Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1073 results about "Surface corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface corrosion – Caused by either direct chemical or electrochemical attack, it appears as a general roughening, etching, or pitting of the surface of a metal, frequently accompanied by a powdery deposit of corrosion products.

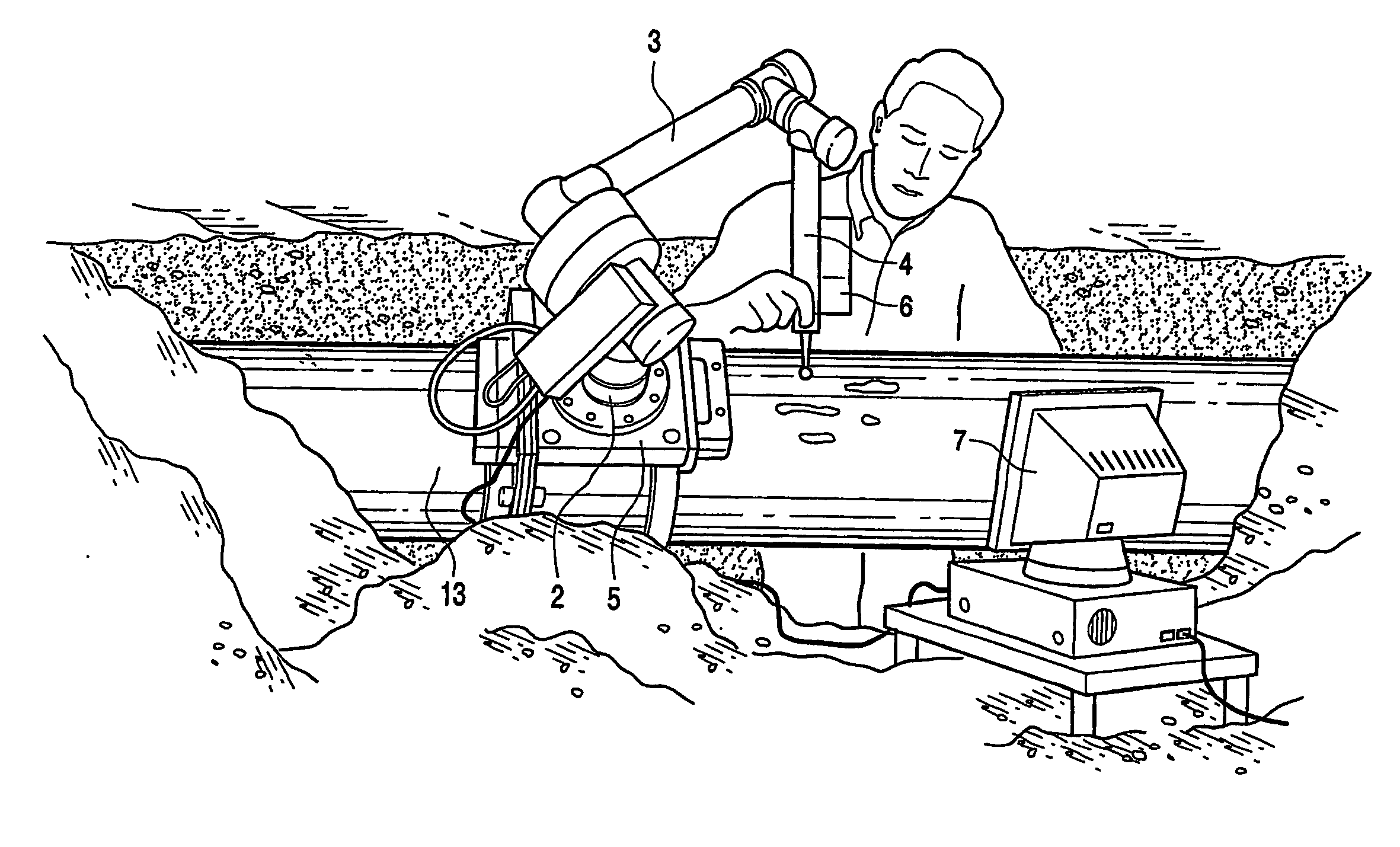

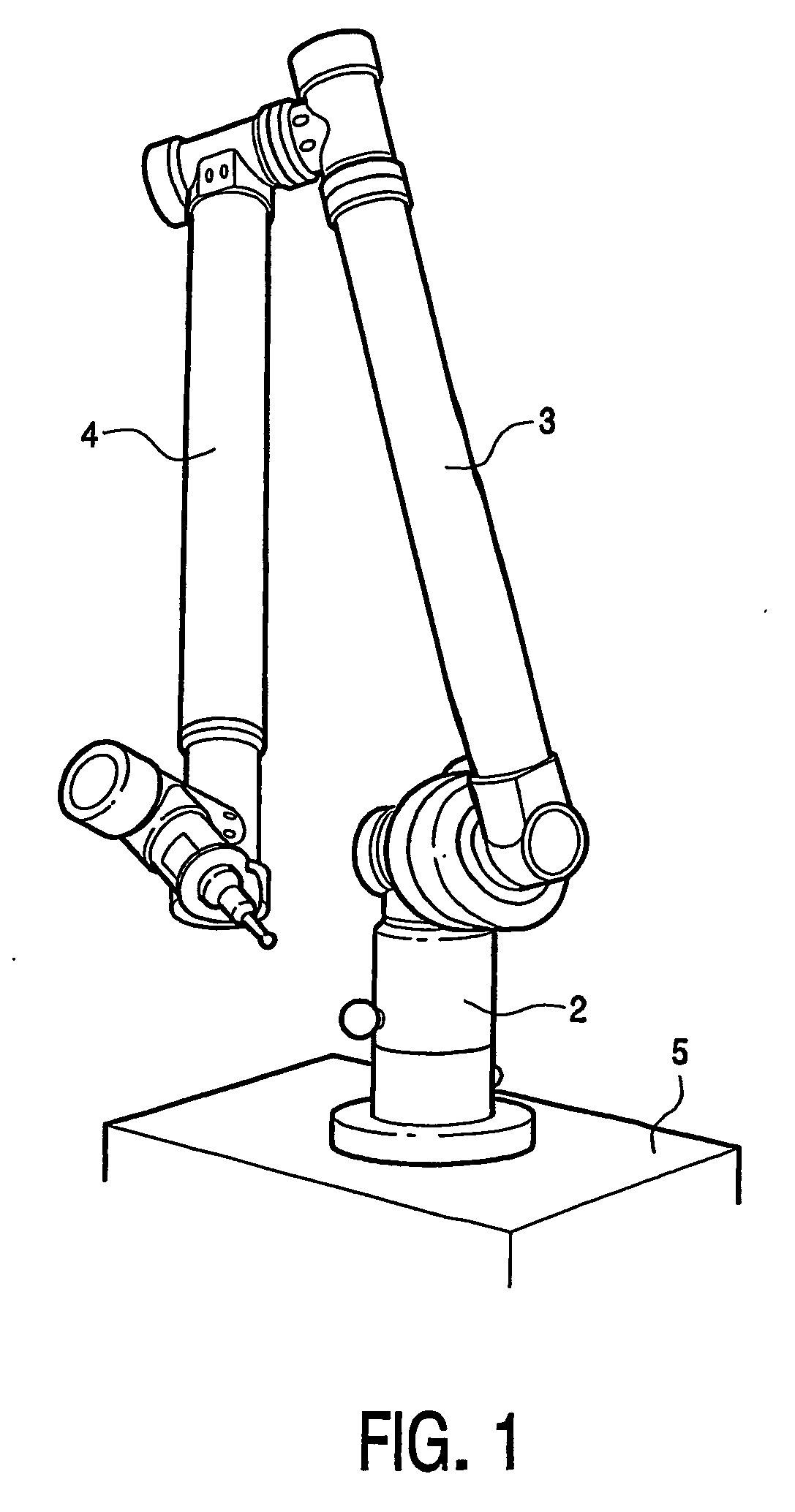

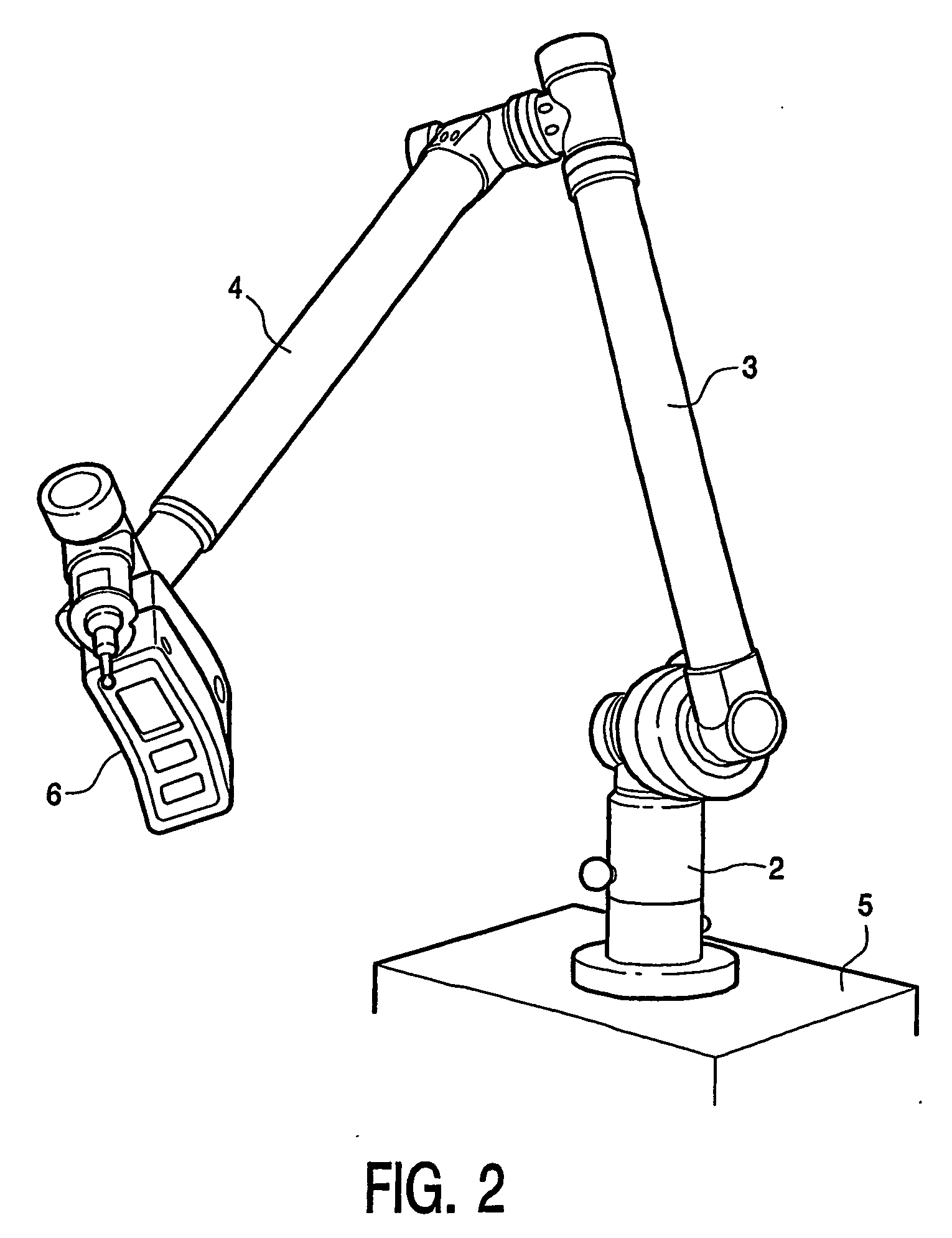

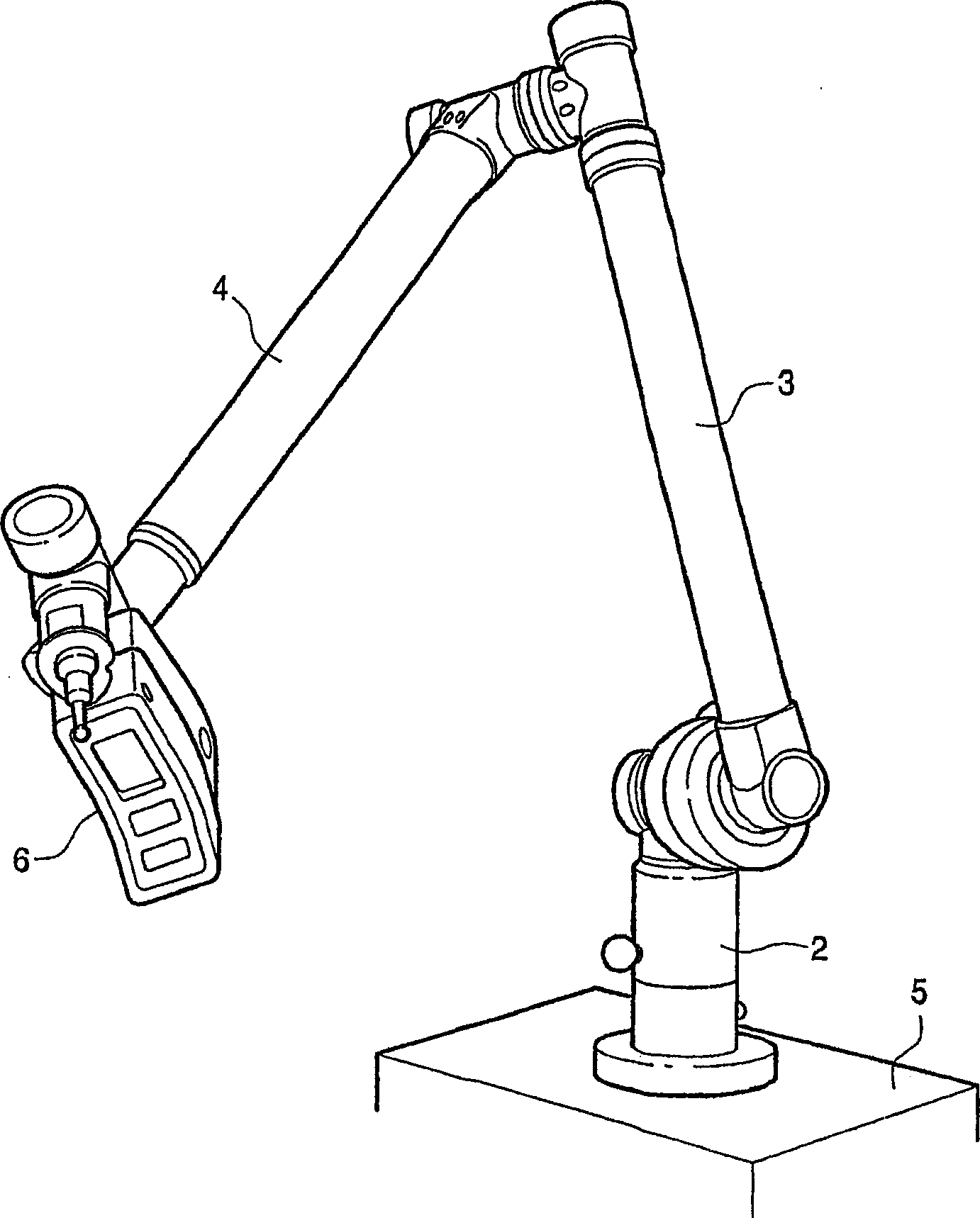

Method and apparatus for scanning corrosion and surface defects

InactiveUS20060288756A1Readily usable outputAccurately determineAnalysing solids using sonic/ultrasonic/infrasonic wavesWave based measurement systemsSurface conditionsPrediction system

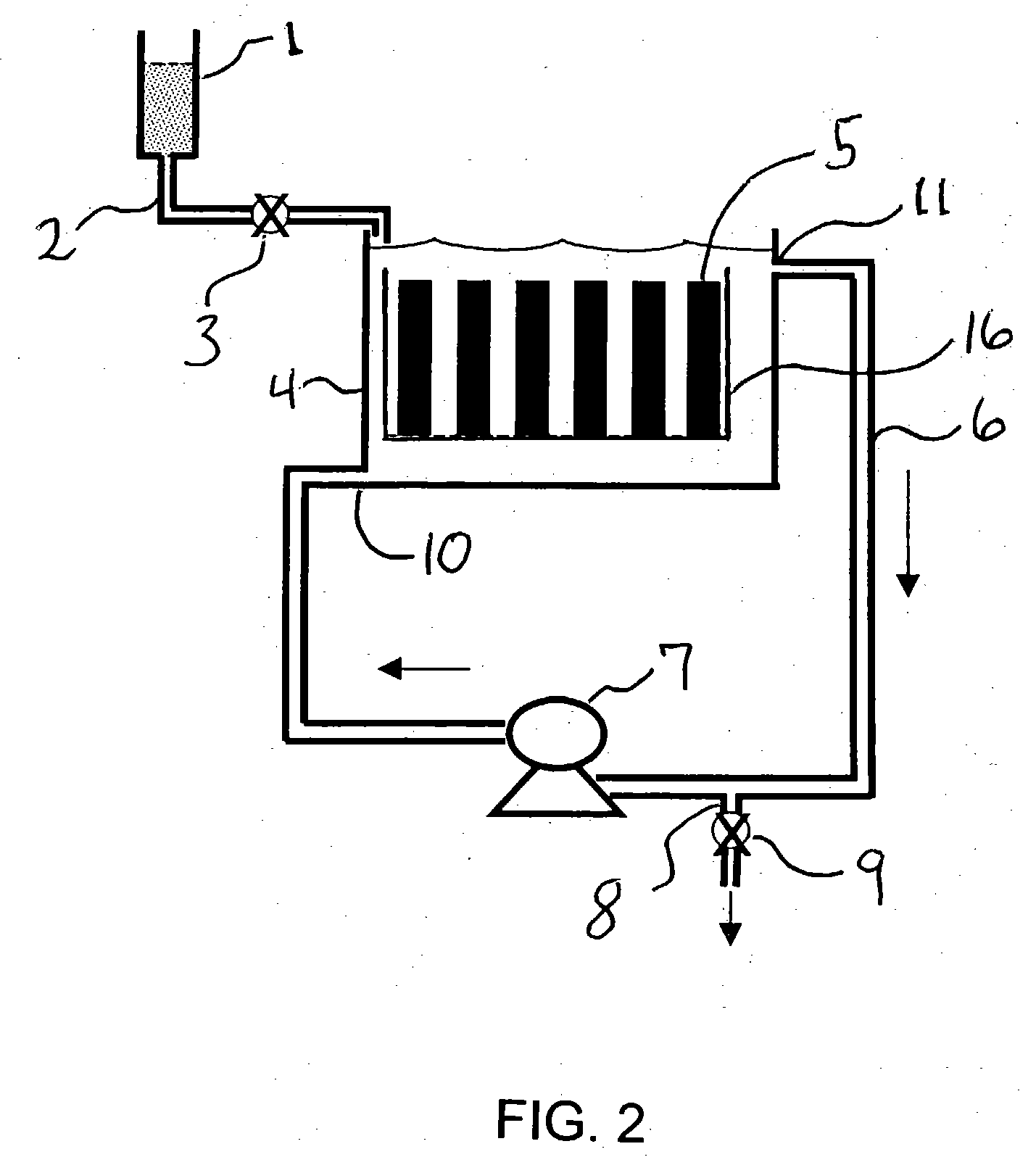

The present invention relates to a method and an apparatus for determining the life span for secure use of a pipeline comprising the steps of a) defining an area for surface corrosion analysis on the pipeline, b) providing a corrosion scanning system for scanning the defined area on the pipeline, c) localizing and measuring the corrosion on the surface of the defined area by means of the corrosion scanning system, d) determining the remaining wall-thickness of the pipeline at the defined area by means of the corrosion scanning system, and e) processing the surface condition data related to corrosion at the defined area obtained in steps c) and d) to determine the life span for secure use of the pipeline. In another aspect the present invention relates to a corrosion scanning system for performing for performing the method according to the invention. In another aspect the invention relates to a prediction system for predicting the secure life span of a pipeline.

Owner:DE MEURECHY GUIDO D K

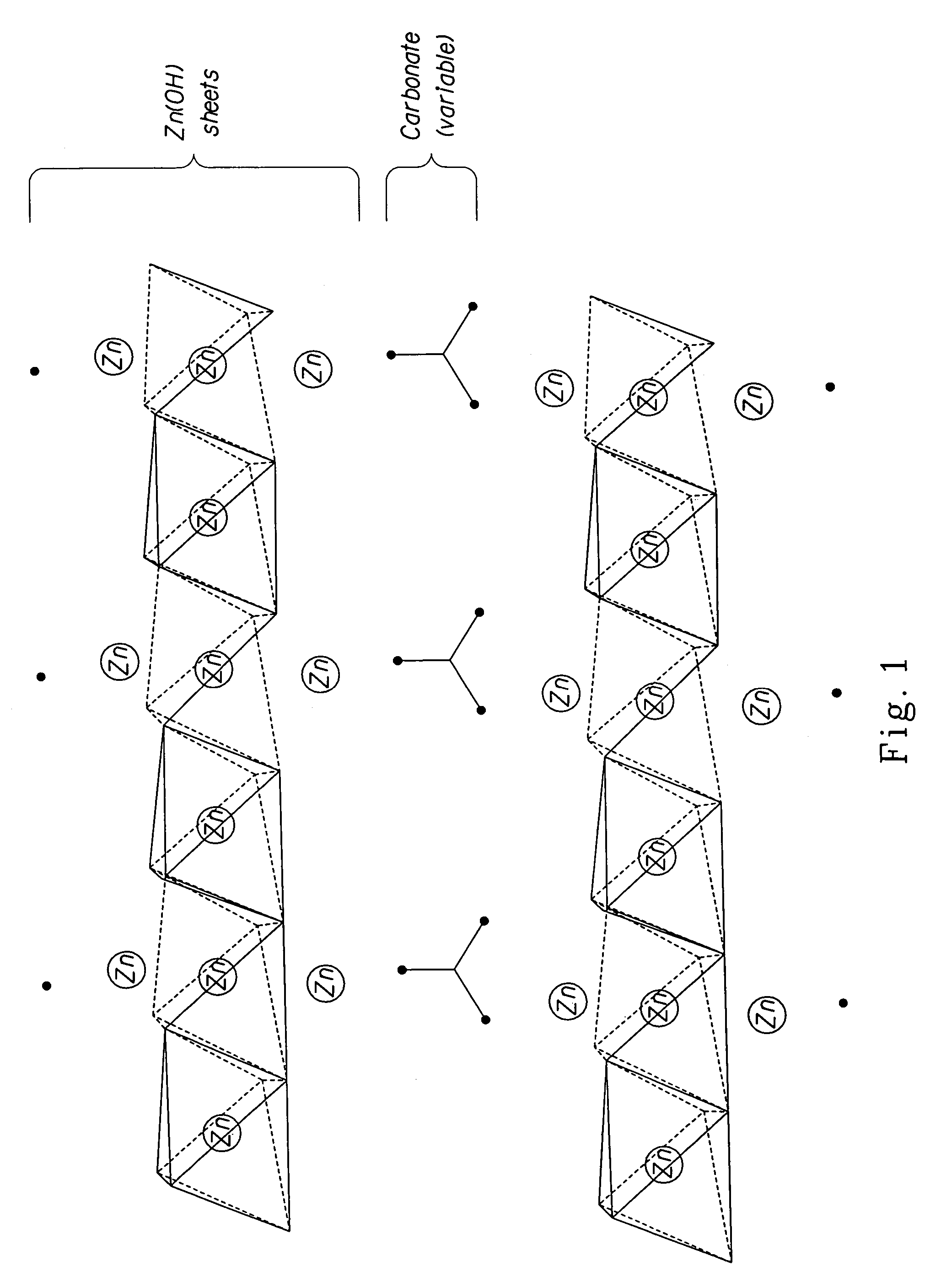

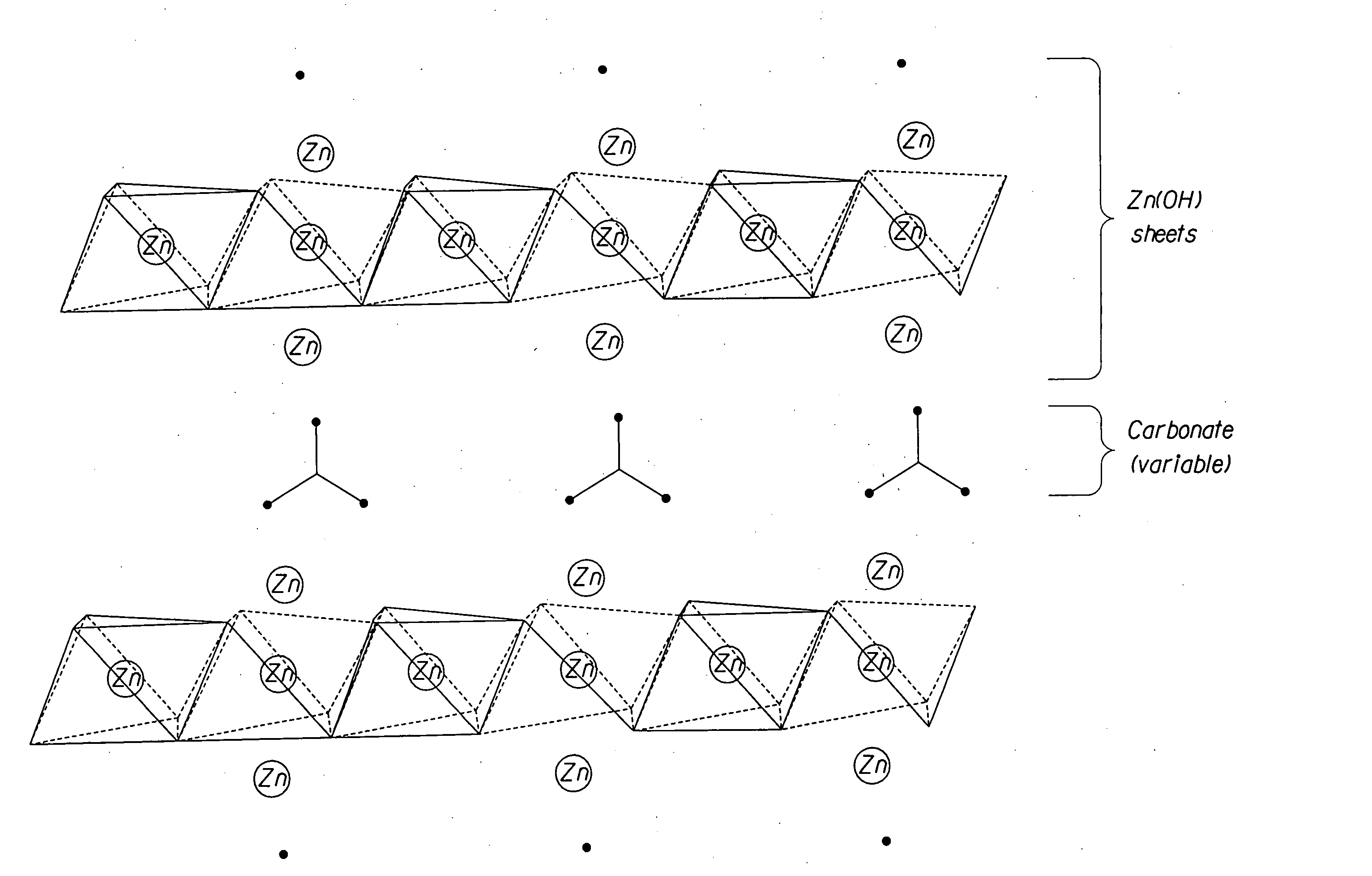

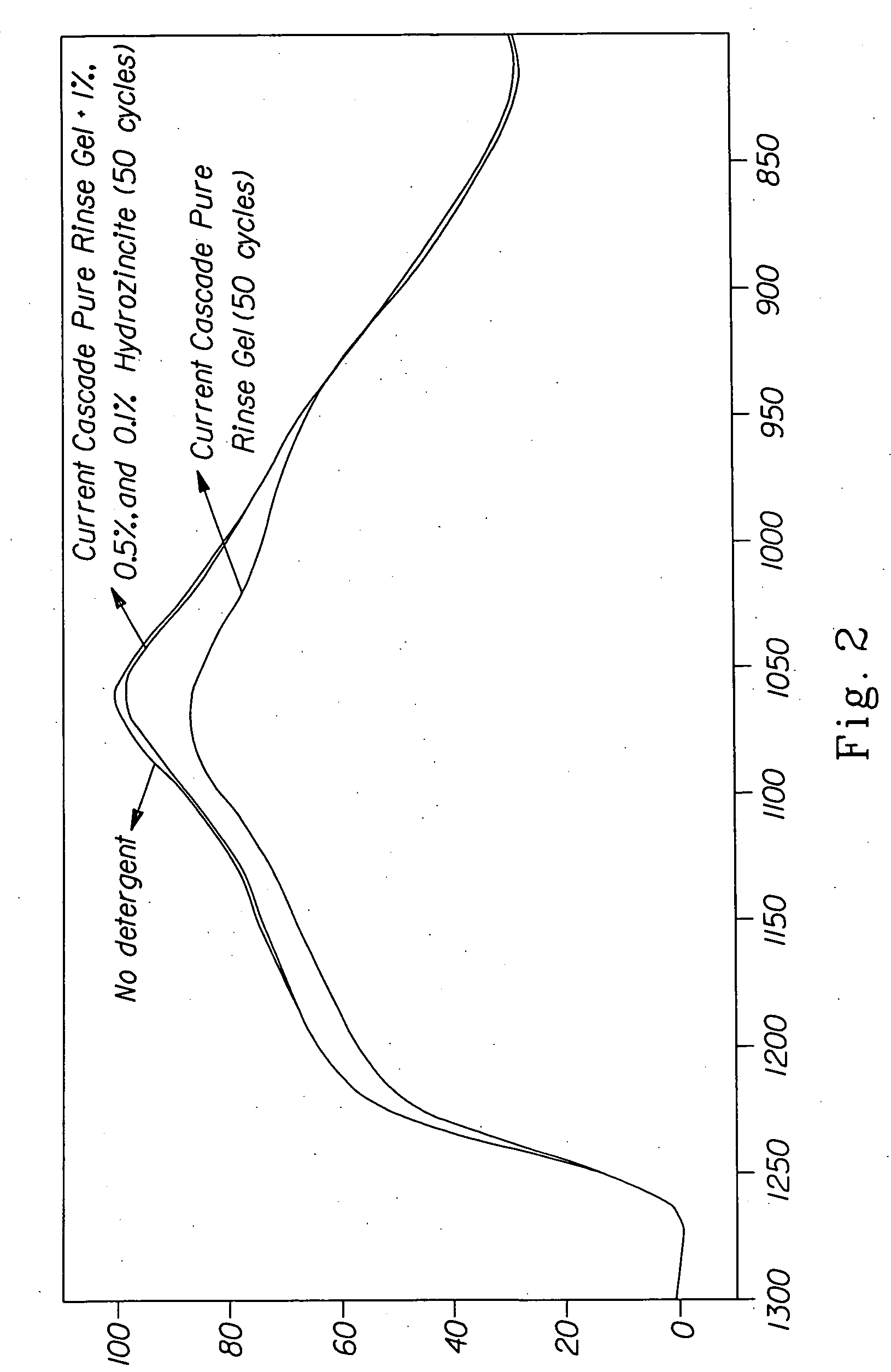

Compositions for protecting glassware from surface corrosion in automatic dishwashing appliances

InactiveUS7271138B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhysical chemistryZinc

Owner:PROCTER & GAMBLE CO

Methods and composition for cleaning and passivating fuel cell systems

ActiveUS20050245411A1Organic detergent compounding agentsAnionic surface-active compoundsFuel cellsSolvent

A cleaner-passivator composition and method for treating a fuel cell cooling system are described. The cleaner-passivator comprises a complexing agent, a surfactant, a corrosion inhibitor, and a solvent. The cleaner-passivator reduces the contaminants circulating in the fuel cell coolant system that contribute to increasing conductivity in the fuel cell coolant. In addition, the passivator reduces the surface corrosion in the fuel cell system.

Owner:PRESTONE PROD CORP

Metal surface treating agent

InactiveCN102051611AReduce corrosion rateReduce surface tensionMetallic material coating processesMetasilicateChemical conversion

The invention relates to a metal surface treating agent which comprises the following components: silicate or metasilicate, chitosan, corrosion inhibitor, surfactant, antioxidant, wetting agent, film-forming additive, ethanol and water, wherein one or more of nanosized titanium dioxide, zirconium oxide or zirconium fluoride are evenly mixed with silicate or metasilicate and account for 3wt%-25wt% of silicate or metasilicate; the particle size of nanosized titanium dioxide, zirconium oxide or zirconium fluoride is less than 100nm; the degree of deacetylation of chitosan is 55%-100%; and the pH value of the composite is adjusted to 5.0-9.0. The invention provides the metal surface treating agent which uses environmentally friendly aqueous solution to form a metal chemical conversion film so as to inhibit the surface corrosion of metal; when the metal surface treating agent is used to treat the surface of the cold-rolled steel plate product, the rust-proof effect is especially good; and the metal surface treating agent can not cause environmental pollution and be green and environmentally friendly.

Owner:DALIAN POLYTECHNIC UNIVERSITY

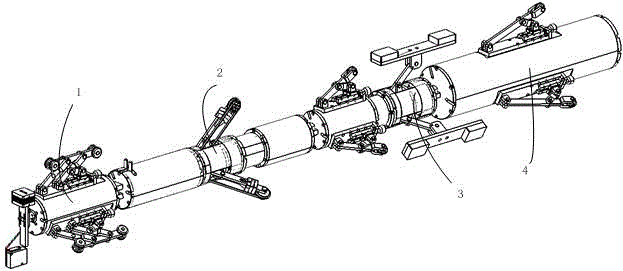

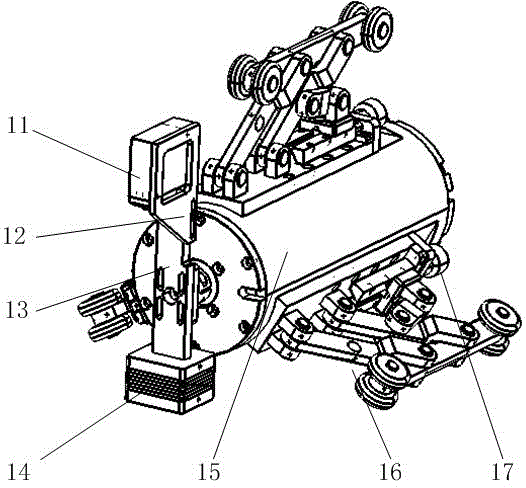

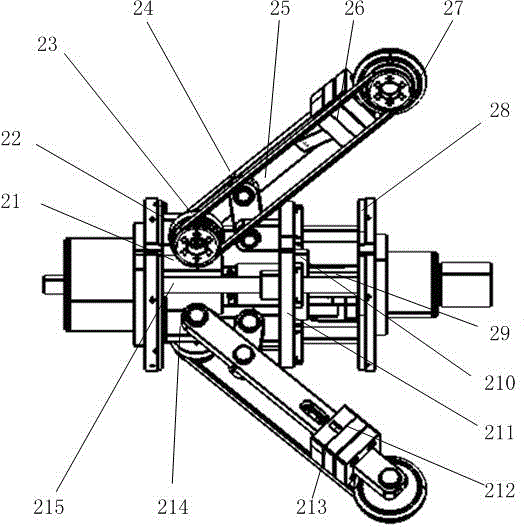

Pipeline detection robot

The invention relates to a pipeline detection robot. The pipeline detection robot mainly comprises a laser detection mechanism (1), a traction mechanism (2), an electromagnetic ultrasonic detection mechanism (3) and an electronic cabin (4), all of which are connected through connecting hinge shafts; the traction mechanism (1) adopts a single-motor all-drive mode and is driven by a turbo-worm synchronous belt to supply a walking power to the robot; the laser detection mechanism (2) comprises a laser displacement sensor, a rotating arm, a counterweight, a support body and the like and is used for measuring surface corrosion and deformation of a pipeline; the electromagnetic ultrasonic detection mechanism (3) comprises a support assembly, a probe and a fixing plate and is used for measuring the wall thickness and the crack defect of the pipeline; the electronic cabin (4) is used for carrying auxiliary components, such as a stepping motor controller, a servo motor driver, a power supply and an FPGA (Field Programmable Gate Array) control panel. The pipeline detection robot disclosed by the invention can be used for finding the defects, such as pipeline corrosion, cracks and deformation, carrying out in-service detection on an oil and gas pipeline in a working process, carrying out targeted repair, maintenance and replacement according to a detection result, reducing the maintenance cost and guaranteeing safe and stable operation of the oil and gas pipeline.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

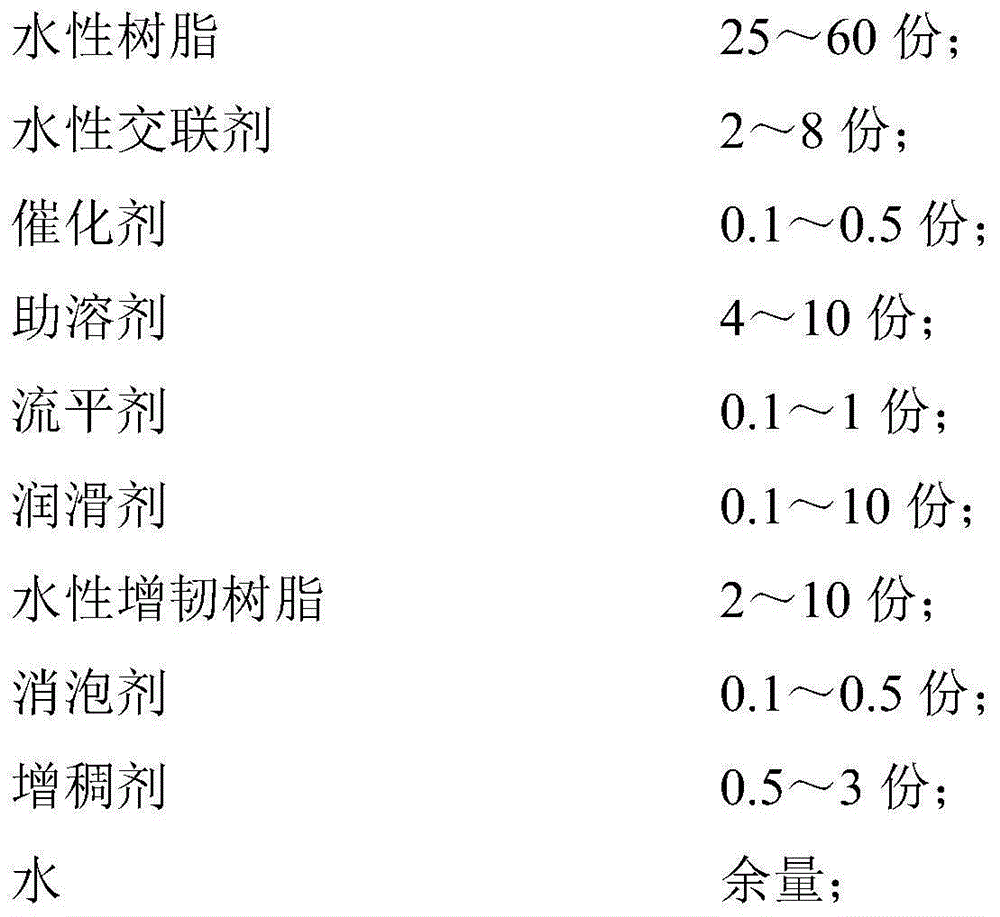

Water-based high-corrosion-resistance coating with excellent stamping performance and preparing method and application of water-based high-corrosion-resistance coating

ActiveCN105038464AEmission reductionReduce pollutionPretreated surfacesAnti-corrosive paintsWater basedMicrometer

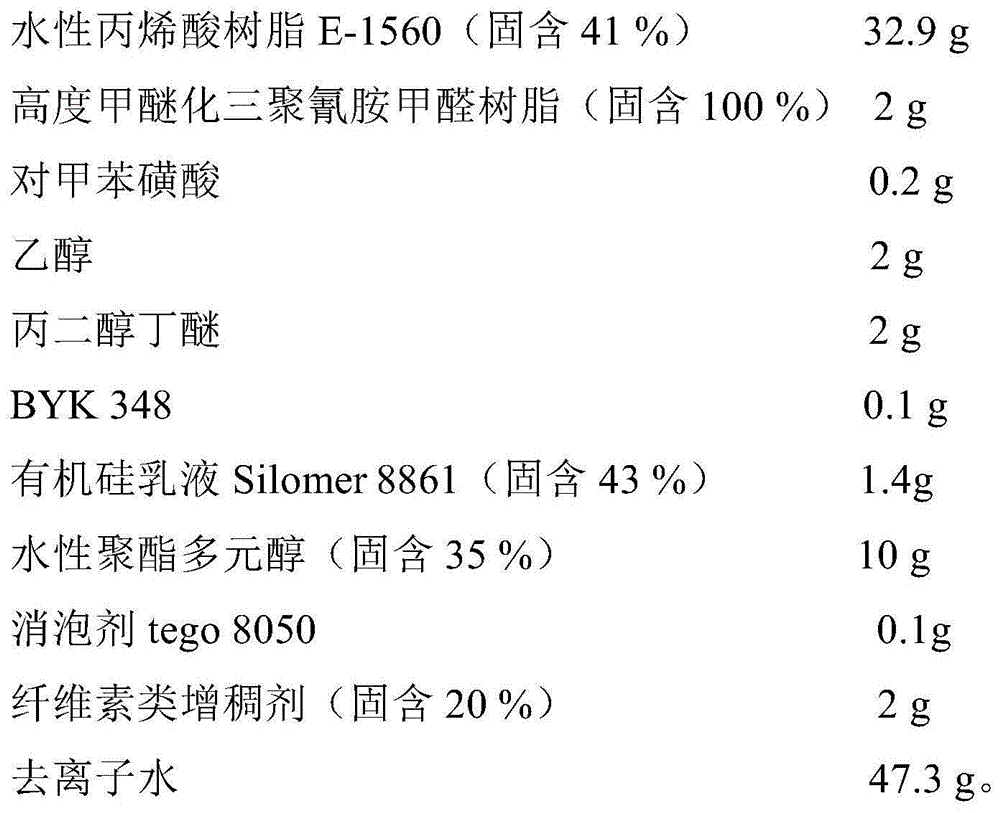

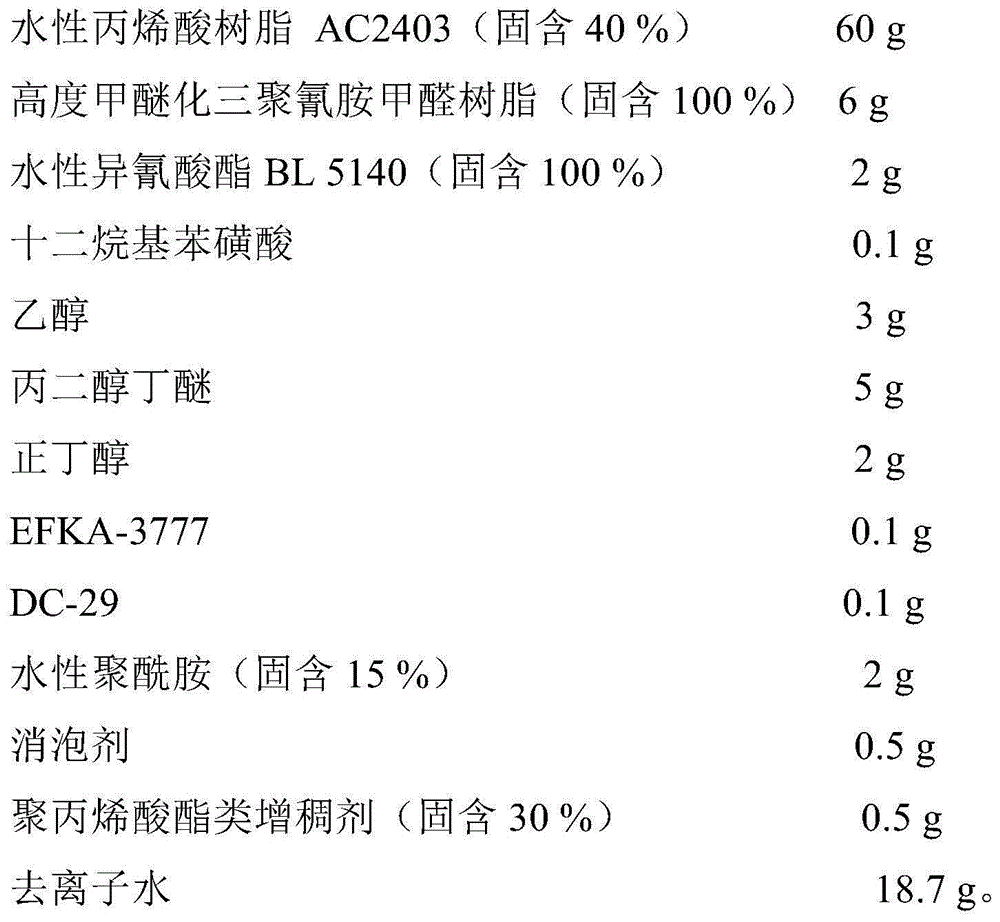

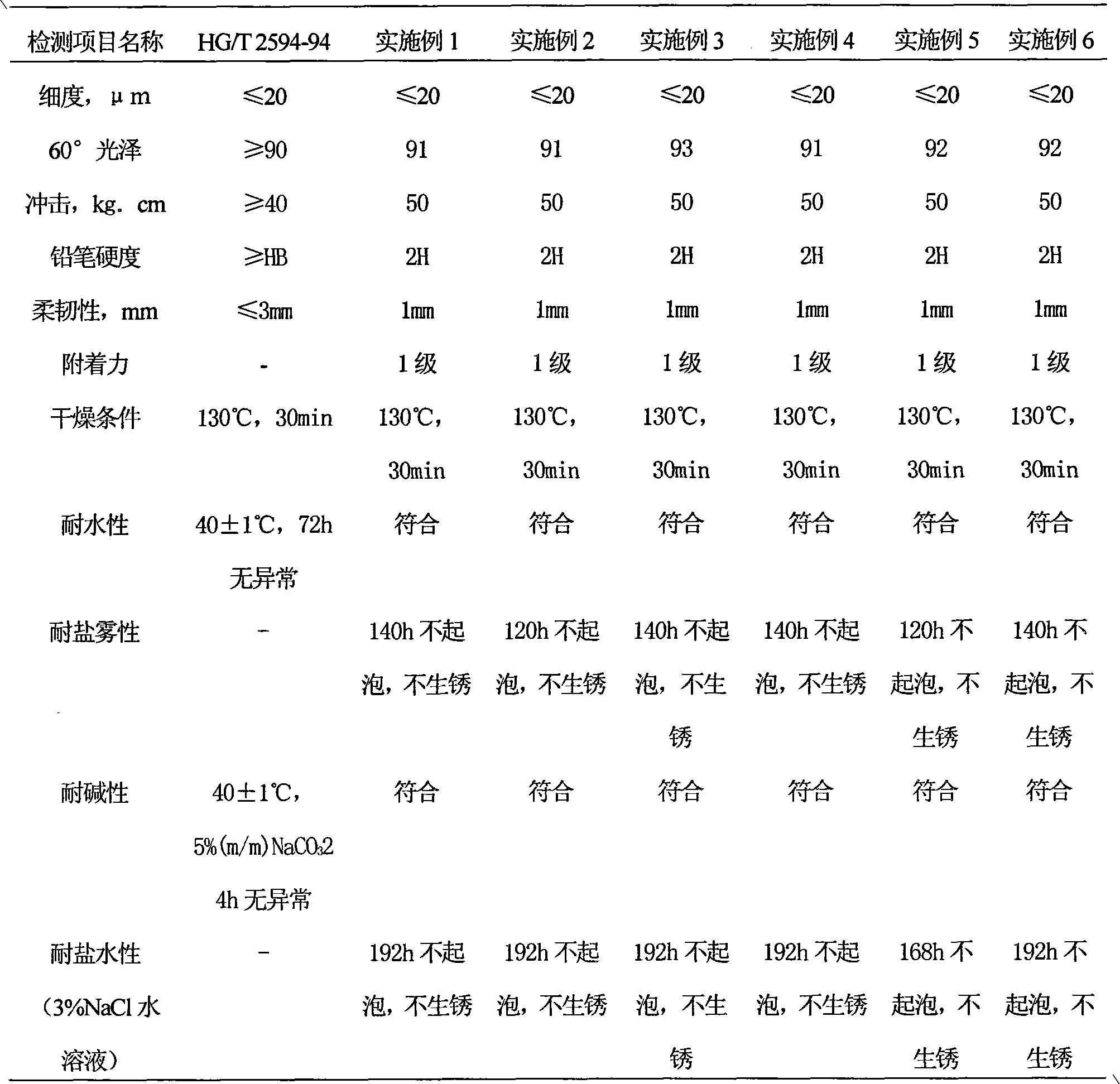

The invention belongs to the technical field of surface corrosion prevention and discloses a water-based high-corrosion-resistance coating with excellent stamping performance and a preparing method and application of the water-based high-corrosion-resistance coating. The coating comprises, by mass, 25-60 parts of water-based resin, 2-8 parts of water-based cross-linking agent, 0.1-0.5 part of catalyst, 4-10 parts of cosolvent, 0.1-1 part of flatting agent, 0.1-10 parts of lubricating agent, 2-10 parts of water-based toughening resin, 0.1-0.5 part of defoaming agent, 0.5-3 parts of thickening agent and the balance water, and the total mass parts of the components are 100 parts. According to the water-based high-corrosion-resistance coating, the water-base resin serves as film forming matter, so that good construction performance is achieved, curing is quick, super corrosion resistance can be obtained when the thickness of the coating is 2-5 micrometers, the performance of resisting neutral salt mist is longer than 2,000 hours, resistance to acid salt mist is longer than 500 h, the corrosion grade can reach 9.8 or higher, and the salt mist resisting performance of the coating is maintained unchanged after stamping or bending is carried out.

Owner:GUANGZHOU HUMAN CHEM

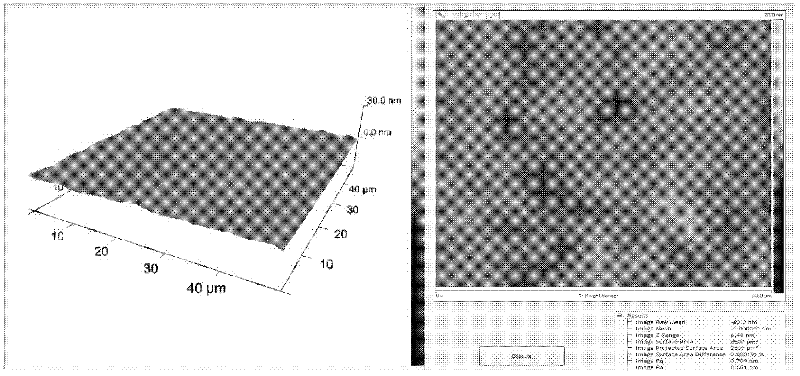

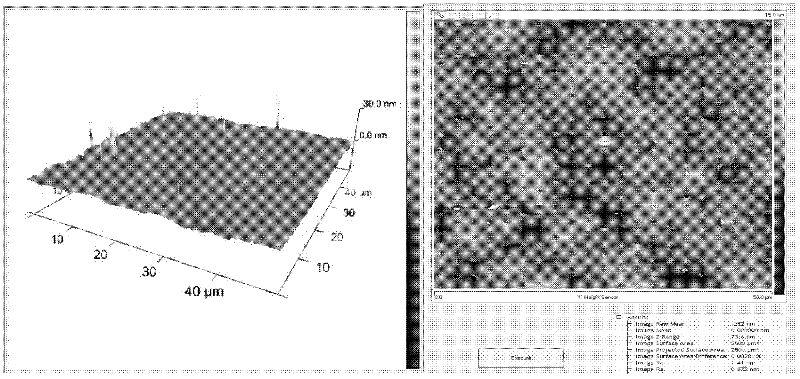

Corrosion-resistant metal surfaces

InactiveUS7507480B2Increase coverageFine structural detailMaterial nanotechnologyFibre treatmentMetal oxide nanoparticlesMetallurgy

Owner:BROOKHAVEN SCI ASSOCS

Environment-friendly type galvanizing metal surface treating agent

InactiveCN101033363AExcellent long-term inhibition of white rustImprove rust resistanceLiquid surface applicatorsAnti-corrosive paintsSilica gelSolvent

The invention provides a kind of metal surface disposal which formes an environment friendly waterbase film to inhibit corrosion of the metal surface, and the disposal particularly brings excellent anti-corrosion properties with the galvanized metal products. The metal surface disposal basically contains following components which take alcohol and water as the solvent: A. silicates, polymerization silicates, fluoride silicates, B. silica (aqueous dispersion of nano) and / or SinOmXR1R2R3, C. phenolic resin and modified phenolic resin, D. stabilizer, E. pH regulator, F. thickener, G. leveling agent, H. film builder, I. wetting agent, J. antioxidant.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Mono-component aqueous metal baking paint and preparation method thereof

The invention discloses a mono-component aqueous metal baking paint and a preparation method thereof. The mono-component aqueous metal baking paint consists of the following components by weight: 40 to 57 percent of tap water, 28 to 34 percent of aqueous acrylic modified polyester resin, 7 to 8.5 percent of amino resin, 1.12 to 1.36 percent of amine modifier, 0.1 to 0.3 percent of wetting dispersing agent A, 0.1 to 0.3 percent of wetting dispersing agent B, 0.01 to 0.1 percent of defoaming agent, 0.5 to 1.2 percent of thickening agent, and 0.2 to 0.6 percent of levelling agent. The mono-component aqueous metal baking paint uses water as a solvent without adding an alcohol / ether cosolvent so that environmental protection is excellent; because of mono-component, the construction is simple and convenient, and the performance is stable; and a paint film is plumpy, the luster is high, the mechanical property is excellent, and the adhesive force is good. The mono-component aqueous metal baking paint is applicable to metal surface corrosion protection and decoration, and can be used as a finishing paint, a priming paint or a coating varnish; and when used for bottom surface integral coating, the mono-component aqueous metal baking paint still has excellent surface effect and protective action.

Owner:GUANGZHOU JOINTAS CHEM

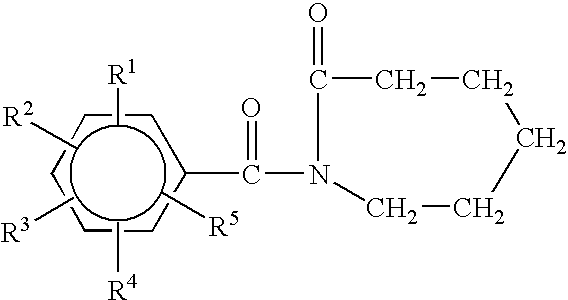

Surface corrosion protection detergent compositions containing polyvalent metal compounds and high levels of low foaming, nonionic surfactants

ActiveUS20060069005A1Improve corrosion resistanceInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSurface corrosionChemistry

Owner:THE PROCTER & GAMBLE COMPANY

Corrosion-resistant silicon nitride ceramics

InactiveUS20060073361A1Prevent peelingLarge coefficientBlade accessoriesMachines/enginesThermal dilatationCrazing

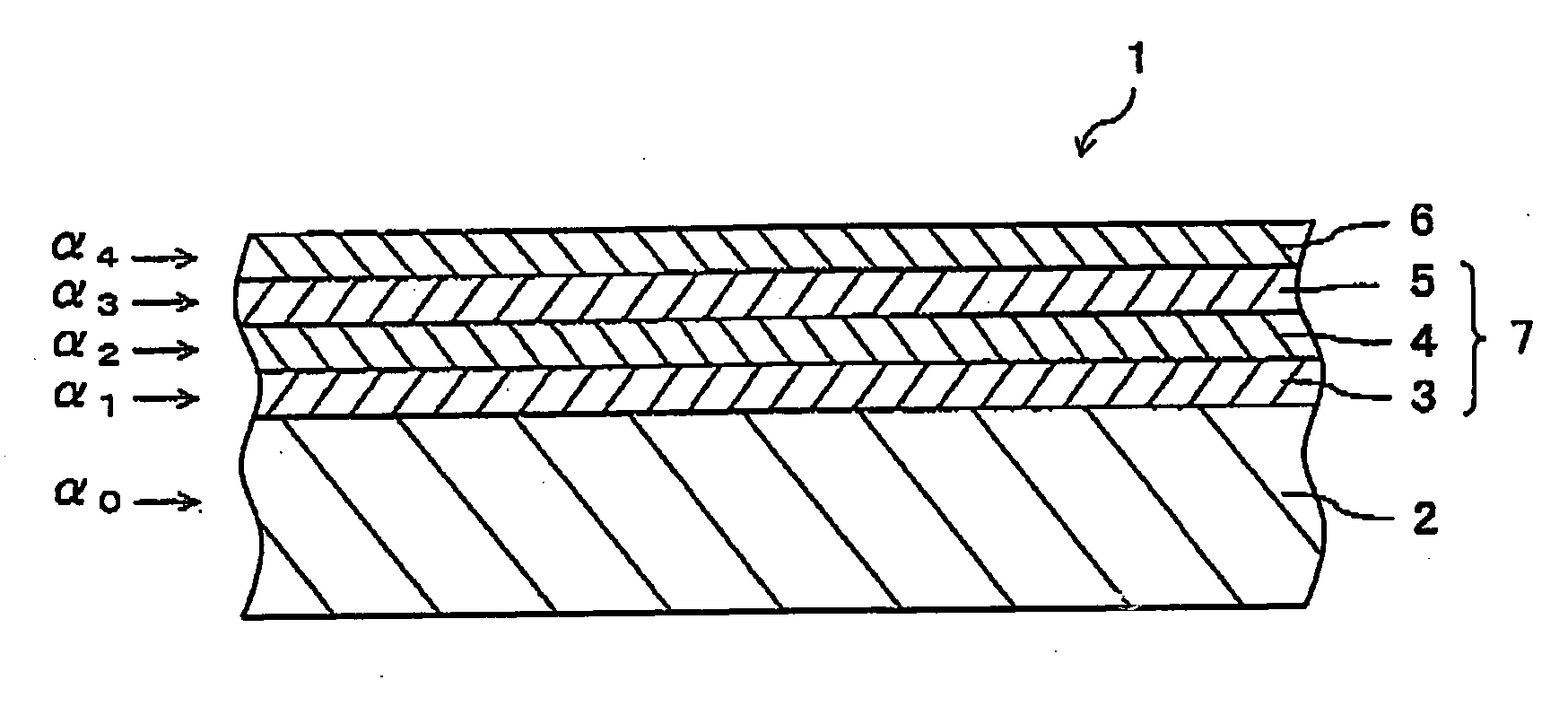

A corrosion-resistant silicon nitride ceramics in which an adhesion enhancing layer (3), a stress relaxing layer (4) and a crack extension preventing layer (5) are laminated in this order on a ceramic substrate (2) composed mainly of silicon nitride, and a surface corrosion-resistant layer (6) composed mainly of zirconium oxide stabilized by an element of the group 3a of the periodic table is laminated. The thermal expansion coefficient (α0) of the ceramic substrate (2), the thermal expansion coefficient (α1) of the adhesion enhancing layer (3), and the thermal expansion coefficient (α2) of the stress relaxing layer (4), the thermal expansion coefficient (α3) of the crack extension preventing layer (5), and the thermal expansion coefficient (α4) of the surface corrosion-resistant layer (6) satisfy the following relational expressions (I) to (III): α0≈α1 (I) α3<α2 (II) α3<α4 (III)

Owner:KYOCERA CORP +2

Manufacturing method for floating type micro-silicon electrostatic gyro/accelerometer sensitive structure

InactiveCN101279713AInhibit sheddingThickness loss is negligibleAcceleration measurement using interia forcesDecorative surface effectsLevitationAccelerometer

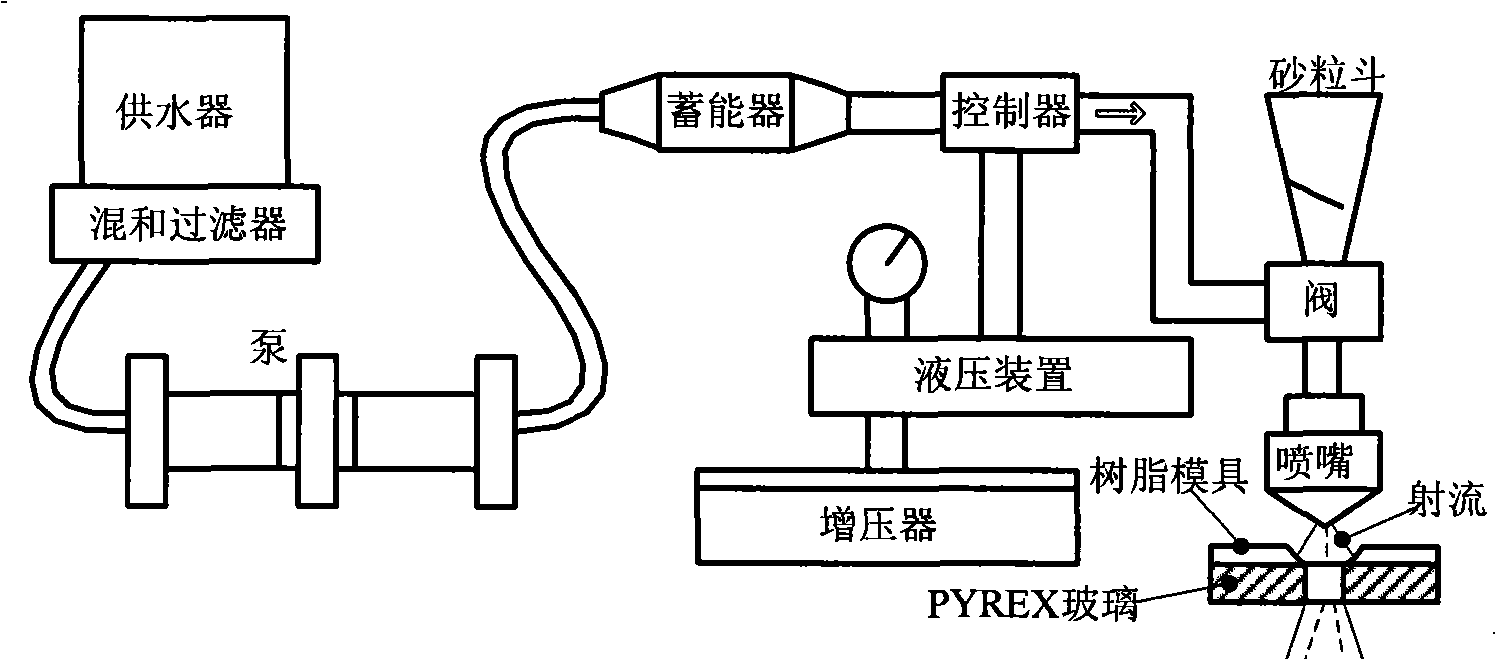

The invention relates to a method for preparing a levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure, which belongs to the technical field of silicon structure processing. The method comprises the steps: glass etching; glass gold splashing: a metal layer raising 400-600 tenthmeters higher than a glass surface; perforating the glass; a first and a second RIE etching for the silicon slice; film beam process: high-temperature dry oxidation and surface corrosion; a first electrostatic bonding for glass and silicon; thinning and polishing to the silicon slice; ICP etching for the silicon slice; a third RIE etching for the silicon slice; a fourth RIE etching for the silicon slice; a second electrostatic bonding for glass and silicon; ICP removal for film beam to prepare the levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure. The method adopts the proposal of sandblasting perforating for perforating the glass, introduces the silicon dioxide film beam as a sacrificial layer and adopts the ICP film beam removal process; the method can effectively solve the problem of adherence of a sandwich microstructure in the second electrostatic bonding and does not need post treatment so that the method has higher efficiency and better compatibility with the MEMS process.

Owner:TSINGHUA UNIV +1

Complete-cycle methods for protecting glassware from surface corrosion in automatic dishwashing appliances

ActiveUS7241726B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater solubleZinc

Complete-cycle methods are provided for protecting glassware from corrosion in automatic dishwashing appliances using a through-the-wash detergent composition, especially detergent compositions comprising zinc-containing materials, in combination with a rinse aid composition, especially rinse aid compositions comprising at least one water-soluble metal salt.

Owner:PROCTER & GAMBLE CO

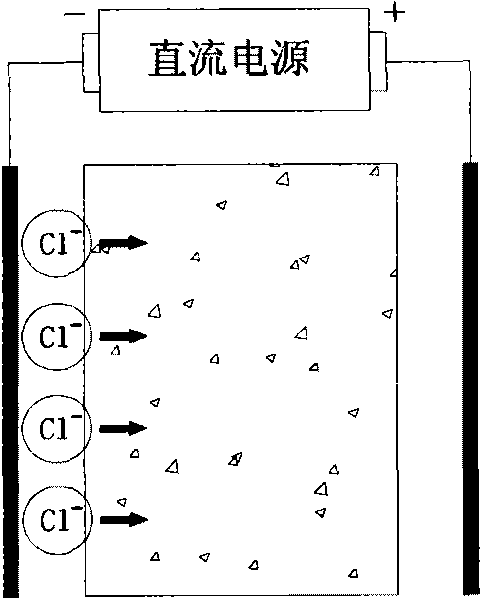

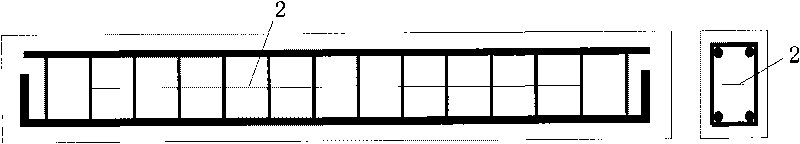

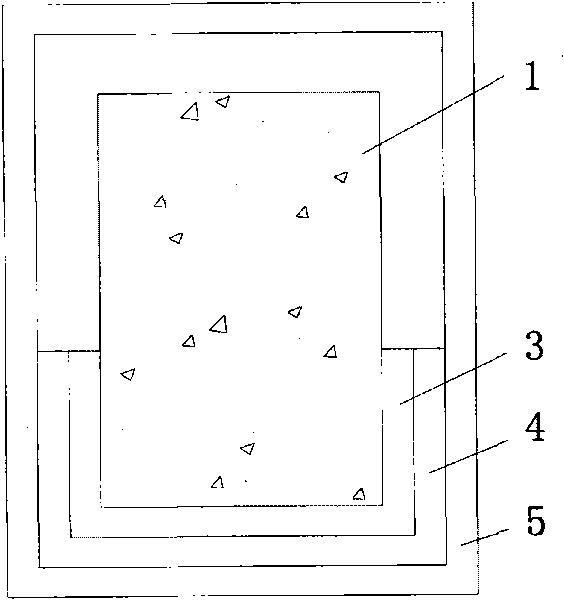

Accelerated test method of non-uniform corrosion in inbuilt electrode simulation concrete

The invention discloses an accelerated test method of non-uniform corrosion in inbuilt electrode simulation concrete. After a concrete test piece is prepared by precating stainless steel sheets in concrete, the concrete test piece is successively performed with electroosmosis treatment, drying and watering cycle and constant-current energization treatment. Under the action of an electric field, chlorid ions accelerate to move into a concrete structure, and reinforcing steel bars in concrete reach the corrosion threshold value in advance so as to simulate the process that chlorid ions enter the concrete structure in the engineering environment. The drying and watering cycle process and little corrosion current speed up to corrode the reinforcing steel bars in the concrete structure, and the developing process of practical corrosion-induced expansive cracks is simulated. The method of the invention can simulate the diffusion process of chlorid ions to concrete in the chloride corrosion environment to realize the non-uniform corrosion and the single-surface corrosion of reinforcing steel bars in concrete, truly reflects the developing process of corrosion-induced expansive cracks in a reinforced concrete structure, and provides an accelerated test method for accessing the corroded property of the reinforced concrete structure.

Owner:ZHEJIANG UNIV

Method and apparatus for scanning corrosion and surface defects

InactiveCN1761871AAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceSurface conditionsPrediction system

The present invention relates to a method and an apparatus for determining the life span for secure use of a pipeline comprising the steps of a) defining an area for surface corrosion analysis on the pipeline, b) providing a corrosion scanning system for scanning the defined area on the pipeline, c) localizing and measuring the corrosion on the surface of the defined area by means of the corrosion scanning system, d) determining the remaining wall-thickness of the pipeline at the defined area by means of the corrosion scanning system, and e) processing the surface condition data related to corrosion at the defined area obtained in steps c) and d) to determine the life span for secure use of the pipeline. In another aspect the present invention relates to a corrosion scanning system for performing for performing the method according to the invention. In another aspect the invention relates to a prediction system for predicting the secure life span of a pipeline.

Owner:吉多·D·K·德莫莱奇

Method for preparing coating with metal surface corrosion inhibition and self-repair functions

InactiveCN101613543AShape is not limitedUnlimited sizeAnti-corrosive paintsTectorial membraneLayer by layer self assembly

The invention belongs to the field of anticorrosion materials, and relates to a green and environment-friendly method for protecting metal from corroding, which can particularly control metal corrosion for long time effectively, and play a role in self-repairing the metal surface to a certain extent. The method is characterized in that an inhibitor molecule and polyelectrolyte are alternately deposited on the surface of a silicon dioxide nano-particle through green environment-friendly type metal inhibitor micromolecules and polyelectrolyte by adopting layer-by-layer self-assembly technology and utilizing the penetrating controllability of a polyelectrolyte self-assembly membrane so as to prepare a functional nano-particle with the inhibitor and the polyelectrolyte self-assembly composite membrane which are coated on the surface; and the prepared functional nano-particle is mixed with sol-gel to prepare the functional sol-gel membrane coated on the metal surface to be protected. The coating has the function of metal surface self-repairing, and ensures that the inhibitor molecules released by the functional membrane are adsorbed on the metal surface to reform a protecting membrane in a coating damaged microsection to play a certain role in self repairing. The method is applicable to corrosion protection of various metals.

Owner:UNIV OF SCI & TECH BEIJING

Composition and Processes of a Dry-In-Place Trivalent Chromium Corrosion-Resistant Coating for Use on Metal Surfaces

ActiveUS20070187001A1Comparable performanceQuality improvementSurface reaction electrolytic coatingSolid state diffusion coatingAqueous solutionMetal

Corrosion resistant coatings are formed on aluminum by contacting with aqueous solutions containing trivalent chromium ions and fluorometallate ions, the solutions being substantially free of hexavalent chromium. Trivalent chromium films formed on the aluminum surface when tested in 5% NaCl salt spray chamber showed corrosion resistance in excess of 168 hours. Trivalent chromium coated aluminum also serves as an effective base for paint primers.

Owner:HENKEL KGAA

Novel PCB copper reduction etching liquid and manufacturing technology

The invention discloses novel PCB copper reduction etching liquid. The novel PCB copper reduction etching liquid comprises components including 1-100 mL / L of sulfuric acid, 1-100 mL / L of hydrogen peroxide, 1 g / L-100 g / L of hydrogen peroxide stabilizer, 1 g / L-100 g / L of a copper ion complexing agent, 0.1 g / L-10 g / L of a surface active agent, 1 g / L-100 g / L of accelerator, 0.1 g / L-10 g / L of copper surface corrosion inhibitor and 0.1 g / L-10 g / L of needle hole inhibitor. The invention further provides a method for preparing the PCB copper reduction etching liquid. The tolerance of copper ions of the prepared PCB copper reduction etching liquid is high, the etching speed is high, the copper surface is bright and not prone to oxidization, and the needle hole defect is not likely to be generatedafter abnormally-crystallized copper crystals are subjected to copper reduction etching.

Owner:湖南互连微电子材料有限公司

Quaternary ammonium carbonates and bicarbonates as anticorrosive agents

InactiveUS20050003978A1Avoid corrosionInorganic/elemental detergent compounding agentsCationic surface-active compoundsBicarbonateMetal substrate

Quaternary ammonium carbonates, bicarbonates, and mixtures thereof as anti-corrosive agents. The present disclosure relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds, to metal substrates having these anticorrosive coatings, and to aqueous cleaning solutions containing these compounds.

Owner:LONZA INC

Methods for protecting glassware from surface corrosion in automatic dishwashing appliances

InactiveUS20050119154A1Inorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPhysical chemistryZinc

Methods for protecting glassware from surface corrosion during automatic dishwashing using through-the-wash automatic dishwashing detergent compositions, especially detergent compositions comprising zinc-containing materials are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Polishing composition capable of improving silicon wafer polishing accuracy and preparation method thereof

InactiveCN102408837AOvercome precisionOvercome CorrosivityPolishing compositions with abrasivesPhysical chemistrySilicon dioxide

The invention discloses a polishing composition capable of improving silicon wafer polishing accuracy and a preparation method thereof, and belongs to the technical field of chemical and mechanical polishing. The polishing composition consists of the following components in percentage by weight: 0.05-50 percent of functionalized silicon dioxide sol, 0.001-1 percent of oxidant, 0.001-5 percent of chelating agent, 0.001-10 percent of alkaline compound, 0.001-1 percent of surfactant and the balance of de-ionized water, wherein the functionalized silicon dioxide sol is aminated silicon dioxide sol. After a silicon wafer is polished by the polishing component, the surface accuracy of the wafer is higher, the surface corrosion is less, the polishing speed is high, and the flatness is high.

Owner:TSINGHUA UNIV +2

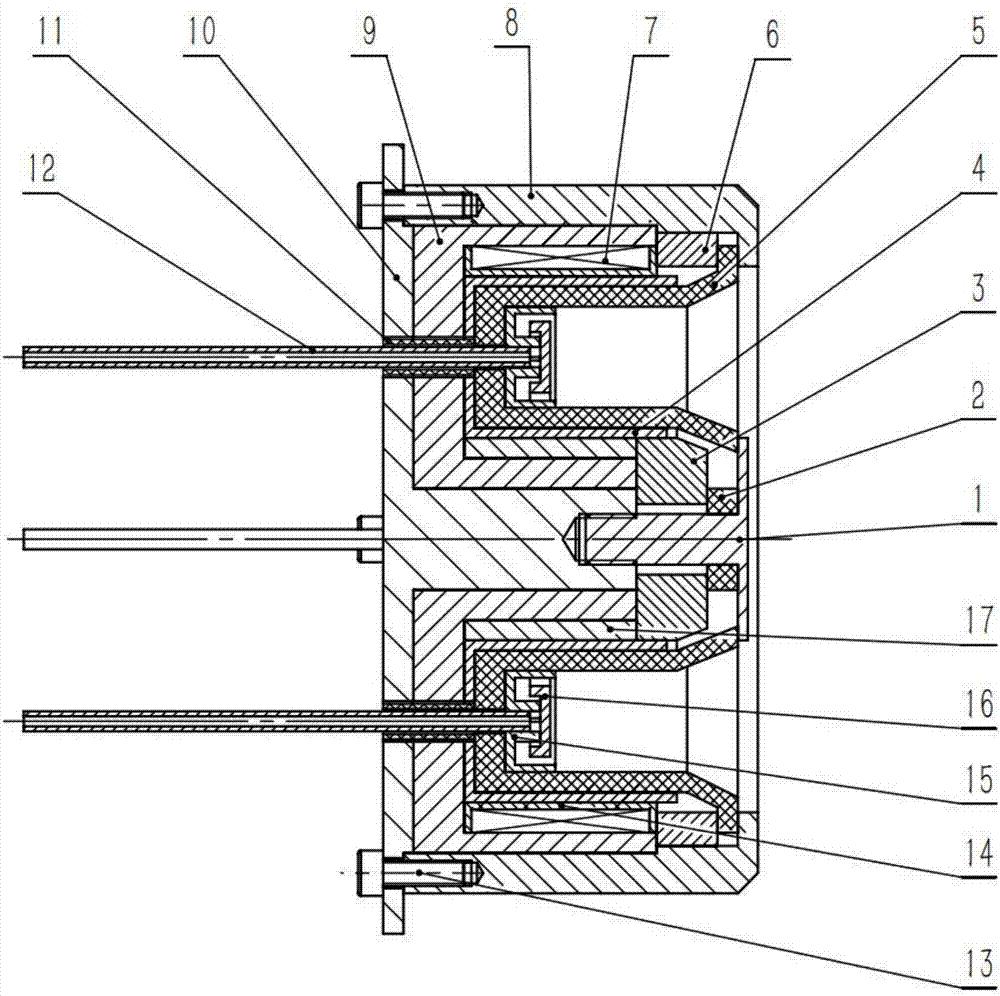

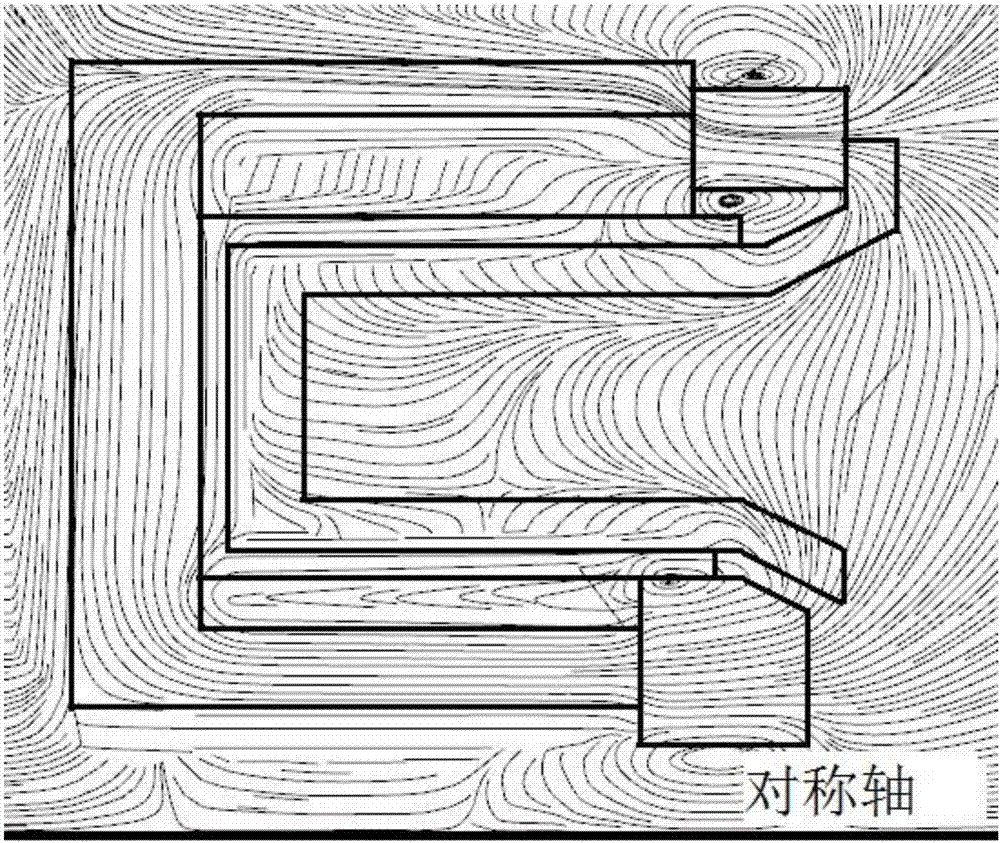

Magnetic field-adjustable low-power Hall thruster with magnetic shielding effect

ActiveCN107165794AReduce corrosionExtend your lifeMachines/enginesUsing plasmaElectricityMagnetic shield

The invention discloses a magnetic field-adjustable low-power Hall thruster with a magnetic shielding effect, and belongs to the technical field of electric propulsion. Along with diversification of spaceflight task demands, more attention is paid to the low-power Hall thruster; but low power of the Hall thruster causes the problems of short life and low efficiency; and the problems are related to the geometric size of a discharge channel of the Hall thruster, the magnetic field configuration and strength and the like. The magnetic shielding theory is introduced in the design of the low-power Hall thruster; a permanent magnet is used for generating a high magnetic field; a double-magnetic-screen structure is used for forming a magnetic shielding magnetic field in the discharge channel to limit the plasma movement, so that the wall surface corrosion is weakened, and the life is prolonged; meanwhile, the power consumption of the Hall thruster is greatly reduced through use of the permanent magnet, and is not higher than 100 W; and in addition, the invention further designs a heat conduction structure in the thruster for preventing influence on the performance of the permanent magnet due to too high thermal load.

Owner:BEIHANG UNIV

Copper chemical and mechanical polishing combination

InactiveCN102329572AReduce surface residueReduce surface corrosion defectsPolishing compositions with abrasivesCompound (substance)Copper

The invention discloses a copper chemical and mechanical polishing combination, which belongs to the technical field of microelectronic auxiliary materials and ultra-precision machining processes. The copper chemical and mechanical polishing combination comprises abrasive particles, an oxidant, a complexing agent, a polishing accelerating agent and a pH regulator. The copper chemical and mechanical polishing combination is characterized by further comprising a long chain corrosion inhibitor and a surface active agent. By using the polishing combination provided by the invention, surface residues, particularly surface granular residues, can be obviously decreased; surface corrosion defects can be obviously decreased; a higher removal speed rate is obtained; and the polishing combination provided by the invention further has the advantages of simple process, cheap price, low cost and the like.

Owner:SHENZHEN LEAGUER MATERIAL +2

Washing method of washing-difficult reworked piece of crystalline silicon solar battery

InactiveCN102634800ASolve the problem of difficult cleaning rework filmImprove pass rateAfter-treatment detailsSolar batteryCrystalline silicon

The invention discloses a washing method of a washing-difficult reworked piece of a crystalline silicon solar battery. The method comprises the following three steps of: removing phosphorosilicate glass or a Si3N4 film of a battery piece by utilizing a HF solution; carrying out surface corrosion on a silicon wafer by utilizing a surface corrosion solution so as to simultaneously remove residual abnormal tracks on the silicon wafer to achieve the aim of cleanly washing the washing-difficult reworked piece; removing impurities including SiO2 and the like generated in a corrosion process through washing with the HF solution; and then removing the impurities including metal ions and the like through washing with a HCl solution. After the washing-difficult reworked piece is treated by the washing method, the reworked piece is subjected to repeated dispersion and a back working procedure so that the final conversion efficiency of the battery piece can reach the level of a normal battery piece; and the appearance of the battery piece is the same as that of the normal battery piece so as to achieve the aim of reworking and washing. Through the washing with the washing method disclosed by the invention, the yield of the washing-difficult reworked piece is improved to 95% from previous 50% after the washing-difficult reworked piece is reworked.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Simultaneous testing method for metal atmospheric corrosion behavior and used device thereof

InactiveCN101017127AEasy to disassembleEasy to installWeather/light/corrosion resistanceSurface corrosionSurface level

This invention relates to one device to test metal materials gas erosion by use of Kelvin detector and quartz micro balance, which comprises the following steps: in testing, sealing the deposited Pt or Au film of quartz slices and removing oil and drying; depositing the aim metal into quartz transistor slice outer surface; adjusting the gas case flow; using SKP scan electrode surface level distribution by use of QCM test electrode surface mass change; the said device cannot be touched without loss on metal surface erosion level.

Owner:OCEAN UNIV OF CHINA

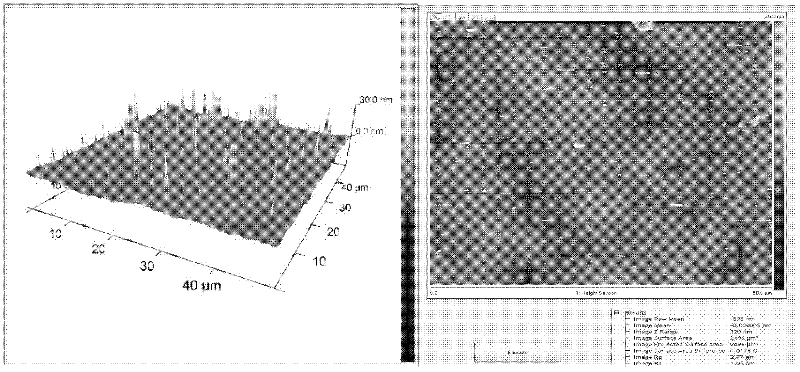

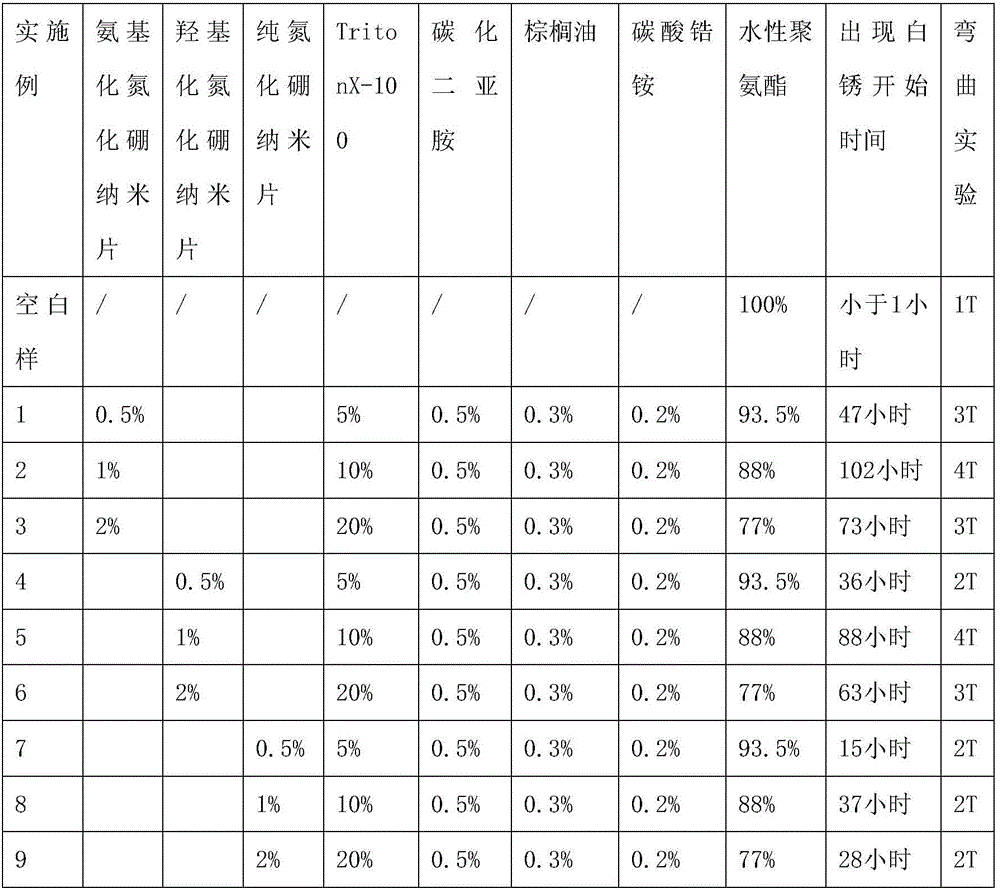

Preparation methods of metal surface treatment agent containing nano boron nitride and corrosion-resistant coating

ActiveCN106010181AGood dispersionGood compatibilityFireproof paintsLiquid surface applicatorsSolid componentSalt spray test

The invention provides a metal surface treatment agent containing nano boron nitride. The metal surface treatment agent is prepared from waterborne resin, a dispersing agent, boron nitride and coating additives, wherein the mass of the solid component in the waterborne resin is 77%-93.5% that of the total solid components of a coating, the mass of the dispersing agent is 5%-20% that of the total solid components of the coating, the mass of boron nitride is 0.5%-2% that of the total solid components of the coating, and the mass of the coating additives is 0.5%-1% that of the total solid components of the coating. The invention further provides a preparation method of the metal surface treatment agent containing nano boron nitride and a method for preparing a corrosion-resistant coating. It is proved through salt spray tests that the composite coating has ultra-high corrosion resistance. The metal surface treatment agent is waterborne paint, the formula does not contain any solvent except water, therefore, emission of volatile organic compounds does not exist, and the metal surface treatment agent meets the environmental protection requirement and is suitable for surface corrosion prevention of metal substrates in industrialized production.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Production method of aluminium alloy hot extrusion bar used for high-quality aviation blade

The invention discloses a production method of an aluminium alloy hot extrusion bar used for a high-quality aviation blade, and relates to a production method of an aluminium alloy hot extrusion bar, aiming at solving the problems of serious segregation, strong deformation resistance, large ingot cracking tendency, excessive extrusion cracking scrap and low extrusion speed. The method comprises the following steps: preparation of molten aluminium alloy, hot top casting of a circular ingot, homogenizing annealing of the ingot, hot extrusion of a bar, finishing of the bar, T73 thermal treatment, AA-level flaw detection. The alloy component of the aluminium alloy hot extrusion bar produced according to the method can meet standard requirement, and thus solving the problem of casting crack of circular ingots, improving the hot-working character of short ingots, and reducing compound segregation scrap and extrusion cracking scrap; stress corrosion resistance can be continuously realized in 30 days and nights, surface corrosion is relatively light, and the percent of pass of an oxidized surface after a component of a forge piece of a user is machined.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method of inhibiting corrosion of copper plated or metallized surfaces and circuitry during semiconductor manufacturing processes

InactiveUS20050008532A1Efficient ConcentrationAvoid corrosionOrganic chemistrySemiconductor/solid-state device testing/measurementSurface corrosionFluorescence

An treatment bath for use in the manufacture of copper plated or metallized semiconductor devices and a method of inhibiting corrosion of copper plated or metallized surfaces and circuitry in the semiconductor devices immersed in an aqueous fluid in a treatment bath comprising adding to the aqueous fluid an effective corrosion inhibiting amount of one or more aromatic triazole corrosion inhibitors; fluorometrically monitoring the concentration of aromatic triazole corrosion inhibitors in the aqueous fluid; and adding additional aromatic triazole corrosion inhibitor to the aqueous fluid to maintain an effective corrosion inhibiting concentration of the aromatic triazole corrosion inhibitor in the aqueous fluid.

Owner:ECOLAB USA INC

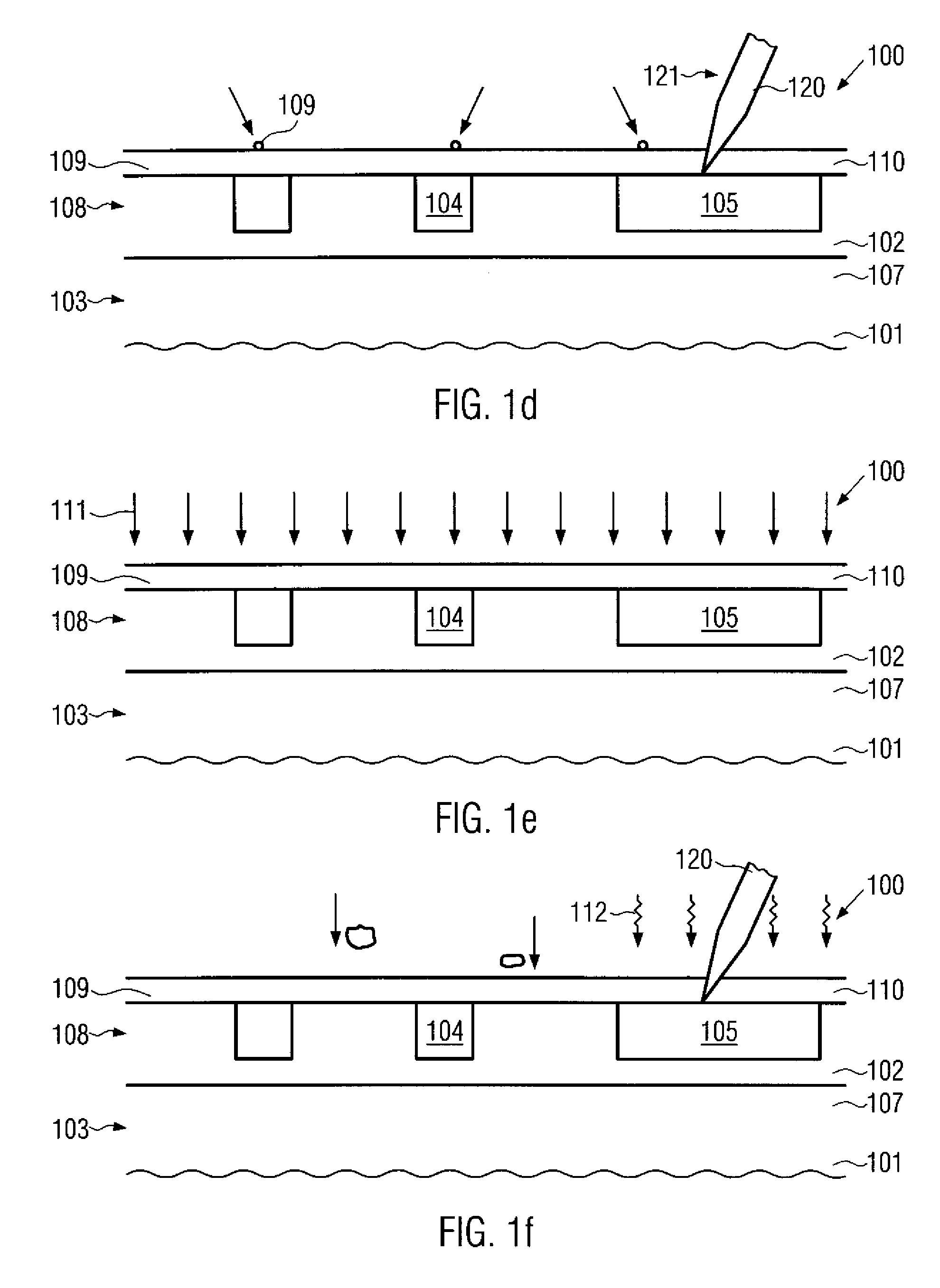

Method of reducing contamination by providing a removable polymer protection film during microstructure processing

InactiveUS20080026492A1Reduce exposureEffective protectionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest proceduresSurface corrosion

By providing a protective layer in an intermediate manufacturing stage, an increased surface protection with respect to particle contamination and surface corrosion may be achieved. In some illustrative embodiments, the protective layer may be used during an electrical test procedure, in which respective contact portions are contacted through the protective layer, thereby significantly reducing particle contamination during a respective measurement process.

Owner:ALSEPHINA INNOVATIONS INC

Corrosion protection agents for treating glassware surfaces

InactiveUS20050153868A1Reduce surface corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPreservativeZinc

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com