Method for preparing functional nylon 6 fiber based on melt direct spinning technology

A melt direct spinning and functionalization technology, applied in the field of nylon materials, can solve the problems of low polymer number average molecular weight, oligomer control, slow reaction speed, etc., to improve melt quality, reduce oligomer content, The effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

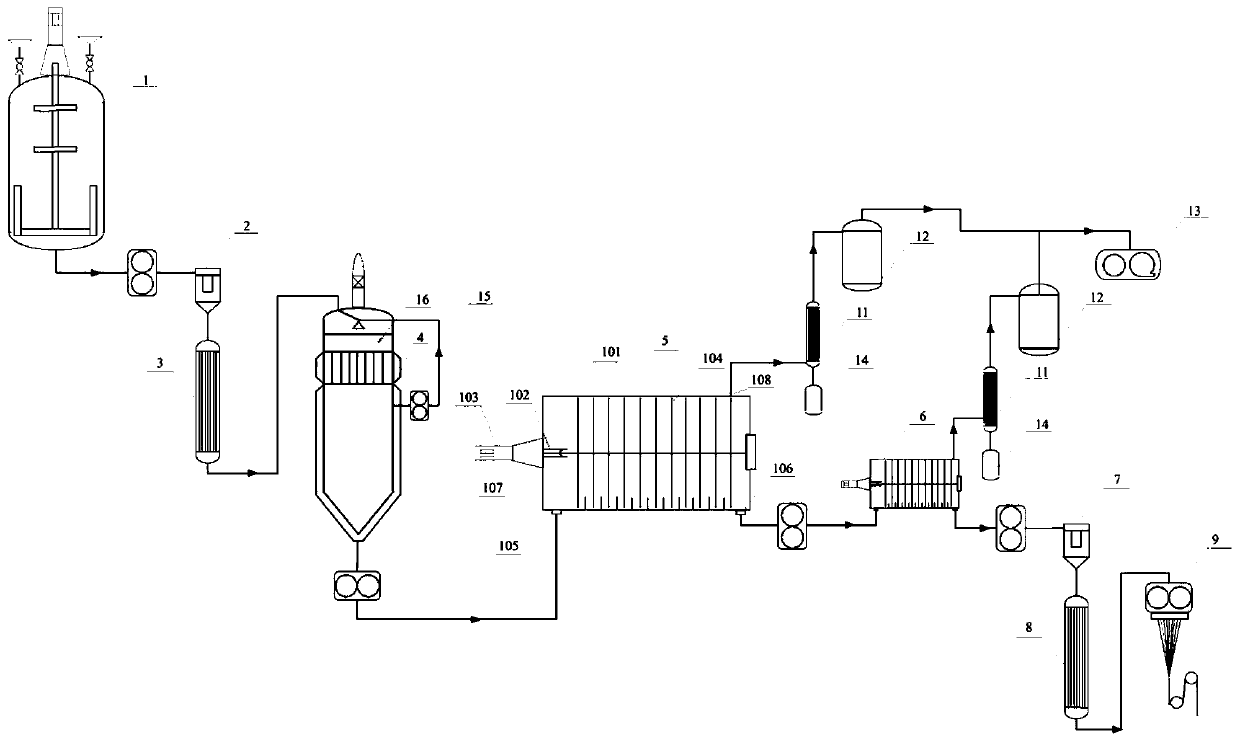

Method used

Image

Examples

Embodiment 1

[0087] The first step: at a temperature of 75°C, caprolactam, HOOC (CH 2 ) 7 COOH, deionized water, zinc oxide and NH 2 (CH 2 ) 4 COOH was mixed in proportion, and stirred for 40min under the condition of mechanical stirring (1000r / min); wherein relative to caprolactam, the amount of deionized water added was 1.8wt%, HOOC (CH 2 ) 7 The amount of COOH added is 0.14wt%, NH 2 (CH 2 ) 4 The addition of COOH is 0.56wt%, and the addition of zinc oxide is 2wt%;

[0088] The second step: After the mixture obtained in the first step is heated by the melt pump and the pre-heater, it is transported to the ring-opening kettle for ring-opening reaction. The polymerization temperature is controlled at 210 ° C, and the polymerization pressure is controlled at 1.2 MPa; the reaction time is The 0.6h prepolymer is transported to the top of the tower by a melt pump, mixed with fresh caprolactam, and the reflux rate is 1.6wt% of the caprolactam flow rate. When the following conditions ar...

Embodiment 2

[0095] The first step: at a temperature of 130°C, caprolactam, HOOC (CH 2 ) 5 COOH, deionized water, zinc borate, and NH 2 (CH 2 ) 6 COOH was mixed in proportion, and stirred for 30min under the condition of mechanical stirring (200r / min); wherein relative to caprolactam, the amount of deionized water added was 4.8wt%, HOOC (CH 2 ) 5 The amount of COOH added is 0.15wt%, NH 2 (CH 2 ) 6 The addition of COOH is 0.05wt%, and the addition of zinc borate is 5wt%;

[0096] The second step: After the mixture obtained in the first step is heated by the melt pump and the pre-heater, it is transported to the ring-opening kettle for ring-opening reaction. The polymerization temperature is controlled at 248 ° C, and the polymerization pressure is controlled at 0.08 MPa; the reaction time is The 1.1h prepolymer is transported to the top of the tower by a melt pump, mixed with fresh caprolactam, and the reflux rate is 0.5wt% of the flow rate of caprolactam. When the following condit...

Embodiment 3

[0103] The first step: at a temperature of 98°C, caprolactam, HOOC (CH 2 ) 6 COOH, deionized water, titanium dioxide and NH 2 (CH 2 ) 4 COOH was mixed in proportion, and stirred for 50min under the condition of mechanical stirring (150r / min); wherein relative to caprolactam, the amount of deionized water added was 2.5wt%, HOOC (CH 2 ) 6 The amount of COOH added is 0.33wt%, NH 2 (CH 2 ) 4 The addition of COOH is 0.3wt%, and the addition of titanium dioxide is 1.5wt%;

[0104] The second step: After the mixture obtained in the first step is heated by the melt pump and the pre-heater, it is transported to the ring-opening kettle for ring-opening reaction. The polymerization temperature is controlled at 238 ° C, and the polymerization pressure is controlled at 0.8 MPa; the reaction time is The 0.9h prepolymer is transported to the top of the tower by a melt pump, mixed with fresh caprolactam, and the reflux rate is 0.9wt% of the flow rate of caprolactam. When the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com