UV-cured adhesive for plastic and preparation method thereof

A technology of adhesives and ultraviolet light, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., to achieve the effects of fast curing speed, simple and easy operation, and improved shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

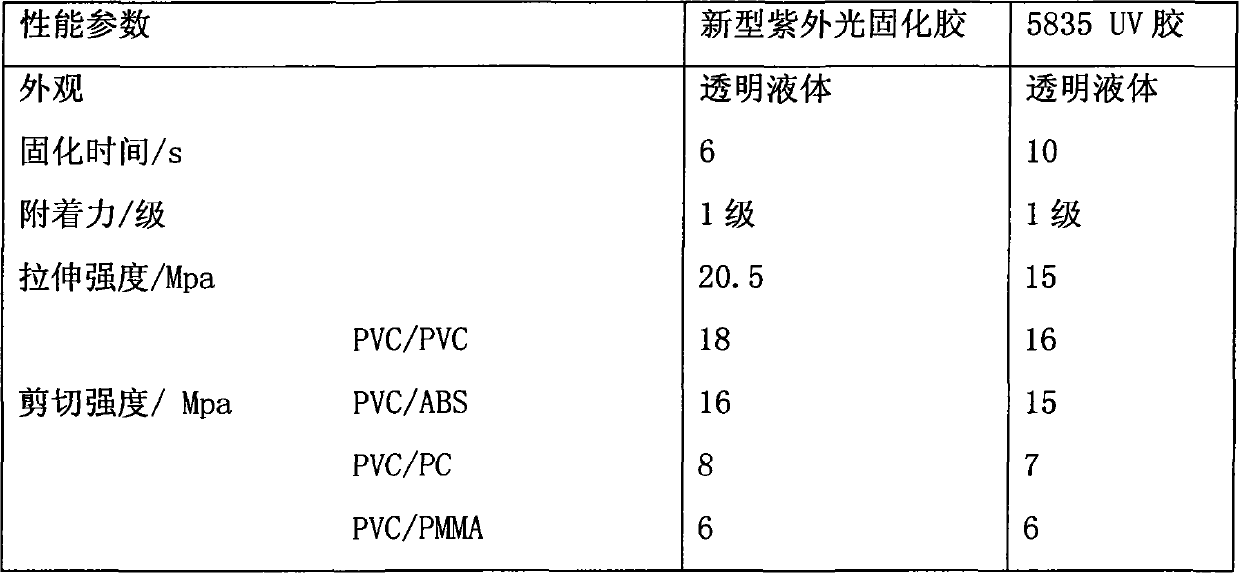

Embodiment 1

[0024] A preparation method of an ultraviolet light-curable adhesive for plastics, comprising the following steps and process conditions:

[0025] (1) Preparation of polyurethane acrylate: under uniform stirring at 80rpm, polyethylene glycol (PEG) is added dropwise to 3-isocyanate-3,5,5-trimethylcyclohexyl isocyanate (IPDI), and the temperature is raised to 45 ℃, every 30 minutes, measure the free content of isocyanate group (-NCO) with di-n-butylamine titration method, when -NCO reacts 45% (the weight ratio of isocyanate group and raw material during detection), add catalyst dibutyltin di Luuric acid ester (DBTL), then add hydroxyethyl methacrylate (HEMA), heat up to 60 ° C, and add 2,6-di-tert-butyl p-cresol; stir to disperse evenly, every 30 minutes, use Di-n-butylamine titration method measures the free content (-NCO%) of isocyanate group, and the mass percent to-NCO free content is less than 0.5% (the ratio of raw material gross weight during the isocyanate group that rec...

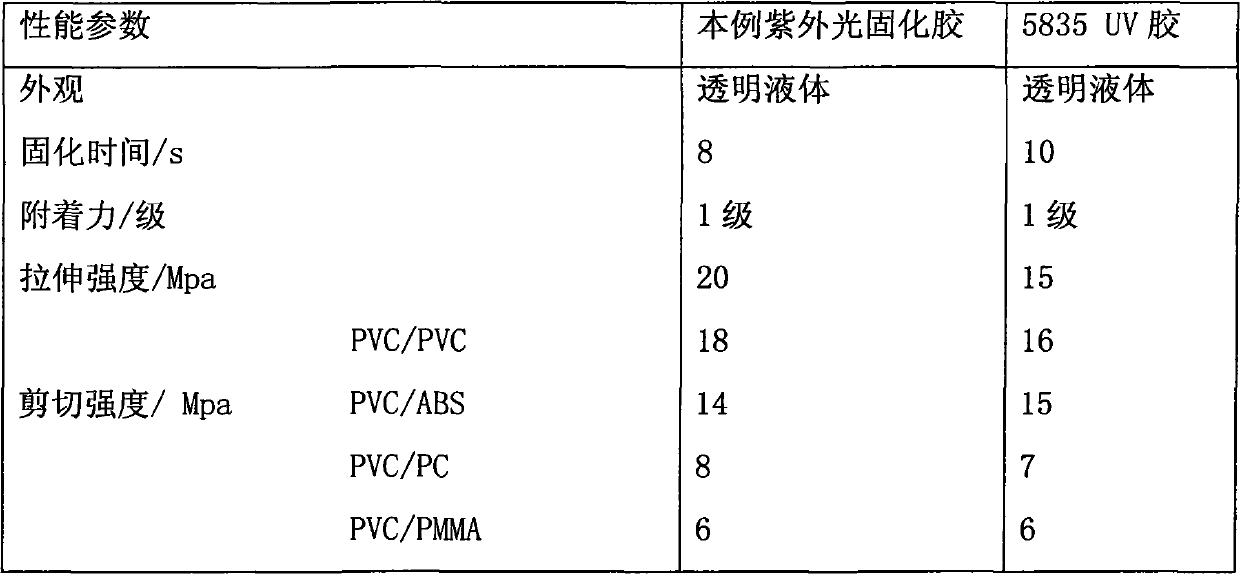

Embodiment 2

[0038] (1) Preparation of polyurethane acrylate: under uniform stirring at 80rpm, polyethylene glycol (PEG) is added dropwise to 3-isocyanate-3,5,5-trimethylcyclohexyl isocyanate (IPDI), and the temperature is raised to 50 ℃, every 30 minutes, use the di-n-butylamine titration method to measure the mass percentage of isocyanate group relative to the mixture in the reactor at this time (-NCO%), when -NCO reacts 50%, add the catalyst dibutyltin dimonthly silicon acid ester (DBTL), then add hydroxyethyl methacrylate (HEMA), heat up to 70°C, and add 2,6-di-tert-butyl-p-cresol; stir and disperse evenly until the free content of -NCO reaches 0.4% (mass percentage) to stop the reaction; when the temperature in the bottle drops to 45° C., add absolute ethanol and react for 25 minutes to obtain a colorless viscous liquid that is polyurethane acrylate. Wherein, the molar ratio of polyethylene glycol (PEG), 3-isocyanate-3,5,5-trimethylcyclohexyl isocyanate (IPDI), and hydroxyethyl methac...

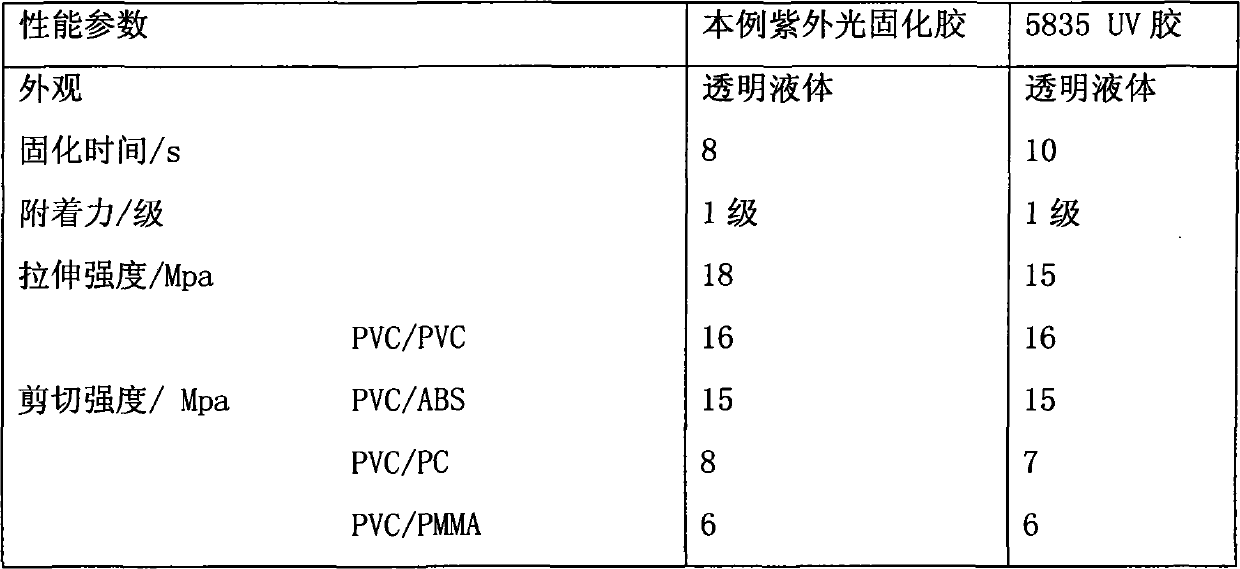

Embodiment 3

[0045] (1) Preparation of polyurethane acrylate: under uniform stirring at 80rpm, polyethylene glycol (PEG) is added dropwise to 3-isocyanate-3,5,5-trimethylcyclohexyl isocyanate (IPDI), and the temperature is raised to 50 ℃, every 30 minutes, use the di-n-butylamine titration method to measure the mass percentage of isocyanate group relative to the mixture in the reactor at this time (-NCO%), when -NCO reacts 50%, add the catalyst dibutyltin dimonthly silicon acid ester (DBTL), then add hydroxyethyl methacrylate (HEMA), heat up to 70°C, and add 2,6-di-tert-butyl-p-cresol; stir and disperse evenly until the free content of -NCO reaches 0.4% (mass percentage) to stop the reaction; when the temperature in the bottle drops to 45° C., add absolute ethanol and react for 25 minutes to obtain a colorless viscous liquid that is polyurethane acrylate. Wherein, the molar ratio of polyethylene glycol (PEG), 3-isocyanate-3,5,5-trimethylcyclohexyl isocyanate (IPDI), and hydroxyethyl methac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com