Preparation method of dimer acid polyol and application thereof in polyurethane foam

A technology of polyurethane foam and dimer acid is applied in the field of bio-derived polymer materials, which can solve the problems of non-degradability and environmental pollution of polymer materials, and achieve the effects of reducing dependence, high hydroxyl value and functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 169.8g of dimer acid and 27.6g of glycerol into a 500ml four-neck flask, then dropwise add 0.17g of dibutyltin dilaurate, feed nitrogen on one side, and add a water separator and condensing reflux device on the other side , Heat the oil bath to 140°C, stir for 20h, and measure the acid value and hydroxyl value.

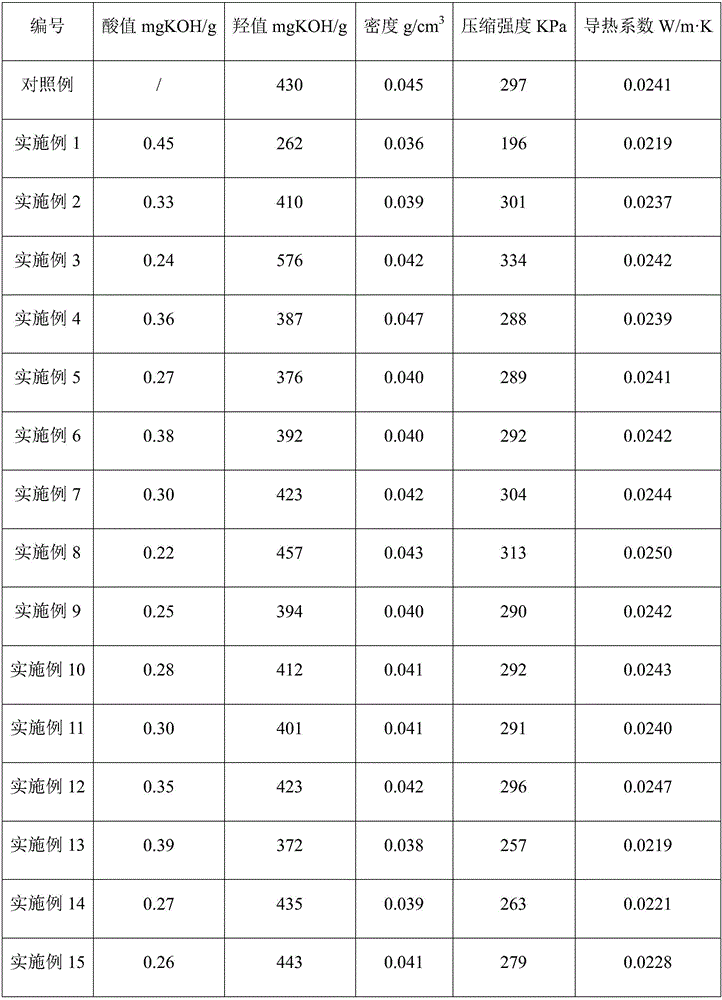

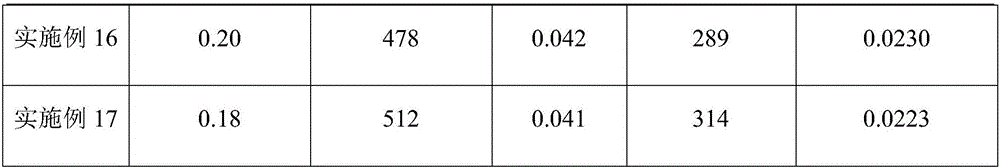

[0039] Weigh 30g of the dimer acid polyol prepared above in a 250ml plastic cup, then add 0.60g of silicone oil, 0.15g of catalyst, 0.30g of water, 6.00g of 141b, mechanically stir at 700r / min for 3min, and then use the isocyanate index of 1.1 Add PM-200, stir at 2500r / min for 7s, pour the mixture into a mold, wait for 24 hours of aging, and cut samples for testing. The test results are shown in Table 1.

Embodiment 2

[0041] Add 169.8g of dimer acid and 55.2g of glycerol into a 500ml four-neck flask, then dropwise add 0.17g of dibutyltin dilaurate, feed nitrogen on one side, and add a water separator and condensing reflux device on the other side , Heat the oil bath to 140°C, stir for 20h, and measure the acid value and hydroxyl value.

[0042] Weigh 30g of the dimer acid polyol prepared above in a 250ml plastic cup, then add 0.60g of silicone oil, 0.15g of catalyst, 0.30g of water, 6.00g of 141b, mechanically stir at 700r / min for 3min, and then use the isocyanate index of 1.1 Add PM-200, stir at 2500r / min for 7s, pour the mixture into a mold, wait for 24 hours of aging, and cut samples for testing. The results are shown in Table 1.

Embodiment 3

[0044] Add 169.8g of dimer acid and 82.8g of glycerol into a 500ml four-neck flask, then dropwise add 0.17g of dibutyltin dilaurate, feed nitrogen on one side, and add a water separator and condensing reflux device on the other side , Heat the oil bath to 140°C, stir for 20h, and measure the acid value and hydroxyl value.

[0045] Weigh 30g of the dimer acid polyol prepared above in a 250ml plastic cup, then add 0.60g of silicone oil, 0.15g of catalyst, 0.30g of water, 6.00g of 141b, mechanically stir at 700r / min for 3min, and then use the isocyanate index of 1.1 Add PM-200, stir at 2500r / min for 7s, pour the mixture into a mold, wait for 24 hours of aging, and cut samples for testing. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com