Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2458 results about "Saturated carboxylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

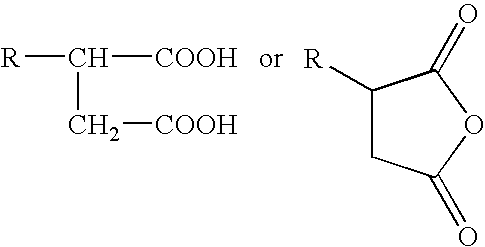

A carboxylic acid is a molecule that contains at least one carbon double bonded to an oxygen, and single bonded to an oxygen in an OH group. The double bond means that carbon is only bonded to 3 atoms, therefore the carboxylic acid group is not saturated.

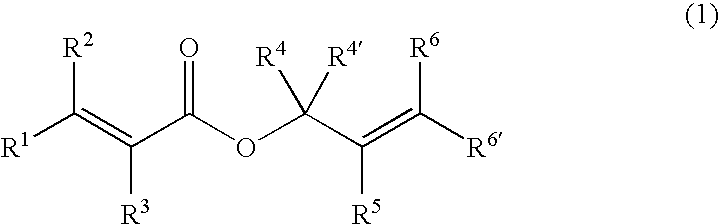

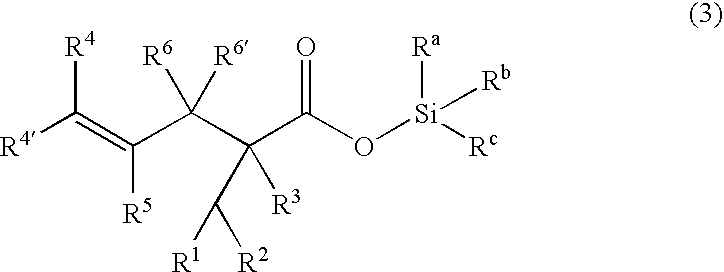

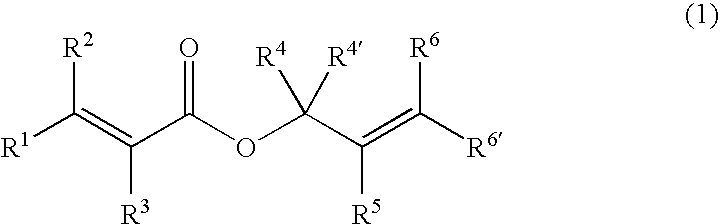

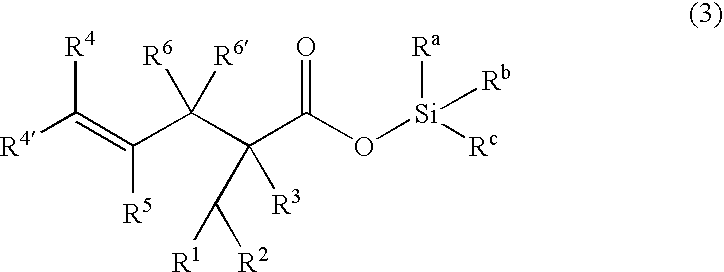

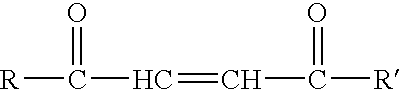

Processes of making gamma,delta-unsaturated carboxylic acid and silyl ester thereof, carboxyl group-containing organosilicon compound and process of making

ActiveUS7307178B2Few stepsHigh yieldSilicon organic compoundsPreparation from carboxylic acid esters/lactonesCarboxyl radicalPerylene derivatives

A γ,δ-unsaturated carboxylic acid silyl ester is prepared by reacting an α,β-unsaturated carboxylic acid ester with a hydrosilane or hydrosiloxane in the presence of tris(pentafluorophenyl)borane. γ,δ-Unsaturated carboxylic acid derivatives are readily prepared through fewer steps and in high yields.

Owner:SHIN ETSU CHEM CO LTD

Processes of making gamma,delta-unsaturated carboxylic acid and silyl ester thereof, carboxyl group-containing organosilicon compound and process of making

ActiveUS20050070729A1High yieldFew stepsSilicon organic compoundsPreparation from carboxylic acid esters/lactonesCarboxyl radicalPerylene derivatives

A γ,δ-unsaturated carboxylic acid silyl ester is prepared by reacting an α,β-unsaturated carboxylic acid ester with a hydrosilane or hydrosiloxane in the presence of tris(pentafluorophenyl)borane. γ,δ-Unsaturated carboxylic acid derivatives are readily prepared through fewer steps and in high yields.

Owner:SHIN ETSU CHEM IND CO LTD

Low-chlorine, polyolefin-substituted, with amine reacted, alpha-beta unsaturated carboxylic compounds

A composition of matter comprising an amine acylated with a hydrocarbyl group substituted carboxylic acylating agent containing an average of from 1.3 to 1.6 groups derived from α,β-unsaturated carboxylic compounds per Mn of the hydrocarbyl group, wherein the hydrocarbyl group has Mn determined by GPC ranging from 1500 to 3000, the amine comprises polyamine bottoms and said acylated amine has total base number (TBN) ranging from 17 to 35. A method for preparing the composition, lubricating oils containing the composition and, in another embodiment, lubricating oil compositions of this invention further comprising a metal overbased sulfonate detergent.

Owner:THE LUBRIZOL CORP

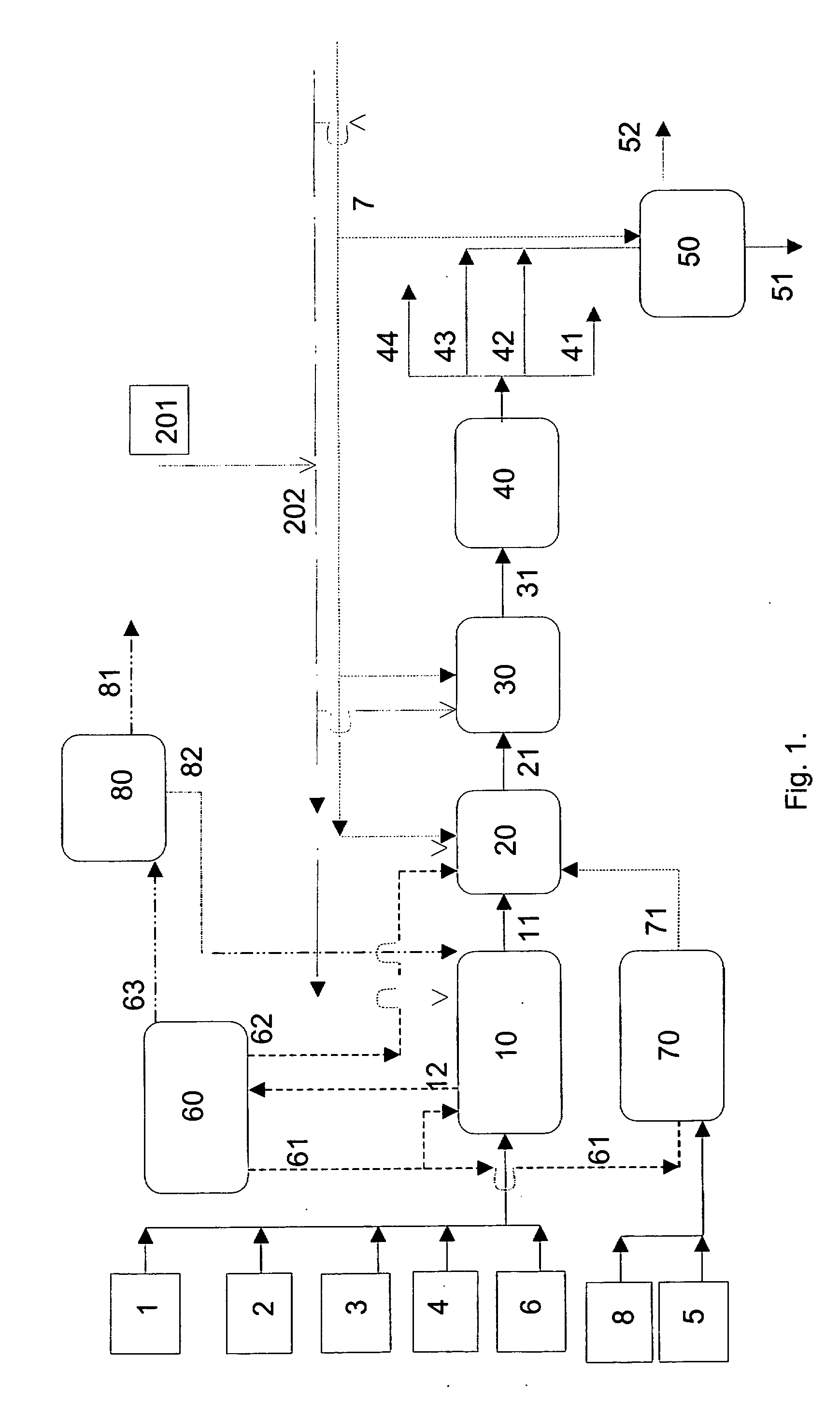

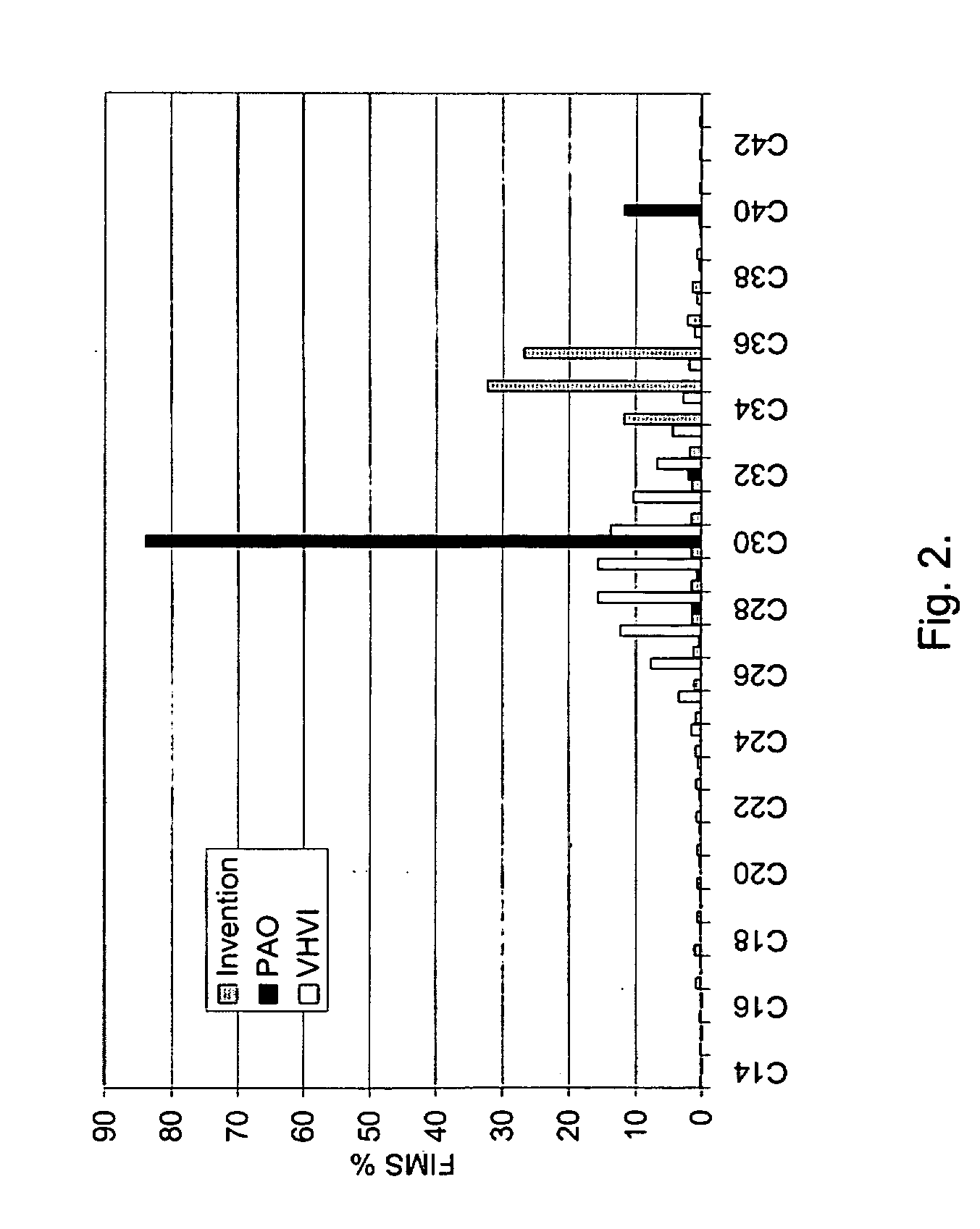

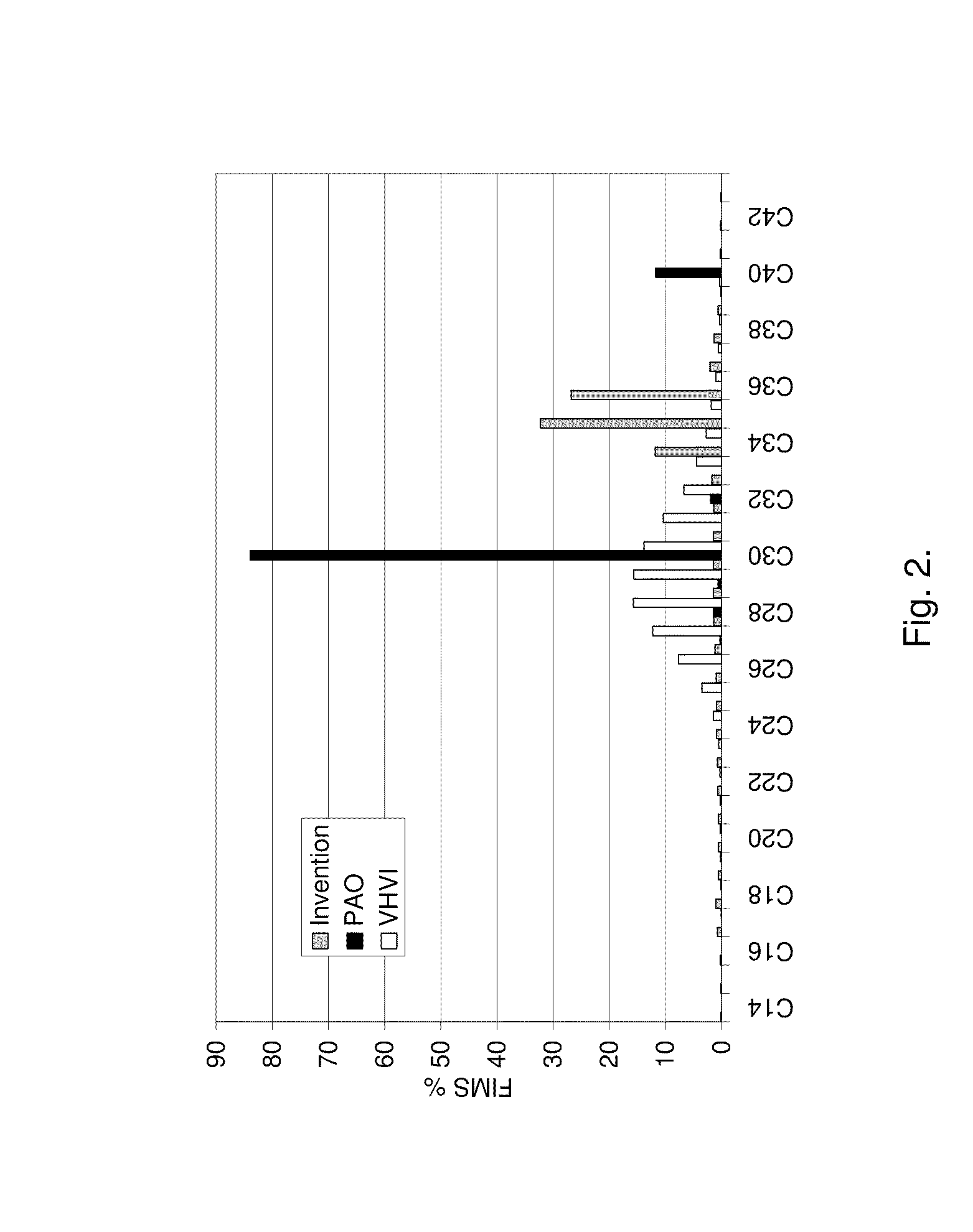

Process for producing a saturated hydrocarbon component

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

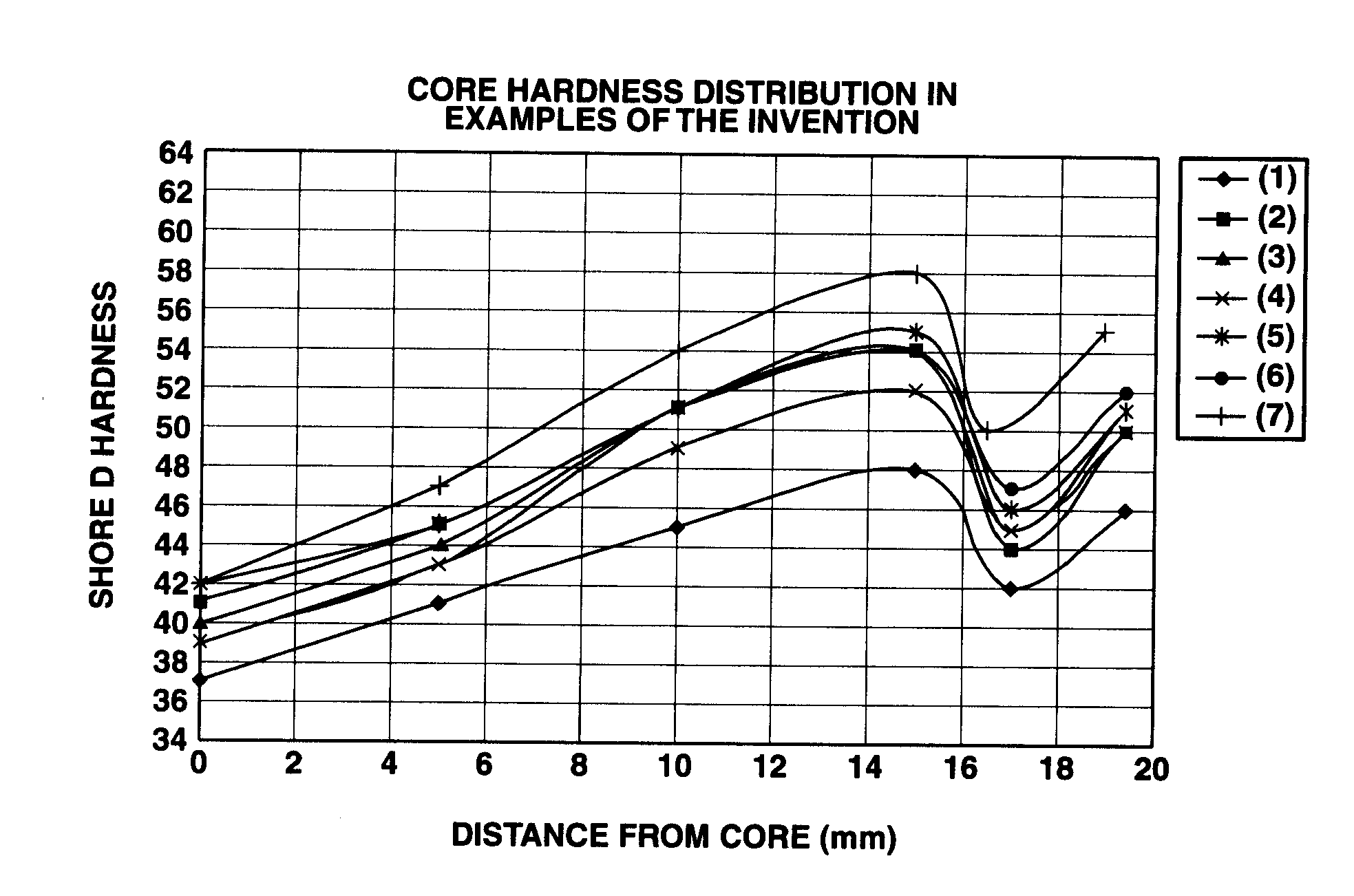

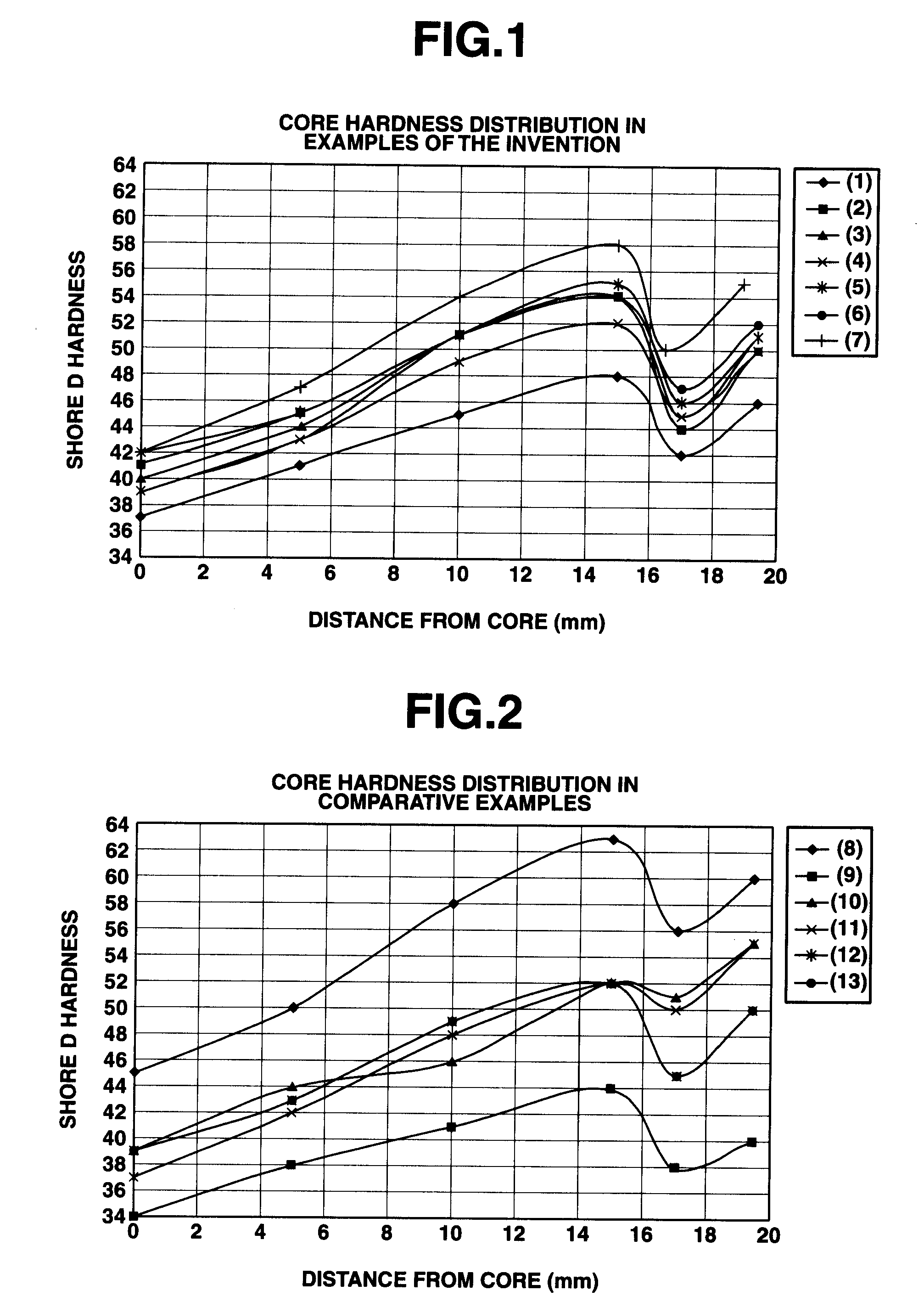

Multi-piece solid golf ball

InactiveUS7086969B2Improve spin performanceIncrease total distance traveledGolf ballsSolid ballsPtru catalystSulphur compound

Owner:BRIDGESTONE SPORTS

Highly-neutralized ethylene copolymers

Melt-processable, highly-neutralized ethylene, C3 to C8 alpha,beta ethylenically unsaturated carboxylic acid copolymers and process for making them. Copolymers are made by incorporating a C4 to less than a C36 aliphatic, mono-functional organic acid and neutralizing greater than 90% to 100% of the acid groups present concurrently with or subsequently to the incorporation of the organic acid.

Owner:PERFORMANCE MATERIALS NA INC

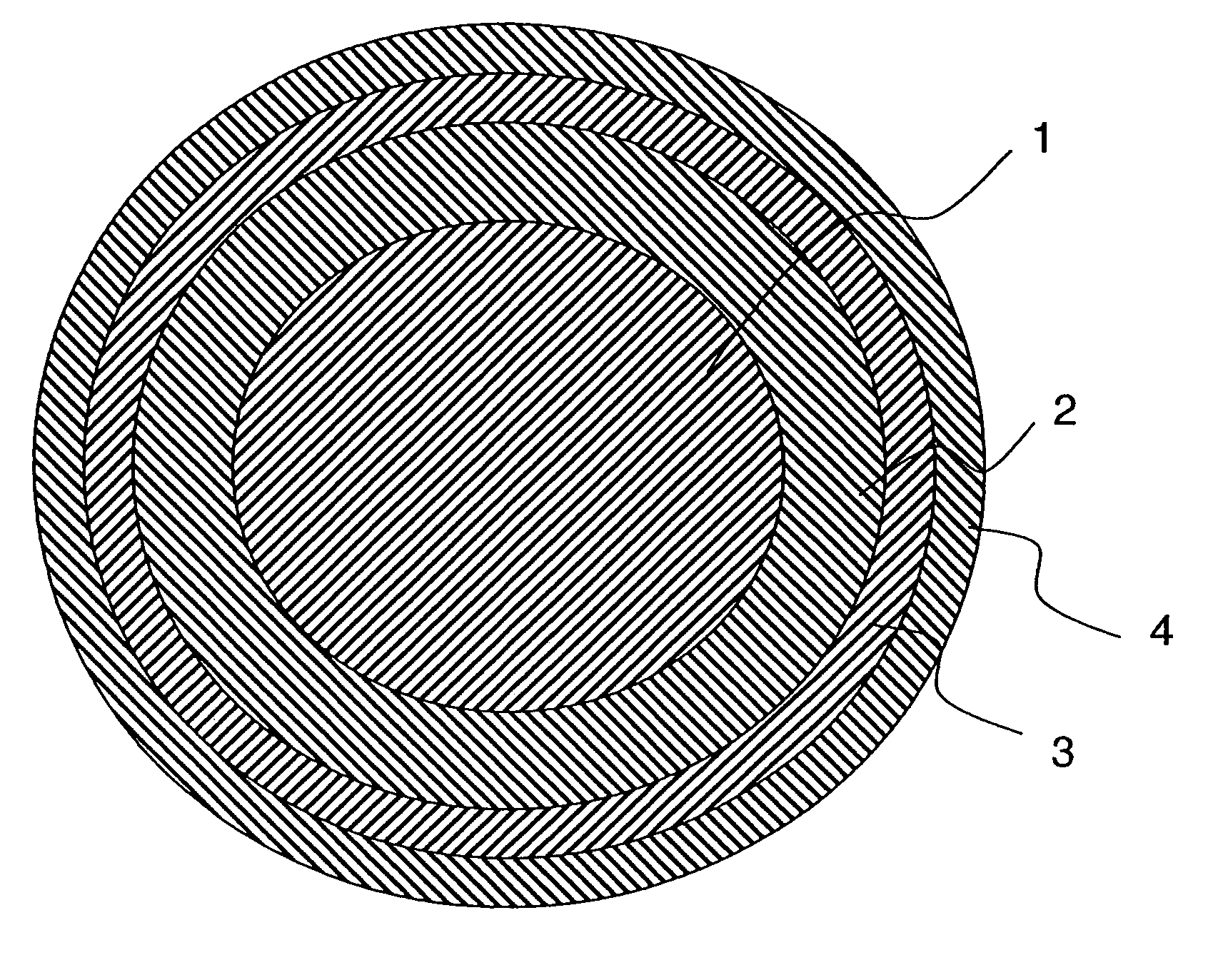

Golf ball

InactiveUS7226367B2Improve productivityIncrease elasticityGolf ballsSolid ballsPtru catalystEngineering

A golf ball comprises a solid core consisting of a center core and an outer core, wherein at least one of cores is made of a rubber composition comprising 100 parts by weight of a base rubber including. 60 to 100% by weight of a polybutadiene containing at least 60% by weight of cis-1,4-bond, having a Mooney viscosity (ML1+4 (100° C.)) of at least 52, and synthesized using a rare-earth catalyst, 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, 5 to 80 parts by weight of an-inorganic filler, and an organic peroxide, and wherein the center core has a JIS-C hardness of 40 to 60 on its center and a JIS-C hardness of 55 to 75 on its surface and the difference therebetween is at least 10, the outer core is harder than the surface hardness of the center core, the cross-sectional hardness of 1 mm outside from the border between the center core and the outer core is from 65 to 85 on a JIS-C hardness, the surface of the outer core has a JIS-C hardness of 75 to 95.

Owner:BRIDGESTONE SPORTS

Thermoplastic resin compositions suitable for use in transparent laminates

InactiveUS20070289693A1Synthetic resin layered productsGlass/slag layered productsClear LayerPolymer science

The present invention is an improved polymeric resin composition comprising units derived from ethylene, from about 20 wt % to about 30 wt % units derived from an α,β-unsaturated carboxylic acid having from 3 to 8 carbons, and optionally an effective amount of at least one additive selected from the group consisting of hindered amine light stabilizers, UV light absorbers, and thermal stabilizers. Resins of the present invention are particularly suitable for preparing transparent laminates useful as glazing elements that provide a greater measure of safety than non-laminated glazing elements.

Owner:EI DU PONT DE NEMOURS & CO

Solar cell encapsulant layers with enhanced stability and adhesion

The present invention provides a solar cell module comprising at least one encapsulant layer which has 1) a total thickness of from about 0.1 to about 20 mils and 2) at least one surface layer made of ionomers containing a finite amount of polymerized residues of α-olefins and from about 18 to about 25 wt % of polymerized residues of α,β-ethylenically unsaturated carboxylic acids. The present invention also provides a process of manufacturing the solar cell module.

Owner:DOW GLOBAL TECH LLC

Golf ball

The invention provides a golf ball composed of, at least in part, a molded and crosslinked material obtained from a rubber composition made of a base rubber, a filler, an organic peroxide, an α,β-unsaturated carboxylic acid and / or metal salt thereof, and a copper salt of a saturated or unsaturated fatty acid. The molded rubber composition has a very high rebound, and is thus useful as a golf ball core for achieving an excellent flight performance.

Owner:BRIDGESTONE SPORTS

Solid golf ball

A golf ball has a cover member and a core member. The cover member contains: 3 to 30 parts by weight of a thermoplastic elastomer containing polyamide; 5 to 50 parts by weight of a terpolymer ionomer containing ethylene, (meth)acrylic acid, and (meth)acrylic ester; 30 to 80 parts by weight of a copolymer ionomer containing ethylene and (meth)acrylic acid; and 1 to 20 parts by weight of an epoxidized-diene-based block copolymer. The core member is formed by vulcanizing a rubber composition containing: 100 parts by weight of a base rubber, A parts by weight of an alpha, beta-unsaturated carboxylic acid or a metal salt thereof, B parts by weight of an organic peroxide, and C parts by weight of a sulfide where A, B, and C satisfies the relationship:andA lies in the range from 25 to 45.

Owner:DUNLOP SPORTS CO LTD

Solid golf ball

InactiveUS20080312008A1Improve spin performanceIncrease distanceGolf ballsSolid ballsOrganosulphur compoundPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a thermoplastic polyurethane and (B) a polyisocyanate compound, which resin blend contains a polyisocyanate compound in at least some portion of which all the isocyanate groups on the molecule remain in an unreacted state, and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Flame retardant composition

Owner:NIPPON YUNIKAA

Process for producing water-absorbing resin

InactiveUS20050085604A1Prevent discolorationNo discolorationAbsorbent padsBaby linensPolymer scienceProduced water

A process for preparing a water-absorbent resin made from an α,β-unsaturated carboxylic acid as an essential monomer characterized in that the process comprises allowing a metal chelating agent to be present at any step in the process in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid; and adding a reducing agent or an oxidizing agent thereto in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid before initiation of drying and / or during drying of a gelated product containing a water-absorbent resin obtained by polymerization.

Owner:SUMITOMO SEIKA CHEM CO LTD

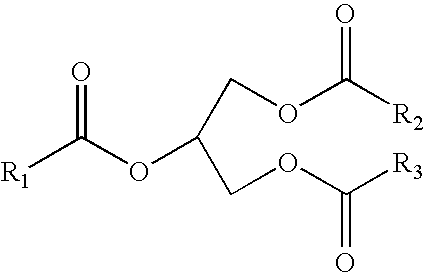

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

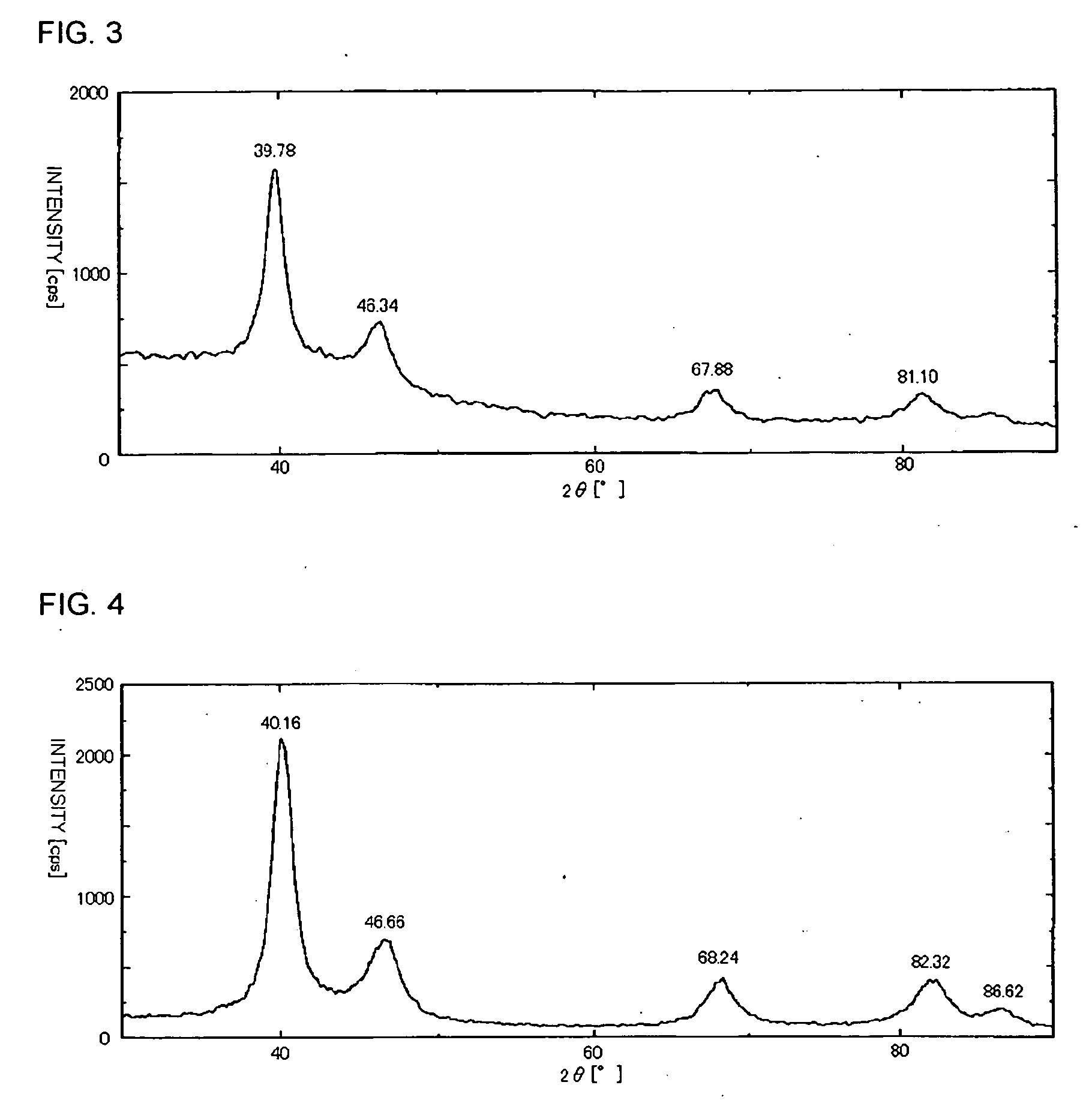

Carbon-intersticed metallic palladium, palladium catalyst and method for preparation thereof, and method for producing alpha,beta-unsaturated carboxylic acid

InactiveUS20060068989A1High yieldOrganic compound preparationCatalyst activation/preparationPalladium catalystMetal

A carbon-insertion-type palladium metal in which an amount of inserted carbon is 0.16 mol or more with respect to 1.0 mol of a palladium metal, and a carbon-insertion-type palladium metal in which a crystal face distance of a (111) face of a palladium metal is 2.270 Å or more are useful as raw materials of a palladium catalyst for use in an α,β-unsaturated carboxylic acid preparation reaction, and the like. The carbon-insertion-type palladium metal can preferably be prepared by reduction of palladium in a palladium compound having a chlorine content of 0 to 300 ppm.

Owner:MITSUBISHI RAYON CO LTD

Solid golf ball

InactiveUS20080194359A1Large deformationIncreased durabilityGolf ballsSolid ballsAntioxidantRare earth

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes from 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, from 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer has a thickness of from 0.5 to 1.9 mm, and a Shore D hardness at the surface of from 50 to 70. The ball has at least one intermediate layer between the core and the cover, any one of which intermediate layer or layers has a surface hardness in Shore D units of from 40 to 60, the intermediate layer or layers having a total thickness of from 0.9 to 7.0 mm. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

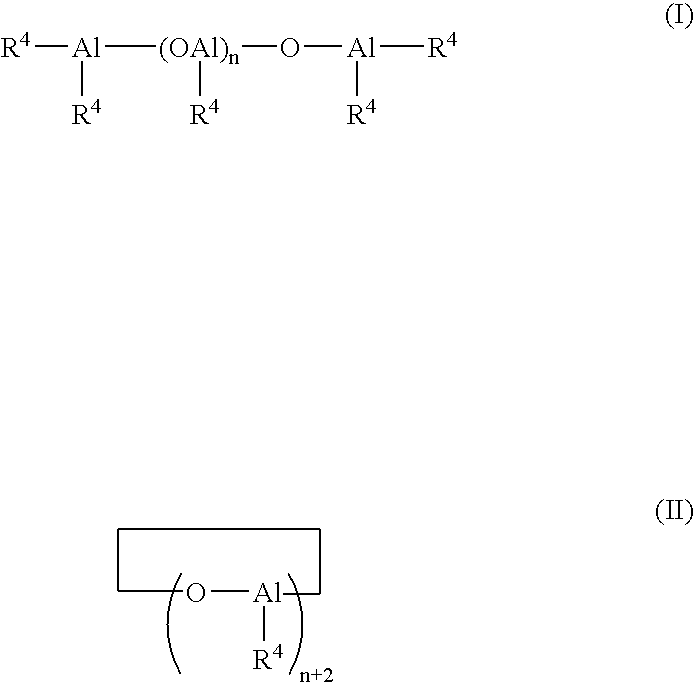

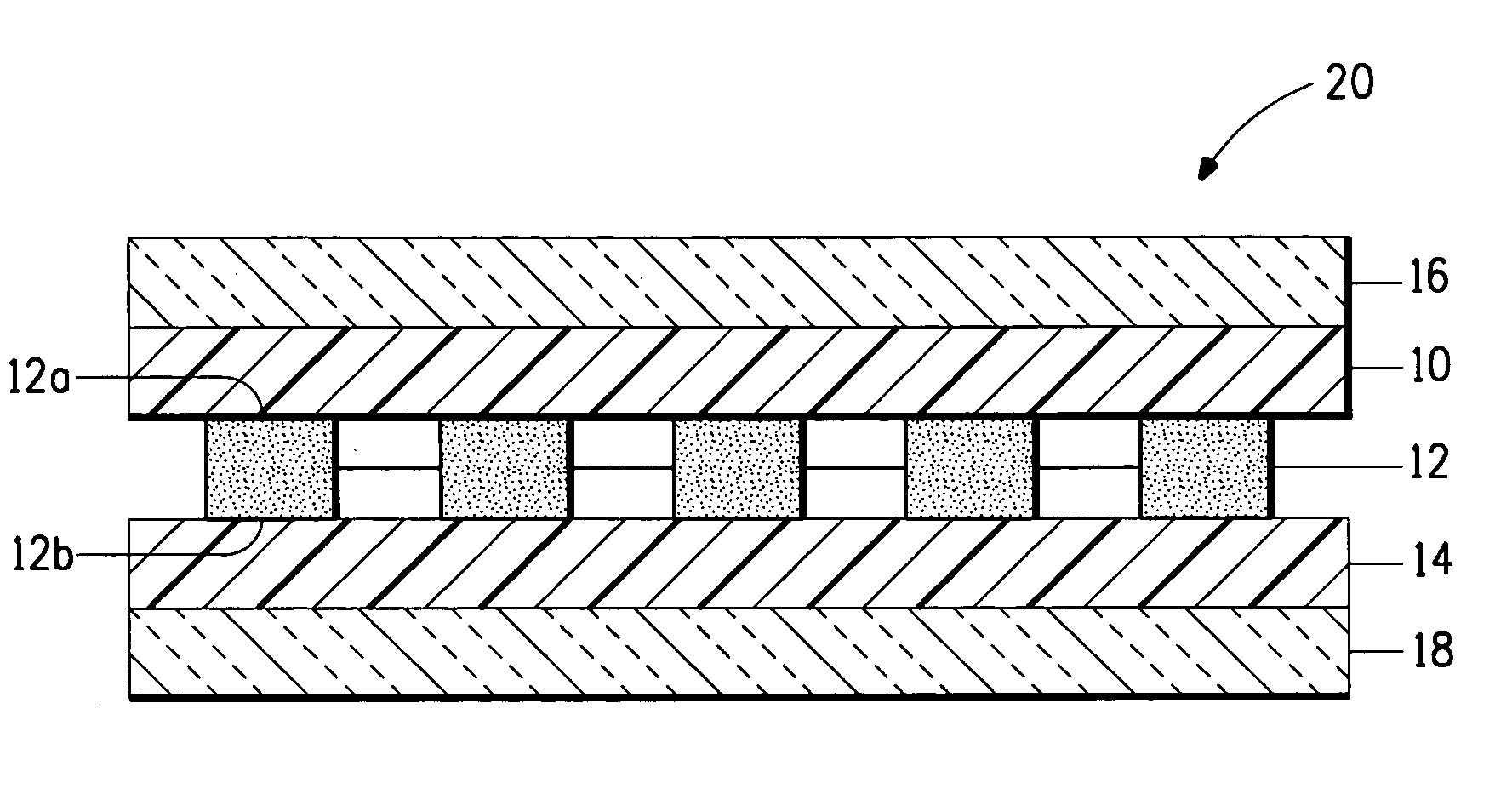

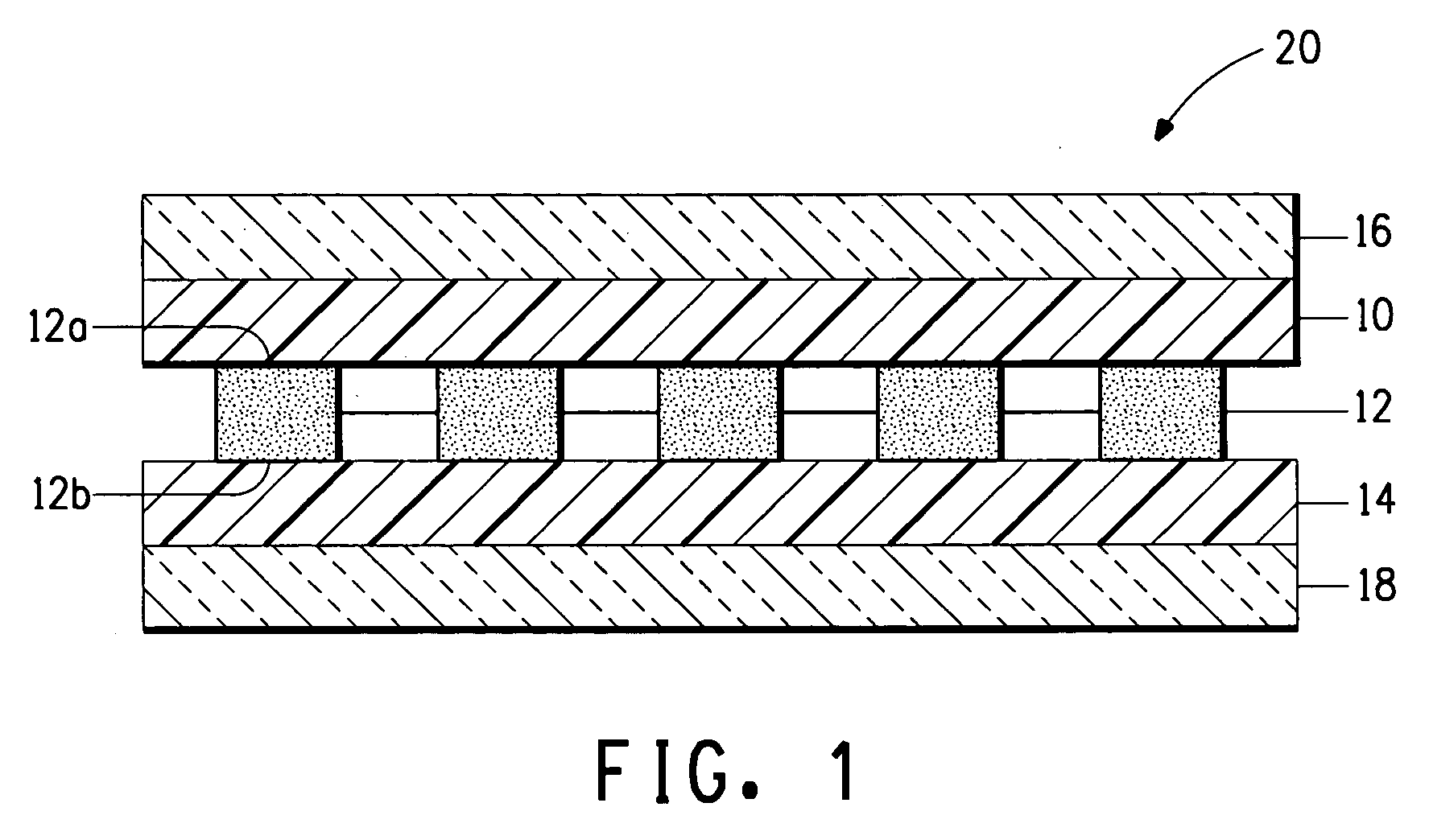

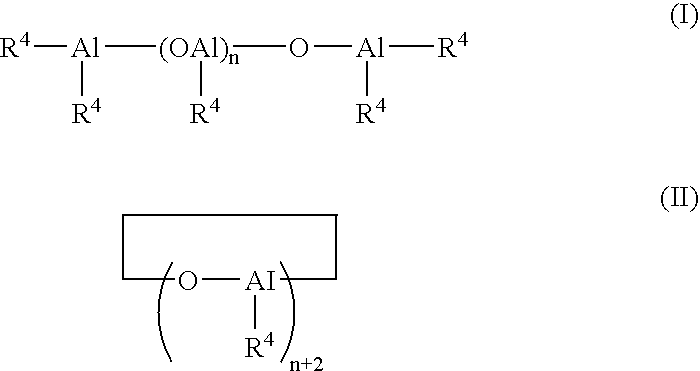

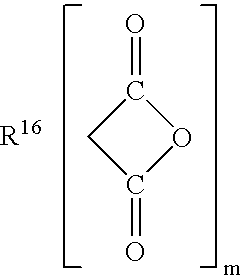

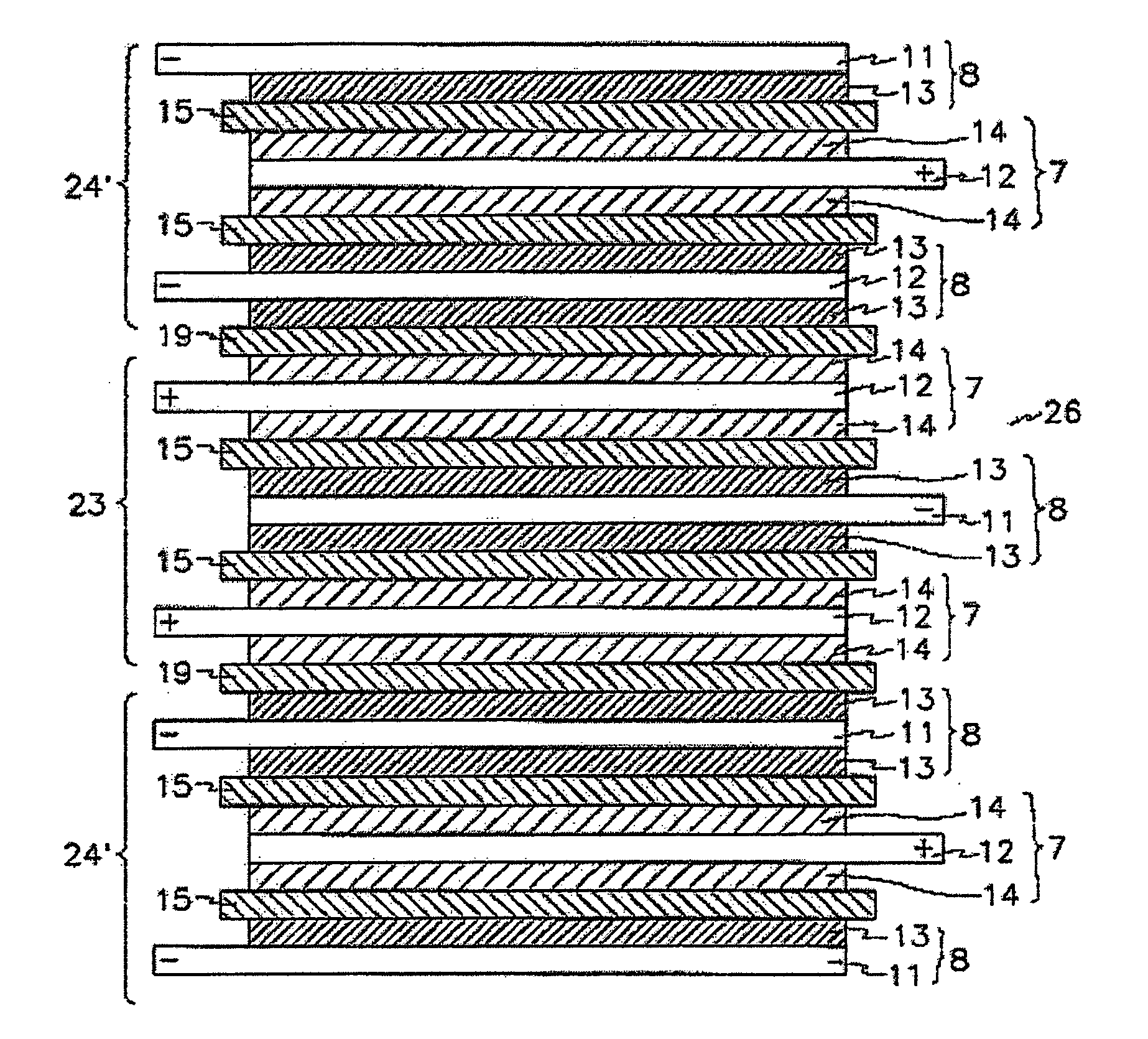

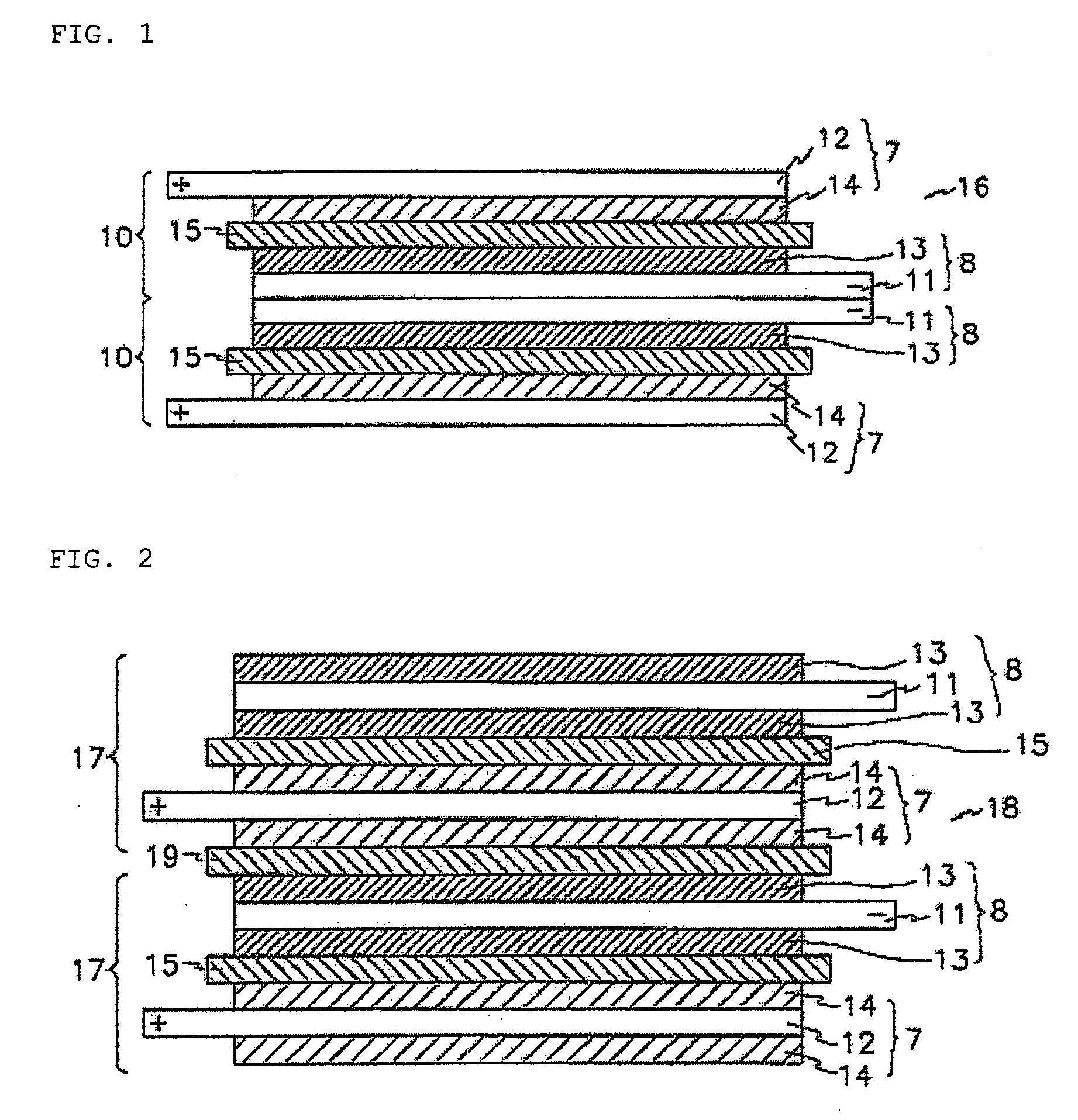

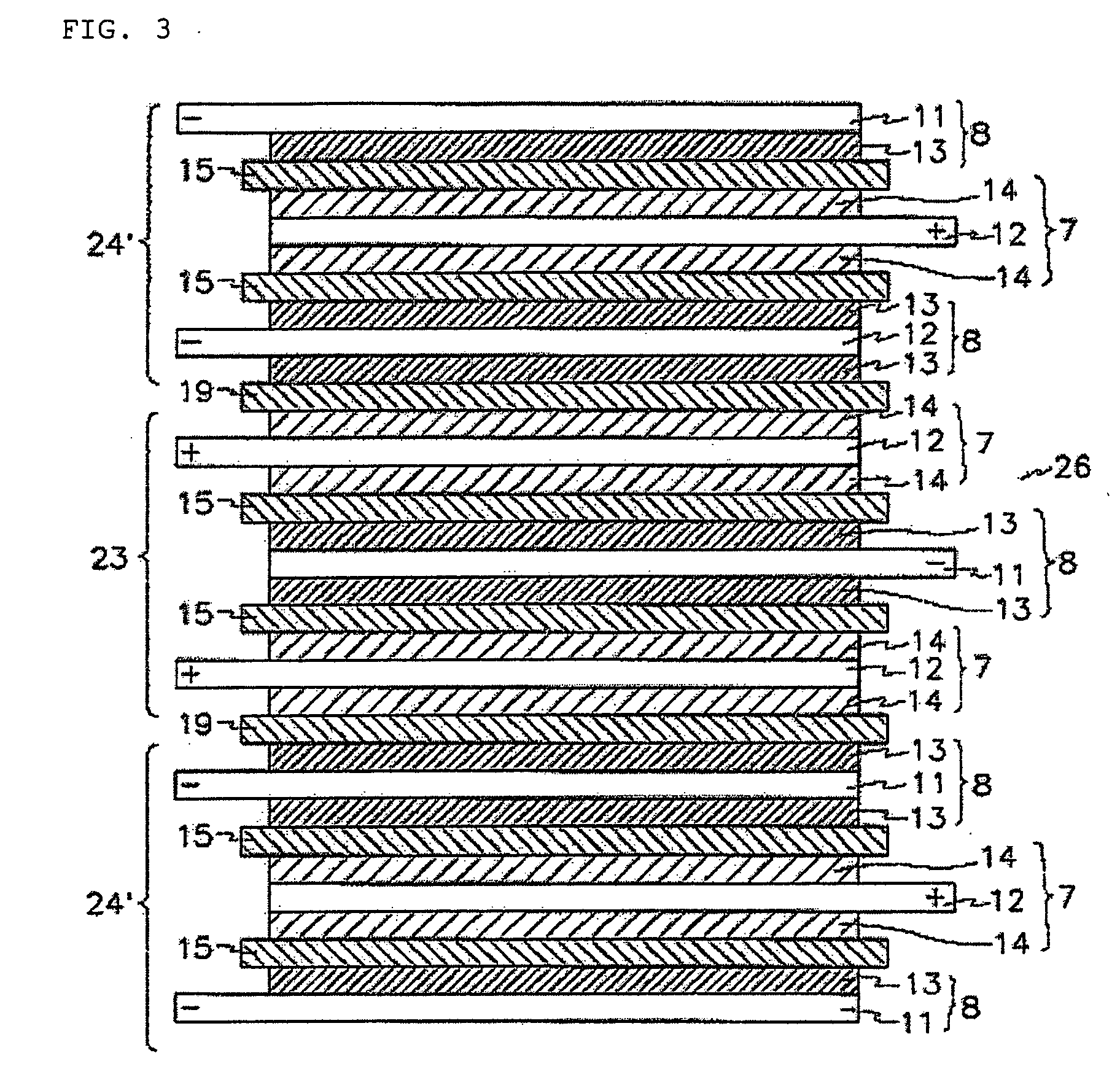

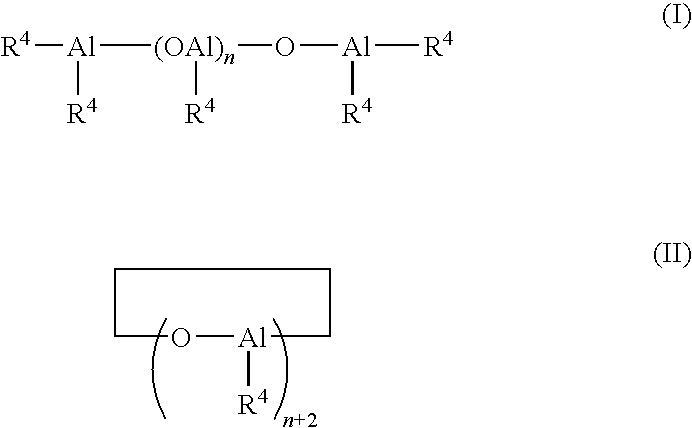

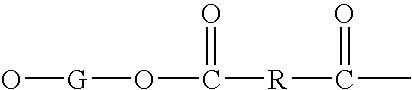

Polymer binder for electrochemical device comprising multiply stacked electrochemical cells

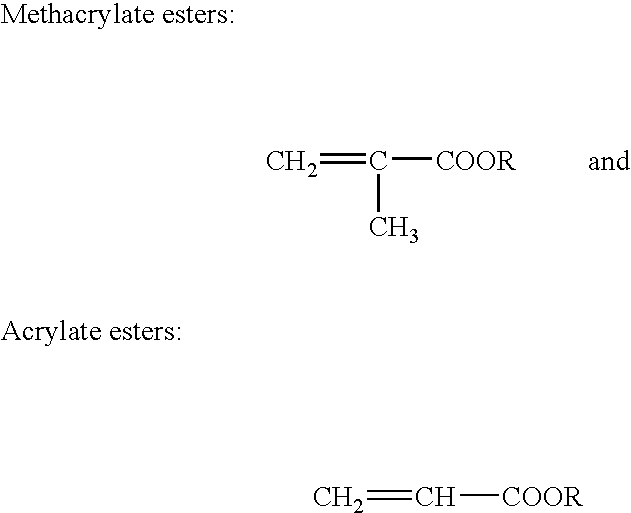

ActiveUS20060275661A1Increase in bulk energy densityHighly-integratedLarge-sized flat cells/batteriesFinal product manufactureMethacrylateMeth-

Disclosed is an electrochemical device, which comprises: (A) a binder comprising polymer particles obtained from the polymerization of: (a) 20-70 parts by weight of a (meth)acrylic acid ester monomer; (b) 20-60 parts by weight of a vinyl monomer; and (c) 0.01-30 parts by weight of an unsaturated carboxylic acid monomer, based on 100 parts by weight of a binder polymer; and (B) electrochemical cells stacked multiply by using the binder, wherein the binder allows electrode active material particles in an electrode to be fixed and interconnected among themselves and between the electrode active material and a collector, and the electrode and a separator that is in contact with the electrode are bonded to each other by way of hot fusion. The binder is also disclosed. The binder has excellent adhesion and thermal bonding characteristics, and thus is useful for an electrochemical device comprising multiply stacked electrochemical cells, and can improve the overall quality of a battery.

Owner:LG CHEM LTD

Method of manufacturing a golf ball

The present invention relates to an industrially beneficial method of manufacturing golf balls which includes the steps of pre-preparing a masterbatch of an unsaturated carboxylic acid and / or a metal salt thereof by mixing an unsaturated carboxylic acid and / or a metal salt thereof with a rubber material, preparing a rubber composition that contains the rubber material by using the masterbatch, and employing a material obtained by molding the rubber composition under heat as a golf ball component. The masterbatch is composed of:(A) from 20 to 100 wt % of a modified polybutadiene obtained by a modification reaction wherein a polybutadiene having a vinyl content of from 0 to 2%, a cis-1,4 bond content of at least 80% and an active end is modified at the active end with at least one type of alkoxysilane compound, and(B) from 80 to 0 wt % of a diene rubber other than Ingredient A.such that ingredients A and B are included in a combined amount of 100 wt %, and(C) an unsaturated carboxylic acid and / or a metal salt thereof.

Owner:BRIDGESTONE SPORTS

Thermoplastic resin compositions suitable for use in transparent laminates

ActiveUS20060182983A1Synthetic resin layered productsCellulosic plastic layered productsPolymer resinEthylene

The present invention is an improved polymeric resin composition comprising or consisting essentially of from about 70 wt % to about 79 wt % units derived from ethylene and from about 21 wt % to about 30 wt % units derived from an α,β-unsaturated carboxylic acid having from 3 to 8 carbons. Resins of the present invention are particularly suitable for preparing transparent laminates useful as glazing elements that provide a greater measure of safety than non-laminated glazing elements. Laminates of the present invention have 3% haze or less without the addition of amines.

Owner:DOW GLOBAL TECH LLC

Highly-neutralized thermoplastic copolymer center for improved multi-layer core golf ball

InactiveUS7652086B2Fibre treatmentSynthetic resin layered productsOrganic acidCoefficient of restitution

A golf ball comprising a center comprising a highly-neutralized thermoplastic copolymer of ethylene and an α,β-unsaturated carboxylic acid, the acid being 100% neutralized by a salt of an organic acid, a cation source, or a suitable base of the organic acid; a cover; and an intermediate layer disposed between the center and the cover; wherein the golf ball has a first coefficient of restitution of 0.81 or greater when measured at an incoming velocity of 125 ft / s; and a sphere resulting from a combination of the center and the intermediate layer has a compression of 60 or greater.

Owner:ACUSHNET CO

Solid golf ball

InactiveUS20080214325A1Increase elasticityImprove low temperature performanceGolf ballsSolid ballsAntioxidantRare earth

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes from 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, from 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a polyurethane material and (B) a polyisocyanate compound, which resin blend includes a polyisocyanate compound in at least some portion of which all the isocyanate groups on a molecule remain in an unreacted state. The cover layer has a thickness of from 0.5 to 2.5 mm and a Shore D hardness at the surface of from 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Thermoplastic resin compositions suitable for use in transparent laminates

ActiveUS7763360B2Synthetic resin layered productsCellulosic plastic layered productsClear LayerPolymer resin

The present invention is an improved polymeric resin composition comprising or consisting essentially of from about 70 wt % to about 79 wt % units derived from ethylene and from about 21 wt % to about 30 wt % units derived from an α, β-unsaturated carboxylic acid having from 3 to 8 carbons. Resins of the present invention are particularly suitable for preparing transparent laminates useful as glazing elements that provide a greater measure of safety than non-laminated glazing elements. Laminates of the present invention have 3% haze or less without the addition of amines.

Owner:DOW GLOBAL TECH LLC

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

Label film with improved adhesion

The invention relates to the use of a biaxially oriented polyolefin film as a label film. The inventive film consists of a base layer and at least one cover layer. Said cover layer contains as the main component a copolymer or terpolymer consisting of one alkene and unsaturated carboxylic acids or the esters thereof and low amounts of an additive. The cover layer is characterized by excellent and divers adhesion to various polymer materials from which containers are formed. It is no longer necessary to apply adhesives, primers, coatings etc. in a separate step after production of the film.

Owner:TRESPAPHAN

Golf ball material and golf ball

InactiveUS6894097B2Improve thermal stabilitySpeed up the flowSynthetic resin layered productsGolf ballsGolf BallThermal stability

A mixture having good thermal stability, flow and moldability and suitable as a golf ball-forming material is obtained when a base resin comprising a (metal ion-neutralized) olefin-unsaturated carboxylic acid-unsaturated carboxylate ternary random copolymer and optionally a (metal ion-neutralized) olefin-unsaturated carboxylic acid binary random copolymer is blended with specific proportions of a fatty acid and / or fatty acid derivative and a basic inorganic metal compound capable of neutralizing acidic groups left unneutralized in the base resin and fatty acid. Using the same material, high-rebound golf balls can be effectively manufactured.

Owner:BRIDGESTONE SPORTS

Process for producing a saturated hydrocarbon component

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

Multi-piece solid golf ball

ActiveUS20050075196A1High reboundImprove flight performanceGolf ballsSolid ballsRare earthCarboxylic acid

A multi-piece solid golf ball has a solid core obtained by molding and vulcanizing a rubber composition which includes (A) a base rubber containing a polybutadiene synthesized using a rare-earth catalyst, (B) an unsaturated carboxylic acid and / or a metal salt thereof, (C) an organic sulfur compound, (D) an inorganic filler and (E) an organic peroxide. The core is enclosed within a mantle of one or more layer which is made primarily of a thermoplastic resin and has a Durometer D hardness of 30 to 70. The mantle is enclosed within a cover which is made primarily of a thermoplastic polyurethane and which has a Durometer D hardness of 40 to 60 that is lower than the Durometer D hardness of the outermost layer of the mantle. This construction provides the golf ball with an outstanding rebound.

Owner:BRIDGESTONE SPORTS

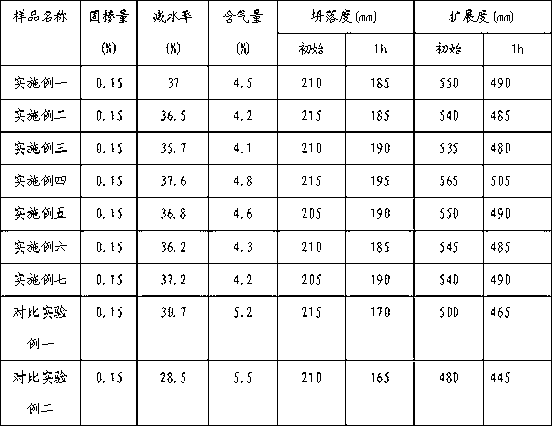

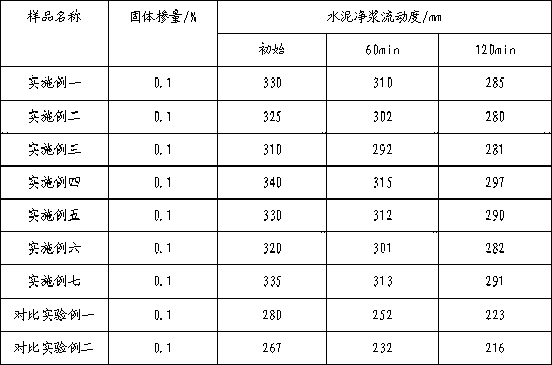

Polycarboxylic acid water reducing agent, preparation method and application thereof

The invention relates to a polycarboxylic acid water reducing agent, a preparation method and an application thereof, and belongs to the technical field of concrete additives. The polycarboxylic acid water reducing agent is prepared by using industrializedly produced isobutenol polyether or isoamylenol polyether with relatively good performances as a monomer A, unsaturated carboxylic acid, unsaturated acid anhydride or unsaturated ester as a monomer B and unsaturated sulfonic acid and salts thereof as a monomer C, according to a water reducing agent functional group theory and a polycarboxylic acid water reducing agent molecule design theory; and co-polymerizing the monomer A, B and C. A polycarboxylic acid water reducing agent product is obtained in a water solution via a one-step method, under initiation of a redox initiation system, by introducing carboxyls or ester groups having the functions of delayed coagulation and slump resistance, and the sulfonic acid groups having high water reducing effect into the molecular structure of the water reducing agent and controlling a material ratio and material-feeding modes. Besides, cost can be further reduced by selecting a proper redox system to make the polymerization carried out at a low temperature. The method is suitable for industrialize production.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

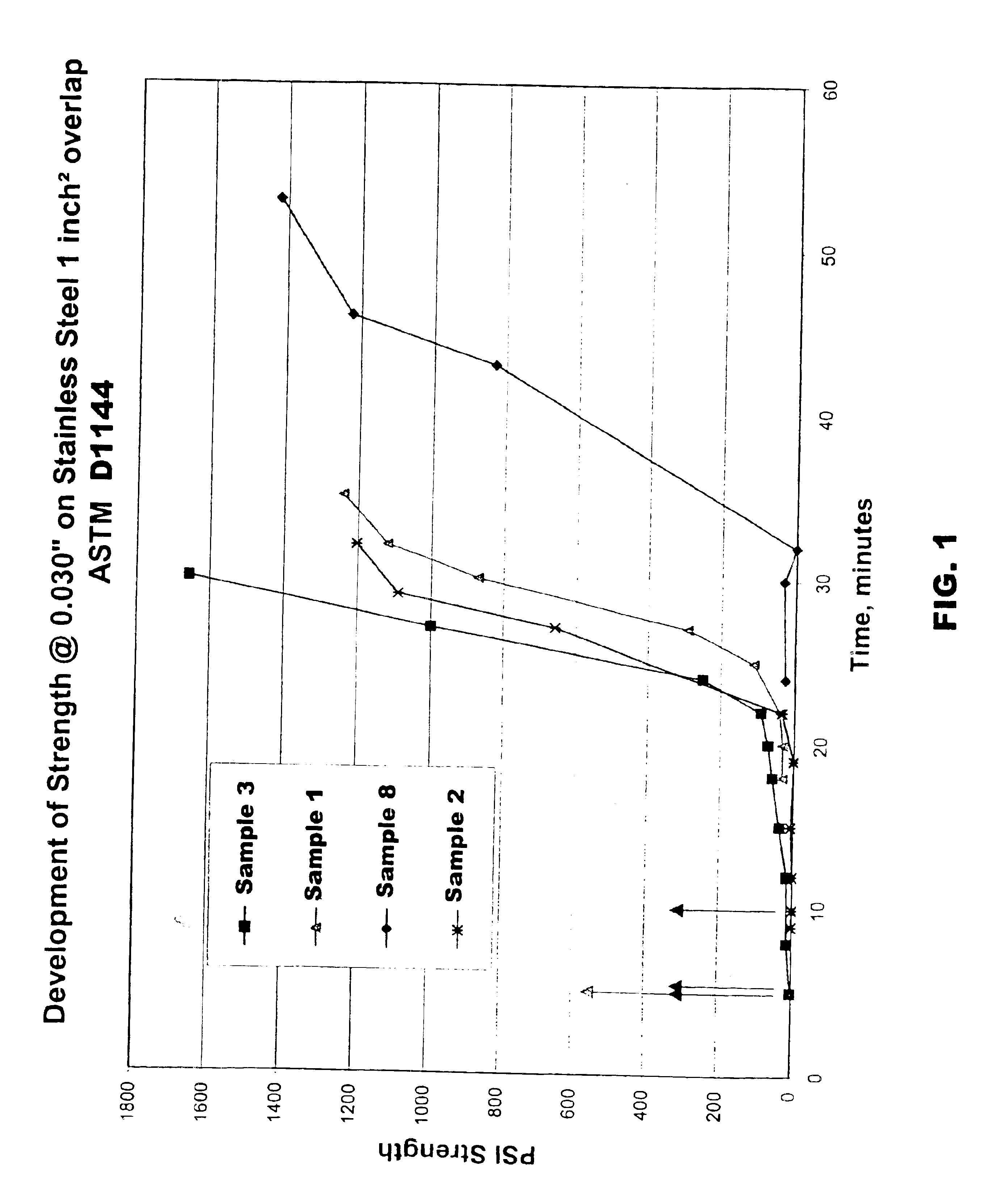

Two-part structural adhesive systems and laminates incorporating the same

InactiveUS6869497B2Improve handlingExtended opening timeSynthetic resin layered productsEster polymer adhesivesMolybdateAdhesive

A two-part adhesive systems exhibiting improved fixture and open times are disclosed. In one embodiment, the system includes (a) an adhesive part being a mixture formed from (I) an ethylenically unsaturated monomer, (II) a metal molybdate, (III) a metal salt of an ethylenically unsaturated carboxylic acid in an amount less than 3 weight percent, and (IV) an ethylenically unsaturated carboxylic acid, and (b) an activator part which includes a free radical generator. In another embodiment, the system includes the above-described adhesive part substantially free of a metal salt of an ethylenically unsaturated carboxylic acid. Curable adhesives and laminates prepared with the two-part system are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com