Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Satisfactory adhesiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

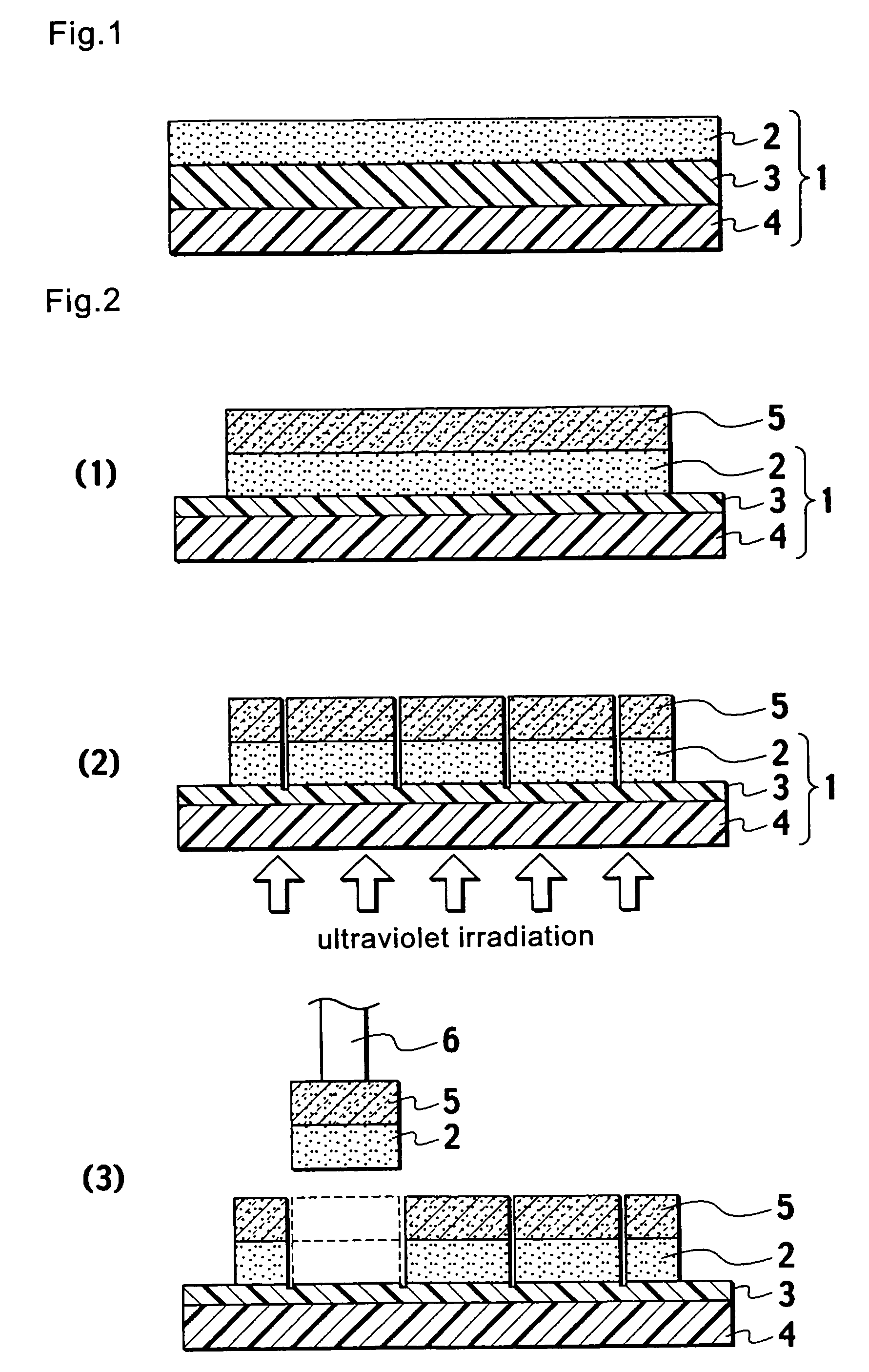

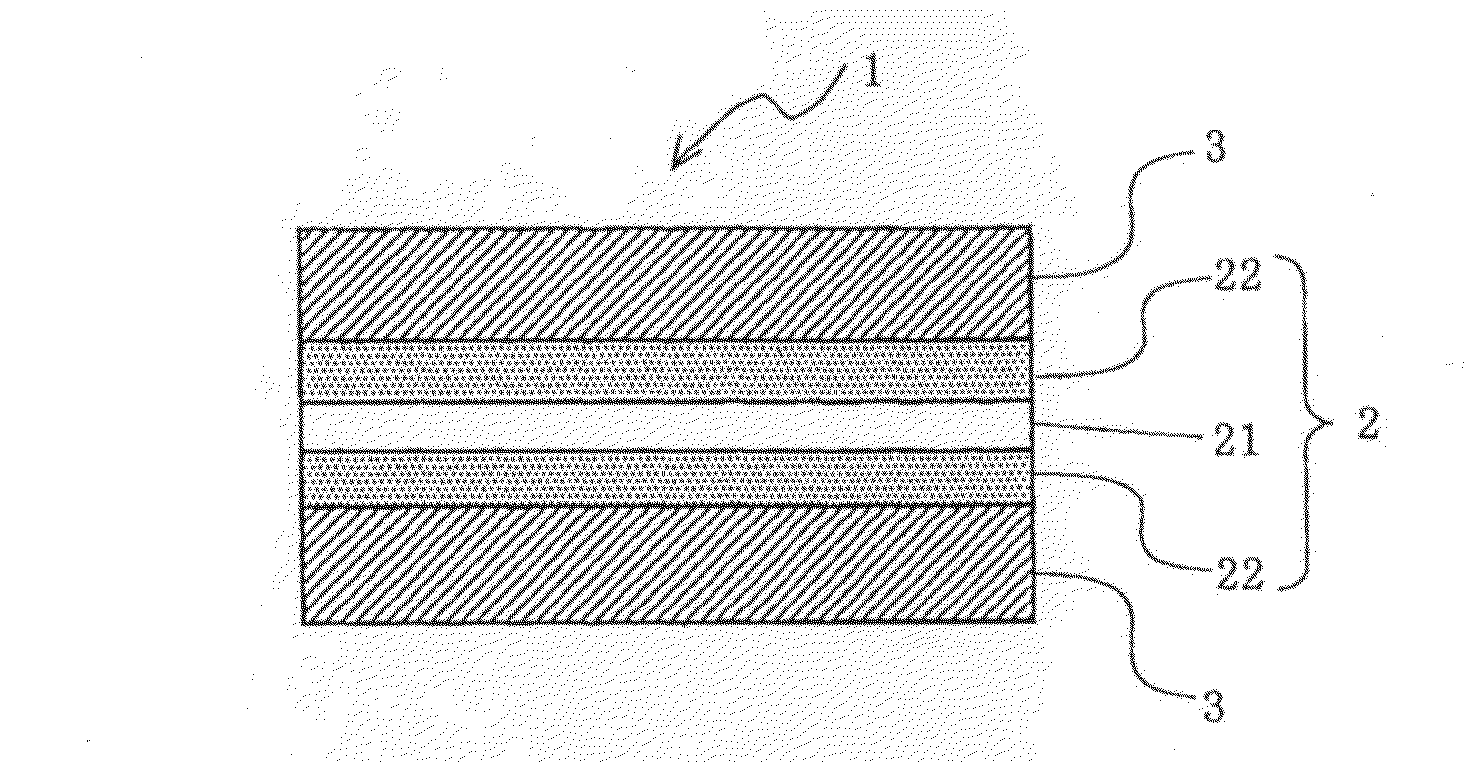

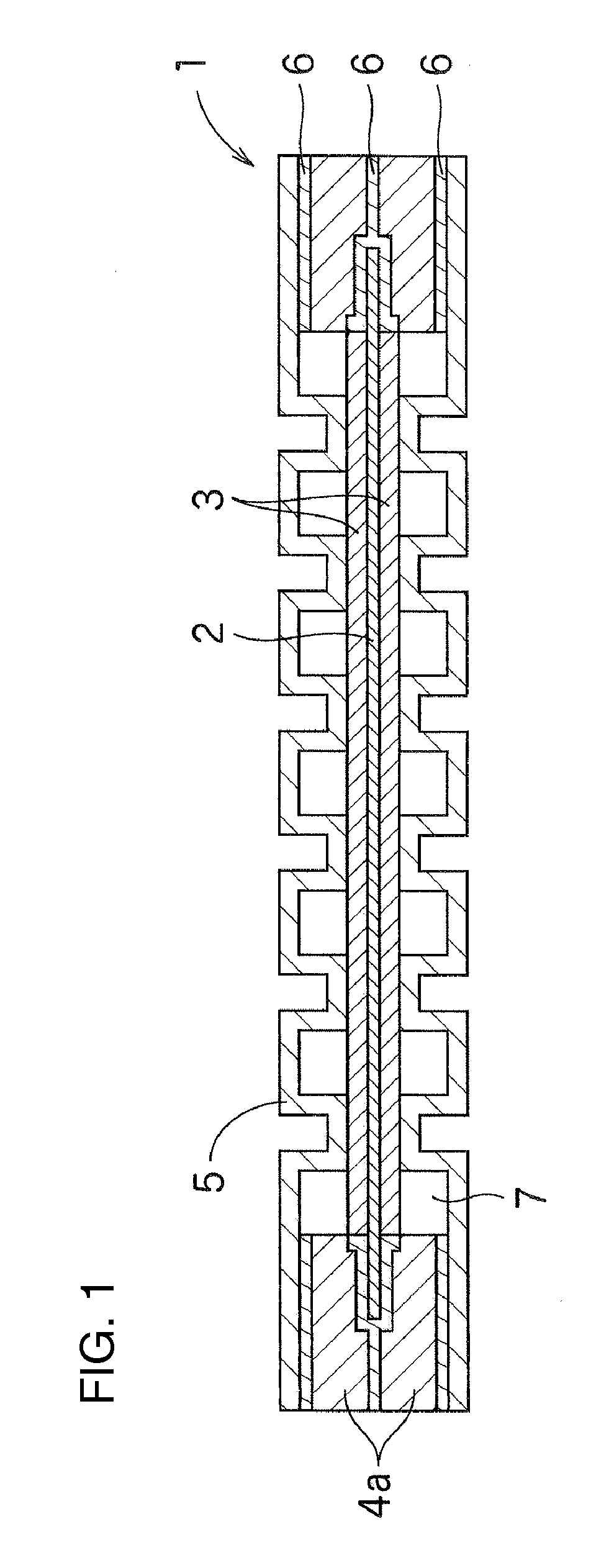

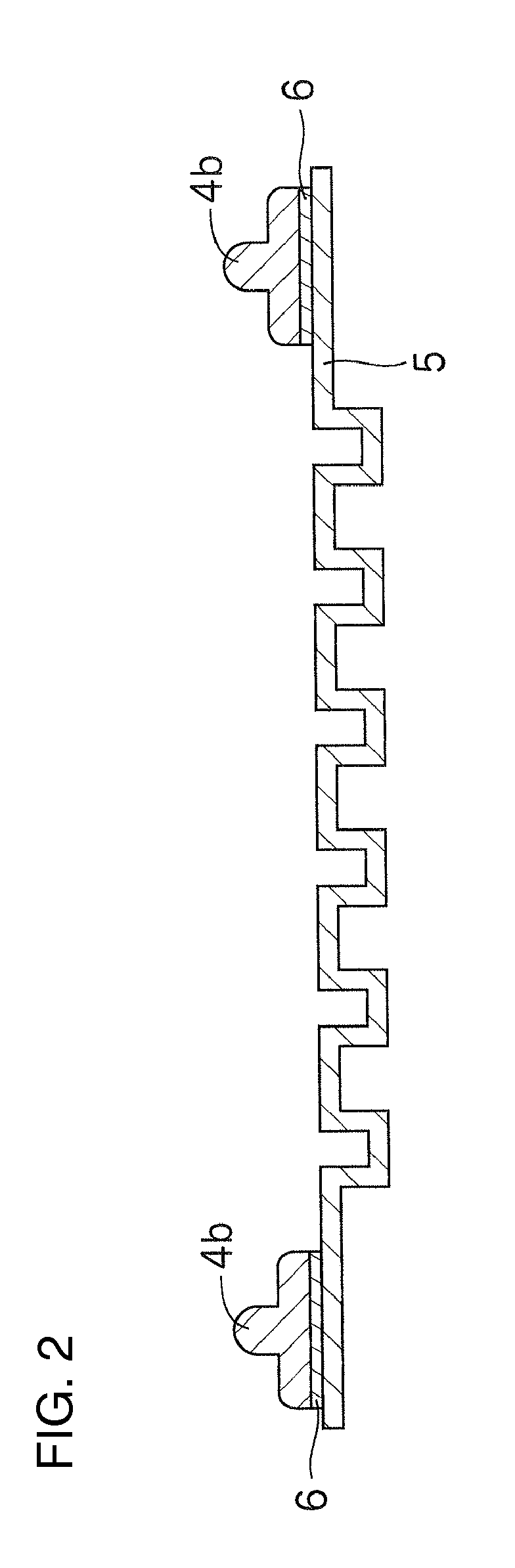

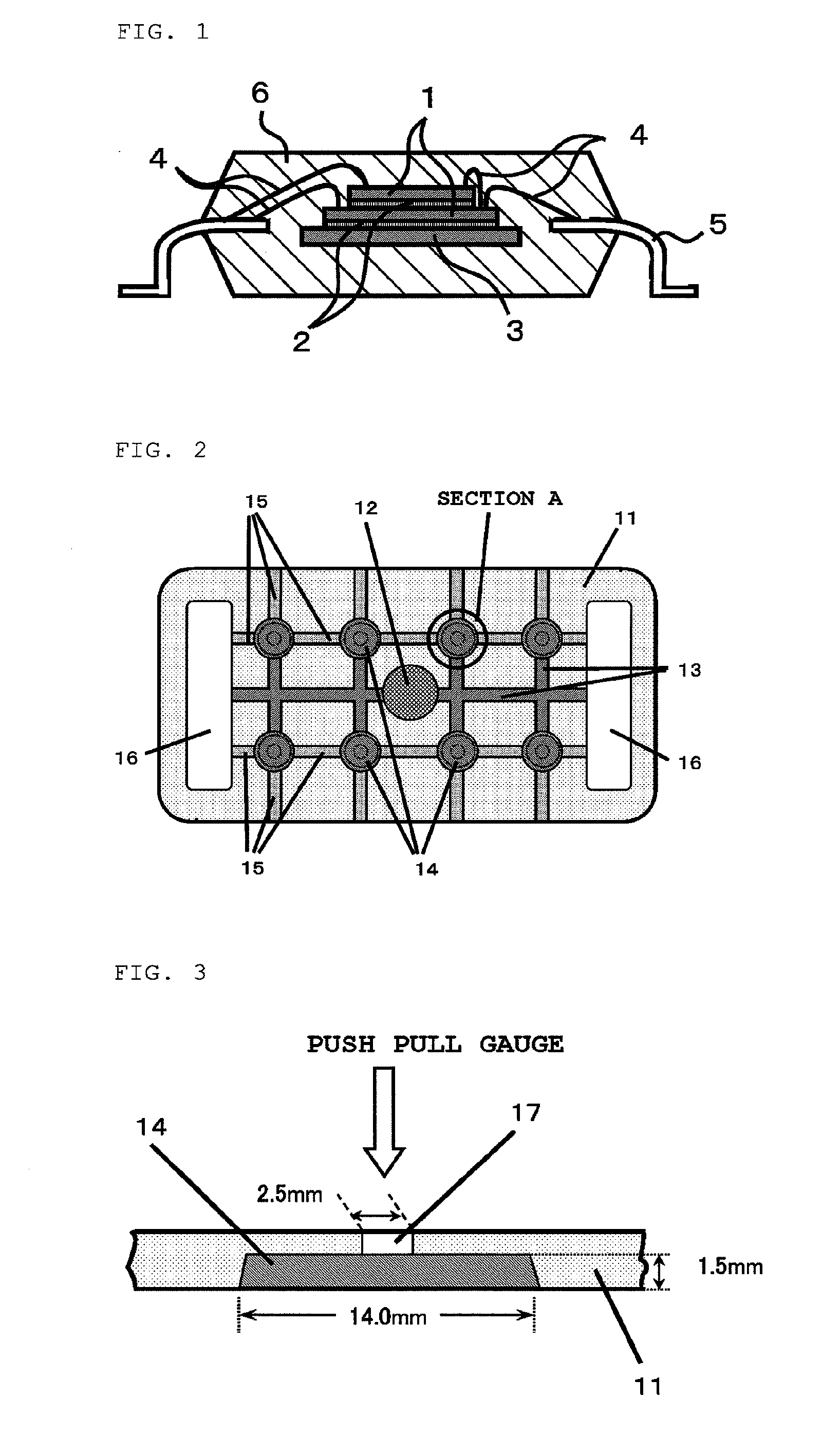

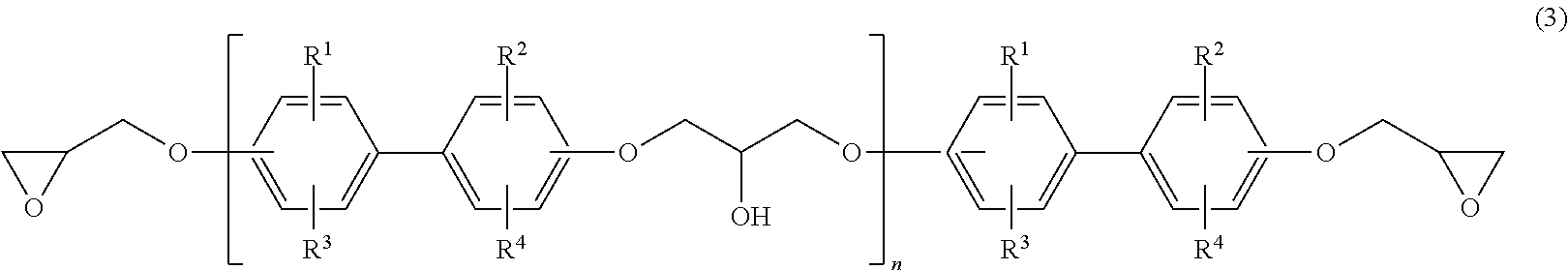

Dicing/die bonding sheet

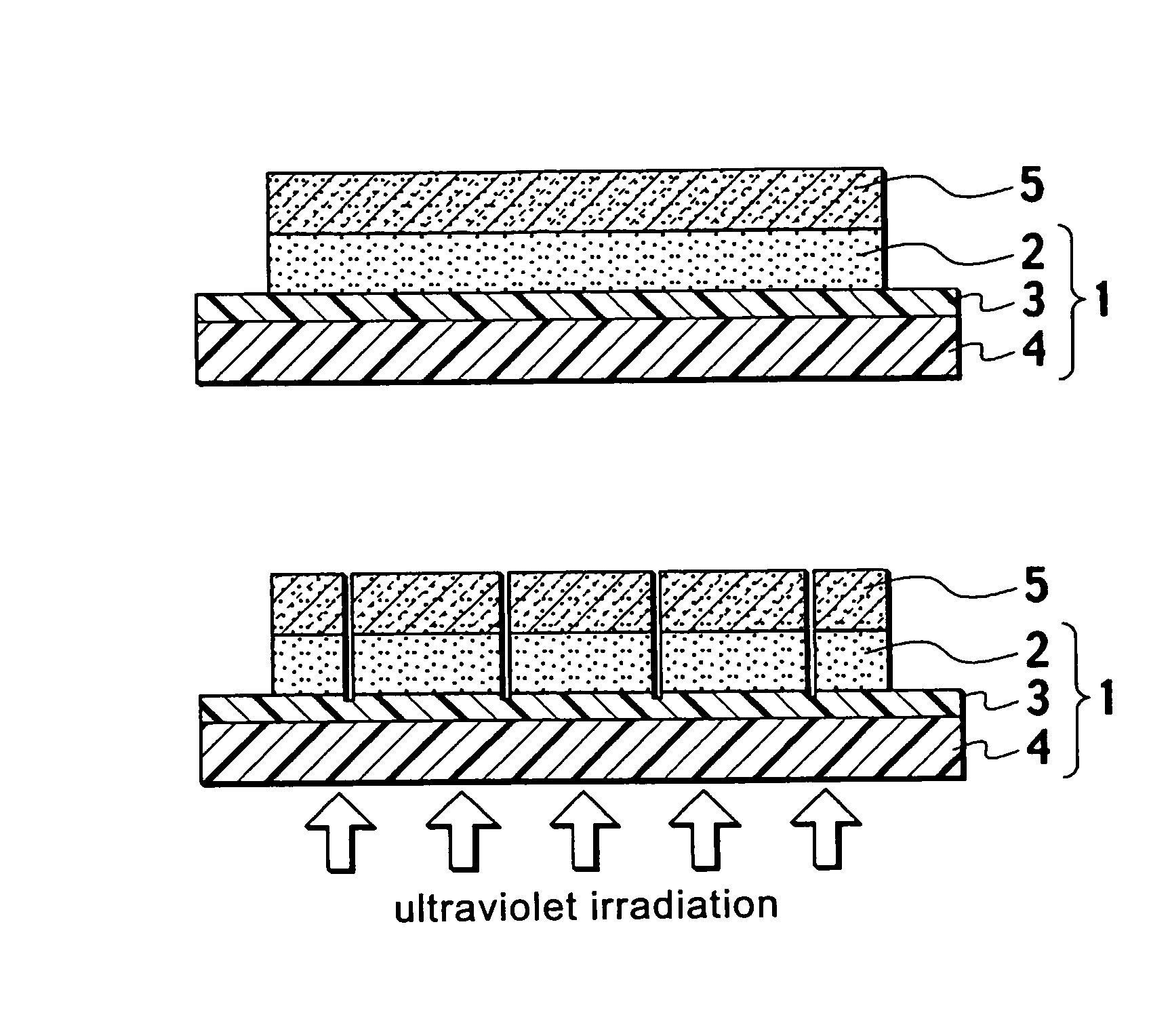

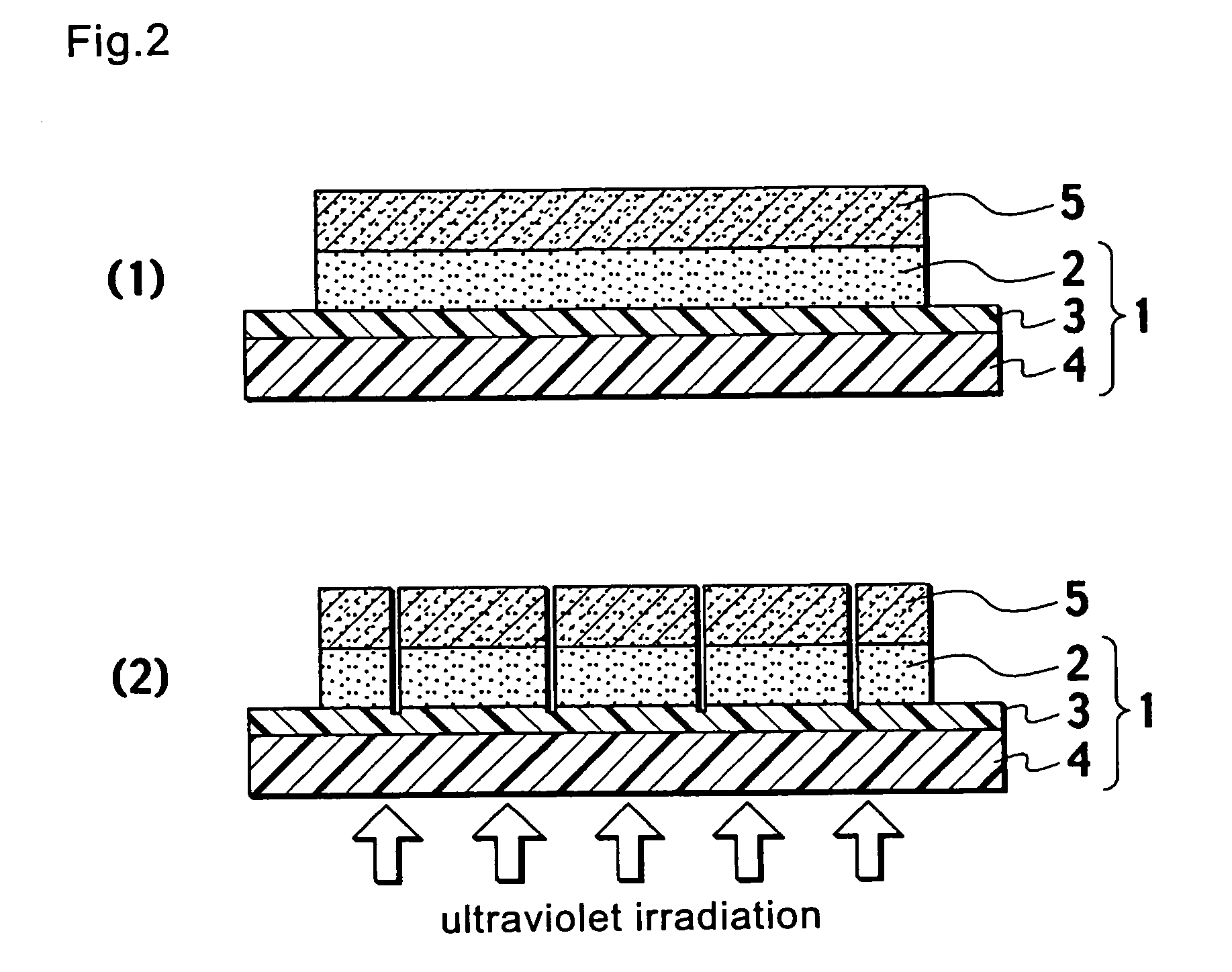

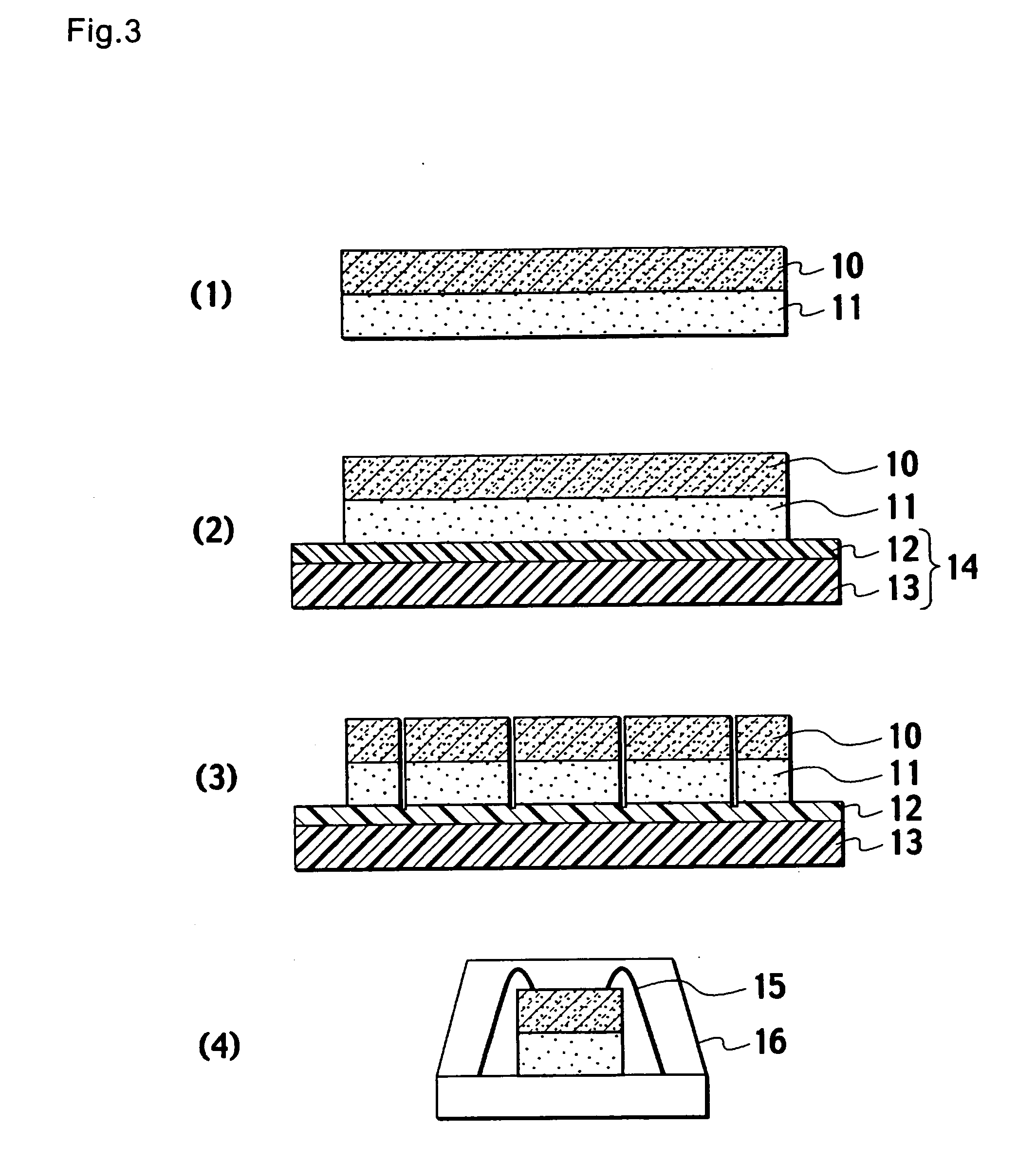

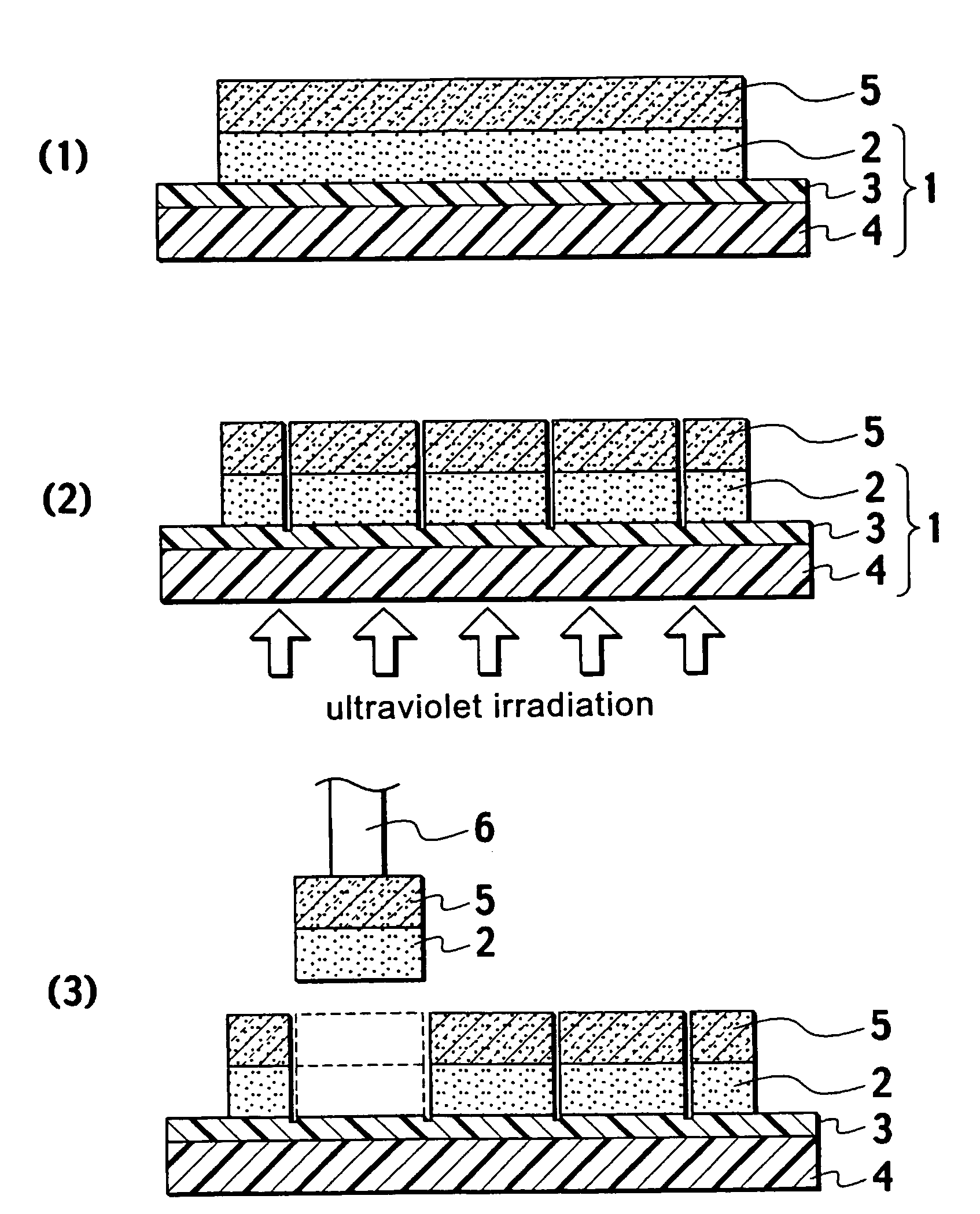

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

Dicing/die bonding sheet

ActiveUS7517724B2Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

Owner:RESONAC CORPORATION +1

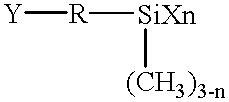

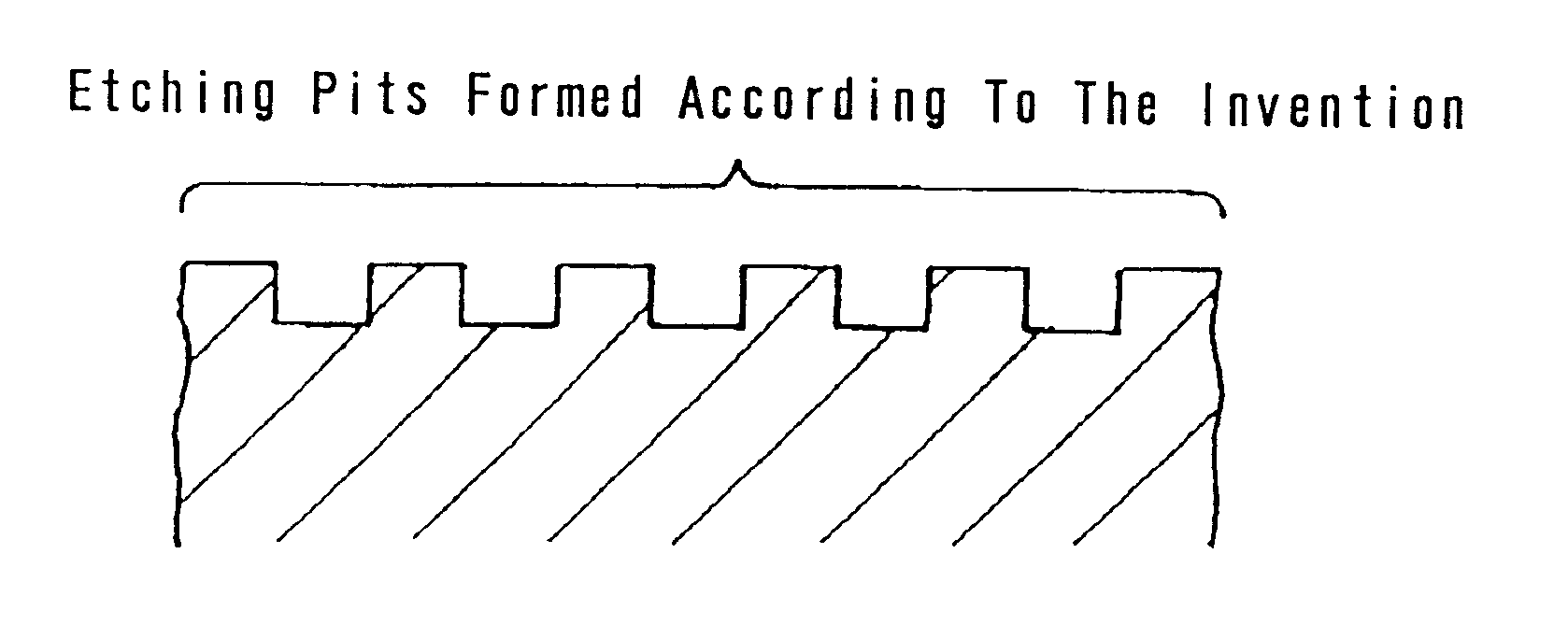

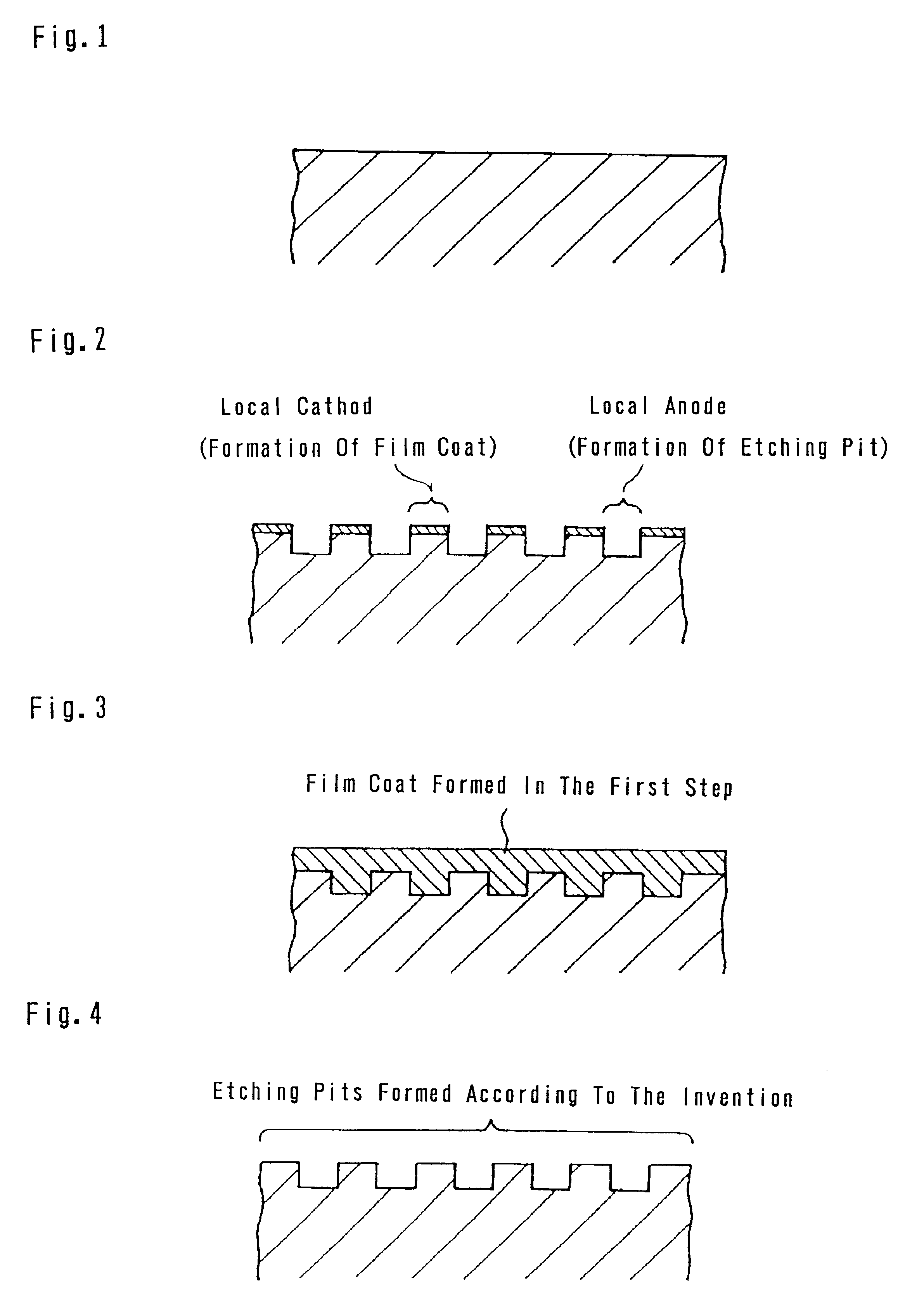

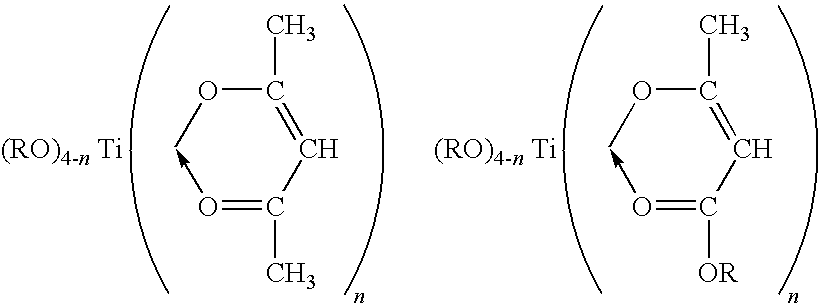

Surface treatment process of metallic material and metallic material obtained thereby

InactiveUS6183570B1Improve adhesionSatisfactory adhesivenessSolid state diffusion coatingThin layerMetallic materials

There is provided a surface treatment method of metal that can endow the surface of a metallic material with strong bonding force in a simple process regardless of the profile and the substance of the metallic material as well as a metallic material obtained by such a method. The method comprises a first step of conducting a chemical etching process accompanied by formation of a film coat on the metal surface and a second step of chemically removing the film coat formed on the metal surface in the first step. If necessary, it may further comprise a third step of forming a thin layer on the metal surface after the second step.

Owner:NIHON PARKERIZING

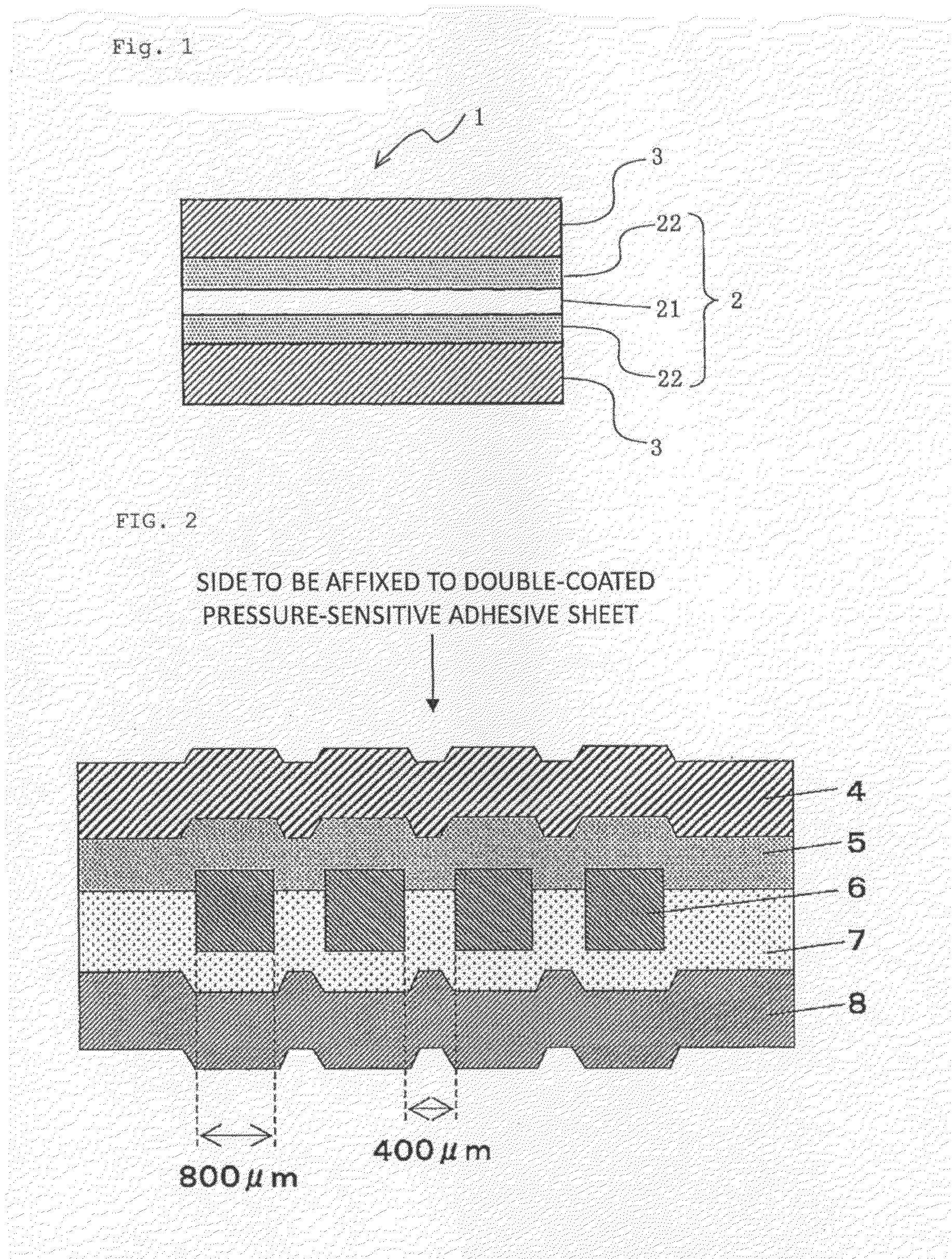

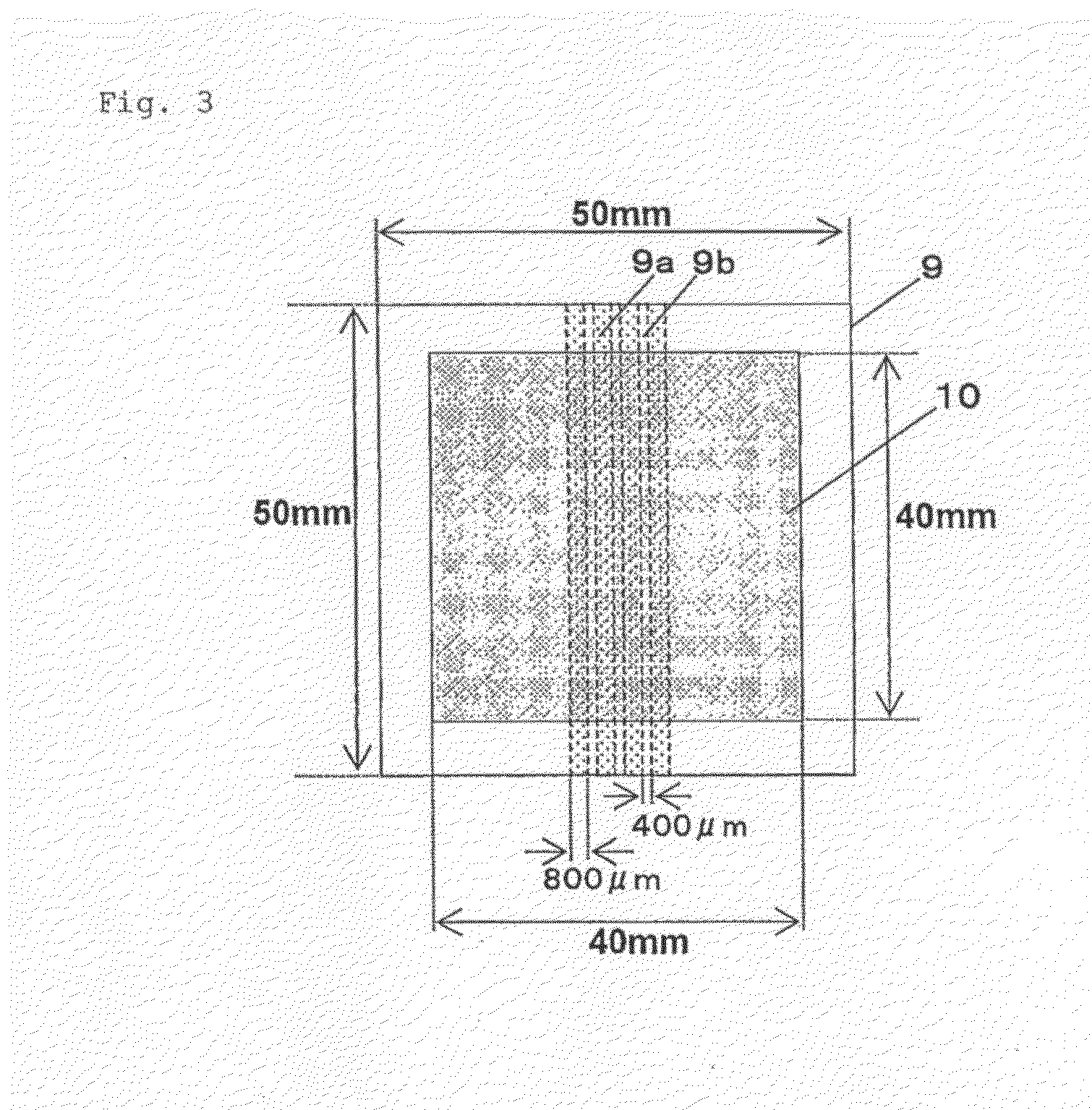

Double-coated pressure sensitive adhesive sheet

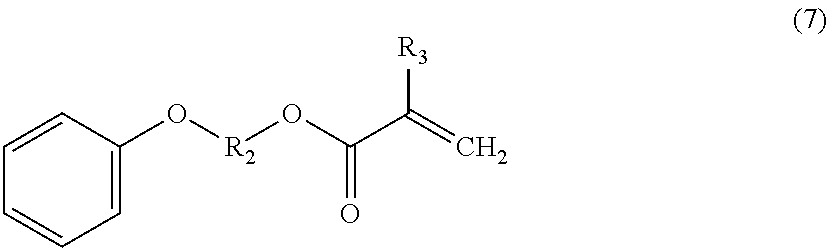

InactiveUS20100209649A1Easy to processSatisfactory adhesivenessFilm/foil adhesivesAdhesive articlesMeth-Flexible electronics

Disclosed is a double-coated pressure-sensitive adhesive sheet which includes at least a pressure-sensitive adhesive unit including a plastic base film and, present on or above both surfaces thereof, pressure-sensitive adhesive layers; and non-silicone release liners present on both surfaces of the pressure-sensitive adhesive unit. The pressure-sensitive adhesive layers are each formed from an acrylic polymer containing, as essential monomer components, an alkyl (meth)acrylate whose alkyl moiety being a linear or branched-chain alkyl group having 2 to 14 carbon atoms and a polar-group-containing monomer. The pressure-sensitive adhesive unit has a thickness of 60 to 160 μm, and each of the two pressure-sensitive adhesive layers of the pressure-sensitive adhesive unit has a thickness of 20 μm or more. The adhesive sheet excels in processability and fittability around bumps and is usable for fixing a flexible printed circuit board or for fixing a hard disk drive component.

Owner:NITTO DENKO CORP

Primer for footwear constituting members, method for producing same, footwear constituting member, and footwear

InactiveUS20150315400A1Improve adhesionSatisfactory adhesivenessCoatingsFootwearPolymer sciencePolyolefin

The present invention provides a primer for footwear constituting members, wherein the primer includes an acid-modified polyolefin resin and a medium; the acid-modified polyolefin resin is a copolymer including an olefin unit and an unsaturated carboxylic acid unit; the copolymer includes as the olefin unit, a propylene unit (A) and an olefin unit (B) other than the propylene unit; the mass ratio (A / B) between the propylene unit (A) and the olefin unit (B) other than the propylene unit is 60 / 40 to 95 / 5; and the content of the unsaturated carboxylic acid unit is 0.1 to 10 parts by mass in relation to 100 parts by mass of the total amount of (A) and (B).

Owner:UNITIKA LTD

Urethane resin composition, coating agent, laminate, and leather-like sheet, use of urethane resin composition for forming surface skin layer of leather-like sheet

InactiveUS20130136913A1Satisfies secondary adhesivenessReduce polaritySynthetic resin layered productsAnimal housingPolyolAdhesive

A problem to be solved by the present invention is to provide a urethane resin composition capable of forming a film having excellent adhesiveness to an adhesive, a putty material, and the like and having excellent durability such as moisture-heat resistance, hydrolysis resistance, and the like. The present invention relates to a urethane resin composition containing a urethane resin (C) produced by reacting a polyol (A) with a polyisocyanate (B), the polyol (A) containing a polyether polyol (a1), which has an oxyethylene structure (a1-1) and an oxyalkylene structure (a1-2) other than the oxyethylene structure (a1-1), and a polyoxytetramethylene glycol and / or a polycarbonatediol (a3), wherein the polyether polyol has a ratio by mass [(a1-1) / (a1-2)] of the oxyethylene structure (a1-1) to the oxyalkylene structure (a1-2) in a range of 3 / 7 to 9 / 1, and the ratio by mass of the polyether polyol (a1) is 10% by mass to 50% by mass.

Owner:DAINIPPON INK & CHEM INC

Polyfunctional vinyl aromatic copolymer, process for producing the same, and resin composition

InactiveUS8404797B2Improve the heating effectIncrease resistanceSurgical adhesivesPhotomechanical apparatusPolymer scienceEnd-group

Owner:NIPPON STEEL CHEMICAL CO LTD

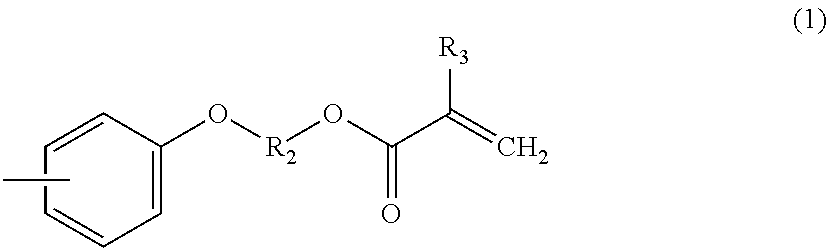

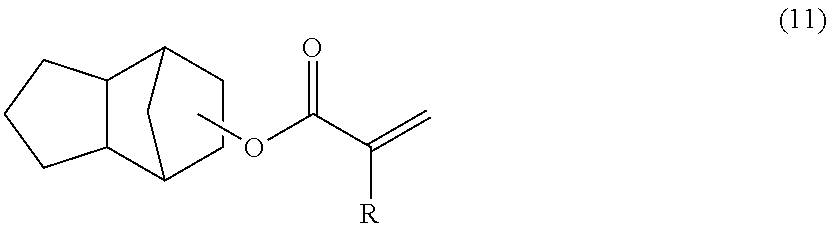

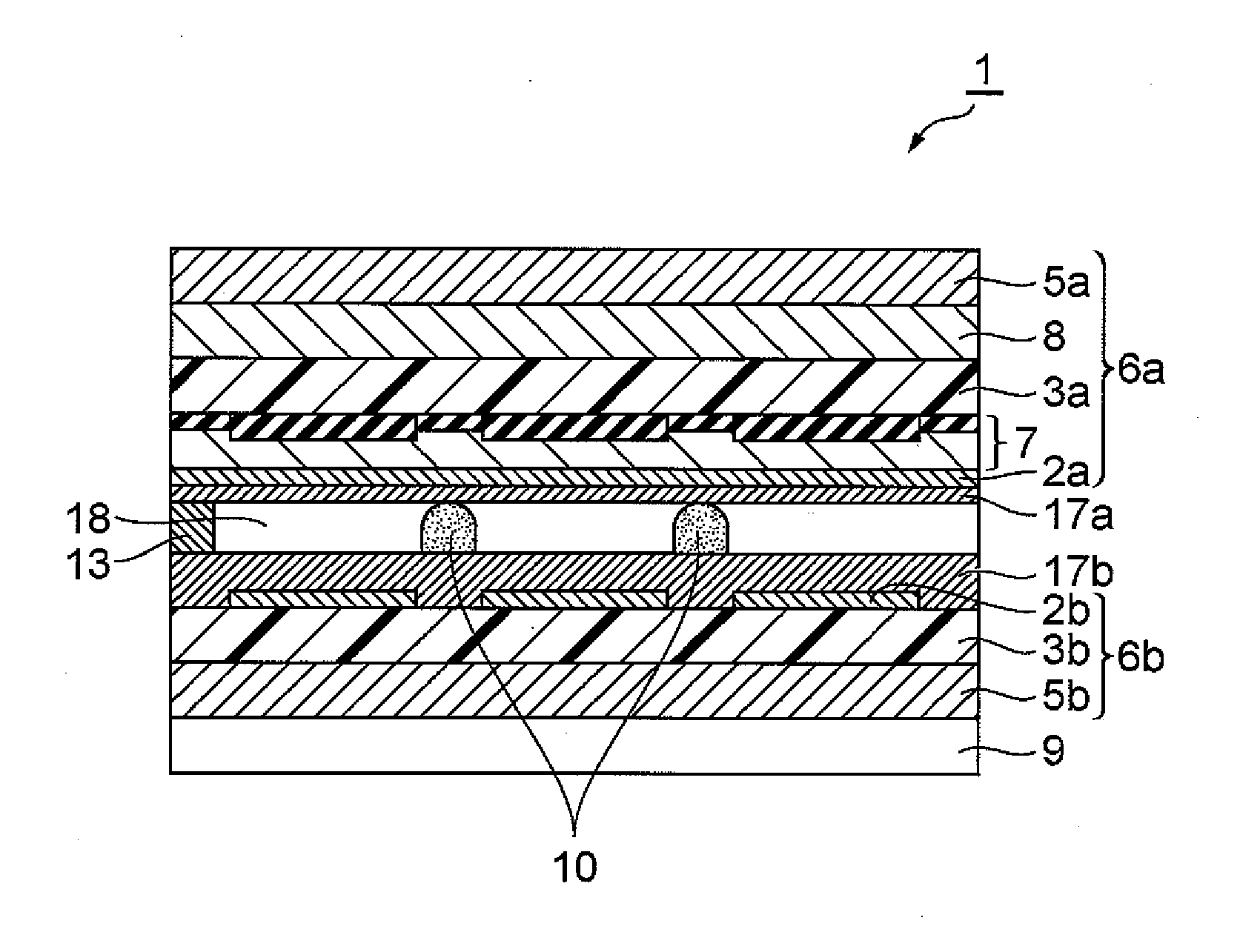

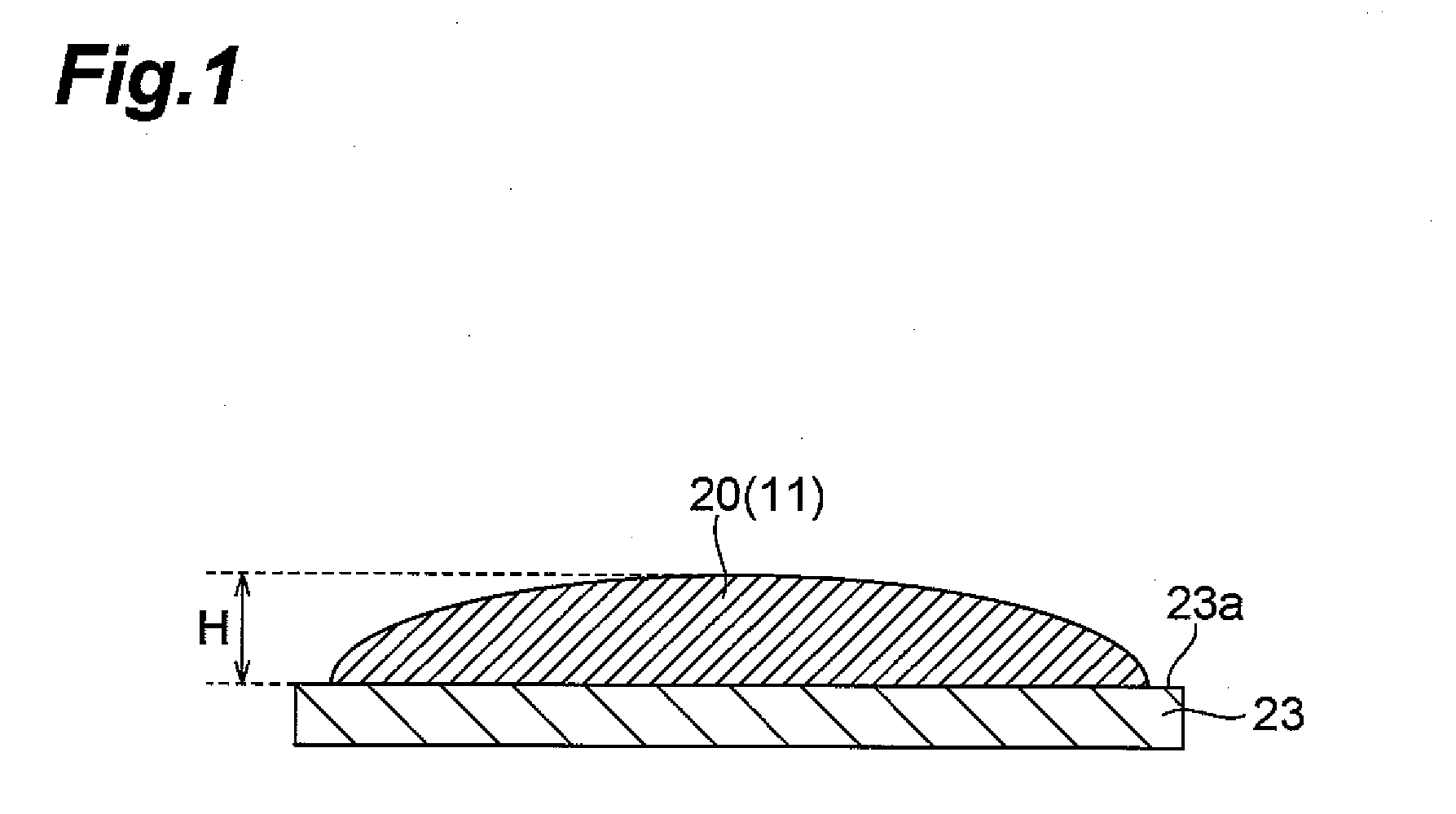

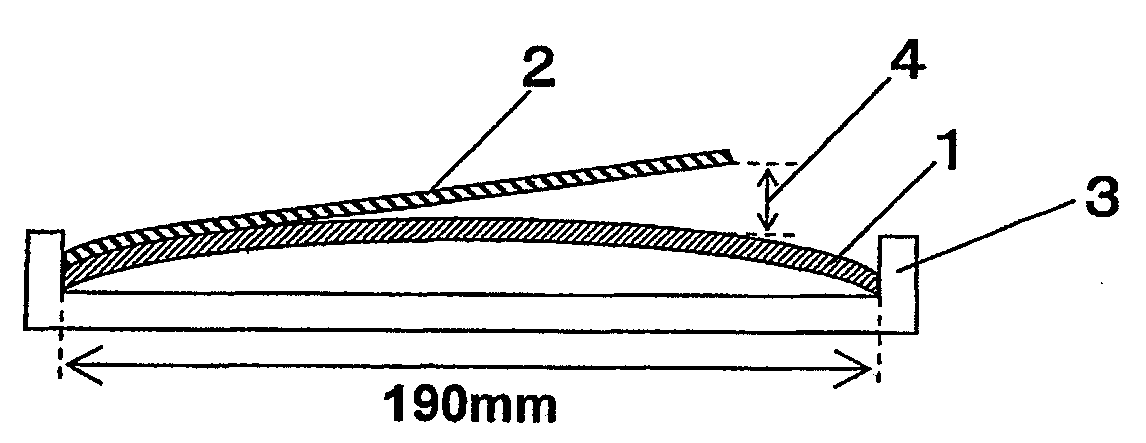

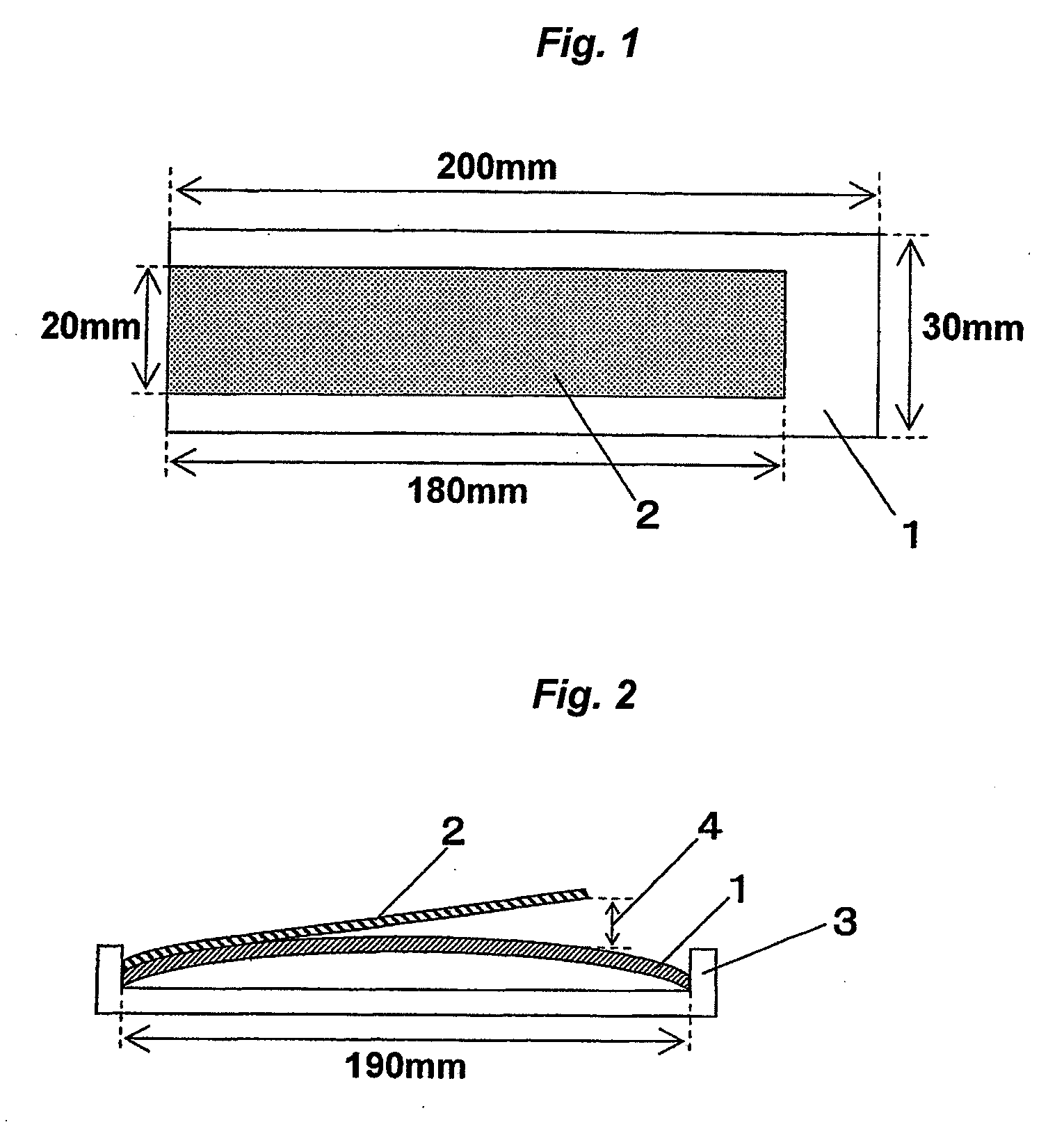

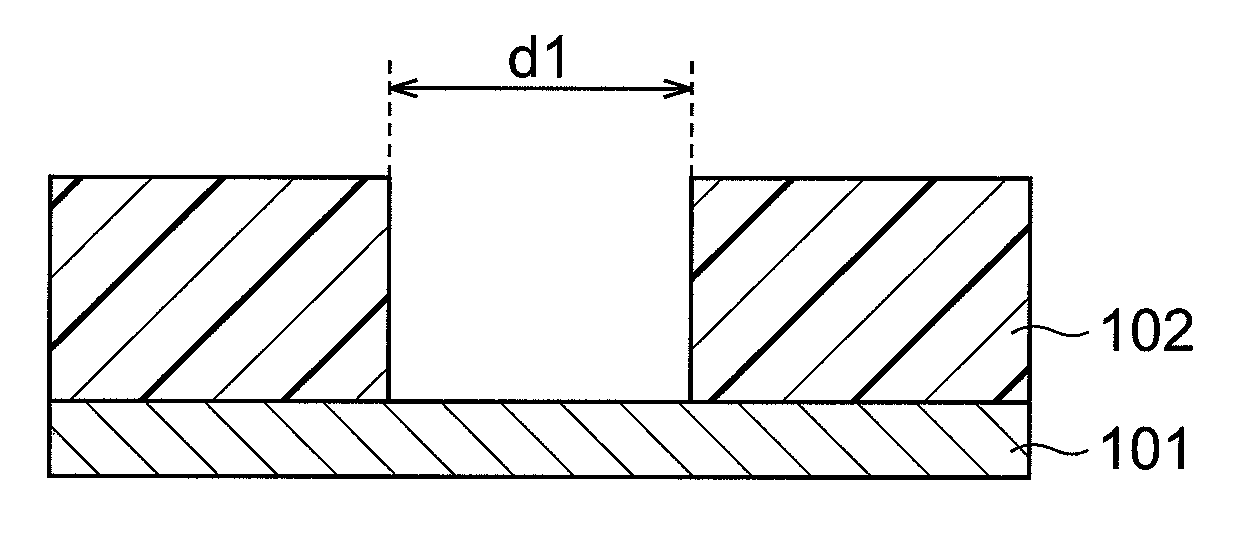

Process for producing spacer for liquid crystal display apparatus, ink for spacer formation, liquid crystal display appartus and process for manufacturing the same

InactiveUS20110141428A1Solve the lack of heightExcellent positional precisionNon-linear opticsCrystallographyLiquid-crystal display

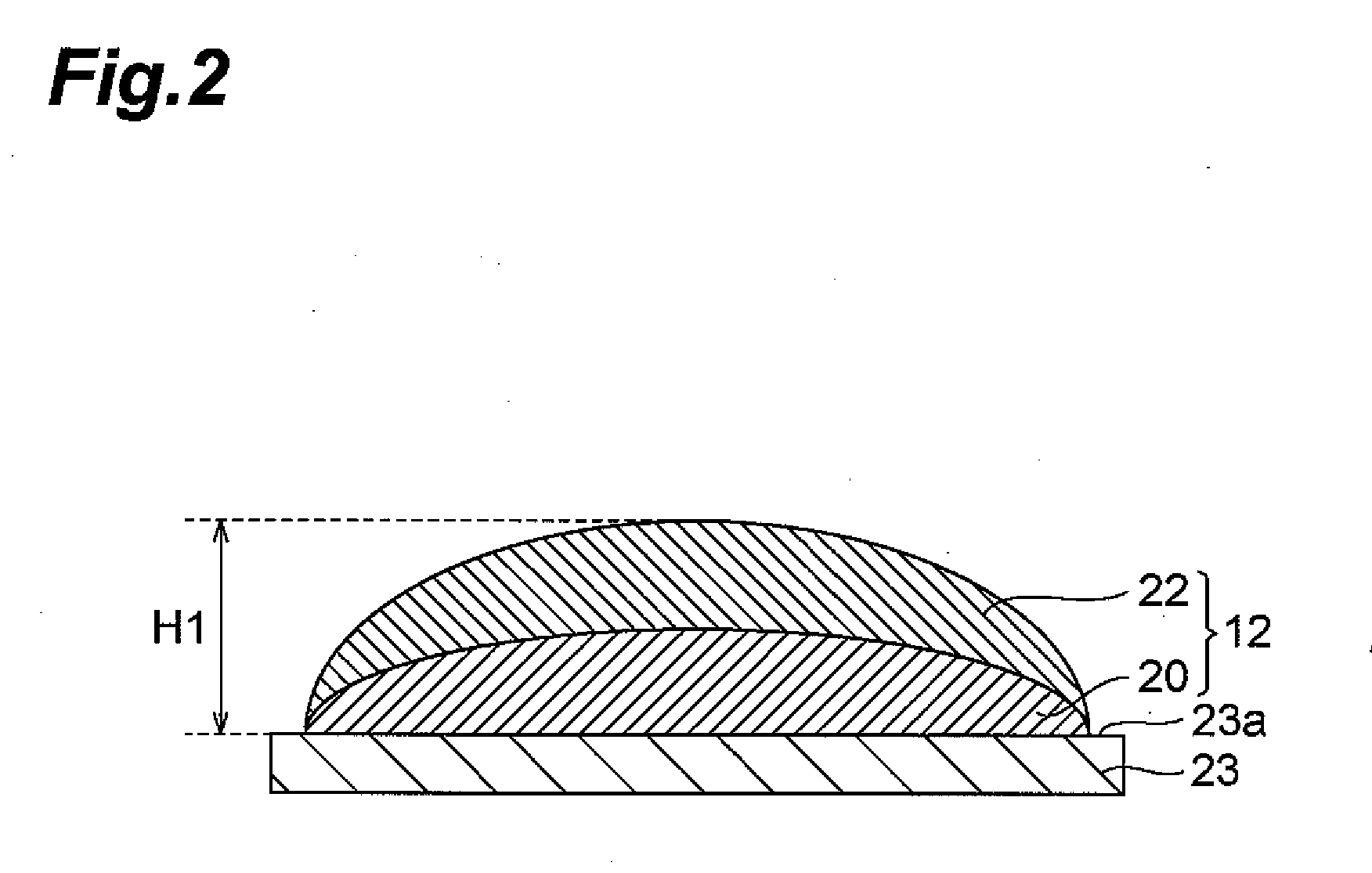

A process for producing a spacer for a liquid crystal display apparatus whereby an ink-jet method is used to print droplets composed of an ink that contains a resin and a solvent that dissolves it but that contains essentially no solid particles on a substrate 23, and the solvent is removed from the droplets on the substrate 23 to form a spacer 11 situated at a prescribed location on the substrate 23, wherein A in the following formula (1) is −10 to 15 mJ / m2, where X mN / m is the surface tension of the ink at 25° C. and Y mJ / m2 is the surface free energy of the substrate 23 at 25° C.A=X−Y (1)

Owner:HITACHI CHEM CO LTD

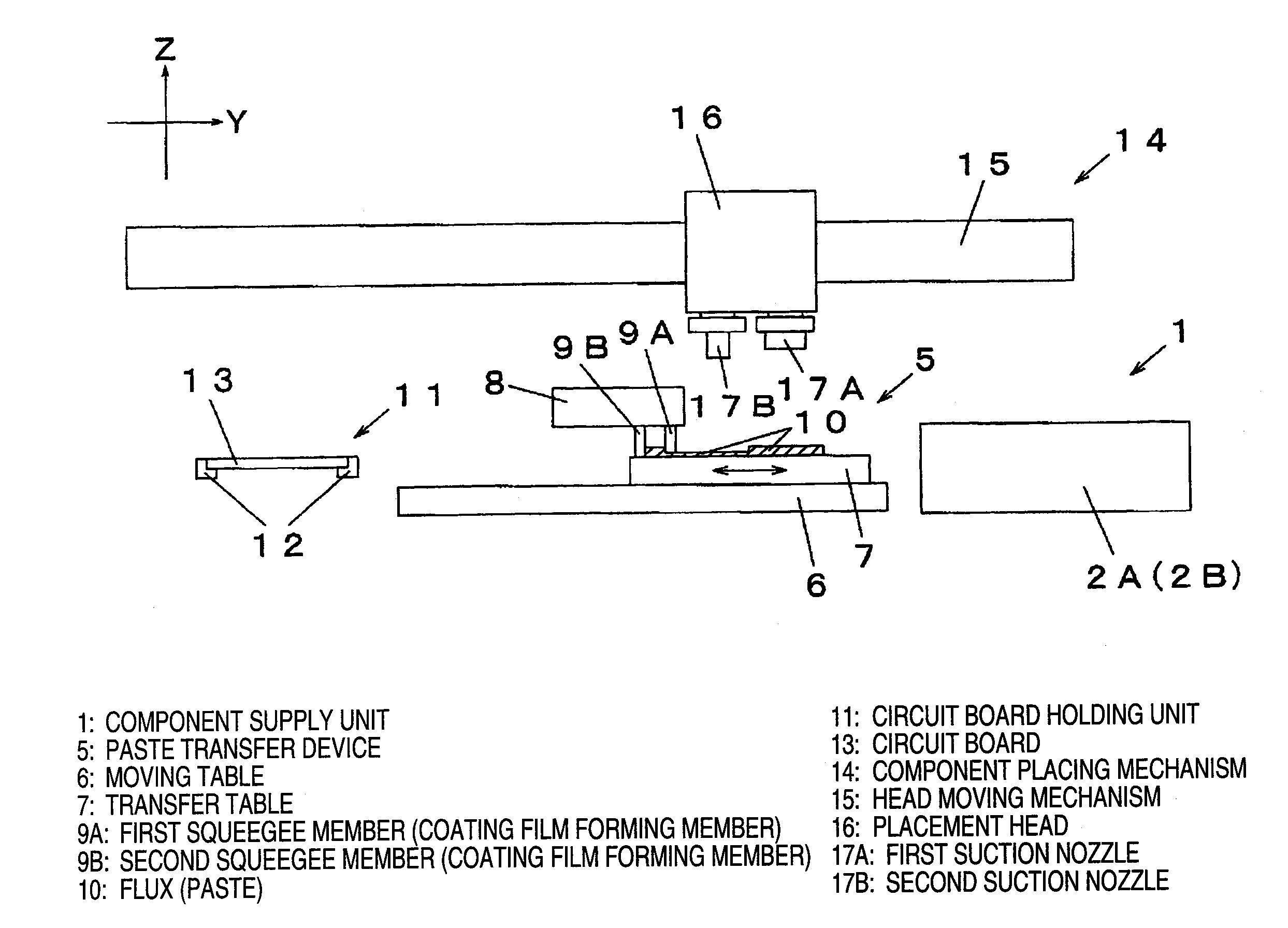

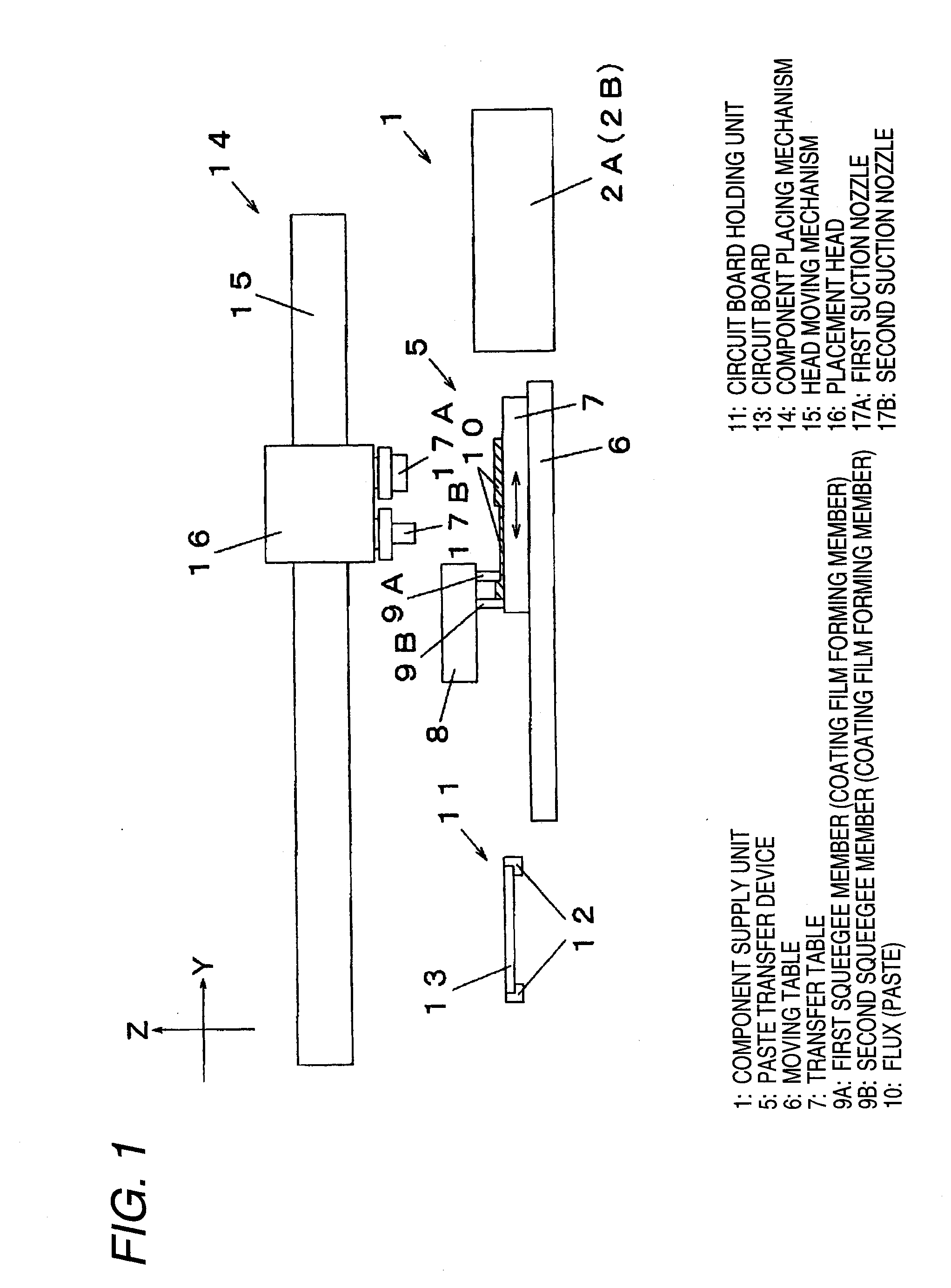

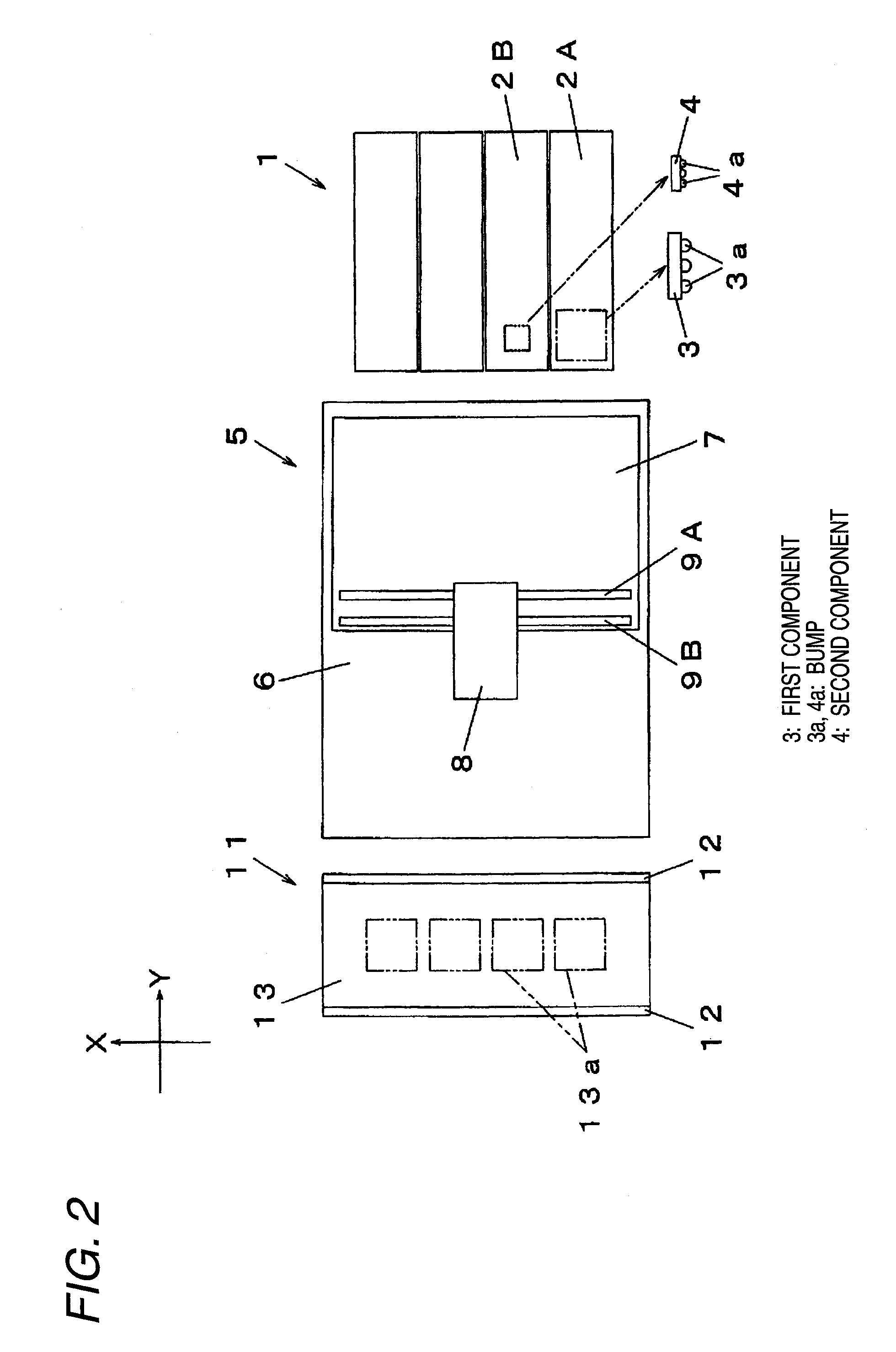

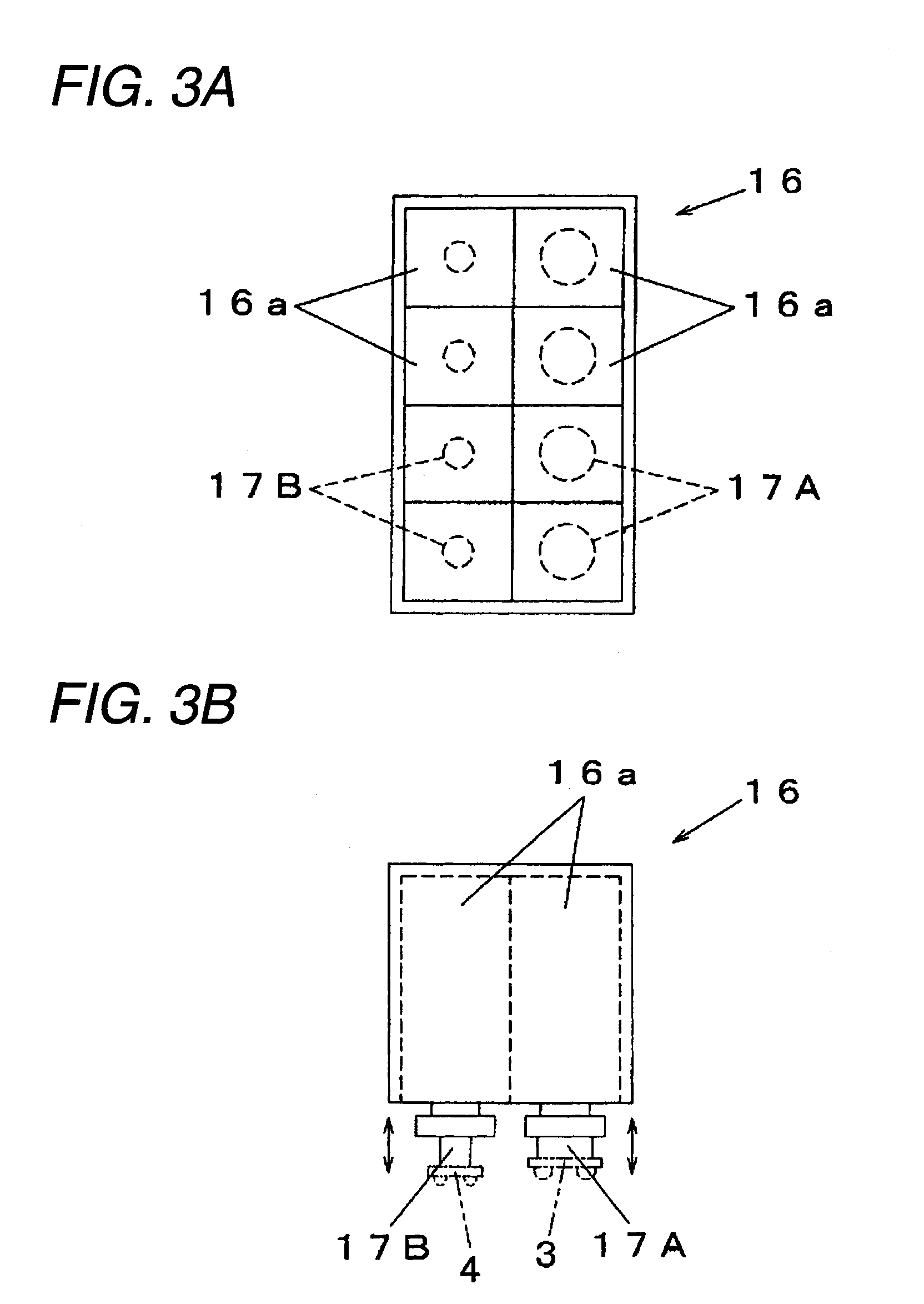

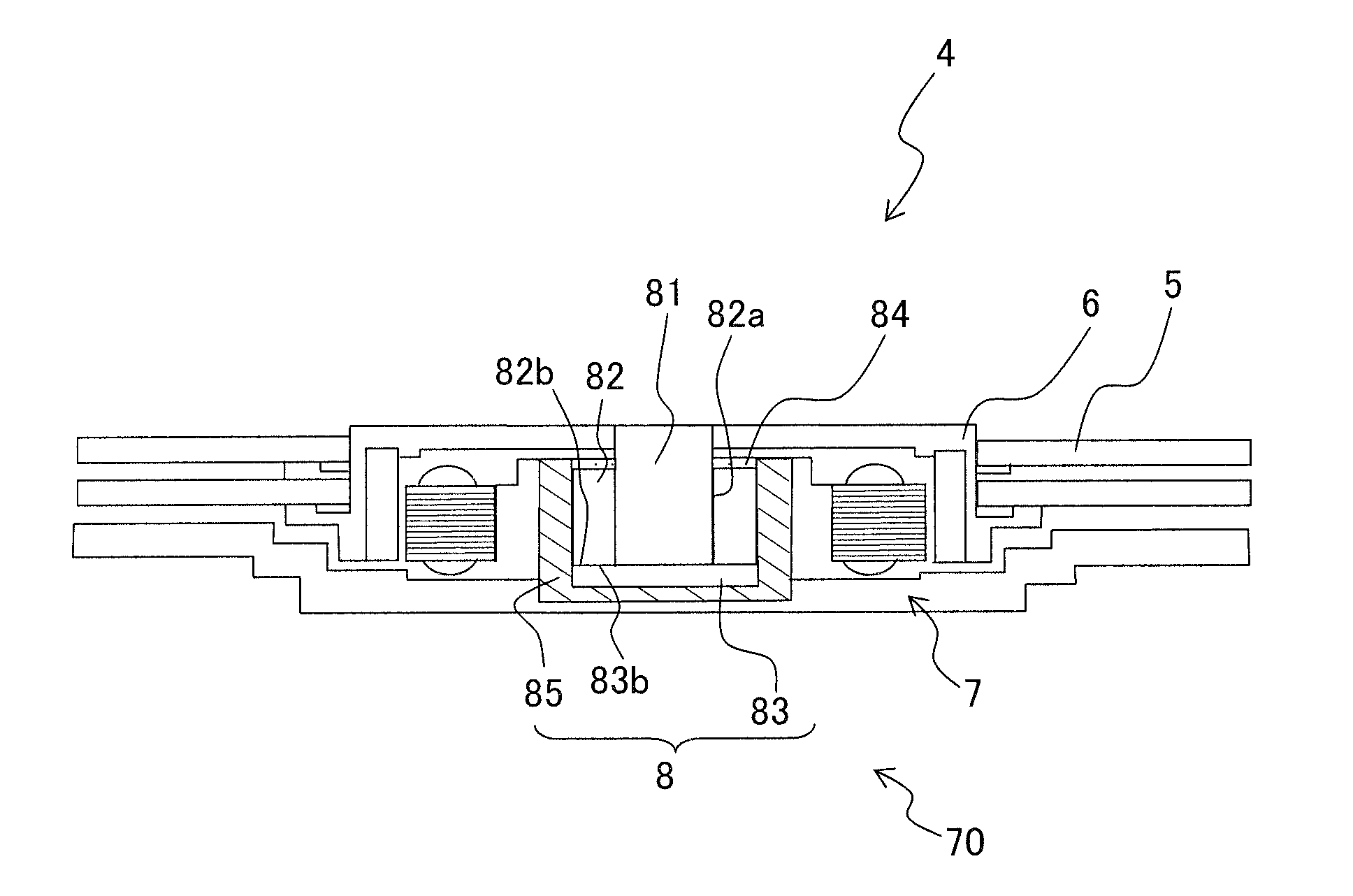

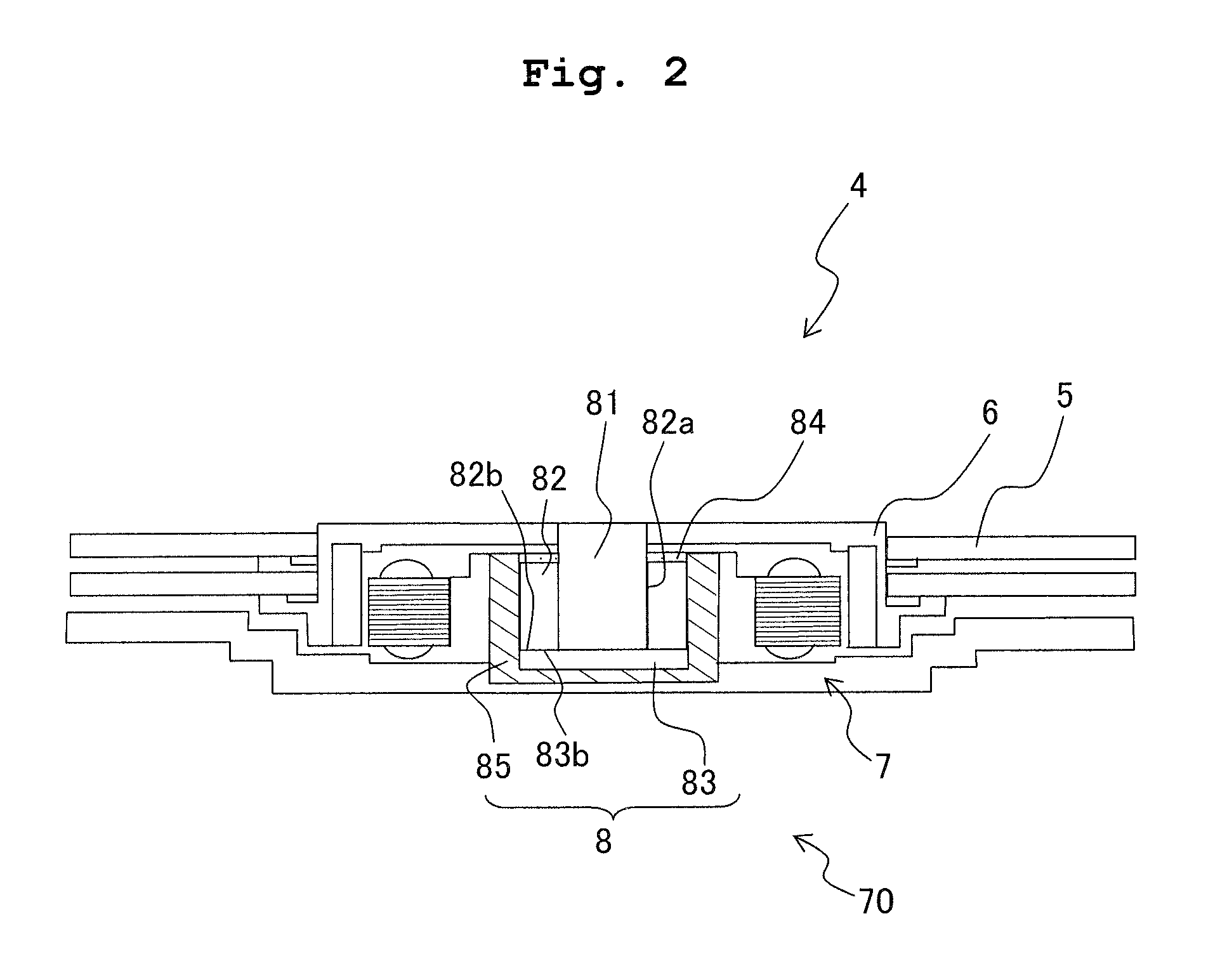

Component mounting apparatus and component mounting method

InactiveUS7712652B2Components is relatively effectiveSatisfactory adhesivenessPrinted circuit assemblingCooking-vessel materialsSolder pasteMechanical engineering

Owner:PANASONIC CORP

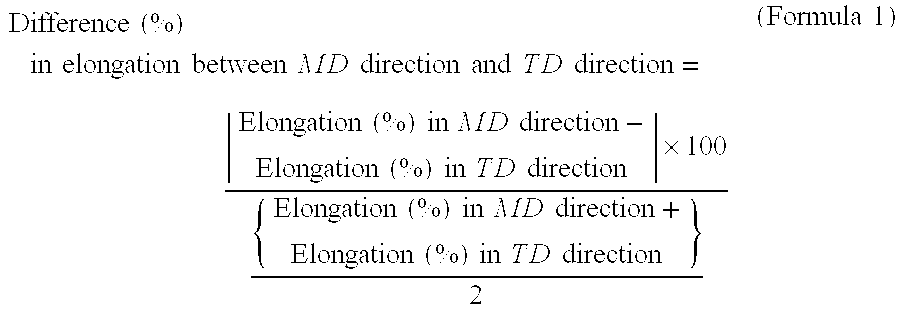

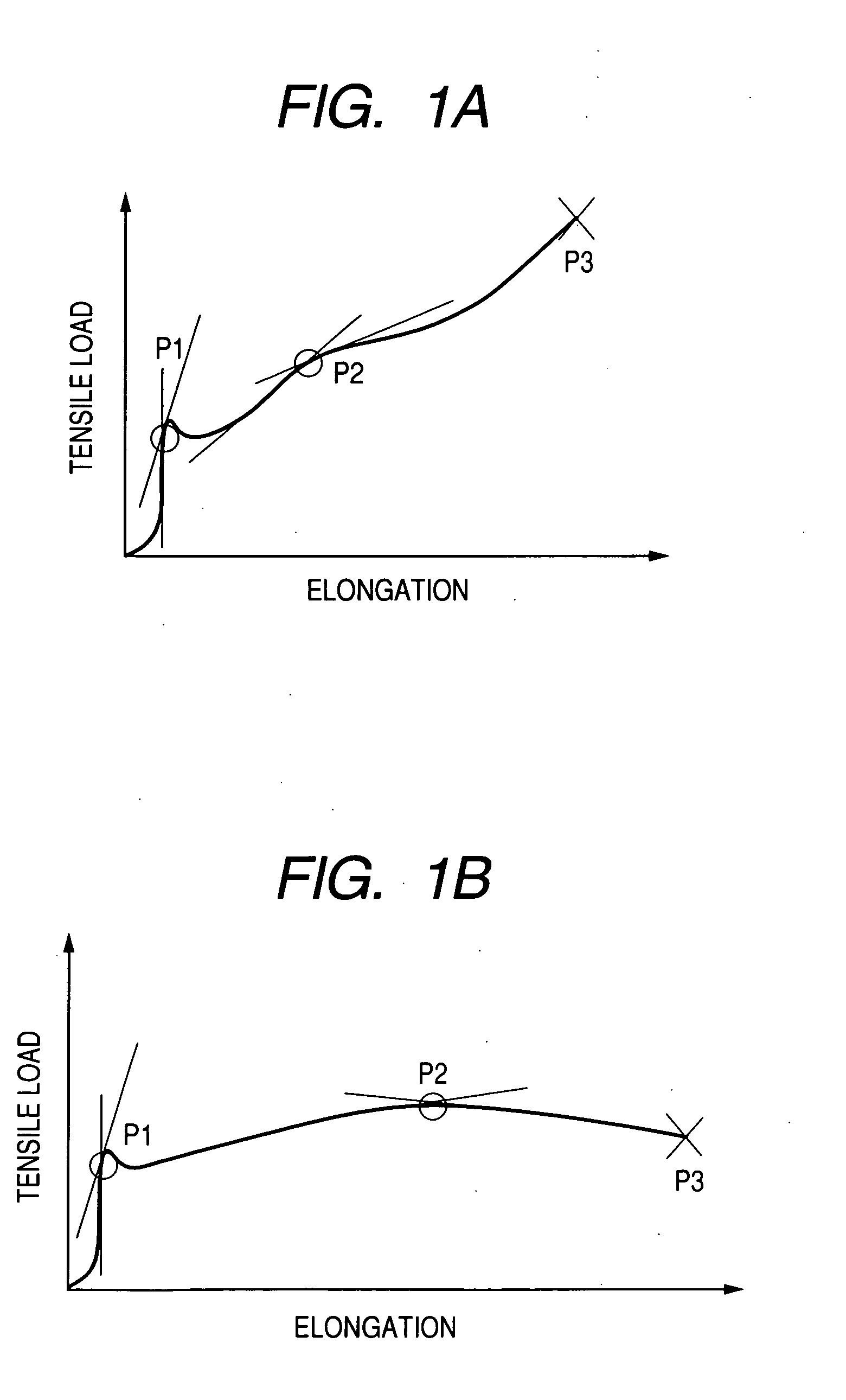

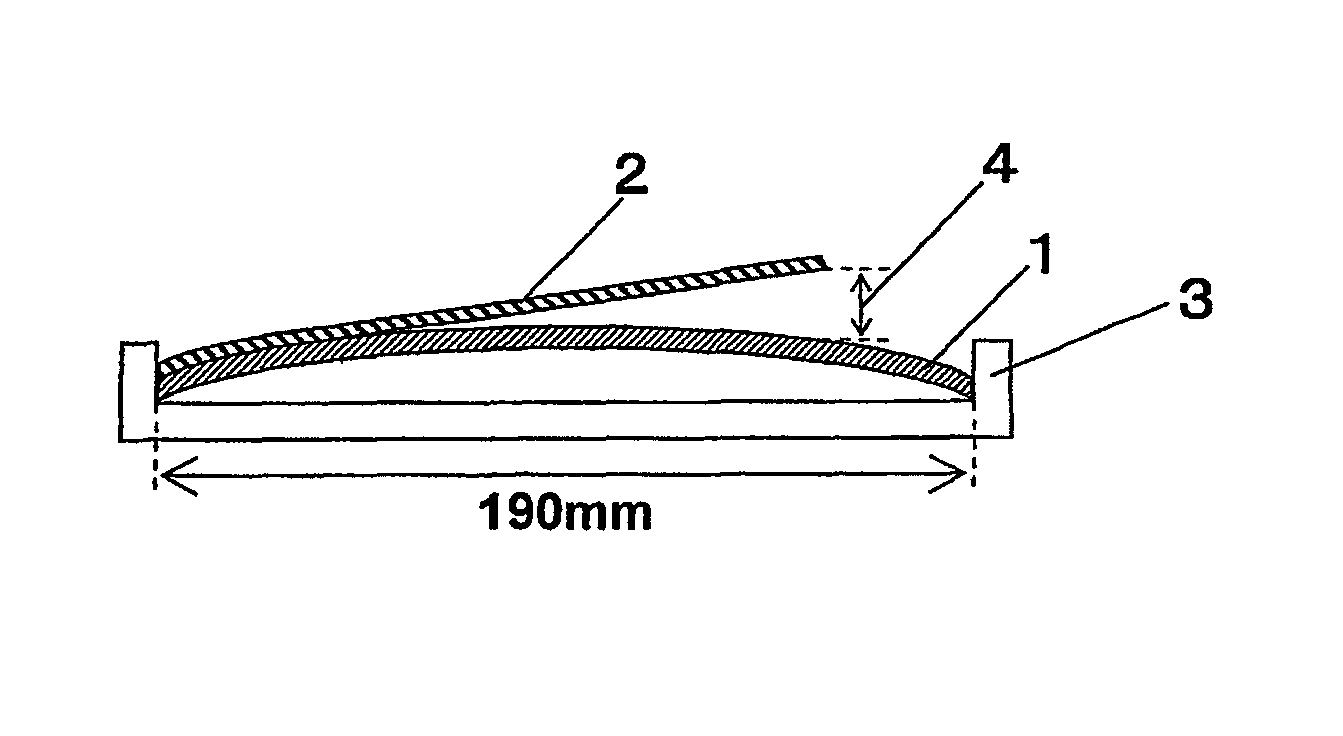

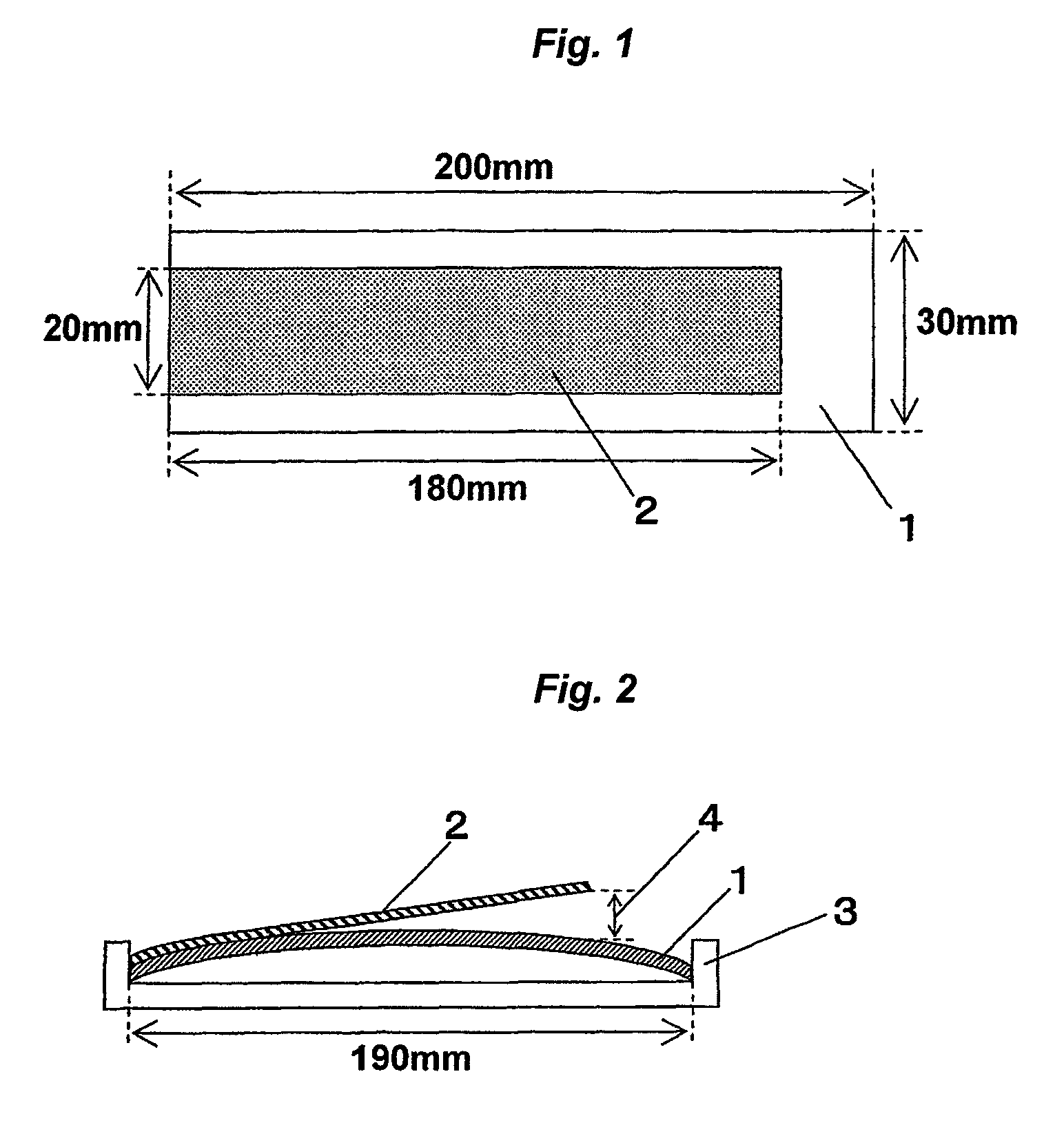

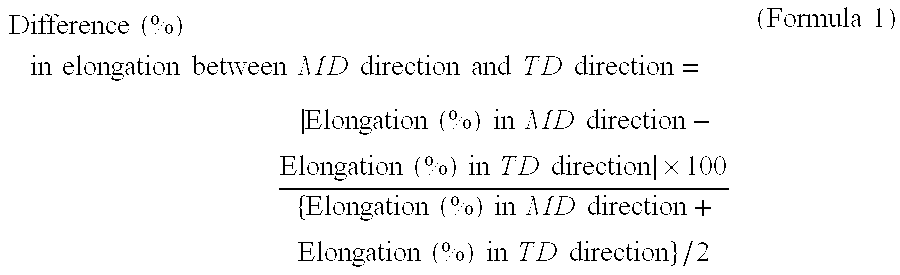

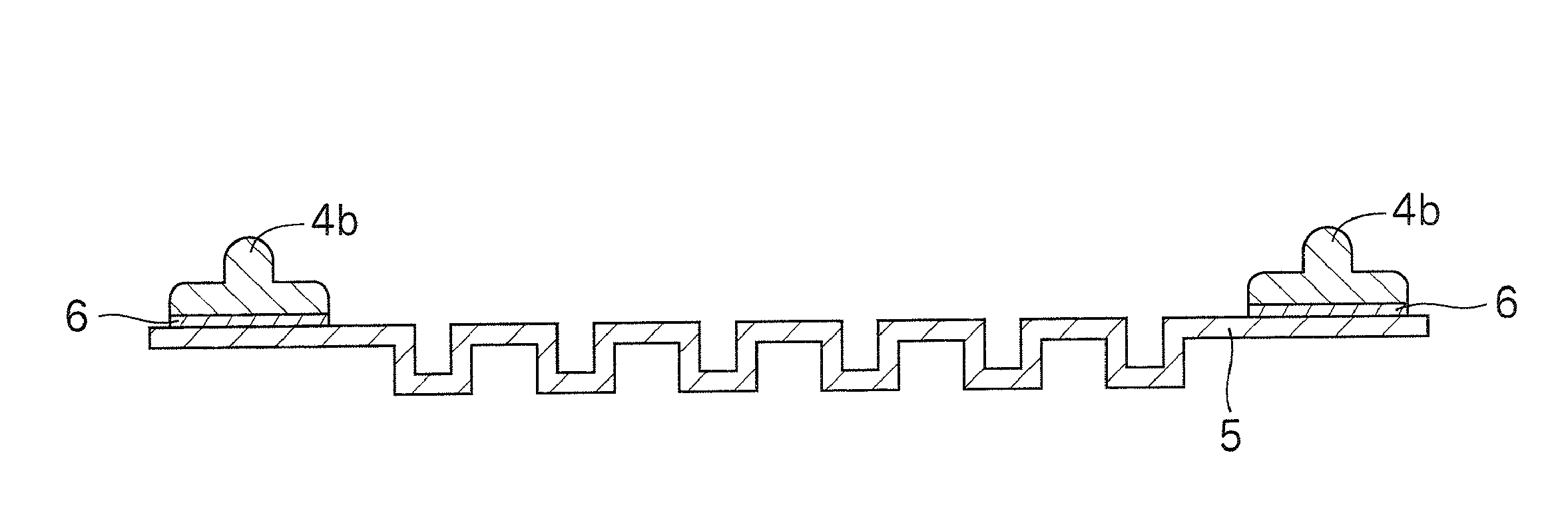

Double-sided adhesive tape for fixing decorative sheet for speaker and method for attaching decorative sheet for speaker to housing

InactiveUS20090272491A1Improve adhesionStable separationAdhesive processesSynthetic resin layered productsEngineeringNonwoven fabric

The present invention provides a double-sided adhesive tape for fixing a decorative sheet for speaker, which includes a nonwoven fabric substrate, an acrylic pressure-sensitive adhesive layer A disposed on one side of the nonwoven fabric substrate and an acrylic pressure-sensitive adhesive layer B disposed on the other side of the nonwoven fabric substrate, in which the adhesive tape has a tensile strength in the tape flow (MD) direction of 8 N / 10 mm or more and a tensile length in the width (TD) direction of 8 N / 10 mm or more. The double-sided adhesive tape is excellent in the adhesion performance to a housing and a decorative sheet for speaker and at the same time, has excellent releasability ensuring that when separating the decorative sheet portion, smooth separation can be attained without leaving a residue of tape or pressure-sensitive adhesive on the housing portion.

Owner:NITTO DENKO CORP

Process for producing nitrile rubber-metal laminate

InactiveUS20100190018A1Prevent peelingEffectively used as seal materialPretreated surfacesSuperimposed coating processPolymer scienceNitrile rubber

A nitrile rubber solution prepared by dissolving and dispersing into an organic solvent a nitrile rubber composition comprising 100 parts by weight of nitrile rubber, 40 parts by weight or more of carbon black having a DBP oil absorption amount of 30-100 ml / 100 g (according to ASTM D1765-91), 15-100 parts by weight of silica having particle sizes of 0.01-0.1 μm, 0-40 parts by weight of other inorganic filler than the carbon black and silica, and 5-20 parts by weight of an organic peroxide, and preferably further containing 2-10 parts by weight of a silane coupling agent is applied to an adhesive layer on one side or both sides of a metallic sheet, followed by vulcanizing the coated layer, thereby forming a rubber layer.

Owner:NOK CORP

Propylene block copolymer

InactiveUS20060178486A1Satisfactory hydrophilicitySatisfactory adhesivenessCoatingsAdhesivesPolymer scienceHalogen

A polymer is provided which, even when no halogen such as chlorine is contained therein, has satisfactory adhesiveness and applicability in coating to propylene polymers as substrates and which has surface hydrophilicity. It is a propylene block copolymer characterized by being represented by the following formula (I): PP-a-R (I) (wherein PP represents a polypropylene segment in which the proportion of pentads represented by mmmm to all pentads is 10-60%; symbol a represents a group which connects PP to R; and R represents a polymer segment containing polar groups).

Owner:MITSUBISHI CHEM CORP

Sliding member, component and noise reducing method for mechanical apparatus, excluding those used for image forming apparatus

A sliding member (excluding that used for an image forming apparatus), which can maintain a satisfactory friction coefficient and reduce generation of a rubbing sound (noise) caused by a continuously sliding member, is provided. A component and a mechanical apparatus using the sliding member, and a method for reducing noise caused from a mechanical apparatus, are also provided. Additionally, a coating agent composition is provided for preparing the sliding member. The sliding member has a lubricating film contacting another member, wherein an arithmetic average roughness Ra based on JIS B0601 (2001) of a surface of the lubricating film is from 0.01-1.0 μm, and the lubricating film comprises 100 parts by mass of a coat-formable resin binder (A) and 5 to 200 parts by mass of a solid lubricant (B).

Owner:RICOH KK +1

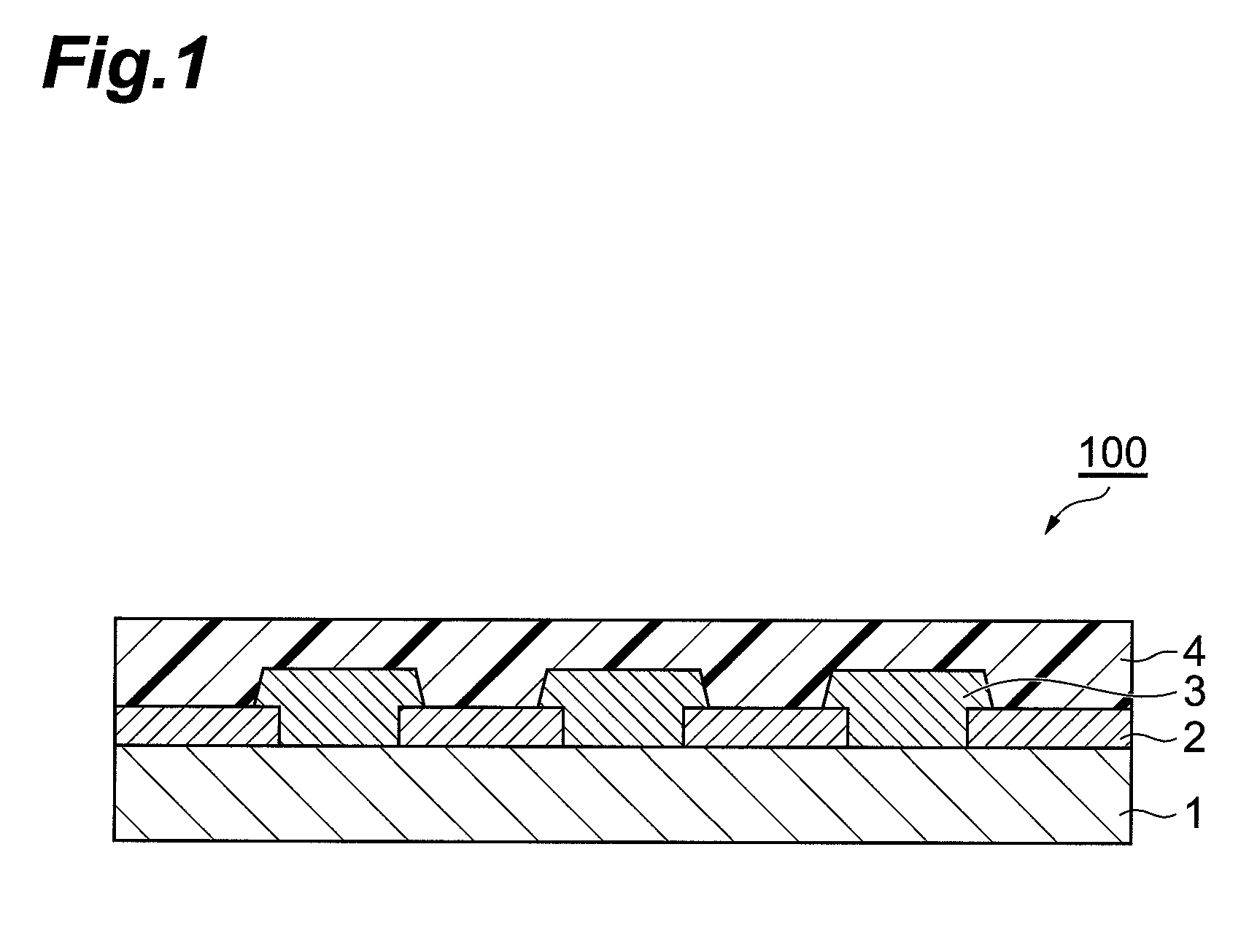

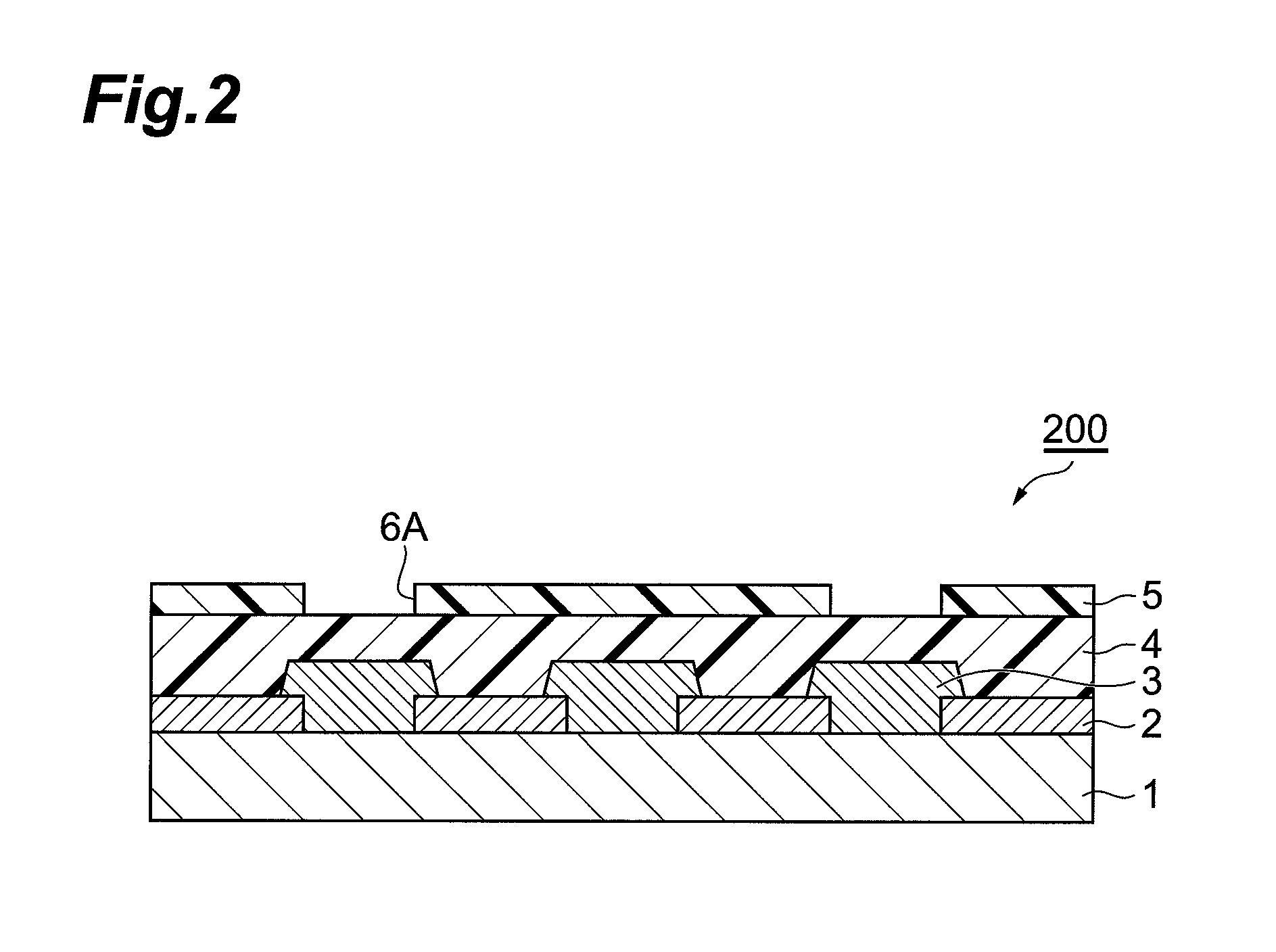

Component mounting apparatus and component mounting method

InactiveUS20070262118A1Satisfactory adhesivenessComponents is relatively effectiveCooking-vessel materialsPrinted circuit assemblingSolder pasteMechanical engineering

First components and second components in which bumps are formed on the lower surface thereof and laminate structures are formed by mounting them to stack with each other on a circuit board 13 are picked up from a component supply unit 1 using a placement head 16, and by lifting and lowering the placement head 16 holding the first components and the second components relative to a paste transfer device 5 supplying a flux 10 in the manner such as coating films having two types of different thicknesses, the flux 10 is supplied to the bumps of the plurality of components in a bundle using a transfer coating method. With such a configuration, it is possible to efficiently perform a component mounting with a satisfactory adhesiveness by ensuring an optimal amount of application quantity of a paste.

Owner:PANASONIC CORP

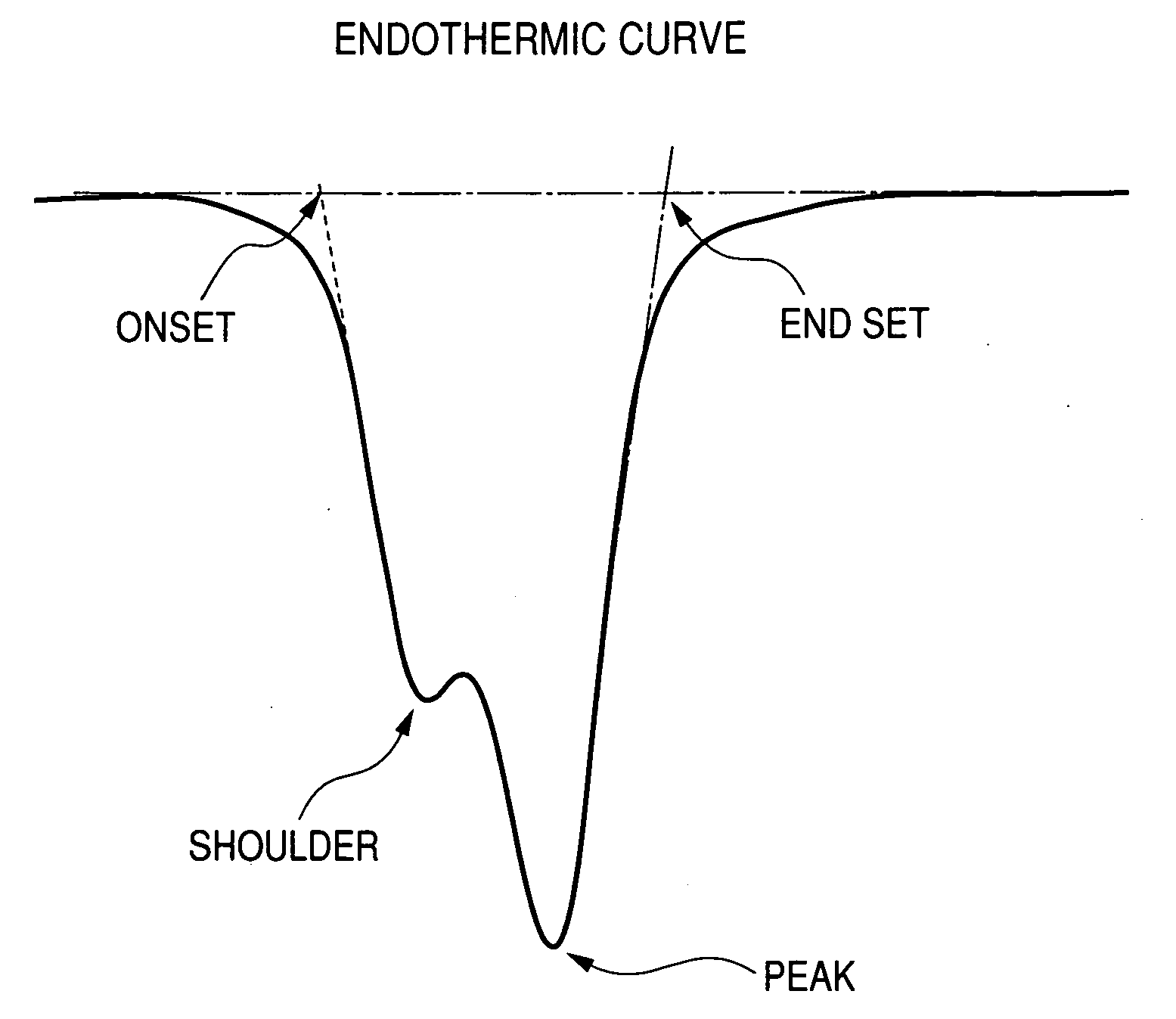

Tetrafluoroethylene resin molded article, expanded tetrafluoroethylene resin molded article, producing methods therefor, composite member, filter, impact deformation absorber and sealing material

ActiveUS20090029136A1Improve deformation abilityImprove impact absorption performanceSemi-permeable membranesMembranesTetrafluoroethyleneShell molding

A tetrafluoroethylene resin molded article obtained by fusing PTFE by heating a tetrafluoroethylene resin by heating, and then executing a gradual cooling or a cooling including a holding at a temperature equal to or higher than 313° C. and lower than 321° C. for 10 minutes or longer, and having, when heated to 365° C., then cooled to 245° C. with a rate of −1° C. / min, and then heated to 365° C. with a rate of 10° C. / min, a heat of fusion which, within a range from 296 to 343° C., is equal to or larger than 32 J / g and less than 47.8 J / g, a porous article obtained by expanding the molded article, and a composite article, a filter, an impact deformation absorber and a sealing material utilizing the molded article or the porous article.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

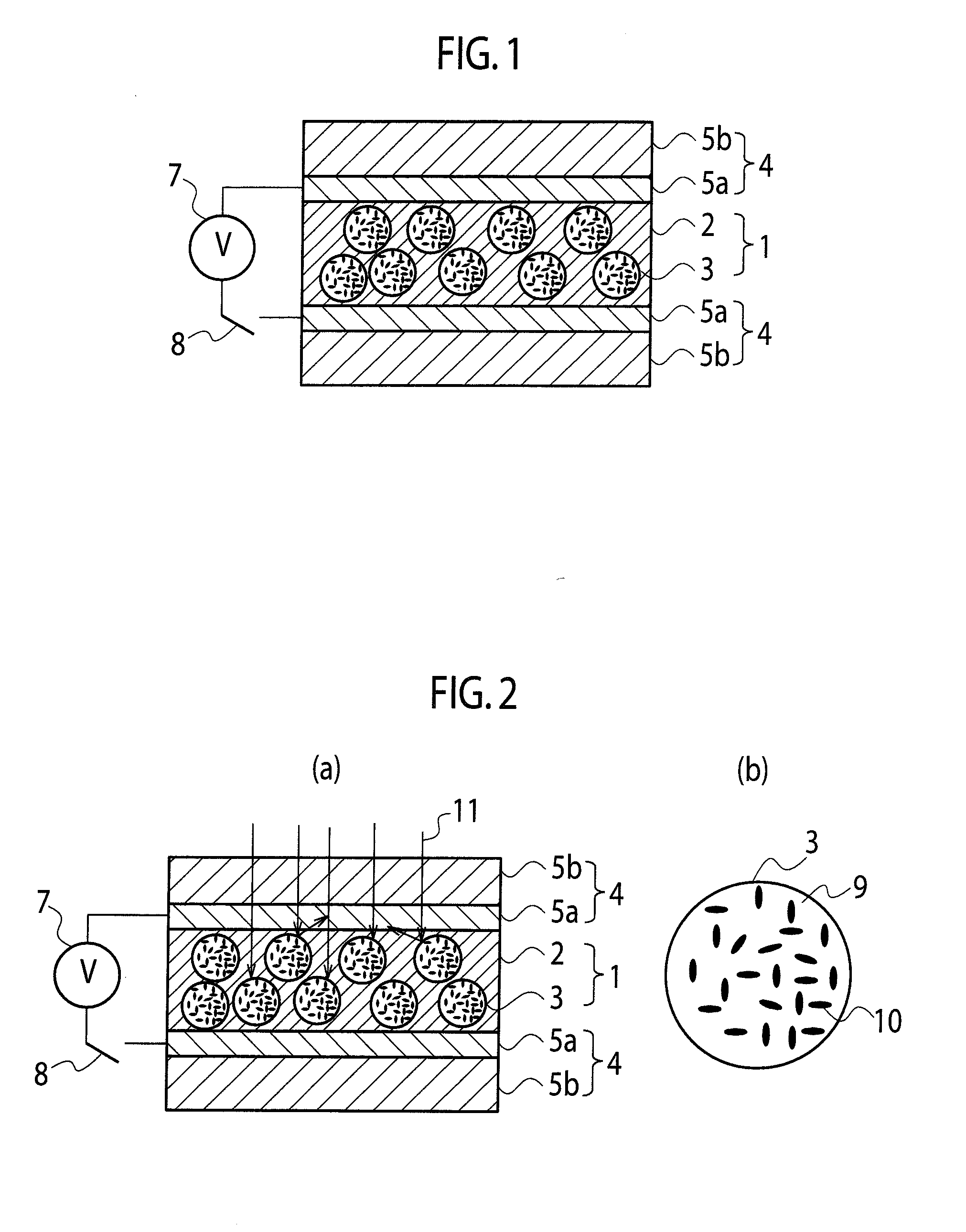

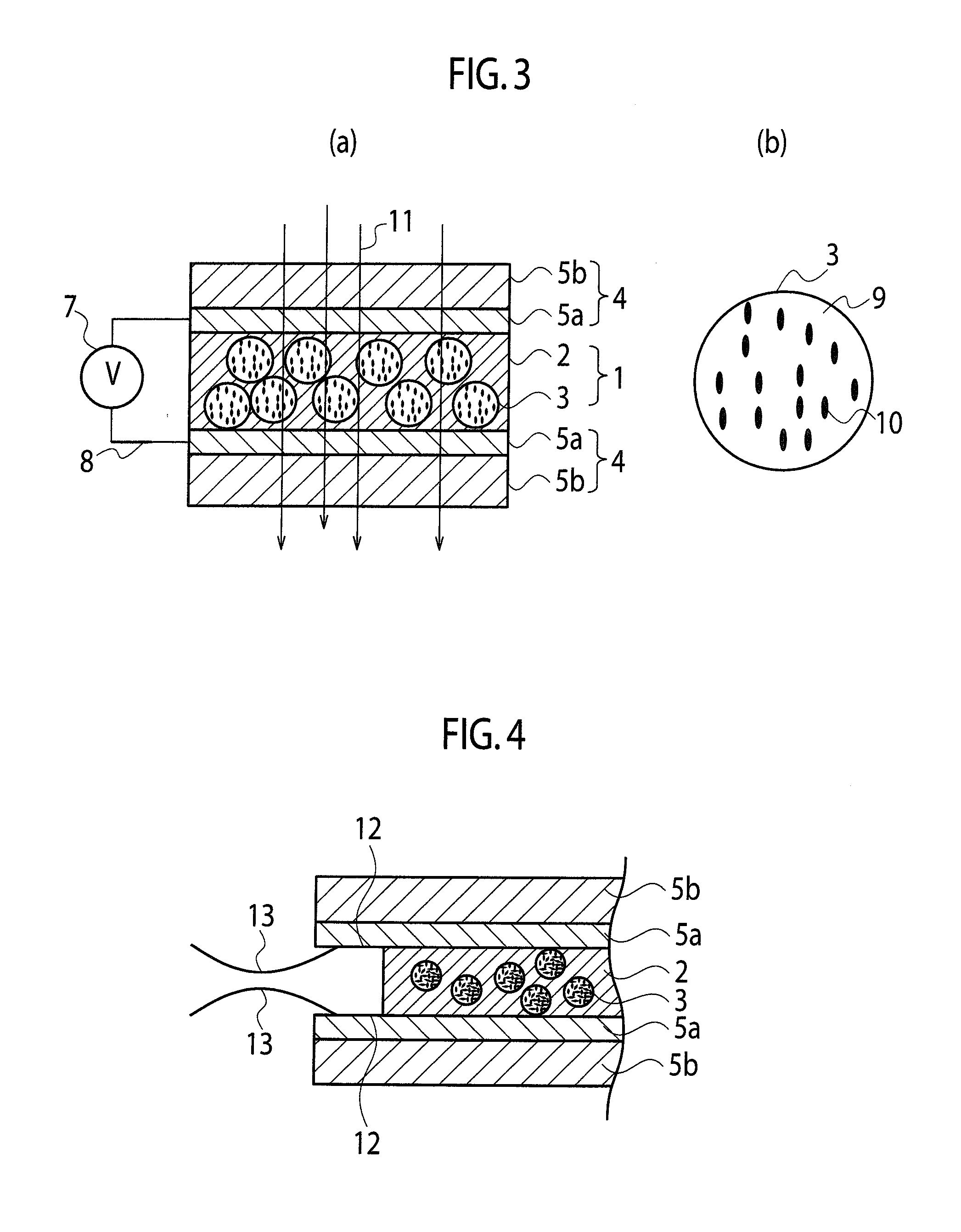

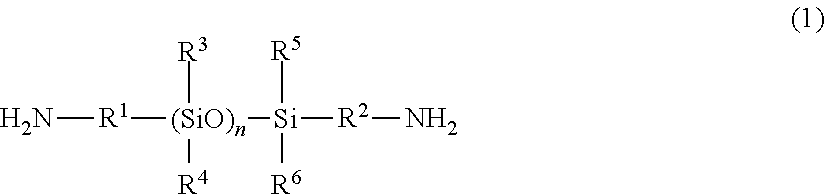

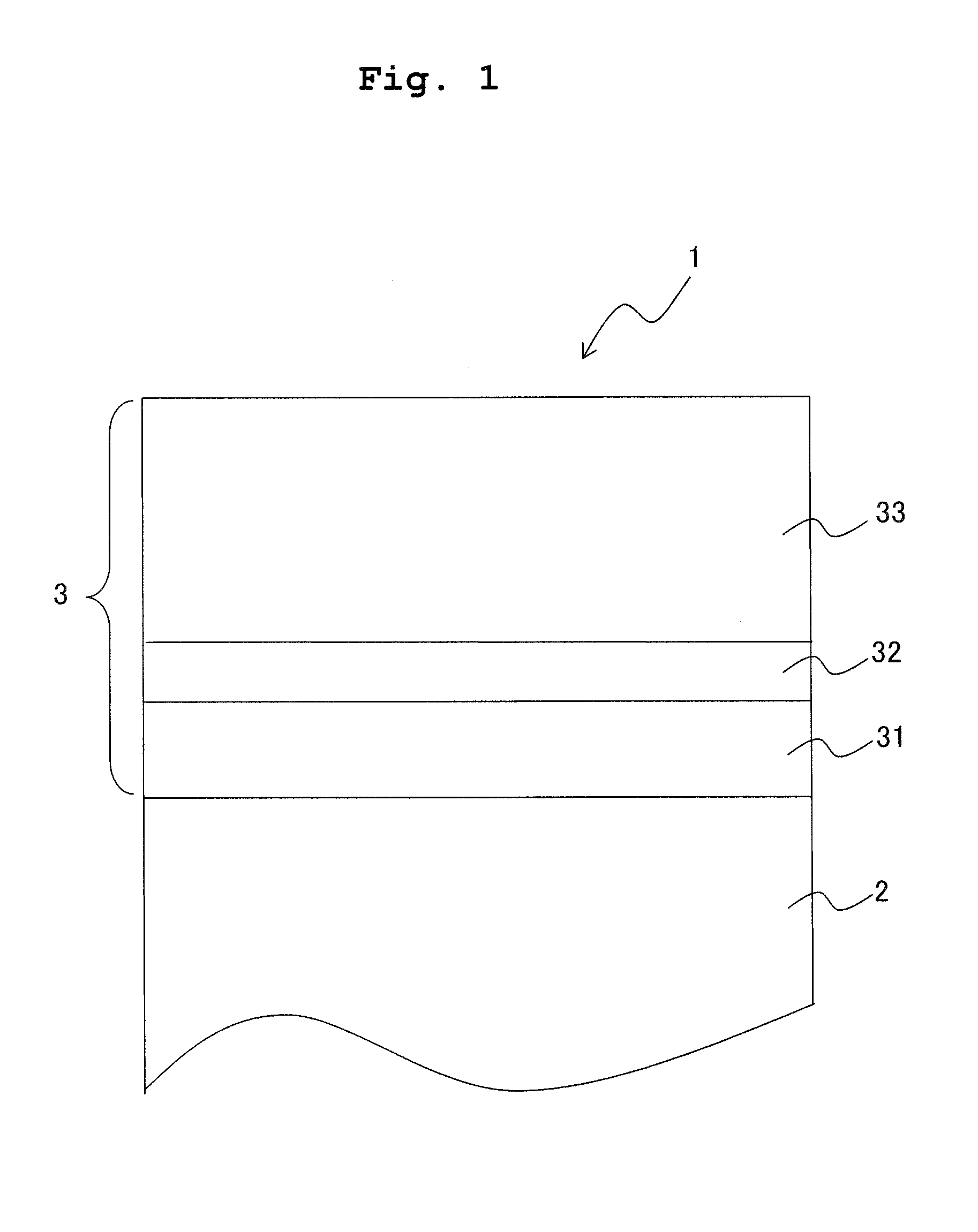

Light control film

ActiveUS20120314276A1Excellent radio wave transparencySatisfactory adhesivenessCoatingsNon-linear opticsConductive polymerResin matrix

Disclosed is a light control film comprising: two of transparent conductive resin substrates each having a transparent conductive layer and a transparent resin substrate; and a light control layer interposed between the two transparent conductive resin substrates to be in contact with the transparent conductive layer sides, the light control layer containing: a resin matrix; and a light control suspension dispersed in the resin matrix, wherein the transparent conductive layer contains: an organic binder resin; and a conductive polymer. The present invention can provide a light control film having satisfactory adhesiveness between the light control layer and the transparent conductive layer and having excellent radio wave transparency.

Owner:RESONAC CORP

Hot-melt adhesive material for induction heating

InactiveUS20120202057A1Improve adhesion strengthImprove the level ofSynthetic resin layered productsThin material handlingPolyolefinHot melt

The present invention provides a laminate in which a formed article as an adherend is adhered without impairing the external designability and touch of the formed article, and a hot-melt adhesive material which is suitable for dielectric heating that does not cause thermal damage directly to a formed article. Having reached the idea that a configuration might be useful, in which an adhesive having satisfactory adhesiveness to both metal and resin materials is laminated on a metal layer for selectively heating a hot-melt adhesive layer by dielectric heating, the present inventor has made extensive studies and found that an adhesive material in which a layer of an adhesive including a modified polyolefin resin is laminated on a metal layer, is capable of adhesion without impairing the designability of an adherend by induction heating.

Owner:KANEKA CORP

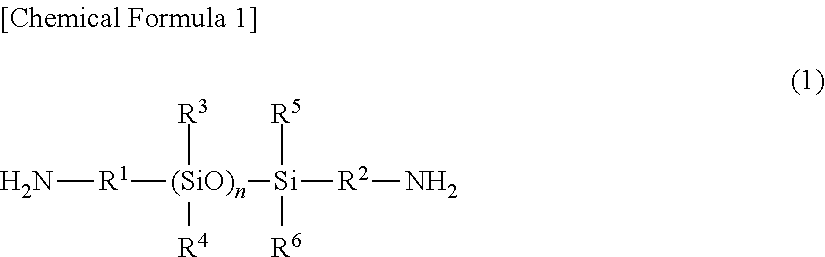

Polyimide resin, resin composition and laminated film that use same

InactiveUS20150017370A1Improve adhesionAvoid it happening againFilm/foil adhesivesSynthetic resin layered productsDecompositionGlass transition

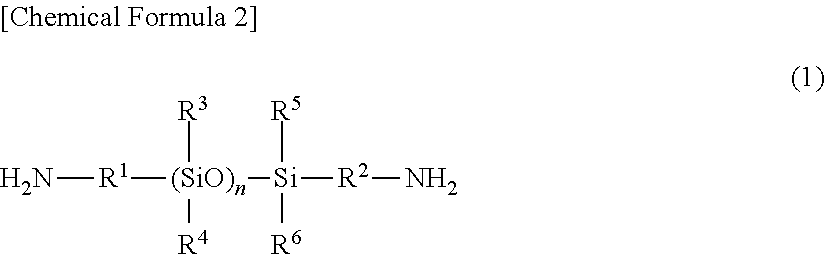

An object is to provided a polyimide resin that is prevented from generation of volatiles due to decomposition or the like even at high temperatures equal to or higher than 250° C. and has good adhesiveness, and a resin composition and a laminated film using the same. Provided is a polyimide resin having at least a tetracarboxylic dianhydride residue and a di-amine residue and having a glass transition temperature of 30° C. or lower, wherein a residue of a polysiloxane di-amine represented by general formula (1) is contained as the di-amine residue,wherein n is a natural number and the average calculated from the average molecular weight of the polysiloxane di-amine is within the range of from 5 to 30; R1 and R2 may be the same or different and each represent an alkylene group having 1 to 30 carbon atoms or a phenylene group; R3 to R6 may be the same or different and each represent an alkylene group having 1 to 30 carbon atoms, a phenyl group, or a phenoxy group.

Owner:TORAY IND INC

Double-sided adhesive tape for fixing decorative sheet for speaker and method for attaching decorative sheet for speaker to housing

InactiveUS8202594B2Improve adhesionReduce surface glossAdhesive processesWoven fabricsEngineeringNonwoven fabric

The present invention provides a double-sided adhesive tape for fixing a decorative sheet for speaker, which includes a nonwoven fabric substrate, an acrylic pressure-sensitive adhesive layer A disposed on one side of the nonwoven fabric substrate and an acrylic pressure-sensitive adhesive layer B disposed on the other side of the nonwoven fabric substrate, in which the adhesive tape has a tensile strength in the tape flow (MD) direction of 8 N / 10 mm or more and a tensile length in the width (TD) direction of 8 N / 10 mm or more. The double-sided adhesive tape is excellent in the adhesion performance to a housing and a decorative sheet for speaker and at the same time, has excellent releasability ensuring that when separating the decorative sheet portion, smooth separation can be attained without leaving a residue of tape or pressure-sensitive adhesive on the housing portion.

Owner:NITTO DENKO CORP

Positive-type photosensitive resin composition, method for producing resist pattern, semiconductor device, and electronic device

ActiveUS8461699B2High sensitivity and resolutionGood adhesivenessPhotosensitive materialsSemiconductor/solid-state device detailsAcrylic resinImage resolution

The positive tone photosensitive composition of the invention comprises an alkali-soluble resin having a phenolic hydroxyl group, a compound producing an acid by light, a thermal crosslinking agent and an acrylic resin. It is possible to provide a positive tone photosensitive composition that can be developed with an aqueous alkali solution, has sufficiently high sensitivity and resolution, and can form a resist pattern with excellent adhesiveness and thermal shock resistance.

Owner:RESONAC CORPORATION

Silicone foam sheet and method of producing the same

ActiveUS20190001618A1Excellent removabilitySatisfactory adhesivenessAdhesive articlesSynthetic resin layered productsElastic modulusChemistry

Provided is a silicone foam sheet that expresses excellent bubble removability, that has satisfactory adhesiveness with an adherend and satisfactory sealability, that maintains the expression of these effects even when its thickness is reduced, that preferably expresses a stable modulus of elasticity over a region from a low-temperature region to a high-temperature region, and that suppresses both of its compression set in the low-temperature region and its compression set in the high-temperature region to low levels. Also provided is a method of producing such silicone foam sheet. The silicone foam sheet comprises an open-cell structure having a thickness of from 10 μm to 3,000 μm, wherein wherein an open-cell ratio is 90% or more, an average cell diameter of the silicone foam sheet is from 1 μm to 50 μm, and 90% or more of all cells therein has a cell diameter of 80 μm or less.

Owner:NITTO DENKO CORP +1

Seal member for fuel cell and fuel cell seal body using same

ActiveUS9543596B2Satisfactory sealing propertyLow elastic modulusSolid electrolyte fuel cellsSealing/support meansCross-linkFuel cells

A sealing member to be used for sealing a constituent member of a fuel cell is provided, the sealing member including a cross-linked product of a rubber composition, in which the rubber composition contains the following components (A) and (B). With this, rubber elasticity is maintained without being lost even under extremely low temperature conditions, and in the case where the sealing member is used in a fuel cell sealed body, an excellent sealing property is exhibited. (A) a rubber component including at least one of an ethylene-propylene rubber or ethylene-propylene-diene rubber having a ratio of ethylene-ethylene diad distribution of at most 29 mol %. (B) a cross-linking agent including an organic peroxide.

Owner:SUMITOMO RIKO CO LTD

Oil-in-water silicone emulsion composition

ActiveUS9029428B2Excellent surface hardnessHigh elongationCosmetic preparationsOther chemical processesColloidal silicaPolymer science

Provided is an oil-in-water silicone emulsion composition that has a low silicone oligomer content, and that can form, even without the use of an organotin compound as a curing catalyst, a cured film that exhibits satisfactory strength and satisfactory adherence to a substrate, through the removal of water fraction. An oil-in-water silicone emulsion composition comprising (A) 100 mass parts of a polyorganosiloxane that contains in each molecule at least two groups selected from the group consisting of a silicon-bonded hydroxyl group, alkoxy group, and alkoxyalkoxy group, (B) 0.1 to 200 mass parts of a colloidal silica, (C) 0.1 to 100 mass parts of an aminoxy group-containing organosilicon compound that has in each molecule an average of two silicon-bonded aminoxy groups, (D) 1 to 100 mass parts of an ionic emulsifying agent, (E) 0.1 to 50 mass parts of a non-ionic emulsifying agent, and (F) 10 to 500 mass parts of water.

Owner:DOW TORAY CO LTD

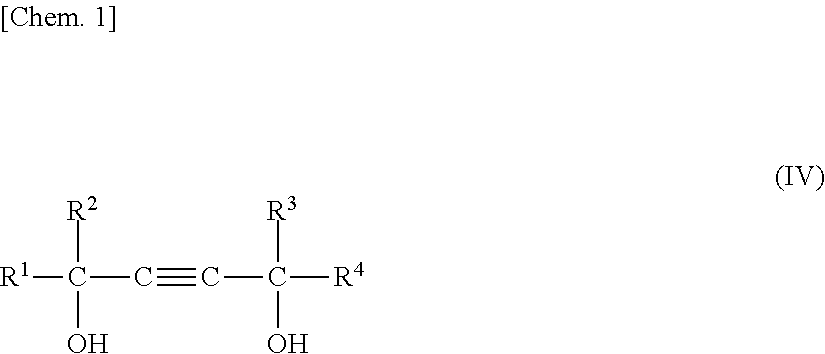

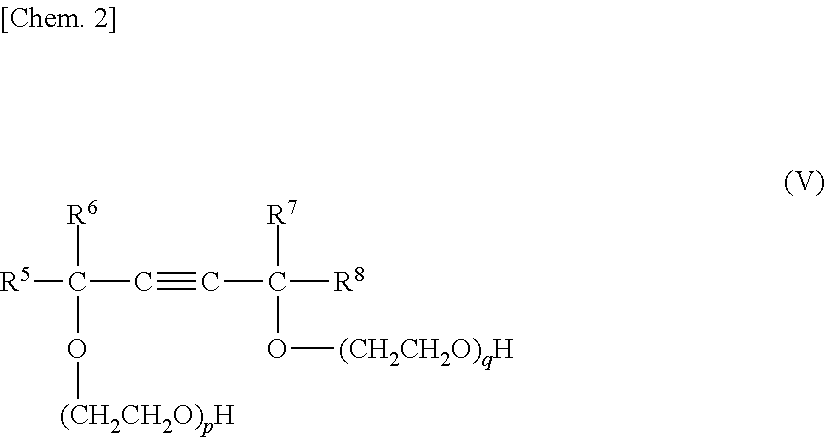

Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveUS20130034730A1High bonding strengthImprove removabilityNon-macromolecular adhesive additivesInksPolymer scienceMeth-

Provided is a water-dispersible acrylic pressure-sensitive adhesive composition capable of forming a removable pressure-sensitive adhesive layer which has satisfactory resistance to increase in adhesive strength and a good appearance and less causes staining on an adherend. The removable water-dispersible acrylic pressure-sensitive adhesive composition includes an acrylic emulsion polymer (A) formed from constitutive monomers essentially including 70 to 99.5 percent by weight of a (meth)acrylic alkyl ester and 0.5 to 10 percent by weight of a carboxyl-containing unsaturated monomer based on the total amount of the constitutive monomers; a water-insoluble crosslinking agent (B); an acetylenic diol compound (C); and a specific polyether defoaming agent (D). The acetylenic diol compound (C) has an HLB of less than 13, and the polyether defoaming agent (D) has a PO in a content of from 70 to 100 percent by weight and a number-average molecular weight of from 1200 to 4000.

Owner:NITTO DENKO CORP

Oil-In-Water Silicone Emulsion Composition

ActiveUS20130143989A1Excellent surface hardnessHigh elongationCosmetic preparationsToilet preparationsColloidal silicaOligomer

Provided is an oil-in-water silicone emulsion composition that has a low silicone oligomer content, and that can form, even without the use of an organotin compound as a curing catalyst, a cured film that exhibits satisfactory strength and satisfactory adherence to a substrate, through the removal of water fraction. An oil-in-water silicone emulsion composition comprising (A) 100 mass parts of a polyorganosiloxane that contains in each molecule at least two groups selected from the group consisting of a silicon-bonded hydroxyl group, alkoxy group, and alkoxyalkoxy group, (B) 0.1 to 200 mass parts of a colloidal silica, (C) 0.1 to 100 mass parts of an aminoxy group-containing organosilicon compound that has in each molecule an average of two silicon-bonded aminoxy groups, (D) 1 to 100 mass parts of an ionic emulsifying agent, (E) 0.1 to 50 mass parts of a non-ionic emulsifying agent, and (F) 10 to 500 mass parts of water.

Owner:DOW TORAY CO LTD

Primer for footwear constituting members, method for producing same, footwear constituting member, and footwear

InactiveUS9556352B2Improve adhesionSatisfactory adhesivenessCoatingsFootwearPolymer sciencePolyolefin

The present invention provides a primer for footwear constituting members, wherein the primer includes an acid-modified polyolefin resin and a medium; the acid-modified polyolefin resin is a copolymer including an olefin unit and an unsaturated carboxylic acid unit; the copolymer includes as the olefin unit, a propylene unit (A) and an olefin unit (B) other than the propylene unit; the mass ratio (A / B) between the propylene unit (A) and the olefin unit (B) other than the propylene unit is 60 / 40 to 95 / 5; and the content of the unsaturated carboxylic acid unit is 0.1 to 10 parts by mass in relation to 100 parts by mass of the total amount of (A) and (B).

Owner:UNITIKA LTD

Sliding member and fluid dynamic pressure bearing apparatus

InactiveUS20130154419A1Simple structureSatisfactory frictional wear resistance propertyShaftsLiquid cushion bearingsTectorial membraneDiamond-like carbon

There is provided a sliding member including: a substrate; and a protective film provided on the substrate, wherein the protective film is composed only of a metal base layer provided on the substrate, a low-hardness diamond-like carbon layer provided as a single layer on the metal base layer, and a high-hardness diamond-like carbon layer provided as a single layer directly on the low-hardness diamond-like carbon layer. The sliding member has the protective film which has excellent frictional wear resistance property and satisfactory adhesion property to the substrate, regardless of having a simple structure.

Owner:MINEBEAMITSUMI INC

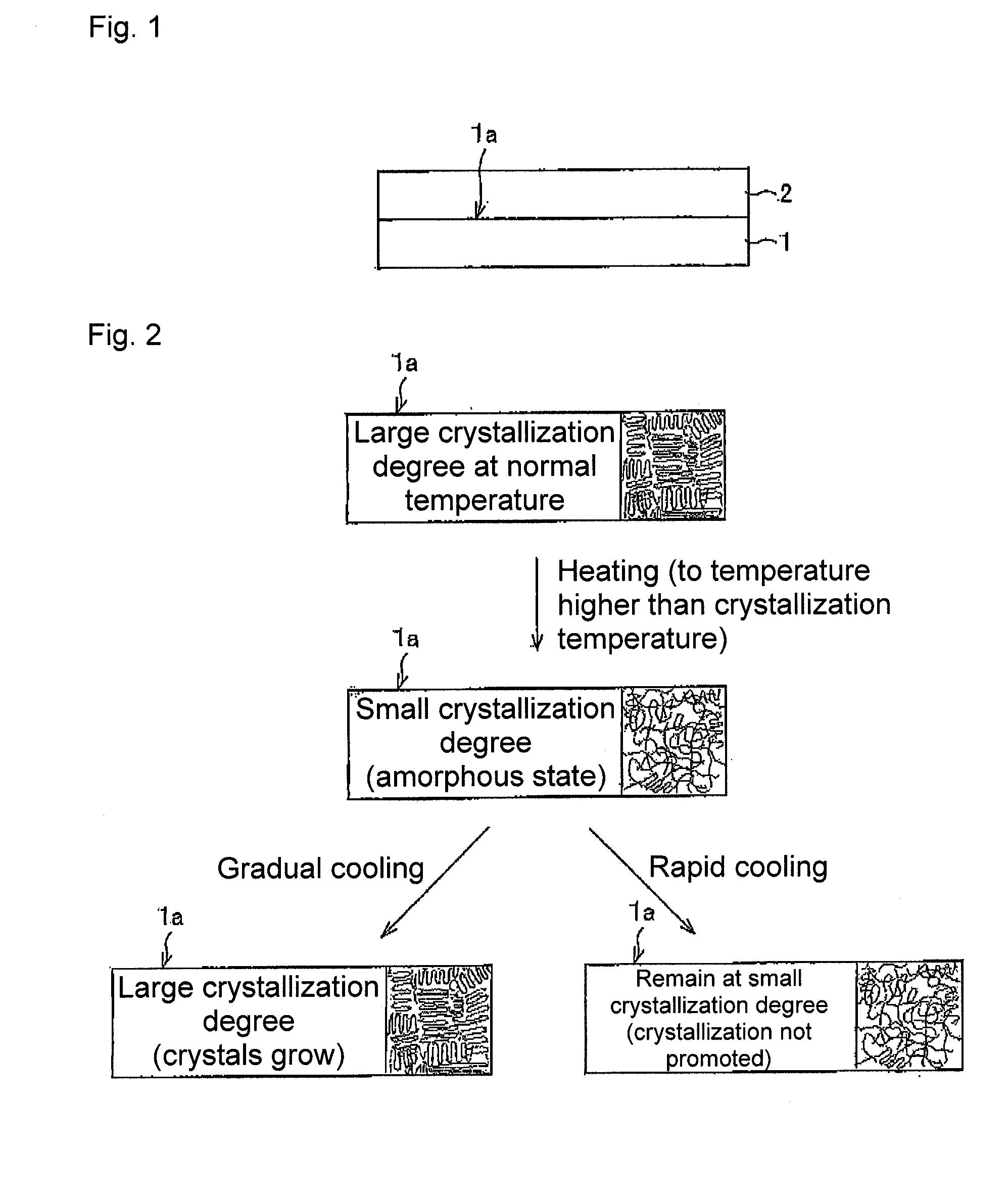

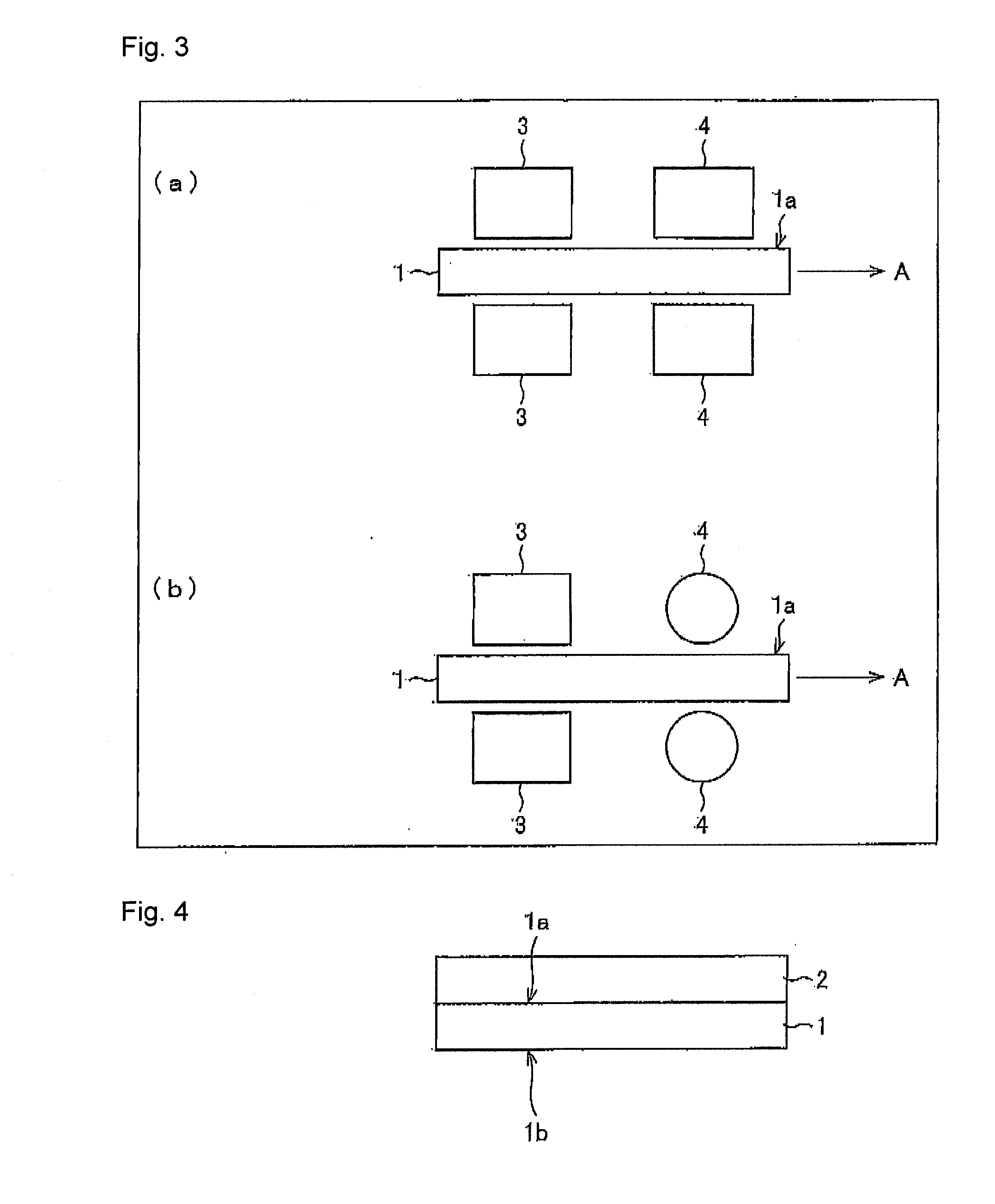

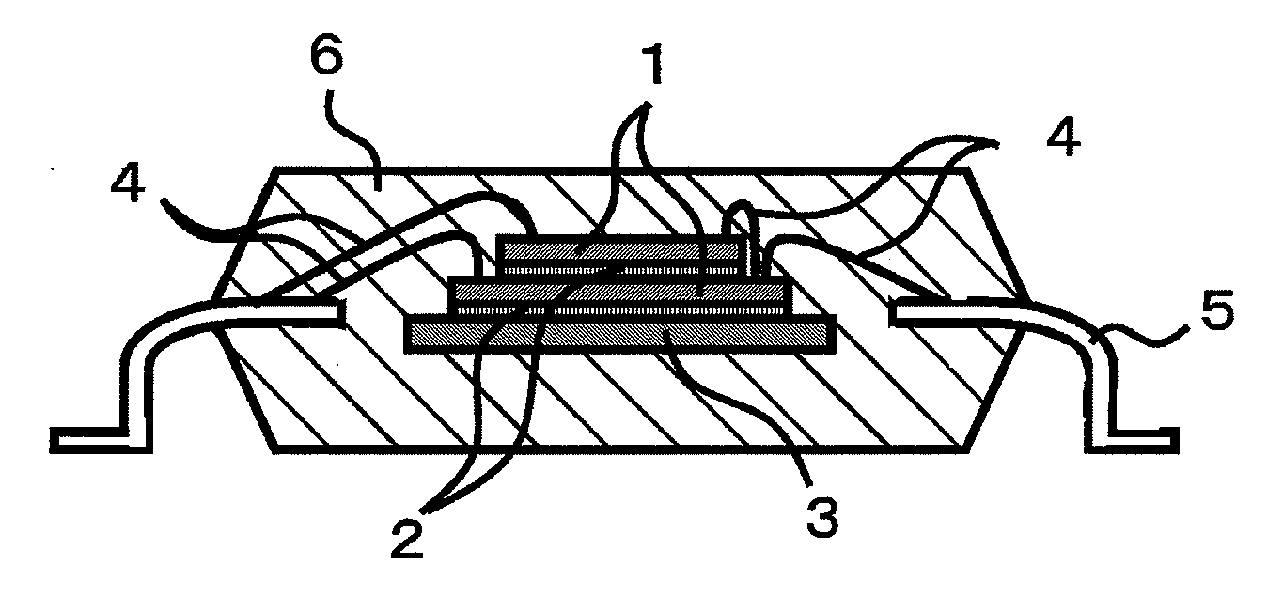

Organic device and method for manufacturing organic device

InactiveUS20110052130A1AdhesivenessImprove adhesionSynthetic resin layered productsOptical articlesPolymer scienceCrystallinity

An organic device has a substrate made of polymer, and a polymer layer adhered on the substrate. A crystallization degree of an adhesive surface with the polymer layer in the substrate is smaller than a crystallization degree of an interior of the substrate. In a manufacturing method for manufacturing an organic device including a substrate made of polymer; and having a polymer layer adhered on the substrate, the manufacturing method includes performing a low crystallization process on an adhesive surface with the polymer layer in the substrate to have a crystallization degree lower than a crystallization degree of an interior of the substrate.

Owner:ORMON CORP

Silicone foam sheet and method of producing the same

ActiveUS10857758B2Excellent bubble removabilitySatisfactory adhesivenessAdhesive articlesSynthetic resin layered productsPolymer scienceCompression set

Provided is a silicone foam sheet that expresses excellent bubble removability, that has satisfactory adhesiveness with an adherend and satisfactory sealability, that maintains the expression of these effects even when its thickness is reduced, that preferably expresses a stable modulus of elasticity over a region from a low-temperature region to a high-temperature region, and that suppresses both of its compression set in the low-temperature region and its compression set in the high-temperature region to low levels. Also provided is a method of producing such silicone foam sheet. The silicone foam sheet comprises an open-cell structure having a thickness of from 10 μm to 3,000 μm, wherein an open-cell ratio is 90% or more, an average cell diameter of the silicone foam sheet is from 1 μm to 50 μm, and 90% or more of all cells therein each has a cell diameter of 80 μm or less.

Owner:NITTO DENKO CORP +1

Epoxy resin composition for semiconductor encapsulation, and semiconductor device using the same

InactiveUS9048187B2Satisfactory adhesivenessGood moldabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

Disclosed are an epoxy resin composition for semiconductor encapsulation containing (A) an epoxy resin, (B) a curing agent, (C) an inorganic filler material, (D) a hydrocarbon compound having structures of formula (1) and formula (2), and (E) a hydrocarbon compound having an ester group; and a semiconductor device including a semiconductor element encapsulated with the epoxy resin composition for semiconductor encapsulation.CH2—CH2 (1)CH═CH (2)

Owner:SUMITOMO BAKELITE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com