High hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction

A bio-based polyol and epoxy vegetable oil technology, which is applied in the preparation of oxygen-containing compounds, organic compounds, carboxylic acid amides, etc., can solve the problems of unfavorable performance and impact of polyurethane, and achieve no need for catalysts and avoid cross-linking reactions , swing" chain short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

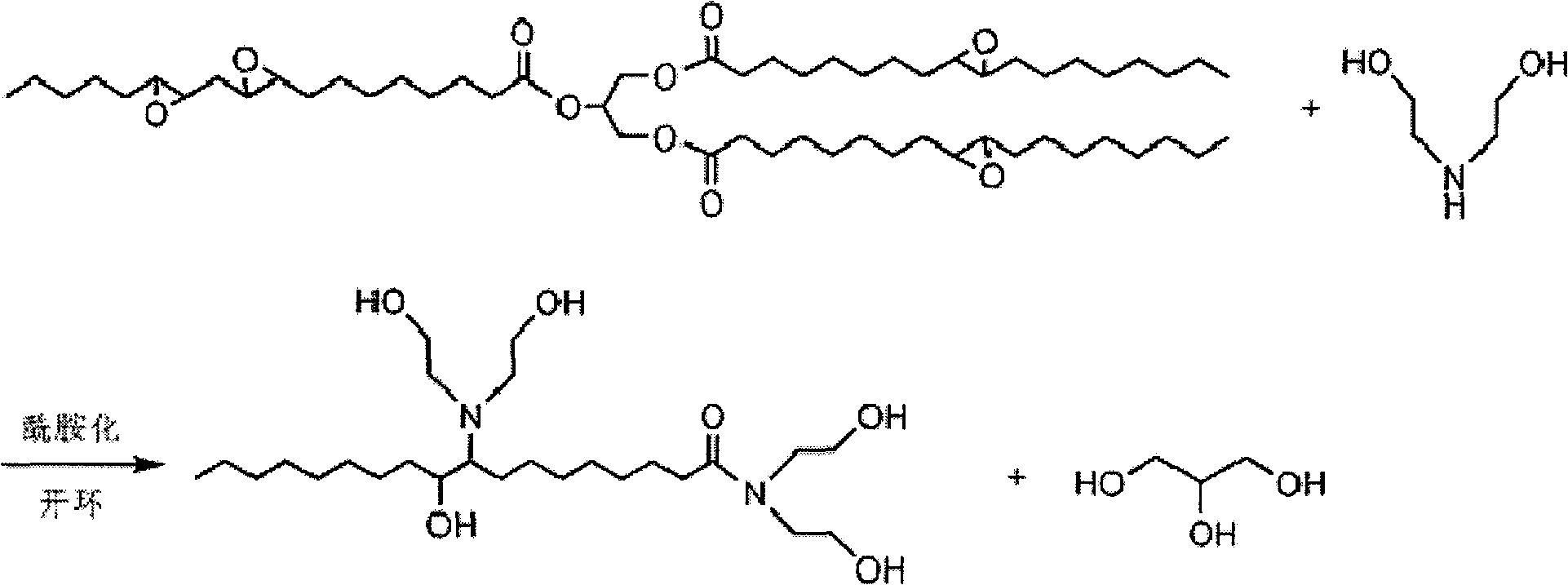

[0032] In the preparation method of the novel bio-based polyol proposed by the invention, two reactions of ring opening and amidation are completed in one step, and the process flow is short.

[0033] The preparation method of the novel bio-based polyol proposed by the present invention has non-toxic and non-volatile raw materials, no catalyst is needed for the reaction, no separation of reaction products is required, and the reaction temperature is low, so it has good environmental friendliness and is easy to realize industrialization.

Embodiment 1

[0036] Add 95 grams of epoxidized soybean oil and 79 grams of diethanolamine (the molar ratio of epoxy group to secondary amino group is 1:1) into a 500 ml three-necked flask, heat the oil bath to 115 ° C, and react for 8 hours under stirring to obtain bio-based The polyol product is an orange-red oily liquid with a hydroxyl value of 718mgKOH / g.

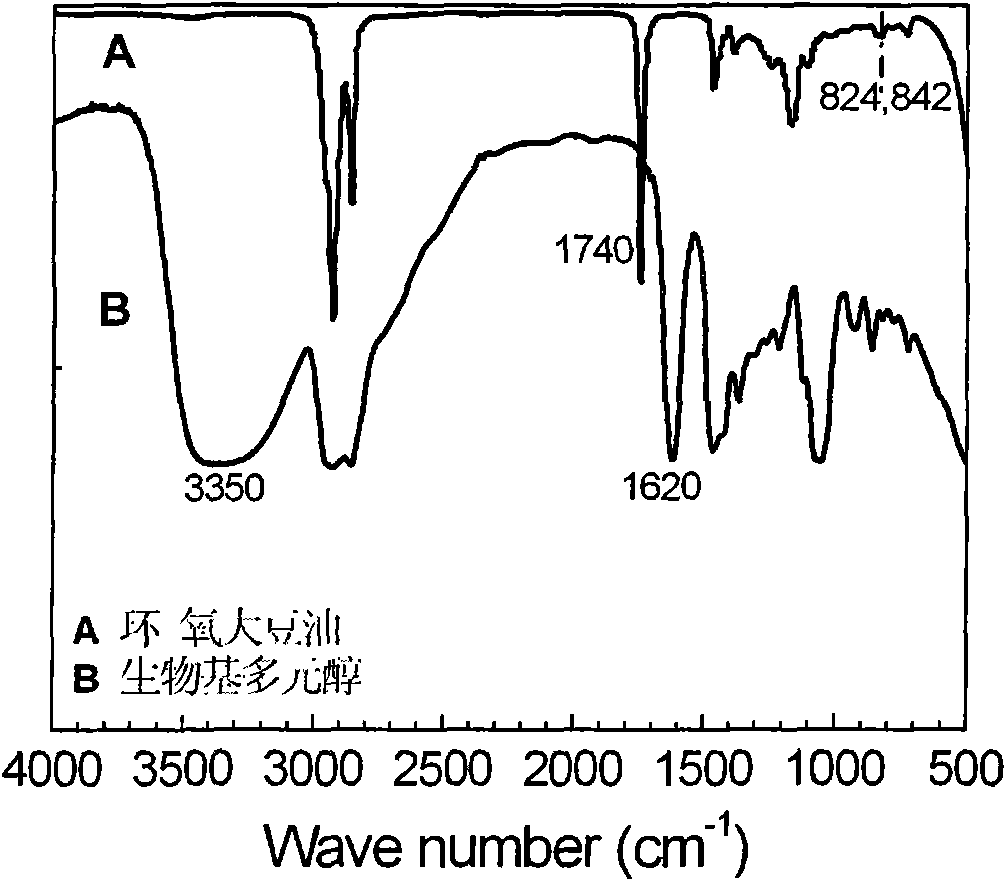

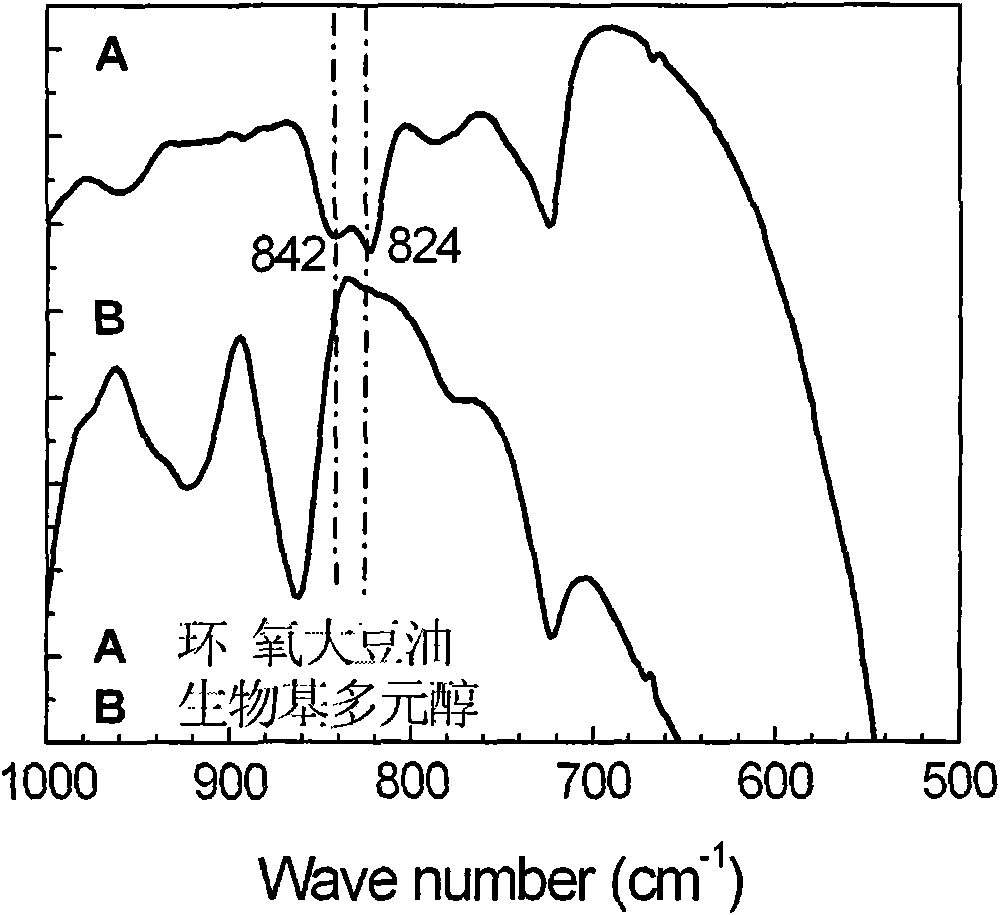

[0037] The infrared spectrograms of the raw material epoxy soybean oil and the product are shown in figure 1 with figure 2 . The ester group characteristic absorption peak of epoxidized soybean oil is at 1740cm -1 , the characteristic absorption peak of epoxy group is at 824cm -1 and 842cm -1 ; In the product, the characteristic absorption peak of the ester group becomes very small, and the characteristic absorption peak of the epoxy group disappears, while at 1620cm -1 Appeared the characteristic absorption peak of amide group, at 3350cm -1 The characteristic broad absorption peak of the hydroxyl group appeared nearby, which ...

Embodiment 2

[0039] Add 95 grams of epoxidized soybean oil and 86.9 grams of diethanolamine (the molar ratio of epoxy group to secondary amino group is 1:1.1) into a 500 ml three-necked flask, heat the oil bath to 80 ° C, and react for 16 hours under stirring to obtain bio-based The polyol product is an orange-red oily liquid with a hydroxyl value of 760mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com