Ultra-low carbon steel wire rod for electric conduction and production method thereof

A technology of ultra-low carbon steel and production methods, applied in the field of metallurgy, can solve problems such as unsatisfactory, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

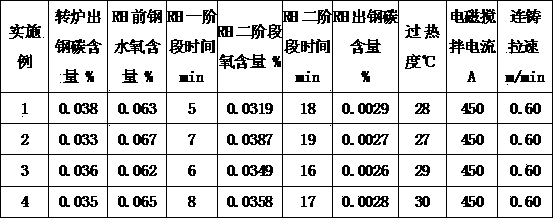

[0033] Embodiment smelting, continuous casting and rolling production process parameters are as table 2:

[0034] Table 2 Example smelting, continuous casting production process parameter list

[0035]

[0036] Embodiment rolling production process parameter is as table 3:

[0037] Table 3 Example rolling production process parameter table

[0038] Example Entering double module temperature ℃ Spinning temperature ℃ Roller speed m / s Fan, insulation cover 1 892 915 0.25 closure 2 884 908 0.25 closure 3 894 912 0.25 closure 4 885 906 0.25 closure

[0039] Grain size and performance test result after embodiment wire rod rolling are as table 4:

[0040] Table 4 The results of the grain size and performance inspection of the wire rod after rolling in the embodiment

[0041] Example Grain sizeum Tensile strength MPa Area reduction % Conductivity % 1 20-40 278 85 15.5 2 20-40 286 84 15.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com