Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174 results about "Cell diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The average cell in our body is about 50 micrometers (0.05 mm) in diameter. Indeed, if you were to average the diameter of all the cells on the planet, the average would certainly be far less than that because most of the cells on this planet are bacteria and the average bacterial cell is 3-5 micrometers in diameter.".

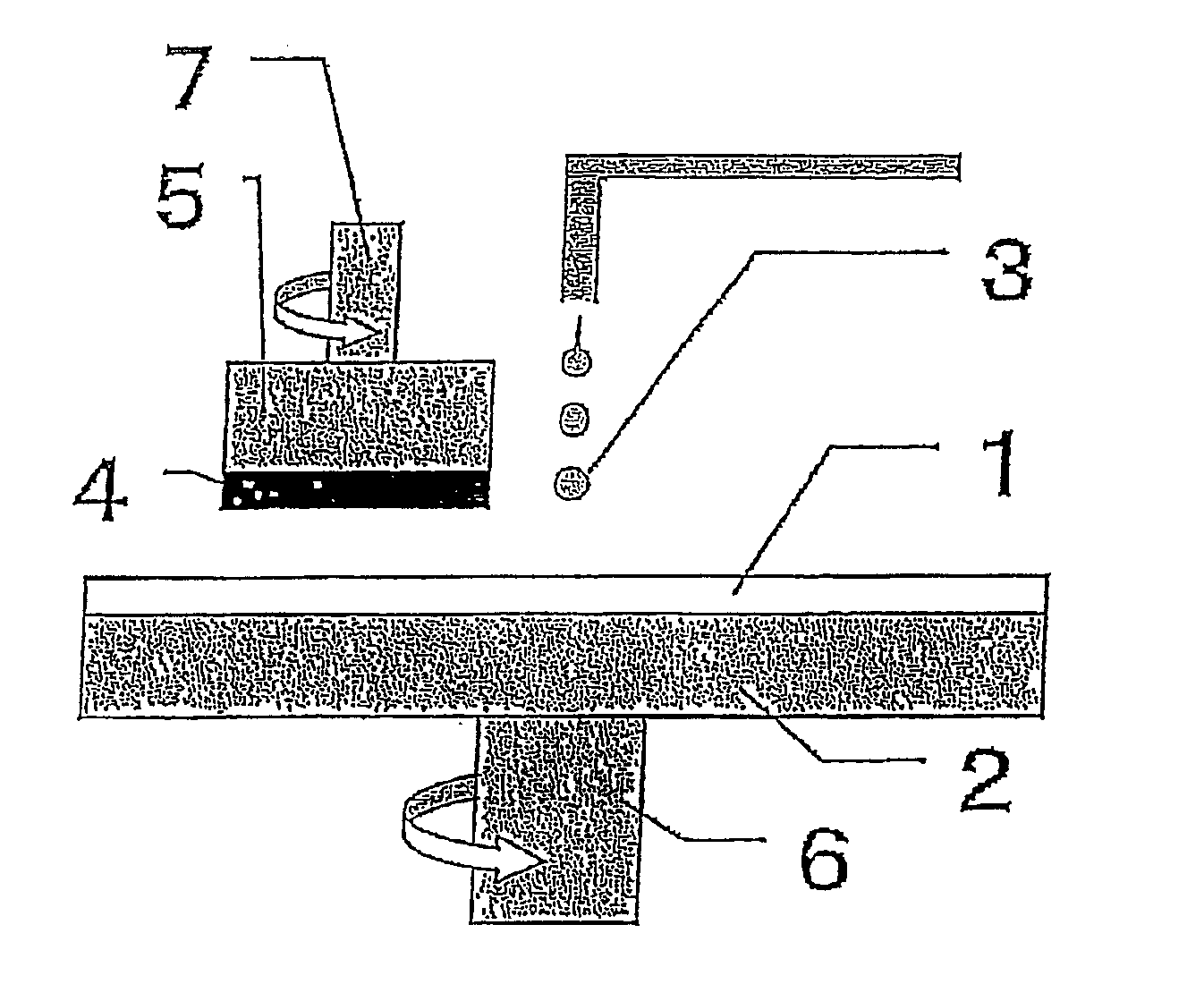

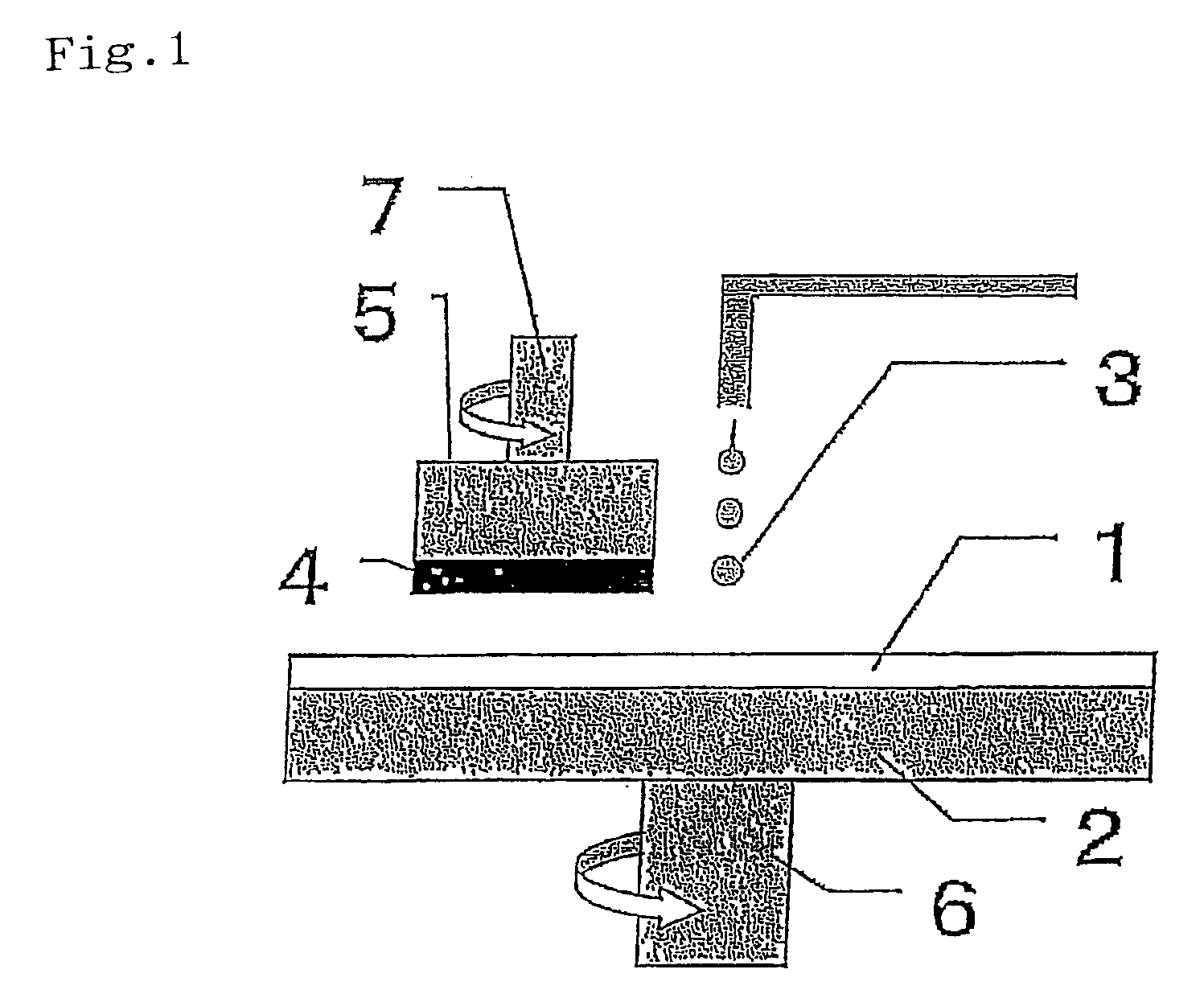

Polishing pad and a method for manufacturing the same

ActiveUS20100029185A1Good adhesivenessIncreased durabilityAdhesive processes with surface pretreatmentAbrasion apparatusHydrogenChemical compound

An object of the invention is to provide a polishing pad excellent in durability and in the adhesiveness between a polishing layer and a base material layer. The first invention relates to a polishing pad comprising a polishing layer arranged on a base material layer, wherein the polishing layer comprises a thermosetting polyurethane foam having roughly spherical interconnected cells having an average cell diameter of 20 to 300 μm, the polyurethane foam comprises an isocyanate component and an active hydrogen-containing compound as starting components, and the active hydrogen-containing compound comprises 30 to 85% by weight of a high-molecular-weight polyol having 2 to 4 functional groups and a hydroxyl value of 20 to 100 mg KOH / g.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

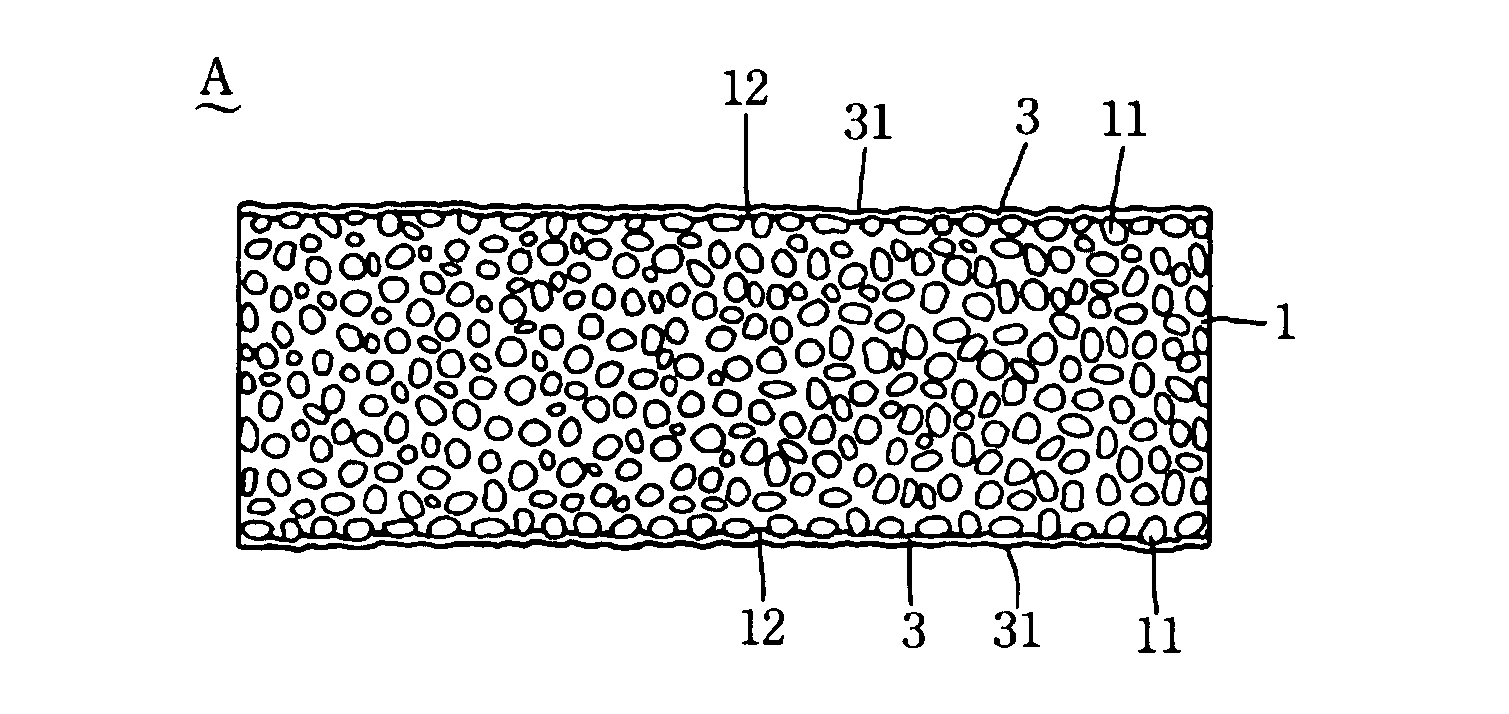

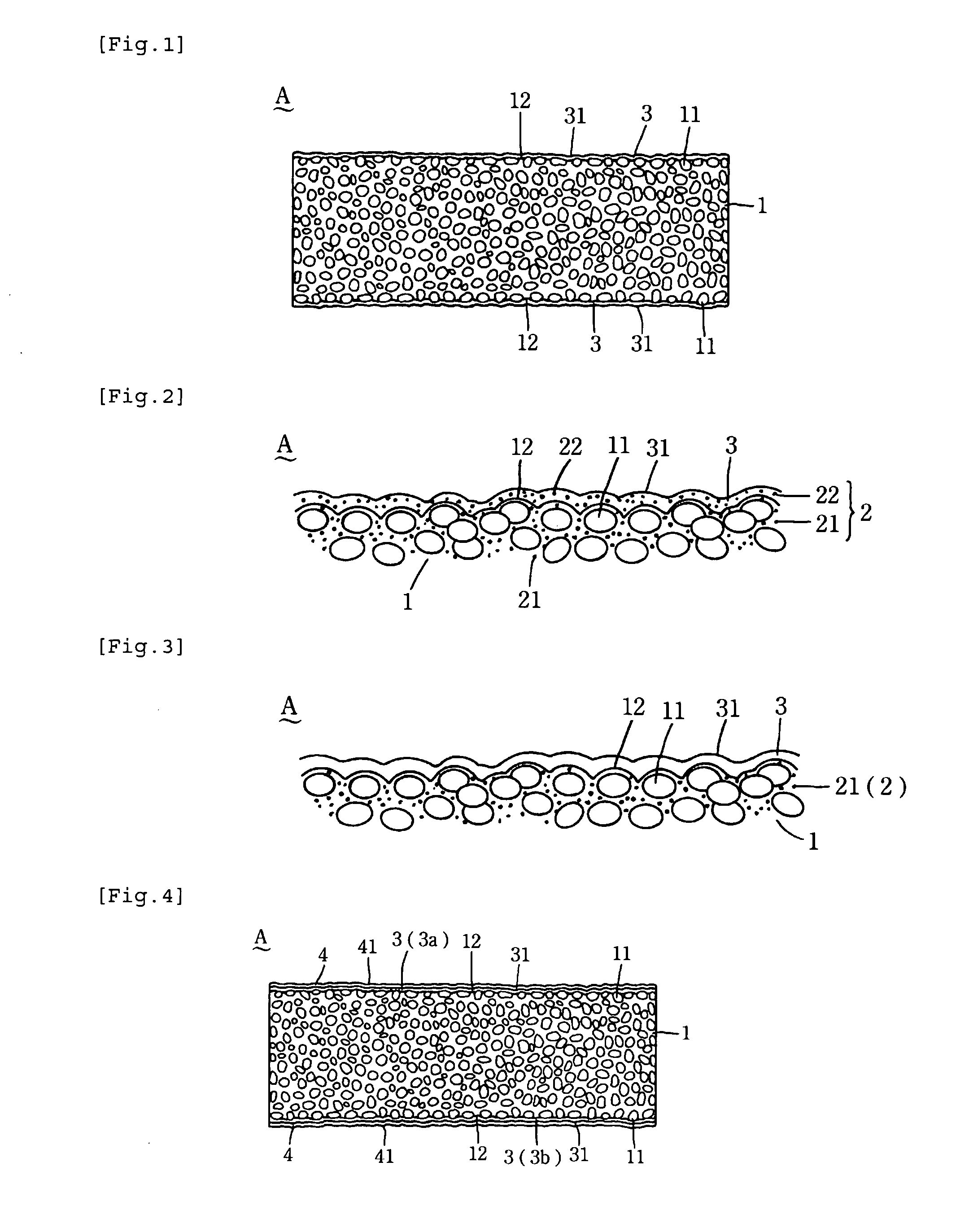

Foamed Sheet for Reflector, Reflector, and Method for Producing Foamed Sheet for Reflector

InactiveUS20090068402A1Easy to adjustEffective reflectionMirrorsDiffusing elementsRefractive indexPolypropylene

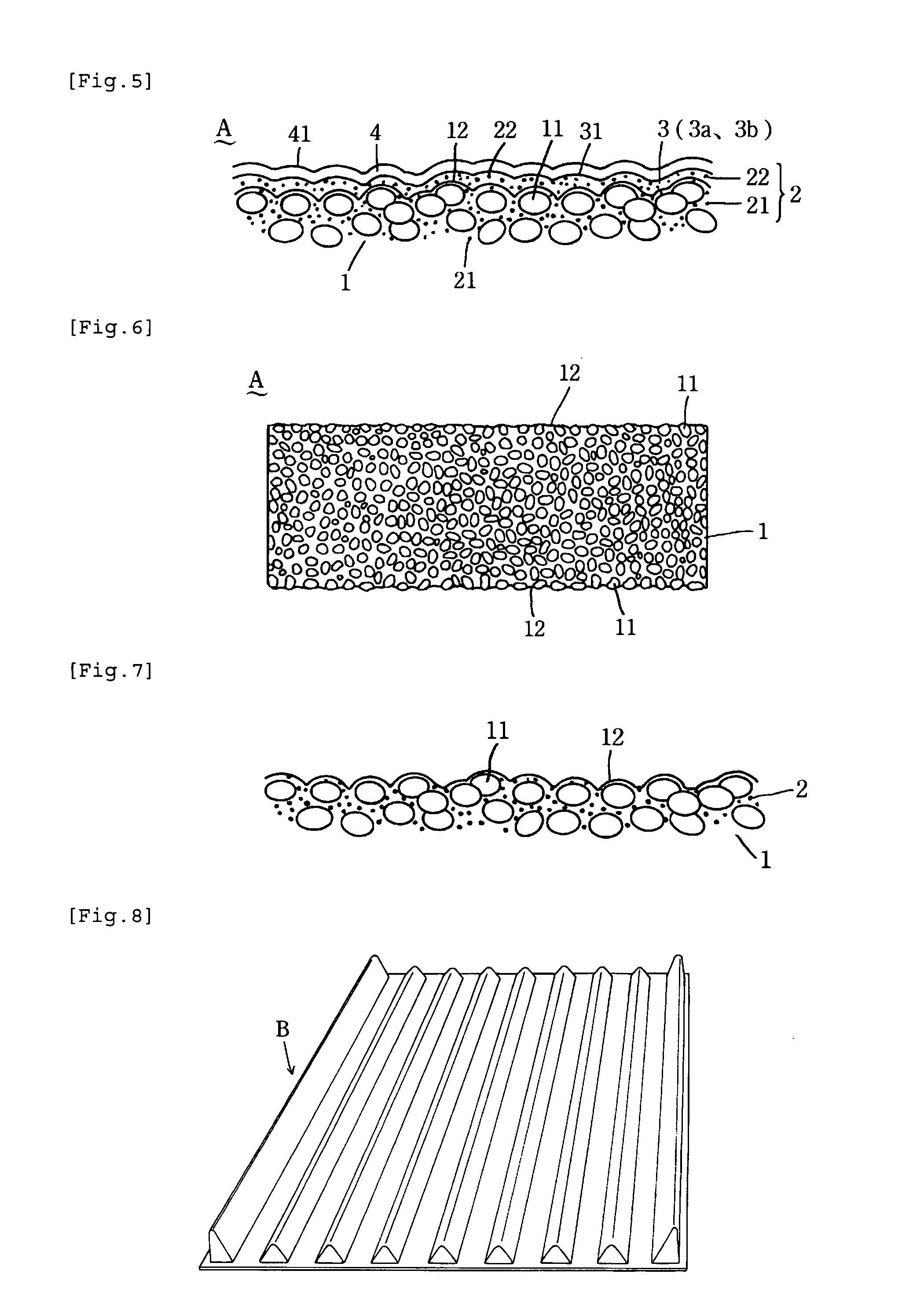

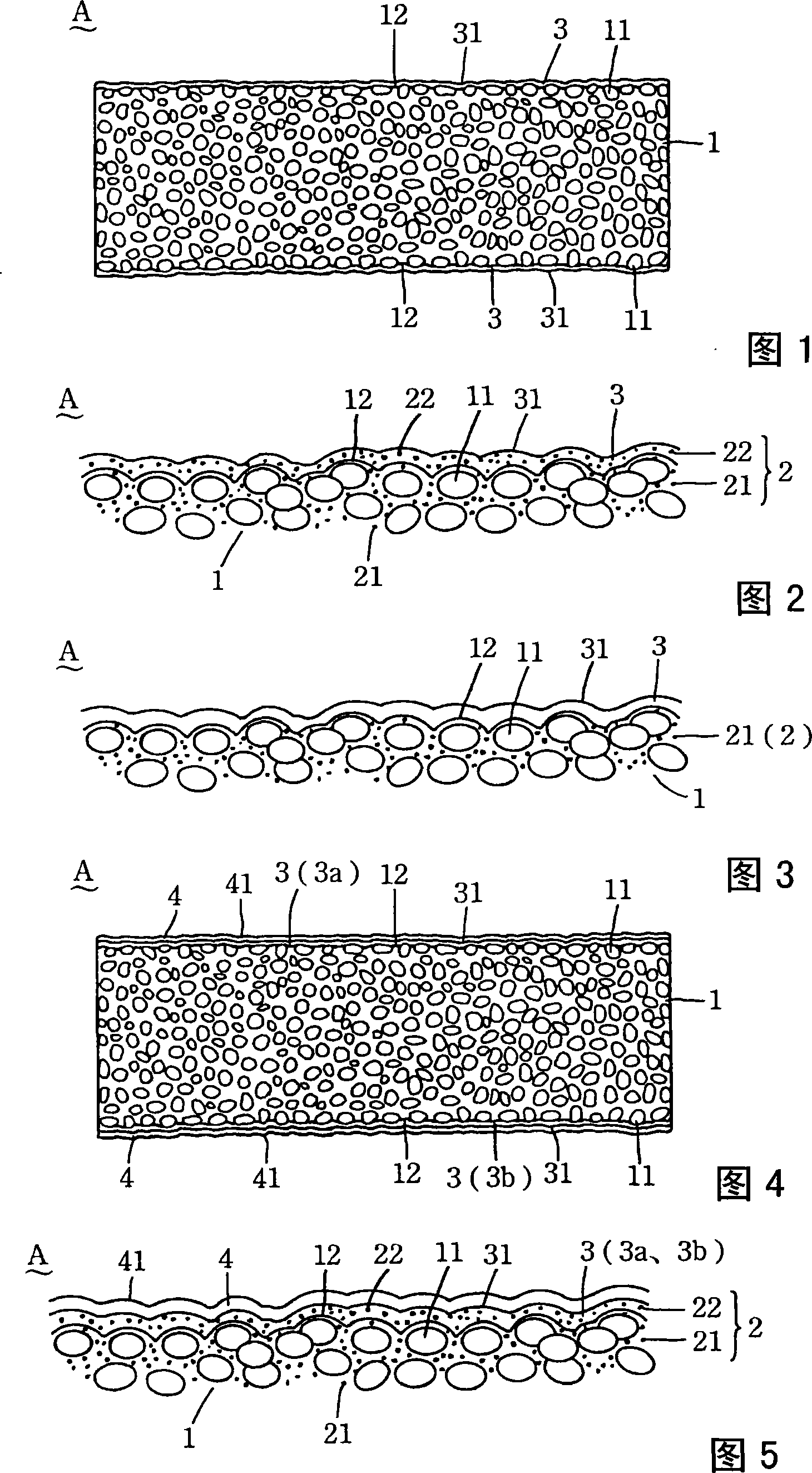

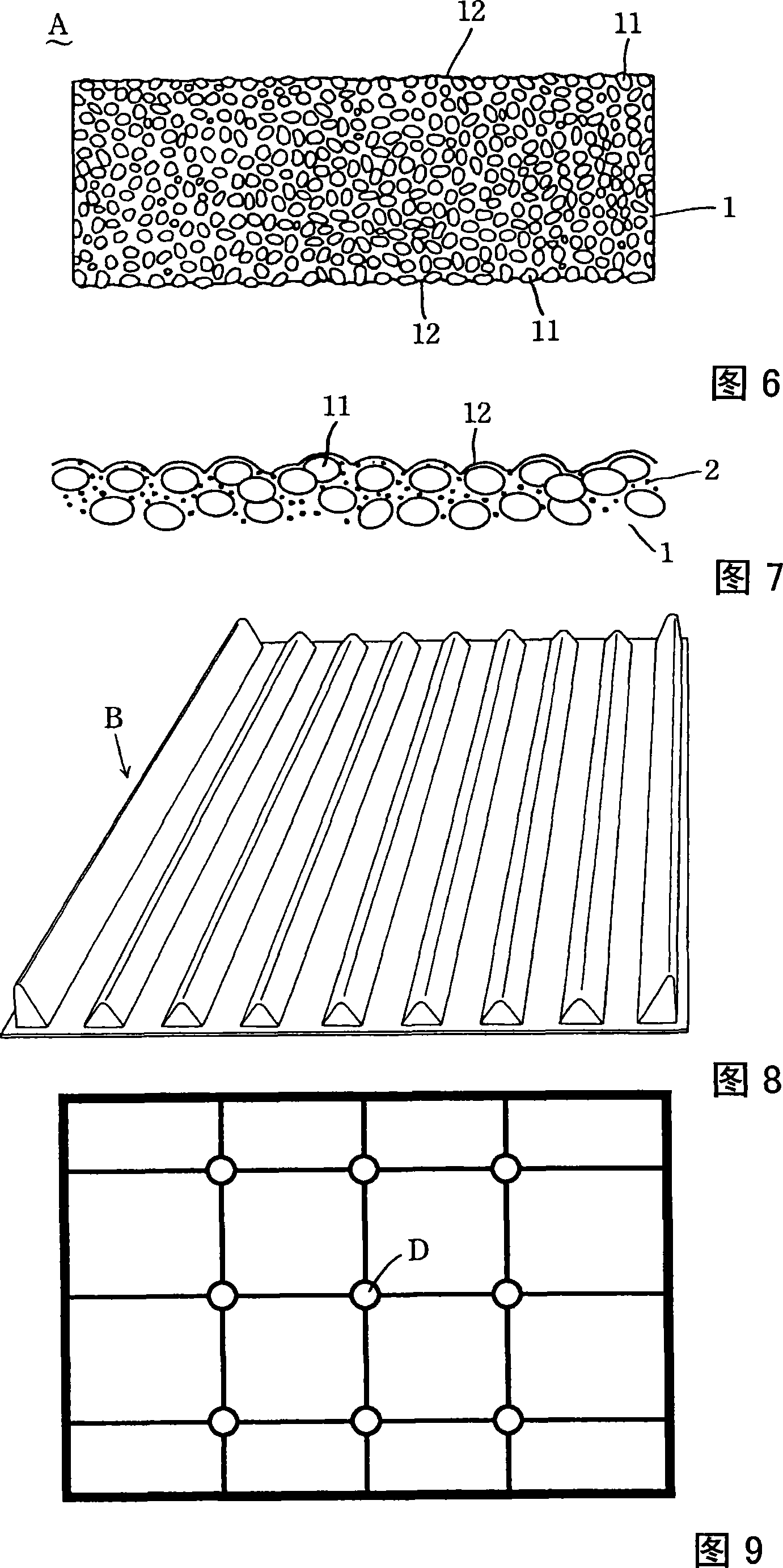

The present invention provides a foamed sheet for a reflector which can be transformed to a reflector having a desired shape by thermoforming.A foamed sheet A for a reflector of the present invention is characterized by being a foamed sheet for a reflector including a polypropylene-based resin foamed sheet 1 which has an average cell diameter of from 50 to 650 μm and at least one surface which is an uneven surface 12 formed by cells 11 located in the vicinity of the surface, and a polypropylene-based resin non-foamed sheet 3 integrally laminated on the polypropylene-based resin foamed sheet 1 in conformity with the uneven surface 12 and having an uneven surface 31, wherein the foamed sheet A for a reflector contains an inorganic filler in an amount of from 50 to 200 g / m2, the whole or part of the inorganic filler is contained in the polypropylene-based resin foamed sheet 1, a refractive index of an inorganic filler 2 differs by 1.0 or more from a refractive index of the polypropylene-based resin, and the foamed sheet A for a reflector has an overall thickness of from 0.2 to 2.0 mm and a light reflectance of 97% or more.

Owner:SEKISUI PLASTICS CO LTD

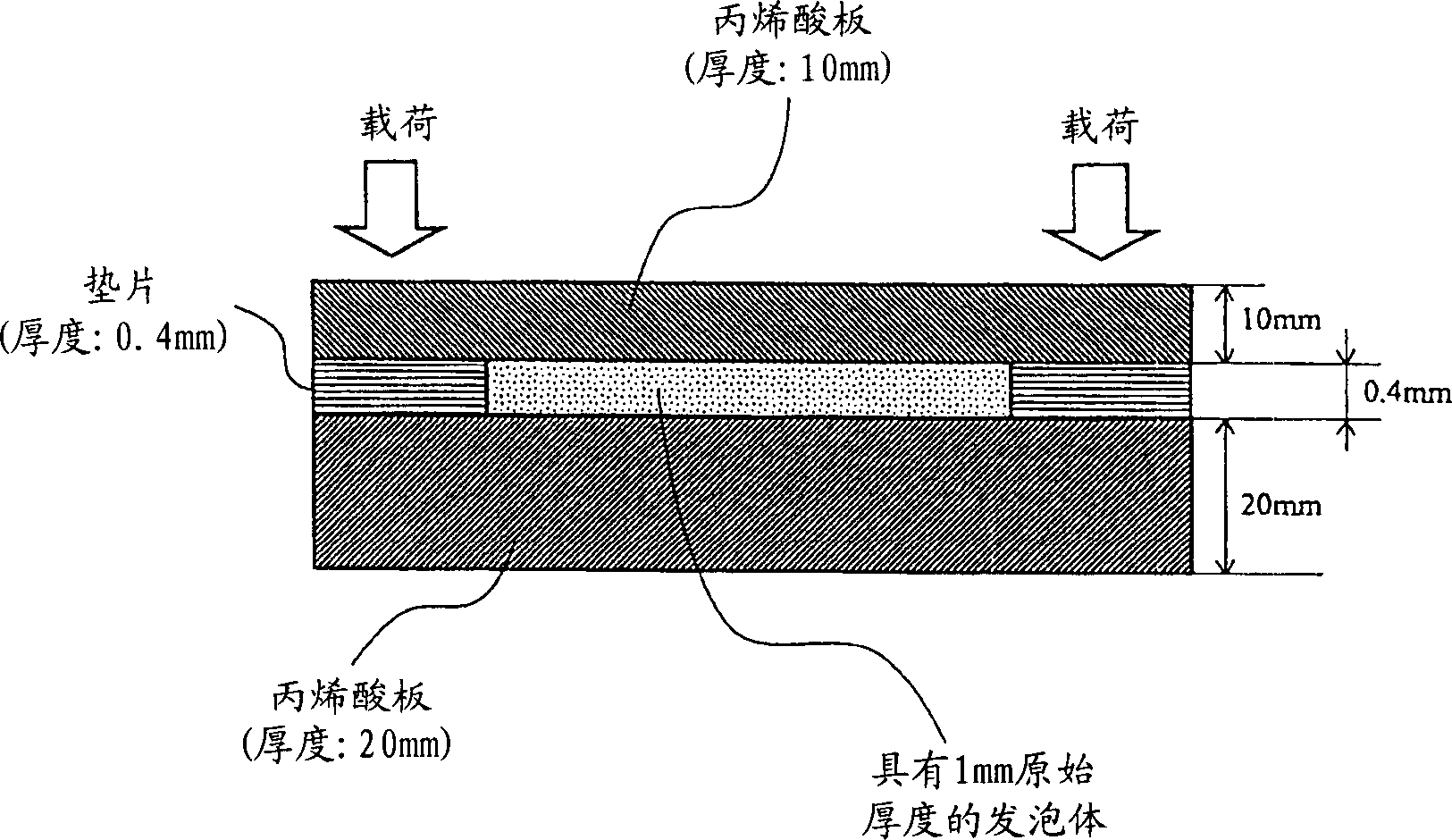

Resin foam and foam sealing material

InactiveUS20130017391A1Excellent in dustproofnessImprove AssemblabilityOther chemical processesFilm/foil adhesivesApparent densityCell diameter

There is provided a resin foam excellent in dustproofness and assemblability.The resin foam has a repulsive stress at 80% compression (repulsive stress when a resin foam is compressed by 80% of the initial thickness) of 1.0 to 9.0 N / cm2 and a tensile modulus of elasticity of 5.0 to 14.0 MPa. Preferably, the resin foam further has an average cell diameter of 10 to 180 μm and an apparent density of 0.01 to 0.10 g / cm3.

Owner:NITTO DENKO CORP

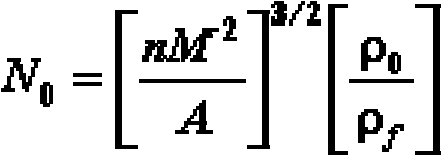

Method for preparing biodegradable polylactic acid foaming material

The invention discloses the composition of a biodegradable polylactic acid (PLA) foaming material and a preparation method thereof. The method for preparing the biodegradable polylactic acid foaming material comprises the following steps: blending polylactic acid (PLA) and aliphatic-aromatic co-polyester toughening agent in a screw extruder; loading the extrudate into the fluid of supercritical CO2 to swell, so that the CO2 can be fully dissolved in the blended materials; then, releasing the pressure at a high rate, so as to supersaturate the CO2 in the composite material, thus achieving the thermodynamic instability; and nucleating and foaming to obtain the biodegradable PLA foaming material, wherein the toughening agent is particularly poly(butylenes adipate-co-terephthalate) (PBAT) in the invention. The method of the invention is capable of preparing the PLA foaming material with the cell diameter thereof being 0.9056mu m to 5.250mu m and the cell density thereof being 2.05*1,019 pieces / cm<3> to 2.01*1,022 pieces / cm<3>. The invention as a green and environment-friendly technique can improve the material performance and reduce the cost.

Owner:SHANGHAI JIAO TONG UNIV

Polishing pad

InactiveUS6705934B1Reduce global step heightDepression depressionOther chemical processesSemiconductor/solid-state device manufacturingSurface layerHardness

The present invention relates to a polishing pad which is characterized in that it is of micro rubber A-type hardness at least 80°, has closed cells of average cell diameter no more than 1000 mum, is of density in the range 0.4 to 1.1 and contains polyurethane and polymer produced from a vinyl compound. When planarizing local unevenness on a semiconductor substrate with the polishing pad relating to the present invention, the polishing rate is high, the global step height is low, dishing does not readily occur at the metallic interconnects, clogging and permanent set of the surface layer region do not readily occur and the polishing rate is stable.

Owner:TORAY IND INC

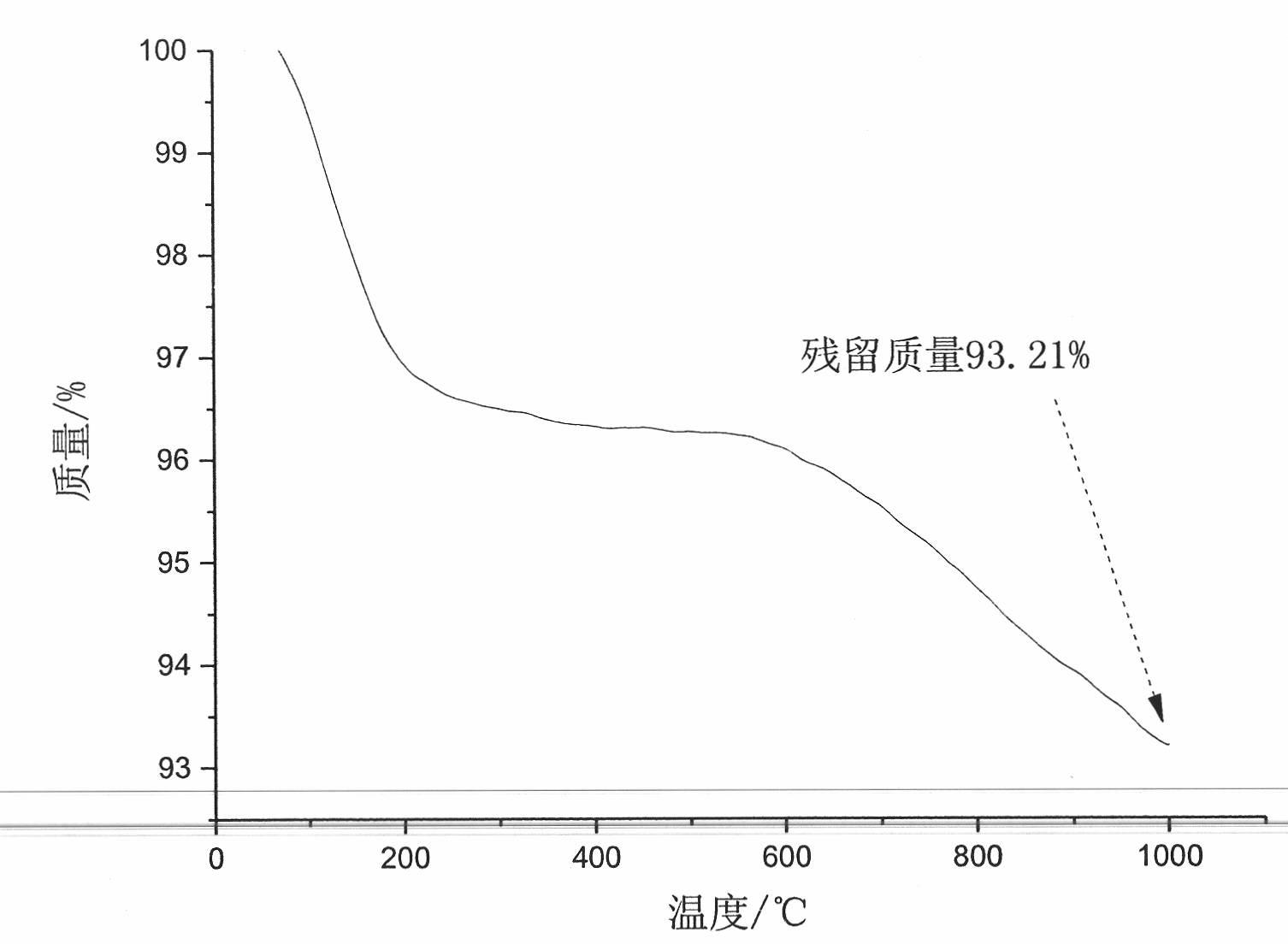

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

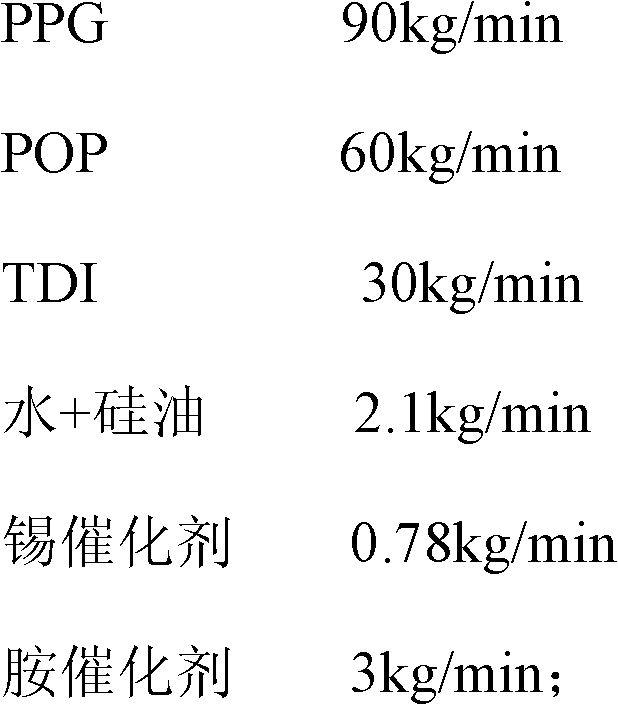

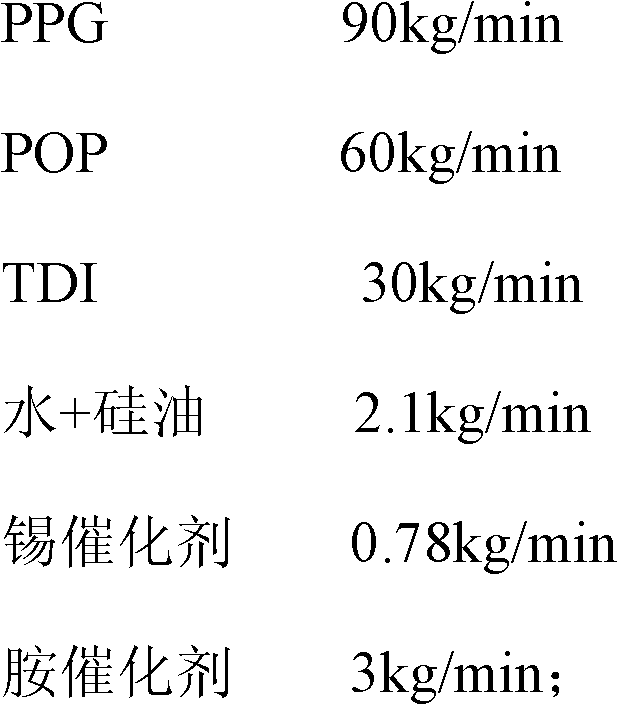

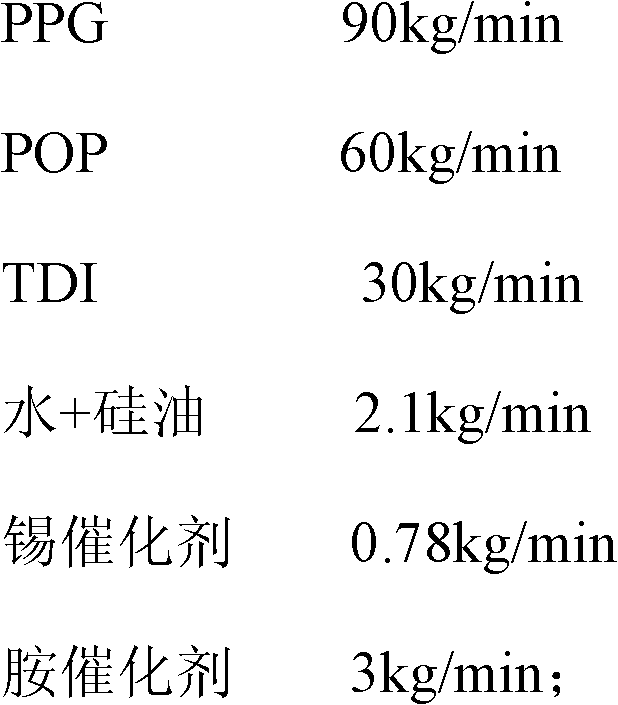

Flexible polyurethane foam and production process

The invention discloses flexible polyurethane foam and a production process for preparing the flexible polyurethane foam. A mixture of polyether, isocyanate, water, a catalyst and foam stabilizer is formed by reacting by means of one-step continuous foaming process, wherein the polyether consists of PPG (polypropylene glycol) and POP (polyether polyol), and the proportion of 2,4-TDI (toluene diisocyanate) to 2,6-TDI, which are isomers of TDI of isocyanate, ranges from 75-85:15-25. High-density foam with apparent density up to 80kg / m3 is produced by means of the one-step continuous foaming process and has the advantages of high production capacity and fine cell-opening performance as compared with molding foam. The foam produced by the process has high density up to 80kg / m3 under the condition of continuous production as compared with common block foam, so that the cell diameter of the foam is thick, and the foam is high in elasticity and bearing capacity.

Owner:ZHEJIANG CHUANYANG SPONGE

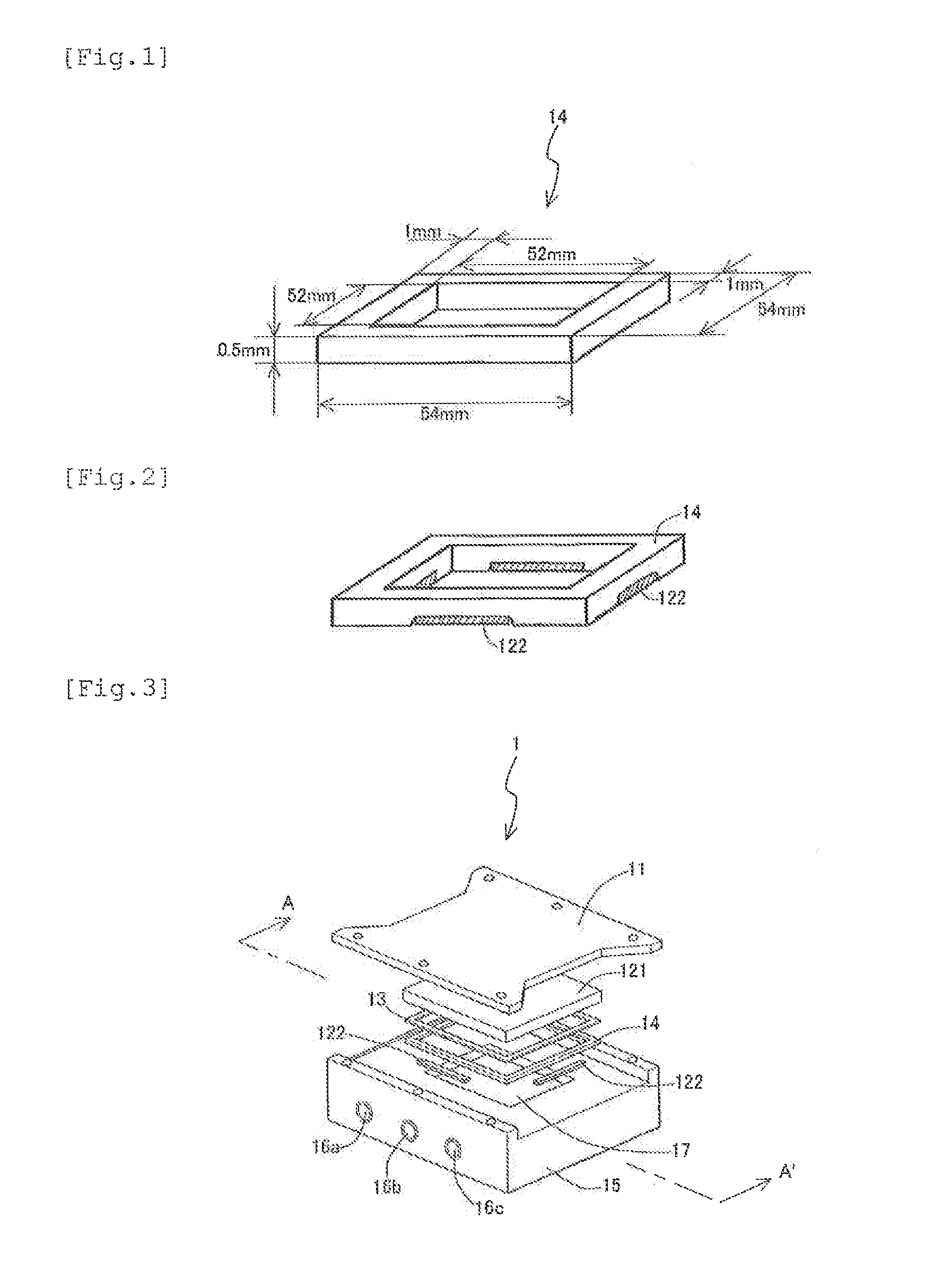

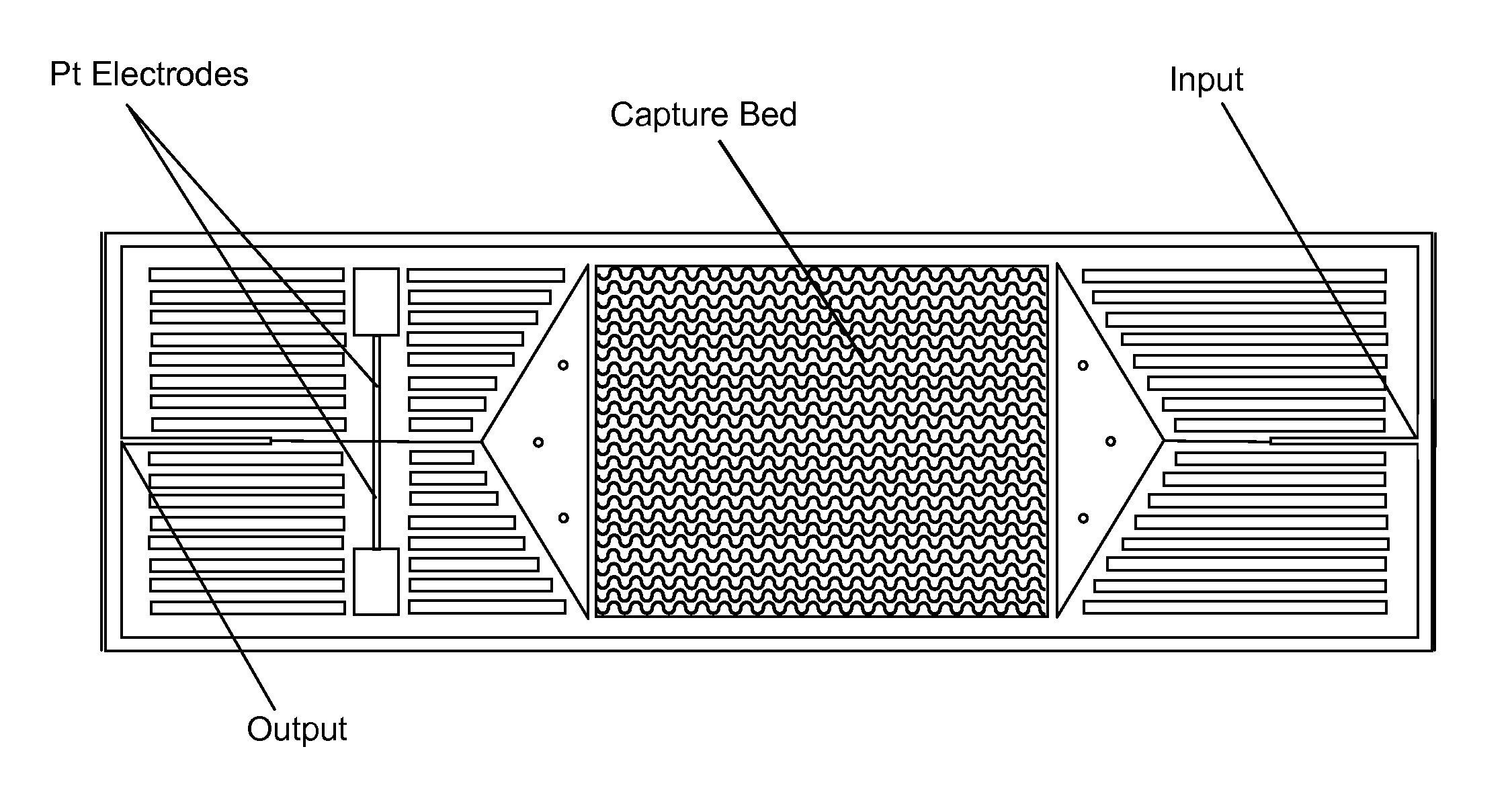

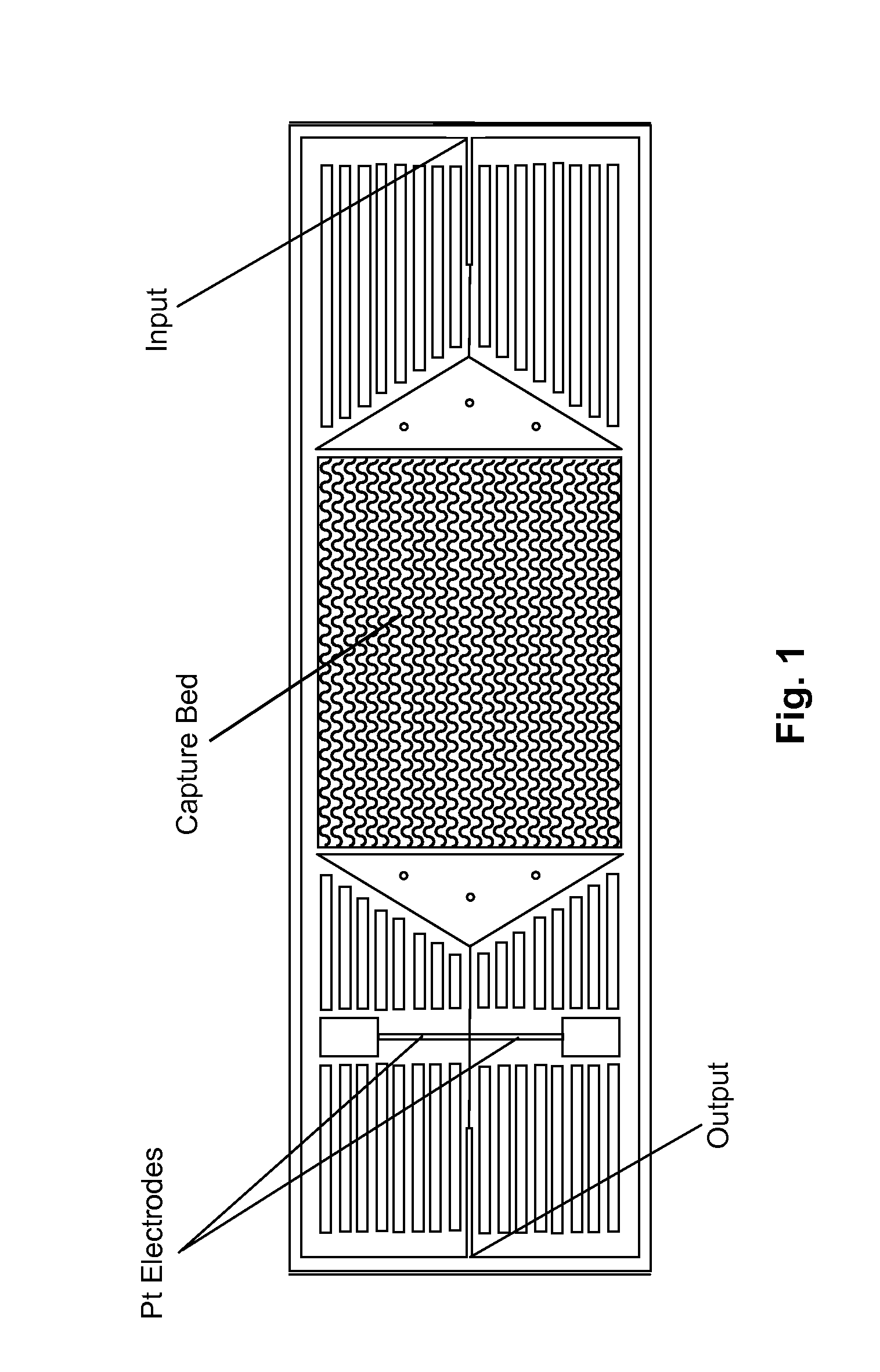

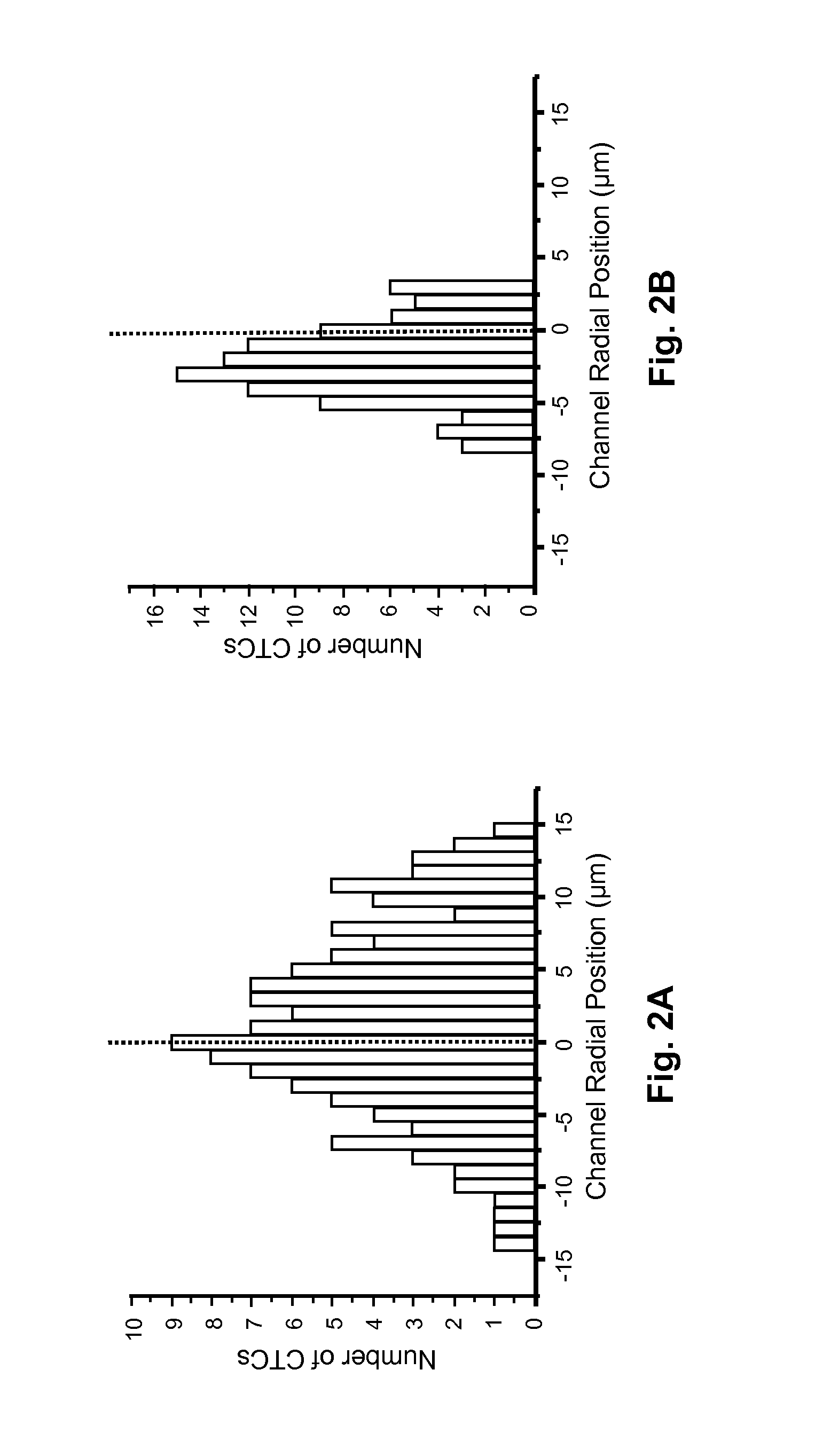

Microfluidic Isolation of Tumor Cells or Other Rare Cells from Whole Blood or Other Liquids

ActiveUS20120100521A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellPathogenic bacteria

Microdevices are disclosed to efficiently, accurately, and rapidly isolate and enumerate rare cells, such as circulating tumor cells, from liquids such as whole blood. The system employs multiple parallel meandering channels having a width on the order of 1-2 cell diameters. The microdevices can be produced at low-cost, may readily be automated, and in many instances may be used without pre-processing of the sample. They may be used to isolate and enumerate rare cells, including for example the detection and diagnosis of cancers, cancer staging, or evaluating the effectiveness of a therapeutic intervention, or detecting pathogenic bacteria. The device may optionally be used to nondestructively capture and later to release target cells.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

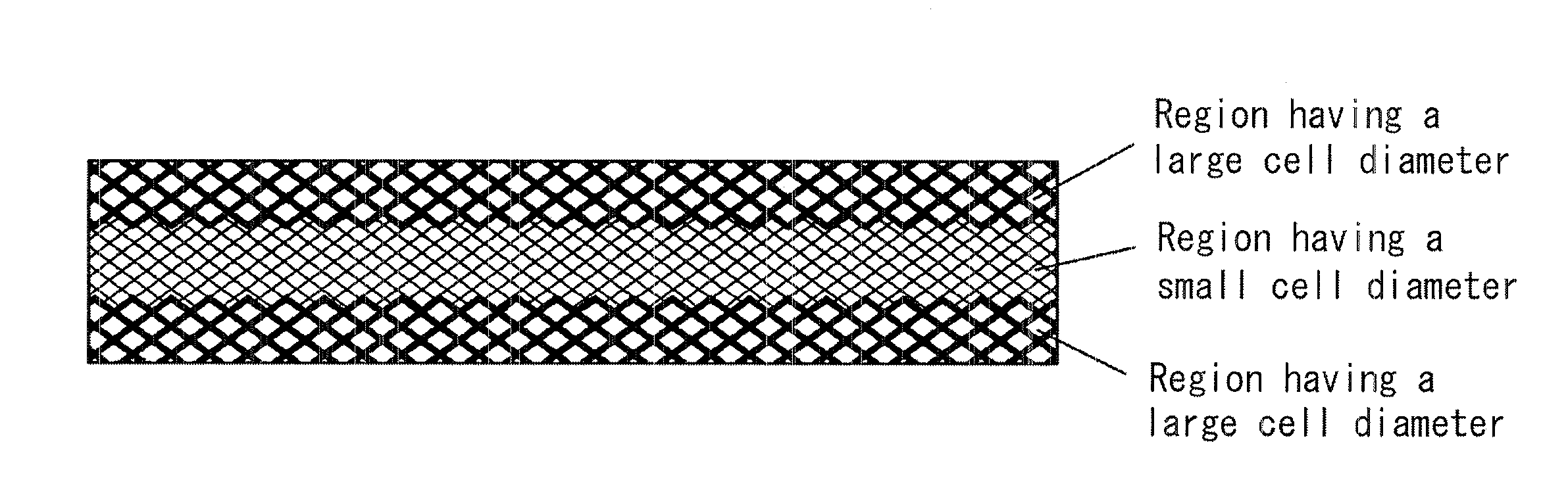

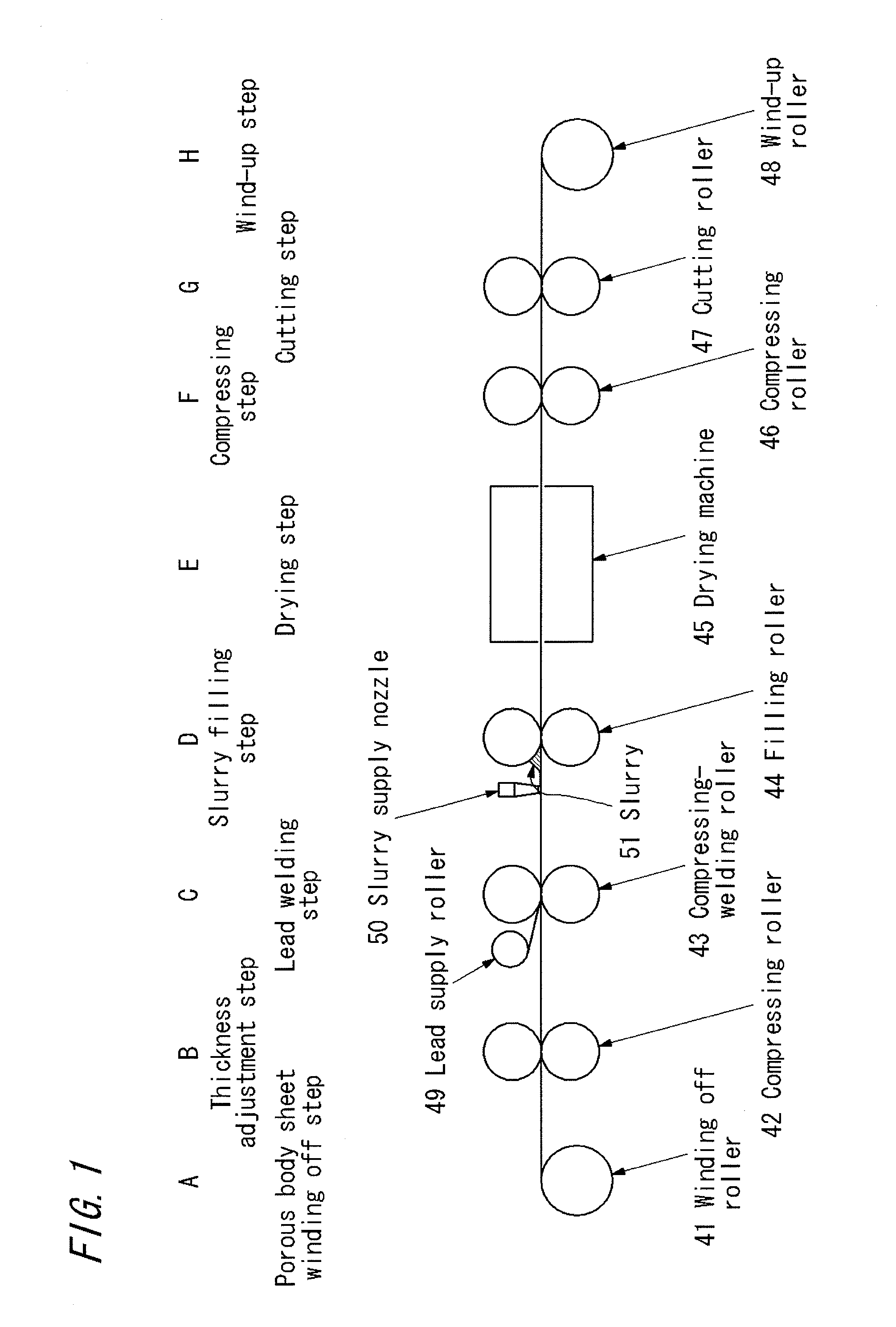

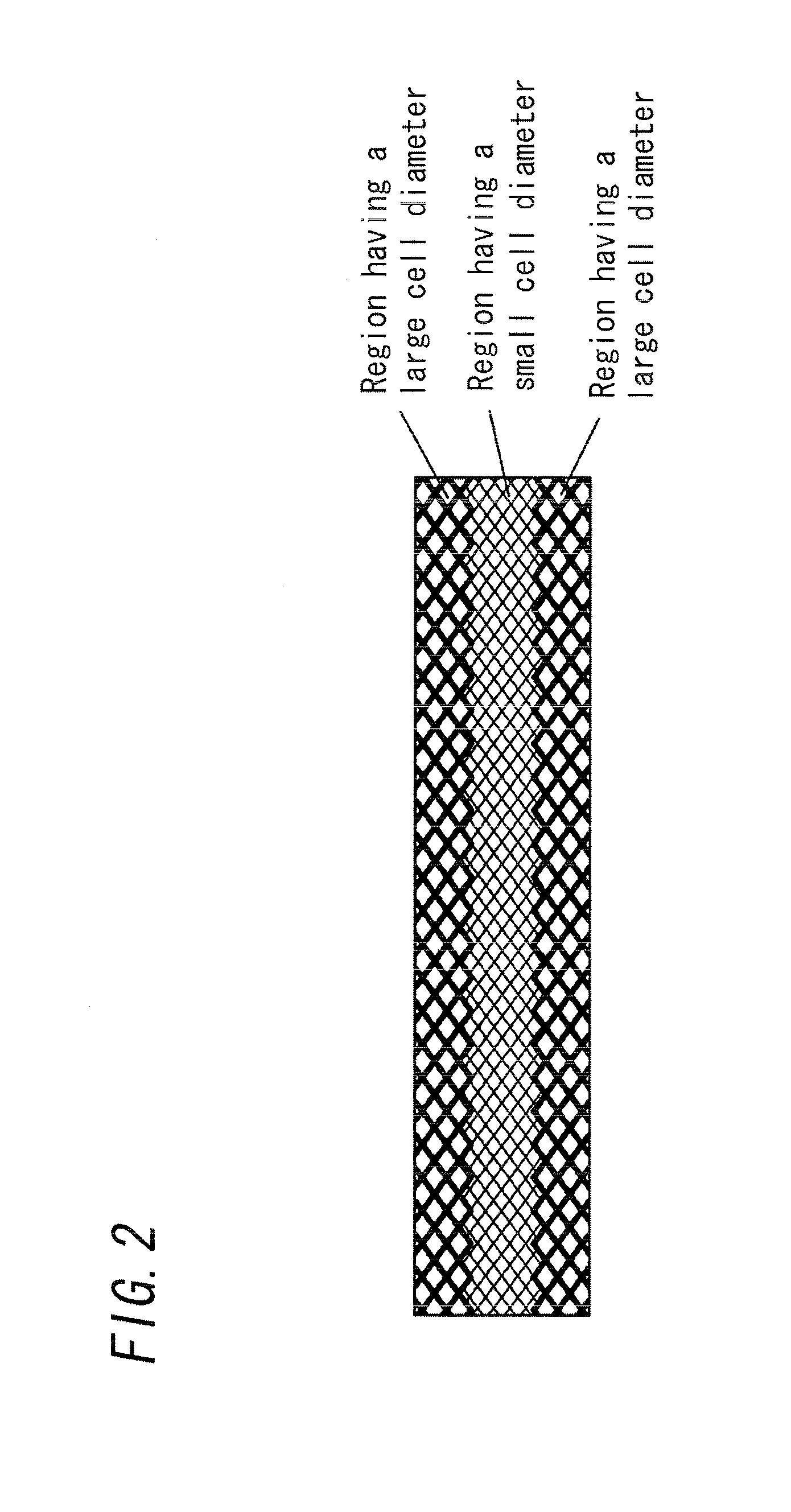

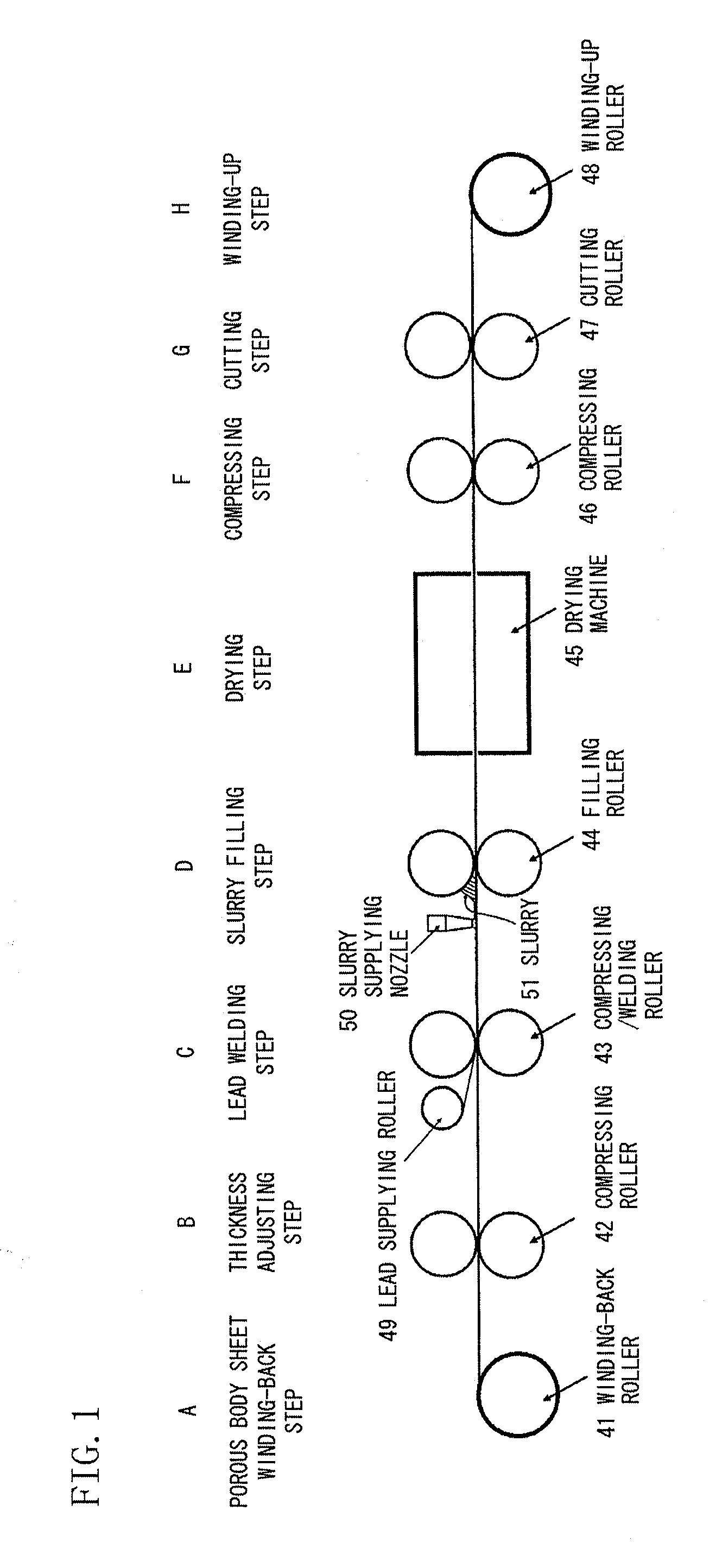

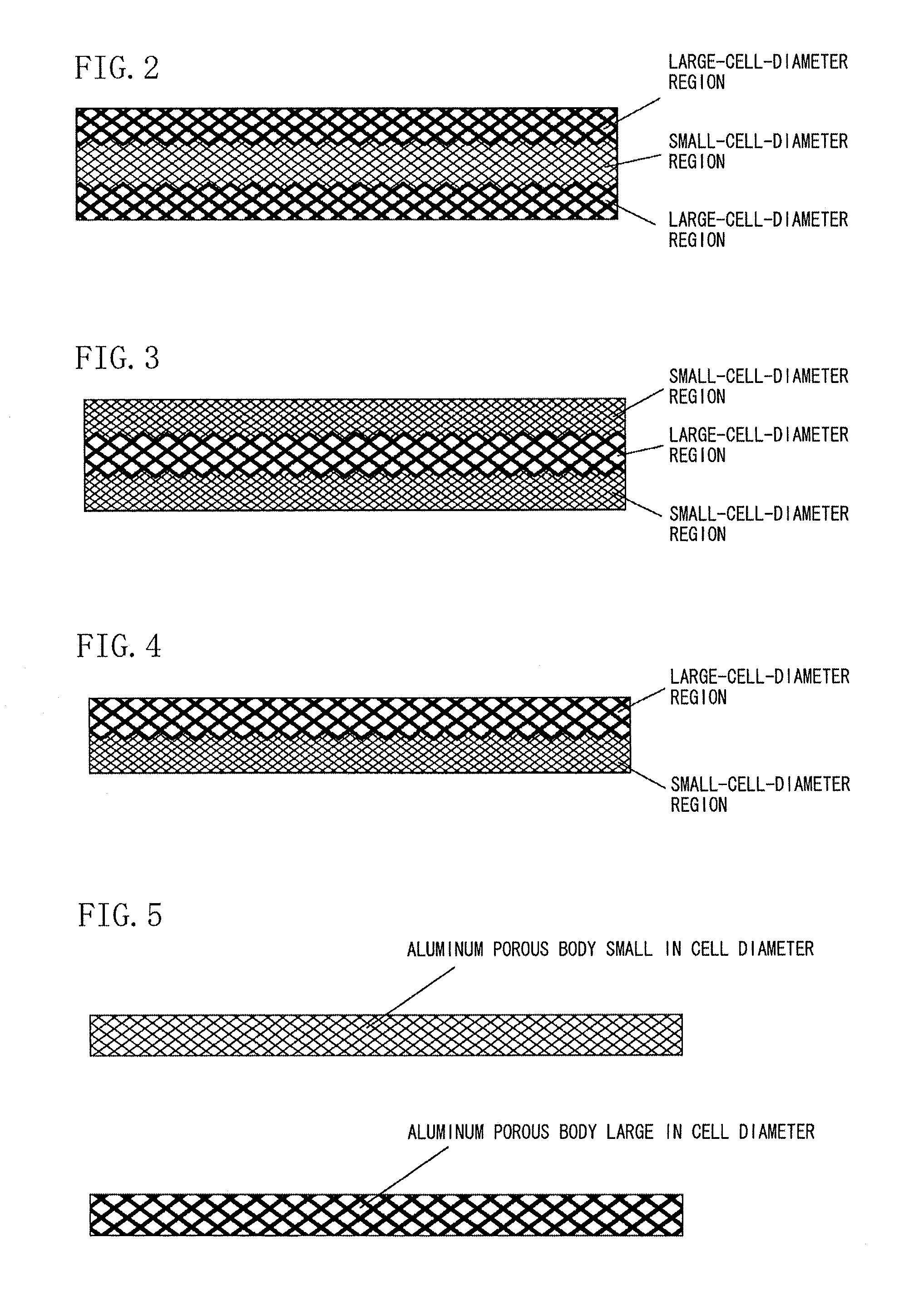

Three-dimensional network aluminum porous body, electrode using the aluminum porous body, and nonaqueous electrolyte battery, capacitor and lithium-ion capacitor with nonaqueous electrolytic solution, each using the electrode

InactiveUS20130004844A1Reduce industrial production costIncrease currentNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesLithium-ion capacitorCurrent collector

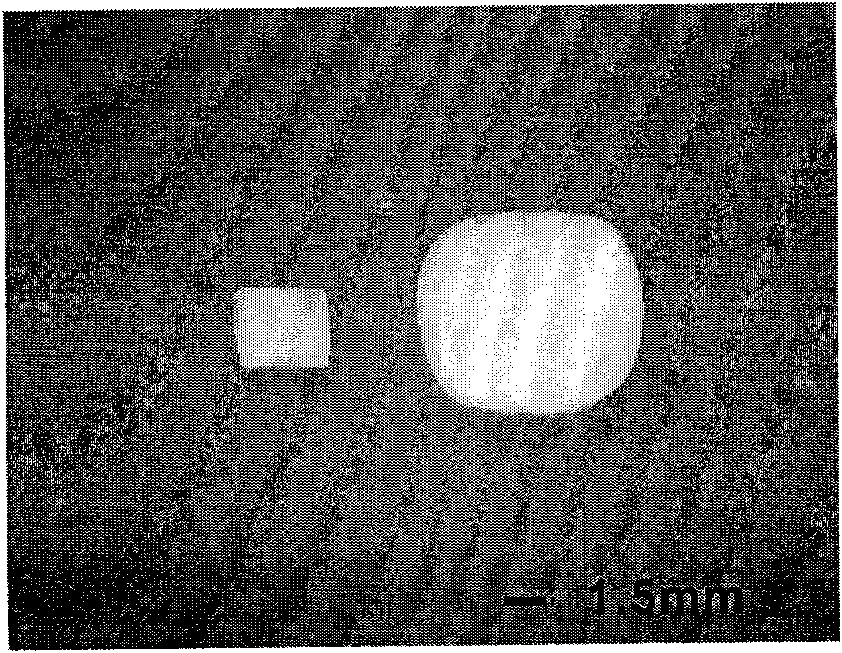

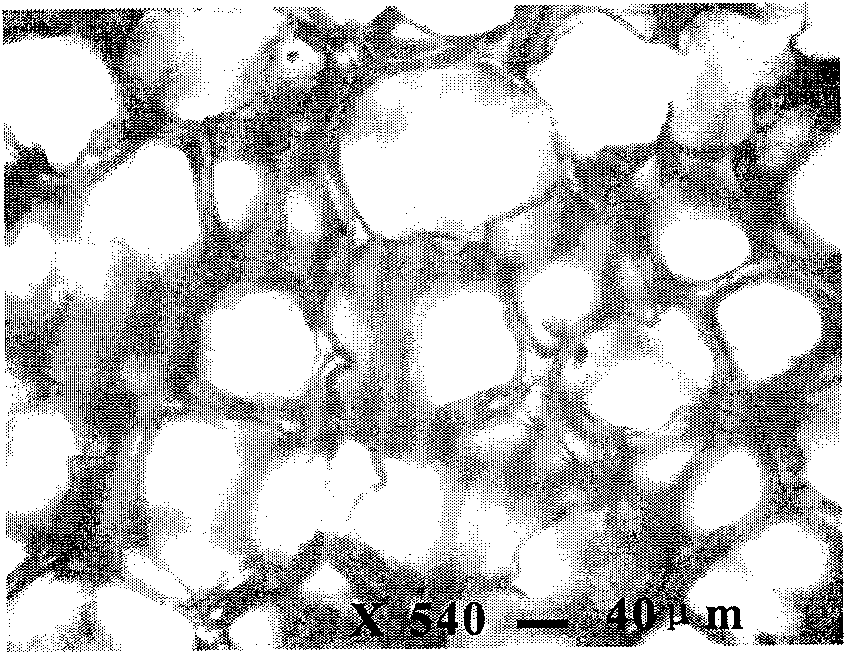

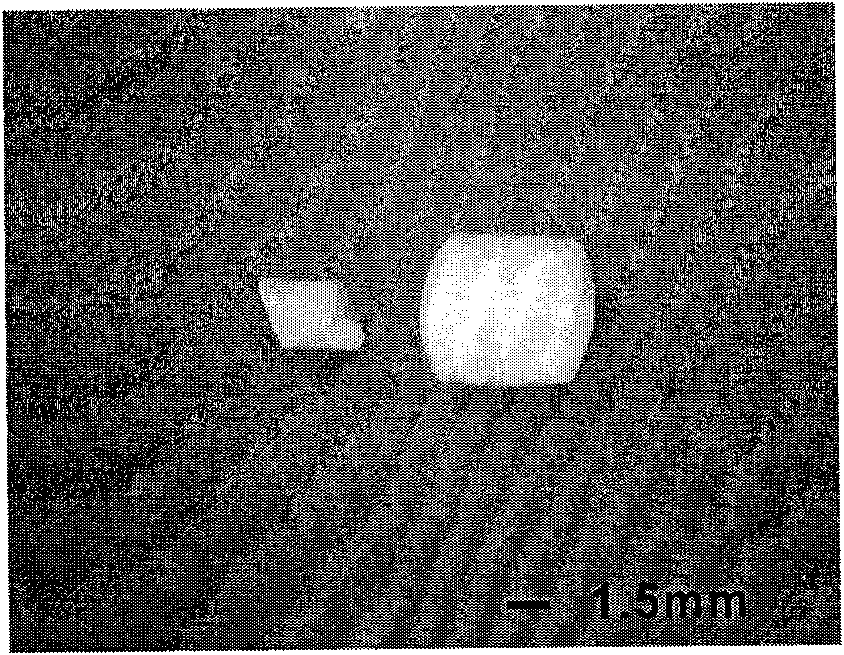

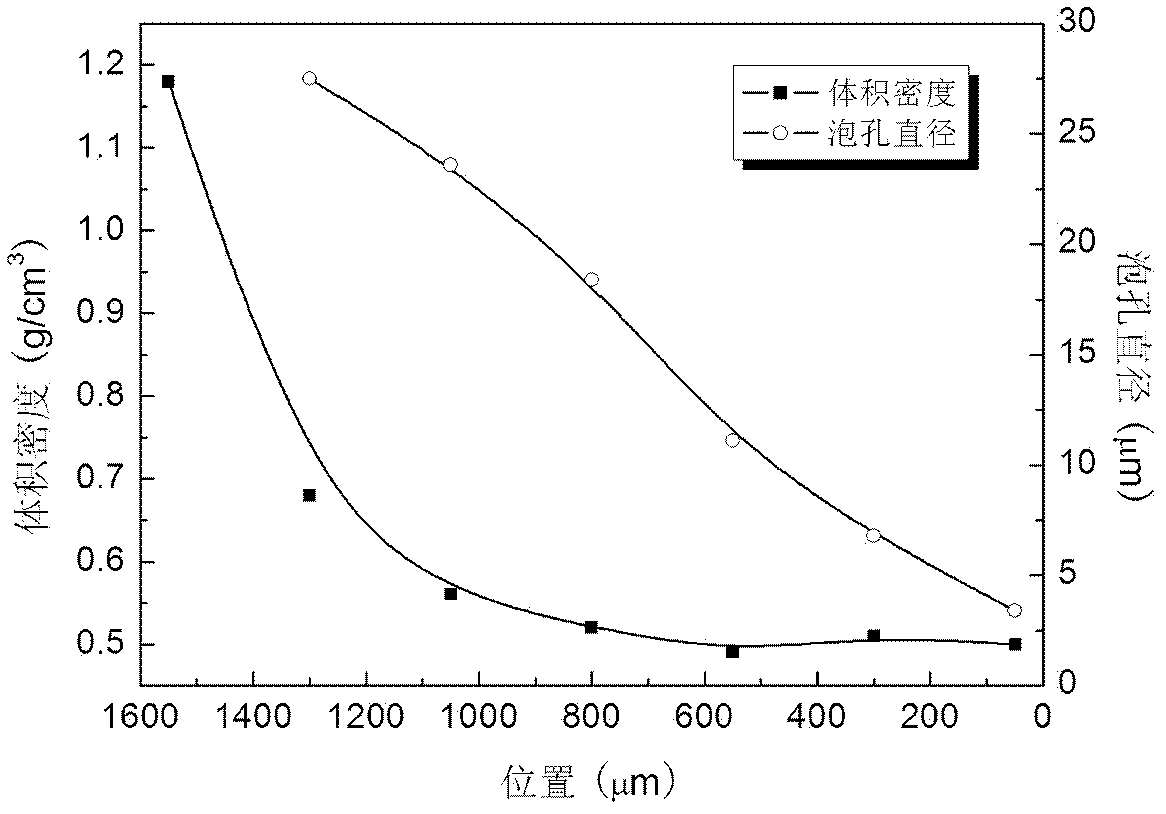

The present invention provides a three-dimensional network aluminum porous body in which the cell diameter of the three-dimensional network aluminum porous body is uneven in the thickness direction, and a current collector and an electrode respectively using the aluminum porous body, and a production method thereof. That is, such a sheet-shaped three-dimensional network aluminum porous body for a current collector has a cell diameter uneven in the thickness direction. Particularly, it is preferred that when a cross section in the thickness direction of the three-dimensional network aluminum porous body is divided into three regions of a region 1, a region 2 and a region 3 in this order, the average of the cell diameter in the region 1 and the cell diameter in the region 3 differs from the cell diameter in the region 2.

Owner:SUMITOMO ELECTRIC IND LTD +1

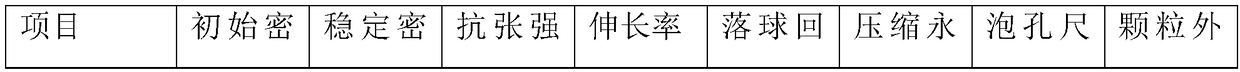

Extruded and foamed thermoplastic polyurethane elastomer particle and preparation method thereof

ActiveCN108239386AProduction environmental protectionSimple preparation processThermoplastic elastomerThermoplastic polyurethane

The invention relates to an extruded and foamed thermoplastic polyurethane elastomer particle and a preparation method thereof. The particle contains the following components in percentage by mass: (A) 65%-90% of a thermoplastic polyurethane elastomer, (B) 2%-30% of a thermoplastic resin polymer, (C) 0.5%-15% of a compatilizer and (D) 0.1%-5% of a foaming nucleating agent. The preparation method of a TPU formed particle comprises the following steps: uniformly mixing the thermoplastic polyurethane elastomer, the thermoplastic resin polymer, the compatilizer and the foaming nucleating agent, putting the mixture into melt extrusion equipment, and carrying out granulation, so as to obtain a blending alloy particle; and putting the blending alloy particle into foaming extrusion equipment, carrying out melting plastification so as to obtain a melt, dissolving supercritical carbon dioxide into the melt, foaming by virtue of a mouth mold, and carrying out underwater dicing, so as to obtain the formed particle. The prepared thermoplastic polyurethane foamed particle is stable in size and basically does not shrink, the surface is bright and plumy, and the diameters of foamed holes are uniform.

Owner:WANHUA CHEM GRP CO LTD

Process for the preparation of closed cell rigid polyurethane foams

Owner:DOW GLOBAL TECH LLC

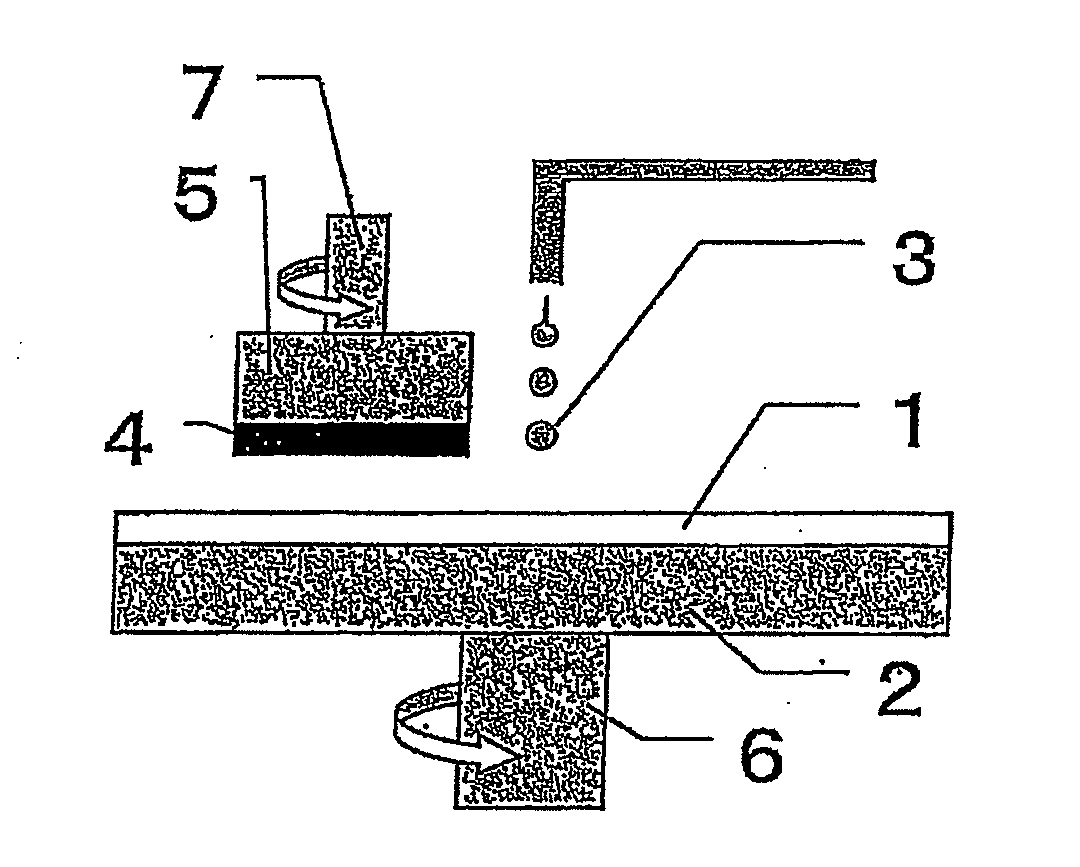

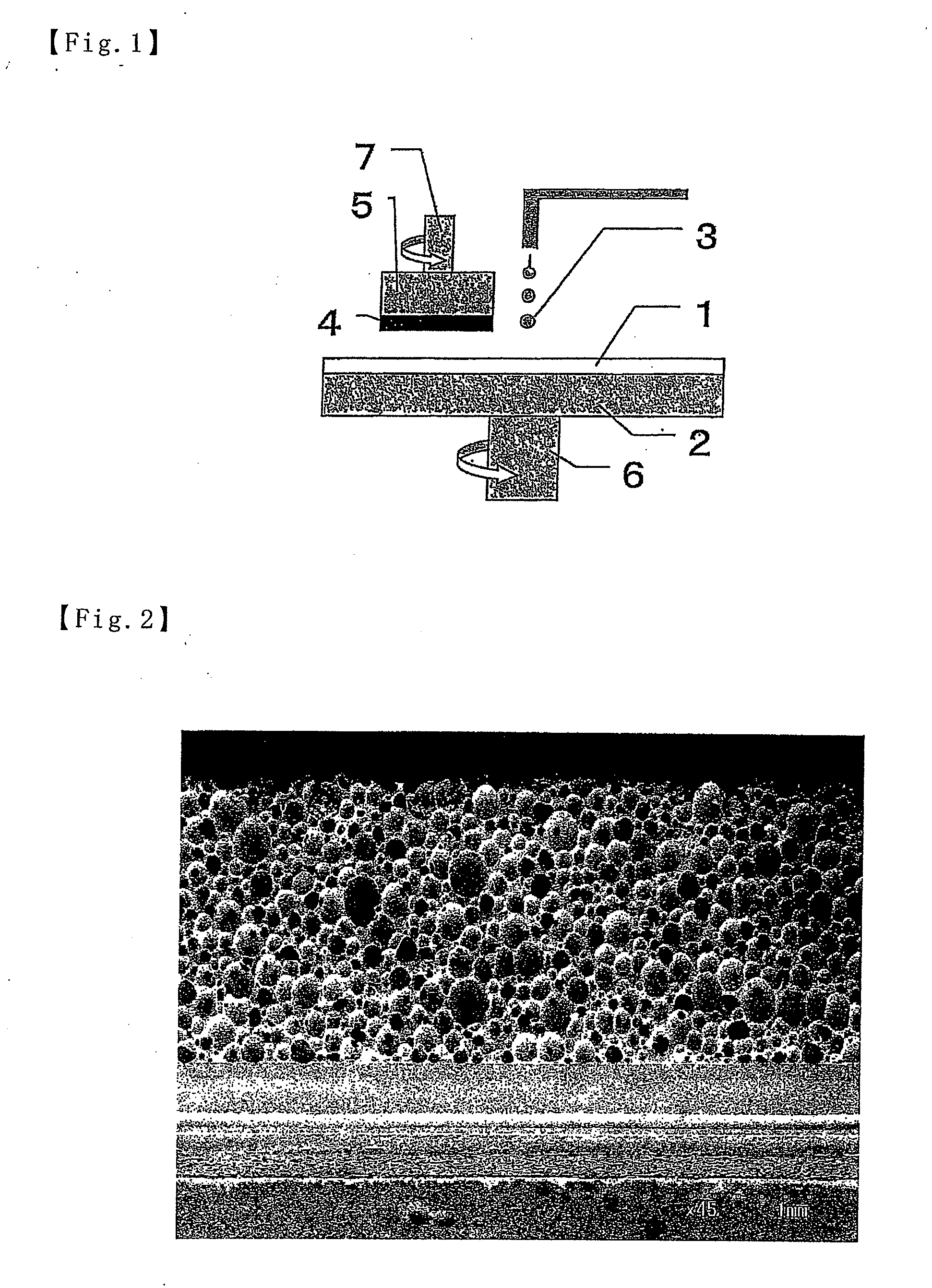

Polishing pad and method for producing same

ActiveUS20110256817A1High thickness accuracyShorten break-in timeAbrasion apparatusSemiconductor/solid-state device manufacturingMetallurgyCell diameter

An object of the invention is to provide a polishing pad that achieves a high polishing rate and has high thickness precision so that the break-in time (dummy polishing time) can be shortened, and to provide a method for producing same. The invention is directed to a polishing pad including a base material layer and a polishing layer provided on the base material layer, wherein the polishing layer includes a thermoset polyurethane foam having roughly spherical interconnected cells with an average cell diameter of 35 to 200 μm, and the polishing layer has a storage modulus E′ (40° C.) of 130 to 400 MPa at 40° C., a ratio of storage modulus E′ (30° C.) at 30° C. to storage modulus E′ (60° C.) at 60° C. [E′(30° C.) / E′(60° C.)] of 1 to less than 2.5, and a ratio of storage modulus E′ (30° C.) at 30° C. to storage modulus E′ (90° C.) at 90° C. [E′(30° C.) / E′(90° C.)] of 15 to 130.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

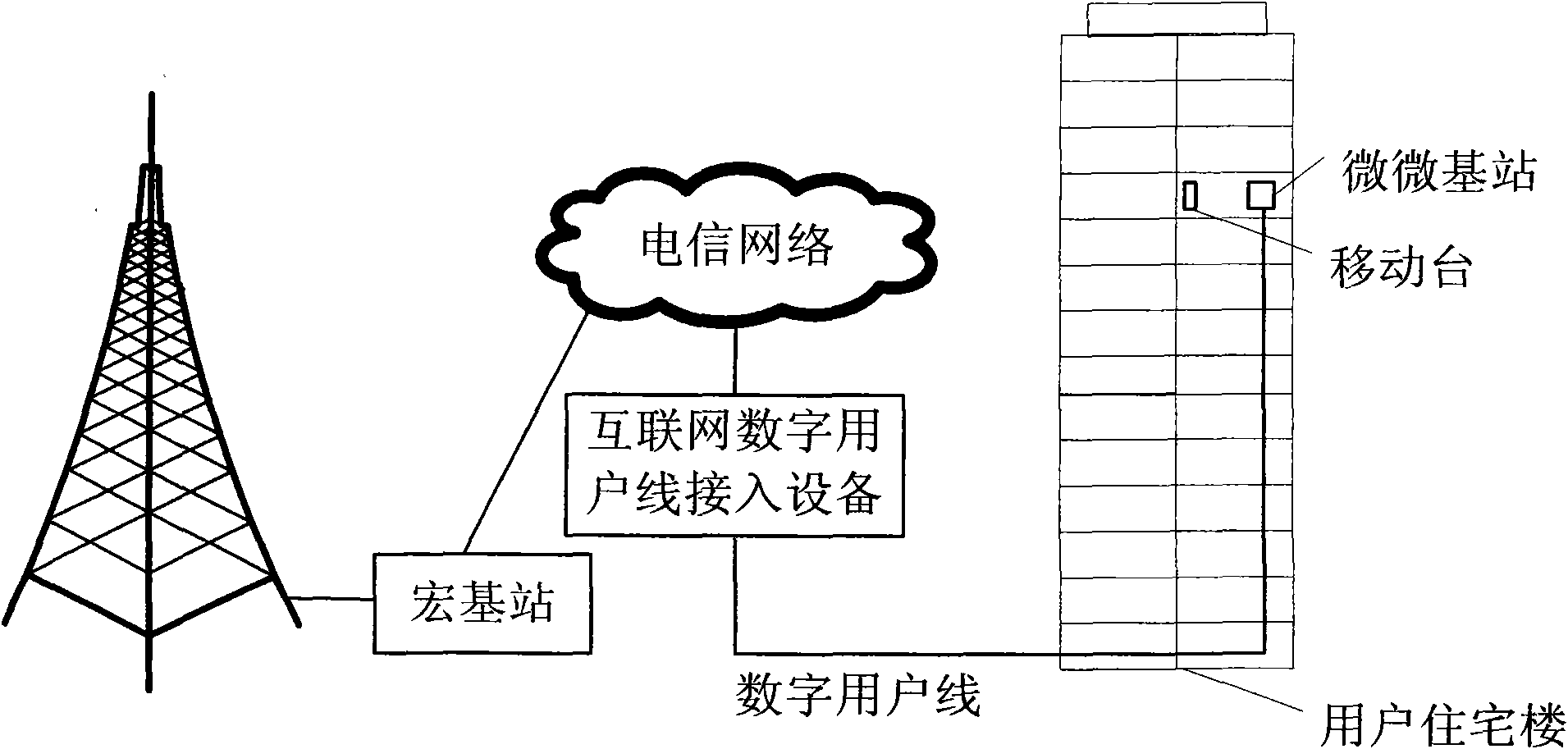

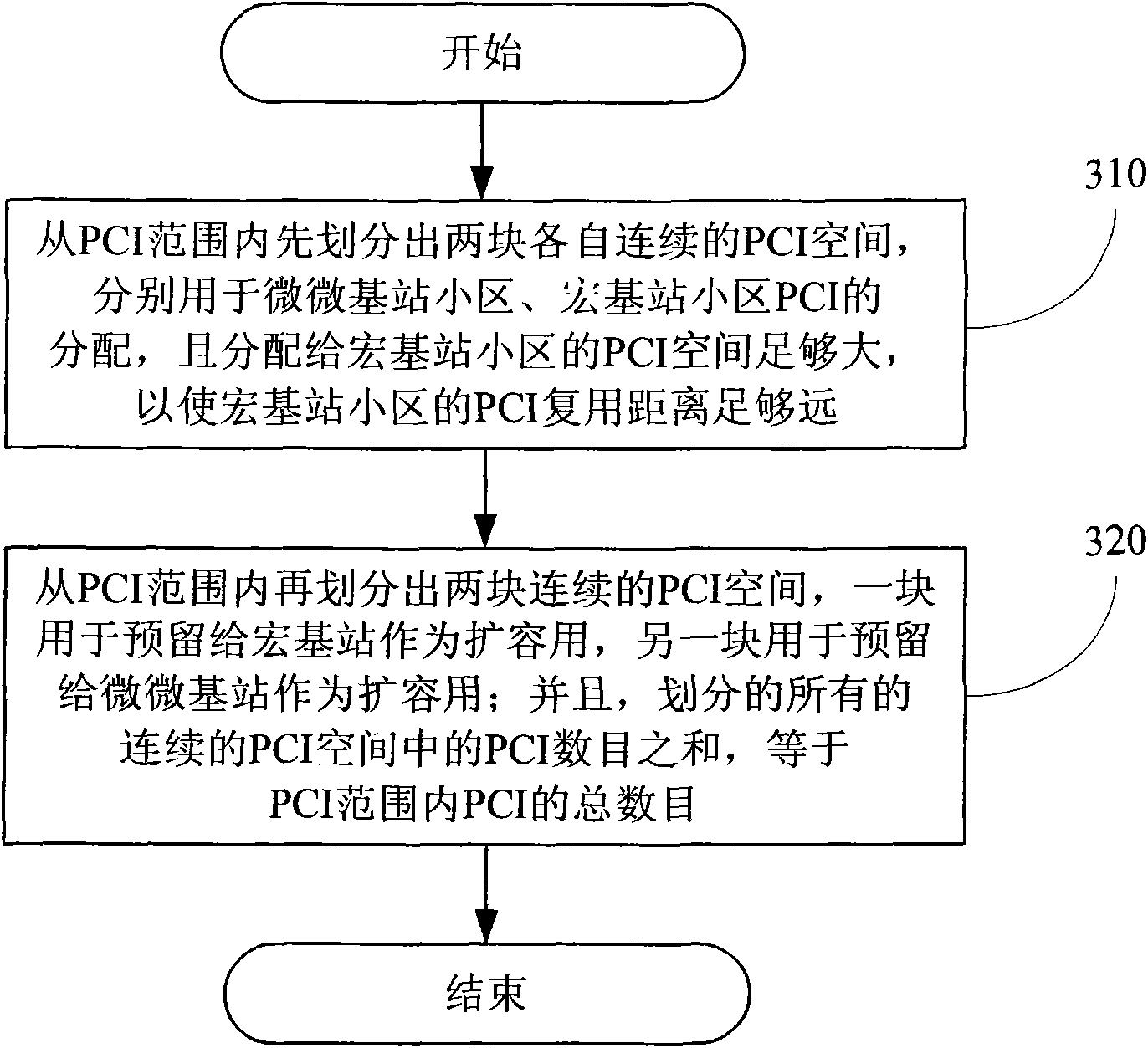

Distribution method of PCIs (Physical Cell Identities) in long-term evolution network

The invention discloses a distribution method of PCIs (Physical Cell Identities) in a long-term evolution network. The method comprises the following steps of: firstly, partitioning two respectively continuous PCI spaces in a PCI range, wherein one is used for distributing PICs in a picocell, and the other is used for distributing PCIs in a micro base cell; distributing a PCI space large enough to the micro base cell so that the PCI multiplexing distance in the micro base cell is far enough, which means the multiplication of ring number of enough macrocell clusters forming the micro base by the cell diameter, and the enough large PCI space means that the number of the distributed PCIs is at least equal to the total cell number of the enough macrocell clusters. On the premise that the macrocell clusters and the picocell are ensured to use different PCI spaces, the PCI multiplexing distance of the macrocell is far enough, PCI conflict probability among picocells is lower, and resources are preserved for network expansion.

Owner:ZTE CORP

Method for preparing poly hexane diacid-terephthalic acid-butylene terephthalate foaming material

The invention discloses a method for preparing a foaming material of poly adipic acid-terephthalic acid-butylene, which belongs to the technical field of biodegradable polymer materials. The method comprises the following steps of: placing the poly adipic acid-terephthalic acid-butylene (PBAT) material into CO2 fluid in a supercritical state to swell so as to massively dissolve the CO2 in the PBAT material; simultaneously keeping enough intensity and size stability of the PBAT material; and allowing the CO2 in the PBAT material to supersaturate through rapid pressure relief to form thermodynamic instability so as to nucleate and foam to obtain the foaming material of the poly adipic acid-terephthalic acid-butylene. The method can obtain the obturator PBAT foaming material with the cell diameter of between 22.10 and 119.02 microns and the cell density of between 2.62 x 10 <6> and 4.51 x 10 <8> per cubic meter.

Owner:SHANGHAI JIAO TONG UNIV

Process for producing porous polyimide and porous polyimide

A porous polyimide having a finely cellular structure and having a low dielectric constant and heat resistance. The porous polyimide can be produced by a process comprising adding a dispersible compound to a polyimide precursor to form a micro-domain structure in which the dispersible compound is dispersed in the polymer so as to have a size smaller than 10 mum and then removing the dispersible compound by extraction with supercritical carbon dioxide to thereby make the precursor porous, wherein the interaction parameter χAB between the polyimide precursor A and the dispersible compound B is larger than 3. This porous polyimide has an average cell diameter smaller than 5 mum and a dielectric constant of 3 or lower.

Owner:NITTO DENKO CORP

Polishing pad

ActiveUS8167690B2Increased durabilityPoor durabilityAbrasion apparatusSemiconductor/solid-state device manufacturingMetallurgyCell diameter

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

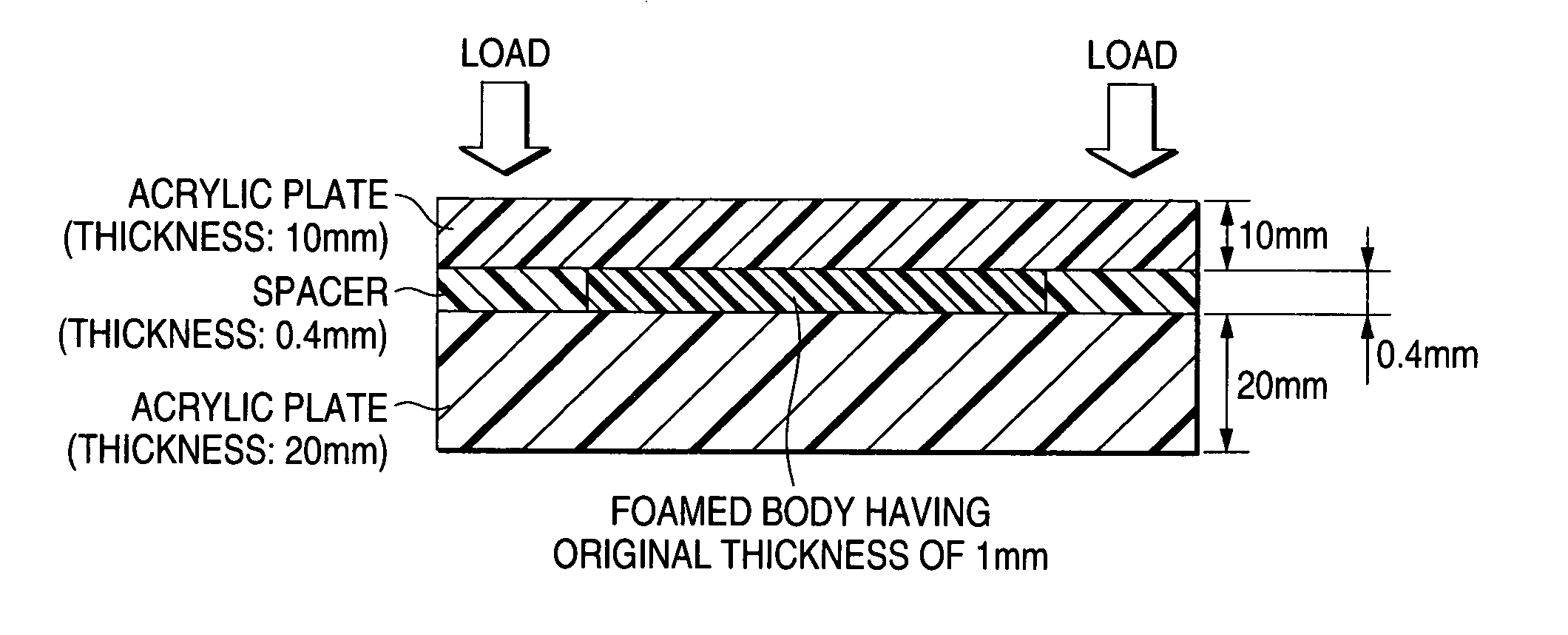

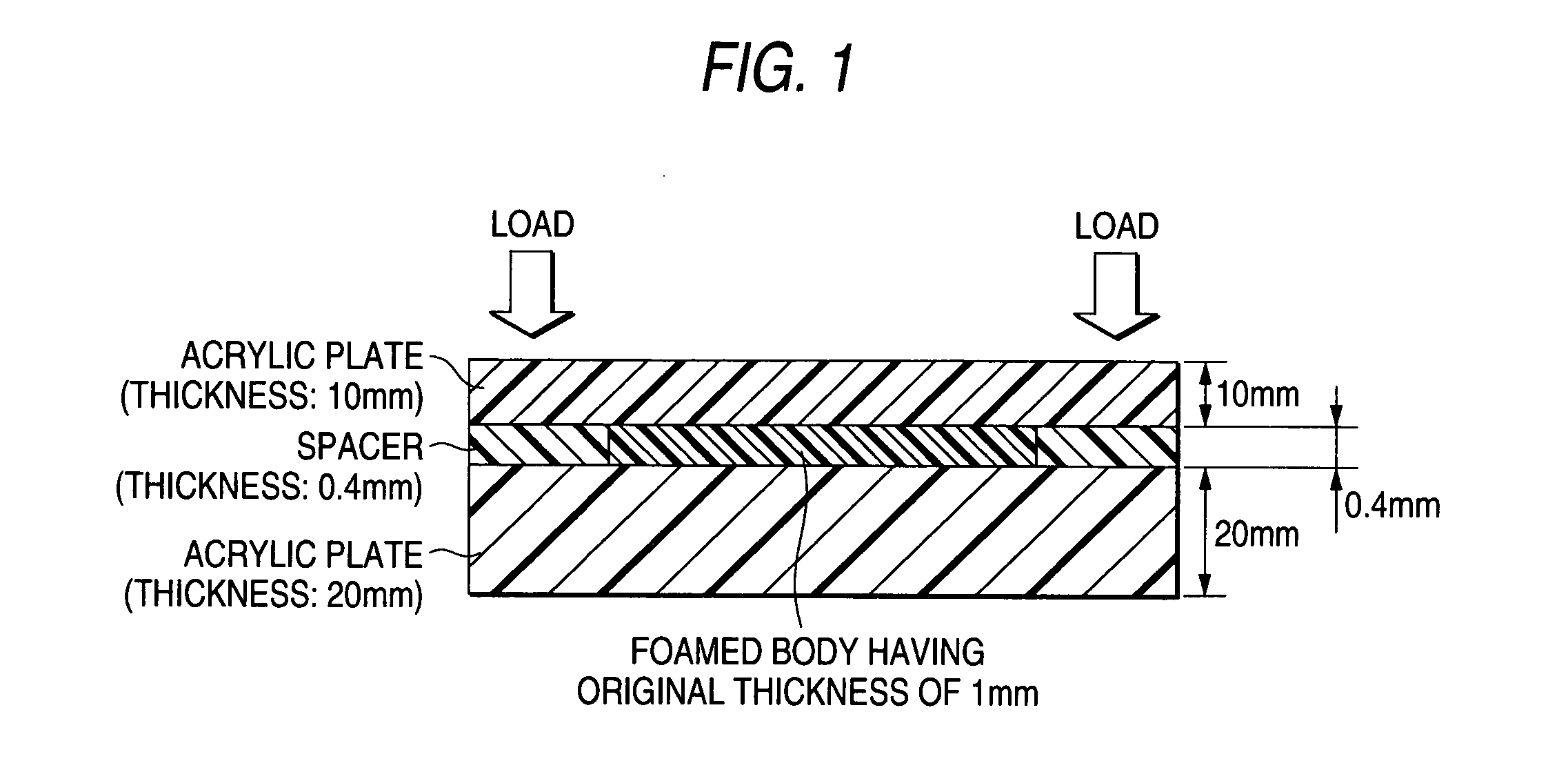

Foamed dustproof material and dustproof structure using foamed dustproof material

InactiveUS20050053779A1Improve dustproof effectReduce gapContact surface shape/structureOther chemical processesApparent densityVolumetric Mass Density

A foamed dustproof material which comprises a foamed body, wherein the foamed body has an average cell diameter of from 10 to 90 μm, a load against repulsion upon compressing to 50% of from 0.1 to 3.0 N / cm2, and an apparent density of from 0.01 to 0.10 g / cm3.

Owner:NITTO DENKO CORP

Biodegradable material poly(hexanedioic acid-para-phthalic acid-butanediol ester) foaming particles preparation method

The invention discloses a biodegradable material poly(hexanedioic acid -para-phthalic acid-butanediol ester) (PBAT) foaming particles preparation method which is characterized in that the preparation method comprises the following steps: placing PBAT particles in an airtight container of which the temperature is 120-142 DEG C and the volume is 25 times or more than 25 times of the total volume of the particles, injecting 8-20MPa of pressure gas in the container, keeping the temperature and the pressure for 5-30min, and then relieving the pressure in a speed of 5-20MPa / s to the normal pressure to obtain the PBAT foaming particles. The cell diameter of the PBAT foaming particles is 10-260mu m and the density is 0.13-0.35g / cm<3>. The invention has simple process, easy operation, short production cycle and low cost, thus being applicable to the industrialized production.

Owner:浙江博发新材料股份有限公司

Preparation method of polymethyl methacrylate (PMMA) cellular gradient material

The invention relates to a preparation method of a polymethyl methacrylate (PMMA) cellular gradient material. The method specifically comprises: placing a unidirectionally opened die loaded with PMMA into an autoclave, controlling the oriented adsorption of highpressure carbon dioxide in PMMA to form a concentration gradient, with the pressure of the carbon dioxide controlled at 10-30MPa and the temperature maintained at 50-150DEG C, preserving the heat and pressure for 1-60min, then conducting pressure releasing, and finally cooling a sample to room temperature with an ice-water mixture, thus obtaining the cellular gradient material. A cellular structure with a small cell diameter and a thin cell wall forms in a high concentration carbon dioxide diffusion area on the surface layer, a cellular structure with a large cell diameter and a thick cell wall forms in a low concentration area of the central section, and the innermost layer is compact PMMA matrixes. The porosity of the sample changes from high to low continuously from the surface layer to the inner layer. With a cell diameter controlled at micron magnitude, the gradient material provided in the invention has good dimensional stability, wide porosity variation range and high mechanical strength.

Owner:WUHAN UNIV OF TECH

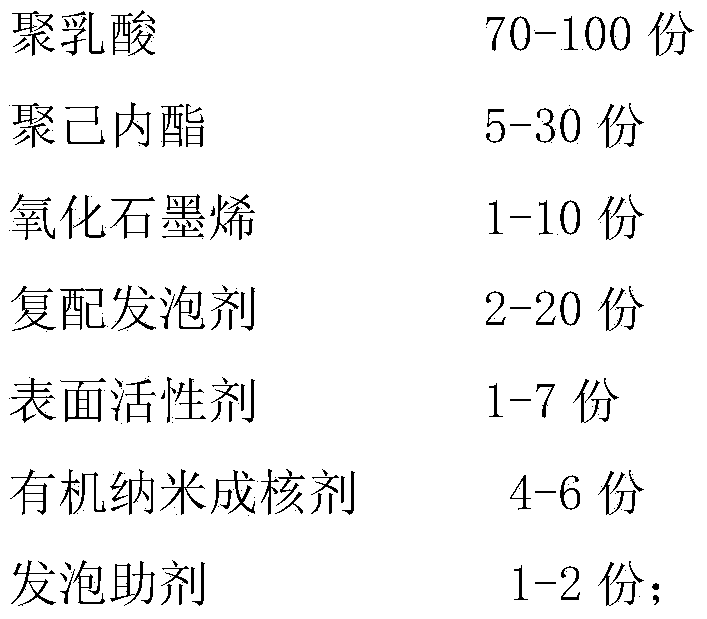

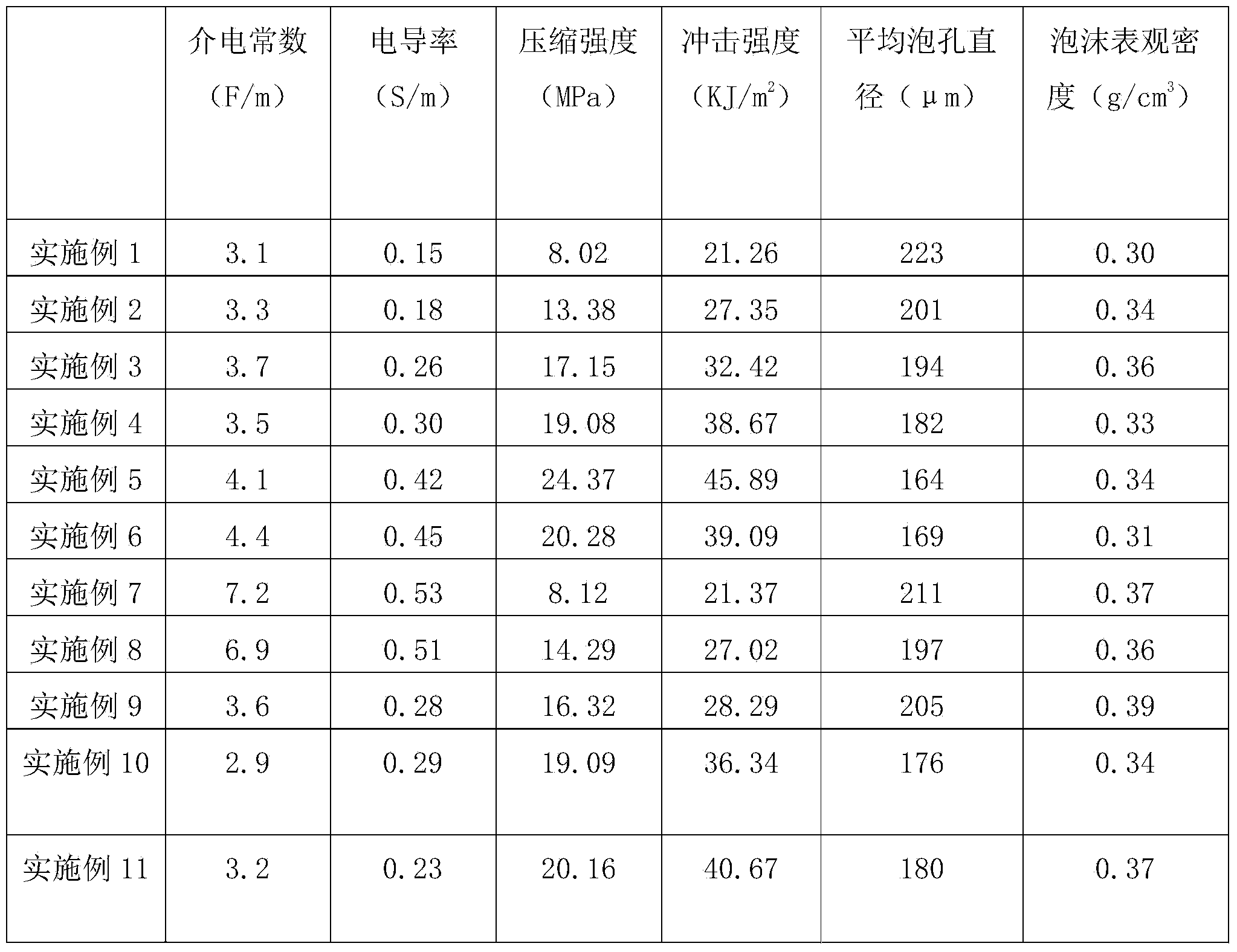

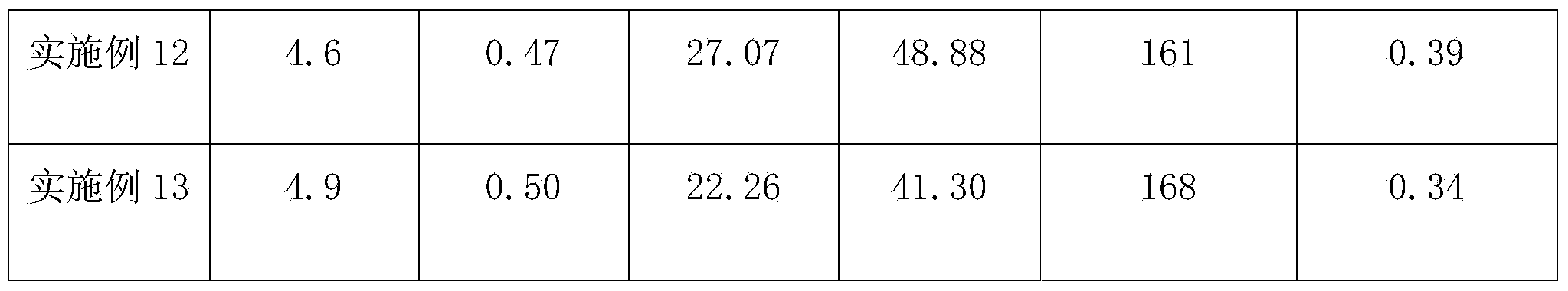

Oxidized graphene modified foam material and preparation method thereof

The invention discloses an oxidized graphene modified foam material which comprises the following constituents by weight parts: 70 to 100 parts of polylactic acid, 5 to 30 parts of polycaprolactone, 1 to 10 parts of oxidized graphene, 2 to 20 parts of a compound foaming agent, 1 to 7 parts of a surfactant, 4 to 6 parts of an organic nano-nucleating agent, and 1 to 2 parts of a blowing promotor. The oxidized graphene modified foam material is 2 to 9 F / m in dielectric constant, 0.10 to 0.80 S / m in electric conductivity, 0.10 to 0.90 g / cm<3> in performance density, 5 to 30 MPa in compression strength, 10 to 85 KJ / m<2> in impact strength, and 100 to 300 [Mu]m in average cell diameter. The oxidized graphene modified foam material is simple and feasible in technology, and can be used for economically and effectively preparing polylactic acid-based complex foaming conductive material which is excellent in conductibility and comprehensive mechanical property, high in heat resistance and controllable in density.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

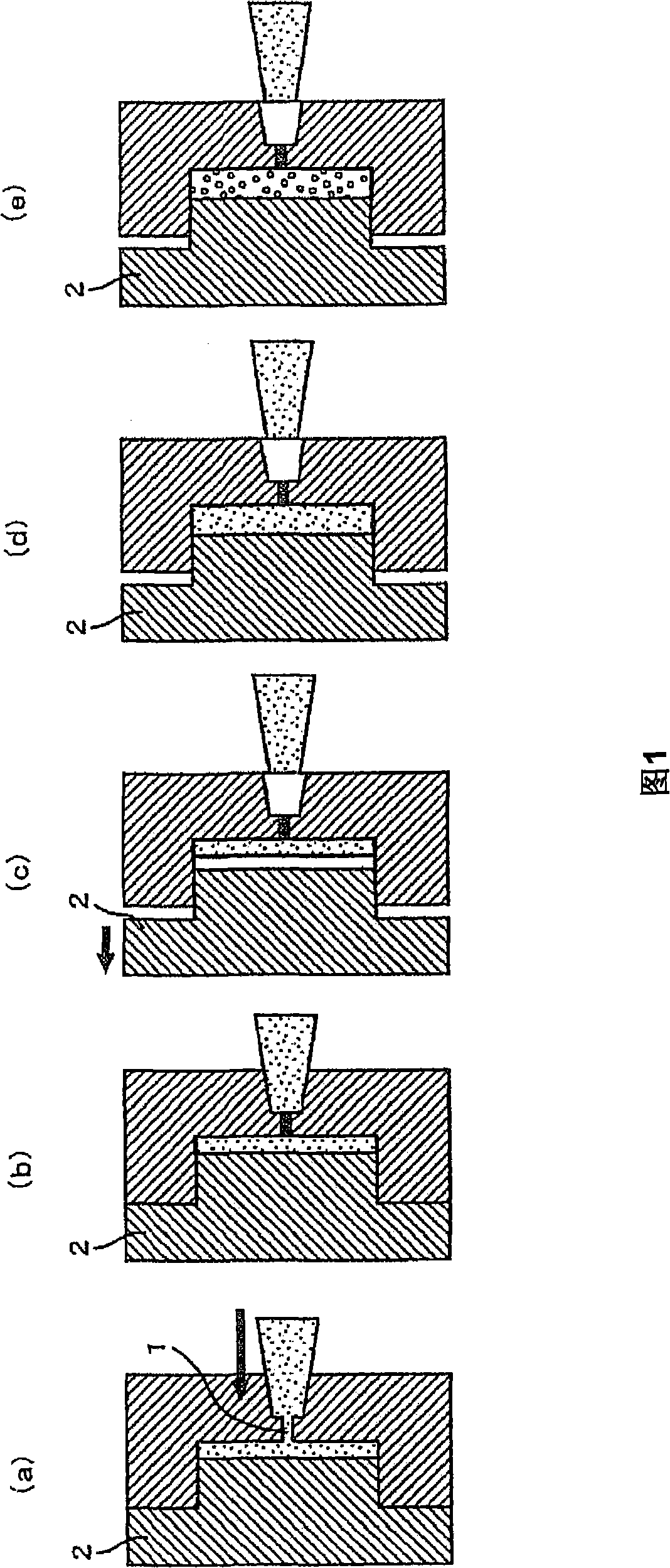

Layered sheets and processes for producing the same

InactiveUS20110151240A1Improve flatnessImprove suppression propertiesSynthetic resin layered productsSolid-state devicesHardnessCell diameter

Provided herein is a process for producing a layered sheet. The process involves preparing a cell dispersed urethane composition by a mechanical foaming method. The cell dispersed urethane composition is applied to a base material sheet and cured to produce a polyurethane foam layer of uniform thickness. A releasing sheet may be utilized to make the thickness of the polyurethane foamed layer uniform. Also, provided herein is a layered sheet produced by the above process. The polyurethane foamed layer may have spherical fine cells having an average cell diameter of 20 to 300 μm. The polyurethane foamed layer may have a specific gravity of 0.2 to 0.5. The polyurethane foamed layer may also have a Asker C hardness of 10 to 50 degrees.

Owner:TOYO TIRE & RUBBER CO LTD

Foamed dustproof material and dustproof structure using foamed dustproof material

ActiveCN1618918AImprove dust resistanceGood flexibilityContact surface shape/structureOther chemical processesPolymer sciencePolymer chemistry

A foamed dustproof material which comprises a foamed body, wherein the foamed body has an average cell diameter of from 10 to 90 mu m, a load against repulsion upon compressing to 50% of from 0.1 to 3.0 N / cm<2>, and an apparent density of from 0.01 to 0.10 g / cm<3>. <IMAGE>

Owner:NITTO DENKO CORP

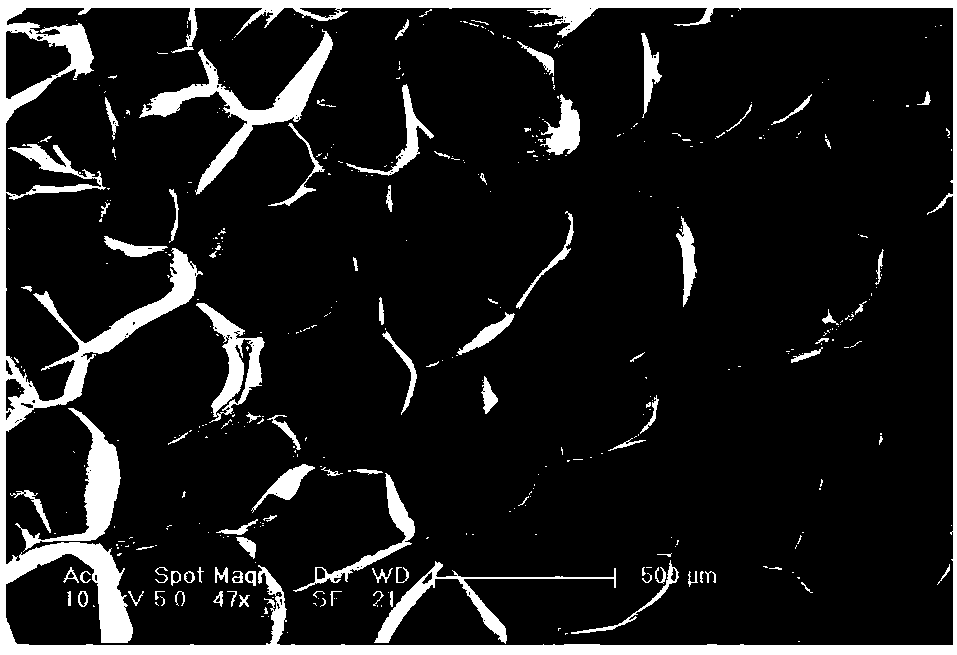

Three-dimensional net-like aluminum porous body, electrode using the aluminum porous body, nonaqueous electrolyte battery using the electrode, and nonaqueous electrolyte capacitor using the electrode

ActiveUS20120115035A1Reduce industrial costsImprove the effect of current collectionHybrid capacitor electrolytesLiquid electrolytic capacitorsCapacitorMaterials science

Provided are a three-dimensional net-like aluminum porous body in which the diameter of cells in the porous body is uneven in the thickness direction of the porous body; a current collector and an electrode each using the aluminum porous body; and methods for producing these members. The porous body is a three-dimensional net-like aluminum porous body in a sheet form, for a current collector, in which the diameter of cells in the porous body is uneven in the thickness direction of the porous body. When a cross section in the thickness direction of the three-dimensional net-like aluminum porous body is divided into three regions of a region 1, a region 2 and a region 3 in this order, the average cell diameter of the regions 1 and 3 is preferably different from the cell diameter of the region 2.

Owner:SUMITOMO ELECTRIC IND LTD +1

Fine-cell polyvinyl chloride foam material and preparation method thereof

Belonging to the technical field of foam materials, the invention provides a fine-pore polyvinyl chloride foam material and a preparation method thereof. The invention solves the technical problems oflarge and uneven cells of cross-linked rigid polyvinyl chloride foams, easy degradation and gelatinization of plate core, and long steam curing time and low efficiency of preparation method in the prior art. The foam material provided by the invention comprises 100 parts by weight of polyvinyl chloride resin, 0-80 parts by weight of anhydride, 0-20 parts by weight of an epoxy compound, 30-150 parts by weight of isocyanate, 5-20 parts by weight of a foaming agent 1, 0-5 parts by weight of a foaming agent 2, 2-20 parts by weight of a foaming agent 3, 0-4 parts by weight of a catalyst, 0-3 partsby weight of a surfactant and 5-20 parts by weight of a thermal stabilizer, and the cell diameter of the foam material is 300microm-100microm. The foam material can reduce the cell diameter of foam material, lower the absorption of resin in a composite material preparation process, reduce the product weight, and avoid plate core degradation and gelatinization.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

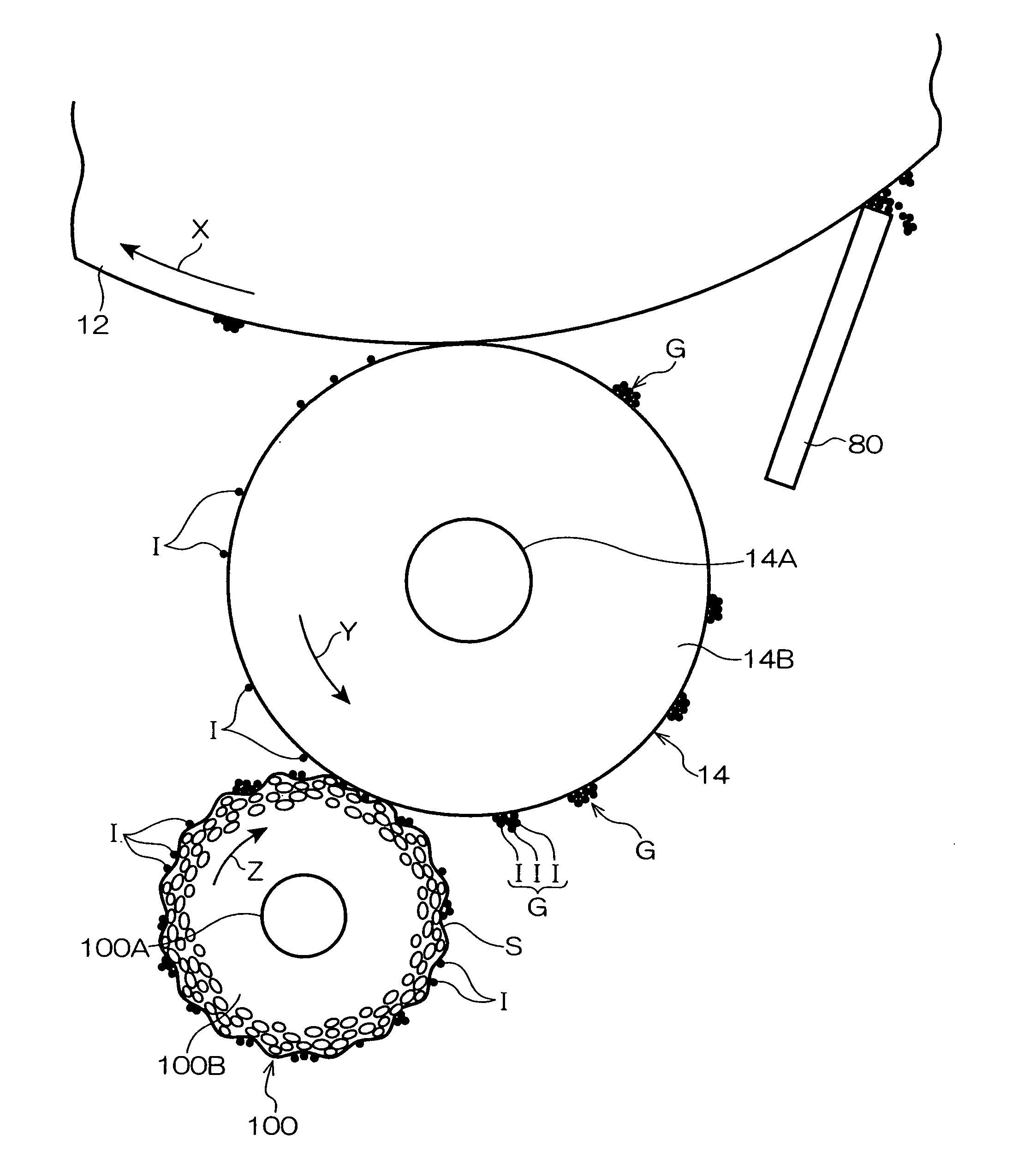

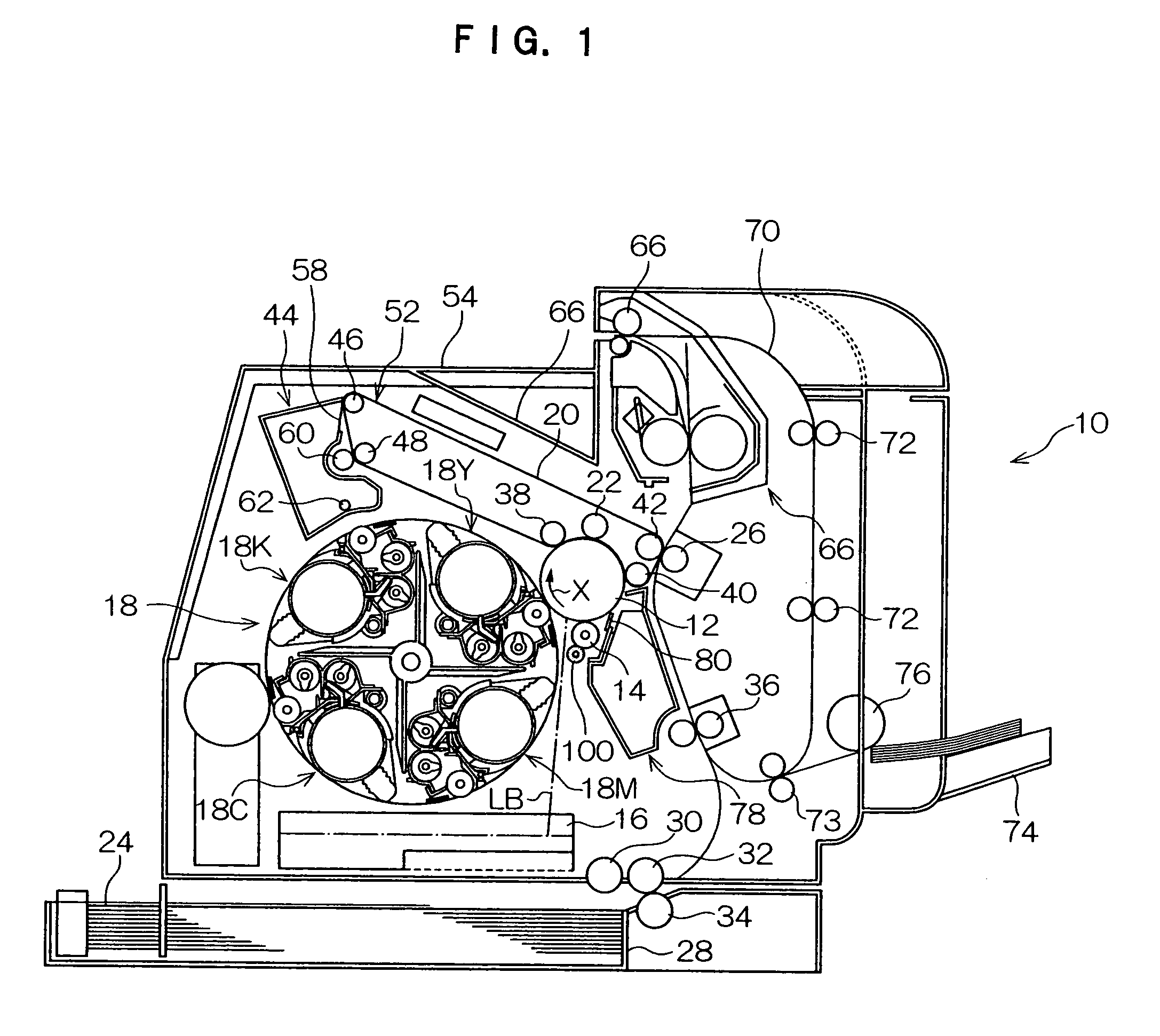

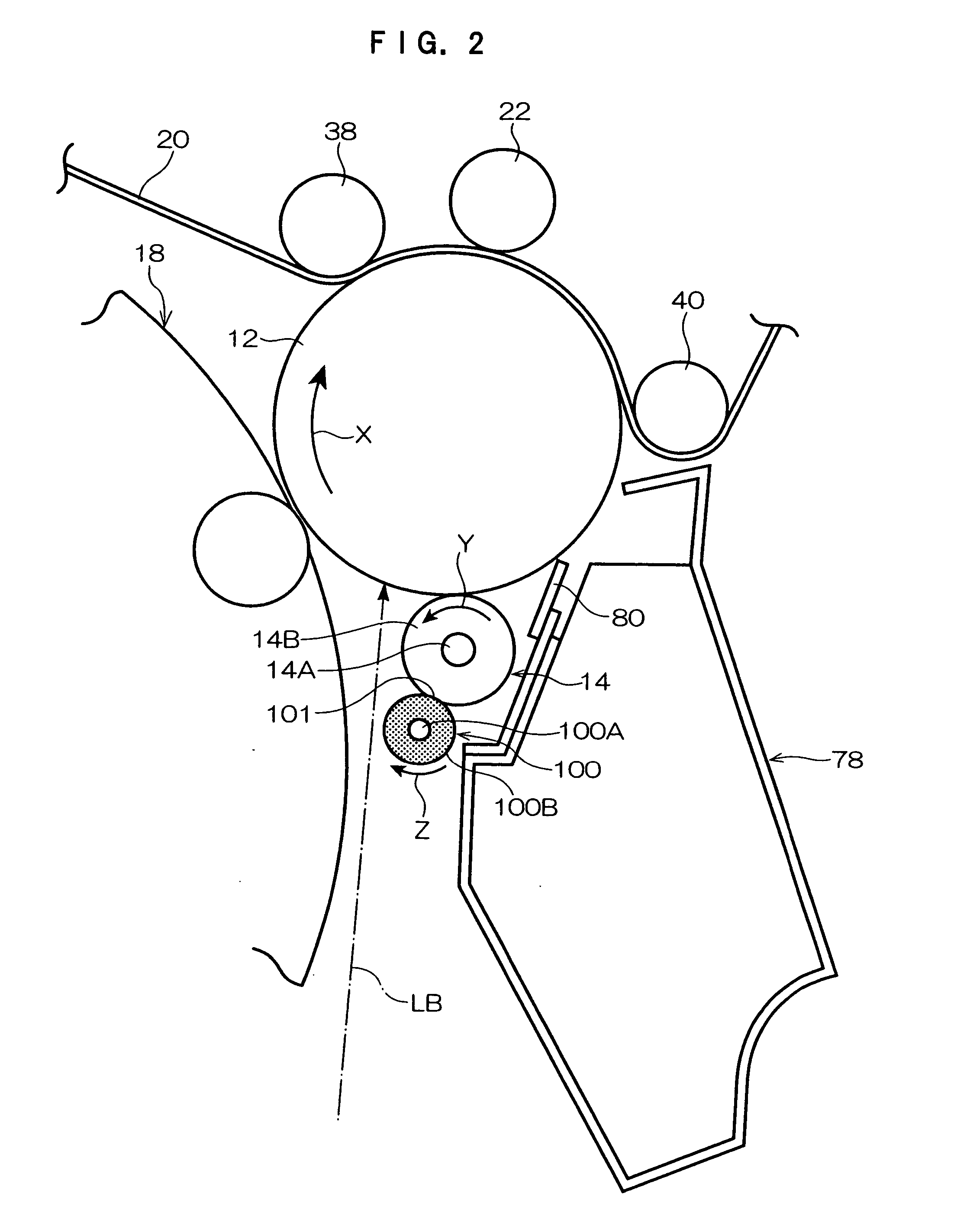

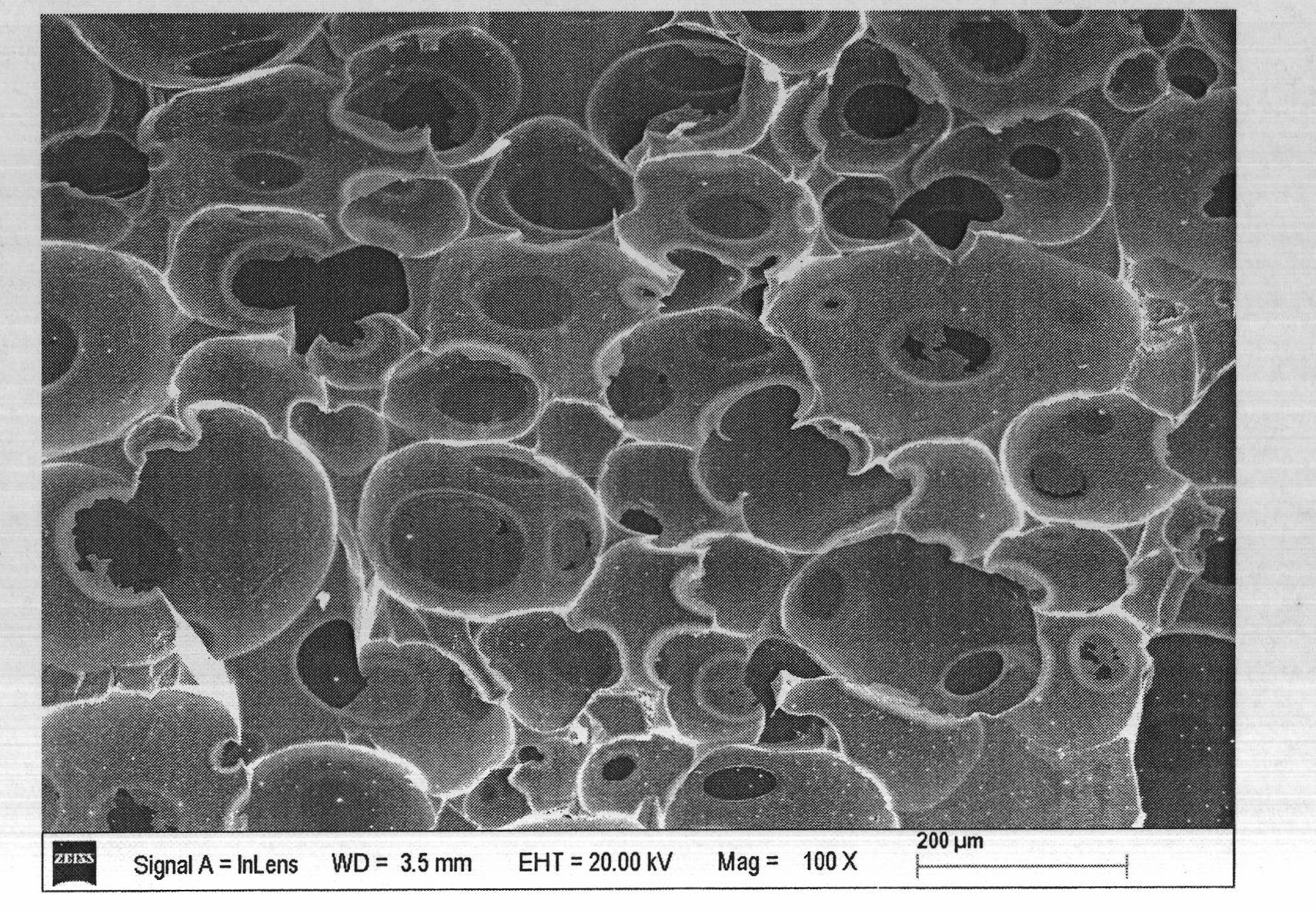

Image forming apparatus and cleaning method therefor

An image forming apparatus includes an image bearing member, a charging roll that charges the image bearing member by rotating in contact with the image bearing member, and a cleaning member that removes materials adhered to the surface of the charging roll by contacting the surface of the charging roll. The cleaning member includes a foam body having an average cell diameter of 0.18 mm to 1.0 mm, and a ten point height of irregularities (Rz: JIS B0601-1982) of the charging roll is 1 μm to 17 μm.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method for preparing carbon foam material from biomass tar

The invention provides a method for preparing a carbon foam material from biomass tar. First condensed polycyclic aromatic hydrocarbon resin is synthesized by the biomass tar; and then the synthesized resin is subjected to oxidation, foaming and carbonization to obtain the carbon foam. The prepared carbon foam has the advantages of spatial net structure, high open porosity, the density of 0.2 to 1g / cm<3>, the cell diameter of 50 to 500mu m, the compressive strength of 13.4MPa, and high thermal stability.

Owner:BEIJING UNIV OF CHEM TECH +1

Foam sheet of crosslinked polyolefin resin,process for producing the same and pressure-sensitive adhesive tape

InactiveUS20060177642A1Increase flexibilityImprove heat resistanceFilm/foil adhesivesLayered productsPolyolefinHeat resistance

The present invention provides a crosslinked polyolefin-based resin-extruded foam sheet capable of reducing its thickness while retaining excellent flexibility and heat resistance. The crosslinked polyolefin-based resin foam sheet of the present invention is obtained by feeding a polyolefin-based resin and a thermally degradable blowing agent to an extruder, melting and kneading them, extruding the kneaded material through the extruder into a sheet to form an expandable polyolefin-based resin sheet, and expanding the sheet. Herein, a degree of crosslinking of the crosslinked polyolefin-based resin foam sheet is 5 to 60% by weight, an aspect ratio of a cell (MD average cell diameter / CD average cell diameter) is 0.25 to 1, and the polyolefin-based resin contains 40% by weight or more of a polyethylene-based resin obtained using a metallocene compound containing a tetravalent transition metal as a polymerization catalyst.

Owner:SEKISUI CHEM CO LTD

Polylactic acid foamed sheet and preparation method thereof

The invention relates to a polylactic acid foamed sheet and a preparation method thereof. The foaming ratio of the polylactic acid foamed sheet is 20 to 30 times; the pore density is 10.2-13.4*10<9> pores for each cubic centimeter; the diameter of pores is 4 to 15 [mu]m, and the thermal deformation temperature is 95 to 105 DEG C. According to the preparation method, polylactic acid is taken as thematrix, a nucleating agent and a chain extender are added to obtain a mixture; the mixture is extruded in a double screw extruder to obtain polylactic acid foamed modified resin; then the modified resin and optionally picked color master batch are added into the hopper of a foaming extruder composed of two extrusion systems, which are serially connected; the mixture is melted and plasticized in the primary extruding system, then a foaming agent is added, then the mixture is mixed and cooled in the secondary extruding system to obtain low temperature homogenous melt; the melt is extruded fromthe head of a controllable foaming machine, and finally the foamed sheet is obtained after sizing cooling, part spreading, and rolling. The provided polylactic acid foamed sheet has the advantages ofhigh foaming ratio, good foaming performance, good heatproof property, good pore structure, simple technology, and controllable cost.

Owner:COFCO GROUP +2

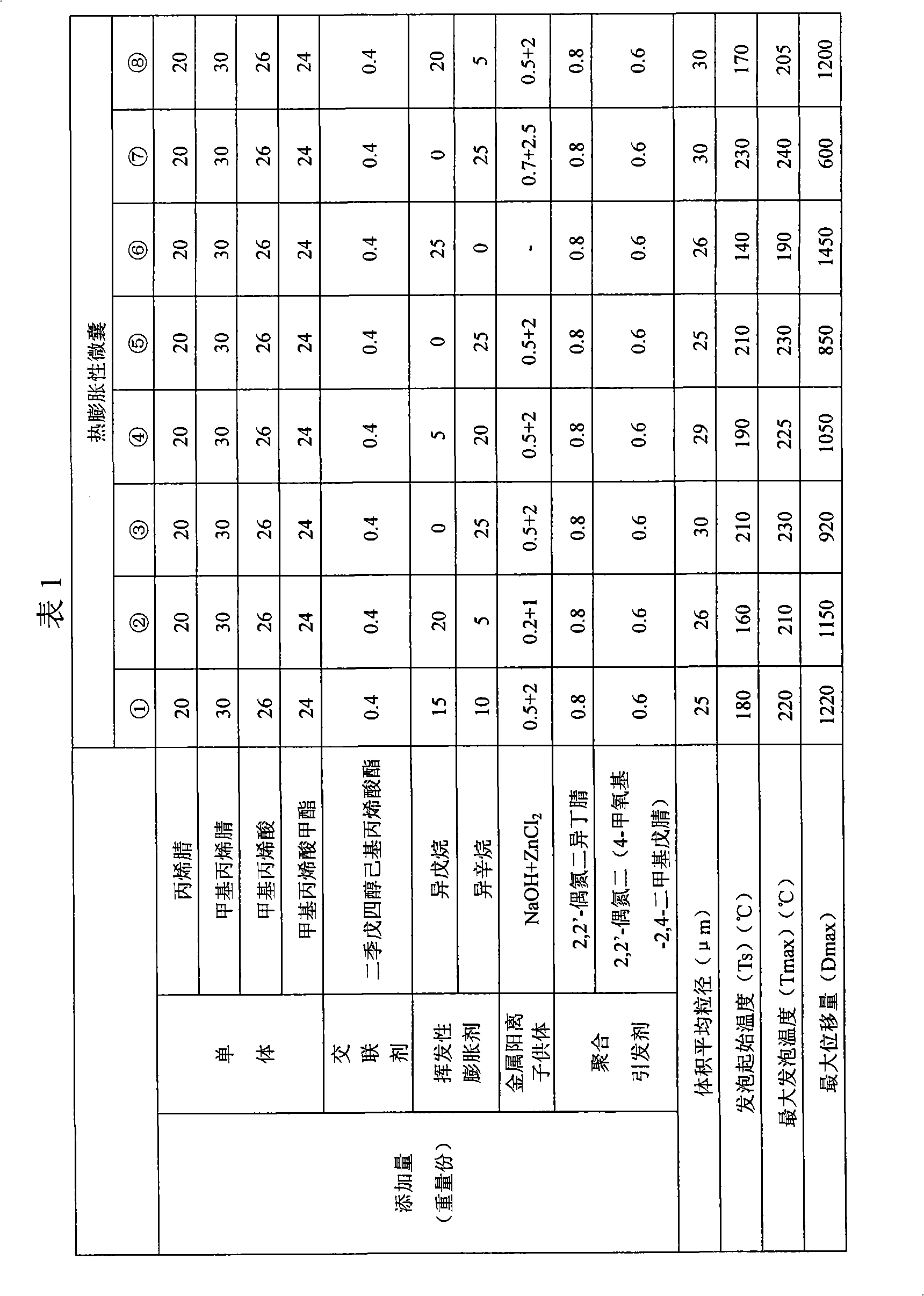

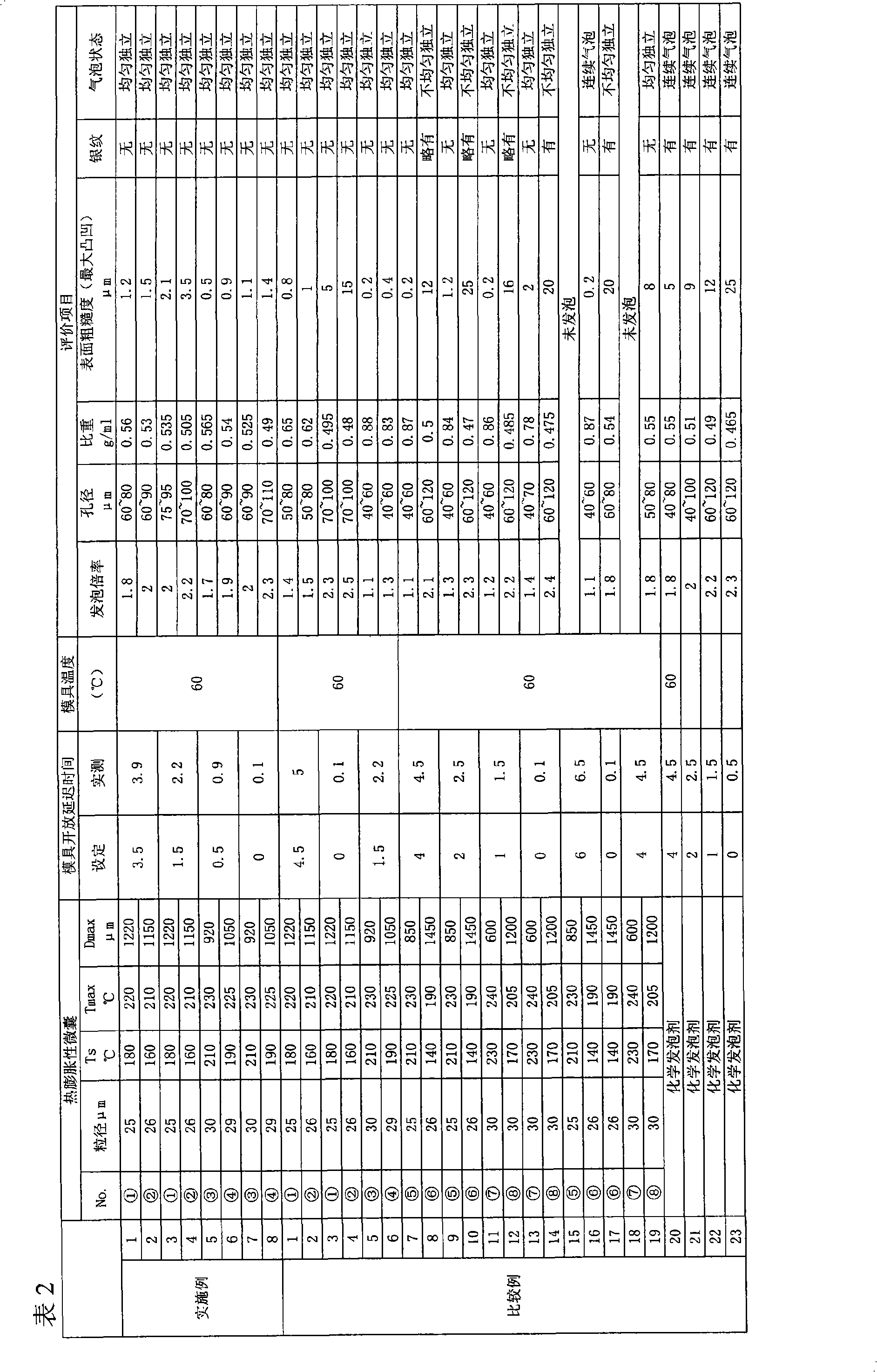

Molded foam article and method of producing molded foam article

It is intended to provide a molded foam article which has a high foaming ratio and a light weight and shows an excellent appearance with no surface coarsenss, and a method of producing a molded foam article whereby, in the case of using heat expandable microcapsules in injection molding, the heat expandable microcapsules can evenly expand to give a molded foam article having a high foaming ratio and an excellent appearance. A molded foam article having evenly distributed individual cells characterized in that the cell diameter is from 60 to 120 [mu]m, the specific gravity is 0.6 g / ml or less and the surface roughness is 4 [mu]m or less.

Owner:SEKISUI CHEM CO LTD

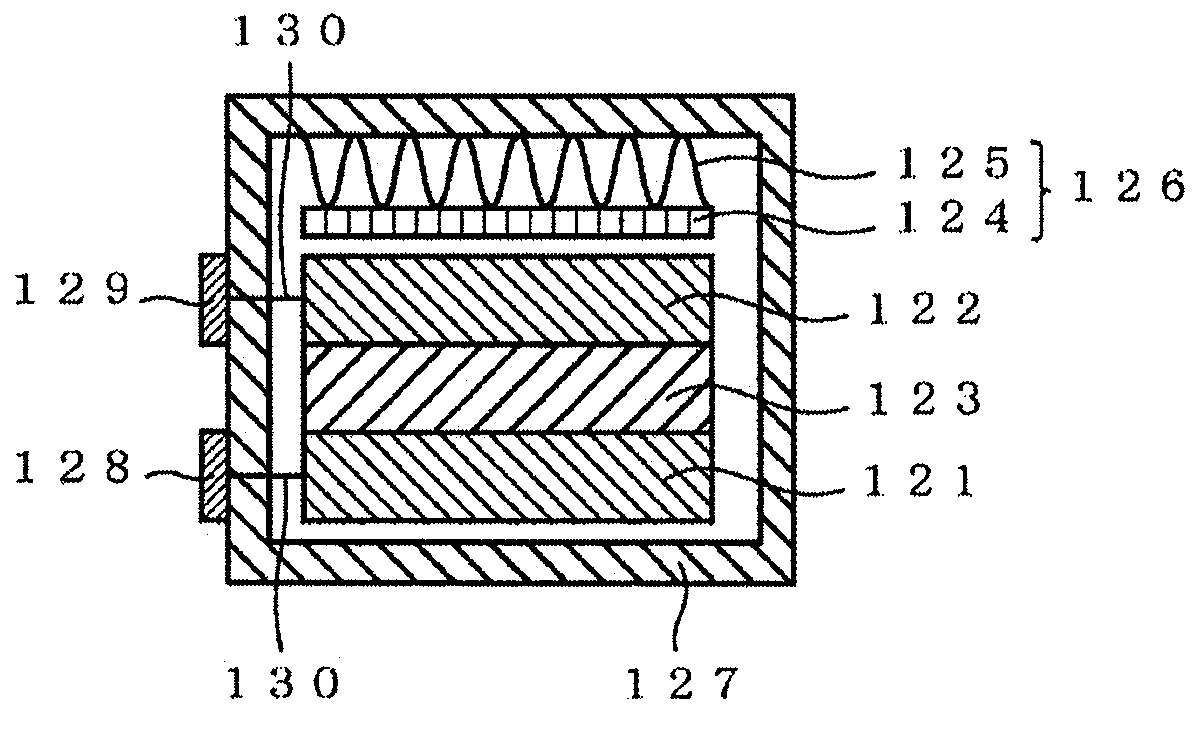

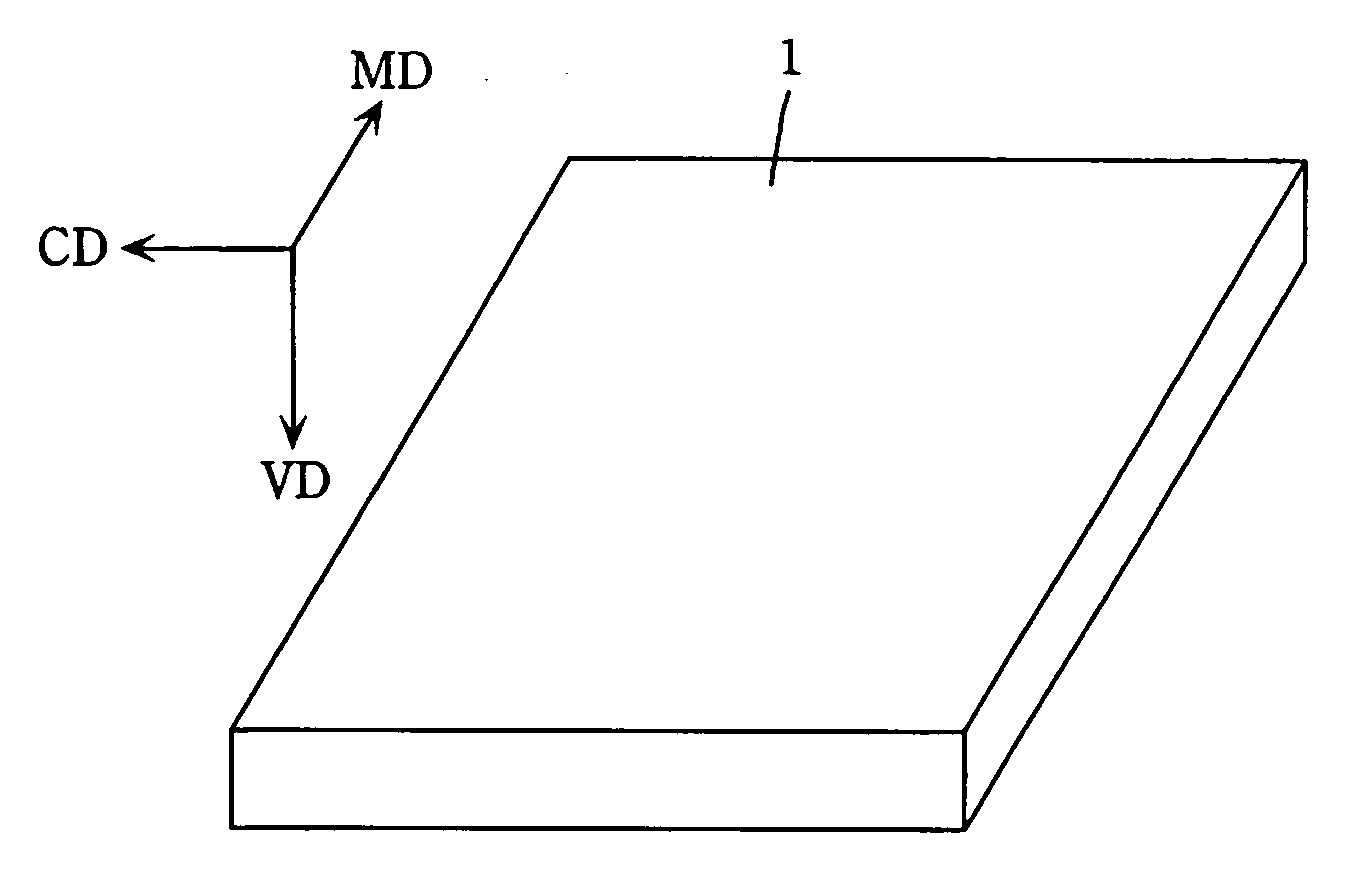

Foamed sheet for reflectors, reflectors, and process for production of the sheet

InactiveCN101156090AHigh light reflectivityEffectively display light reflectivityMirrorsDiffusing elementsRefractive indexEngineering

A foamed sheet for reflectors which can be thermoformed into reflectors having desired shapes. A foamed sheet (A) for reflectors, characterized by being constituted of a foamed sheet (1) of a polypropylene resin which has a mean cell diameter of 50 to 650[mu]m and at least one uneven surface (12) formed by cells (11) present in the neighborhood of the surface and a non-foamed sheet (3) of the polypropylene resin which is united with the sheet (1) by lamination in such a way that the sheet (3) lies on the sheet (1) along the uneven surface (12) to form an uneven surface (31), by containing an inorganic filler (2) in an amount of 50 to 200g / m<2>, the whole or part of which filler is contained in the sheet (1), and by having a difference in refractive index of 1.0 or above between the inorganic filler (2) and the polypropylene resin, a thickness of the sheet (A) of 0.2 to 2.0mm, and a light reflectance of 97% or above.

Owner:SEKISUI PLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com