Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286results about How to "Improve impact absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

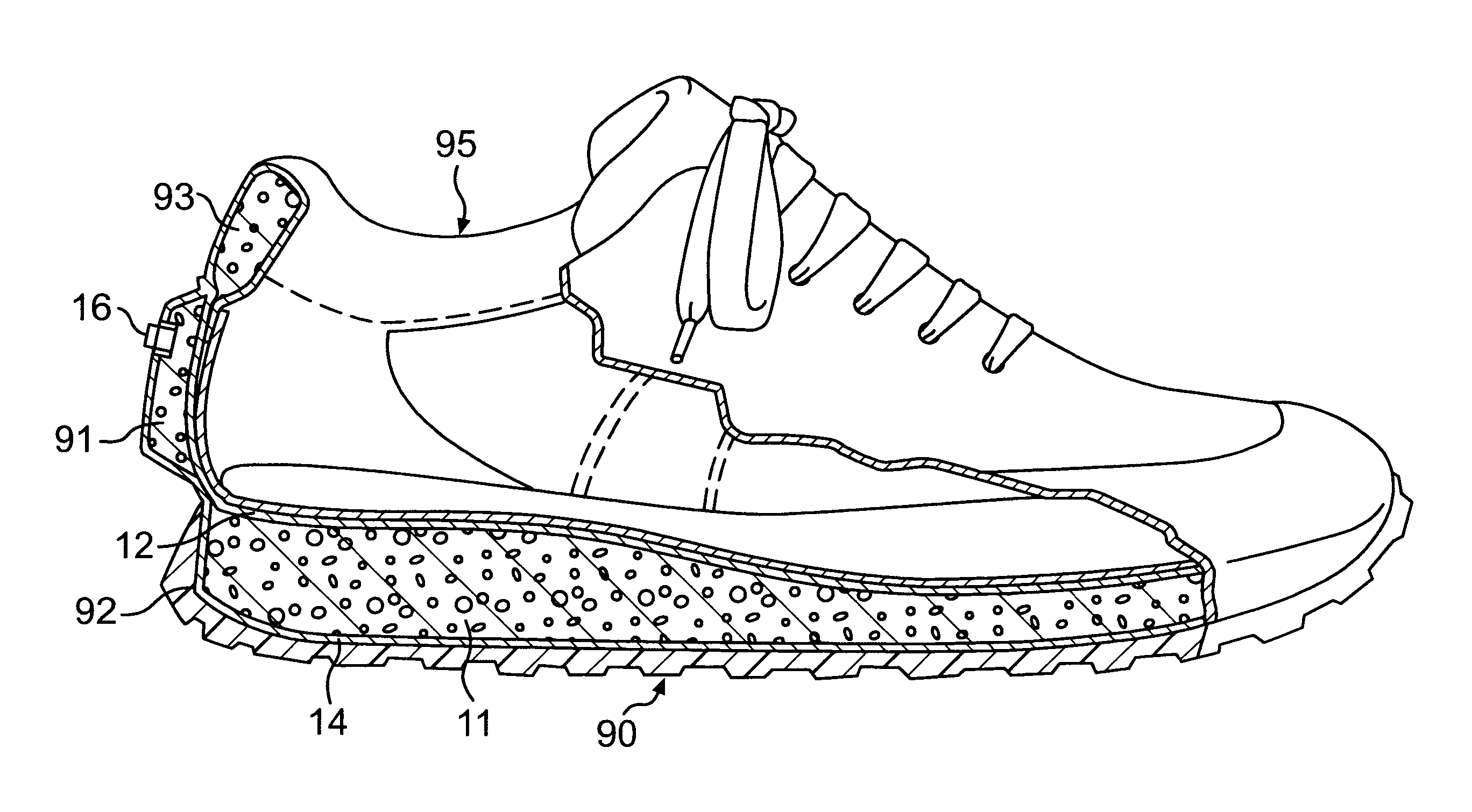

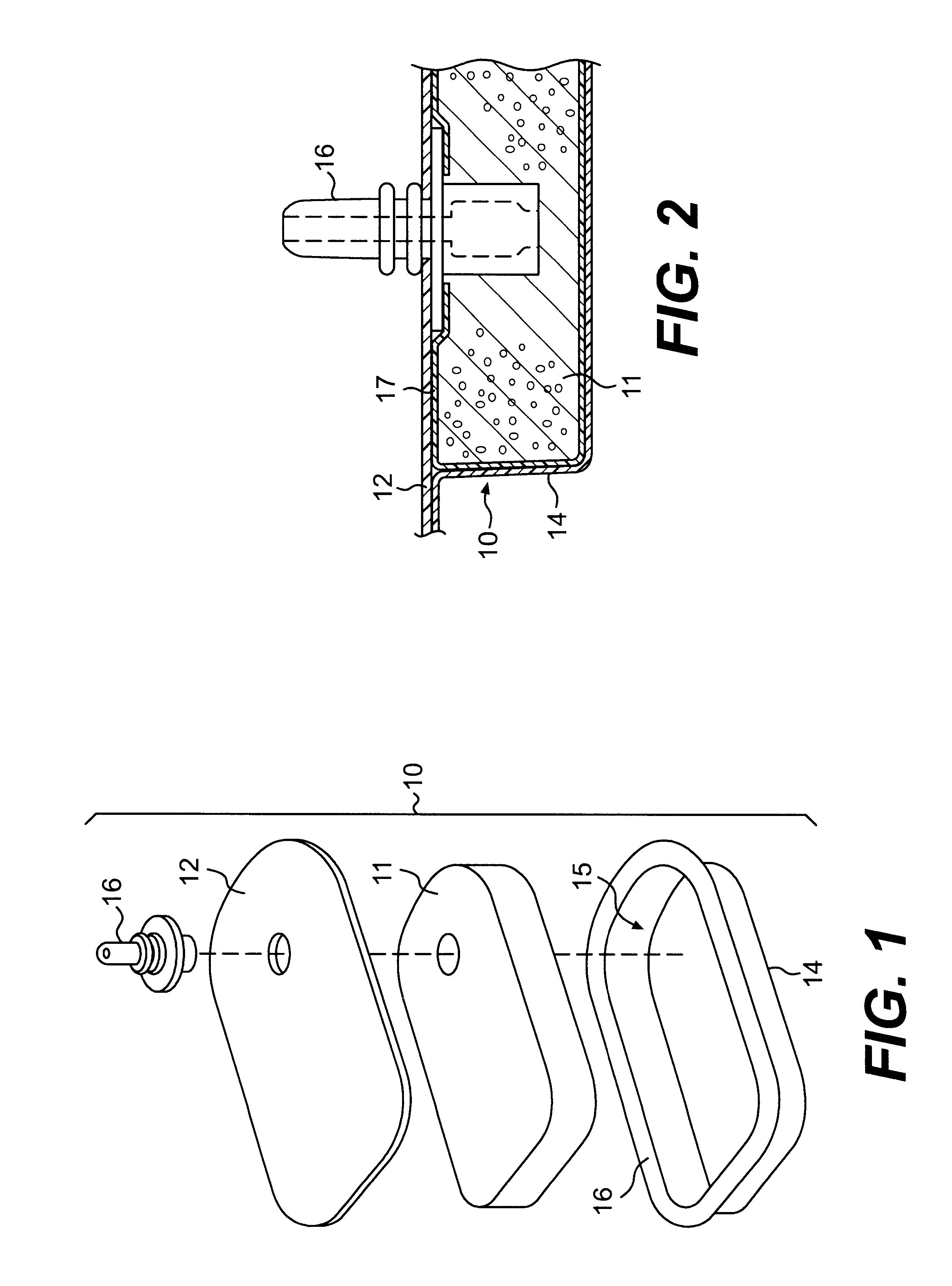

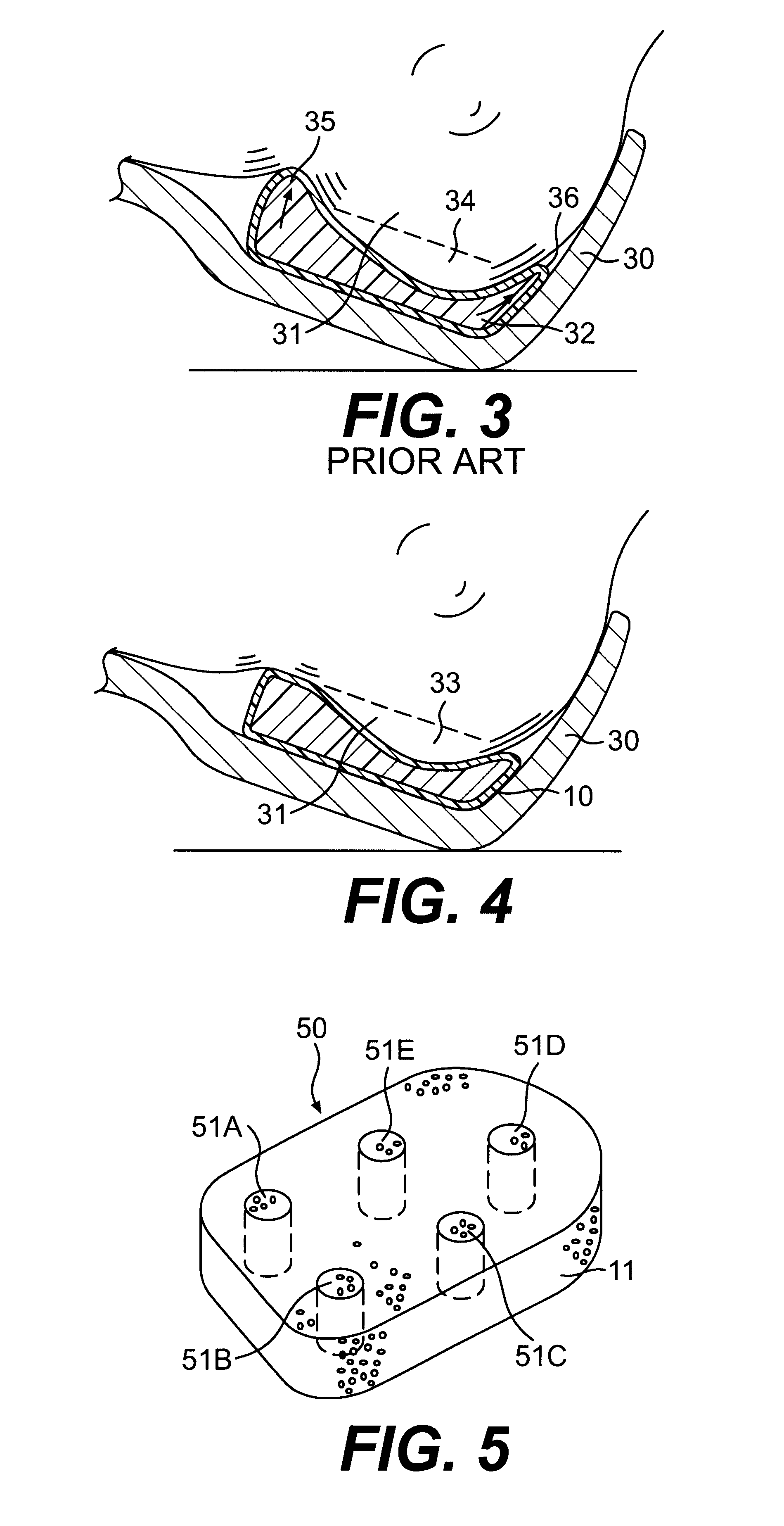

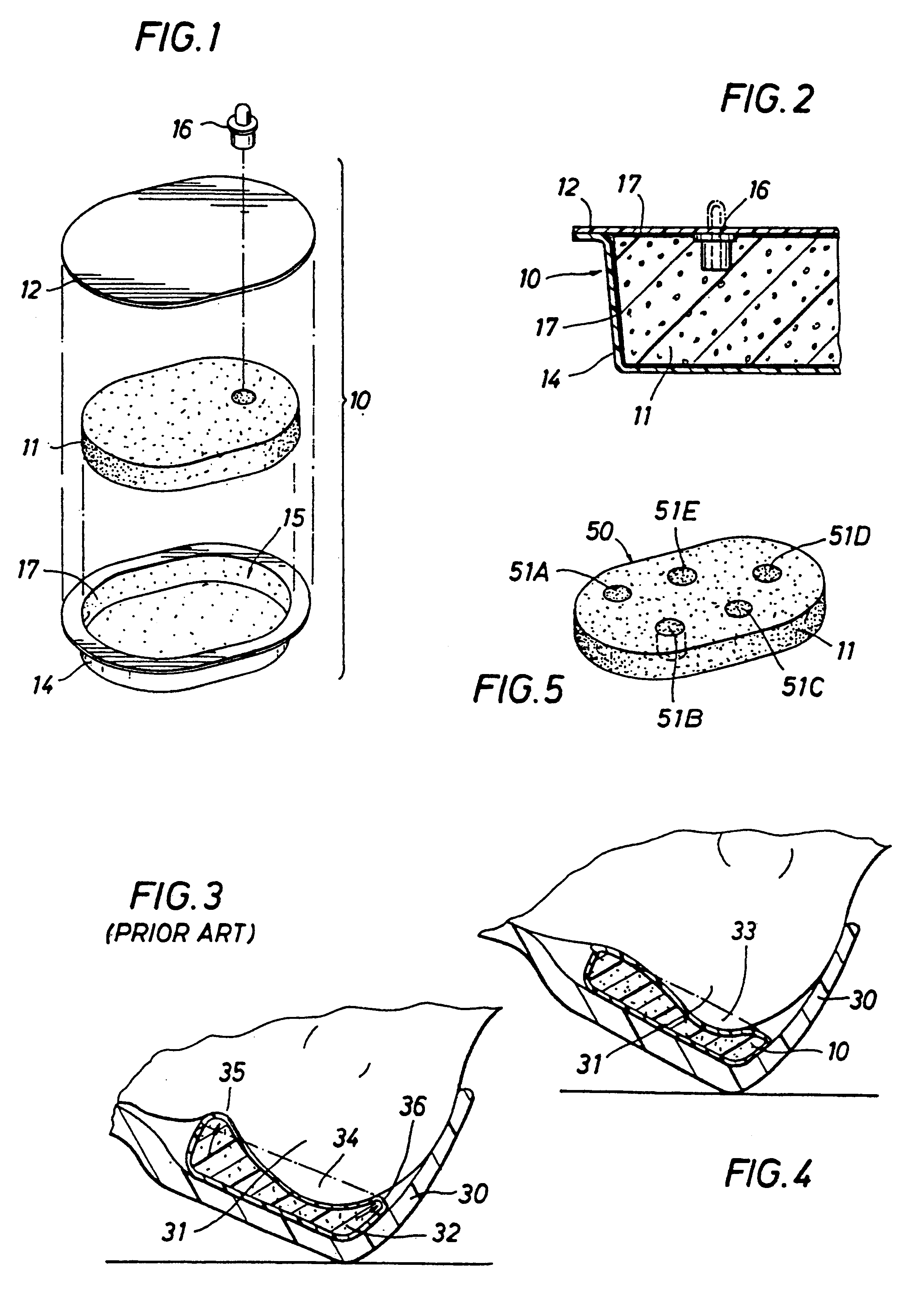

Impact absorbing composites and their production

InactiveUS6425195B1Improve efficiencyImprove impact absorption performanceSolesLayered productsInternal pressureEngineering

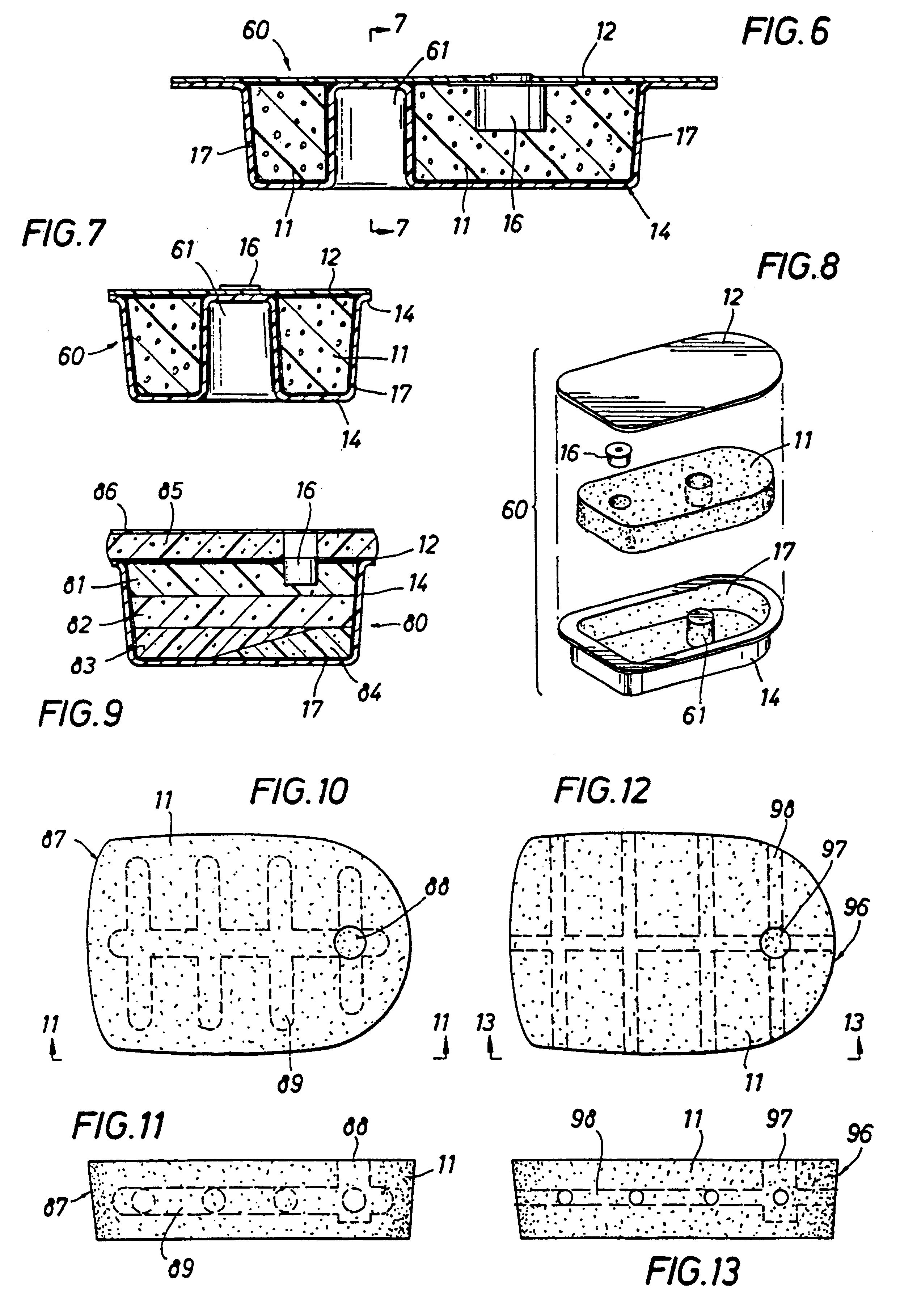

An improved composite for absorbing and dispersing impacting forces is disclosed. The composite includes a flexible plastic enclosure defining an internal cavity. The flexible enclosure is generally impermeable to air and capable of having its internal pressure changed. The composite further includes a foam core filling the cavity and retained within the cavity and adhered on substantially all of its external surface to the internal surface of the cavity. The cavity can be pressurized for higher impact absorbance. Methods for fabricating the composites are disclosed, as well.

Owner:DONZIS BYRON A

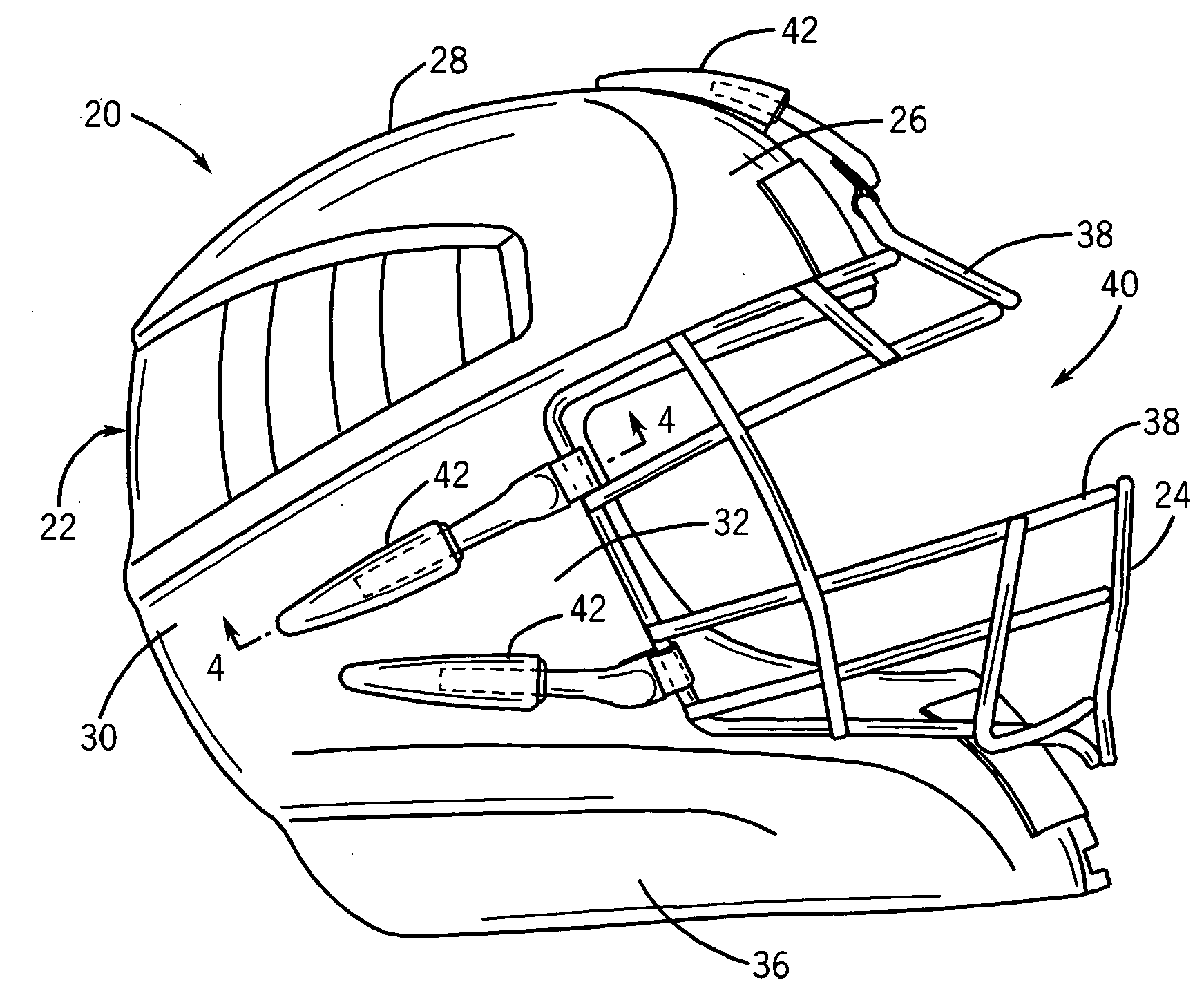

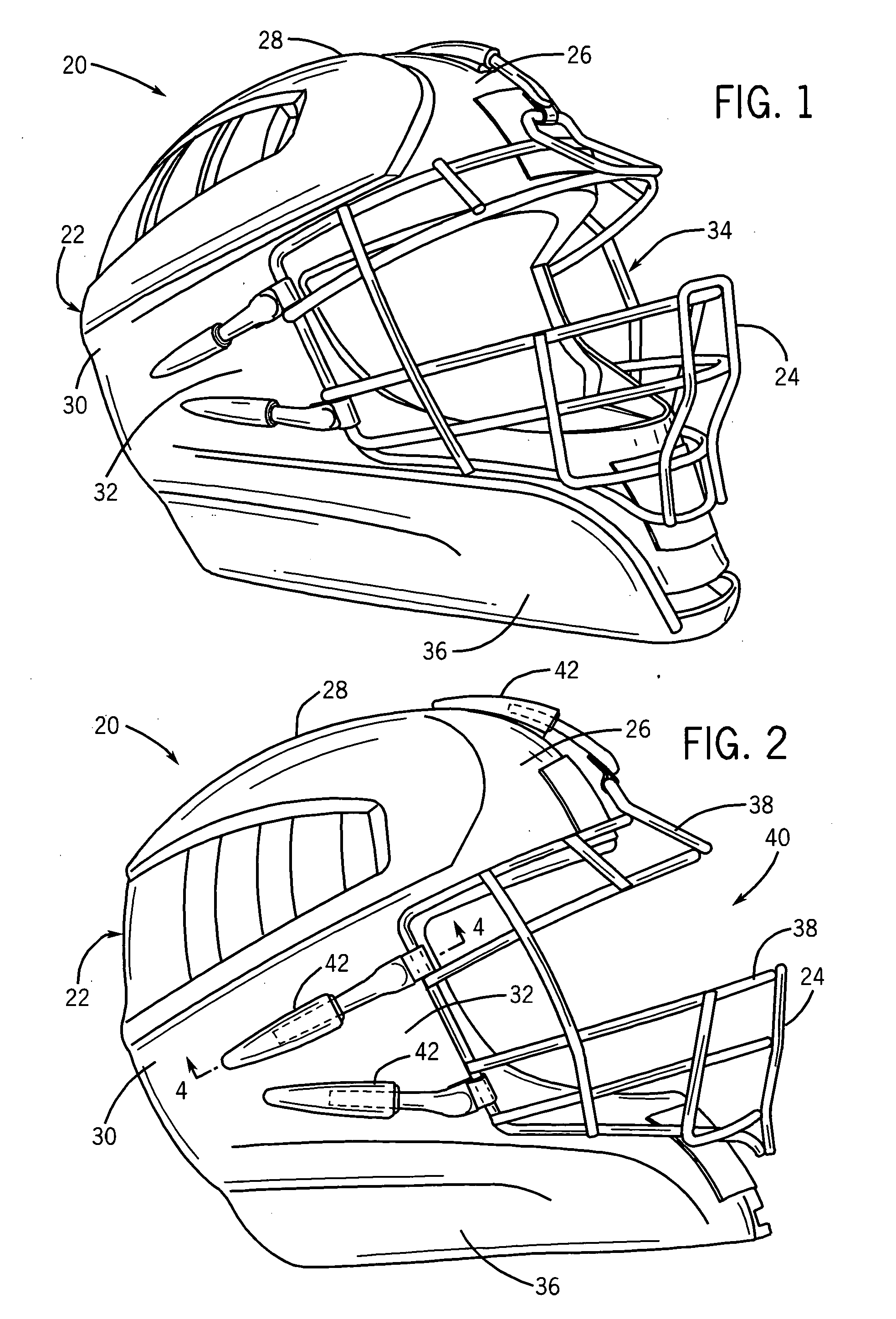

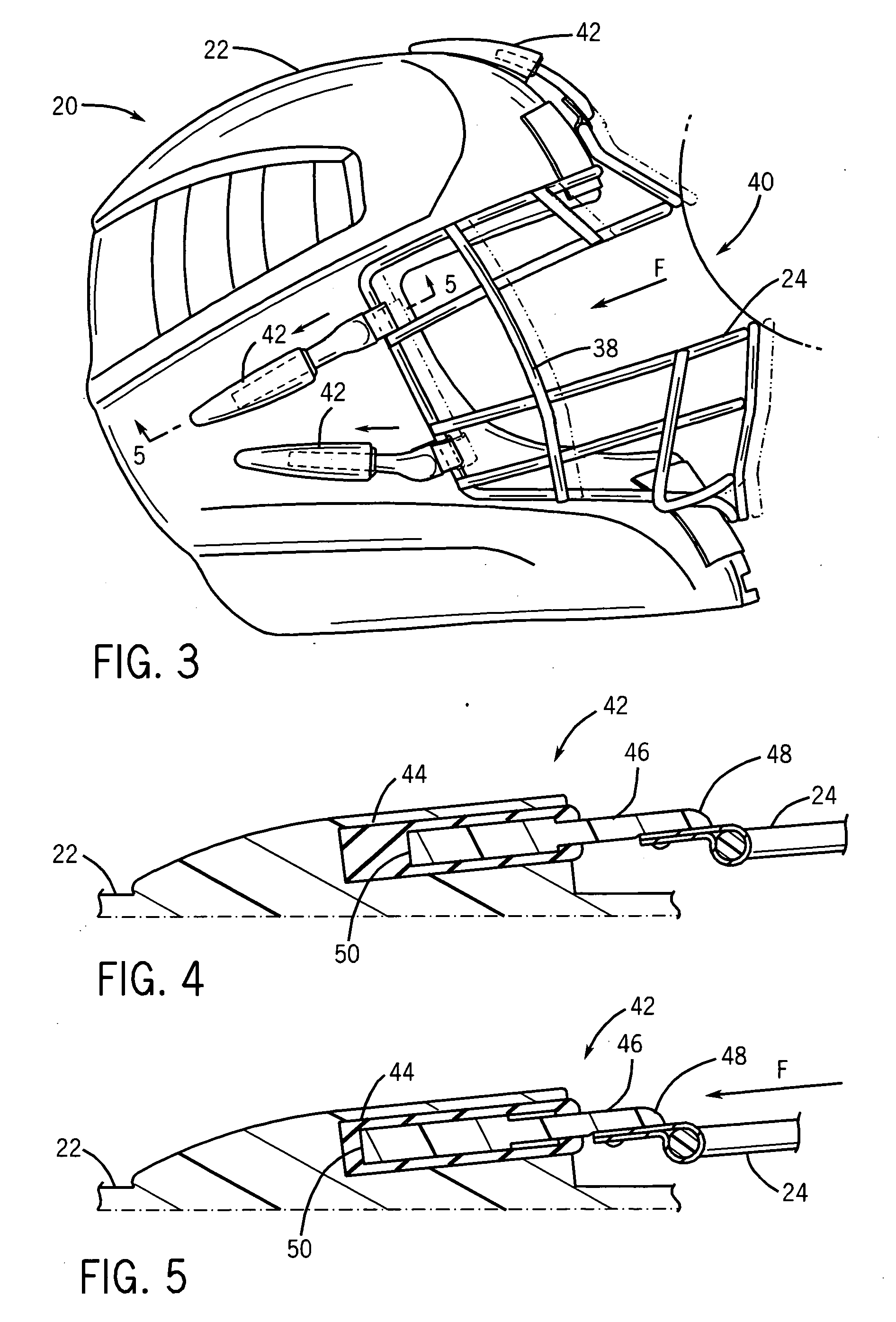

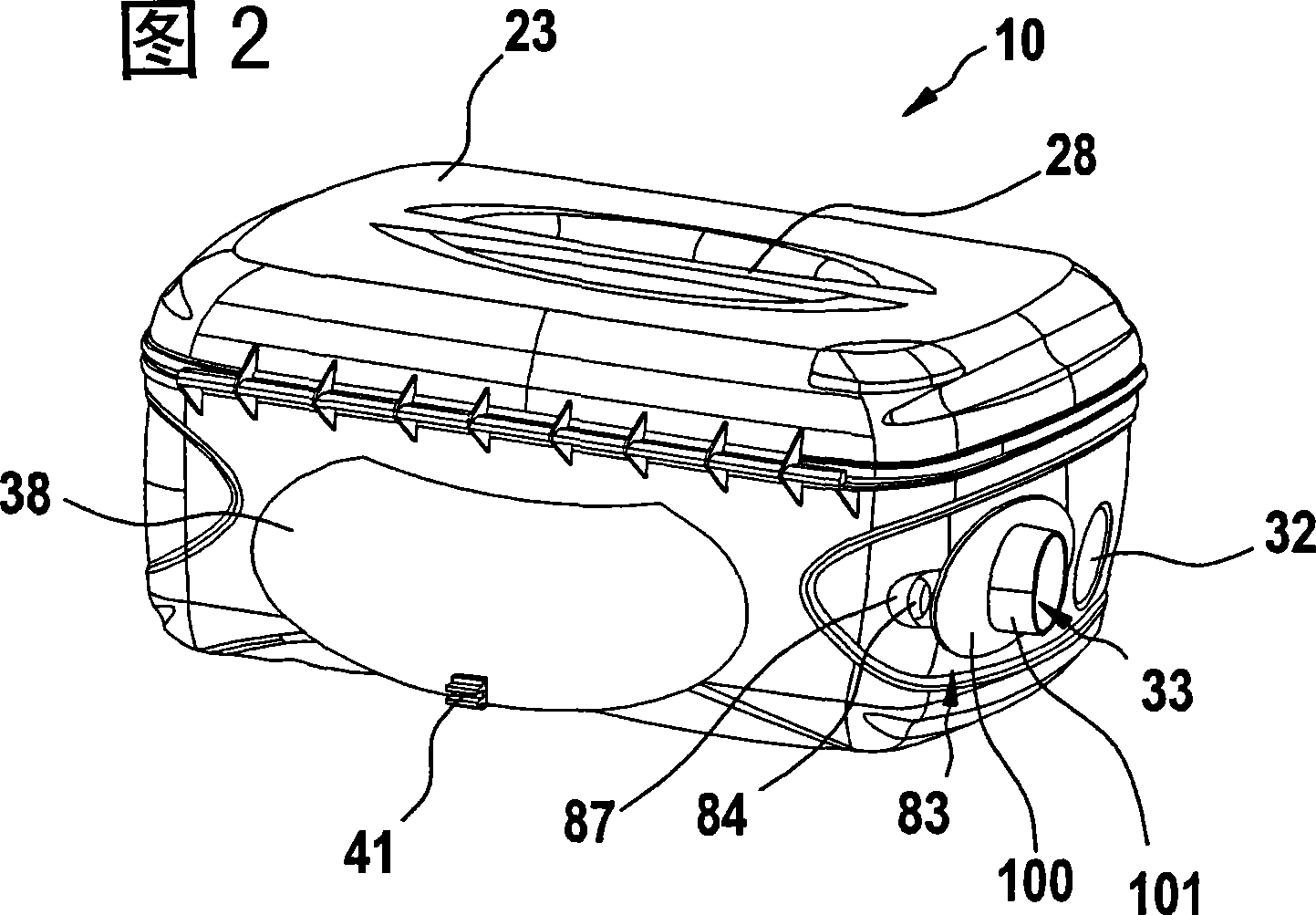

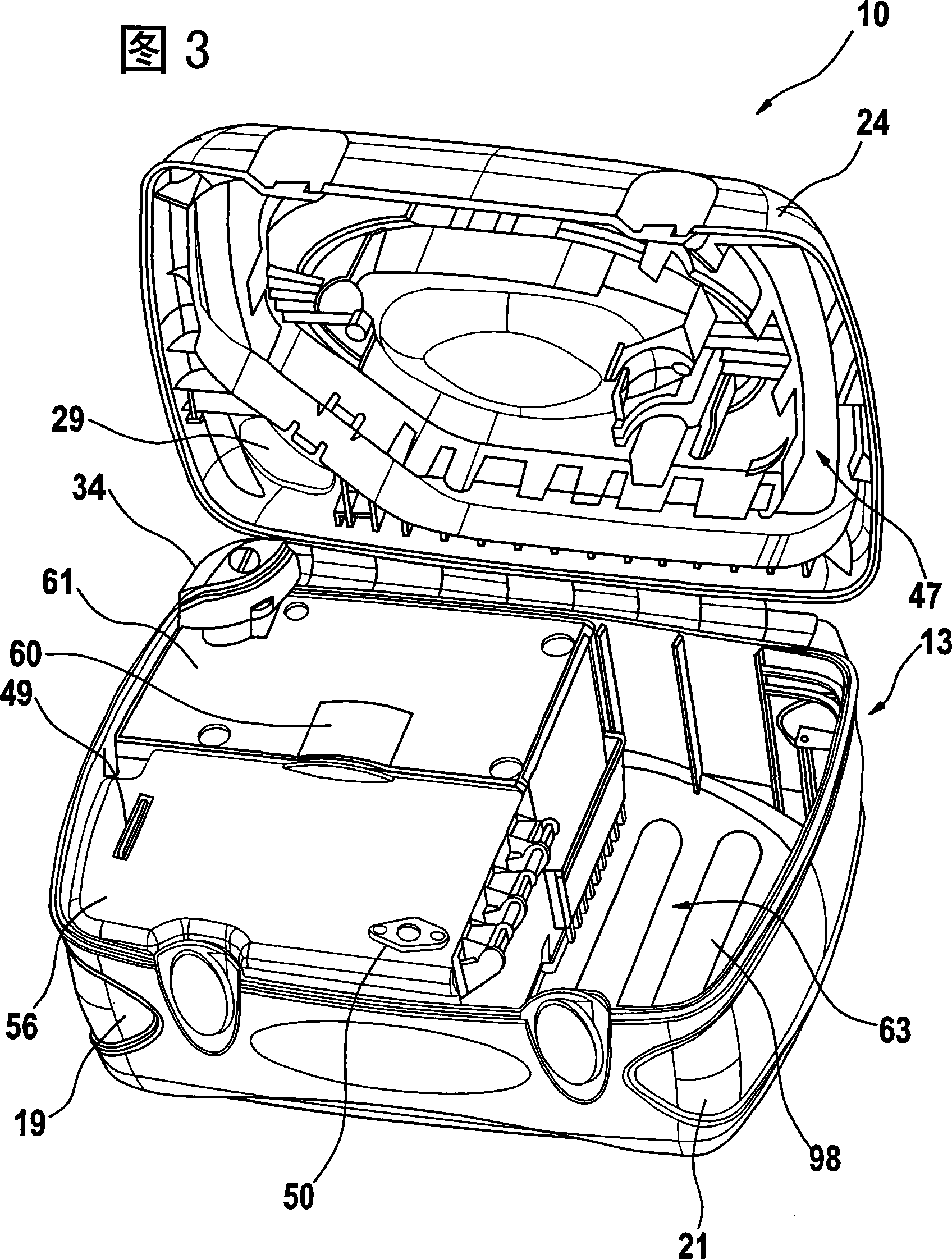

Shock-absorbing facemask attachment assembly

InactiveUS20080163410A1High percentage of impact energyDistribute large amountEye treatmentHatsEngineeringImpact energy

A facemask coupled to a sports helmut such that it will absorb a very high percentage of the impact energy from a ball or other oncoming force. The shock-absorbing facemask attachment assembly includes a housing attached to a helmet. An insert may be coupled to the facemask and the housing such that the insert is pushed further into the housing in response to an applied force. Alternatively, one or more springs may be coupled to the facemask and the housing such that the springs are compressed further toward the housing in response to an applied force. As another alternative, a spring assembly may include at least one spring coupled to the helmet and the housing and at least one spring coupled to the facemask and the housing.

Owner:WILSON SPORTING GOODS

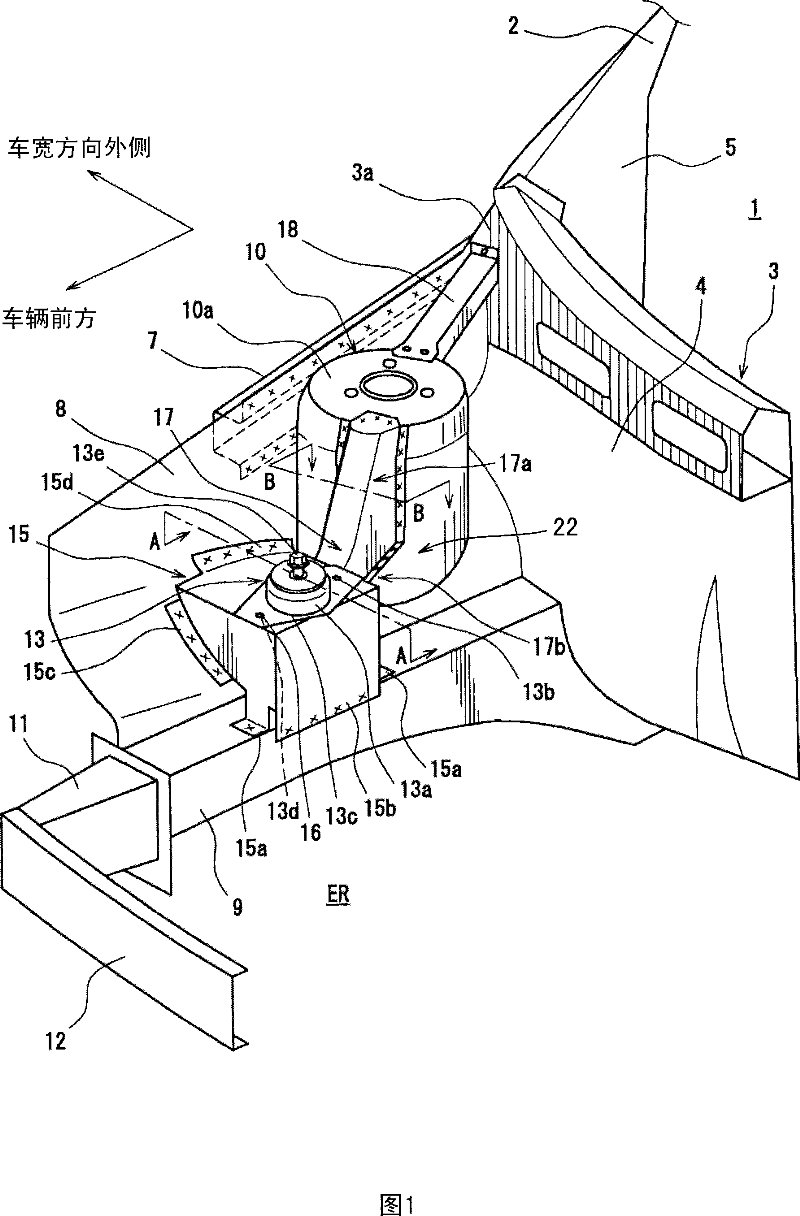

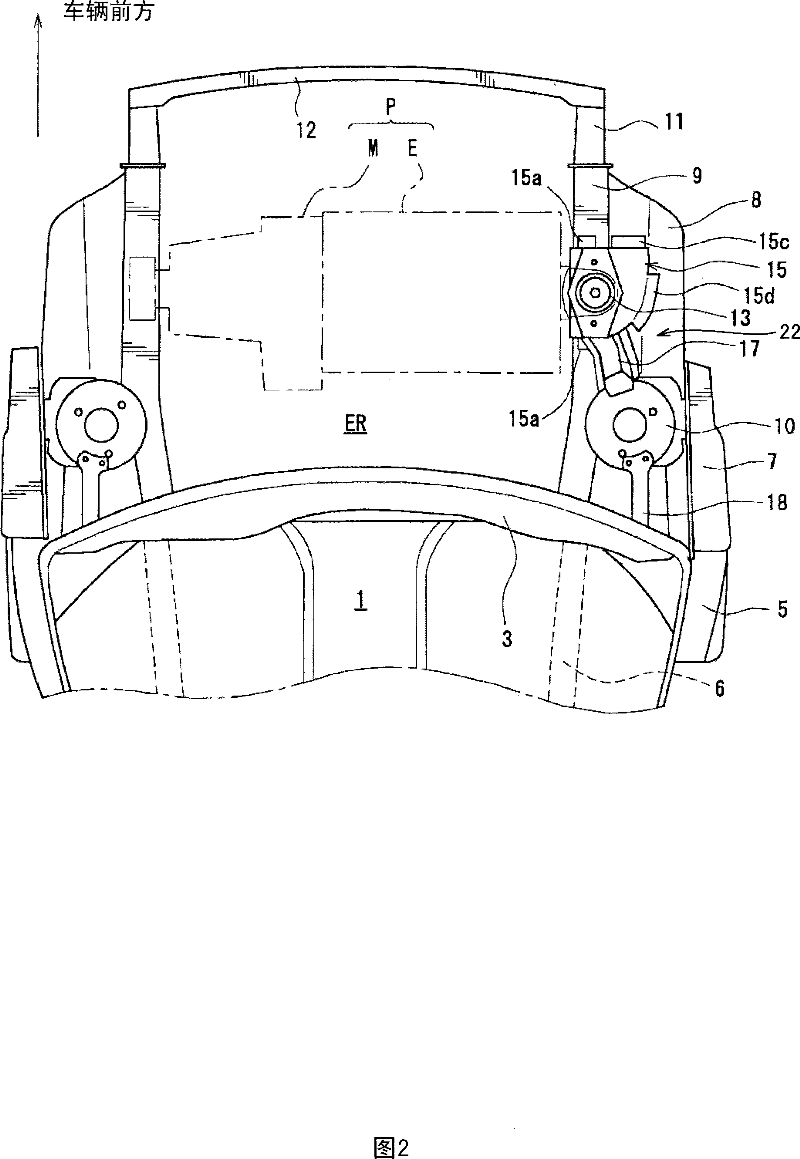

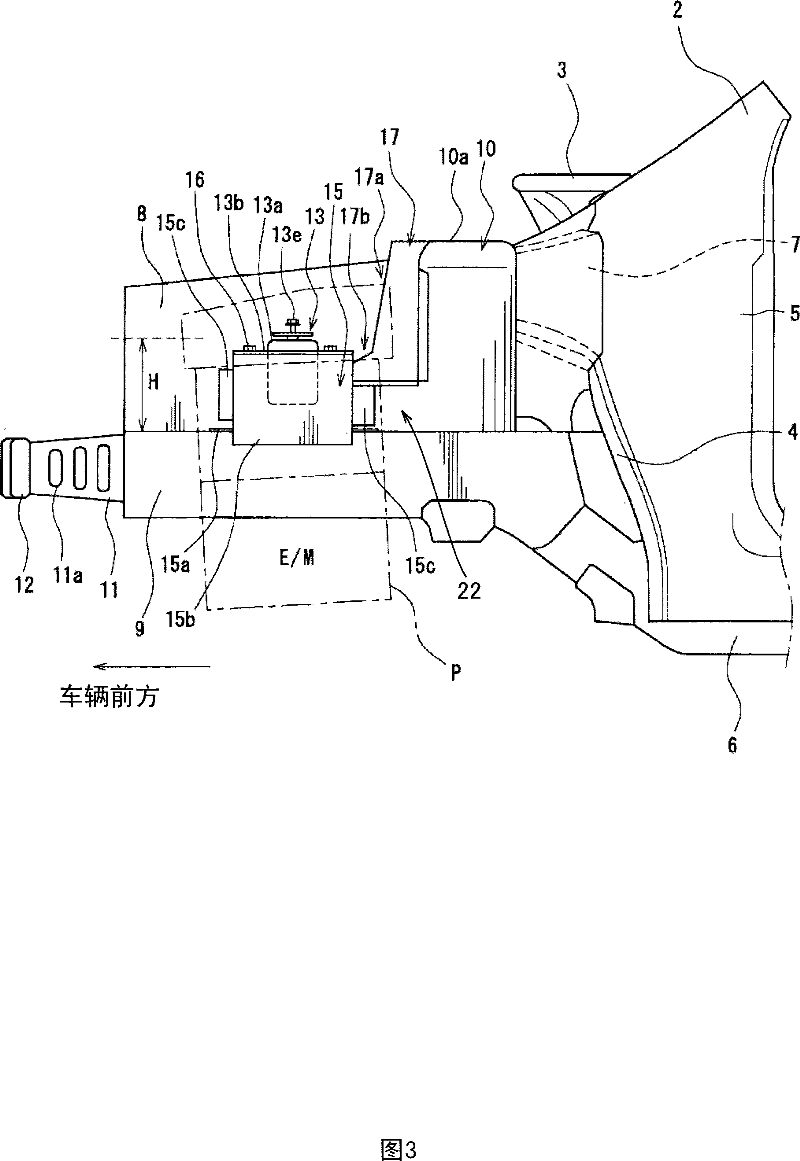

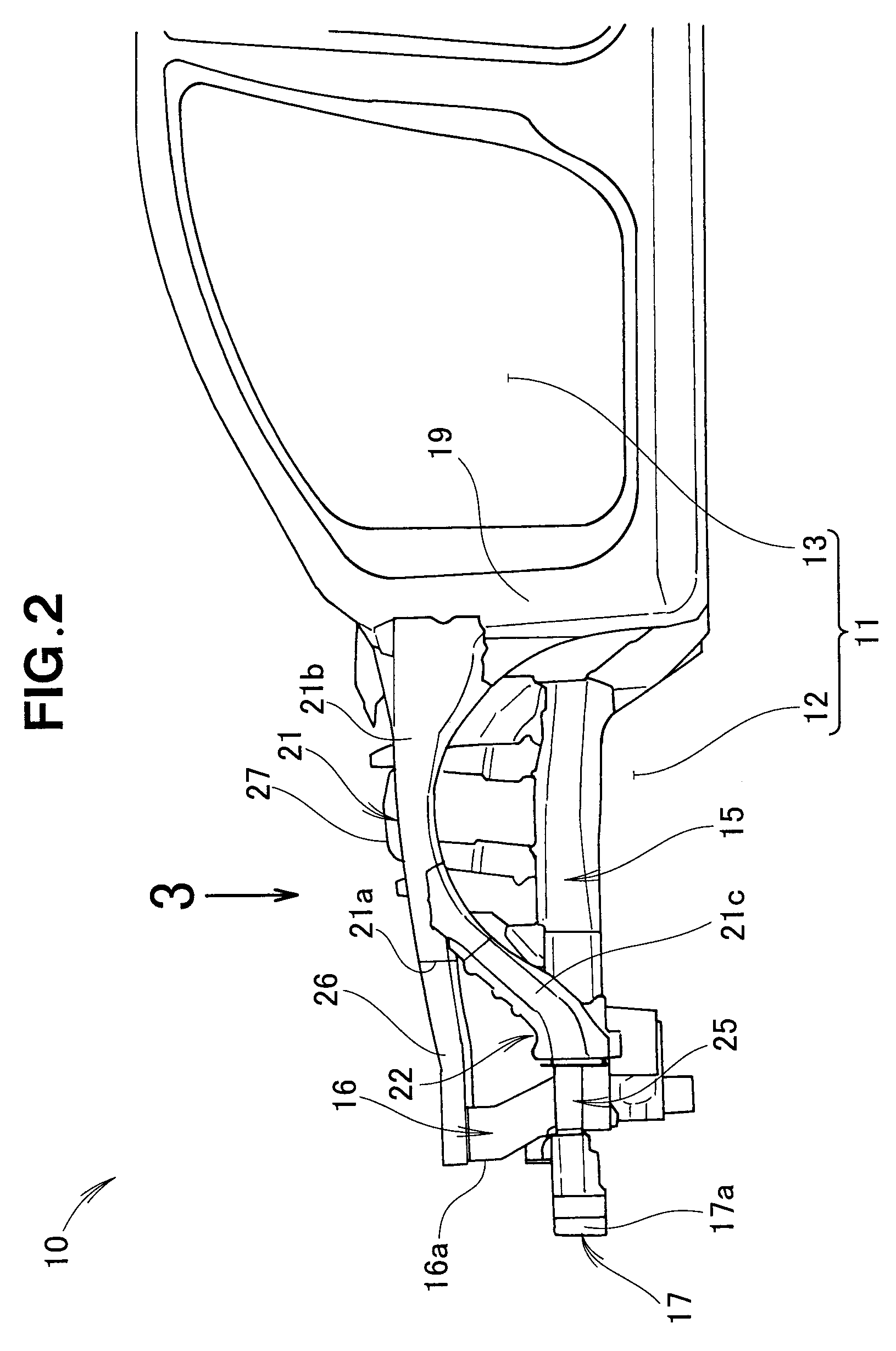

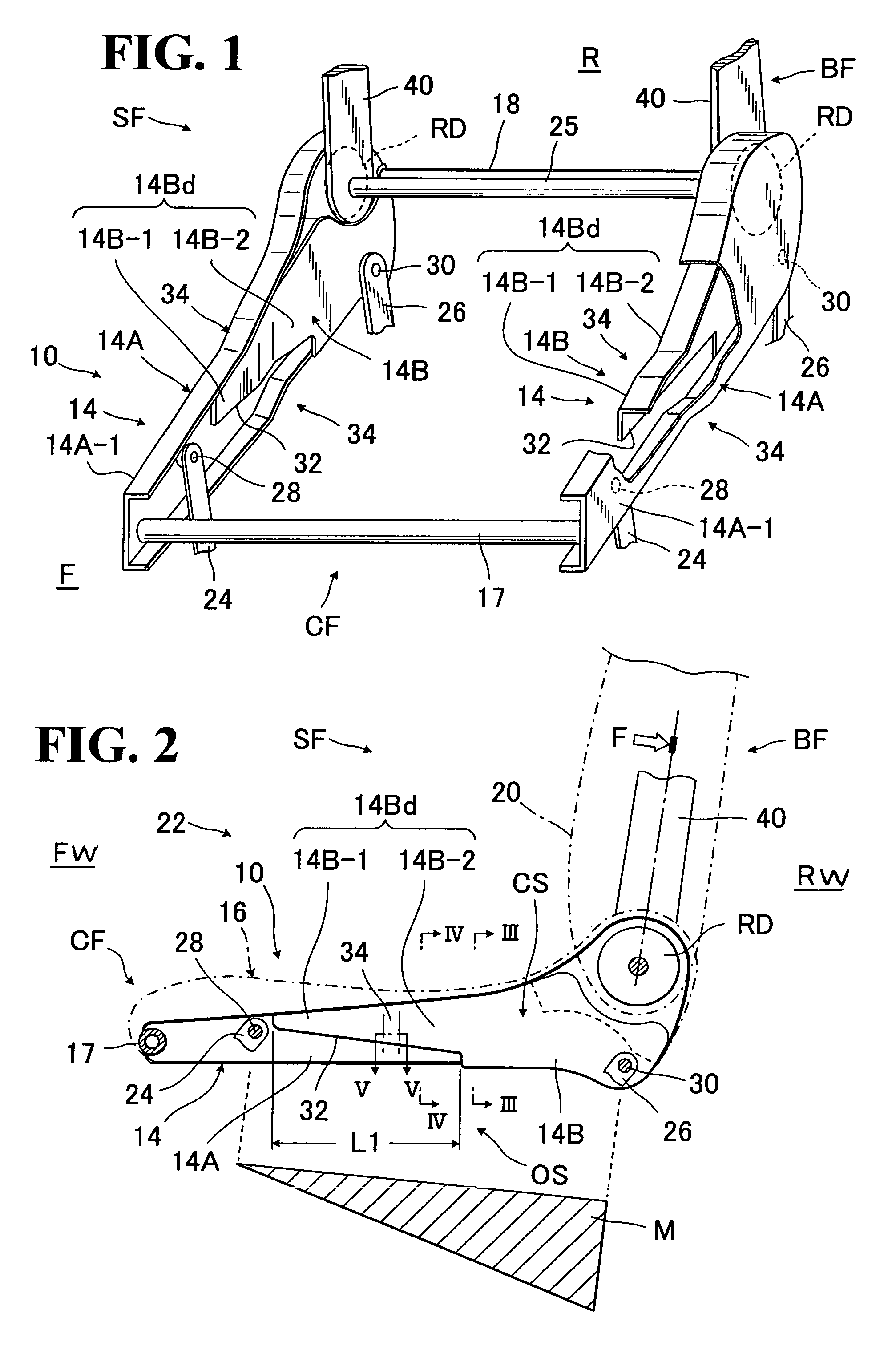

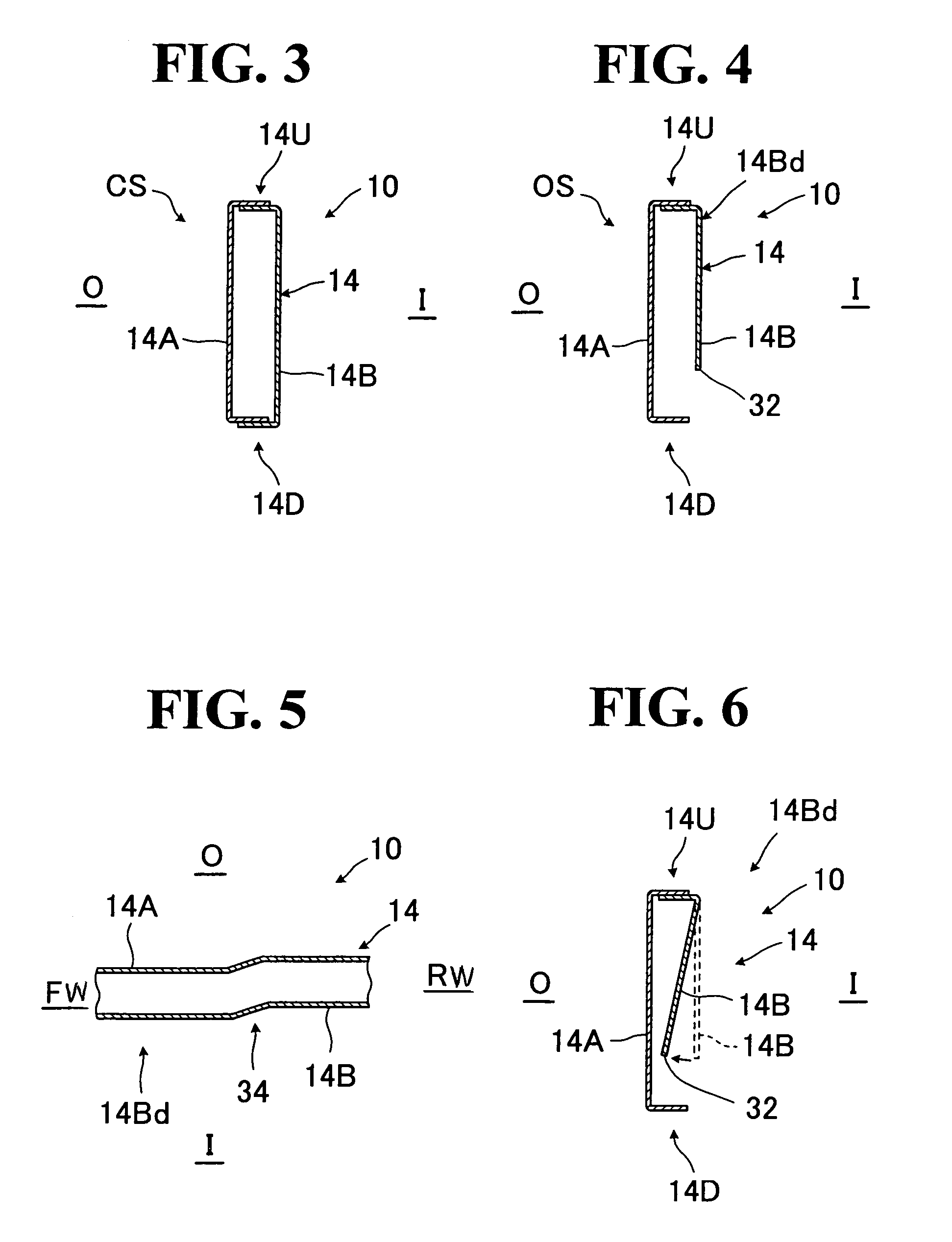

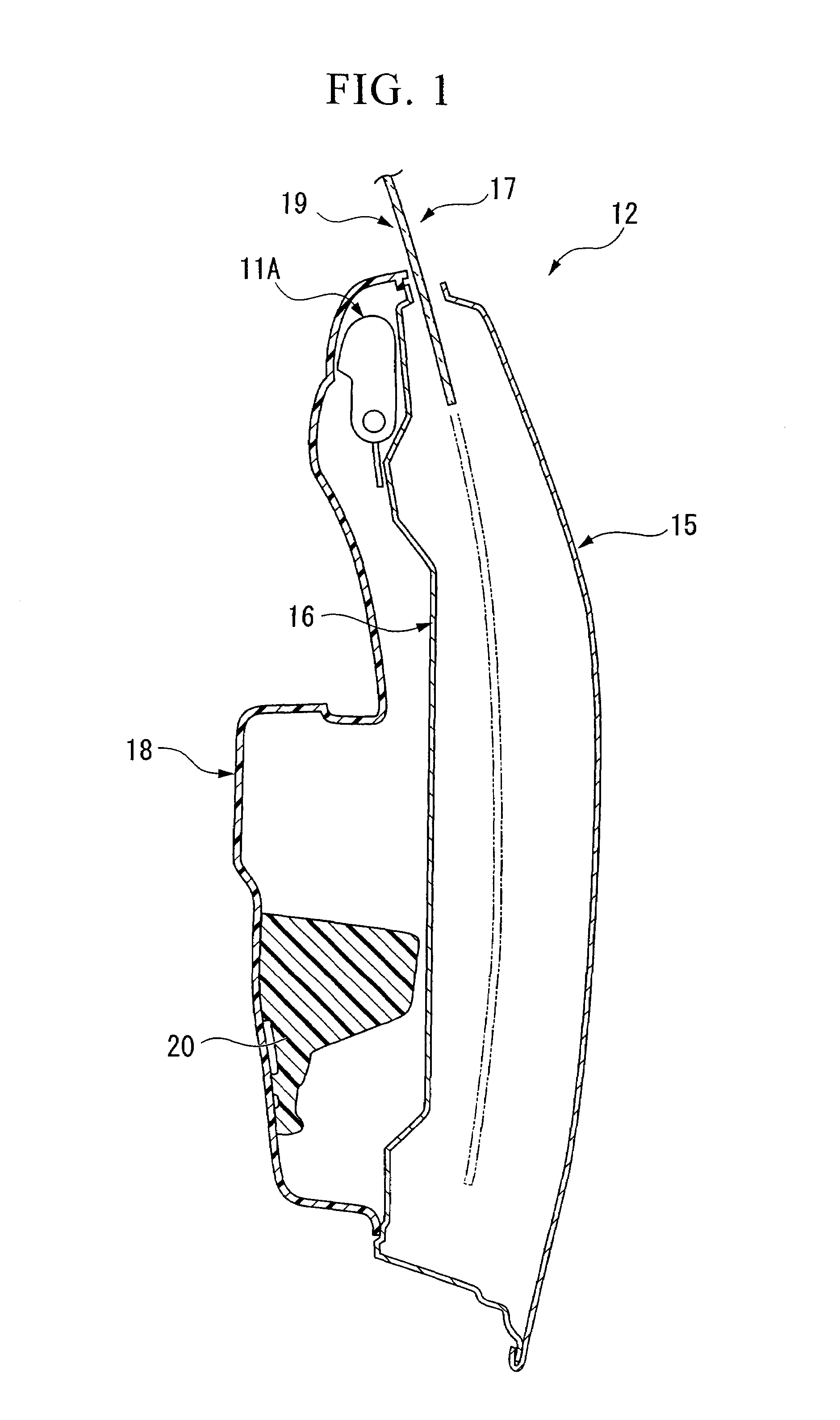

Vehicle front body structure

InactiveCN101037118AImprove the delivery effectImprove impact absorption performanceSuperstructure subunitsSuspension towerAxial compression

The present inventive vehicle front body structure, comprises a front side frame provided so as to project forward from a dash panel; an apron member provided so as to project substantially forward at a location that is outside the vehicle width direction of the front side frame; a suspension tower portion provided so as to at least partly protrude in an engine room for at least partly accommodating a front suspension vibration damper therein, the suspension tower portion being engaged with the apron member and the front side frame; an engine mount provided at the front side frame in front of the suspension tower portion so as to support a side portion of a power plant; and a first connecting member provided so as to straightly interconnect an upper portion of the suspension tower portion and a portion of the front side frame that is located in front of the engine mount, the member being disposed so as to overlap with the engine mount in a top view. The present invention provide a front structure of vehicle body for transmitting a collision load working on a front side frame to an upper portion of a vehicle body which is capable of absorbing the energy caused by the axial compression of the front side frame by suppressing any upward bend of the front side frame by reliably dispersing the collision load to the upper portion of the vehicle body while arranging an engine mount on the front side frame.

Owner:MAZDA MOTOR CORP

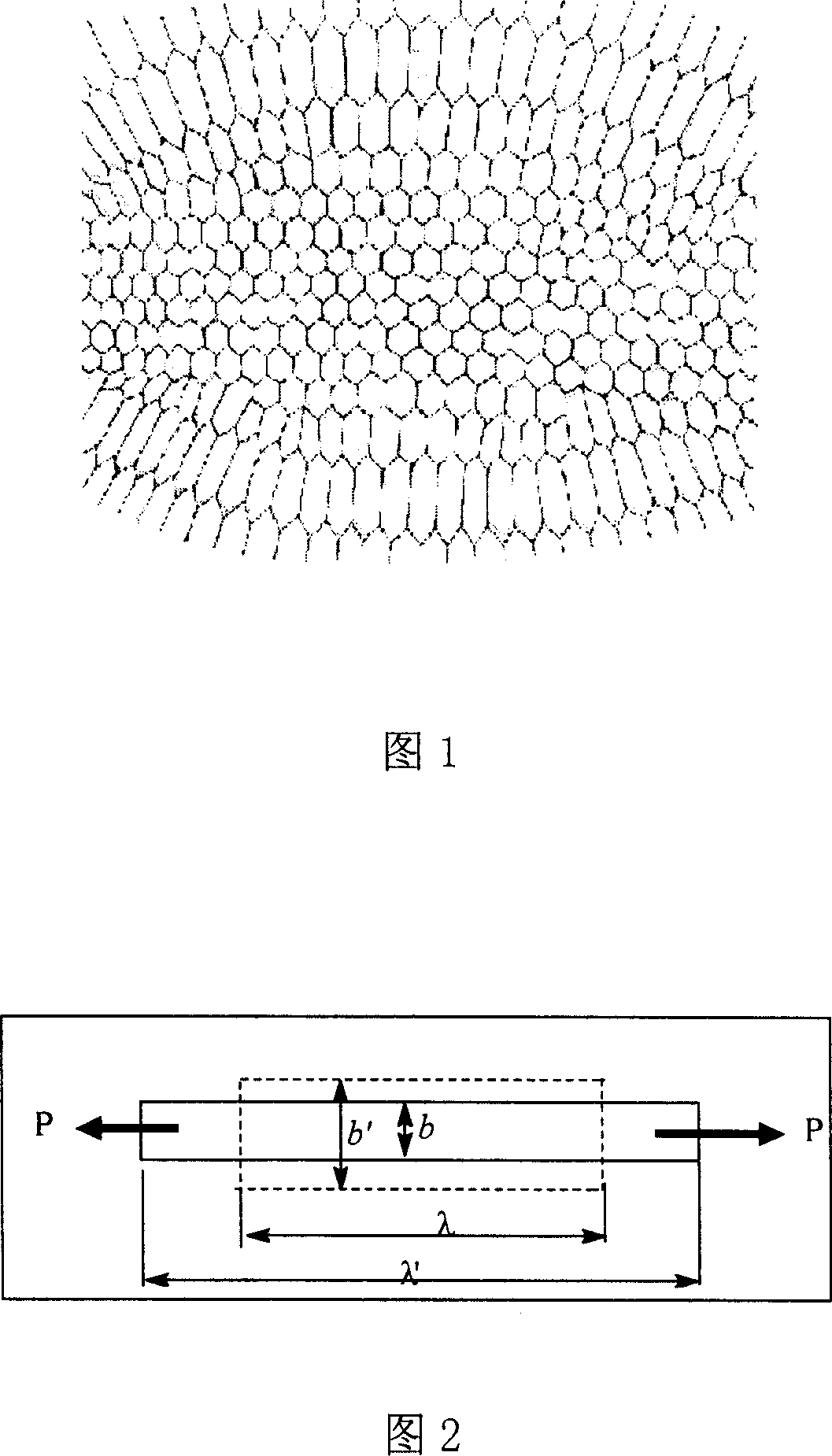

Negative poisson's ratio material and its preparing method and use

InactiveCN1986621AImprove stress resistanceImprove impact absorption performanceSynthetic resin layered productsHoneycomb likeHoneycomb structure

The present invention relates to composite polymer material, and is especially stretching material with negative Poisson's ratio and its preparation process and use. The foamed material obtained through secondary foaming process or screw extrusion foaming process has microscopic double fan-shaped composite structure with middle layer of regular honeycomb structure, outer layer of ordered gradually lengthened arrangement and micropores of 80-150 micron size. The foamed material has the mechanical performance of perpendicularly expanding while being stretched and perpendicularly contracting while being extruded. By means of special preparation process, the foamed material may have raised compression resistance, shock absorption, rebound elasticity and other mechanical performance. The unique mechanical performance makes the material possess application in composite board, waste water treatment, deep water job and other fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

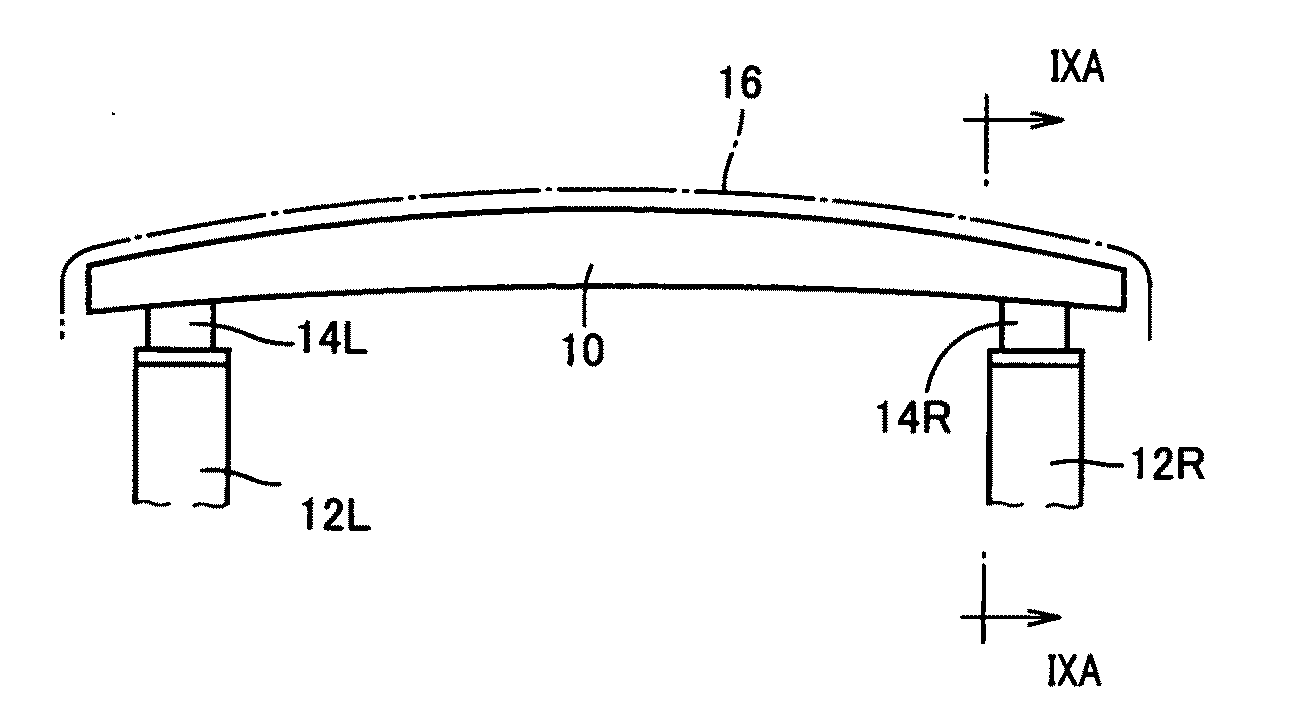

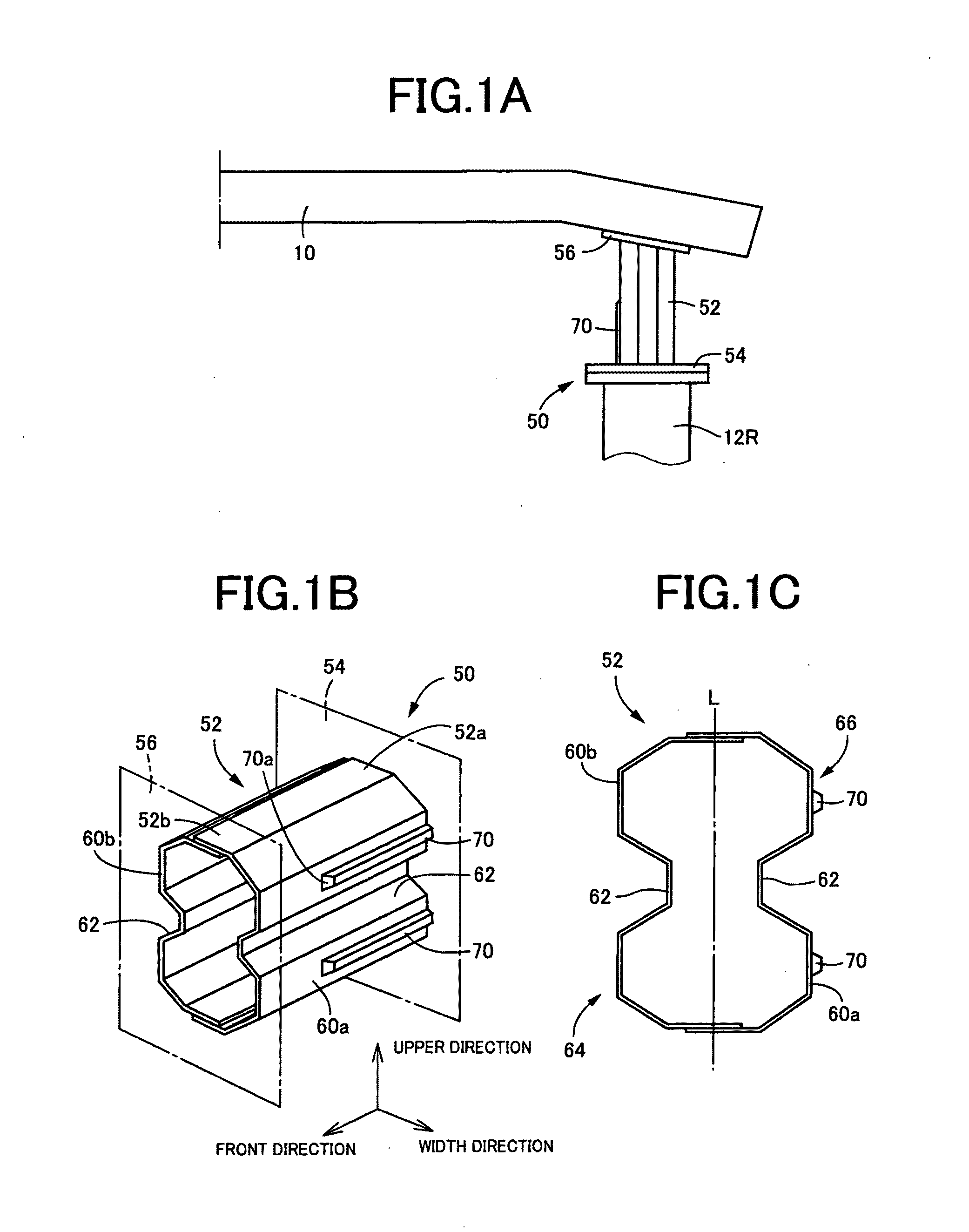

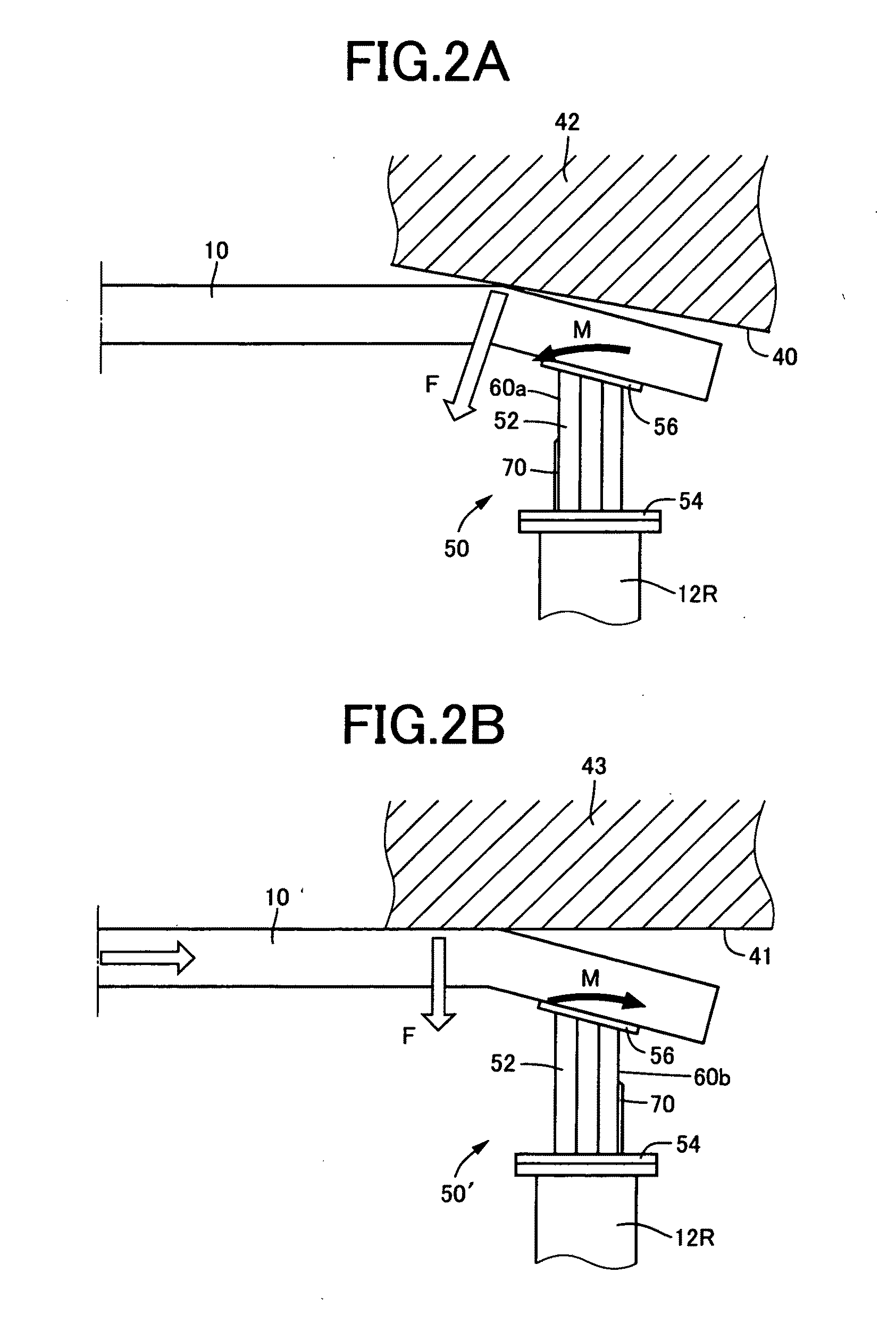

Impact absorbing member for vehicle

ActiveUS20110187135A1Improve impact absorption performanceIncrease supplyElastic dampersBumpersEngineeringMechanical engineering

Of side wall portions (60a, 60b) of a tubular body portion (52) mainly constituting an impact absorbing member (50), a wider side wall portion (60a) on the vehicle inner side is provided with a projecting rib (70) projects outward in the direction perpendicular to the axis of the body portion. The projecting rib (70) extends from an axial end (52a) adjacent to a mounting plate (54) and parallel to the axial direction of the body portion. Therefore, even when an impact load is applied to the impact absorbing member (50) in an oblique direction with respect to the vehicle to generate a moment load, the existence of the projecting rib (70) prevents the impact absorbing member from falling down laterally. Accordingly, excellent impact-absorbing properties are stably obtained. The projecting rib (70) is formed not to reach the load input side, i.e., the axial end (52b) adjacent to a mounting plate (56), where collapse starts. Therefore, no load increase occurs in a crash initial stage to well maintain impact-energy-absorbing properties.

Owner:TOYODA IRON WORKS CO LTD

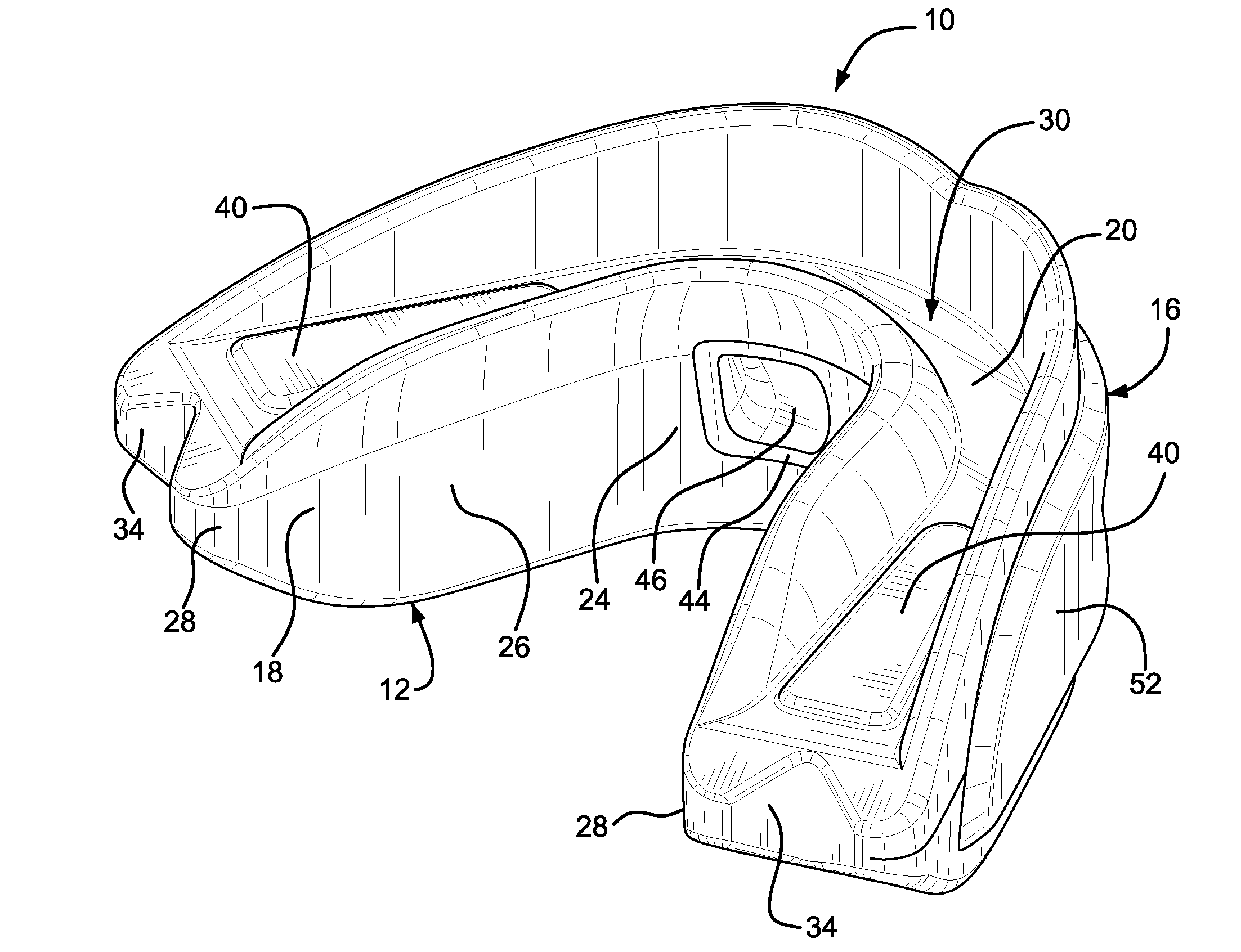

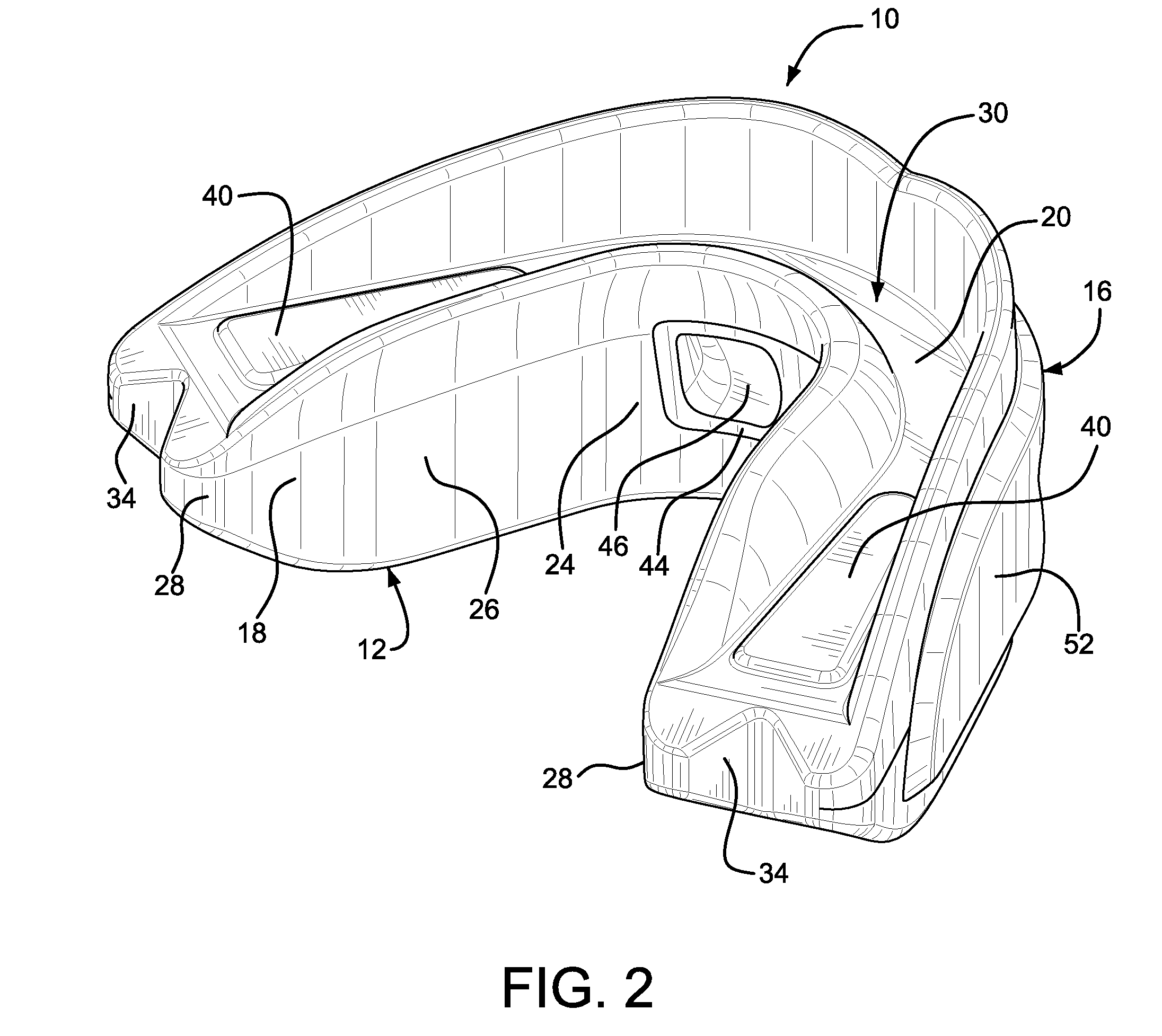

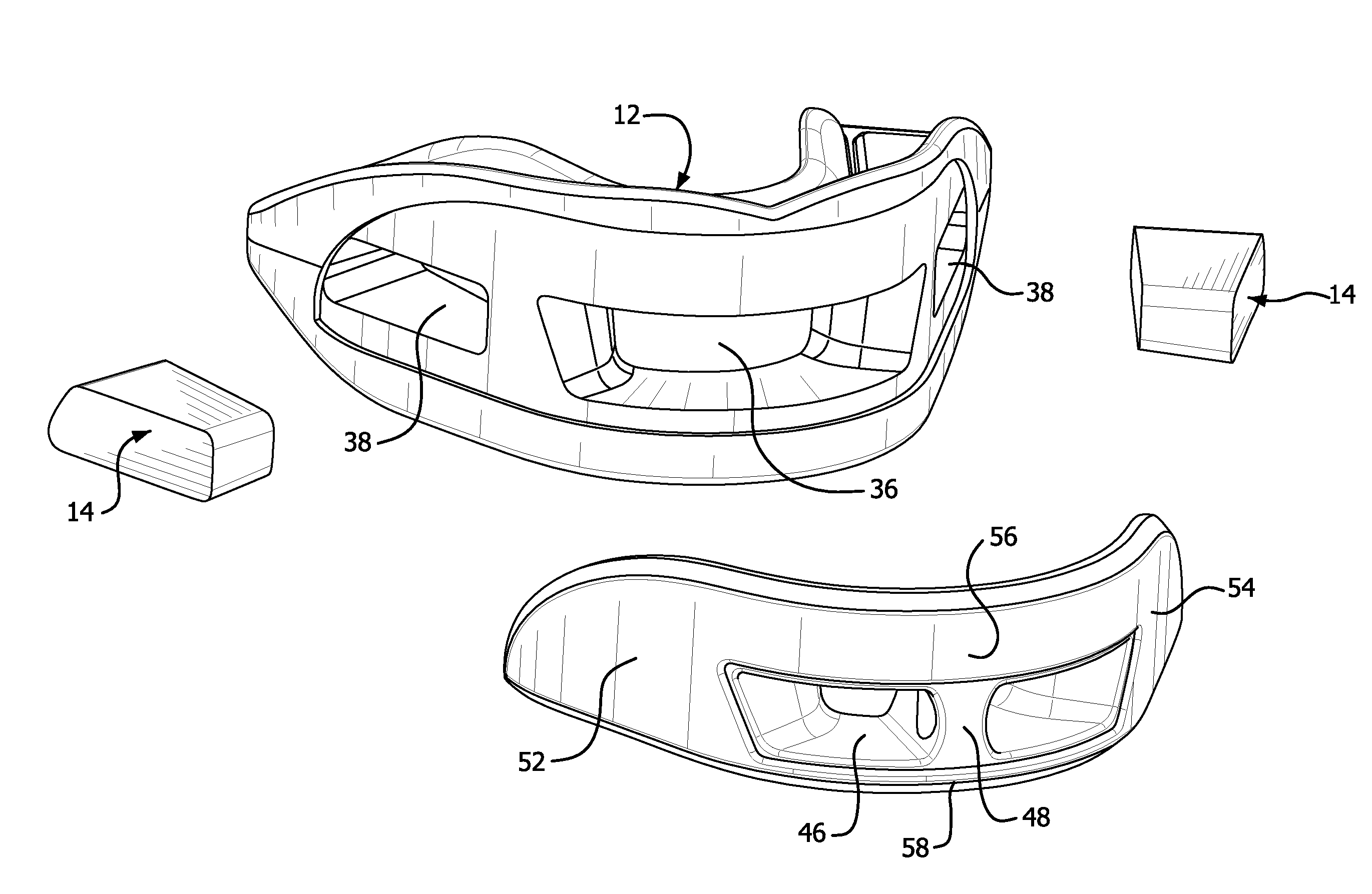

Shock absorbing dental appliance

InactiveUS20110005531A1Improve impact absorption performanceTransfer shockRespiratorsTeeth fillingPlastic materialsEngineering

A dual arch dental appliance including a body which contains a pair of impact absorbing members located in molar regions of the arches. The impact absorbing members are selected from plastic material that exhibits high impact absorption coupled with low resilience or rebound. The result is an appliance which transfers minimal shock to the wearer. The appliance preferably further includes a bumper for providing enhanced impact protection to all of the user's upper and lower teeth. An airway opening is preferably provided to facilitate breathing when the appliance is clenched between the teeth. A post may be provided for structural reinforcement of the airway opening and, optionally, for receiving a tether for fastening the device to a helmet.

Owner:MANZO JOSEPH S

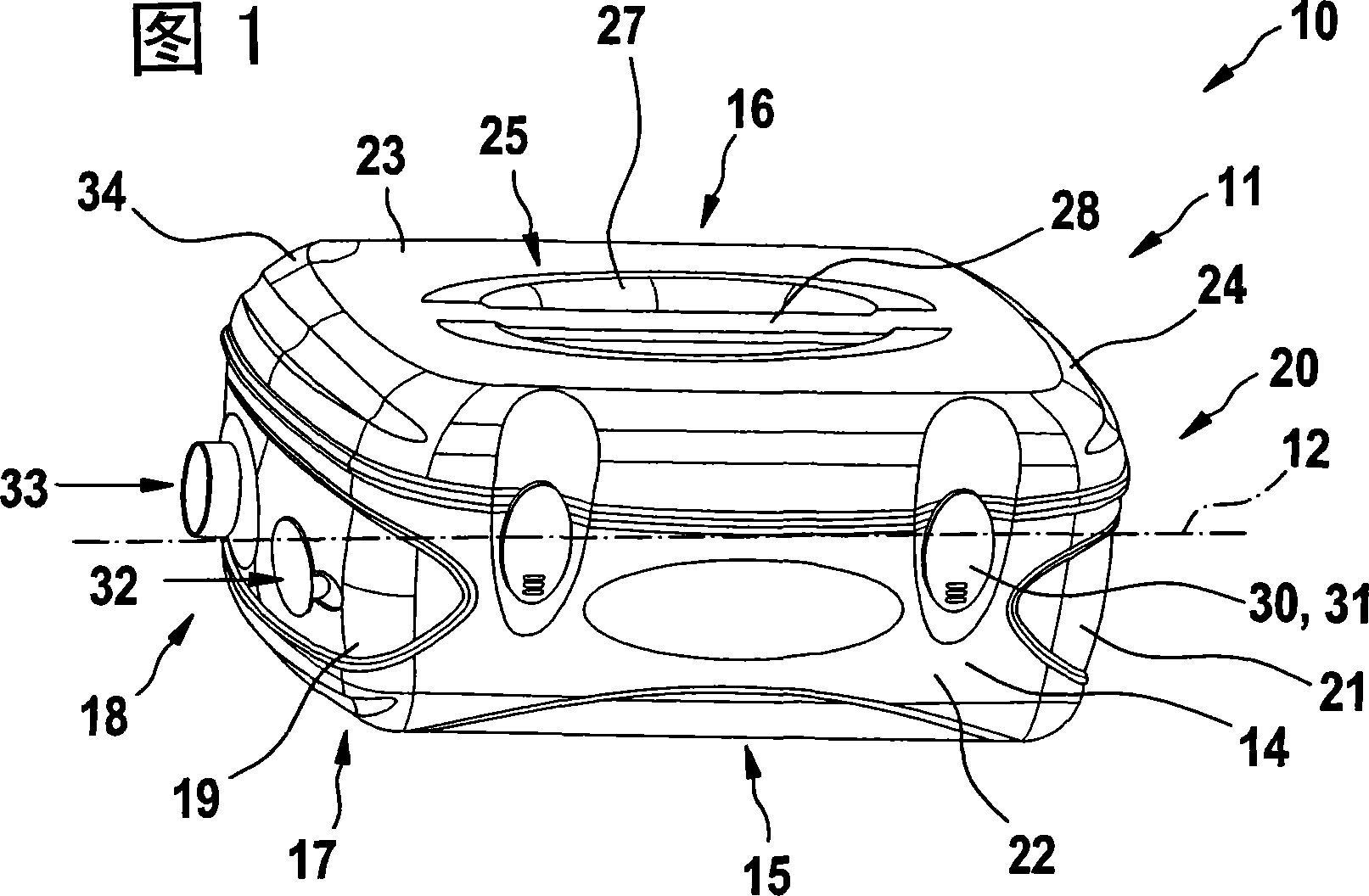

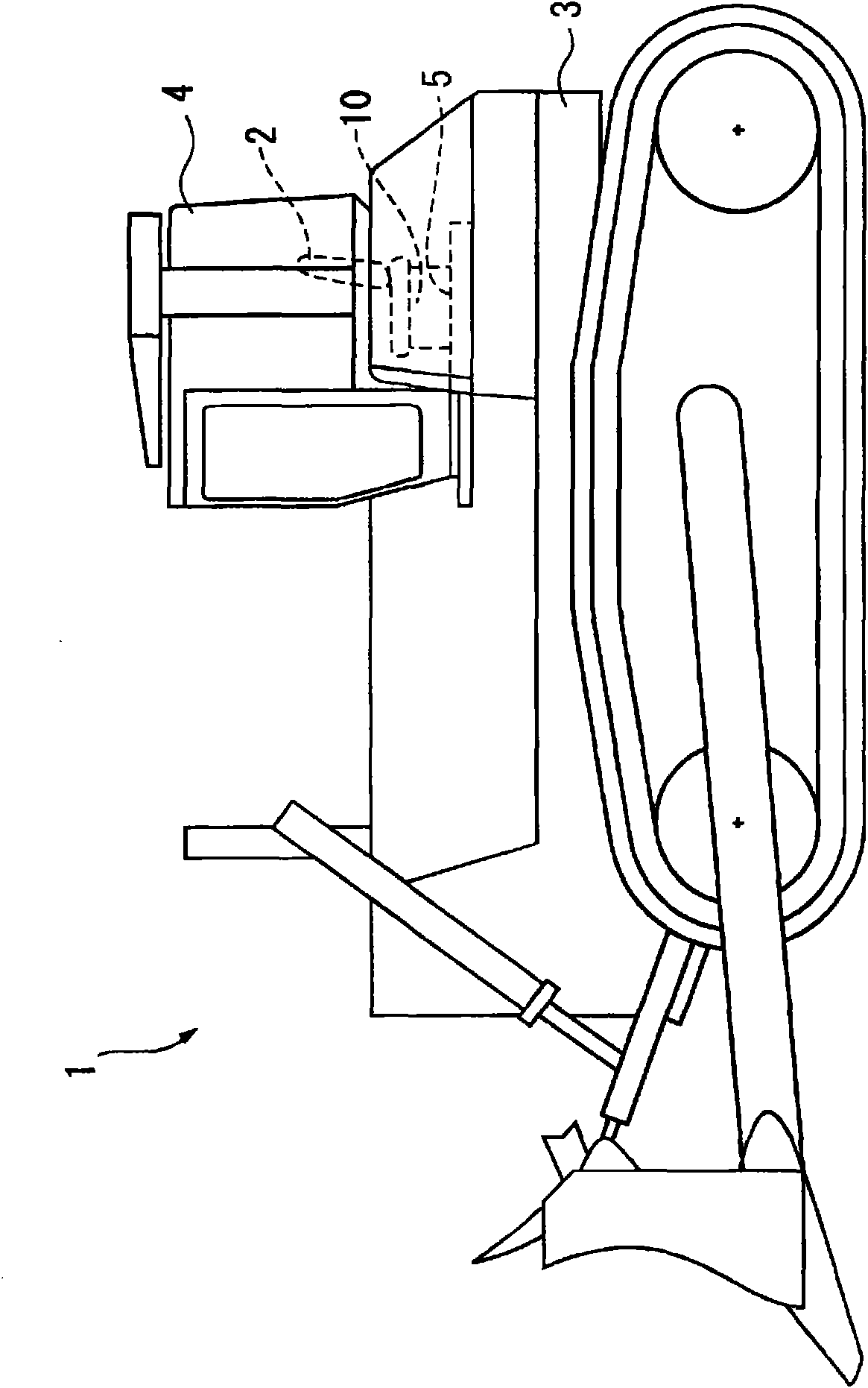

Mobile driving mechanism

InactiveCN101068661AImprove working powerPlace stableSuction cleaner storing devicesWork tools storageJoint arthrodesisHand held

Owner:ROBERT BOSCH GMBH

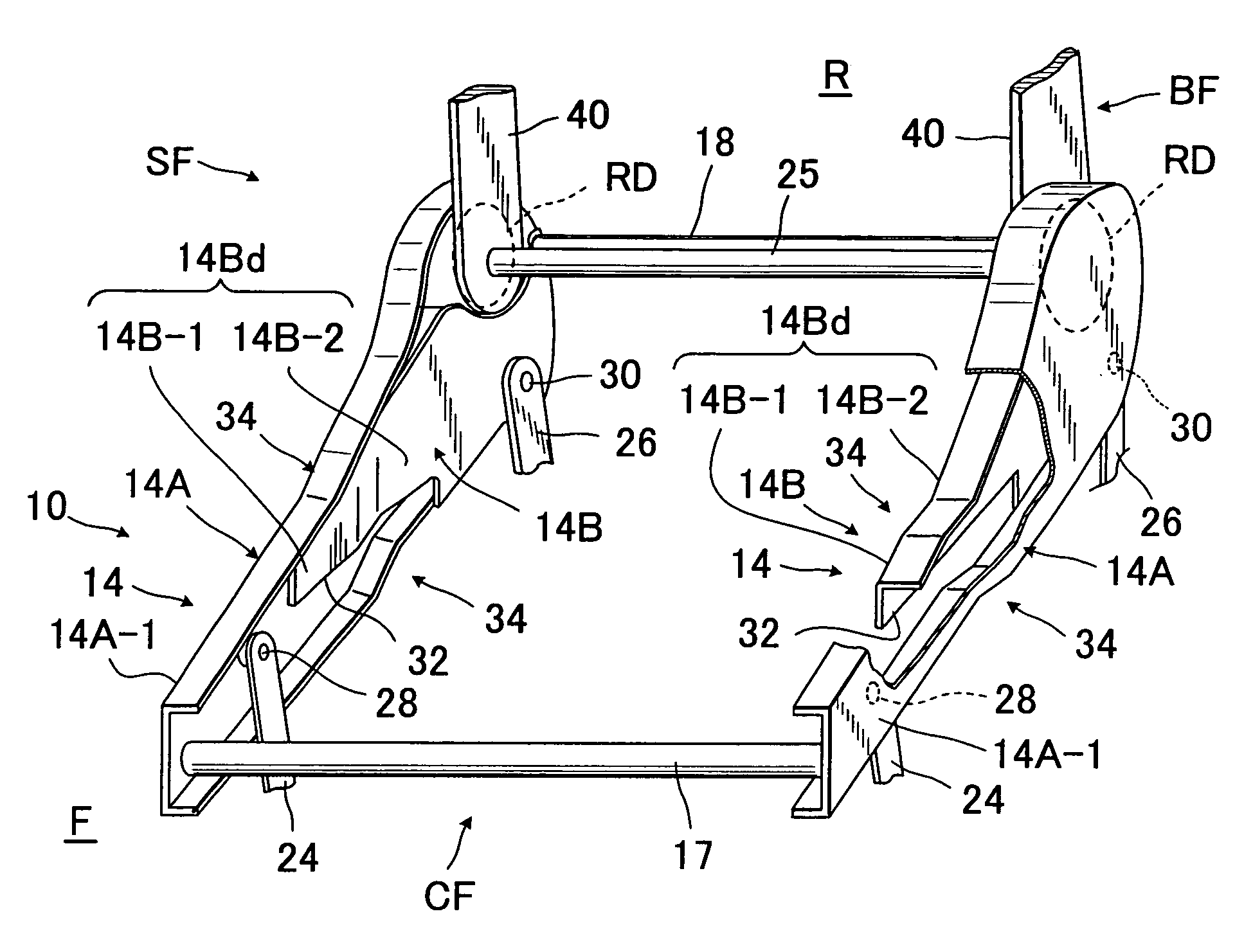

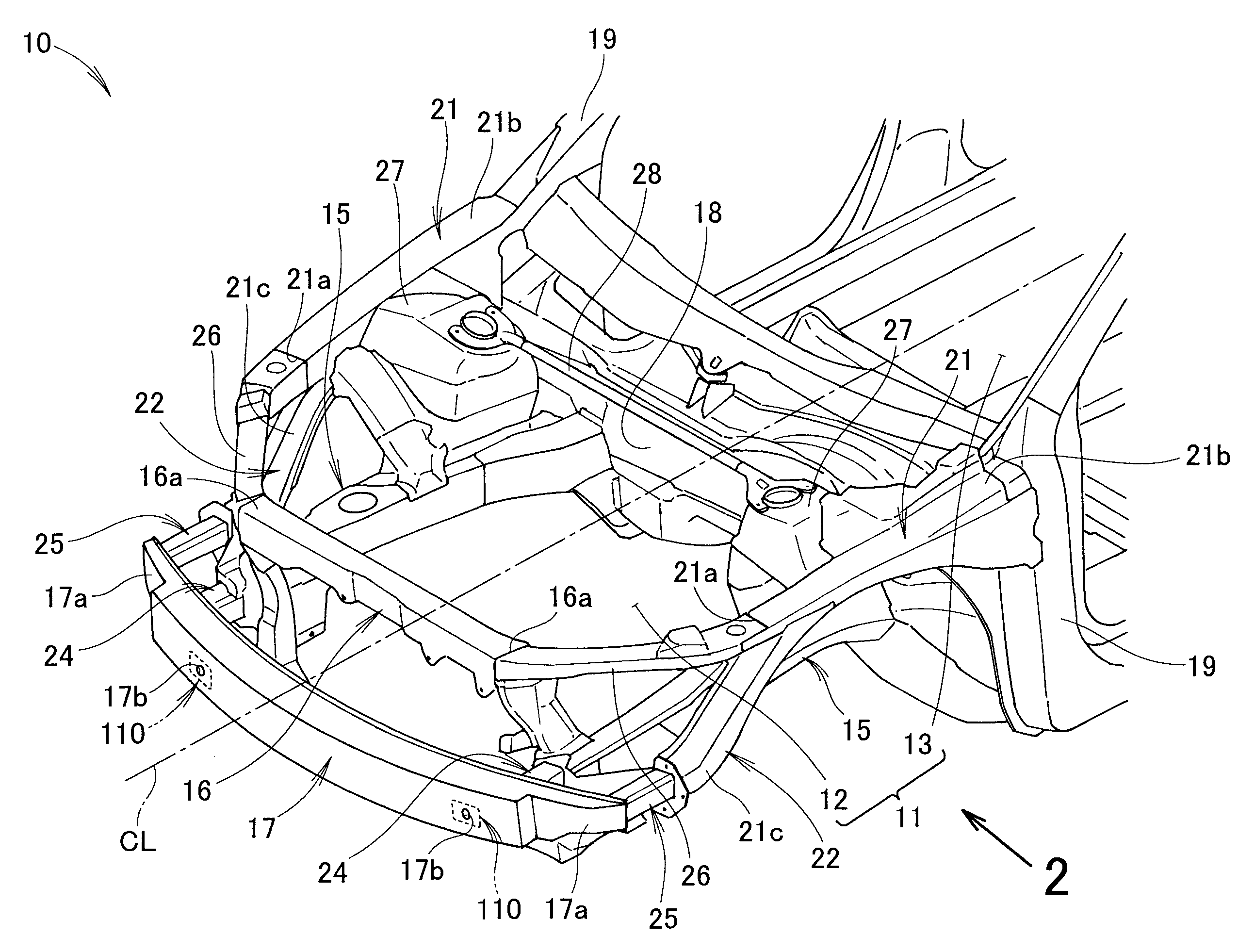

Front vehicle body structure

ActiveUS20130249245A1Improve abilitiesImprove impact absorption performanceVehicle seatsUnderstructuresEngineeringTension member

On each of left and right sides of a vehicle body, a gusset is provided spaced in a rearward direction of a vehicle body from the distal end of a front side frame by a predetermined distance, a tension member extends between and interconnects the distal end of the front side frame and an outer end portion of the gusset so as to prevent the gusset from peeling off the front side frame, and a mounting plate spans between and interconnects the respective front ends of an inner bumper beam extension extending forward from the front end of the front side frame and an outer bumper beam extension extending forward from the front end of an upper member. A bumper beam is joined to the mounting plates on the left and right sides of the vehicle body.

Owner:HONDA MOTOR CO LTD

Impact absorbing composites and their production

InactiveUSRE37705E1Efficient impact absorptionImprove efficiencyLastingInsolesInternal pressureEngineering

An improved composite for absorbing and dispersing impacting forces is disclosed. The composite includes a flexible plastic enclosure defining an internal cavity. The flexible enclosure is generally impermeable to air and capable of having its internal pressure changed. The composite further includes a foam core filling the cavity and retained within the cavity and adhered on substantially all of its external surface to the internal surface of the cavity. The cavity can be pressurized for higher impact absorbance. Methods for fabricating the composites are disclosed, as well.

Owner:DONZIS BYRON A

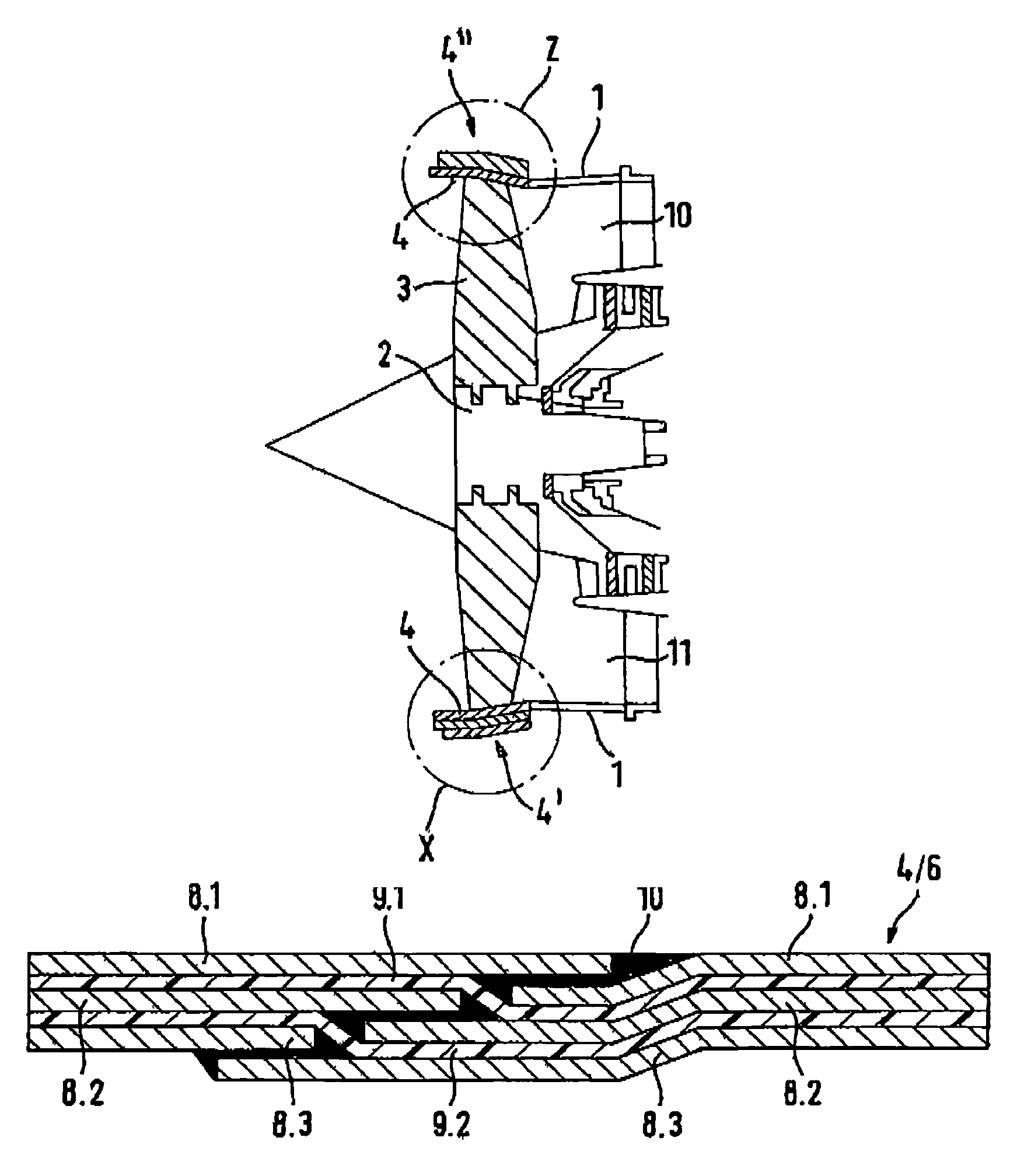

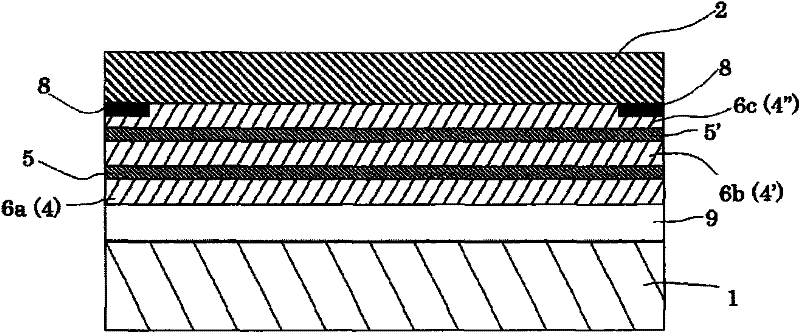

Protective ring for the fan protective casing of a gas turbine engine

InactiveUS7076942B2Improve impact absorption performanceReduce weightEfficient propulsion technologiesSafety/regulatory devicesFiberAbsorption capacity

A protective ring (4) for the fan blades (2, 3) of a gas turbine engine includes a material combination of metal bands and polymer-bonded fiber-weave layers interconnected in alternating arrangement. The protective ring thus formed, which is characterized by tough-elastic properties and low weight, can be used as a full containment (4′) with sufficiently large wall thickness or as a penetration containment (4″) with smaller wall thickness and with a trapping layer arranged on the outer circumference. As a full containment, the protective ring has impact-absorption capacity, as a penetration containment it prevents a further destruction of the broken-through protective ring.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Shock absorbing material

InactiveCN101838472AGood flexibilityImprove impact absorption performanceFlexible coversWrappersVolumetric Mass DensityPore diameter

Owner:NITTO DENKO CORP

Vehicle end portion structure

InactiveUS7992926B2Guaranteed normal transmissionImprove impact absorption performanceVehicle seatsUnderstructuresCrumple zoneMechanical engineering

A front end portion of a side member functions as a crumple zone during a collision with another vehicle or the like. A radiator support is attached via a bracket to this crumple zone. When another vehicle or the like collides with the side member, the radiator support separates from the side member. When another vehicle or the like collides with the radiator support, external force applied in the rear direction to the radiator support is transmitted to the side member.

Owner:TOYOTA JIDOSHA KK

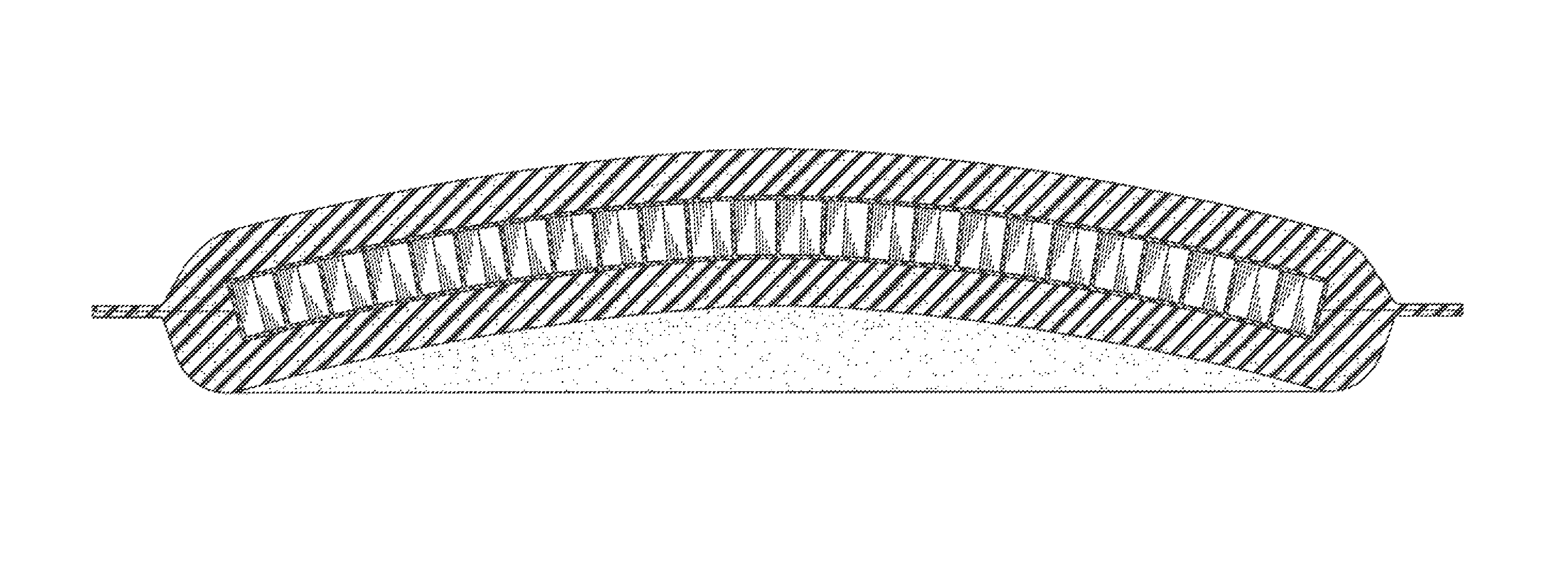

Compliant impact protection pad

ActiveUS20090307829A1Improve impact performanceImprove impact absorption performanceUndergarmentsProtective garmentPhysical medicine and rehabilitationHip protector

A hip protector pad absorbs impact energy at a vulnerable area of a greater trochanter of an adult human hip. The pad has a continuous sheet of flexible honeycomb material having faces covered with a cover material and a layer of compliant and resilient foam on an inner side and an outer side of the honeycomb material. The pad is flexible to conform to a shape of the hip area. The cover material reduces a penetration of the foam into cells of the honeycomb material when subjected to impact. The pad is effective to reduce an impact of a fall of an adult human on the vulnerable area to be below an average adult human hip fracture impact level.

Owner:COMFIHIPS

Impact absorption structure of vehicle seat

InactiveUS7360832B2Simple structureImprove impact absorption performancePedestrian/occupant safety arrangementSeat framesEngineeringSupport point

Impact absorption structure is provided in side frame element of seat cushion frame, wherein the side frame element is basically of a closed cross-section portion therein, including forward and backward support points therein. In the structure, an opened cross-section area is defined in the closed cross-section by forming a cut-away portion in a lower part of a forward local region of such closed cross-section portion between the forward and backward support points, so that the opened cross-section area is deformable at said cut-away portion by a great load transmitted from a seat back frame thereto, thereby absorbing a corresponding impact.

Owner:TACHI S CO LTD

High manganese high strength steel sheets with excellent crashworthiness and method for manufacturing of it

InactiveUS20090074605A1High elongationImprove impact absorption performanceMetal rolling arrangementsNiobiumManganese

There are provided a high-workability high strength steel sheet with excellent workability due to the high elongation and excellent crashworthiness due to the high yield strength, and a method for manufacturing of it. The high manganese steel sheet includes, by weight: carbon (C): 0.2 to 1.5%, manganese (Mn): 10 to 25%, aluminum (Al): 0.01 to 3.0%, phosphorus (P) 0.03% or less, sulfur (S): 0.03% or less, nitrogen (N): 0.040% or less, at least one selected from the group consisting of silicon (Si): 0.02 to 2.5%, titanium (Ti): 0.01 to 0.10% and niobium (Nb): 0.01 to 0.10%, and the balance of Fe and other inevitable impurities. The high manganese steel sheet may be a hot-rolled steel sheet, a cold-rolled steel sheet, or a plated steel sheet, and is suitable for elaborate internal sheets as well as structural members of a car body since it has press workability due to the high elongation and high strain hardening index. Also, the high manganese steel sheet may be used for parts such as a front side member of an automobile since, among its characteristics, the steel sheet has an excellent impact absorbing ability.

Owner:POHANG IRON & STEEL CO LTD

Front vehicle body structure

ActiveUS8857902B2Improve abilitiesImprove impact absorption performanceVehicle seatsUnderstructuresEngineeringTension member

Owner:HONDA MOTOR CO LTD

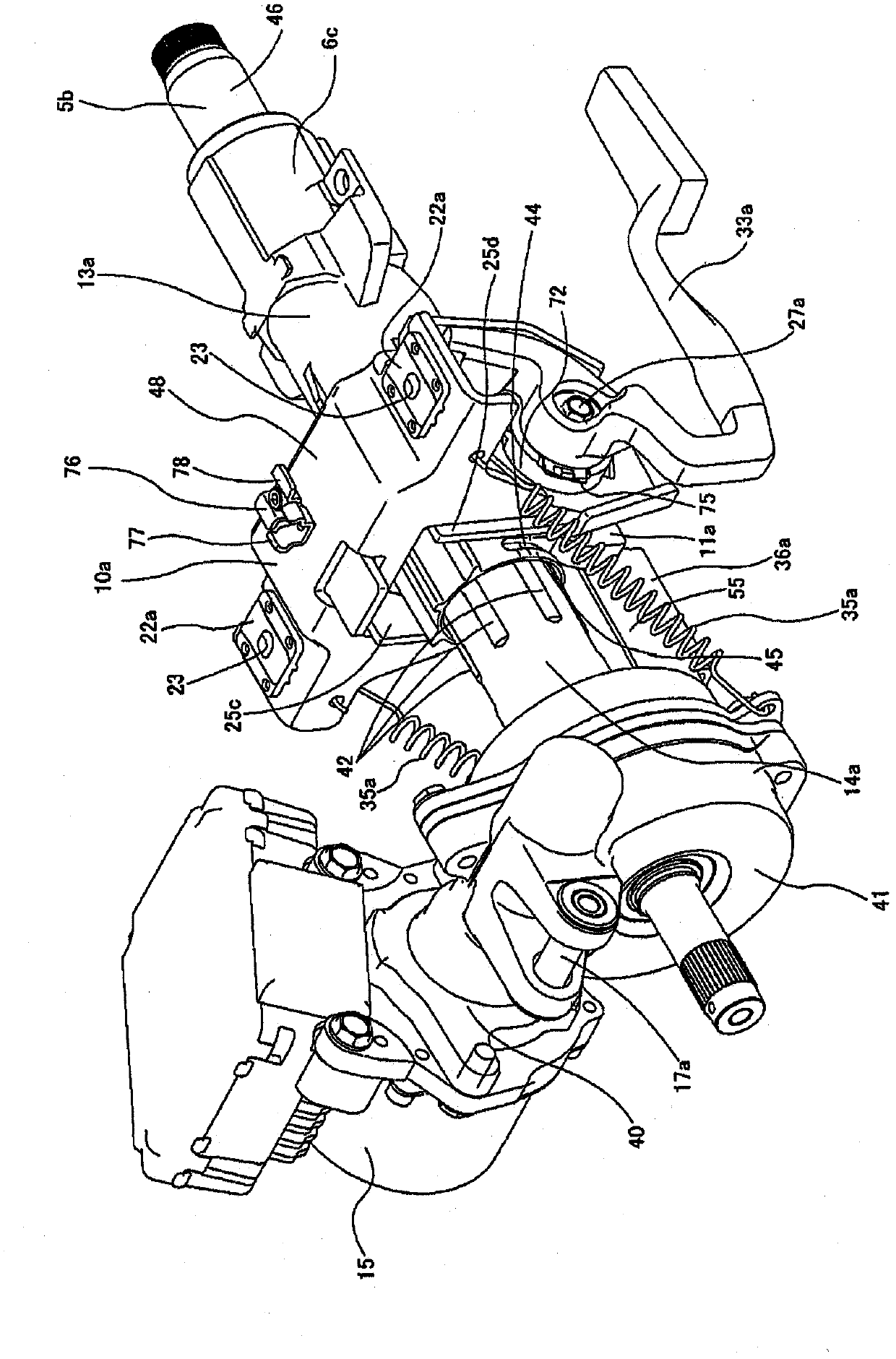

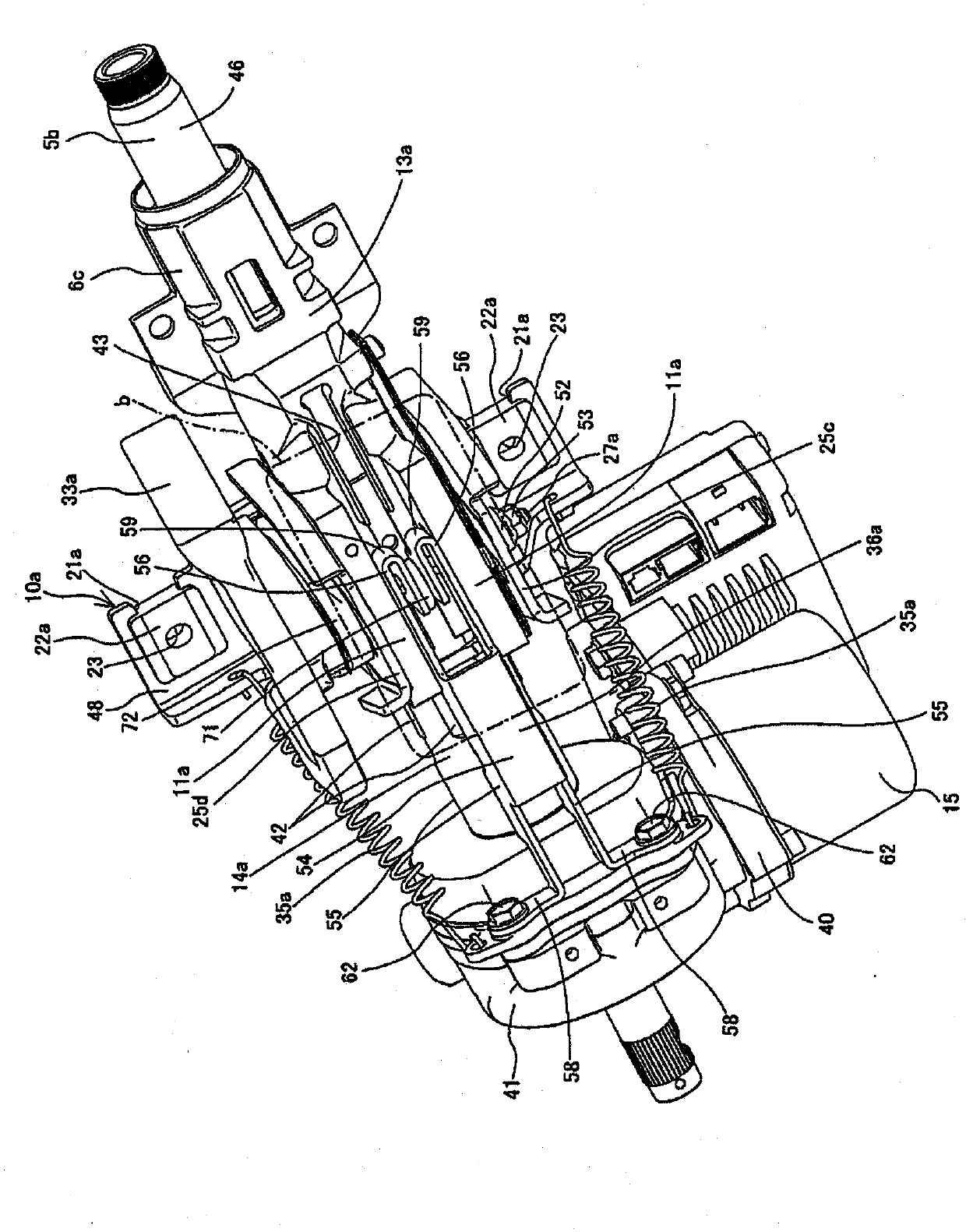

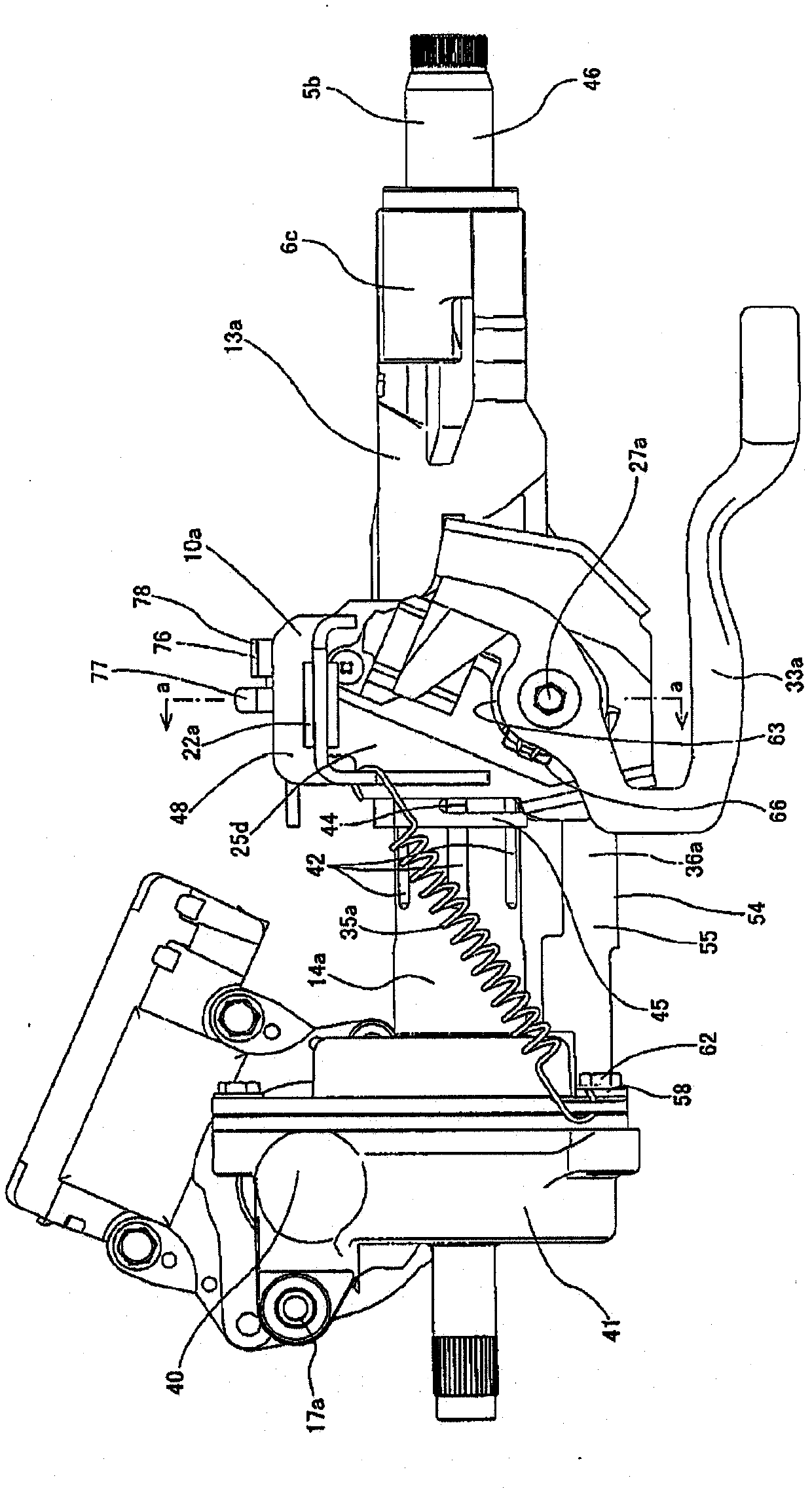

Shock-absorbing steering device

ActiveCN102438879AImprove performanceEnsure degrees of freedomElectrical steeringSteering columnsEngineeringMechanical engineering

In order to configure a shock-absorbing steering device which achieves excellent performance at a low-cost whilst maintaining design freedom, the device is provided with: a tightening rod (27a) which is displaced forward, together with an outer column (13a), during secondary impact; and energy absorbing members (36a, 36b) which are provided in the gap between a locking pin (63) or a housing (16) not displaced forward during secondary impact, are formed from members which plastically deform in accordance with the forward displacement of the outer column (13a) which occurs during secondary impact, and which absorb part of the impact energy by means of the relative movement of the plastic deformation. Part of the energy absorbing members (36a, 36b) is fixed to the tightening rod (27a), and the plastic deformation of the members (36a, 36b) is limited in the width-ways direction by a pair of held wall sections (11a) in the outer column (13a).

Owner:NSK LTD

Shock absorbing dental appliance

InactiveUS8496009B2Improve impact absorption performanceTransfer shockRespiratorsTeeth fillingPlastic materialsEngineering

A dual arch dental appliance including a body which contains a pair of impact absorbing members located in molar regions of the arches. The impact absorbing members are selected from plastic material that exhibits high impact absorption coupled with low resilience or rebound. The result is an appliance which transfers minimal shock to the wearer. The appliance preferably further includes a bumper for providing enhanced impact protection to all of the user's upper and lower teeth. An airway opening is preferably provided to facilitate breathing when the appliance is clenched between the teeth. A post may be provided for structural reinforcement of the airway opening and, optionally, for receiving a tether for fastening the device to a helmet.

Owner:MANZO JOSEPH S

Air bag device

InactiveUS7581751B2Improve impact absorption performanceWell formedPedestrian/occupant safety arrangementSurface plate

An air bag device comprising an air bag that is disposed between an under-window panel and a lining that covers a cabin interior side thereof and deploys upward along an inside surface of the window; and an impact absorption member that interposes between the air bag and the lining.

Owner:HONDA MOTOR CO LTD +1

Surface material for ball and ball

ActiveUS7566488B2Improve wear resistanceGreat abrasionHollow inflatable ballsHollow non-inflatable ballsElastomerBall game

A skin material for balls which is a sheet-form material comprising a base layer and formed on one side there of a coating layer made of a polymeric elastomer, characterized in that (1) the coating layer is composed of three layers (C-1), (C-2), and (C-3) disposed in this order from the surface side, (2) the layer (C-3) on the base layer side is made of a porous polymeric elastomer, (3) the layer (C-1) on the surface side is made of a polymeric elastomer containing a pressure-sensitive adhesive, and (4) the coating layer comprises one or more polymeric elastomers which have or do not have fine through-holes extending from the surface side to the base layer; and a ball having the skin material bonded to the surface. The skin material for ball-game balls brings about excellent wet gripping and is excellent also in wearing resistance and impact absorption.

Owner:TEIJIN CORDLEY

Vehicle front structure

ActiveUS20110309655A1Reliably transmitReduce deformationVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

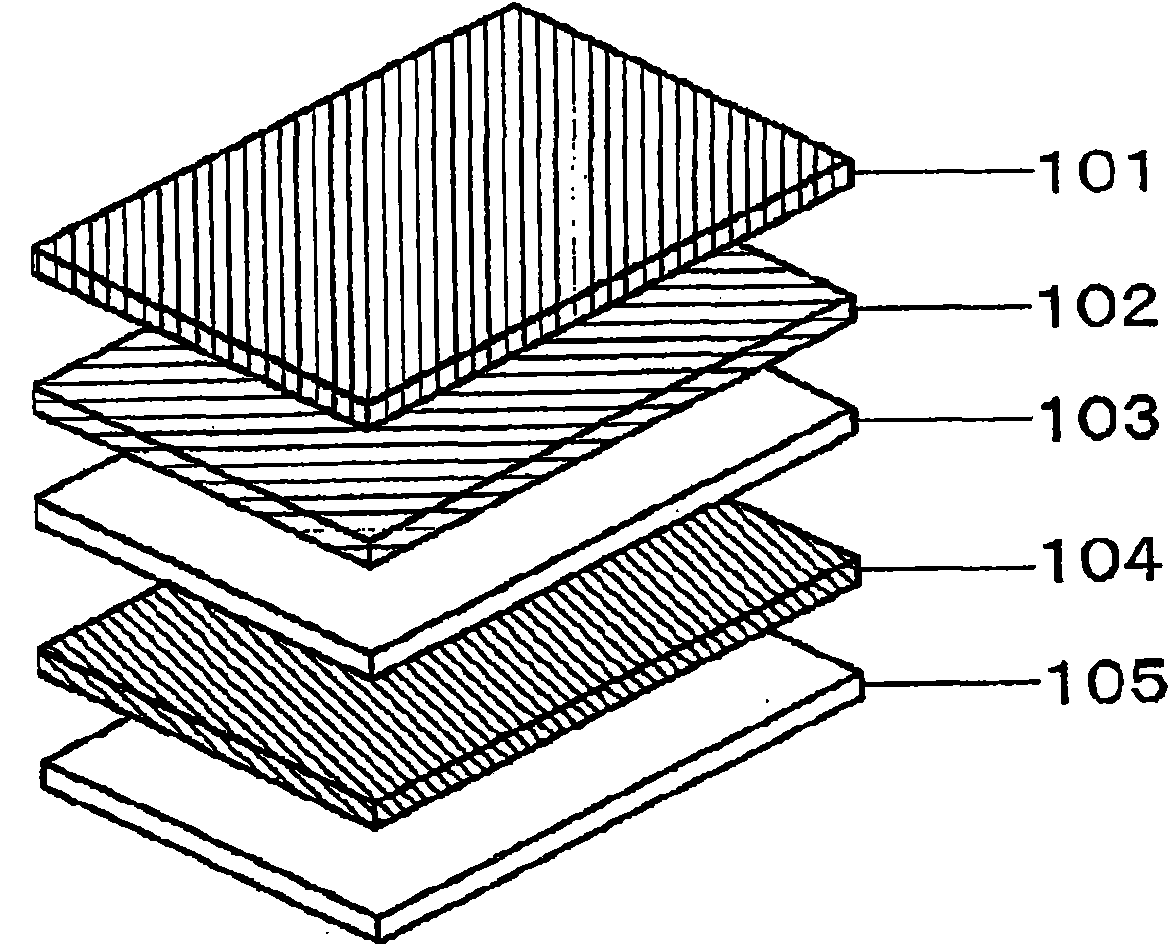

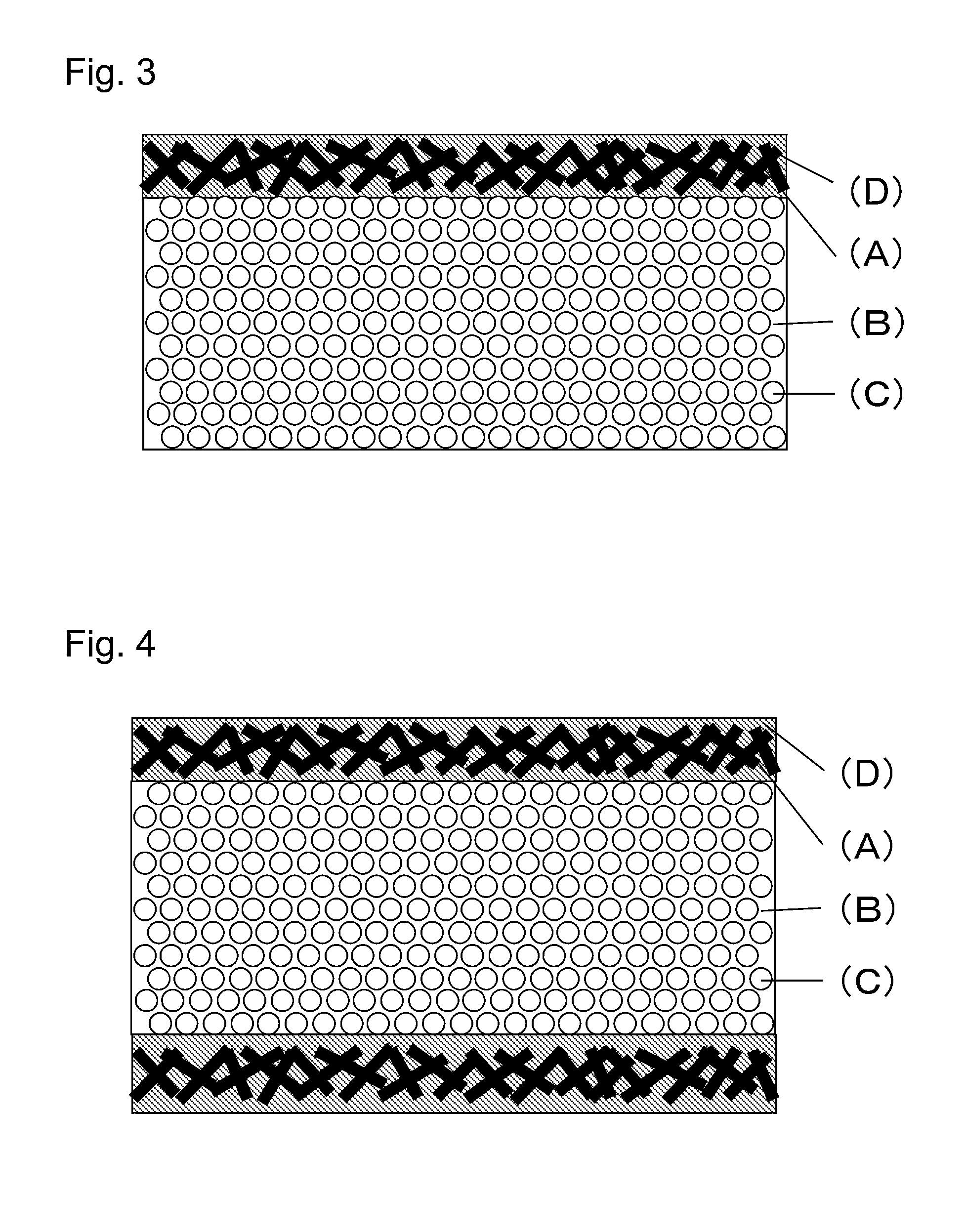

Prepreg, fiber-reinforced composite material, and process for producing prepreg

InactiveUS20130130584A1Improve rigidityHigh strengthSynthetic resin layered productsLaminationPolyolefinThermoplastic elastomer

There is provided a prepreg which contains components (A) to (C) as mentioned below, wherein the component (A) is arranged on one surface or both surfaces of a layer comprising the components (B) and (C): (A) a nonwoven fabric comprising a thermoplastic elastomer and / or a polyolefin each of which has a value of tan θ of 0.06 or more at 10° C. as measured in a viscoelasticity measurement and is incompatible with the component (B); (B) a first epoxy resin composition; and (C) a reinforcing fiber. There are also provided a fiber-reinforced composite material which has excellent rigidity, strength, and vibration-damping performance, a prepreg which can be used suitably for the production of the fiber-reinforced composite material, and a process for producing the prepreg.

Owner:TORAY IND INC

Formula and its production for shock-absorbing EVA foaming sectional material

InactiveCN1982363AExcellent shock absorptionImprove impact absorption performanceFoaming agentMetallurgy

Formula of shock-absorbing EVA foaming sections and its production are disclosed. The formula consists of vinyl-vinyl acetate multi-polymer 30 proportion, styrene-isoprene-styrene block multi-polymer 25 proportion, vinyl-acrylic acid multi-polymer 10 proportion, hydrated magnesium silicate 20 proportion, zinc oxide 1.5 proportion, bridging agent 1.2 proportion, bridging auxiliaries, foaming agent 3.25 proportion and colorant 3 proportion. The process is carried out by blending, internally mixing, open milling, tying to obtain plate and grain, mold pressing or injection mold pressing, grinding while cutting for foaming plate and secondary foaming. It can be used to produce EVA sole.

Owner:郭廷志

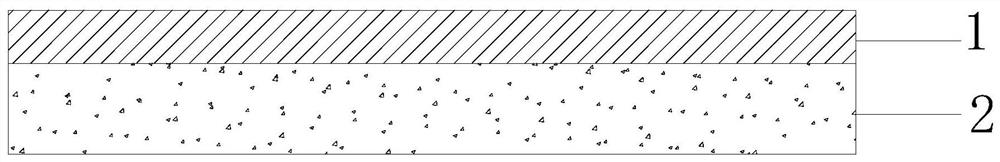

Impact-absorbing sheet

InactiveCN1760564AImprove fracture performanceAvoid enteringAdhesive articlesSynthetic resin layered productsEngineeringMono layer

Owner:NITTO DENKO CORP

Acrylic foamed damping foam and preparation method thereof

InactiveCN112680139AExcellent shock absorptionIncreased durabilityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceMicrosphere

The invention discloses acrylic foaming damping foam which is applied to an OLED module and comprises a release film layer and an acrylic foam layer, the release film layer and the acrylic foam layer are overlapped together, the acrylic foam layer is formed by coating and drying acrylic foam coating liquid, and the acrylic foam coating liquid is prepared from the following components in parts by weight: an acrylic polymer, a curing agent, foamed microspheres, an inorganic filler, a dispersing agent, an inorganic pigment and an organic solvent. The acrylic foam tape prepared by the invention can absorb impact force, has excellent impact absorbability, can be widely applied to the periphery of liquid crystal as a buffer material by utilizing the characteristics, cannot cause water decomposition due to overhigh humidity, and has excellent durability.

Owner:CYBRID TECHNOLOGIES INC

Compliant impact protection pad

ActiveUS8732869B2Improve impact performanceImprove impact absorption performanceChemical protectionHeat protectionHip protectorHoneycomb

A hip protector pad absorbs impact energy at a vulnerable area of a greater trochanter of an adult human hip. The pad has a continuous sheet of flexible honeycomb material having faces covered with an optional cover material and a layer of compliant and resilient foam on an inner side and an outer side of the honeycomb material. The pad is flexible to conform to a shape of the hip area. The pad is effective to reduce an impact of a fall of an adult human on the vulnerable area and minimizes the chance of a hip fracture resulting from the fall.

Owner:COMFIHIPS

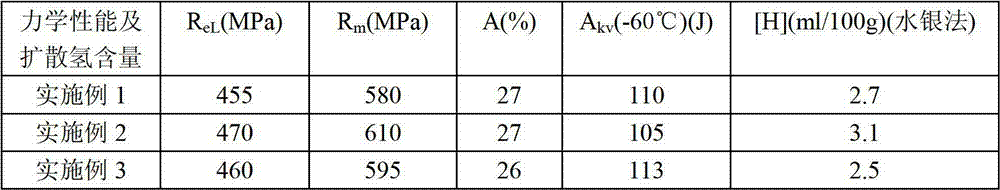

Ultralow-hydrogen high-toughness submerged arc welding flux core and submerged arc flux-cored wire

InactiveCN102848103AEasy to operateImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaBorideCrack resistance

The invention relates to an ultralow-hydrogen high-toughness submerged arc welding flux core and a submerged arc flux-cored wire. The welding flux core comprises the following components of: CaF2, Na2SiF6, ReF, BaCO3, CaCO3, MgO, TiO2, SiO2, ZrO2, boride, Na2O, K2O, Mn, Al-Mg, Ni, Ti, Si, Re and the balance of Fe. When the welding flux core is matched with a high-alkalinity sintering welding flux, the weld metal has the impact absorbed power of more than 80J at the temperature of 60 DEG C below zero; when the welding flux core is matched with a low-hygroscopicity smelting welding flux, the weld metal has the impact absorbed power of more than 90J at the temperature of 40 DEG C below zero; and when the welding flux core is matched with any one welding flux, weld diffusion hydrogen content is less than 5ml / 100g. The standard specific ultralow-hydrogen range is achieved; and the submerged arc flux-cored wire is high in cold crack resistance, has high in fracture toughness value, is suitable for low-alloy high-strength steel and can be used for welding important structures.

Owner:TIANJIN UNIV +1

High-strength high-toughness submerged arc welding wires

InactiveCN103273213AImprove impact absorption performanceStable welding wire qualityArc welding apparatusWelding/cutting media/materialsCopper platingAlloy

The invention discloses high-strength high-toughness submerged arc welding wires. Chemical components of the wires comprise, by weight, 0.05-0.10% of C, no more than 0.20% of Si, 0.6-1.20% of Mn, 3.00-3.8% of Ni, 0.01-0.05% of Ti, 0.001-0.005% of B, no more than 0.02% of Cu, no more than 0.008% of S, no more than 0.010% of P, no more than 0.005% of As, no more than 0,005% of Sb, no more than 0.005% of Sn, no more than 0.006% of N, no more than 0.05% of O and the balance Fe and unavoidable impurities. A manufacturing method sequentially comprises the steps of molten iron desulphurization, converter iron smelting, LF furnace refining, continuous casting, wire rolling, coil rod shelling, acid picking, borax coating, wire drawing and copper plating, and then the finished welding wires with the diameters being respectively 3.2mm and 4.0mm are manufactured. Fracture toughness delta0 (-10 DEG C) is more than or equal to 0.25mm, the welding wires are applicable to 420-460 MPa level low-alloy high-strength steel, and the welding wires can be used in welding of the important structures like ocean engineering structures, bridges, ships and pressure vessels.

Owner:TIANJIN UNIV +1

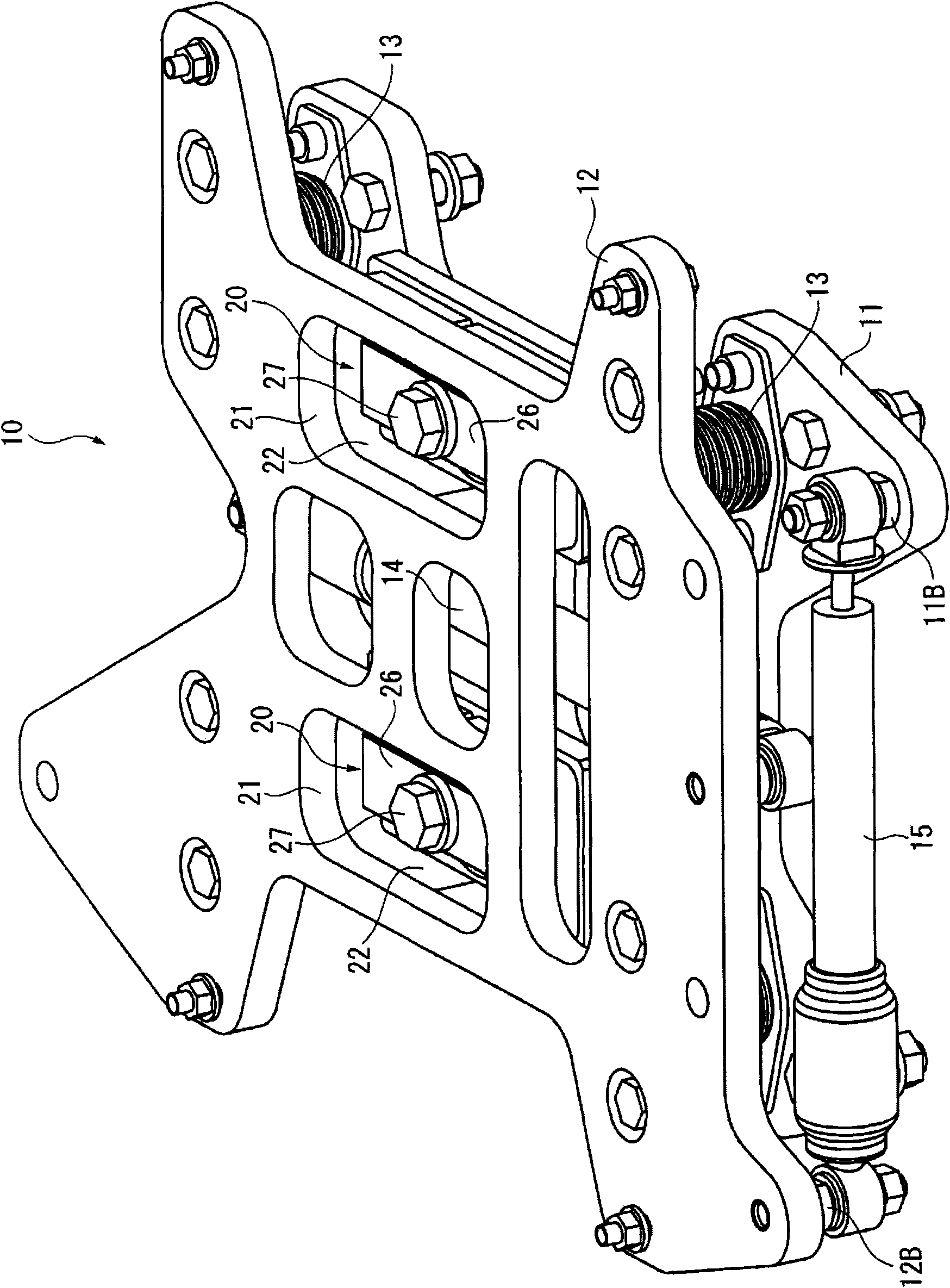

Damping device

InactiveCN101641482AReduce the impactImprove impact absorption performanceVehicle seatsNon-rotating vibration suppressionLeft directionEngineering

A damping device (10) comprises laminated rubbers (13) interposed at four corners between a support having the floor plate of a construction machine and a movable body having the seat body of operator, and a pair of dampers (14, 15) having one end fixed to the lower supporting plate (11) on the support side and the other end fixed to the upper supporting plate on the movable body side.The laminated rubbers (13) are arranged while spaced apart in the front / back direction and the right / left direction with reference to the seating direction of the operator. One damper (14) is arranged along the front / back direction at a position corresponding to the center in the right / left direction between the laminated rubbers (13) arranged in the right / left direction, and the other damper (15) is arrangedalong the right / left direction on the front side of the center in the front / back direction between the laminated rubbers (13) arranged in the front / back direction.

Owner:KOMATSU LTD

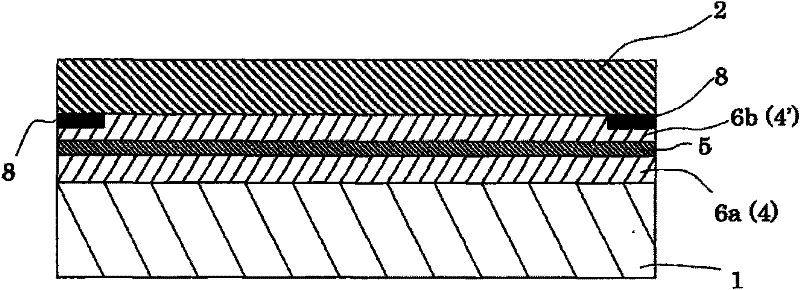

Optical ultraviolet curable resin composition, cured product and display device

InactiveCN102558459AGood workabilityLong-term stability of moisture resistanceStatic indicating devicesCarbonyl groupLiquid resin

The invention provides an optical ultraviolet curable resin composition, a cured product and a display device, wherein the ultraviolet curable resin composition is a liquid resin composition and cured by irradiation with ultraviolet light; the heat resistance, the light resistance, and the moisture resistance, namely optically superior qualities are stably kept for a long time and the re-stripping property, the shock-resistance absorption and operation are excellent. The optical ultraviolet curable resin composition comprises (A) a polymer obtained by reacting polyether glycol (a-1) with alpha, beta unsaturated carbonyl compound (a-2) with function group reacted with the hydroxyl group; and (B) a photopolymerization initiator, wherein the functional group is preferably isocyanic acid ester or carboxyl group as the unsaturated carbonyl, preferably a (meth ) acryl. The resin composition is used for laminating at least two kinds of components selected from a component of the display device namely a display panel, a protection plate, and a laminar function part.

Owner:NIPPON SHOKUBAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com