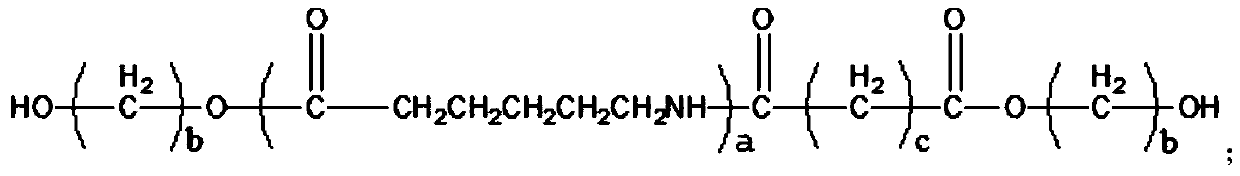

A kind of bio-based degradable polyamide 6 copolymer and preparation method thereof

A bio-based, polyamide technology, applied in melt spinning, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve problems such as uneven distribution of fiber strength, inability to crystallize copolymers, and broken filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A preparation method of bio-based degradable polyamide 6 copolymer, the specific steps are as follows:

[0070] (1) At a temperature of 75°C, polyamide 66 salt and NH 2 (CH 2 ) 4 A mixture of COOH (mass ratio 1:1), caprolactam, HOOC (CH 2 ) 2 COOH and deionized water were mixed with mechanical stirring to obtain a mixture, HOOC(CH 2 ) 2 The amount of COOH added is 11wt% of the added amount of caprolactam, the amount of deionized water added is 2wt% of the added amount of caprolactam, polyamide 66 salt and NH 2 (CH 2 ) 4 The addition amount of the mixture of COOH is 0.2wt% of the addition amount of caprolactam, the rotating speed of mechanical stirring is 80r / min, and the time is 10min;

[0071] (2) Prepolymerize the mixture to obtain a dibasic acid-terminated polyamide 6 prepolymer. The temperature of the prepolymerization is 220° C., the pressure is 0.5 MPa, the atmosphere is nitrogen, and the termination condition is polyamide 6 prepolymer. The number average...

Embodiment 2

[0078] A preparation method of bio-based degradable polyamide 6 copolymer, the specific steps are as follows:

[0079] (1) At a temperature of 100°C, mix polyamide 66 salt with NH 2 (CH 2 ) 6 A mixture of COOH (mass ratio 1:1), caprolactam, HOOC (CH 2 ) 3 COOH and deionized water were mixed with mechanical stirring to obtain a mixture, HOOC(CH 2 ) 3 The amount of COOH added is 17wt% of the added amount of caprolactam, the amount of deionized water added is 2.5wt% of the added amount of caprolactam, polyamide 66 salt and NH 2 (CH 2 ) 6 The addition amount of the mixture of COOH is 0.8wt% of the addition amount of caprolactam, the rotating speed of mechanical stirring is 150r / min, and the time is 30min;

[0080] (2) Prepolymerize the mixture to obtain a dibasic acid-terminated polyamide 6 prepolymer. The temperature of the prepolymerization is 280° C., the pressure is 1.3 MPa, the atmosphere is nitrogen, and the termination condition is polyamide 6 prepolymer. The numbe...

Embodiment 3

[0087] A preparation method of bio-based degradable polyamide 6 copolymer, the specific steps are as follows:

[0088] (1) At a temperature of 85°C, caprolactam, HOOC (CH 2 ) 5 COOH, deionized water and polyamide 66 salt were mixed with mechanical stirring to obtain a mixture, HOOC(CH 2 ) 5 The addition amount of COOH, deionized water and polyamide 66 salt is 5wt%, 4.5wt% and 0.2wt% of the added amount of caprolactam, respectively, the speed of mechanical stirring is 100r / min, and the time is 60min;

[0089] (2) Prepolymerize the mixture to obtain a dibasic acid-terminated polyamide 6 prepolymer. The temperature of the prepolymerization is 240° C., the pressure is 2 MPa, the atmosphere is nitrogen, and the termination condition is polyamide 6 prepolymerization The number average molecular weight of the body is 2000, and the terminal amino group content is 0.8mmol / kg;

[0090] (3) The mixture of bio-based propylene glycol and bio-based pentanediol (mass ratio is 1:1), polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com