Damping device

A technology of anti-vibration device and shock absorber, which is applied in the directions of transportation and packaging, vibration suppression adjustment, non-rotational vibration suppression, etc. It can solve the problems of not fully improving the comfort of the operator, and achieve the suppression of front and rear bumps or sideways movement , Improve riding comfort, excellent elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

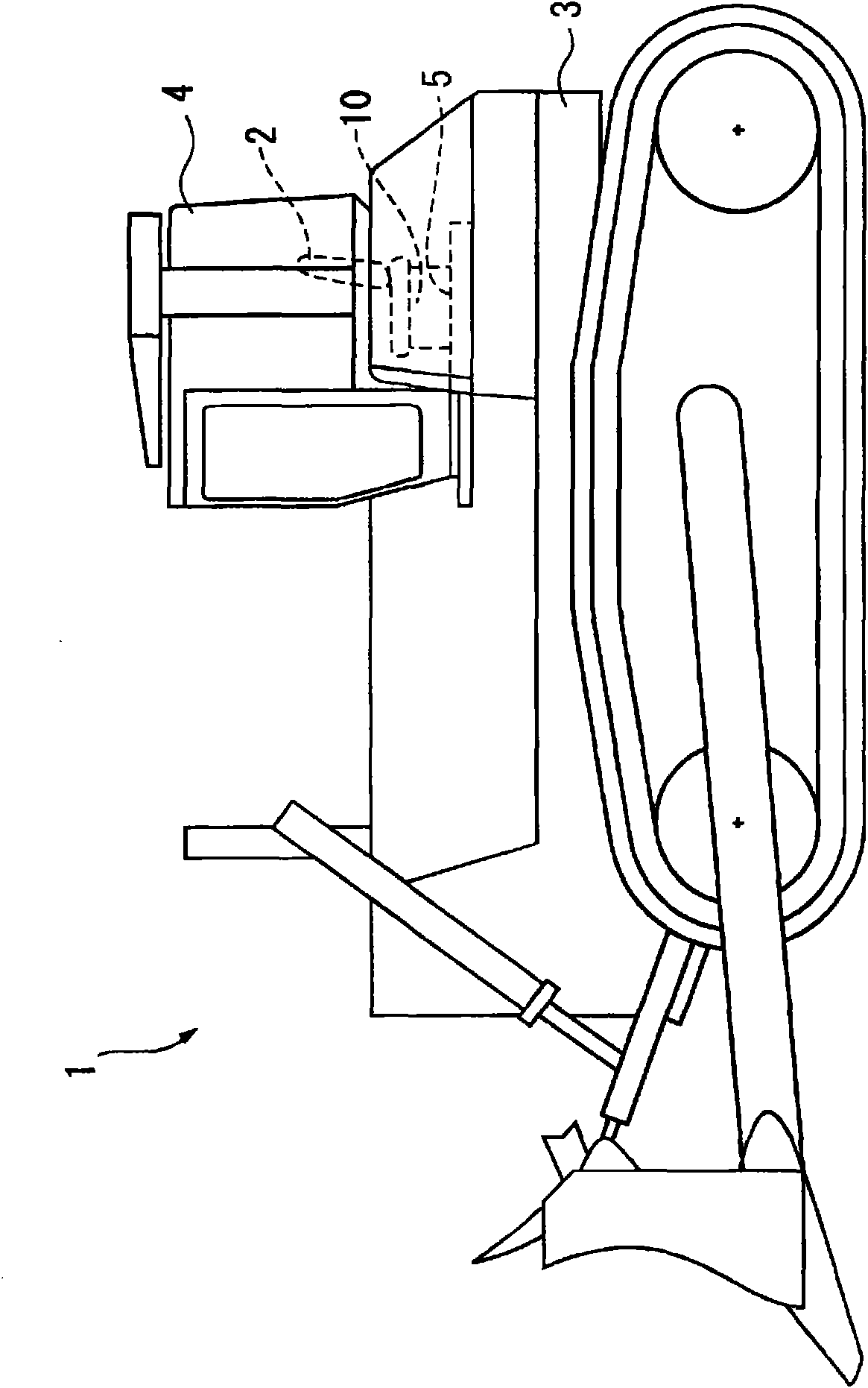

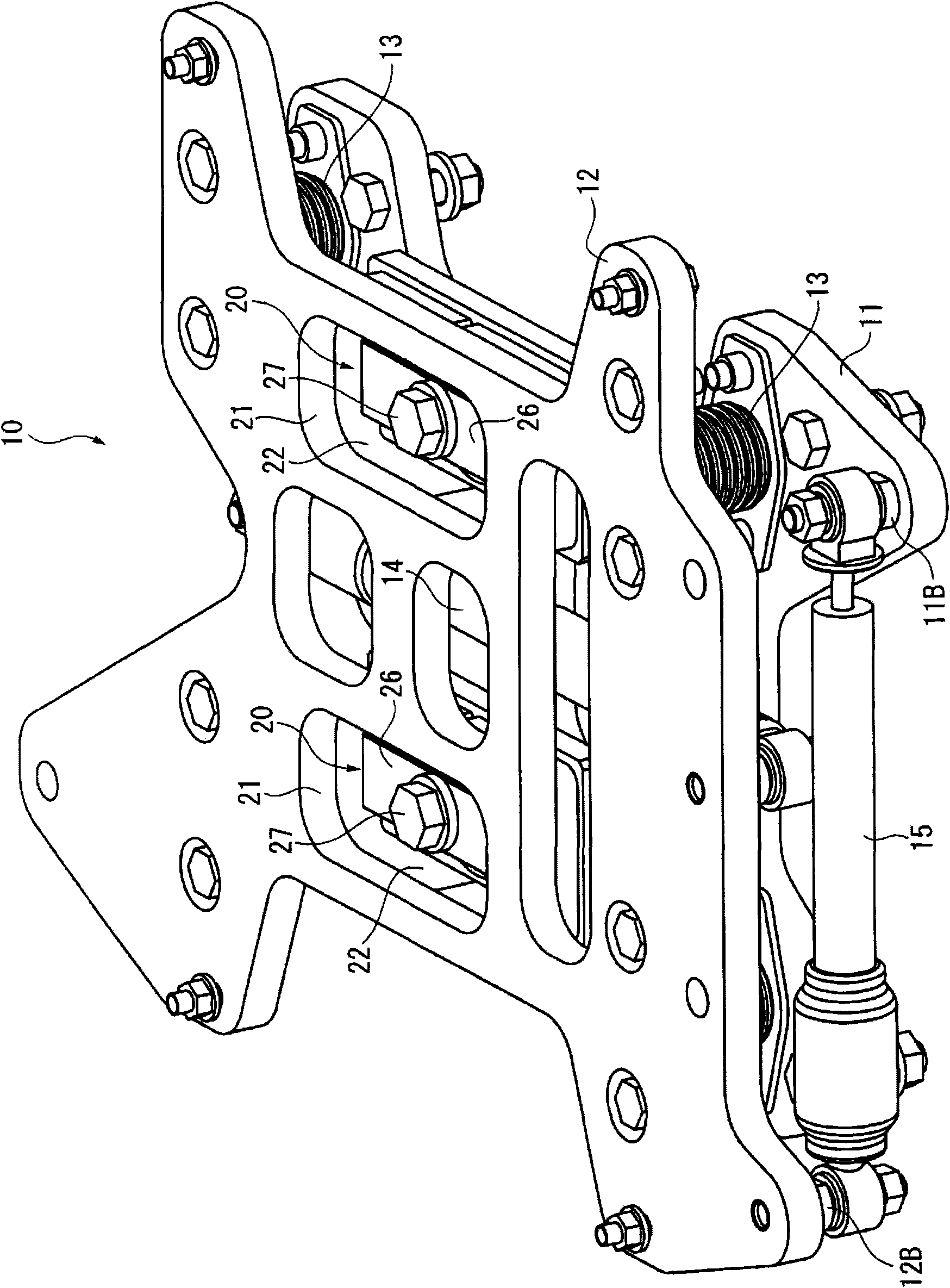

[0032] figure 1 It is a side view schematically showing a bulldozer 1 as a construction machine to which the anti-vibration device 10 of the present embodiment is applied, figure 2 It is a perspective view showing the seat portion to which the anti-vibration device 10 is attached. The anti-vibration device 10 is installed under the seat body 2 of the bulldozer 1 . Specifically, a cab 4 is provided on the vehicle frame 3 of the bulldozer 1 , and in the cab 4 , the anti-vibration device 10 is installed between the floor 5 and the seat body 2 .

[0033] To be more specific, as figure 2 As shown, in the anti-vibration device 10 and the bottom plate 5 ( figure 1 ) is provided with a seat rotation mechanism 6, through handle operation, the seat body 2 and the anti-vibration device 10 can be rotated together within a specified angle range. In addition, the seat body 2 positioned on the anti-vibration device 10 has a seat cushion 2A composed of the operator's backrest and a se...

no. 2 approach 〕

[0048] exist Figure 7 In the second embodiment shown in the perspective view of , the shock absorber 15 in the left-right direction is disposed inside the pair of laminated rubbers 13 on the front side. Specifically, the damper 15 is located on the front side with respect to the center of the front and rear laminated rubbers 13 , and is disposed close to the front laminated rubbers 13 . Regarding other structures, although there are differences in the specific shape of the lower support plate 11, the direction of the shock absorber 14 along the front-rear direction, etc., they are basically the same as those of the first embodiment described above.

[0049] Therefore, in this embodiment, since the arrangement positions of the shock absorbers 14 and 15 are also T-shaped, and the shock absorbers 15 are located on the front side compared to the center of the front and rear laminated rubber 13, the rear side stack can be reduced. The effect of the damping force of the layer rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com