Process for preparing modified non-crystal carbon film by metal iron implantation

A technology of metal ion implantation and amorphous carbon film, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of restricting wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Compression of the sputtering target: 400 mesh graphite powder in 10 8 Under the pressure of Pa, it is pressed into a graphite target with a thickness of about 2.5mm and a diameter of 60mm.

[0022] (2) Wash the monocrystalline silicon wafer (111) in 90°C hydrogen peroxide and concentrated sulfuric acid (volume ratio 3:7) for 20 minutes, rinse it with distilled water, dry it, place it in a DC magnetron sputtering deposition chamber, and evacuate it to Residual air pressure 1×10 -3 Pa, the deposition atmosphere is Ar, the deposition pressure is about 1.0Pa, the substrate negative pressure is -120V, the target voltage is 700V, the deposition time is 10min, and the thickness is about 100nm.

[0023] (3) Silver ion implantation is carried out on a metal ion implanter, using a φ6 silver rod as a target source, accelerating voltage 50kV, arc current 60A, average beam current 0.5mA, implantation dose 5×10 15 ions / cm 2 , the vacuum degree was kept at 1.2×10 during the in...

Embodiment 2

[0026] (1), (2) steps are with embodiment 1.

[0027] (3) Change the silver in Example 1 into chromium, arc current 40A, average beam current density 1.5mA, implant dose 3×10 16 ions / cm 2 . Other steps are the same as in Example 1.

Embodiment 3

[0029] Preparation of silver ion implanted amorphous carbon film on stainless steel and bearing steel.

[0030] (1) The steps are the same as in Example 1.

[0031] (2) Grind the stainless steel and bearing steel blocks on No. 400, 600, 800, and 1000 water sandpaper in sequence, and then pass through AI 2 o 3 Polish to a surface roughness Ra of less than 0.05 μm. Ultrasonic cleaning in ethanol and acetone respectively for 20 minutes, dried and sent to the DC magnetron sputtering deposition chamber.

[0032] (3) All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

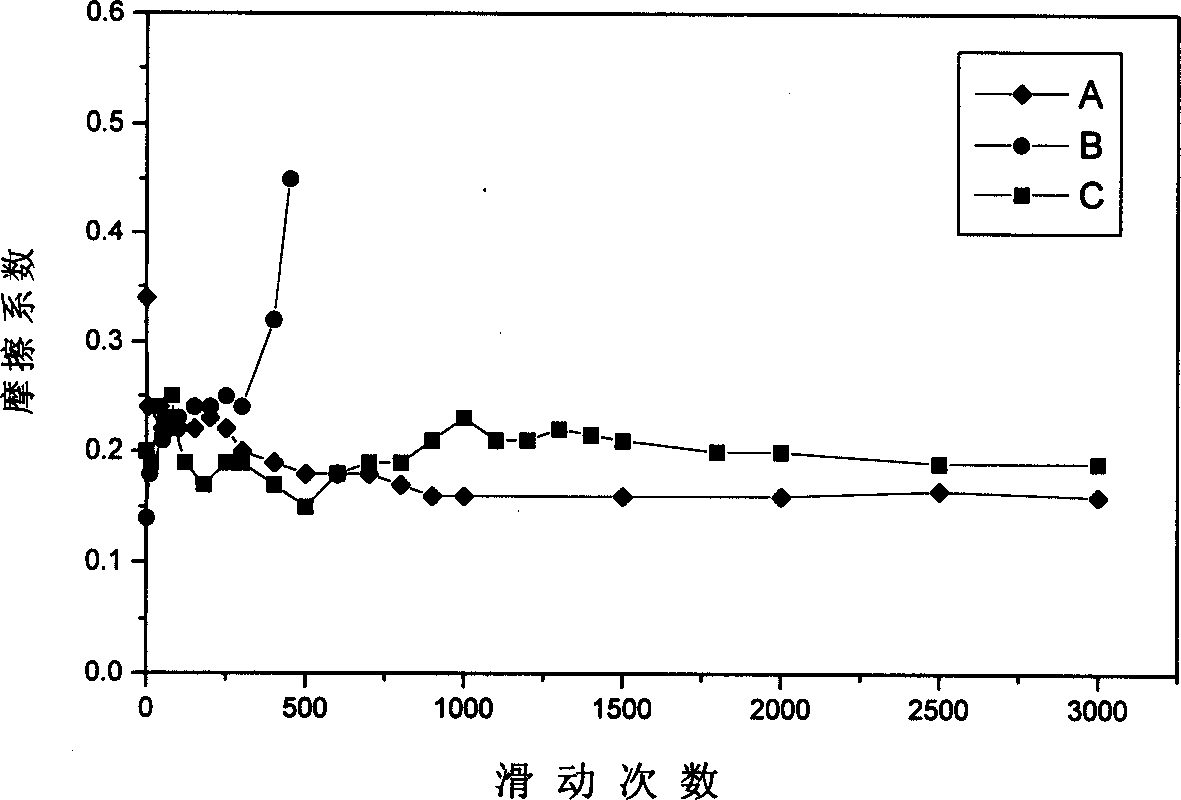

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com