Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

379 results about "Liquid core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The liquid outer core of the Earth is the conducting fluid, free electrons being released from metals, such as Fe (iron) and Ni (nickel), by friction and heat. Variations in the global magnetic field represent changes in fluid flow in the core.

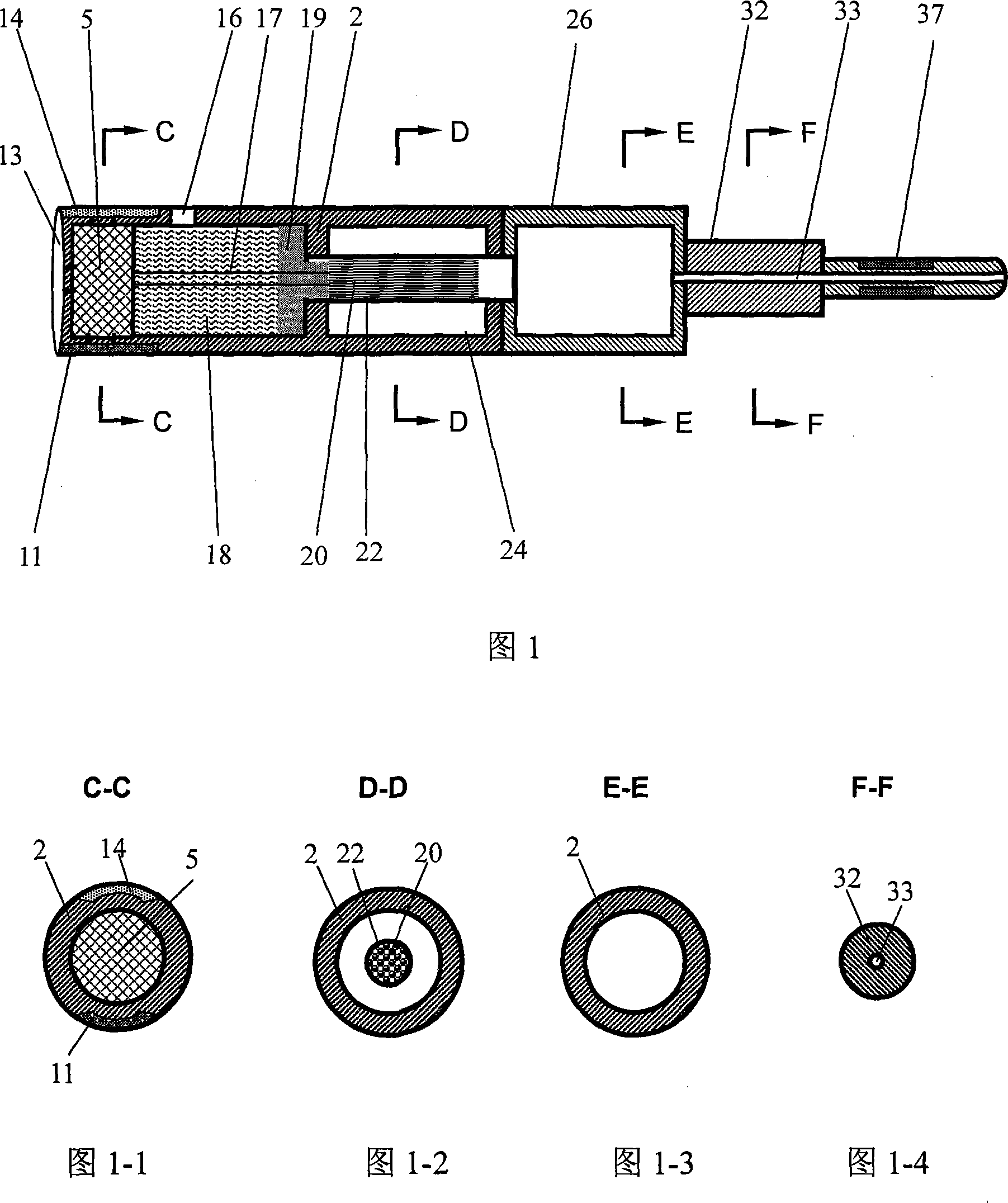

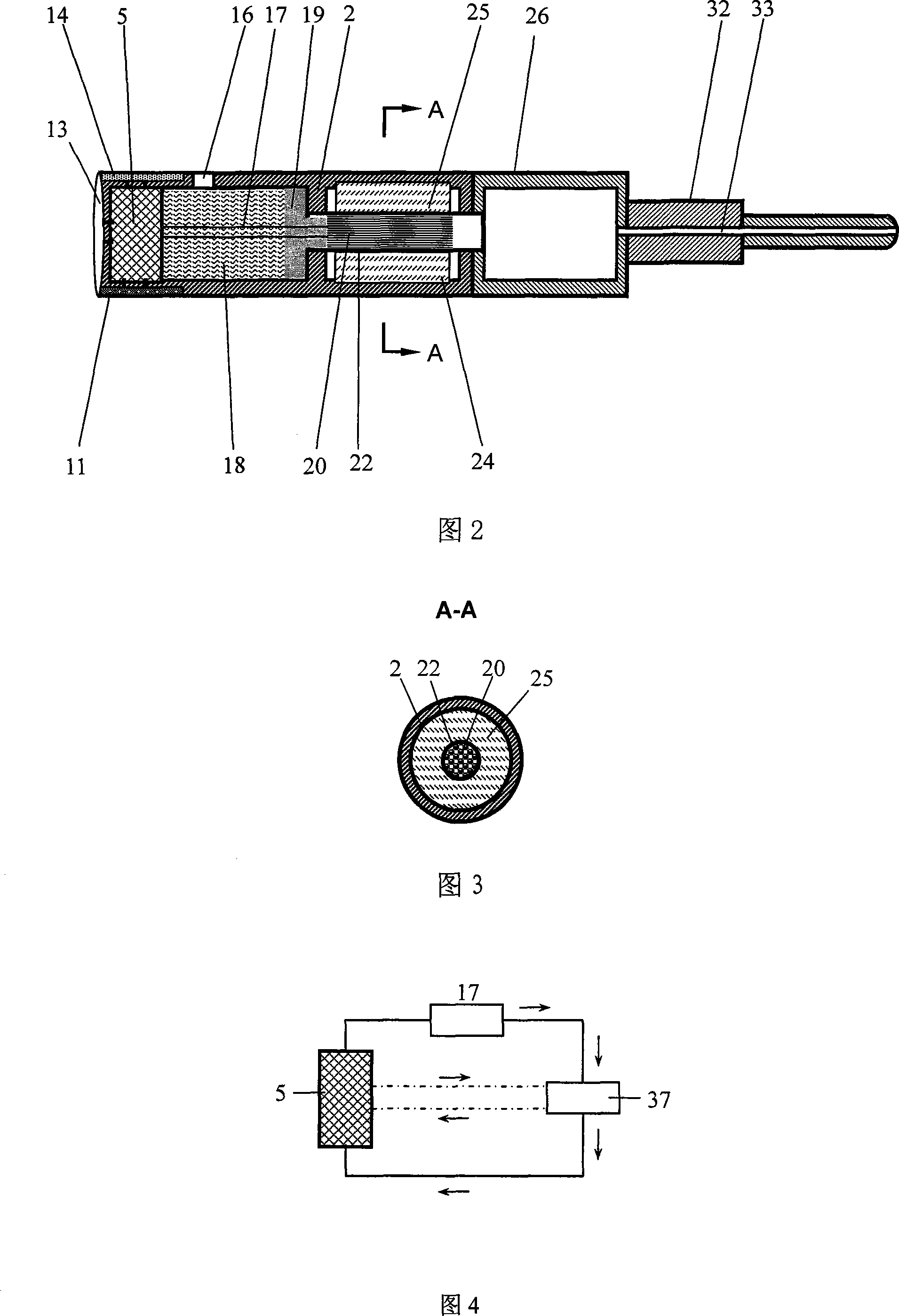

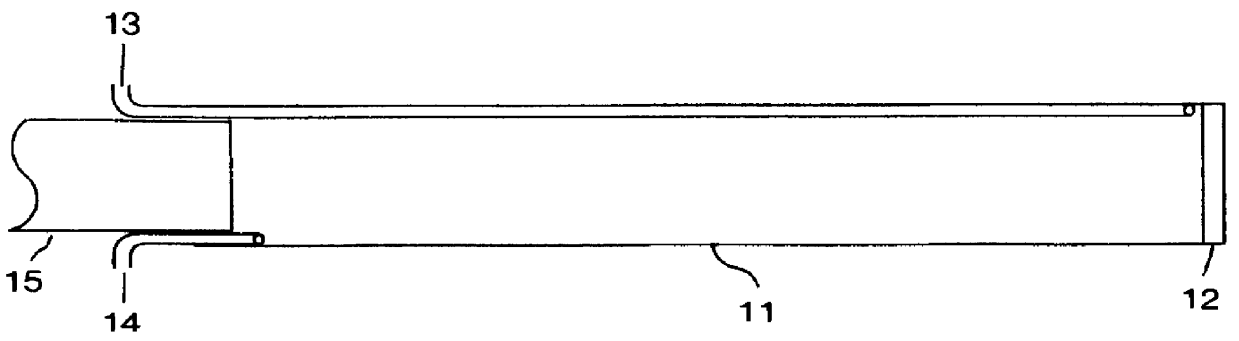

Electronic cigarette having nanometer sized hyperfine space warming atomizing functions

ActiveCN101116542ALarge amount of atomizationConcentrated use of energy and high efficiencyMedical devicesTobacco devicesMouth pieceElectricity

An electric-cigarette undertaking nanometer dimension fineness space heating pulverization to nicotine solution comprises a cigarette pole and a cigarette holder connected with the front end of the cigarette pole. The cigarette pole is a hollow rod shape cigarette pole welded with a plug at the back end. The intracavity of the cigarette pole is provided with a rechargeable battery, a liquid storage tank for storing nicotine solution, an imbibition liquid core arranged at the front end of the liquid storage tank and contacted with the nicotine solution, and a heater of space heating pulverization arranged inside the heating cavity positioned in the front part of the cigarette pole. The wall of the cigarette pole corresponding to the liquid storage tank is provided with a liquid inlet communicated with the liquid storage tank. Any place of the wall of the cigarette pole is provided with an electric heating switch. The center of the cigarette holder is provided with a hollow pipe which extends into the cigarette pole. The wall of front part of the cigarette holder is provided with a piezoelectric press sensor. The back end of the cigarette pole is provided with a recharging connection device which can charge the rechargeable battery through outer power. The piezoelectric press sensor is communicated with the rechargeable battery all the time. The electric heating switch, the piezoelectric press sensor and the rechargeable battery constitute a circuit loop. The invention has the advantages of convenient assembly and installation, easy carry, wide application and convenient use.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Optical analysis technique and sensors for use therein

InactiveUS6020207AMaterial analysis by observing effect on chemical indicatorChemiluminescene/bioluminescenceLiquid coreChemical species

The detection of a chemical specie of interest is accomplished by immobilizing sensing molecules on the inner wall of a liquid core optical waveguide, the waveguide comprising a capillary tube and the sensing molecules being selected to interact with the specie of interest carried by the liquid which forms the waveguide core. The interaction produces a change in an optical characteristic of the waveguide which may be detected by illuminating the waveguide with analysis light.

Owner:WPI TAG ACQUISITION LLC

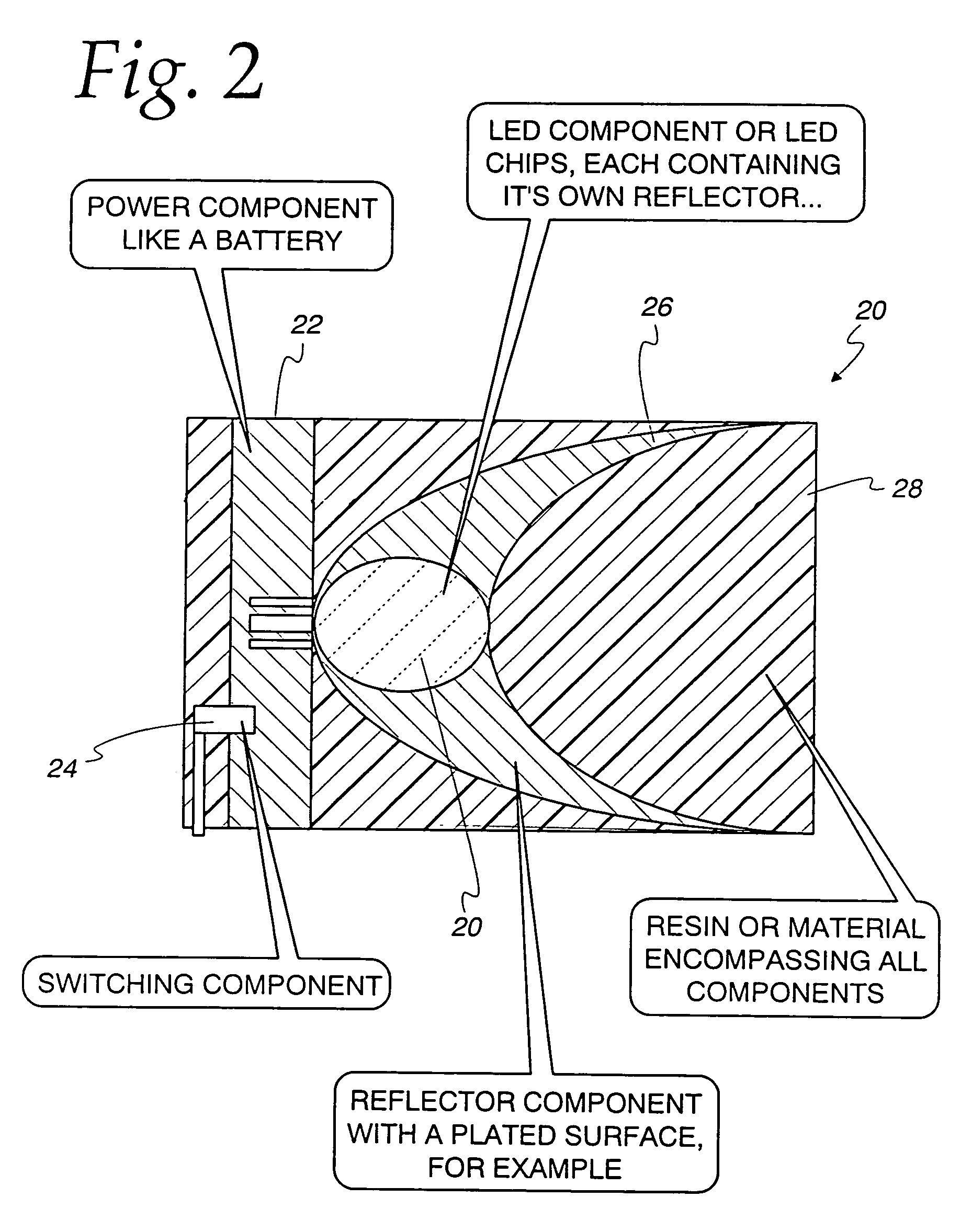

Light emitting medium and illumination system

Owner:ZARIAN JAMES ROUBEN +1

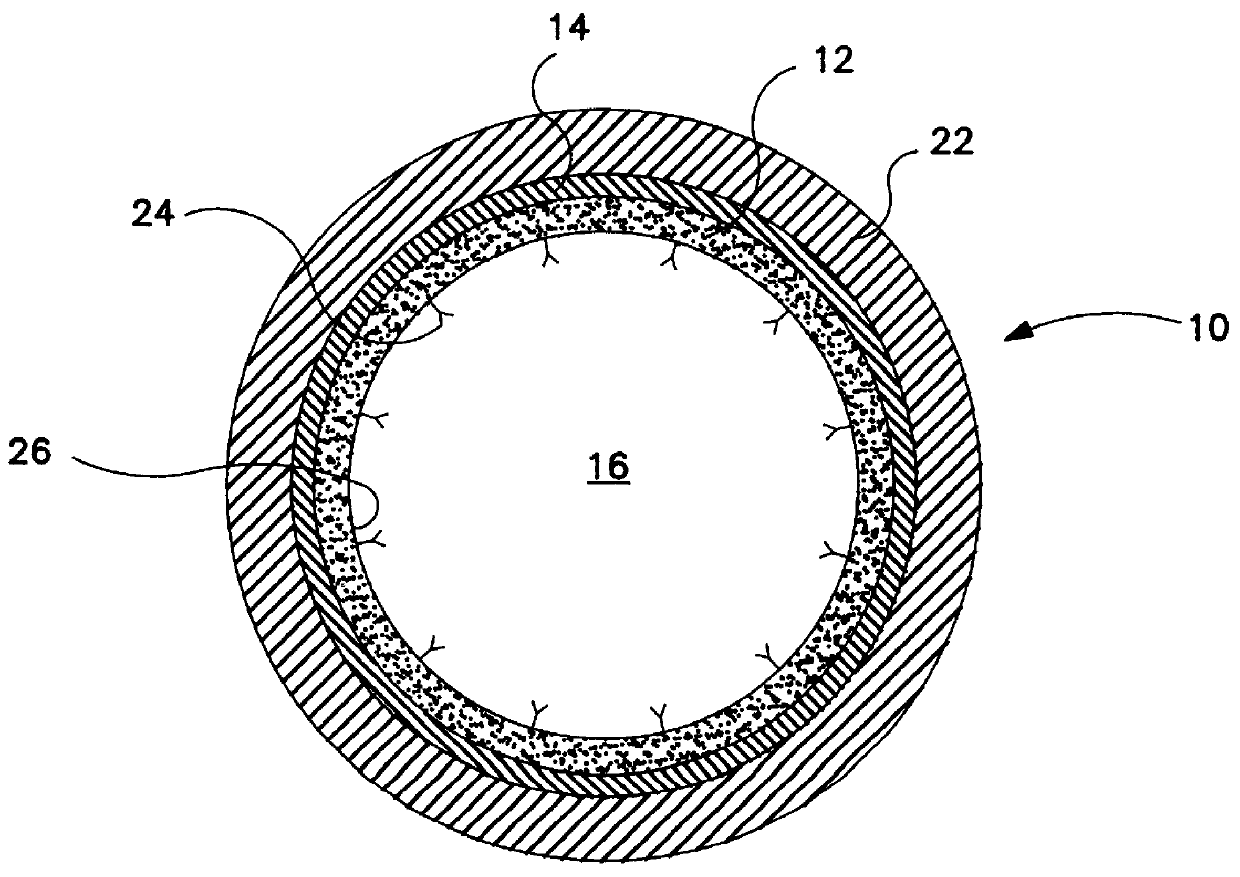

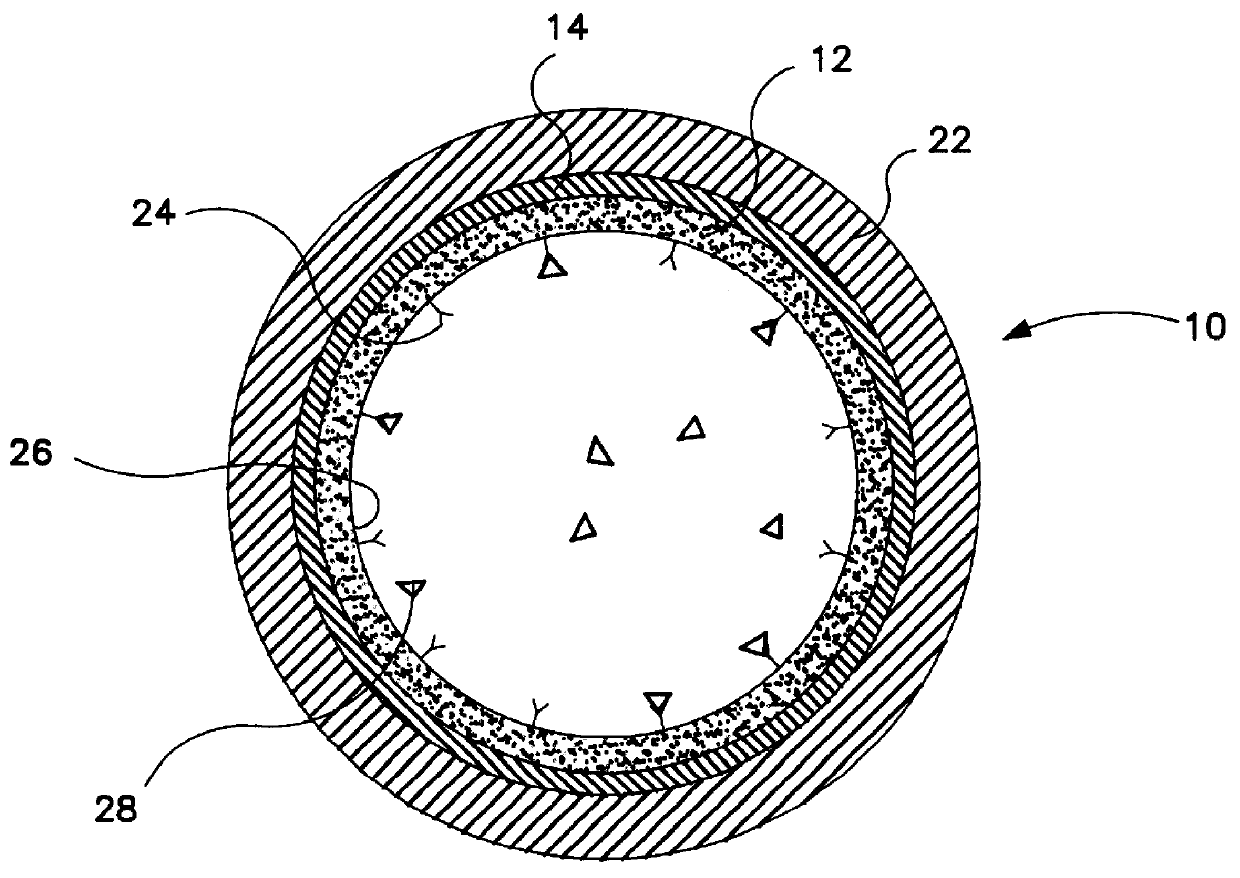

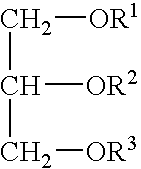

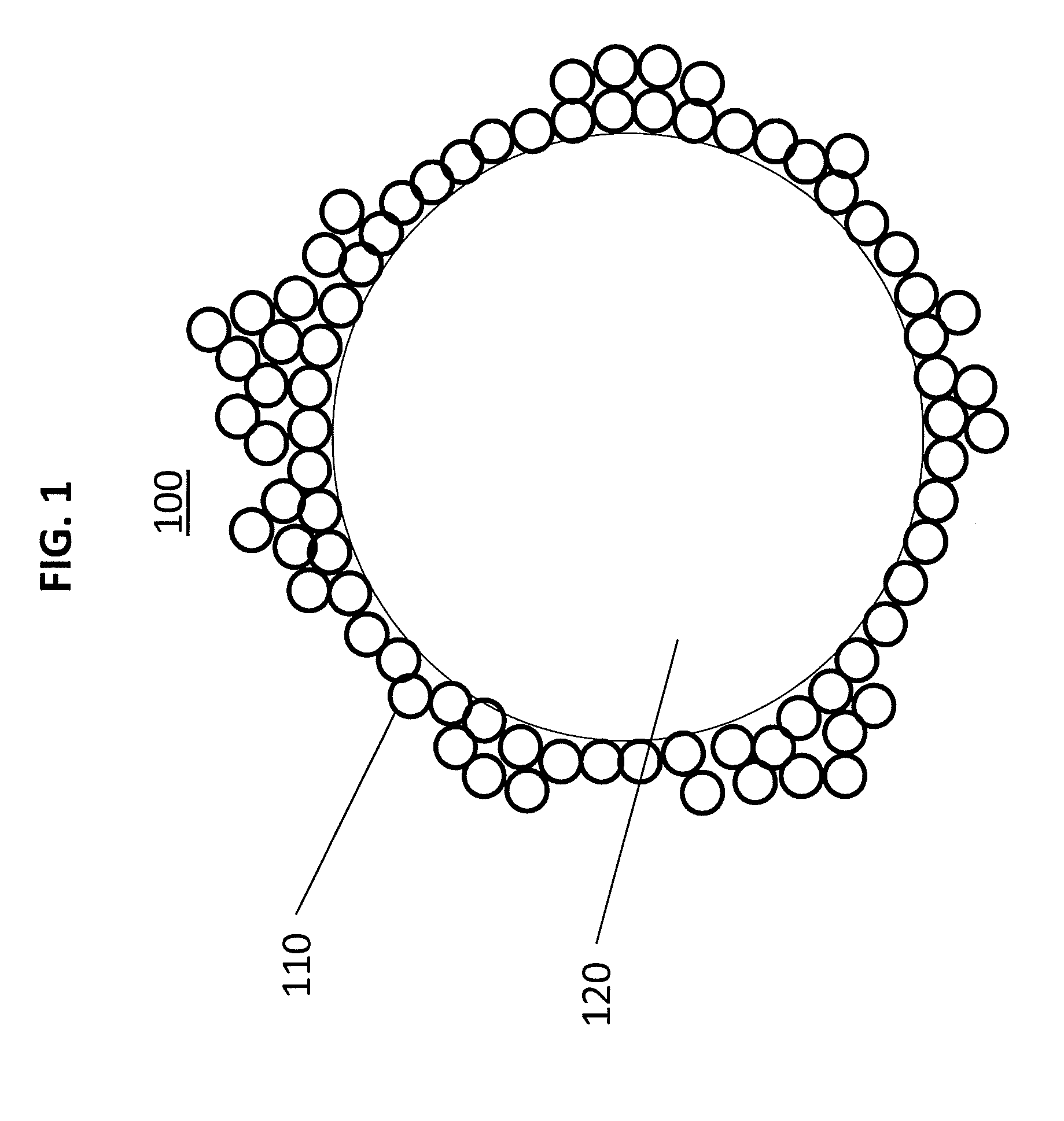

Aqueous liquid laundry detergent compositions with visible beads

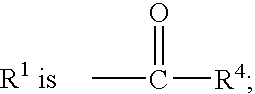

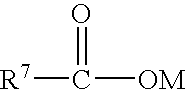

InactiveUS7169741B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLiquid coreSemipermeable membrane

Disclosed are aqueous liquid laundry detergent compositions which are in the form of an externally structured aqueous liquid matrix having dispersed therein a plurality of visibly distinct beads. Such beads are prepared so as to be in the form of a liquid core surrounded by a semi-permeable membrane formed by interaction of a cationic polymeric material with an anionic polymeric material. Such beads are stable in the aqueous liquid detergent compositions herein yet disintegrate substantially upon their introduction via the composition into agitated dilute aqueous laundering liquors.

Owner:THE PROCTER & GAMBLE COMPANY

Product for treating the skin comprising a polyamine microcapsule wall and a skin lightening agent

The present invention features a product including a water-insoluble substrate and a plurality of microcapsules comprising a microcapsule wall surrounding a liquid core, and the use thereof.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Chemical sensing techniques employing liquid-core optical fibers

A gas or vapor permeable optical fiber waveguide with a liquid core is employed as a probe for the detection or measurement of a chemical specie of interest by filling the waveguide core region with a reagent liquid which undergoes a change in an optical characteristic thereof when exposed to the chemical specie and then inserting the filled waveguide into an environment in which the chemical specie may be present. The chemical specie, if present, will permeate through the waveguide wall and react with or be absorbed in the core liquid. Sensitivity is enhanced by controlling the pressure differential across the waveguide wall and / or by shaping the waveguide to enlarge the surface area. When the reaction generates light, the devices which detect that light will be shaped and disposed to maximize the collection thereof.

Owner:WORLD PRECISION INSTR

Aqueous liquid laundry detergent compositions with visible beads

InactiveUS20050043200A1Non-ionic surface-active compoundsOrganic detergent compounding agentsLiquid coreLiquid laundry detergent

Disclosed are aqueous liquid laundry detergent compositions which are in the form of an externally structured aqueous liquid matrix having dispersed therein a plurality of visibly distinct beads. Such beads are prepared so as to be in the form of a liquid core surrounded by a semi-permeable membrane formed by interaction of a cationic polymeric material with an anionic polymeric material. Such beads are stable in the aqueous liquid detergent compositions herein yet disintegrate substantially upon their introduction via the composition into agitated dilute aqueous laundering liquors.

Owner:THE PROCTER & GAMBLE COMPANY

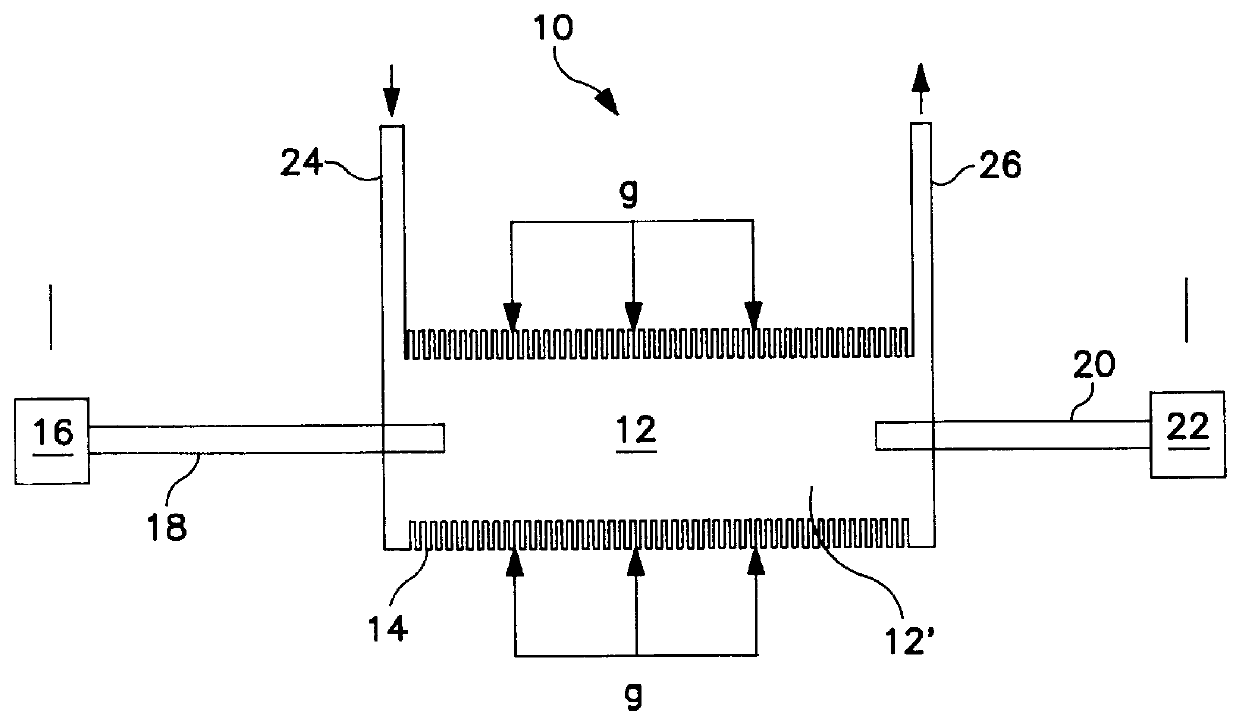

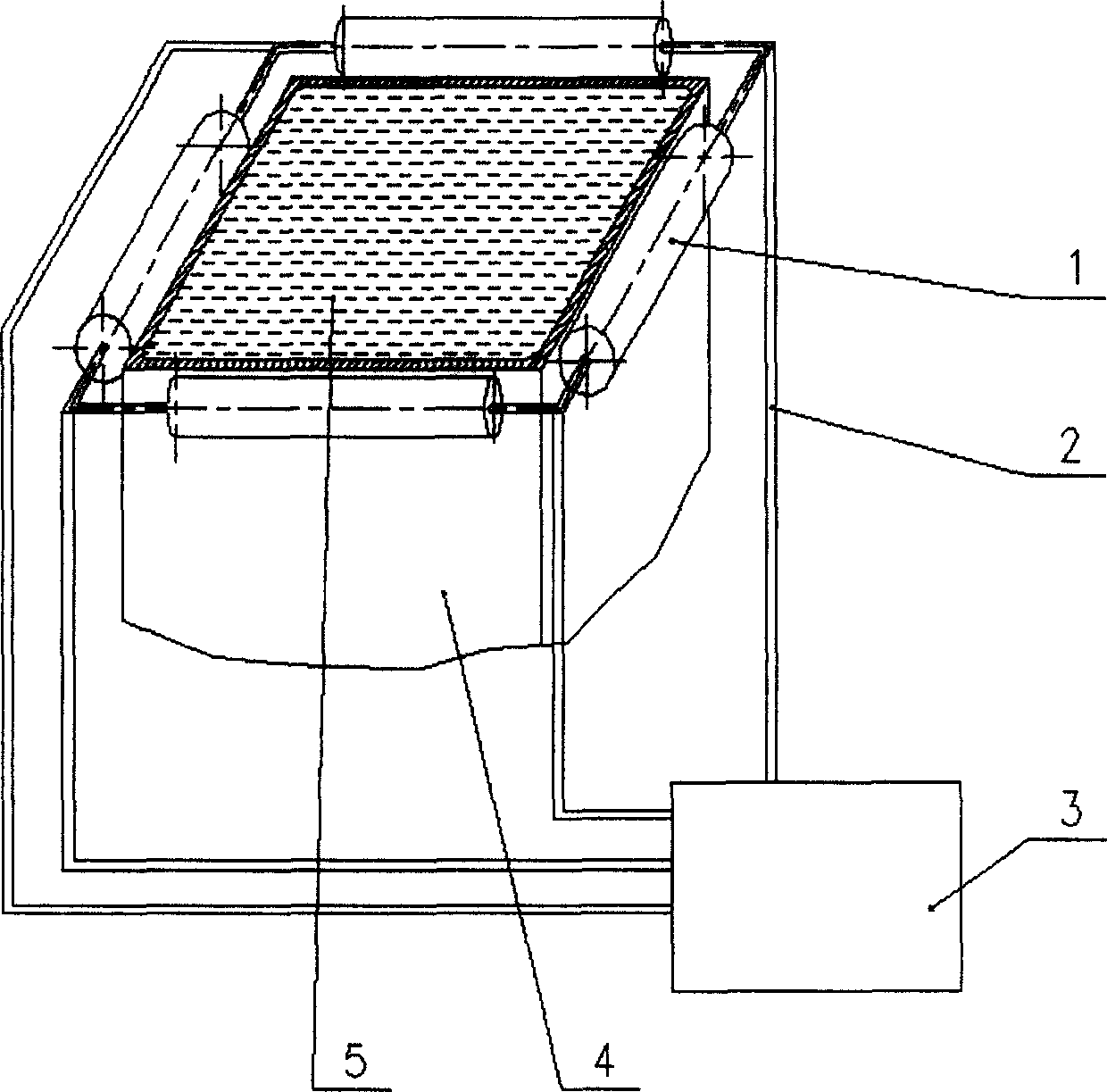

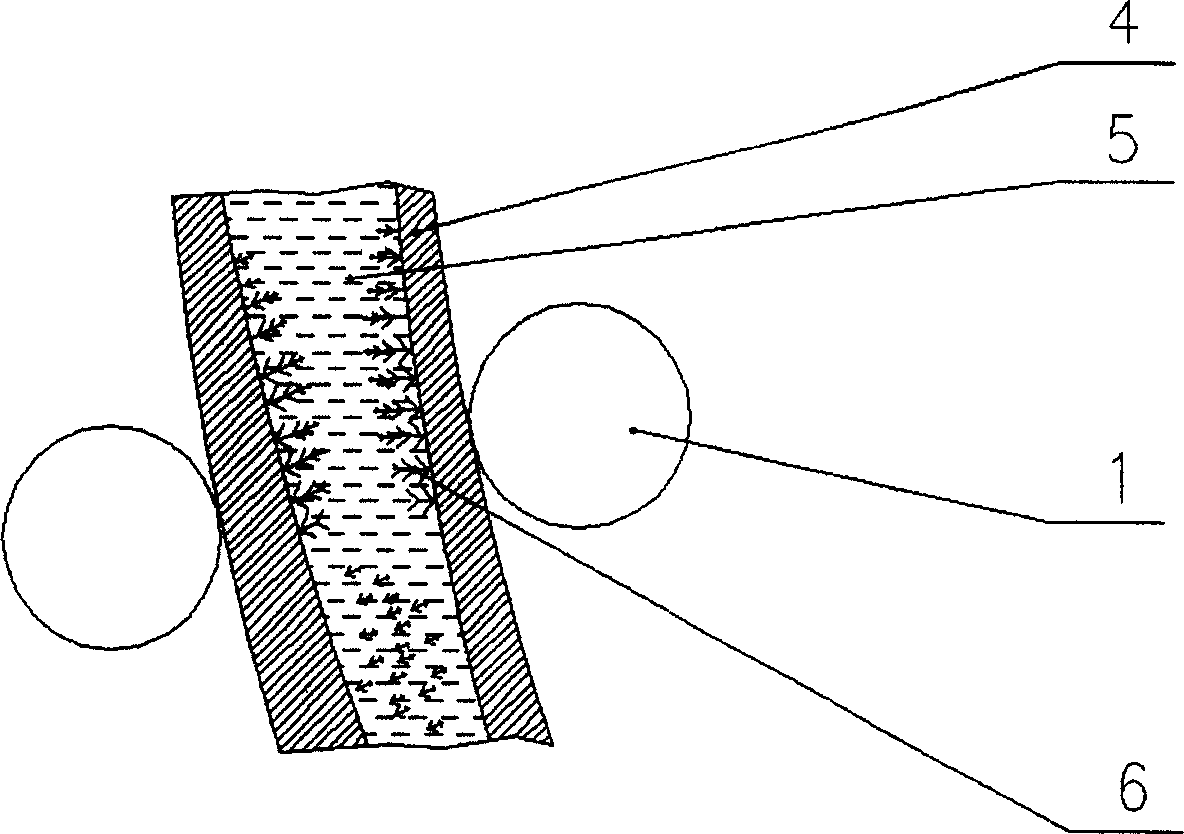

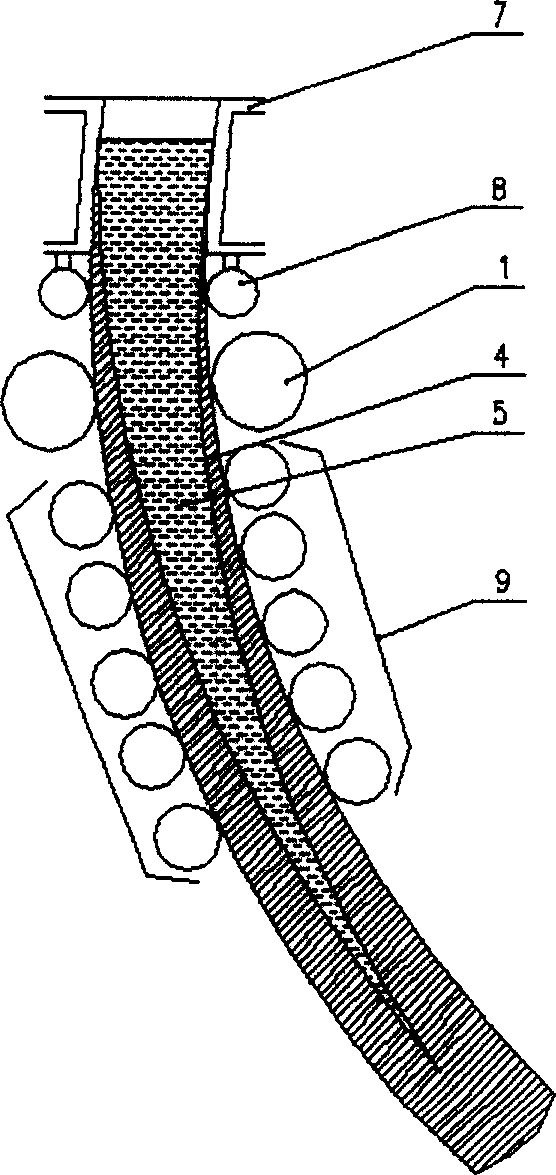

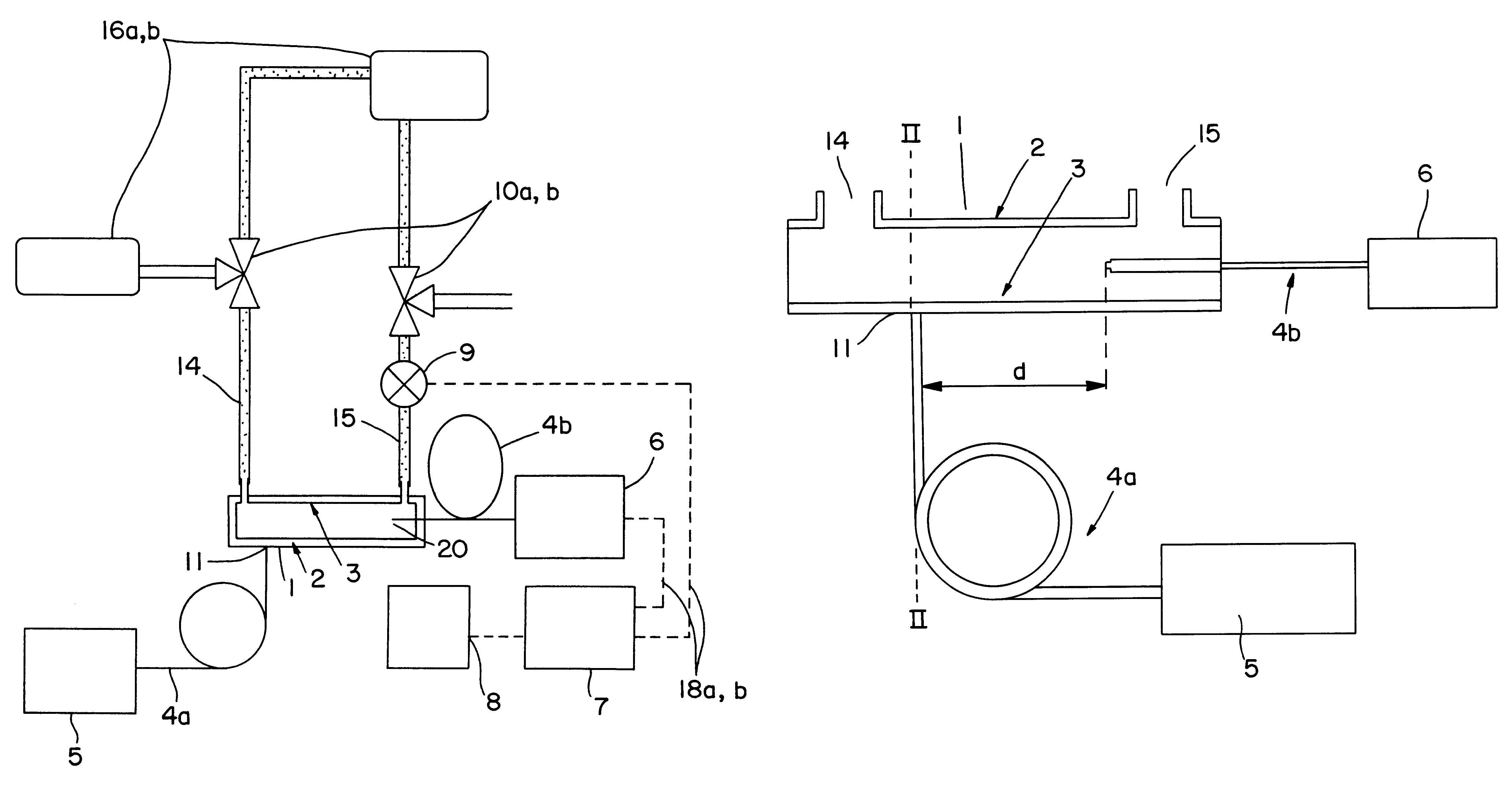

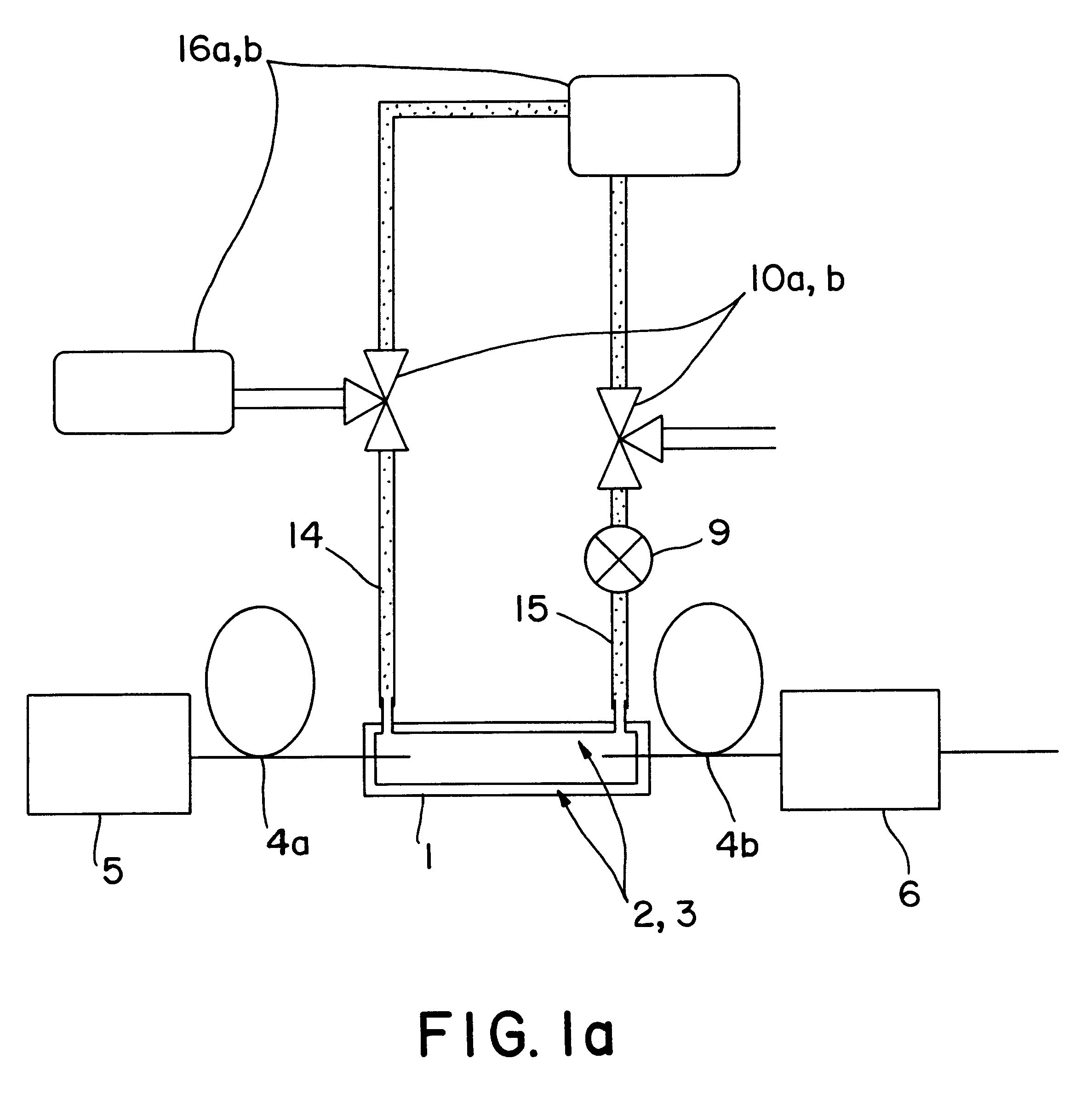

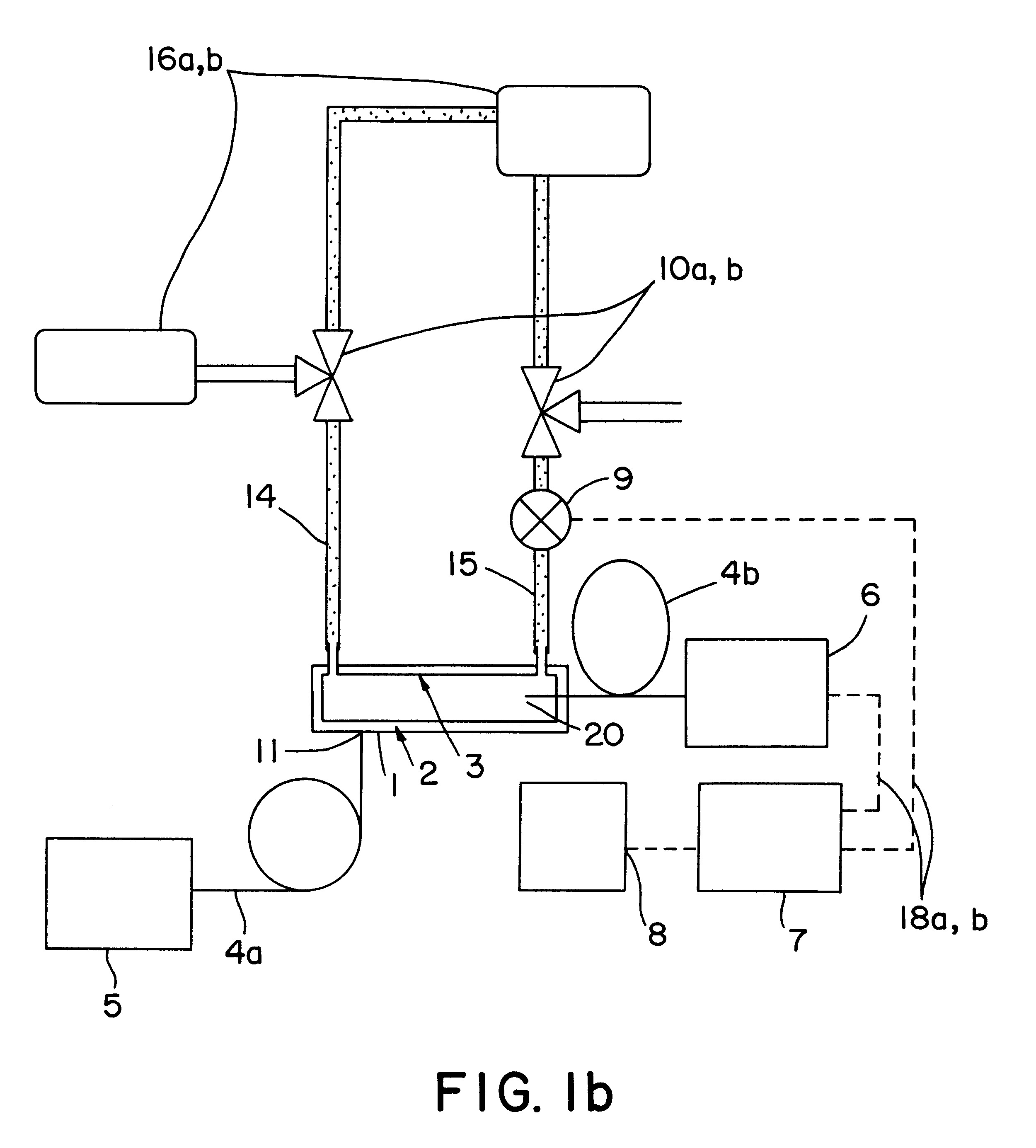

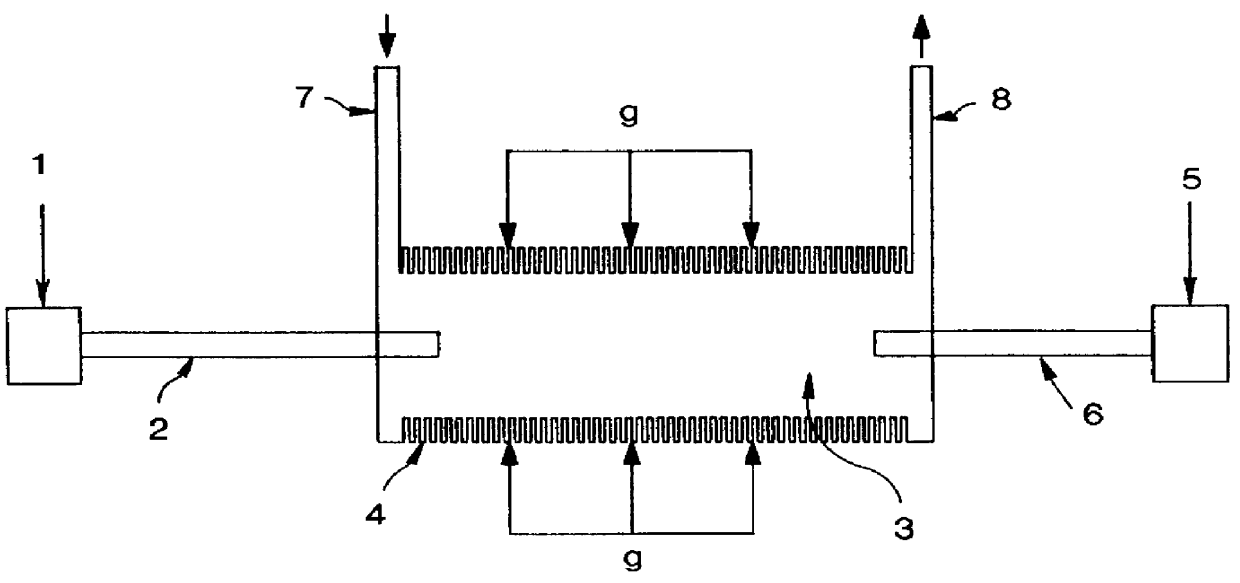

Method for improving continuous casting blank quality and vibration support roller device

The present invention belongs to the field of continuous metal blank casting technology, and is especially the method of raising continuous cast blank quality and the vibrating support roller apparatus. While the vibrating support roller closely contacting the casing of the continuously cast blank casing rotates synchronously with cast blank, it vibrates in the direction perpendicular to the cast blank thickness or in the direction parallel to the blank drawing under the drive of the vibration source, and the vibration is transferred to the solidifying shell of the liquid core via contact. The vibrating support roller apparatus consists of vibrating support roller, vibration transferring pipeline and vibration generating source. The present invention can improve the quality of the continuous cast blank obviously.

Owner:CENT IRON & STEEL RES INST

Apparatus for optically-based sorting within liquid core waveguides

InactiveUS20060257089A1Improve reflectivityEasy to classifyCladded optical fibreMaterial analysis by optical meansLiquid coreNanoparticle

The present invention is related to an apparatus for the sorting of particles in a fluid medium flowing within a liquid-core waveguide, by combining customized light intensity patterns formed inside the waveguide, and diluting the suspension of particles (i.e., cells, blood, nanoparticles, etc.) flowing within the fluid medium of the waveguide. With this customized light intensity pattern, which controls the optical forces introduced by the light confined within the waveguide, and the control of the hydrodynamic forces introduced by the liquid flow (or multiple channel liquid flows), the sorting of particles can be achieved.

Owner:ARRYX INC

Hollow optical waveguide for trace analysis in aqueous solutions

InactiveUS6385380B1Improve transmittanceReflection becomes largeCladded optical fibreFluorescence/phosphorescenceLiquid coreLength wave

Low concentrations of substances dissolved in liquids are detected by coupling analysis / excitation light into the liquid core of an optical waveguide in the form of a capillary. When the substance of interest is to be excited to cause the emission of fluorescent light, the excitation light is transversely coupled into the hollow core of the waveguide and the generated fluorescent light is kept in the optical path of the waveguide for as long as possible. The invention also contemplates the use, in either an absorption or fluorescence mode, of specially treated fused silica fibers to deliver analysis / excitation light with very short wavelengths into the liquid core of an optical waveguide.

Owner:WPI TAG ACQUISITION LLC

Chemical sensing techniques employing liquid-core optical fibers

A permeable optical fiber waveguide with a liquid core is employed as a probe for the detection or measurement of a chemical specie of interest by filling the waveguide core region with a light transmitting reagent liquid which undergoes a change in an optical characteristic thereof when exposed to the chemical specie and then inserting the filled waveguide into an environment in which the chemical specie may be present. The chemical specie, if present, will permeate through the waveguide wall and react with or be absorbed in the core liquid.

Owner:WPI TAG ACQUISITION LLC

Microcapsules produced from blended sol-gel precursors and method for producing the same

The present invention features microcapsule particles with an oil or aqueous liquid core, and shell composed of a blend of metal or semi-metal oxide polymers. Methods for preparing and using the microcapsule particles in personal care, therapeutic, cosmetic and cosmeceutic products are also provided.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES +1

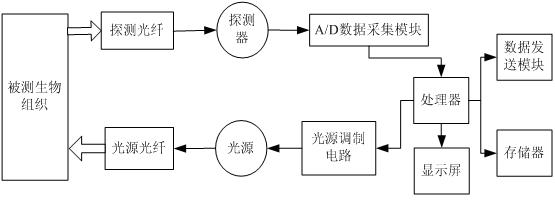

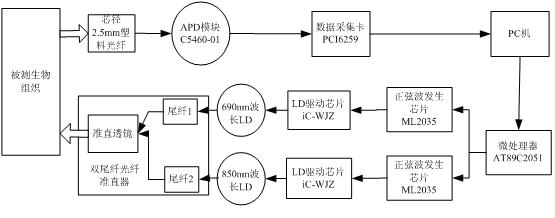

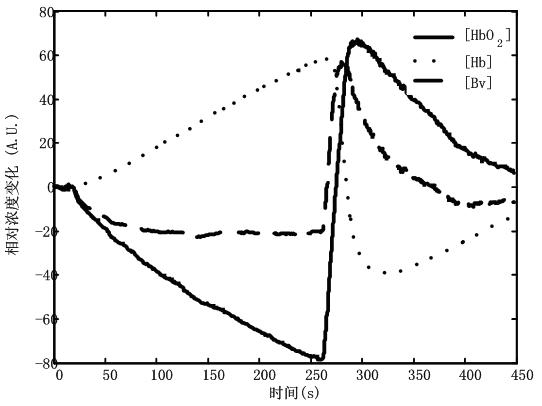

Optical fiber near-infrared spectrometer

InactiveCN101849821AReduce noise levelImprove time resolutionBlood flow measurementNoise levelSinusoidal modulation

The invention relates to an optical fiber near-infrared spectrometer in the technical field of medical devices. The optical fiber near-infrared spectrometer uses multi-tail optical fiber collimator as light source optical fiber, uses a number lock technology as a technical scheme for weak signal extraction, uses a laser diode with a PD as a light source for sinusoidal modulation, uses an avalanche photodiode (APD) or photomultiplier tube (PMT) as a detector, and uses thick core-diameter plastic optical fiber, liquid-core optical fiber, silica optical fiber, a silica optical fiber bundle or glass optical fiber bundle as detection optical fiber. The invention has the advantages that the instrument can conduct nondestructive real-time hemodynamic parameter detection to biological tissues sheltered by hairs, the noise level of the instrument is low, the time resolution is high, the stability is high, the price is cheap, the hardware circuit design is greatly simplified and the portability of the instrument is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

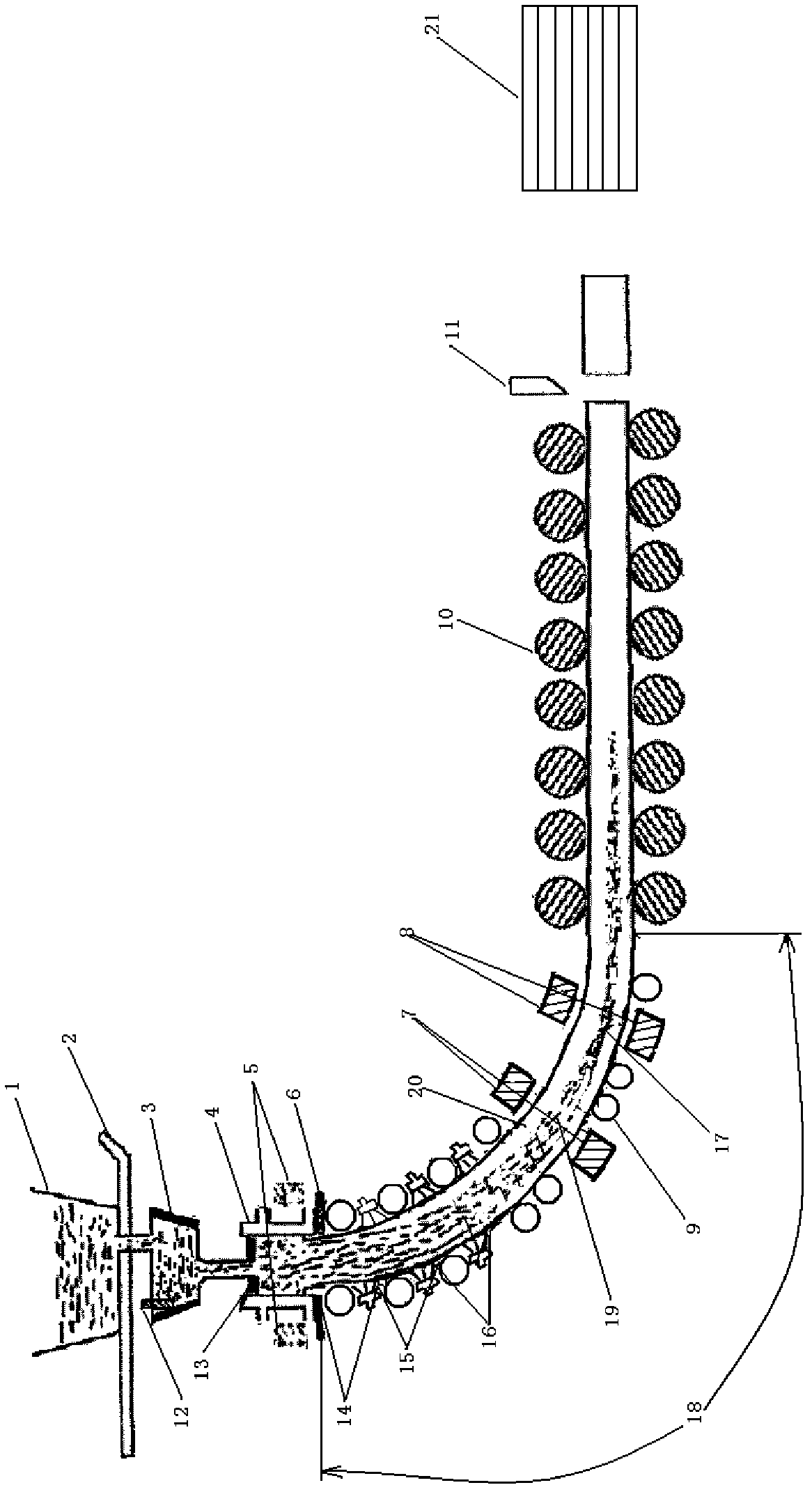

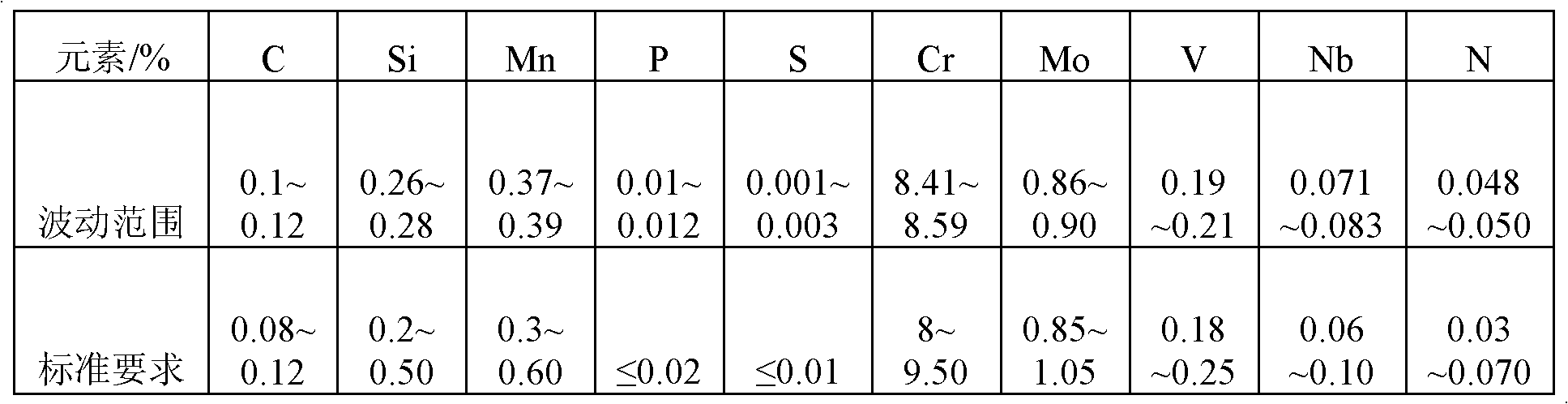

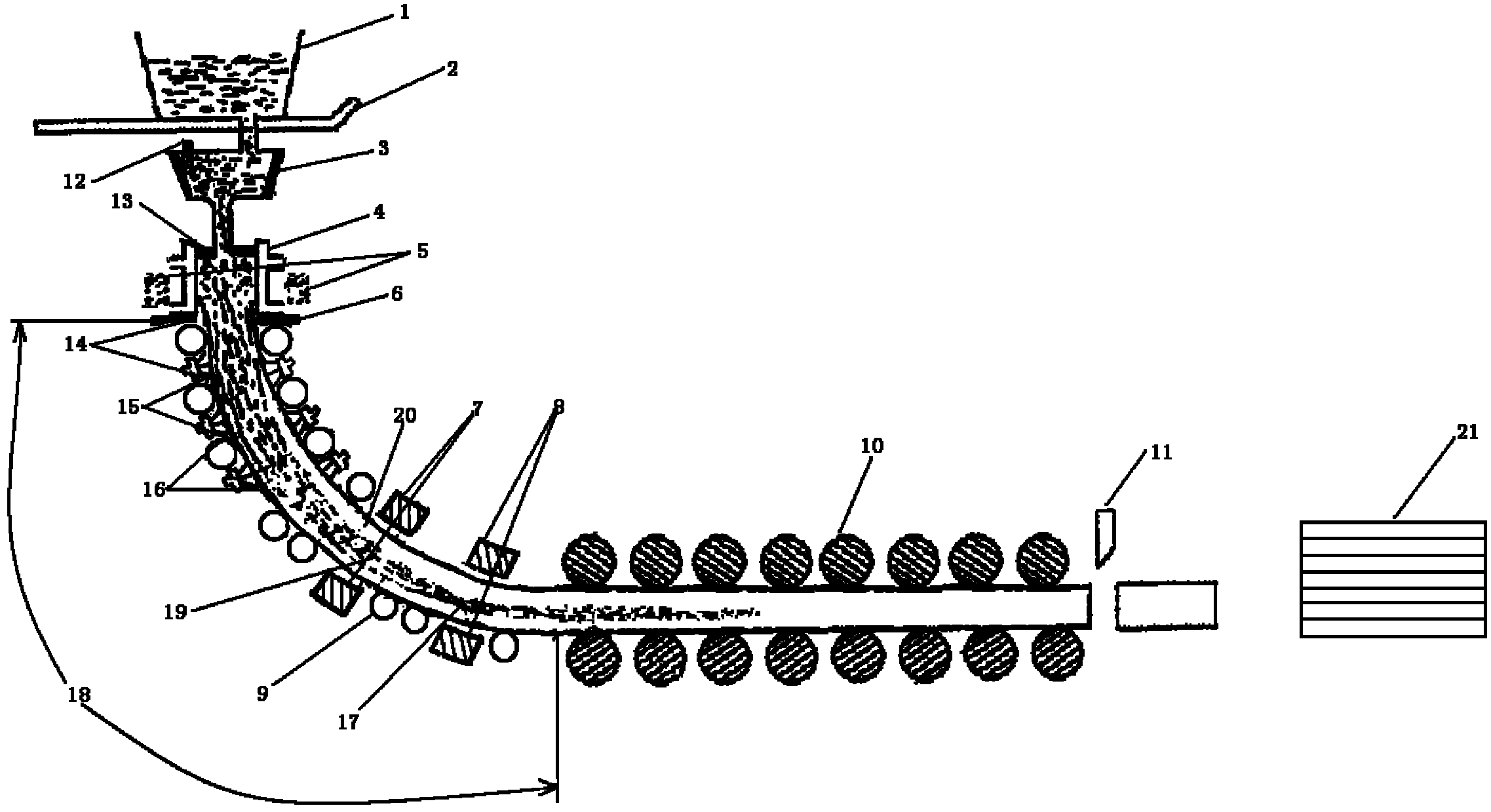

Continuous-cast P91-steel round pipe billet and production process thereof

The invention provides a continuous-cast P91-steel round pipe billet and a production process thereof. The production process includes 1) injecting molten steel into a tundish (3) and controlling degree of superheat of molten steel; 2) adding mold flux (13) to the surface of molten steel of a crystallizer (4) and solidifying the molten steel into a billet casing (20) with a liquid core (19); 3) stirring the front of the solidified molten steel by the aid of a one-way rotary magnetic field, applying a thrust force to the liquid core of the cast billet by a traveling wave magnetic field, and stirring the tail end (17) of the solidified molten steel by a two-way alternative rotary magnetic field; 4), drawing the billet casing to an arc guide segment (18) to form an initial round billet and cooling the initial round billet by a secondary cooling region which is divided into three sections; 5) straightening the cooled cast billet by eight rollers; and 6) cutting the cast billet into fixed-length billet sections by torch flame and annealing the same to obtain continuous-cast round pipe billets. The round pipe billets produced by the production process solves the problems that diameters of round pipe billets in the prior art are too small and surface cracks, middle cracks and straightened cracks of the round pipe billets in large diameter are hard to meet industry requirements.

Owner:HENGYANG VALIN STEEL TUBE

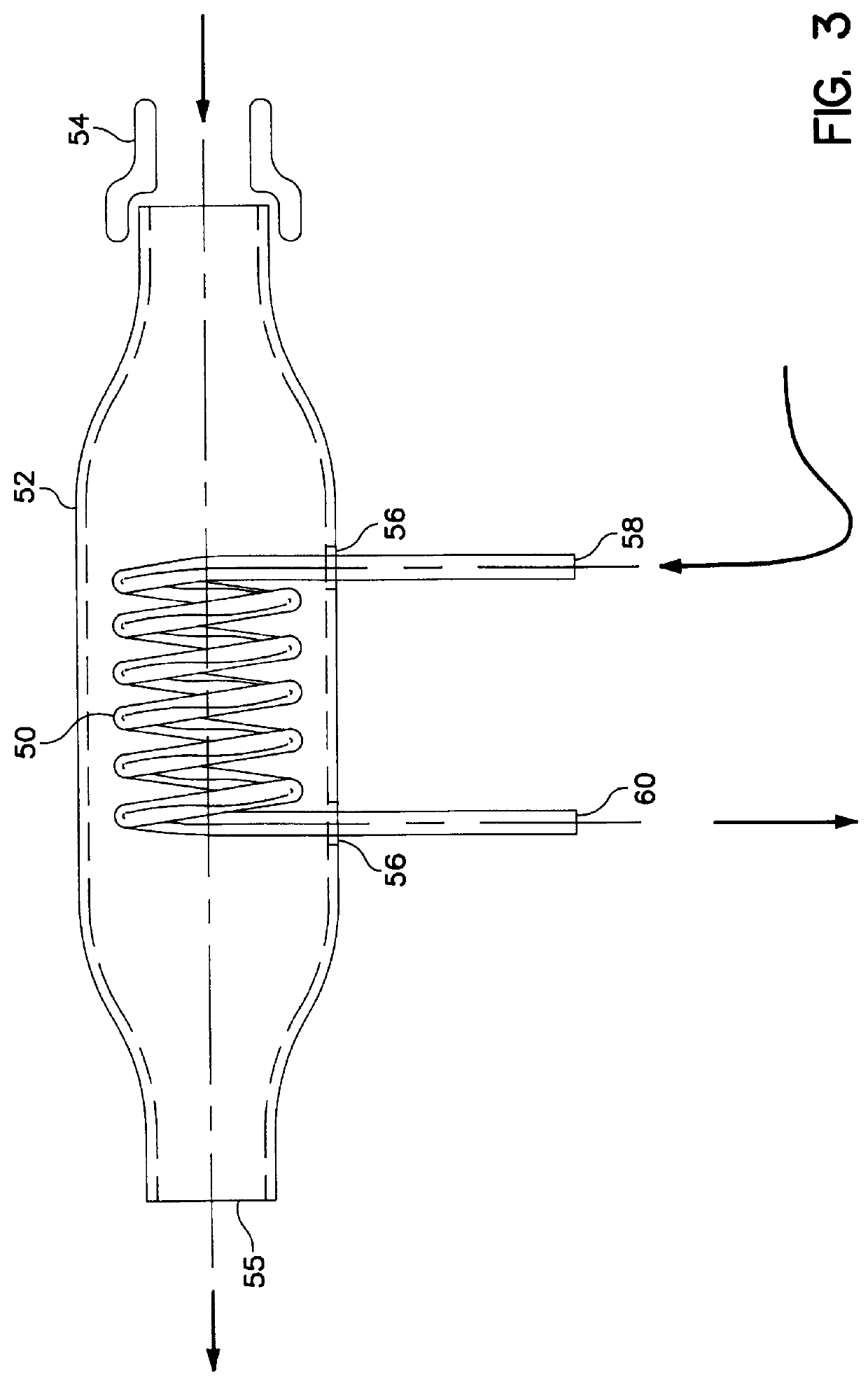

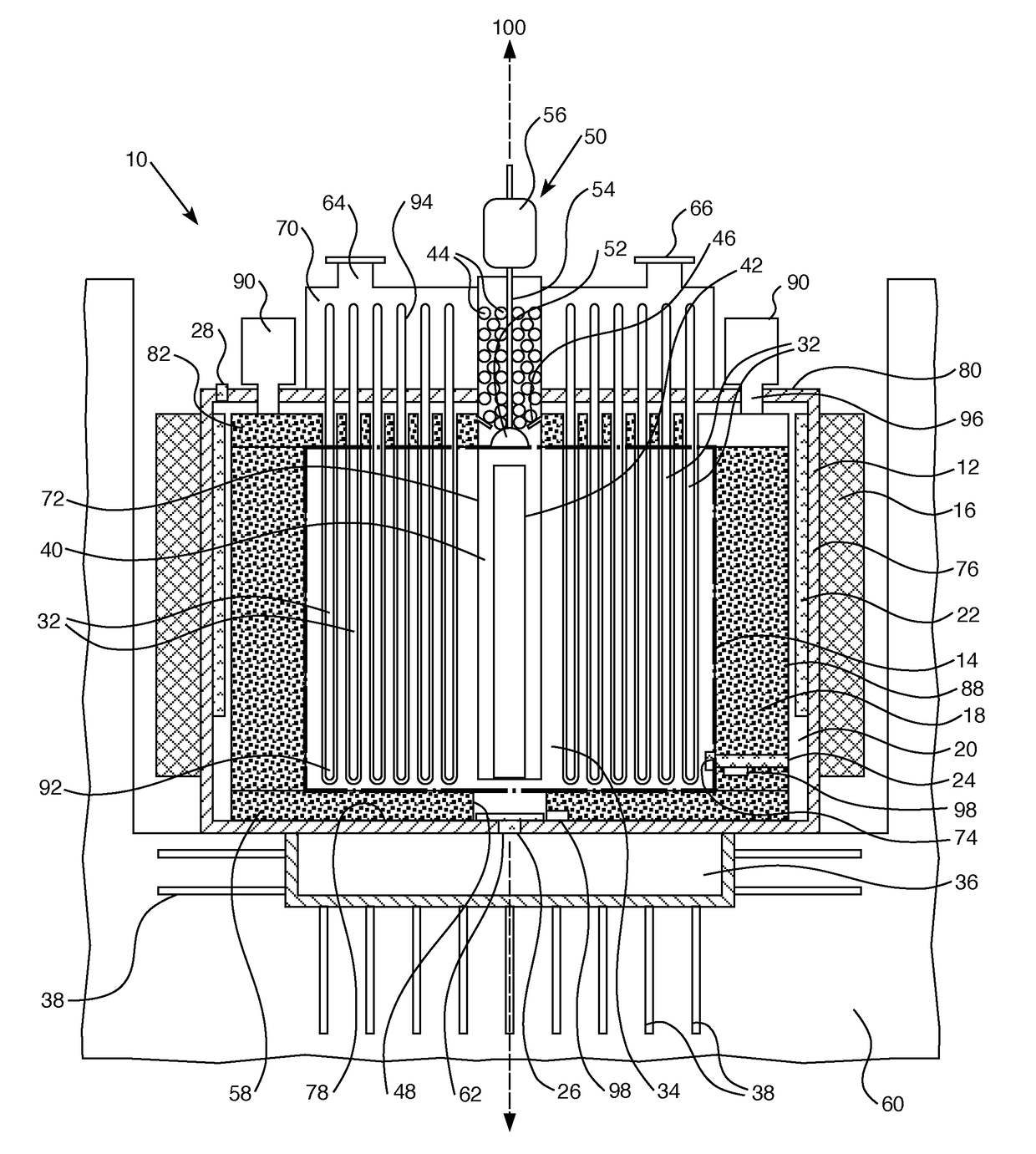

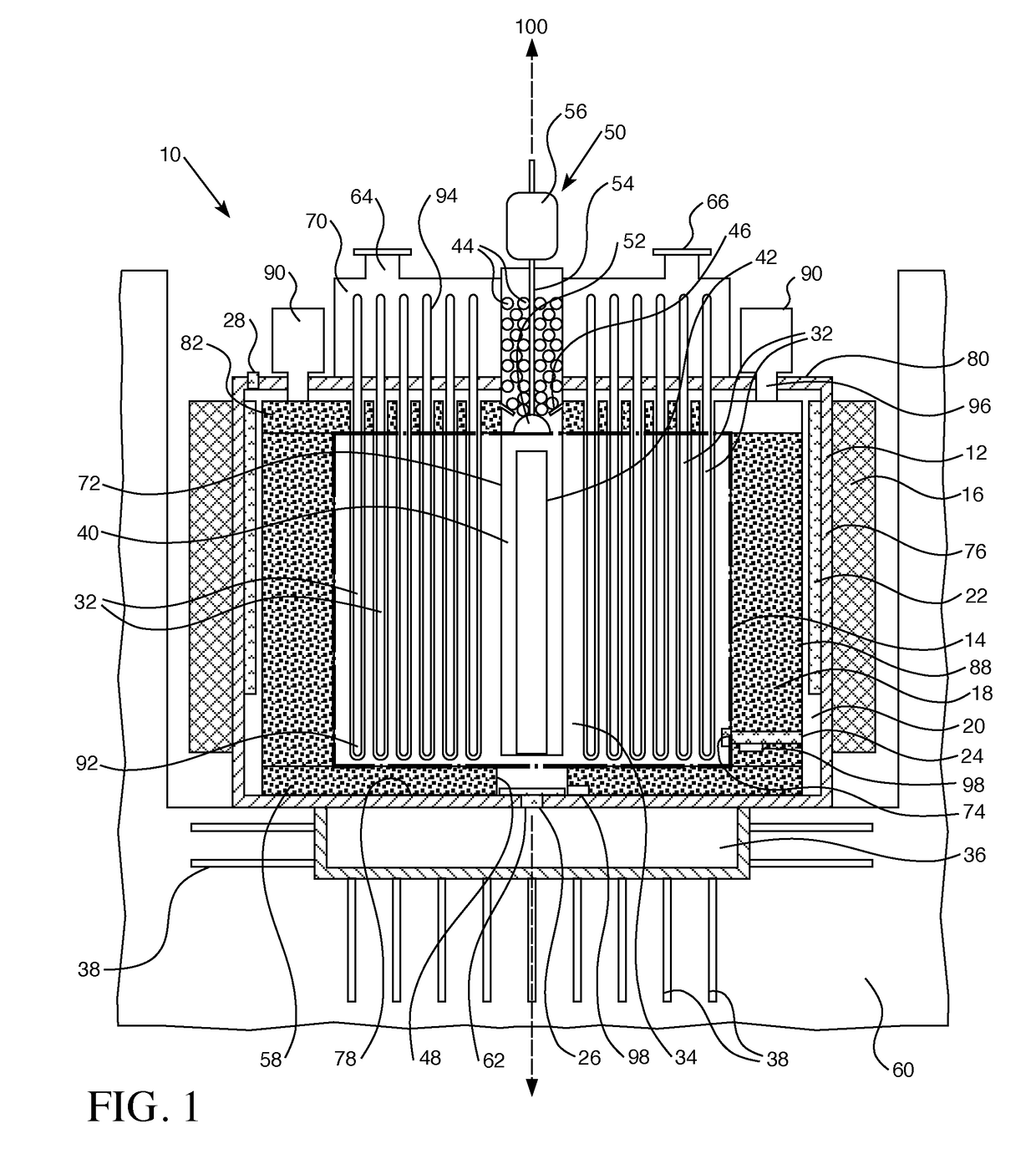

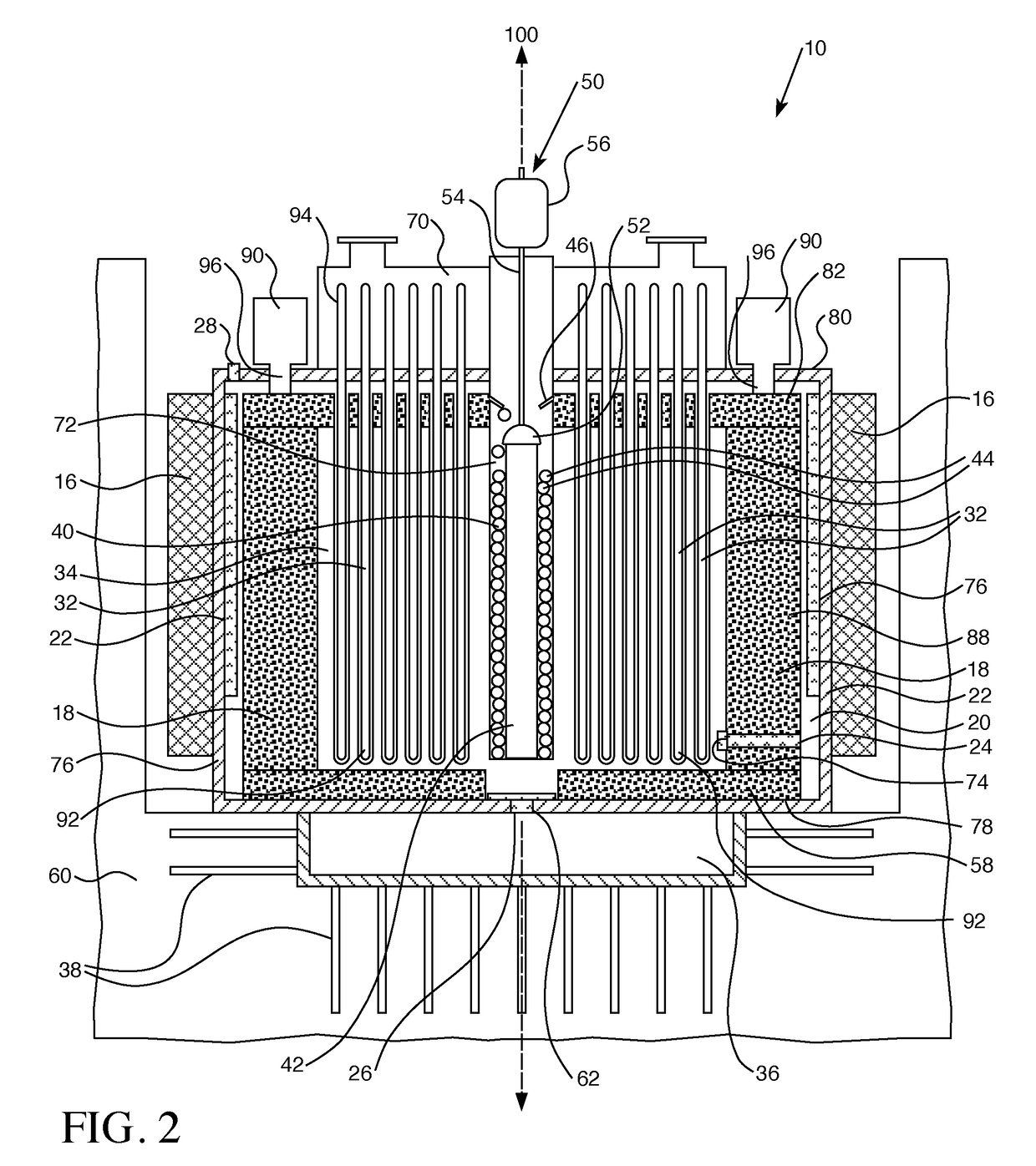

Heat pipe molten salt fast reactor with stagnant liquid core

A molten salt reactor is described that includes a containment vessel, a reactor core housed within the containment vessel, a neutron reflector spaced from the containment vessel and positioned between the core and the containment vessel, a liquid fuel comprised of a nuclear fission material dissolved in a molten salt enclosed within the core, a plurality of heat transfer pipes, each pipe having a first and a second end, wherein the first end is positioned within the reactor core for absorbing heat from the fuel, a heat exchanger external to the containment vessel for receiving the second end of each heat transfer pipe for transferring heat from the core to the heat exchanger, and at least one and preferably two or more reactor shut down systems, where at least one may be a passive system and at least one or both may be an active or a manually operated system. The liquid fuel in the core is kept within the core and heat pipes are used to carry only the heat from the liquid core to the heat exchanger.

Owner:WESTINGHOUSE ELECTRIC CORP

Anhydrous Powder-to-Liquid Particles

A powder comprising core / shell particles having an average particle size of less than 1000 microns, each particle comprising: 1) a liquid core that is substantially free of water and comprises a polar liquid having a percent surface polarity of at least 24%, and 2) a shell comprising hydrophobic particles, is provided. The powder is stable and advantage

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

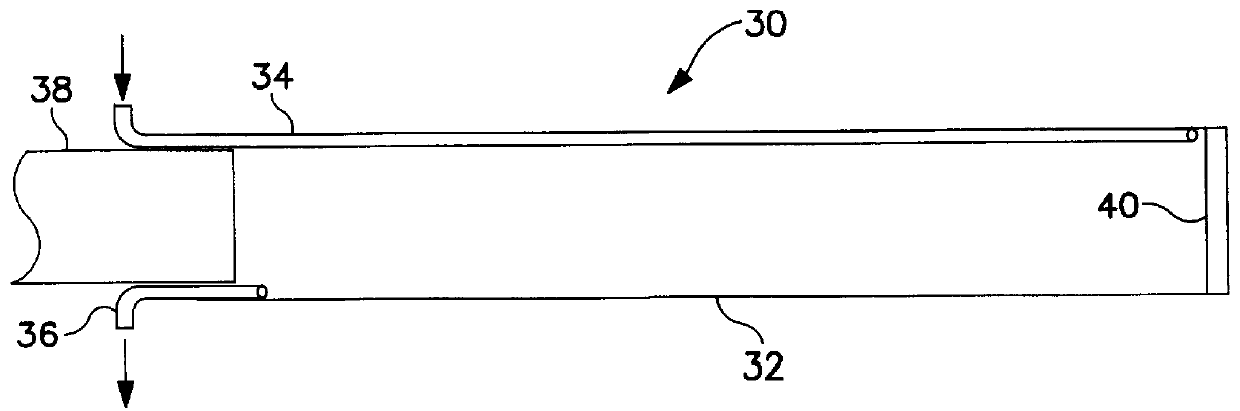

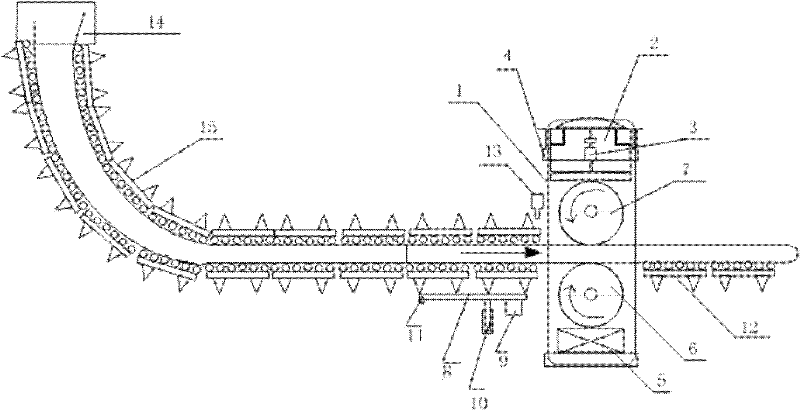

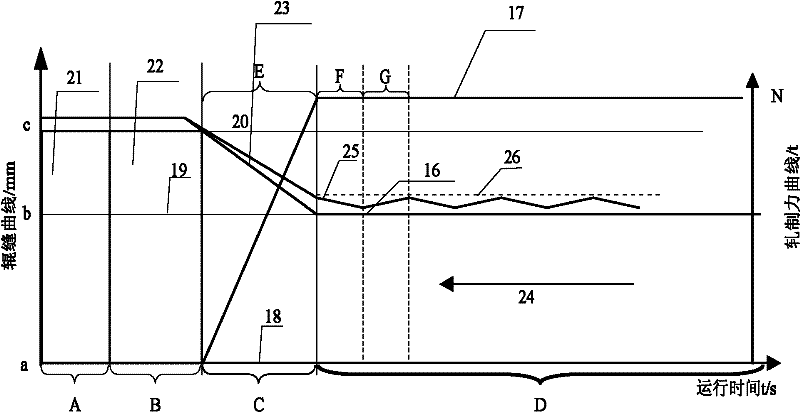

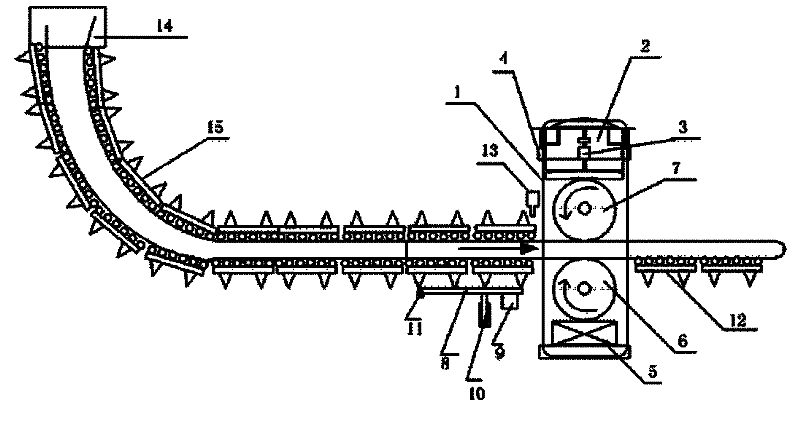

Method for rolling liquid core under heavy reduction rate by virtue of online thickness regulating roll by utilizing continuous casting machine

ActiveCN102189102AQuality improvementExempt from reheatingRoll force/gap control deviceMetal rolling arrangementsReduction rateLiquid core

The invention relates to a method for rolling a liquid core under heavy reduction rate by virtue of an online thickness regulating roll by utilizing a continuous casting machine. The method comprises the following steps of: when two rolling mills are loaded, setting a target thickness, feeding back the thickness value in real time and detecting oil pressure, carrying out conversion on a rolling force to judge whether the rolling force is higher than a limit value, if the rolling force is lower than the limit value, stabilizing rolling until the rolling is finished; if the rolling force is higher than the limit value, regulating and judging the rolling force again; if the target thickness is changed in the rolling process, calculating thickness variation by virtue of a rolling process computer, regulating roll gap of the two rolling mills to be the target thickness, and judging whether the rolling force is higher than the limit value again. In the method provided by the invention, a rolling signal can be changed to change the target thickness in the rolling process, and a wedge-shaped blank is rolled. By applying the method provided by the invention, the quality of a continuous casting can be better improved, the continuous casting and the wedge-shaped blank can be rolled, and the time of a process is reduced while the yield is improved; meanwhile, structure of equipment is simple, investment is less, control is simple, reliability is high, and energy can be greatly saved, thus the method has a good popularization and application prospect.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

Seamless filled capsules

Spherical capsule having a liquid core and a seamless solid shell surrounding the core, in which: the diameter of the capsule is in the range of 4-8 mm; the thickness of the shell is in the range of 20-200 μm; the shell thickness to capsule diameter ratio is in the range of 0.004-0.04; the shell contains 70-90% (m / m) gelatin and 10-30% (m / m) plasticizer, based on the solids content of the shell; and the core has a flavoring content in the range of 1-100% (m / m), based on the total mass of the core.

Owner:SYMRISE GMBH & CO KG

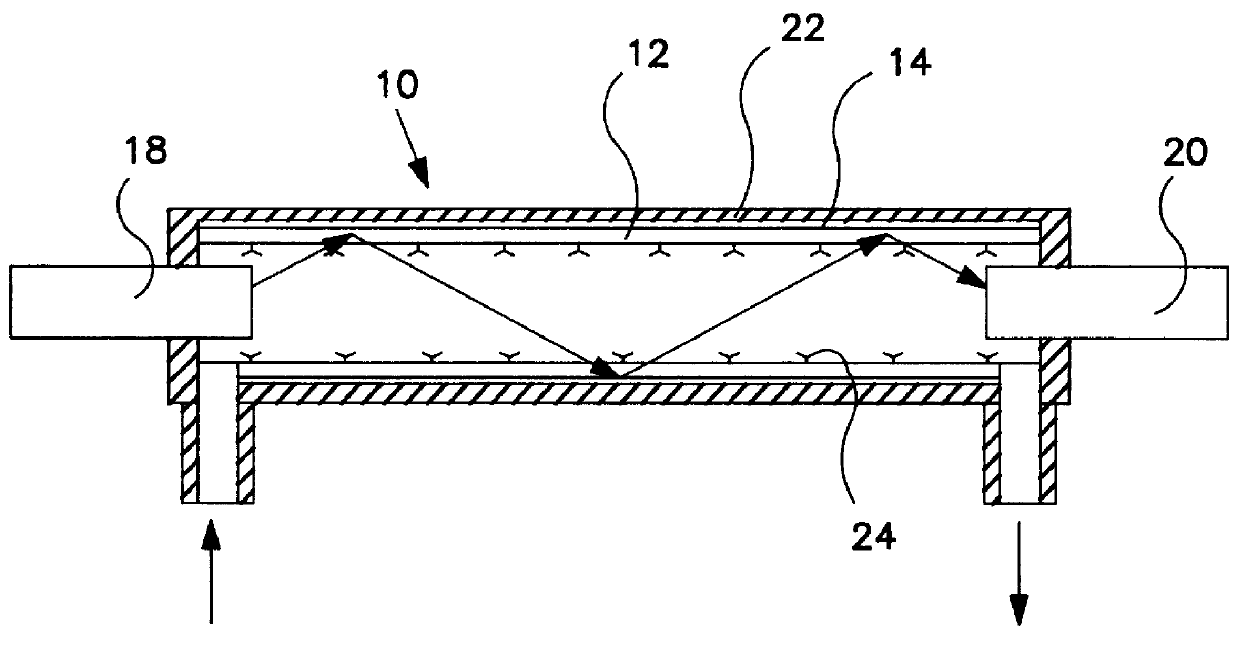

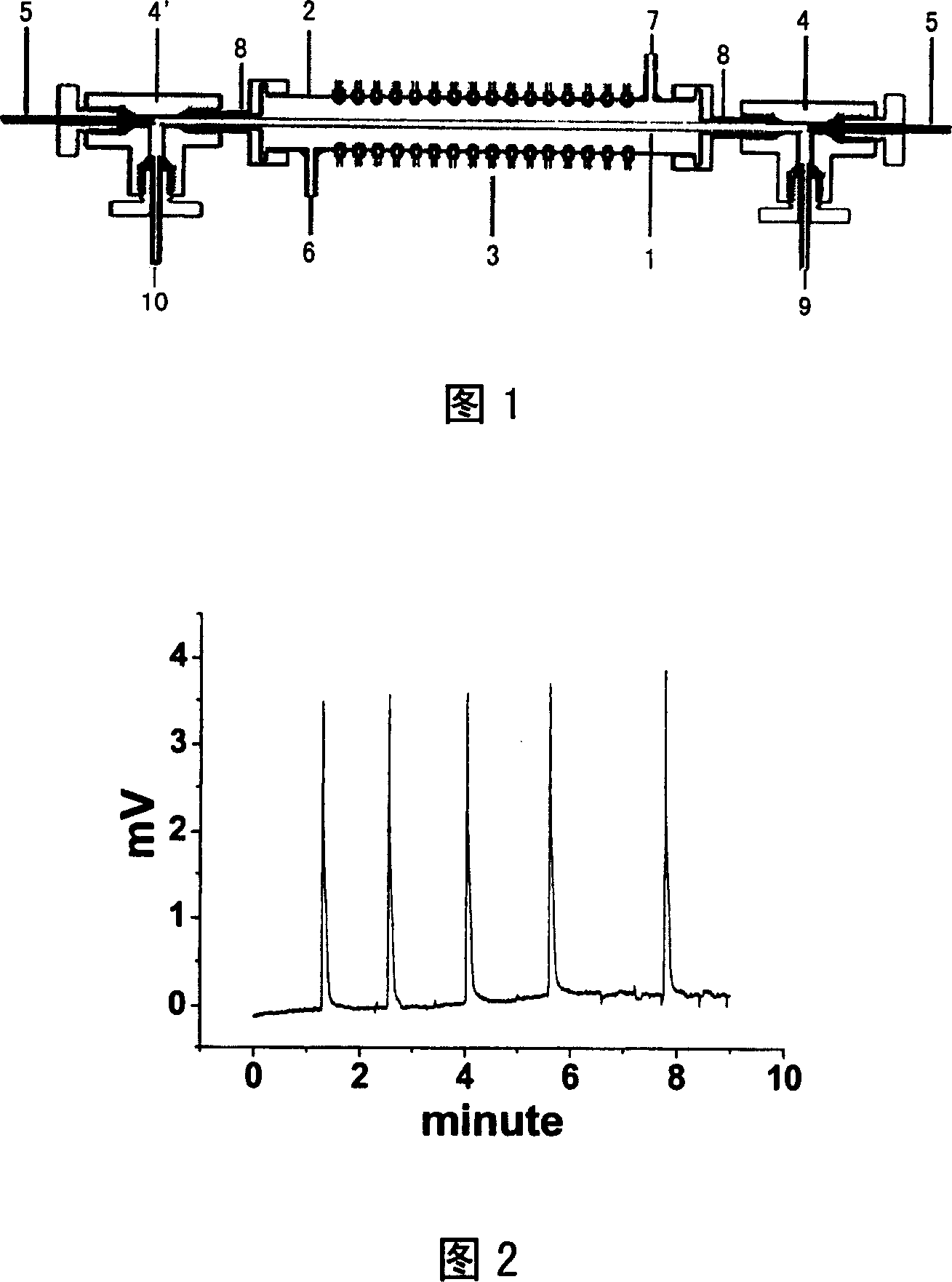

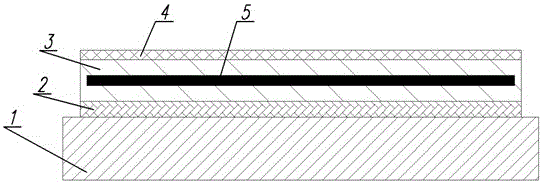

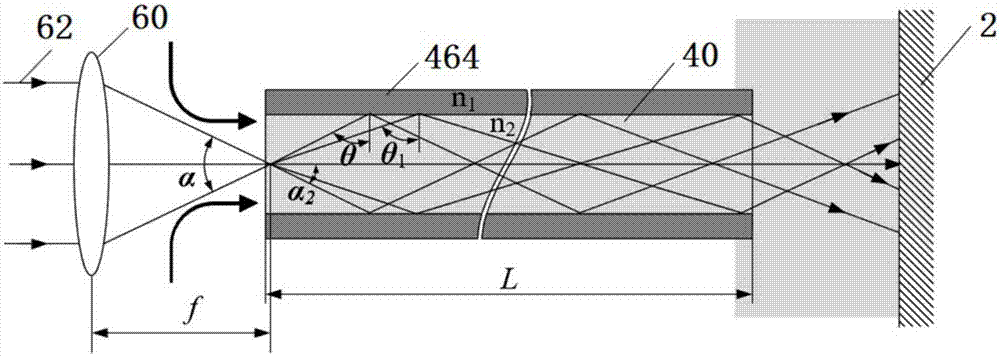

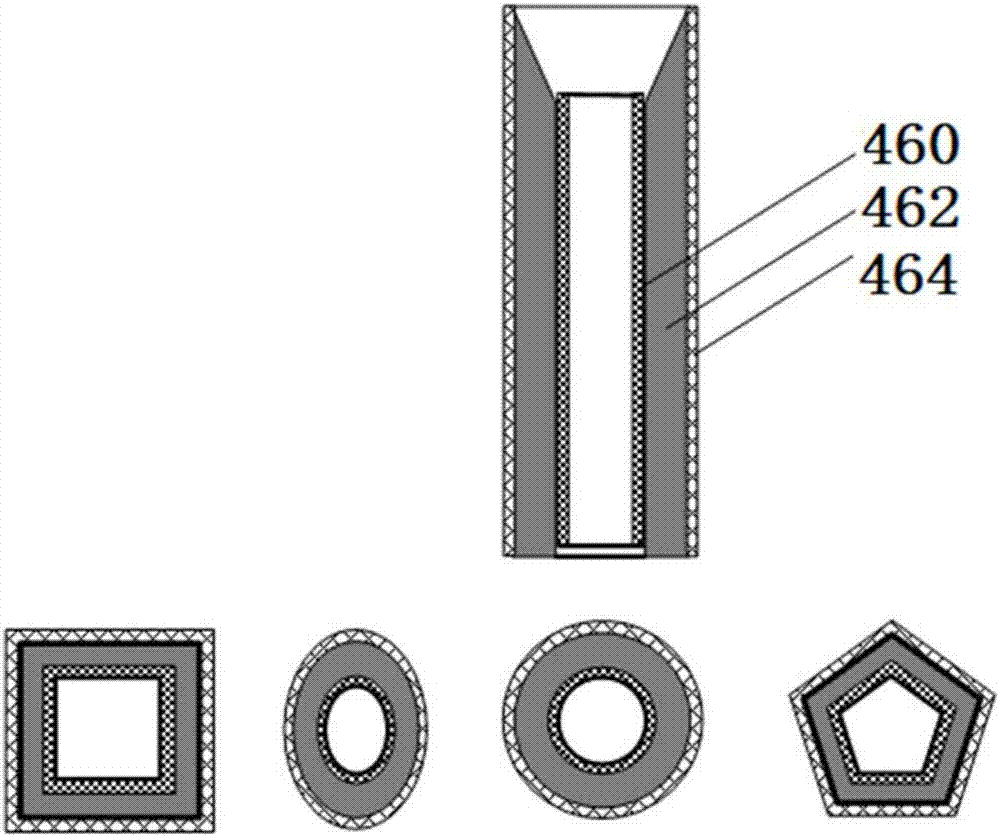

Sandwich liquid core waveguide structure investigating pond

InactiveCN101000299AReduce intensityImprove signal-to-noise ratioMaterial analysis by optical meansLiquid coreTotal internal reflection

The invention relates to sandwich type liquid core wave guide structure detecting pool. It is made up of liquid core optical fiber, circulating pool body, duplex fitting, common optical fiber. The center of the circulating pool body is traversed by one liquid core optical fiber. Its two sides are set liquid inlet and outlet. Its pool wall is set light source hole. And its two ends are respectively connected with one duplex fitting. One of them has circulating pool inlet. And another has outlet to connect with outer separating and analyzing system. The refraction index of the injected liquid is more than 1.31 of the liquid core wave guide to form thick-thin-thick sandwich type structure in the circulating pool that means forming a layer of liquid wall structure with full internal reflection ability at the outer side of the liquid core optical fiber which can prevent side emitting light from entering its inner to reduce scattered light strength, increase detecting signal to noise ratio.

Owner:INST OF CHEM CHINESE ACAD OF SCI

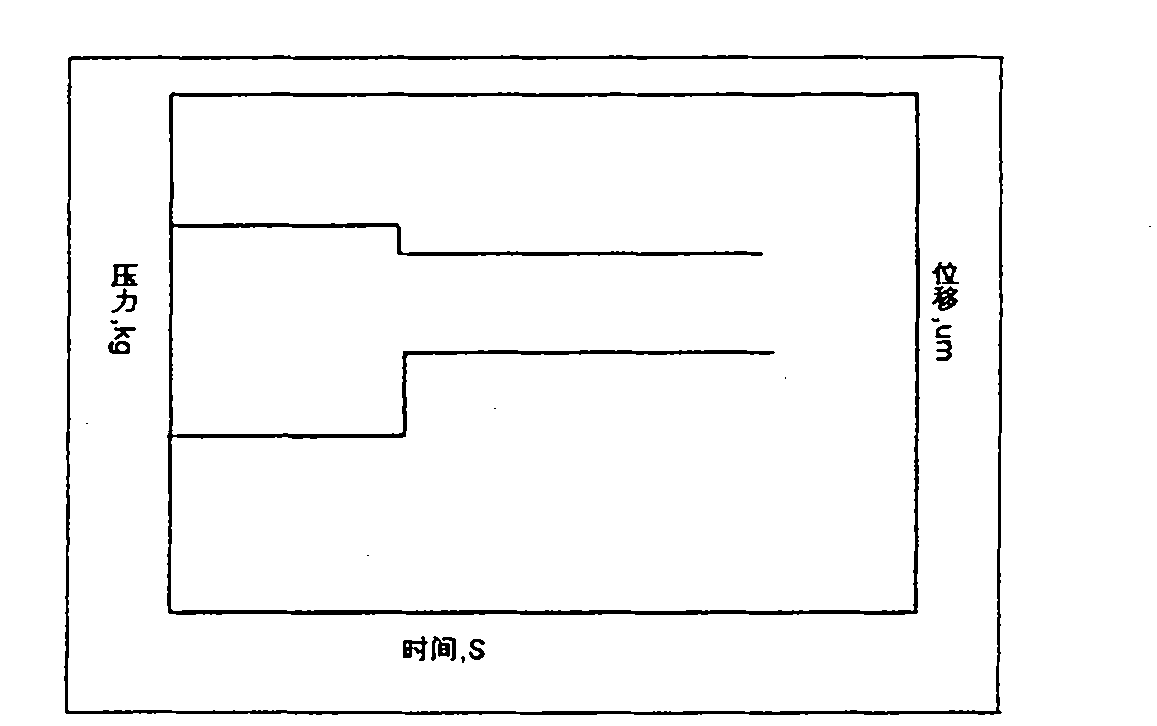

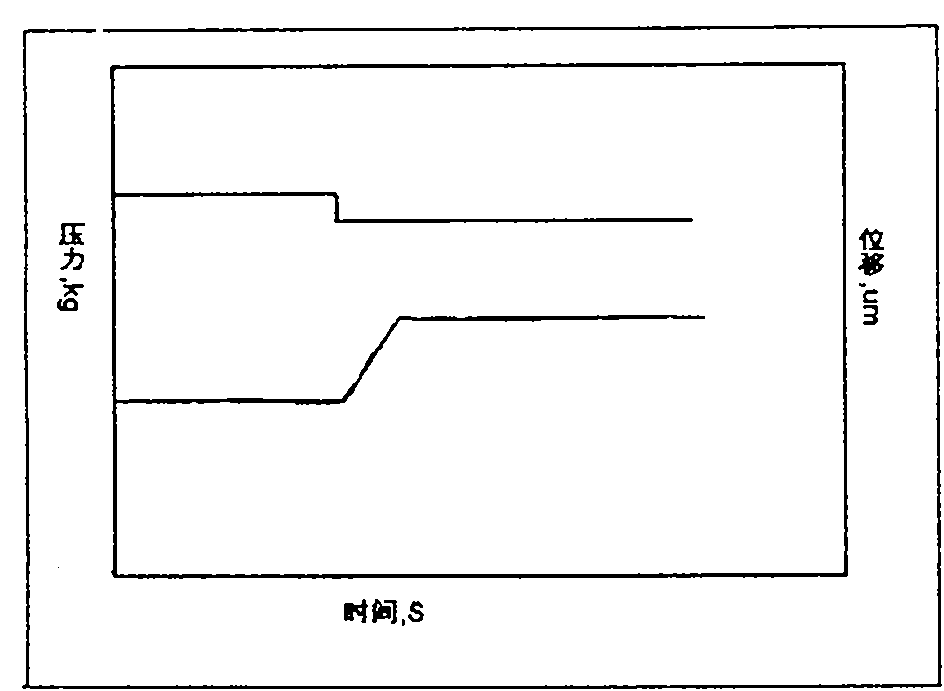

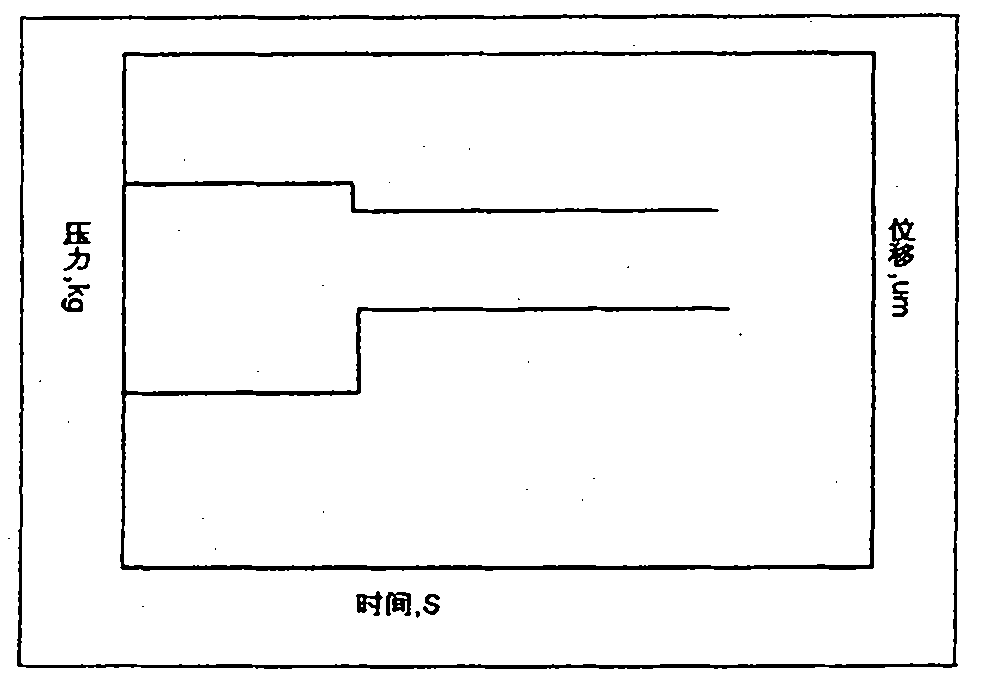

Dynamic soft reduction method for detecting tail end of solidified liquid core of casting blank based on pressure feedback

The invention relates to a dynamic soft reduction method for detecting the tail end of a solidified liquid core of a casting blank based on pressure feedback, belonging to the technical field of metallurgy continuous casting control. The method comprises the following steps of: firstly, establishing a control platform for remotely and automatically adjusting roll gaps of all sector sections on a continuous casting machine, and calculating the stress of the casting blank in different sector sections by utilizing the detection result of pressure sensors installed on all the sector sections; detecting the stress difference of the casting blank in each sector section during roll gap variation by changing the roll gap contraction size of each sector section; judging the position of the tail end of the solidified liquid core of the casting blank according to the stress difference between the casting blank with the liquid core and the casting blank without the liquid core; and finally, dynamically adopting different reduction quantities in all sector sections of a casting machine by using a soft reduction control system according to the position of the tail end of the liquid core judged by the method. The method for judging the tail end of the solidified liquid core of the casting blank is directly obtained by calculating the real-time stress of the casting blank. Because the calculation of casting blank surface temperature and blank shell thickness does not need a large quantity of mathematical models, the calculation method is simple and effective and ensures the stability and the execution efficiency of a casting machine control system.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Artificial skin flexible tactile sensor measurement device

ActiveCN105738012AImprove flexibilityMultidimensionalForce measurement using piezo-electric devicesHuman bodyFiber

An artificial skin flexible tactile sensor measurement device belongs to the technical field of a tactile sensor. The artificial skin flexible tactile sensor measurement device is composed of a bionic epidermal tissue layer, a bionic dermal tissue layer, a bionic subcutaneous tissue layer and an artificial skin adhering base. The bionic subcutaneous tissue layer is uniformly applied on the outer surface of the artificial skin adhering base. The bionic dermal tissue layer is uniformly applied on the outer surface of the bionic subcutaneous tissue layer. The bionic dermal tissue layer is internally provided with three liquid core PVDF piezoelectric polymer fibers. The bionic epidermal tissue layer is uniformly applied on the outer surface of the bionic dermal tissue layer. The artificial skin flexible tactile sensor measurement device is mounted on the arm of a robot. The robot with tactile feeling can utilize the artificial skin flexible tactile sensor measurement device for obtaining a plurality of property characteristics of a target object, thereby finishing more complicated tasks by the robot through identifying the object. Furthermore the artificial skin flexible tactile sensor measurement device has wide application range in researching fields of sports, rehabilitation, human body biomechanics, etc.

Owner:YANGZHOU UNIV

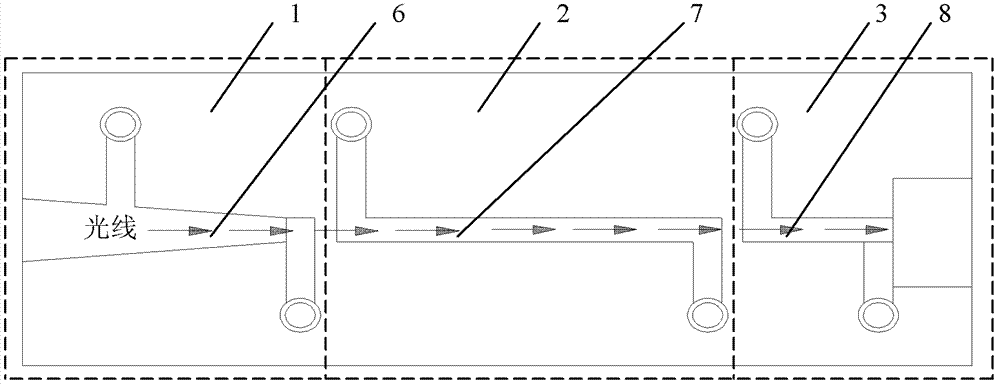

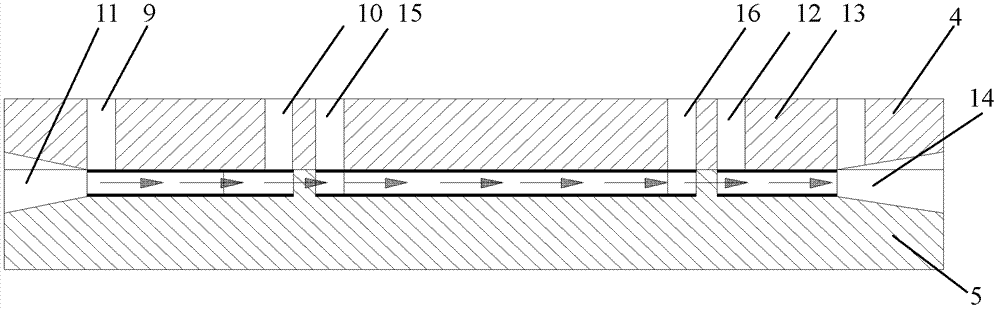

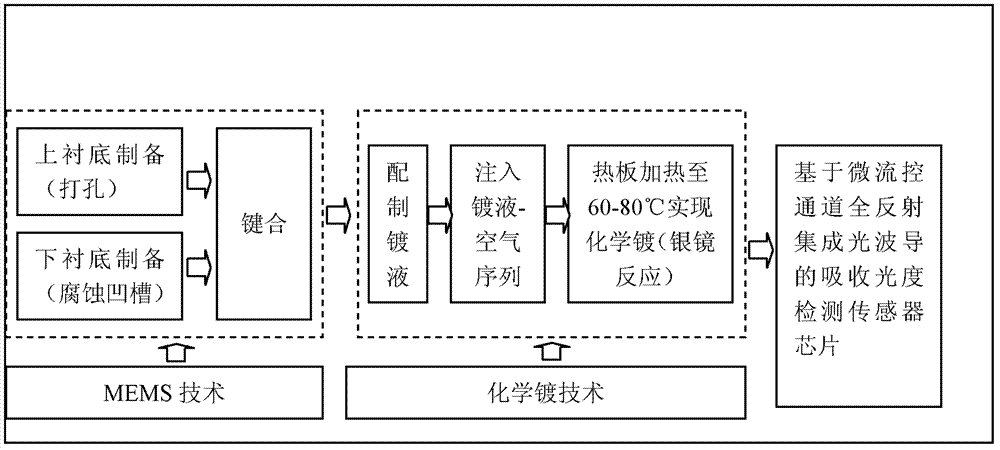

Absorption luminosity detecting sensor based on micro-fluid control channel full-reflection integration light waveguide

ActiveCN102954938APrecise alignmentLaboratory glasswaresColor/spectral properties measurementsLiquid coreFluid control

The invention discloses an absorption luminosity detecting sensor based on micro-fluid control channel full-reflection integration light waveguide, relating to a sensor technology. An optical full-reflection thin film can be selectively prepared in a micro-fluid control channel by using a chemical deposition method, so that the entire integration of a transmission channel and a detection channel of light in micro-fluid control optical detection can be realized. Light with a special wavelength enters an absorption pool through incident light waveguide, spreads inside the absorption pool along liquid core light waveguide and is partially absorbed by a solution to be detected, and finally enters a silicon light diode through emergent light waveguide, thus finishing the luminosity detection. In-situ preparation of the light waveguide on the micro-fluid control chip can be realized through the sensor provided by the invention, so that the integration and the reliability of a absorption luminosity method detection chip based on the micro-fluid control technology can be greatly improved. The absorption luminosity detecting sensor has very important reference meanings on the development of a fluorescence method and a chemiluminiscence method based on micro-fluid control optical detection.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

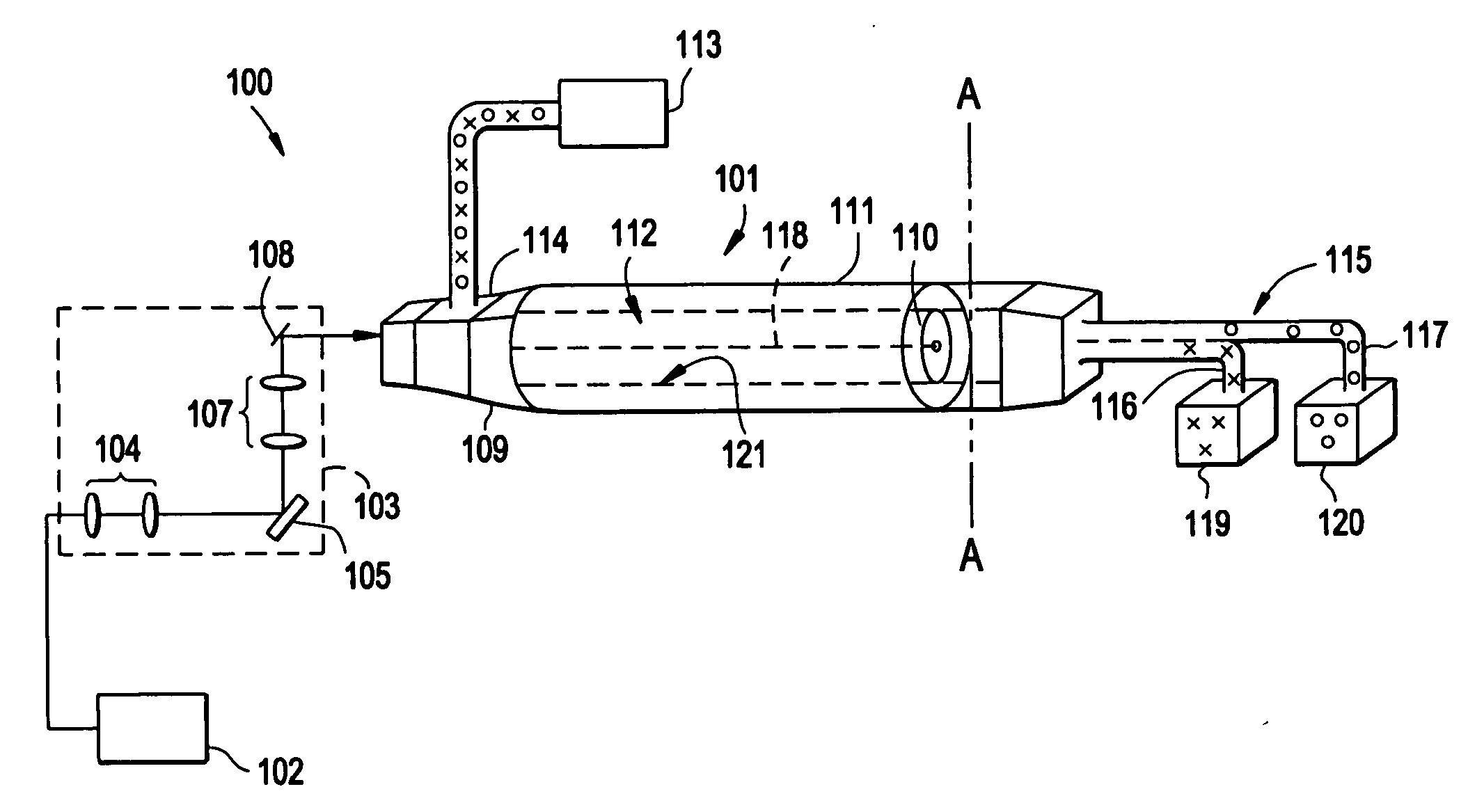

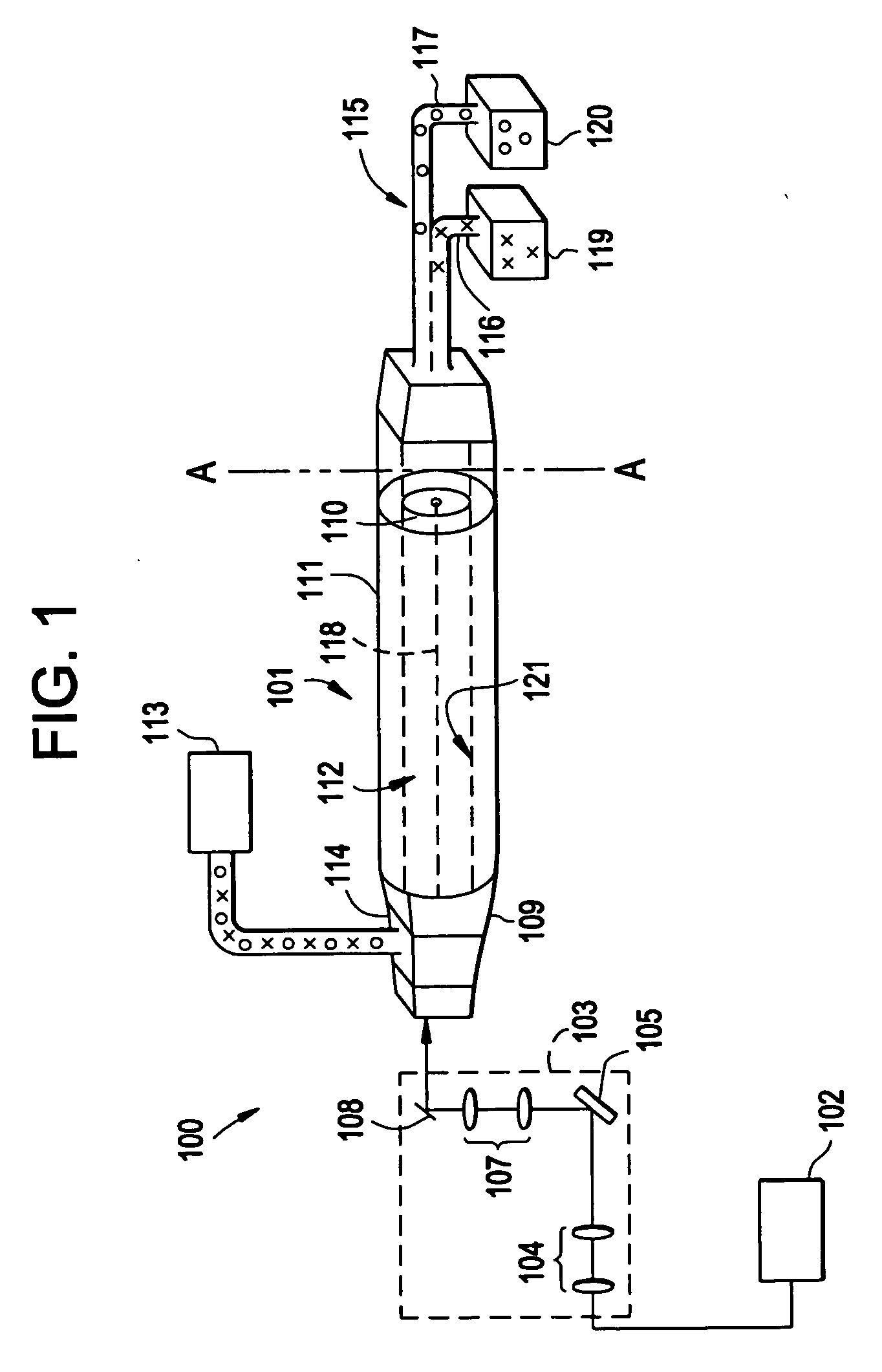

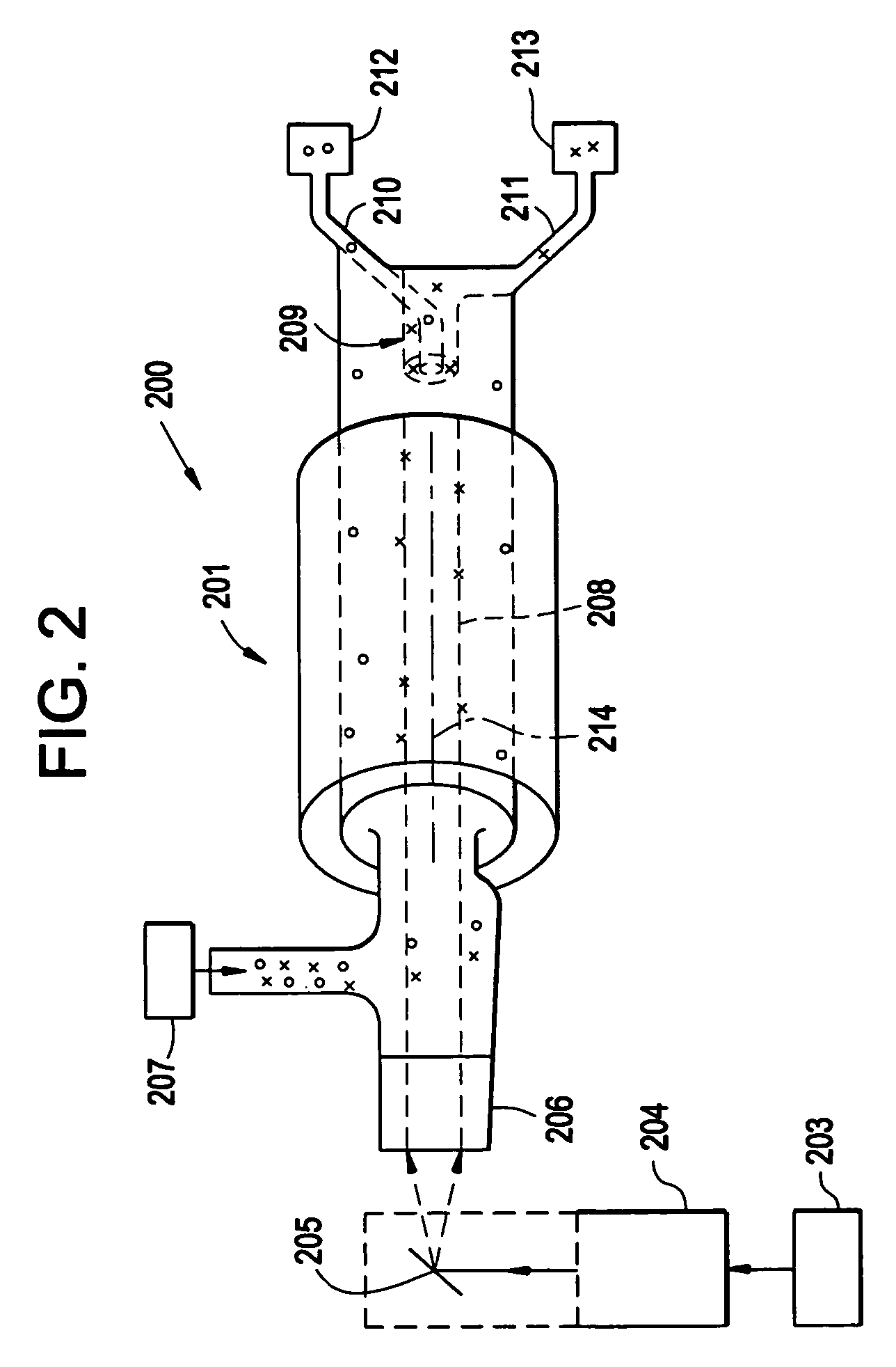

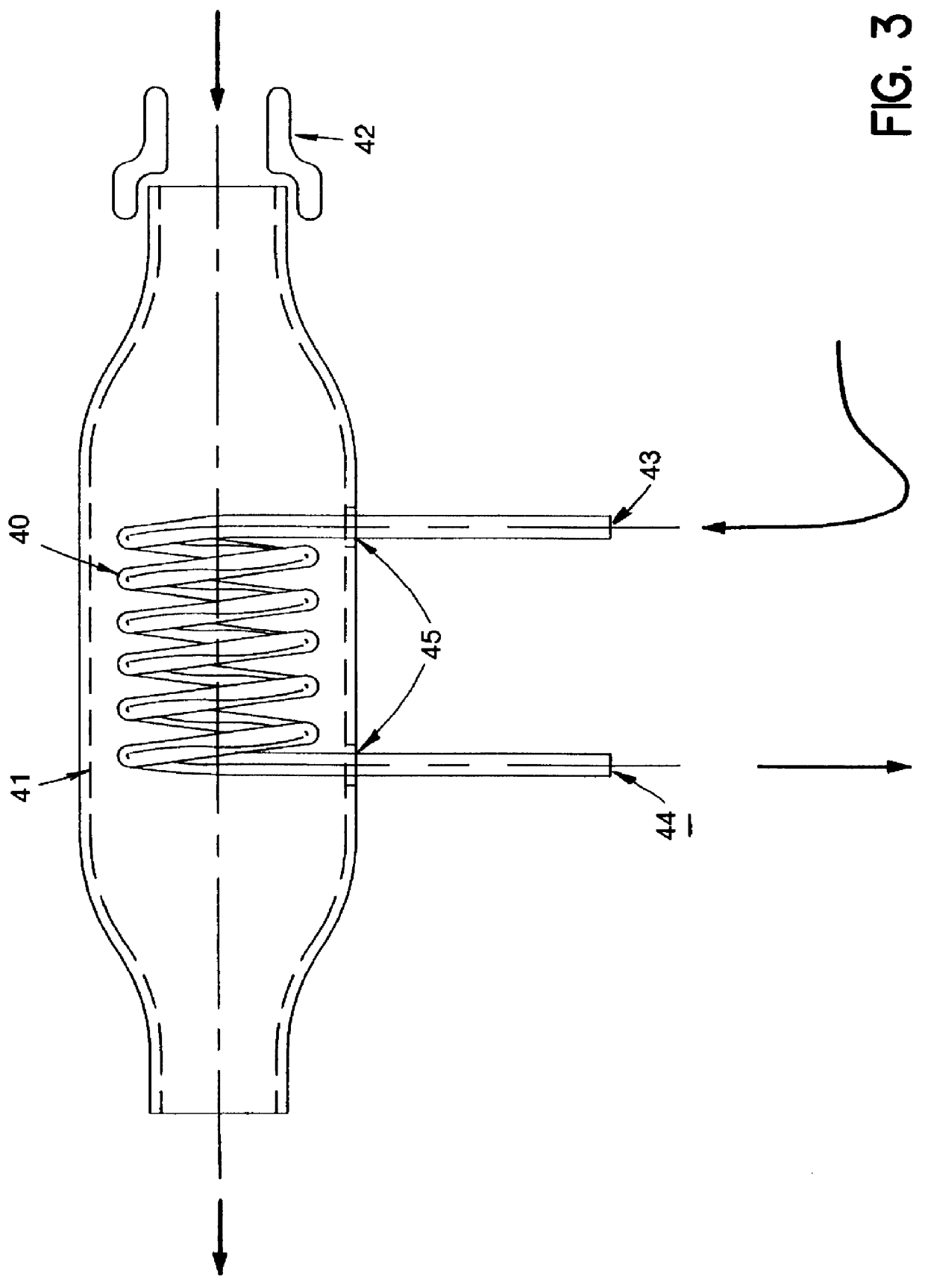

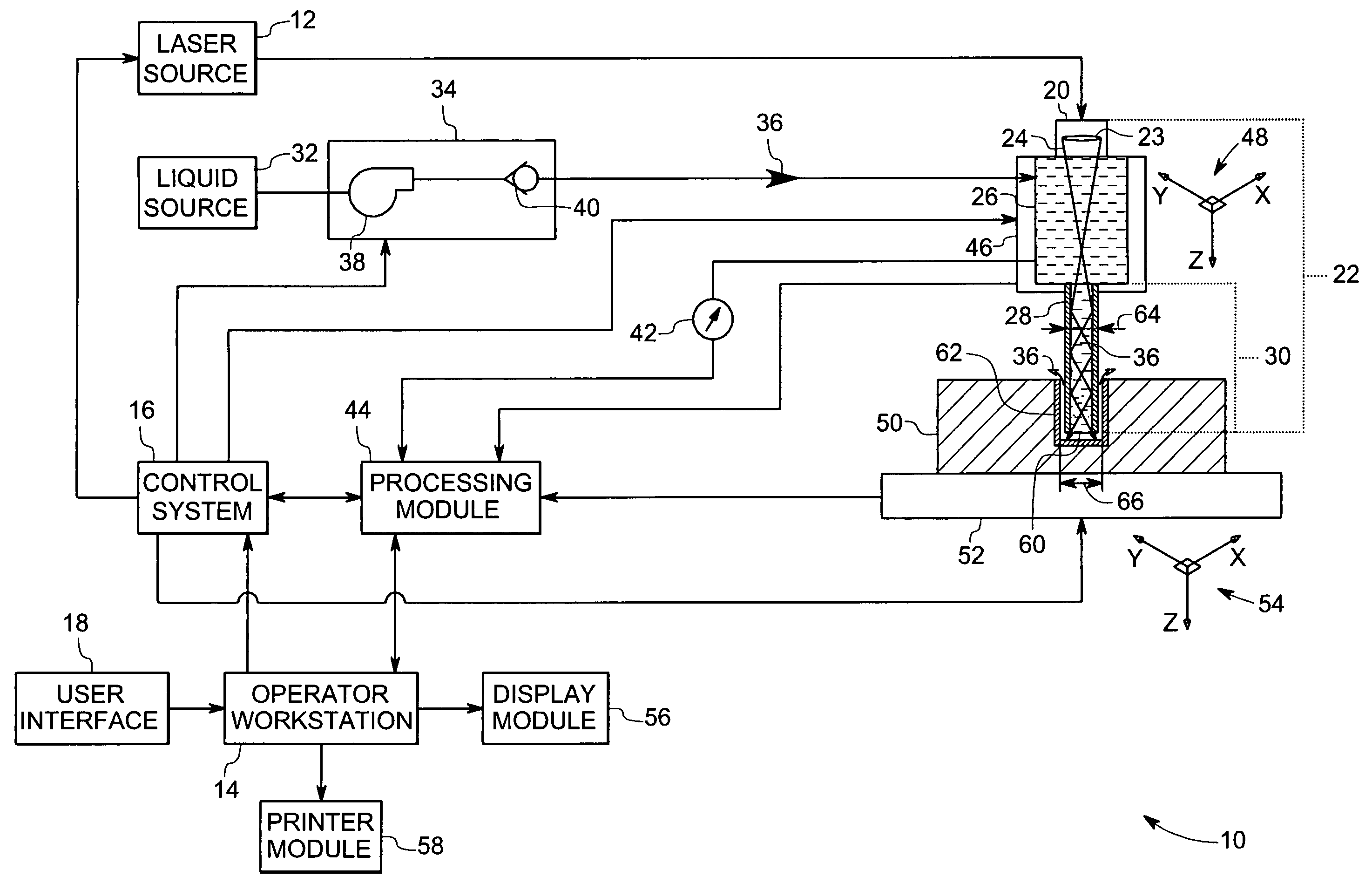

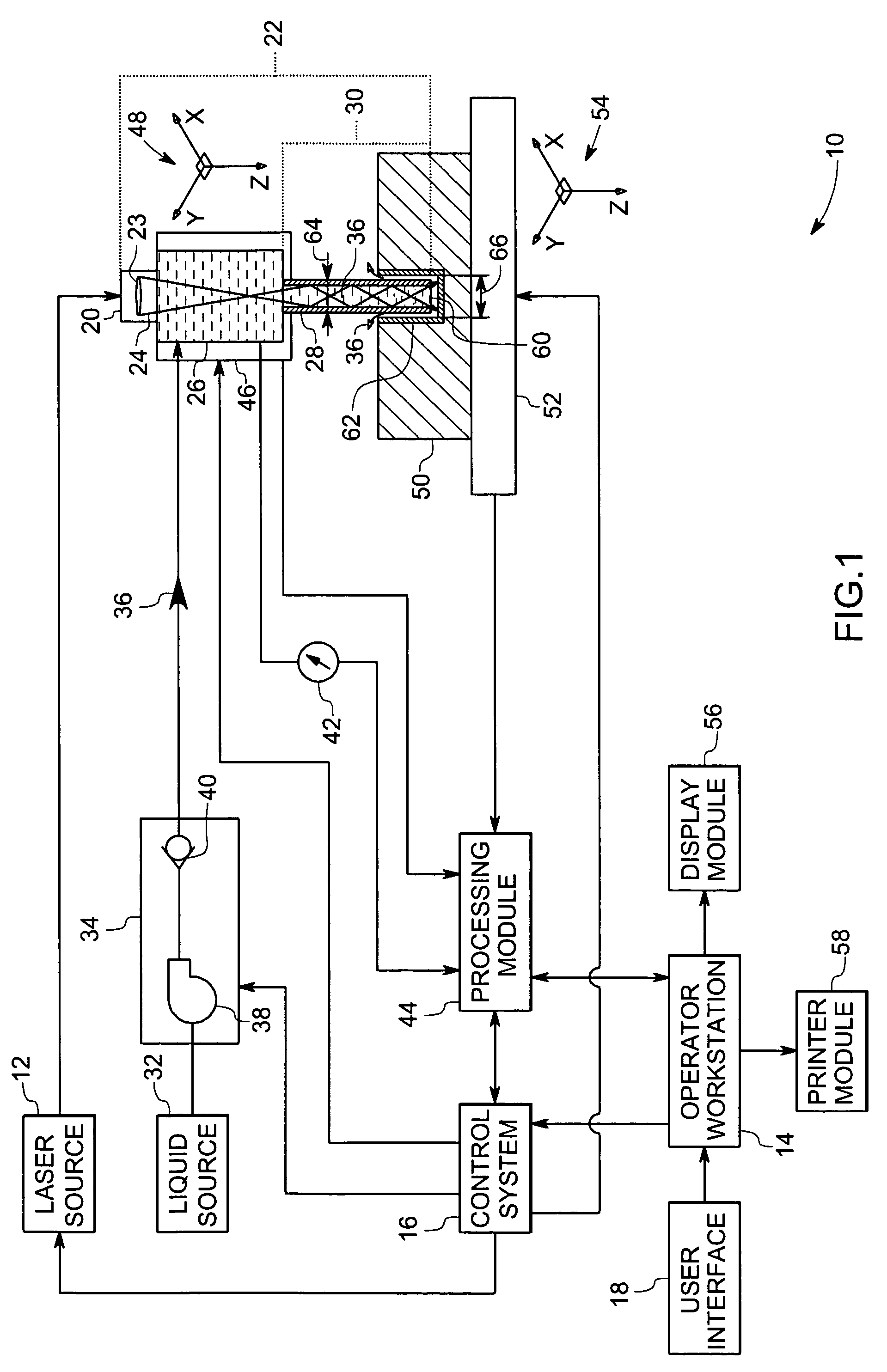

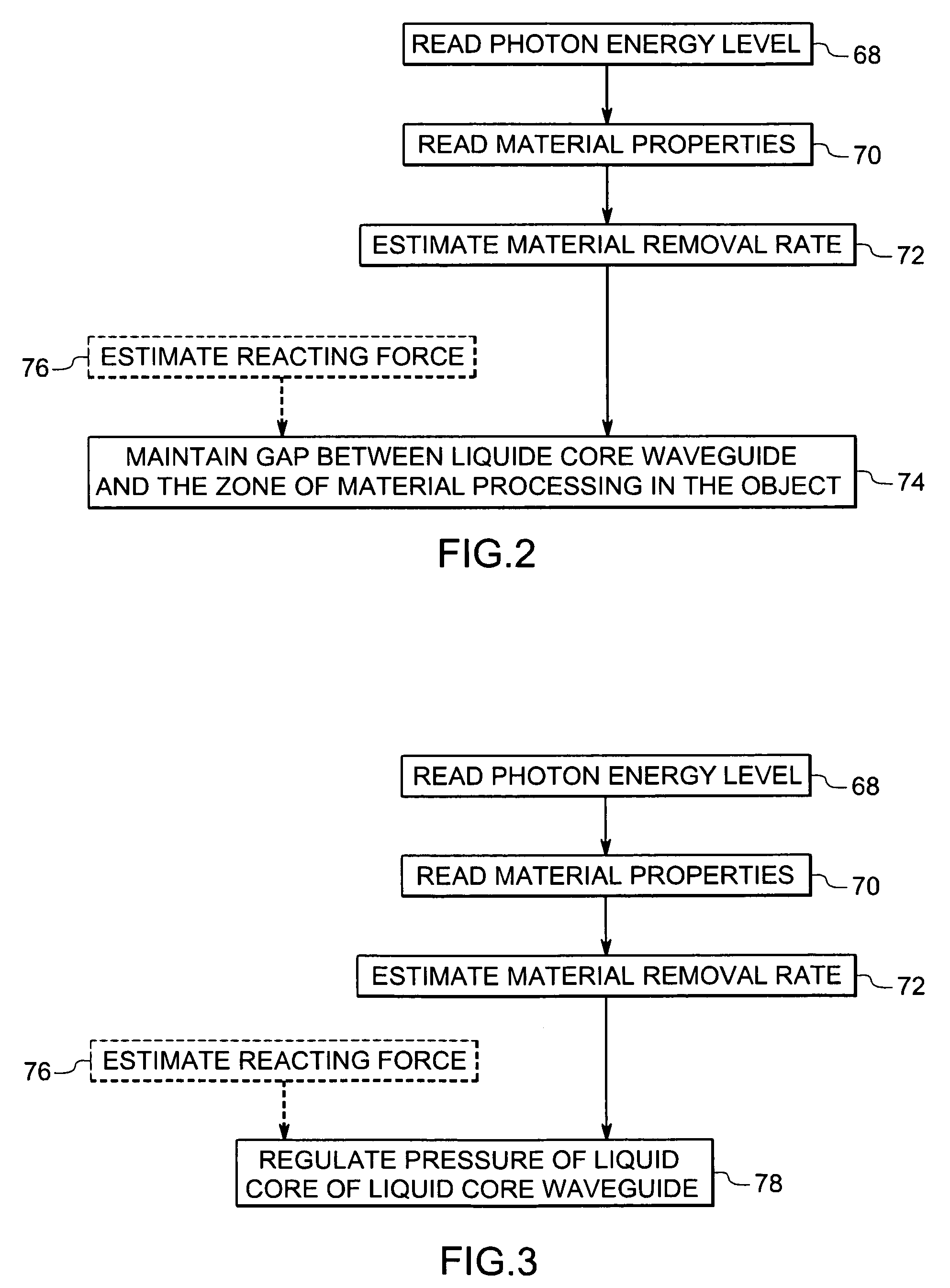

Photon energy material processing using liquid core waveguide and a computer program for controlling the same

A liquid core waveguide photon energy material processing system is provided. The system includes a photon energy source configured to generate a high intensity photon beam for material processing. The system also includes a liquid core waveguide configured to transmit the high intensity photon beam towards at least one object for material processing. The liquid core waveguide in-turn includes a liquid core having a first refractive index and a cladding element having a second refractive index and configured to guide the liquid core, wherein the first refractive index is higher than the second refractive index. The system further includes a liquid source configured to generate the liquid core. The liquid core includes a liquid solution.

Owner:GENERAL ELECTRIC CO

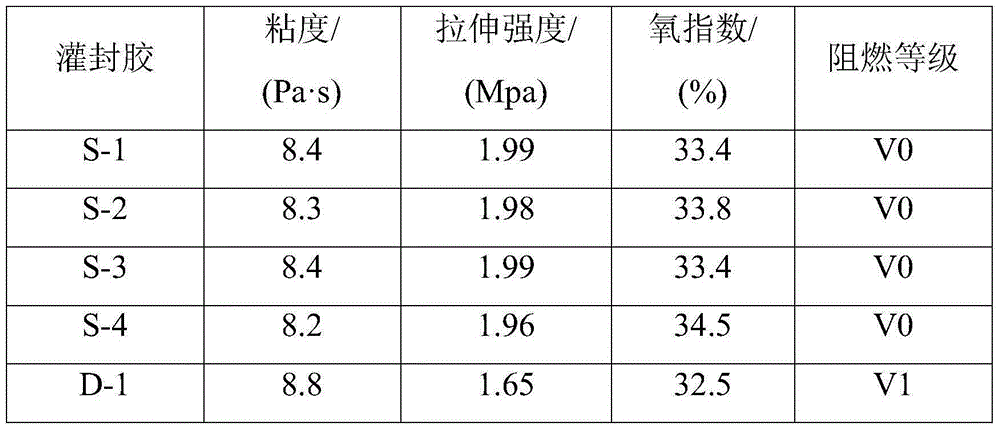

Flame-retardant microcapsule as well as preparation method and application thereof

InactiveCN105218714AColorless, odorless, low boiling pointLow boiling pointNon-macromolecular adhesive additivesMicroballoon preparationInternal pressureLiquid core

The invention discloses a flame-retardant microcapsule as well as a preparation method and application thereof. The flame-retardant microcapsule comprises a core material and a coating layer coating at the outer side of the core material, wherein the core material is liquid heptafluoropropane or liquid hexafluoropropane; and the coating layer is a polymethacrylate polymer and is prepared by polymerization by virtue of a suspension polymerization method. The flame-retardant microcapsule can be used as a flame-retardant filler singly, and also can be used as a flame-retardant filler together with magnesium hydroxide / aluminum hydroxide for preparing an electronic-pouring sealant in combination. The flame-retardant microcapsule disclosed by the invention is high in thermal stability and good in penetration resistance, and cannot generate leakage of the core material in a normal state; and only when subjected to high-temperature combustion, the coating layer is softened and the liquid core material is vaporized at the same time so that the internal pressure is increased and results in expansion breakage of the coating layer, and then the core material is released at last to quickly retard inflaming and put out a fire, so that the flame-retardant microcapsule has a broad use prospect in the field of preparation of the electronic-pouring sealant.

Owner:浙江中天东方氟硅材料股份有限公司

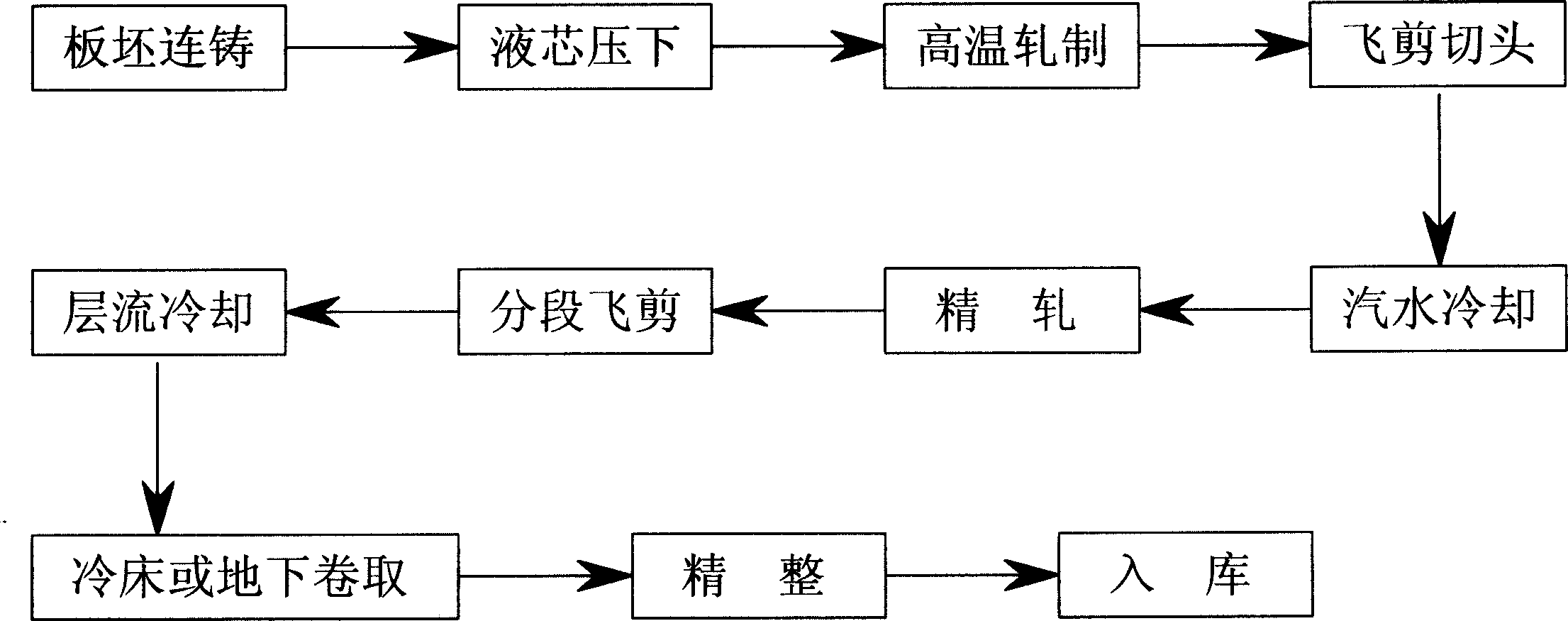

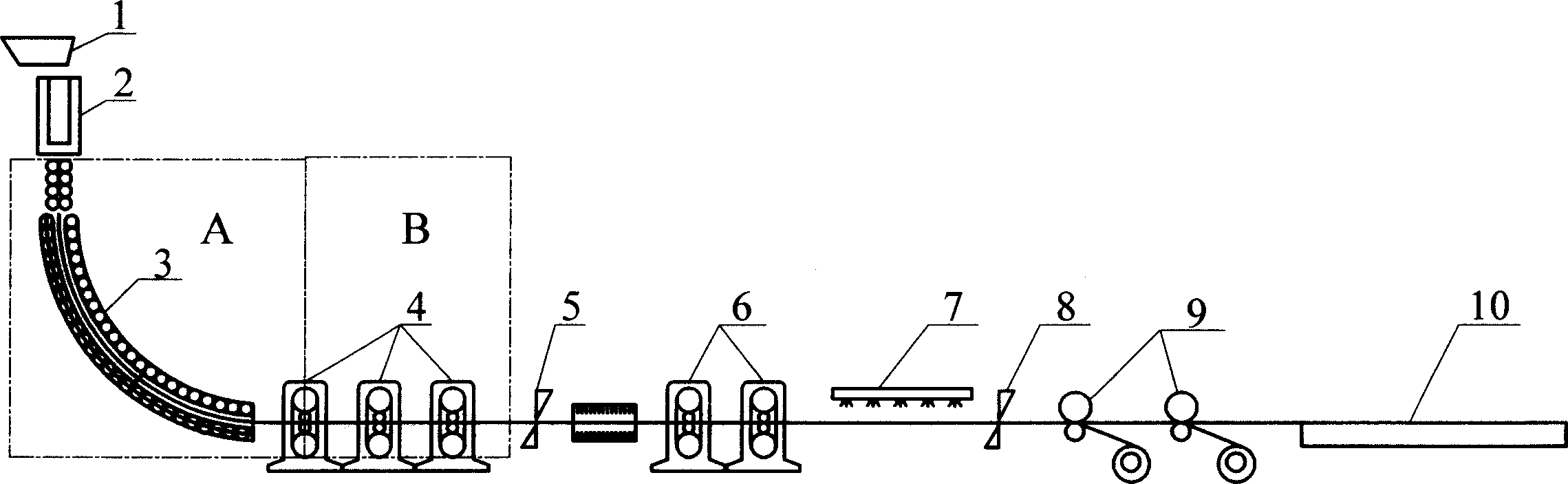

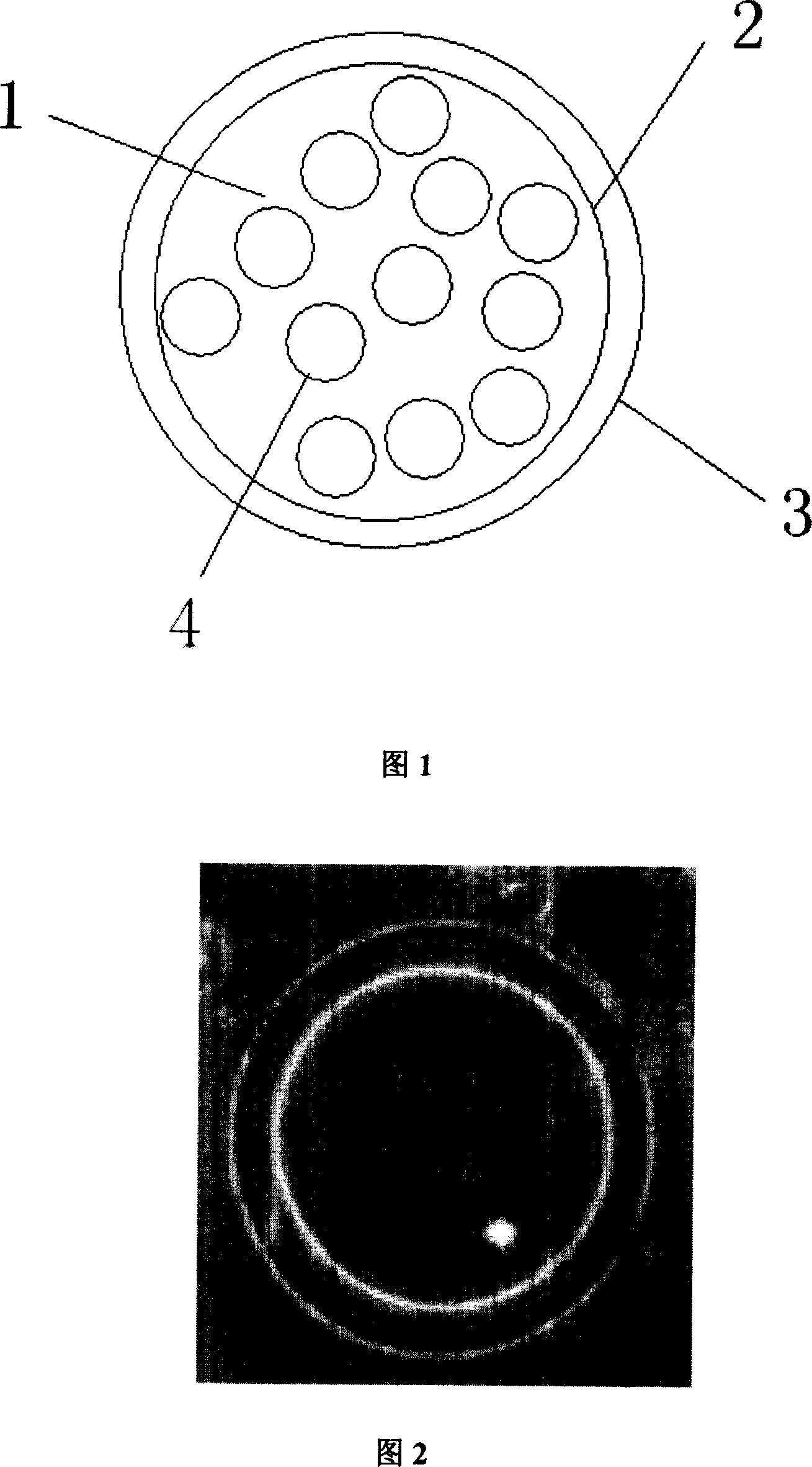

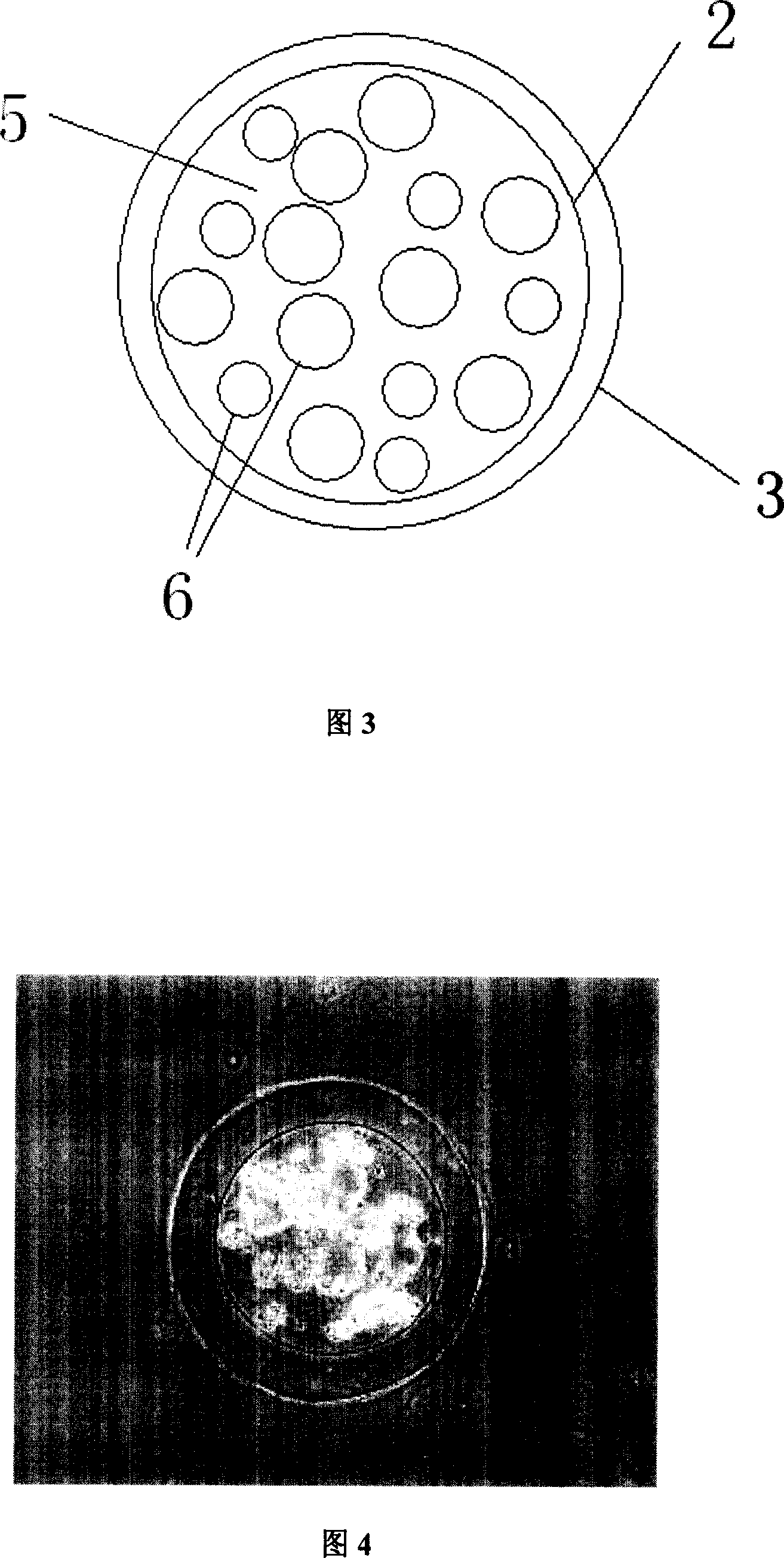

Medium thick plate continuously casting and head-less rolling process

The continuously casting and head-less rolling process for moderately thick plate includes the following steps: continuously casting plate blank, depressing liquid core, high temperature rolling, end cutting with flying shear, steam water cooling, finish rolling, sectional shearing, laminated cooling, cold bed or ground winding, finishing and warehousing. The present invention has raised metal yield, lowered fuel and power consumption, low end cutting rate, less rolling gates, and high output and finished product rate.

Owner:SHENYANG STEEL

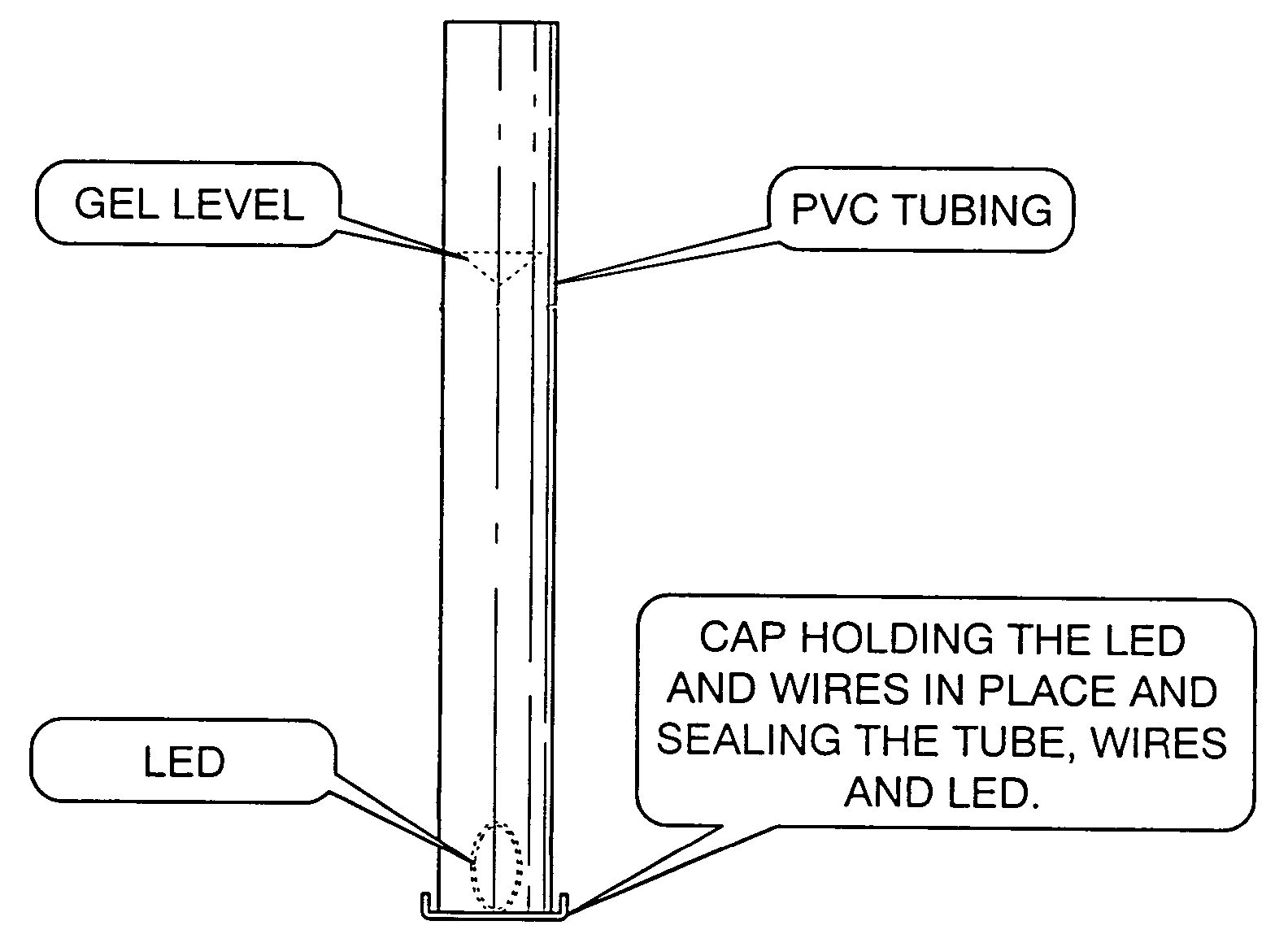

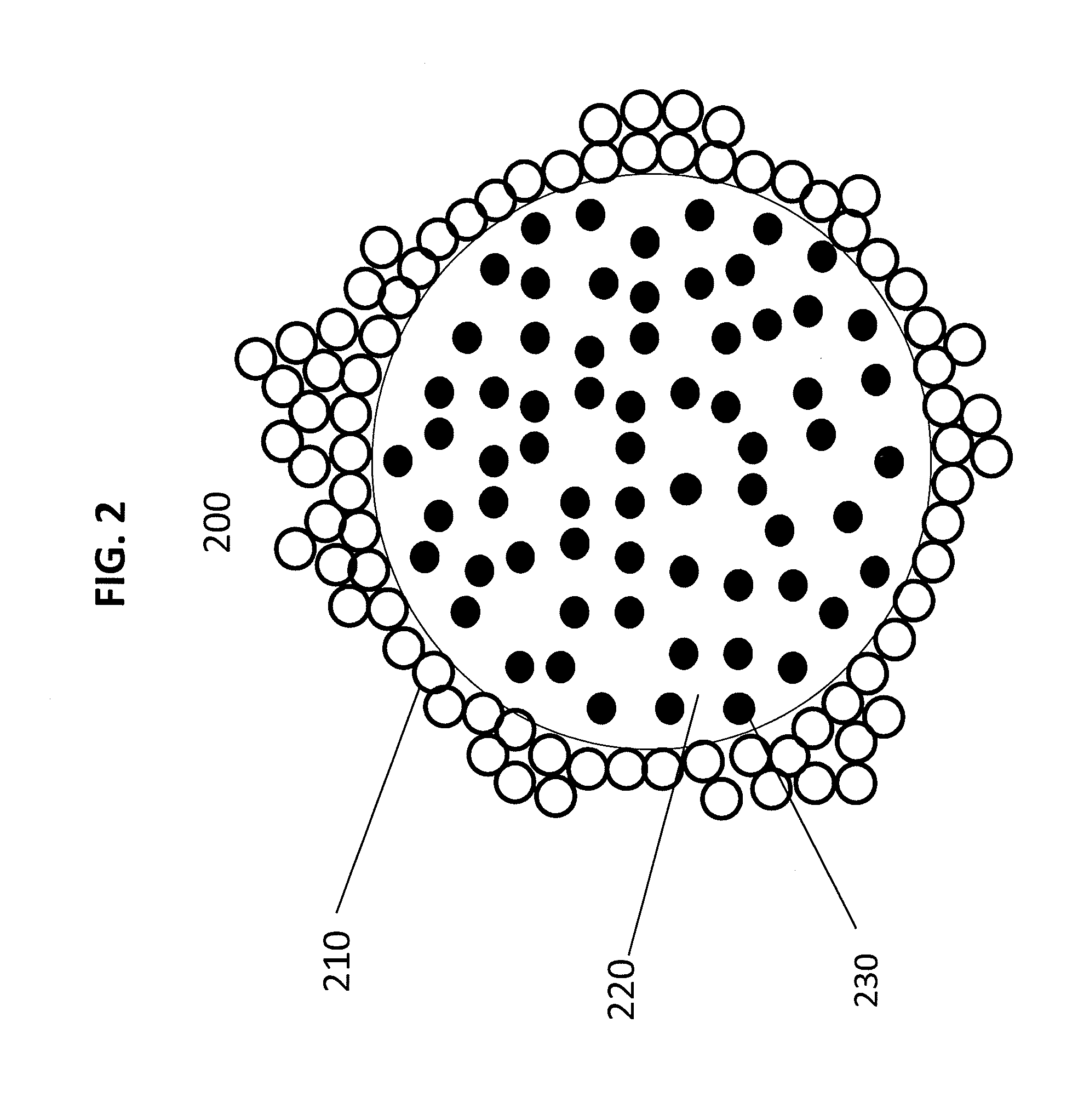

Method for producing liquid core microcapsule by electrostatic spraying

InactiveCN101152623AUniform particle sizeGood encapsulation performanceMicroballoon preparationMicrocapsule preparationCelluloseSprayer

The invention provides a method for preparation of liquid core microcapsule with static sprayer: calcium chloride solution of 2-3 percent is mixed with thickening agent and then is uniformly mixed with core material substance; a certain amount of mixed solution is taken out and then is put into solution containing sodium alginate of 0.6-1.5 percent with static sprayer while adopting a flat needle for adhesive deposite or an injection needle as a nozzle; after capsulated, liquid core sodium alginate microcapsule is filtered and then is cleaned with purified water; then liquid core sodium alginate microcapsule is put into calcium chloride solution for continuous solidification of 5-10 minutes; then microcapsule is filtered and then is cleaned with purified water; at last microcapsule is stored in storage solution with calcium ion concentration of 0.05-0.01 percent. High viscosity malt dextrin or sodium carbonxymethyl cellulose or xanthan gum is adopted as thickening agent. Microcapsule prepared with the invention has liquid core, with uniform particle size, good sacculation performance, simple process and high membrane thickness, therefore, microcapsule has high mechanical strength and can be widely used in the field of pharmaceutical chemical engineering, artificial organ implantation and food processing, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

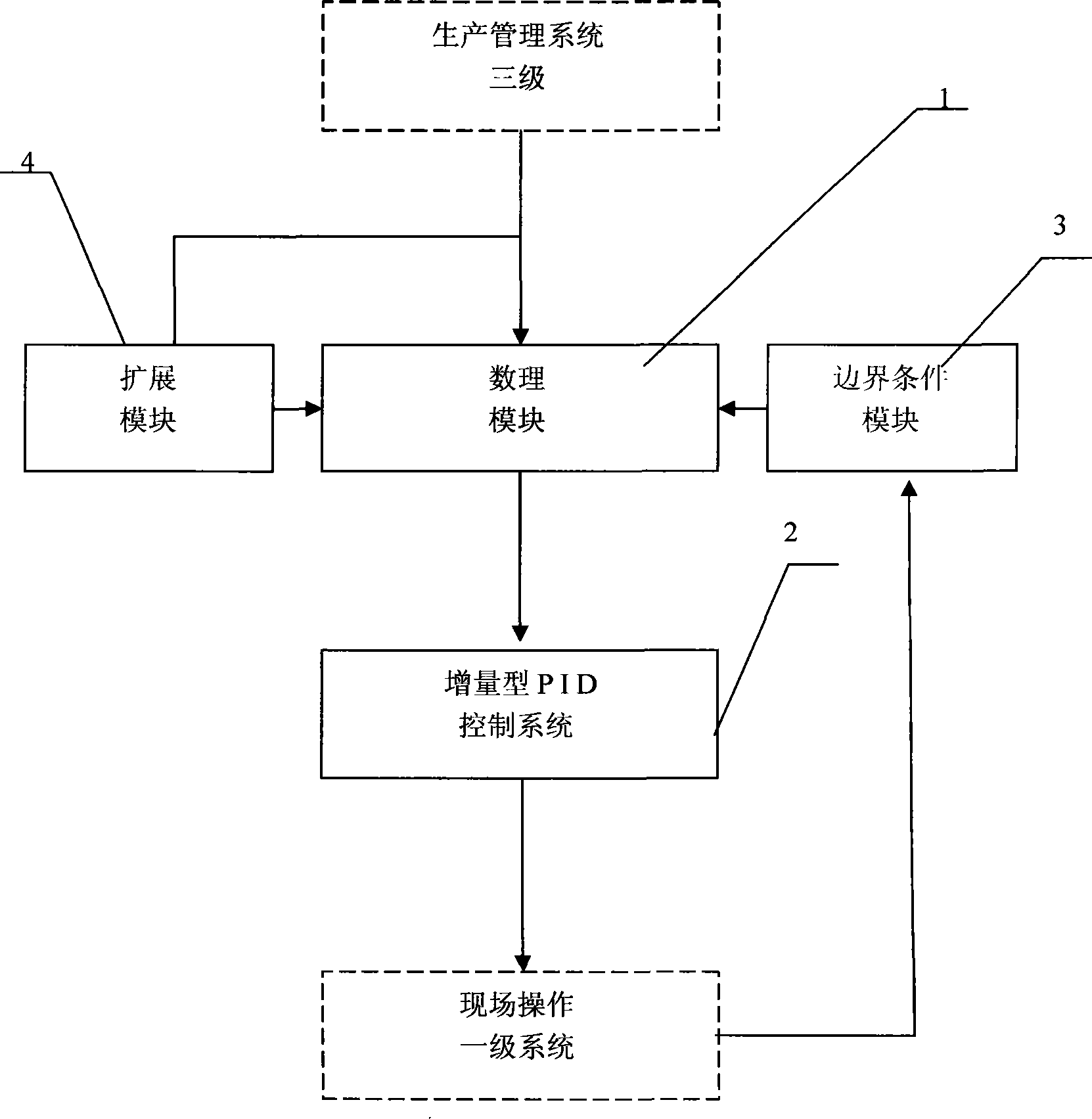

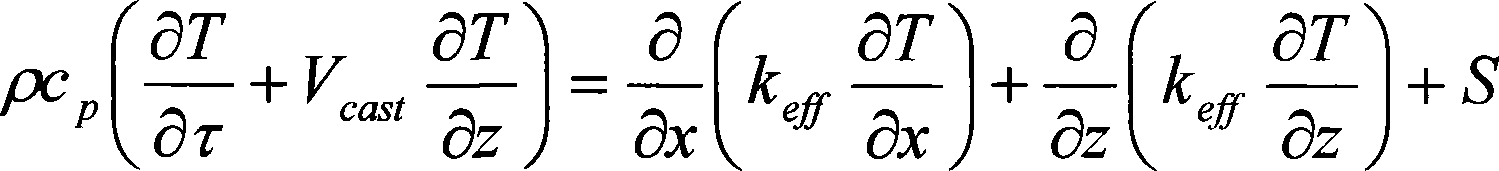

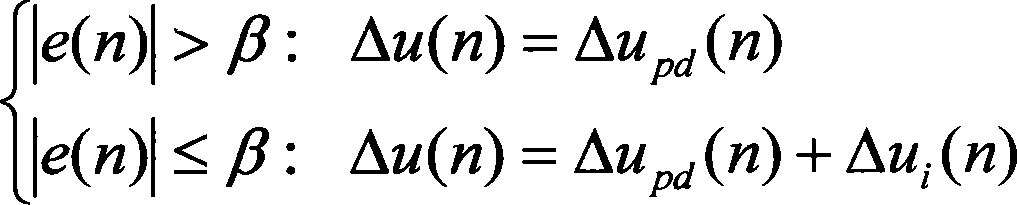

Continuous casting billet secondary cooling dynamic control system

InactiveCN101187812AImprove stabilityTemperature controlTotal factory controlProgramme total factory controlLiquid coreMode control

The invention provides a secondary cooling mode control system of a continuous casing slab which can change as the change of the technology and can adjust water flow quantity in time, and has stable casting slab setting process and little temperature fluctuating on the surface, and can get excellent casing slab quality. The invention comprises a mathematical module and an increment-type PID control system, the mathematical module substitutes an in-site technological parameter into a non-stationary setting-heat transferring equation, the equation is established on the basis of a structural parameter of a casting machine, solving and calculating are proceeded by the equation, and the equation determines the effect relationship of the changing of the parameter to the surface temperature of the casting slab, the depth of a liquid core, and the terminal position of the freezing point, which dynamically displays the positions of the casting slab temperature field and the freezing end. The increment-type PID control system adjusts water quantity according to calculating the differential value between the temperature field and a target temperature field, temperature difference ratio, and temperature difference accumulation degree. The invention is applicable to the technology control of secondary cooling section of continuous casting.

Owner:ANGANG STEEL CO LTD

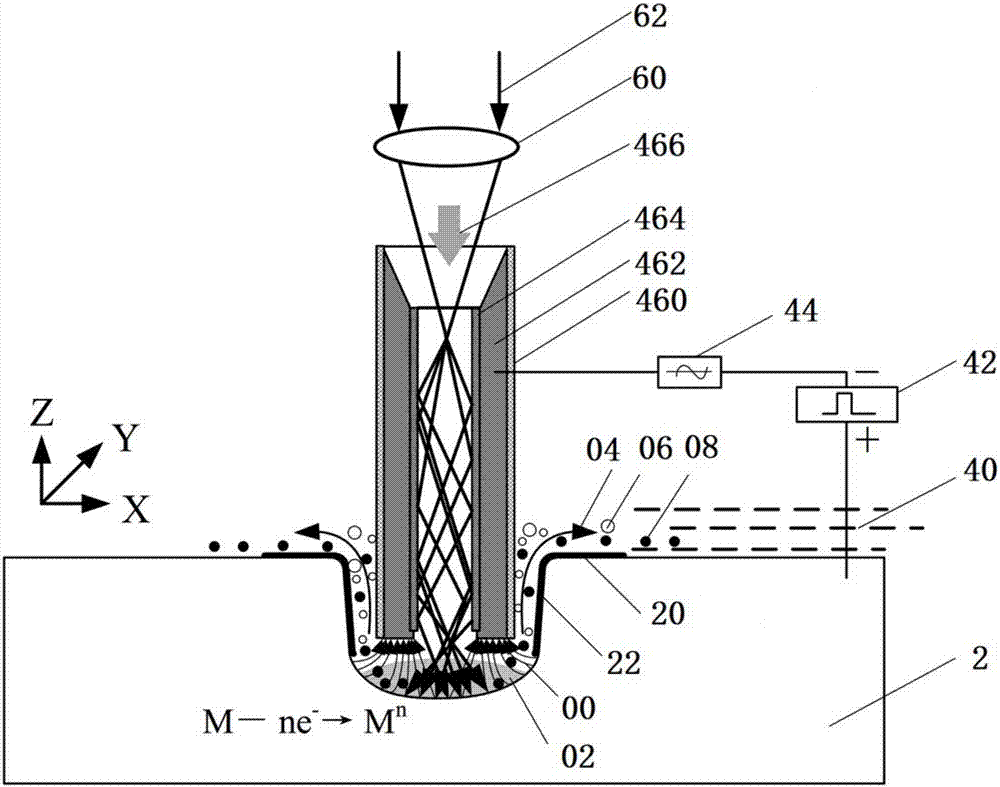

Laser-intervening micro-electrochemical machining method and device

The invention discloses a laser-intervening micro-electrochemical machining method. The laser-intervening micro-electrochemical machining method comprises at least the following steps that a tool electrode and a to-be-machined workpiece are connected with a negative electrode and a positive electrode of a power supply correspondingly; lasers and an electrolyte are transmitted through the tool electrode to a machining area of the to-be-machined workpiece; and after the power supply is switched on, micro-electrochemical machining is conducted, the tool electrode is fed towards the to-be-machinedworkpiece, and a target structure is obtained. In the laser-intervening micro-electrochemical machining method and a laser-intervening micro-electrochemical machining device, laser beams are transmitted through liquid core optical fibers to the deep machining area in a full reflection mode, large-depth coupling of a laser energy field and electrochemical machining is achieved, and efficient machining of a micro-structure with the large depth-diameter ratio can be achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Compositions and methods for enhancing the topical application of a benefit agent including powder to liquid particles and a second powder

A powder is disclosed including core / shell particles having an average particle size of less than 1000 microns, each particle contains a liquid core that is substantially free of water and includes a polar liquid having a percent surface polarity of at least 24% and a shell comprising hydrophobic particles; and at least one second powder comprising a benefit agent. The powder can be used to topically administer the active ingredient to a human or animal.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

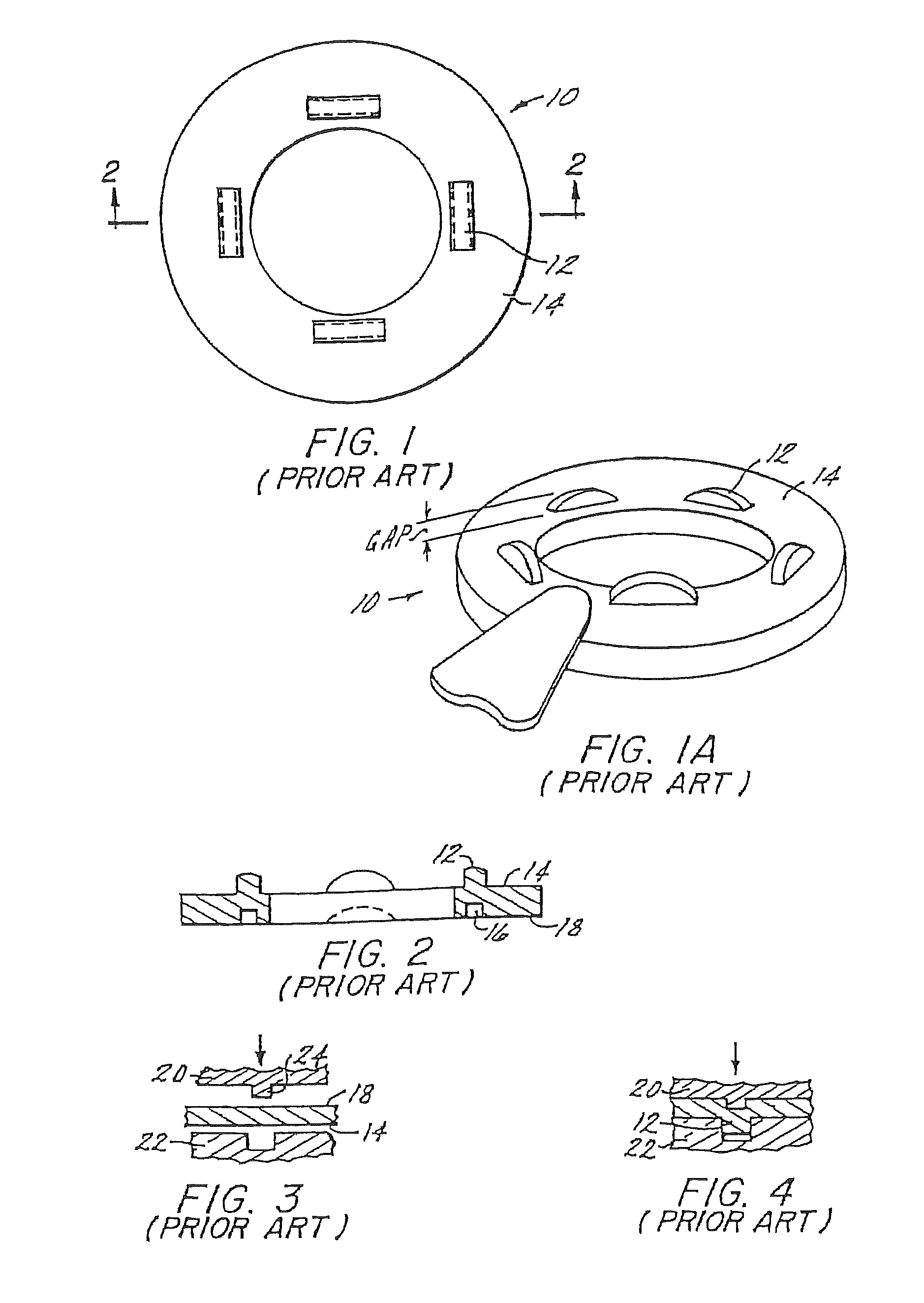

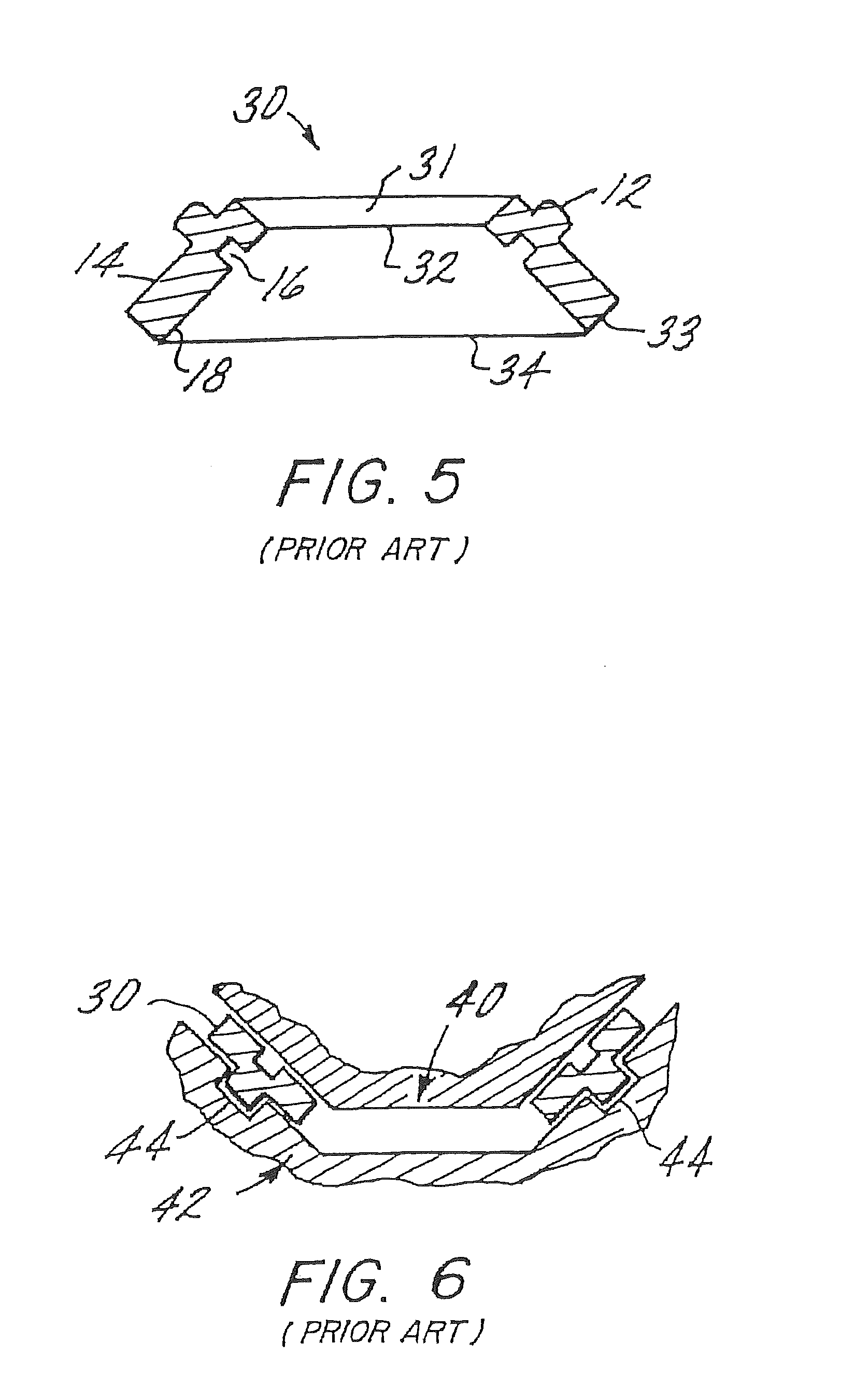

Method of making direct tension indicating washers

A method of making a direct tension indicating washer including: forming a first surface having a discrete protuberance formed thereon; forming a second surface having a discrete indentation formed opposite the protuberance; and positioning an indicating material in the indentation, wherein the indicating material has a cured skin on an outside of the indicating material and a liquid core in an interior of the indicating material.

Owner:APPLIED BOLTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com