Foamed dustproof material and dustproof structure using foamed dustproof material

A technology of dustproof and foamed body, applied in the field of foamed dustproof material and dustproof structure, can solve the problem of unnecessary consideration of the compression and repulsion force of dustproof material, and achieve the effect of good flexibility and good dustproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

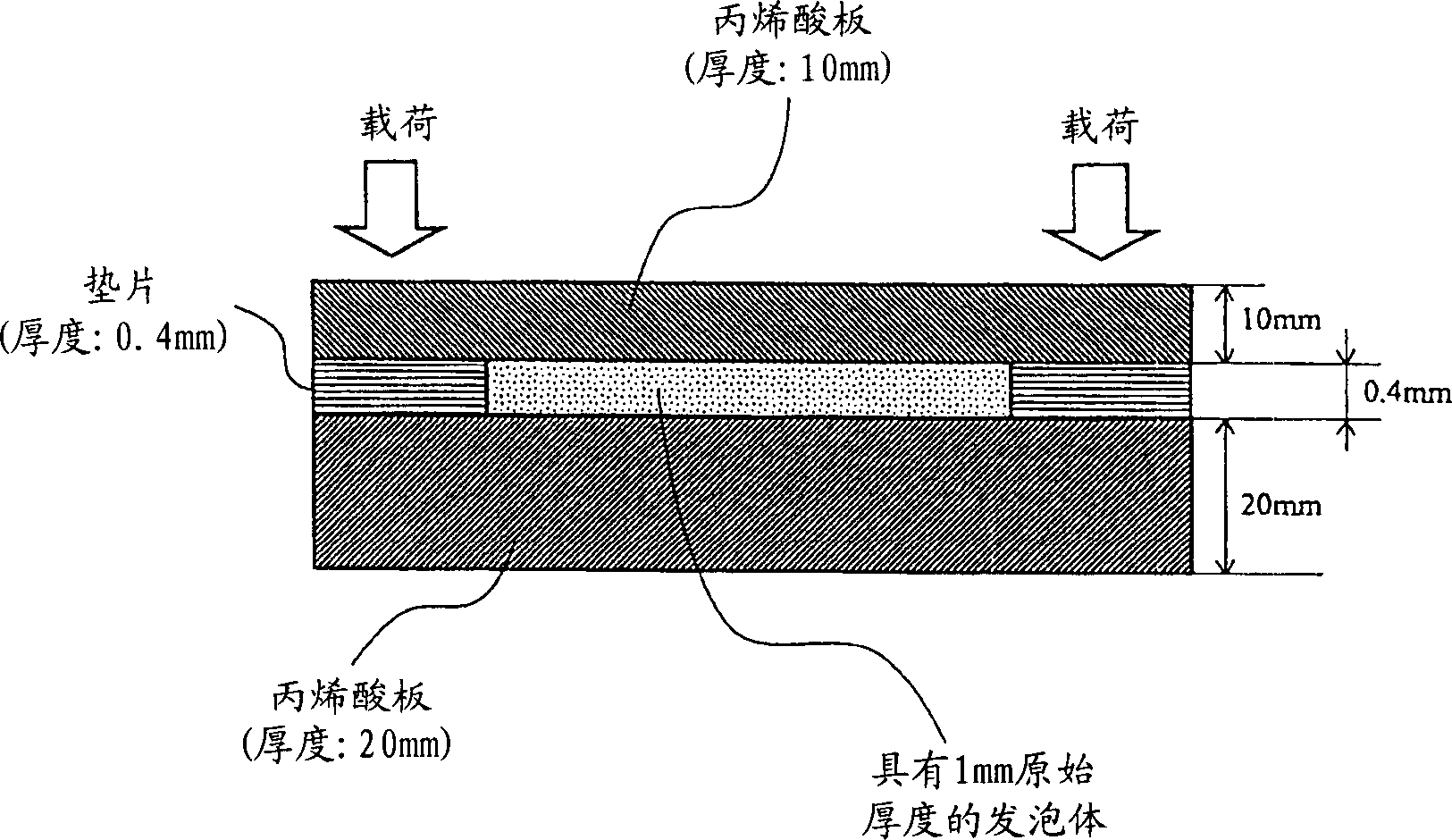

Image

Examples

Embodiment 1

[0119] 45 parts by weight of polypropylene, 45 parts by weight of polyolefin elastomer, 10 parts by weight of polyethylene, 10 parts by weight of magnesium hydroxide, and 10 parts by weight of carbon were prepared in a double It was kneaded at a temperature of 200° C. in a shaft kneader and extruded into strands, which were then cooled with water and molded into pellets. The pellets were placed in a single-screw extruder manufactured by Japan Steel Works Co., Ltd., and carbon dioxide gas was injected into the extruder at a pressure of 13 MPa in an environment of 220° C., and the pressure was lowered to 12 MPa after the injection was completed. .

[0120]Carbon dioxide gas was injected at a rate of 5% by mass based on the total amount of the polymer. After being sufficiently saturated with carbon dioxide gas, the mixture is cooled to a temperature suitable for foaming, and then extruded from a die to obtain a foamed body. The foam thus obtained has an average pore diameter of...

Embodiment 2

[0122] 30 parts by weight of polypropylene, 60 parts by weight of polyolefin elastomer, 10 parts by weight of polyethylene, 10 parts by weight of magnesium hydroxide, and 10 parts by weight of carbon in a twin-screw kneader manufactured by Japan Steel Works Co., Ltd. kneaded at a temperature of 200° C., and extruded into strands, which were then cooled with water and granulated. The pellets were placed in a single-screw extruder manufactured by Japan Steel Works Co., Ltd., and carbon dioxide gas was injected into the extruder at a pressure of 13 MPa in an environment of 220° C., and the pressure was lowered to 12 MPa after the injection was completed. .

[0123] Carbon dioxide gas was injected at a rate of 5% by mass based on the total amount of the polymer. After being sufficiently saturated with carbon dioxide gas, the mixture is cooled to a temperature suitable for foaming, and then extruded from a die to obtain a foamed body. The foam thus obtained has an average pore di...

Embodiment 3

[0125] 60 parts by weight of polypropylene, 30 parts by weight of polyolefin elastomer, 10 parts by weight of polyethylene, 10 parts by weight of magnesium hydroxide, 10 parts by weight of carbon and 1 part by weight of monoglyceride stearate in a It was kneaded at a temperature of 200° C. in a twin-screw kneader manufactured by Japan Steel Works Co., Ltd., and extruded into a strand, which was then cooled with water and pelletized. The pellets were placed in a single-screw extruder manufactured by Japan Steel Works Co., Ltd., and carbon dioxide gas was injected into the extruder at a pressure of 13 MPa in an environment of 220° C., and the pressure was lowered to 12 MPa after the injection was completed. .

[0126] Carbon dioxide gas was injected at a rate of 5% by mass based on the total amount of the polymer. After being sufficiently saturated with carbon dioxide gas, the mixture is cooled to a temperature suitable for foaming, and then extruded from a die to obtain a foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com