Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "High hydroxyl value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxypolyacrylate emulsion, and preparation method and application thereof

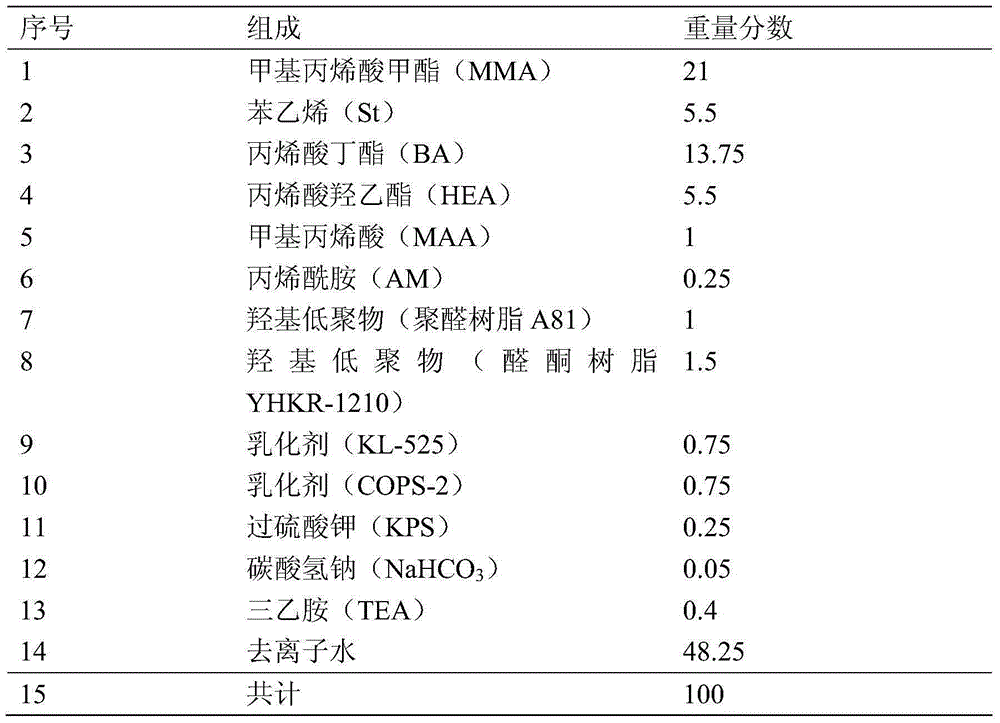

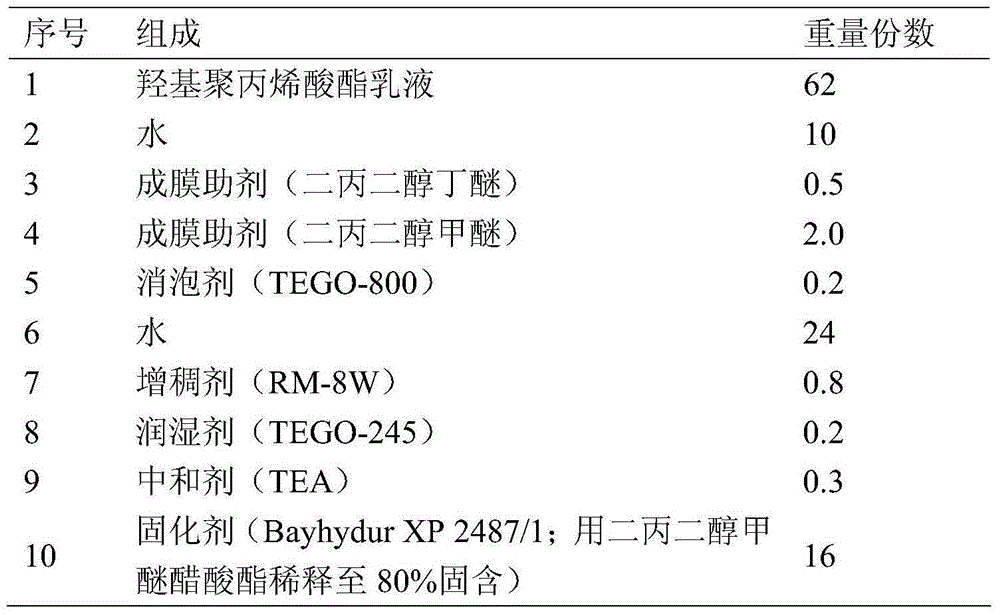

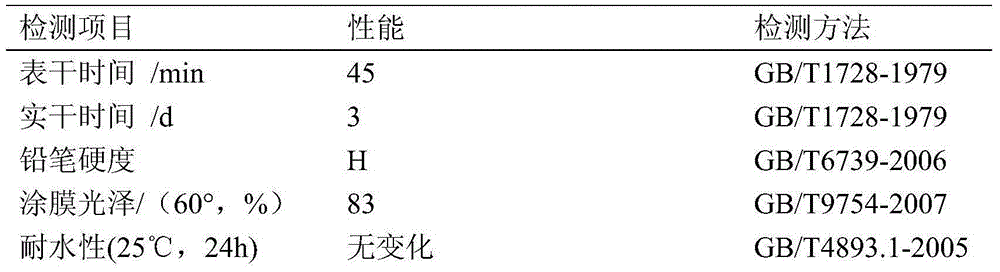

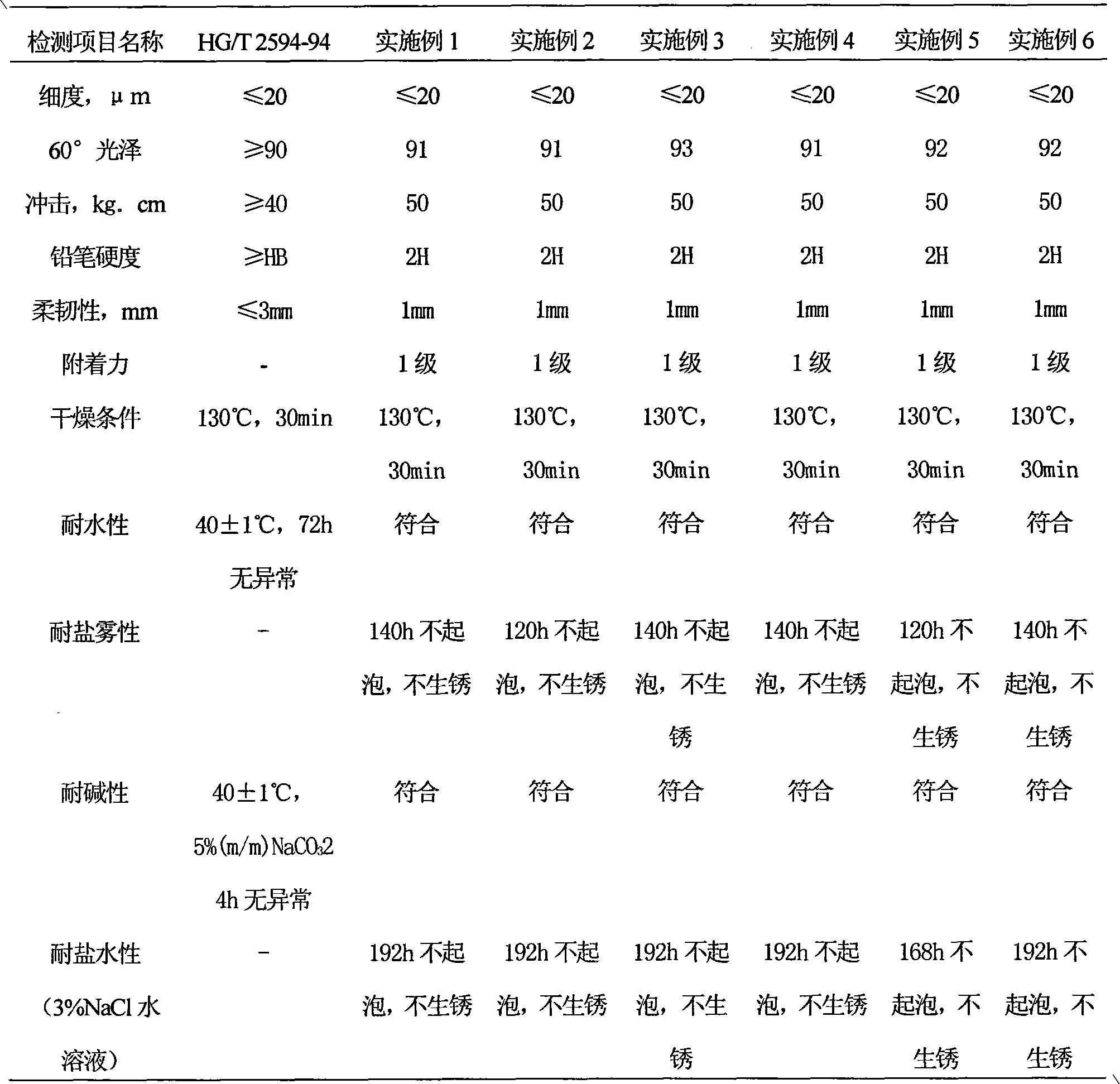

ActiveCN105061665AHydroxyl content is easy to adjustLarge adjustment rangePolyurea/polyurethane coatingsSodium bicarbonateMethacrylate

The invention discloses a hydroxypolyacrylate emulsion, and a preparation method and an application thereof. The preparation method comprises the following steps: weighing an acrylate monomer and / or a metacrylate monomer, a hydroxyacrylate monomer, an acrylic monomer, an acrylate function monomer and a hydroxy oligomer, uniformly mixing to prepare a monomer mixture, weighing 10-15% of the monomer mixture, and emulsifying by using an emulsifier to prepare a seed pre-emulsion for later use; and adding the emulsifier, sodium bicarbonate and deionized water into a reaction kettle, stirring, rising the temperature of a reaction system, adding an initiator, stabilizing, adding the seed pre-emulsion in a dropwise manner, stabilizing, adding the remaining monomer mixture and the remaining initiator in a dropwise manner, heating, slaking, cooling, neutralizing, carrying out heat insulation, cooling, and discharging to obtain the hydroxypolyacrylate emulsion. A film made by using an aqueous dual-component polyurethane coating prepared from the hydroxypolyacrylate emulsion and an aqueous polyisocyanate curing agent has the advantages of high hardness, high luster and excellent chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

Mono-component aqueous metal baking paint and preparation method thereof

The invention discloses a mono-component aqueous metal baking paint and a preparation method thereof. The mono-component aqueous metal baking paint consists of the following components by weight: 40 to 57 percent of tap water, 28 to 34 percent of aqueous acrylic modified polyester resin, 7 to 8.5 percent of amino resin, 1.12 to 1.36 percent of amine modifier, 0.1 to 0.3 percent of wetting dispersing agent A, 0.1 to 0.3 percent of wetting dispersing agent B, 0.01 to 0.1 percent of defoaming agent, 0.5 to 1.2 percent of thickening agent, and 0.2 to 0.6 percent of levelling agent. The mono-component aqueous metal baking paint uses water as a solvent without adding an alcohol / ether cosolvent so that environmental protection is excellent; because of mono-component, the construction is simple and convenient, and the performance is stable; and a paint film is plumpy, the luster is high, the mechanical property is excellent, and the adhesive force is good. The mono-component aqueous metal baking paint is applicable to metal surface corrosion protection and decoration, and can be used as a finishing paint, a priming paint or a coating varnish; and when used for bottom surface integral coating, the mono-component aqueous metal baking paint still has excellent surface effect and protective action.

Owner:GUANGZHOU JOINTAS CHEM

High hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction

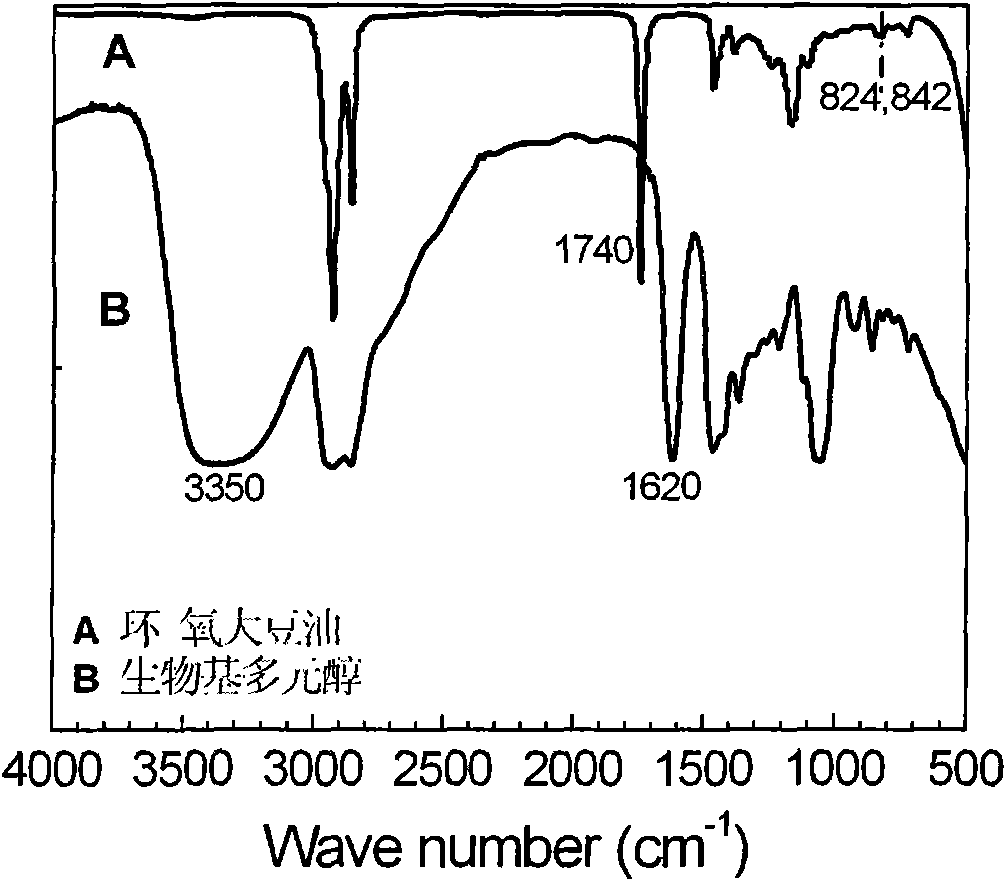

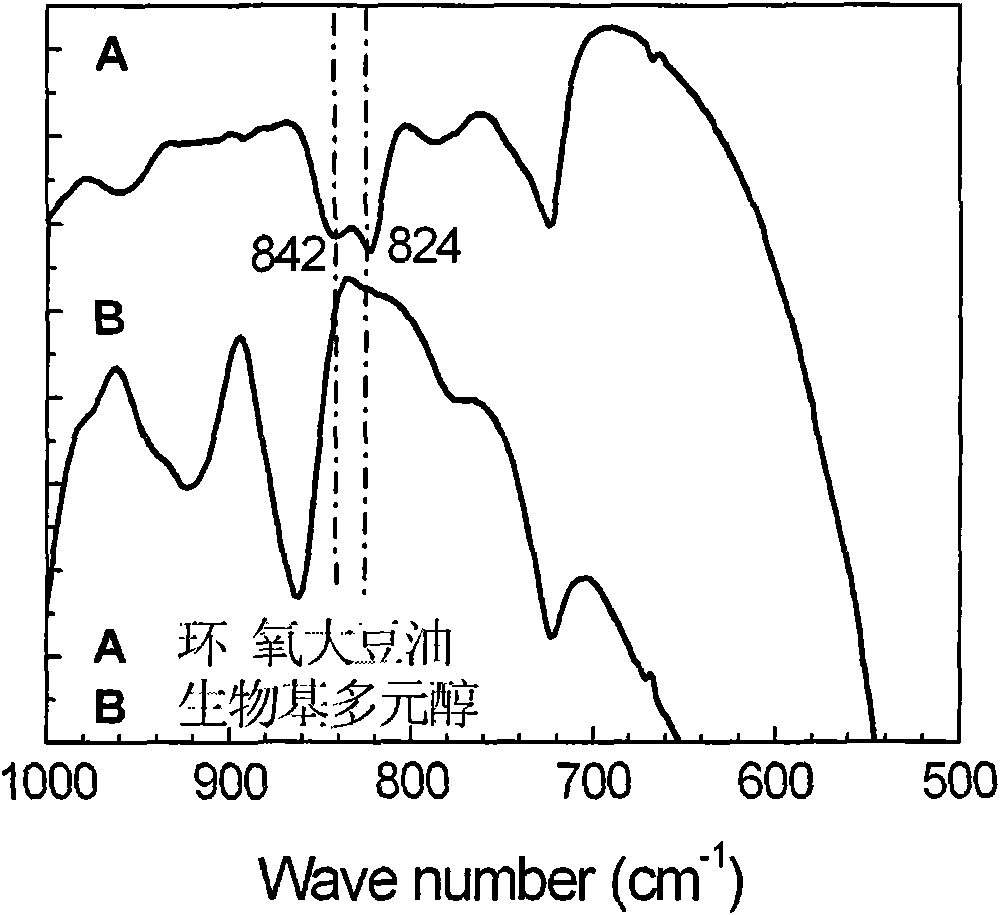

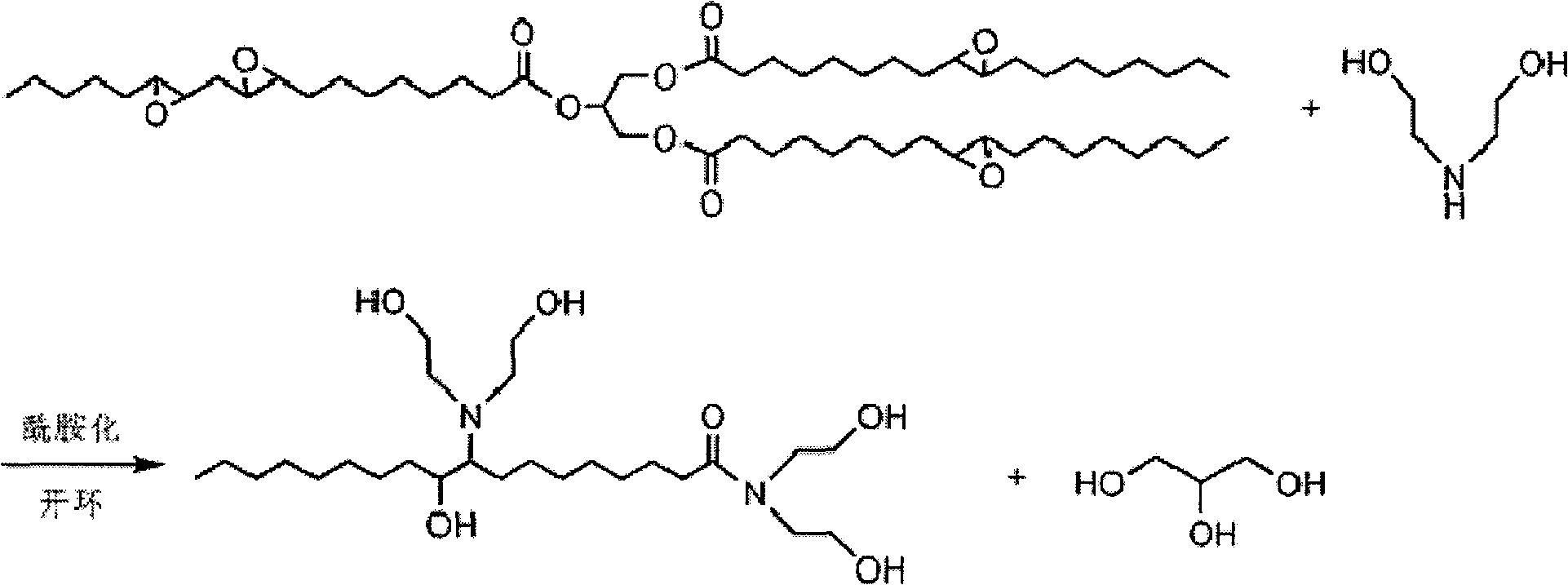

InactiveCN101659627AHigh hydroxyl valueHigh primary hydroxyl contentOxygen-containing compound preparationOrganic compound preparationEpoxyVegetable oil

The invention discloses a high hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction, which is obtained by the following one preparing step: accordingto the molar ratio of epoxy group to amino group being 1:1-1:1.1, leading the epoxidized vegetable oil and diolamine to simultaneously generate epoxy group ring opening reaction and ester group amidation reaction at the temperature of 80-140 DEG C for 2-16 hours, thus obtaining bio-base polyol. The high hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-stepreaction is a novel bio-base polyol, and has the characteristics of high hydroxyl valve, high primary hydroxyl group content, short 'swing' chain, low viscosity and the like. The novel method for preparing the bio-base polyol is characterized by completing ring opening and amidation reactions by one step, having short processing procedures, capability of avoiding cross linking reaction, no need of catalyst, and no need of separating steps, being environment friendly, and easy to realize industrialized production, and the like.

Owner:ZHEJIANG UNIV

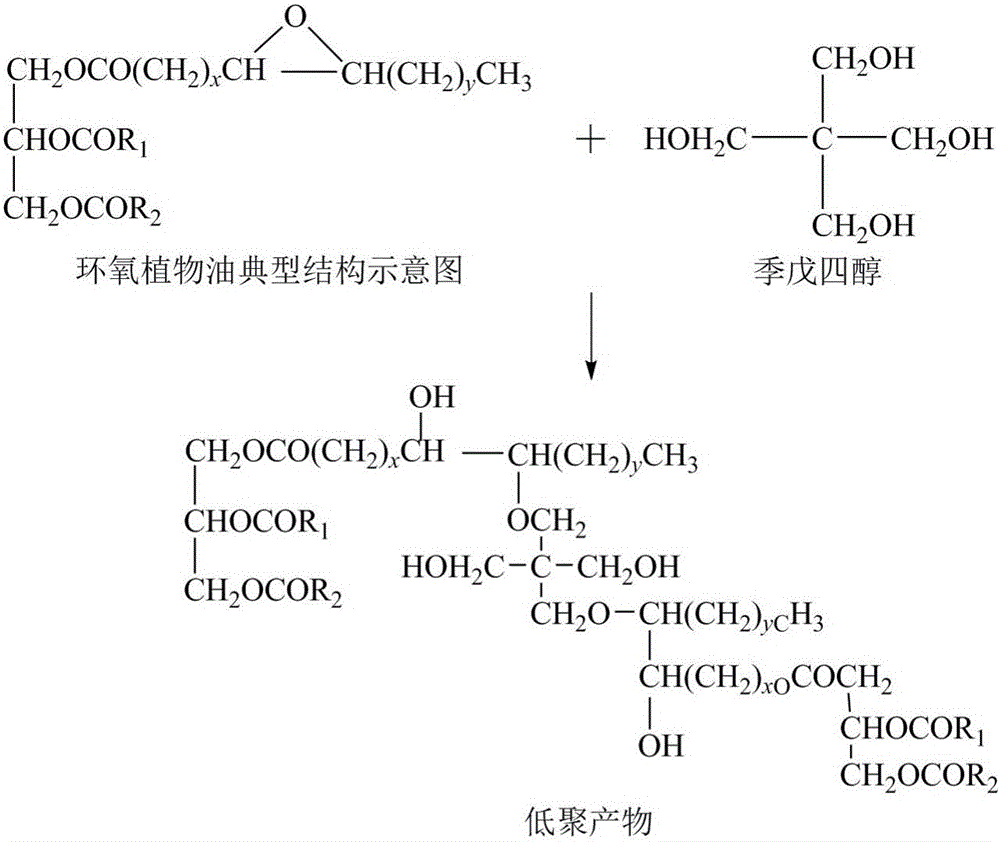

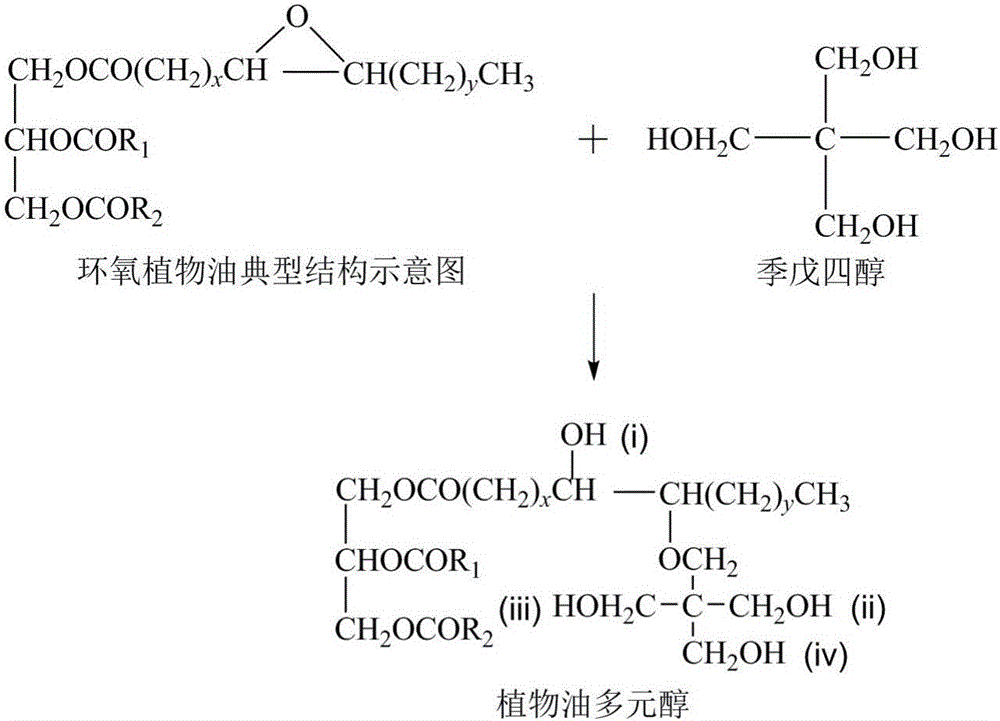

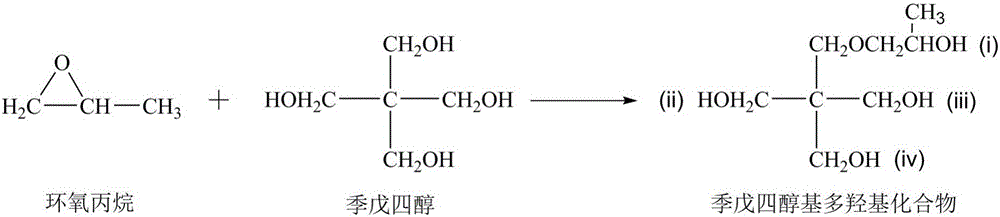

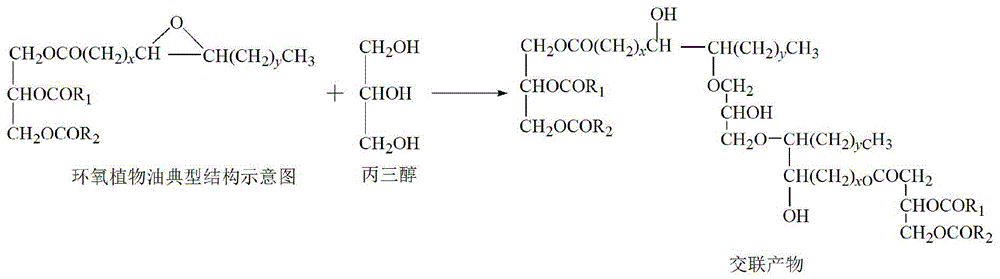

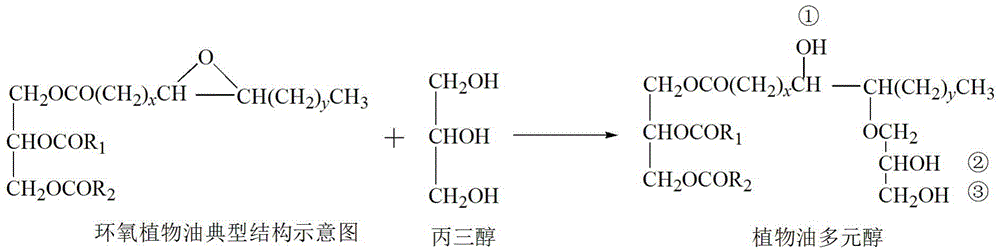

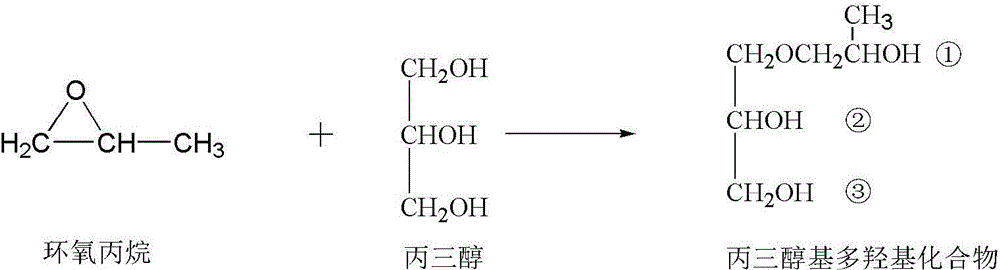

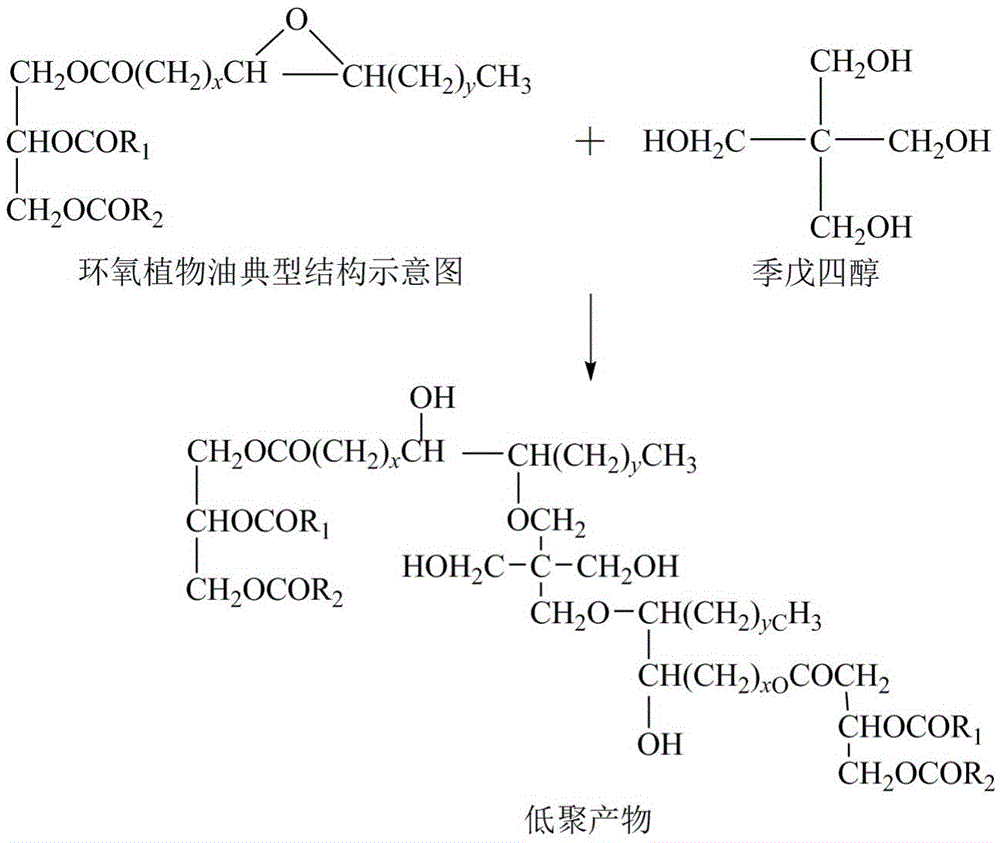

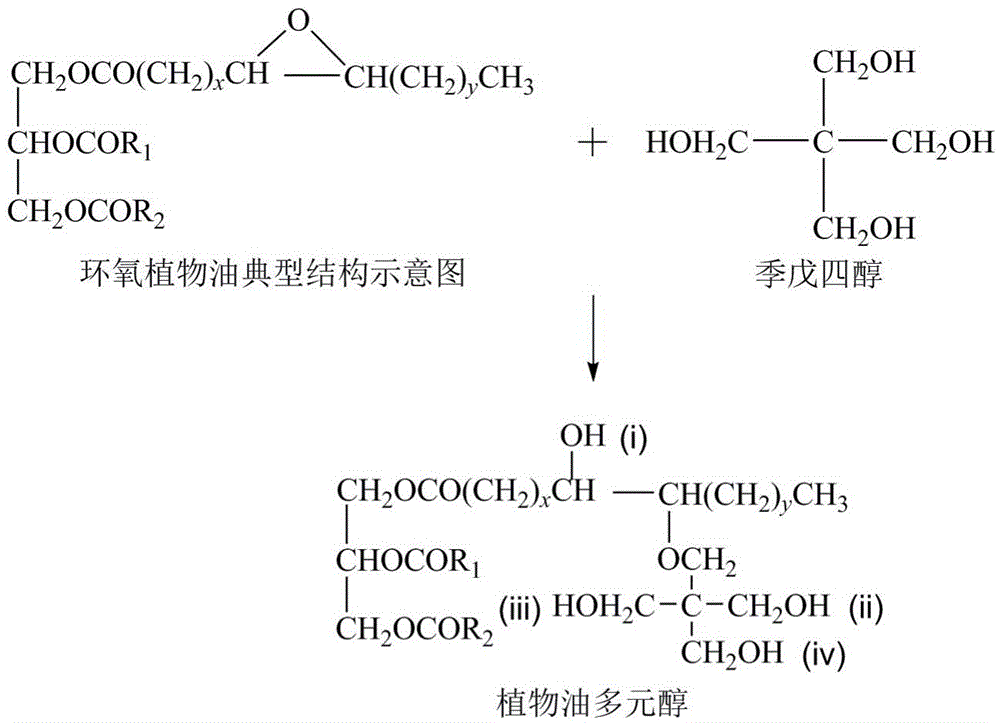

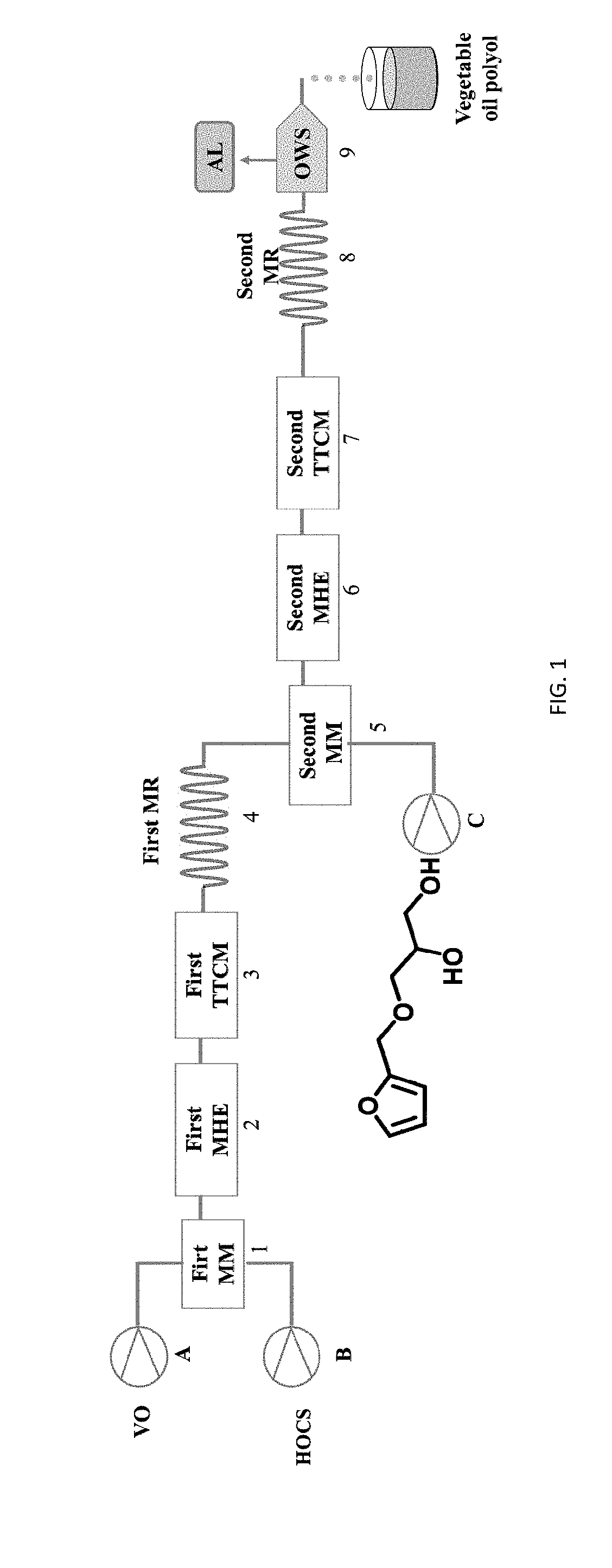

Vegetable oil polyols with high hydroxyl value as well as preparation method and application of vegetable oil polyols

ActiveCN105669450ANovel structureHigh hydroxyl valuePreparation by ester-hydroxy reactionOrganic compound preparationVegetable oilTransesterification

The invention discloses vegetable oil polyols with high hydroxyl value as well as a preparation method and an application of the vegetable oil polyols. The vegetable oil polyols are prepared from epoxidized vegetable oil and a polyhydroxyl compound through a ring-opening reaction and transesterification. Compared with the prior art, a novel ring-opening reagent is used, the prepared vegetable oil polyols are novel in structure and low in viscosity, has high hydroxyl value and primary hydroxyl content and short pendant chains, are distributed more uniformly and can completely replace traditional petrochemical polyols to be applied to preparation of a polyurethane foam material. Meanwhile, the method adopts simple process, postprocessing is not needed for a product, the method is quite suitable for industrial production, the reaction efficiency can be increased especially after selection of a tubular reactor, generation of side reactions is controlled, and energy consumption is reduced.

Owner:NANJING TECH UNIV

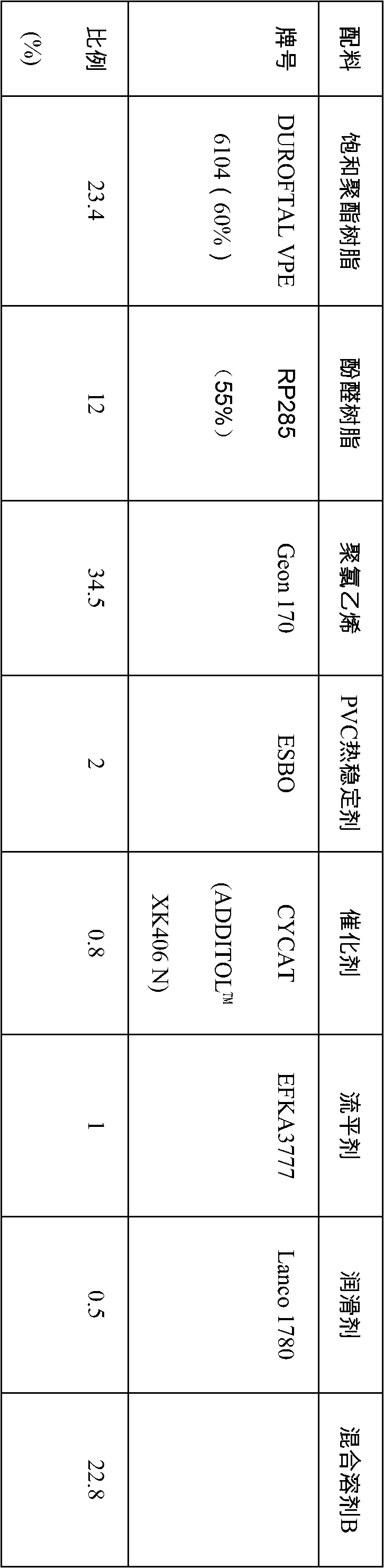

High polymer chemistry coal and rock mass reinforcer for coal mines

InactiveCN103408721ALow viscosityHigh hydroxyl valueDrilling compositionDiamineDibutyl tin dilaurate

The invention provides a high polymer chemistry coal and rock mass reinforcer for coal mines and solves the problems of the existing polyurethane reinforcing material, such as high price, inflammable and toxic properties, poor performance stability and the like. The high polymer chemistry coal and rock mass reinforcer for coal mines provided by the invention comprises components A and B which are the same in volume, wherein the component A consists of polyether polyol, catalyst and fire retardant, and the component B is polyaryl polymethylene isocyanate; the polyether polyol has more than 3 functional groups, hydroxyl value of 450-550 and molecular weight of 300-500; the catalyst is composed of dibutyltin dilaurate and triethylene diamine; and the fire retardant is composed of methyl methylphosphonate, tri(1,3-dichloro-2-propyl) phosphate and sodium silicate. The high polymer chemistry coal and rock mass reinforcer for coal mines provided by the invention belongs to polyurethane grouting agents and silicate modified polyurethane grouting agents, and is an environment-friendly material with resin content of 100% and no volatile organic compounds, and all indexes of the reinforcer completely accord with AQ1089-2011 quality standard of high polymer material for reinforcing coal and rock mass in coal mines.

Owner:DATONG COAL MINE GRP

Low viscosity polymer polyols characterized by a high hydroxyl number

The present invention relates to novel polymer polyols which have low viscosities and high hydroxyl numbers, and to a process for the preparation of these novel polymer polyols. These polymer polyols have hydroxyl numbers of ≧20, solids contents of about 30 to about 65% by weight and a viscosity that is less than or equal to: be[2.7c]. These comprise the reaction product of a base polyol, a preformed stabilizer and at least one ethylenically unsaturated monomer, in the presence of a free-radical polymerization initiator and at least one polymer control agent. The base polyol has a hydroxyl number of 60 to 1900, a functionality of 1 to 10, and an equivalent weight of 30 to 900.

Owner:BAYER MATERIALSCIENCE AG

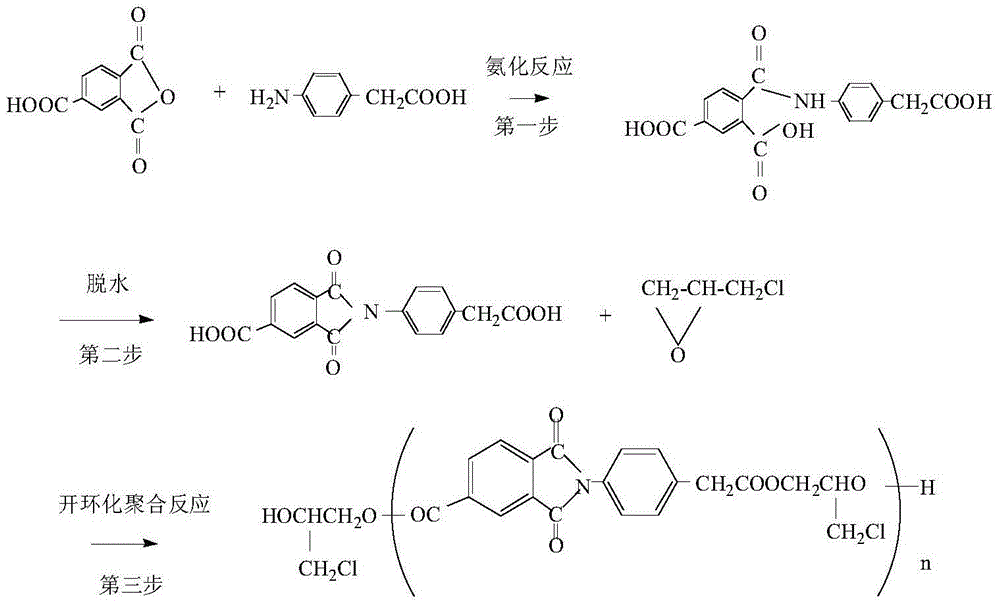

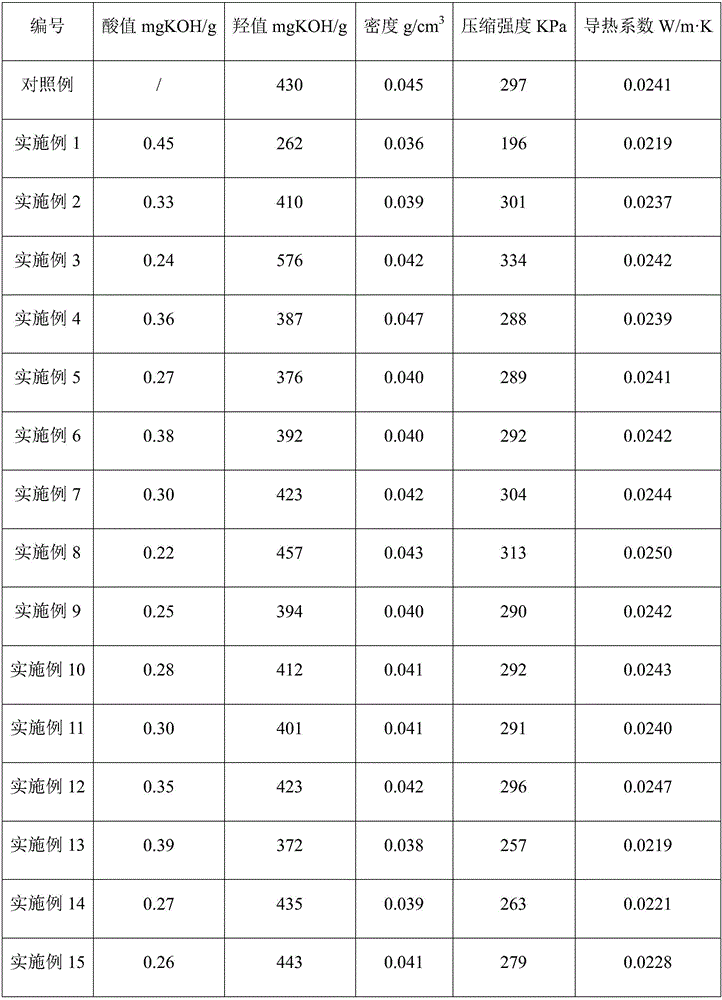

High-strength polyurethane rigid foam as well as preparation method and application thereof

ActiveCN104672420AIncrease internal rotation resistanceImprove rigidityRigid structureAromatic amine

The invention discloses high-strength polyurethane rigid foam, as well as a preparation method and application thereof. The invention introduces a benzoyl imide reinforced polyurethane modifier with a rigid structure; the benzoyl imide reinforced polyurethane modifier, the corresponding high-viscosity aromatic amine polyether polyol, low functionality polyether polyol, special silicon oil for increasing isotropy of the foam, a catalyst with a specific structure, water and a foaming agent are used for preparing the premixed polyether polyols and react with the polyisocyanates to generate the high-strength polyurethane foam. The polyurethane rigid foam provided by the invention has the characteristics of low batch charging density, high compressive strength, low heat conductivity coefficient and good size stability under low temperature, and can be used in the household appliance inside insulating materials such as the fridge, the refrigerator, the solar energy, the gas water heater and the disinfection cabinet.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

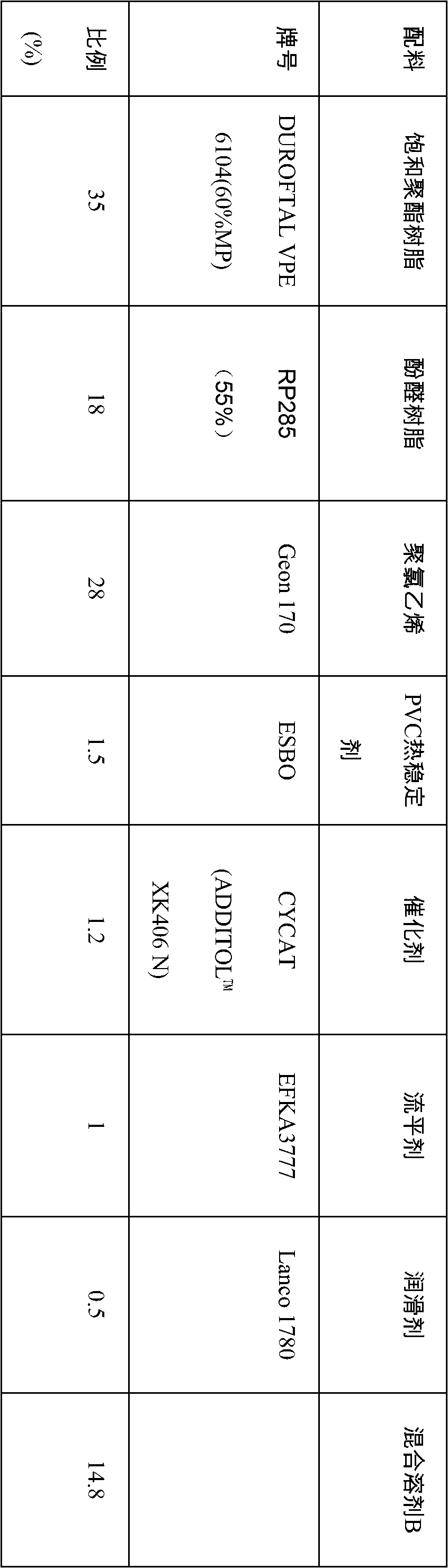

Coating composition and application of coating composition to metal base material

The invention discloses a coating composition and an application of the coating composition to a metal base material. The solid content of the coating composition is 40-70%. The coating composition comprises the following components of, by weight, 5-60% of saturation polyester resins, 0-25% of crylic acid resins, 2-30% of crossing-link agents, 20-80% of polyvinyl chloride homopolymer, 0-15% of additives, 0-40% of pigments and the balance dilution solvents, wherein average molecular weight Mn of the saturation polyester resins is 3000-8000, the vitrification temperature of the saturation polyester resins is 10-20 DEG C, the acid value of the saturation polyester resins is 0-5, the hydroxyl value of the saturation polyester resins is 30-90, and the saturation polyester resins are free of neopentyl glycol. The coating composition is free of bisphenol-A diglycidyl glycerol ether (BADGE) and bisphenol A (BPA). According to the coating composition, the polyester resins which meet requirements can be easily obtained, improved space of resin performances is large, 40%-70% of the solid content of final products can be achieved, and a large quantity of organic solvents are saved.

Owner:HANGZHOU CPMC +1

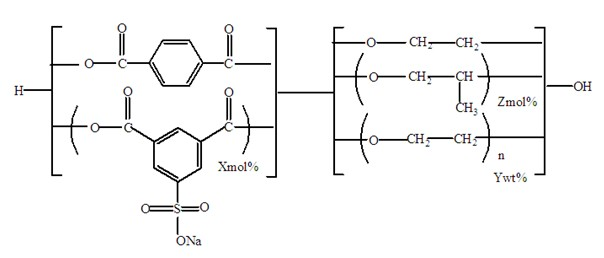

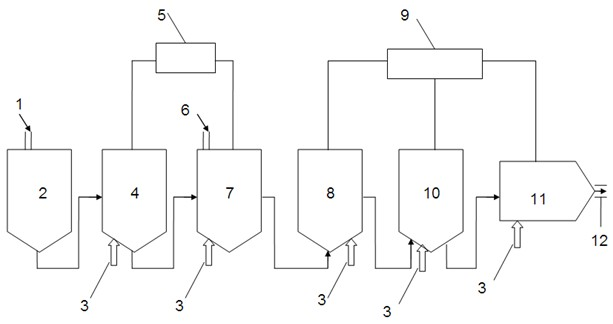

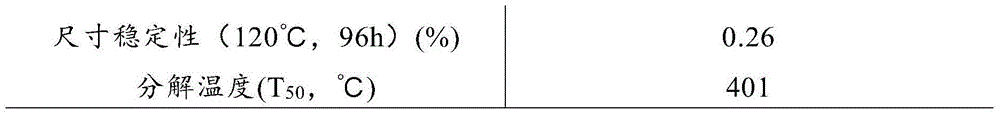

Hydrophilic copolyester slices prepared by continuous method and preparation method thereof

InactiveCN102504224AChange molecular structureImprove hydrophilicityMonocomponent polyesters artificial filamentArtifical filament manufactureCopolyesterDibasic acid

The invention discloses a continuous method for preparing hydrophilic copolyester slices and the hydrophilic copolyester slices prepared by the preparation method. The preparation method of the hydrophilic copolyester slices prepared by the continuous method comprises the following steps: continuously and uniformly adding pure terephthalic acid, ethylene glycol, benzene dibasic acid binary alcohol ester-5-sodium sulfonate, polydibasic alcohol, other dibasic alcohols, a delustering agent and the like into a beating kettle in proportion, performing esterification, prepolycondensation and polycondensation reactions, discharging, pelletizing and drying to get the hydrophilic copolyester slices. A continuous polymerization device is adopted for synthesis; and in the prepared hydrophilic copolyester slices, the molecular structure of polyester is changed by adding hydroxyl-containing components and inorganic powder into copolyester slices, thus the hydrophilic property is good. The preparation method is simple, the manufacturing process has no special requirements on the polymerization device, and the hydrophilic copolyester slices can be produced on existing domestic or imported equipment, so that the production cost is slow and industrial production is easy to realize.

Owner:DONGHUA UNIV

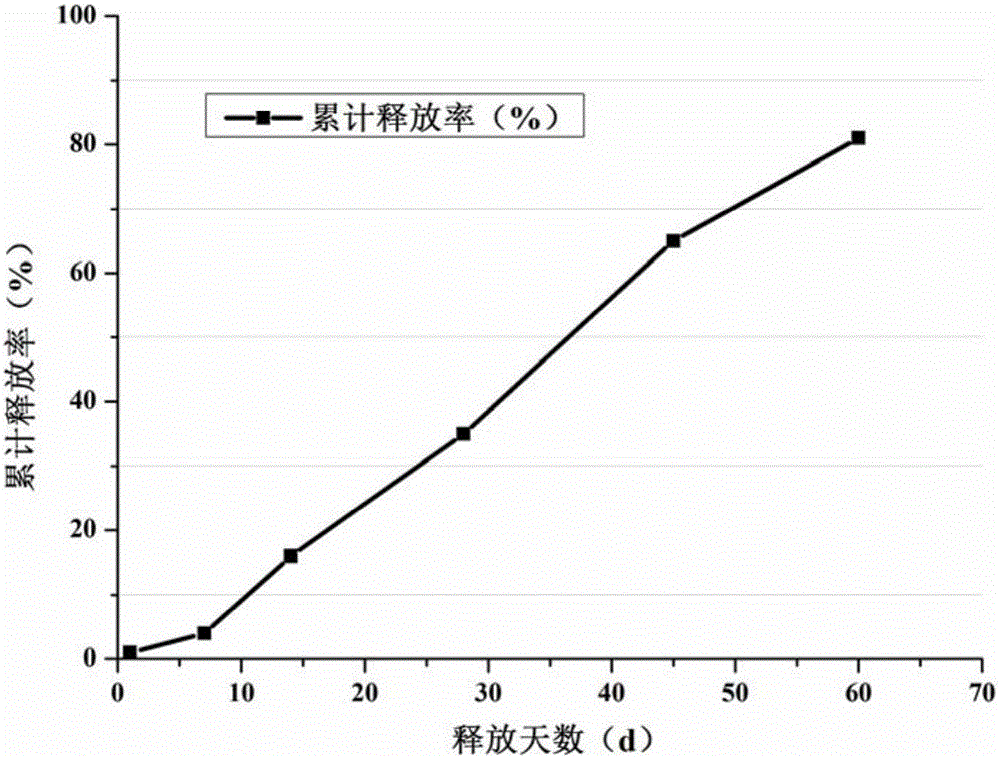

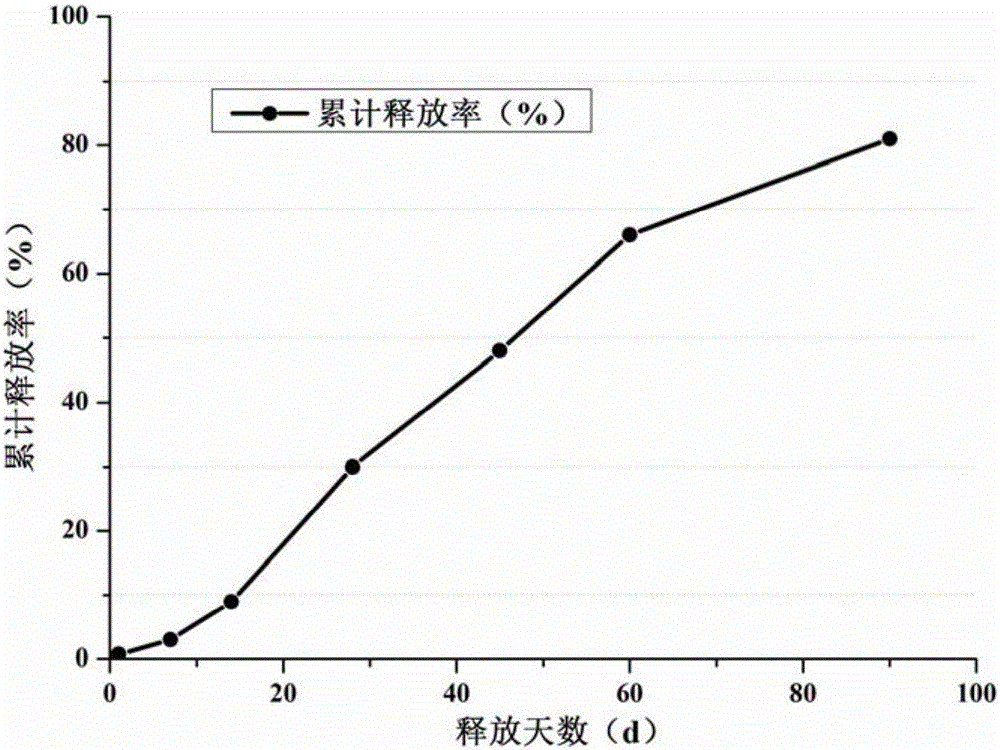

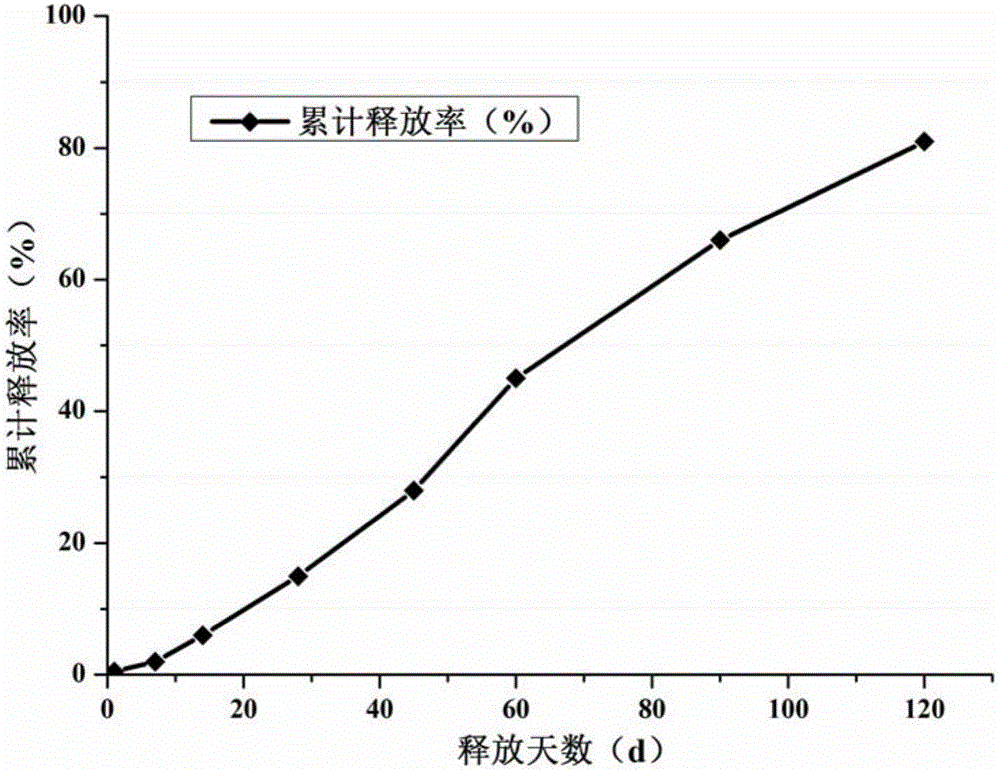

Preparation of castor oil-based coating material and application of castor oil-based coating material in controlled-release fertilizers

InactiveCN106045674AHigh hydroxyl valueHigh reactivityLayered/coated fertilisersFertilizer mixturesCarboxylic acidCastor oil

The invention relates preparation of castor oil-based coating material and application of the castor oil-based coating material in controlled-release fertilizers. Epoxidized castor oil is prepared from castor oil as a raw material by using a non-solvent method under acid catalysis by using small-molecular carboxylic acid and hydrogen peroxide as modifiers; then, small-molecular alcohols and alcohol amines are used as ring-opening reagents to prepare the modified castor oil coating material 200-400 mgKOH / g in hydroxyl value under the action of a solid acid catalyst. The modified castor oil coating material and isocyanate are used as component A and component B respectively to prepare a modified castor oil coated controlled-release fertilizer by using non-solvent in-situ reaction coating technology. The controlled-release fertilizer is green, the production process of the fertilizer is simple, the controlled release effect is good and stable, and controlled-release fertilizers with different release periods may be prepared by changing coating amount.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

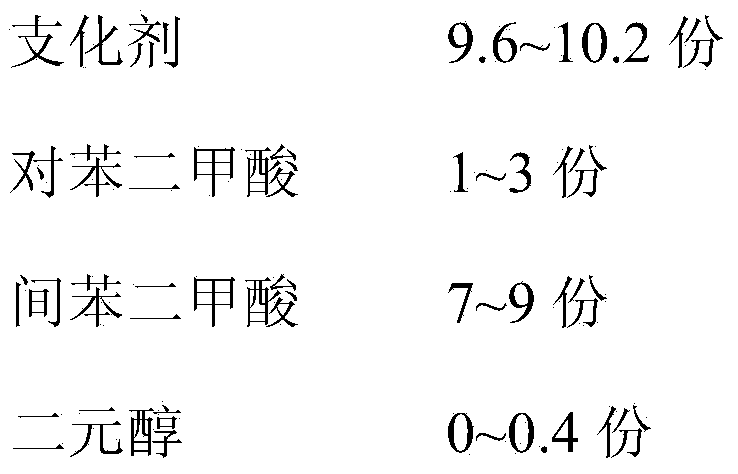

Polyester resin and synthesis method thereof

InactiveCN103467714AHigh hydroxyl valueGood matting effectPowdery paintsPolyester coatingsChemistryDiol

The invention relates to polyester resin and a synthesis method thereof. The polyester resin comprises the following raw material components in parts by mass: 45-53 parts of aromatic binary acid, 40-50 parts of a branching agent, 0-10 parts of dihydric alcohol and 0-0.01 part of an esterification catalyst; the polyester resin is synthesized by melt phase polycondensation. The polyester resin has an ultrahigh hydroxyl value, has acceptable glass-transition temperature, can be used for preparing an AB dry-blending extinction powder coating and has a favorable extinction effect.

Owner:ANHUI SHENJIAN NEW MATERIALS

Vegetable oil polyalcohol as well as preparation method and application of vegetable oil polyalcohol

InactiveCN104610540ANovel structureHigh hydroxyl valueOrganic compound preparationCarboxylic acid esters preparationVegetable oilPetrochemical

The invention discloses vegetable oil polyalcohol as well as a preparation method and an application of the vegetable oil polyalcohol. The vegetable oil polyalcohol is prepared by carrying out ring-opening reaction on epoxy vegetable oil and a polyhydroxy compound. Compared with the prior art, the vegetable oil polyalcohol prepared by adopting a novel ring-opening reagent is novel in structure, high in hydroxyl value, low in viscosity and capable of completely substituting the traditional petrochemical polyalcohol to be applied to preparation of a polyurethane foam material. Meanwhile, the preparation method disclosed by the invention is simple in process; the obtained vegetable oil polyalcohol does not need to be after-treated and is very suitable for industrial production; and particularly, after a tubular reactor is selected, the reaction efficiency can be increased, the side reaction can be controlled, and the energy consumption can be reduced.

Owner:NANJING UNIV OF TECH

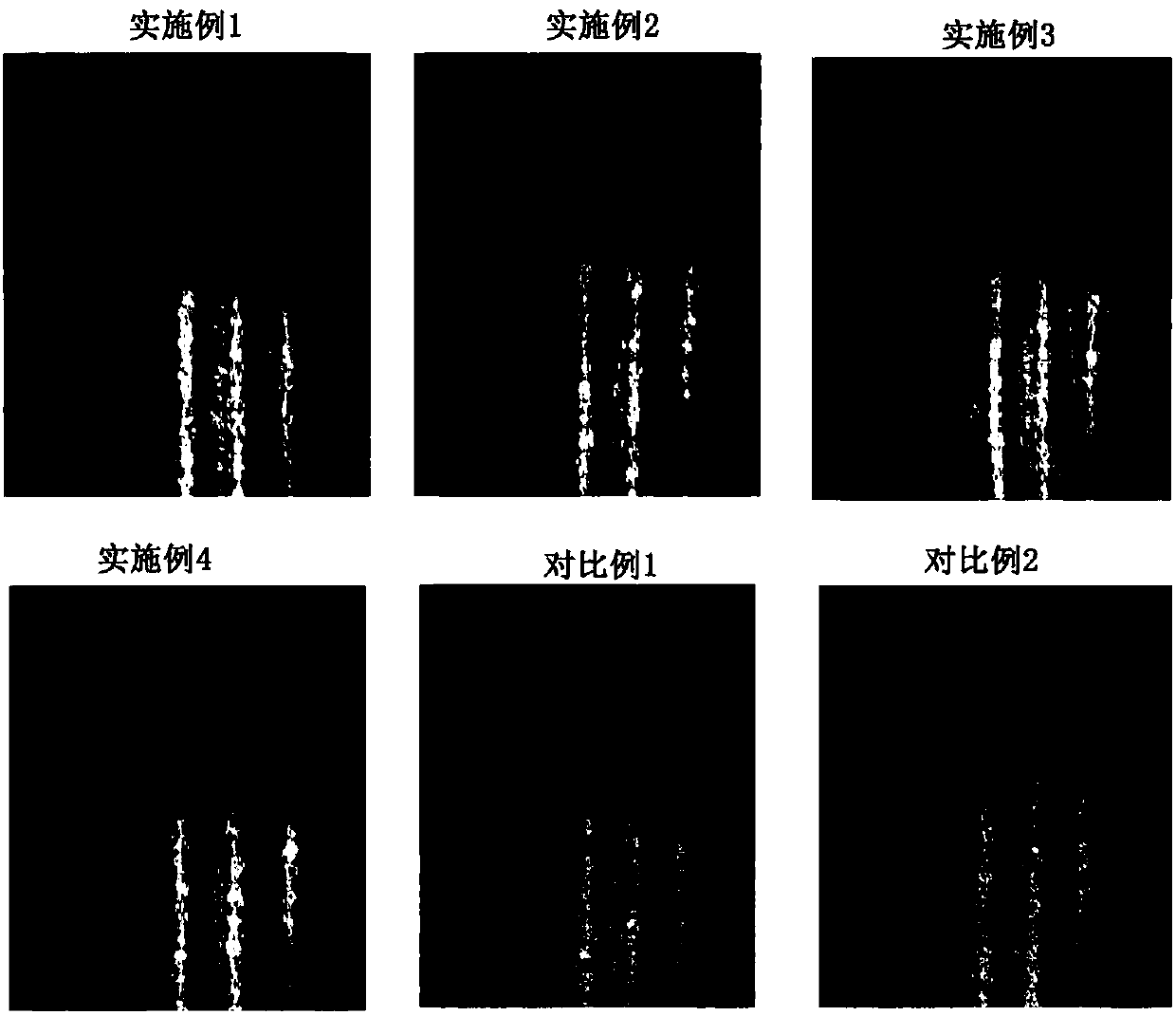

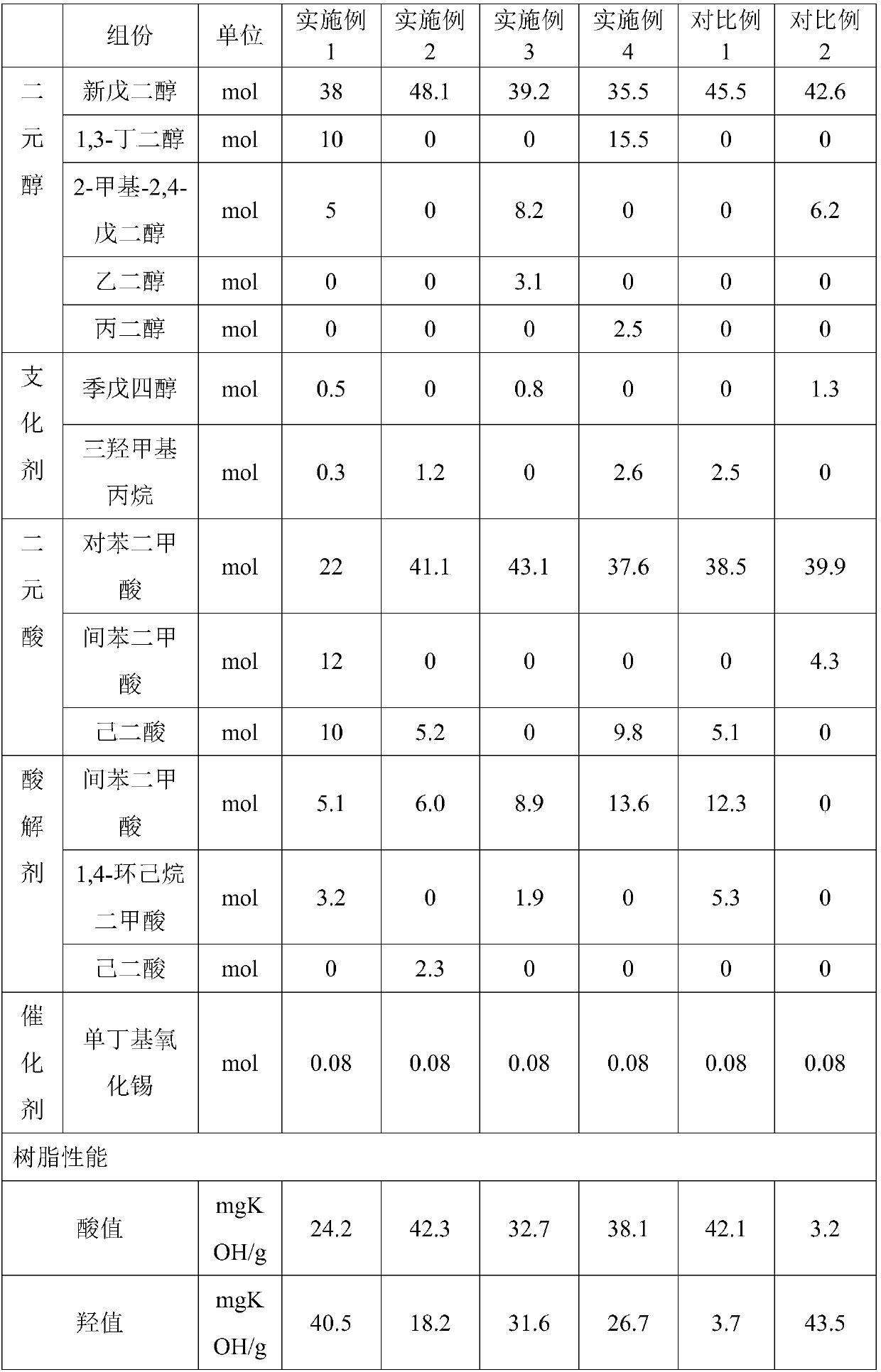

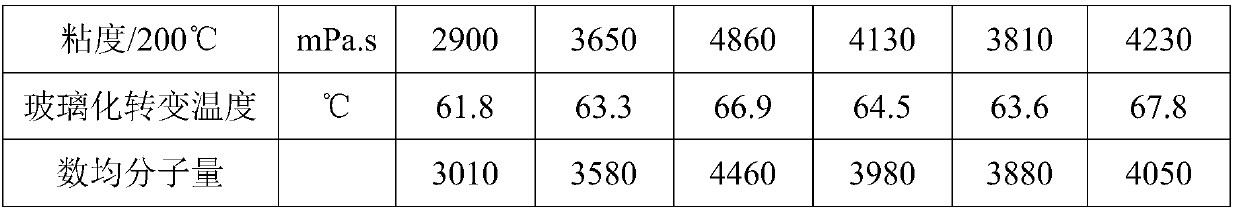

Bifunctional polyester resin for powder coating and preparation method of polyester resin

InactiveCN107868235ASimple structureImprove performancePowdery paintsPolyester coatingsSolventGlass transition

The invention discloses bifunctional polyester resin for a powder coating. The polyester resin has two functional groups including a terminal carboxyl group and a terminal hydroxyl group and has the acid value of 20-45 mgKOH / g, the hydroxyl value of 15-45 mgKOH / g, the viscosity of 2,600-5,200 mPa.s at the temperature of 200 DEG C, the number-average molecular weight of 3,000-4,500 and the glass transition temperature of 61-69 DEG C; the polyester resin is mainly prepared from components in mole percent as follows: 44mol%-55mol% of dibasic alcohol, 40mol%-46mol% of binary acid, 0.1mol%-3.0mol%of a branching agent, 4mol%-15mol% of an acidulate agent and 0.01mol%-0.10mol% of an esterification catalyst through melt polymerization. The polyester resin has outstanding comprehensive properties in the aspects of leveling performance, mechanical property, weather fastness, boiling resistance, heat resistance, solvent resistance, heat transfer printing property and the like. The invention alsodiscloses a preparation method of the bifunctional polyester resin for the powder coating.

Owner:GUANGZHOU KINTE IND

Vegetable oil polyhydric alcohol as well as preparation method and application of vegetable oil polyhydric alcohol

InactiveCN105541621ANovel structureHigh hydroxyl valueOrganic compound preparationCarboxylic acid esters preparationVegetable oilAlcohol

The invention discloses vegetable oil polyhydric alcohol as well as a preparation method and application of the vegetable oil polyhydric alcohol. The vegetable oil polyhydric alcohol is prepared by a ring-opening reaction of epoxy vegetable oil and a polyhydroxy compound. Compared with the prior art, the vegetable oil polyhydric alcohol prepared by adopting a novel ring opening agent has a novel structure, a high hydroxyl value and low viscosity, and can be used for completely replacing traditional petrochemical polyhydric alcohol to be applied to preparation of a polyurethane foam material. Meanwhile, the method is simple in process and the obtained product does not need to be subjected to post treatment and is very suitable for industrialized production; particularly, after a tubular reactor is selected, the reaction efficiency can be improved, a side reaction is controlled and the energy consumption is reduced.

Owner:NANJING TECH UNIV

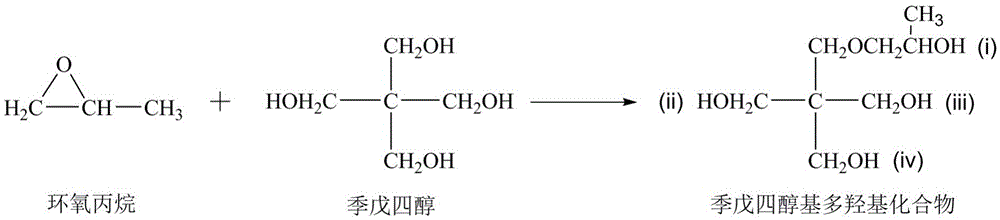

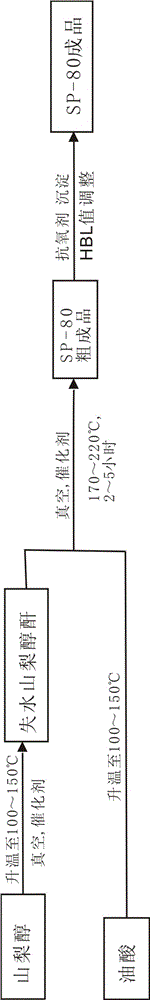

Synthetic method of emulsifier SP-80 for emulsion explosive

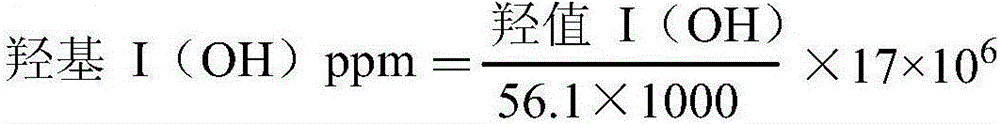

ActiveCN102910994AHigh viscosityHigh hydroxyl valueNon-explosive/non-thermic compositionsEmulsion explosiveHydroxyl value

The invention discloses a synthetic method of an emulsifier SP-80 for an emulsion explosive. The synthetic method comprises the following steps: 1) etherifying sorbitol and a catalyst for 50-90 minutes at the temperature of 100-150 DEG C in a vacuum state to generate sorbitan anhydride; and 2) uniformly mixing the sorbitan anhydride, oleic acid and the basic catalyst, and esterifying for 2-5 hours at the temperature of 170-220 DEG C to generate the emulsifier SP-80 for the emulsion explosive as an early finished product. According to the synthetic method of the emulsifier SP-80 for the emulsion explosive, the problem of producing the SP-80 by a one-step method can be solved, the emulsifier SP-80 with excellent quality can be continuously and quickly produced by adopting a two-step method, and the produced emulsifier is higher in viscosity and is higher in hydroxyl value.

Owner:GEZHOUBA YIPULI HUBEI CHANGTAI CIVIL EXPLOSIVE

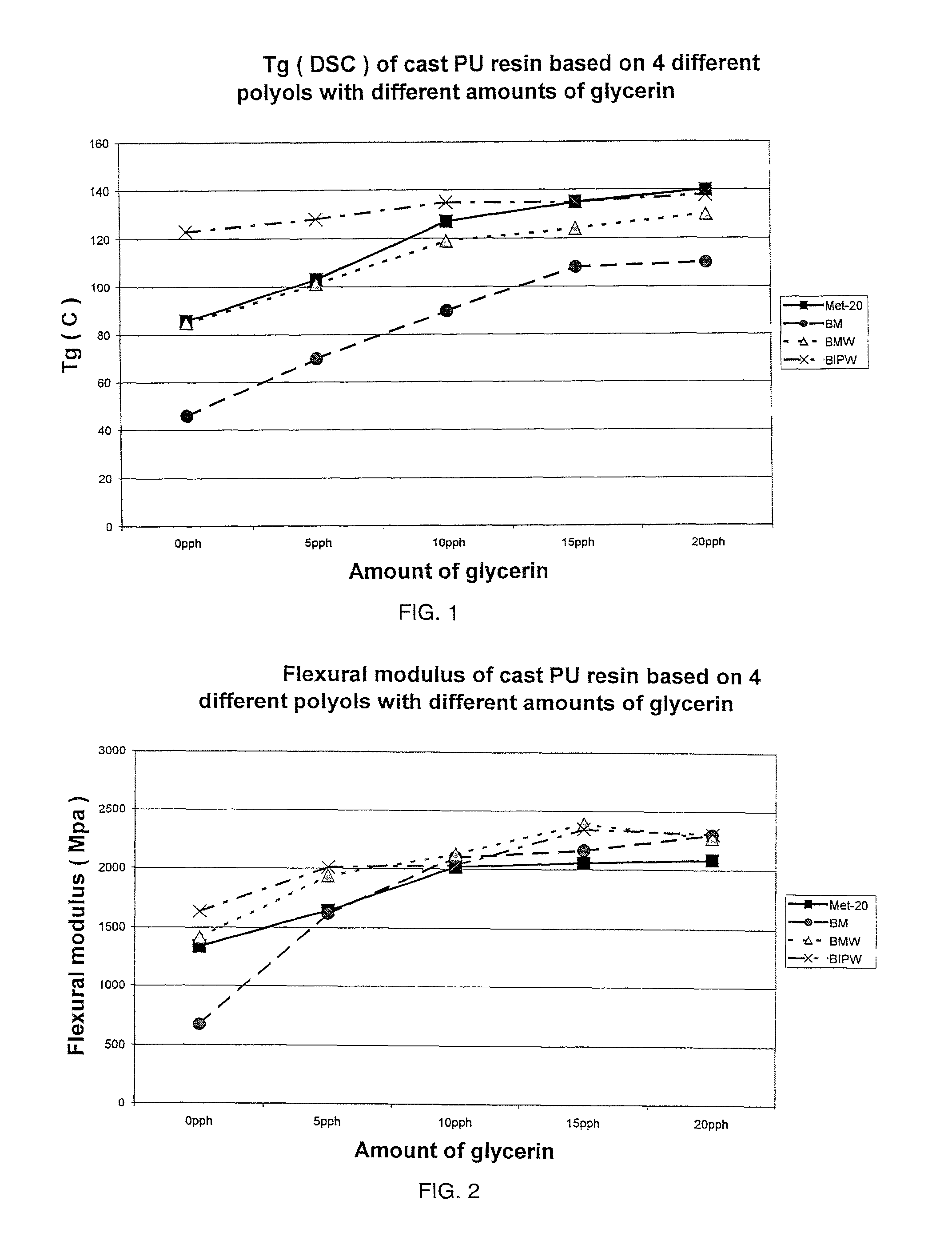

Polymer concrete and method for preparation thereof

InactiveUS7977424B2High hydroxyl valueImprove structural performanceSolid waste managementBuilding constructionsPolymer sciencePtru catalyst

A soy-based polyol is mixed with an isocyanate and aggregate to produce a soy-based polyurethane having superior mechanical properties. The aggregate composition may be varied to obtain different mechanical properties, as can the amount of resin. The resin may be crosslinked using a low molecular weight polyol, such as glycerine, to also improve structural performance. A catalyst may be added to accelerate curing time without reducing structural performance.

Owner:PETROVIC ZORAN +3

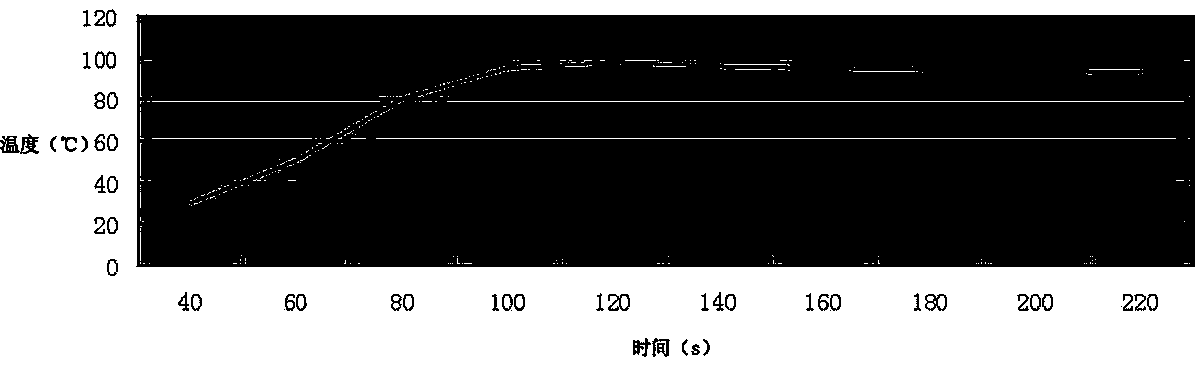

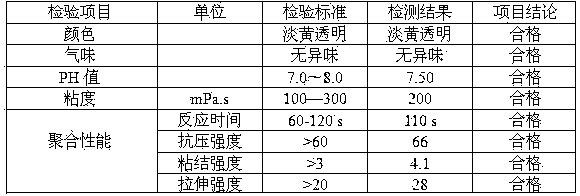

High polymer grouting material and preparation method thereof

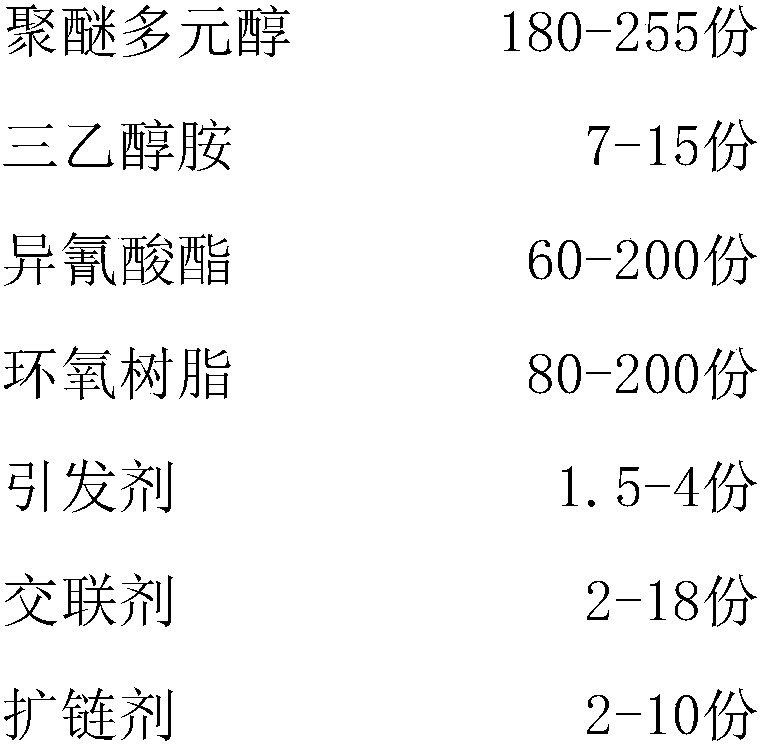

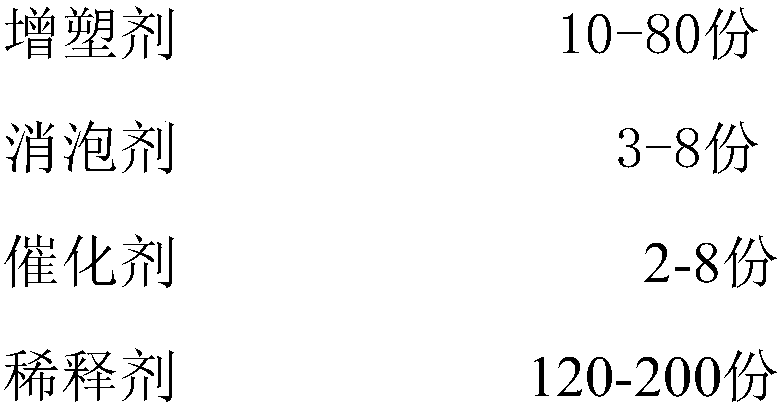

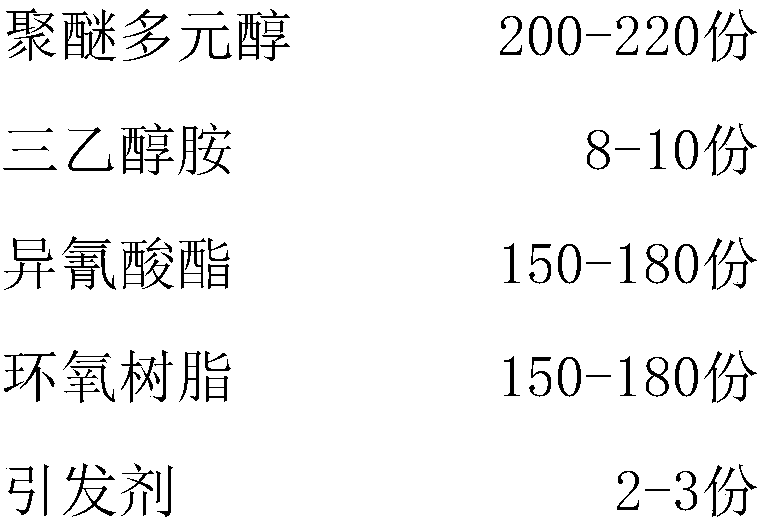

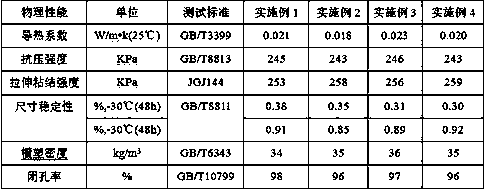

The invention relates to the technical field of grouting materials and specifically relates to a high polymer grouting material and a preparation method thereof. The high polymer grouting material isprepared from an ingredient A and an ingredient B according to a proportion of (1.8 to 2.5) to 1, wherein the ingredient A is prepared from the raw materials of polyether glycol, triethanol amine, isocyanate, epoxy resin, an initiator, a cross-linking agent and a chain extender; the ingredient B is prepared from the raw materials of a plasticizer, a defoaming agent, a catalyst and a diluent. The high polymer grouting material disclosed by the invention has the advantages of good permeability and short curing time; strength of cured condensate is high, bonding to the concrete is formthe cured condensate has concrete bonding firmness, and a cured part has good permeable resistance; furthermore, a construction technology is simple, and normal-temperature curing under the dry and moist conditions is achieved.

Owner:GUANGDONG UNIV OF SCI & TECH

Polyurethane heat preservation material

The invention relates to a heat preservation material, and discloses a polyurethane heat preservation material. The heat preservation material is prepared by mixing and foaming the following raw materials in parts by weight: 70 to 100 parts of 1, 6-hexamethylene diisocyanate, 40 to 80 parts of polyether glycol I, 10 to 30 parts of polyether glycol II, 3 to 6 parts of expanded vermiculite, 5 to 8 parts of nanosilicon dioxide, 10 to 20 parts of a foaming agent, 1 to 5 parts of dihydroxyethyl amine monoisopropanolamine and 1 to 5 parts of a foam stabilizer, wherein the polyether glycol I is lignin polyether glycol; the polyether glycol II is polyether glycol polymerized by modified sunflower seed oil serving as a starting agent and epoxypropane serving as a polymeric monomer. The heat preservation material is higher in compressive strength, tensile strength and impact strength, and meanwhile, phenomena of deformation, bulging, ridging and even cracking of a water tank are avoided.

Owner:GUANGXI JISHUN ENERGY TECH

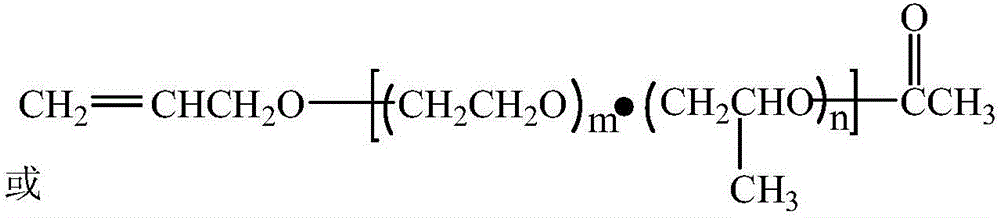

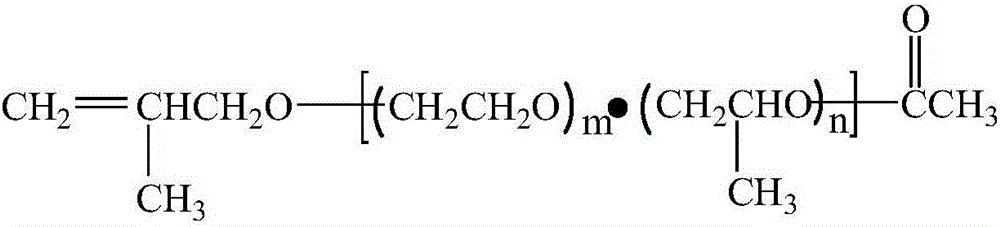

Acetyl terminated polyester and preparation method thereof

The invention relates to acetyl terminated polyester and a preparation method thereof and belongs to the technical field of organic high-molecular compound synthesizing. The acetyl terminated polyester uses polyether and acetic anhydride as the raw materials. The preparation method is characterized in that after condensation reflux reaction, most of acid is removed by a nitrogen bubbling manner under a vacuumizing condition, the rest acetic acid and acetic anhydride are removed through a falling-film evaporator under high-vacuum condition, and co-boiling solvent, the acetic acid and the acetic anhydride to obtain the acetyl terminated polyester. The preparation method used for synthesizing the acetyl terminated polyester is high in termination rate, clean in alcohol removing, and the like.

Owner:ZHEJIANG HUANGMA TECH

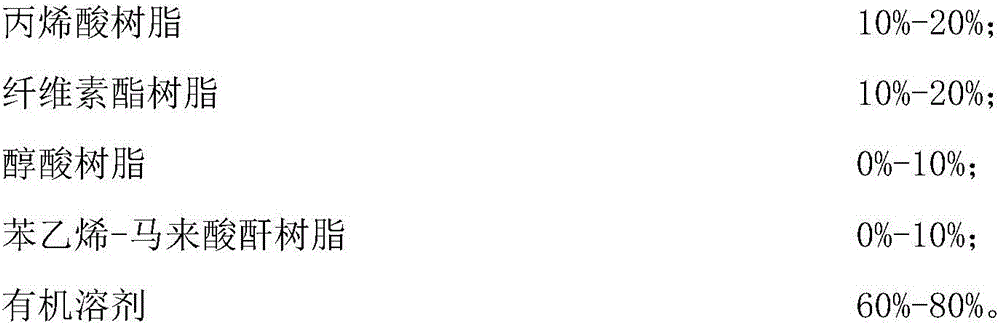

Low-VOC easy-to-offset-printing cold wave release layer coating and preparation method thereof

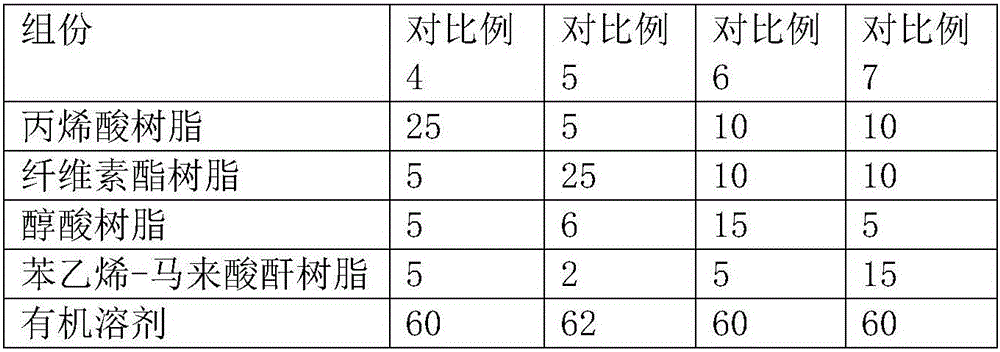

The invention provides a low-VOC easy-to-offset-printing cold wave release layer coating and a preparation method thereof. The coating is prepared from the following components in percentages by weight: 10% to 20% of acrylic resin, 10% to 20% of cellulose ester resin, 0% to 10% of alkyd resin, 0% to 10% of styrene-maleic anhydride resin and 60% to 80% of an organic solvent. Compared with the prior art, the coating has the advantages of adjustable and controllable stripping quality, excellent offset printing performance and low raw material cost; moreover, the coating adopts a benzene-free system, and has the characteristic of low VOC content.

Owner:SHANGHAI WEIKAI CHEM

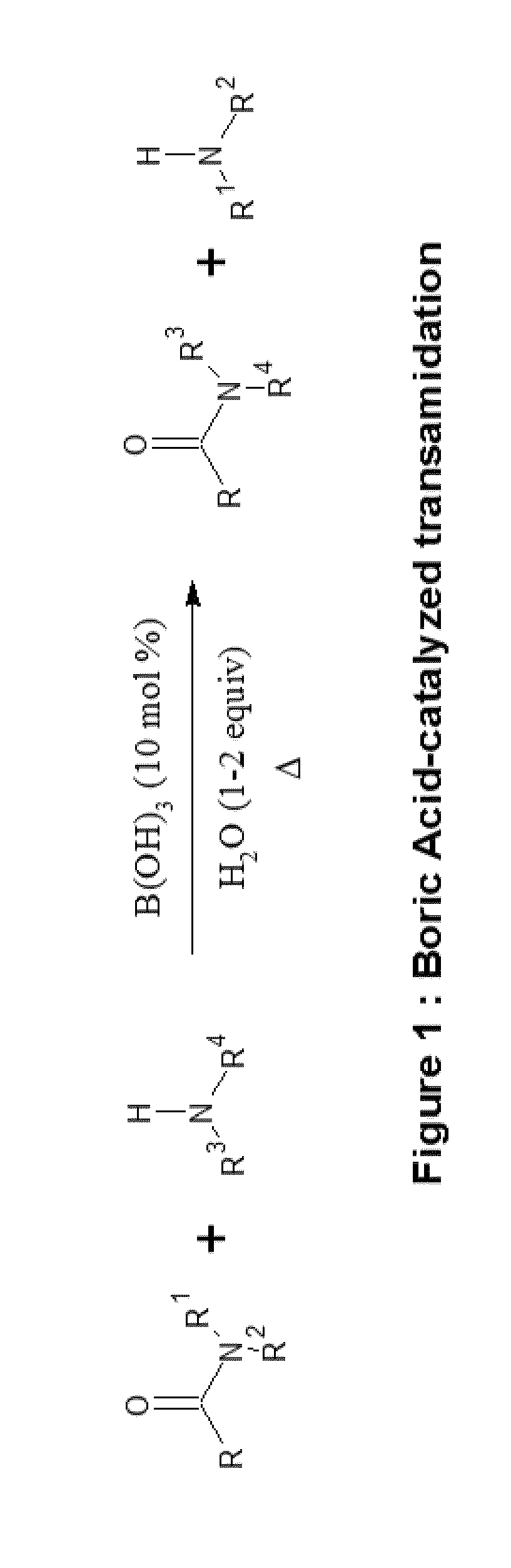

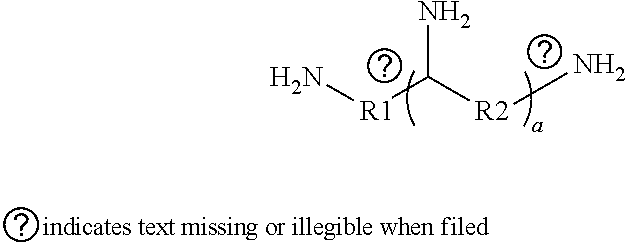

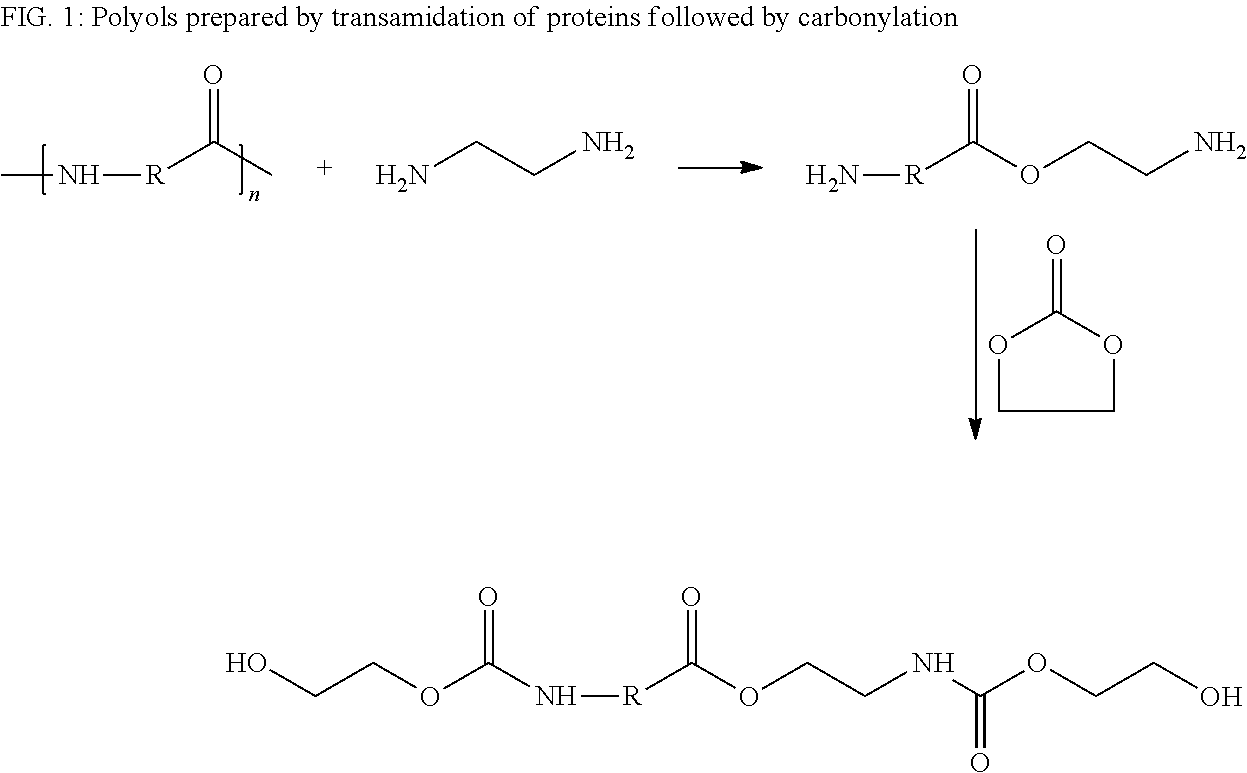

Polyols from protein biomass

InactiveUS20150291741A1Improve responseHigh hydroxyl valueProtein composition from vegetable seedsDepsipeptidesDiamineBiomass

A process of producing multi-hydroxy polyols, the process comprising providing a biomass material and transamidating the biomass material with an amine selected from the group consisting essentially of a diamine and an alkanolamine, to provide low molecular weight derived amino-acids or derived oligomers of proteins. Thereafter, reacting the derived amino-acids or derived oligomers with a carbonate to provide hydroxyl terminated urethane oligomers.

Owner:MICHIGAN STATE UNIV

Rigid polyurethane foam and preparation method thereof

The invention discloses a rigid polyurethane foam and a preparation method thereof. The preparation method of the rigid polyurethane foam comprises the following steps: premixing 100 parts by weight of hyperbranched polyurethane polyol with 1-10 parts by weight of foam stabilizer, adding 100-250 parts by weight of organic isocyanate or modified isocyanate to the pre-mixture and then curing at 30-100 DEG C for 12 hours to 3 days, thus obtaining the rigid polyurethane foam, wherein the hyperbranched polyurethane polyol is prepared by use of the following steps: reacting a polyhydroxylated compound with a diisocyanate monomer to obtain a first-generation hyperbranched prepolymer; on the basis of the isocyanate group content of the first generation hyperbranched prepolymer, adding the polyhydroxylated compound again and reacting to obtain the hyperbranched polyurethane polyol. The rigid polyurethane foam prepared by use of the method is high in strength, good in temperature resistance, good in dimensional stability and low in heat conductivity coefficient, and can be applied to the fields of thermal insulation, gap filling and supporting, wood-imitation materials and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Hydroxyl coumarone resin and preparation method thereof

ActiveCN105566569AImprove performanceGood compatibilityCoumarone-indene polymer adhesivesCoatingsChemical reactionEthyl cinnamate

The invention provides a hydroxyl coumarone resin and preparation method thereof, and belongs to the field of resin preparation. The hydroxyl coumarone resin is prepared from a polymerizable component-containing mixture and 4-hydroxystyrene or 4-hydroxyl methyl cinnamate or 4-hydroxyl ethyl cinnamate, and the polymerizable component-containing mixture is obtained through distilling a heavy benzene fraction of coal tar; and polymerizable components comprise indene and coumarone, and the mass of 4-hydroxystyrene or 4-hydroxyl methyl cinnamate or 4-hydroxyl ethyl cinnamate is 1-20% of the mass of the polymerizable components. The hydroxyl coumarone resin contains hydroxyl groups, so the hydroxyl value of coumarone resin is substantially improved, and the coumarone resin has good compatibility with polar resins; and the coumarone resin carrying the hydroxyl groups chemically reacts with other components to form interpenetrating network crosslinking, so the performances of coatings and adhesives are further improved.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

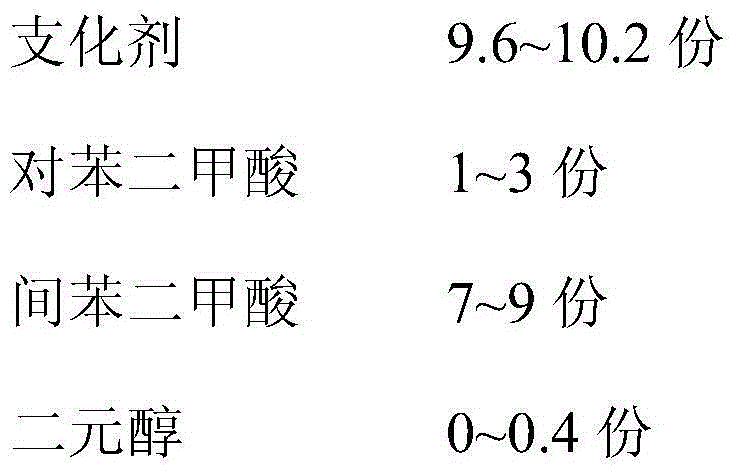

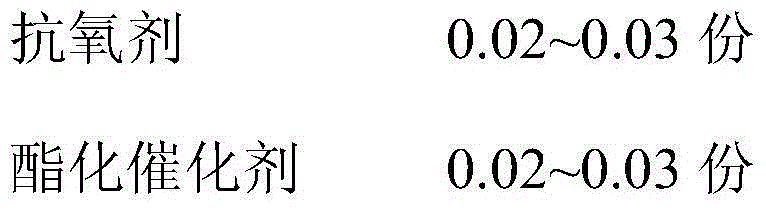

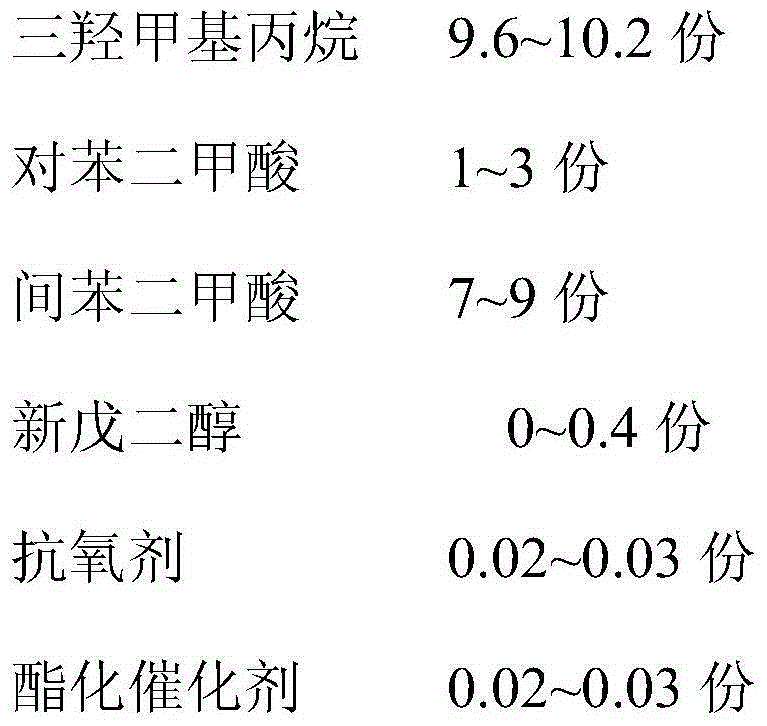

Terminal hydroxyl polyester resin for co-extrusion extinction powder coating and preparation method of terminal hydroxyl polyester resin

InactiveCN104448266AGood storage stabilityReduce glossPowdery paintsPolyester coatingsLeveling effectExtinction

The invention discloses terminal hydroxyl polyester resin for co-extrusion extinction powder coating and a preparation method of the terminal hydroxyl polyester resin. The terminal hydroxyl polyester resin comprises trimethylolpropane, terephthalic acid, isophthalic acid, neopentyl glycol, an antioxygen and an esterification catalyst. Compared with the prior art, the synthesized polyester resin has the advantages that the glass transition temperature Tg of the polyester resin is higher than 51 DEG C; the polyester resin can provide a good storage stability; the viscosity is 2800-3000mPa.s (200 DEG C), and a good leveling effect can be provided due to the low viscosity; the polyester resin has a high hydroxyl value, carries out co-extrusion extinction with a low hydroxyl value, and has low luster being 7-10 percent.

Owner:ANHUI SHENJIAN NEW MATERIALS

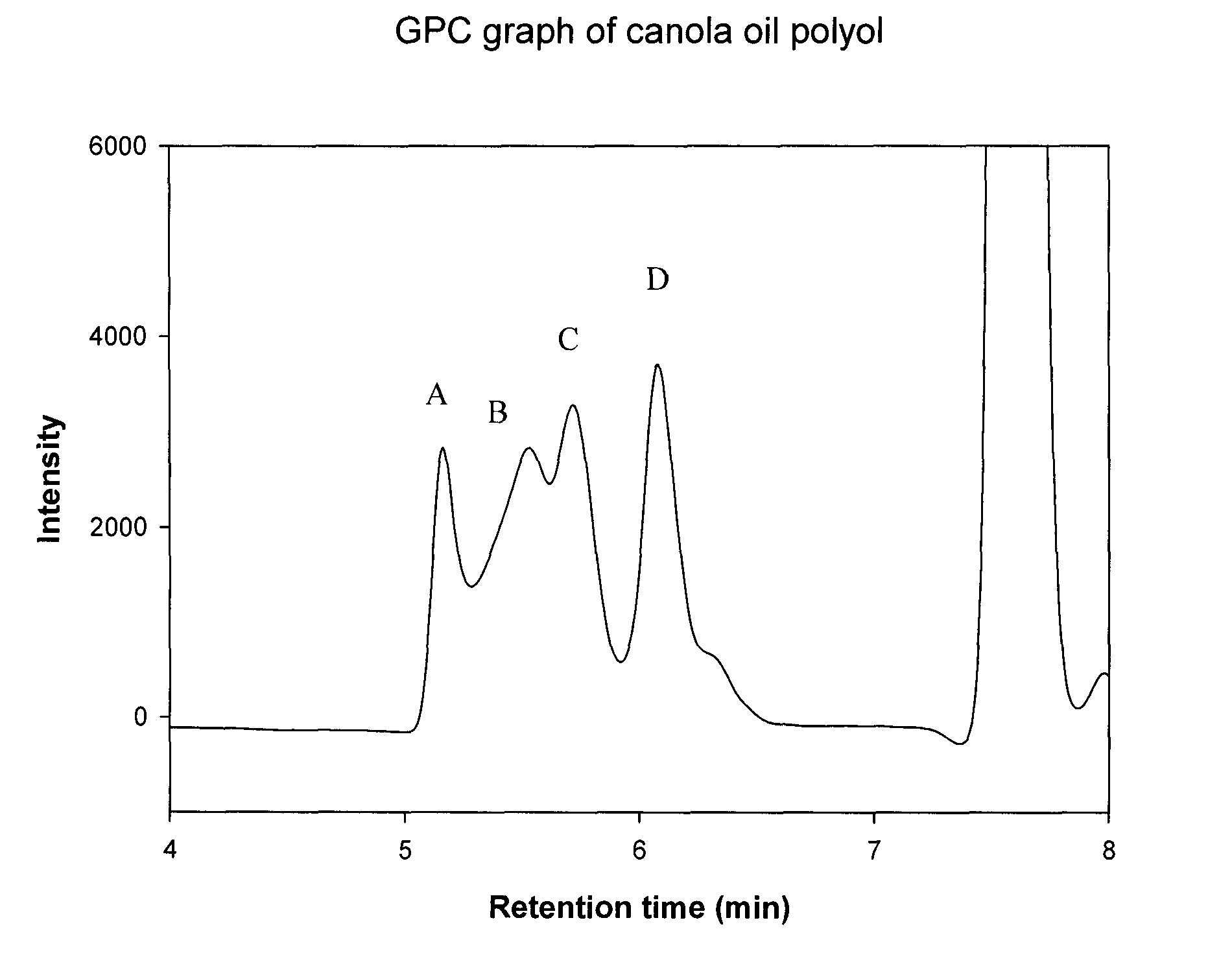

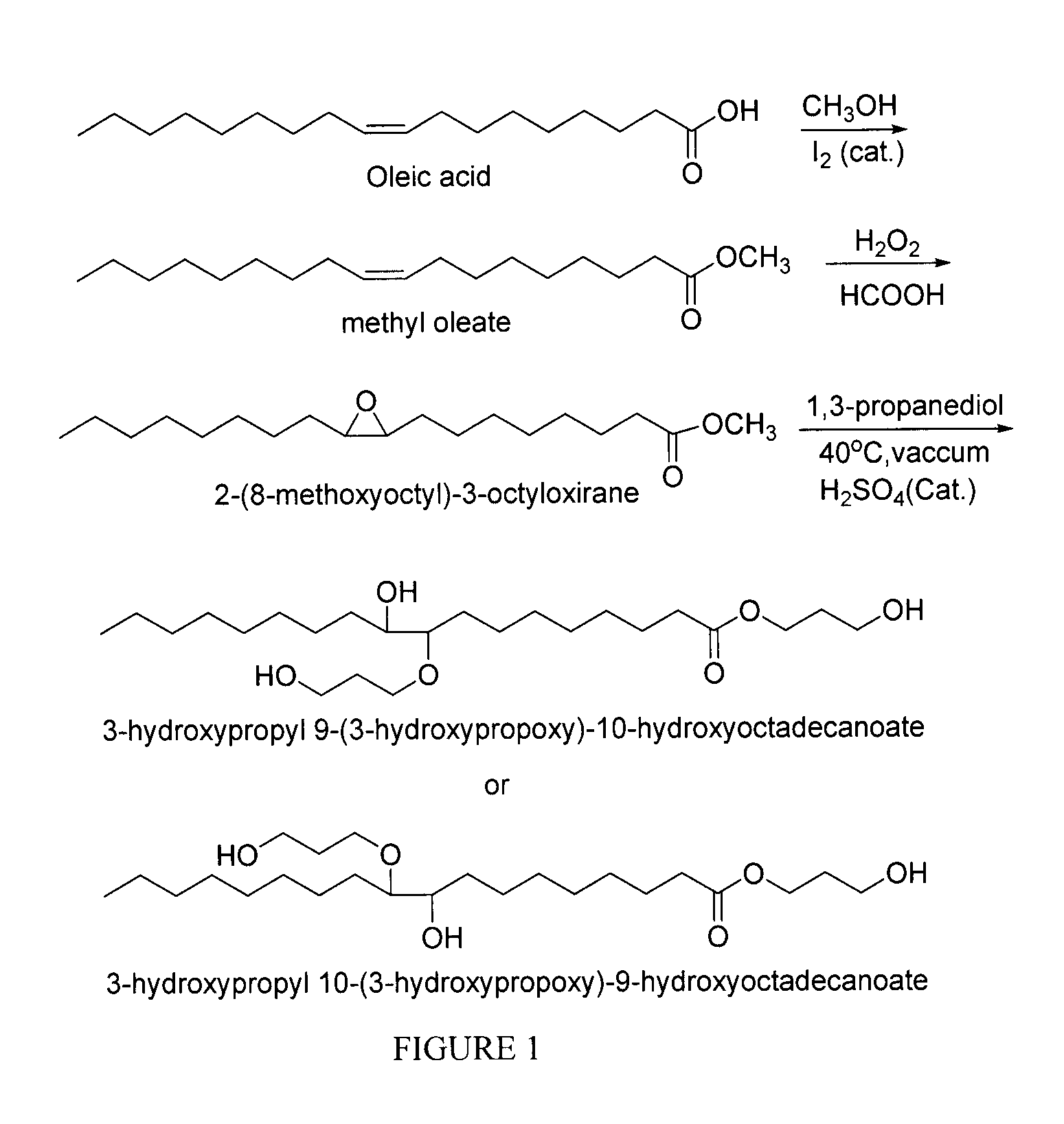

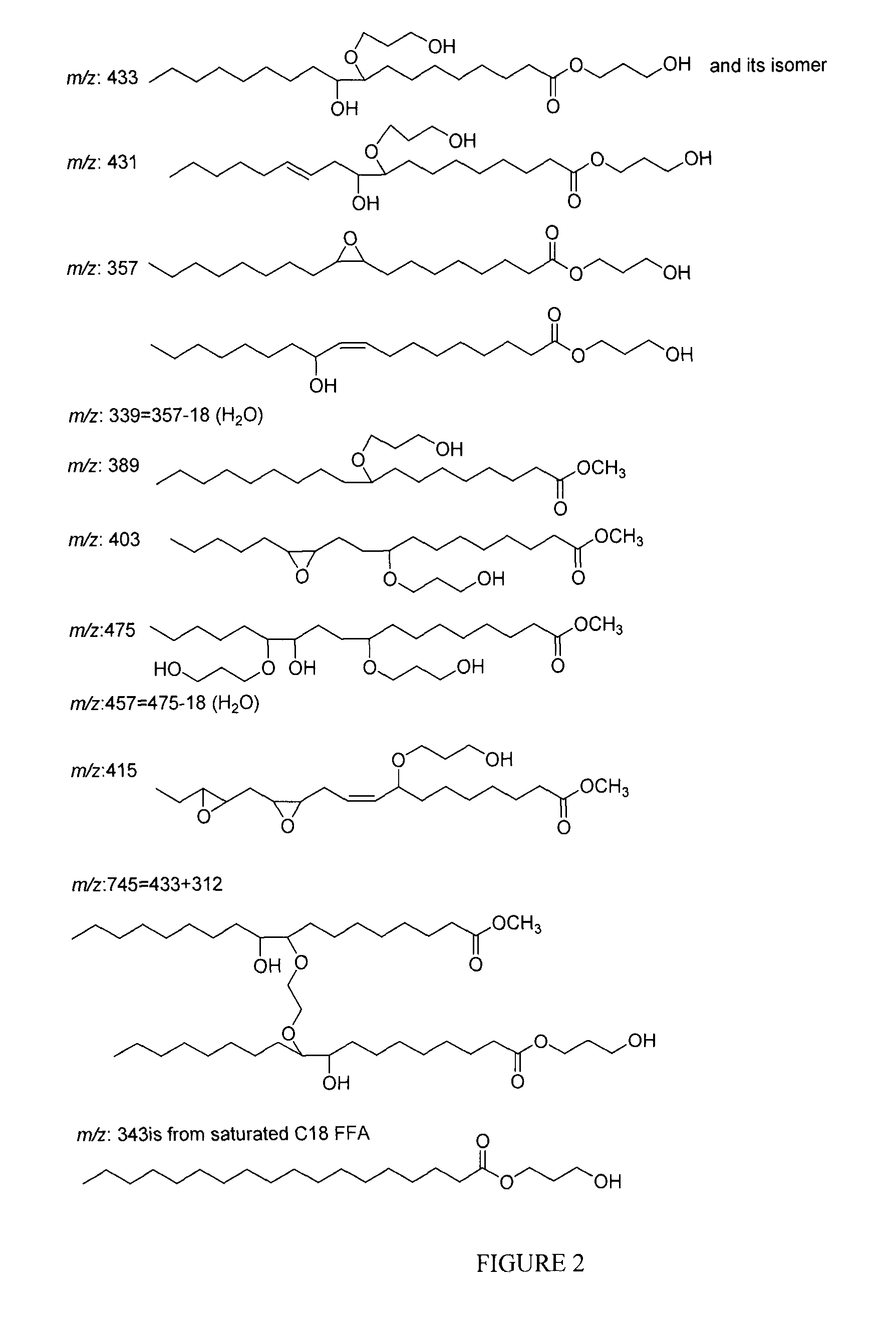

Polyol synthesis from fatty acids and oils

ActiveUS9216940B2Low viscosityReduce molecular weightFatty acid esterificationFatty acids production/refiningIodo fatty acidPolyol synthesis

A method for preparing polyols from fatty acid substrates such as free fatty acids, alkyl esters of fatty acids, mono-glycerides, diglycerides, and triglycerides. The method comprises the steps of (a) epoxidizing an unsaturated fatty acid substrate and (b) hydroxylating the epoxidized fatty acid substrate with at least one diol to produce a polyol or a blend of polyols. The method may be varied to produce polyols with desired functionality, molecular weights, or viscosity.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Preparation method of dimer acid polyol and application thereof in polyurethane foam

The invention discloses a preparation method of dimer acid polyol and an application thereof in polyurethane foam, and belongs to the field of biological source high polymer materials. According to the preparation method of the dimer acid polyol, provided by the invention, dimer acid and propanetriol are used as raw materials, and bis(lauroyloxy)dioctyl tin, zinc acetate, tetrabutyl titanate and the like are used as catalysts to perform an esterification reaction to obtain polyhydroxyl polyol. The dimer acid polyol provided by the invention has the advantages that the raw materials are wide in source, can be extracted from common plants, and are nontoxic and harmless. The polyurethane foam prepared by using the dimer acid polyol has the characteristics of good mechanical properties and excellent thermal insulation property.

Owner:CHANGZHOU UNIV

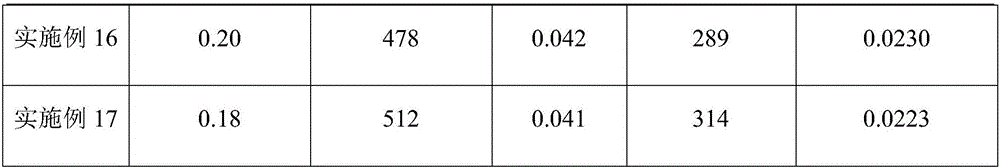

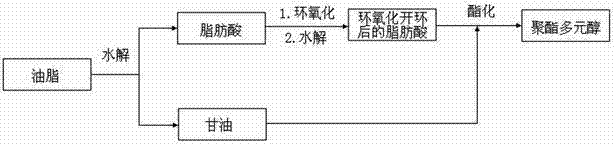

Preparation method for polyester polyol by grease restructuring

ActiveCN102199090ASpecial structureReduce the impactOrganic compound preparationCarboxylic acid esters preparationPolyesterAcetic acid

The invention discloses a preparation method for polyester polyol by grease restructuring, comprising the following steps: carrying out a basic hydrolysis on grease raw materials to prepare aliphatic acid and glycerin; weighing to take certain mass proportion of aliphatic acid, acetate, hydrogen peroxide (30%) and a catalyst, wherein m aliphatic acid: m acetate : m hydrogen peroxide : m sulfuric acid = 100:0-50:40-150:1-5, and adding the aliphatic acid, acetate and the catalyst into a reactor simultaneously; adding the hydrogen peroxide dropwisely for 1 hour to 2 hours at a temperature of 40 DEG C, standing the mixture for reaction for 2 to 4 hours at a temperature of 60 DEG C, and carrying our a ring opening hydrolysis for 1 hour to 2 hours in backflow state; carrying out phase splittingon the oxidized product, adding glycerin and an esterification catalyst into the organic phase, and carrying out esterification for 1 hour to 2 hours at a temperature of 180 DEG C under the conditionof reduced pressure (5-10 Kpa). Therefore, aliphatic acid polyester polyol with an acid value of 1 to 10 mg KOH / g and a hydroxyl value of 280 to 410 mg KOH / g is obtained.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Totally bio-based vegetable oil polyol and preparation method and use thereof

InactiveUS20190119496A1High viscosityImprove mechanical propertiesOrganic chemistryChemical/physical/physico-chemical microreactorsState of artVegetable oil

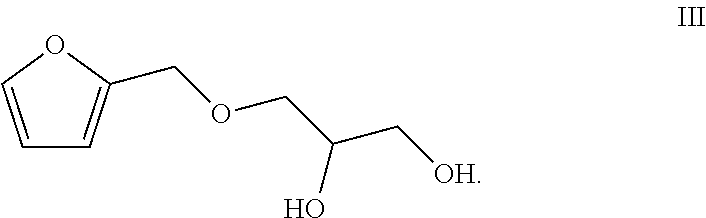

A method comprises enabling epoxy vegetable oil to react with a compound of a formula III in a second microstructured reactor to obtain the vegetable oil polyol. Compared with the existing technology, the present invention adopts a novel, environment-friendly ring-opening agent, the obtained polyol is novel in structure, high in hydroxyl value, even in distribution and low in viscosity, and can completely replace traditional petrochemical polyol to be applied to the preparation of polyurethane foam materials.

Owner:NANJING UNIV OF TECH

Hydroxyl-terminated polyester resin for co-extrusion extinction powder paint

PendingCN104327257AGood storage stabilityReduce glossPowdery paintsPolyester coatingsLeveling effectAlcohol

The invention discloses hydroxyl-terminated polyester resin for co-extrusion extinction powder paint. The hydroxyl-terminated polyester resin comprises a branching agent, terephthalic acid, isophthalic acid, dihydric alcohol, an antioxidant and an esterification catalyst. Compared with the prior art, the polyester resin synthesized in the invention has the advantage that the glass transition temperature Tg of the polyester resin is higher than 51 DEG C and good storage stability can be provided; the viscosity is 2800-3000mPa.s (200 DEG C) so as to provide good leveling effects, a hydroxyl value is relatively high so as to have very low gloss of 7-10% as low-hydroxyl-value co-extrusion extinction.

Owner:ANHUI SHENJIAN NEW MATERIALS

Organic silicon modified vegetable oil-based polyol, preparation method thereof and application thereof

InactiveCN110951029AImprove mechanical propertiesImprove thermal stabilityGroup 4/14 element organic compoundsEpoxyPolymer science

The invention discloses organic silicon modified vegetable oil-based polyol, a preparation method thereof and application thereof. The method comprises the steps of mixing N-(beta-aminoethyl)-gamma-aminopropylmethyldimethoxysilane, and epoxy eleostearic acid monoglyceride with an epoxy value of 3% according to a molar ratio of epoxy groups to N-(beta-aminoethyl)-gamma-aminopropylmethyldimethoxysilane of 2: 1 to 3: 1, and carrying out a ring-opening reaction to obtain the organic silicon modified vegetable oil-based polyol. The polyol replaces part of polyether polyol and is uniformly stirred with a silicon dioxide microcapsule flame retardant to prepare compound polyol, the compound polyol is used for preparing polyurethane foam, the prepared polyurethane foam has good mechanical properties, thermal stability and flame retardance, and the limit oxygen index can reach 23.5%.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com