Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

334results about "Pressure vessel components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

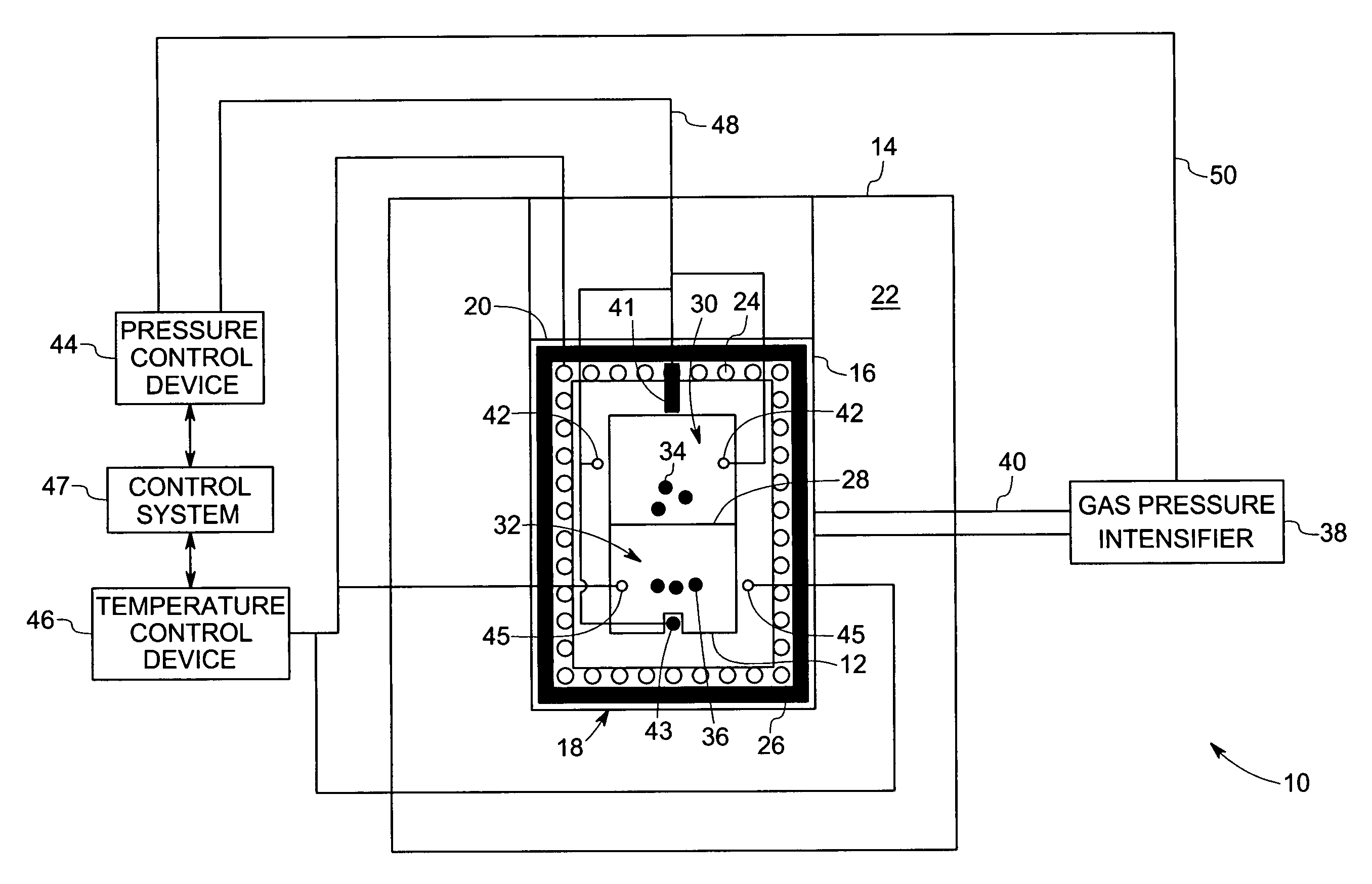

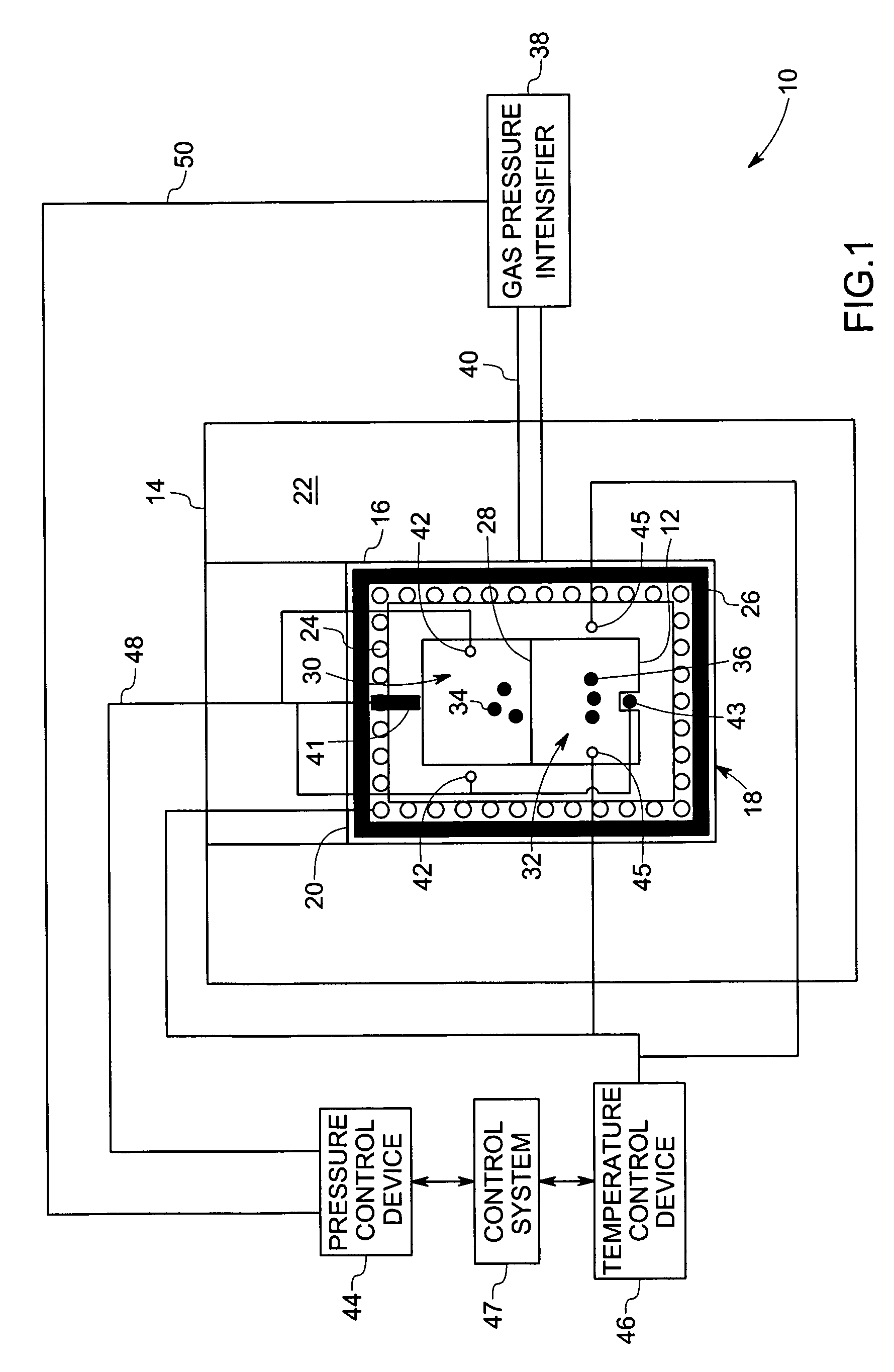

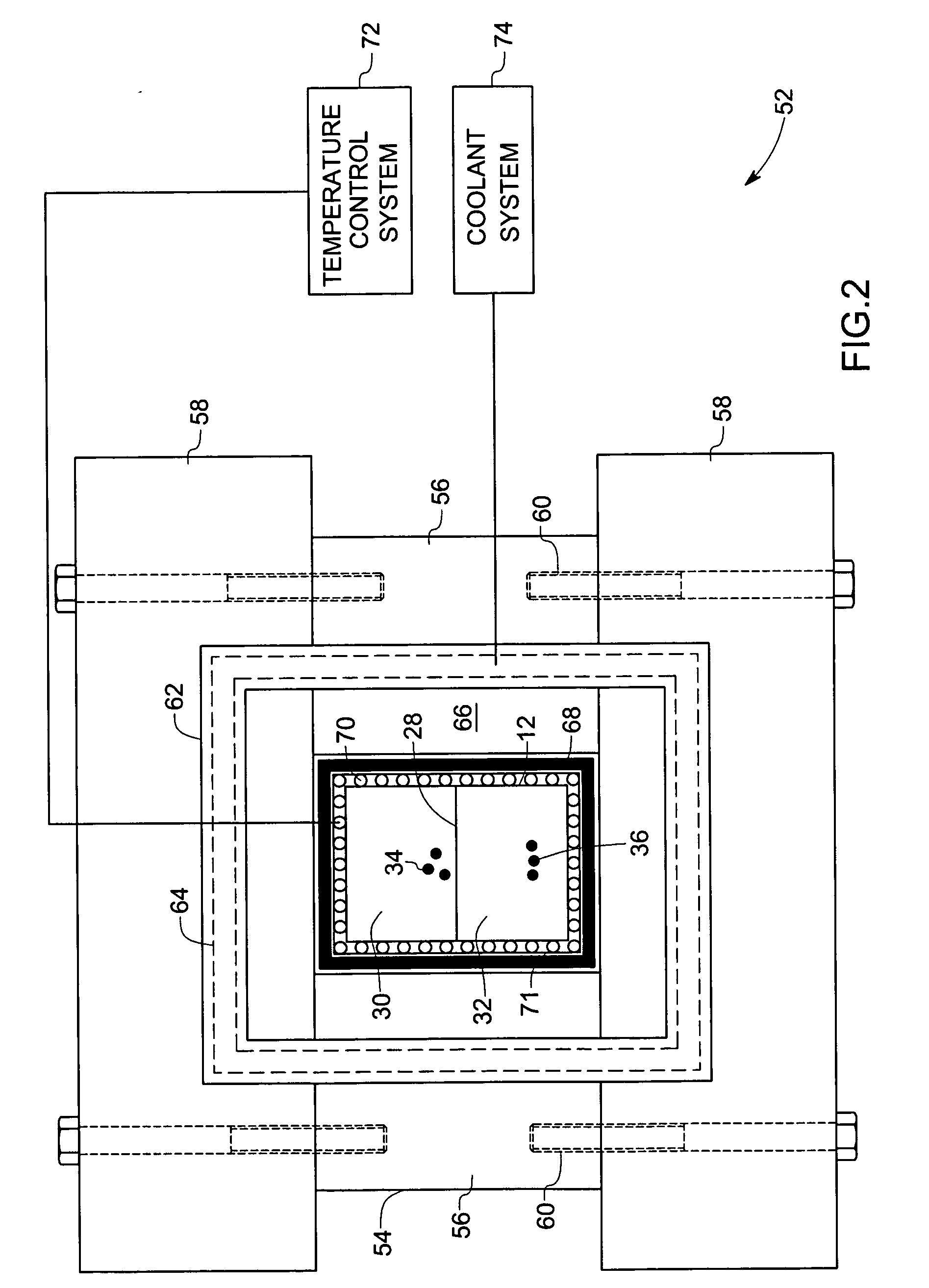

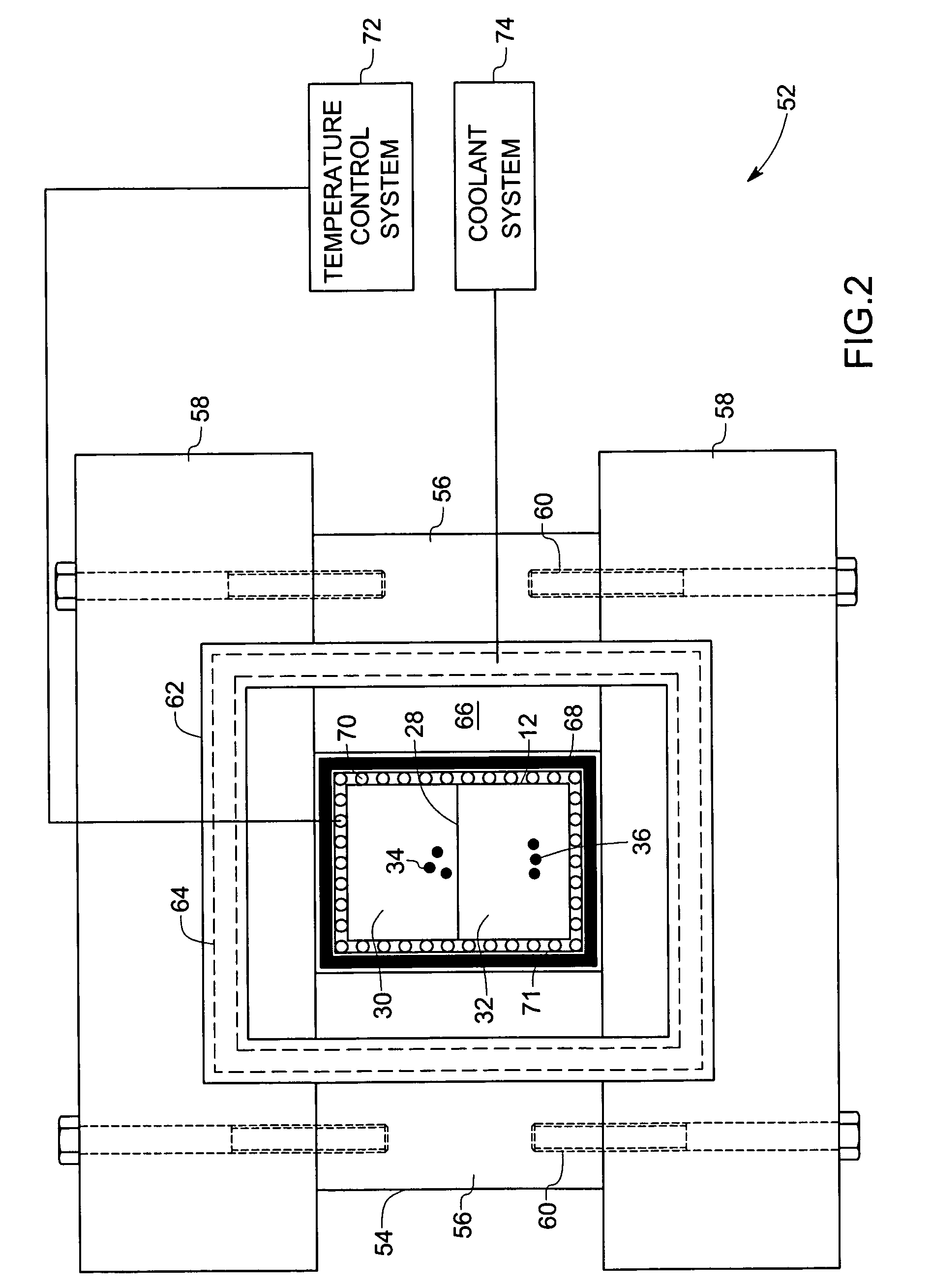

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS20060177362A1After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS7704324B2After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

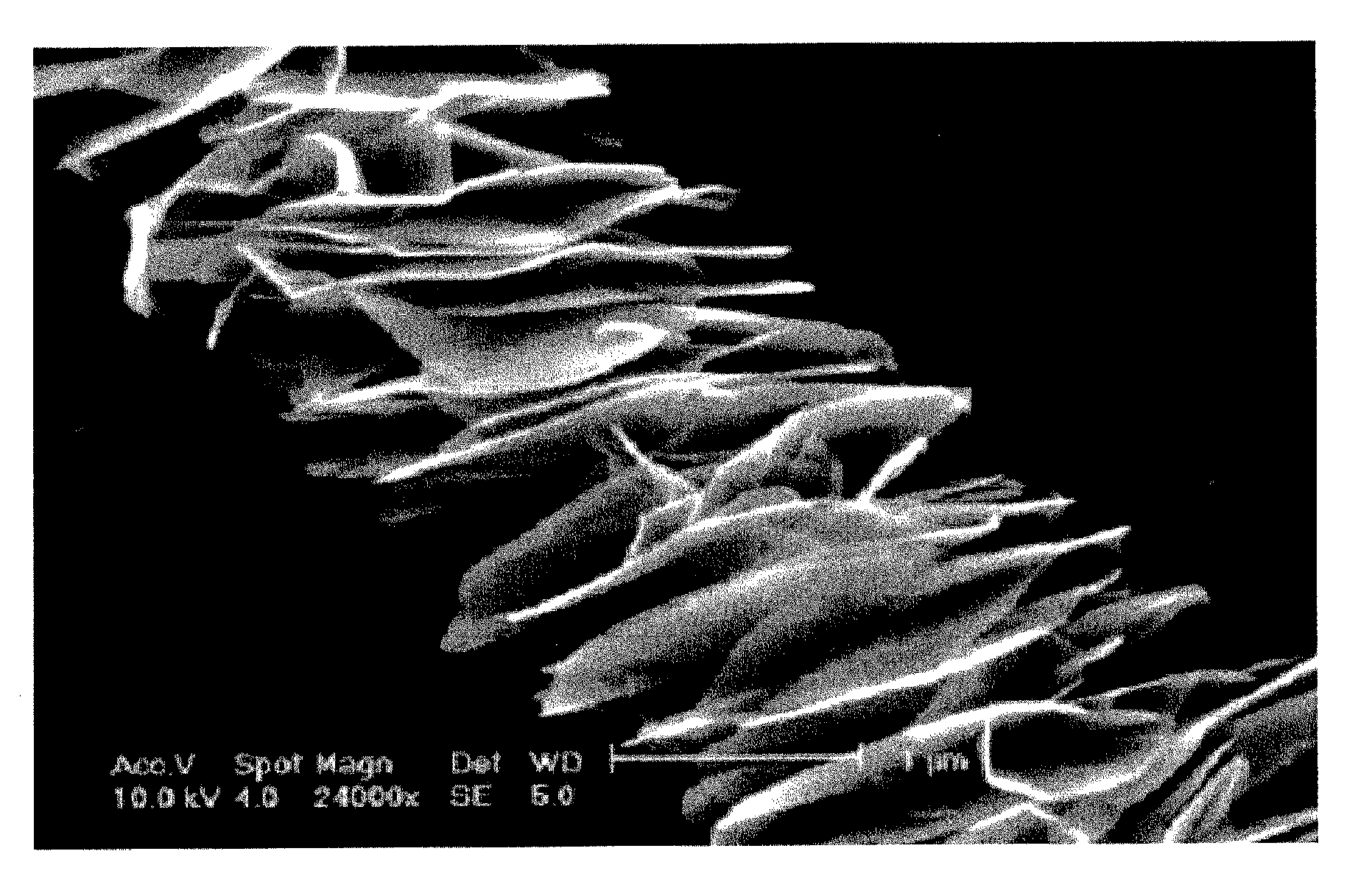

Carbon material and method for producing same

ActiveUS20120315482A1High crystallinityShorten the time periodFrom gel stateMaterial nanotechnologyPrillLithium-ion battery

There are provided a cluster of thin sheet graphite crystals or the like which is useful as an electrode material for lithium ion batteries, hybrid capacitors and the like, and a method for efficiently producing the same at high productivity. The method is one for producing a cluster of thin sheet graphite crystals composed of aggregates in such a state that thin sheet graphite crystals extend from the inside toward the outside, comprising charging a powdery and / or particulate material of an organic compound pre-baked to an extent of containing remaining hydrogen in a graphite vessel, and subjecting the powdery and / or particulate material together with the vessel to hot isostatic pressing treatment (HIP treatment) using a compressed gas atmosphere under the predetermined conditions.

Owner:INCUBATION ALLIANCE

Method and device for producing silicon monoxide

ActiveCN108821292ASimple processShort processSilicon oxidesPressure vessel componentsSilicon monoxideSilicon oxygen

The invention provides a method and device for producing silicon monoxide. The method disclosed by the invention is mainly characterized in that a silicon-containing substance such as silicon oxide, monatomic silicon, silicon-containing gas (liquid) , and non-completely oxidized silicon, particularly dried solid silicon powder separated from diamond wire silicon cutting waste slurry is subjected to further oxidation (including incomplete oxidation), reduction or addition of silicon dioxide to approach to an ideal ratio of generation of silicon monoxide, and then a silicon monoxide gas is formed under a condition facilitating overflow of silicon monoxide, and then the gas is condensed into rod-shaped, plate-shaped, granular or powdery silicon monoxide. In one embodiment, an oxide layer (SiO2) on the surface of silicon particles (Si) is controlled, so that a silicon monoxide precursor can be prepared, and the preparation process can be oxidization of the silicon or reduction of overly-oxidized silicon-oxygen compounds, and optionally, in another embodiment of the present application, a silicon monoxide powder can be directly produced by utilizing incomplete oxidation of a silicon-containing gas.

Owner:储晞

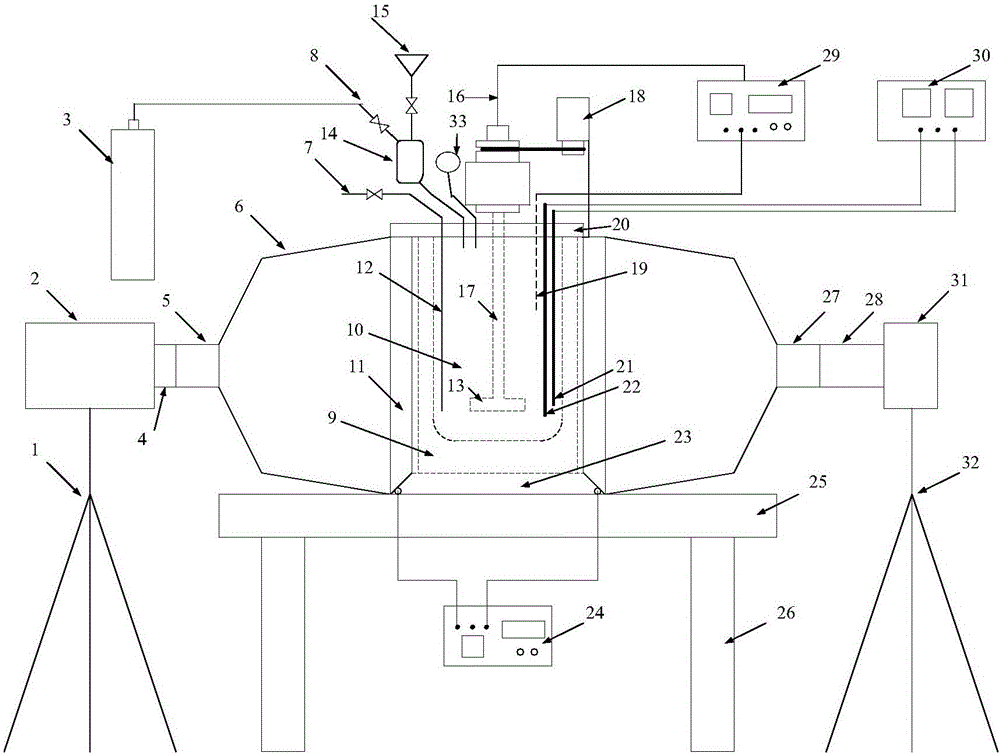

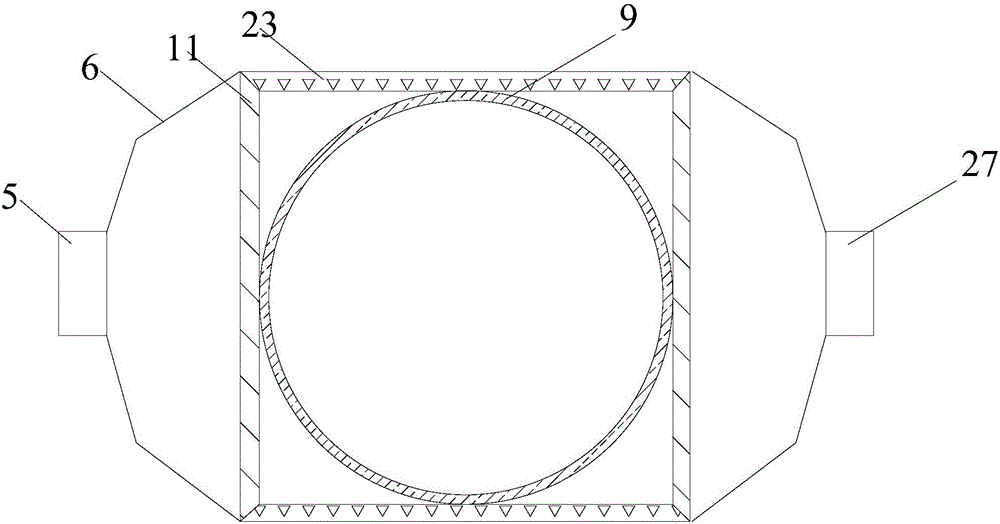

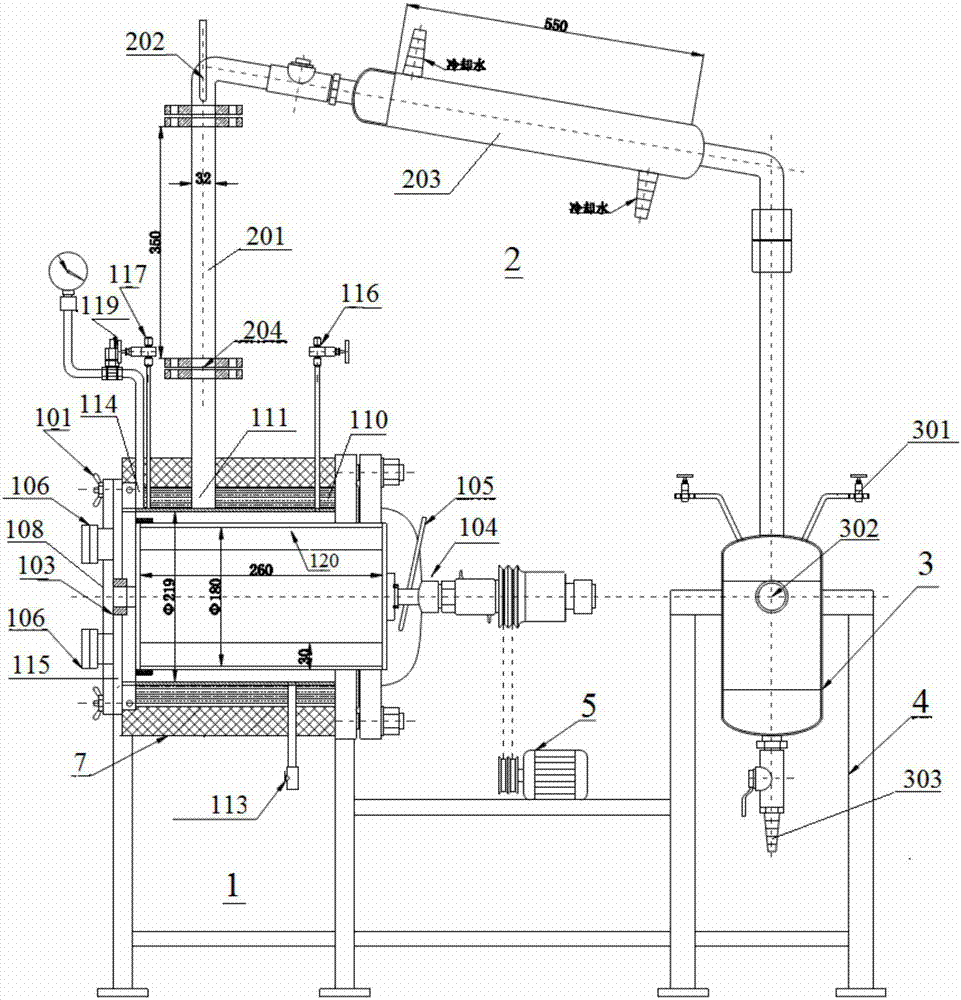

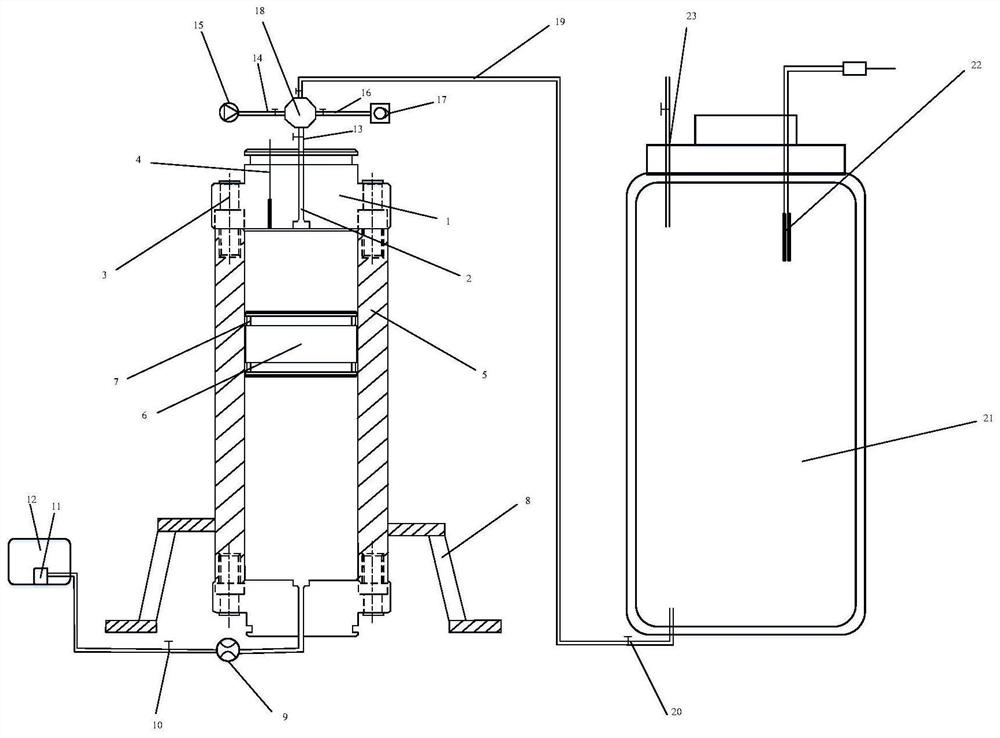

Visual reaction kettle and visualized experimental system and method for replacing natural gas hydrate

InactiveCN106000229AEasy to control temperatureSimple structureGaseous fuelsChemical/physical/physico-chemical stationary reactorsGas cylinderData acquisition

The invention relates to a visual reaction kettle and a visualized experimental system and method for replacing natural gas hydrate. The reaction kettle used by the system comprises a barrel, a front flange, a rear flange and glass; the front flange, the rear flange and the barrel are each of a hollow structure, the glass is embedded on the hollow structure of the front flange and the hollow structure of the rear flange respectively, and the front flange, the rear flange and the glass are used for sealing the barrel; the barrel is provided with multiple connectors; the system comprises a sampling tank, a vacuum pump, a first natural gas bottle, a carbon dioxide gas bottle, a second natural gas bottle, an environmental climate case, a beaker, a sensor, an image acquisition device and a data acquiring and processing device. By means of the experimental system, the process of replacing the natural gas hydrate with carbon dioxide at different phase states can be carried out, macroscopic thermodynamic and dynamic data in the replacing process is obtained, and meanwhile the dynamic characteristics, the heat-fluid-solid coupling phenomenon and the hydrate form change in the replacing process are recorded; the visual reaction kettle and the visualized experimental system and method for replacing the natural gas hydrate can be used for observing the natural gas hydrate generation phenomenon.

Owner:SUN YAT SEN UNIV

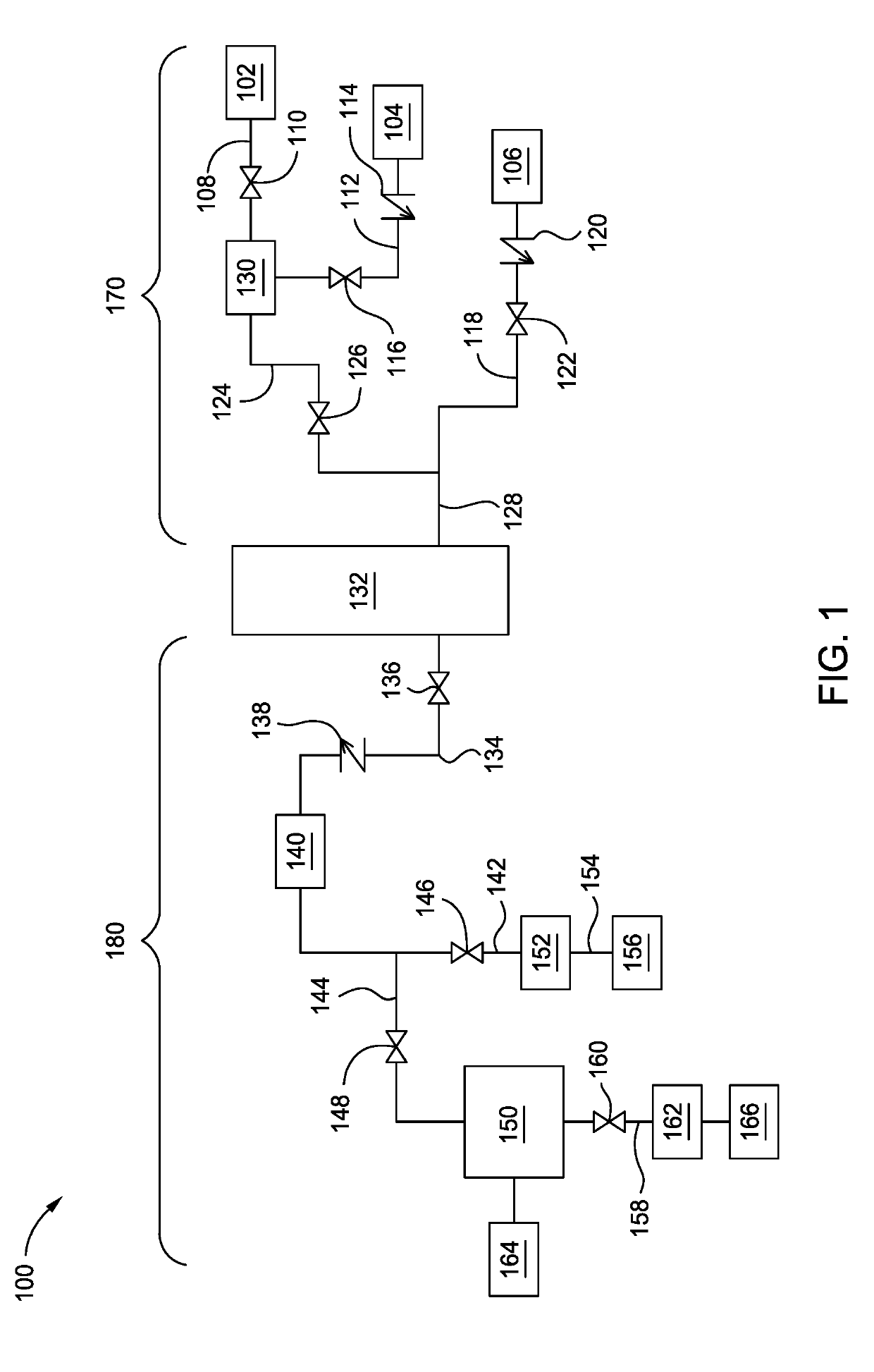

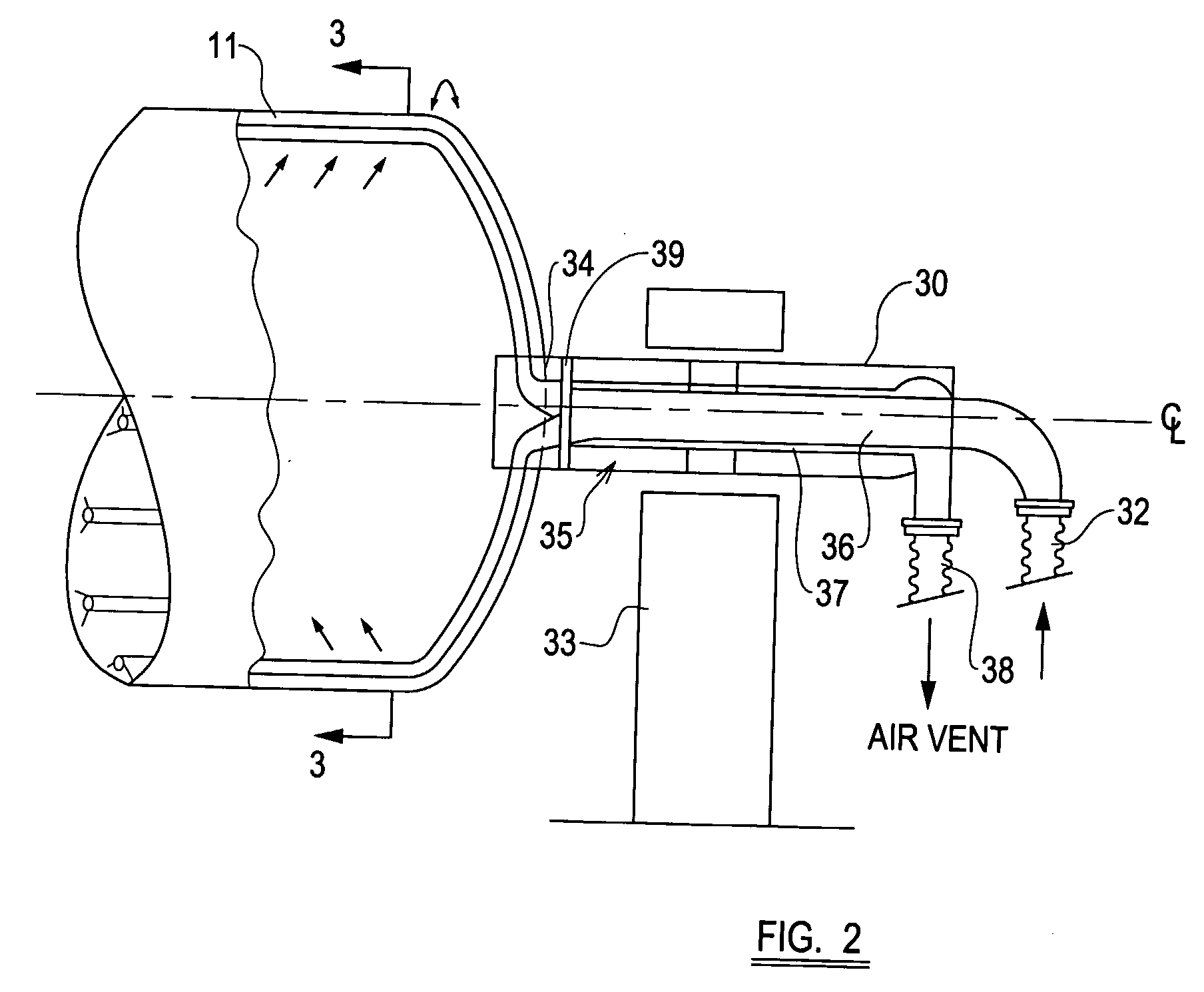

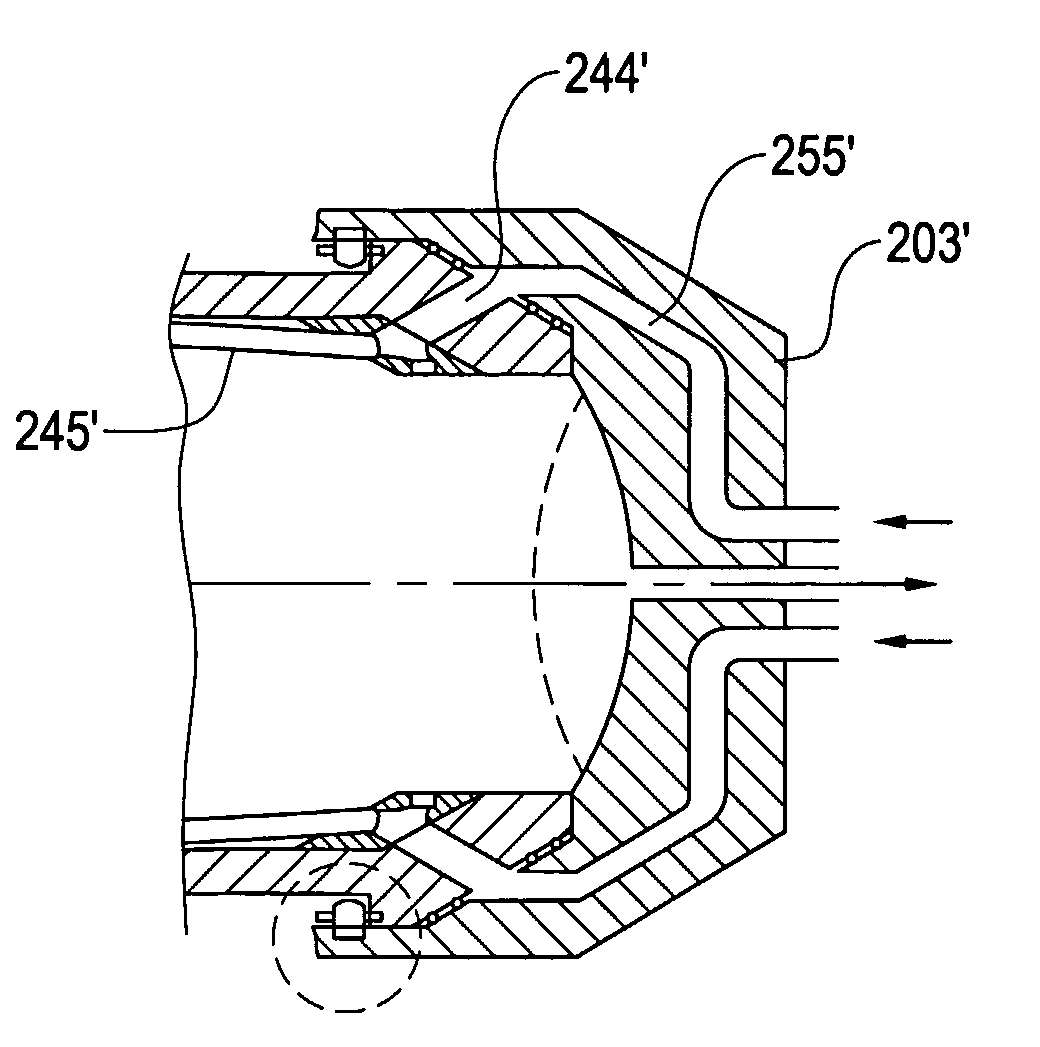

Condenser system for high pressure processing system

ActiveUS20190157074A1Semiconductor/solid-state device manufacturingSteam trapsEngineeringHigh pressure

Embodiments described herein relate to a high pressure processing system with a condenser and methods for utilizing the same. The processing system includes a process chamber, a boiler, a condenser, and one or more heat exchangers. The boiler generates a fluid, such as a vapor or supercritical fluid, and delivers the fluid to the process chamber where a substrate is processed. After processing the substrate, the system is depressurized and the fluid is delivered to the condenser where the fluid is condensed.

Owner:APPLIED MATERIALS INC

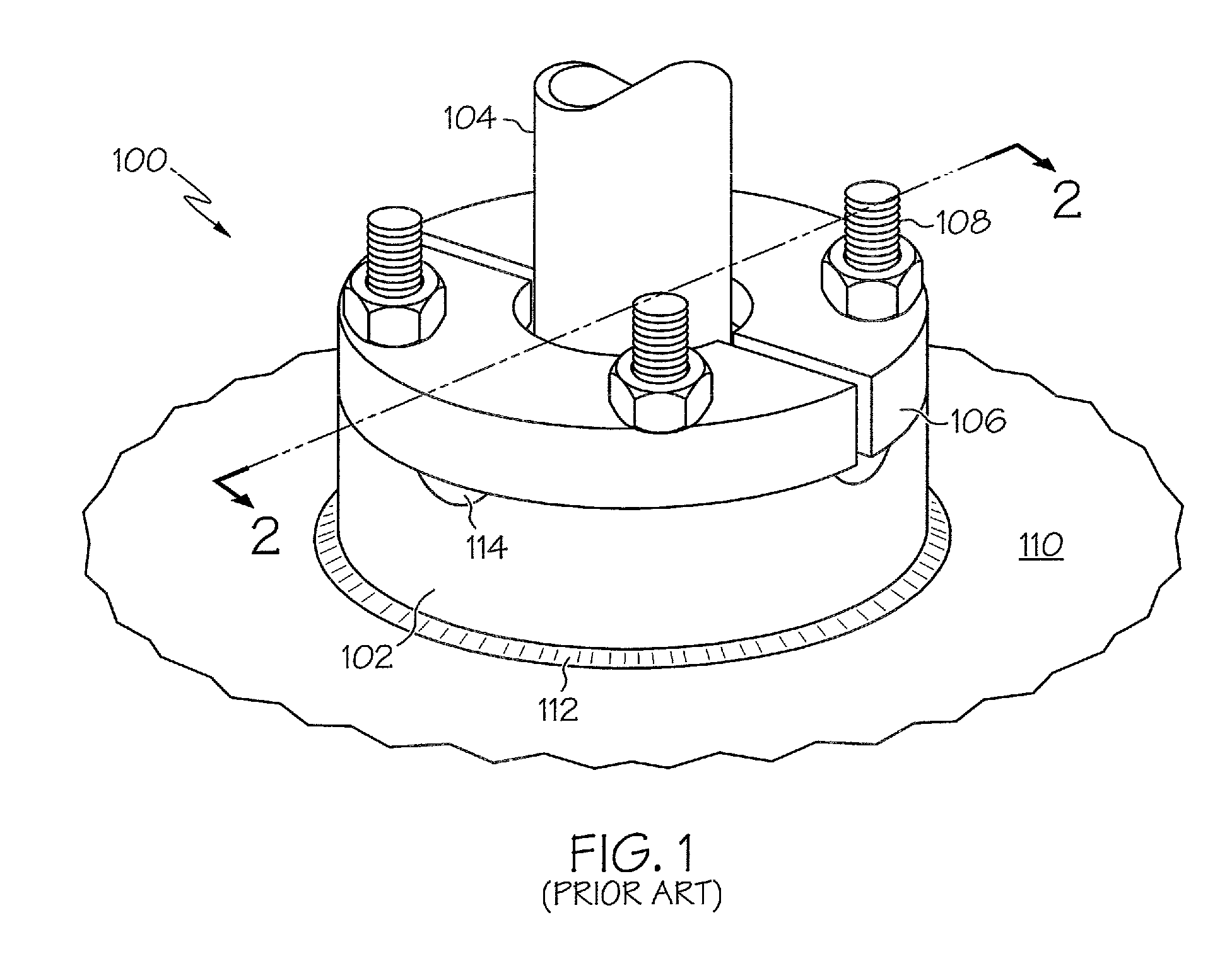

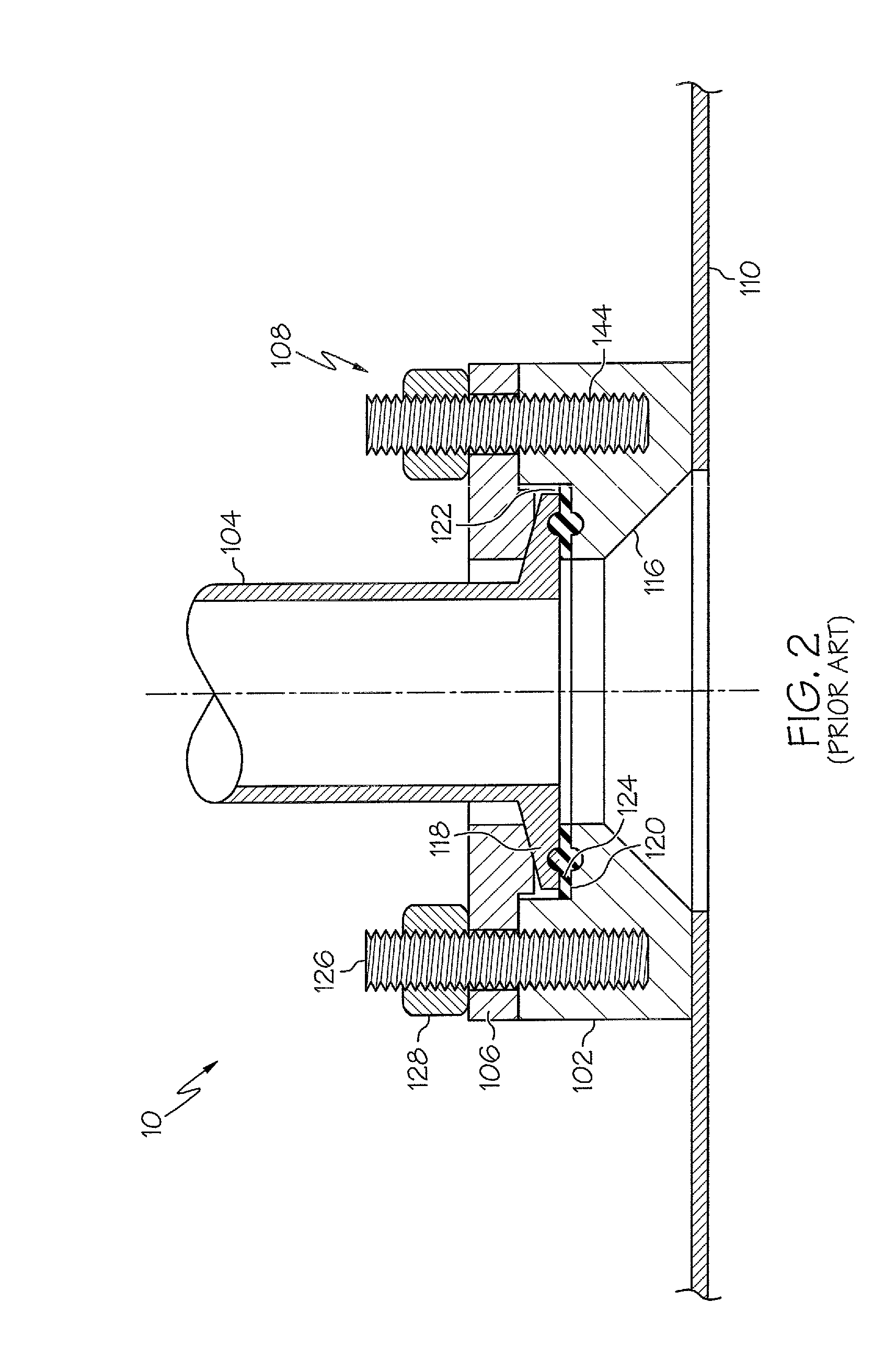

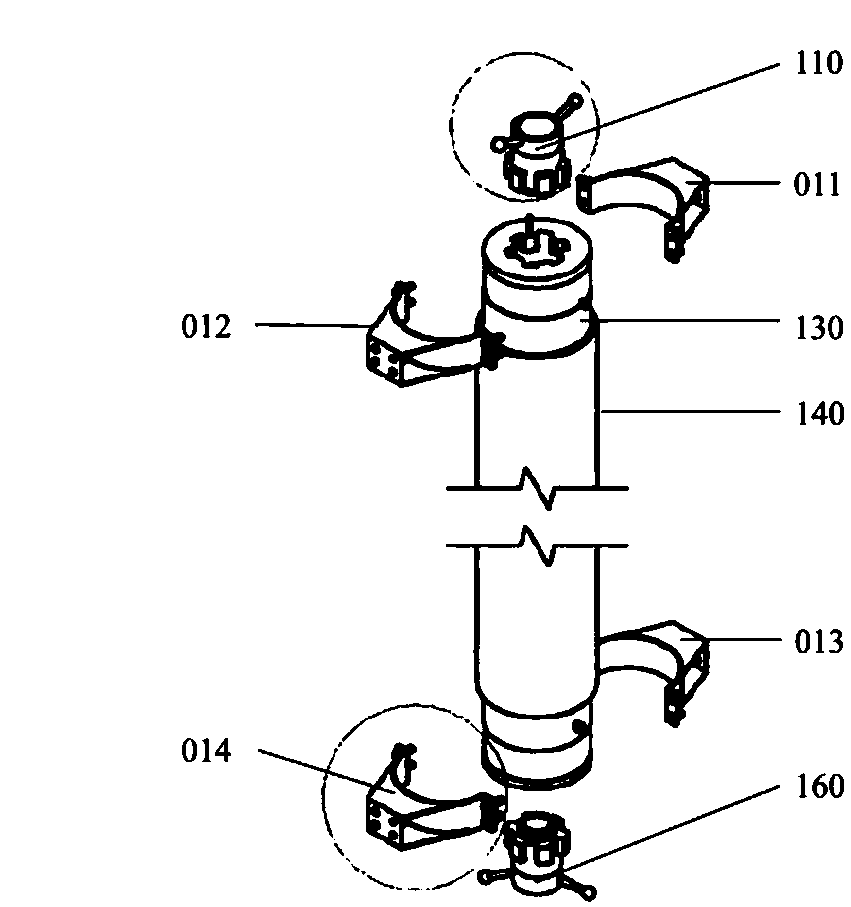

Clamp adapter assembly

A clamp adapter assembly for connecting an instrument to a pressure vessel. The clamp adapter assembly allows an operator to convert a bolt connection base known in the art into a base suitable for utilizing a clamped connection similarly known in the art. The connection assembly includes a bottom plate, at least one fastener to fasten the bottom plate to a base, a top retaining plate, and a clamp. The peripheral portions of the bottom plate and top retaining plate may be beveled in order to be received within a tri-clamp. The top retaining plate may include two sections that overlappingly engage one another.

Owner:SRM

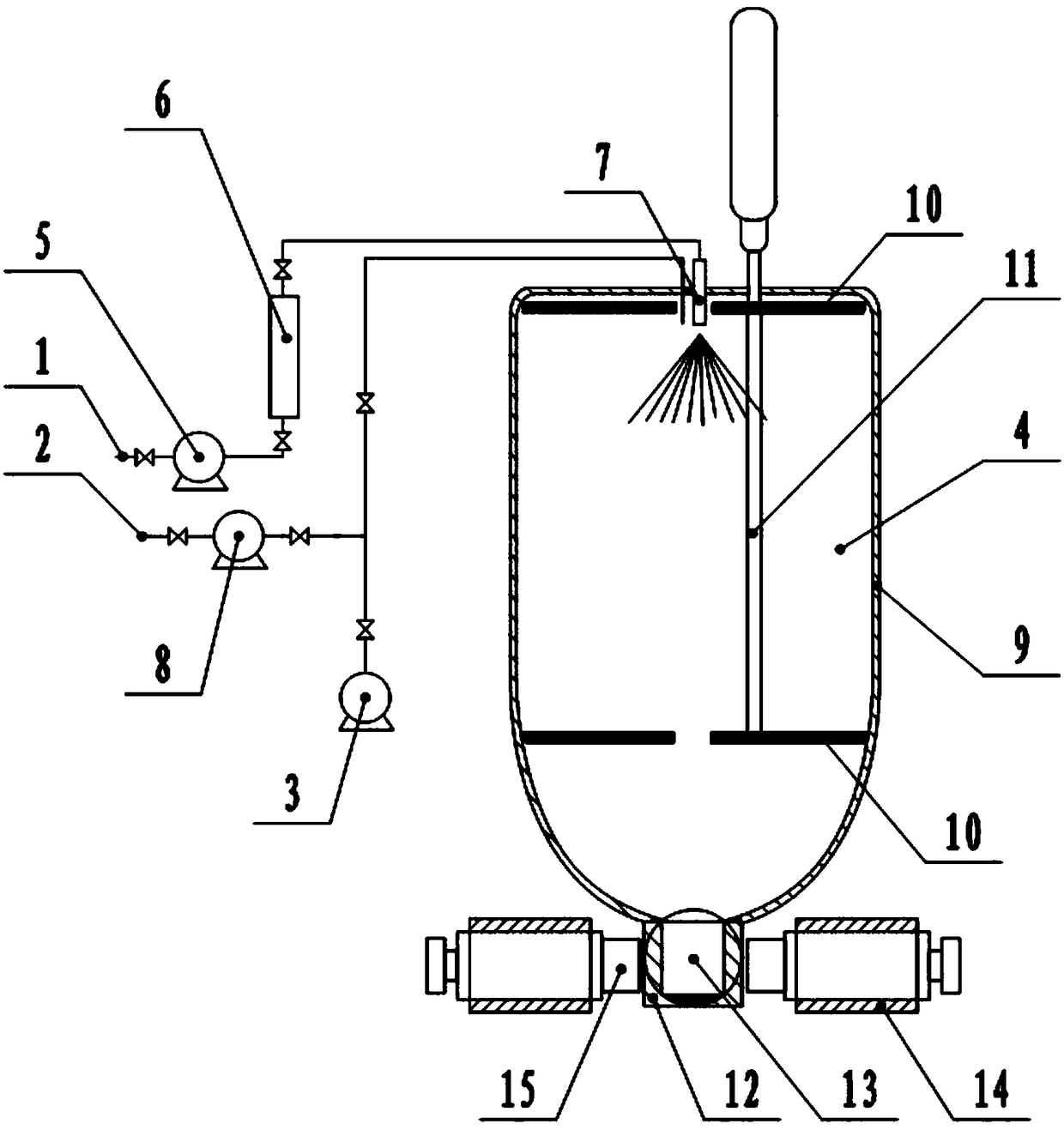

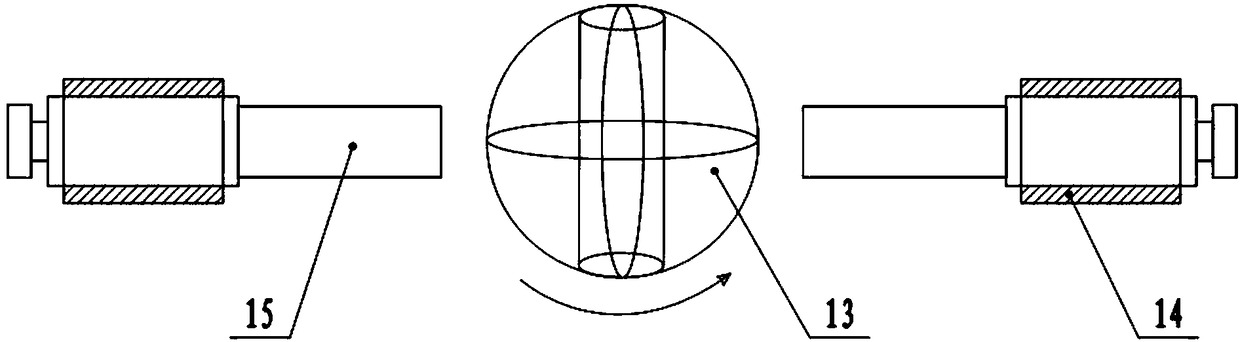

Device for rapidly and continuously preparing gas hydrate

InactiveCN108160003AImprove the efficiency of storage and transportationControl generationPressure vessel componentsPressure vessels for chemical processTemperature controlData acquisition

The invention discloses a device for rapidly and continuously preparing a gas hydrate. The device comprises a reactor with an outer water jacket, a gas supply unit for supplying a gas source to the reactor, an ice liquid supply unit for supplying an ice liquid to the reactor, a temperature control unit for controlling the temperature of the outer jacket, a hydrate filtering and collecting unit connected to the reactor and used for filtering and collecting produced hydrate crystals, and a data acquisition and processing unit for acquiring and recording the temperature and pressure data of the reactor. The rear end of the hydrate filtering and collecting unit is connected to the ice liquid supply unit through a quick-connecting valve. The device solves the problem that the conventional hydrate formation device has no a complete hydrate formation process, produces internal retention in the stirred slurry or on a magneton and has no a continuous reaction process. The experimental device issimple and economical, is easy to operate, produces a complete and uniform gas hydrate and improves the efficiency of gas storage and transportation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

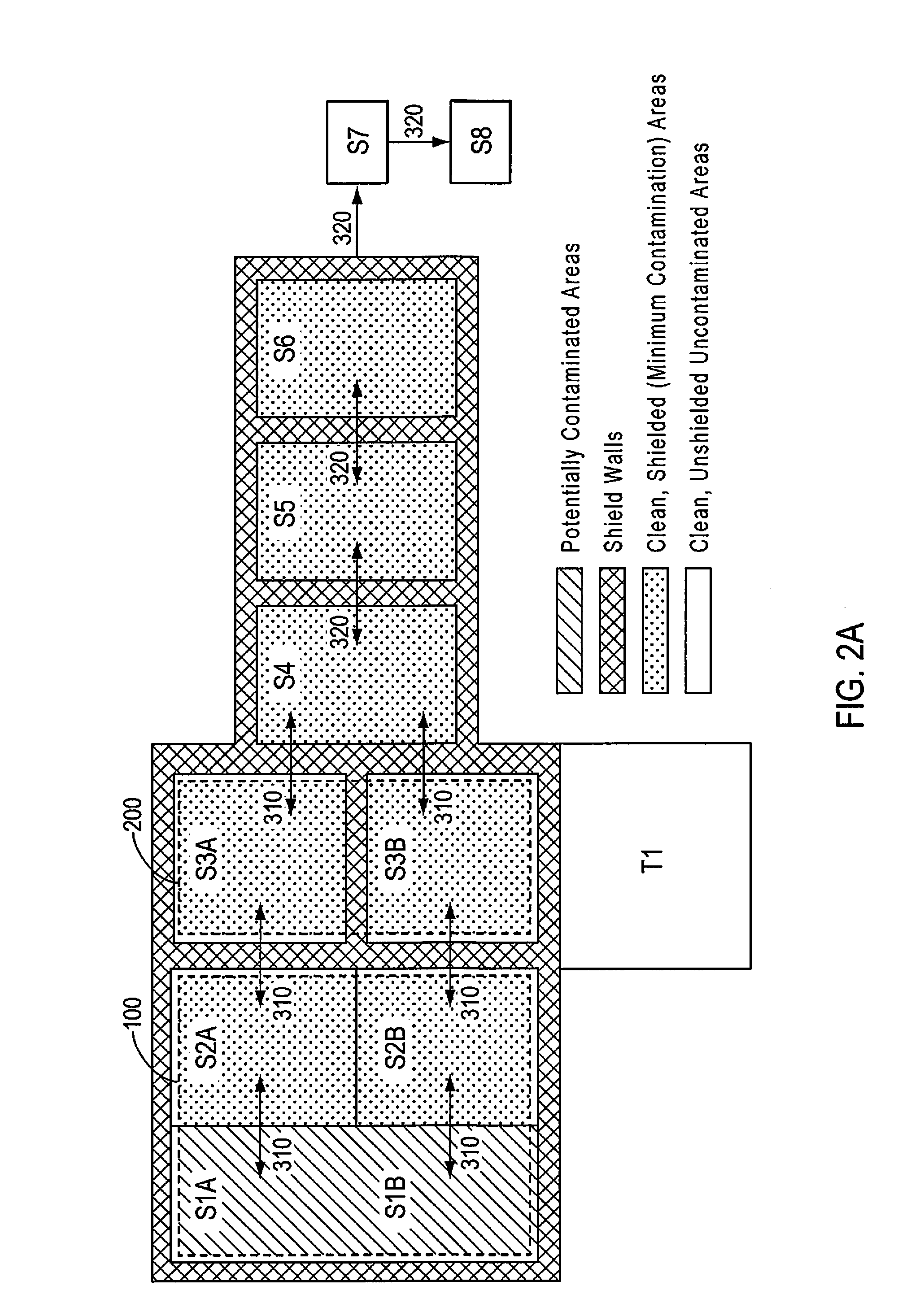

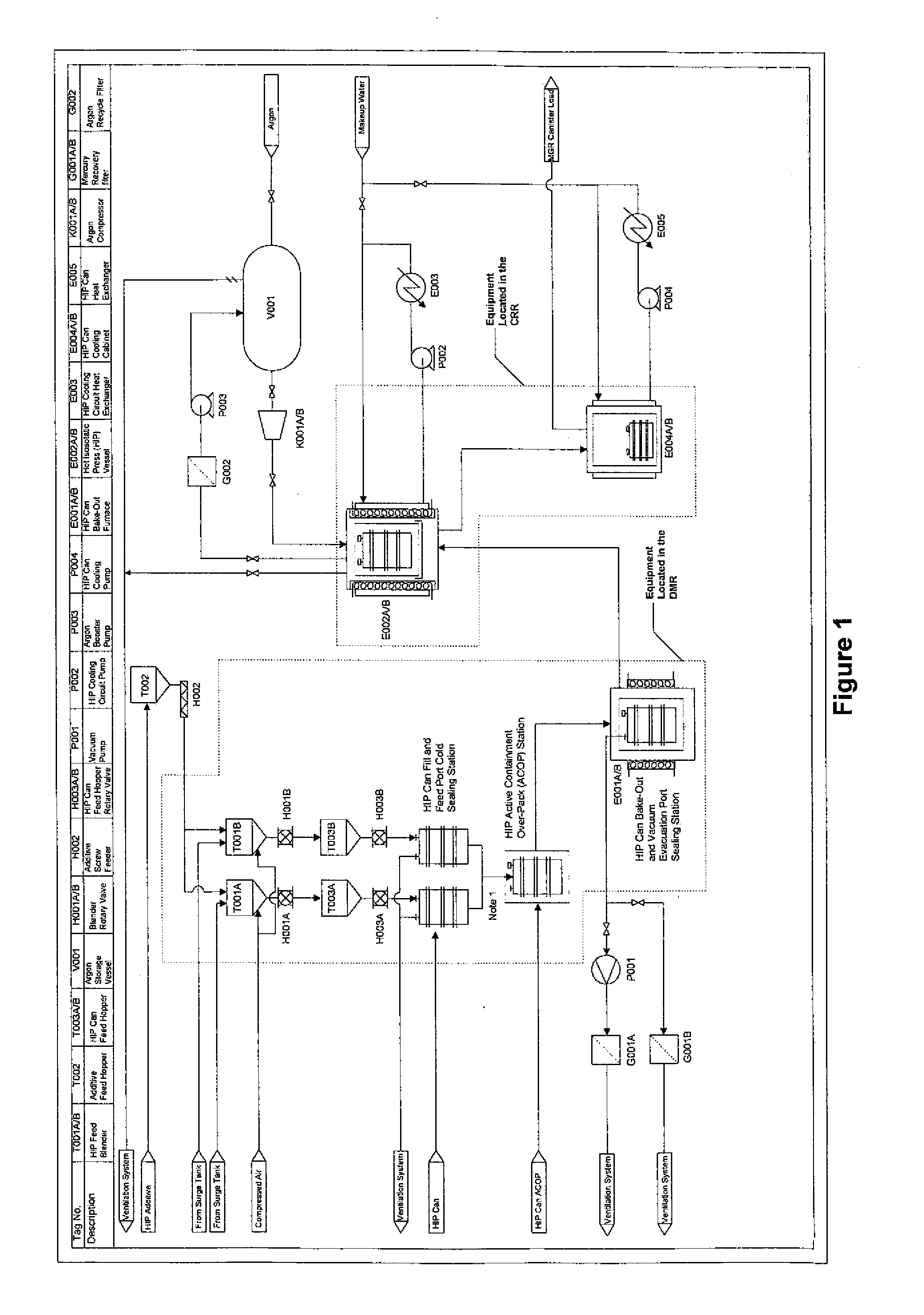

Methods of consolidating radioactive containing materials by hot isostatic pressing

ActiveUS8754282B2Reduce processing timeGlass furnace apparatusOhmic-resistance heatingZirconoliteHollandite

The present disclosure relates to a method of consolidating a calcine comprising radioactive material, the method comprising mixing 60-80% (by weight) of a radionuclide containing calcine with at least one non-radioactive additive, such as an oxide, and hot isostatic pressing the mixture to form a stable monolith of glass / ceramic. In one embodiment, the ratio of radionuclide containing calcine to additives is about 80:20 by weight, wherein the non-radioactive additive comprises oxides such as BaO, CaO, Al2O3, TiO2, SiO2 and others, that combine with the waste elements and compounds to form a ceramic mineral or glass / ceramic material, after hot isostatic pressing. Non-limiting examples of mineral phases that may be formed are: hollandite (BaAl2Ti6O16), zirconolite (CaZrThO7), and perovskite (CaTiO3).

Owner:AMERICAN ISOSTATIC PRESSES

Methods of consolidating radioactive containing materials by hot isostatic pressing

The present disclosure relates to a method of consolidating a calcine comprising radioactive material, the method comprising mixing 60-80% (by weight) of a radionuclide containing calcine with at least one non-radioactive additive, such as an oxide, and hot isostatic pressing the mixture to form a stable monolith of glass / ceramic. In one embodiment, the ratio of radionuclide containing calcine to additives is about 80:20 by weight, wherein the non-radioactive additive comprises oxides such as BaO, CaO, Al2O3, TiO2, SiO2 and others, that combine with the waste elements and compounds to form a ceramic mineral or glass / ceramic material, after hot isostatic pressing. Non-limiting examples of mineral phases that may be formed are: hollandite (BaAl2Ti6O16), zirconolite (CaZrThO7), and perovskite (CaTiO3).

Owner:AMERICAN ISOSTATIC PRESSES

Condenser system for high pressure processing system

ActiveUS10685830B2Semiconductor/solid-state device manufacturingSteam trapsProcess engineeringMechanical engineering

Embodiments described herein relate to a high pressure processing system with a condenser and methods for utilizing the same. The processing system includes a process chamber, a boiler, a condenser, and one or more heat exchangers. The boiler generates a fluid, such as a vapor or supercritical fluid, and delivers the fluid to the process chamber where a substrate is processed. After processing the substrate, the system is depressurized and the fluid is delivered to the condenser where the fluid is condensed.

Owner:APPLIED MATERIALS INC

Device and method for continuously preparing blocky combustible ice

PendingCN108192684ARapid productionImprove self-protection performanceGaseous fuelsSolid fuelsProcess engineeringHigh pressure

The invention discloses a device and a method for continuously preparing blocky combustible ice, and relates to the technical field of preparation of combustible ice. The device comprises a water inlet pipe, a gas inlet pipe, a vacuum pump and a reactor, wherein the water inlet pipe is communicated with an inner cavity of the reactor sequentially by means of a booster pump, a precooling system anda high-pressure atomizer; the gas inlet pipe is communicated with the inner cavity of the reactor by means of a gas booster pump; the vacuum pump is communicated with the inner cavity of the reactor;a cavity is arranged on the outer surface of the reactor; the cavity of the reactor is internally and fully filled with circulation cooling water. The device and the method have the beneficial effects that the synthesis of the combustible ice can be continuously carried out in the reactor, and the system does not need to be stopped when the synthesized combustible ice is taken out; the synthesized combustible ice is molded by one step by means of a compacting device, the natural gas saturation is high, and the gas storage capacity per unit volume is high; the synthesized blocky combustible ice is good in self-protection effect, and can be used for long-distance transportation of natural gas; the device is not only suitable for the combustible ice, but is also suitable for synthesis of other hydrates such as a carbon dioxide hydrate.

Owner:QINGDAO INST OF MARINE GEOLOGY

Two-component home decoration seam beautifying agent and preparation method thereof

ActiveCN112724901AOil-resistantScrub resistantShaking/oscillating/vibrating mixersNon-macromolecular adhesive additivesUltraviolet lightsFirming agent

The invention discloses a two-component home decoration seam beautifying agent and a preparation method thereof, and belongs to the technical field of seam beautifying agents, the two-component home decoration seam beautifying agent is prepared by mixing a component A and a component B according to a weight ratio of 1: (1-1.3), wherein the component A is prepared from the following raw material components in parts by weight: 80-100 parts of modified epoxy resin; 5-8 parts of a reactive diluent; 6-8 parts of a thixotropic agent; 0.05 to 0.1 part of a defoaming agent; 0-3 parts of a coupling agent; 0.1-0.3 part of an ultraviolet light absorber; and 0.1 to 0.2 part of an antioxidant; The component B is prepared from the following raw material components in parts by weight: 70-85 parts of an alicyclic amine modified curing agent; 2-5 parts of an accelerant; 6-8 parts of a thixotropic agent; and 3-6 parts of an extender pigment. The preparation method comprises the following steps: weighing; preparing the component A; and preparing the component B. The two-component home decoration seam beautifying agent has the advantages of no water absorption, oil stain resistance, easiness in cleaning, scrubbing resistance, no blackening and mildewing, high adhesive force and high curing speed.

Owner:HUNAN KOSEN NEW MATERIAL

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveCN101163540AUltra-high pressure processesPressure vessel componentsPressure differencePressure controlled ventilation

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

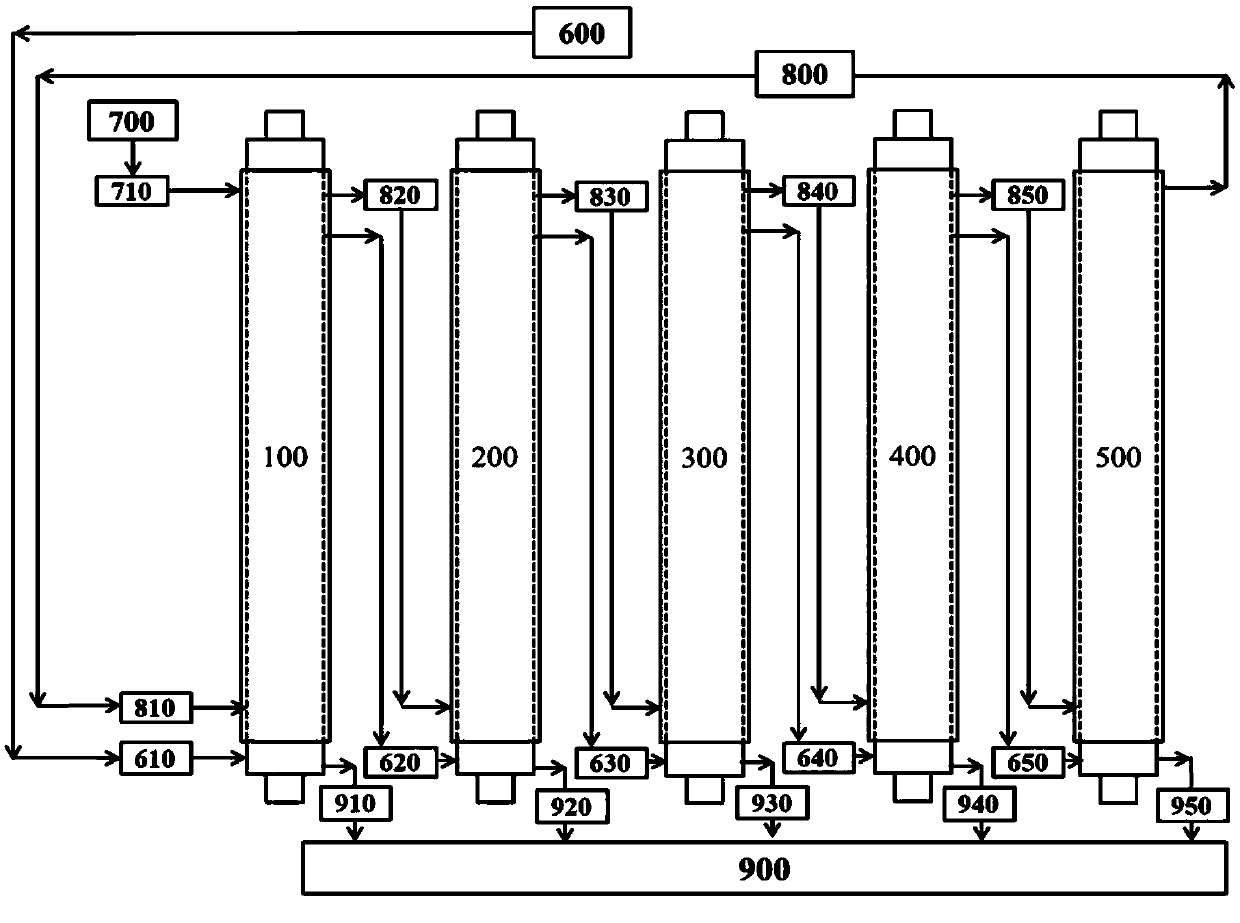

Multipurpose supercritical fluid device

InactiveCN110624477APressure vessel componentsPressure/vacuum vesselsBiochemical engineeringPreservation fluid

A multipurpose SCF device comprises: a raw material feeding assembly which comprises a raw material storage tank and a feeding pump; an SCF control assembly which comprises a carbon dioxide storage tank, a normal pressure pump, a booster pump and first to fifth SCF connecting assemblies, wherein the carbon dioxide storage tank, the normal pressure pump and the booster pump are sequentially connected in series; a heat preservation control assembly which comprises a heat preservation fluid storage tank, a pump, and first to fifth heat preservation connecting assemblies, wherein the heat preservation fluid storage tank and the pump are sequentially connected in series; an SCF tank body assembly which comprises at least five SCF tank bodies, wherein each SCF tank body comprises an upper cover,a lower cover, a tank main body and a heat preservation jacket; and a product collecting assembly which comprises one or more product storage tanks used for collecting products from the first to fifth SCF tank bodies, wherein the upper cover and the upper part of each SCF tank body of the SCF tank body assembly are combined in a quick release manner, and the lower cover and the lower part of eachSCF tank body of the SCF tank body assembly are combined in a quick release manner.

Owner:台湾三益创价生技有限公司 +1

Static reinforced rapid continuous generation device and static reinforced rapid continuous generation method for natural gas hydrate

ActiveCN109097120AEasy to removeAccurate and efficient temperature controlGaseous fuelsPressure vessel componentsNuclear engineeringDistributor

The invention discloses a static reinforced rapid continuous generation device and a static reinforced rapid continuous generation method for a natural gas hydrate. The device comprises a feed liquidtank, a reactor and a refrigeration system thereof, a temperature control system and a pressure control system, a natural gas buffer tank, a compressor, a hydrate storage tank as well as pipelines andvalves for connecting the components. The method comprises the following steps: water and an accelerator are fed into the feed liquid tank, and are mixed and prepared into an aqueous solution; the aqueous solution enters from the top of the reactor; liquid flows down along the inner wall of the reactor in a film shape under the action of a liquid uniform distributor in the reactor and is subjected to heat exchange with the inner wall of the reactor in the flowing process, so that a liquid film is distributed along the axial temperature of the reactor in a gradient form; natural gas is introduced from the bottom of the reactor and makes countercurrent contact with the liquid film to form a hydrate film; the hydrate film separates from the reactor wall under the action of a blade in the reactor and forms hydrate slurry with the solution; the hydrate slurry flows into a hydrate storage tank. The static reinforced rapid continuous generation device and the static reinforced rapid continuous generation method disclosed by the invention have the advantages of simple preparation method and device, rapid generation of the natural gas hydrate, high heat transfer efficiency and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

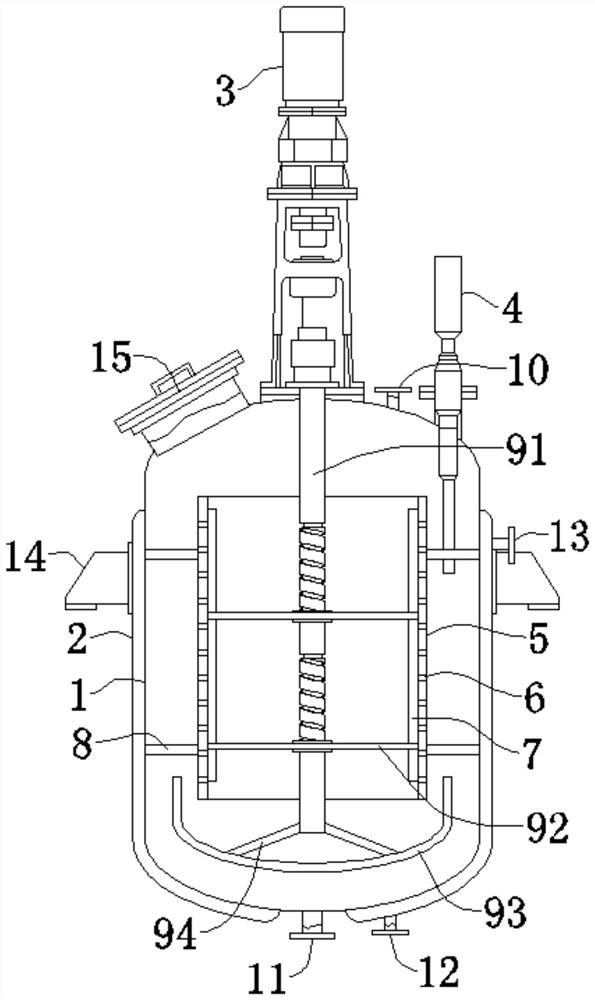

Multifunctional analysis high-pressure reaction kettle and application method thereof

ActiveCN106268514AAchieve heatingEfficient heatingChemical/physical/physico-chemical stationary reactorsPressure vessel componentsPotential measurementGas cylinder

The invention provides a multifunctional analysis high-pressure reaction kettle and an application method thereof, and belongs to the field of pressure leaching reaction system experiments and analysis equipment. The multifunctional analysis high-pressure reaction kettle comprises a high-pressure reaction kettle, a microwave-proof protection cover, a photographing device, an illumination device and a potential measurement device; the multifunctional analysis high-pressure reaction kettle is further provided with a high-pressure reaction kettle controller, a stirring paddle, a stirring shaft, a motor, a speed measuring lead wire, a thermocouple, a charging funnel, a charging tank, a discharging guide pipe, a discharging hole, a pressure meter and a gas bottle. The high-pressure reaction kettle can be heated by microwaves, and has visualized observation and potential analysis determination functions; the invention provides a comprehensive measurement method. The high-pressure reaction kettle is simple in structure and convenient to operate; observation of a behavior rule of air bubbles in the kettle and determination of the potential of a reaction system can be very easily realized through a high-speed camera under a microwave heating condition in the high-pressure reaction kettle, and an electron transferring condition of main reactants in a reaction process is judged.

Owner:NORTHEASTERN UNIV

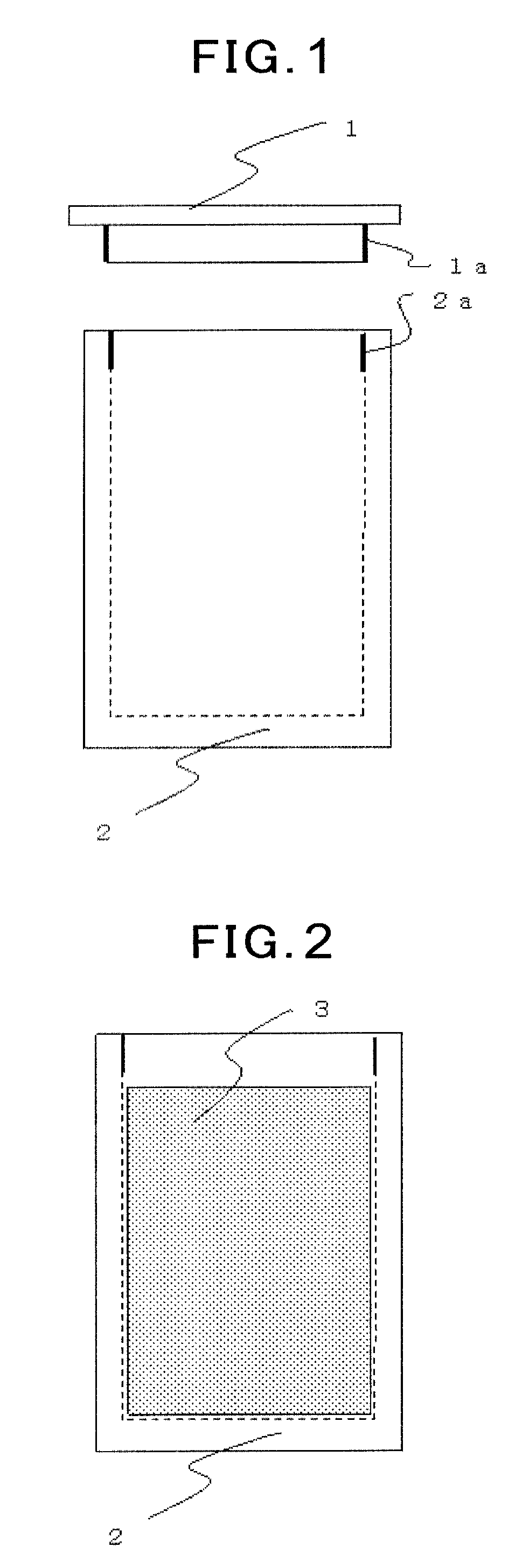

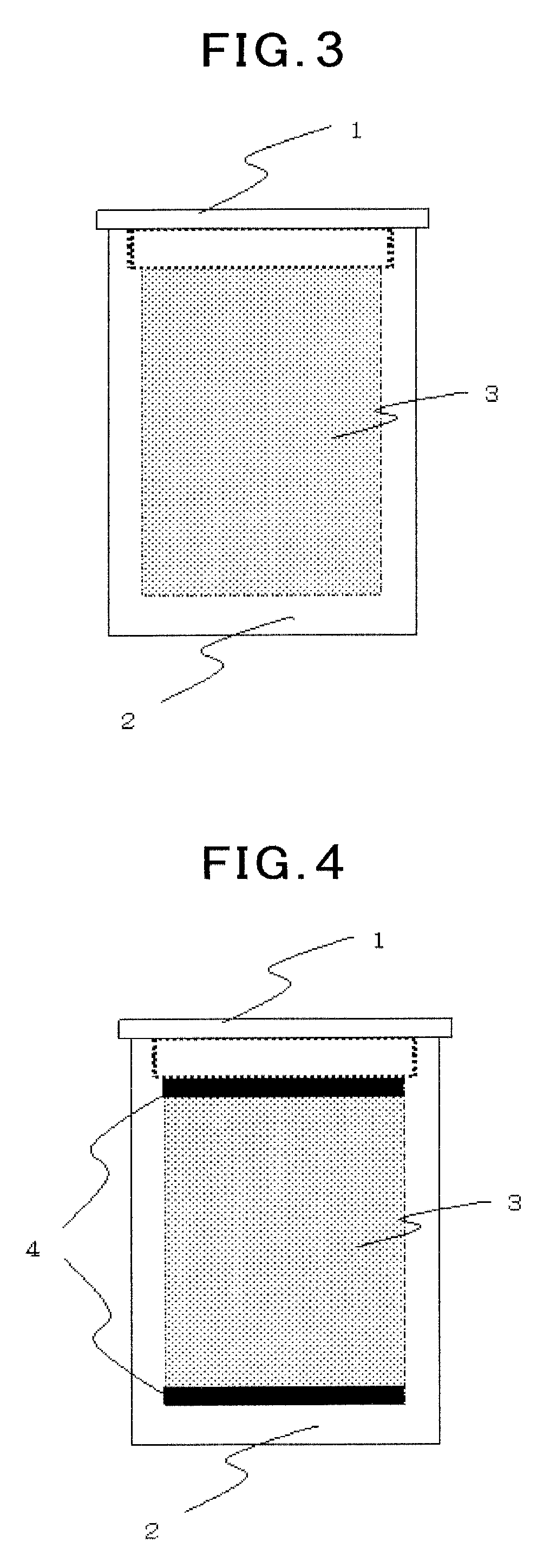

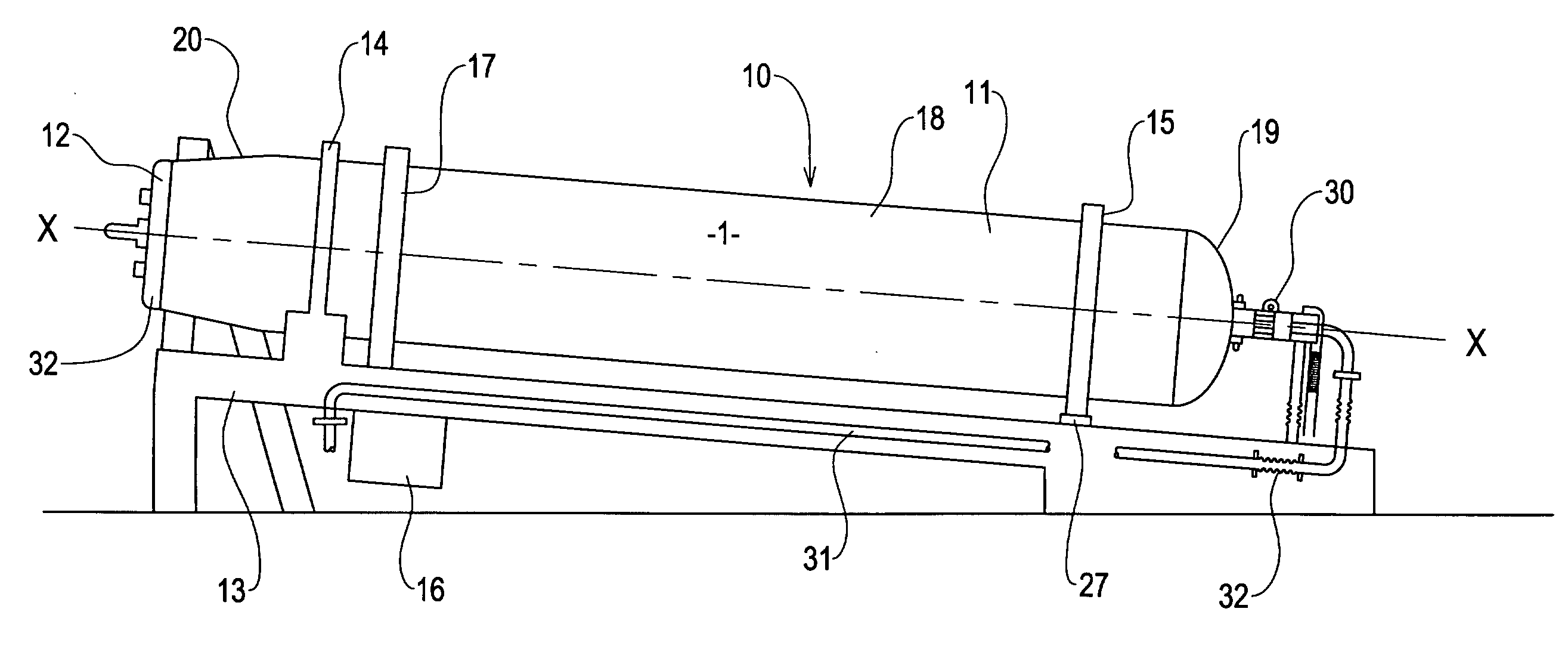

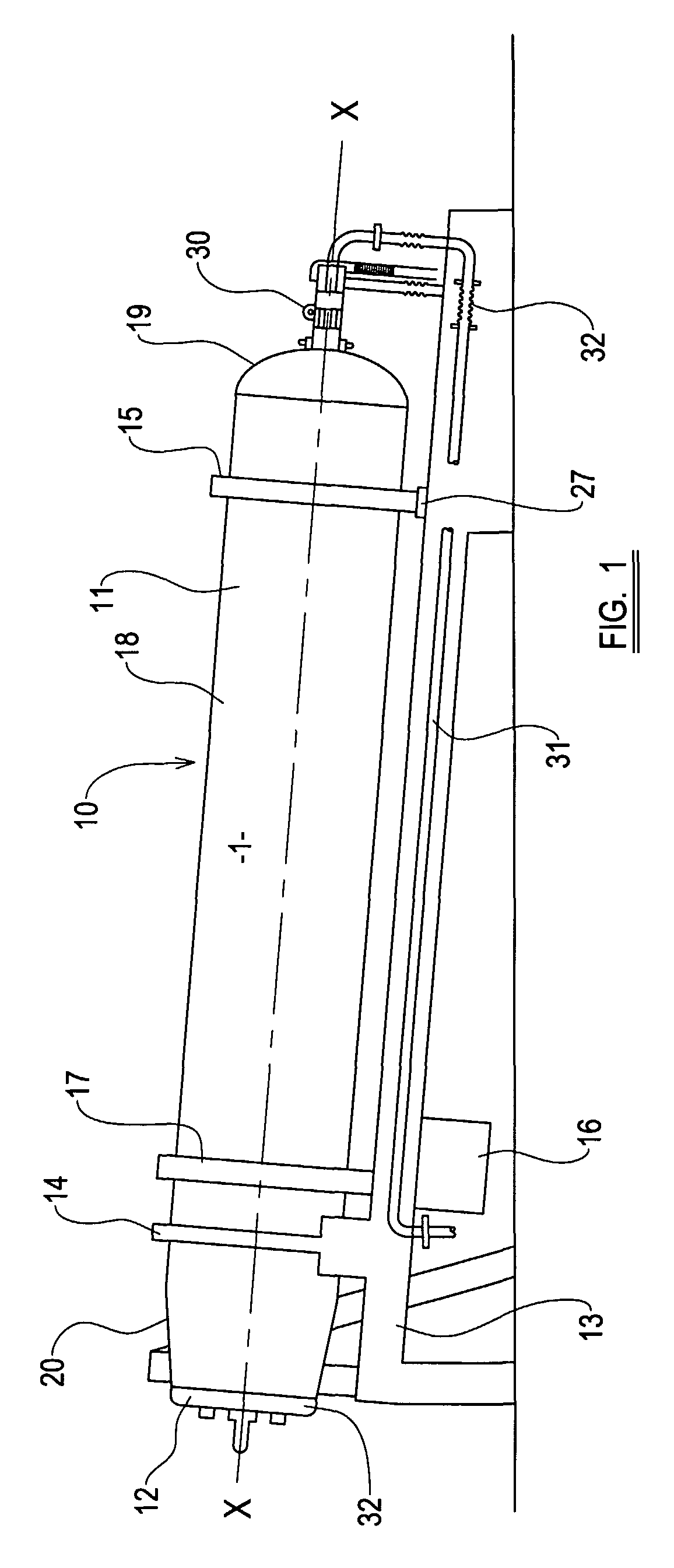

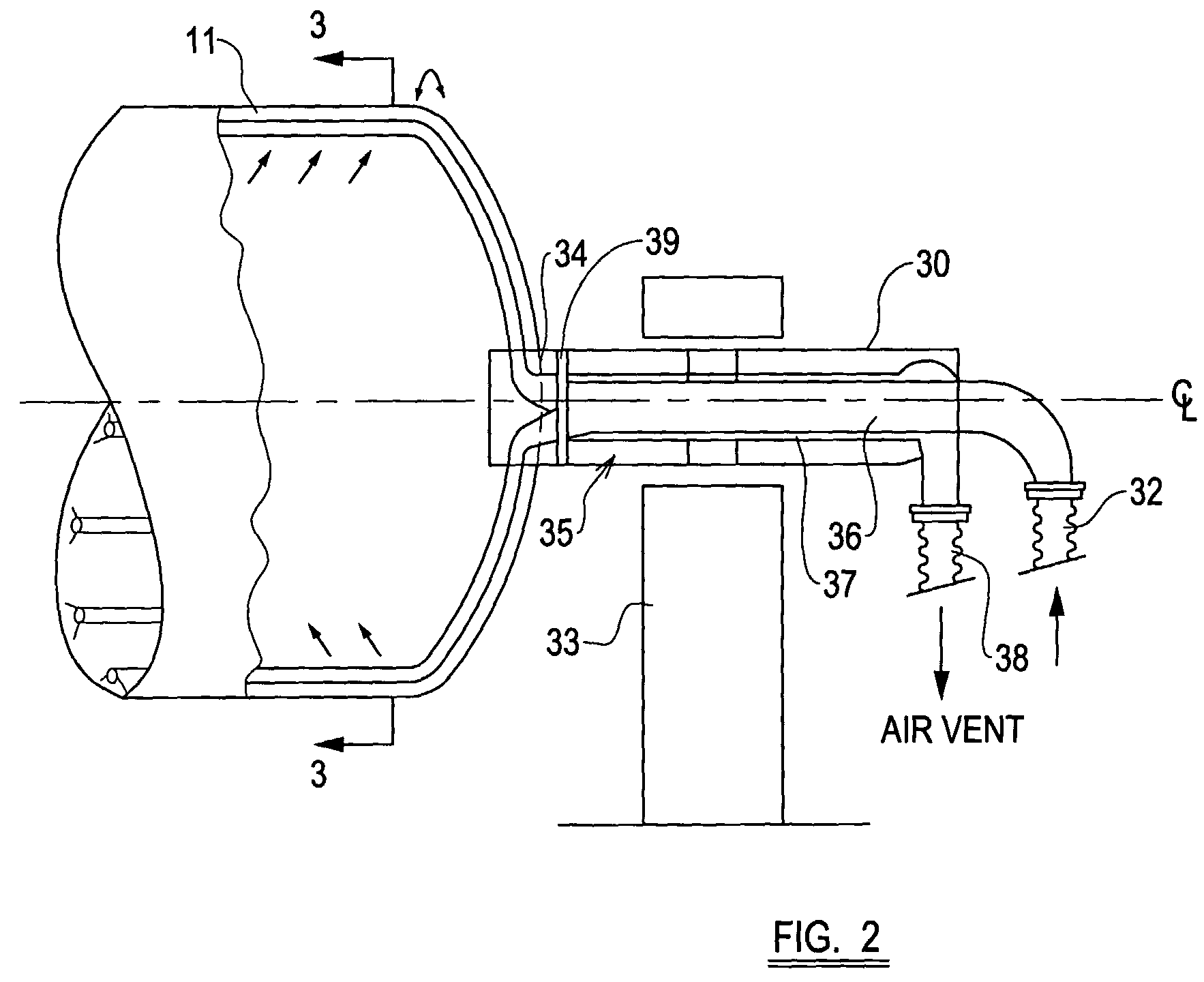

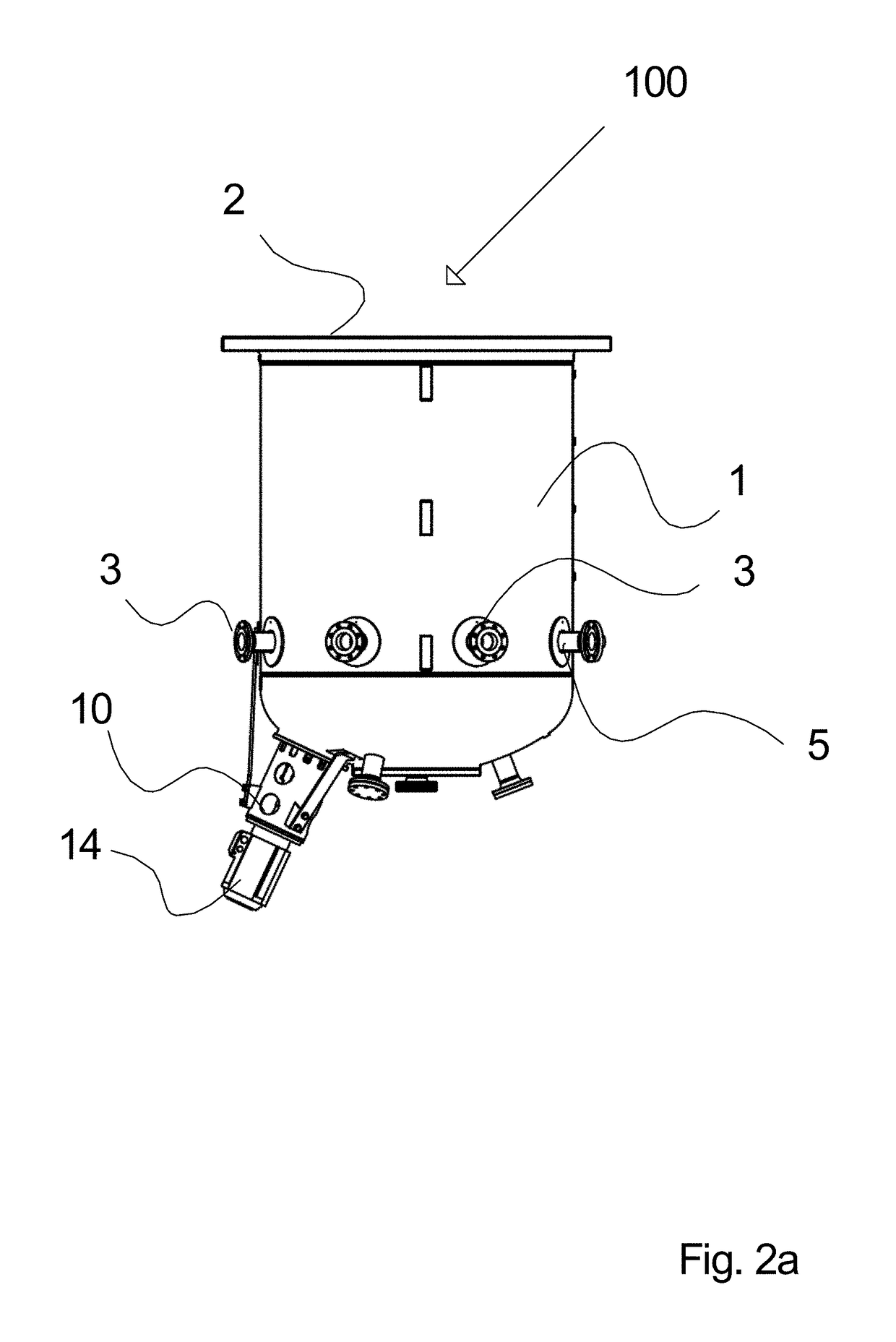

Autoclave

A waste treatment apparatus having an autoclave that includes a pressure vessel (11) having a first mouth part (20) to receive waste material and a second mouth part (19) to discharge treated material, with the autoclave being rotatable at a longitudinal axis to agitate the waste material during treatment and to discharge waste material from the autoclave.

Owner:ESTECH EURO

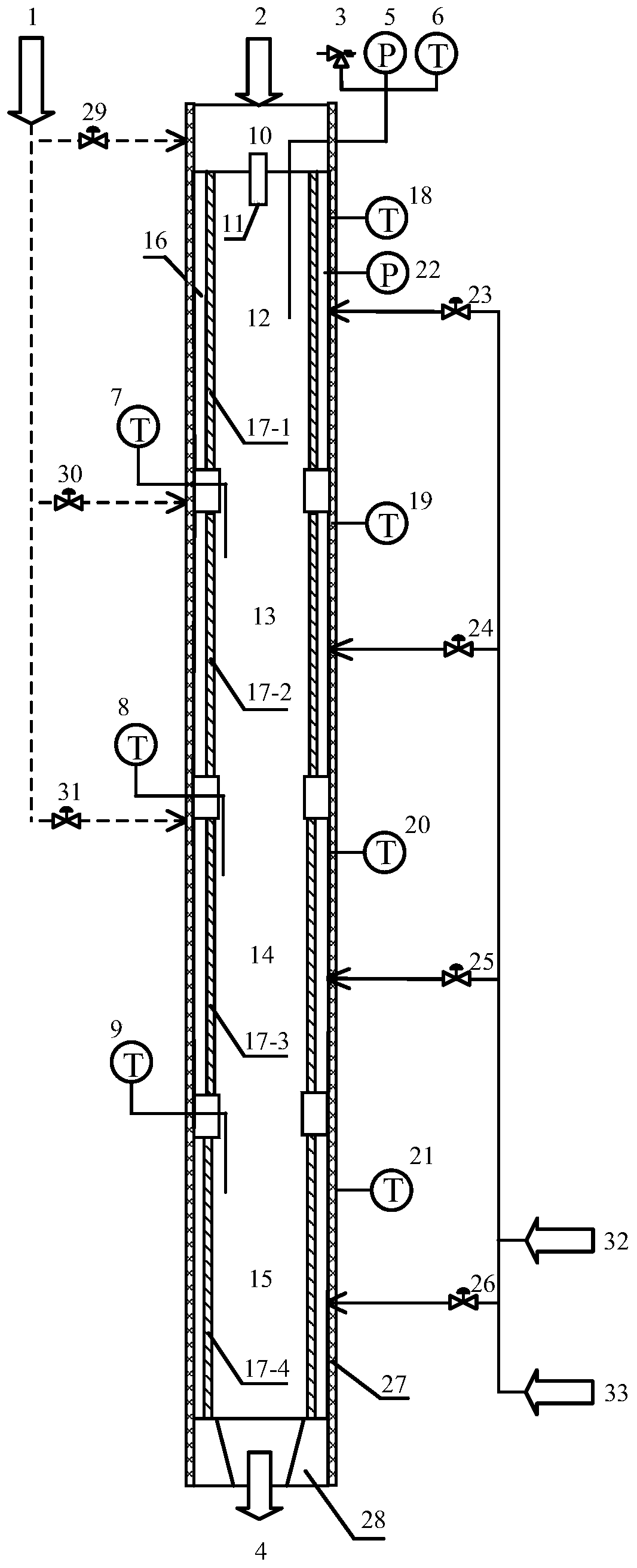

Tubular evaporation wall reactor used for supercritical water oxidation treatment

InactiveCN110124584AIncrease throughputLess investmentPressure vessel componentsPressure vessels for chemical processManufacturing cost reductionInorganic salts

The invention discloses a tubular evaporation wall reactor used for supercritical water oxidation treatment. According to the reactor provided by the invention, evaporation wall structure reactors areconnected, each evaporation wall section independently adjust a water volume to form an excellent protective water film, segmentation oxygen implantation is adopted to avoid local overheating of thereactor, temperature partition zones are arranged in the reactor to dissolve precipitated inorganic salts while ensuring high-efficiency organic matter degradation, reactor corrosion and salt deposition blocking are avoided while treatment capacity amplification of the reactor is solved, a pressure bearing function and a corrosion resistant function are separated, the manufacturing costs are reduced, and the system economy is improved; and meanwhile, safe and stable operation of the reactor is guaranteed through a perfect temperature and pressure monitoring system, and the technology is more suitable for industrial large-scale applications.

Owner:GUANGXI UNIV

Clamp adapter assembly

ActiveUS20100229353A1Increase the areaSnap fastenersSleeve/socket jointsBolt connectionPressure vessel

The present invention is directed towards a clamp adapter assembly for connecting an instrument to a pressure vessel. The clamp adapter assembly of the present invention allows an operator to convert a bolt connection base known in the art into a base suitable for utilizing a clamped connection similarly known in the art. The connection assembly includes a bottom plate, at least one fastener to fasten the bottom plate to a base, a top retaining plate, and a clamp. The peripheral portions of the bottom plate and top retaining plate may be beveled in order to be received within a tri-clamp. The top retaining plate may include two sections that overlappingly engage one another.

Owner:SRM

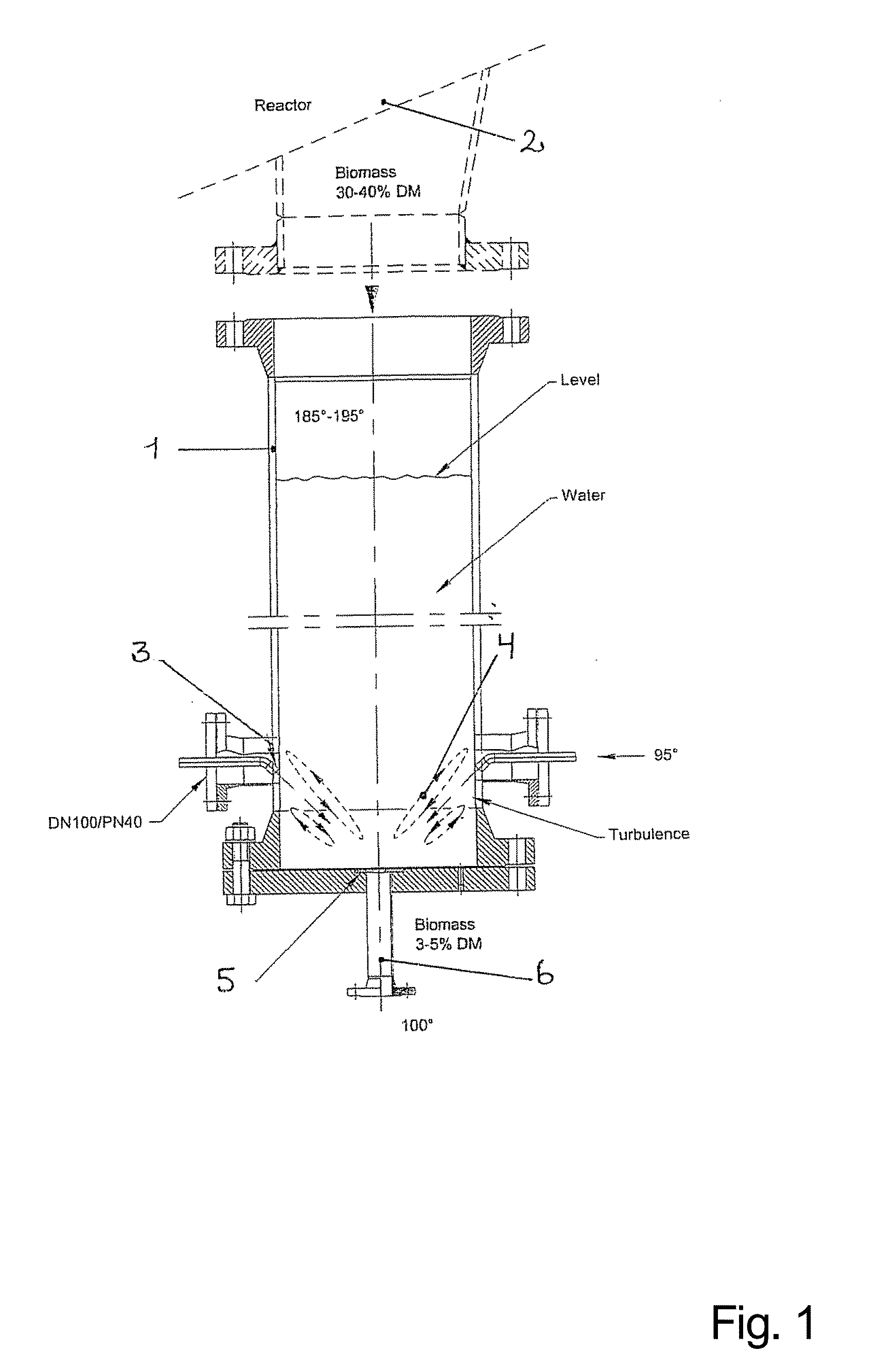

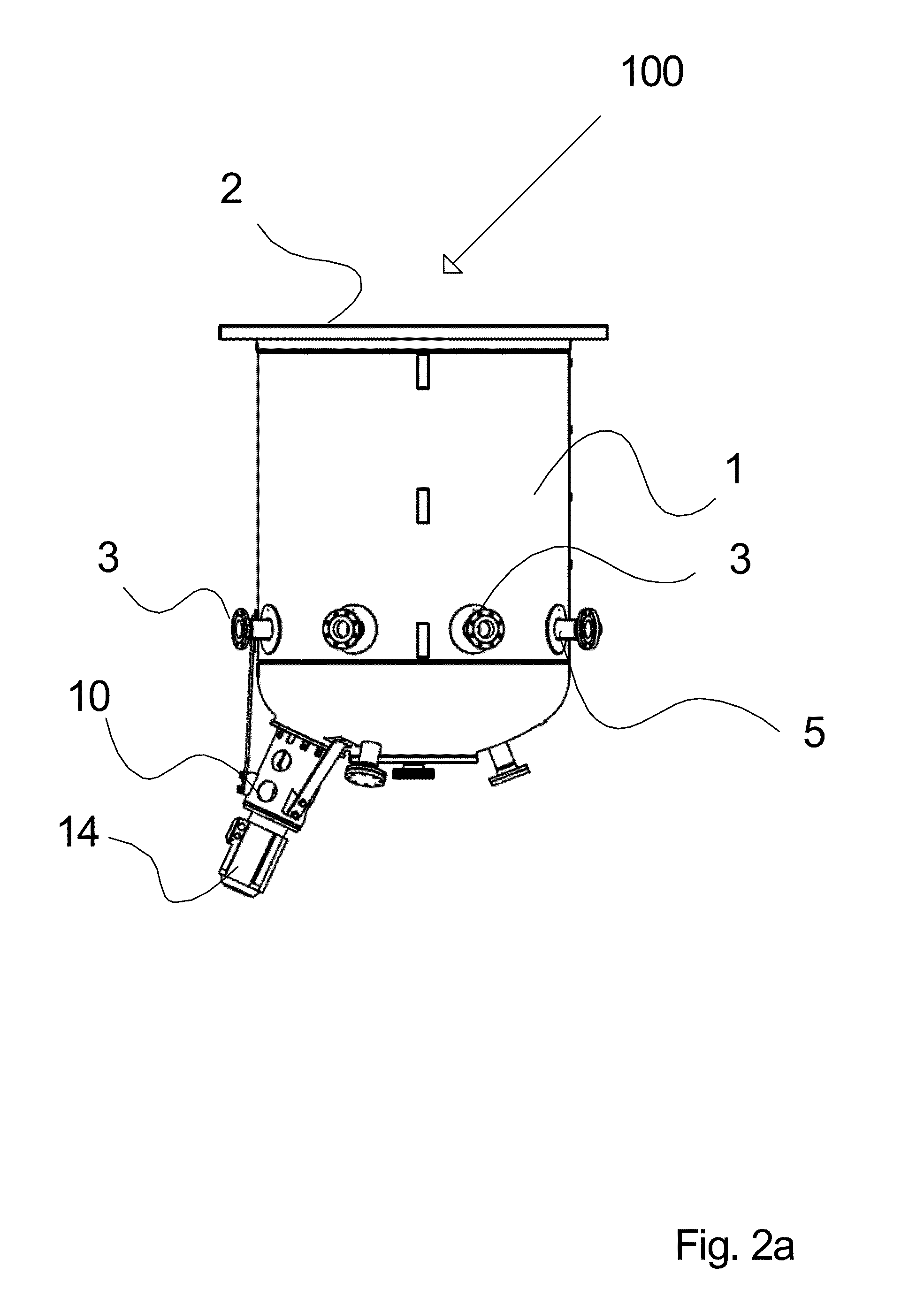

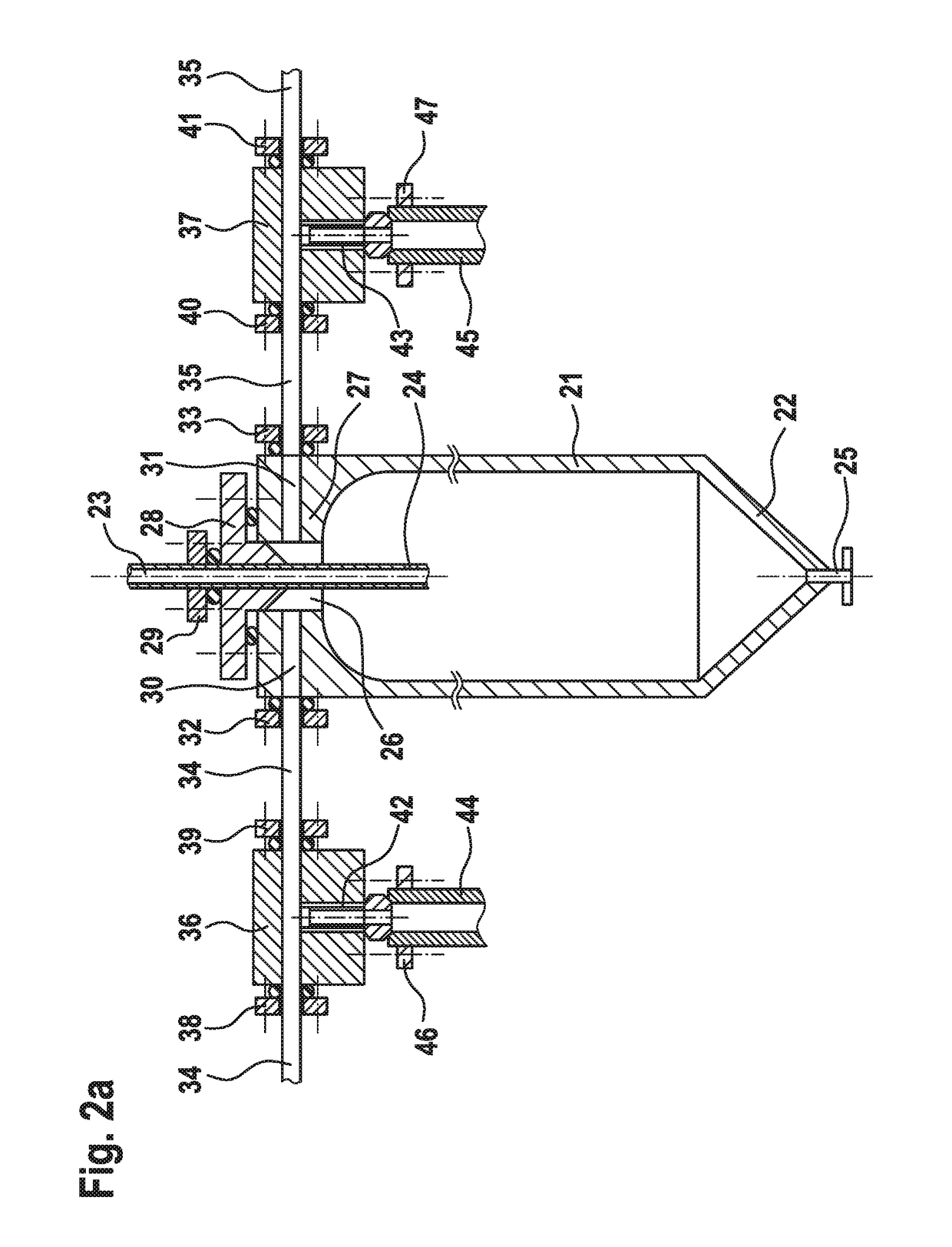

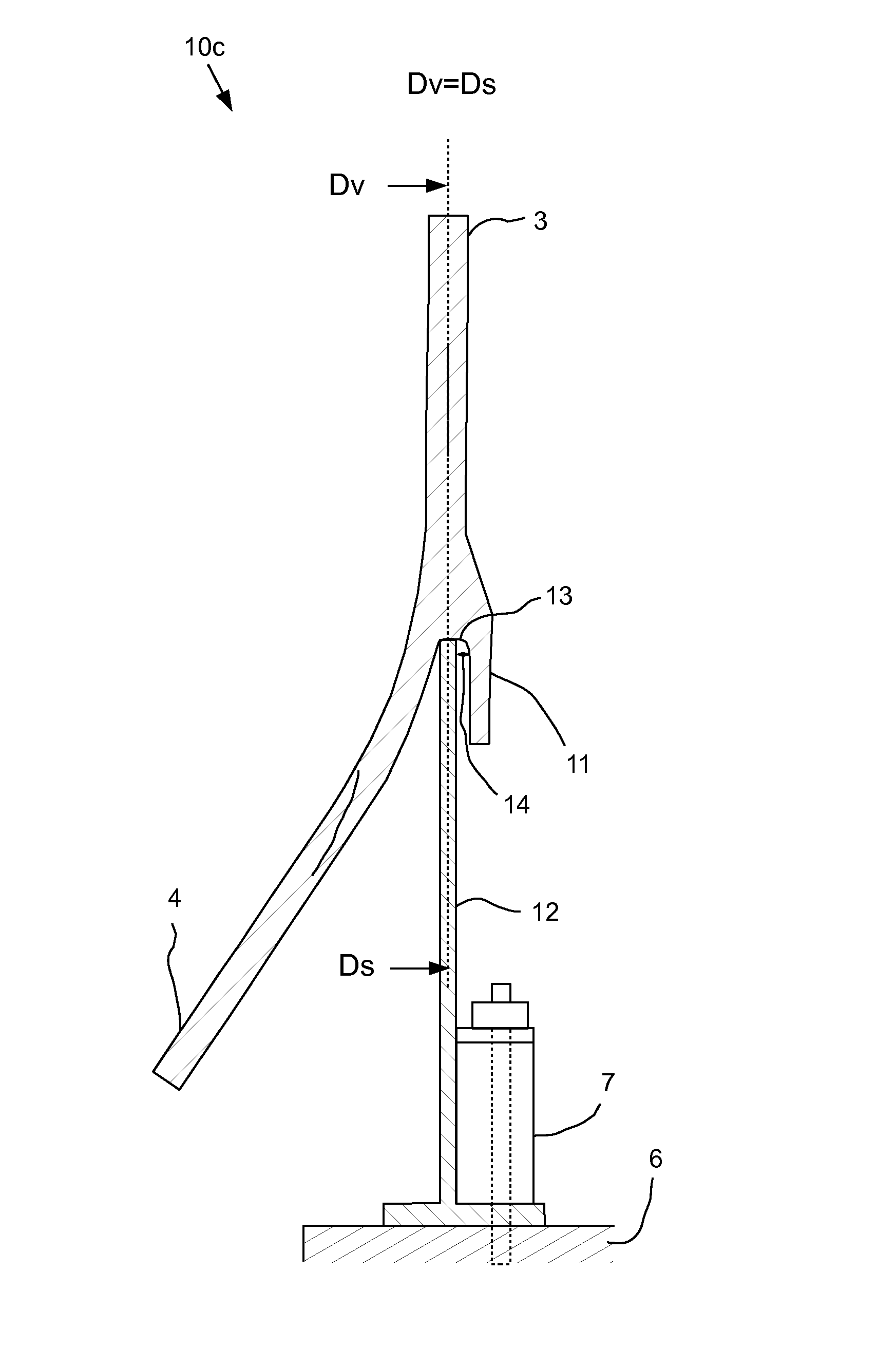

Improved device for discharging pretreated biomass from higher to lower pressure regions

ActiveUS20160215448A1Increase productionReduce lossesPretreatment with water/steamBiofuelsSlurryHigh pressure

Provided is a discharge device for discharging pretreated biomass from a pressurized reactor. The device comprises:a vessel having an opening to a high pressure region at the top, and configured to be connected with a pressurized biomass pretreatment device;one or more inlet openings situated along the sides of the vessels through which water or liquid may be added;an orifice or valve at a lower part of said vessel, said orifice or valve being configured to eject pretreated biomass, optionally into a pipeline.The discharge device is characterised in that it comprises mechanical agitation means, said agitation means comprising an agitation element arranged in the interior of said vessel at a lower part of said vessel, and being configured to provide agitation of the content of said vessel, wherein said agitation means being adapted to withstand a pressure in the interior of a said vessel of 10 bar or more. The agitation means provides for a temperature equalization within a specific vertical range of heights of an aqueous slurry present in said vessel, thereby eliminating disadvantages of the prior art devices and methods.

Owner:INBICON AS

Reaction kettle, device and method for testing solubility of natural gas under high-temperature and high-pressure conditions

PendingCN112611675AGuaranteed tightnessGuaranteed stabilityComponent separationFuel testingSolubilityThermodynamics

The invention discloses a reaction kettle, device and method for testing the solubility of natural gas under high-temperature and high-pressure conditions. The reaction kettle comprises a kettle body and a heating device, wherein the kettle body is internally divided into a dissolution reaction cavity and a gas pressurization cavity, the gas pressurization cavity is internally divided into a pressurization cavity I and a pressurization cavity II, and a buffer cavity is formed in the pressurization cavity I; a high-pressure sealing piston is arranged in the pressurizing cavity II to divide the pressurizing cavity II into a first pressurizing cavity II and a second pressurizing cavity II; the dissolution reaction cavity is provided with a gas sampling port, a temperature sensor, a pressure sensor and a liquid inlet / outlet; the pressurizing cavity I is provided with an air source inlet, a one-way valve I is arranged in the air source inlet and connected with the buffer cavity, the buffer cavity is connected with the dissolution reaction cavity through an air outlet pipe I, and a one-way valve II is arranged on the air outlet pipe I; and the buffer cavity is connected with a first pressurizing cavity II through a gas outlet pipe II, spacer fluid is arranged in a second pressurizing cavity II, and a pressure-bearing liquid inlet is formed in the second pressurizing cavity II. The device can accurately measure solubility of natural gas under high temperature and high pressure.

Owner:中海石油(中国)有限公司海南分公司 +1

Waste cotton-polyester blended fabric component separation method

ActiveCN107308905AAvoid damageImprove separation efficiencyPlastic recyclingPressure vessel componentsRefluxPolyester

The invention discloses a waste cotton-polyester blended fabric component separation method, adopting a horizontal type rotation alcoholysis separation device. The device comprises an outer barrel with a heating device, and a rotatable inner barrel with a filter net; the outer barrel is connected with a reflux condensing device, a motor and a vacuum system. The method comprises the following steps: a waste cotton-polyester blended fabric is put into the inner barrel, and an alcoholysis agent, a catalyst and the like are added into the outer barrel; the material in the inner barrel and the alcoholysis agent make alcoholysis reaction in a rotation state; after alcoholysis is finished, the material is spin-dried in the inner barrel by centrifugation, and a liquid alcoholysate is discharged out along; after centrifugation is finished, a vacuum condensing system is started to distill off and recycle a small amount of the residual alcoholysis agent in the material in a negative pressure state, and then solid cotton yarn remained after alcoholysis separation is pushed out by a mechanical pushing rod. According to the method, stirring is not needed, so the problem of performance loss caused by twining and stirring of the remanent cotton yarn is solved; besides, the problems of the alcoholysis agent remained in the remanent cotton yarn, discharge difficulty and the like are solved, thus efficiently and conveniently separating and recycling waste cotton-polyester blended fabric components.

Owner:温州天成纺织有限公司

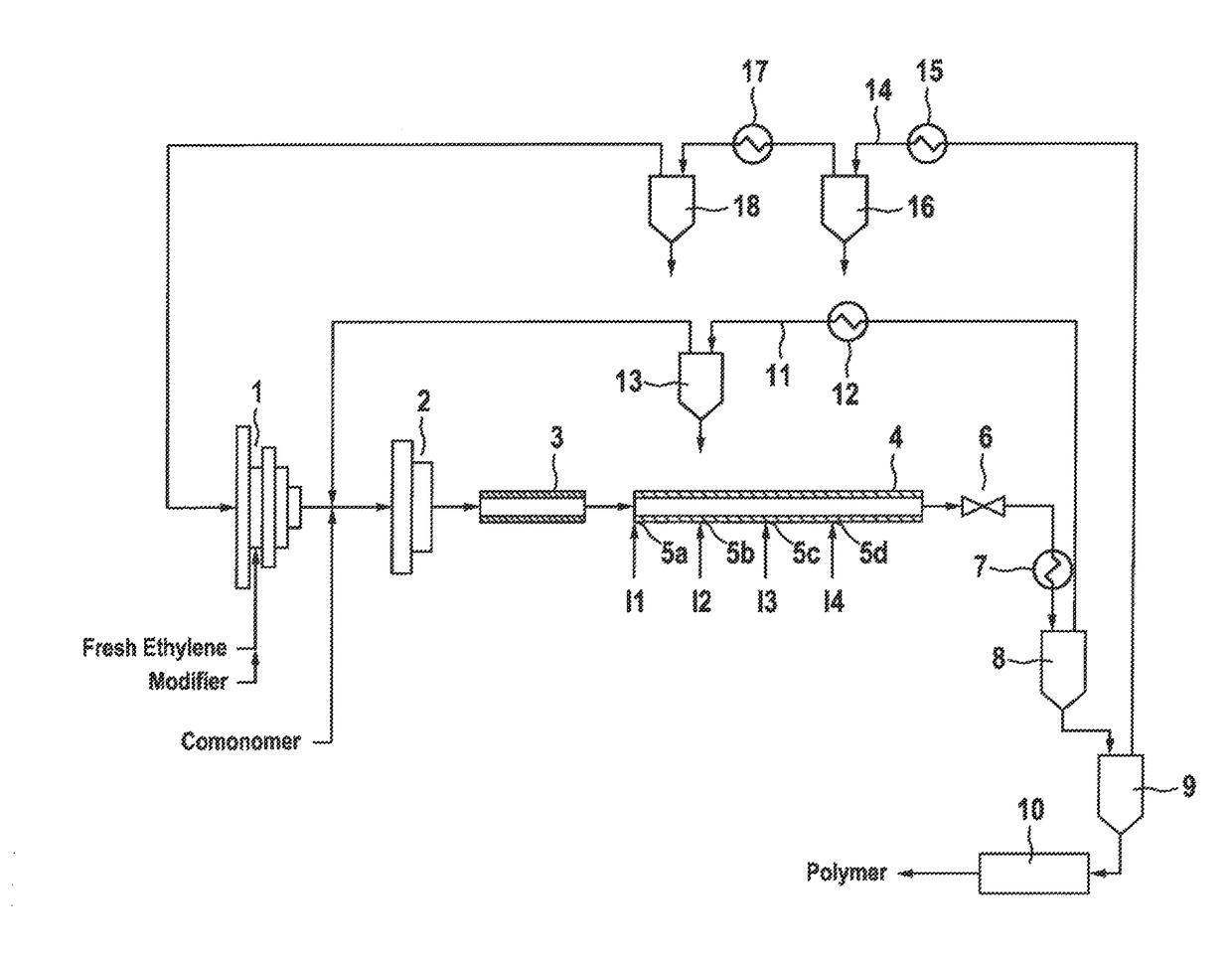

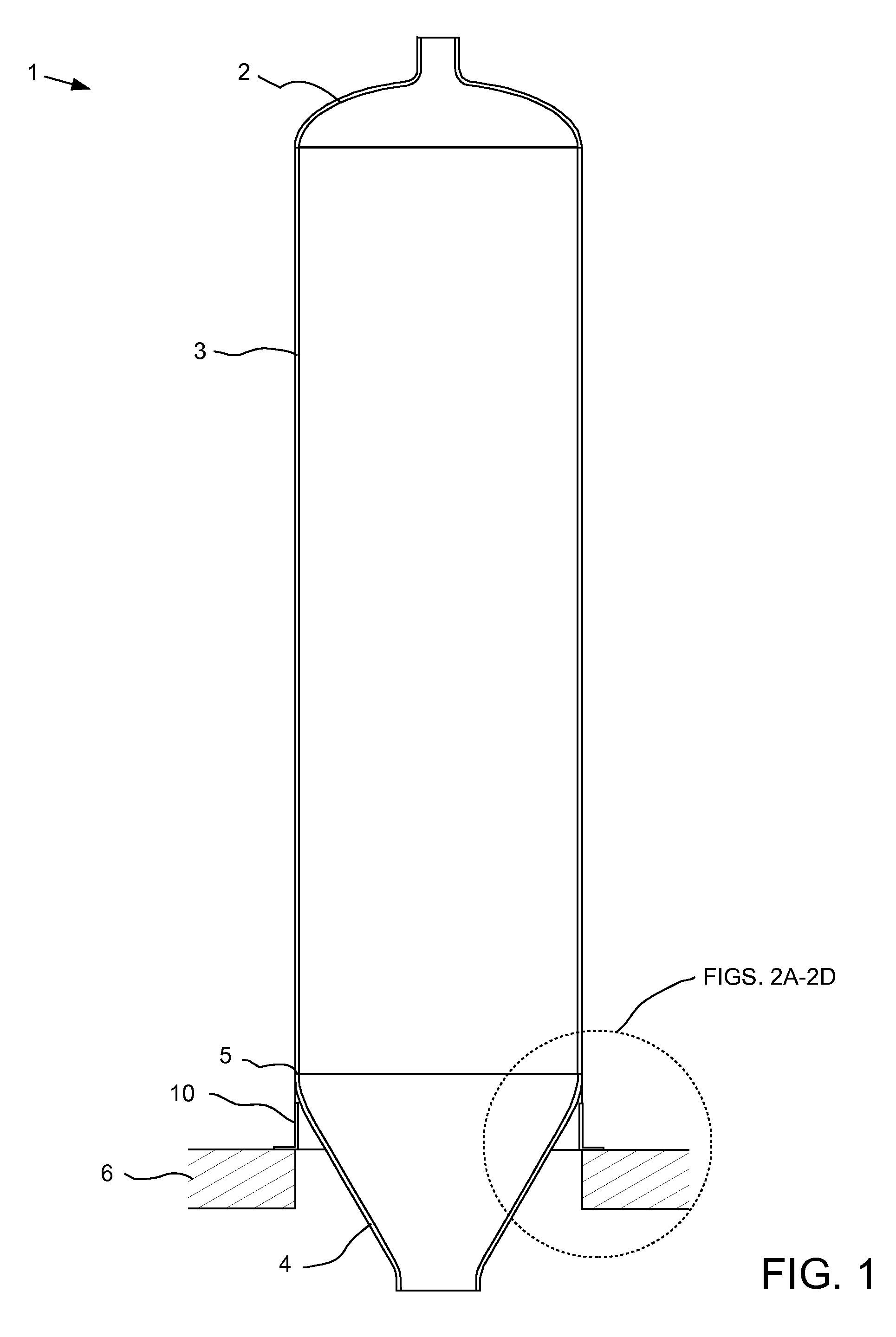

Vessel for separating components of a reaction mixture obtained by high-pressure polymerization of ethylenically unsaturated monomers with integrated bursting discs

ActiveUS9637569B2Simple designEconomically constructedLiquid degasification regulation/controlFlash degasificationPolymer scienceEngineering

The present disclosure relates to a vessel for separating, at a pressure of from 10 MPa to 50 MPa, a composition comprising liquid components and gaseous components into a liquid fraction and a gaseous fraction, whereinthe separation vessel has a vertically arranged cylindrical shape,has at its top a manhole, which is surrounded by a thickened by a part of the separation vessel wall;and bears at least one bursting disc which is held by a bursting disc holder which is installed pressure-tight within a boring in the thickened part of the separation vessel wall.

Owner:BASELL POLYOLEFINE GMBH

Autoclave

A waste treatment apparatus having an autoclave that includes a pressure vessel (11) having a first mouth part (20) to receive waste material and a second mouth part (19) to discharge treated material, with the autoclave being rotatable at a longitudinal axis to agitate the waste material during treatment and to discharge waste material from the autoclave.

Owner:ESTECH EURO

Device for discharging pretreated biomass from higher to lower pressure regions

ActiveUS10087578B2Increase productionReduce lossesPretreatment with water/steamBiofuelsSlurryEqualization

Provided is a discharge device for discharging pretreated biomass from a pressurized reactor. The device comprises:a vessel having an opening to a high pressure region at the top, and configured to be connected with a pressurized biomass pretreatment device;one or more inlet openings situated along the sides of the vessels through which water or liquid may be added;an orifice or valve at a lower part of said vessel, said orifice or valve being configured to eject pretreated biomass, optionally into a pipeline.The discharge device is characterised in that it comprises mechanical agitation means, said agitation means comprising an agitation element arranged in the interior of said vessel at a lower part of said vessel, and being configured to provide agitation of the content of said vessel, wherein said agitation means being adapted to withstand a pressure in the interior of a said vessel of 10 bar or more. The agitation means provides for a temperature equalization within a specific vertical range of heights of an aqueous slurry present in said vessel, thereby eliminating disadvantages of the prior art devices and methods.

Owner:INBICON AS

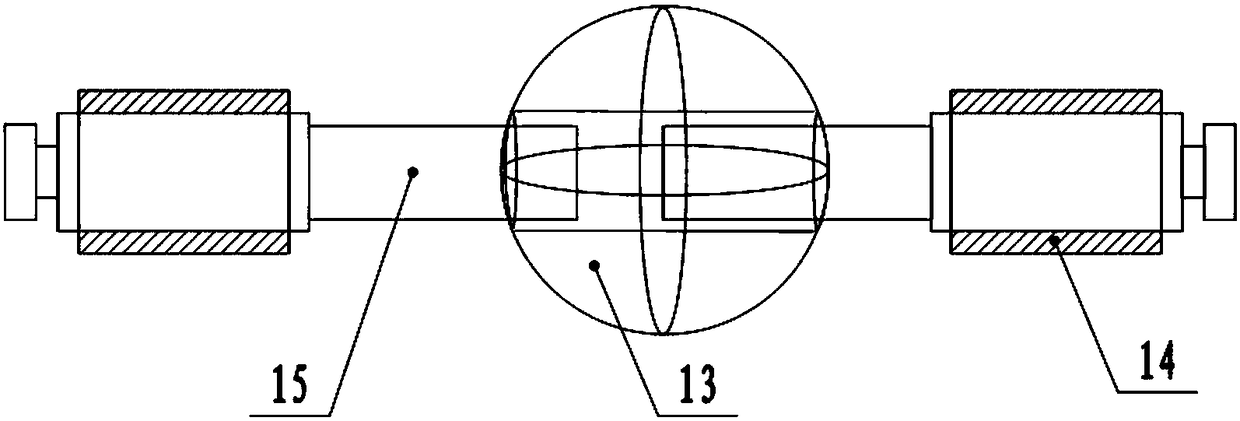

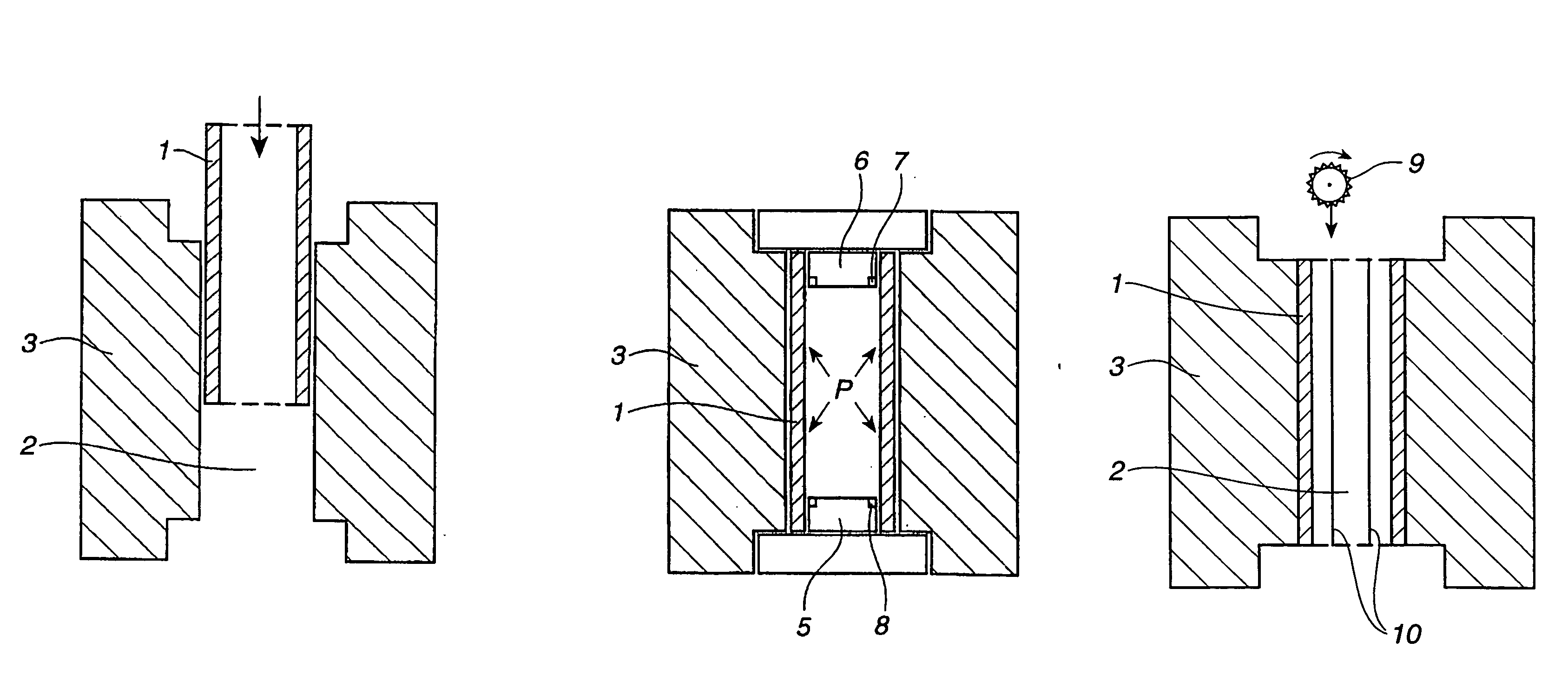

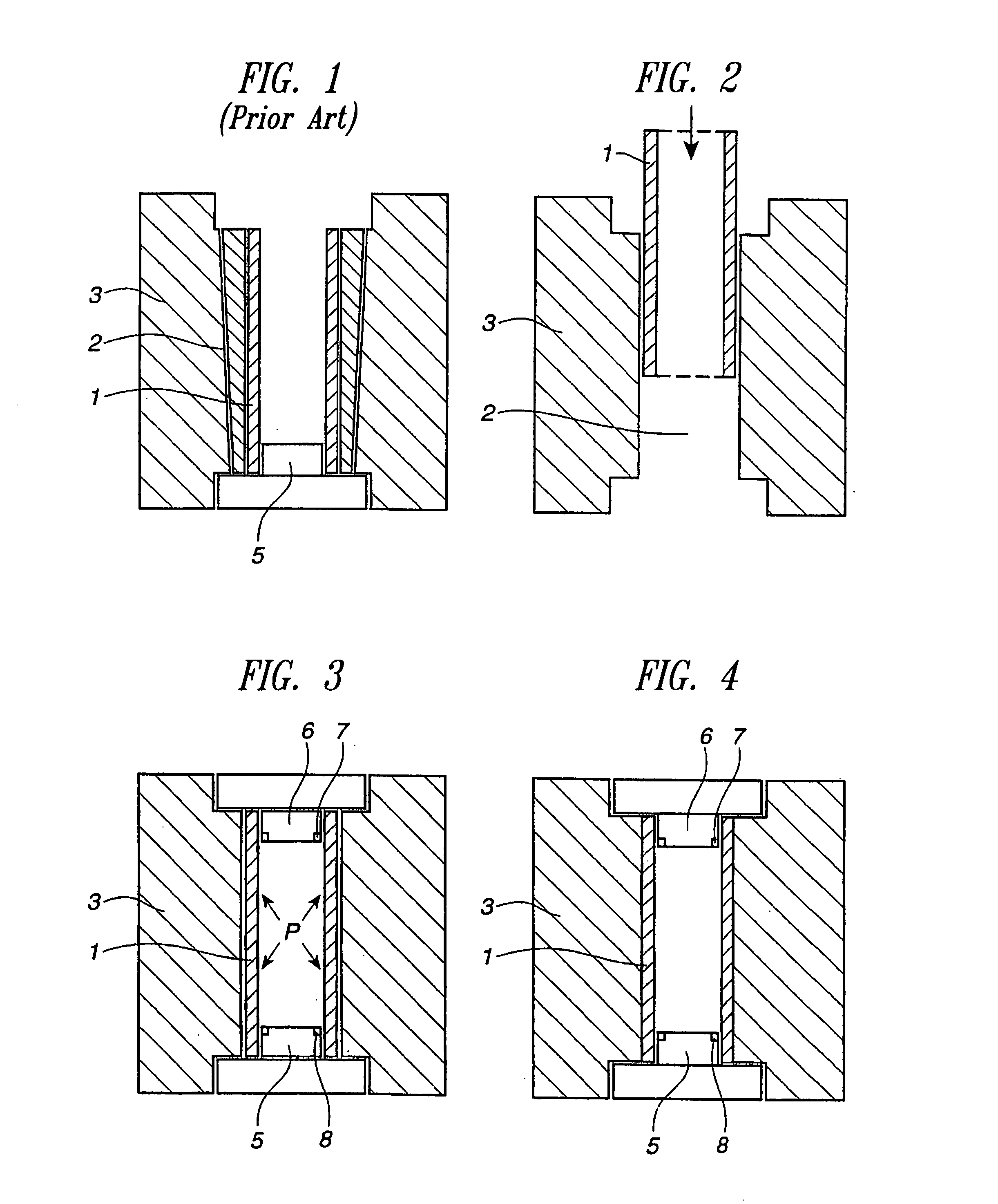

Device and method for a high pressure press

InactiveUS6895856B1Easy to replaceLess-expensive to manufactureUltra-high pressure processesFood preservationPre stressPre stressing

A method to provide a high pressure press with a replaceable wear liner. The wear liner is first inserted into the cylindrical pressure chamber of the press and the pre-stressed by the application of an excess pressure above the yield point. The excess pressure is sufficient to increase the diameter of the wear liner and produce a residual radial compressive stress that holds the wear liner in place. When the wear liner is removed from the press it is dismantled. The advantage of the invention is that the replaceable wear liner, and a high pressure press comprising it, may be relatively inexpensive to produce and the replaceable wear liner may be quickly and simply replaced.

Owner:AVURE TECH

Pressure vessel skirt for accommodating thermal cycling

ActiveUS8905260B2Restrict movementLarge containersPressure vessel componentsEngineeringPressure vessel

Owner:HOUSTON ENG SOLUTIONS

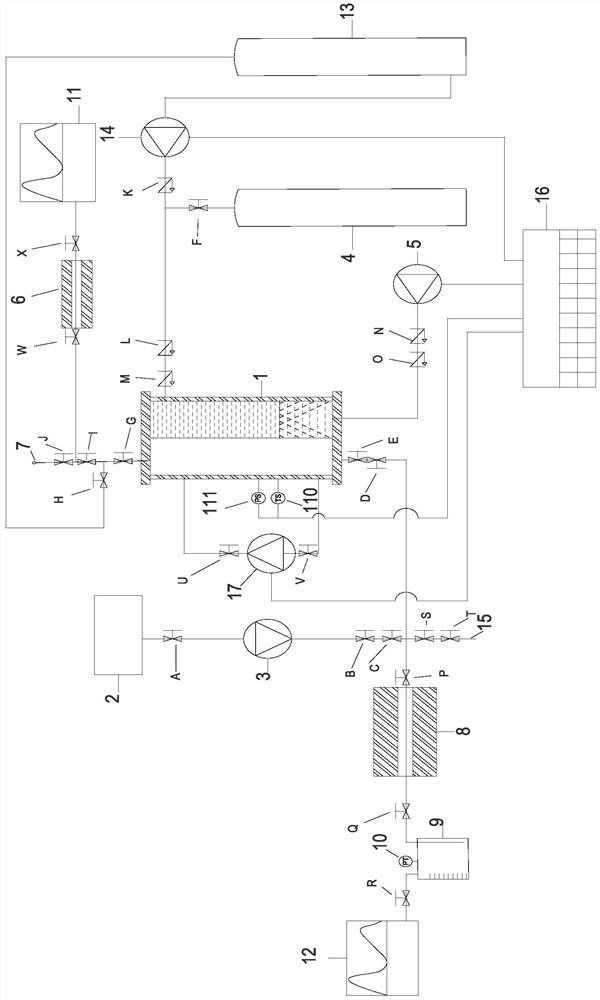

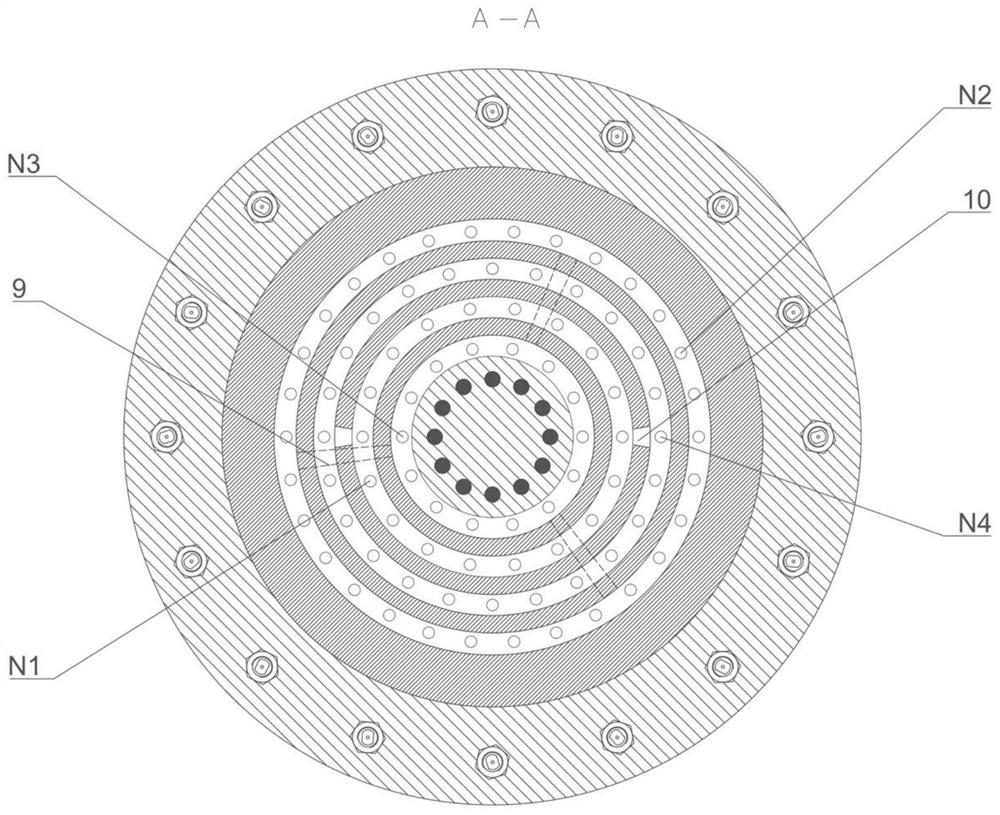

Controllable heating-heat regeneration device for preparing nano-powder by supercritical hydrothermal synthesis technology

ActiveCN111632568AIncrease contactEasy to recycleChemical/physical/physico-chemical stationary reactorsPressure vessel componentsHeater RodEngineering

The invention discloses a controllable heating-heat regeneration device for preparing nano-powder by a supercritical hydrothermal synthesis technology. Cold and hot fluid inlet and outlet flow channels are formed in a shunt matrix; a cold fluid forward flow channel, a cold fluid reverse flow channel, a hot fluid forward flow channel and a hot fluid reverse flow channel are arranged in a heat exchange matrix, electric heating rods are arranged in a central layer, a cold fluid connecting cavity, an upper annular cavity A, an upper annular cavity B and an upper annular cavity C are formed in theupper part of the heat exchange matrix, a lower annular cavity A, a lower annular cavity B, a lower annular cavity C and a lower annular cavity D are formed in the lower part of the heat exchange matrix, the hot fluid inlet flow channel, the upper annular cavity A, the hot fluid forward flow channel, the lower annular cavity B, a heat communication flow channel, the lower annular cavity C, the hotfluid reverse flow channel, the upper annular cavity B and the hot fluid outlet flow channel form a hot fluid loop; and the cold fluid inlet flow channel, the upper annular cavity C, the cold fluid forward flow channel, the lower annular cavity D, a cold communication flow channel, the lower annular cavity A, the cold fluid reverse flow channel, the cold fluid connecting cavity and the cold fluidoutlet flow channel form a cold fluid loop. According to the invention, the preheating temperature can be accurately controlled, the floor space is reduced, and heater microchannelizationI is achieved.

Owner:XI AN JIAOTONG UNIV

Intermediate gas concentration adjusting piston pressure device of high-temperature and high-pressure kettle and gas distribution method

ActiveCN111729612APrecise control of concentrationReal-time supplementProcess control/regulationPositive displacement pump componentsThermodynamicsEngineering

The invention discloses an intermediate gas concentration adjusting piston pressure device of a high-temperature and high-pressure kettle and a gas distribution method. The piston pressure device comprises a gas concentration adjusting piston pressure device and the high-temperature and high-pressure kettle; the proportion and concentration of corrosive gas can be accurately adjusted through the gas concentration adjusting piston pressure device; intermediate gas is stored and filled into the high-temperature and high-pressure kettle according to experiment requirements, the actual corrosion process on site is accurately simulated, meanwhile, corrosive gas can be supplemented in real time in the experiment period, and dynamic gas distribution in the high-temperature and high-pressure corrosion experiment process is achieved. The device has the advantages of high-temperature resistance, high-pressure resistance, corrosion resistance, simple structure and convenience in operation, the concentration ratio of corrosive gas in the high-temperature and high-corrosion experiment process is accurately controlled to be kept unchanged, and the reliability of a high-temperature and high-pressure corrosion experiment result is improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com