Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

948results about "Modified epoxy resin adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

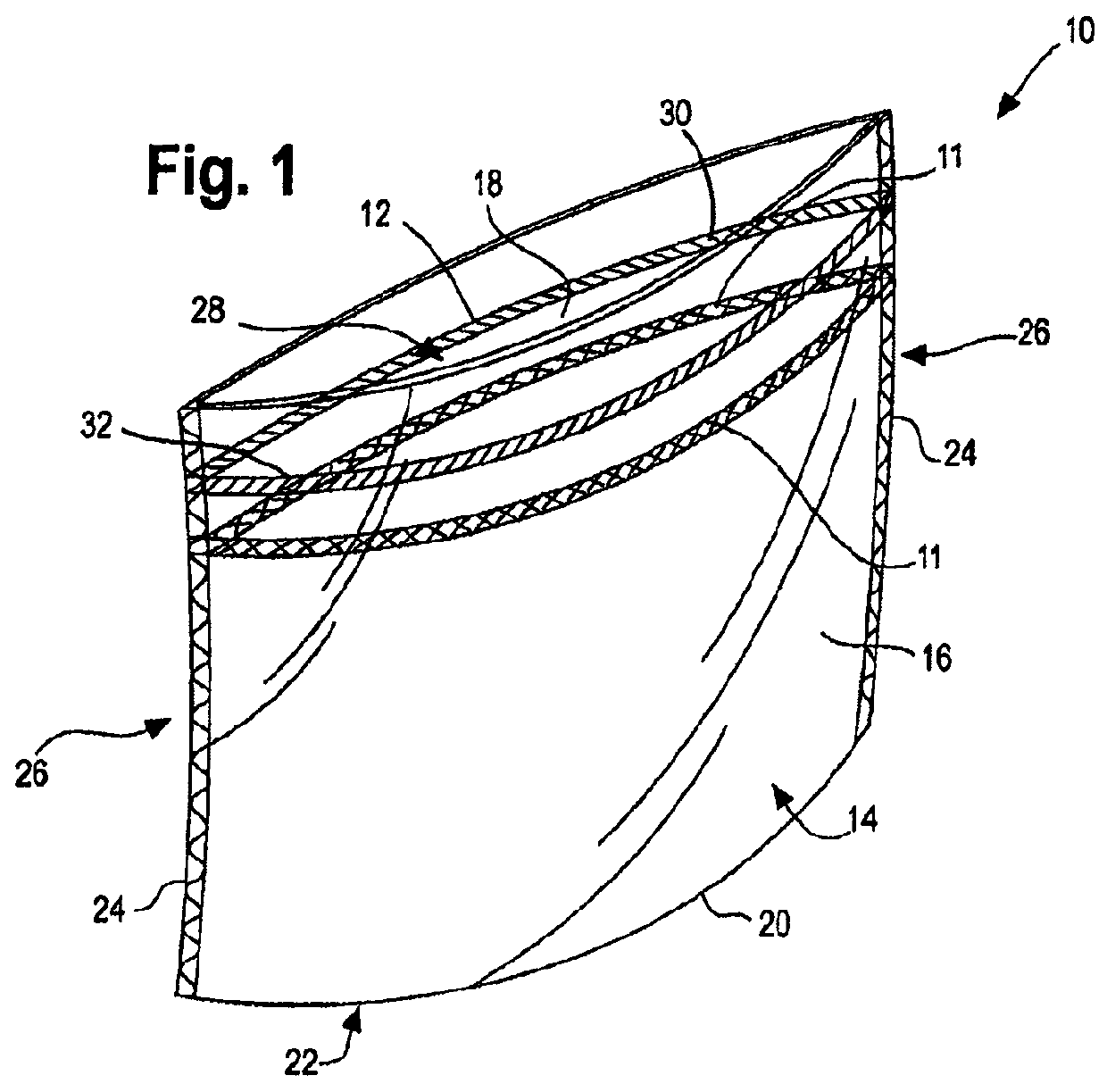

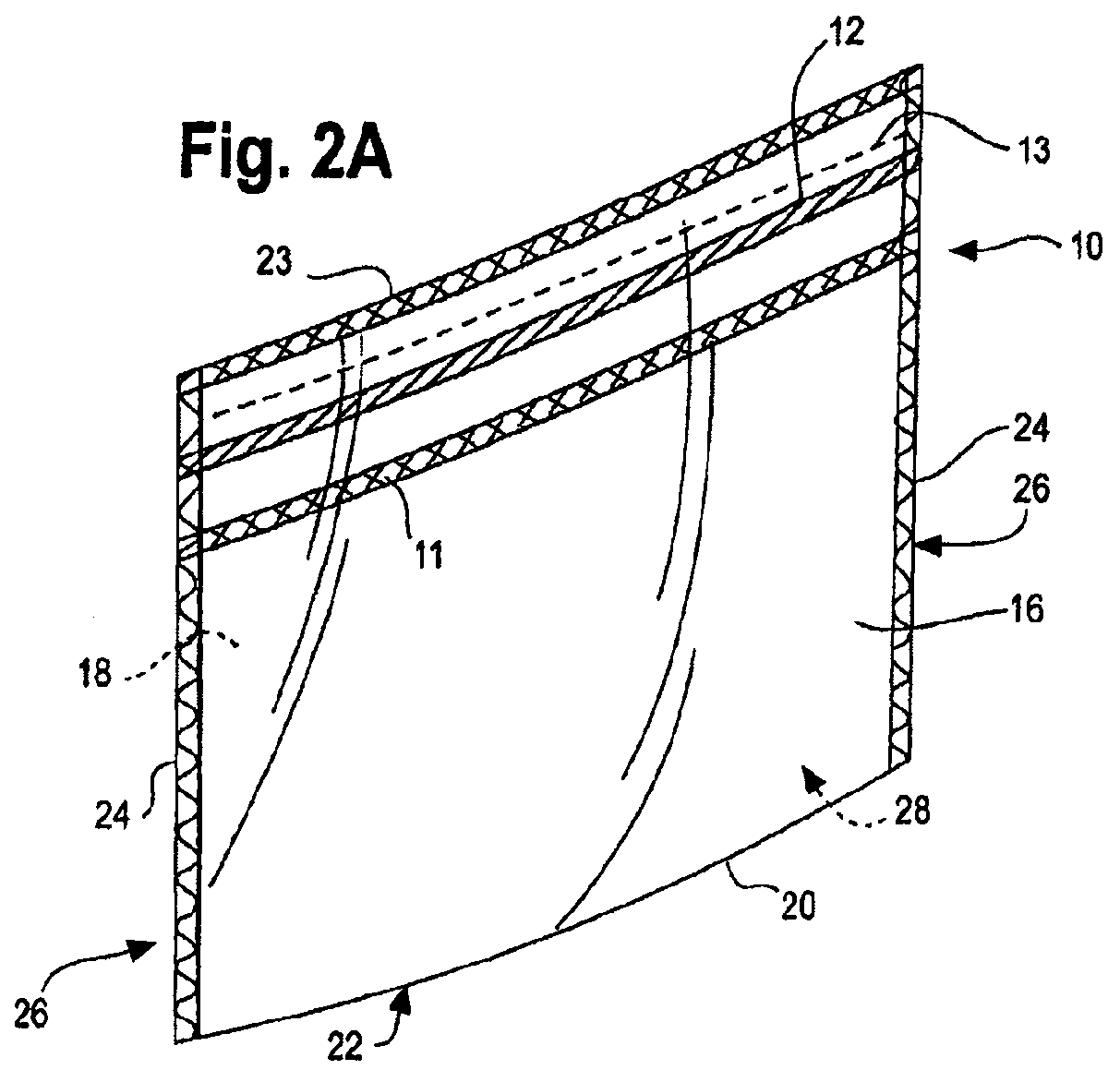

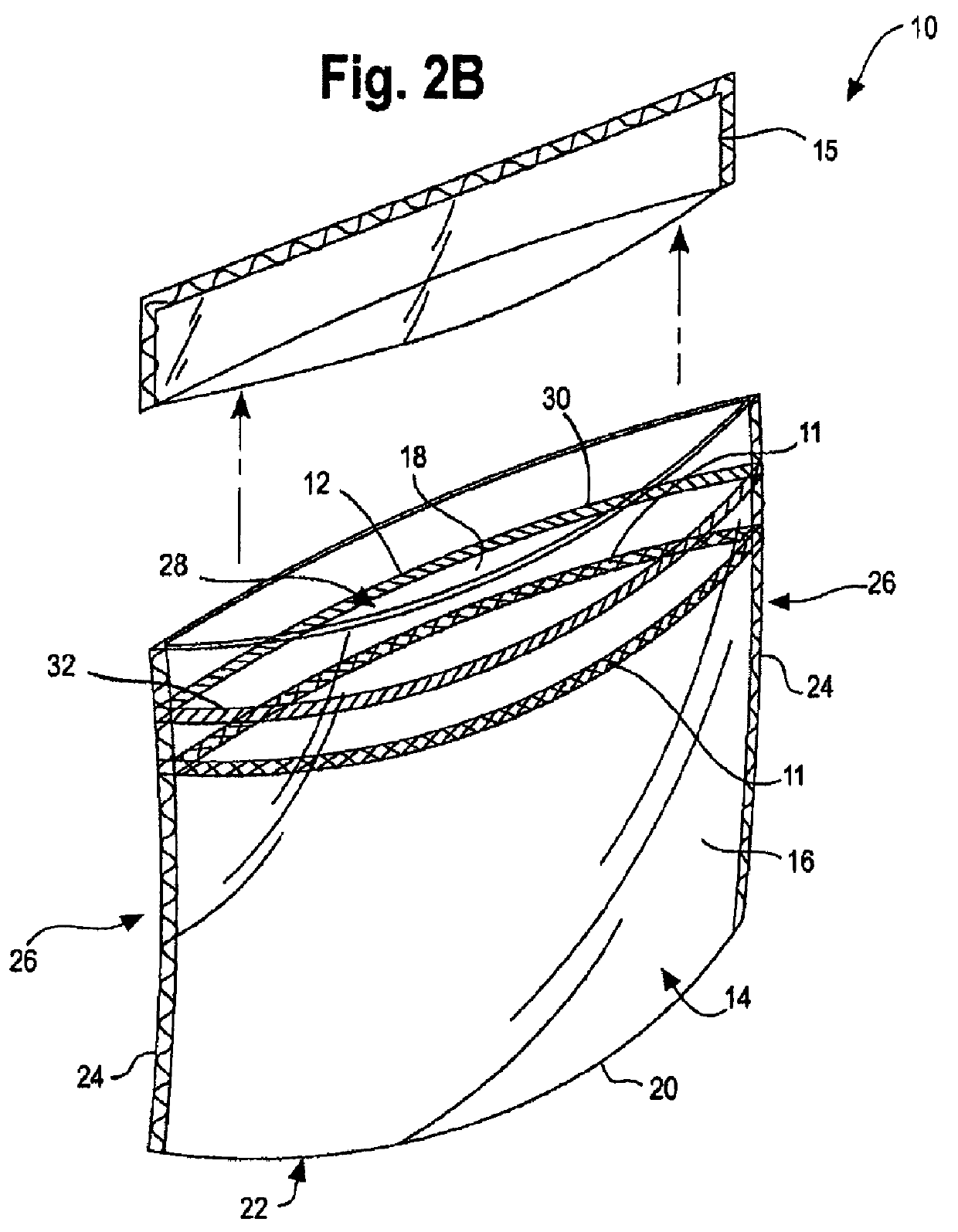

Cationic and hybrid radiation curable pressure sensitive adhesives for bonding of optical discs

InactiveUS6180200B1Improve adhesionImprove adhesion qualityTelevision system detailsNon-macromolecular adhesive additivesAdhesive bondingPressure sensitive

Cationic and hybrid radiation-curable pressure sensitive adhesive compositions for digital versatile discs and other substrates, a method for bonding versatile digital disc layers together with a cationic or hybrid radiation-curable pressure sensitive adhesive, and a digital versatile disc bonded by cationic or hybrid radiation-curable pressure sensitive adhesive.

Owner:DSM IP ASSETS BV

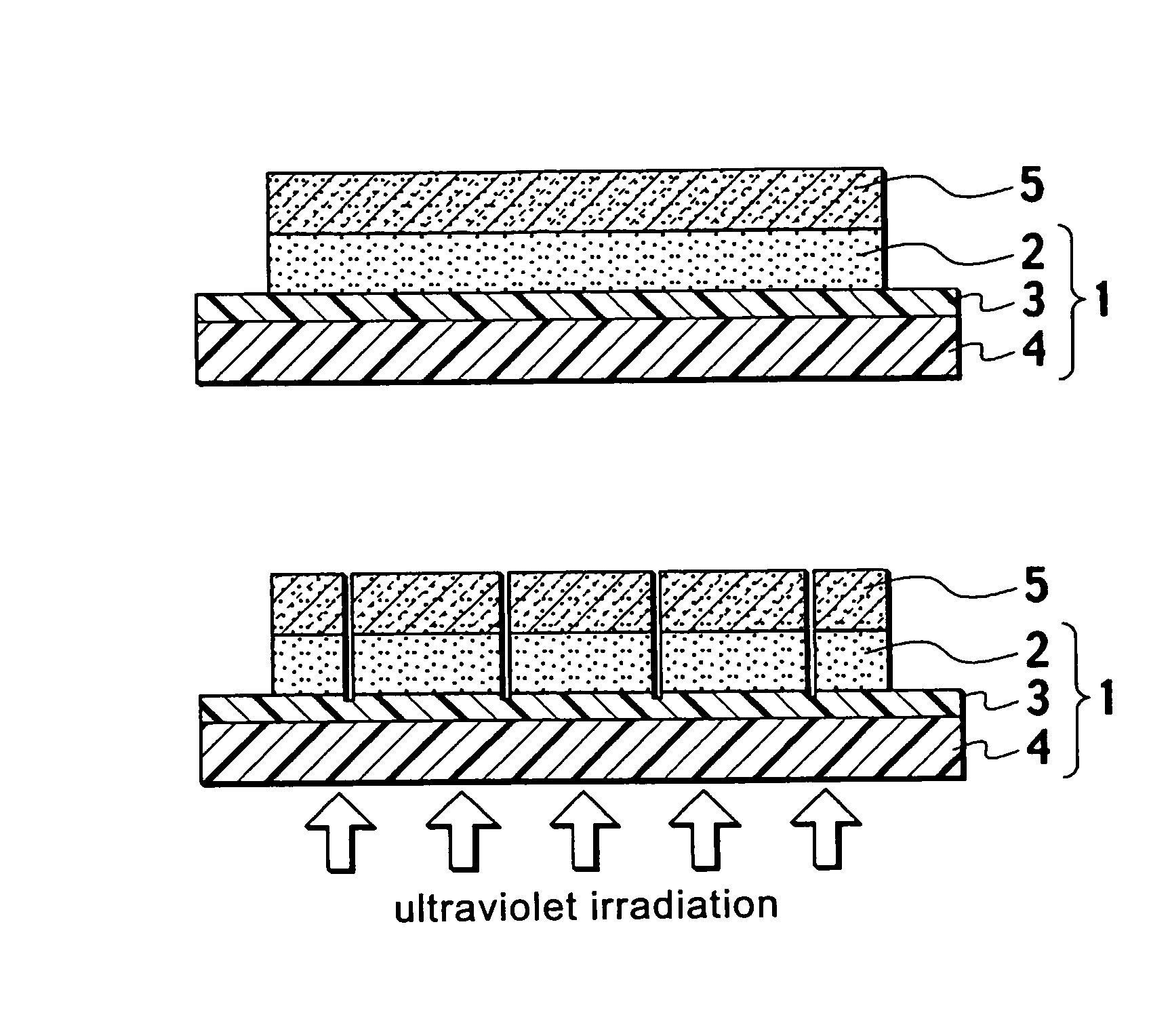

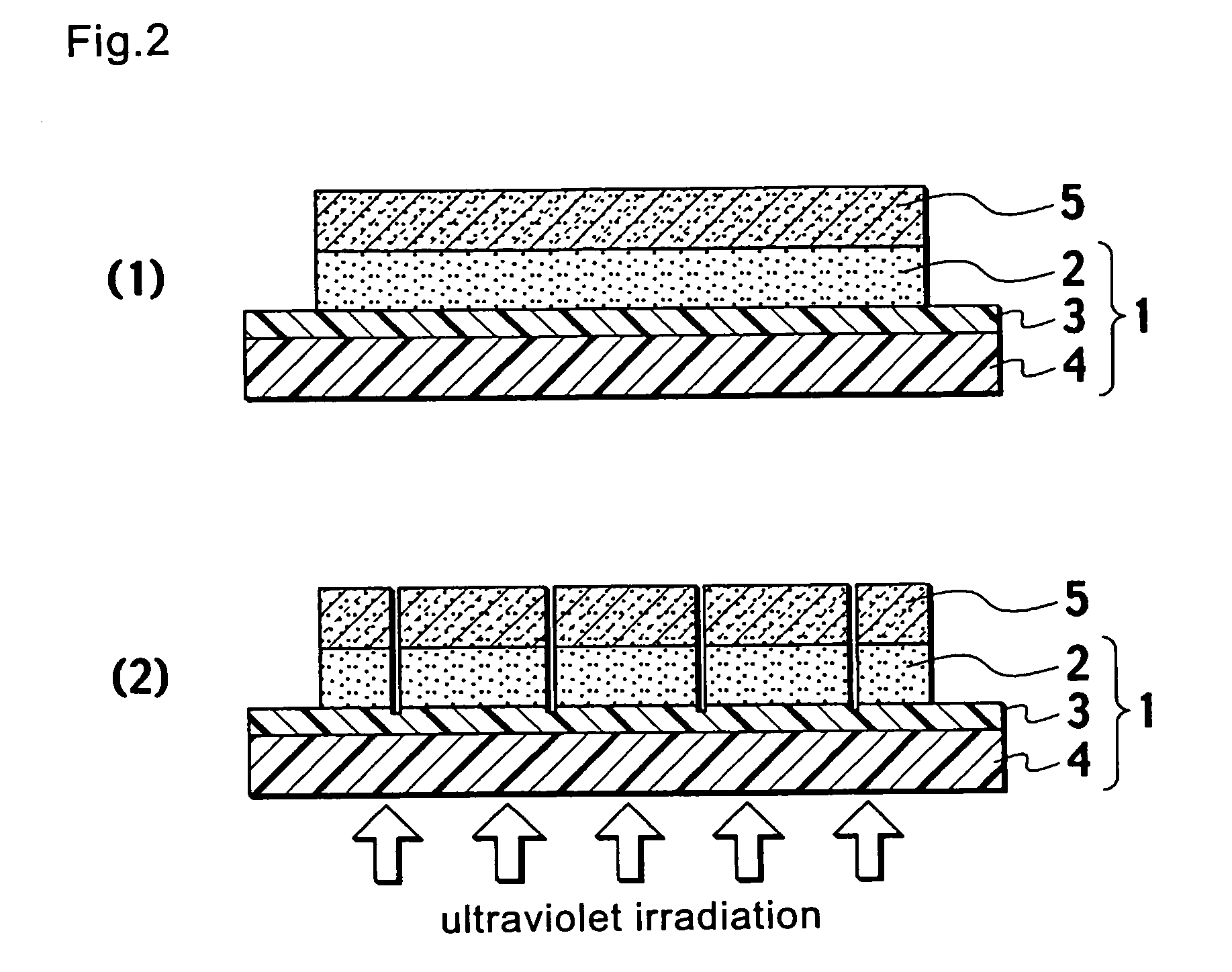

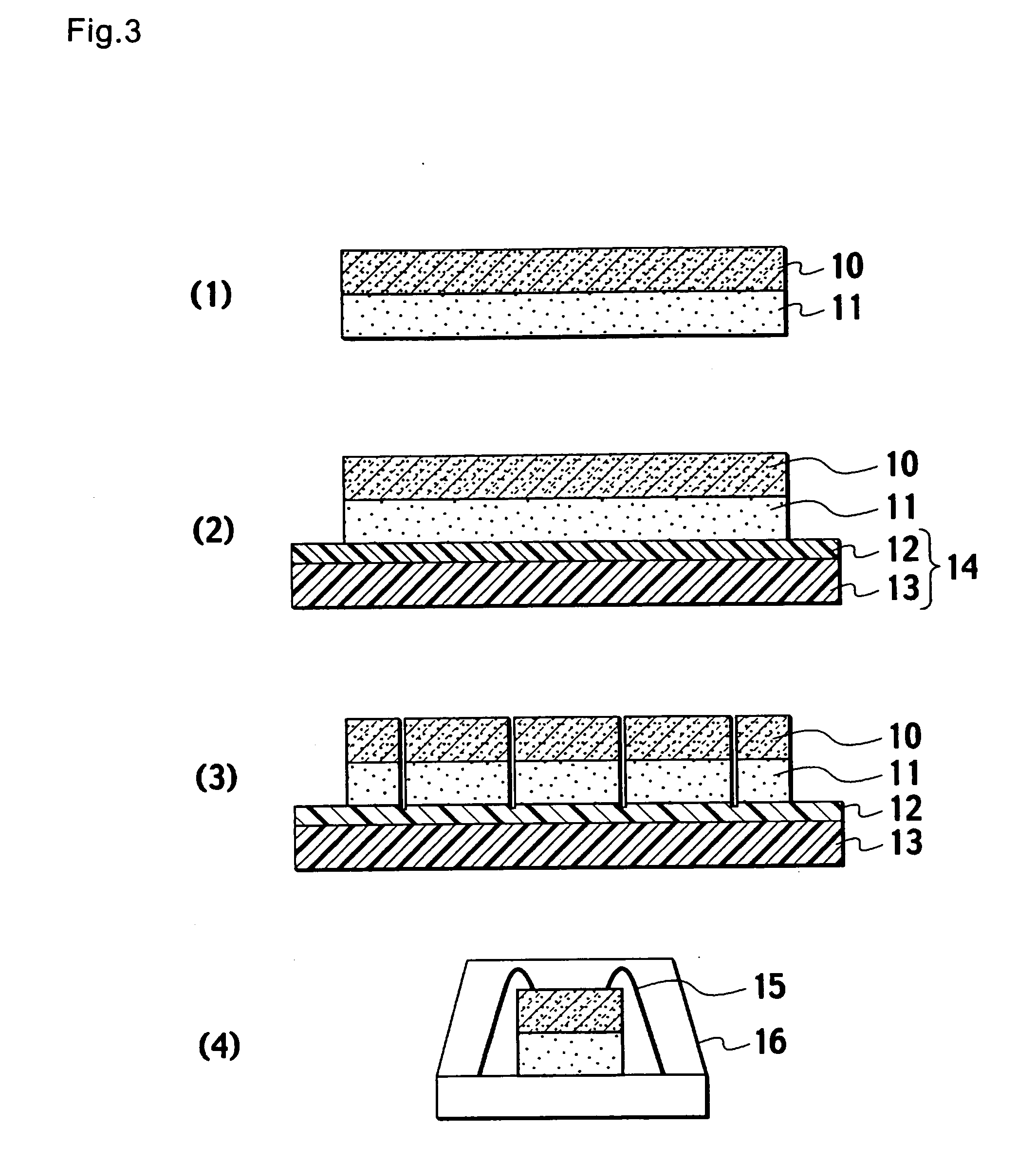

Dicing/die bonding sheet

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

Substrate for flexible organic optoelectronic device and preparation method thereof

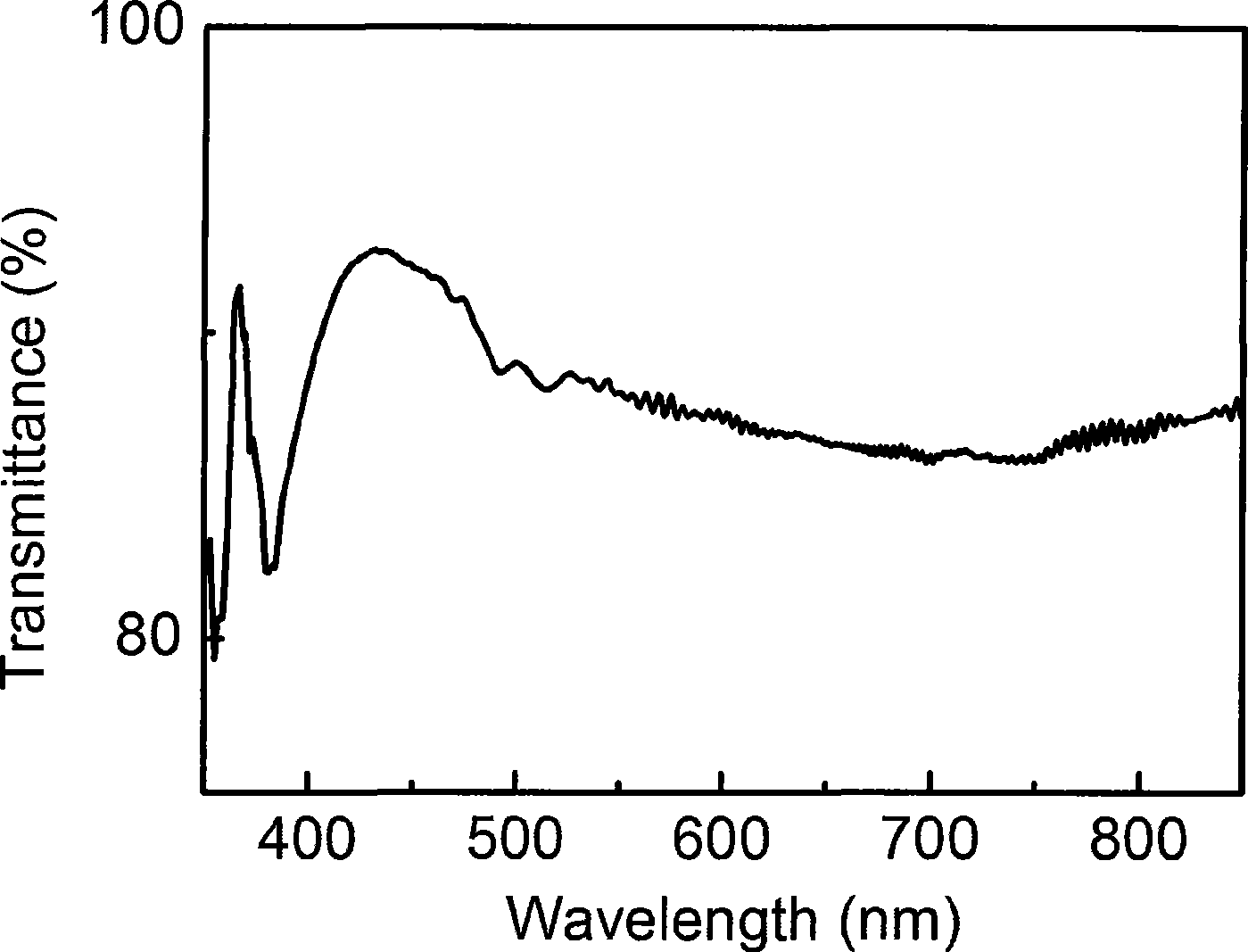

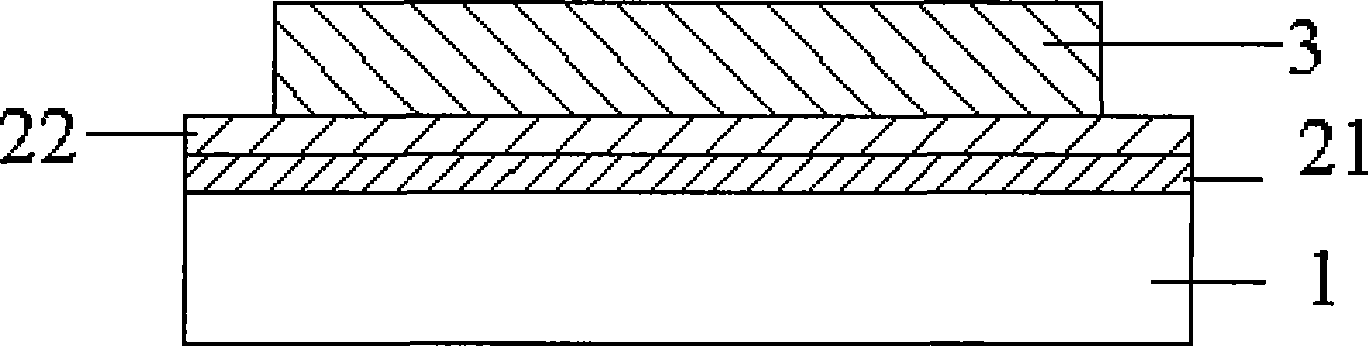

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

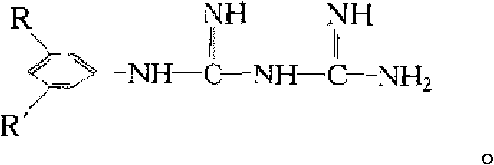

Preparation method for high strength solventless epoxy adhesive

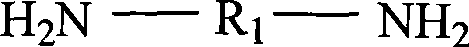

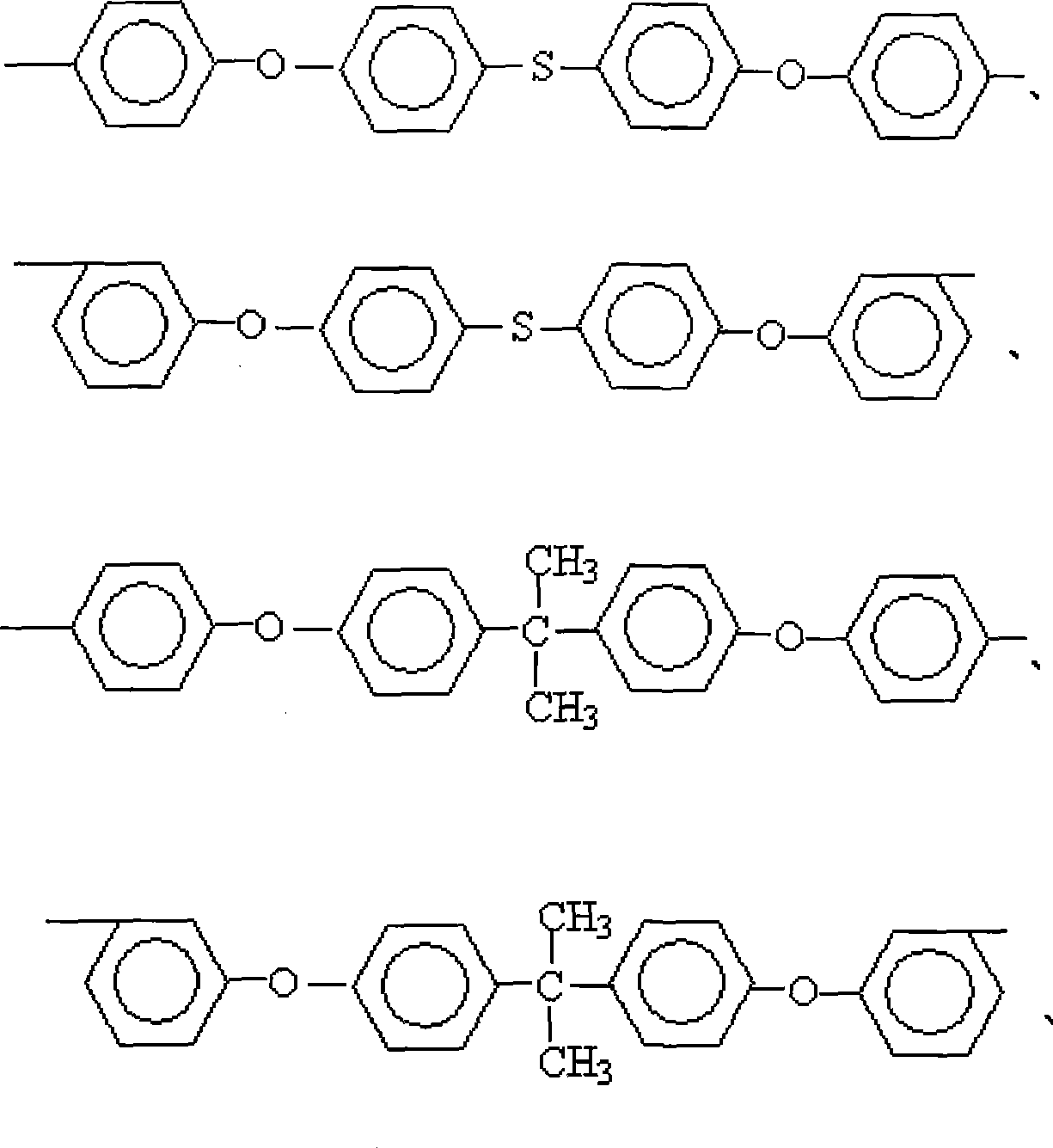

InactiveCN101544879AConvenient sourceSimple preparation processModified epoxy resin adhesivesDiluentHigh intensity

The invention relates to a preparation method for a high strength solventless epoxy adhesive. The preparation method comprises the following steps: carrying out reaction on an aromatic primary diamine and an epoxy resin for 0.5 to 2 hours at 60 to 100 DEG C, adding an active flexibilizer, and carrying out reaction for 1 to 3 hours at 80 to 110 DEG C to obtain a modified sticky epoxy resin system; and adding an active diluent and a curing agent in the modified epoxy resin system, and stirring the mixture evenly to obtain the high strength solventless epoxy adhesive. The preparation method has a simple process, low cost, convenient operation and convenient reaction raw material sources, and is capable of completing the preparation process in a general device and facilitates realization of the industrialized production. In addition, the viscosity of the high strength solventless epoxy adhesive reaches 15 to 1,000 Pa.s at 25 DEG C; the bond strength maximally reaches 35 MPa; and the high strength solventless epoxy adhesive has bright application prospect.

Owner:DONGHUA UNIV

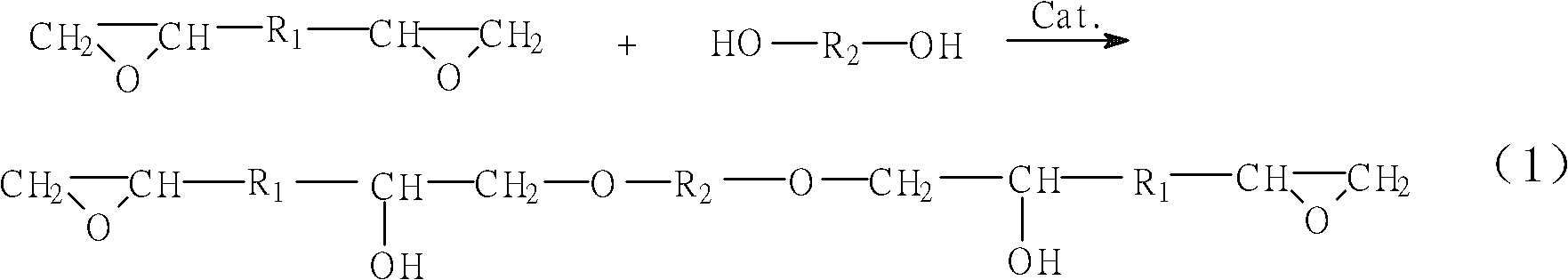

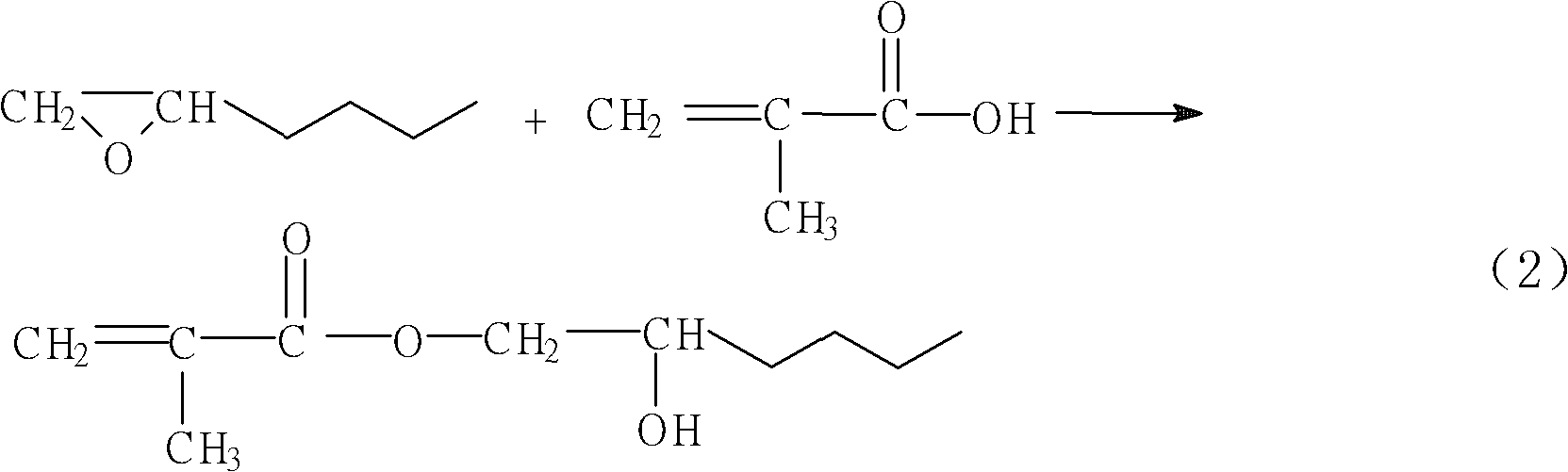

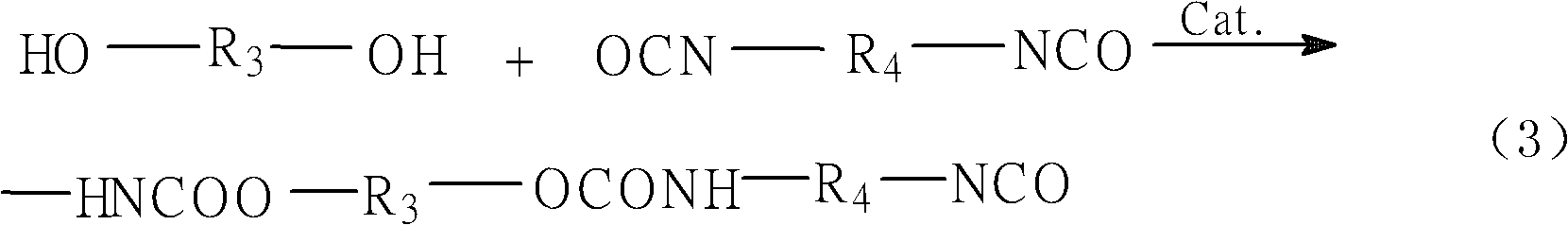

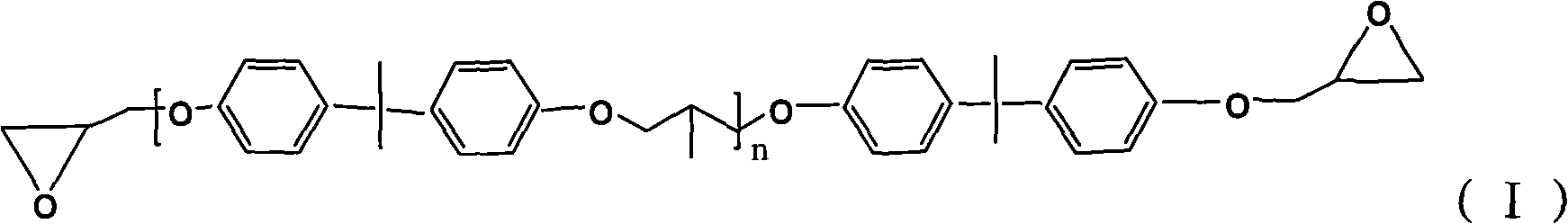

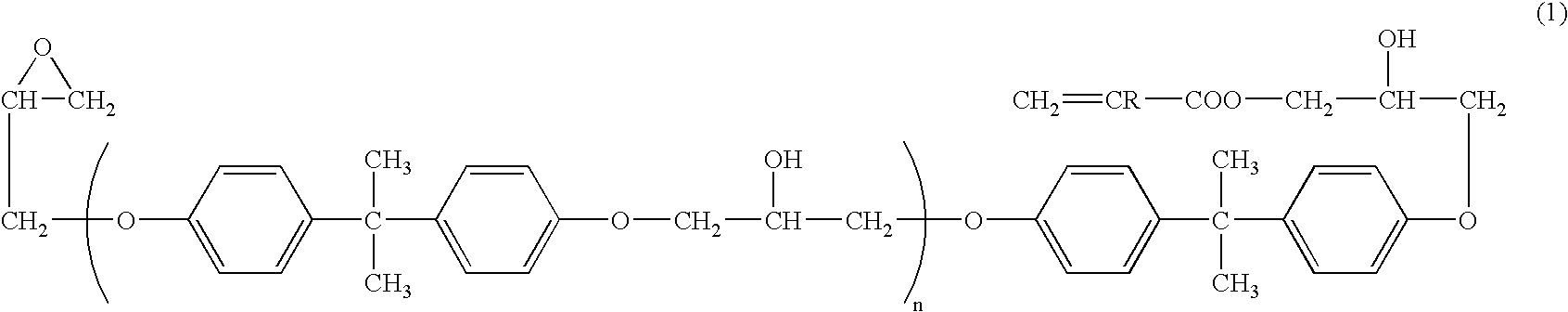

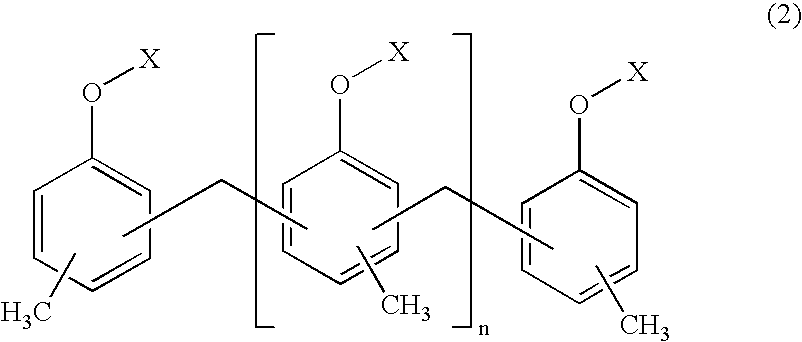

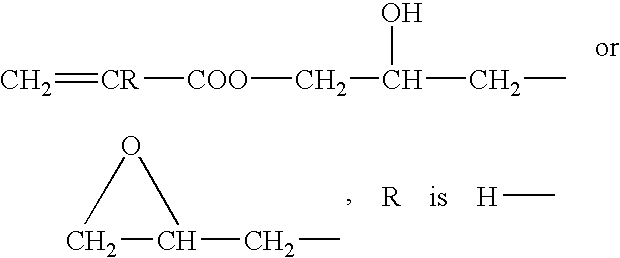

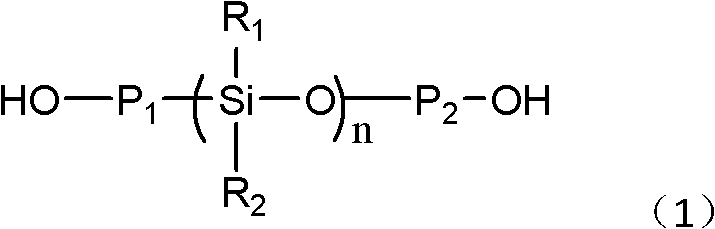

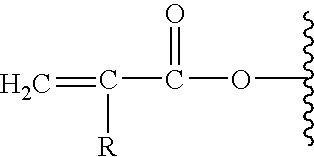

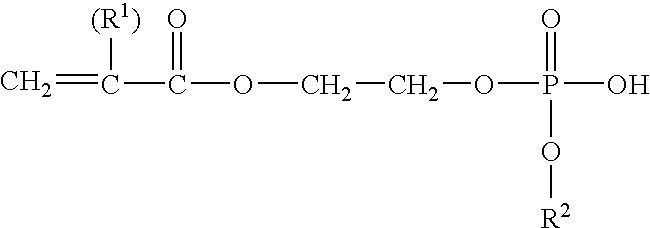

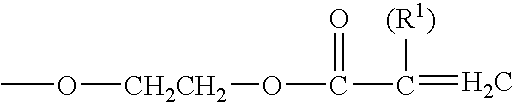

Preparation method and application of resin having double curing groups

InactiveCN101824152AHigh viscosityTo achieve the effect of initial bondingPolyureas/polyurethane adhesivesInksEpoxyUV curing

The invention discloses a preparation method and application of resin having double curing groups. The resin having double curing groups comprises epoxy monoacrylate and polyurethane acrylate chain segments and has the following structure. The molecule of the resin having double curing groups has an acrylate double bond (a curing free radical) and an epoxy group (a curing or thermally curing anion), so the brittleness of a cured film is reduced and the flexibility of the cured film is improved and the resin can be used in ultraviolet curing paint, adhesive and ink. The resin can improve large shrinkage factor of a single acrylate free radical curing system and large brittleness and poor flexibility of the UV curing film and the like and can also solve the problem that a several-resin mixed compounding system has unstable performance, uneven local curing, poor compatibility among resin and the like.

Owner:SHENZHEN POLYTECHNIC

High purity photo-thermal curing adhesive and preparation method thereof

InactiveCN101654607AHigh purityAdequate bond strengthModified epoxy resin adhesivesNon-linear opticsEpoxyAdhesive

Owner:YANTAI DARBOND TECH

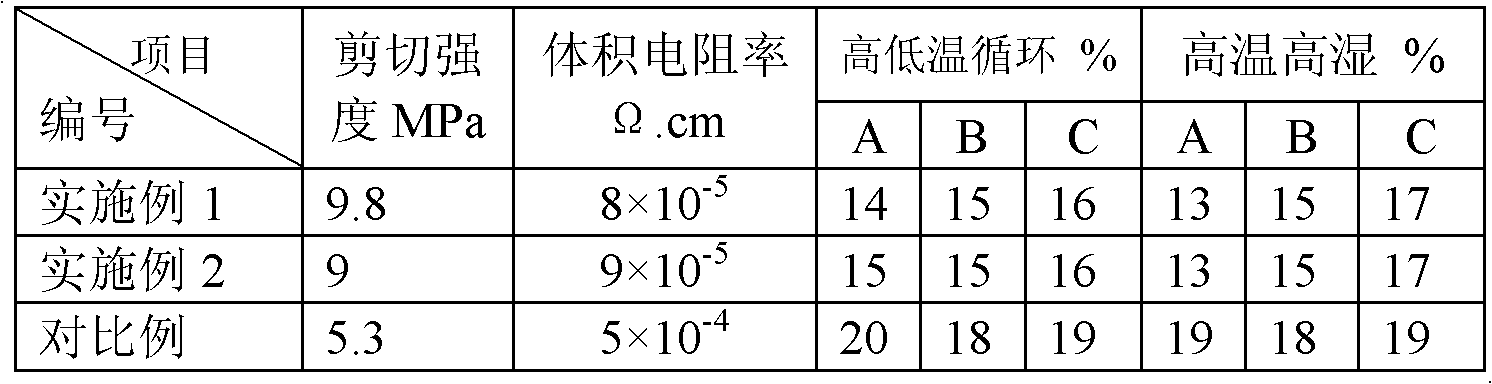

Conductive silver paste for microelectronic packaging and preparation method thereof

InactiveCN102086364AIncrease contactReduce bulk resistivityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxySilver paste

The invention discloses a conductive silver paste for microelectronic packaging, which contains the following components in parts by mass: 10-12 parts of liquid epoxy resins, 9-10 parts of diluents, 10-13 parts of spherical silver powder, 50-57 parts of platy silver powder, 0.5-1.5 parts of latent curing agents, 0.2-0.8 part of curing promoter, 1-2 parts of coupling agents, 0.5-1 part of conductive promoters, 0.5-1 part of aging resister and 1.5-2.3 parts of toughening agents. The body resistivity of the conductive silver paste prepared by the invention reaches 10-5 omega.cm, the shear strength is greater than 9MPa, and the conductive silver paste has stable contact resistance; and after low-temperature circulation, high-temperature humidity aging tests and other aging tests, the shear strength, the impact-resistant toughness and the contact resistance change are all less than 18%. The prepared conductive silver paste is suitable for microelectronic packaging and has the advantages of stable contact resistance and strong impact resistance.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Synthesis and application of light-cured polyurethane-acrylic acid-epoxy resin adhesive

The invention relates to a novel polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer, a synthesis method of the pre-polymer, a high-performance ultraviolet (UV) cured polyurethane modified acrylic acid epoxy resin adhesive prepared from the pre-polymer and application of the UV cured adhesive to bonding of a nylon membrane material and a polyurethane or modified polyurethane elastic body. A method for preparing the photosensitive pre-polymer comprises the following steps of: 1, synthesizing a lower-viscosity epoxy acrylic ester pre-polymer; 2, preparing a pre-polymer of urethane acrylate resin; and 3, mixing or reacting the two pre-polymers in a certain ratio so as to obtain the polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer. A polyurethane-acrylic acid-epoxy resin UV cured adhesive is further prepared by adding a photoinitiator, a photosensitive diluent, a light curing crosslinking agent, other necessary aids and the like.

Owner:BEIHANG UNIV

Photocuring and thermocuring conductive adhesive and preparation method

ActiveCN102127386ALiquidConnectivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention discloses a photocuring and thermocuring conductive adhesive, which is prepared by mixing photosensitive high polymer, diluent monomer, conducting particles, photoinitiator, polymerization inhibitor, epoxy resin, epoxy active diluting agent, latent curing agent and latent promoting agent, grinding the mixture, and stirring and dispersing in a planetary manner. The curing temperature of the product is low, and deep curing can be realized; after being cured, the adhesive has high adhesiveness and high solvent resistance; and the adhering strength is high, the resistivity is low, and the requirements of microelectronic packaging technique for LED chips, liquid crystal materials, glass substrates, thin film circuits, PCB circuit boards and the like can be met.

Owner:东莞市新懿电子材料技术有限公司

Double-solidification system fast-flowing underfill and preparation method thereof

InactiveCN102010686AGuaranteed reliabilityFast flowOther chemical processesEpoxynovolac adhesivesEpoxyPolyol

The invention discloses a double-solidification system fast-flowing underfill and a preparation method thereof. The underfill comprises the following raw materials in parts by weight: 30-80% of epoxy resin, 10-50% of epoxy acrylate, 5-30% of acrylate, 2-20% of polyol, 1-20% of silane coupling agent, 0.3-4% of cationic initiator, 0.1-3% of radical initiator and 0.1-0.5% of carbon black; and the preparation method comprises the following steps of: weighing the epoxy resin and the cationic initiator in the proportion, putting in a reaction kettle and stirring into a uniform solution; weighing the epoxy acrylate, the acrylate, the polyol, the silane coupling agent, the radical initiator and the carbon black in the proportion, putting in the reaction kettle in sequence, mixing and stirring to obtain the finished product of the double-solidification system fast-flowing underfill.

Owner:YANTAI DARBOND TECH

Adhesive Composition, Adhesive Sheet and Production Process for Semiconductor Device

ActiveUS20080124839A1High package reliabilityImprove reliabilityLayered productsSemiconductor/solid-state device detailsUnsaturated hydrocarbonSemiconductor chip

An adhesive composition is characterized by including an acrylic polymer, an epoxy thermosetting resin having an unsaturated hydrocarbon group and a thermosetting agent. The adhesive composition achieves high reliability in a package in which a semiconductor chip of reduced thickness is mounted even when exposed to severe reflow conditions. An adhesive sheet having an adhesive layer comprising the above adhesive composition and a production process for a semiconductor device using the above adhesive sheet are also provided.

Owner:LINTEC CORP

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

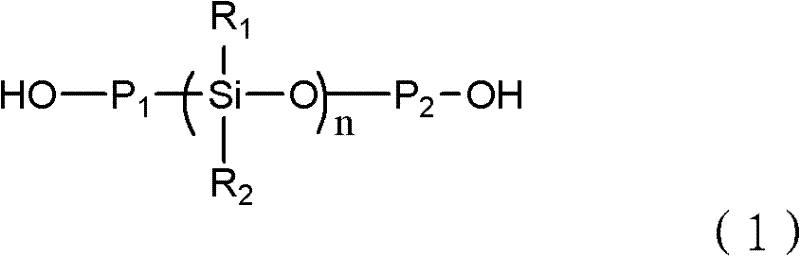

Liquid crystal sealant composition

ActiveCN102516916AHigh reactivityFast curingModified epoxy resin adhesivesNon-linear opticsEpoxyOperability

The invention provides a liquid crystal sealant composition, which is an ultraviolet / thermal dual curable resin composition for sealing liquid crystal by a one drop fill (ODF) process, and comprises the following components in parts by weight: 40-80 parts of acrylic acid modified hyperbranched organosilicon epoxy resin, 2-15 parts of grafted hyperbranched epoxy resin coupling agent, 0.5-8 parts of photoinitiator, 5-25 parts of latent epoxy resin curing agent, and 5-40 parts of filler. The inventive composition has good coating operability and high bonding strength, solves the problem of contamination to liquid crystal existing in the conventional sealing material, and increases the bonding strength between a substrate and cured liquid crystal sealant, thus a liquid crystal display panel with high display performance and excellent quality can be manufactured, and the production efficiency is greatly improved.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Low-tack, UV-cured pressure sensitive adhesive suitable for reclosable packages

UV-cured pressure sensitive adhesive including one or more UV-curable acrylic oligomers, one or more tack control components, and, optionally, an elastomeric material is described herein. The adhesive includes an adhesive component ratio of the various adhesive components effective to provide desired first peel adhesions and subsequent peel adhesions.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Ultraviolet light curing material

InactiveCN102516866AIncrease profitPromote cross-linking and curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiluentUltraviolet lights

The present invention relates to an ultraviolet light curing material, which comprising the following components by weight percentage: 40-60%of light cured resin; 25-45% of light curing diluent; 2-10% of photoinitiator; 0-0.8% of ultraviolet storage stabilizer; 0.5-30%of nano filler; 0.2-1% of leveling agent. On the basis of addition of light cured resin, the light curing diluent and the photoinitiator in the ultraviolet light curing material, the nano filler is added, the ultraviolet light respectively reflects to all directions through small particles, so that the light is scattered, the utilization rate of the ultraviolet light can be increased, the crosslinking and curing speed can be accelerated, and the curing energy can be reduced.

Owner:YANTAI DARBOND TECH

Preparation method of novel dual-cured UV curing binder

InactiveCN104449542AAdhesive processesNon-macromolecular adhesive additivesMetallic materialsDouble bond

The invention relates to a preparation method of a novel dual-cured UV curing binder, and belongs to the technical field of binder industry. The novel dual-cured UV curable binder is prepared by using radical polymerizable resins such as common urethane acrylate, epoxy acrylate and unsaturated polyester as main binding materials, using a double bond-containing reactive diluent as a solvent, and using a UV initiator and a thermal initiator as a compound initiator, supplemented by other binding agents. During curing, a certain initial binding power is firstly obtained by UV curing, and higher binding power is obtained by secondary curing through heating or oxygen isolation. The preparation method provided by the invention not only has the advantages of high curing speed of the traditional light curing binders, but also has the advantages of effectively avoiding the generation of internal stress in the curing process of the traditional light curing binder, and improving the binding strength of the binder; the binder has excellent solvent resistance, high binding strength, and low cost. The binder is widely used for binding glass and glass, glass and metal materials and other transparent materials.

Owner:JIANGNAN UNIV

Light-curing edge sealing adhesive

ActiveCN103865470ASuitable for adhesionSuitable stabilityPolyureas/polyurethane adhesivesModified epoxy resin adhesivesAdhesive cementHydrofluoric acid

The invention discloses a light-curing adhesive and in particular relates to an ultraviolet-curing adhesive. The light-curing adhesive comprises the following components in percentage by mass: 10%-75% of matrix resin, 5%-50% of auxiliary resin, 10%-70% of activated monomer of acrylate, allyl compound or vinyl compound, 5%-15% of adhesion accelerator, 1%-10% of photoinitiator and 0.5-10% of auxiliary agent. The light-curing adhesive provided by the invention has fast curing capability, high bonding strength and low internal stress; an obtained cured layer is soft and has excellent hydrofluoric acid resistance.

Owner:惠晶显示科技(苏州)有限公司

UV-cured adhesive for plastic and preparation method thereof

InactiveCN101906284AImprove flexibilityImprove curing speedPolyureas/polyurethane adhesivesModified epoxy resin adhesivesAdhesiveDiluent

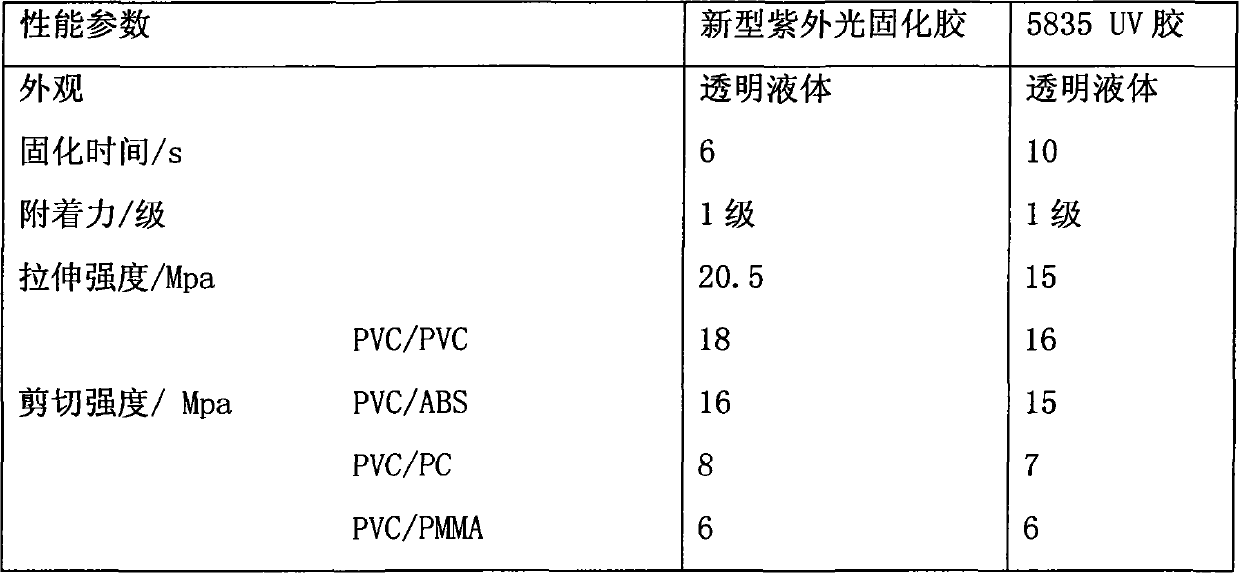

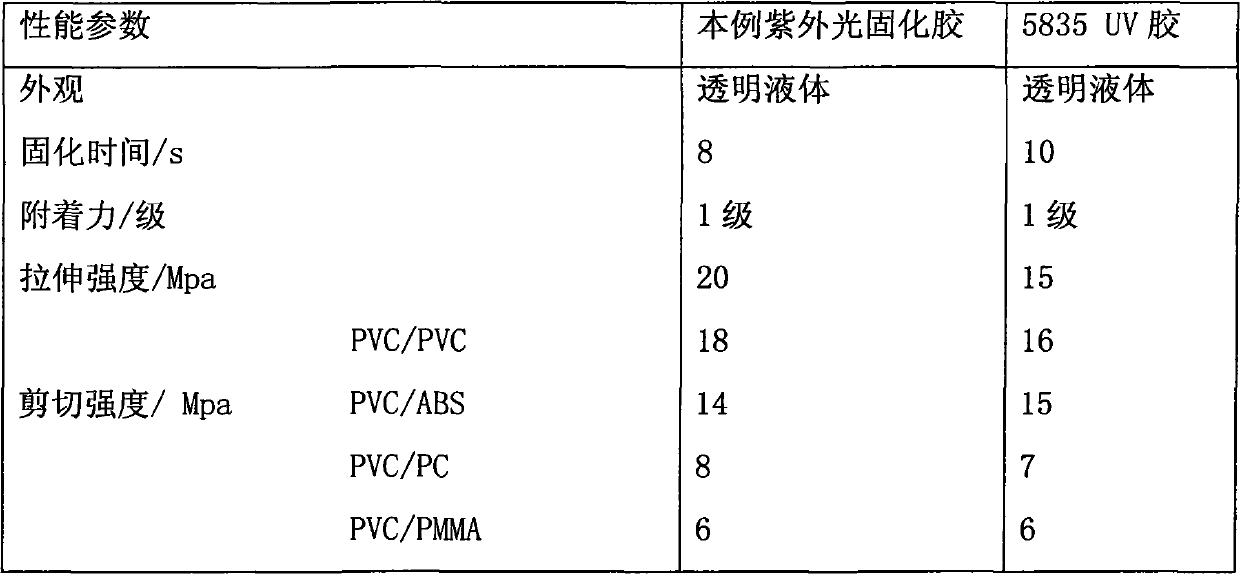

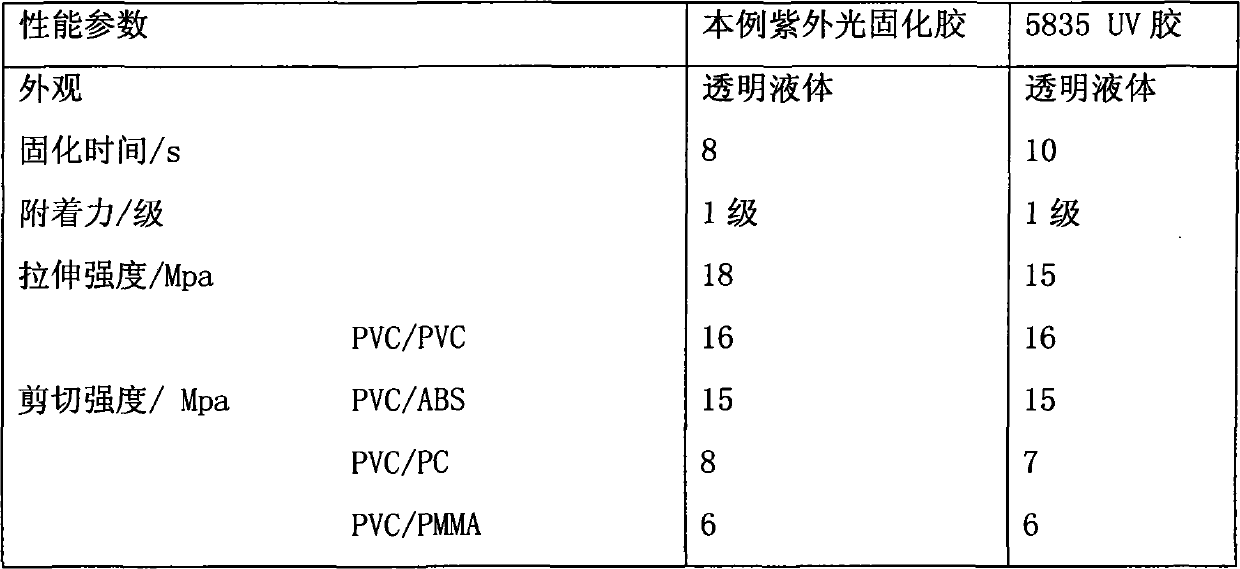

The invention discloses a novel UV-cured adhesive for plastic and a preparation method thereof. The UV-cured adhesive is prepared by the following steps of: adding polyurethane acrylate and a monomer diluent into an epoxy acrylate resin, stirring at the constant temperature of between 50 and 55 DEG C for 3 to 4 hours, and adding a photoinitiator, an accelerating agent and a polymerization inhibitor; and regulating the temperature to between 60 and 70 DEG C, stirring at the constant temperature for 1 to 2 hours and discharging to prepare the novel UV-cured adhesive. The UV-cured adhesive comprises the following components in percentage by weight: 30 to 60 percent of polyurethane acrylate, 10 to 30 percent of epoxy acrylate resin, 4 to 5 percent of photoinitiator, 25 to 65 percent of monomer diluent, 0.1 to 0.9 percent of accelerating agent and 0 to 0.2 percent of polymerization inhibitor. The product is mainly applied to adhesion of PVC, ABS, PC, PMMA and other plastics, and has the advantages of no solvent, simple and easy operation and suitability for mass production.

Owner:SOUTH CHINA UNIV OF TECH

Wind-power class bi-component epoxy adhesive and preparation method thereof

InactiveCN101550325AQuick releaseAvoid high temperature damageModified epoxy resin adhesivesAliphatic amineResin adhesive

The invention discloses a wind-power class bi-component epoxy adhesive and a preparation method thereof. The epoxy adhesive is made from a main component A mainly consisting of epoxide resin and a filler and a curing agent component B and characterized in that the component A, according to percentage by weight, contains 50 percent to 68 percent of acrylic acid modified epoxide resin, 1 percent to 10 percent of high-property heat filler, 2 percent to 10 percent of epoxide diluter, 10 percent to 25 percent of thixotropic agent and 0.5 percent to 12.5 percent of additive, and the component B is divided into aliphatic amine, polyetheramine, alicyclic amine mixed-type general curing agent; and the mixing proportion of the component A and the component B is 100:30-100:50 according to portions by weight. The invention can improve exothermic peak temperature property during the curing reaction of epoxide resin adhesive and the toughness of the epoxy adhesive, thus being applicable to the cementation of large-scale composite material structural pieces, particularly meeting the requirements for low exothermic peak temperature in wind-power leaf pectization technology.

Owner:YANTAI DARBOND TECH

Photocurable adhesive composition

Owner:ETERNAL MATERIALS CO LTD

Temperature-resistant, corrosion-resistant and high-adhesion adhesive and preparation method thereof

ActiveCN102559120AImprove impact resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseThermoplastic

The invention discloses a temperature-resistant, corrosion-resistant and high-adhesion adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The temperature-resistant, corrosion-resistant and high-adhesion adhesive consists of two components, i. e., an adhesive A and an adhesive B, in the weight ratio of 100:1-10, wherein the adhesive A consists of chemical plasticizing vinyl ester resin, a polymerization inhibitor, a low shrinkage agent, a free radical curing solvent, gas-phase silicon dioxide, inorganic filler, a coupling agent, a defoaming agent, color paste or paint, a promoter and a promotion additive; and the adhesive B consists of phthalic ester, peroxide and inertial powder filler. The adhesive provided by the invention has the performance of heat resistance, corrosion resistance, penetration resistance, adhesion, positioning, impact resistance and the like, can be formed into different types at normal temperature, and medium and high temperature, is easy and convenient to operate, can bring the unique advantage of the adhesive into full play on some occasions requiring to paying attention to corrosion resistance, adhesion, heat resistance and the like, and is suitable for mutual adhesion among a continuous cellulose material, a concrete material, a metal material, stone, FRP (Fiber Reinforce Plastic), thermoplastic plastic and the like.

Owner:浙江天和树脂有限公司 +1

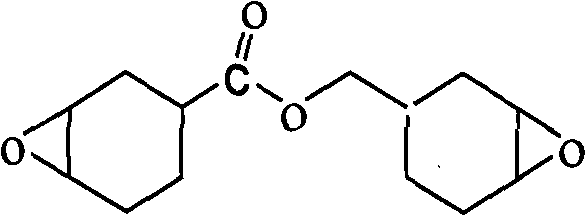

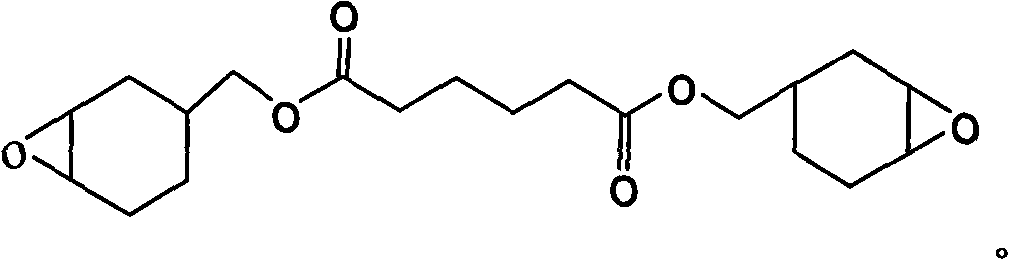

Photocuring adhesive used for adhering optic glass lenses and preparation method thereof

ActiveCN102167962AHigh refractive indexCuring shrinkage is smallModified epoxy resin adhesivesVinyl etherAdhesive

The invention discloses a photocuring adhesive used for adhering optic glass lenses, which consists of the following components in percentages by weight: 50-80% of main resin, 10-40% of auxiliary resin, 5-20% of active monomer, 4-4.5% of photo initiator and 0.5-1% of auxiliary. The main resin is alicyclic epoxy resin. The auxiliary resin is modified epoxy acrylate resin. The active monomer is oneor a mixture of vinyl ether monomers and acrylate monomers. The photo initiator is a radical photo initiator and a cation photo initiator. The auxiliary is a coupling agent. The photocuring optic adhesive has the characteristics of high curing speed, high refraction rate, high light transmittance, low curing shrinkage rate, small thermal deformation, strong adhesion force, small smell, yellowing resistance and the like.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

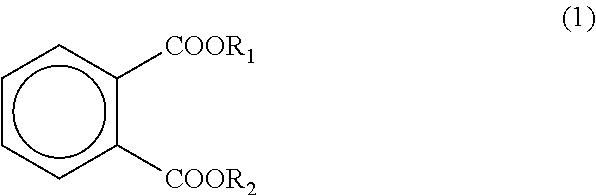

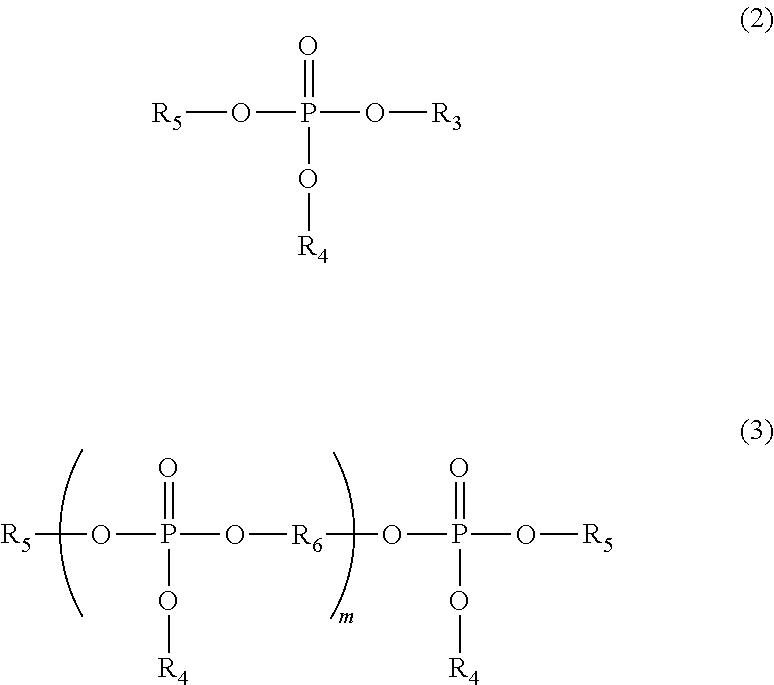

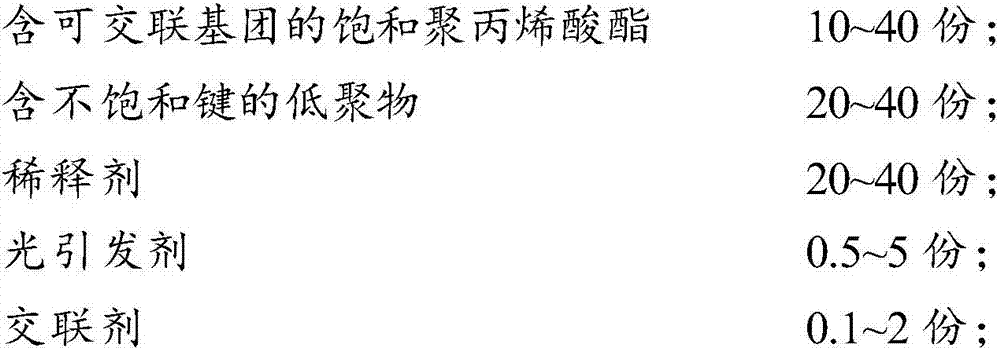

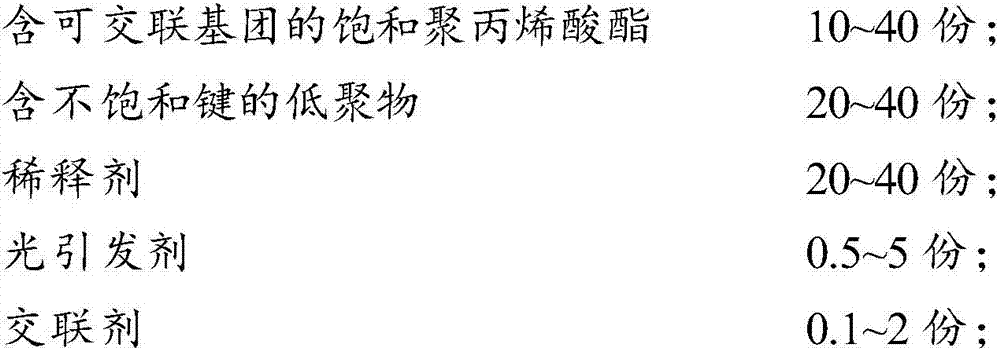

OCA optical cement and OCA optical cement film

ActiveCN107353854AImprove performanceImprove wettabilityNon-macromolecular adhesive additivesFilm/foil adhesivesOligomerDiluent

The invention belongs to the field of optical cement, in particular to OCA optical cement and an OCA optical cement film. The OCA optical cement comprises, by weight, 10-40 parts of saturated polyacrylate with cross-linkable groups, 20-40 parts of oligomers with unsaturated bonds, 20-40 parts of diluent, 0.5-5 parts of photoinitiator and 0.1-2 parts of cross-linking agent. According to the OCA optical cement and the OCA optical cement film, components of the optical cement is subjected to optimization selection, and the OCA optical cement with excellent performance is obtained; the OCA optical cement is excellent in coating wettability, and shrinkage holes cannot exist on a base material in coating; the OCA optical cement film prepared from the optical cement has higher viscidity, residual gum does not easily exist when the optical cement film is attached to a display material, and the cement film has better stripping performance. The invention further provides the OCA optical cement film, the OCA optical cement film is formed after coating and solidifying of the OCA optical cement and has higher viscidity and better stripping performance.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Adhesive composition, coating composition, primer using same, inkjet ink, adhesive method, and laminate

InactiveCN103025839AHigh transparencyImprove surface smoothnessDuplicating/marking methodsSynthetic resin layered productsEpoxyVinyl ether

This adhesive composition and coating composition contains 10 to 30 mass % of an epoxy resin (a), 25 to 55 mass % of an oxetane compound (b), 25 to 55 mass % of a vinyl ether compound (c), 1 to 15 mass % of a denaturant (d) (wherein the sum of the aforementioned components (a) to (d) is 100 mass %), and 3 to 15 parts by mass of a photopolymerization initiator (e) in relation to 100 parts by mass of the sum of the aforementioned components (a) to (d).

Owner:RIKEN TECHNOS CORP +1

Glass reinforced UV adhesive and preparation method thereof

ActiveCN104745140AMeet the needs of mass productionGood adhesionPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveAntioxidantAcrylic resin

The invention discloses a glass reinforced UV adhesive and a preparation method thereof. The glass reinforced UV adhesive is prepared from the following raw materials in percentage by weight: 30-50% of an oligomer, 40-60% of an active monomer, 3-10% of a photoinitiator and 1-10% of an auxiliary, wherein the oligomer is one or more of polyurethane acrylate, polybutadiene acrylate, epoxy acrylate, pure acrylic resin and polyesteracrylate; the active monomer is one or more of monofunctional, bifunctional and multifunctional acrylates; the photoinitiator is one or more of free radical photoinitiators; the auxiliary is one or more of an adhesion promoter, a defoamer, a flatting agent, a wetting agent and an antioxidant. According to the glass reinforced UV adhesive disclosed by the invention, the strength of the glass is enhanced, and the glass can undergo severe process conditions in the preparation process, can be blended into different colors and is stable in performance.

Owner:广州惠利电子材料有限公司

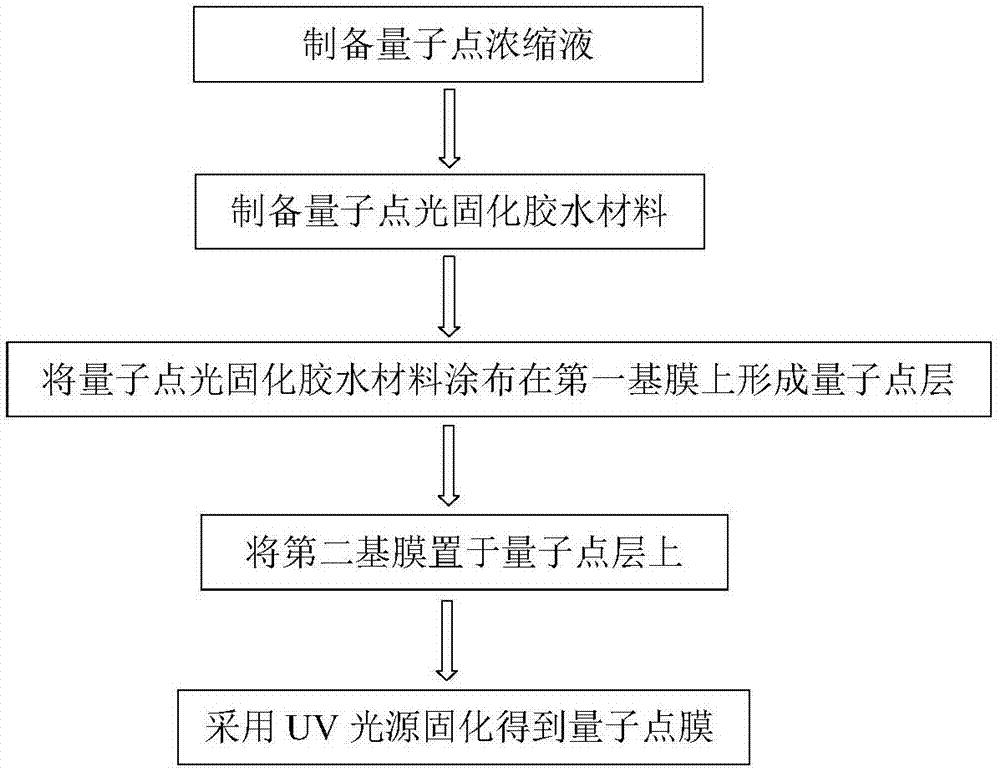

Quantum dot film and preparation method thereof

InactiveCN106863935AUniform and stable dispersionAvoid direct contactLamination ancillary operationsNon-macromolecular adhesive additivesQuantum dotSolid content

The invention relates to a quantum dot film and a preparation method thereof applied to the field of optical display. The quantum dot film comprises a first base film, a quantum dot layer and a second base film, wherein the quantum dot layer is positioned between the first base film and the second base film, and the quantum dot layer comprises photo-curing glue, a quantum dot nano-material dispersed in the photo-curing glue, and a light diffusing agent. The preparation method comprises the following steps: preparing a quantum dot concentrated liquid, preparing a photo-curing glue material, forming the quantum dot layer on the first base film, placing the second base film on the quantum dot layer and forming a film by photo-curing. The quantum dot film and the preparation method thereof provided by the invention have the beneficial effects that the quantum dot nano-material is uniformly and stably dispersed in a photo-curing glue system with 100% solid content, so that the obtained quantum dot film has high quantum luminescence efficiency; the film is formed by photo-curing without heat curing, quantum dots cannot be damaged due to high temperature; on the one hand, the working procedures are reduced, and the production efficiency is improved; on the other hand, the equipment investment and energy consumption are reduced, and the production cost is reduced.

Owner:WUHAN BAOLI LIANGCAI TECH CO LTD

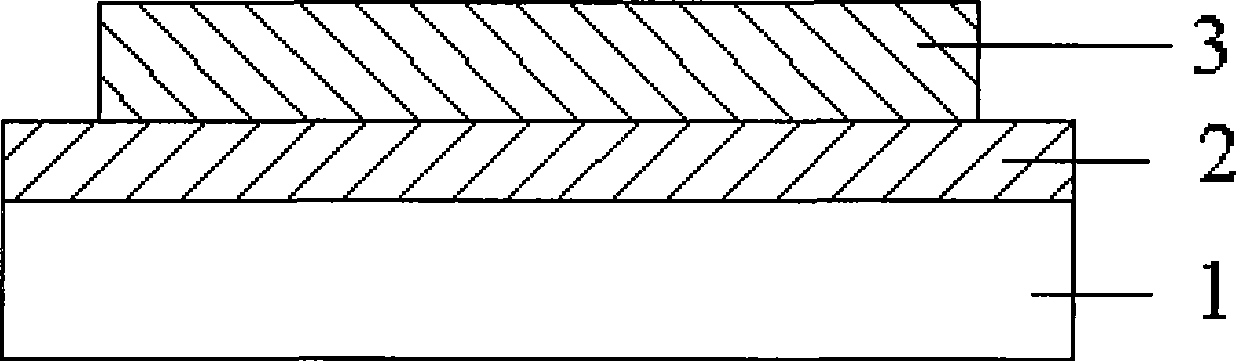

Cationic and hybrid radiation-curable adhesives for bonding of optical discs

InactiveUS6455121B1Improve bindingImprove impact resistanceTelevision system detailsNon-macromolecular adhesive additivesAdhesive bondingPressure sensitive

Owner:DSM IP ASSETS BV

Flowable non-sagging adhesive compositions

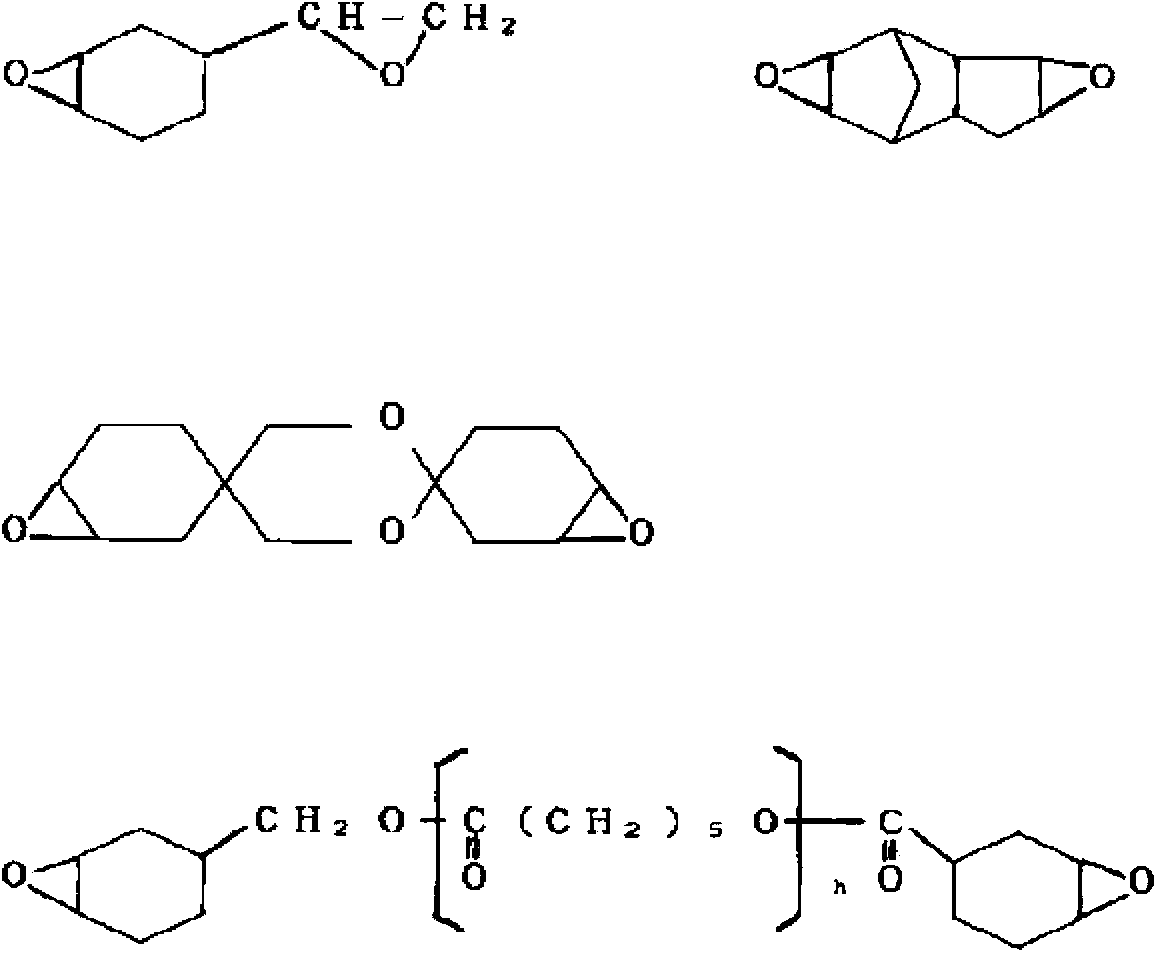

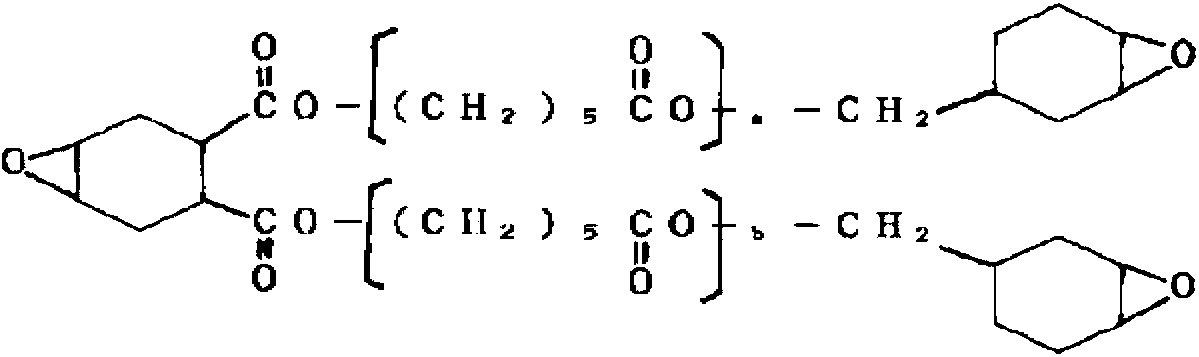

InactiveUS20100065210A1Low viscosityHigh viscosityEster polymer adhesivesModified epoxy resin adhesivesPolymer scienceBis epoxide

This invention provides an acrylic epoxy adhesive as a two part composition, wherein each part is of suitable viscosity for use in pumping apparatus, but after mixing, the composition increases in viscosity, so that it will not sag, drip, or migrate after application to a surface during the open time. This effect is achieved with a reactive acid component that gels on mixing with the epoxy portion of the composition. Also provided is a method of preparing the adhesive composition, and method of using the composition to form laminated materials.

Owner:HENKEL CORP

Adhesive for polarizing plate and polarizing plate including the same

ActiveUS20140072731A1Improve adhesionLow viscosityLiquid crystal compositionsOrganic chemistryEthylene HomopolymersGlass transition

The present invention relates to an adhesive composition including 100 parts by weight of a first epoxy compound having a glass transition temperature of a homopolymer of not less than 120° C., 30 parts by weight to 100 parts by weight of a second epoxy compound having a glass transition temperature of a homopolymer of not more than 60° C., and 0.5 parts by weight to 20 parts by weight of a cationic photopolymerization initiator, and a polarizing plate using the same.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

Vinylester resin stone adhesive and preparation method thereof

InactiveCN101974304AImprove heat resistanceImprove performanceModified epoxy resin adhesivesHigh riseDefoaming Agents

The invention discloses a vinylester resin stone adhesive and a preparation method thereof. The adhesive consists of a component A and a component B, and can be used by simply mixing the component A and the component B in a mass ratio of 100:2-3, wherein the component A consists of a mixed resin of vinylester resin, a filler, a thickener, a pigment, a defoaming agent, a coupling agent, a promoter and a polymerization inhibitor; and the component B consists of a hyperoxide curing agent, a plasticizer and a filler. The adhesive is suitable for adhering stone for high-rise buildings and metal, or paving stone materials such as marble and ceramic tile, making patterns with stone materials, jointing the stone materials and stopping holes in the stone materials. The production cost of the adhesive is low, and the adhesion force of the adhesive is higher than that of common marble adhesive; the cured shrinkage and deformation rate of the adhesive is low, the heat resistance and corrosion resistance of the adhesive are high; the manufacturability of the operation of the method is high, the gelation time and setting time of the adhesive in a low-temperature and water-containing environment are short, and the adhesive can be used in some damp and highly-corrosive environments. The adhesive is an upgraded substitute for marble adhesive and can replace part of substituted double-component epoxy adhesive.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com