Preparation method of AlCrCuFeNi high-entropy alloy bearing coating

A high-entropy alloy, coating technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problem that the service life and fatigue resistance of bearings are difficult to fundamentally solve, and it is difficult to manufacture high-end and high-precision bearings , Unable to determine the performance impact of new elements, etc., to achieve the effect of great practicability and promotion value, improving bearing capacity and wear resistance, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

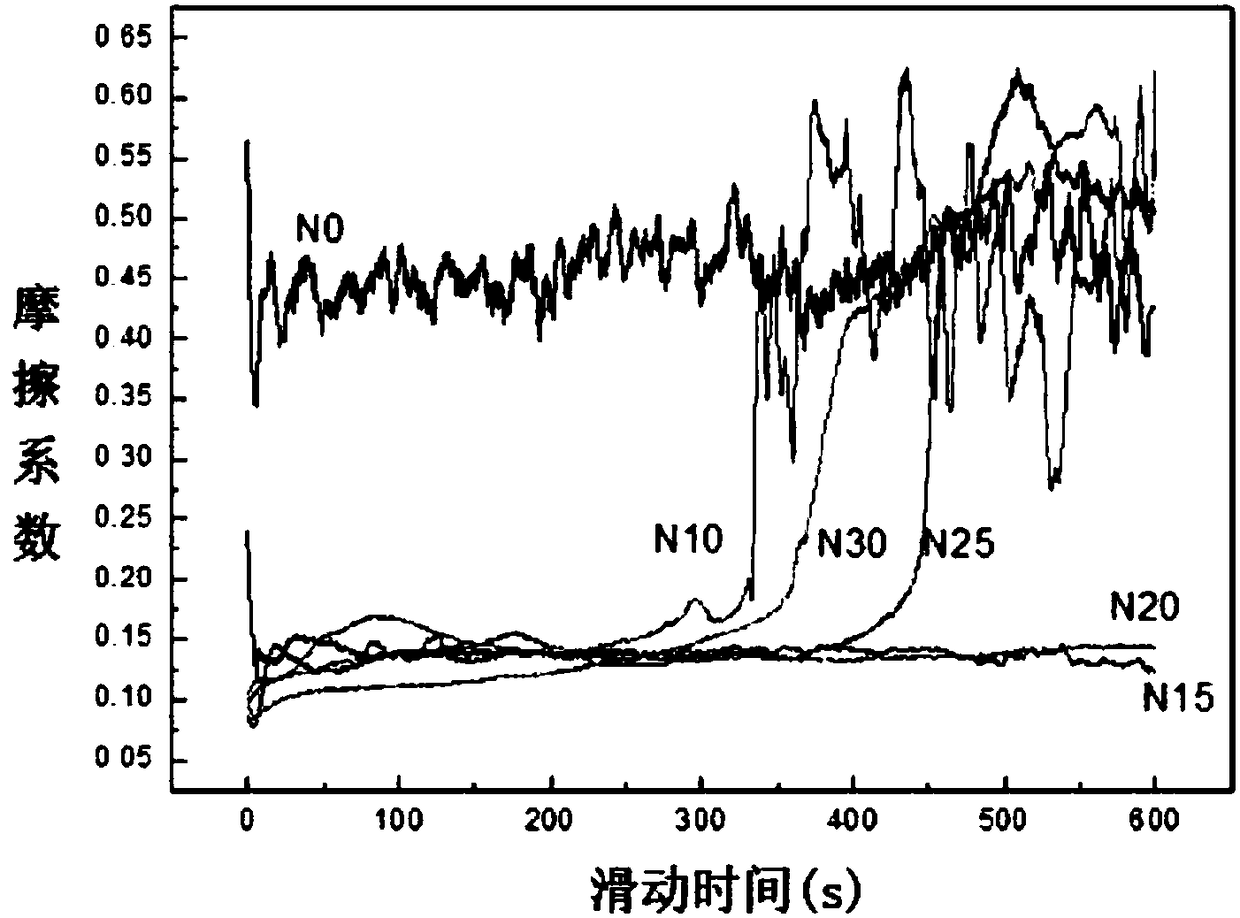

[0032] Examples 1-6 Prepare AlCrCuFeNi high-entropy alloy nitride film coatings for bearing materials according to the above preparation method, the difference is that the nitrogen flow rates in Examples 1-6 are 0%, 10%, 15%, and 20% respectively , 25% and 30%; through the SEM scanning electron microscope to observe the film section, the results are as attached figure 1 Shown, test the thin film coating hardness and the friction and wear coefficient of embodiment 1-6 by national standard, the result is as table 1 and attached figure 2 shown.

[0033] Table 1: Hardness data of coatings under different nitrogen flow rates

[0034]

[0035] It can be seen from the above table 1 that as the proportion of nitrogen gas is increased, the proportion of nitrogen gas participating in the reaction increases, and the hardness of the film layer shows a trend of first increasing and then decreasing. When the proportion of nitrogen gas reaches 20%, the film layer hardness reaches a maximu...

Embodiment 7-11

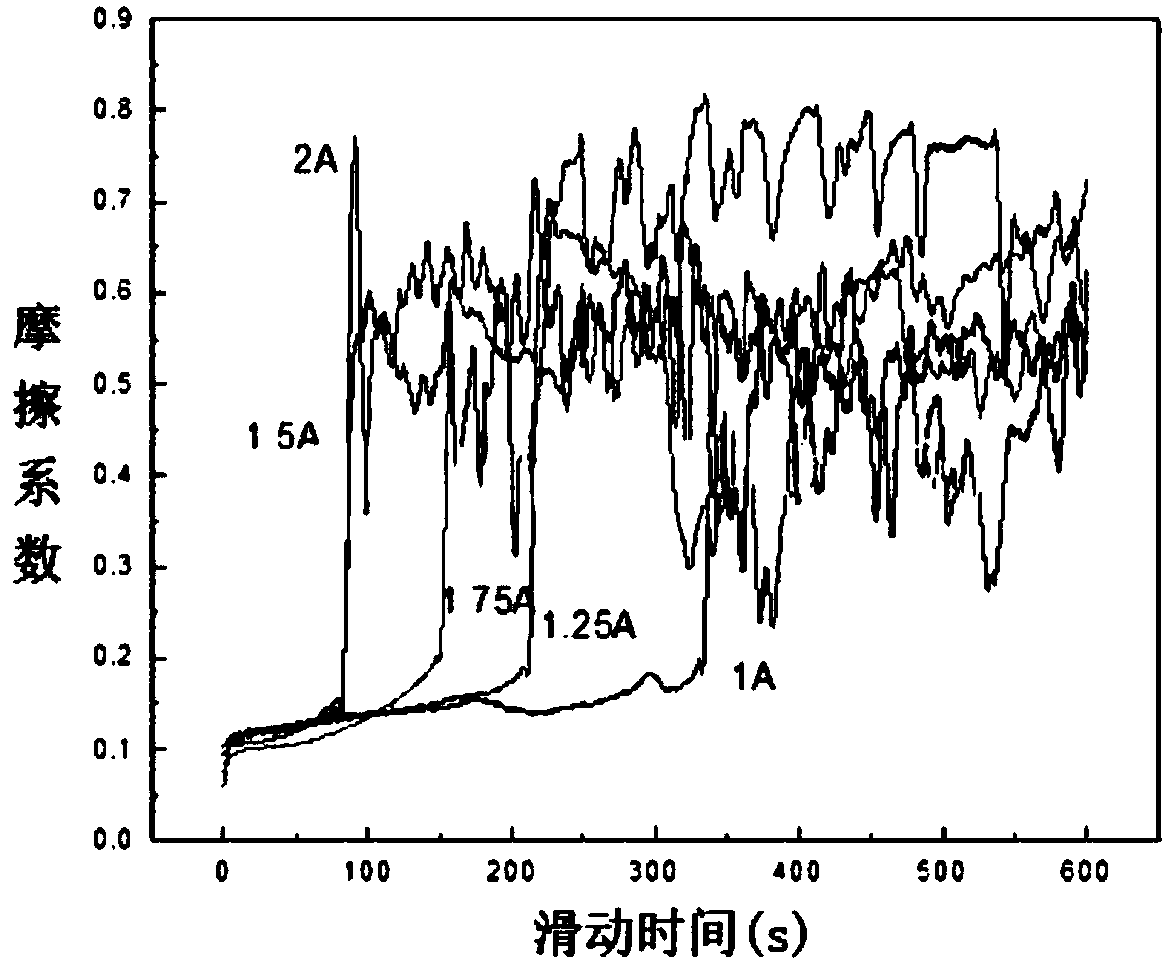

[0038] Examples 7-11 Prepare AlCrCuFeNi high-entropy alloy nitride film coatings for bearing materials according to the above preparation method, the difference is that the sputtering currents of Examples 7-11 are 1A, 1.25A, 1.5A, 1.75A and 2A, test the hardness and friction and wear coefficient of the film coating according to the national standard, the results are shown in Table 2 and attached image 3 shown.

[0039] Table 2 Hardness data of coatings under different sputtering currents

[0040]

[0041] It can be seen from the above table 2 that when the substrate bias voltage is -50v, the hardness of the film is 10.46GPa, and when the substrate bias voltage increases to -80v, the hardness value decreases to 8.42GPa; with the further increase of the substrate bias voltage, the hardness value increases to 13.35GPa (-110v) and 13.74GPa (-150v).

[0042] See attached image 3 , the films sputtered under different substrate bias conditions all appear in the stage where th...

Embodiment 12-15

[0044] Examples 12-15 Prepare AlCrCuFeNi series high-entropy alloy nitride film coatings for bearing materials according to the above preparation method, the difference is that the substrate bias voltages of Examples 12-15 are 50V, 80V, 110V and 150V respectively, according to national standards Test the hardness and the coefficient of friction and wear of the film coating, the results are shown in Table 3 and attached Figure 4 shown.

[0045] Table 3 Hardness data of coatings under different substrate biases

[0046]

[0047] It can be seen from the above Table 3 that as the current increases, the crystallization properties of the film are improved and the compactness is increased. As the current continues to increase, the hardness of the film gradually decreases, and when it reaches 1.75A, the hardness is 9.63GPa. When the current increased to 2A, the film hardness increased to 11.29GPa.

[0048] See attached Figure 4 , the coefficient of friction of films sputtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com