Fine-cell polyvinyl chloride foam material and preparation method thereof

A polyvinyl chloride foam and foam material technology, applied in the field of foam materials, can solve the problems of easy degradation and gelatinization of the board core, long steam curing time, unevenness, etc., and achieve shortened steam treatment time, light weight and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of above-mentioned microporous polyvinyl chloride foam material, the steps are as follows:

[0051] When the polyvinyl chloride resin is a paste resin, the first step is: weigh various materials according to the proportion, mix them evenly to obtain a paste material, add the paste material into the mold, close the mold, the molding temperature is 150-200°C, and press The pressure is 11-30MPa, the molding time is 30-50s / mm, cooled to 25-100°C, and the mold is opened to obtain a foamed molded product;

[0052] When the polyvinyl chloride resin is a suspension resin or a mixture of suspension resin and paste resin, step 1 is: weigh various materials according to the proportion, mix them evenly to obtain suspension materials, add the suspension materials to the mold, and close the mold, 50-110 After preheating at ℃ for 5-30 minutes, heat until the molding temperature is 150-200℃, pressurize until the molding pressure is 11-30MPa, the molding time is 3...

Embodiment 1

[0070] The fine-pore polyvinyl chloride foam material is composed of 100 parts by weight of PVC paste resin, 5 parts by weight of bisphenol A glycidyl ether, 60 parts by weight of PMDI, 10 parts by weight of azobisisobutyronitrile and 4 parts by weight of sodium bicarbonate.

[0071] The preparation method of above-mentioned microporous polyvinyl chloride foam material:

[0072] First weigh the above-mentioned materials according to the proportion, mix them evenly, add them into a mold with a cavity of 22 mm in thickness, carry out foaming and molding at a temperature of 170°C and a pressure of 16MPa, keep warm for 11 minutes, cool to 80°C and open the mold to obtain Foam moldings;

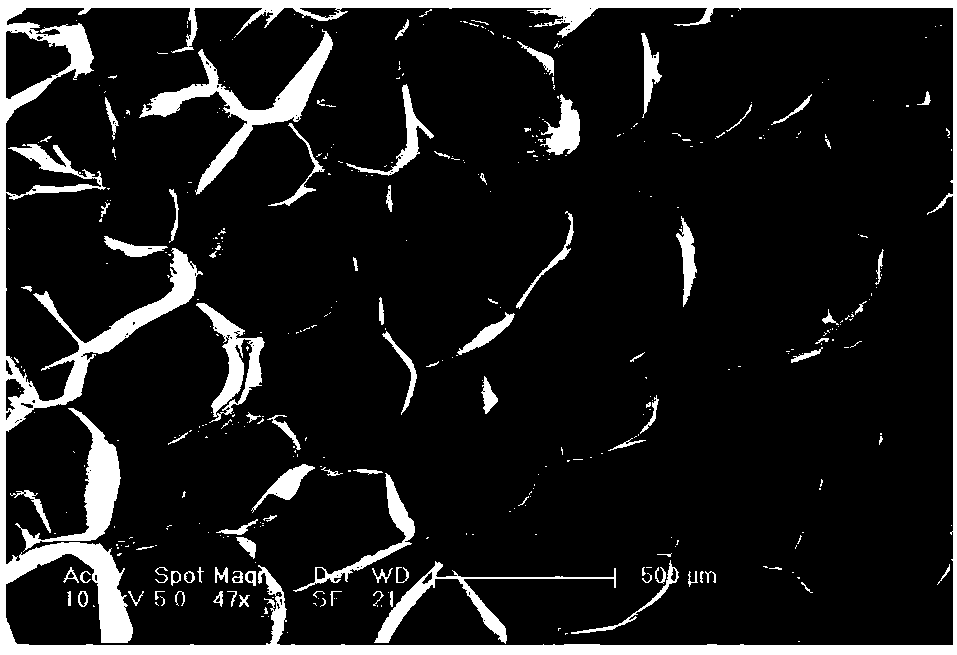

[0073] Then the foamed molded product obtained was placed in hot water at 95°C for secondary foaming for 40 minutes, and finally placed in saturated water vapor at 65°C for 2 days for crosslinking, and the cell diameter of the obtained foam was 250 μm.

[0074] Figure 4 Be the scanning electron...

Embodiment 2

[0076] Fine cell polyvinyl chloride foam material, by 100 weight parts polyvinyl chloride paste resin, 10 weight parts acid anhydride phthalic anhydride, 5 weight parts trimethylolpropane glycidyl ether, 45 weight parts toluene diisocyanate (TDI), 7 parts by weight of azobisisobutyronitrile, 0.5 parts by weight of azodicarbonamide, 4 parts by weight of potassium bicarbonate, 1 part by weight of sodium bicarbonate, 0.5 parts by weight of N', N", N"'-tri(two methylaminopropyl) symmetrical hexahydrotriazine, 3 parts by weight of water-soluble silicone oil and 5 parts by weight of organotin 181.

[0077] The preparation method of above-mentioned microporous polyvinyl chloride foam material:

[0078] First weigh the above-mentioned materials according to the proportion, mix them evenly, and get the paste material, put the paste material into the mold, close the mold, the molding temperature is 150°C, the molding pressure is 30MPa, the molding time is 50s / mm, and cooled to 25°C, op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com