Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

593 results about "Argon flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy surface strengthening method using laser melting and coating

InactiveCN101012561APrevent excessive meltingPrevent collapseMetallic material coating processesLaser beam welding apparatusSoluble glassWavelength

The invention discloses a reinforcing method of aluminium alloy surface fused and covered by laser, which comprises the following steps: 1. predisposing aluminium alloy base; 2. allocating laser fusing and covering material with the bulk rate of Al-Si alloy powder and SiC ceramic powder at 1:(4-2); setting the Si content in the Al-Si alloy at 10-15(wt%) with grain size at - 140-+325; setting the grain size of SiC at -200; 2. modulating evenly blended fusing and covering material into paste through soluble glass; coating on the surface of aluminium alloy with thickness at 0.8-1.2mm; drying at 100-150 deg.c for 0.5-2h; 4. adopting crossflow CO2 laser to irradiate the coated layer on the surface of aluminium alloy base; setting the output power of laser at 3-4kW and optical beam scanning velocity at 2-5mm / s and optical spot dimension at 1-4mm; protecting fusing pond through high-purity argon in the laser fusing and covering course with argon flow at 20-30L / min.

Owner:TIANJIN POLYTECHNIC UNIV

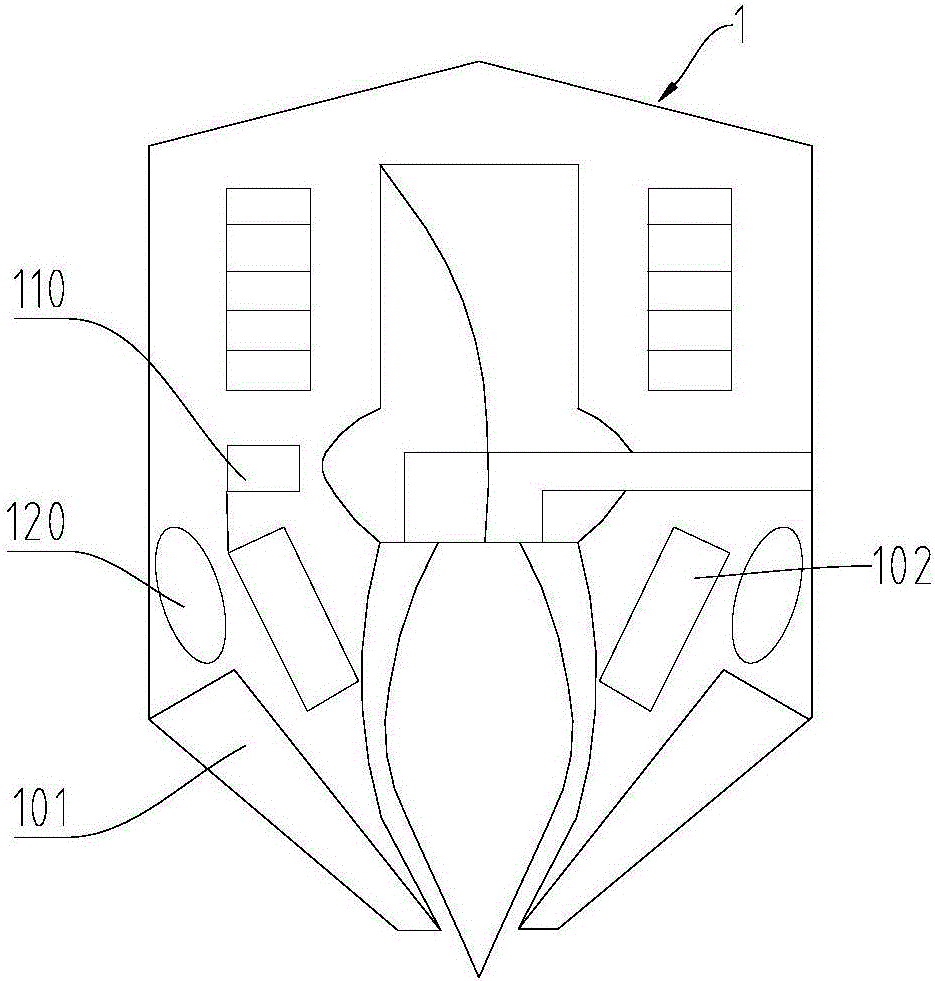

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

Forming copper powder suitable for 3D printing, and manufacturing method and purposes of forming copper powder

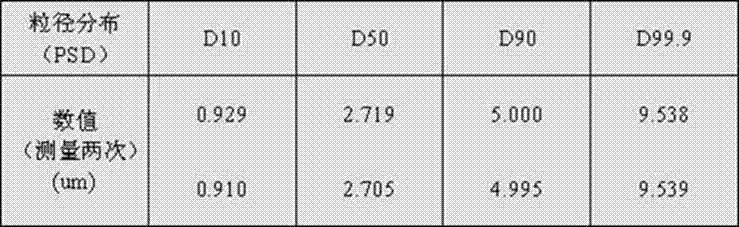

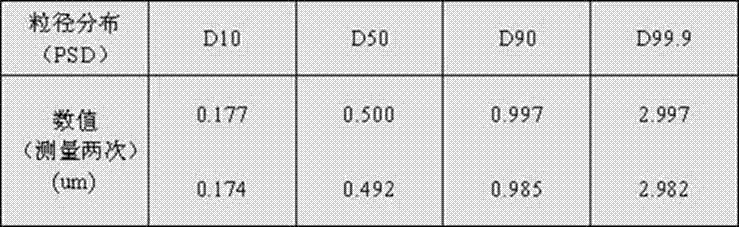

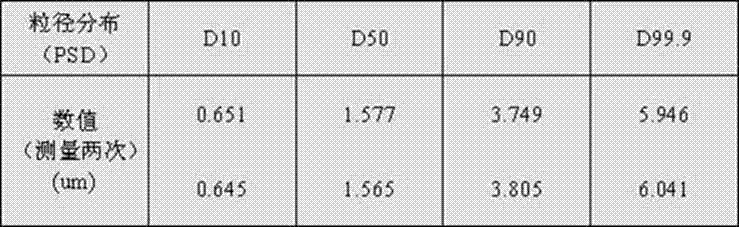

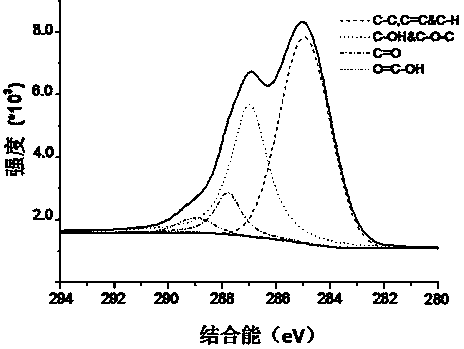

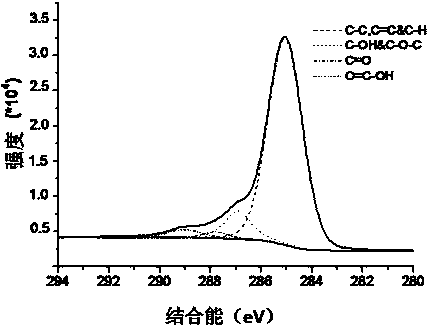

The invention belongs to the field of materials for 3D printing, and discloses forming copper powder suitable for 3D printing and a manufacturing method of the forming copper powder. The method comprises the steps that TU0 oxygen-free copper is smelted to 1250 DEG C-1400 DEG C by adopting an argon shield furnace, impurities mixed in fused copper liquid are removed by blowing argon at the bottom of the furnace, the copper liquid is completely fused, and temperature evenness is achieved. The fused copper liquid is injected into a tundish crucible by being protected by the argon, the copper liquid flows through a gas atomization nozzle through the tundish crucible and a guide nozzle under stable micropressure, preheated sound-speed argon flow ejected by the gas atomization nozzle washes the surface of the copper liquid to produce shear force and extrusion force, so that the copper liquid deforms, the diameter of the liquid flow becomes smaller and smaller, small liquid drops are formed finally, and then spherical metal powder is manufactured in an atomization chamber in a cooled mode. The 3D printing copper powder manufactured in the method is high in powder obtaining rate, the degree of sphericity is high, the oxygen content is less than 500 ppm, the grain size is less than 10 microns, and distribution is narrow.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

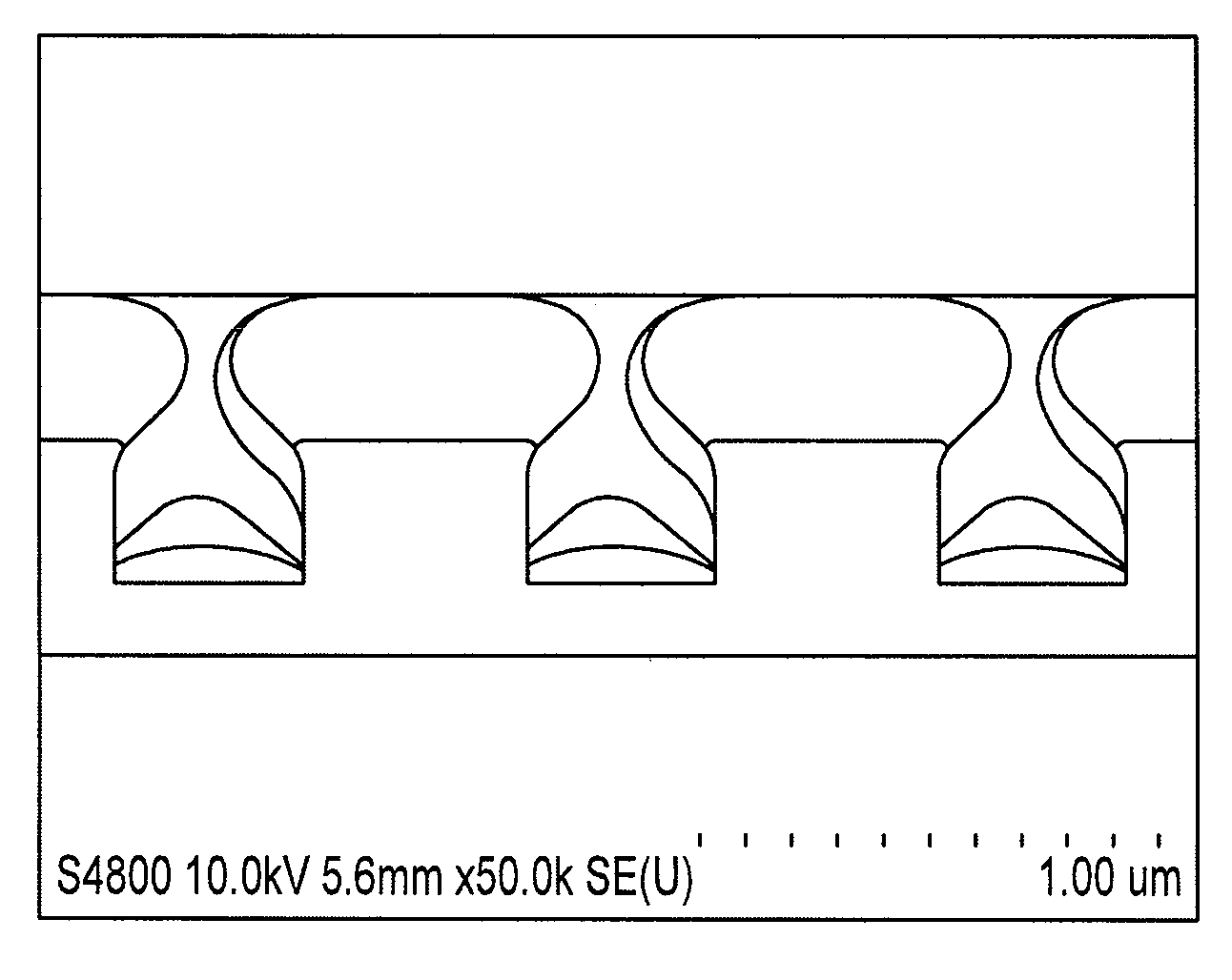

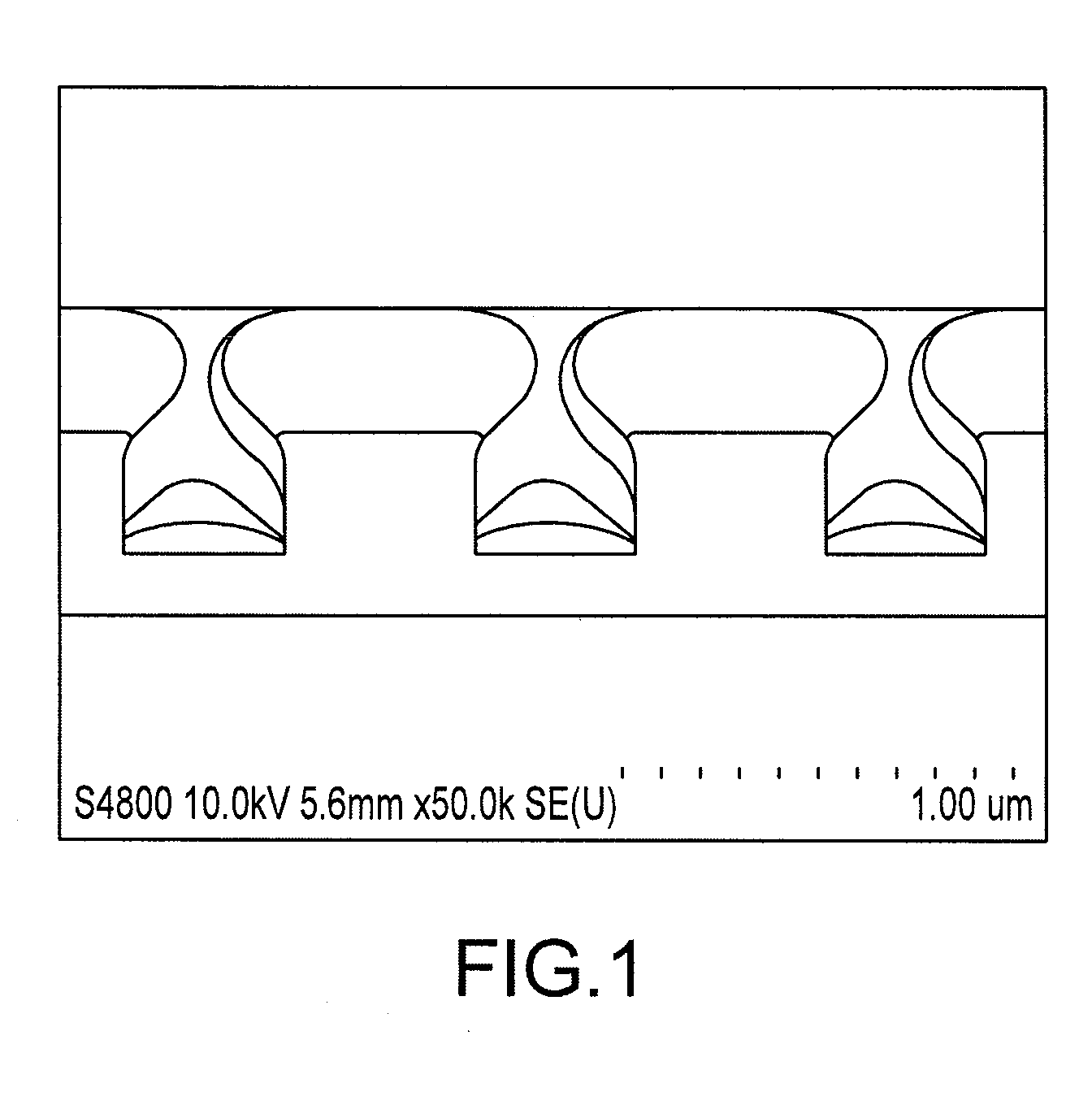

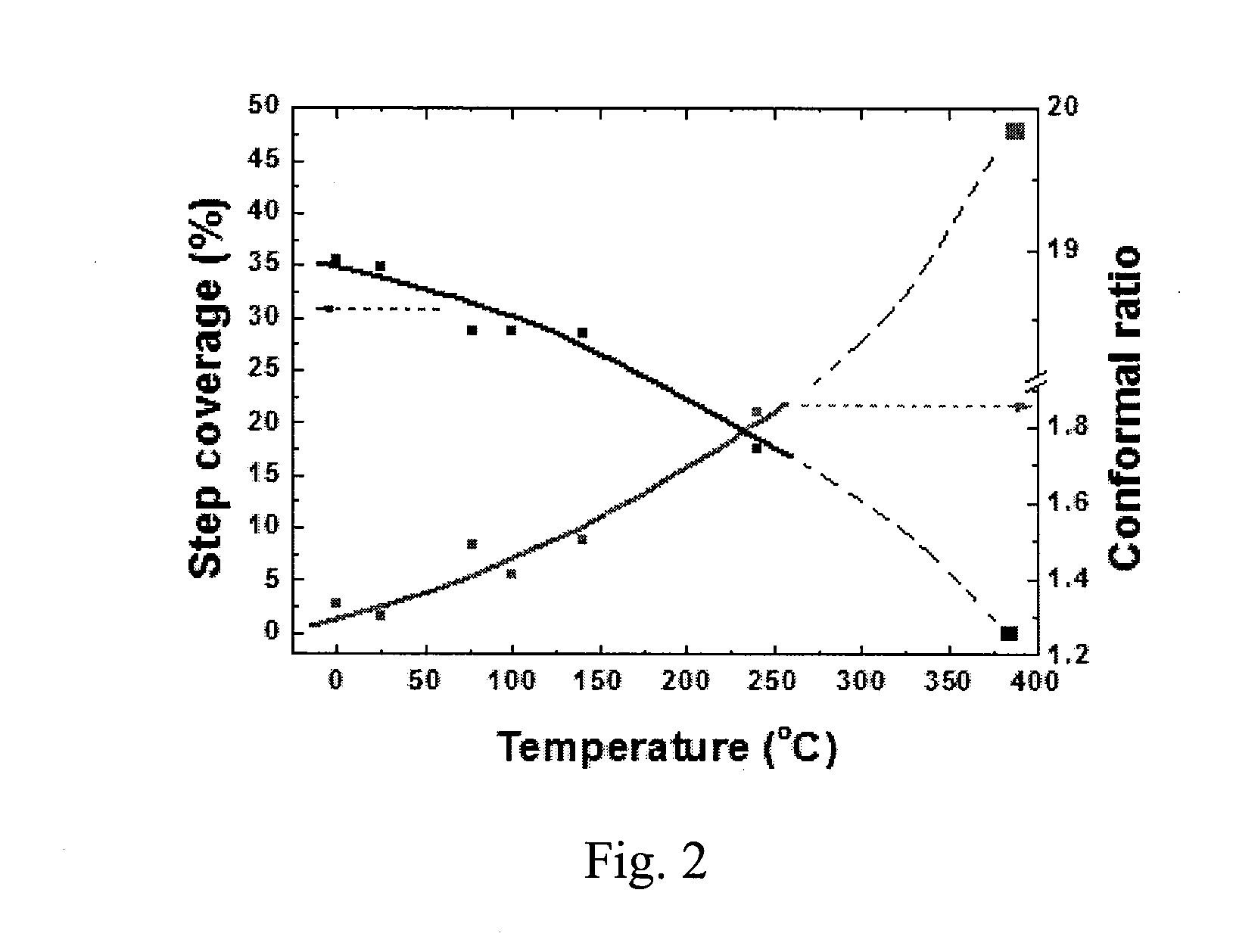

Method of forming highly conformal amorphous carbon layer

ActiveUS20100291713A1Easily ionizedReduce riskSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCarbon layerSemiconductor

A method of forming a conformal amorphous hydrogenated carbon layer on an irregular surface of a semiconductor substrate includes: vaporizing a hydrocarbon-containing precursor; introducing the vaporized precursor and an argon gas into a CVD reaction chamber inside which the semiconductor substrate is placed; depositing a conformal amorphous hydrogenated carbon layer on the irregular surface of the semiconductor substrate by plasma CVD; and controlling the deposition of the conformal ratio of the depositing conformal amorphous hydrogenated carbon layer. The controlling includes (a) adjusting a step coverage of the conformal amorphous hydrogenated carbon layer to about 30% or higher as a function of substrate temperature, and (b) adjusting a conformal ratio of the conformal amorphous hydrogenated carbon layer to about 0.9 to about 1.1 as a function of RF power and / or argon gas flow rate,

Owner:ASM JAPAN

Ladle furnace use nitrogen gas nitrogen alloying process

The invention relates to a ladle furnace use nitrogen gas nitrogen alloying process. The process comprises the following steps: a) smelting nitrogen-contained stainless steel, controlling the components of the molten steel except the nitrogen to the targeted components, and controlling a nitrogen flush initial temperature at 30 to 50 DEG C above a refining treatment out-station temperature; b) during the nitrogen bottom blowing for the smelting of the nitrogen-contained stainless steel in the LF furnace, adding 1 to 20 ppm of nitrogen to each standard cube of nitrogen; c) during the nitrogen bottom blowing for the micro-alloying treatment, controlling the nitrogen flow at 6 to 120m<3> / h and the nitrogen flush pressure at 0.60 to 0.80 MPa; and d) when the nitrogen bottom blowing is finished, carrying out the argon bottom blowing for 4 to 6 minutes with the argon flow of 2 to 20 m<3> / h so as to average the stainless steel components and temperature. The process adds the nitrogen alloying function through the nitrogen bottom flowing to the ladle furnace (LF) in the prior stainless steel production process so as to replace a nitro alloy, make the nitrogen-contained stainless steel carry out continuous and stable nitrogen alloying in the ladle furnace, improve the purity of the molten steel, and consequently improve the molten steel quality and reduce the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD +1

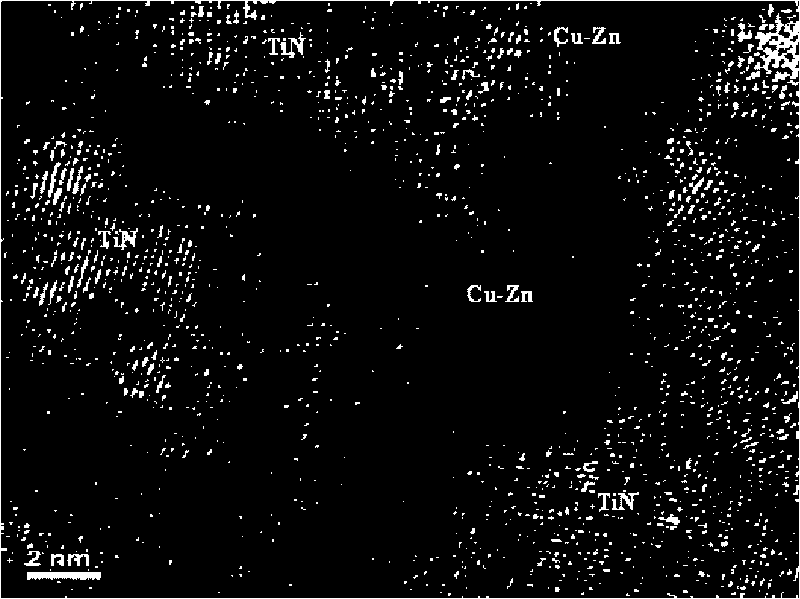

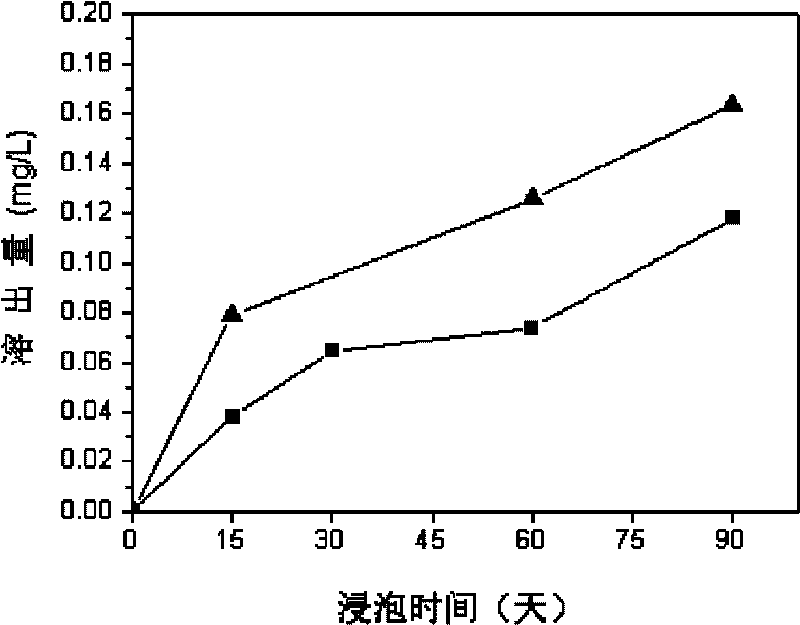

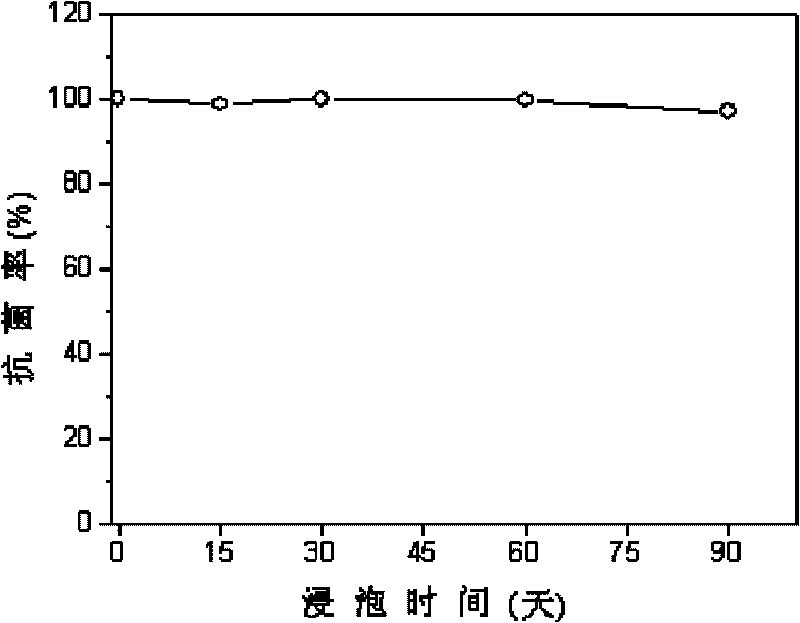

Method for preparing slow-release type skeleton-type TiN/Cu-Zu metal layer antibacterial film

InactiveCN101705468AGood dissolution effectDissolution rate is stableBiocideVacuum evaporation coatingSputter cleaningNitrogen gas

The invention discloses a method for preparing a slow-release type skeleton-type TiN / Cu-Zu metal layer antibacterial film and relates to a preparation method of an antibacterial film, which solves the problem that an antibacterial film prepared by the conventional method has poor durability of antibacterial effect. The method has the following steps of: 1. putting a matrix on a target platform of a vacuum room; and then heating to 200 DEG C and sputter cleaning for 20 min; 2. rotating the target platform of the vacuum room under the condition that argon flow is 6sccm, nitrogen flow is 2sccm, deposition pressure is 0.56Pa, and the deposition bias of the matrix is compound bias; and alternately depositing TiN layers and metal layers on the surface of the matrix till the total thickness of film layers is 0.1 micrometer-10 micrometers to obtain the slow-release type skeleton-type TiN / Cu-Zu metal layer antibacterial film. After the slow-release type skeleton-type TiN / Cu-Zu metal layer antibacterial film is soaked for three months, the ion dissolving speed is not reduced, and the antibiosis rate against colibacillus can still reach above 97%.

Owner:HARBIN INST OF TECH

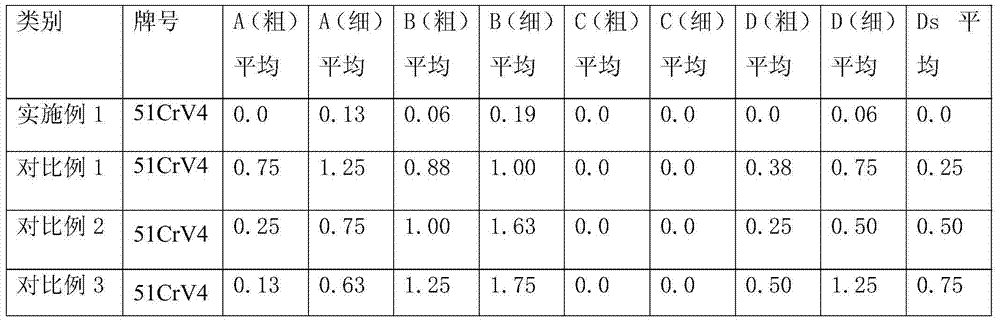

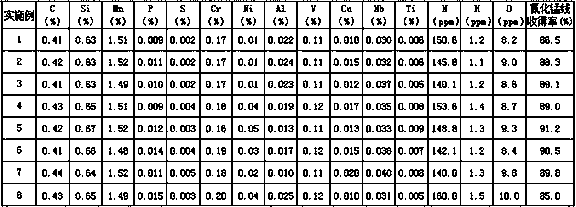

Smelting process of Cr-Mn series spring steel

ActiveCN104745765AImprove liquiditySolve the problem of high alkalinity slag and difficult adsorption and inclusionElectric furnaceProcess efficiency improvementNon-metallic inclusionsSmelting process

The invention belongs to the field of metallurgy and discloses a smelting process of Cr-Mn series spring steel. The smelting process of Cr-Mn series spring steel comprises the following steps: (1) by taking a low-sulfur molten iron and a high-quality steel scrap as the electric furnace smelting iron and steel materials, controlling the electric furnace end point carbon content to greater than 0.15%; (2) adding active lime and composite refining slag in the electric furnace tapping process, and adding calcium carbide to perform pre-deoxidation in the tapping process; (3) feeding an Al line in an argon station before LF refining; (4) producing high basicity white slag in the refining earlier stage and controlling the basicity of slag in the refining middle and later stages to 1.5-2.5; (5) controlling the ultimate vacuum front argon flow to 15-25 L / min and controlling the ultimate vacuum late argon flow to 30-45 L / min; (6) adding a granular alkaline covering agent and a carbonized rice hull to perform double protection by VD emptying; and (7) stabilizing the speed of continuous casting to 0.8-0.9 m / min, and controlling the degree of superheat to 20-30 DEG C. By adopting the process, the non-metallic inclusion content in the molten steel is reduced.

Owner:ZENITH STEEL GROUP CORP +1

Titanium tube welding gas protection cover of fixed welding gun

InactiveCN102909465AImprove protectionSimple structureSupport devices with shieldingTitaniumWelding process

The invention discloses a titanium tube welding gas protection cover of a fixed welding gun. The titanium tube welding gas protection cover comprises an arc-shaped aluminum housing, an argon lead-in tube, an internal gas sifter, a welding gun fixing device and a side surface rubber groove. During the welding process, the protection cover covers a part needed to be welded, and the welding gun is bound to the welding gun fixing device by using a ferrule, then gas is led into the protection cover through the argon lead-in tube, and then argon flow is uniformly distributed to the surface of a welding part through the gas sifter, and finally the side surface rubber groove is filled with rubber so as to enhance argon shield. As the welding gun is fixed to the gas protection cover through the ferrule, a welder fills a welding wire into a welding operation hole by one hand and rotates the gas protection cover by another hand so as to finish the welding operation. The titanium tube welding gas protection cover of the fixed welding gun is simple in structure and convenient to operate, and has a remarkable gas protection effect.

Owner:TIANJIN UNIV

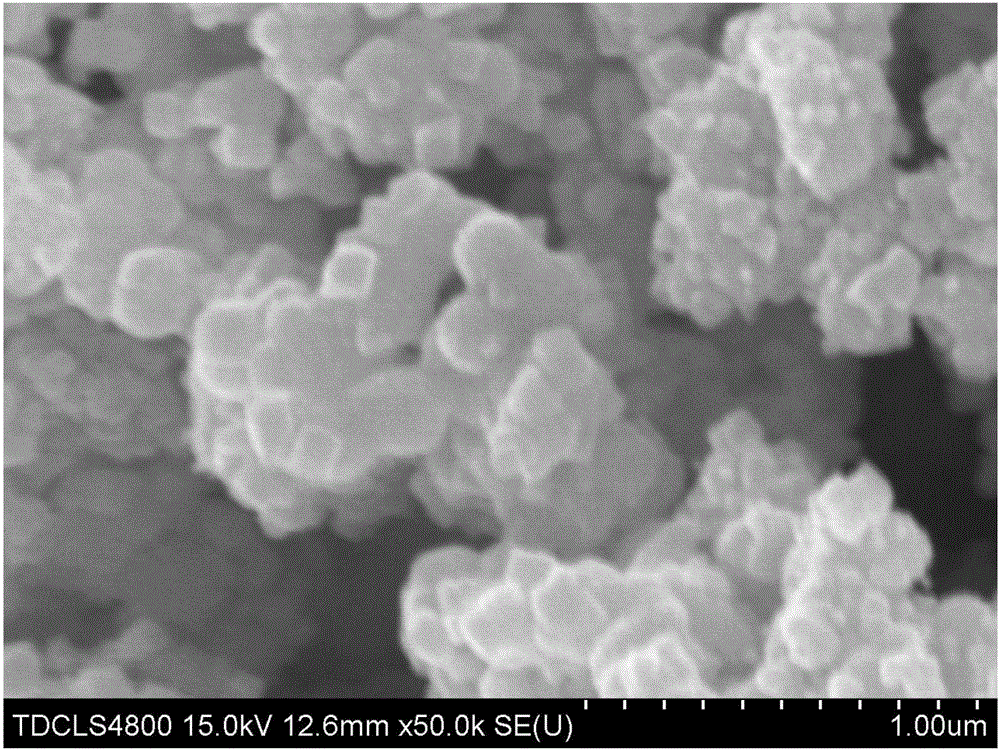

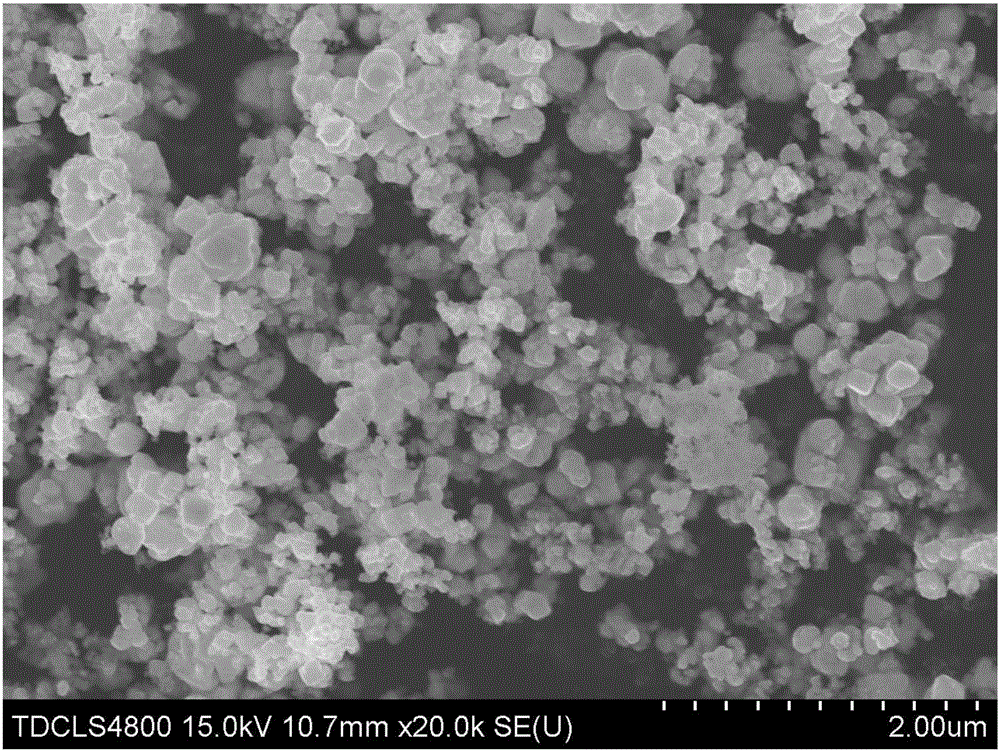

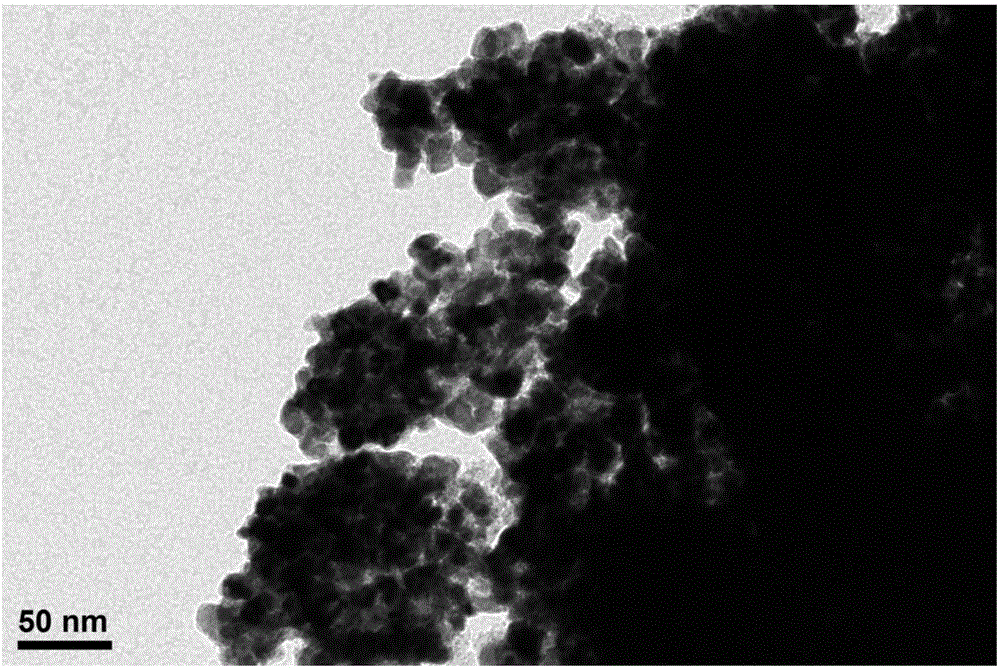

Preparation method of superfine yttrium oxide doped tungsten composite precursor powder

ActiveCN106564927AImprove uniformityGuaranteed purityRare earth metal oxides/hydroxidesNanotechnologyAmmonium paratungstateDissolution

The invention relates to a preparation method of superfine yttrium oxide doped tungsten composite precursor powder. The preparation method comprises the steps: dissolving ammonium paratungstate, yttrium nitrate hexahydrate and a surfactant into water, and carrying out sufficient dispersion and dissolution through mechanical stirring and ultrasonic treatment to prepare a solution; adding concentrated HNO3 into the solution under stirring and ultrasonics to carry out precipitation reaction to form a suspension liquid; adding absolute ethyl alcohol into the suspension liquid to further react, filtering the reacted suspension liquid, and cleaning a precipitate by using absolute ethyl alcohol or distilled water; after drying the precipitate, grinding the precipitate to obtain composite powder, then, placing the composite powder into a tube furnace, and calcining the composite powder in a nitrogen or argon flow to obtain W-Y2O3 composite oxide powder; and carrying out two-step reduction in the tube furnace by using pure hydrogen to obtain the superfine yttrium oxide doped tungsten composite precursor powder. The average grain size of the powder reaches about 10nm, and the uniformity of the grain size is good. Meanwhile, Y2O3 is also uniformly doped, which provides a good basis for subsequent calcination for obtaining fine-grain compact tungsten-based alloy.

Owner:TIANJIN UNIV

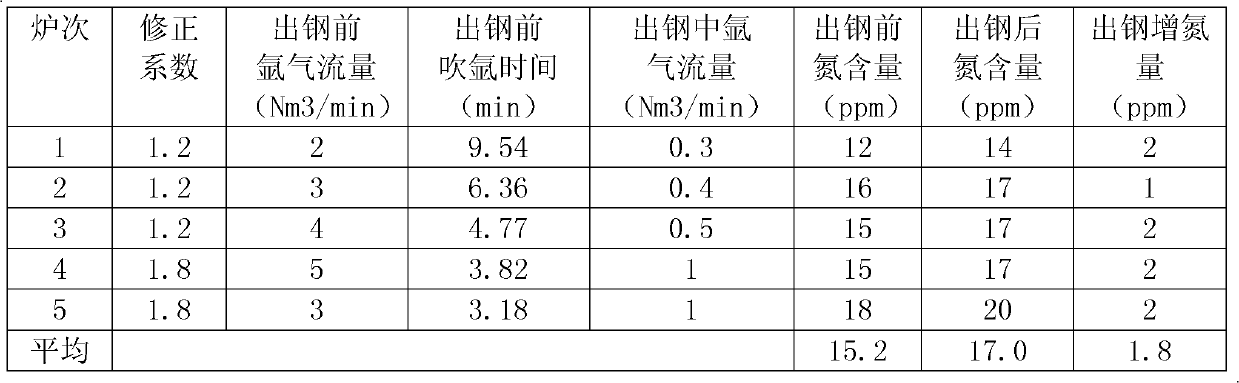

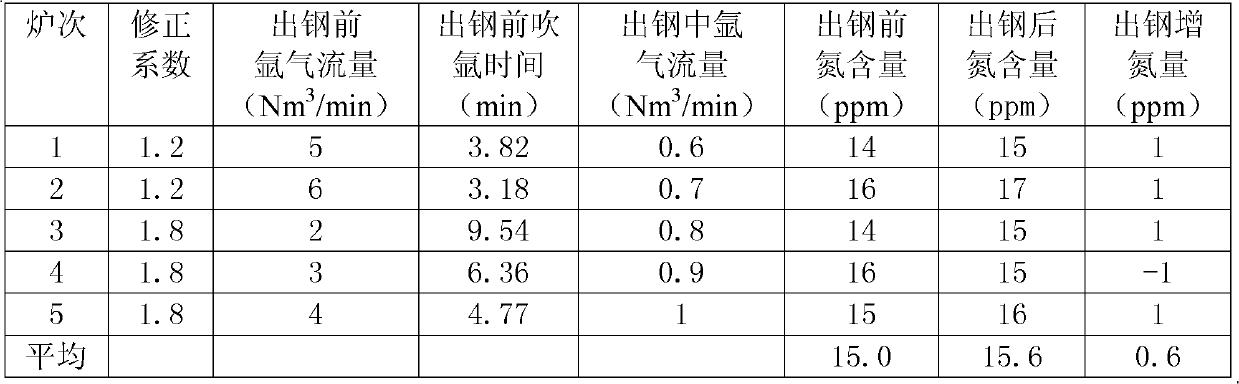

Method for prevention of nitrogen increase in molten steel during steel tapping from a converter

InactiveCN102559983AAvoid Nitrogen ProblemsReduce total nitrogenManufacturing convertersContinuous/uninterruptedNitrogen

The invention provides a method for prevention of nitrogen increase in molten steel during steel tapping from a converter, which comprises the steps of controlling the argon blowing time and argon flow before and during steel tapping from the converter, and blowing argon to the steel ladle in two segments or uninterruptedly till the finish of steel tapping. Thereafter, air in the steel ladle can be evacuated by the argon blown in to prevent the molten steel in the ladle contacting with air while tapping and to keep the molten steel in the ladle under the protection of argon all the time, which not only prevents molten steel contacting with air to cause nitrogen increase, but also removes the nitrogen [N] that can easily adsorb on the surface of the bubbles from the molten steel with the float and discharge of nitrogen bubbles. The method of the invention is simple and easy to implement and operate, and can remarkably reduce the possibility of nitrogen increase in the molten steel during tapping, so that the nitrogen increase in the molten steel can be controlled below 3ppm after tapping.

Owner:ANGANG STEEL CO LTD

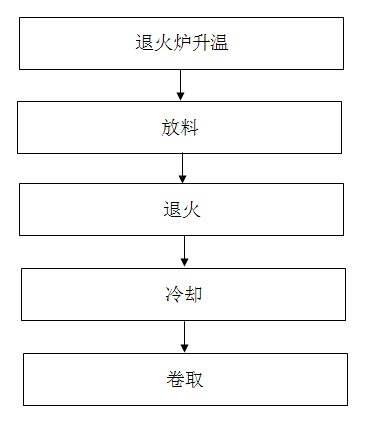

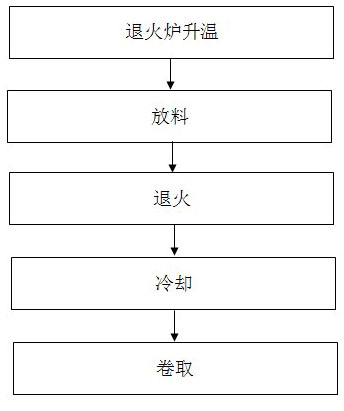

Process for annealing cold rolled pure titanium and titanium alloy roll by continuous bright annealing furnace

InactiveCN102051566AFast annealingIncrease productivityFurnace typesHeat treatment furnacesTemperature controlTitanium

The invention provides a process for carrying out continuous bright annealing treatment on a cold rolled pure titanium and titanium alloy belt roll by a continuous bright annealing furnace, which comprises the following steps of: placing a pure titanium and titanium alloy roll on a decoiling machine, welding a belt head of the titanium roll with a belt tail of a leading belt and repeatedly and continuously annealing; sequentially cleaning and drying at the speed of 2-6m per minute according to the difference of roll thickness and finally leading into a continuous bright annealing furnace; filling argon as inert protective gas into the annealing furnace, wherein the argon flow is 30-50m<3> per hour, and the annealing temperature is 600-950 DEG C; after cooling, leading out of an outlet of the annealing furnace and recoiling into a roll on a coiling machine of the outlet. The invention has the advantages of high annealing speed, high productivity, precise temperature control, and the like and solves the problems of poor physical and chemical performance of products, increased hardness, reduced plasticity and elasticity, and the like caused by the reason that an annealed product is easy to generate a surface polluted layer.

Owner:JIANGSU CHENGFEI PRECISION ALLOY

Ferro-titanium alloying method for titaniferous stainless steel

The invention relates to a ferro-titanium alloying method for titaniferous stainless steel, which comprises the following steps of: I) after slagging off and AOD (Argon Oxygen Decarburization) tapping, removing slag and keeping the thickness of the remained slag being not more than 50mm; II) making a slag steel bag again and hanging in an LF (Low Frequency) finery, adding lime and fluorite for making the slag again, blowing argon from bottom and powerfully stirring and slagging or electrifying and slagging; III) deoxidizing, adding aluminum powder in surface slag, keeping total bottom blowingflow being 600-1,000Nl / min, and stirring for 3-5min; IV) before discharging molten steel, starting to feed a silico-calcium line, and then softly stirring; and V) adding ferro-titanium for alloying, keeping the bottom blowing argon flow close to the side of a feeding port being 500-700 Nl / min and the one away from the side of the feeding port being 100-200Nl / min, adding 2.5-3.5kg ferro-titanium in a ton of molten steel, keeping the bottom blowing flow being 200-300 Nl / min per piece and stirring, and then adjusting the total flow of bottom blowing double-tube being not more than 200NL / min, andsoftly stirring. According to the ferro-titanium alloying method for titaniferous stainless steel, the titanium-feeding time is short and a crystallizer water port is prevented from being plugged during a continuous casting process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Tungsten electrode argon arc welding method for filler wires of titanium alloy and aluminum alloy

The invention discloses a tungsten electrode argon arc welding method for filler wires of a titanium alloy and an aluminum alloy. The method comprises the following steps of: cleaning the surfaces to be connected of the titanium alloy and the aluminum alloy and the surfaces of Al-Mg alloy system welding wires for filling; horizontally splicing a titanium alloy plate with an aluminum alloy plate; controlling the heat distribution by means of tungsten electrode argon arcs, and performing tungsten electrode argon arc welding on the filler wires; and simultaneously protecting the front surface and the rear surface by using pure argon in the welding process, wherein the welding process parameters are as follows: 12 to 15 V of welding voltage, 90 to 120 A of welding current, 50 to 80 mm / min of welding speed, and 10 to 15 L / min of argon flow. The tungsten electrode argon arc welding method for the filler wires of the titanium alloy and the aluminum alloy has the advantages of convenience for operation, stable performance of joints, low cost, convenience for popularization and application and the like and is particularly suitable for welding of the titanium alloy and an aluminum magnesium alloy.

Owner:SHANDONG UNIV

Method for preparing p-type zinc oxide film

InactiveCN1461044AConcentration control is convenientThe principle is simpleFinal product manufactureVacuum evaporation coatingAtmospheric airNitrogen gas

The method for preparing p-type zinc oxide film by using magnetron sputtering process is characterized by that it uses metal zinc as target for magnetron sputtering, and introduces nitrogen gas or nitrogen gas and oxygen gas into working gas argon gas as reactant gas, makes the pressure of magnetron sputtering vacuum chamber be 10(-1)Pa-10(o)Pa, the ratio of nitrogen flow and argon flow be in the range of 1:10-1:1, and the ratio of oxygen flow anjd argon flow be in the range of 0:1-1:1, then makes the obtained nitrogen-oxygen-zinc film undergo the process of heat treatment in atmosphere or oxygen atmosphere, its heat treatment temp. is 300-500 deg.c and treatment time is 0.5-5 hr. so as to obtain the invented product.

Owner:ZHEJIANG UNIV

Preparation method of AlCrCuFeNi high-entropy alloy bearing coating

InactiveCN108411272AHigh purityImprove compactnessVacuum evaporation coatingSputtering coatingHigh entropy alloysMetallurgy

The invention discloses a preparation method of an AlCrCuFeNi high-entropy alloy bearing coating. The preparation method of the AlCrCuFeNi high-entropy alloy bearing coating comprises polishing a matrix, and then ultrasonic-cleaning the matrix through acetone and blow-drying the cleaned matrix; placing the matrix inside the vacuum cavity of a magnetically controlled spluttering machine, vacuumizing the vacuum cavity, programming parameters including target current, matrix bias and argon flow, and depositing film coating through a direct current magnetically controlled spluttering process. Thepreparation method of the AlCrCuFeNi high-entropy alloy bearing coating improves the bearing capacity and the wearing resistance of bearings through coating materials and manners, thereby prolonging the service life of the bearings.

Owner:SHANGHAI DIANJI UNIV

Method for controlling nitrogen content of low nitrogen steel

InactiveCN102787202AAvoid Nitrogen ProblemsEliminate downgradesManufacturing convertersProcess efficiency improvementVacuum pumpingLow nitrogen

The invention provides a method for controlling the nitrogen content of a low nitrogen steel, a converter smelting process comprises the following steps: a ratio of high molten iron and low scrap steel is used, wherein the tapping temperature is no less than 1700 DEG C, ferrosilicon is used for preparing silicon to 0.4%, a gas cover is declined during a whole course of oxygen blowing period; the high carbon with carbon weight at 0.05-0.07% is used when tapping, carbon tapping can be carried out at a time, argon is not blown during the tapping process and at an argon station; a RH refining process comprises the following steps: the argon flow can be controlled at 150N1 / h from vacuum-pumping, the deep vacuum treatment time is controlled in 8-12 minutes, static duration after adding an alloy is 7-9 minutes; argon is continuously blown during continuous casting, and argon is used for casting protection. The method of the invention can effectively solve the nitrogen addition problem in steel, the nitrogen sample content in the argon station is controlled at 0.0011-0.0013%, the nitrogen sample content after finishing the RH treatment is controlled at 0.0013-0.0015%, and the nitrogen sample content of the finished products is controlled at 0.0016-0.0020%, and the degrading and steel judgment accidents due to improper component of the finished product nitrogen can be thoroughly eliminated.

Owner:ANGANG STEEL CO LTD

Wire filling tungsten electrode argon-arc welding process for TA15 titanium alloy and austenitic stainless steel

InactiveCN102744502AOvercome limitationsAvoid restrictionsArc welding apparatusWelding/cutting media/materialsOxygenCopper

The invention discloses a dissimilar material connection process for TA15 titanium alloy and austenitic stainless steel, which comprises the following steps of: before welding, polishing surfaces to be connected of the TA15 titanium alloy and the austenitic stainless steel which are flattened by abrasive paper so as to ensure the roughnesses of the surfaces to be welded to reach Ra1.6 to 3.2; cleanly polishing the surfaces of pure copper welding wires by the abrasive paper; horizontally abutting and placing the TA15 titanium alloy and an austenitic stainless steel sheet which have equivalent size specifications and forming a single-sided V-shaped groove with an angle of 30 degrees to 45 degrees at one side of the TA15 titanium alloy, wherein an assembling gap is 0.05mm to 0.15mm and the specification of a truncated edge is 1 to 2mm; adding the pure copper welding wires between the TA15 titanium alloy and an austenitic stainless steel connecting piece, carrying out weld preheating on the TA15 titanium alloy and an austenitic stainless steel weldment by adopting oxy-acetylene flame, controlling the heat distribution to carry out wire filling tungsten electrode argon-arc welding and protecting a welding region by adopting pure argon, wherein the welding process has parameters of a welding voltage of 12 to 15V, a welding current of 80 to 100A, a welding speed of 100 to 130mm / min and an argon flow of 10 to 15L / min; and after welding, immediately covering the weldment with asbestos cloth to carry out heat preservation and moving the asbestos cloth until the temperature is cooled to below 50 DEG C.

Owner:SHANDONG UNIV

Preparation method of aluminum alloy wear-resistant coating

InactiveCN103103469AImprove bindingHigh bonding strengthMolten spray coatingWear resistantSand blasting

The invention relates to a preparation method of an aluminum alloy wear-resistant coating. The preparation method comprises the following steps of: carrying out sand blasting roughening treatment on the surface of an aluminum alloy matrix; spraying a metal alloy coating on the surface of the aluminum alloy matrix by using a plasma spraying system; subsequently spraying ceramic powder on the metal alloy coating by using the plasma spraying system so as to obtain the aluminum alloy wear-resistant coating, wherein the parameters of the plasma spraying process are as follows: the spraying distance is 80-100mm, the powder feeding rate is 60-65g / min, the argon flow is 30-40L / min, the hydrogen flow is 7-9L / min, the current is 55A and the voltage is 60-65V. The metal alloy coating is a Ni-Al alloy coating. The granularity of the Ni-Al alloy powder is 50-100mu m. The preparation method has the beneficial effects that the aluminum alloy wear-resistant coating with good binding strength is prepared by using a plasma spraying process, and due to the introduction of a Ni-Al transit layer, the aluminum alloy can be well bonded with the coating.

Owner:龙口市丛林铝材有限公司

Production method of nano-grade spherical silica powder

InactiveCN102951643AHigh purityUniform particle size distributionNanotechnologySilicon compoundsGranularitySpherical shaped

The invention provides a production method of nano-grade spherical silica powder, which is carried out in a reaction system which consists of a high-temperature evaporator, a particle controller and a collector which are communicated in sequence. The method comprises the following steps of: adding a silicon briquette with purity of more than or equal to 99.9 percent into the high-temperature evaporator, vacuumizing the reaction system, introducing argon to allow the pressure inside the reaction system to be between 75 and 150kPa; starting a plasma gun, and heating the silicon briquette into silicon vapor; regulating the flow rate of argon to be between 15 and 120m<3> / h to deliver the silicon vapor into the particle controller, and curing to form silicon powder particles; delivering the silicon powder particles into the collector by virtue of the argon flow to allow the silicon powder particles to be attached in the collector, and concentrating to obtain the nano-grade spherical silicon powder with purity of more than or equal to 99.9 percent, particle diameter of between 10 and 3,000nm and spherical shape. The nano-grade spherical silicon powder produced by using the method is high in purity and uniform in granularity distribution, and the particle diameter can be controlled in any range of between 10 and 3,000nm.

Owner:NINGBO GUANGBO NEW NANOMATERIALS STOCK

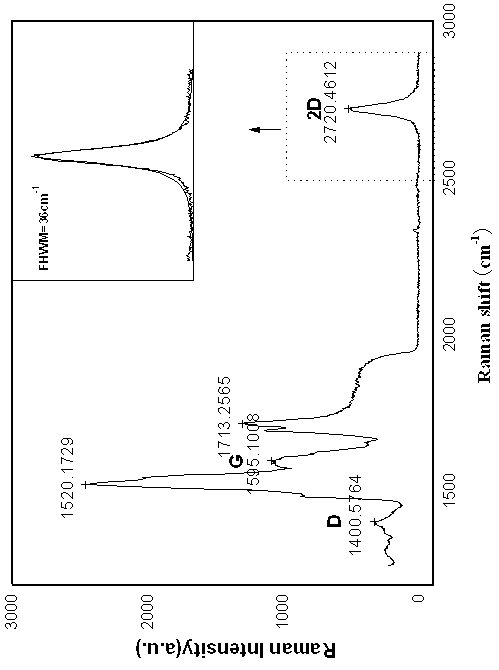

Preparation method of graphene

InactiveCN104030281AHigh degree of reductionEasy to operateCarbon compoundsHydrogen concentrationArgon atmosphere

The invention discloses a preparation method of graphene, which comprises the following steps: (1) breaking graphite oxide into small pieces by a mechanical shearing or ball milling way; and (2) in a hydrogen nitrogen or hydrogen argon atmosphere, heating the small pieces of graphite oxide to 250-500 DEG C in the conditions that the volume concentration of hydrogen is 1-19%, the concentration of nitrogen or argon is 99-81%, the gas flow rate is 10-100mL / min and the heating speed is 5-35 DEG C per minute; preserving heat for 5-120min; and enabling the hydrogen nitrogen or hydrogen argon flow to drop to room temperature or naturally cooling to room temperature to obtain graphene. The invention provides a safe and low-cost method for preparing graphene through hydrogen reduction based on the reduction and stripping at low hydrogen concentration and low temperature of the small pieces of graphite oxide. The method is simple to operate, and the obtained graphene has relatively high reduction degree.

Owner:NANCHANG UNIV

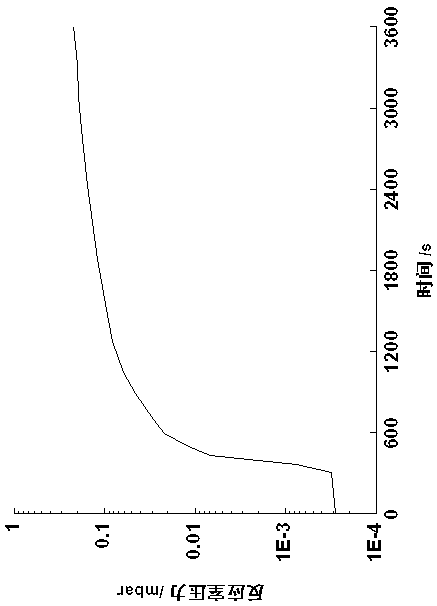

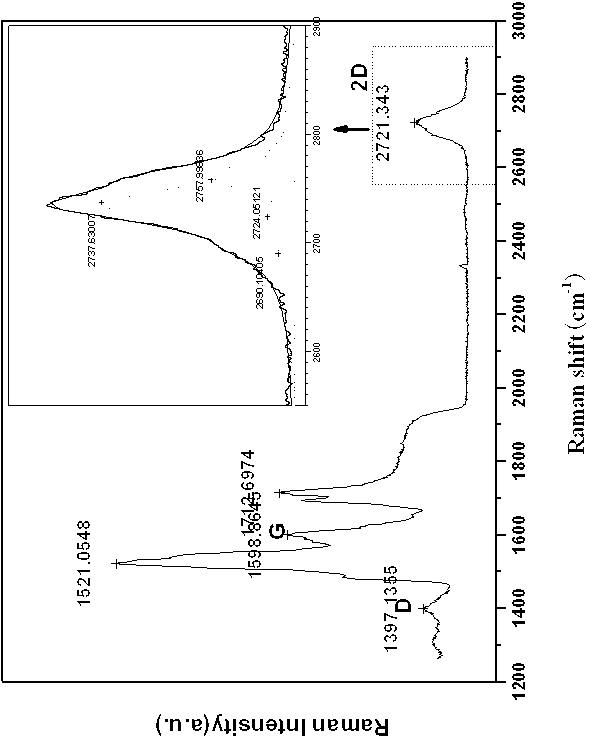

Method for manufacturing low layer number graphene film on silicon carbide substrate

ActiveCN102936009AReduce the amount of residual hydrogenAvoid sublimationGrapheneCarbonizationGraphite

The present invention relates to a method for manufacturing a low layer number graphene film on a silicon carbide substrate. The method comprises the following process steps: 1) selecting a silicon surface silicon carbide substrate, and placing on a graphite base having a tantalum carbide coating; 2) carrying out system heating; 3) reducing a reaction chamber temperature to less than 1200 DEG C; 4) increasing argon flow; 5) carrying out system heating; 6) reducing argon flow, and reducing reaction chamber pressure to 0-1 mbar; 7) continuously adopting a mechanical pump to control a reaction chamber vacuum degree; 8) adopting a molecular pump to control the reaction chamber vacuum degree, and starting a carbonization process; 9) closing heating, and introducing argon; 10) reducing the reaction chamber temperature to 1000 DEG C, and closing argon; and 11) reducing the reaction chamber temperature, introducing argon to the reaction chamber to achieve atmospheric pressure, opening the chamber, and taking the sheet. The method has the following advantages that: graphene film formation can be promoted, sublimation of silicon atoms in the SiC substrate during heating and cooling processes can be effectively inhibited, and the carbonization process is easily controlled so as to achieve low layer number graphene film preparation.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

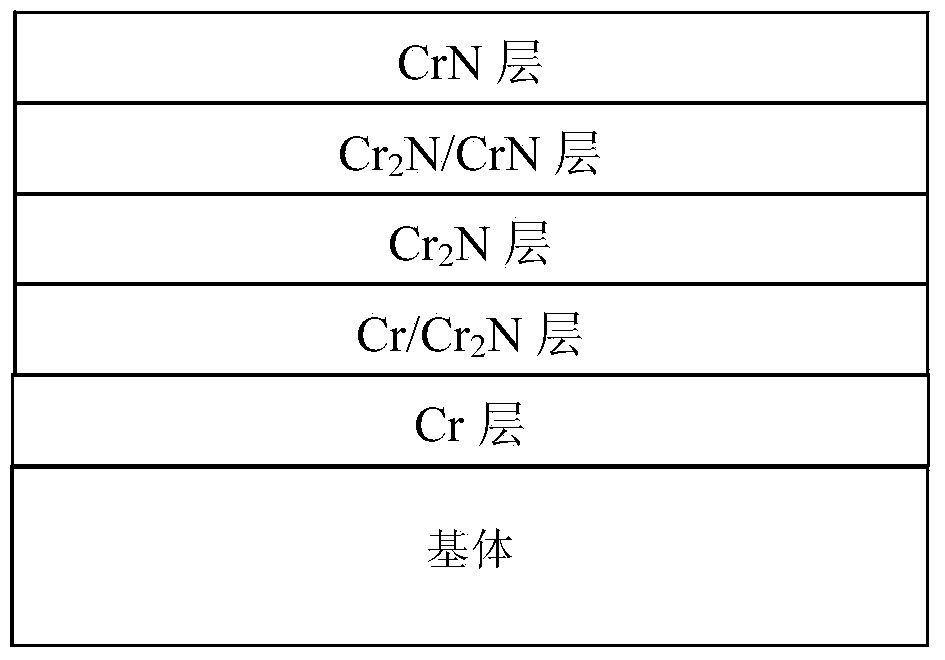

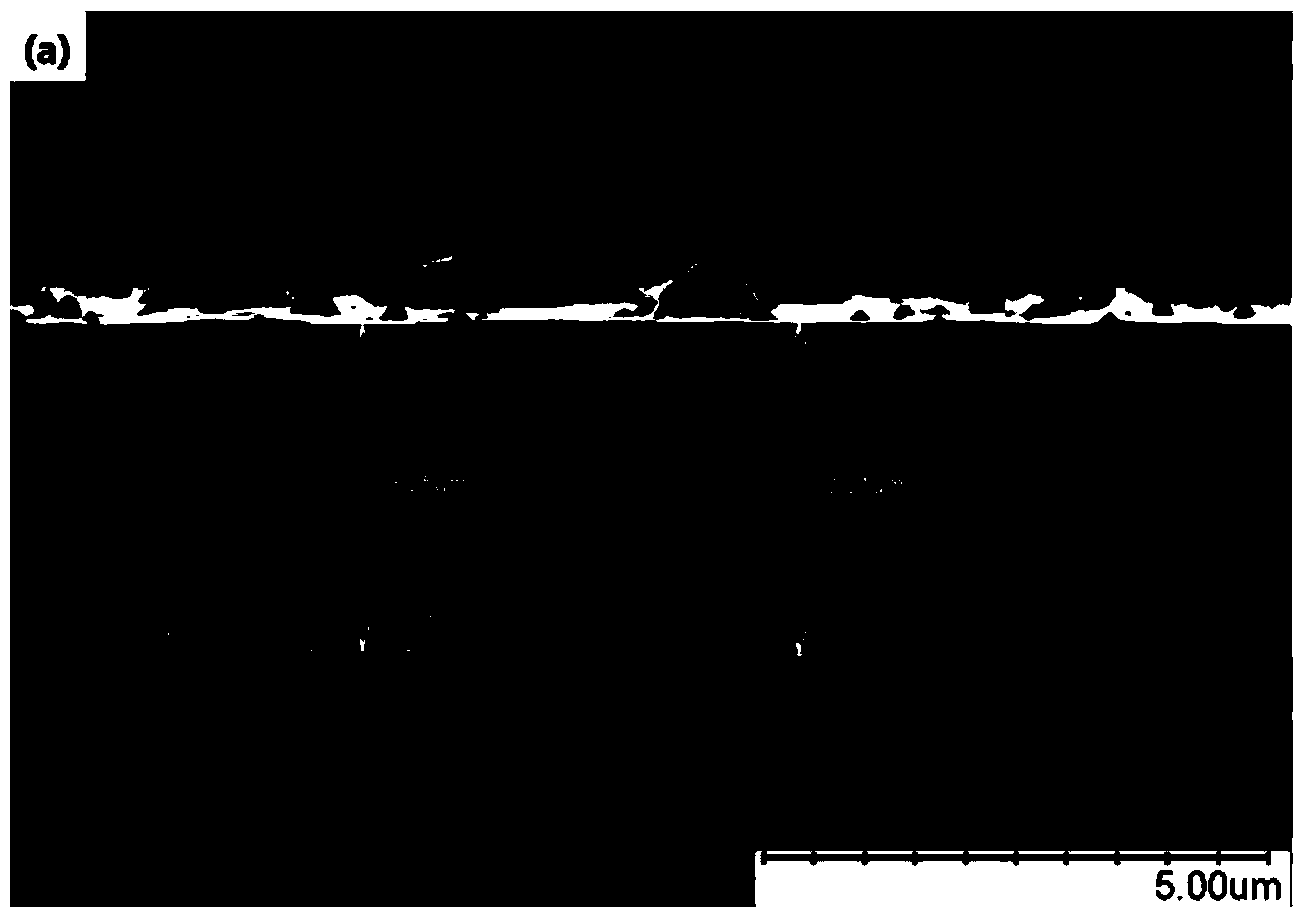

Composite coating on surface of valve sealing piece and preparation method for composite coating

ActiveCN103522627AImprove load bearing and wear resistanceAvoid failureVacuum evaporation coatingSputtering coatingNitrogen gasIon plating

The invention provides a composite coating on the surface of a valve sealing piece. The coating takes the valve sealing piece as a base body and consists of a Cr layer, a Cr / Cr2N layer formed by mixing Cr and Cr2N, a Cr2N layer, a Cr2N / CrN layer formed by mixing the Cr2N and CrN, and a CrN layer. Compared with an existing CrN coating with a single structure, the composite coating with multiple layers of gradients has the advantages that the bearing and anti-abrasion capability and the corrosion resistance are improved. Furthermore, the composite coating is prepared by a multi-arc ion plating technology, and the respective layers are obtained by sequentially performing deposition on the surface of the base body by controlling the argon flow, the nitrogen flow and the deposition time; the preparation method is simple and feasible; batch production can be realized; the composite coating has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

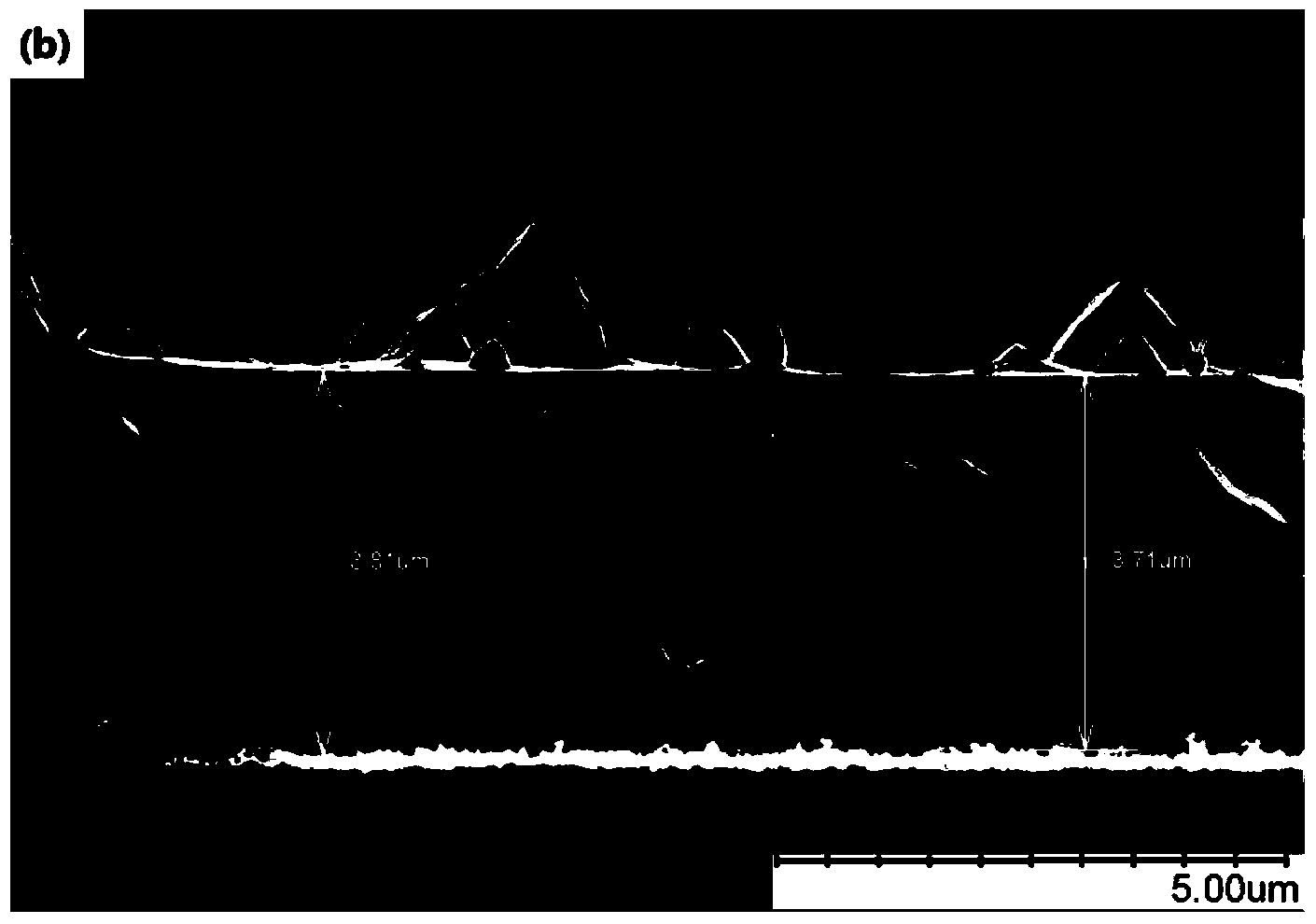

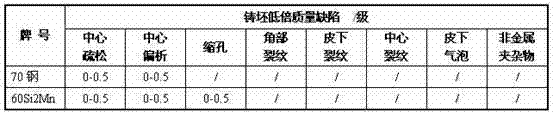

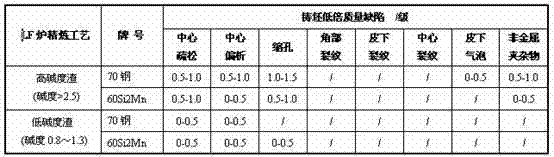

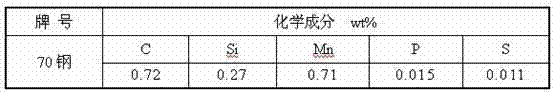

Ladle furnace low alkalinity slag refining process

The invention provides ladle furnace low alkalinity slag refining process. According to the process, bottom blowing of argon to ladles is carried out in the whole course of steel making and tapping, and ferrosilicon, silicon-calcium-barium and high carbon ferromanganese are sequentially added into the ladles for deoxidation and alloying; under the condition that argon flow is 30 to 50 NL / min, argon is blown to the liquid steel for two to three minutes, electrodes are inserted to melt slag, and the slag is modified; the liquid steel is heated to a temperature of 1580 to 1600 DEG C, and alkalinity of the slag is controlled to be 0.8 to 1.3; under the condition that argon flow is 20 to 30 NL / min, argon is blown to the liquid steel for 25 to 30 minutes, and components of the slag are controlled. Therefore, compound inclusion particles with a low melting point and good plastic deformation are formed in the liquid steel and float upward rapidly, which is beneficial for effective removal of inclusions in the liquid steel, thereby substantially improving cleanliness of the liquid steel, obviously enhancing quality of billets, enabling defects of billets like looseness, cracks, segregationand non-metallic inclusions to be greatly reduced, the content of micro inclusions, especially inclusions of B type oxides and D type oxides, in steel products to be substantially reduced and the steel products to meet subsequent processing requirements of 70 high carbon steel wires and 60 Si2Mn spring steel.

Owner:WUKUN STEEL

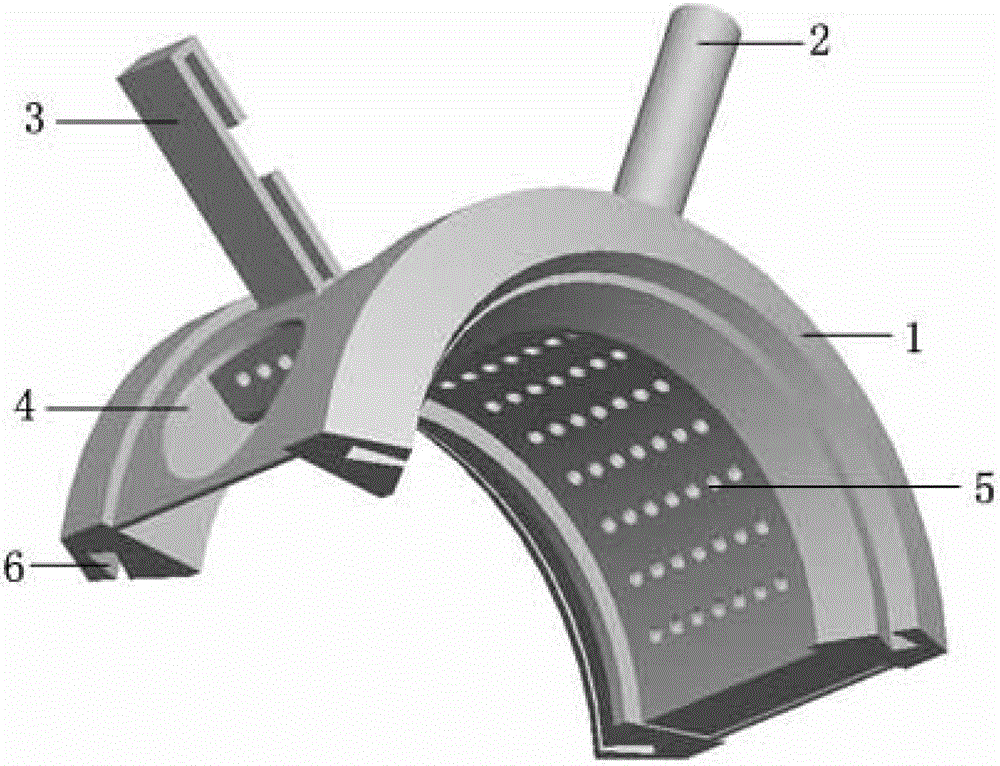

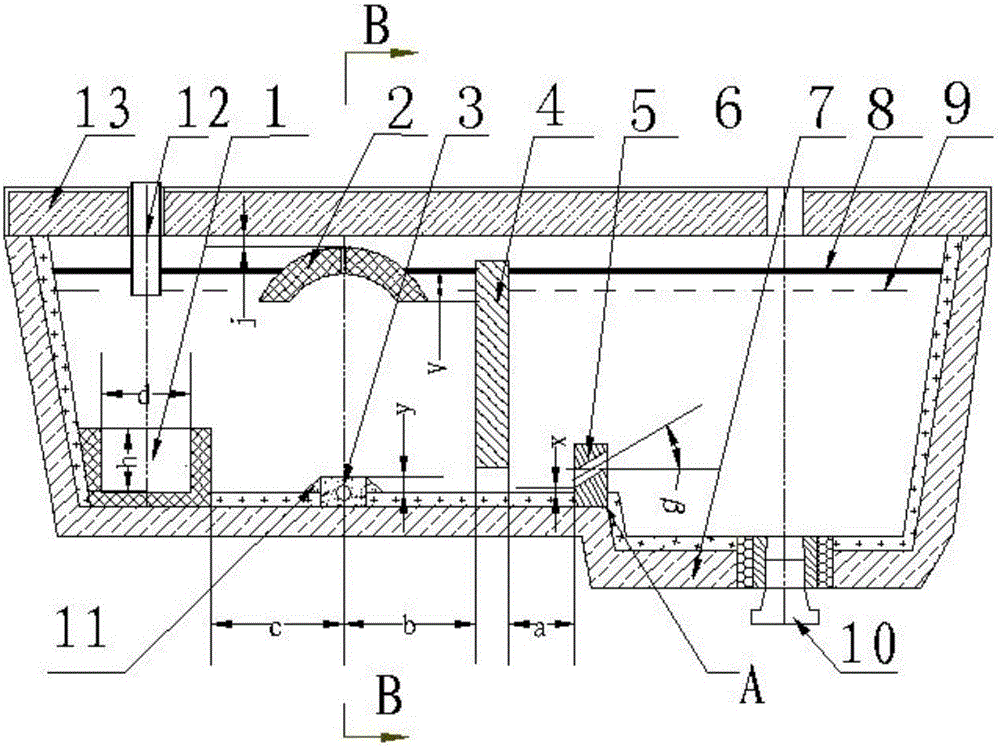

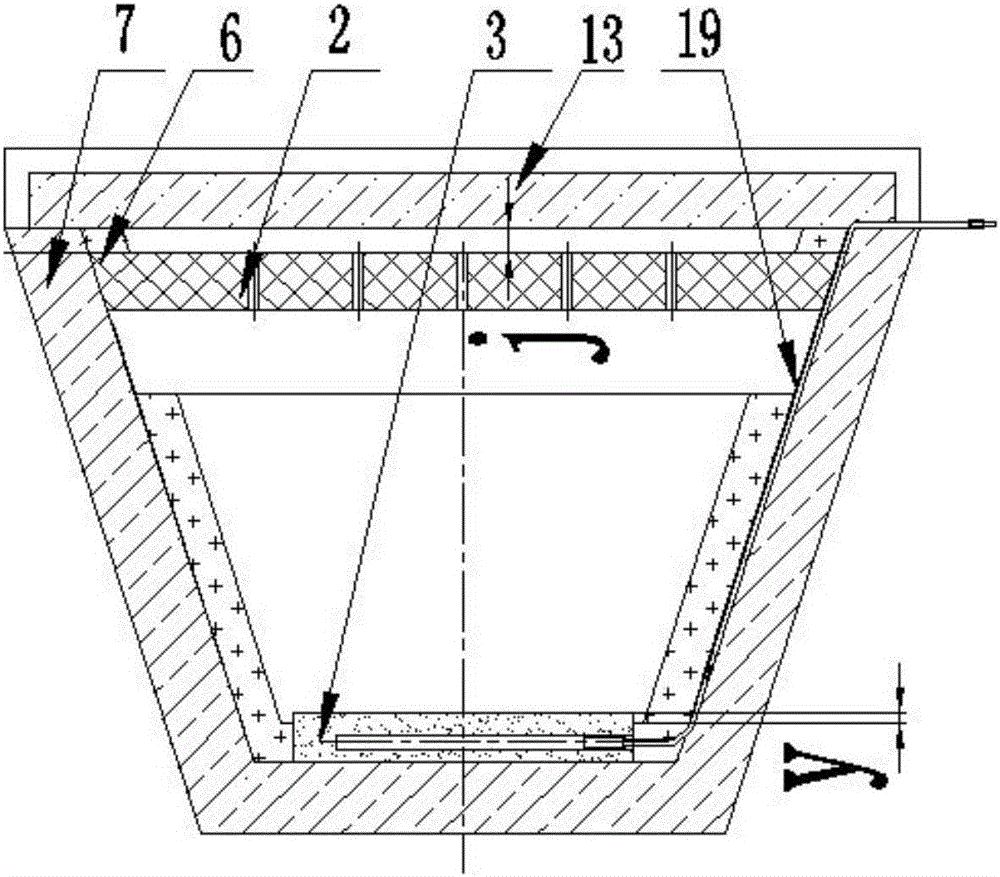

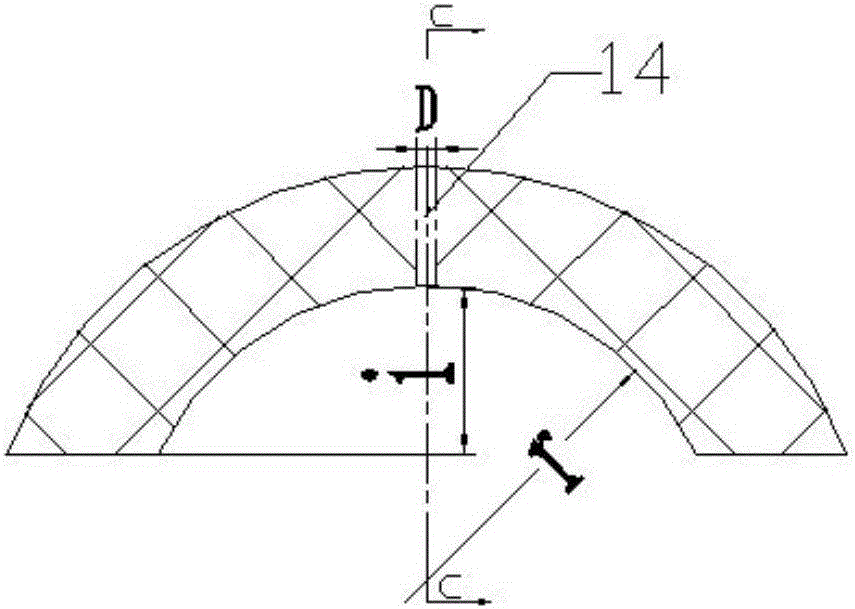

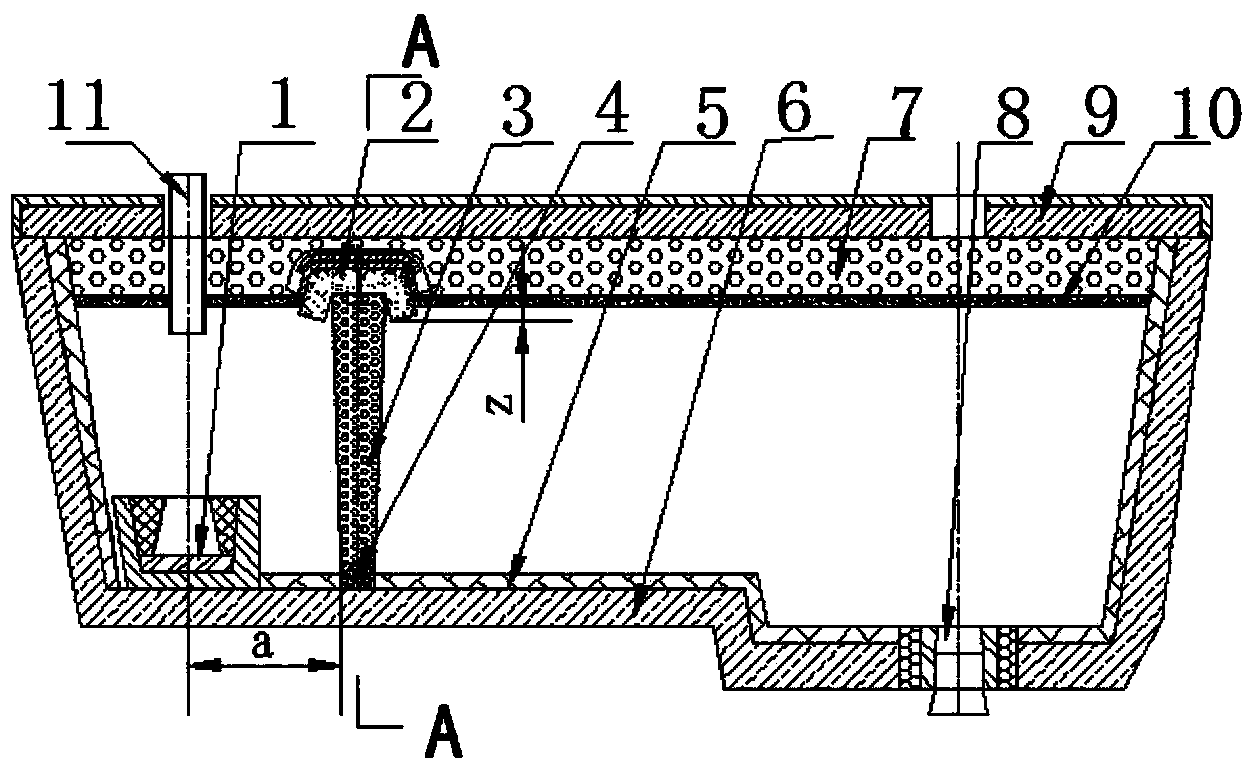

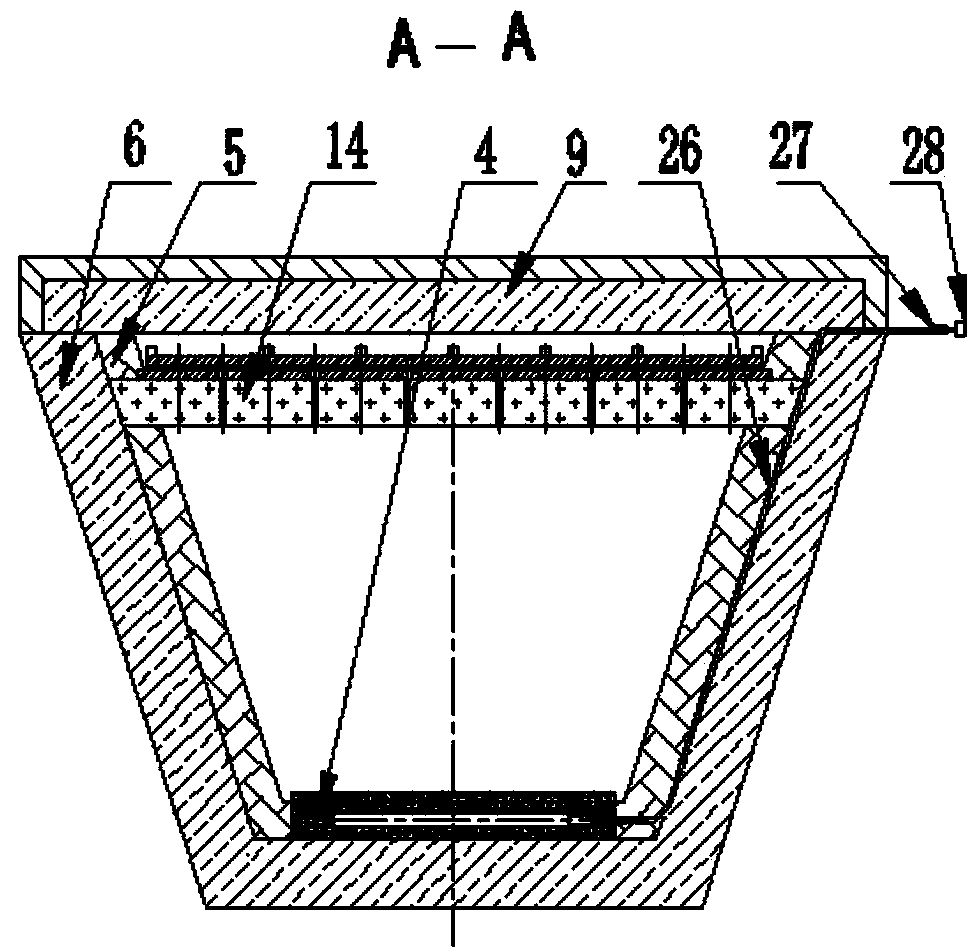

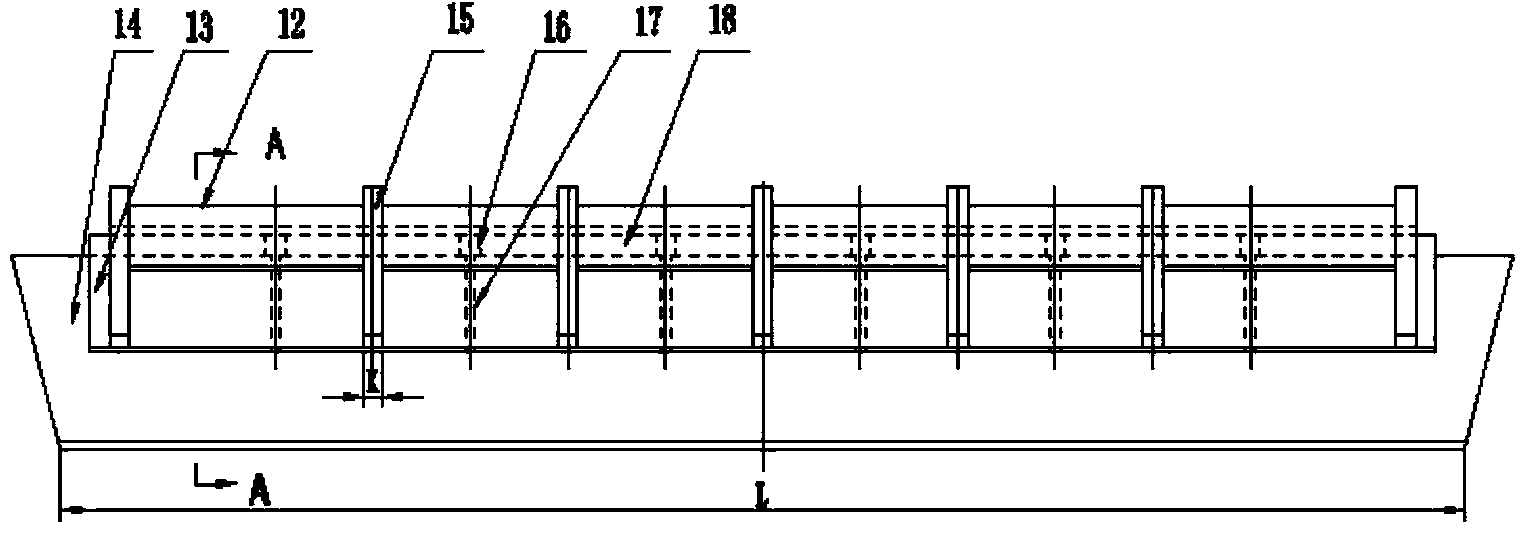

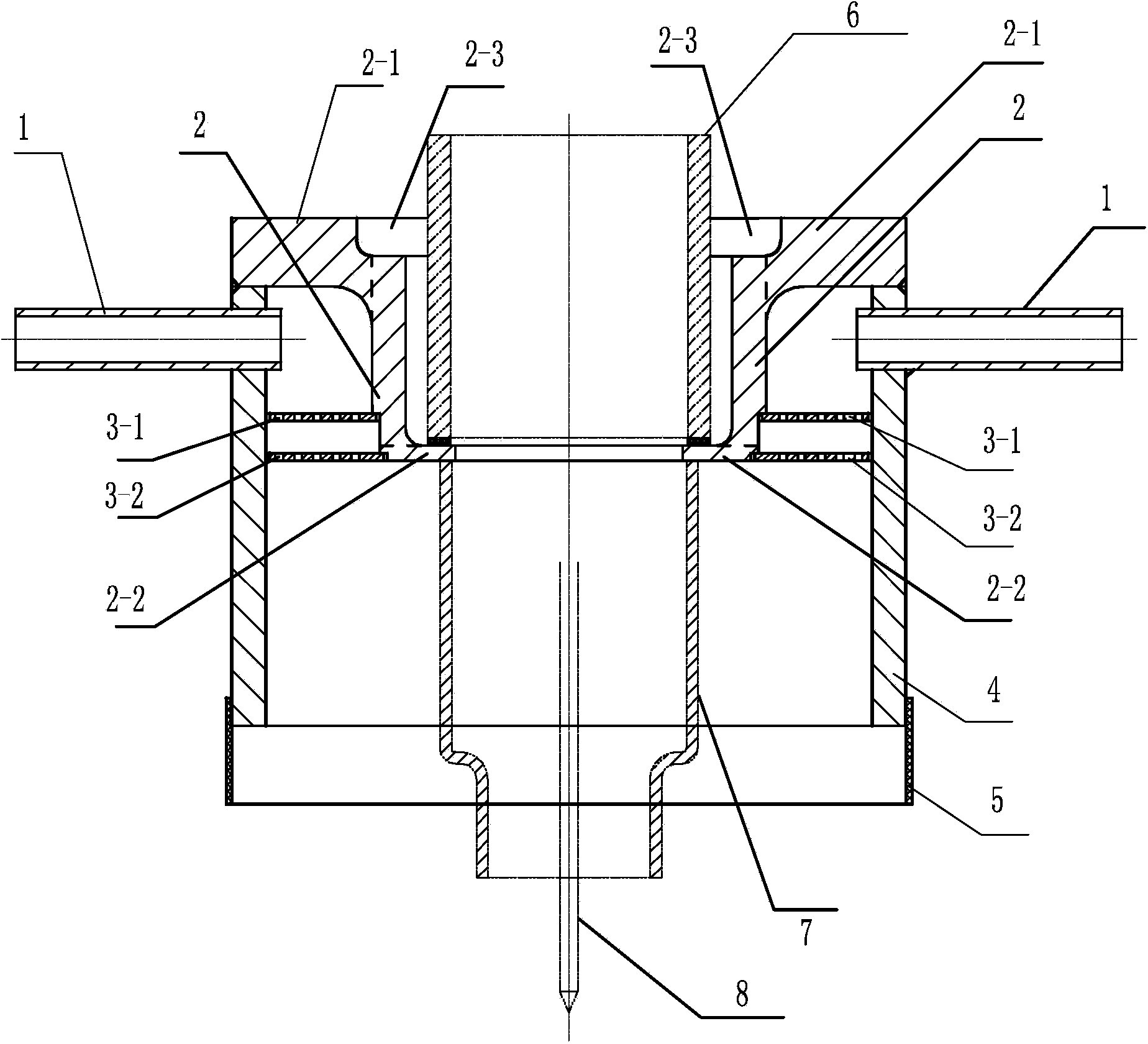

Covered argon blowing refining device for slab continuous casting tundish strip-shaped air brick and argon control method

The invention relates to a covered argon blowing refining device for a slab continuous casting tundish strip-shaped air brick and an argon control method. The device comprises a turbulent controller (1), a dipping cover (2), the strip-shaped air brick (3), a retainer wall (4) and an inclined hole stop dam (5); the dipping cover (2) is positioned rightly above the strip-shaped air brick (3); the lower end of the dipping cover (2) is dipped below a lowest pouring liquid level (9) of molten steel in a continuous-cast ladle exchange process tundish; an argon blowing control system PLC is adopted to collect and upload a pressure value of a first pressure gauge (22a), a flow value of a special metallurgy mass-flow controller (25) and a pressure value of a second pressure gauge (22b) into a continuous casting foundation automatic system database through ethernet communication; an argon flow automatic control instruction of the argon blowing control system PLC is performed; and the argon flow is automatically adjusted according to the net weight change of the molten steel in the tundish, so that the precise control is realized, and the effect of the tundish removing inclusions in the molten steel is improved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Smelting method of non-quenched and tempered steel

ActiveCN110055450AImprove purityReduced activityManufacturing convertersProcess efficiency improvementSmelting processCalcium cyanamide

The invention discloses a smelting method of non-quenched and tempered steel. The smelting method comprises the working procedures of converter smelting, LF refining, VD vacuum treatment and continuous casting, and comprises the specific technological steps that (1) nitrogen is blown at the bottom in the whole converter smelting process, and converter high-carbon drawing and tapping is carried out; (2) diffusion deoxidation is carried out in the LF refining process, good deoxidation and desulfurization effects are guaranteed, and the N content of molten steel after LF finishing is 75-90ppm; (3) VD vacuum treatment is carried out, wherein the content of N in the molten steel after hollow breaking is 50-60 ppm, after hollow breaking, soft blowing time is larger than or equal to 30 min, and argon flow is smaller than or equal to 25 L / min; and (4) continuous casting adopts crystallizer stirring and tail-end stirring, medium-high carbon tundish covering agent and medium-carbon crystallizercovering slag are used, and continuous casting billets are cooled slowly in an off-line mode. According to the smelting method of the non-quenched and tempered steel, the nitrogen content yield is stable, the performance of the non-quenched and tempered steel is good, calcium cyanamide (CaCN2) is not adopted, environmental pollution is small, the feeding amount of the manganese nitride wire is small, and the production cost is low.

Owner:石钢京诚装备技术有限公司

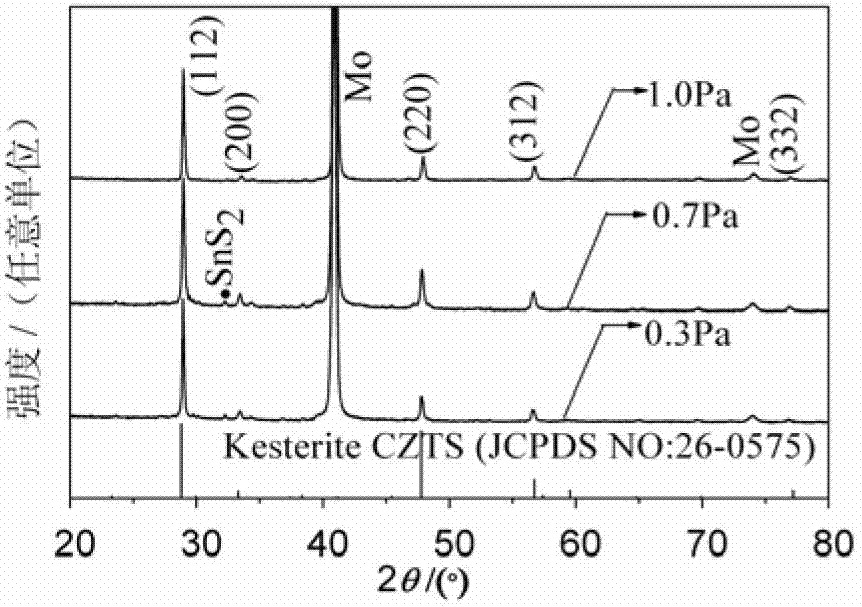

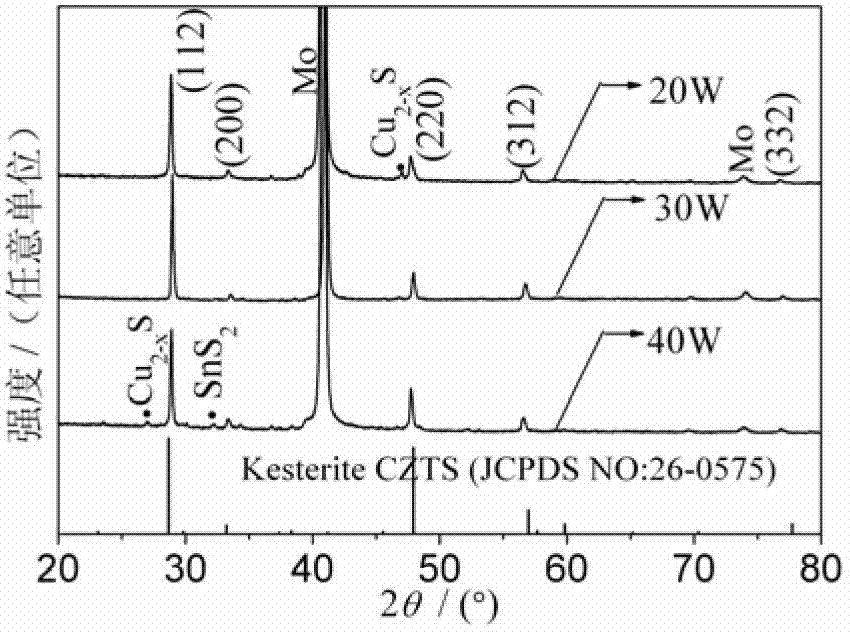

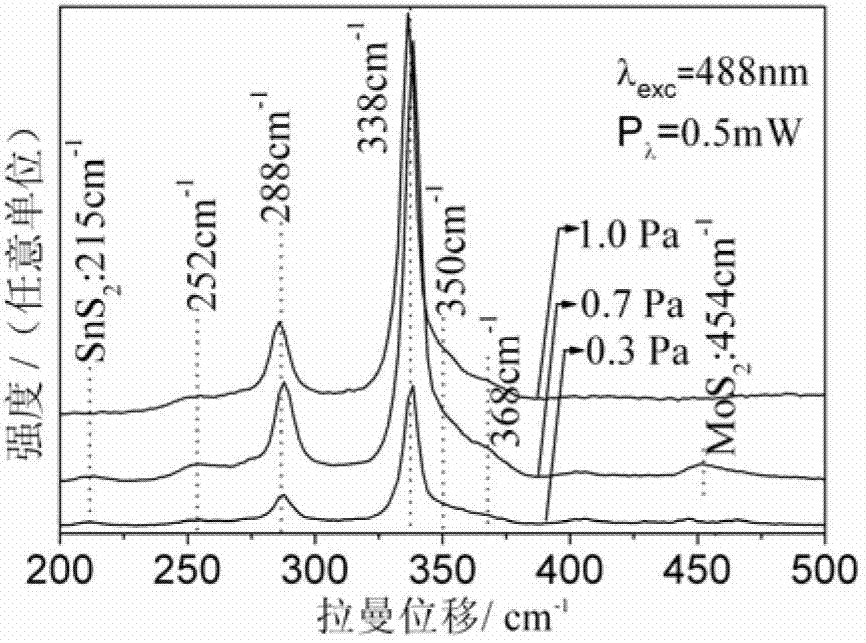

Method of preparing copper-zinc tin-sulphur solar cell absorbed layer thin film

InactiveCN103165748AReduce difficultyLow costFinal product manufactureVacuum evaporation coatingVulcanizationAlloy

The invention discloses a method of preparing a copper-zinc tin-sulphur solar cell absorbed layer thin film. The method of preparing the copper-zinc tin-sulphur solar cell absorbed layer thin film comprises the following steps: 1) a substrate can be soaked in acetonum, ethyl alcohol and deionized water in sequence, the substrate can be cleaned ultrasonically and then the substrate can be blow-dried to be reserved; 2) a direct current magnetron sputtering system can be used and a copper (Cu)-zinc (Zn)-stannum (Sn) alloy can be used as target materials to be in signal-target sputtering. Vacuum degree is above 3.5*10-4 pascals, sputtering power is 10-50 watts and working air pressure is 0.2-1.2 pascals so as to obtain a Cu-Zn-Sn precursor thin film; 3) under the condition that argon can be entered into a vacuum and the argon flow is in 35-50 standard-state cubic centimeter per minute, the temperature of the Cu-Zn-Sn precursor thin film and powdered sulfur can be respectively raised to 200-250 DEG C. The powdered sulfur can be kept under 200-250 DEGC in 5.5-6.5 hours and then the powdered sulfur can be cooled naturally; after the substrate is kept under the temperature of 200-250 DEGC in 10-15 minutes, the temperature can be increased to 500-600 DEGC to be in vacuum vulcanization for 30-40 minutes. After the substrate is naturally cooled, the copper-zinc tin-sulphur solar cell absorbed layer thin film can be obtained. The method of preparing the copper-zinc tin-sulphur solar cell absorbed layer thin film has the advantages of being easy to operate, strong in controllability, good in repeatability and capable of preparing high quality copper-zinc tin-sulphur solar cell absorbed layer thin film in large areas. The method is an environmental friendly preparation method.

Owner:NINGBO UNIV

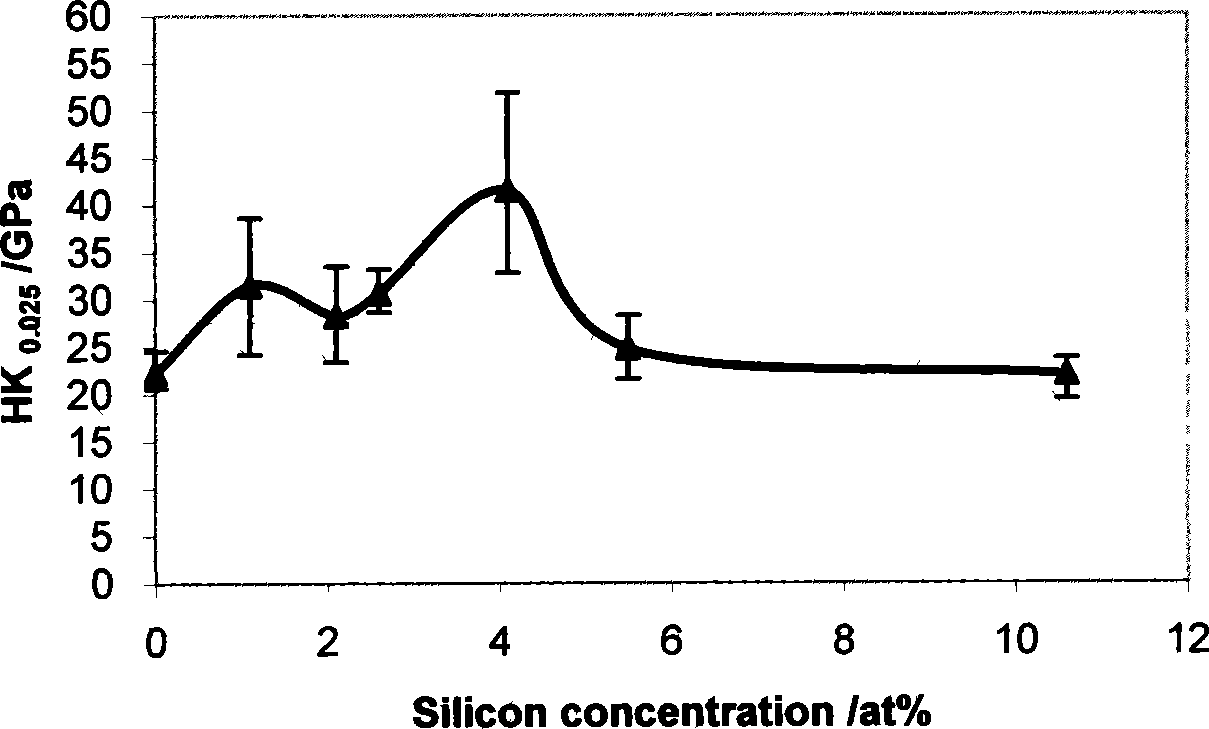

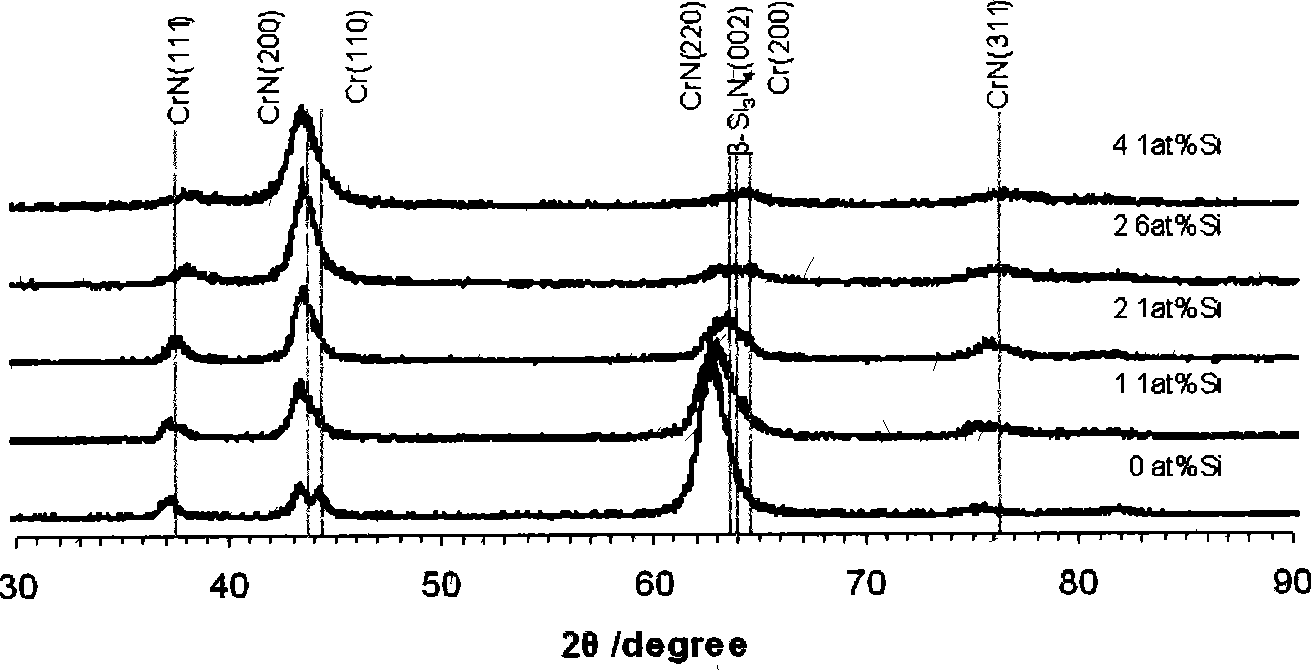

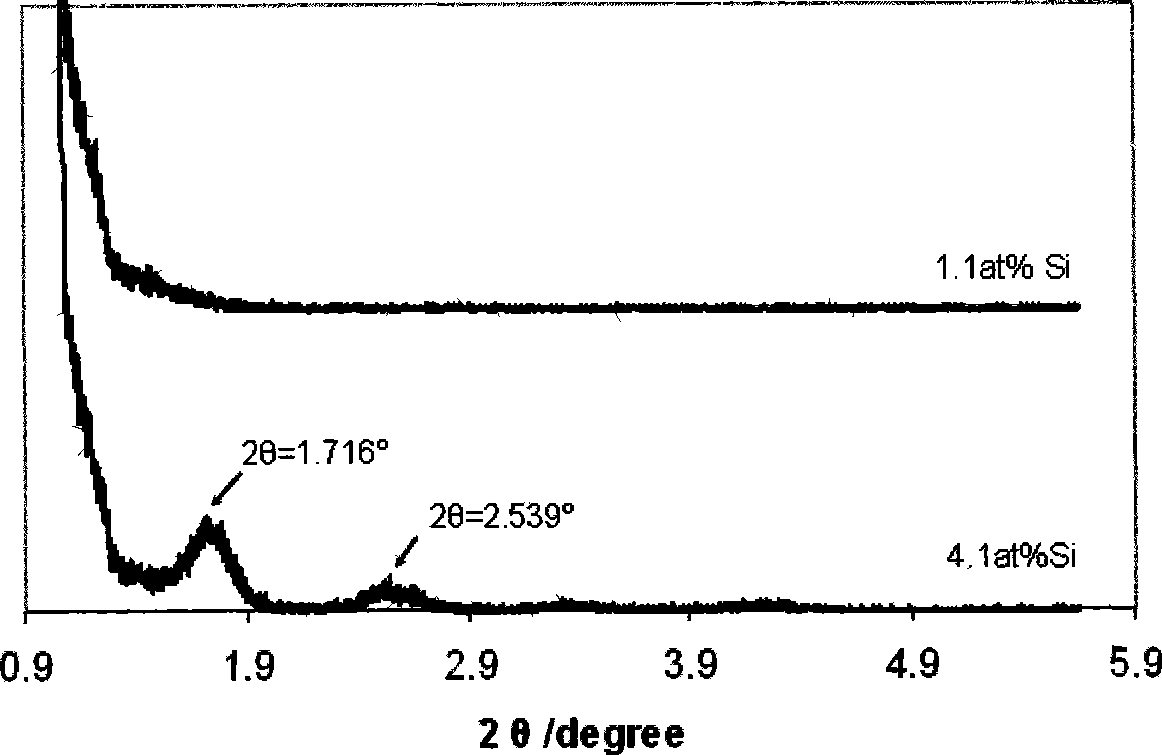

Glass-hard low-frictional coefficient nano-multi-layer amplitude modulation structure coating and preparation method thereof

InactiveCN101367286AHigh hardnessReduce coefficient of frictionLayered productsVacuum evaporation coatingCritical loadNitrogen gas

The invention belongs to a surface engineering technology and in particular relates to a high-hardness and low-friction coefficient plating layer with a nanometer multilayered amplitude modulation structure and a method for preparing the same. A Cr-Si-N plating layer is plated by an unbalance magnetron sputtering ion plating method in a closed magnetic field. In preparation, the input power of Cr target current is 2 kilowatts; and the input power of Si target current is changed within the range between 0.3 and 0.7 kilowatt so as to adjust the content of silicon in the plating layer. When a CrN transition layer and the Cr-Si-N plating layer are deposited, the flow of the introduced argon gas is 10 sccm; and the bias voltage of direct current pulse is 60 volt below zero. When the CrN transition layer and the Cr-Si-N plating layer are deposited, the flow of nitrogen gas is used and positioned in a light emission spectrum device on the near surface of the Cr target for carrying out the closed-loop control so as to accurately modulate the compositions of the plating layer. The plating layer has the nanometer multilayered amplitude modulation structure which in turn consists of a base layer, a Cr interface layer, a CrN transition layer and a Cr-Si-N amplitude modulation structural layer with CrN and Si3N4 arranged outwards at intervals; the outermost layer is the Cr-Si-N amplitude modulation structural layer, wherein the amplitude modulation wavelength of the Cr-Si-N amplitude modulation structural layer is less than 50 nanometers; the hardness is larger than 20 GPa; the highest hardness exceeds 20 GPa; and the Cr-Si-N amplitude modulation structural layer has excellent film-based binding strength (a scuffing method determines that the critical load is larger than 85 newtons) and has friction coefficient of less than 0.5 between WC balls. A plating layer material can be used for mechanical parts under the condition of high-load service and cutters.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Refining device and method for removing liquid steel inclusions in continuous casting tundish

The invention relates to a refining device and method for removing liquid steel inclusions in a continuous casting tundish. The refining device comprises a turbulence controller, a refining cover and air curtain ventilation bricks. The two side ends of the refining cover are fixed to a permanent lining on the wall of the tundish, the lower end of the refining cover is immersed into liquid steel below a steel slag layer inside the tundish, the refining cover is located over the air curtain ventilation bricks and is opposite to the air curtain ventilation bricks, a gas channel is formed in the body of the refining cover, the two ends of the gas channel are communicated with a gap between a tundish cover and the steel slag layer inside the tundish, gas exhaust holes communicated with the gas channel are formed in the body of the refining cover and are opposite to the air curtain ventilation bricks, large-flow argon is blown in through the air curtain ventilation bricks, an air curtain barrier with the large continuous intensity is formed between the air curtain ventilation bricks and the refining cover, the inclusions are captured and are adsorbed and removed by the steel slag layer, the argon flows through the gas channel and forms argon seal between the steel slag layer inside the tundish and the tundish cover, the steel slag face is protected, secondary oxidation of liquid steel is avoided, the cleanliness of the liquid steel is greatly improved, and the 0.5 level of the four kinds of inclusions in LHG2 steel reaches more than 90%.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Auxiliary protection gas hood of automatic TIC welder head

ActiveCN103934556AExpand the scope of protectionPrevent oxidationShielding gas supply/evacuation devicesArgon flowEngineering

The invention relates to an auxiliary protection gas hood of an automatic TIC welder head, and belongs to the field of machining. The auxiliary protection gas hood aims to solve the problem that oxidation of metal welding occurs easily near a welding pool in the welding process due to a small protection range of a welding nozzle of a traditional welder. According to the auxiliary protection gas hood, argon enters the auxiliary protection gas hood through a gas-guide tube, the turbulence phenomenon of the argon is reduced through filtering of a first netted plate and a second netted plate, and the argon around a welding gun forms a stable auxiliary argon flow field, so that the area outside of the nozzle of the welding gun and inside of the auxiliary protection gas hood is in the effective protection range of the argon, a good protection effect is achieved at the two sides of the welding pool in the automatic welding process of the easily oxidized metal tungsten electrode argon arc, and oxidation of titanium alloy and other easily oxidized metal is avoided. In the welding process, the auxiliary protection gas hood of the automatic TIC welder head and the welding gun form a whole, and the auxiliary protection gas hood swings along with the welding gun. The auxiliary protection gas hood of the automatic TIC welder head is suitable for the welding of the titanium alloy and other easily oxidized metal.

Owner:HARBIN TURBINE +1

Method for preparing carbon material surface ceramic coat

Owner:HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com