Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2848 results about "Tundish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The word tundish originates from a shallow wooden dish with an outlet channel, fitting into the bunghole of a tun or cask and forming a kind of funnel for filling it. These were originally used in brewing.

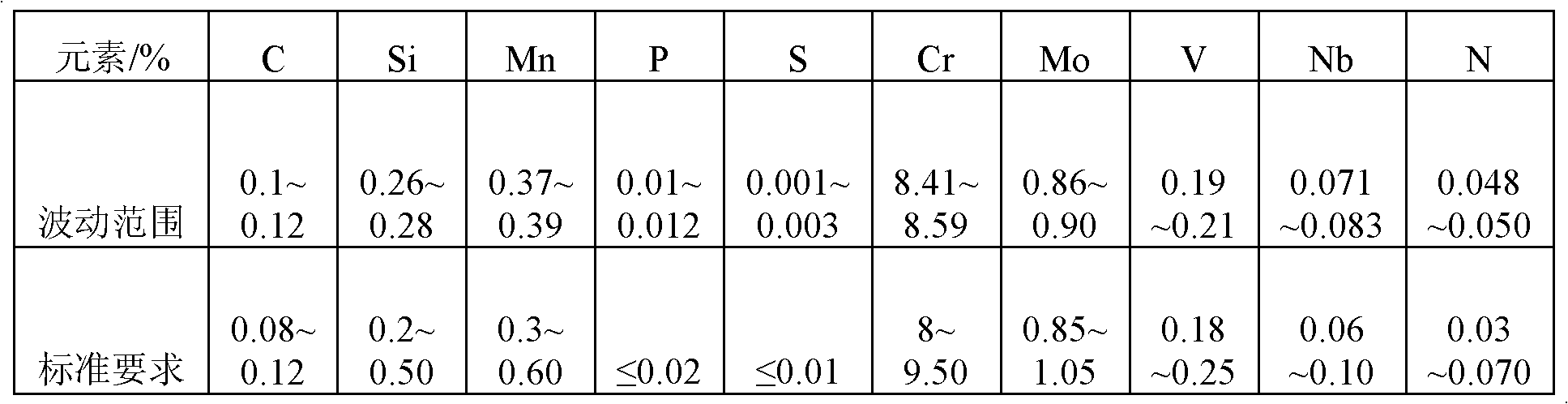

CrMnTi narrow hardenability strip pinion steels and method of manufacture

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

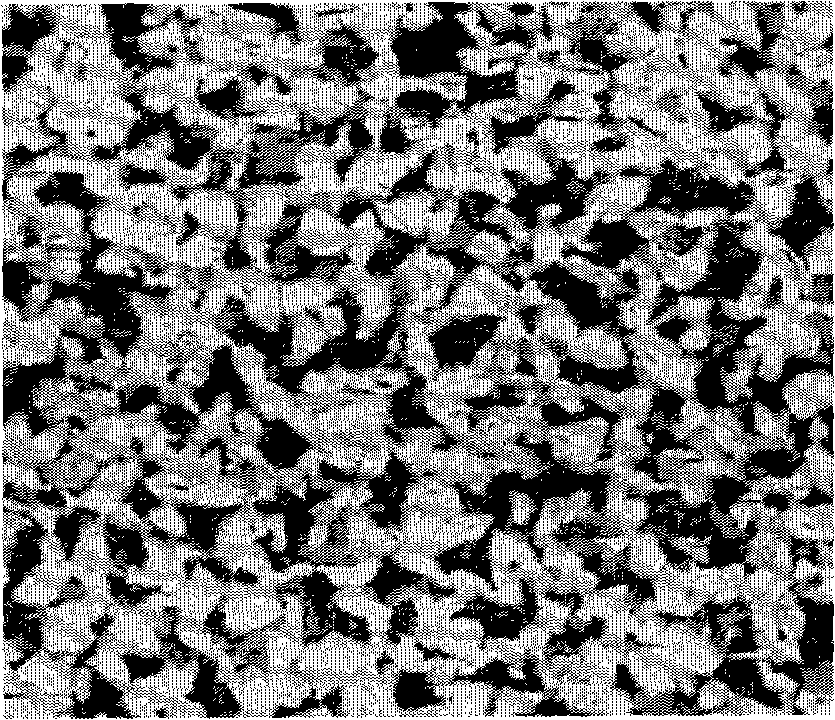

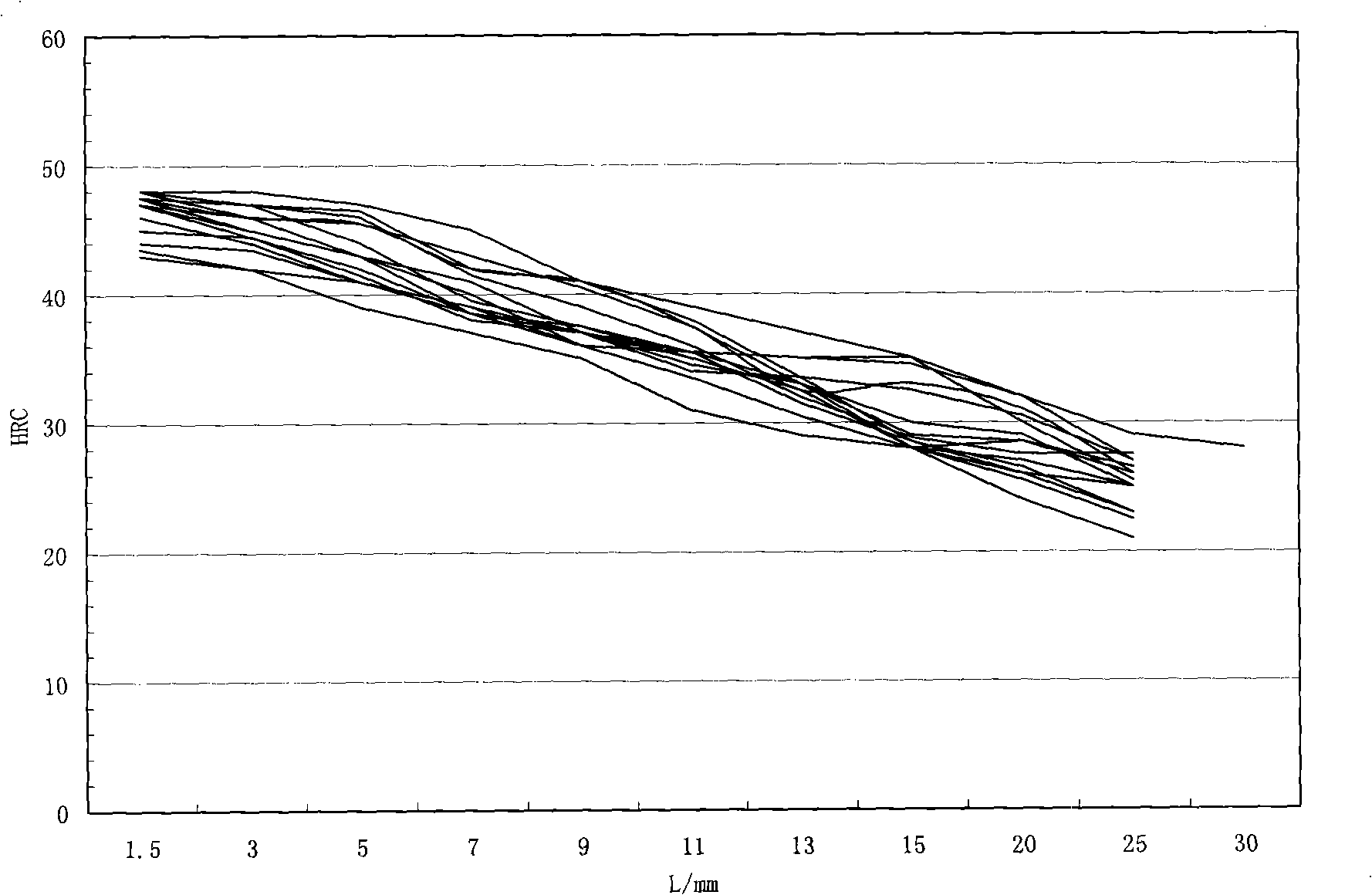

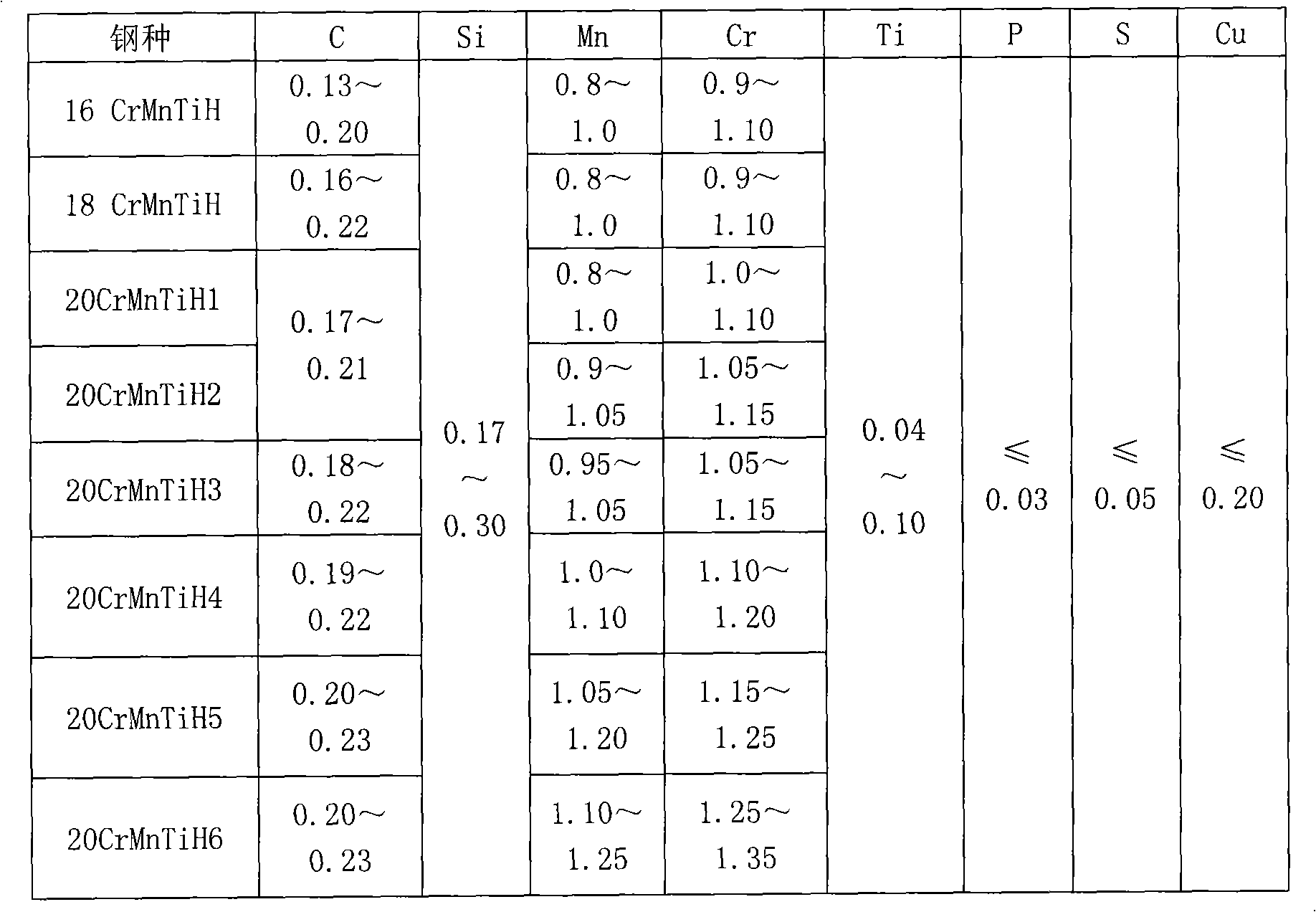

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

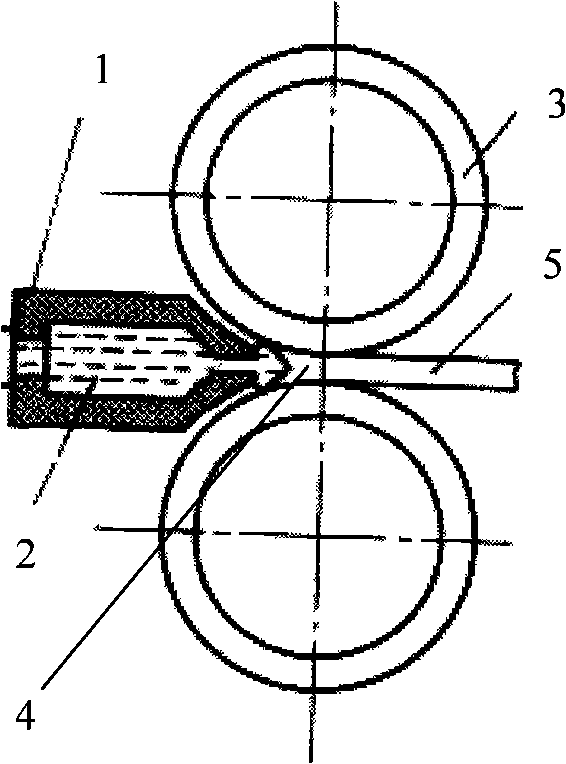

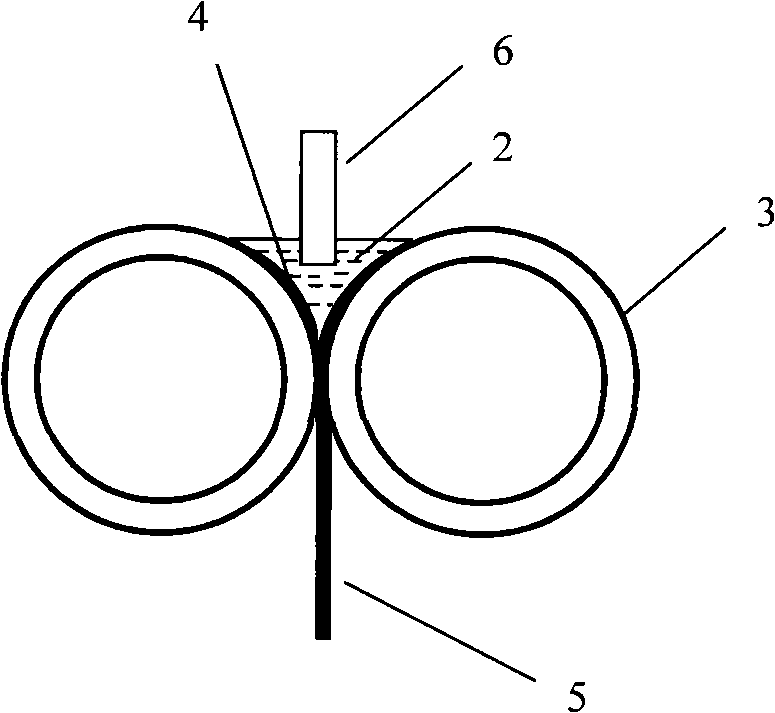

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

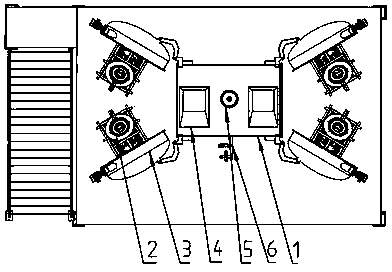

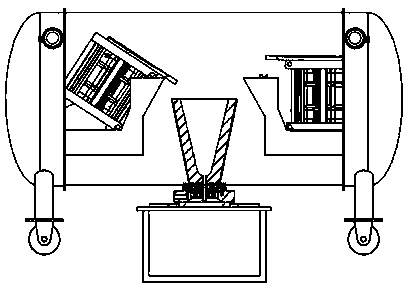

Device for preparing semi-solid alloy rheological slurry or blank

ActiveCN101618438AOvercome the disadvantages of large and complex structure and high investment costLow investment costCrucibleSemi solid

The invention discloses a device for preparing semi-solid metal and alloy slurry, which mainly comprises an electromagnetic stirrer, an insulating layer, an external cooling controller, a valve, a draft tube, a preparation crucible, an insulating crucible cover, a standing crucible, a melting crucible and a thermocouple. The middle part of the preparation crucible is provided with an internal cooling controller, and the outer wall of the internal cooling controller forms a clearance with the inner wall of the preparation crucible. The device can be connected with a press-casting machine, an extruder, a continuous casting machine and a forging machine, wherein the press-casting machine consists of a press-casting fixed die, a press-casting movable die, an injection chamber and a punch head; the extruder consists of a right extrusion die profile, a left extrusion die profile, an extrusion cylinder and an extrusion rod; the continuous casting machine consists of a tundish, a crystallizer, a cooling water nozzle and a traction mechanism; and the forging machine consists of a forging die cavity and a forging die. The device has the advantages that the device has simple and compact structure, low investment cost and strong practicability; the temperature field and tissue of the prepared slurry are distributed evenly; the semi-solid alloy slurry is pure, does not bubble and has good self cleanness; and the device can produce large-specification semi-solid slurry or blank, and is quite suitable for the preparation and formation of the semi-solid slurry or the blank.

Owner:有研金属复材技术有限公司

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

Method for improving center density of continuous cast slabs of high-level building steel

The invention discloses a method for improving center density of continuous cast slabs of high-level building steel. In the continuous casting process, the drawing speed of a casting machine is controlled to be 0.75 m / min-0.90 m / min; solidification tail end heavy reduction is adopted; dynamic secondary cooling control is adopted, and meanwhile, soft reduction and heavy reduction are adopted for carrying out reduction according to the distribution solid phase rate; and the superheat degree of tundish molten steel is controlled to range from 20 DEG C to 30 DEG C. According to the method, technical measures of stabilizing the drawing speed of the casting machine, reducing the superheat degree of tundish, carrying out secondary cooling dynamic control, carrying out solidification tail end heavy reduction control and the like are mainly applied comprehensively to reduce center porosity of the cast slabs of the high-building steel, then the center density of the cast slabs is improved, and internal quality of rolled materials is improved. For the cast slabs produced through the method, after implementation is carried out, the effect is better than that of an existing soft reduction technology, the center density is higher, the overall quality is better, and the use requirement of the high-building steel can be met better.

Owner:TANGSHAN IRON & STEEL GROUP +2

Method for directly restoring and recovering copper iron from smelting copper slag

ActiveCN102952952AMeet the requirements of energy saving and emission reductionEfficient recyclingProcess efficiency improvementGas emission reductionMolten stateOxygen

The invention belongs to the field of metallurgy, and particularly relates to a method for directly restoring and recovering copper iron from smelting copper slag. The method comprises the following steps of: transferring high-temperature molten state copper slag to a high-temperature reducing furnace by a tundish, jetting oxygen to previously desulfurize, adding slagging constituent to keep temperature, jetting natural gas to carry out smelting reduction, slowly cooling to 1096 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 7.3at% Cu-Fe copper alloy melt and gamma pig iron, or slowly cooling to 850 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 2.7at% Cu-Fe copper alloy melt and gamma pig iron. According to the method provided by the invention, the total recovery use of valuable components, i.e. copper, iron and the like, can be realized, and the alloy melt obtained by the reduction smelting is slowly cooled and separated to obtain copper-rich alloy and low-sulfur gamma pig iron, so that separation of copper and iron is realized and the additional values of products can be improved.

Owner:NORTHEASTERN UNIV

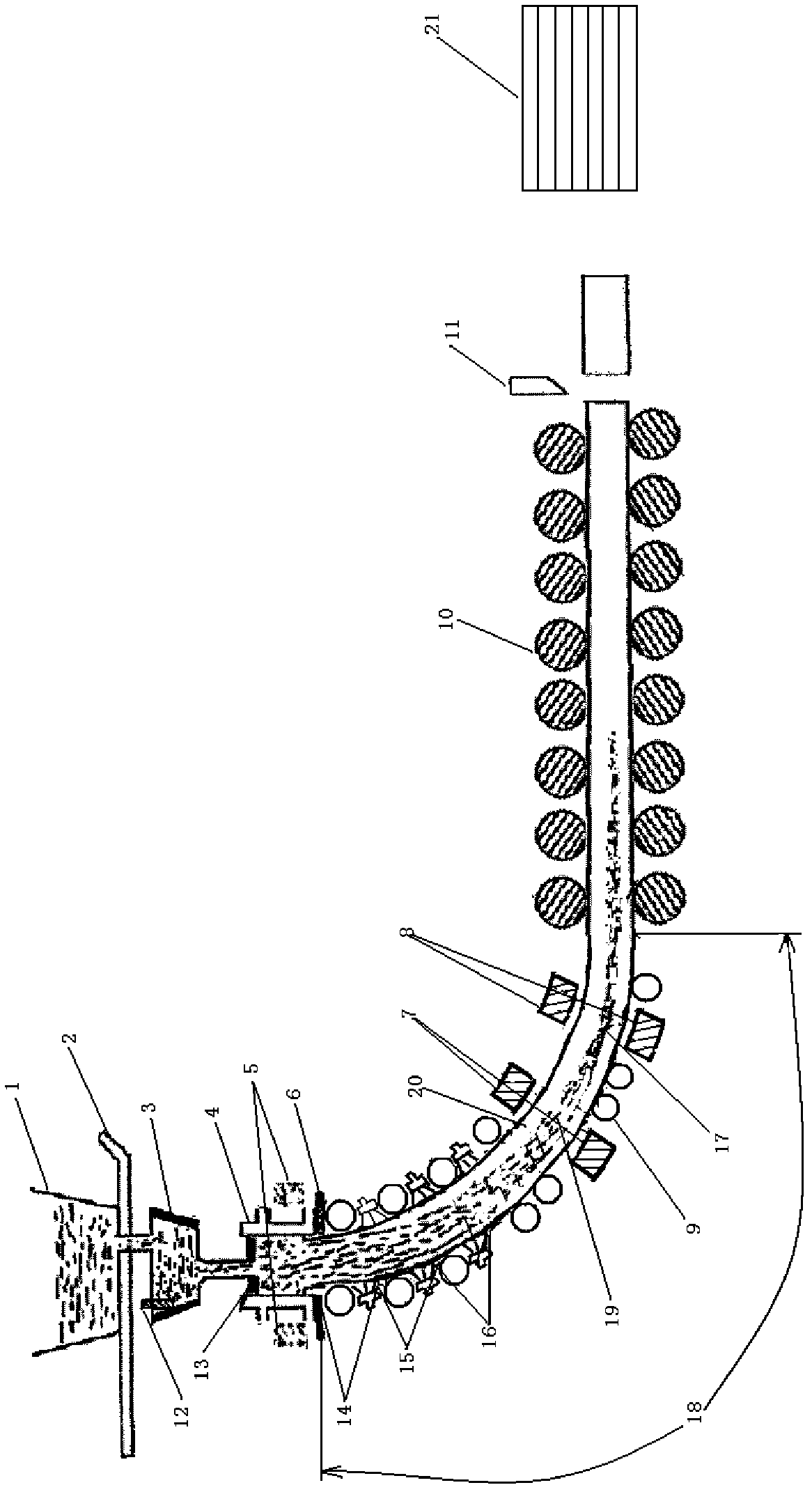

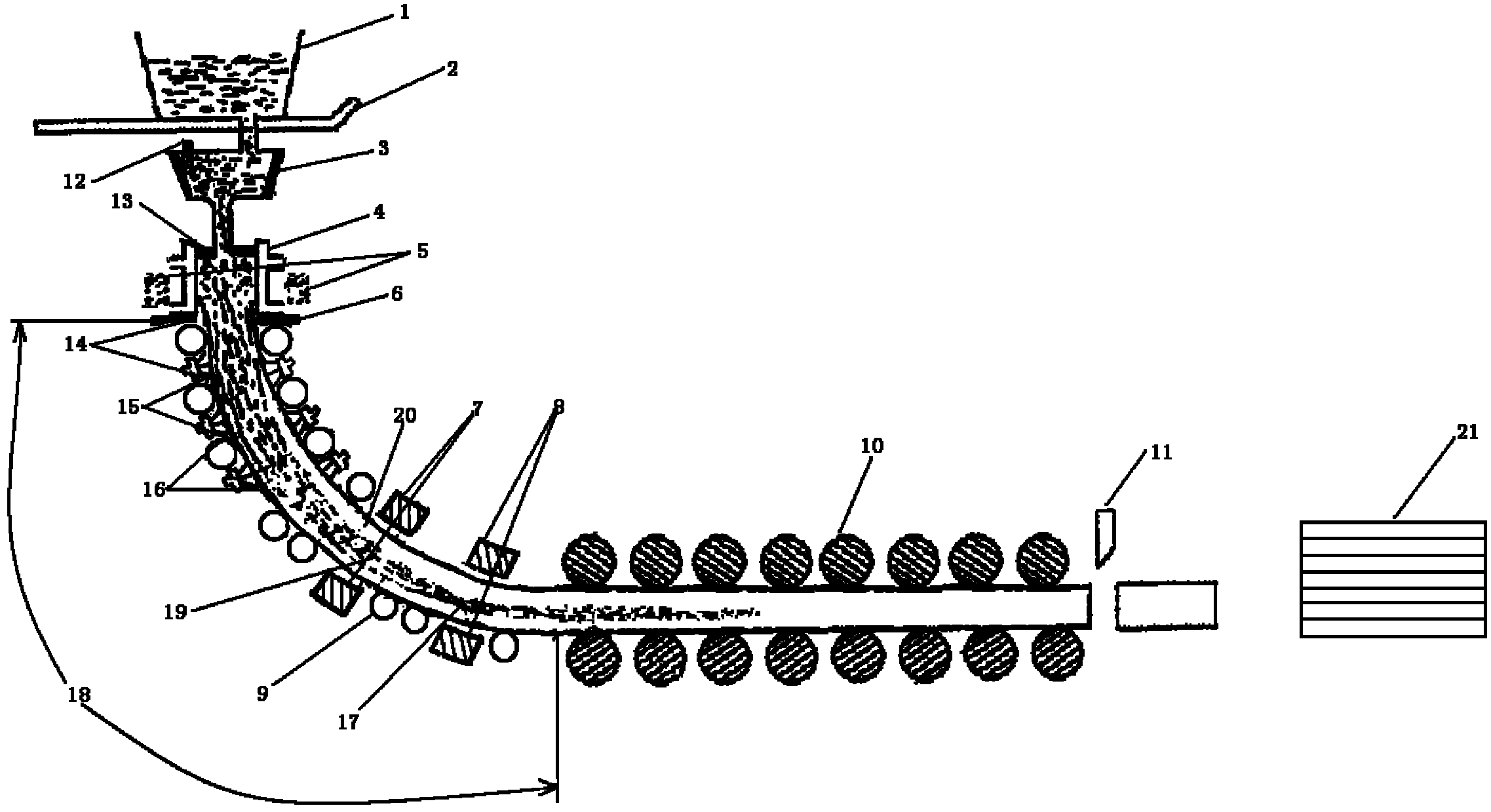

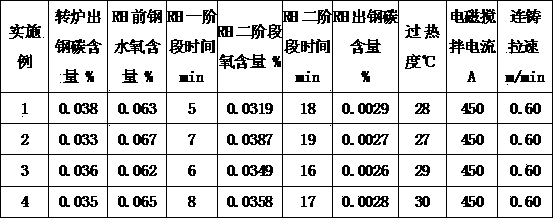

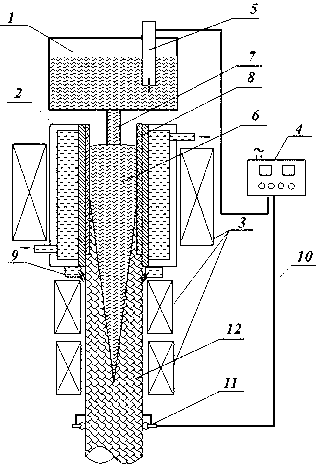

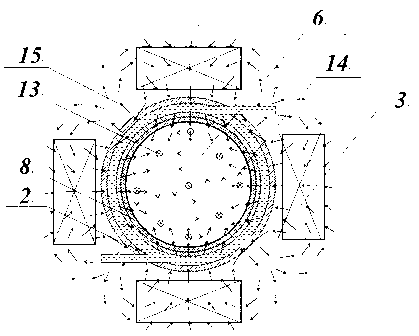

Continuous-cast P91-steel round pipe billet and production process thereof

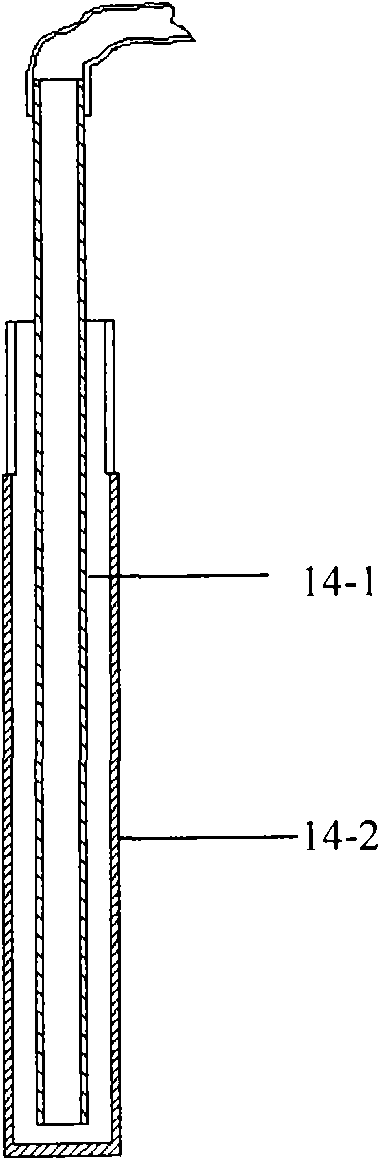

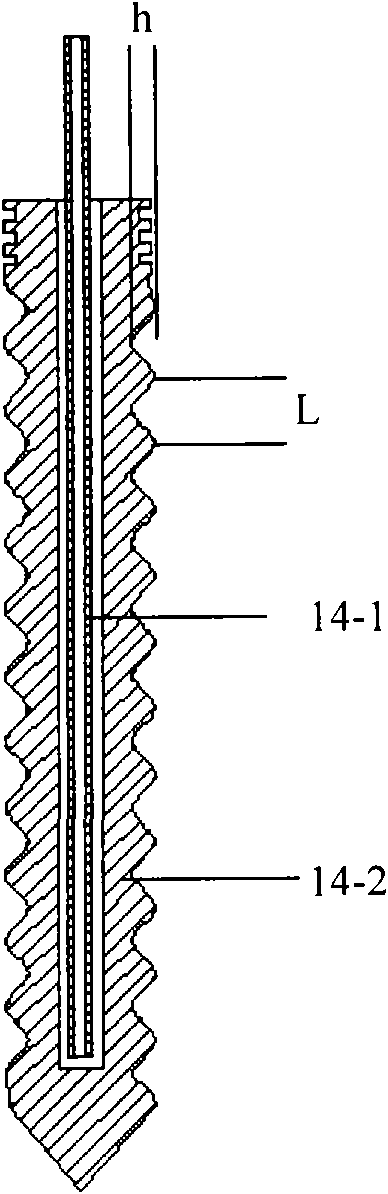

The invention provides a continuous-cast P91-steel round pipe billet and a production process thereof. The production process includes 1) injecting molten steel into a tundish (3) and controlling degree of superheat of molten steel; 2) adding mold flux (13) to the surface of molten steel of a crystallizer (4) and solidifying the molten steel into a billet casing (20) with a liquid core (19); 3) stirring the front of the solidified molten steel by the aid of a one-way rotary magnetic field, applying a thrust force to the liquid core of the cast billet by a traveling wave magnetic field, and stirring the tail end (17) of the solidified molten steel by a two-way alternative rotary magnetic field; 4), drawing the billet casing to an arc guide segment (18) to form an initial round billet and cooling the initial round billet by a secondary cooling region which is divided into three sections; 5) straightening the cooled cast billet by eight rollers; and 6) cutting the cast billet into fixed-length billet sections by torch flame and annealing the same to obtain continuous-cast round pipe billets. The round pipe billets produced by the production process solves the problems that diameters of round pipe billets in the prior art are too small and surface cracks, middle cracks and straightened cracks of the round pipe billets in large diameter are hard to meet industry requirements.

Owner:HENGYANG VALIN STEEL TUBE

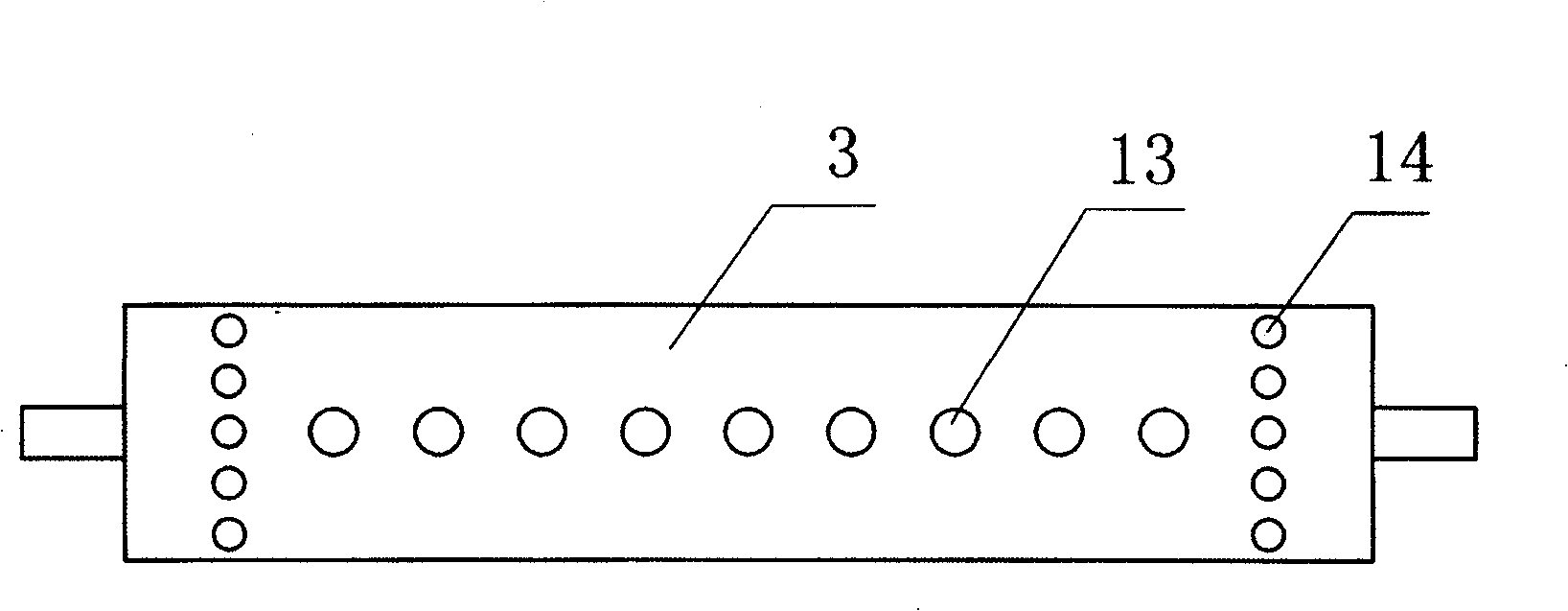

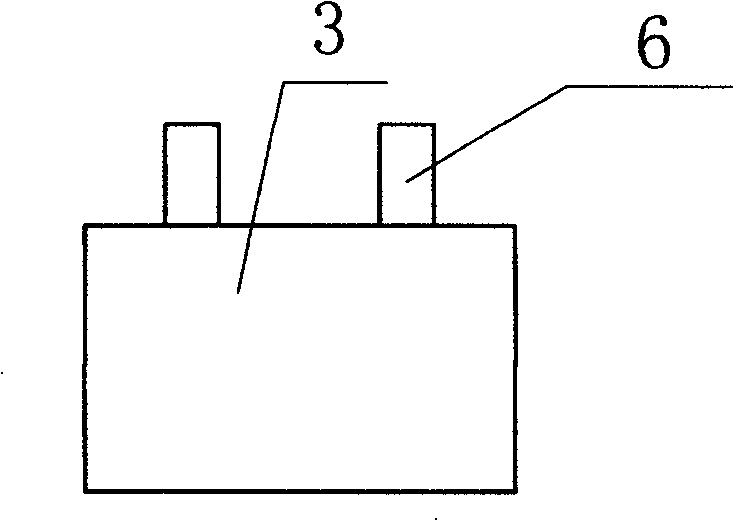

Refractory material for casting a rare-earth alloy and its production method as well as method for casting the rare-earth alloys

InactiveUS20030109372A1Improve melt flowImprove heat resistanceMelt-holding vesselsMuffle furnacesRare earthRefractory

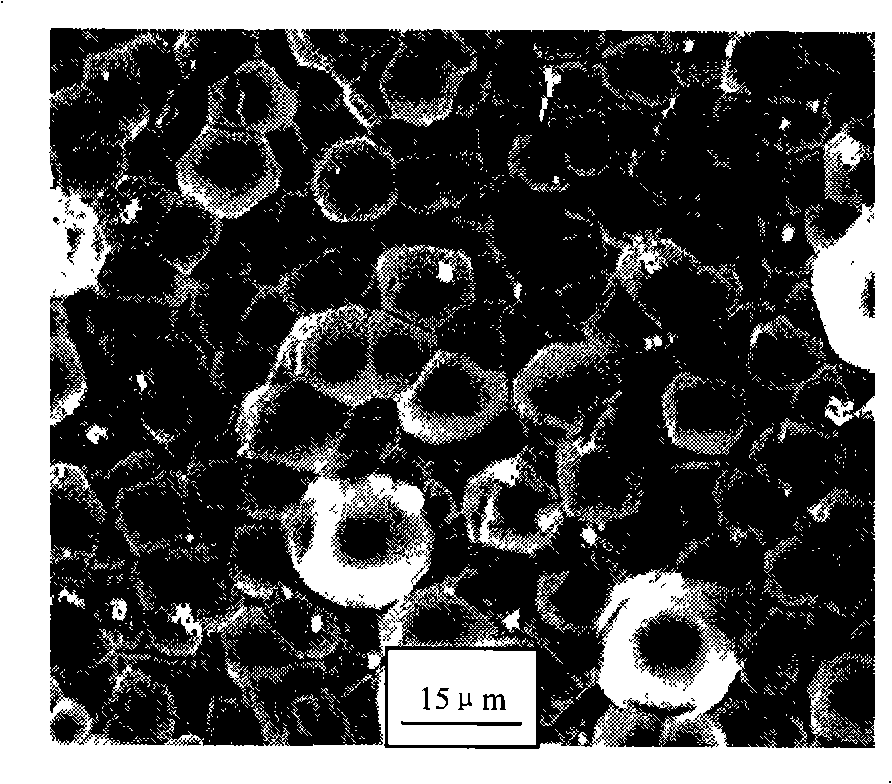

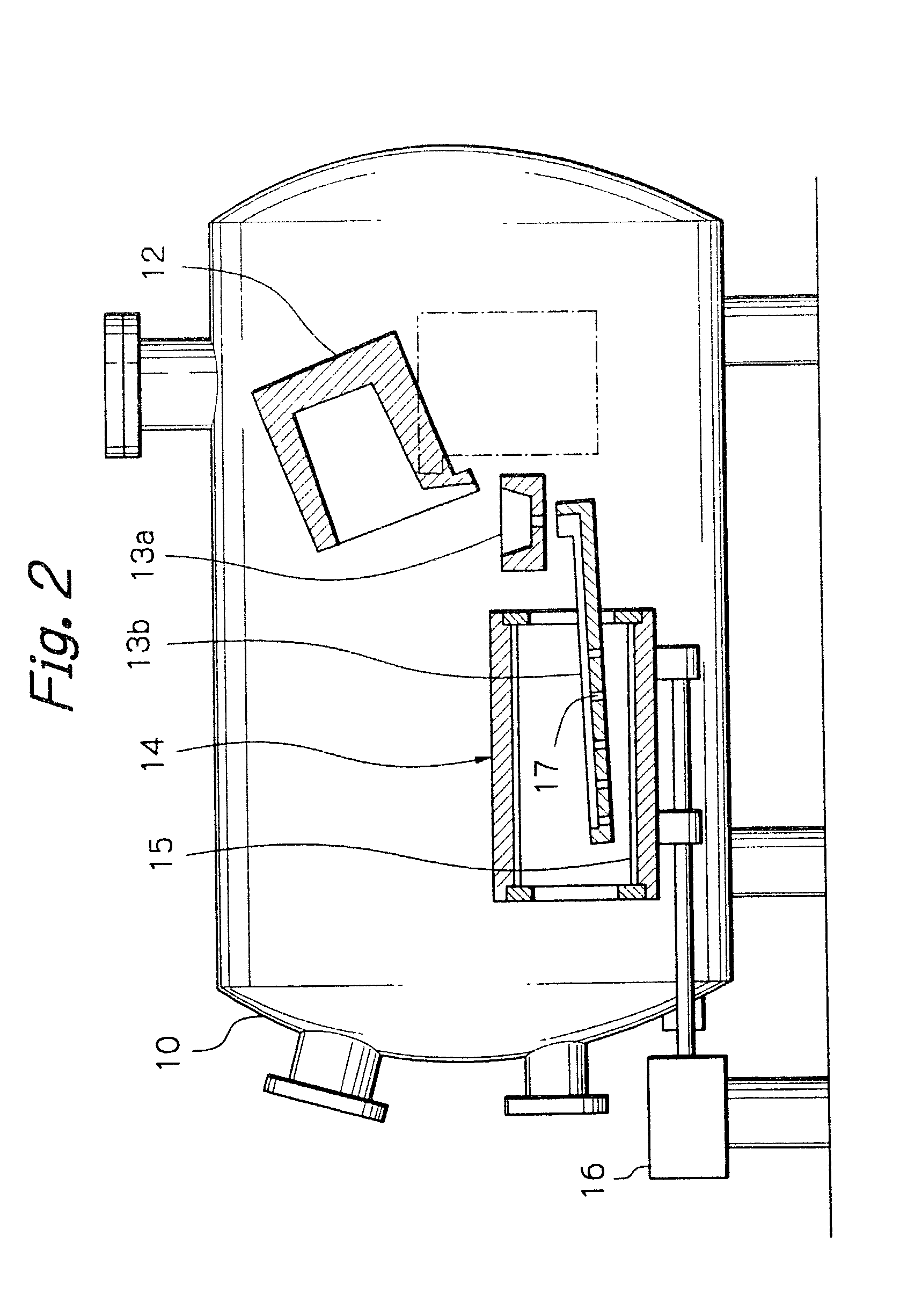

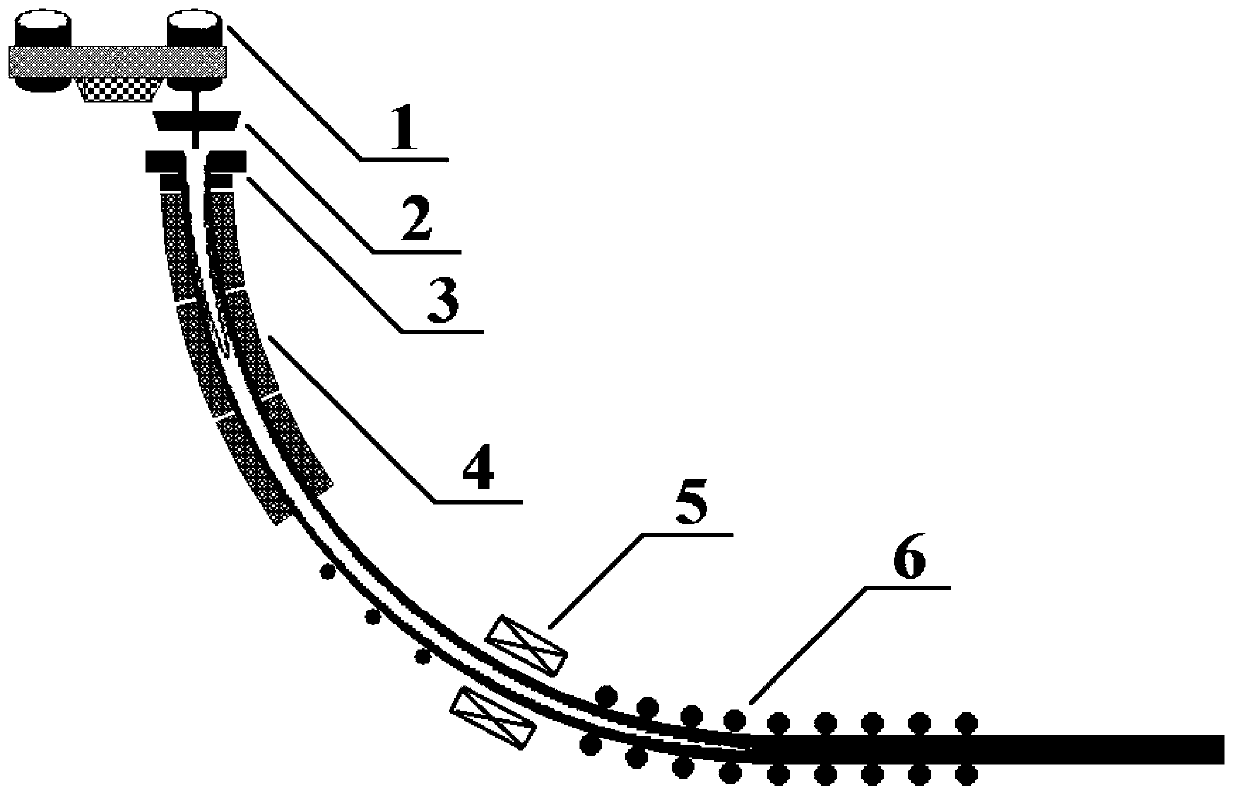

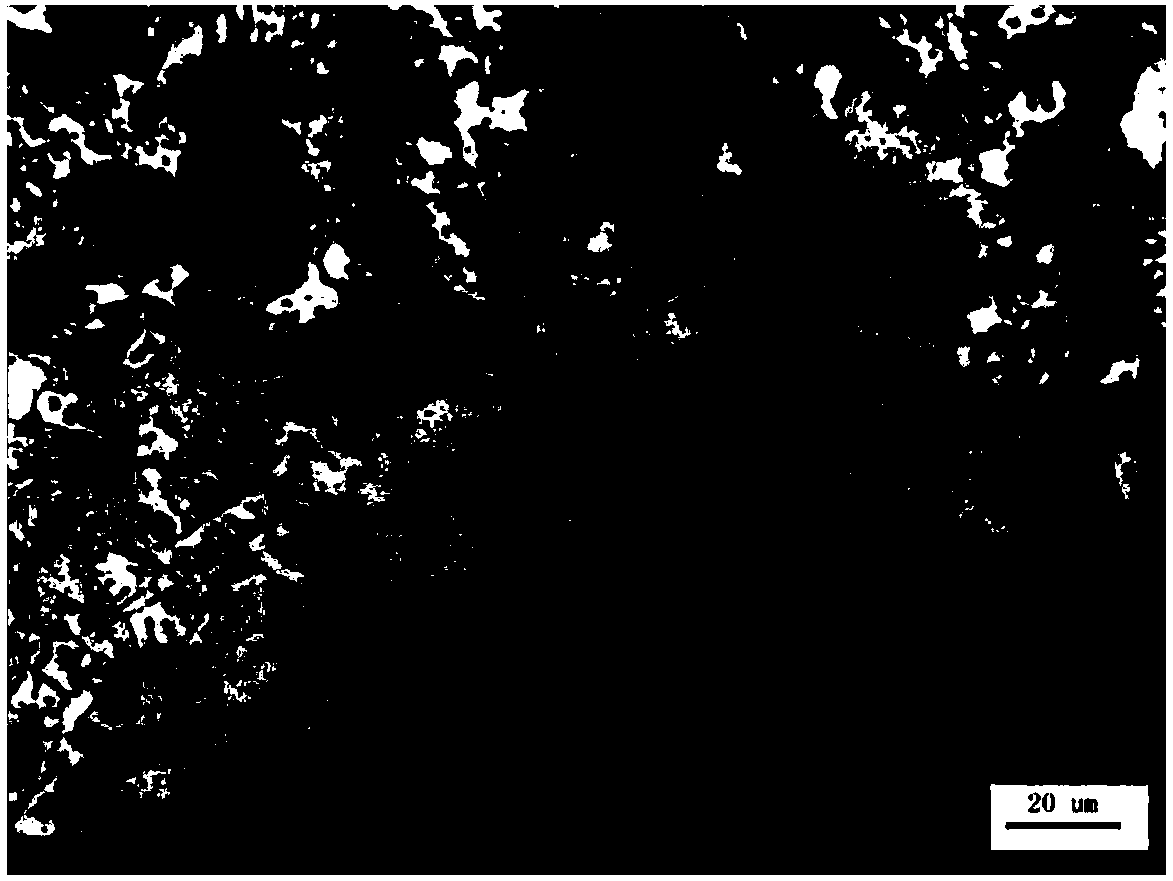

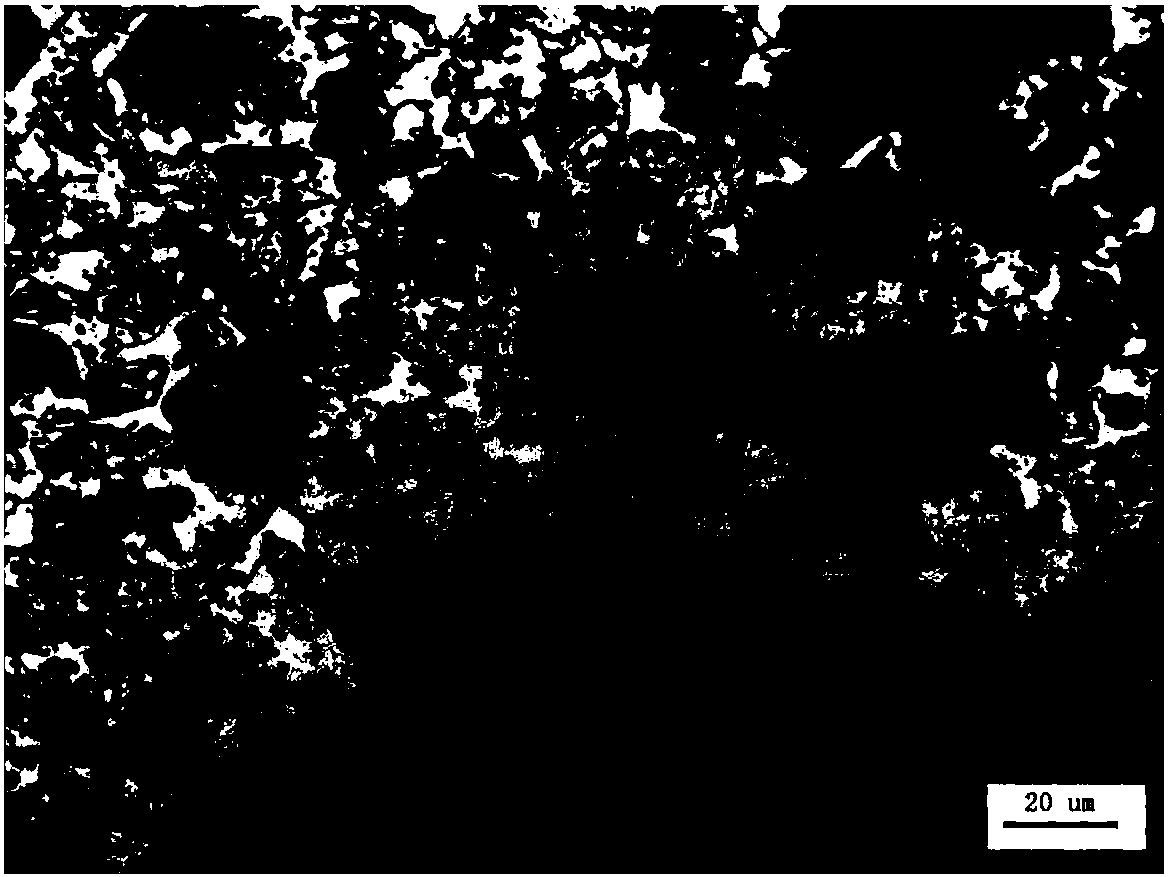

Rare-earth alloy is cast into a sheet (6) or the like by using a tundish (3, 13). The refractory material of the tundish used for casting does not necessitate preheating for improving the flowability of the melt (2). The refractory material used essentially consists of 70 wt % or more of Al2O3 and 30 wt % or less of SiO2, or 70 wt % or more of ZrO2 and 30 wt % or less of one or more of Y2O3, Ce2O3, CaO, MgO, Al2O3, TiO2 and SiO2. The refractory material has 1 g / cm3 or less of bulk density, has 0.5 kca / (mh° C.) or less of thermal conductivity in the temperature range of from 1200 to 1400° C., and has 0.5 wt % or less of ratio of ignition weight-loss under the heating condition of 1400° C. for 1 hour.

Owner:SHOWA DENKO KK

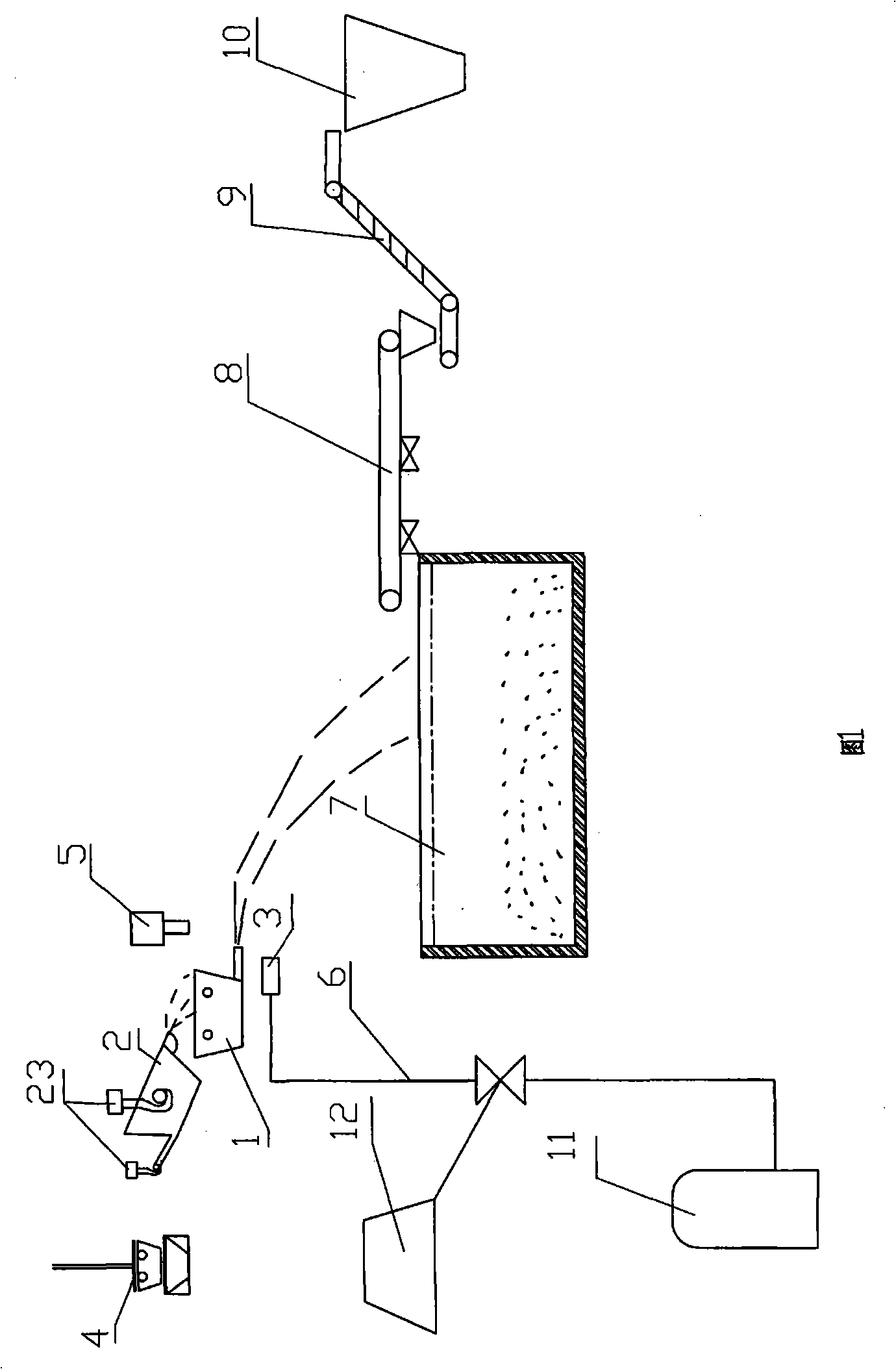

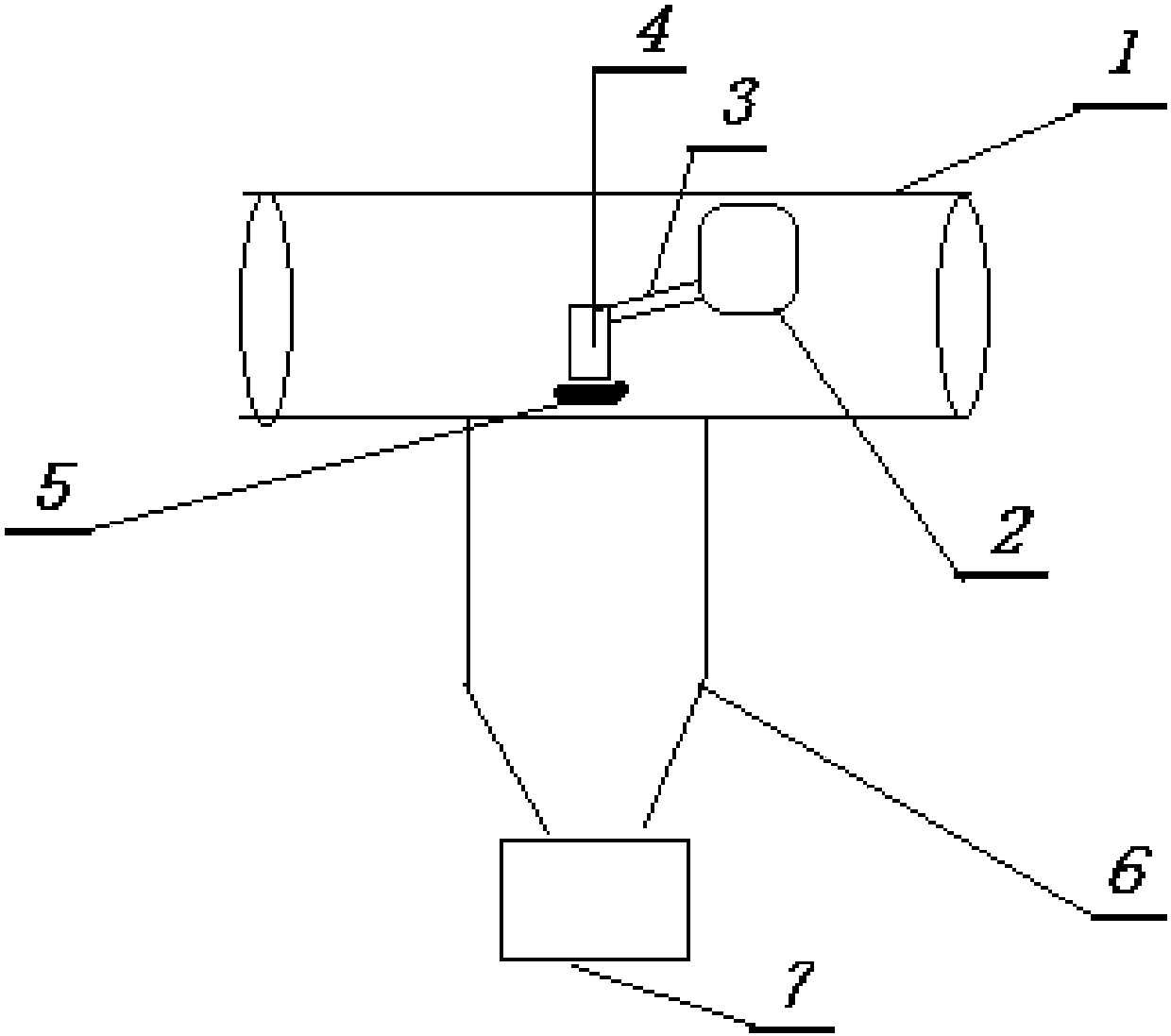

Wind-crushing water-cooling granulating method and device for high-temperature liquid-state steel slag, granulating steel slag and use thereof

ActiveCN101259991ALarge reaction interfaceImproved React interfaceSolid waste managementSlagLiquid state

The invention provides a wind-crushing water-cooling granulating method of high-temperature liquid steel slag, a granulating device and granulated steel slag and use thereof. The invention belongs to the industrial waste comprehensive utilization filed and particularly relates to the treatment and the utilization of high-temperature liquid steel slag. The wind-crushing water-cooling granulating method of high-temperature liquid steel slag comprises the following steps: liquid steel slag flowing out from a tundish is granulated in the air through the high-speed compressed airflow ejected by a granulator; the granulated steel slag is dropped into a water pool so as to be cooled down; moreover, the pressure of the compressed air is controlled between 0.59 MPa and 0.70 MPa, and the degree of superheat of the liquid steel slag is controlled above 110 DEG C. The granulating device comprises a tundish, a granulator and a water pool, and is characterized in that: a tundish rapid heating-up device is arranged near the granulator; and a compressed air pipe is connected with a compressed air pressure automatic display monitoring device. The final blow rate of steel slag is increased from the 80 percent of the prior art to 95 percent and the steel slag has fine particle diameter; moreover, because unstable phase is eliminated, the steel slag can be directly used in the preparation of cement concrete of various strength grade labels from C30 to C80.

Owner:MAANSHAN IRON & STEEL CO LTD

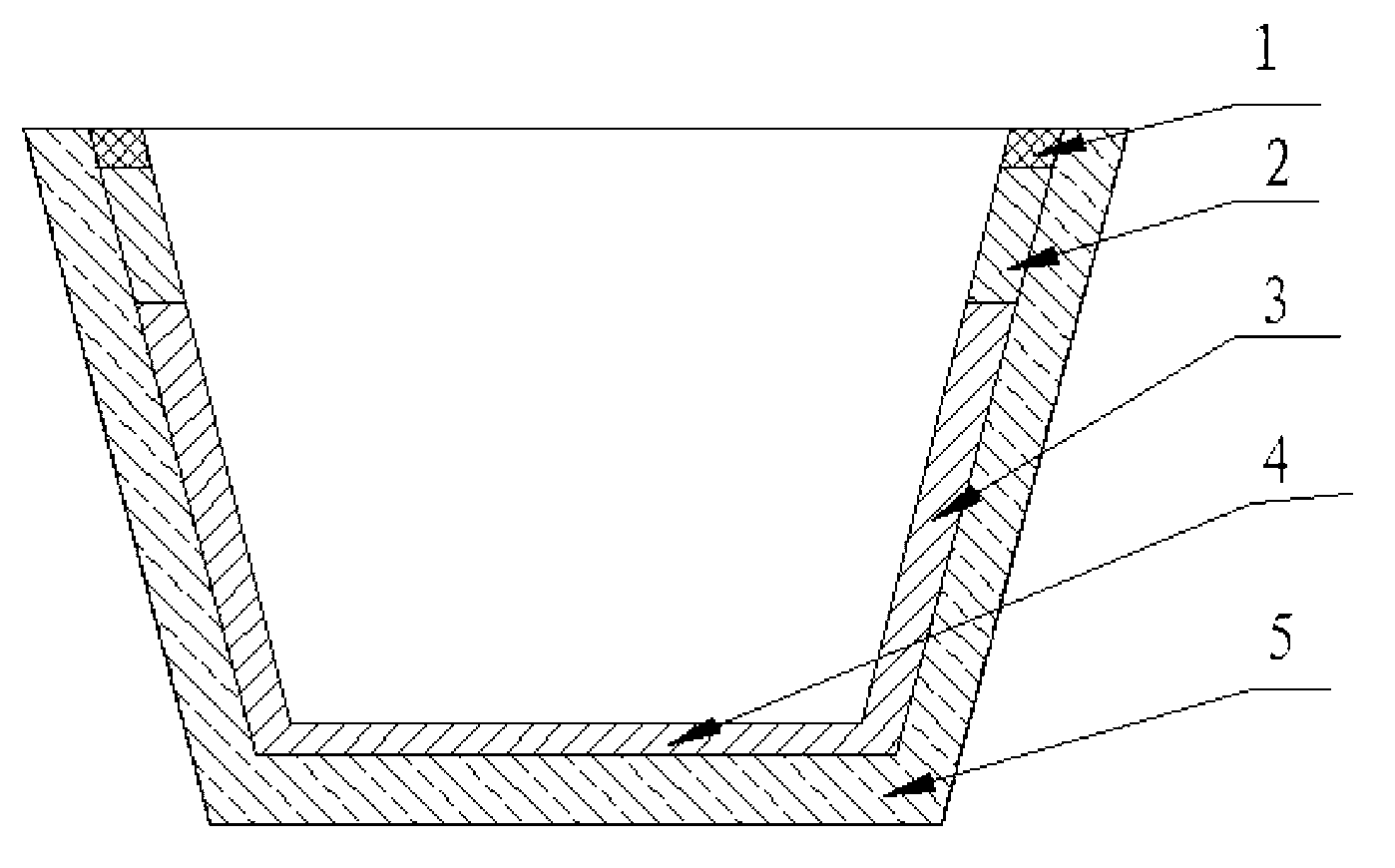

Classifying and recycling process for waste magnesia carbon bricks produced after use of steel tundish working linings as well as dry material and coating material for tundish

ActiveCN103319189AAchieving RecyclabilityMaximize regeneration valueSolid waste disposalBrickGranularity

The invention relates to a classifying and recycling process for waste magnesia carbon bricks produced after use of steel tundish working linings as well as a dry material and a coating material for a tundish. The waste magnesia carbon bricks produced after use of the steel tundish working linings are subjected to recovery processing and are classified into reclaimed materials with three grain levels, i.e., the granularity is more than or equal to 3mm and less than 5mm, the granularity is more than or equal to 1mm and less than 3mm and the granularity is less than 1mm; the reclaimed materials with the granularity more than or equal to 3mm and less than 5mm and the granularity more than or equal to 1mm and less than 3mm are used as raw materials to prepare the dry material for the tundish, and the dry material is used for carrying out continuous casting on a slag line 2 and a tundish wall 3 and a tundish bottom 4 below the slag line 2 of the tundish working lining; the reclaimed materials with the granularity more than or equal to 1mm and less than 3mm and the granularity less than 1mm are used as raw materials to prepare the coating material for the tundish, and the coating material for the tundish is used for carrying out continuous costing on a tundish edge 1 above the slag line of the tundish working lining. The invention further provides a construction method for manufacturing the combined continuous casting tundish working lining by adopting the dry material and the coating material for the tundish. According to the classifying and recycling process, the dry material and the coating material for the tundish and the construction method, the classifying and recycling rate of the waste magnesia carbon bricks produced after use of the steel tundish working linings reaches 100 percent.

Owner:LAIWU IRON & STEEL GRP

Magnesia chrome carbon coating and preparation method thereof

The invention pertains to the technical field of non-metal refractory materials, which relates to a magnesia chrome carbon coating and a preparation method thereof. The magnesia chrome carbon coating is researched and developed by taking waste magnesia carbon bricks as raw materials. The proportioning ratio of the waste magnesia carbon bricks is more than 65 percent, thereby increasing the recycling quantity of the waste magnesia carbon bricks and lowering the production cost of the magnesia chrome carbon coating. The magnesia chrome carbon coating can be used as the coating of continuous casting tundish working lining and as the patching material of the lower groove working lining of an RH vacuum furnace. The magnesia chrome carbon coating made from the components can bear the erosion and scouring of high-temperature molten steel (1550 DEG C to 1650 DEG C) for more than 24 hours and has good resistance to erosion, scouring and oxidation.

Owner:LAIWU IRON & STEEL GRP

Method for replacing tundish of crystallizer at high liquid level

The invention provides a method for replacing tundish of a crystallizer at high liquid level, belonging to the field of steel-making. Before the tundish is replaced in a continuous casting way, the molten steel in the crystallizer is lifted up to the position of 50mm at the upper edge of a crystallizer copper plate; when the pouring is started, the initial pulling speed is 0.4m / min; within 1.5 minutes after starting, the slag skin is removed and the liquid surface is stabilized; subsequently the pulling speed is promoted to 0.1m / min at the increment of 0.1m / min per 20 seconds; within 30 seconds, the thickness of the adjusting and protecting slag is measured; subsequently the pulling speed is promoted to 1.0m / min at the increment of 0.1m / min per 25 seconds and the liquid level of the crystallizer is stabilized; after the liquid level of the crystallizer is stabilized for 1 minutes, an automatic liquid level control device is arranged in the liquid; after the automatic liquid level control device is arranged in the liquid for 1 minutes, the dipping type water gap insertion depth is adjusted to comply with the technological requirement; after the liquid level is stabilized for 2 minutes, the pulling speed is promoted; the promotion amplitude is 0.05m / min and the liquid level is stabilized for 1.5 minutes when the pulling speed is promoted by 0.05m / min; subsequently whether the tundish temperature complies with the steel type specification is determined; and the pulling speed is promoted to the target pulling speed. The method has the advantages of effectively avoiding the steel suspension accident of the crystallizer owning to the splashing of the molten steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Forming copper powder suitable for 3D printing, and manufacturing method and purposes of forming copper powder

The invention belongs to the field of materials for 3D printing, and discloses forming copper powder suitable for 3D printing and a manufacturing method of the forming copper powder. The method comprises the steps that TU0 oxygen-free copper is smelted to 1250 DEG C-1400 DEG C by adopting an argon shield furnace, impurities mixed in fused copper liquid are removed by blowing argon at the bottom of the furnace, the copper liquid is completely fused, and temperature evenness is achieved. The fused copper liquid is injected into a tundish crucible by being protected by the argon, the copper liquid flows through a gas atomization nozzle through the tundish crucible and a guide nozzle under stable micropressure, preheated sound-speed argon flow ejected by the gas atomization nozzle washes the surface of the copper liquid to produce shear force and extrusion force, so that the copper liquid deforms, the diameter of the liquid flow becomes smaller and smaller, small liquid drops are formed finally, and then spherical metal powder is manufactured in an atomization chamber in a cooled mode. The 3D printing copper powder manufactured in the method is high in powder obtaining rate, the degree of sphericity is high, the oxygen content is less than 500 ppm, the grain size is less than 10 microns, and distribution is narrow.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Tundish covering agent for pure steel, and its making method

InactiveCN1461680AReduce energy consumptionReduce manufacturing costProcess efficiency improvementAdhesiveCupola furnace

A granular or spherical hollow covering agent of tundish for high-purity steel is prepared from the prefused grog chosen from hydrated lime, calcium carbonate, quartz sand, etc. the raw material including calcium carbonate, bauxite and quartz sand, and the adhesive through prefusing the powdered grog, mixing with raw material, grinding, stirring, adding additive and shaping. Its preparing process is also disclosed. Its advantages are no reaction on molten steel, and high quality of steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Tundish dry ribration material for continuous casting and its preparation method

InactiveCN1651352ANo irritating smellEasy constructionMelt-holding vesselsPolyvinyl alcoholRefractory

A lining material of tundish for conticasting is prepared from 6 primary raw materials including sintered magnesium sand, electrosmelted magnesium sand, forsterite, light forsterite, etc and 9 secondary raw materials including water glass, sodium tripolyphosphate, dextrin, starch, etc through proportionally mixing, stirring, loading in mould, vibrating, baking at 150-400 deg.C and demoulding.

Owner:WUHAN UNIV OF SCI & TECH

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

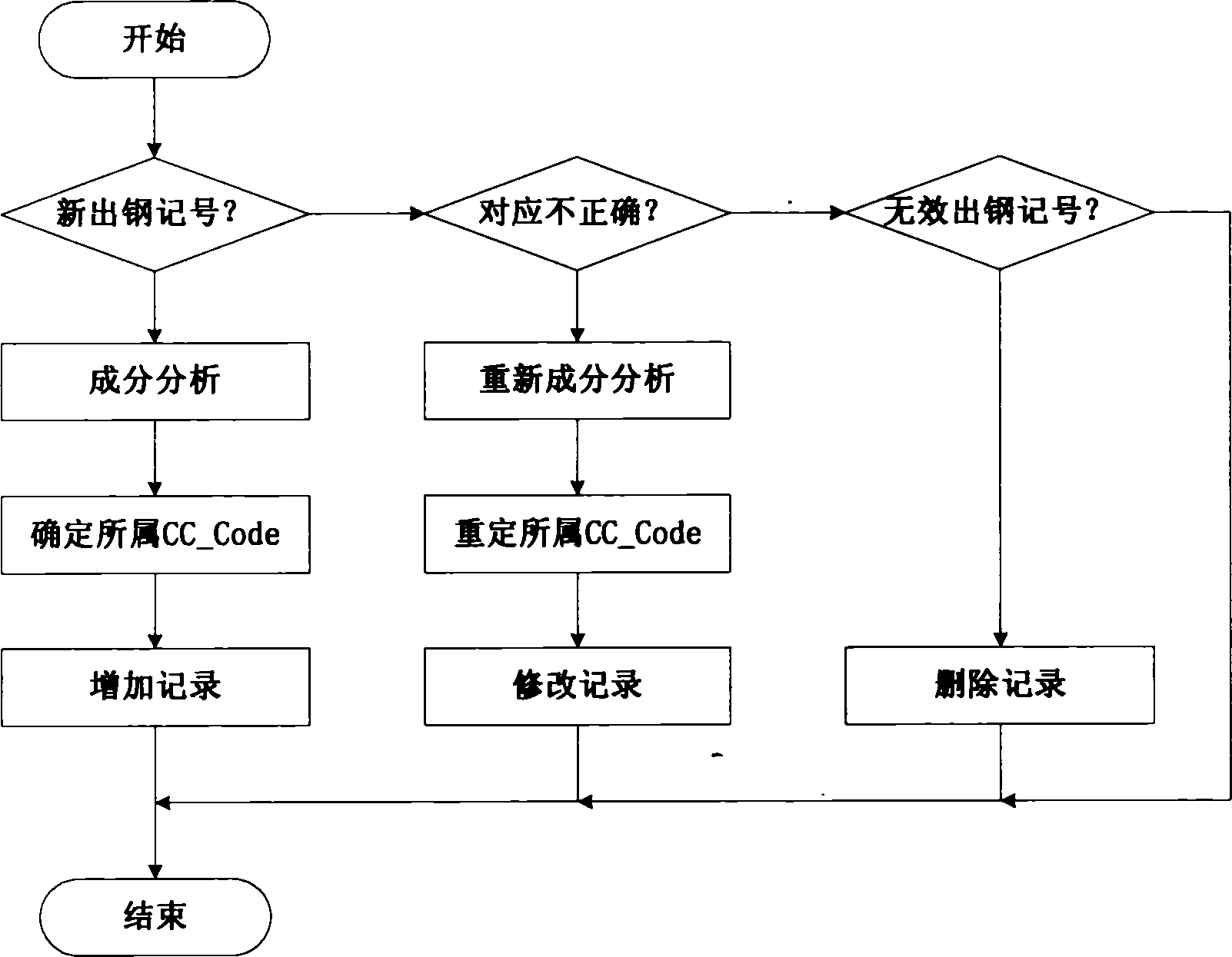

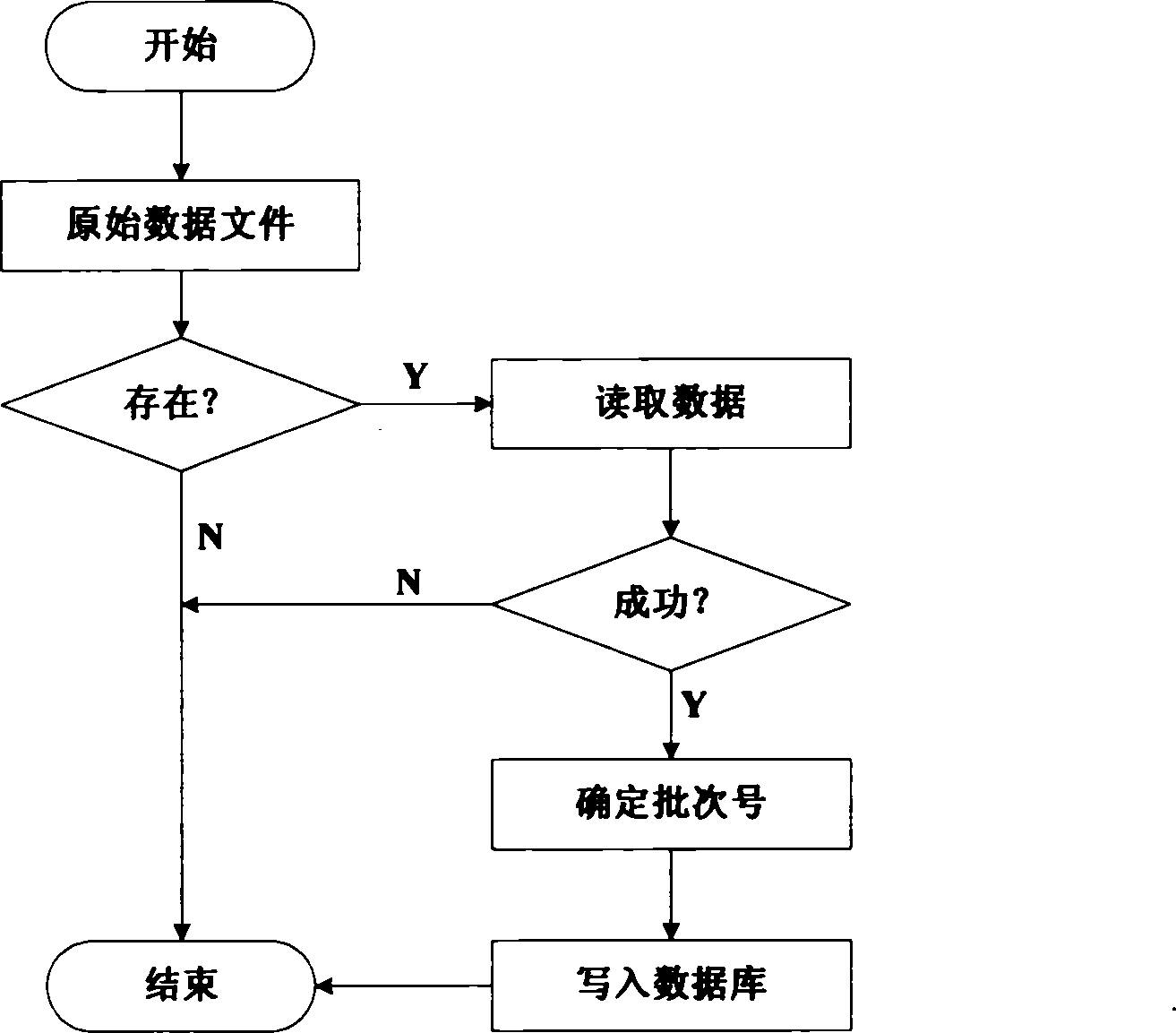

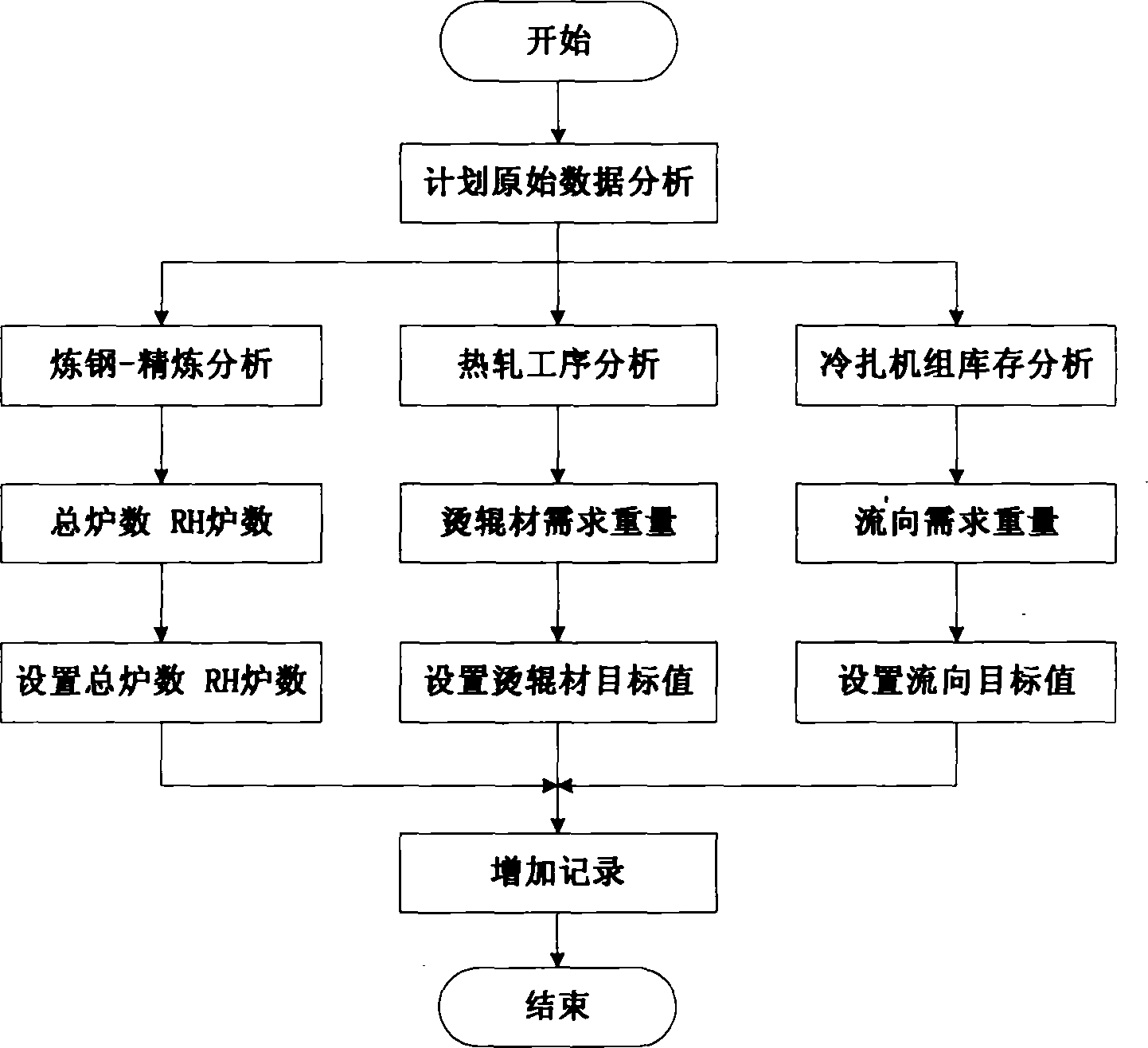

Steelmaking-continuous casting tundish batch plan method and system

The invention relates to a steel-smelting-continuous casting middle pack batch plan and relative system, wherein said system comprises arc static parameter setting module, original data download module, batch plan demand setting module, model algorism parameter setting module, middle pack batch plan automatic generating module, plan index stat display module, plan result stat display module, producing plan artificial adjusting module, and producing plan upload module. And said method uses middle pack batch plan math model, uses two-stage multi nearby field forbidden search algorism, to fix how the furnace time is batched into the middle pack to realize multi-furnace continuous casting, to maximize the casting number, and reduce the cost. The invention can improve the plan efficiency, reduce labor density, improve plan quality and optimize production.

Owner:NORTHEASTERN UNIV

Iron-rich high-entropy alloy powder material for 3D printing and preparation method thereof

ActiveCN105950947AHigh sphericityGranularity controllableAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysGuide tube

The invention discloses an iron-rich high-entropy alloy powder material for 3D printing and a preparation method thereof. The molar ratio of the iron-rich high-entropy alloy powder material FexAlCoCrNiB0.3 is as follows: the molar weight of Fe is 2 to 3, the molar weights of Al, Co, Cr and Ni are 1, the molar ratio of B is 0.3, and B is added in an Ni-B alloy form. The iron-rich high-entropy alloy powder material is prepared through a medium frequency induction melting gas atomization one-step method, namely, a metal liquid subjected to medium frequency induction melting and refining is directly fed into a gas atomization device through a guide tube and a tundish to be atomized for powder material preparation. According to the iron-rich high-entropy alloy powder FexAlCoCrNiB0.3material prepared through the method, a phase structure is composed of solid solutions of simple face-centered cubic and body-centered cubic structures, and a product is good in degree of sphericity, controllable in particle size, uniform in components, low in oxygen content and good in fluidity; and according to the preparation method provided by the invention, the technology is simple, the energy consumption is low, the control is easy, the product quality is stable, and the method is applicable to large-scale industrial production, pollution-free to the environment, and environment-friendly in utilization.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

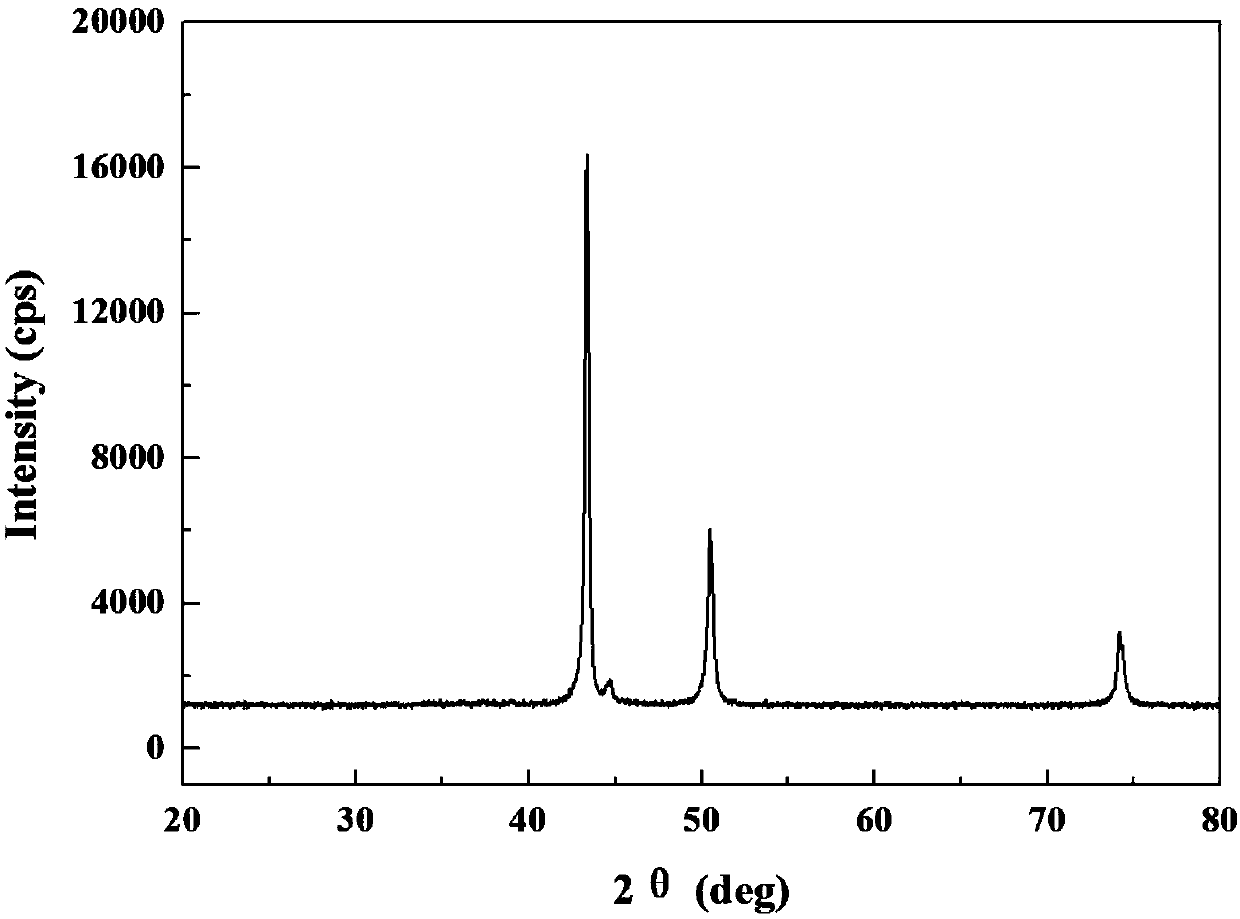

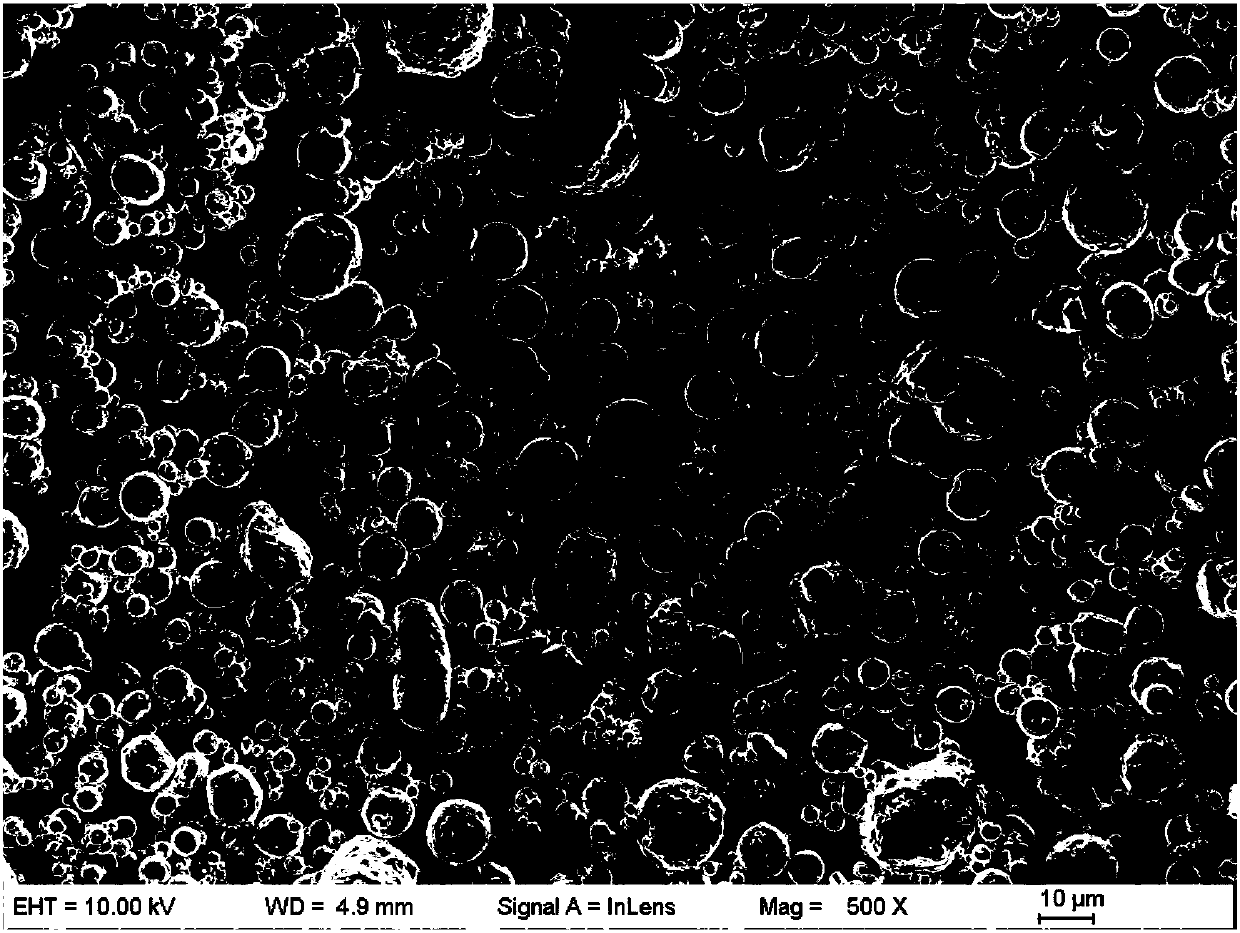

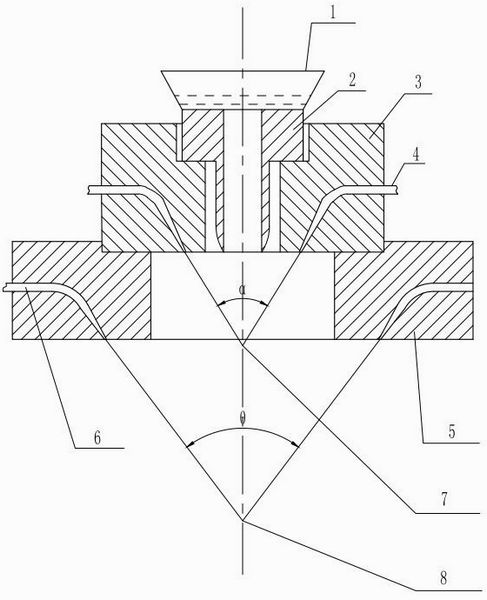

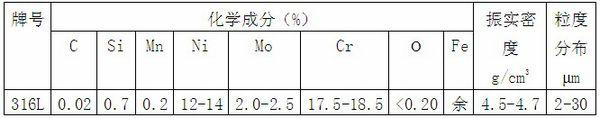

Method for producing spherical stainless steel powder material by using high pressure water atomization method

The method discloses a method for producing a spherical stainless steel powder material by using a high pressure water atomization method, which comprises the following steps: preparing required stainless steel raw materials according to the contents of components in the grade of the spherical stainless steel powder; adding the stainless steel raw materials into an intermediate frequency induction heating furnace, wherein the degree of superheat of melt is 150-200DEG C; pouring the molten metal of the stainless steel raw materials into a crucible, and enabling the molten metal to flow from the tundish, wherein the flow velocity of the molten metal is 38-45g / s; spraying the high-pressure water from an atomizer nozzle, wherein the jet angle of the atomizer nozzle is 10-20 degrees, the pressure of the high-pressure water is 35-90MPa, and the water flow quantity is 3.3-6m<3> / min. The nozzle of the atomizer is a double-layer annular ring nozzle. The spherical stainless steel powder produced by the method of the invention has even components, high sphericity, and low cost, and the method is simple to operate.

Owner:SHIJIAZHUANG TIEDAO UNIV

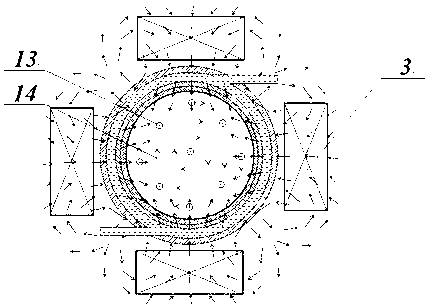

Ultra-low carbon steel wire rod for electric conduction and production method thereof

InactiveCN103469061AMeet the use requirementsReduce manufacturing costMetal/alloy conductorsWire rodChemical composition

The invention provides an ultra-low carbon steel wire rod for electric conduction and a production method thereof. The ultra-low carbon steel wire rod for electric conduction comprises the following chemical compositions: 0.002-0.005% of C, 0.004-0.010% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.0050-0.0080% of total oxygen, and less than or equal to 0.0050% of total aluminum. The carbon content of smelted steel tapped from a converter is less than or equal to 0.040%, and the oxygen content of molten steel is 0.060-0.070%; natural decarburization is performed for 5-8 minutes in the first stage of RH refining; in the second stage of RH refining, after the carbon content is reduced to below 0.0030%, oxygen blowing is performed for 15-20 minutes, and a low-carbon or carbon-free steel ladle is adopted for smelting; the superheat degree of molten steel of a continuous casting tundish is less than or equal to 30 DEG C, the electromagnetic stirring current is greater than or equal to 400A, and the pulling rate is 0.5-0.7 m / min; the temperature of an entry double-module is 880-900 DEG C, the spinning temperature is 900-920 DEG C, the roller-bed speed is 0.2-0.4 m / s, and fans are completely closed. The electric conductivity of the wire rod disclosed by the invention is greater than or equal to 15%, the tensile strength is less than or equal to 300 MPa, and the area reduction index is greater than or equal to 80%, and the wire rod can partially replace copper conducting materials, thereby reducing the production cost.

Owner:ANGANG STEEL CO LTD

Lining material of tundish for conticasting

InactiveCN1382541AHigh strengthImprove slag erosion resistanceMelt-holding vesselsSoft clayRefractory

A lining material of tundish for conticasting contains magnesium sand (80-95 wt.%), alumina (1-10 wt.%), soft clay (1-5 wt.%) and thermoplastic organic compound (2-15 wt.%). Its advantages are high strnegth, anticorrosion power, and high conticasting productivity.

Owner:朱德智

Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

The invention discloses a low-energy-consumption electromagnetic stirring method for continuous casting. The hot top composite novel low-energy-consumption electromagnetic stirring technique is used. A hot top is arranged in a crystallizer, a steady magnetic field with no energy consumption and low energy consumption is exerted on the periphery simultaneously, an electrode bar is inserted in a tundish, a roller electrode is arranged at the solidifying tail end of a continuous casting billet, and therefore alternating current can be exerted on all non-solidification metal melts between the crystallizer and the solidifying tail end. The alternating current and an additional steady magnetic field are acted with each other so as to enable all the non-solidification metal melts in the whole continuous casting billet in a continuous casting process to generate electromagnetic stirring force for driving the continuous casting melts to rotate clockwise and counterclockwise, thereby stirring non-solidification structures, smashing dendrites of solidification front edges of the melts, refining the solidification structures, reducing segregation and cracks. The invention further provides a metal continuous casting device which can be applied to a continuous casting process of various molten metals prone in segregation and draw an alloy continuous casting billet with refined solidification structure, small segregation and no crack.

Owner:SHANGHAI UNIV +1

Continuous casting bloom soft press technology based on tail end electromagnetic stirring

ActiveCN103121092AReduce dependenceThe effect of electromagnetic stirring is greatThermodynamicsHeat transmission

The invention provides a continuous casting bloom soft press technology based on tail end electromagnetic stirring and belongs to the field of metal casting. The continuous casting bloom soft press technology based on the tail end electromagnetic stirring is characterized in that after a tail end electromagnetic stirring device is arranged on a second cooling area, a previous air cooling area is straightened. The thickness of a liquid core controlling the position of the stirring device occupies 30% to 55% of the thickness of a casting blank through a solidification heat transmission mathematical model. Stirring current of the tail end electromagnetic stirring device is 350A to 750A and stirring frequency is 3Hz to 8Hz. When soft press and straightening are conducted simultaneously, complete solidification of liquid phase among columnar crystals is guaranteed and meanwhile total press amount of a press intersection is controlled to be 10mm to 25mm, liquid steel superheat degree of a tundish is 20 DEG C to 30DEG C, dragging speed of a continuous casting machine is 0.35m / min to 0.75m / min, and therefore internal quality of a continuous casting bloom is remarkably improved and high quality rolled metal is guaranteed. Continuous casting bloom bearing steel manufactured through the technology is continuously manufactured for over 10 boilers, occurrence of internal cracks is avoided, a central organization is dense and even, the rate that a center contracting hole <=1.0 reaches 97.54%, center C segregation is controlled to be under 1.06 and thus the internal quality of the bearing steel is remarkably improved.

Owner:UNIV OF SCI & TECH BEIJING

Steel with excellent processing performance for gardening tool and production method thereof

The invention discloses steel with excellent processing performances for a gardening tool and a production method thereof. The steel comprises the following components of, by weight, 0.45%-0.65% of C,0.1%-0.40% of Si, 0.5%-1.5% of Mn, 0.1%-0.5% of Cr, 0.02%-0.05% of Al, less than or equal to 0.4% of Ni, less than or equal to 0.5% of Cu, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method comprises the following steps that deoxidation is carried out by adopting Al, and time of argon blowing in tundish is larger than or equal to 10 minutes, the casting superheat degree is less than or equal to 25 DEG C, the thickness of a casting blank is 130-200 mm; charing temperature of the casting blank is larger than or equal to 500 DEG C; heating temperature is 1100-1200 DEG C, the temperature is kept for 2-5 hours, the rolling speed is 5-15 m per second, rolling start temperature is larger than or equal to 1080 DEG C, and rolling finish temperature is larger than or equal to 920 DEG C; and the cold speed is less than or equal to 20 DEG C per second, the casting blank is coiled at the temperature of 650-730 DEG C, then is put into a slow cooling pit for heat preservation and slow cooling for more than or equal to 48 hours, is cooled to below 200 DEG C, and then is air-cooled to the room temperature. According to steel with the excellent processing performances for the gardening tool and the production method thereof, the steel plate has excellent formability and wear resistance.

Owner:ANGANG STEEL CO LTD

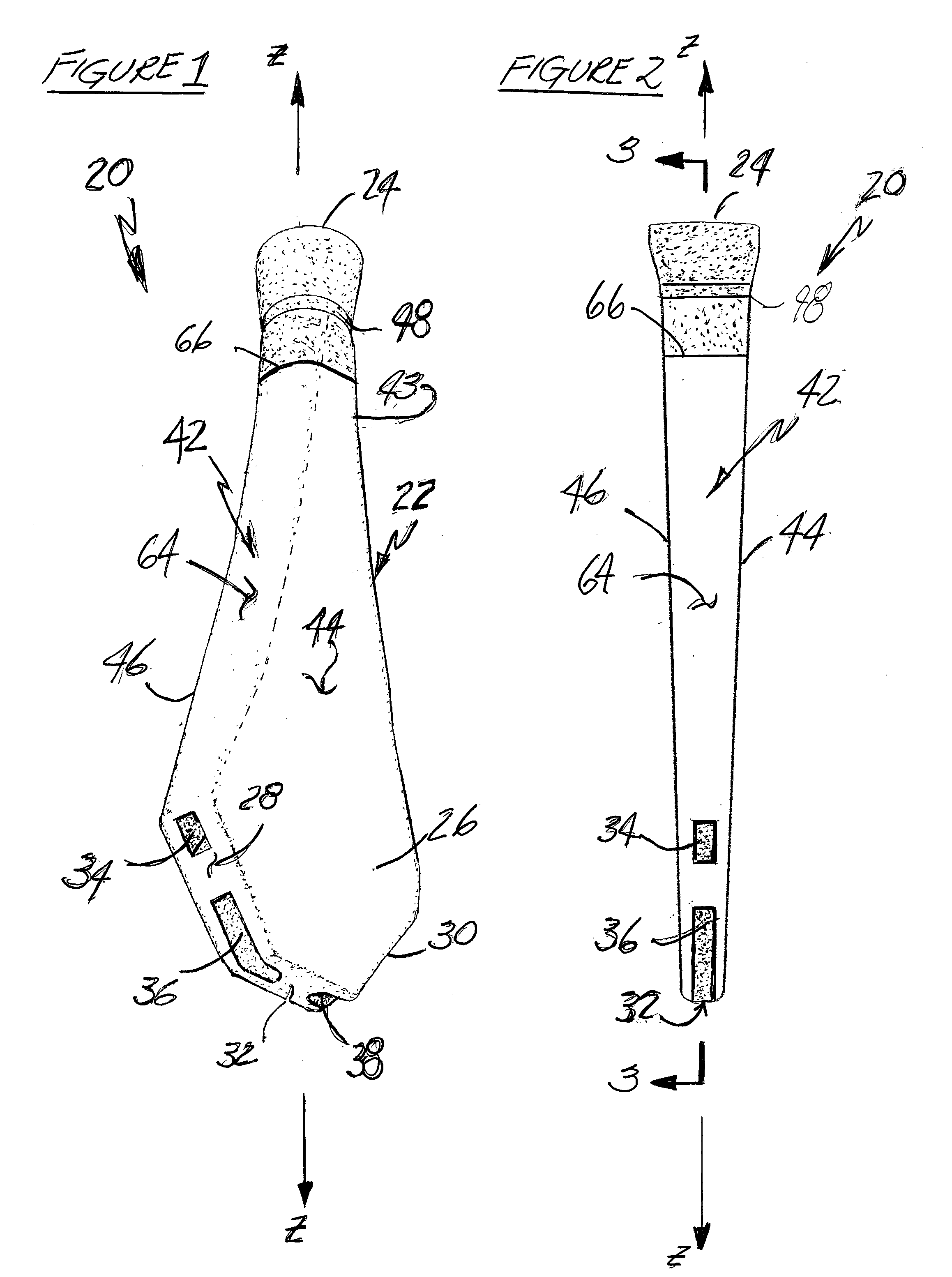

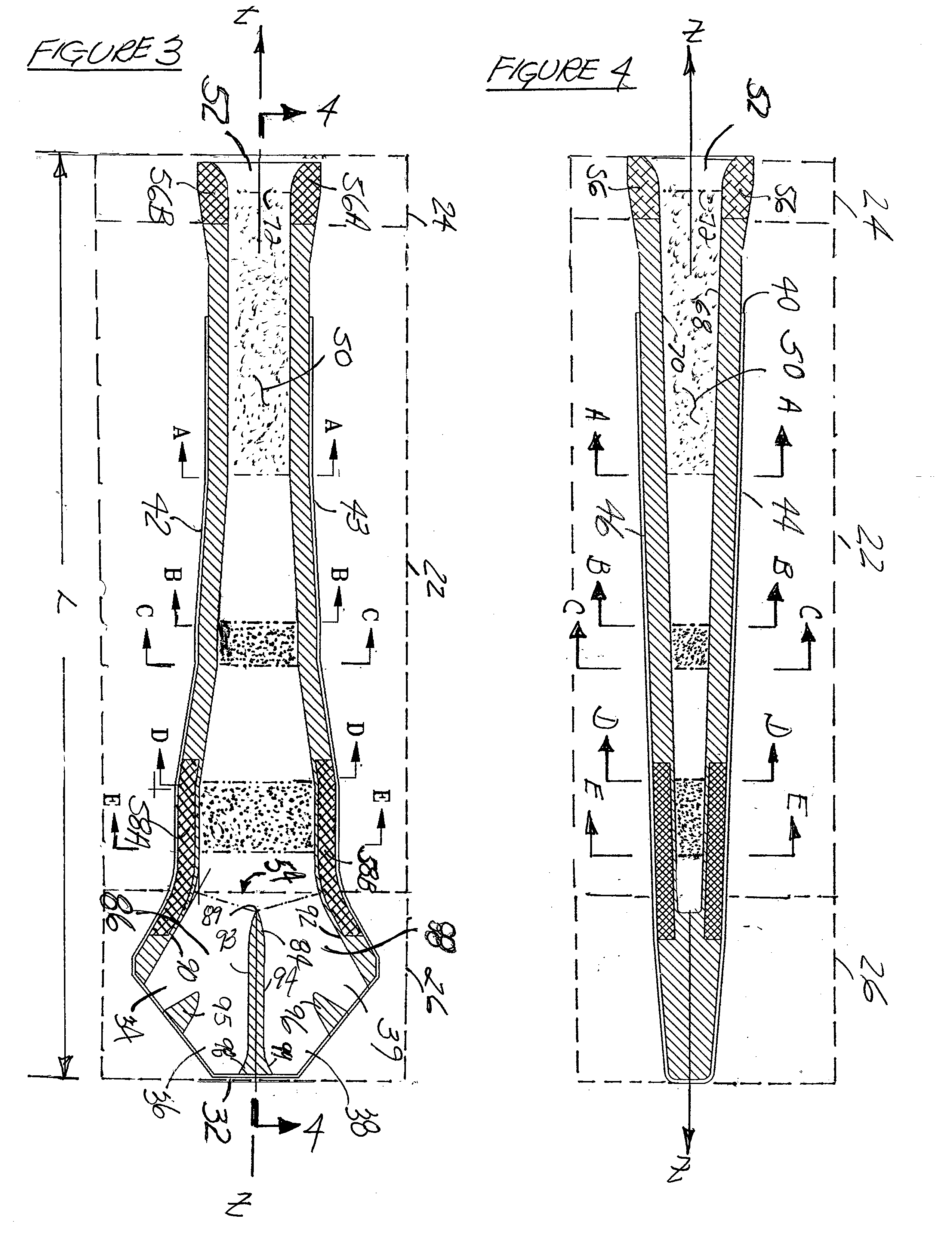

Submerged entry nozzle

InactiveUS20060243760A1Increase flow dynamicsMinimizing steel flow turbulenceMelt-holding vesselsMolten metal pouring equipmentsMetallurgyThin slab

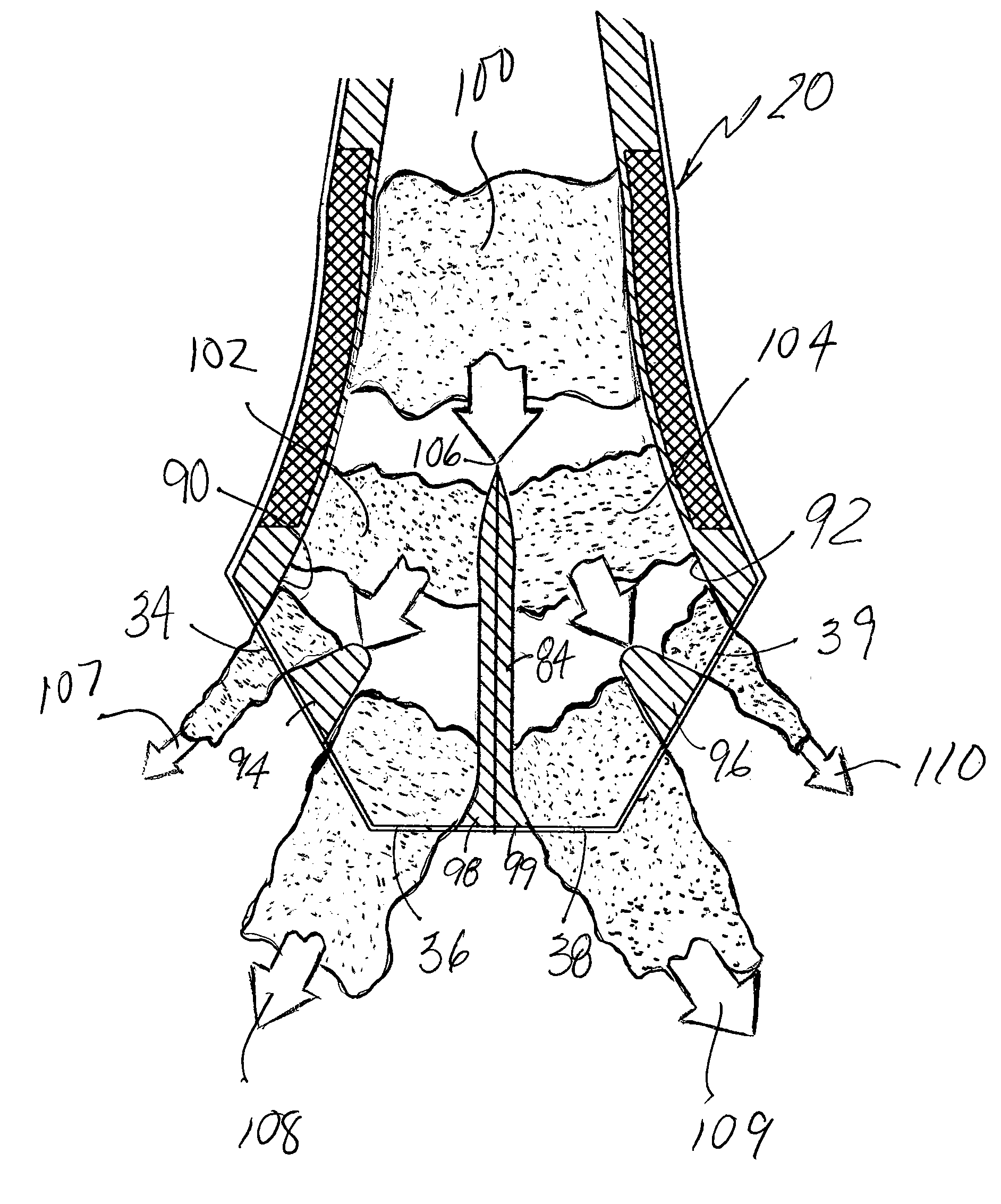

A nozzle for transferring molten steel in a thin slab continuous casting machine from the tundish to the mold which provides at least two areas of stream compression below the major changes in section required to transition from the entry diameter to the rectangular submerged portion of the nozzle.

Owner:NUCOR CORP

Vacuum or gas protection smelting and casting equipment for continuous production

ActiveCN104232898AEasy to replaceIncrease productivityIncreasing energy efficiencyShielding gasVacuum chamber

The invention provides vacuum or gas protection smelting and casting equipment for continuous production. According to the specific technical scheme, a multi-door multi-furnace horizontal vacuum smelting chamber 1 is adopted; after a vacuum environment is provided by a vacuum unit or a protection gas is introduced, a material enters a smelting furnace 2 by virtue of a replacement chamber sealed charging device 4, wherein when a valve on the first floor is opened, and a valve on the second floor is closed, a material is charged; when the valve on the first layer is closed, and the valve on the second floor is closed, vacuumizing or protective gas replacement is carried out; when the valve on the first floor is closed, and the valve on the second floor is opened, a material enters a smelting furnace 2; after metal is heated and super-fused, a spot casting mechanism 3 is started, the molten metal is poured and injected into a current-limited casting pouring tundish 5; after one furnace of two devices in the vacuum smelting chamber is completely poured and cast, the other furnace takes turns to cast; a pressure detection device 6, an observation hole, an infrared temperature detector and the like are arranged on the furnace shell of the horizontal vacuum chamber; and the aim of continuous production can be achieved by means of alternating circulated charging for smelting and casting of multiple furnaces.

Owner:HUNAN JUTA TECH

Method for improving bearing steel casting blank center compactness

The invention relates to a continuous casting method, in particular to a method for improving the bearing steel casting blank center compactness. According to the technical scheme, the method for improving the bearing steel casting blank center compactness includes the steps that in the continuous casting process, the pull speed of a casting machine is controlled to range from 0.50 m / min to 0.65 m / min, the degree of superheat of tundish molten steel is controlled to range from 20 DEG C to 30 DEG C, the curing tail end heavy reduction manner is adopted, soft reduction and heavy reduction are carried out according to the distribution solid fraction, heavy reduction is started from fs=0.9, and heavy reduction is carried out through a convex type roller at fs=1.0. By means of the method for improving the bearing steel casting blank center compactness, bearing steel casting blank center porosity can be effectively controlled, and the casting blank center compactness is obviously improved.

Owner:NORTHEASTERN UNIV

Production technique of lead treated steel

Owner:NANJING NANGANG IND DEV CO LTD

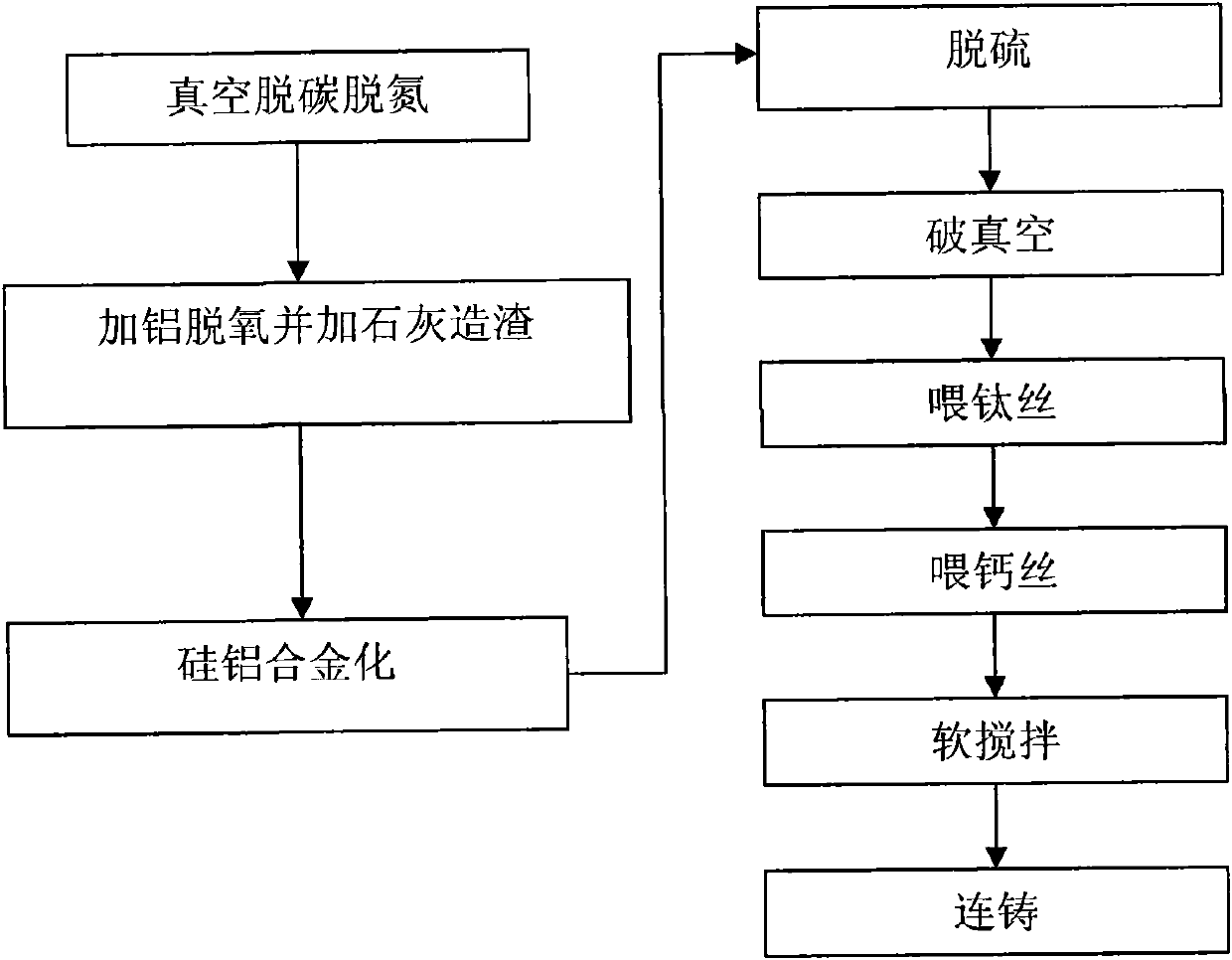

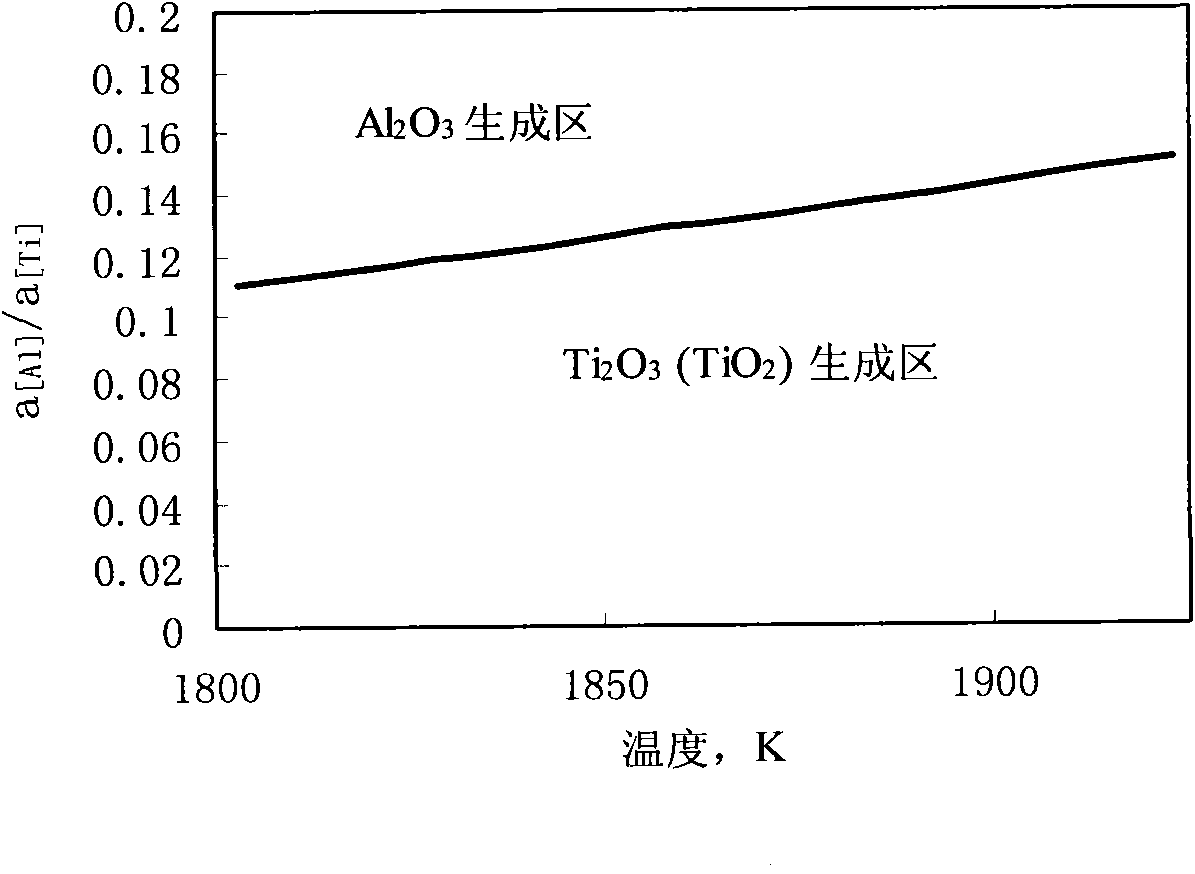

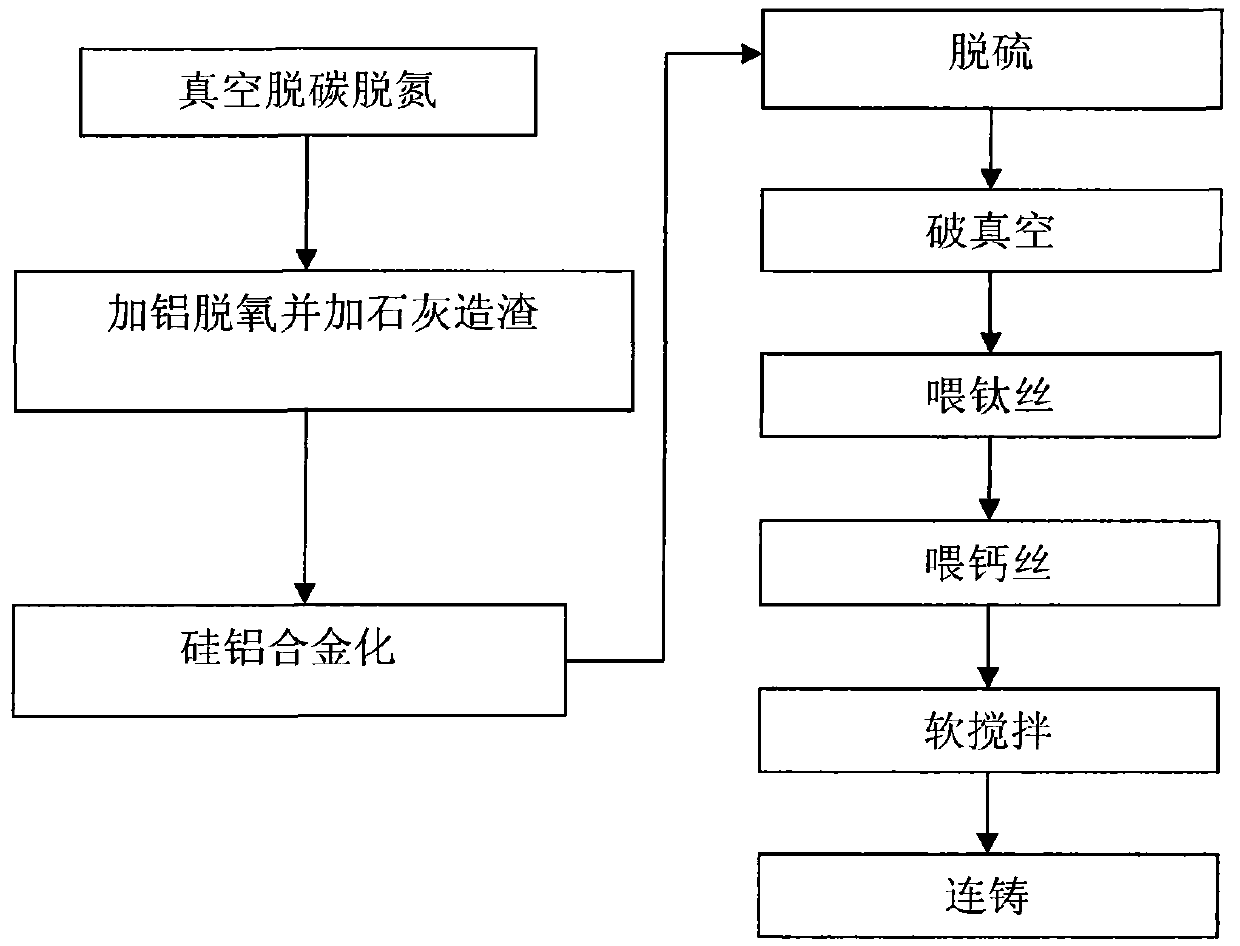

Production method of ultralow-oxygen titanium-containing ferrite stainless steel

The invention discloses a production method of ultralow-oxygen titanium-containing ferrite stainless steel, which comprises the following steps: 1) preparing molten ferrite stainless steel under a vacuum condition in a vacuum oxygen blowing decarburization furnace, wherein the carbon mass percentage content and nitrogen mass percentage content in the molten ferrite stainless steel are both less than 0.01 percent; 2) performing deoxidization, namely adding 6 to 12 kilograms of aluminum block or grains into each ton of steel and adding 10 to 28 kilograms of active lime into each ton of steel; 3) alloying silicon and aluminum, namely adding 2 to 9 kilograms of silicoferrite which contains 70 to 80 percent of silicon into each ton of steel and adding 0 to 1 kilogram of aluminum blocks or grains into each ton of steel, wherein the aluminum content is 0.02 to 0.1 percent; 4) performing desulphurization; (5) breaking vacuum; 6) softly stirring; 7) feeding titanium wires; 8) feeding silicon and calcium wires, wherein the calcium content is 5 to 30ppm; 9) softly stirring; and 10) continuously casting. The method can be used for producing ultralow-oxygen titanium-containing ferrite stainless steel, prevent or inhibit forming magnesia alumina spinel which are harmful impurities in a production process, improve product quality, prevent the water gap of tundish from being blocked in a continuous casting process and guarantee smooth production.

Owner:BAOSHAN IRON & STEEL CO LTD

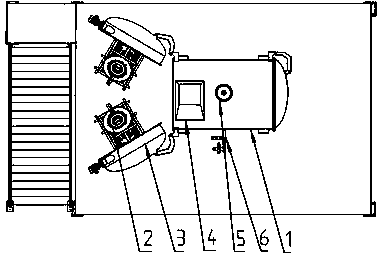

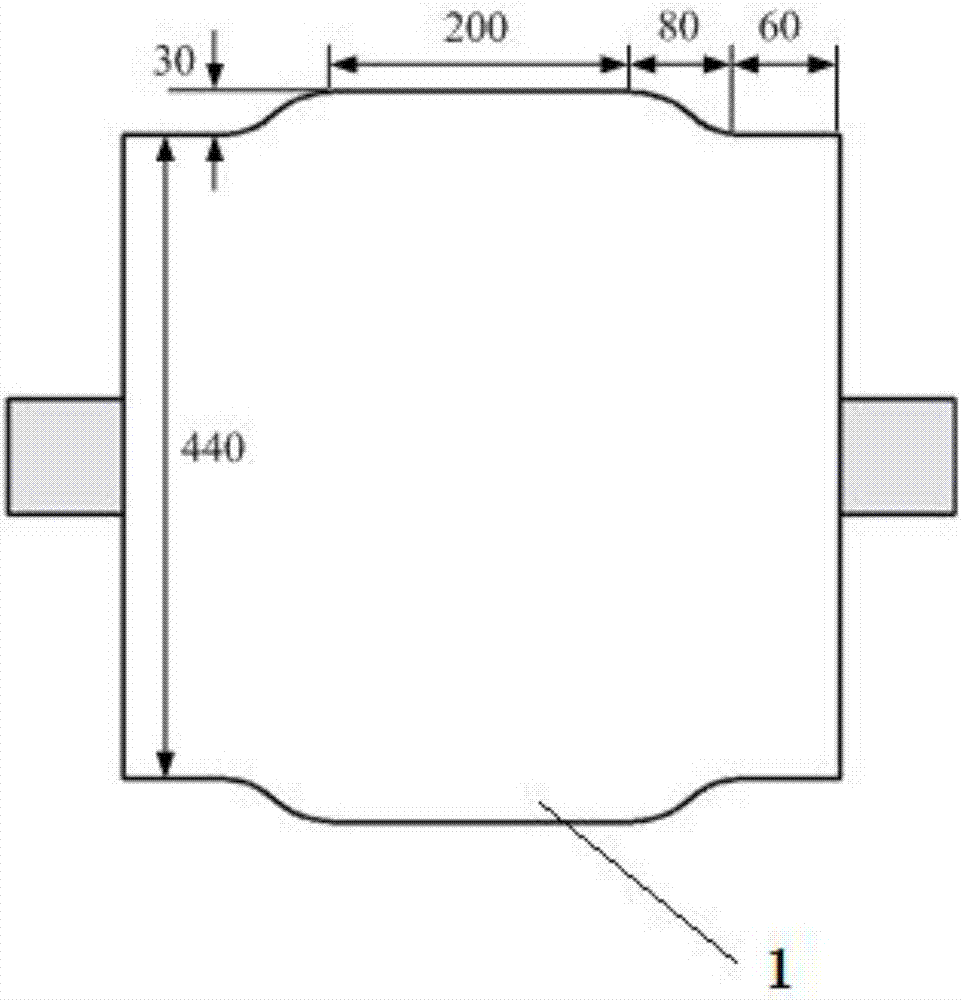

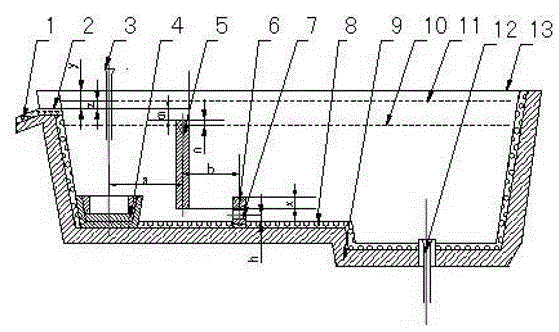

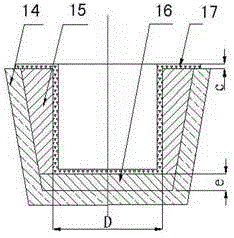

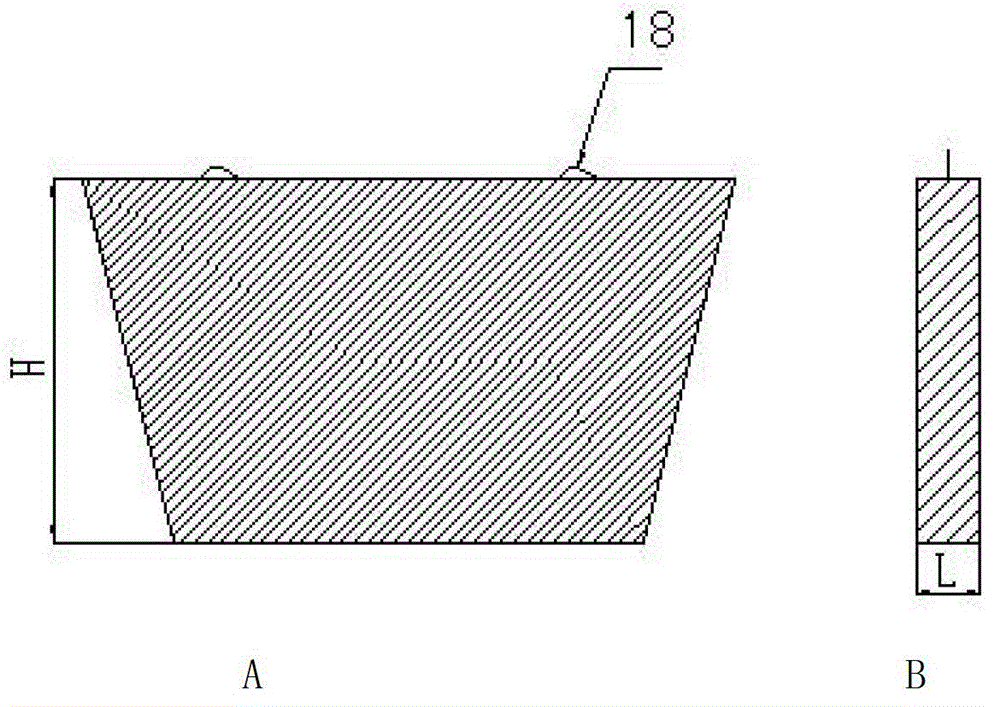

Tundish flow control device for slab casting machine, preparation method thereof and slagging method using tundish flow control device

ActiveCN102744393AReduce the balanceImprove erosion resistanceMelt-holding vesselsCasting cleaning apparatusSlab casterSlag

The invention relates to a tundish flow control device for a slab casting machine, a preparation method of the tundish flow control device and a slagging method using the tundish flow control device, and belongs to the technical field of the ferrous metallurgy slab casting tundish technology. The tundish flow control device for the slab casting machine comprises a turbulence controller, a slag blockage weir and a slag blockage dam, and is characterized in that the upper edge of the slag blockage weir (5) is higher than the highest liquid level (10) of molten steel normally poured by the tundish, but is lower than the working face of tundish overflow port coating (1); the slag blockage weir (5) and the slag blockage dam (6) are vertically staggered; two ends of the slag blockage dam (6) are respectively provided with a through hole; a center distance a between the slag blockage weir (5) and the turbulence controller (4) is 400-600mm; and a center distance b between the slag blockage weir (5) and the slag blockage dam (6) is 300-400mm. After the tundish flow control device for the slab casting machine is adopted, slab tundish injection residue can be reduced by more than 25%, the service life of the flow control device is improved by one time and is above 14 hours, and the production cost of continuous casting refractory material is lowered by more than 30%.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com