Double metal cyanide catalyst preparation method

A double metal cyanide and catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as increasing costs, achieve high production efficiency, The effect of short production cycle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

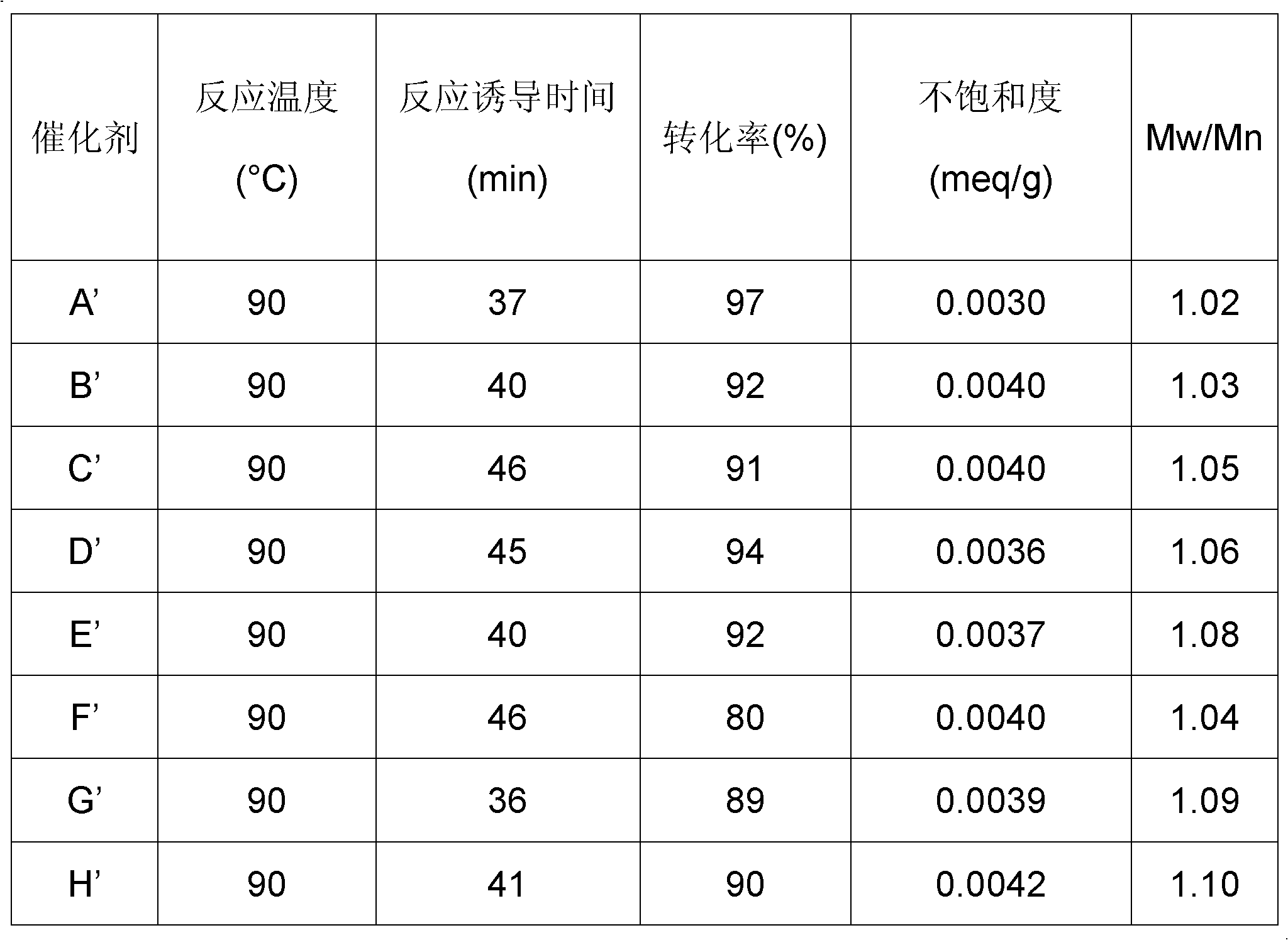

Examples

Embodiment 1

[0024] Add 30 grams of zinc chloride to 225 mL of deionized water, and then add 117 grams of tert-butanol to form a metal salt mixture, marked as S1. Add 12 g of potassium hexacyanocobaltate to 225 mL of deionized water to form an aqueous cyanide solution, labeled S2.

[0025] The rotation speed of the hypergravity reactor was adjusted to 1800rpm and stabilized for 30 minutes. S1 and S2 were pumped from different inlets into the supergravity reactor for mixing at a feed rate of 6 mL / min. At the same time, return the effluent from the supergravity reactor to the reactor, circulate for one hour at a temperature of 10°C, stop the supergravity reactor, and centrifuge the collected white slurry liquid to remove the solvent. Dry under vacuum at 50°C to constant weight to obtain a white powder solid A, which is a double metal cyanide catalyst.

Embodiment 2

[0027] Add 300 grams of zinc chloride to 2250 mL of deionized water, and then add 1170 grams of tert-butanol to form a metal salt mixture, marked as S1. Add 131.6 g of potassium hexacyanoferrate to 2250 mL of deionized water to form an aqueous cyanide solution, labeled S2.

[0028] Adjust the rotating speed of the supergravity reactor to 20000rpm and keep it stable for 40 minutes. S1 and S2 were pumped from different inlets into the supergravity reactor for mixing at a feed rate of 60 mL / min. At the same time, the slip-out liquid in the supergravity reactor is returned to the reactor, circulated for 1.5 hours at a temperature of 30° C., the supergravity reactor is stopped, and the collected white slurry liquid is centrifuged to remove the solvent. Dry to constant weight under vacuum at 50°C, and finally obtain yellow solid powder B.

Embodiment 3

[0030] The water-soluble metal salt of the present embodiment is 35.84 grams of zinc sulfate, and the water-soluble cyanide is 12 grams of potassium hexacyanocobaltate. Others are the same as in Example 1 and are operated according to its process steps to obtain white solid powder C at last.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com