TPU sheet foaming process

A sheet and process technology, applied in the field of polymer preparation, can solve problems such as uncontrollable product quality, cumbersome procedures, and low production efficiency, and achieve the effects of reducing production equipment investment, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

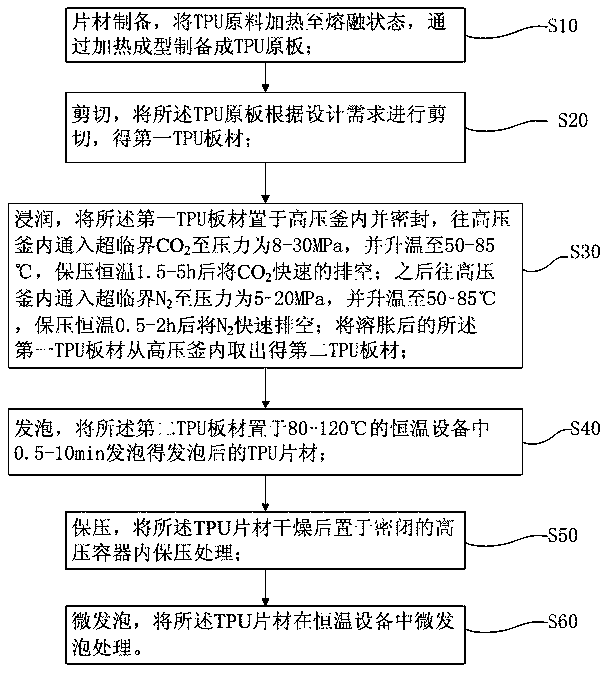

Method used

Image

Examples

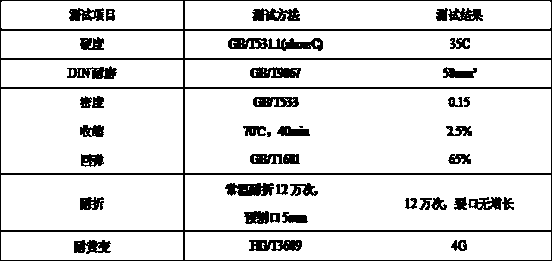

Embodiment 1

[0040] S10 sheet material preparation, heating the TPU raw material with a hardness of 85A to a molten state, and preparing a 4mm thick TPU original plate by heating and forming; S20 shearing, cutting the TPU original plate into a first TPU plate of 15*7cm; S30 Infiltration, the first TPU plate is placed in a 5L autoclave and sealed, and supercritical CO is introduced into the autoclave 2 to a pressure of 15MPa, and the temperature was raised to 60°C, and the CO 2 Evacuate quickly; then pass supercritical N into the autoclave 2 to a pressure of 5MPa, and the temperature was raised to 50°C, and the N 2 Empty quickly; take out the swollen first TPU sheet from the autoclave to obtain a second TPU sheet; S40 foaming, place the second TPU sheet in a constant temperature device at 95°C for 3 minutes to foam to obtain foaming The final TPU sheet; S50 holding pressure, the TPU sheet is dried and placed in a closed high-pressure container, and 0.5:1 CO is introduced into the high-pre...

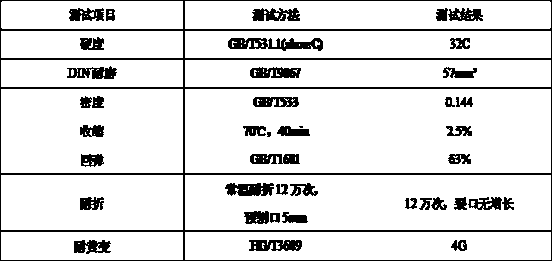

Embodiment 2

[0045] S10 sheet material preparation, heating the TPU raw material with a hardness of 85A to a molten state, and preparing a 1.8 thick TPU original plate by heating and forming; S20 shearing, cutting the TPU original plate into a first TPU plate of 15*15cm; S30 Infiltration, the first TPU plate is placed in a 5L autoclave and sealed, and supercritical CO is introduced into the autoclave 2 to a pressure of 13MPa, and the temperature was raised to 55°C, and the CO 2 Evacuate quickly; then pass supercritical N into the autoclave 2 to a pressure of 5MPa, and the temperature was raised to 55°C, and the N 2 Rapid emptying; take out the swollen first TPU sheet from the autoclave to obtain the second TPU sheet; S40 foaming, place the second TPU sheet in a constant temperature device at 85°C for 30s to obtain foaming The final TPU sheet; S50 pressure keeping, the TPU sheet is dried and placed in a closed high-pressure container, and 1:1 CO is passed into the high-pressure container....

Embodiment 3

[0050] S10 sheet material preparation, heating the TPU raw material with a hardness of 85A to a molten state, and preparing a 3mm thick TPU original plate by heating and forming; S20 shearing, cutting the TPU original plate into a first TPU plate of 15*7cm; S30 Infiltration, the first TPU plate is placed in a 5L autoclave and sealed, and supercritical CO is introduced into the autoclave 2 to a pressure of 15MPa, and the temperature was raised to 55°C, and the CO 2 Evacuate quickly; then pass supercritical N into the autoclave 2 to a pressure of 5.5MPa, and the temperature was raised to 55°C, and the N 2 Fast emptying; take out the swollen first TPU sheet from the autoclave to obtain a second TPU sheet; S40 foaming, place the second TPU sheet in a water bath constant temperature equipment at 90°C for 2.5 minutes to foam to obtain The TPU sheet after foaming; S50 holding pressure, the TPU sheet is dried and placed in a closed high-pressure container, and 0.8:1 CO is introduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com