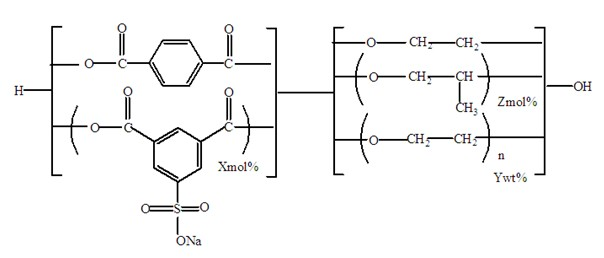

Hydrophilic copolyester slices prepared by continuous method and preparation method thereof

A hydrophilic, copolyester technology, applied in the field of polyester modification, can solve the problem of no obvious increase in fiber moisture regain, and achieve the effects of good hydrophilic performance, easy industrial production, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

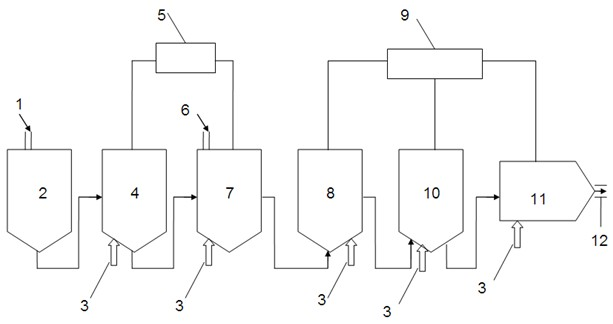

Method used

Image

Examples

Embodiment 1

[0053] Feed PTA at 20000kg / h (120481.93mol / h), EG at 8590.36kg / h (138554.22mol / h) and 1,2-PDO at 183.35kg / h (2409.64mol / h) The feed rate is respectively added to the beating kettle 2 from the first feed port 1 for beating; the above-mentioned slurry is continuously and uniformly transported to the first esterification kettle 4 for esterification reaction, and the reaction of the first esterification kettle 4 The temperature is 240°C, and the reaction time is 200 minutes; then it is transported to the second esterification tank 7 through a delivery pump, and at the same time, SIPE is fed at a rate of 643.90kg / h (1807.23mol / h), and PEG6000 is fed at a rate of 2000kg / h h (333.33mol / h) feed rate, TiO 2 At a feed rate of 100kg / h (1251.88mol / h), antimony acetate at a feed rate of 6kg / h (20.07mol / h) and triphenyl phosphate at a feed rate of 4kg / h (12.26mol / h) , from the second feed port 6 evenly added to the second esterification tank 7, the reaction temperature of the second esteri...

Embodiment 2

[0056] Feed PTA at a feed rate of 20000kg / h (120481.93mol / h) and EG at a feed rate of 8590.36kg / h (138554.22mol / h), respectively, from the feed port 1 into the beating tank 2 for beating; The slurry is continuously and uniformly transported to the first esterification tank 4, the reaction temperature of the first esterification tank 4 is 240°C, and the reaction time is 200 minutes; then it is transported to the second esterification tank 7 by a delivery pump, and at the same time, Respectively feed SIPE at 643.90kg / h (1807.23mol / h), PEG6000 at 2000kg / h (333.33mol / h), 1,2-PDO at 183.35kg / h (2409.64mol / h ) feed rate, TiO 2 At a feed rate of 100kg / h (1251.88mol / h), antimony acetate at a feed rate of 6kg / h (20.07mol / h) and triphenyl phosphate at a feed rate of 4kg / h (12.26mol / h) , from the second feed port 6 evenly added to the second esterification tank 7, the reaction temperature of the second esterification tank 7 is 250 ° C, the reaction time is 90 minutes; In the polyconden...

Embodiment 3

[0059] Feed PTA at 20000kg / h (120481.93mol / h), EG at 8590.36kg / h (138554.22mol / h) and 1,2-PDO at 733.4kg / h (9638.56mol / h) The feed rate is respectively added to the beating kettle 2 from the feed port 1 for beating; the above-mentioned slurry is continuously and uniformly transported to the first esterification kettle 4, and the reaction temperature of the first esterification kettle 4 is 240 ° C. The time is 200 minutes; then transported to the second esterification tank 7 by the delivery pump, at the same time, SIPE is fed at a feed rate of 2575.6kg / h (7228.92mol / h), PEG6000 is fed at a rate of 200kg / h (33.33mol / h) ) feed rate, TiO 2 At a feed rate of 400kg / h (5007.51mol / h), antimony acetate at a feed rate of 6kg / h (20.07mol / h) and triphenyl phosphate at a feed rate of 4kg / h (12.26mol / h) , from the second feed port 6 evenly added to the second esterification tank 7, the reaction temperature of the second esterification tank 7 is 250 ° C, the reaction time is 90 minutes; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com