Preparation method of polymethyl methacrylate (PMMA) cellular gradient material

A polymethyl methacrylate, gradient material technology, applied in the field of gradient materials, can solve the problem of no polymer-based cell gradient material literature research report, etc., and achieve the effects of good dimensional stability, high mechanical properties, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0026] 1. Fully dry the PMMA particles, melt and extrude them into a one-way open mold at 200°C, and then put the one-way open mold filled with polymer materials into the autoclave.

[0027] 2. Introduce a small amount of carbon dioxide to purge for 3 minutes, then raise the temperature of the autoclave to 50°C, then use a plunger pump to inject carbon dioxide to reach 28MPa, and saturate at constant temperature and pressure for 60 minutes to form a carbon dioxide / PMMA system with a concentration gradient.

[0028] 3. Quickly unscrew the pressure relief valve to release the pressure to normal pressure, then go to the heating device, put the autoclave into the ice-water mixture to cool down, and obtain the cell gradient material.

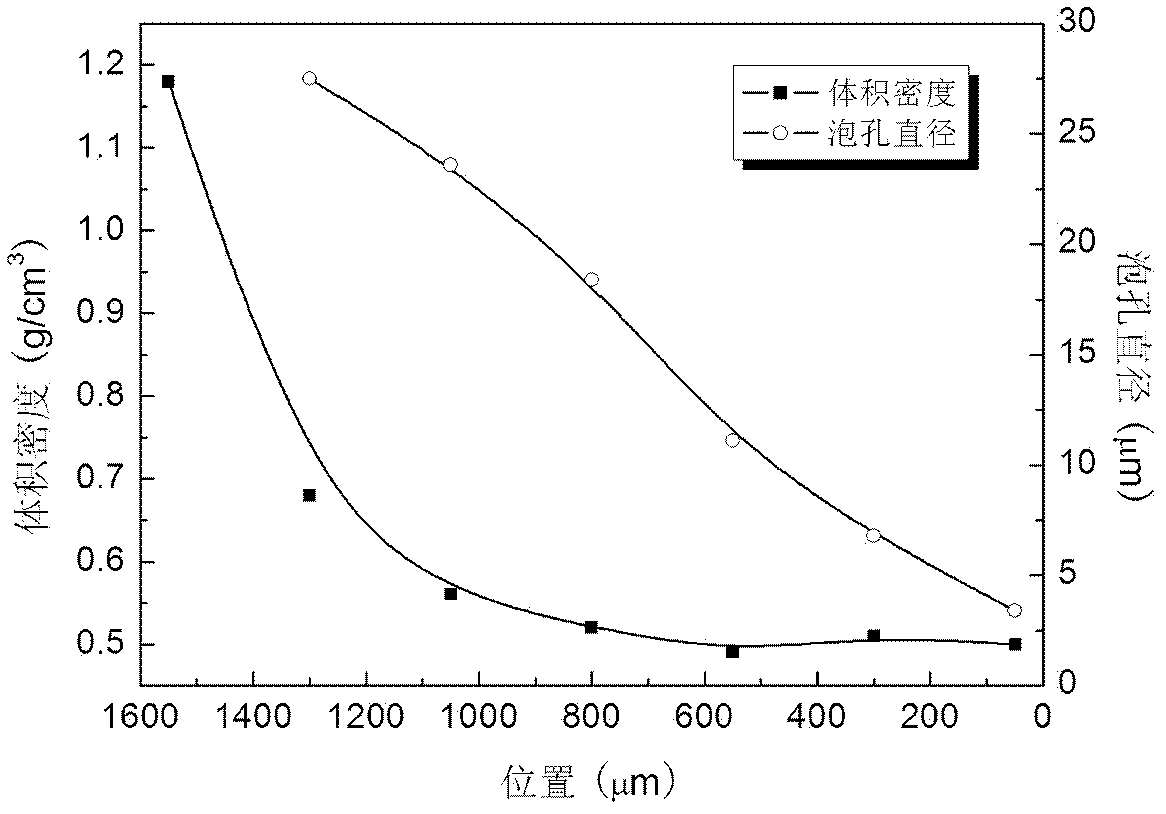

[0029] The cell structure of the cell gradient material is as follows figure 1As shown, better cell gradient structure can be obtained. The diffusion depth of supercritical carbon dioxide in the PMMA sample is 1386 μm, and a pore structure with smal...

specific example 2

[0031] 1. Fully dry the PMMA particles, melt and extrude them into a one-way open mold at 200°C, and then put the one-way open mold filled with polymer materials into the autoclave.

[0032] 2. Inject a small amount of carbon dioxide to purge for 3 minutes, then raise the temperature of the autoclave to 110°C, then use a plunger pump to inject carbon dioxide to 20MPa, and saturate at constant temperature and pressure for 10 minutes to form a carbon dioxide / PMMA system with a concentration gradient.

[0033] 3. Quickly unscrew the pressure relief valve to release the pressure to normal pressure, then remove the heating device, put the autoclave into the ice-water mixture to cool down, and obtain the cell gradient material.

[0034] The cell structure of the cell gradient material is as follows image 3 As shown, better cell gradient structure can be obtained. The diffusion depth of supercritical carbon dioxide in the PMMA sample is 1404 μm, and a pore structure with smaller di...

specific example 3

[0036] 1. Fully dry the PMMA particles, melt and extrude them into a one-way open mold at 200°C, and then put the one-way open mold filled with polymer materials into the autoclave.

[0037] 2. Inject a small amount of carbon dioxide to purge for 3 minutes, then raise the temperature of the autoclave to 140°C, then use a plunger pump to inject carbon dioxide to reach 28MPa, and saturate at constant temperature and pressure for 1 minute to form a carbon dioxide / PMMA system with a concentration gradient.

[0038] 3. Quickly unscrew the pressure relief valve to release the pressure to normal pressure, then remove the heating device, put the autoclave into the ice-water mixture to cool down, and obtain the cell gradient material.

[0039] The cell structure of the cell gradient material is as follows Figure 4 As shown, better cell gradient structure can be obtained. The diffusion depth of supercritical carbon dioxide in the PMMA sample is 1485 μm, and a pore structure with small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com