Inflatable intervertebral disc replacement prosthesis

a technology of intervertebral discs and prostheses, which is applied in the field of prosthetic intervertebral disc replacement systems, can solve the problems of accelerating the degeneration of neighboring intervertebral discs, deterioration of natural discs, etc., and achieves the effect of restoring sufficient disc space height and mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

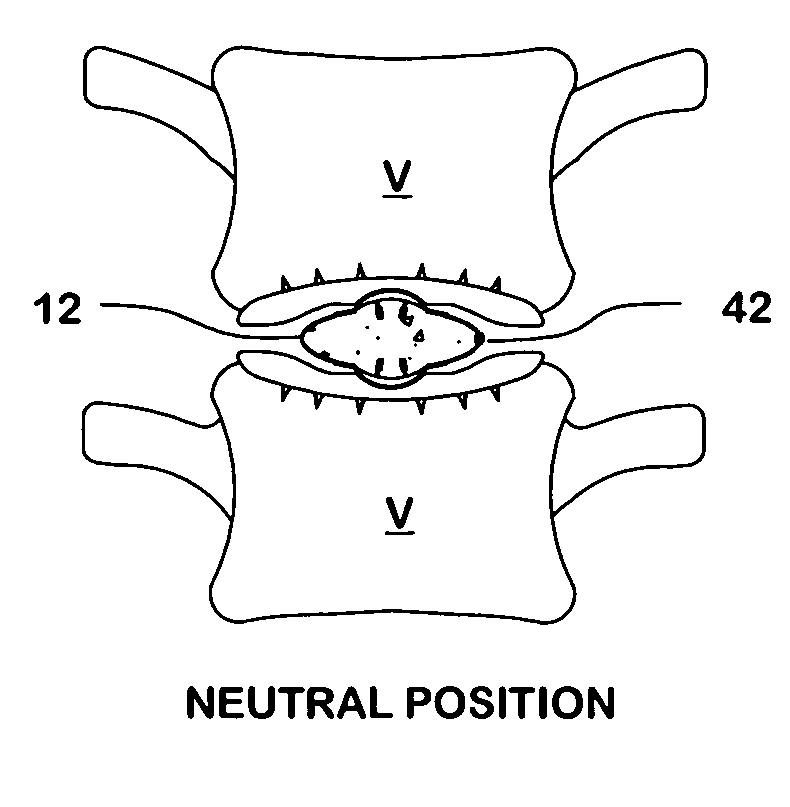

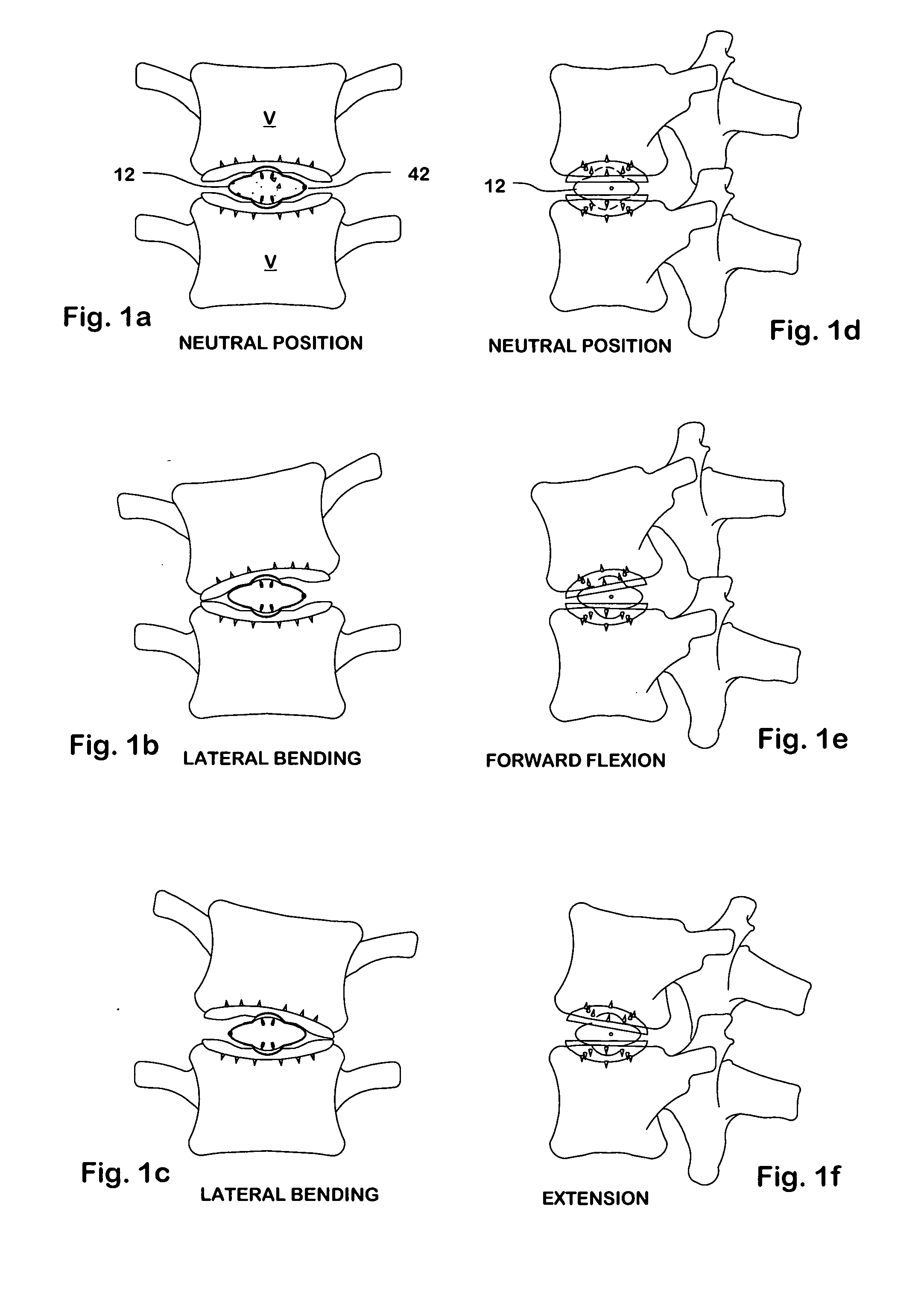

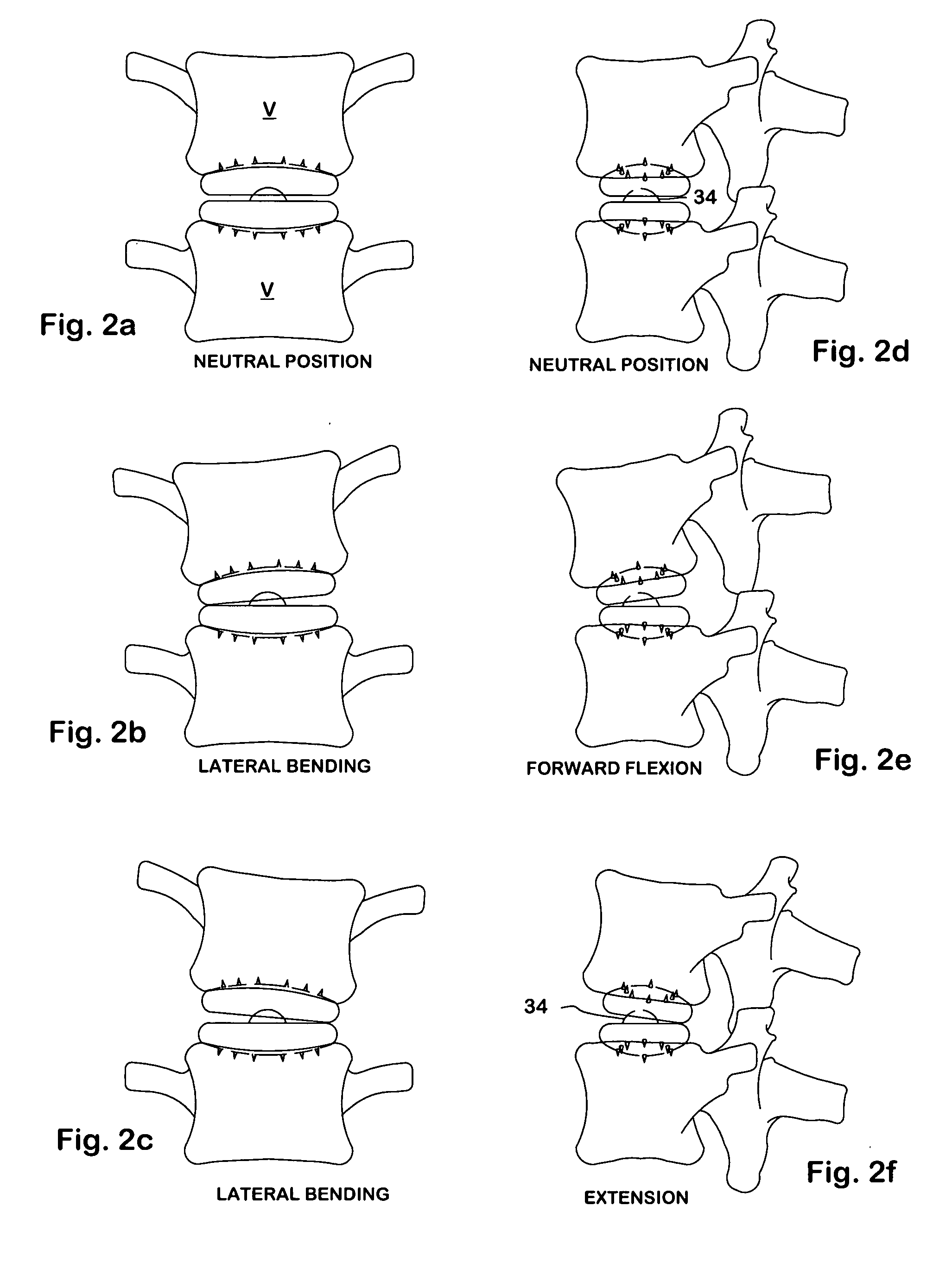

[0030] The drawings show several embodiments of the invention, having the characteristic feature that each prosthesis has at least one chamber 12 which can be inflated to conform to various intervertebral spaces.

[0031] Preferably, each chamber 12 is provided with studs 14, fingers, corrugations or other projecting structures designed to dig into the cranial and caudal surfaces of the vertebrae “V” against which they bear, to keep the prosthesis in place. The chamber 12 is at least partially made of a flexible material, not only so that it can expand, but also so that is can be collapsed to a small size, so that it can be inserted by minimally invasive techniques. The chamber wall 20 may be a strong fabric material, for example Kevlar, or it may be made of a strong polymeric film such as polypropylene. In the case of Kevlar, which is not substantially stretchable, the chambers may advantageously be formed in a particular shape, which will be attained on inflation, corresponding to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| structures | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| stretchable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com