Micro-foaming plastic floor and production technology thereof

A technology of plastic flooring and production technology, which is applied in the direction of architecture, building structure, floor, etc., can solve problems such as complex production technology, and achieve the effect of improving mechanical properties, improving usability, and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

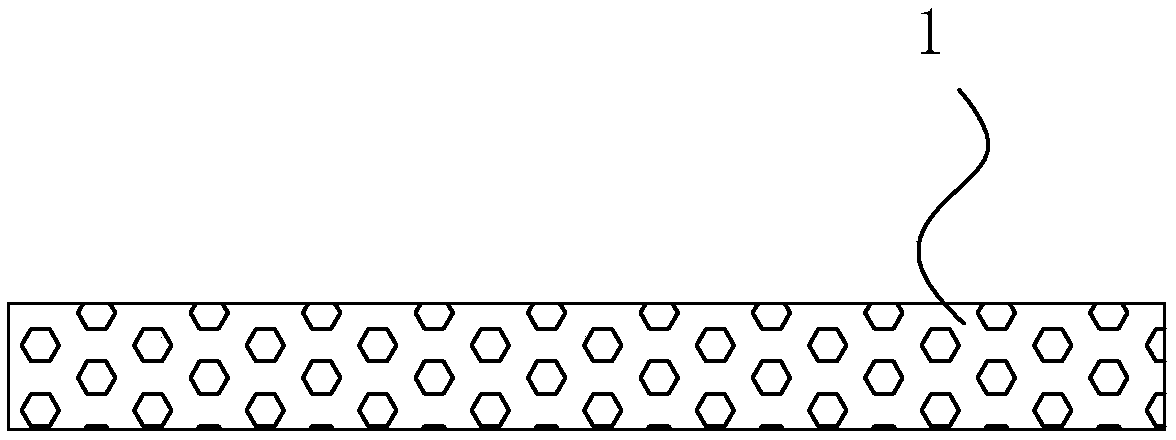

[0040] A kind of microfoam plastic floor, refer to figure 1 As shown, it includes a layer of base material layer 1. The base material layer 1 is formed by physical foaming method of plastic raw material. The plastic raw material can be selected from any one of PVC, PE, and PP. One of the plastic raw materials is weighed Then it is added to the barrel of the injection molding machine and plasticized under the shear force of the screw of the injection molding machine and the heating of the heating ring. At this time, the physical foaming agent is directly injected into the end of the melting section of the screw and mixed evenly with the melt formed by the plastic raw material, and then High pressure and high speed are injected into the mold cavity, and the pressure is suddenly reduced in the mold cavity, so that a large amount of supersaturated gas in the melt is separated out, thereby forming a microporous substrate layer 1. The diameter of the cells in the substrate layer 1 is...

Embodiment 2

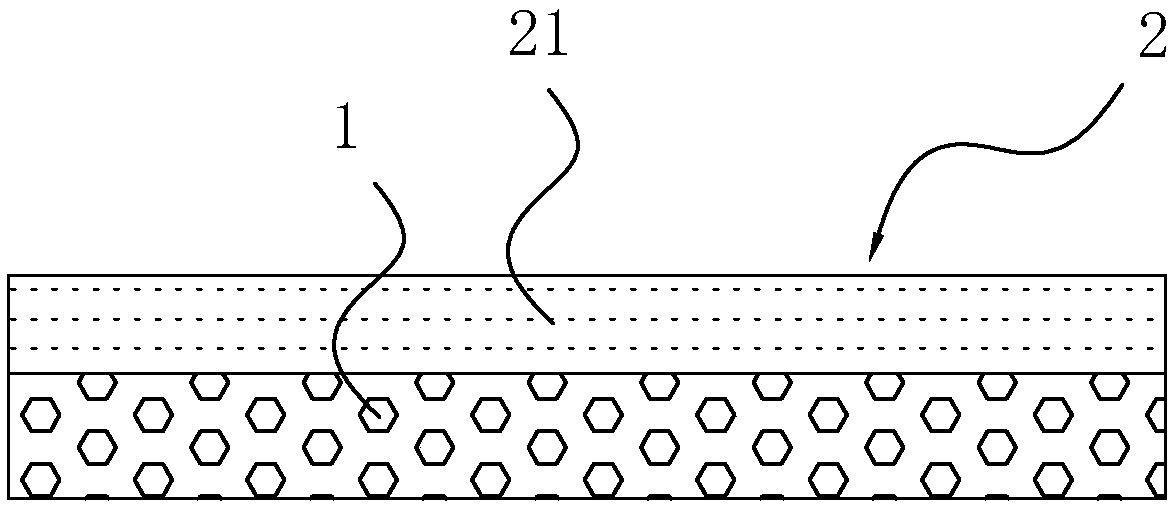

[0043] A microfoamed plastic floor, the difference from Embodiment 1 is that with reference to figure 2 As shown, a surface layer 2 is compounded on the upper surface of the substrate layer 1 by bonding or hot pressing, and the surface layer 2 is a transparent wear-resistant layer 21 made of PVC material.

Embodiment 3

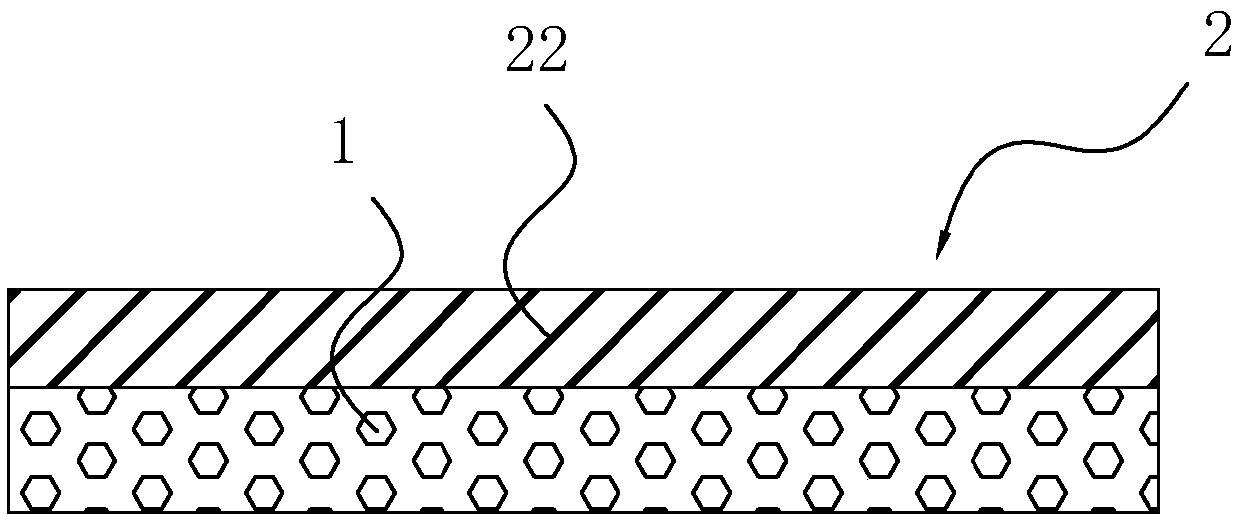

[0045] A microfoamed plastic floor, the difference from Embodiment 1 is that with reference to image 3 As shown, a surface layer 2 is laminated on the upper surface of the substrate layer 1 by bonding or hot pressing. The surface layer 2 is a color filter layer 22 made of PVC material, and ink patterns are printed on the color filter layer 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com