Substrate for flexible organic optoelectronic device and preparation method thereof

A technology for optoelectronic devices and substrates, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., and can solve problems such as poor adhesion between thin films and substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

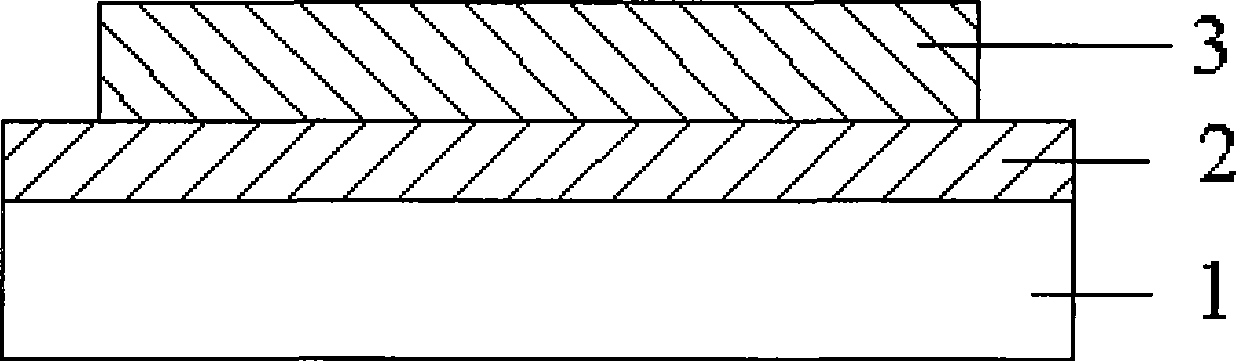

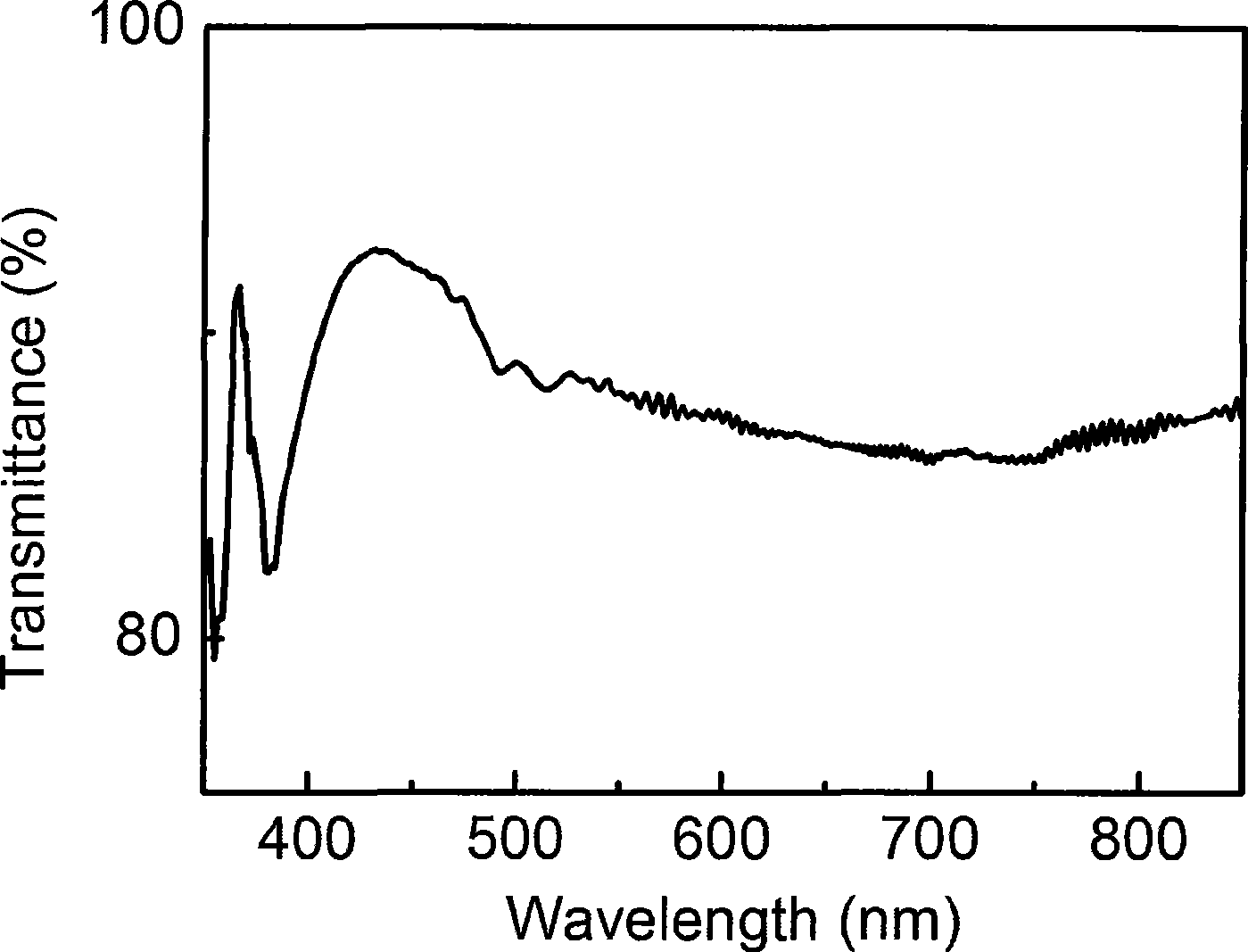

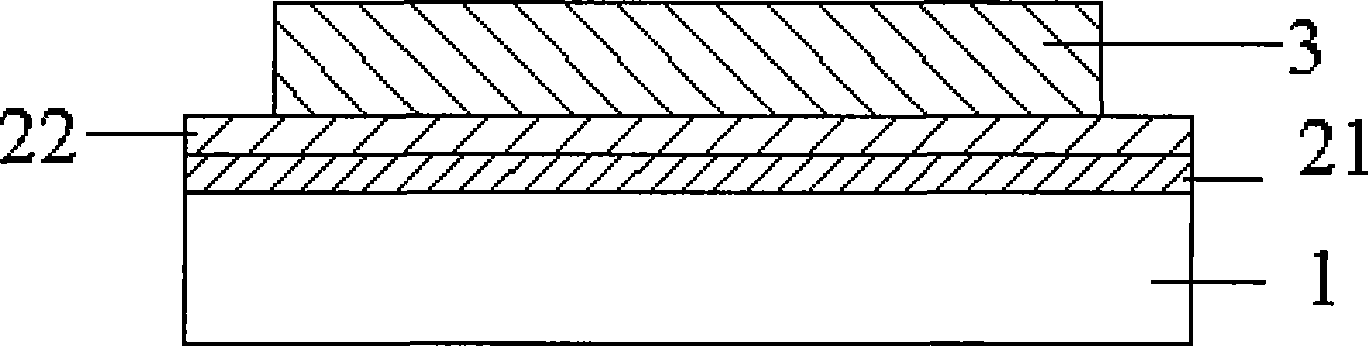

[0157] Such as figure 1 As shown in the substrate structure, the flexible substrate 1 adopts a flexible polyethylene terephthalate polymer (PET) substrate, and the adhesive layer 2 adopts a single-layer free radical UV curing agent-isocyanate thermal curing agent dual curing system, which is electrically conductive. Film 3 is a DC magnetron sputtered ITO transparent conductive film. The transmittance test curve is as figure 2 shown.

[0158] The preparation method is as follows:

[0159] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the PET substrate, and dry it with dry nitrogen after cleaning;

[0160] ② Stir the adhesive diluted 1:10 with ethanol for 20 hours, then spin-coat on the PET surface at a speed of 2000 rpm for one minute, and the film thickness is about 100 nanometers;

[0161] Wherein the ratio of adhesive raw material components is:

[0162] Acrylic resin (free radical UV curing agent) 30-40 parts

[0163] ...

Embodiment 2

[0173] Such as figure 1 As shown in the substrate structure, the flexible substrate 1 is a flexible metal foil substrate, the adhesive layer 2 is a dual curing system of a single-layer free radical UV curing agent-epoxy resin thermal curing agent, and the conductive film 3 is DC magnetron sputtering. ITO transparent conductive film.

[0174] The preparation method is as follows:

[0175] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the PET substrate, and dry it with dry nitrogen after cleaning;

[0176] ② Stir the adhesive diluted 1:10 with ethanol for 20 hours, then spin-coat on the surface of the flexible metal foil substrate at a speed of 2000 rpm for one minute, and the film thickness is about 100 nanometers;

[0177] Wherein the ratio of adhesive raw material components is:

[0178] Unsaturated polyester resin (free radical UV curing agent) 30-40 parts

[0179] Epoxy resin (heat curing agent) 35~45 parts

[0180] Mult...

Embodiment 3

[0189] Such as figure 1 As shown in the substrate structure, the flexible substrate 1 adopts a flexible PET substrate, the adhesive layer 2 adopts a single-layer epoxy cationic UV curing agent-amino resin thermal curing agent dual curing system, and the conductive film 3 is a polymer PEDOT:PSS conductive film.

[0190] The preparation method is as follows:

[0191] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the PET substrate, and dry it with dry nitrogen after cleaning;

[0192] ② Stir the adhesive diluted 1:10 with ethanol for 20 hours, then spin-coat on the PET surface at a speed of 2000 rpm for one minute, and the film thickness is about 100 nanometers;

[0193] Wherein the ratio of adhesive raw material components is:

[0194] Epoxy resin (cationic UV curing agent) 35-45 parts

[0195] Amino resin (thermal curing agent) 40-45 parts

[0196] Thinner (vinyl ether monomer) 4.0~9 parts

[0197] Cationic photoinitiator (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com