Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4009 results about "Chain segment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain Segment. A chain segment is a conceptual object that may be usefully related to the length over which the polymer chain has a persistent conformation.

Oxygen scavenging condensation copolymers for bottles and packaging articles

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

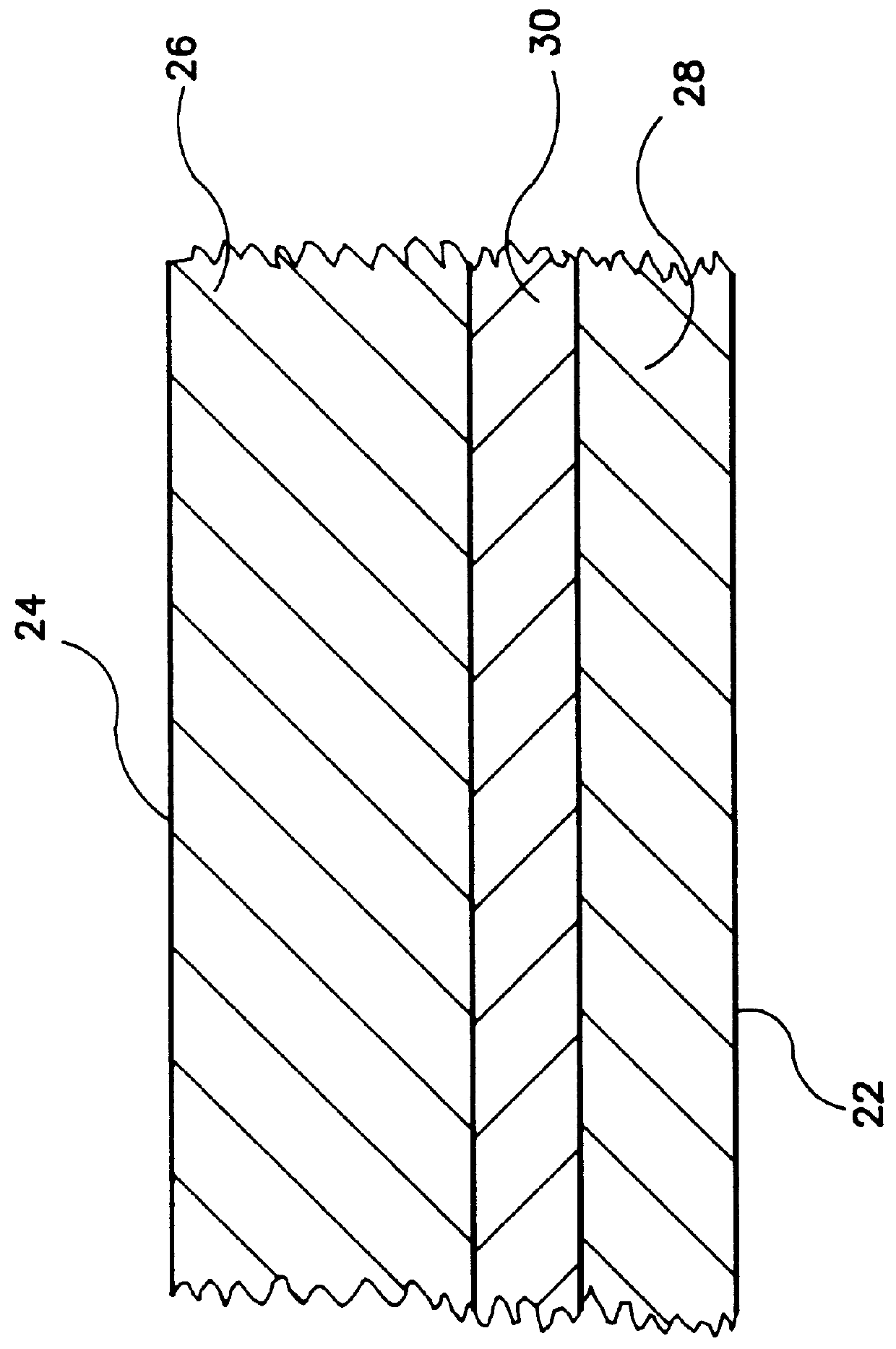

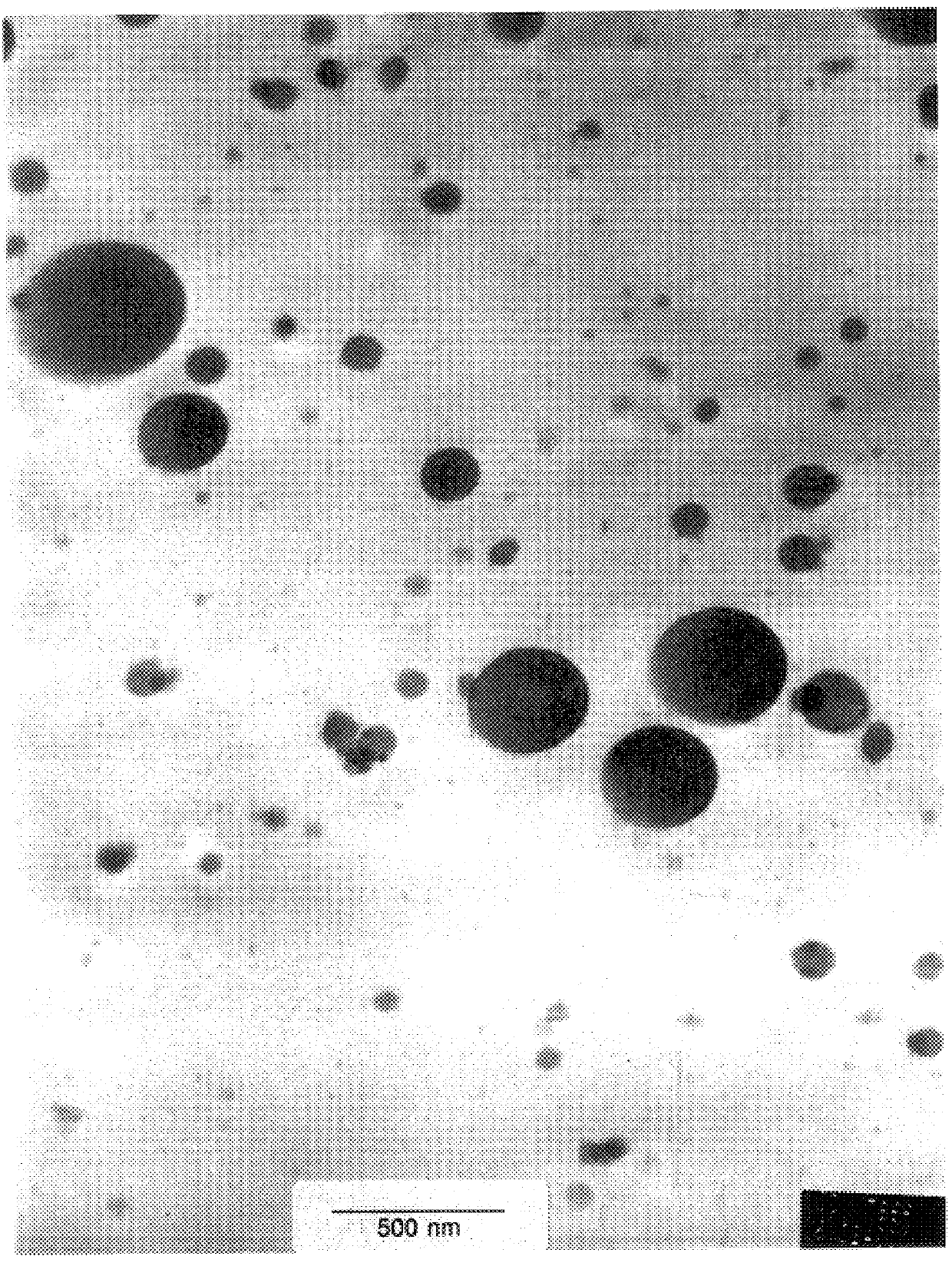

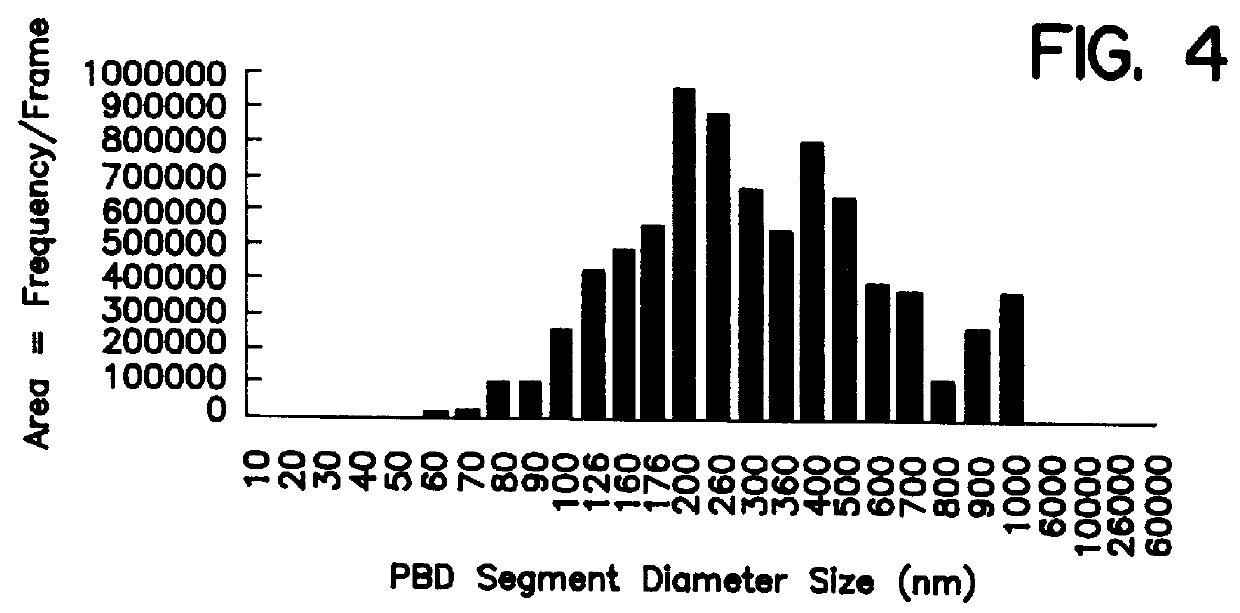

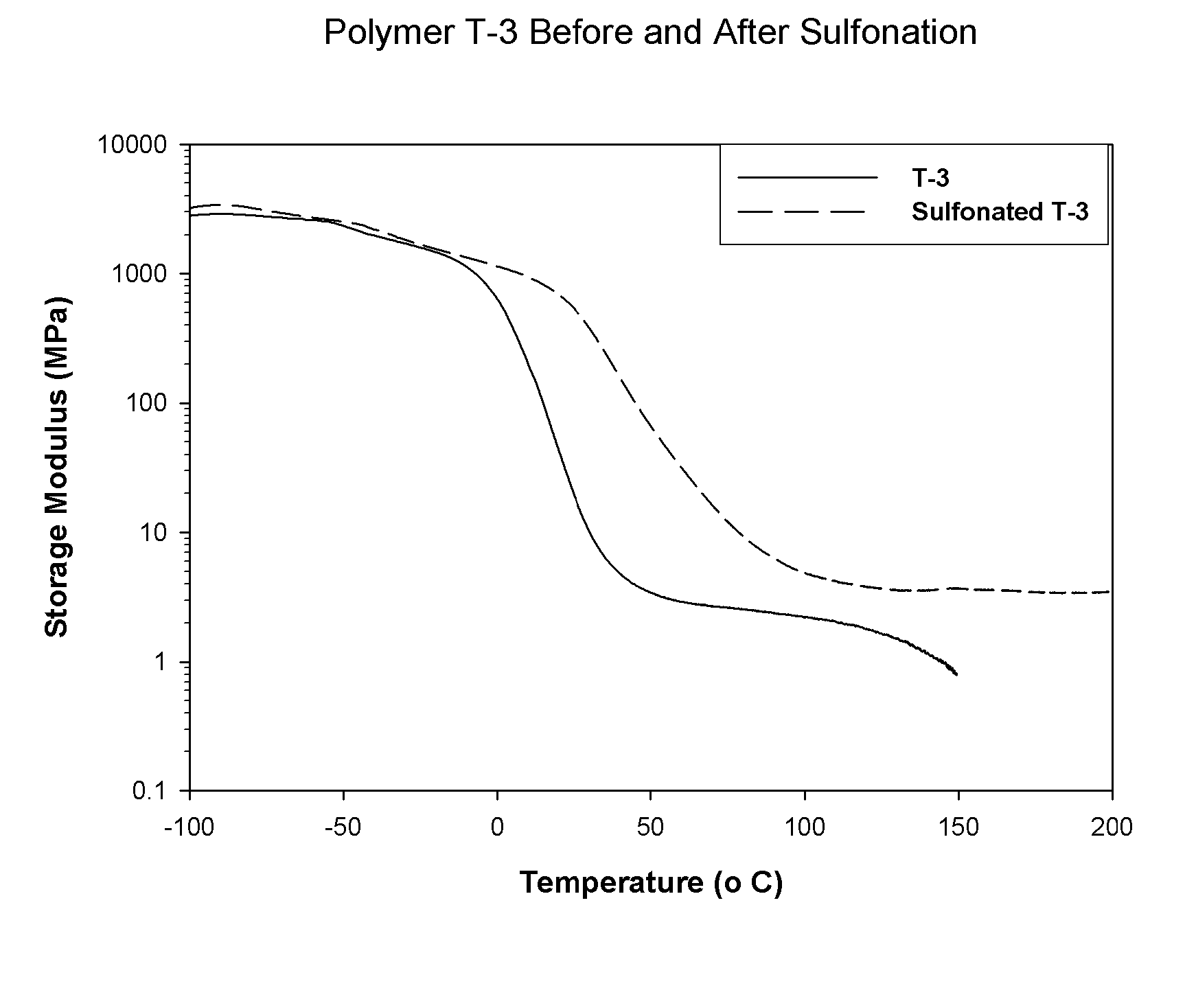

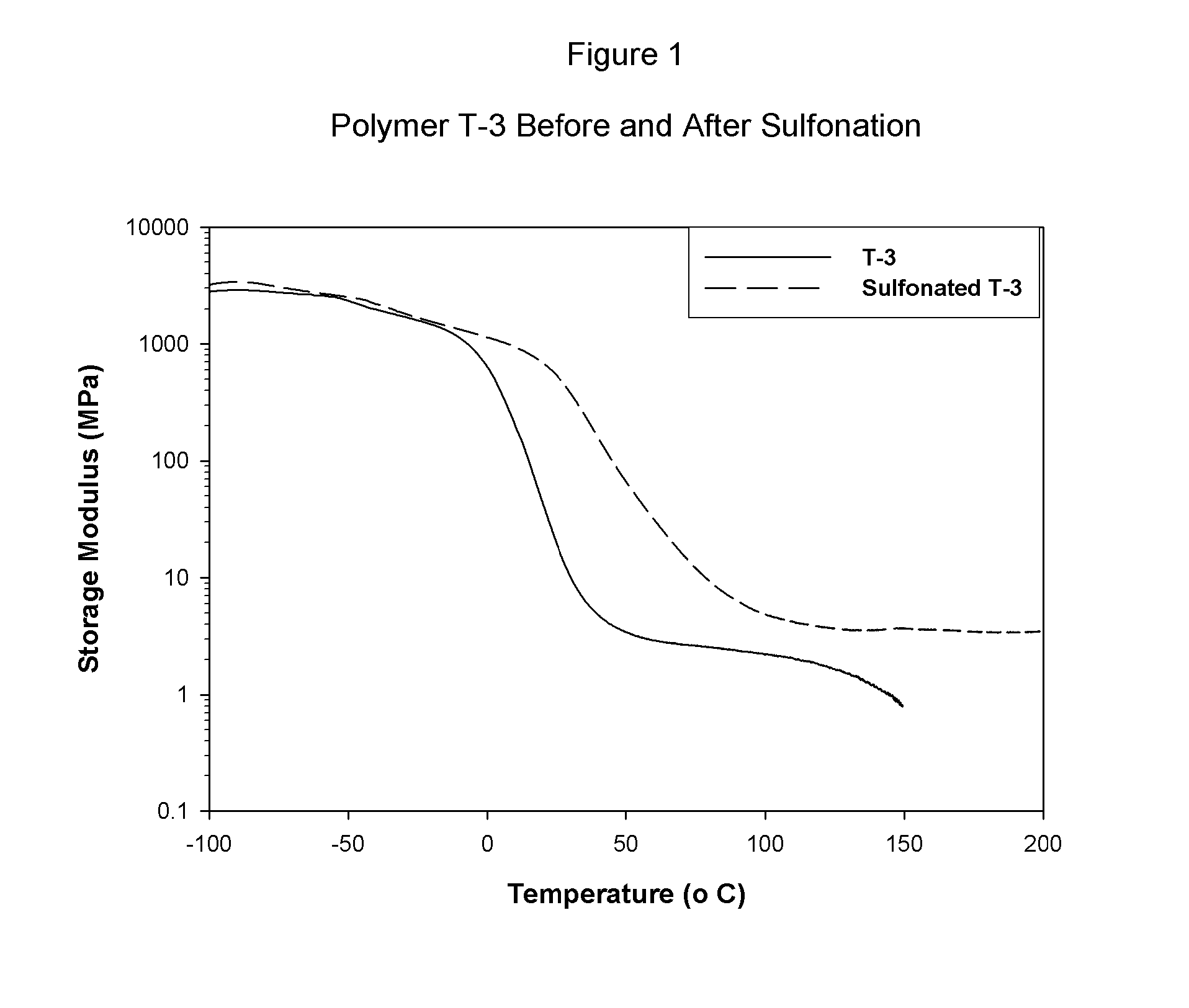

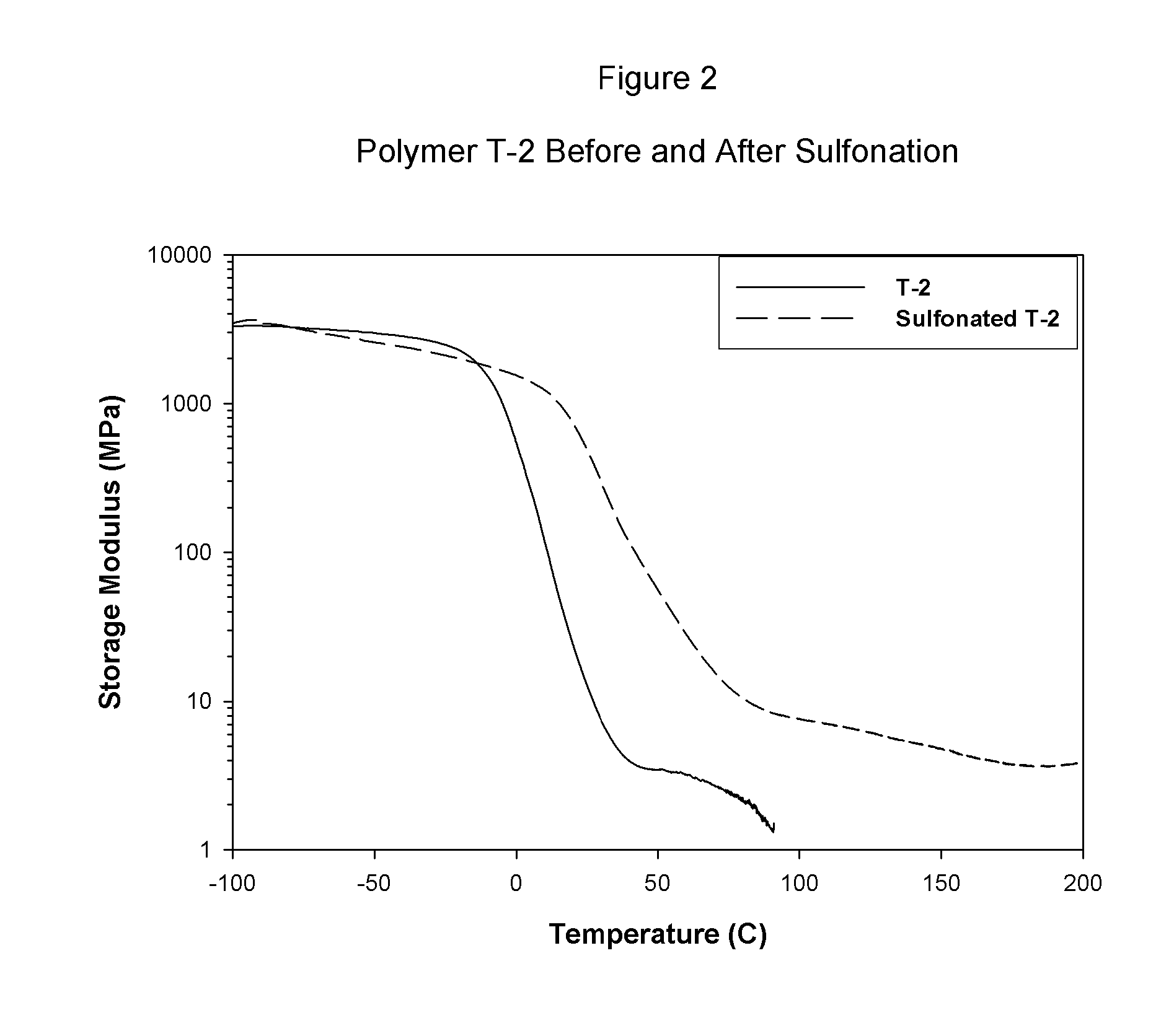

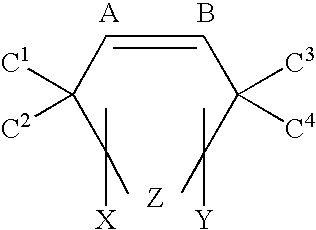

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

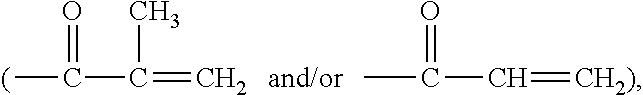

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

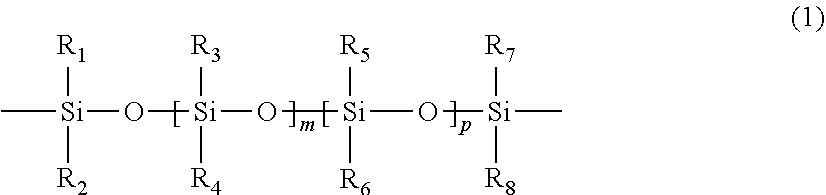

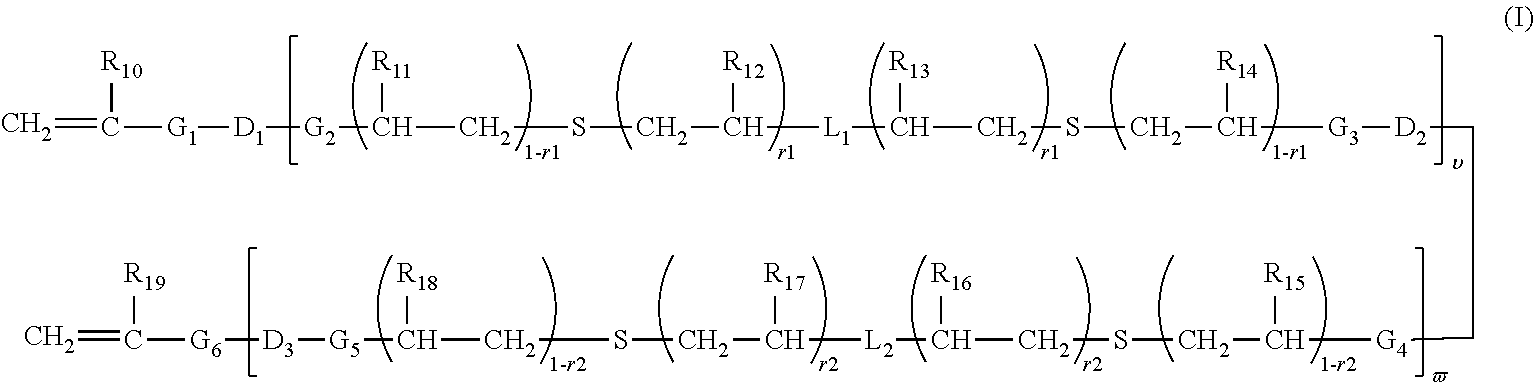

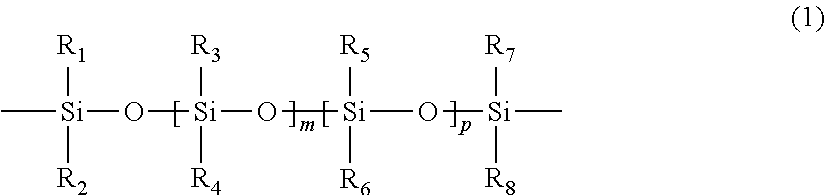

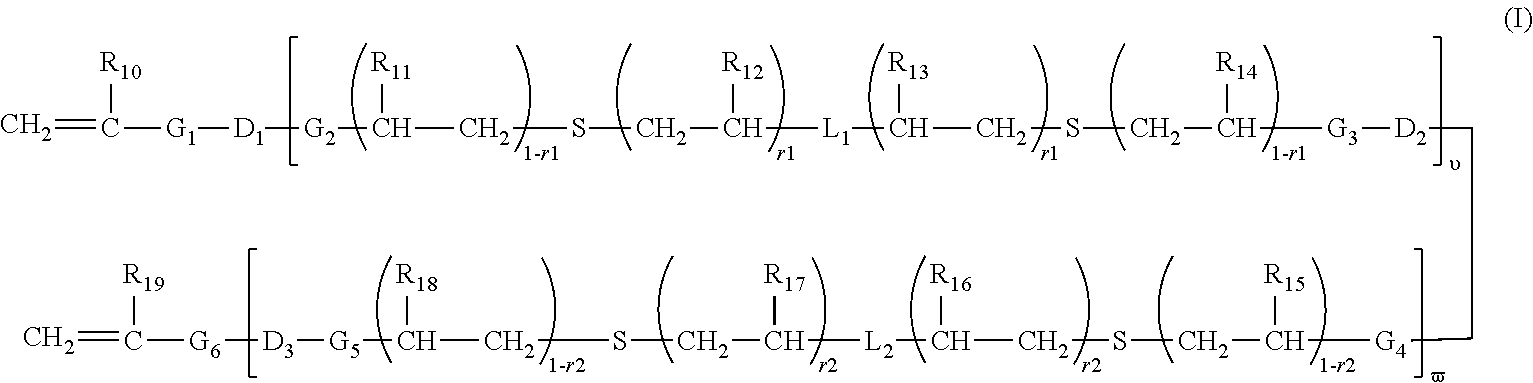

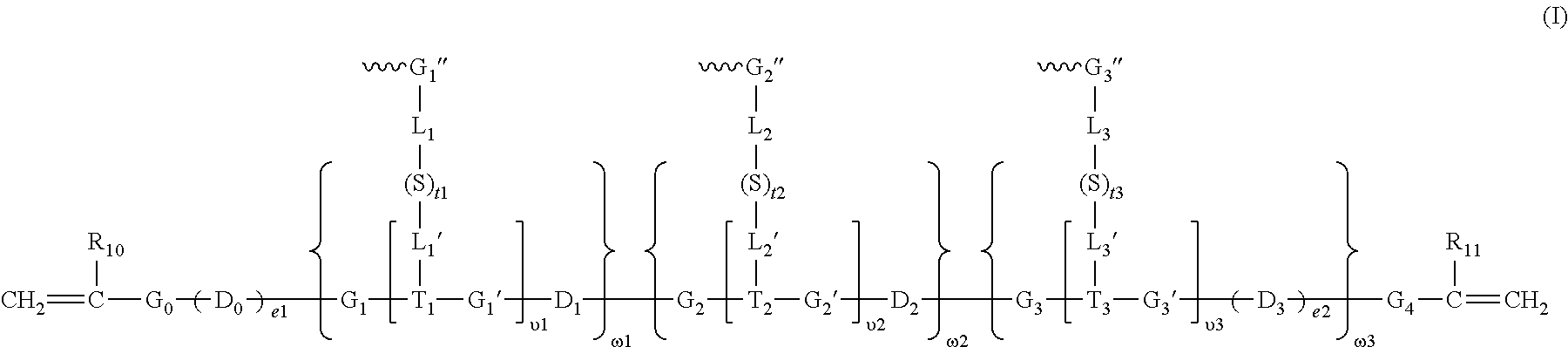

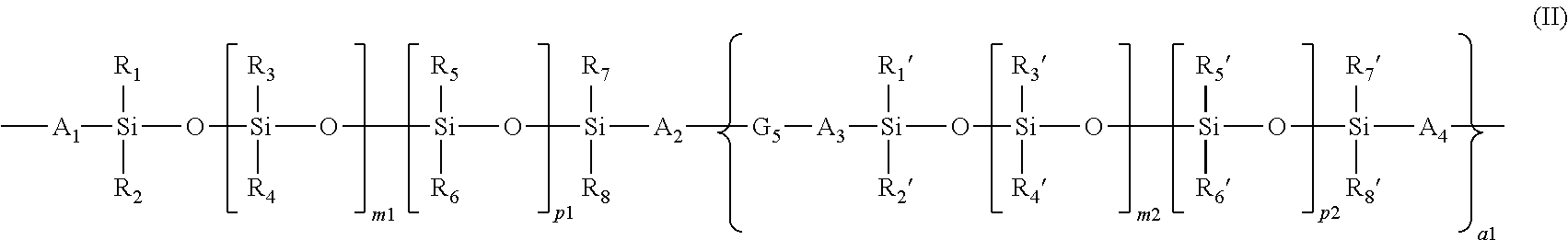

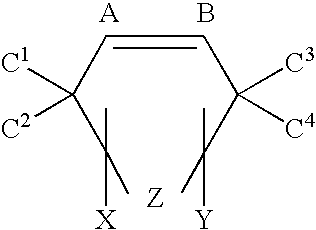

Polymerizable chain-extended polysiloxanes with pendant hydrophilic groups

The invention provide a class of chain-extended polysiloxane crosslinkers which comprises (1) at least two polysiloxane segments, wherein each pair of adjacent polysiloxane segments is linked by one divalent organic radical which includes at least one pendant hydrophilic group (hydroxyl and / or carboxyl groups) or at least one dangling hydrophilic polymer chain and a di-thioether linkage —S-DR-S— in which DR is a divalent organic radical; and (2) two terminal ethylenically unsaturated groups. The present invention is also related to a polymer comprising crosslinking units derived from chain-extended polysiloxane crosslinker of the invention and to ophthalmic lenses comprising such a polymer.

Owner:ALCON INC

Polypropylene block-copolymer resin and process for producing it

Polypropylene block-copolymer resin exhibiting high melt tension and improved moldability with balanced stiffness and impact resistance may be molded at high speed into large-sized articles, including, stretched films, with good appearance and resistance to deformation. The block copolymer includes a higher molecular weight polypropylene segment, a lower molecular weight polypropylene segment and an ethylene alpha-olefin copolymer segment. When subjected to dissolution fractionation m paraxylene, a large proportion is insoluble at 23° C. but soluble at 135° C., and a smaller portion is soluble at 23° C. The block copolymer has a melt flow rate of 0.01 to 5 g / 10 min at 230 C. (2.16 kg) and a molecular weight distribution Mw / Mn of 6-20 and Mz / Mw of at least 3.5. A continuous multistage polymerization may be used to form the block copolymer.

Owner:PRIME POLYMER CO LTD

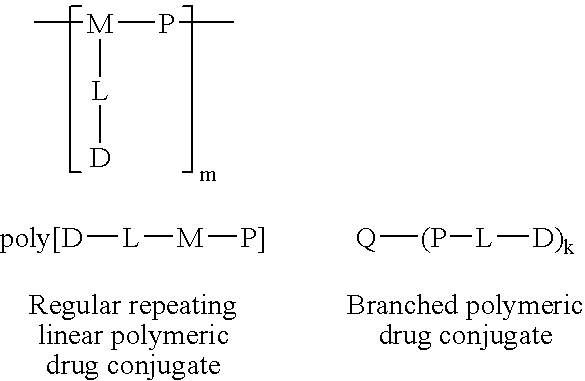

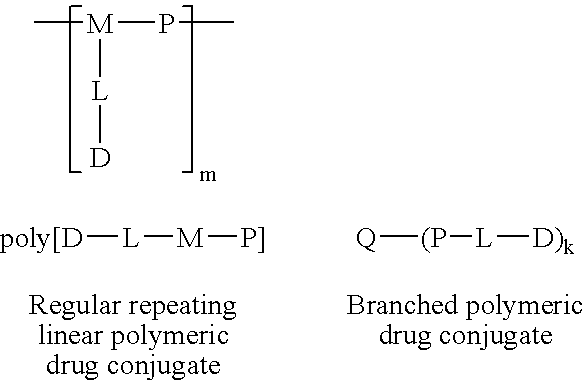

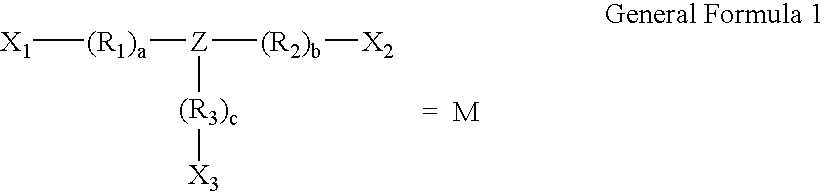

Polymeric conjugates for tissue activated drug delivery

InactiveUS20040228831A1Simple methodAbsorption bioactivityPeptide/protein ingredientsPharmaceutical non-active ingredientsChemical MoietyActive agent

The present invention relates to a polymeric drug conjugate with one or more biologically active agents conjugated via an enzymatically cleavable linker to either a regular repeating linear unit comprising a water soluble polymer segment and a multifunctional chemical moiety, or a branched polymer comprising two or more water soluble polymer segments each bound to a common multifunctional chemical moiety, as well as to methods of making such conjugates. The present invention is also directed to pharmaceutical compositions comprising such conjugates and to the use of such conjugates to treat pathological conditions.

Owner:VECSTREETCARED

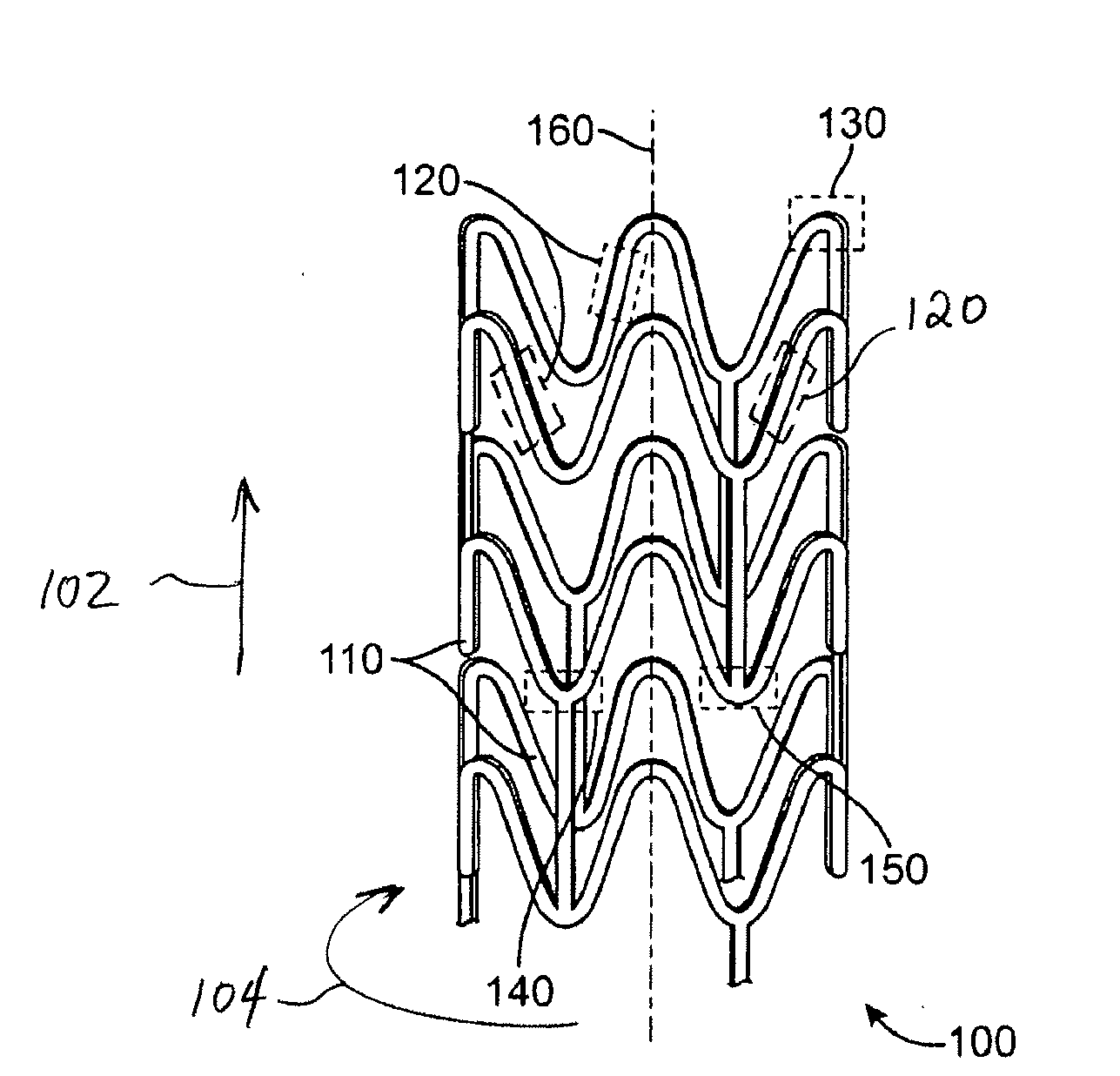

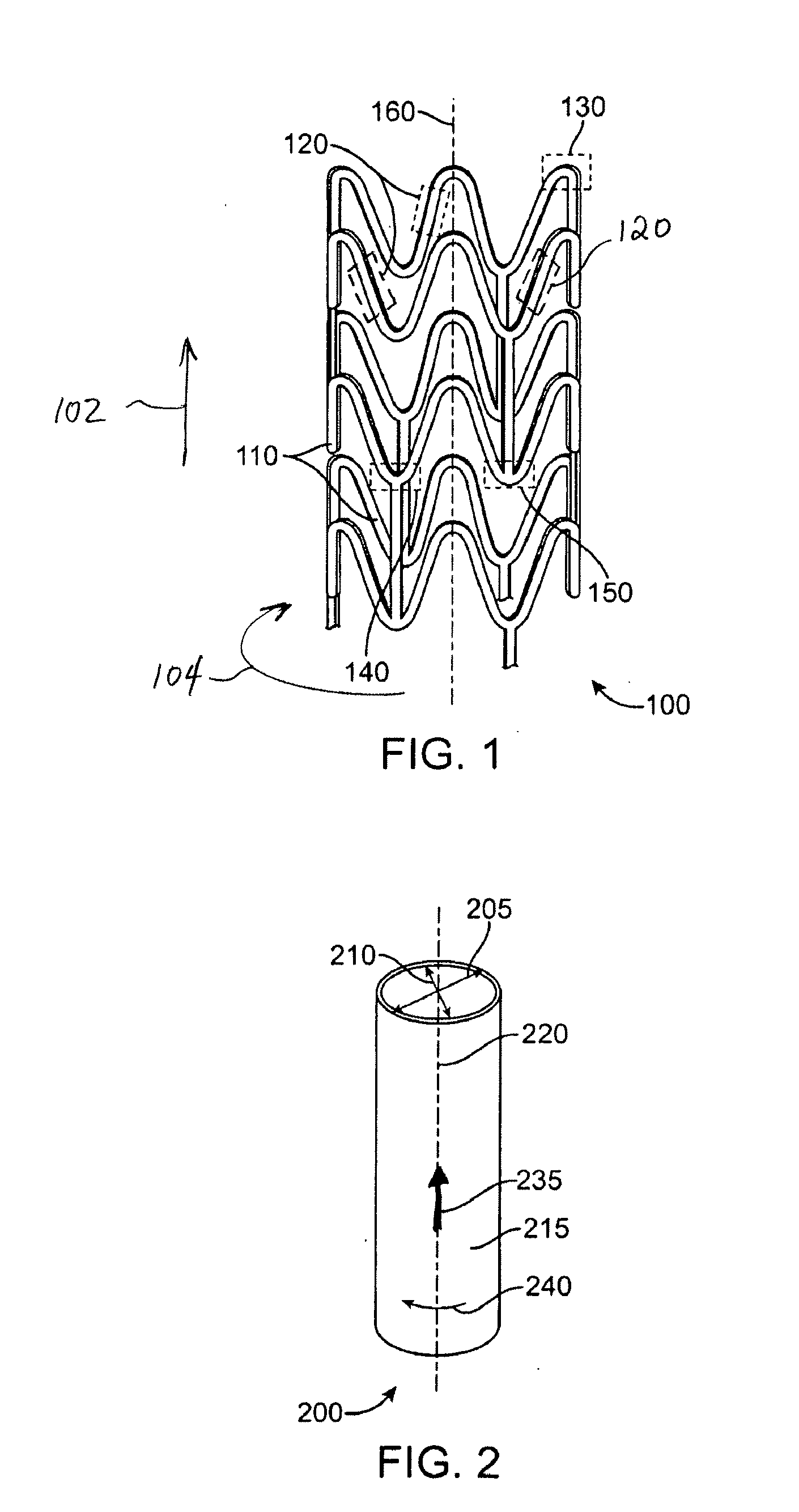

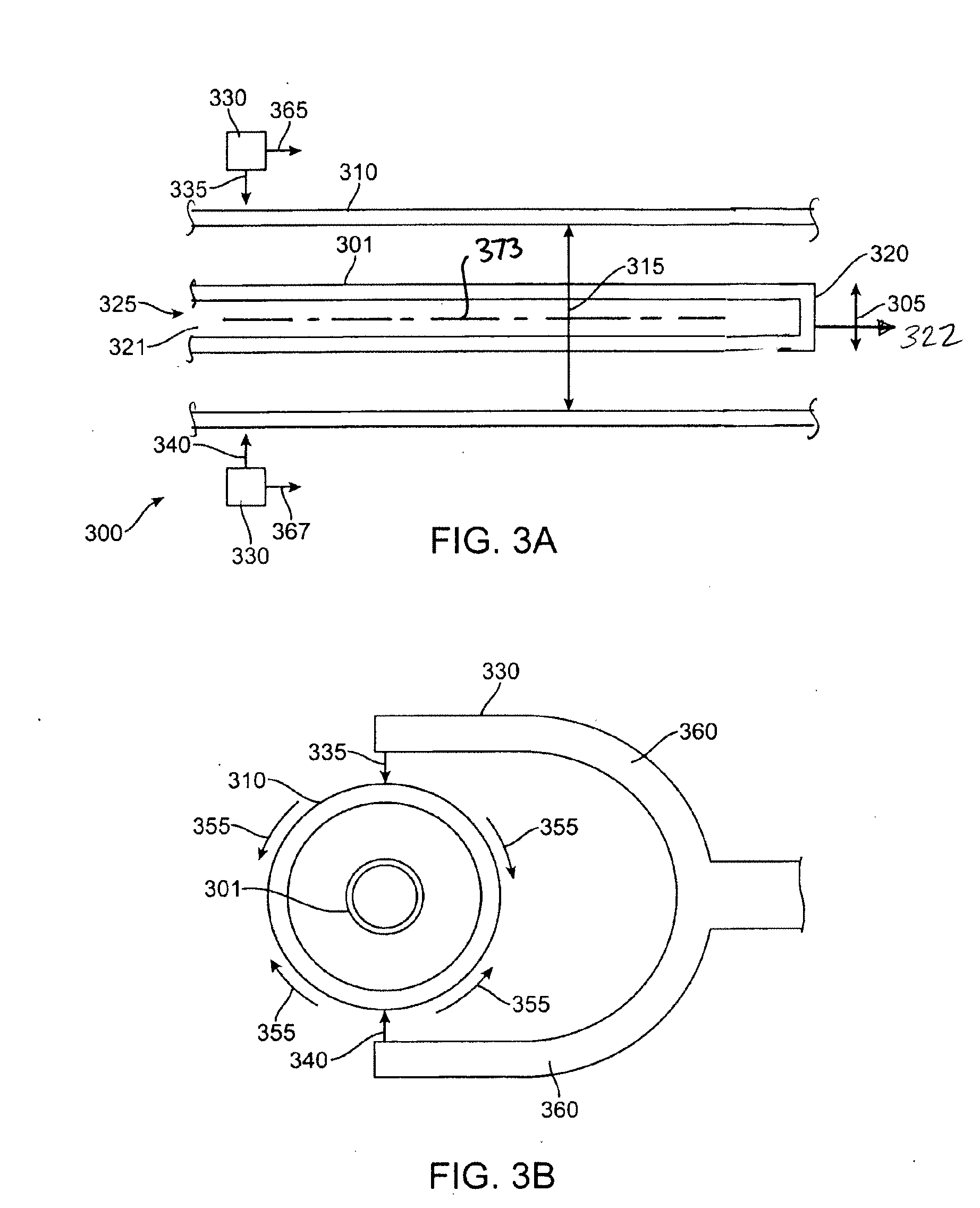

Polymeric Stent and Method of Making Same

A stent may be formed from a PLLA tubular polymer construct that is deformed in a blow mold. A desirable polymer morphology resulting in improved stent performance is obtained with a selected radial axial expansion ratio from about 20% to about 70%, a selected radial expansion ratio from about 400% to about 500%, a selected axial rate of deformation propagation at or about 0.3 mm / minute, a selected expansion pressure at or about 130 psi, and a selected expansion temperature that does not exceed 200 deg F. The tubular polymer construct may also be made of PLGA, PLLA-co-PDLA, PLLD / PDLA stereocomplex, and PLLA-based polyester block copolymer containing a rigid segment of PLLA or PLGA and a soft segment of PCL or PTMC.

Owner:ABBOTT CARDIOVASCULAR

Polymerizable chain-extended polysiloxanes with pendant hydrophilic groups

The invention provide a class of chain-extended polysiloxane crosslinkers which comprises (1) at least two polysiloxane segments, wherein each pair of adjacent polysiloxane segments is linked by one divalent organic radical which includes at least one pendant hydrophilic group (hydroxyl and / or carboxyl groups) or at least one dangling hydrophilic polymer chain and a di-thioether linkage —S-DR—S— in which DR is a divalent organic radical; and (2) two terminal ethylenically unsaturated groups. The present invention is also related to a polymer comprising crosslinking units derived from chain-extended polysiloxane crosslinker of the invention and to ophthalmic lenses comprising such a polymer.

Owner:ALCON INC

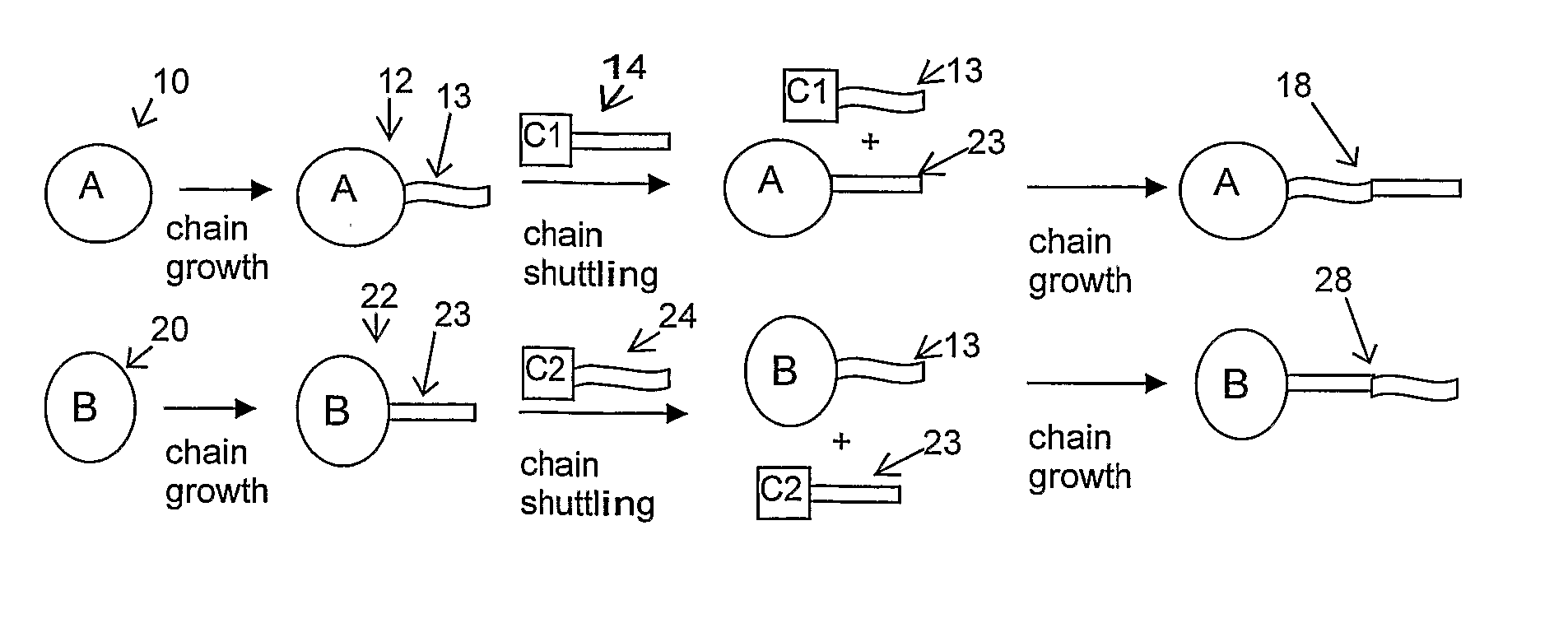

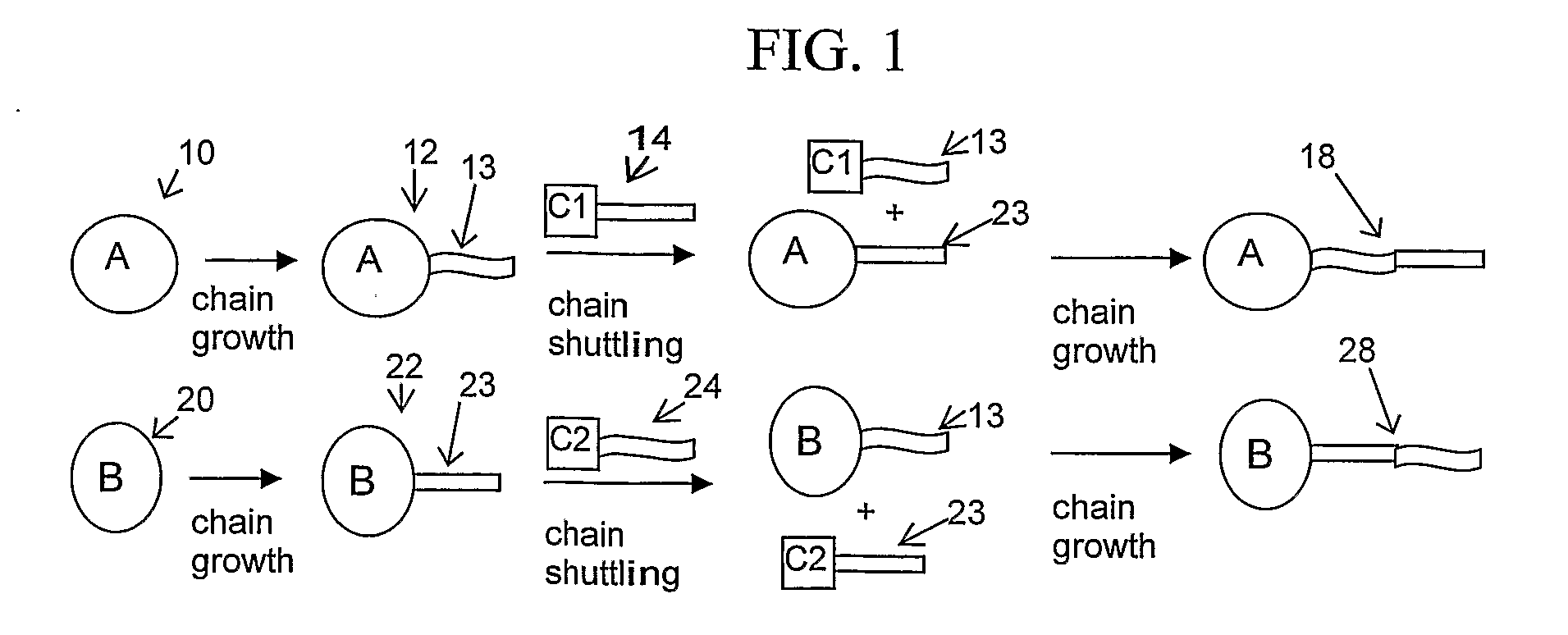

Catalyst composition comprising shuttling agent for ethylene copolymer formation

ActiveUS20070167315A1High efficiencyImprove efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationChain walking

A composition for use in forming a multi-block copolymer from a single polymerizable monomer, said copolymer containing therein two or more segments or blocks differing in branching index, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first olefin polymerization catalyst, (B) a second olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, at least one of catalyst (A) or catalyst (B) being capable of forming a branched polymer by means of chain walking or reincorporation of in situ formed olefinic polymer chains, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

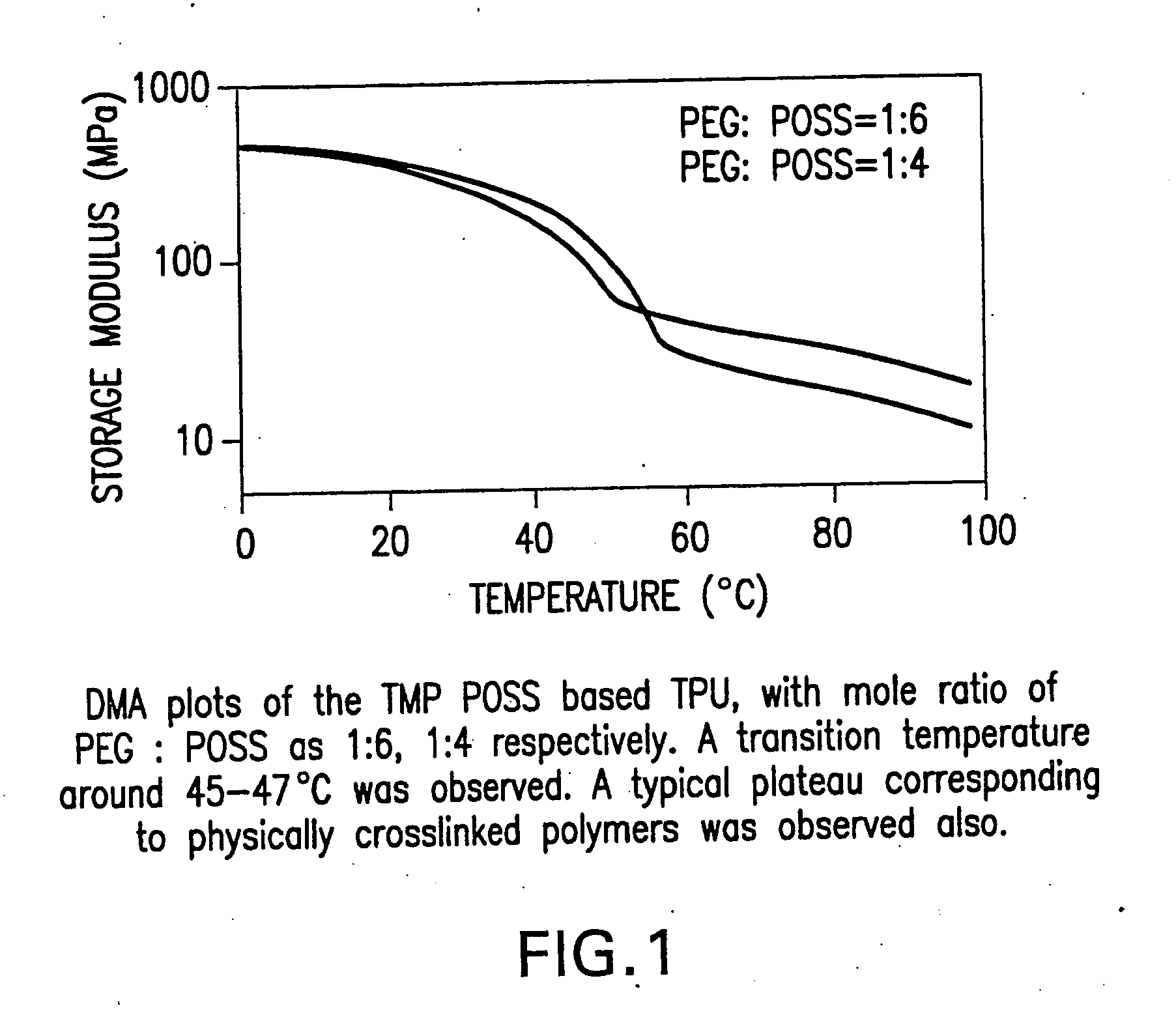

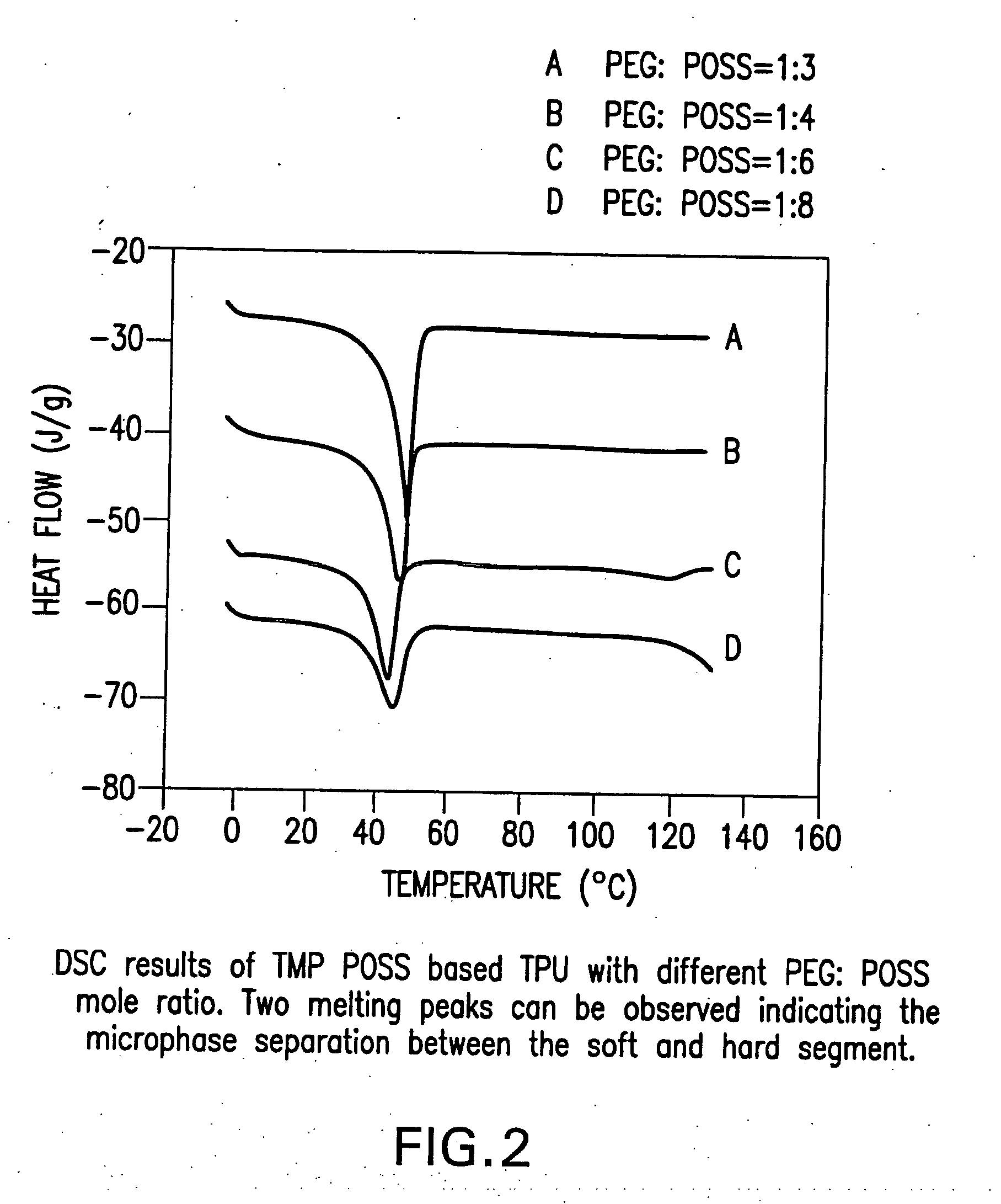

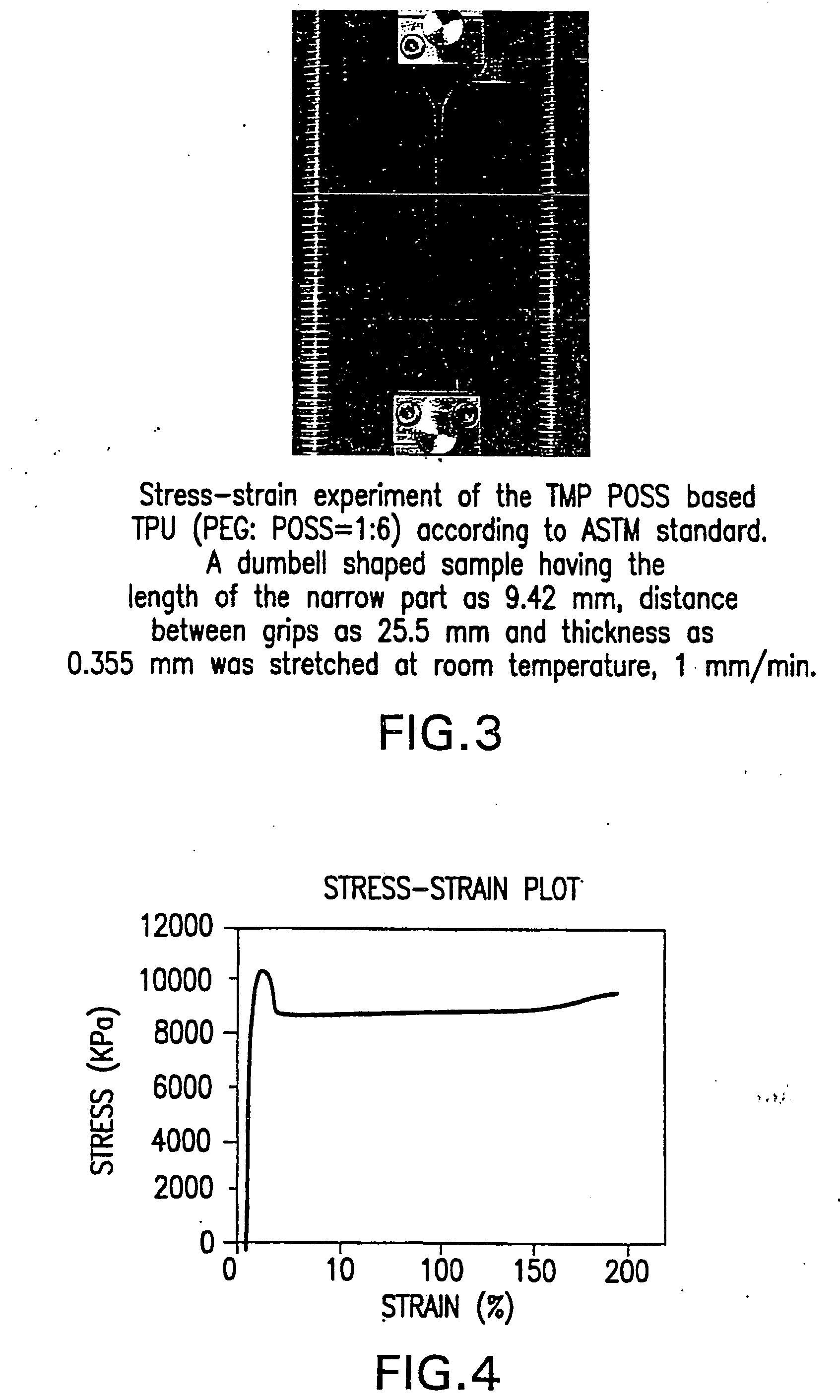

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Olefin block copolymers, processes for producing the same and uses thereof

Olefin block copolymers (A-1) are disclosed represented by the formula (I) PO1-g1-B1 . . . (I) wherein PO1 is a segment comprised of repeating units derived from an olefin having 2 to 20 carbon atoms, g1 is an ester, ether, amide, imide, urethane, urea, silylether or carbonyl linkage, and B1 is a segment containing an unsaturated hydrocarbon or a hetero atom. The olefin block copolymers are suitable for uses in adhesives, various molded articles such as construction and civil engineering materials, automobile interior and exterior materials, gasoline tanks, electric and electronic parts, medical care and sanitation materials, materials of miscellaneous goods, resin materials having environmental degradation properties, films and sheets, modifiers and dispersions.

Owner:MITSUI CHEM INC

Chain-extended polysiloxane crosslinkers with dangling hydrophilic polymer chains

The invention provide a class of linear chain-extended polysiloxane crosslinkers which comprises two terminal ethylenically unsaturated groups, at least two polysiloxane segments, and dangling hydrophilic polymer chains each covalently attached to a divalent organic radical separating each pair of adjacent polysiloxane segments. The present invention is also related to a polymer comprising crosslinking units derived from chain-extended polysiloxane crosslinker of the invention and to ophthalmic lenses comprising such a polymer.

Owner:ALCON INC

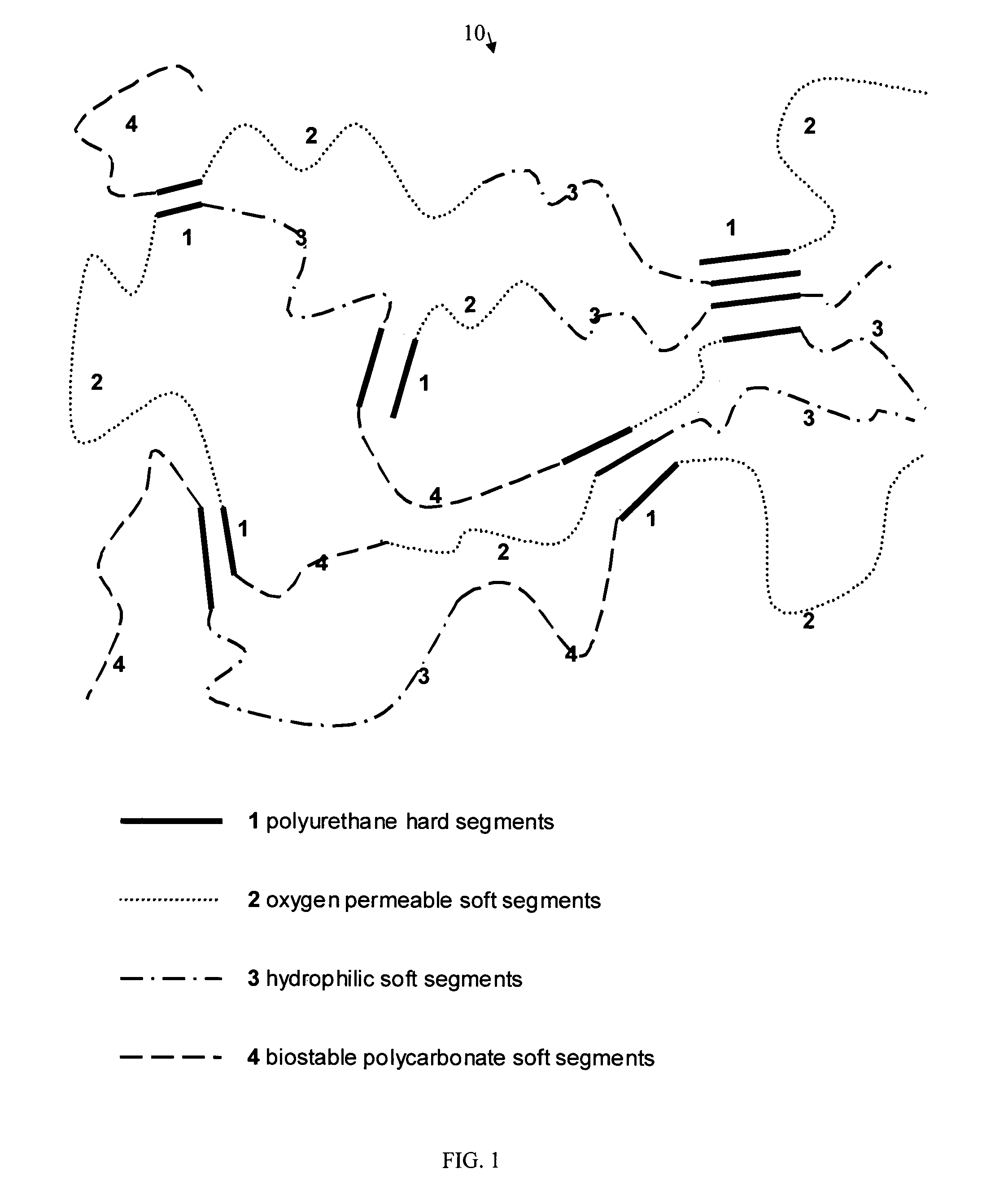

Permselective structurally robust membrane material

ActiveUS7157528B2Easy to understandWeaken energyImmobilised enzymesBioreactor/fermenter combinationsOxygenSoft segment

Owner:THE POLYMER TECH GROUP

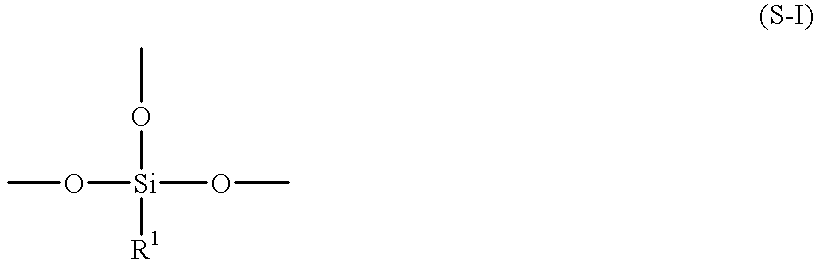

Process for preparing aqueous resin, aqueous curable resin composition, aqueous paint, and method for formation of coating therefrom

InactiveUS6268440B1Good storage stabilityImprove curing effectGroup 4/14 element organic compoundsFibre treatmentWater basedCarbon number

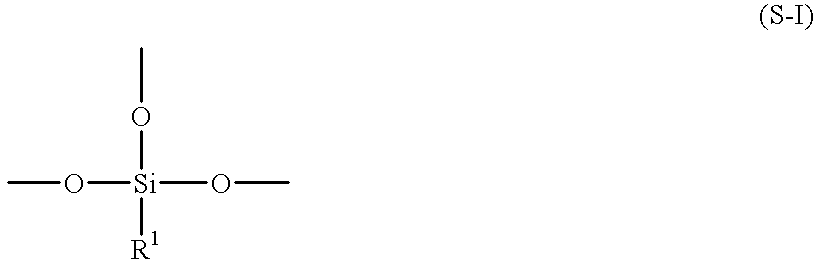

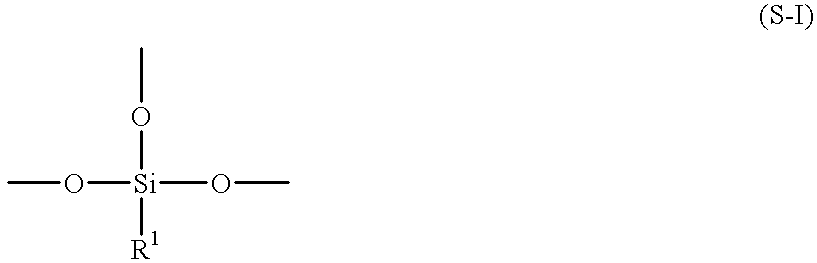

A water-base resin has both excellent storage stability and excellent curability at room temperature, the water base resin being obtained by mixing a composite resin (C) and a polysiloxane (D), bringing about a condensation reaction partially between them if necessary, and thereafter dispersing or dissolving the resulting mixture or partially condensed product into a water-base medium, wherein the composite resin (C) comprises a polysiloxane segment (A) and a polymer segment (B), the polysiloxane segment (A) having at least one silicon atom selected from the group consisting of a silicon atom bearing at least one organic group having a total carbon number of at least 3 together with at least one hydrolyzable group and / or at least one hydroxyl group, a silicon atom bearing one hydrolyzable group or one hydroxyl group together with two groups selected from the group consisting of methyl groups and ethyl groups, and a silicon atom bearing at least one triorganosiloxy group together with at least one hydrolyzable group and / or at least one hydroxyl group, and the polymer segment (B) having at least one type of hydrophilic group selected from the group consisting of an anionic group, a cationic group, and a non-ionic group, and wherein the polysiloxane (D) has a hydrolyzable group bonded to a silicon atom and / or a hydroxyl group bonded to a silicon atom, the polysiloxane (D) having a structure represented by the following structural formula (S-I) as an essential structural unit:(wherein R1 in the formula denotes a methyl group or an ethyl group). A water-base curable resin composition comprising the water-base resin as an essential component produces a cured material which possesses excellent resistance stain during outdoor exposure as well as excellent durability such as acid rain resistance and gloss retention during outdoor exposure.

Owner:DAINIPPON INK & CHEM INC

Biologically related substances modified by multifunctional H-type polyethylene glycol derivative

ActiveCN104530413ALow immunogenicityImprove distributionPharmaceutical non-active ingredientsFluorescencePolyethylene glycol

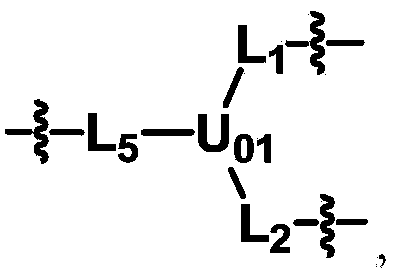

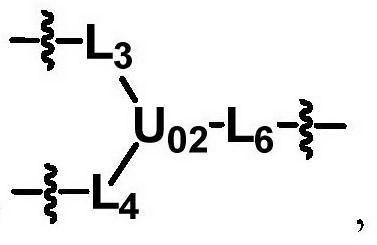

The invention discloses biologically related substances modified by a multifunctional H-type polyethylene glycol derivative. The derivative comprises a linear main axis LPEG and four PEG branched chains, and n1, n2, n3 and n4 are polymerization degrees of the branched chains, respectively; U1 and U2 are trivalent branching groups connecting the main axis LPEG with two PEG branched chains; F1 and F2 contain functional groups or their protected forms R01, and the number of R01 is one or more than one. Any linking group in the molecule or linking groups formed with adjacent heteroatom groups are stable or degradable; any PEG chain segment in the molecule independently shows polydispersity or monodispersity. One H-type molecule can modify multiple types of or multiple biologically related substances; the modified product has a flexible branching structure, a high drug loading capacity, optimized pharmacokinetics and tissue distribution, and can also carry two biologically related substances with different functions, so as to generate fluorescence property or targeting function.

Owner:XIAMEN SINOPEG BIOTECH

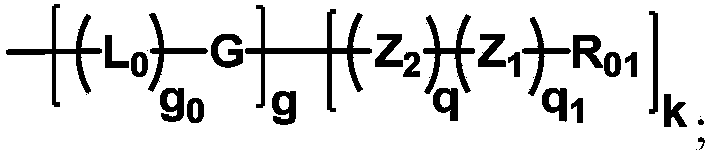

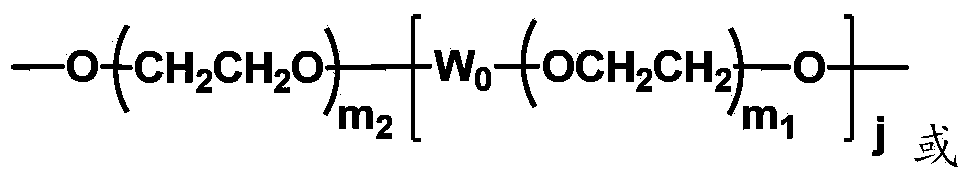

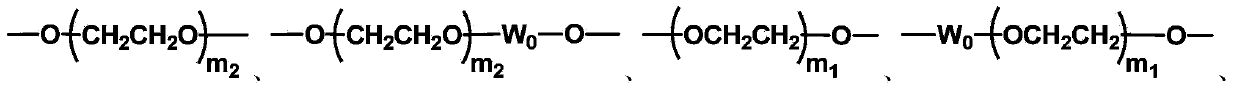

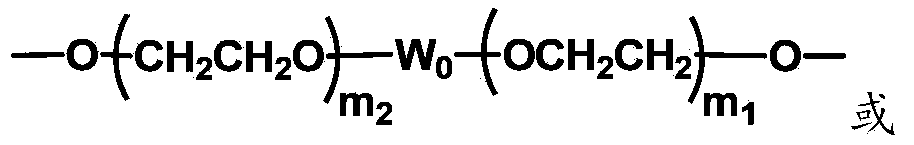

Multifunctional H-type polyethylene glycol derivative and preparation method thereof

ActiveCN104530417AIncrease the number ofImprove modification efficiencyPolymer sciencePolyethylene glycol

The invention discloses a multifunctional H-type polyethylene glycol derivative and a preparation method thereof. The structure is as shown in formula (1) in the description, wherein a linear main axis LPEG and four PEG branched chains are included, and n1, n2, n3 and n4 are polymerization degrees of the branched chains, respectively; U1 and U2 are trivalent branching groups connecting the main axis LPEG with two PEG branched chains; F1 and F2 contain functional groups or their protected forms R01, and contain or do not contain branching groups G, and correspondingly, the number of R01 is one or more than one; F1 is the same as or different from F2; any linking group in the molecule or linking groups formed with adjacent heteroatom groups are stable or degradable; any PEG chain segment in the molecule independently shows polydispersity or monodispersity. The functionalized polyethylene glycol is diverse in branching structure and branching arm length, is adjustable and easily-controllable in various parameters and performance indexes, and is wide in application.

Owner:XIAMEN SINOPEG BIOTECH

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7091297B2High modulusSufficient cross-linkingStentsOther chemical processesPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligomeric silsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated POSS and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Amphiphilic block copolymer and preparation method thereof, micelle drug delivery system formed by copolymer and anti-tumor drug

ActiveCN103772686AGood compatibilityIncrease forcePowder deliveryEther/acetal active ingredientsPolyesterPolyethylene glycol

The invention relates to an amphiphilic block copolymer and a preparation method thereof, and a micelle drug delivery system formed by the copolymer and an anti-tumor drug. The amphiphilic block copolymer comprises a hydrophilic chain segment and a hydrophobic chain segment, and the end of the hydrophobic chain segment is sealed by hydrophobic radicals. According to the amphiphilic block copolymer disclosed by the invention, methoxy polyethylene glycol (or polyethylene glycol)-polyester segmented copolymer with generally recognized safety is taken as a base material, and terminated hydroxyl hydrophobic radicals of the polyester chain segment are modified, thus the compatibility of hydrophobic chain segments in drug molecules and segmented copolymers is improved, and mutual acting force is increased; through a self-assembling method, the drug can be solubilized in micelle hydrophobic cores of the amphiphilic block copolymer, and the drug molecules are limited in the micelle cores so as not to be likely to be dissolved out, thus drug delivery micelle with high stability is obtained.

Owner:SUZHOU LEINA PHARMA RES DEV

Methods for producing di-block polymers

The current major way of making nanofibers is electrospinning. However, the minimum fiber diameter is limited to be about 300–500 nm, which is not compliant with the physical definition of nano structures (in the region of 1 to 100 nm). Futher, the productivity is relatively low. This invention provides a method for manufacturing a nano-sized di-block polymer including at least a hard-segment polymer and a soft-segment polymer. First, a sample containing the hard-segment polymer, the soft-segment polymer, and a catalyst is dissolved in a first solvent. Then the dissolved sample is cast on substrate, and then the first solvent to is removed form a dried sample. Finally, the nano-sized di-block polymer is formed by crew-cutting.

Owner:THE HONG KONG POLYTECHNIC UNIV

Polyester DTY fiber and preparation method thereof

ActiveCN108385186AHigh molecular weightNarrow molecular weightSpinning head liquid feederFilament/thread formingFiberThermal insulation

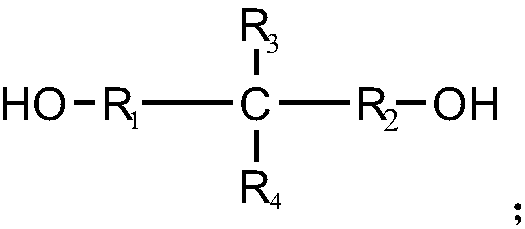

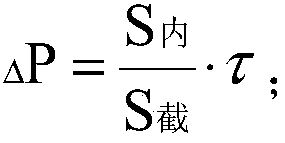

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, and winding to preparethe polyester POY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method; the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atomnumber of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the obtained fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

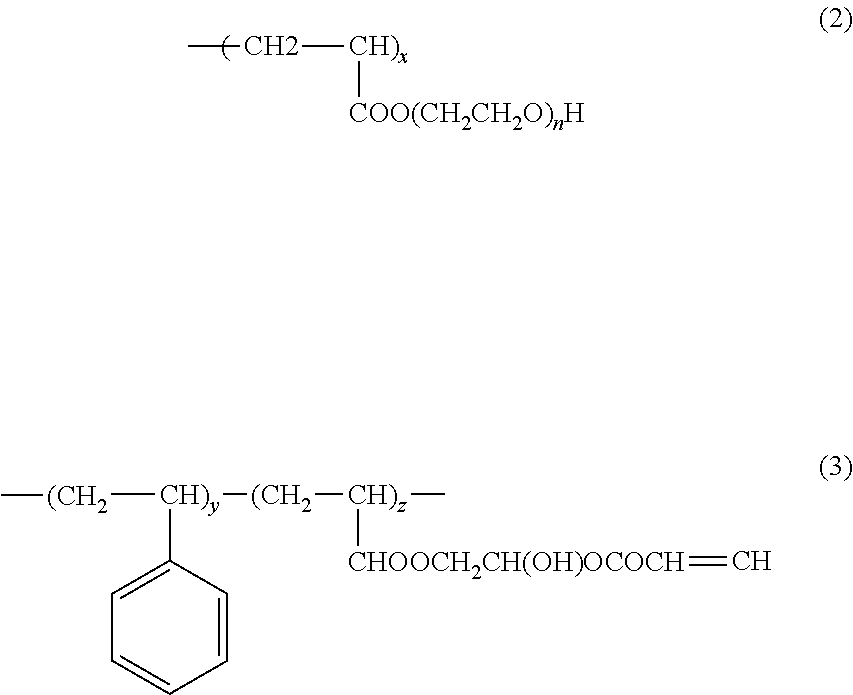

Photopolymerizable polymer micelle, method of producing the same, and ink composition containing photopolymerizable polymer micelle

A photopolymerizable polymer micelle includes a spherical micelle that encapsulates a hydrophobic photopolymerization initiator, the spherical micelle being formed by a block copolymer having a hydrophilic block segment and a hydrophobic block segment, the block copolymer having a number average molecular weight exceeding 10000, and the hydrophobic block segment at least partially having a radically polymerizable group.

Owner:SEIKO EPSON CORP

Polyester flax-like type different shrinkage composite yarn and preparation method thereof

ActiveCN108130624ASimple preparation processImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

The invention relates to a polyester flax-like type different shrinkage composite yarn and a preparation method thereof. Firstly, a modified polyester yarn POY and a modified polyester yarn FDY are prepared respectively, then the modified polyester yarn POY and the modified polyester yarn FDY are compounded to prepare the polyester flax-like type different shrinkage composite yarn; the chromatic aberration [delta]E of the prepared polyester flax-like type different shrinkage composite yarn is less than 0.200; a bundle of the yarn POY or FDY extruded by a same spinneret plate contains a singleyarn shaped in a Chinese character 'wang' manner and a five-leaf single yarn; a molecular chain of modified polyester consists of a diol chain segment with a branched chain, and diol with the branchedchain has the structural formula defined in the specification, wherein R1 and R2 are straight-chain alkylene with the carbon atom number of 1-3 , R3 is alkyl with the carbon atom number of 1-5, and R4 is alkyl with the carbon atom number of 2-5. The method is simple and reasonable, and the prepared composite yarn has good fluffy property and moisture absorption and perspiration elimination properties.

Owner:JIANGSU HENGLI CHEM FIBER

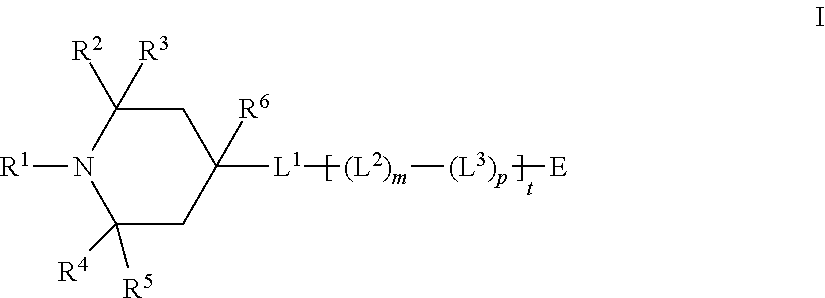

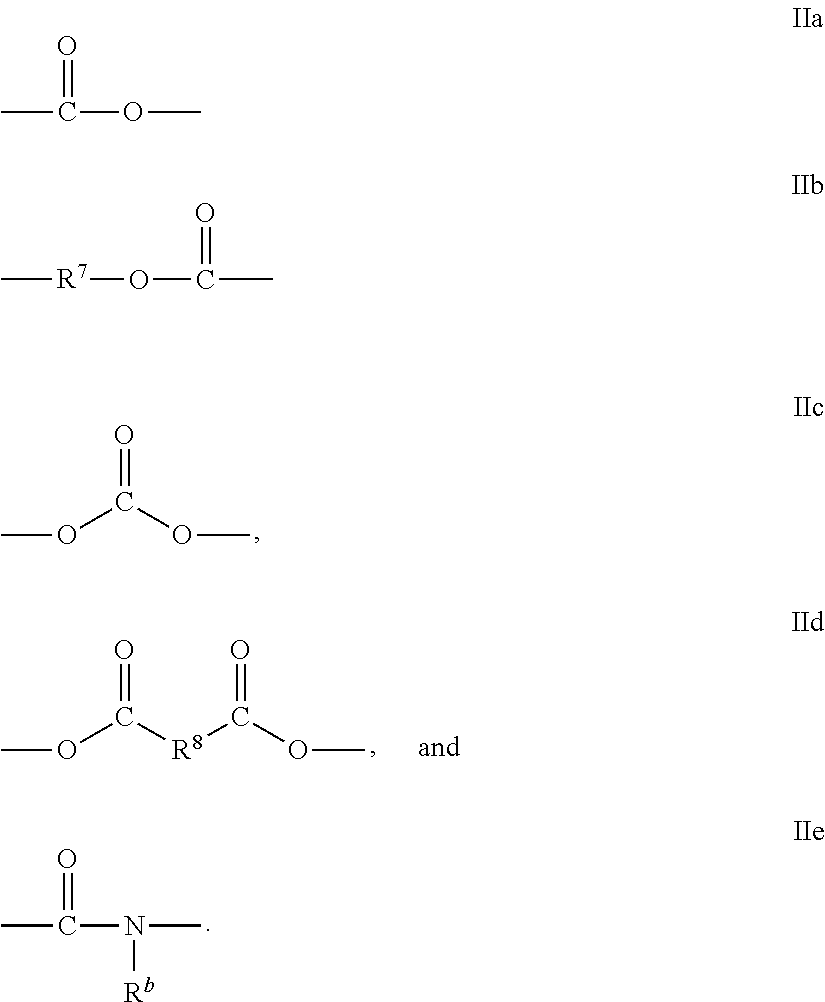

Mesogenic stabilizers

The present invention relates to compounds represented by the following Formula I,in which R1-R6 can each independently be selected from hydrogen or hydrocarbyl (e.g., methyl); L1 is a divalent linking group, such as a bond or —OC(O)—R8—C(O)O—, where R8 can be divalent hydrocarbyl (e.g., —CH2CH2—); each L2 independently represents a flexible segment, such as divalent linear or branched C1-C25 alkyl; each L3 independently represents a rigid segment including, for example, optionally substituted phenylen-1,4-diyl groups; t is from 1 to 4; m and p are each independently from 0 to 4 for each t, provided that the sum of m and p is at least 1 for each t; and E can be hydrogen or hydrocarbyl. The present invention also relates to compositions, such as liquid crystal compositions, and articles, such as optical elements, that include the compound represented by Formula I.

Owner:TRANSITIONS OPTICAL INC

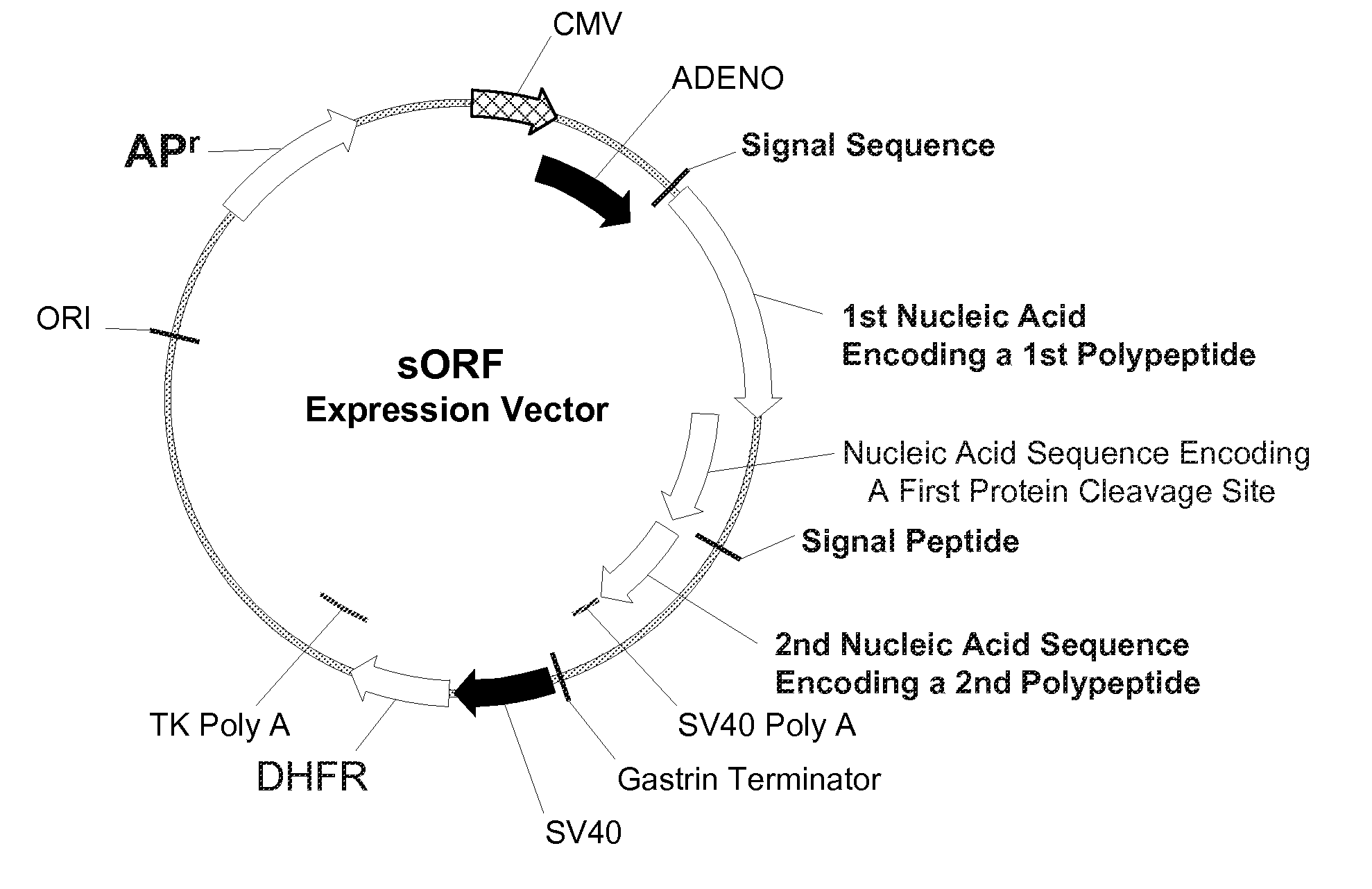

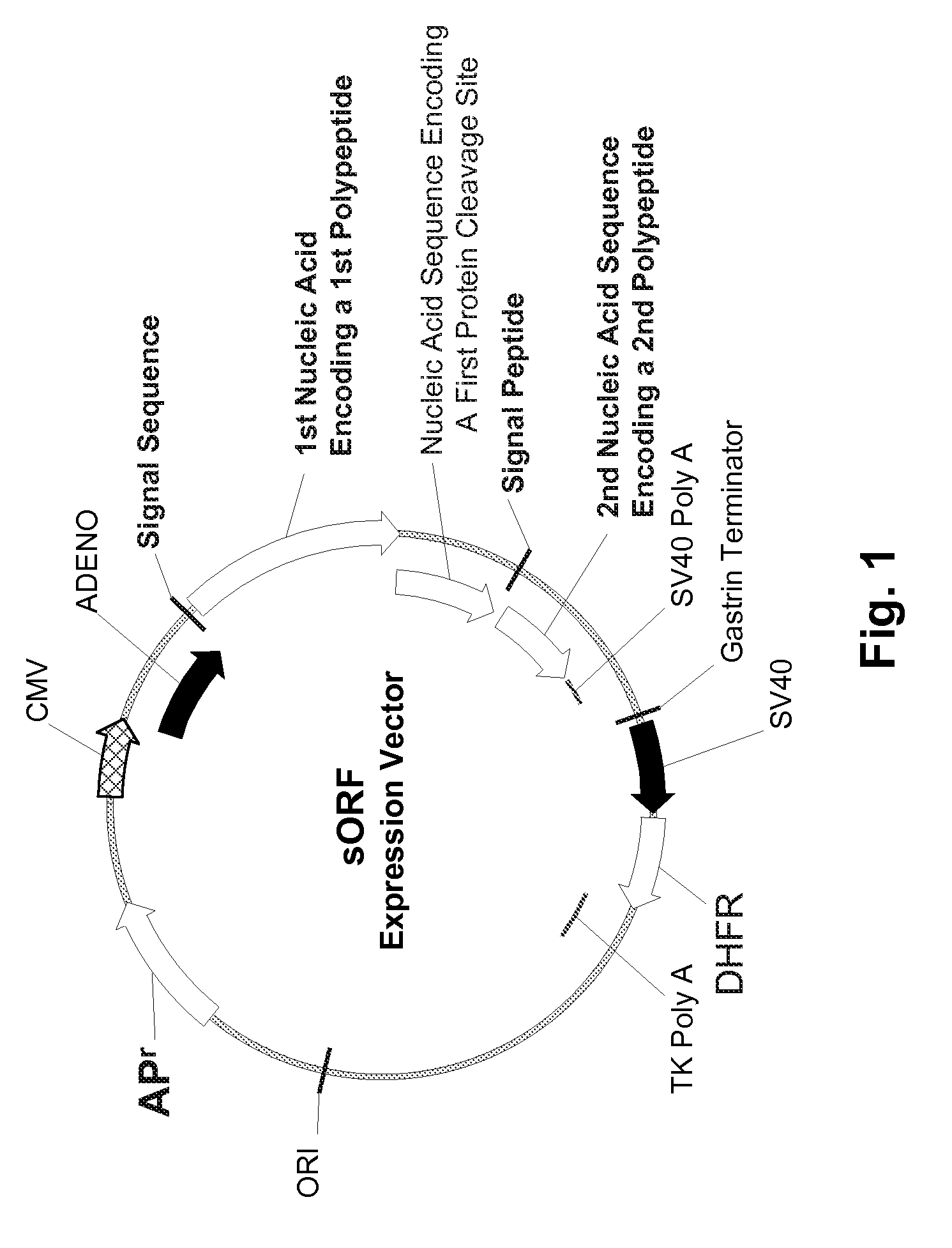

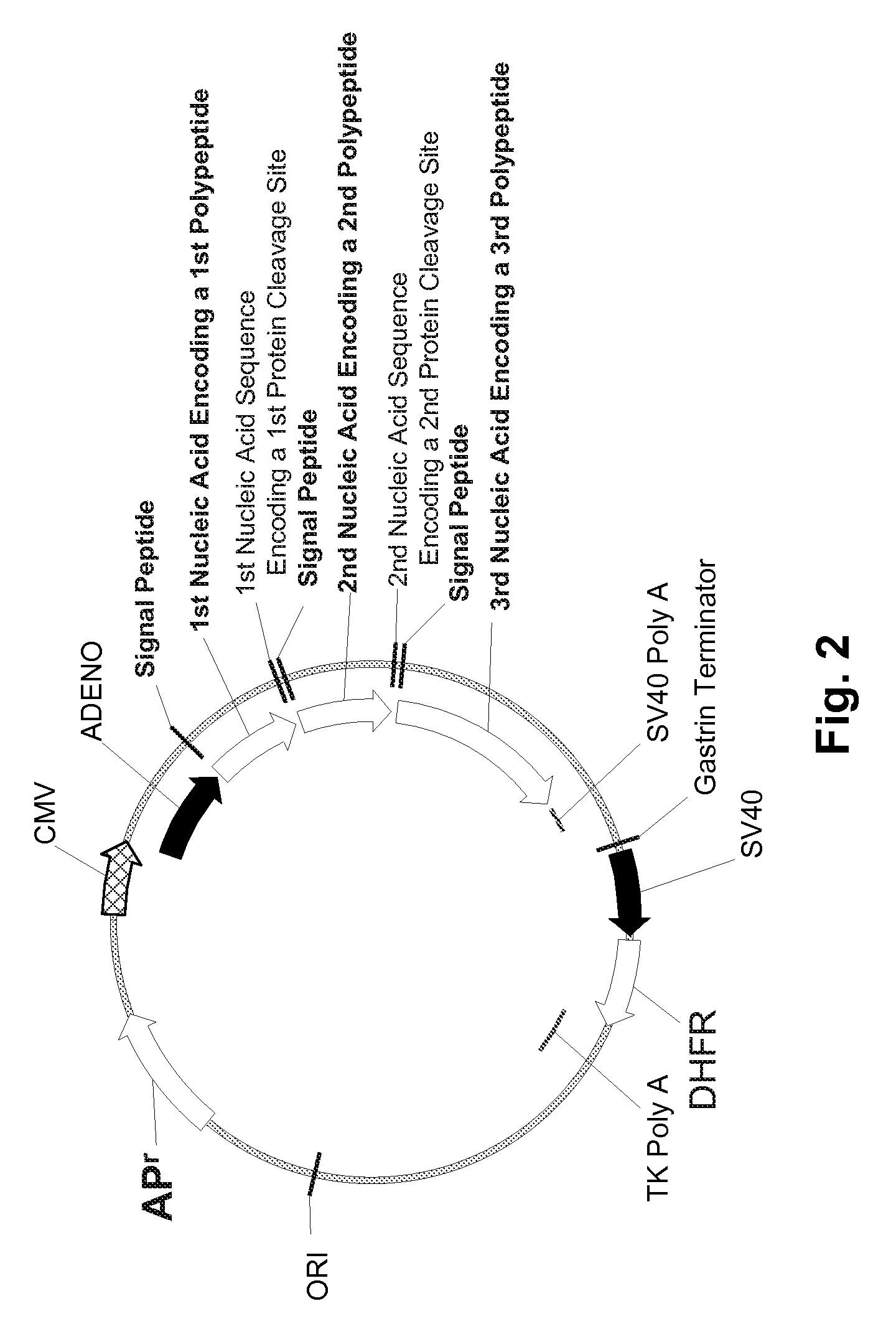

Multiple Gene Expression including sORF Constructs and Methods with Polyproteins, Pro-Proteins, and Proteolysis

InactiveUS20070065912A1Efficient expressionImprove economyFungiFusion with post-translational modification motifOpen reading frameADAMTS Proteins

Disclosed are useful constructs and methods for the expression of proteins using primary translation products that are processed within a recombinant host cell. Constructs comprising a single open reading frame (sORF) are described for protein expression including expression of multiple polypeptides. A primary translation product (a pro-protein or a polyprotein) contains polypeptides such as inteins or hedgehog family auto-processing domains, or variants thereof, inserted in frame between multiple protein subunits of interest. The primary product can also contain cleavage sequences such as other proteolytic cleavage or protease recognition sites, or signal peptides which contain recognition sequences for signal peptidases, separating at least two of the multiple protein subunits. The sequences of the inserted auto-processing polypeptides or cleavage sites can be manipulated to enhance the efficiency of expression of the separate multiple protein subunits. Also disclosed are independent aspects of conducting efficient expression, secretion, and / or multimeric assembly of proteins such as immunoglobulins. Where the polyprotein contains immunoglobulin heavy and light chain segments or fragments capable of antigen recognition, in an embodiment a selectable stoichiometric ratio is at least two copies of a light chain segment per heavy chain segment, with the result that the production of properly folded and assembled functional antibody is made. Modified signal peptides, including such from immunoglobulin light chains, are described.

Owner:ABBOTT LAB INC

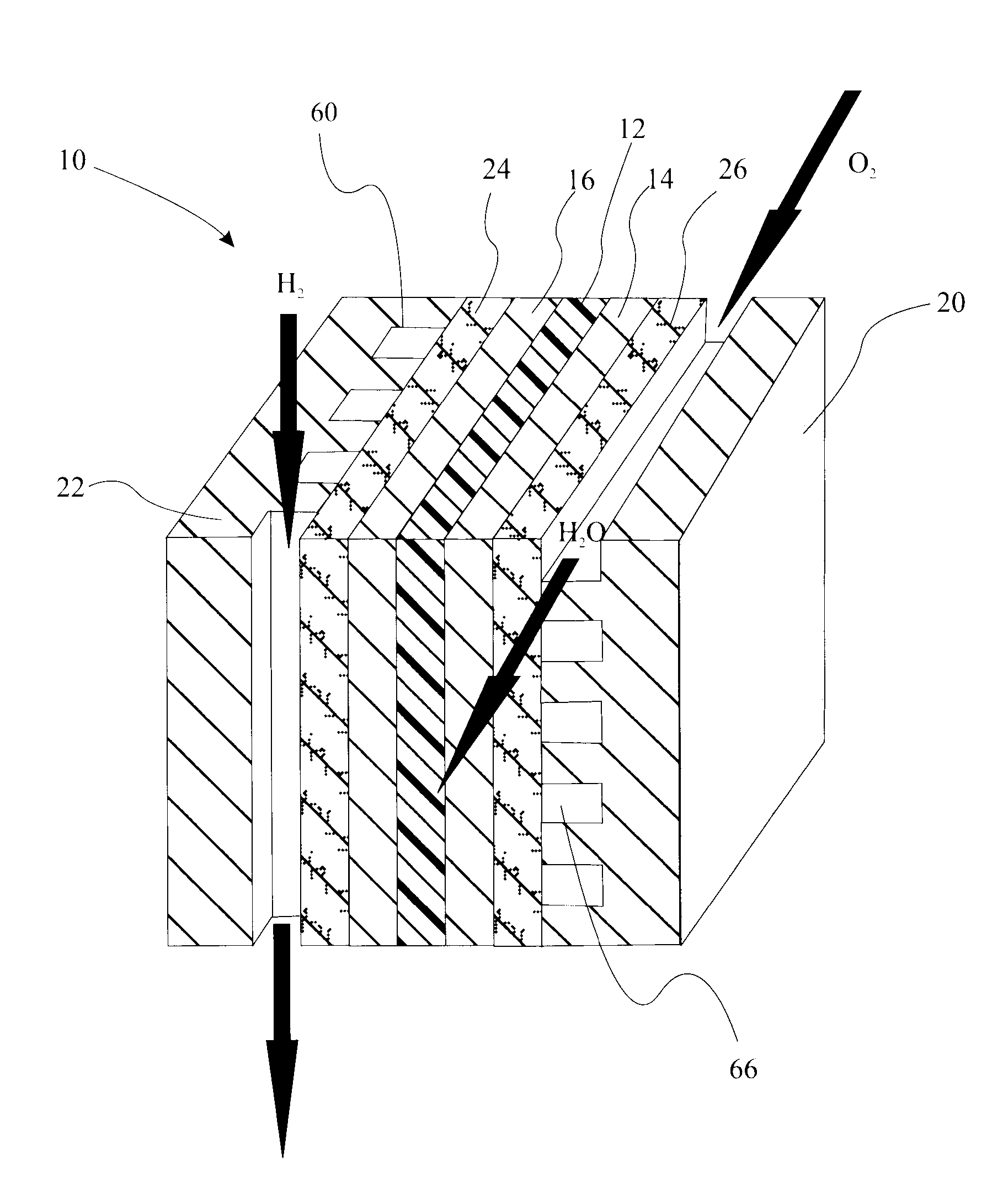

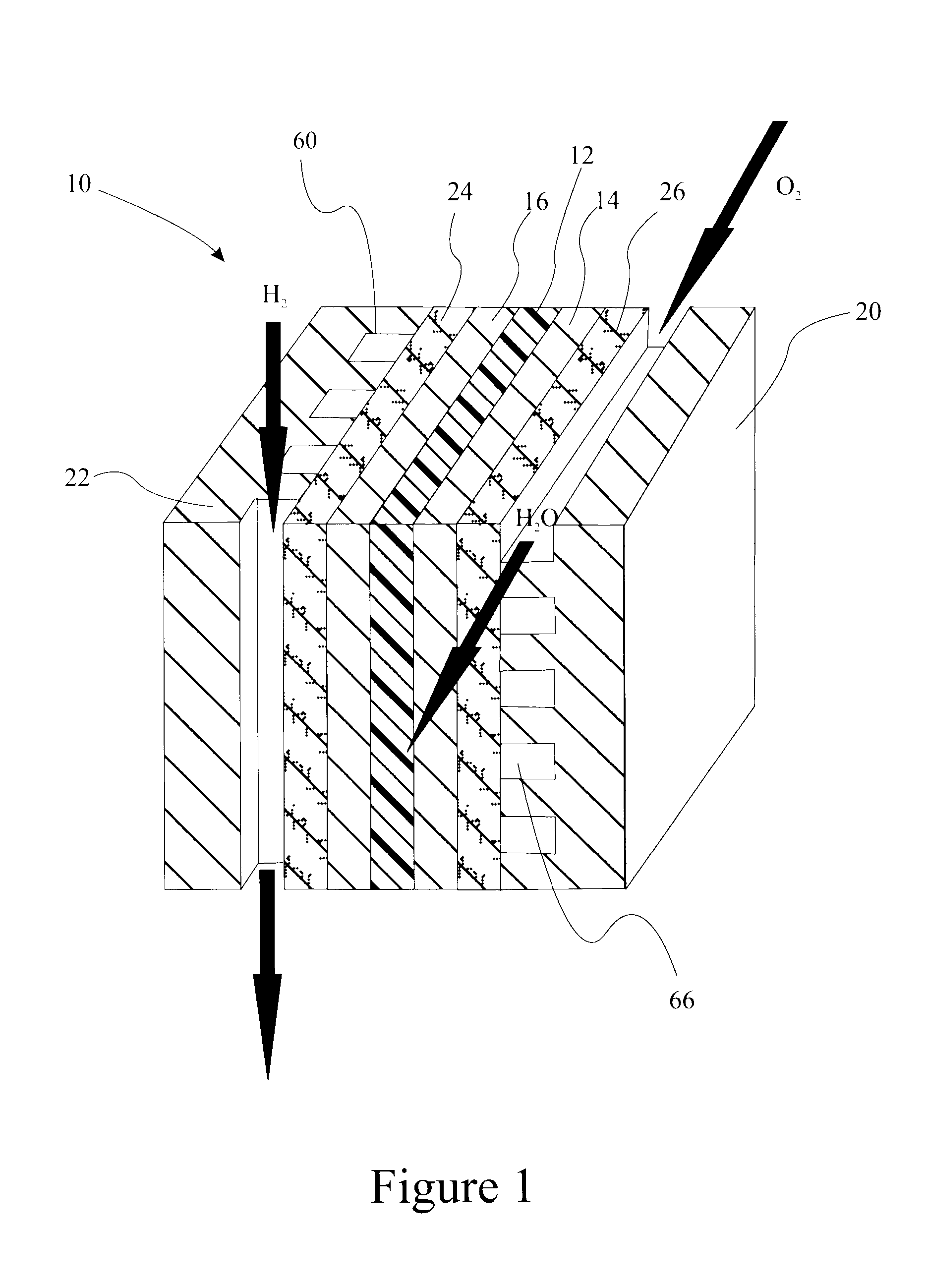

Sulfonated perfluorocyclobutane block copolymers and proton conductive polymer membranes

A sulfonated aromatic perfluorocyclobutane block copolymer comprises a hydrophobic perfluorocyclobutane ether chain segment and a hydrophilic sulfonated perfluorocyclobutane ether chain segment. The sulfonated perfluorocyclobutane copolymer may be used to make proton conductive membranes and membrane electrode assemblies in fuel cells. Processes of making the block copolymer through thermal coupling reactions are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

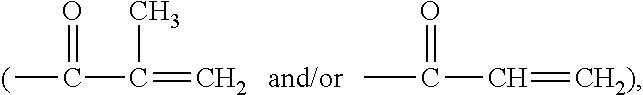

Oxygen scavenger block copolymers and compositions

InactiveUS7754798B2Well formedEasy to processOther chemical processesConductive materialThermoplasticPolyester

An oxygen scavenger composition includes a block co-polymer having at least one block including a polyester condensation polymer segment having cycloalkenyl group(s) or functionality directly or indirectly bonded to the polymer chain of said block, and having at least one second block including a polymer segment of a thermoplastic, film forming material. The block copolymer has been found to act as an oxygen scavenger agent under both ambient and refrigerated conditions, to be compatible with conventional film forming packaging materials, and to provide compositions exhibiting low tack which can be readily formed and processed using conventional film forming equipment. A packaging material, such as a film or laminated product suitable for packaging applications, can include the oxygen scavenger composition.

Owner:CRYOVAC ILLC

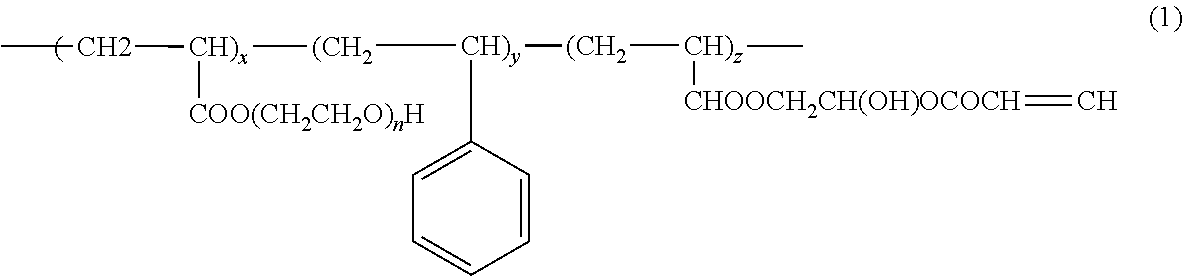

Preparation method and application of resin having double curing groups

InactiveCN101824152AHigh viscosityTo achieve the effect of initial bondingPolyureas/polyurethane adhesivesInksEpoxyUV curing

The invention discloses a preparation method and application of resin having double curing groups. The resin having double curing groups comprises epoxy monoacrylate and polyurethane acrylate chain segments and has the following structure. The molecule of the resin having double curing groups has an acrylate double bond (a curing free radical) and an epoxy group (a curing or thermally curing anion), so the brittleness of a cured film is reduced and the flexibility of the cured film is improved and the resin can be used in ultraviolet curing paint, adhesive and ink. The resin can improve large shrinkage factor of a single acrylate free radical curing system and large brittleness and poor flexibility of the UV curing film and the like and can also solve the problem that a several-resin mixed compounding system has unstable performance, uneven local curing, poor compatibility among resin and the like.

Owner:SHENZHEN POLYTECHNIC

Water-soluble stabilized self-assembled polyelectrolytes

InactiveUS20030059398A1Pharmaceutical non-active ingredientsGranular deliveryPolyelectrolyteHydrophilic polymers

The present invention is directed toward water-soluble supramolecular self-assemblies and a process for their preparation via micellization of polyelectrolytes through the use of hydrophobic monomeric units. In this invention the polyelectrolyte segment ultimately forms the core of the supramolecular assembly whereas the shell consists of uncharged hydrophilic polymers or oligomers. It has been determined that the inclusion of the hydrophobic co-monomers to the polyelectrolyte segment forming the micelle core leads to a structure of enhanced stability.

Owner:LABOPHARM BARBADOS LTD 36646

Method for Preparing Branched Functionalized Polymers Using Branched Polyol Cores

Owner:NEKTAR THERAPEUTICS INC

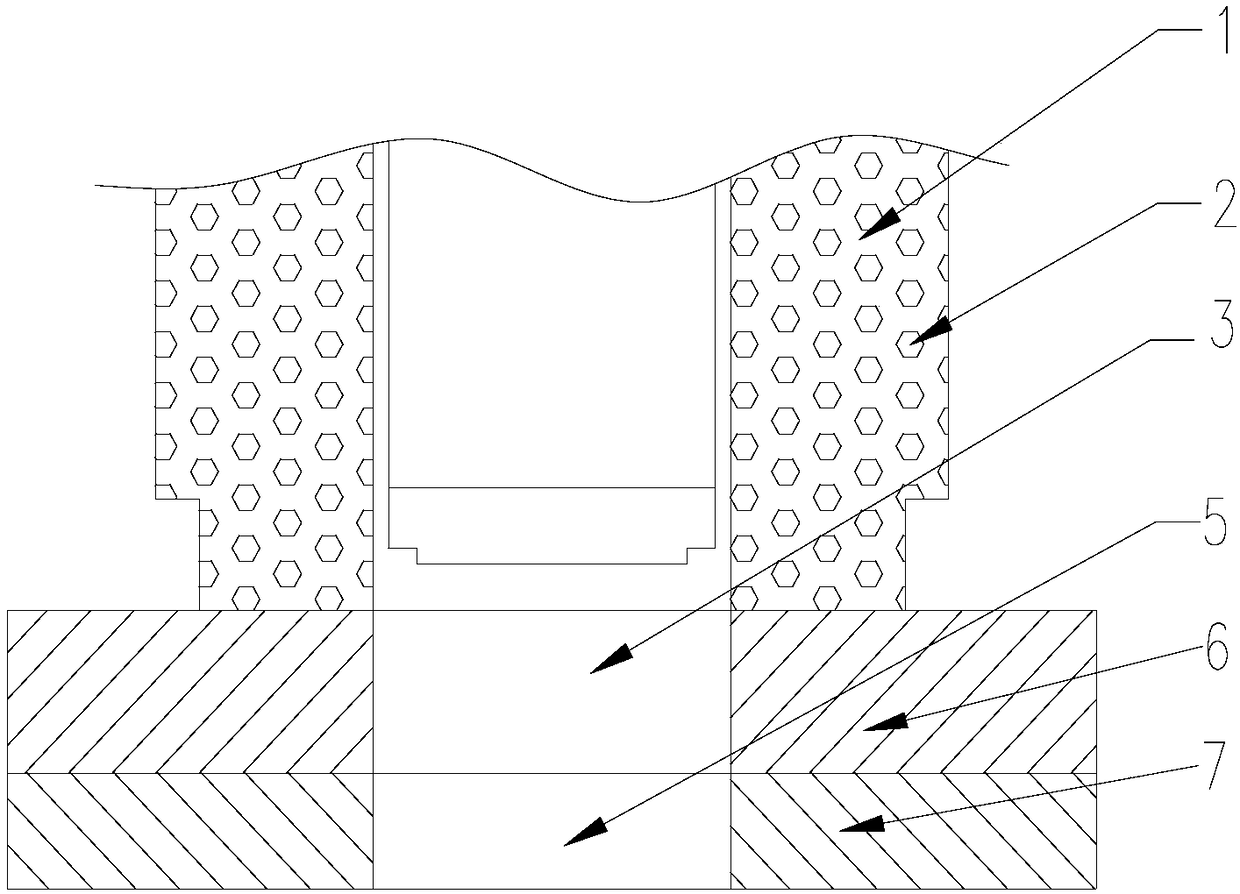

Polyacrylate water-based adhesive for electrode materials of lithium ion battery, preparation method of adhesive and electrode plates of lithium ion battery

ActiveCN104356979AAvoid pollutionAvoid harmAcid polymer adhesivesEster polymer adhesivesWater basedCross-link

The invention relates to a polyacrylate water-based adhesive for electrode materials of a lithium ion battery, a preparation method of the adhesive and electrode plates of the lithium ion battery. The adhesive is a cross-linked high-solid-content polyacrylate water-based adhesive; the polymer molecule chain segment of the adhesive comprises a hydrophilic segment and a lipophilic segment which are cross-linked through a cross-linking agent to form a spatial reticular structure. The electrode plates produced by the adhesive cannot fall off in charge and discharge processes, the adhesive has a relatively good adhesion effect on the positive and negative electrode materials of the lithium ion battery, and the expansion of electrode plates of graphite anode materials, especially silicon-based materials can be inhibited.

Owner:YANYI NEW ENERGY TECH CO LTD

Polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer and preparation method thereof

InactiveCN102181060AEasy to manufacturePrecise control of relative contentDibutyl tin dilauratePolyethylene glycol

The invention relates to a polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer and a preparation method thereof. The molecular weight of polyvinyl alcohol is 20,000-80,000; the molecular weight of a polypeptide chain segment is 4,000-8,000; and the molecular weight of a polyethylene glycol chain segment is 350-750. The preparation method comprises the following steps of: (1) synthesizing a polypeptide homopolymer which contains an end-NCO radical: adding the polypeptide homopolymer, diisocyanate, dibutyltin dilaurate serving as a catalyst and dimethyl sulfoxide serving as a solvent into a reactor for reacting to obtain a target product; (2) synthesizing a polyvinyl alcohol-polypeptide graft copolymer: adding the polypeptide homopolymer which contains the end-NCO radical, the solvent and the catalyst into the reactor, adding polyvinyl alcohol and reacting to obtain a target product; and (3) synthesizing a polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer: adding the polyvinyl alcohol-polypeptide graft copolymer, the solvent and the catalyst into a drying reactor, adding polyethylene glycol monomethyl ether and reacting to obtain a target product.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com