Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

545results about "Flash degasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

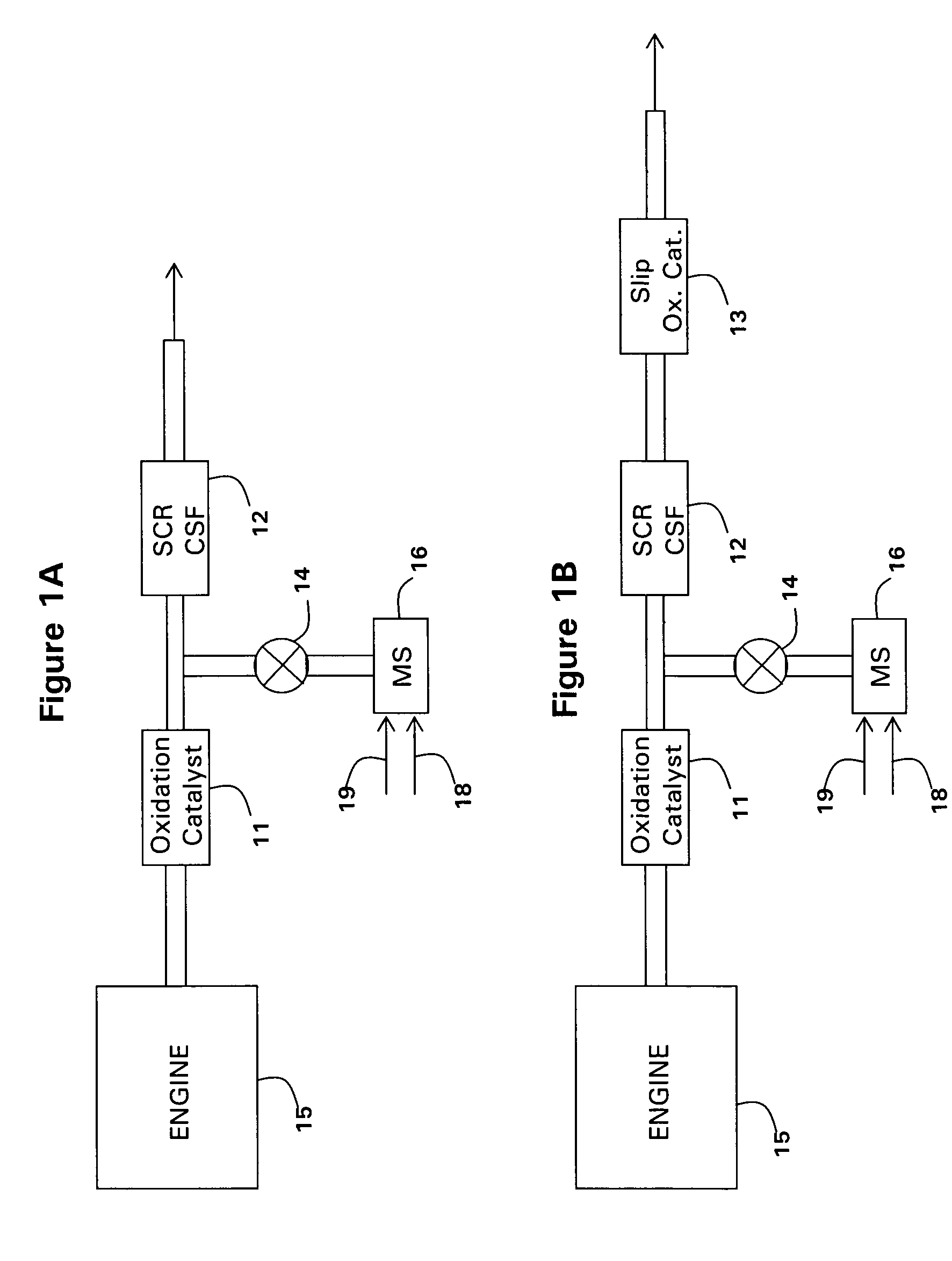

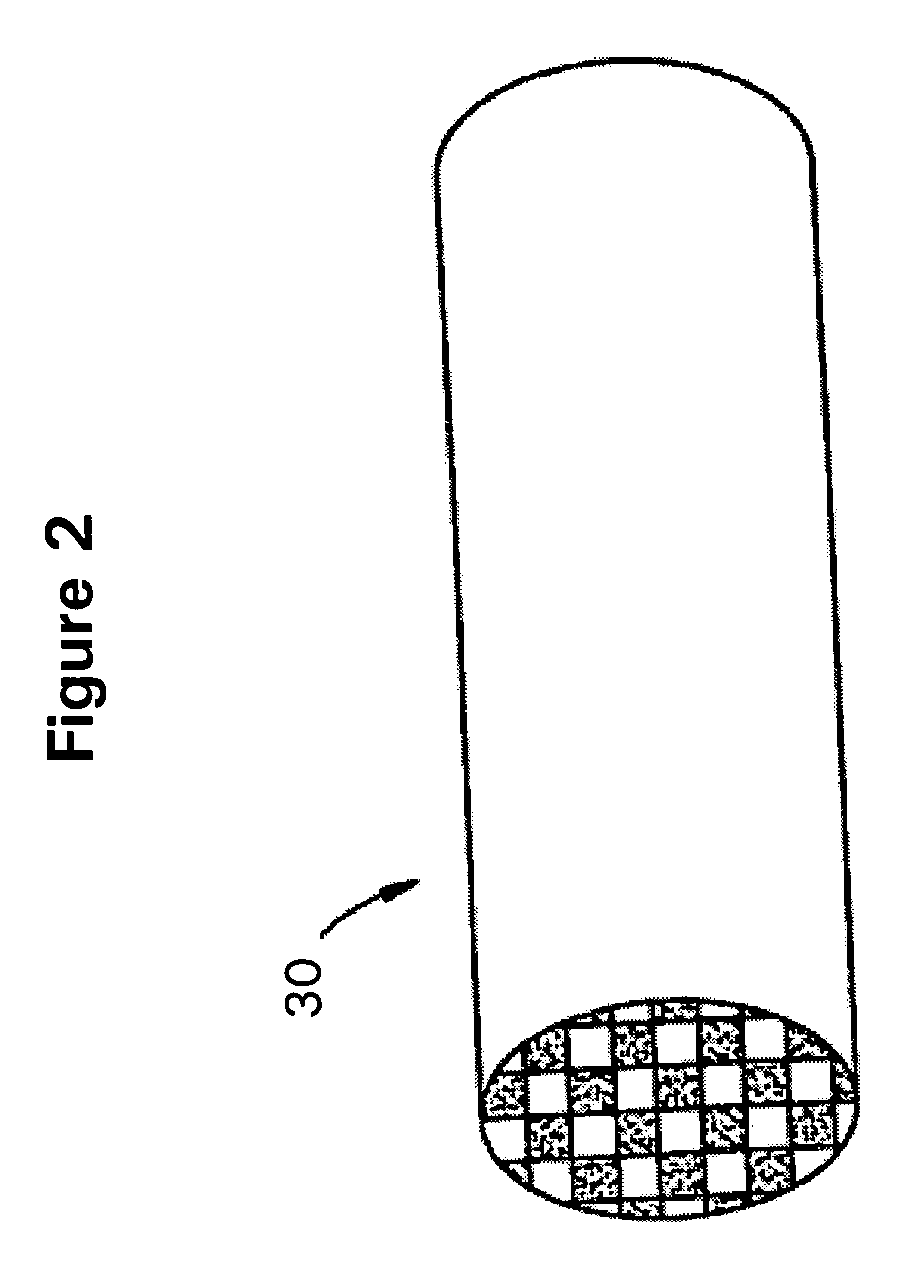

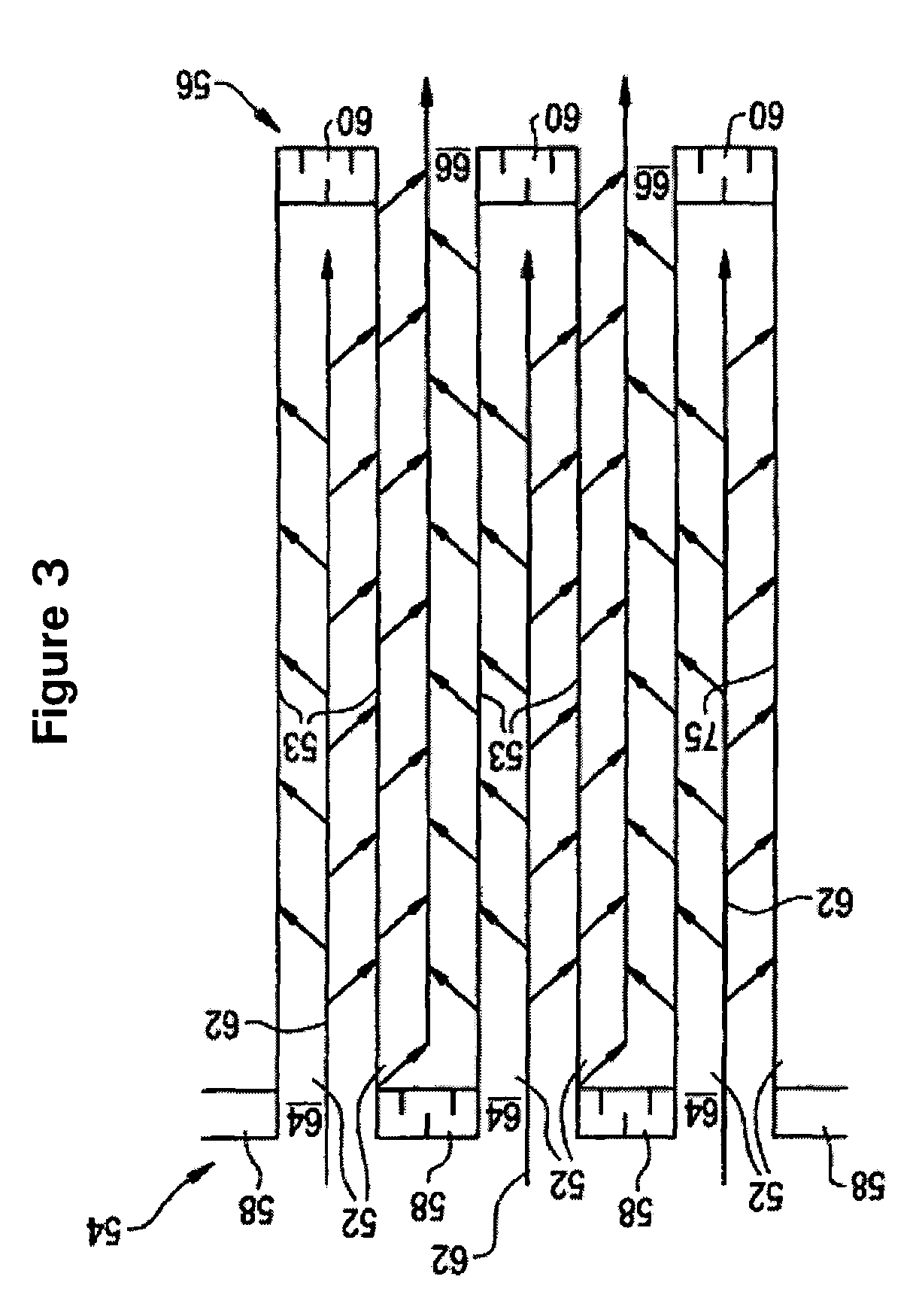

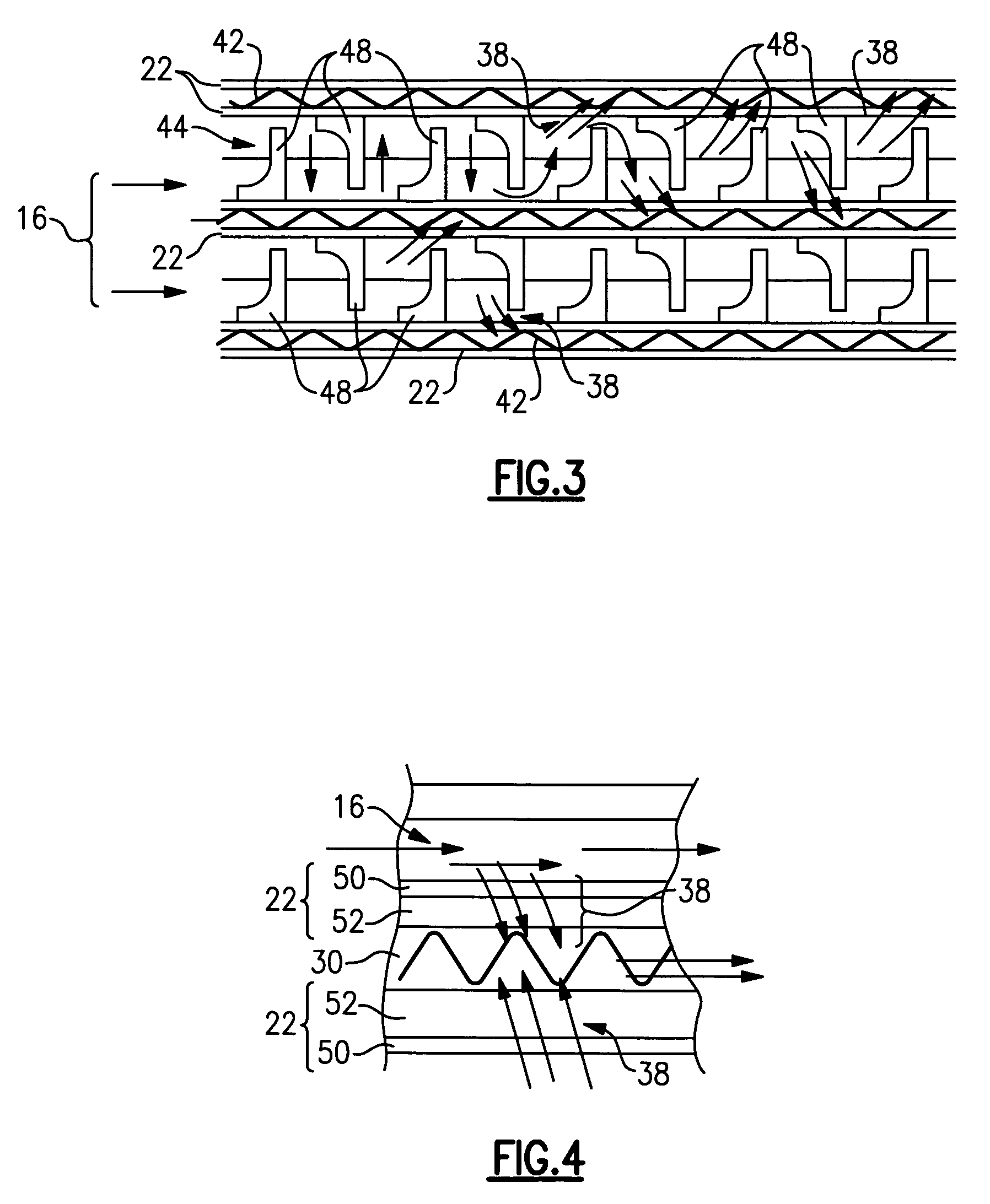

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

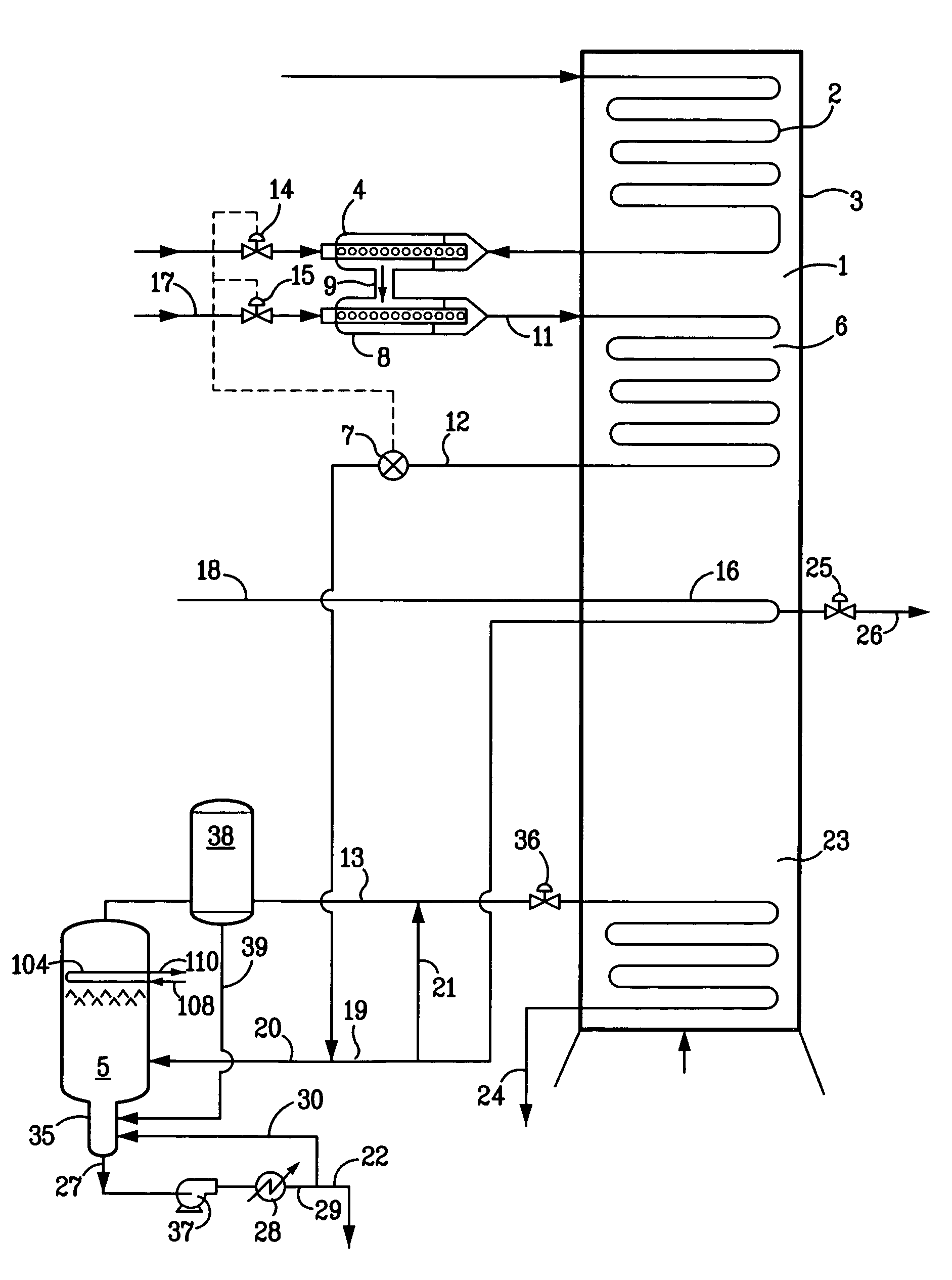

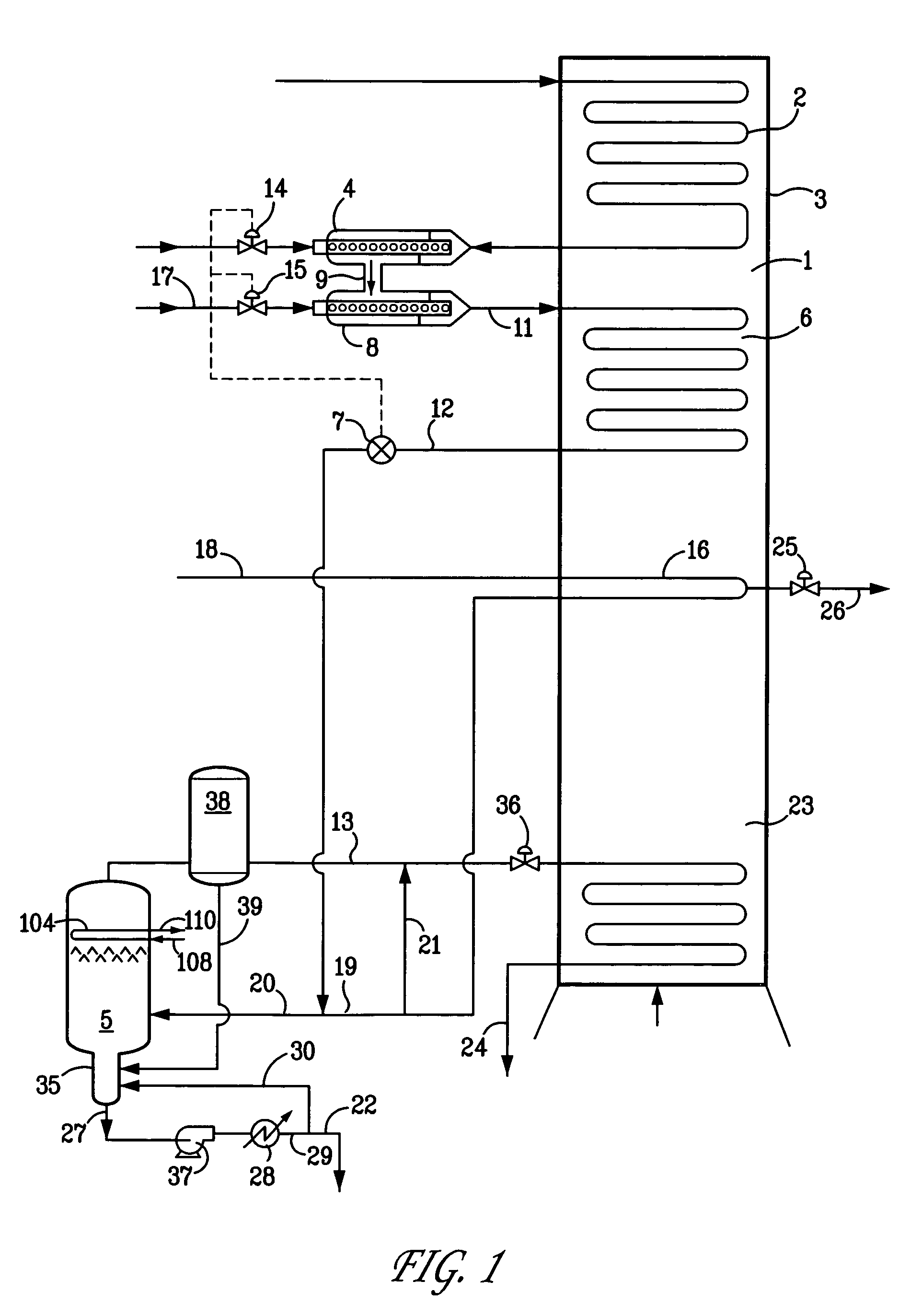

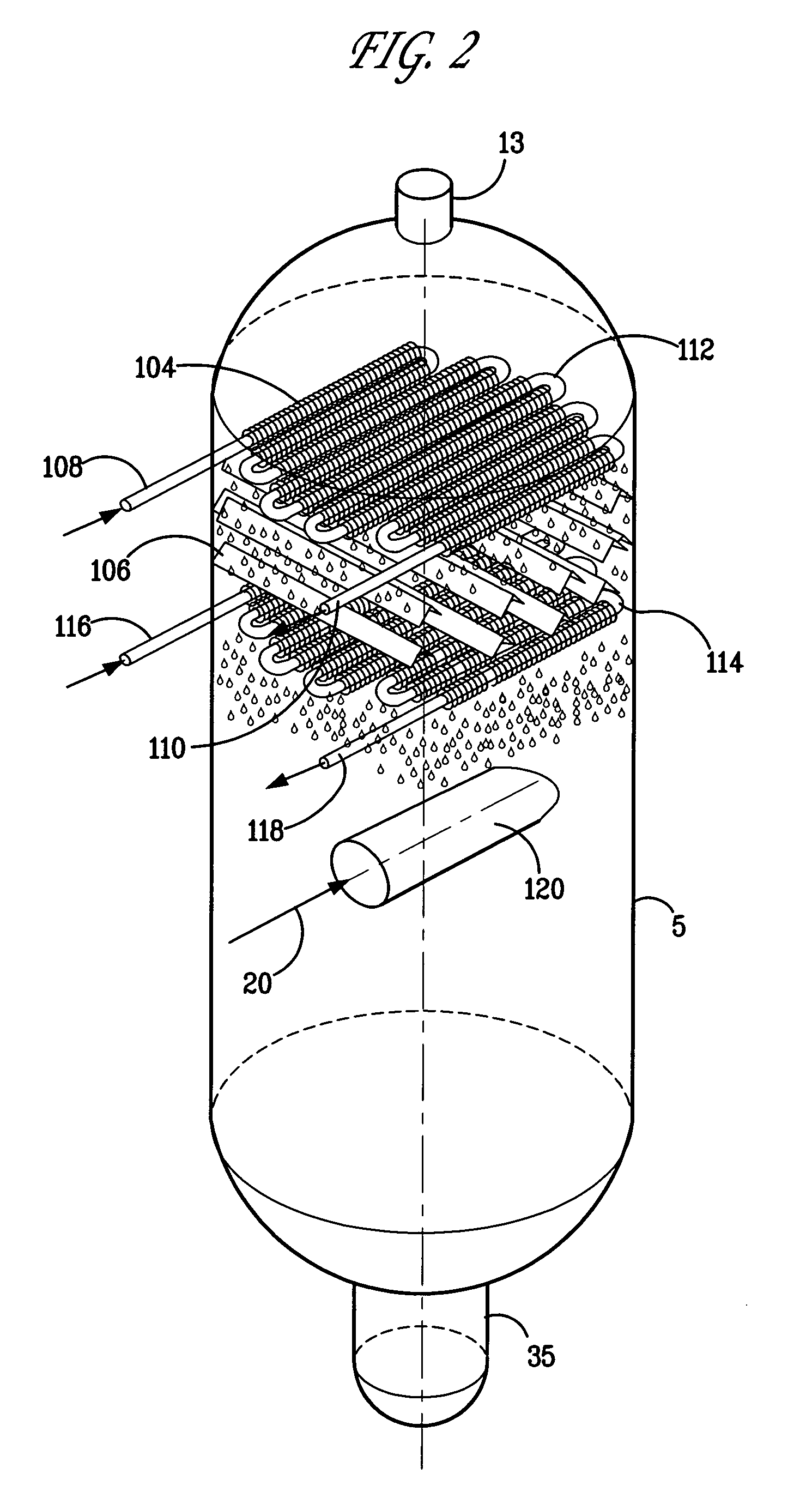

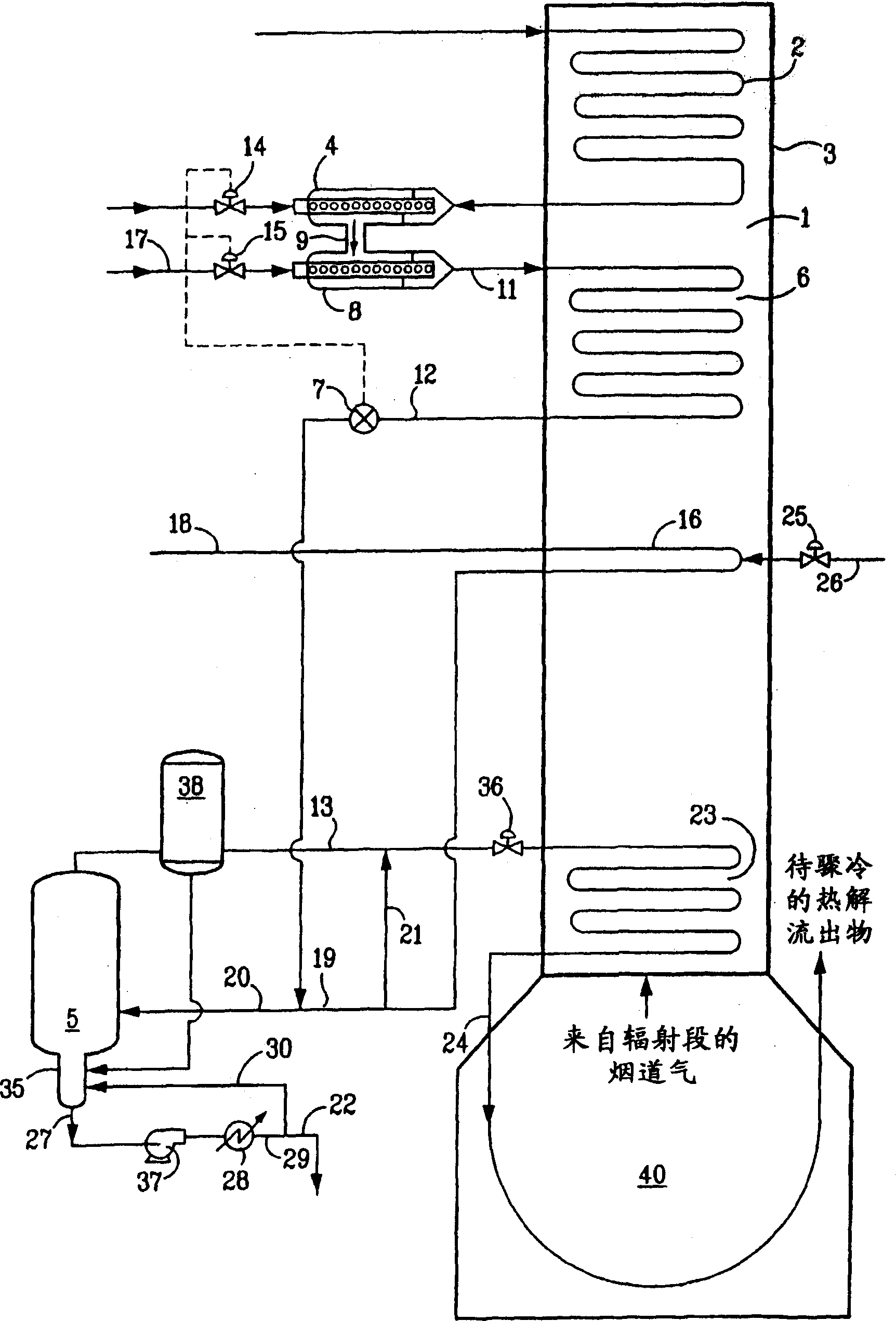

Cracking hydrocarbon feedstock containing resid utilizing partial condensation of vapor phase from vapor/liquid separation to mitigate fouling in a flash/separation vessel

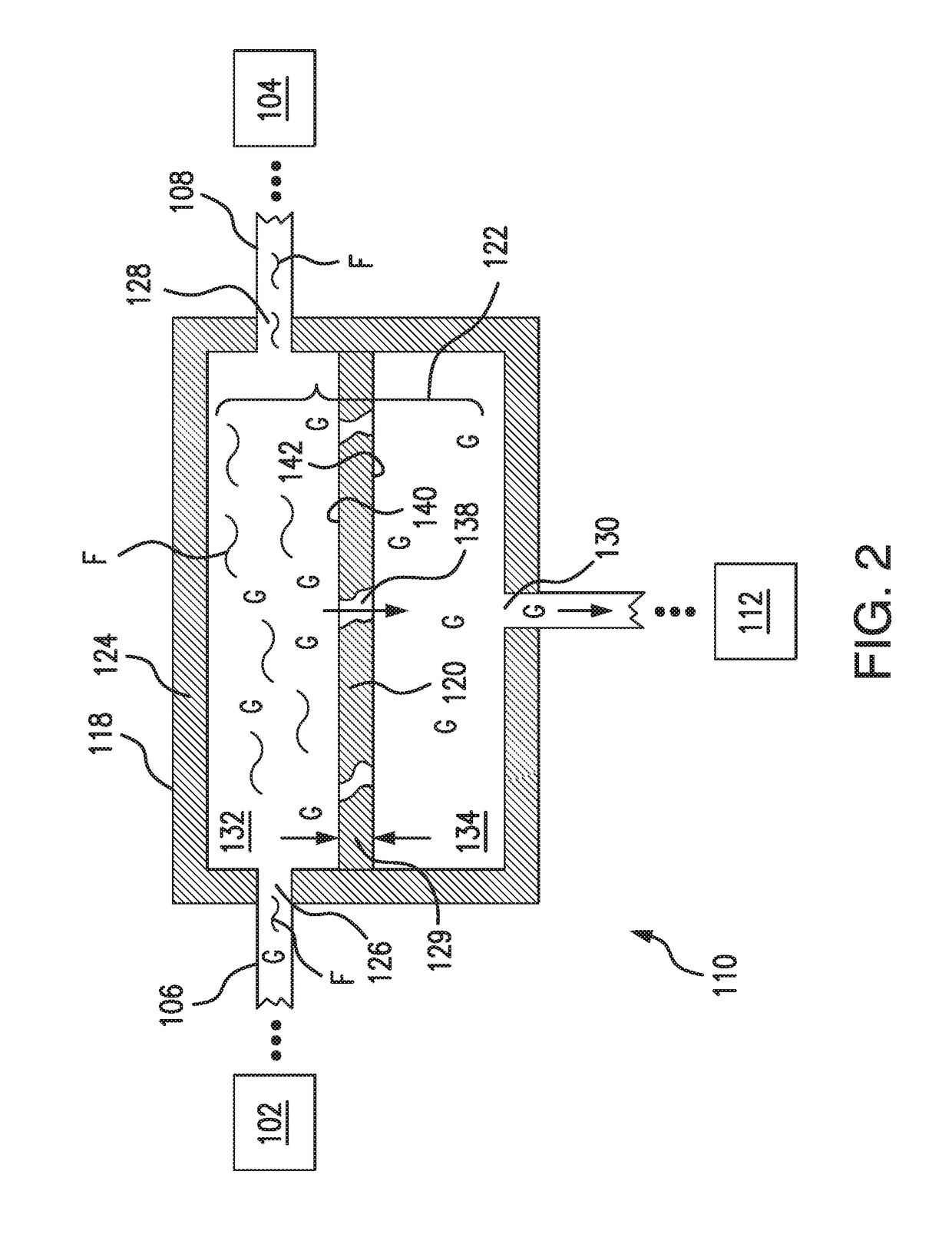

A process is provided for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, optionally further heating the mixture, flashing the mixture within a flash / separation vessel to form a vapor phase and a liquid phase, partially condensing the vapor phase by contacting with a condenser within the vessel, to condense at least some coke precursors within the vapor while providing condensates which add to the liquid phase, removing the vapor phase of reduced coke precursors content as overhead and the liquid phase as bottoms, heating the vapor phase, cracking the vapor phase in a radiant section of a pyrolysis furnace to produce an effluent comprising olefins, and quenching the effluent and recovering cracked product therefrom. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

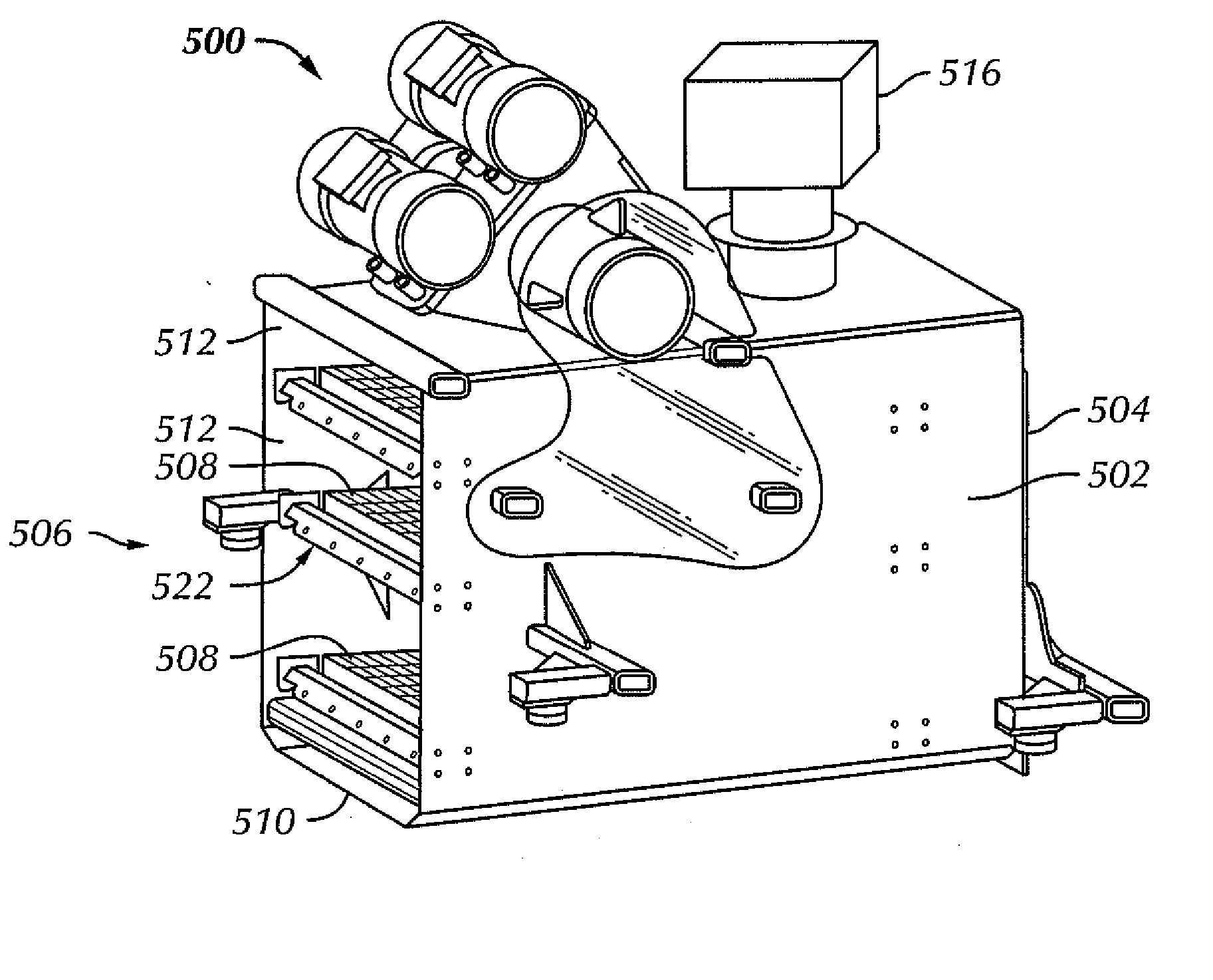

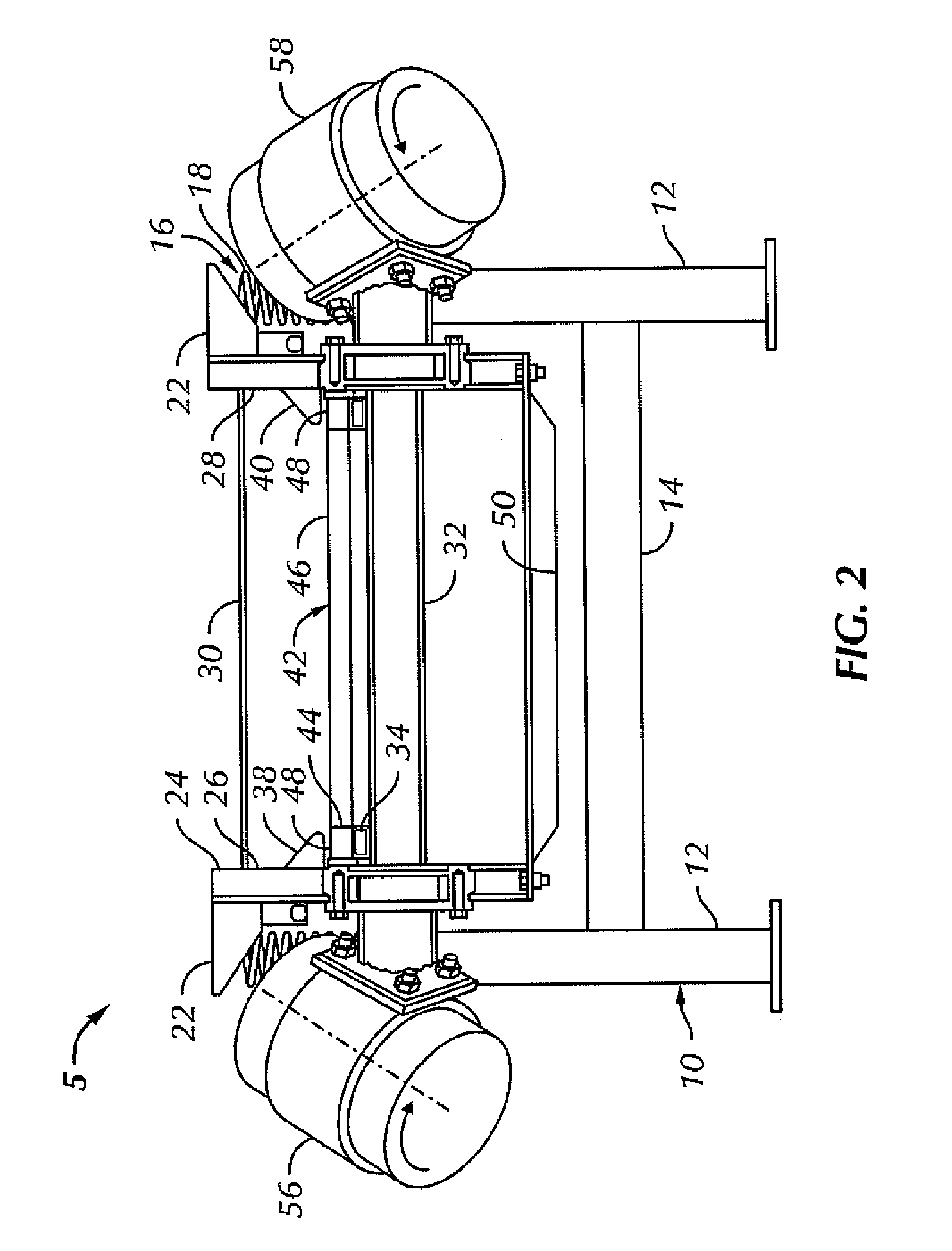

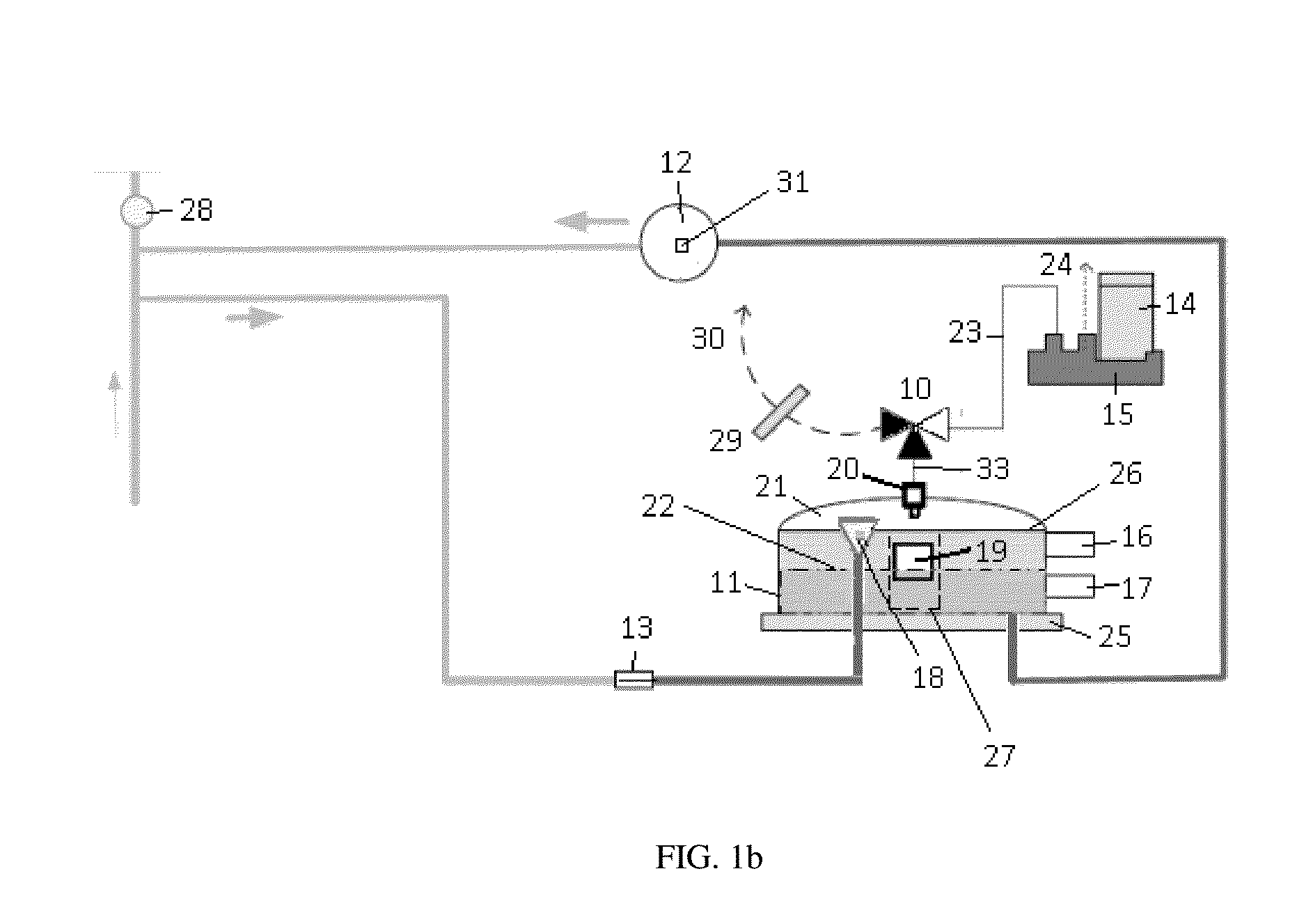

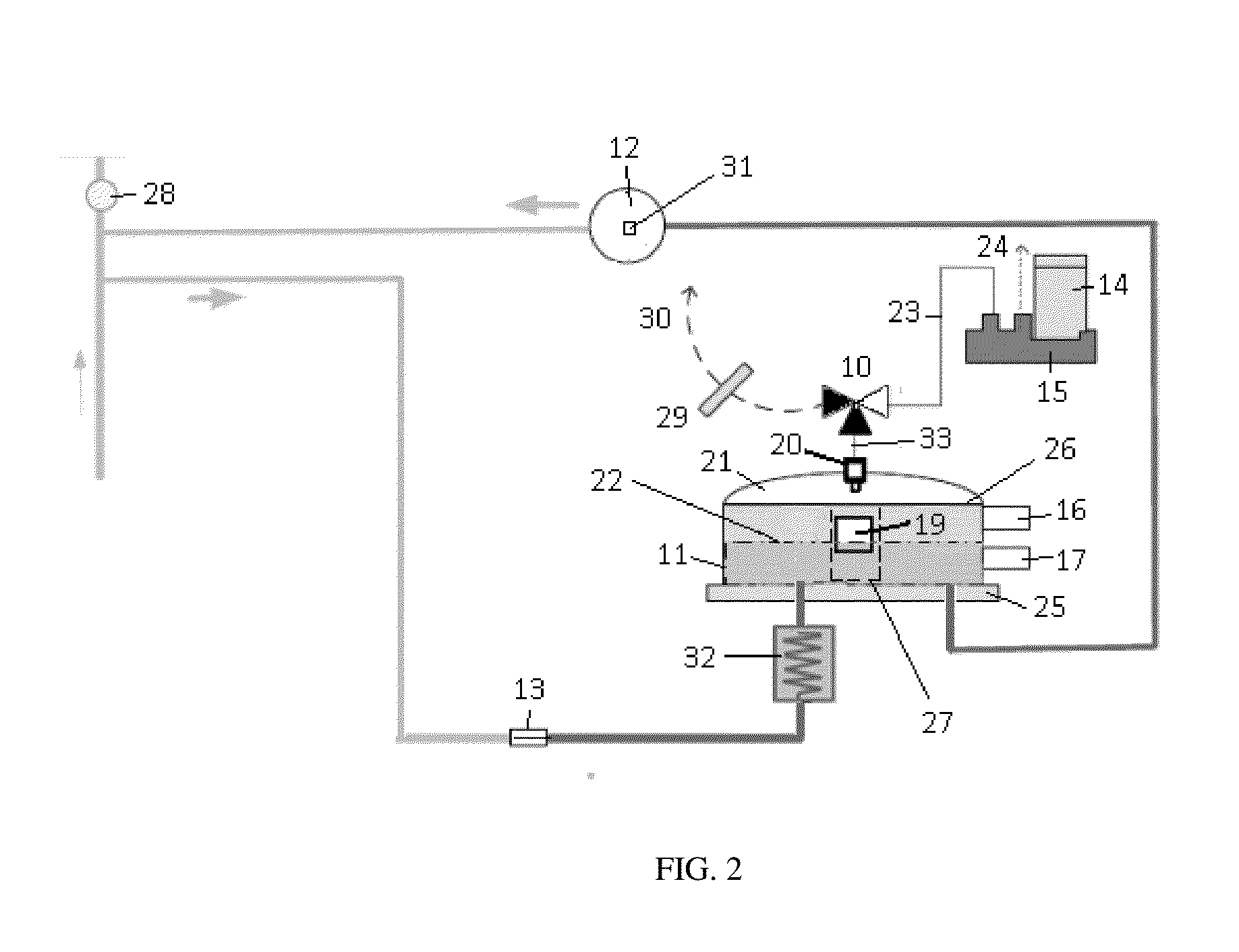

Shaker and degasser combination

A system for separating components of a slurry is disclosed, the system including a housing; a basket for holding at least one shaker screen, the basket movably mounted in the housing; at least one vibrator coupled to the basket; a sump disposed below the basket to collect at least a portion of the slurry passing through the at least one shaker screen; a pressure differential device fluidly connected to the sump for developing a pressure differential across the at least one shaker screen; and a toggling device for toggling the pressure differential across the screen. A system including a degassing chamber fluidly connected to a sump and a pressure differential device, wherein the degassing chamber is disposed between the sump and the pressure differential device, and a fluid conduit fluidly connected to the degassing chamber for recovering a degassed fluid is also disclosed.

Owner:MI

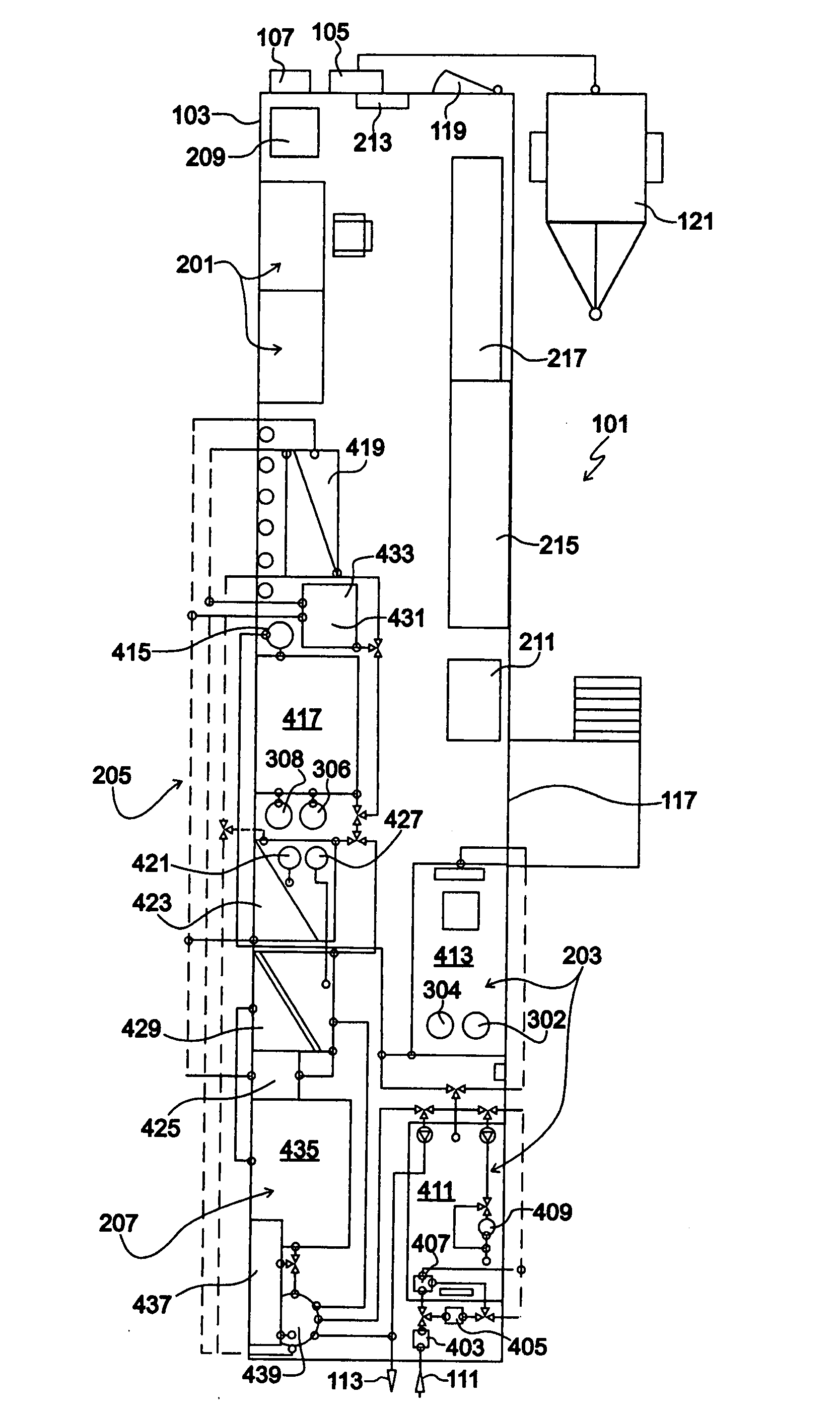

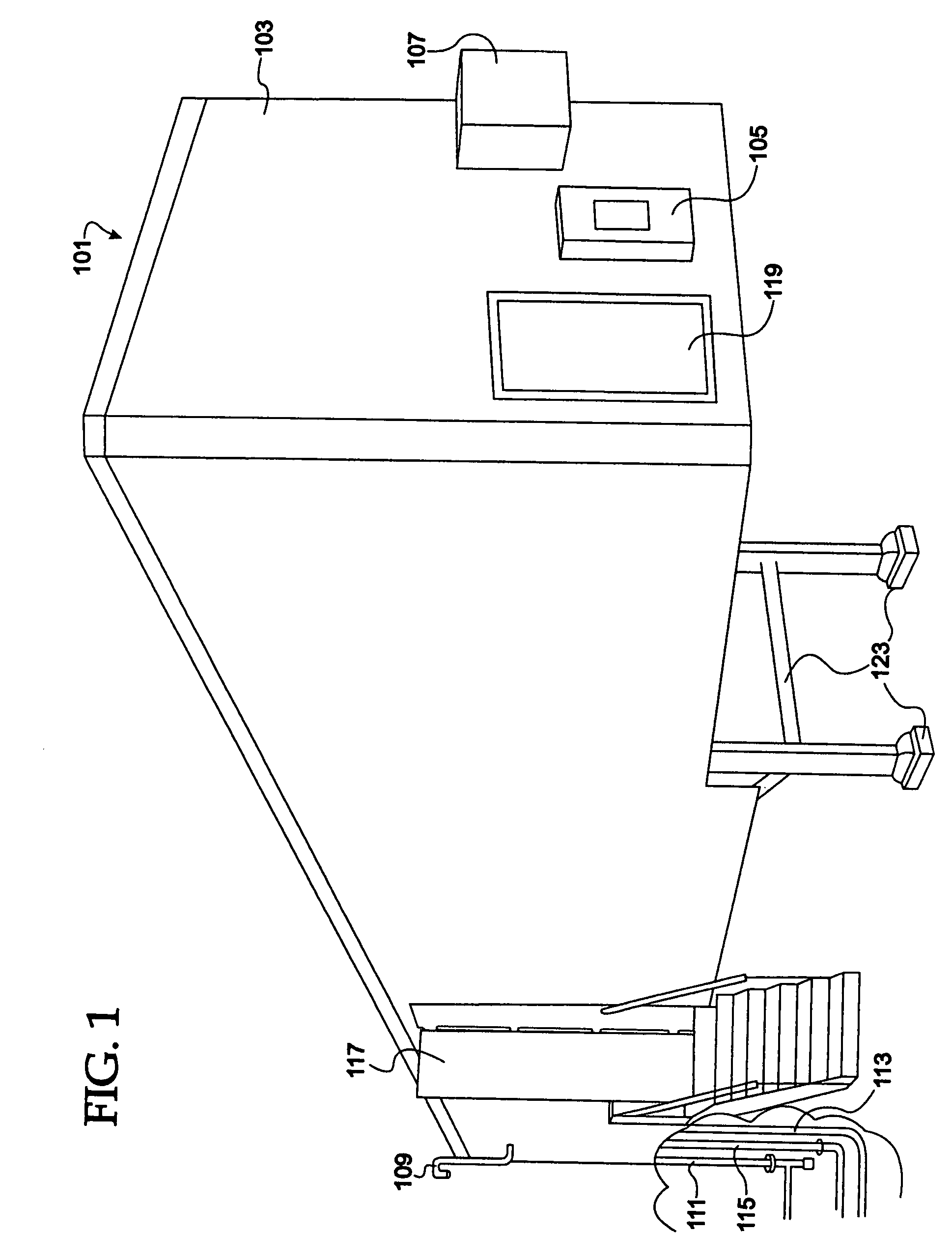

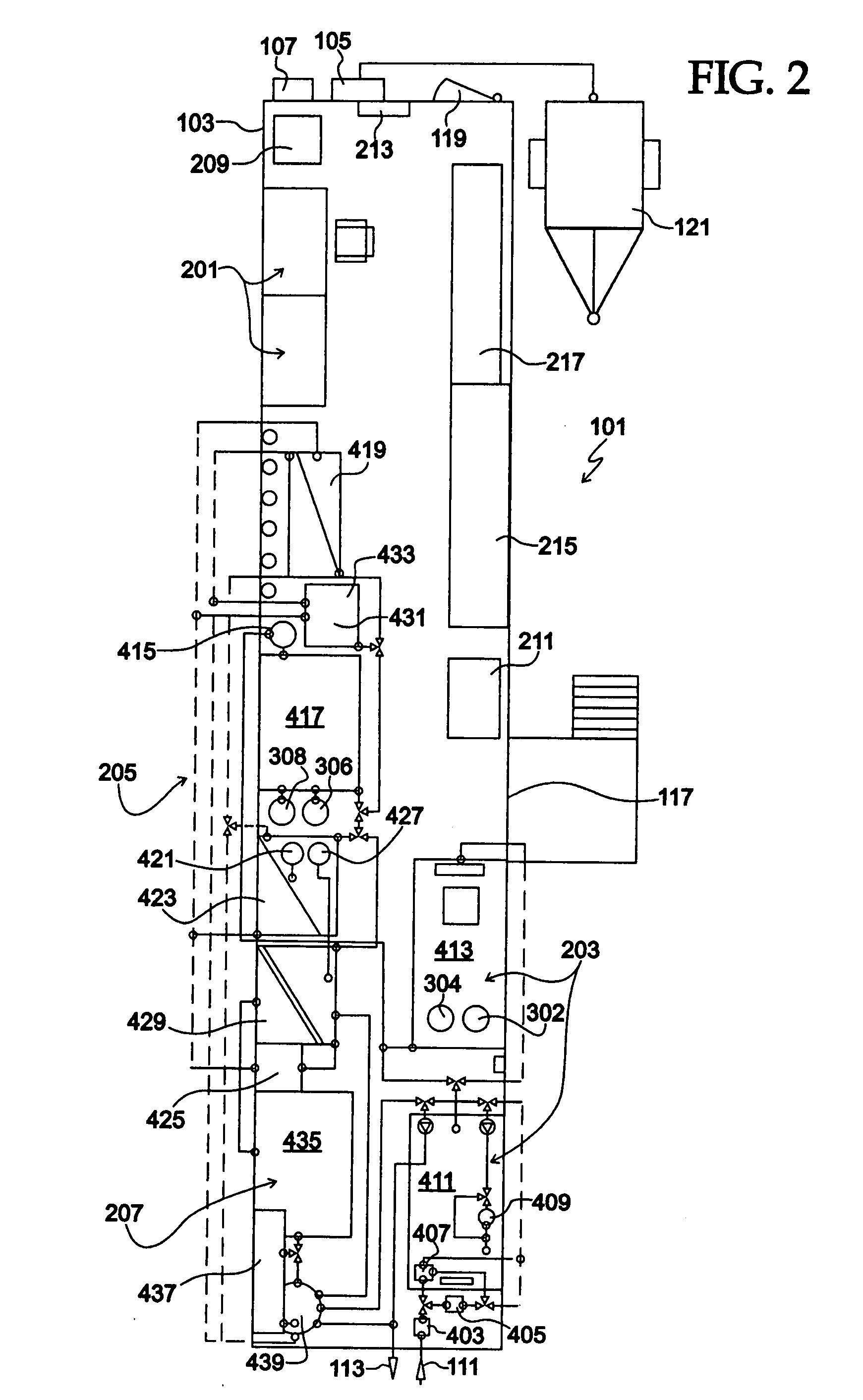

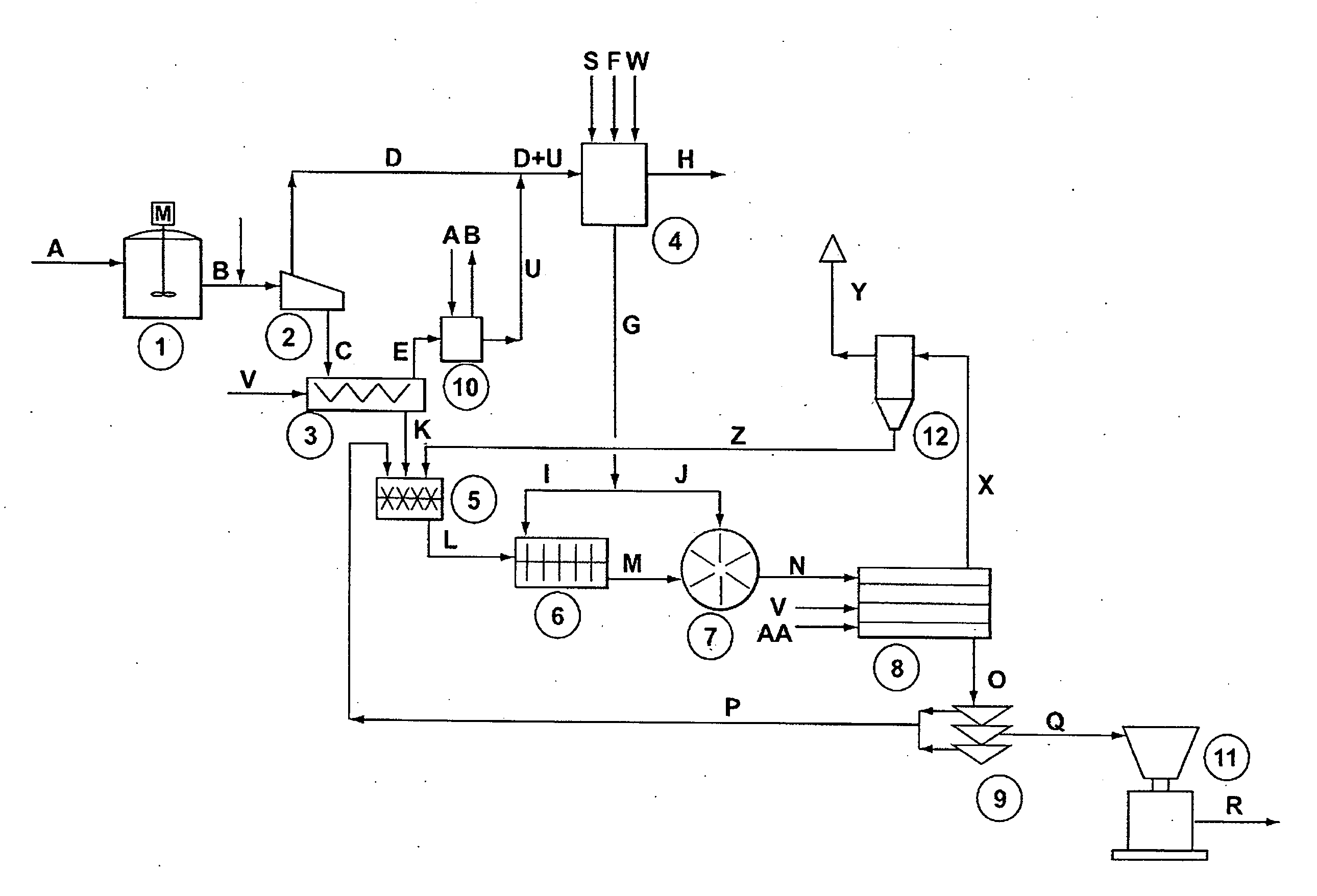

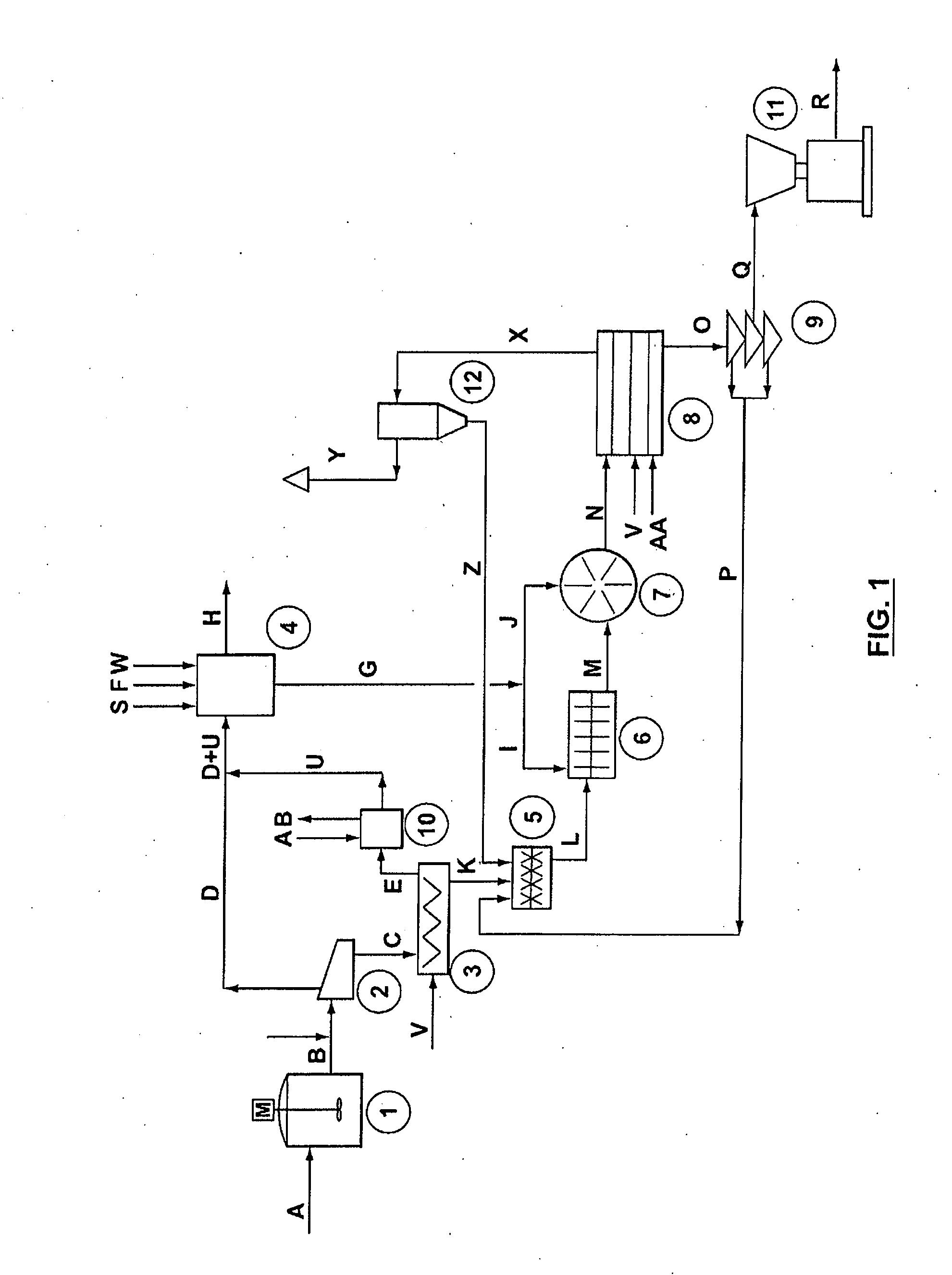

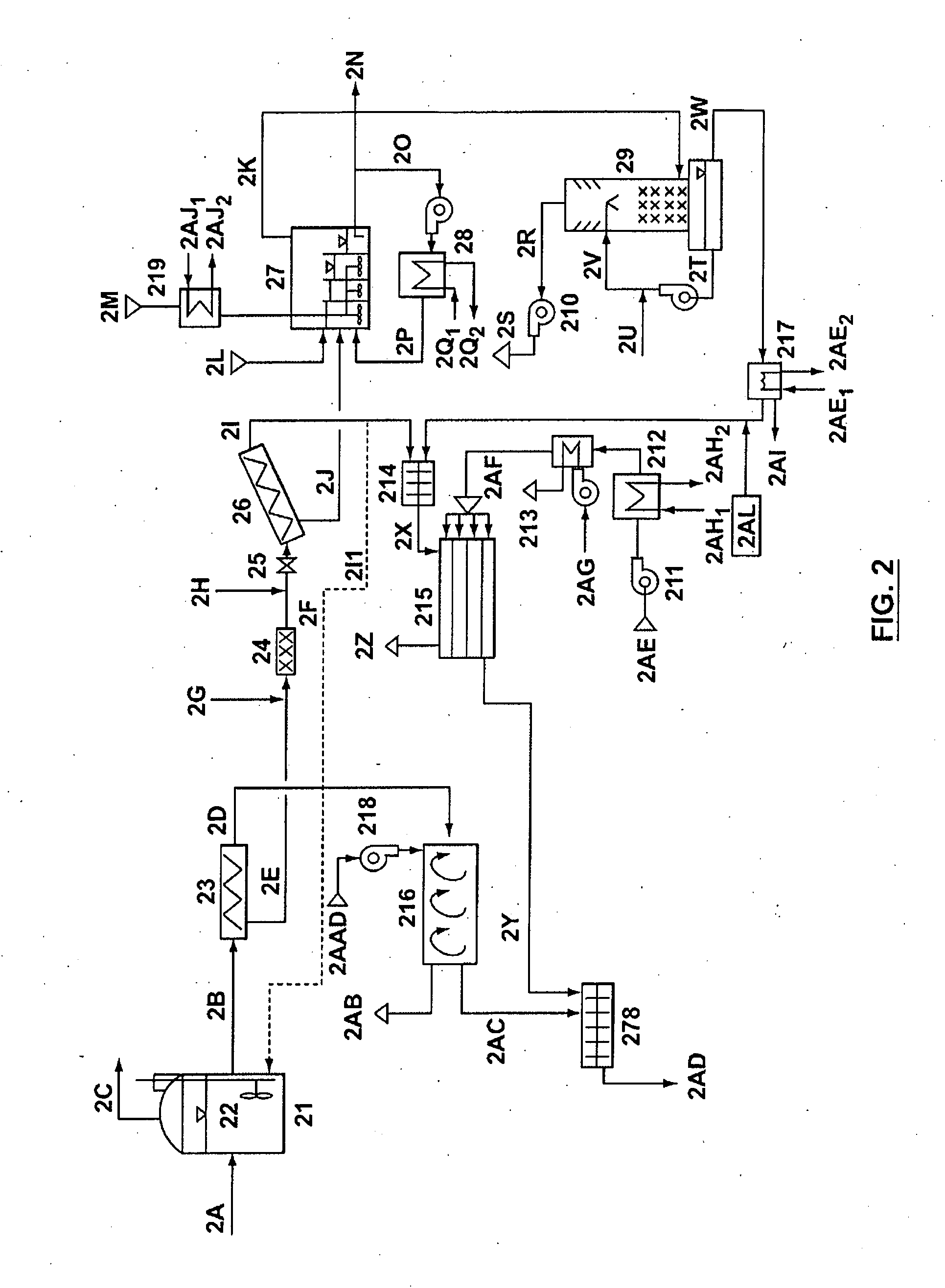

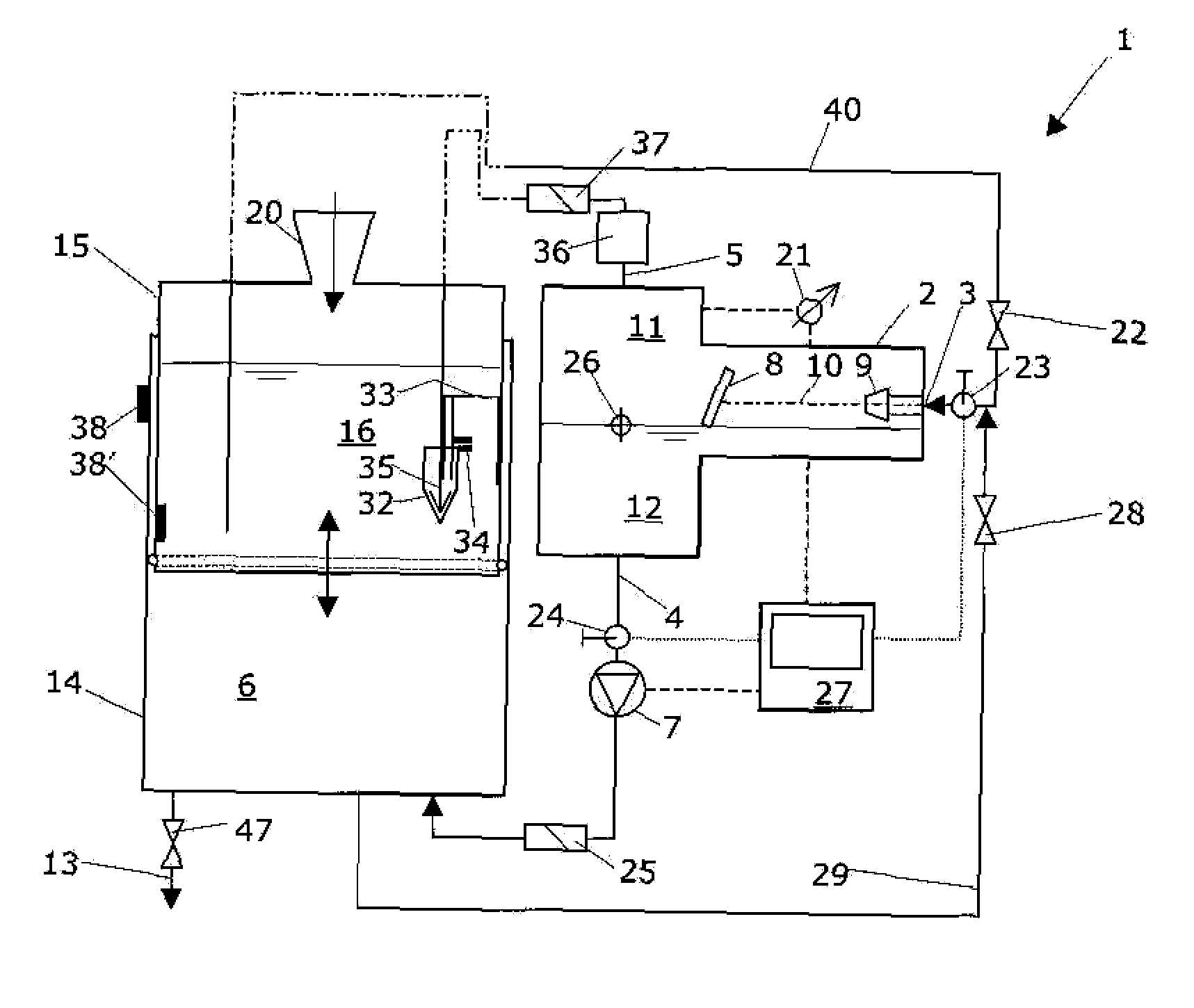

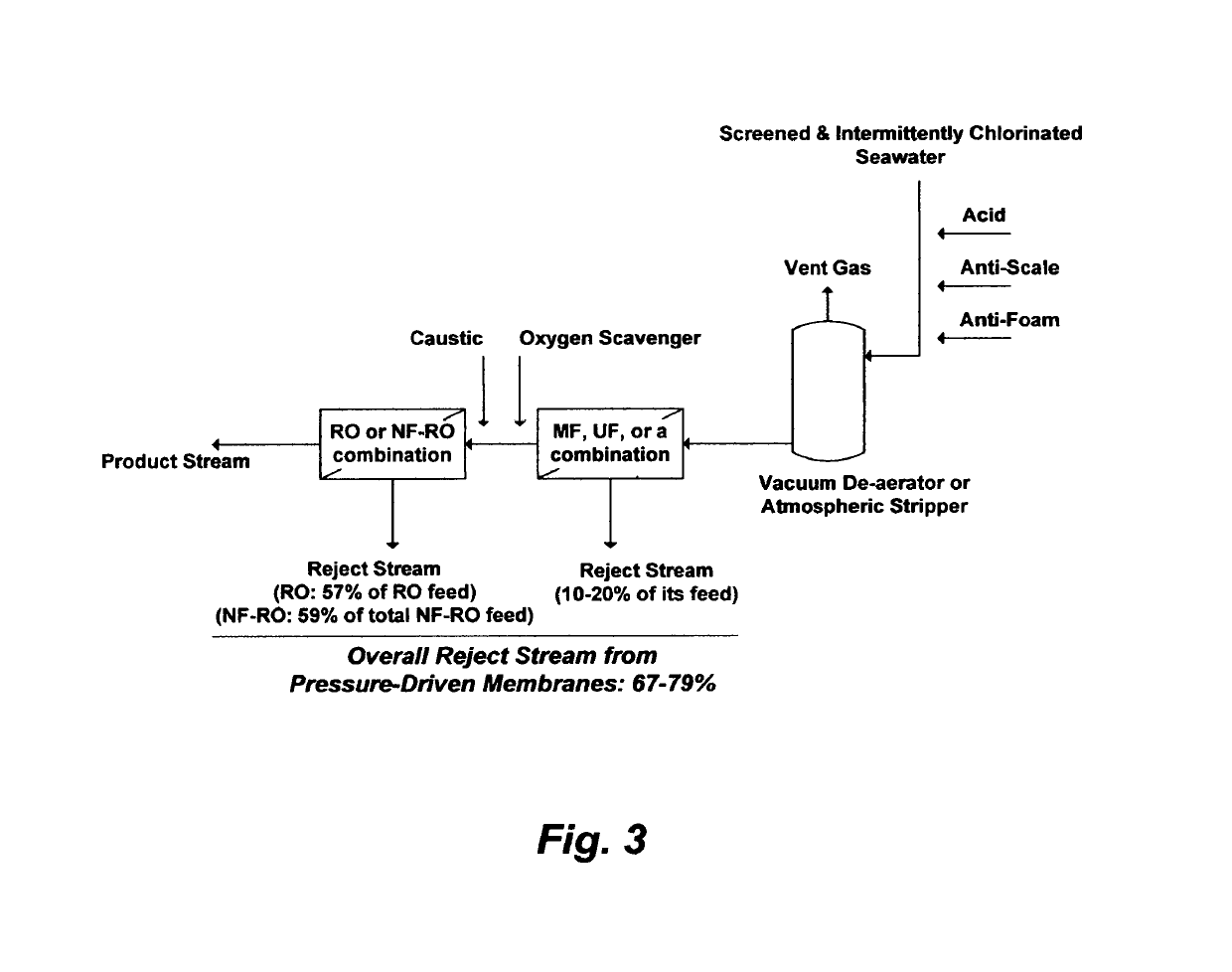

Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

InactiveUS20090032446A1Reduce financial riskHigh continuity of operationReverse osmosisFlash degasificationIon exchangeReverse osmosis

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus are housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies are also disclosed.

Owner:ROCKWATER RESOURCE

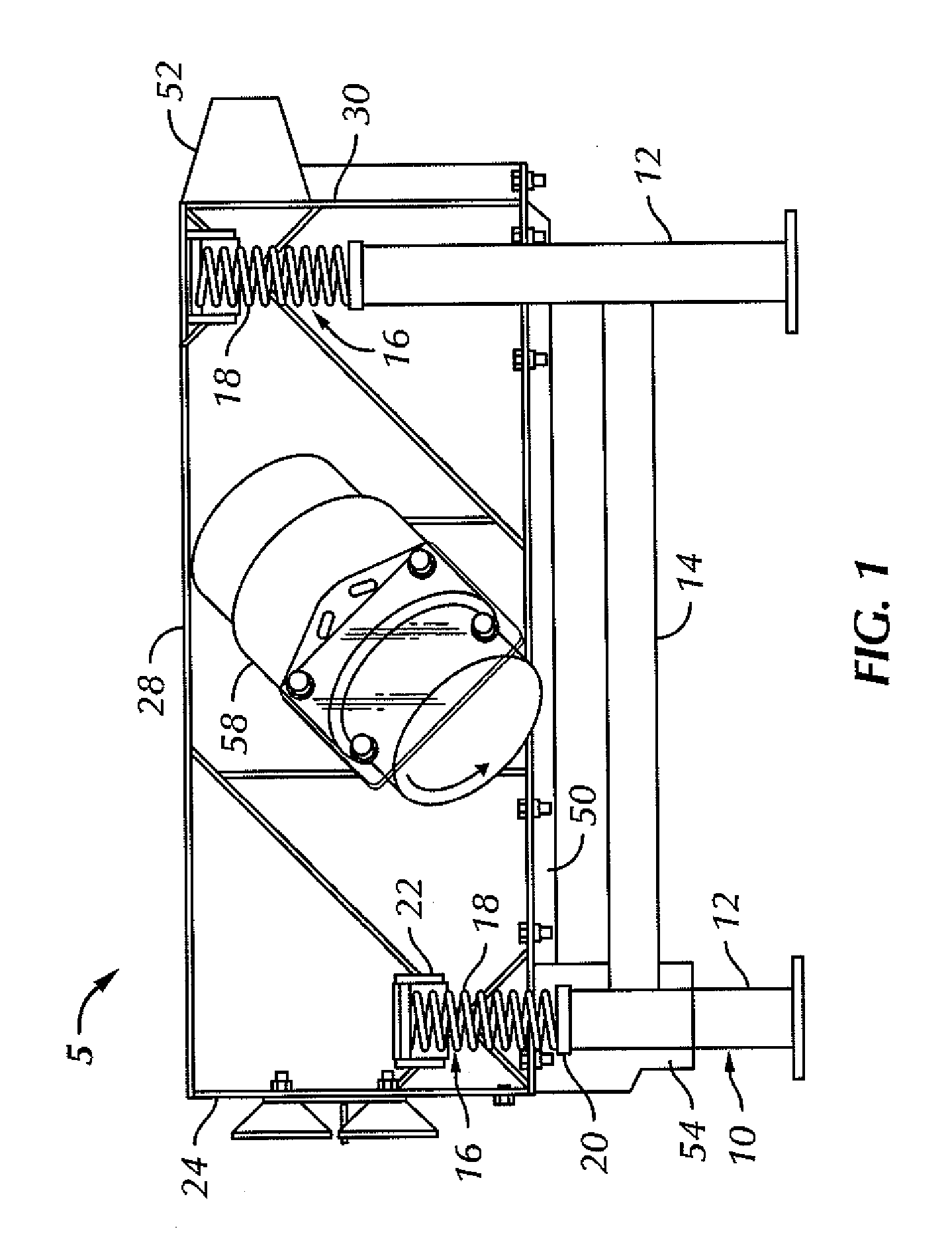

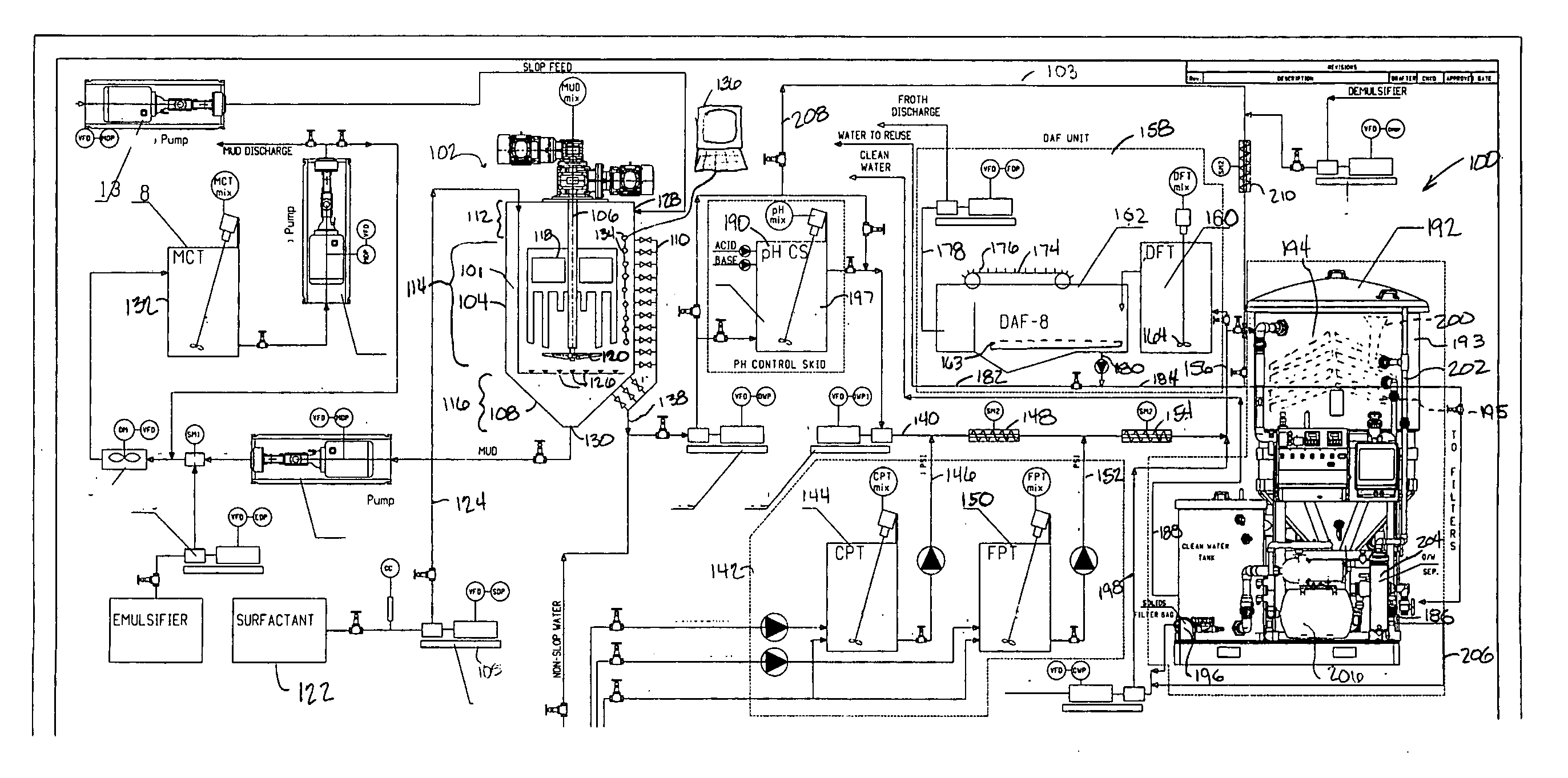

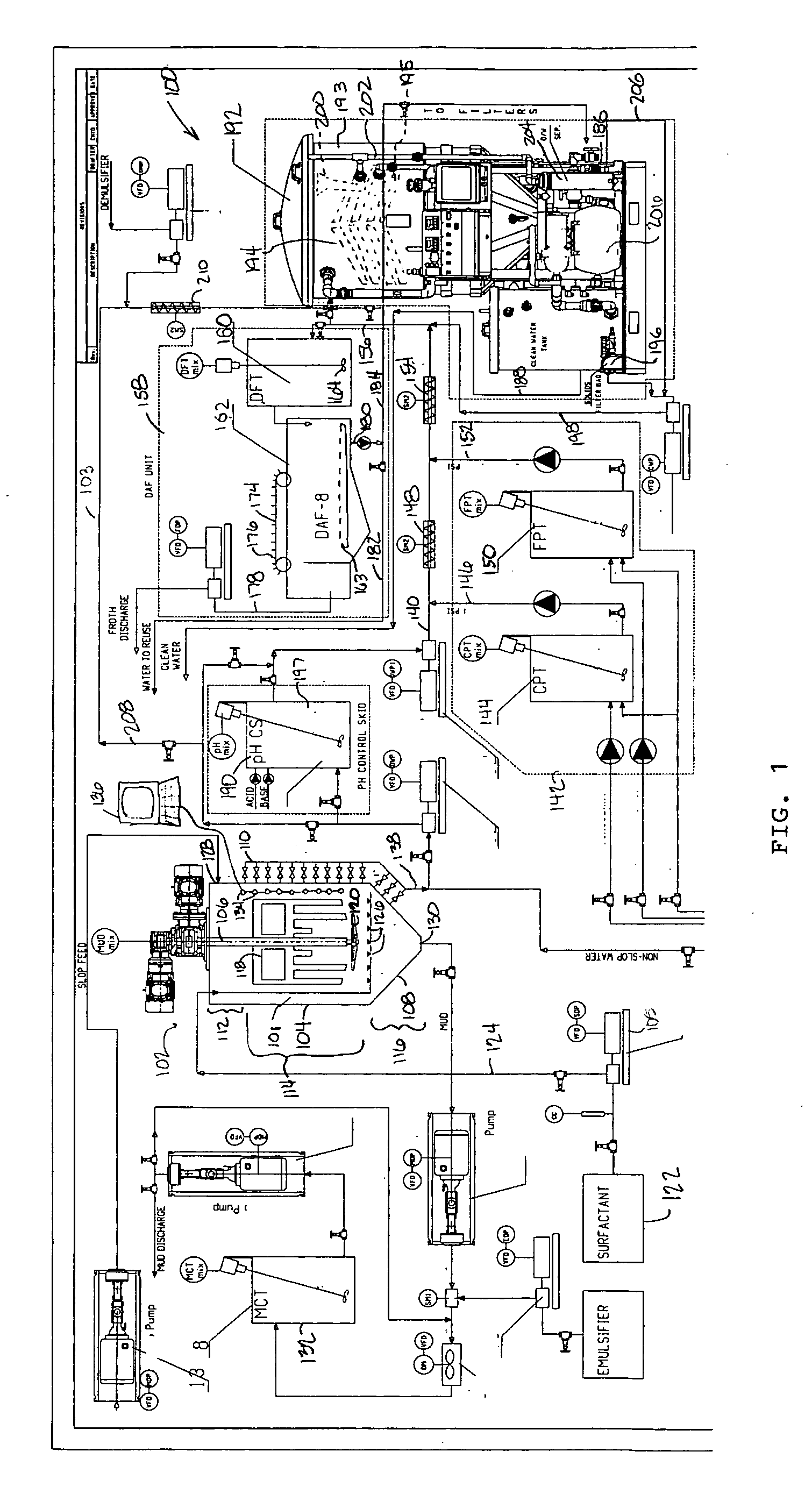

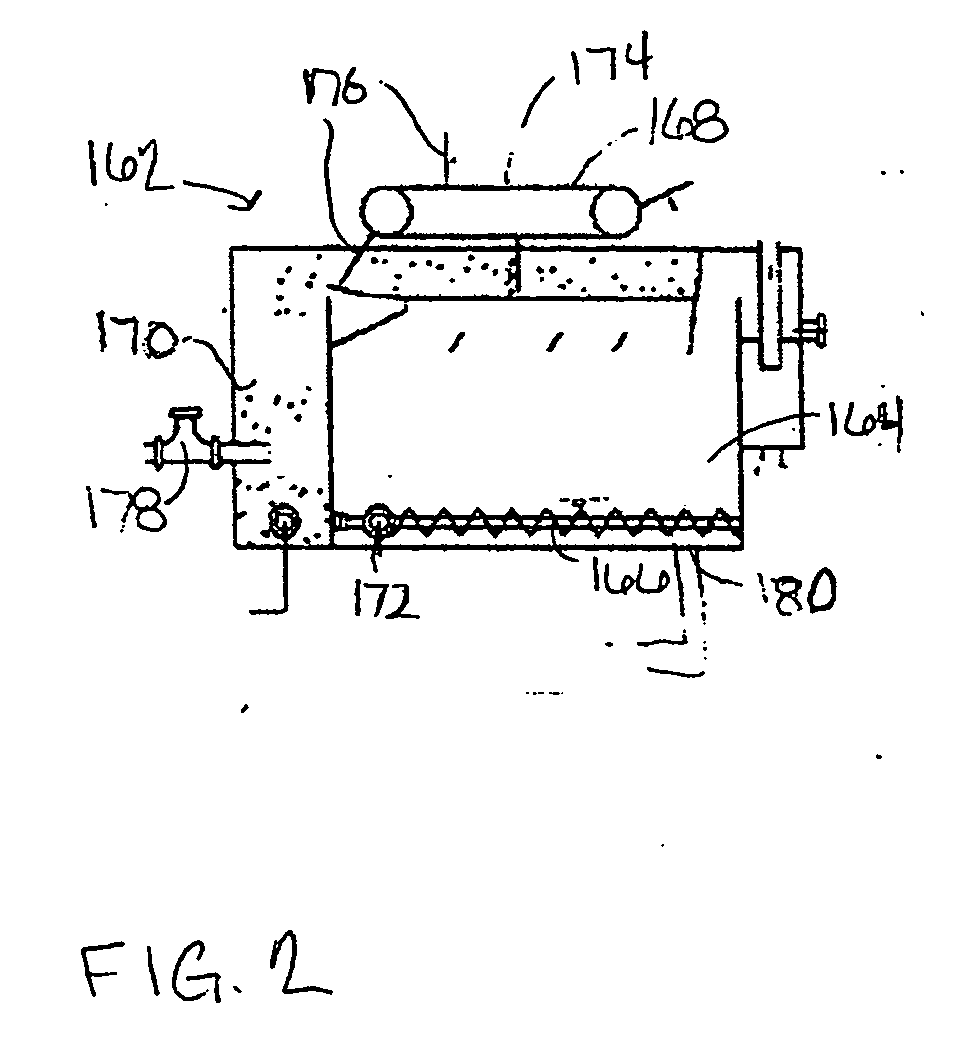

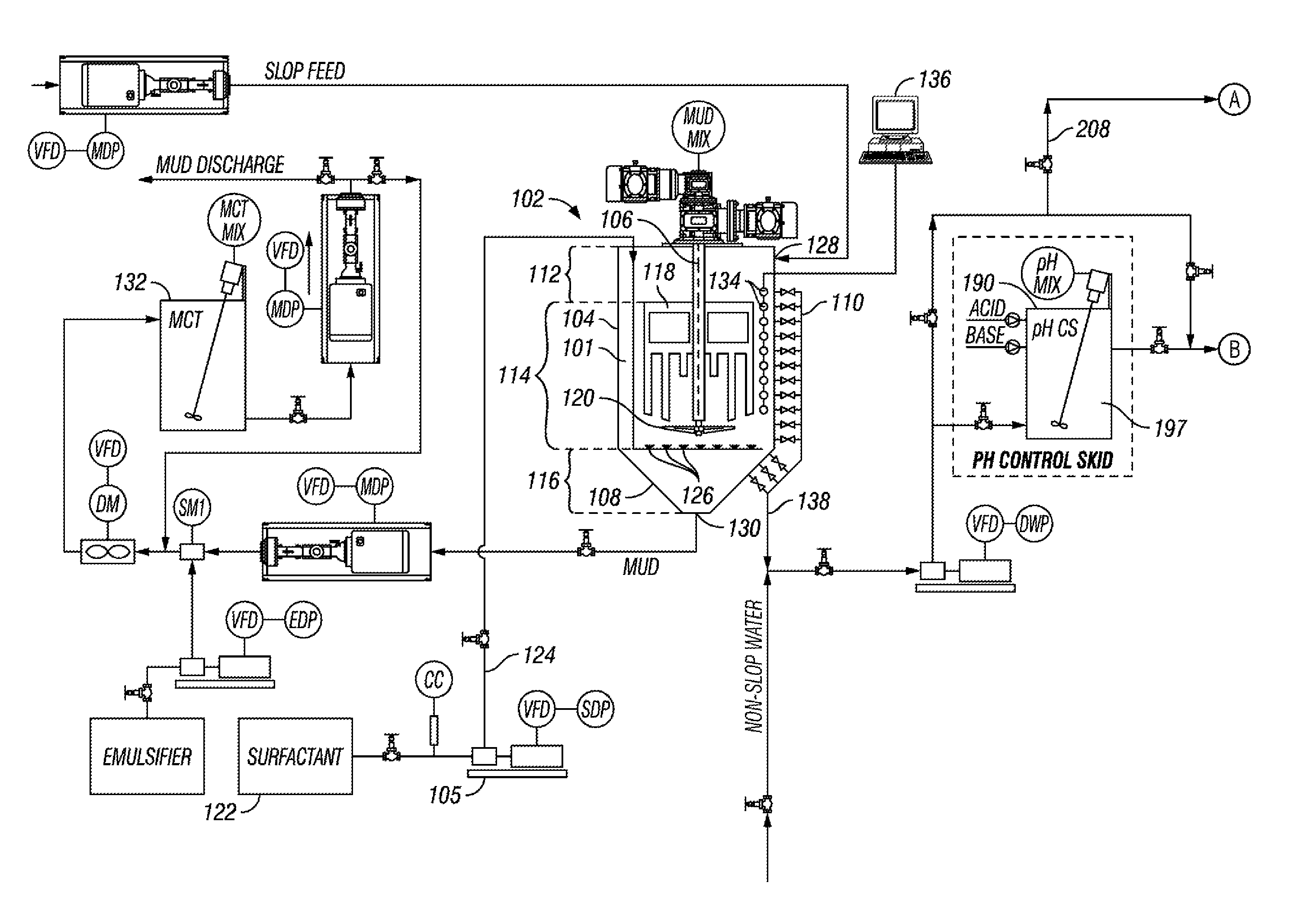

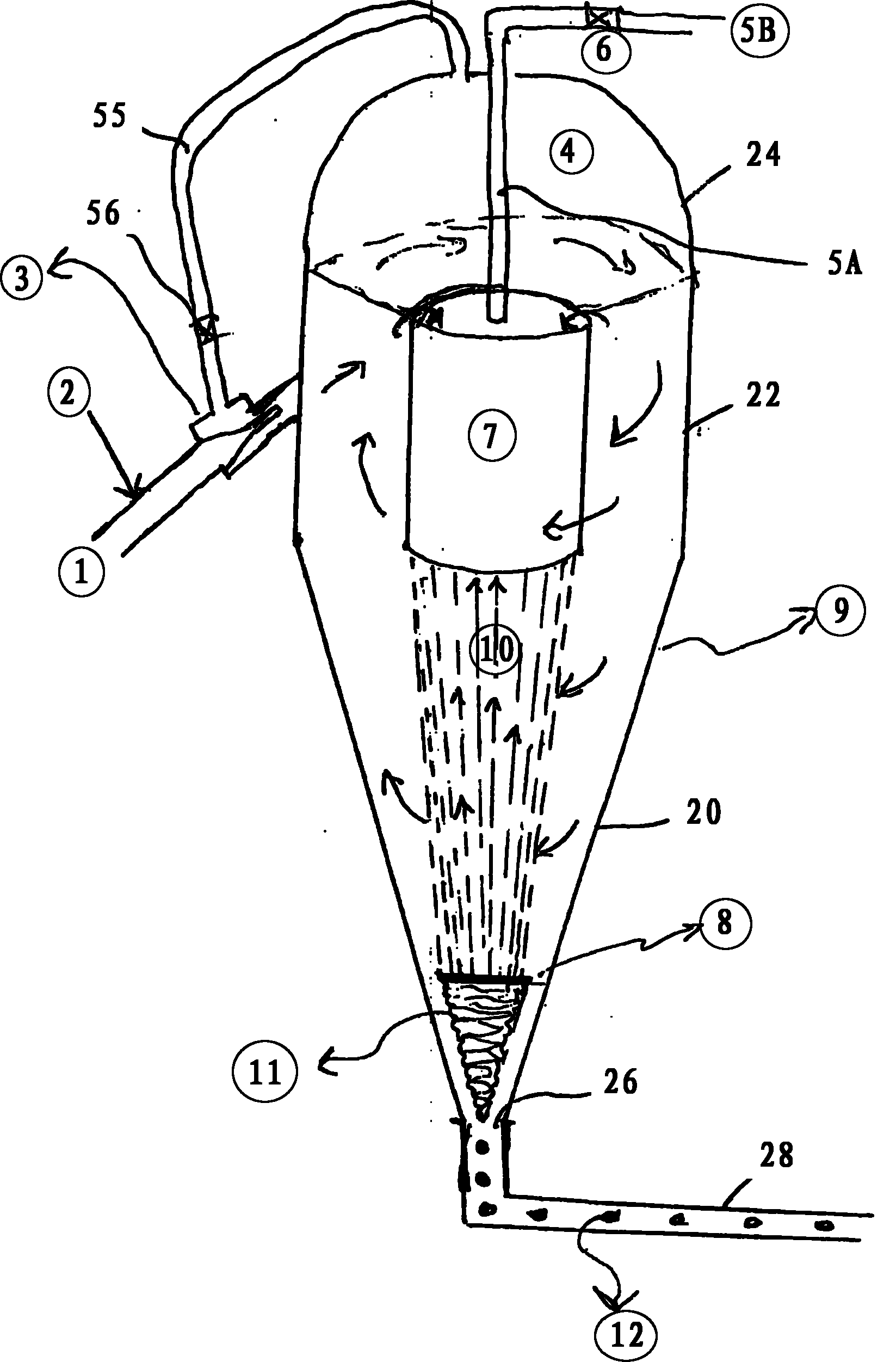

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS20060186056A1Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

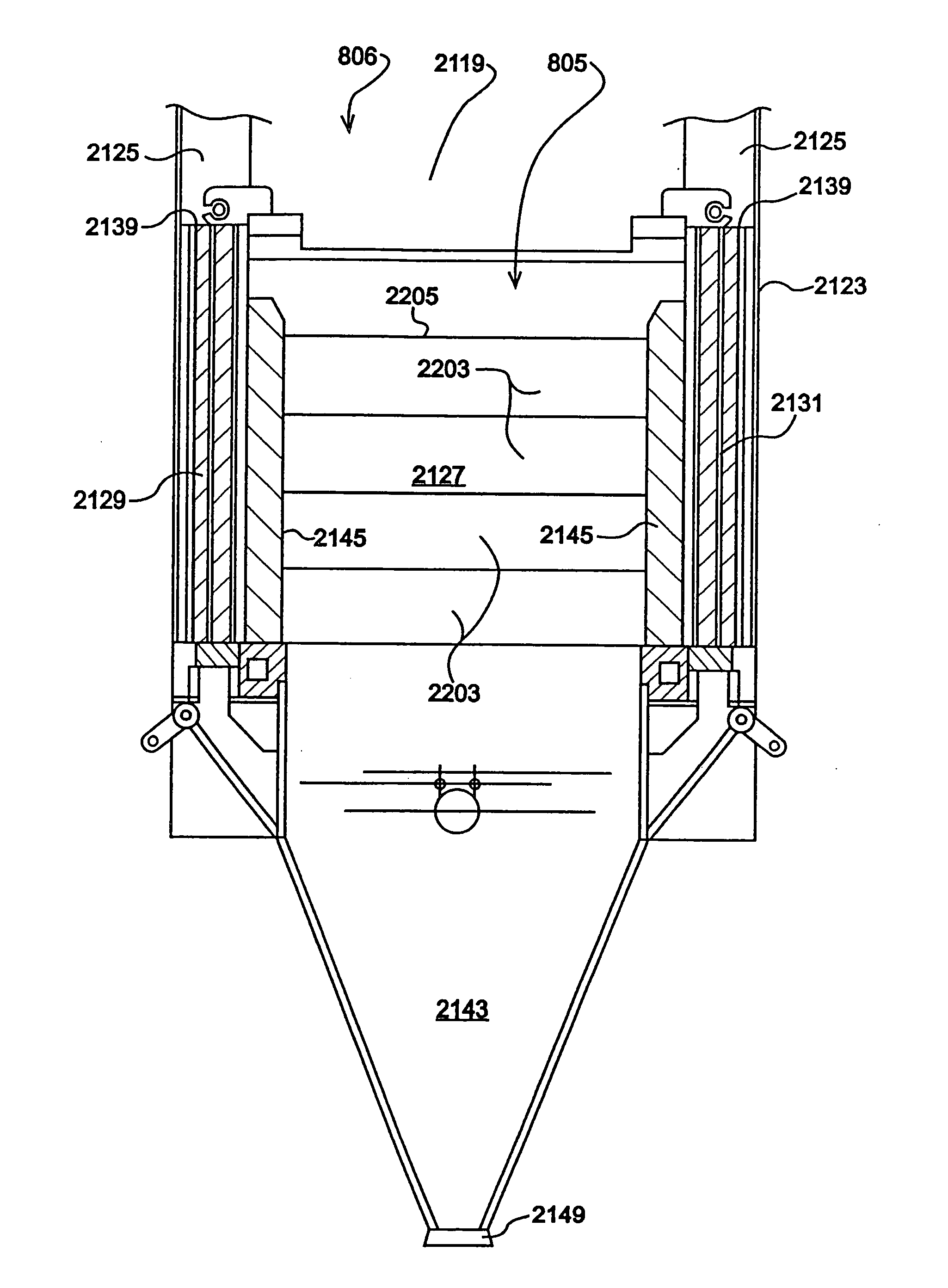

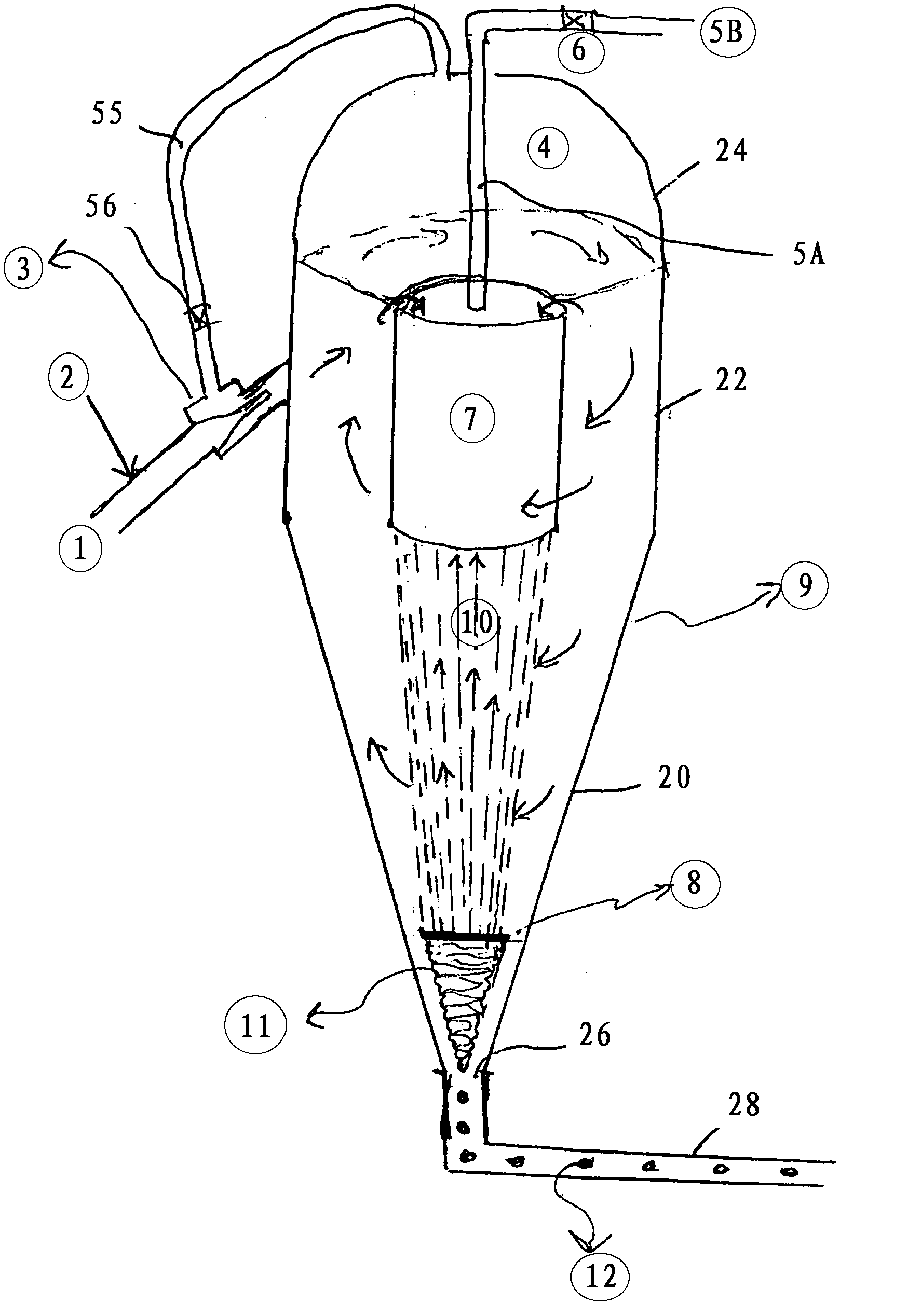

Steam cracking of hydrocarbon feedstocks containing salt and/or particulate matter

ActiveCN1957068AReduce depositionAvoid depositionThermal non-catalytic crackingEthylene productionStructural engineeringHydrocarbon

A highly efficient vapor / liquid separation apparatus for treating a flow of vapor / liquid mixtures of hydrocarbons and steam comprises a substantially cylindrical vertical drum having an upper cap section, a middle section comprising a circular wall, a lower cap section, a tangential inlet to introduce hydrocarbon / steam mixtures, an overhead vapor outlet, and a bottom outlet for liquid. The vessel also comprises an annular structure located in the middle section, comprising i) an annular ceiling section extending from the circular wall and ii) a concentric internal vertical side wall to which the ceiling section extends. The annular structure blocks upward passage of vapor / liquid mixtures along the circular wall beyond the ceiling section, and surrounds an open core having sufficient cross-sectional area to permit vapor velocity low enough to avoid significant entrainment of liquid.

Owner:EXXONMOBIL CHEM PAT INC

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS7497954B2Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

Organics and nutrient recovery from anaerobic digester residues

Sludge from an anaerobic digester is treated to recover one or more of fibers, or solids or liquids with a high nutrient content. The solids or liquids can be used as a fertilizer. The fibers can be used in a plant growing medium. Solids are separated from liquids in the sludge and dried. The solids may be dried to produce a flake or pellet. Ammonia in the liquids is recovered and used to produce a concentrated acidic ammonium salt solution. This solution may be mixed with the solids to produce a nitrogen enhanced solid. The fibers and solids or liquids can also be used in combination to produce an enhanced plant growing medium. A device and process for removing ammonia from a liquid can be used in the system or separately.

Owner:ANAERGIA

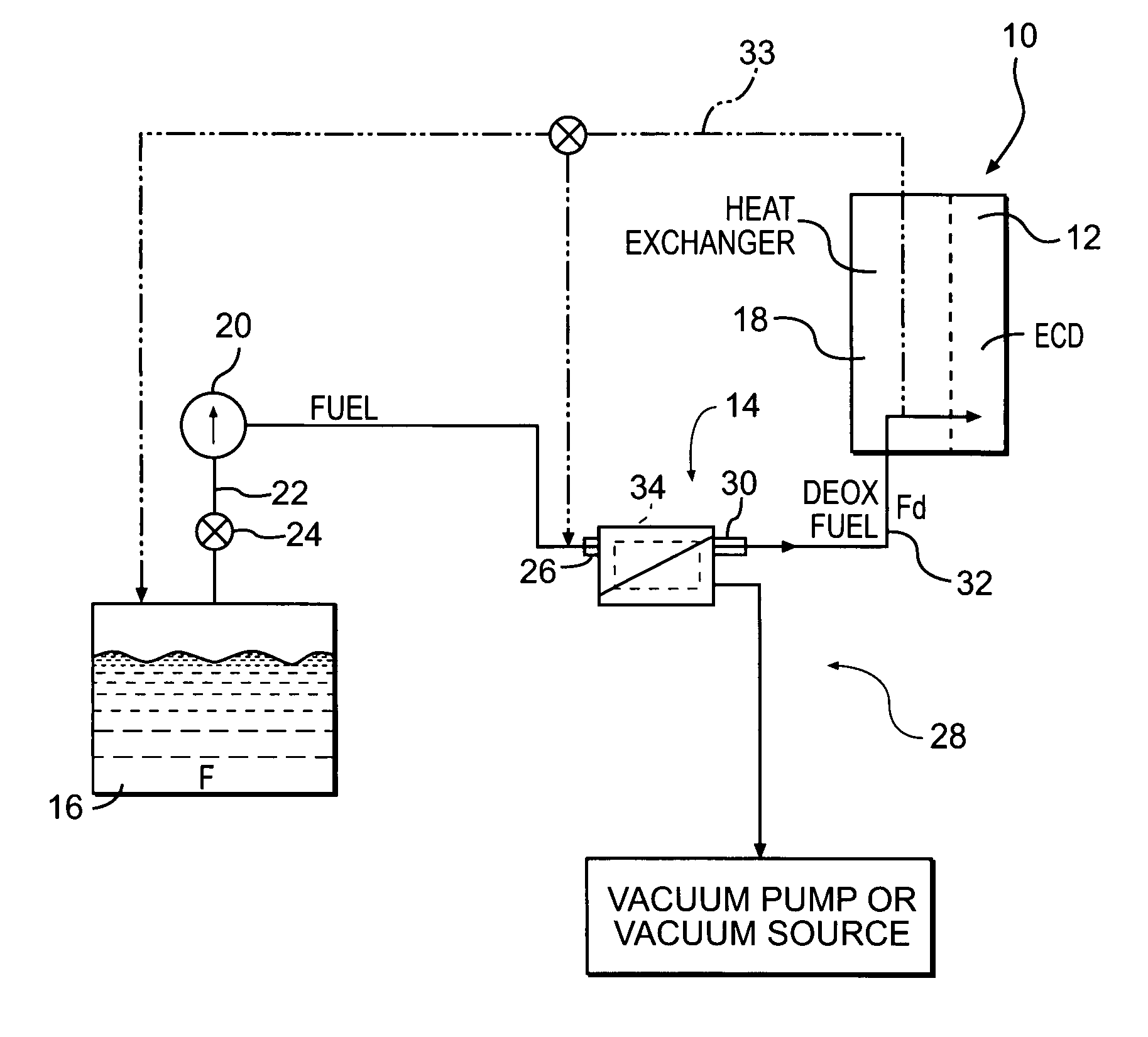

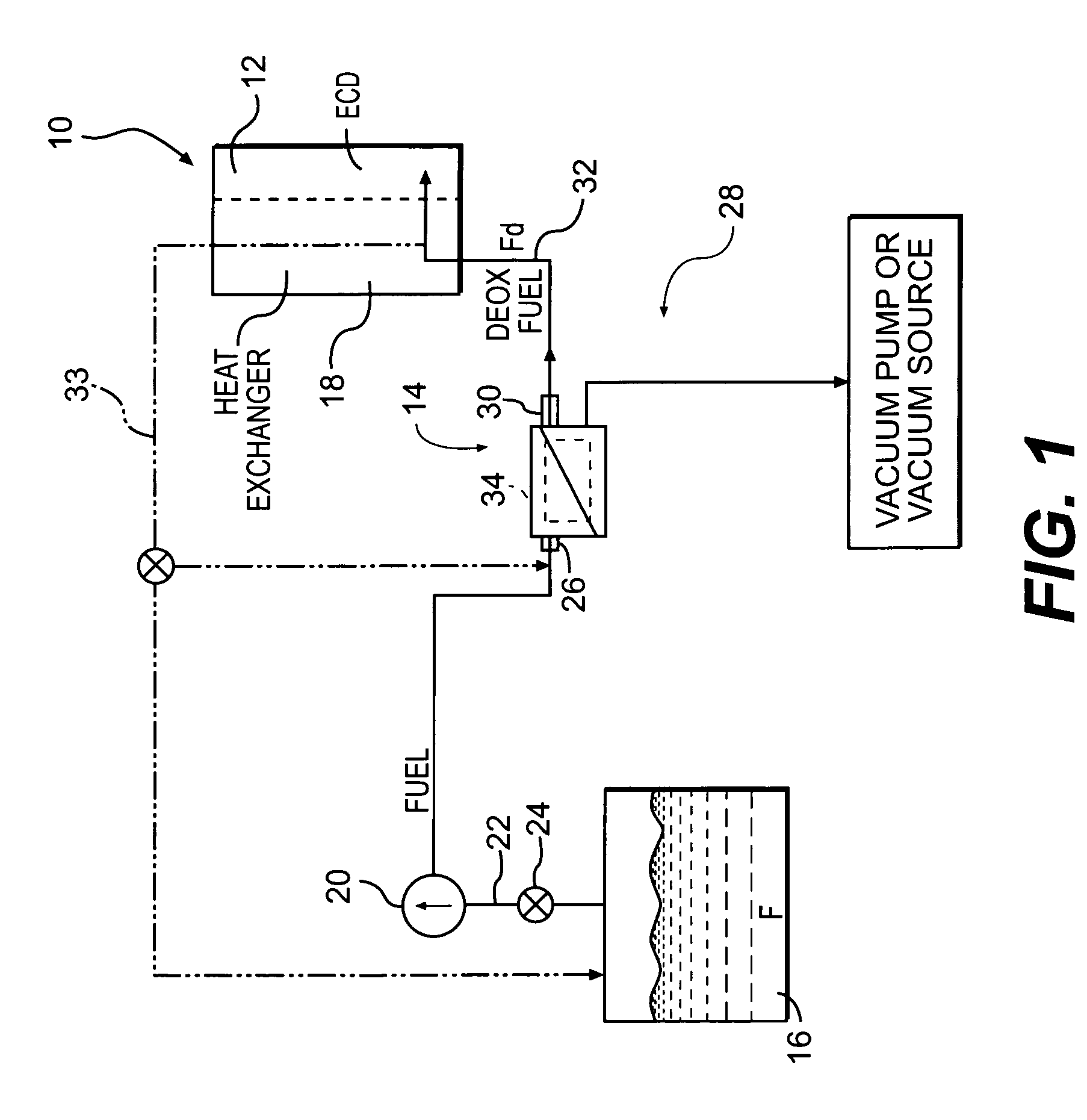

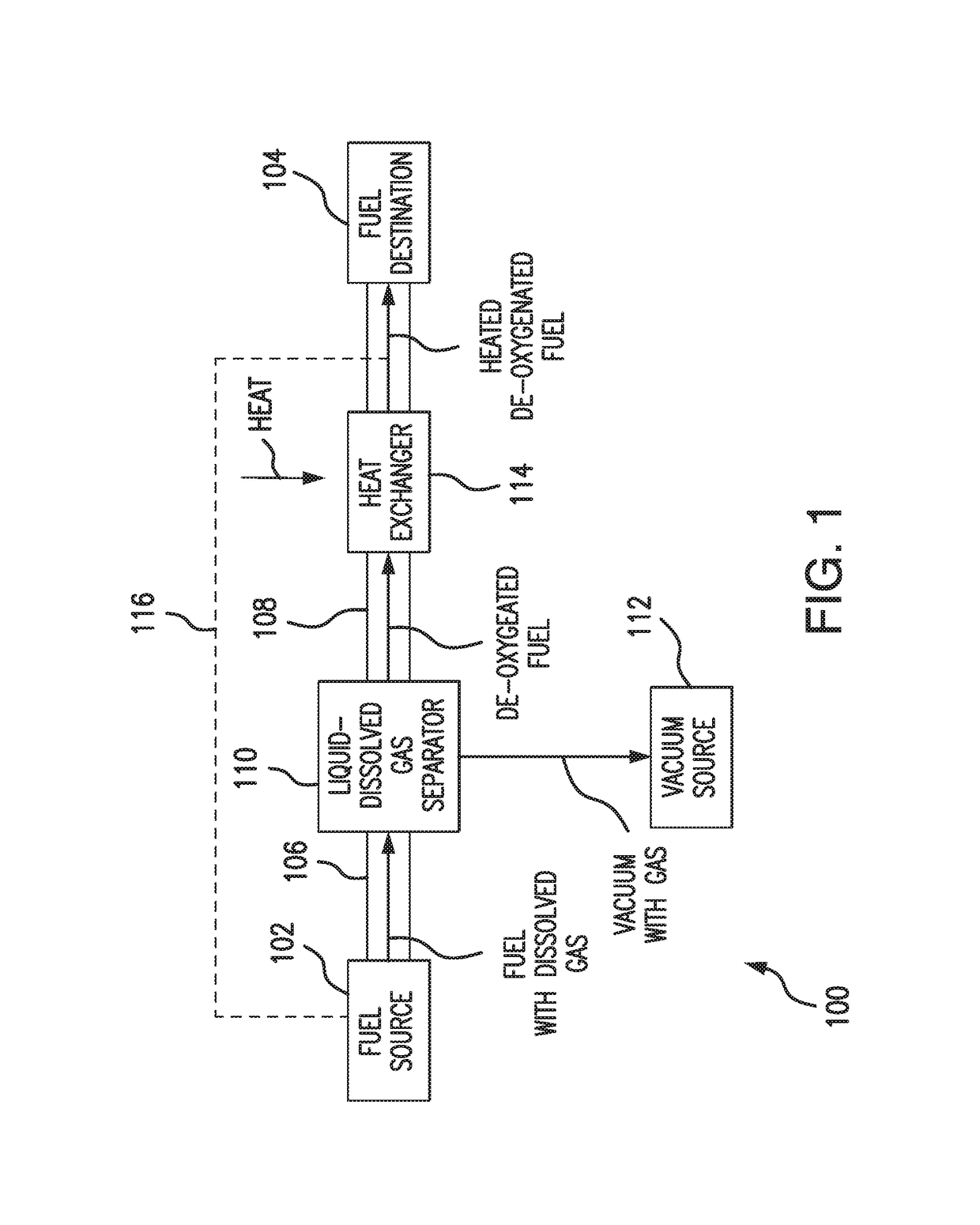

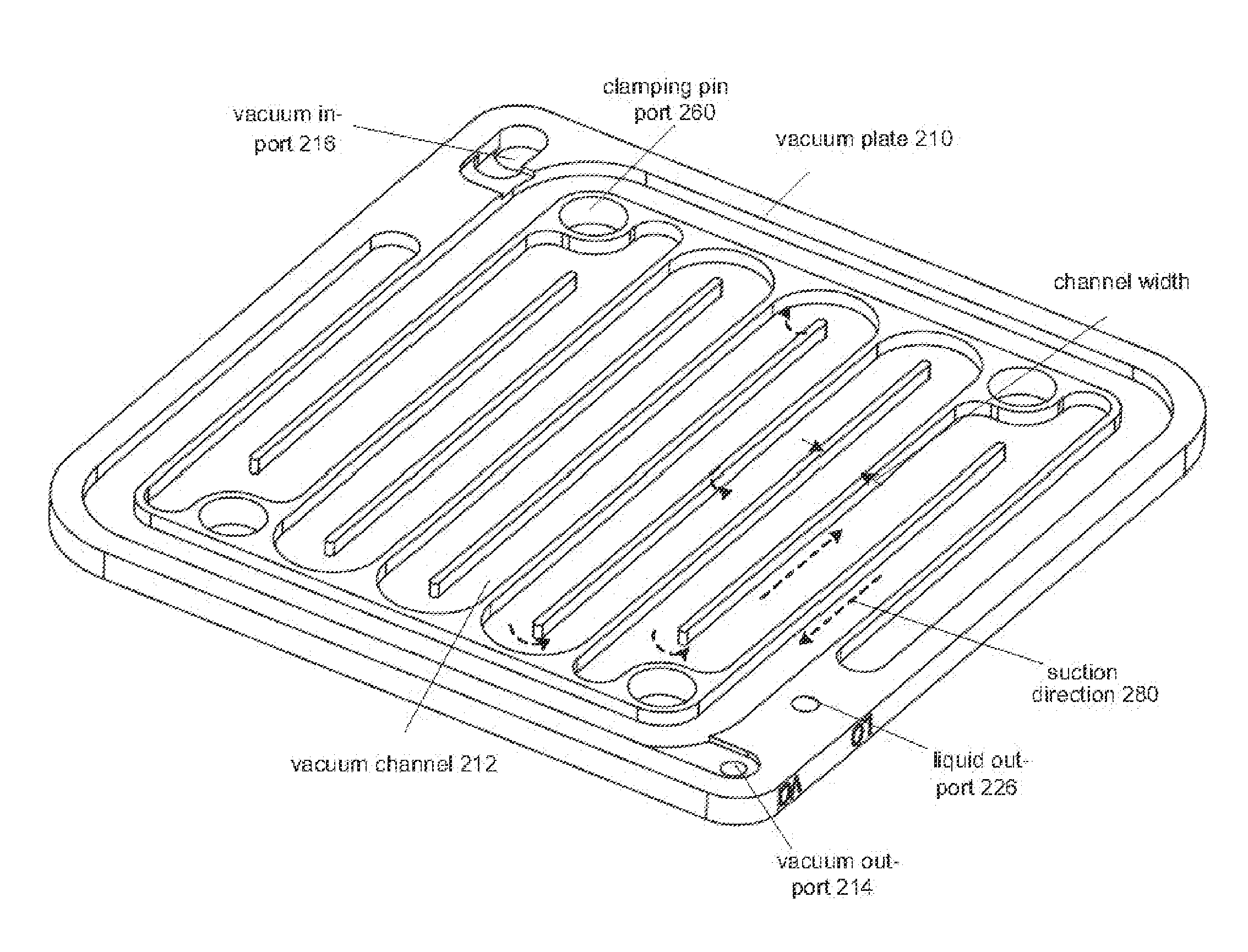

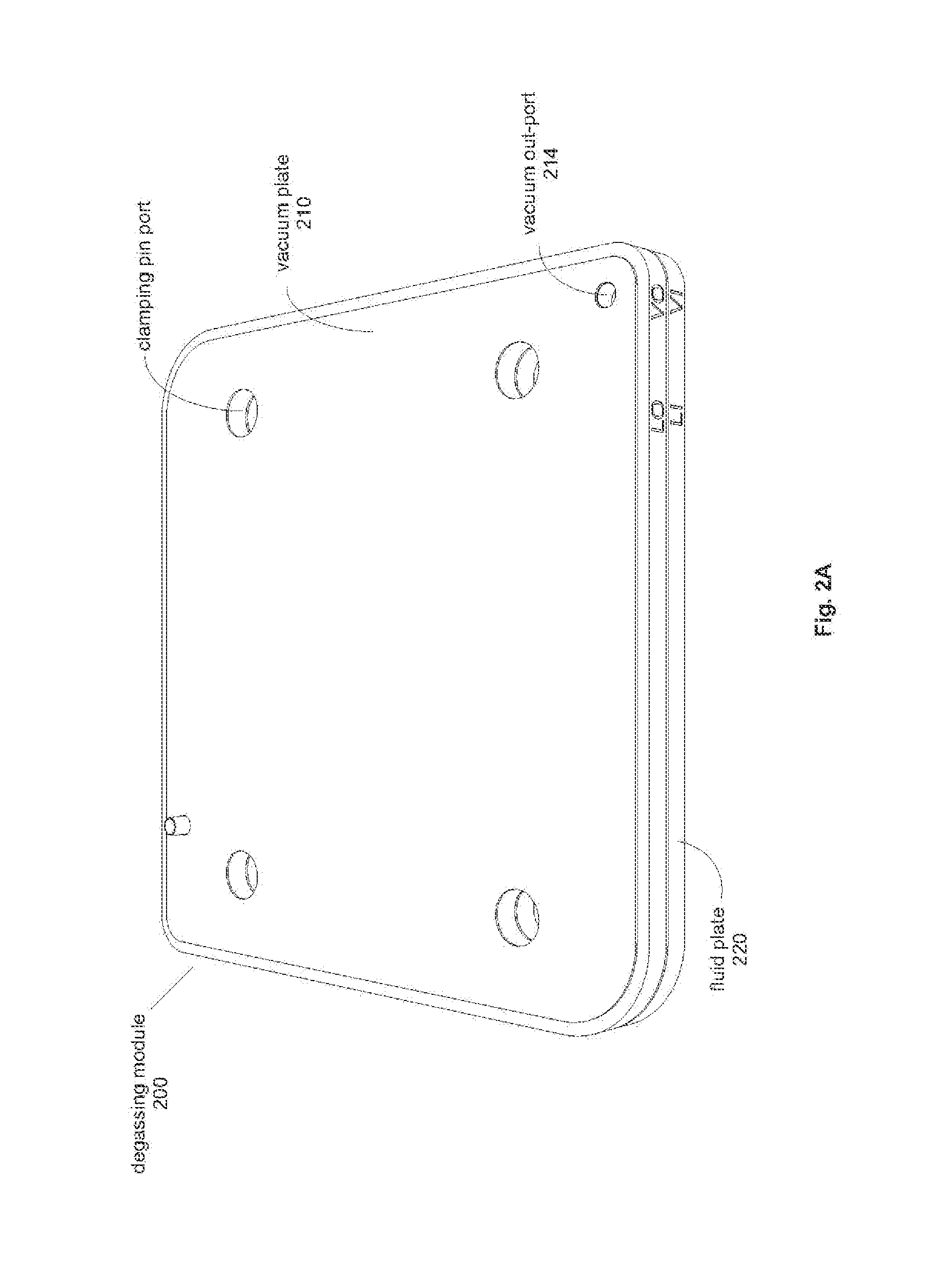

Fuel deoxygenation system with non-metallic fuel plate assembly

ActiveUS7569099B2Improve diffusivityCost-effectiveDispersed particle filtrationSolid sorbent liquid separationPorous substrateMetallic materials

Owner:RTX CORP

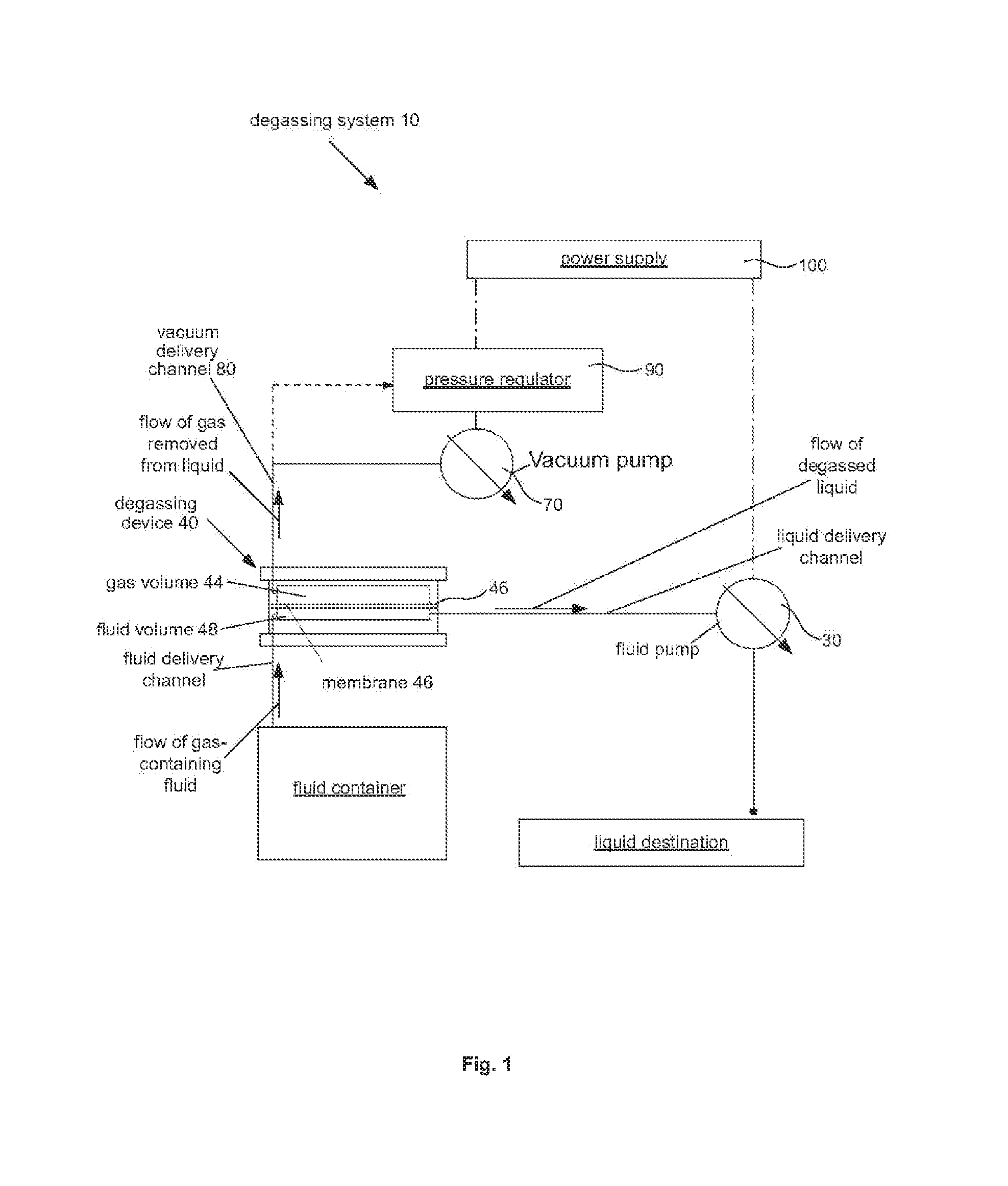

Degassing system for dialysis

The degassing system can include a degassing vessel and can utilize a vacuum pump and a fluid pump located downstream of the degassing vessel to control the pressure within the degassing vessel in order to control the concentration of gases in fluid exiting the degassing system. The degassing system can further comprise sensors in communication with the pumps to control the rate of flow and pressure through the degassing system. The degassing system may be placed in a dialysate flow path to remove dissolved gases including carbon dioxide from the dialysate.

Owner:MOZARC MEDICAL US LLC

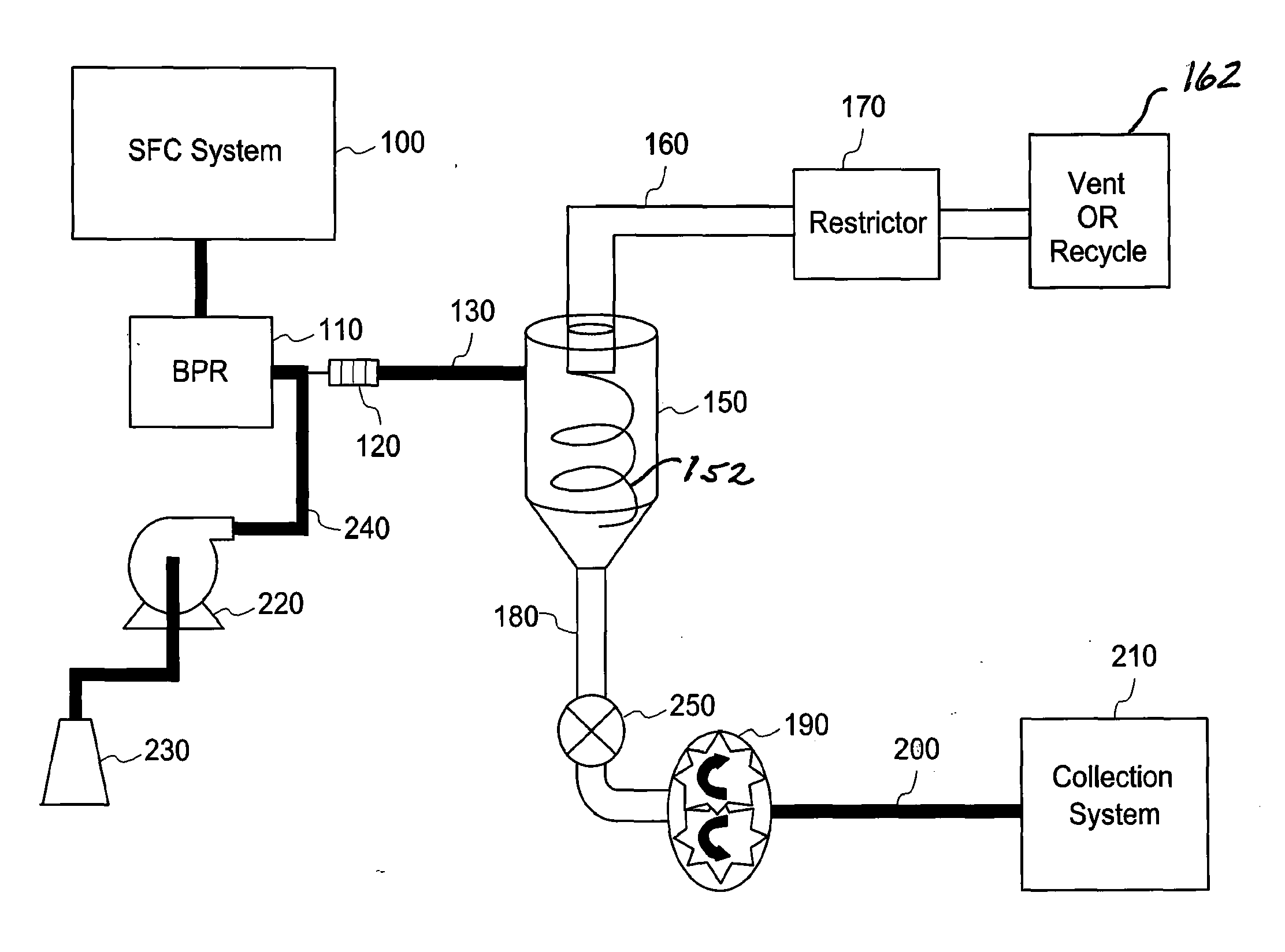

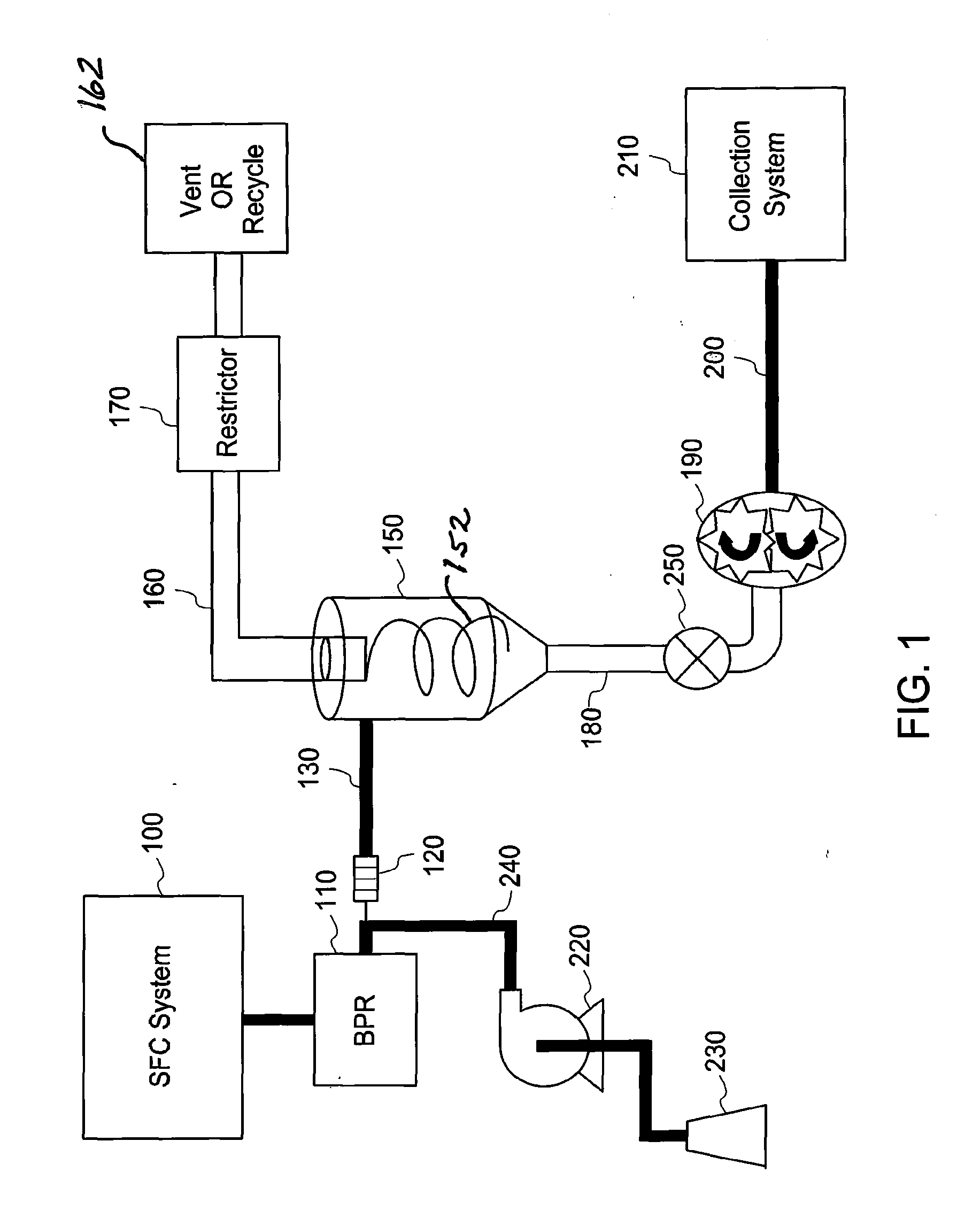

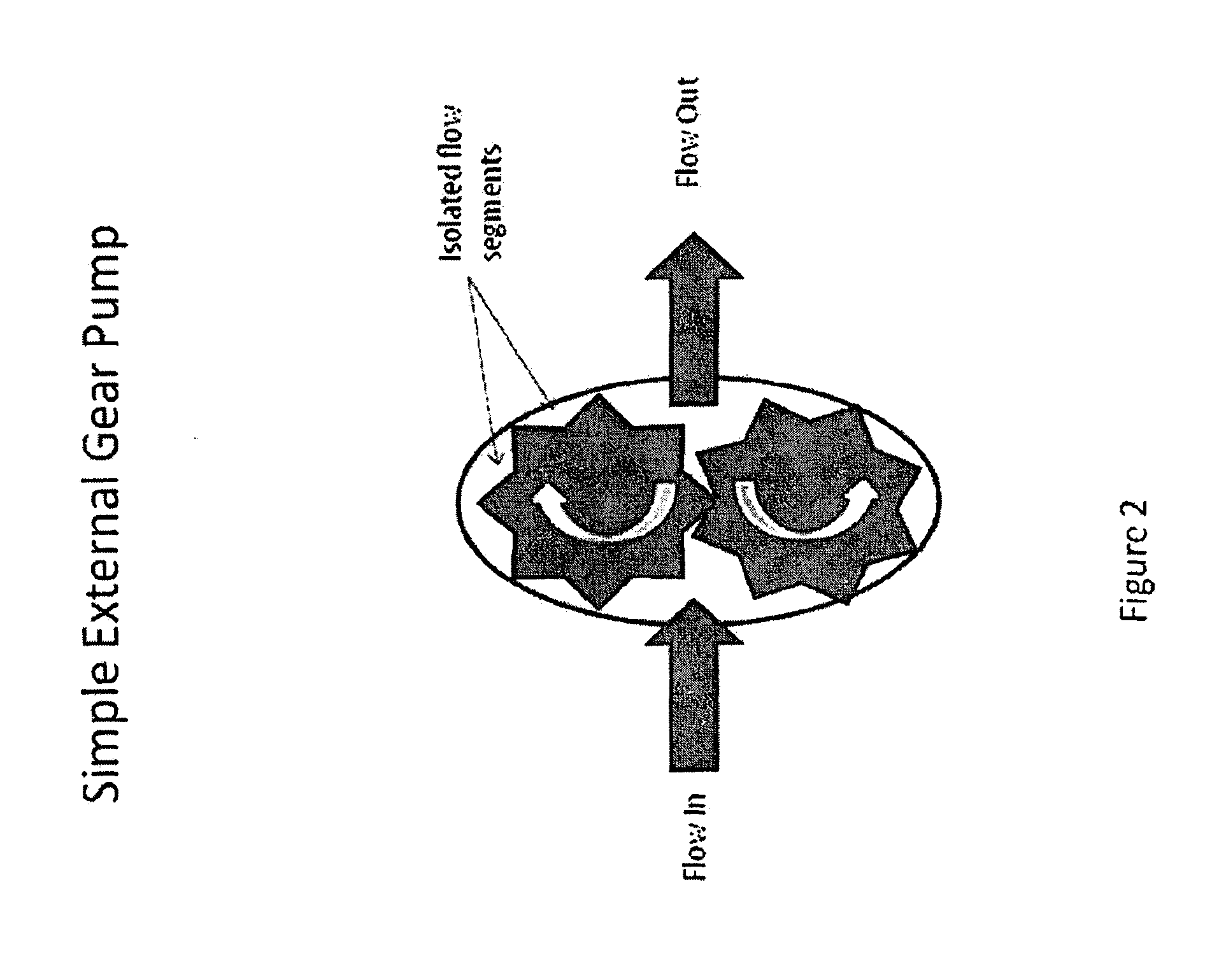

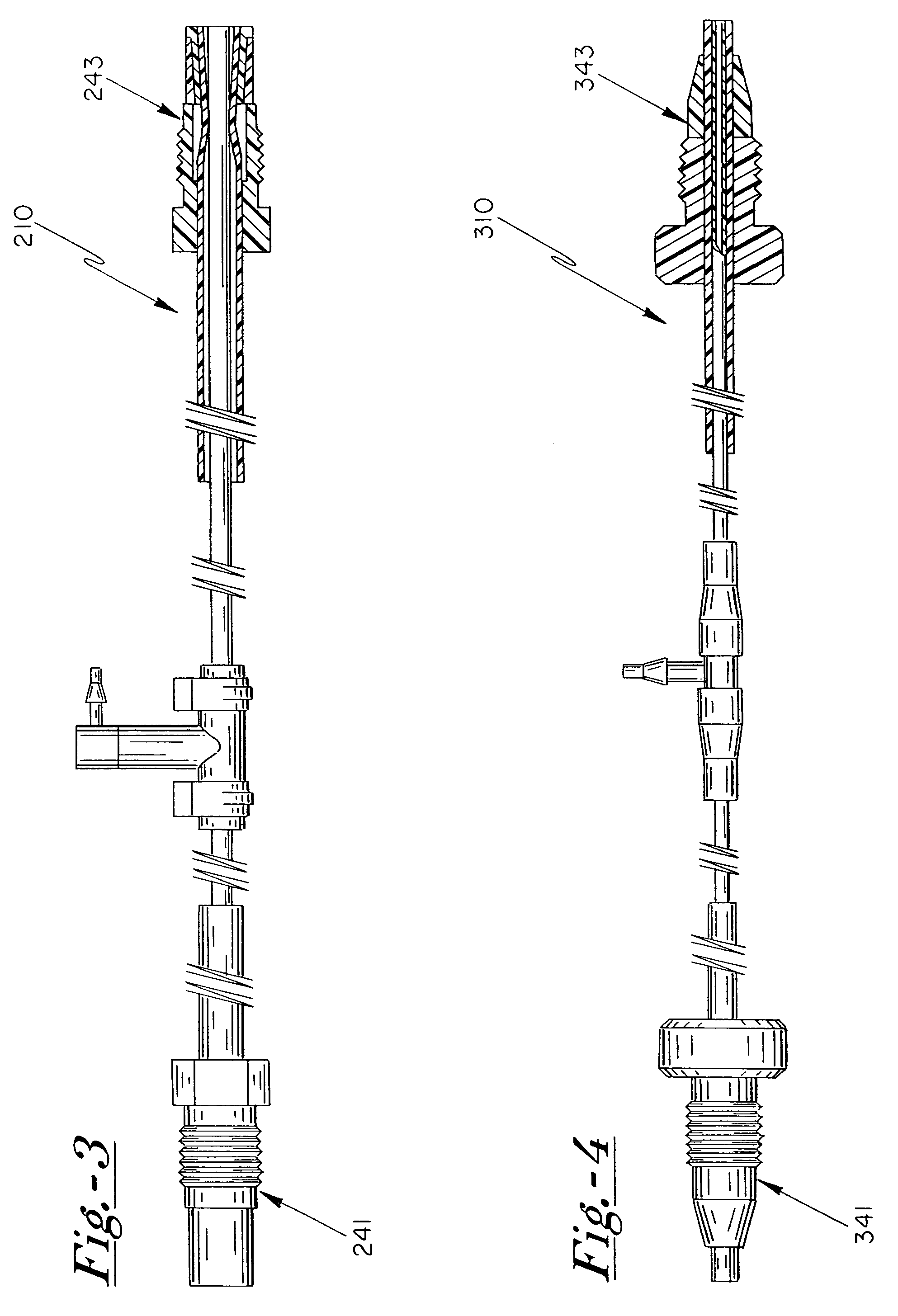

System and process for an active drain for gas-liquid separators

ActiveUS20130180404A1Deterministic drainingSolid sorbent liquid separationLiquid degasification regulation/controlIsolation valveVapor–liquid separator

An apparatus and process to effectively create an active drain for high and low pressure gas-liquid separator. The invention accomplishes a deterministic drainage rate of variable volume and viscosity liquid fractions from the separator. The mechanisms and methods thereof create a flow path from the separator that dramatically favors controlled liquid flow over a wide range of flow rates and viscosities while restricting gas flow. The invention is a superior method of drainage over conventional systems that employ pressure, vacuum, isolation valves and / or passive flow restrictors to achieve drainage of the separators. The embodiments are primarily directed to the fields of preparative supercritical fluid chromatography (SFC) and supercritical fluid extraction (SFE). An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

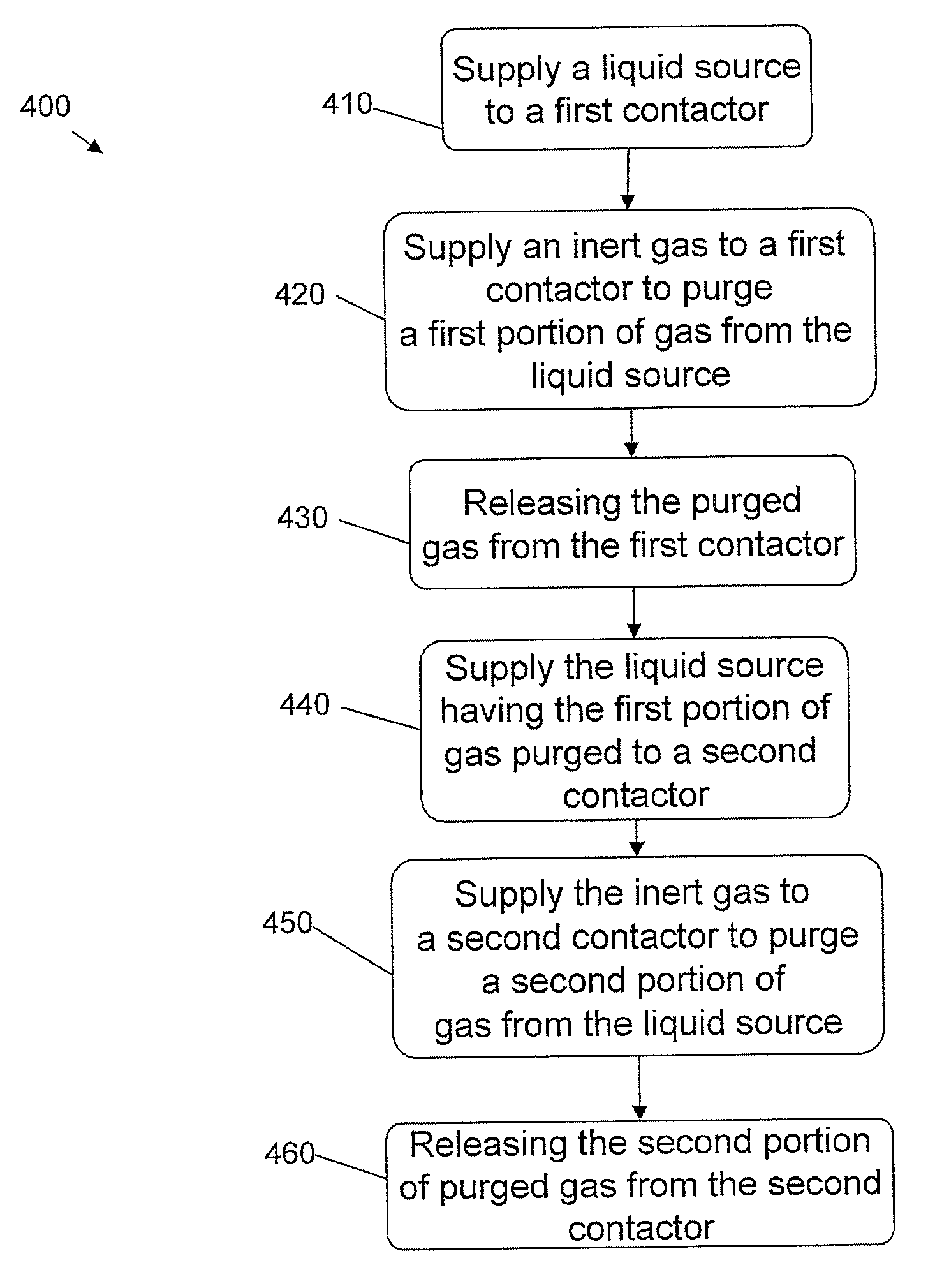

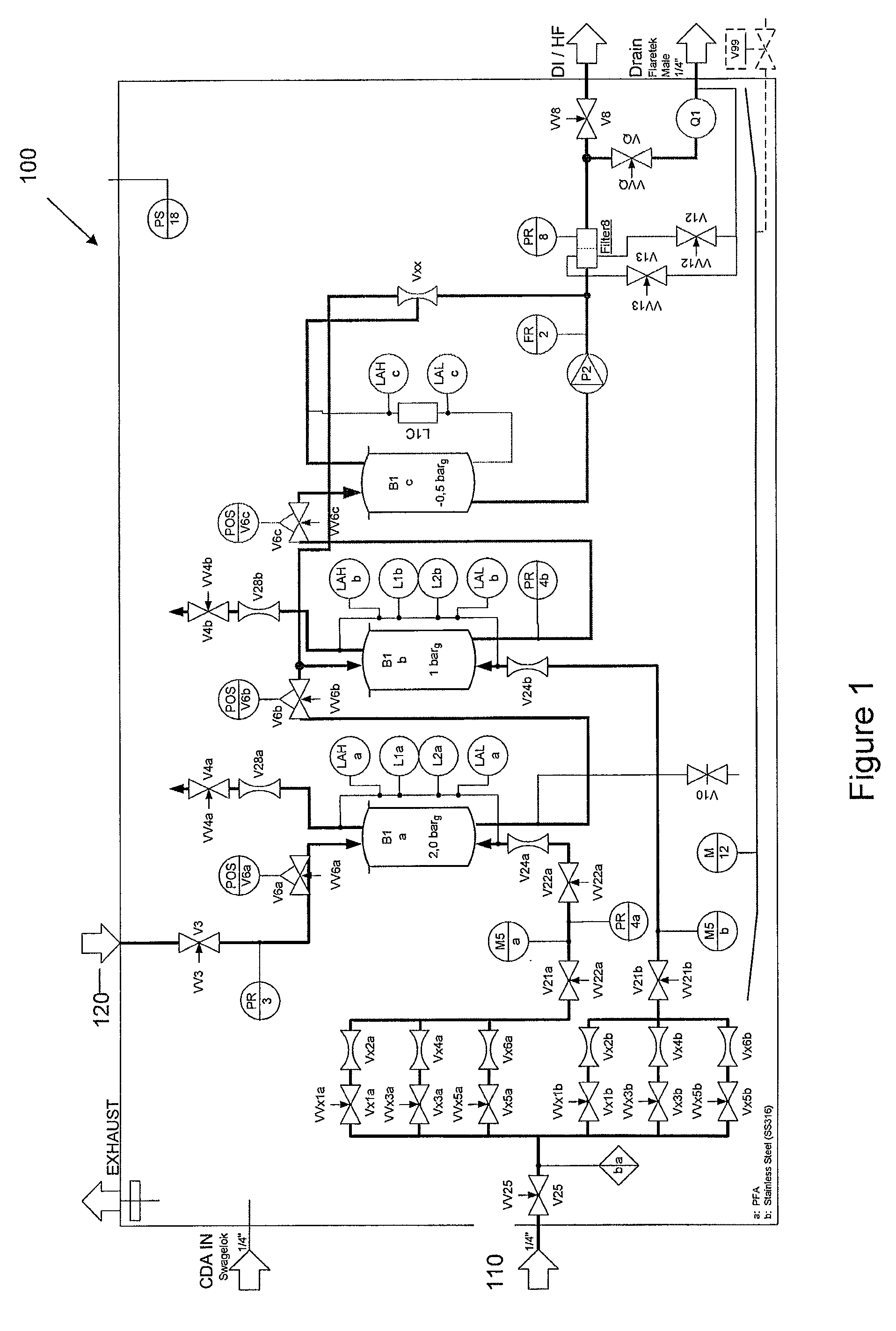

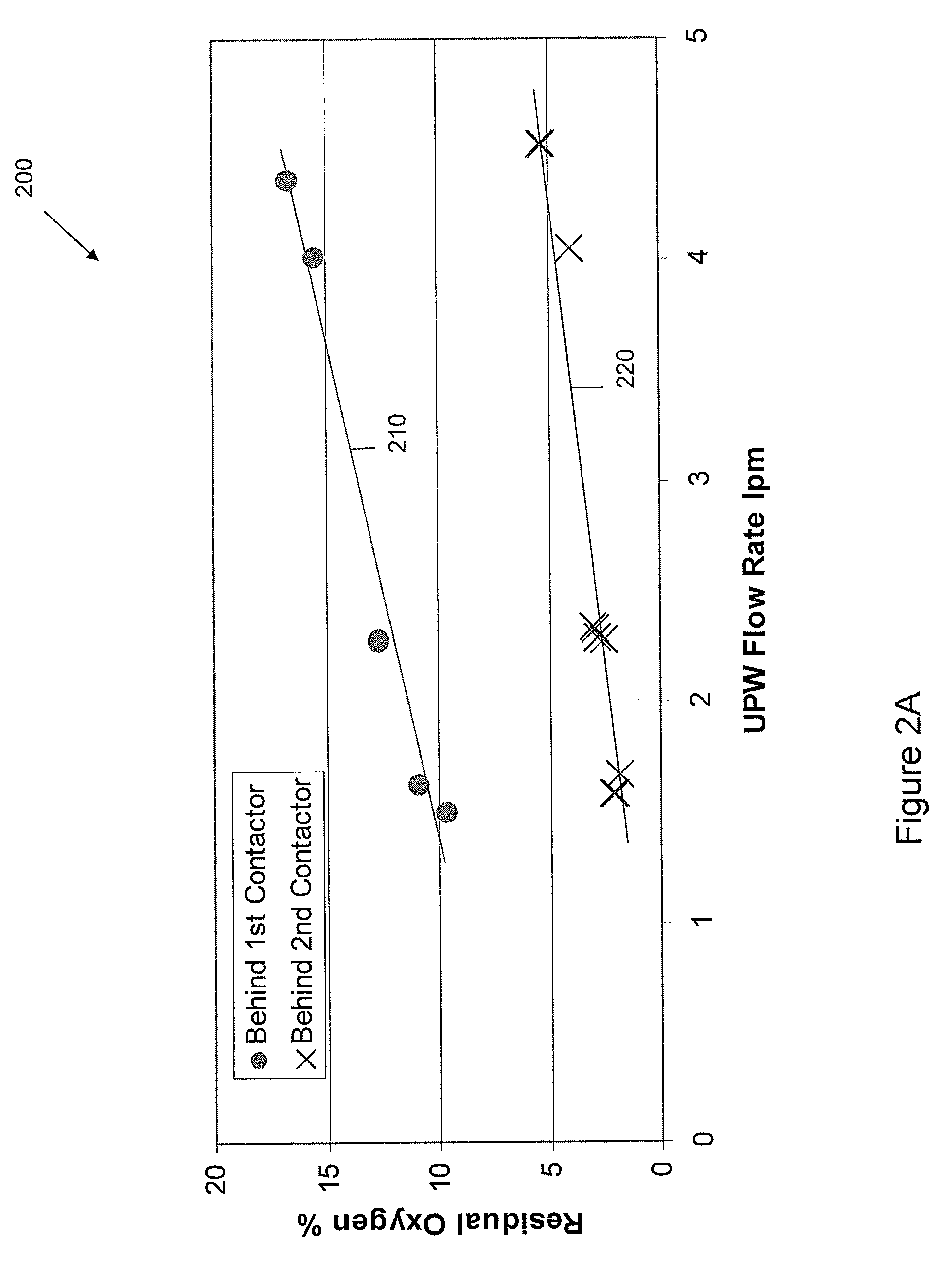

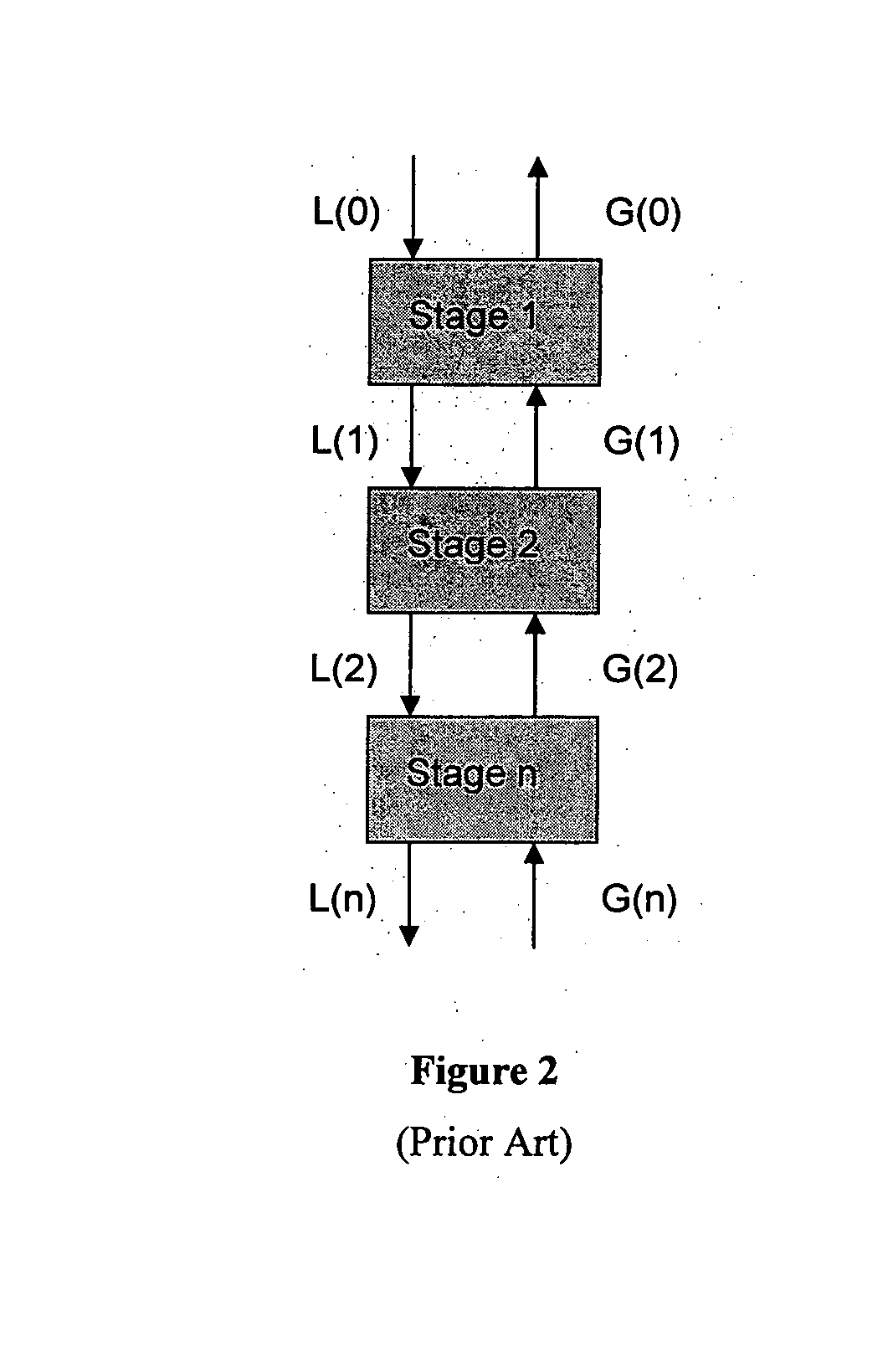

System to remove Dissolved Gases Selectively from Liquids

ActiveUS20120279396A1Reduce consumptionExtend your lifeLiquid degasification with auxillary substancesUsing liquid separation agentEnvironmental engineeringContactor

A system to purge dissolved gases selectively from liquids can include a first contactor having two first contactor inlets and two first contactor outlets. The first contactor can receive liquid from a liquid source at a first inlet of the first contactor and an inert gas source at a second inlet of the first contactor, the inert gas can purge a first portion of gas from the liquid source. The first portion of purged gas exits the first contactor at a first outlet of the first contactor. The second contactor can receive input from the second outlet of the first contactor and the inert gas, the inert gas purges a second portion of the gas from the liquid source. The second portion of purged gas can exit the second contactor at a first outlet of the second contactor.

Owner:MKS INSTR INC

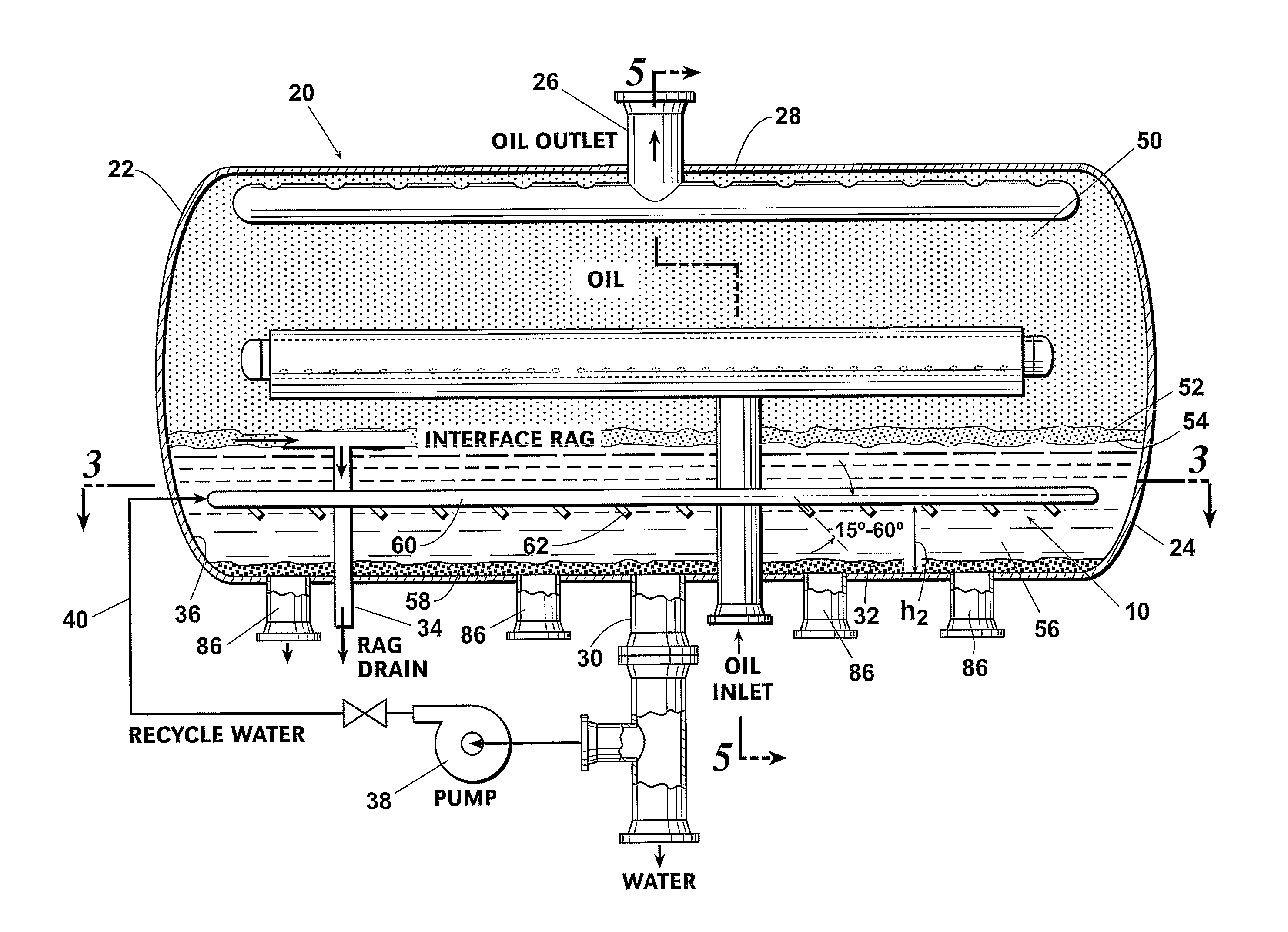

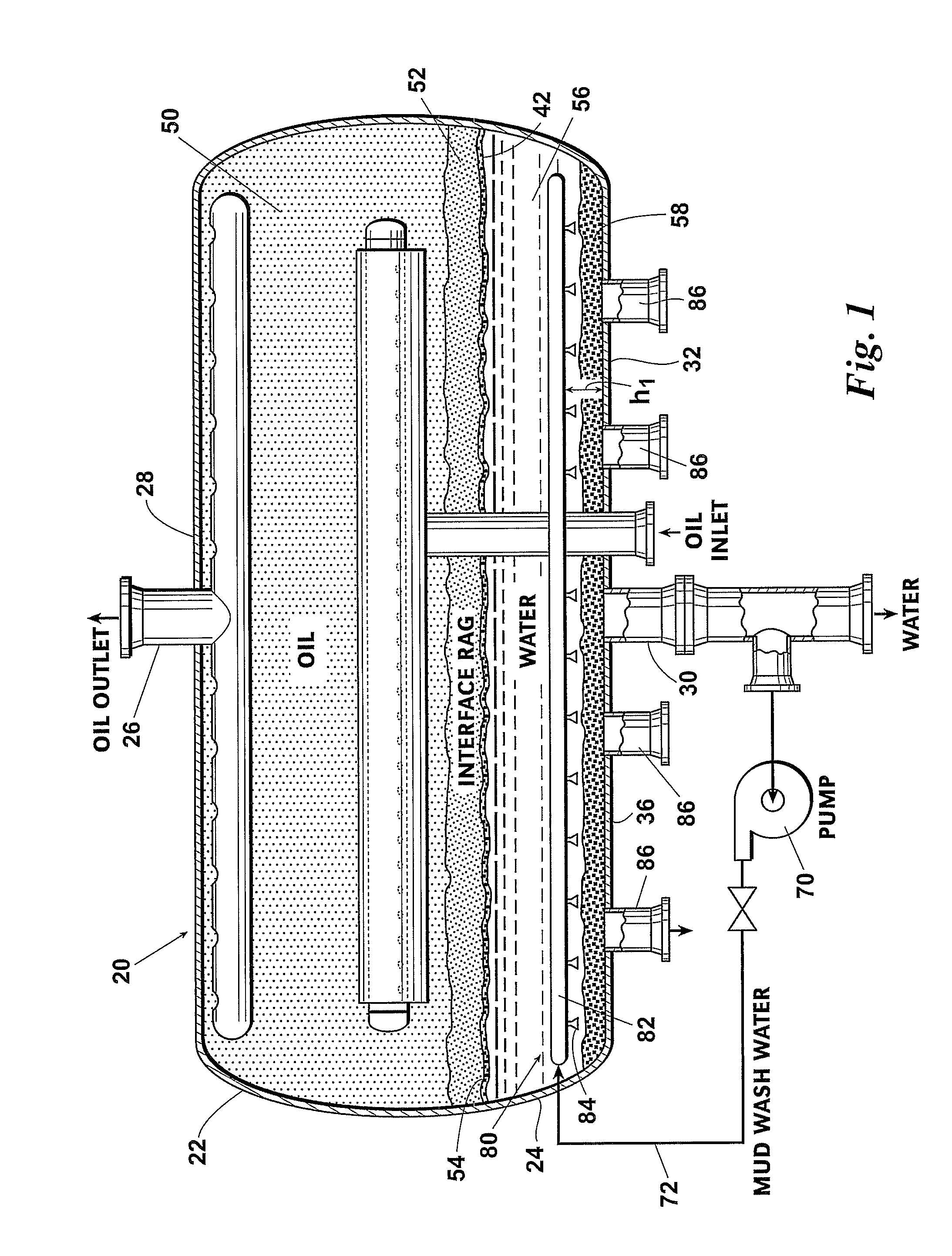

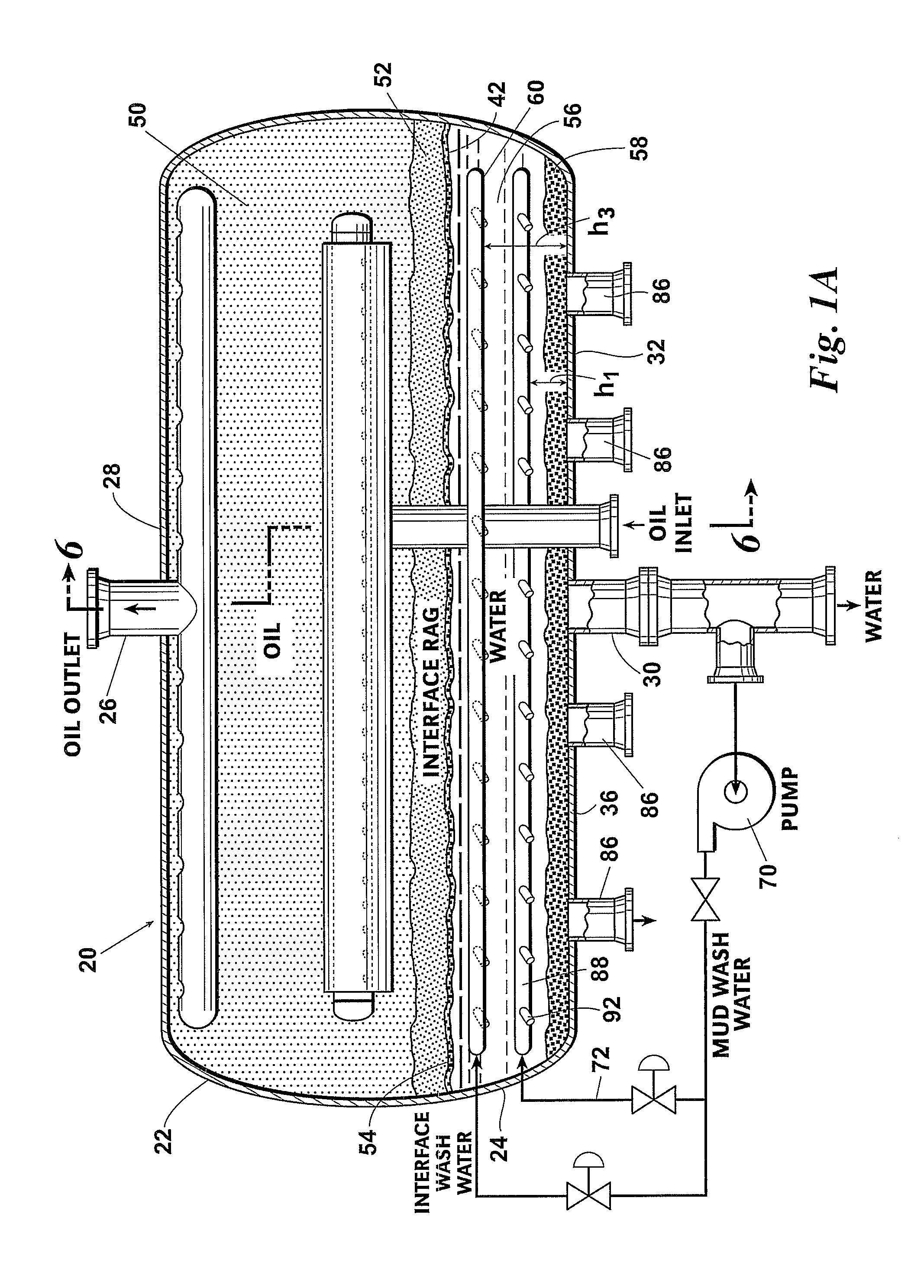

Interface and Mud Control System and Method for Refinery Desalters

ActiveUS20130083620A1Slow and continuous agitationLiquid separation auxillary apparatusDewatering/demulsification with mechanical meansVertical planeEngineering

A method and system for controlling an interface emulsion layer and mud layer within a desalter vessel includes injecting a water flow through a plurality of nozzles arranged about a piping circuit located in the brine water layer. Each nozzle is oriented toward an interior space of the desalter vessel and is arranged oblique to the piping circuit. The water flow through the plurality of nozzles causes a horizontal and vertical rotation of a volume of water that is effective for suspending solids in the water and promoting a collapse of the interface emulsion layer. The water flow through each nozzle, which may be a recycled water flow, is preferably in a range of 1 to 3 fpm and each nozzle is preferably oriented at an angle of about 15° and 60° in a horizontal plane and a downward angle of about 15° and 60° in a vertical plane.

Owner:CAMERSON INT CORP

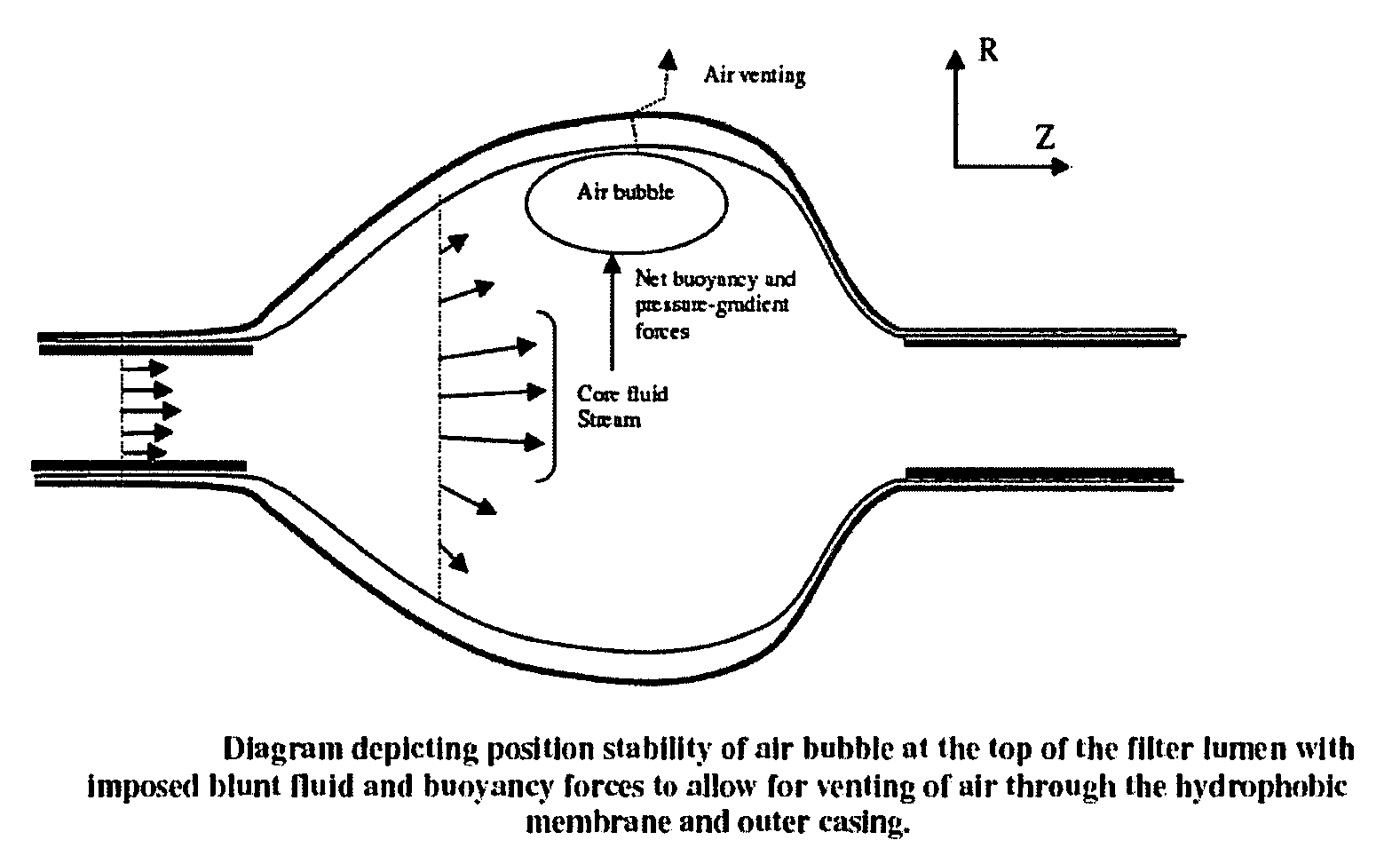

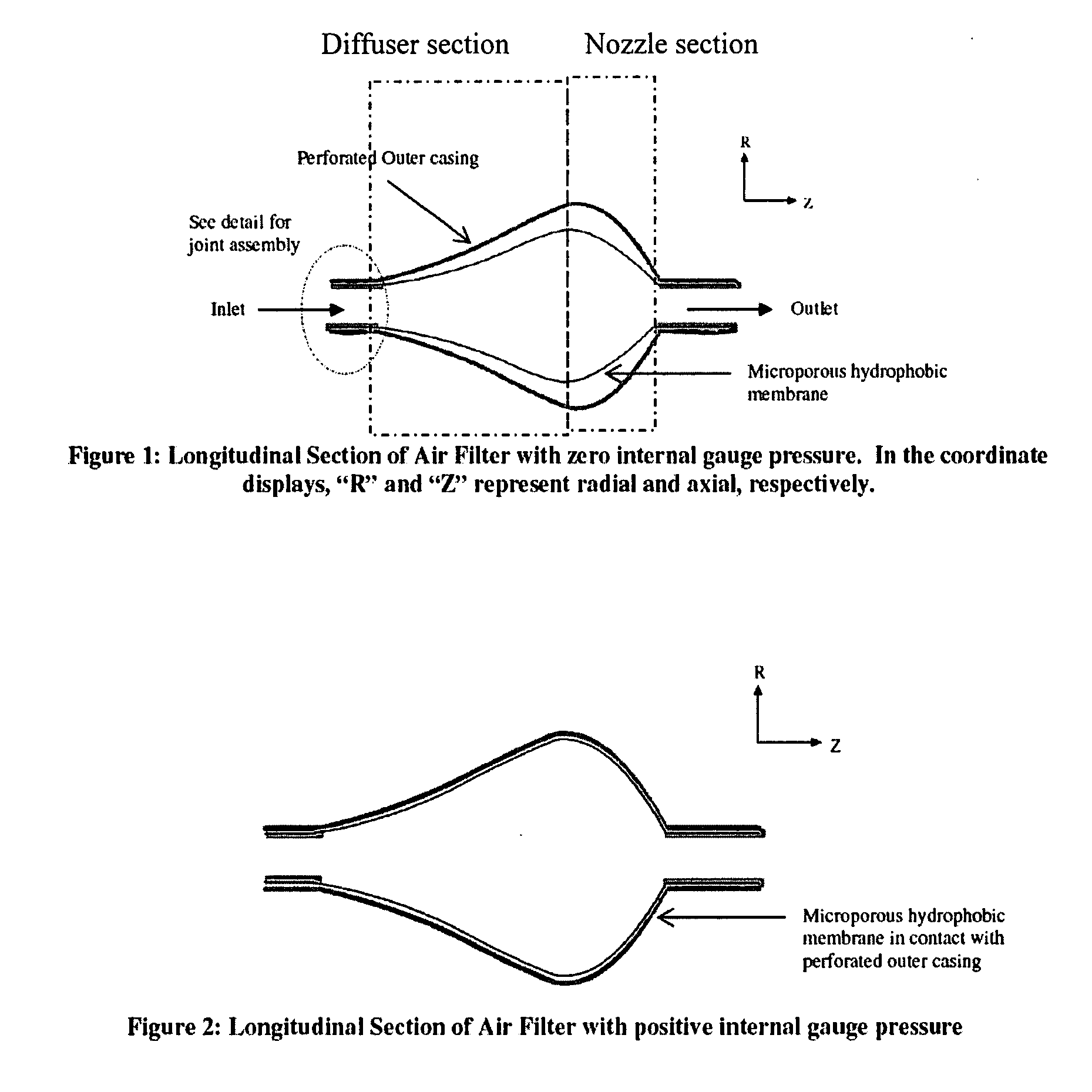

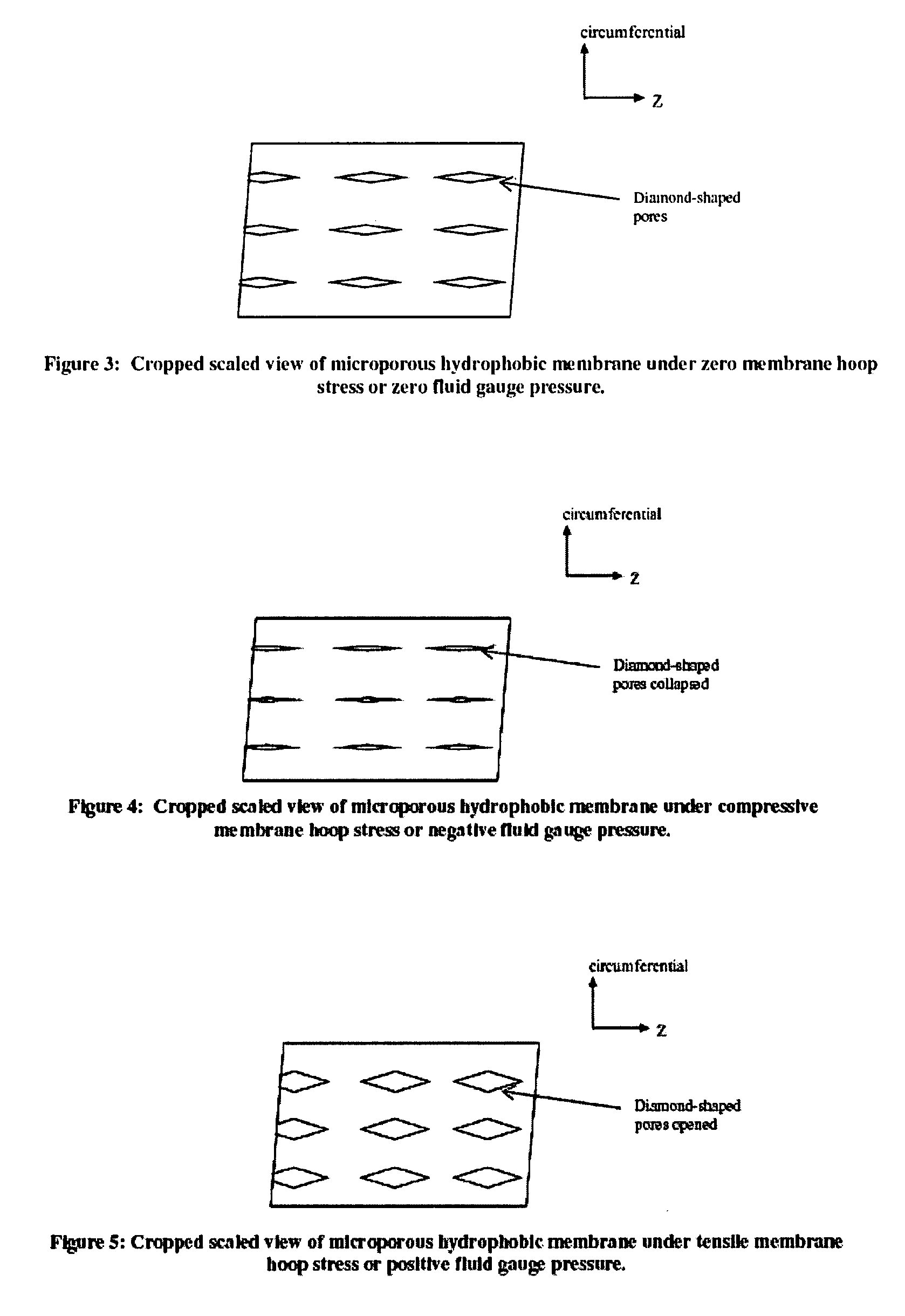

Open lumen air filtration for liquid lines

ActiveUS20100218679A1Improve filtering effectLow flow resistanceIsotope separationLiquid degasification by filtrationLiquid lineAir filtration

Devices and systems for capturing and removing accumulated gas bubbles in a liquid-carrying line wherein the device is an expanded double-layered chamber designed and adapted to be integrally placed within the flow pathway of a liquid-carrying line. The device allows insertion of tubes and wires through the device while in use without occlusion of the fluid flow path and without interruption of the bubble-removing function. The efficiency of the air venting and bubble-removing process is not dependent on the fluid flow rate under stable flow conditions, and the device works to remove air bubbles under a range of orientations.

Owner:HEKMAT NEEMA +1

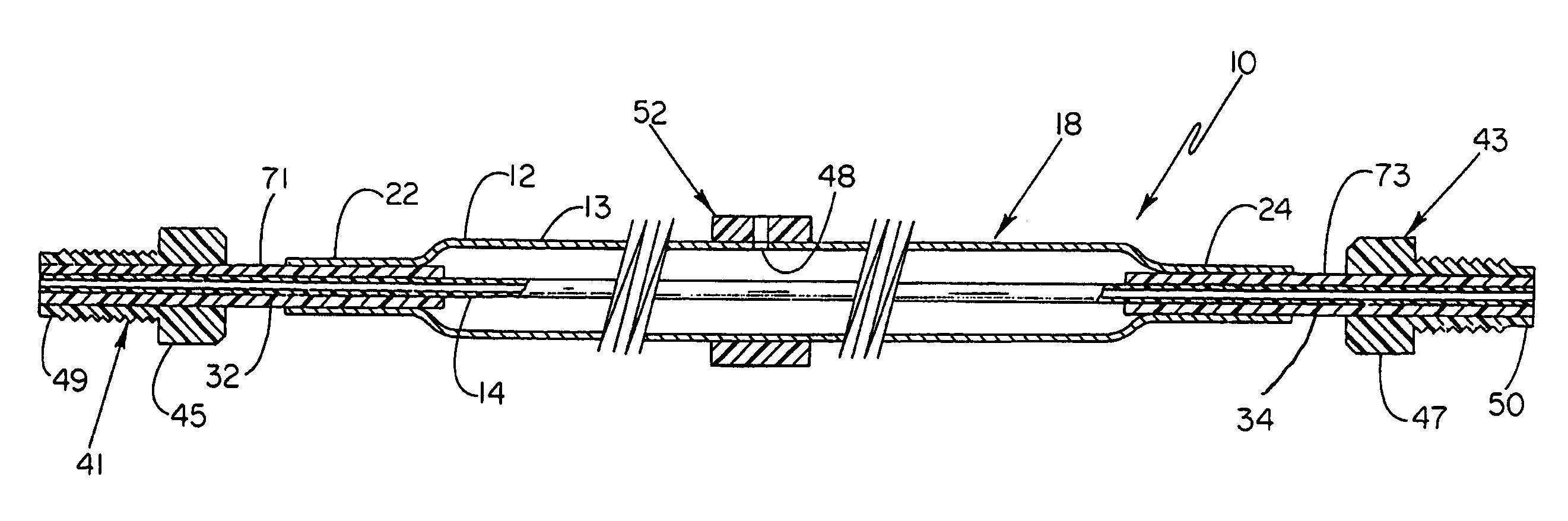

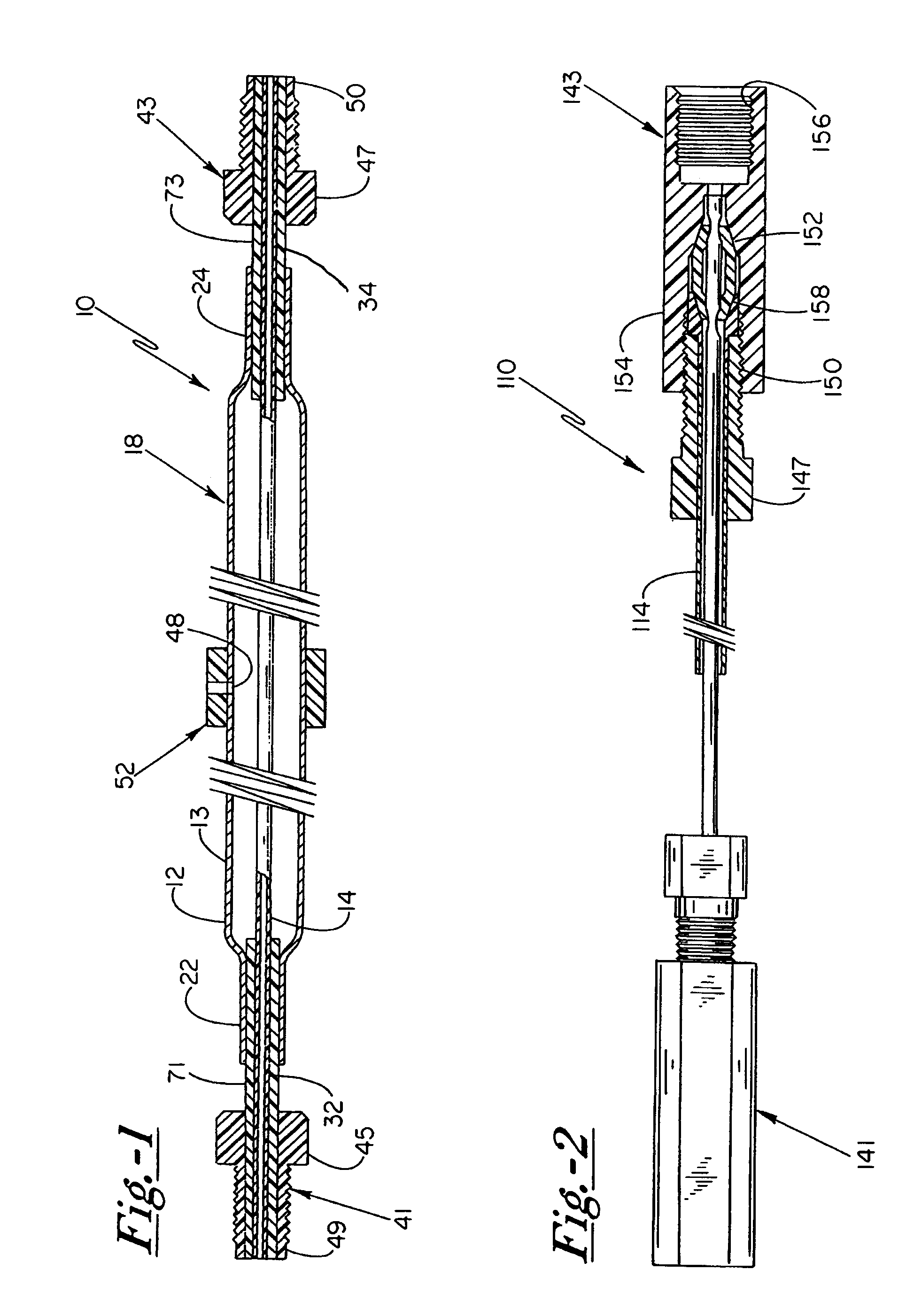

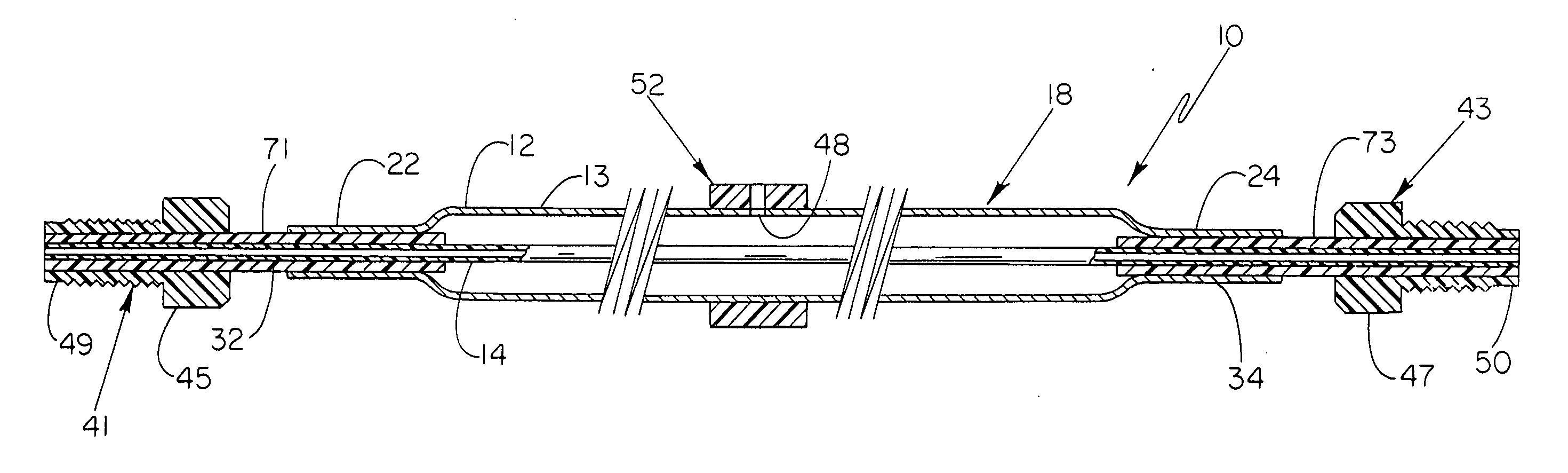

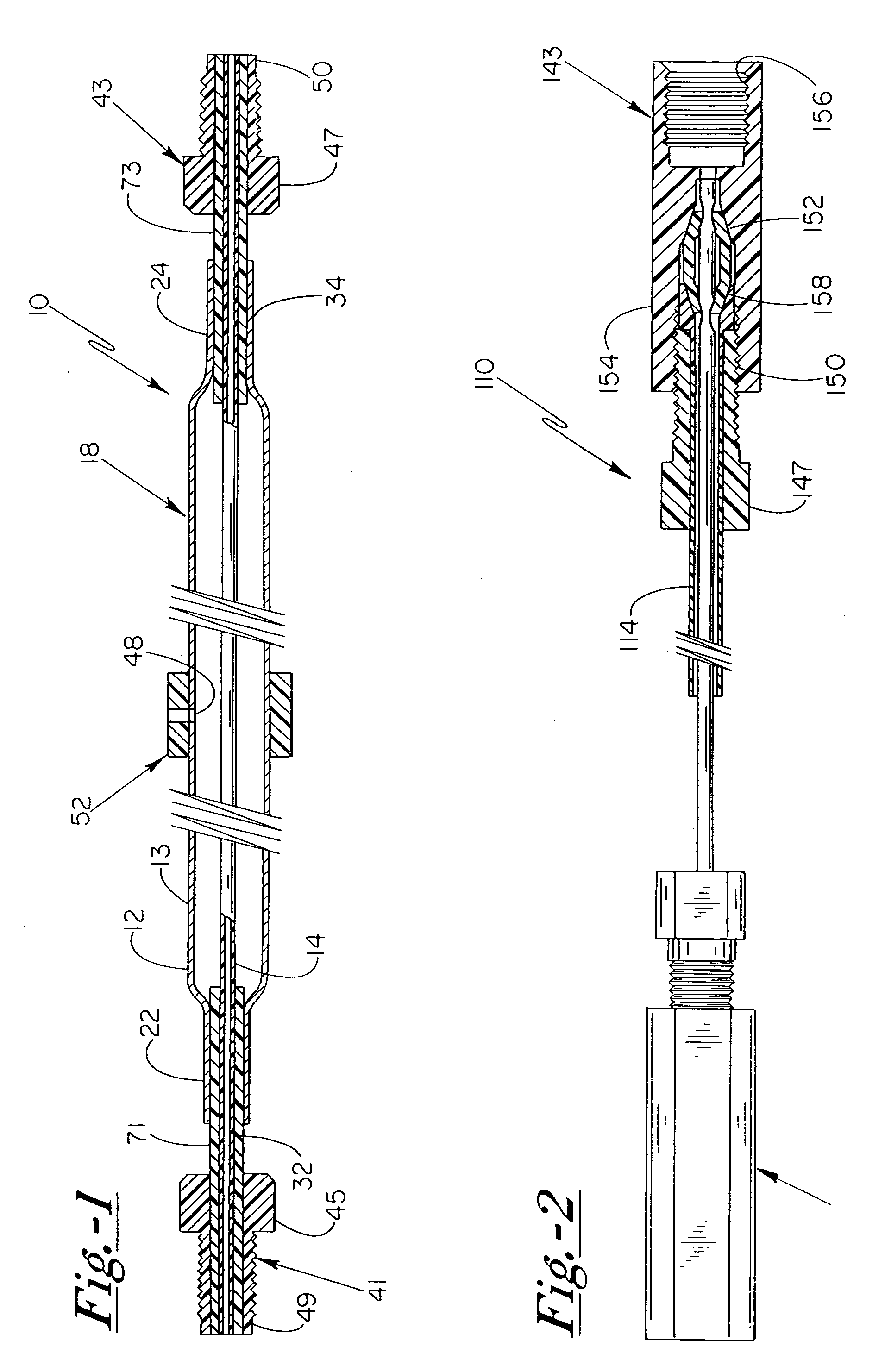

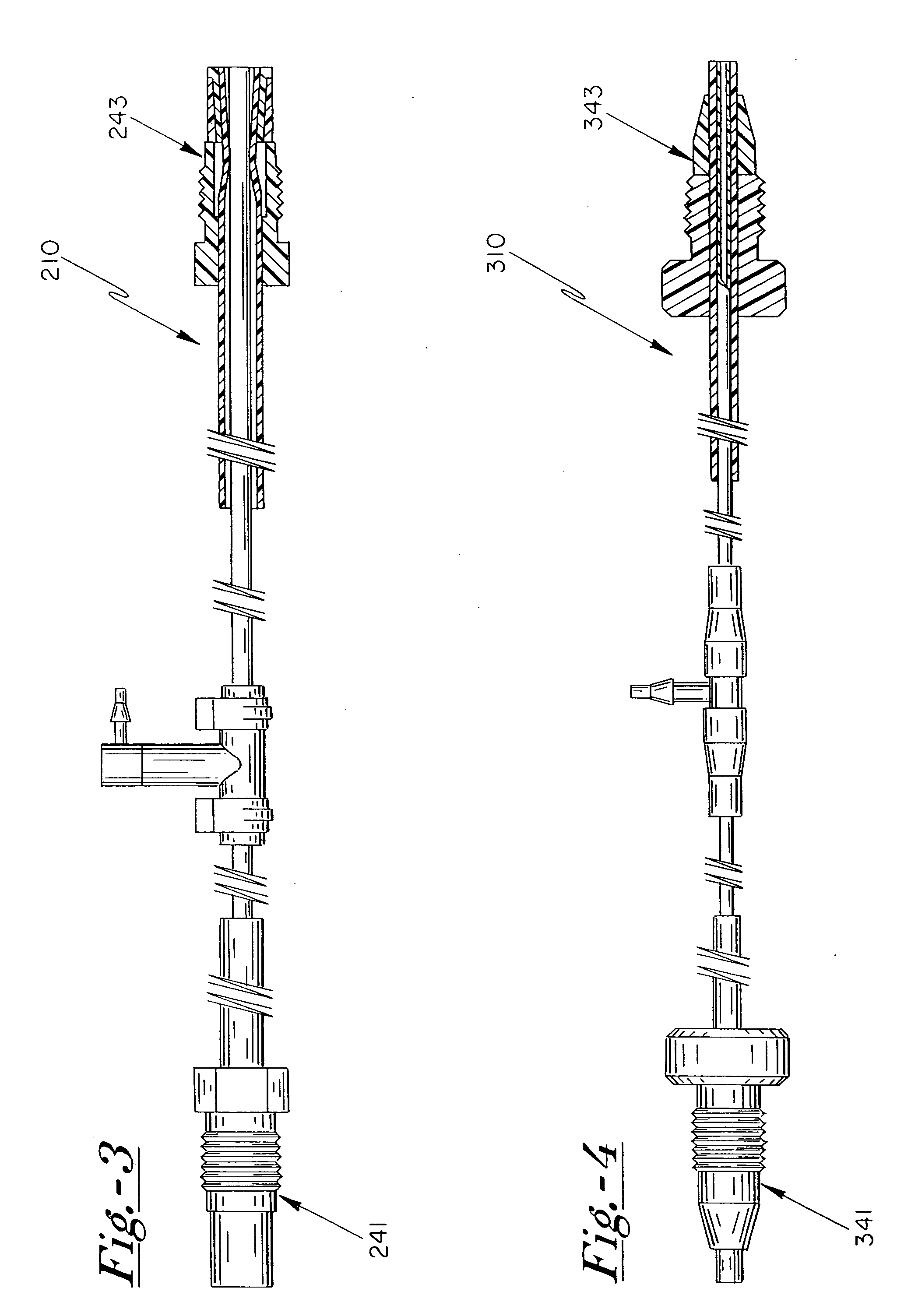

Axial transfer line degassing

Owner:IDEX HEALTH & SCI

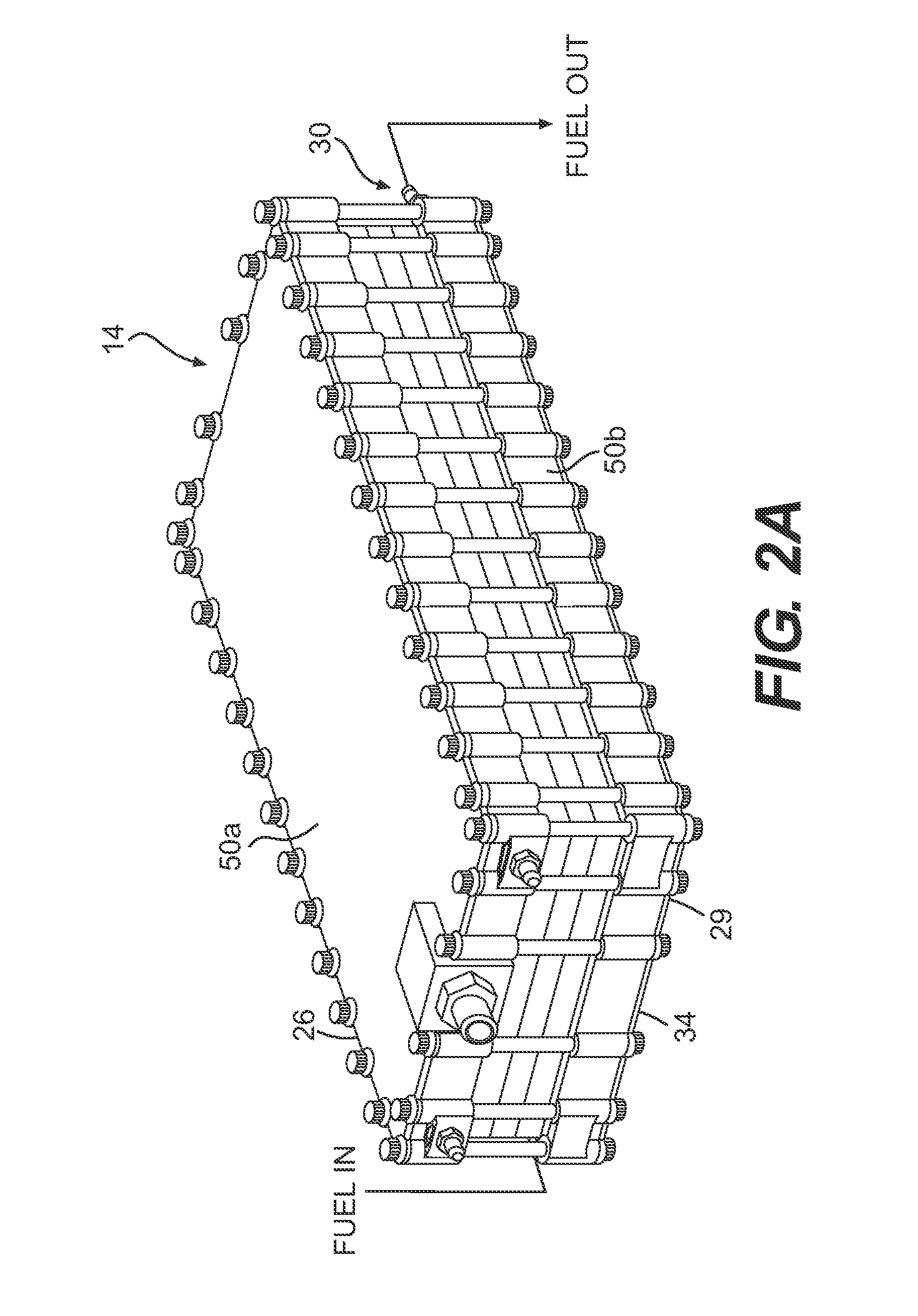

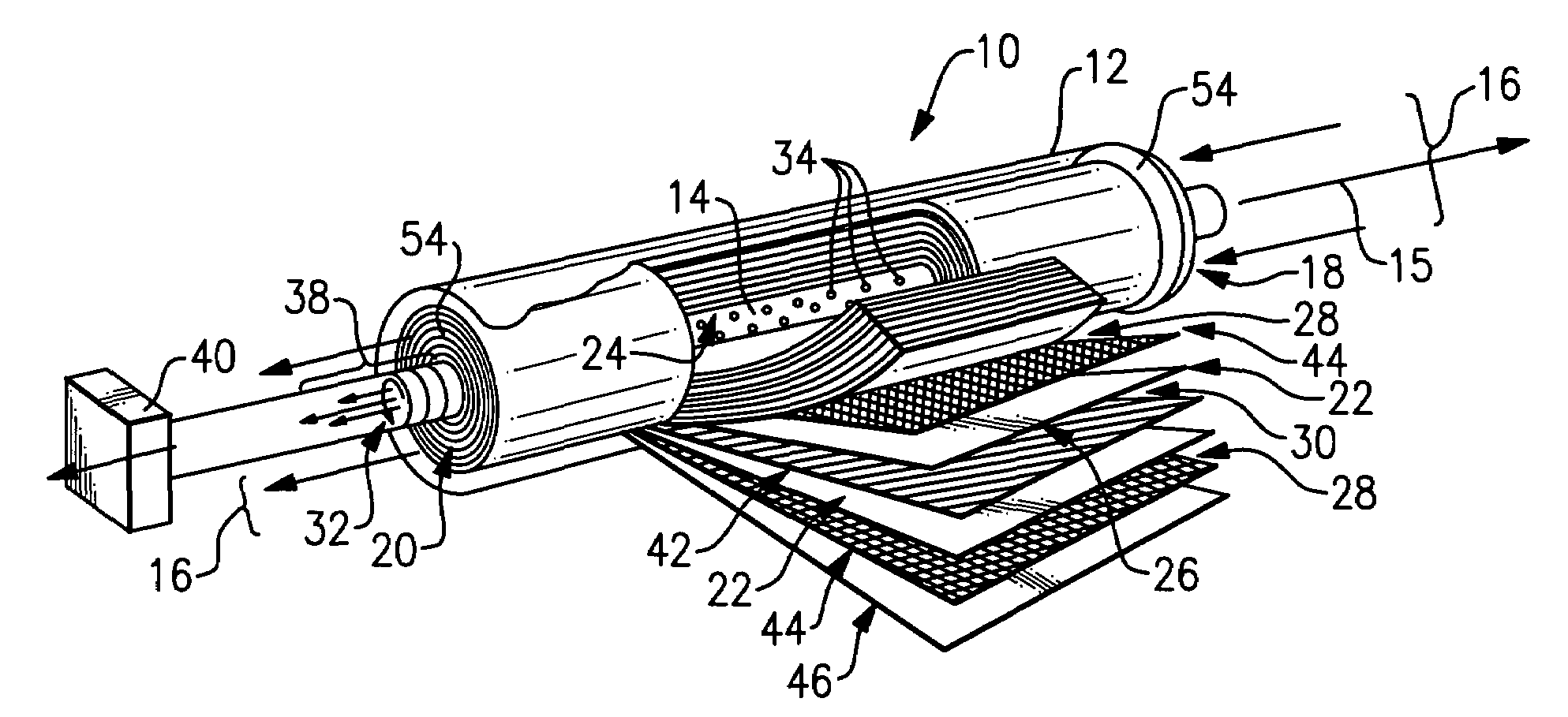

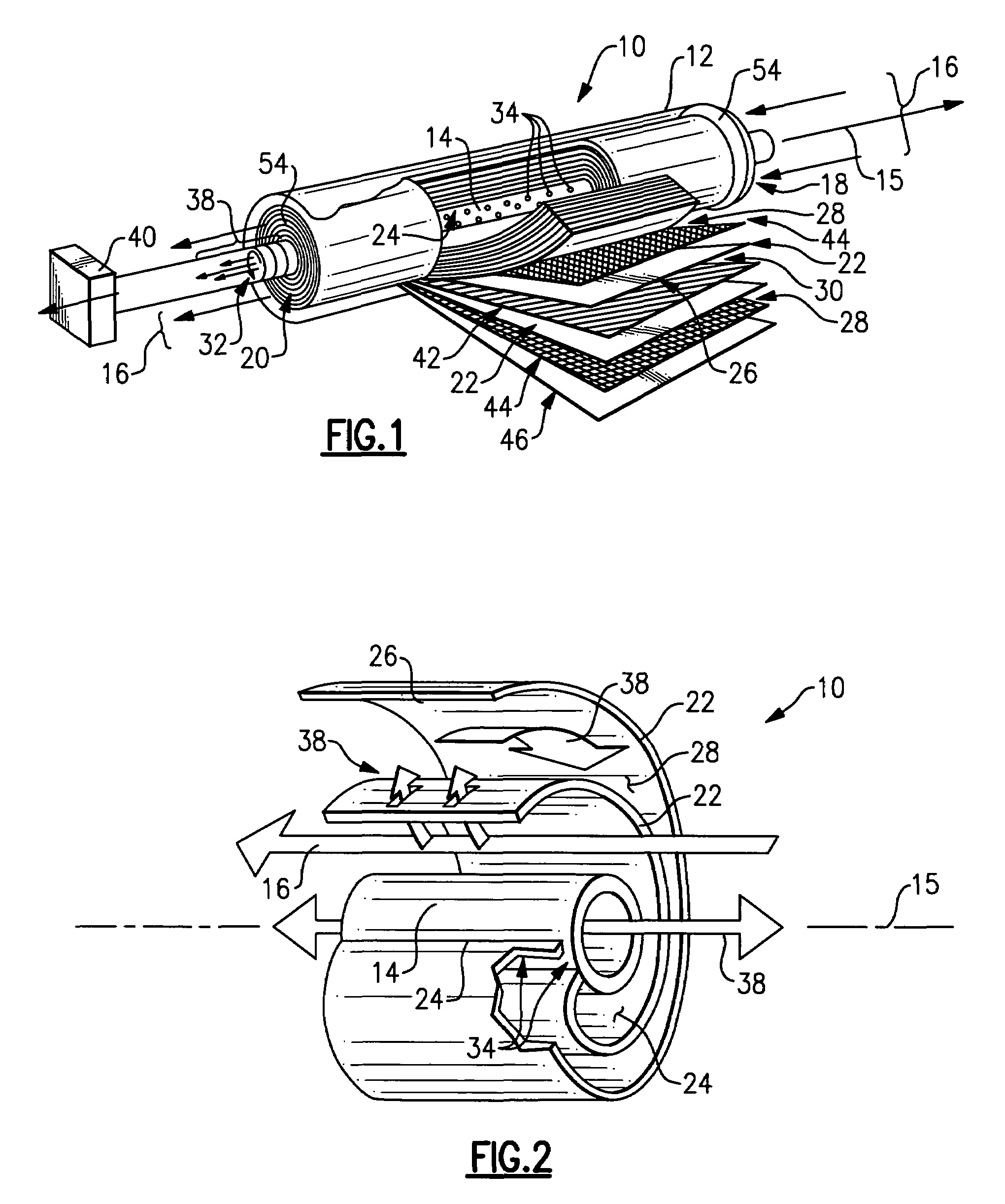

Spiral wound fuel stabilization unit for fuel de-oxygenation

ActiveUS7393388B2Increase the use of spaceReduce weightSemi-permeable membranesFuel tank safety measuresSpiral woundEnvironmental engineering

A deoxygenator includes a plurality of permeable membranes spirally wound about an exhaust tube for removing dissolved oxygen from a hydrocarbon fuel. The permeable membrane is spirally wrapped about the exhaust tube and defines fuel passages and exhaust passages. The fuel passages and exhaust passages alternate such that each fuel passage is bounded on each adjacent side by an exhaust passage. An oxygen partial pressure differential is generated across the permeable membrane to draw dissolved oxygen from fuel in the fuel passage. The dissolved oxygen is then communicated through openings about the circumference of the exhaust tube and out the deoxygenator.

Owner:MEMBRANE TECH & RES +1

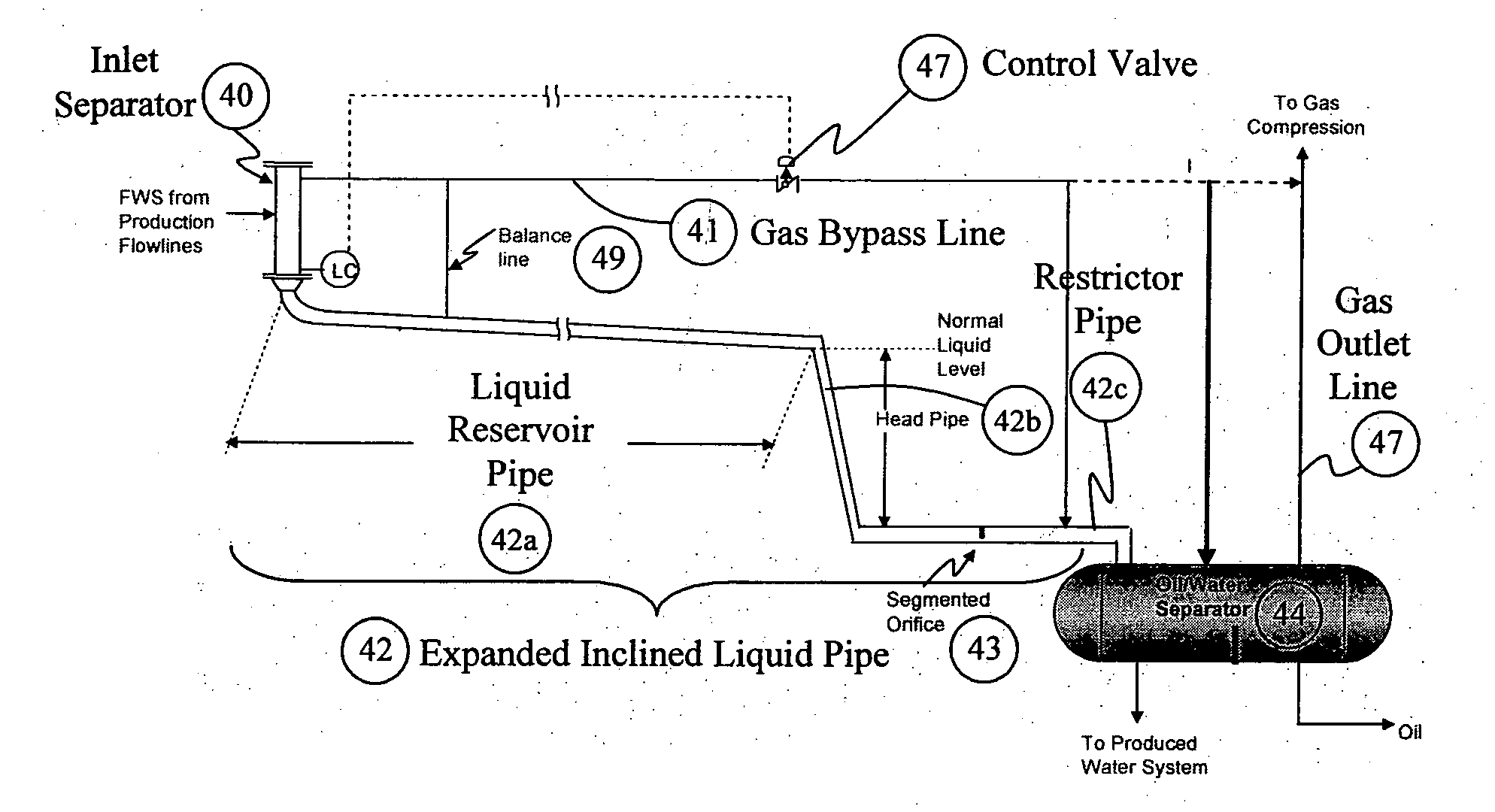

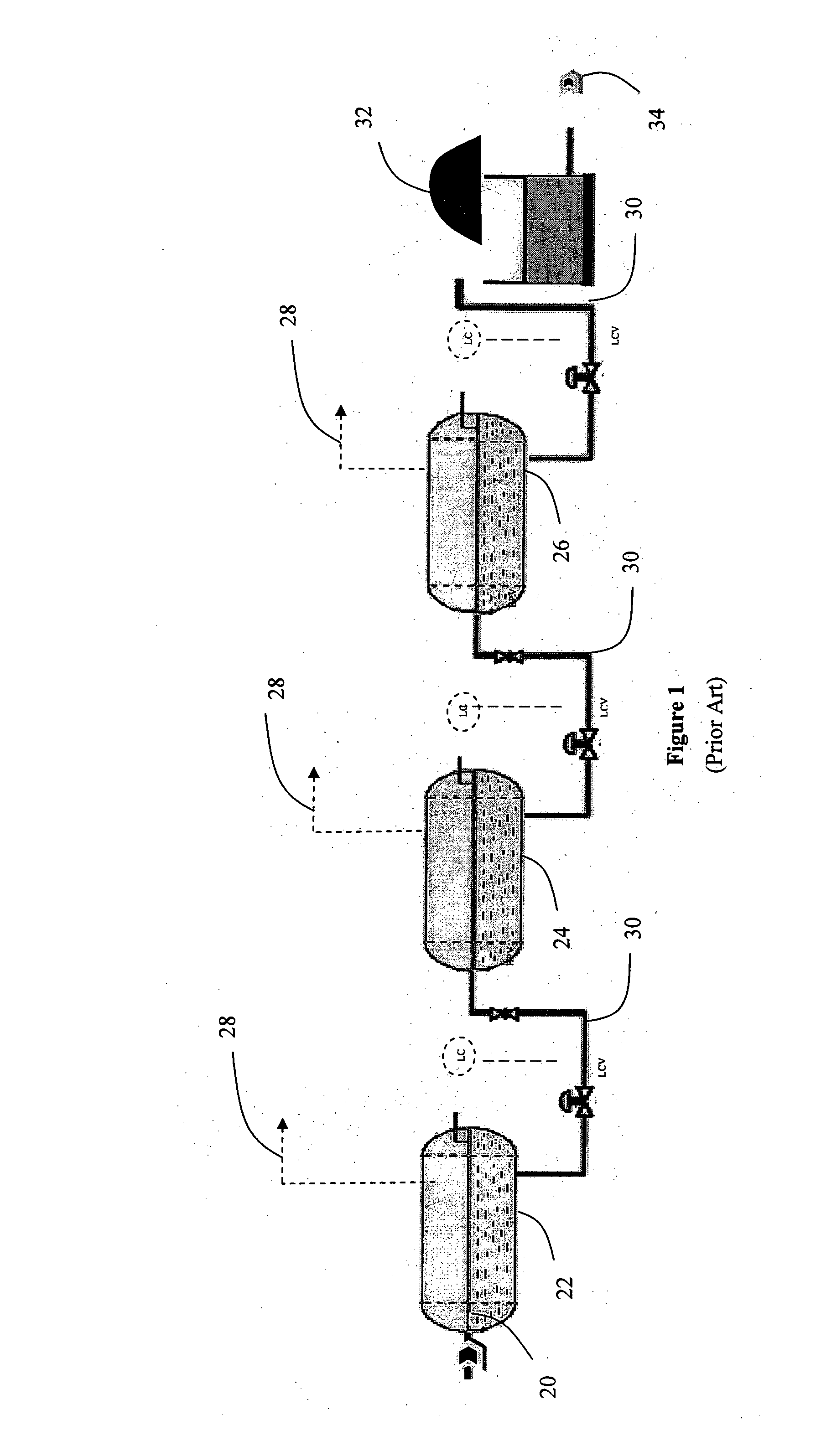

Slug Suppressor Apparatus and Crude Oil Stabilization Assembly and Process Therefor

InactiveUS20120160103A1Effective functionMinimal controlLiquid degasification regulation/controlFlash degasificationEngineeringSuppressor

A slug suppressor apparatus comprising an inlet separator capable of gas-liquid separation of full well stream fluid and expanded inclined liquid pipe for dampening slugs. The inlet separator has an inlet for receiving the full well stream fluid, a separated gas outlet in its upper section, and a separated liquid outlet in its lower section. The separated gas outlet and the separated outlet are operationally connected to a gas bypass line and the expanded inclined liquid pipe respectively. The expanded inclined liquid pipe has means for dampening liquid slugs and is connectable to a 3-Phase separator.

Owner:NGLTECH

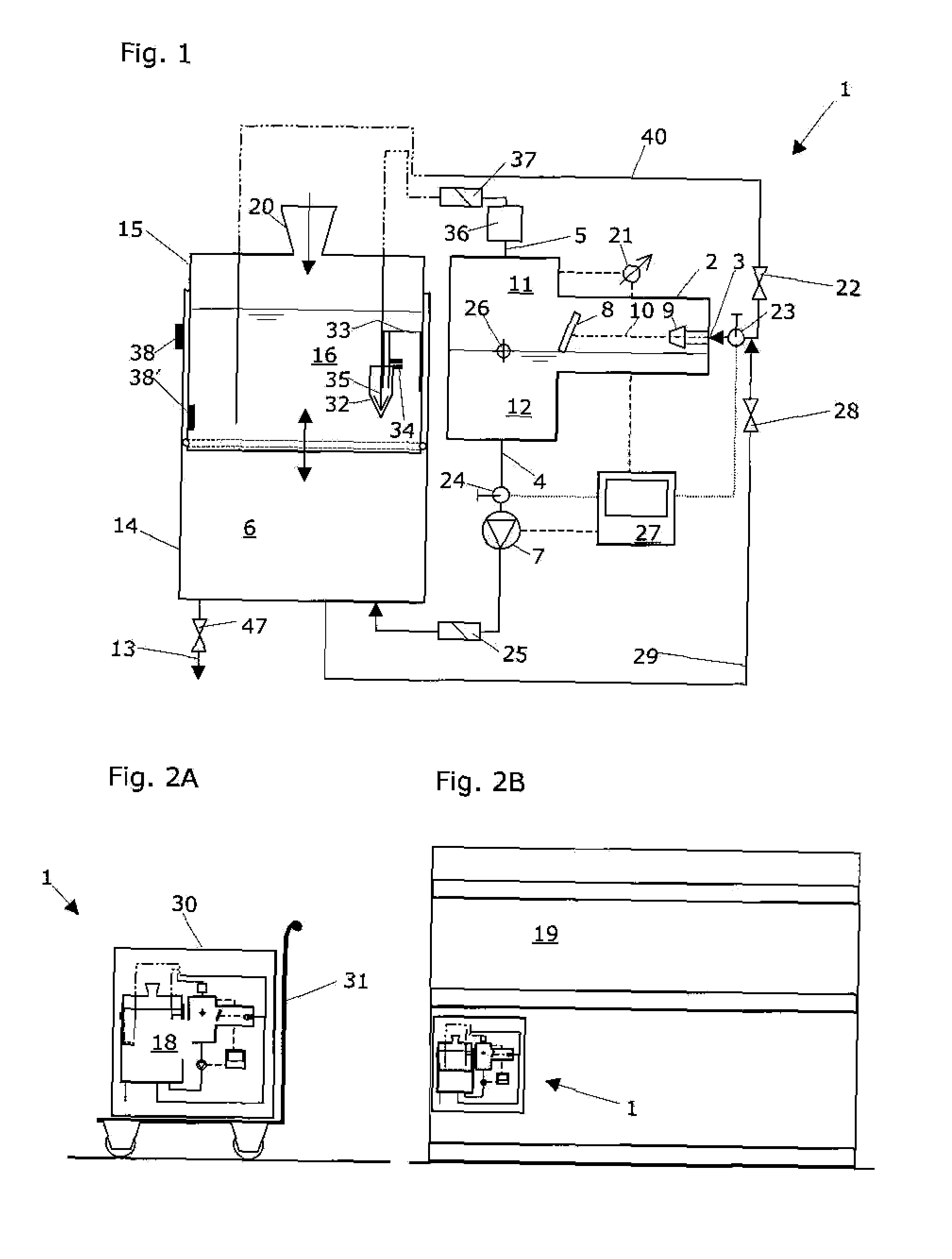

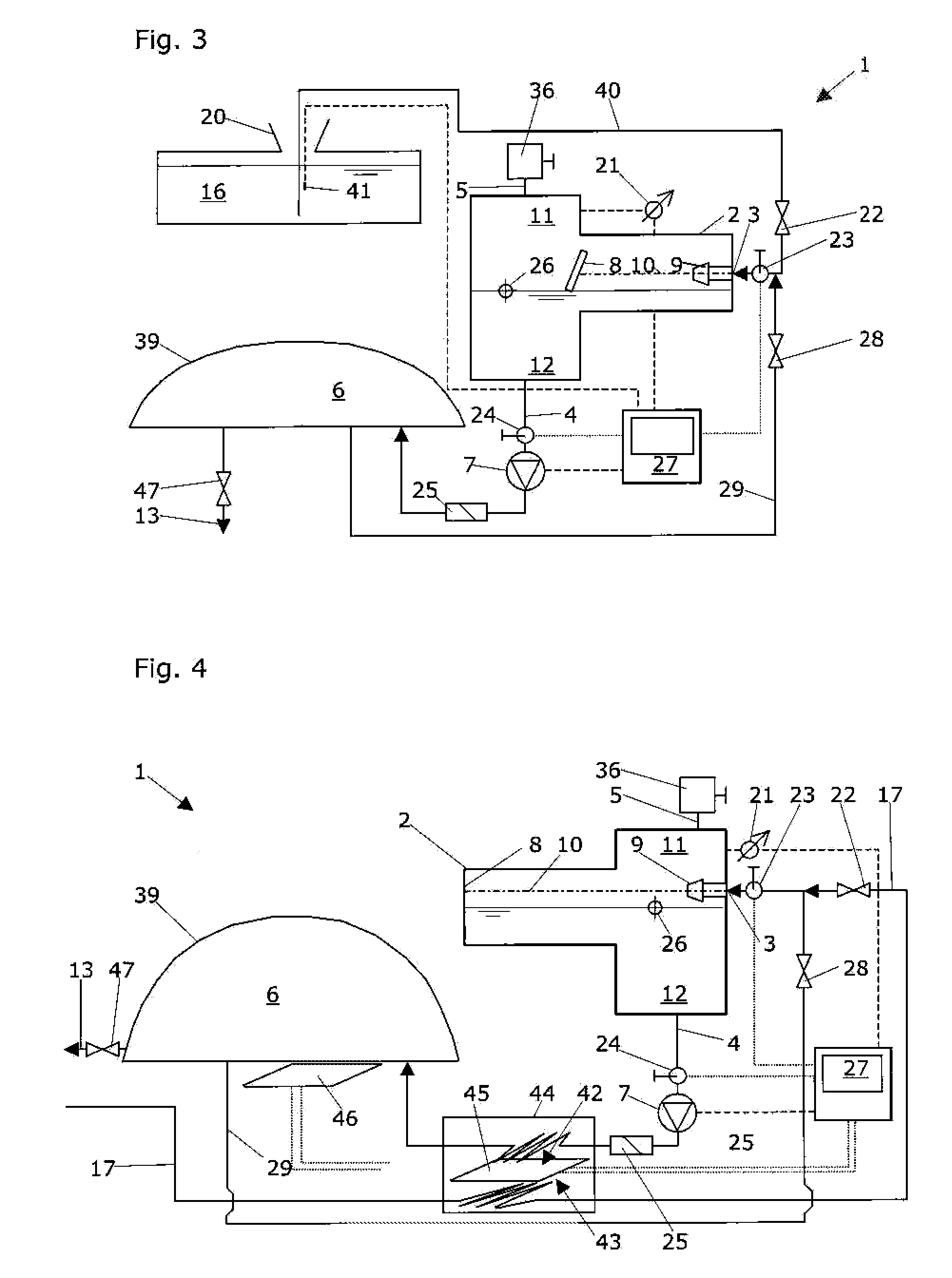

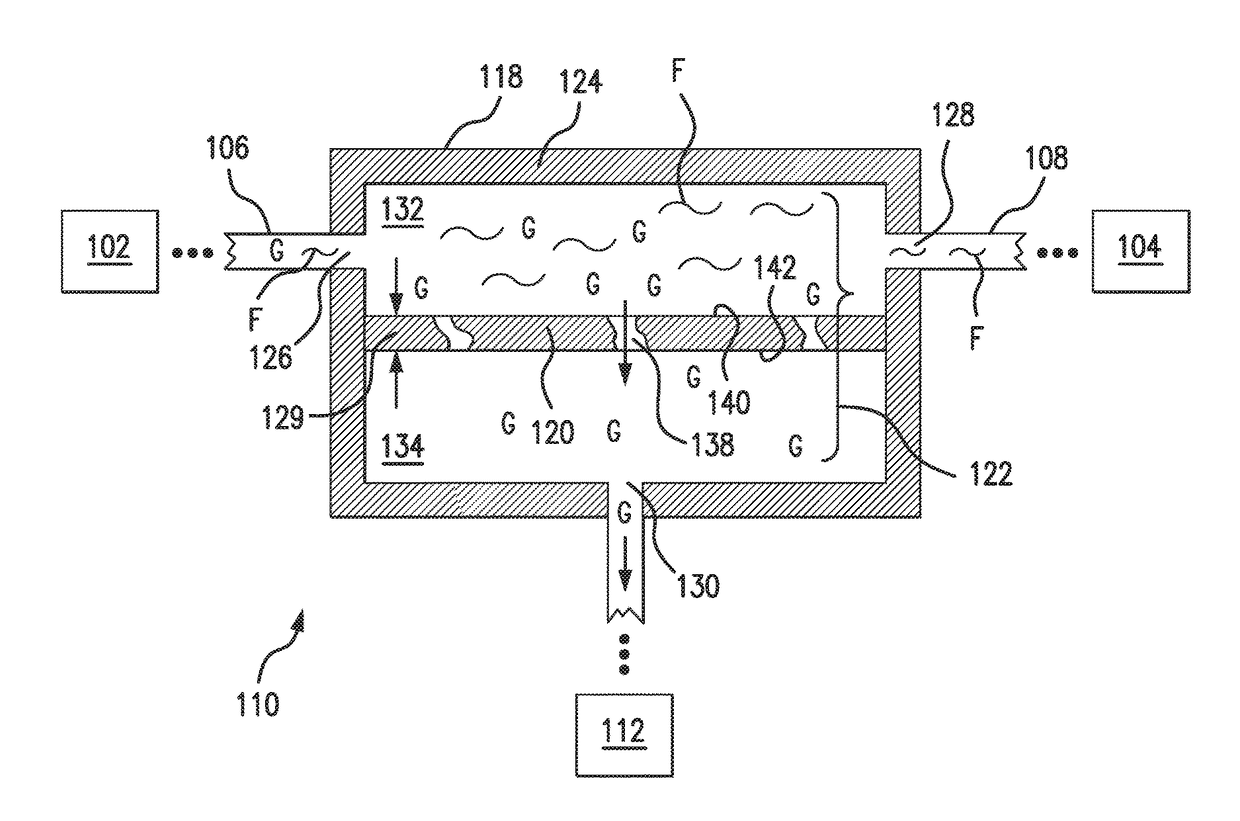

Conditioning device for liquid handling system liquids

InactiveUS20070140916A1Analysis using chemical indicatorsLiquid degasification regulation/controlLine tubingEngineering

A device for conditioning a system liquid for a liquid handling apparatus has a degassing chamber for degassing the system liquid, with a system liquid injection point, a system liquid drain line and a gas train line. The device has a collection chamber for degassing liquid, which is separated from the degassing chamber and is connected via a recirculation pump to the system liquid drain line. At least one such device can be integrated into a mobile facility for conditioning a system liquid for a liquid handling apparatus. A liquid handling workstation having at least one such liquid handling apparatus for pipetting or dispensing liquid samples with the aid of a system liquid or such a liquid handling apparatus may also comprise at least one such device.

Owner:TECAN TRADING AG

Liquid-dissolved gas separators

Owner:HAMILTON SUNDSTRAND CORP

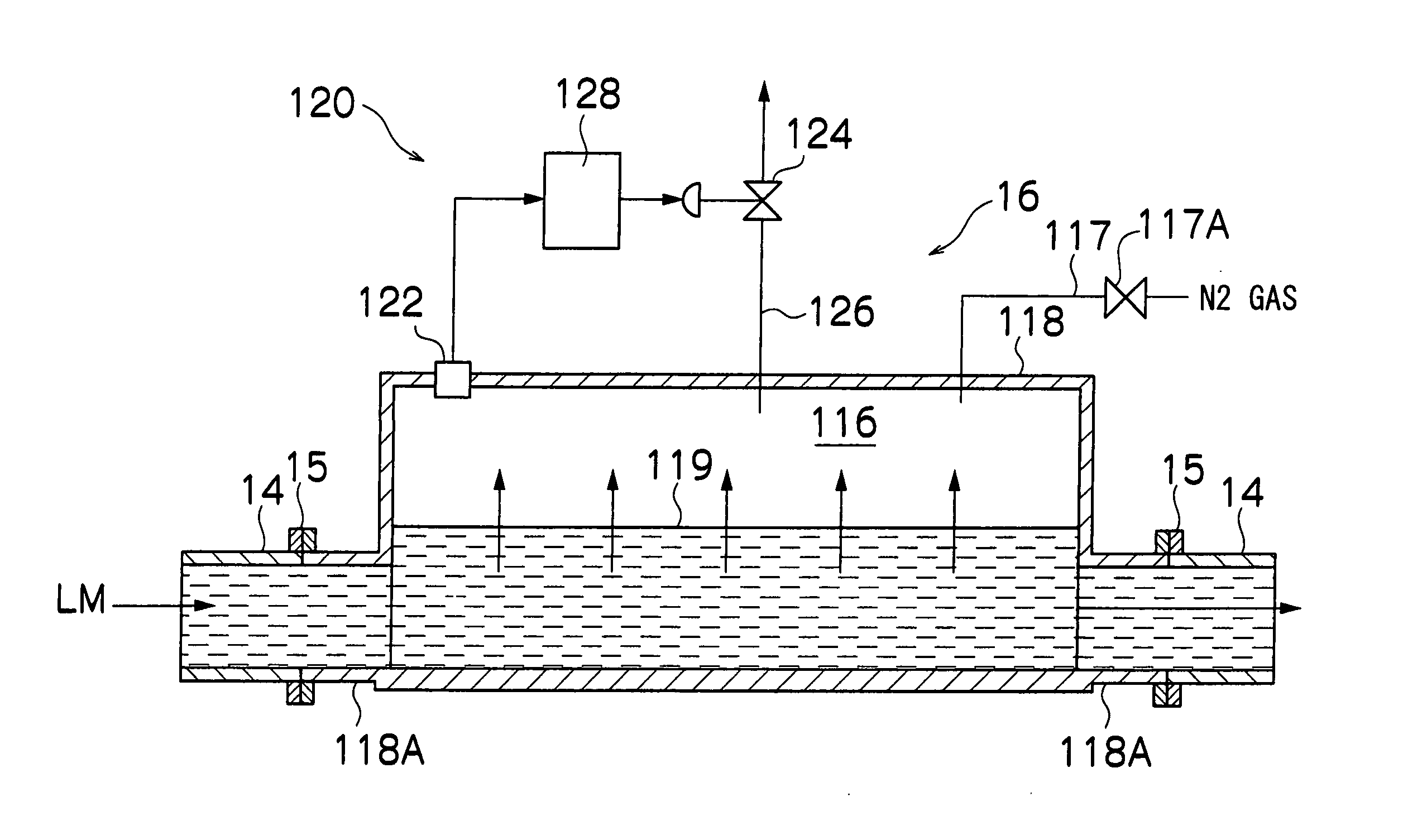

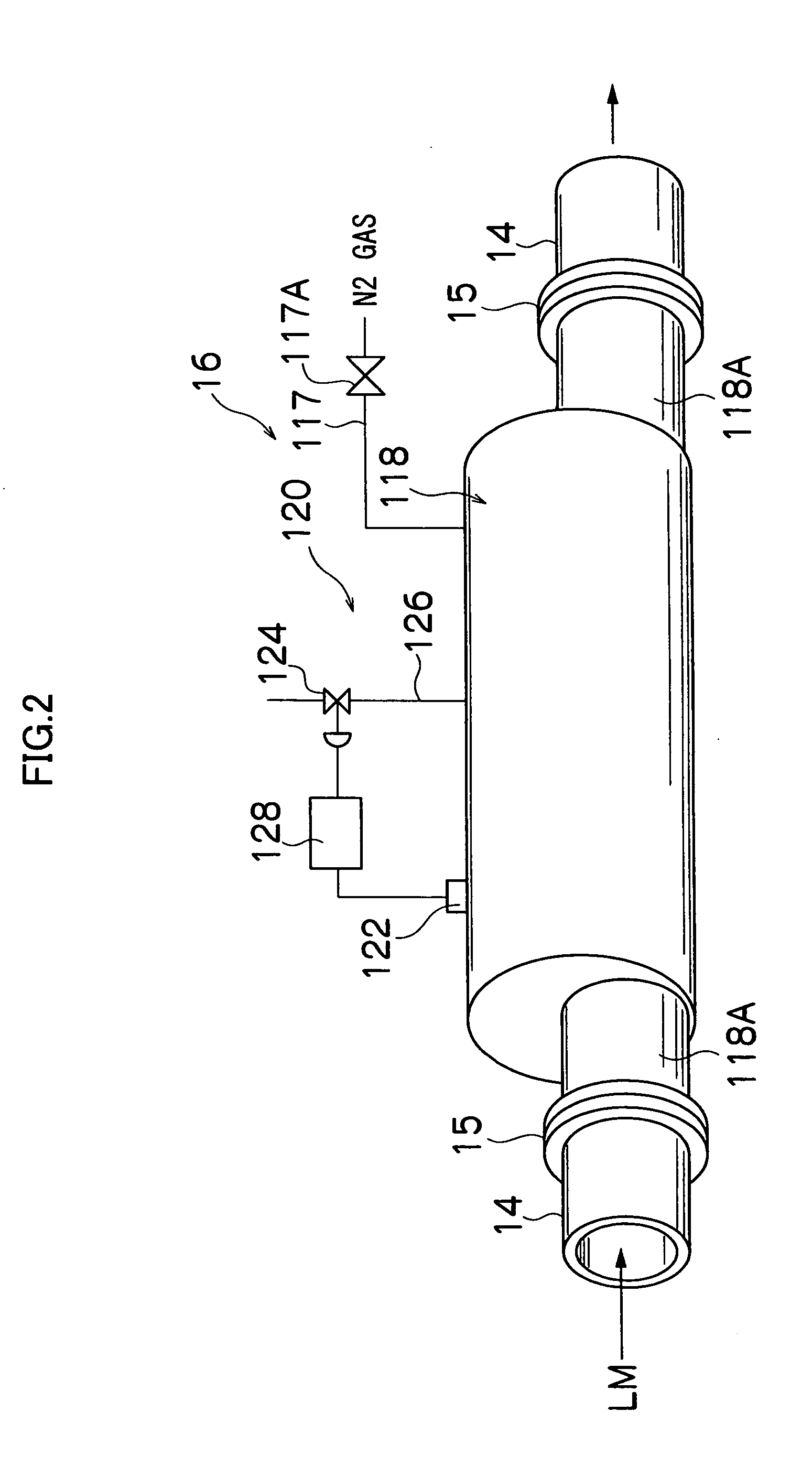

Gas-liquid separation method and unit

InactiveUS20050109211A1Small particle sizePreferable monodispersibilityDispersed particle filtrationFlash degasificationAir liquid interfaceChemistry

When a reaction liquid is passed through a gas-liquid separation pipe having a larger volume per unit length than the volume per unit length of a pipe, a headspace part into which gas can be released is formed above the gas-liquid separation pipe, and the byproduct gas generated by the reaction changes into bubbles, moves upward in the reaction liquid, and is continuously released from a gas-liquid interface into the headspace part. While the gas is removed in the gas-liquid separation pipe, the pressure of the headspace part is controlled so as to be constant by a pressure adjustment device.

Owner:FUJIFILM CORP +1

Axial transfer line degassing

Owner:IDEX HEALTH & SCI

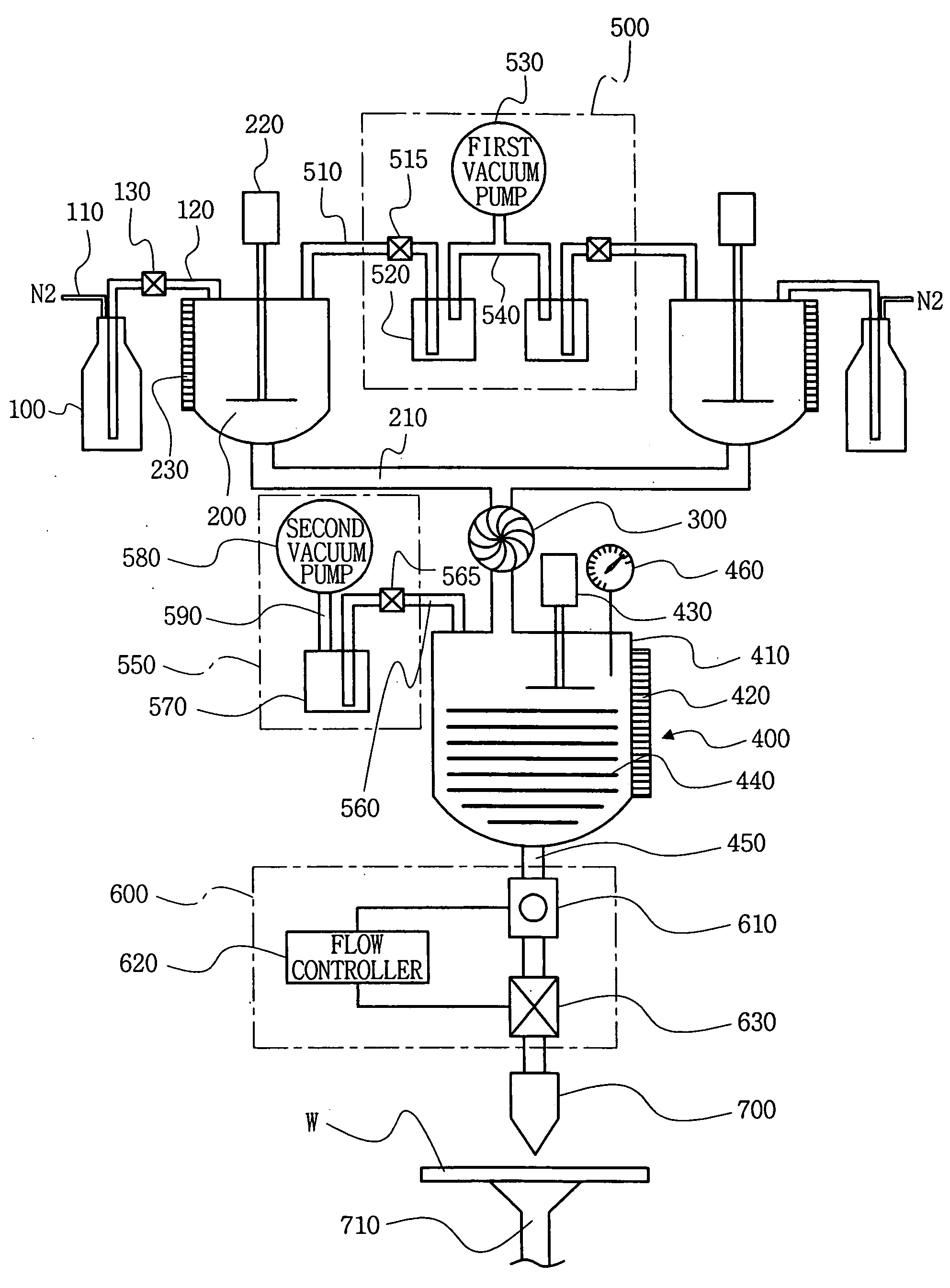

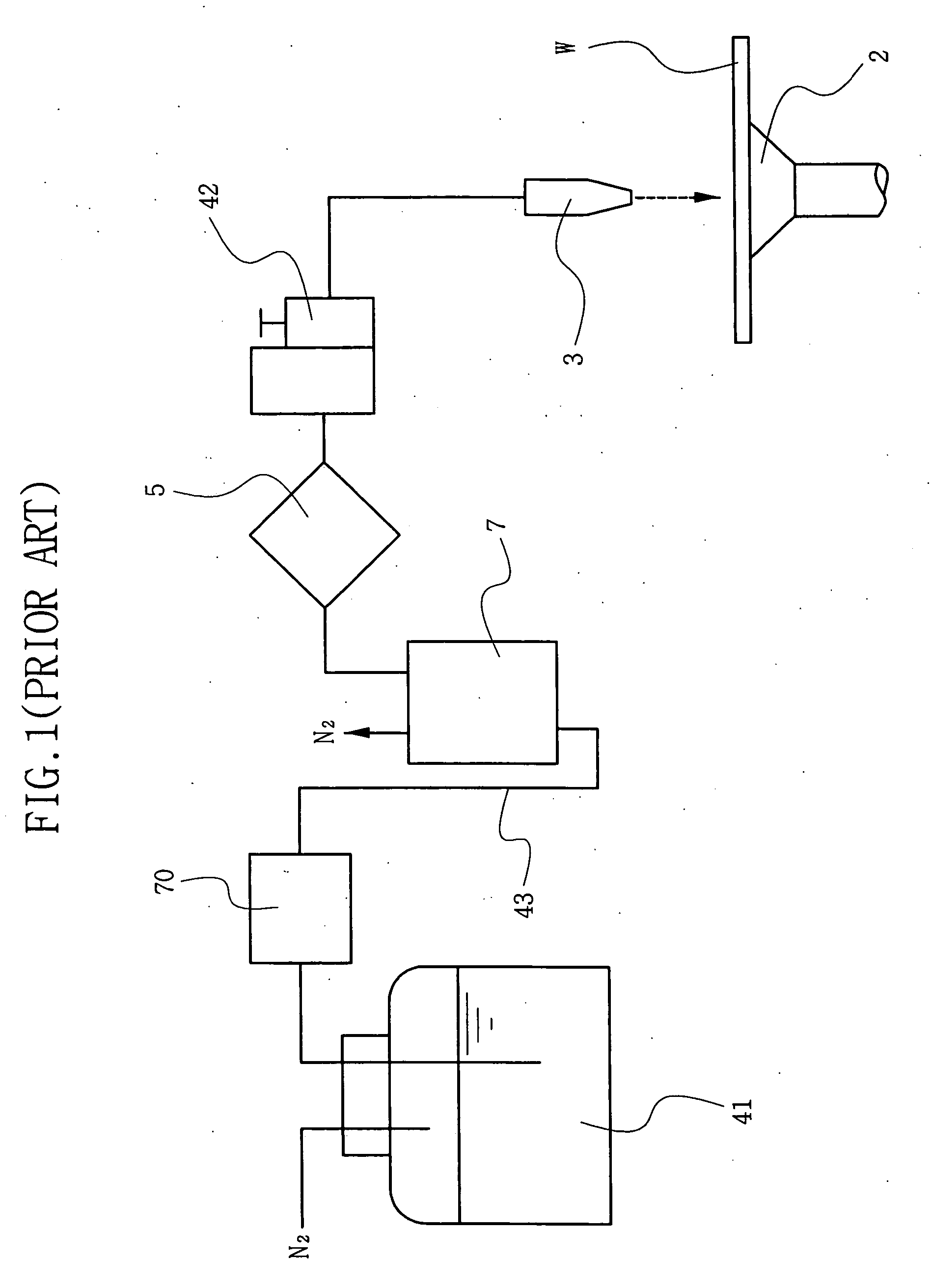

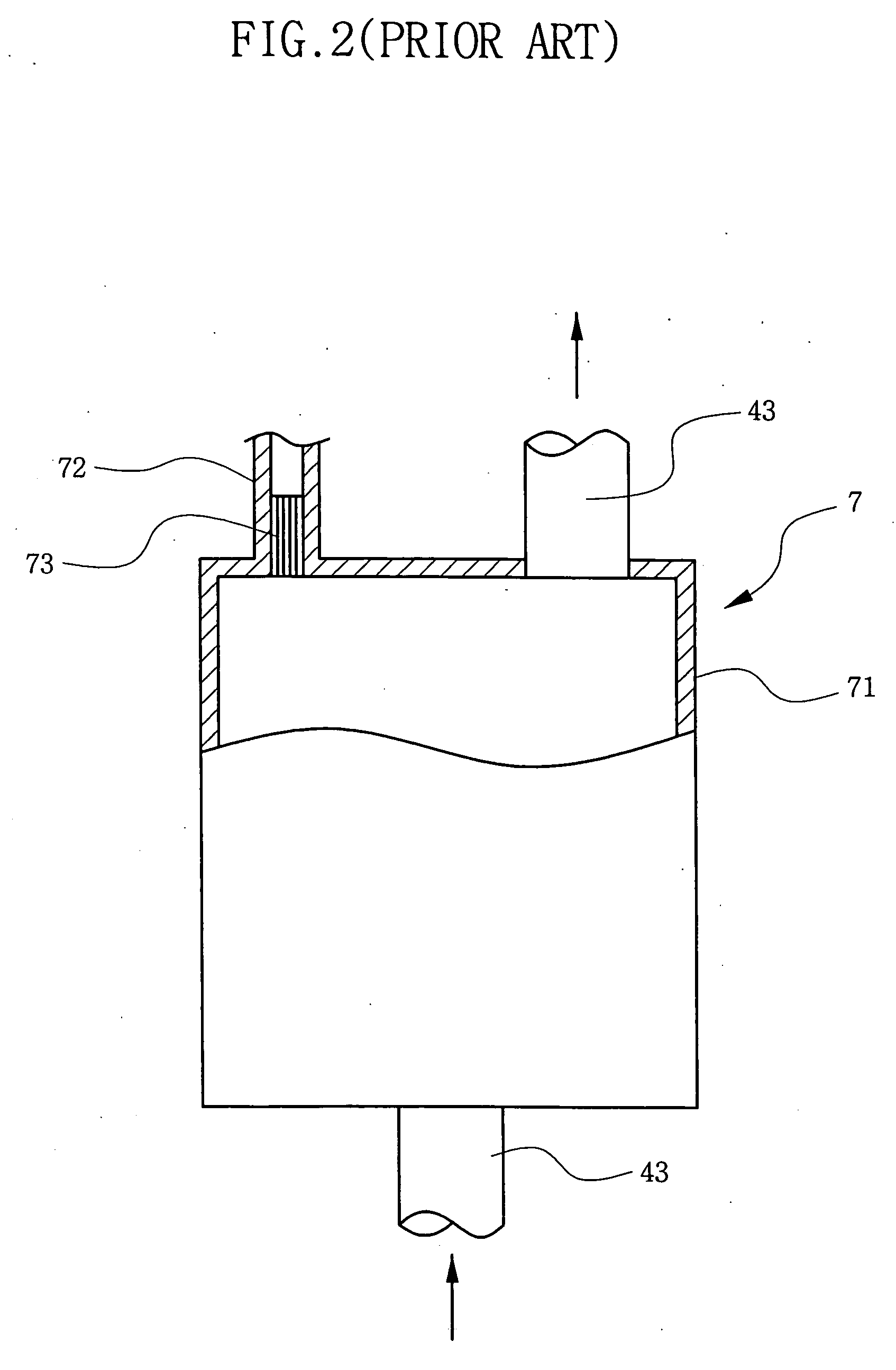

Apparatus for dispensing photo-resist in semiconductor device fabrication equipment

ActiveUS20070119307A1Increase and maximize productive yieldImprove reliabilityLiquid surface applicatorsUsing liquid separation agentResistProcess engineering

A photo-resist dispensing apparatus is disclosed and comprises; a tank adapted to hold a photo-resist solution, a pump unit adapted to pump the photo-resist solution from the tank, a filter unit adapted to receive the photo-resist solution from the pump unit, and at least one of a first gas discharge unit connected to the tank and adapted to remove gas bubbles from the photo-resist solution held in the tank, and a second gas discharge unit connected to the filter unit and adapted to remove gas bubbles from the photo-resist solution in the filter.

Owner:SAMSUNG ELECTRONICS CO LTD

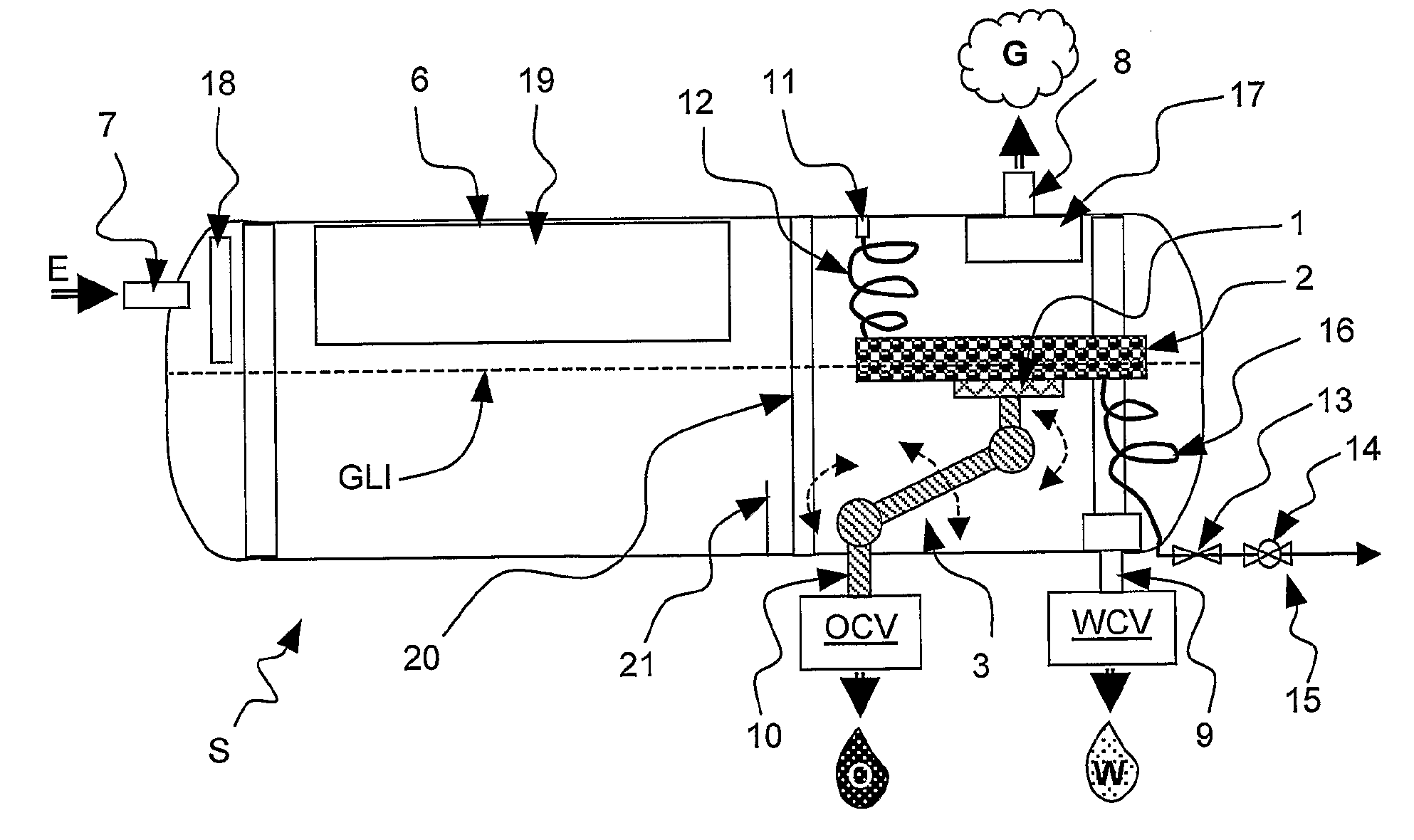

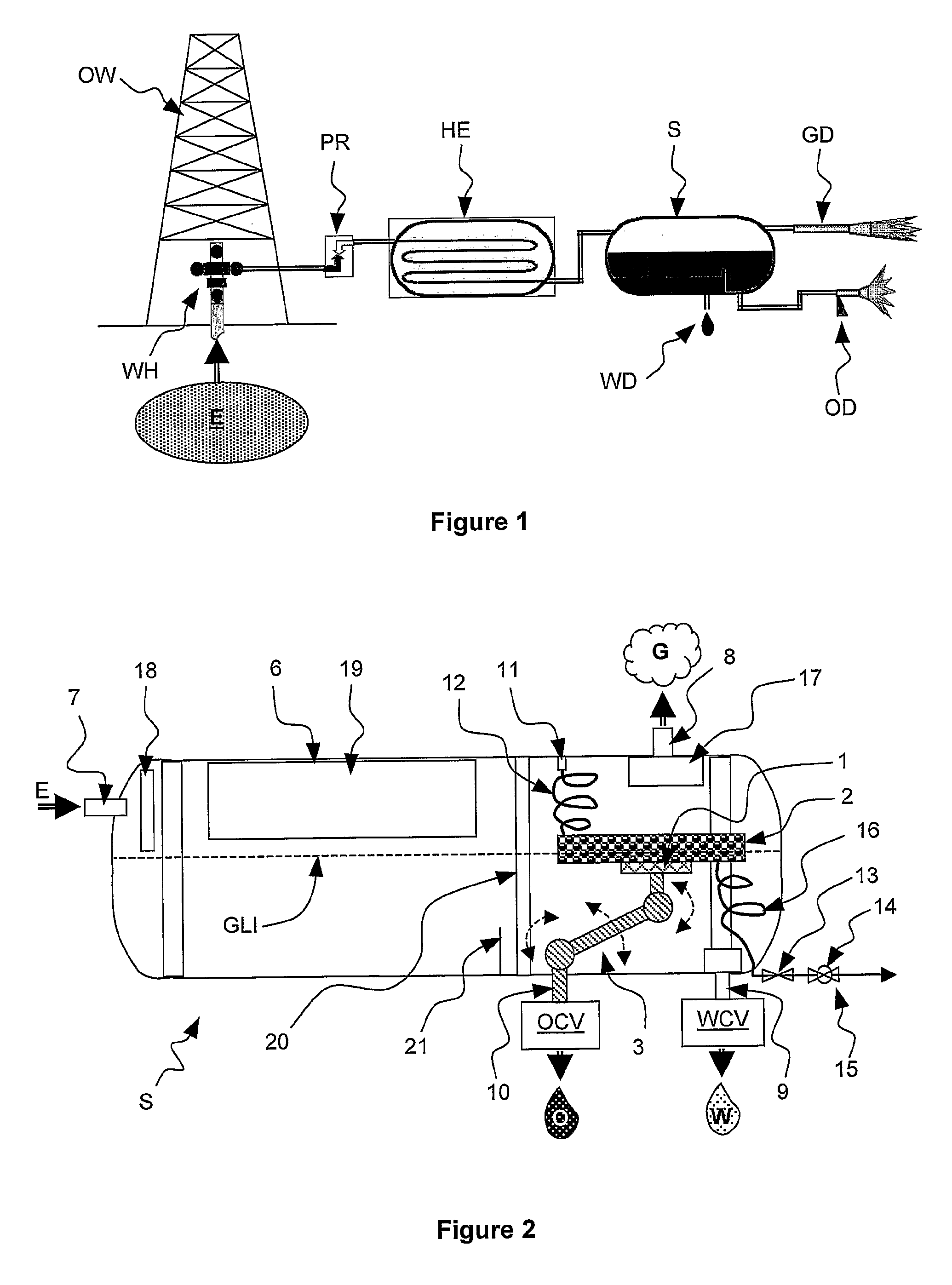

Gravity Separator For A Multi-Phase Effluent

InactiveUS20080105616A1Easy to adjustEasy maintenanceLiquid displacementFlash degasificationGas phaseWastewater

A gravity separator S separates a liquid phase O and a gas phase G from a multiphase fluid mixture E. The gravity separator comprises a collector 1 for collecting the liquid phase O, and outlet 8 for extracting the gas phase G and a draining circuit 3 coupled to the collector 1 for draining the liquid phase O out of the separator.The gravity separator S further comprises a floating assembly 2 coupled to the collector 1. The floating assembly is arranged to float at an interface GLI between the liquid phase and the gas phase so that the collector is positioned in the multiphase fluid mixture present in the gravity separator S for collecting substantially the liquid phase O.

Owner:SCHLUMBERGER TECH CORP

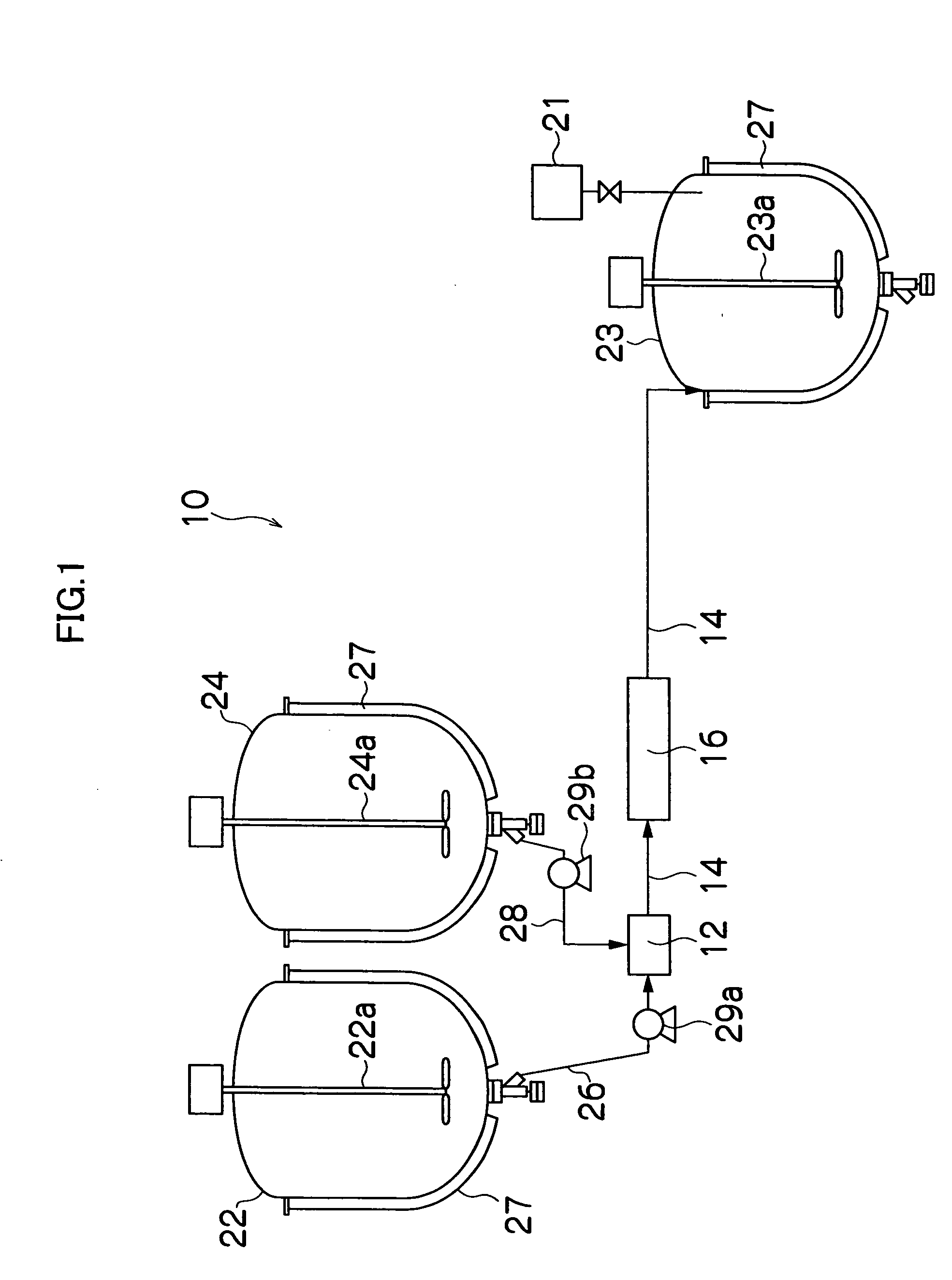

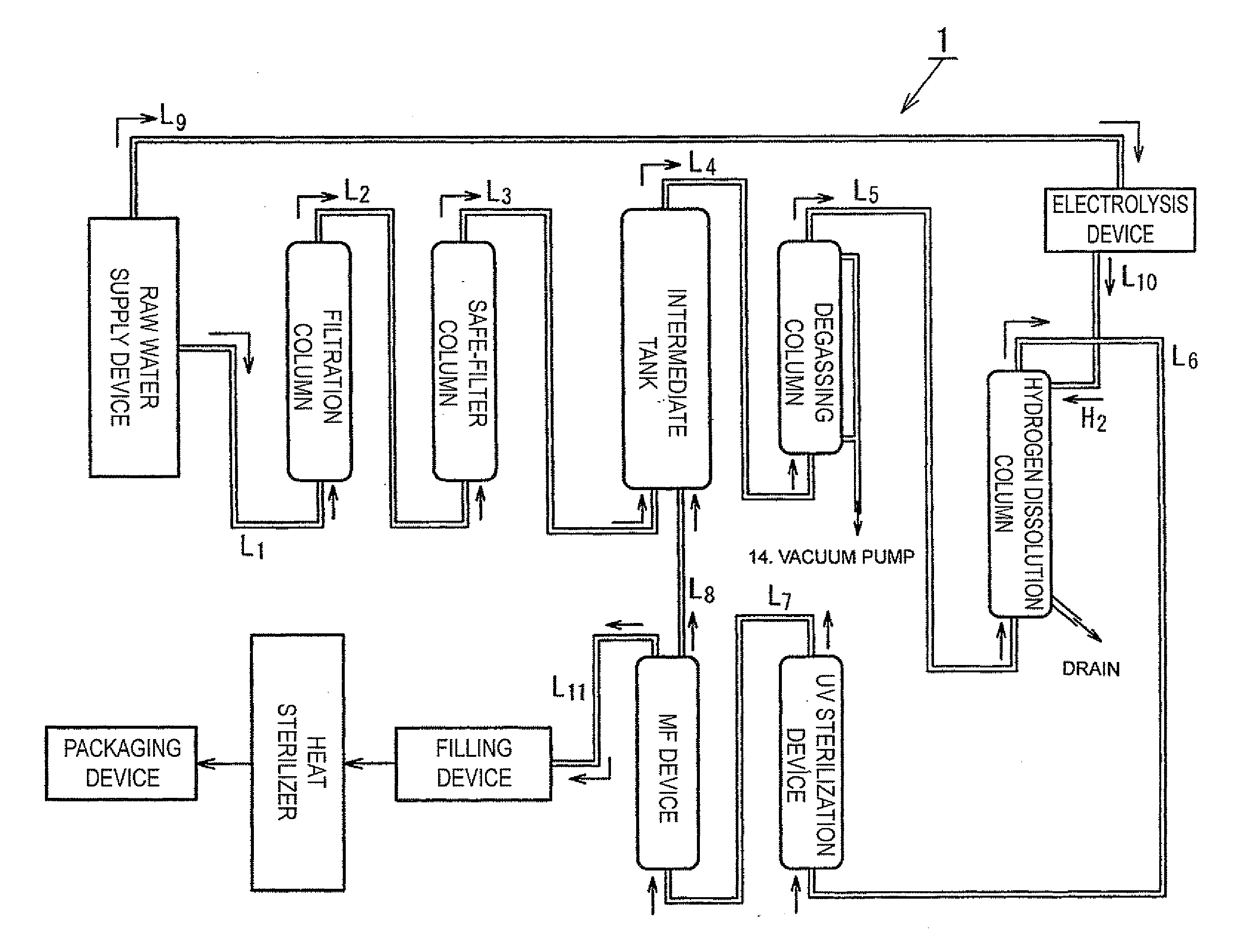

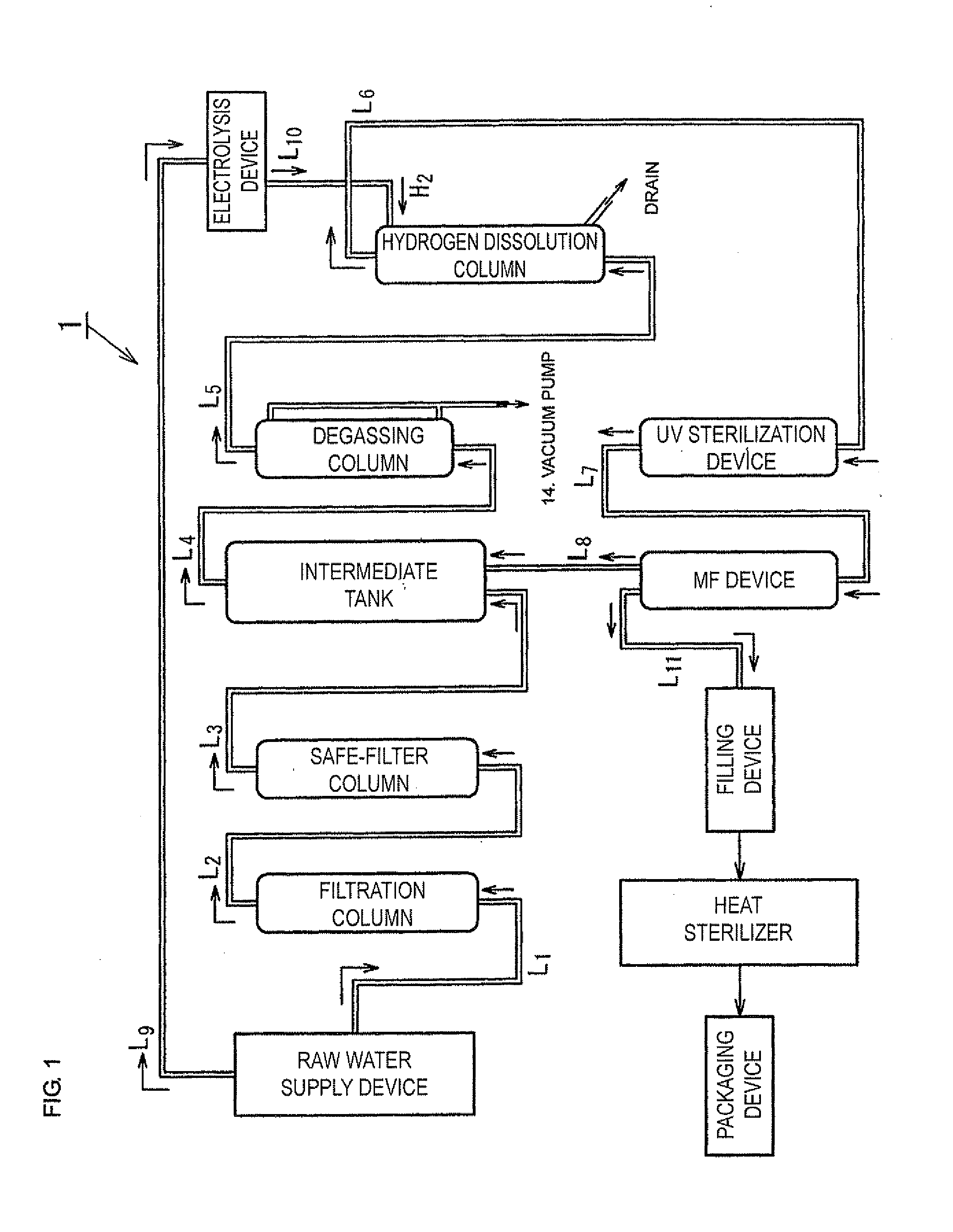

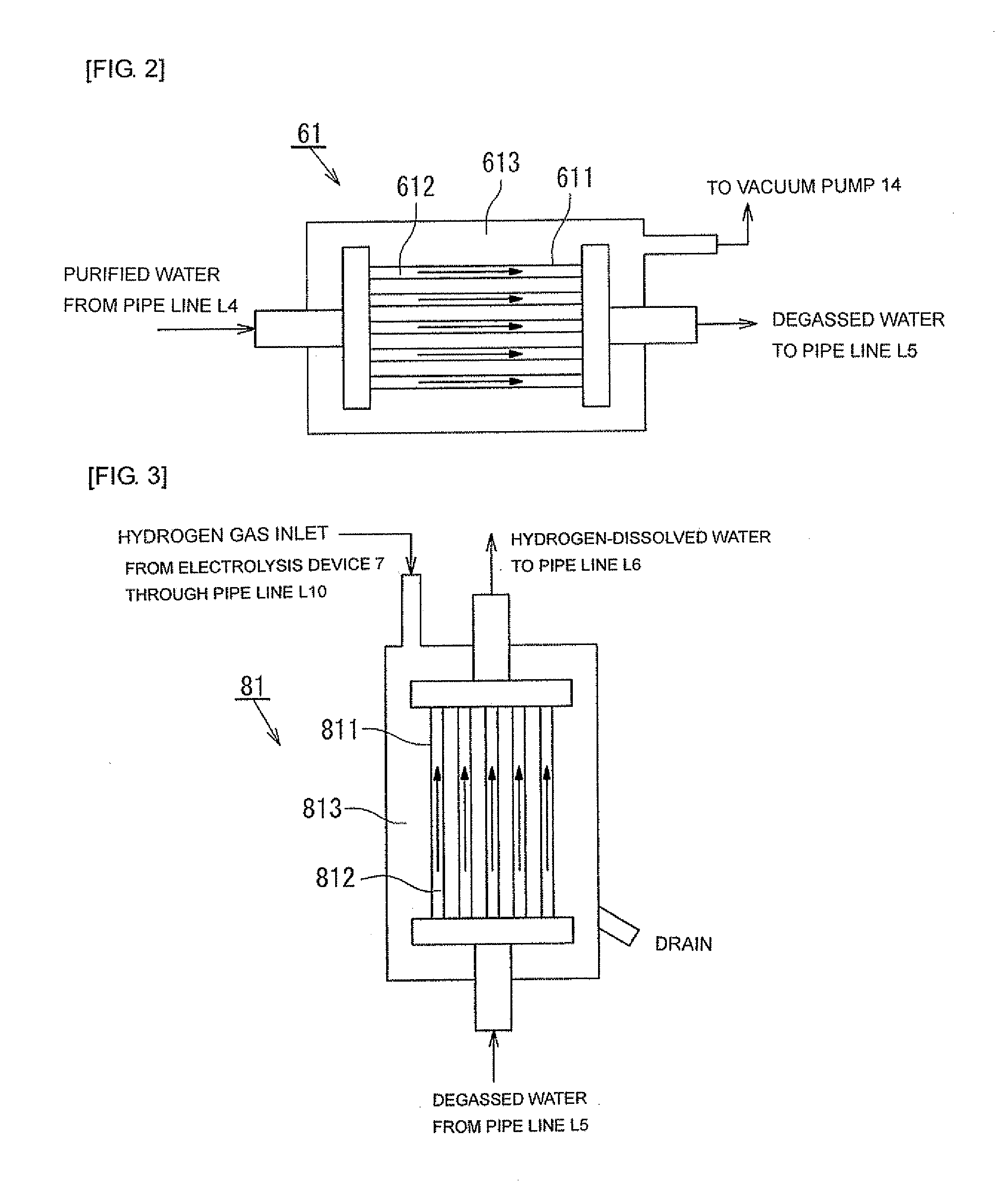

Process for producing hydrogen-containing water for drinking

InactiveUS20120070540A1Efficiently dissolving hydrogenEffective dissolutionFlow mixersLiquid degasification by filtrationDegasserDissolution

There is provided a process for producing hydrogen-containing water for drinking, by which the dissolved hydrogen concentration of the obtained hydrogen water can be more efficiently increased. A process for continuously producing hydrogen-containing water for drinking, comprising (a) a purifying step of filtering and purifying water as a raw material; (b) a degassing step of degassing the purified water supplied to a degasser; (c) a hydrogen-dissolving step of dissolving hydrogen gas in the degassed water supplied to a hydrogen dissolution device; (d) a sterilizing step of sterilizing the hydrogen-dissolved water supplied to a sterilizer; (e) a filling step of filling the hydrogen-containing water supplied to a filling device in a sealed container and transferring the filled water product to a heat sterilizer; and (f) a heat-sterilizing step of heat-sterilizing the water product supplied to the heat sterilizer, wherein part of the hydrogen-containing water obtained in the step (d) is returned to the degasser in the step (b) and the water is circulated through the steps (b) to (d).

Owner:SHEFCO

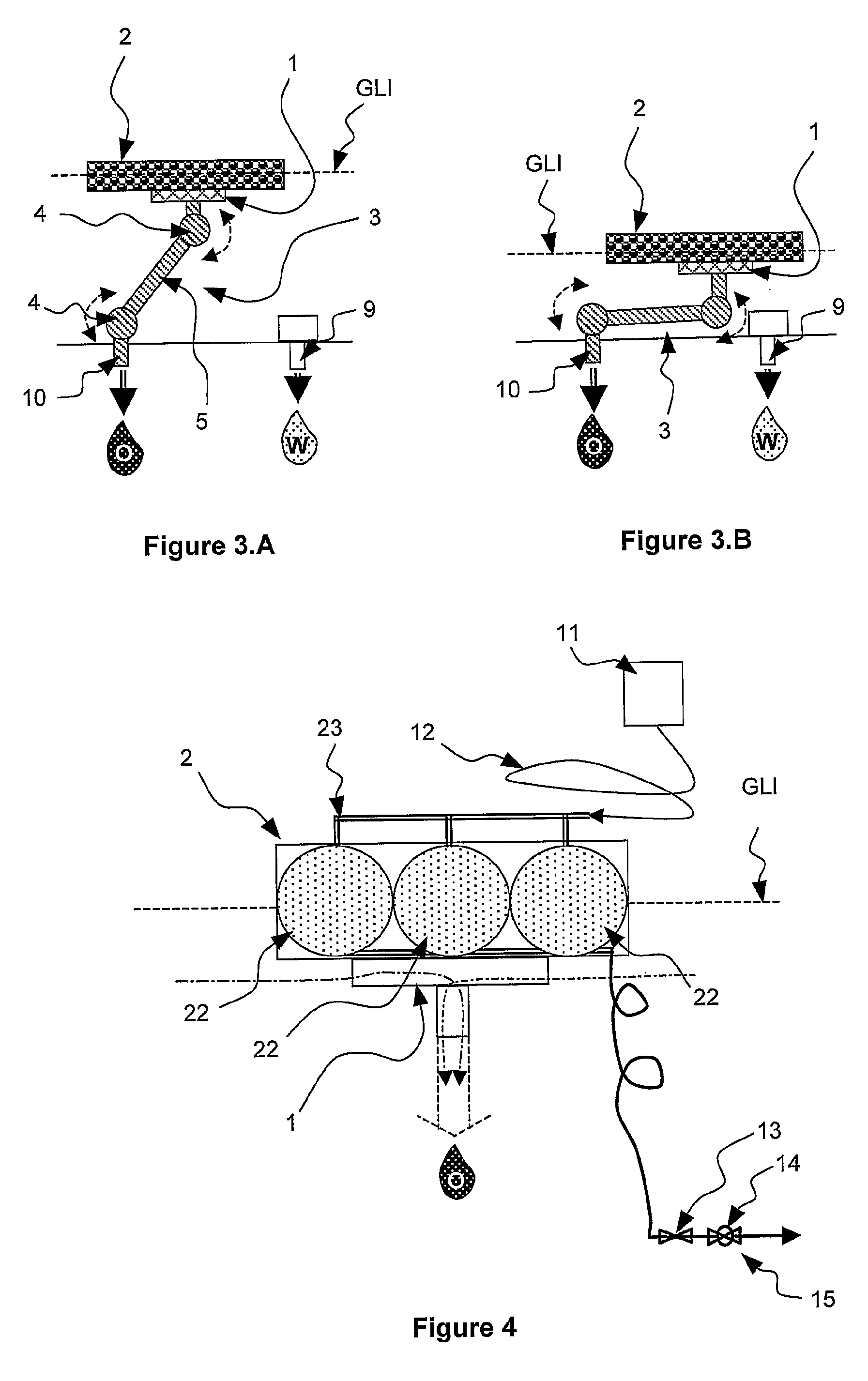

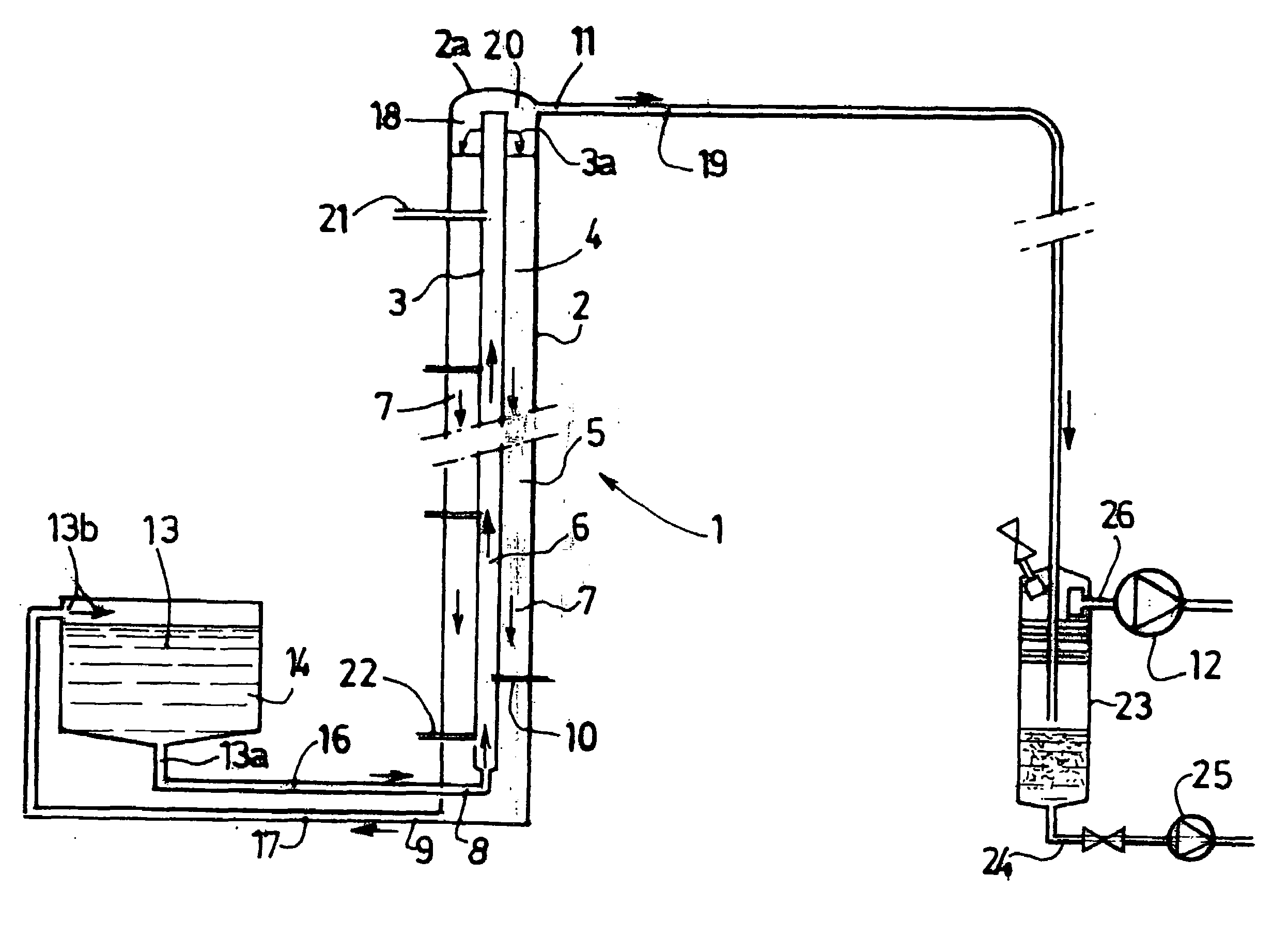

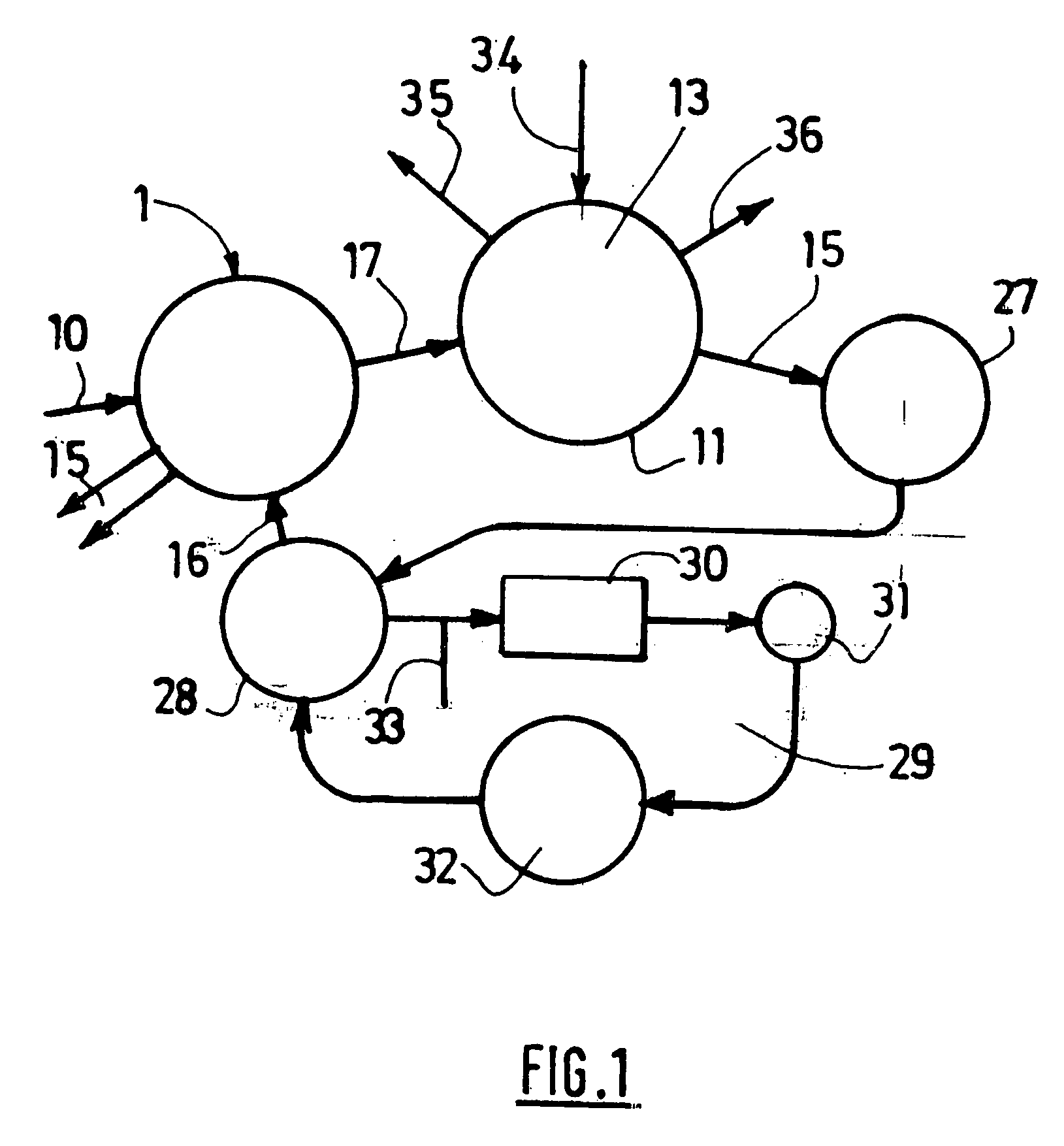

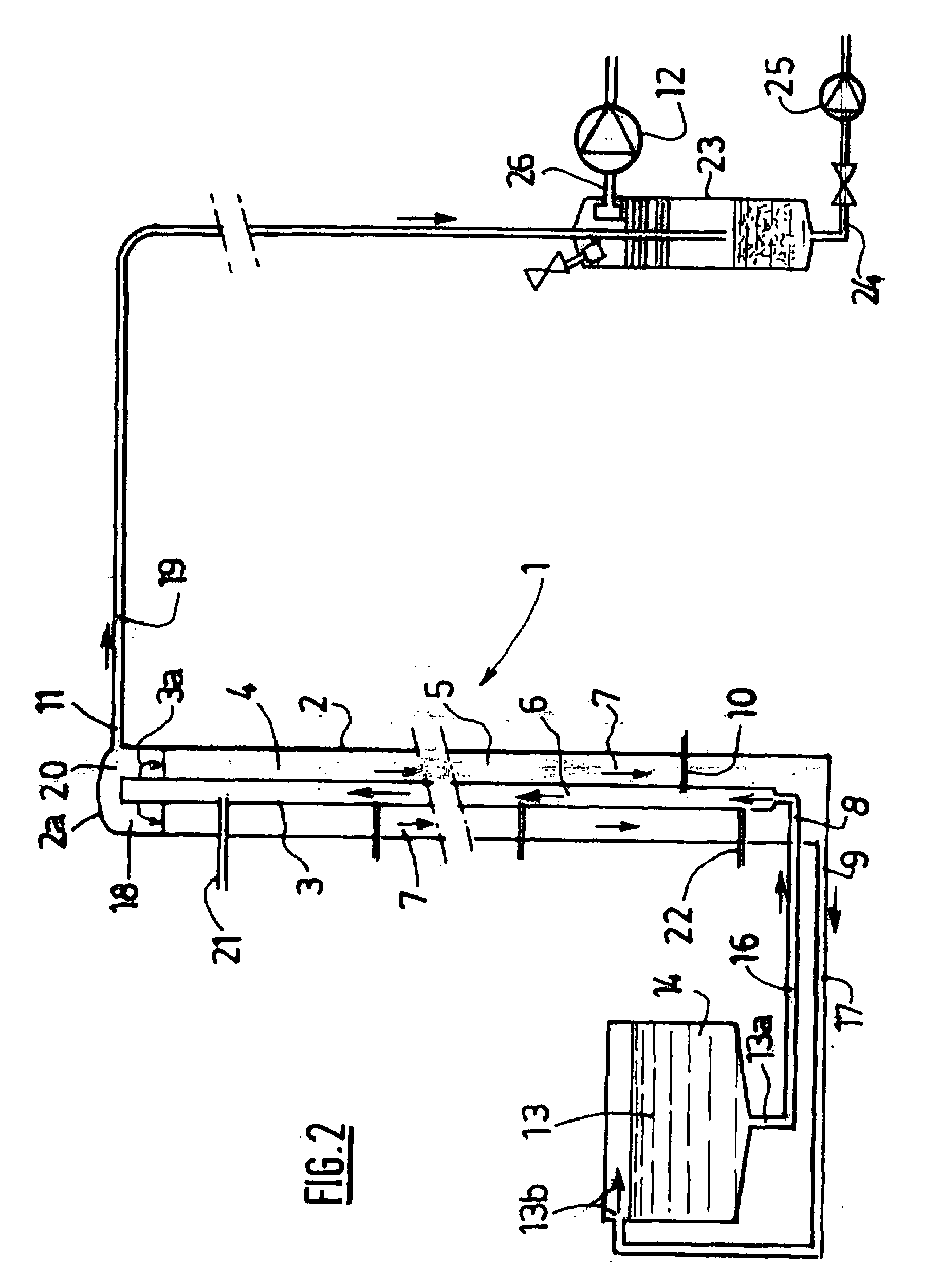

Method and installation for treating an aqueous effluent, in order to extract at least one dissolved gaseous compound; application to aquaculture in recirculated aqueous medium

ActiveUS20080011679A1Improve dissolved gas extraction yieldAlgae productsMicroorganismsGas phaseAquatic product

The present invention relates to a method for treating an aqueous effluent comprising at least one dissolved gaseous compound, for example carbon dioxide, consisting in at least partially separating said compound from said effluent, in order to obtain a treated aqueous phase, depleted of said compound, a method according to which:(a) an upflow liquid column of the aqueous effluent is established, by injecting and distributing into said column, at the bottom, a gas phase less rich in said compound than the aqueous effluent, for example air or oxygen, said gas phase being distributed in said column in the form of bubbles whereof the volume increases upward, whereby a mixed liquid / gas stream is obtained at the top,(b) the mixed liquid / gas stream is separated into a liquid stream constituting the treated aqueous phase, and an offgas stream enriched with said gaseous compound,characterized in that the mixed liquid / gas stream is separated under vacuum by establishing a gas headspace between the liquid stream and the gas stream, and by aspirating the latter.

Owner:INST NAT DES +1

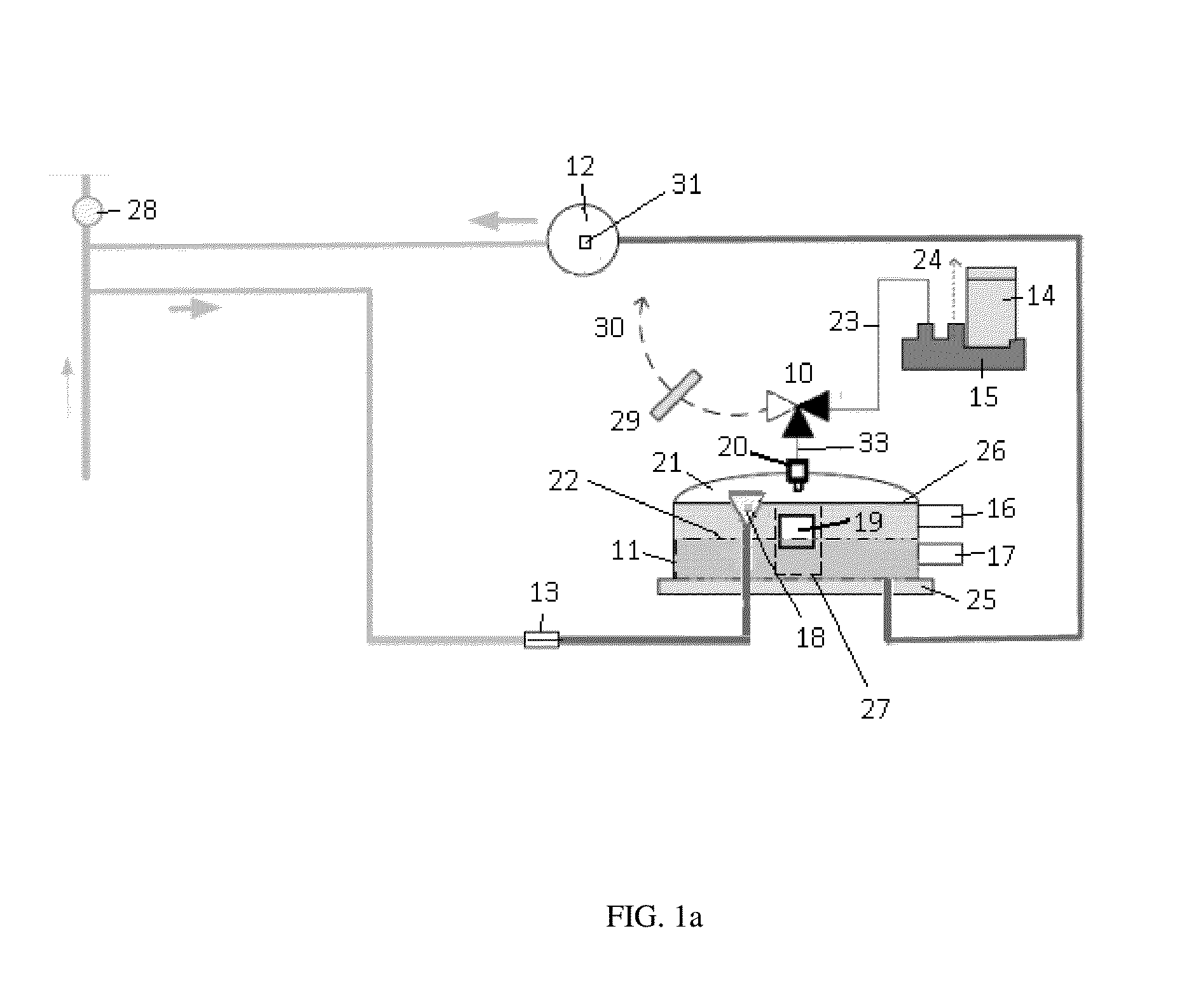

Three phase electrocoagulation effluent treatment apparatus and methods

InactiveUS20100116686A1Reduce maintenanceMeet cutting requirementsElectrolysis componentsReverse osmosisElectrocoagulationSludge

Electrocoagulation effluent treatment apparatus and methods are disclosed, the apparatus including a primary electrocoagulation reactor chamber having treatment electrodes maintained therein and an effluent inlet and treated effluent outlet. An integrated flotation chamber is located above the reaction chamber, a vacuum device connectable with a vacuum source being received in the flotation chamber and including a foam intake and an output. A sludge chamber is defined below and integrated with the primary reaction chamber and has a settled sludge output.

Owner:ROCKWATER RESOURCE

Device and Method for Degassing of Liquids

InactiveUS20140157983A1Isotope separationLiquid degasification by filtrationEngineeringElectrical and Electronics engineering

Owner:STRATEC BIOMEDICAL AG

Apparatus and method for separation of phases in a multiphase flow

InactiveCN102438758AExtended dwell timeSmall sizeWater/sewage treatment by centrifugal separationReversed direction vortexEngineeringInorganic materials

A device is disclosed for the separation of liquid-liquid phase and / or a liquid-gas phase where one or more of the phases is suspended in water and has a bubble / drop / particle size in the sub micron and micron area, and / or fine particular organic or inorganic material is present in one or more of the phases. There is also disclosed a method and a use for the device.

Owner:SORBWATER TECH AS

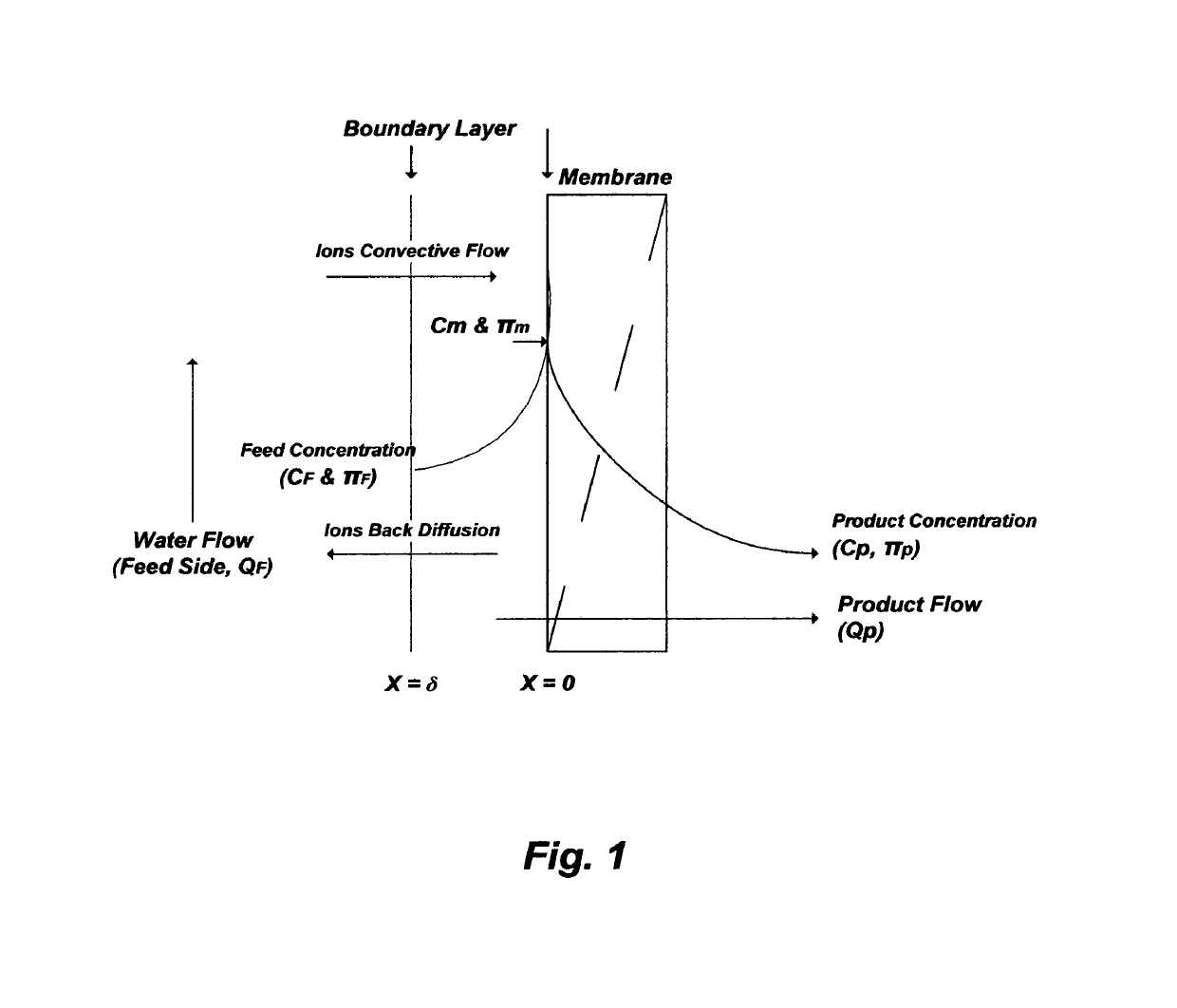

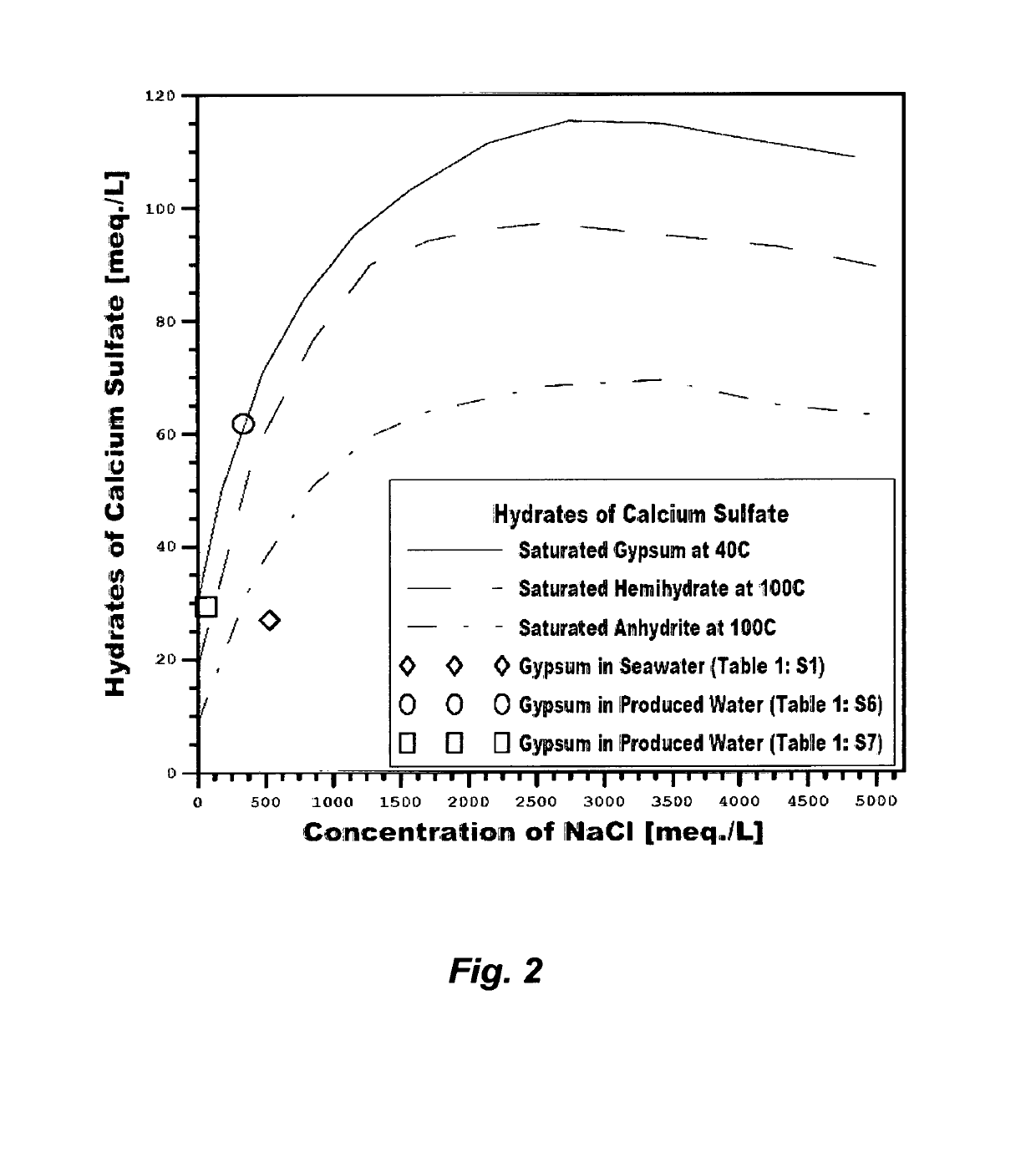

Vertical integration of source water desalination

ActiveUS10336638B1Facilitates absorbing sulfur dioxideRecover usefulGeneral water supply conservationSeawater treatmentSaline waterDesalination

There is provided herein a system and method for effectively de-scaling source water and producing useful inorganic compounds. As a result of the effective de-scaling, a much needed effective desalination system and method is also provided, which maximizes distillate production, minimizes operating costs, reduces reject brine and produces scale-depleted reject brine. Yet, as a result of the effective de-scaling, an effective flue gas scrubbing system and method is further provided, which not only aids in protecting the environment but also aids in enhancing the performance of the effective desalination system and method.

Owner:BADER MANSOUR S

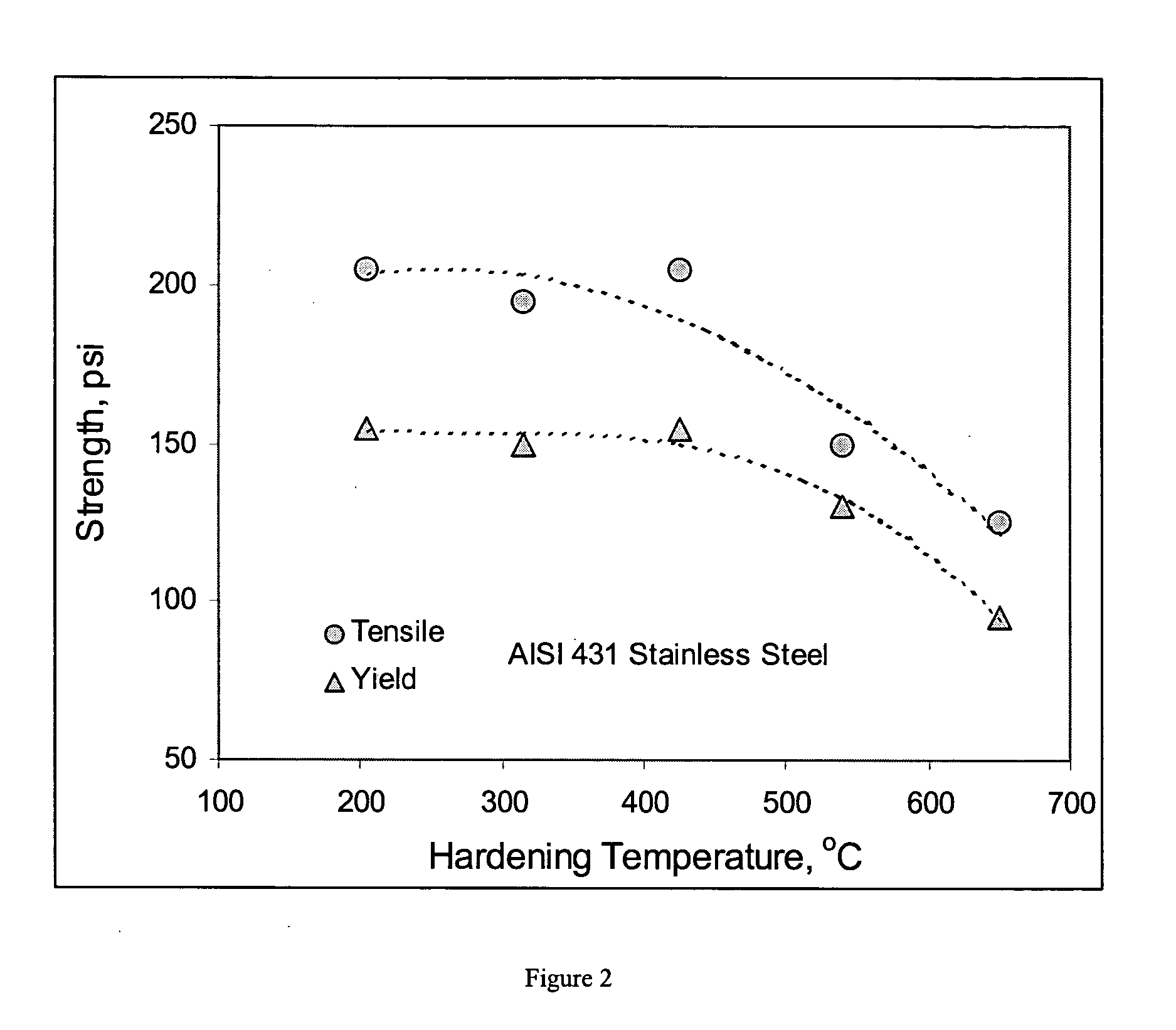

Heat treated devolatilizer nozzle

InactiveUS20050097748A1Drying using combination processesEvaporationSpray nozzleUltimate tensile strength

A method is provided for perforating a steel plate, forming a devolatilizer nozzle from the steel plate, and heat treating the devolatilizer nozzle. The devolatilizer nozzle may have a yield strength of at least about 110 ksi, and a tensile strength of at least about 140 ksi. The perforations in the steel plate are holes in the nozzle and may be no more than about 0.05 inches in diameter. The thickness of the steel plate may be from about 0 to about 0.75 inches. The nozzle may include at least about 500,000 perforations where the center-to-center hole distance may be at least about 0.08 inches. The capacity of the devolatilizer nozzle may be from about 0 to about 75,000 pounds per hour.

Owner:FINA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com