Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209results about How to "Solve the lack of height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

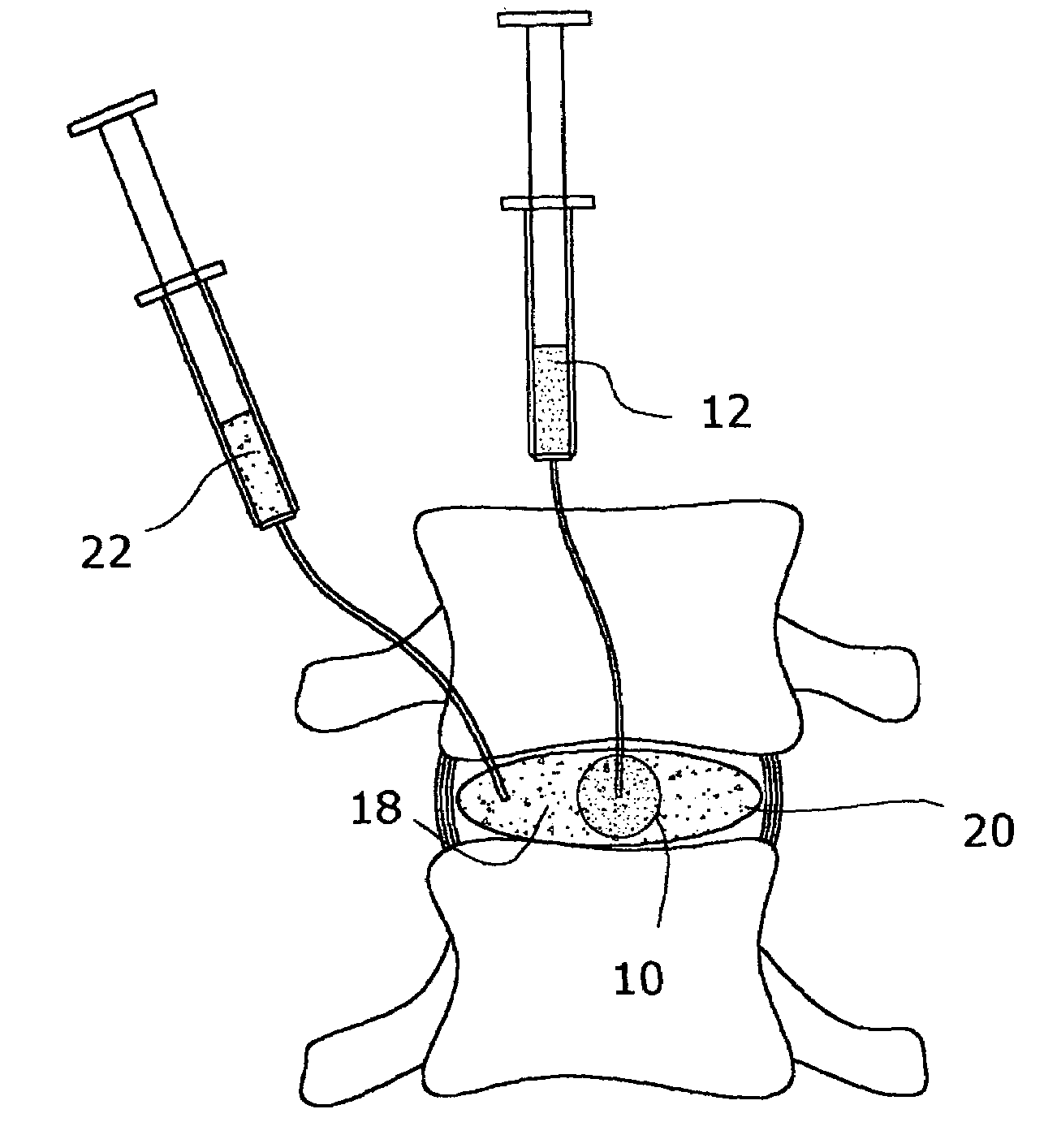

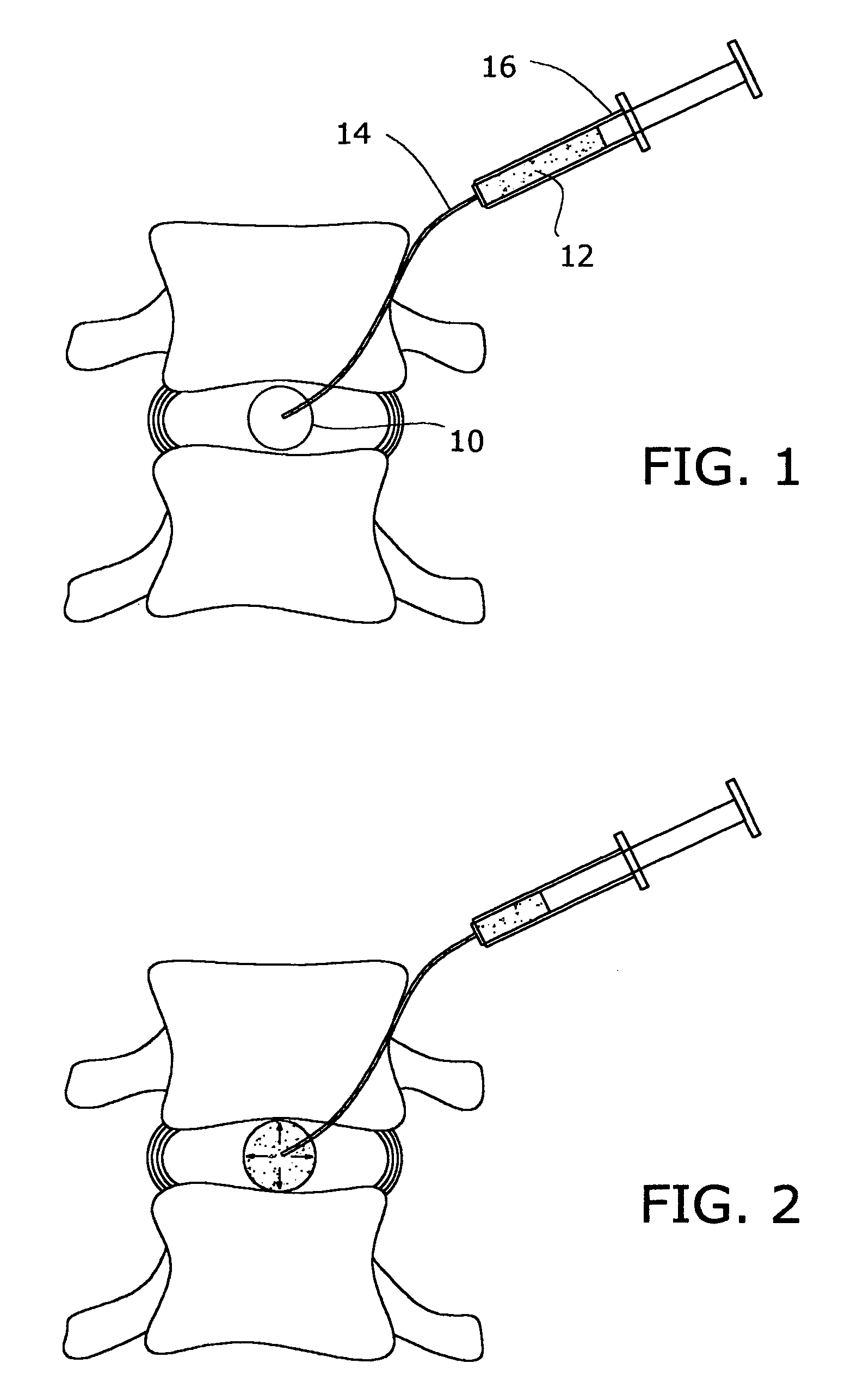

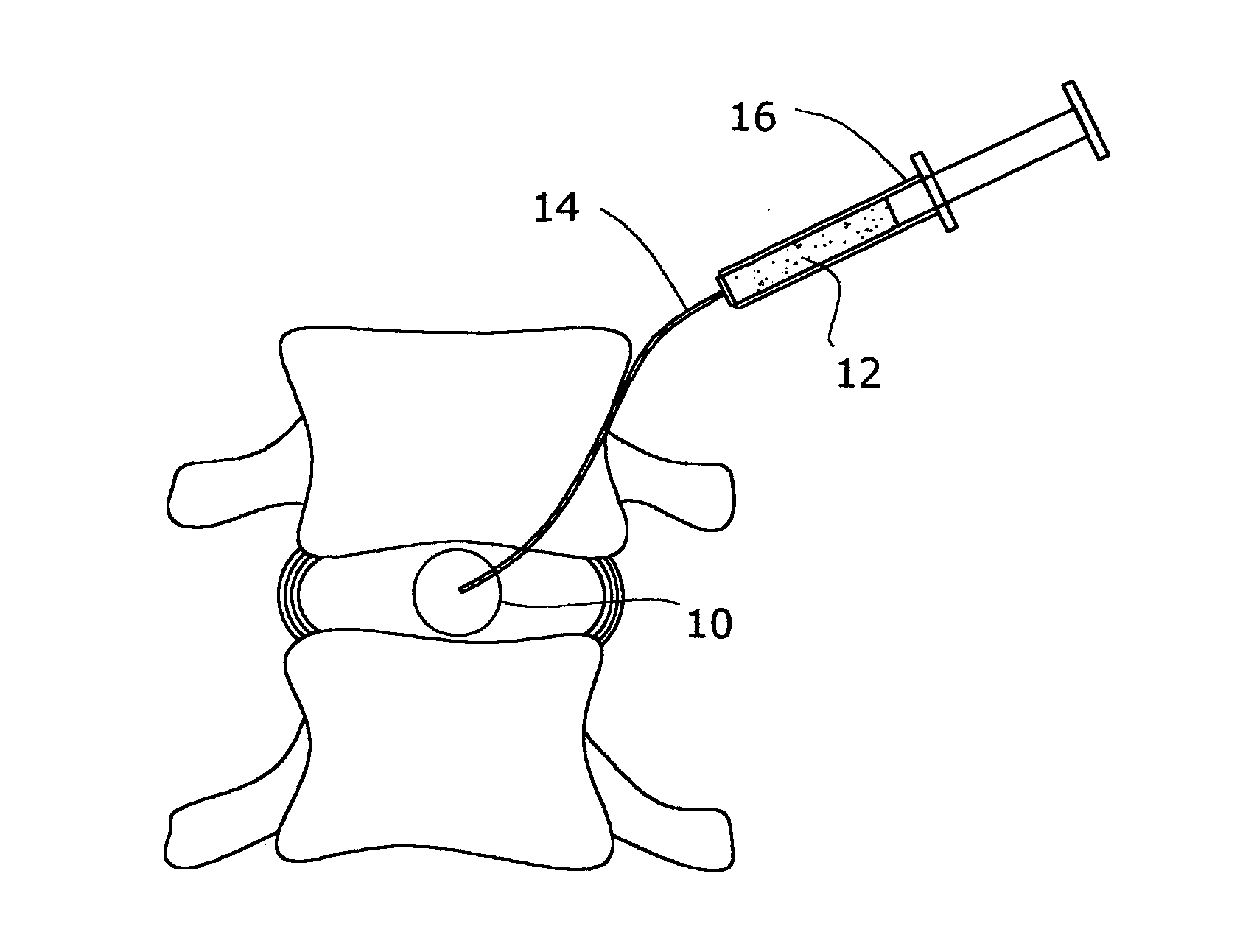

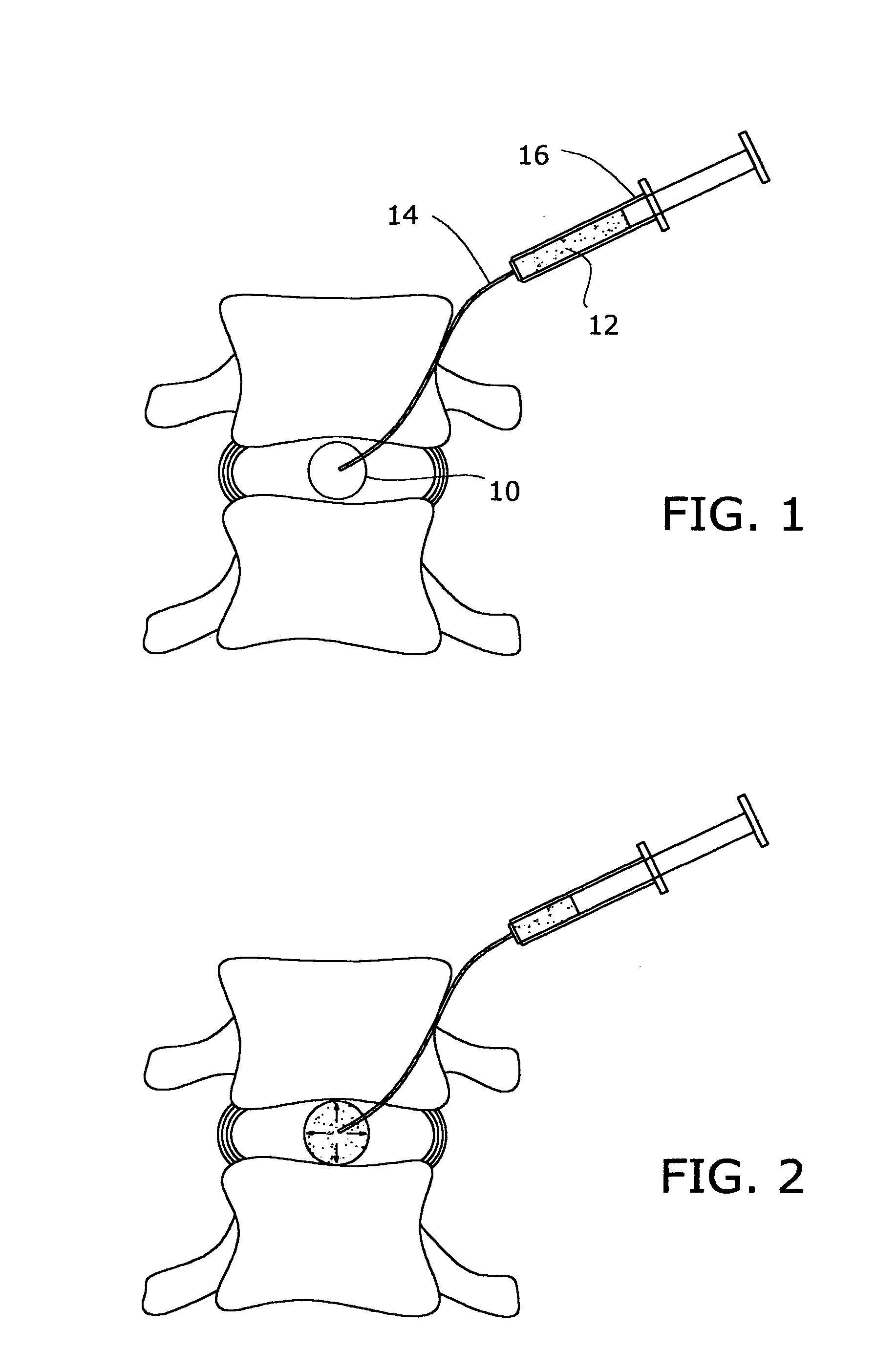

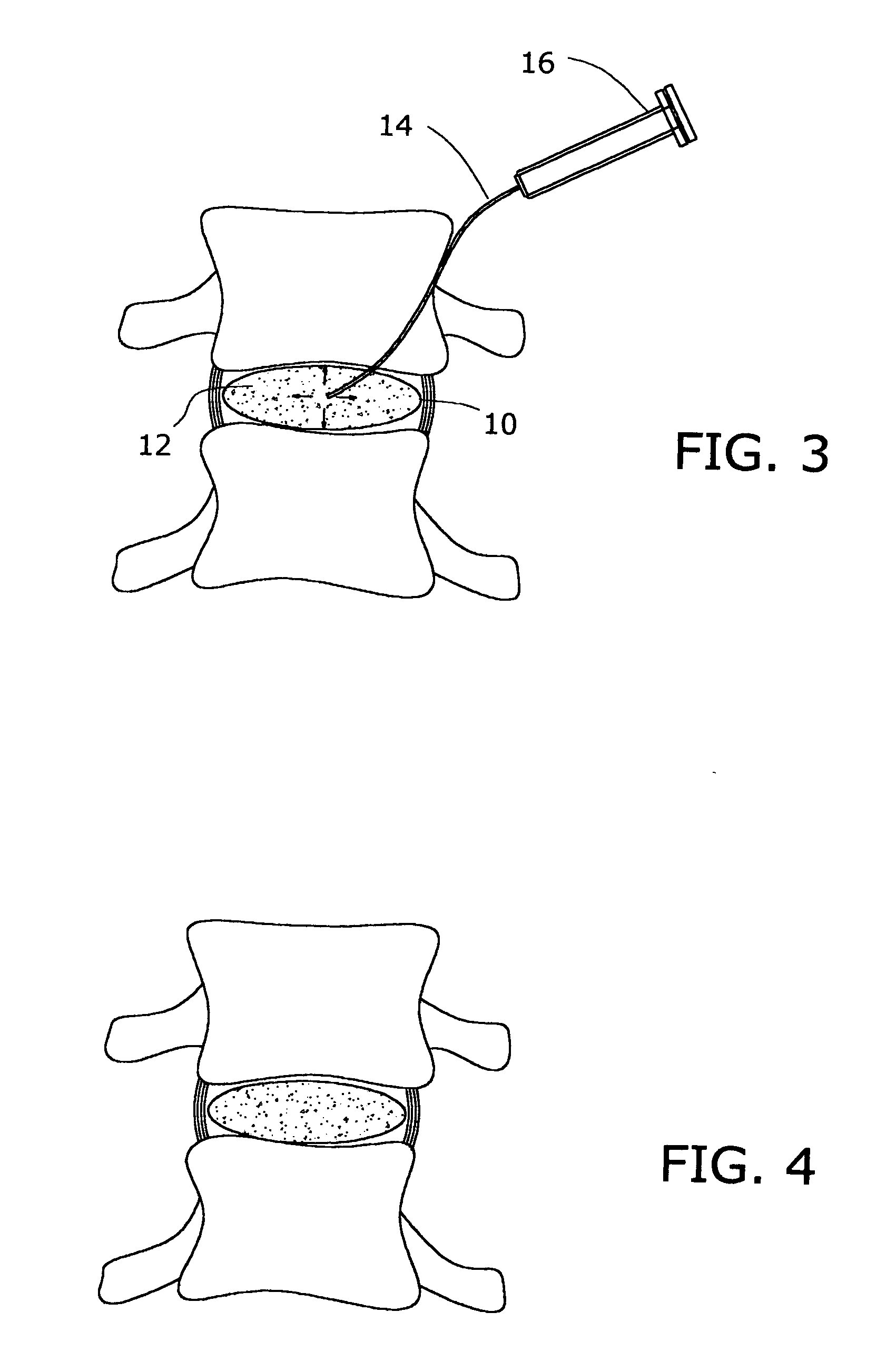

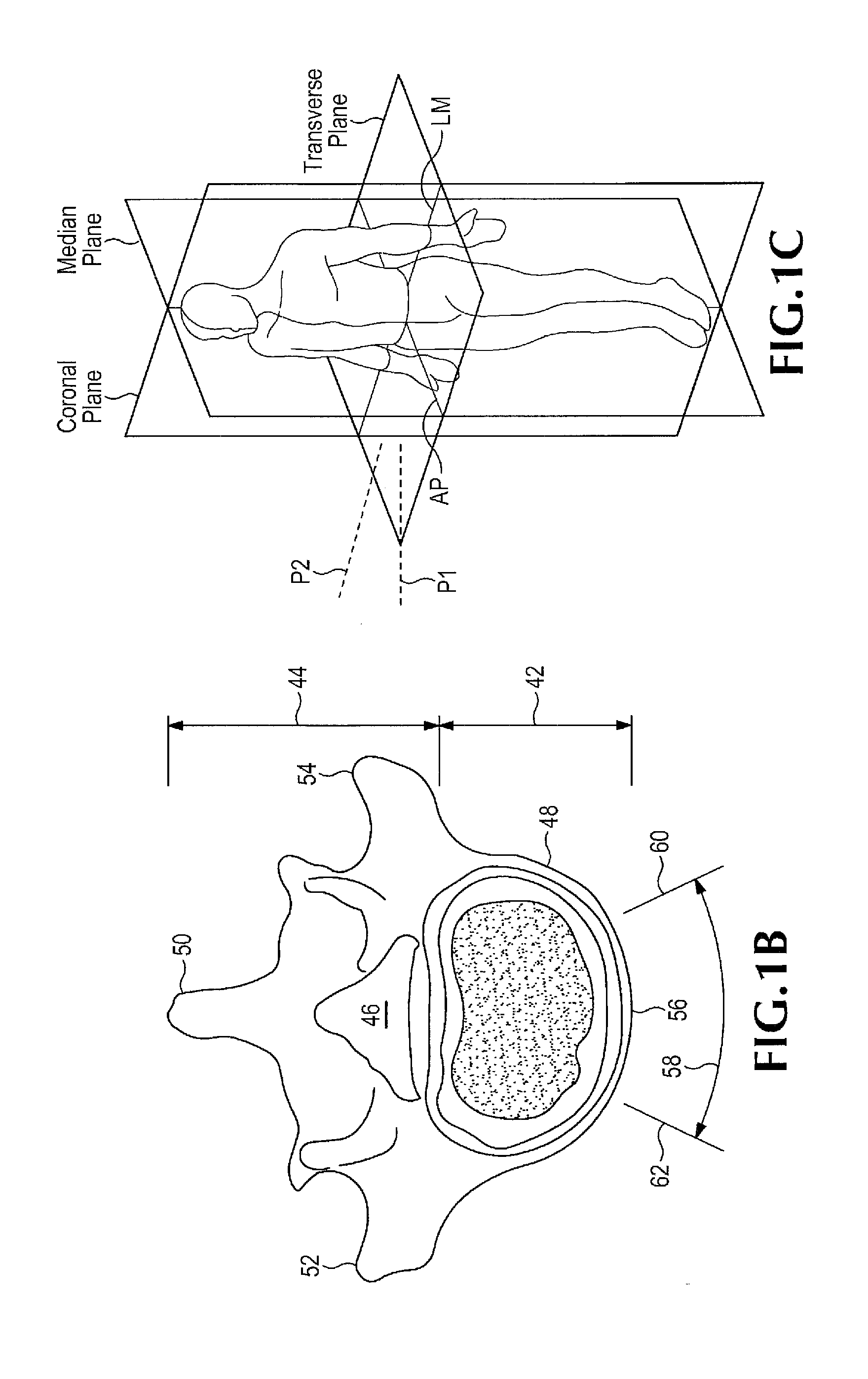

Inflatable nuclear prosthesis

InactiveUS6958077B2Reduce and eliminate abnormal stressSolve the lack of heightJoint implantsSpinal implantsMedicineProsthesis

The nucleus of an intervertebral disc is replaced with a construct including a distendable sack or balloon which is inflated with a hardenable material and is detached in situ when the injected material has hardened. Alternatively, two nested balloons may be inserted, and then filled with materials which have different hardnesses when cured, to simulate a natural disc.

Owner:SUDDABY LOUBERT

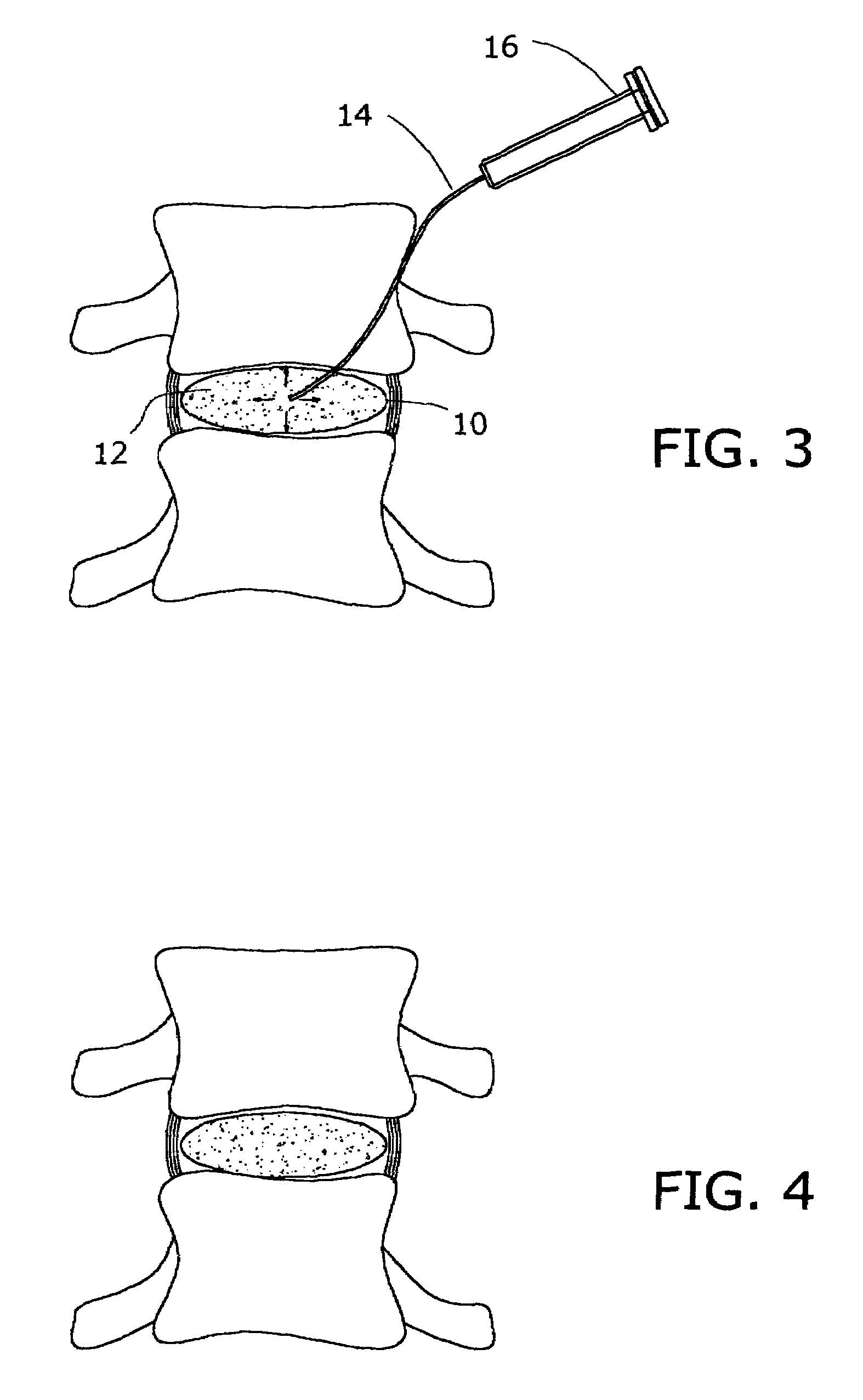

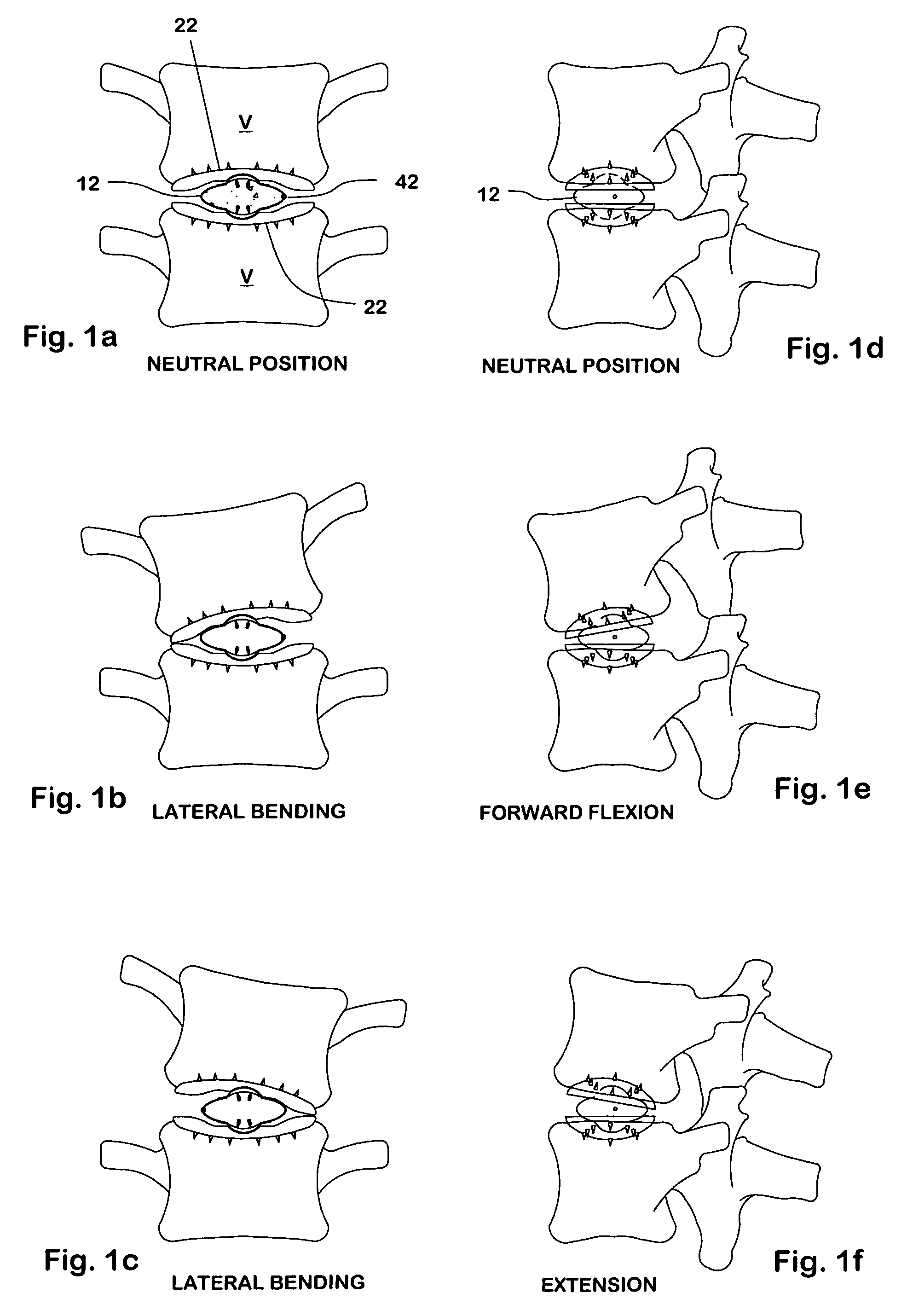

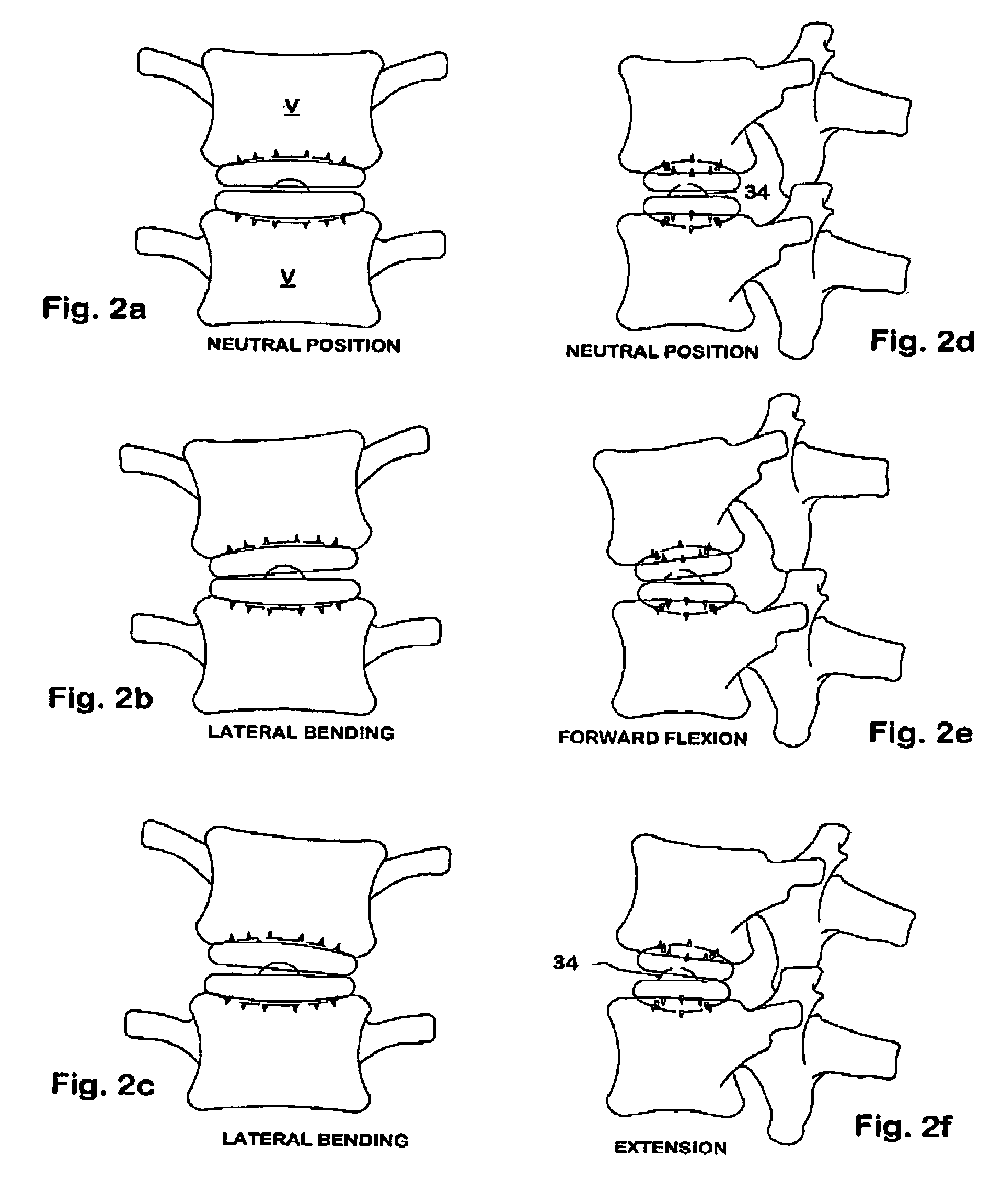

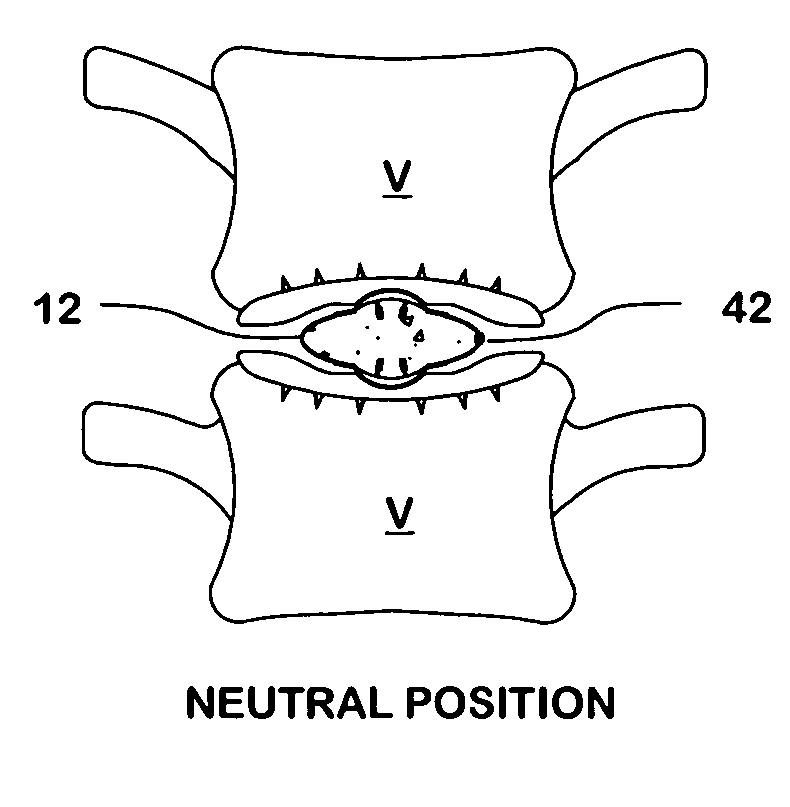

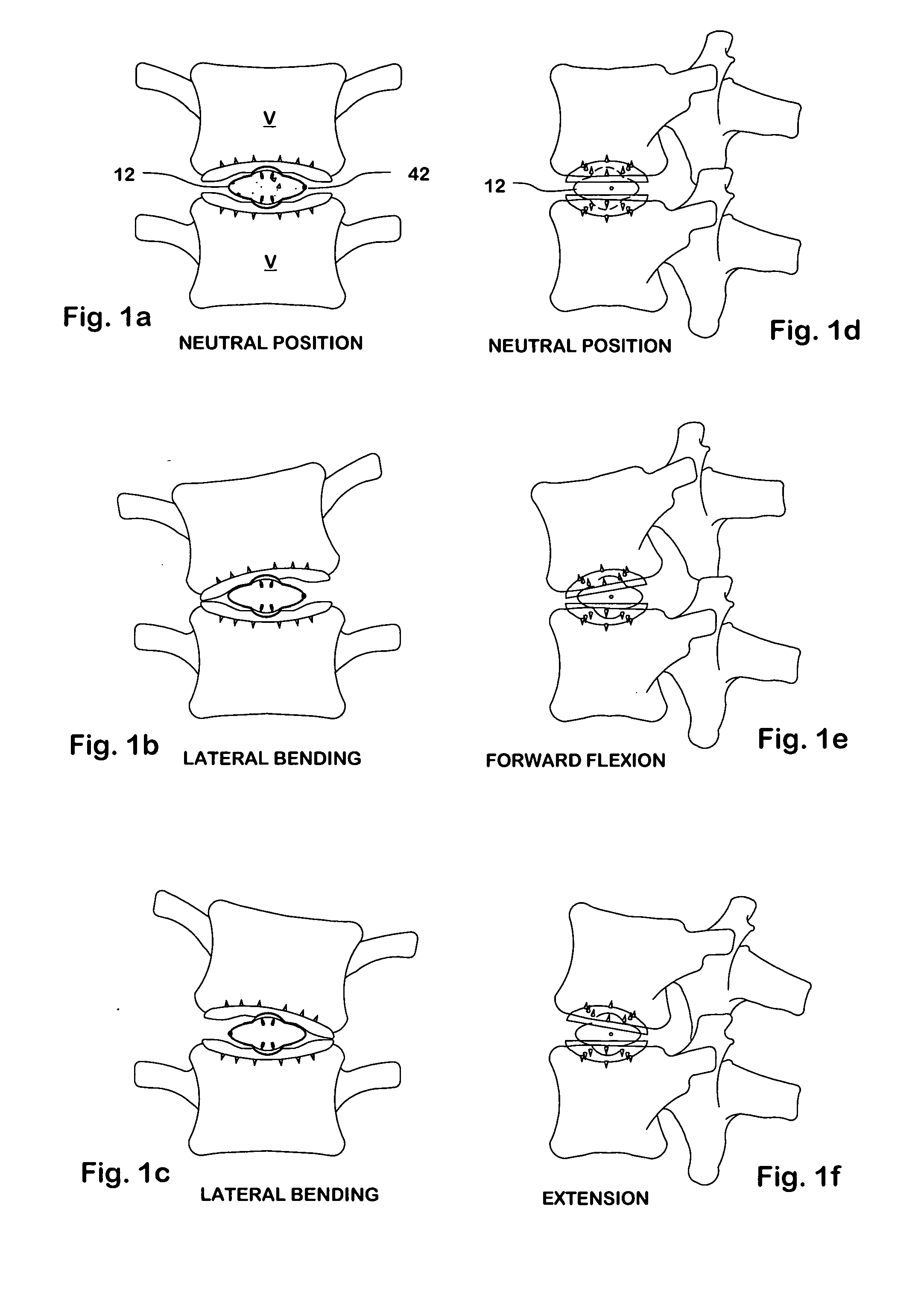

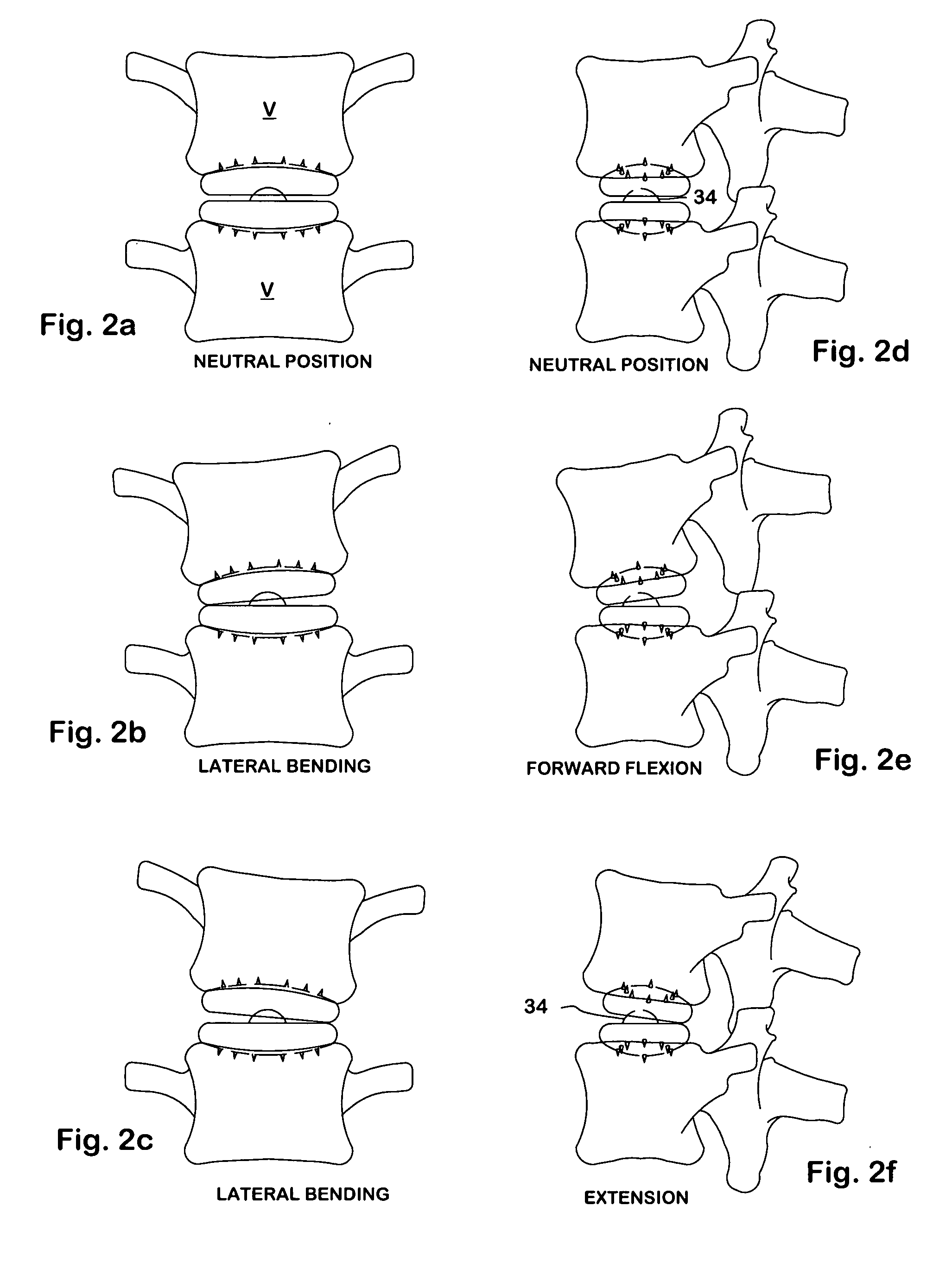

Inflatable intervertebral disc replacement prosthesis

ActiveUS6969405B2Solve the lack of heightPromote adequate mobilityJoint implantsSpinal implantsDegenerative changeLess invasive surgery

An intervertebral disc replacement prosthesis which can be implanted in a collapsed state, then expanded within the disc space such that minimally invasive surgical techniques may be employed for its insertion, and, by virtue of its expandable nature, ligaments can be restored to proper tension, facet joints can be unloaded posteriorly to inhibit degenerative changes, and functional mobility of the intervertebral segment can be restored.

Owner:SUDDABY LOUBERT

Inflatable nuclear prosthesis

ActiveUS20050027358A1Restores sufficient disc space heightRestore mobilityJoint implantsSpinal implantsMedicineProsthesis

The nucleus of an intervertebral disc is replaced with a construct including a distendable sack or balloon which is inflated with a hardenable material and is detached in situ when the injected material has hardened. Alternatively, two nested balloons may be inserted, and then filled with materials which have different hardnesses when cured, to simulate a natural disc.

Owner:SUDDABY LOUBERT

Inflatable intervertebral disc replacement prosthesis

InactiveUS20050267580A1Solve the lack of heightPromote adequate mobilityJoint implantsSpinal implantsDegenerative changeLess invasive surgery

Owner:SUDDABY LOUBERT

System and method for performing spinal fusion

InactiveUS7618423B1Adequate disk heightSolve the lack of heightBone implantSpinal implantsSpinal columnSpinal fusion

A system and associated methods for performing spinal fusion, involving the use of a graft holder assembly, a locking assembly, and a pair of bone graft implants to simultaneously introduce the bone graft implants into a disc space to thereafter effect spinal fusion.

Owner:NUVASIVE

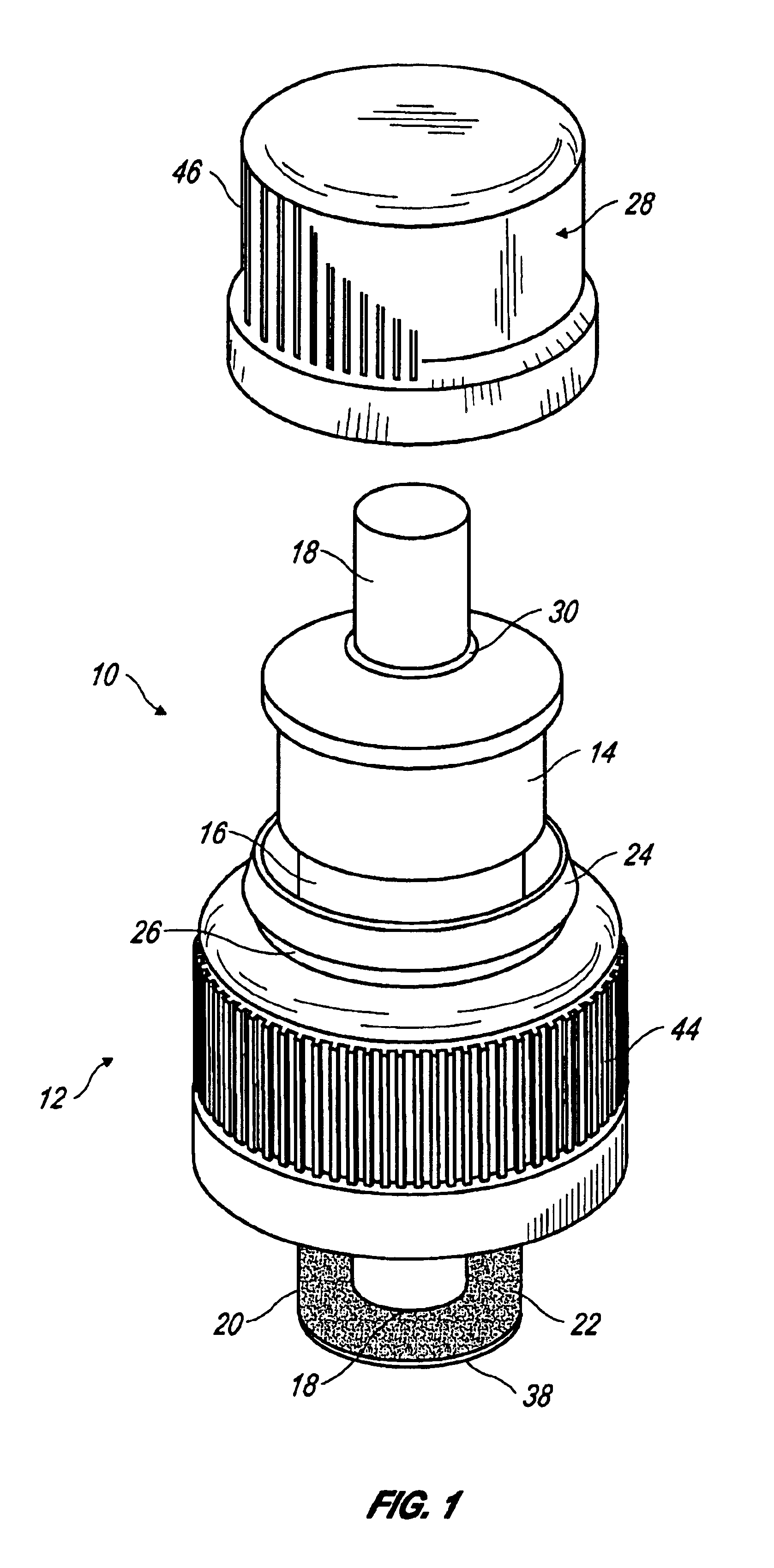

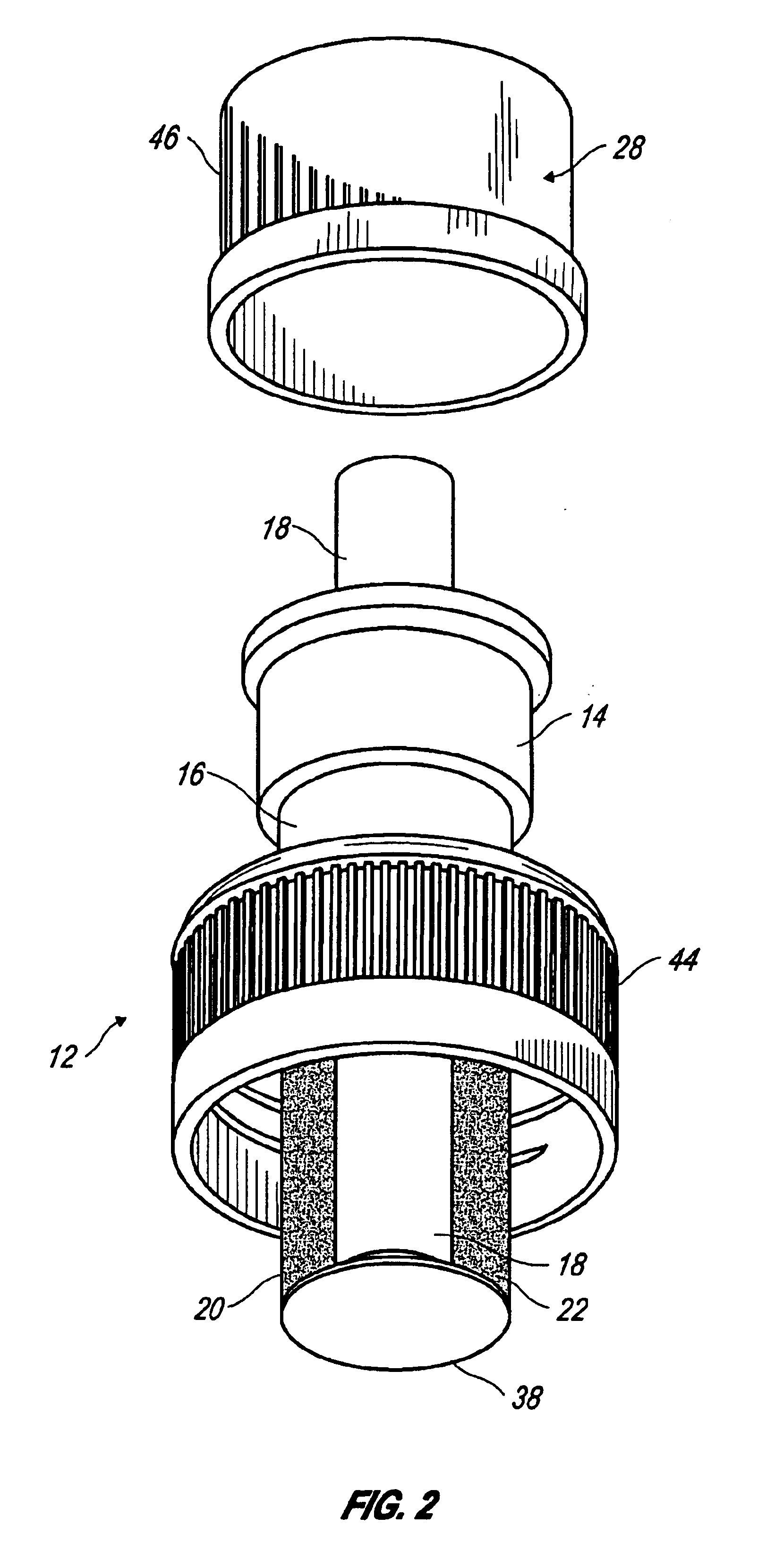

Container closure containing a mix

InactiveUS6854595B2Increase varietySolve the lack of heightCapsBottlesEngineeringMechanical engineering

A container closure to be attached to a liquid container around a container opening of a liquid container. The container closure includes a storage compartment which includes a mix, such as powder or concentrated liquid. The storage compartment includes a seal or a rotating member to seal the mix within the storage compartment. A plunger unseals the seal or the rotating member is rotated to allow the mix to be mixed with the liquid in a liquid container to flavor the liquid when the container closure is attached to the liquid container.

Owner:KISER DANNY

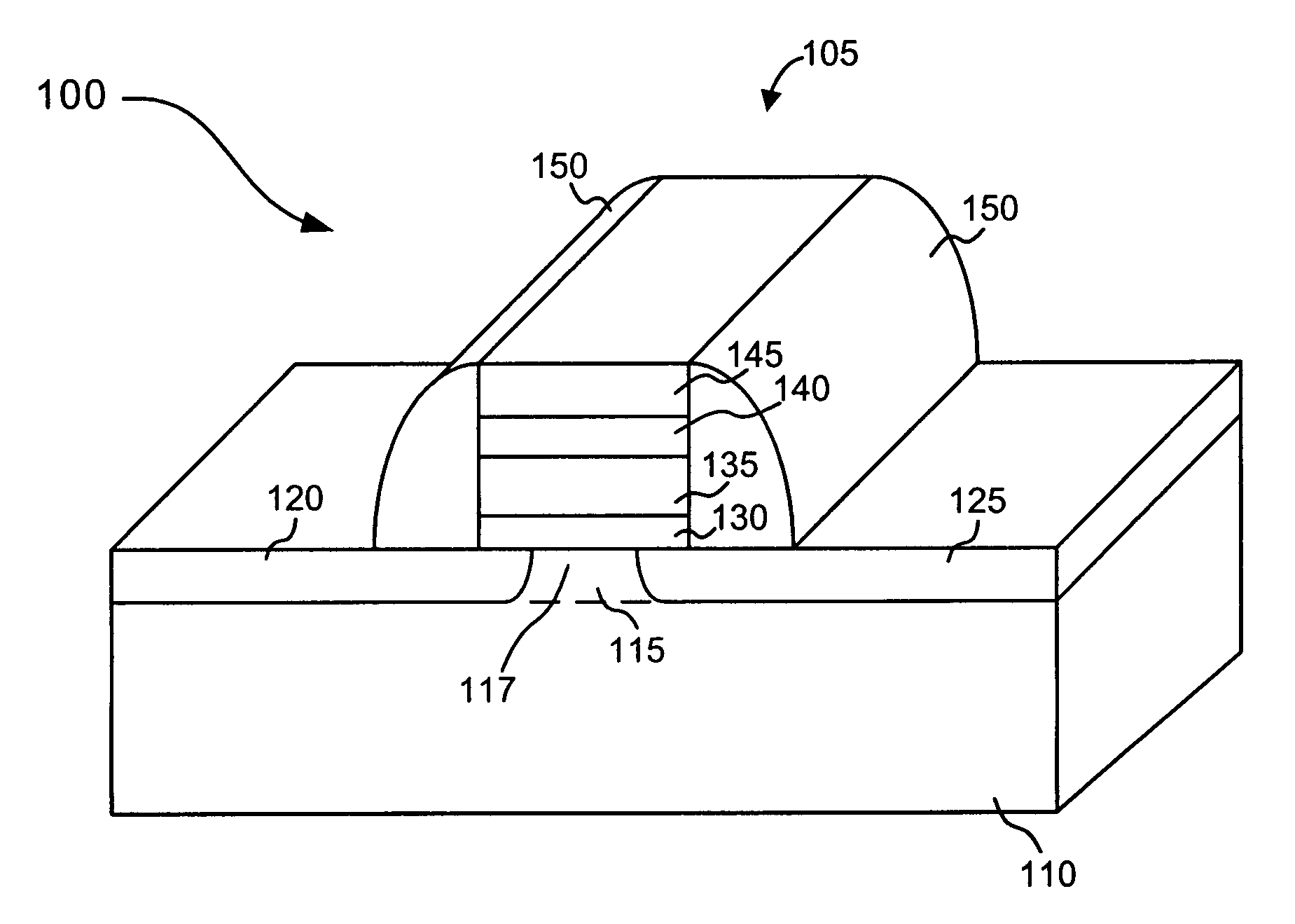

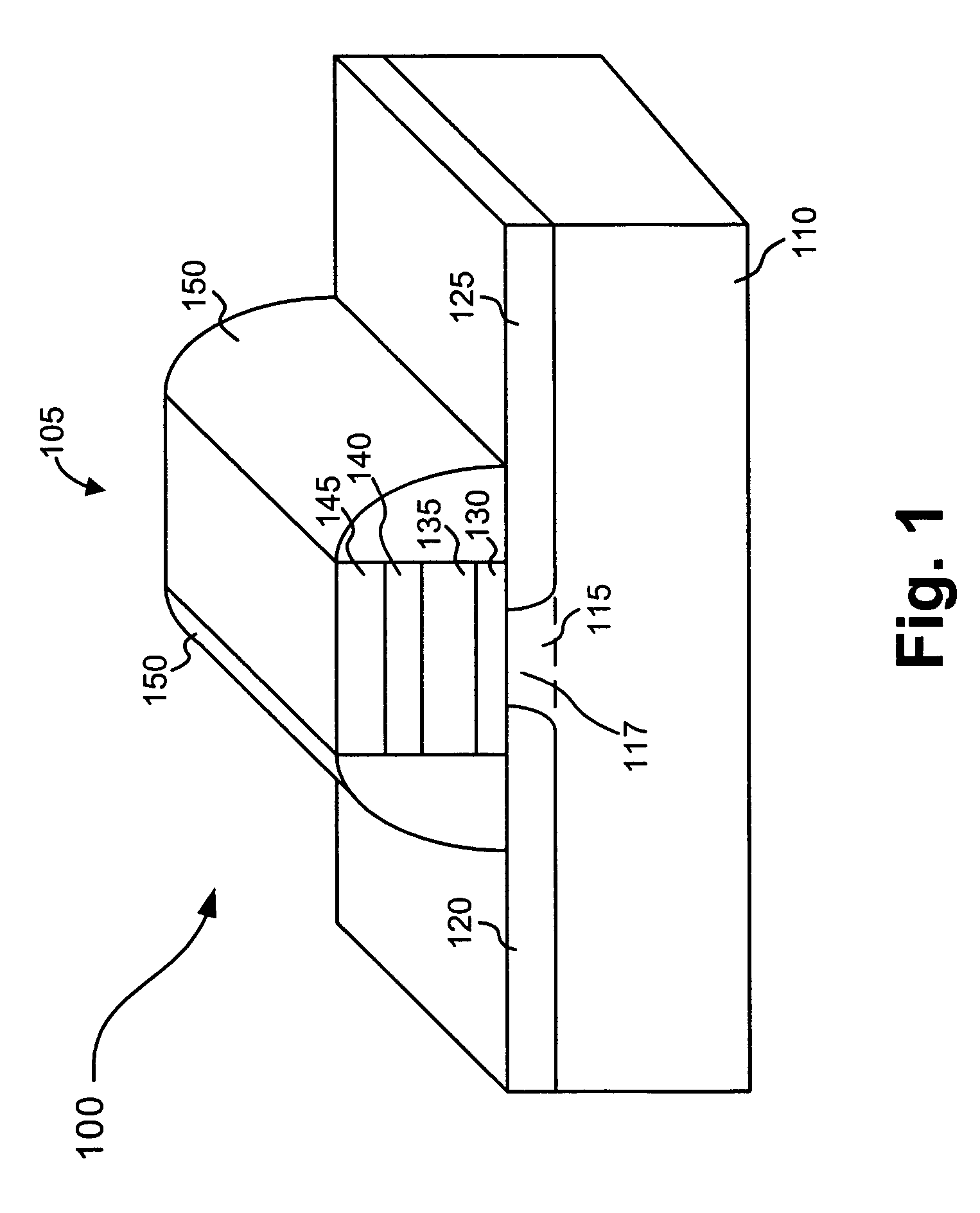

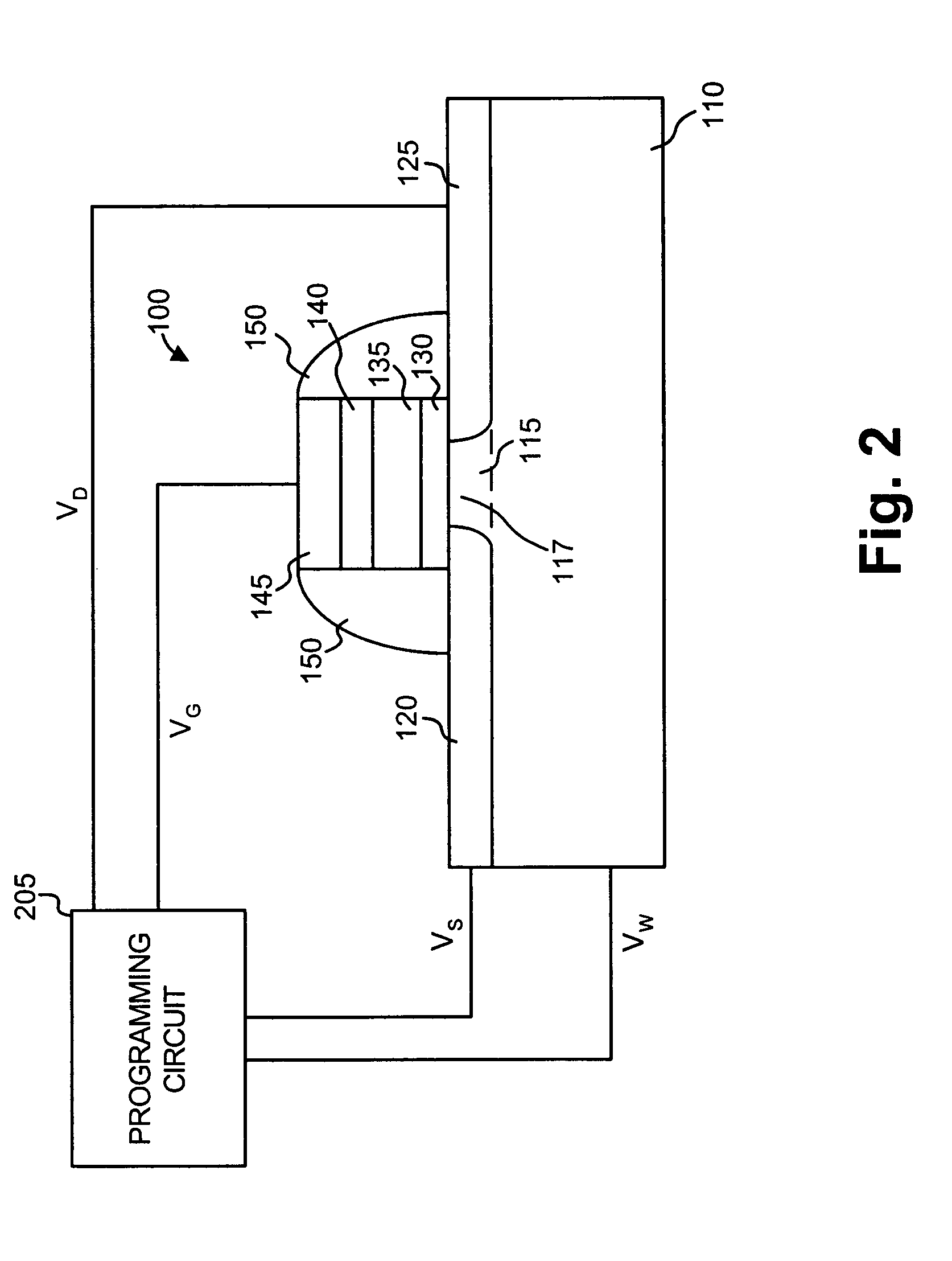

Memory cell having enhanced high-K dielectric

ActiveUS7365389B1Reduce leakage currentSolve the lack of heightSemiconductor/solid-state device manufacturingSemiconductor devicesFowler nordheimDielectric layer

A semiconductor memory device may include an intergate dielectric layer of a high-K, high barrier height dielectric material interposed between a charge storage layer and a control gate. With this intergate high-K, high barrier height dielectric in place, the memory device may be efficiently erased using Fowler-Nordheim tunneling.

Owner:SPANSION LLC

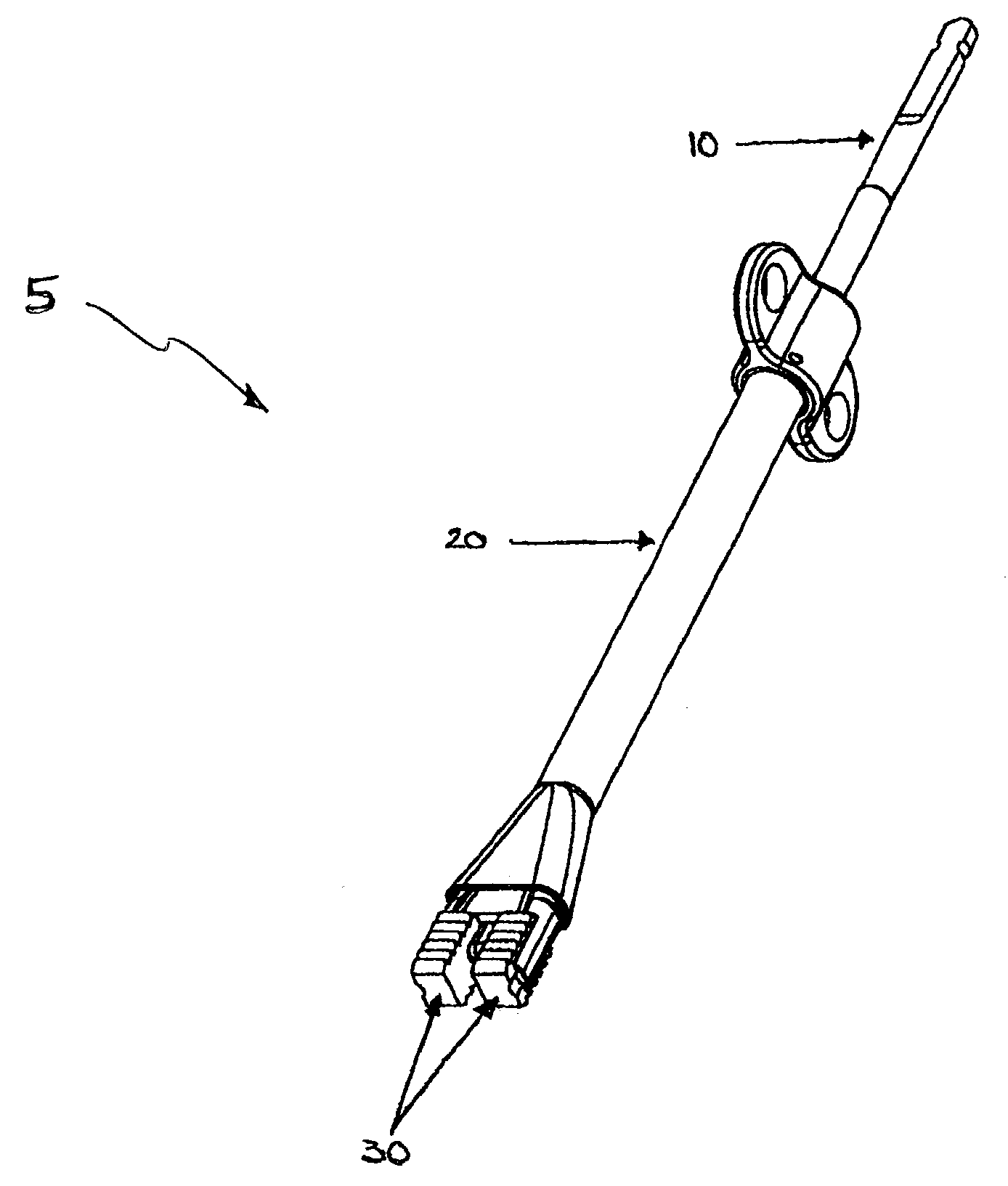

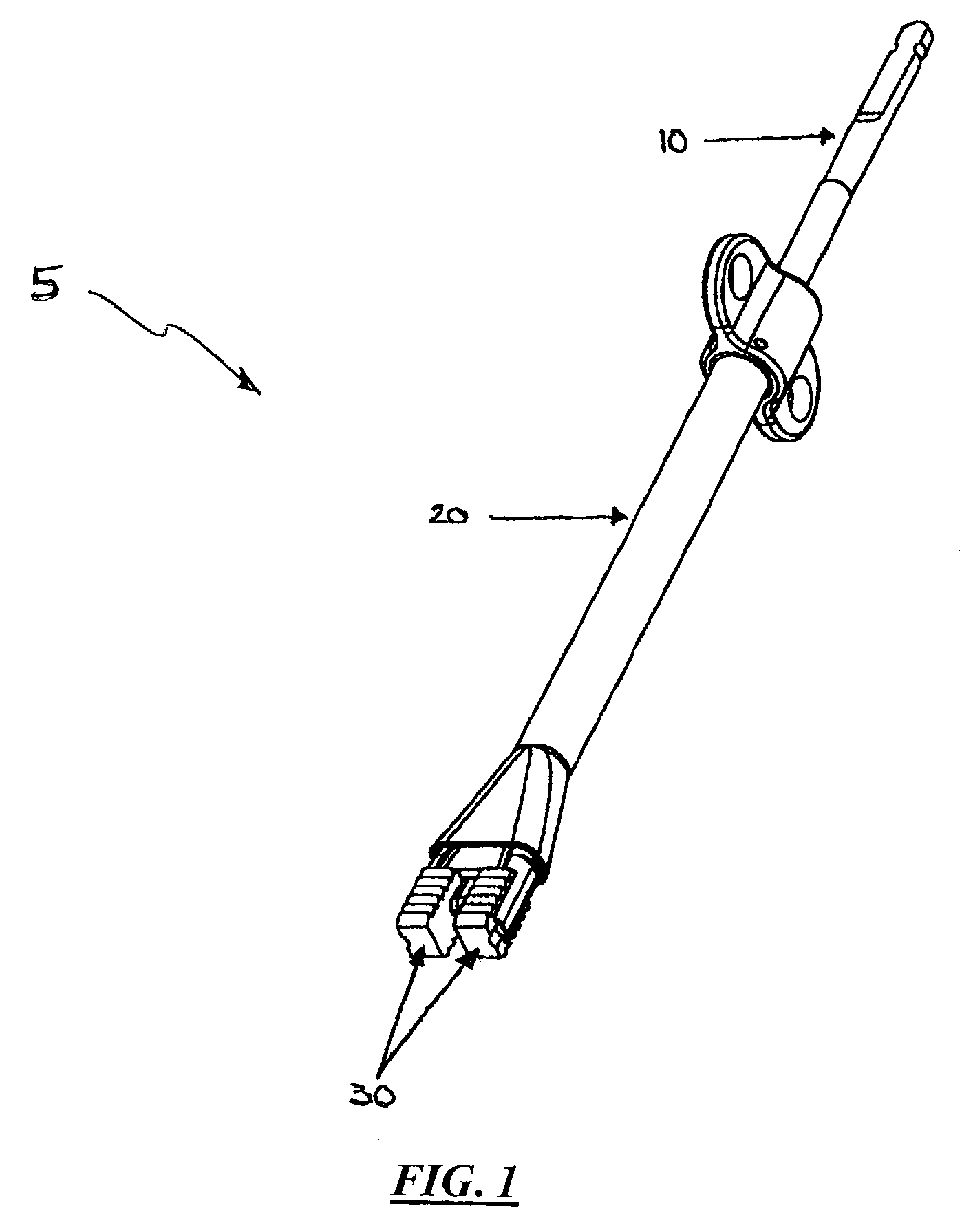

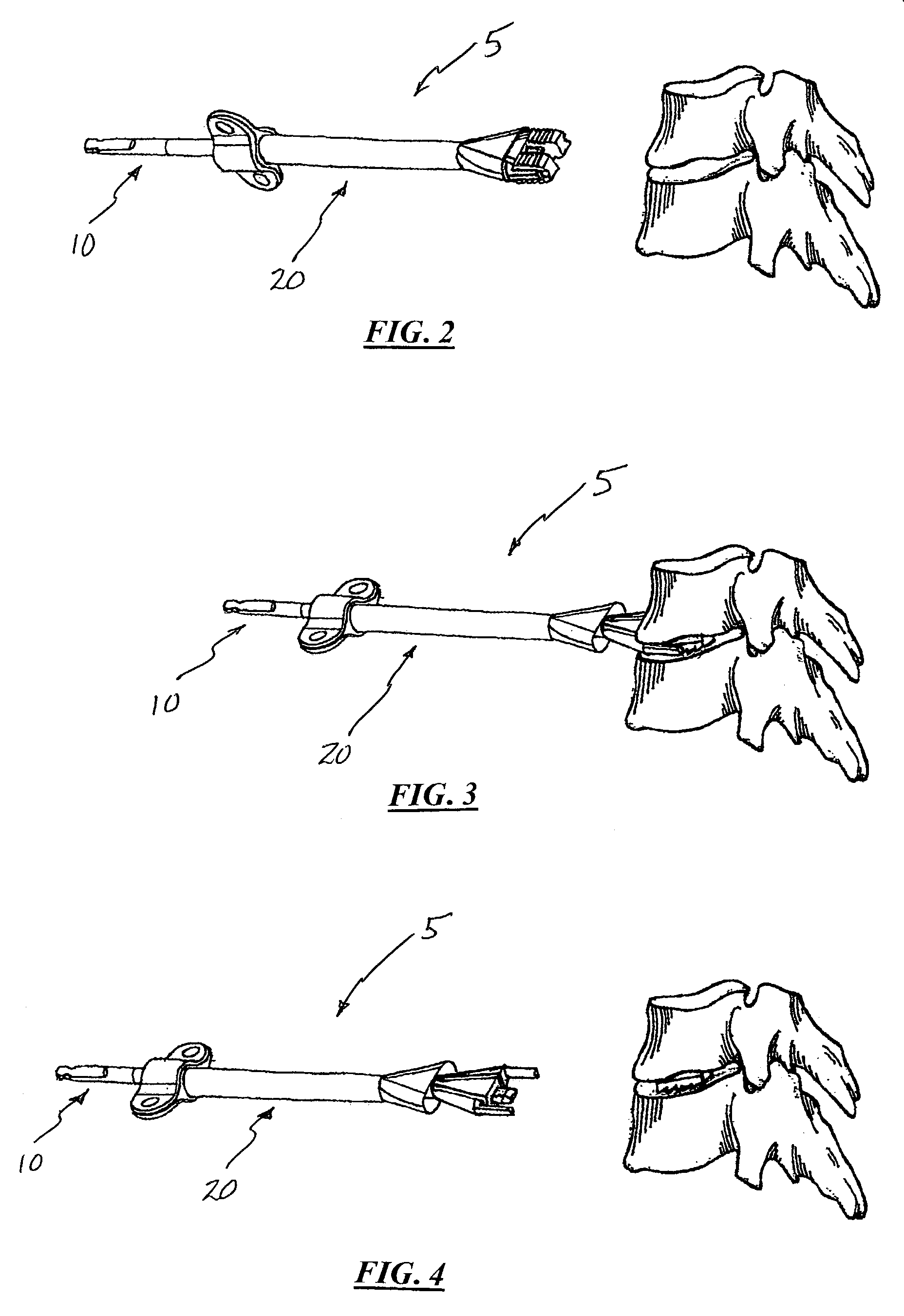

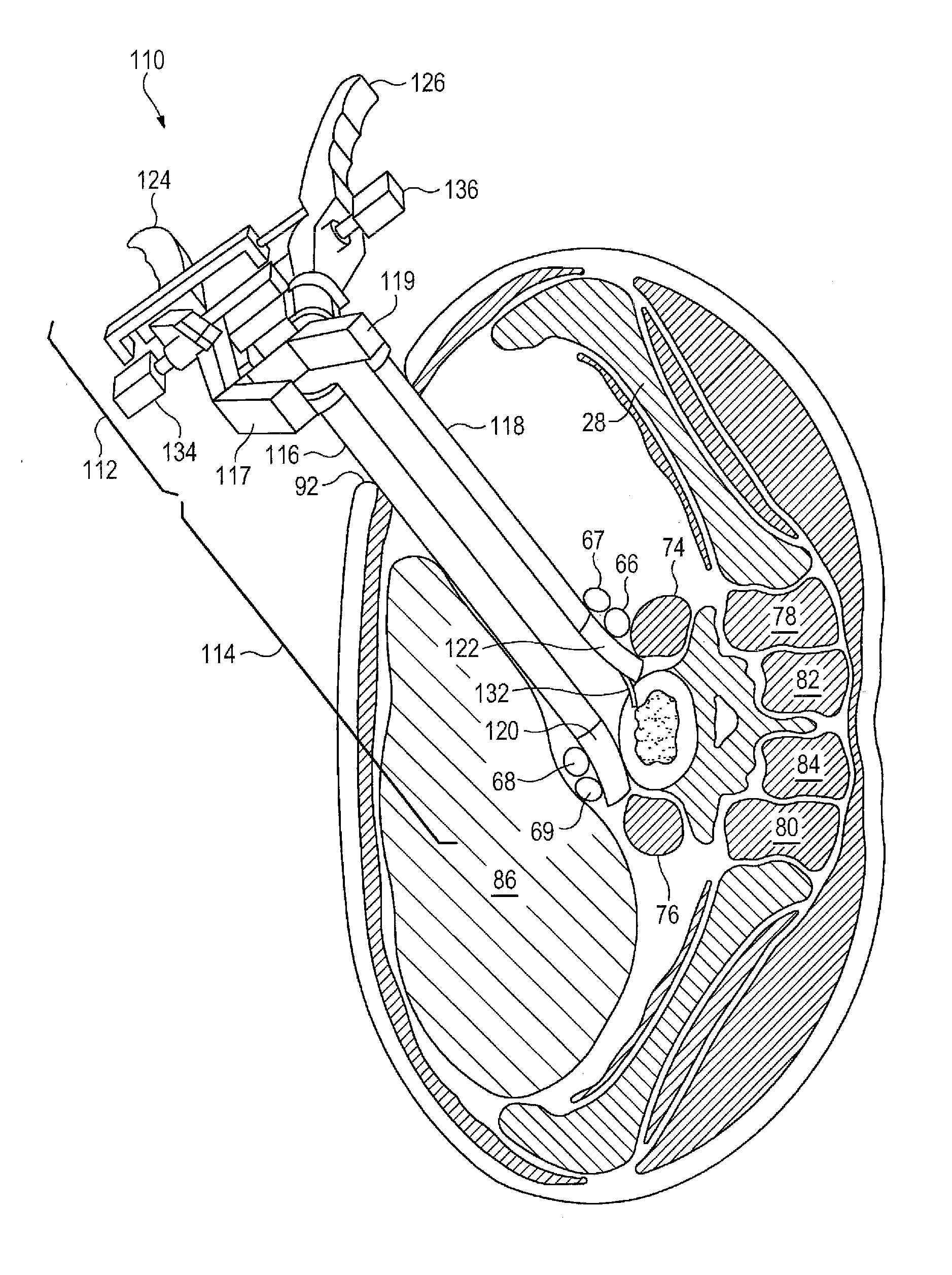

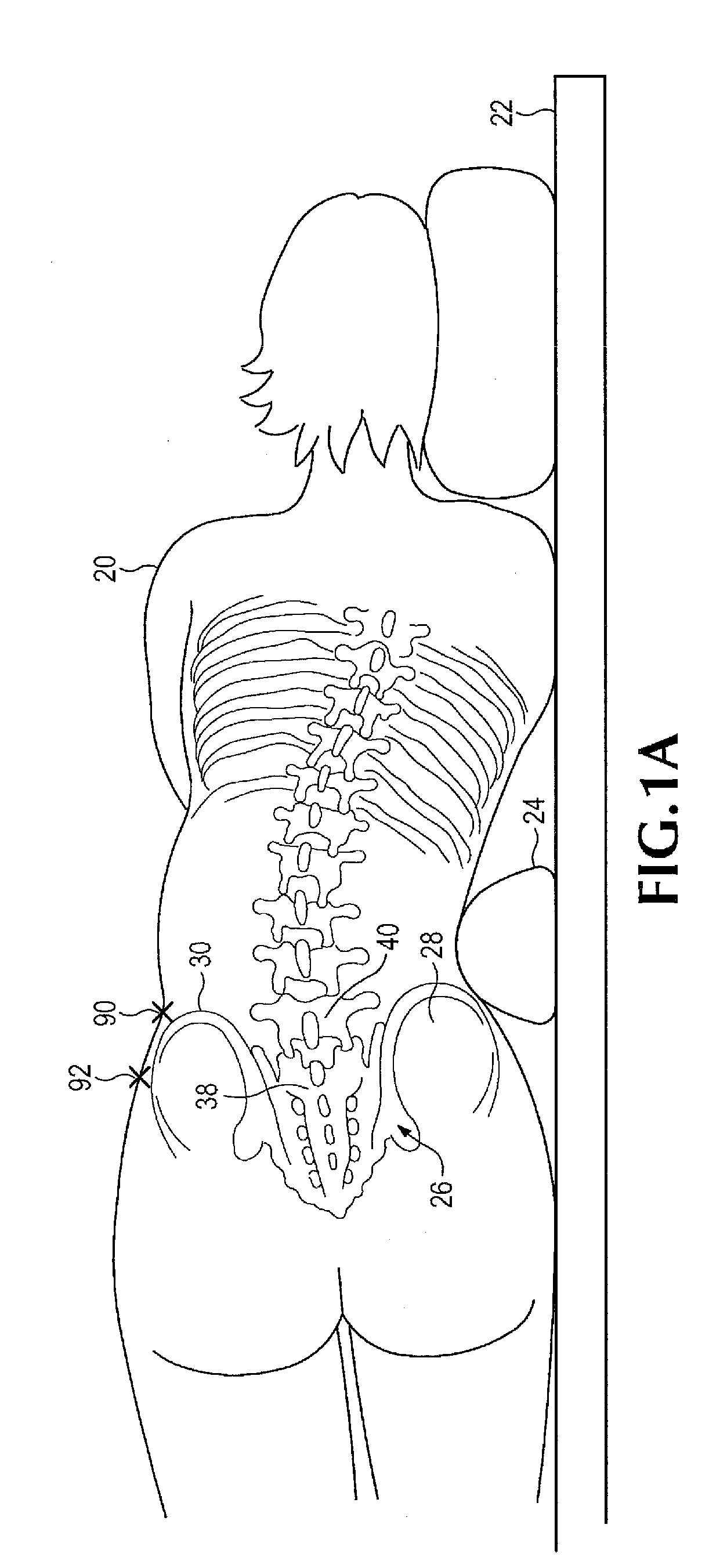

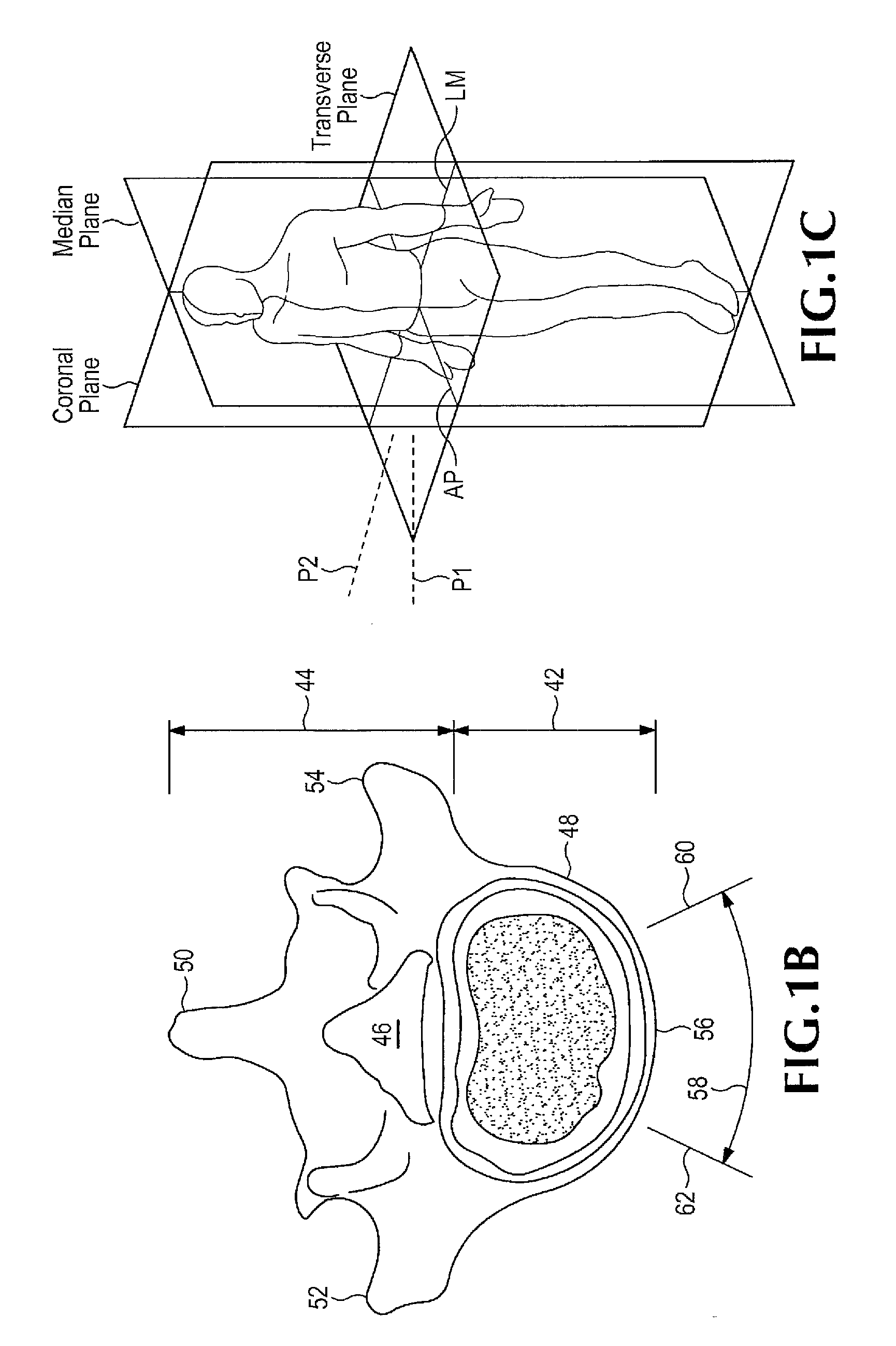

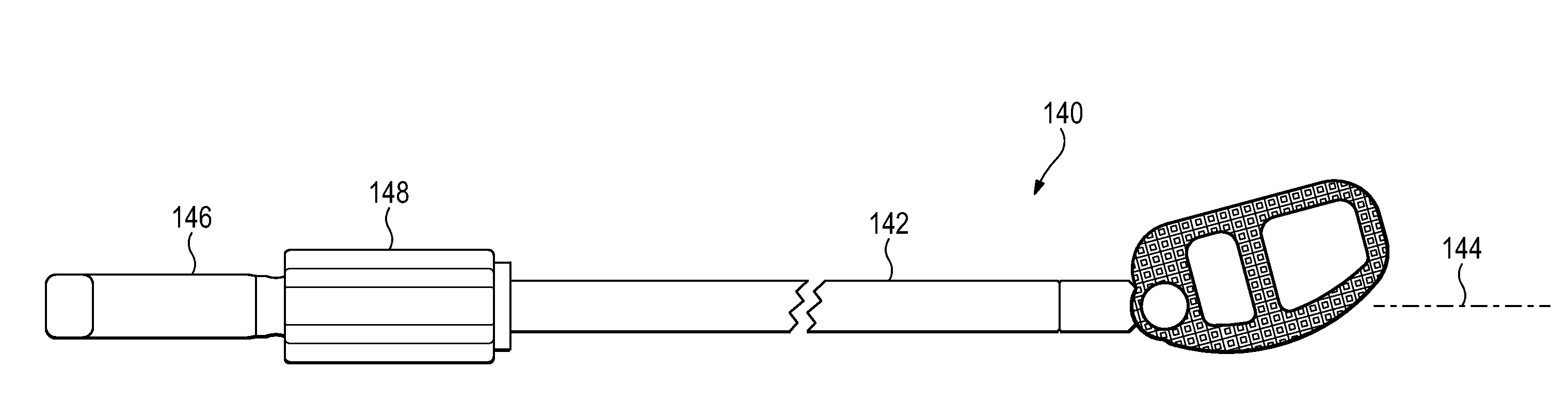

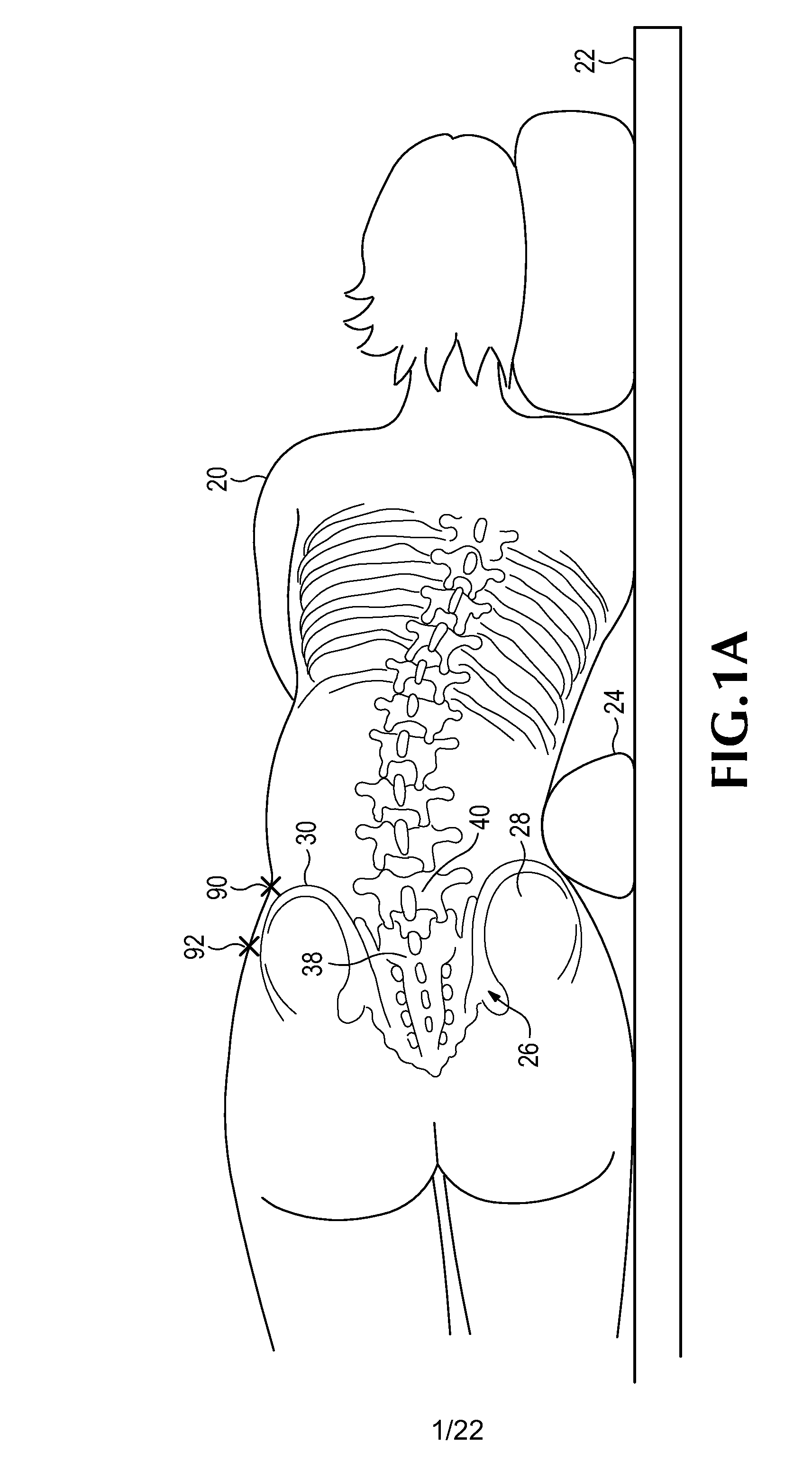

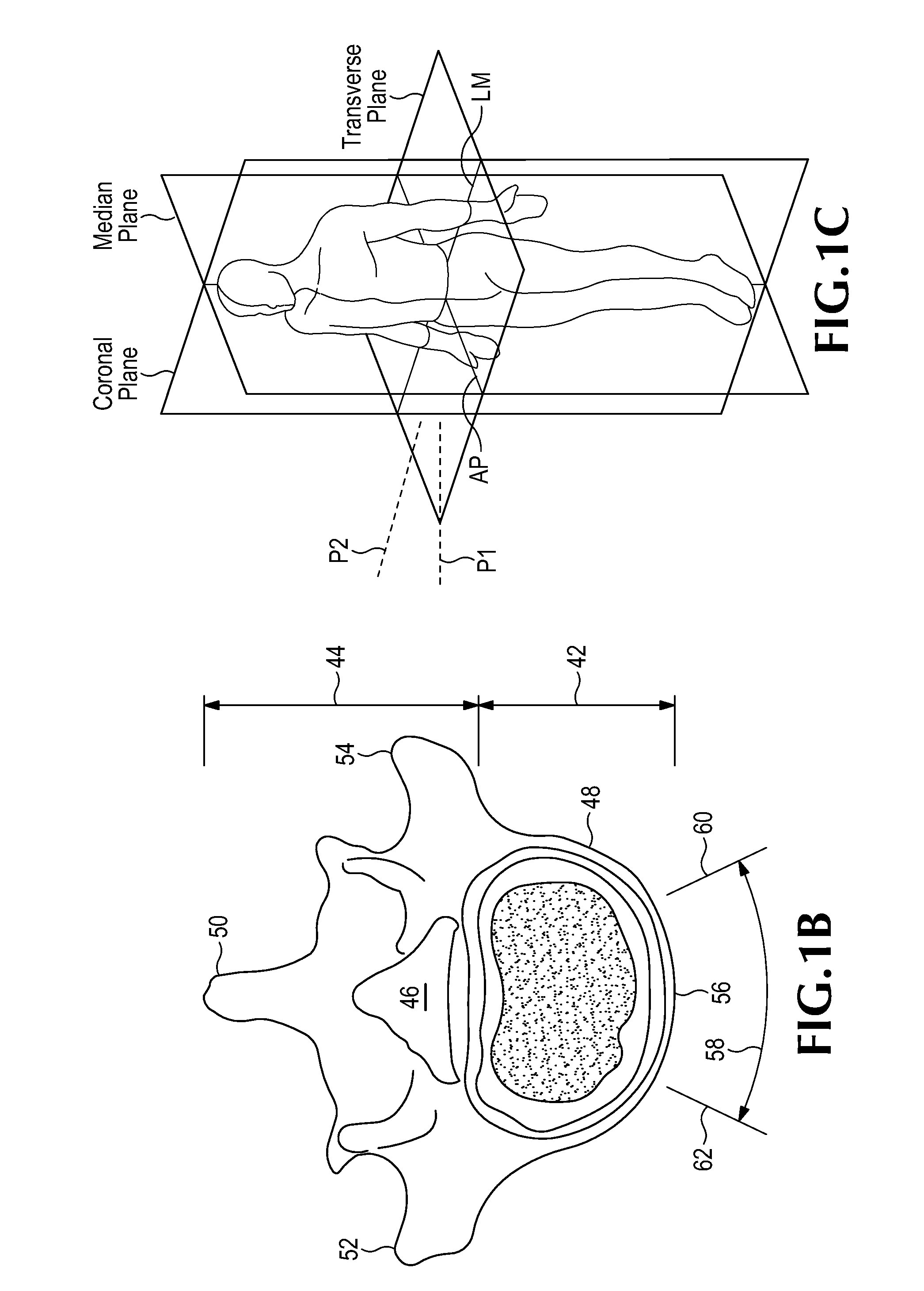

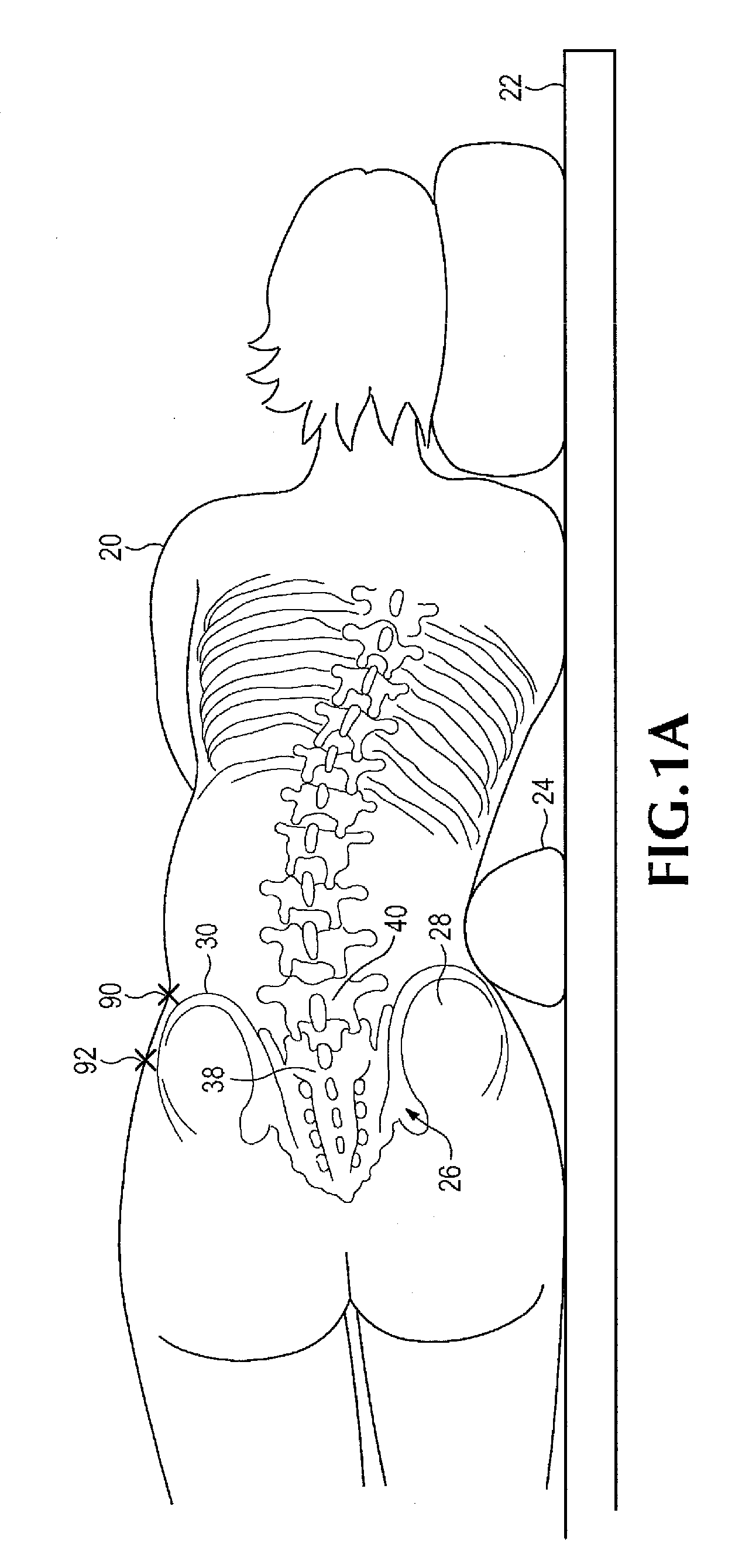

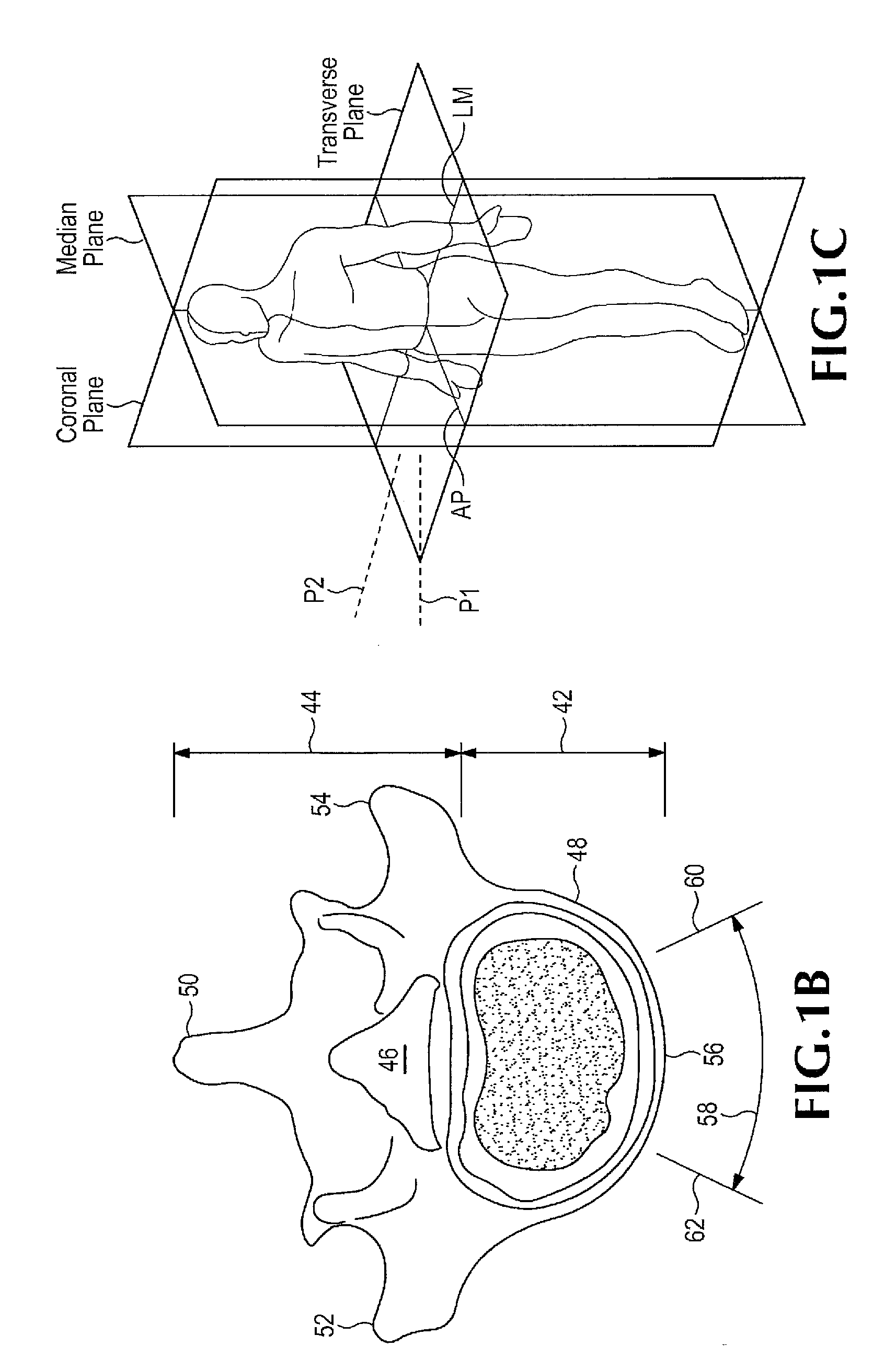

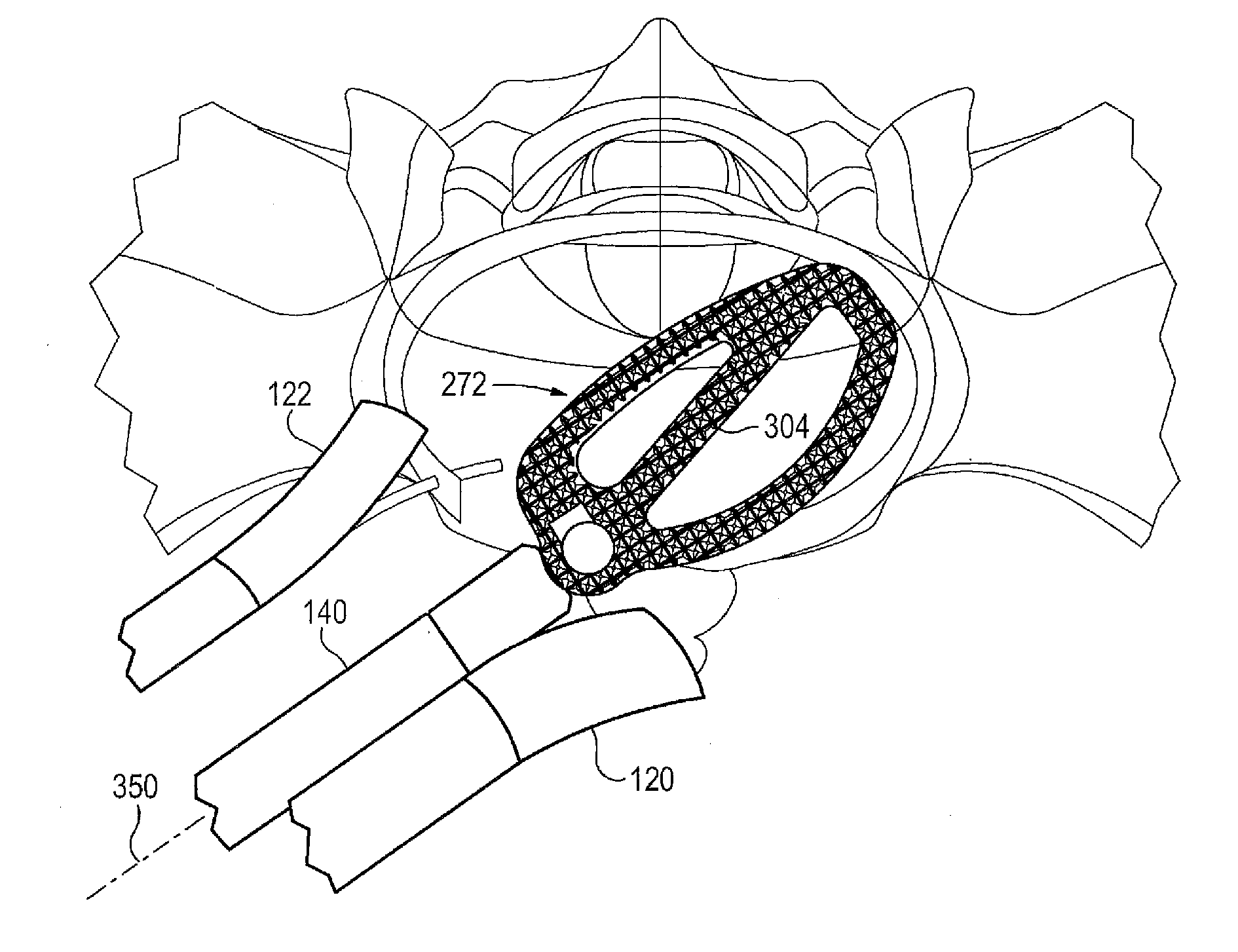

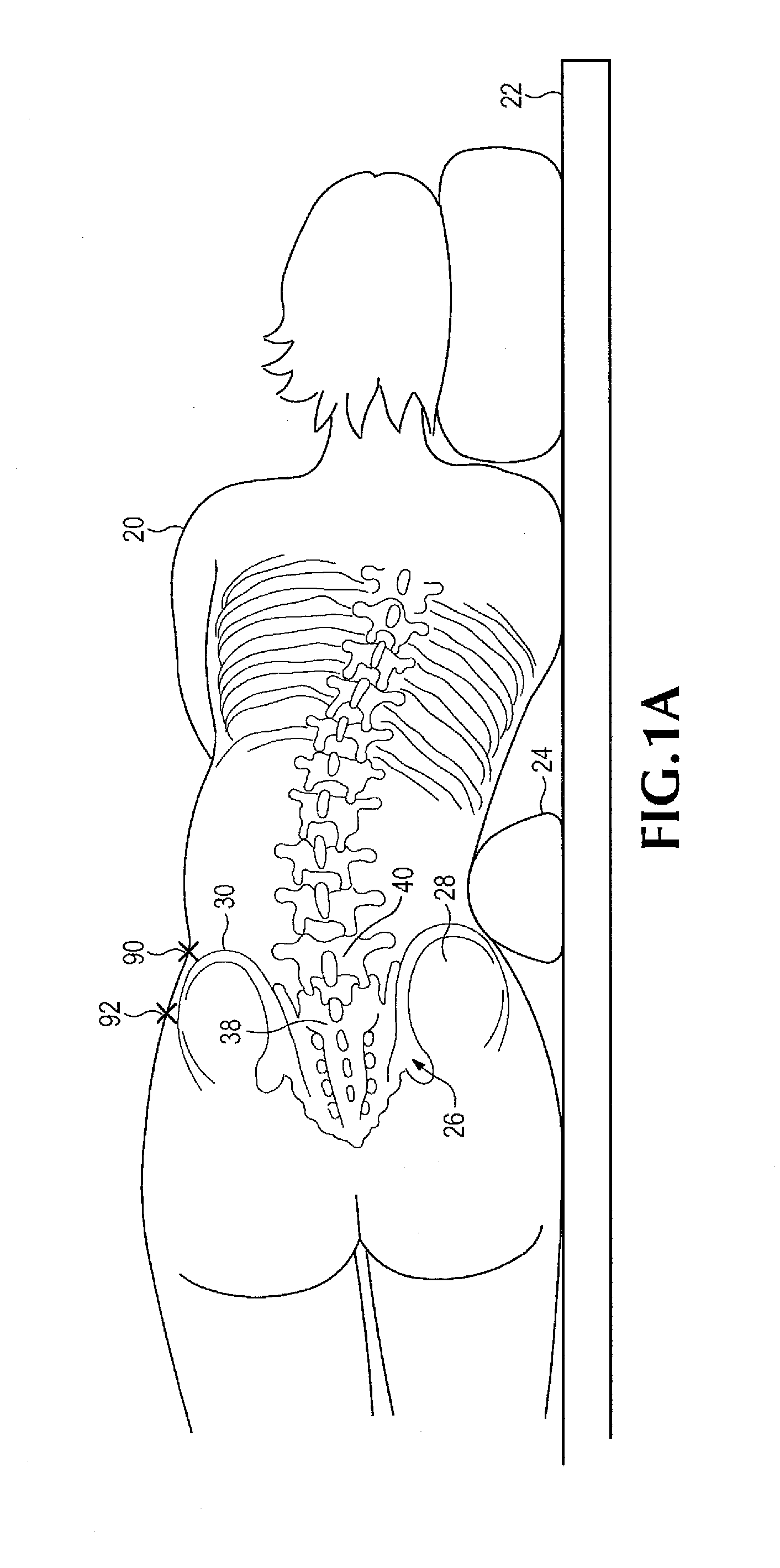

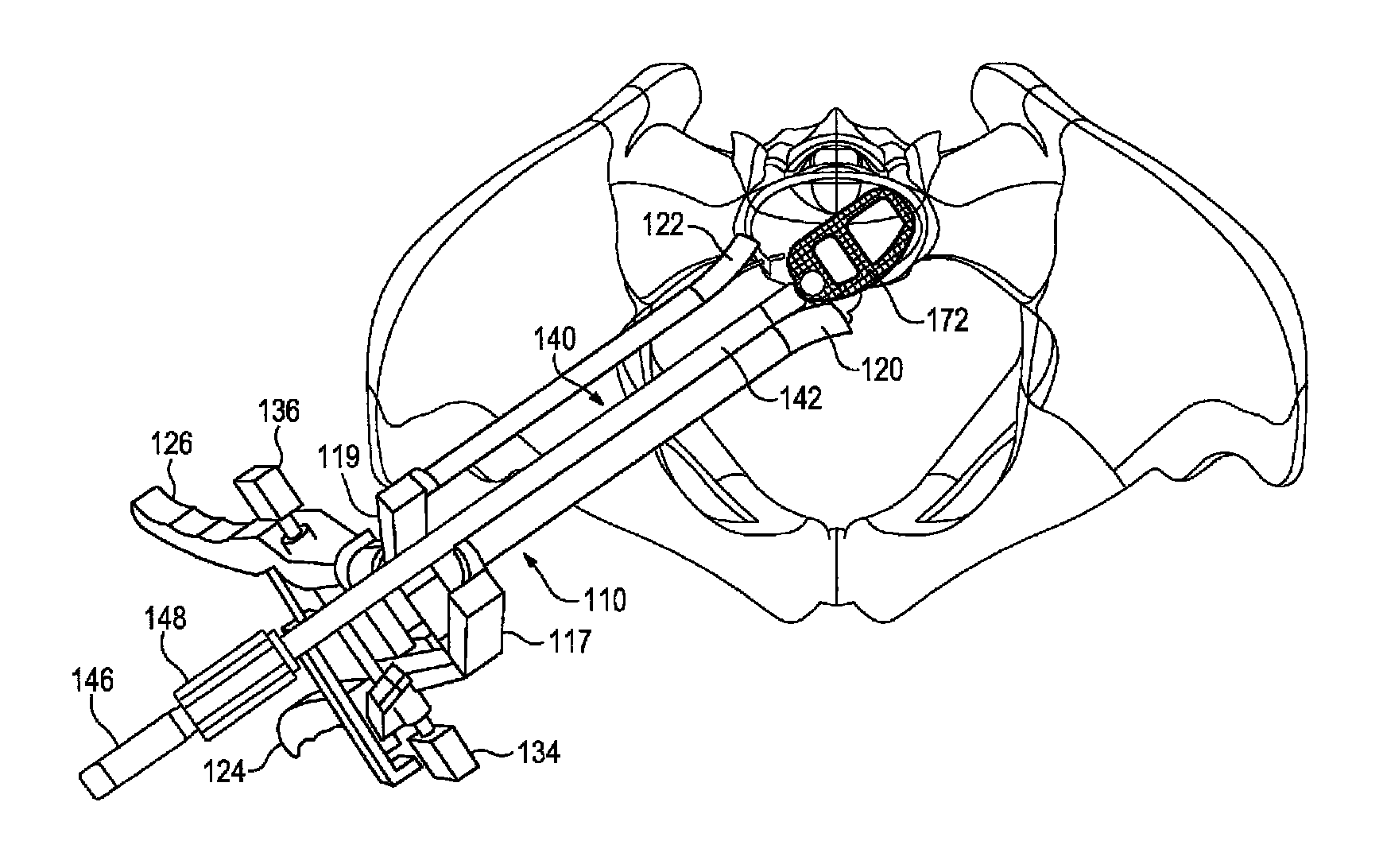

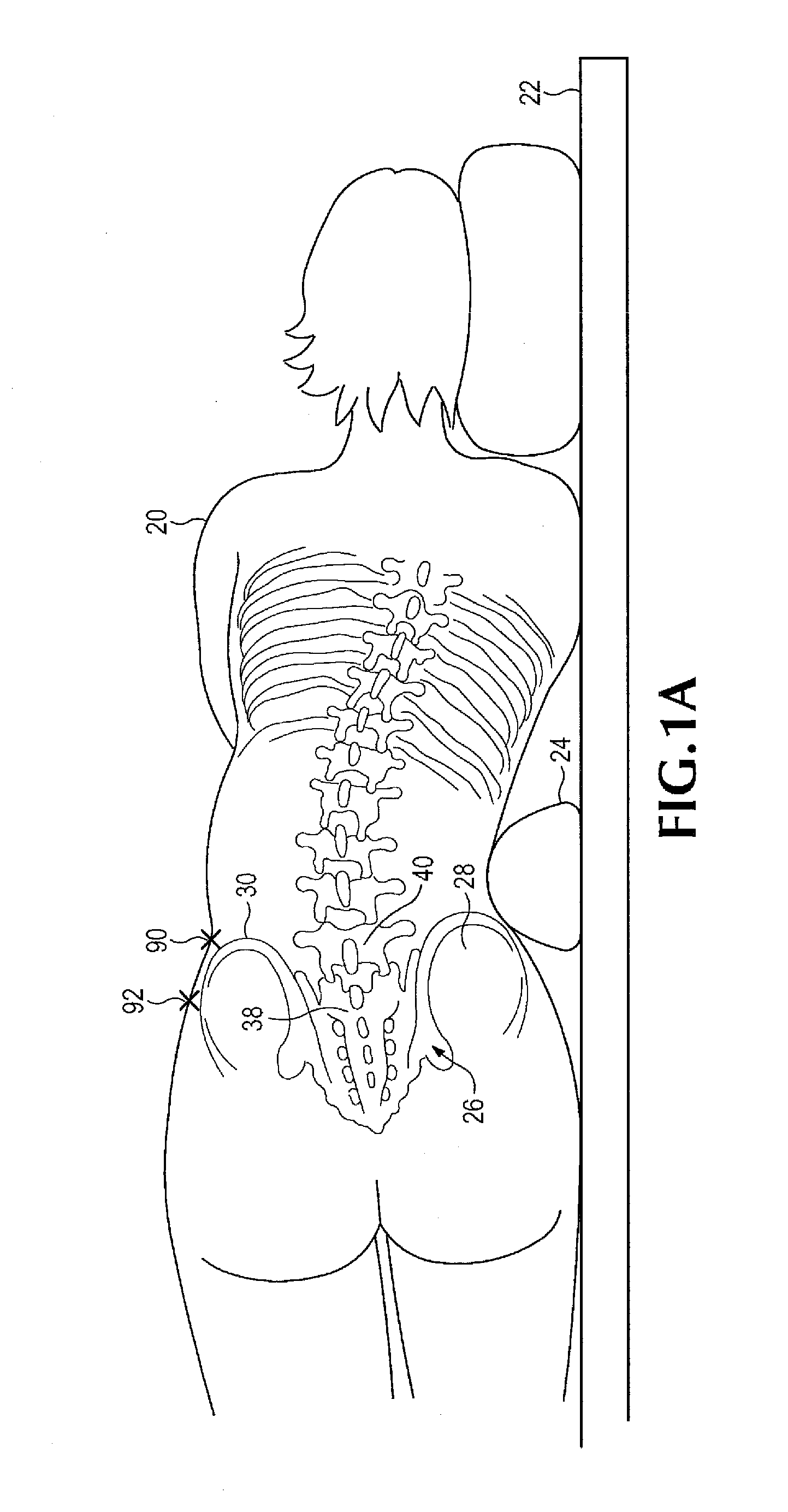

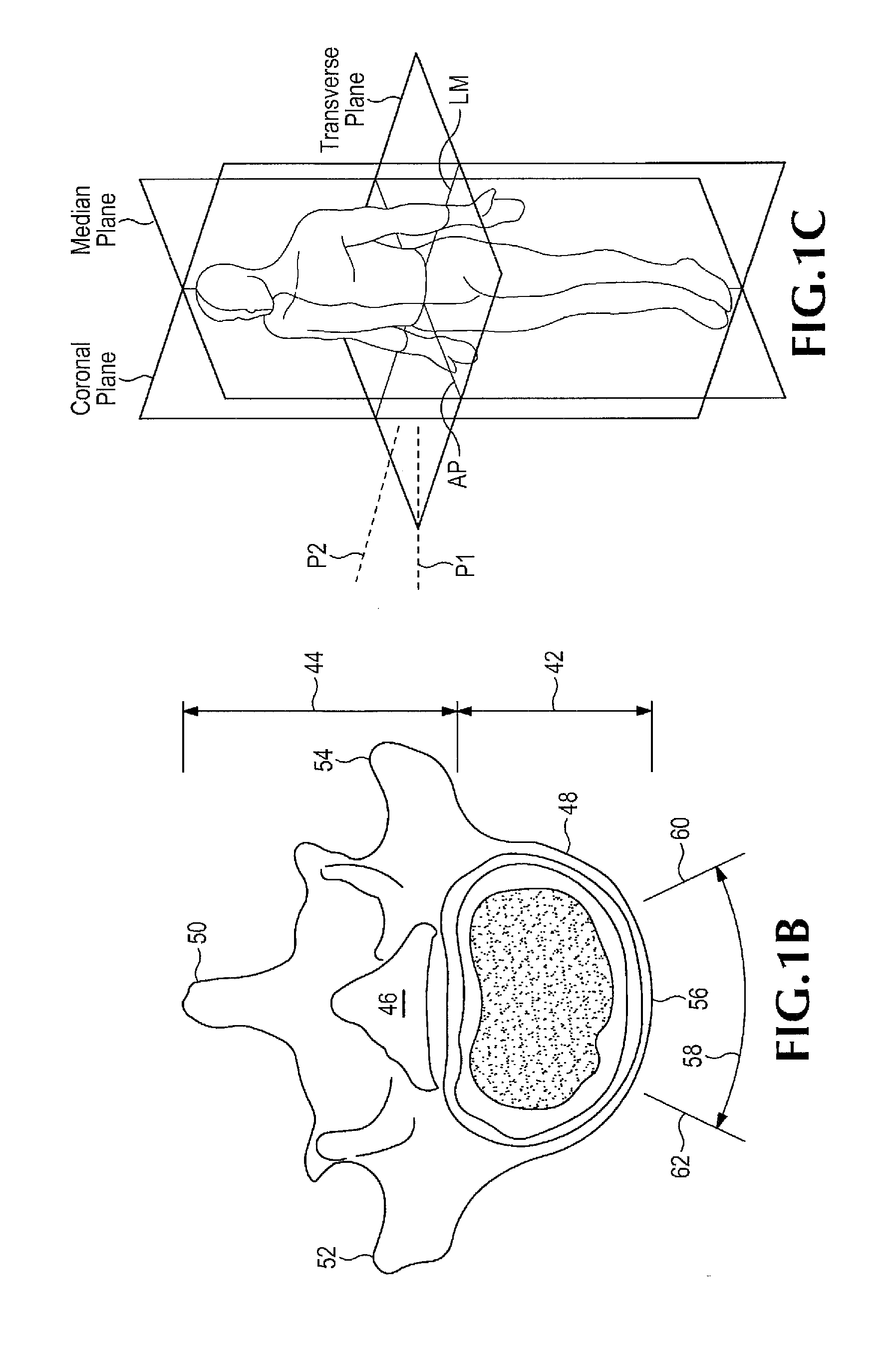

Retractor for use during retroperitoneal lateral insertion of spinal implants

InactiveUS20120010472A1Realize distributionMinimize traumaSurgerySpinal implantsSpinal columnIntervertebral spaces

A method is disclosed for introducing a spinal disc implant into an intervertebral space of a subject. The subject is placed in a lateral position, and the anterior face of the spinal disc intervertebral space is accessed, between the L5 and S1 vertebrae, from an anterior and lateral retroperitoneal approach. An operative corridor to the anterior face of the spinal disc space is established by introducing a retractor instrument anterolaterally to the spinal disc space between the anterior superior iliac spine and the anterior inferior iliac spine. The damaged spinal disc contents are removed from the intervertebral space through the operative corridor, and the implant is advanced into the intervertebral space at an oblique angle and pivoted to position the implant substantially laterally within the intervertebral space. Elongated retractor and insertion instruments, as well as a modified disc implant, are also disclosed for carrying out the method.

Owner:SPANN SCOTT

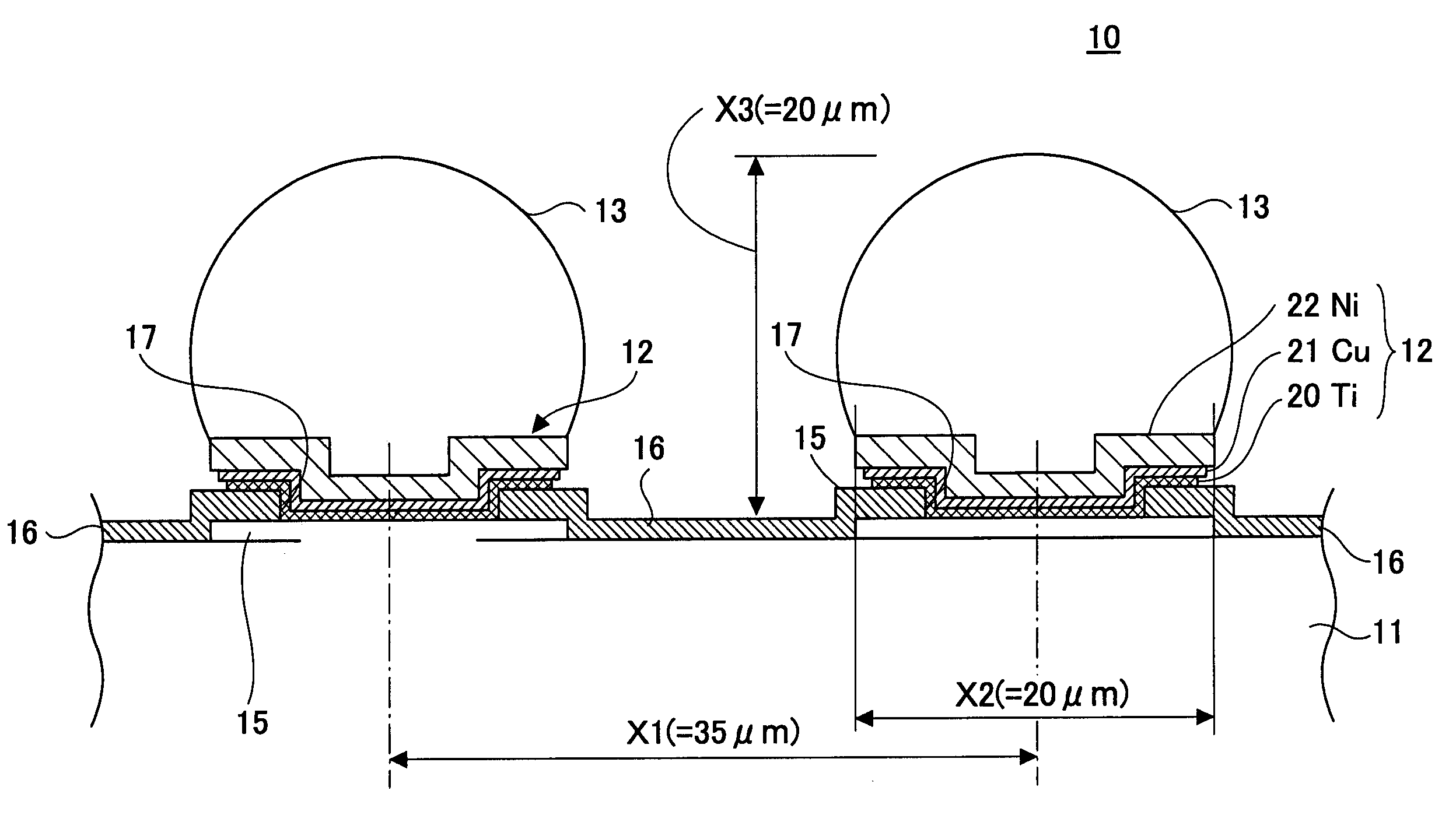

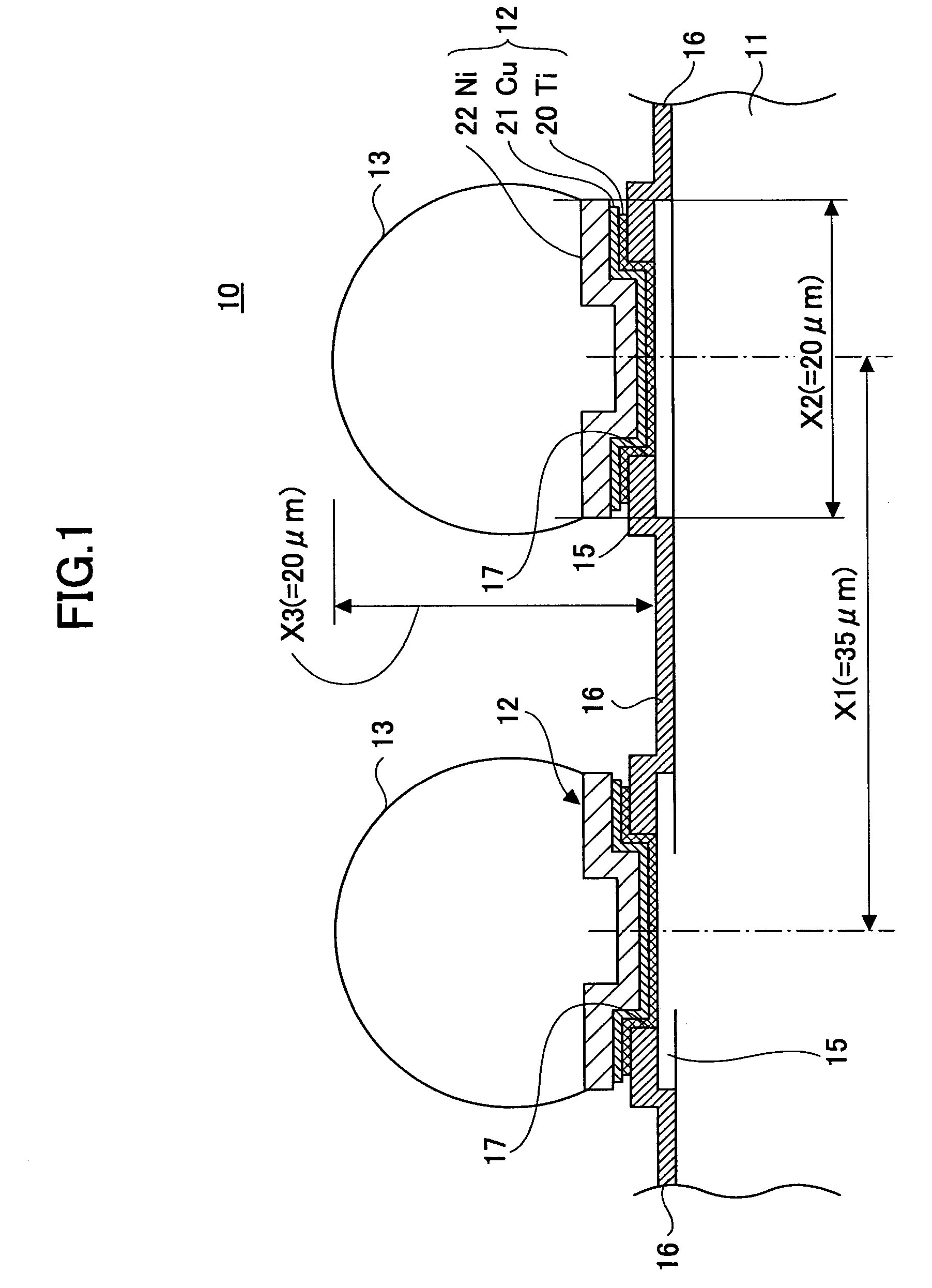

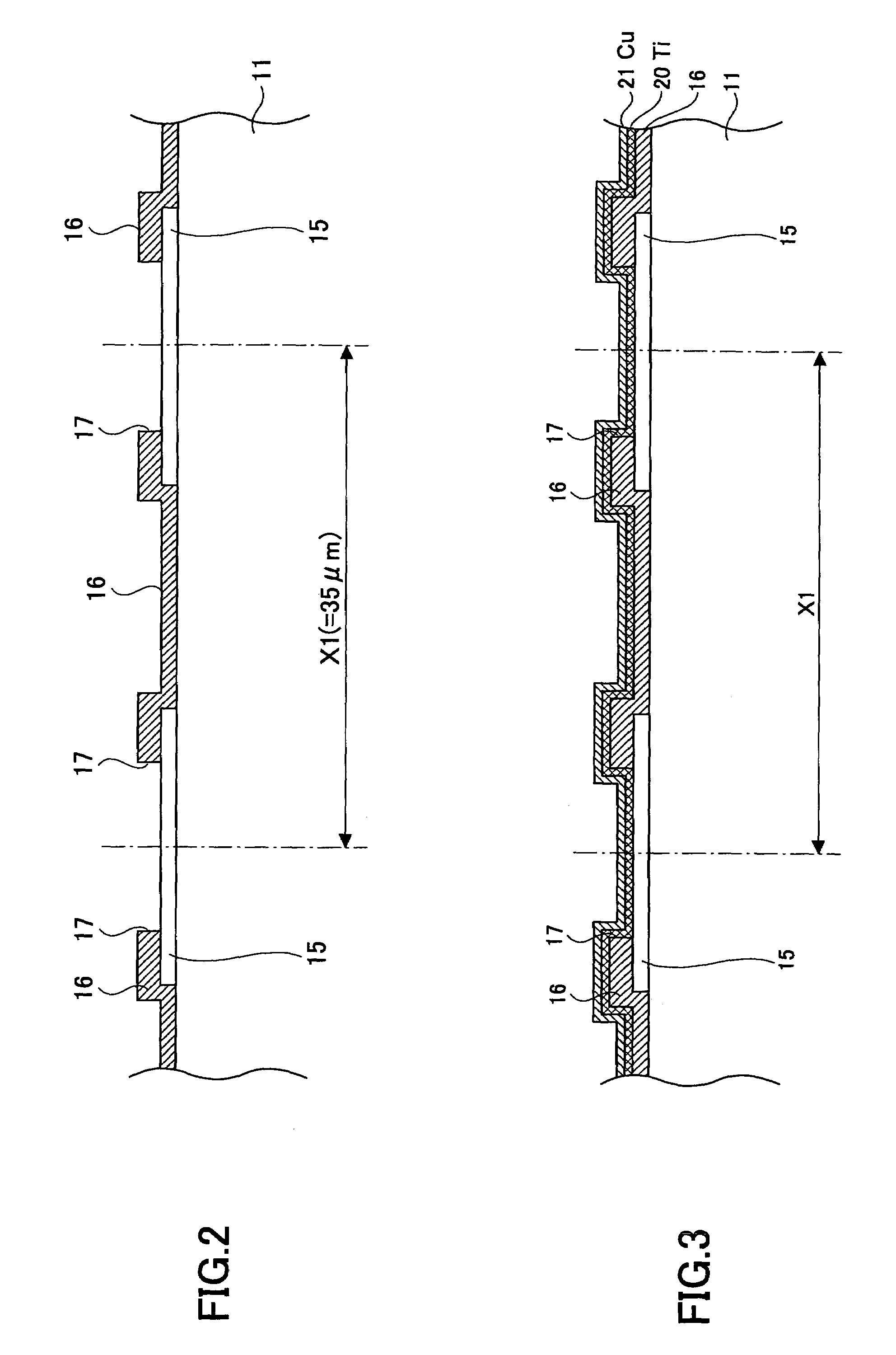

Semiconductor device and method of fabricating the same

InactiveUS7064436B2High aspect ratioHigh bonding reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrode arraySemiconductor

A semiconductor device includes a semiconductor substrate and an array of protruding electrodes arranged at a pitch X1. Each of the protruding electrodes has a height X3 and is formed on a barrier metal base of diameter X2 coupled to an electrode arranged on the semiconductor substrate so as to satisfy the relations (X1 / 2)≦X2≦(3*X1 / 4) and (X1 / 2)≦X3≦(3*X1 / 4).

Owner:FUJITSU LTD

Minimally-invasive retroperitoneal lateral approach for spinal surgery

InactiveUS20120035730A1Realize distributionMinimize traumaSurgerySpinal implantsSpinal columnIntervertebral spaces

A method is disclosed for introducing a spinal disc implant into an intervertebral space of a subject. The subject is placed in a lateral position, and the anterior face of the spinal disc intervertebral space is accessed, between the L5 and S1 vertebrae, from an anterior and lateral retroperitoneal approach. An operative corridor to the anterior face of the spinal disc space is established by introducing a retractor instrument anterolaterally to the spinal disc space between the anterior superior iliac spine and the anterior inferior iliac spine. The damaged spinal disc contents are removed from the intervertebral space through the operative corridor, and the implant is advanced into the intervertebral space at an oblique angle and pivoted to position the implant substantially laterally within the intervertebral space. Elongated retractor and insertion instruments, as well as a modified disc implant, are also disclosed for carrying out the method.

Owner:PANTHEON SPINAL

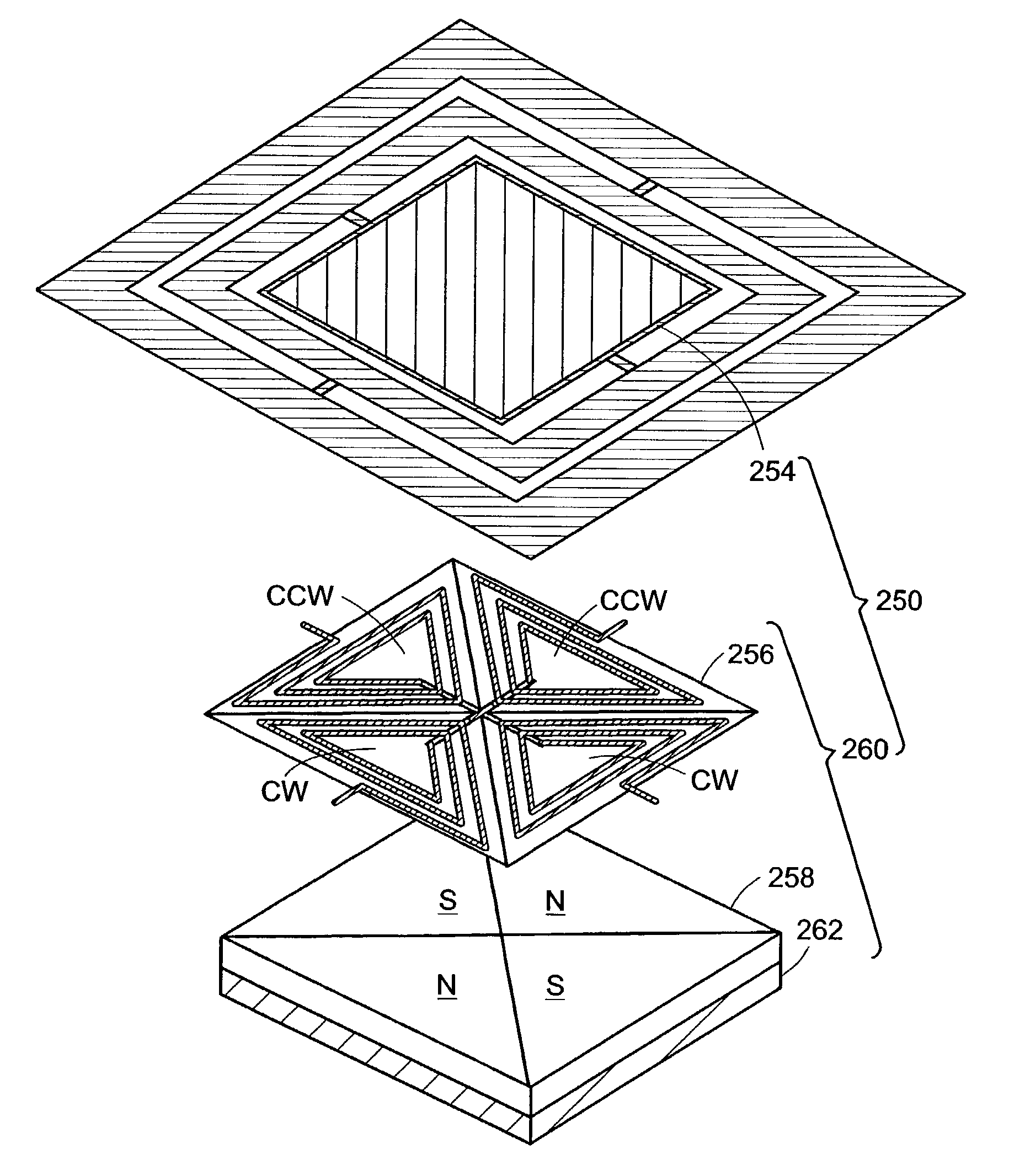

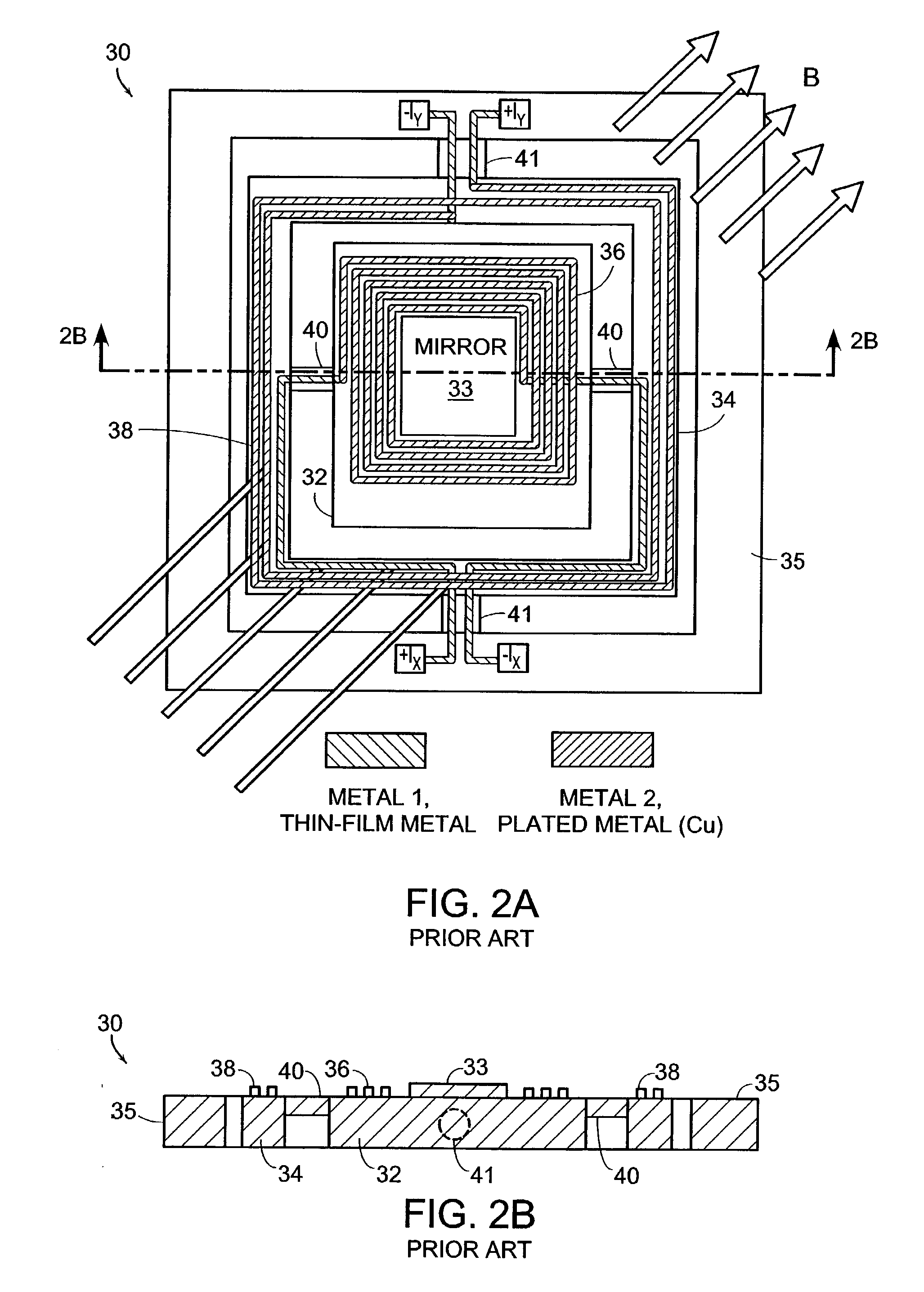

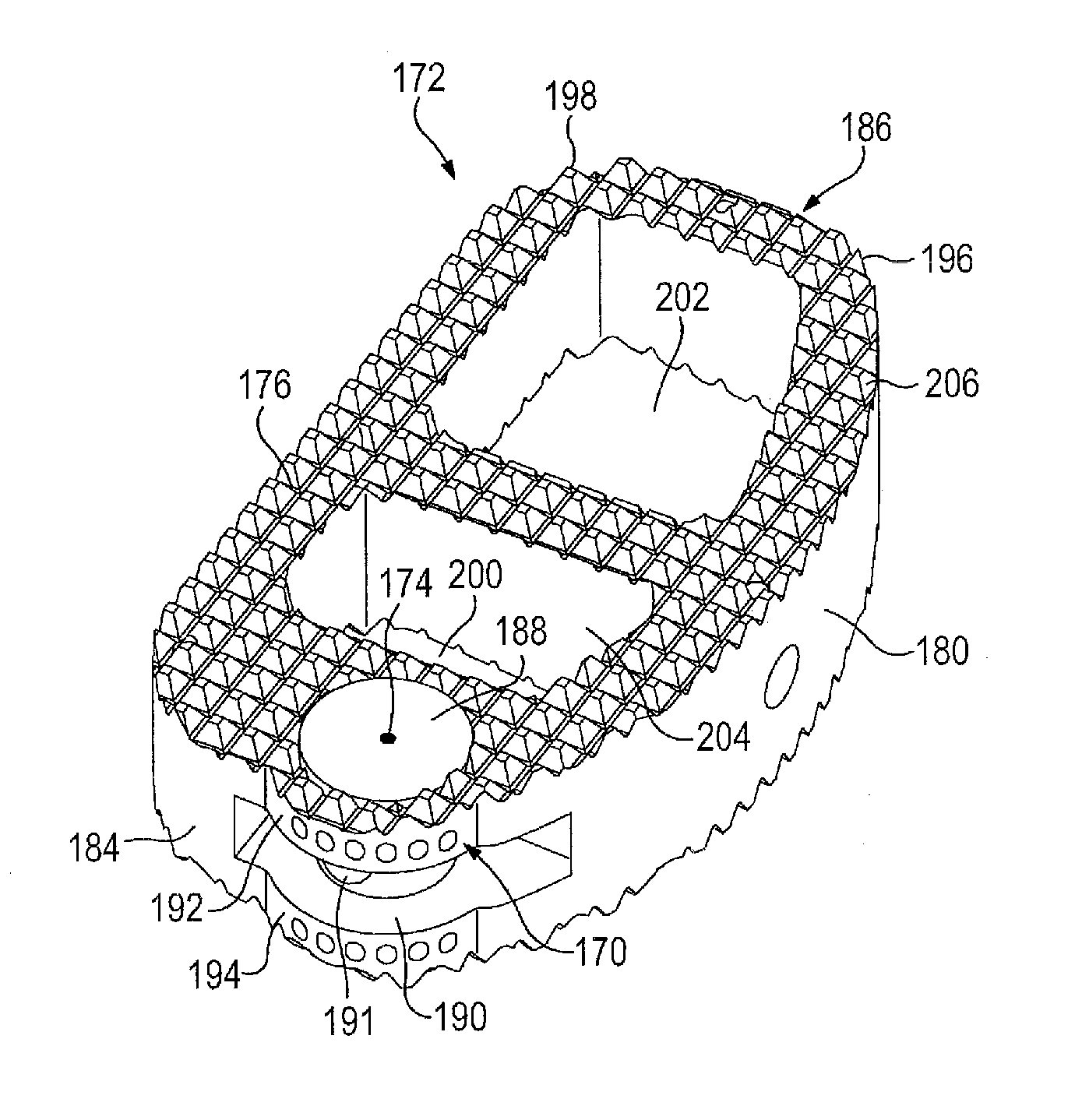

Magnetically actuated microelectromechanical devices and method of manufacture

One embodiment is directed to a mirror device (for a device such as an optical switch, scanner or projector) having a movable mirror structure with an attached magnet. The mirror structure is movably mounted on a base structure, which includes an actuation coil for controlling movement of the mirror structure. Another embodiment is directed to a mirror device (in a device such as an optical switch, scanner or projector) having a high mirror fill factor. The device includes a mirror mounted on a support member, which is connected to a gimbal frame. The support member includes an enlarged portion configured to at least partially extend over the gimbal frame. The mirror substantially covers the enlarged portion of the support member, thereby providing the device with a high mirror fill factor. A further embodiment is directed to a mirror support structure for a movable mirror device (in a device such as an optical switch, scanner or projector). The mirror support structure includes a post member and an enlarged lid member, one of which includes a plurality of holes and the other of which includes a corresponding plurality of projections. The post and lid members are assembled by positioning the projections in the corresponding holes.

Owner:CORNING INC

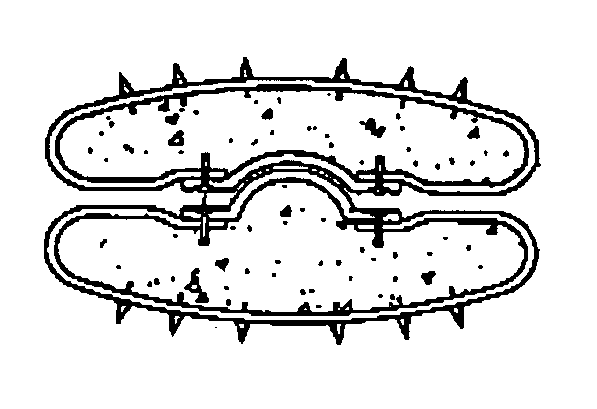

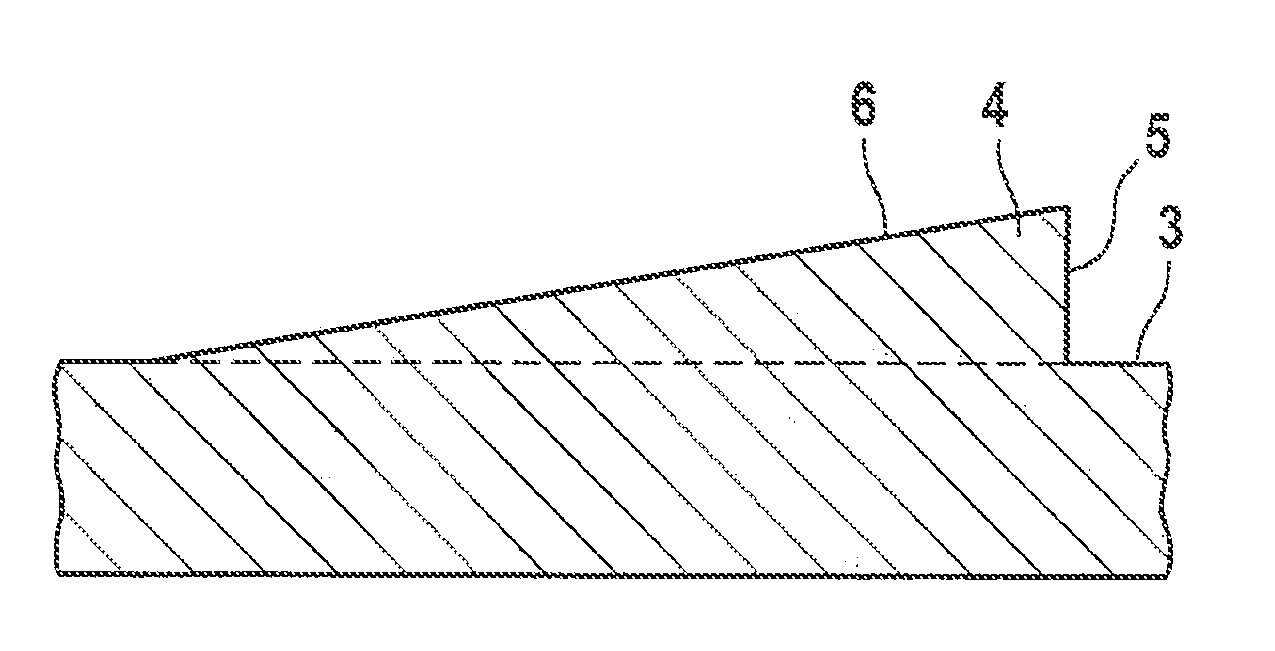

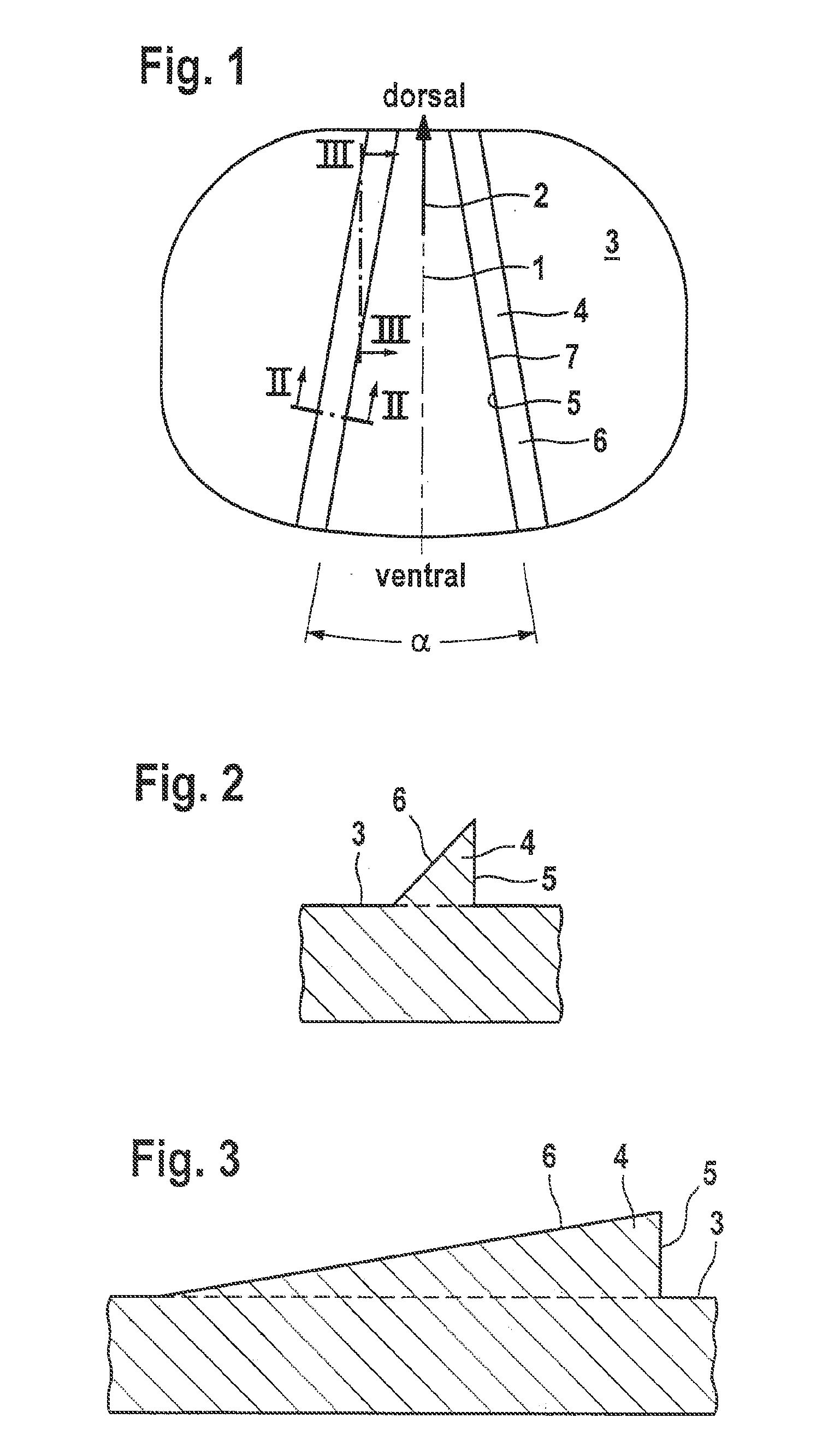

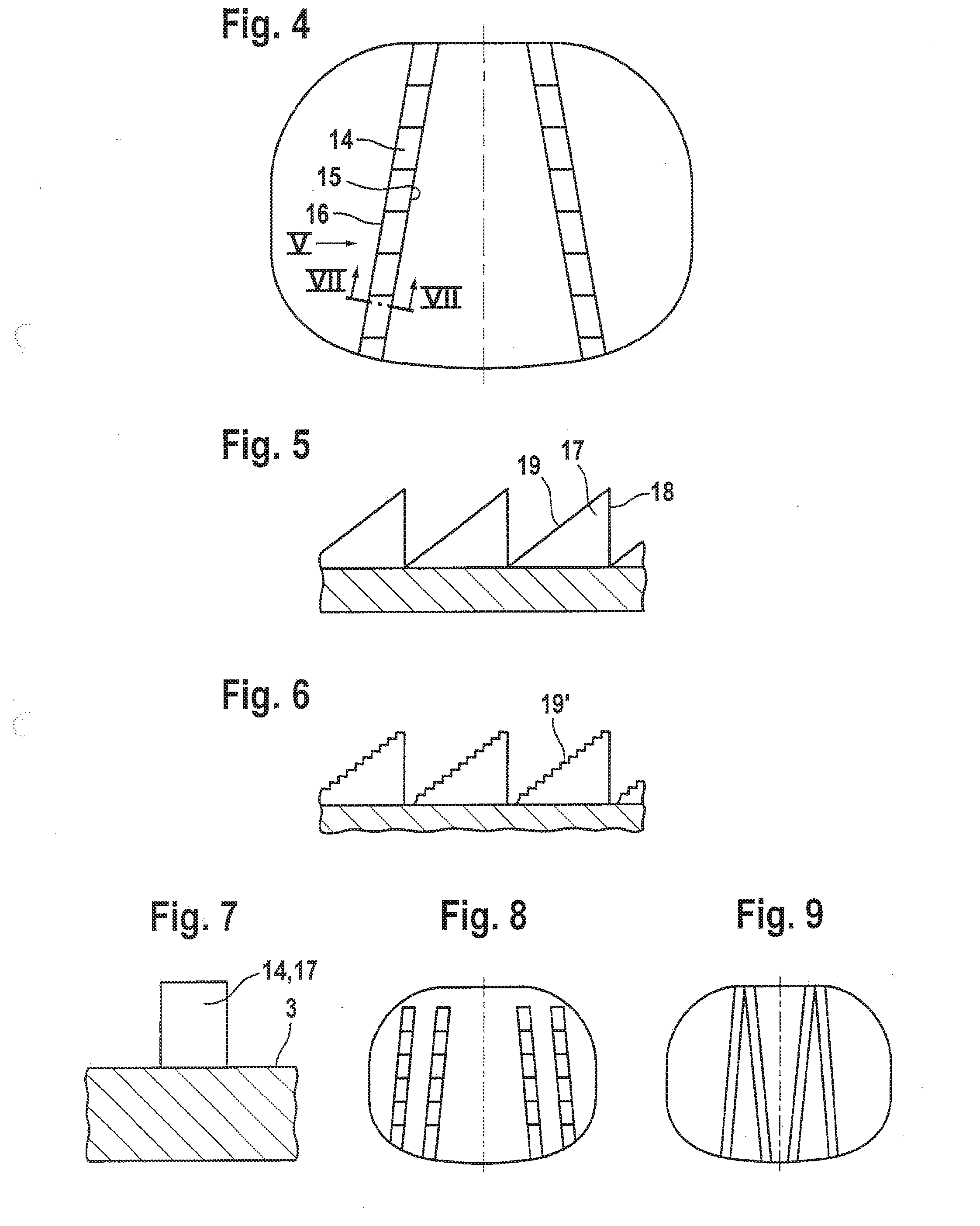

Intervertebral prosthesis with self-tapping fixing projections

An intervertebral prosthesis, in particular for the cervical spine, has two attachment plates connected in an articulated manner. The attachment surfaces of the attachment plates, which are configured for attachment to adjacent vertebral bodies have a base surface configured to bear on the surface of the vertebral bodies, and self-tapping fixing projections rising from the base surface. These fixing projections are formed by at least one pair of ribs which extend in opposite directions obliquely with respect to a predetermined implantation direction and whose side faces oriented more away from the implantation direction are steeper than their side faces oriented more in the implantation direction. The ribs can be toothed.

Owner:CERVITECH INC

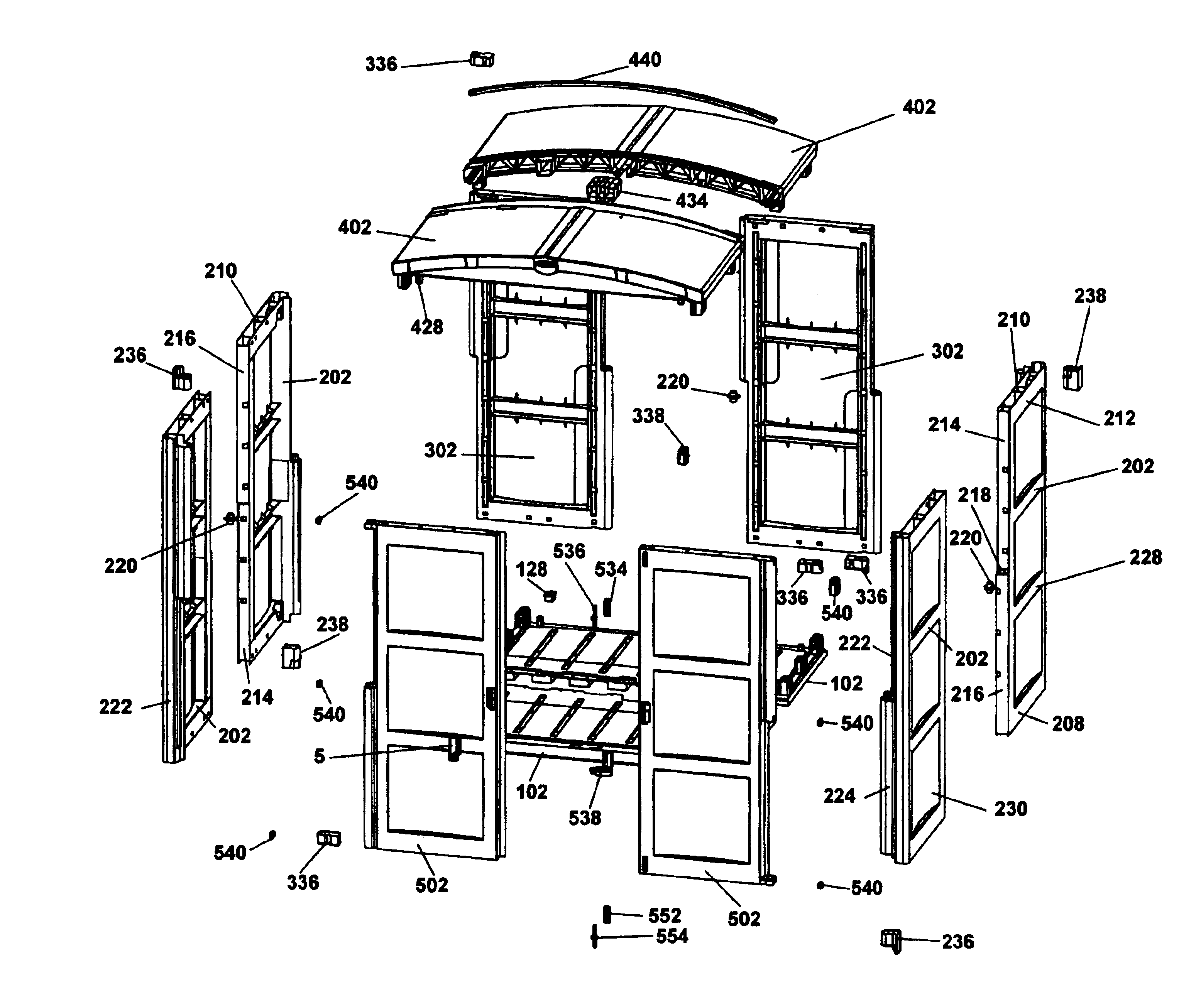

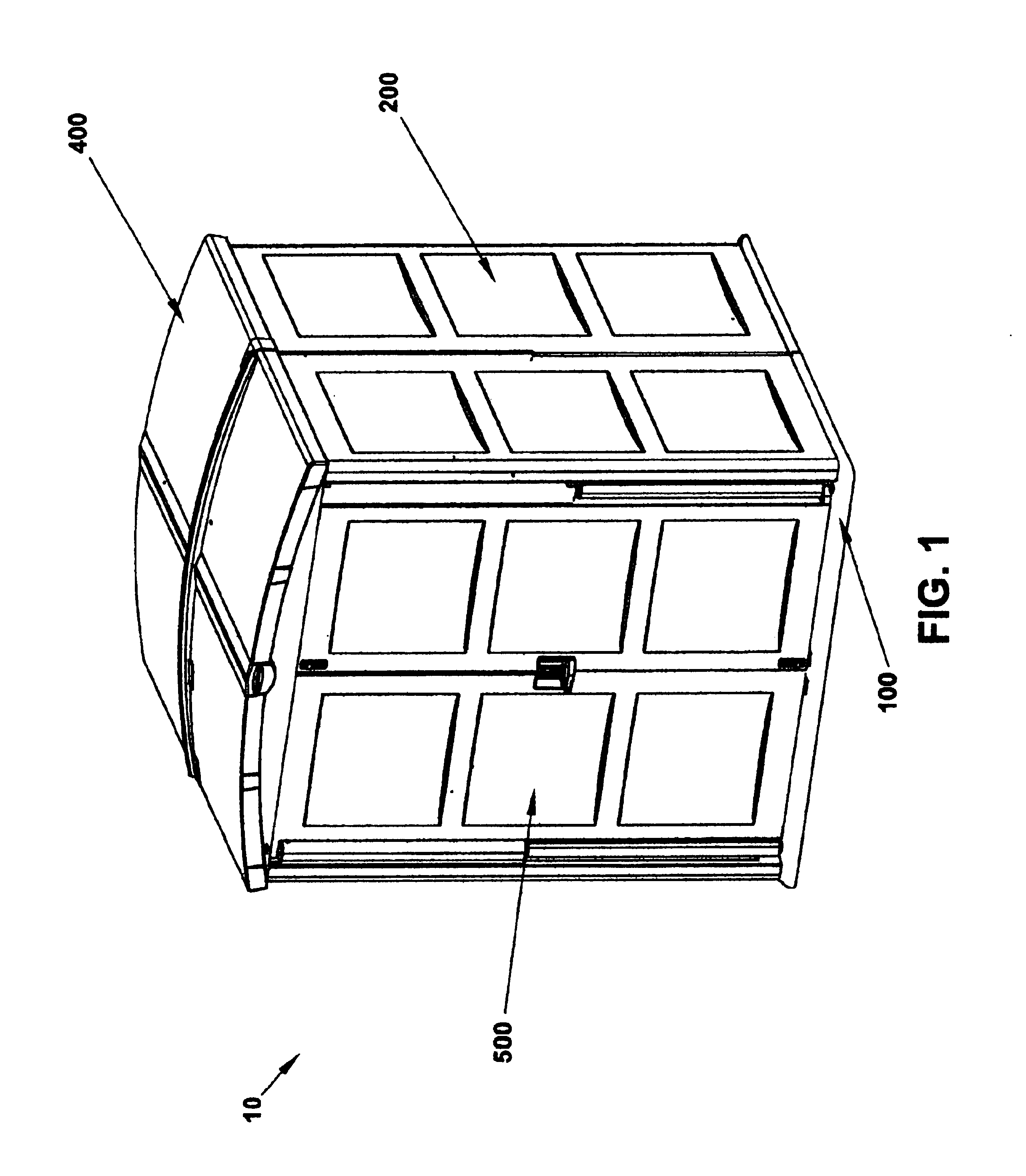

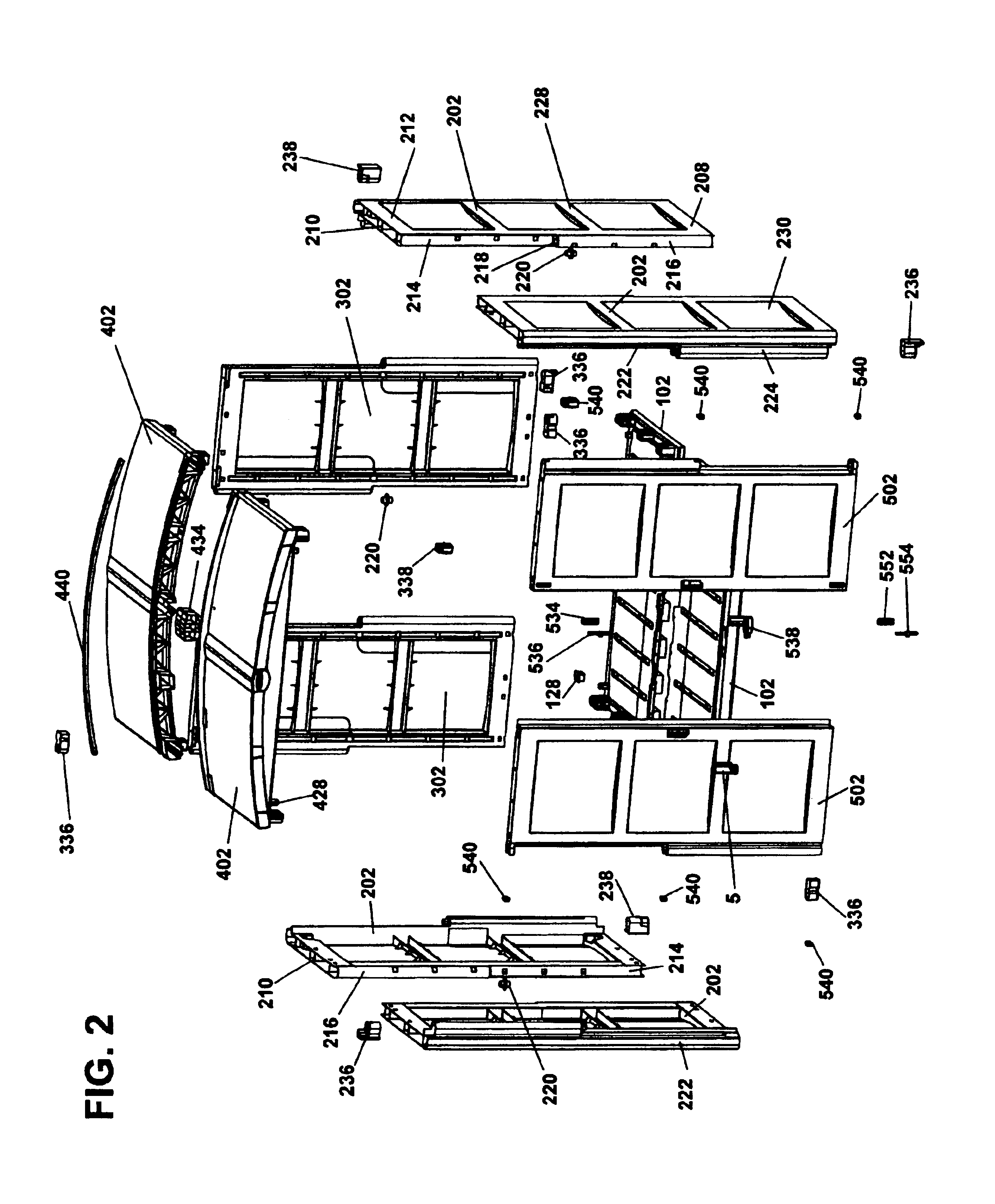

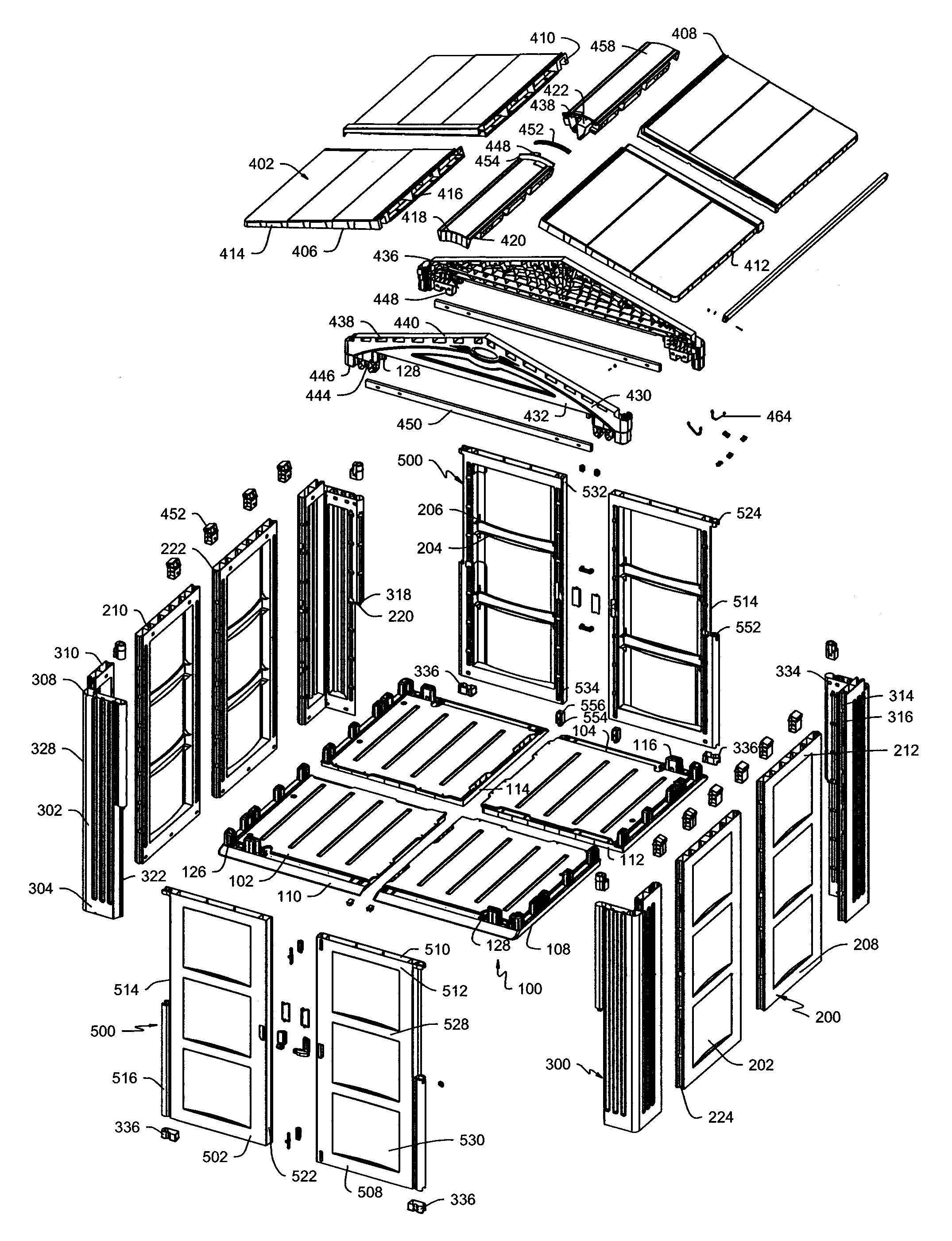

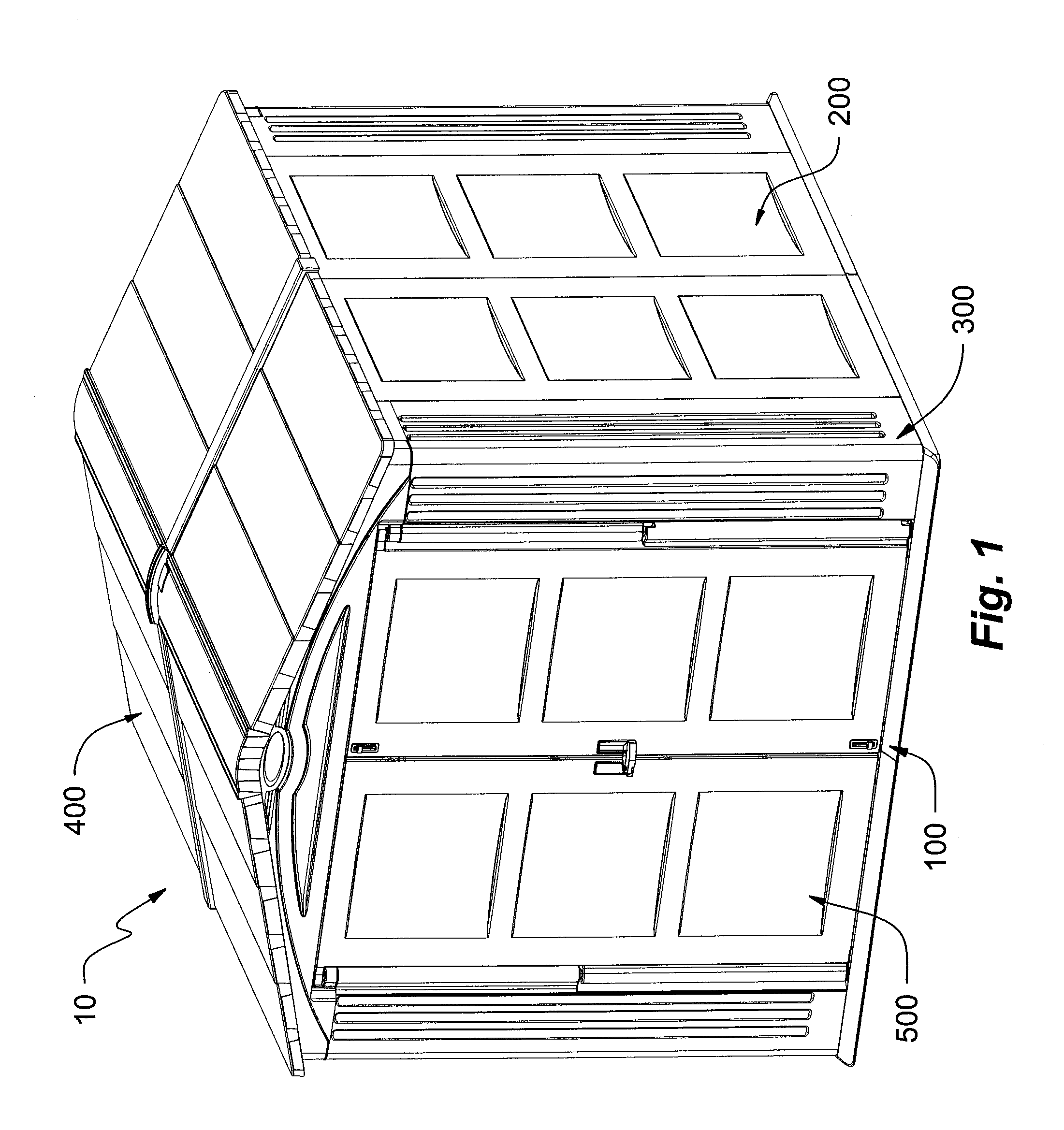

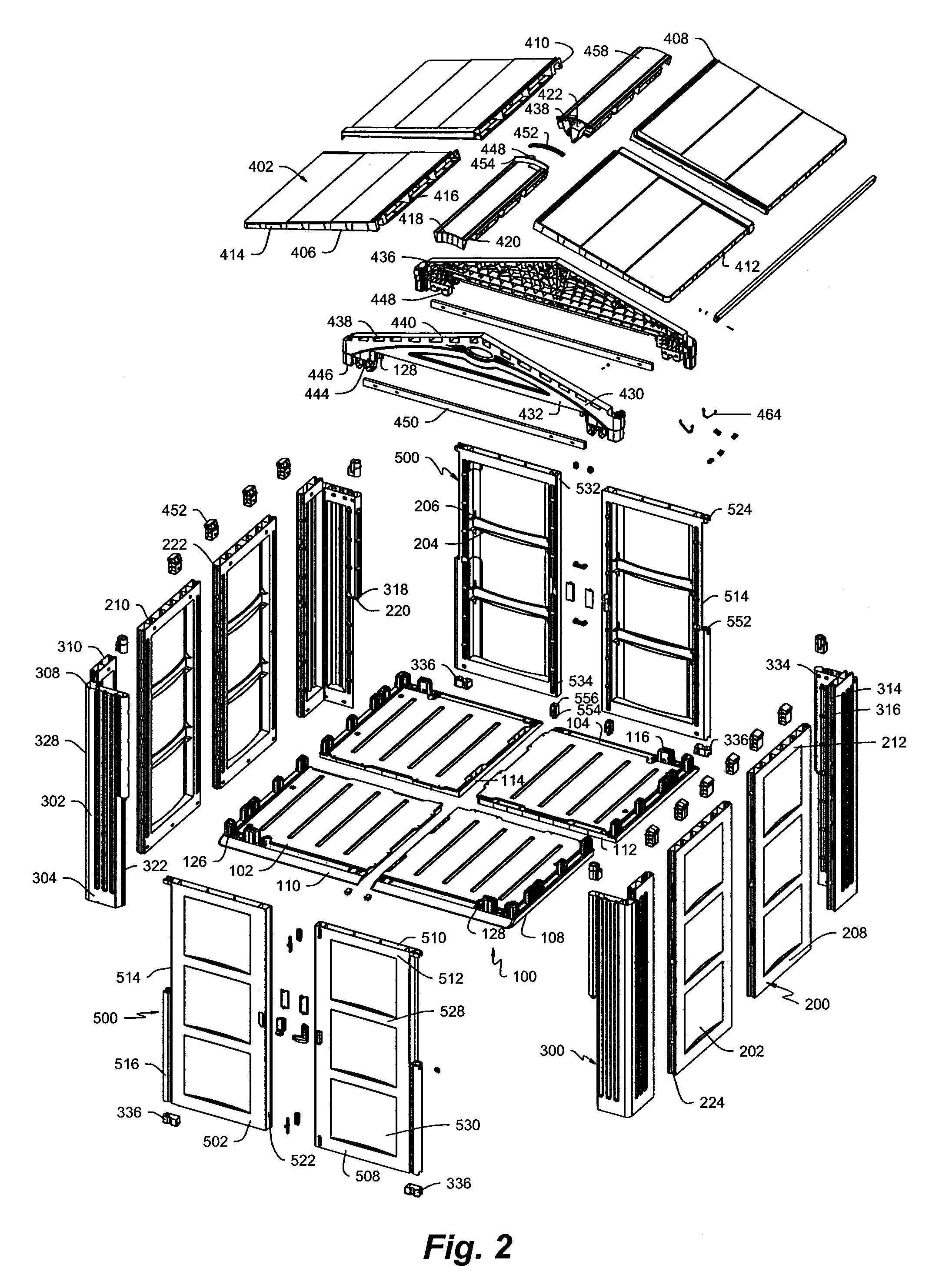

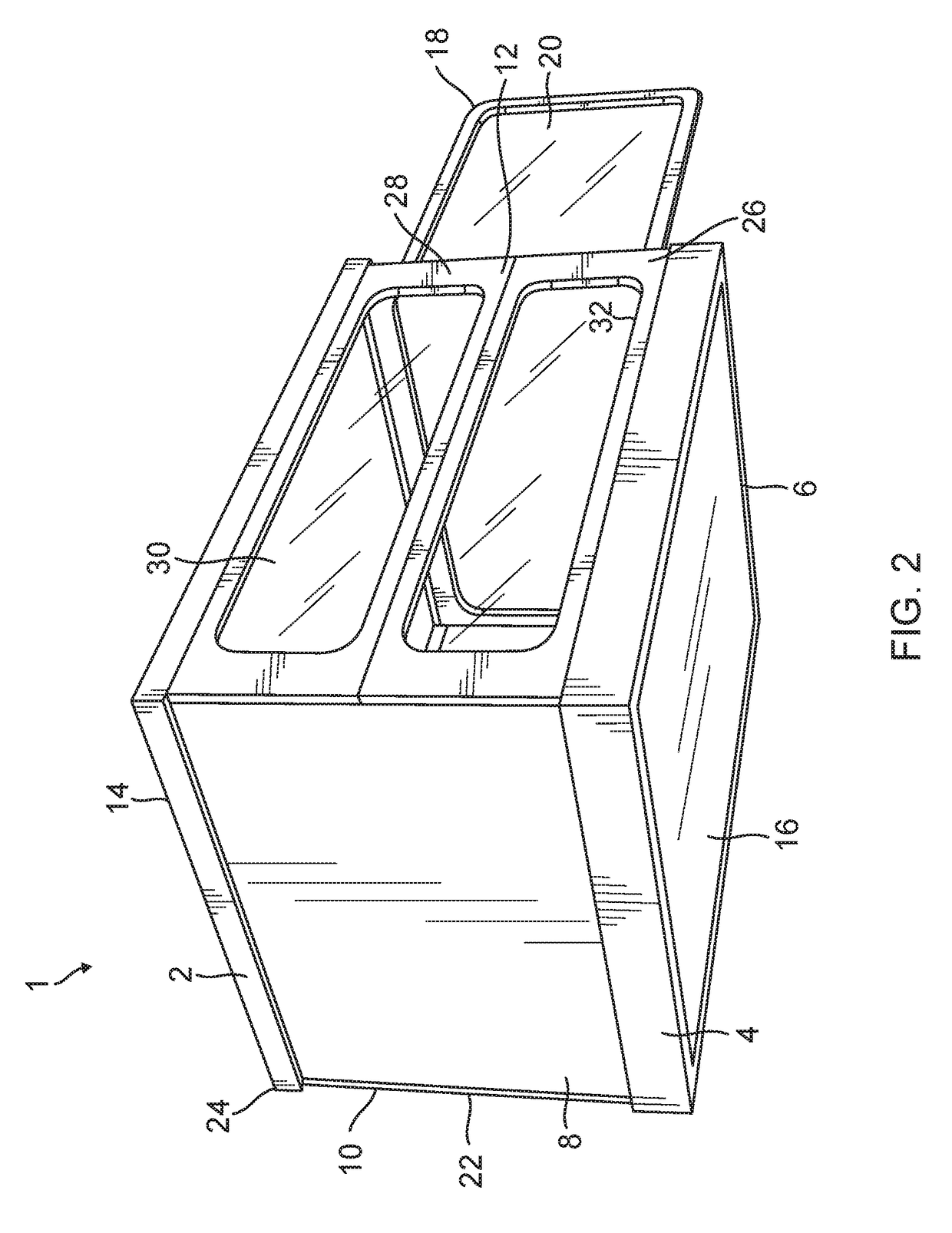

Plastic panel enclosure system

InactiveUS6892497B2Shape miniaturizationEasy constructionBuilding roofsWallsInjection mouldingBilateral symmetry

The present invention provides a system, or kit, of injection molded panels having integrated connectors which combine to form an enclosure, commonly in the form of a utility shed. The bilaterally symmetrical panels are formed of injection molded plastic to interlock with one another without the need for separate I-beam connectors. The ends of the wall panels have cavities to accept both roof and floor outwardly projecting interlocking posts for interlocking cooperative engagement which serve to rigidly connect the components together. The bilateral symmetry of the wall, roof, floor and door components also minimizes component shapes and simplifies enclosure construction.

Owner:SUNCAST

Ergonomic wheelchair seat

InactiveUS6032975ASolve the lack of heightCarriage/perambulator accessoriesDiagnosticsWheelchairEngineering

A wheelchair seat assembly (16) including a seat (30,36), and back rest assembly (49). Back rest assembly (49) includes lateral pelvic supports (52) for carrying pelvic bolster pads (62), an outer shell piece (50) and an inner shell piece (28) adjustably secured to each other, torso supports (76) and a head rest assembly (88). Outer shell piece (50) has a deep concave shape while inner shell piece (28) has a shallow concave shape, which creates a gap (120). Gap (120) provides space for receiving torso supports (76) and head rest assembly (88) in a manner that these two components can be adjusted without interfering with the back rest cushion and without causing discomfort for the user.

Owner:SUNRISE MEDICAL (US) LLC

Spinal implant for use during retroperitoneal lateral insertion procedures

InactiveUS20120010717A1Realize distributionMinimize traumaSurgerySpinal implantsSpinal columnIntervertebral space

A method is disclosed for introducing a spinal disc implant into an intervertebral space of a subject. The subject is placed in a lateral position, and the anterior face of the spinal disc intervertebral space is accessed, between the L5 and S1 vertebrae, from an anterior and lateral retroperitoneal approach. An operative corridor to the anterior face of the spinal disc space is established by introducing a retractor instrument anterolaterally to the spinal disc space between the anterior superior iliac spine and the anterior inferior iliac spine. The damaged spinal disc contents are removed from the intervertebral space through the operative corridor, and the implant is advanced into the intervertebral space at an oblique angle and pivoted to position the implant substantially laterally within the intervertebral space. Elongated retractor and insertion instruments, as well as a modified disc implant, are also disclosed for carrying out the method.

Owner:SPANN SCOTT

Method of retroperitoneal lateral insertion of spinal implants

ActiveUS20120010715A1Realize distributionMinimize traumaSurgerySpinal implantsSpinal columnIntervertebral spaces

A method is disclosed for introducing a spinal disc implant into an intervertebral space of a subject. The subject is placed in a lateral position, and the anterior face of the spinal disc intervertebral space is accessed, between the L5 and S1 vertebrae, from an anterior and lateral retroperitoneal approach. An operative corridor to the anterior face of the spinal disc space is established by introducing a retractor instrument anterolaterally to the spinal disc space between the anterior superior iliac spine and the anterior inferior iliac spine. The damaged spinal disc contents are removed from the intervertebral space through the operative corridor, and the implant is advanced into the intervertebral space at an oblique angle and pivoted to position the implant substantially laterally within the intervertebral space. Elongated retractor and insertion instruments, as well as a modified disc implant, are also disclosed for carrying out the method.

Owner:PANTHEON SPINAL

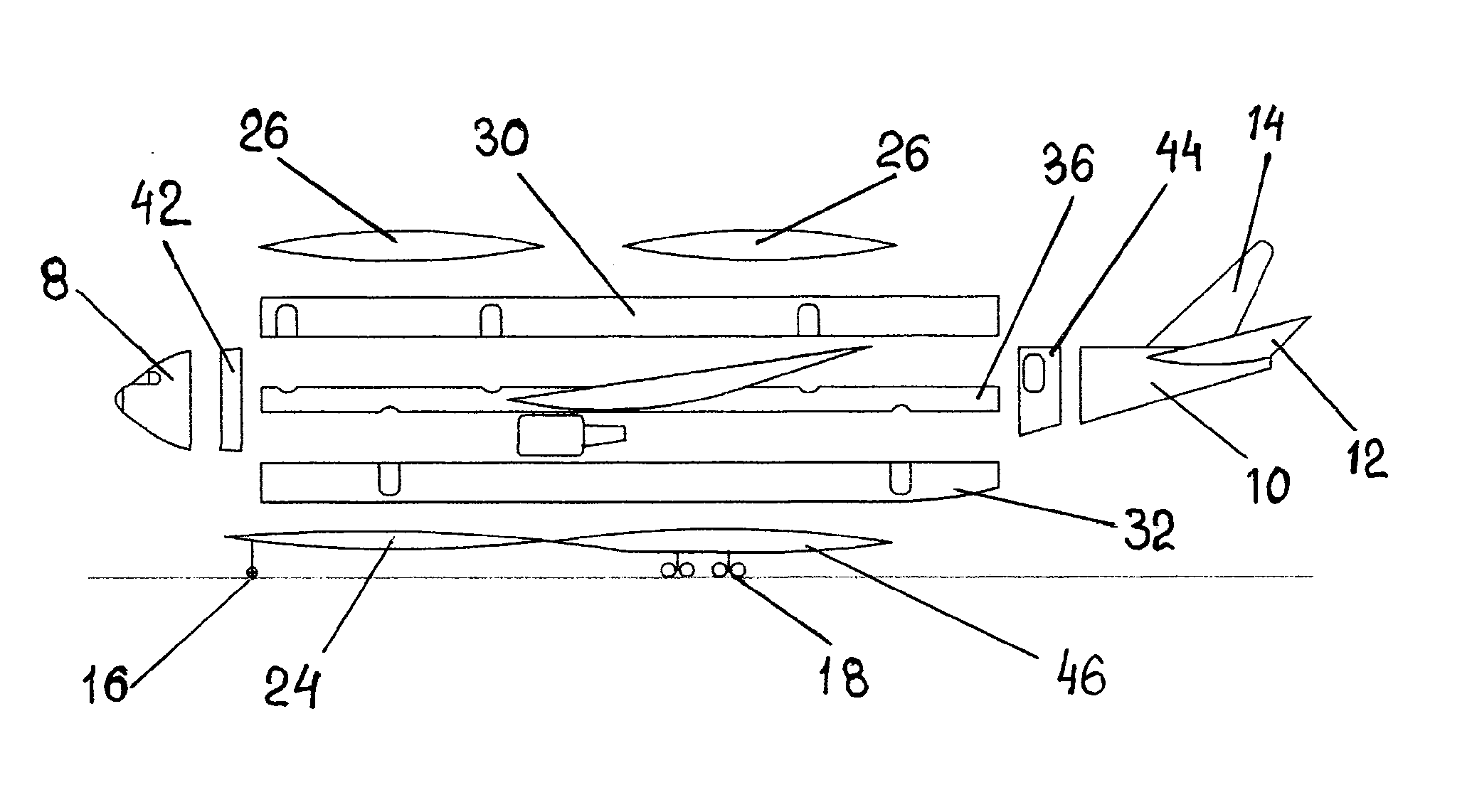

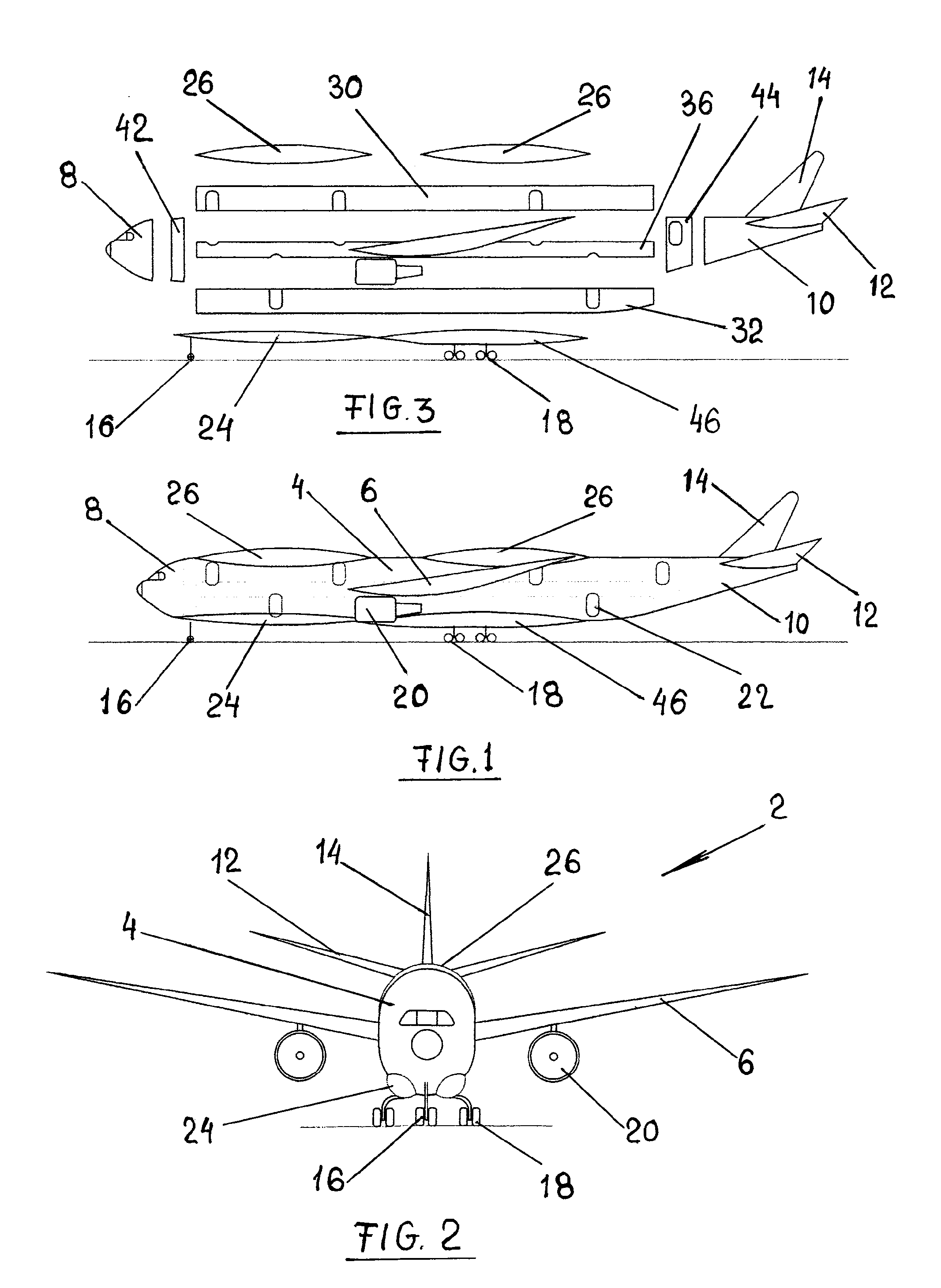

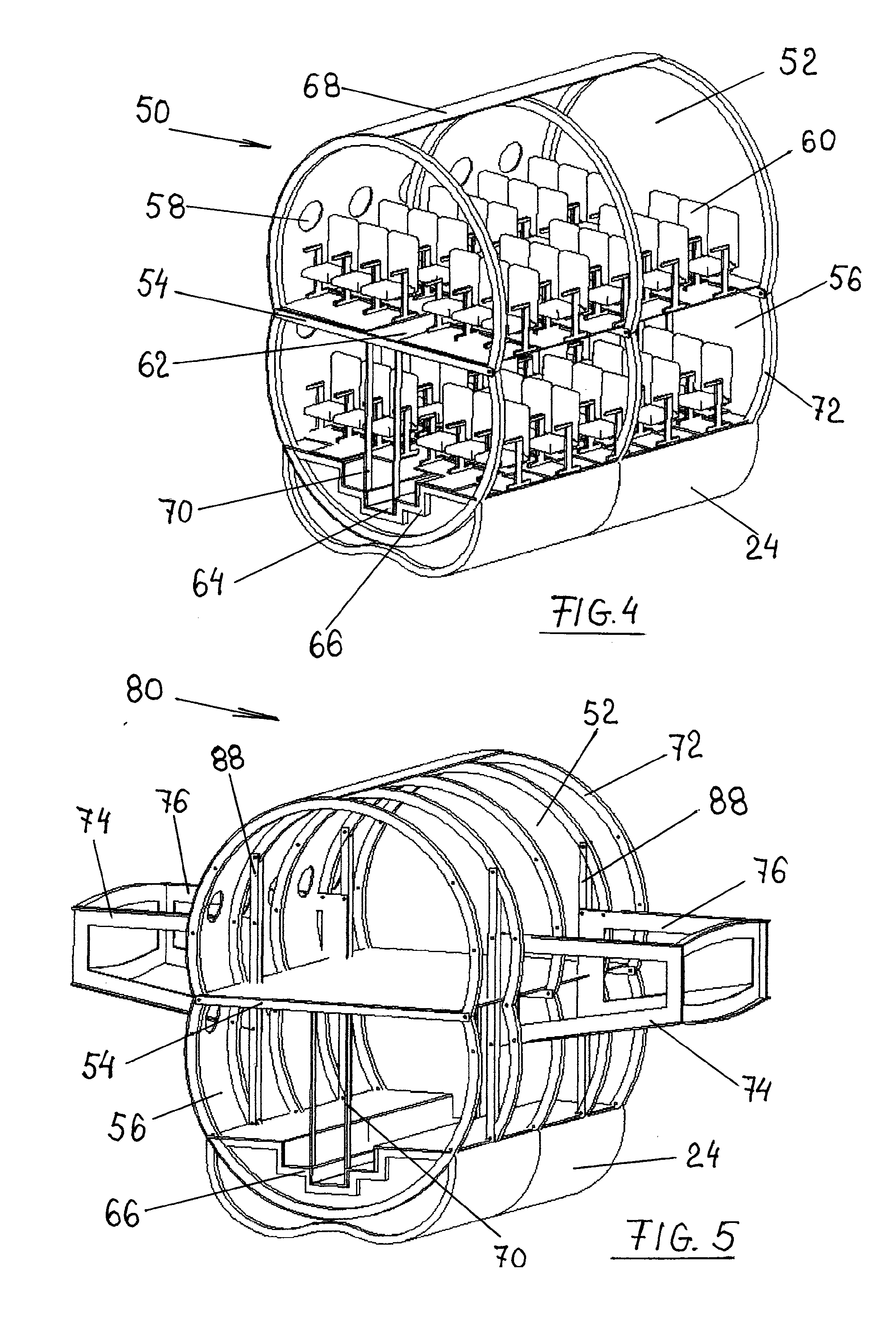

Multi deck aircraft

InactiveUS20100187352A1Improve efficiencyMinimizing fuselage shell thicknessFuselage framesPower plant fuel tanksWetted areaFlight vehicle

The invention relates to multi deck passenger aircraft, having passenger cabins and / or service facilities arranged on the upper and lower deck and inner load bearing cell structure provided within aircraft body. The present invention is also directed toward methods for manufacturing derivative multi deck aircrafts. Energy absorbing, floatable cargo containers (24) attached to fuselage belly. External fuel tanks (26) displaced on the top of fuselage. Center wing region of the fuselage is using for arranging rows of seats and service facilities. Addition seating configuration for narrow and wide bodied aircraft is provided. Multi deck seating configuration significantly reduces per passenger operating cost over existing technology. Less fuel per passenger is required since there is less airframe weight and wetted area per passenger. Due to the lower overall cost per passenger seat within the multi deck seating structure, the net profit and return on investment in the aircraft are also increased.

Owner:MR MICHAEL YAVILEVICH

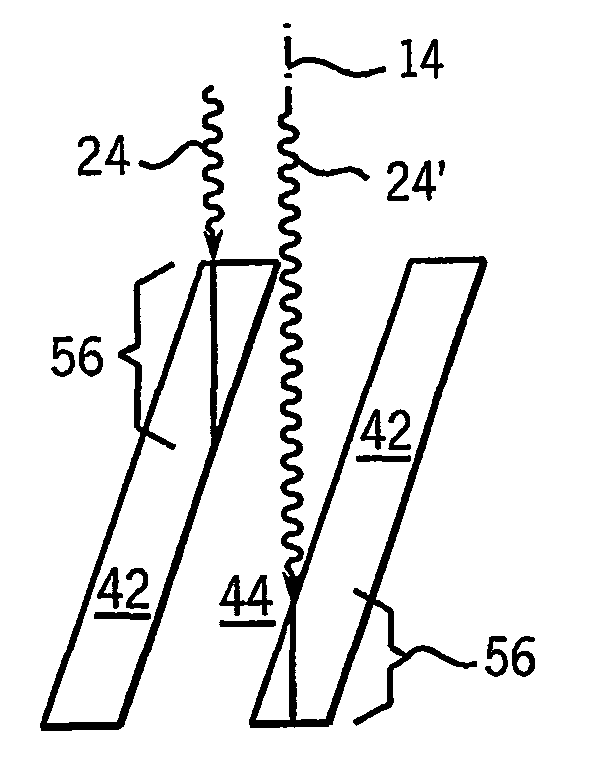

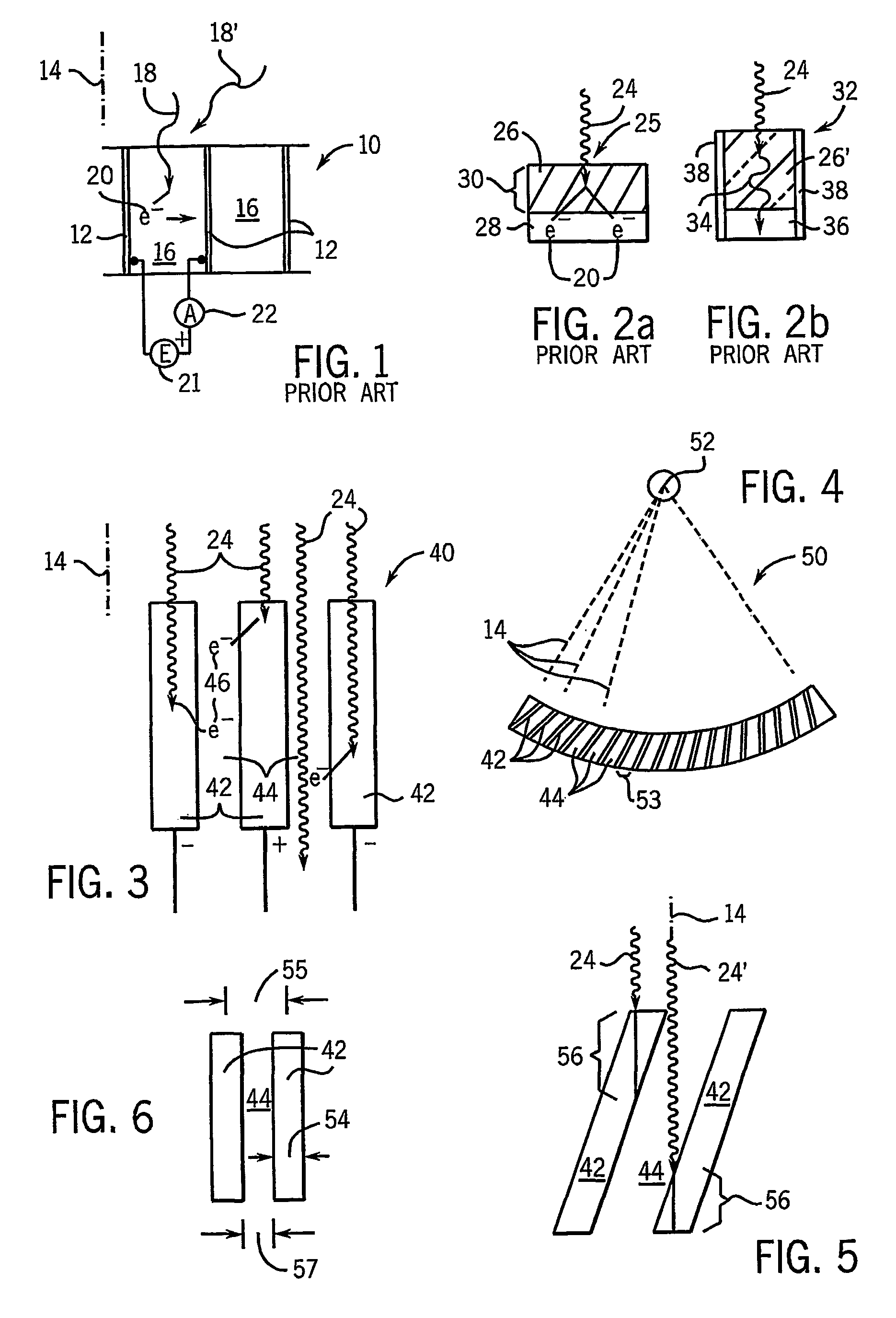

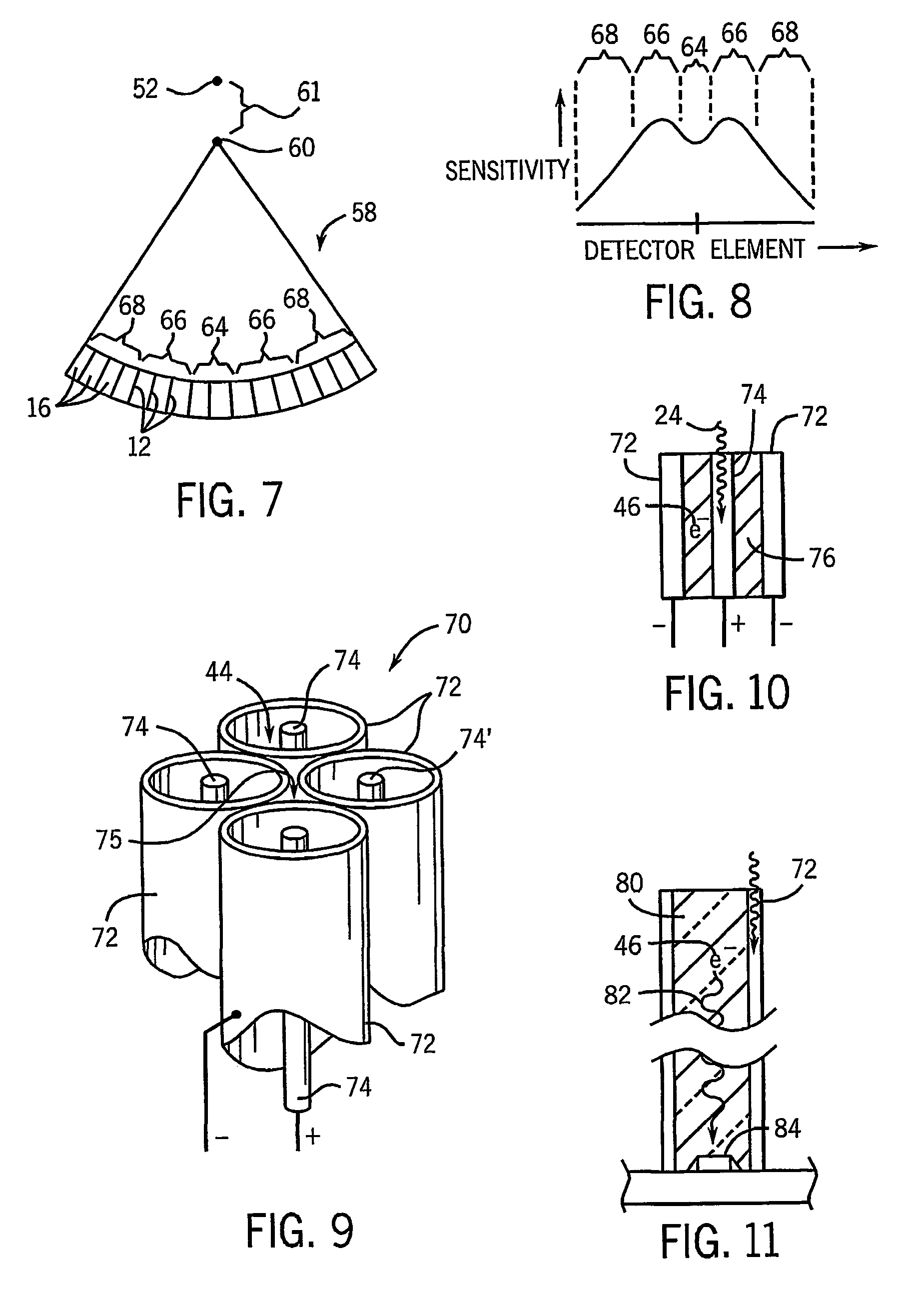

Radiation detector with converters

InactiveUS7186986B2Avoid reabsorptionSolve the lack of heightElectric discharge tubesMaterial analysis by optical meansSecondary electronsReady to use

A high efficiency radiation detector employs longitudinally extending converter elements receiving longitudinally propagating radiation to produce high-energetic electrons received by detector structures in interstitial spaces. The secondary electron generation in this architecture allows great freedom in selection of converter materials and thickness. A variety of detector mechanisms may be used including ionization-type detectors or scintillation-type detector.

Owner:WISCONSIN ALUMNI RES FOUND

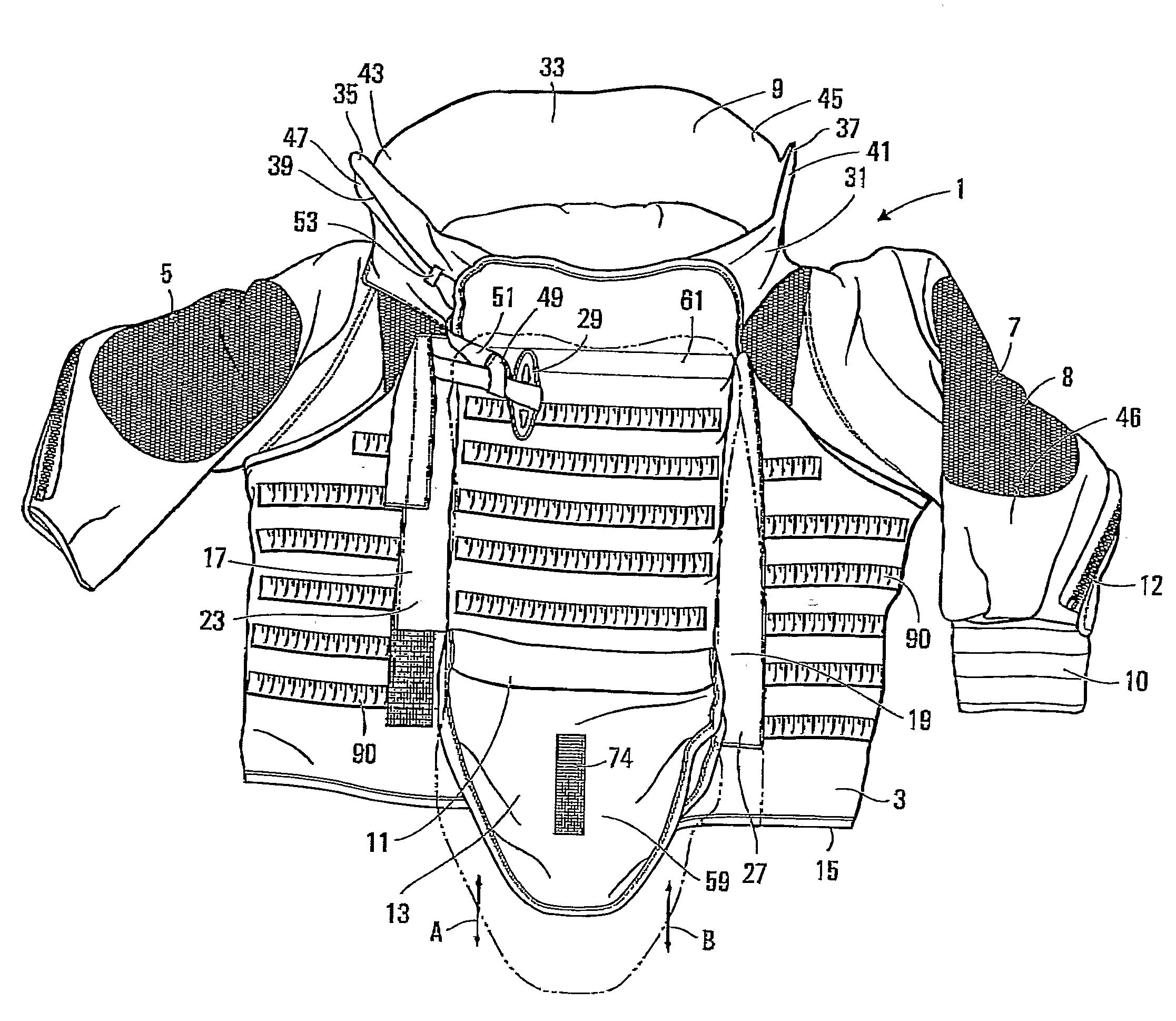

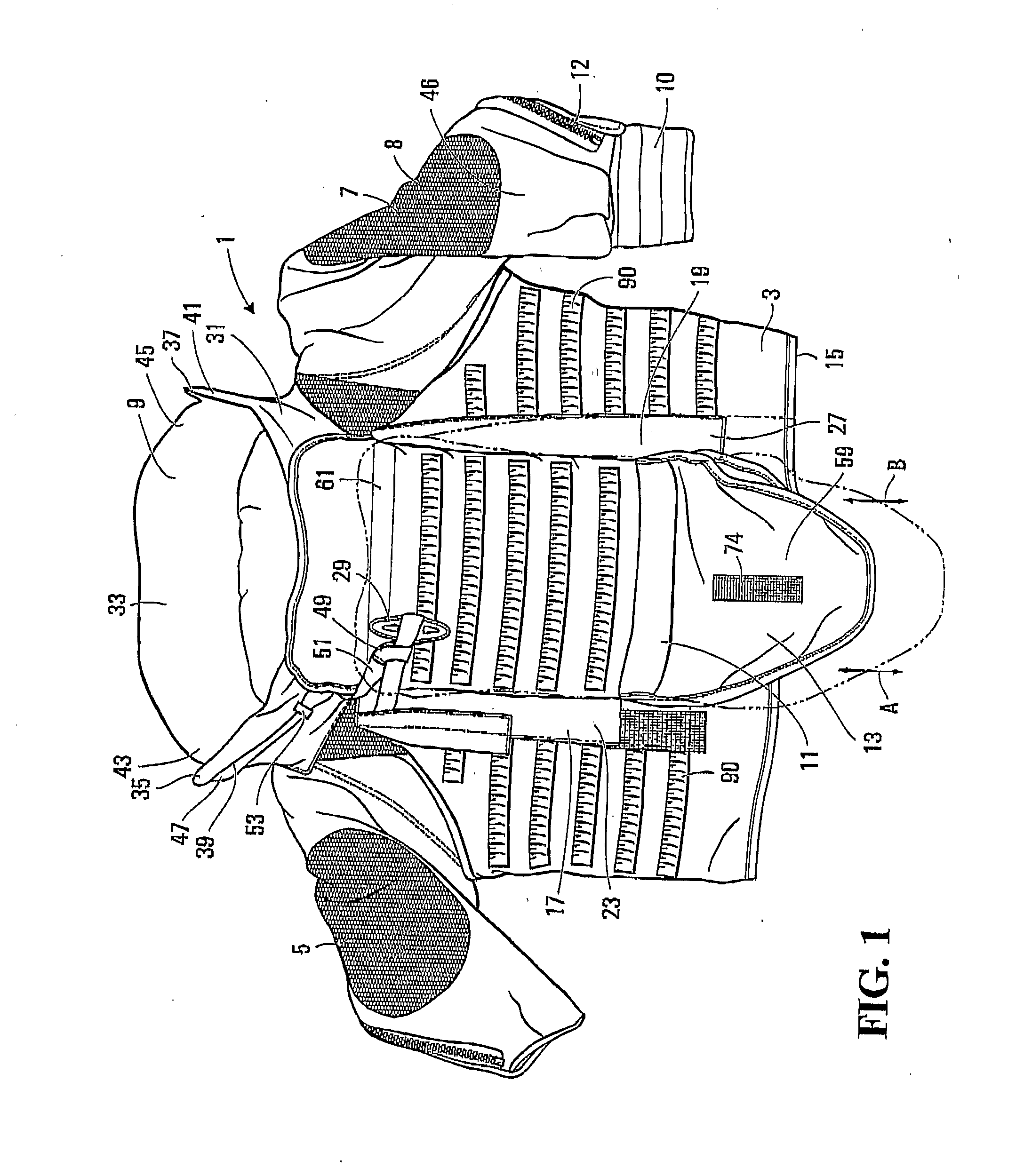

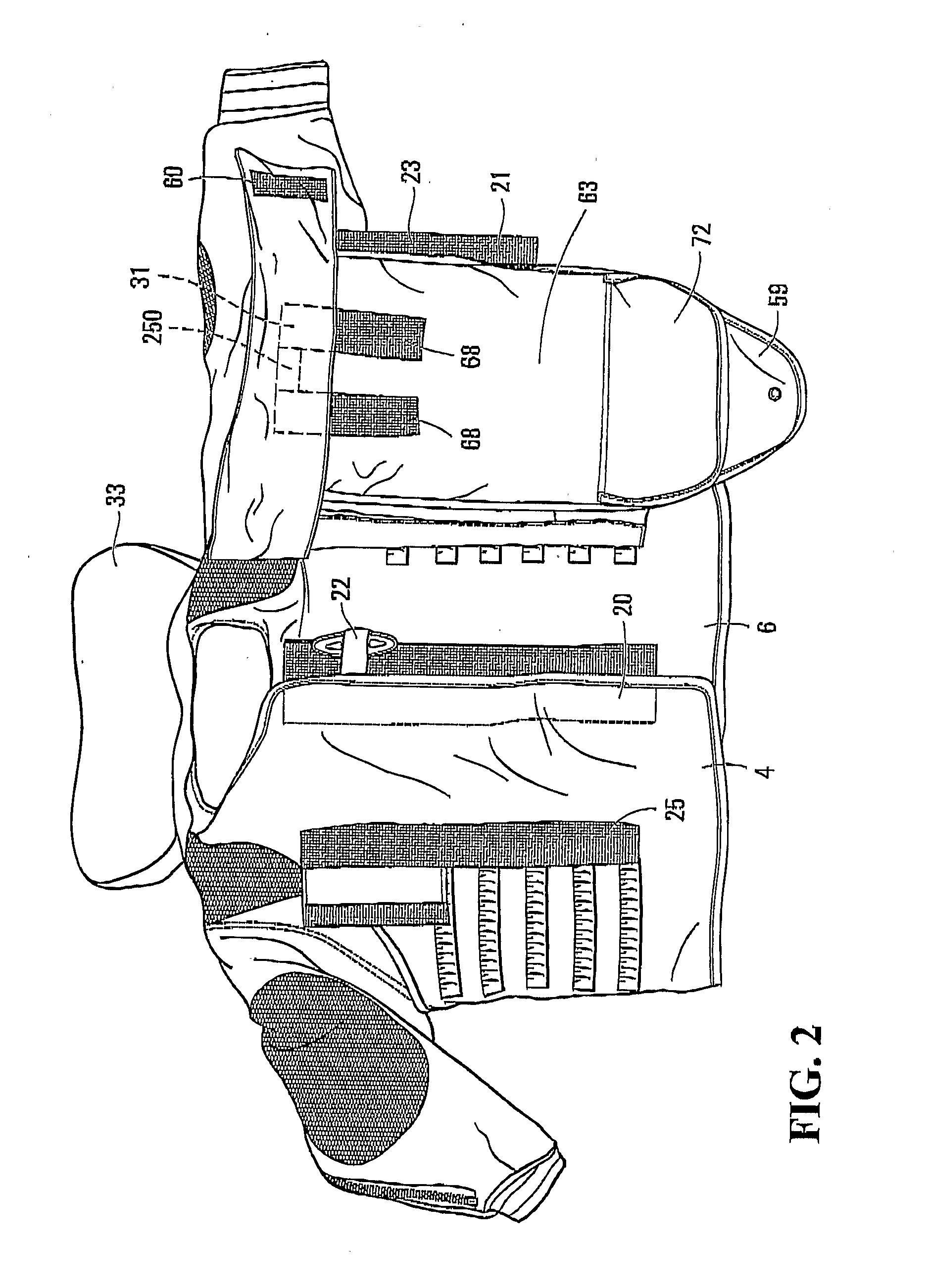

Protective Garment

ActiveUS20080134419A1Solve the lack of heightImprove versatilityChemical protectionHeat protectionEffective lengthMechanical engineering

A protective garment is provided and includes a jacket having various releasably mounted protective components. The jacket includes a protective collar of ballistic resistant fabric for protecting the neck of a wearer and has front and rear portions which are releasably connected together at opposed side portions of the collar so that the front and rear portions can fold down when not in use. A protective plate is releasably fastened to the front of the jacket and the fastening mechanism allows the plate to be held in a number of different vertical positions. The jacket also includes a rear pocket for housing a rear protective plate. The sleeves of the jacket include a sleeve extension which is slideably mounted to the main sleeve to vary its effective length.

Owner:MUSTANG SURVIVAL ULC +1

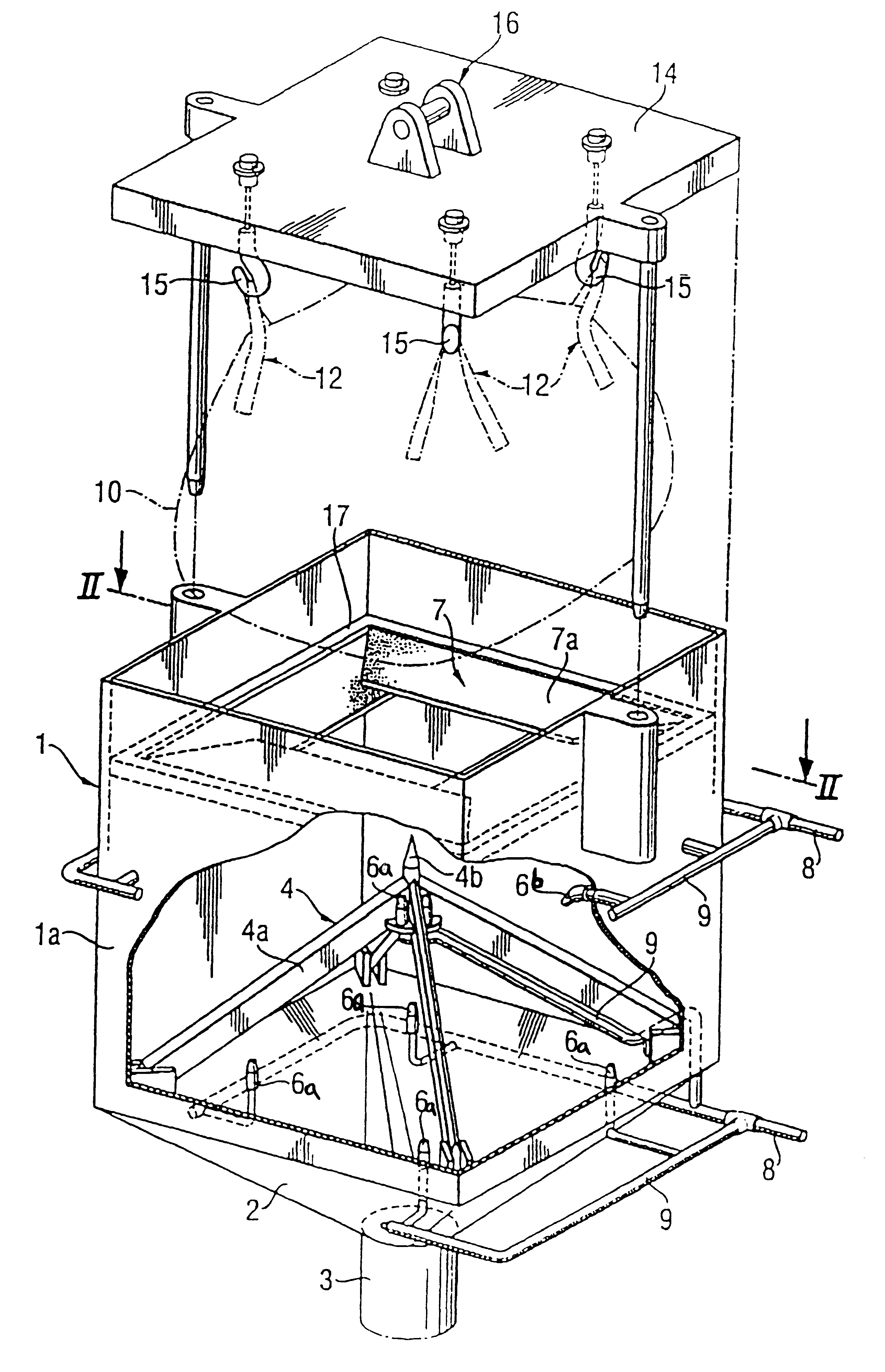

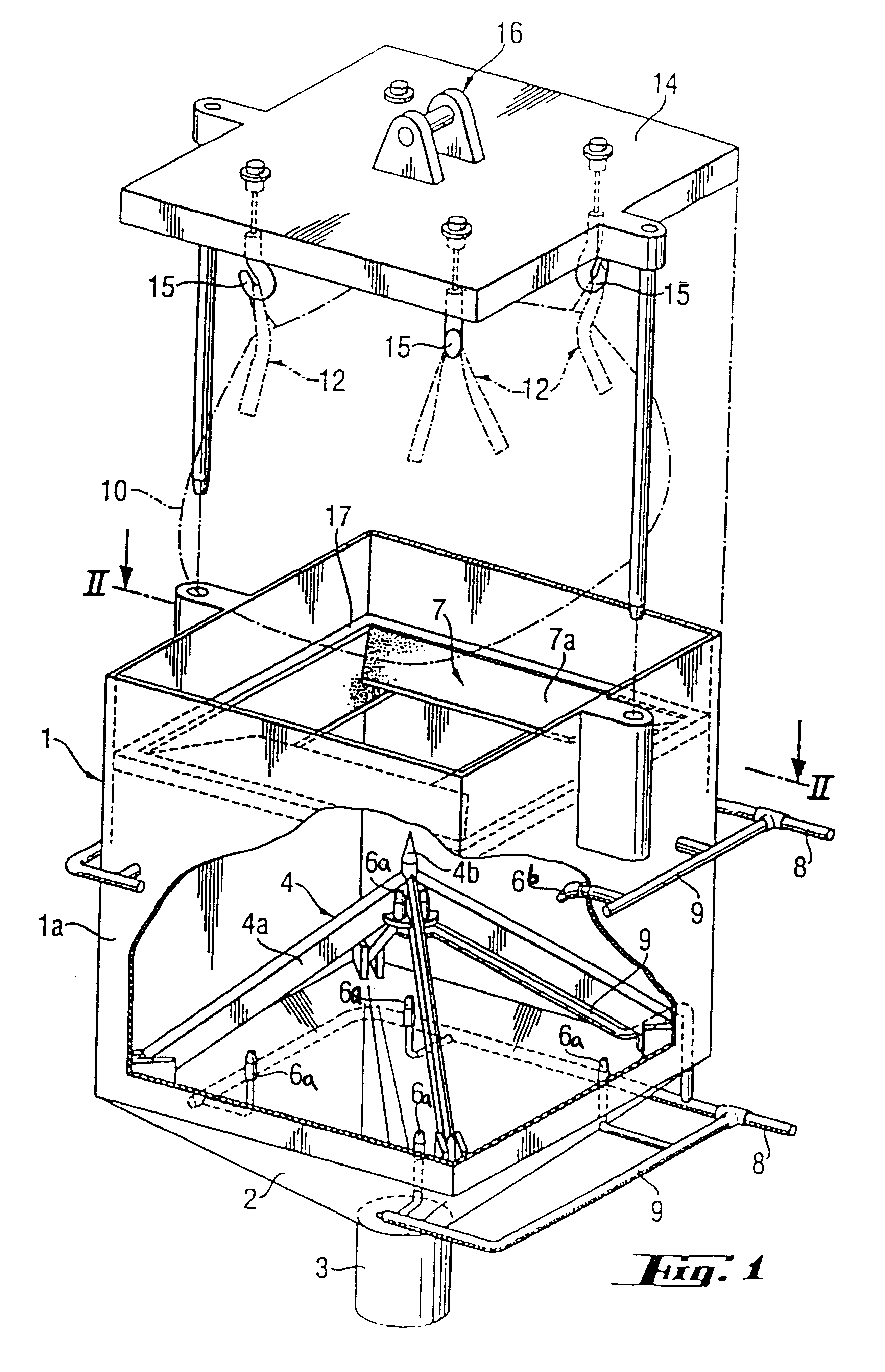

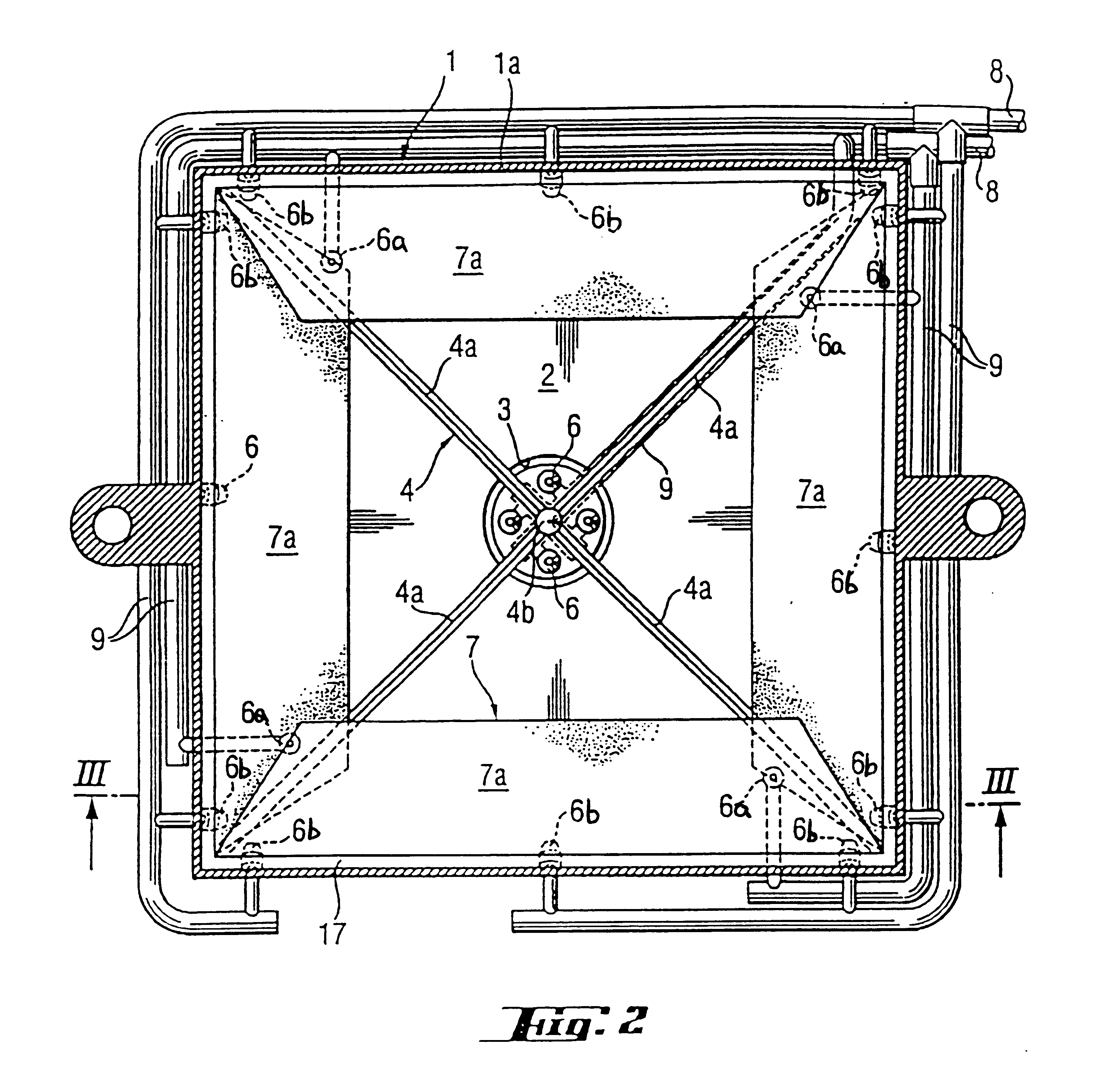

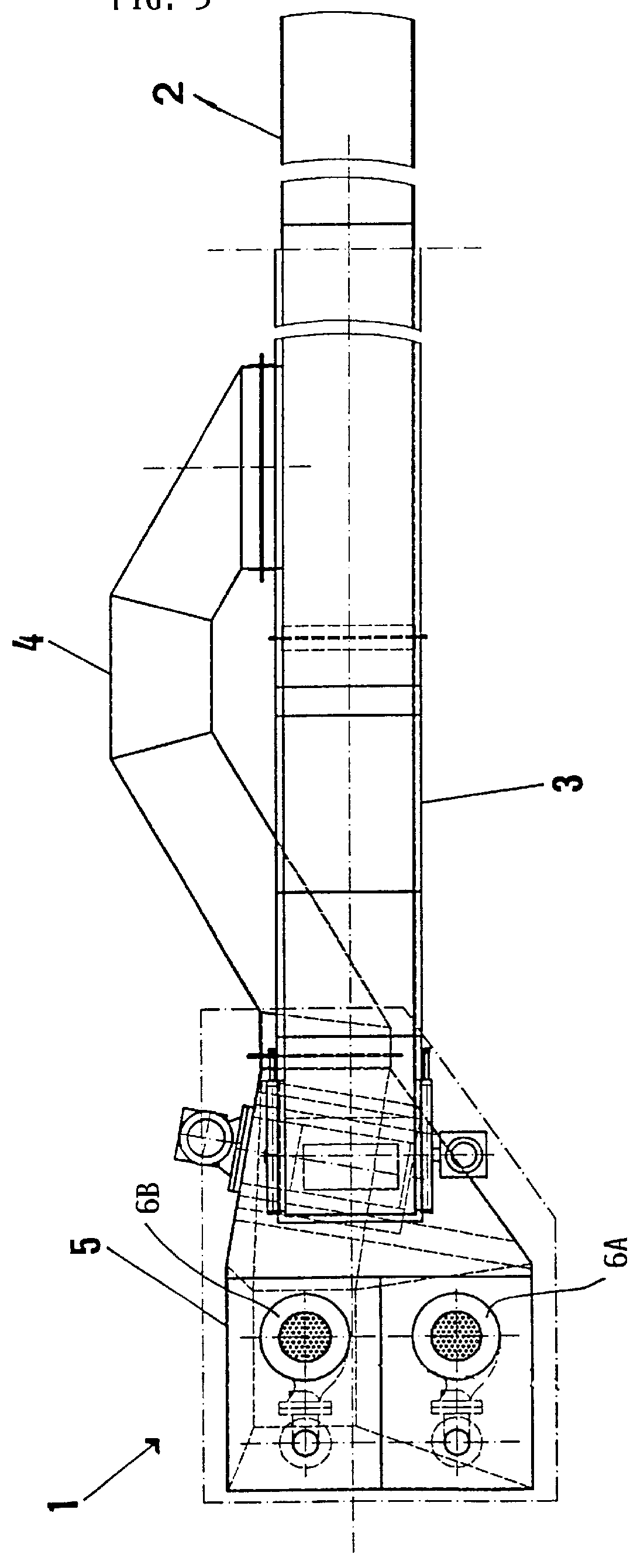

Emptying station for bulk bags, and process of emptying bulk bags in the station

This emptying station is suited for emptying contents from bulk bags, especially bulk bags containing particulate hazardous materials as their contents. The emptying station includes a bulk-bag receptacle body having a top opening and bottom outlet, a bulk-bag cutting subassembly in the receptacle body, a raisable and lowerable top closure, and a sealing structure. The cutting subassembly includes at least three cutters each having an associated blade facing upwards, with the cutters collectively arranged to define a pyramid having an apex, and puncture pin positioned at the apex to point upwardly. In operation, a bulk bag is suspended from the top closure, then lowered with the top closure to pass the bulk bag into the receptacle body and cause the substantially flat bottom of the bulk bag to be pieced by the puncture pin and cut by the blades of the cutters to start emptying contents from the bulk bags to the bottom outlet. The sealing structure seals gaps formed between inner surfaces of the side walls and the bulk bag to prevent dust from escaping through the top opening. As the bulk bag is emptied, the top closure continues to lower until the top closure is positioned in a closed state in the top opening. Spray nozzles are preferably arranged in the receptacle body for external and / or internal rinsing of the emptied bulk bag.

Owner:DEGUSSA AG

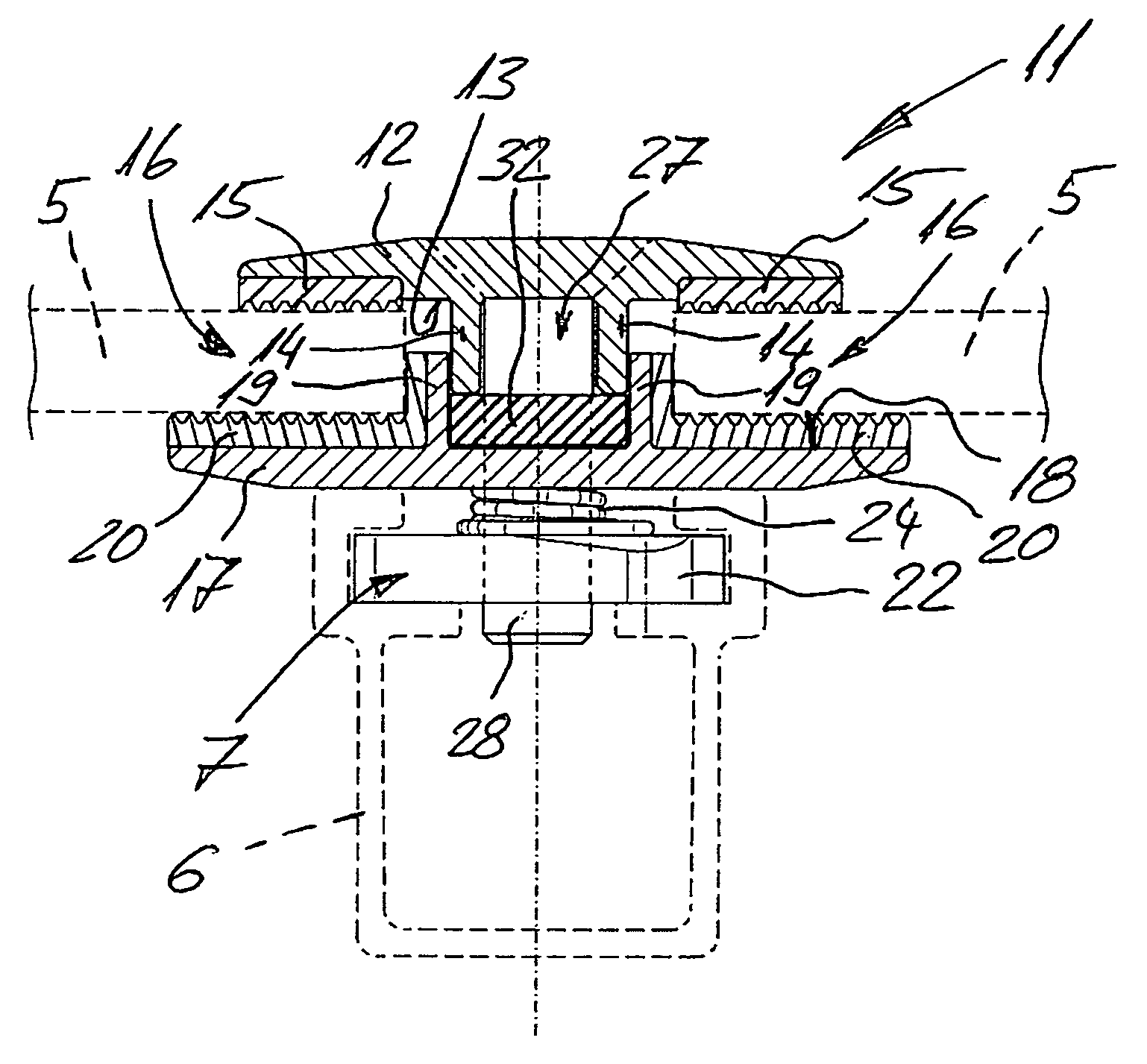

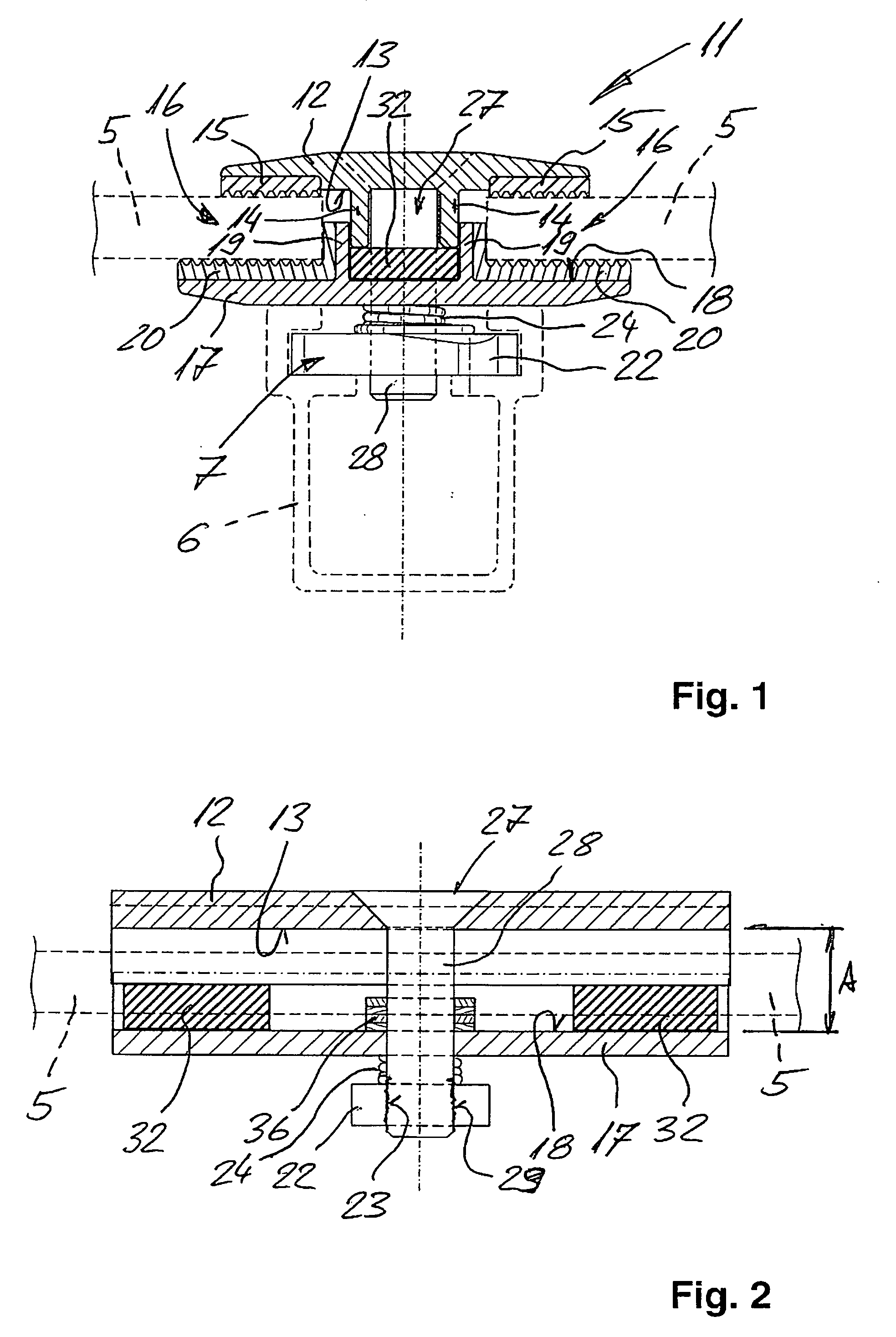

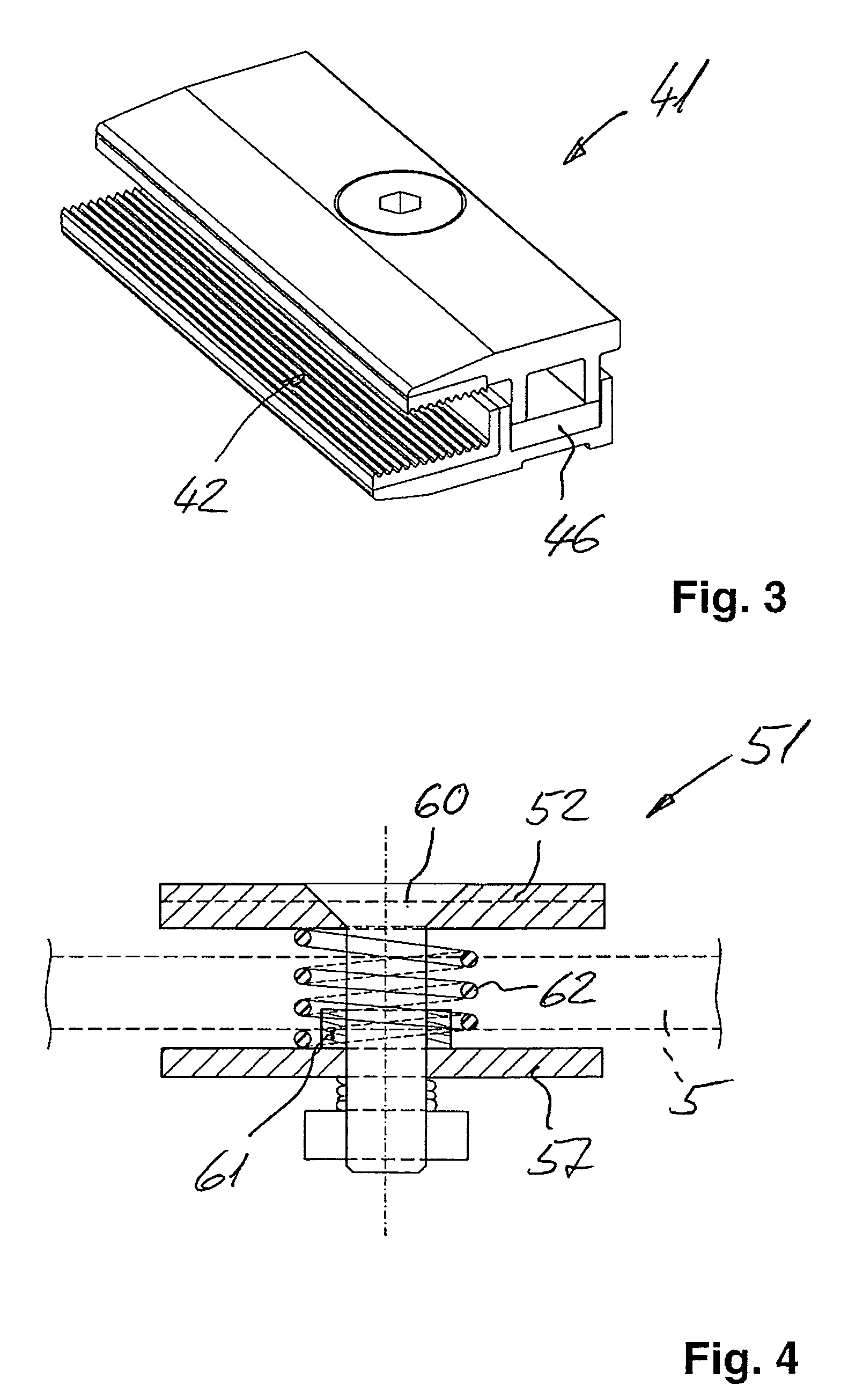

Mounting device for securing plate-shaped elements

InactiveUS20090200443A1Simple and rapid mounting of mountingOptimizationSolar heating energyCandle holdersEngineeringMechanical engineering

Owner:HILTI AG

Plastic expandable utility shed

InactiveUS7395634B2Improves Structural IntegrityIncrease shell rigidityBuilding roofsWallsEngineeringInjection moulding

The present invention provides a system, or kit, of injection molded panels having integrated connectors which combine to form an enclosure, commonly in the form of a utility shed. The panels are formed of injection molded plastic to interlock with one another without the need for separate I-beam connectors. The ends of the wall panels have cavities to accept both roof and floor outwardly projecting locking posts for interlocking cooperative engagement which serve to rigidly connect the components together. The symmetry of the wall, roof, floor and door components also minimizes component shapes and simplifies enclosure construction.

Owner:SUNCAST

Collapsible Shelter

ActiveUS20170335561A1Easy to carryImprove protectionPhotovoltaic supportsSpecial buildingEngineeringRigid wall

Owner:OUTLIER CAMPERS LLC

Method of retroperitoneal lateral insertion of spinal implants

ActiveUS9451940B2Realize distributionMinimize traumaSurgeryJoint implantsSpinal columnIntervertebral spaces

A method is disclosed for introducing a spinal disc implant into an intervertebral space of a subject. The subject is placed in a lateral position, and the anterior face of the spinal disc intervertebral space is accessed, between the L5 and S1 vertebrae, from an anterior and lateral retroperitoneal approach. An operative corridor to the anterior face of the spinal disc space is established by introducing a retractor instrument anterolaterally to the spinal disc space between the anterior superior iliac spine and the anterior inferior iliac spine. The damaged spinal disc contents are removed from the intervertebral space through the operative corridor, and the implant is advanced into the intervertebral space at an oblique angle and pivoted to position the implant substantially laterally within the intervertebral space. Elongated retractor and insertion instruments, as well as a modified disc implant, are also disclosed for carrying out the method.

Owner:PANTHEON SPINAL

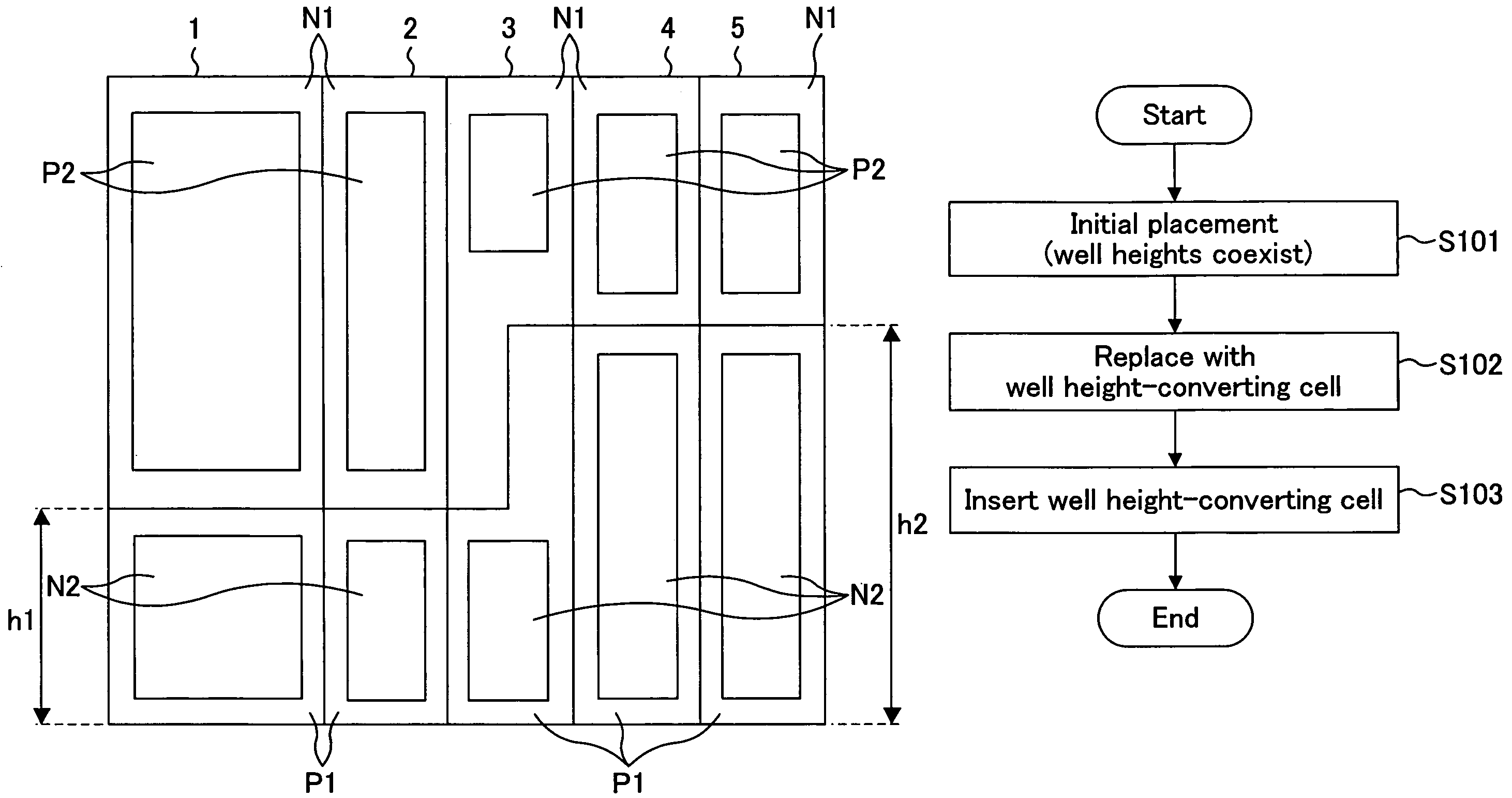

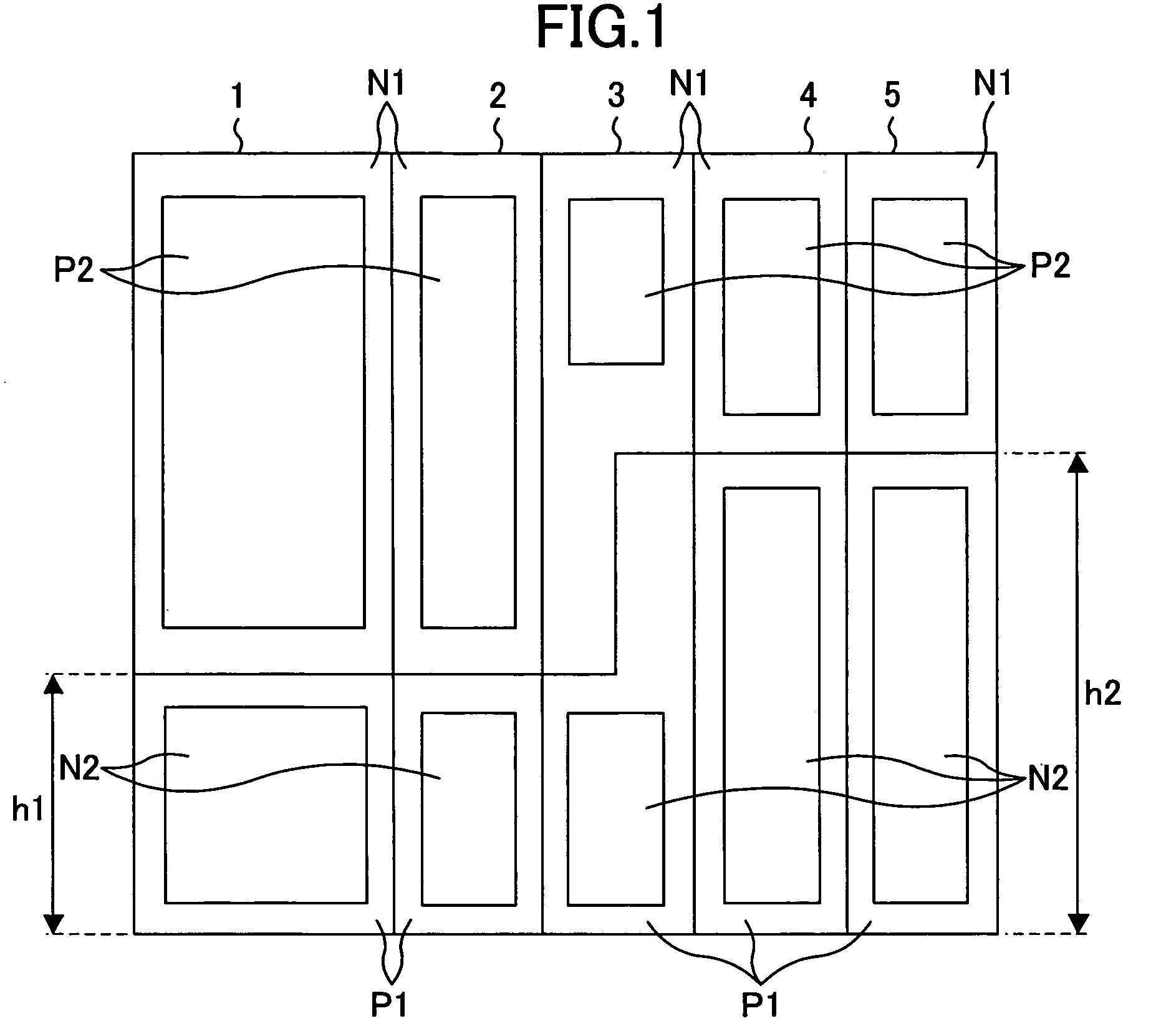

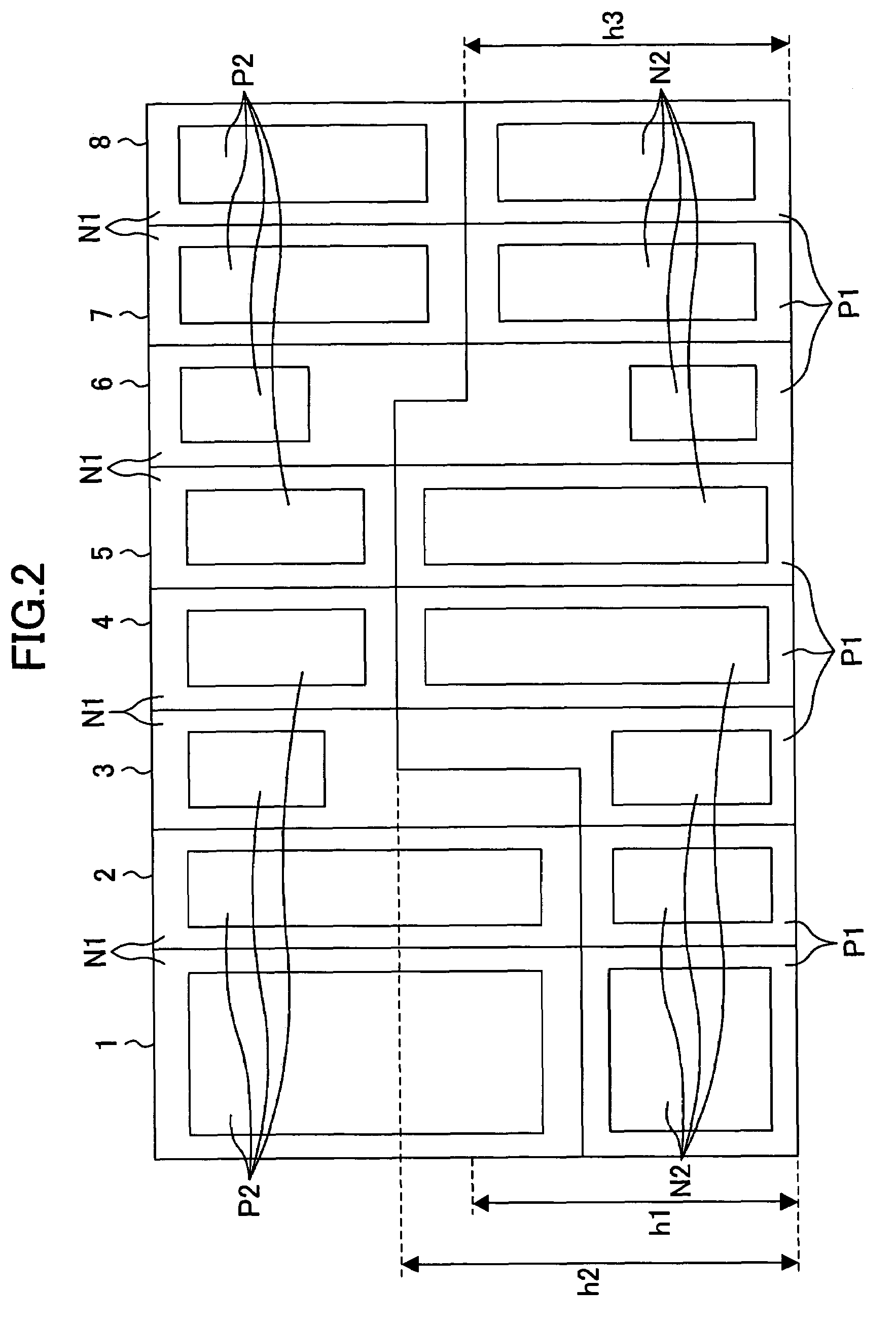

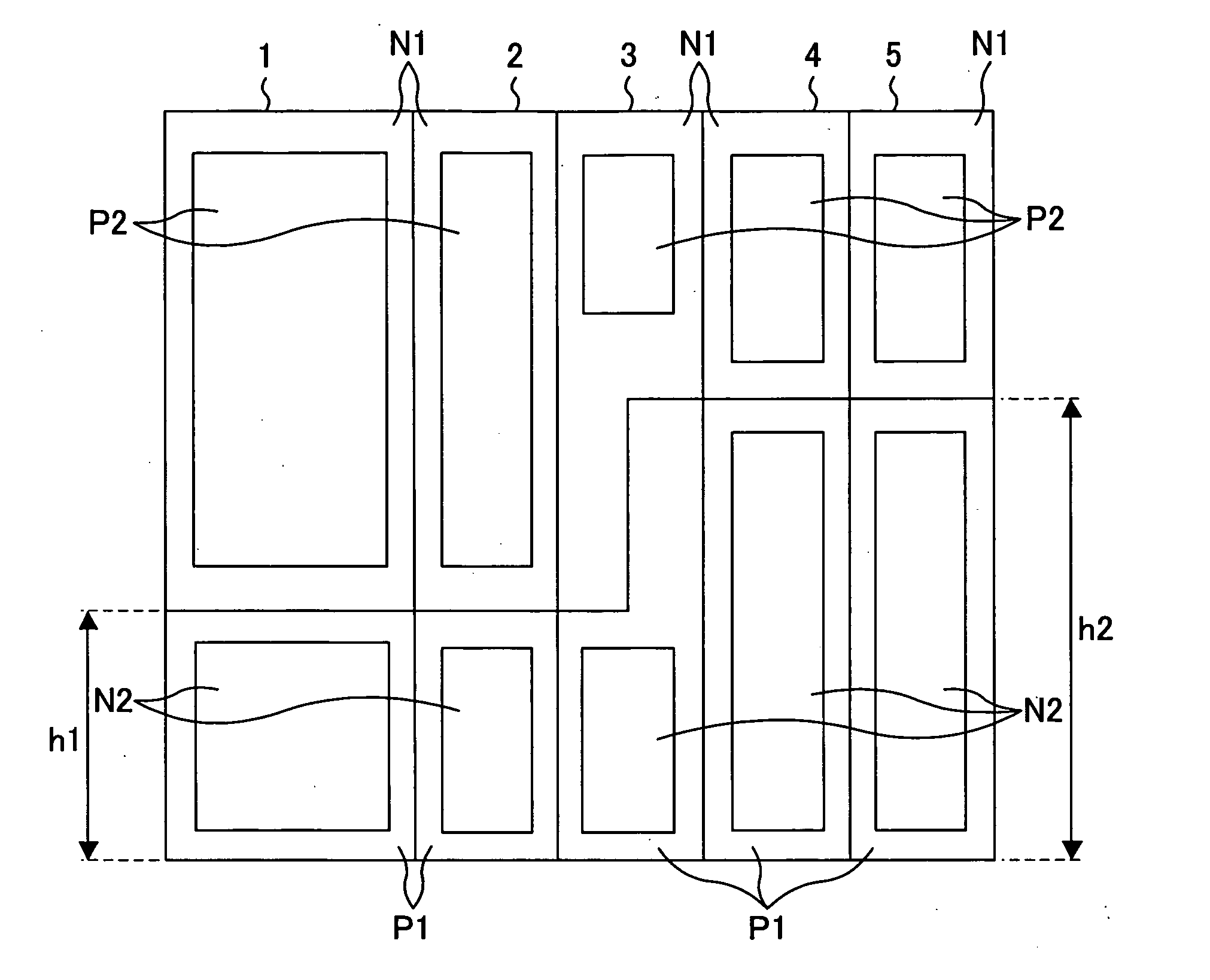

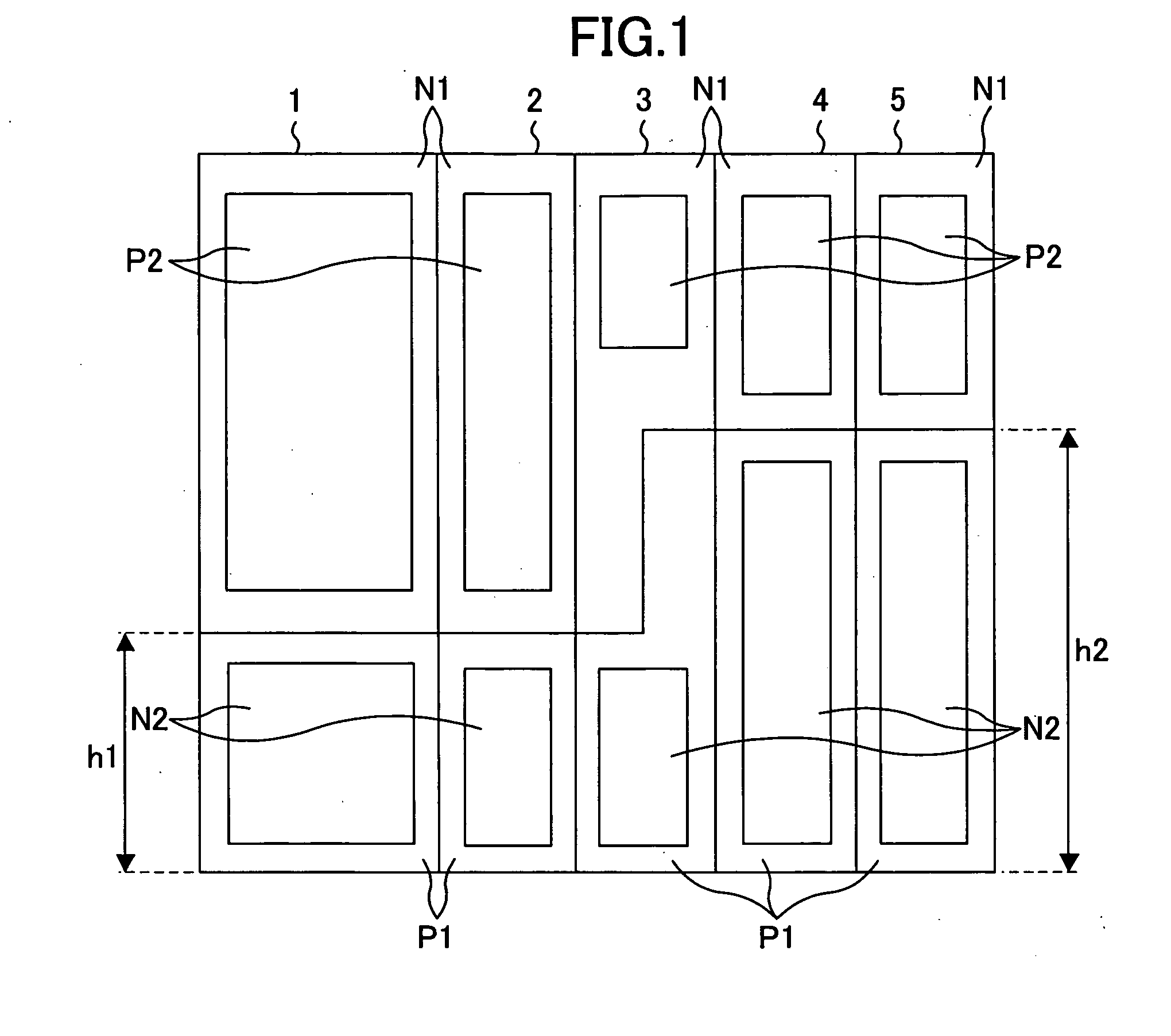

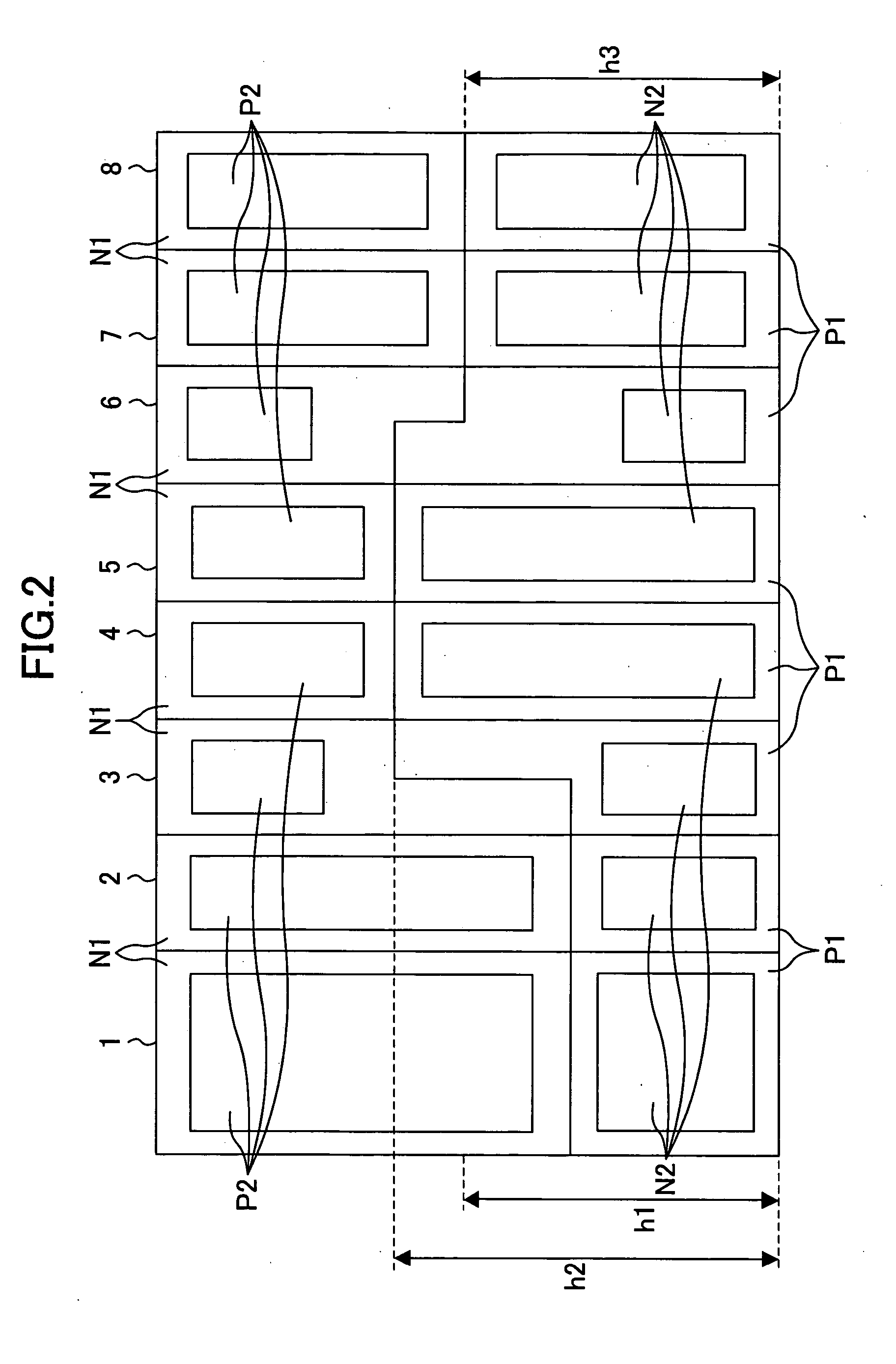

Standard cell, standard cell library, semiconductor device, and placing method of the same

InactiveUS7302660B2Satisfactory level of area efficiencySolve the lack of heightSolid-state devicesSemiconductor/solid-state device manufacturingBorder lineEngineering

Of a plurality of standard cells in which an N-well region and a P-well region are vertically formed, some standard cells have a border line between the N-well region and the P-well region which is set to be a low height (first height), and other standard cells have a border line between the N-well region and the P-well region which is set to be a high height (second height), depending on the size of a transistor formed in the standard cell. Although these standard cells have different border lines, a standard cell for linking the border lines is provided. In such a standard cell, an empty space is created by forming a small-size transistor therein, and the empty space is utilized so that, for example, a left end of the border line is set to have the first height and a right end of the border line is set to have the second height, whereby the border line is converted so as to link the heights therein.

Owner:SOCIONEXT INC

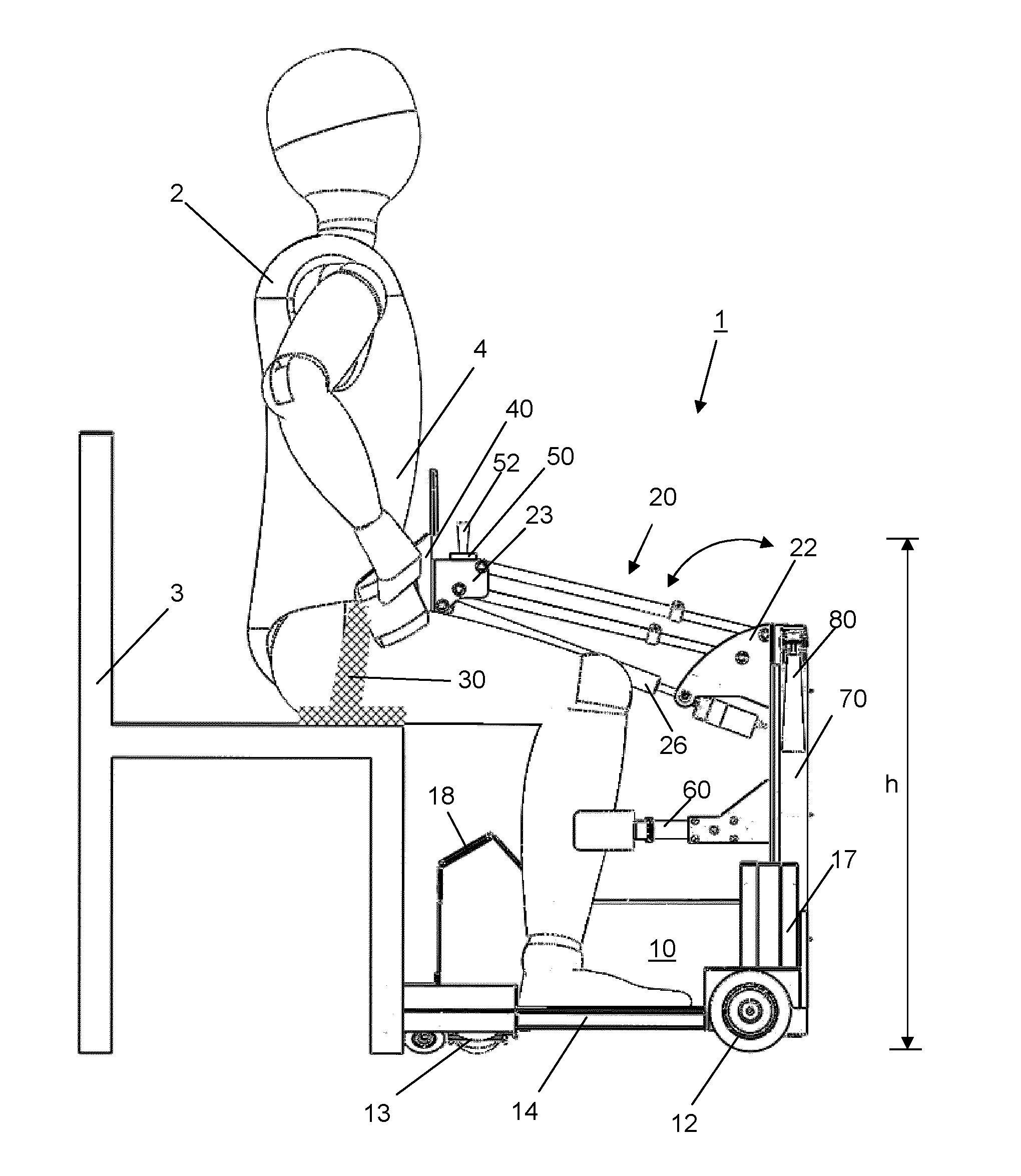

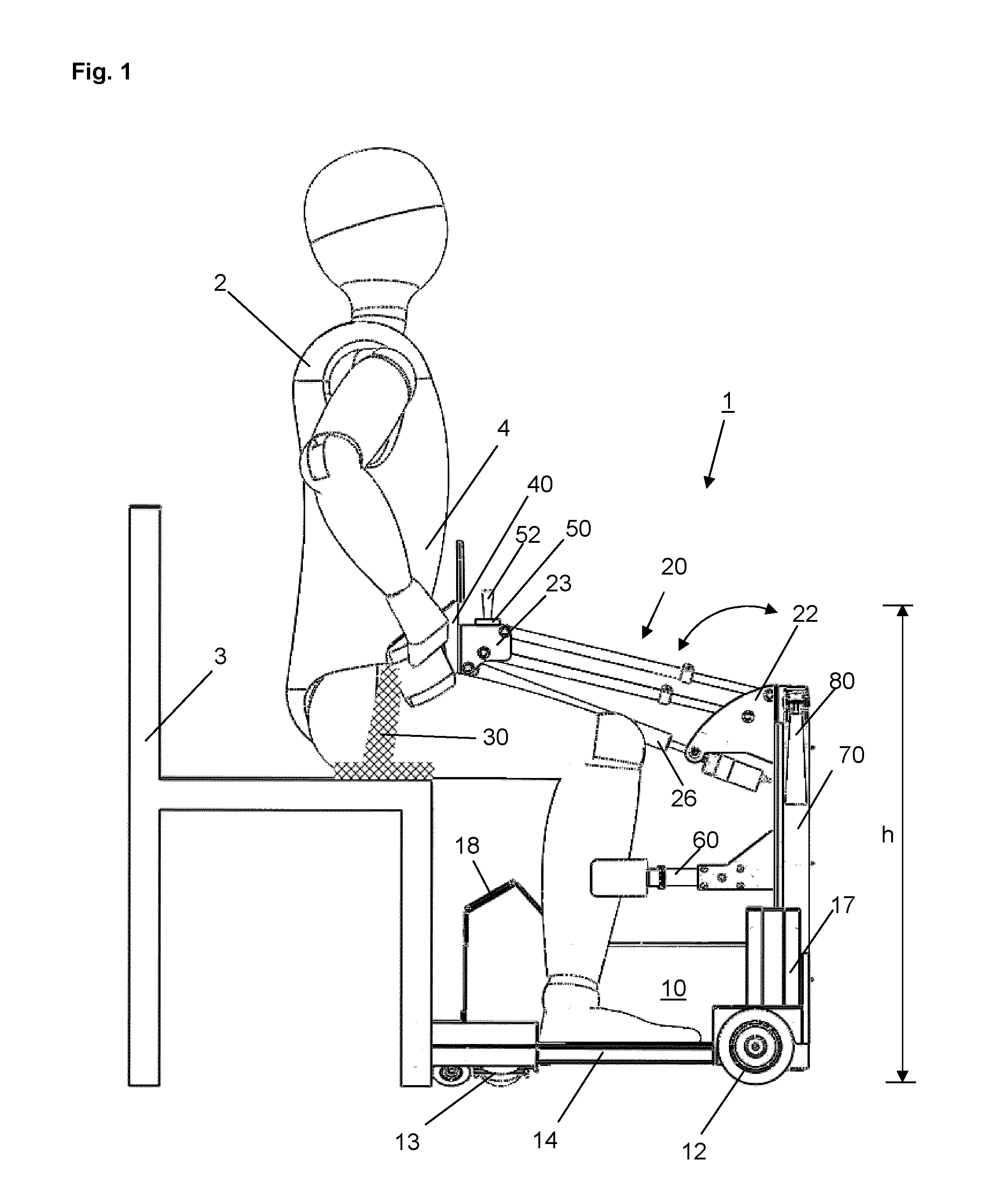

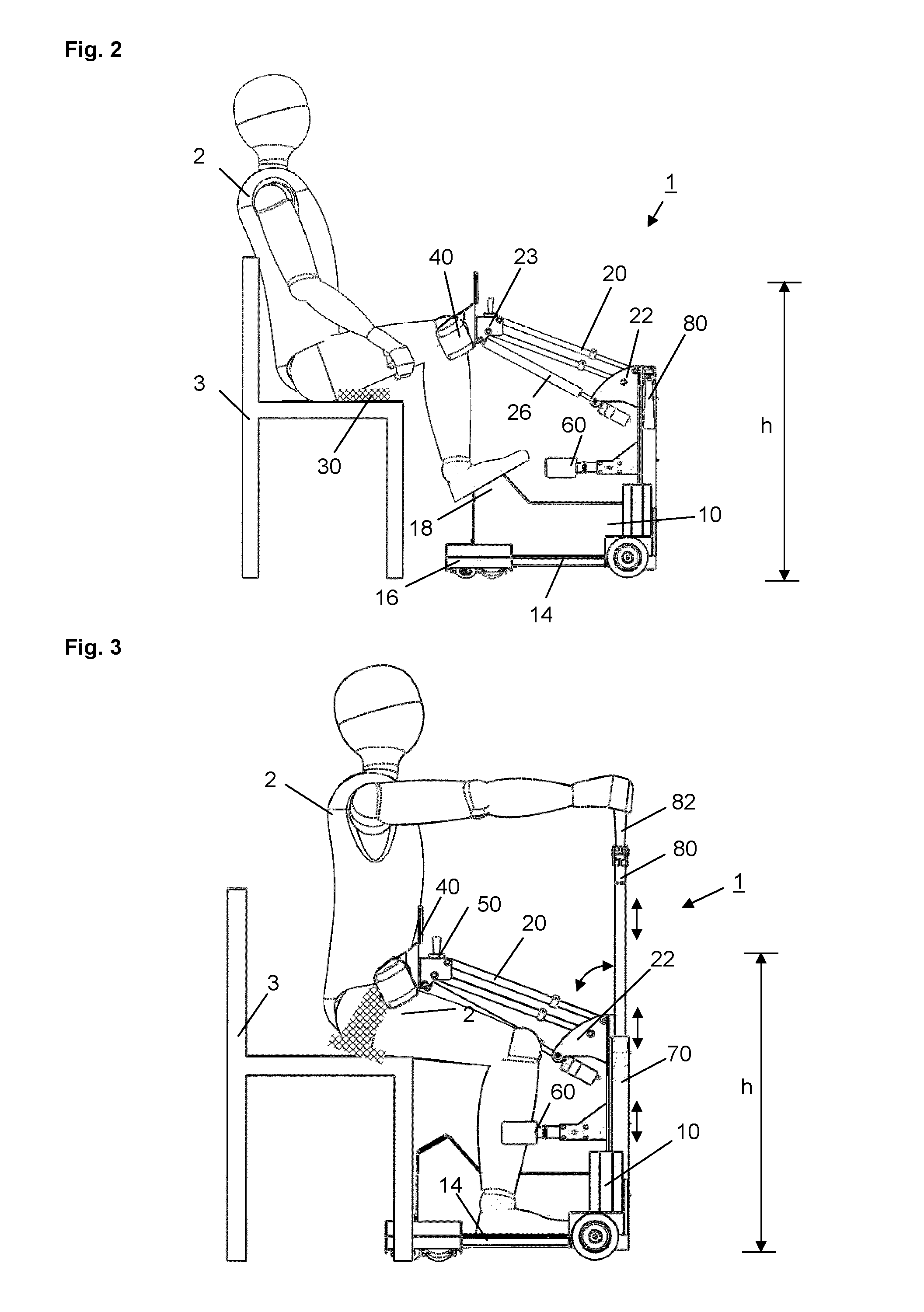

Mobility device for physically disabled people

ActiveUS20150190293A1Easy to set upSolve the lack of heightWheelchairs/patient conveyanceNursing bedsPhysical medicine and rehabilitationStanding Positions

Mobility device for physically disabled people 1, comprising a chassis 10 with at least one motor for maneuvering the entire mobility device 1; a pivot arm 20, which at its lower end 22 is pivotably connected to the chassis 10; and a pelvis support 40, which is connected to an upper end 23 of the pivot arm 20; wherein a physically disabled person 2 can sit with the pelvis support 40 attached to its body, can move around with the mobility device 1 in a standing position on the chassis 10, and can change on its own from sitting to standing position, wherein all elements of the mobility device 1 except the elements directly contacting the body of the person 2 extending above pelvis height h of the sitting person 2 can be lowered or moved to or below this height h. The present invention further comprises a method for erecting of a sitting physically disabled person 2 and for fixing of the person 2 in standing position onto a motor-driven mobility device 1.

Owner:MATIA ROBOTICS MEKATRONIK SISTEMLER AR GE MUHENDISLIK YAZILIM SANAYI VE TICARET ANONIM SIRKETI

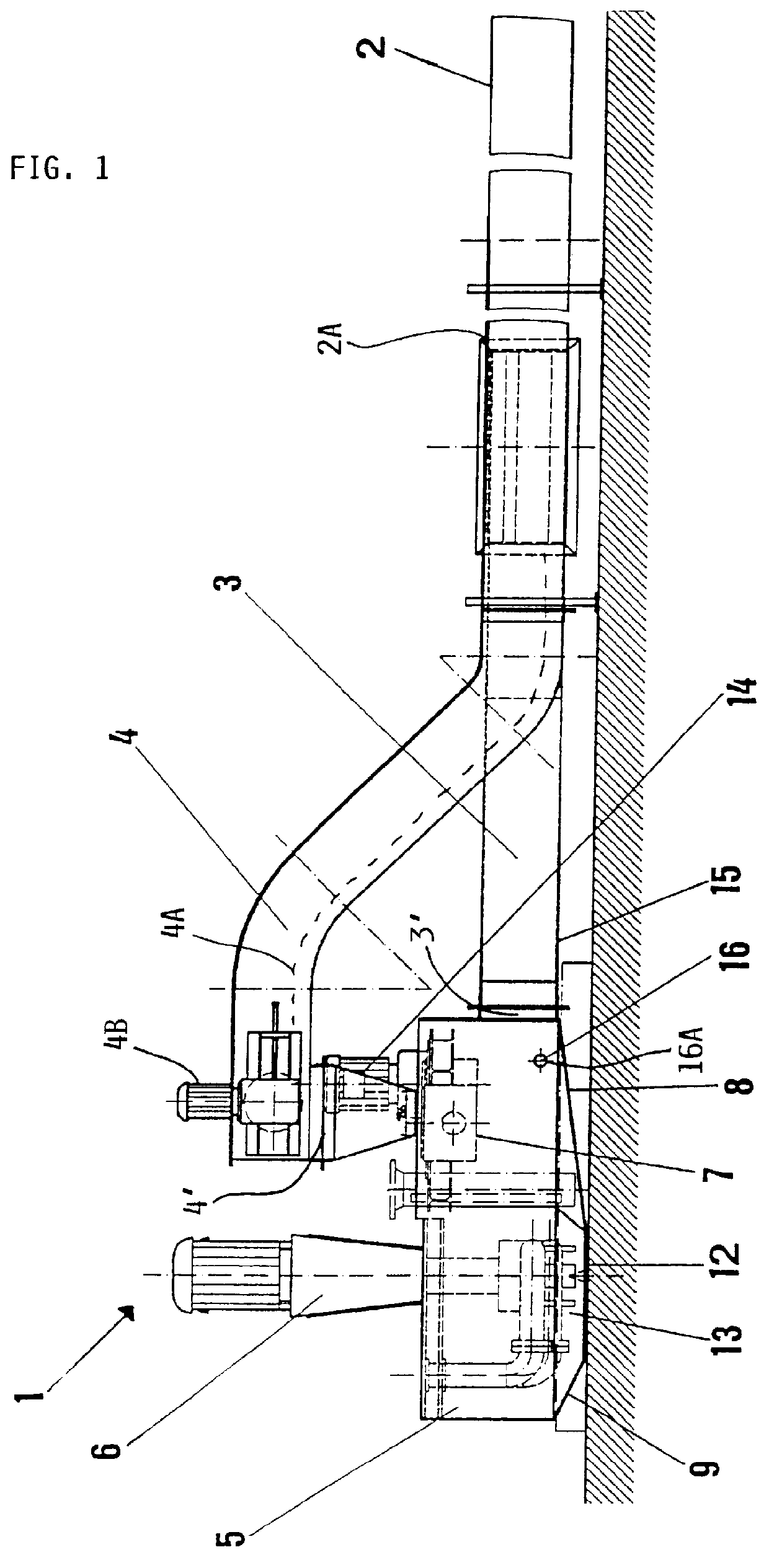

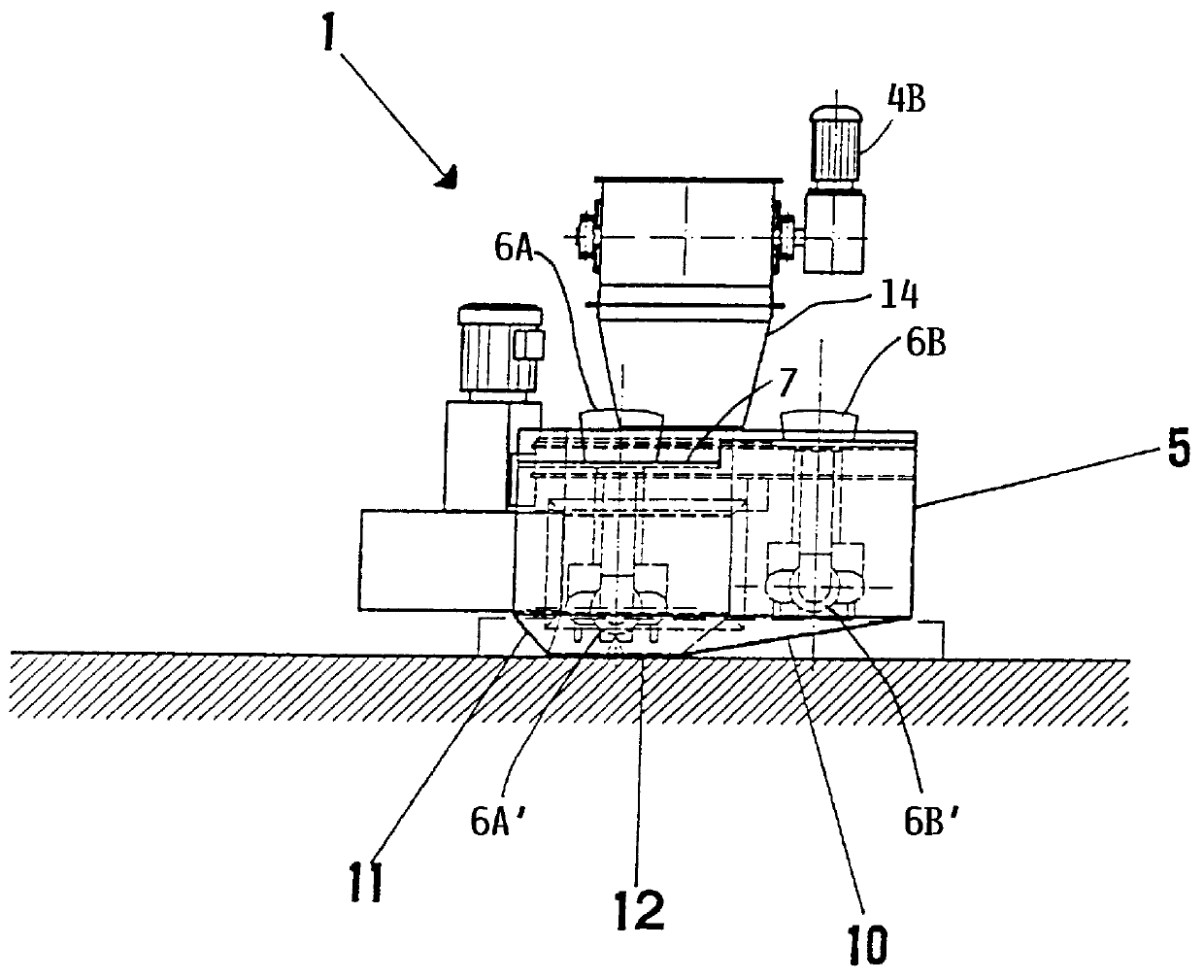

Pumping station for a cooling and lubricating fluid containing particulate matter

A pumping station for pumping a cooling and lubricating fluid containing particulate matter such as machining chips has a compact structure with a relatively low total structural height, while still assuring that the chips are conveyed with the fluid to the pump suction inlet, without settling-out or accumulating in the apparatus. The pumping station (1) includes a collecting container (5) with at least one pump (6) arranged therein, a chip breaker (7) and a supply conduit arrangement. The supply conduit arrangement includes a supply line (2) through which the cooling and lubricating fluid containing the machining chips is received from a machining tool or transfer station. Furthermore, two branch lines (3) and (4) are interposed and connected between the supply line (2) and the collecting container (5). A first branch line (3) conveys the fluid, from which the chips have been removed, with a slight downward slope toward the collecting container (5). The second branch line (4) conveys the chips that have been removed from the fluid flow. A scraper conveyor or the like conveys the chips upward through the second branch line (4), and the outlet end of the branch line (4) is arranged directly above the chip breaker (7), which in turn is arranged above the outlet end of the fluid conveying branch line (3). The comminuted chips thus fall from the breaker (7) directly into the flow of fluid, in which the chips are then entrained and carried along into the sump (13) of the collecting container (5), where the chips and fluid are sucked and pumped away by the pump (6).

Owner:MANN HUMMEL GMBH +1

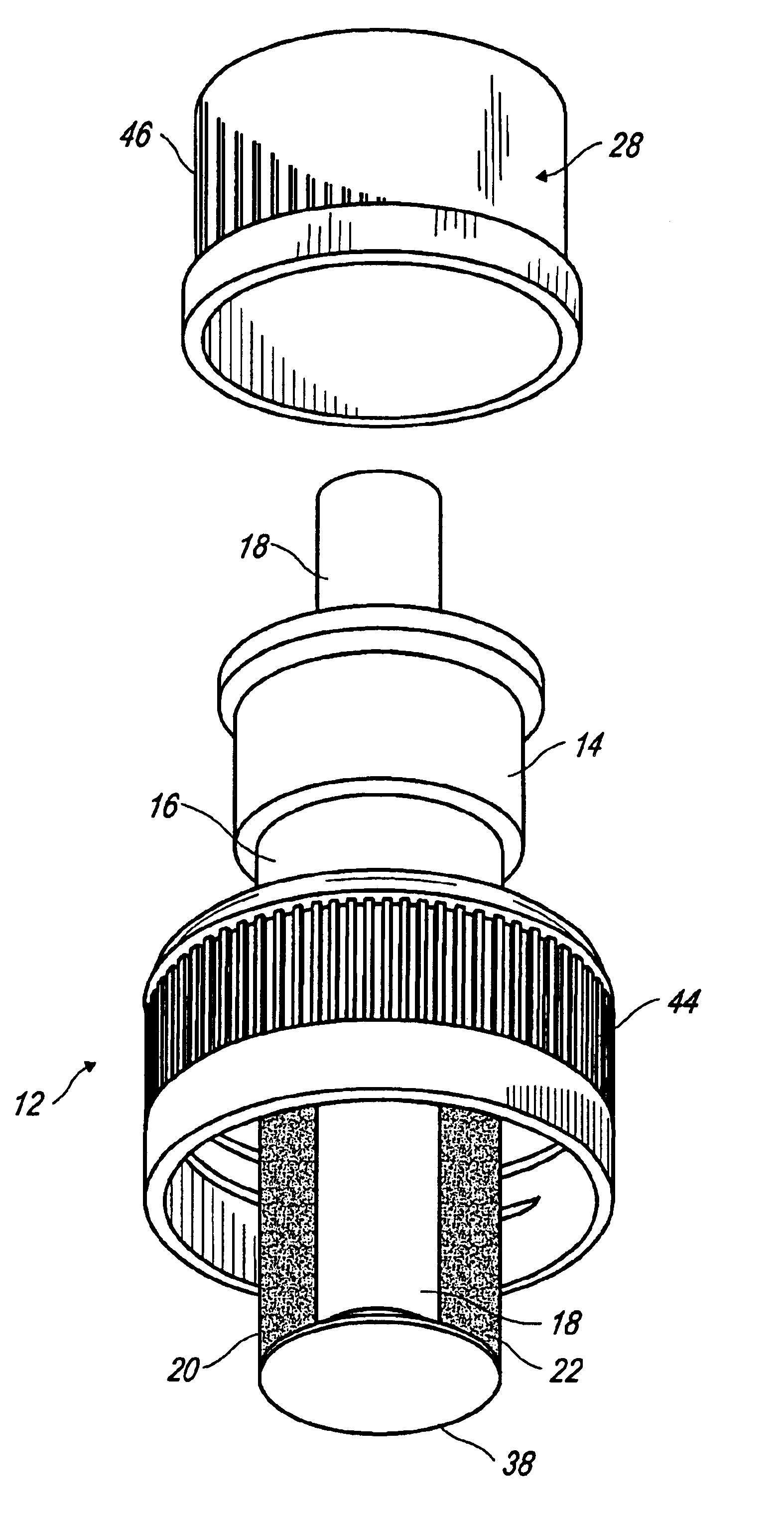

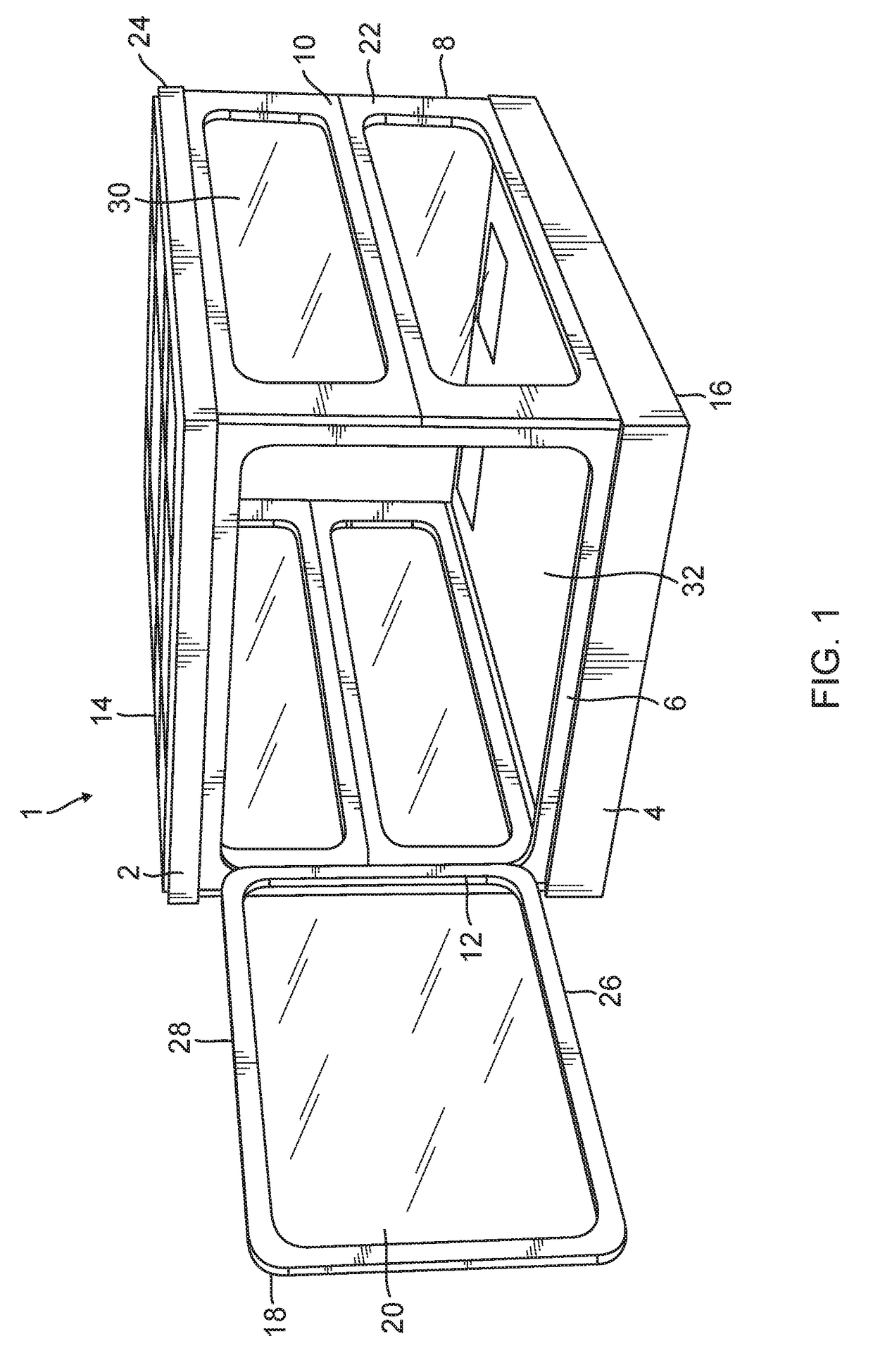

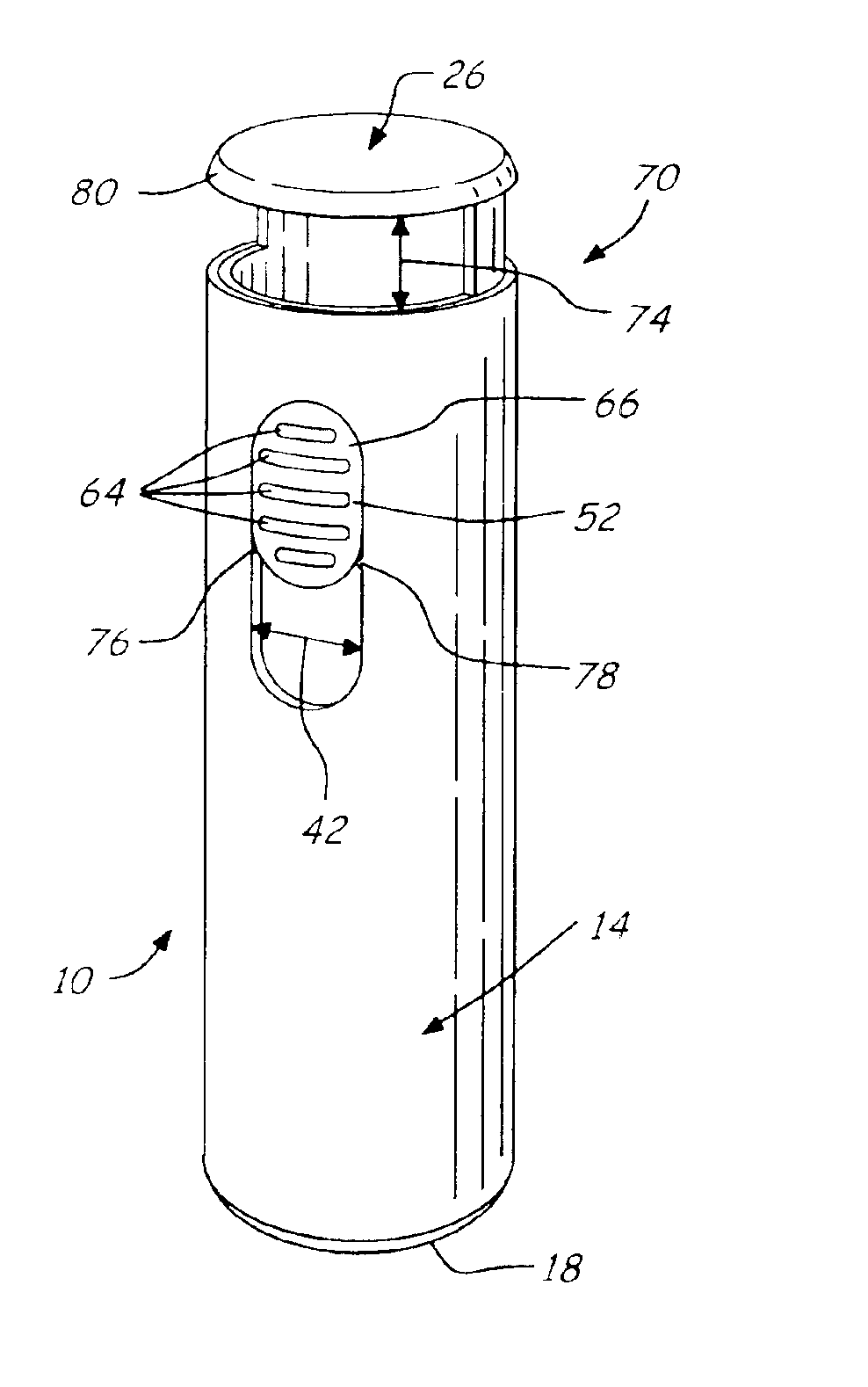

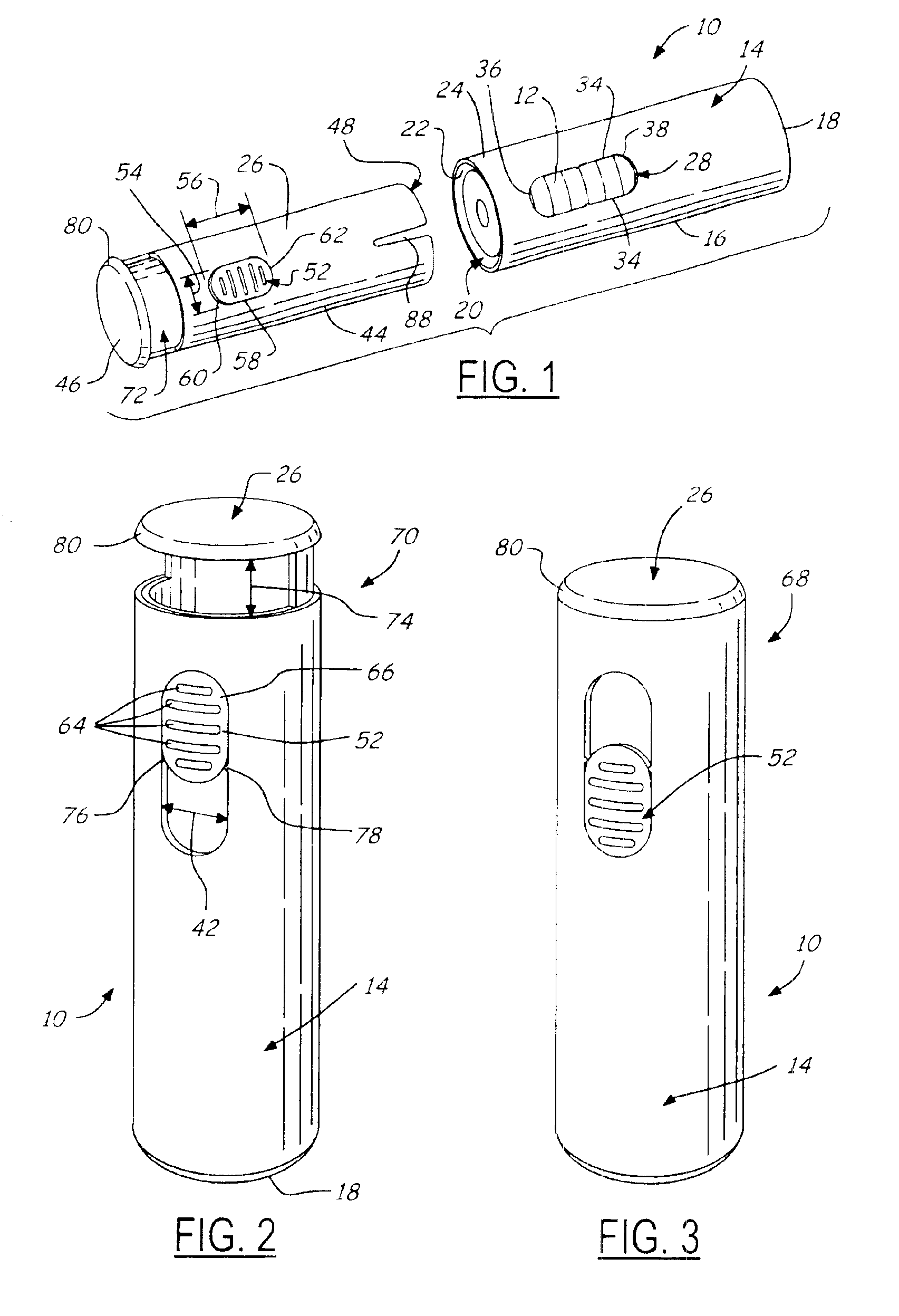

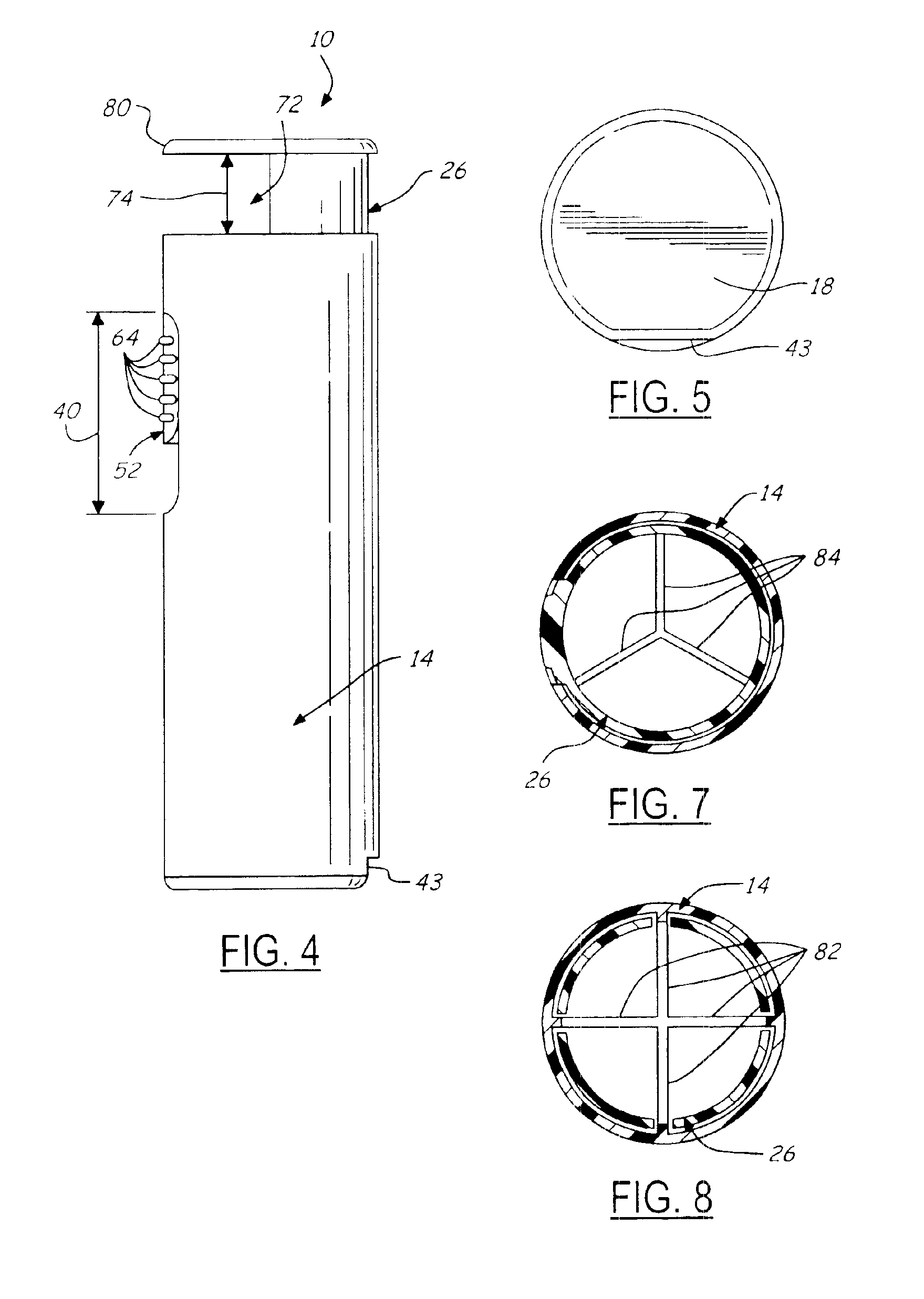

Mint roll package

ActiveUS6953131B2Reduce widthSolve the lack of heightSmall article dispensingCoin-freed apparatus detailsEngineeringVertical control

A package assembly 10 for the storage and distribution of a plurality of stacked mints 12 is provided. The package assembly 10 includes a cylindrical outer shell 14 including a shell sidewall 16, a shell bottom surface 18, and a shell open top 20. The shell sidewall 16 includes a sidewall inner surface 22 and a sidewall outer surface 24. A vertical control slot 28 is formed in the shell sidewall 16, the vertical control slot 28 having a control slot height 40 and a control slot width 42. At least one retention protrusion 78 is formed onto a slot side edge 34 such that the control slot width 42 is reduced in the location of the at least one retention protrusion 78. A cylindrical inner insert 26 including an insert sidewall 44, an insert top surface 46, and an insert open bottom 48, is formed to house the plurality of stacked mints 12. The cylindrical inner insert 26 is positioned within the cylindrical outer shell 14 such that the insert open bottom 48 faces the shell bottom surface 18. A control pad 52 is formed onto and protrudes outwards from the insert sidewall 44. The control pad 52 is positioned within the vertical control slot 28 and is movable such that the cylindrical inner insert 26 can be moved between a closed position 68 and an open position 70. The control pad 52 has a control pad width 54 such that said control pad 52 engages the at least one retention protrusion 78 when in the closed position 68 and such that the cylindrical inner insert 26 is resisted from moving into the open position 70. A dispensing chamber 72 is formed in the insert sidewall 44 adjoining the insert top surface 46. The dispensing chamber 72 is covered by the shell sidewall 16 when the cylindrical inner insert 26 is in the closed position 68. The dispensing chamber 72 is positioned outside the cylindrical outer shell 14 when the cylindrical inner insert 26 is in the open position 70. The dispensing chamber 72 has a dispensing chamber height 74 sufficient to allow one of the plurality of stacked mints 12 to be removed from the cylindrical inner insert 26.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Standard cell, standard cell library, semiconductor device, and placing method of the same

InactiveUS20060138464A1Increase in area can be suppressedReduce numberSolid-state devicesSemiconductor/solid-state device manufacturingStandard cellEngineering

Of a plurality of standard cells in which an N-well region and a P-well region are vertically formed, some standard cells have a border line between the N-well region and the P-well region which is set to be a low height (first height), and other standard cells have a border line between the N-well region and the P-well region which is set to be a high height (second height), depending on the size of a transistor formed in the standard cell. Although these standard cells have different border lines, a standard cell for linking the border lines is provided. In such a standard cell, an empty space is created by forming a small-size transistor therein, and the empty space is utilized so that, for example, a left end of the border line is set to have the first height and a right end of the border line is set to have the second height, whereby the border line is converted so as to link the heights therein.

Owner:SOCIONEXT INC

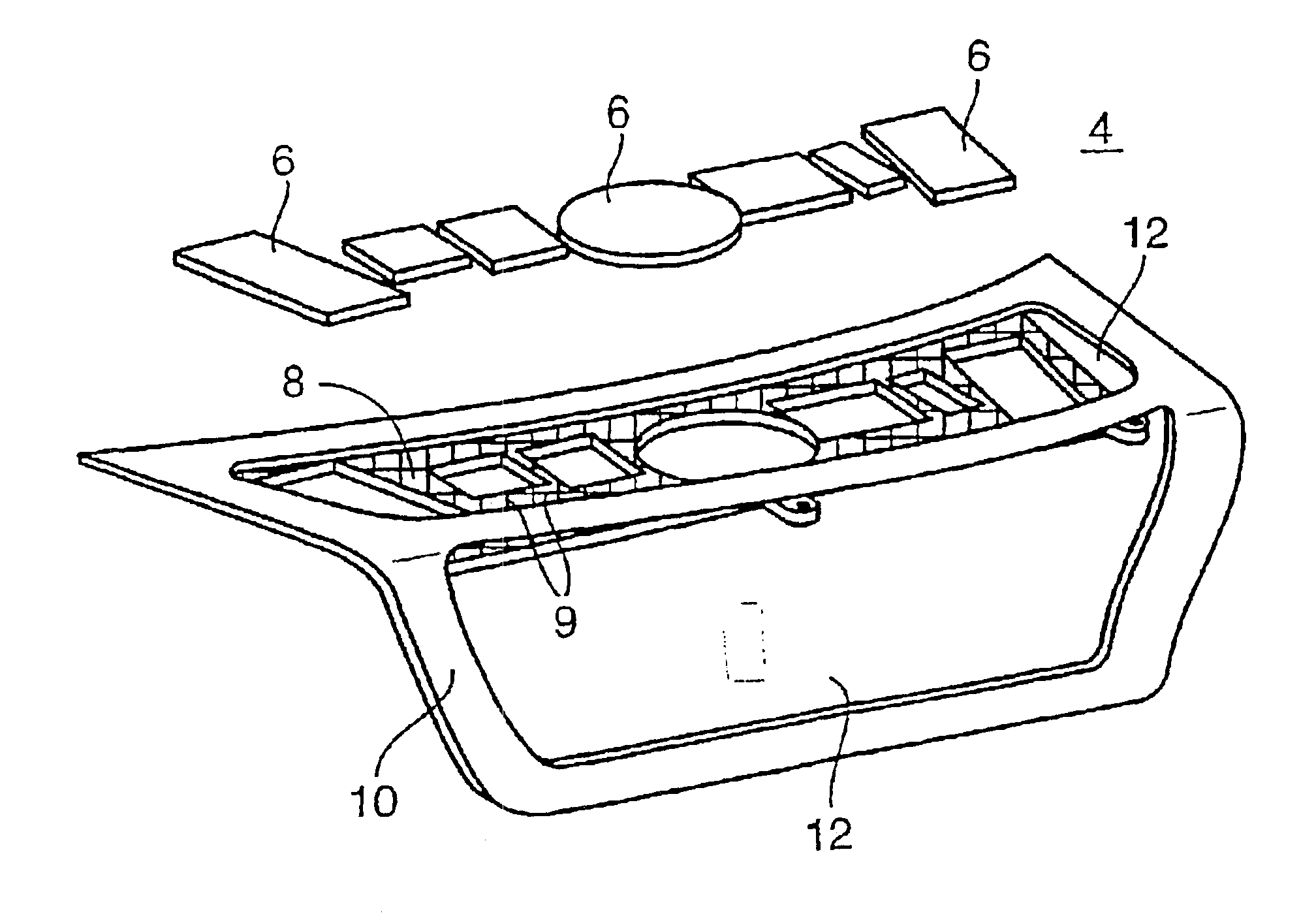

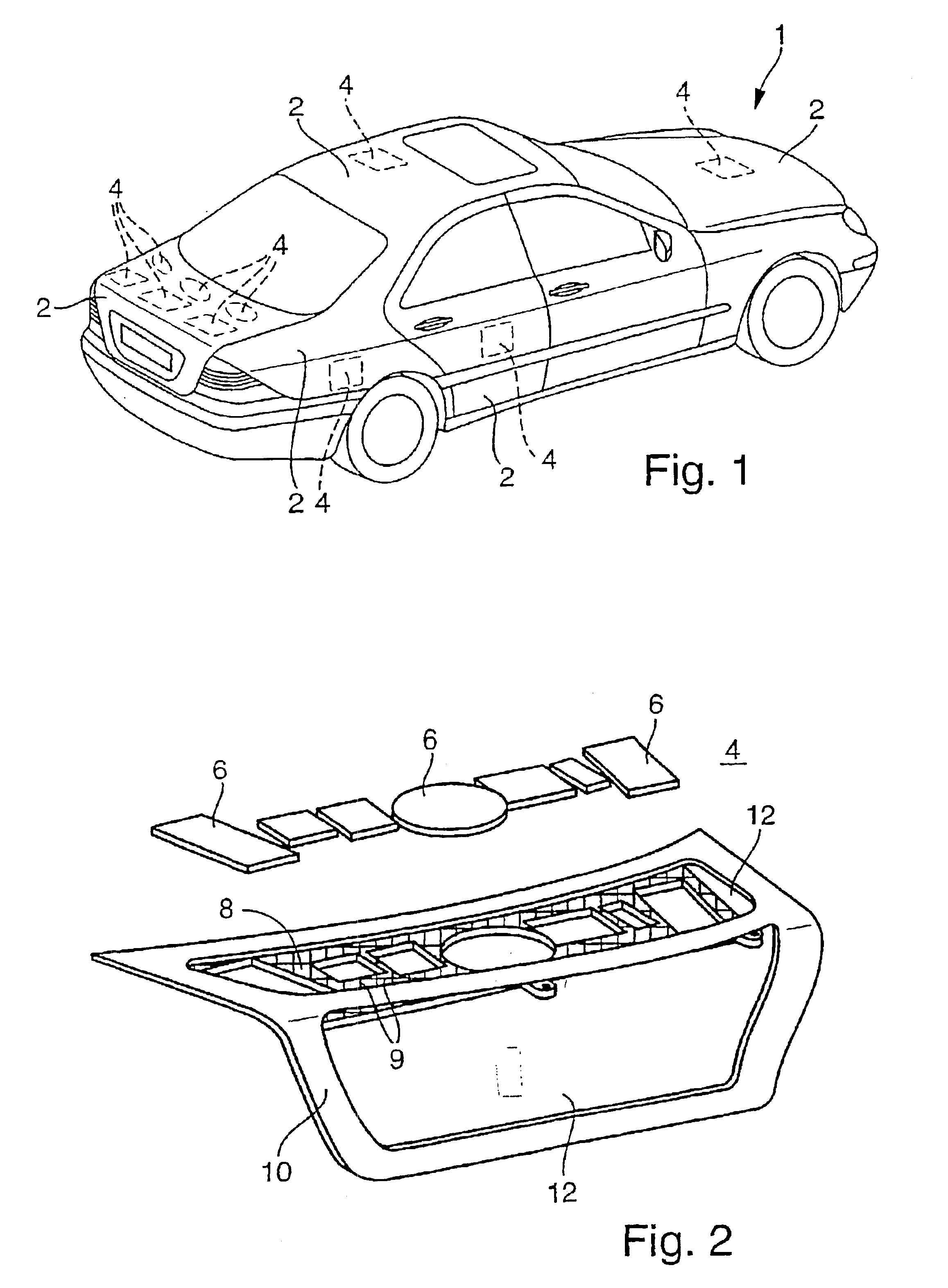

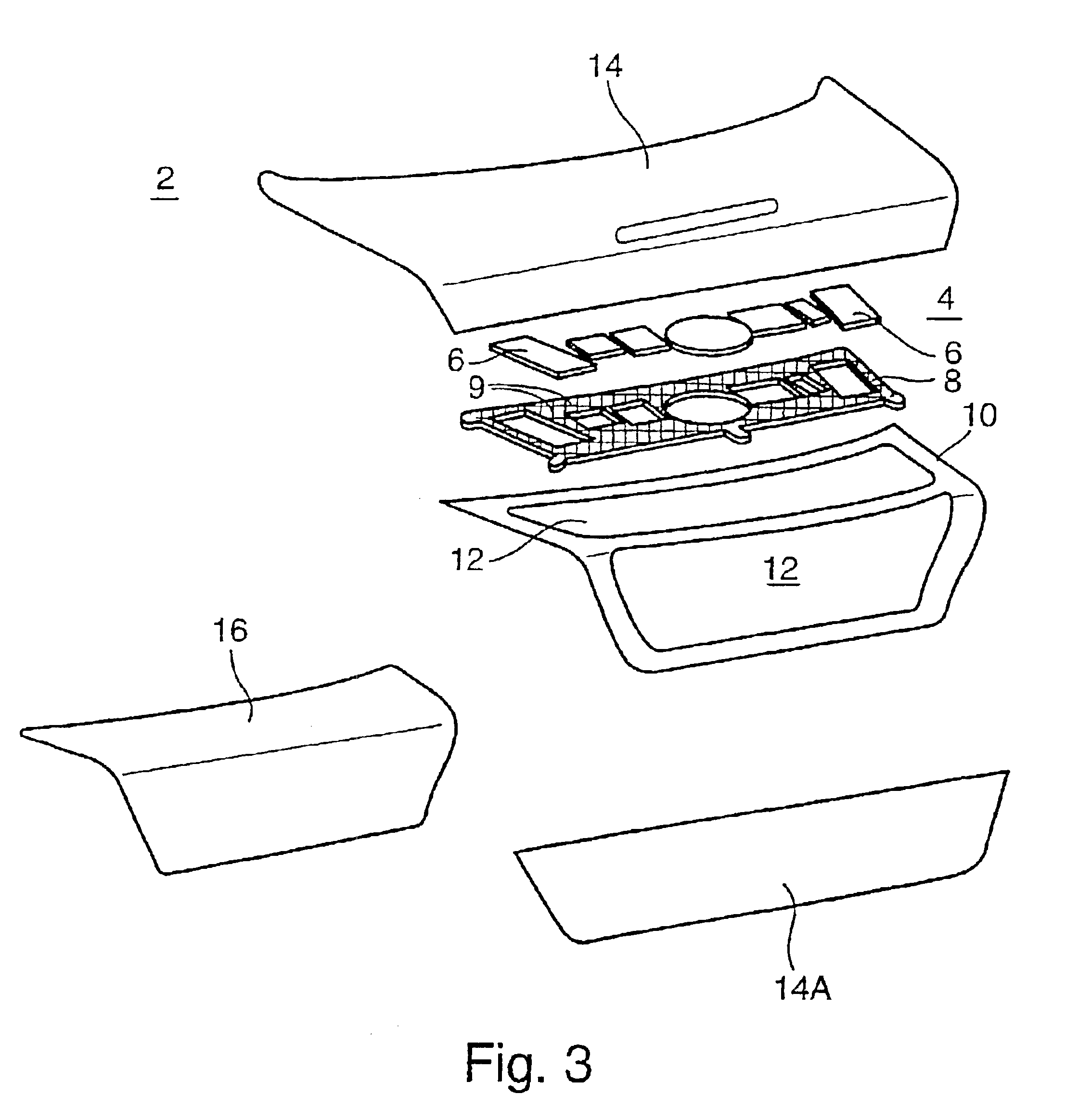

Bodywork part with integrated antenna

InactiveUS6900769B2Large installation spaceWithout expenditureAntenna adaptation in movable bodiesProtective material radiating elementsEngineeringIntegrated antenna

A bodywork part (2) is provided with an integrated antenna arrangement (4) and with a carrier unit (8) on which the antenna arrangement (4) is detachably arranged. This construction permits an antenna to be integrated and replaced easily.

Owner:MONTAPLAST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com