METHOD OF PRODUCING HIGH PURITY SiOx NANOPARTICLES WITH EXCELLENT VOLATILITY AND APPARATUS FOR PRODUCING THE SAME

a technology of high purity and volatility, applied in the field of high purity siox nanoparticles, can solve the problems of nanoscale silicon particles providing cracking or short circuit of anodes, carbon electrodes have limitations in application to anodes for next generation lithium ion batteries, and can only be used in electrode manufacturing processes, etc., to achieve the effect of high purity, short time and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

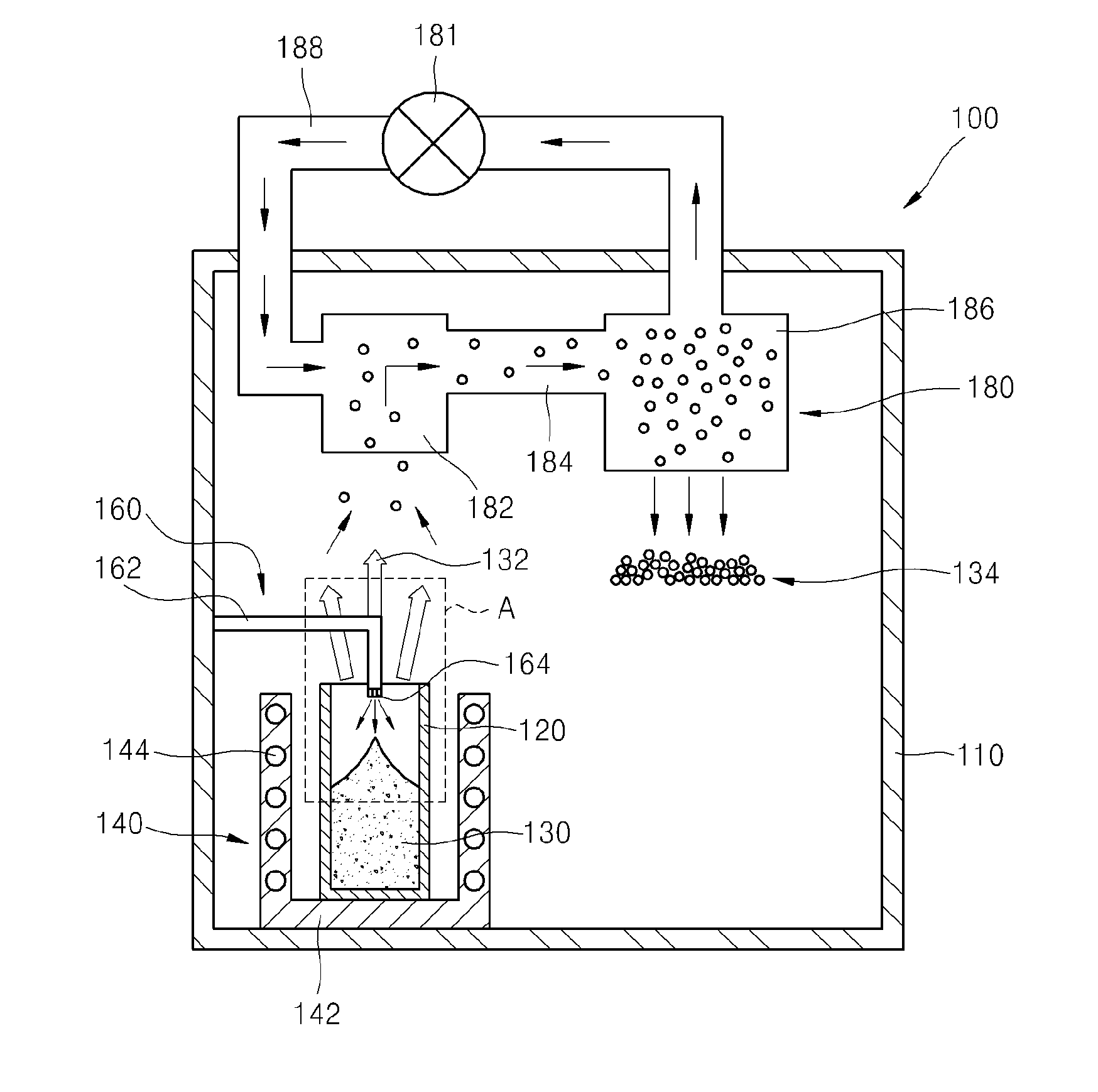

[0076]Next, the constitution and functions of the invention will be explained in more detail with reference to the following example. The example is provided for illustrative purposes only and is not to be in any way construed as limiting the invention.

[0077]A description of details apparent to those skilled in the art will be omitted.

1. Preparation of SiOx nanoparticles

[0078]First, raw silicon is charged into a crucible. The crucible has an outer diameter of 90 mm, an inner diameter of 60 mm, and a height of 150 mm, and includes 12 slits separated at an interval of 1 mm at 15 degrees from each other.

[0079]An induction coil having a diameter of 8 mm was turned 10 times around the crucible from an upper portion of the crucible, and AC current was applied at a frequency of 6.7 kHz to the crucible through the induction coil.

[0080]With 250 g of raw silicon charged into the crucible, a vacuum chamber was kept at a vacuum of 5˜10 Torr for 1 hour or more and Ar gas was ejected into the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Volatility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com