Coating composition and application of coating composition to metal base material

A composition and coating technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of low solid content, limited space for adjustment and improvement of coating performance, large molecular weight, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

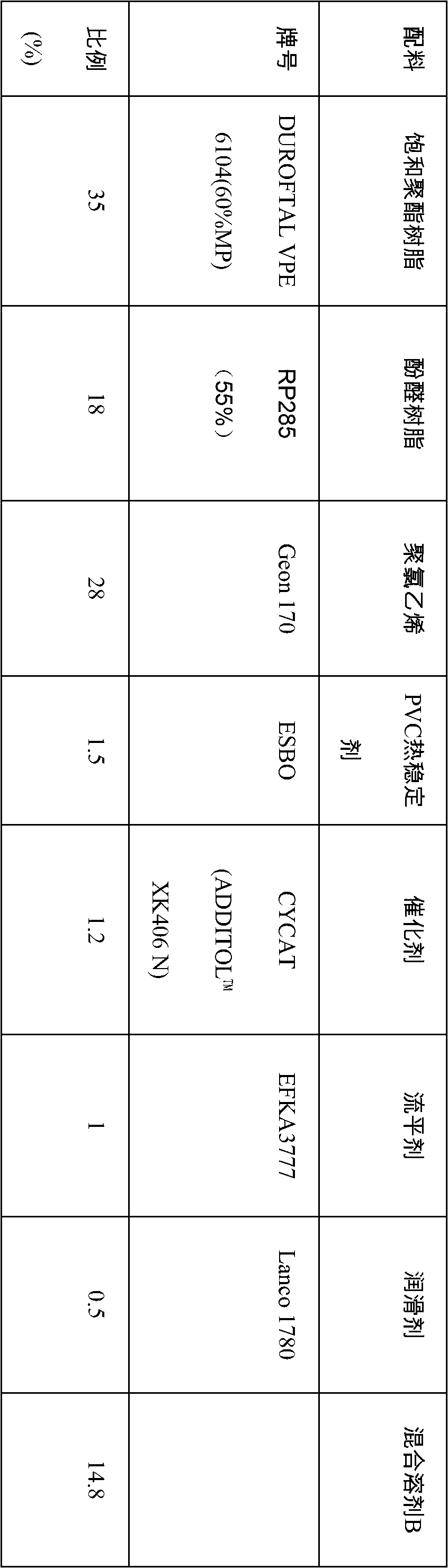

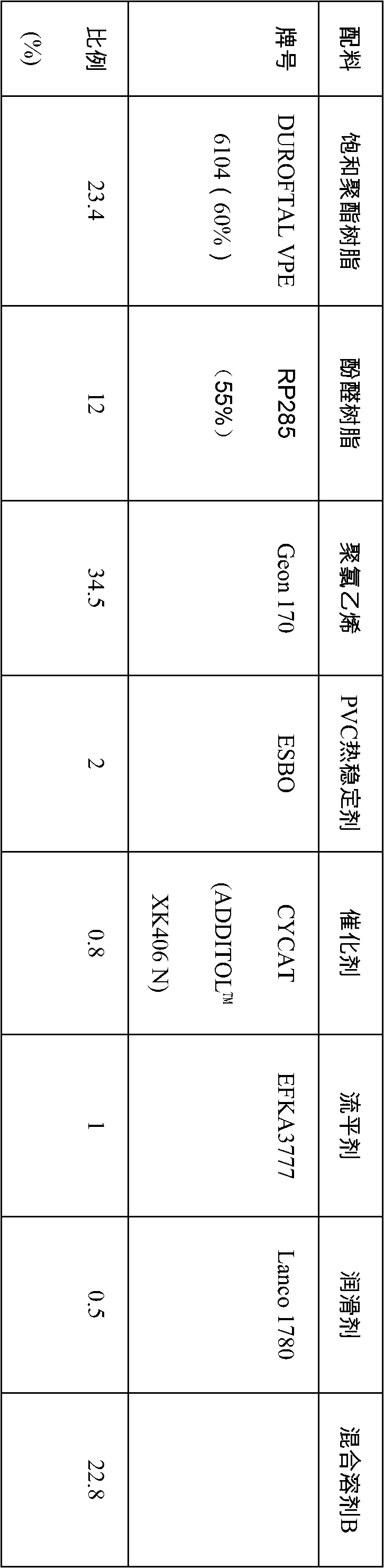

[0041] The raw material components and component contents are shown in Table 2-10, wherein the percentage is the weight percentage of each component actually added, not based on the dry weight of the component. Table 1 is the proportion of epoxy phenolic coatings, only for comparison. First add PVC to the solvent to disperse at high speed. Due to frictional heat, the temperature will continue to rise. Use cooling water to control the temperature below 45°C, disperse and cool to room temperature, then weigh and add other ingredients, stir and mix evenly, and filter to obtain a coating combination for metal substrates. things. Mixed solvent A in Table 1-10 is xylene 35%, n-butanol 25%, propylene glycol methyl ether 30% and DBE 10%, mixed by weight; mixed solvent B is solvent oil solvesso 150#45%, propylene glycol methyl ether Acetate 30%, isophorone 15% and DBE 10%, mixed by weight.

[0042] The raw material composition of table 1 epoxy phenolic comparison coating

[0043] ...

Embodiment 1

[0045]

Embodiment 2

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com