Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High number average molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable linear random copolyester and its preparation method and uses

ActiveCN1807485AGood colorSimple operation processMonocomponent polyesters artificial filamentPolyester coatingsCopolyesterStructural unit

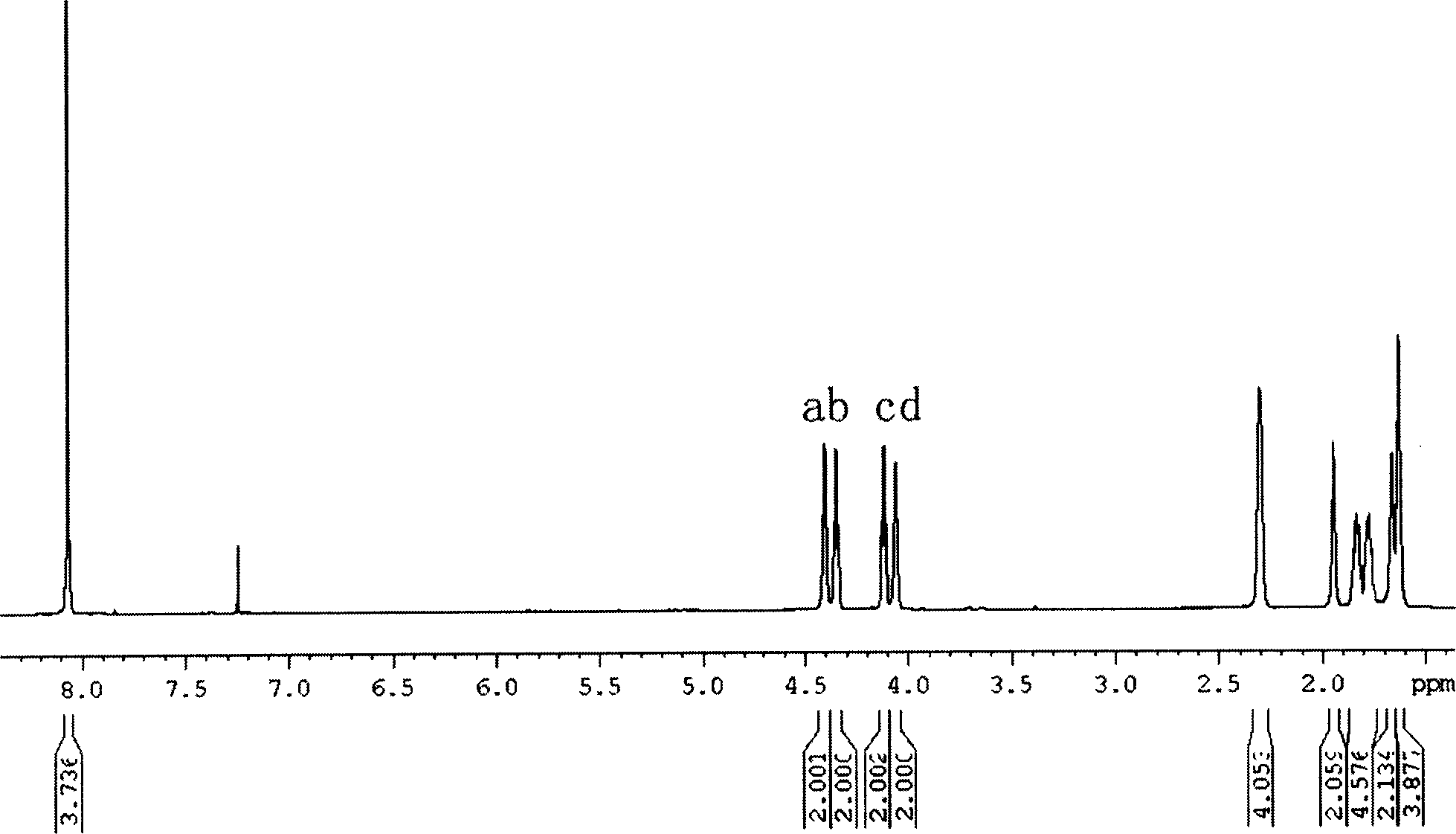

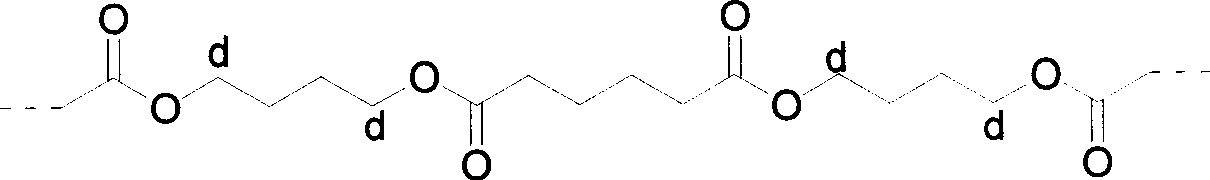

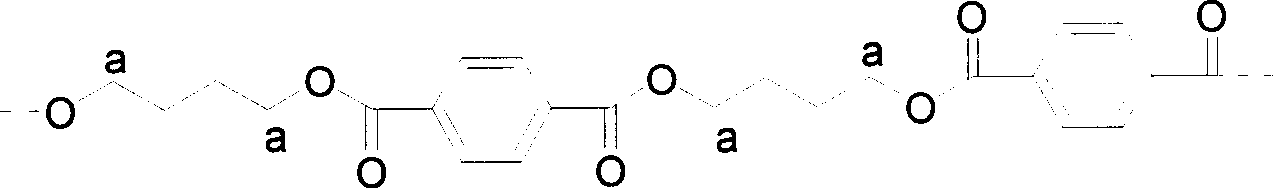

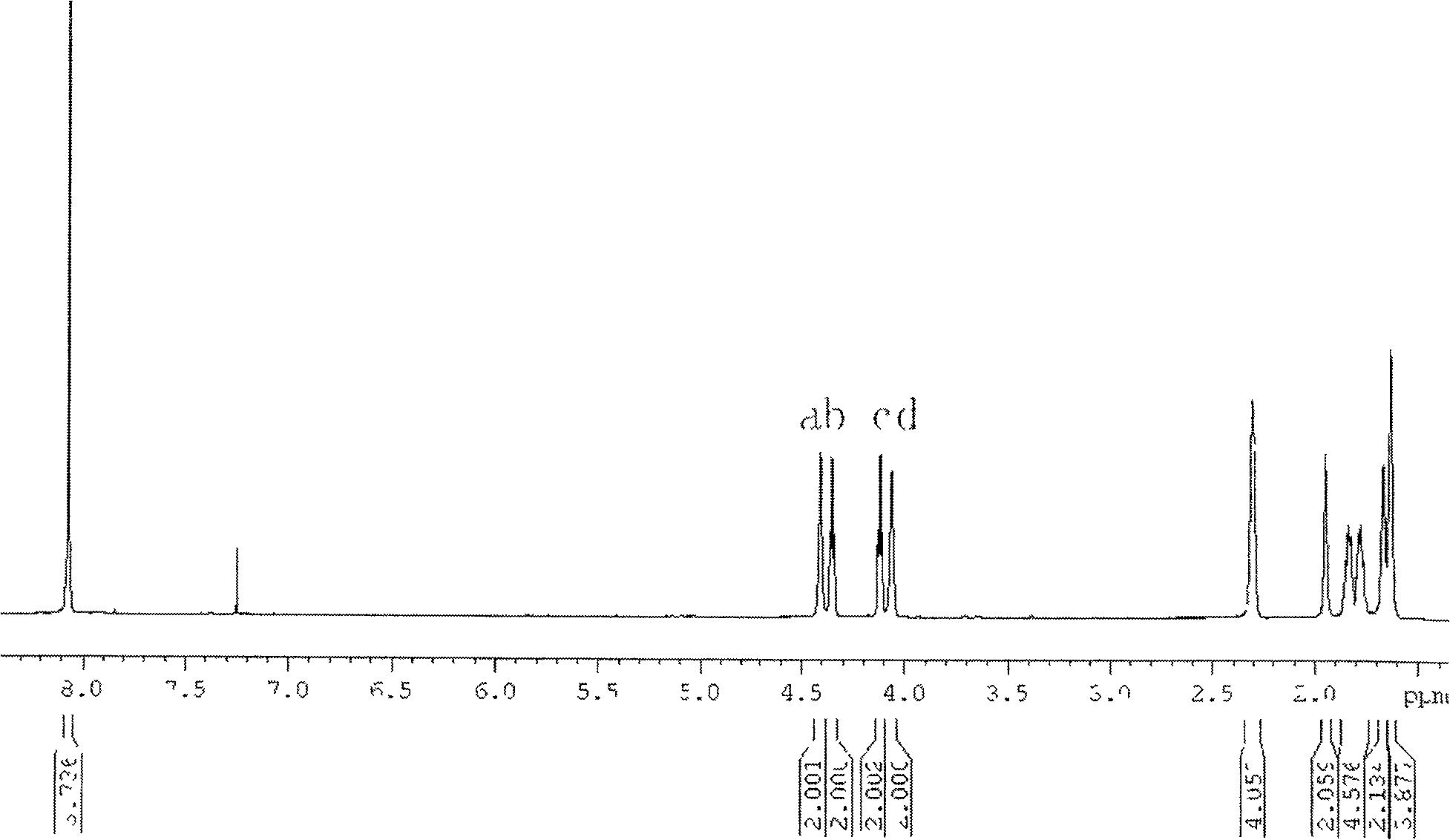

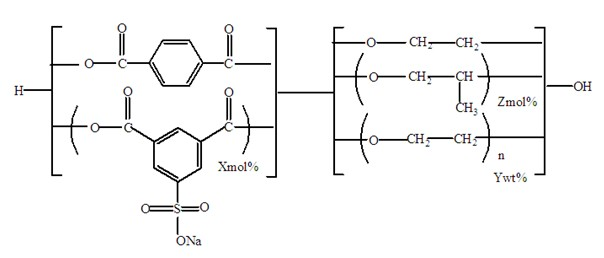

The invention discloses a biodegradable linear random copolyester, its preparation method and uses, wherein the copolyester has a structural unit of (1), wherein m is an integer of 2-10, n is an integer of 0-8, p is an integer of 2-10, m, n, p are identical or different, x is an integer of 1-10, y is an integer of 1-10, the average molecular weight Mw of the copolyester is 100,000-600,000g / mol, its molecular weight distribution is 1.2-3, which is measured through GPC method. The copolyester can be widely applied into section bar, film, fabric and coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aliphatic polycarbonate with high molecular weight and preparation method thereof

The invention discloses aliphatic polycarbonate with high molecular weight and a preparation method thereof. The method comprises the following steps: in inert atmosphere, gradually heating divalent alcohol and carbonic ester under the action of a catalyst to complete an ester exchange reaction, and completely removing methyl alcohol generated in the process of the reaction to obtain a prepolymerof the aliphatic polycarbonate; and adding a polycondensation catalyst into the reaction system, and carrying out a polycondensation reaction in vacuum to obtain a product. The method has low cost ofraw materials and higher utilization ratio, reduces the cost of the product greatly, overcomes the defect of high cost of biodegradable materials, uses less dosage of catalyst in the reaction process,and avoids the complicated catalyst separation process. The aliphatic polycarbonate obtained by the method is white crystalline solid, has the number average molecular weight of between 6,000 and 2*10<5>, and can be directly used as plastics, does not contain an ether bond in the main chain of the polycarbonate, is a crystalline polymer, and greatly improves the heat-resistant quality of the polymer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Biodegradable linear random copolyester and its preparation method and uses

ActiveCN100429256CGood colorSimple operation processMonocomponent polyesters artificial filamentPolyester coatingsFiberPolymer science

The invention discloses a biodegradable linear random copolyester, its preparation method and uses, wherein the copolyester has a structural unit of (1), wherein m is an integer of 2-10, n is an integer of 0-8, p is an integer of 2-10, m, n, p are identical or different, x is an integer of 1-10, y is an integer of 1-10, the average molecular weight Mw of the copolyester is 100,000-600,000g / mol, its molecular weight distribution is 1.2-3, which is measured through GPC method. The copolyester can be widely applied into section bar, film, fabric and coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing polyester by using rare earth catalyst

This invention publishes a synthesis method for polyesters from rare earth catalysts. In this method, single-kettle operation is adopted. One of the compounds of titanium, stibium and zincum is chosen as the catalyst C1 for transesterification and esterification and is added into the reaction kettle with monomer raw materials before reaction. After a certain period of prepolymerization, a rare earth metal compound as catalyst C2 is added for vacuum condensation polymerization. It is due to the single-kettle operation that this invention has the advantages of simplified technique, accelerated polymerization reaction, promoted product molecular weight, reduced side reactions and significantly improved color of polyester product.

Owner:CHINA PETROLEUM & CHEM CORP +1

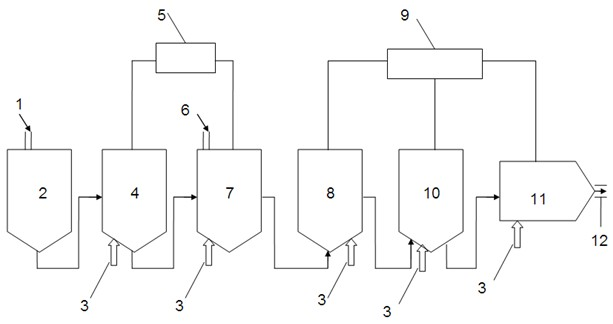

Hydrophilic copolyester slices prepared by continuous method and preparation method thereof

InactiveCN102504224AChange molecular structureImprove hydrophilicityMonocomponent polyesters artificial filamentArtifical filament manufactureCopolyesterDibasic acid

The invention discloses a continuous method for preparing hydrophilic copolyester slices and the hydrophilic copolyester slices prepared by the preparation method. The preparation method of the hydrophilic copolyester slices prepared by the continuous method comprises the following steps: continuously and uniformly adding pure terephthalic acid, ethylene glycol, benzene dibasic acid binary alcohol ester-5-sodium sulfonate, polydibasic alcohol, other dibasic alcohols, a delustering agent and the like into a beating kettle in proportion, performing esterification, prepolycondensation and polycondensation reactions, discharging, pelletizing and drying to get the hydrophilic copolyester slices. A continuous polymerization device is adopted for synthesis; and in the prepared hydrophilic copolyester slices, the molecular structure of polyester is changed by adding hydroxyl-containing components and inorganic powder into copolyester slices, thus the hydrophilic property is good. The preparation method is simple, the manufacturing process has no special requirements on the polymerization device, and the hydrophilic copolyester slices can be produced on existing domestic or imported equipment, so that the production cost is slow and industrial production is easy to realize.

Owner:DONGHUA UNIV

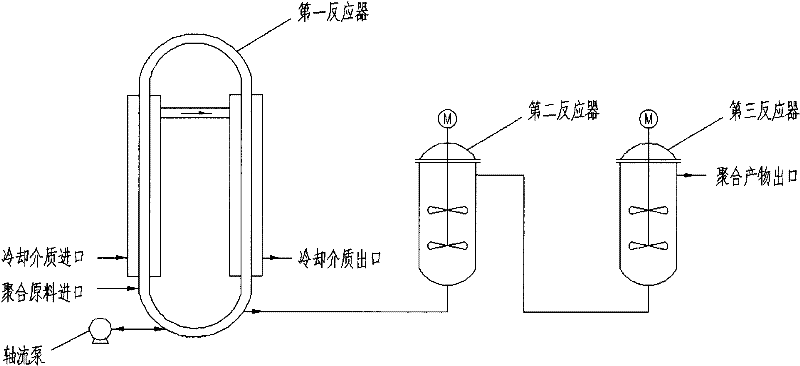

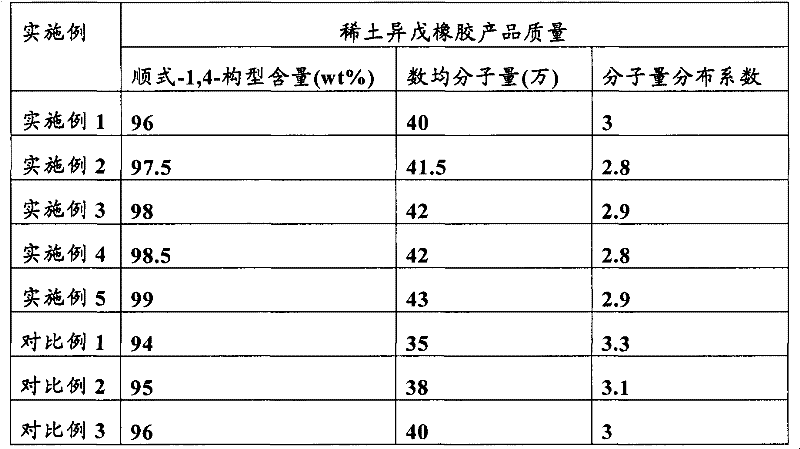

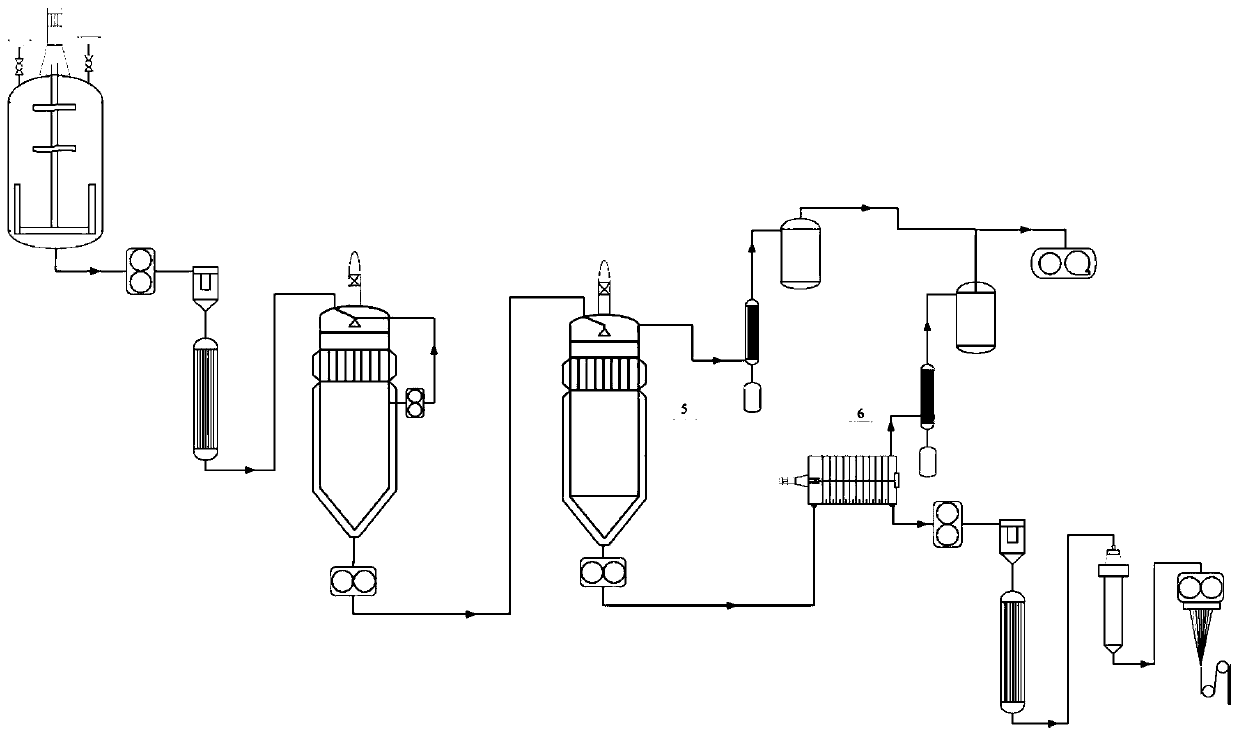

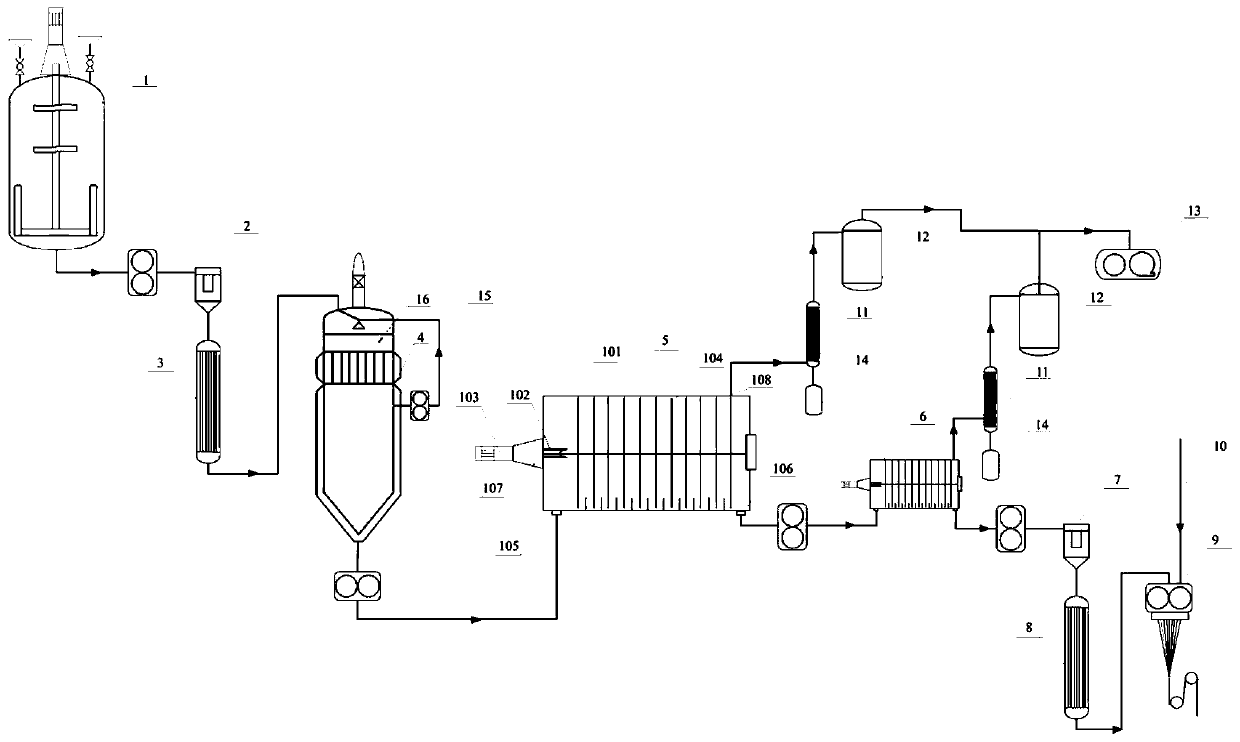

Polymerization method for preparing rare earth isoprene rubber

ActiveCN102532379AIncrease the heat exchange areaAvoid "hanging on the wall" phenomenonRare earthContinuous stirred-tank reactor

The invention relates to a polymerization method for preparing rare earth isoprene rubber, which adopts at least three reactors which are in series connection to conduct a solution polymerization reaction of an isoprene monomer, wherein a first reactor is an annular tube reactor which adopts isothermal operation, a following reactor is a continuous stirrer tank reactor which adopts heat insulation operation. By means of the method, the cis-form-1,4-configuration content of obtained gathering rare earth isoprene rubber can be high as 98wt%, the number-average molar mass can reach over 0.4 million, and molecular weight distribution coefficient is smaller than 3.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solution method for synthesizing butyl rubber

The invention relates to a solution method for synthesizing butyl rubber. A mixture of C4-C8 monoolefine monomers and C4-C14 polyene hydrocarbon monomers is taken as a raw material, and in a system that hexane and chloromethane are solvents, polymerization reaction is initiated by an initiating system to prepare butyl rubber polymer, wherein the reaction pressure is normal pressure, the reaction temperature ranges from 0 to -90DEG C, and the initiating system has the concentration of 0.01-0.001mol / L, and is prepared by dissolving a main initiator, namely deionized water and a coinitiator, namely aluminum alkyl dihalide by using a polar solvent CH2Cl2 for mixing, and adding alkylol amines; the molar ratio of the coinitiator to the main initiator is 1:1-10:1, and the molar ratio of a third component to the main initiator is 1:10-1:25; and the adding amount of the mixed solvent is 1 to 50 times volume of the polymerization monomers. According to the method, reaction is mild, polymerization temperature is improved, the stability and initiation efficiency of the initiators are high, and the molecular weight distribution of the product is narrow.

Owner:PETROCHINA CO LTD

Olefin-unsaturated carboxylic acid polymer and preparation method thereof

InactiveCN109694434AGood thermal stabilityBroad industrial application prospectsSaturated carboxylic acidAlkene

The invention relates to the field of polymers, and discloses an olefin- unsaturated carboxylic acid polymer and a preparation method thereof. The olefin- unsaturated carboxylic acid polymer is directly obtained by copolymerization, the carboxylic acid content is 0.4-20 mol %, the number-average molecular weight is 7000-1200000, the density is 0.880-0.950 g / cm<3>, and the polymer does not containalkali metal salts. The olefin- unsaturated carboxylic acid polymer disclosed by the invention has relatively high carboxylic acid content and number average molecular weight; a catalyst disclosed bythe invention can realize the copolymerization reaction at a relatively low pressure, and has relatively good thermal stability and relatively high polymerization activity; and the preparation methoddisclosed by the invention is adopted, the molecular weight and the branching degree of the olefin -unsaturated carboxylic acid copolymer can be controlled within a wide range, under the condition that no catalyst is loaded and no emulsifier is added, the polymer with good particle morphology can be prepared, and the polymer has a wide industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyester for 3D printing, and preparation method thereof

The invention discloses a polyester for 3D printing, and a preparation method thereof. According to the present invention, an aromatic dibasic acid or a dimethyl ester thereof, an aliphatic dibasic acid or a dimethyl ester thereof, and diol are used as monomers and are subjected to a normal pressure esterification reaction in the presence of a nucleation agent, a branching agent, a filler and a catalyst, heating pressure reducing is performed after the esterification reaction is completed, and a condensation polymerization reaction is performed to obtain the copolyester material, wherein the aromatic dibasic acid is an aromatic C6-C10 dibasic acid, the aliphatic dibasic acid is an aliphatic C2-C10 dibasic acid, the diol is a C2-C10 diol, and the branching agent is a polybasic acid or a polyol. According to the present invention, the obtained material has advantages of high elongation at break, large number average molecular weight, low melt index and degradability, and can be used as a3D printing material.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Melting direct-spinning method of copolymerized modified low-melting-point nylon fibers

ActiveCN111304771ADisruption of regularityLow melting pointMonocomponent copolyamides artificial filamentEvaporationNylon materialCaprolactam

The present invention relates to the field of nylon materials, and discloses a melting direct-spinning method of copolymerized modified low-melting-point nylon fibers. The method comprises the steps of 1) material preparation, wherein caprolactam, a copolymerized modified component, an end-capping agent, water and a catalyst are heated and mixed; 2) ring opening, wherein a mixture is heated for ring opening; 3) pre-polycondensation, wherein a pre-polymerization reaction and devolatilization are performed; 4) final polycondensation, wherein a final polycondensation reaction and devolatilizationare performed; 5) devolatilization before spinning; and 6) spinning, wherein a product is directly conveyed to spinning threads for spinning to obtain the copolymerized modified low-melting-point nylon fibers. According to the method, the copolymerized modified component is added for destroying the regularity of nylon molecular chains and reducing the hydrogen bond density and crystallinity of the nylon molecular chains, thereby achieving the purpose of lowering the melting point of nylon; and according to different varieties and content of added copolymerized components, the melting point ofthe nylon can be controlled to be 90-200 DEG C, so that the application range of the low-melting-point nylon is greatly expanded.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Nylon cable sheath material for polyester chain extender and preparation method thereof

The invention discloses a nylon cable sheath material for a polyester chain extender and a preparation method thereof. The nylon cable sheath material is characterized in that the raw material formula mainly comprises long-chain nylon, polyester and a compatilizer. The preparation method comprises the following steps: feeding the materials in the material formula to a closed mixer to mix for 3-15 minutes after preparing; pelletizing at 200-270 DEG C by using a twin-screw extruder, so as to prepare the nylon cable sheath material for the polyester chain extender. The nylon cable sheath material disclosed by the invention is applied to extruding and molding. The nylon cable sheath material has the advantages of being high in molecular weight, excellent in processability, heat resistant, low-temperature resistant, wearable, and good in chemical resistance, can be applied to a cable sheath, and still has excellent cracking resistance in a harsh low-temperature environment.

Owner:中广核三角洲(江苏)塑化有限公司

Preparation method of polycarbosilane

The invention relates to the technical field of organosilicon and provides a preparation method of polycarbosilane in order to solve the problems in polycarbosilane preparation at present. The preparation method is characterized by taking chloromethyl chlorosilane as a raw material, synthesizing a polycarbosilane intermediate in an organic solvent and then preparing the polycarbosilane by using a reducing agent. The preparation method provided by the invention has the advantages that the operation is convenient, and the time is shortened; meanwhile, the number-average molecular weight of the prepared polycarbosilane is higher, and the demands of preparing an organic functional material can be met.

Owner:湖南昌威新材料科技有限公司

Olefin-unsaturated carboxylic acid polymer and preparation method thereof

InactiveCN109694435AHigh number average molecular weightParticles in good shapePolymer sciencePtru catalyst

The invention relates to the field of polymers, and discloses an olefin- unsaturated carboxylic acid polymer and a preparation method thereof. The olefin- unsaturated carboxylic acid polymer is directly obtained by copolymerization, the carboxylic acid content is 0.2-15mol %, the number-average molecular weight is 5000-200000, the melting point is 45 ~ 130 DEG C, the density is 0.910 ~ 1.000 g / cm<3>, and the polymer does not contain alkali metal salts. The olefin- unsaturated carboxylic acid polymer disclosed by the invention has relatively high carboxylic acid content and number average molecular weight; a catalyst disclosed by the invention can realize the copolymerization reaction at a relatively low pressure, and has relatively good thermal stability and relatively high polymerizationactivity; and the preparation method disclosed by the invention is adopted, the molecular weight and the branching degree of the olefin -unsaturated carboxylic acid copolymer can be controlled withina wide range, under the condition that no catalyst is loaded and no emulsifier is added, the polymer with good particle morphology can be prepared, and the polymer has a wide industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing polyester-nylon composite fibers by melt direct spinning

ActiveCN111394831AReduced extractables contentQuality assuranceTextile/flexible product manufactureChemical/physical/physico-chemical stationary reactorsPolyesterFiber

The invention relates to the field of nylon materials, and discloses a method for preparing polyester-nylon composite fibers by melt direct spinning. The method comprises the following steps of 1) burdening, specifically, heating and mixing caprolactam, an end-capping reagent, water and a catalyst to obtain a mixture; 2) ring opening; 3) pre-polycondensation, specifically, carrying out a pre-polycondensation reaction and devolatilization; 4) final polycondensation, specifically, carrying out a final polycondensation reaction and devolatilization; 5) devolatilizing before spinning; and 6) spinning, specifically, directly conveying nylon melt and polyester melt which are devolatilized before spinning to a composite spinning assembly, performing extruding, cooling, oiling, stretching and winding to obtain the polyester-nylon composite fibers. By means of the method, direct spinning after nylon melt polymerization can be achieved, slices do not need to be prepared in advance, and the content of hot water extractables and cyclic dimers in the nylon melt can be effectively controlled; and composite spinning is carried out on the nylon melt and the polyester melt to obtain the polyester-nylon composite fibers in different composite forms.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Double metal cyanide catalyst preparation method

ActiveCN103183712AHigh activitySimple methodOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesHypergravityCyanide

The invention relates to a double metal cyanide catalyst preparation method, which comprises the following steps: preparing water-soluble metal salt and water to obtain a solution with 0.01-2mol / L, adding alcohol or ether and / or ketone, ester or aldehyde, wherein weight ratio of alcohol or ether to water-soluble metal salt is 0.01-4.0: 1, the weight ratio of ketone, ester or aldehyde to the water-soluble metal salt is 0.01-4.0: 1; preparing water-soluble cyanide and water to obtain a solution with 0.01-2mol / L; respectively sending a metal salt mixed liquor and the cyanide aqueous solution to a rotary hypergravity reactor with rate of 0.1mL / min-60L / min, reacting for 0.6-1.5 hours under temperature condition of 10-50 DEG C; centrifuging and dewatering the obtained material liquid, and drying at 40-50 DEG C under vacuum to constant weight to obtain the double metal cyanide catalyst. The double metal cyanide catalyst preparation method has the advantages of simple technology and high production efficiency, and is suitable for continuous industrialization production.

Owner:PETROCHINA CO LTD

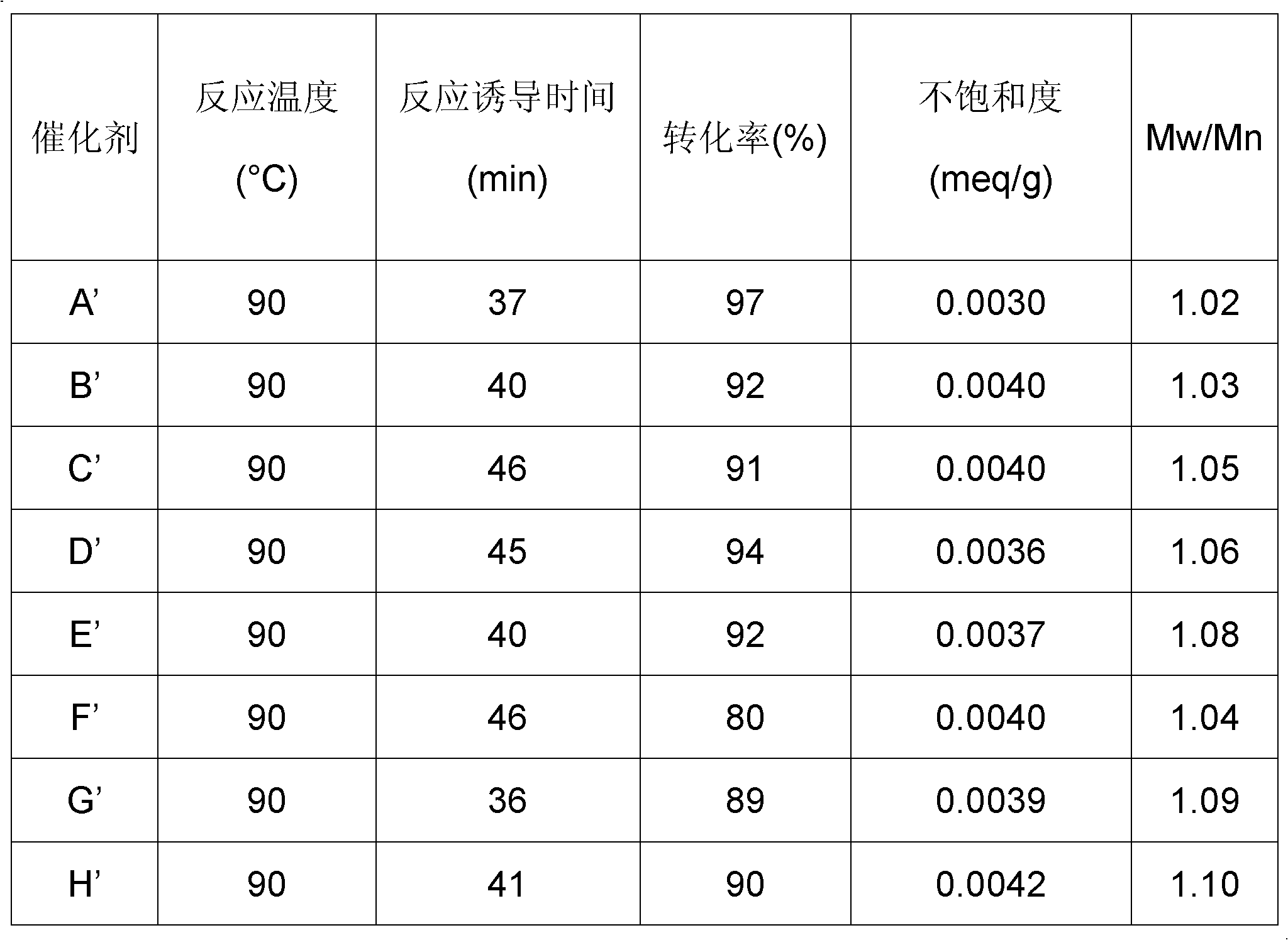

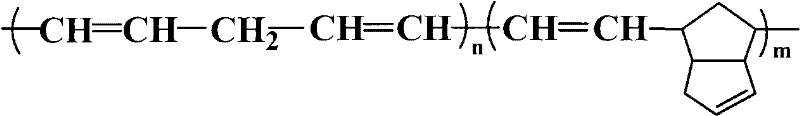

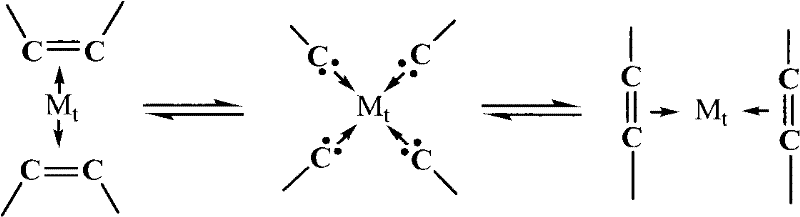

Poly (cyclopentadiene-dicyclopentadiene) copolymer and synthesis method thereof

The invention discloses a poly (cyclopentadiene-dicyclopentadiene) copolymer and a synthesis method thereof. Cyclopentadiene and dicyclopentadiene which are taken as polymerization monomers are subjected to ring-opening metathesis copolymerization to form a novel high polymer material. By adjusting the rate of the dicyclopentadiene in the comonomers, the content of a fat ring chain structure in the poly (cyclopentadiene-dicyclopentadiene) copolymer is adjusted, so that various high polymer materials with different properties and purposes are synthesized. Moreover, the dicyclopentadiene is used as one of the monomers and applied to preparing rubber materials, and a monomer ratio of the cyclopentadiene to the dicyclopentadiene is adjusted, so that the generated random copolymer has higher number-average molecular weight and proper Mooney viscosity.

Owner:青岛德明力兴新材料股份有限公司

Method for preparing butyl rubber polymer

InactiveCN102020740AHigh number average molecular weightImprove conversion ratePolymer scienceChloride

The invention relates to a method for preparing a butyl rubber polymer. In the method, a mixture of C4-C8 monoolefine monomer and C4-C14 polyene monomer serving as a main material is subjected to polymerization at the temperature of between -90 and -70 DEG C and in absence of water and oxygen by taking the mixture of ionized water, hexane and monoalkyl aluminum dihalide as a catalyst and the mixture of methyl chloride and hexane as a solvent to form the butyl rubber polymer. The method has the advantages of simplicity, high polymerization temperature, low cost, high stability and initiation efficiency of the catalyst, high number average molecular weight of a product, high conversion rate and narrow molecular weigh distribution.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

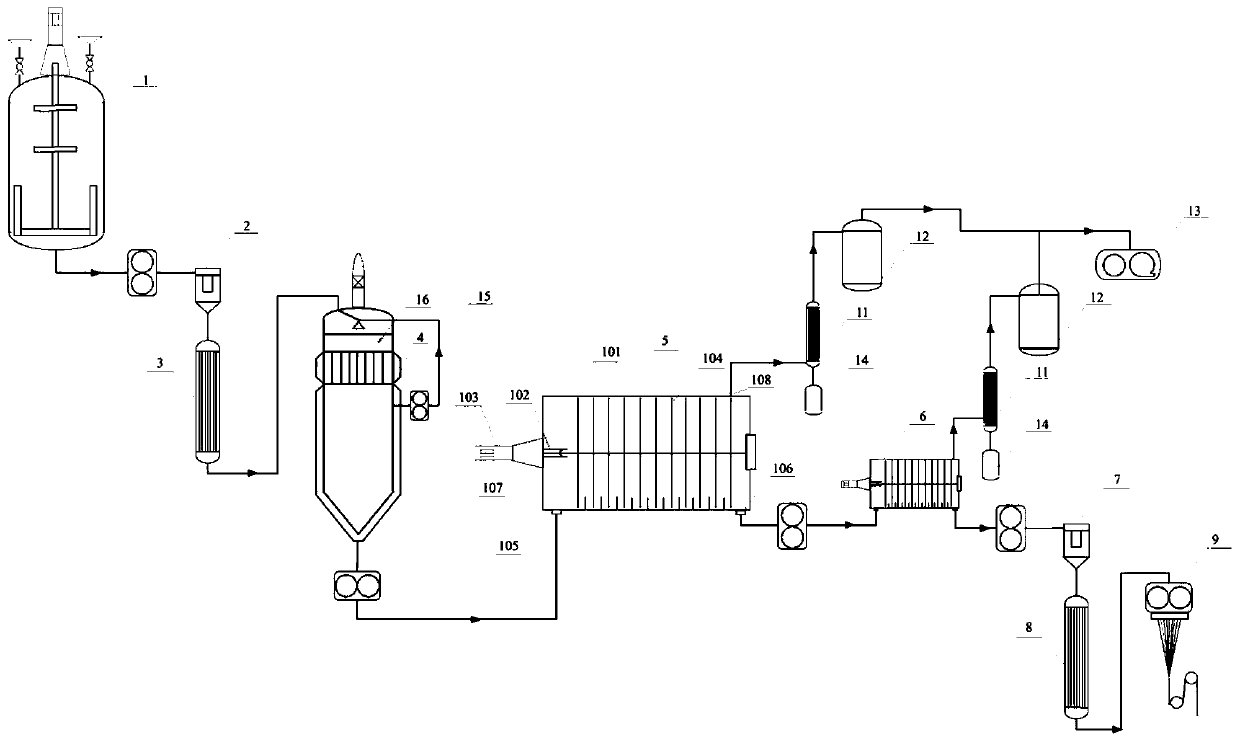

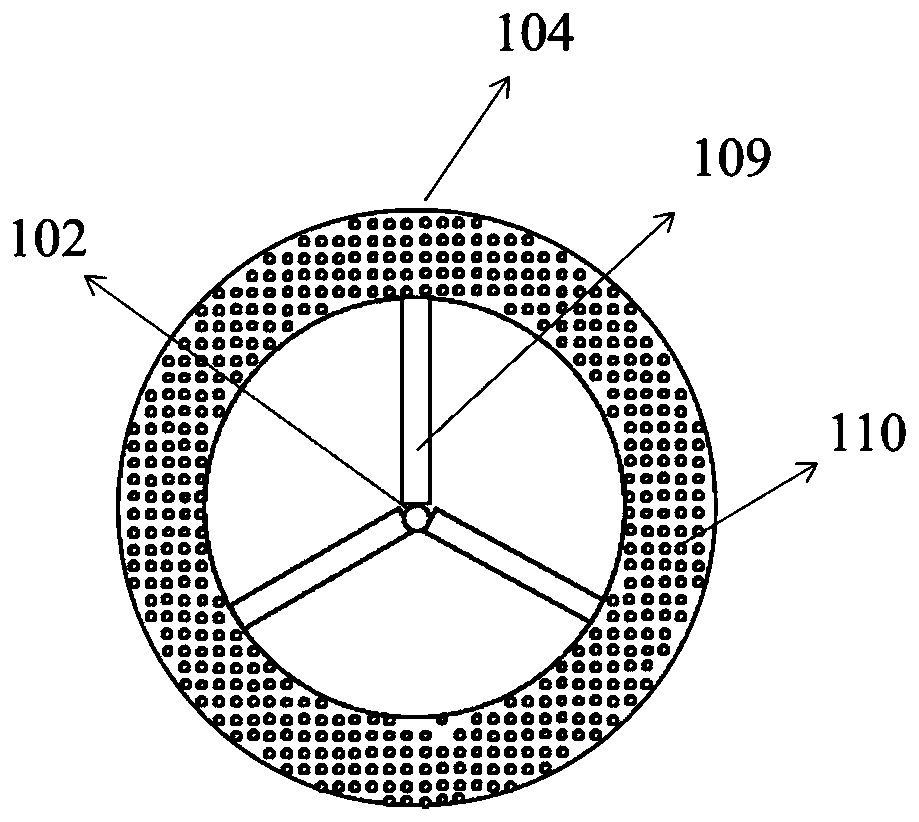

Melt direct processing caprolactam polymerization method

ActiveCN111393633AHigh number average molecular weightIncrease profitChemical/physical/physico-chemical stationary reactorsComposite materialNylon material

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

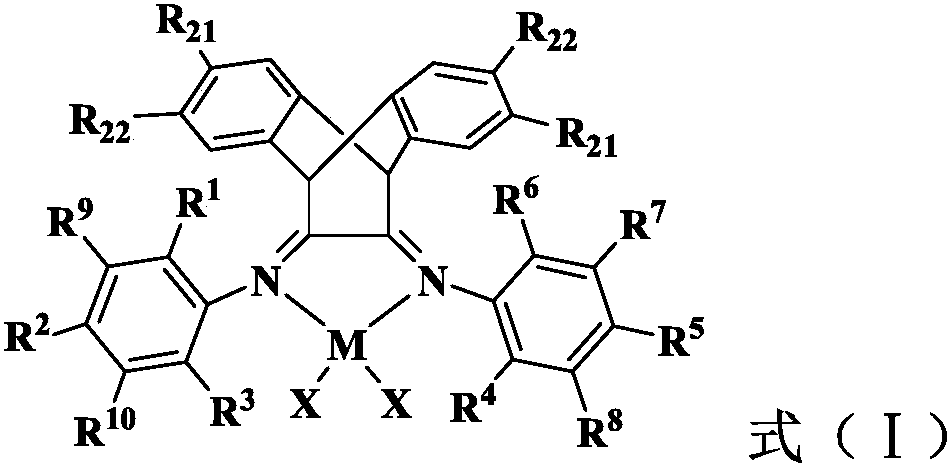

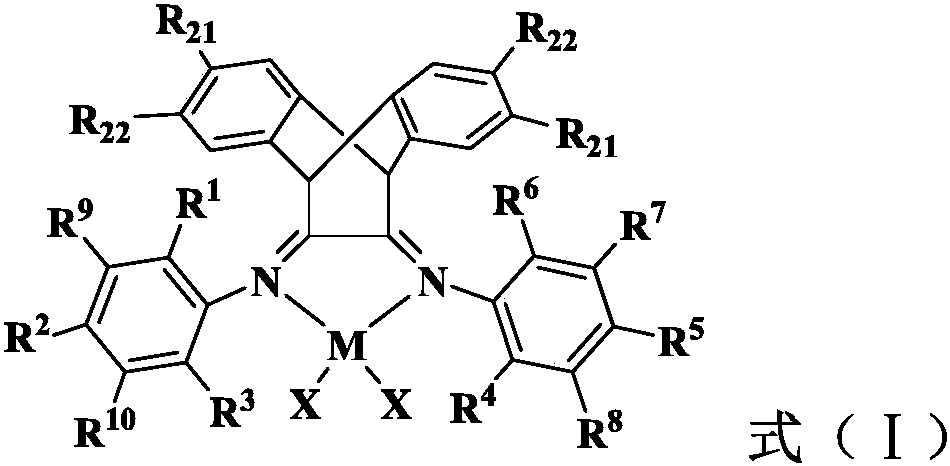

Late transition metal catalyst for olefin polymerization and preparation method thereof

The invention provides a late transition metal catalyst for olefin polymerization with a structural formula (I), which is characterized by introducing a wedge-shaped dendritic molecule having certain space volume and more symmetrical spatial position of substituent into a ligand structure, successfully avoiding chain transfer reaction of propylene and effectively preventing the propylene from attacking the active site from the side chain. When the catalyst for the olefin polymerization is used for propylene polymerization together with an aluminium alkyl compound, the polymerization activity is remarkably improved, the activity of the catalyst can reach 105g polypropylene / mol Fe*h, and in particular, the number-average molecular weight and degree of isotacticity of the polymerization product are enhanced. The number-average molecular weight is far more than 15000g / mol, and the degree of isotacticity is close to 85%. M is a transition metal selected from Fe, Co or Ni.

Owner:PETROCHINA CO LTD

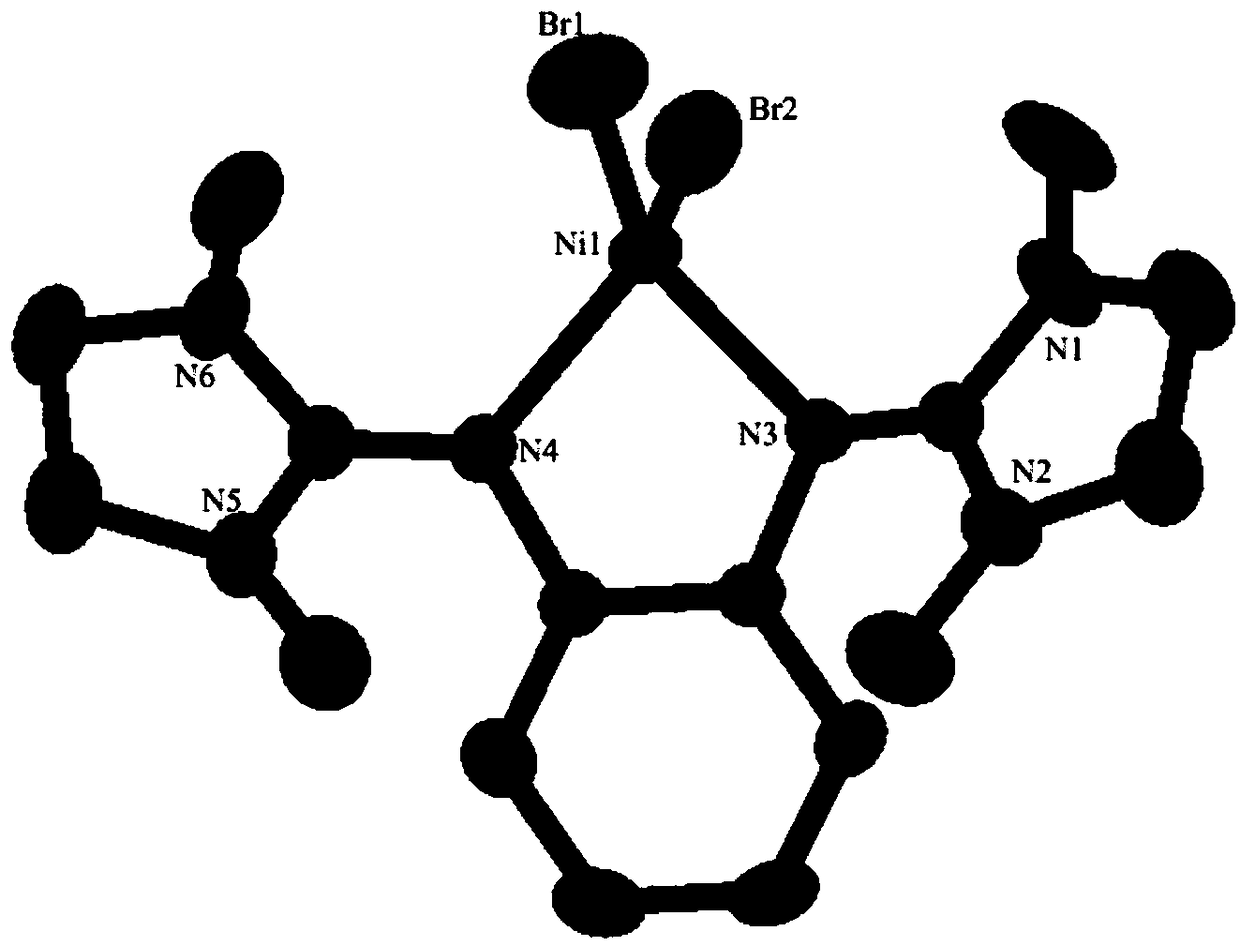

Ni-Pd metal complex as well as preparation method, application and product thereof and application of product

ActiveCN109320559AImprove activity stabilityImprove thermal stabilityNickel organic compoundsArylHalogen

The invention relates to a Ni-Pd metal complex as well as a preparation method, application and a product thereof and application of the product. The Ni-Pd complex is prepared through reaction of a phenylenediamine imidazolidine ligand and a metal precursor, and the structural formula of the prepared Ni-Pd metal complex is shown as follows: (the formula is shown in the description), wherein in theformula, R1-R12 are independently selected from hydrogen, alkyl, substituendum of alkyl, alkoxy, alkyl sulphanyl, halogen, nitryl, aryl and substituendum of aryl, M is Ni<2+> or Pd<2+>, and X and Y are independently selected from halogen and alkyl. The product of the Ni-Pd metal complex is mainly obtained by compounding the Ni-Pd metal complex and a promoter, and the Ni-Pd metal complex and the product thereof can both be used for catalyzing polymerization of olefine monomer. The method is easy to operate, the prepared Ni-Pd metal complex and the product thereof have high activity and good thermal stability, the number-average molecular weight and the insertion rate of the olefine polymer obtained through catalysis are high when the Ni-Pd metal complex is used for catalyzing the olefine monomer, and the Ni-Pd metal complex has very good popularization value.

Owner:DONGHUA UNIV

A kind of preparation method of polycarbosilane

The invention relates to the technical field of organosilicon and provides a preparation method of polycarbosilane in order to solve the problems in polycarbosilane preparation at present. The preparation method is characterized by taking chloromethyl chlorosilane as a raw material, synthesizing a polycarbosilane intermediate in an organic solvent and then preparing the polycarbosilane by using a reducing agent. The preparation method provided by the invention has the advantages that the operation is convenient, and the time is shortened; meanwhile, the number-average molecular weight of the prepared polycarbosilane is higher, and the demands of preparing an organic functional material can be met.

Owner:湖南昌威新材料科技有限公司

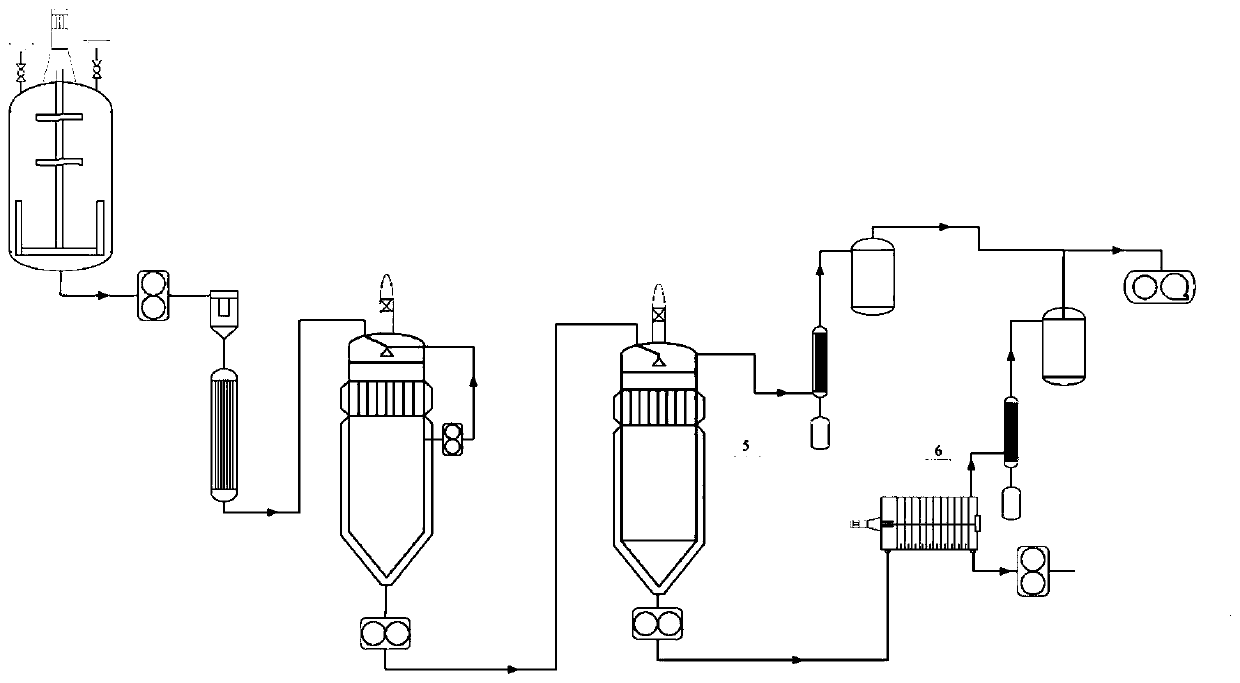

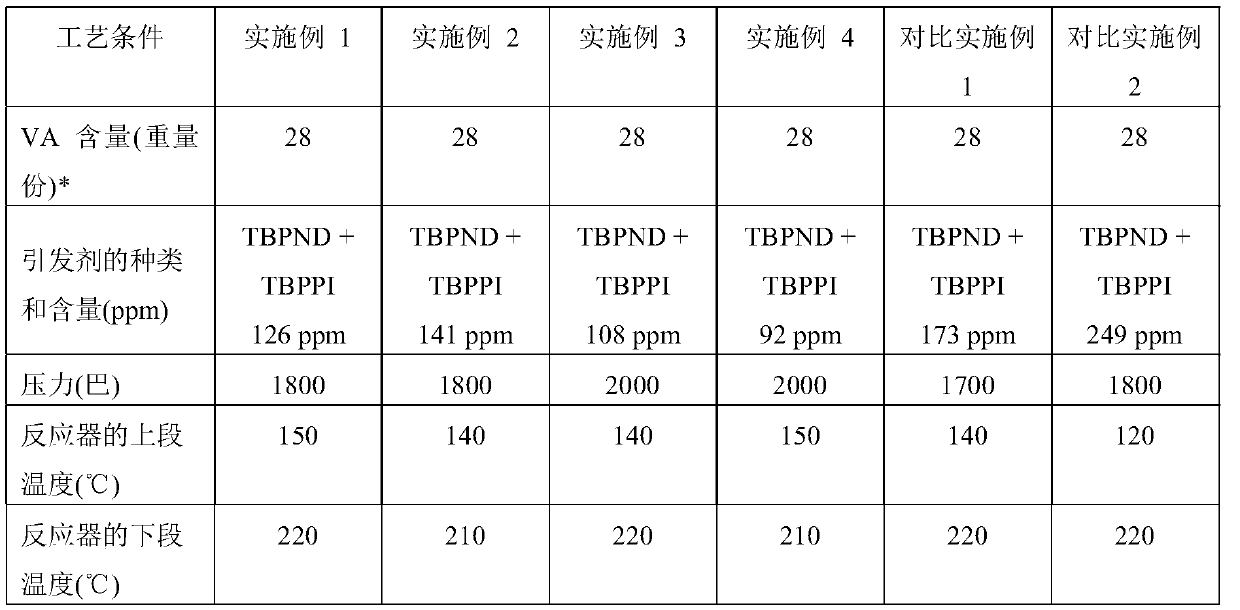

Method for preparation of ethylene vinylacetate copolymer

ActiveCN110891986AHas a linear structureHigh number average molecular weightPressure vessels for chemical processPolymer scienceEthylene

The present invention relates to a method for preparation of an ethylene vinylacetate copolymer wherein a polymerization condition is controlled with the aid of an autoclave reactor to improve mechanical strength of the copolymer.

Owner:LG CHEM LTD

Method for preparing functional nylon 6 fiber based on melt direct spinning technology

ActiveCN111575825AReduced extractables contentQuality assuranceChemical/physical/physico-chemical stationary reactorsMelt spinning methodsNylon materialEndcapping

The invention relates to the field of nylon materials, and discloses a method for preparing functional nylon 6 fiber based on the melt direct spinning technology. The method comprises the steps that firstly, burdening is conducted, caprolactam, an end-capping reagent, water and a catalyst are heated and mixed, and a mixture is obtained; secondly, ring opening is conducted; thirdly, pre-polycondensation is conducted, and the pre-polycondensation reaction and devolatilization are conducted; fourthly, final polycondensation is conducted, and the final polycondensation reaction and devolatilization are conducted; and fifthly, devolatilization is conducted before spinning; and sixthly, spinning is conducted, and the functional nylon 6 fiber is obtained. In the first step, functional componentsare added, or before devolatilization before spinning in the fifth step, functional nylon master batches containing functional components are added. The method can be divided into two parallel schemes, the functional components can be directly added in the first step, or the functional nylon master batches containing functional components are added before devolatilization in the fifth step. According to the method, fusion direct spinning is directly conducted after the functional components are added, devolatilization is conducted during pre-polycondensation and final polycondensation, and theproblem about poor functional component scattering can be solved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

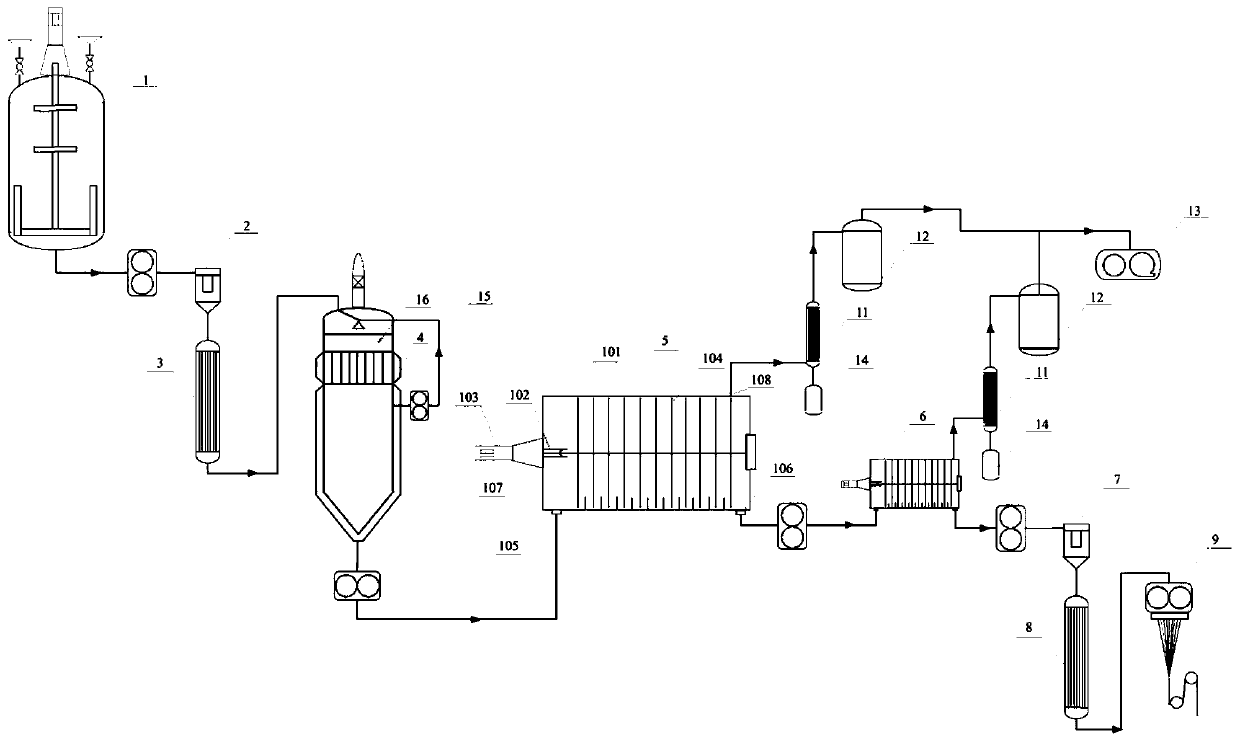

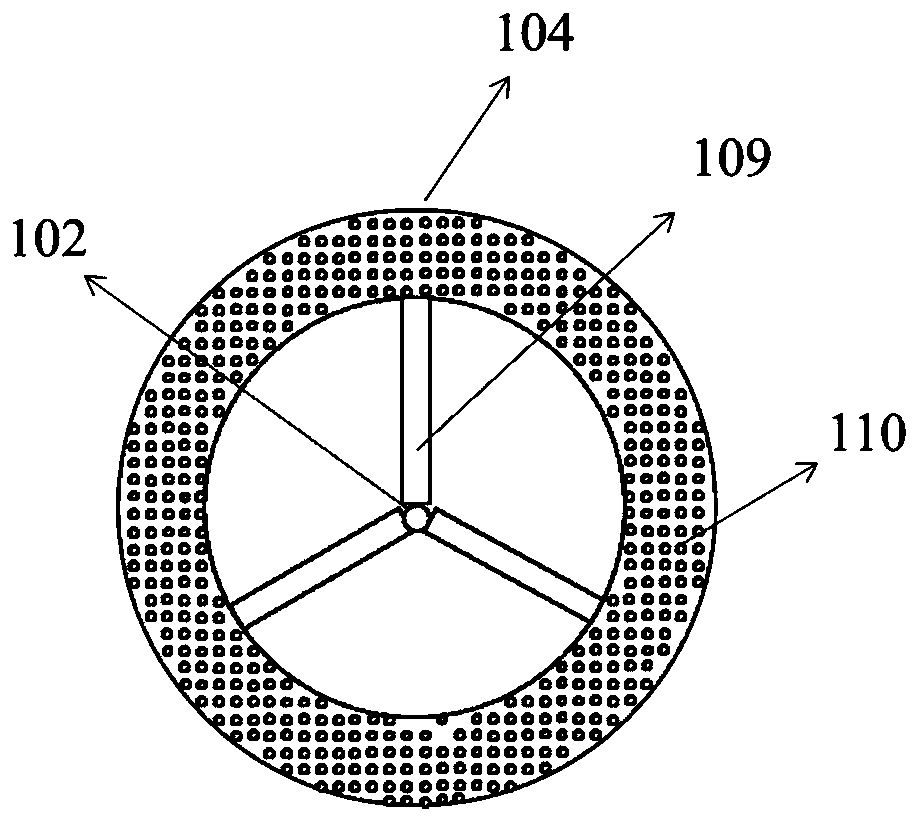

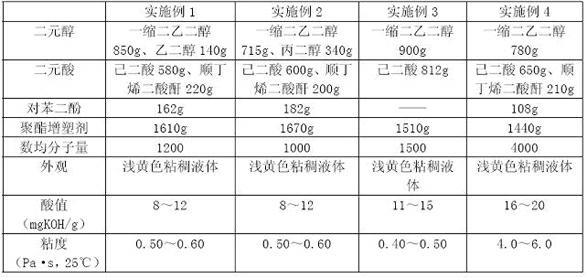

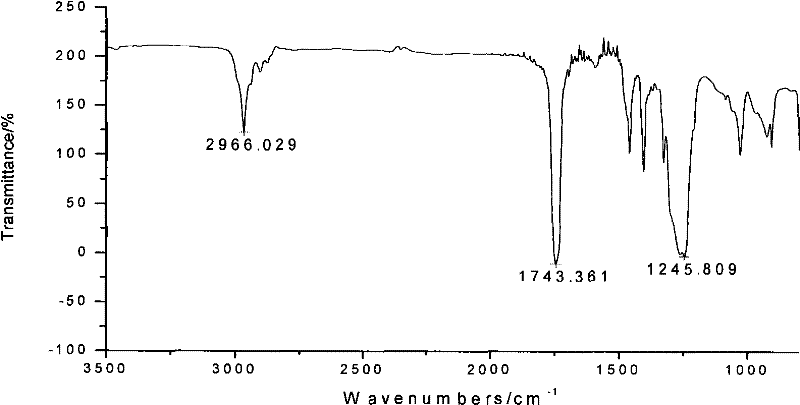

Polyester plasticizer for leading glass fiber to form felt and preparation method of polyester plasticizer

ActiveCN102432854AHigh number average molecular weightGood compatibilityMacromolecular adhesive additivesPolyesterFiber

The invention discloses a polyester plasticizer for leading glass fiber to form a felt and a preparation method of the polyester plasticizer. The polyester plasticizer is prepared from dihydric alcohol and dibasic acid. The preparation method comprises the following steps of: 1) adding the dihydric alcohol and the dibasic acid into a reactor, introducing nitrogen, stirring, rising the temperature to be 200-220 DEG C, and under the temperature, reacting till the acid value of the system is less than or equal to 20mgKOH / g; and 2) reducing the temperature to be 180-190 DEG C, adding hydroquinone, cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer; or directly cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer. In the invention, the compatibility of the polyester plasticizer and a bonding agent for leading the glass fiber to form the felt is good, the softness and the impregnability of a glass-fiber chopped felt can be improved and the use range is wide.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Preparation method of aliphatic polycarbonate with high molecular weight

The invention discloses aliphatic polycarbonate with high molecular weight and a preparation method thereof. The method comprises the following steps: in inert atmosphere, gradually heating divalent alcohol and carbonic ester under the action of a catalyst to complete an ester exchange reaction, and completely removing methyl alcohol generated in the process of the reaction to obtain a prepolymerof the aliphatic polycarbonate; and adding a polycondensation catalyst into the reaction system, and carrying out a polycondensation reaction in vacuum to obtain a product. The method has low cost ofraw materials and higher utilization ratio, reduces the cost of the product greatly, overcomes the defect of high cost of biodegradable materials, uses less dosage of catalyst in the reaction process, and avoids the complicated catalyst separation process. The aliphatic polycarbonate obtained by the method is white crystalline solid, has the number average molecular weight of between 6,000 and 2*10<5>, and can be directly used as plastics, does not contain an ether bond in the main chain of the polycarbonate, is a crystalline polymer, and greatly improves the heat-resistant quality of the polymer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Modified vinyl acetate-acrylate copolymerization emulsion with high solubility and high glass transition temperature and preparation method thereof

A disclosed modified vinyl acetate-acrylate copolymerization emulsion with high solubility and high glass transition temperature comprises, in percent by mass, 40%-60% of vinyl acetate, 0.1%-5% of a bridged ring structure copolymerization monomer, 0.1%-5% of butyl acrylate, 0.1%-4.5% of oxirane-epoxypropane block polymer 1, 0.1%-4.5% of oxirane-epoxypropane block polymer 2, 0.1%-1% of a sulfosuccinate derivative, 0.5%-1% of a persulfate initiator, 0.1%-0.5% of a pH conditioning agent, and 25%-40% of water. The obtained emulsion product possesses extremely good storage stability and relatively high solid content. A film formed by the emulsion possesses relatively high glass transition temperature and rapid dissolving performance in styrene.

Owner:NANJING JINGJINYUAN TECHN IND

Non-ionic epoxy emulsifier, preparation method thereof and waterborne epoxy emulsion

The invention provides a non-ionic epoxy emulsifier, a preparation method thereof and a waterborne epoxy emulsion. In order to solve the problems of low molecular weight and poor emulsifying effect of the non-ionic epoxy emulsifier prepared by the existing process, the invention provides the preparation method of the non-ionic epoxy emulsifier. The preparation method comprises the steps of mixing polyethylene glycol, a catalyst and part of a solvent to obtain a mixed solution; mixing the epoxy resin and the residual organic solvent to obtain an epoxy resin diluent; dropwise adding the epoxy resin diluent into the mixed solution, and carrying out heat preservation reaction to obtain a reaction solution; and removing the catalyst and the solvent in the reaction liquid through reduced pressure distillation. The content of free polyethylene glycol in a system can be effectively reduced by improving a synthesis process, a raw material ratio and the like, a series of high-molecular-weight epoxy resin emulsifiers are synthesized by investigating the influence of a catalyst removal mode, the synthesis process and the raw material ratio on a product structure, and the non-ionic epoxy emulsifier has the advantages of good emulsifying performance, less toxicity, less pollution and the like.

Owner:AFCONA CHEM HAIMEN +1

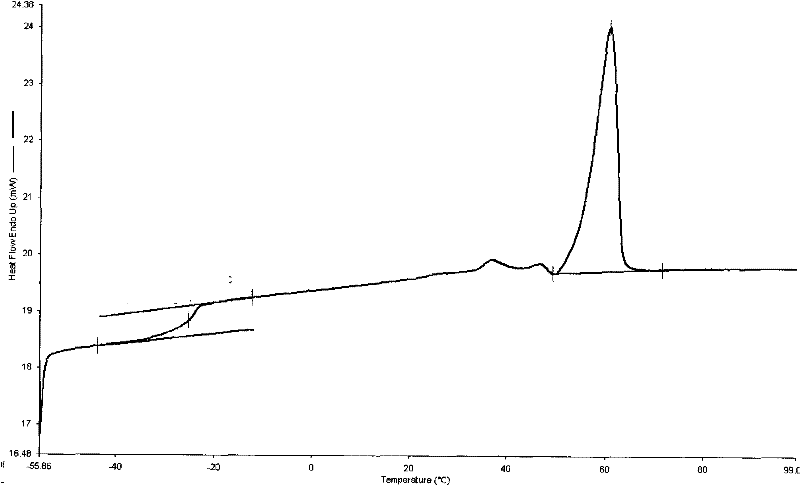

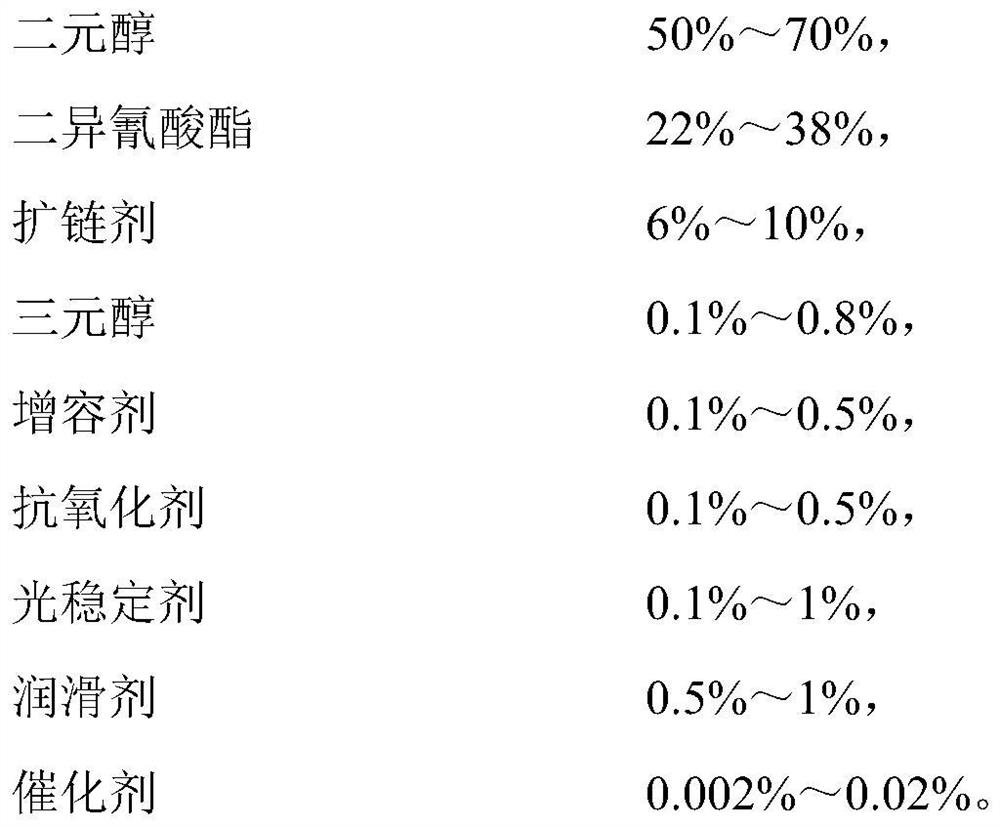

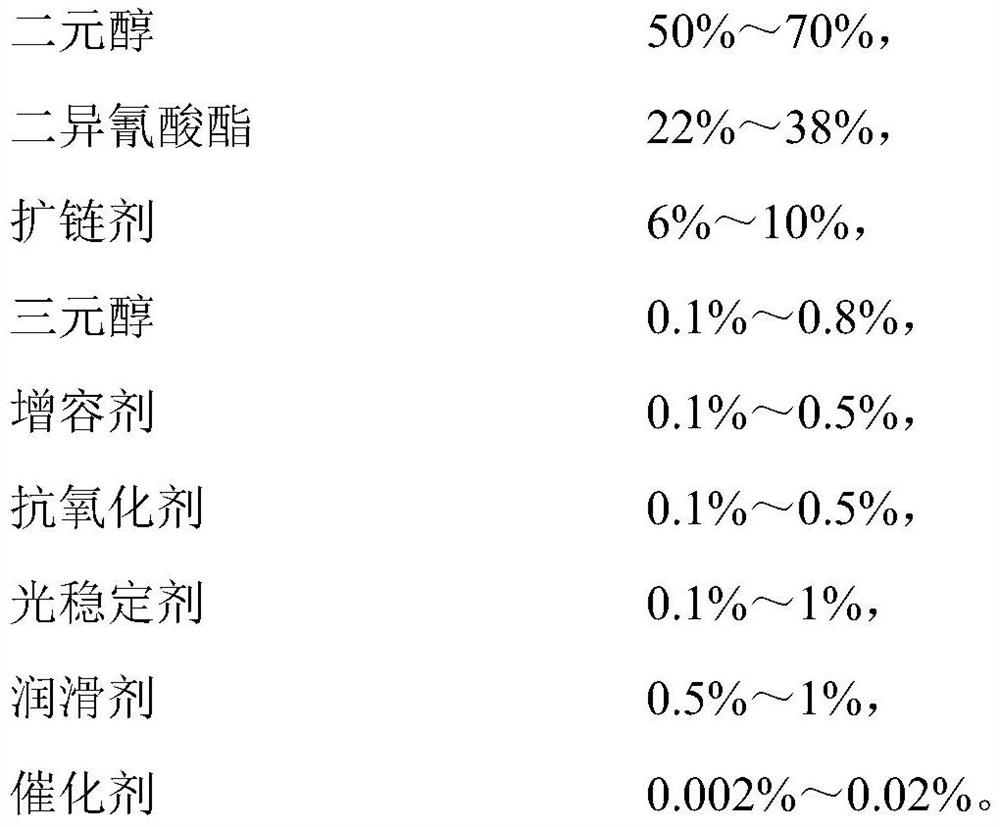

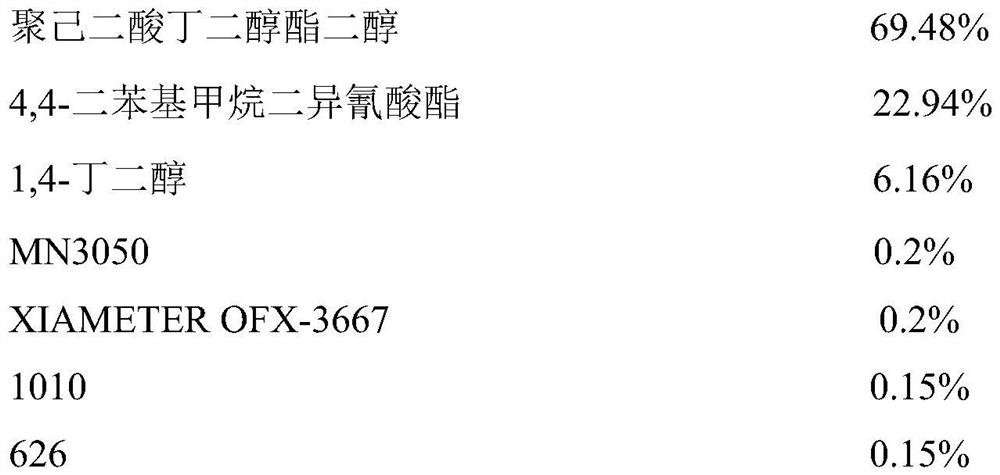

Soft segment cross-linked thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN111995729AHigh number average molecular weightLow compression setPolyurethane elastomerPolymer science

The invention belongs to the technical field of thermoplastic polyurethane elastomers, and particularly relates to a soft segment cross-linked thermoplastic polyurethane elastomer and a preparation method thereof. The soft segment cross-linked thermoplastic polyurethane elastomer is prepared from the following raw materials in percentage by weight: 50 to 70 percent of dihydric alcohol, 22 to 38 percent of diisocyanate, 6 to 10 percent of chain extender, 0.1 to 0.8 percent of trihydric alcohol, 0.1 to 0.5 percent of bulking agent, 0.1 to 0.5 percent of antioxidant, 0.1 to 1 percent of light stabilizer, 0.5 to 1 percent of lubricating agent and 0.002 to 0.02 percent of catalyst. The synthesized polyurethane elastomer contains a certain amount of soft segment chemical crosslinking, the compression deformation of the product can reach 20-25%, the light transmittance can reach 91% or above, and the softening temperature is increased by 20-30 DEG C compared with a conventional system. The preparation method is simple and easy to implement, the melt viscosity is stable and controllable, and the method can be widely applied to the fields of oil seals, trundles, shoe materials, high-temperature oil pipes and the like.

Owner:SHANDONG INOV POLYURETHANE

Method for preparing maleic rosin hydroxyethyl methacrylate polymer from rosin

InactiveCN110746528ALess side effectsFacilitate subsequent processingNatural resin chemical modificationPolymer science(Hydroxyethyl)methacrylate

The invention relates to a method for preparing a maleic rosin hydroxyethyl methacrylate polymer from rosin. The method comprises the following operation steps: 1) adding rosin into a reaction kettle,performing heating to complete melting of rosin, adding maleic acid and a catalyst, and carrying out a thermal reaction to generate maleic rosin; 2) carrying out a reaction of maleic rosin with hydroxyethyl methacrylate in butyl acetate to prepare maleic rosin hydroxyethyl methacrylate; and 3) carrying out a polymerization reaction of the maleic rosin hydroxyethyl methacrylate to prepare the maleic rosin hydroxyethyl methacrylate polymer. The method provided by the invention can eliminate a conjugate double bond to form a relatively stable six-membered ring internal double bond structure by using a D-A reaction under the premise of not destroying a structure of rosin, at the same time the occurrence of side reactions is effectively reduced, the subsequent processing is facilitated, a double bond structure of hydroxyethyl methacrylate is used for polymerization, the reactivity is high, the yield is effectively improved, and the needs of industrial large-scale production applications are met.

Owner:广东省邦得利新材料技术有限公司

Prefabricated asphalt block and asphalt layer formula

ActiveCN111206467BImprove construction qualityReduce labor intensitySingle unit pavingsBuilding insulationsWeather resistanceArchitectural engineering

The invention relates to the field of asphalt prefabricated blocks, in particular to an assembled asphalt prefabricated block and its formula. The invention discloses an assembled asphalt prefabricated block, which is characterized in that it includes a bottom plate, an adhesive layer and an asphalt layer from bottom to top; the shape of the asphalt prefabricated block is a cuboid or a cube, and the bottom plate is a groove structure with an open upper end. Both the adhesive layer and the asphalt layer are arranged in the groove structure. The invention solves the problem in the prior art that road surfaces such as sandy ground are generally in an environment with large temperature differences, and the temperature is low in the morning and evening in summer, and the temperature is low in winter for a long time, thus greatly reducing the weather resistance of the asphalt pavement. The invention adopts the factory standard prefabrication of asphalt concrete pavement, the construction quality is more reliable, and intelligent equipment can be used, which is beneficial to reduce labor intensity and cost at the same time.

Owner:广州市市政实业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com