Continuous-cast P91-steel round pipe billet and production process thereof

A production process and round tube billet technology, which is applied in the field of P91 steel round tube billets, can solve the problems of small diameter of round tube billets, middle cracks and cracks in the center of straightening cracks, etc., so as to avoid straightening cracks and cracks Defects, the effect of avoiding the generation of surface cracks and intermediate cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

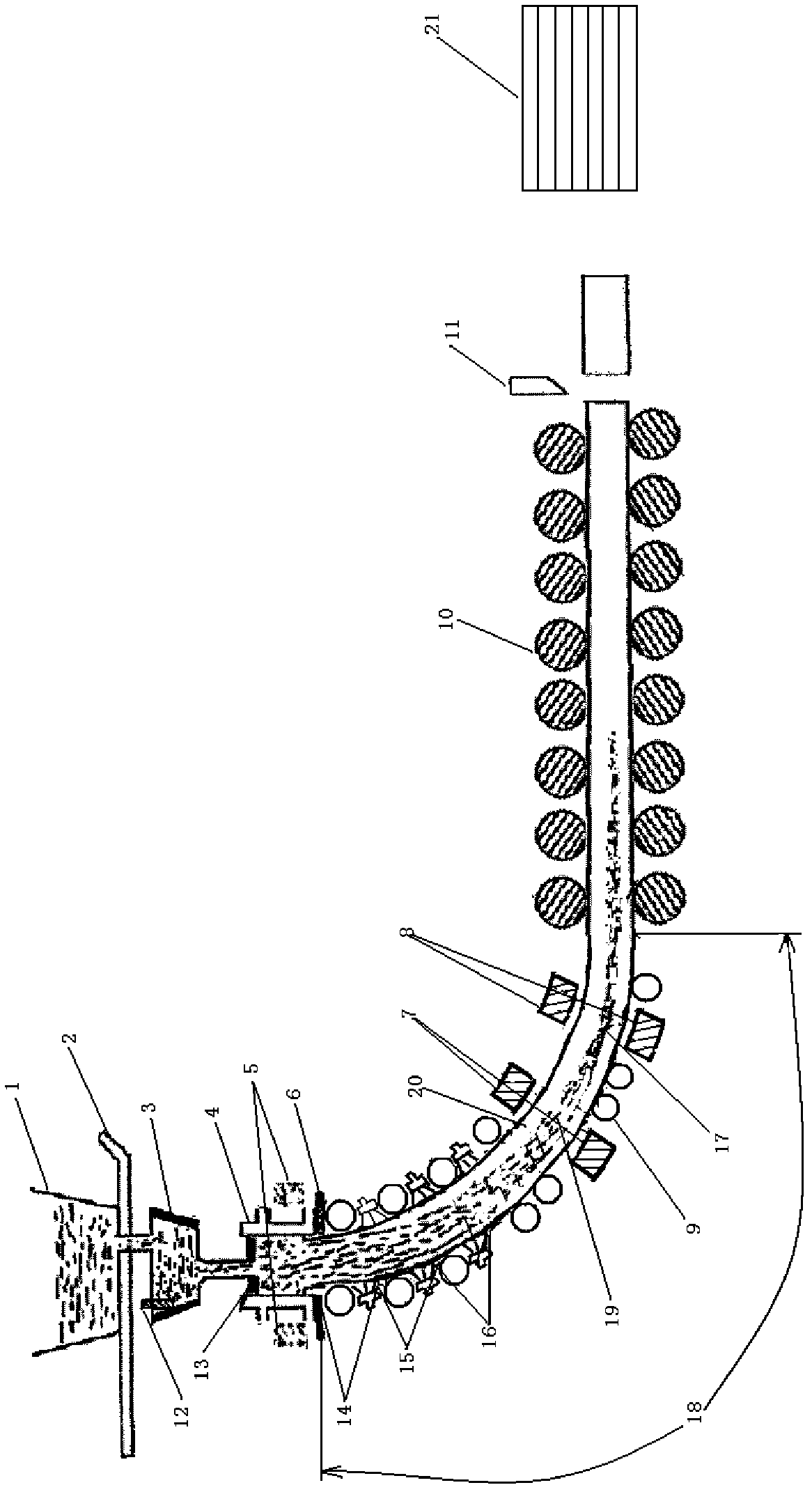

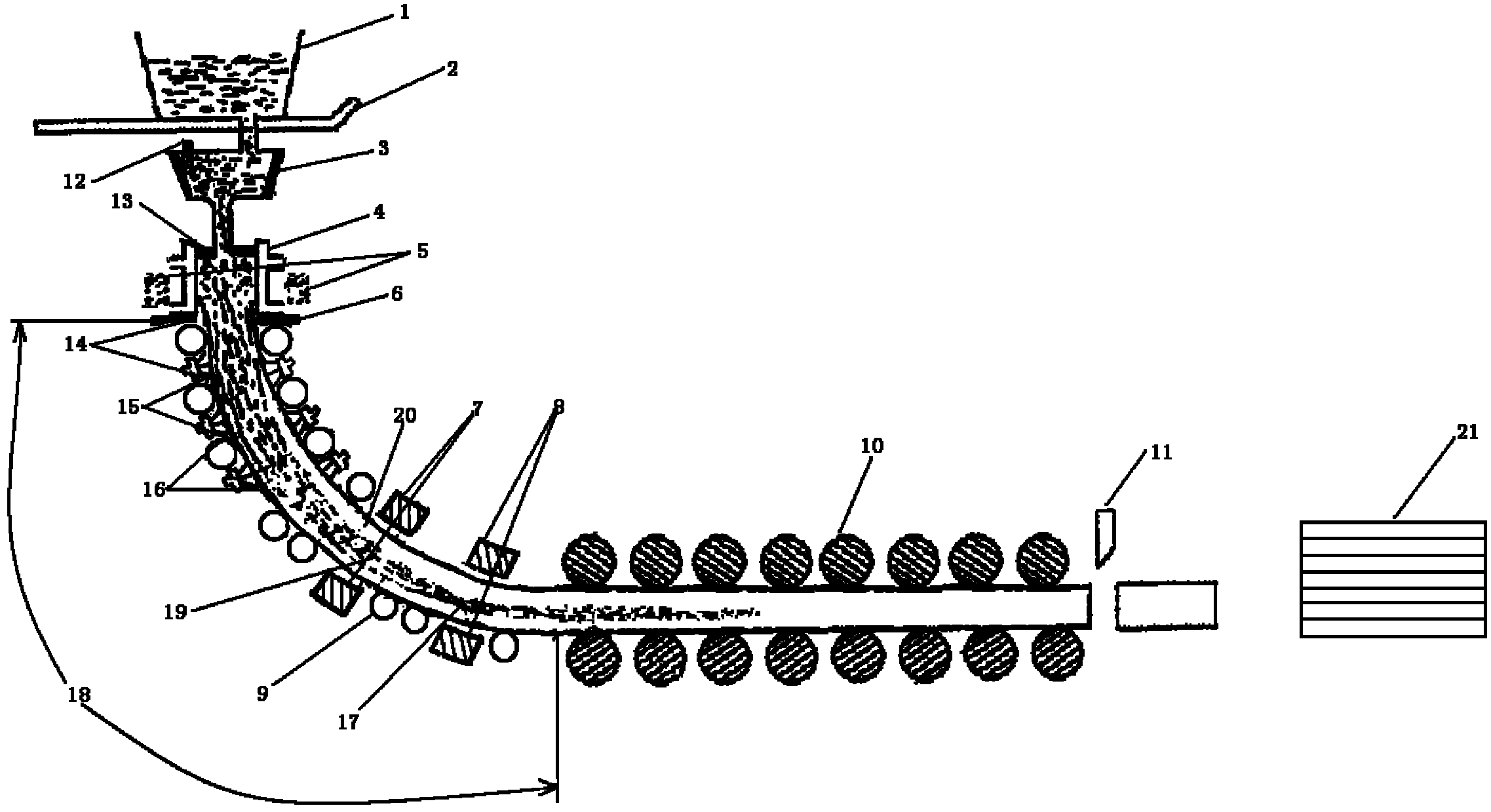

Method used

Image

Examples

Embodiment 1

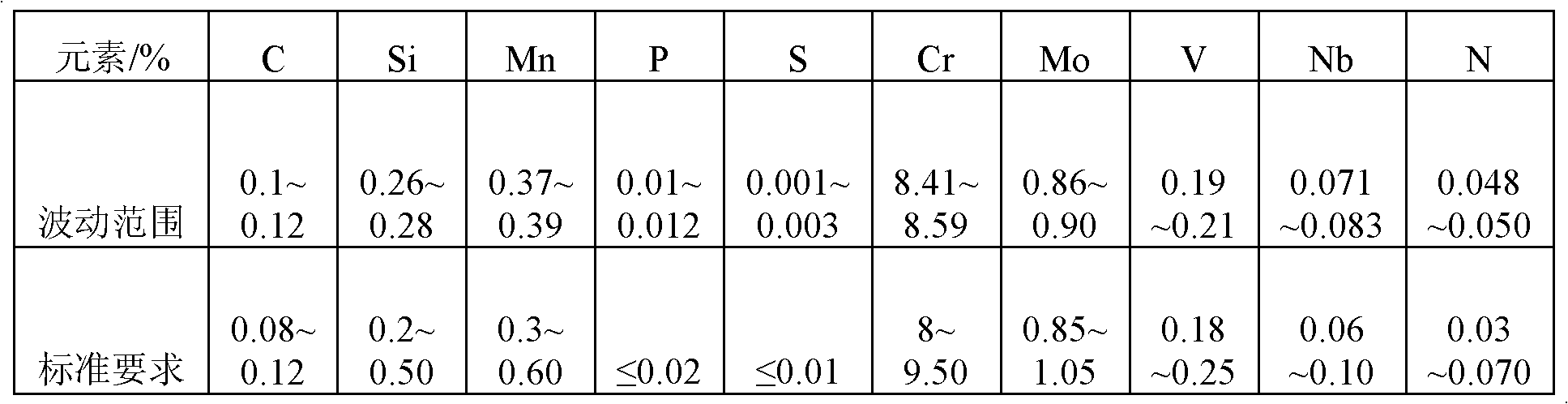

[0040] A. 45-ton electric furnace smelting: use high-quality scrap steel and molten iron as raw materials, and the proportion of molten iron added is 60%; input electric energy and oxygen into the electric furnace to melt the charged charge into molten steel, control the chemical composition of the slag, and input 45m 3 Oxygen per ton of steel, slag flows out intermittently and lime is added; the carbon content in molten steel is controlled to be ≤0.02%, and the phosphorus content to be ≤0.004%.

[0041] B. Ladle furnace refining: when the electric furnace is tapping, the molten steel temperature reaches above 1700°C, and 3.5t of micro-carbon ferrochrome (wherein, the carbon content is not more than 0.06%, and the chromium content is not less than 65%), low-carbon manganese 120kg of iron, 80-120kg of silicon-calcium-barium alloy, 30kg of aluminum particles, 250kg of synthetic slag, 450kg of lime, carbon powder and silicon powder 1:1 are mixed evenly and added, and the mass cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com