Conductive adhesive for LED (light emitting diode) packaging and preparation method of conductive adhesive

A technology of conductive adhesive and conductive powder, which is applied in the direction of conductive adhesives, circuits, adhesives, etc., can solve the problems of not many products required for use, low thermal conductivity, and the inability to use conductive adhesives, etc., to achieve high conductivity, high Good thermal conductivity, thermal conductivity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

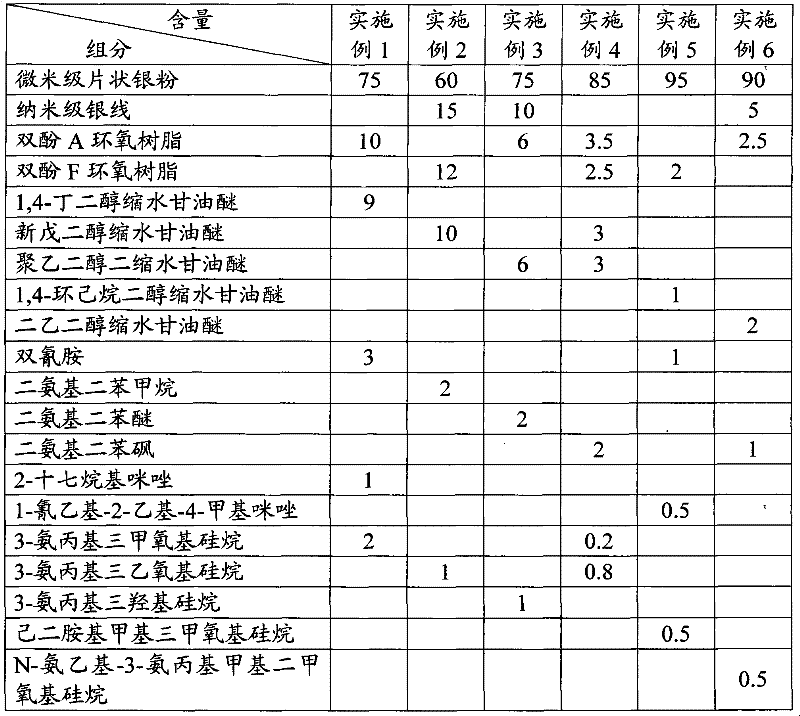

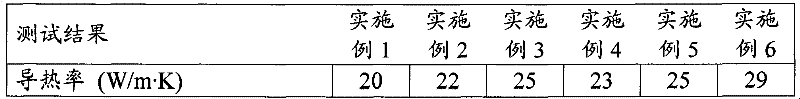

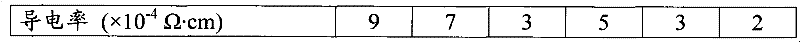

[0023] At room temperature, weigh the raw materials according to the weight ratio of each component in Example 1 in Table 1, bisphenol A epoxy resin and 1,4-butanediol glycidyl ether were mixed for 10 minutes until uniform, and then Add dicyandiamide, 2-heptadecyl imidazole and 3-aminopropyltriethoxysilane, mix at room temperature for 10 minutes to form a homogeneous mixture, and then grind it through a three-roll machine until it becomes a fine and uniform mixture, then add the particle size range The conductive adhesive can be prepared by mixing 0.5 micron to 100 micron micron flake silver powder at a low speed for 30 minutes at room temperature.

Embodiment 2

[0025] At room temperature, weigh the raw materials according to the weight ratio of each component in Example 2 in Table 1, mix bisphenol F epoxy resin and neopentyl glycol glycidyl ether for 10 minutes until uniform, and then add diamino Diphenylmethane and 3-aminopropyltriethoxysilane were mixed at room temperature for 10 minutes to form a homogeneous mixture, and then ground by a three-roll machine until it became a fine and uniform mixture, and then added micron-sized particles with a particle size range of 0.5 microns to 100 microns The flake silver powder and the nano-scale silver wire with a wire diameter ranging from 50 nanometers to 1 micron and a length ranging from 1 micron to 100 microns can be mixed in a low-speed vacuum at room temperature for 30 minutes to prepare a conductive adhesive.

Embodiment 3

[0027] At room temperature, weigh the raw materials according to the weight ratio of each component in Example 3 in Table 1, mix bisphenol A epoxy resin and polyethylene glycol diglycidyl ether for 10 minutes until uniform, and then add diamino Mix diphenyl ether and 3-aminopropyltrihydroxysilane for 10 minutes at room temperature to form a homogeneous mixture, and then grind it on a three-roll machine until it becomes a fine and uniform mixture, then add micron-sized flakes with a particle size range of 0.5 microns to 100 microns The conductive adhesive can be prepared by mixing silver powder and nano-scale silver wires with wire diameters ranging from 50 nanometers to 1 micron and lengths ranging from 1 micron to 100 microns in a low-speed vacuum at room temperature for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com