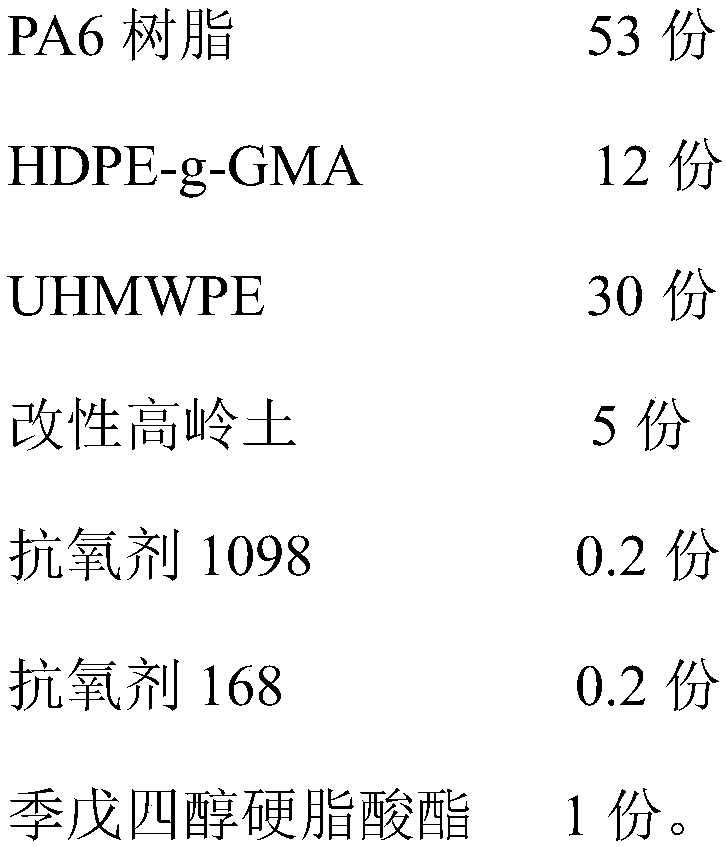

Light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene/nylon 6 micro-foaming composite material and preparation method thereof

A technology of ultra-high molecular weight and composite materials, which is applied in the field of ultra-high molecular weight polyethylene/nylon 6 micro-foamed composite materials and its preparation, which can solve the problems of low water absorption, easy collapse of cells, and difficult processing, and achieve high impact The effect of strength and excellent rigidity-toughness balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

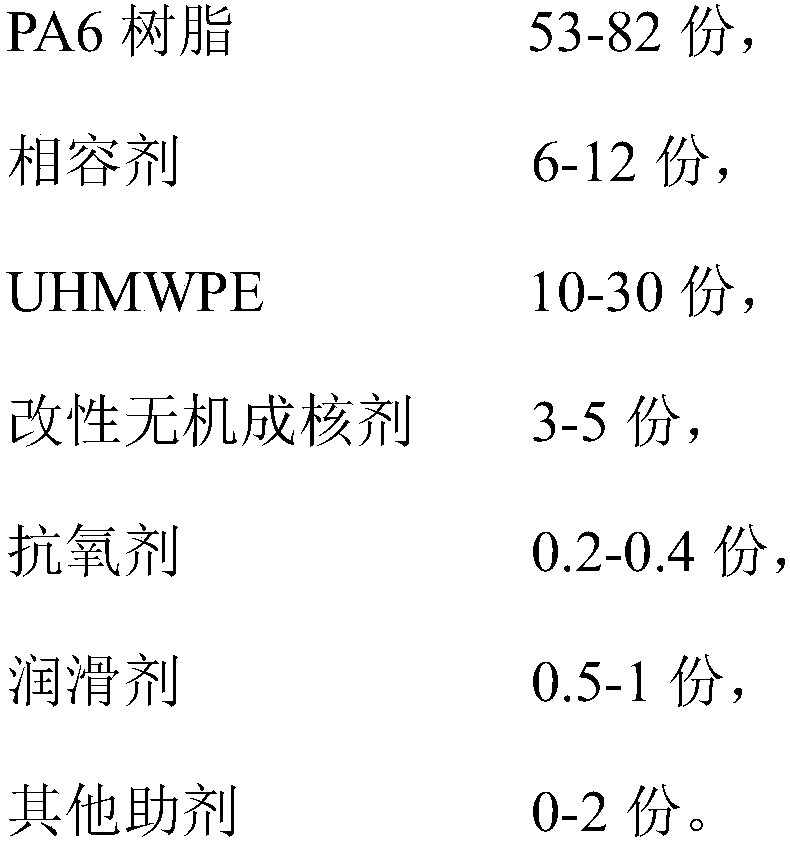

[0030] In this embodiment, the ultra-high molecular weight polyethylene / nylon 6 micro-foaming composite material with light weight, high toughness and low water absorption is prepared from the following raw materials in parts by weight:

[0031]

[0032] Concrete preparation method comprises the following steps:

[0033] (1) Weigh 3 parts of silicon dioxide, add it into a 30mL solution reactor prepared with water:coupling agent KH550 according to the volume ratio of 90:10, stir and reflux at 70°C for 24h, cool down to room temperature, and then use high-speed Centrifuge in a centrifuge, and dry the product in a vacuum oven at 40°C for 24 hours to obtain coupling-treated silica;

[0034] (2) Add the silica and GMA that have been coupled in step (1) into the reactor at a weight ratio of 1:0.5, pass through nitrogen protection, stir and reflux at a constant temperature of 60°C for 24 hours, cool down to room temperature, and then use a high-speed centrifuge Perform centrifuga...

Embodiment 2

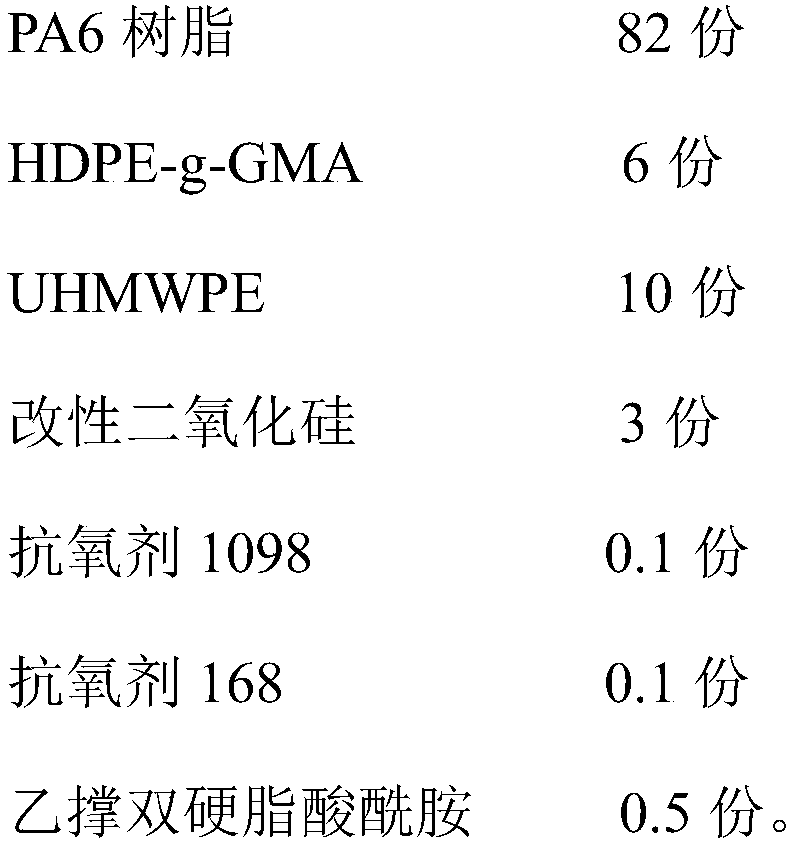

[0038] In this embodiment, the ultra-high molecular weight polyethylene / nylon 6 micro-foaming composite material with light weight, high toughness and low water absorption is prepared from the following raw materials in parts by weight:

[0039]

[0040] Concrete preparation method comprises the following steps:

[0041] (1) Weigh 5 parts of kaolin, add water:coupling agent KH550 according to the volume ratio of 90:10 into a 30mL solution reactor, stir and reflux at 60°C for 48h, cool down to room temperature, and then use a high-speed centrifuge Carry out centrifugation, and dry the product in a vacuum oven at 60°C for 30 hours to obtain coupling-treated kaolin;

[0042] (2) Add the kaolin and GMA coupling treated in step (1) into the reactor according to the weight ratio of 1:2, pass through the nitrogen protection, stir and reflux at a constant temperature of 50°C for 48h, cool down to room temperature, and then centrifuge with a high-speed centrifuge , the product was ...

Embodiment 3

[0046] In this embodiment, the ultra-high molecular weight polyethylene / nylon 6 micro-foaming composite material with light weight, high toughness and low water absorption is prepared from the following raw materials in parts by weight:

[0047]

[0048] Concrete preparation method comprises the following steps:

[0049] (1) Weigh 5 parts of silicon dioxide, add it into a 30mL solution reactor prepared by water:coupling agent KH550 according to the volume ratio of 90:10, stir and reflux at 65°C for 36h, cool down to room temperature, and then use high-speed Centrifuge in a centrifuge, and dry the product in a vacuum oven at 50°C for 48 hours to obtain coupling-treated silica;

[0050] (2) Add the silica and GMA that have been coupled in step (1) into the reactor at a weight ratio of 1:1, pass through the nitrogen protection, stir and reflux at a constant temperature of 65°C for 36 hours, cool down to room temperature, and then use a high-speed centrifuge Centrifuge. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com