Preparation method of novel dual-cured UV curing binder

A dual-curing, ultraviolet light technology, applied in the direction of bonding method, adhesive type, polyurea/polyurethane adhesive, etc., can solve problems such as easy generation of internal stress, decrease in bond strength, decrease in bond strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 2-4g of 2,2-dimethoxy-2-phenylacetophenone, 2-3g of benzoyl peroxide, dissolve in 15-20g of hydroxyethyl acrylate, then add 2-4g of silicon dioxide, Stir evenly, then add 5-10g of hexanediol dimethacrylate, 2g of acrylic acid, 3-5g of γ-(methacryloyloxy)propyltrimethoxysilane, 10-20g of liquid polybutadiene, polybutadiene Ester type urethane acrylate 40-60g, stir in a high-speed disperser for 5 minutes, and finally use zirconia beads as the sanding medium, disperse in the sand mill for 2-3 hours, pay attention to cooling with cold water in the jacket of the sand mill to ensure that all The dispersed material temperature should not exceed 45°C.

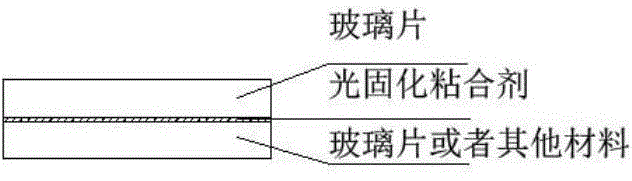

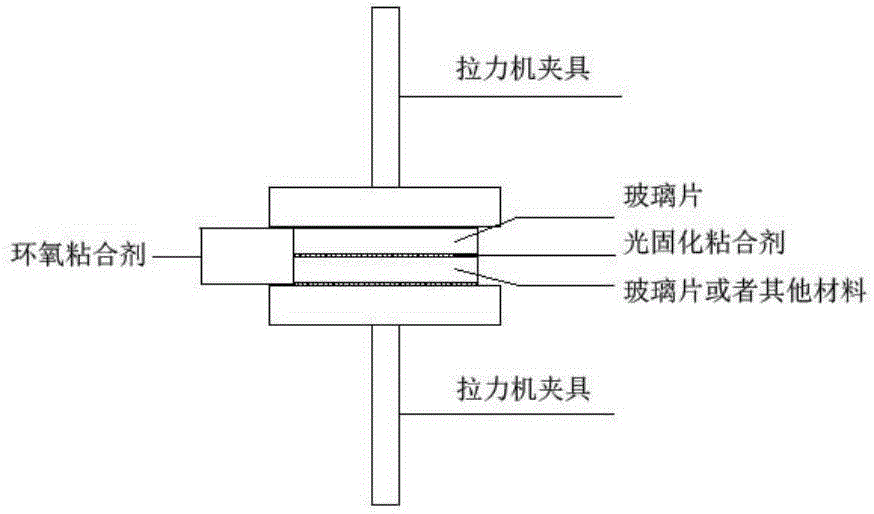

[0021] The prepared light-curing adhesive is used for bonding experiments. The method is to first wipe two 1cm*1cm glass sheets (or 1 glass sheet and 1 other material) with absolute ethanol to remove grease, and then follow the figure 1 Apply glue as shown, the glue layer is as uniform as possible, and then cure twice. F...

Embodiment 2

[0025] Weigh 2-4g of benzophenone, 2-3g of cumene hydroperoxide, 1-2g of saccharin, 0.5-1g of p-tert-butylcatechol, dissolve in 15-20g of isobornyl methacrylate, and then add 2-4g of bentonite, 5-10g of nano-calcium carbonate, stir evenly, then add 5-10g of hexanediol dimethacrylate, 2g of methacrylic acid, γ-(methacryloyloxy)propyltrimethoxysilane 3-5g, liquid polybutadiene 10-20g, epoxy acrylate 40-60g, stir in a high-speed disperser for 5 minutes, and finally use zirconia beads as the sanding medium, disperse in the sand mill for 2-3 hours, pay attention to the sand Cool water through the jacket of the mill to ensure that the temperature of the dispersed material does not exceed 40°C.

[0026] The configured light-curing adhesive was subjected to a bonding experiment, and the bonding method was the same as in Example 1, and then cured twice. For the first curing, place the bonded sample under a 500w UV lamp, expose for 20s, and reserve the sample for bond strength measurem...

Embodiment 3

[0030] Weigh 1-1.5g of benzophenone, 1-1.5g of 2-hydroxy-methylphenylpropan-1-one, 2-3g of azobisisobutyronitrile, 0.5-1g of hydroquinone, dissolve in 15 -20g of isobornyl acrylate, then add 2-4g of bentonite, 5-10g of nano-calcium carbonate, stir evenly, then add 5-10g of isooctyl acrylate, 5- 10g, 3-5g of γ-aminopropyltriethoxysilane, 10-20g of liquid polybutadiene, 40-60g of polyether polyurethane acrylate, stirring in a high-speed disperser for 5min, and finally using zirconia beads as For sanding medium, disperse in the sand mill for 2-3 hours, and pay attention to cooling with cold water in the jacket of the sand mill to ensure that the temperature of the dispersed material cannot exceed 40°C.

[0031] The configured light-curing adhesive was subjected to a bonding experiment, and the bonding method was the same as in Example 1, and then cured twice. For the first curing, place the bonded sample under a 500w UV lamp, expose it for 20s, and reserve the sample for bond st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com