Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

540 results about "Direct current magnetron sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar selective coating having higher thermal stability useful for harnessing solar energy and a process for the preparation thereof

InactiveUS20070196670A1Easy to optimizeImprove thermal stabilitySolar heat devicesVacuum evaporation coatingAbsorptanceEngineering

The present invention provides an improved solar selective multilayer coating having higher thermal stability and a process for the preparation thereof. Solar selective coatings having higher thermal stability are useful in solar steam generation, solar steam turbines to produce electricity and also on automobile engine components. In the present invention, a tandem stack of three layers of TiAlN, TiAlON and Si3N4 is deposited on metal and non-metal substrates at room temperature using a planar reactive direct current magnetron sputtering process. The first two layers function as the absorber and the third antireflection layer further enhances the coating's absorptance. The solar selective coatings were annealed in air and vacuum to test the thermal stability at different temperatures and durations. The coatings of the present invention deposited on copper substrates are stable in air up to a temperature of 625° C. for a duration of 2 hours and exhibit higher solar selectivity in the order of 9-10 and these coating also show no change in the absorptance and the emittance values even after vacuum annealing at 600° C. for 3 hours. Coatings deposited on copper substrates showed no significant degradation in the optical properties even after continuous heating in air at 525° C. for 50 hours. The solar selective coatings of the present invention exhibit high hardness, high oxidation resistance, chemical inertness and stable microstructure.

Owner:COUNCIL OF SCI & IND RES

Transparent conductive film for flat panel displays

ActiveUS20040086717A1High transmittanceLow electric resistanceSolid-state devicesVacuum evaporation coatingTransmittanceIndium

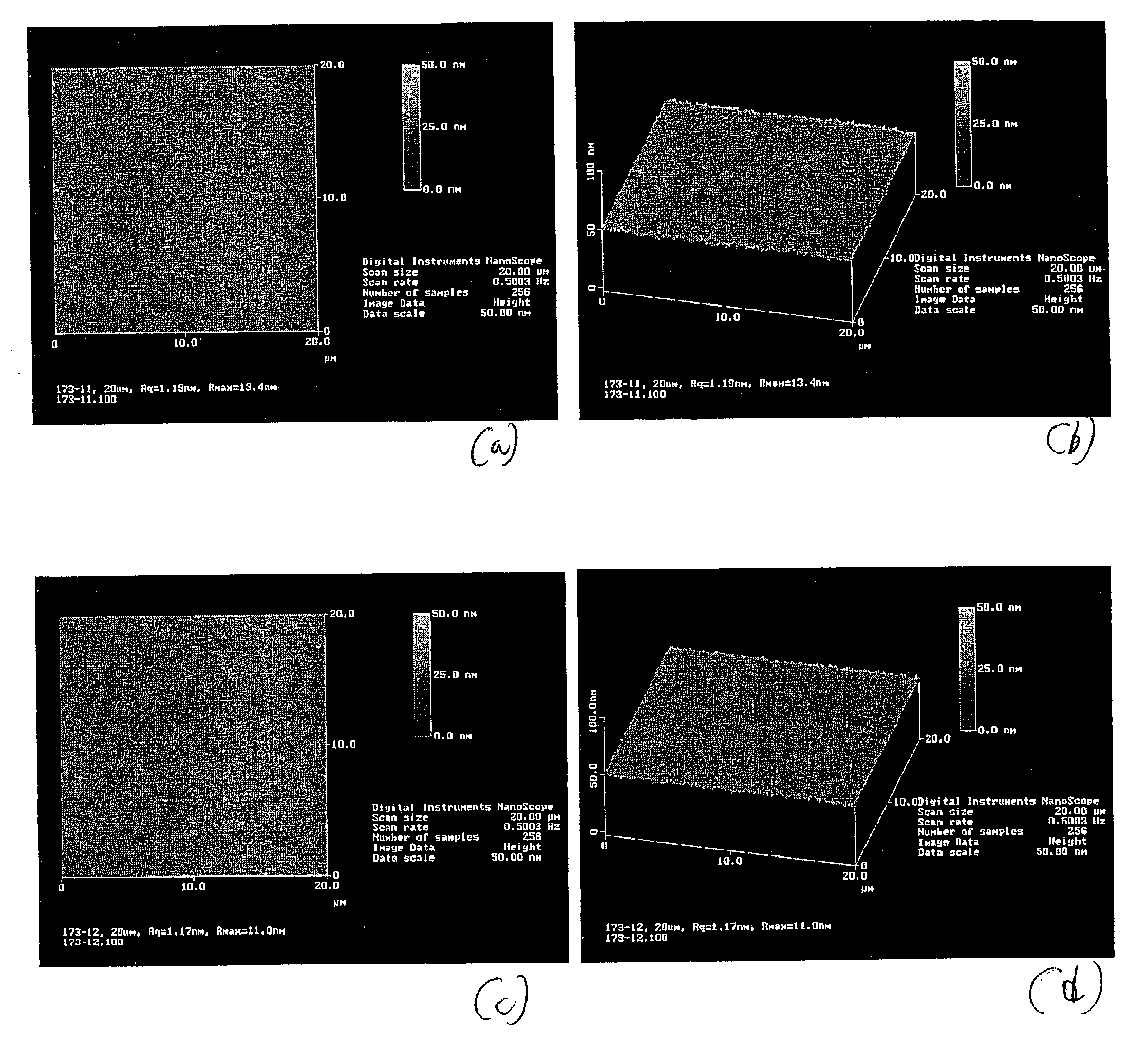

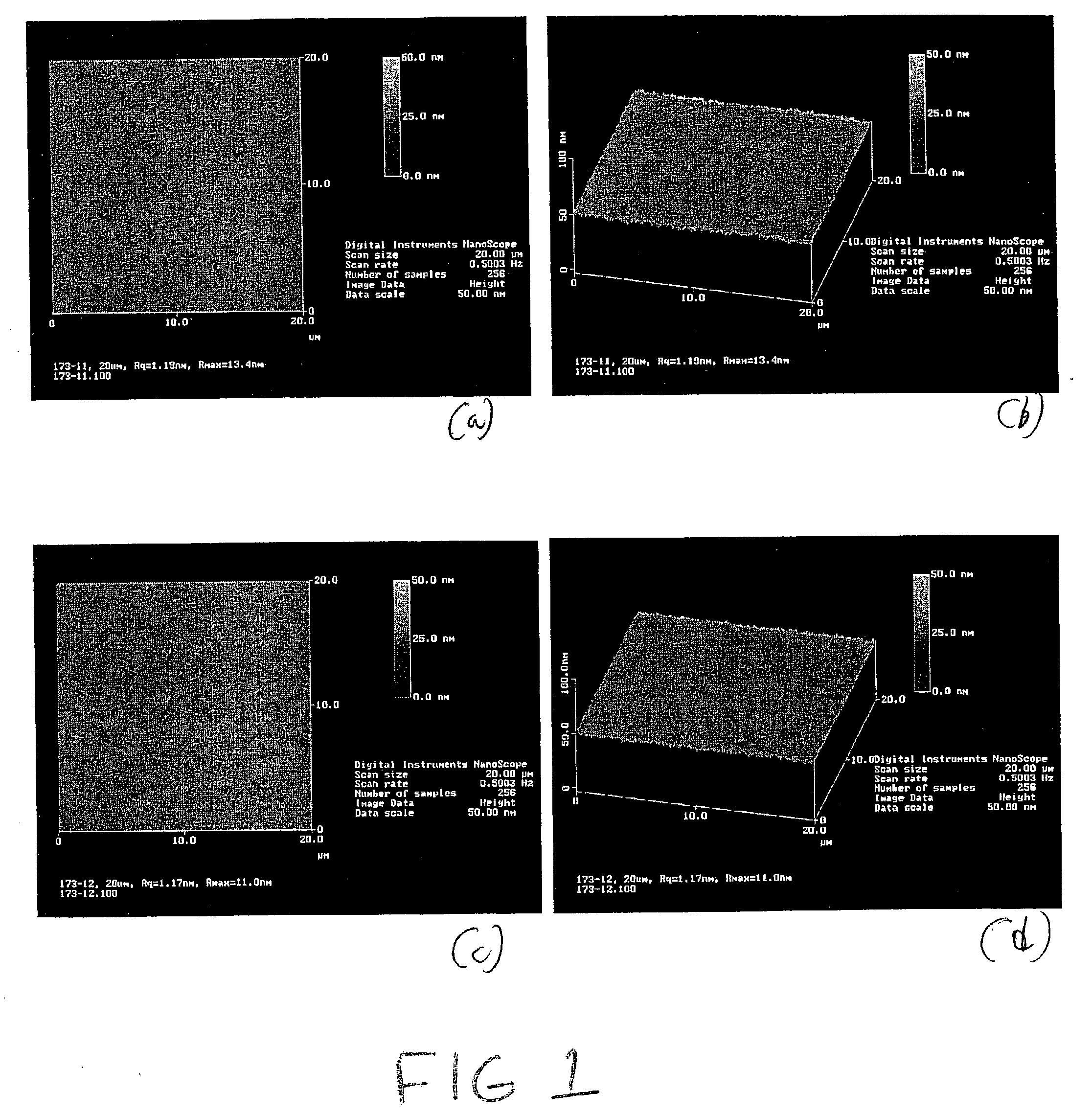

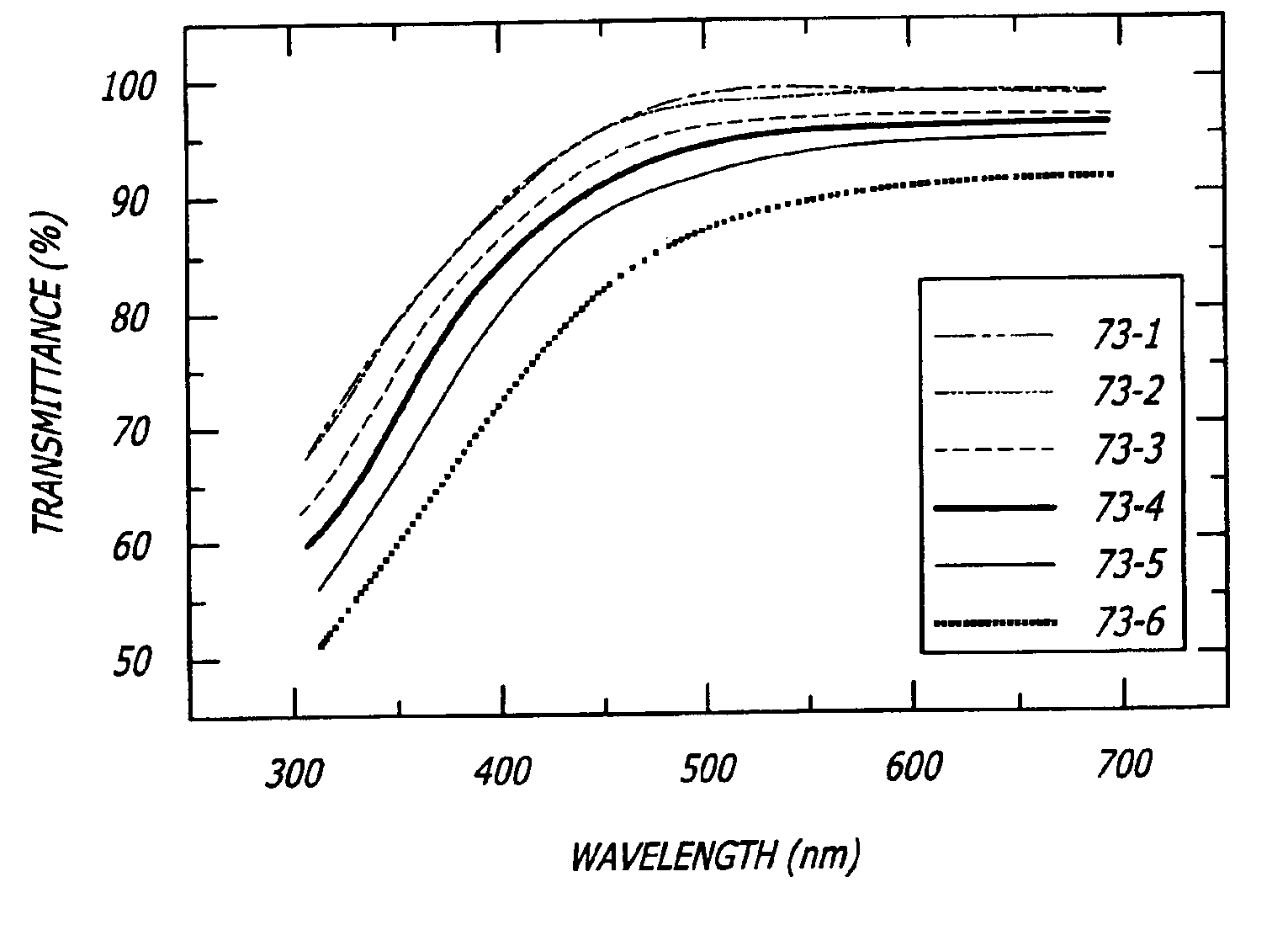

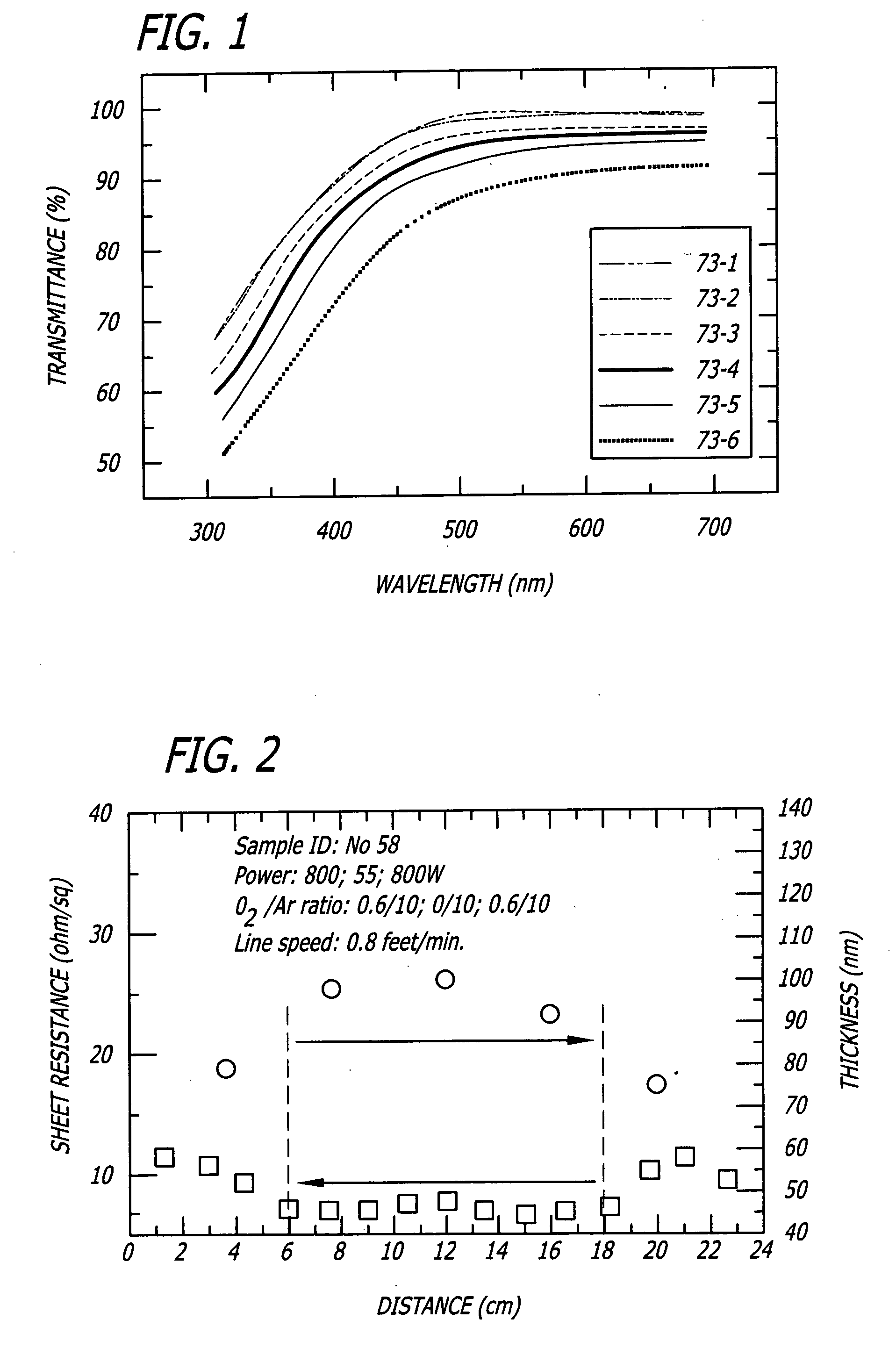

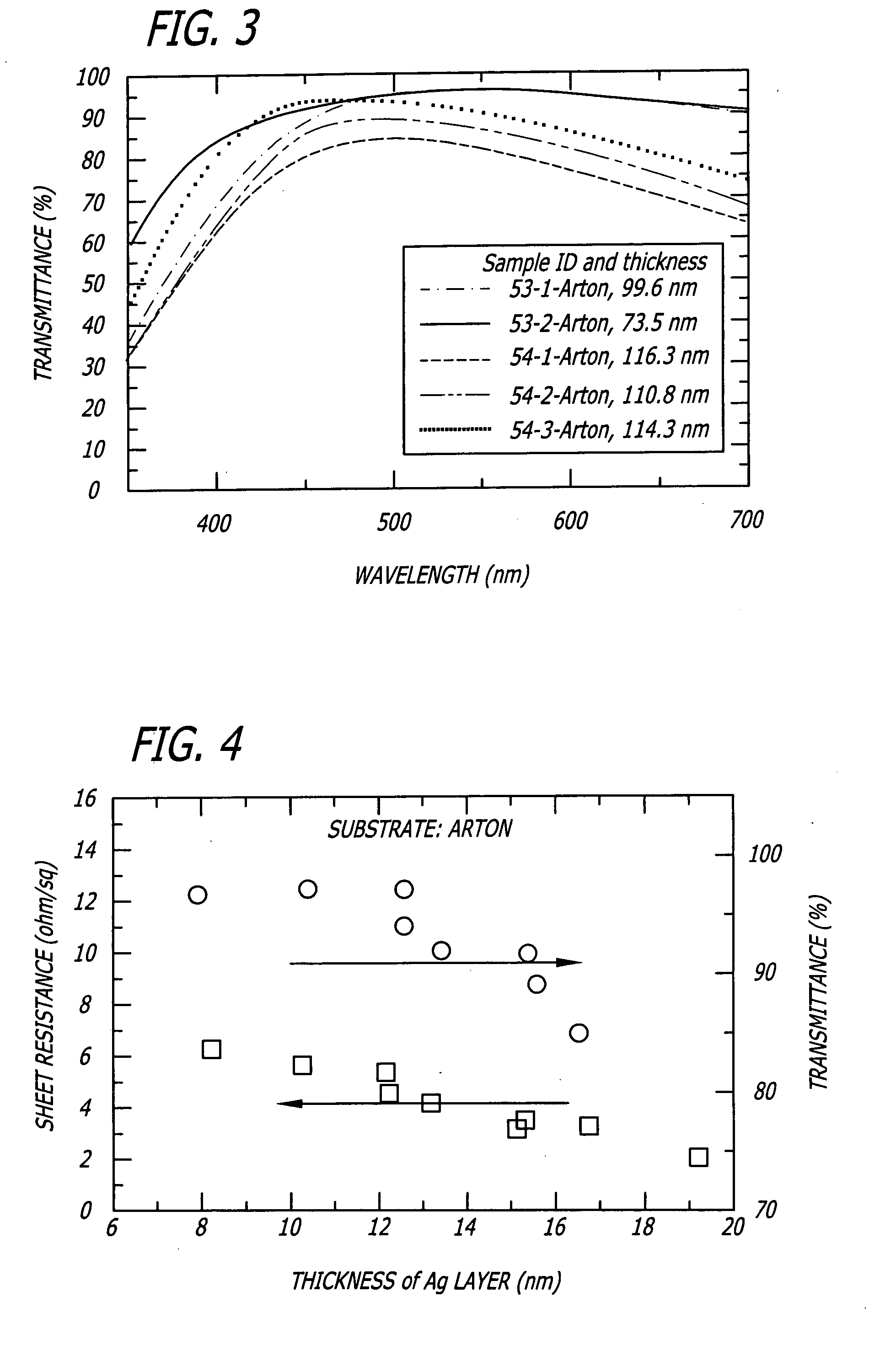

Transparent conductive films for flat panel displays and methods for producing them are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film, the multi-layered conductive metallic film comprising two layers of an alloy selected from the group consisting of indium cerium oxide (InCeO) and indium tin oxide (ITO) surrounding a layer of an alloy of silver, palladium, and copper (Ag / Pd / Cu); and (3) collecting the composite film in continuous rolls. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising a multilayered film as described above formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 80% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the multi-layered metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:XYLON LLC

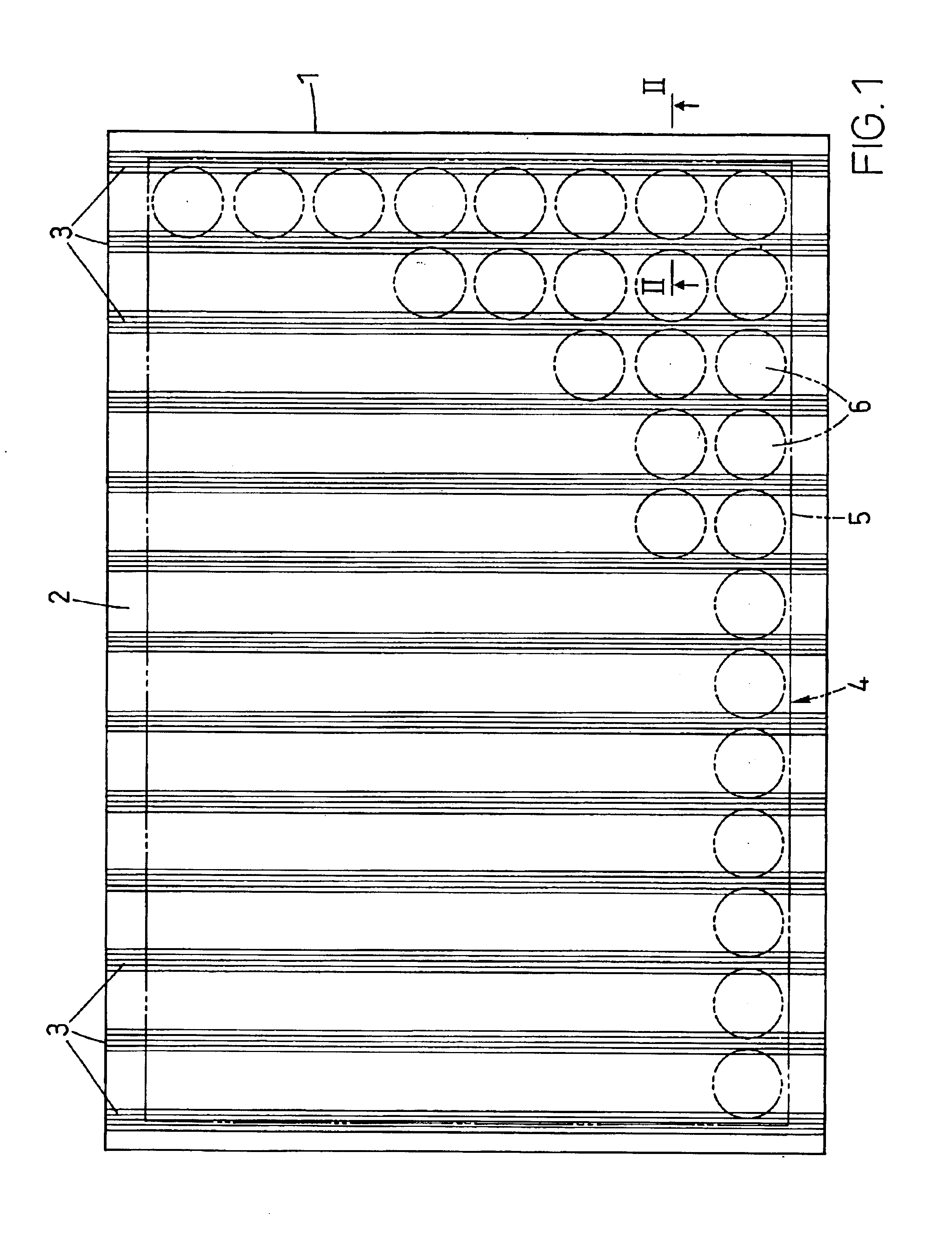

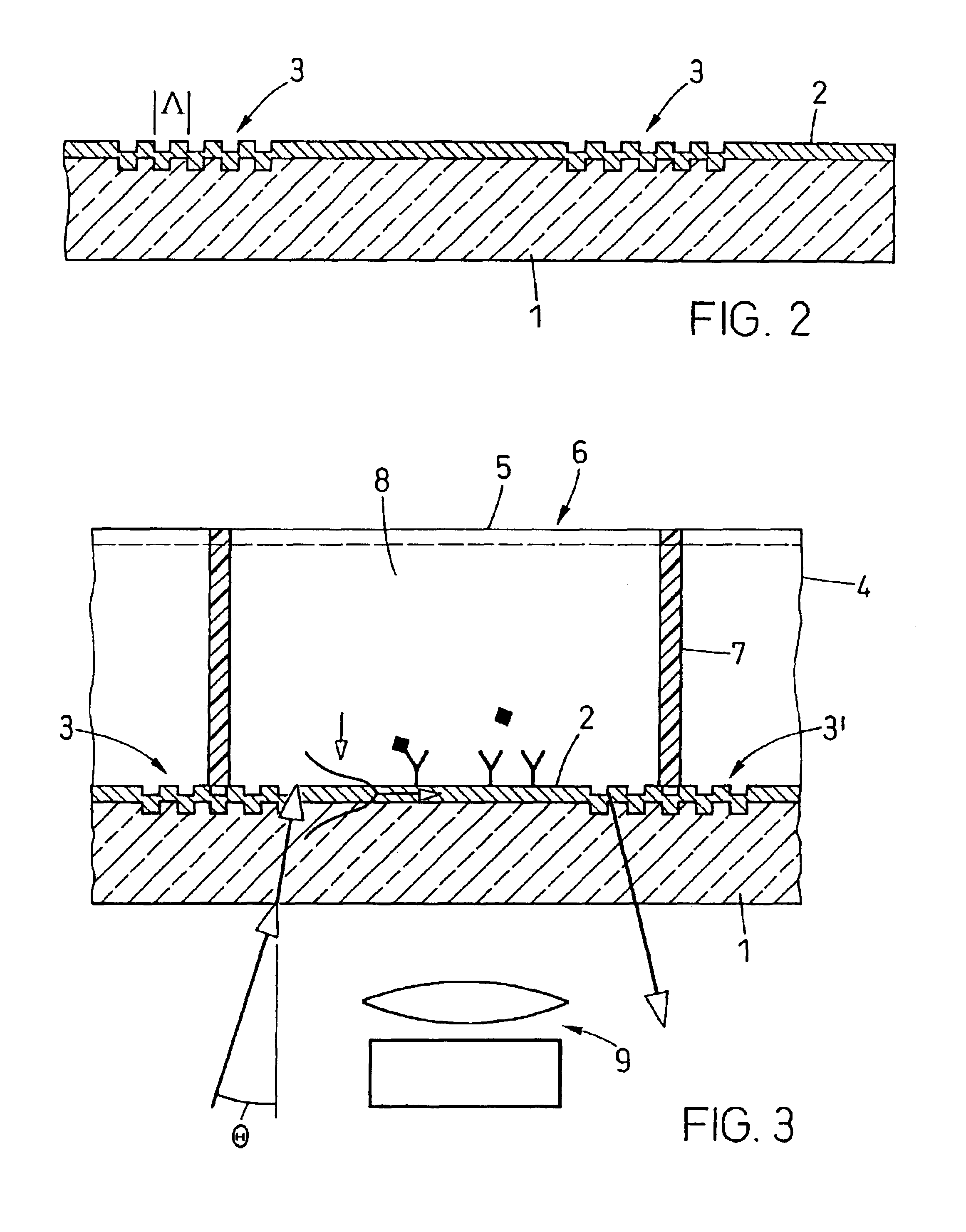

Method for producing a grid structure, an optical element, an evanescence field sensor plate, microtitre plate and an optical communication engineering coupler as well as a device for monitoring a wavelength

InactiveUS6873764B2Improve accuracyLow effortCladded optical fibreMaterial analysis by observing effect on chemical indicatorGratingPulsed DC

Owner:OERLIKON TRADING AG TRUEBBACH

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

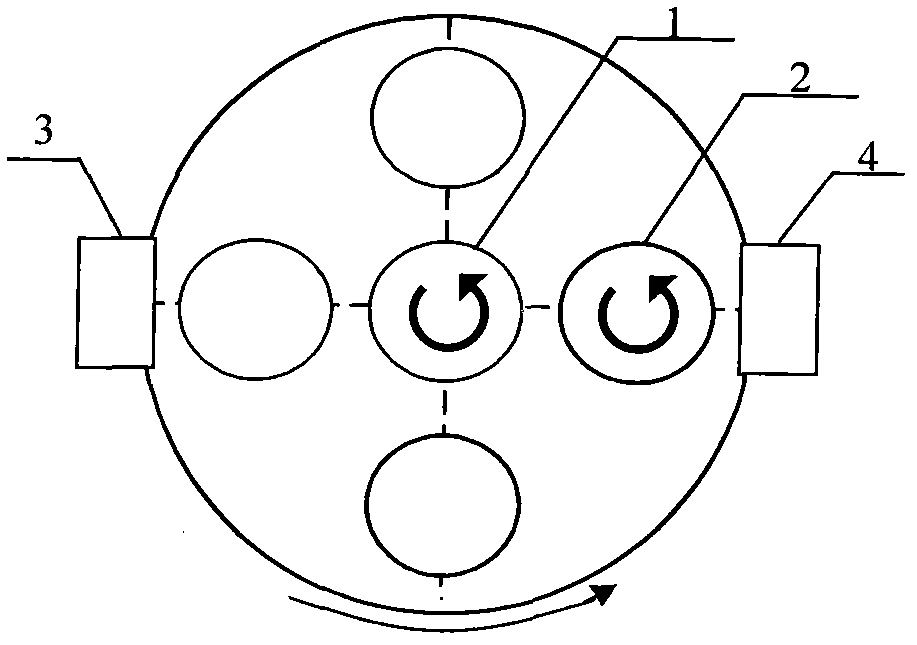

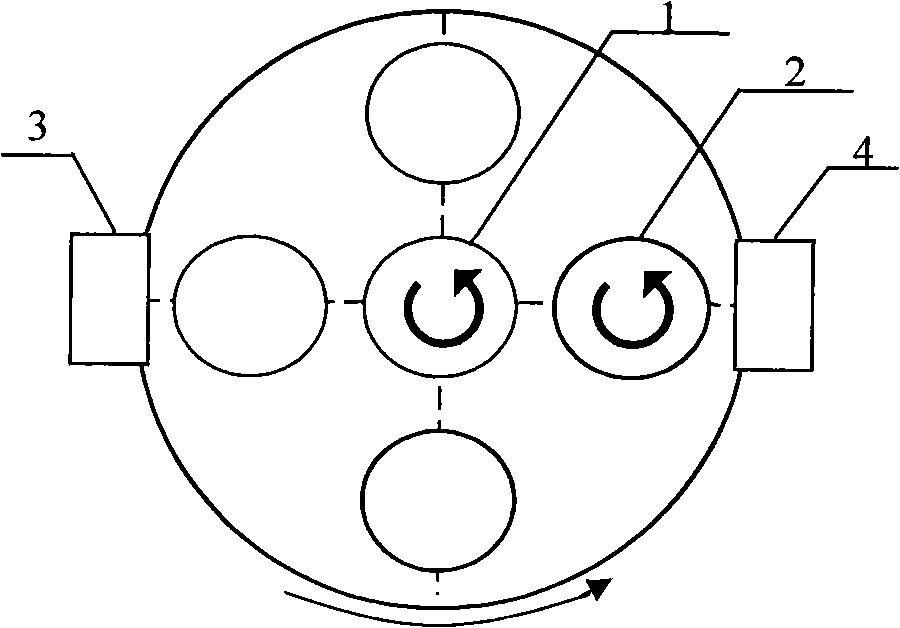

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

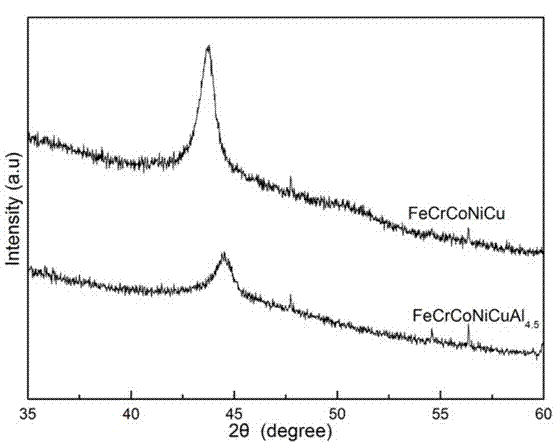

Multi-element high-entropy alloy film and preparation method thereof

ActiveCN103898463AUniform thicknessInhibition formationVacuum evaporation coatingSputtering coatingHigh entropy alloysEvaporation

Owner:ZHEJIANG UNIV

Method for roll-to-roll deposition of optically transparent and high conductivity metallic thin films

InactiveUS6811815B2Excellent propertyHigh light transmittanceLayered productsPrinted circuit aspectsComposite filmRms roughness

Methods for roll-to-roll deposition of optically transparent and high conductivity metallic thin films are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film; and (3) collecting the composite film in continuous rolls. Typically, the thin conductive metallic film is an InCeO-Ag-InCeO film. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising InCeO-Ag-InCeO film formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 90% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the InCeO / Ag / InCeO metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:STREAMING SALES

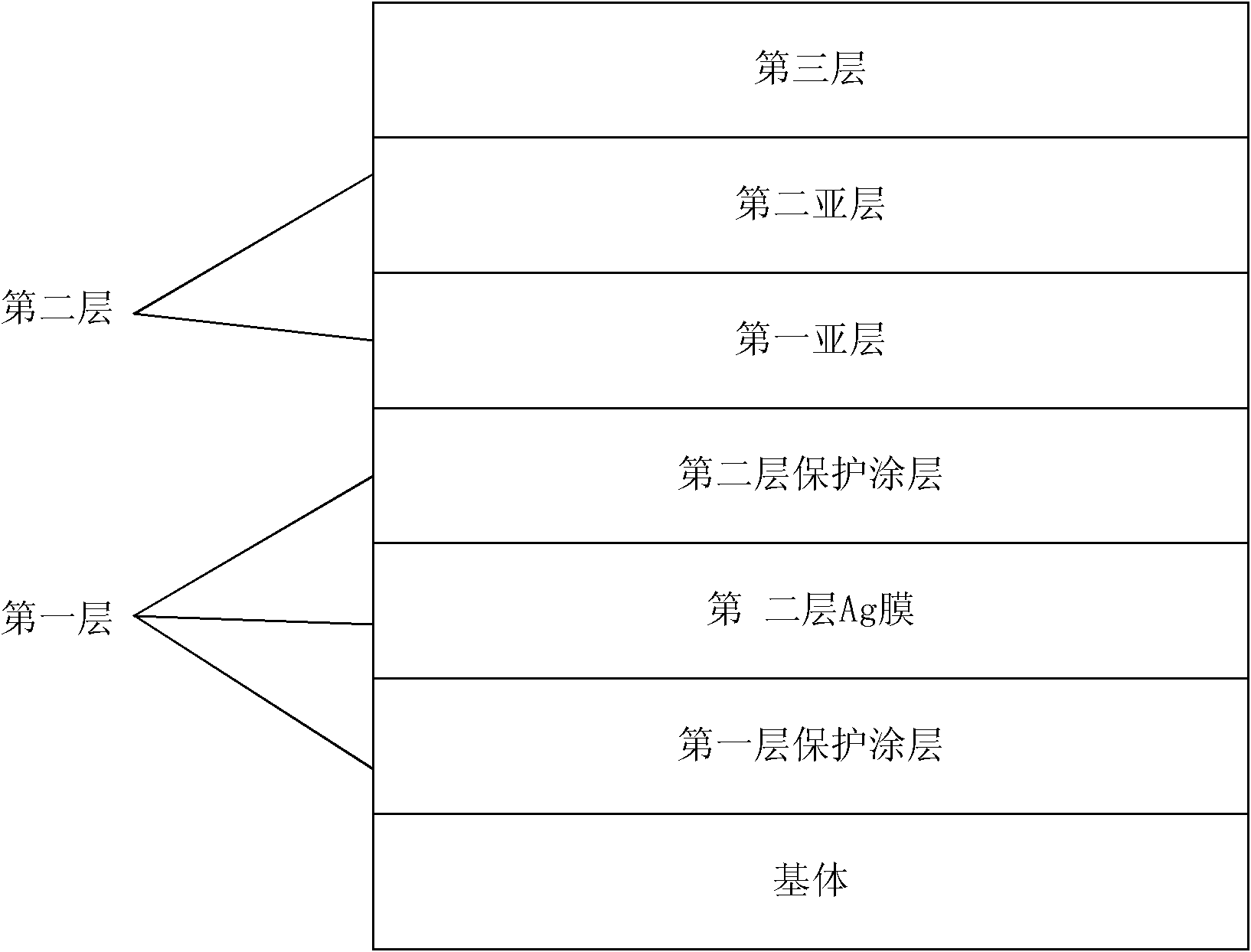

Cr series high-temperature solar selective absorbing coating and preparation method thereof

ActiveCN102102918ALow absorption rateSimple preparation processSolar heat devicesVacuum evaporation coatingMiddle infraredTectorial membrane

The invention discloses a Cr series high-temperature solar selective absorbing coating and a preparation method thereof. The coating consists of an infrared reflection layer, an absorption layer and an antireflection layer in turn from the bottom to the surface, wherein the first infrared reflection layer consists of three membranes; the middle infrared reflection layer is a Ag membrane of which the upside and downside are plated with a protective film that is any one of a chromic oxide (Cr2O3) film and an aluminum oxide (Al2O3) film respectively; the second absorption layer has two sub-layer structures both of the which are AlCrN+AlCr films, the volume percentage of the first sub-layer AlCr is greater than that of the second sub-layer AlCr; and the third antireflection layer is any one of Cr2O3 film and Al2O3 film. The preparation method comprises the steps of: preparing the infrared emission layer on the substrate surface by adopting a pure metal target magnetron sputtering process; preparing the second absorption layer on the first layer by adopting a Cr target and Al target middle-frequency magnetron sputtering process; and preparing the third antireflection layer on the second layer by adopting a metal target middle-frequency magnetron sputtering process.

Owner:北京天瑞星光热技术有限公司

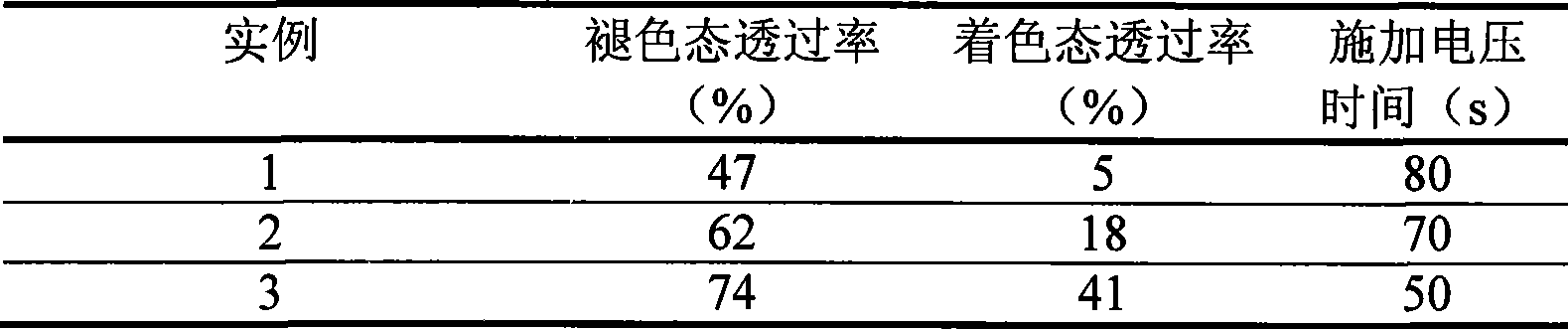

Method for producing full-solid electrochromic device

InactiveCN101510038ALarge adjustment range of visible light transmittanceQuick responseNon-linear opticsAll solid stateTransmittance

Owner:ZHEJIANG UNIV

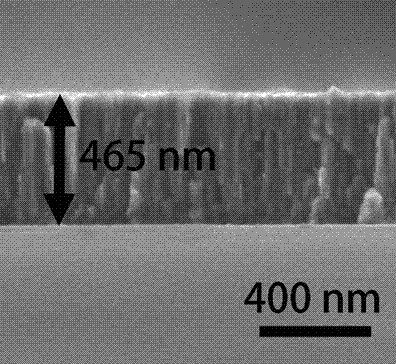

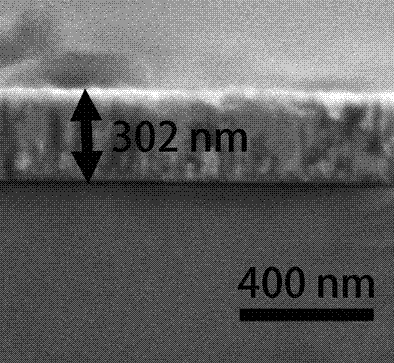

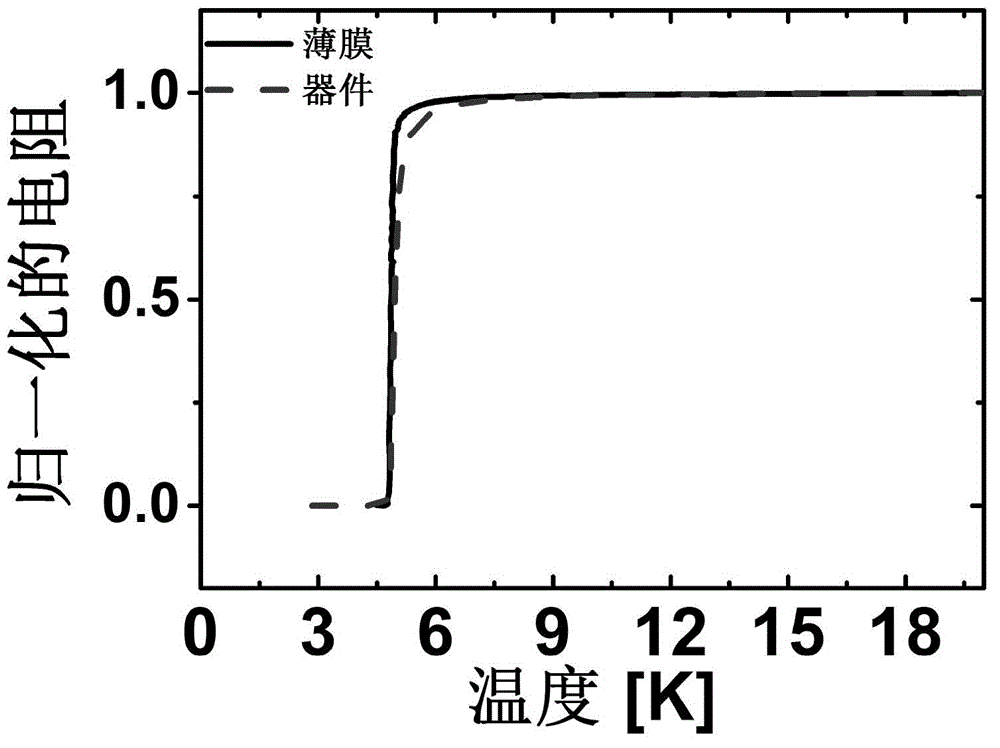

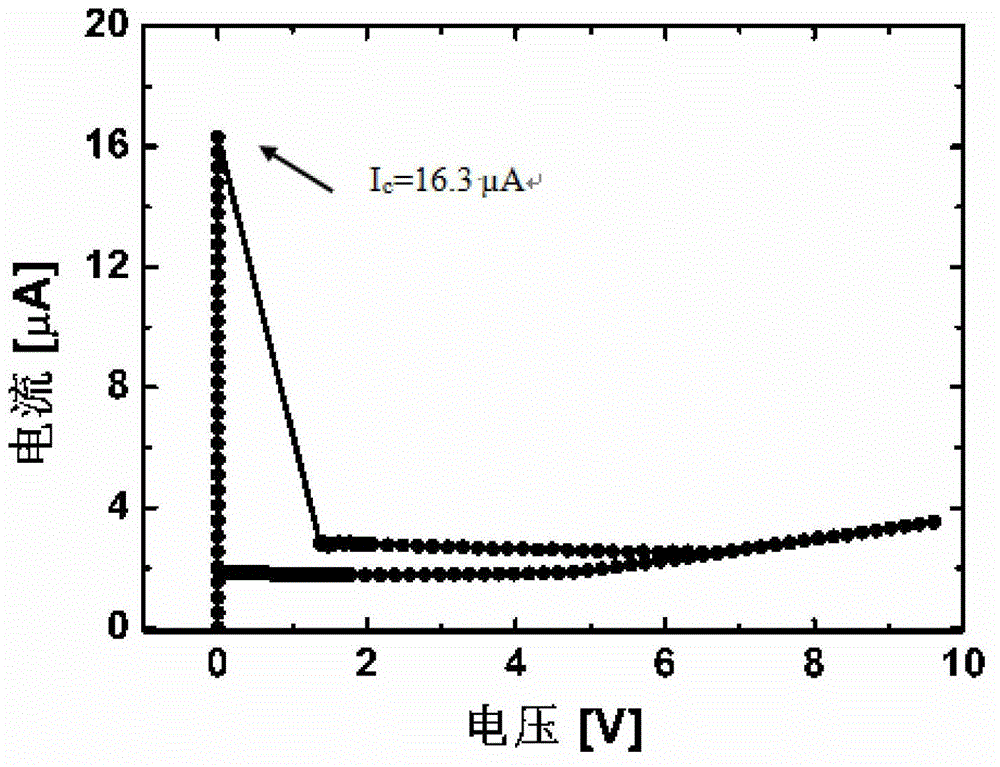

Manufacturing method for nanowire single-photon detector based on specially doped superconducting niobium film material

ActiveCN102916083AProtected superconducting propertiesIncrease the critical current densityVacuum evaporation coatingSputtering coatingNanowireNiobium

The invention discloses a manufacturing method for a nanowire single-photon detector based on a specially doped superconducting niobium film material. The manufacturing method comprises the following steps: carrying out ultrasonic cleaning and blow-drying on a substrate; carrying out Ar ion cleaning; growing a specially doped superconducting Nb film in a direct current magnetron sputtering way; carrying out spin-coating on an electron beam resist, carrying out electron beam lithography on the electron beam resist, and drawing a wire pattern with the width not more than 100nm on the electron beam resist; etching in a reaction ion etching way, and transferring the line pattern onto the Nb film to form a Nb nanowire; cleaning the residual electron beam resist, carrying out spin-coating on a photoresist on the surface of a sample, and forming an electrode pattern on the photoresist in a deep ultraviolet exposure way; and growing an electrode. According to the manufacturing method, the difficult problems of low superconducting transition temperature, low critical current density and short photoresponse wavelength of an SNSPD (Superconducting Nanowire Single Photon Detector) manufactured by the conventional Nb material are solved.

Owner:NANJING UNIV

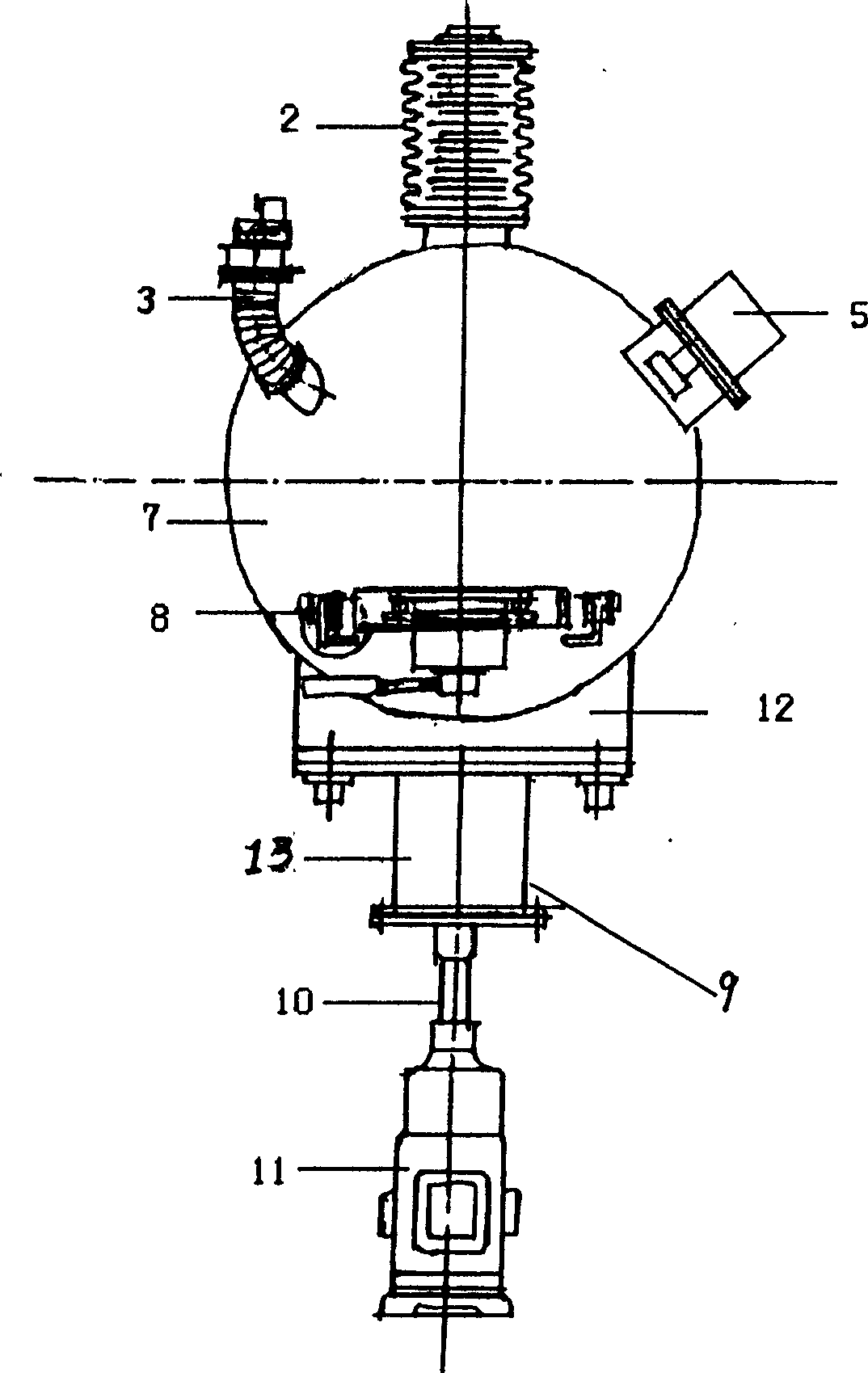

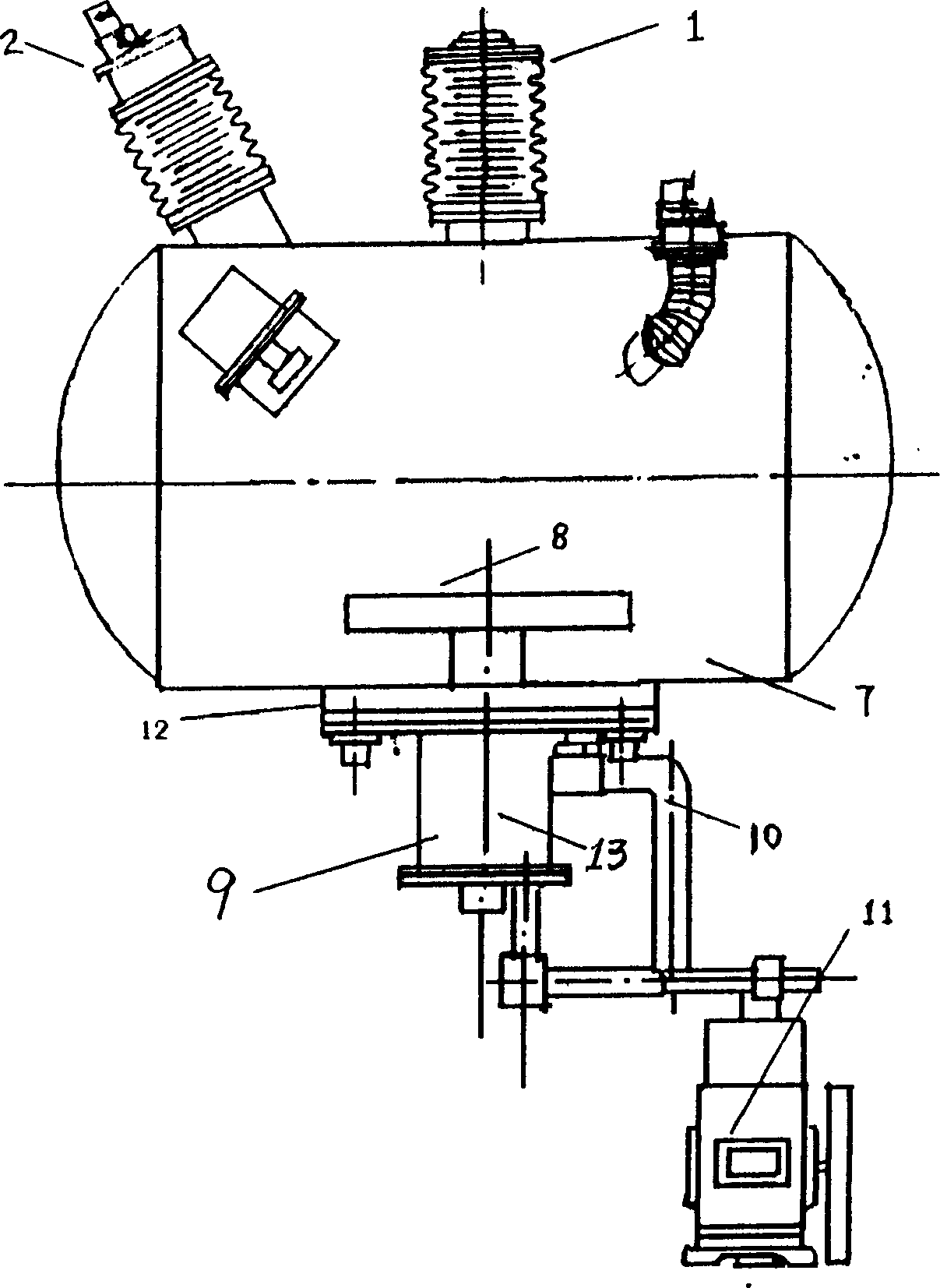

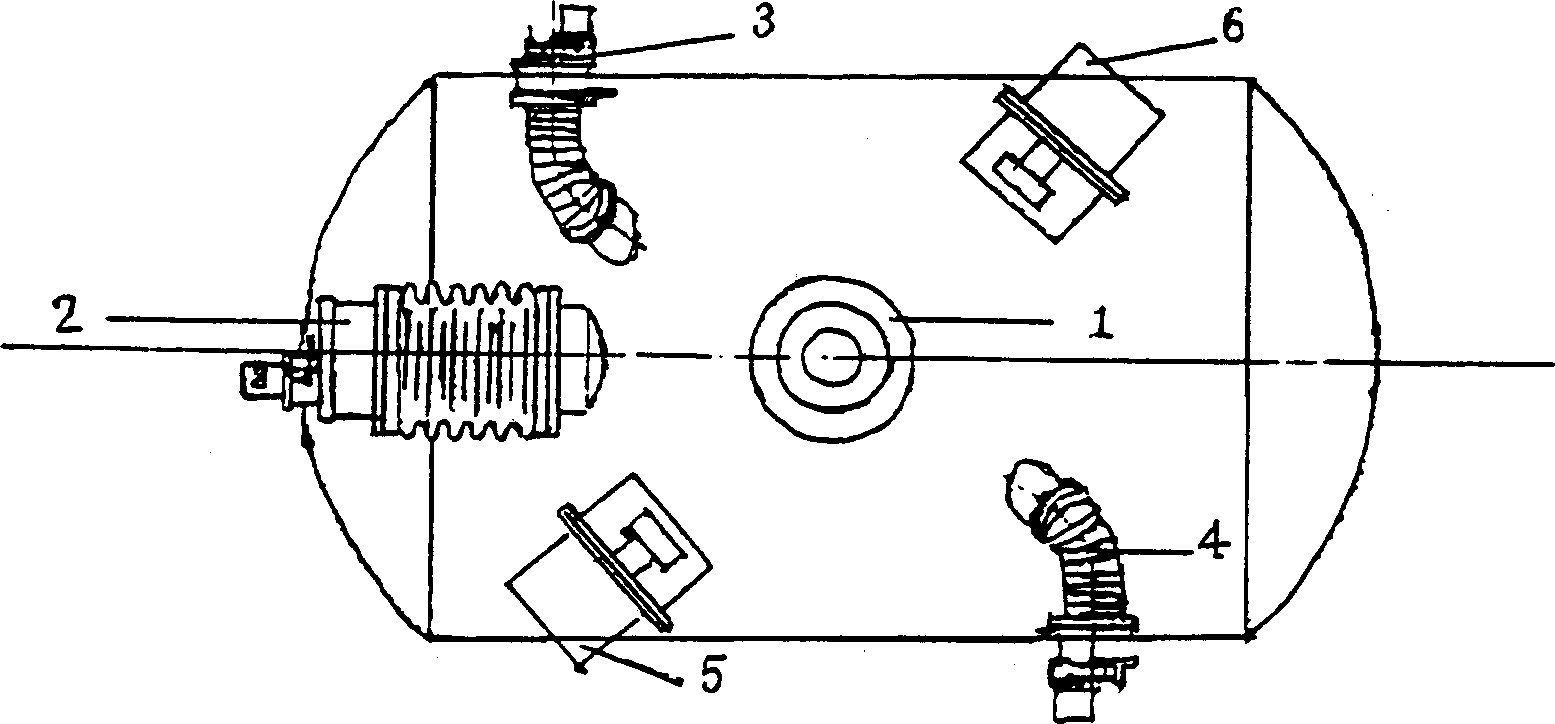

Ion implanted composite coating film apparatus

InactiveCN1472360AVersatilityReduce manufacturing costVacuum evaporation coatingSputtering coatingVacuum pumpingIntermediate frequency

A composite ion implantation plating equipment is composed of 6 ion source (gas ion source, metal ion source, DC magnetically controlled sputter target source, MF-pulse magnetically controlled sputter target source and two DC magnetic filter arc ion source), a vacuum chamber containing a multi-purpose bench, and a vacuumizing system for said vacuum chamber.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for roll-to-roll deposition of optically transparent and high conductivity metallic thin films

InactiveUS20040001915A1High light transmittanceLower resistancePrinted circuit aspectsSynthetic resin layered productsSputteringComposite film

Methods for roll-to-roll deposition of optically transparent and high conductivity metallic thin films are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film; and (3) collecting the composite film in continuous rolls. Typically, the thin conductive metallic film is an InCeO-Ag-InCeO film. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising InCeO-Ag-InCeO film formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 90% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the InCeO / Ag / InCeO metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:STREAMING SALES

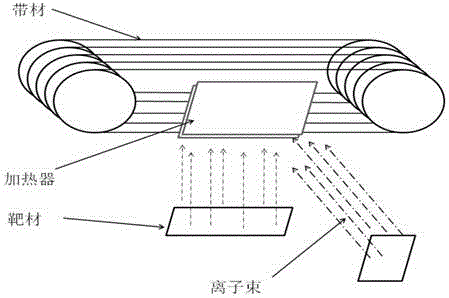

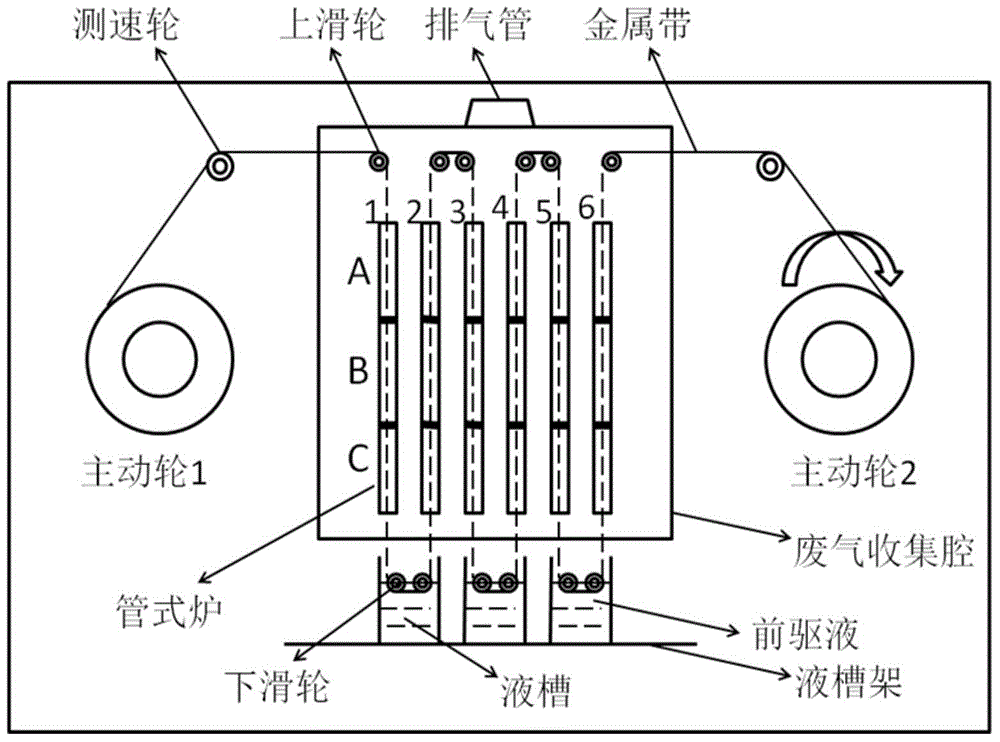

Low-cost preparing method for high-temperature superconductive coated conductor strip

ActiveCN103985479AReduce thicknessImprove manufacturing speedSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorRadio frequency magnetron sputtering

The invention provides a low-cost preparing method for a high-temperature superconductive coated conductor strip and belongs to the technical field of manufacturing of high-temperature superconductive materials. The low-cost preparing method comprises the following steps that (1) the surface of a metal base band is cleaned; (2) by the adoption of the chemical solution deposition planarization (SDP) method, an isolating layer is prepared on the metal base band; (3) by the adoption of an ion beam auxiliary radio frequency magnetron sputtering method (IBAD-MgO), a biaxial texture magnesium oxide layer is prepared on the isolating layer; (4) a lanthanum manganate layer is prepared by the adoption of the radio frequency magnetron sputtering method; (5) a cerium oxide layer is prepared by the adoption of a direct-current magnetron reactive sputtering method; (6) a superconductive layer is prepared by the adoption of a metal organic deposition decomposition method (MOD); (7) a silver protective layer is prepared by the adoption of a direct-current magnetron sputtering method; (8) annealing is conducted in high-purity oxide; (9) a copper stable layer is arranged in an electroplating mode according to use requirements. According to the low-cost preparing method for the high-temperature superconductive coated conductor strip, through comprehensive application of physical preparation methods and chemical preparation methods, high-temperature superconductive strips can be produced in a large-scale mode at low cost.

Owner:赵遵成

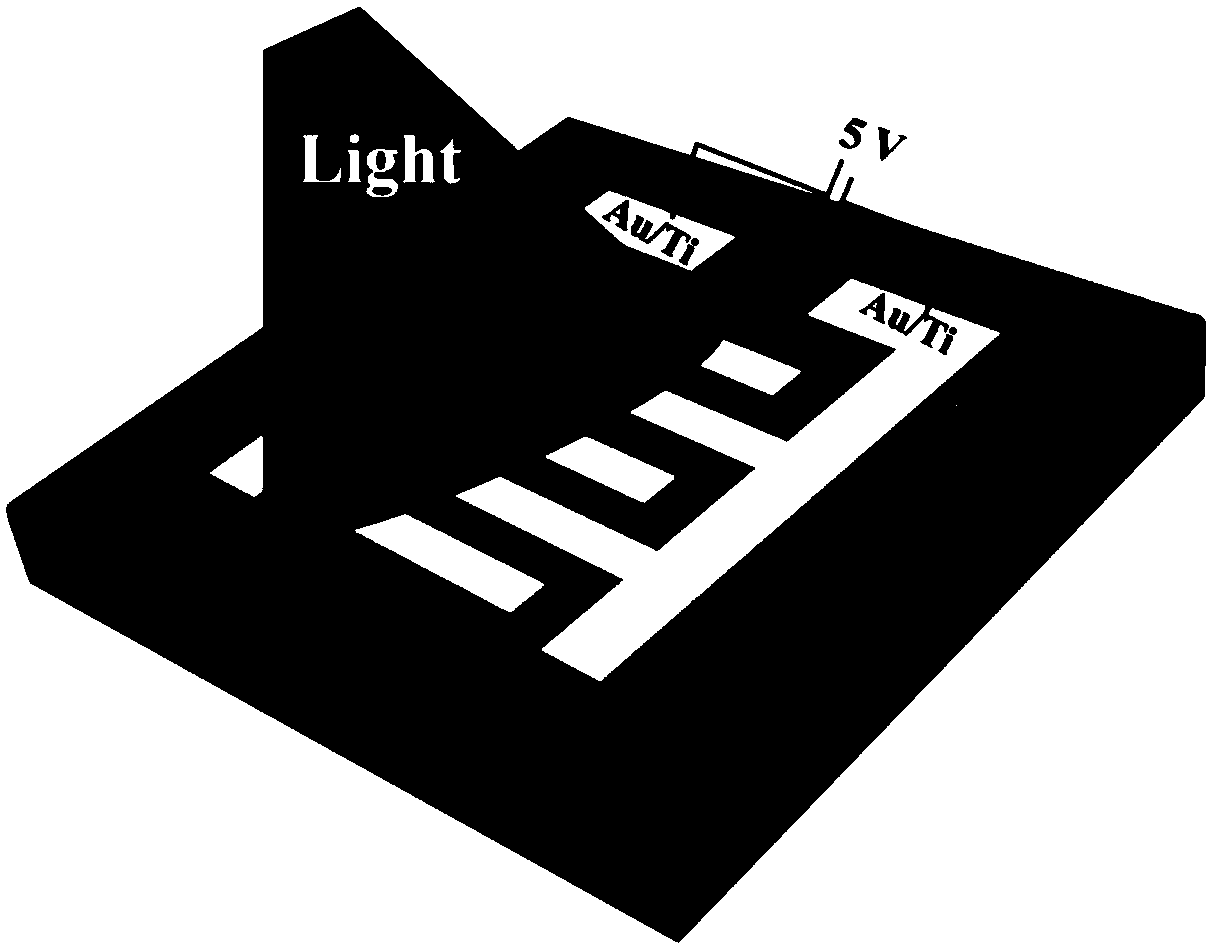

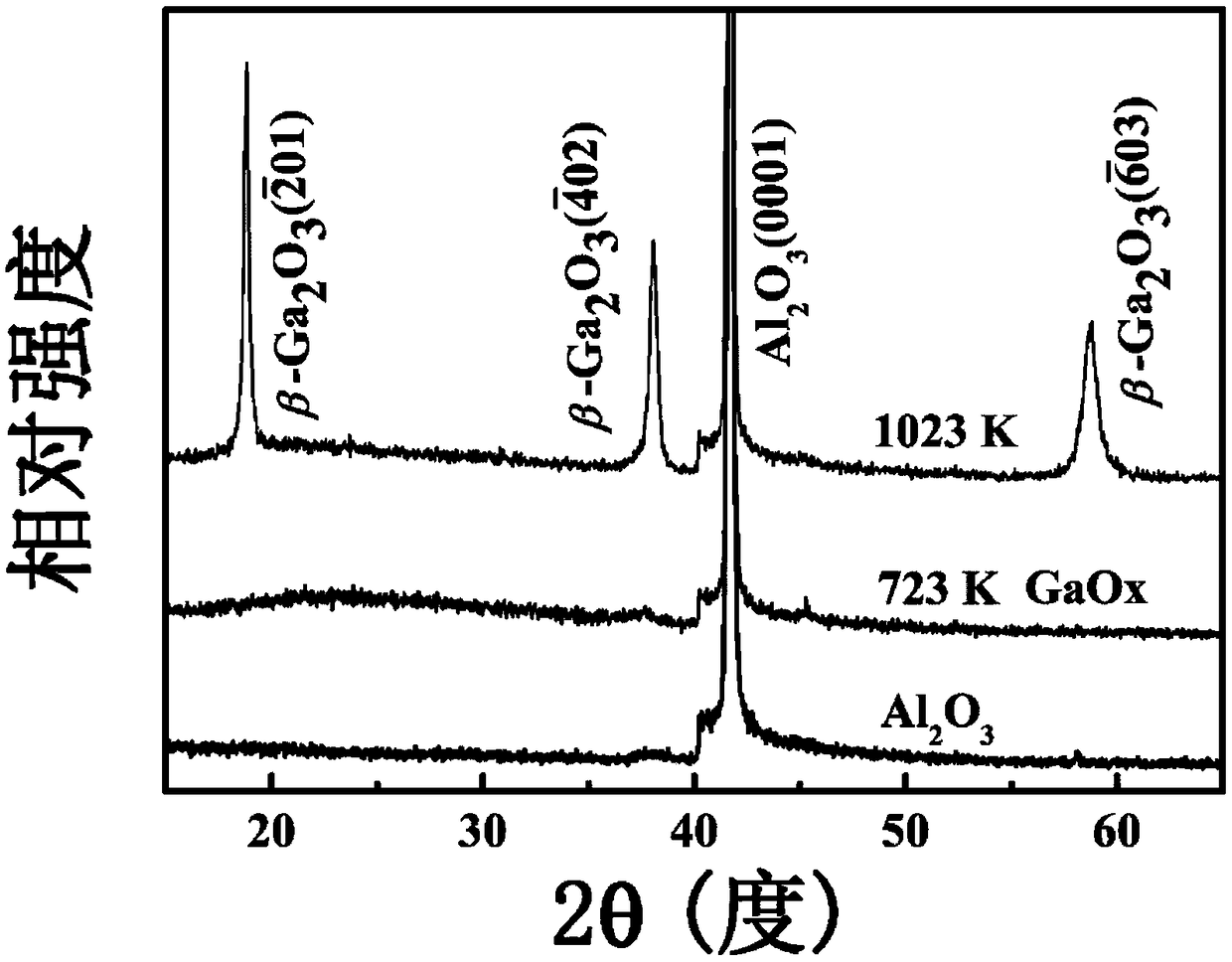

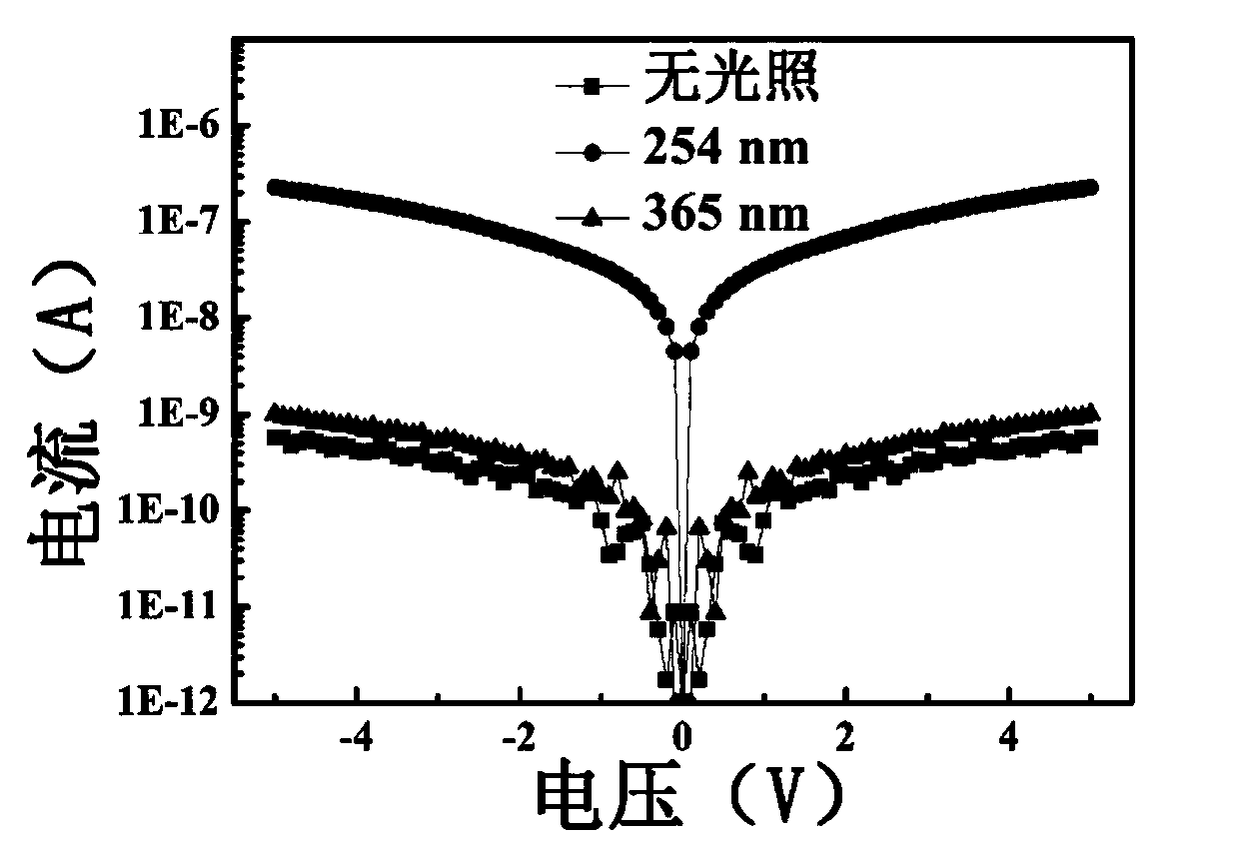

Solar blind ultraviolet photoelectric detector based on amorphous gallium oxide film and preparation method thereof

InactiveCN108666395AUniform textureLow growth temperatureFinal product manufactureVacuum evaporation coatingManufacturing technologyRadio frequency magnetron sputtering

The invention discloses a solar blind ultraviolet photoelectric detector based on an amorphous gallium oxide film and a preparation method thereof, and belongs to the technical field of photoelectricdetectors. The method comprises the steps that the crystal face (0001) Al2O3 is adopted as a substrate, and the substrate is cleaned; then, the cleaned substrate is fed into a settling chamber, a radio frequency magnetic control sputtering technology is applied to the substrate to grow a gallium oxide film; finally, a hollow interdigital mask plate is used for shielding on the amorphous gallium oxide film, a direct current magnetic control sputtering method is adopted for sputtering an interdigital metal electrode on the interdigital mask plate to obtain the solar blind ultraviolet photoelectric detector, the structure is an MSM type sandwiched structure, and the Al2O3 substrate, the amorphous gallium oxide film material and the Ti / Au interdigital metal electrode are arranged from bottom to top. The manufacturing technology is simple, the repeatability is good, dark current is small, the stability is high, the response speed is high, the ultraviolet visible restrain ratio is high, andthe detector conforms to the energy-saving and emission-reducing theory, is suitable for large-scale production, and has the wide development prospect.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Process for preparing modified non-crystal carbon film by metal iron implantation

InactiveCN1363715AImprove wear resistanceNo flaking was foundVacuum evaporation coatingSputtering coatingCarbon filmGas phase

A metal iron implantation process for preparing modified non-crystal carbon film features that the graphite and metal are used to prepare a modified and physical gas-phase deposited layer by CD magnetically controlled sputter and ion implantation. Its advantages are high antiwear and lubricating performance and simple preparing process.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of AlCrCuFeNi high-entropy alloy bearing coating

InactiveCN108411272AHigh purityImprove compactnessVacuum evaporation coatingSputtering coatingHigh entropy alloysMetallurgy

The invention discloses a preparation method of an AlCrCuFeNi high-entropy alloy bearing coating. The preparation method of the AlCrCuFeNi high-entropy alloy bearing coating comprises polishing a matrix, and then ultrasonic-cleaning the matrix through acetone and blow-drying the cleaned matrix; placing the matrix inside the vacuum cavity of a magnetically controlled spluttering machine, vacuumizing the vacuum cavity, programming parameters including target current, matrix bias and argon flow, and depositing film coating through a direct current magnetically controlled spluttering process. Thepreparation method of the AlCrCuFeNi high-entropy alloy bearing coating improves the bearing capacity and the wearing resistance of bearings through coating materials and manners, thereby prolonging the service life of the bearings.

Owner:SHANGHAI DIANJI UNIV

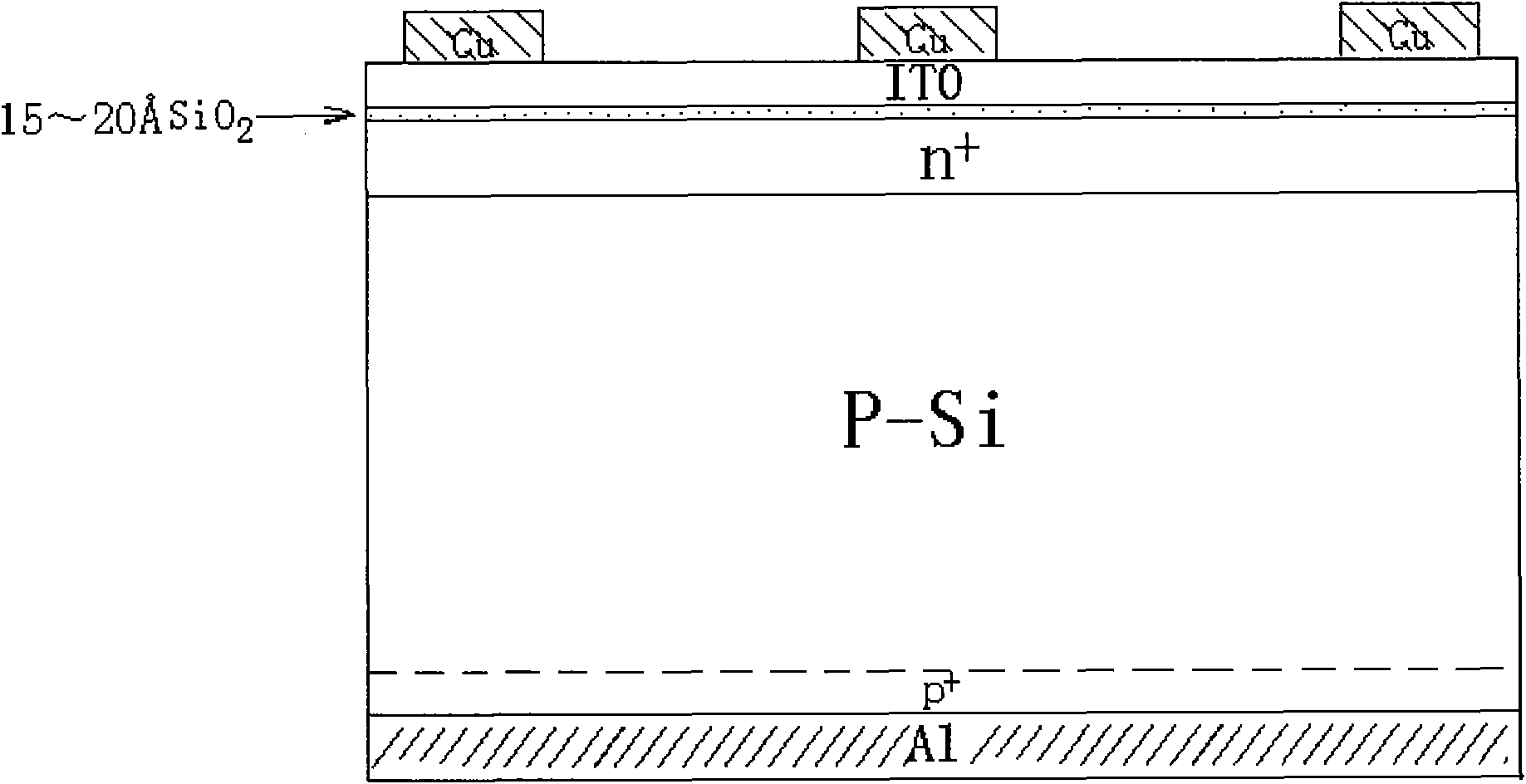

Novel SINP silicone blue-violet battery and preparation method thereof

InactiveCN101587913AImprove quantum efficiencyReduce the impactFinal product manufacturePhotovoltaic energy generationRadio frequency magnetron sputteringSingle crystal

he invention relates to a novel SINP silicone blue-violet battery and a preparation method thereof. The invention uses shallow junctions formed from thermally diffused phosphorus, an ultra-thin SiO2 layer formed by low-temperature thermal oxidization and an ITO dereflection / collection electrode film formed by RF magnetron sputtering to prepares a novel ITO / SiO2 / np blue-violet reinforced SINP silicone photo-battery. Preparation method of the invention is to take a silicon single crystal flake which is P type, and has crystallographic orientation of 100, electric resistivity of 2 2omega.cm and thickness of 220mu m, as a substrate. The substrate is cleaned and is etched by routine chemistry, and then is thermally diffused by POC3 liquid source to form n regions (the invention prepares two pieces of novel SINP photo-batteries, one being routine SINP photo-battery having emitting region square resistance of 10 Omega / square and junction depth of 1 Mu m, and the other one being SINP silicone blue-violet battery having emitting region square resistance of 37 Omega / square and junction depth of 0.4 Mu m). Removing the phosphorosilicate glass (HF:H2O=1:10) at front face; steaming Al at back of the silicon chip; thermally oxidizing the silicon chip at 400 to 500 DEG C and condition of V2:O2=4:1 for 15 to 30min to generate a layer of 15 to 20 ultra-thin SiO2 layer, and at the same time alloying the Al at the back. Then RF magnetron sputtering the ITO dereflection / collection electrode film (ITO film is also deposited on the glass to study electrooptical characteristic thereof) having high transmittance and high conductivity, and sputtering a Cu gate electrode by metal mask direct-current magnetron. Finally, cutting the outer edge part of the battery by a diamond excircle downward cutting / a dicing saw so as to prevent short circuit of the edge of the photo-battery.

Owner:SHANGHAI UNIV

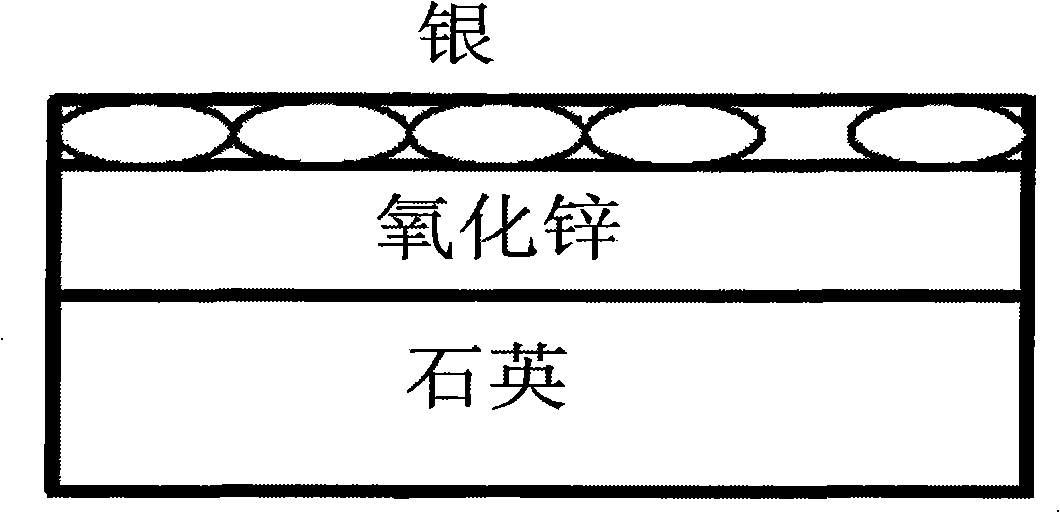

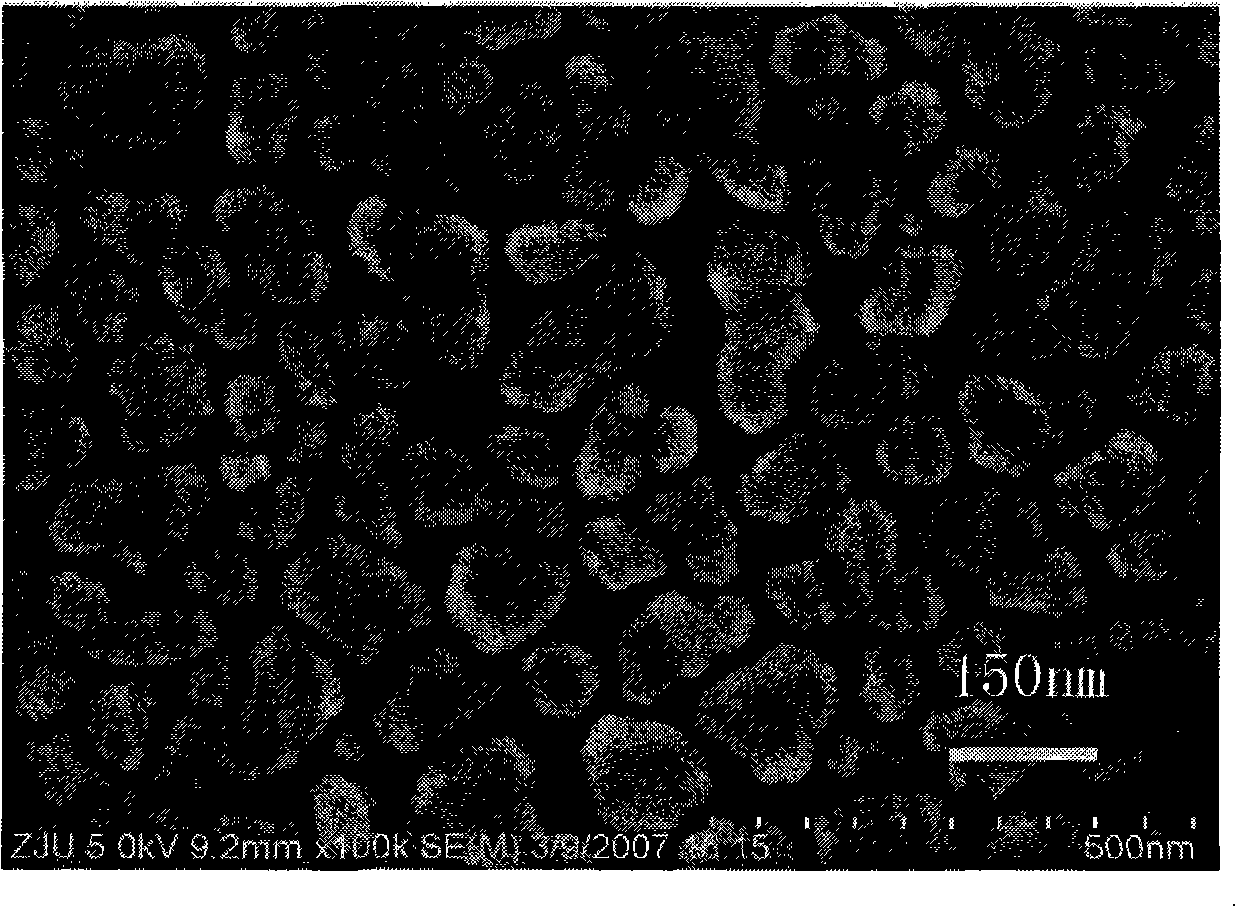

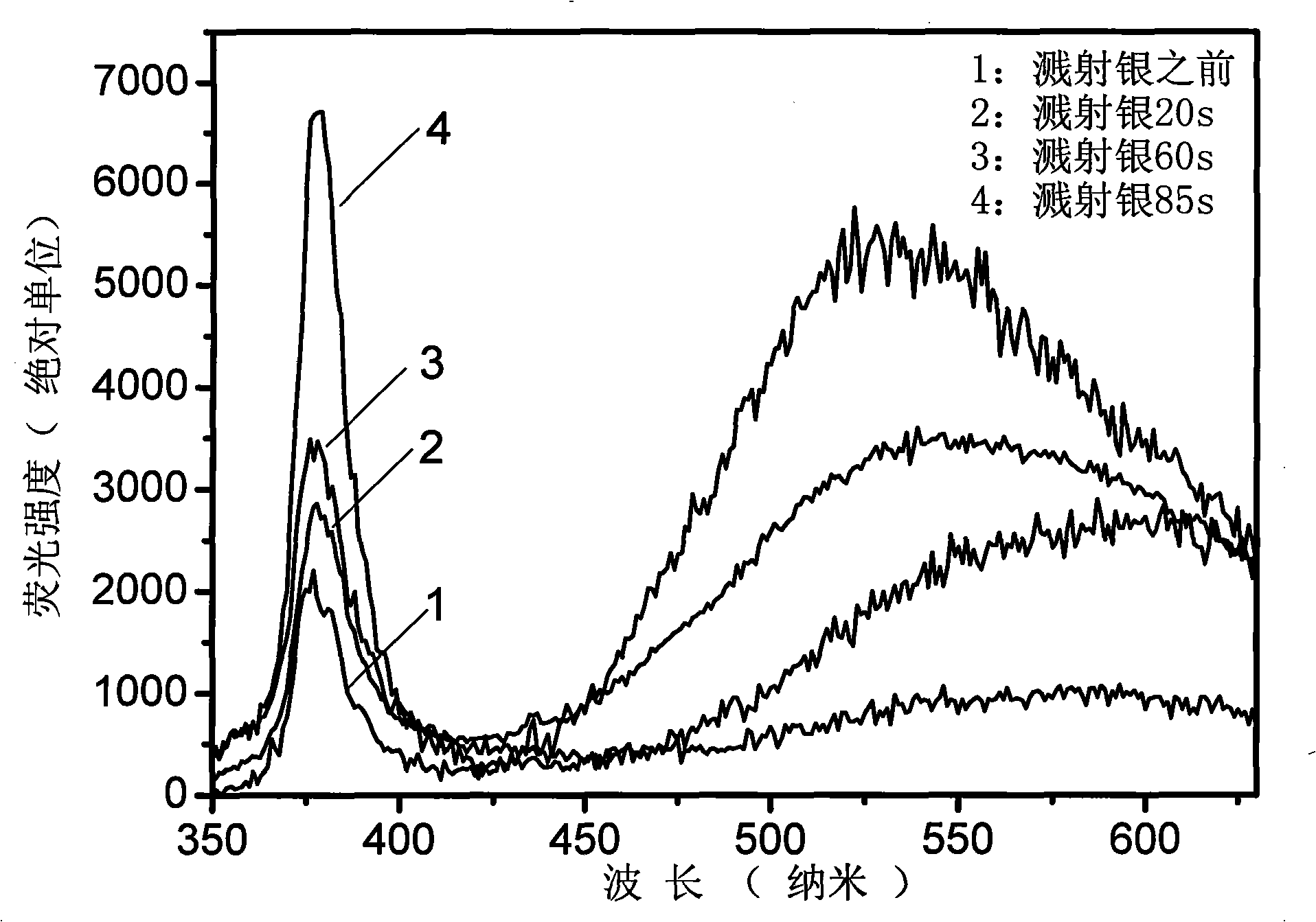

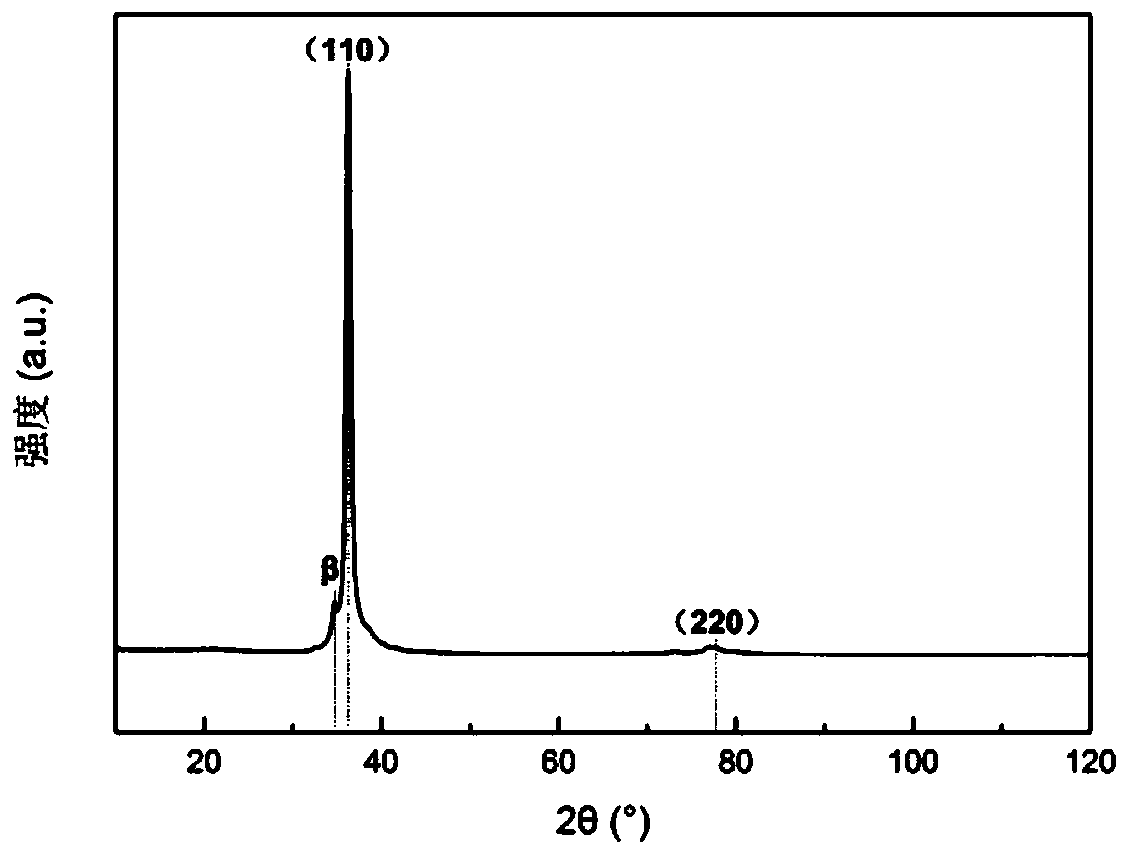

Method for reinforcing zinc oxide thin membrane luminescence

InactiveCN101270468AImprove luminous efficiencyHigh luminous intensityVacuum evaporation coatingSputtering coatingSputteringLuminescence

The invention discloses a method for enhancing a zinc oxide film to shine which adopts magnetron sputtering to grow silver nanoparticles on the zinc oxide film. The preparation of the invention relates to: putting a quartz floor with a grown zinc oxide film into the reaction chamber of a DC reaction magnetron sputtering device; depositing the silver nanoparticles on the zinc oxide film by DC magnetron sputtering. The invention can be adopted to enhance the shining efficiency of the zinc oxide film. The method is simple, the structure of the whole shining system is easy; the shining enhancing can be controlled by the sputtering time; besides, interband shining enhancing and defect shining quenching can be realized simultaneously; the method can be used for enhancing the shining intensity of the shining materials like zinc oxide, etc.

Owner:ZHEJIANG UNIV

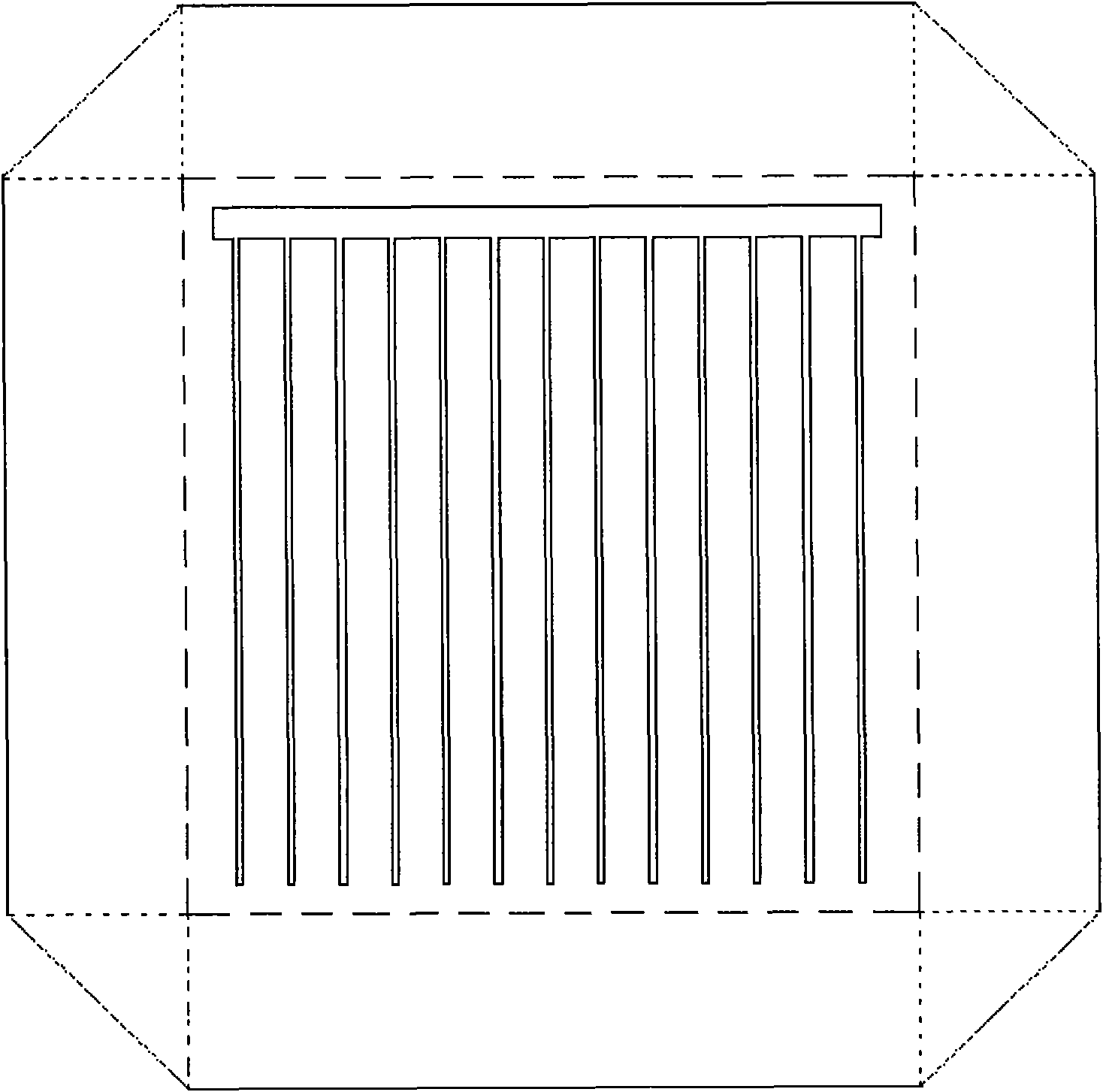

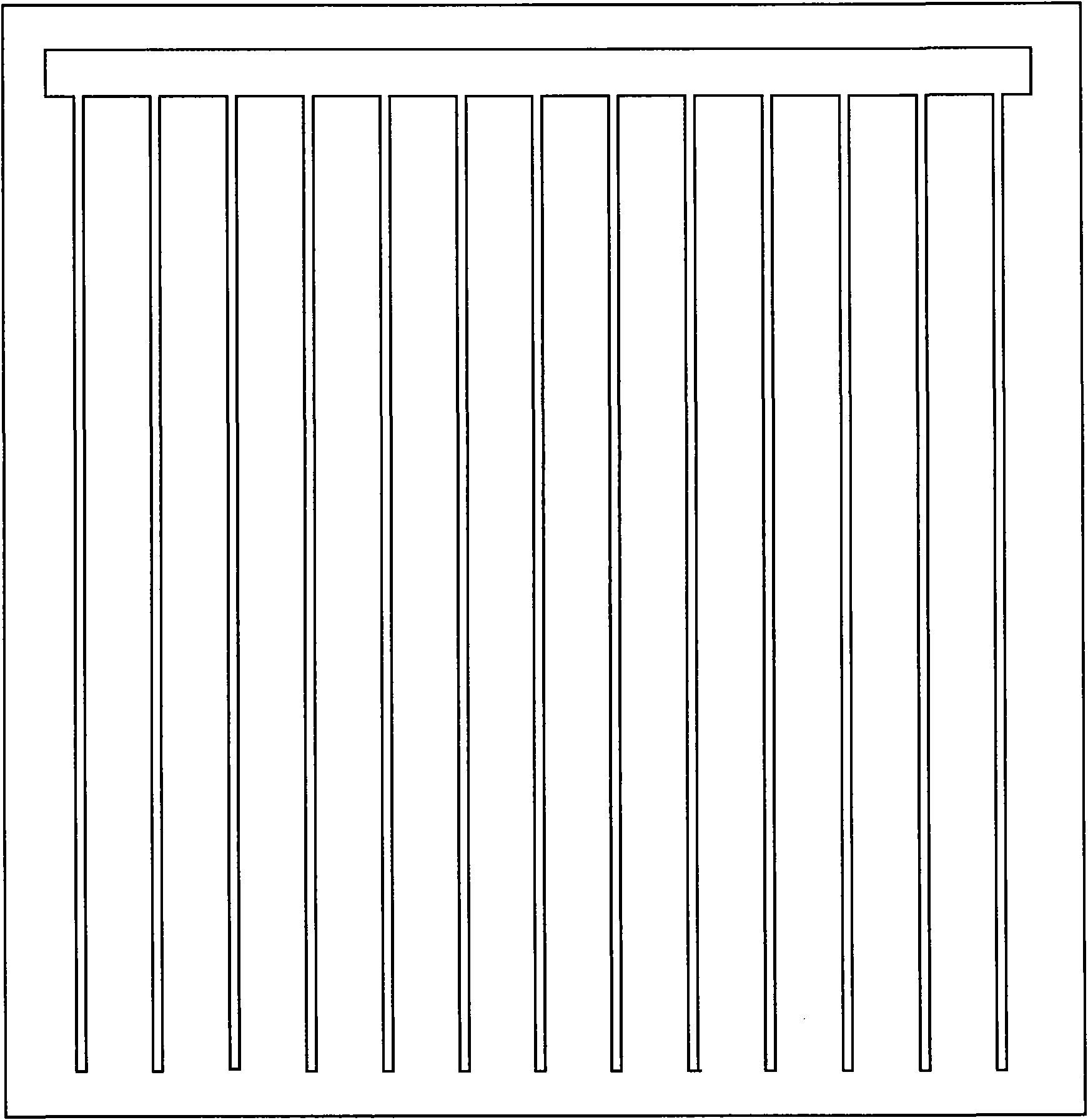

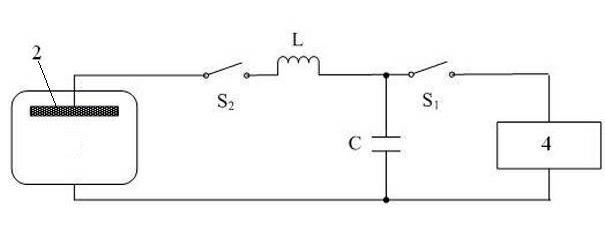

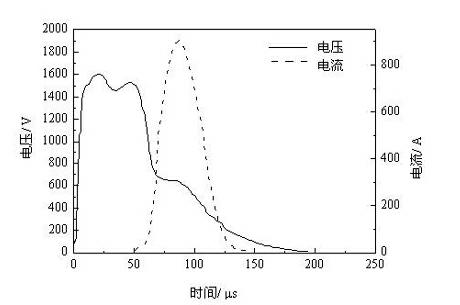

Ionization-rate-controllable coating device based on high-power impulse magnetron sputtering

InactiveCN102108492AReduce lag timeGuaranteed deposition rateElectric discharge tubesVacuum evaporation coatingLow voltageEngineering

The invention relates to an ionization-rate-controllable coating device based on high-power impulse magnetron sputtering, which comprises a vacuum sputtering system, a low-voltage direct-current power system, a high-voltage impulse power system, a PLC (Programmable Logic Controller) central control system and a computer, wherein the low-voltage direct-current power system provides a low-voltage current for the vacuum system, and the high-voltage impulse power system provides a high-voltage impulse current for the vacuum system; the PLC central control system is used for controlling the vacuum system, low-voltage direct-current power system and high-voltage impulse power system; and the PLC and computer are used for transmitting and controlling data. The invention effectively shortens the delay time of the impulse current due to the preset direct-current voltage, effectively ensures the film deposition rate by coupling the direct-current magnetron sputtering, and establishes a plasma ionization-rate-adjustable HIPIMS (high-power impulse magnetron sputtering) technique, thereby providing technical support for research in related science.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

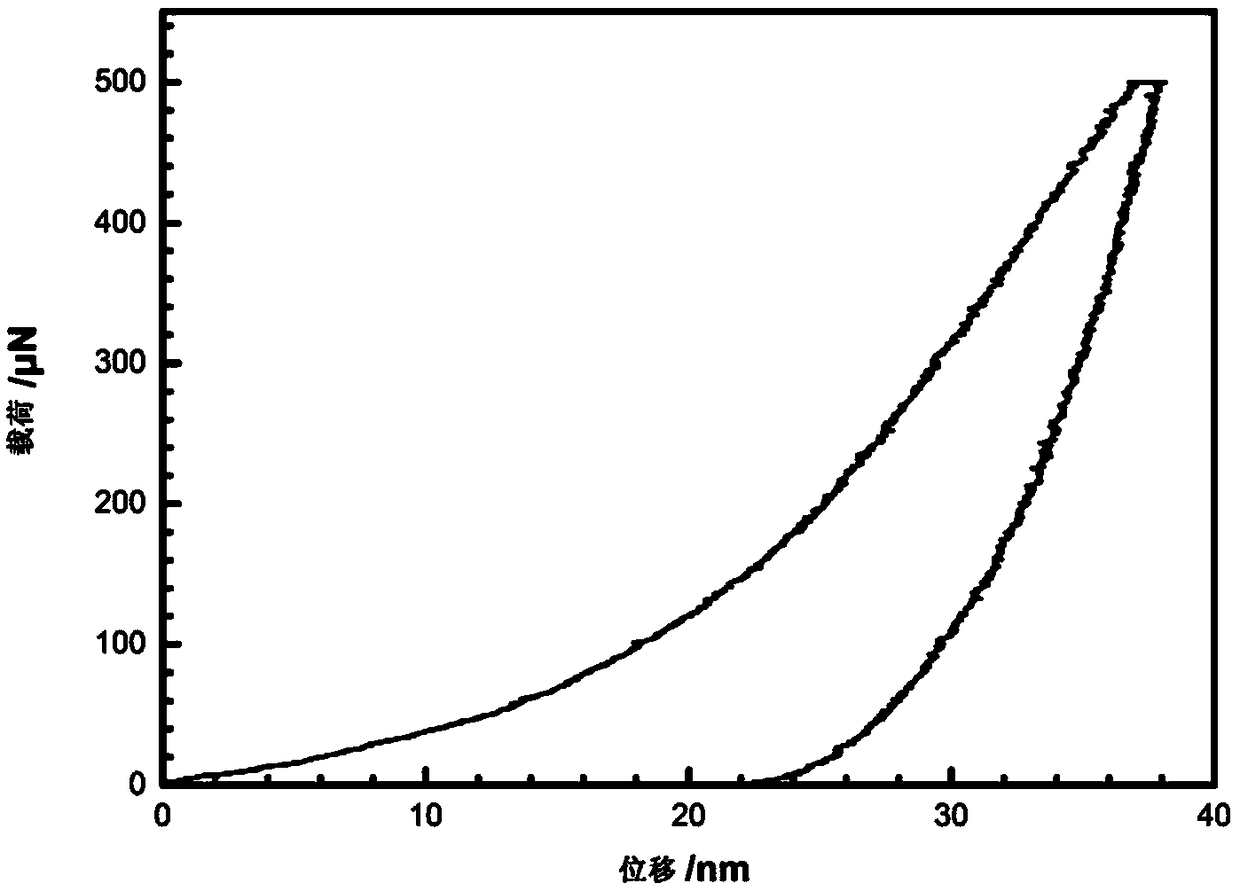

Preparation method of high-hardness quaternary infusible high-entropy alloy film

ActiveCN108796444AHigh purityImprove compactnessVacuum evaporation coatingSputtering coatingVacuum pumpingSputtering

The invention discloses a preparation method of a high-hardness quaternary infusible high-entropy alloy film. The preparation method comprises the following steps of cleaning and blow-drying a matrixSi wafer and putting the matrix Si wafer into a sample injection chamber to conduct reverse sputtering to further clean surface impurities; transmitting the matrix to a spluttering cavity, mounting atarget and conducting heating and continuous vacuum pumping on the matrix Si wafer after high-vacuum pumping; introducing argon, directly connecting the target with a DC power supply, setting the sputtering power and bias voltage, adjusting the working air pressure and conducting pre-sputtering to clean impurities on the surface of the target; opening a sample disk baffle and conducting rotation to start sputtering; cooling a sample to the indoor temperature in a vacuum environment of the sputtering cavity after completion of sputtering and then taking the sample out; and testing the nanomdentation hardness of the film. According to the preparation method, the film is deposited through the DC magnetron sputtering method, and the quaternary infusible high-entropy alloy film with the smoothsurface and uniform film thickness is obtained. The film is composed of BCC and a few of HCP solid solution.

Owner:XI AN JIAOTONG UNIV

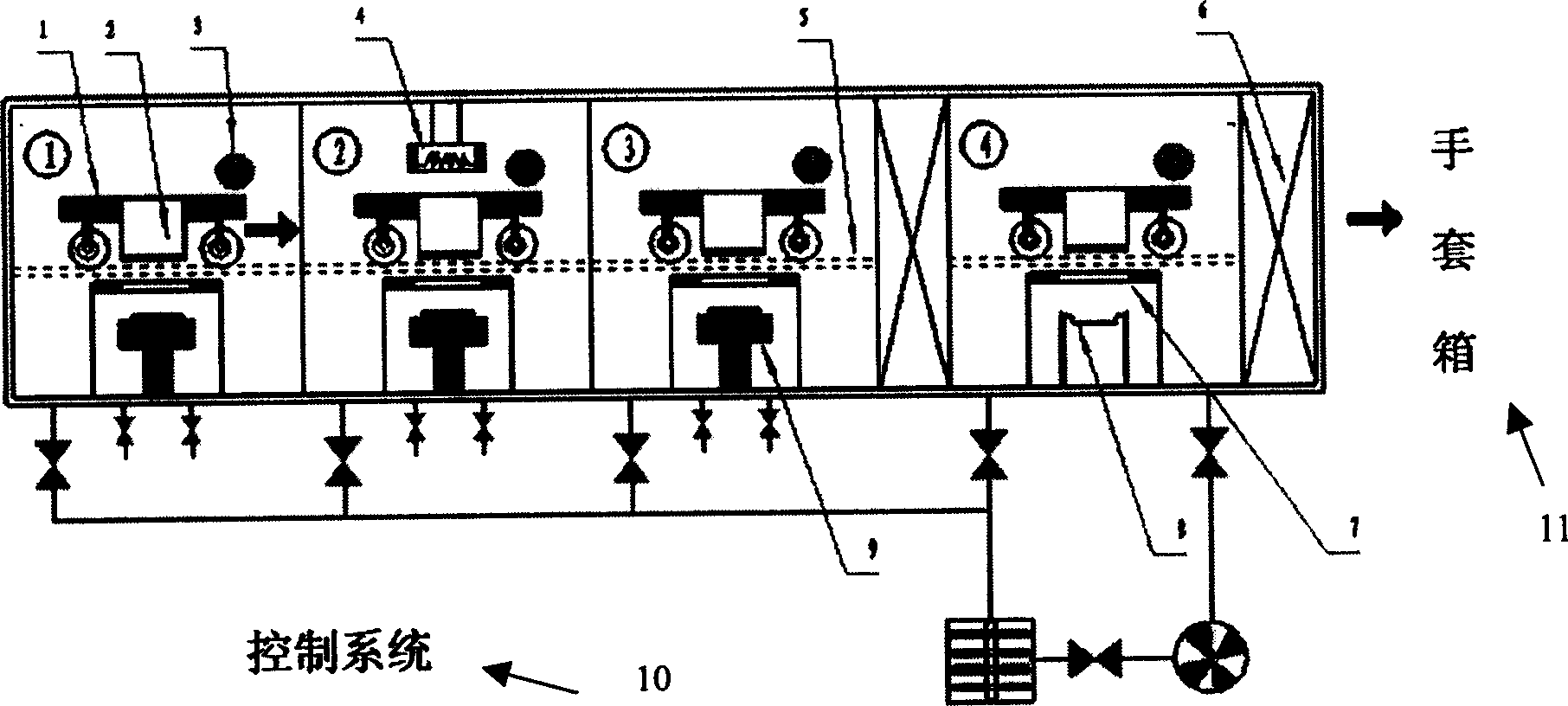

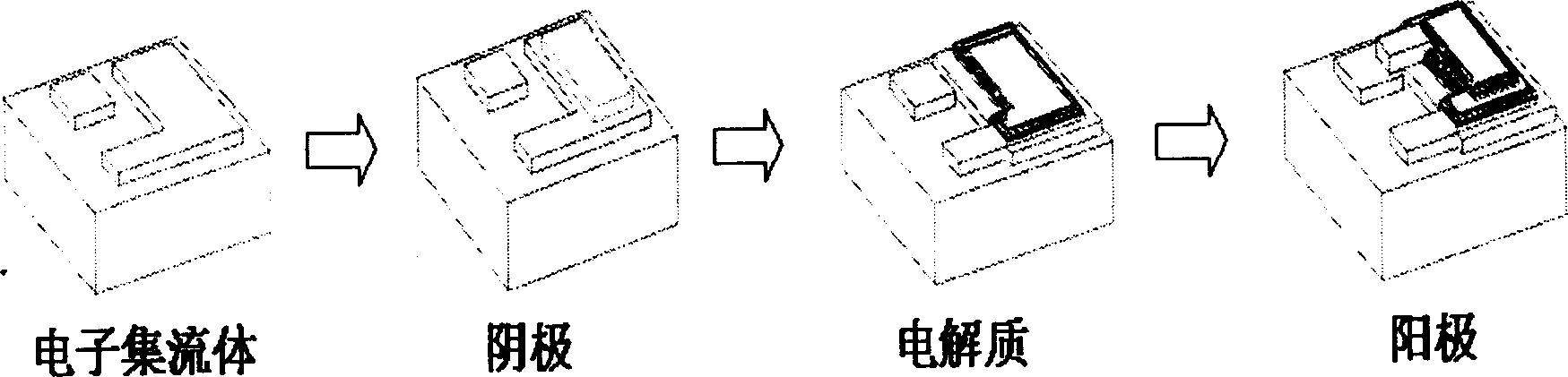

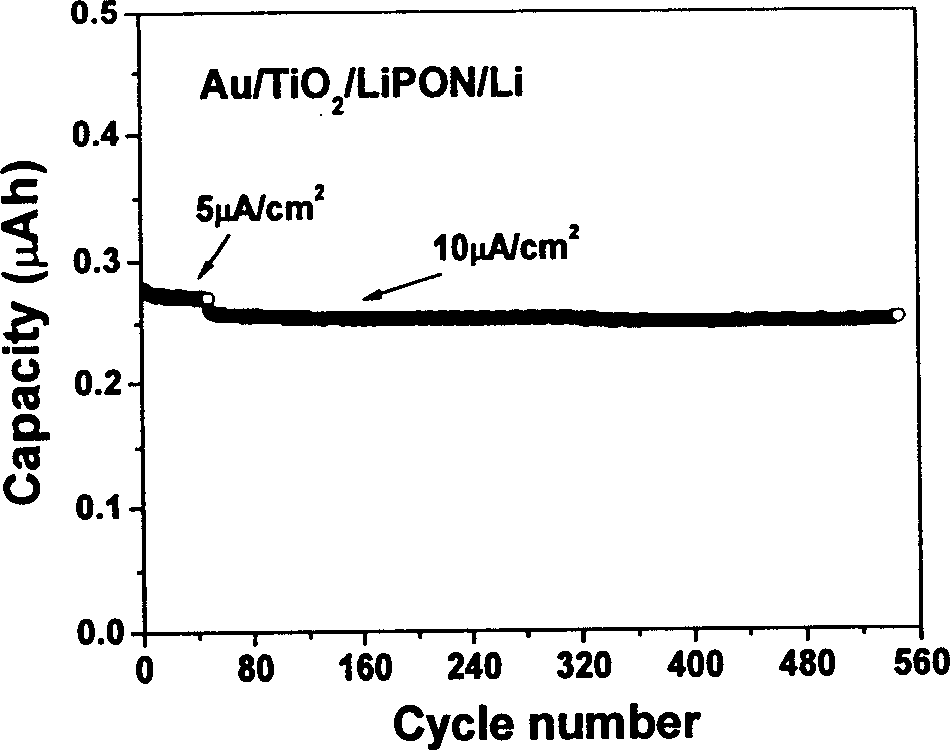

Device and method for preparing solid thin-membrane lithium battery by in-situ deposition

InactiveCN1747217ASmall interface resistanceSmall charge transfer resistanceFinal product manufactureVacuum evaporation coatingRadio frequency magnetron sputteringEngineering

The equipment for preparing solid film Li-ion battery by in-situ deposition process comprises four chambers for depositing film, and a glove box. Different kind of films are prepared in different chamber: DC magnetron sputtering chamber is used to prepare electronic current collector film; DC or RF magnetron sputtering chamber is used to prepare each cathode film; RF magnetron sputtering chamber is used to prepare each electrolyte film; vacuum heat evaporation chamber is used to prepare each metal anode film.

Owner:FUDAN UNIV

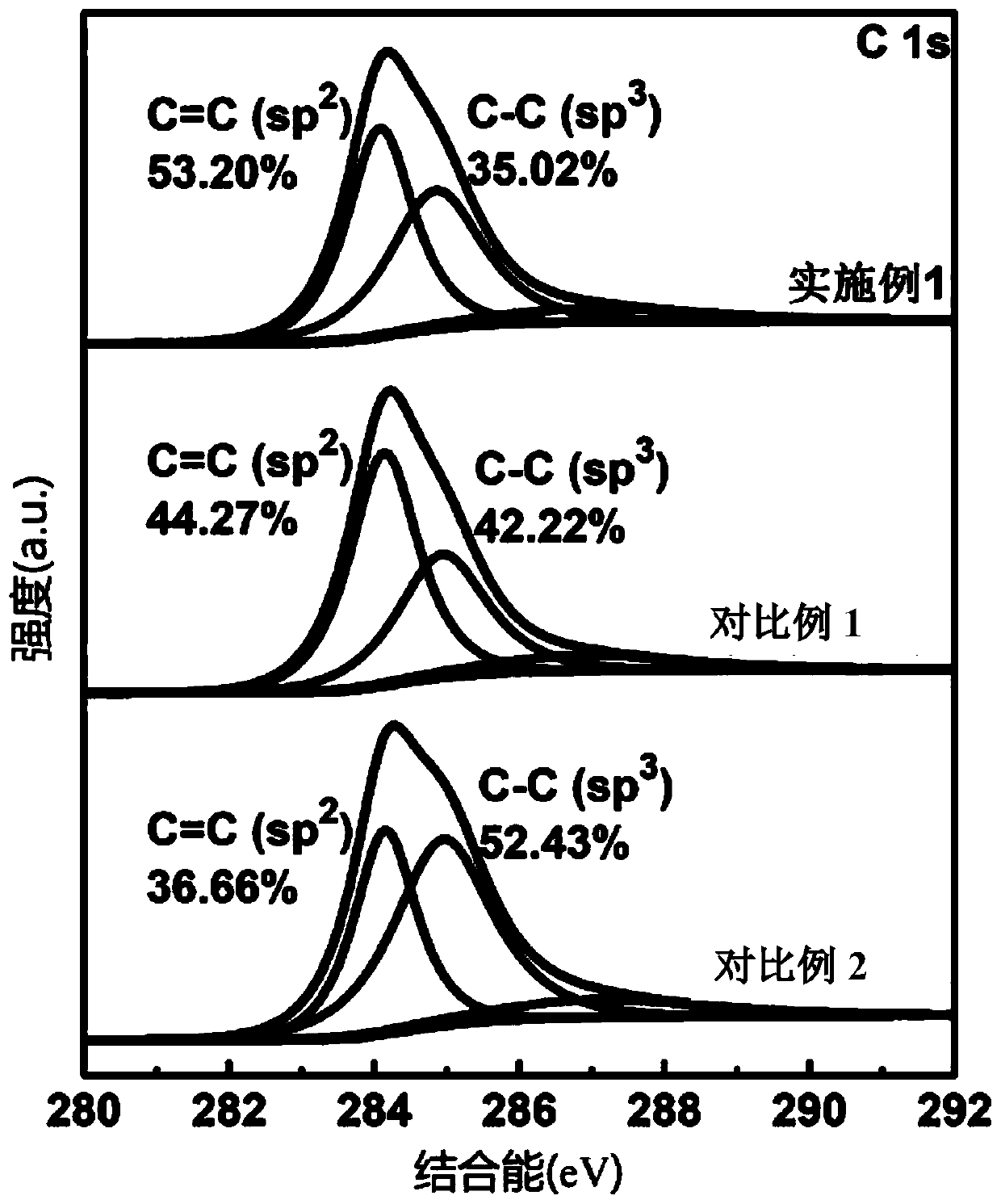

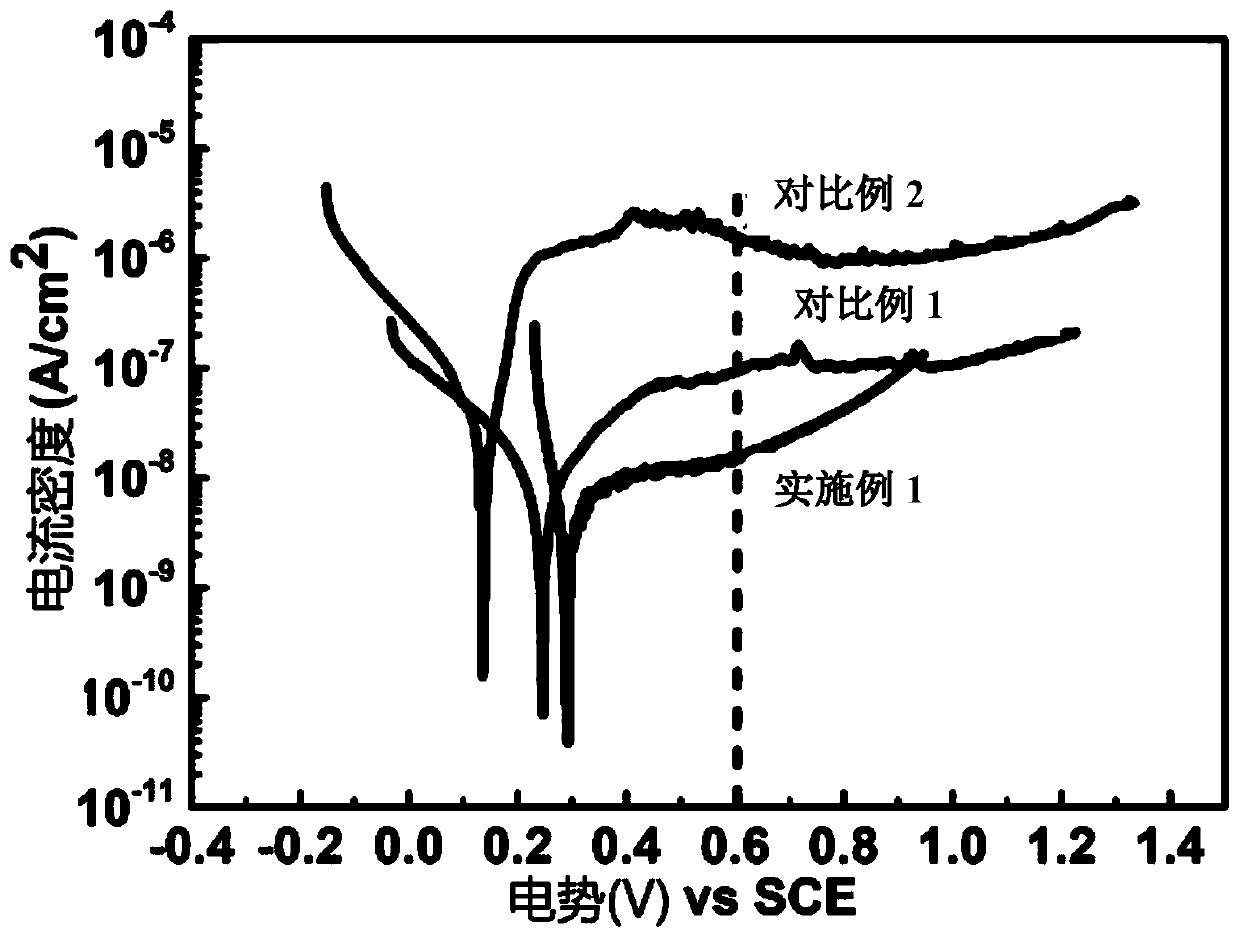

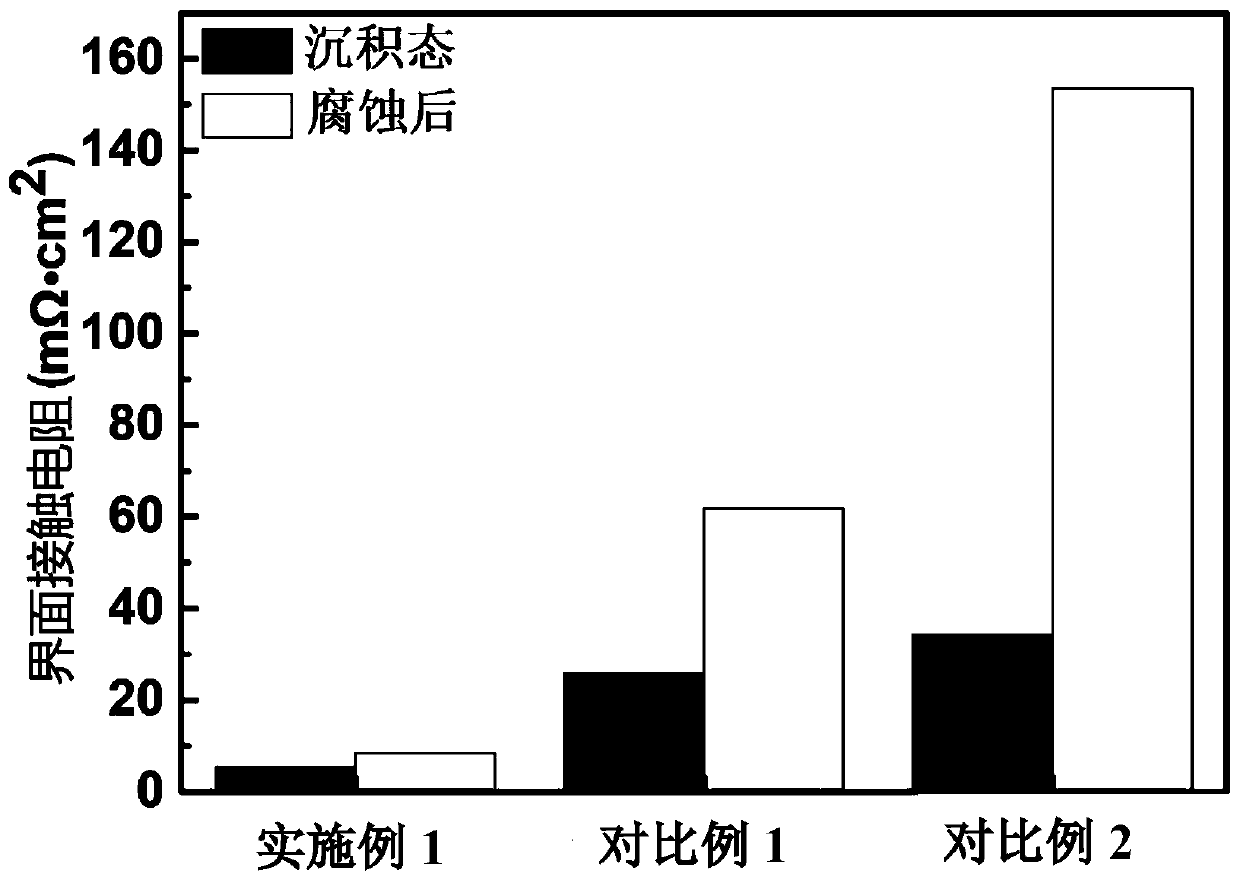

Metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and preparation method and application thereof

ActiveCN110684946ASmooth structureSmooth internal structure Dense structureVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and a preparation method and application thereof. The preparation method of the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer comprises the following steps: with a chromium target as the target, a high-power pulse magnetron sputtering technology is adopted to deposit a chromium transition layer on the surface of a metal bipolar plate; with a graphite target as the target, a direct-current magnetron sputtering technology isadopted to deposit an amorphous carbon layer on the surface of the chromium transition layer to obtain the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer; and process conditions adopted by the direct-current magnetron sputtering technology comprises the sputtering source center magnetic field intensity of 40-60 mT, the edge magnetic field intensity of 10-20 mT and the power of 0.8-1.0 kW. The provided chromium transition layer is smooth in surface and compact in internal structure, and can effectively improve the film base bonding strength; and meanwhile, through optimization of an amorphous carbon layer preparation process, the amorphous carbon layer achieves excellent electric conductivity and corrosion resistance, and can permanently and effectively protect the metal bipolar plate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

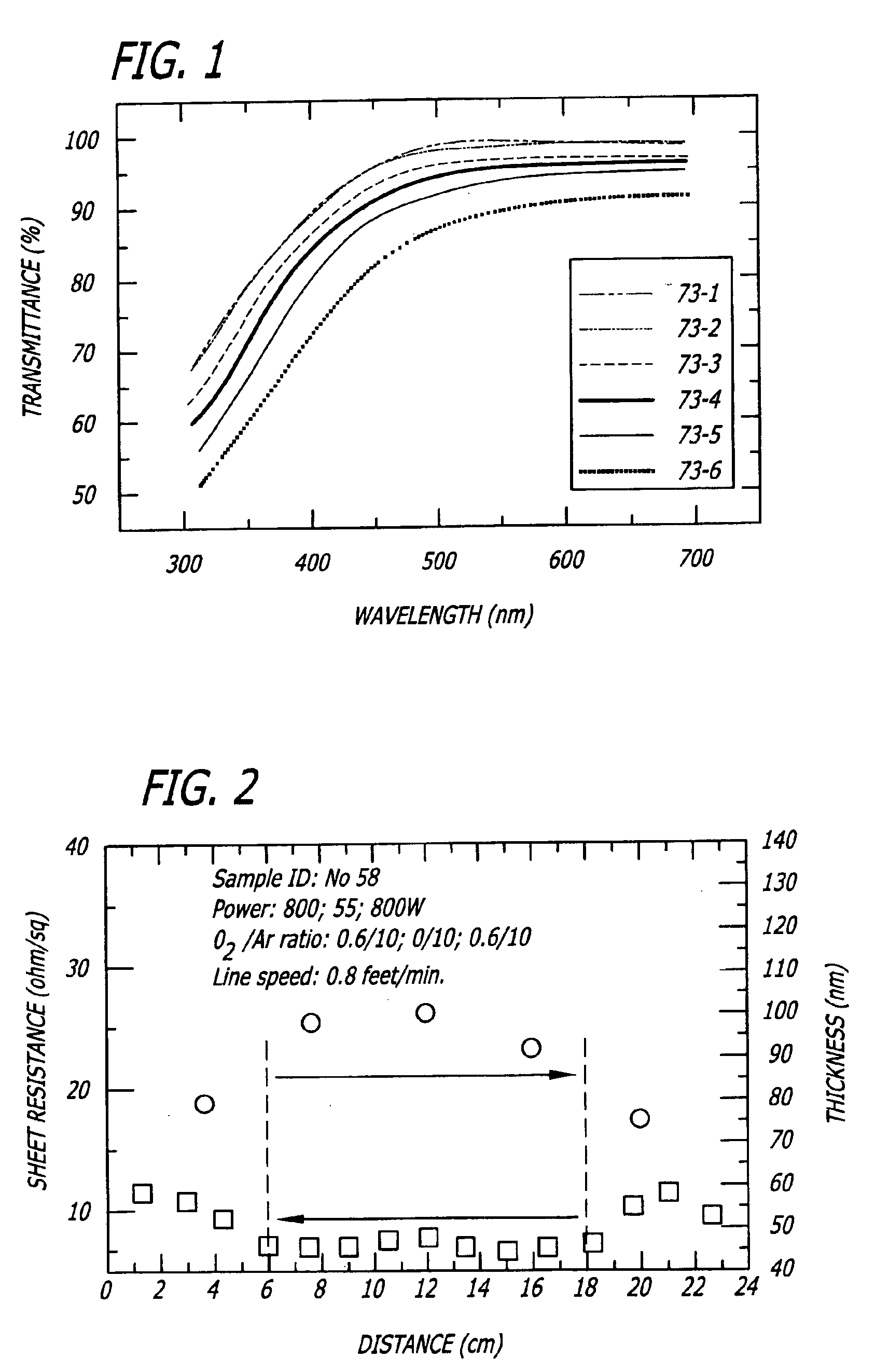

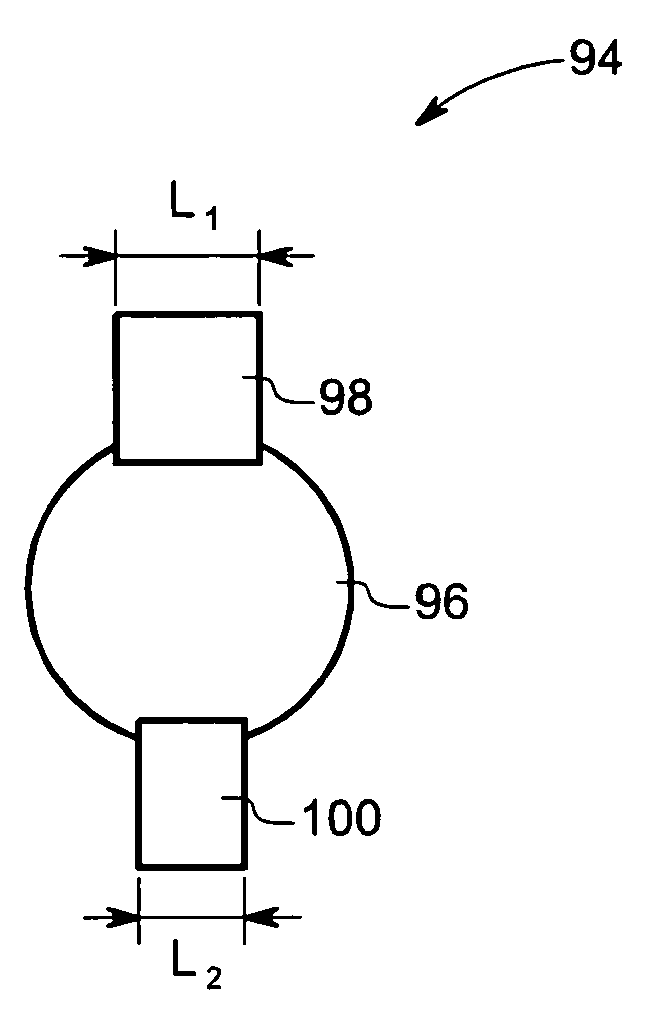

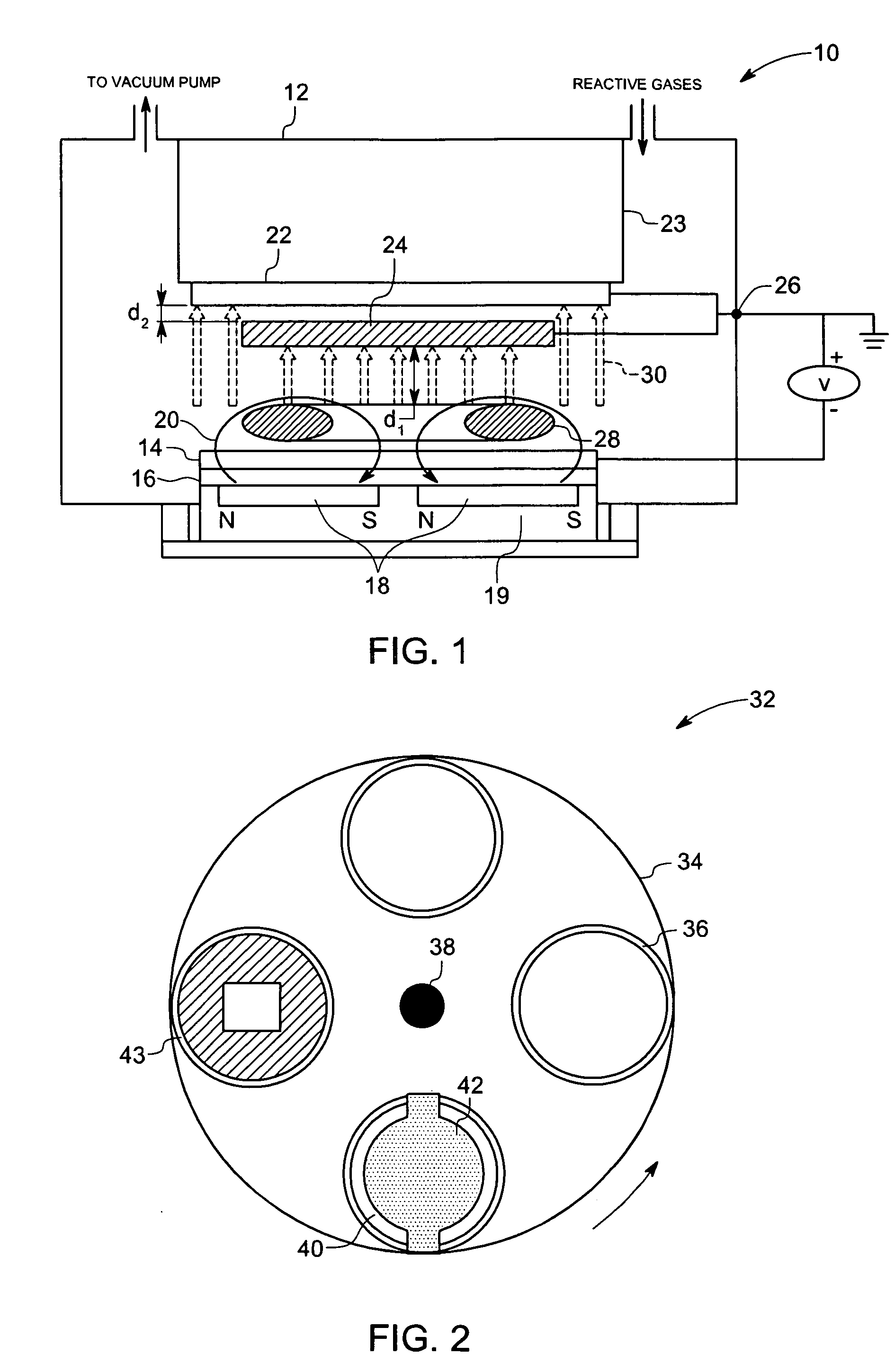

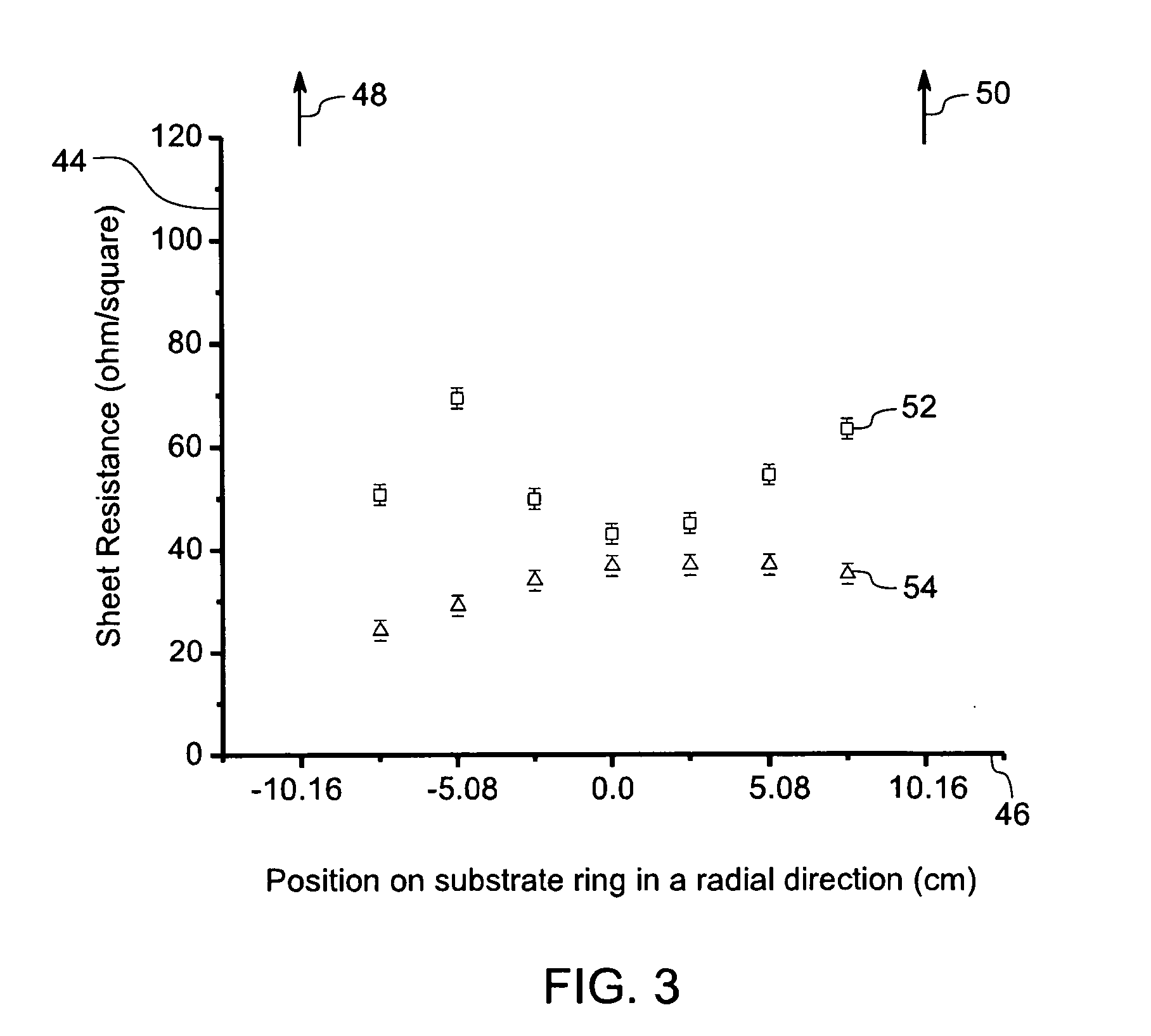

Optoelectronic devices having electrode films and methods and system for manufacturing the same

ActiveUS20070159065A1Improve uniformityLow resistivityDischarge tube luminescnet screensLamp detailsSputteringEngineering

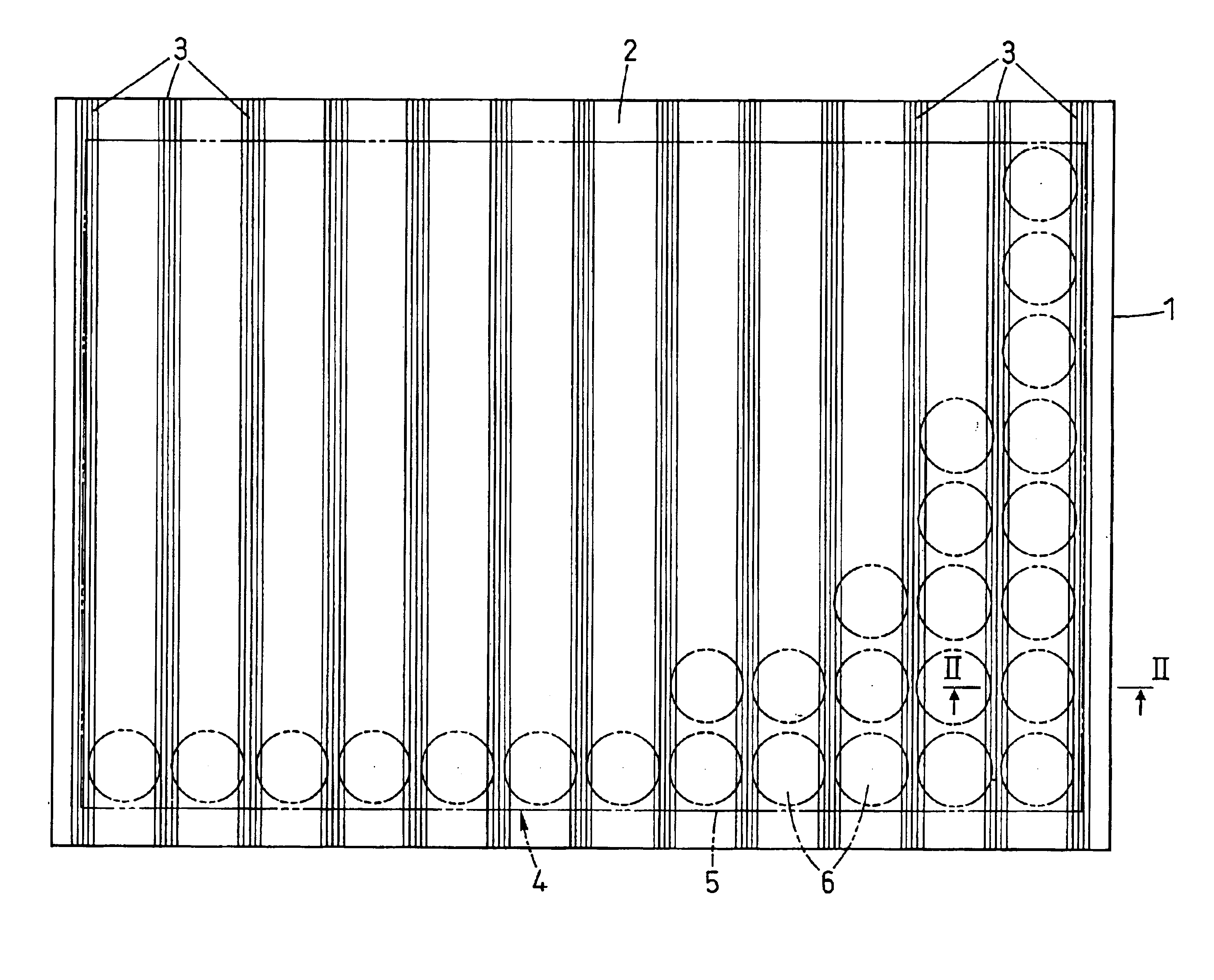

A method and system for DC magnetron sputtering deposition of films on plastic substrates. The method includes using a shield to block deposition in a spatial region corresponding to a plasma region formed during magnetron sputtering. An optoelectronic device including an amorphous electrode film is also disclosed.

Owner:BOE TECH GRP CO LTD

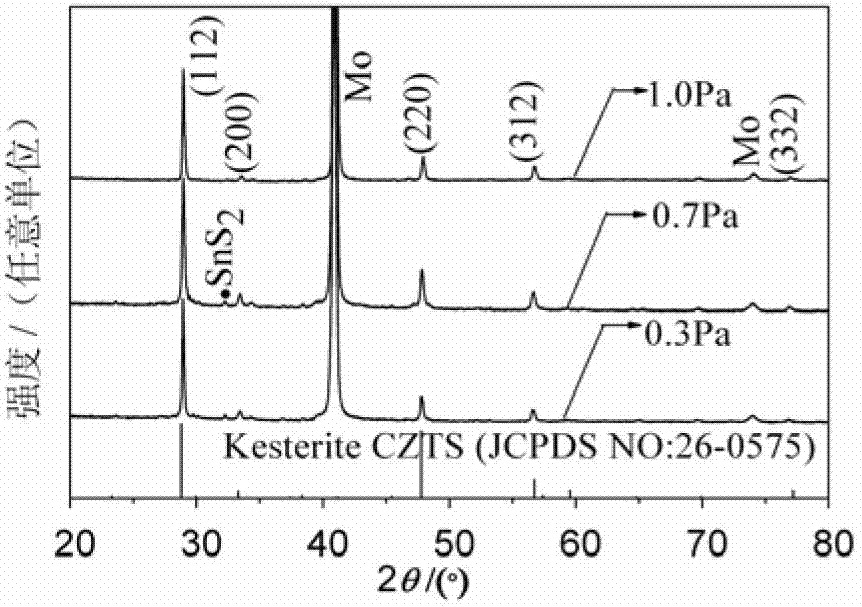

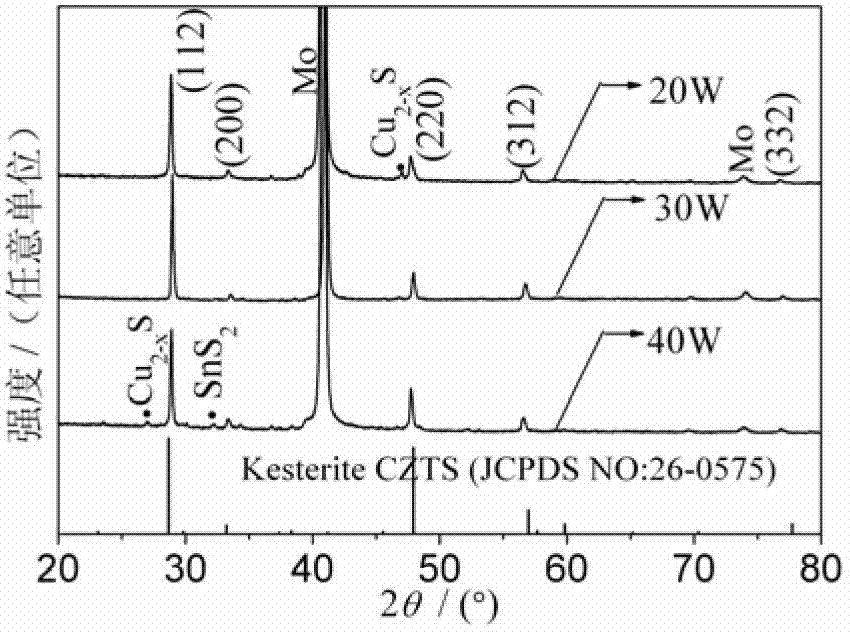

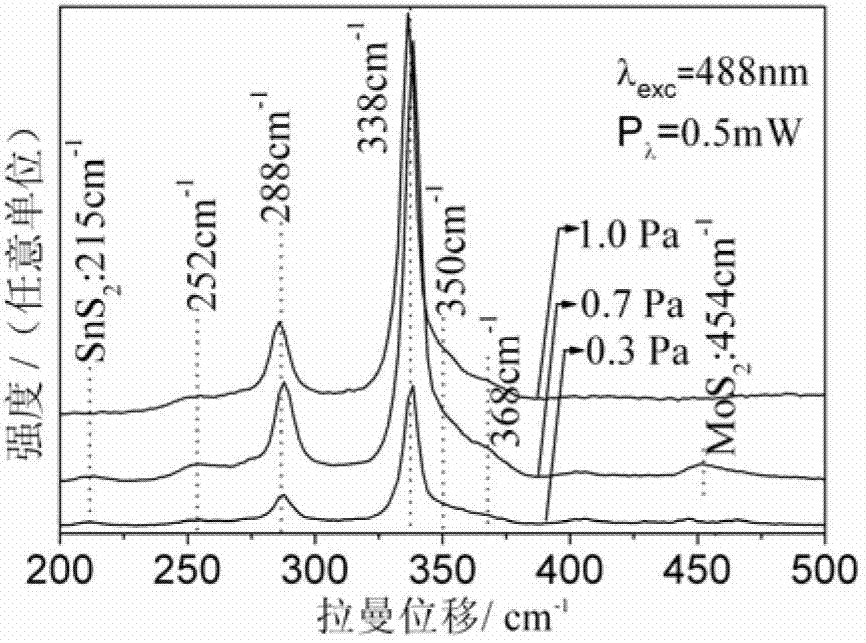

Method of preparing copper-zinc tin-sulphur solar cell absorbed layer thin film

InactiveCN103165748AReduce difficultyLow costFinal product manufactureVacuum evaporation coatingVulcanizationAlloy

The invention discloses a method of preparing a copper-zinc tin-sulphur solar cell absorbed layer thin film. The method of preparing the copper-zinc tin-sulphur solar cell absorbed layer thin film comprises the following steps: 1) a substrate can be soaked in acetonum, ethyl alcohol and deionized water in sequence, the substrate can be cleaned ultrasonically and then the substrate can be blow-dried to be reserved; 2) a direct current magnetron sputtering system can be used and a copper (Cu)-zinc (Zn)-stannum (Sn) alloy can be used as target materials to be in signal-target sputtering. Vacuum degree is above 3.5*10-4 pascals, sputtering power is 10-50 watts and working air pressure is 0.2-1.2 pascals so as to obtain a Cu-Zn-Sn precursor thin film; 3) under the condition that argon can be entered into a vacuum and the argon flow is in 35-50 standard-state cubic centimeter per minute, the temperature of the Cu-Zn-Sn precursor thin film and powdered sulfur can be respectively raised to 200-250 DEG C. The powdered sulfur can be kept under 200-250 DEGC in 5.5-6.5 hours and then the powdered sulfur can be cooled naturally; after the substrate is kept under the temperature of 200-250 DEGC in 10-15 minutes, the temperature can be increased to 500-600 DEGC to be in vacuum vulcanization for 30-40 minutes. After the substrate is naturally cooled, the copper-zinc tin-sulphur solar cell absorbed layer thin film can be obtained. The method of preparing the copper-zinc tin-sulphur solar cell absorbed layer thin film has the advantages of being easy to operate, strong in controllability, good in repeatability and capable of preparing high quality copper-zinc tin-sulphur solar cell absorbed layer thin film in large areas. The method is an environmental friendly preparation method.

Owner:NINGBO UNIV

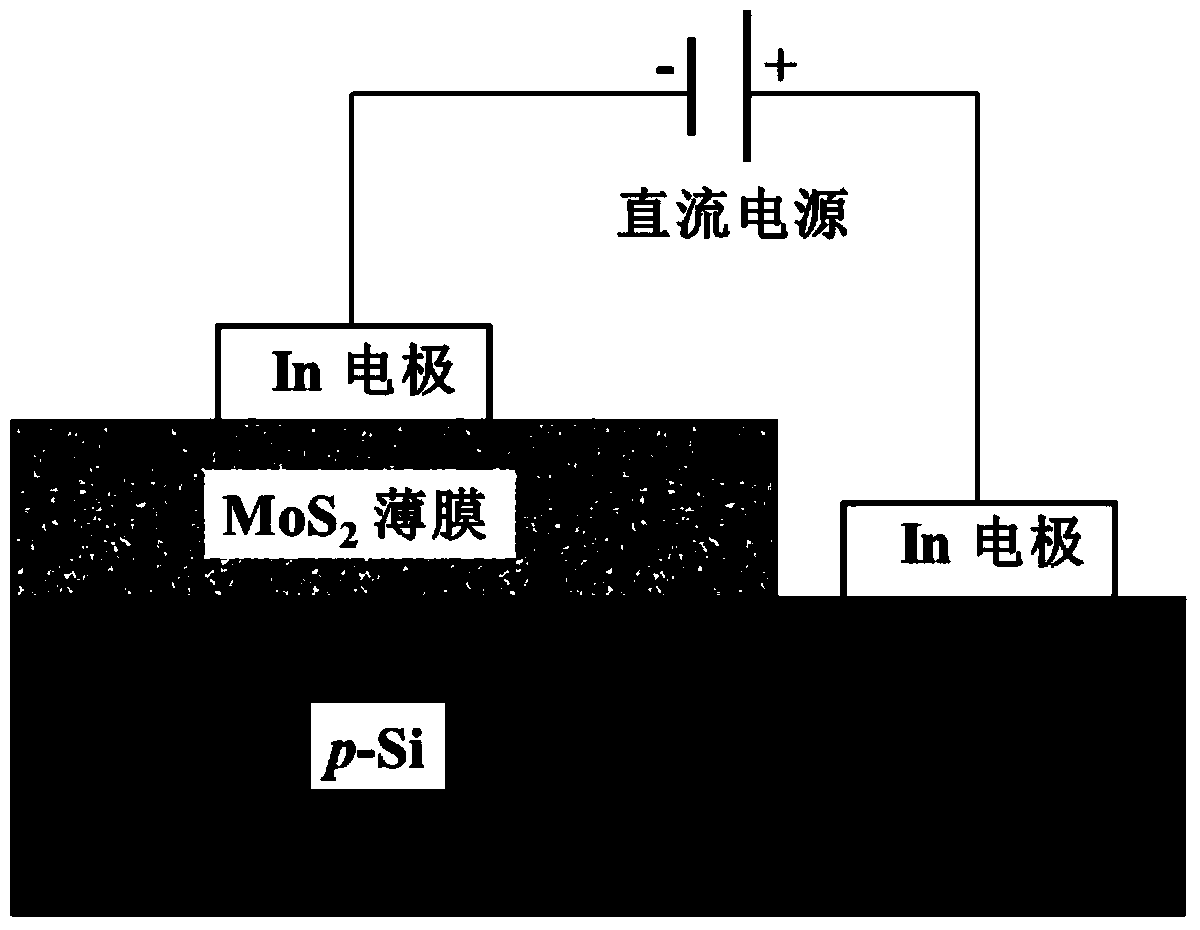

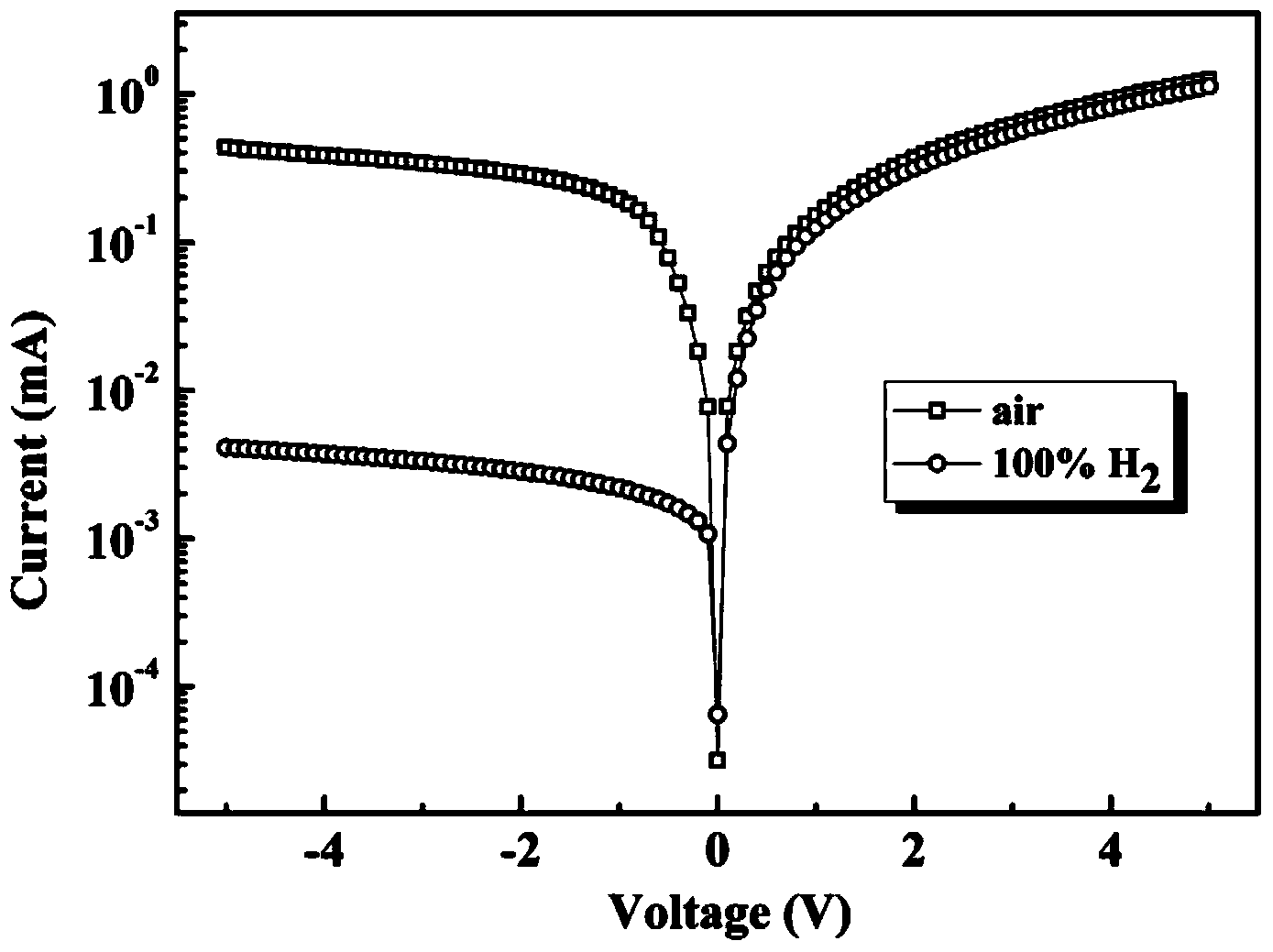

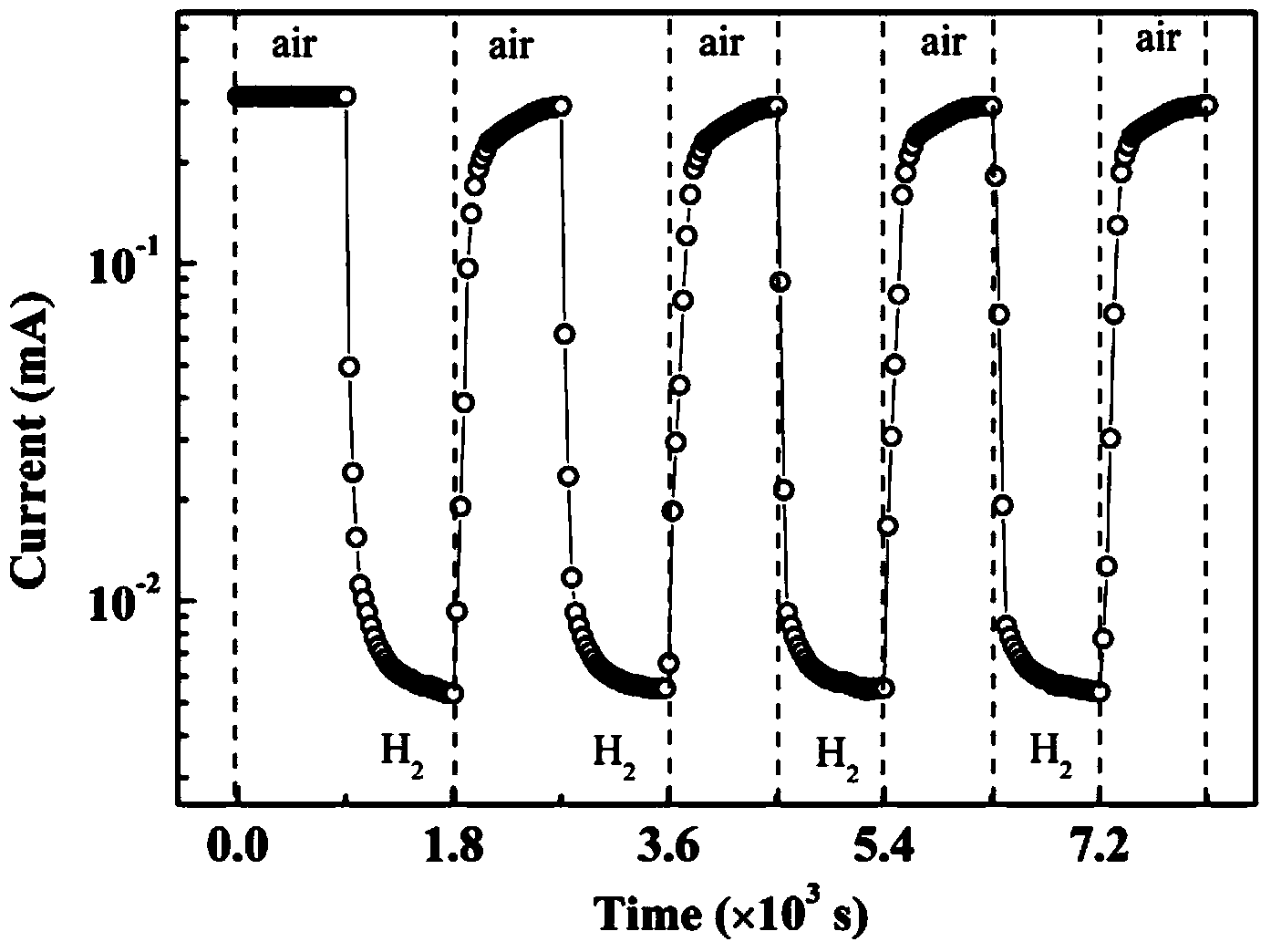

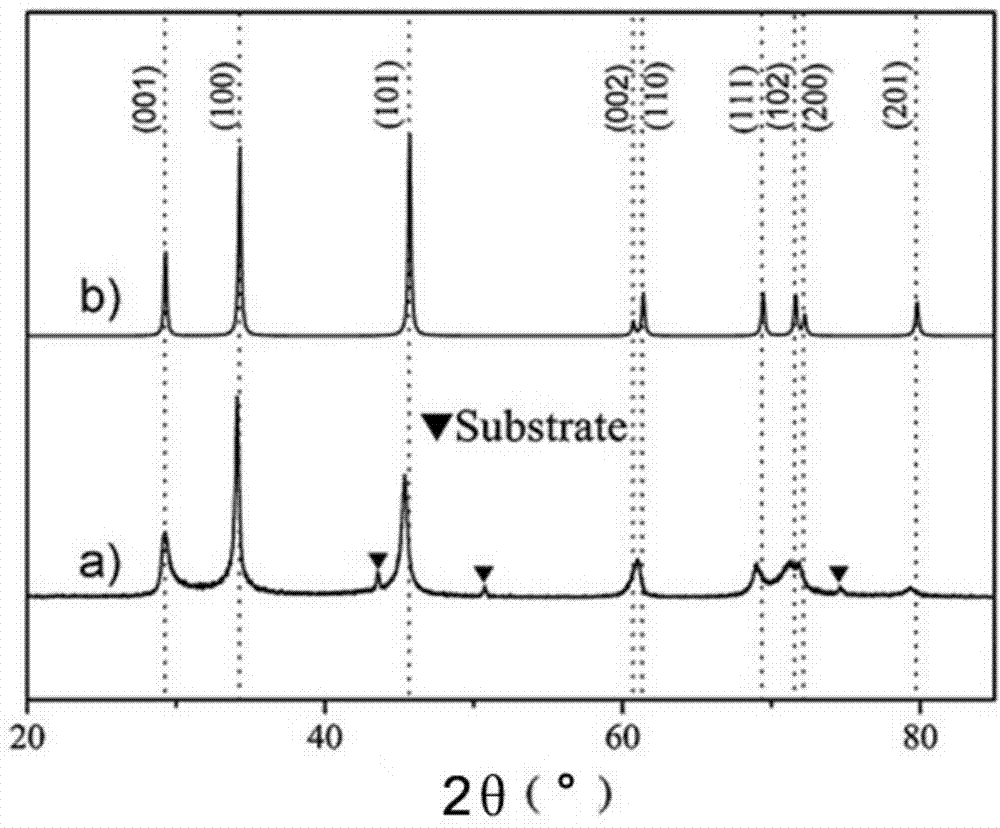

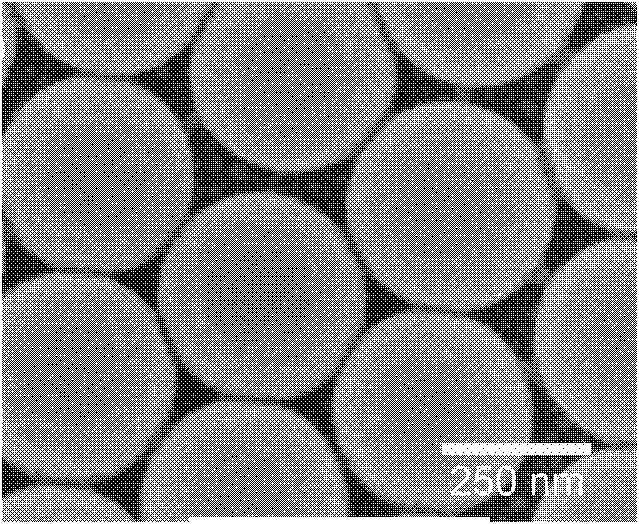

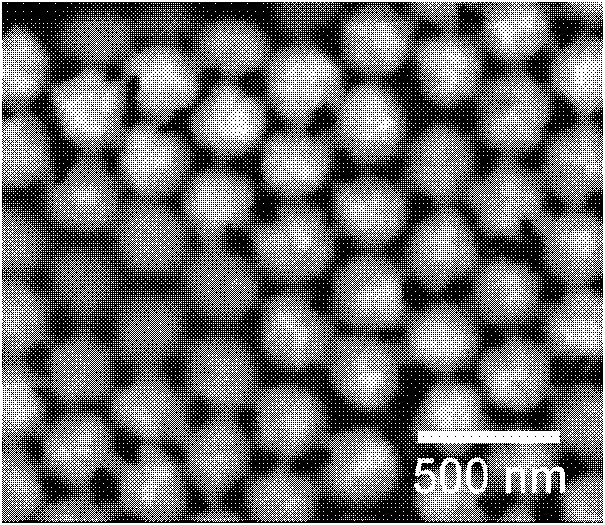

Molybdenum disulfide/silicon heterogeneous film component with hydrogen sensitivity effect as well as preparation method and application thereof

InactiveCN104049022AEliminate dependenciesObvious response characteristicsMaterial analysis by electric/magnetic meansDirect current magnetron sputteringElectrical transport

The invention discloses a molybdenum disulfide (MoS2) / silicon (Si) heterogeneous film component with a hydrogen sensitivity effect as well as a preparation method and application thereof. The MoS2 / Si heterogeneous film component comprises a Si substrate and a MoS2 film layer which is deposited on the surface of the Si substrate by a direct current magnetron sputtering technology. According to the preparation method, by depositing the MoS2 film on the surface of the Si substrate, the MoS2 / Si heterogeneous film component having an H2 sensitivity effect is prepared by virtue of H2 adsorption of the MoS2 film and electrical transport amplification action of a semiconductor heterogeneous interface. Test results show that under the condition of pure H2, when impressed voltage is -5V, the electric current of the MoS2 / Si heterogeneous film component is reduced by two orders of magnitude; meanwhile, the heterogeneous film component shows obvious response to H2 concentration change. Compared with an existing semiconductor type H2 sensing component, the MoS2 / Si heterogeneous film component has advantages of having obvious H2 response performance, and being good in repeatability, high in reliability and free of dependence on oxygen atmosphere condition and noble metal.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

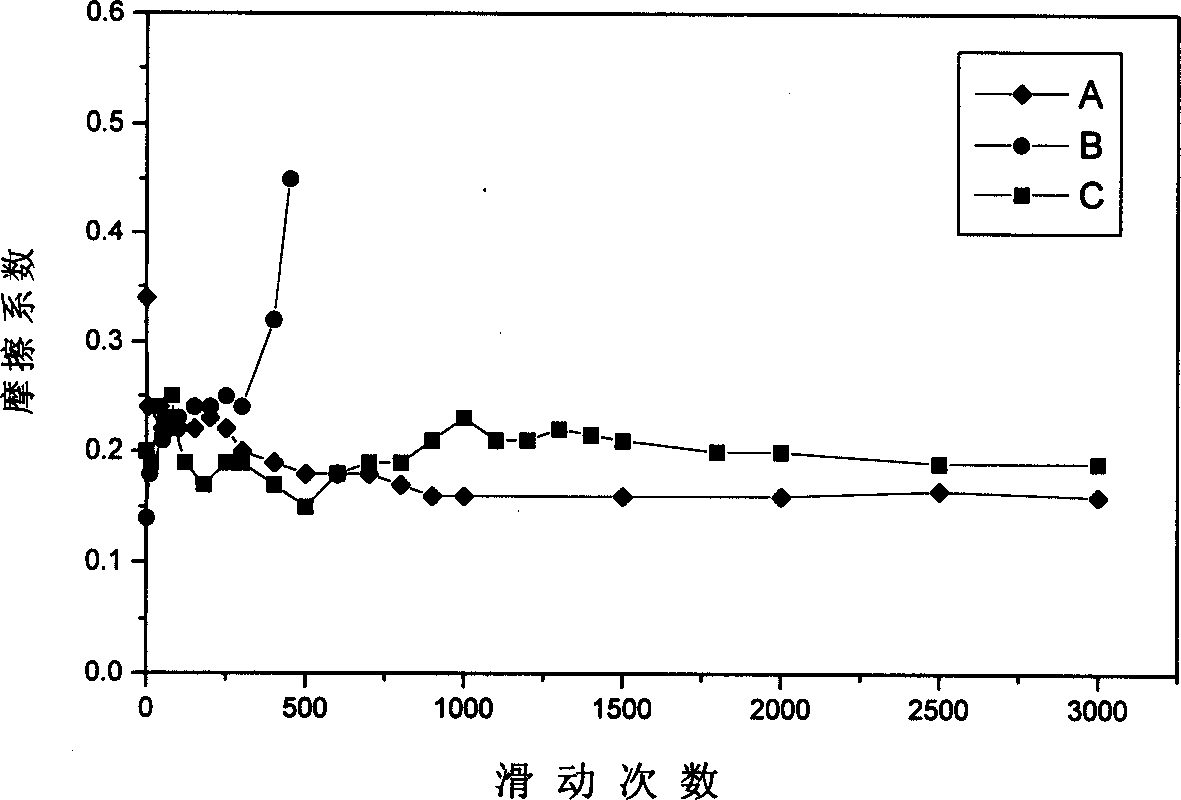

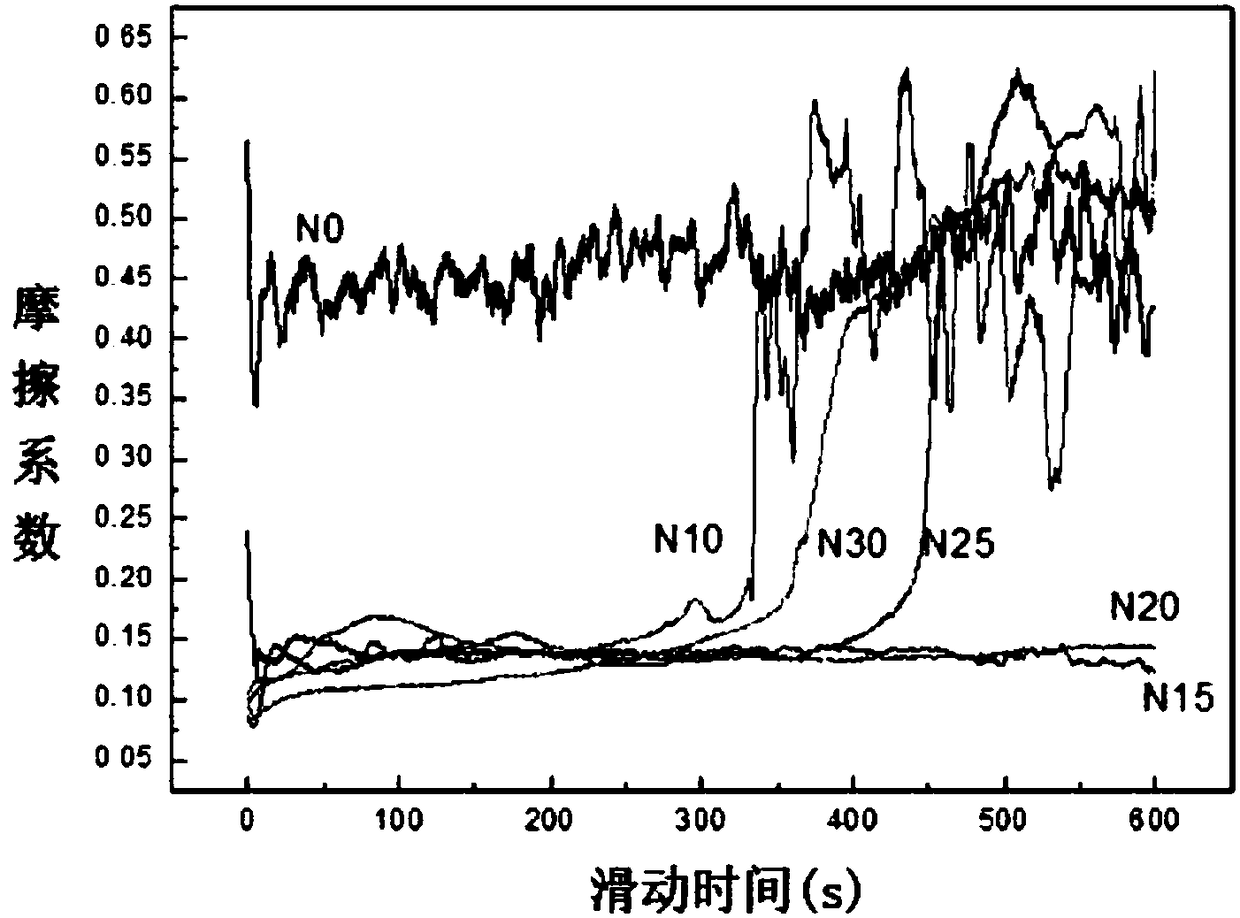

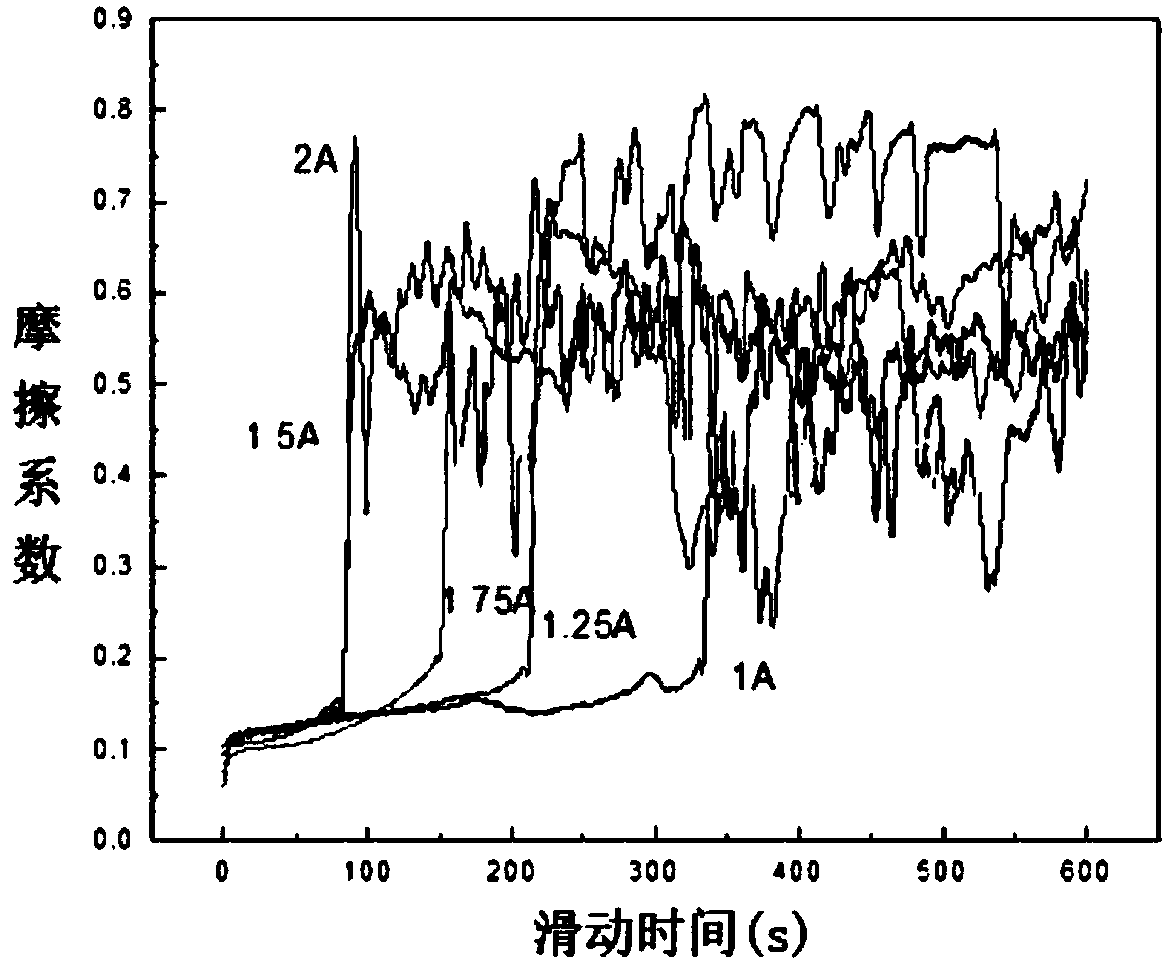

AlB2 type WB2 hard coating and preparation technology thereof

InactiveCN104513954AImprove performanceBest friction and wear resistanceVacuum evaporation coatingSputtering coatingDeposition temperatureWear resistant

The invention discloses an AlB2 type WB2 hard coating and a preparation technology thereof, and belongs to the technical field of depositing a hard and wear-resistant coating on the surface of a metal material. Through regulating and controlling the coating composition, the deposition temperature, and substrate bias voltage, and adopting a direct current (DC) magnetron sputtering method, a WB2 (AlB2 type) hard and wear-resistant coating can be successfully formed on a high-speed steel or hard alloy substrate. The formed coating has the advantages of high microscopic hardness, low average friction coefficient, and low wear rate. The WB2 (AlB2 type) hard coating is successfully synthesized, thus the hardness and wear-resistant performance of the surfaces of cutters or tools are both prominently improved, and the coating also has an important meaning for theory research and practical application of superhard boride coatings.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

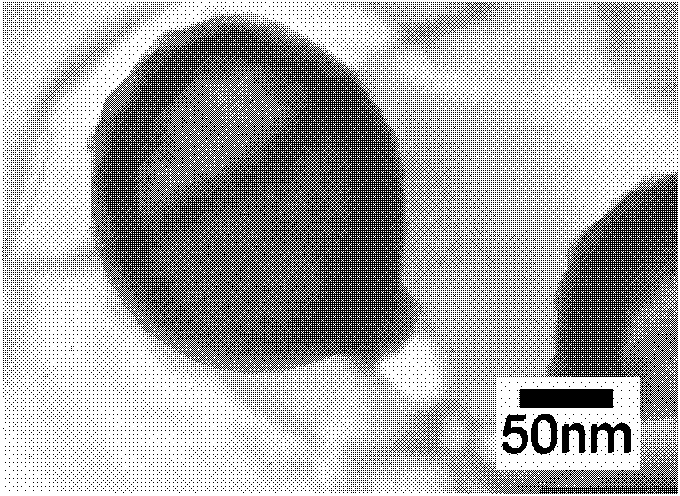

Preparation method of noble metal/submicron spherical shell arrays

InactiveCN102212790AUniform sizeOrderly rowsVacuum evaporation coatingSputtering coatingSurface-enhanced Raman spectroscopyMicrosphere

The invention discloses a preparation method of noble metal / submicron spherical shell arrays, which comprises the following steps: firstly, self-assembling submicron polystyrene microsphere arrays with different diameters on quartz and other substrates; then, depositing noble metal layers on the polystyrene microsphere arrays through direct current magnetron sputtering; and finally, carrying out heat treatment in a vacuum chamber to remove the polystyrene microsphere templates. In the method, the growing process is simple and controllable, and the prepared spherical shell arrays are uniform in dimension and are regularly arranged; and by regulating the thickness of the noble metal layers, the spherical shell arrays with different surface plasmon resonance peaks can be obtained and can be used in the fields such as biosensors, photonic crystals, surface-enhanced Raman spectra, luminescent spectra and the like.

Owner:ZHEJIANG UNIV

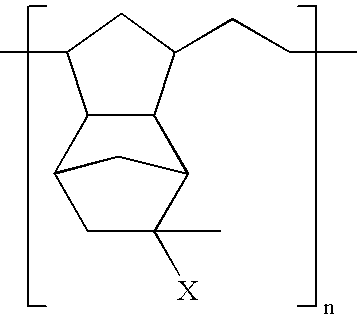

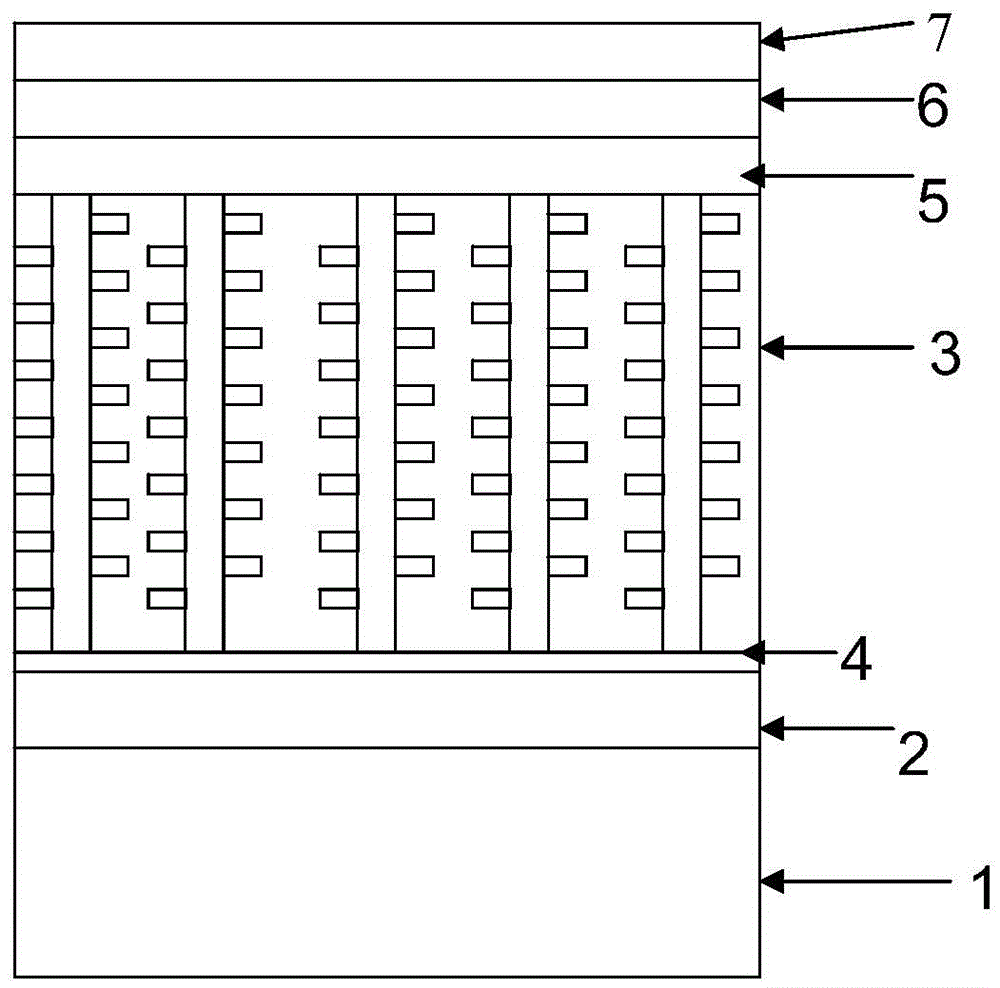

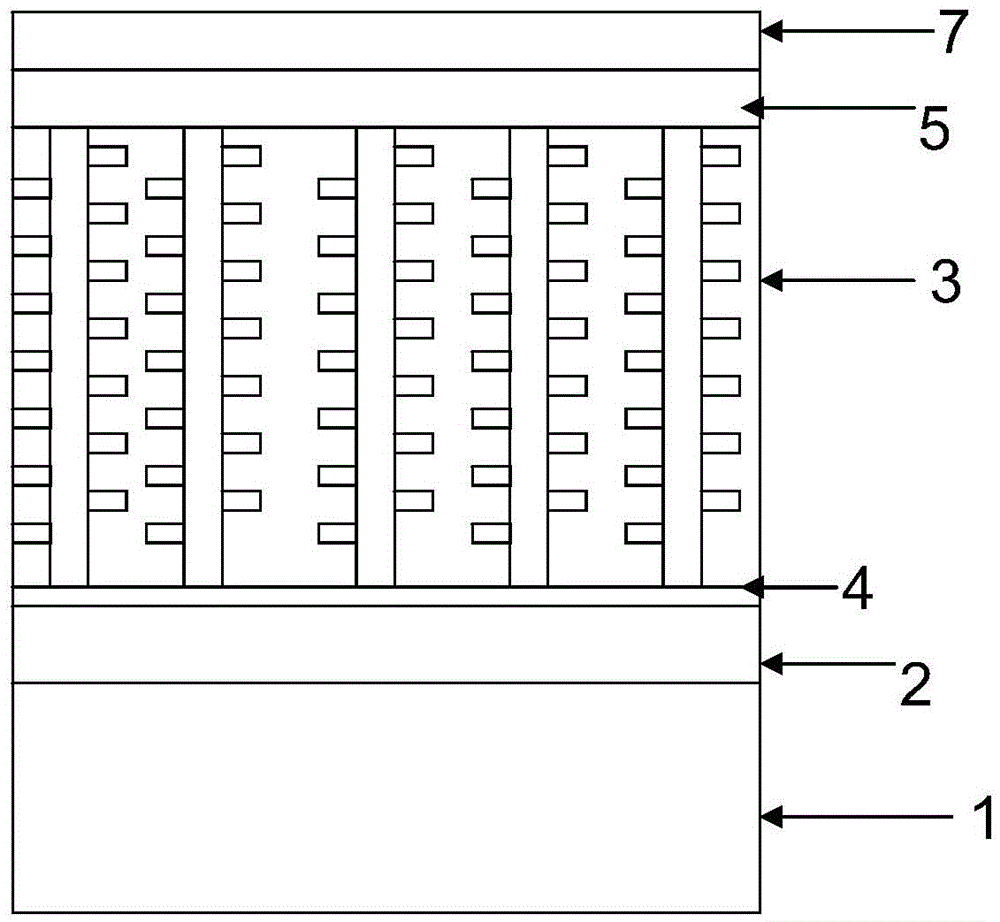

Perovskite solar cell and preparation method thereof

ActiveCN105552236ALow costIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingNanowireNano structuring

The invention discloses a perovskite type solar cell and a preparation method thereof. The perovskite type solar cell includes a substrate, a transparent conductive electrode, a novel electron transport layer, a perovskite layer, a hole transport layer and a metal electrode. According to the perovskite type solar cell of the invention, a hard substrate such as a glass substrate and a flexible substrate such as a polyimide (PI) or PET or PEN substrate can be selected as the substrate; and one kind of or a plurality of kinds of components selected from FTO, ITO, AZO or IZO can be adopted as the transparent conductive electrode. According to the preparation method of the perovskite type solar cell, radio-frequency direct-current magnetron sputtering or double-target direct-current magnetron sputtering can be adopted. Plasma etching or corrosion is performed on a prepared transparent conductive electrode, so that a surface form with a certain degree of roughness can be formed. The novel electron transport layer is of a nano wire (column, tube and sphere) and hybrid nano structure, which is prepared by using a hydrothermal method or an electron beam evaporation method. If the electron transport layer is applied to the perovskite type solar cell, an electron transport path can be decrease, recombination can be reduced, the utilization ratio of photo-generated carriers can be improved, and short-circuit current and the performance of the cell can be improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

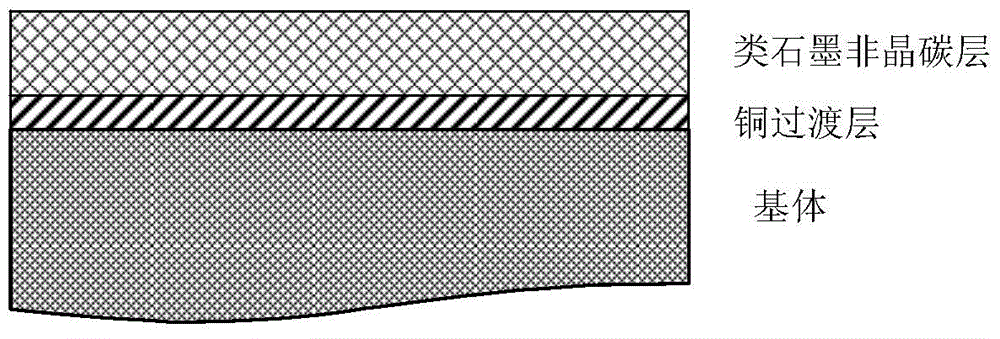

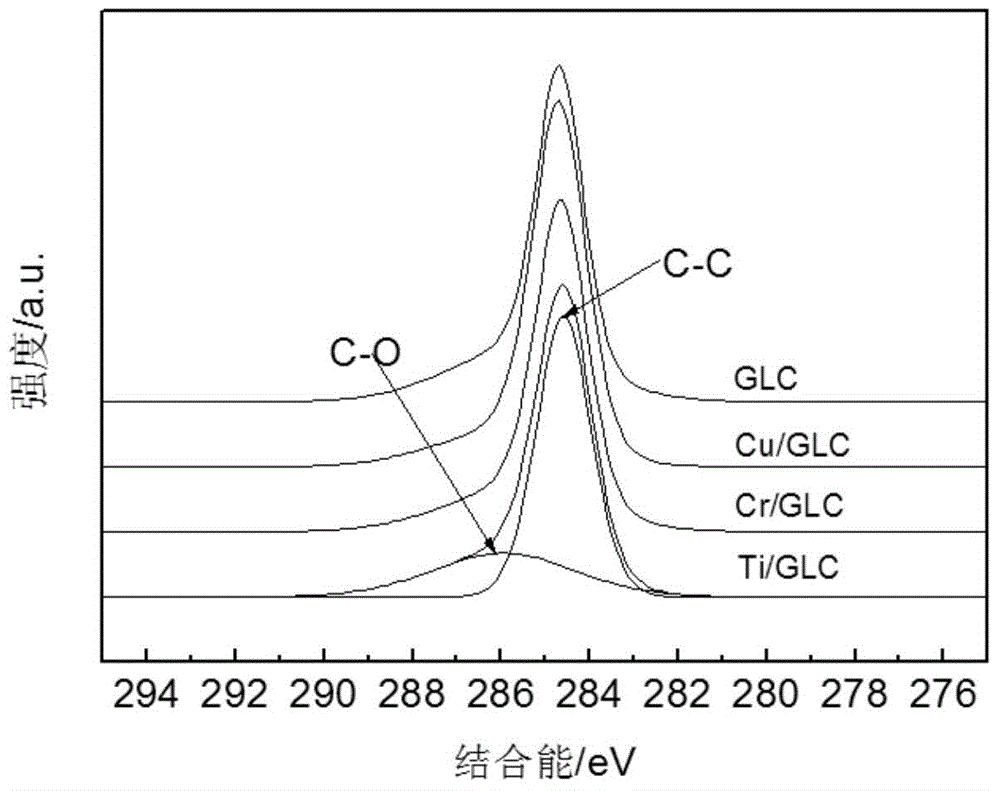

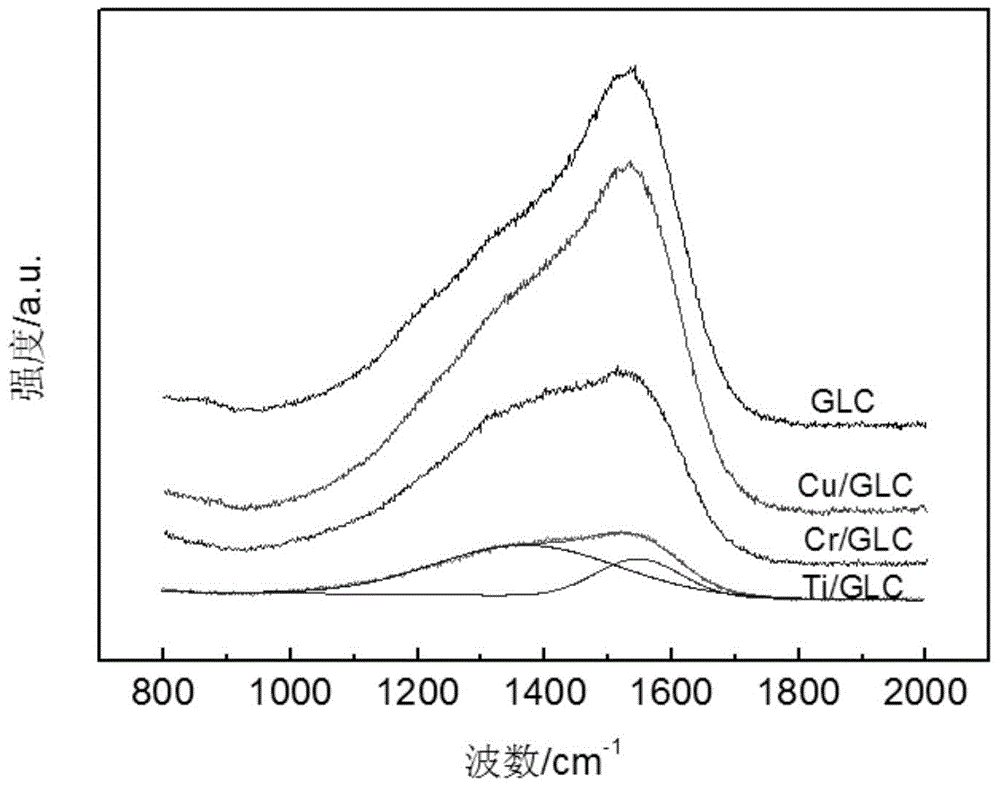

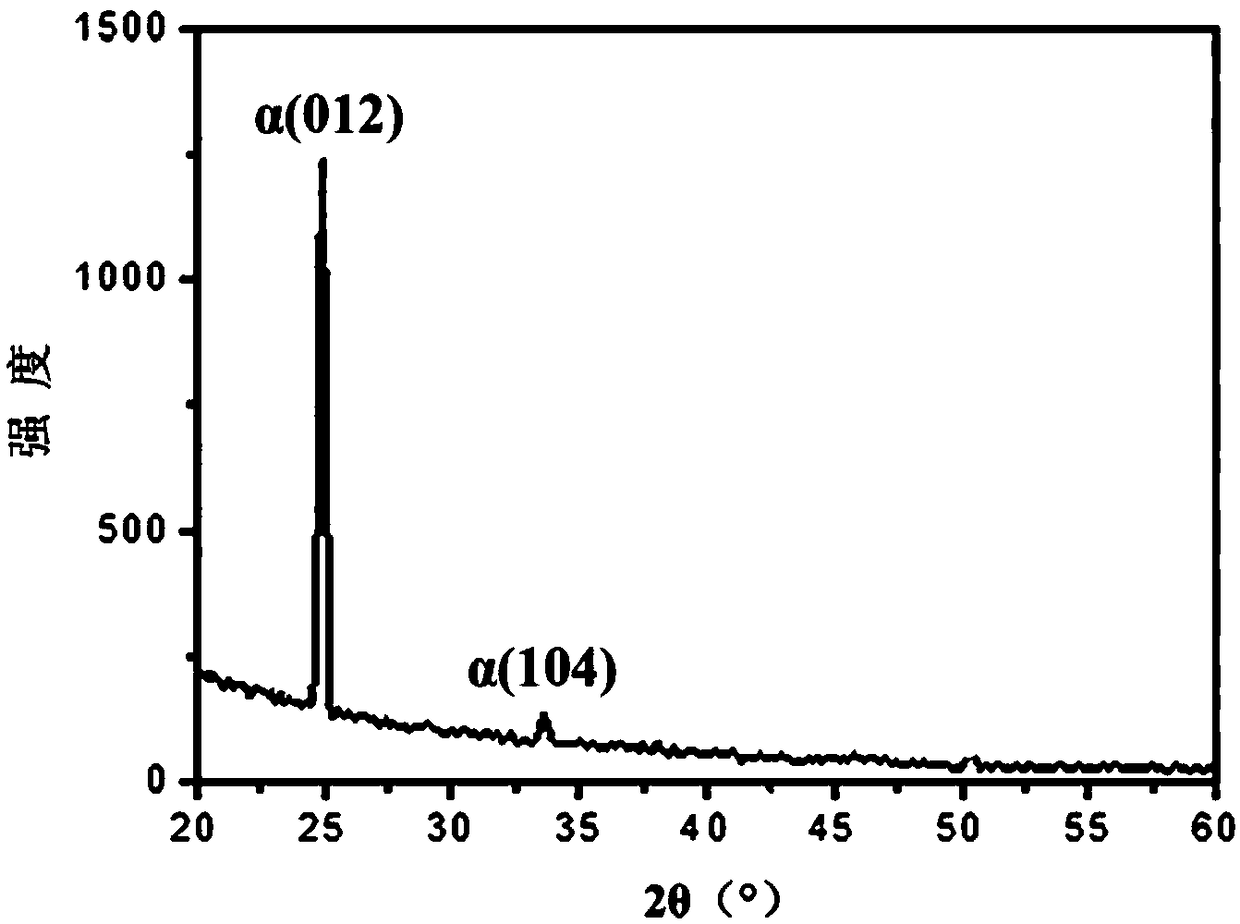

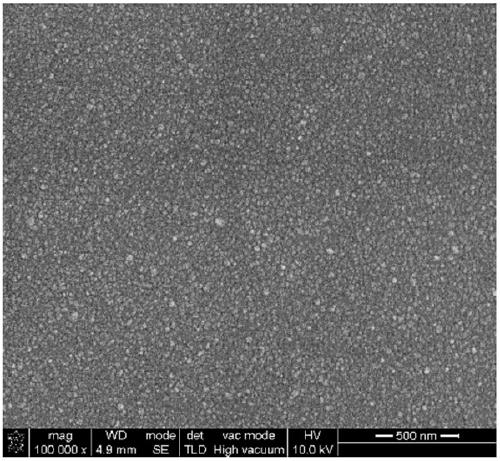

Carbon-based coating having high electrical conductivity on surface of substrate and preparation method of coating

InactiveCN104388902ALow resistivityMultiple free electronsVacuum evaporation coatingSputtering coatingCarbon coatingSurface layer

The invention provides a carbon-based coating having high electrical conductivity on the surface of a substrate. The coating is composed of a copper transition layer and a graphite-like amorphous carbon surface layer; the deposition method of the coating is a DC magnetron sputtering method. Compared with the prior art, the carbon-based coating having high electrical conductivity on the surface of the substrate is capable of ensuring that the structure of the amorphous carbon coating is mainly in the sp2 bond state to reduce the specific resistance, and meanwhile, the copper transition layer is advantageous for inducing the chain scission of the aromatic cyclic sp2 structure in the graphite-like amorphous carbon surface layer and more sp2 chain structures can be formed to increase free electrons, and therefore, the specific resistance of the carbon coating is further reduced and the electrical conductivity of the same is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Three-layer film structure coating layer and fabrication method thereof

ActiveCN109082641AReduce stressPrevents Diffusion Adhesive WearVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringSuperalloy

The invention belongs to the technical field of fabrication of a metal coating layer, and discloses a three-layer film structure coating layer and a fabrication method thereof. The three-layer film structure coating layer comprises a dual-phase Cr+Alpha-(Al, Cr)2O3 matrix pasting layer, a single phase Alpha-(Al, Cr)2O3 support layer and a single-phase nanometer Alpha-Al2O3 surface layer. The fabrication method comprises the steps of sequentially depositing the Cr+Alpha-(Al, Cr)2O3 matrix pasting layer and the Alpha-(Al, Cr)2O3 support layer by DC magnetron sputtering and by a CrAl alloy target; and obtaining the single-phase nanometer Alpha-Al2O3 surface layer by radio-frequency magnetron sputtering by an Al+Alpha-Al2O3 compost target. The surface working layer of the obtained coating layer is of a single-phase nanometer Alpha-Al2O3 structure, the coating layer is high in hardness, good in toughness, high in high-temperature thermal stability, low in friction coefficient during friction with a metal matrix and is firmly combined with a matrix such as high-speed steel, a hot work die steel and high-temperature alloy.

Owner:SOUTH CHINA UNIV OF TECH

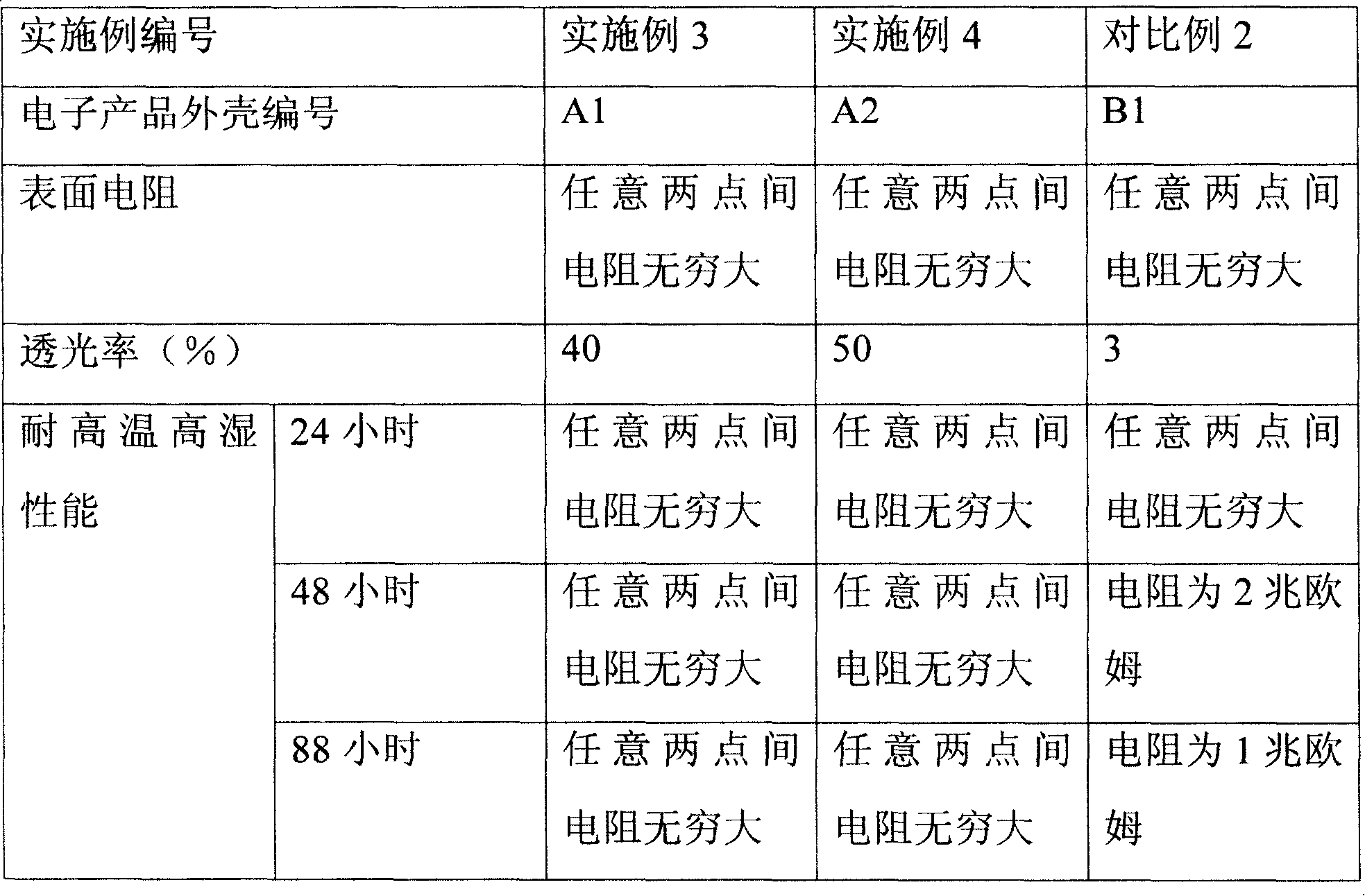

Method for preparing electronic product shell

InactiveCN101200796AWith light transmittanceTo achieve light-transmitting decorative effectVacuum evaporation coatingSputtering coatingSputteringTransmittance

The invention provides a preparation method of an electronic product casing, including forming a tin coating on matrix materials. The method of forming the tin coating on the matrix materials is a DC magnetic control sputtering coating method which includes imposing voltage on a magnetic control target to sputter and deposit target materials of the magnetic control target on the matrix materials under the sputtering condition. The target materials are tin. The sputtering condition results in that the thickness of the tin coating is not larger than 100nm. The preparation method of the electronic product coating provided by the invention uses the DC magnetic control sputtering coating method to form the tin coating on the matrix materials and control the sputtering condition to keep the thickness of the tin coating to be within 100nm. Therefore, the obtained casing is provided with certain transmittance and the light transmission decoration effect is achieved.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com