Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Small cell diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polymer-based conductive microporous foam composite material

The invention discloses a preparation method of a polymer-based conductive microporous foam composite material. The method comprises the following steps of: filling conductive fillers into a polymer to prepare a polymer-based composite material through blending methods of solution blending, melt blending or in-situ polymerizing and the like; preparing a composite material blank with a certain thickness from the polymer-based composite material by die pressing under vacuum; placing the composite material blank into a foaming high-pressure reactor, and dissolving supercutical fluid serving as foaming agent in the composite material blank; and foaming the composite material blank through a quick pressure releasing method or quick heating method when the supercutical fluid in the composite material blank is saturated, and then cooling to shaping the foamed composite material blank. According to the preparation method, the nontoxic pollution-free supercutical fluid is taken as the foaming agent, thus, the preparation method has the advantages of environmental protection, safety, stability, etc. The preparation method serves as a conductive foam material preparation technology with good application prospect.

Owner:SICHUAN UNIV

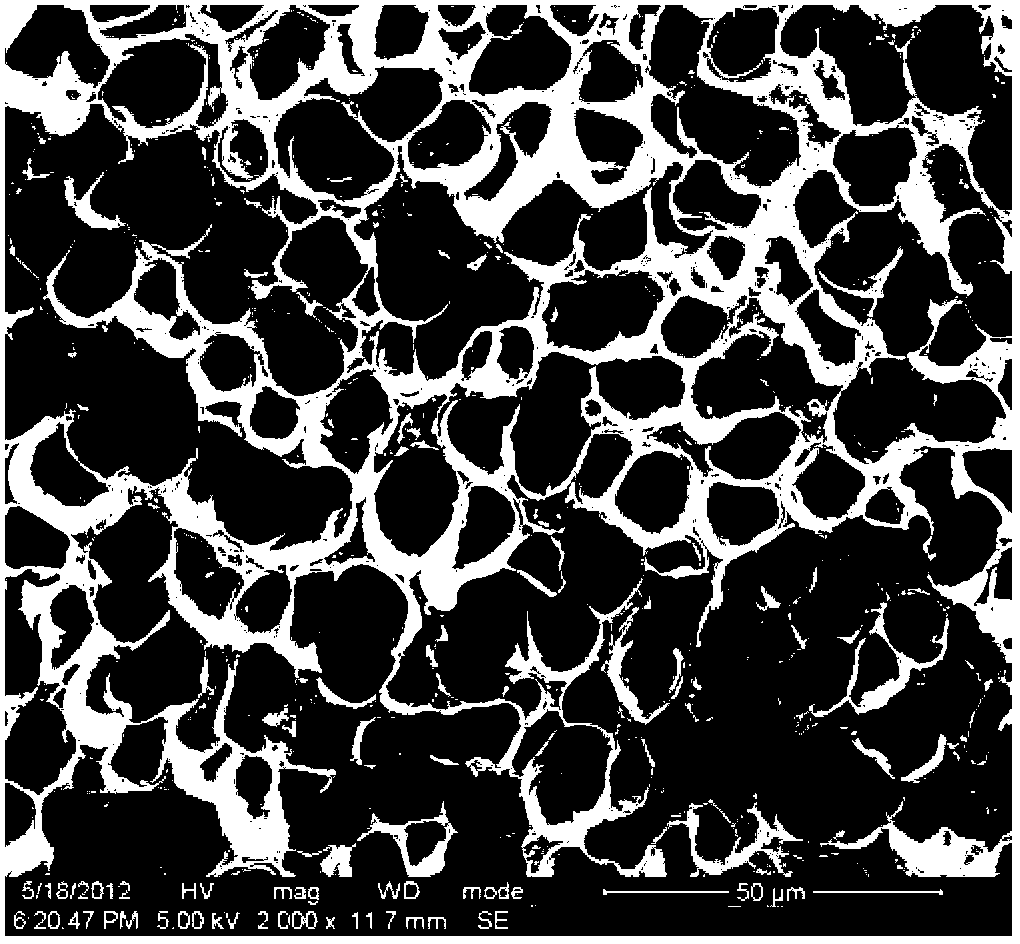

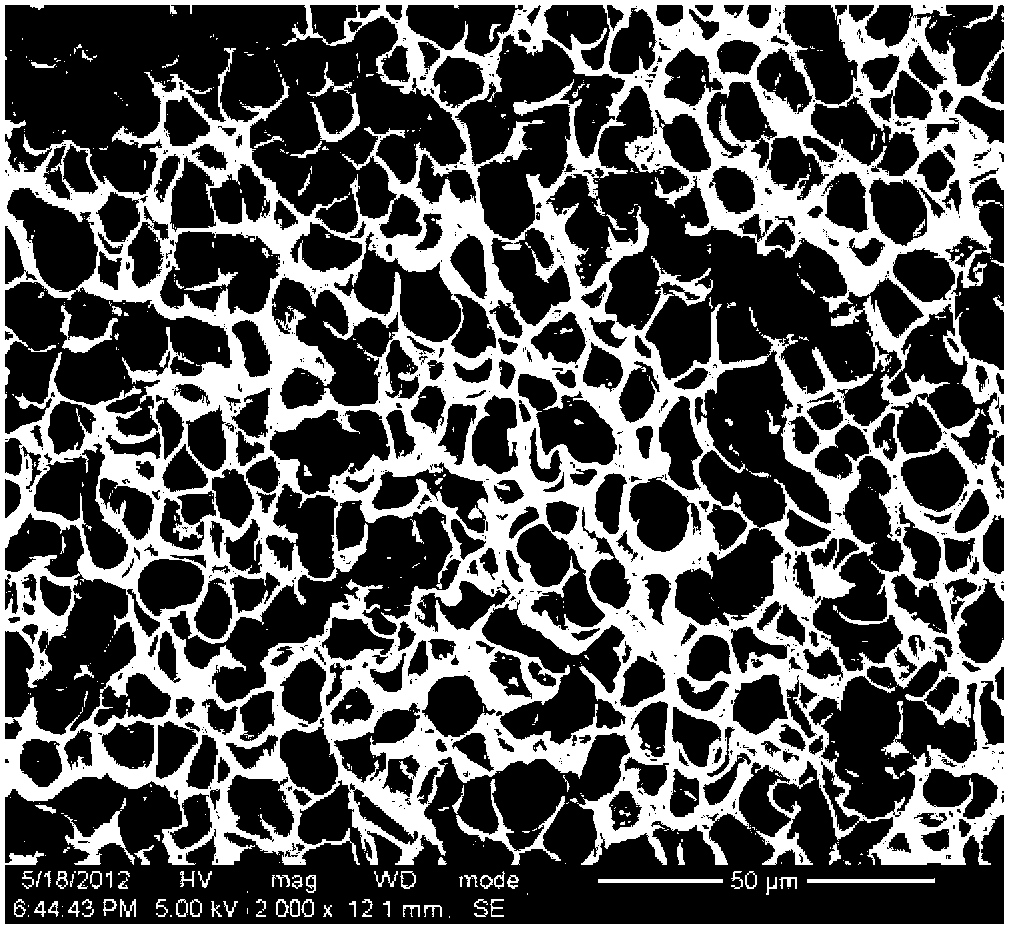

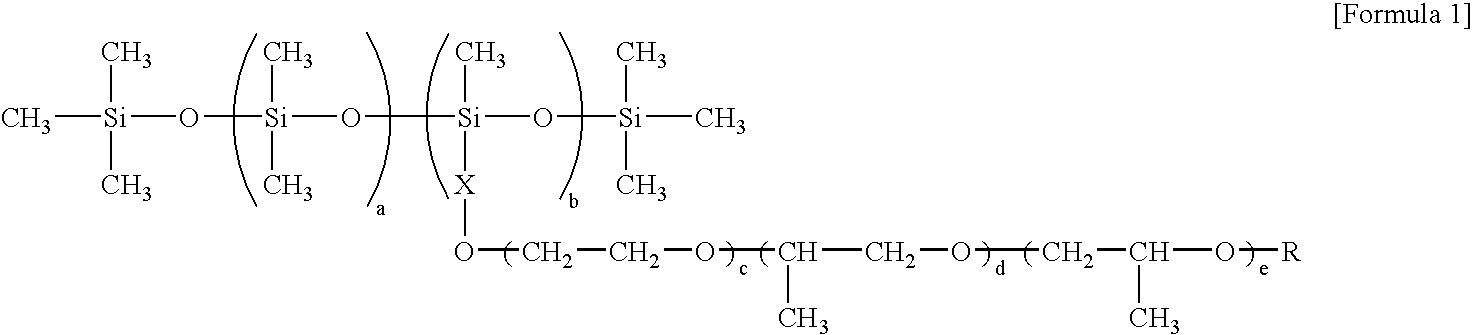

Polishing pad

ActiveUS20090047872A1Reduce polishing rateReduce the overall diameterSemiconductor/solid-state device manufacturingPrinted circuit manufactureEndcappingContinuous use

To provide a polishing pad which is insusceptible to clogging of groove with abrasive particles and grinding dusts during polishing, and leads to little decrease in polishing rate even after long-term continuous use. A polishing pad of the present invention has a polishing layer formed of polyurethane resin foam having fine-cells, and asperity structure formed in a polishing surface of the polishing layer, and is featured in that the polyurethane resin foam is a reaction cured product between isocyanate-terminated prepolymer containing high-molecular-weight polyol component and isocyanate component, and a chain extender, and contains a silicon-based surfactant having combustion residue of not less than 8 wt %.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

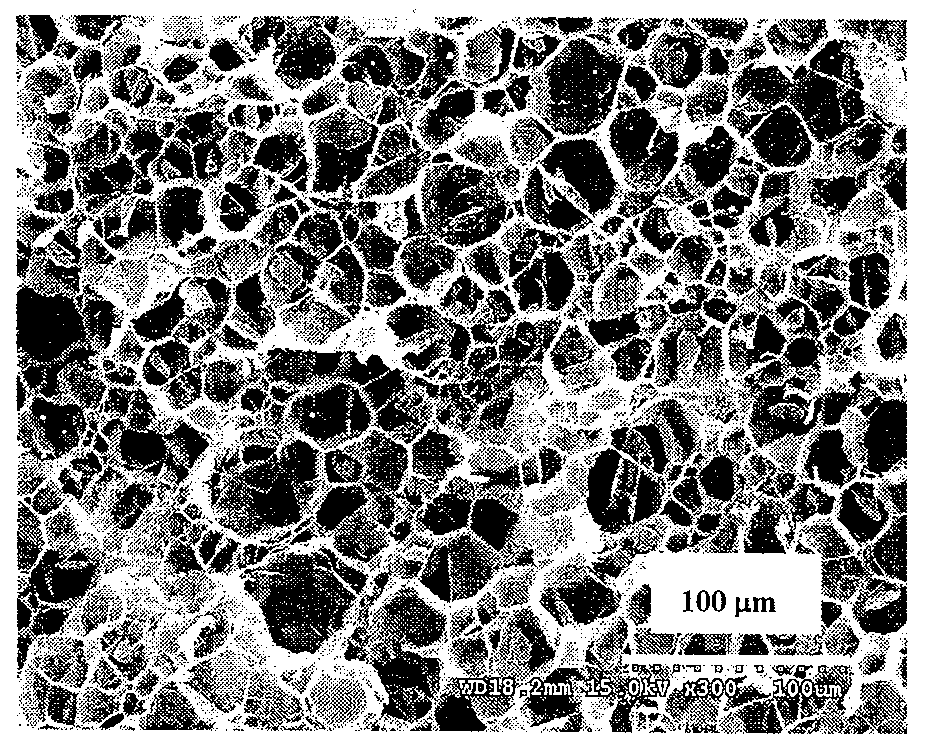

Fine-cell polyvinyl chloride foam material and preparation method thereof

Belonging to the technical field of foam materials, the invention provides a fine-pore polyvinyl chloride foam material and a preparation method thereof. The invention solves the technical problems oflarge and uneven cells of cross-linked rigid polyvinyl chloride foams, easy degradation and gelatinization of plate core, and long steam curing time and low efficiency of preparation method in the prior art. The foam material provided by the invention comprises 100 parts by weight of polyvinyl chloride resin, 0-80 parts by weight of anhydride, 0-20 parts by weight of an epoxy compound, 30-150 parts by weight of isocyanate, 5-20 parts by weight of a foaming agent 1, 0-5 parts by weight of a foaming agent 2, 2-20 parts by weight of a foaming agent 3, 0-4 parts by weight of a catalyst, 0-3 partsby weight of a surfactant and 5-20 parts by weight of a thermal stabilizer, and the cell diameter of the foam material is 300microm-100microm. The foam material can reduce the cell diameter of foam material, lower the absorption of resin in a composite material preparation process, reduce the product weight, and avoid plate core degradation and gelatinization.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method for polymer-based density-gradient foam material

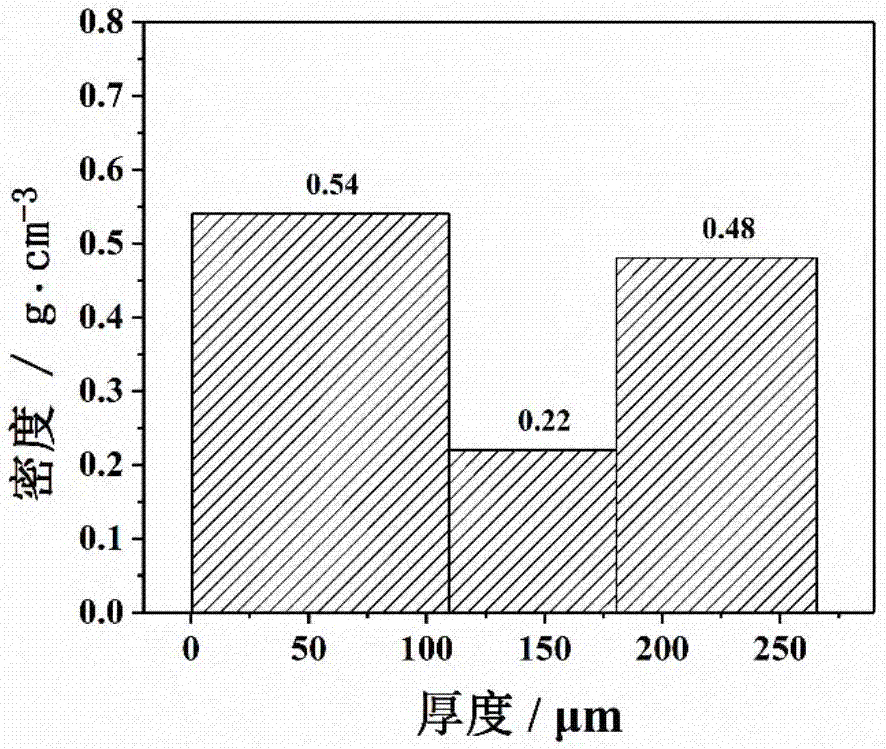

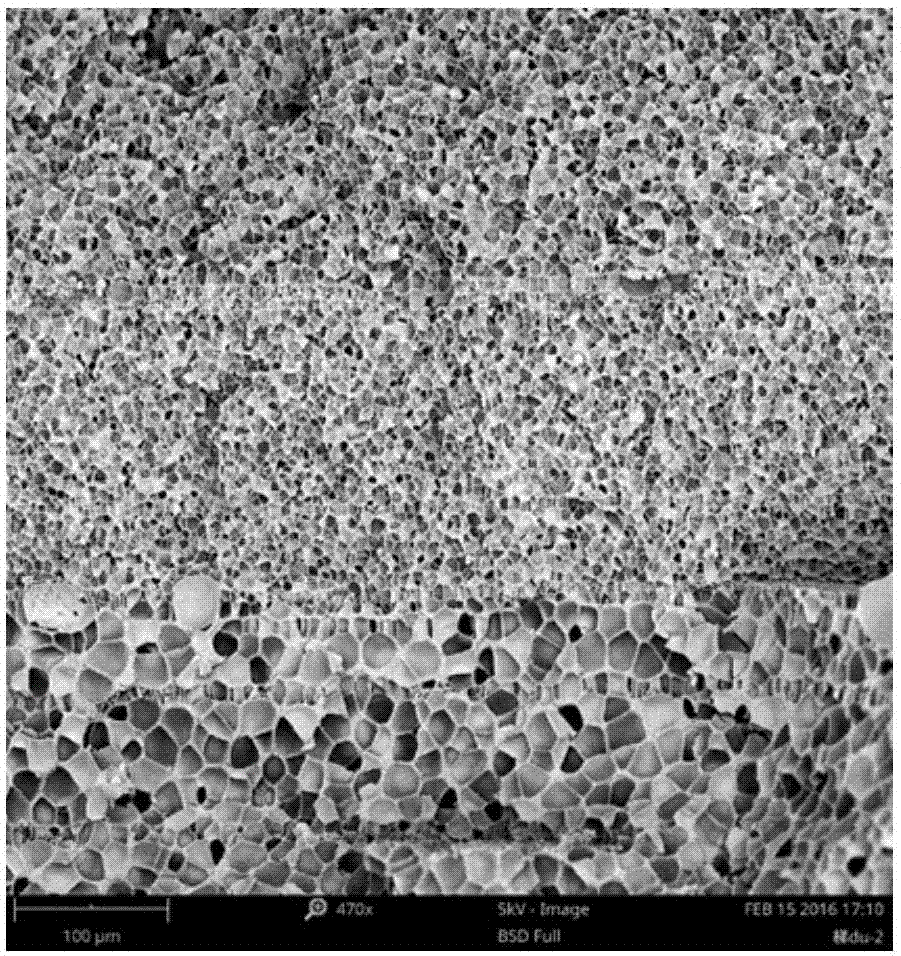

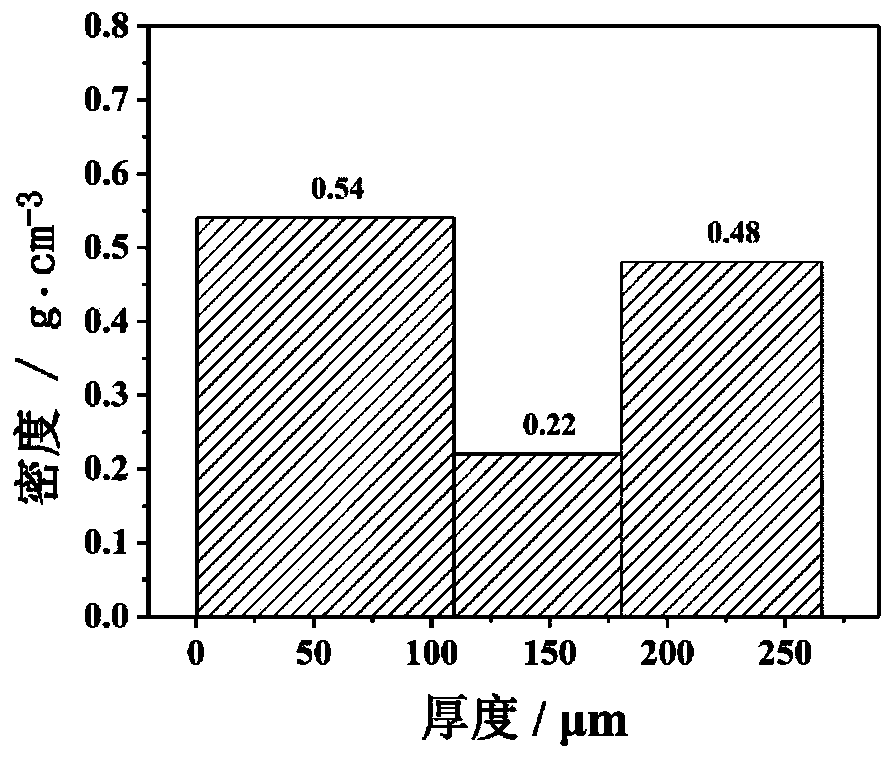

The invention discloses a preparation method for a polymer-based density-gradient foam material. The preparation method specifically comprises the following steps: firstly, mixing a mixed system of micron metal particles and a polymer through high-temperature mixing to obtain composite material melts with different densities; secondly, carrying out melting hot-pressing on the melts at a high temperature separately to obtain a density-gradient composite material; and finally, foaming the density-gradient composite material through supercritical carbon dioxide foaming to obtain the polymer-based density-gradient foam material. According to the preparation method disclosed by the invention, the polymer-based density-gradient foam material is prepared from combining a lamination hot-pressing process with a supercritical carbon dioxide foaming technology, the density of the material is adjustable in a range from 0.2g / cm<3> to 1.96g / cm<3>, and the density of a sample presents gradient change at different positions; the diameter of the material is in a micron scale, and the material is high in dimensional stability, structural controllability and mechanical strength, and has wide application prospects in the fields of cushion packaging, impact protection, aerospace, transportation, building energy conservation and the like.

Owner:WUHAN UNIV OF TECH

Micro foaming injection moulding plasticizing device and its producing process

The micro forming and injection molding apparatus and production process belongs to the field of polymer material processing technology. The micro forming and injection molding apparatus of the present invention is provided with one non-return valve in the gas injecting port, one head non-return valve before the screw, one middle non-return valve on the screw in the position corresponding to the upstream of the gas injecting port, and one nozzle capable of being controlled for opening or closing in the most front of the machine barrel, so that it can avoid the flow of the high pressure melt to the gas system and the escape of gas. By means of the apparatus and the production process of the present invention, high quality foamed product may be obtained.

Owner:BEIJING UNIV OF CHEM TECH

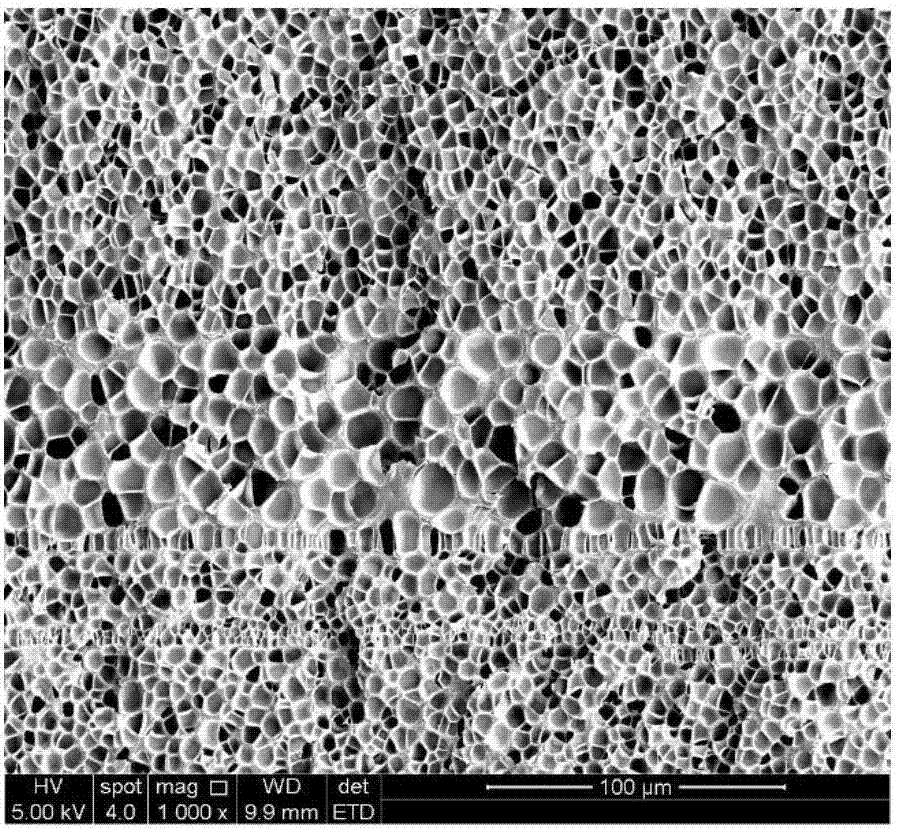

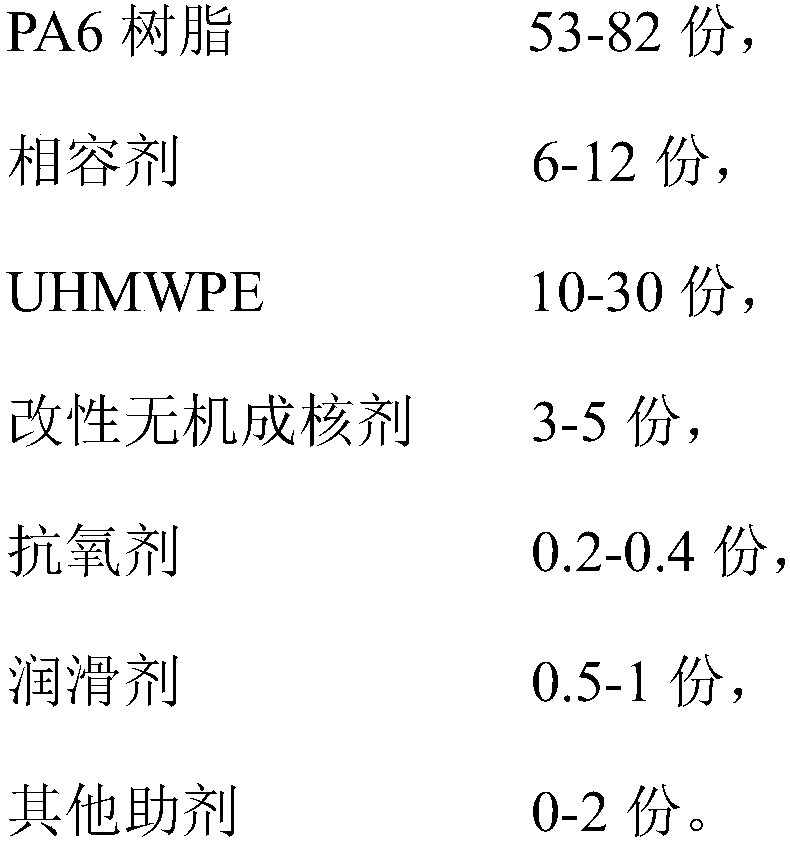

Light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene/nylon 6 micro-foaming composite material and preparation method thereof

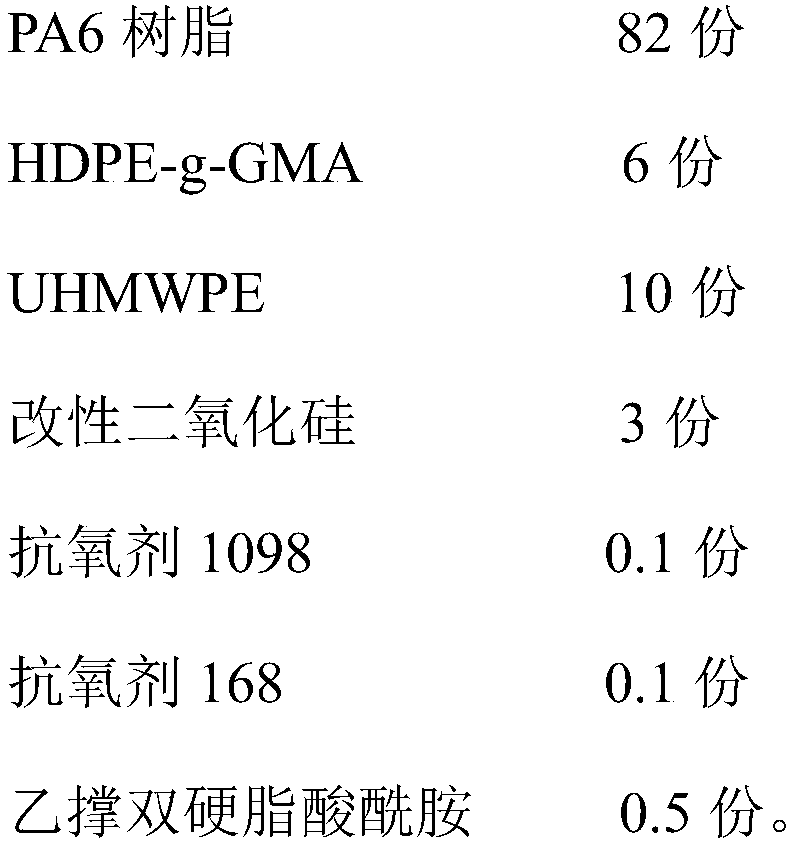

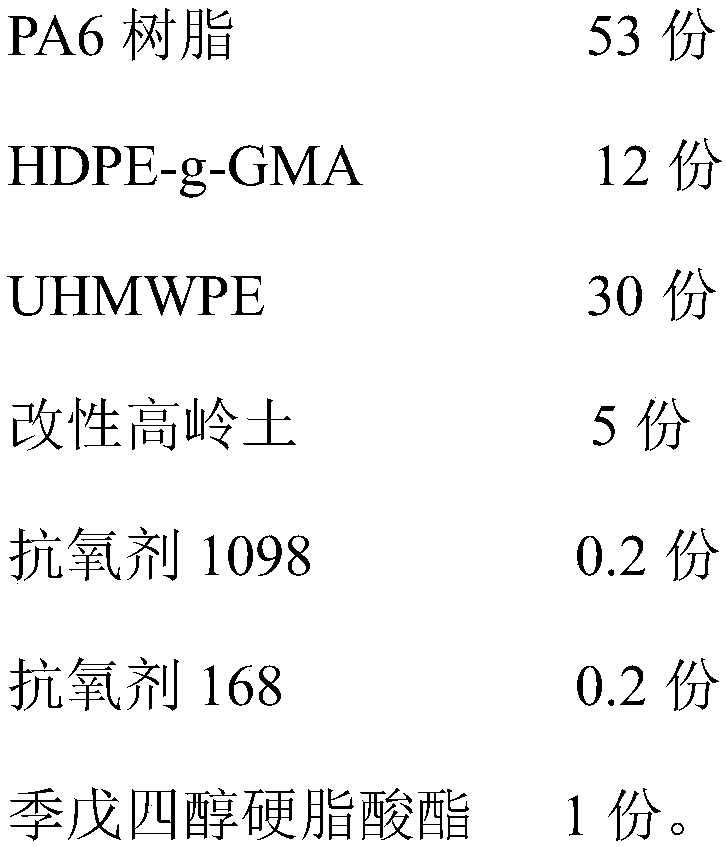

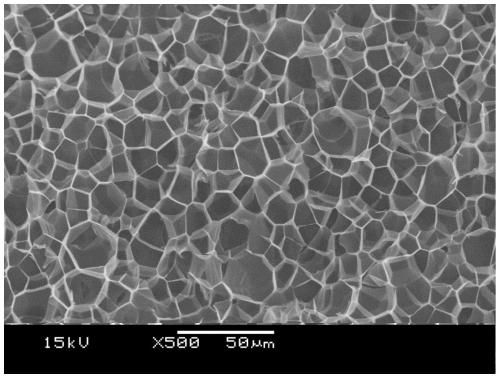

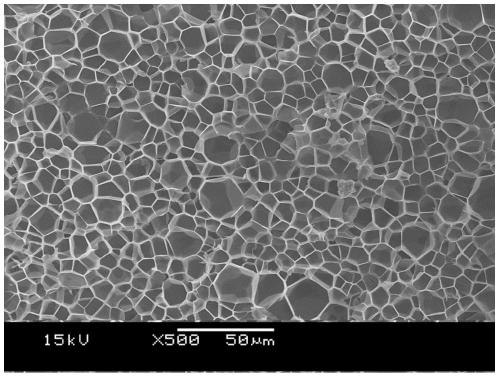

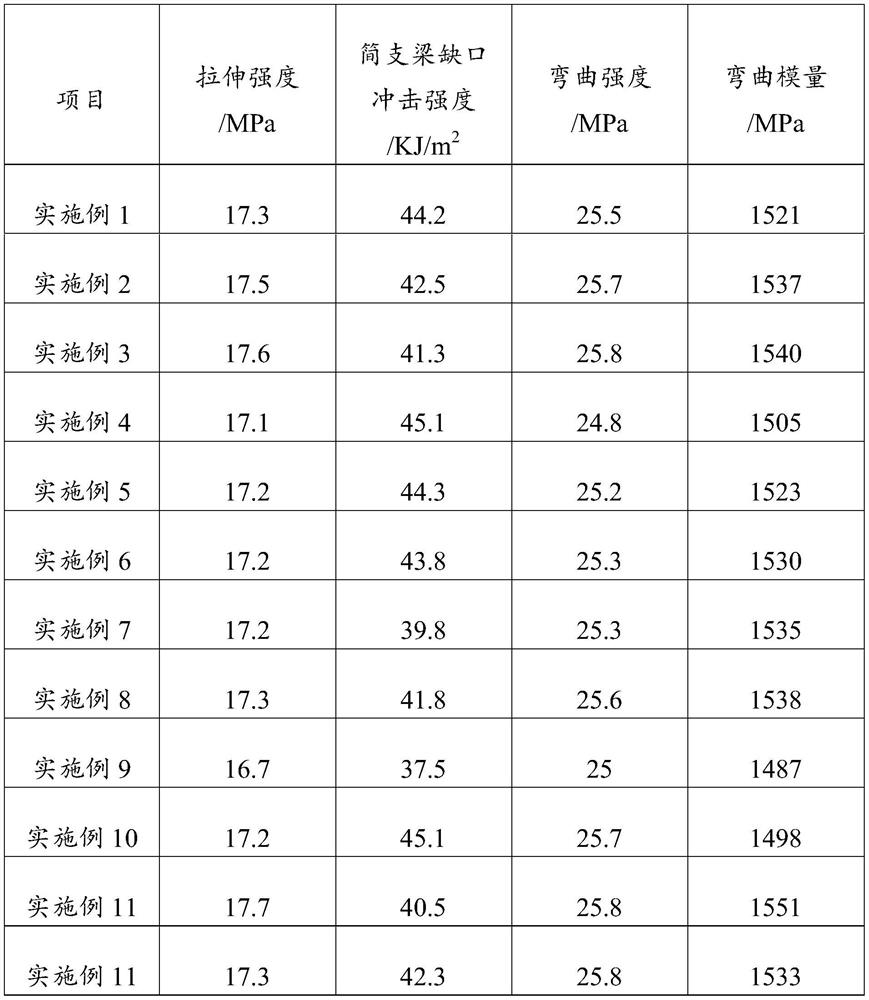

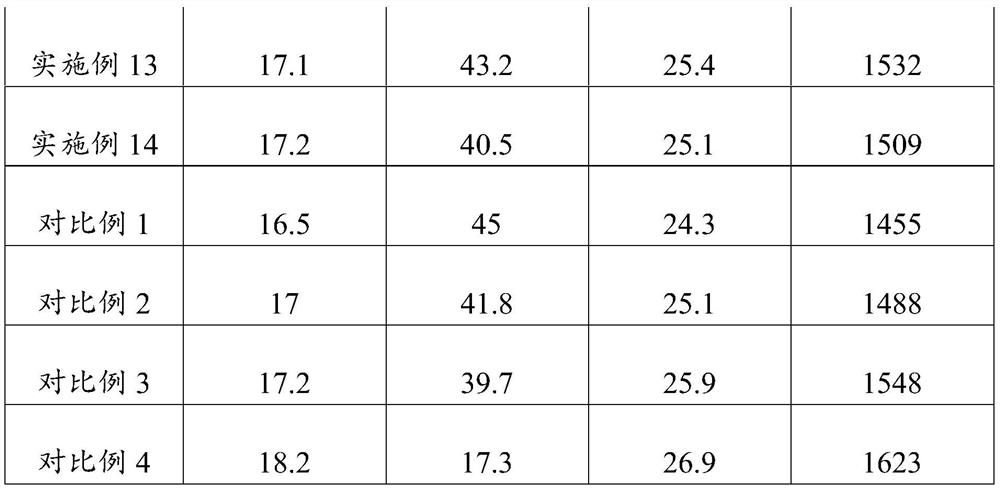

The invention discloses a light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene (UHMWPE) / nylon 6 micro-foaming composite material and a preparation method thereof. The composite material is prepared from 97 to 99 weight percent of a polyamide composite material and 1 to 3 weight percent of a chemical foaming agent, wherein the polyamide composite material is prepared from the following components in parts by weight: 53 to 82 parts of PA6 (Polyamide 6), 6 to 12 parts of a compatilizer, 10 to 30 parts of UHMWPE, 3 to 5 parts of a modified inorganicnucleating agent, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricant and 0 to 2 parts of other auxiliary agents. According to the light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene / nylon 6 micro-foaming composite material, HDPE (High-density Polyethylene)-g-GMA (Glycidyl Methacrylate) is used as an interface bulking agent so that the interface binding force between the UHMWPE and the PA6 is enhanced, the impact strength of the PA6 is improved and the water absorption ratio of the PA6 is reduced; meanwhile, three-phase chain sections are mutually entwisted so that the melt strength of the PA6 is improved; the modified inorganic nucleating agent is subjected to chemical grafting modification through KH550 and GMA and the heterogeneous nucleation effect is remarkable; a dense bubble nucleation point is formed and the micro-foaming material with dense, fine and smooth bubble pores is obtained; the material has the characteristics of light weight, high impact strength, low water absorption ratio, high wear resistance and the like; foaming is realized through direct injection molding and a technology is simple; the material is widely applied to a lightweight technology of automobiles, household appliances, electronics and electrical appliances and the like.

Owner:ORINKO NEW MATERIAL CO LTD

Foamed material prepared from nano-calcium-carbonate-filled polypropylene/polyethylene blend and preparation process thereof

The invention provides a foamed material prepared from a nano-calcium-carbonate-filled polypropylene / polyethylene blend and a preparation process thereof. The foamed material comprises the following components in parts by weight: 100-120 parts of polypropylene plastic, 10-15 parts of polyethylene matrix, 1-5 parts of foaming agent, 1-10 parts of nano calcium carbonate and 1-1.5 parts of coupling agent. The preparation process comprises the following steps: firstly uniformly mixing polypropylene, the polyethylene matrix, nano calcium carbonate and the coupling agent in weight proportion; then carrying out melt blending and granulating on the mixture at the temperature of 160-180 DEG C, and carrying out extrusion molding by virtue of an extrusion machine; and finally heating the molded material for 3-10 minutes, adding the foaming agent, mixing, foaming at the temperature of 185-200 DEG C, extruding and foaming by virtue of the extrusion machine at the extrusion machine temperature of 170-200 DEG C and cooling the extruded foam to obtain a product. In the preparation method provided by the invention, the polypropylene / polyethylene blend is filled with nano calcium carbonate and has a better foam shape, foam density and foamed material density than other foamed materials, and simultaneously the obtained product has the advantages of excellent impact strength and physical and mechanical properties.

Owner:CHANGSHU JIANGSHUN PLASTIC PROD

Cement foaming agent preparation process

The present invention provides a cement foaming agent and the cement foaming agent is formed by compounding modified nano-silica and a foaming agent AC. After foaming, the cell diameter is significantly reduced while the cell density is relatively improved. The nano-silica has particular morphological characteristics so that the nanocomposite foaming agent can be dispersed more uniformly into the cement. The cement foaming agent provided by the invention achieves uniform dispersion into the cement so as to reduce the amount of local foaming, and meanwhile the composite foaming agent has the advantage of a nano-composite material.

Owner:凤阳九龙新型建材有限公司

Lightweight polystyrene foam material with small pore size, and preparation method thereof

The invention discloses a preparation method of a polystyrene foam material. The method comprises the following steps: blending polystyrene and polydimethylsiloxane to obtain a polystyrene / polydimethylsiloxane blend; and foaming the polystyrene / polydimethylsiloxane blend under the condition of supercritical CO2 to obtain the polystyrene / polydimethylsiloxane composite material, wherein the number weight molecular weight of the polydimethylsiloxane can be 2000-17000 g / mol. The preparation method is simple in process, free of bad smell and by-products, good in environment friendliness, safe and environmentally friendly in additive and capable of meeting the development requirements of related fields. The polystyrene foam material is high in nucleation density, small in cell diameter, high infoaming ratio and environment-friendly.

Owner:EAST CHINA UNIV OF SCI & TECH

Polishing pad

ActiveUS8094456B2Reduce rateReduce the overall diameterSemiconductor/solid-state device manufacturingPrinted circuit manufactureContinuous useCombustion

To provide a polishing pad which is insusceptible to clogging of groove with abrasive particles and grinding dusts during polishing, and leads to little decrease in polishing rate even after long-term continuous use. A polishing pad of the present invention has a polishing layer formed of polyurethane resin foam having fine-cells, and asperity structure formed in a polishing surface of the polishing layer, and is featured in that the polyurethane resin foam is a reaction cured product between isocyanate-terminated prepolymer containing high-molecular-weight polyol component and isocyanate component, and a chain extender, and contains a silicon-based surfactant having combustion residue of not less than 8 wt %.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

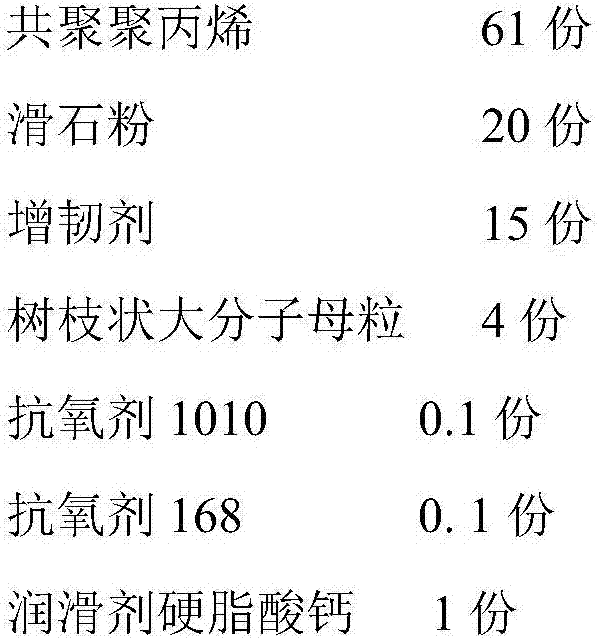

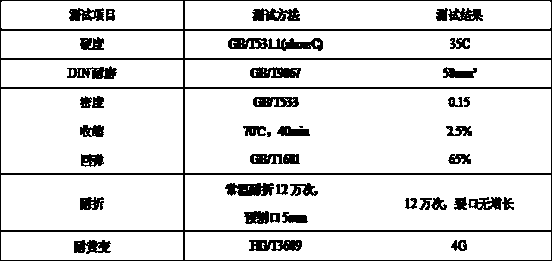

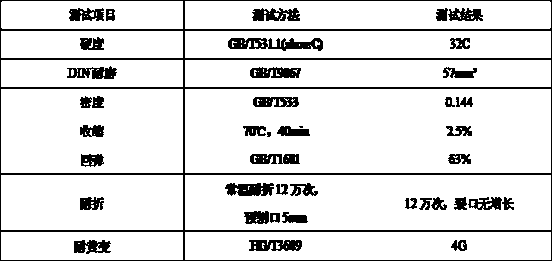

Polypropylene injection molding chemical micro-foamed composite material and preparation method thereof

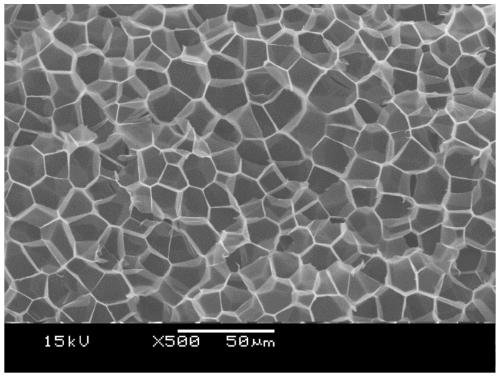

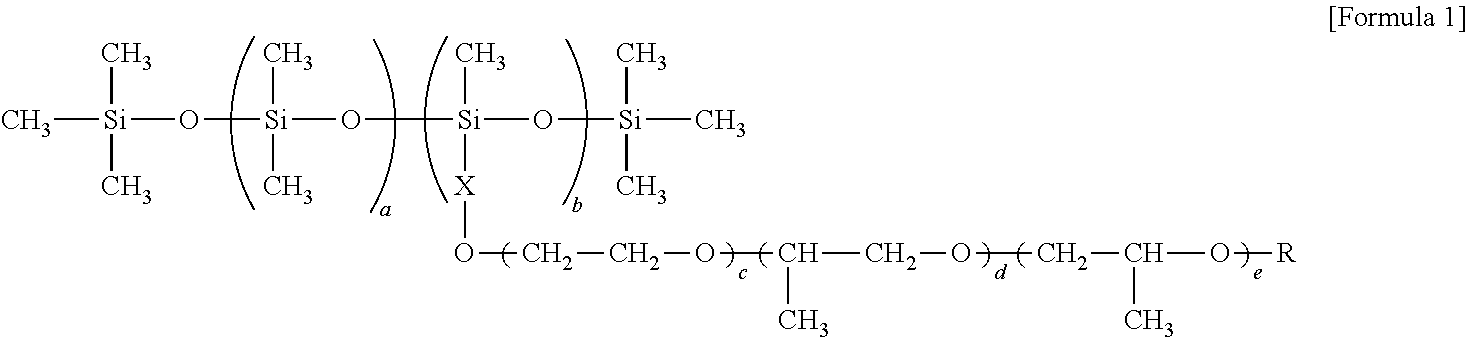

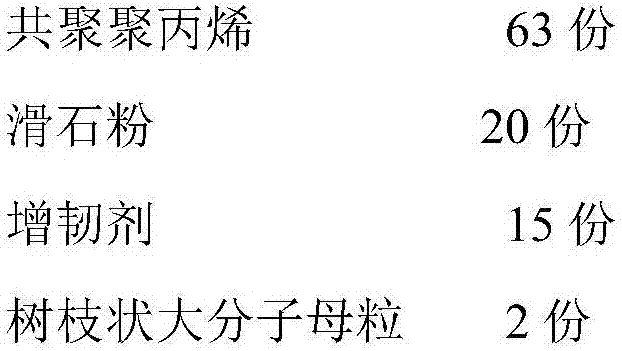

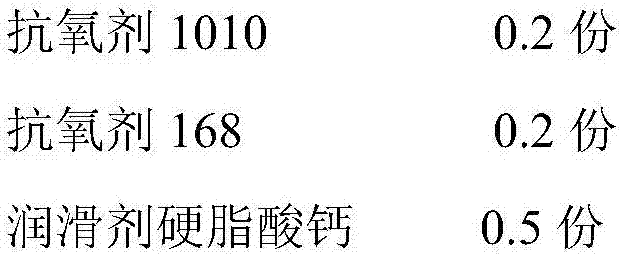

The invention provides a preparation method of a polypropylene injection molding chemical micro-foamed composite material. The polypropylene micro-foamed composite material is prepared by uniformly mixing a polypropylene composite material and a foaming agent and molding an obtained mixture by adopting a secondary mold opening process, wherein the polypropylene composite material is prepared from the following materials in parts by weight: 57 to 63 parts of polypropylene, 0.1 to 25 parts of talcum powder, 0.1 to 20 parts of flexibilizer, 2 to 10 parts of dendritic macromolecule master batch, 0.2 to 0.4 part of antioxidant, 0.5 to 1 part of lubricating agent, and 0 to 3 parts of other additives, wherein the chemical foaming agent is sodium hydrogen carbonate master batch of LDPE carriers. Melt strength of the polypropylene composite system is mutually entangled and regulated with a matrix by virtue of the special dendritic structure of the dendritic macromolecule, after the foaming, a core layer presents in an obvious sandwiched structure, the diameter of a foam hole is 60 micrometers, and the foam holes are uniform and dense; and in addition, the heat insulation, sound insulation and noise reduction can be achieved, a novel solution is provided for developing the light-weight material, and the prepared polypropylene injection molding chemical micro-foamed composite material can be widely applied to products such as automotive interior door panels, instrument panels.

Owner:ORINKO NEW MATERIAL CO LTD

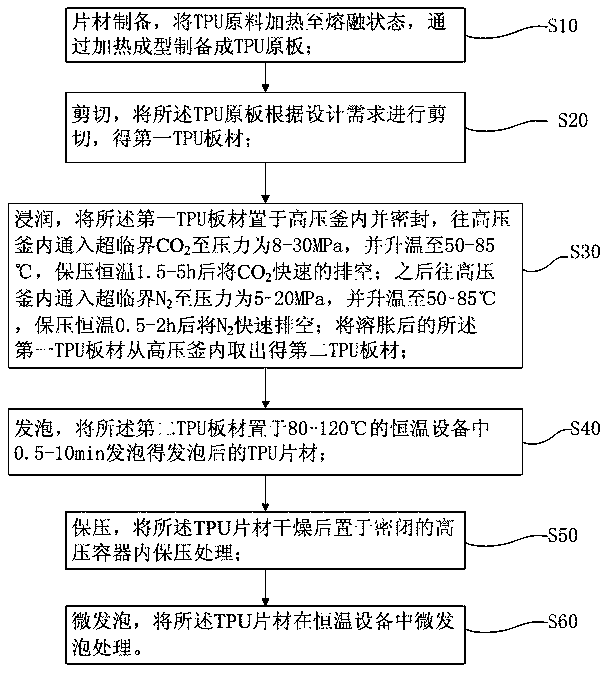

TPU sheet foaming process

The invention provides a TPU sheet foaming process which comprises the following steps: preparing a sheet to obtain a TPU raw plate; shearing to obtain a first TPU plate; soaking, namely putting the first TPU plate into a high-pressure kettle, sealing, introducing supercritical CO2 into the high-pressure kettle until the pressure is 8-30MPa, heating to 50-85 DEG C, maintaining the pressure and theconstant temperature for 1.5-5 hours, and quickly emptying CO2; introducing supercritical N2 into the high-pressure kettle until the pressure is 5-20 MPa, heating to 50-85 DEG C, maintaining the pressure and the constant temperature for 0.5-2 hours, and quickly emptying N2; taking out the swollen first TPU plate from the high-pressure kettle to obtain a second TPU plate; and foaming to obtain theTPU sheet. The invention discloses a TPU sheet foaming process. The TPU sheet is directly prepared through foaming by adopting an infiltration process combining supercritical CO2 and supercritical N2, the product prepared by adopting the process is good in flatness and plumpness, the phenomena of edge curling and the like are avoided, the production convenience is provided for downstream manufacturers, and the equipment investment of the downstream manufacturers is greatly reduced.

Owner:锋特(福建)新材料科技有限公司

Foaming material prepared by blending plant straw filled polypropylene/polyethylene and preparation process

The invention provides a foaming material prepared by blending plant straw filled polypropylene / polyethylene. The foaming material comprises the following raw materials in parts by weight: 60-80 parts of polypropylene plastic, 20-40 parts of polyethylene substrate, 1-5 parts of foaming agent, 40-50 parts of plant straw powder, 1-2 parts of coupling agent, 3-5 parts of heat stabilizer and 0.5-1 part of lubricating agent. The preparation process comprises the following steps: preparing the plant straw powder, and then treating the plant straw powder with the coupling agent; evenly mixing the polypropylene plastic, the polyethylene substrate, the foaming agent, the plant straw powder treated by the coupling agent, the heat stabilizer and the lubricating agent; carrying out fusion blending and pelleting on the mixture, and carrying out extrusion molding; and finally, heating the sectional material, adding the foaming agent for mixing, extruding and foaming in an extrusion machine, and cooling to obtain the product, wherein the temperature of the extrusion machine is controlled between 180 DEG C and 200 DEG C. The product prepared by the process in the invention has better bubble form,foaming density and density of the foaming material as compared with the other foaming materials; and simultaneously, the product has excellent impact strength and physical and mechanical properties.

Owner:陆希悦

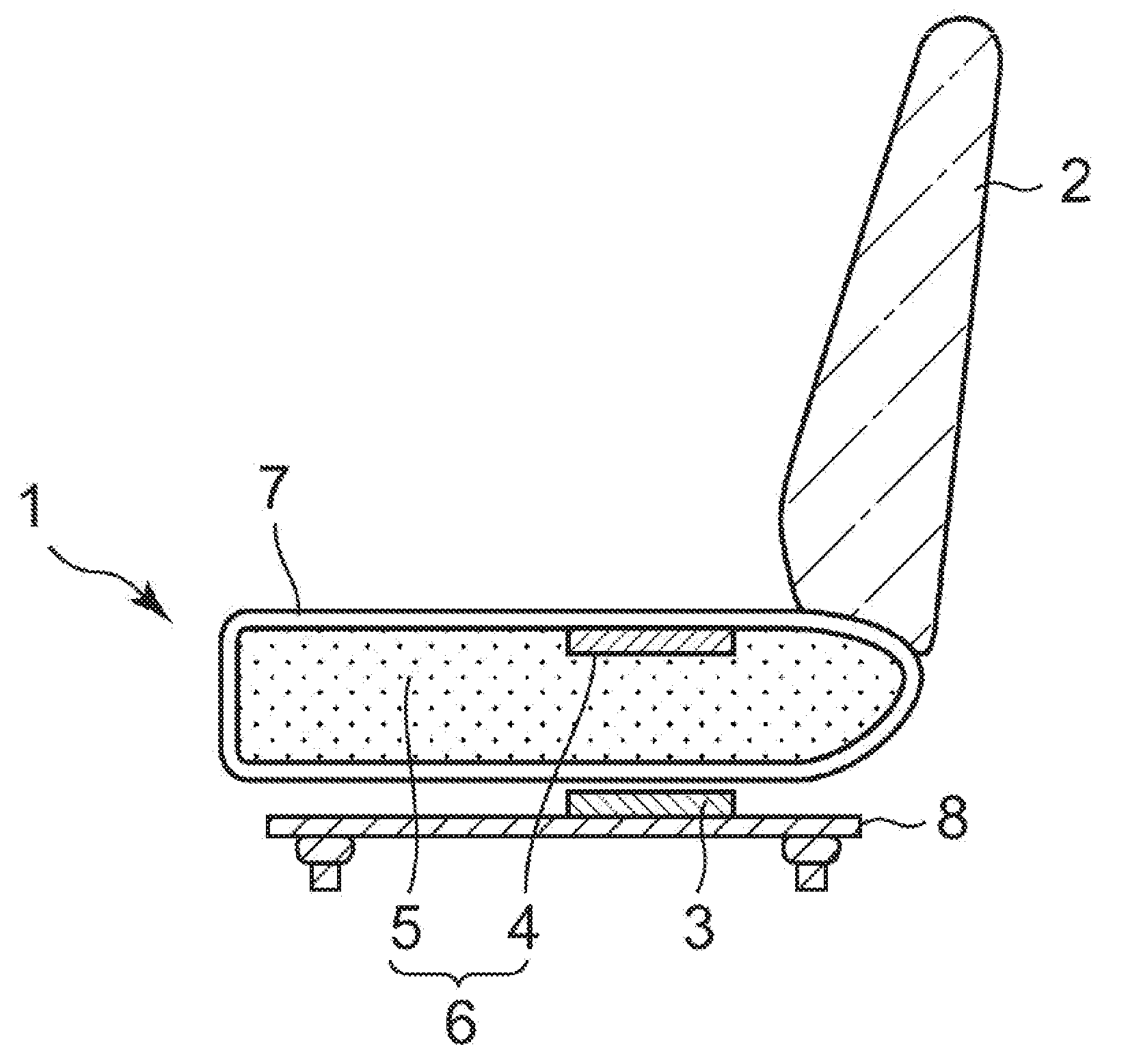

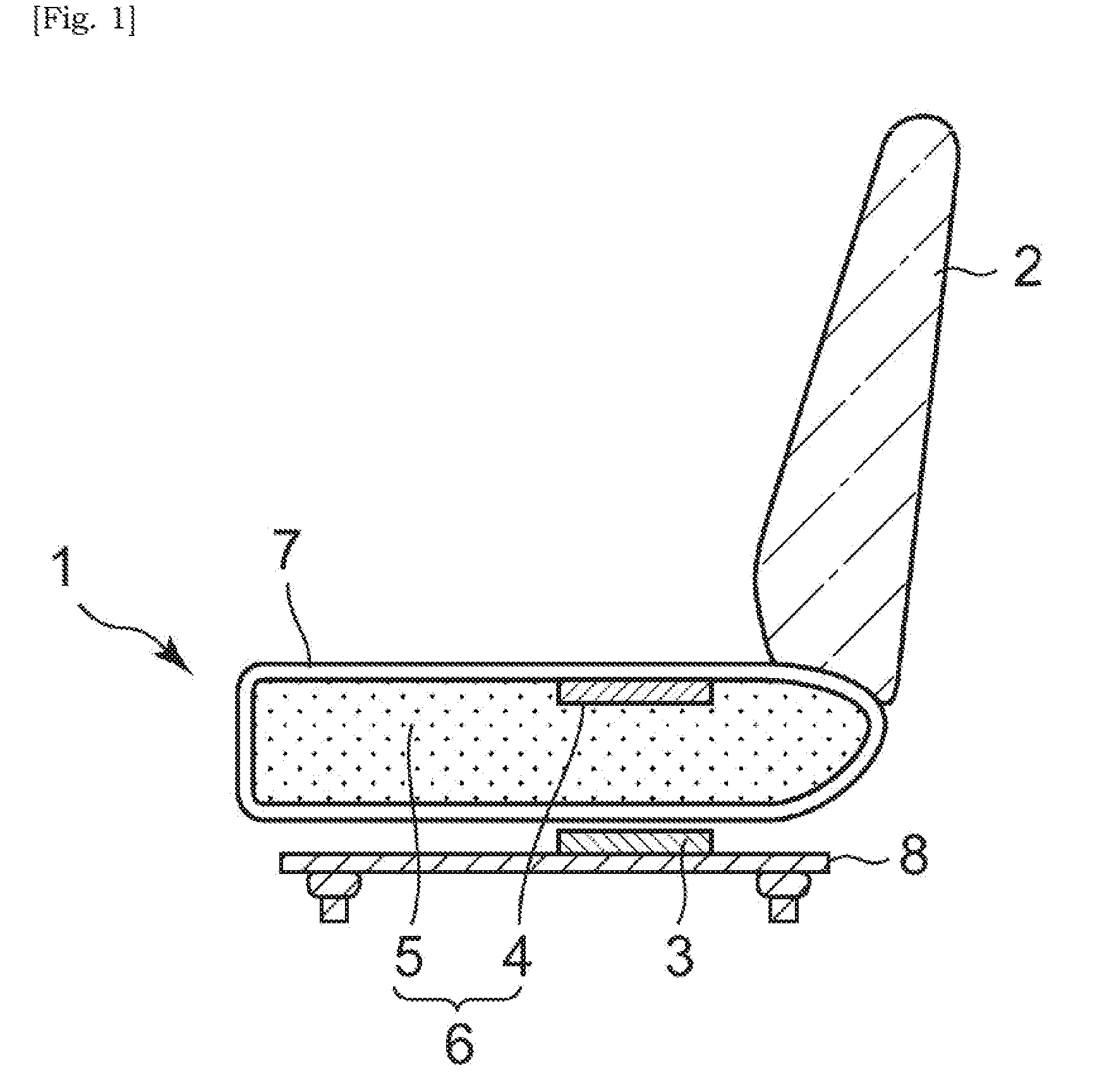

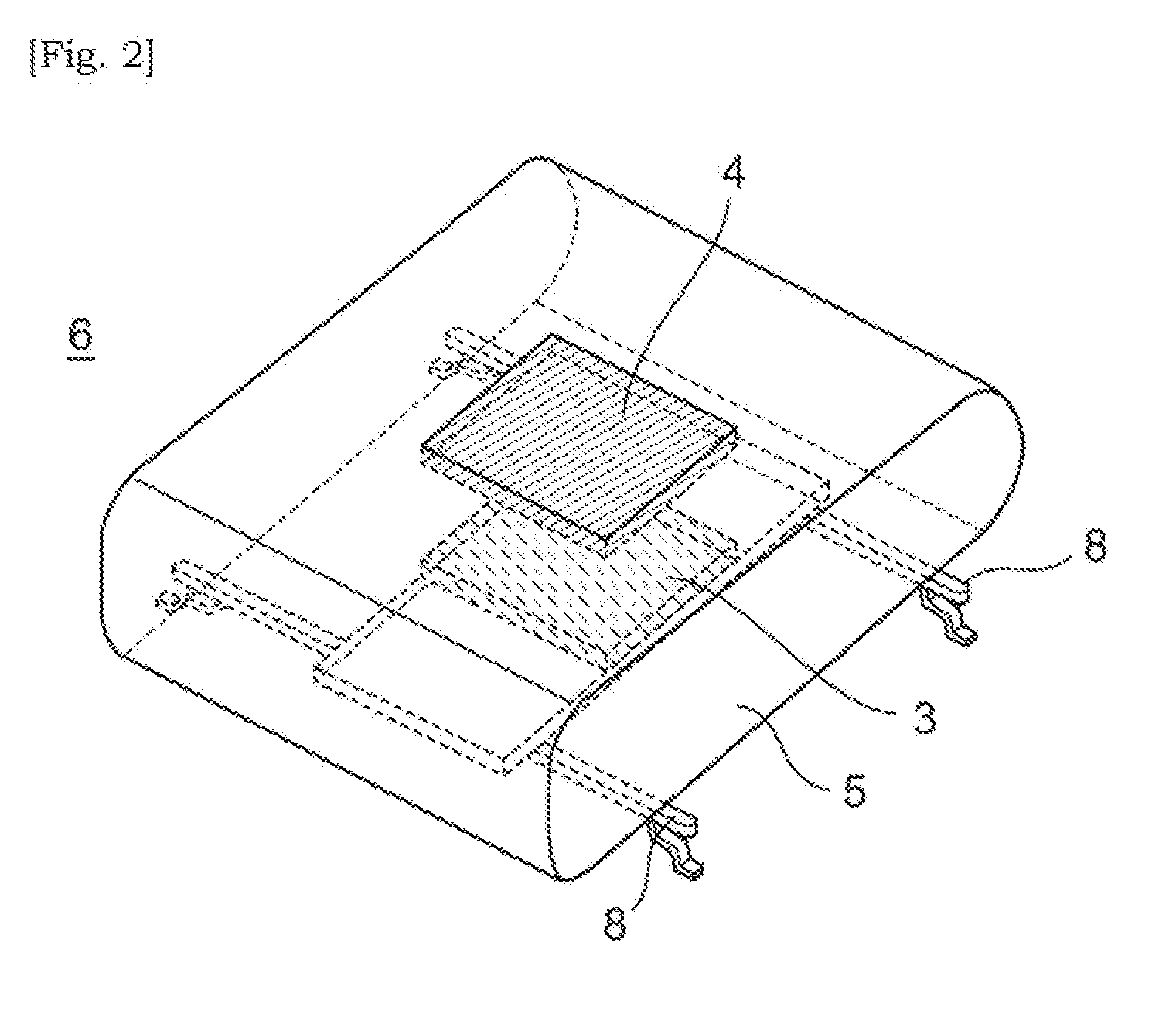

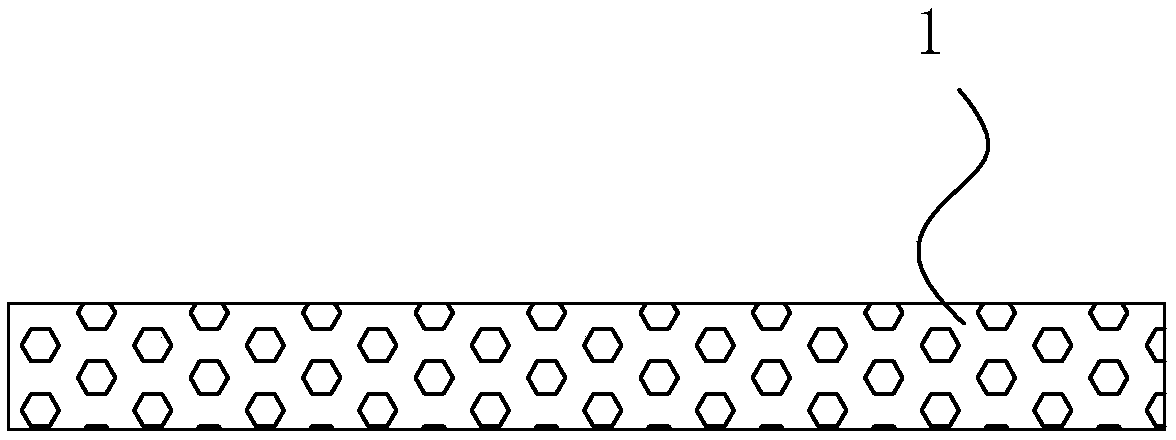

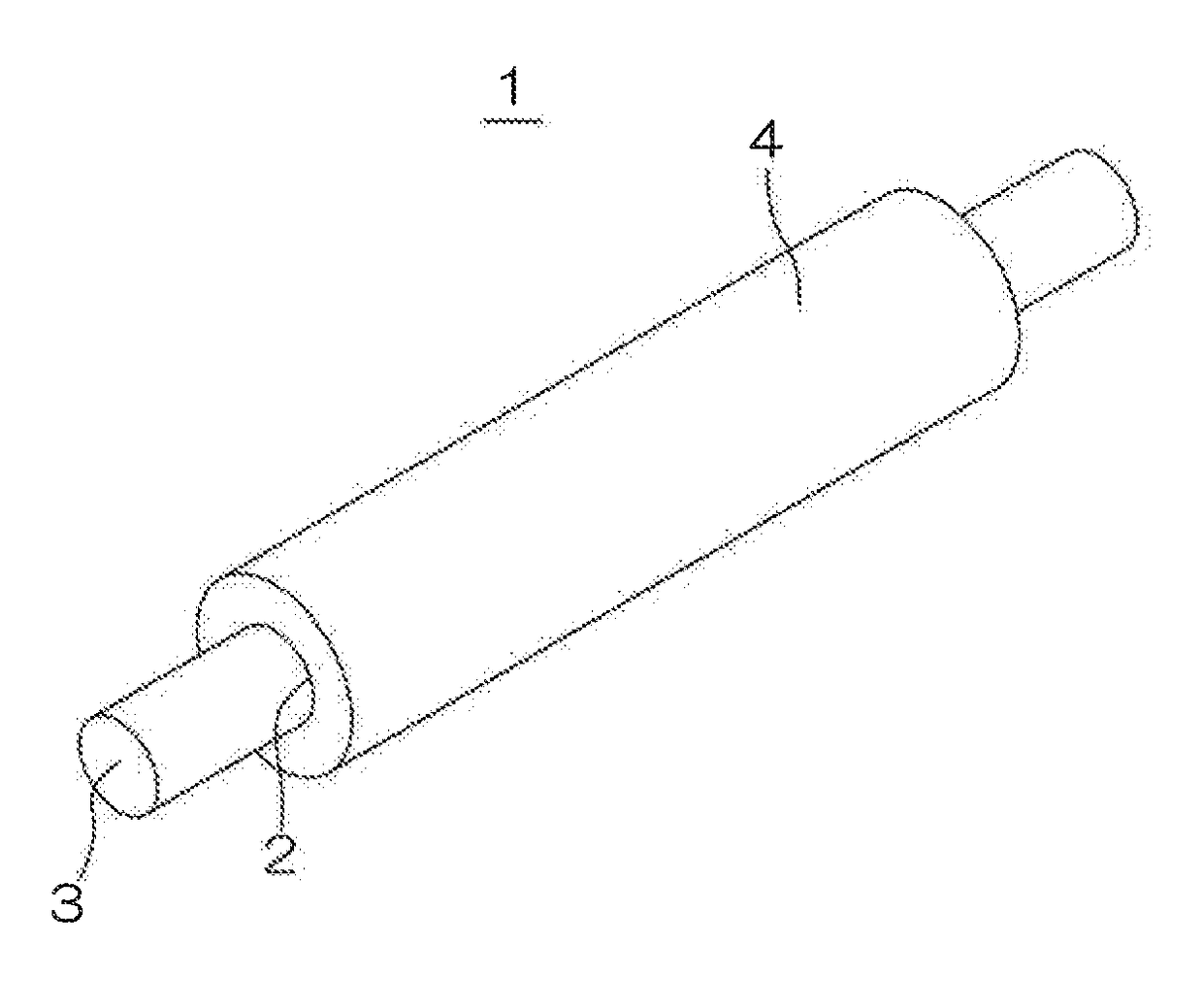

Deformation detection sensor and production of the same

InactiveUS20160305760A1Improve stabilityNot easy to peel offVehicle seatsForce measurement by measuring magnetic property varationPolymer chemistryPolymer

The present invention provides a deformation detection sensor which combines a magnetic resin dispersing a magnetic filler in a resin with a magnetic sensor, of which durability of long period of use is highly enhanced.The present invention thus provides a deformation detection sensor which comprises:a magnetic resin-containing polymer foam which comprises a magnetic resin, in which a magnetic filler is contained, and a polymer foam in which the magnetic resin is included, anda magnetic sensor that detects a magnetic change caused by a deformation of the magnetic resin-containing polymer foam,wherein an average cell diameter of cells of the polymer foam in the vicinity of an interface between the magnetic resin and the polymer foam is smaller than that of cells of a center portion of the polymer foam, and a production thereof.

Owner:TOYO TIRE & RUBBER CO LTD

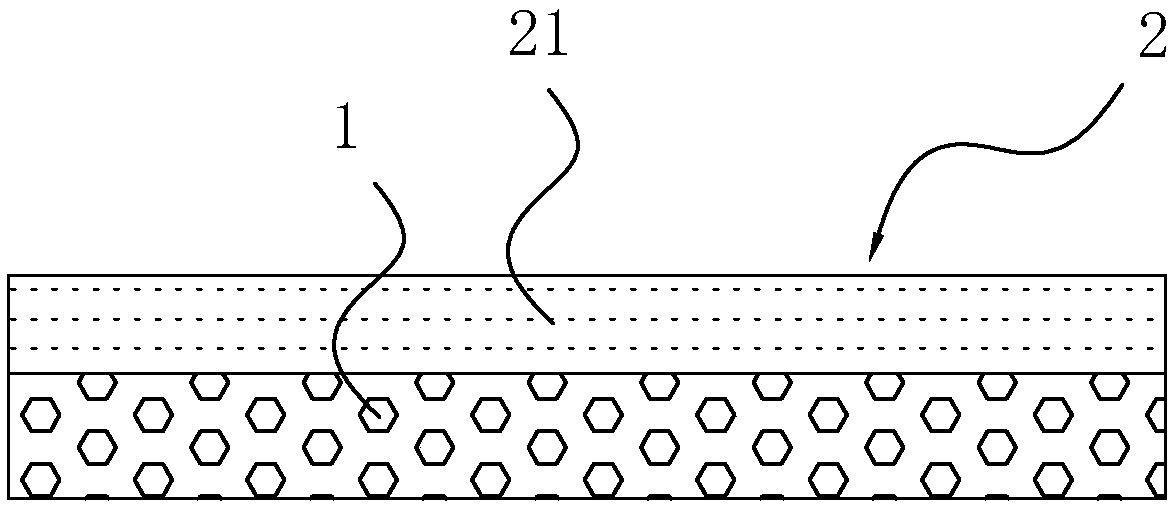

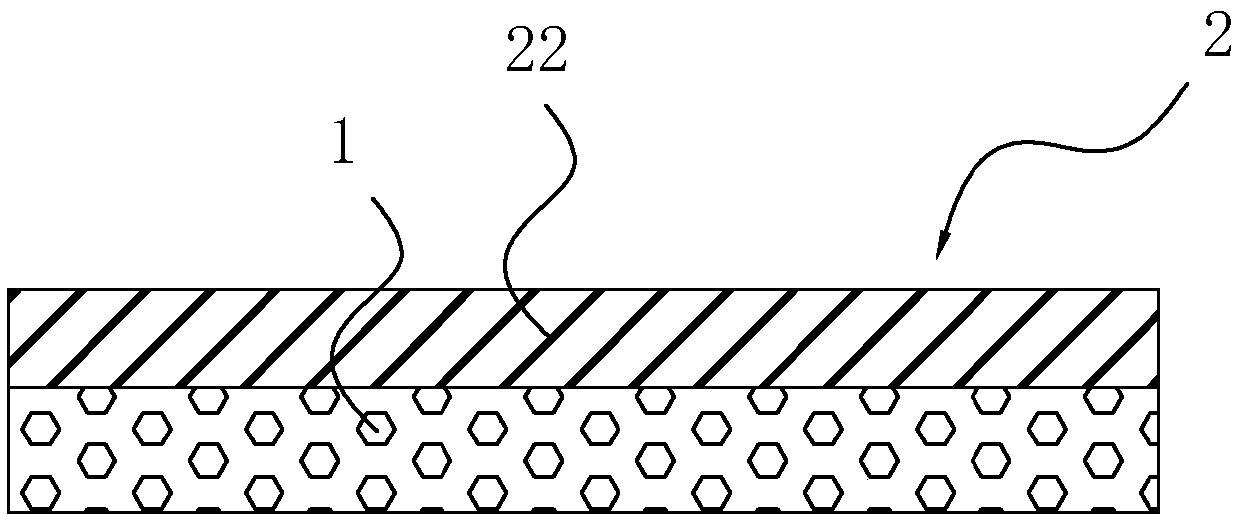

Micro-foaming plastic floor and production technology thereof

The invention discloses a micro-foaming plastic floor and a production technology thereof, and relates to the field of floors. The micro-foaming plastic floor comprises a base material layer formed through a physical foaming method, and the base material layer is selected from a plastic raw material, wherein the plastic raw material is one of PVC, PE and PP; a surface layer is compounded on the upper surface of the base material layer, and the surface layer comprises one or more of an abrasion-resistant layer and a color film layer; and a non-woven fabric is compounded on the upper surface ofthe base material layer. The production technology comprises the following steps of A, blending, B, extrusion molding, and C, compounding. According to the micro-foaming plastic floor and the production technology thereof, the lightweight floor can be achieved, and the foot feel is improved in the using process.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

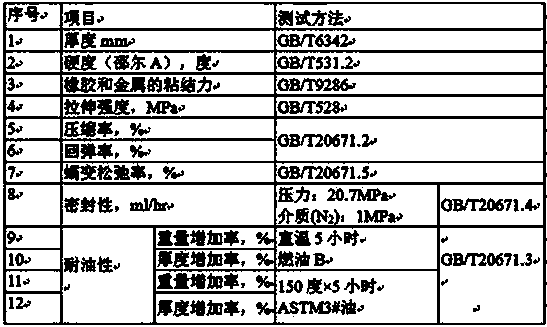

Preparation method of anti-attenuation gasket

ActiveCN109703035AImprove performanceImprove sealingDomestic articlesFlat articlesMaterials preparationUltrasound attenuation

The invention provides a preparation method of an anti-attenuation gasket, belonging to the technical field of sealing material preparation. The preparation method of the anti-attenuation gasket is characterized in that the anti-attenuation gasket comprises a spring steel belt and a foaming rubber layer; the foaming rubber layer is arranged on one side or two sides of the spring steel belt, and the preparation method is characterized by comprising the following steps of: carrying out surface treatment to the spring steel belt; preparing the foaming rubber; carrying out compounding, curing, checking, stamping forming and ribbing treatment on the foaming rubber and the spring steel belt sequentially so as to obtain a finished product. The foaming rubber and the spring steel belt provided bythe invention are tightly bonded, and are not easy to peel off, the product is environment-friendly, nontoxic and odorless, has a large compression amount, good rebound resilience and good flexibility, and a framework adopts the spring steel belt, so that the framework can maintain elasticity for a long time due to a honeycomb structure of the foaming rubber after being stressed, and the moment can be maintained for a long time without attenuation.

Owner:南阳天一密封股份有限公司

Process for preparing expanded product of thermoplastic resin

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyol composition for rigid polyurethane foam and production method for rigid polyurethane foam

A polyol composition for a rigid polyurethane foam, which comprises polyol compounds, and water as a blowing agent, and which is mixed with a polyisocyanate component to react therewith, and thereby forming the rigid polyurethane foam, wherein the polyol compounds comprise a polyether polyol (A) which is a polymer made from an alkylene oxide and has an average functional group number of 2 to 4 and a weight-average molecular weight of 3000 to 8000, and a short glycol (B) having a molecular weight less than 250, and the water is contained in an amount of 20 to 100 parts by weight for 100 parts by weight of the polyol compounds.

Owner:TOYO TIRE & RUBBER CO LTD

Preparation method of alkali-resistant fire extinguishing agent

InactiveCN107252545AIncrease fire extinguishing areaEffective large area fire extinguishingFire extinguisherAqueous solutionBall mill

The invention discloses a preparation method of an alkali-resistant fire extinguishing agent. The preparation method comprises the steps that (1) hydrophobic solid particles are put into air-drying equipment to be fully air-dried; (2) the hydrophobic solid particles are put into a ball mill to be subjected to ball milling; (3) a foaming agent, a stabilizing agent and the hydrophobic solid particles are put into a stirrer to be mixed and stirred; (4) a solute is put into clear water and mixed to form an aqueous solution, and the mixture of the foaming agent, the stabilizing agent and the hydrophobic solid particles in the step (3) is added into the aqueous solution to form the fire extinguishing agent; and (5) the obtained fire extinguishing agent is contained in a pressure-resistant container, and 1.8-2.3 atmospheric pressure is applied to the fire extinguishing agent for storage. According to the preparation method, the step of ball milling of the hydrophobic solid particles is added; the unit diameter of the hydrophobic solid particles is obviously reduced so that the hydrophobic solid particles can be attached to the surface of a burning object more uniformly; the hydrophobic solid particles are used in cooperation with foam generated by the foaming agent, and an isolation film can be rapidly formed under a high-temperature burning environment to extinguish a fire quickly.

Owner:四川省科拓梦无人机科技有限公司

Preparing method of fire extinguishing agent made of ammonium dihydrogen phosphate dry powder

InactiveCN107823837ASmall cell diameterUniform adhesionFire extinguisherFoaming agentAqueous solution

The invention discloses a preparation method of a fire extinguishing agent made of ammonium dihydrogen phosphate dry powder, which comprises the steps of putting hydrophobic solid particles into an air-drying device for sufficient air-drying; putting the hydrophobic solid particles into a ball mill for ball milling; The step of putting the foaming agent, stabilizer, and hydrophobic solid particles into the agitator for mixing and stirring, and mixing the solute into clear water to form an aqueous solution and adding the foaming agent, stabilizer, and hydrophobic solid particles in step 3 A mixture of solid particles forms a fire extinguishing agent; the obtained fire extinguishing agent is packed in a pressure-resistant container and stored at 1.8-2.3 atmospheres. In the present invention, by adding the step of ball milling the hydrophobic solid particles, the unit diameter of the hydrophobic solid particles is significantly reduced, and can be more uniformly attached to the surface of the burning object, and the foam produced by the foaming agent can be used in a high-temperature burning environment It can quickly form an insulating film and quickly extinguish the fire.

Owner:CHENGDU JUNHE TIANCHENG TECH

Foaming material prepared by blending plant straw filled polypropylene/polyethylene and preparation process

The invention provides a foaming material prepared by blending plant straw filled polypropylene / polyethylene. The foaming material comprises the following raw materials in parts by weight: 60-80 parts of polypropylene plastic, 20-40 parts of polyethylene substrate, 1-5 parts of foaming agent, 40-50 parts of plant straw powder, 1-2 parts of coupling agent, 3-5 parts of heat stabilizer and 0.5-1 part of lubricating agent. The preparation process comprises the following steps: preparing the plant straw powder, and then treating the plant straw powder with the coupling agent; evenly mixing the polypropylene plastic, the polyethylene substrate, the foaming agent, the plant straw powder treated by the coupling agent, the heat stabilizer and the lubricating agent; carrying out fusion blending and pelleting on the mixture, and carrying out extrusion molding; and finally, heating the sectional material, adding the foaming agent for mixing, extruding and foaming in an extrusion machine, and cooling to obtain the product, wherein the temperature of the extrusion machine is controlled between 180 DEG C and 200 DEG C. The product prepared by the process in the invention has better bubble form,foaming density and density of the foaming material as compared with the other foaming materials; and simultaneously, the product has excellent impact strength and physical and mechanical properties.

Owner:陆希悦

Preparing method for water-soluble foam fire-fighting composition

The invention discloses a preparing method for a water-soluble foam fire-fighting composition. The preparing method comprises the steps that hydrophobic solid particles are placed into air drying equipment to be subjected to sufficient air drying; the hydrophobic solid particles are placed into a ball mill for ball milling; a foaming agent, a stabilizer and the hydrophobic solid particles are placed into a stirrer to be mixed and stirred; a solute is placed into clean water to be mixed to form a solution, the solution is added into a mixture of the foaming agent, the stabilizer and the hydrophobic solid particles to form a fire extinguishing agent; and the obtained fire extinguishing agent is contained into a compression resistance container, and 1.8-2.3 units of barometric pressure are applied for storage. According to the preparing method, the step of ball milling of the hydrophobic solid particles is added, the unit diameter of the hydrophobic solid particles is obviously decreased,the hydrophobic solid particles can be attached to the surface of an object catching a fire more evenly, in cooperation with foams generated by the foaming agent, an isolated film can be quickly formed under the high temperature firing environment, and quick extinguishment can be achieved.

Owner:CHENGDU JUNHE TIANCHENG TECH

Polypropylene foam material and preparation method thereof

The invention provides a polypropylene foam material and a preparation method thereof. The polypropylene foam material comprises the following components in parts by weight: 65-90 parts of polypropylene resin; 1-20 parts of toughening agent; 1-20 parts of low-density polyethylene, 5-15 parts of talcum powder, 0.1-1 part of compatilizer, 0.2-2 parts of auxiliaries and a foaming agent. The compatilizer is a polyolefin graft, the polyolefin graft is PP grafted maleic anhydride, POE grafted maleic anhydride or PE grafted maleic anhydride, and the flexibilizer is an ethylene-butylene copolymer or an ethylene-octene copolymer. After the polypropylene foaming material is matched with the polypropylene resin, the low-density polyethylene, the ethylene-butylene copolymer serving as the toughening agent, the ethylene-octene copolymer and the polyolefin graft serving as the compatilizer, the melt strength can be improved, the cell diameter is reduced, foaming is more uniform, the foaming performance of the polypropylene foaming material is improved, and the impact property of the foamed polypropylene foam material can be remarkably improved.

Owner:KINGFA SCI & TECH CO LTD

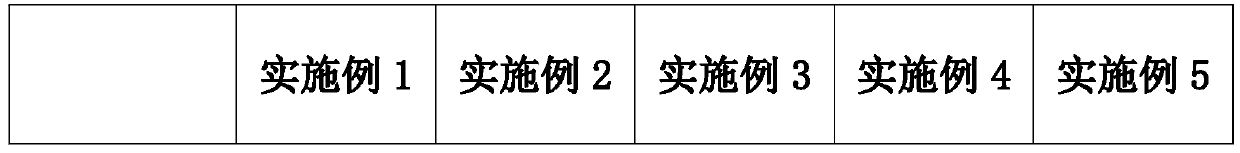

Preparation method of foaming agent master batch

The invention relates to a preparation method of a foaming agent master batch, which comprises the following steps: (1) adding glycerol, oxalic acid and a molecular weight regulator into a reaction kettle, and carrying out heating and dehydrating; and after dehydration is completed, adding a catalyst, and heating the reaction kettle to perform reaction for 4-10h under the conditions of vacuum andnitrogen protection so as to obtain hyperbranched polyester; (2) adding citric acid and a compatibility regulator into the hyperbranched polyester, heating the reaction kettle to perform reaction for2-4h under the conditions of vacuum and nitrogen protection to obtain a reaction product, and cooling the reaction product to obtain a citric acid-loaded hyperbranched polyester composite foaming agent; and (3) mixing matrix resin with the hyperbranched polyester composite foaming agent to a uniform state, and granulating the mixture through a granulator to obtain the foaming agent master batch. The foaming agent master batch has the characteristics of small influence on the flowability of polypropylene melt, high mechanical strength after foaming, low cost, adaptability to other fillers and assistants and the like, and has a wide application prospect in the field of large polypropylene injection molding parts.

Owner:中化石化销售有限公司

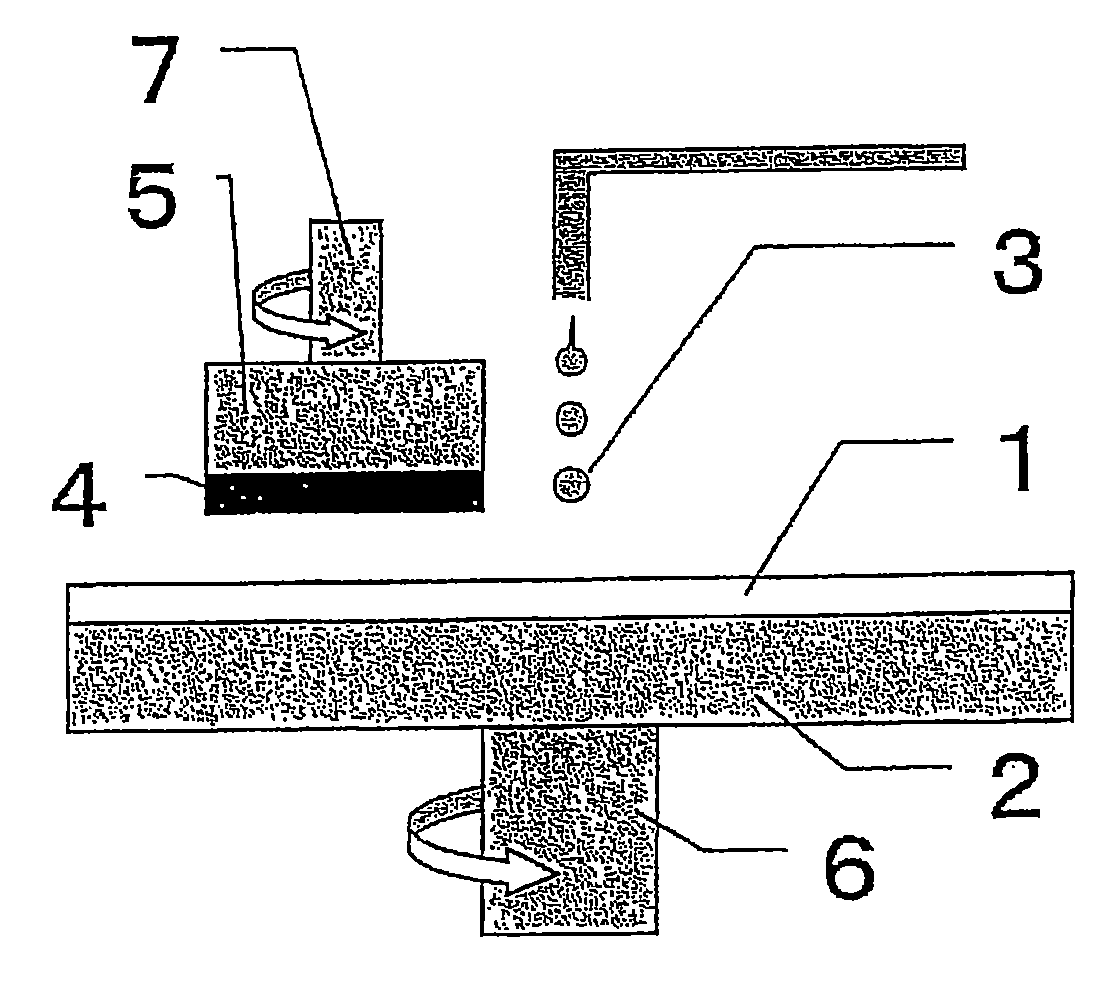

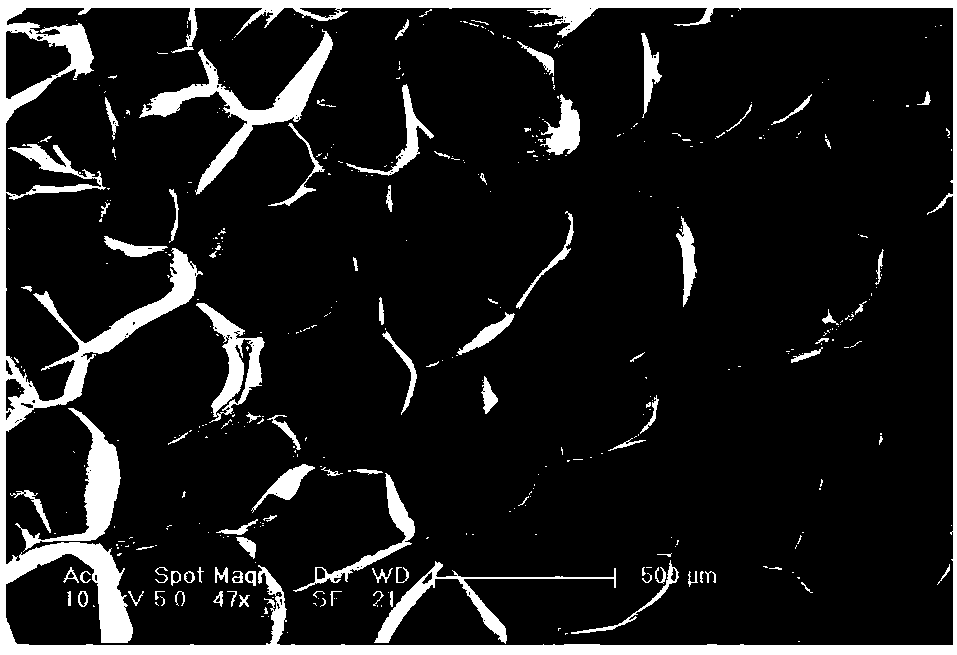

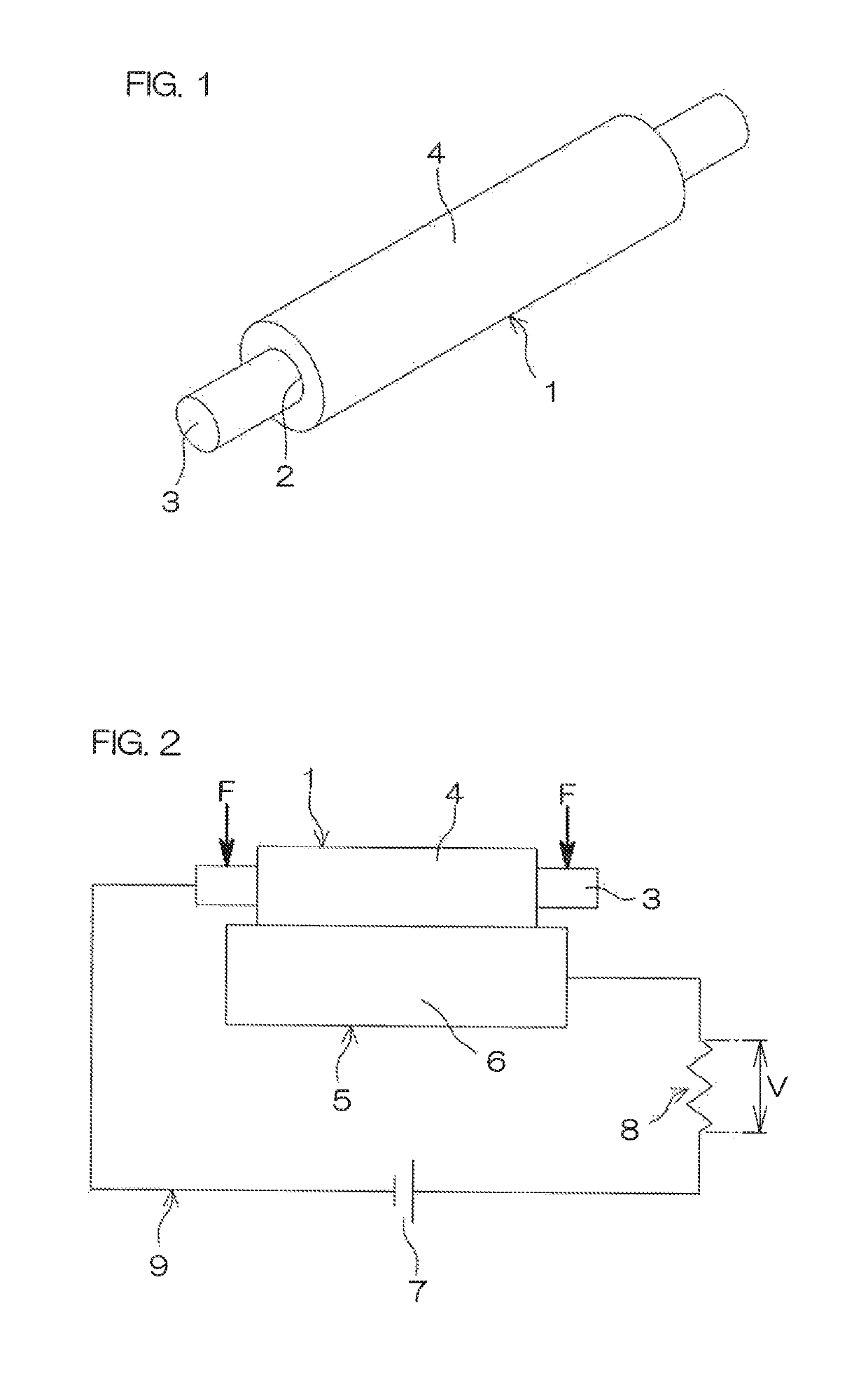

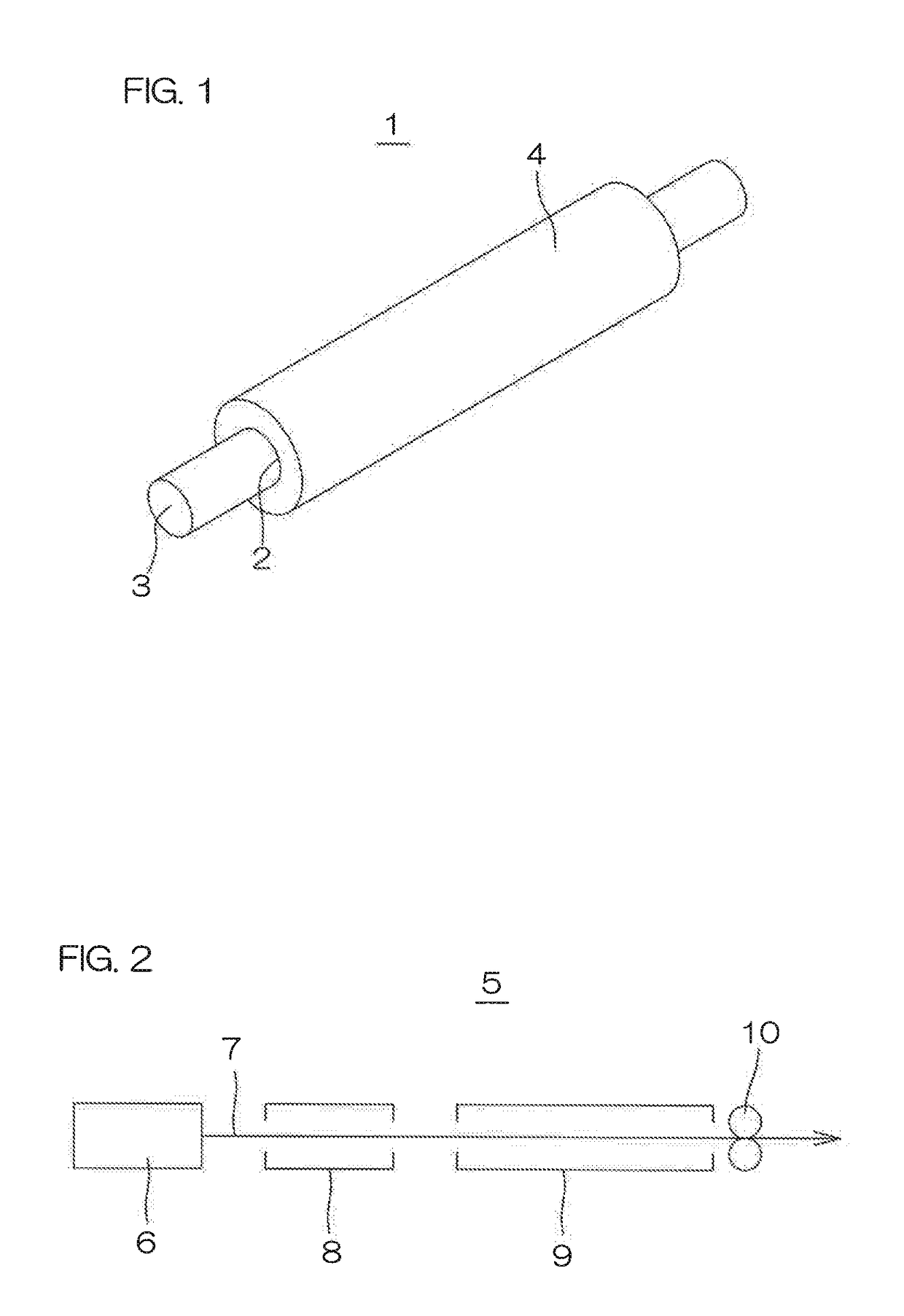

Electrically conductive rubber composition, transfer roller, production method for the transfer roller, and image forming apparatus

ActiveUS10481529B2Small cell diameterImage formationTransfer printingElectrographic process apparatusFoaming agentVulcanization

An electrically conductive rubber composition is provided, which is usable for production of a transfer roller of a highly flexible foam satisfying requirements for cost reduction and weight reduction and having smaller foam cell diameters and, hence, ensuring higher-quality image formation with smaller environment-dependent variations in roller resistance. A transfer roller produced from the electrically conductive rubber composition, a production method for the transfer roller, and an image forming apparatus including the transfer roller are also provided. The electrically conductive rubber composition contains a rubber component including SBR and / or BR, EPDM and epichlorohydrin rubber, a crosslinking component, and 4 to 6 parts by mass of a foaming agent and 1.5 to 2.7 parts by mass of a foaming assisting agent based on 100 parts by mass of the rubber component. The transfer roller (1) is produced by extruding the electrically conductive rubber composition into a tubular body and performing an in-can vulcanization process on the tubular body. The image forming apparatus incorporates the transfer roller.

Owner:SUMITOMO RUBBER IND LTD

Preparing method for foam extinguishing agent based on acidic solution

The invention discloses a method for preparing a foam fire extinguishing agent based on an acidic solution, which comprises the steps of putting hydrophobic solid particles into air-drying equipment for sufficient air-drying; putting the hydrophobic solid particles into a ball mill for ball milling; foaming agent, stabilizer, and hydrophobic solid particles are put into a stirrer for mixing and stirring, and the solute is put into clear water and mixed to form an aqueous solution and add the foaming agent, stabilizer, and hydrophobic solid particles in step 3 The mixture is formed into a fire extinguishing agent; the obtained fire extinguishing agent is packed in a pressure-resistant container and stored at 1.8-2.3 atmospheres. In the present invention, by adding the step of ball milling the hydrophobic solid particles, the unit diameter of the hydrophobic solid particles is significantly reduced, and can be more uniformly attached to the surface of the burning object, and the foam produced by the foaming agent can be used in a high-temperature burning environment It can quickly form an insulating film and quickly extinguish the fire.

Owner:CHENGDU JUNHE TIANCHENG TECH

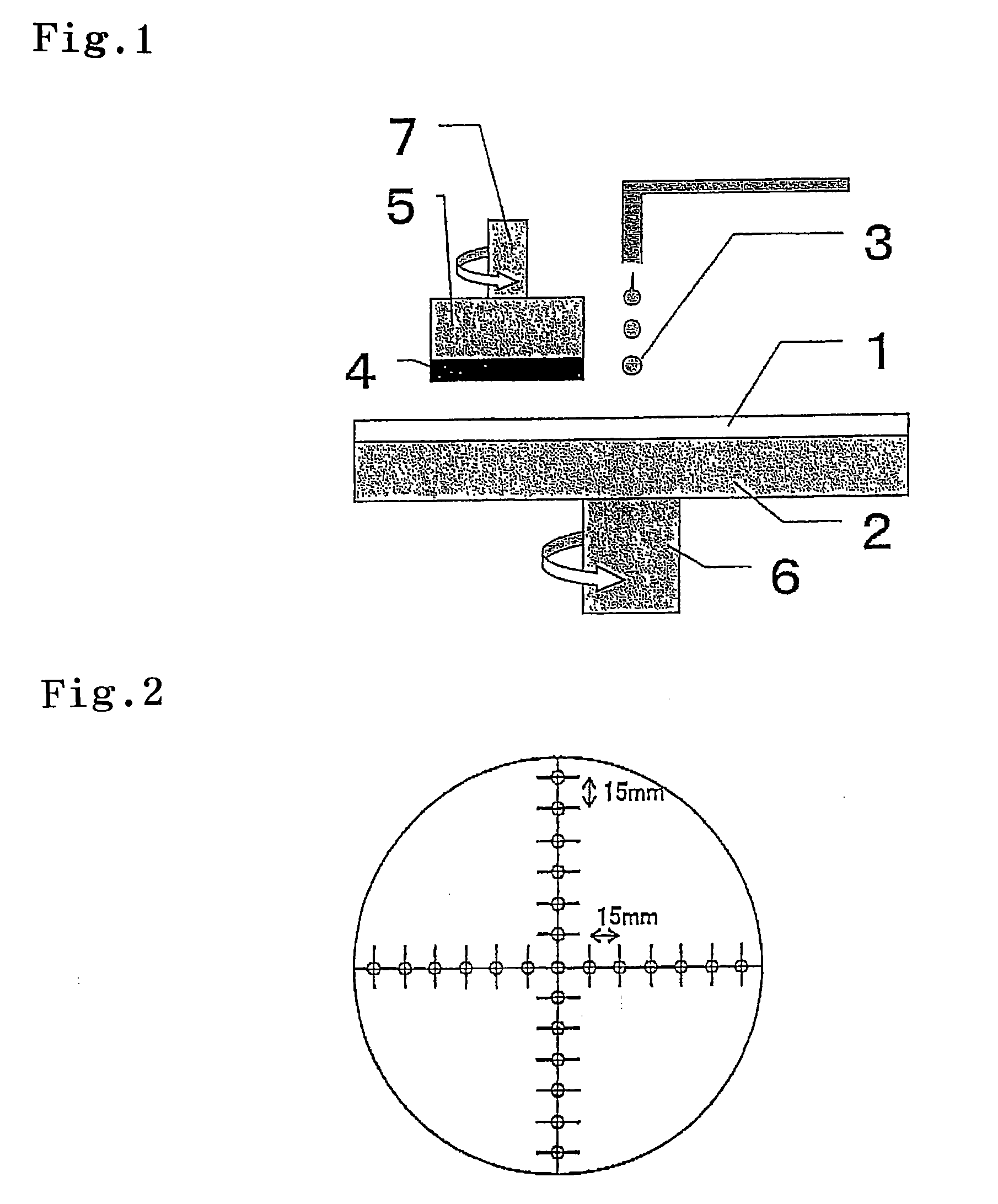

Transfer roller, and production method for the transfer roller

InactiveUS20170329260A1Rubber hardnessSmall cell diameterElectrographic process apparatusDomestic articlesHydrogenSingle stage

An inventive transfer roller (1) is made of a foam formed from an electrically conductive rubber composition containing an electrically conductive rubber, a crosslinking component, and a foaming agent including OBSH and 0.25 to 2.5 parts by mass of sodium hydrogen carbonate based on 1 part by mass of OBSH, and has an Asker-C hardness of not lower than 25 degrees and not higher than 35 degrees and an average foam cell diameter of not greater than 120 μm. Therefore, the transfer roller is flexible with a lower rubber hardness, and has smaller foam cell diameters. An inventive production method includes the steps of: forming the electrically conductive rubber composition into a tubular body; and maintaining the tubular body at a temperature of not lower than 120° C. and not higher than 140° C. to foam the rubber by a single-stage foaming process.

Owner:SUMITOMO RUBBER IND LTD

Preparation method of fire extinguishing agent for liquid fire

InactiveCN107252540ASmall cell diameterUniform adhesionFire extinguisherFoaming agentAqueous solution

The invention discloses a reparation method of a fire extinguishing agent for a liquid fire. The preparation method comprises the steps that hydrophobic solid particles are put into air-drying equipment to be fully air-dried; the hydrophobic solid particles are put into a ball grinder for ball grinding; a foaming agent, a stabilizing agent and the hydrophobic solid particles are put into a stirrer to be mixed and stirred; solutes are put into clear water to be mixed, a water solution is formed to be added into a mixture of the foaming agent, the stabilizing agent and the hydrophobic solid particles in the third step to form the fire extinguishing agent; and the obtained fire extinguishing agent is contained in a pressing resisting container, and 1.8-2.3 atmospheres of pressure are applied for storage. According to the preparation method, the step of carrying out ball grinding on the hydrophobic solid particles is added, the unit diameter of the hydrophobic solid particles is remarkably reduced, the fire extinguishing agent can be attached to the surface of a fire object more evenly, an isolation film can be fast formed under the high-temperature burning environment in cooperation with foam generated by the foaming agent, and fast fire extinguishing is achieved.

Owner:四川省科拓梦无人机科技有限公司

A kind of preparation method of polymer-based density gradient foam material

The invention is a preparation method of a polymer-based density gradient foam material, specifically: firstly, the mixing system of micron metal particles and polymer is mixed at high temperature to obtain composite material melts with different densities; The density gradient composite material is obtained by melting and hot pressing at a high temperature; finally, the density gradient composite material is foamed by supercritical carbon dioxide to obtain a polymer-based density gradient foam material. The present invention adopts laminated hot pressing process combined with supercritical carbon dioxide foaming technology to prepare polymer-based density gradient foam material, and the density range of the material can be 0.2-1.96g / cm 3 It can be adjusted within a certain range, and the density of the sample shows a gradient change at different positions; the diameter of the material is on the order of microns, and it has good dimensional stability, structural controllability and high mechanical strength. Protection, aerospace, transportation, building energy conservation and other fields have broad application prospects.

Owner:WUHAN UNIV OF TECH

Preparation method of covering type isolation fire extinguishing agent

InactiveCN107252550AIncrease fire extinguishing areaRealize large-area fire extinguishingFire extinguisherChemistryBall mill

The invention discloses a preparation method of a covering type isolation fire extinguishing agent. The preparation method comprises the steps that hydrophobic solid particles are put into air-drying equipment to be fully air-dried; the hydrophobic solid particles are put into a ball grinder for ball grinding; a foaming agent, a stabilizing agent and the hydrophobic solid particles are put into a stirrer to be mixed and stirred; solutes are put into clear water to be mixed, a water solution is formed to be added into a mixture of the foaming agent, the stabilizing agent and the hydrophobic solid particles in the third step to form the fire extinguishing agent; and the obtained fire extinguishing agent is contained in a pressing resisting container, and 1.8-2.3 atmospheres of pressure are applied for storage. According to the preparation method, the step of carrying out ball grinding on the hydrophobic solid particles is added, the unit diameter of the hydrophobic solid particles is remarkably reduced, the fire extinguishing agent can be attached to the surface of a fire object more evenly, an isolation film can be fast formed under the high-temperature burning environment in cooperation with foam generated by the foaming agent, and fast fire extinguishing is achieved.

Owner:四川省科拓梦无人机科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com