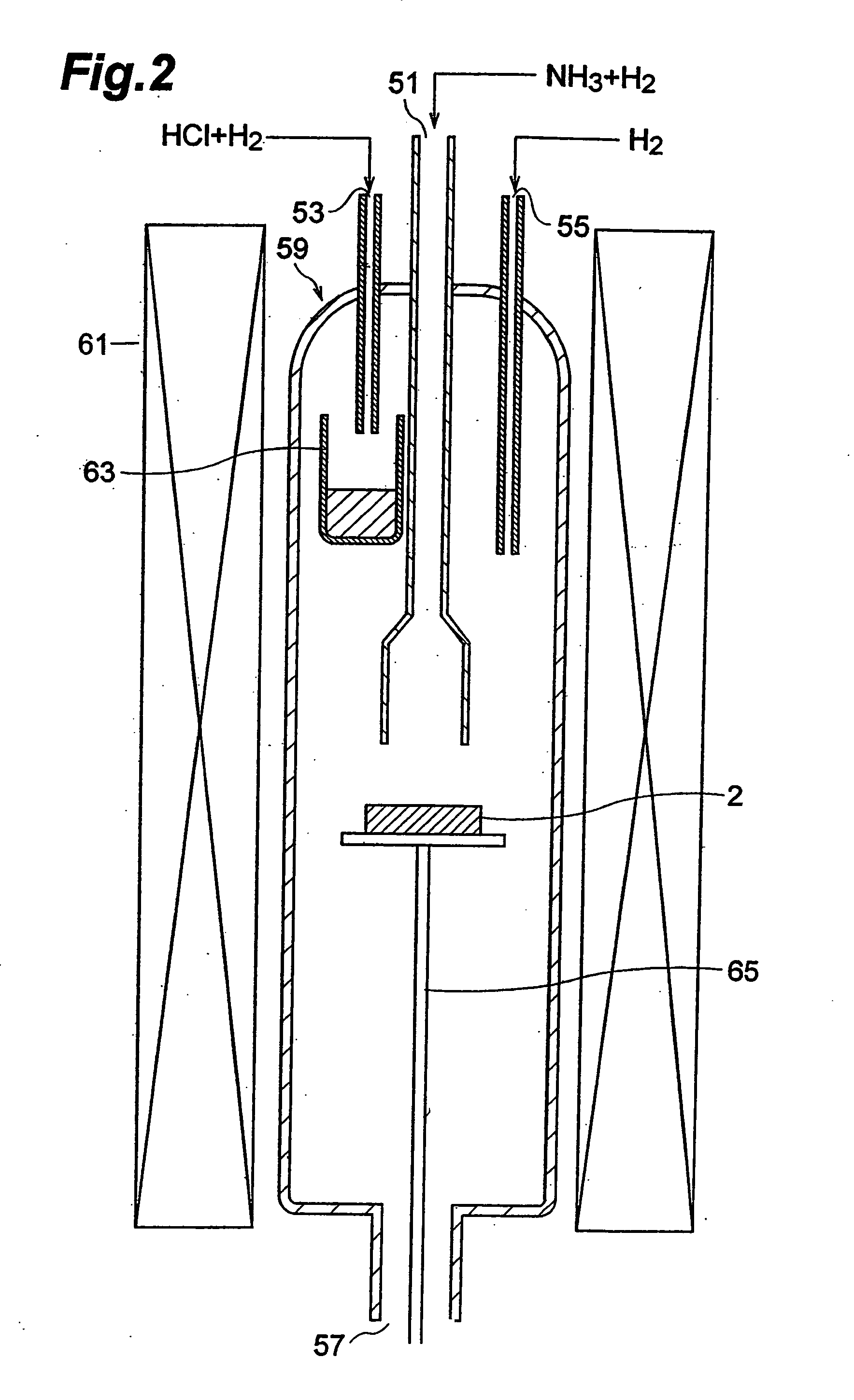

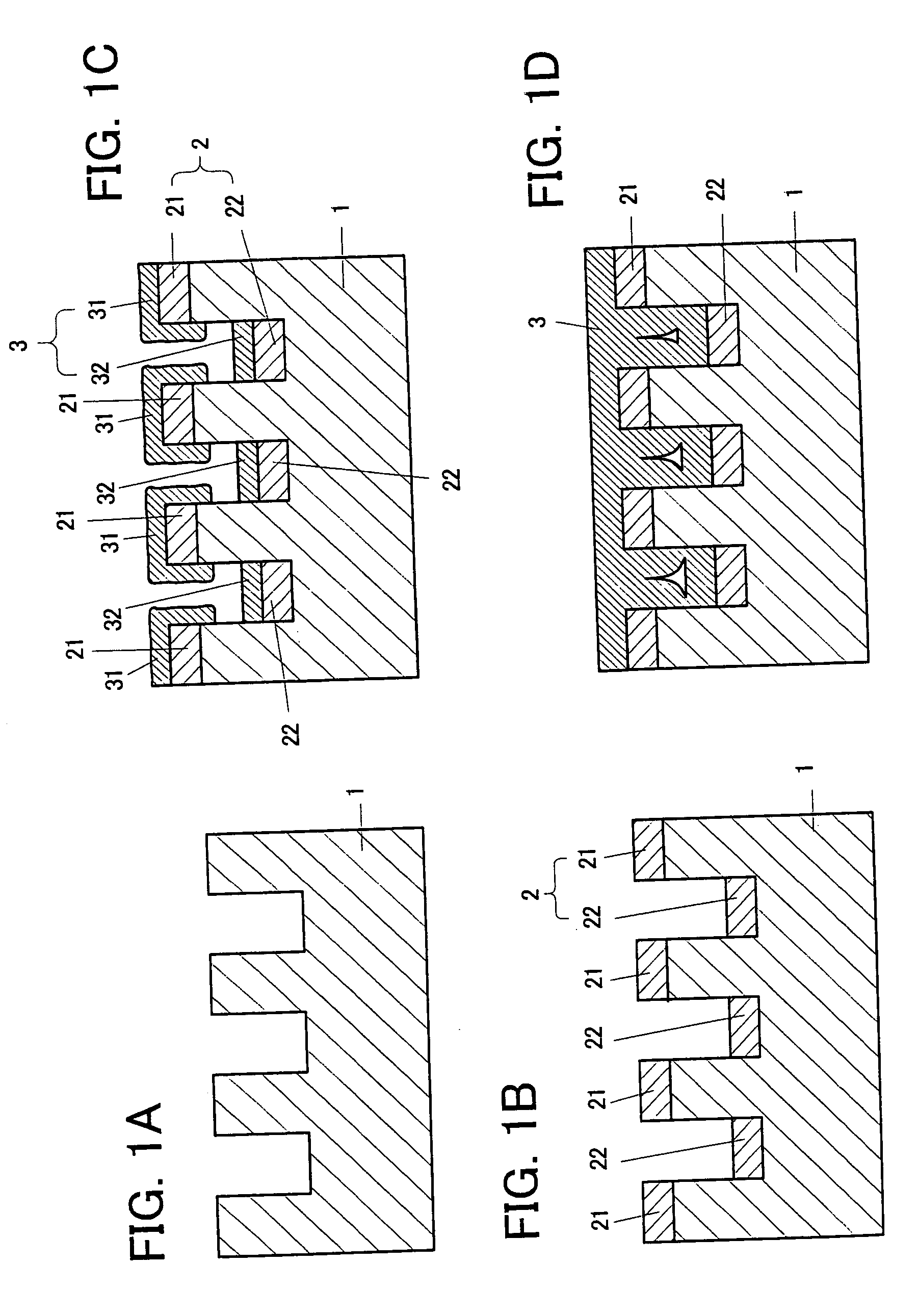

Nitride semiconductor growth method, nitride semiconductor substrate, and nitride semiconductor device

InactiveUS20020046693A1From gel statePolycrystalline material growthCrystallographic defectNitride semiconductors

A method of growing a nitride semiconductor crystal which has very few crystal defects and can be used as a substrate is disclosed. This invention includes the step of forming a first selective growth mask on a support member including a dissimilar substrate having a major surface and made of a material different from a nitride semiconductor, the first selective growth mask having a plurality of first windows for selectively exposing the upper surface of the support member, and the step of growing nitride semiconductor portions from the upper surface, of the support member, which is exposed from the windows, by using a gaseous Group 3 element source and a gaseous nitrogen source, until the nitride semiconductor portions grown in the adjacent windows combine with each other on the upper surface of the selective growth mask.

Owner:NICHIA CORP

Method for dividing substrate

InactiveUS7459377B2Easy to splitLow costLaser detailsSemiconductor laser structural detailsDislocationSubstrate surface

Owner:PANASONIC CORP

Semiconductor light-emitting device and its manufacturing method

InactiveUS7719017B2High mechanical strengthMade smallOptical wave guidanceLaser detailsSilicon oxideLight emitting device

Owner:HAMAMATSU PHOTONICS KK

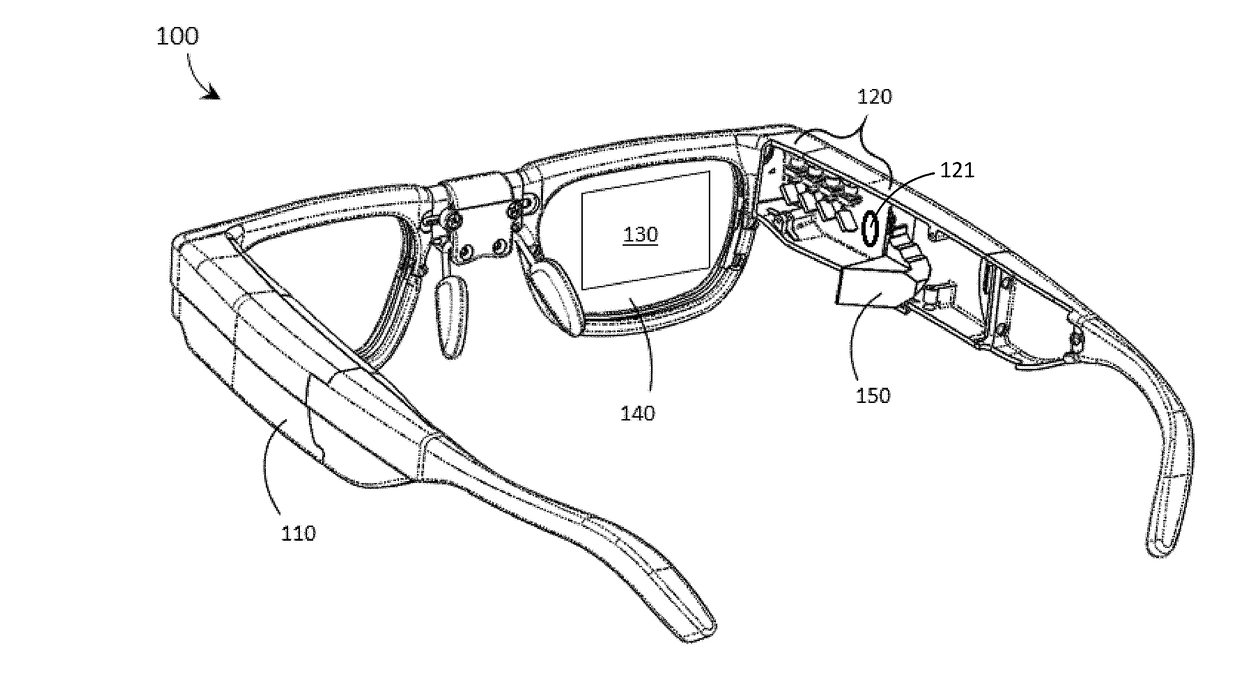

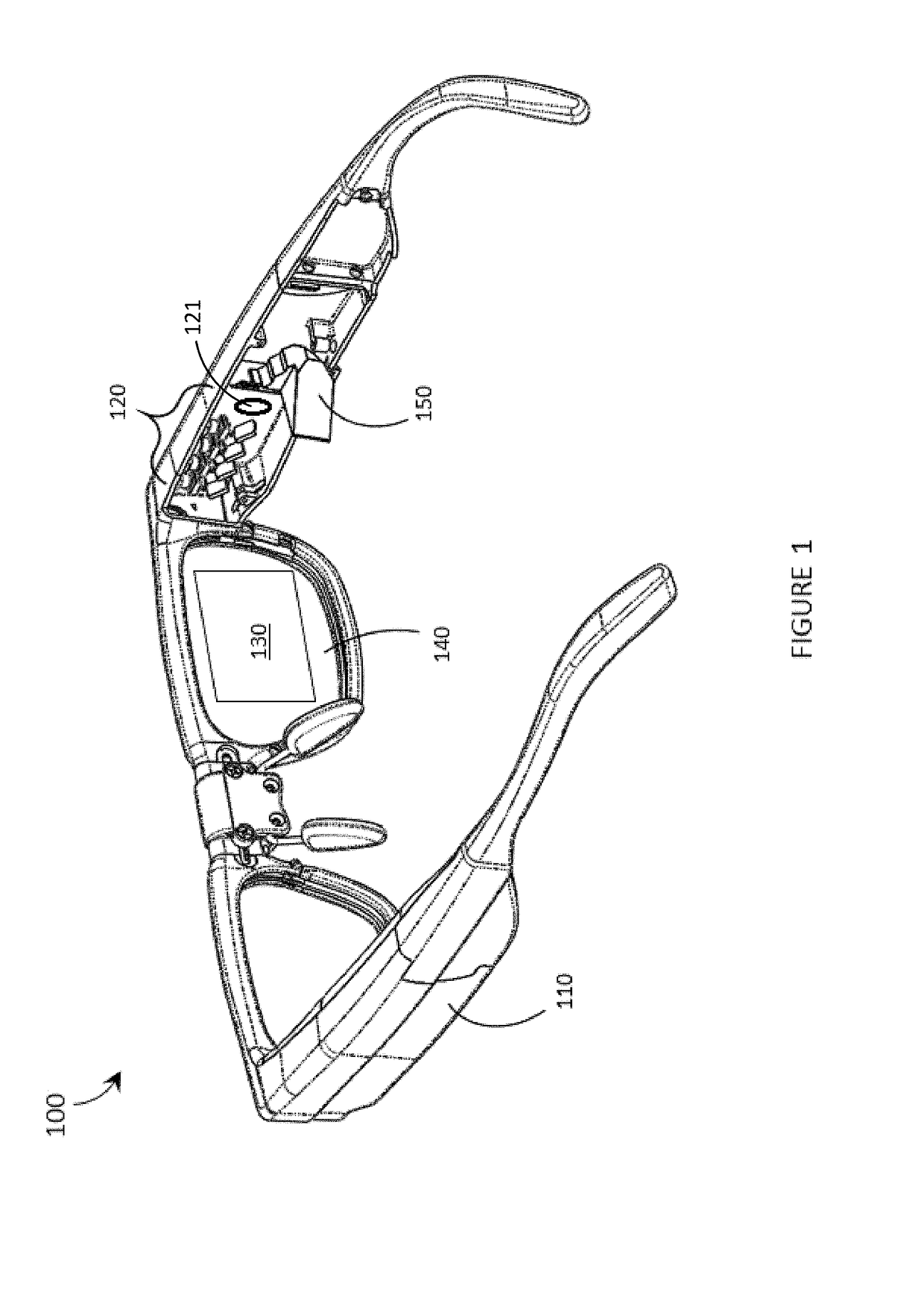

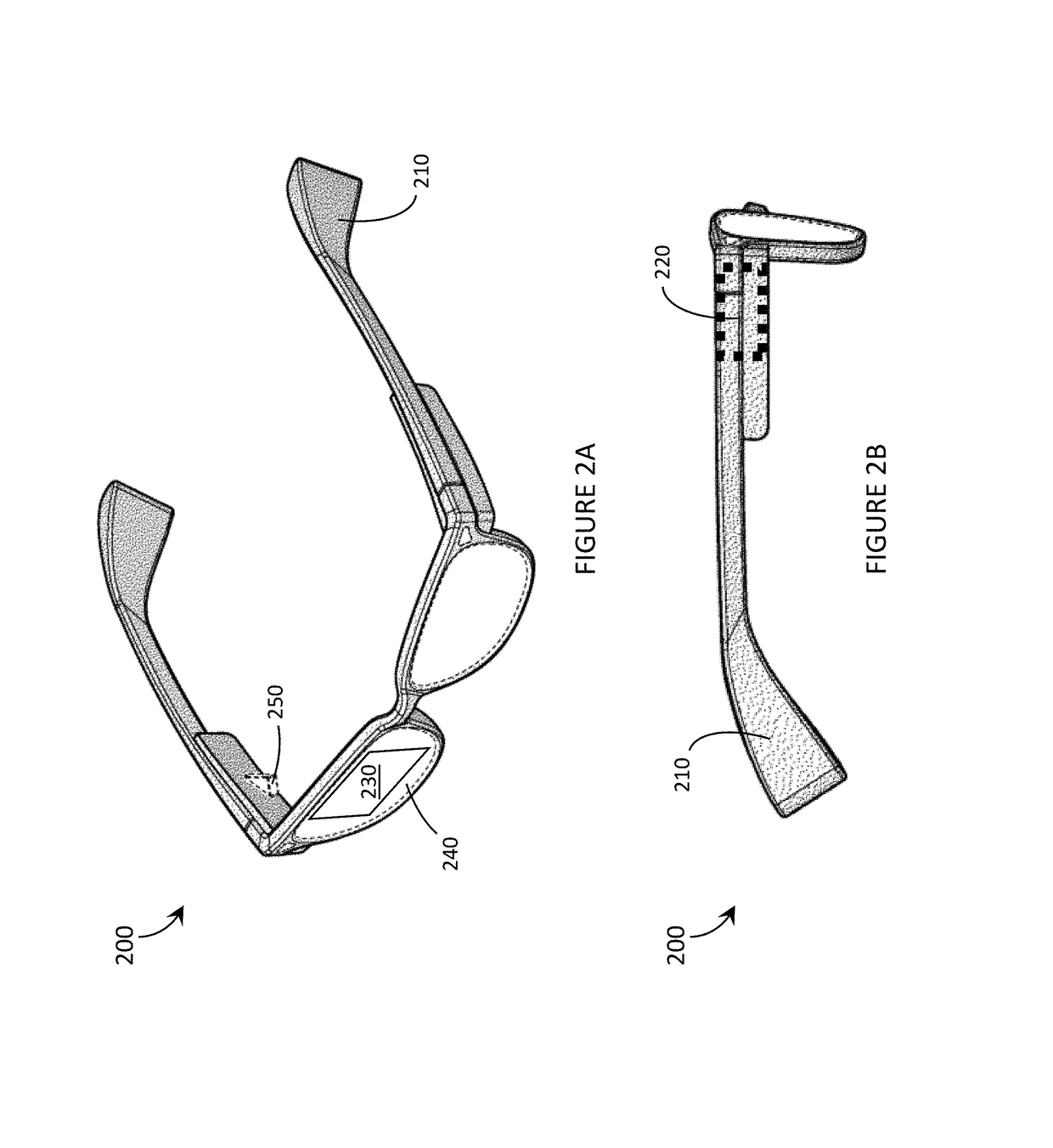

Systems, devices, and methods for focusing laser projectors

ActiveUS20170299956A1Reduce disagreementSemiconductor laser arrangementsNon-optical adjunctsHead-up displayLaser light

Systems, devices, and methods for focusing laser projectors are described. A laser projector includes N≧1 laser diodes, each of which emits laser light having a divergence. Each laser diode is paired with a respective primary or collimation lens to at least reduce a divergence of the laser light that the laser diode produces. Downstream from the primary lens(es) in the optical path(s) of the laser light, a single dedicated secondary or convergence lens converges the laser light to a focus. By initiating the convergence of the laser light at the secondary or convergence lens as opposed to at the primary or collimation lens(es), numerous benefits that are particularly advantageous in laser projection-based wearable heads-up displays are realized.

Owner:GOOGLE LLC

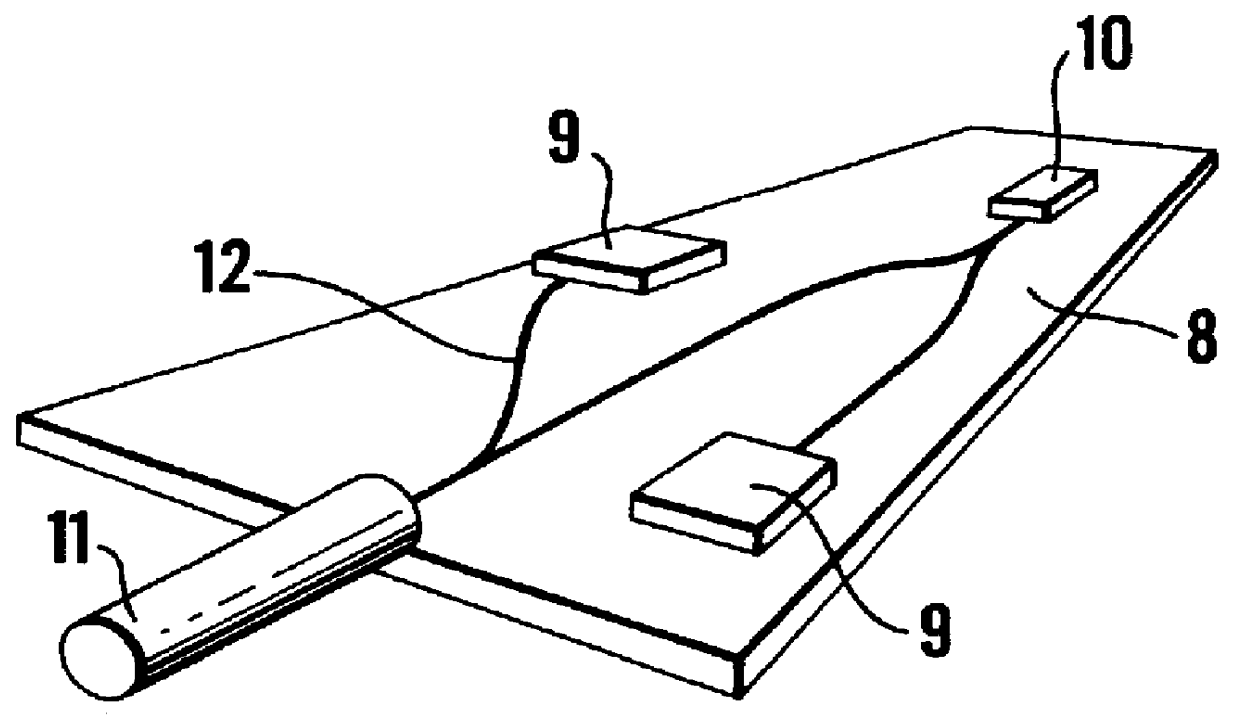

Manufacturing method of semiconductor laser element

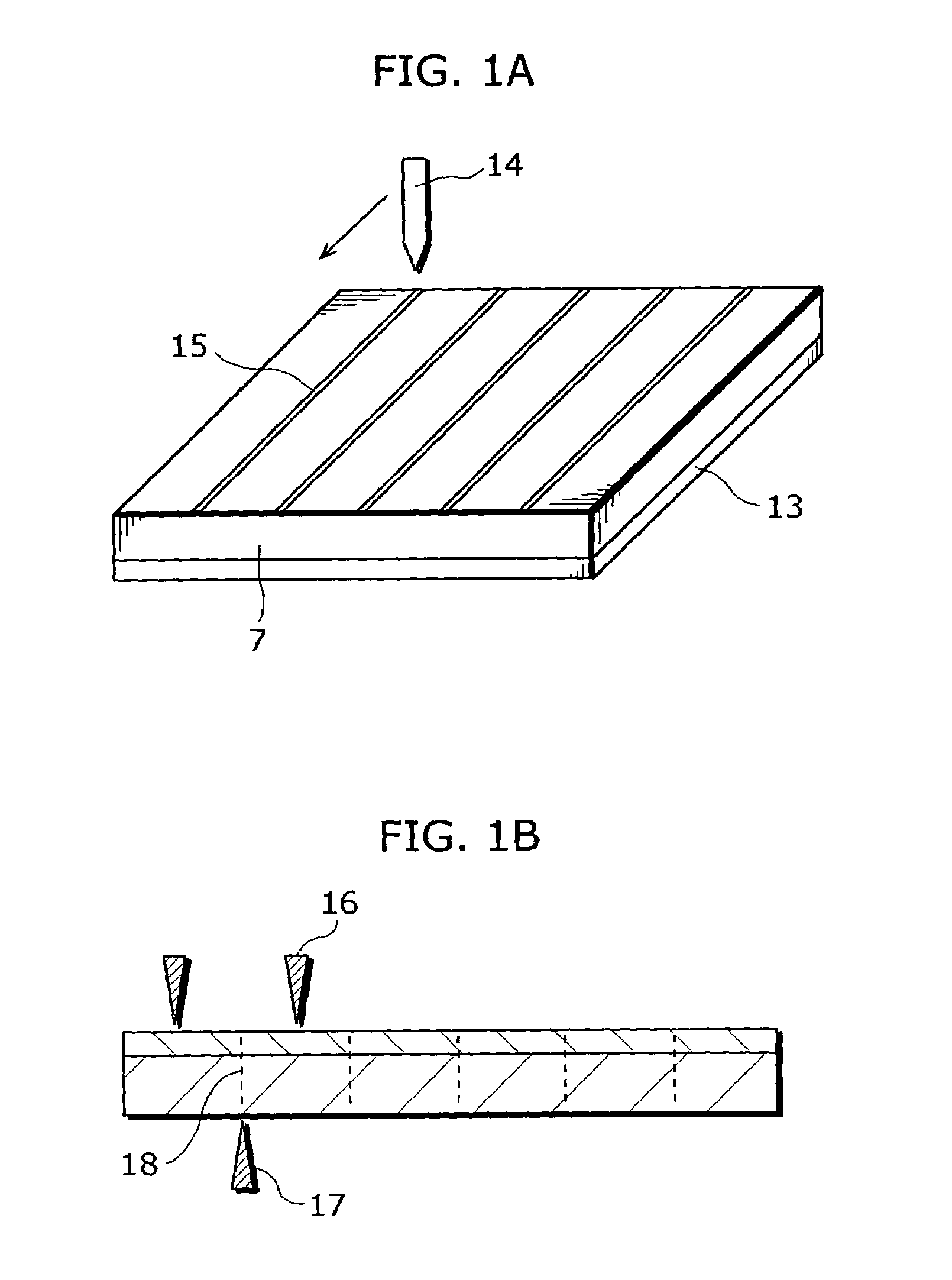

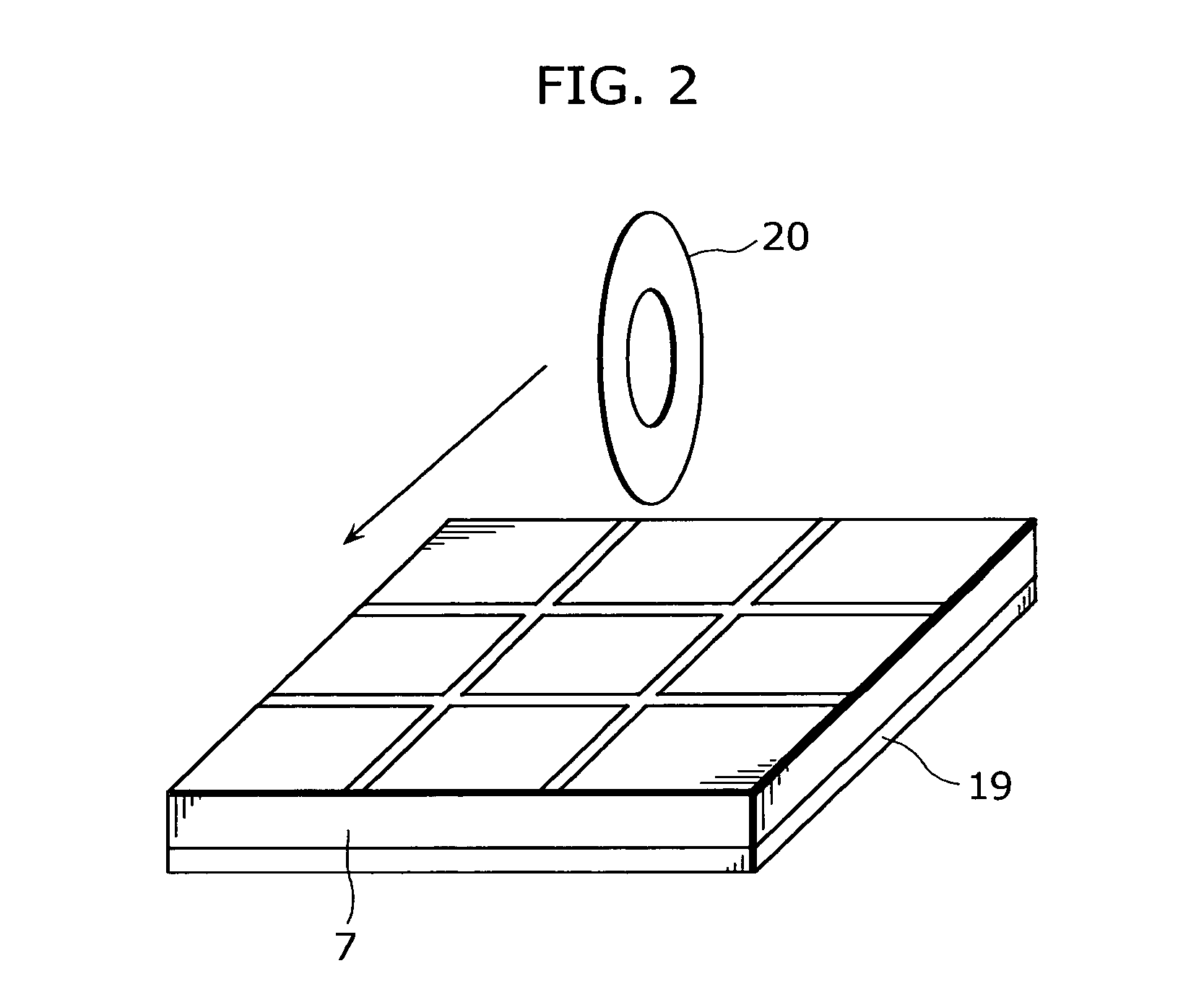

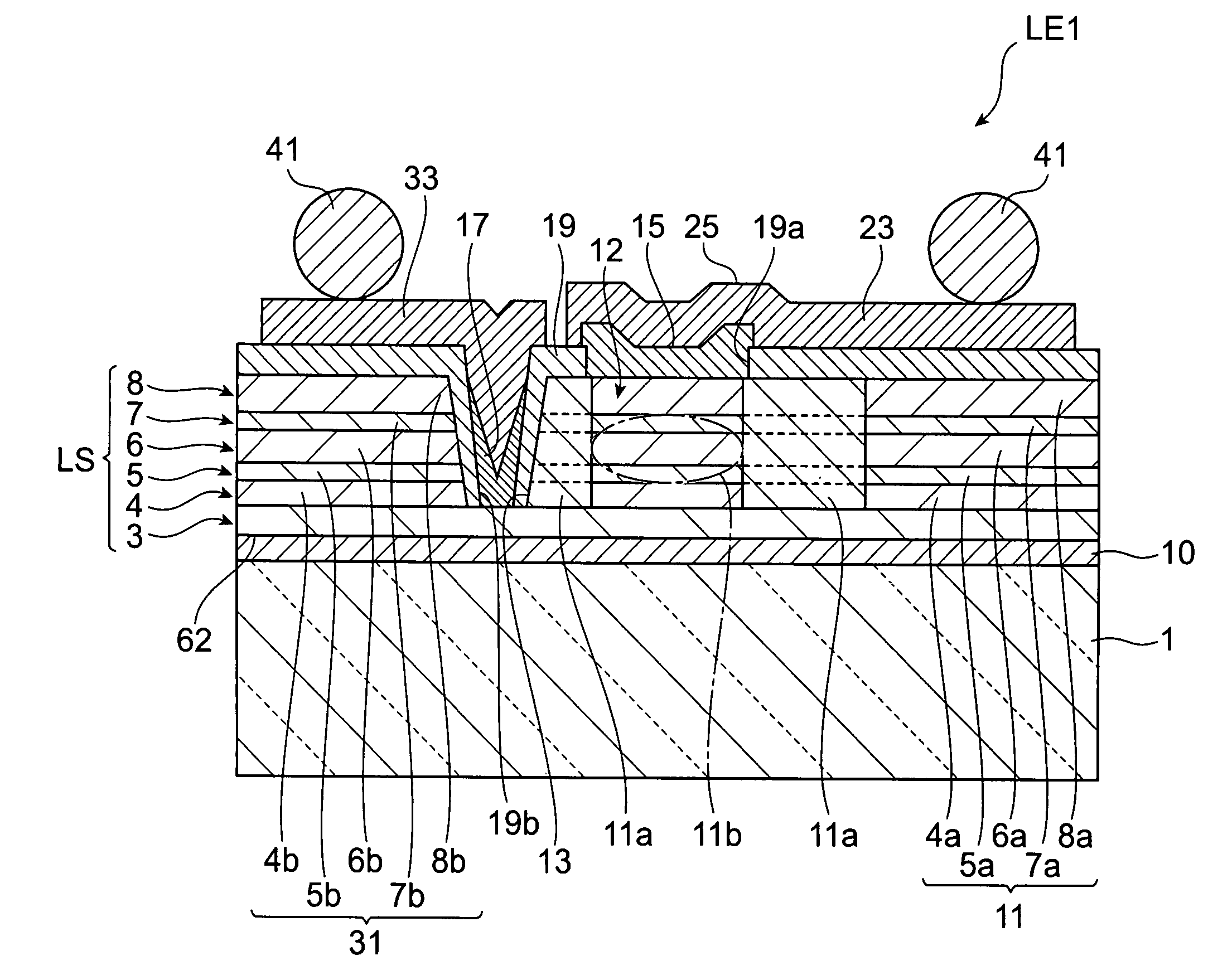

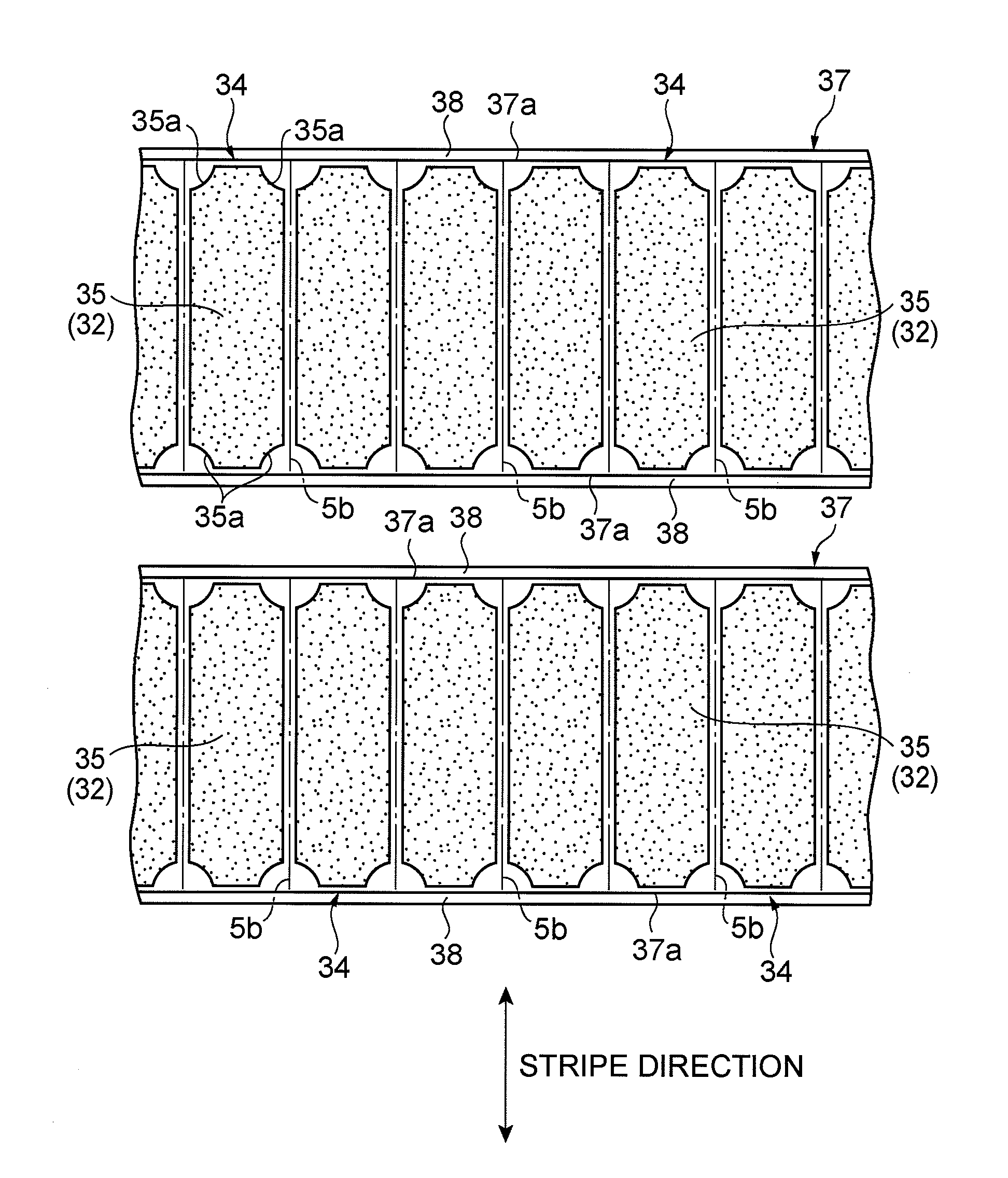

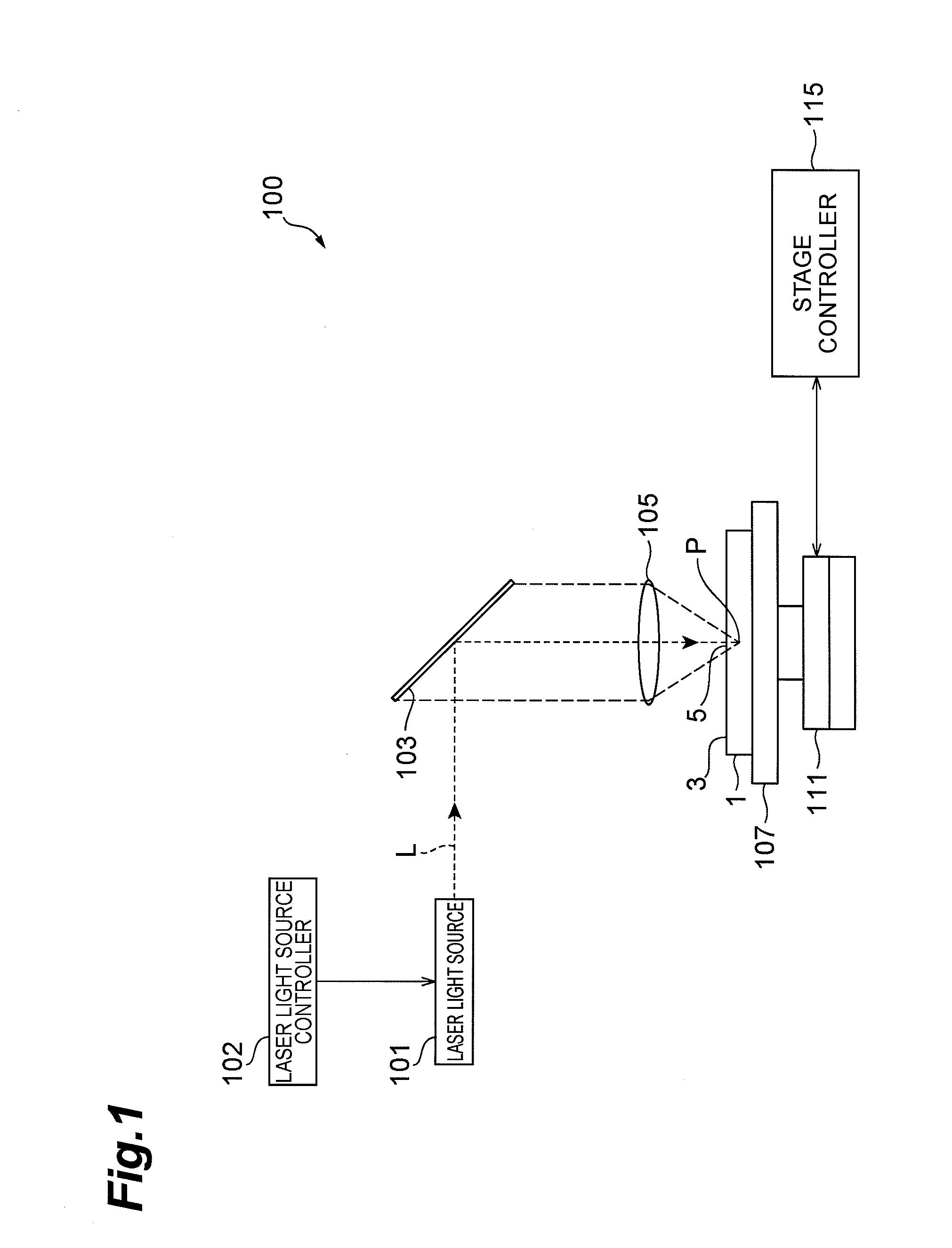

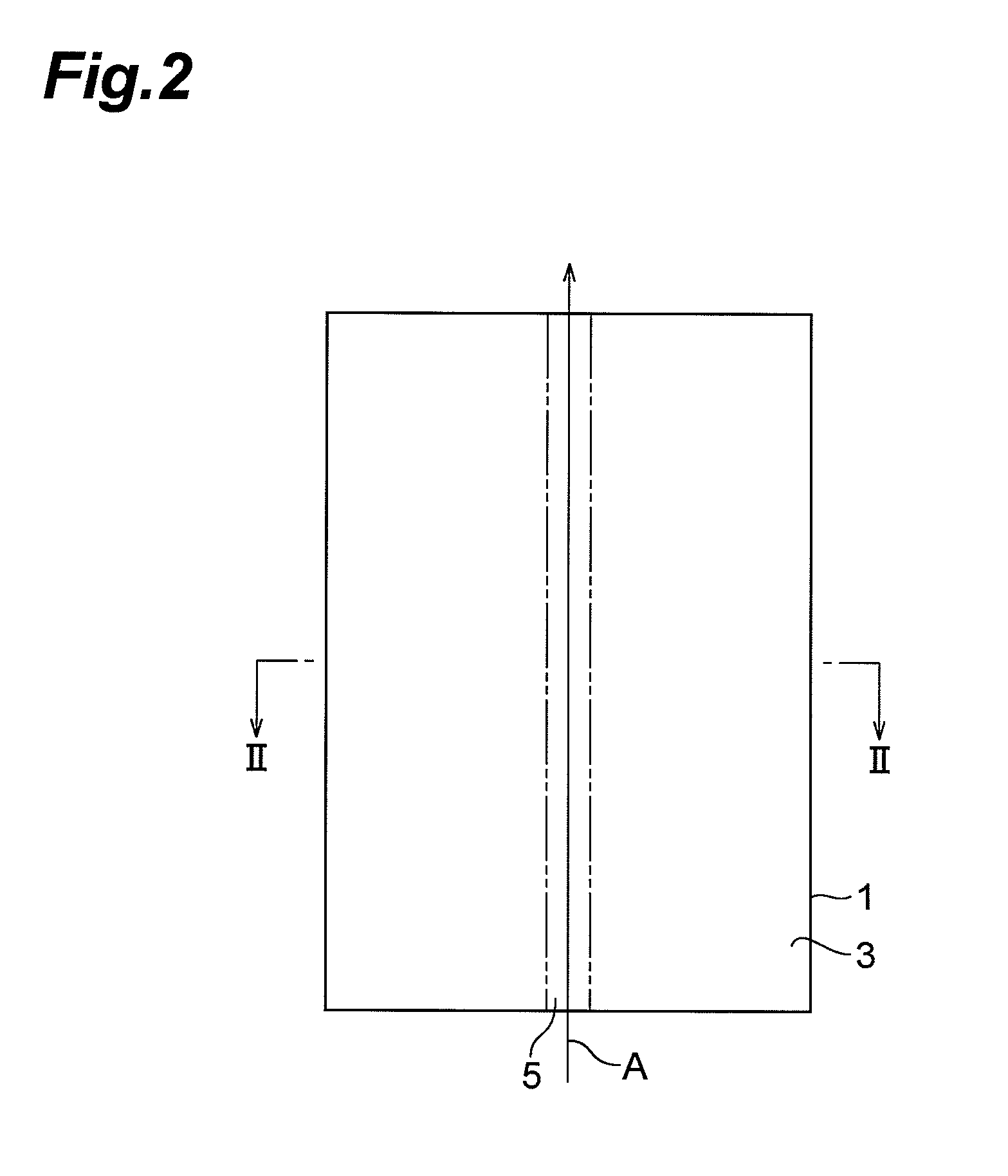

ActiveUS20100240159A1Improve productivitySemiconductor laser structural detailsSemiconductor/solid-state device manufacturingProduction rateLaser light

Starting point regions for cutting 8a, 8b extending along lines to cut 5a, 5b are initially formed in an object to be processed 1. The starting point regions for cutting 8b have modified regions 7b formed by irradiating the object 1 with laser light while locating a converging point within the object 1 and are formed in parts extending along the lines to cut 5b excluding portions 34b intersecting the lines to cut 5a. This makes the starting point regions for cutting 8b much less influential when cutting the object 1 from the starting point regions for cutting 8a acting as a start point, whereby bars with precise cleavage surfaces can reliably be obtained. Therefore, it is unnecessary to form a starting point region for cutting along the lines to cut 5b in each of a plurality of bars, whereby the productivity of semiconductor laser elements can be improved.

Owner:HAMAMATSU PHOTONICS KK

Nitride semiconductor laser device and manufacturing method therefor

InactiveUS20040238810A1Improve smoothnessEasy to operateOptical wave guidancePolycrystalline material growthSingle crystalActive layer

The object of this invention is to provide a high-output type nitride semiconductor laser device comprising a pair of end faces of a resonator. The nitride semiconductor laser device comprises an n-type nitride semiconductor layer or layers, a p-type nitride semiconductor layer or layers and a resonator, provided with an active layer comprising nitride semiconductor containing In therebetween, wherein at least light emitting end face of the resonator is covered with an end face film of single crystal AlxGa1-xN (0<=x<=1) formed at a low temperature not causing damage to the active layer comprising nitride semiconductor containing In.

Owner:AMMONO SP Z O O (PL)

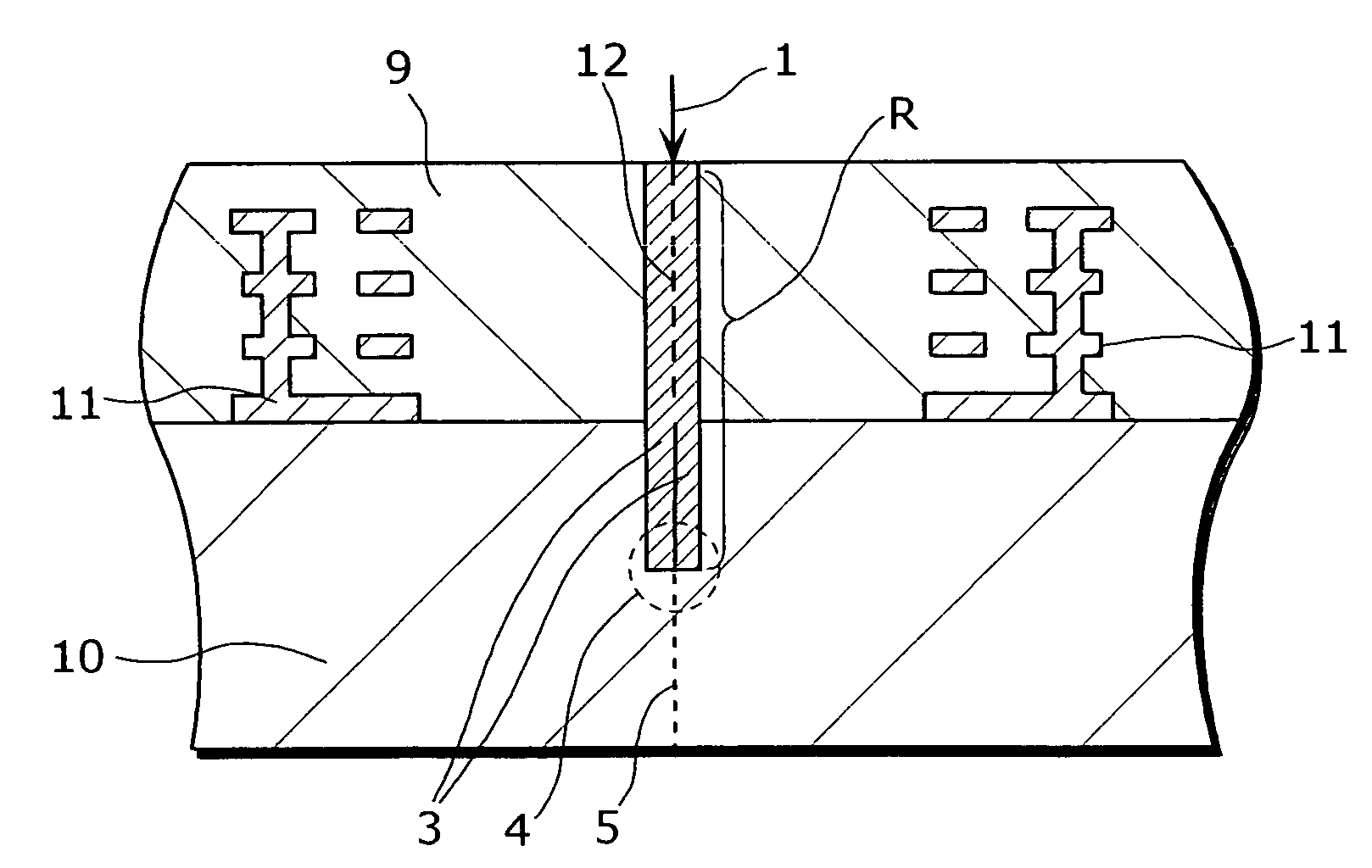

Semiconductor laser, semiconductor device, and their manufacture methods

A substrate is made of SiC. A plurality of AlxGa1-xN patterns (0<=x<=1) is formed on a surface of the substrate and dispersively distributed in an in-plane of the substrate. An AlyGa1-yN buffer layer (0<=y<=1) covers the surface of the substrate and the AlxGa1-xN patterns. A laser structure is formed on the AlyGa1-yN buffer layer. Since the AlGaN buffer layer is grown by using the AlGaN patterns as seed crystals, a dislocation density of a predetermined region in the AlGaN buffer layer can be lowered. The characteristics of a laser structure can be improved by forming the laser structure above the region having a low dislocation density. Since the AlGaN pattern has electric conductivity, the device resistance can be suppressed from being increased.

Owner:FUJITSU LTD

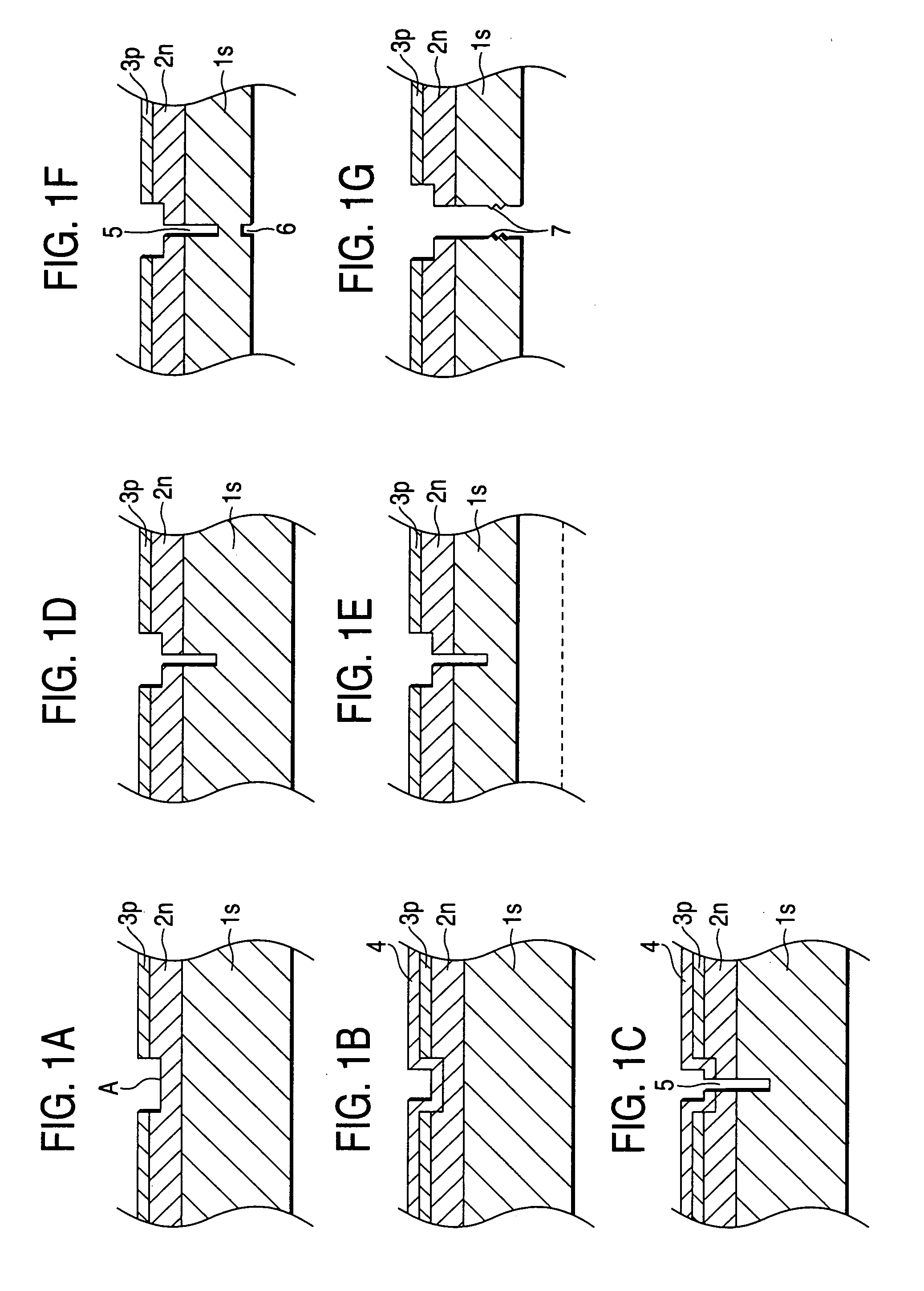

Semiconductor element and method for producing the same

InactiveUS20050186760A1High yieldLow costLaser detailsSemiconductor laser structural detailsEngineeringLaser beams

A plurality of Group III nitride compound semiconductor layers are formed on a substrate for performing the formation of elements and the formation of electrodes. The Group III nitride compound semiconductor layers on parting lines are removed by etching or dicing due to a dicer so that only an electrode-forming layer on a side near the substrate remains or no Group III nitride compound semiconductor layer remains on the parting lines. A protective film is formed on the whole front surface. Separation grooves are formed in the front surface of the substrate by laser beam irradiation. The protective film is removed together with reaction products produced by the laser beam irradiation. The rear surface of the substrate 1s is polished to reduce the thickness of the substrate. Then, rear grooves corresponding to the latticed frame-shaped parting lines are formed in the rear surface of the substrate. The substrate is divided into individual elements along the parting lines.

Owner:TOYODA GOSEI CO LTD

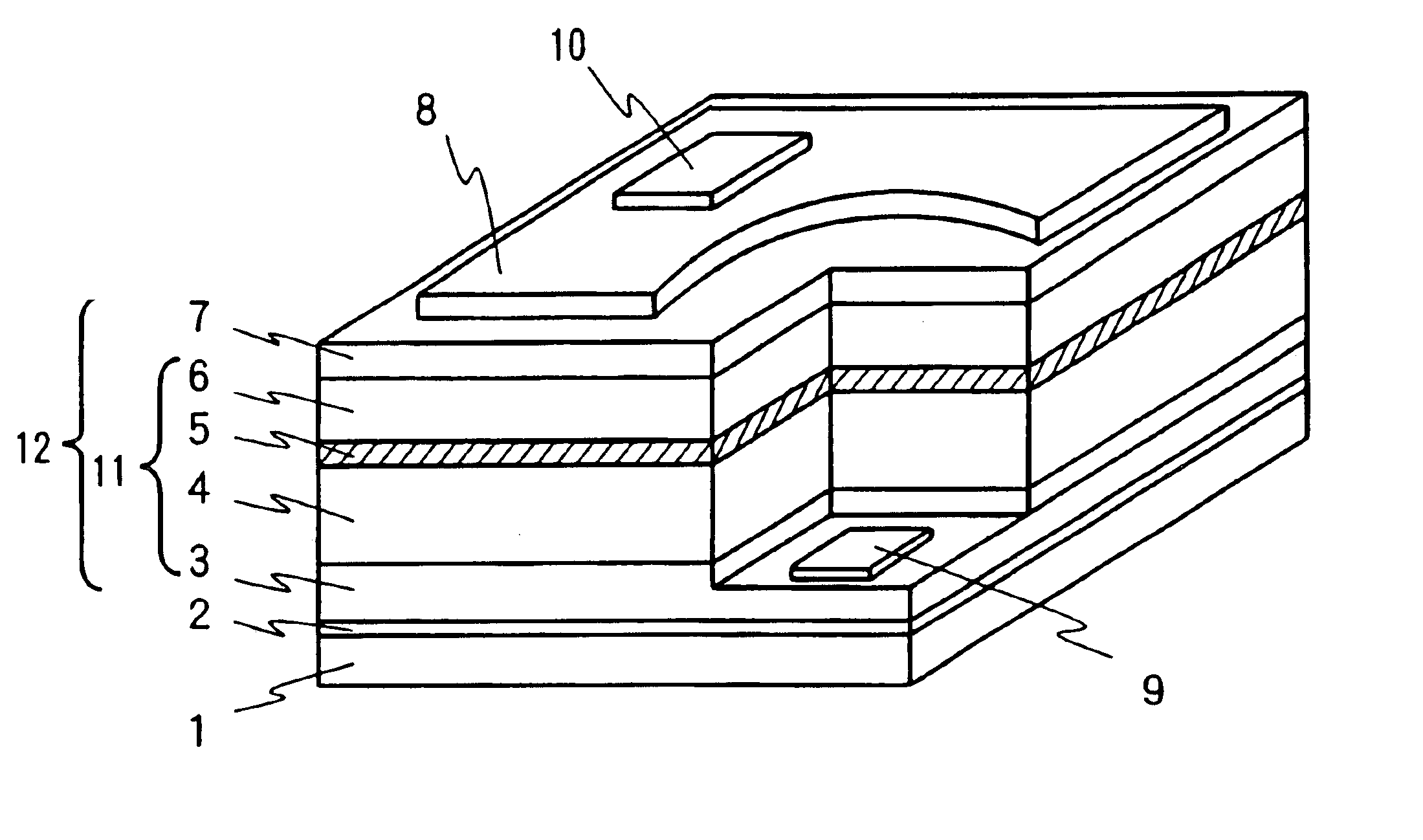

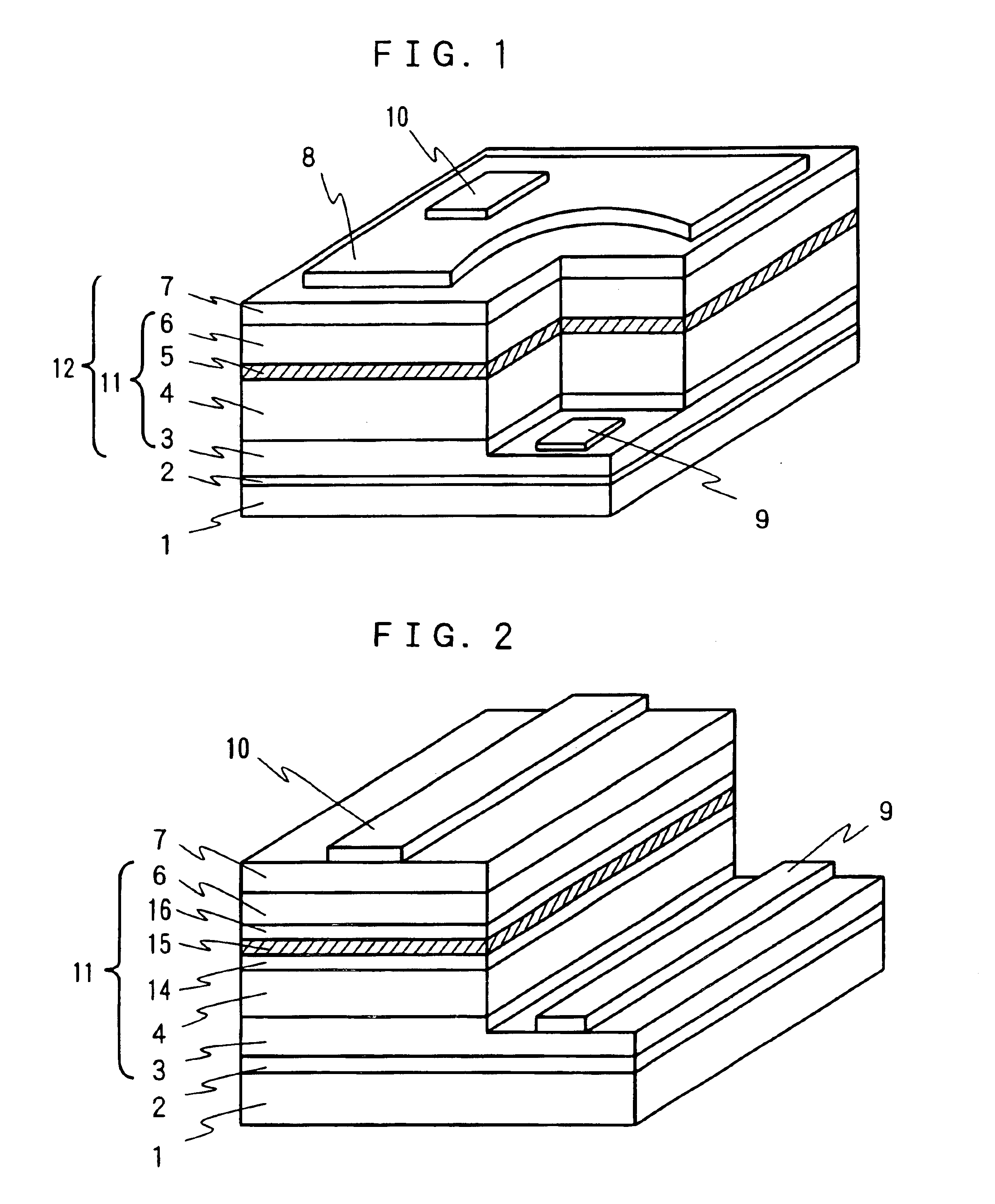

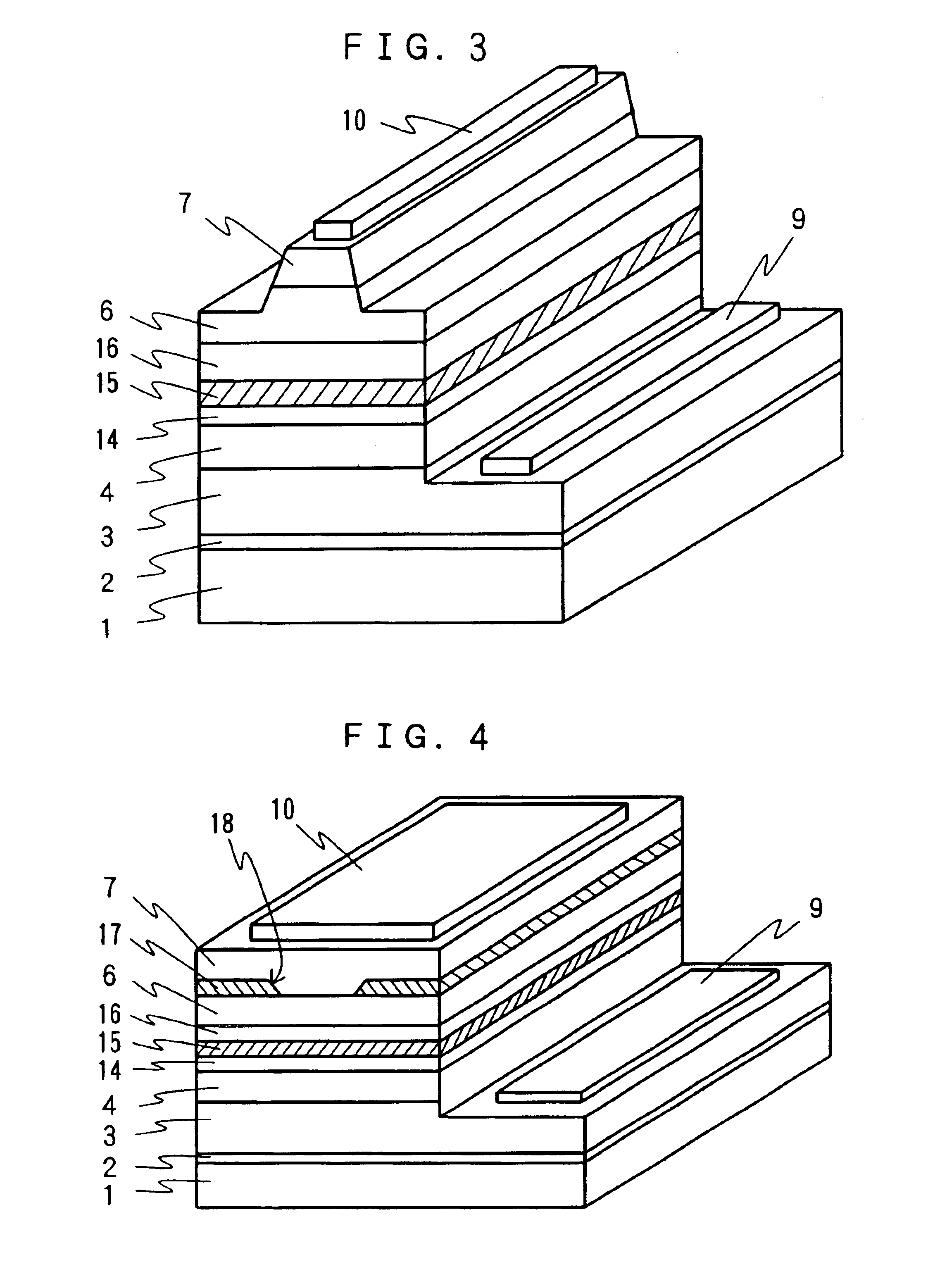

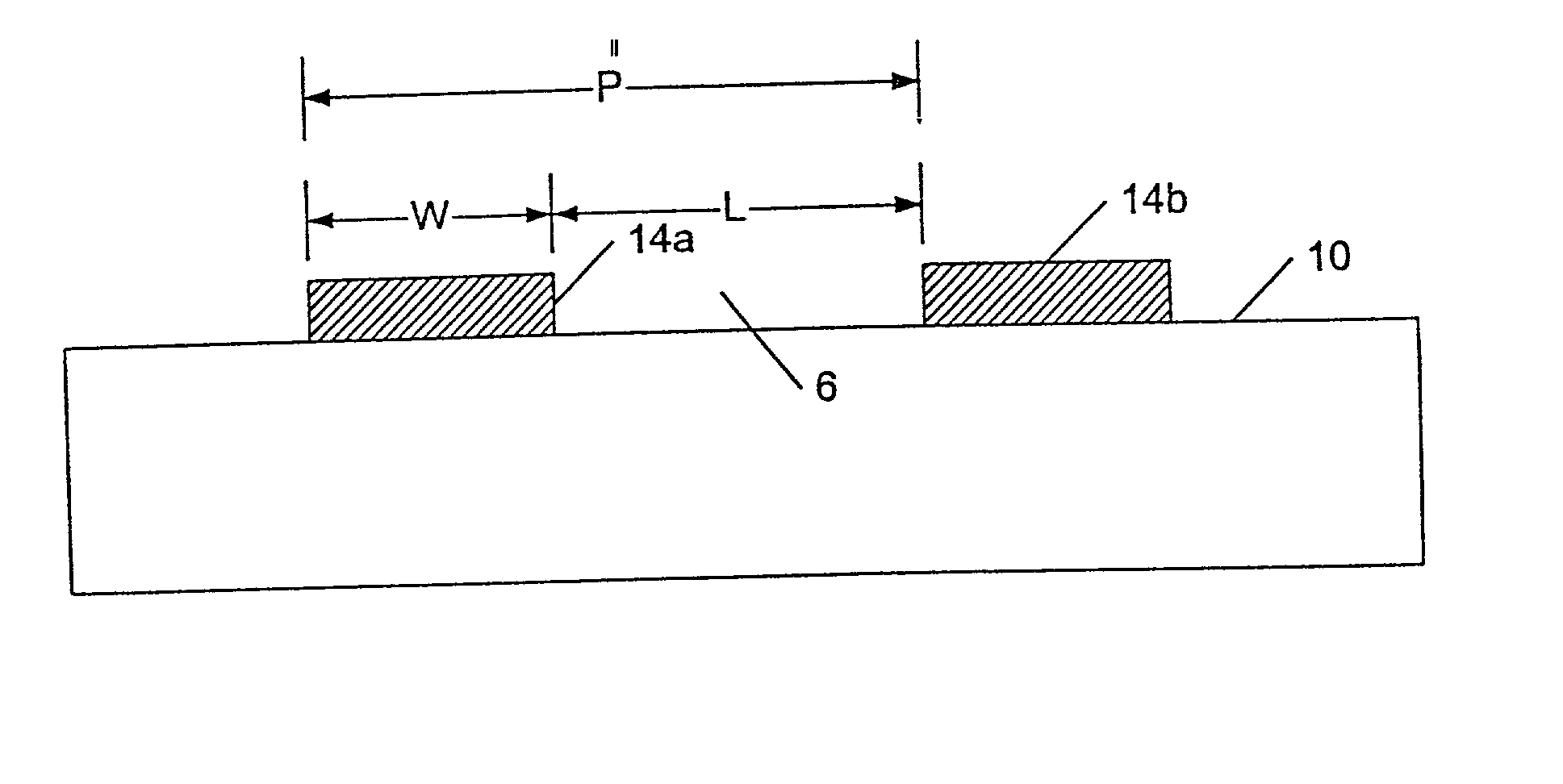

GaN single crystal substrate and method of making the same

InactiveUS20070105351A1Avoid crystal qualityLarge warpagePolycrystalline material growthLaser detailsSingle crystal substrateOptoelectronics

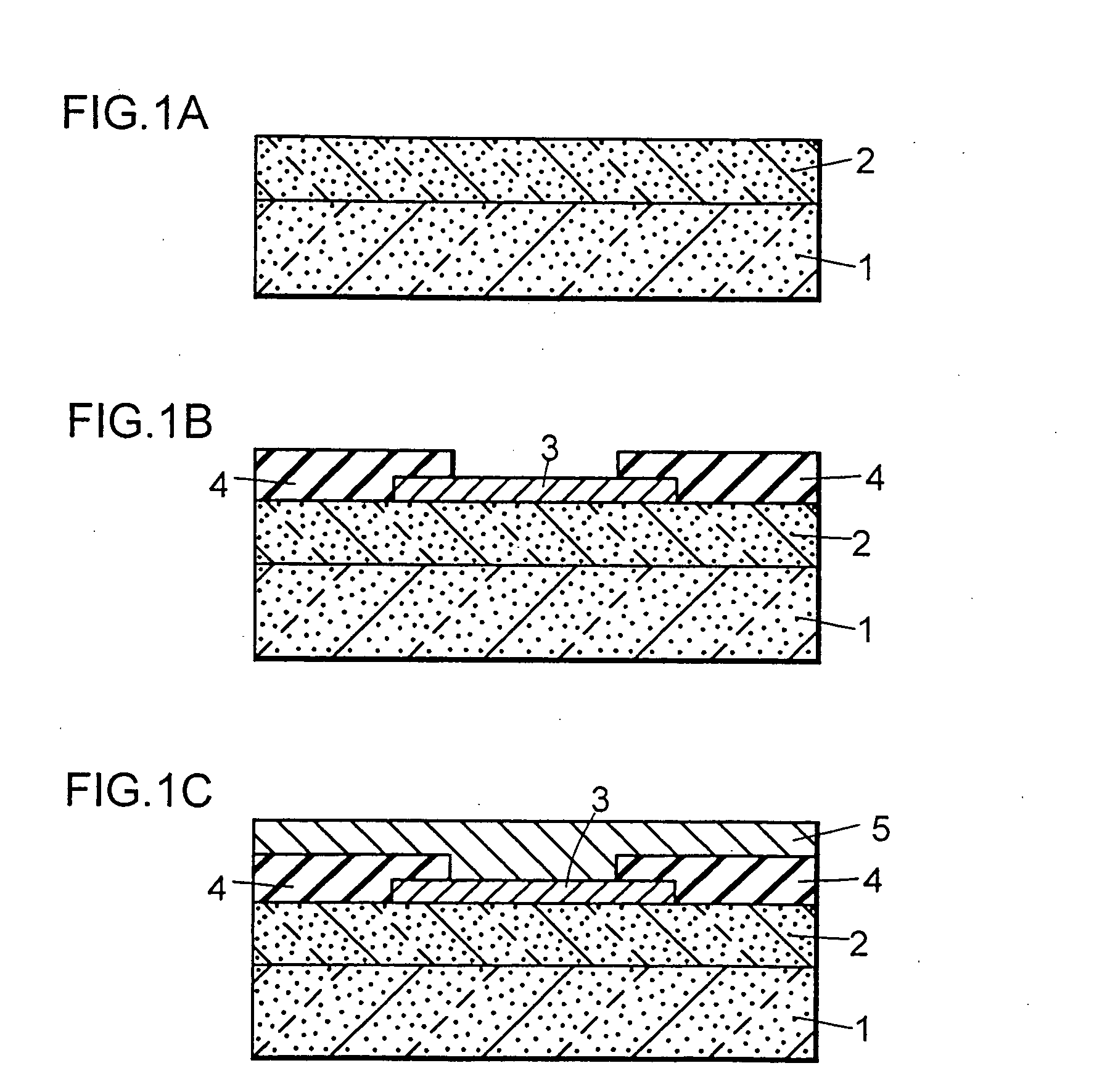

The method of making a GaN single crystal substrate comprises a mask layer forming step of forming on a GaAs substrate 2 a mask layer 8 having a plurality of opening windows 10 disposed separate from each other; and an epitaxial layer growing step of growing on the mask layer 8 an epitaxial layer 12 made of GaN.

Owner:SUMITOMO ELECTRIC IND LTD

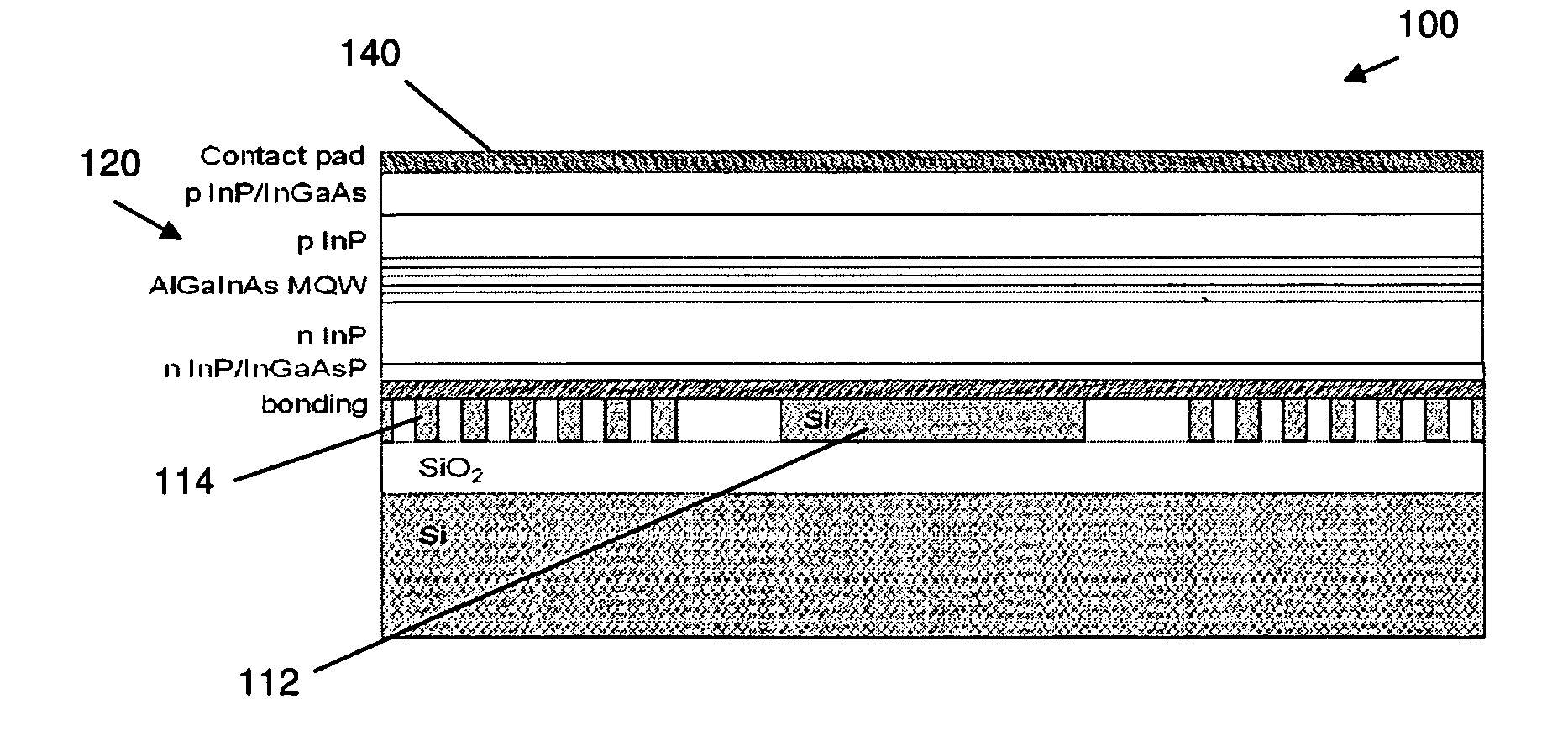

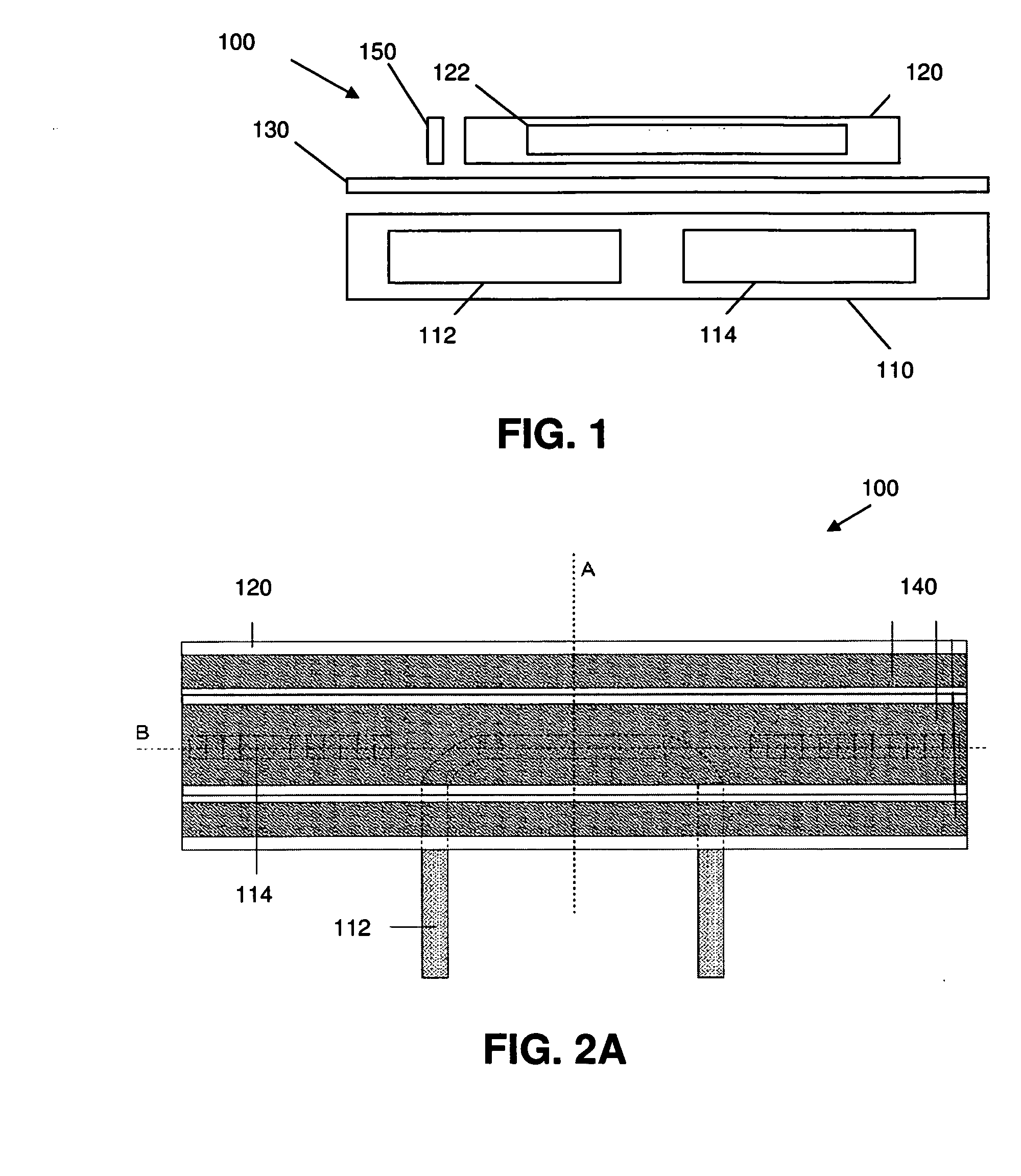

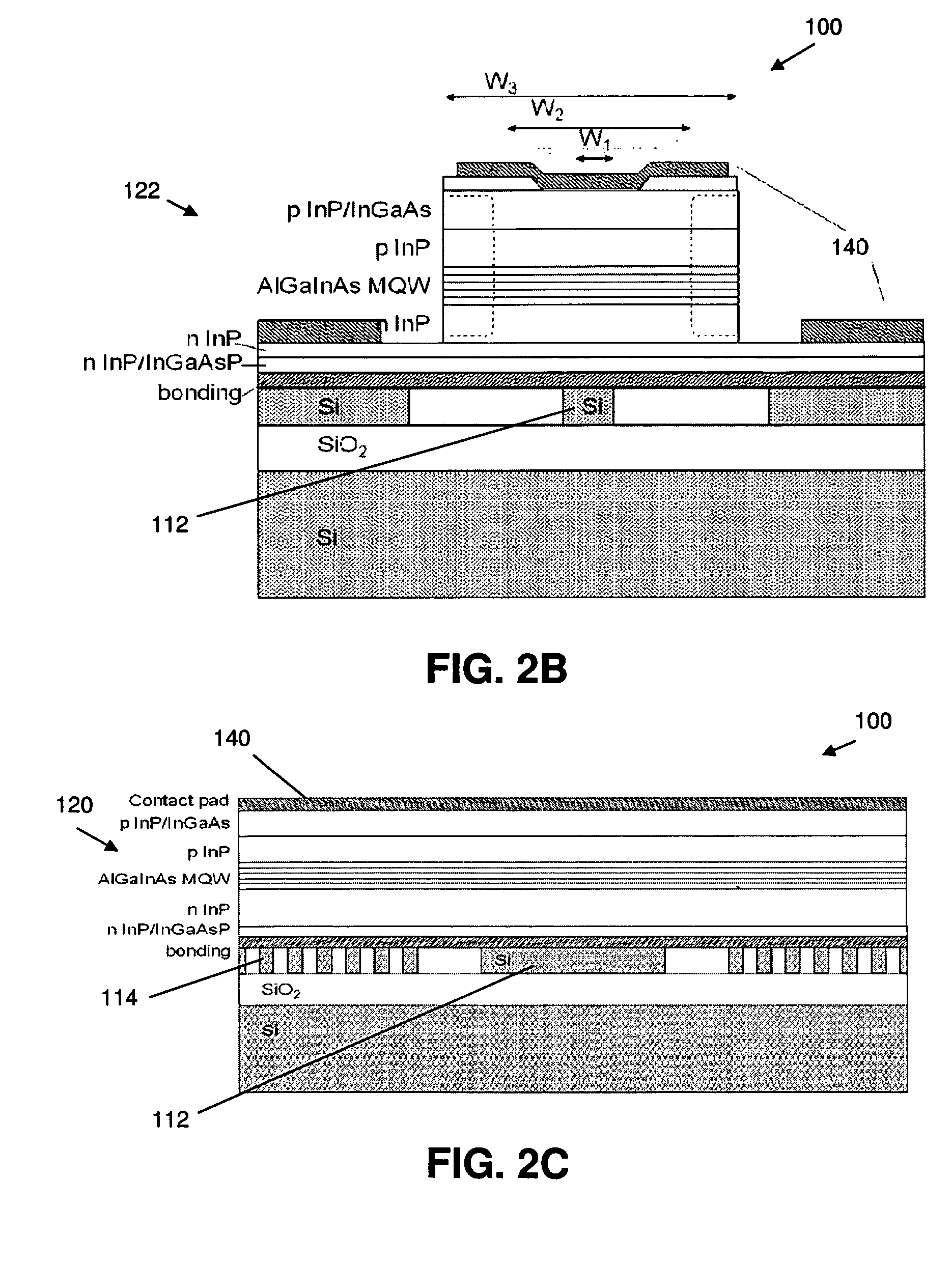

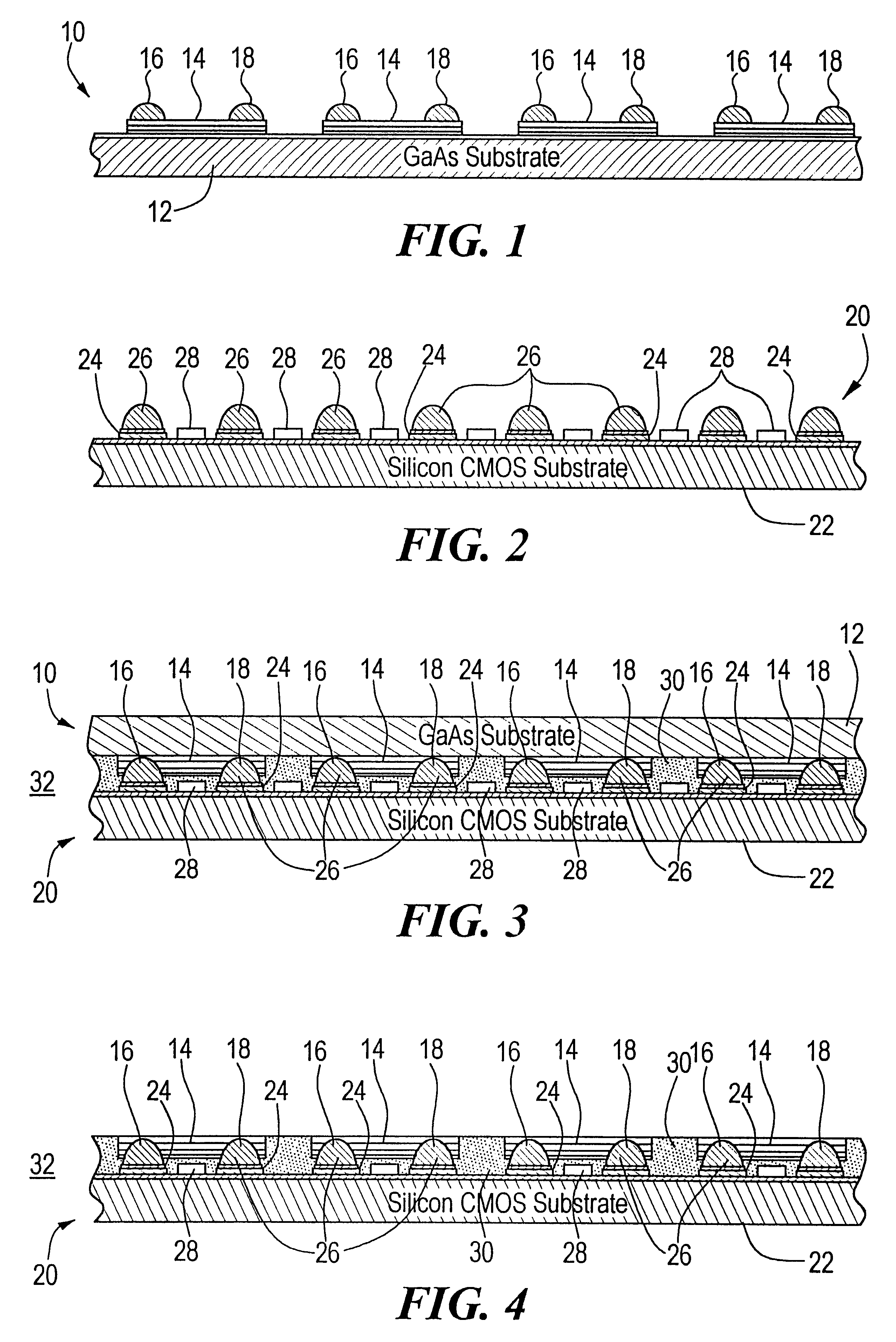

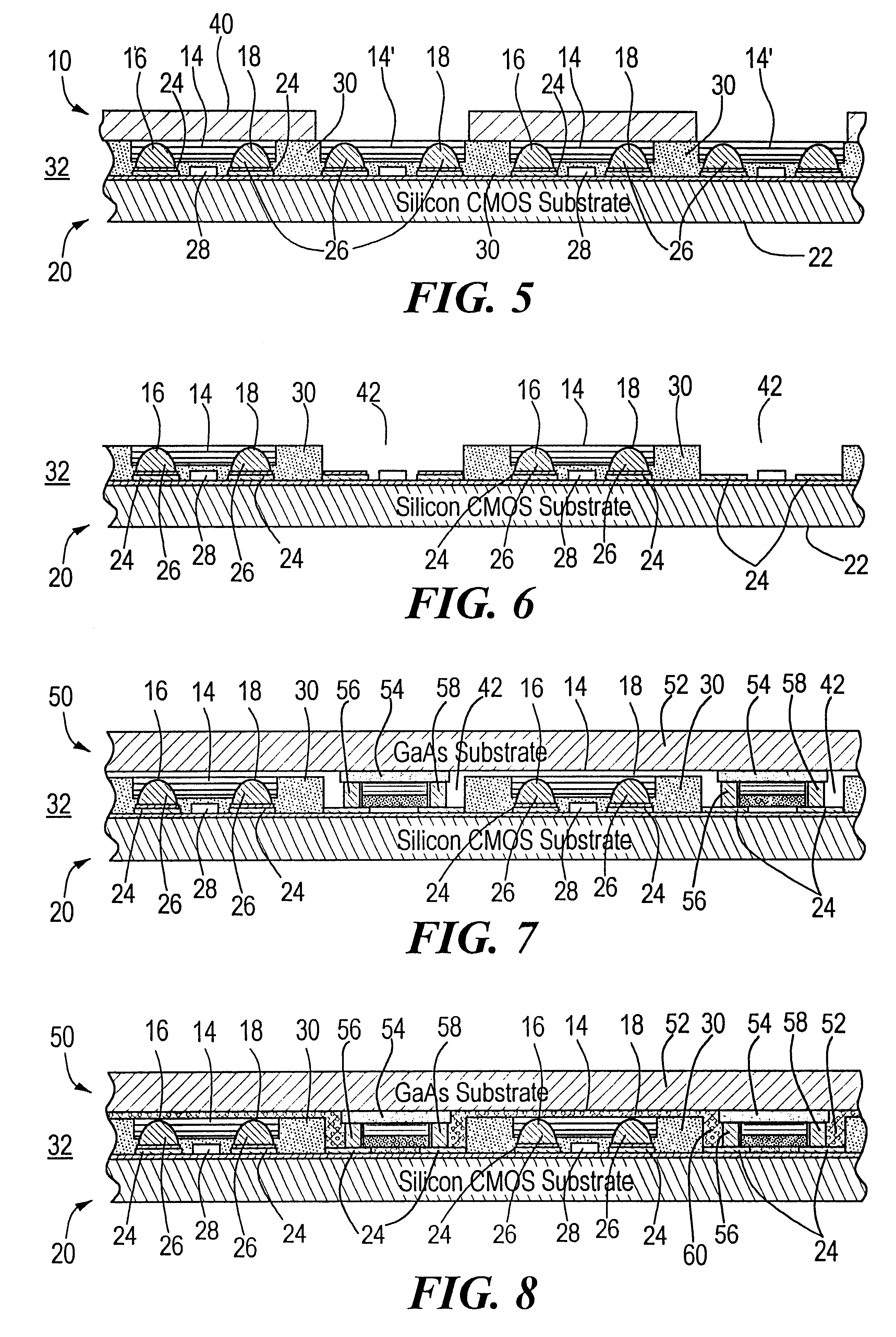

Laser light coupling into soi CMOS photonic integrated circuit

ActiveUS20120320939A1Less complexSmall sizeLaser detailsSemiconductor laser structural detailsSoi cmosCoupling

A hybrid laser for generating radiation includes an optical passive material and an optical active material. The laser includes a first optical waveguide and optical laser components with reflectors in the optical passive material. The first optical waveguide is adapted for coupling out radiation from the hybrid laser. The laser also includes a second optical waveguide defined in the optical active material. The optical laser components include reflectors defining a cavity and furthermore are adapted for providing laser cavity confinement in the first optical waveguide and the second optical waveguide. The second optical waveguide thereby is positioned at least partly over the first optical waveguide so that an evanescent coupling interface is defined between the second optical waveguide and the first optical waveguide and the evanescent coupling interface is positioned within the laser cavity.

Owner:UNIV GENT +1

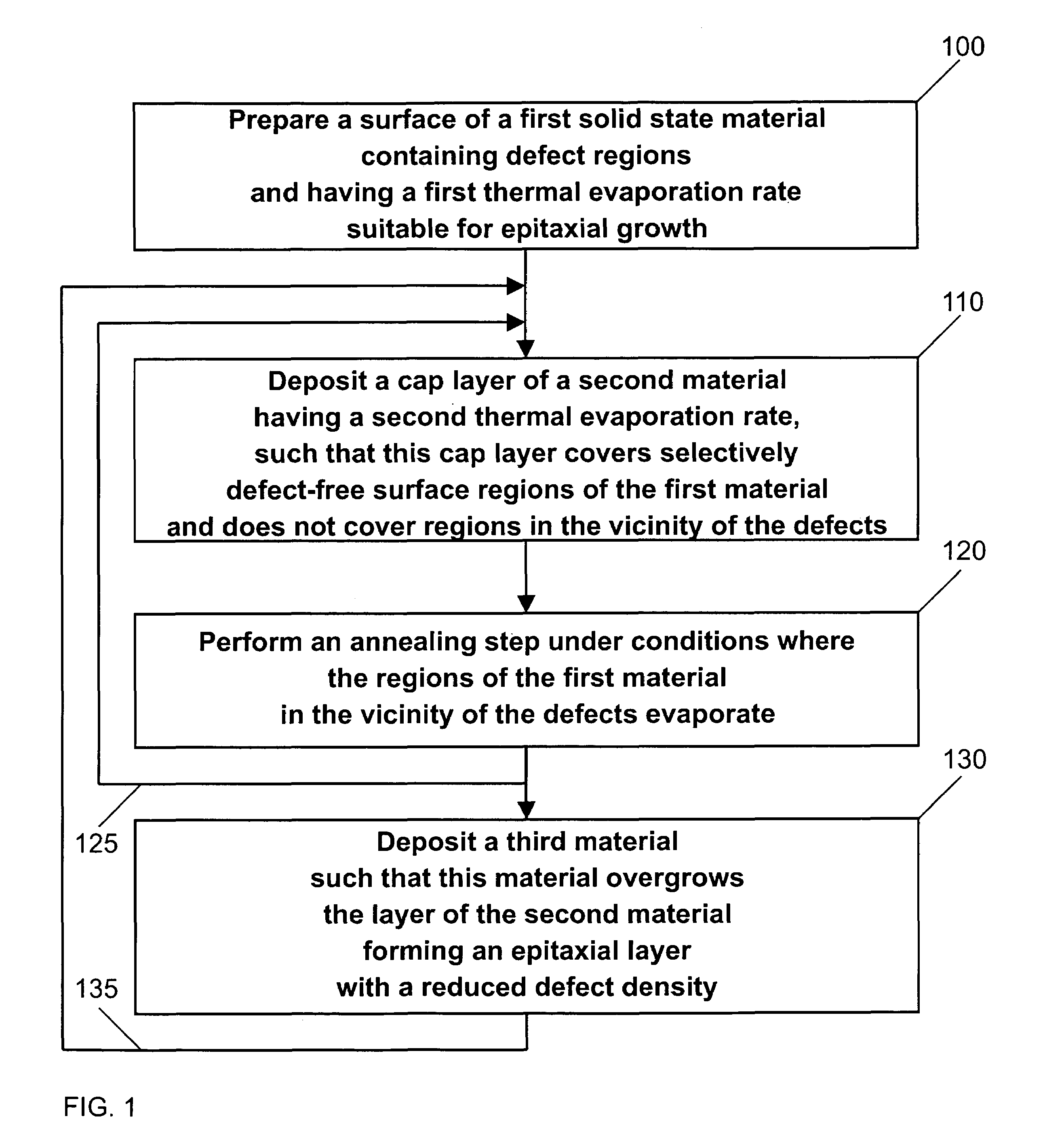

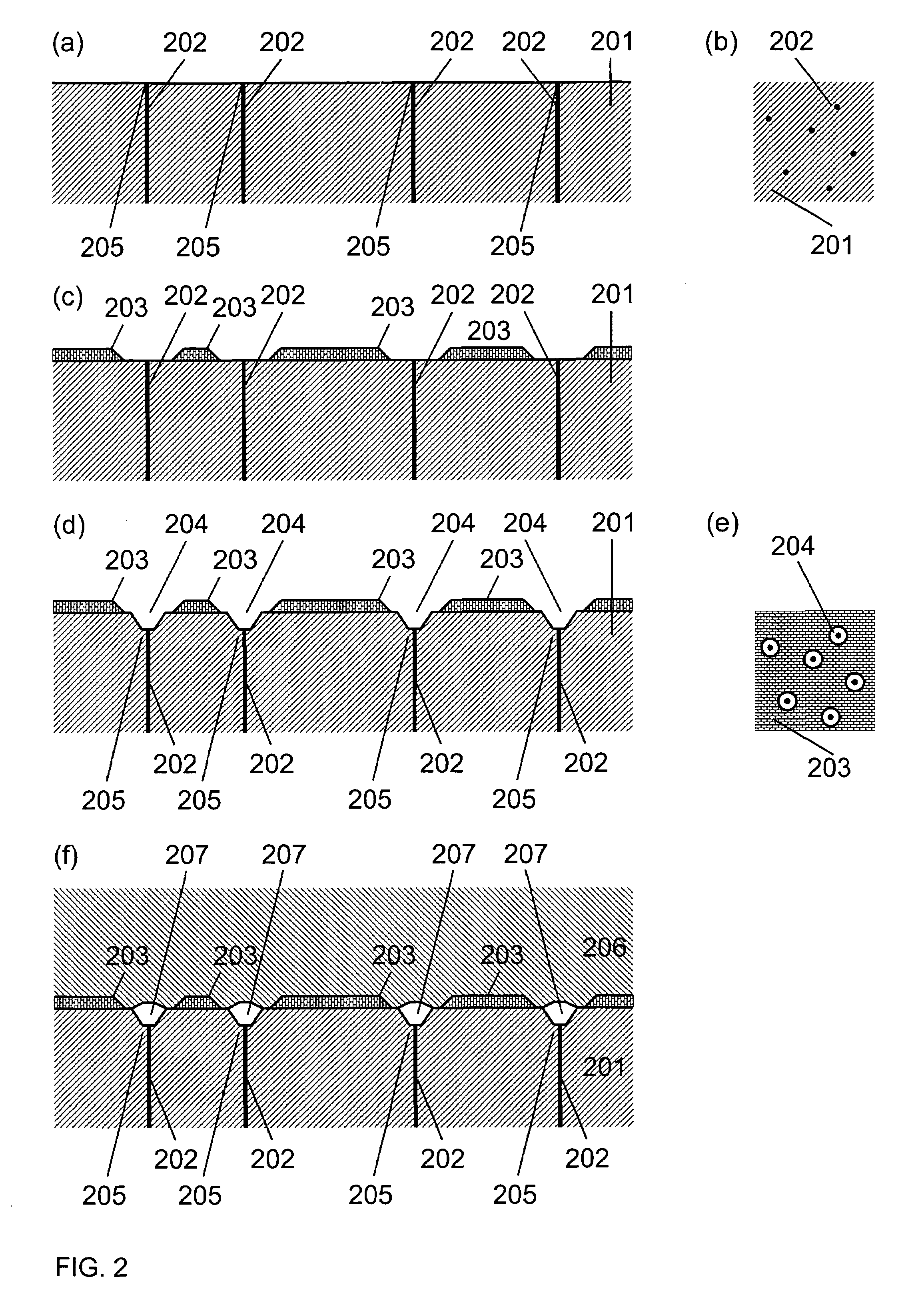

Defect-free semiconductor templates for epitaxial growth

InactiveUS7101444B2Improve high temperature stabilityMaterial nanotechnologyLaser detailsSelective depositionSemiconductor

A semiconductor device includes at least one defect-free epitaxial layer. At least a part of the device is manufactured by a method of fabrication of defect-free epitaxial layers on top of a surface of a first solid state material having a first thermal evaporation rate and a plurality of defects, where the surface comprises at least one defect-free surface region, and at least one surface region in a vicinity of the defects, the method including the steps of selective deposition of a second material, having a high temperature stability, on defect-free regions of the first solid state material, followed by subsequent evaporation of the regions in the vicinity of the defects, and subsequent overgrowth by a third material forming a defect-free layer.

Owner:INNOLUME

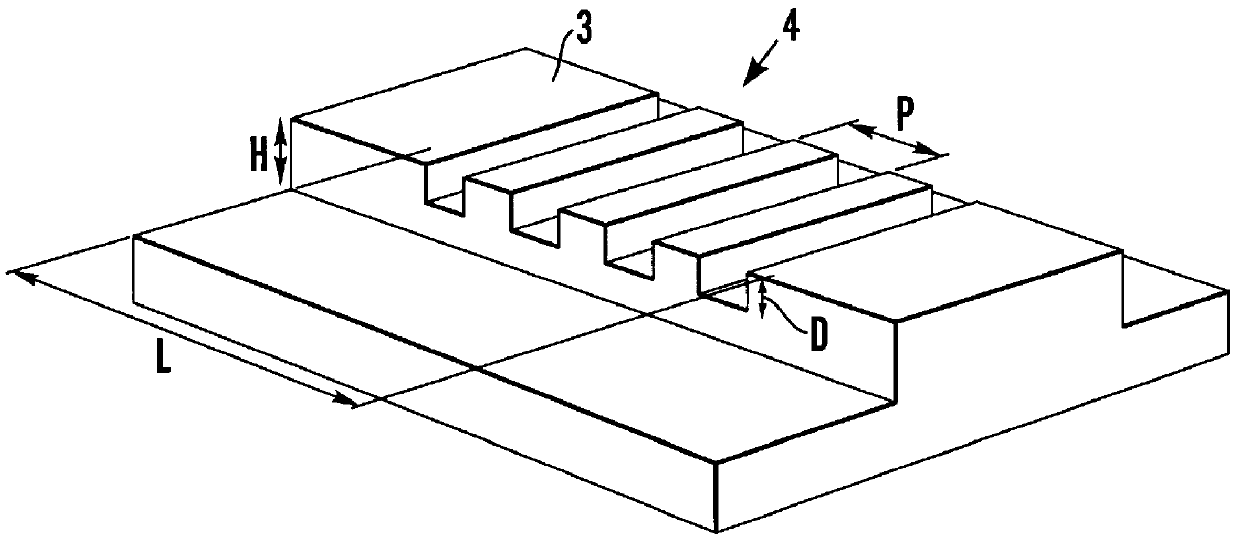

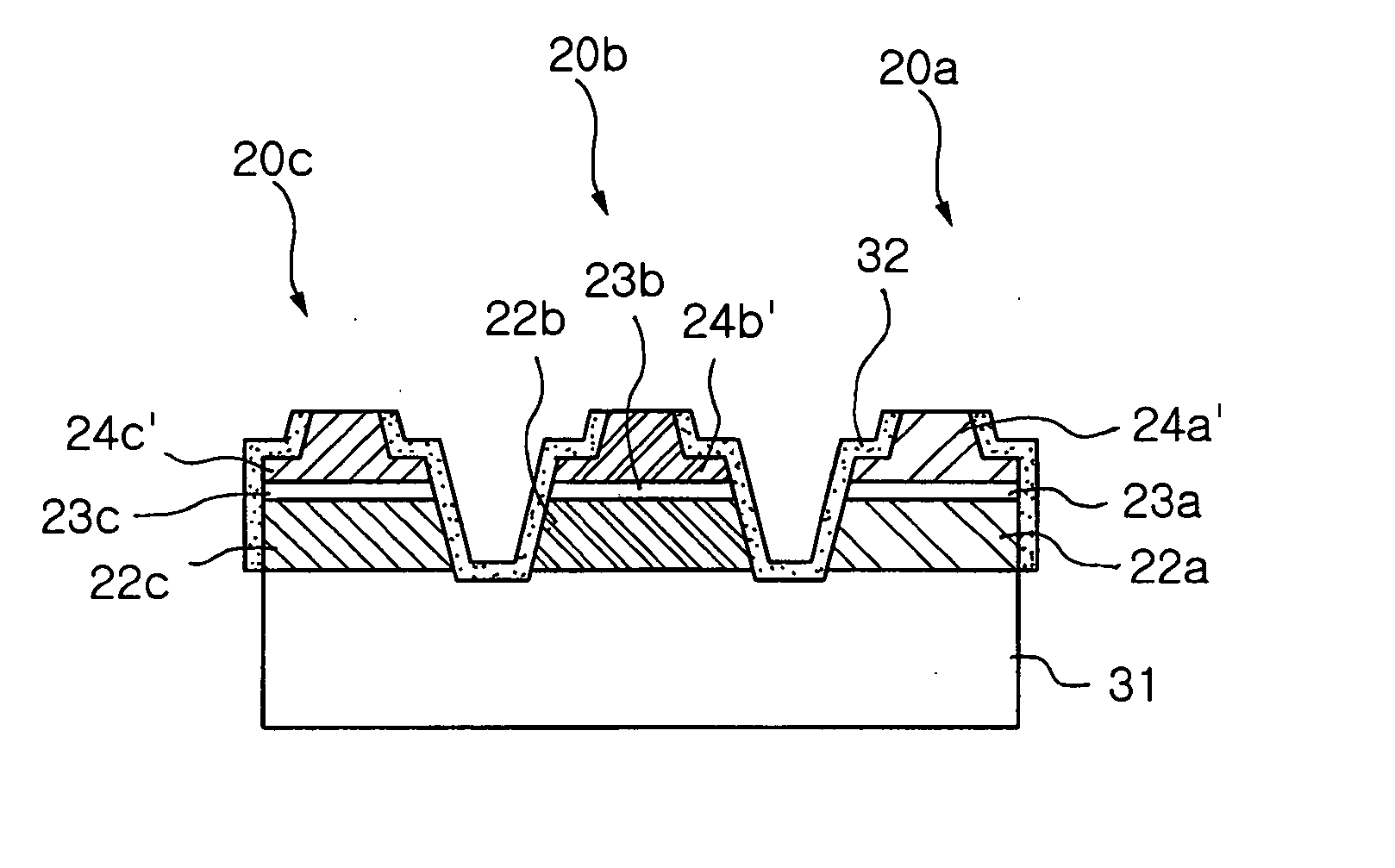

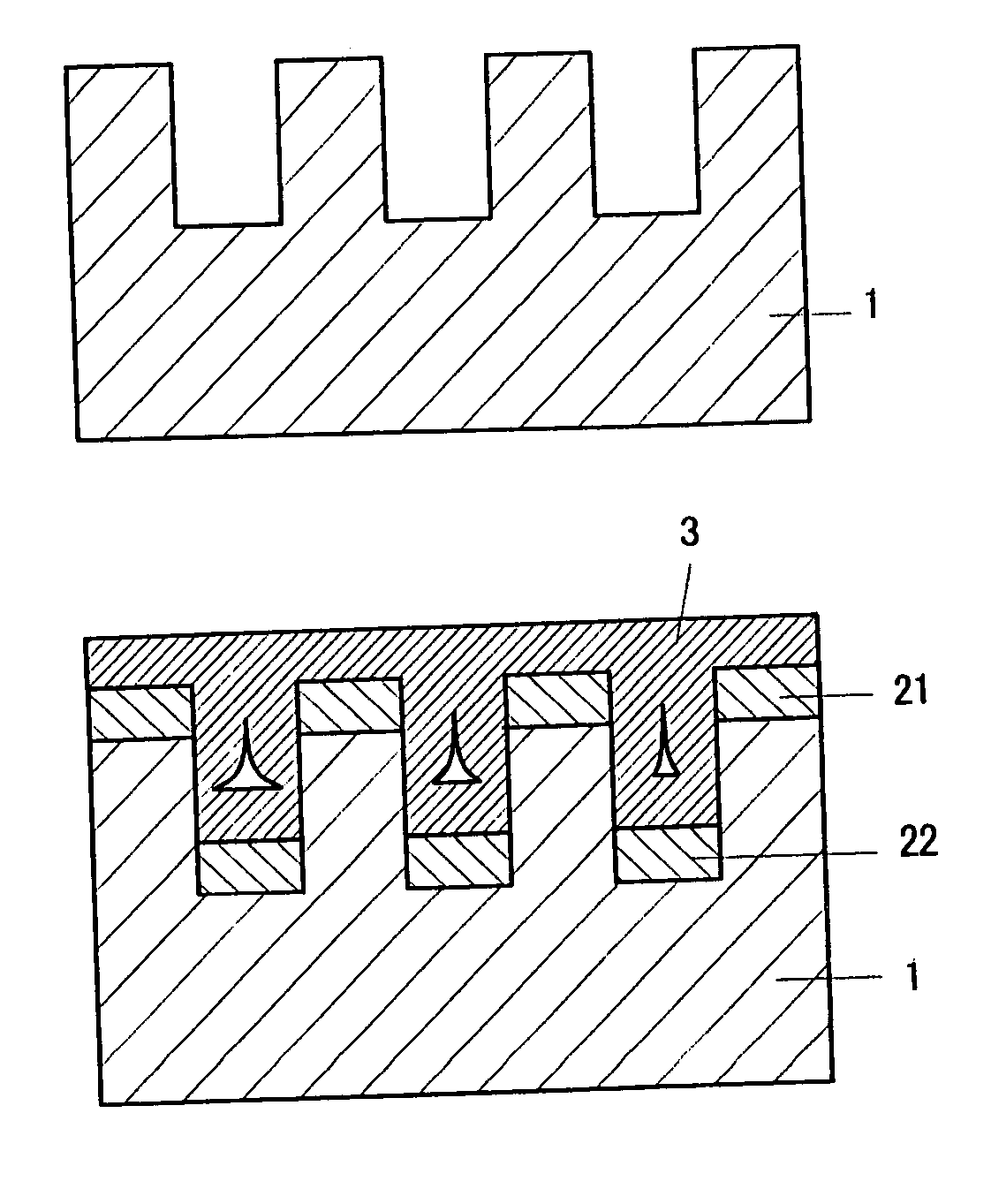

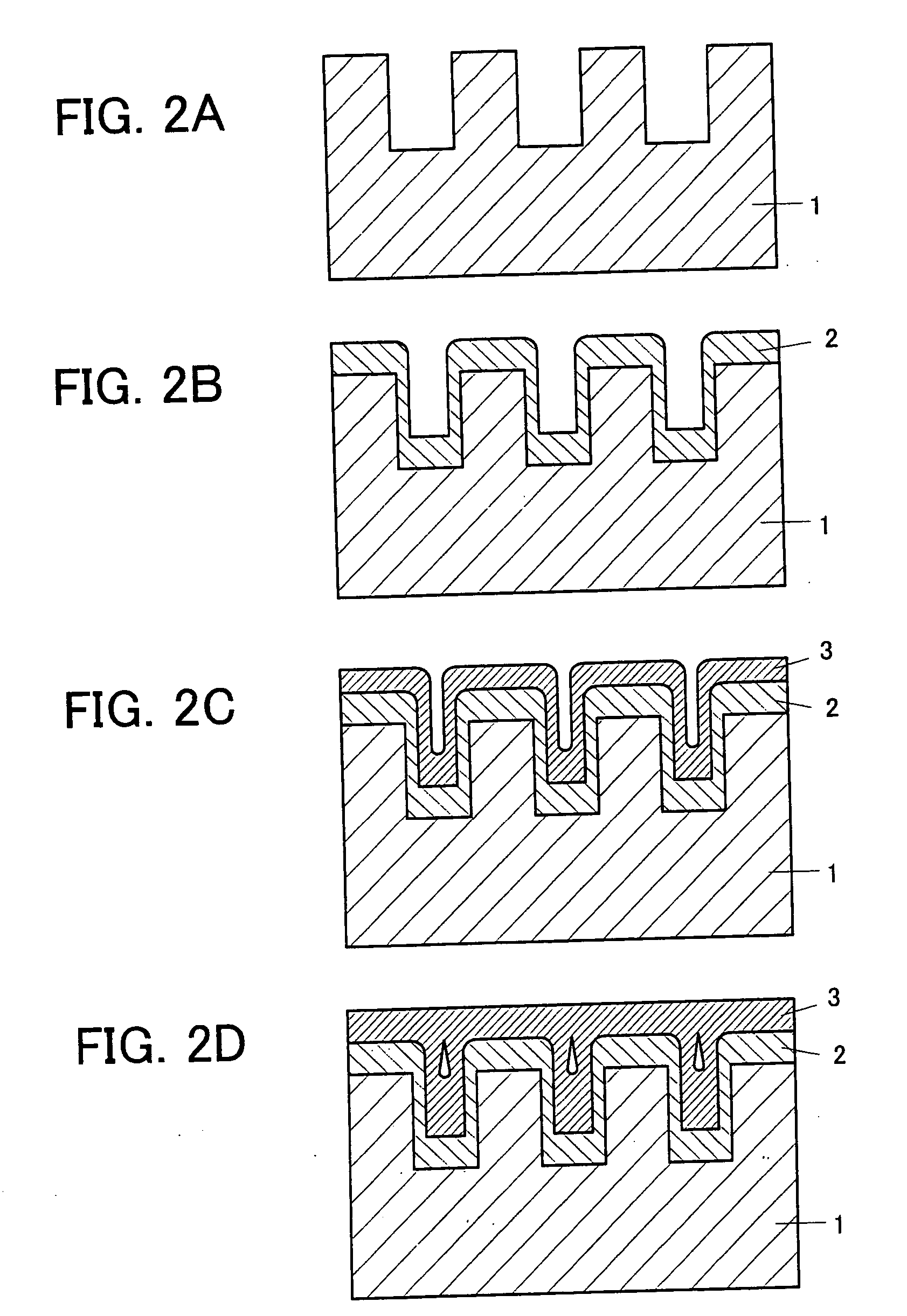

Group III nitride compound semiconductor devices and method for fabricating the same

InactiveUS20060060866A1Avoid problemsQuality improvementLaser detailsSemiconductor laser structural detailsThreading dislocationsDislocation

A sapphire substrate 1 is etched so that each trench has a width of 10 μm and a depth of 10 μm were formed at 10 μm of intervals in a stripe pattern. Next, an AlN buffer layer 2 having a thickness of approximately 40 nm is formed mainly on the upper surface and the bottom surface of the trenches of the substrate 1. Then a GaN layer 3 is formed through vertical and lateral epitaxial growth. At this time, lateral epitaxial growth of the buffer layer 21, which was mainly formed on the upper surface of the trenches, filled the trenches and thus establishing a flat top surface. The portions of the GaN layer 3 formed above the top surfaces of the mesas having a depth of 10 μm exhibited significant suppression of threading dislocation in contrast to the portions formed above the bottoms of the trenches.

Owner:TOYODA GOSEI CO LTD

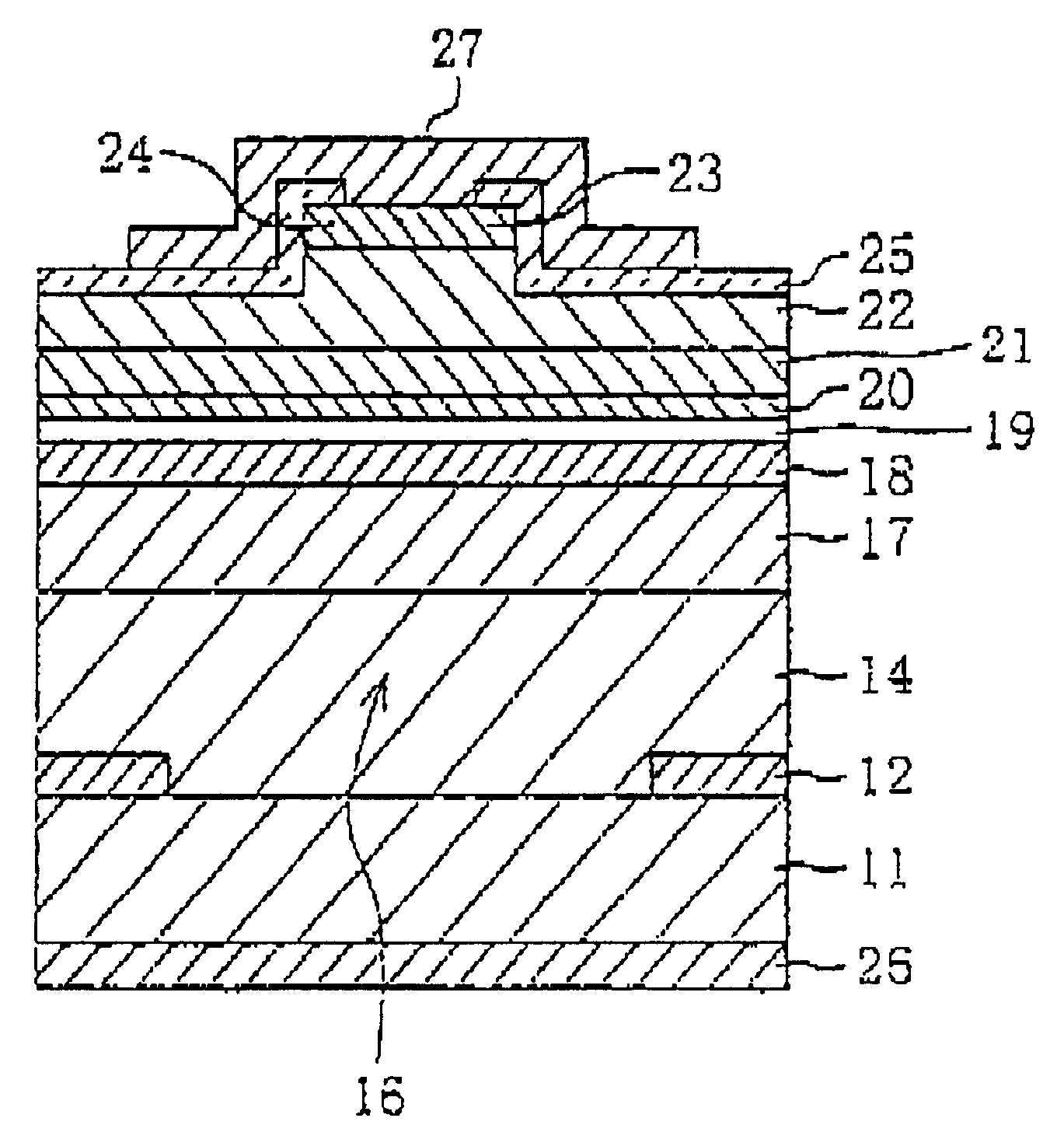

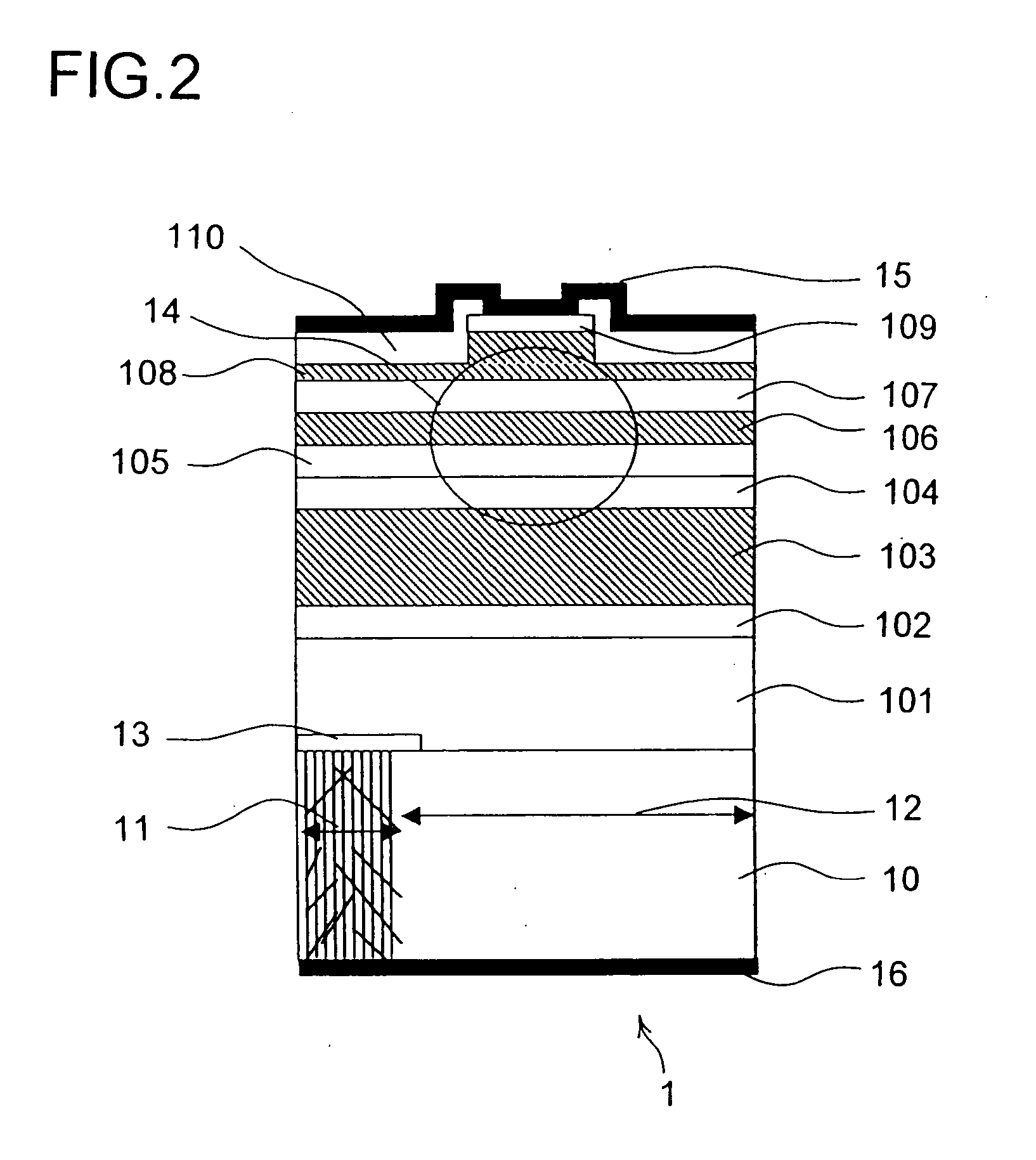

Nitride semiconductor device, its manufacturing method, and semiconductor optical apparatus

InactiveUS20050042787A1Stress minimizationRelaxation stressLaser detailsSemiconductor laser structural detailsHigh densityCrystallographic defect

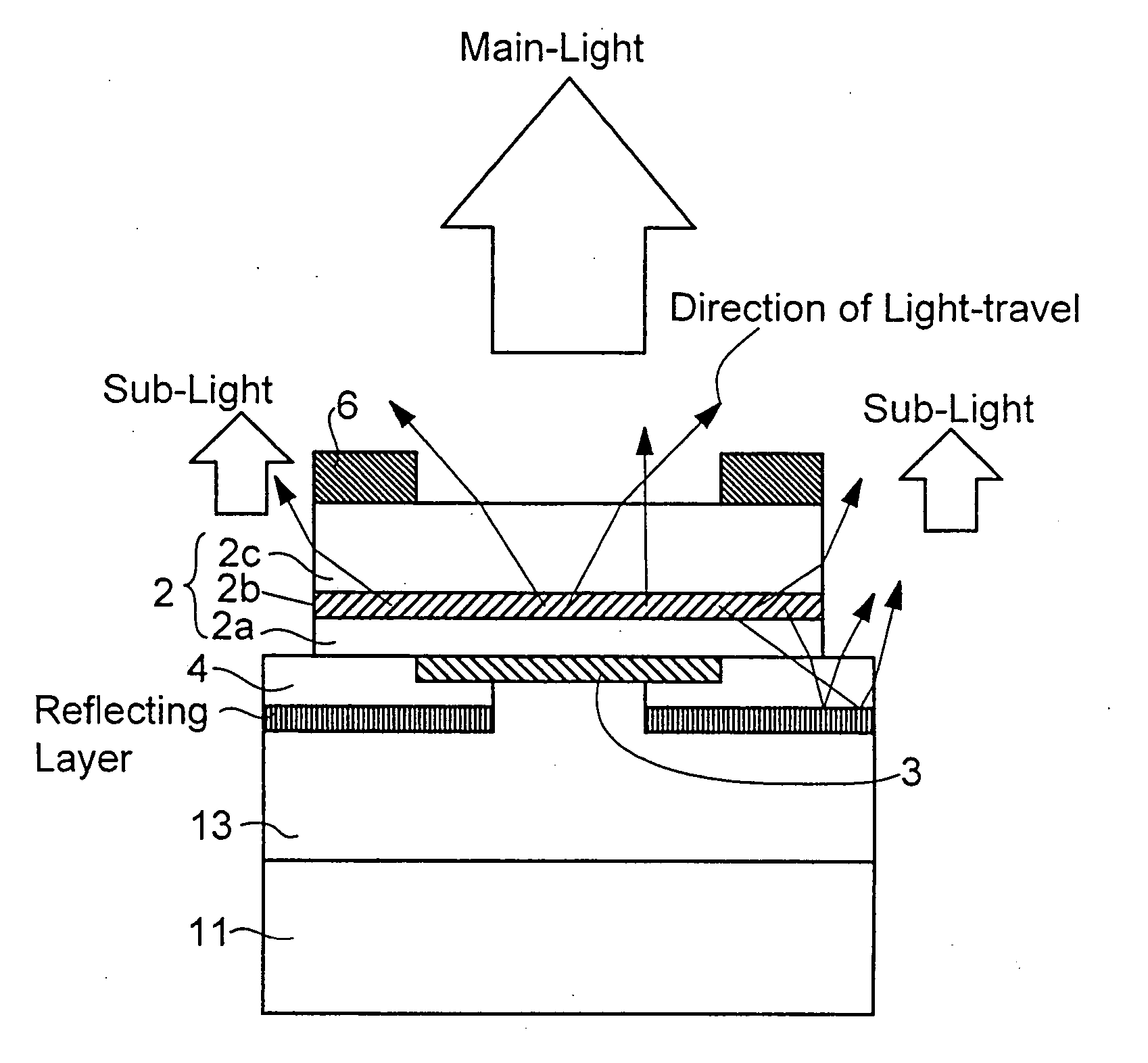

A nitride semiconductor laser device with a reduction in internal crystal defects and an alleviation in stress, and a semiconductor optical apparatus comprising this nitride semiconductor laser device. First, a growth suppressing film against GaN crystal growth is formed on the surface of an n-type GaN substrate equipped with alternate stripes of dislocation concentrated regions showing a high density of crystal defects and low-dislocation regions so as to coat the dislocation concentrate regions. Next, the n-type GaN substrate coated with the growth suppressing film is overlaid with a nitride semiconductor layer by the epitaxial growth of GaN crystals. Further, the growth suppressing film is removed to adjust the lateral distance between a laser waveguide region and the closest dislocation concentrated region to 40 μm or more.

Owner:SHARP KK +1

Group iii nitride semiconductor epitaxial substrate and method for manufacturing the same

InactiveUS20100327228A1Improve crystal qualitySuppressed dislocationPolycrystalline material growthFinal product manufactureThreading dislocationsDislocation

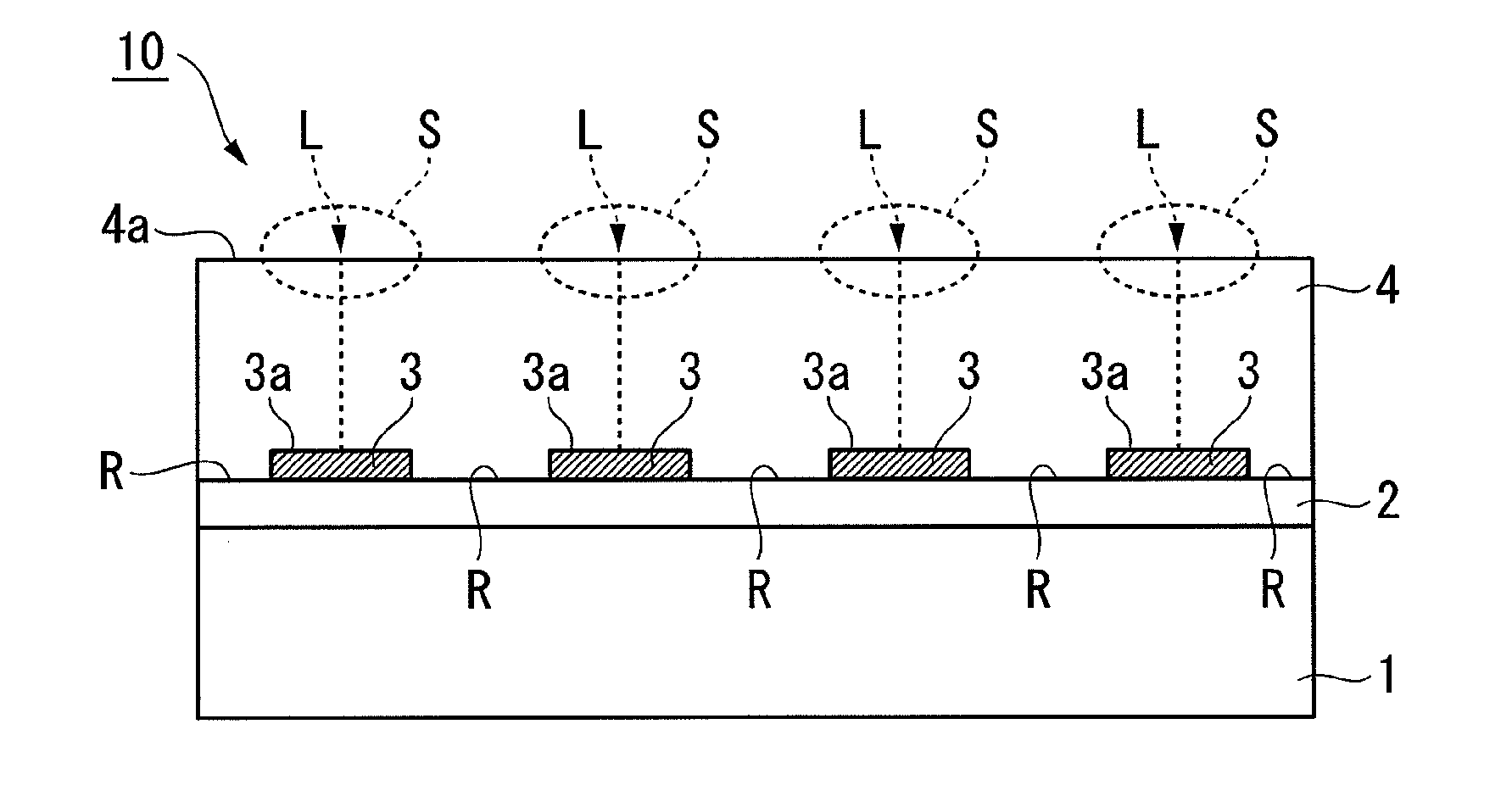

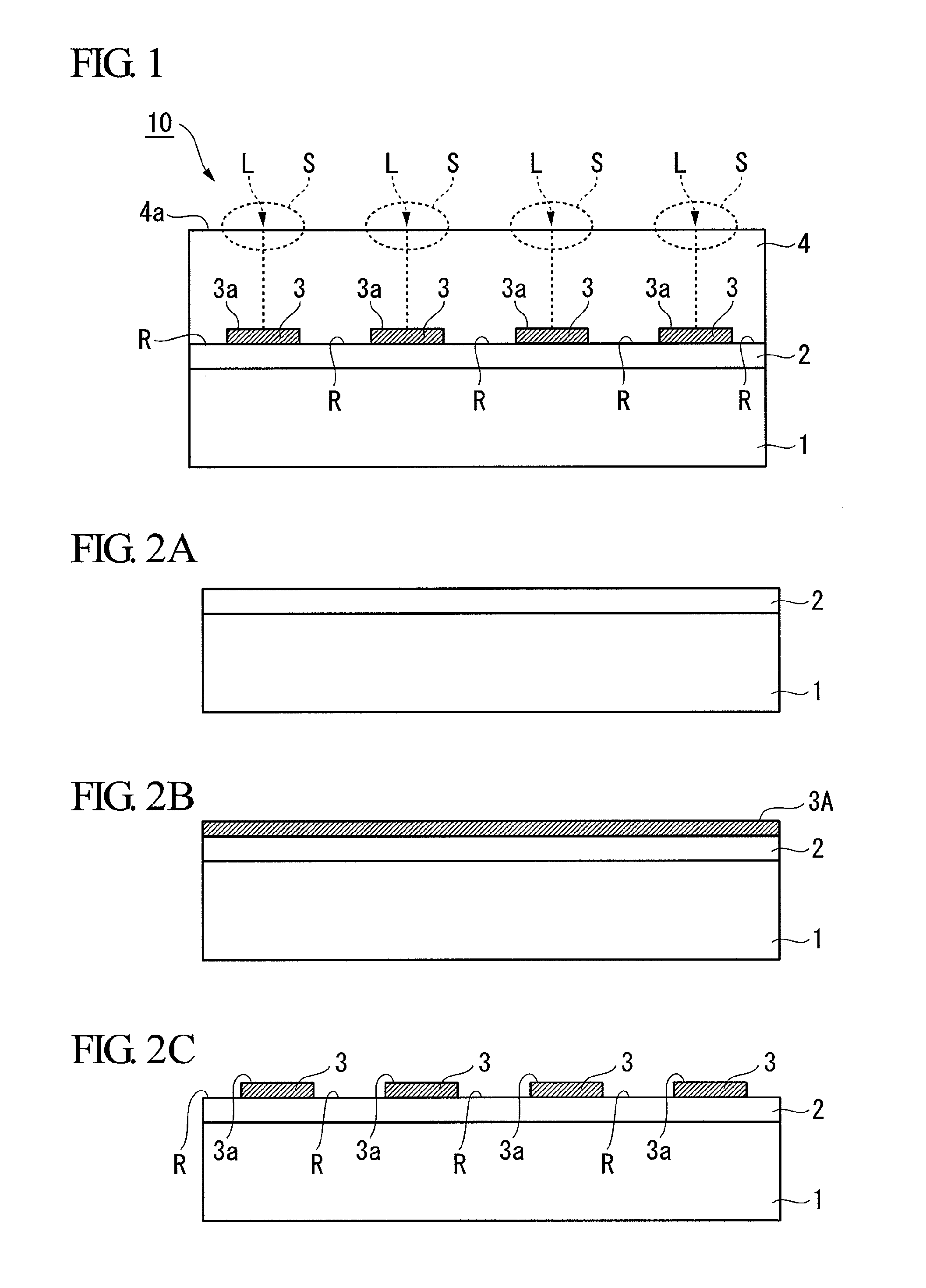

There is provided a group III nitride semiconductor epitaxial substrate which has a suppressed level of threading dislocation in the vertical direction and excellent crystal quality, the group III nitride semiconductor epitaxial substrate including a substrate (1) for growing an epitaxial film; and an ELO layer (4) having a composition of AlxGa1-xN (0≦x≦1) formed either on top of the substrate (1) or on top of a group III nitride layer (2) formed on top of the substrate (1), wherein the ELO layer (4) is a layer formed by using a mask pattern (3), which is composed of carbon and is formed either on top of the substrate (1) or on top of the group III nitride layer (2).

Owner:SHOWA DENKO KK

Opposed terminal structure having a nitride semiconductor element

InactiveUS20050035364A1Improve light extraction efficiencyLower resistanceLaser detailsLaser active region structureEngineeringNitride semiconductors

An opposed terminal structure including a supporting substrate, a first terminal, a nitride semiconductor with a light-emitting layer, and a second terminal. The second terminal forms an opposed terminal structure with the first terminal, which can be formed in a variety of patterns.

Owner:NICHIA CORP

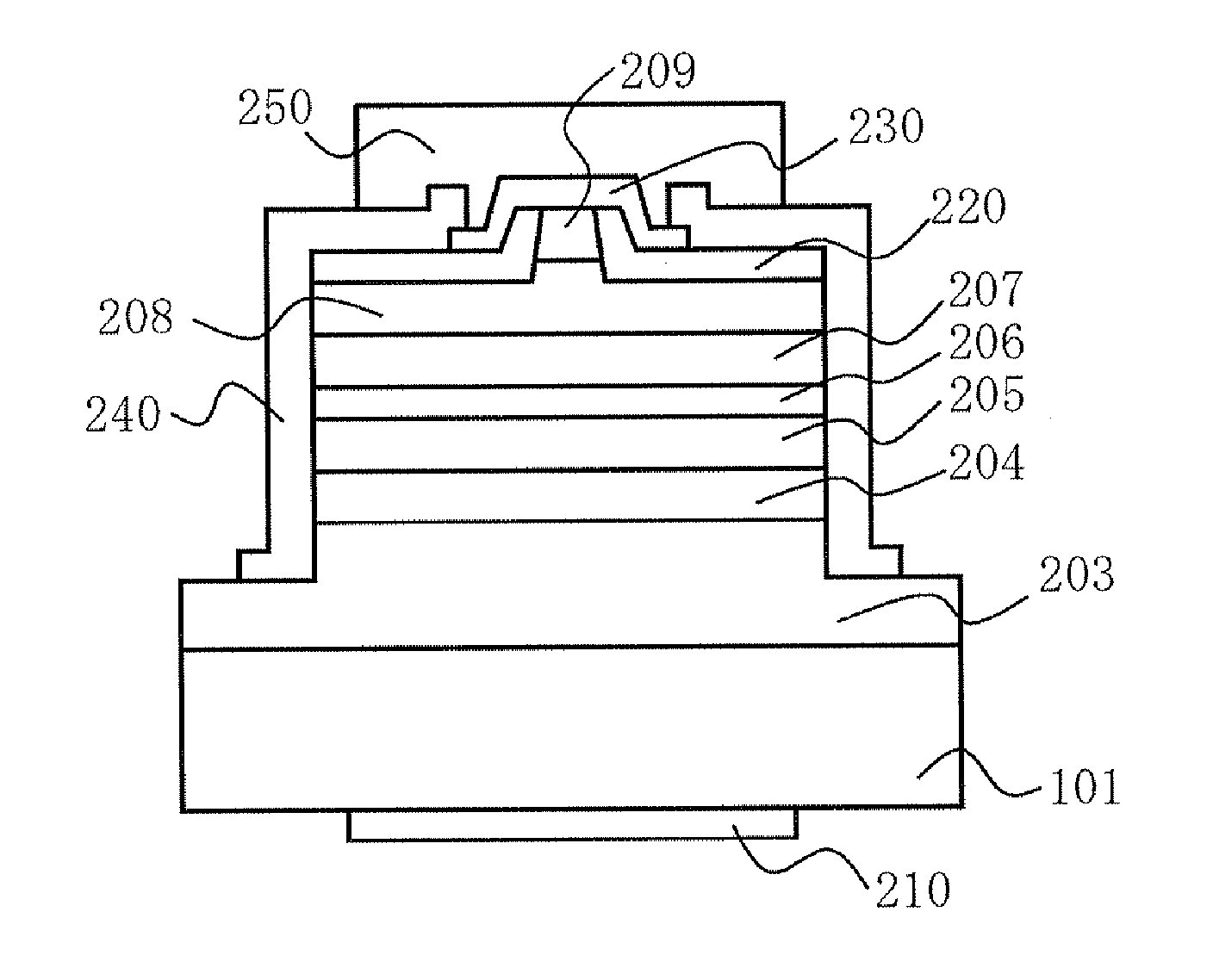

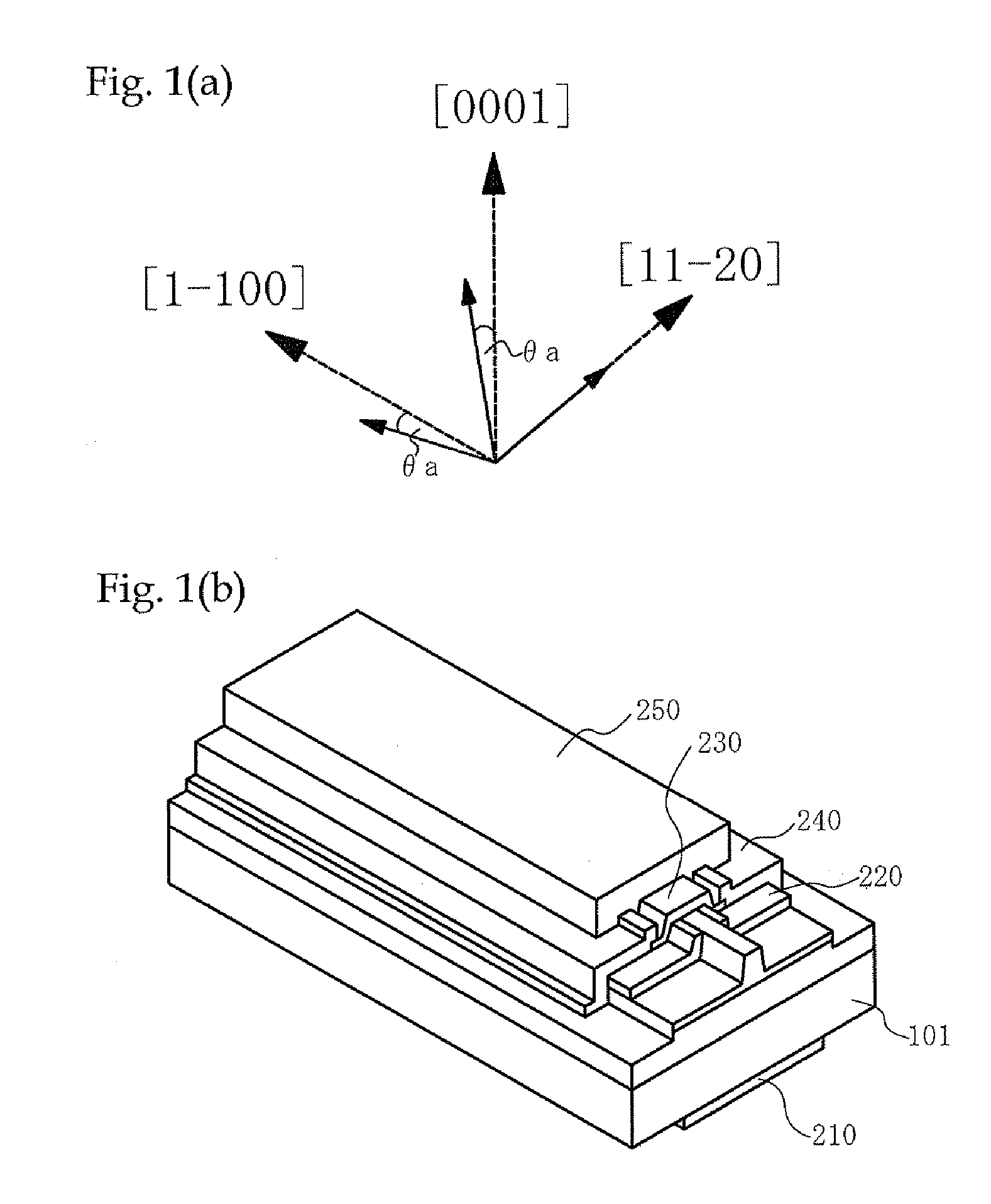

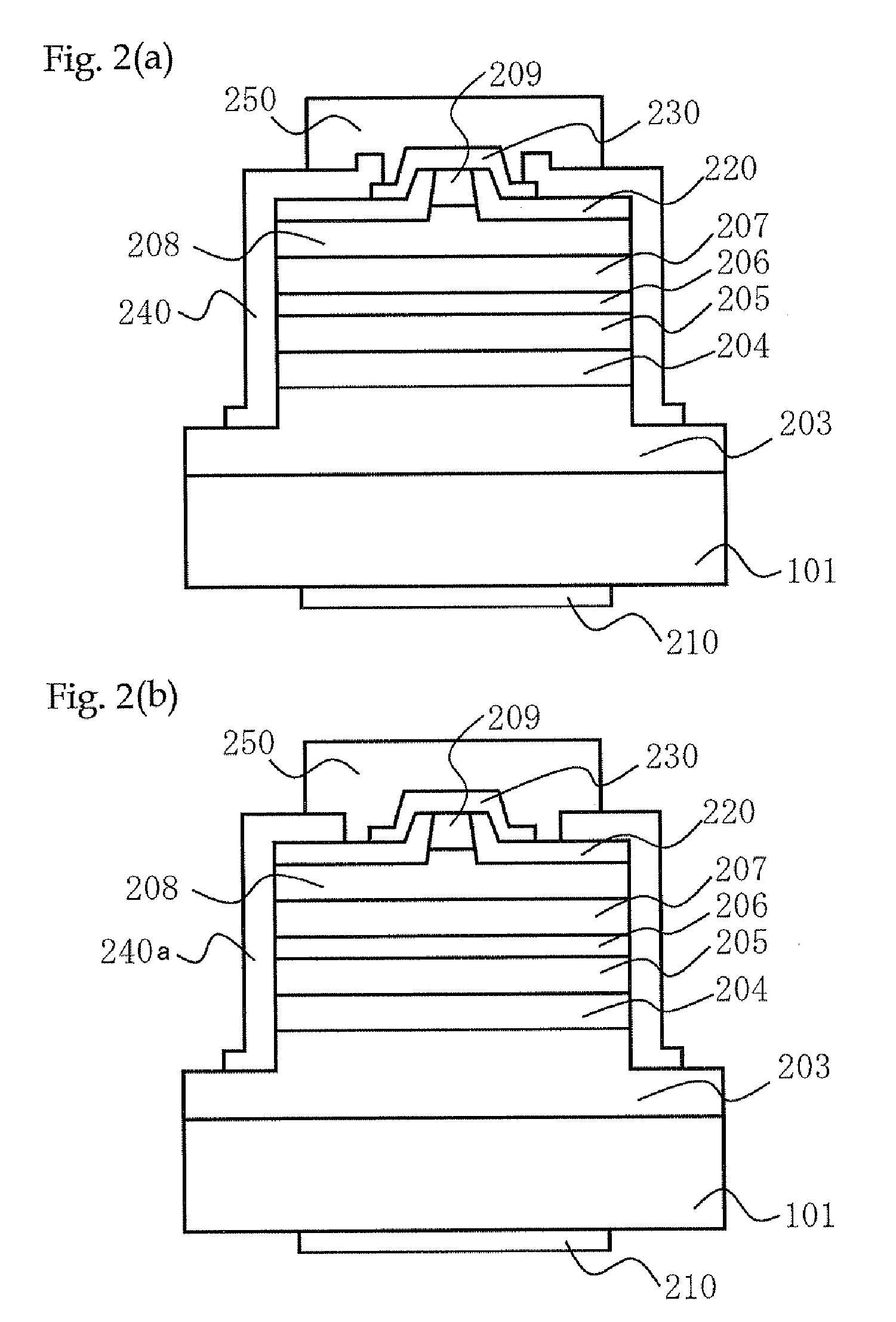

Nitride semiconductor laser device and nitride semiconductor device

ActiveUS20050224783A1Excellent characteristicsProlong lifeOptical wave guidanceLaser detailsIndiumCrystal plane

A nitride semiconductor laser device comprises, on a principle face of a nitride semiconductor substrate: a nitride semiconductor layer having a first conductivity type; an active layer comprising indium, and a nitride semiconductor layer having a second conductivity type that is different from said first conductivity type, and on the surface of which is formed a stripe ridge; said principal face of said nitride semiconductor substrate having an off angle a (θa) with respect to a reference crystal plane, in at least a direction substantially parallel to said stripe ridge.

Owner:NICHIA CORP

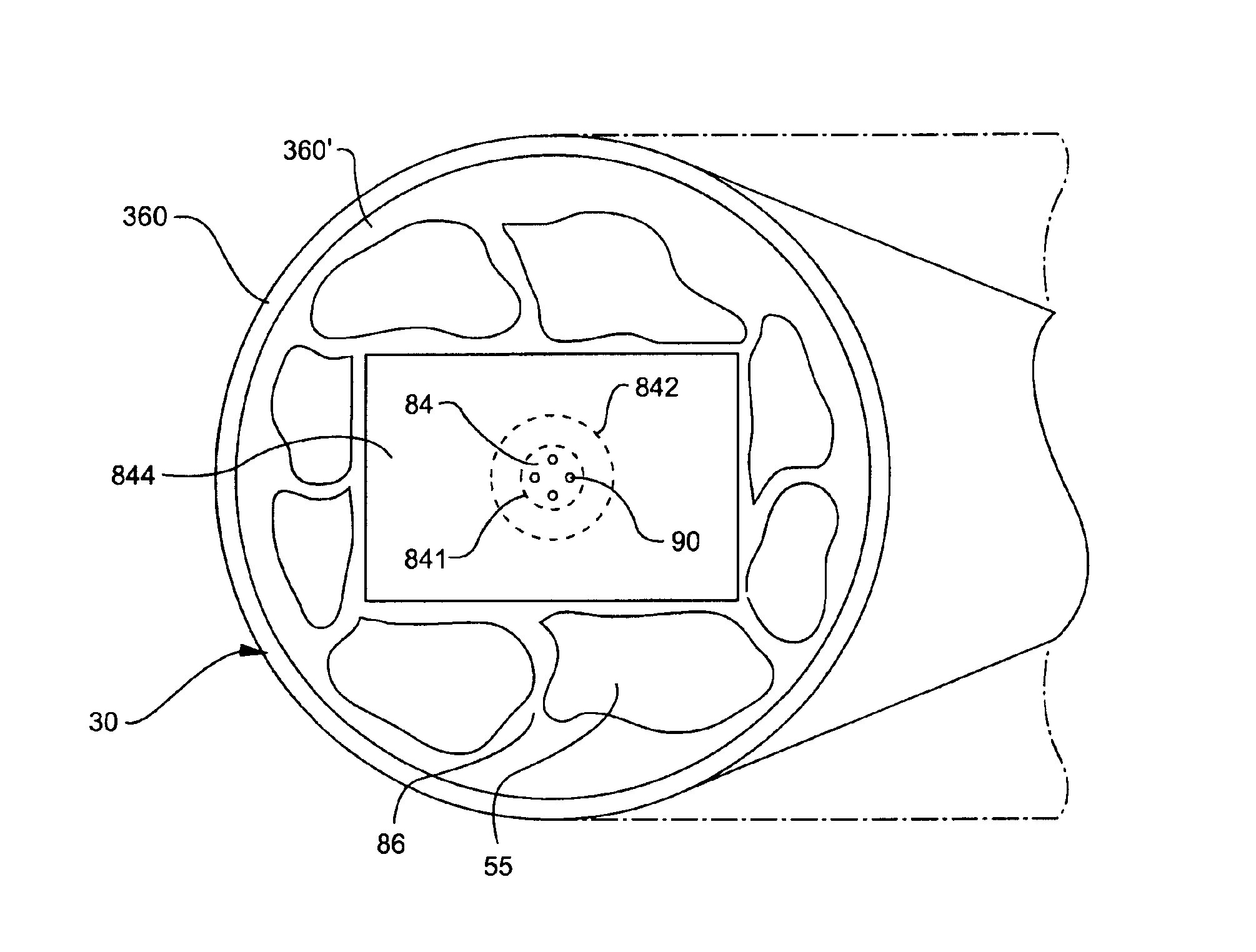

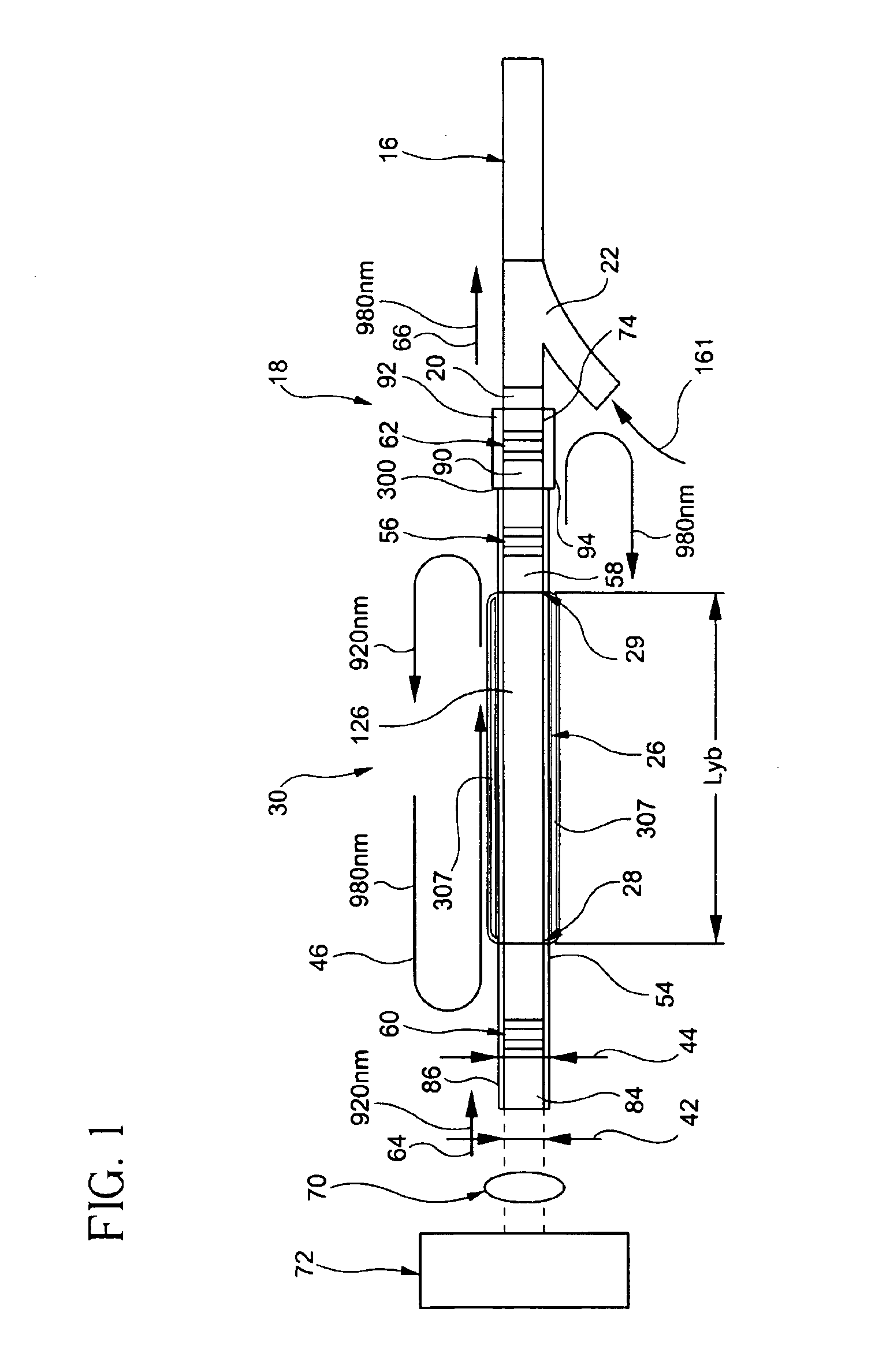

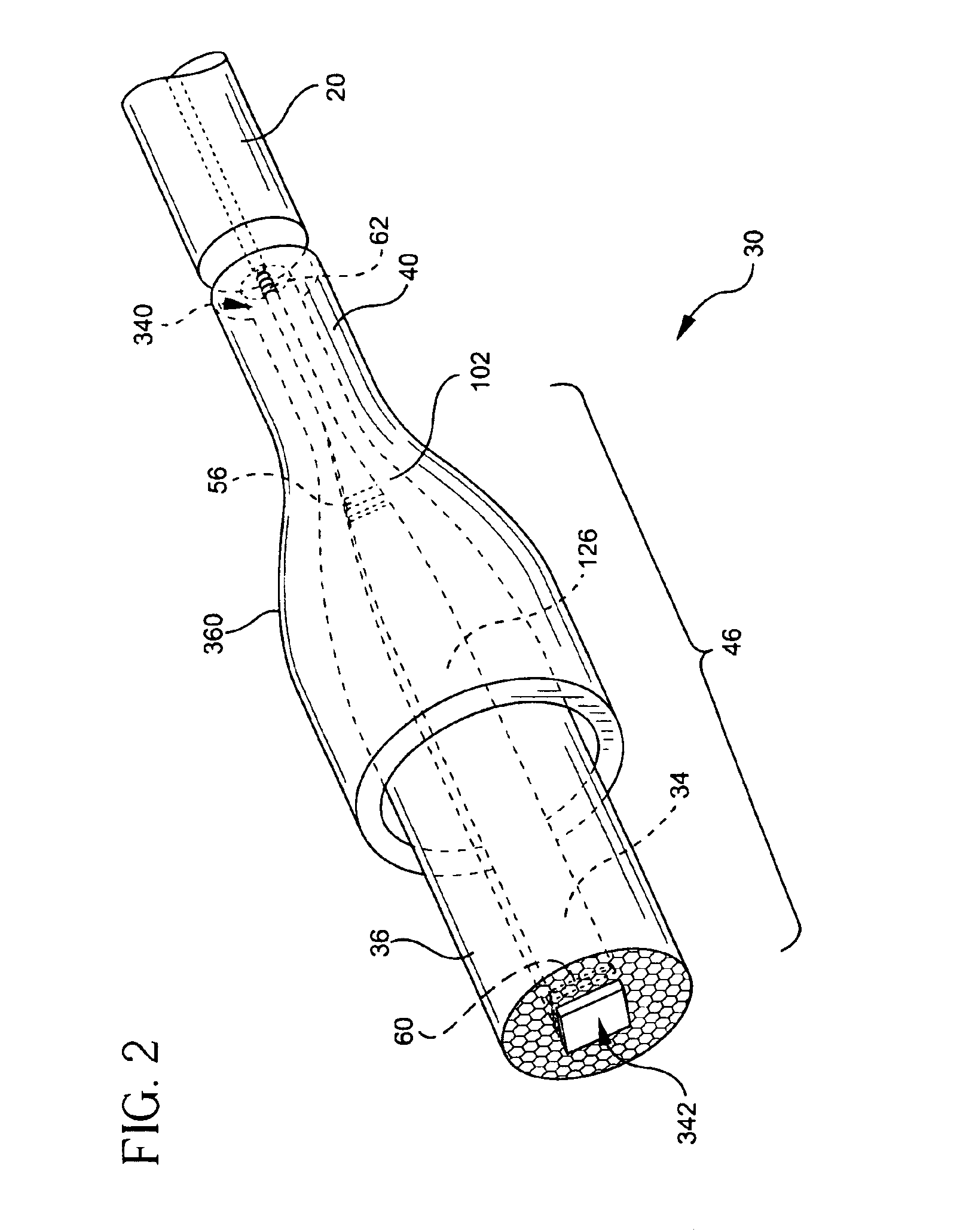

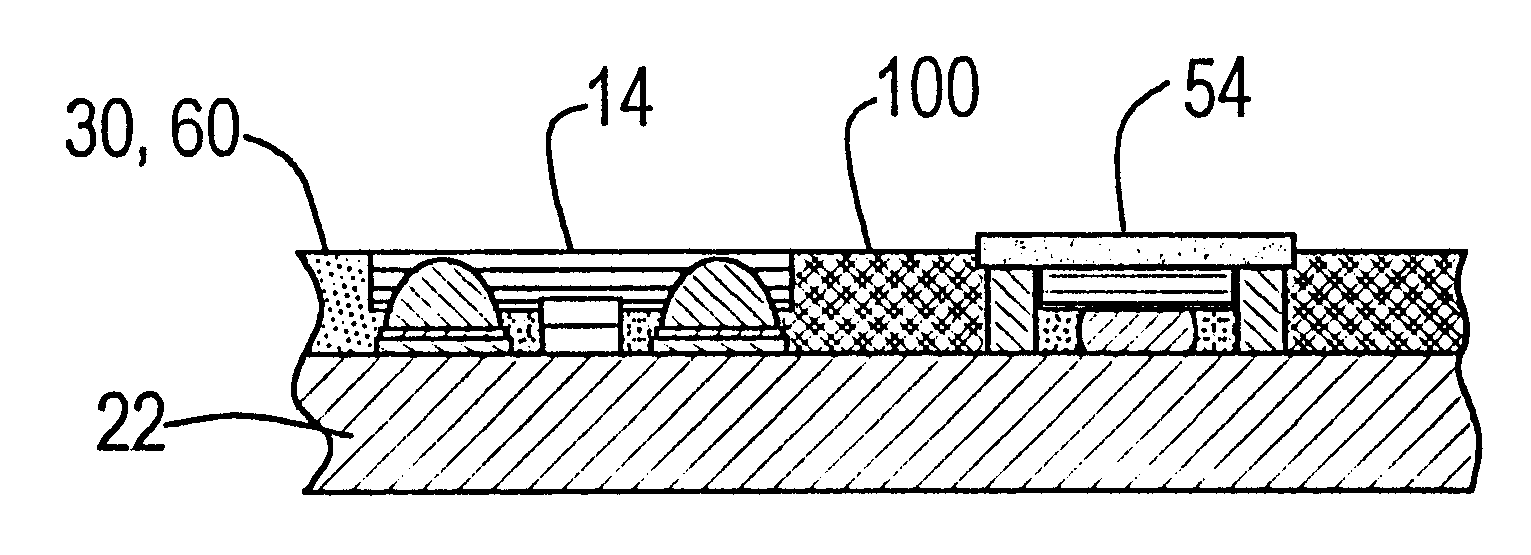

Three-level air-clad rare-earth doped fiber laser/amplifier

InactiveUS6987783B2Facilitates dopingLower effective refractive indexOptical wave guidanceLaser using scattering effectsThree levelAudio power amplifier

An optically-active air-clad fiber (30) includes a core (34, 84) that facilitates doping with an ion optically excitable and having a three-level optical transition when pumped at a first end (28) of an optical cavity (46) by a multimode pump source (72) at a pump wavelength (64) for lasing at a signal wavelength (66) different than the pump wavelength (64) at a second end (29) of the optical cavity (46), the core (34, 84) having a refractive index, wherein the core (34, 84) is transformed from the first end to proximate the second end (29) thereof such that the optically-active fiber (30) is multimode at the pump wavelength proximate to the first end (28), and is single-mode at the signal wavelength proximate to the second end (29). An air-clad (36, 86) surrounds at least one portion of the core (34, 84) and has a lower effective refractive index than the refractive index of the core (34, 84).

Owner:CORNING INC

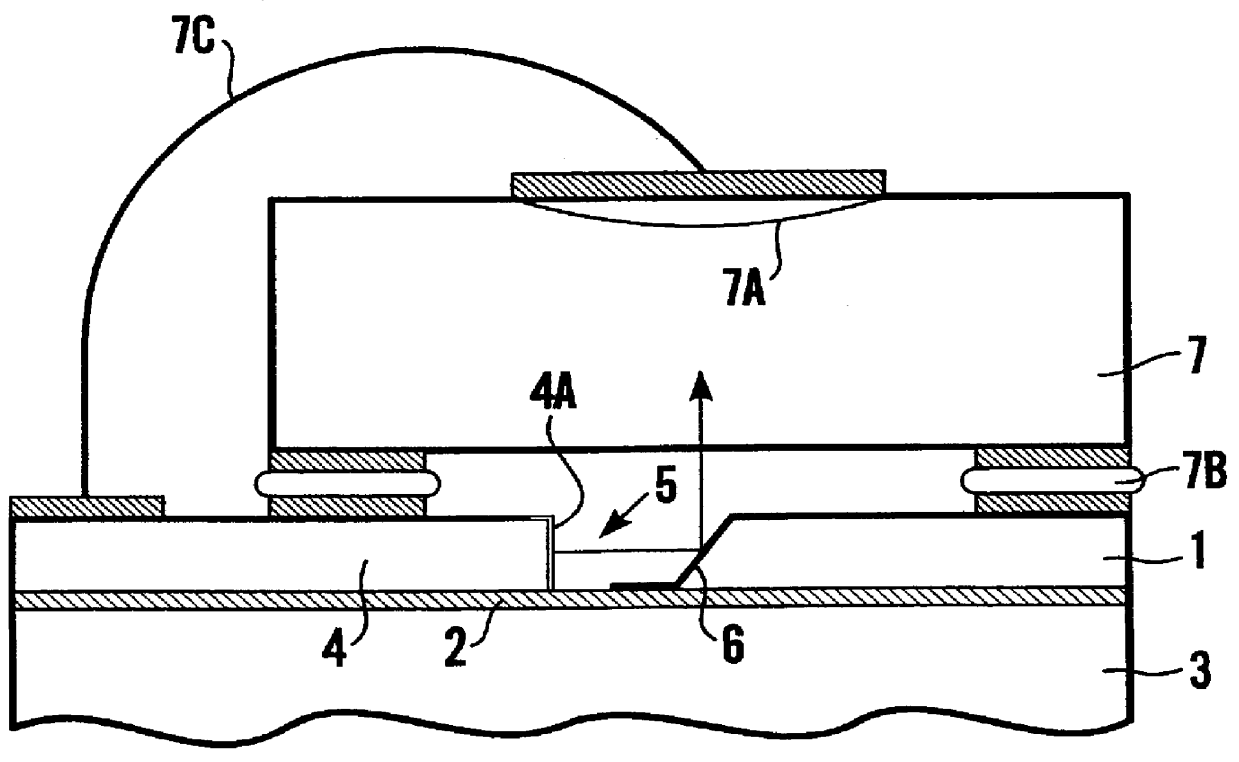

Electro-optical transceiver system with controlled lateral leakage and method of making it

InactiveUS6344664B1Prevent side leakageImprove system performanceLaser detailsSemiconductor laser structural detailsTransceiverEngineering

An electro-optical transceiver system with controlled lateral light leakage and a method of making such a system includes a plurality of emitter devices and detector devices including at least one of each, arranged in a planar array for transmitting and receiving, respectively, energy in a predetermined wavelength and a blocking medium disposed interstitially of the devices and being absorbing at the predetermined wavelength for blocking energy at the predetermined wavelength laterally leaking from an emitter device to one or more detector devices.

Owner:ALTERA CORP

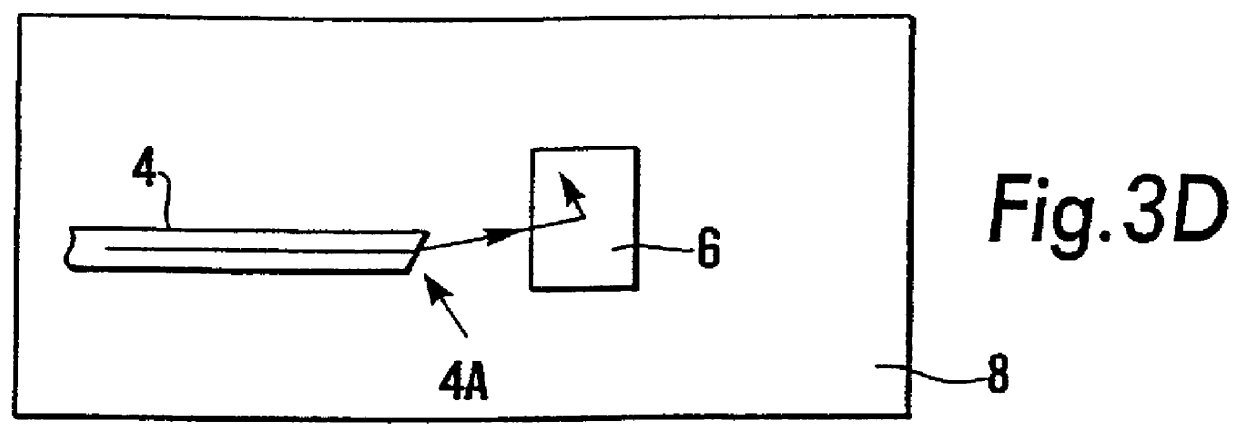

Device for re-directing light from optical waveguide

The device is formed on a silicon-on-insulator chip (which comprises a layer of silicon (1) separated from a substrate (3) by an insulator layer (2)) and comprises an integrated waveguide (4) formed in the silicon layer (1) and a reflective facet (6) formed in a recess in the silicon layer (1). The facet (6) is positioned to redirect light in a desired direction. The waveguide (4) and facet (6) are both formed in the silicon layer (1) so their positions can be defined by the same lithographic steps so they are automatically aligned with each other.

Owner:KOTURA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com