Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9875 results about "Bis epoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

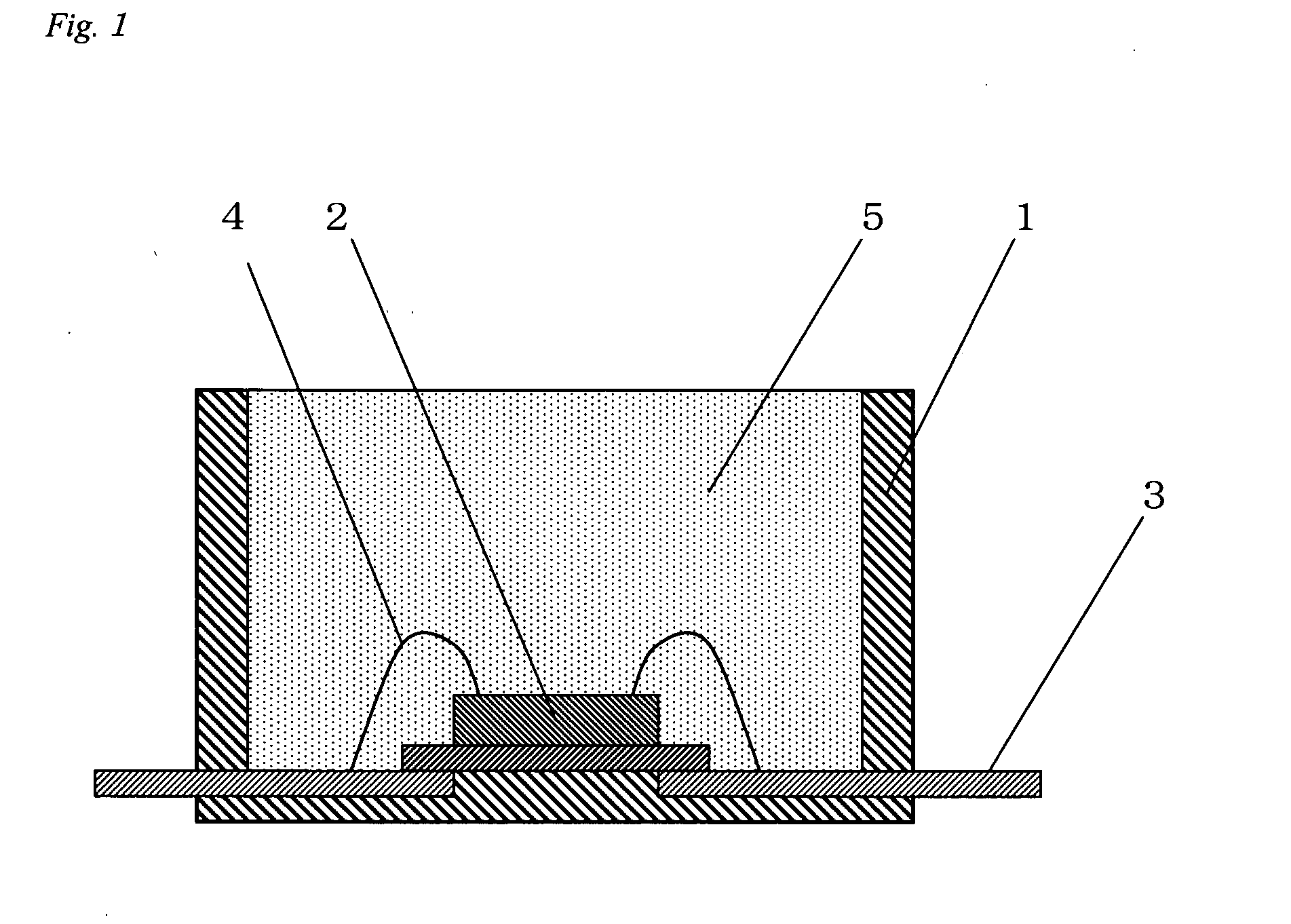

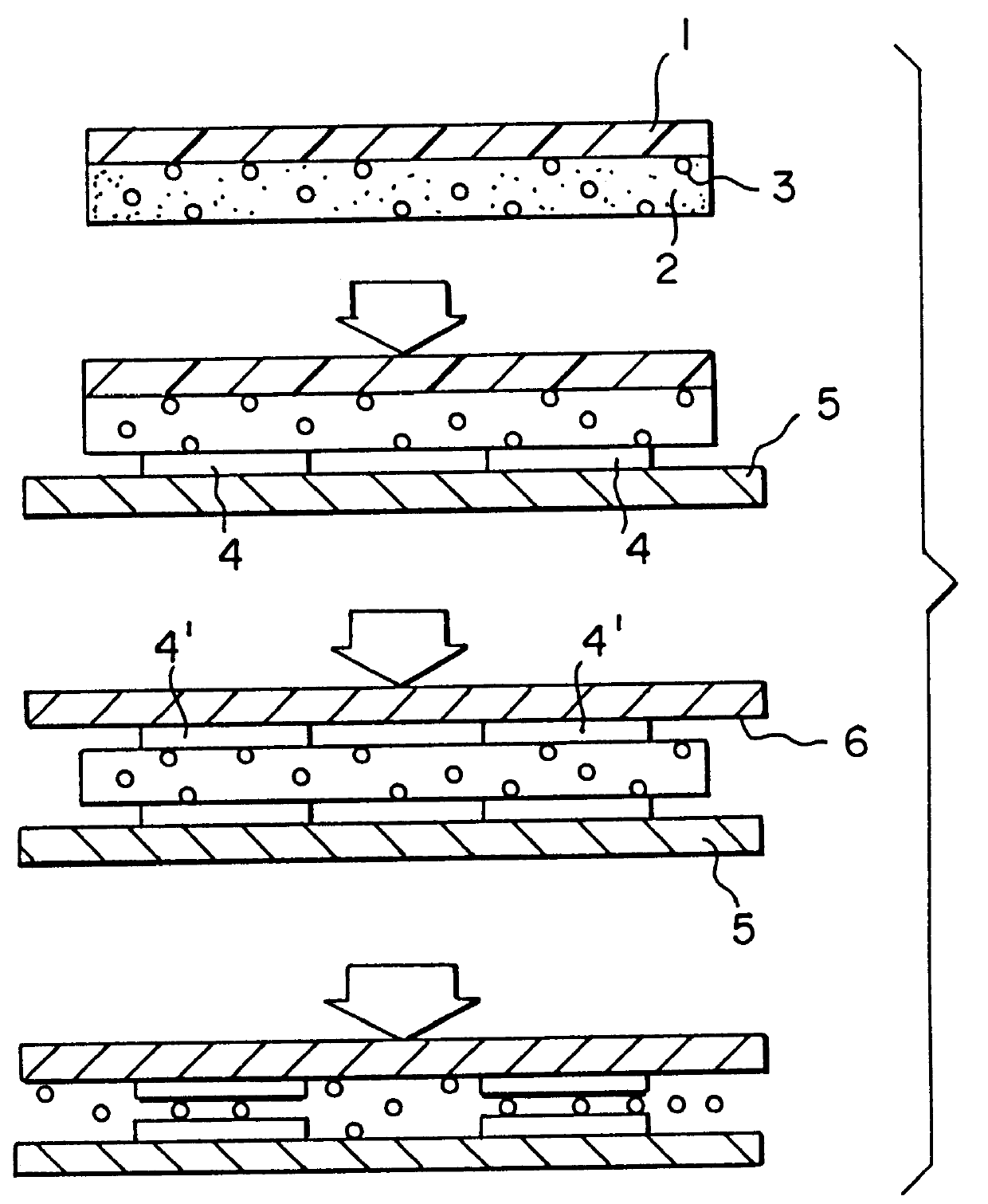

Anisotropic conductive adhesive and method for preparation thereof and an electronic apparatus using said adhesive

InactiveUS6039896AReduce weightEasy to manufactureNon-macromolecular adhesive additivesDigital data processing detailsEpoxyPhosphoric Acid Esters

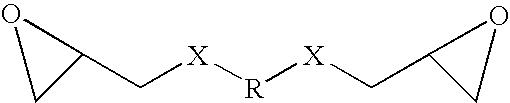

An anisotropic conductive adhesive contains conductive particles dispersed in a resin composition, wherein the resin composition includes a radical polymerization resin (A), an organic peroxide (B), a thermoplastic elastomer (C) and a phosphoric ester (D). The resin composition can further contain an epoxy silane coupling agent (E) represented by formula (2) or (3). The resin composition is mixed with other components after the radical polymerization resin (A), the thermoplastic elastomer (C), the phosphoric ester (D) and the epoxy silane coupling agent (E) are reacted. It is also possible to preliminarily react only the phosphoric ester (D) and the epoxy silane coupling agent (E) and to react the product of the preliminary reaction with the radical polymerization resin (A) and the thermoplastic elastomer (C), and then to add other components. The anisotropic conductive adhesive of the present invention can be used for electrical joining of electronic or electric parts of electrical apparatus.

Owner:SUMITOMO BAKELITE CO LTD

Silicone hydrogel lens with a crosslinked hydrophilic coating

ActiveUS20130118127A1Increased durabilitySpectales/gogglesPackage sterilisationHydrophilic coatingPolymer science

The invention is related to a cost-effective method for making a silicone hydrogel contact lens having a crosslinked hydrophilic coating thereon. A method of the invention involves autoclaving, in a sealed lens package, a silicone hydrogel contact lens having a base coating of polyacrylic acid thereon in an aqueous solution in the presence of a water-soluble, crosslinkable hydrophilic polymeric material having epoxide groups, for a period of time sufficient to covalently attach the crosslinkable hydrophilic polymeric material onto the surface of the silicone hydrogel contact lens through covalent linkages each formed between one epoxide group and one of the carboxyl groups on and / or near the surface of the silicone hydrogel contact lens.

Owner:ALCON INC

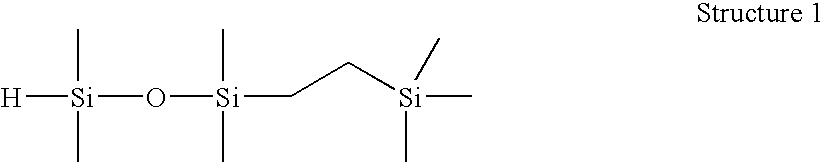

Preparation method of hydrophilic block polyether aminosilicone

InactiveCN102617863AThe reaction steps are simpleThe reaction conditions are mild and simpleFibre treatmentEpoxyAcetic acid

The invention discloses a preparation method of hydrophilic block polyether aminosilicone. The method comprises the following steps of: preparing terminal hydrogen-containing silicone oil: mixing hydrogen-containing double end enclosures, polysiloxane and acid, reacting, adding sodium carbonate under a vacuumizing condition, adjusting the pH, filtering a solid out, and extracting a low-boiling-point substance under reduced pressure to obtain low hydrogen-containing silicone oil; preparing epoxy silicone oil: mixing the obtained terminal hydrogen-containing silicone oil with allyl epoxy polyether and a catalyst, and reacting to obtain epoxy silicone oil; and preparing block polyether aminosilicone: and mixing the obtained epoxy silicone oil, polyetheramine, a catalyst and a solvent, reacting, cooling, adding an emulsifier for emulsifying, and adding glacial acetic acid for adjusting the pH to obtain the block polyether aminosilicone. According to the hydrophilic block polyether aminosilicone prepared with the method, the handfeel of a treated fabric can reach the handfeel of ordinary aminosilicone, and the treated fabric can keep a hydrophilic function permanently, is prevented from yellowing, and has high antistatic property.

Owner:GUANGDONG UNIV OF TECH

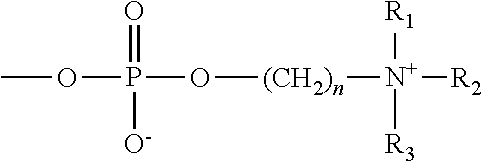

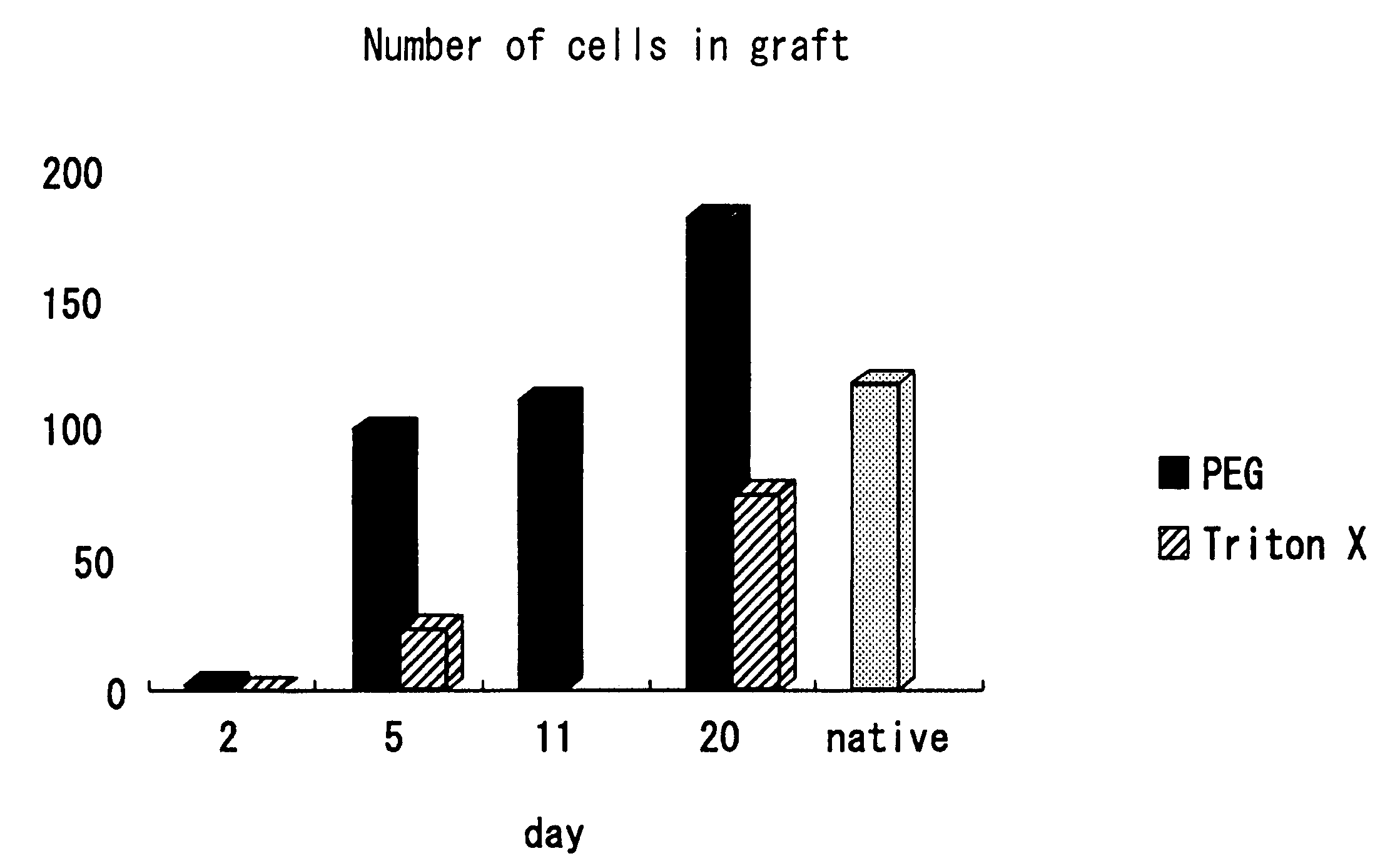

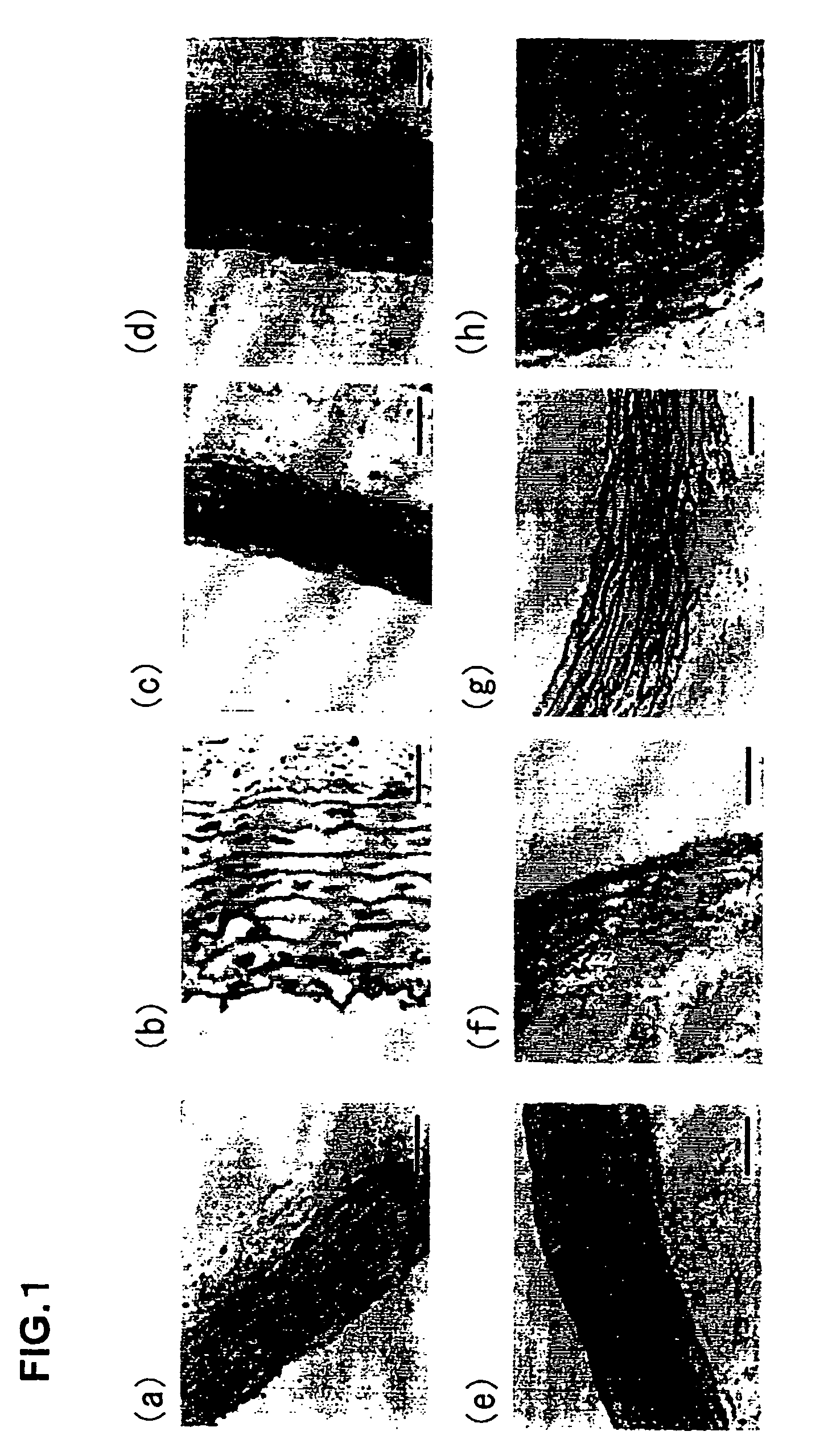

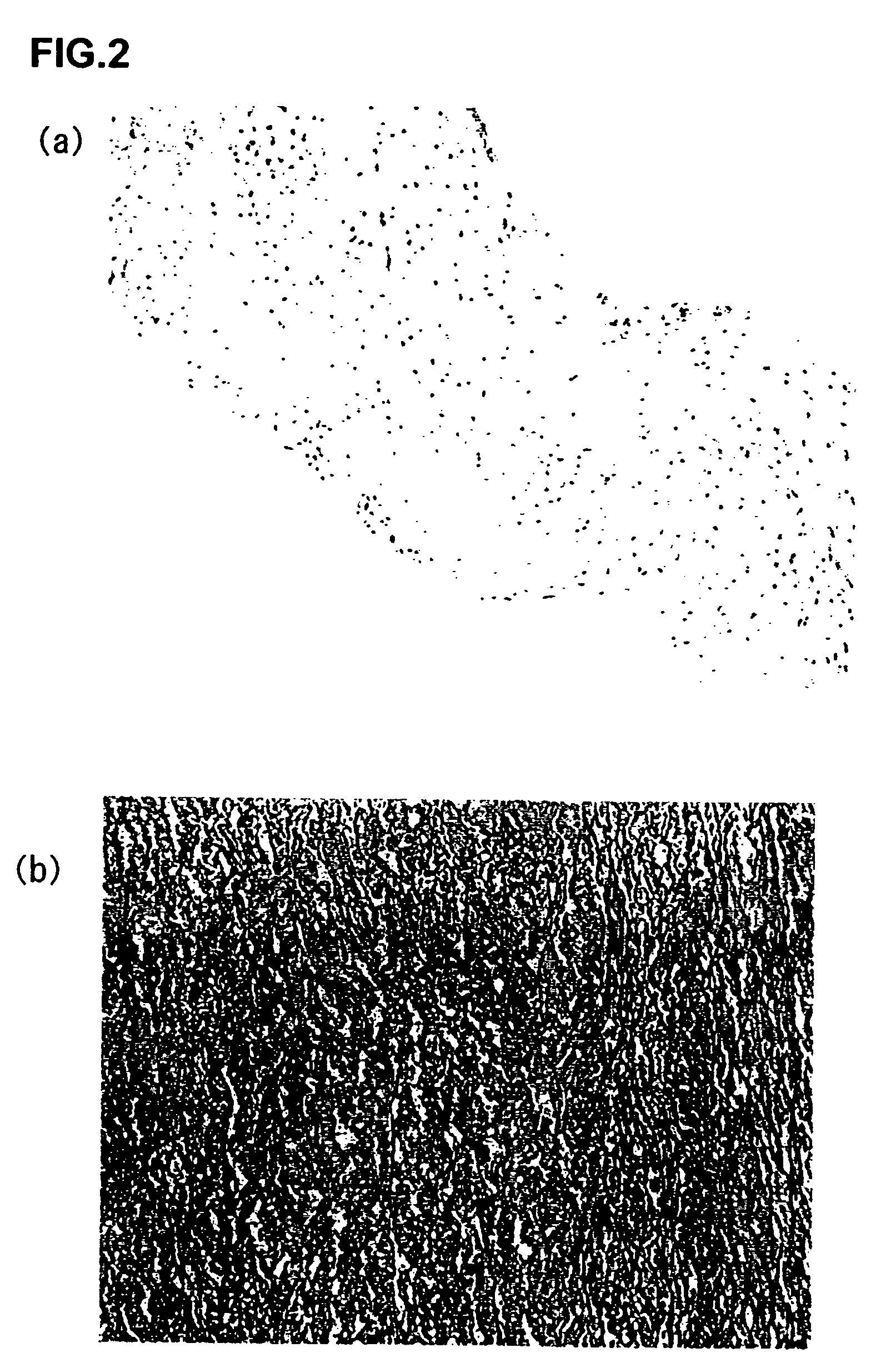

Decellularized tissue

InactiveUS20050256588A1Minimal damageGuaranteed maximum utilizationArtificial cell constructsMammal material medical ingredientsCalcificationDecellularization

An objective of the present invention is to overcome a problem that there is an inverse relationship between the decellularization rate and the strength of tissue. This problem was solved by immersing tissue in a solution containing a non-micellar amphipathic molecule (e.g., a 1,2-epoxide polymer). Thus, the present invention provides decellularized tissue, in which the cell survival rate of the tissue is less than a level at which calcification or an immune reaction is elicited in an organism and the tissue damage rate of the tissue is suppressed to a level which permits clinical applications. Tissue prepared by the above-described treatment preferably retains a certain level of tissue strength. Further, the tissue of the present invention has an effect of performing cell replacement.

Owner:CARDIO +1

BIS epoxy polyesters and food cans coated with a composition comprising same

ActiveUS20070281179A1Loss in molecular weightEnvelopes/bags making machinerySynthetic resin layered productsPolyesterChemistry

Polyesters comprising the reaction product of a polyol and a bis-epoxy reacted with a mono- and / or di-phenolic carboxylic acid and / or ester are disclosed. Food cans coated at least in part on the interior with a composition comprising these polyesters are also disclosed. The composition used on the food cans is substantially free of BPA and BPF and substantially free of BADGE and BFDGE. Food cans coated at least in part on the interior with a composition comprising a polyester having a loss of molecular weight of less than 50% in an acidic medium are also disclosed.

Owner:PPG IND OHIO INC

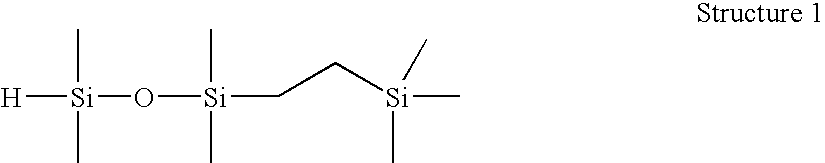

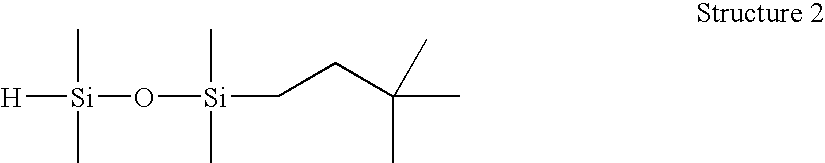

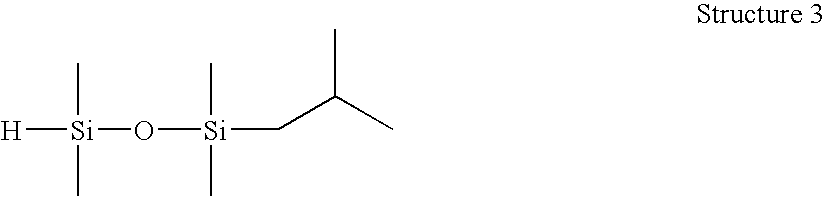

Hydrolysis resistant organomodified disiloxane surfactants

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

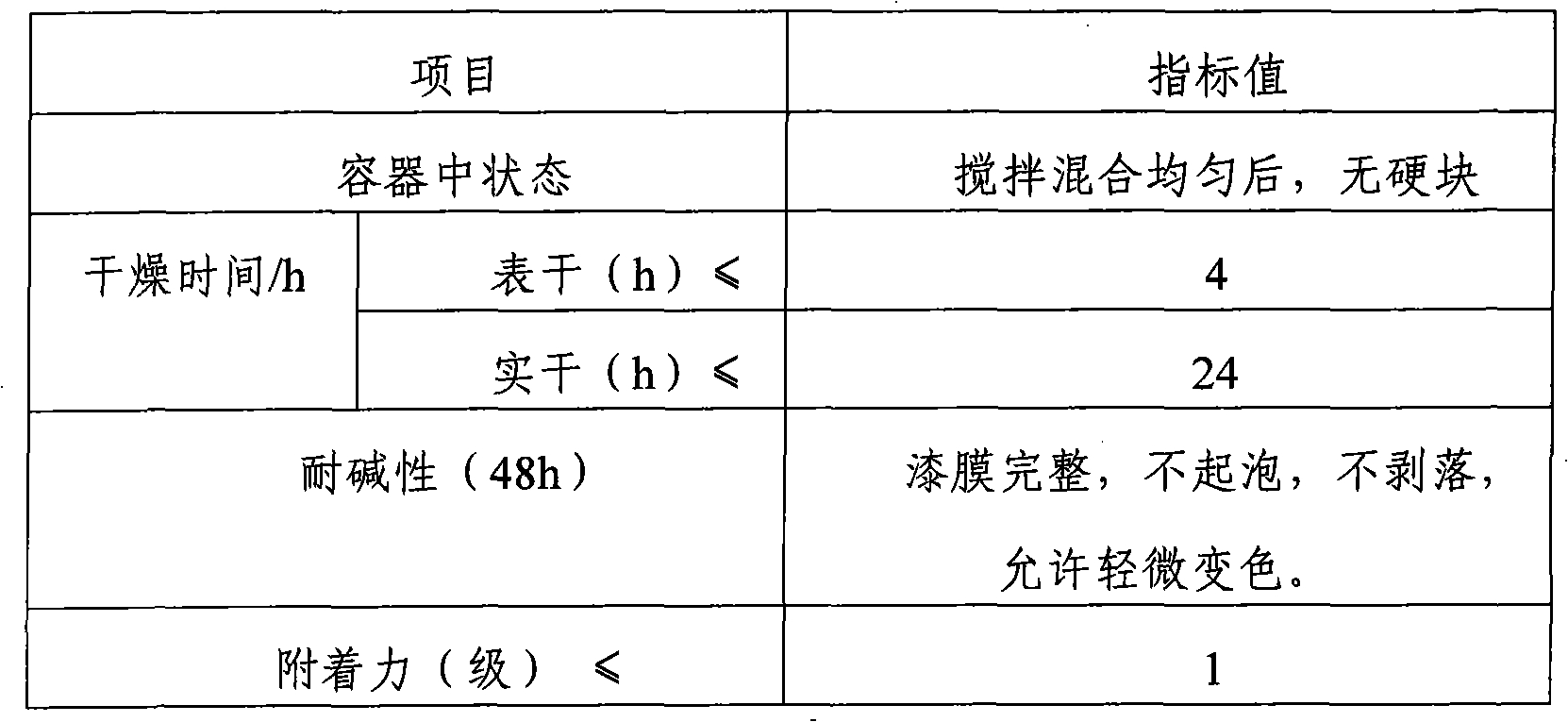

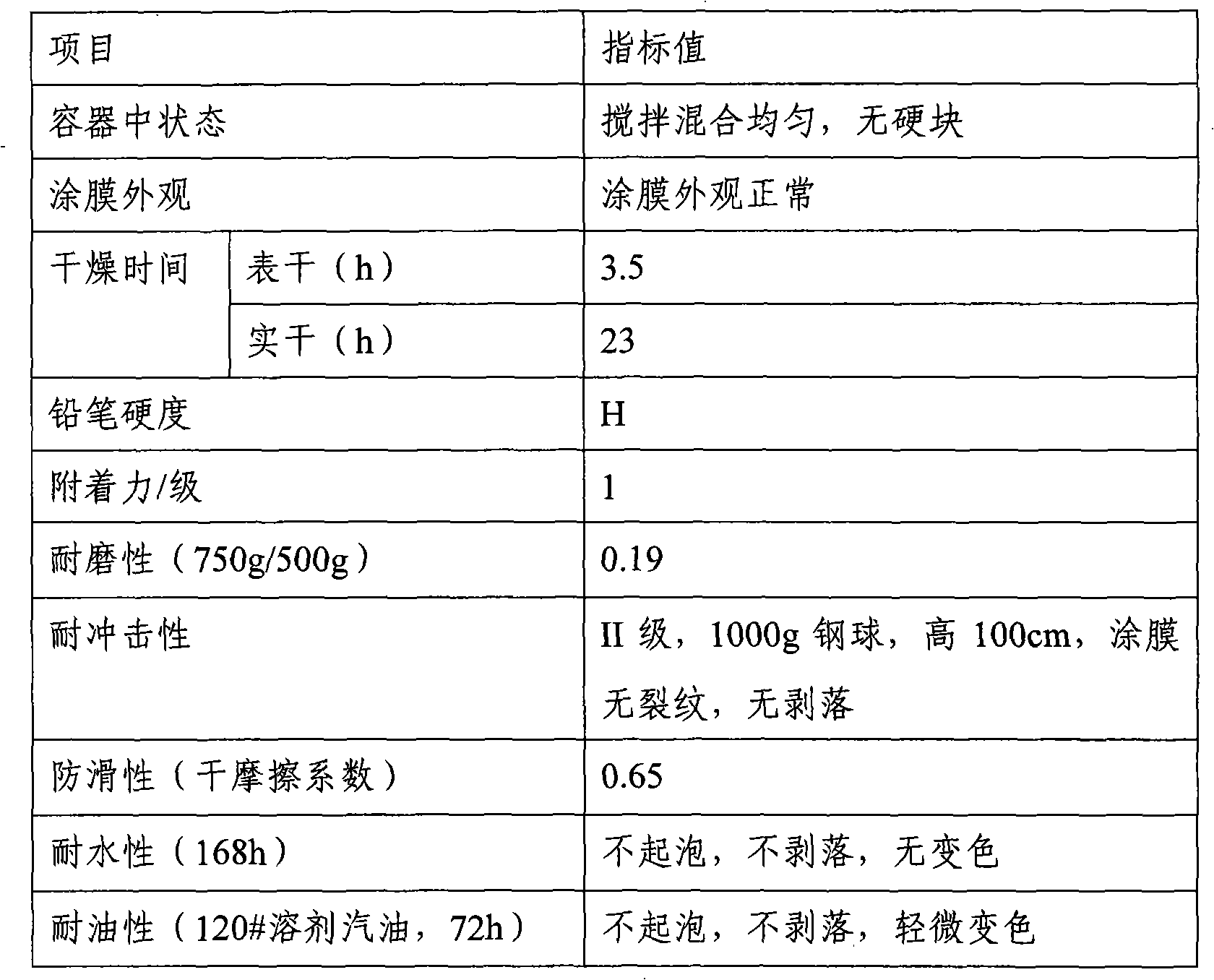

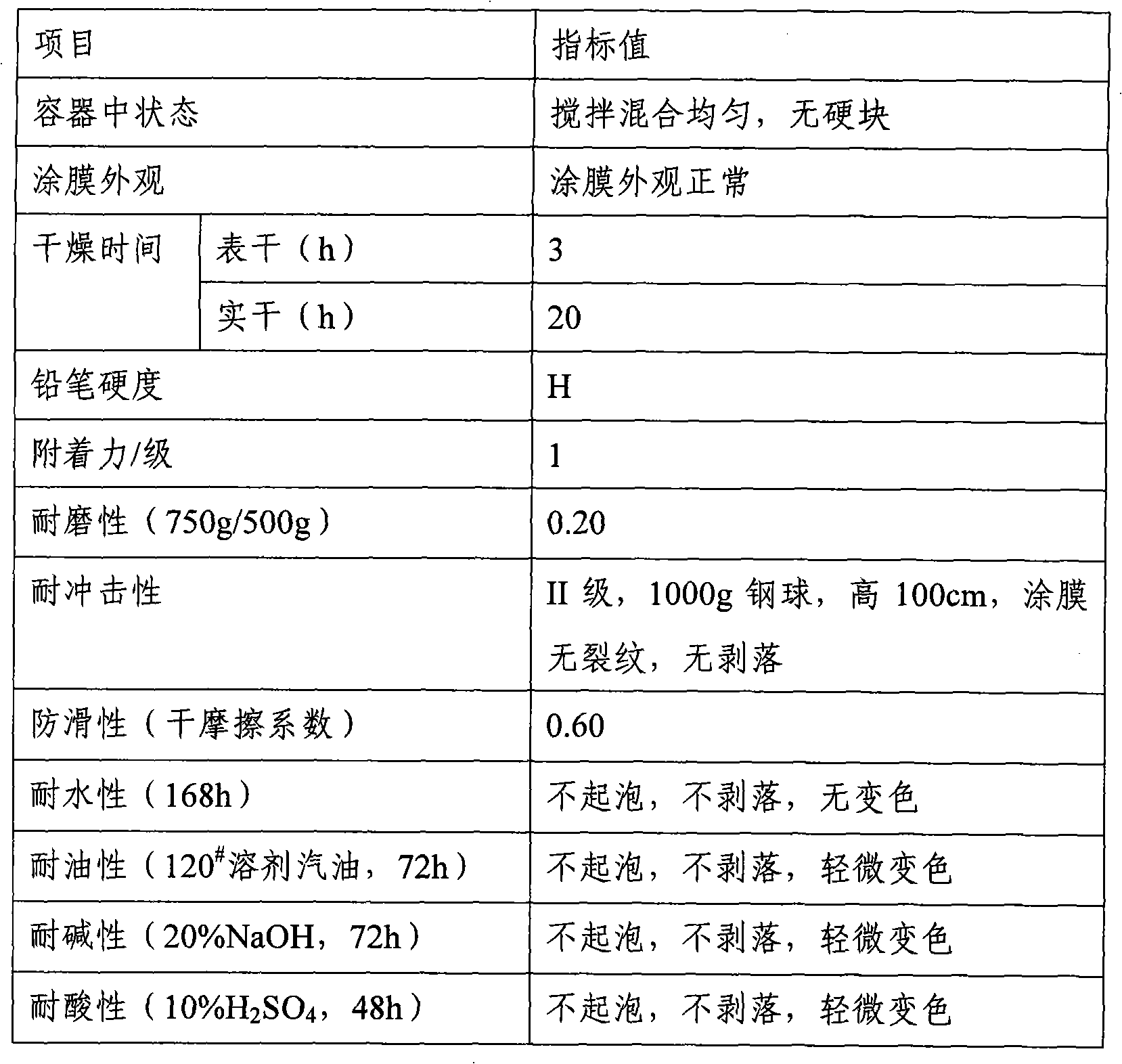

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

Water epoxy paint for ground floor and its mfg. process and construction technology

The invention relates to a water epoxy ground floor coating and its making method and constructing process, where one component is low-molecular weight liquid-state epoxy resin assorted with active diluter in a proper proportion, and the other component is a dispersoid with hydrophilic curing agent as the principal thing, containing water-borne curing agent, water, acid-resistant wearable color filler, various auxiliaries, etc. and its producing method is simple and mainly includes mechanical dispersing and mixing; it does need to clean paint-covered surface as used on humid basal surface; the paint film has excellent properties of oily products and unilateral permeability. It uses water as dispersing medium, has no VOC, safe and environmental-protection.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

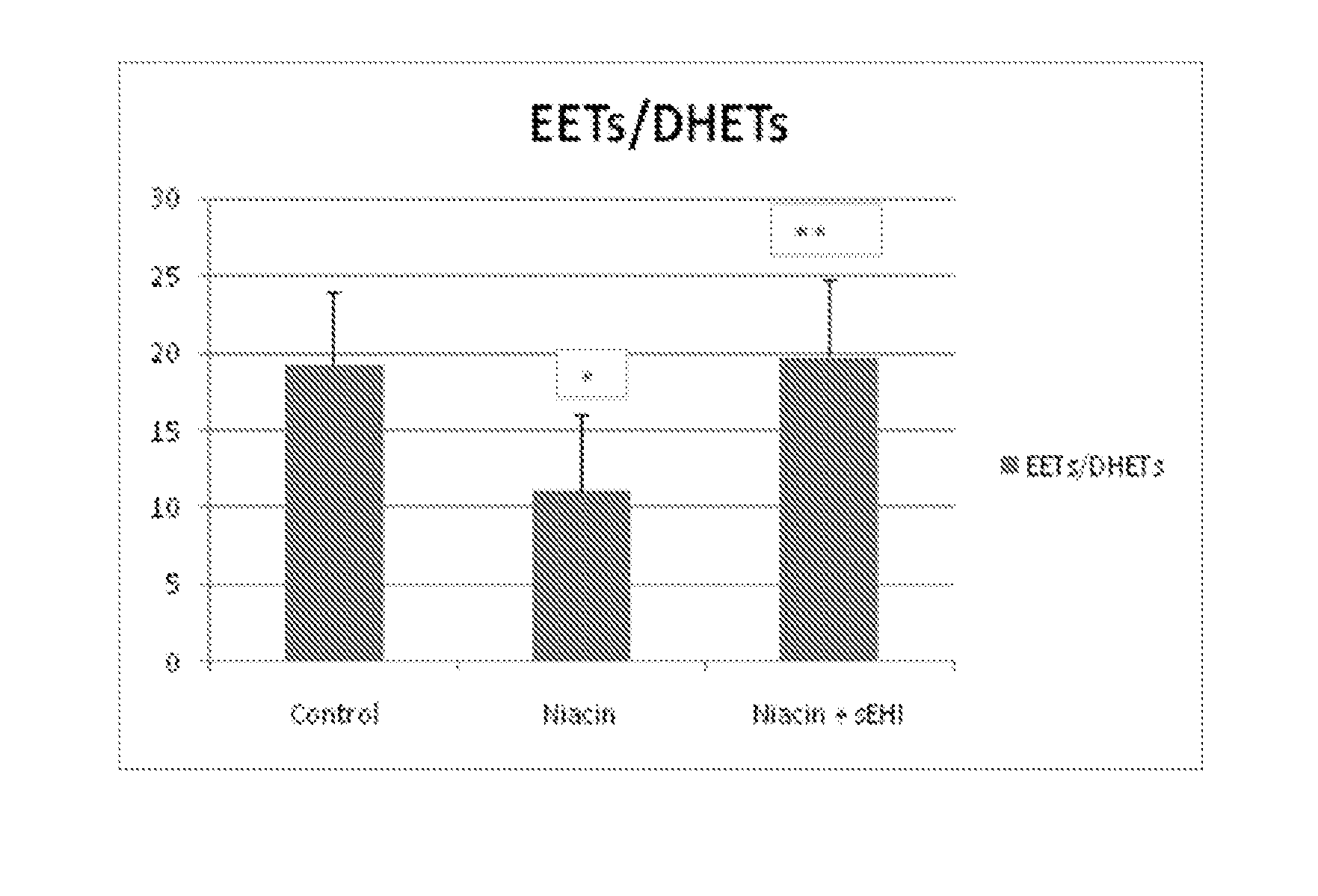

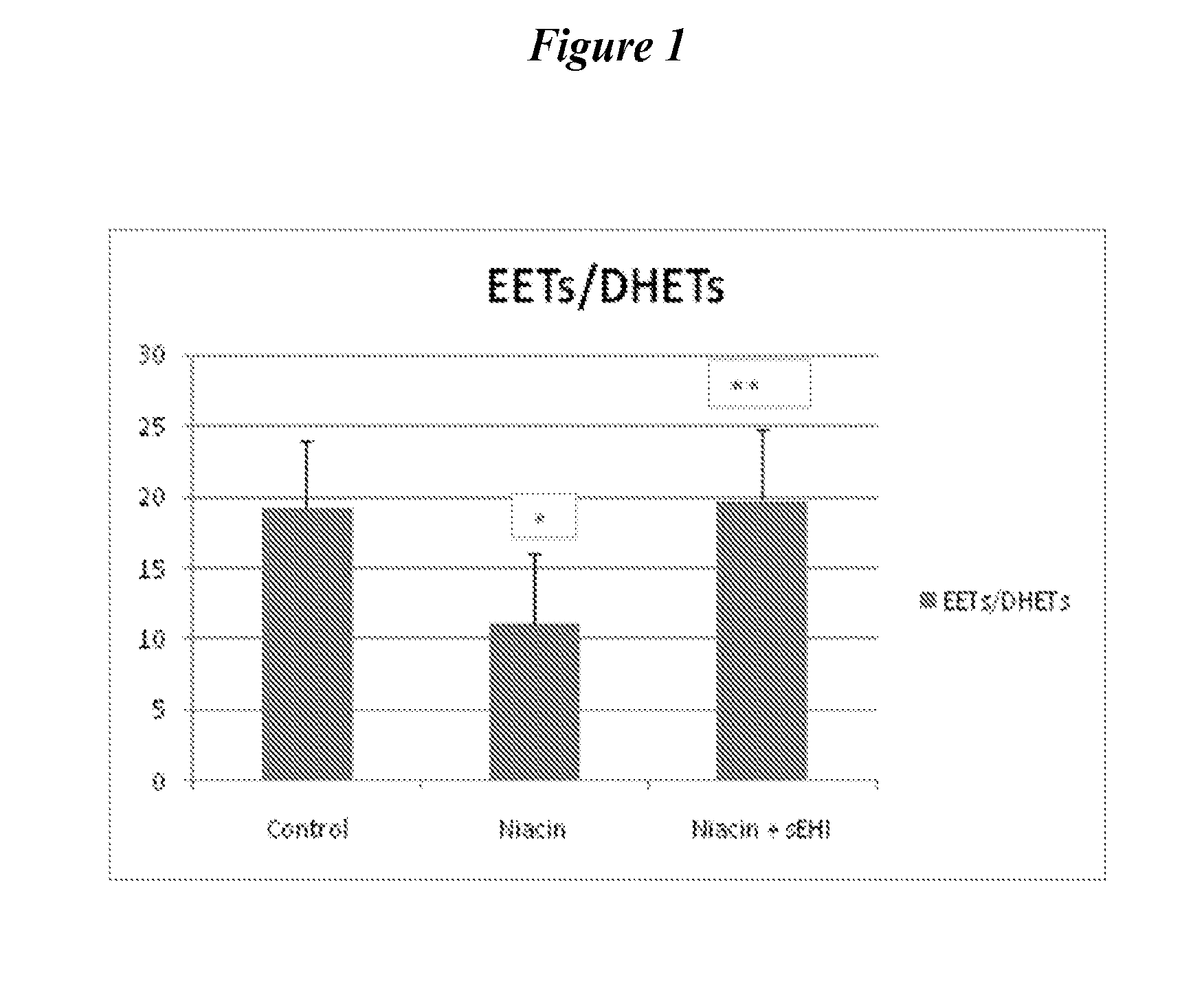

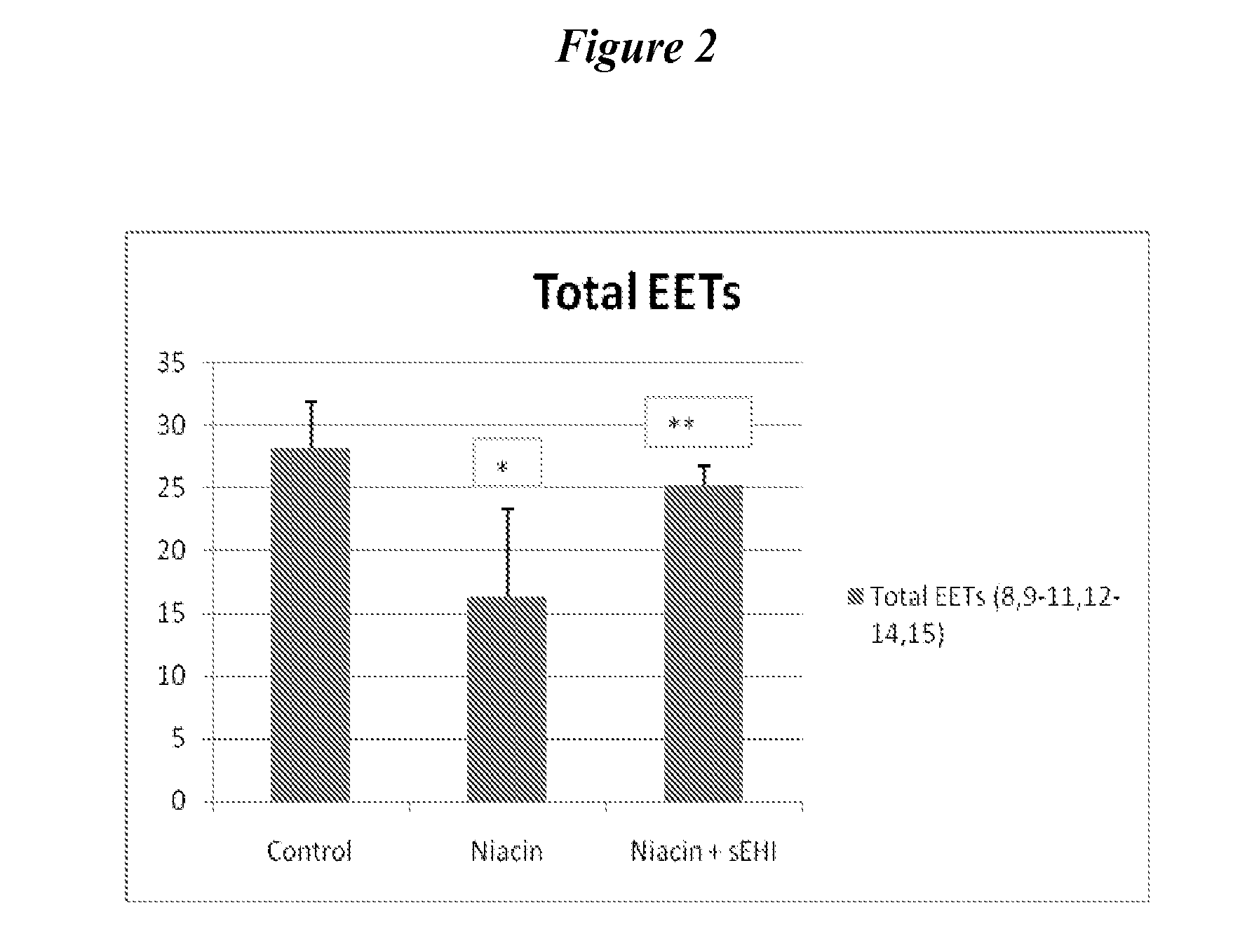

Inhibitors of soluble epoxide hydrolase to inhibit or prevent niacin-induced flushing

InactiveUS20120046251A1Prevent and reduce and block substantial flushingPrevent, reduce or block substantial flushingSalicyclic acid active ingredientsBiocideCutaneous vasodilationSide effect

The invention discloses methods of using cis-epoxyeicosantrienoic acids (“EETs”), inhibitors of soluble epoxide hydrolase (“sEH”), or a combination of an EET and an inhibitor of sEH, to reduce or prevent niacin-induced cutaneous vasodilation (“flushing”) in subjects suffering from this undesirable side effect of receiving therapeutic amounts of niacin.

Owner:SCHAEFER SAUL

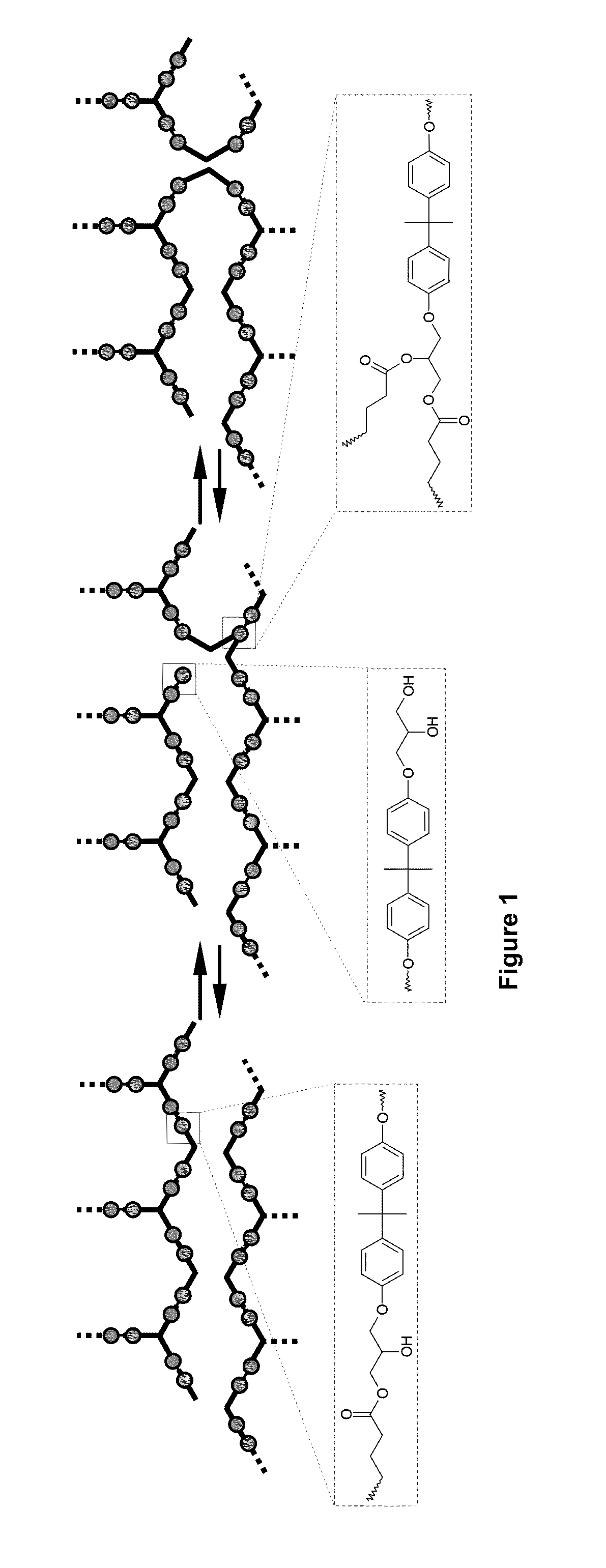

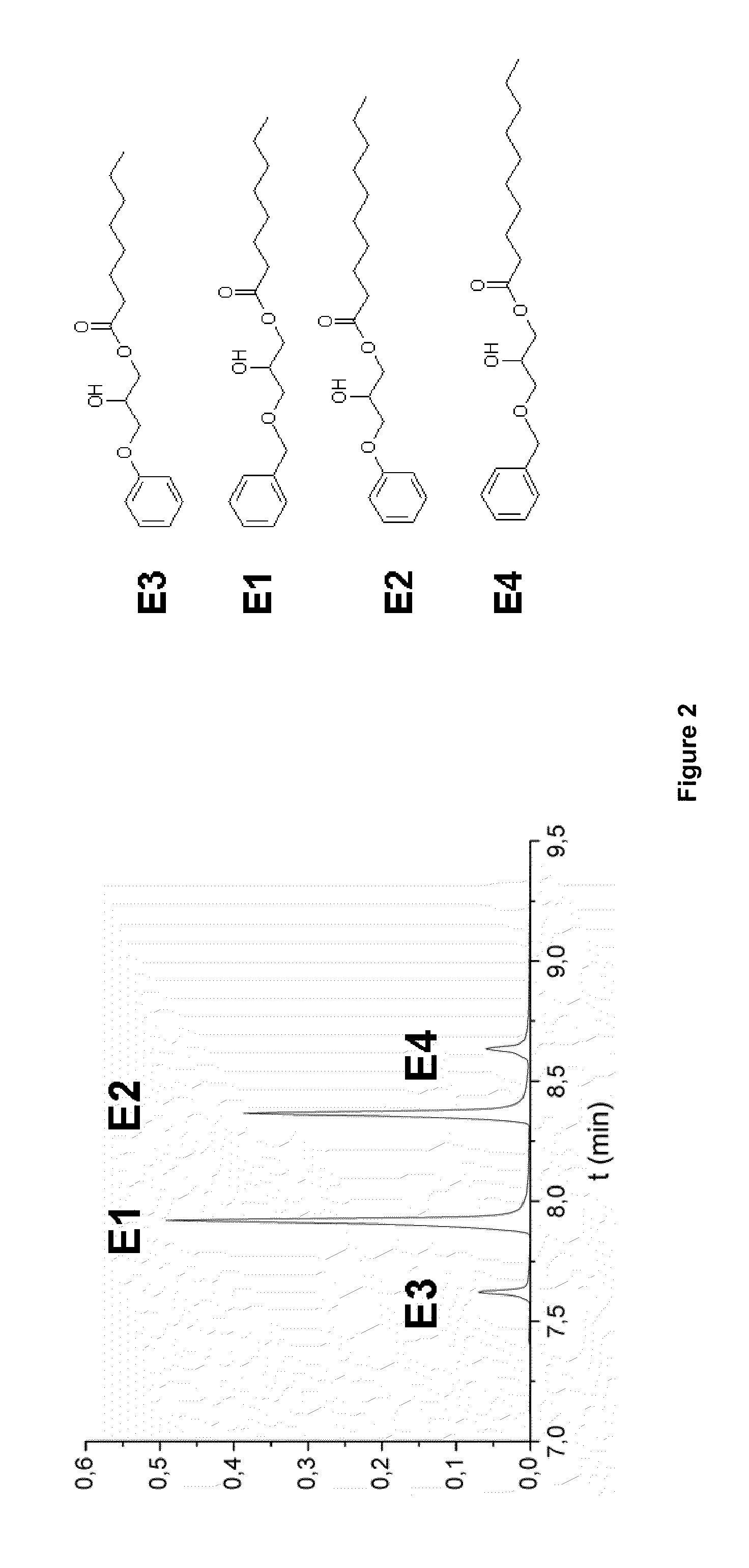

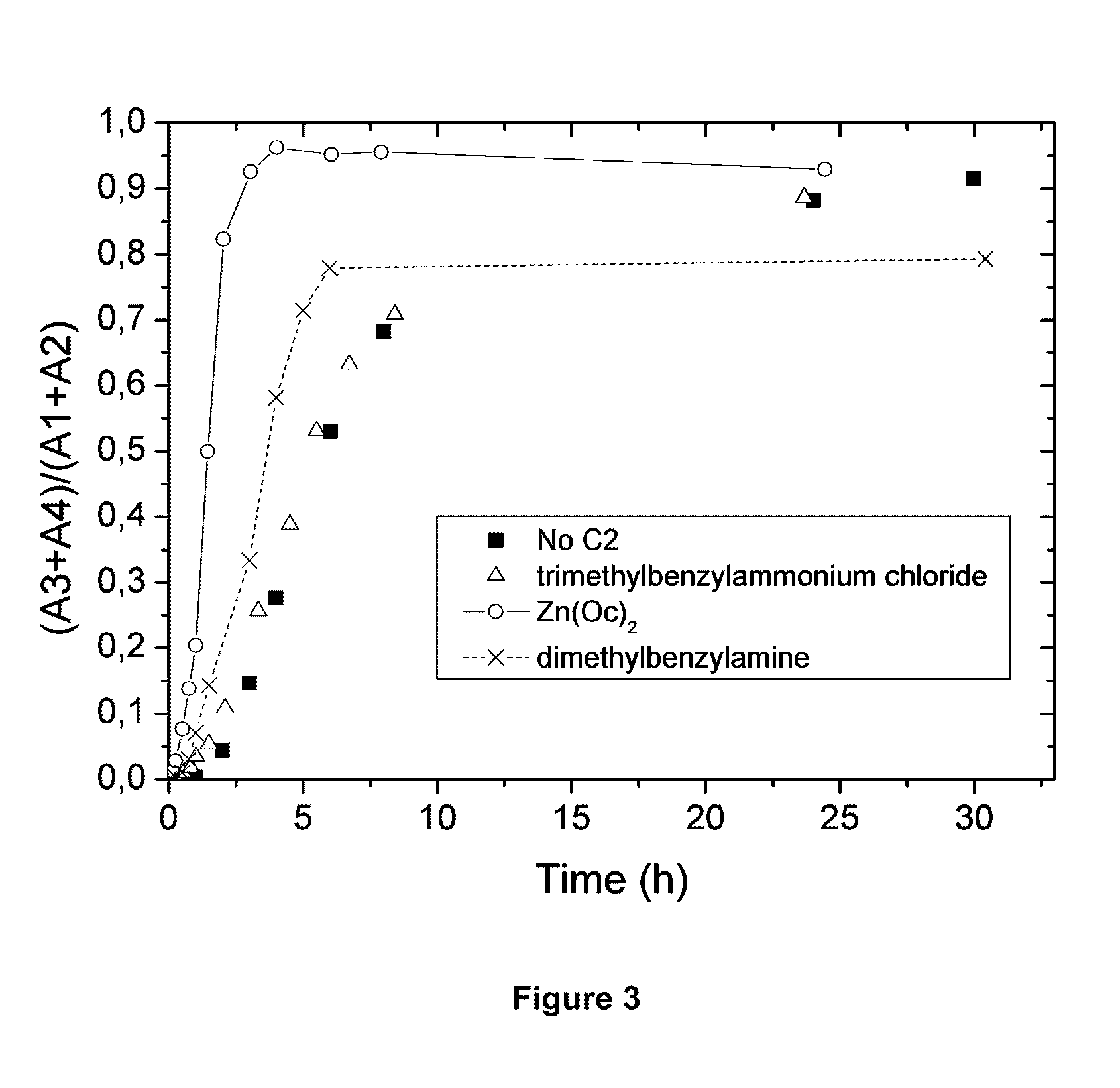

Epoxy Acid Thermoset Resins and Composites that Can Be Hot-Fashioned and Recycled

Resins and thermoset composites comprising them, these materials being able to be hot-fashioned. These compositions resulting from placing at least one thermosetting resin precursor, this thermosetting resin precursor comprising hydroxyl functions and / or epoxy groups, and optionally ester functions, in contact with at least one hardener chosen from carboxylic acids, in the presence of at least one transesterification catalyst whose total molar amount is between 5% and 25% of the total molar amount of hydroxyl and epoxy contained in the thermosetting resin precursor. Process for manufacturing these materials, process for transforming and process for recycling these materials. New solid forms of resins and of thermoset composites that may be used in the implementation of these processes.

Owner:CENT NAT DE LA RECHERCHE SCI +1

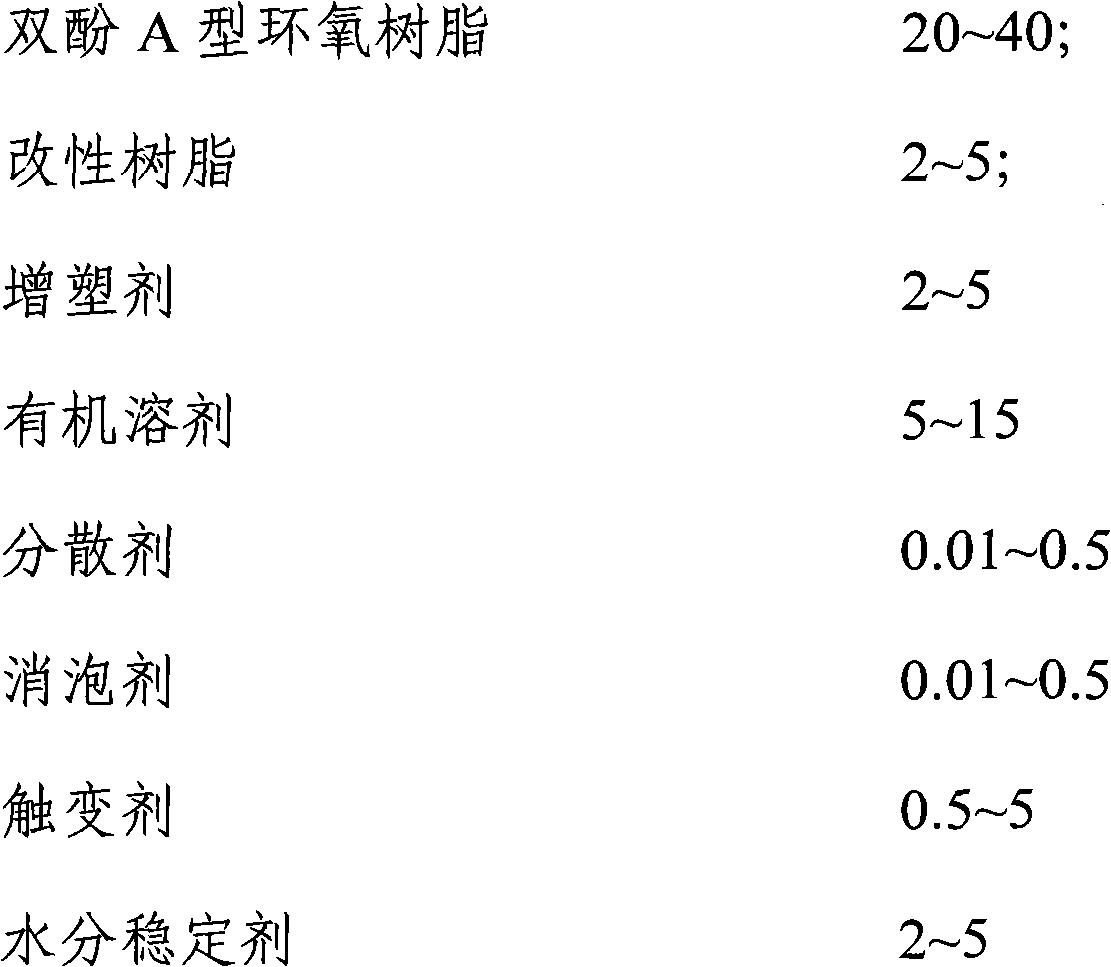

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

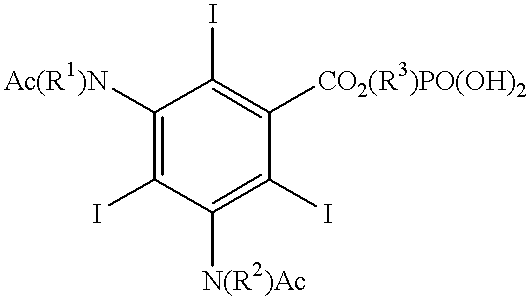

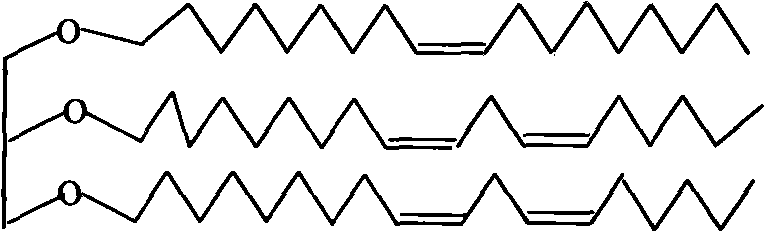

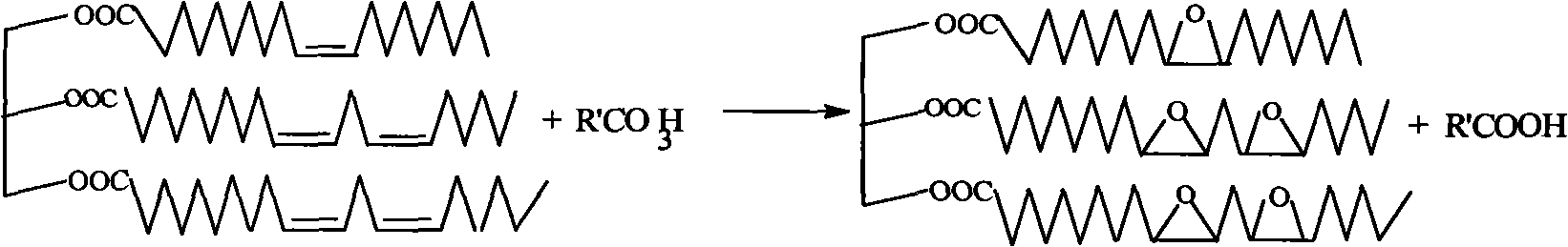

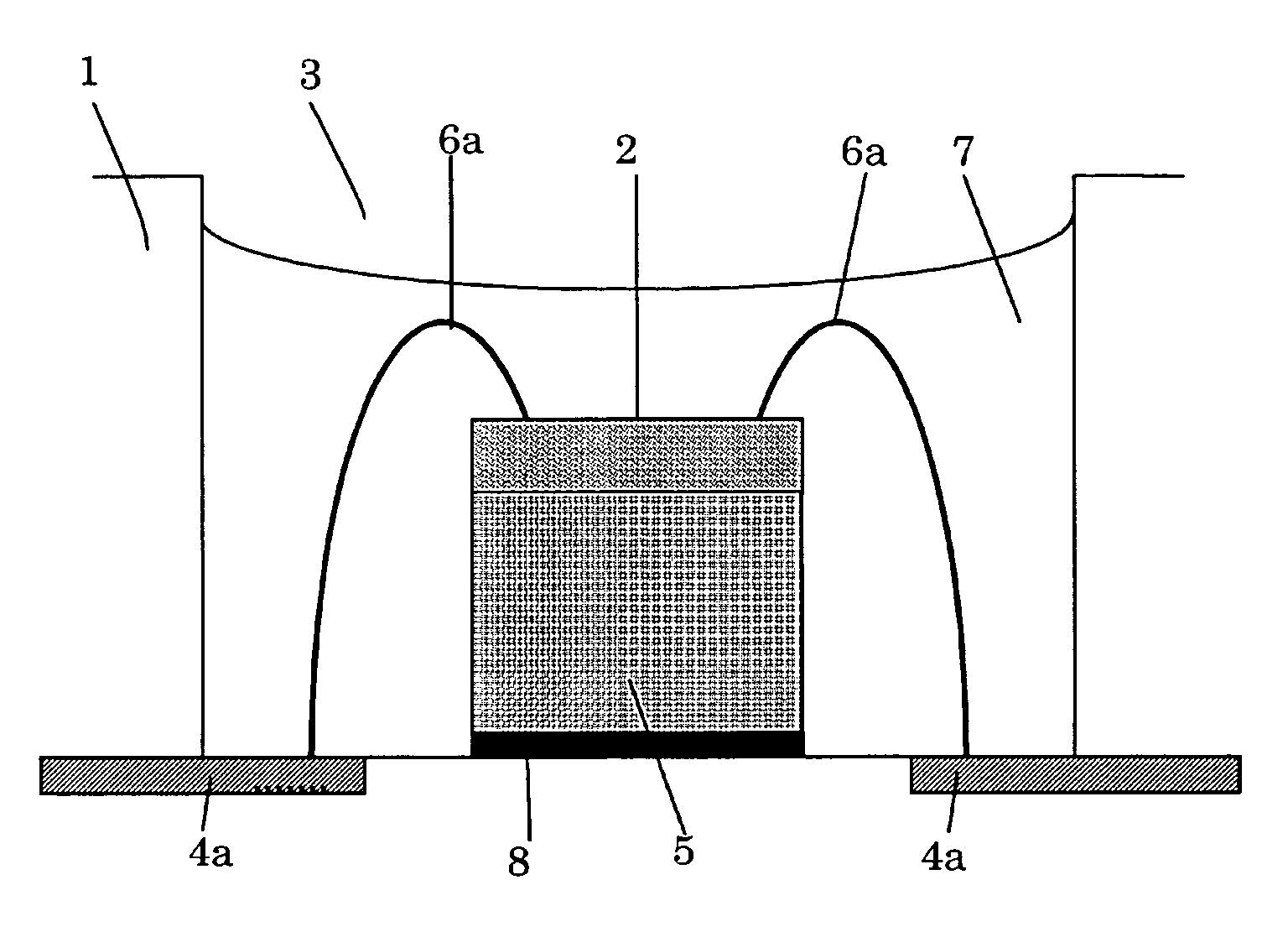

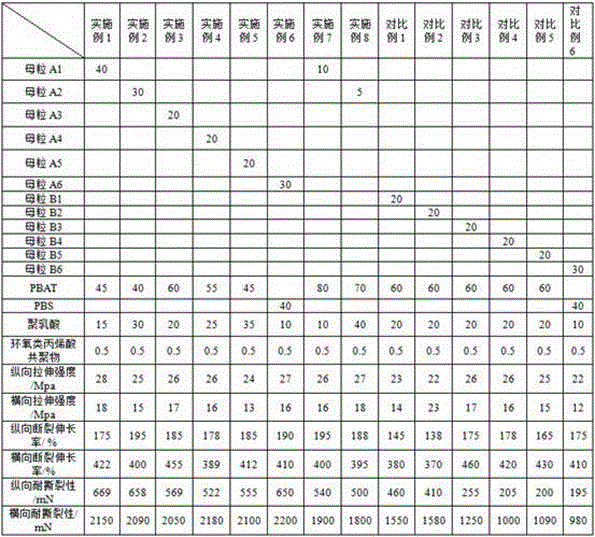

Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process

The present invention relates to a new industrial process for the synthesis of solvate- free 17a-acetoxy-11ss-[4-(N,N-dimethyl-amino)-phenyl]-19-norpregna-4,9-diene-3,20-dione [CDB -2914] of formula (I) which is a strong antiprogestogene and antiglucocorticoid agent. The invention also relates to compounds of formula (VII) and (VIII) used as intermediates in the process. The process according to the invention is the following: i) 3-(ethylene-dioxy)-estra-5(10),9(11)-diene-17-one of formula (X) is reacted with potassium acetilyde formed in situ in dry tetrahydrofuran by known method, ii) the obtained 3-(ethylene-dioxy)-17a-ethynyl-17ss-hydroxy-estra-5(10),9(11)-diene of formula (IX) is reacted with phenylsulfenyl chloride in dichloromethane in the presence of triethylamine and acetic acid, iii) the obtained isomeric mixture of 3-(ethylene-dioxy)-21-(phenyl-sulfinyl)-19-norpregna-5(10),9(11),17(20),20-tetraene of formula (VIII) is reacted first with sodium methoxide in methanol, then with trimethyl phosphite, iv) the obtained 3-(ethylene-dioxy)-17a-hydroxy-20-methoxy-19-norpregna-5(10),9(11),20-triene of formula (VII) is reacted with hydrogen chloride in methanol, then v) the obtained 3-(ethylene-dioxy)-17a-hydroxy-19-norpregna-5(10),9(11l); -diene-20- one of formula (VI) is reacted with ethylene glycol hi dichloromethane in the presence of trimethyl orthoformate and p-toluenesulfonic acid by known method, vi) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-19-norpregna- 5(10),9(11)-diene of formula (V) is reacted with hydrogen peroxide in a mixture of pyridine and dichloromethane in the presence of hexachloroacetone by known method, vii) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-5,10-epoxy-19-norpregn-9(11)-ene of formula (IV), containing approximately a 1:1 mixture of 5a,10a- and 5ss,10ss-epoxides, is isolated from the solution and reacted with a Grignard reagent obtained from 4-bromo-N,N-dimethyl-aniline in tetrahydrofuran.

Owner:RICHTER GEDEON NYRT

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

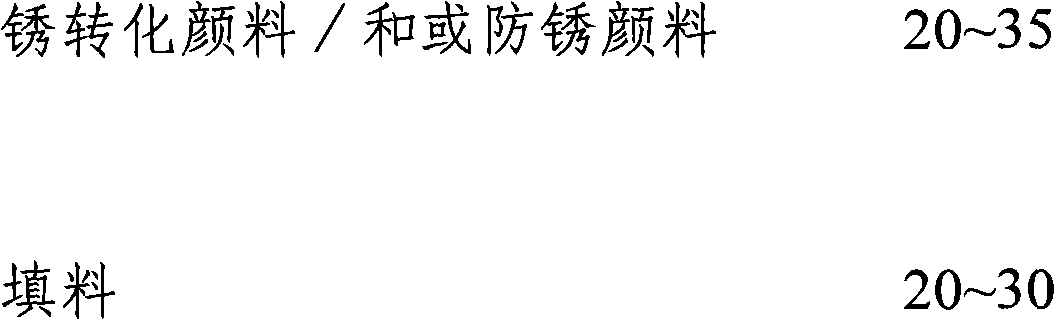

Metal base material corrosion-resistant coating and preparation method thereof

InactiveCN102391779AWeather resistantAnti-corrosionAnti-corrosive paintsEpoxy resin coatingsVinyl esterBis epoxide

The invention discloses metal base material corrosion-resistant coating and a preparation method thereof. The metal base material corrosion-resistant coating comprises the following components in parts by weight: 25 to 30 pats of epoxy modified organic silicon resin, 15 to 20 parts of modified vinyl resin, 1 to 2 parts of nano material, 1 to 3 parts of corrosion-resistant particulate filler, 15 to 18.5 percent of pigment and filler, 1 to 2 parts of antisettling agent, 0.3 to 0.5 part of dispersing agent, 0.5 to 0.8 part of stabilizing agent, 3 to 4 parts of aid and 23 to 26 parts of solvent, wherein the modified vinyl resin comprises according to the weight percentage 50 to 70 % of phenolic aldehyde epoxy vinyl ester resin and 30 to 50 % of flexible vinyl ester resin. The metal base material corrosion-resistant coating is prepared by multiple flows of weighing the raw materials in parts by weight, mixing the raw materials according to certain sequence, dispersing, grinding and the like. The metal base material corrosion-resistant coating has high temperature tolerance, wet resistance, corrosion resistance, weldability and constructability and can be applied in the technical fieldsof processing of various different metals.

Owner:资阳赛特化工有限公司

Low gloss ASA resin

A thermoplastic molding composition comprising a grafted acrylate rubber (ASA) and a gloss reducing agent and a process for making the same are disclosed. The gloss reducing agent is the reaction product of (i) a compound having two or more epoxy groups per molecule and (ii) a compound having two or more amine groups per molecule, with the proviso that the total of epoxy groups of (i) and amine groups of (ii) per molecule is greater than 4. The gloss reducing agent may be either incorporated in ASA as the reaction product of (i) and (ii) or, in the alternative, formed upon the reaction of (i) with (ii) in the course of the thermal processing of the a blend containing ASA, (i) and (ii).

Owner:INEOS ABS JERSEY +1

Process for the production of polyether polyols with a high ethylene oxide content

InactiveUS20110230581A1Simplify preparationSuitable for productionOrganic chemistryOxideEthylene oxide

Polyether polyols with an OH number of from 15 to 120 mg of KOH / g are produced by (i) introducing a mixture of DMC catalyst and a poly(oxyalkylene)polyol or a mixture of DMC catalyst and a polyether polyol (“heel”) obtainable by the process according to the invention is initially into a reactor and (ii) continuously introducing one (or more) low molecular weight starter compound(s) with a (mixed) hydroxyl functionality of from 2.2 to 6.0 and a mixture composed of a) 73 to 80 parts by weight (per 100 parts by weight of a) plus b)) of ethylene oxide and b) 27 to 20 parts by weight (per 100 parts by weight of a) plus b)) of at least one substituted alkylene oxide corresponding to a specified formula into the mixture from step (i). These polyether polyols are particularly useful for the production of flexible polyurethane foams.

Owner:COVESTRO LLC +1

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

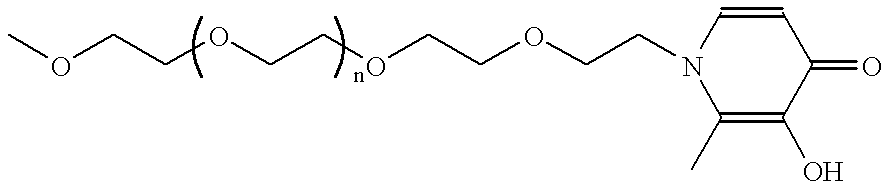

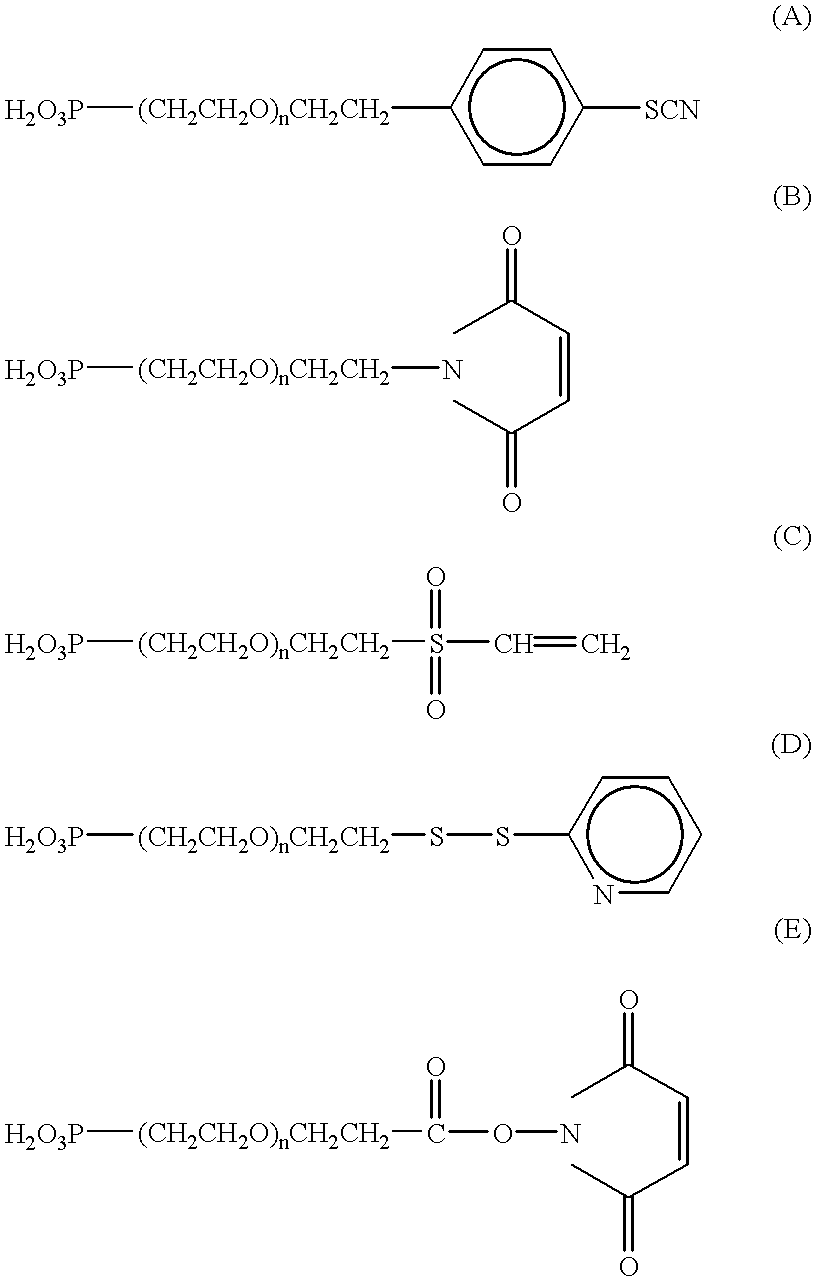

Constrast media

InactiveUS6423296B1Increase productionPowder deliveryBiocideOxidative cleavageComposite nanoparticles

The invention relates to MR contrast media containing composite nanoparticles, preferably comprising a superparamagnetic iron oxide core provided with a coating comprising an oxidatively cleaved starch coating optionally together with a functionalized polyalkyleneoxide which serves to prolong blood residence.

Owner:GE HEALTHCARE AS

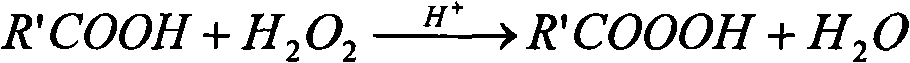

Method for preparing hard polyurethane foam plastics with soybean oil

ActiveCN101314632AImprove water resistanceImprove heat resistancePolyesterFatty acid glycerol esters

The invention provides a method for preparing hard polyurethane foam plastics from soybean oil. The method comprises the steps as follows: (1) carrying out epoxidation including the sub-steps of subjecting soybean oil and epoxidizing agent to reaction to obtain epoxidized soybean oil; (2) carrying out ring-opening reaction including the sub-steps of subjecting epoxidized soybean oil and nucleophilic reagent of reactive hydrogen to the ring-opening reaction of epoxy chemical bond in the presence of a catalyst to obtain mixed hydroxyl fatty acid glyceride; (3) carrying out alcoholysis and esterification including the sub-steps of adding alcohol, heating for alcoholysis to obtain mixed hydroxyl fatty acid monoester, i.e. soybean oil based polyol, and esterifying with organic acid and acid anhydride to generate polyester polyol; and (4) sequentially adding 80-150 weight parts of isocyanate, 0.3-4 weight parts of triethanolamine and 0.5-4 weight parts of foam stabilizer to 100 weight parts of soybean oil based polyol, intensively stirring, adding 0.5-3 weight parts of distilled water, and uniformly foaming while stirring at the high speed.

Owner:NANTONG HAIERMA TECH CO LTD

Primer composition for a fluorinated elastomer or a fluorinated gel

A primer composition for a fluorinated elastomer or a fluorinated gel, said primer composition comprising:100 parts by weight of (a) a linear perfluoro polyether compound having at least two alkenyl groups per molecule, a perfluoro polyether backbone having repeating units represented by the formula, —CaF2aO—, wherein a is an integer of from 1 to 6, and a weight average molecular weight of from 5,000 to 100,000,(b) an organosiloxane compound having one or more fluorine atom and at least two SiH bonds per molecule, in such an amount that a molar ratio of the SiH bond in the organosiloxane compound to the alkenyl group in Component (a) ranges from 0.8 to 5.0,a catalytic amount of (c) a hydrosilylation catalyst,5 to 100 parts by weight of (d) an organosiloxane compound having, per molecule, at least one SiH bond and at least one epoxy group and / or trialkoxysilyl group bonded to a silicon atom of said organosiloxane via an organic group which may have an oxygen atom, and100 to 10000 parts by weight, per total 100 parts by weight of said components (a), (b), (c) and (d), of (e) an organic solvent having a fluorine atom and a boiling point of not higher than 150° C. at atmospheric pressure.

Owner:SHIN ETSU CHEM CO LTD

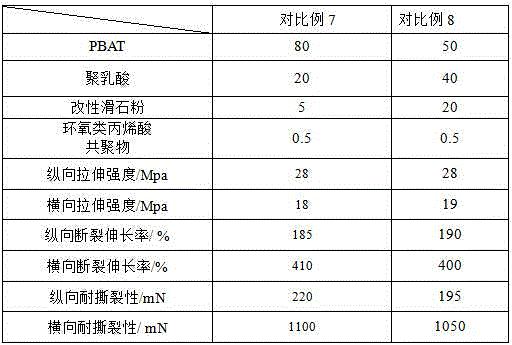

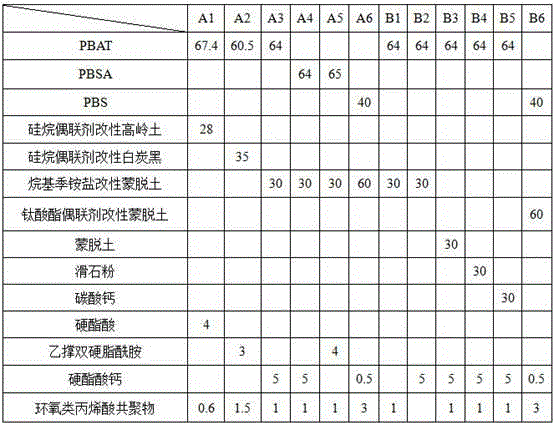

Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

The invention discloses a full-biodegradable composite as well as a preparation method and application of the full-biodegradable composite. The full-biodegradable composite comprises the following components: 5-40 parts of inorganic filler full-biodegradable masterbatches, 40-80 parts of biodegradable copolyester, 10-40 parts of polylactic acid and 0.1-5 parts of a compatilizer, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of the biodegradable copolyester, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of the compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the matrix resin, so that the problem of relatively low tearing strength of a blend film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

Water industrial paint based on organosilicon acrylic acid epoxy ester water dispersion and preparation method thereof

InactiveCN1927968AImprove corrosion resistanceGood physical propertiesEmulsion paintsEpoxyDefoaming Agents

The present invention provides one kind of water thinned industrial paint based on water dispersed organosilicon epoxy acrylate. The water thinned industrial paint is prepared with water dispersed organosilicon epoxy acrylate, inert antirust pigment, active antirust pigment, nanometer material modified antirust pigment, stuffing, dispersant, wetting agent, thickener, drying agent, mildew inhibitor, preservative, defoaming agent, deionized water and other materials. The water thinned industrial paint with water dispersed organosilicon epoxy acrylate as base material can form coating with the features of high mechanical strength and high anticorrosive performance similar to that of epoxy resin as well as the features of high weather resistance and good decoration performance like acrylate resin. The water thinned industrial paint has convenient use and wide application range.

Owner:广州市允升环保科技有限公司

Ultraviolet light curing nano antibacterial woodenware paint and preparation method thereof

InactiveCN1927971AEase of industrial productionNo harmAntifouling/underwater paintsPaints with biocidesLacquerUltraviolet lights

The present invention discloses one kind of ultraviolet ray cured nanometer antibiotic woodenware lacquer and its preparation process. The ultraviolet ray cured nanometer antibiotic woodenware lacquer includes epoxy acrylate, polyurethane acrylate, diluent, nanometer inorganic antiseptic, nanometer inorganic stuffing and photoinitiator. The preparation process includes adding nanometer inorganic antiseptic and nanometer inorganic stuffing into the diluent, stirring to disperse homogeneously, adding epoxy acrylate, polyurethane acrylate and photoinitiator and mixing homogeneously. The woodenware lacquer with nanometer inorganic antiseptic can inhibit the growth and propagation of bacteria and microbes to produce long term antibiotic effect.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Extreme environment surfactant compositions comprising hydrolysis resistant organomodified disiloxane surfactants

Compositions comprising an asymmetric disiloxane surfactant composition comprising a silicone composition comprising a silicone having the formula: MM′where M or M′ comprises an alkylpolyalkyleneoxide bearing substituent selected from the group consisting of: R13(C2H4O)a(C3H6O)b(C4H8O)cR14 and R12SiR5R6(R13(C2H4O)a(C3H6O)b(C4H8O)cR14) that exhibit resistance to hydrolysis over a wide pH range.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

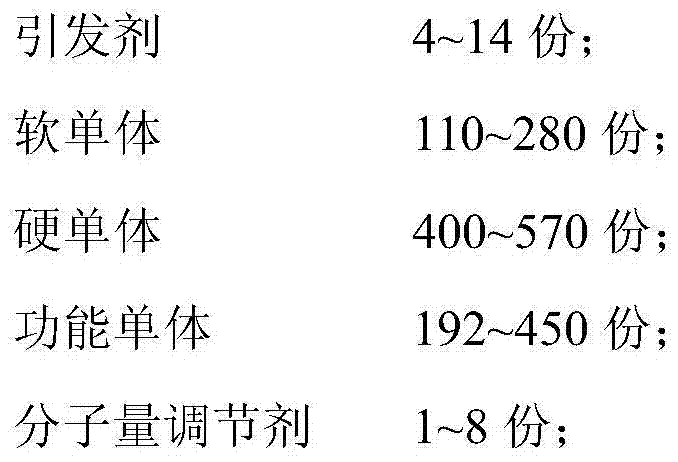

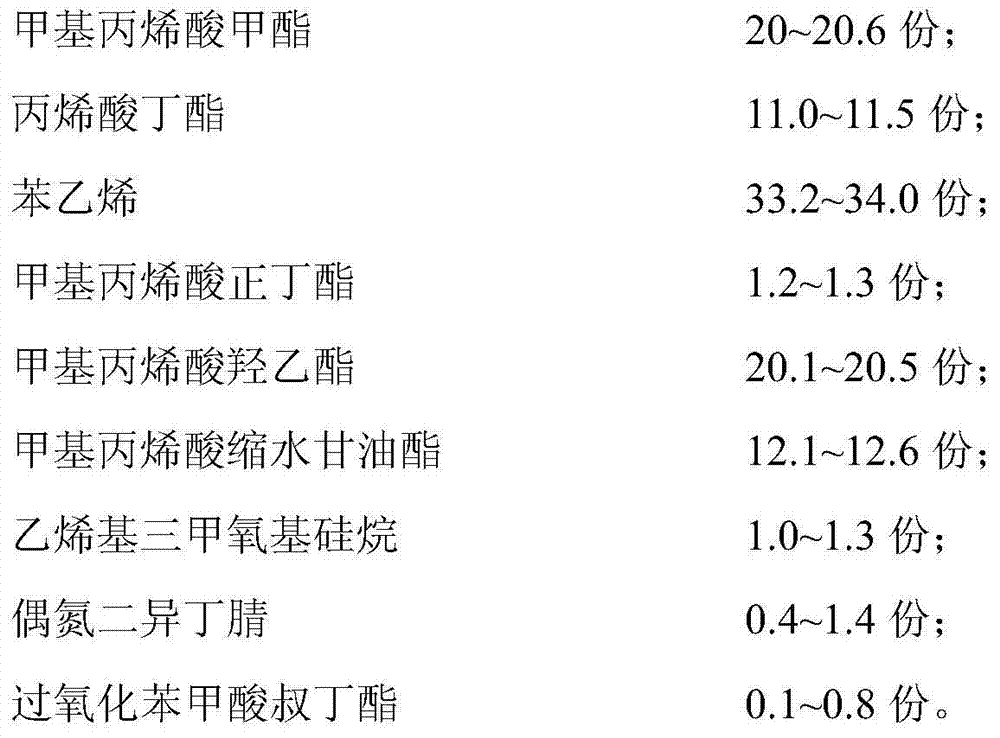

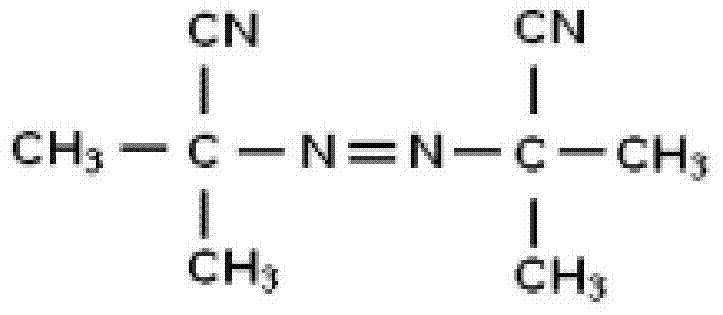

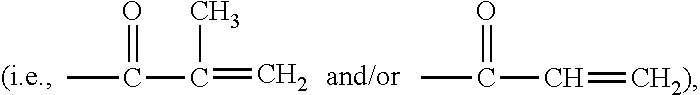

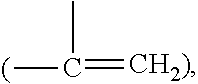

Thermosetting acrylic resin for powder coating as well as synthesis method and applications of thermosetting acrylic resin

The invention relates to thermosetting acrylic resin for a powder coating. The thermosetting acrylic resin is prepared from the following raw materials in parts by mass: 4-14 parts of an initiator, 110-280 parts of soft monomers, 400-570 parts of hard monomers, 192-450 parts of functional monomers, and 1-8 parts of a molecular weight regulator, wherein the soft monomers refer to acrylic acid alkyl ester compounds, and the hard monomers refer to methacrylate, styrene, or compounds of derivatives of methacrylate and styrene. The acrylic resin contains epoxy functional groups and hydroxyl functional groups simultaneously, wherein the epoxy equivalent is 570-630g / mol and the hydroxyl value is 40-50mgKOH / g; the acrylic resin can react with various substances such as carboxyl, amidogen and isocyanate and can be used for powder coating. A coating film, which is formed after the thermosetting powder coating prepared from the acrylic resin in combination with other materials is sprayed, has excellent weather resistance, good leveling performance, outstanding surface hardness, and high glossiness, durability and decorating performance; the powder coating can be used for indoor or outdoor metal sectional materials or building materials. The thermosetting acrylic resin can substitute for TGIC (triglycidyl isocyanurate) to a certain extent so as to avoid the use of the toxic substances.

Owner:阜阳市诗雅涤新材料科技有限公司

Resin composition for interlayer insulation of multilayer printed wiring board, adhesive film and prepreg

ActiveUS20050008868A1Insufficient heat resistanceElectrical controlPrinted circuit aspectsEpoxyElectrical conductor

Resin compositions which comprise the following components (A) to (E) are useful for interlayer insulation of a multilayer printed wiring board: (A) an epoxy resin having 2 or more epoxy group in one molecule and which exists in a liquid state at a temperature of 20° C.; (B) an aromatic epoxy resin having 3 or more epoxy groups in one molecule and an epoxy equivalent of 200 or less; (C) a phenol type curing agent; (D) one or more resins selected from the group consisting of a phenoxy resin, a polyvinyl acetal resin, a polyamide resin, a polyamideimide resin, and mixtures thereof, and having a glass transition temperature of 100° C. or more; and (E) an inorganic filler, wherein: the inorganic filler (E) is present in an amount of 35% by weight or more based on the total weight of the non-volatile components of the resin composition; the epoxy resin (A) and the aromatic epoxy resin (B) are present in a weight ration of from 1:0.3 to 1:2 by weight of epoxy resin (A) to aromatic epoxy resin (B); the epoxy resin (A), the aromatic epoxy resin (B), and the phenol type curing agent (C) are present in relative amounts such that the weight ratio of epoxy groups in the resin composition and phenolic hydroxyl groups in the phenol type curing agent (C) is from 1:0.5 to 1:1.5; and the resin (D) is present in an amount of from 2 to 20% by weight based on the total weight of the non-volatile components of the resin composition. Such resin compositions are useful for interlayer insulation of a multilayer printed wiring board and are capable of forming an insulating layer which has a low thermal expansion coefficient and exhibits excellent peel strength for a conductor layer. Such resin compositions are also useful for preparing adhesive films and prepregs for a multilayer printed wiring boards, as well as multilayer printed wiring boards having an insulating layer formed of a cured product of the resin composition or the prepreg.

Owner:AJINOMOTO CO INC

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

Curable Organopolysiloxane Composition and Semiconductor Device

ActiveUS20110160410A1High refractive indexHigh optical transmittanceSemiconductor/solid-state device detailsSolid-state devicesBonds hydrogenRefractive index

A curable organopolysiloxane composition comprising: (A) an organopolysiloxane that contains in one molecule at least two alkenyl groups and at least 30 mole % of all silicon-bonded monovalent hydrocarbon groups in the form of aryl groups: (B) an organopolysiloxane that contains in one molecule at least two silicon-bonded hydrogen atoms and at least 15 mole % of all silicon-bonded organic groups in the form of aryl groups; (C) a branched-chain organopolysiloxane that contains alkenyl, aryl, and epoxy-containing organic groups; and (D) a hydrosilylation catalyst. The composition is capable of forming a cured body that has a high index of refraction and strong adhesion to substrates.

Owner:DOW TORAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

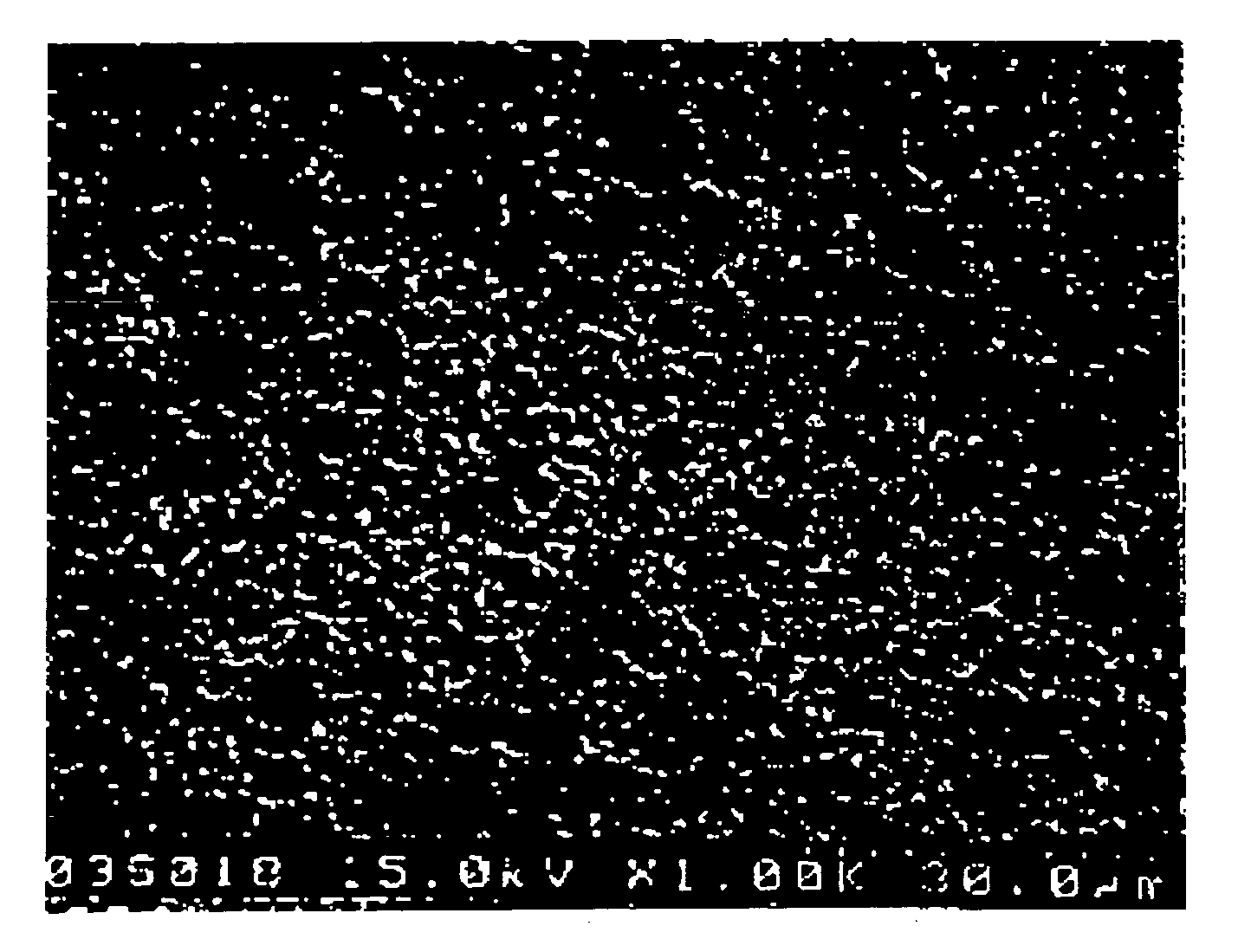

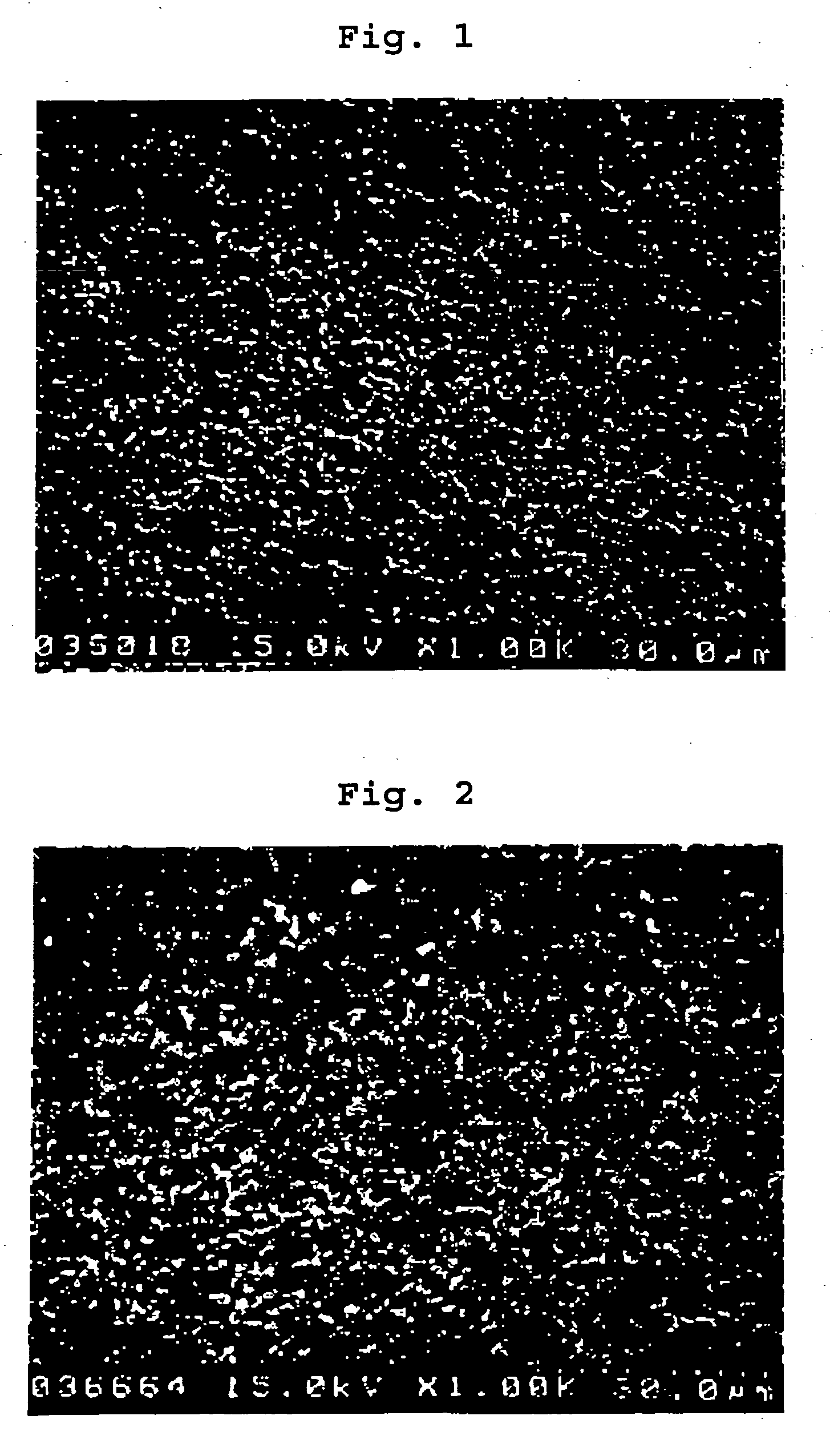

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00221.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00231.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00232.PNG)