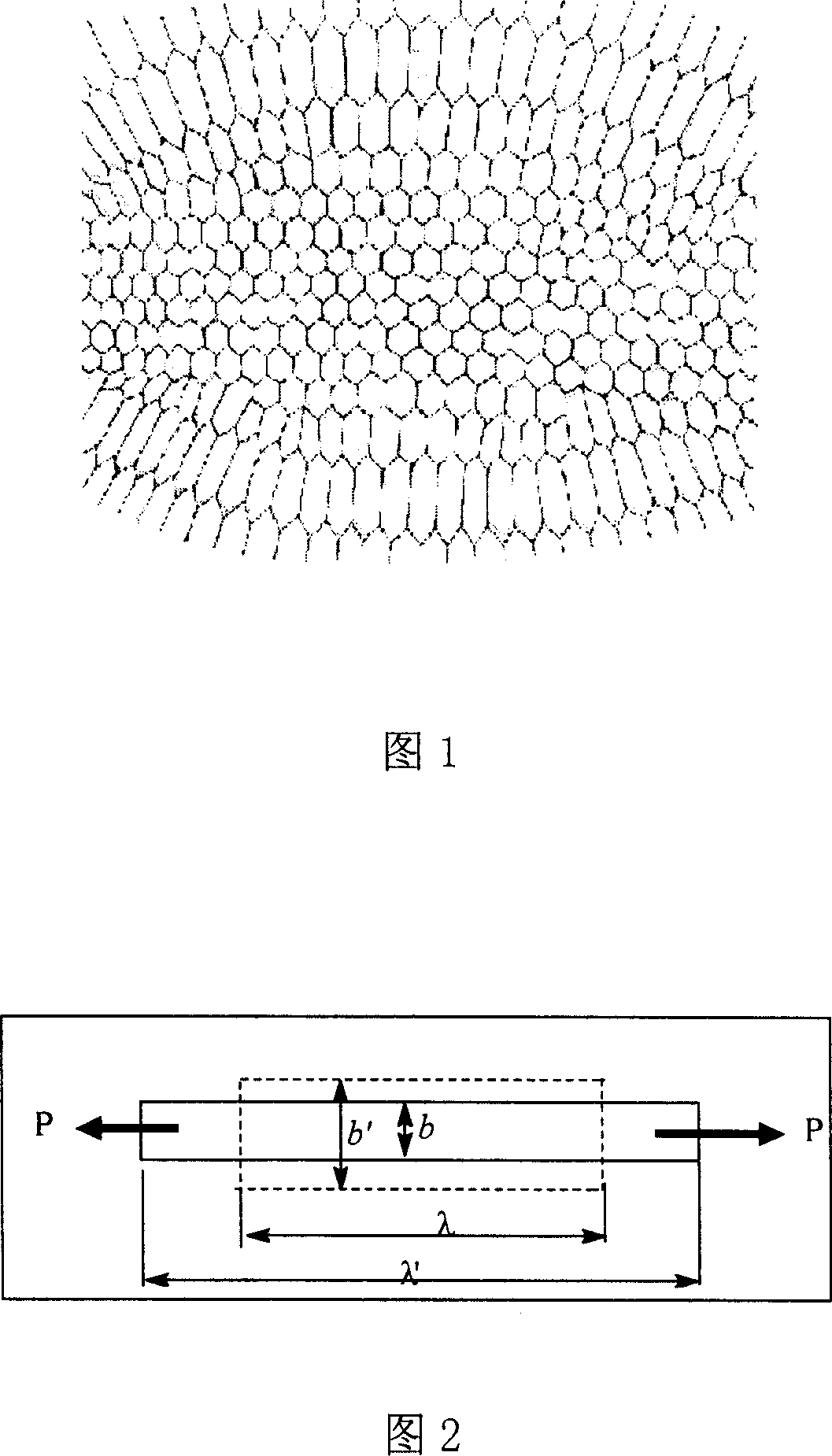

Negative poisson's ratio material and its preparing method and use

A technology of negative Poisson's ratio materials and plates, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as damage tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Starch 70g, PBS 15g, glycerol 8g, sorbitol 5g, azodicarbonamide 1.5g, N,N'-dimethyl-N,N'-dinitrosoterephthalamide 0.5g, Prepare according to the ratio, extrude and granulate in a screw extruder. Add a certain amount of the above-mentioned particles according to the size of the foam to be prepared, uniformly heat the mold at 110-125°C, and keep the temperature for 8-15 minutes. Then cool down to room temperature and take out the product object, as the middle layer, for subsequent use.

[0077] Put the above-made sheet or plate in another fan-shaped mold, in this mold, fix the foamed sheet or plate in the middle of the mold, add the mixture of the above formula to both sides of the middle layer of sheet or plate Material, quickly heat the mold temperature 130 ~ 135 ℃, so that the foamed particles in the cavity quickly fan-shaped foam. Keep warm for 8-15 minutes, then cool down to room temperature, take out the product, and obtain a material with a negative Poisson's rat...

Embodiment 2

[0079] 85 g of starch, 10 g of glycerol, 3 g of triglyceride, and 2.0 g of azodicarbonamide are extruded and granulated in a screw extruder according to a certain ratio. Add a certain amount of the above-mentioned particles according to the size of the foam to be prepared, uniformly heat the mold at 120-125°C, and keep the temperature for 8-15 minutes. Then cool down to room temperature and take out the product object, as the middle layer, for subsequent use.

[0080] Put the above-made sheet or plate in another fan-shaped mold, in this mold, fix the foamed sheet or plate in the middle of the mold, add the mixture of the above formula to both sides of the middle layer of sheet or plate Material, quickly heat the mold temperature 130 ~ 135 ℃, so that the foamed particles in the cavity quickly fan-shaped foam. Keep warm for 8-15 minutes, then cool down to room temperature, take out the product, and obtain a material with a negative Poisson's ratio. The pore diameter of the micr...

Embodiment 3

[0082] Starch 82g, PBS 15g, glycerol 10g, monoglyceride 5g, N,N'-dimethyl-N,N'-dinitrosoterephthalamide 1.5g, azodicarbonamide 1.5g g. According to a certain ratio, it is extruded in a screw extruder, and directly extruded into shape without granulation.

[0083] The temperature of the four zones of the middle layer and the outer layer screw is 90-120°C respectively, the temperature of the extrusion port is 100°C, the initial temperature of the pressure roller and the mold is also 110°C, and the temperature is controlled.

[0084] The outer layer screw extruded foam is bifurcated, and the outer layer foam is added to both sides of the middle layer screw extruded foam, and rolled by double rollers at a temperature of 120-125°C for 1-3 times.

[0085] The rolled material is added to the fan-shaped mold, and the temperature of the fan-shaped mold is controlled at 130-135°C for directional foam molding. Keep warm for 8-15 minutes, then cool down to room temperature, take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com