Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

331results about "Sub-atmospheric pressure processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

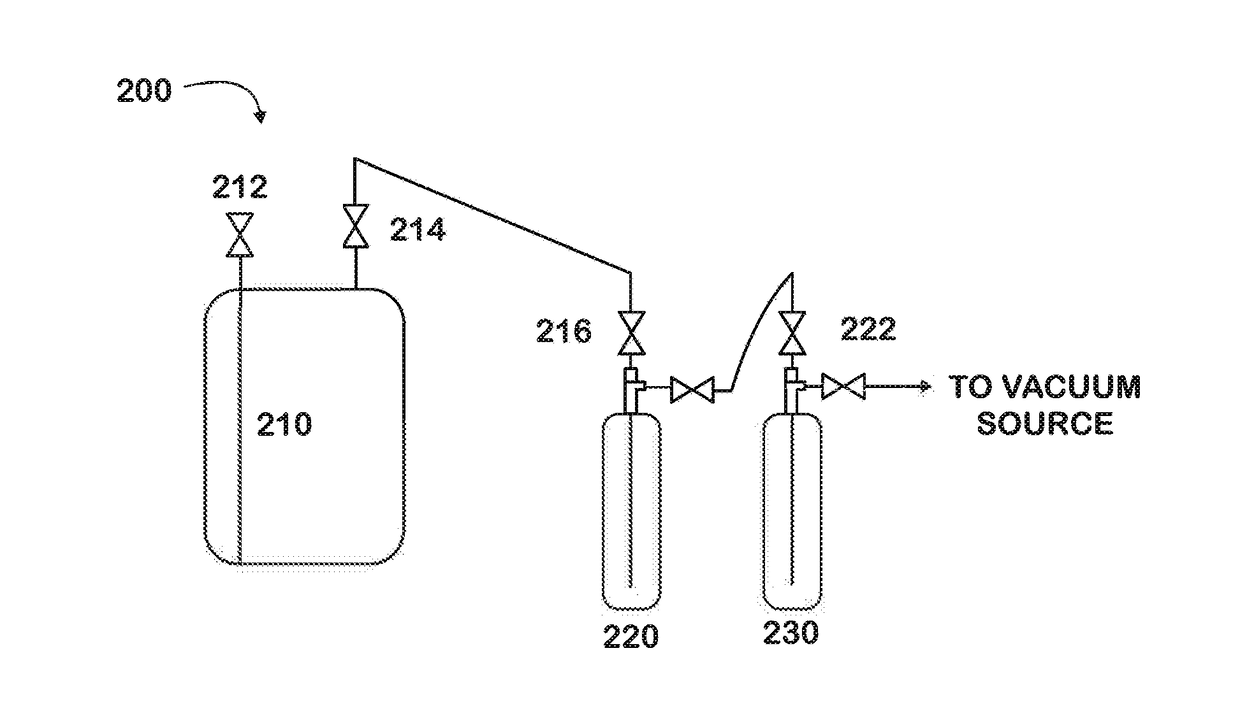

Pressurization type method for manufacturing metal monoatomic layer, metal monoatomic layer structure, and pressurization type apparatus for manufacturing metal monoatomic layer

ActiveUS20190062917A1High surface coverageReduce surface roughnessChemical vapor deposition coatingPressure/vacuum vesselsProduct gasMaterials science

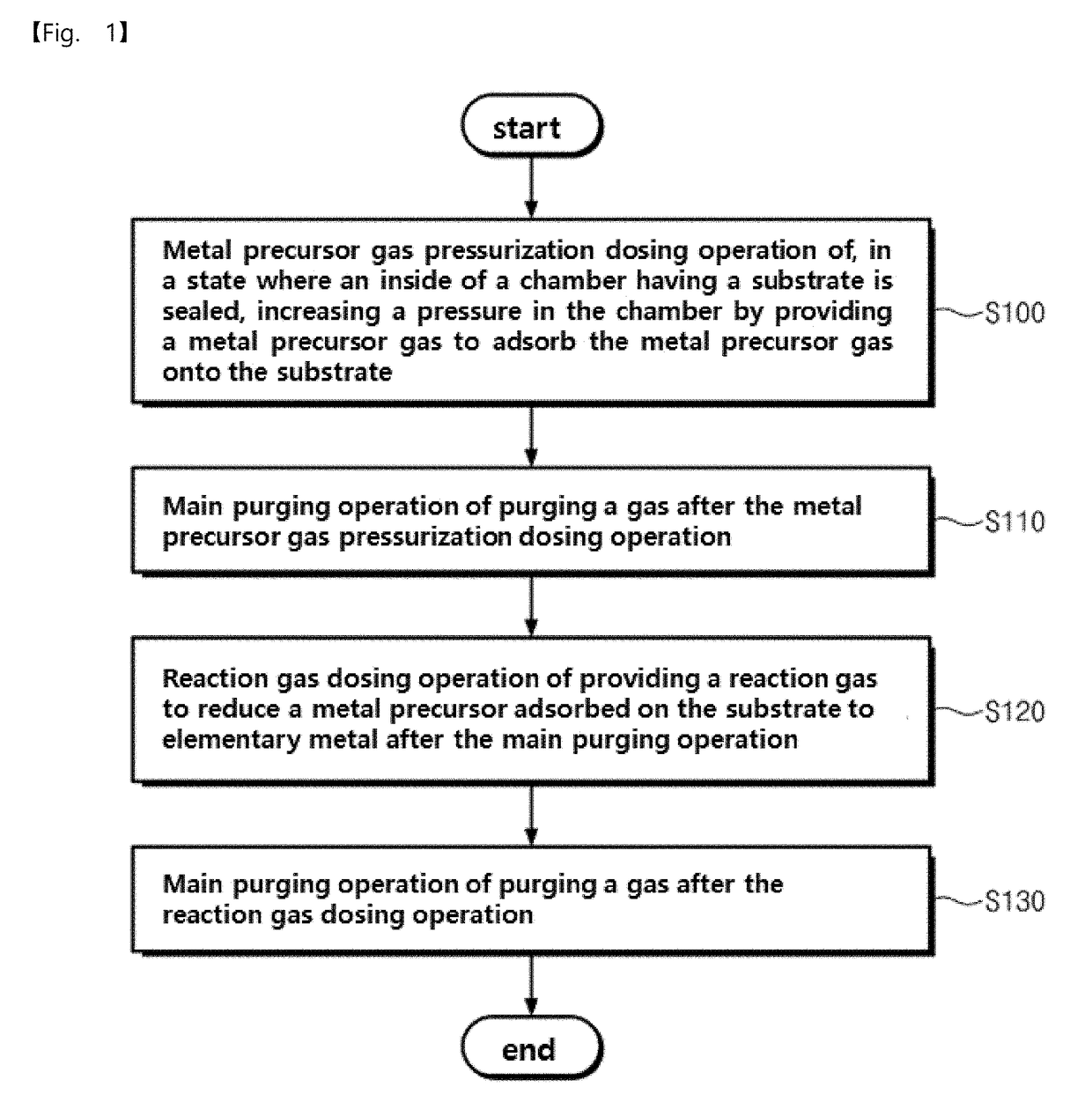

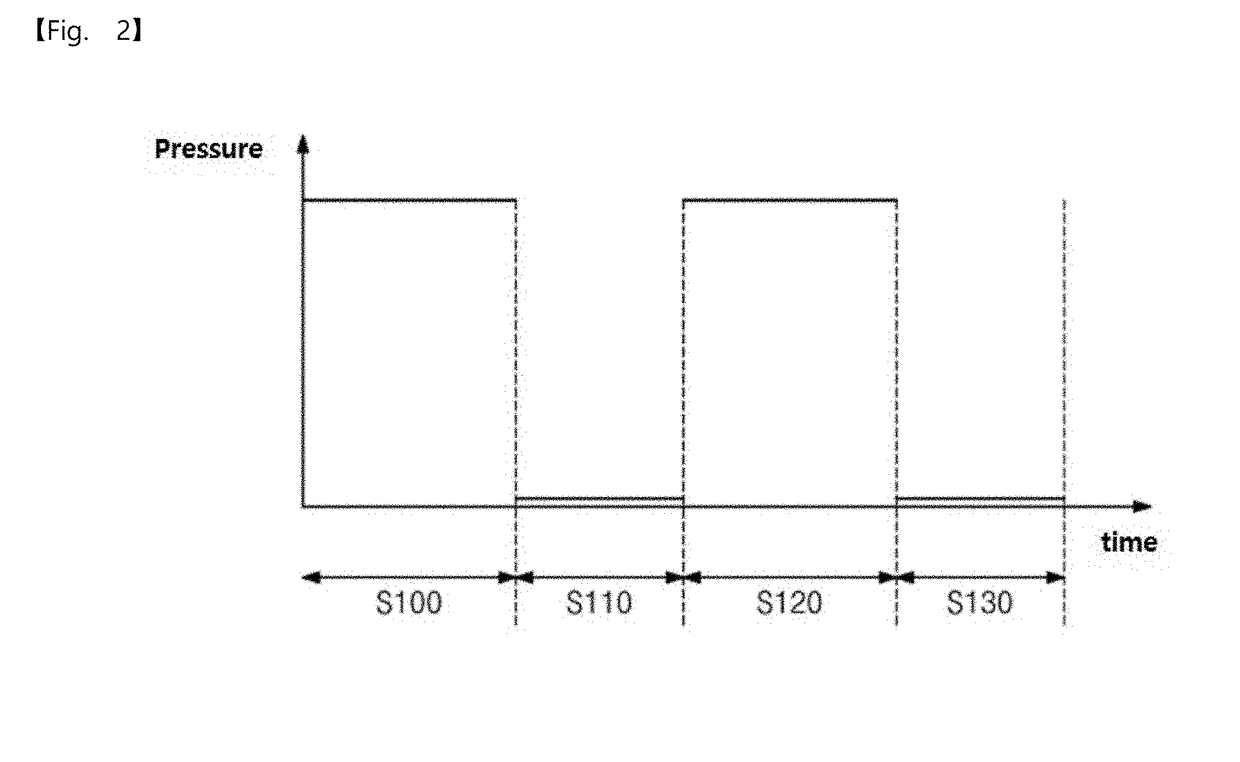

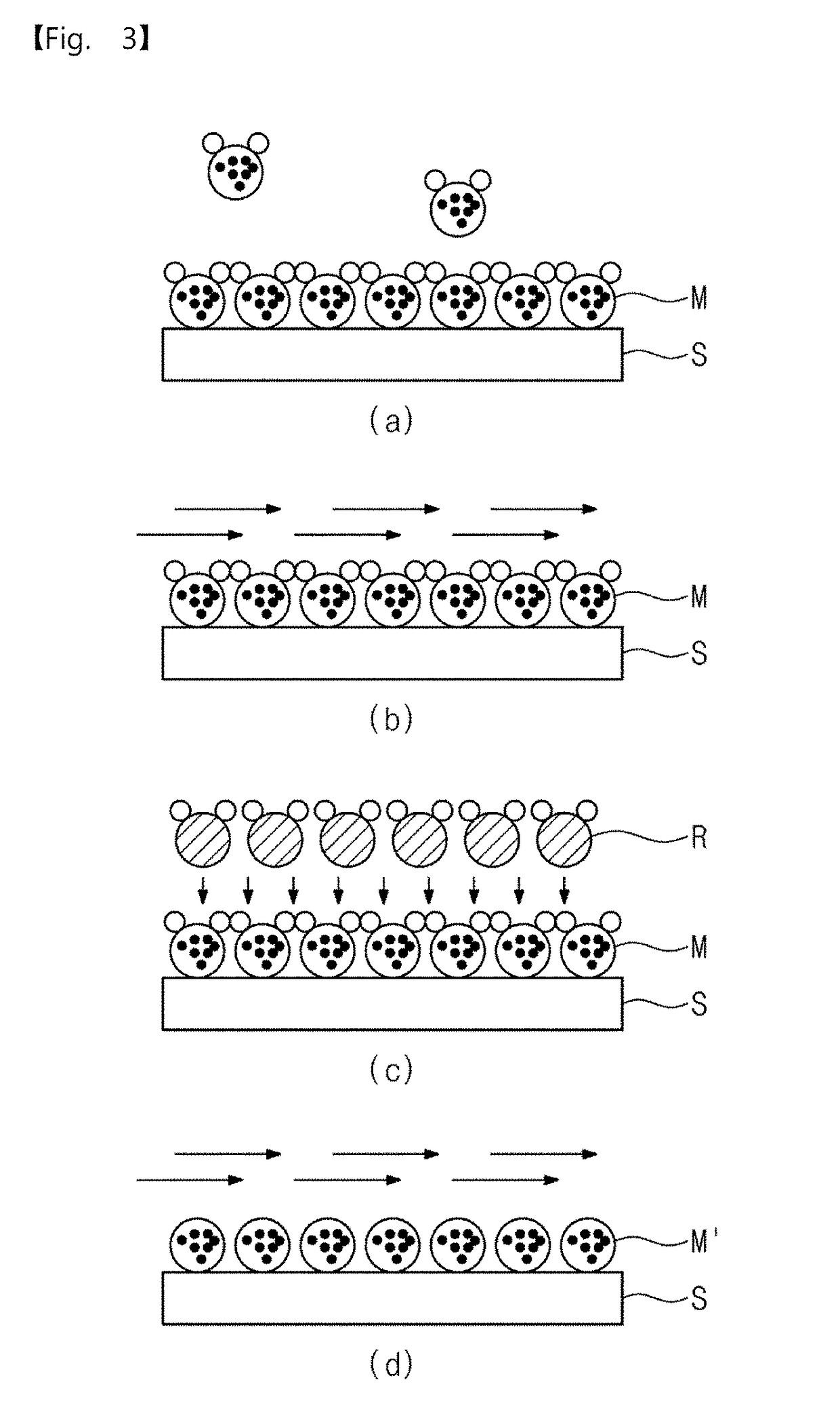

A pressurization type method for manufacturing elementary metal may include a metal precursor gas pressurization dosing operation of, in a state where an outlet of a chamber having a substrate is closed, increasing a pressure in the chamber by providing a metal precursor gas consisting of metal precursors, thereby adsorbing the metal precursors onto the substrate, a main purging operation of purging a gas after the metal precursor gas pressurization dosing operation, a reaction gas dosing operation of providing a reaction gas to reduce the metal precursors adsorbed on the substrate to elementary metal, after the main purging operation, and a main purging operation of purging a gas after the reaction gas dosing operation.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

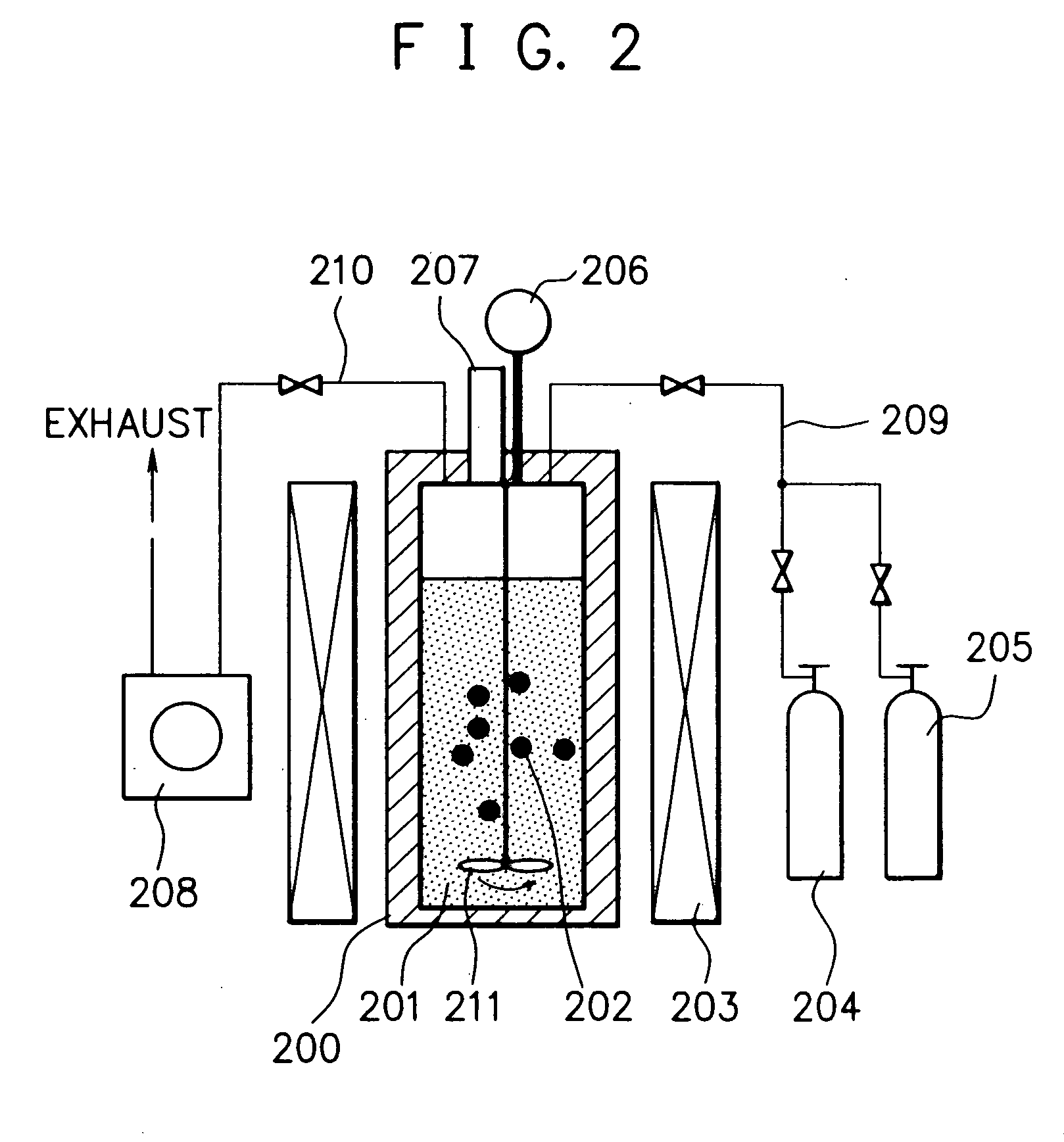

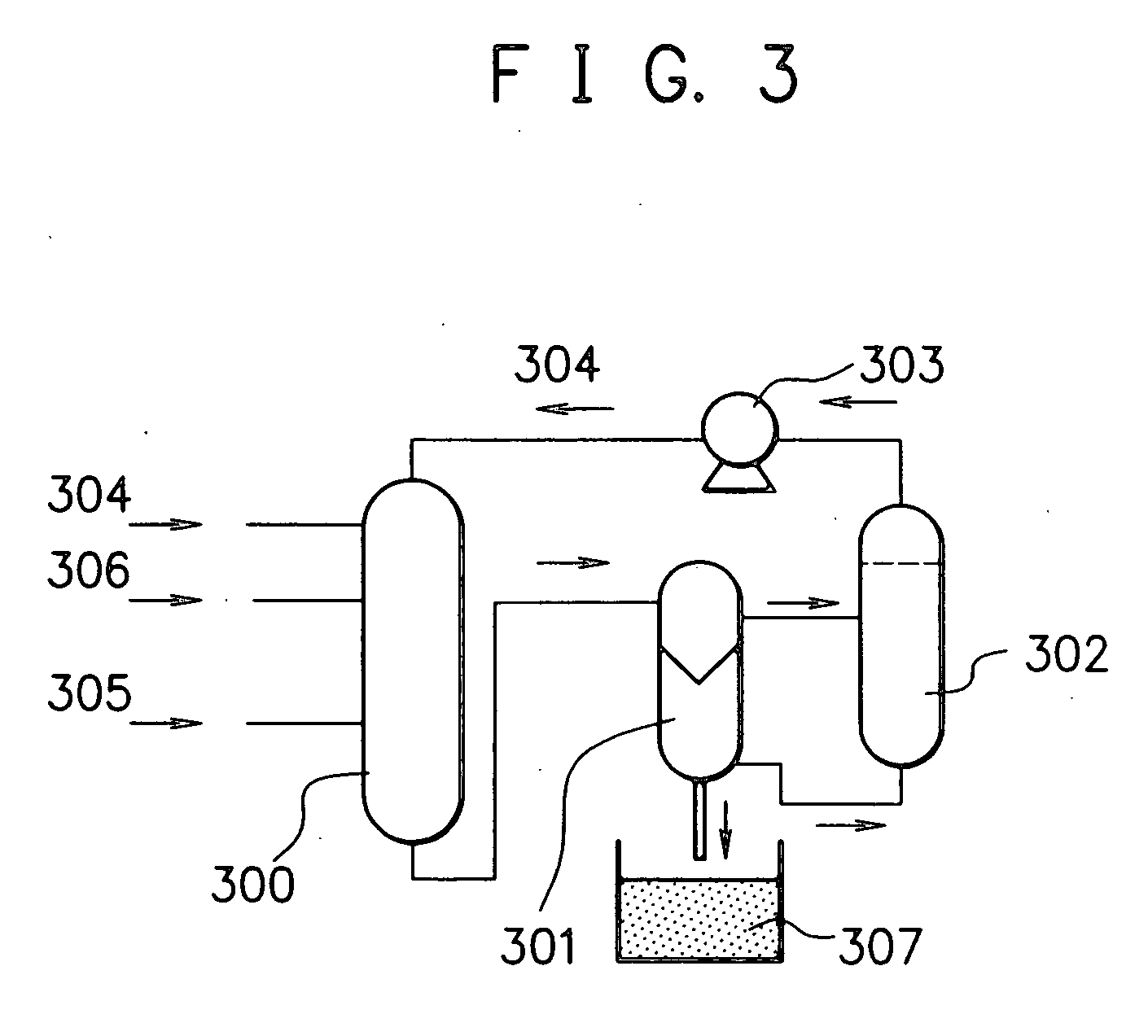

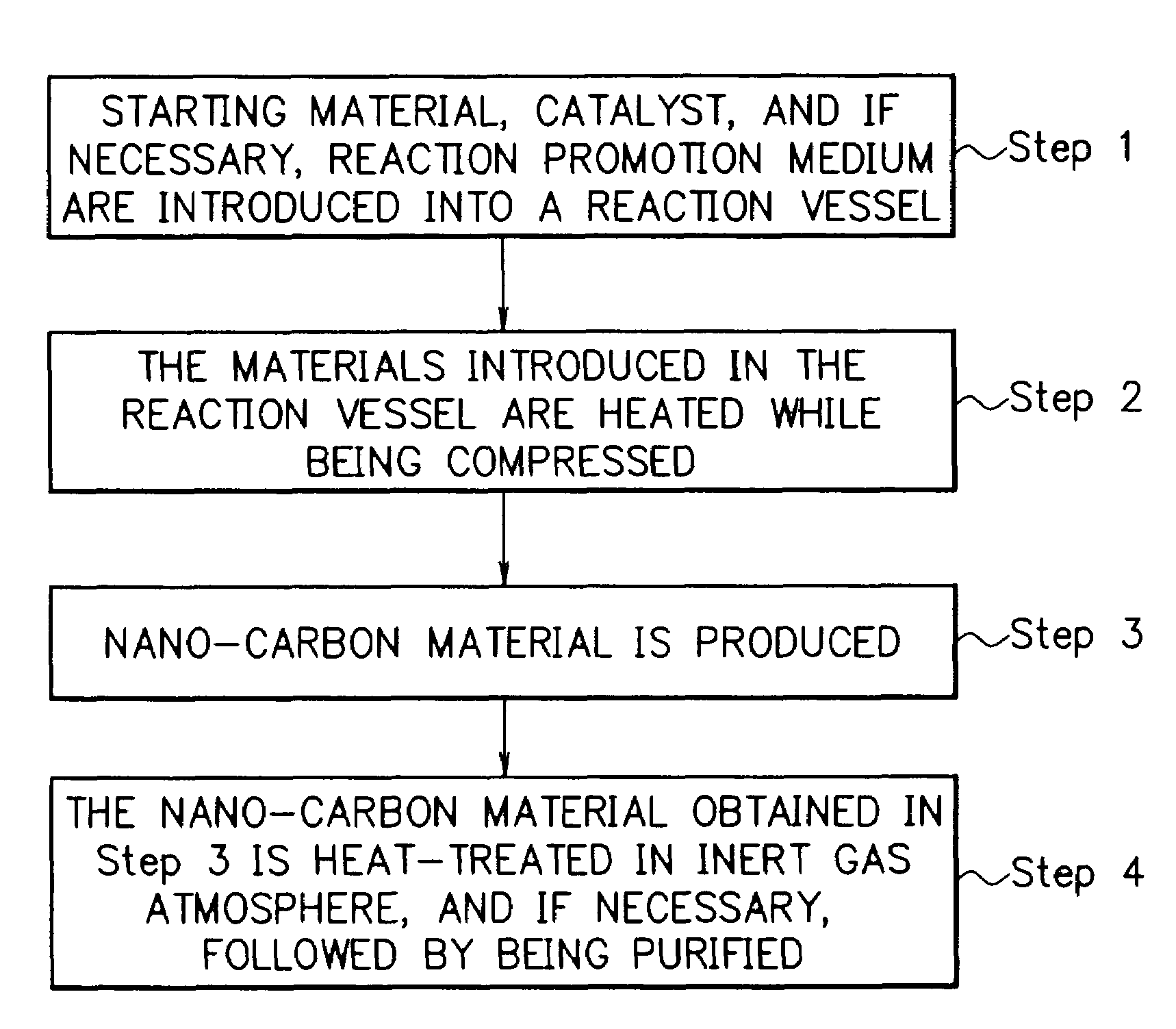

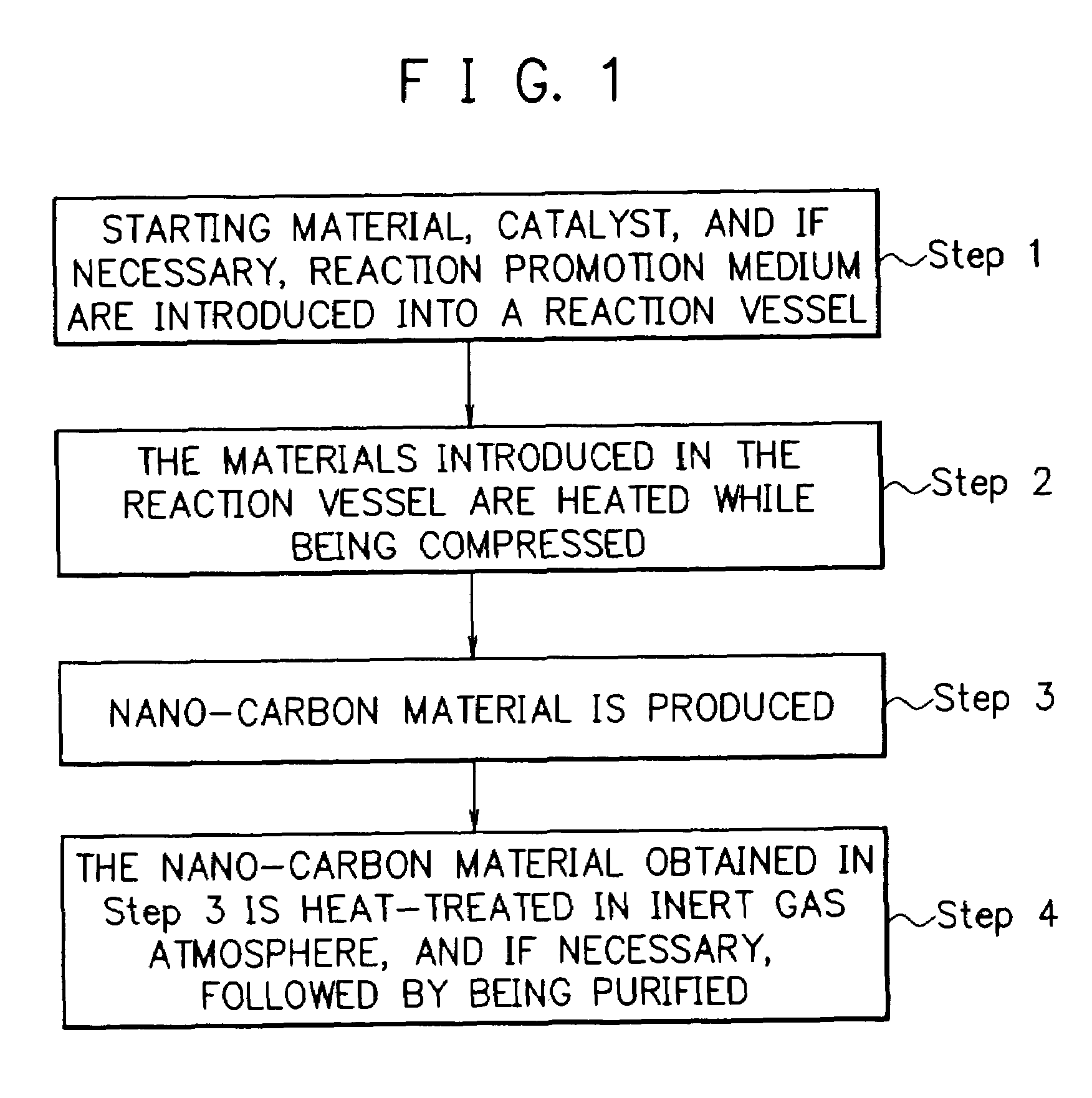

Method for producing nano-carbon materials

InactiveUS20050079119A1Efficiently and quantitatively produceLow production costMaterial nanotechnologyNanostructure manufacturePtru catalystUnsaturated hydrocarbon

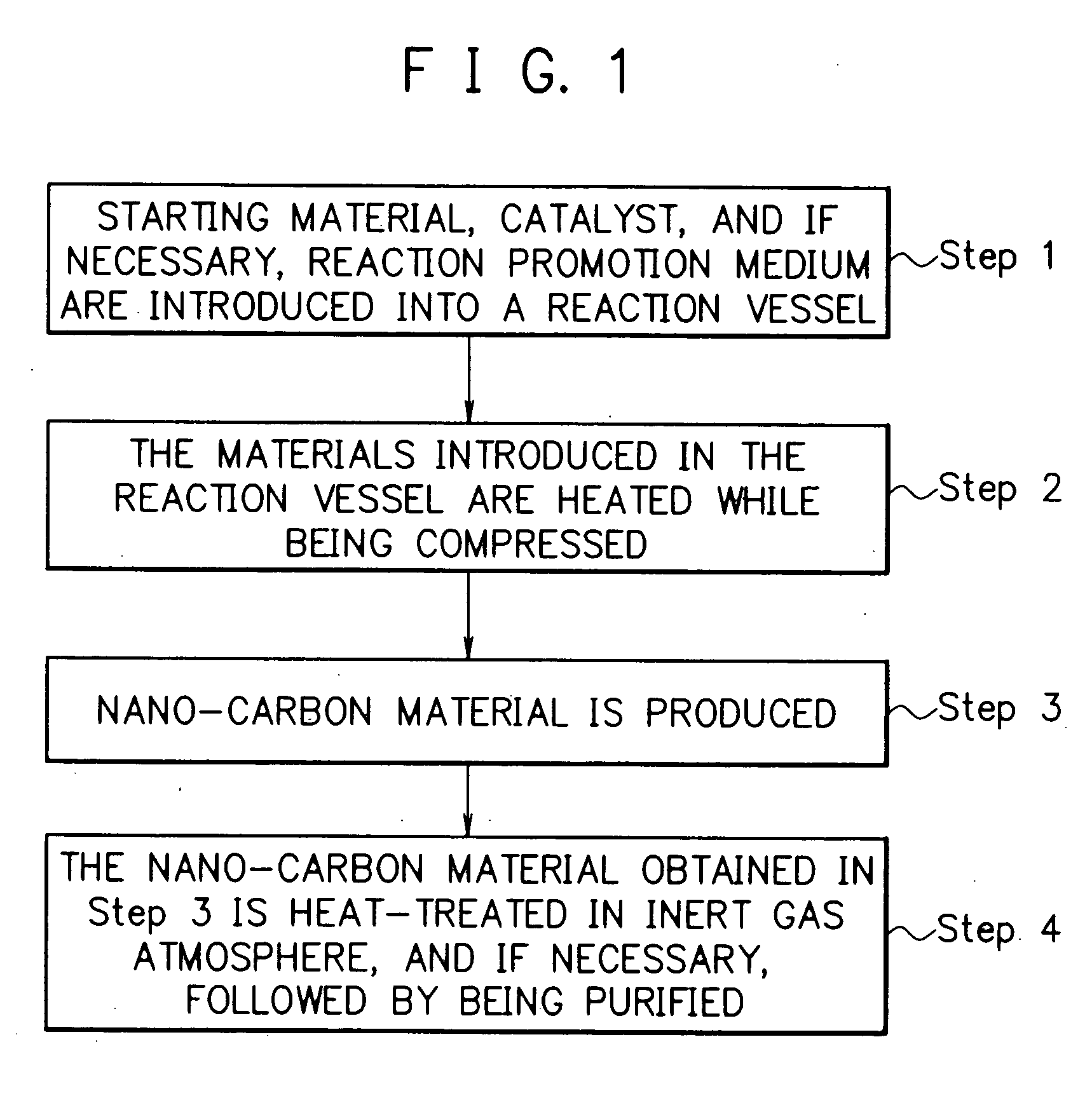

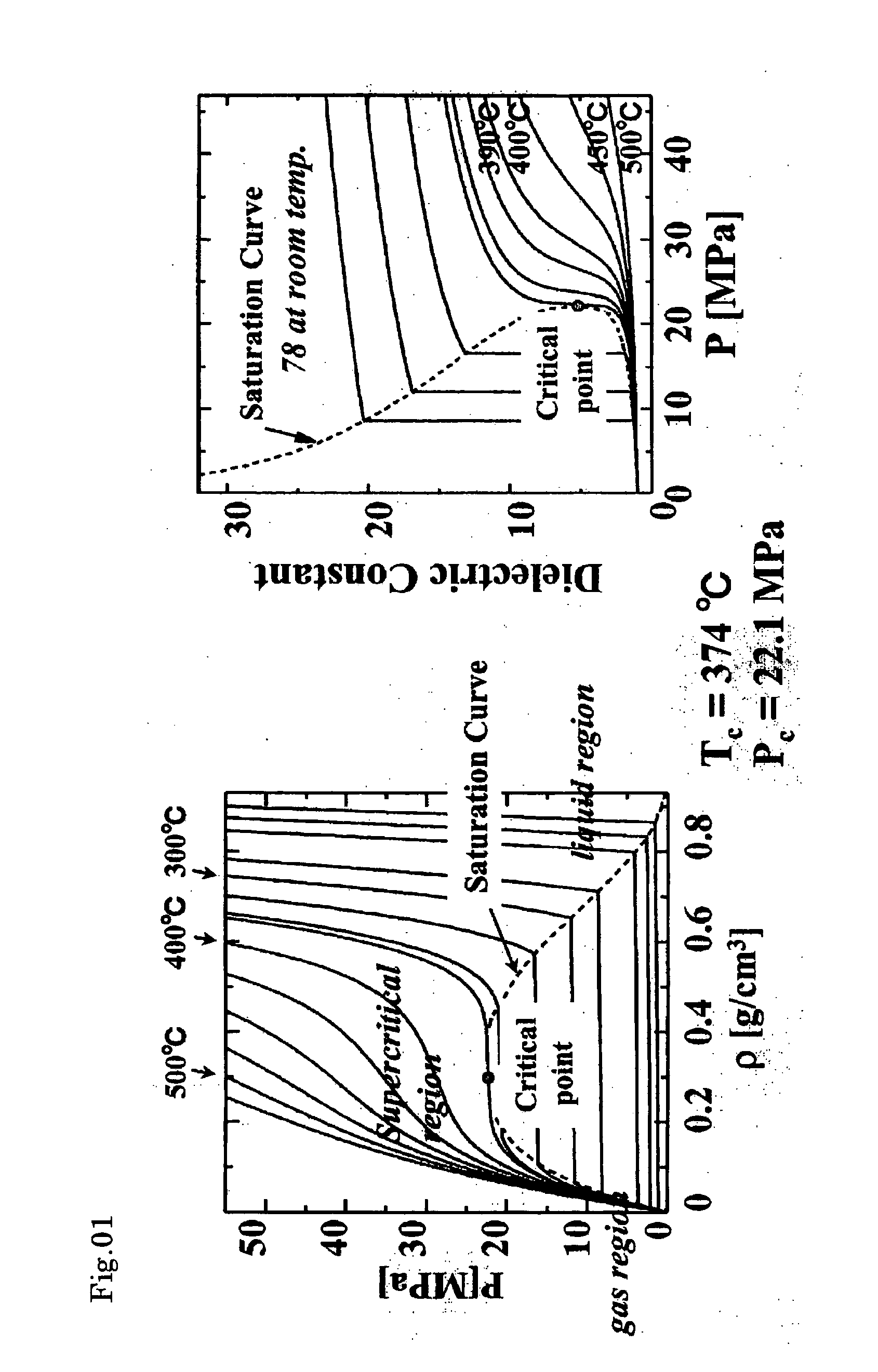

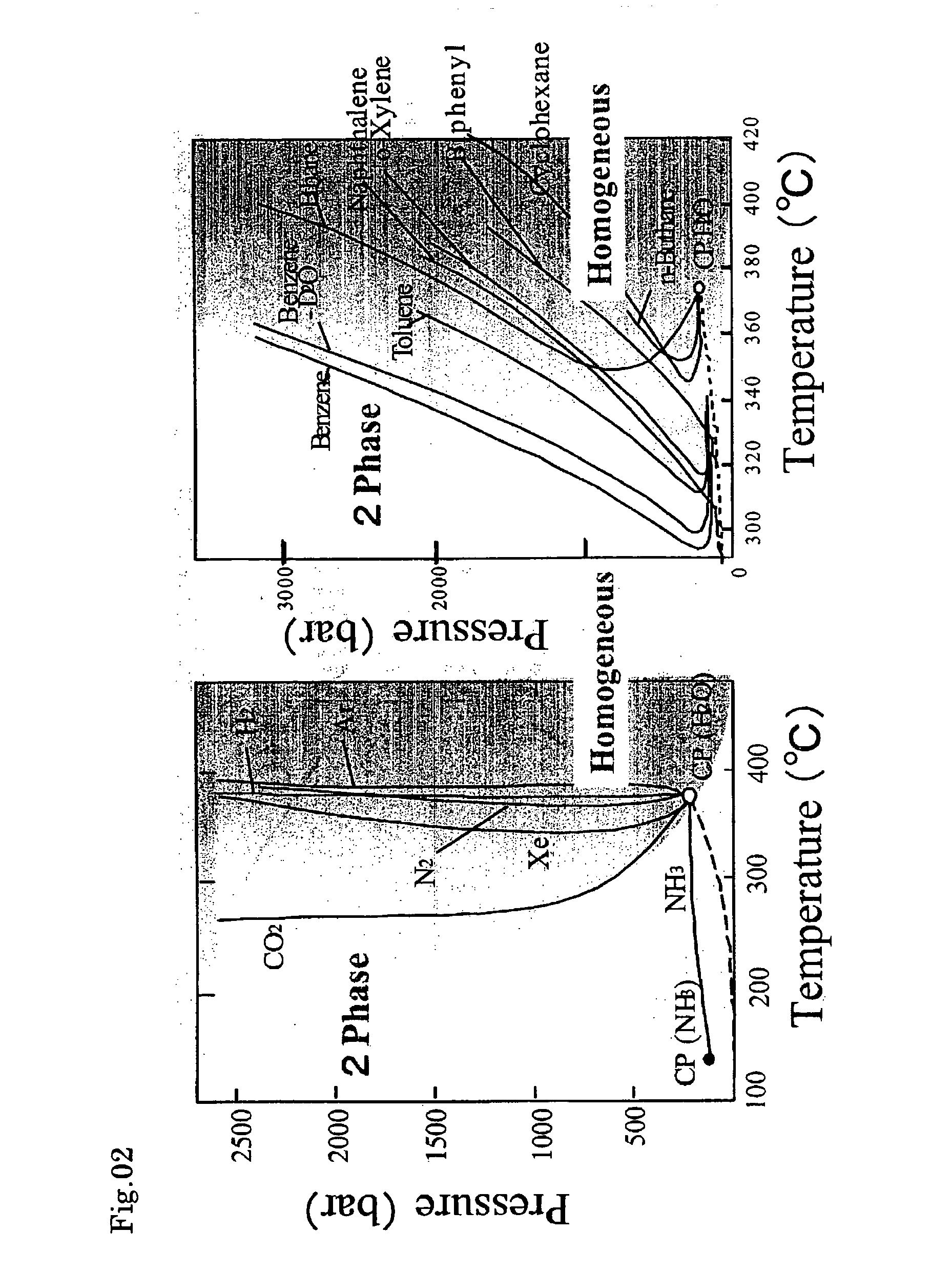

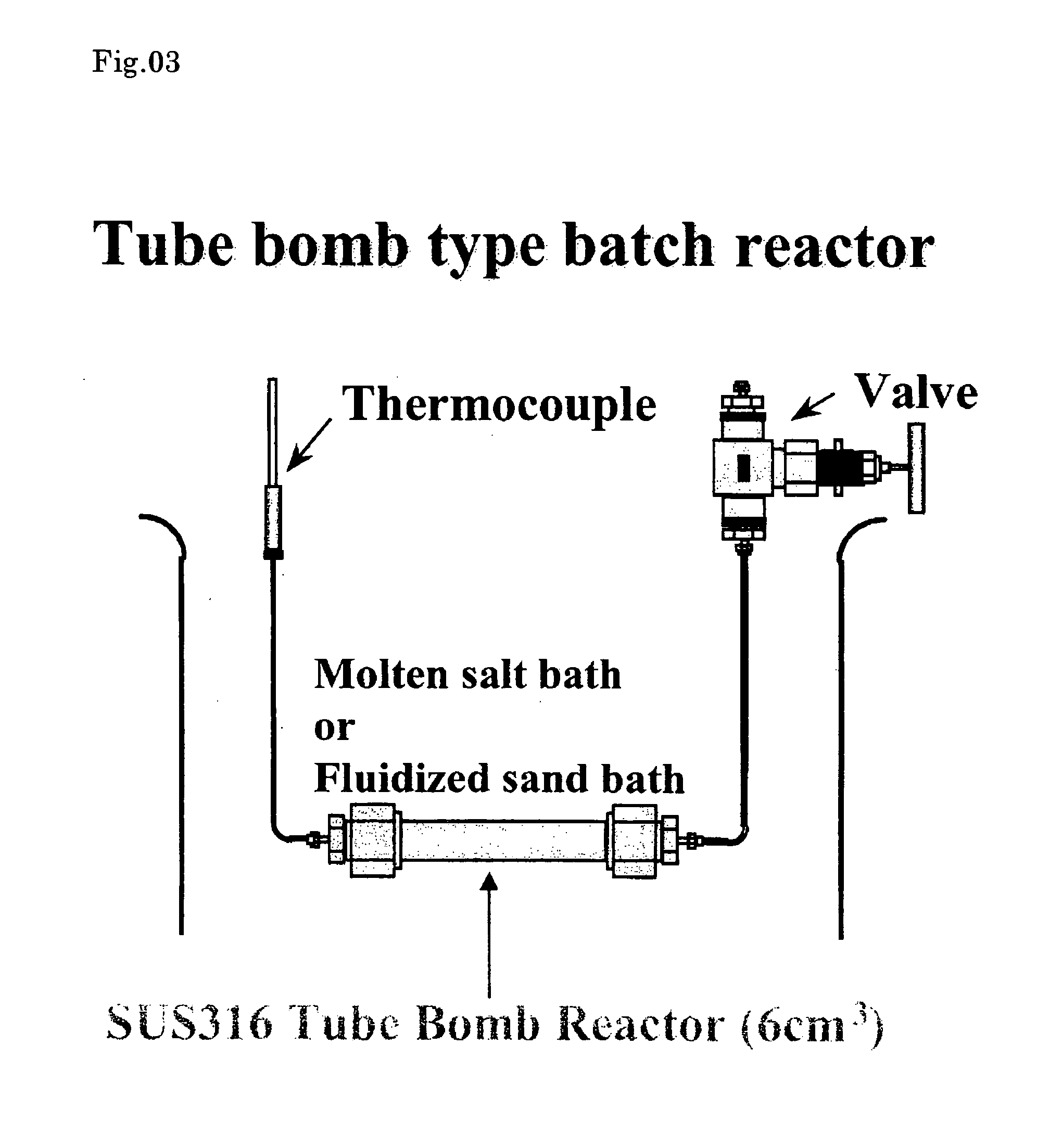

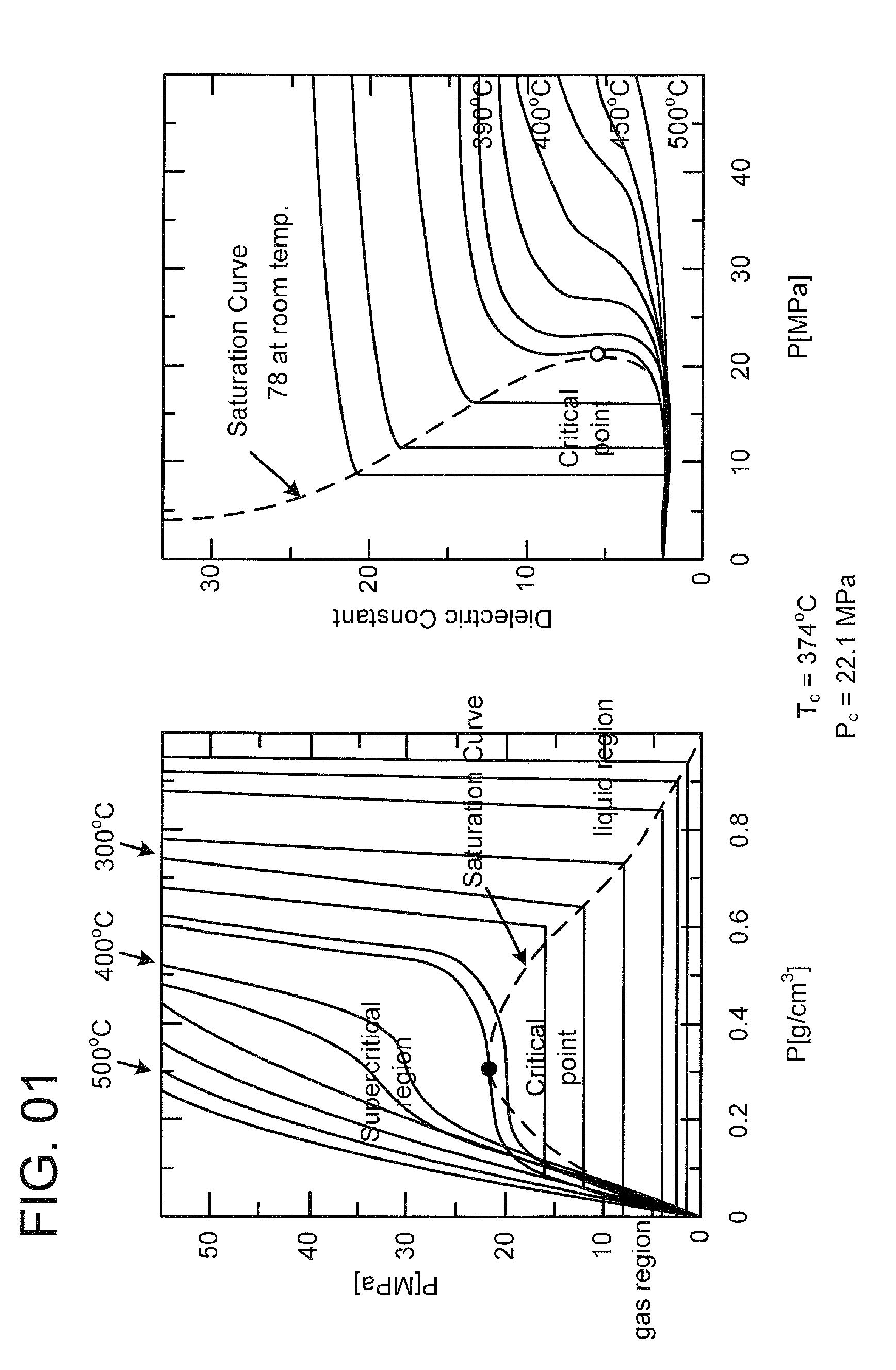

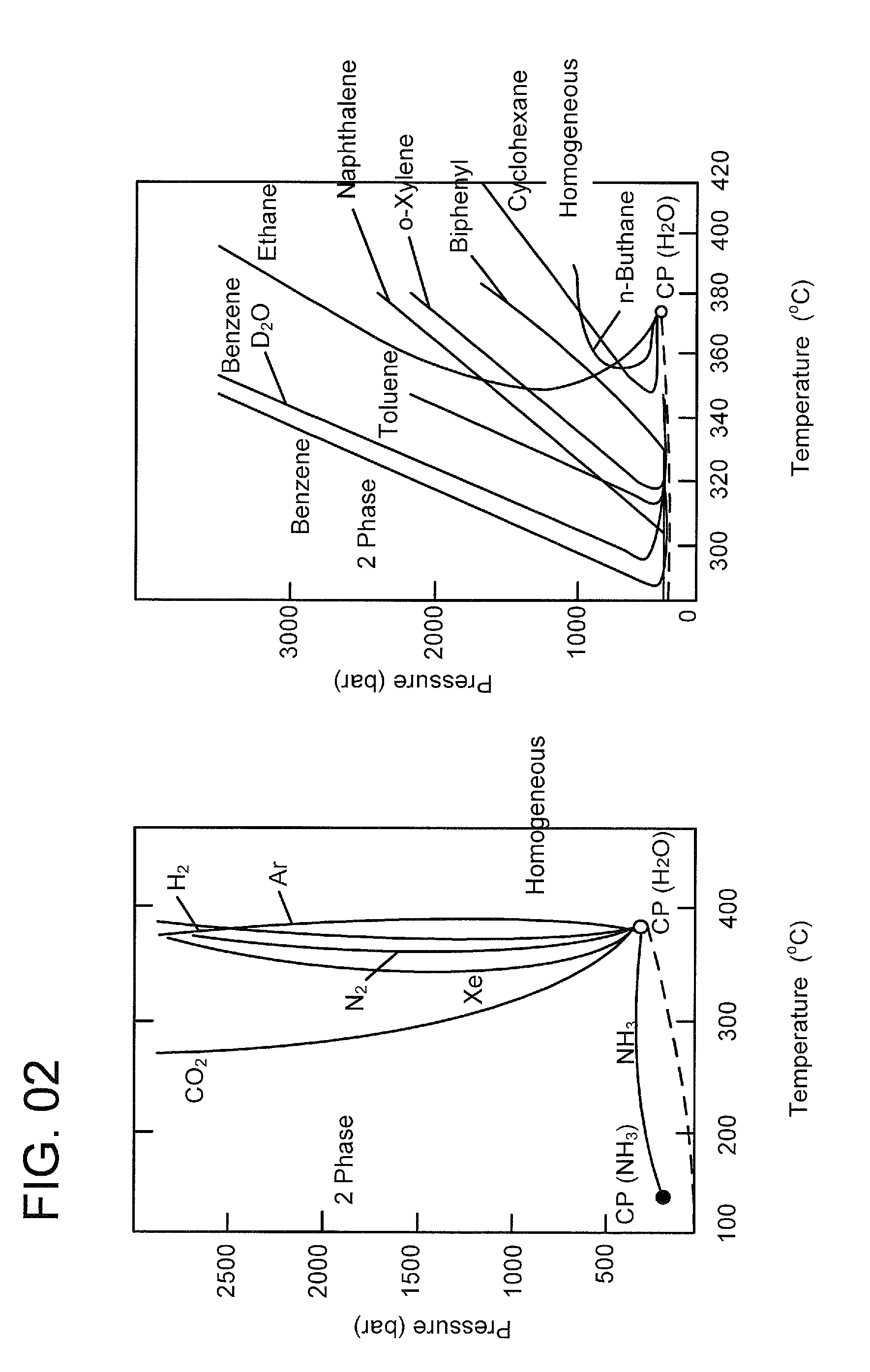

A method for producing nano-carbon materials, having a step wherein a starting material comprising one or more kinds of compounds selected from the group consisting saturated hydrocarbons, unsaturated hydrocarbons, saturated cyclic hydrocarbons, and alcohols whose atomic ratio of the component carbon to the component oxygen is more than 2.0 and a catalyst are together treated at a temperature in a range of from 100 to 800° C. while being compressed at a pressure in a range of from 0.2 to 60 MPa, where said starting material is converted into a supercritical fluid or a subcritical fluid while said supercritical fluid or said subcritical fluid being contacted with said catalyst, or a step wherein said starting material, said catalyst and a supplementary material capable of functioning as a reaction promotion medium are together treated at a temperature in a range of from 100 to 800° C. while being compressed at a pressure in a range of from 0.2 to 60 MPa, where at least said supplementary material is converted into a supercritical fluid or a subcritical fluid and said starting material is contacted with said supercritical fluid or said subcritical fluid formed from said supplementary material while being contacted with said catalyst.

Owner:CANON KK

Method for producing nano-carbon materials

InactiveUS7270795B2Efficiently and quantitatively produceLow production costMaterial nanotechnologyNanostructure manufactureAlcoholUnsaturated hydrocarbon

A method for producing nano-carbon materials, having a step wherein a starting material comprising one or more kinds of compounds selected from the group consisting saturated hydrocarbons, unsaturated hydrocarbons, saturated cyclic hydrocarbons, and alcohols whose atomic ratio of the component carbon to the component oxygen is more than 2.0 and a catalyst are together treated at a temperature in a range of from 100 to 800° C. while being compressed at a pressure in a range of from 0.2 to 60 MPa.

Owner:CANON KK

Organically modified fine particles

ActiveUS20070003463A1Easy transferManganese oxides/hydroxidesGermanium dioxideReaction fieldNanoparticle

A technique for bonding an organic group with the surface of fine particles such as nanoparticles through strong linkage is provided, whereas such fine particles are attracting attention as materials essential for development of high-tech products because of various unique excellent characteristics and functions thereof. Organically modified metal oxide fine particles can be obtained by adapting high-temperature, high-pressure water as a reaction field to bond an organic matter with the surface of metal oxide fine particles through strong linkage. The use of the same condition enables not only the formation of metal oxide fine particles but also the organic modification of the formed fine particles. The resulting organically modified metal oxide fine particles exhibit excellent properties, characteristics and functions.

Owner:SUPER NANO DESIGN CO LTD

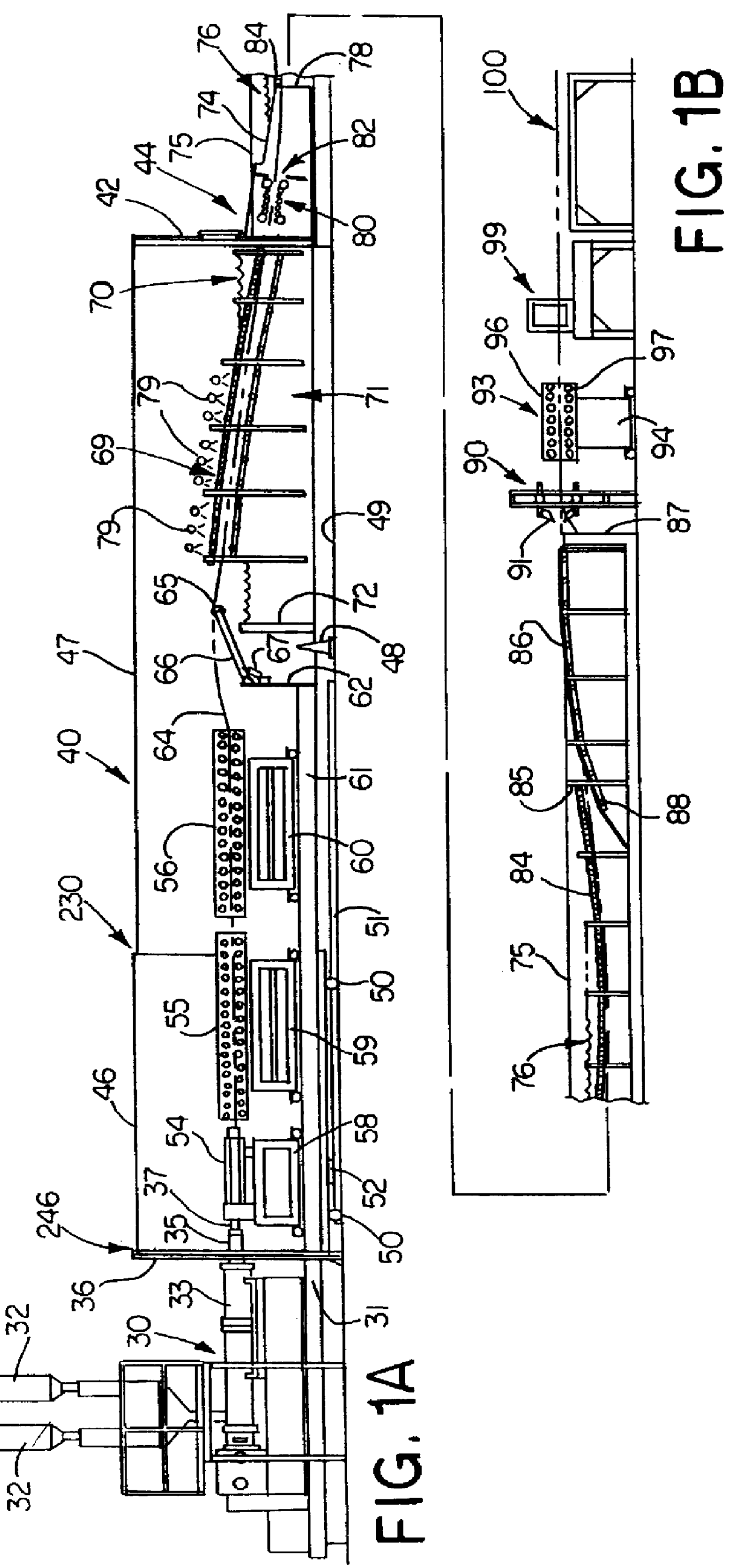

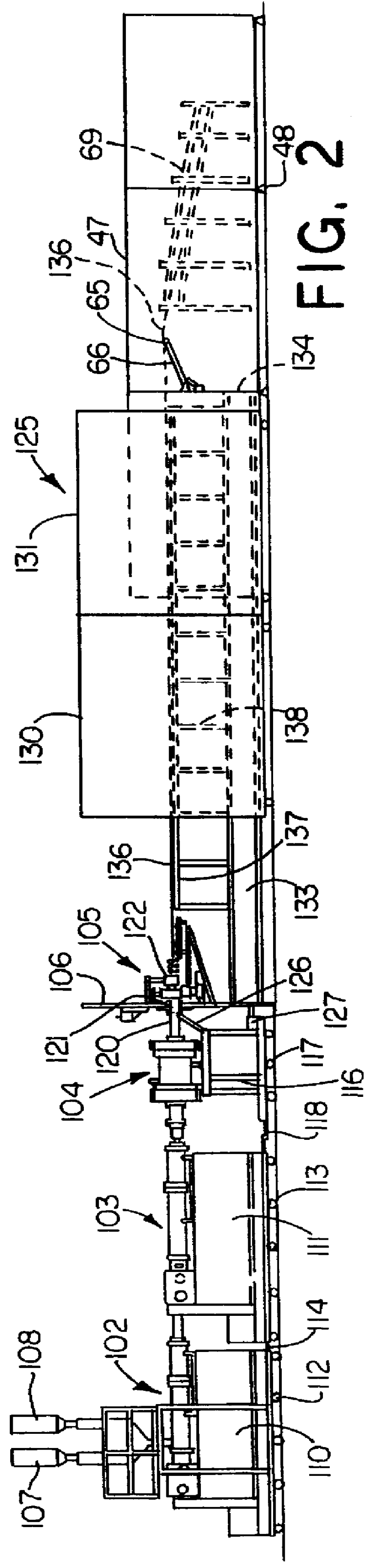

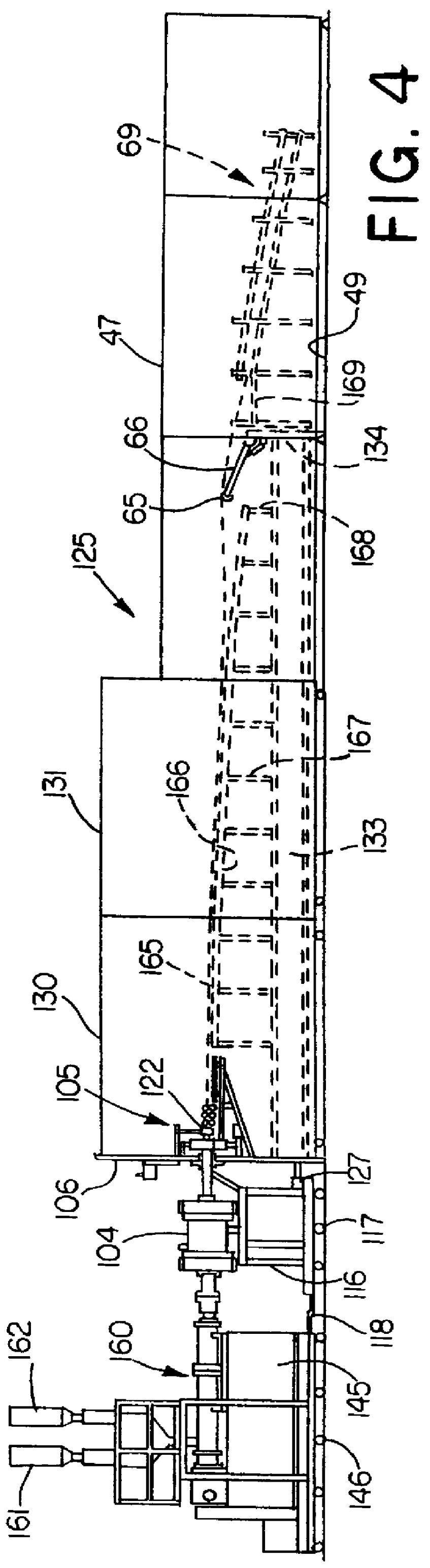

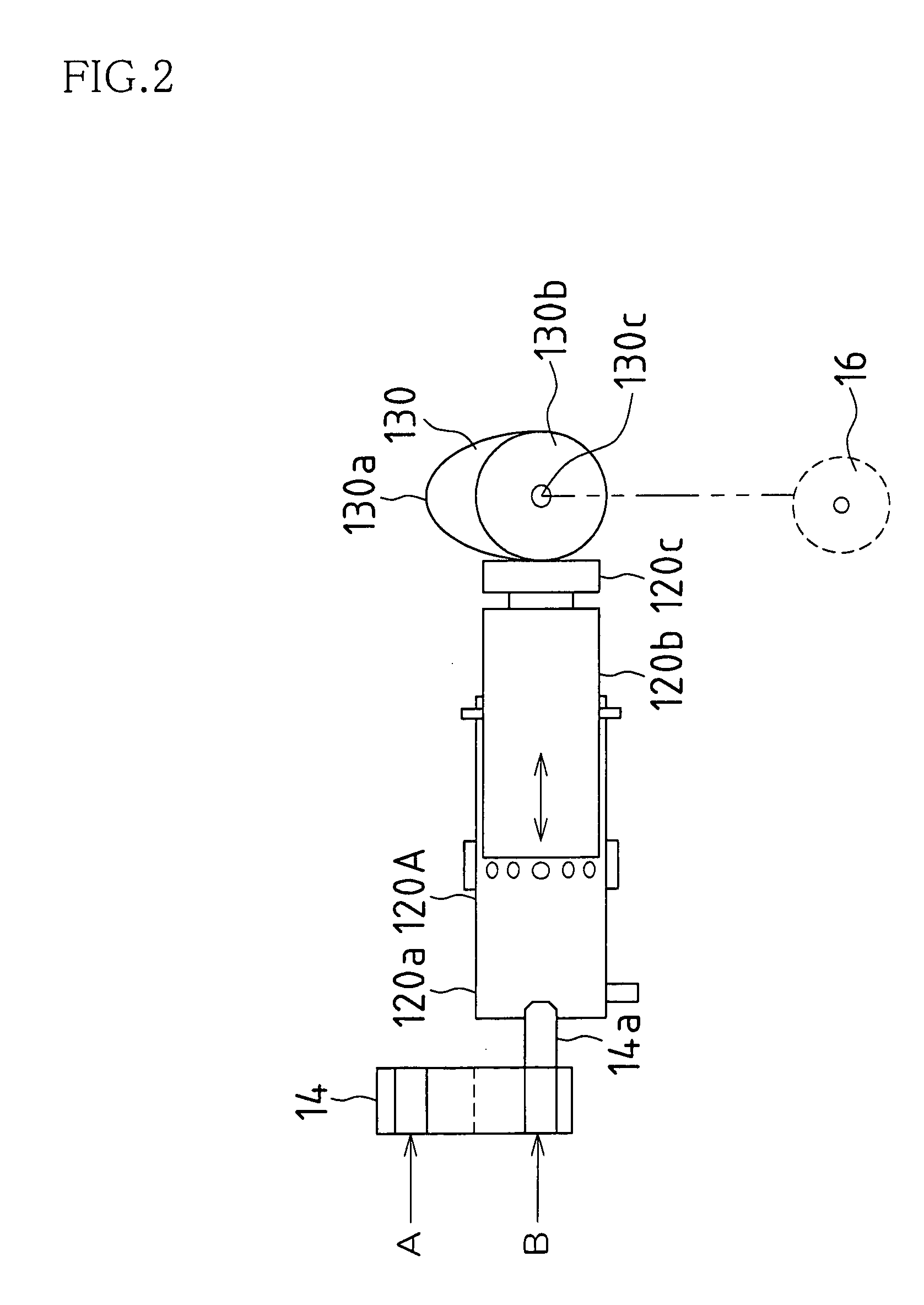

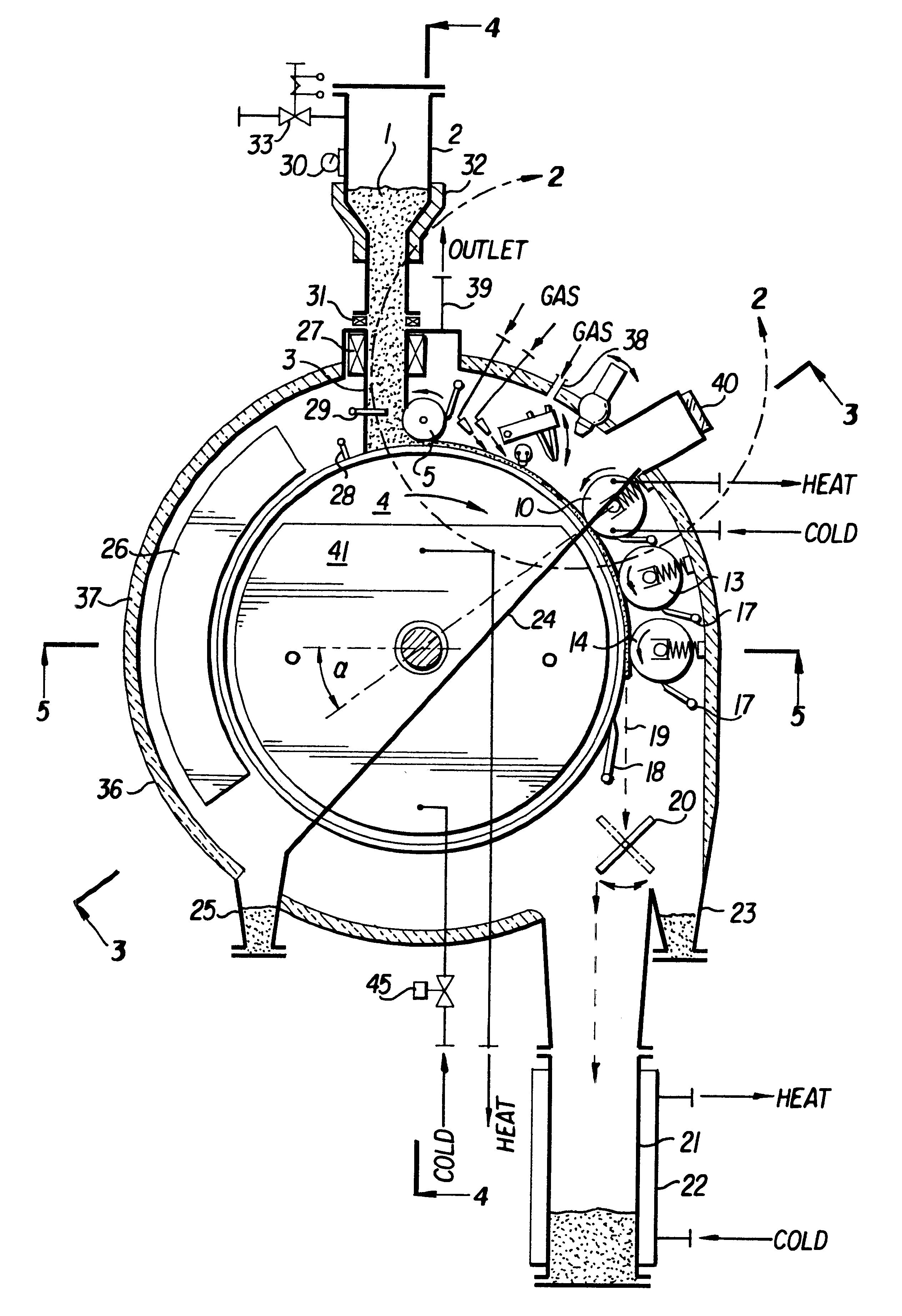

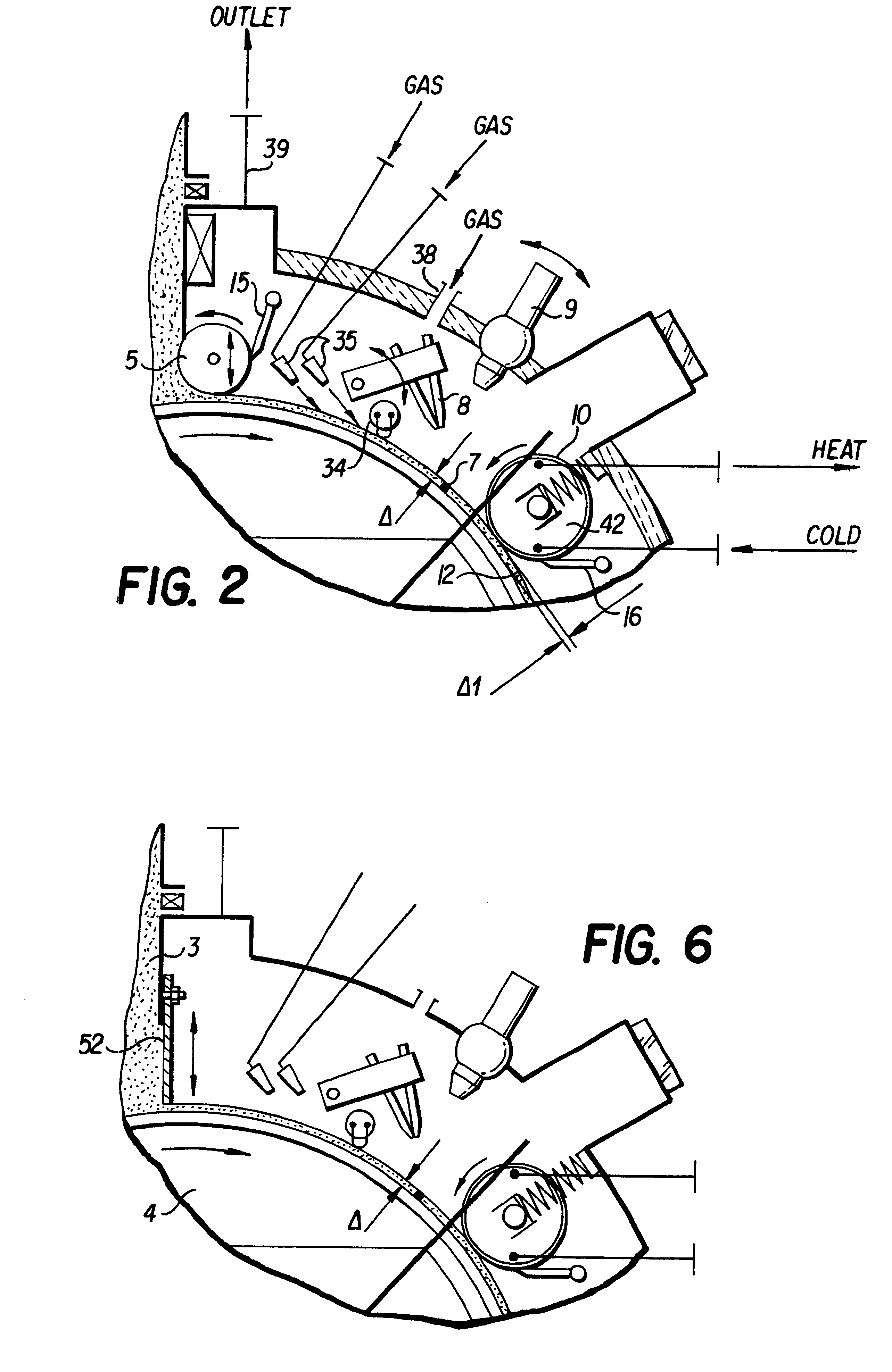

Foam extrusion apparatus

InactiveUS6113374AEasy to disassembleIncrease the sectionConfectionerySweetmeatsNarrow rangeFree rotation

An extrusion system utilizes single or tandem extruders and a mixer-cooler to extrude a foamable extrudate through a die in a sealable chamber. The foamable extrudate is shaped and calibrated within the chamber. The die is mounted on the end of a gel tube projecting through a gland seal in a fixed bulkhead forming the upstream end of the chamber. The gel tube and mixer-cooler are mounted on a movable carriage, movement of which may be used to adjust the die with respect to shaping and calibrating equipment inside the chamber. The mixer-cooler achieves a selected narrow range of uniform viscosity of the melt at the die depending on the size of the product and density. The chamber is preferably a vacuum chamber producing low density foams. The product exits the chamber to atmosphere on a continuous basis through a submerged orifice in a water baffle immersion seal. The mixer-cooler enables a large size low density product to be produced with uniform cellular structure without cell collapse or density gradients, as the product is subjected to the pressure and temperature transformations passing from the chamber to atmosphere through the water. The seal includes the submerged orifice with a free wheeling guiding system upstream of the orifice. Immediately ahead of the guiding system, the parameters of the foam extrudate are sensed to control the configuration of the orifice on a continuous basis. Before the extrudate passes into the water baffle seal it moves over a floating dancer roll, the position of which controls a haul-off such as a vacuum belt at the tail end of the system. This avoids pushing on the extrudate.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

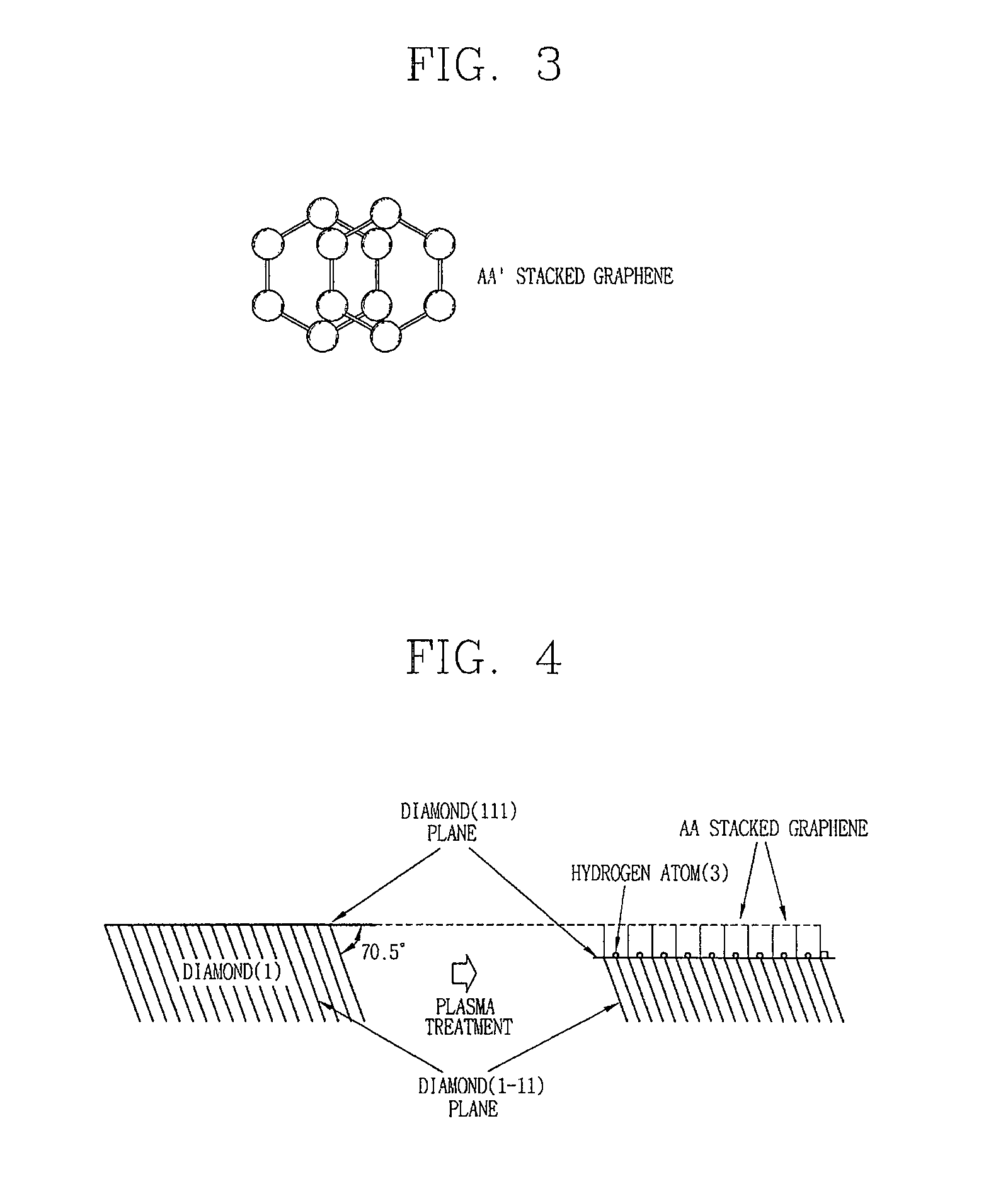

Aa stacked graphene-diamond hybrid material by high temperature treatment of diamond and the fabrication method thereof

InactiveUS20090297854A1Good physical propertiesSimple processPolycrystalline material growthAfter-treatment detailsHydrogenLattice plane

There is provided a fabrication method for an AA stacked graphene-diamond hybrid material by converting, through a high temperature treatment on diamond, a diamond surface into graphene. According to the present invention, if various types of diamond are maintained at a certain temperature having a stable graphene phase (approximately greater than 1200° C.) in a hydrogen gas atmosphere, two diamond {111} lattice planes are converted into one graphene plate (2:1 conversion), whereby the diamond surface is converted into graphene in a certain thickness, thus to fabricate the AA stacked graphene-diamond hybrid material.

Owner:KOREA INST OF SCI & TECH

Organically modified fine particles

A technique for bonding an organic group with the surface of fine particles such as nanoparticles through strong linkage is provided, whereas such fine particles are attracting attention as materials essential for development of high-tech products because of various unique excellent characteristics and functions thereof. Organically modified metal oxide fine particles can be obtained by adapting high-temperature, high-pressure water as a reaction field to bond an organic matter with the surface of metal oxide fine particles through strong linkage. The use of the same condition enables not only the formation of metal oxide fine particles but also the organic modification of the formed fine particles. The resulting organically modified metal oxide fine particles exhibit excellent properties, characteristics and functions.

Owner:SUPER NANO DESIGN CO LTD

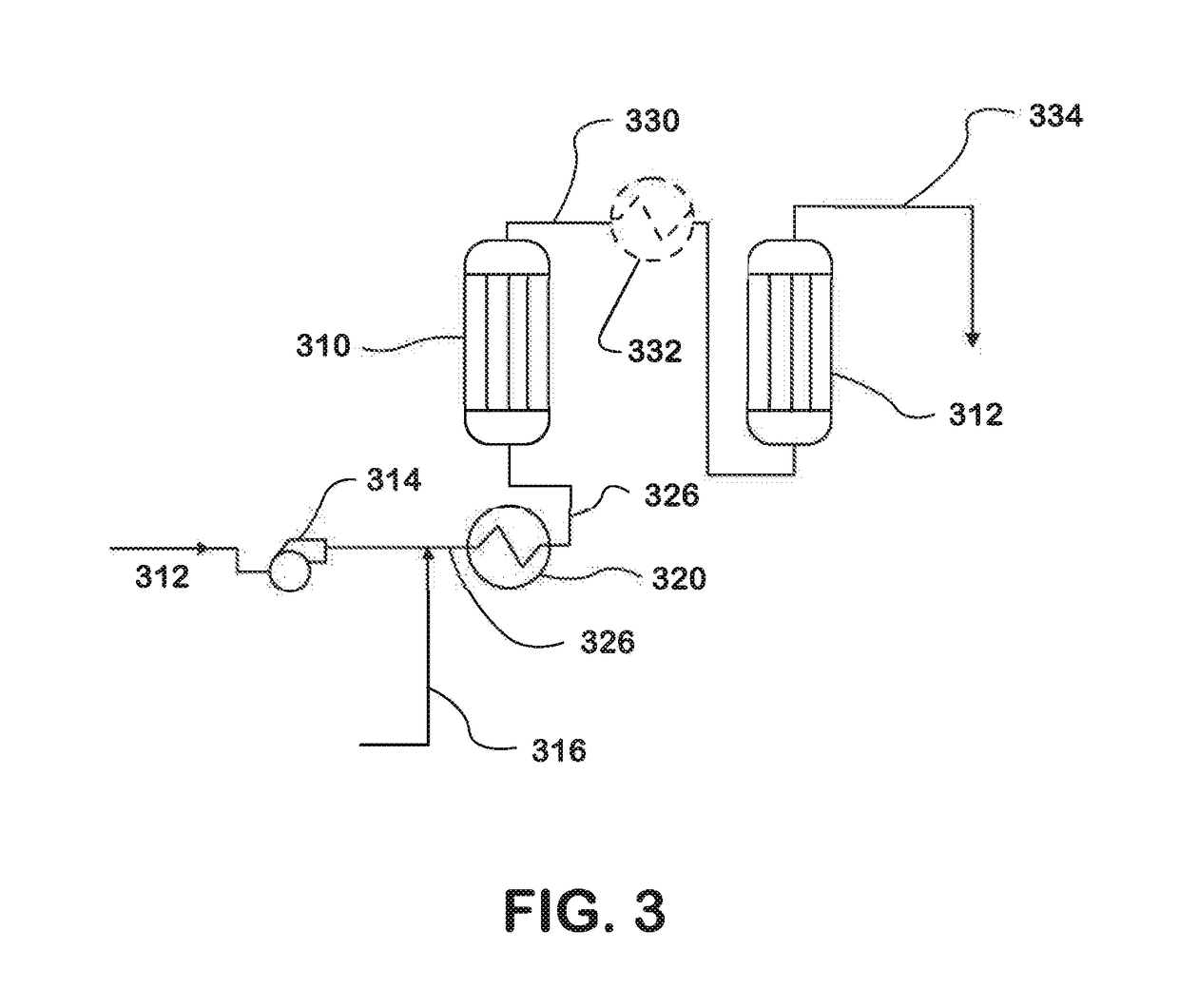

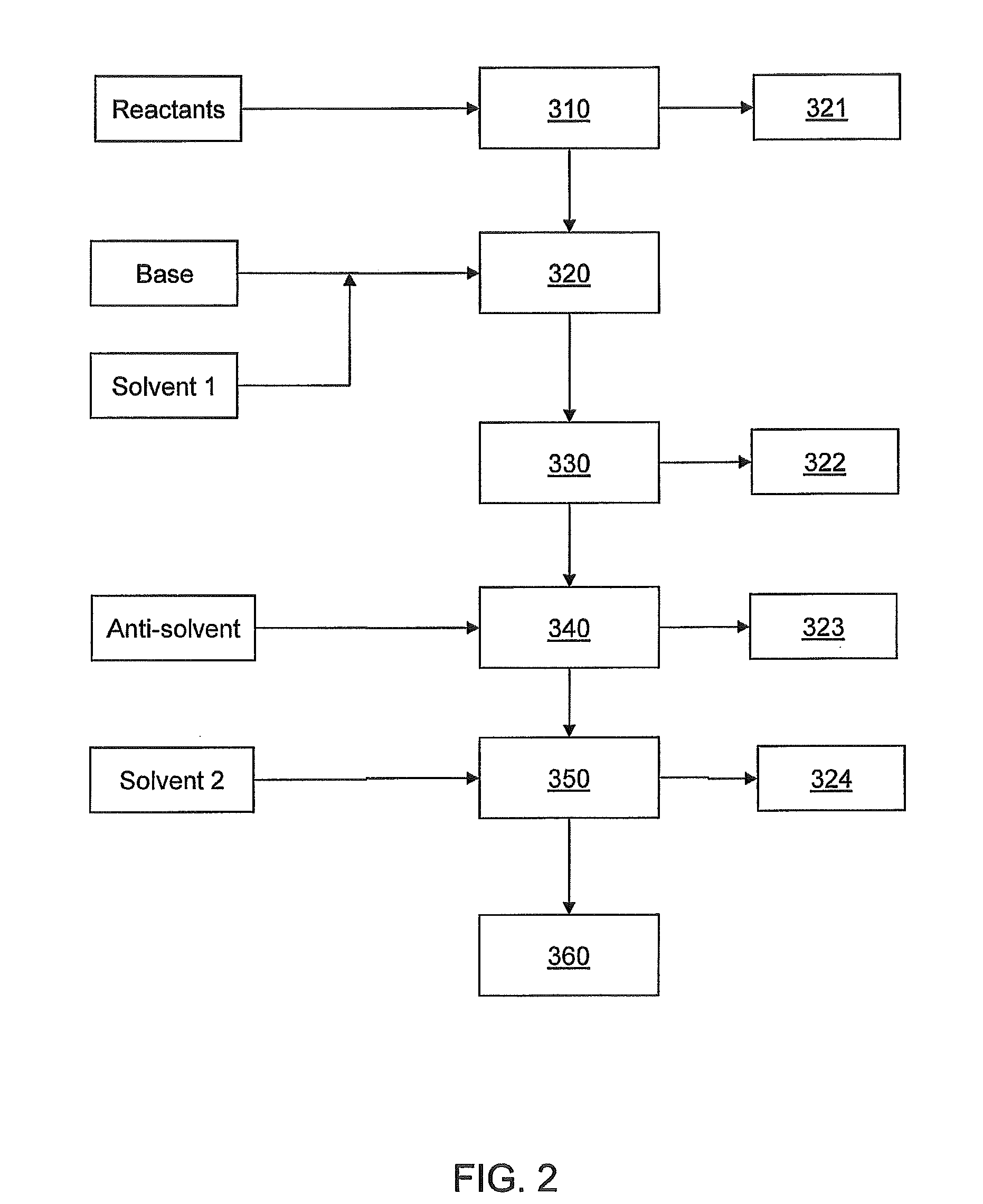

Systems and Processes for Producing Organic Acids Direct from Beta-Lactones

InactiveUS20180305286A1High purityEconomically beneficialGroup 4/14 element organic compoundsOrganic compound preparationOrganic acidReactor system

Provided herein are reactor systems and processes for producing organic acids directly from beta-lactones. Such reactor systems and processes involve the use of a heterogeneous catalyst, such as a zeolite at vapor phase conditions. The reactor systems and processes may use a fixed bed, moving bed or fluidized contacting zone as reactor configurations.

Owner:NOVOMER INC

Method and device for producing silicon monoxide

ActiveCN108821292ASimple processShort processSilicon oxidesPressure vessel componentsSilicon monoxideSilicon oxygen

The invention provides a method and device for producing silicon monoxide. The method disclosed by the invention is mainly characterized in that a silicon-containing substance such as silicon oxide, monatomic silicon, silicon-containing gas (liquid) , and non-completely oxidized silicon, particularly dried solid silicon powder separated from diamond wire silicon cutting waste slurry is subjected to further oxidation (including incomplete oxidation), reduction or addition of silicon dioxide to approach to an ideal ratio of generation of silicon monoxide, and then a silicon monoxide gas is formed under a condition facilitating overflow of silicon monoxide, and then the gas is condensed into rod-shaped, plate-shaped, granular or powdery silicon monoxide. In one embodiment, an oxide layer (SiO2) on the surface of silicon particles (Si) is controlled, so that a silicon monoxide precursor can be prepared, and the preparation process can be oxidization of the silicon or reduction of overly-oxidized silicon-oxygen compounds, and optionally, in another embodiment of the present application, a silicon monoxide powder can be directly produced by utilizing incomplete oxidation of a silicon-containing gas.

Owner:储晞

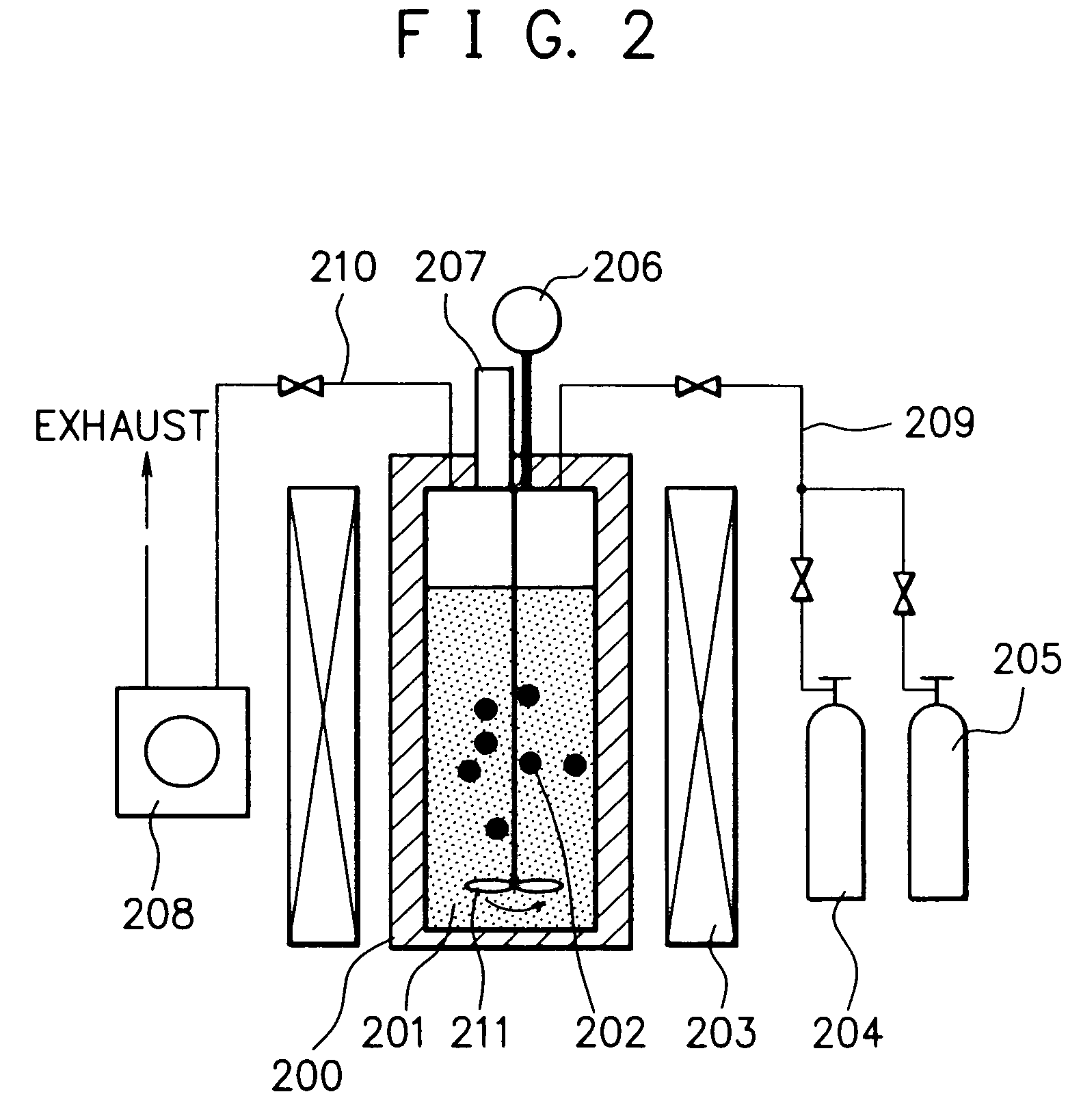

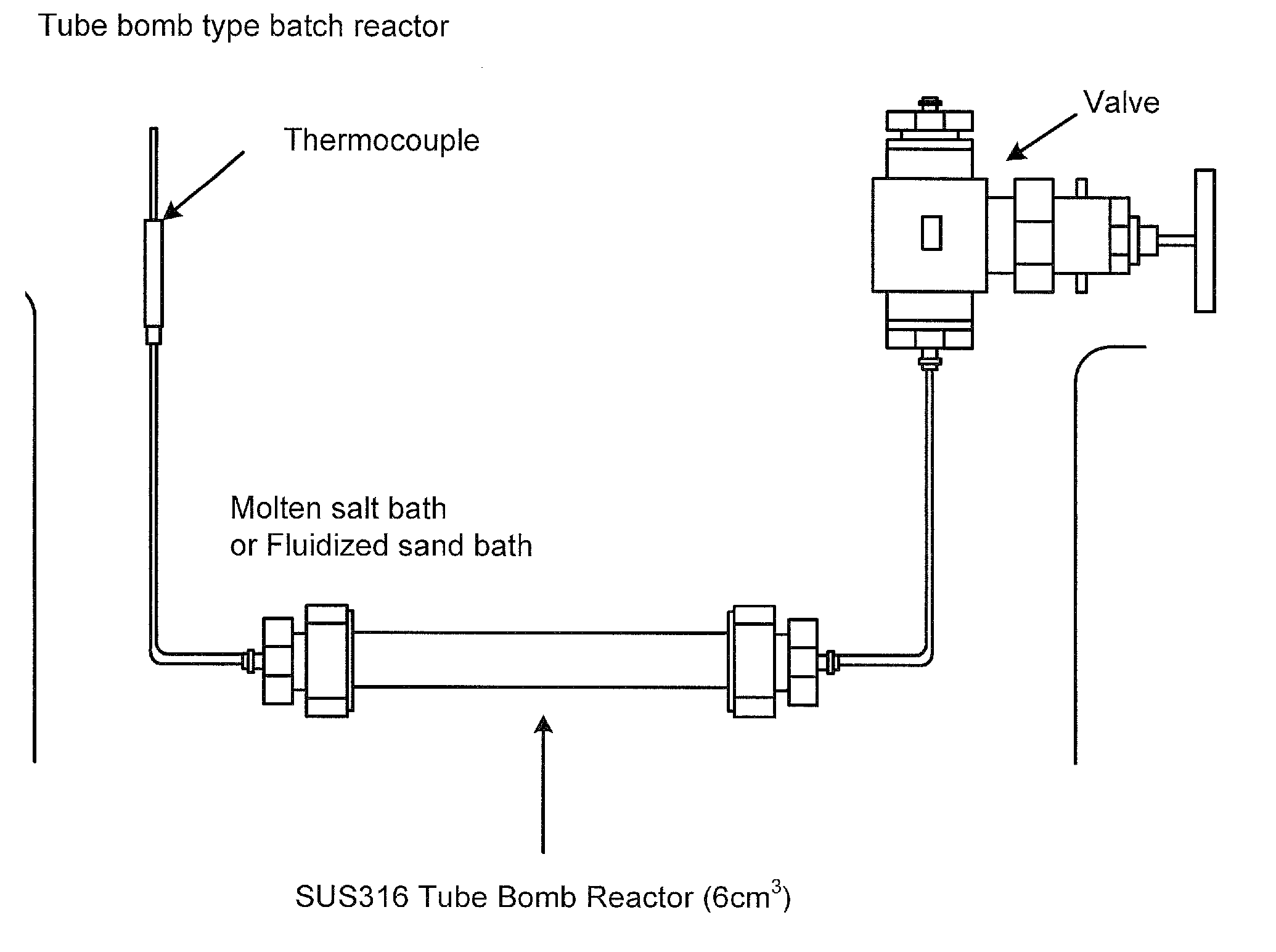

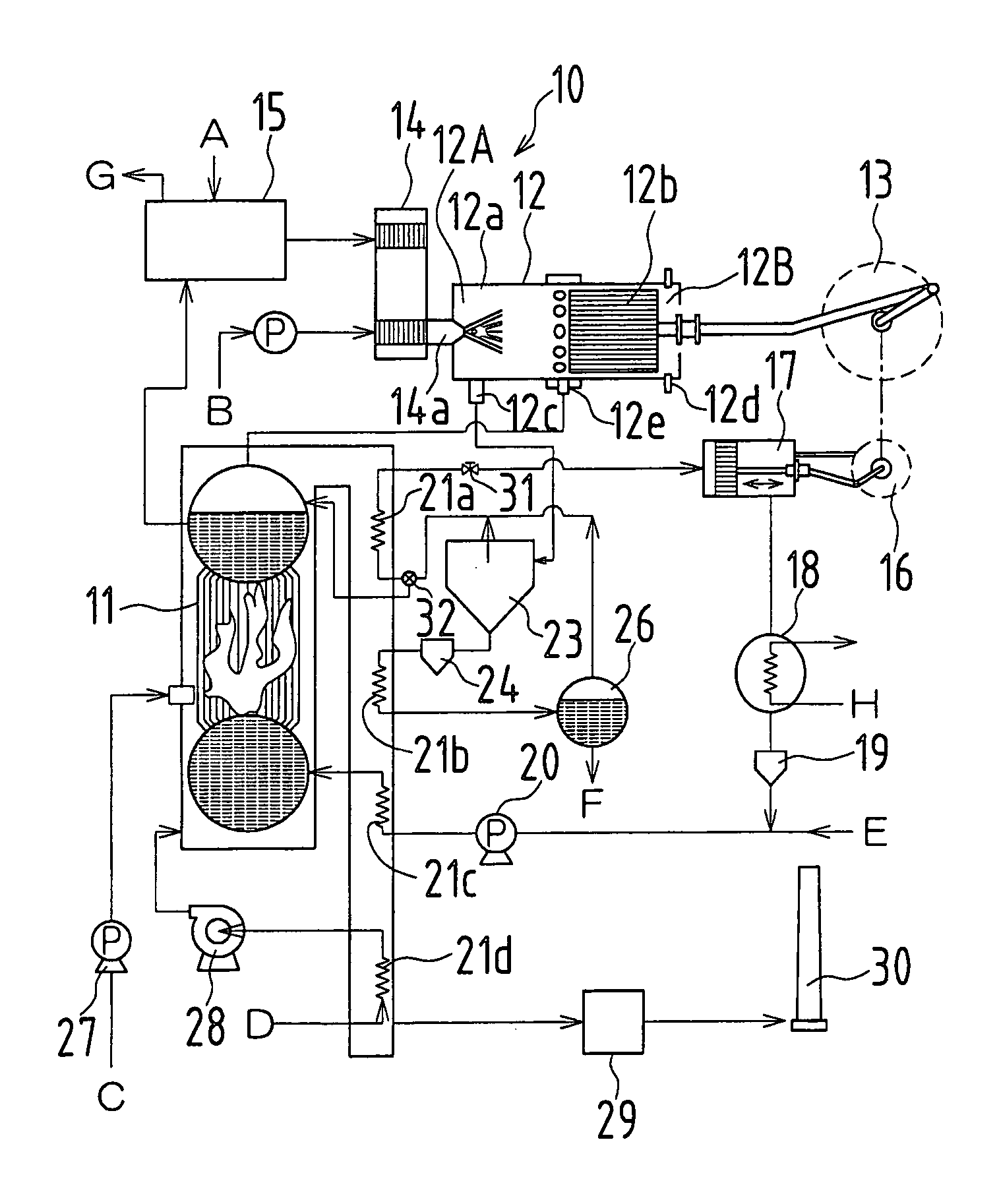

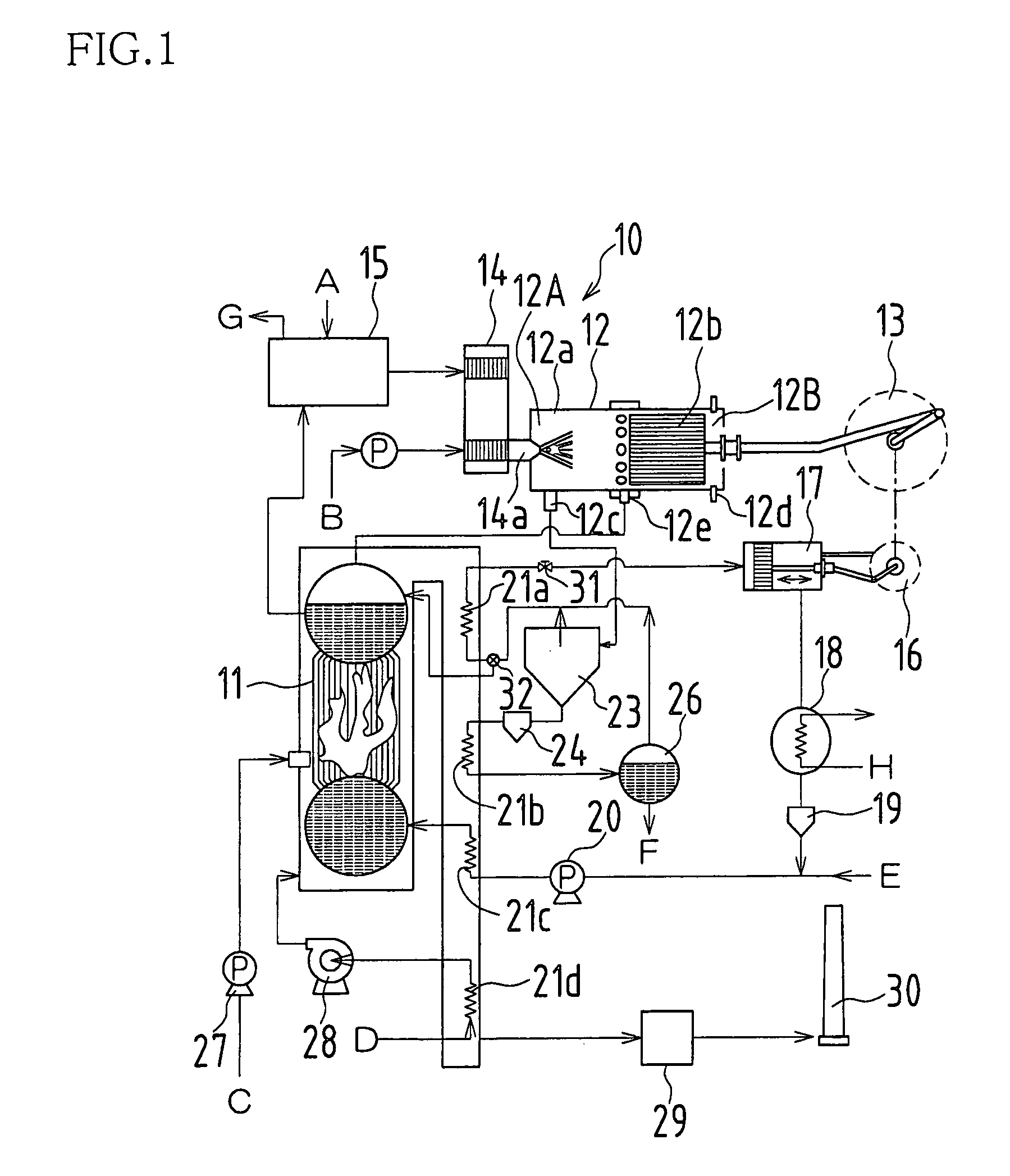

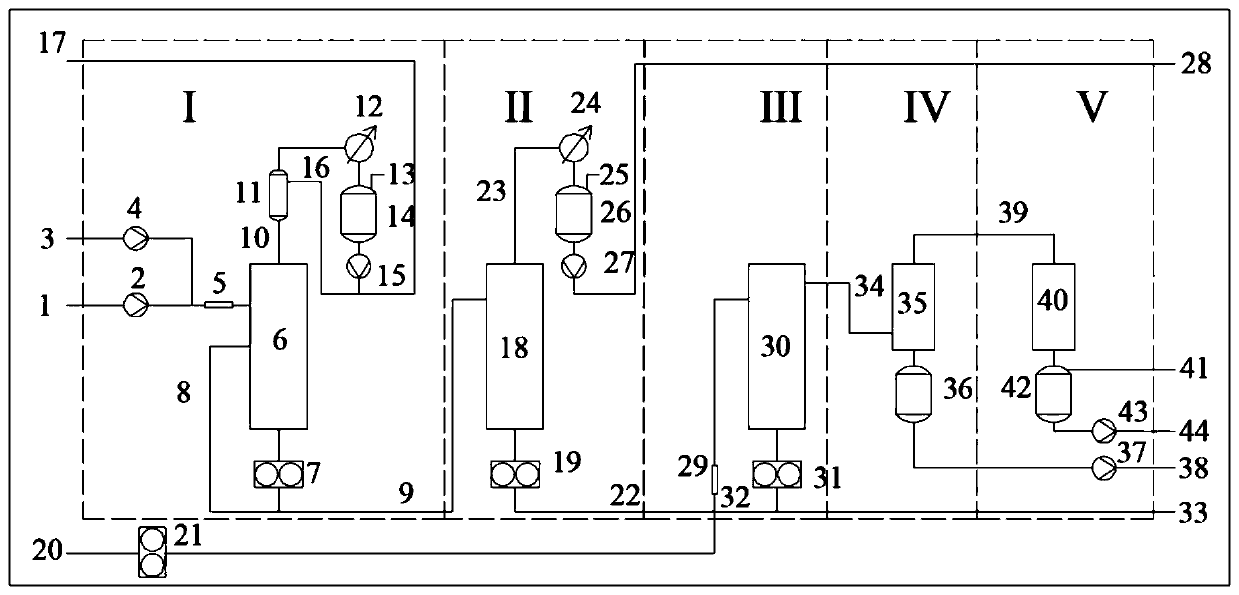

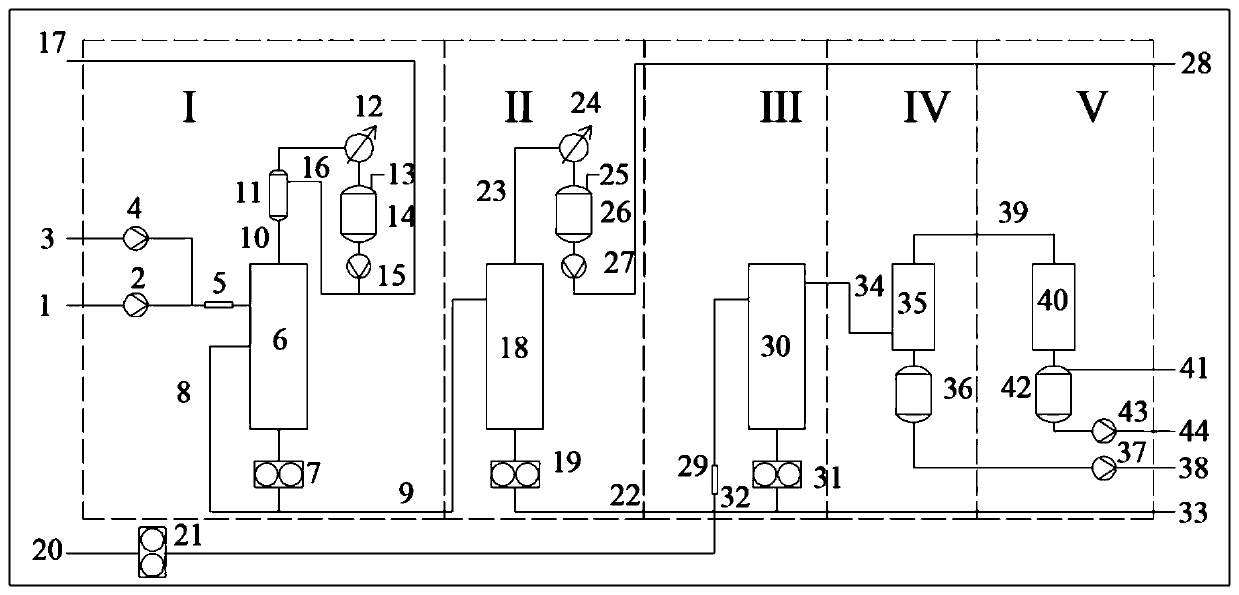

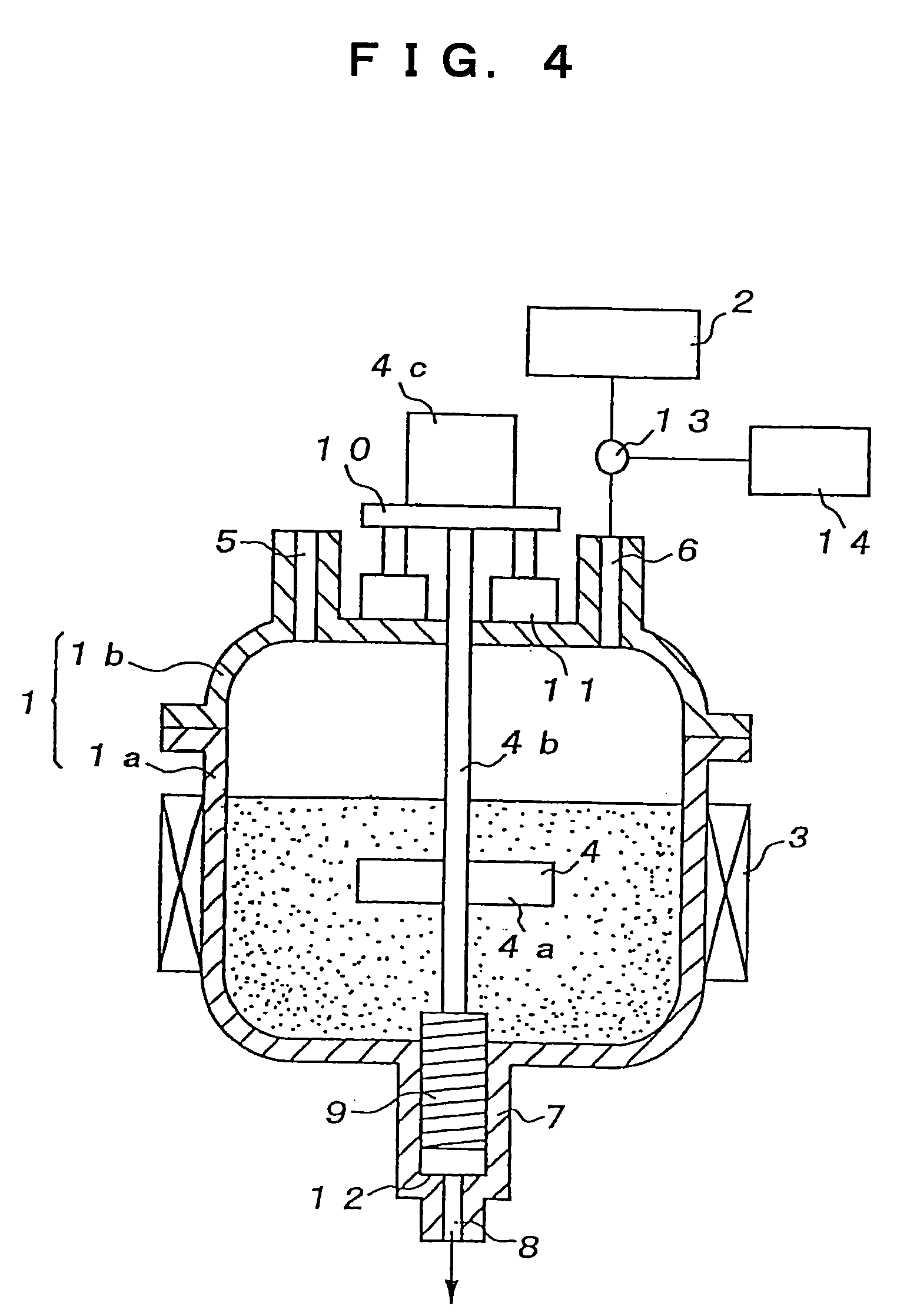

Reaction system of organic substances employing supercritical fluid or subcritical fluid

InactiveUS20040094144A1Less energy consumptionSimple processFatty acid esterificationGas production bioreactorsChemical reactionHigh energy

Disclosed is a reaction apparatus for organic and / or other substance(s) employing supercritical fluid(s) and / or subcritical fluid(s) permitting injection of organic substance(s) and / or other reactant substance(s) in homogeneous state(s) to reactor(s) without occurrence of clogging at location(s) of such injection, and also permitting actuation to occur in industrial fashion and at high energy efficiency. Reactor(s) (12) of this reaction apparatus comprise cylinder(s) (12a) and piston(s) (12b) provided at such cylinder(s) (12a). Actuation in periodic fashion is permitted by operating piston(s) (12b) to compress fluid vapor(s) and obtain supercritical fluid(s) and / or subcritical fluid(s); operating piston(s) (12b) in reverse direction(s) following conclusion of chemical reaction(s) of reactant substance(s), lowering temperature(s) and pressure(s) and stopping reaction(s); and removing, from cylinder(s) (12a), product(s) obtained while at the same time delivering new charge(s) of fluid vapor(s) to cylinder(s) (12a).

Owner:YANMAR CO LTD +2

Reaction apparatus for organic and/or other substances employing supercritical fluid or subcritical fluid

InactiveUS7547539B2Simple processLess energy consumptionFatty acid esterificationGas production bioreactorsChemical reactionHigh energy

Owner:YANMAR CO LTD +2

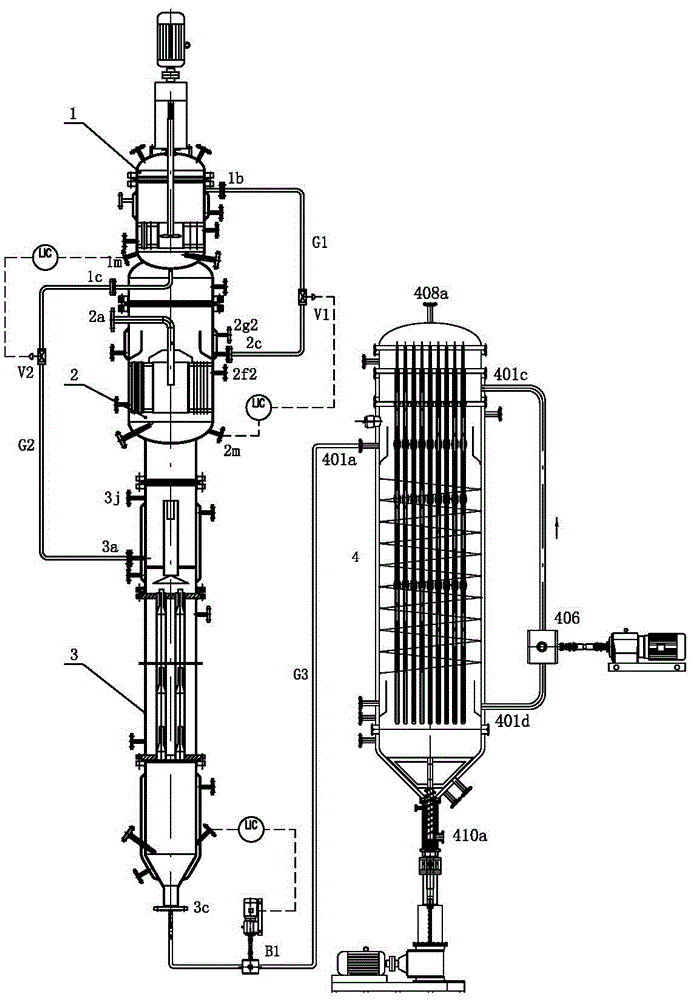

Synthesis method and device for rapidly producing lactide at high yield

ActiveCN111153886AShort manufacturing timeHigh yieldProcess control/regulationOrganic chemistryPoly-L-lactideOligomer

The invention discloses a synthesis method and device for rapidly producing lactide at high yield. The method comprises the steps: adding a lactic acid single component or lactic acid into a catalystdouble component, enabling the mixture to enter an oligomer preparation system through a mixer, increasing the residence time through bottom circulation, synthesizing oligomeric lactic acid, and enabling a gas-phase component to pass through a rectification system, so as to improve the yield of oligomeric lactic acid; removing unreacted lactic acid and water from the oligomeric lactic acid througha purification device; and adding a catalyst into the light-component-removed oligomeric lactic acid, allowing the mixture to pass through a mixer, allowing the mixture to enter a depolymerization reactor, depolymerizing so as to obtain lactide, allowing heavy components to enter the depolymerization reactor again through reflux, and allowing light components to pass through a purification and recovery system so as to obtain the lactide product. With the adoption of the device, lactide can be efficiently synthesized, crude lactide with the yield of 94-98% can be obtained within short residence time of 0.5-5 minutes, the molecular weight of the heavy-component polylactic acid is slowly increased, and the heavy-component polylactic acid can be returned for depolymerization; after the lightcomponents pass through a simple purification system, the content of L-lactide, D-lactide or DL-lactide in the lactide product is 94%-98%, and the content of meso-lactide is 0.5%-5.5%.

Owner:NANJING UNIV +1

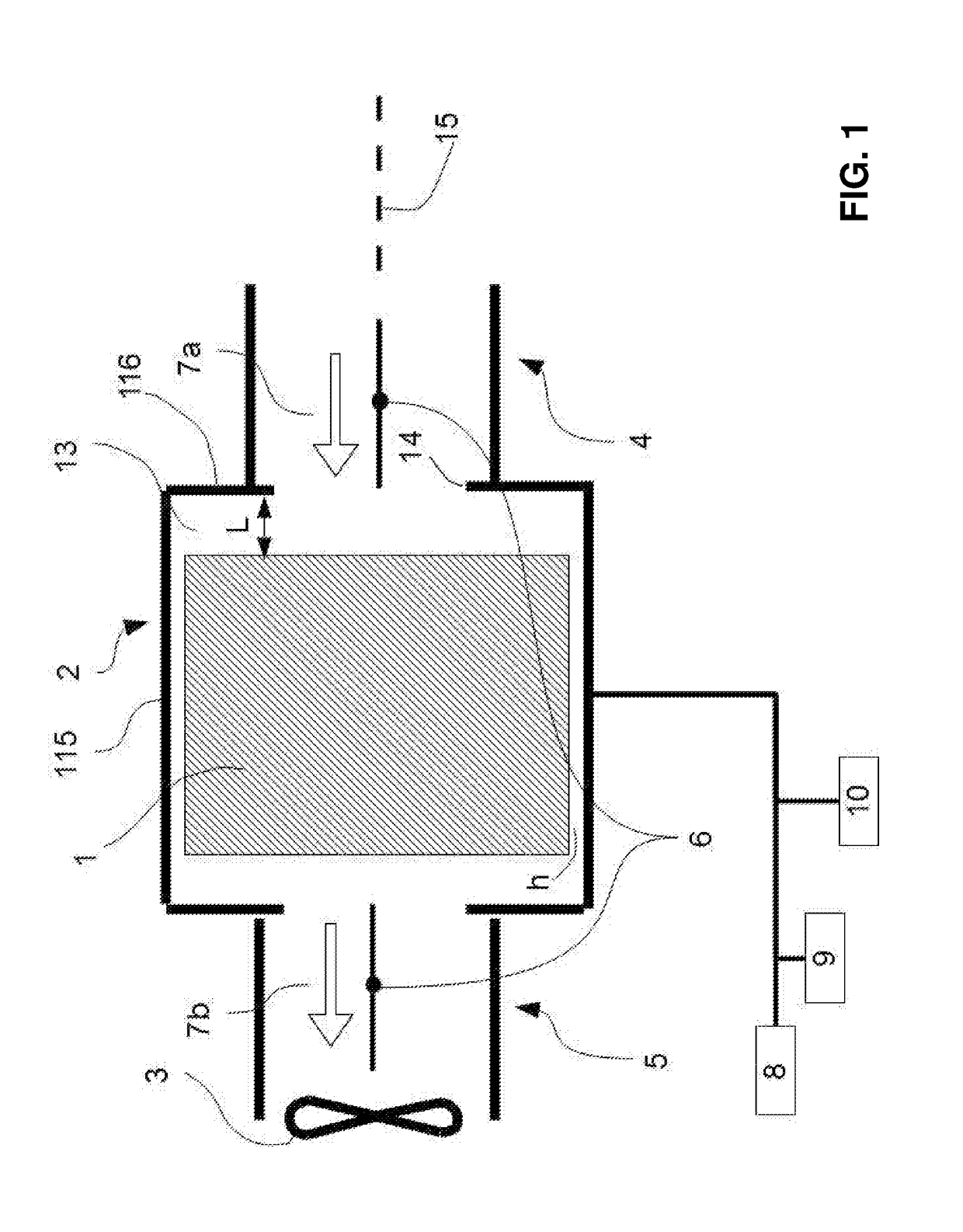

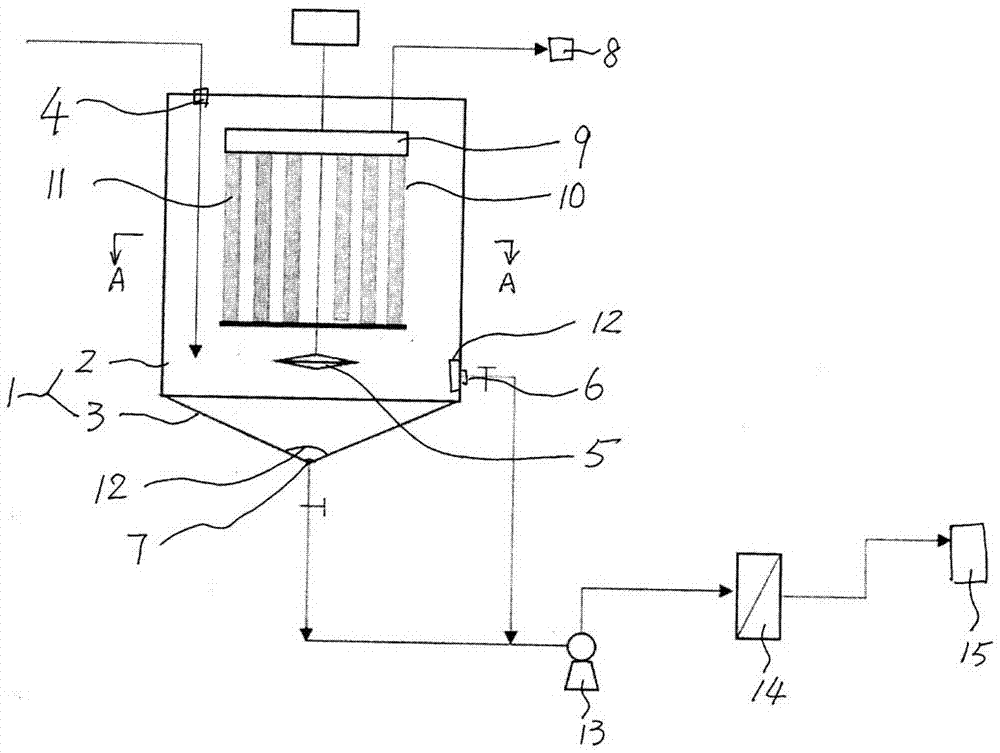

Direct air capture device

ActiveUS20170106330A1Improve mechanical stabilityLarge flow cross sectionGas treatmentDispersed particle separationInterior spaceEngineering

A vacuum chamber (2) for a direct air capture process and enclosing an interior space (13) for housing an adsorber structure (1) is given comprising a contiguous circumferential wall structure (115) along an axis (15), which circumferential wall structure (115) in an axial direction is closed by an inlet and an outlet axial wall (116), respectively, both axial walls (116) comprising at least one closing stainless steel lid (6) allowing for, in an open position, gas to be circulated through the vacuum chamber (2) for passing an adsorber structure (1), and, in a closed position, to close the interior space (13) and to allow evacuation of the interior space (13) down to pressure of 500 mbarabs or less.

Owner:CLIMEWORKS

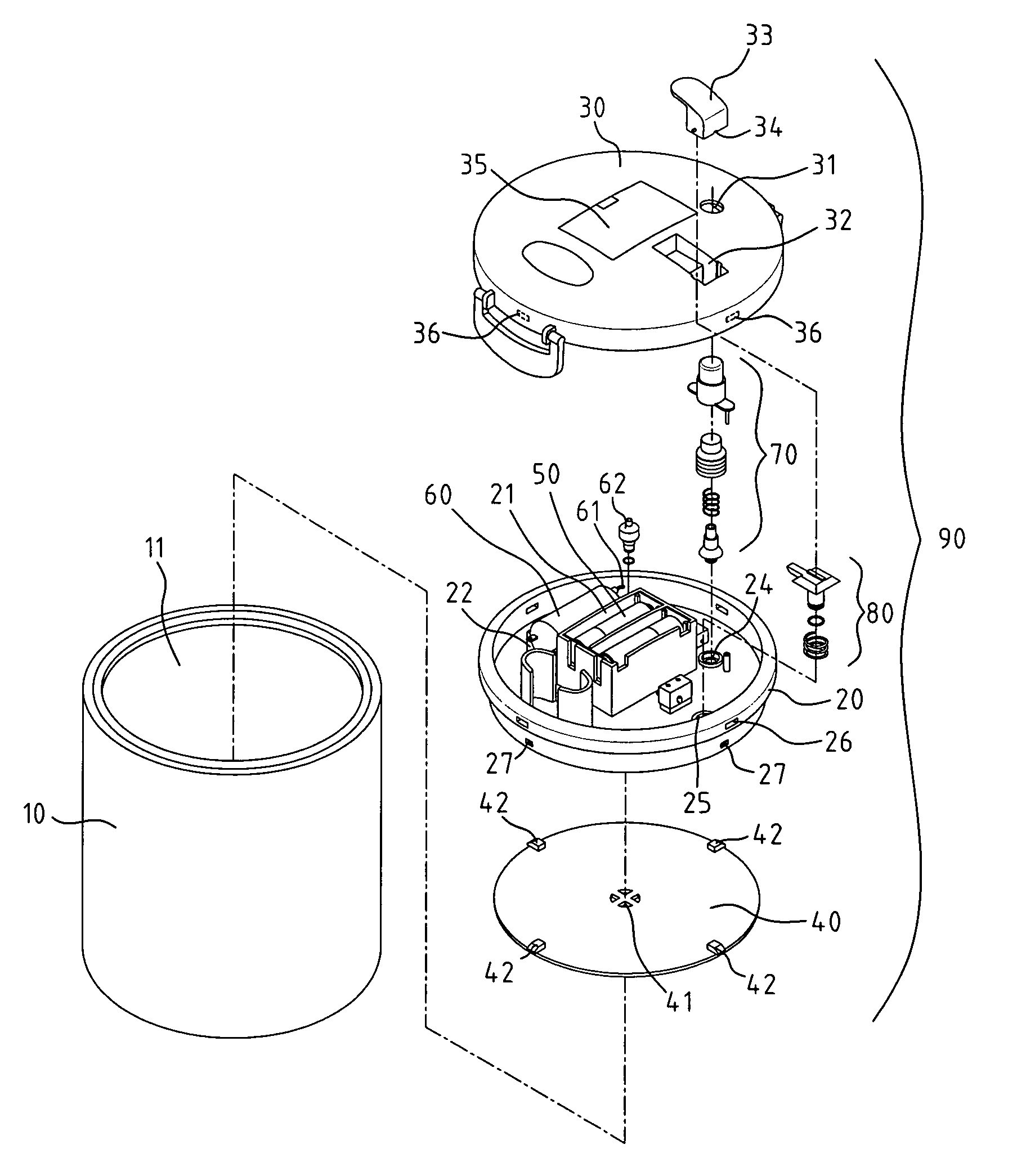

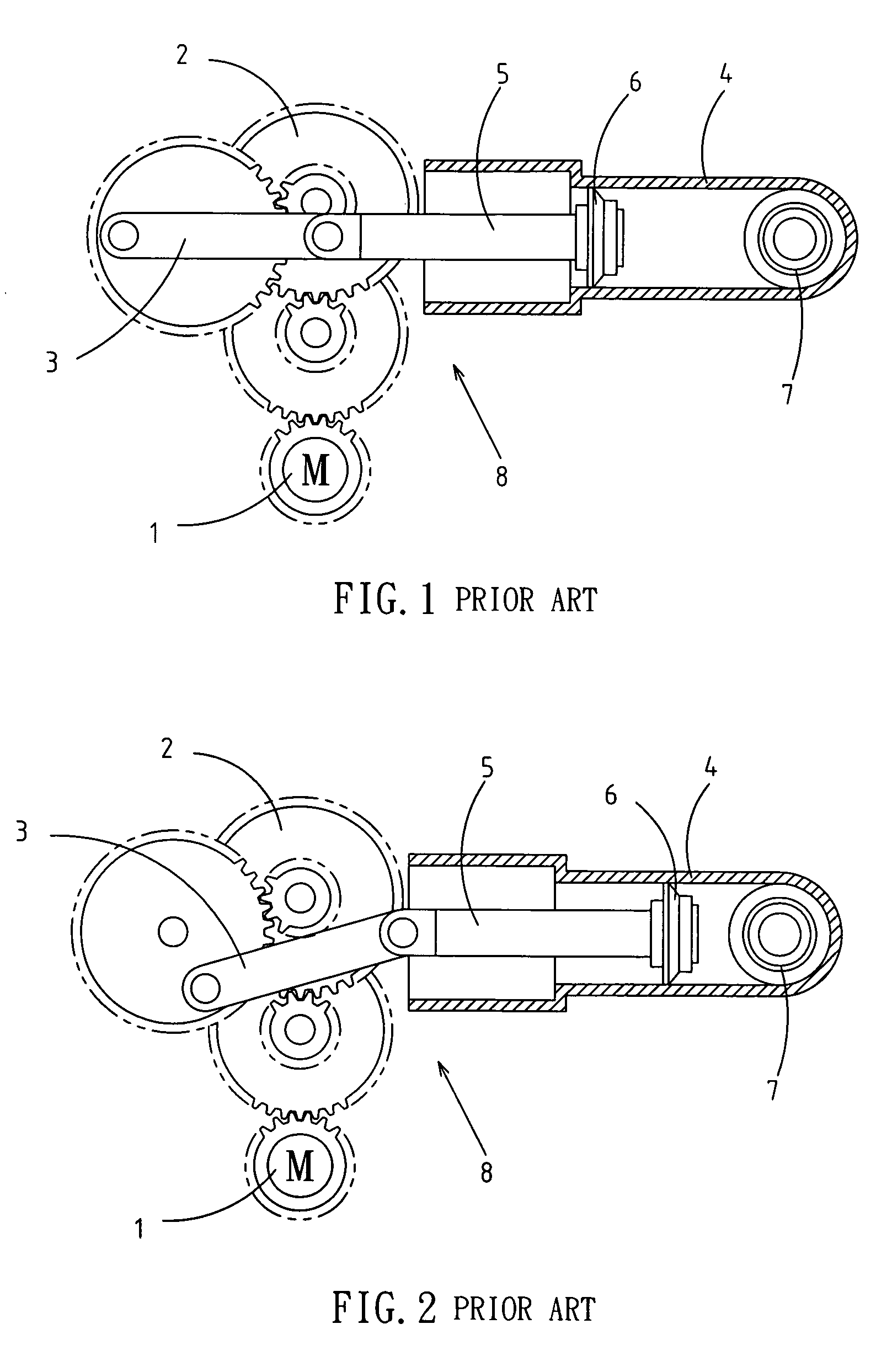

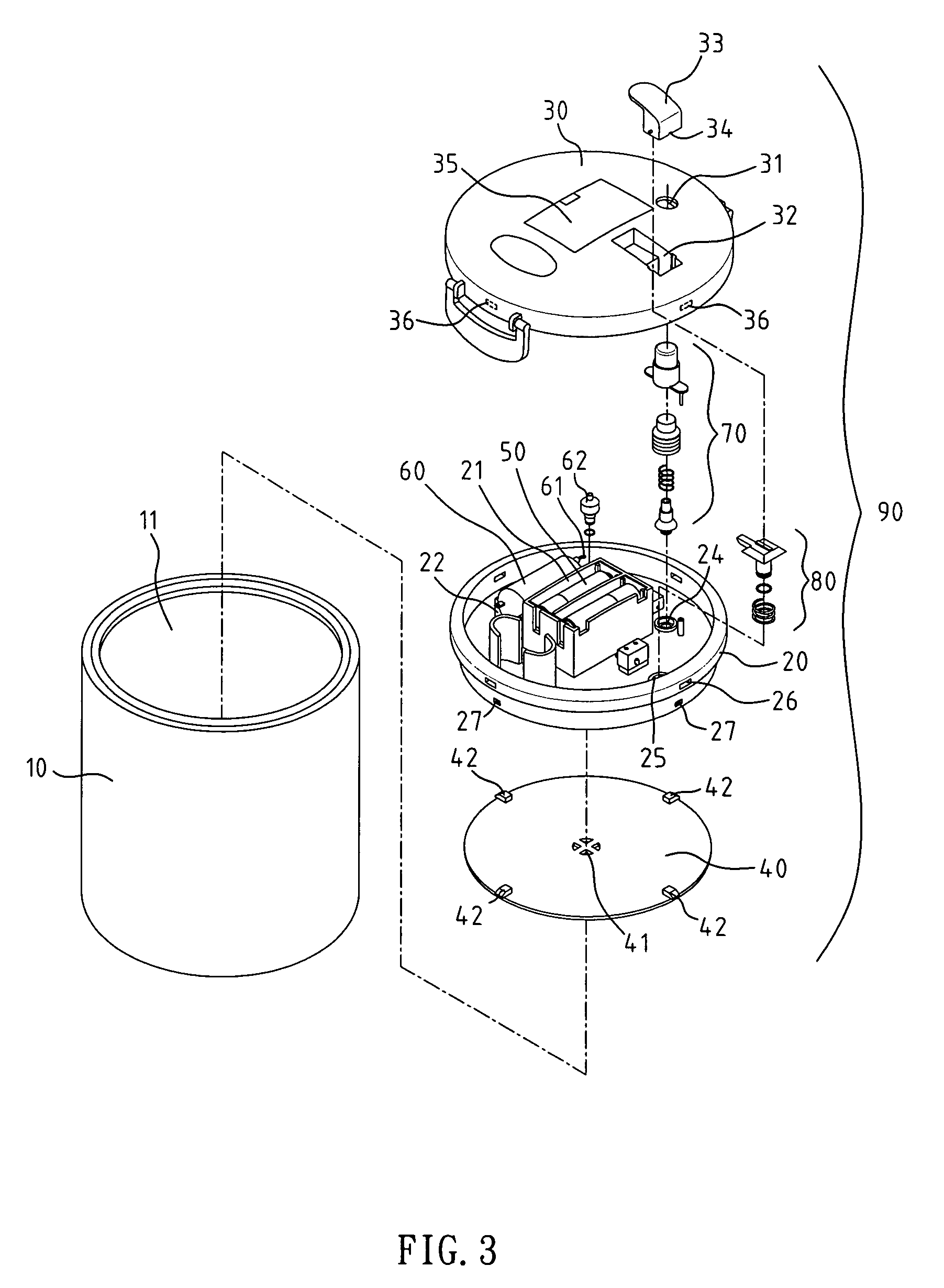

Automatic suction structure of a vacuum container

InactiveUS7721771B2Easy to operateSimple structureLiquid fillingClosuresEngineeringAutomatic testing

The present invention provides an improved automatic suction structure of a vacuum container. The structure includes a pumping unit, a power supply, a vacuum releaser and a vacuum detector. The structure allows for automatic air suction, automatic detection, safety power disconnection and continuous vacuuming as well as easy operation. The present invention guarantees improved quality and convenient operation.

Owner:CHOU MING SHI

Method and special device for heterogeneous catalyzed synthesis of triacetonamine

ActiveCN107033066AHigh yieldReduce the difficulty of separationOrganic chemistryChemical/physical/physico-chemical stationary reactorsHindered amine light stabilizersTriacetone amine

The invention belongs to the technical field of preparation of hindered amine light stabilizer midbody and pharmaceutical midbody triacetonamine, and particularly relates to a method and a special device for heterogeneous catalyzed synthesis of triacetonamine. The technical scheme is that a cone base reaction kettle consisting of a straight cylinder section and a cone cylinder section is applied, and a water knockout drum formed by a tubular type membrane tube is arranged in the cone base reaction kettle; heterogeneous catalyst and acetone are added in the reaction kettle; after stirring and heating, ammonia gas is filled for reaction; the procedures of separating water by the water knockout drum, cooling, stopping mixing, separating water and standing are carried out, and reaction fluid is discharged and filtered to obtain a crude product of triacetonamine; finally, the crude product is rectified to obtain the high-purity triacetonamine product. In the invention, the heterogeneous catalyst is applied to replace the homogeneous catalyst, thus the separating difficulty of the catalyst is reduced, the high saline-alkali waste water generated from separation process of homogeneous catalyst is avoided; the reaction water is separated from the reaction process, the yield of triacetonamine is improved, and the water separating cost of the rectifying technique is reduced. The content of organic matters in separated water of the water knockout drum is low, and water disposal cost is reduced.

Owner:HENGSHUI KAIYA CHEM

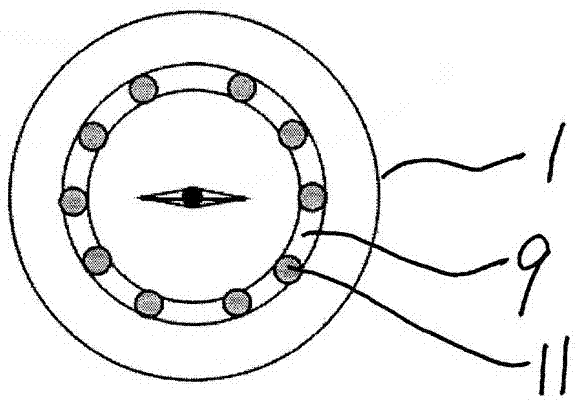

Apparatus for self-propagating high temperature synthesis

InactiveUS6436356B1Carry-out safelyAvoid expansionOxygen/ozone/oxide/hydroxideNitrogen compoundsSelf-propagating high-temperature synthesisInorganic compound

The present invention relates to an apparatus for self-propagating high temperature synthesis of an inorganic compound from a combustible charge mixture of initial ingredients. The apparatus comprises mechanisms for continuously feeding the combustible charge into a reaction chamber and removing the synthesized compound therefrom. The apparatus also contains sensors to control and contain the combustion inside a combustion zone of the reaction chamber.

Owner:COMSYNTECH

Gas hydrate reactor comprising thermoelectric module

Disclosed is a gas hydrate reactor including a supply line for supplying water and gas, a thermoelectric module assembly, a front panel including an observation window, and a housing to which the thermoelectric module assembly and the front panel are attached and into which water and gas are supplied using the supply line so that a gas hydrate is formed therein. This reactor enables rapid and precise temperature control, thus allowing accurate data about properties to be easily acquired in kinetics, phase equilibrium, morphology and microscopic (Raman, XRD, etc.) research of a gas hydrate, thereby leading to the discovery of a gas hydrate production / decomposition mechanism and ensuring important information necessary for a gas hydrate application process.

Owner:KOREA INST OF IND TECH

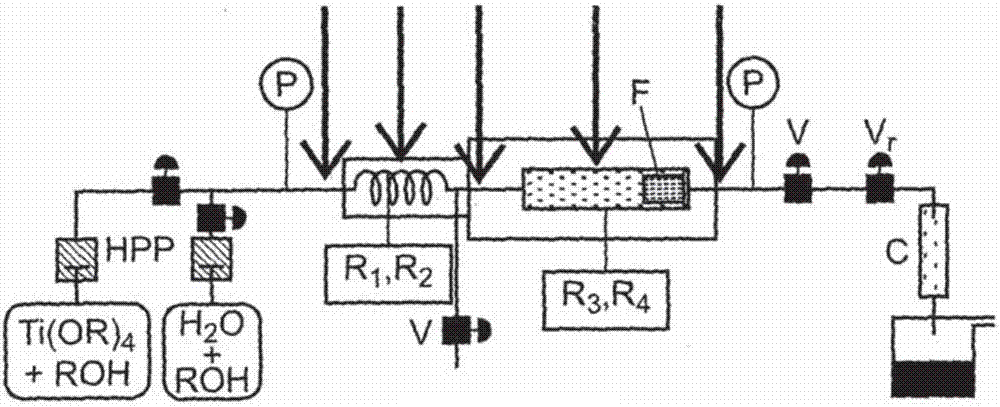

Metal alkoxides, apparatus for manufacturing metal alkoxides, related methods and uses thereof

InactiveUS20090134369A1Organic compound preparationGroup 4/14 organic compounds without C-metal linkagesAlcoholFire retardant

Owner:AUTERRA INC

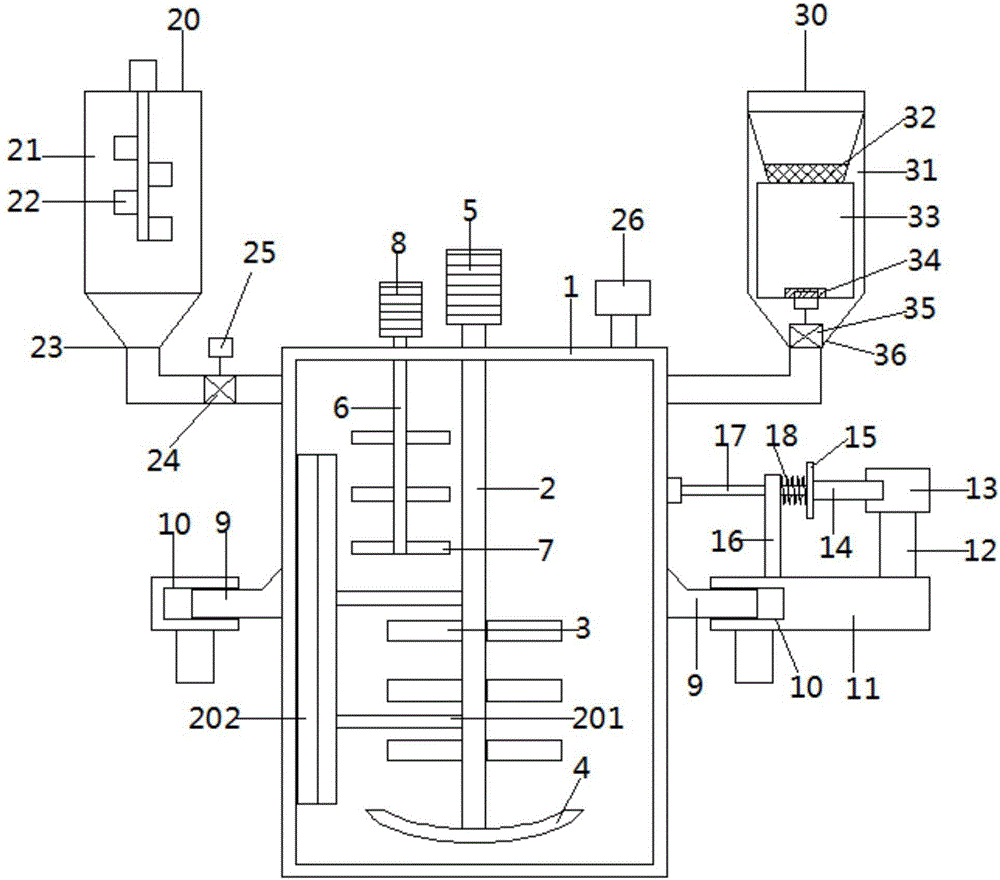

Vacuum reaction device for chemical production

InactiveCN106732189AIncrease reaction rateAvoid wastingRotary stirring mixersTransportation and packagingHydraulic cylinderDischarge efficiency

The invention discloses a vacuum reaction device for chemical production. The vacuum reaction device comprises a kettle body, wherein a particle material feeding opening is formed in the top end of an outer wall of the left side of the kettle body, a powder material feeding opening is formed in the top end of an outer wall of the right side of the kettle body, and a particle material feeding device and a powder material feeding device are arranged on the upper left side and the upper right side of the kettle body. The vacuum reaction device for the chemical production disclosed by the invention can automatically finish a feeding process, achieves automatic and intelligent operation of raw material matching, weighing and feeding and effectively improves production efficiency. Two stirring mechanisms which are vertically arranged are utilized to fully stir materials, the materials can be fully deironed, quality of finished product materials is guaranteed, a scraping and washing hair brush can scrape and wash the inner wall of the reaction kettle, and a hydraulic cylinder can drive the reaction kettle to slide left and right; on one hand, work efficiency of the reaction kettle is further improved; on the other hand, discharging efficiency is improved, material stack is avoided, and trouble in traditional manual cleaning is eliminated.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

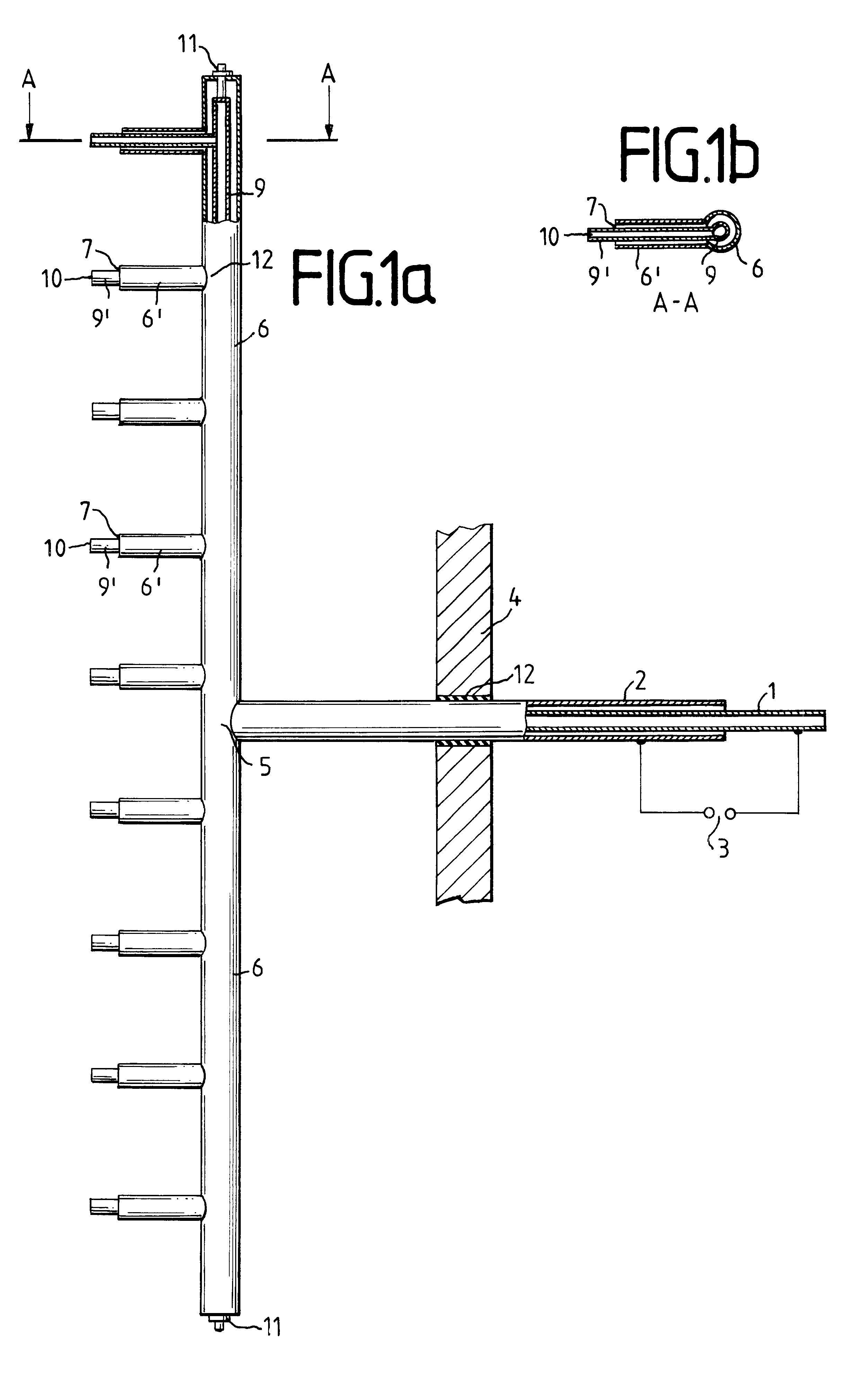

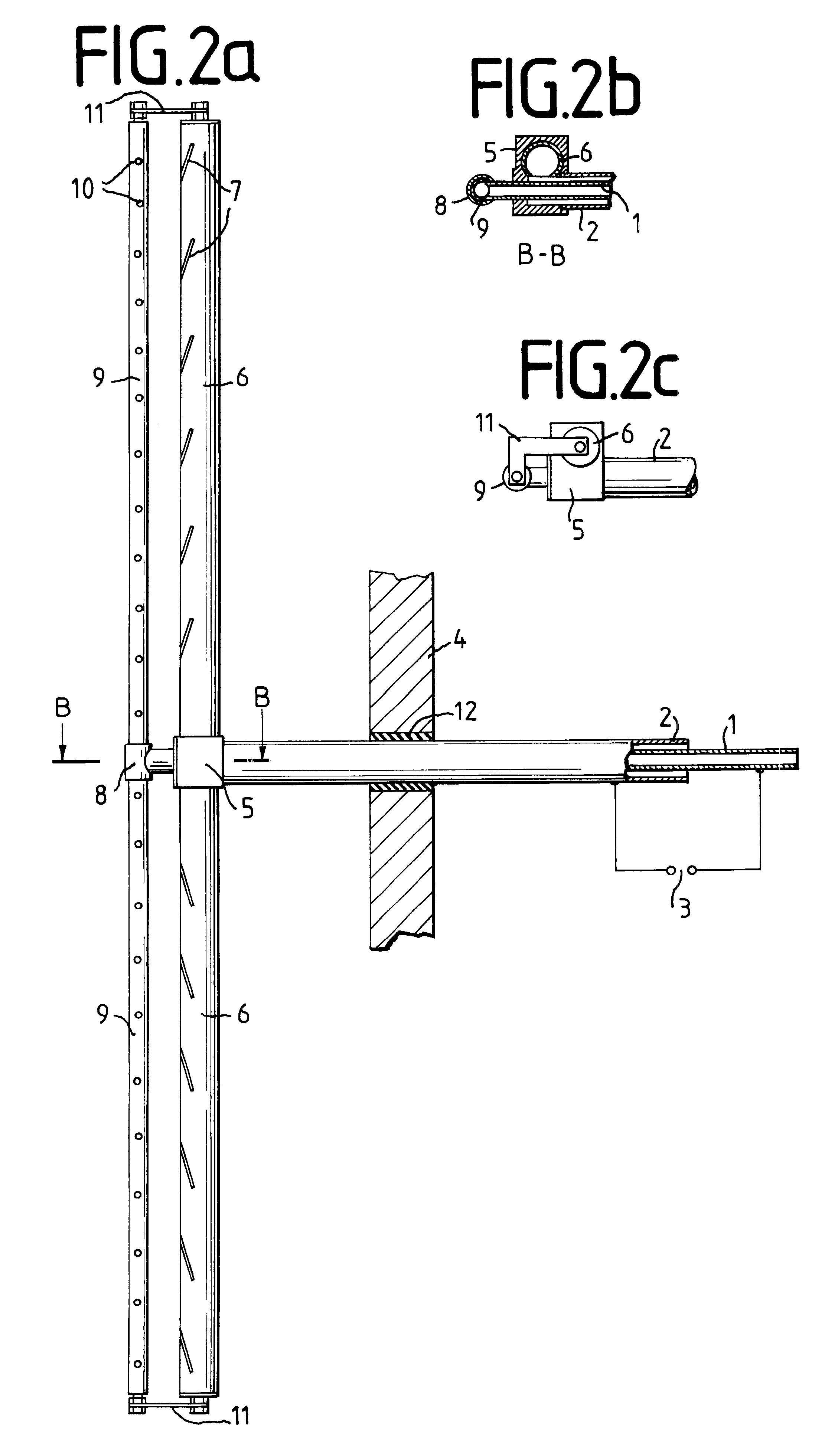

Method for transporting at least one vaporous substance through the wall of a vacuum chamber and into the vacuum chamber and a device for executing and utilizing the method

Method for transporting at least one vaporous substance through the wall (4) of a vacuum chamber and into the vacuum chamber and device for executing and utilizing the method. In the method, a vaporous substance is introduced from the outside through an interior pipe (1) of a double-walled pipe into the vacuum chamber, with electric current from a power supply (3) applied to the interior pipe (1) and exterior pipe (2) of the double-walled pipe.

Owner:APPLIED FILMS GMBH & CO KG

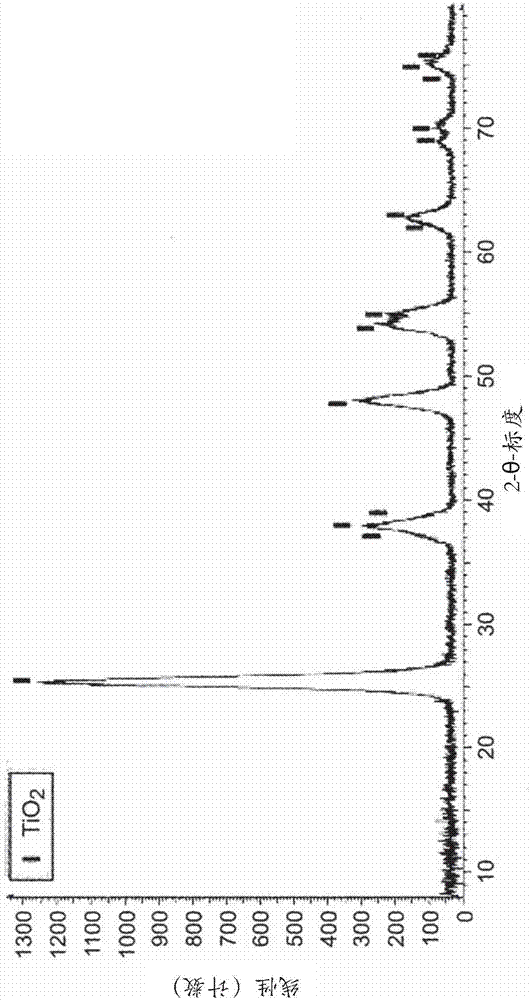

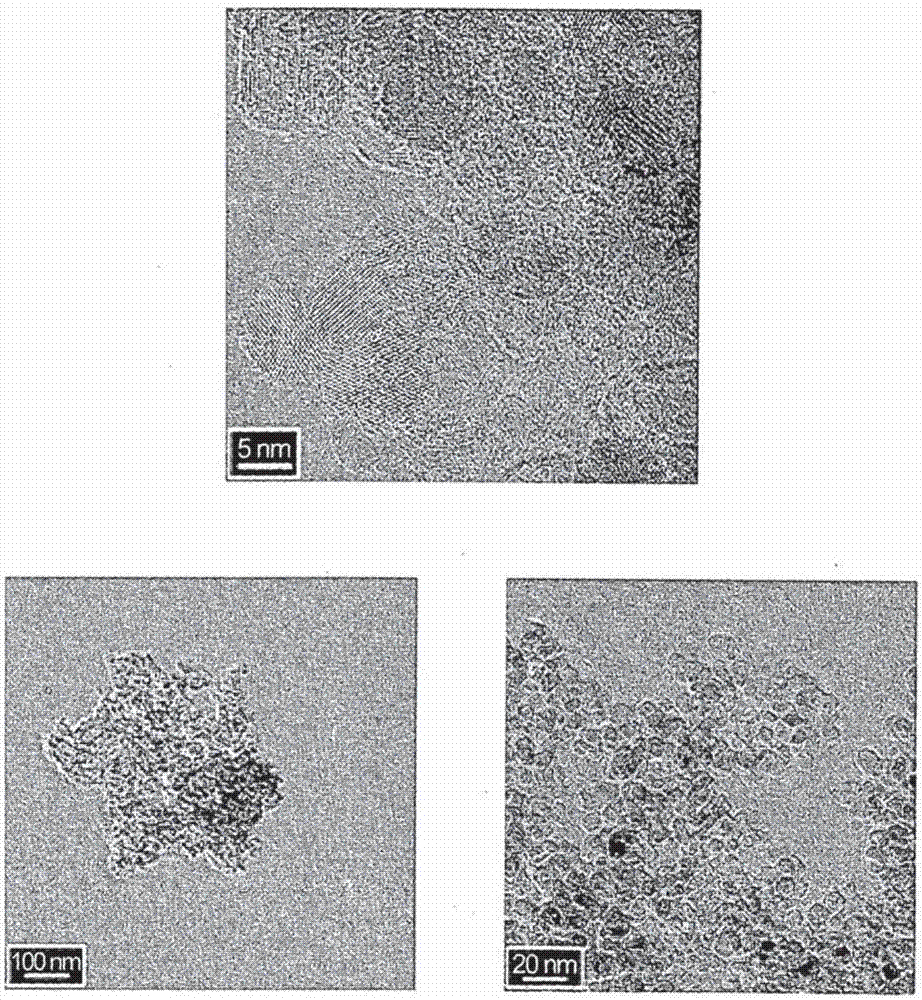

A continuous flow process for manufacturing surface modified metal oxide nanoparticles by supercritical solvothermal synthesis

InactiveCN107278198AControl size distributionOxygen/ozone/oxide/hydroxideTitanium dioxideMetal oxide nanoparticlesContinuous flow

Owner:ESSILOR INT CIE GEN DOPTIQUE +2

Two-component home decoration seam beautifying agent and preparation method thereof

ActiveCN112724901AOil-resistantScrub resistantShaking/oscillating/vibrating mixersNon-macromolecular adhesive additivesUltraviolet lightsFirming agent

The invention discloses a two-component home decoration seam beautifying agent and a preparation method thereof, and belongs to the technical field of seam beautifying agents, the two-component home decoration seam beautifying agent is prepared by mixing a component A and a component B according to a weight ratio of 1: (1-1.3), wherein the component A is prepared from the following raw material components in parts by weight: 80-100 parts of modified epoxy resin; 5-8 parts of a reactive diluent; 6-8 parts of a thixotropic agent; 0.05 to 0.1 part of a defoaming agent; 0-3 parts of a coupling agent; 0.1-0.3 part of an ultraviolet light absorber; and 0.1 to 0.2 part of an antioxidant; The component B is prepared from the following raw material components in parts by weight: 70-85 parts of an alicyclic amine modified curing agent; 2-5 parts of an accelerant; 6-8 parts of a thixotropic agent; and 3-6 parts of an extender pigment. The preparation method comprises the following steps: weighing; preparing the component A; and preparing the component B. The two-component home decoration seam beautifying agent has the advantages of no water absorption, oil stain resistance, easiness in cleaning, scrubbing resistance, no blackening and mildewing, high adhesive force and high curing speed.

Owner:HUNAN KOSEN NEW MATERIAL

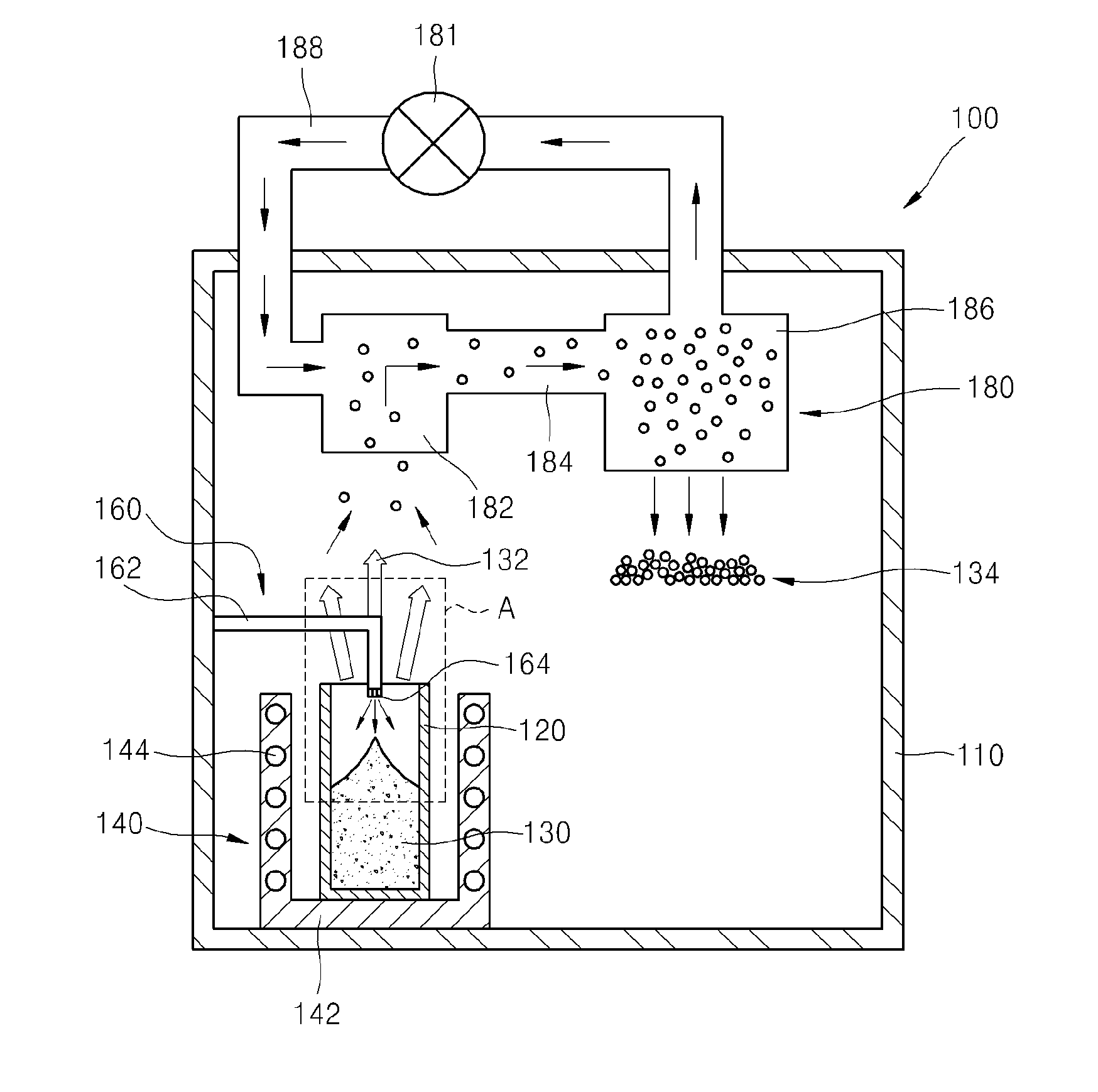

METHOD OF PRODUCING HIGH PURITY SiOx NANOPARTICLES WITH EXCELLENT VOLATILITY AND APPARATUS FOR PRODUCING THE SAME

InactiveUS20120251710A1High purityLow costMaterial nanotechnologyNanostructure manufactureNanoparticleVacuum chamber

The present disclosure provides a method of producing high purity SiOx nanoparticles with excellent volatility and an apparatus for producing the same, which enables mass production of SiOx nanoparticles by melting silicon through induction heating and injecting gas to a surface of the molten silicon. The apparatus includes a vacuum chamber, a graphite crucible into which raw silicon is charged, the graphite crucible being mounted inside the vacuum chamber, an induction melting part which forms molten silicon by induction heating of the silicon material received in the graphite crucible, a gas injector which injects a gas into the graphite crucible to be brought into direct contact with a surface of the molten silicon, and a collector disposed above the graphite crucible and collecting SiOx vapor produced by reaction between the molten silicon and the injected gas.

Owner:KOREA INST OF ENERGY RES

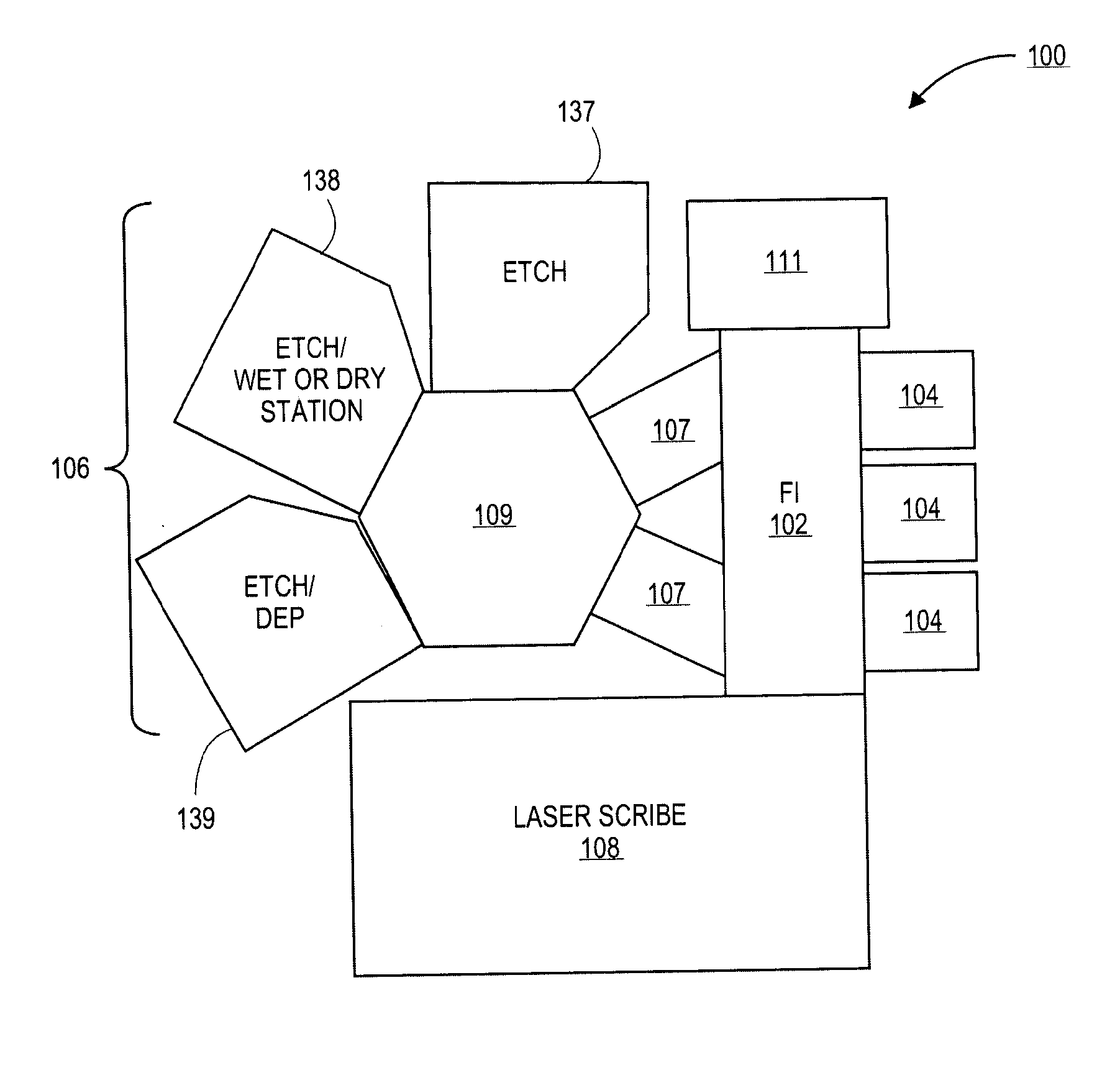

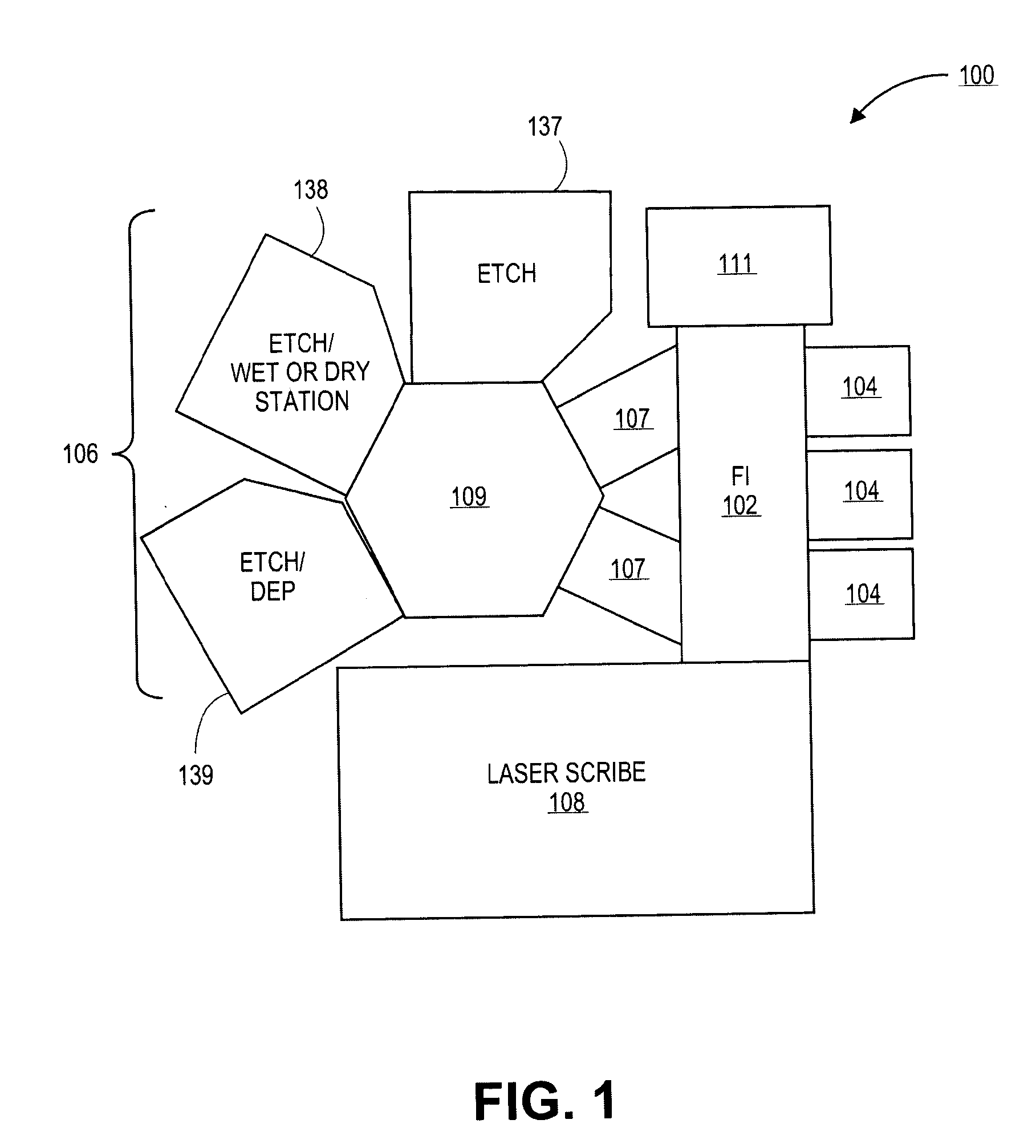

Method of outgassing a mask material deposited over a workpiece in a process tool

ActiveUS20160049313A1Semiconductor/solid-state device manufacturingSub-atmospheric pressure processesProcess engineeringMoisture

Embodiments of the invention include methods and apparatuses for outgassing a workpiece prior to a plasma processing operation. An embodiment of the invention may comprise transferring a workpiece having a mask to an outgassing station that has one or more heating elements. The workpiece may then be heated to an outgassing temperature that causes moisture from the mask layer to be outgassed. After outgassing the workpiece, the workpiece may be transferred to a plasma processing chamber. In an additional embodiment, one or more outgassing stations may be located within a process tool that has a factory interface, a load lock coupled to the factory interface, a transfer chamber coupled to the load lock, and a plasma processing chamber coupled to the transfer chamber. According to an embodiment, an outgassing station may be located within any of the components of the process tool.

Owner:APPLIED MATERIALS INC

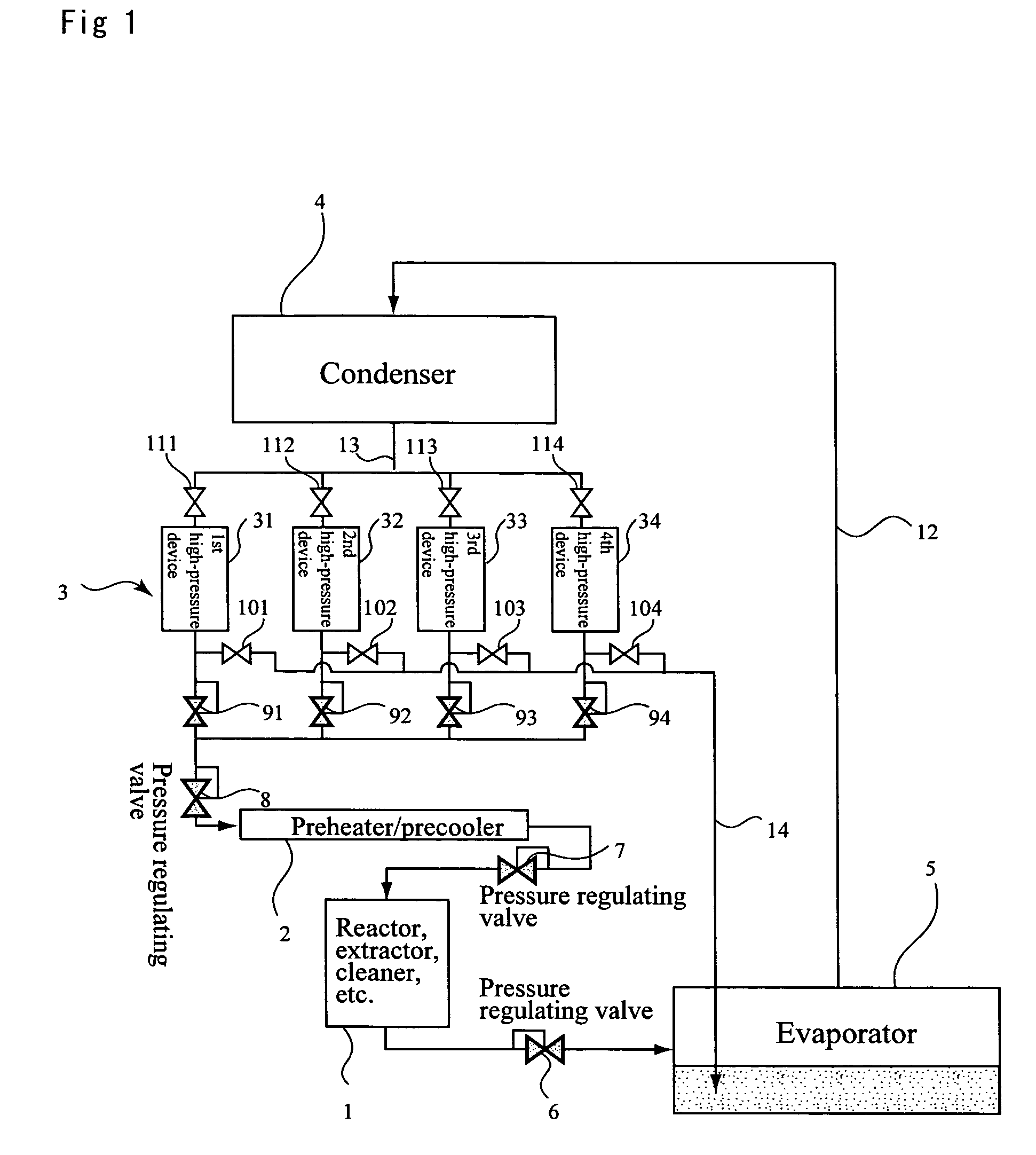

System and device for processing supercritical and subcritical fluid

InactiveUS7335296B2Reduce energy lossSave resourcesProcess control/regulationLiquid separation auxillary apparatusEngineeringThermal expansion

A system for processing supercritical and subcritical fluid capable of bringing the inside of at least one processing container (1) formed in a flow passage into a supercritical or subcritical high pressure field, wherein thermal operation is applied to process fluid to apply thermal expansion to the fluid to produce a pressure difference between the processing container (1) and the outside, whereby a specified temperature and the high pressure field suitable for the processing of the supercritical or subcritical fluid can be provided in the processing container (1).

Owner:TOHOKU TECHNO ARCH CO LTD

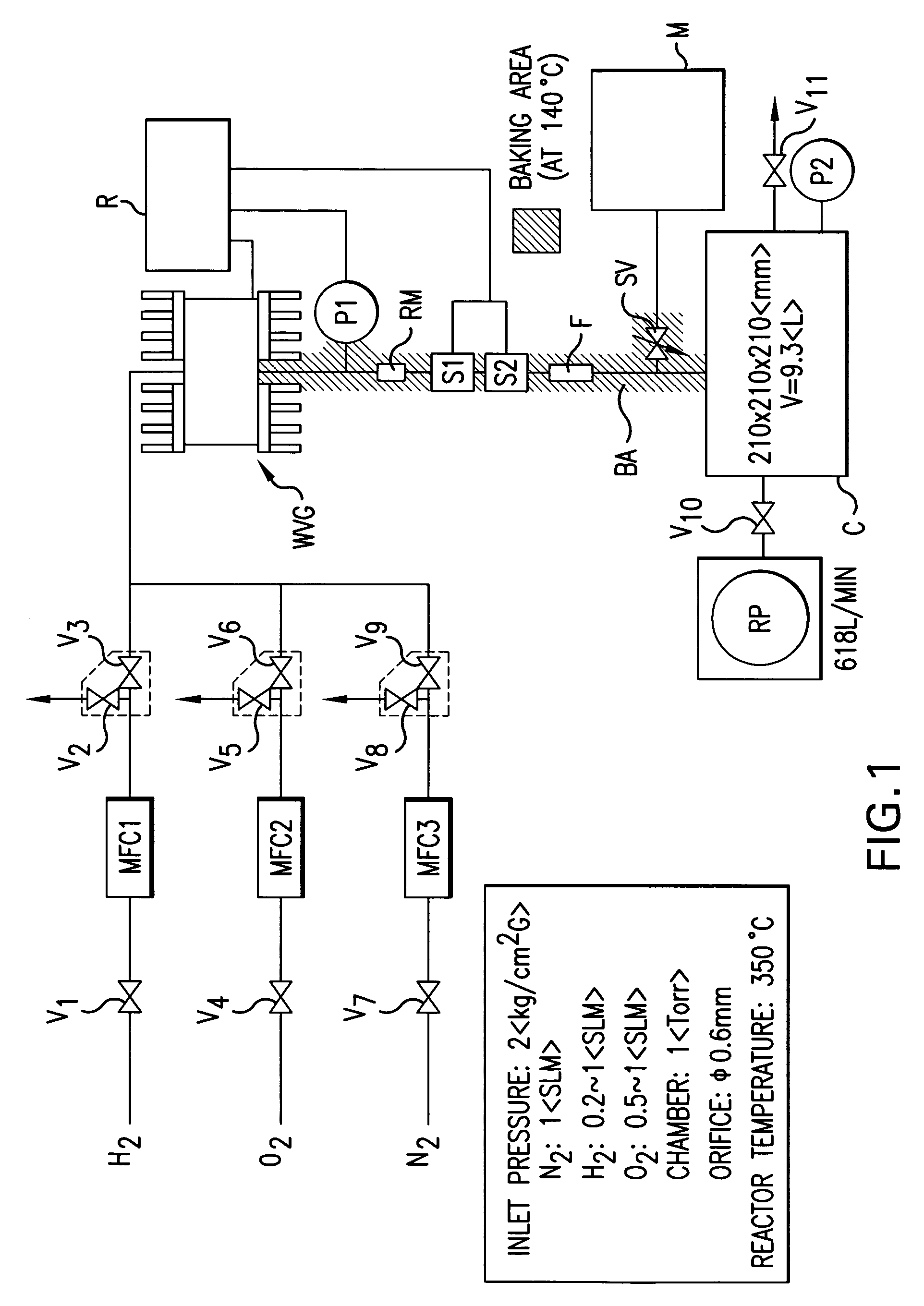

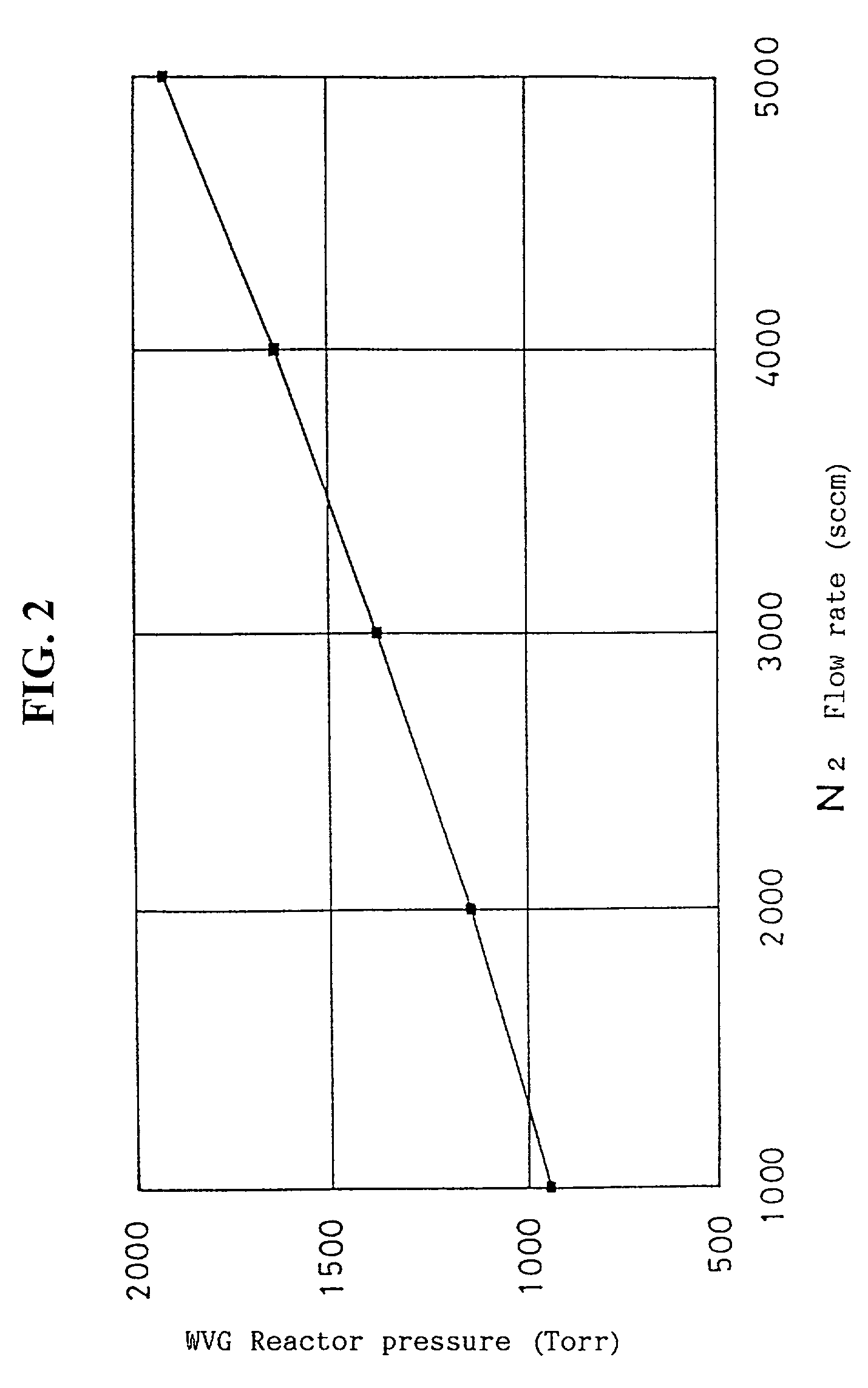

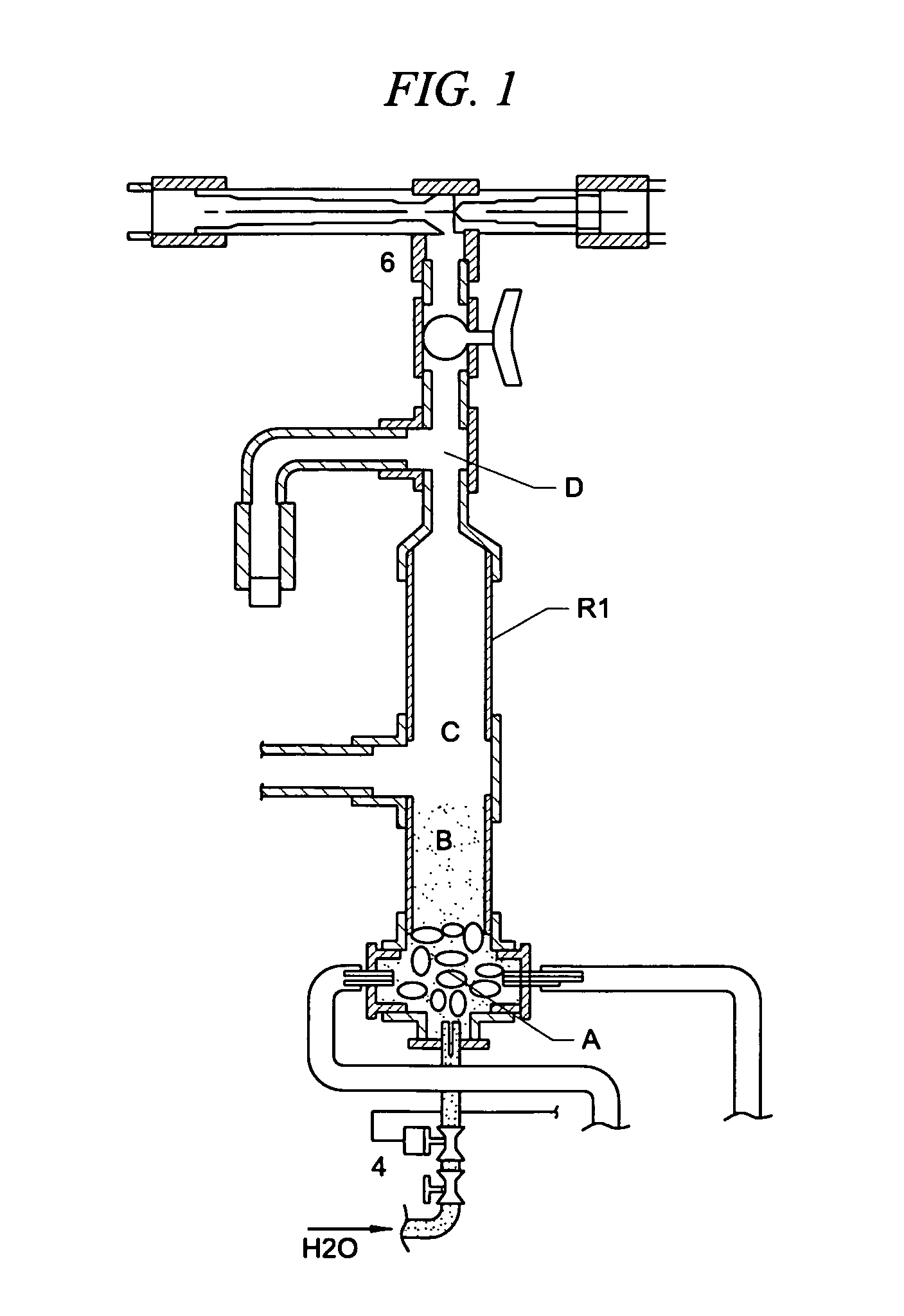

Apparatus and reactor for generating and feeding high purity moisture

InactiveUS7258845B2Rule out the possibilityImprove pressure resistanceCatalytic gas-gas reactionPhysical/chemical process catalystsInternal pressureHydrogen

A safe, reduced pressure apparatus for generating water vapor from hydrogen and oxygen and feeding high purity moisture to processes such as semiconductor production. The apparatus eliminates the possibility of the gas igniting by maintaining the internal pressure of the catalytic reactor for generating moisture at a high level while supplying moisture gas from the reactor under reduced pressure. A heat dissipation reactor improvement substantially increases moisture generation without being an enlargement in size by efficient cooling of the reactor alumite-treated fins.

Owner:FUJIKIN INC +1

Esterification and polymerization double-kettle apparatus

ActiveCN105771868ACompact structureSmall footprintChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsPolymer scienceSmall footprint

The invention relates to an esterification and polymerization double-kettle apparatus. The apparatus comprises an esterification pre-condensation reaction tower and a stirring-free polymerization reactor, wherein a pre-condensation discharging hole of the esterification pre-condensation reaction tower is communicated with a feeding hole of the polymerization reactor through a pre-condensation melt conveying pump; a liquid distribution plate is arranged at the upper part of an inner cavity of the polymerization reactor; a falling-film tube is arranged in the liquid distribution hole; a hot medium heating tube is inserted in an inner cavity of the falling-film tube; the feeding hole of the polymerization reactor and a vacuumizing hole are formed in the outer wall of the upper part of a cylinder body; a discharging spiral and a polymer discharging hole are formed in the bottom of the polymerization reactor; an annular liquid distribution groove is formed in a part, corresponding to the feeding hole of the polymerization reactor, of the inner wall of the cylinder body; a uniform annular gap is reserved in the lower end of the liquid distribution groove; a liquid collection groove is formed in the inner wall of the lower part of the cylinder body; a middle melt outlet communicated with the liquid collection groove is formed in the outer wall of the cylinder body and is communicated with a middle melt inlet through a middle melt conveying pump; the middle melt inlet is formed in the upper part of the liquid distribution plate. The apparatus is compact in structure, small in occupied area and high in production efficiency.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Chlorine Dioxide Stable Solution Production Process

InactiveUS20070152187A1Other chemical processesChemical/physical/physico-chemical nozzle-type rreactorsChlorine dioxidePh control

Production process of chlorine dioxide stable solution that occurs in two phases of pH control, the first phase being an acid one and the second phase a basic one, with two distinct reactors, one for generation of chlorine dioxide and the other for stabilization, the first one being operated under vacuum and the second one under atmospheric pressure. The resulting solution then contains up to 6% chlorine dioxide that becomes active when pH is reduced to a range of 6.5 to 7.5 at the application moment.

Owner:BERACA SABARA QUIMICOS E INGREDIENTES

Production method of biodegradable plastic and apparatus for use in production thereof

InactiveUS20050124782A1Low costShorten the timeChemical/physical/physico-chemical stationary reactorsSub-atmospheric pressure processesPolymer scienceMetal catalyst

The present invention provides a production method of biodegradable plastic in which polylactic acid is directly synthesized from lactic acid without employing the conventional route of polylactic acid synthesis from lactic acid via lactide, and apparatus for use in production thereof. In this way, time required for the synthesis of polylactic acid is strikingly shortened and the production cost is reduced. In the production method of biodegradable plastic, polylactic acid, the main component of biodegradable plastic, is obtained by means of condensation polymerization by dehydration of the raw material, lactic acid, under high temperature and reduced pressure in the presence of a metal catalyst.

Owner:J A WOOLAM JAPAN CORP

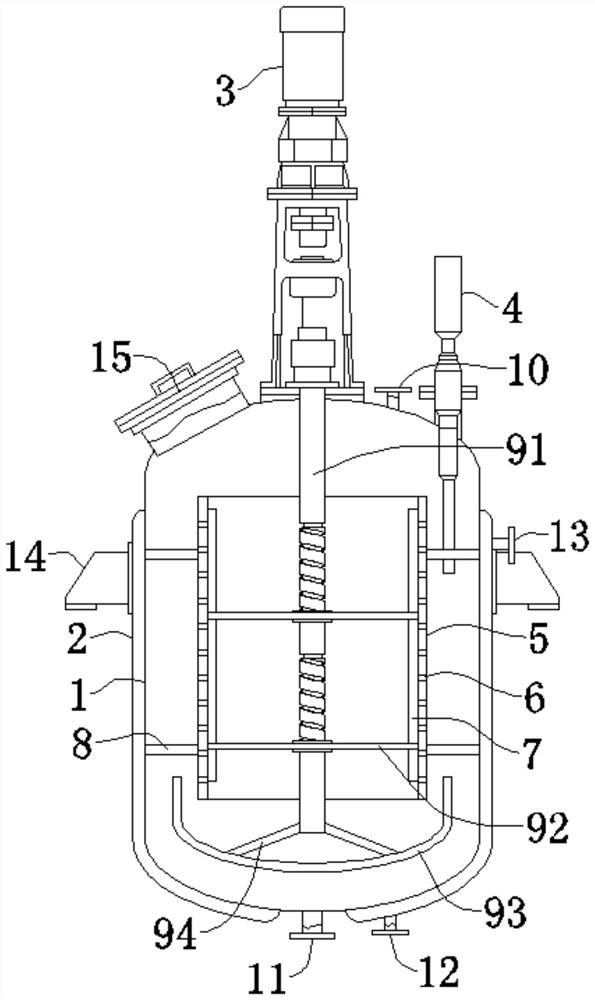

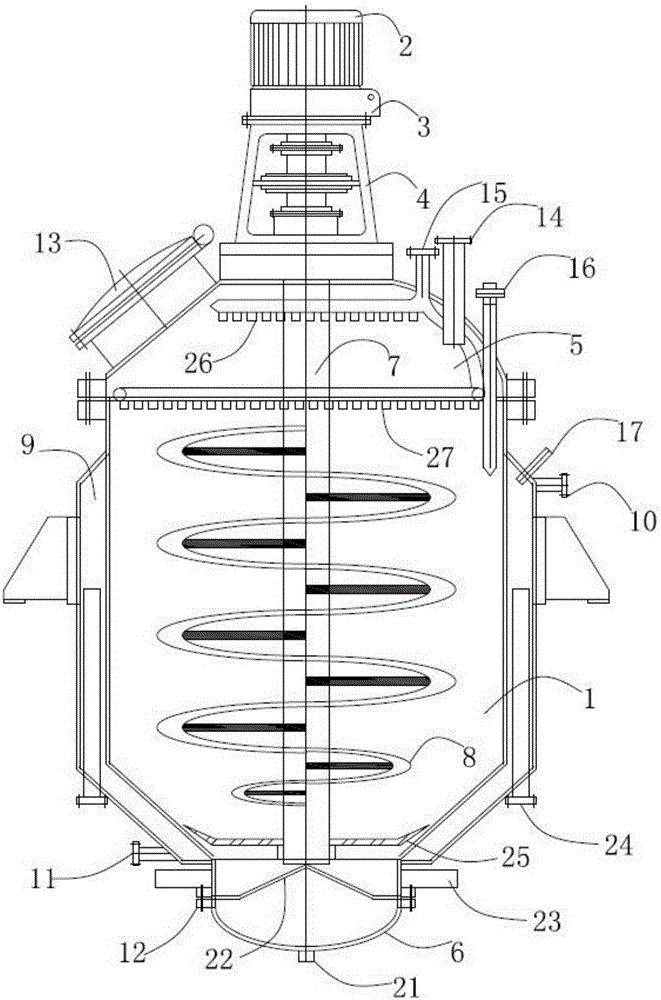

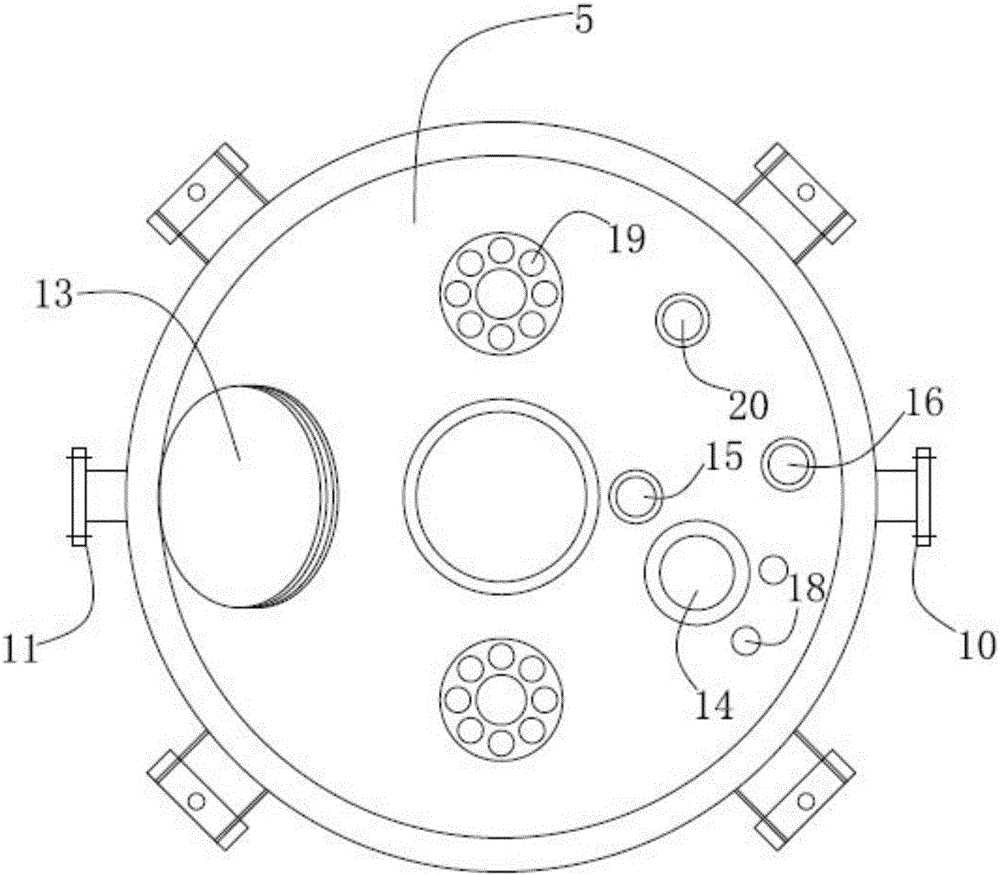

Helical-band-type multifunctional reaction device

InactiveCN105771870AScrape reaction completeLow costChemical/physical/physico-chemical nozzle-type rreactorsStationary filtering element filtersChemical industrySlag

The invention relates to the field of chemical industry and provides a helical-band-type multifunctional reaction device which comprises a kettle and a kettle cover. The helical-band-type multifunctional reaction device is characterized in that a bottom valve is arranged below the kettle, the kettle, the kettle cover and the bottom valve are connectedly fixed through flanges and bolts, a rotating shaft is arranged on the kettle cover and extends into the kettle, a helical-band-type stirring paddle is arranged on the rotating shaft, a scraping plate is arranged at the bottom end of the rotating shaft, a spray port is arranged on the kettle cover and connected with a fixed disc nozzle and a round tube nozzle in the kettle, a heating interlayer is arranged outside the kettle and provided with an electric heating tube in a left-right symmetry manner, a conical filter net is arranged on the flange connecting the bottle valve with the kettle, slag discharging ports are symmetrically arranged on two sides of the conical filter net, and a discharging port is arranged at the center of the bottom of the bottom valve. The helical-band-type multifunctional reaction device has the characteristics of reaction, press filtering and drying, so that a lot of cost is saved in the production process, working efficiency is improved greatly, and great convenience is brought to the production process.

Owner:JIANGXI JINKAI CHEM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com