Preparation method of anti-attenuation gasket

An anti-attenuation and gasket technology, applied in the field of the preparation of anti-attenuation gaskets, can solve the problems of general improvement in the sealing performance of composite panels, and achieve the effects of outstanding creep relaxation resistance, large compression and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

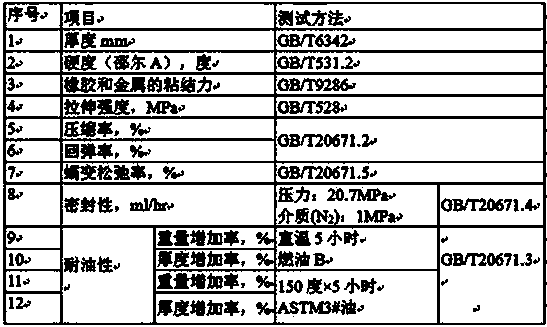

Image

Examples

Embodiment 1

[0027] A preparation method of an anti-attenuation gasket, the anti-attenuation gasket comprises a spring steel strip and a foamed rubber layer, and the foamed rubber layer is arranged on one side of the spring steel strip, comprising the following steps:

[0028] Step S1: Carry out surface treatment to the spring steel strip, in order:

[0029] Cutting: Cut the spring steel strip to the required specifications;

[0030] Degreasing: Use degreasing agent to degrease the surface of the spring steel strip, and the degreasing temperature is: 50°C;

[0031] Water washing: wash the spring steel strip in running water;

[0032] Phosphating: use phosphating solution to phosphate the spring steel strip, and the treatment temperature is 23°C;

[0033] One-time drying: The spring steel strip is dried once, and the temperature of the first-time drying is 80°C;

[0034] Glue coating: apply adhesive evenly on the surface of the spring steel strip;

[0035] Secondary drying: The spring s...

Embodiment 2

[0048] A preparation method of an anti-attenuation gasket, the anti-attenuation gasket comprises a spring steel strip and a foamed rubber layer, and the foamed rubber layer is arranged on both sides of the spring steel strip, comprising the following steps:

[0049] Step S1: Carry out surface treatment to the spring steel strip, in order:

[0050] Cutting: Cut the spring steel strip to the required specifications;

[0051] Degreasing: Use degreasing agent to degrease the surface of the spring steel strip, and the degreasing temperature is 55°C;

[0052] Water washing: wash the spring steel strip in running water;

[0053] Phosphating: use phosphating solution to phosphate the spring steel strip, and the treatment temperature is 25°C;

[0054] One-time drying: The spring steel strip is dried once, and the temperature of the first-time drying is 90°C;

[0055] Glue coating: apply adhesive evenly on the surface of the spring steel strip;

[0056] Secondary drying: Secondary d...

Embodiment 3

[0062] A preparation method of an anti-attenuation gasket, the anti-attenuation gasket comprises a spring steel strip and a foamed rubber layer, and the foamed rubber layer is arranged on both sides of the spring steel strip, comprising the following steps:

[0063] Step S1: Carry out surface treatment to the spring steel strip, in order:

[0064] Cutting: Cut the spring steel strip to the required specifications;

[0065] Degreasing: use degreasing agent to degrease the surface of the spring steel strip, the degreasing temperature is: 52 ℃;

[0066] Water washing: wash the spring steel strip in running water;

[0067] Phosphating: use phosphating solution to phosphate the spring steel strip at a temperature of 15°C;

[0068] One-time drying: The spring steel strip is dried once, and the temperature of the first-time drying is 105°C;

[0069] Glue coating: apply adhesive evenly on the surface of the spring steel strip;

[0070] Secondary drying: Secondary drying of the spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total acidity | aaaaa | aaaaa |

| Free acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com