Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1710results about "Liquid displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filter cartridge assemblies and methods for filtering fluids

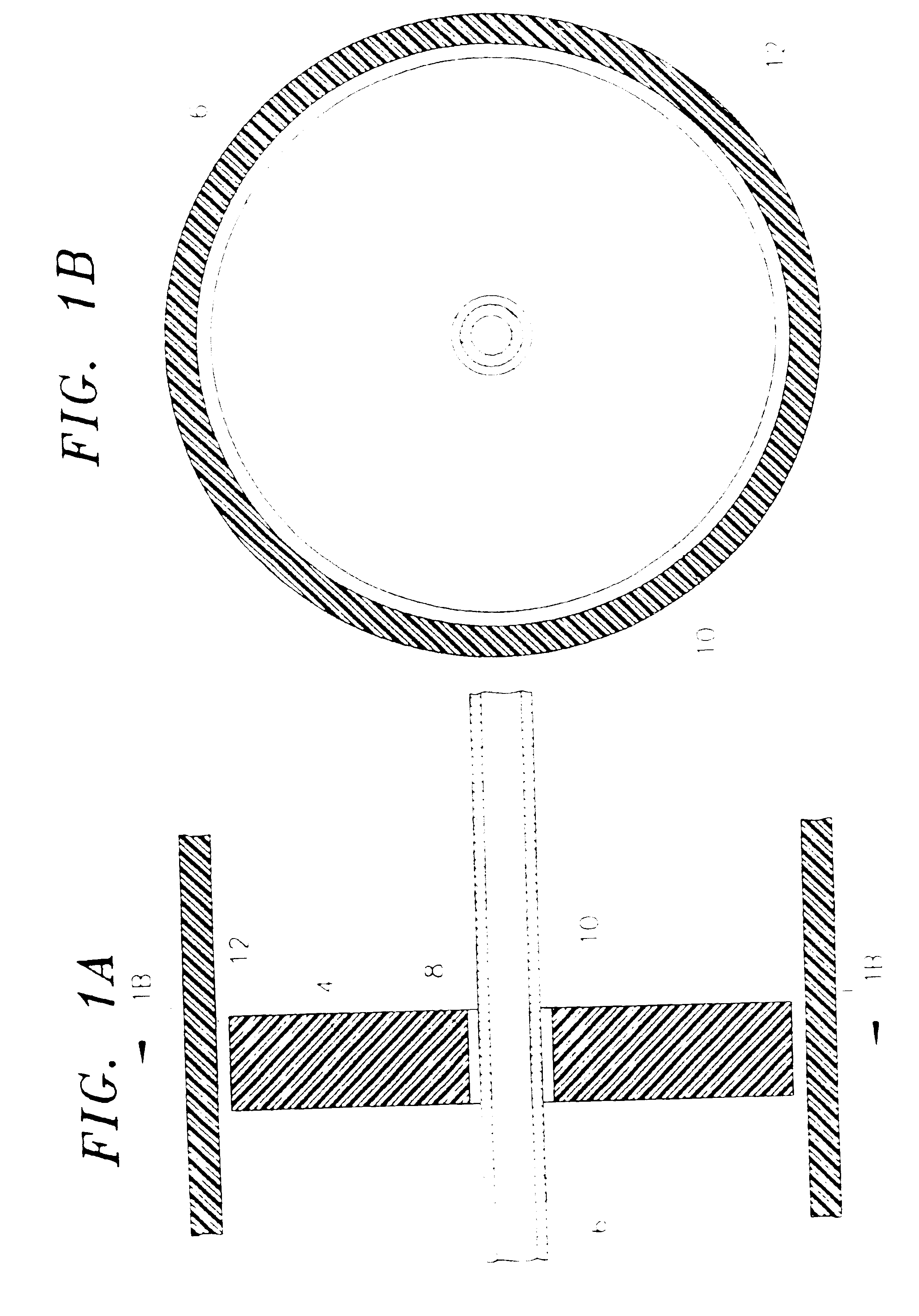

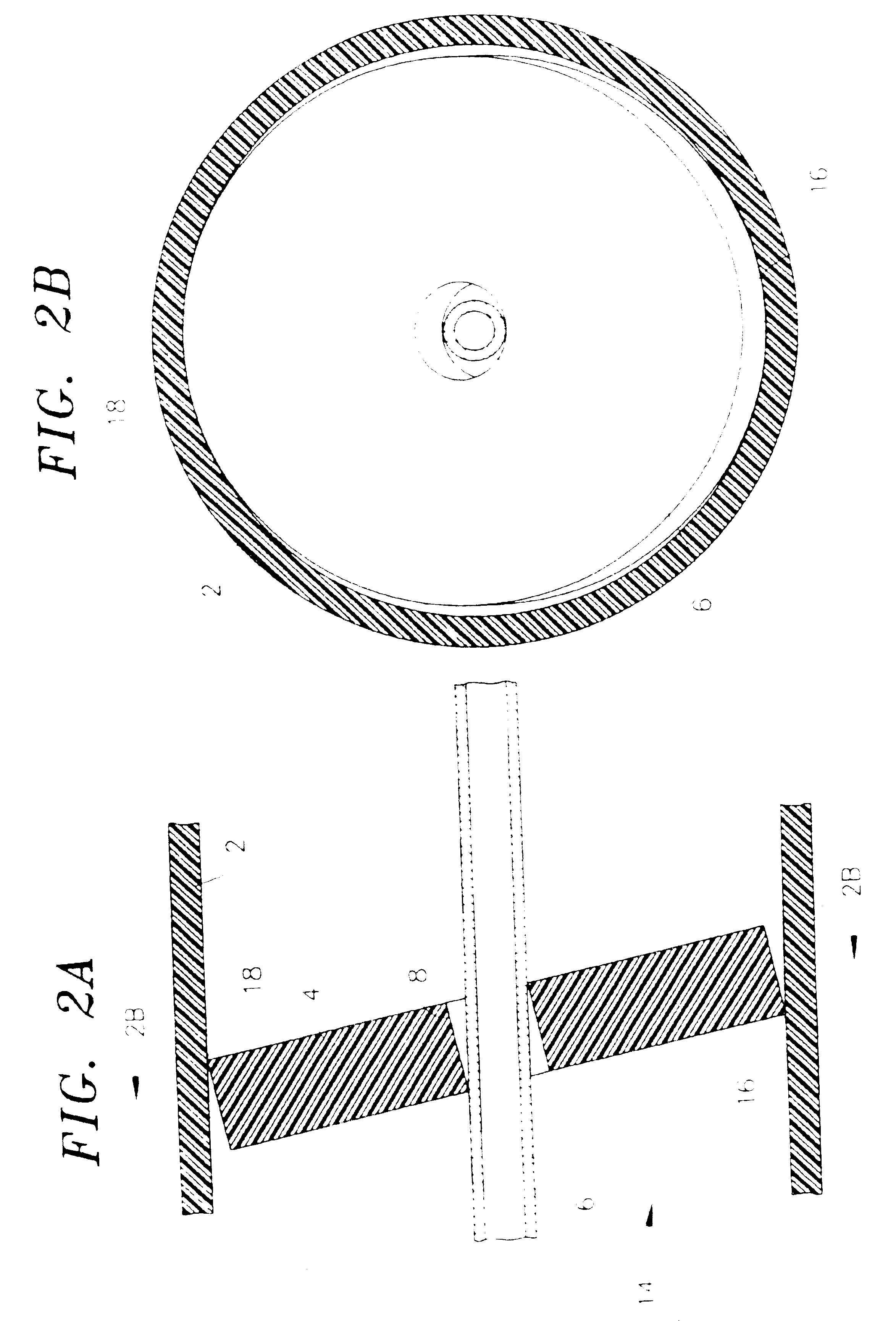

Filter cartridge assemblies and housings are provided and include a tubular housing having an inner wall, an outer wall, a first end, and a second end. The housings include inner walls with shoulders or other radially-inwardly extending flow directors at the intersections of adjacent sections of the tubular body. The assemblies include a plurality of filter media sections within the housing, and each of the plurality of filter media sections preferably has a different filter media composition. One or more of the filter media sections traverses one or more of the shoulders or other radially-inwardly extending flow directors such that the flow directors evenly direct the flow of fluid through the assembly. The assemblies find particular applicability in dialysis systems.

Owner:RENAL SOLUTIONS

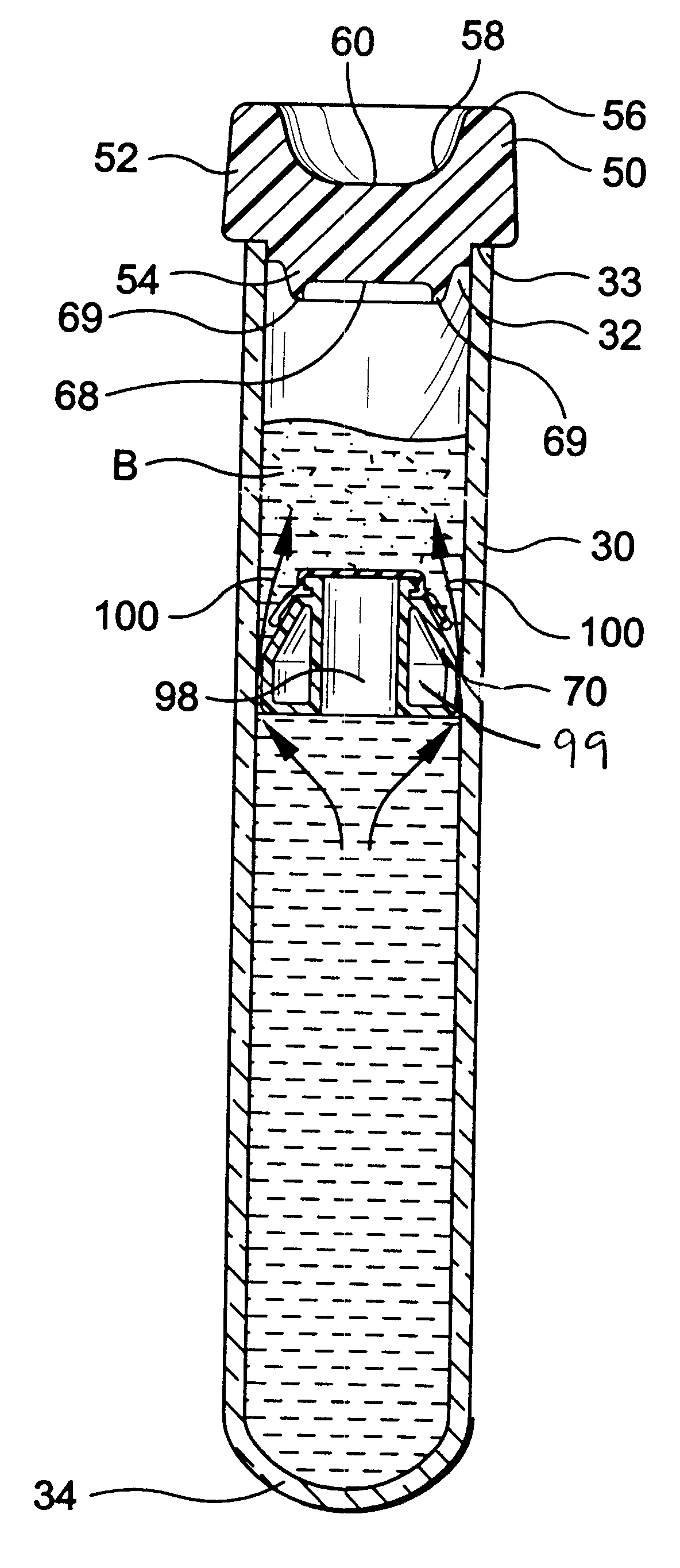

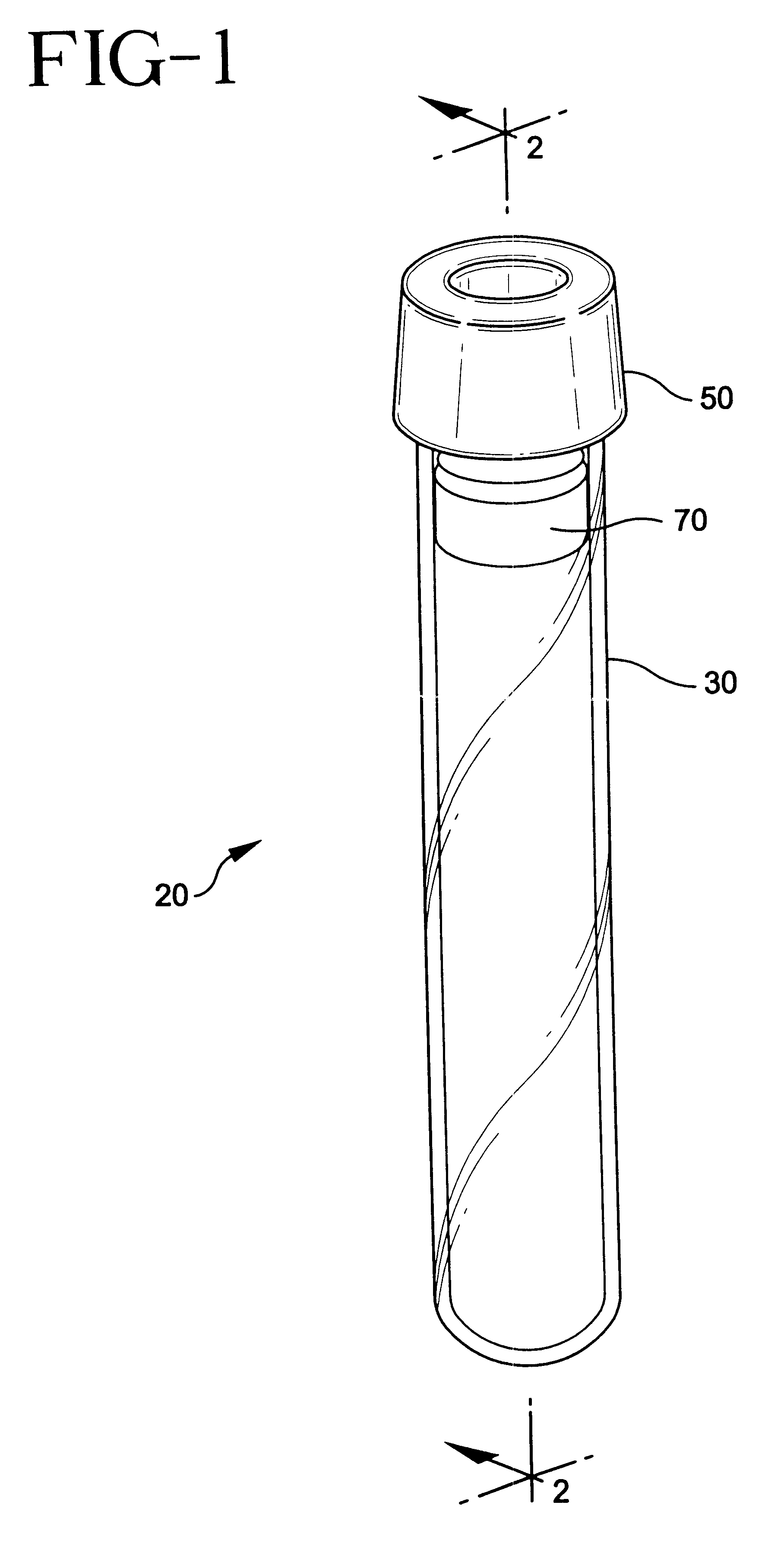

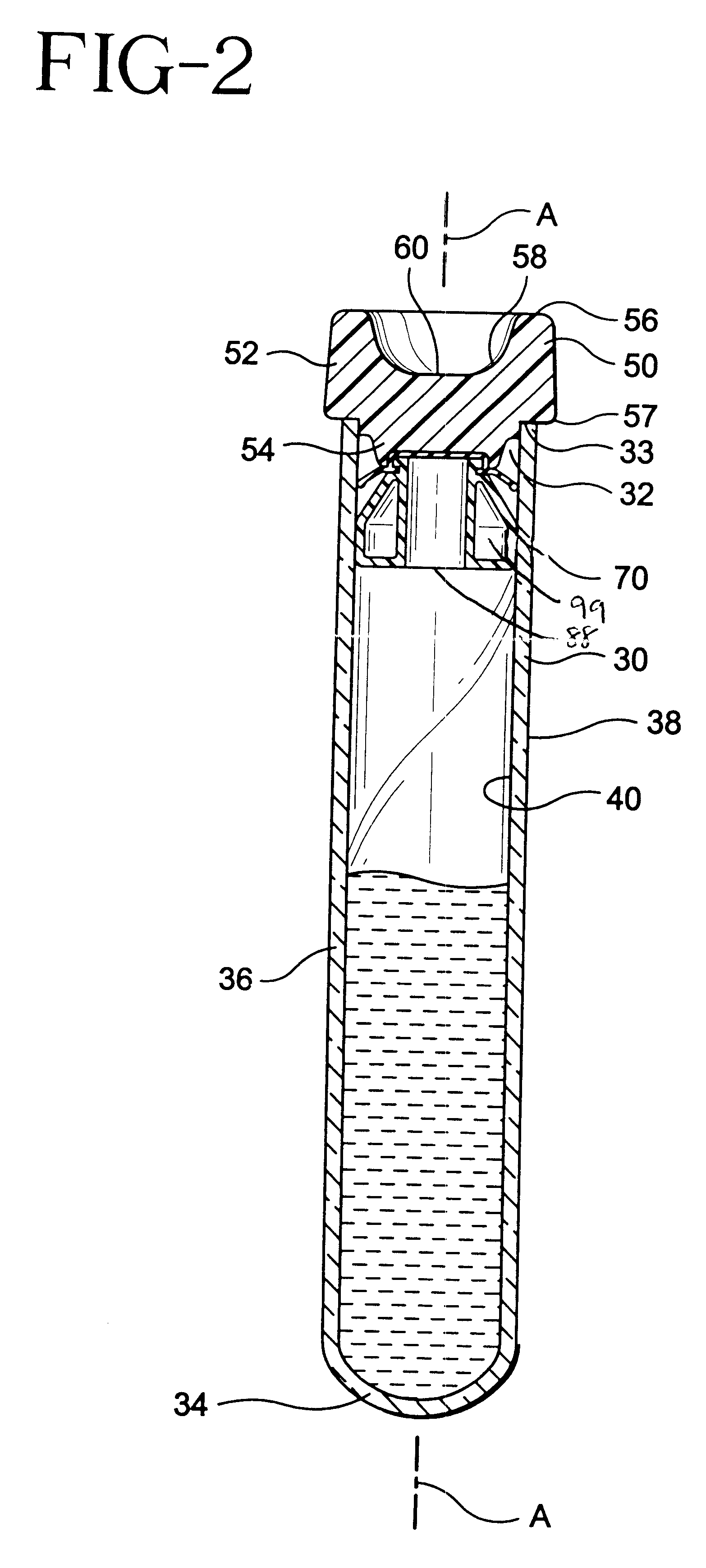

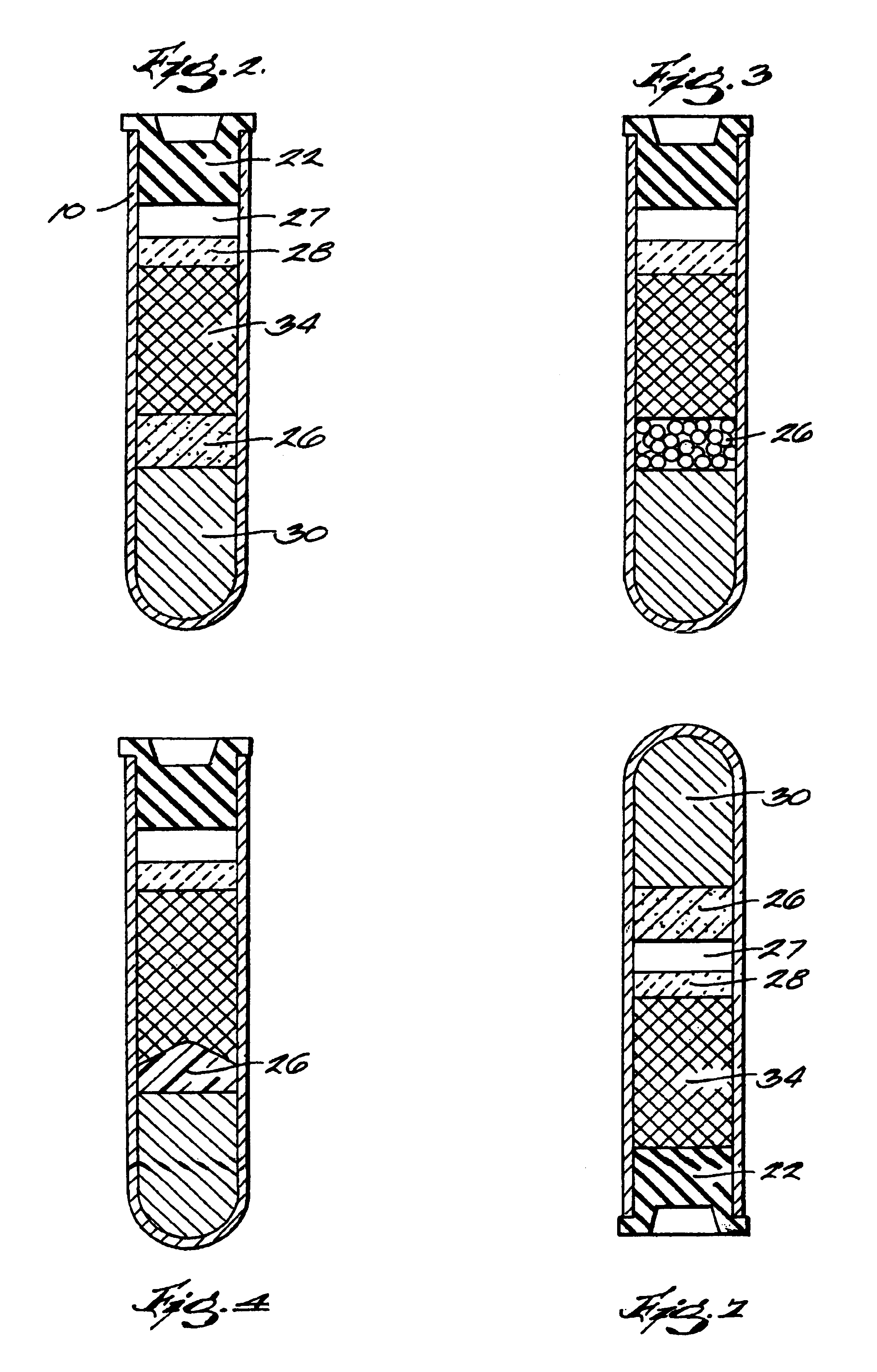

Device and method for separating components of a fluid sample

A device and method is provided for separating heavier and lighter fractions of a fluid sample. The device includes a plurality of constituents comprising a container and a composite element in the container. The composite element is a separator comprising at least two components and more particularly an elastic portion and a plug member. A fluid sample is delivered to the container and the device is subjected to centrifugation whereby the centrifugal load causes the elastic portion of the separator to deform so that the separator migrates into the fluid sample and stabilizes between the heavier and lighter fractions of the fluid sample. The elastic portion of the separator will resiliently return to its initial configuration upon termination of the centrifugal load such that the elastic portion sealingly engages the container and separates the heavier and lighter fractions of the fluid sample.

Owner:BECTON DICKINSON & CO

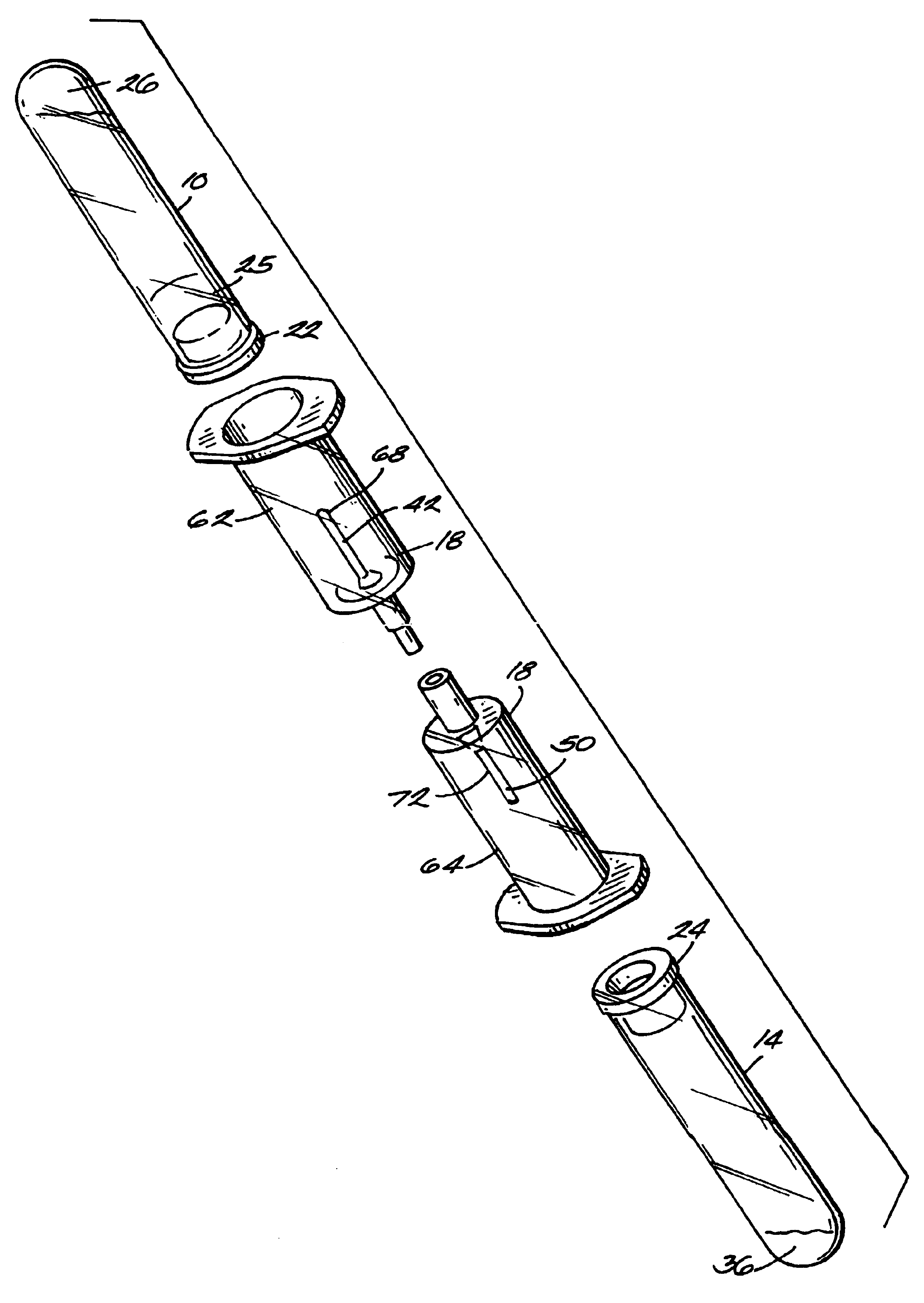

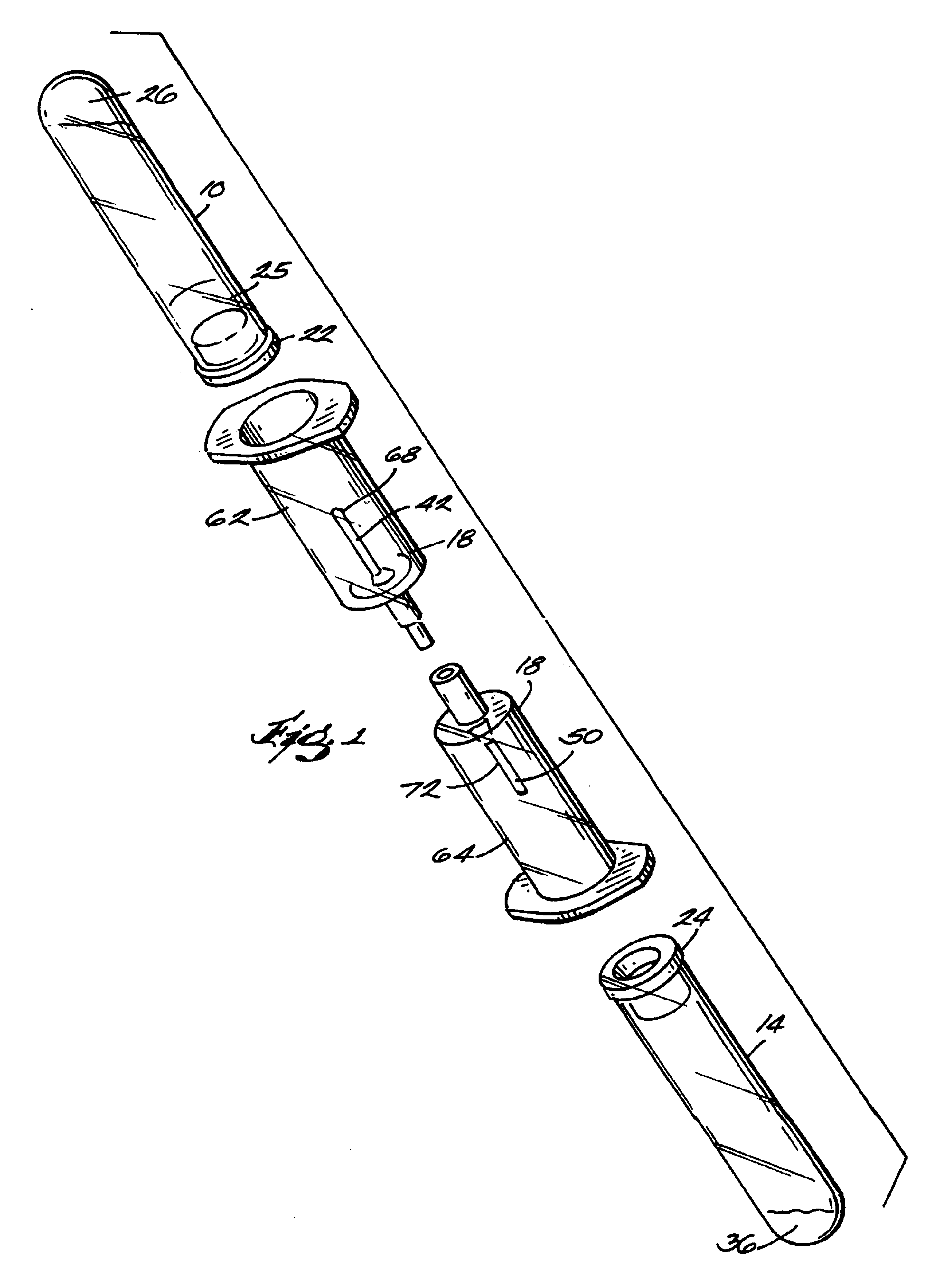

Systems and methods for preparing autologous fibrin glue

The invention provides a system for preparing an autologous solid-fibrin web suitable for regenerating tissue in a living organism. The system includes a sealed primary container containing a separation medium and a low-density high-viscosity liquid. The separation medium separates red blood cells from plasma when the container contains blood and is centrifuged, and the primary container has a first pressure. The system further includes a sealed secondary container containing a calcium-coagulation activator. The secondary container has a second pressure that is less than the first pressure. The system also comprises a transfer device including a cannula having a first end and a second end. The first and second ends puncture the sealed primary and secondary containers in order to provide fluid communication between the first and second containers. The low-density high-viscosity liquid of the primary container blocks flow through the cannula upon entering therein.

Owner:CASCADE MEDICAL ENTERPRISES

Apparatus and method for separating and isolating components of a biological fluid

A device for separating and isolating components of a biological fluid comprising a container for containing the fluid to be processed, a tube cap assembly for closing the container while providing filling and extraction communication therewith, a float assembly disposed within the container for funneling and controlling biological fluid flow into an inverted domed shaped isolation chamber within the float and controlling the biological fluid flow out of the isolation chamber for effecting an encapsulation or a sealed isolation of at least one component or fraction of the biological fluid flow within the isolation chamber during a centrifugation process. The device further comprising a flexible tube for connecting an extraction passageway disposed within the float assembly and an extraction valve of the tube cap assembly for allowing extraction of at least the one component or fraction encapsulated or isolated within the chamber.

Owner:THERMOGENESIS HLDG INC

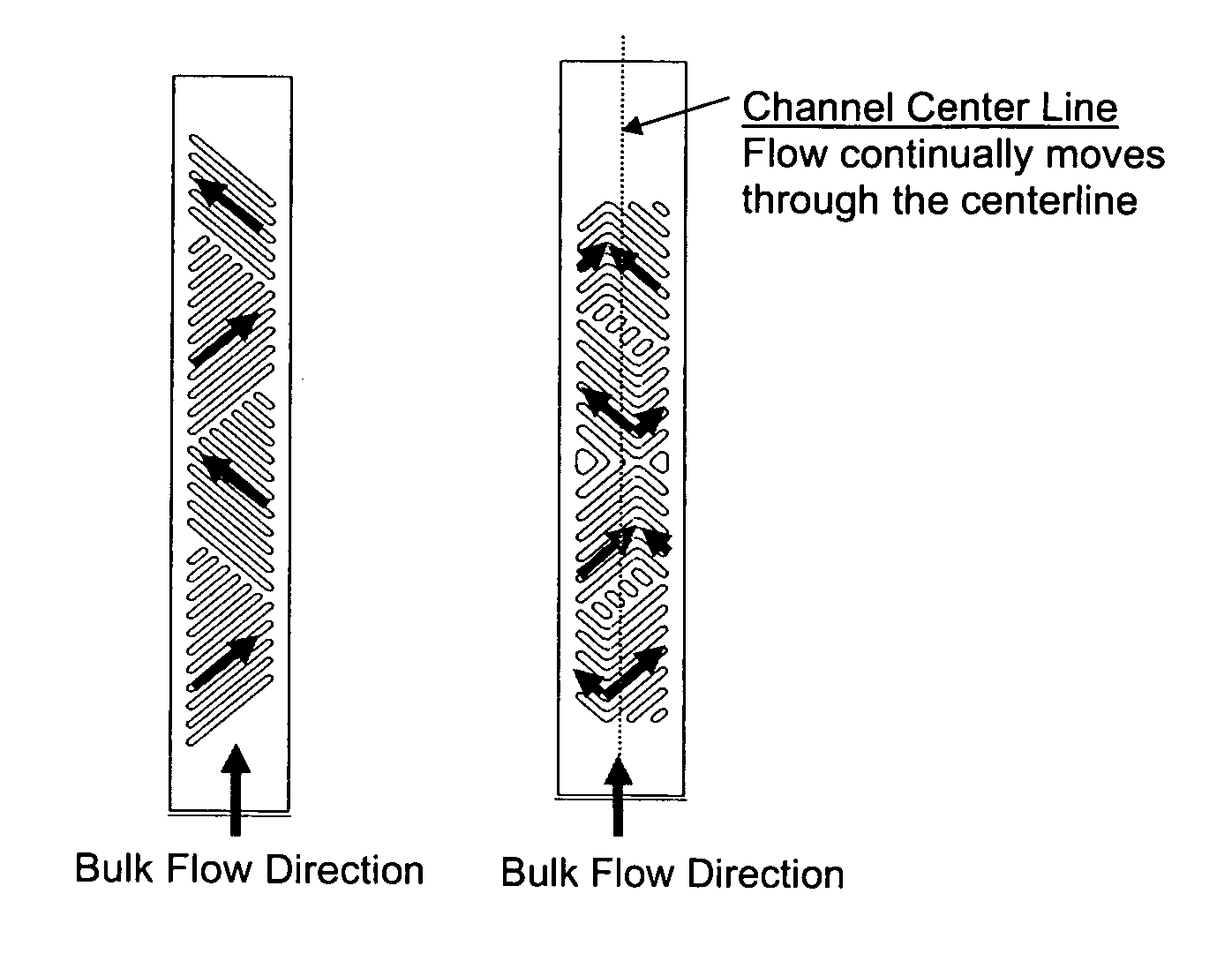

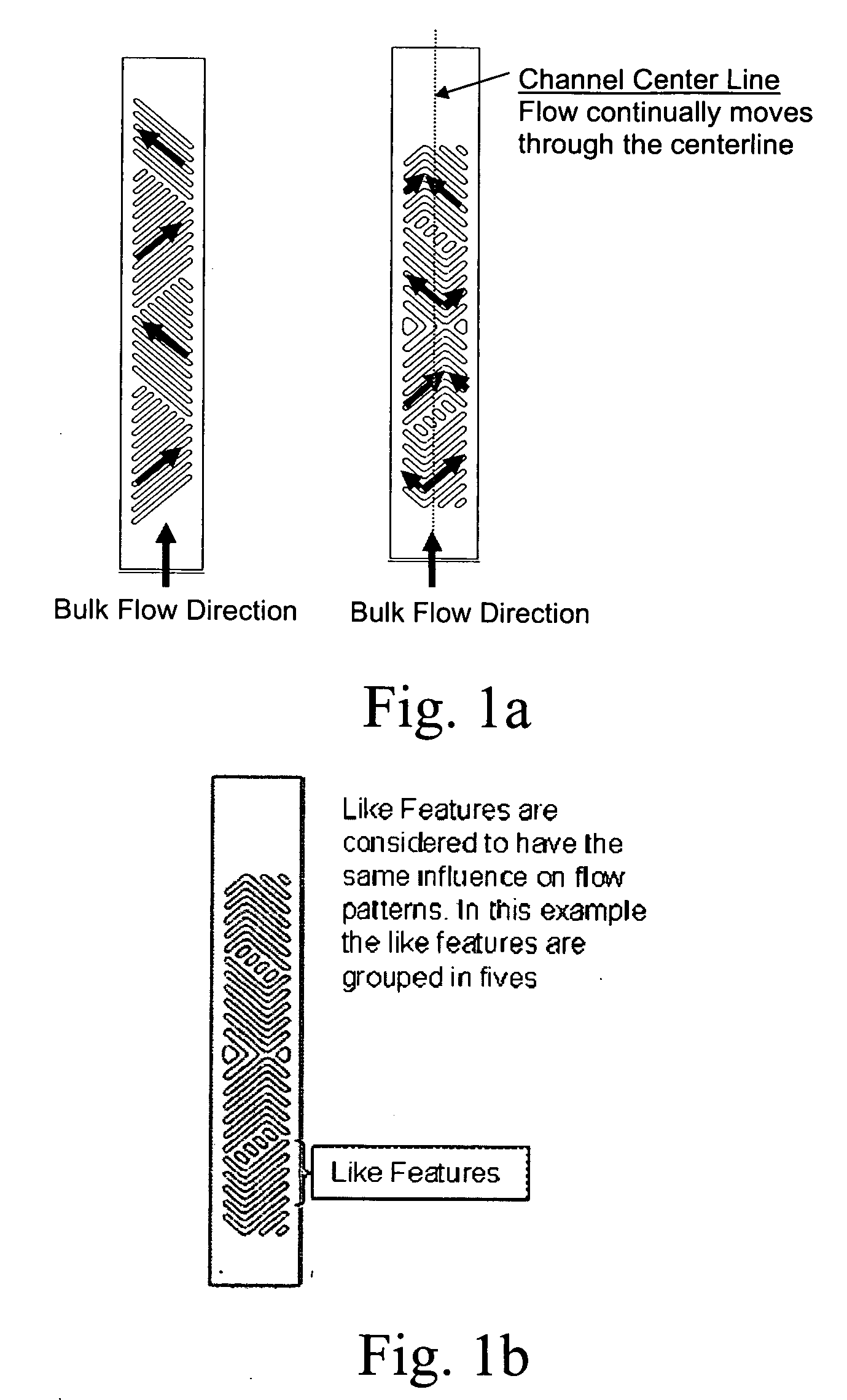

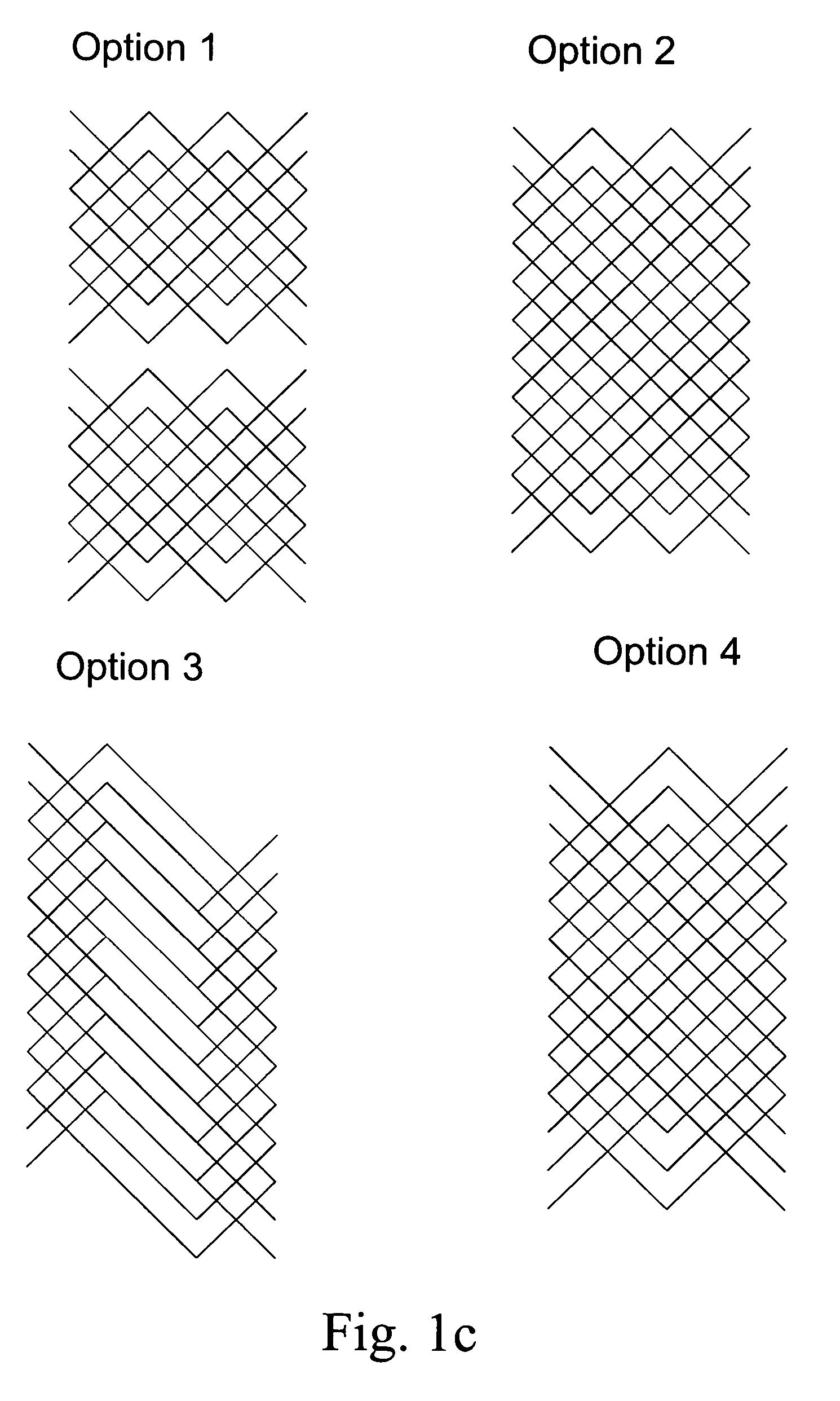

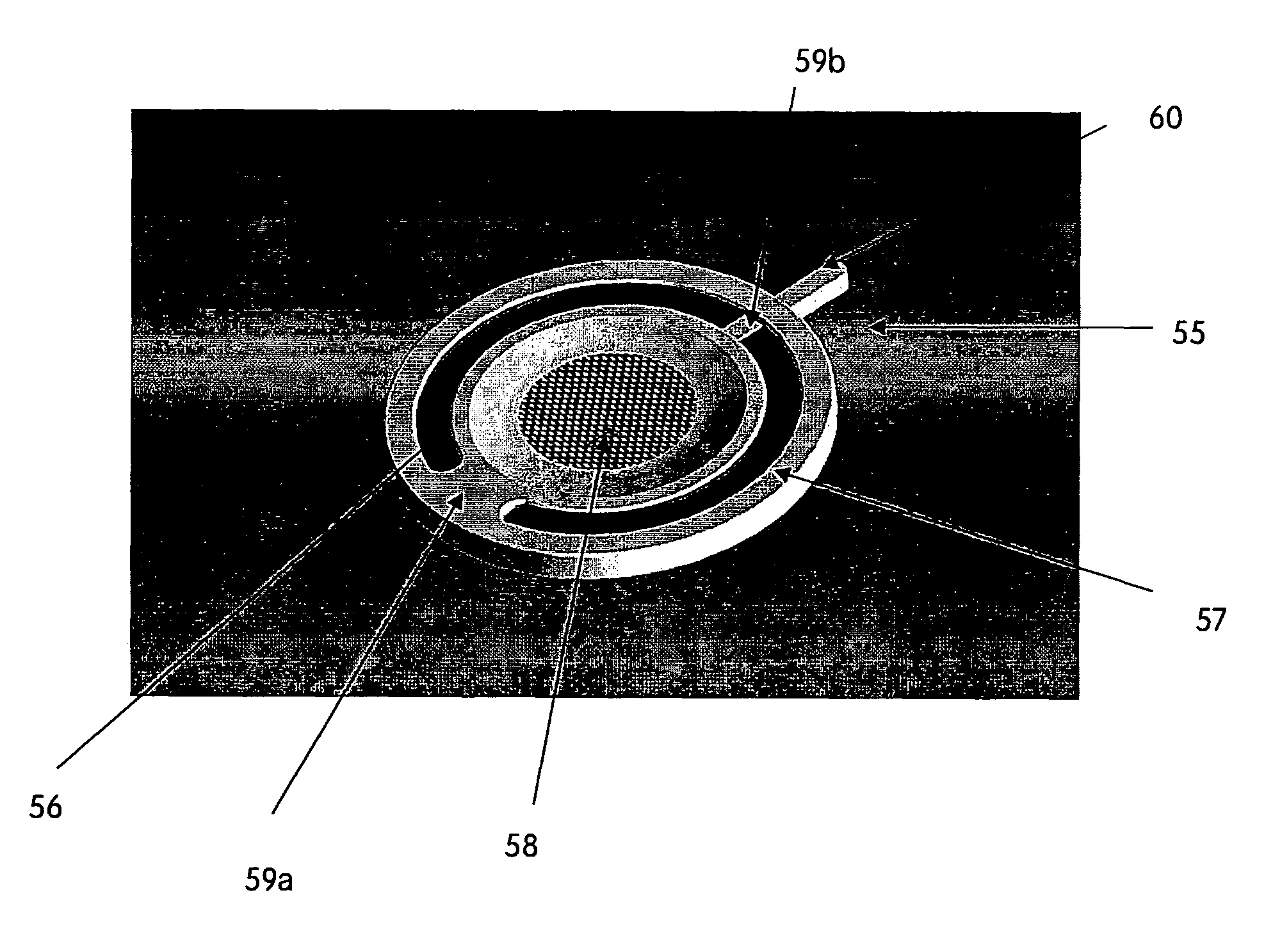

Surface features in microprocess technology

ActiveUS20070017633A1Enhance unit operationEasy to useFlow mixersCircuit elementsEngineeringMechanical engineering

Owner:VELOCYS CORPORATION

Blood component separator disk

InactiveUS7077273B2Improve processing efficiencyControl flowOther blood circulation devicesDispersed particle separationBlood component separatorRed blood cell

A separator disk (4) for use in centrifugal separation of components is designed to automatically position itself during separation at the interface between the supernatant and the remaining components. Preferably the interface is between plasma and red blood cells.

Owner:HARVEST TECH

Process and apparatus for treating implants comprising soft tissue

ActiveUS20050229323A1Simple structureImprove mechanical propertiesSuture equipmentsSolid sorbent liquid separationLigamentBiomedical engineering

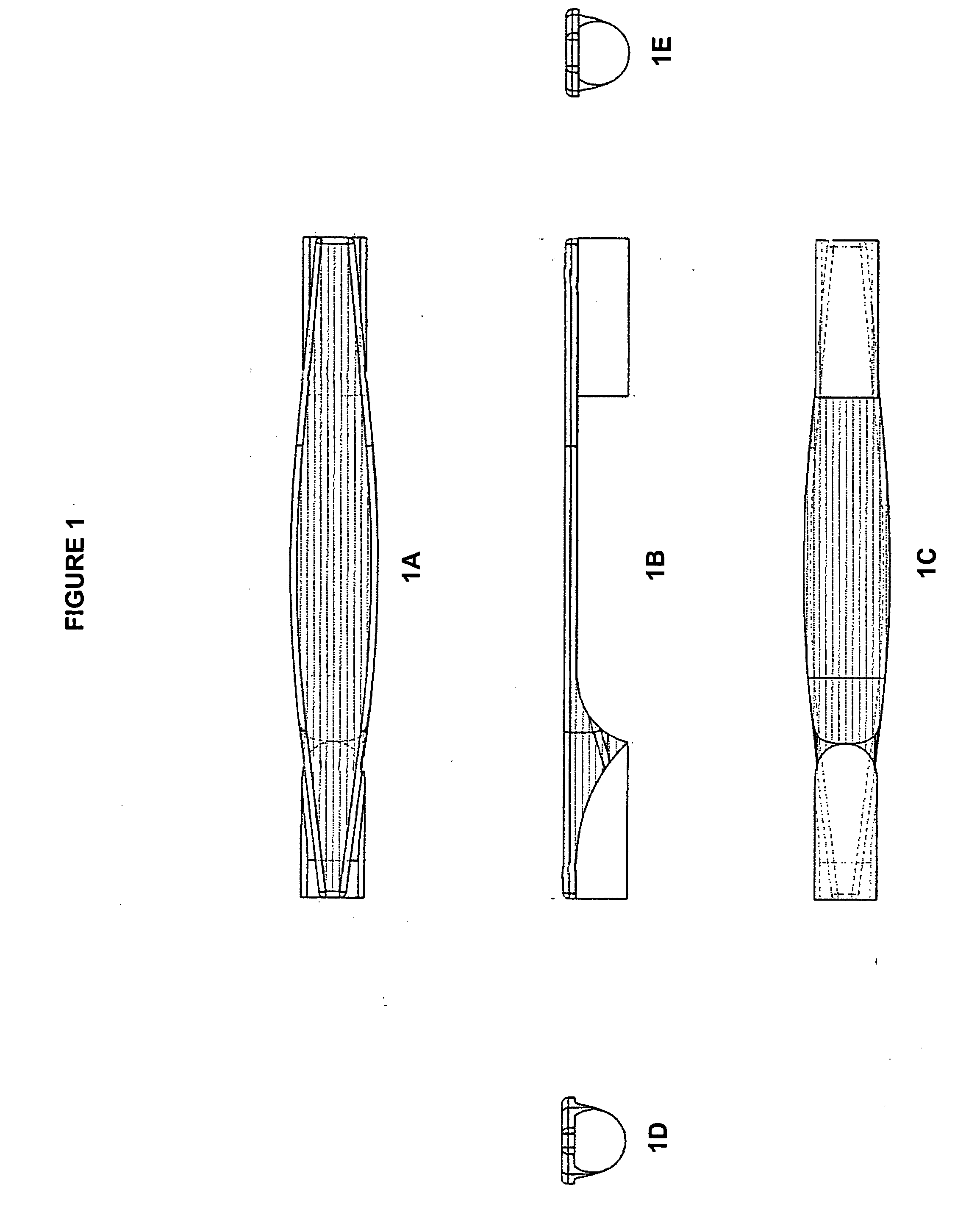

The present invention is directed to the field of implants that include soft tissue. More particularly, the present invention is directed to processes for treating implants that include soft tissues such as tendons and ligaments, and to implants produced by such processes. The present invention is also directed to processes and apparatus for improved processing of implants that include soft tissue, by applying kinematic restraint, preferably tension, to the implant or specific portions of the implants during the treatment, and to implants produced by such processes and apparatus. The present techniques yield soft tissue implants having superior structural, mechanical, and / or biochemical integrity.

Owner:RTI BIOLOGICS INC

Storm water receptor system

InactiveUS6062767AImprove water qualityWater cleaningFatty/oily/floating substances removal devicesClosed chamberEngineering

A storm water receptor having at least one inlet and an outlet positioned at a discharge level lower than the level of the intake provided with a novel, removable divider which divides the receptor into an upper chamber and a lower chamber, having a float-actuated trap door that permits water entering the upper chamber of the catch basin or field inlet to be diverted and flow into the lower chamber until the lower chamber is filled with liquid, at which point the entrance into the lower chamber closes, and water entering the upper chamber passes directly out of the upper chamber through the discharge pipe. In an alternative embodiment of the invention, the float-activated trap door can be replaced with a stationary, removable plate or ramp.

Owner:KIZHNERMAN SAMUIL +1

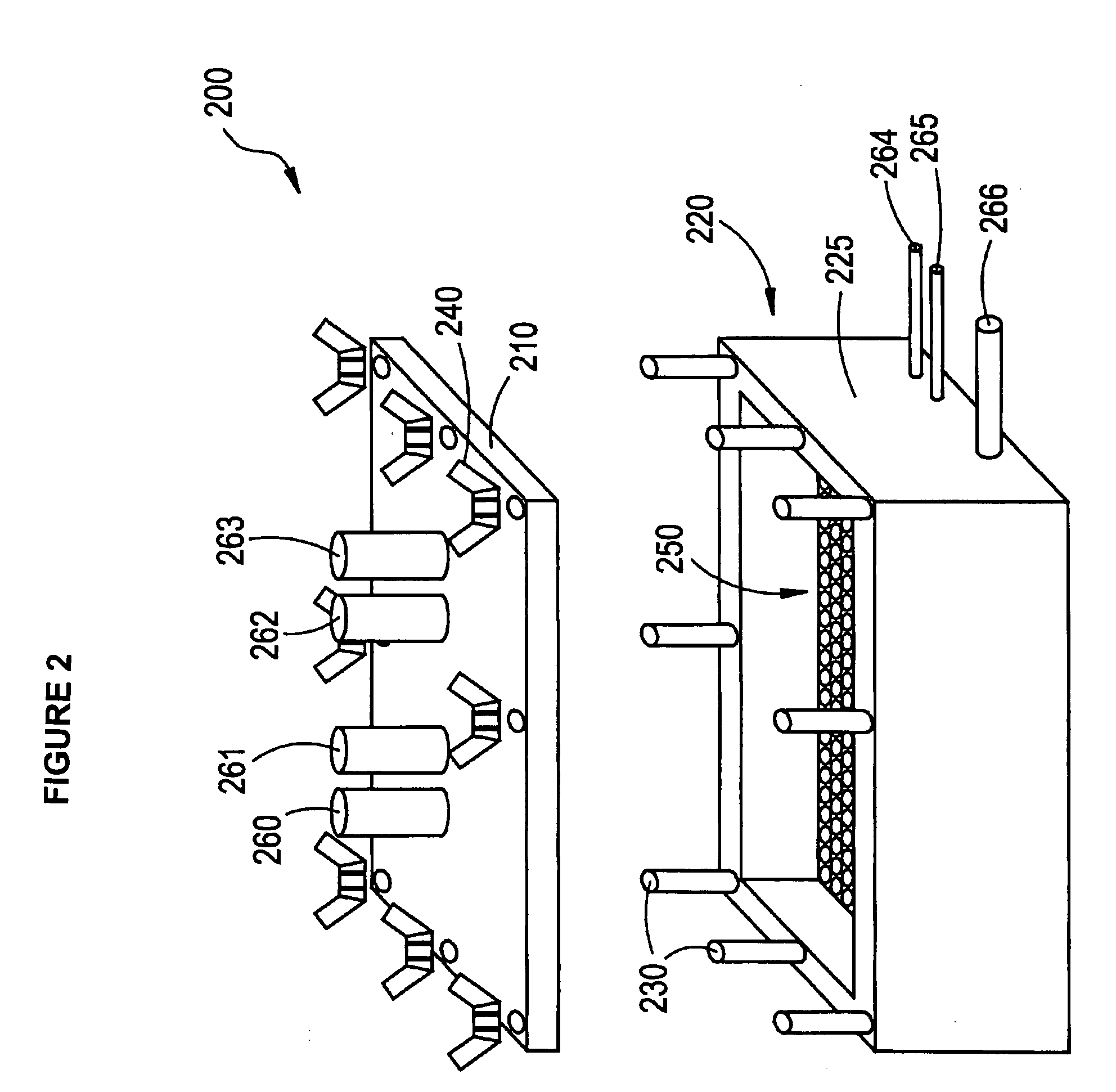

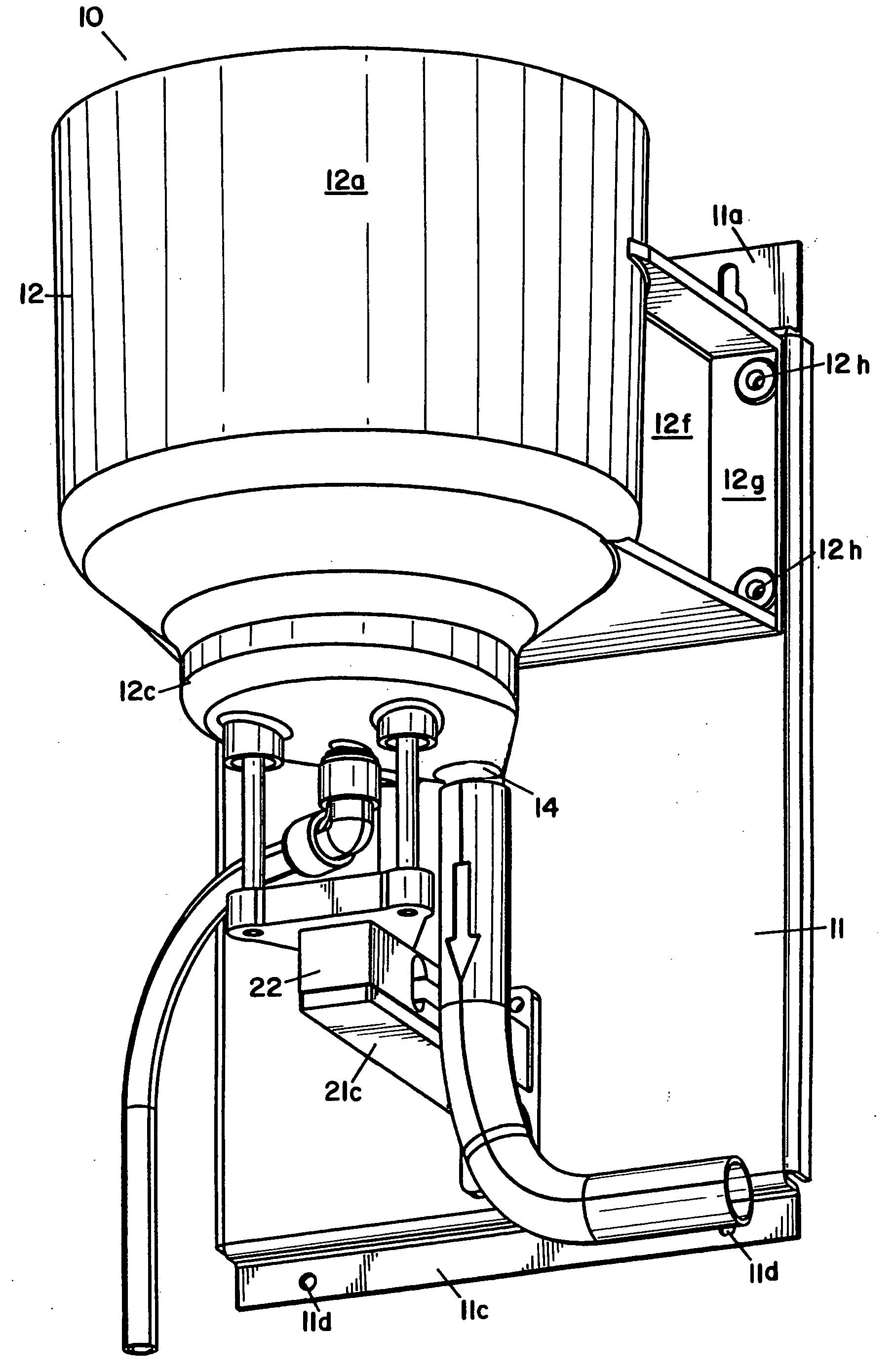

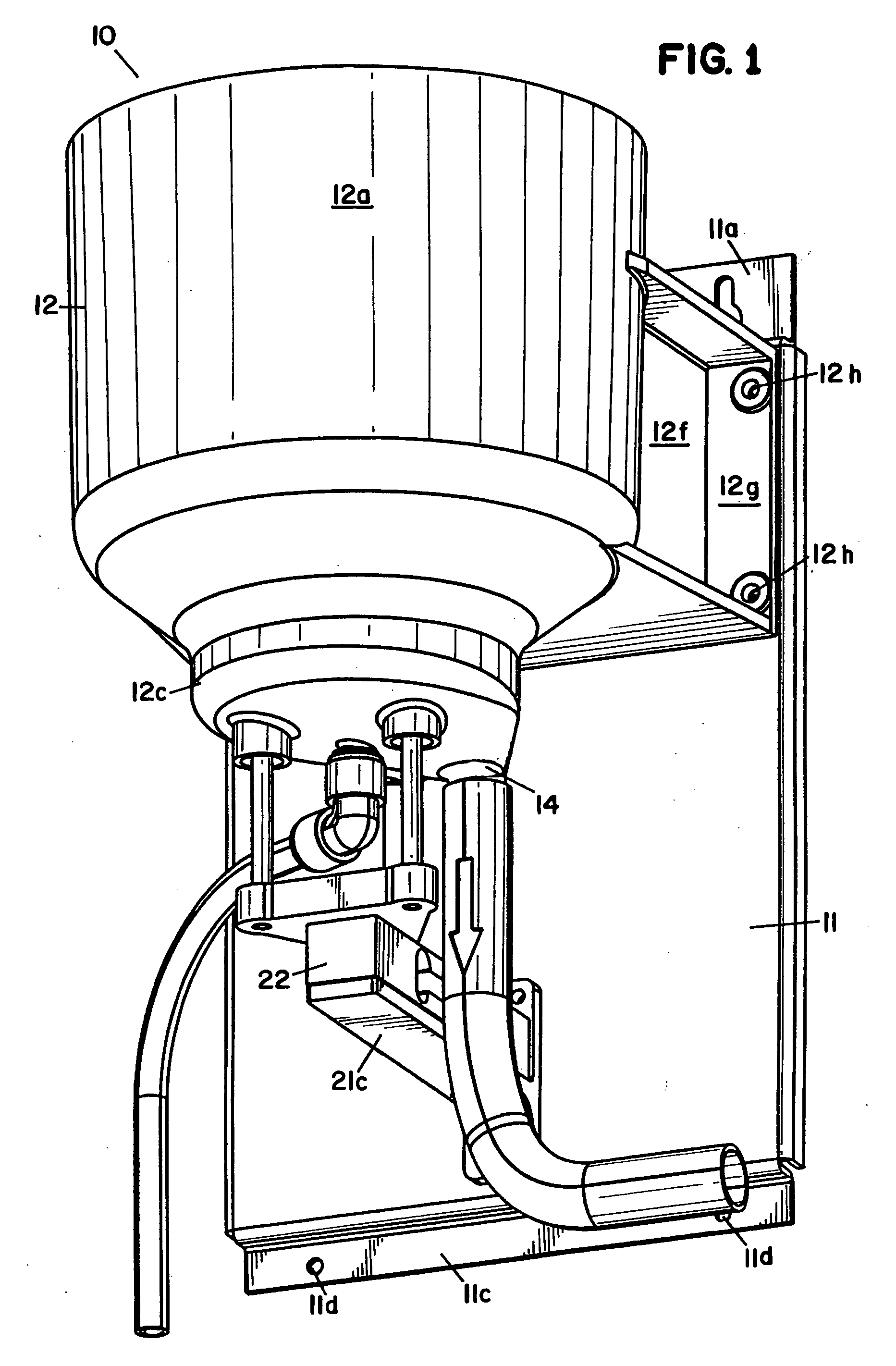

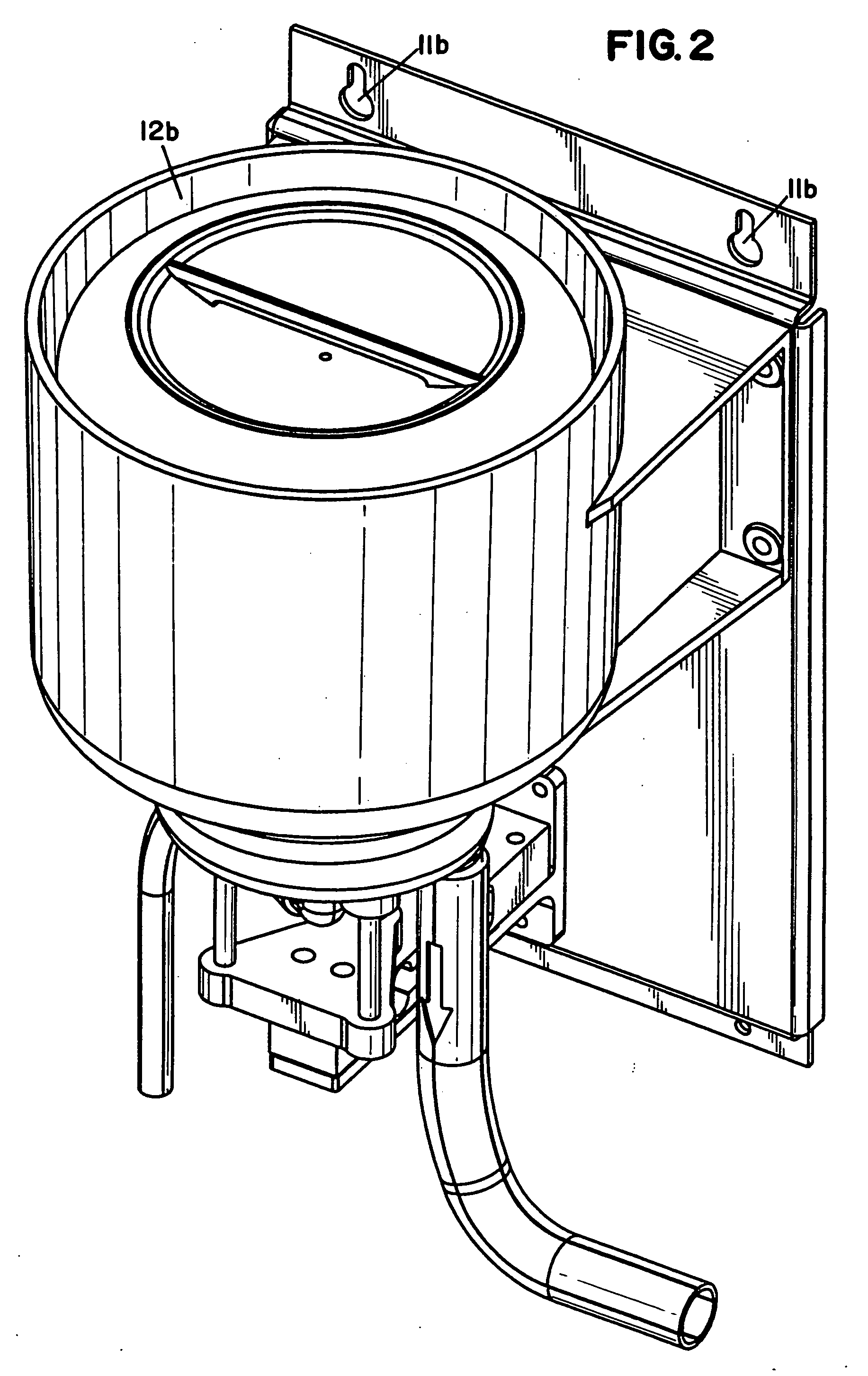

Method and apparatus for mass based dispensing

ActiveUS20040245284A1Excessive shock to the scale is prevented during loadingTableware washing/rinsing machine detailsTransportation and packagingDiluentEngineering

A dispenser (200) dispenses an amount of concentrate in a container (204) using a diluent to form a use solution. A dispenser includes a housing (201). A product holder (210) is positioned to support the container (204) with the concentrate in the cavity of the housing. The product holder (210) carried by a scale (240), wherein weight of the concentrate is concerned. A moveable container holder (215) is moveable between a first position and a second position. The container holder is positioned between the housing (201) and the container (204). A cover (216) is operatively connected to the container holder (215) at a connection. A cam surface is adjacent the housing (201). The cover (216) has a cam (216d) for contacting the cam surface (201a), wherein when the cover (216) is moved from a closed position to an open position, the connection moves upward, thereby carrying the container holder (215) and the container (204) which are moved upward lifting the container (204) off of the product holder (210).

Owner:ECOLAB USA INC

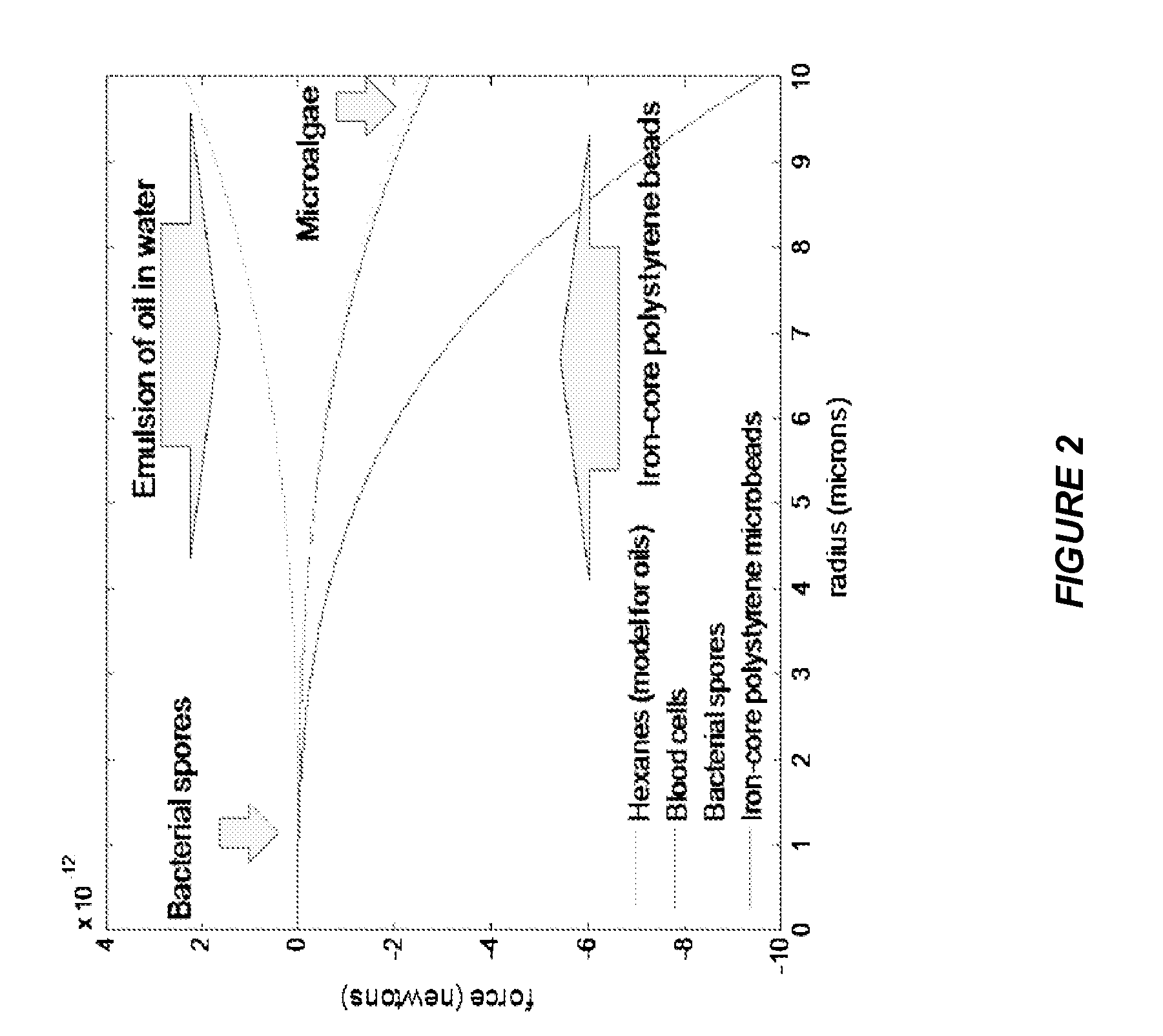

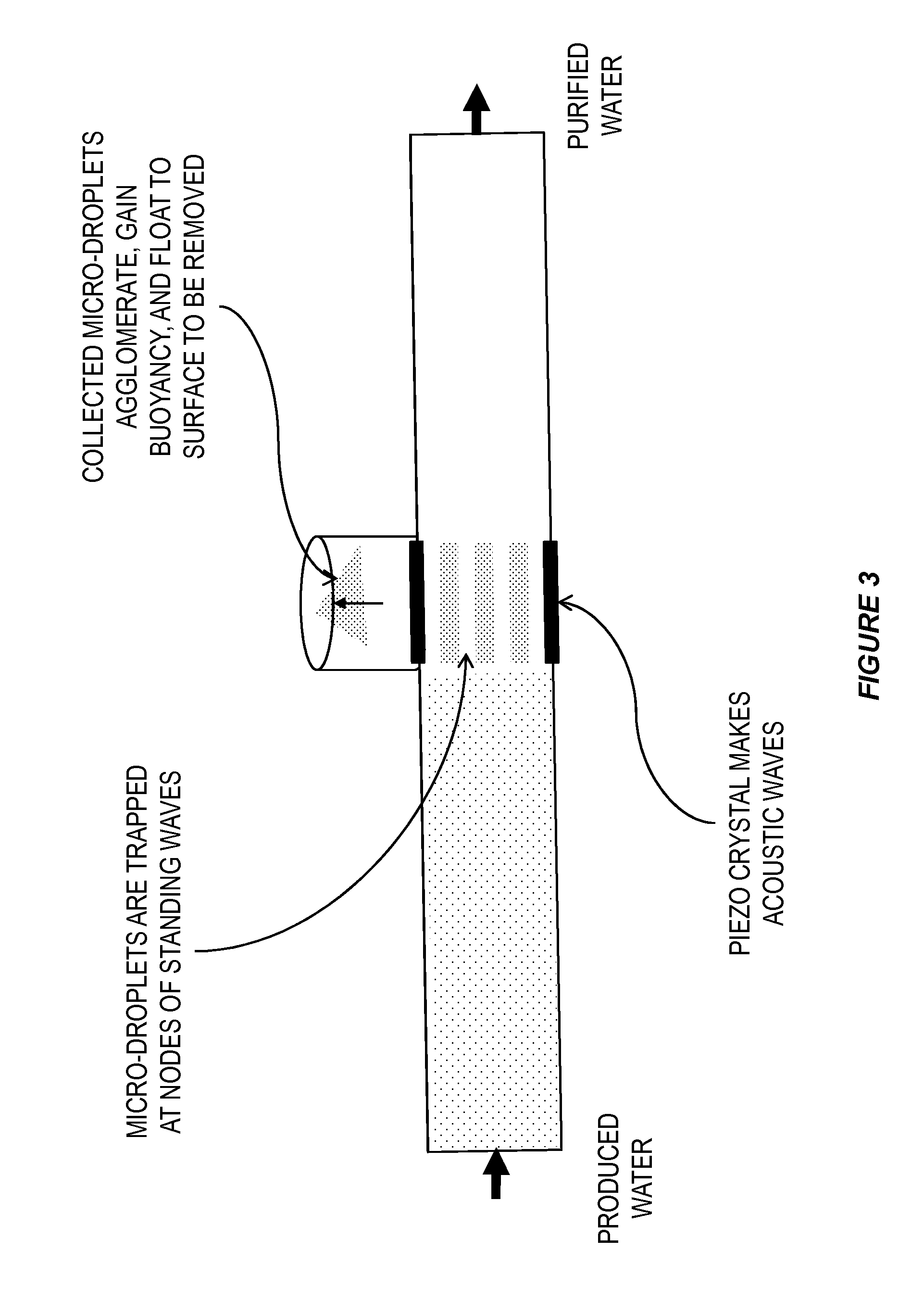

Ultrasound and Acoustophoresis Technology for Separation of Oil and Water, with Application to Produce Water

InactiveUS20110278218A1Maximize acoustic energy transferAvoid enteringWaste water treatment from quariesFatty/oily/floating substances removal devicesEmulsionResonance

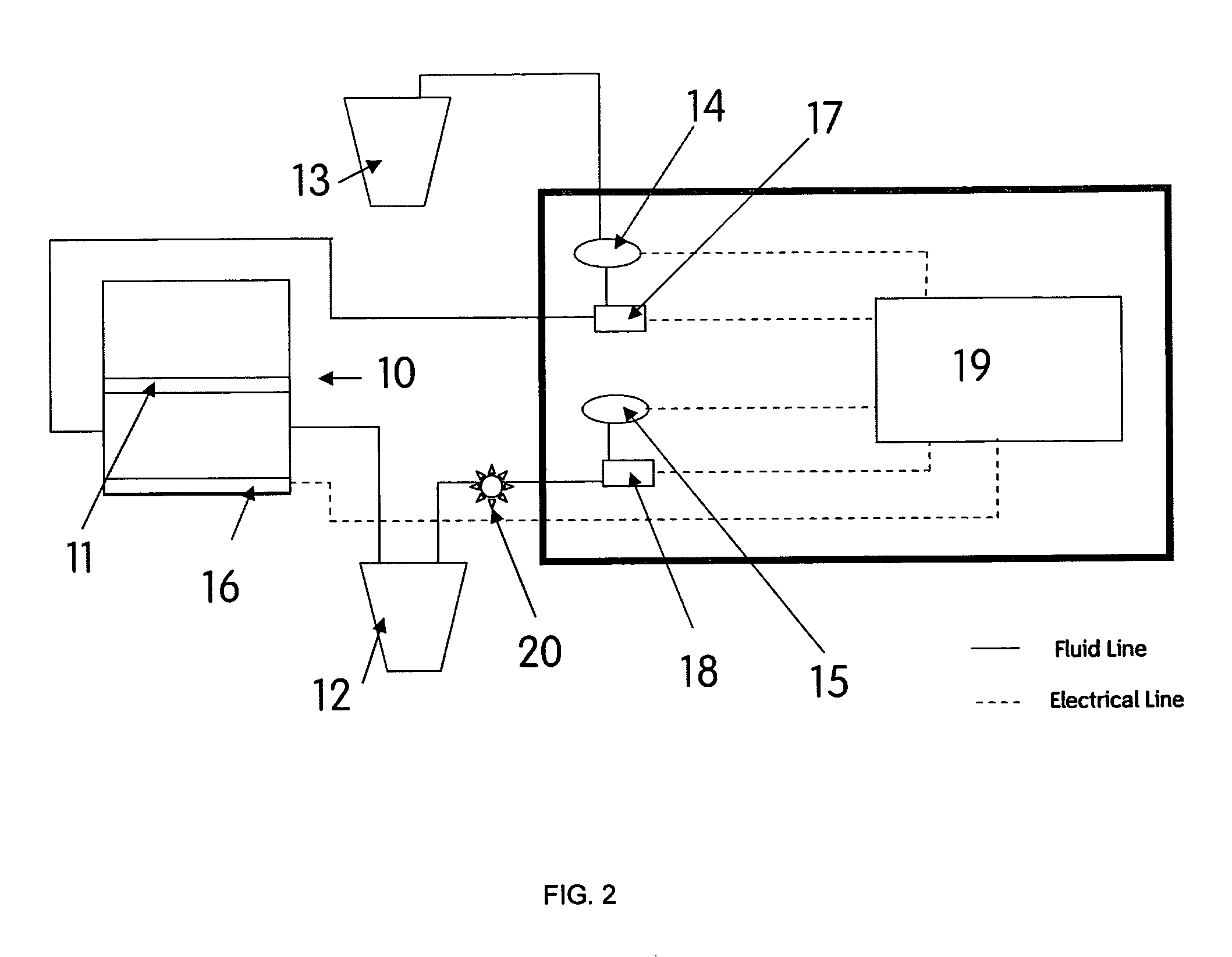

Several prototype systems are described for separating oil and water from emulsions. The systems operate at ultrasonic resonance and are thus low power. Each system contains one or more acoustic transducers operating in the 100 kHz to 5 MHz range. Each system contains flow input for the emulsion and two or more flow outputs for the separated oil and water. Existing prototypes operate from 200 mL / min to >15 L / min. Each uses low power in the range of 1-5 W.

Owner:FLODESIGN SONICS

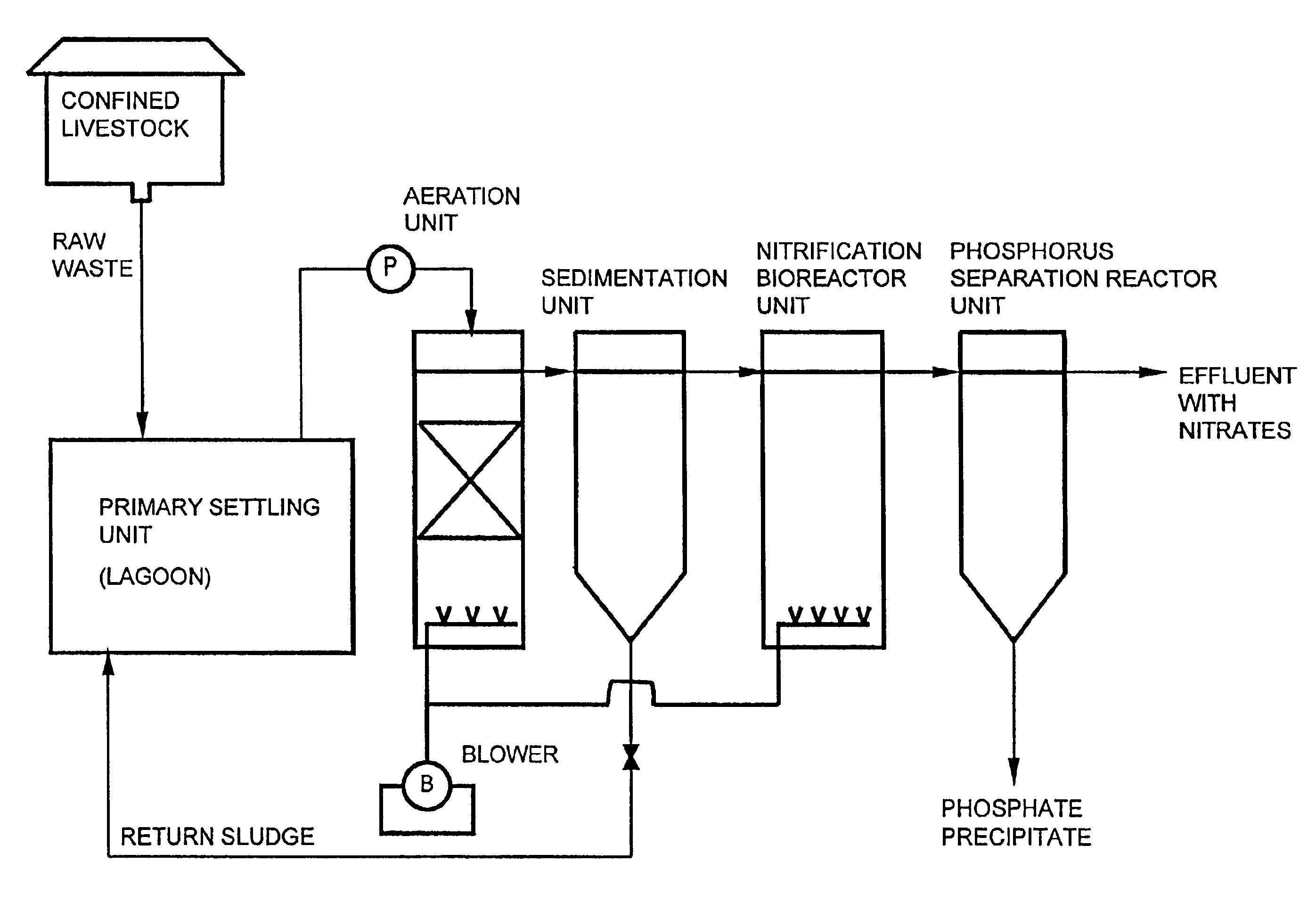

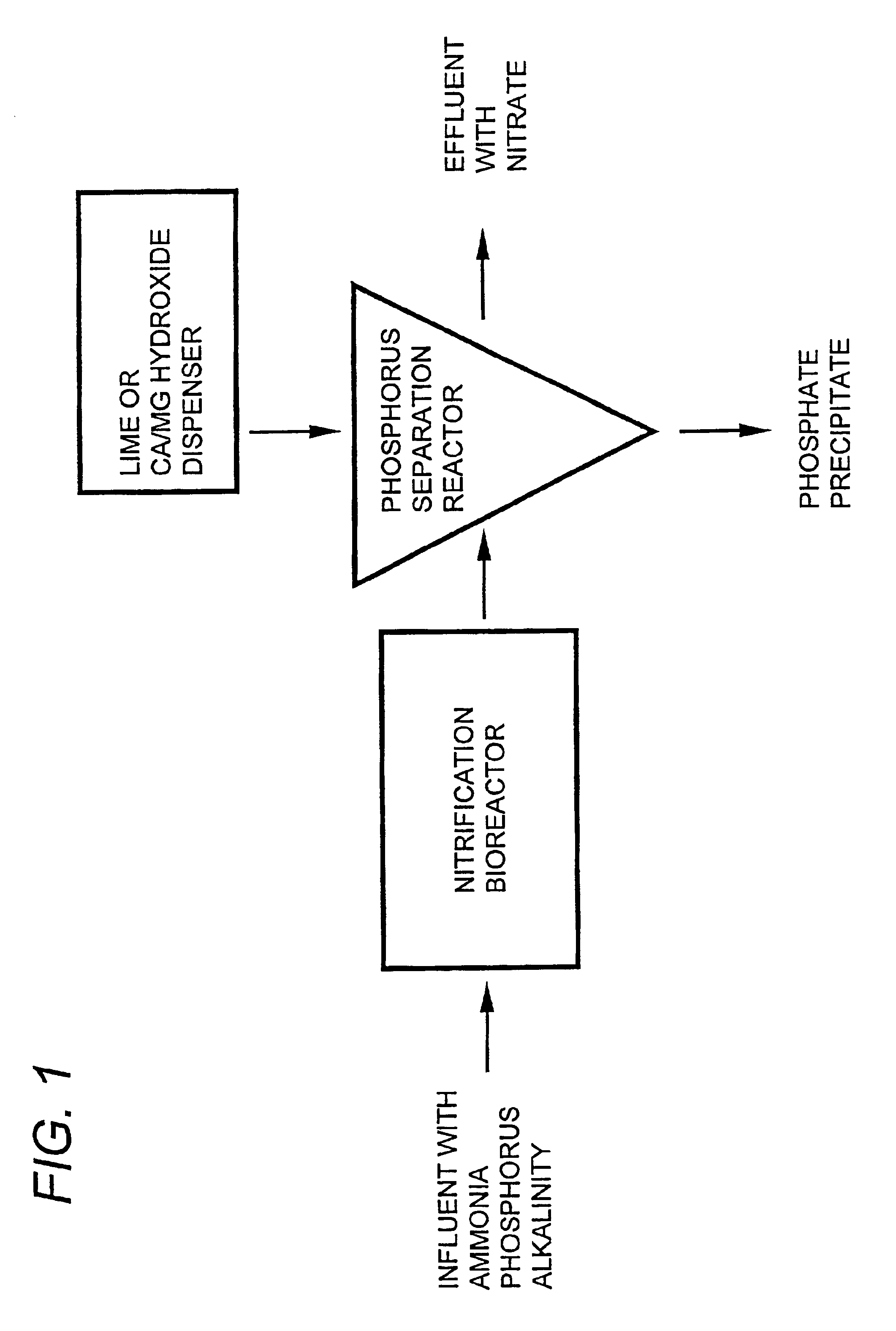

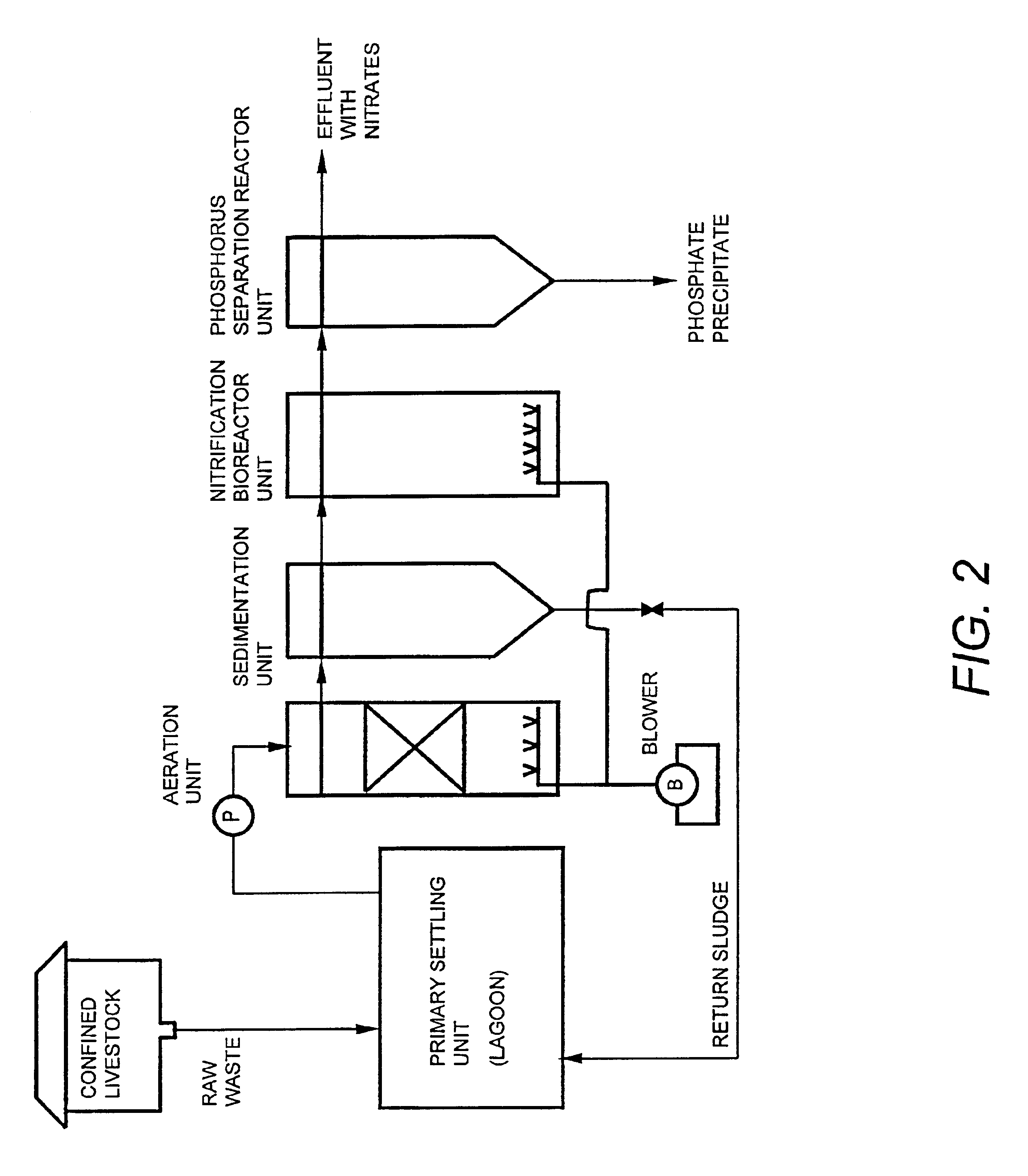

Wastewater treatment system

InactiveUS6893567B1Expand the populationShorten treatment timeTreatment using aerobic processesMixing methodsEnteropathogenic bacteriaTreatment system

Wastewater treatment systems and processes for: removal of solids, pathogens, nitrogen, and phosphorus from municipal and agricultural wastewater include nitrification of wastewater and increasing the pH of the nitrified wastewater by adding a metallic-containing salt and hydroxide to precipitate phosphorus to form a useable effluent having a specified nitrogen:phosphorus ratio that is useful as a fertilizer or spray for remediation of contaminated soils. The presence of infectious microorganism such as enteropathogenic bacteria and picarnoviruses will be reduced in the useable effluent. The precipitated phosphorus is recovered and used to form useable phosphorus products.

Owner:AGRI UNTED STATES OF AMERICA THE AS REPRESENTED BY THE SEC +1

Low temperature interconnection of nanoparticles

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

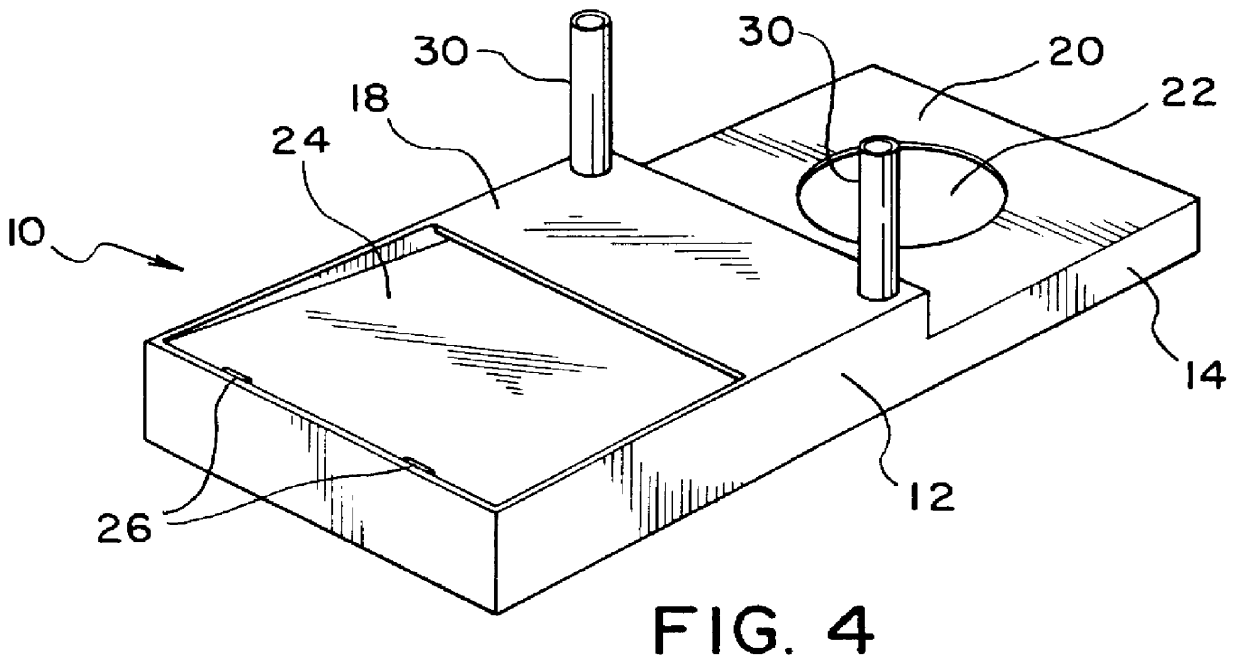

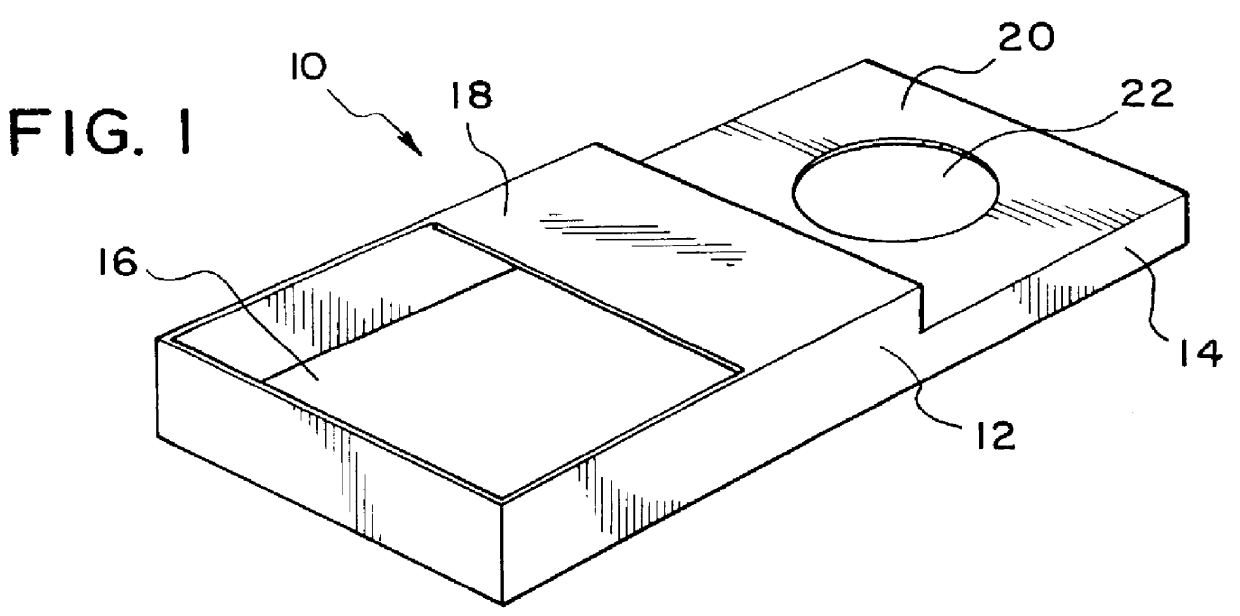

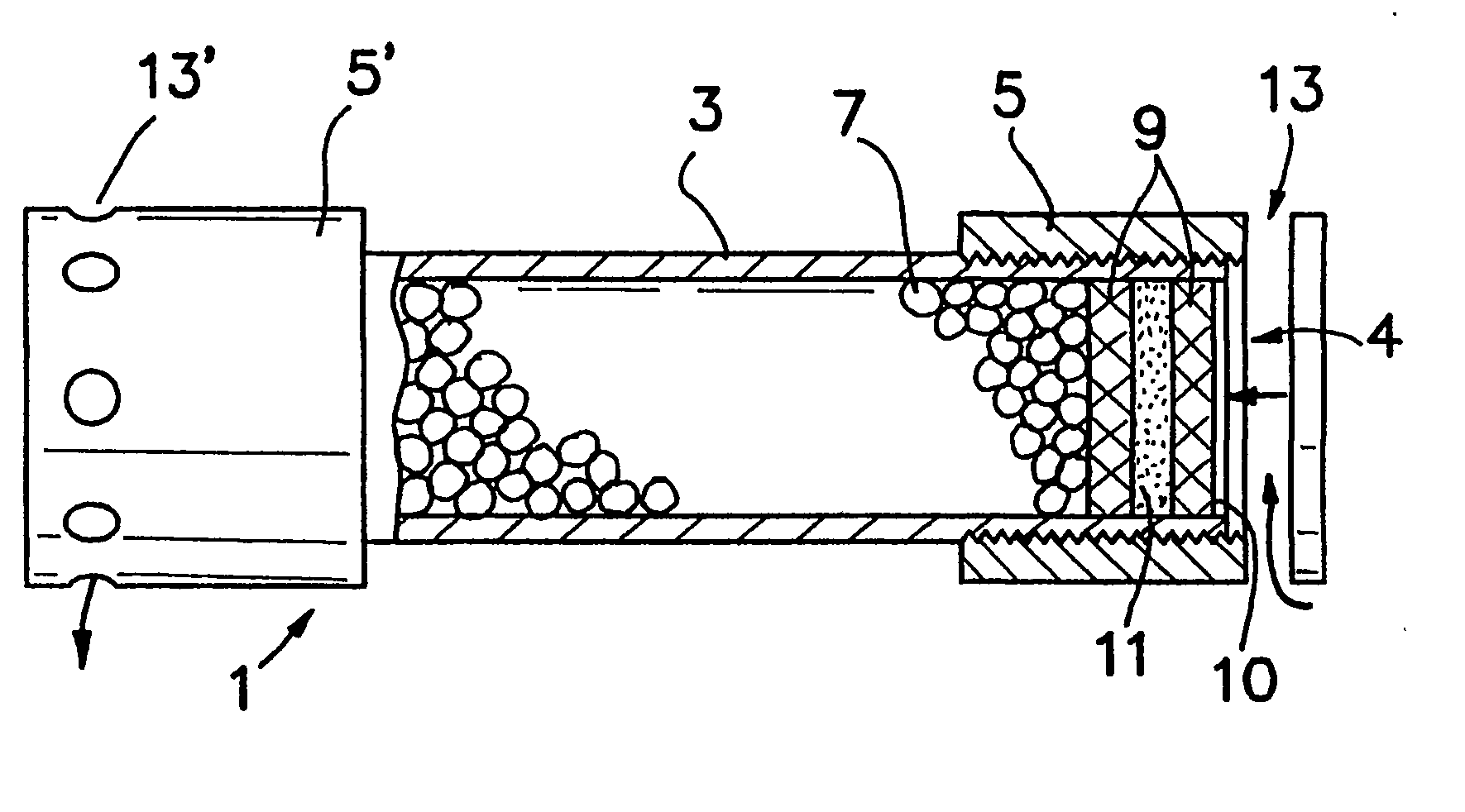

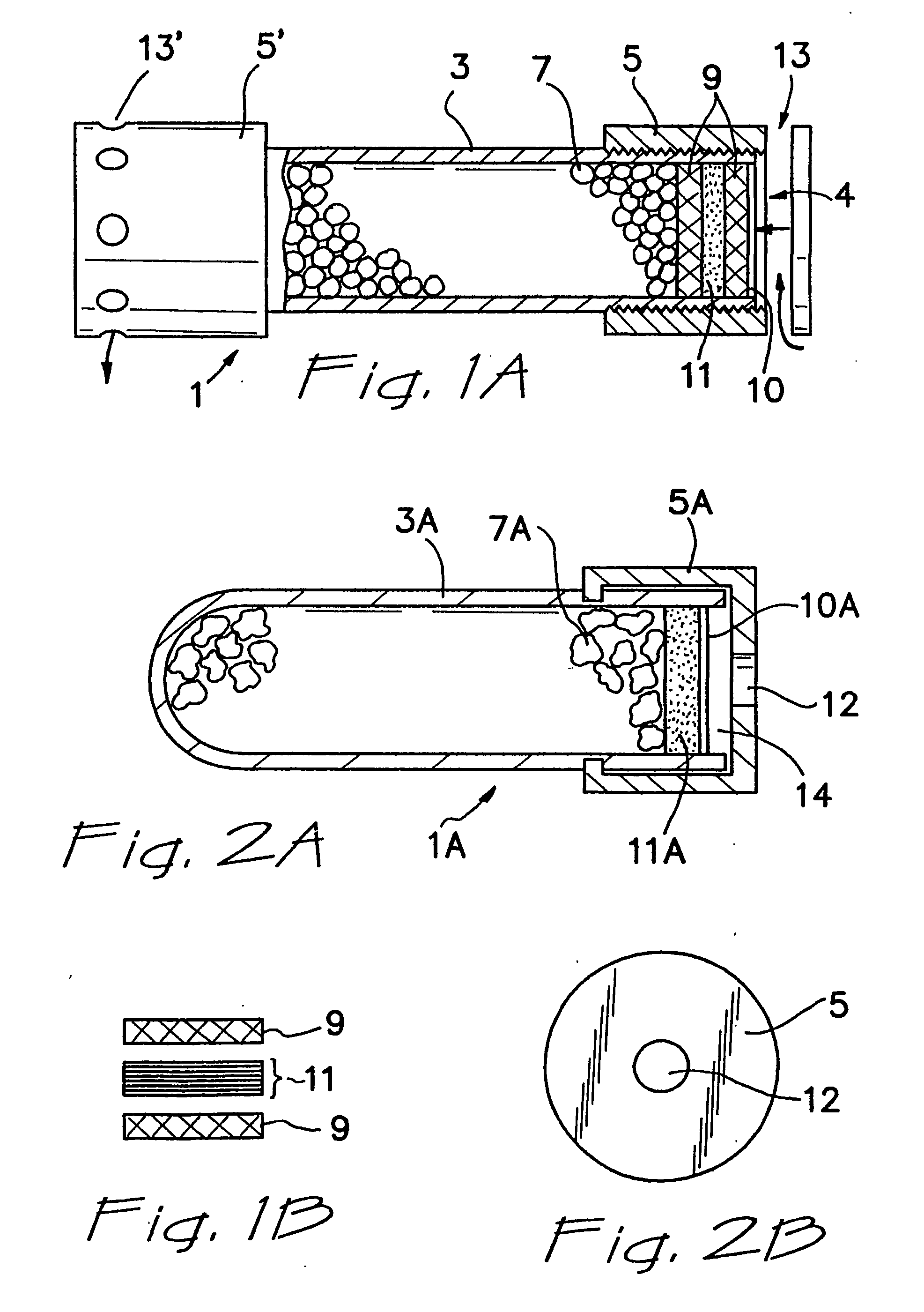

Controlled release of additives in fluid systems

ActiveUS20050019236A1Easy and straightforward to manufacture cost effectivelyCost-effective manufacturingFlow mixersSolid sorbent liquid separationControlled releaseCompound (substance)

A container (1) for releasing a chemical additive (7) in a fluid material selected from a lubricant or hydraulic fluid composition comprises a fluid material-impermeable casing (3) having a hollow interior and an additive composition (7) comprising at least one fluid material-soluble additive. The additive (7) is held within the container (1) by a least one fluid material-permeable element (11) provided at or near an opening (13) in the casing (1) and is effective to provide for release of additive(s) (7) into the fluid material. Methods of releasing additives (7) into fluid material are also provided.

Owner:CUMMINS FILTRATION IP INC +1

Apparatus and method for filter cleaning by ultrasound, backwashing and filter movement during the filtration of biological samples

InactiveUS8273253B2Minimises fouling and clogging of filterImprove overall efficiency and accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsCyclic processVacuum pressure

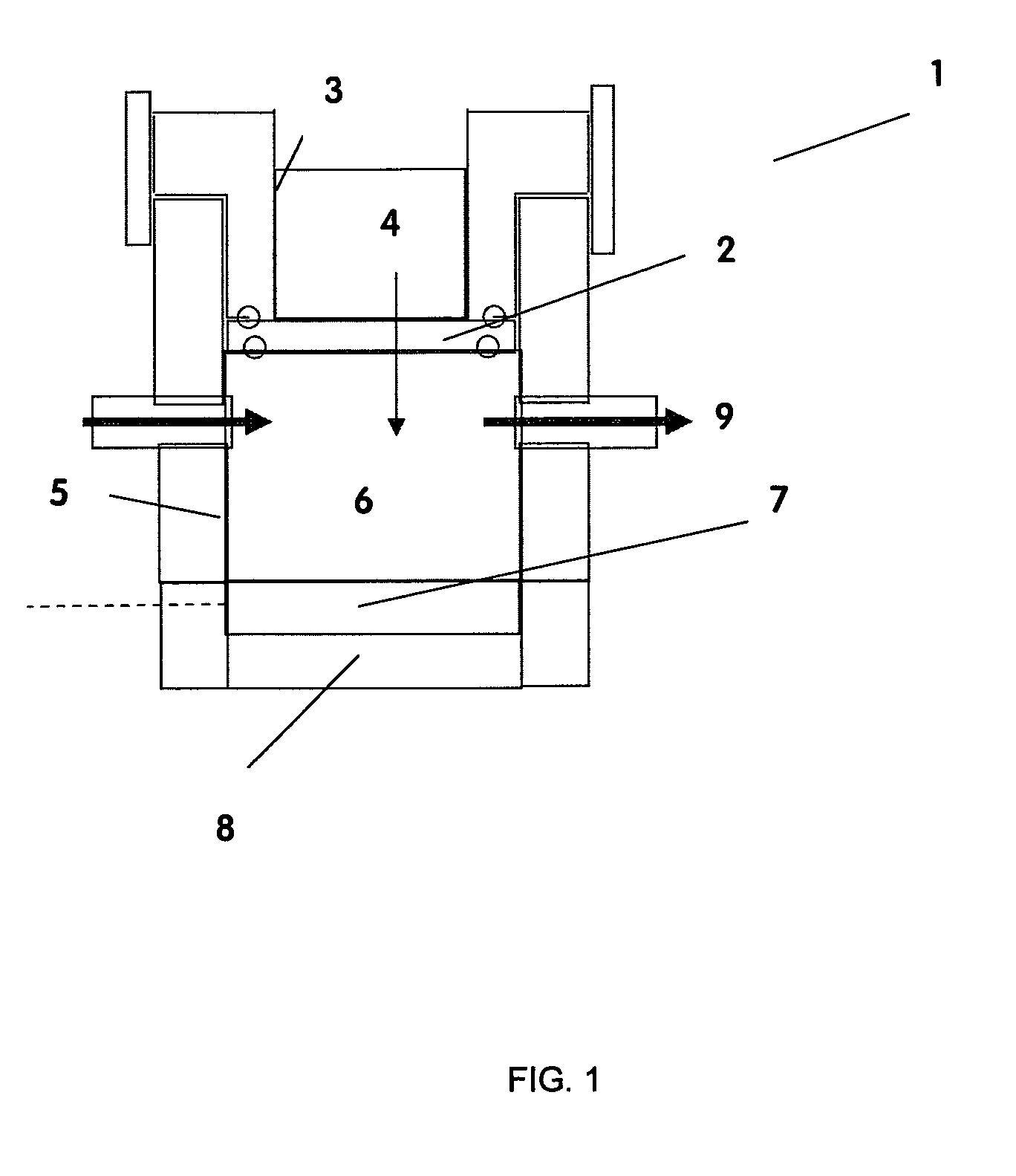

The present application is directed to the separation of—a solid fraction from a fluid sample particularly a therapeutic cellular fraction from a biological sample such as a bone marrow sample by a porous filter (2) which separates a filtration unit (1) into an upper pre-filtration chamber (3) into which a fluid sample (4) requiring cell separation is introduced and a lower post-filtration chamber (5) into which a fluid (6) capable of transmitting an acoustic standing wave is introduced. An acoustic element (8) is coupled to a substrate (7) which is located within and at the bottom of the lower chamber (5) and which resonates in response to the acoustic generating element (8) and generates a standing wave through the two fluid phases and the filter to agitate the sample (4). Simultaneously, a cyclic process of vacuum draw (9). causes movement of the sample (4) downwards through the filter (2). Vacuum pressure, fluid flow rate and frequency of vibration are controlled from a remote unit housing appropriate pumps and valves.

Owner:SMITH & NEPHEW INC

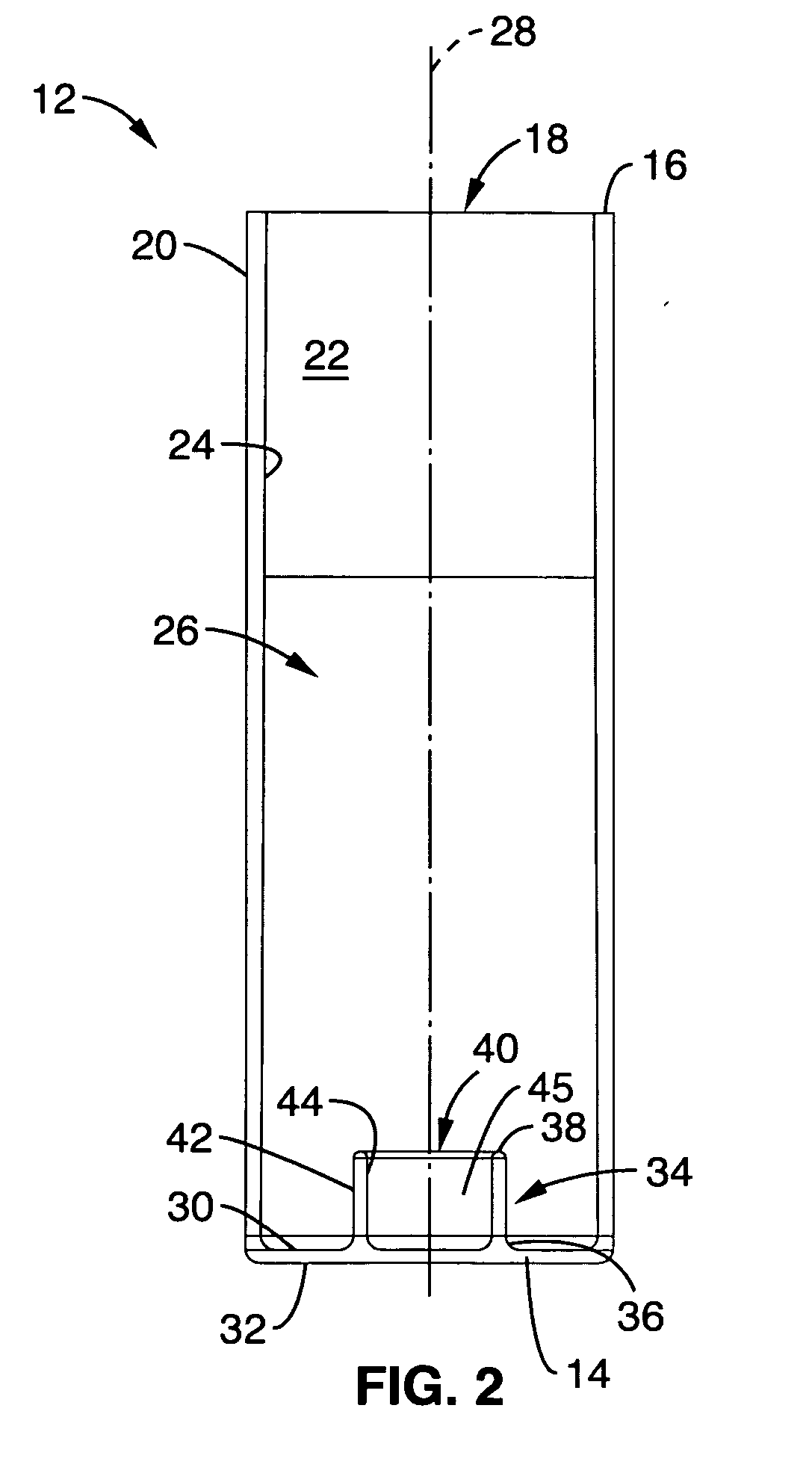

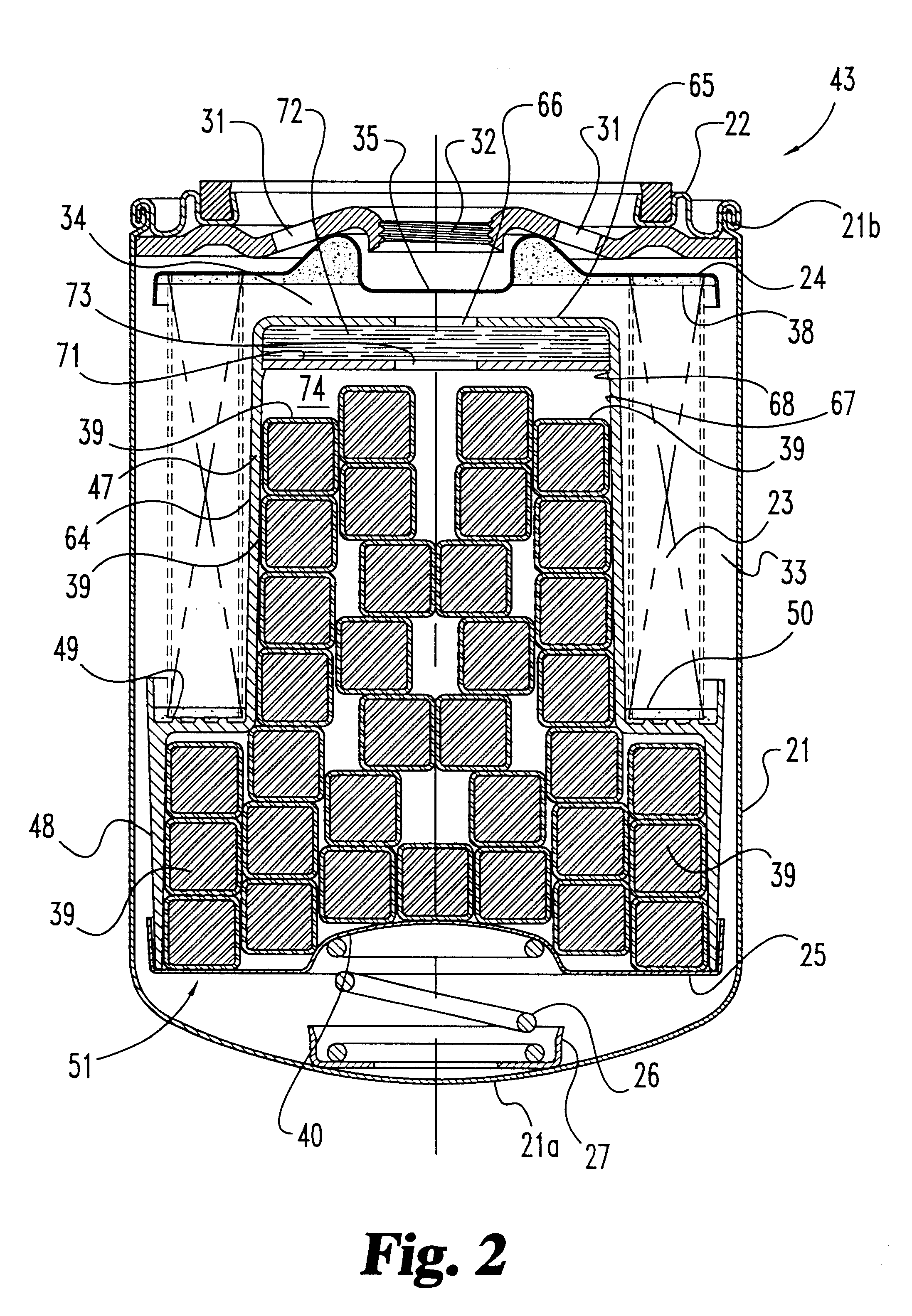

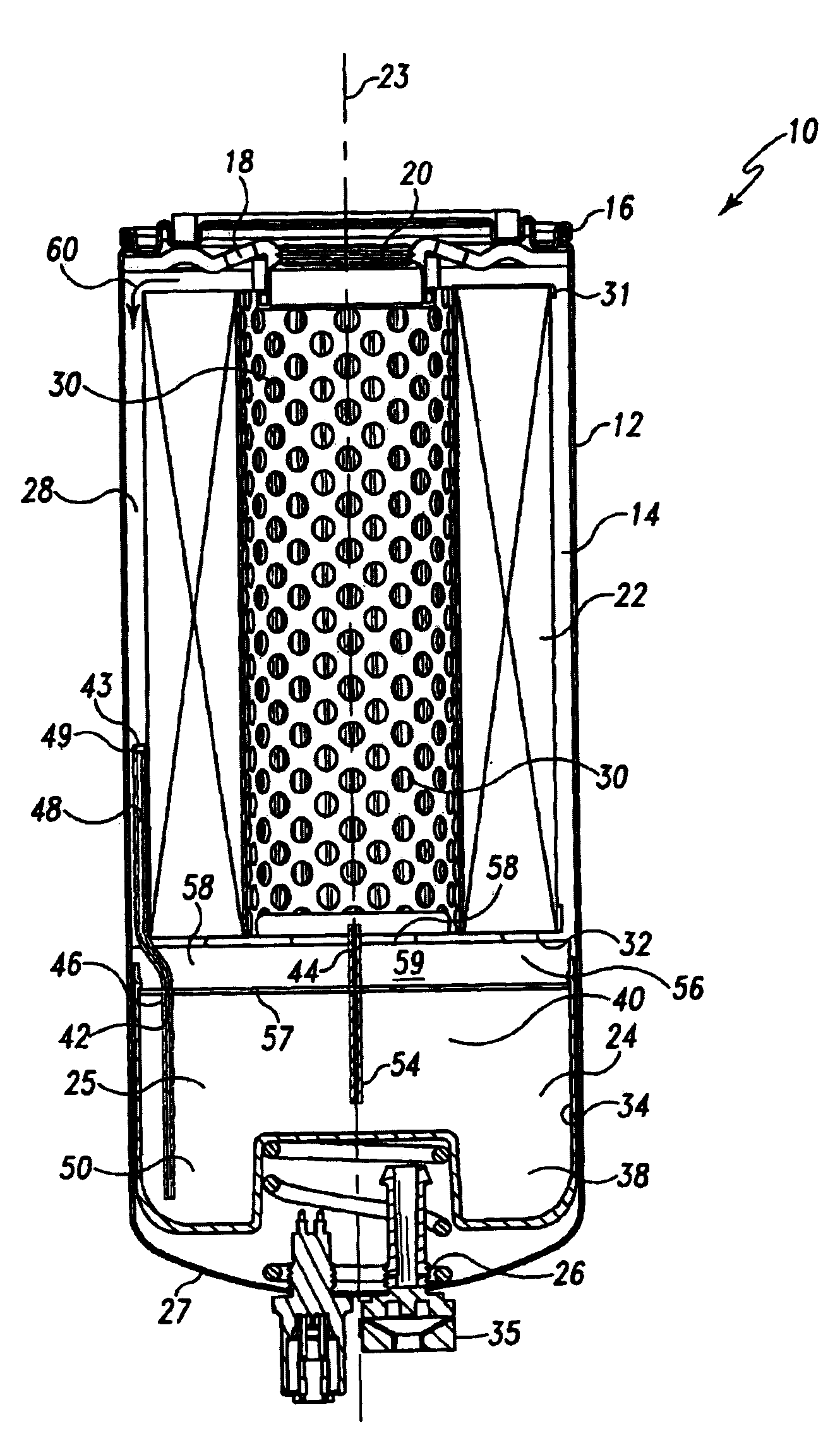

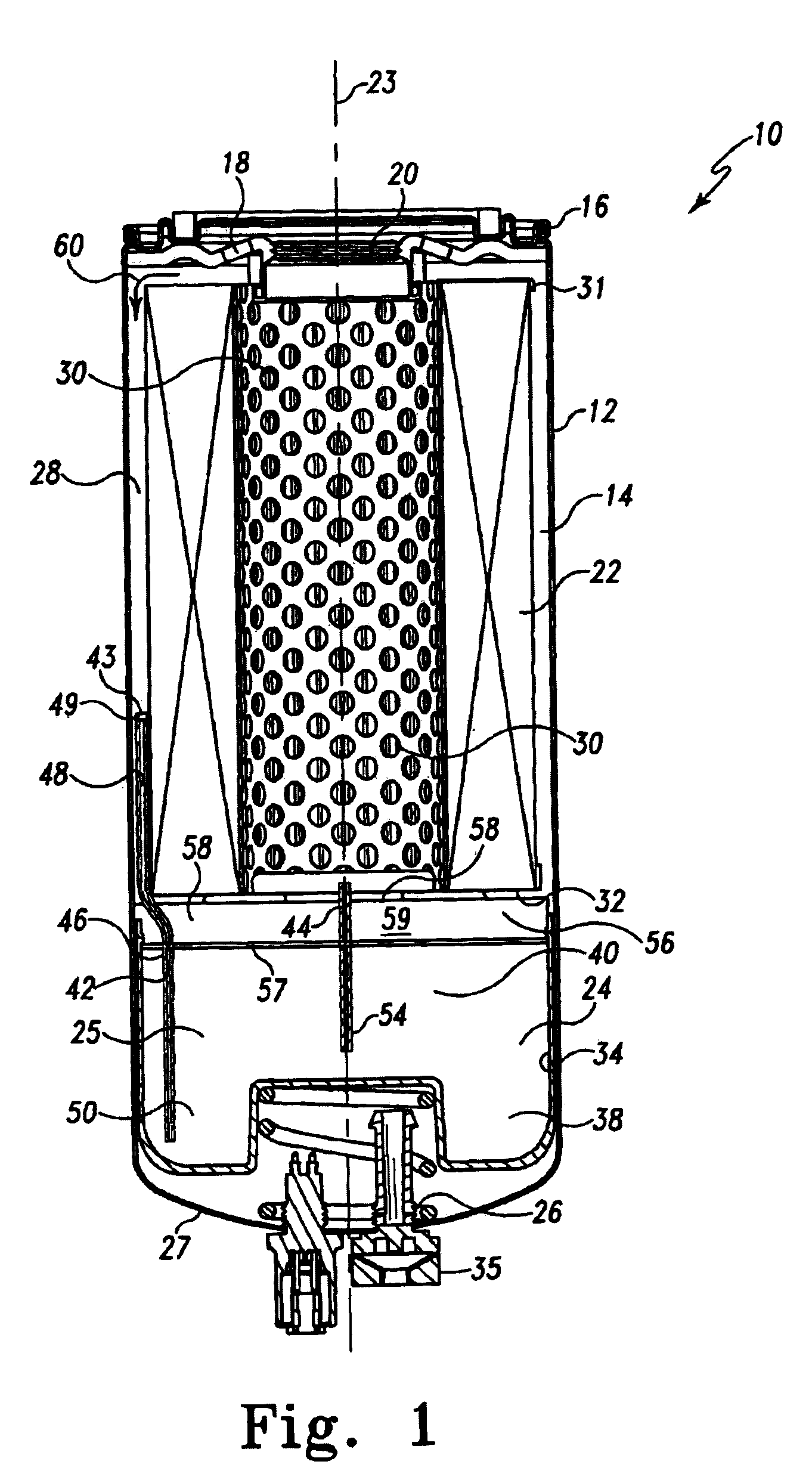

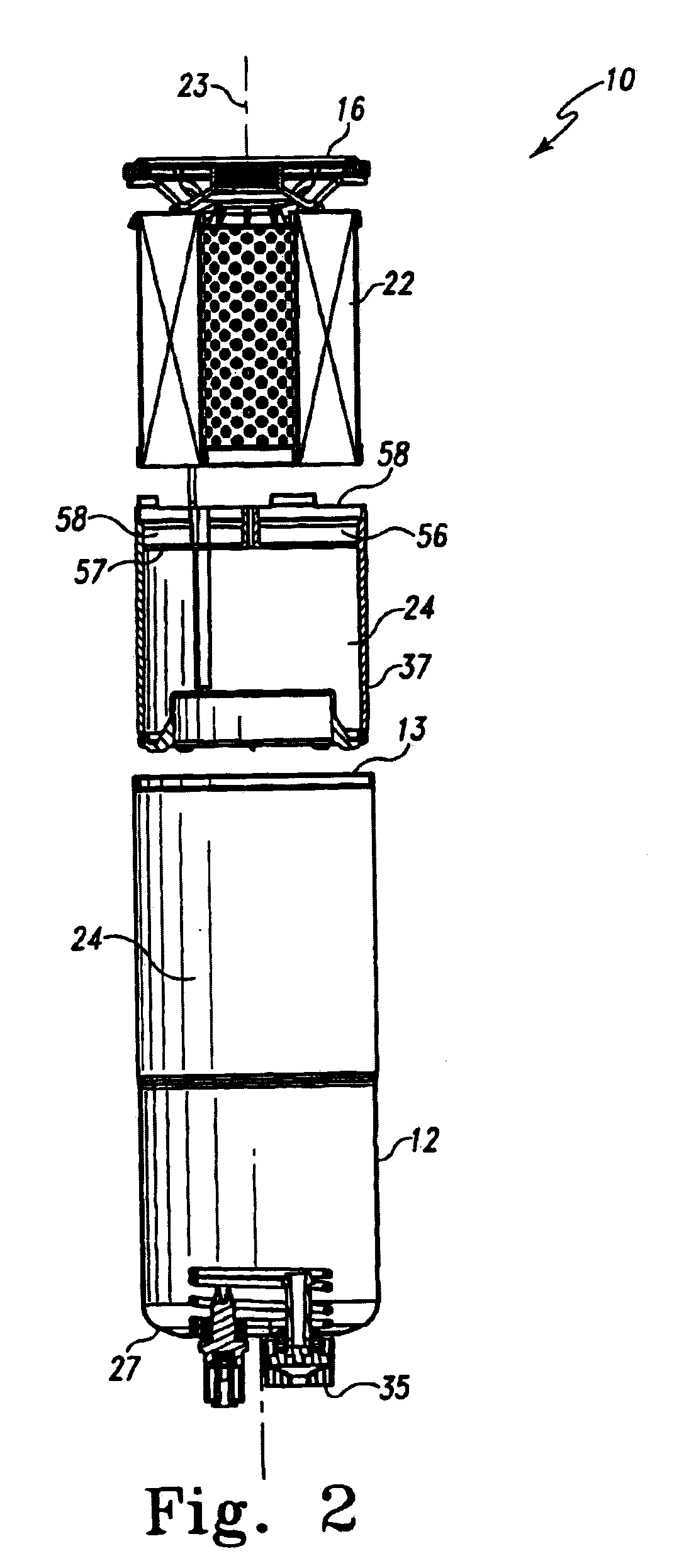

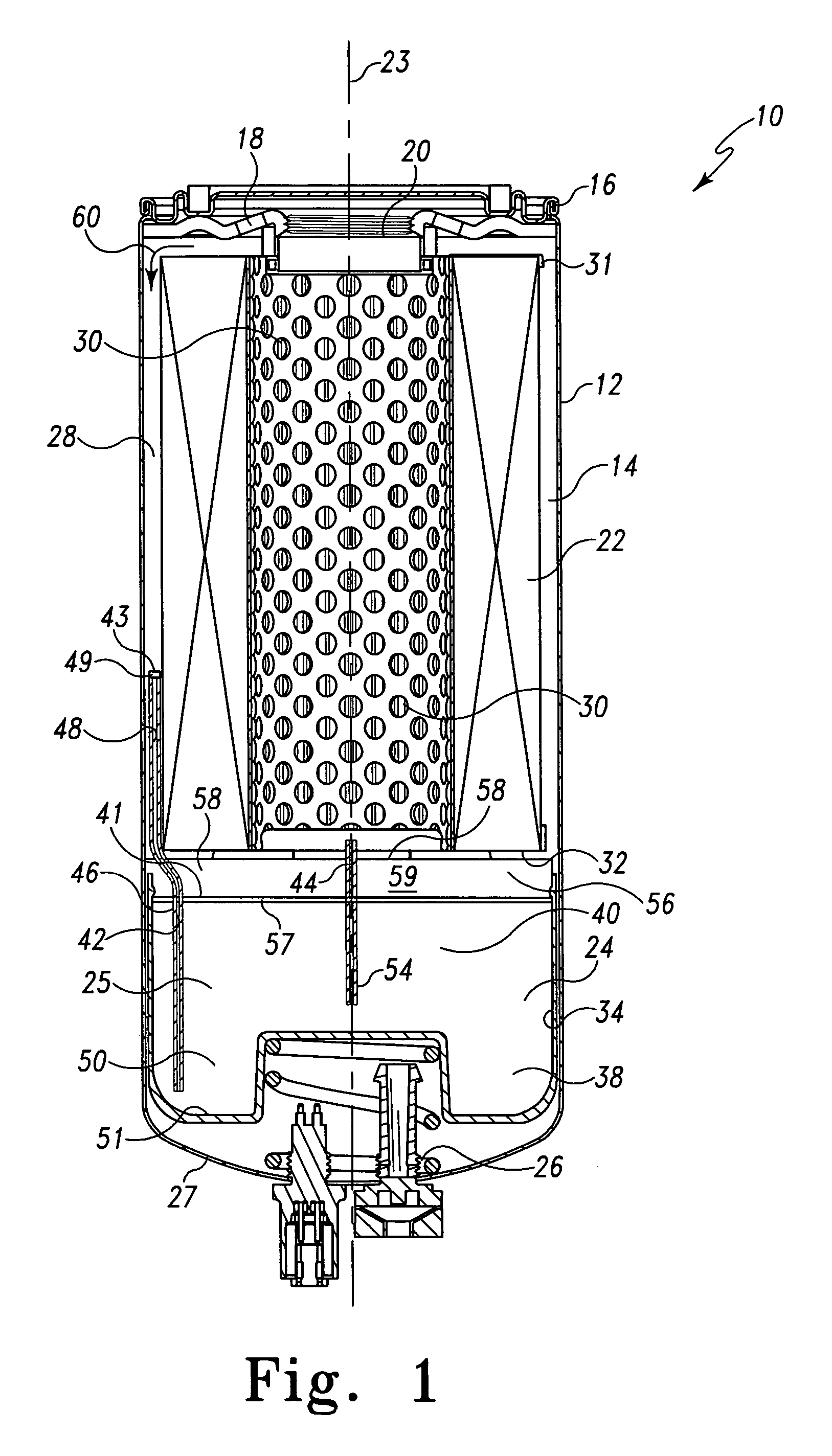

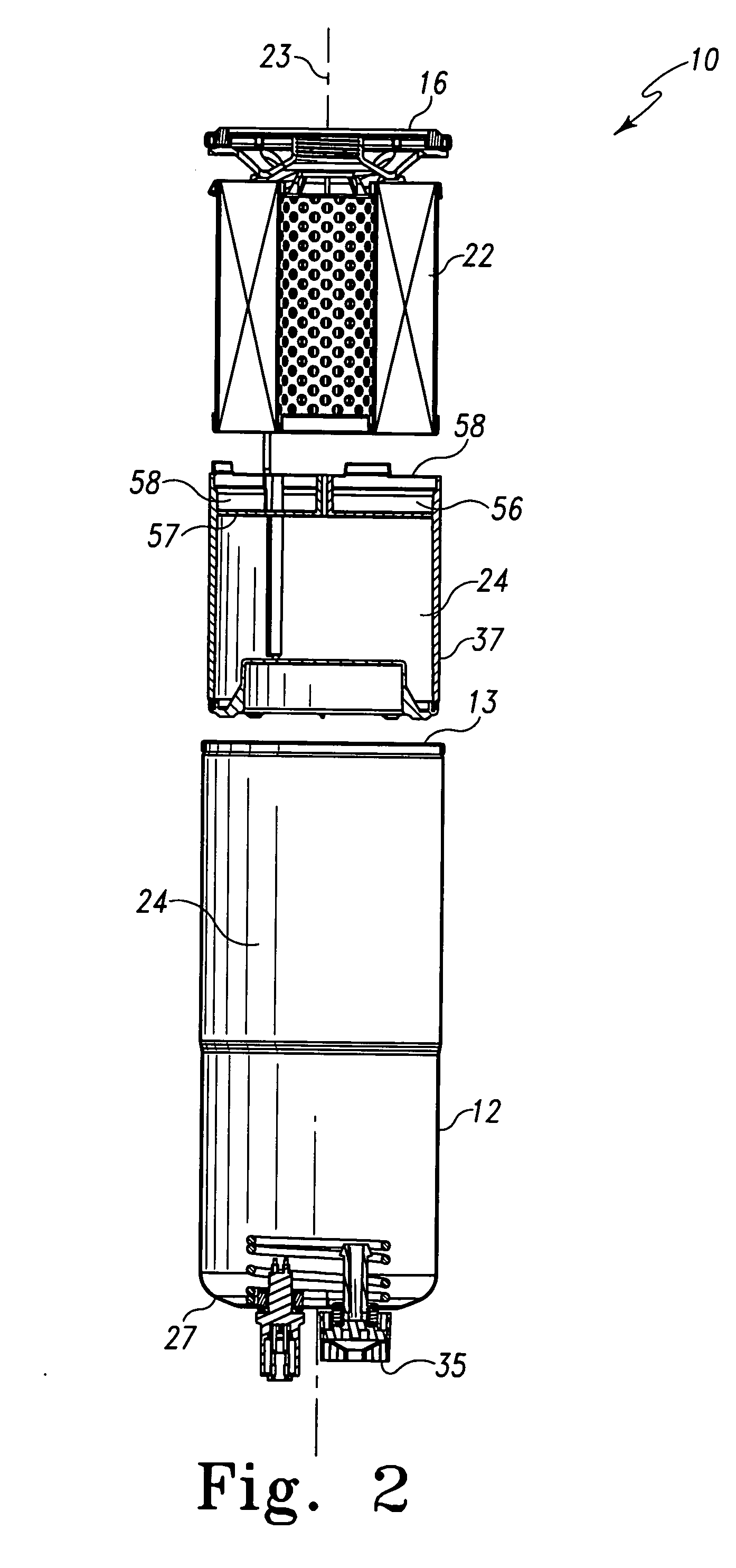

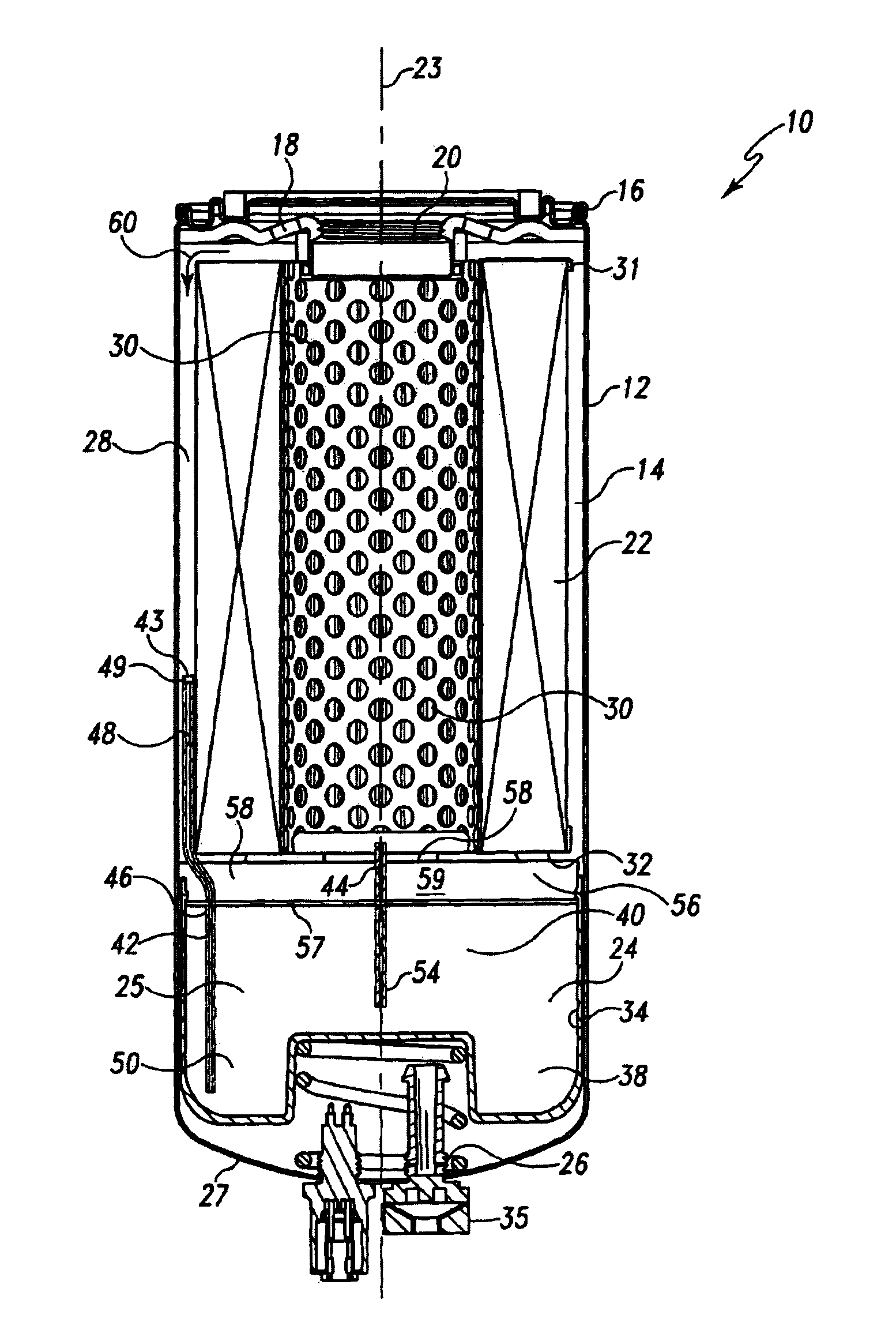

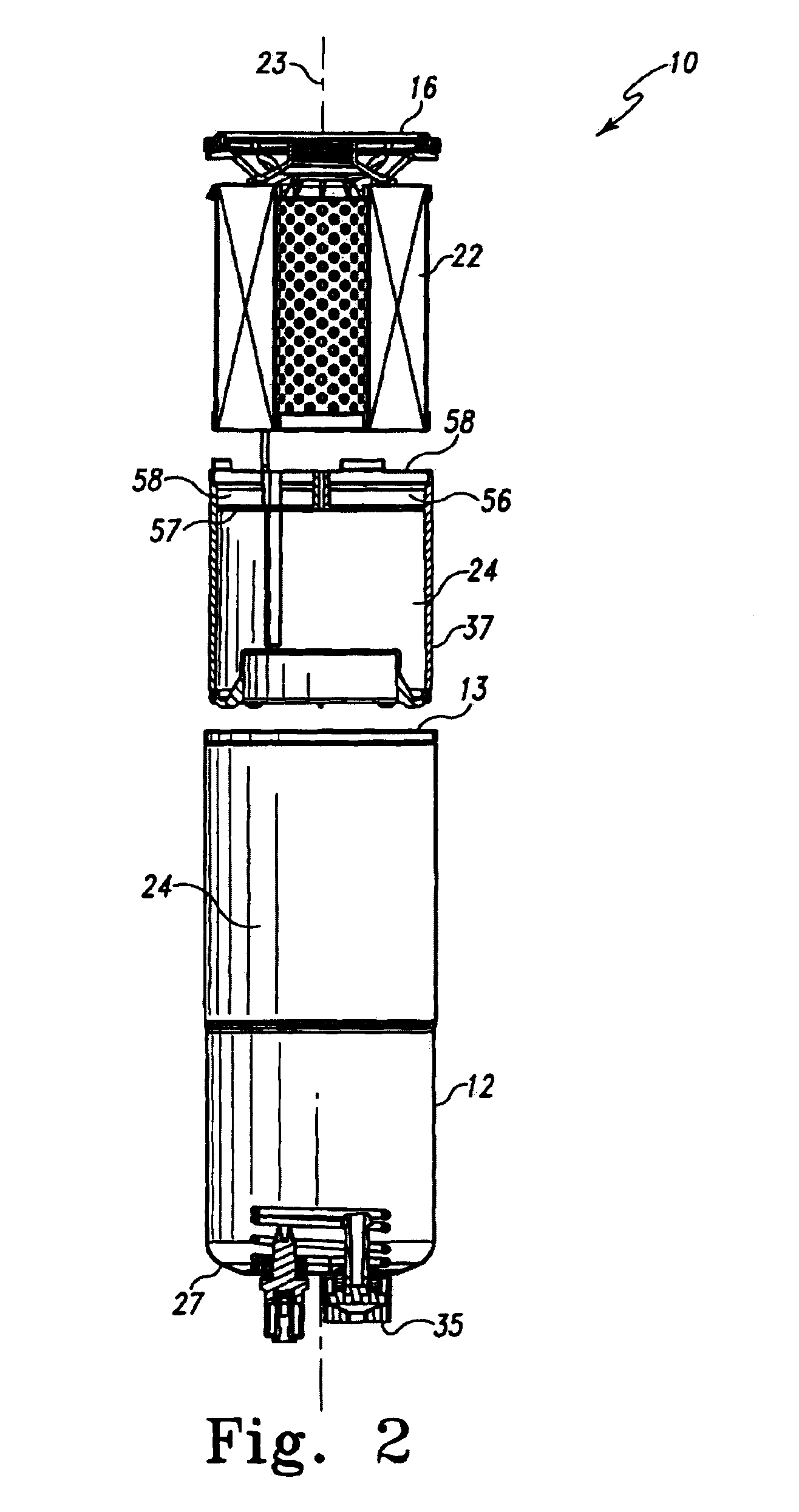

Slow release coolant filter

InactiveUSRE37369E1Transportation and packagingSolid sorbent liquid separationEngineeringCooling fluid

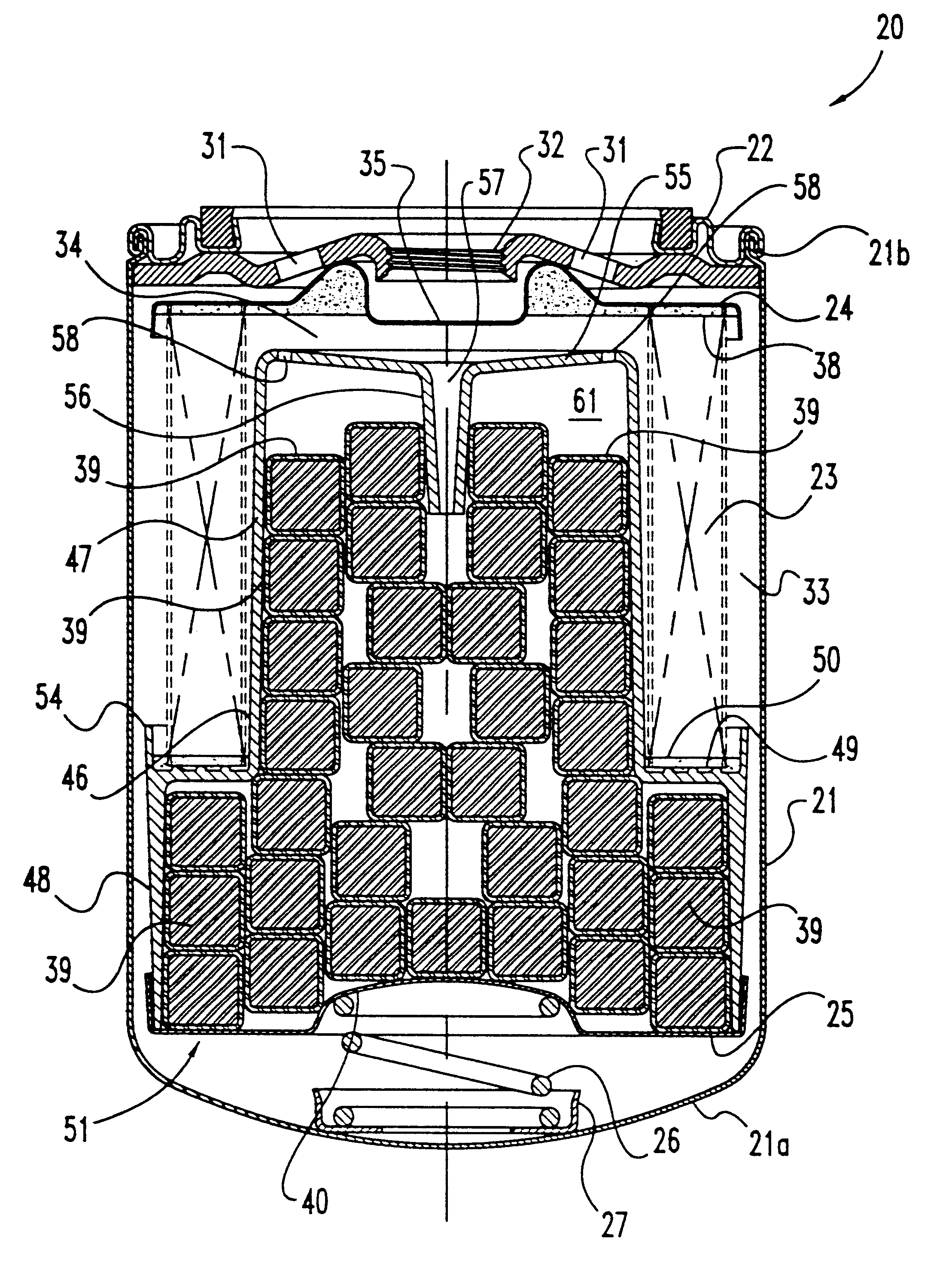

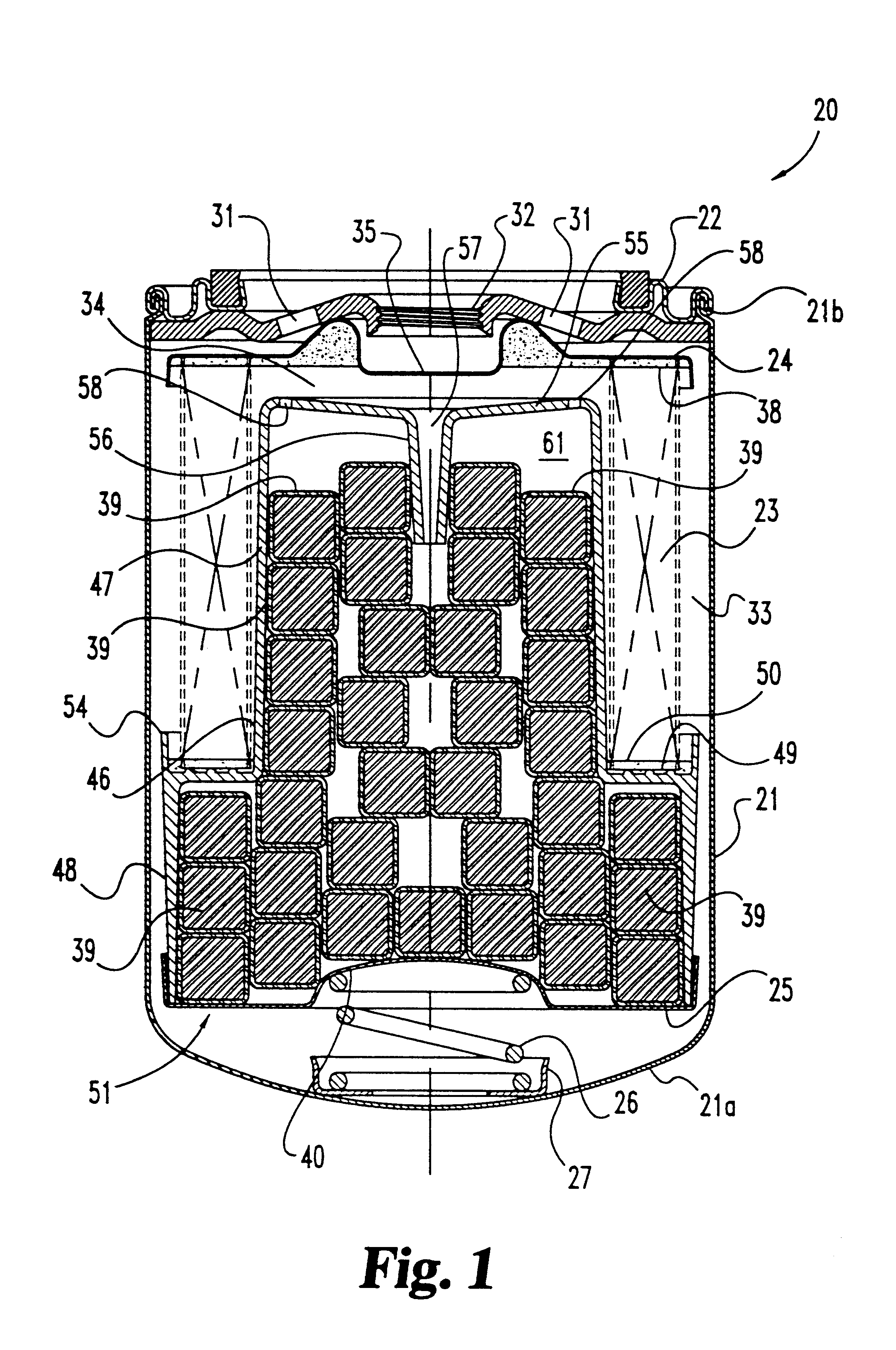

A coolant filter for use in filtering a coolant solution which flows through the coolant filter includes a filter housing assembly which is made up of an outer housing which is crimped to a nutplate which defines an internally threaded flow outlet. A generally cylindrical filter element is positioned inside of the filter housing assembly and a first endplate is bonded to the end of the filter element which is adjacent to the nutplate. An endplate member is provided for attachment to the opposite end of the filter element and is configured in such a way so as to define an interior chamber where supplemental coolant additive pellets are stored. A closing plate is applied across the open end of the interior chamber so as to create an enclosed chamber for the supplemental coolant additive pellets. A slow release mechanism is provided for controlling the rate of release of the supplemental coolant additive from the enclosed chamber into the coolant solution. In one embodiment of the present invention, the slow release mechanism includes a diffusion tube which defines a diffusion orifice. In another embodiment of the present invention, the slow release mechanism includes a semipermeable (or osmotic) membrane wafer. In both instances, the slow release mechanism is positioned between the source of supplemental coolant additive and the flow outlet in the nutplate.

Owner:FLEETGUARD INC

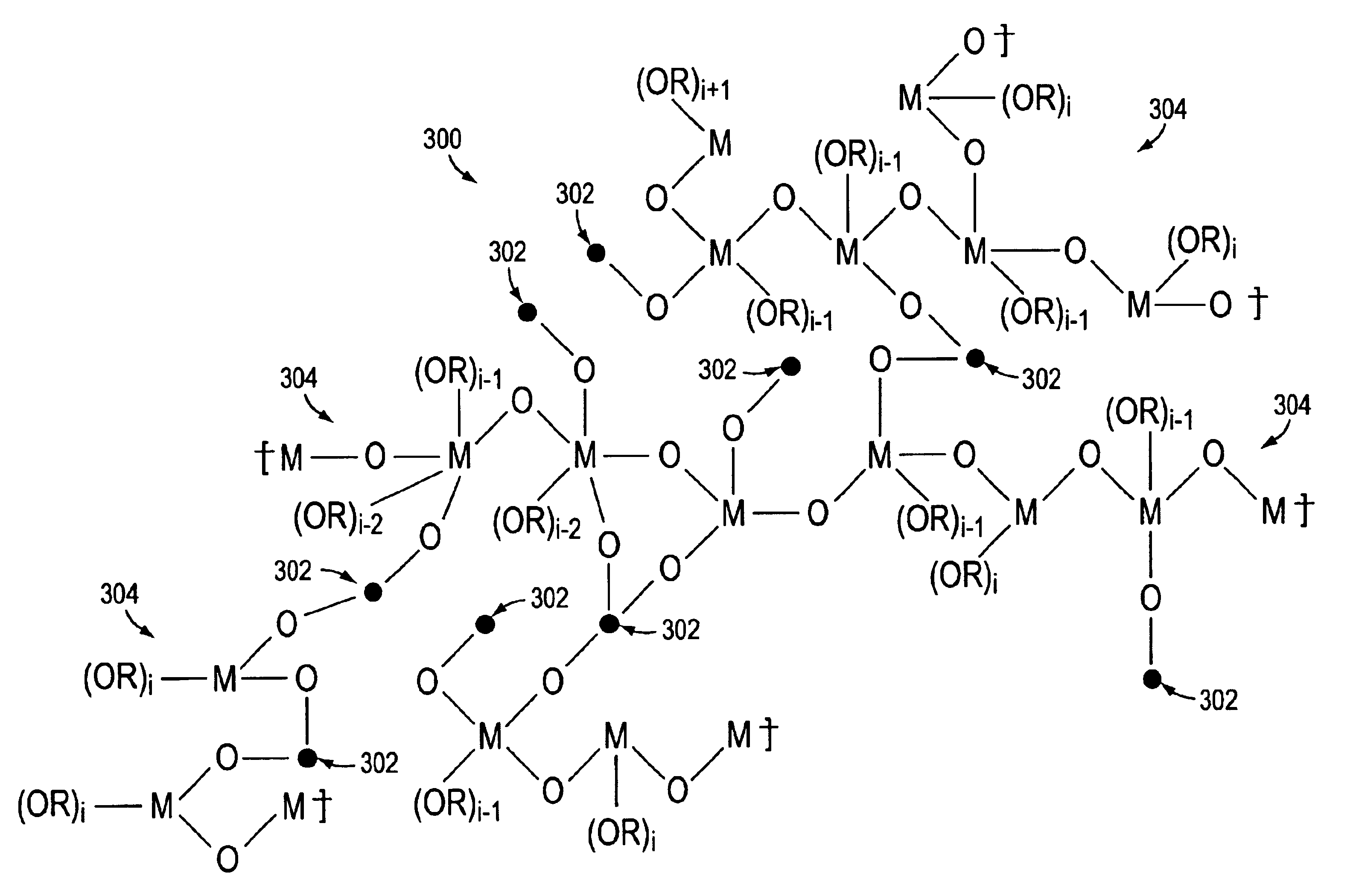

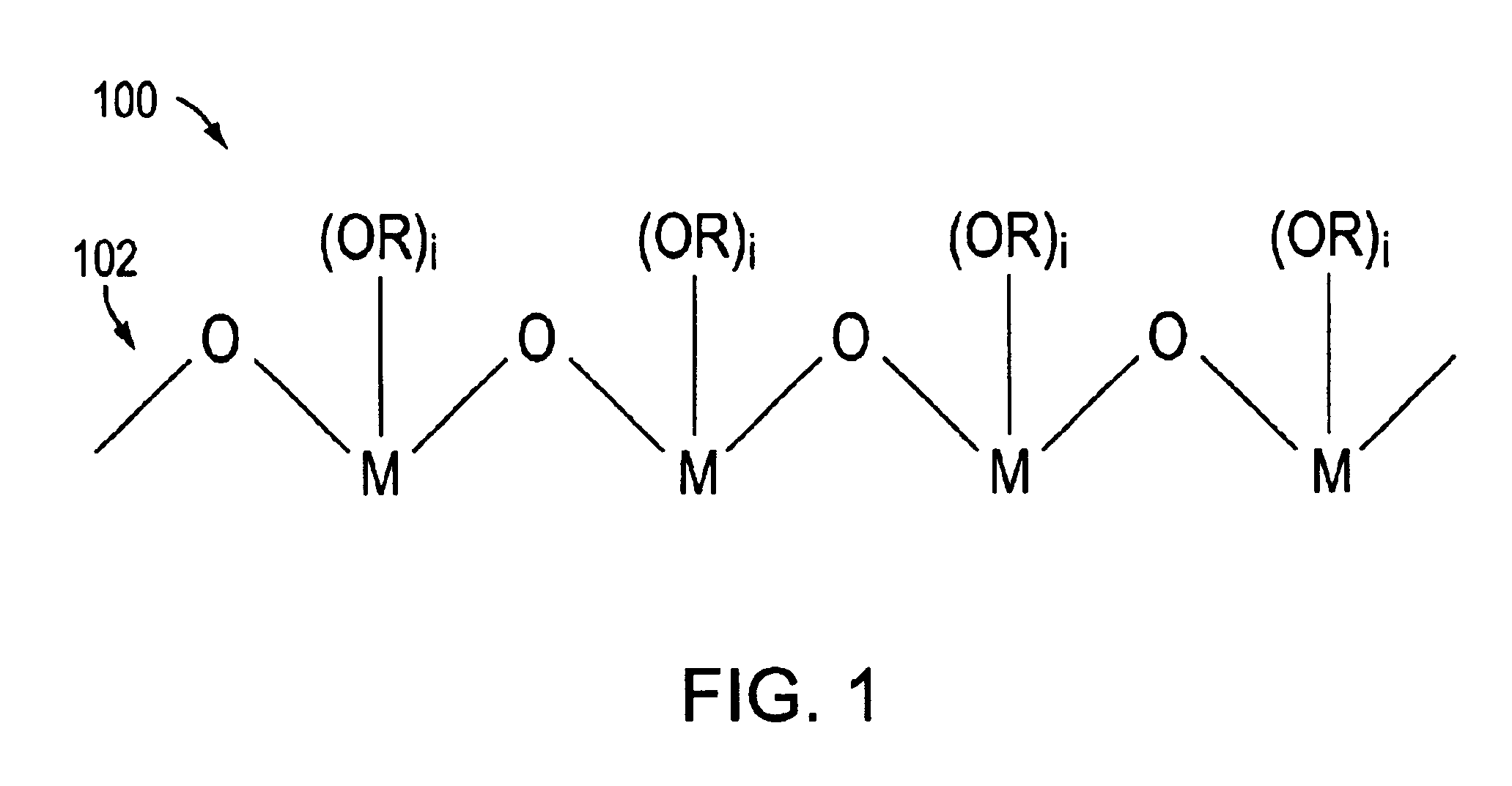

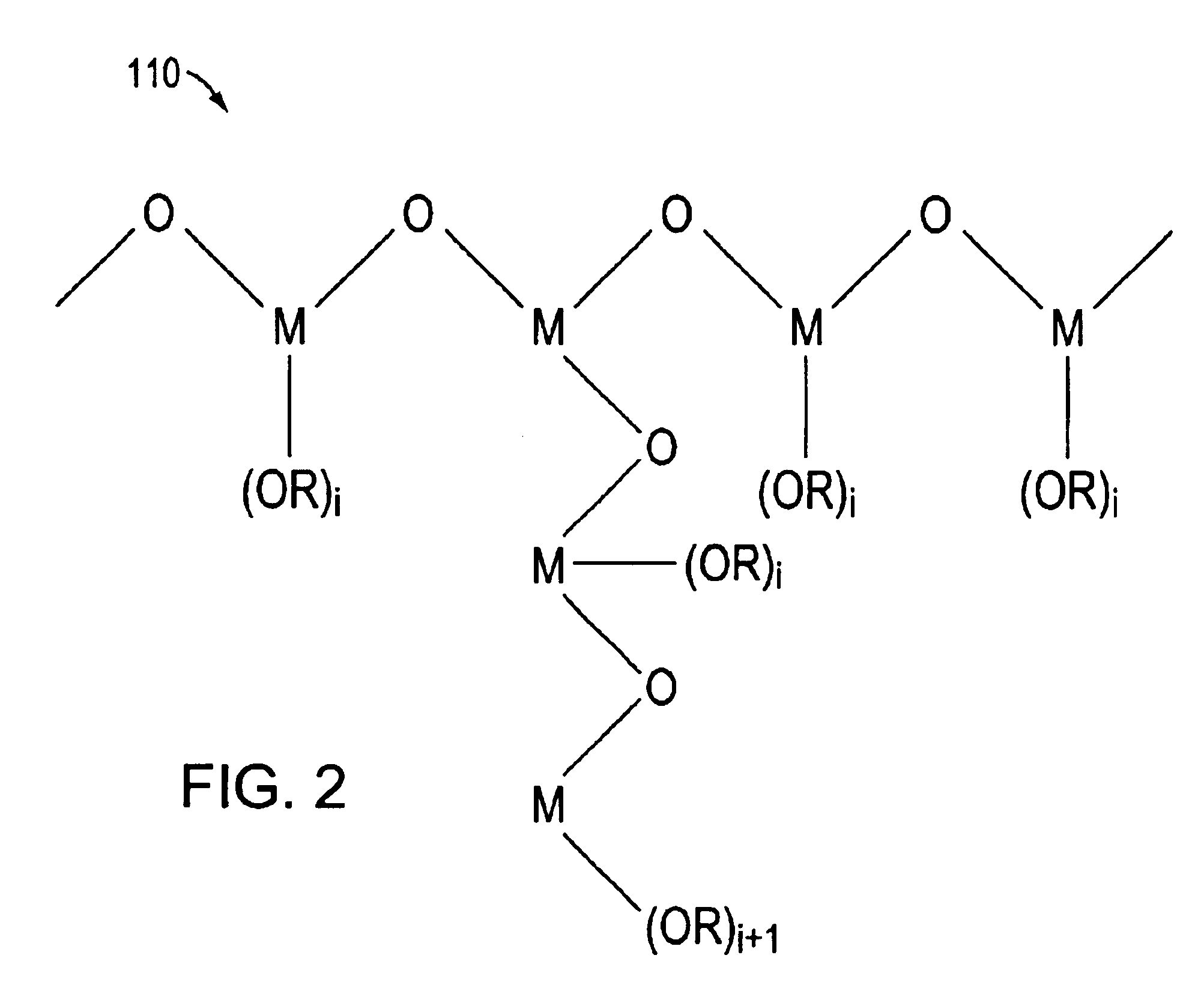

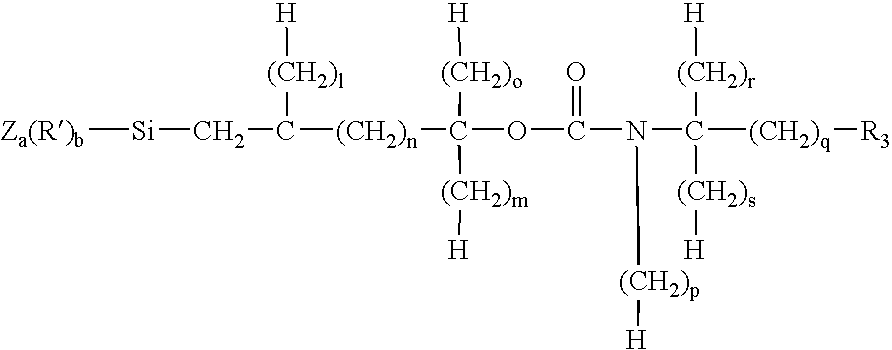

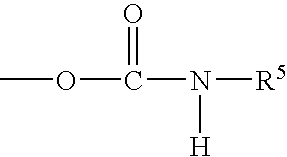

Porous inorganic/organic hybrid particles for chromatographic separations and process for their preparation

InactiveUS7223473B2Chromatographic cation exchangersComponent separationChromatographic separationNew materials

Novel material for chromatographic separations, processes for its preparation, and separations devices containing the chromatographic material. In particular, the disclosure describes porous inorganic / organic hybrid particles having a chromatographically-enhancing pore geometry, which desirably may be surface modified, and that offer more efficient chromatographic separations than that known in the art.

Owner:WATERS TECH CORP

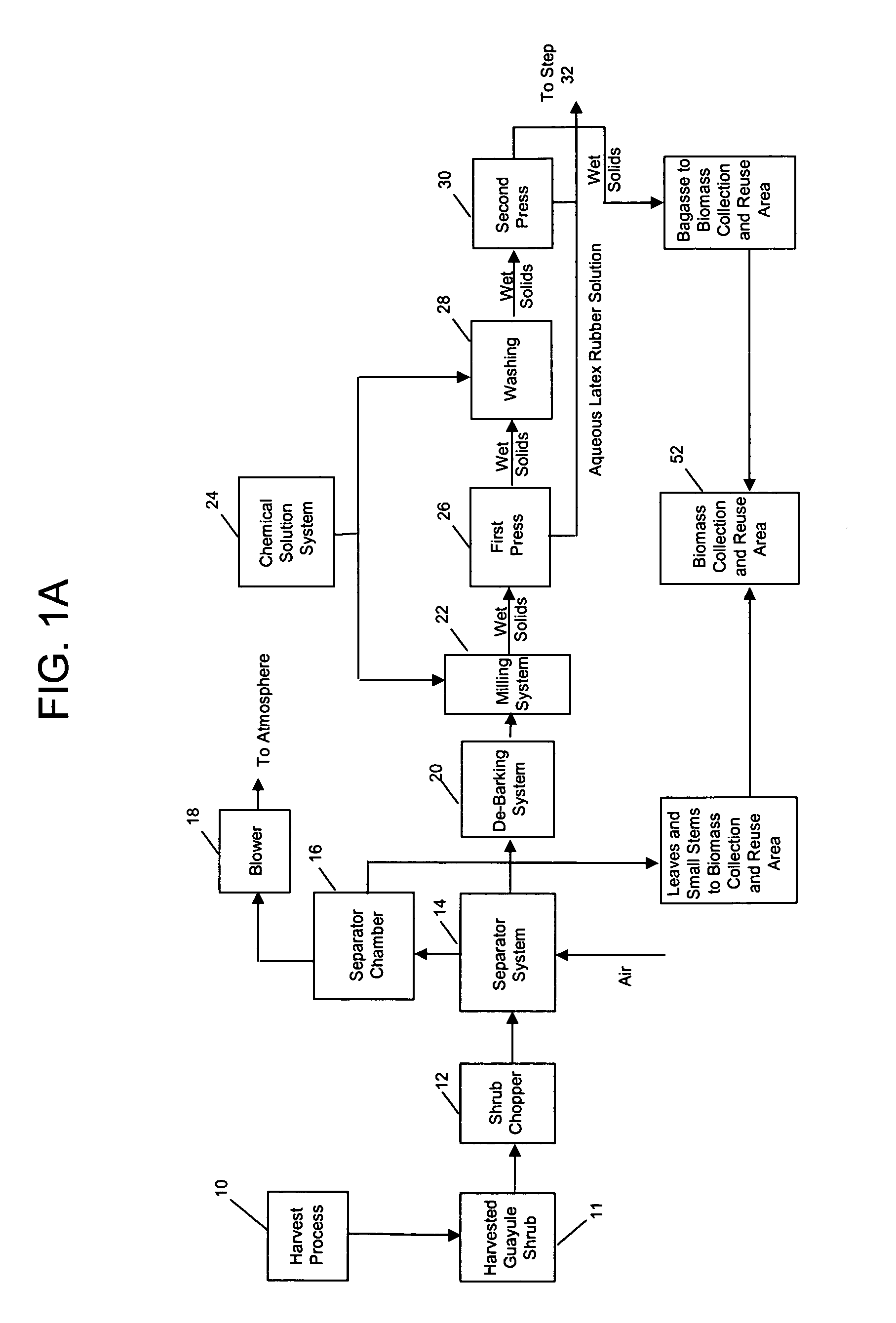

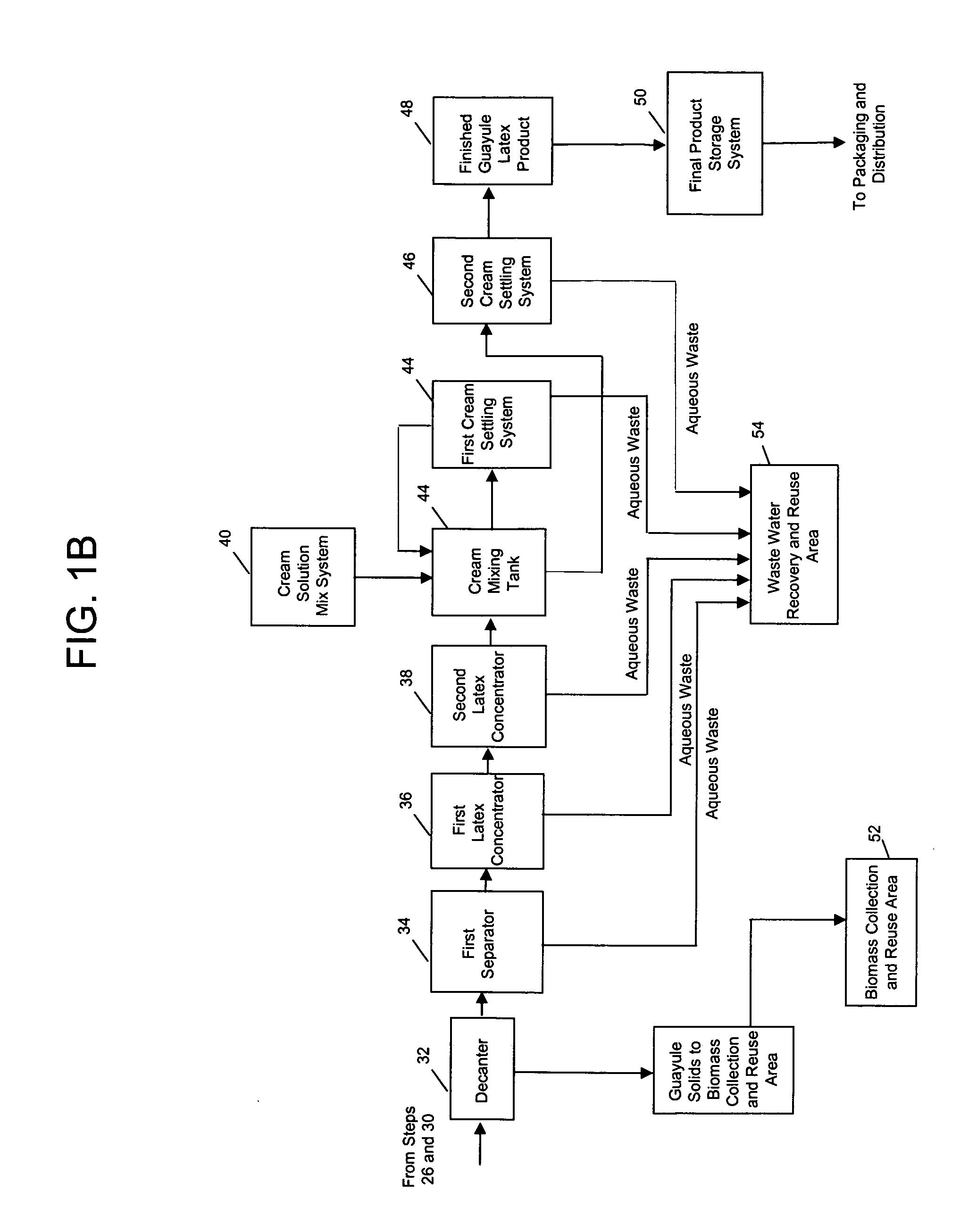

Biopolymer extraction from plant materials

Disclosed is a method and apparatus for the extraction of high molecular weight biopolymers from plants. Specifically, invention described herein relates to the commercial processing of plant material, including that from desert plants native to the southwestern United States and Mexico, such as the guayule plant (Parthenium argentatum), for the extraction of biopolymers, including natural rubbers. More specifically, the invention relates to laboratory to commercial scale extraction of high molecular weight biopolymers from plant materials including the chemical and mechanical processing of the plants and purification of the extracted biopolymer.

Owner:YULEX LLC

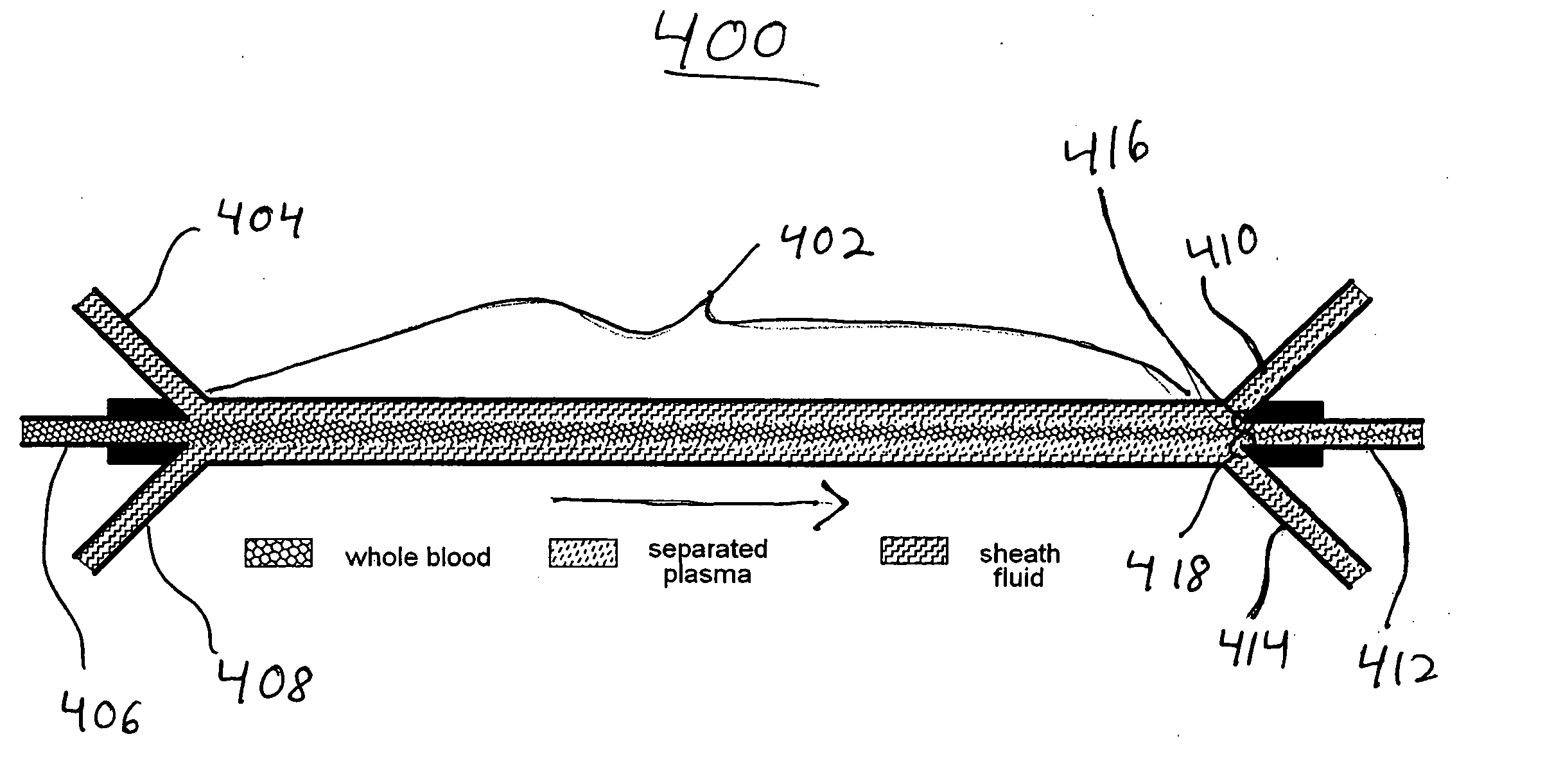

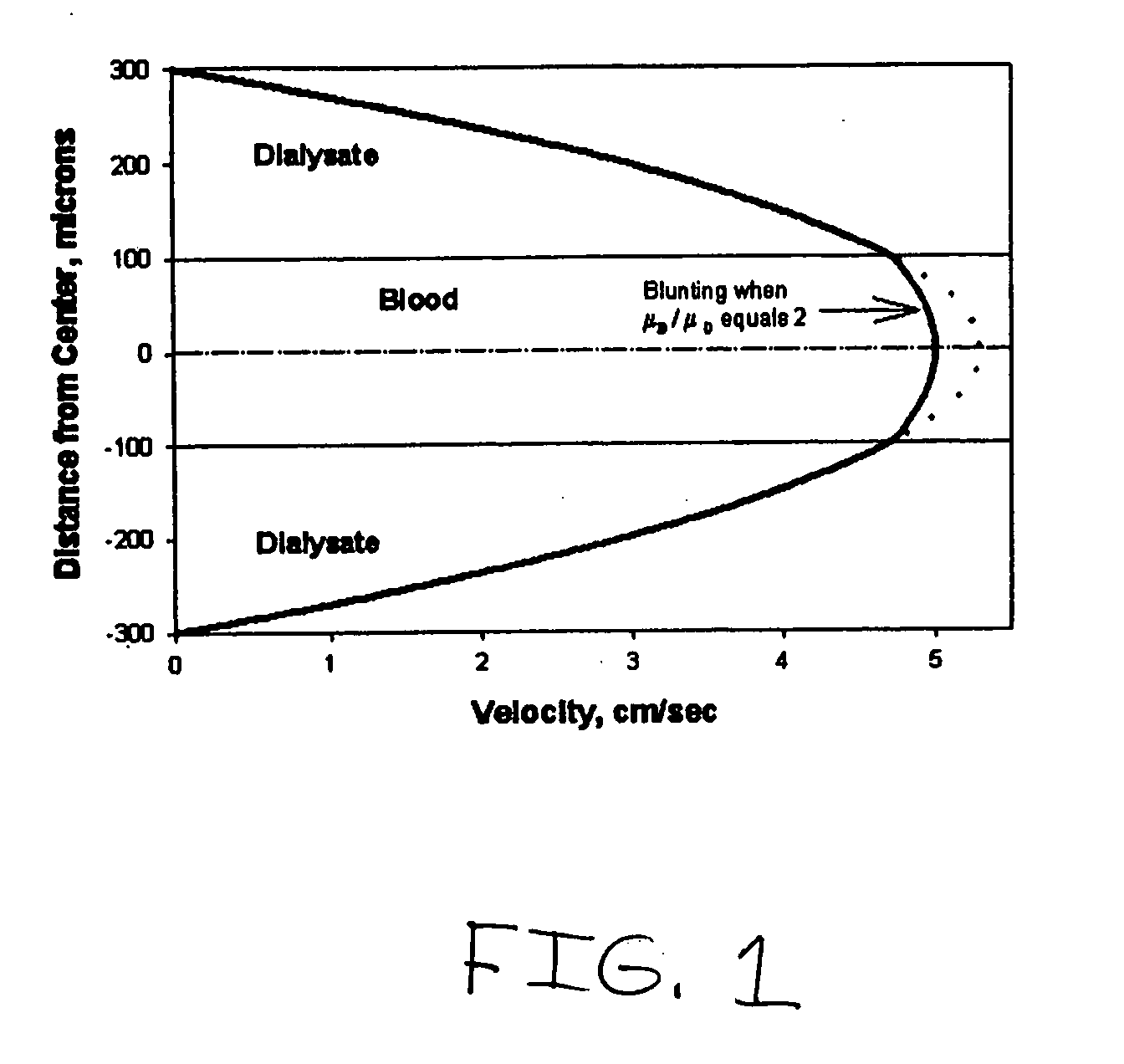

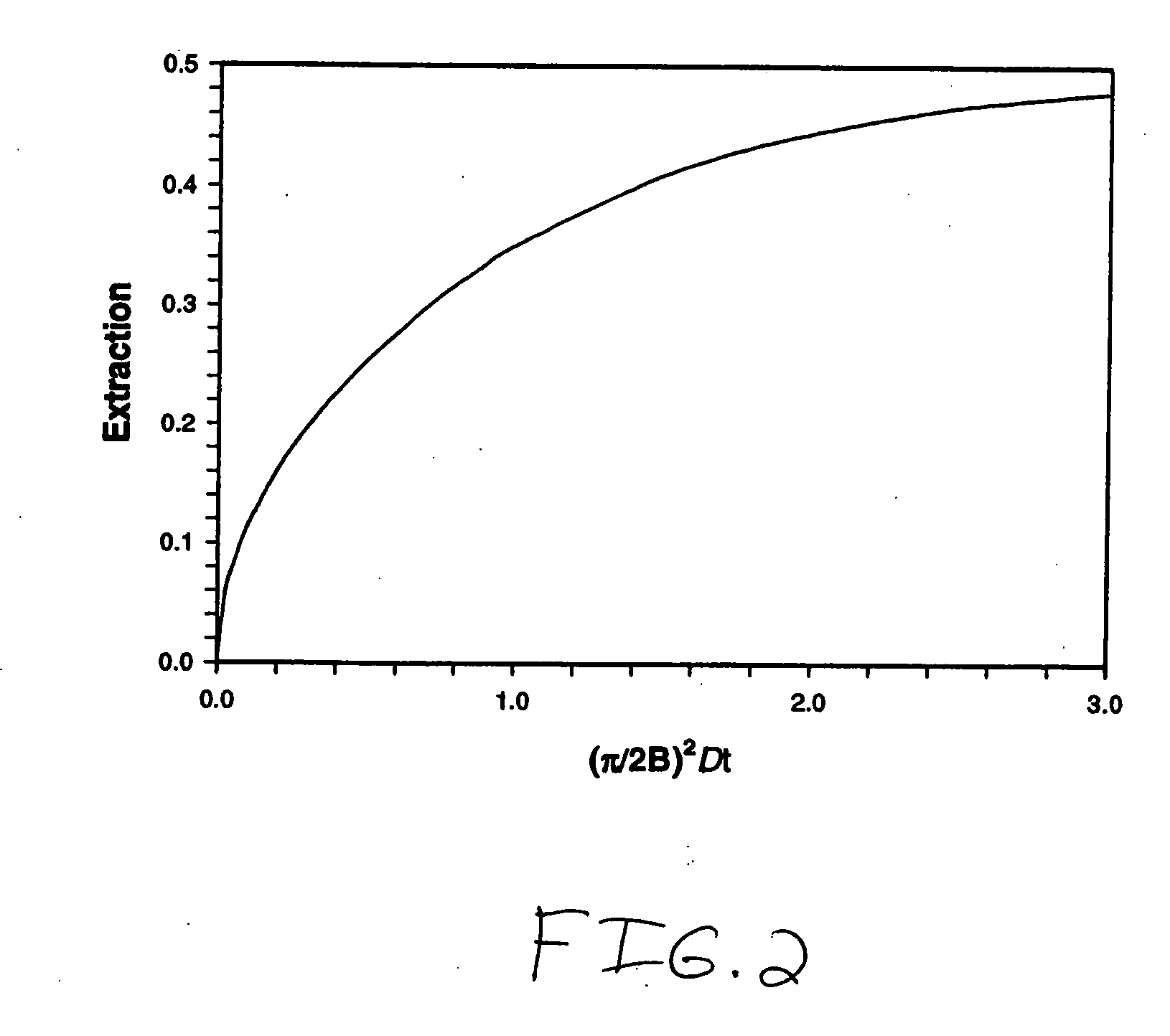

Systems and methods of blood-based therapies having a microfluidic membraneless exchange device

InactiveUS20060076295A1Reduces undesirable activationMinimizing bioincompatibilitiesComponent separationMedical devicesDiffusionThin layer

The present invention is directed to devices, systems and methods for removing undesirable materials from a sample fluid by contact with a second fluid. The sample fluid flows as a thin layer adjacent to, or between, concurrently flowing layers of the second fluid, without an intervening membrane. In various embodiments, a secondary separator is used to restrict the removal of desirable substances and effect the removal of undesirable substances from blood. The invention is useful in a variety of situations where a sample fluid is to be purified via a diffusion mechanism against an extractor fluid. Moreover, the invention may be used for the removal of components from a sample fluid that vary in size. When blood is the sample fluid, for example, this may include the removal of ‘small’ molecules, ‘middle’ molecules, macromolecules, macromolecular aggregates, and cells, from the blood sample to the extractor fluid.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

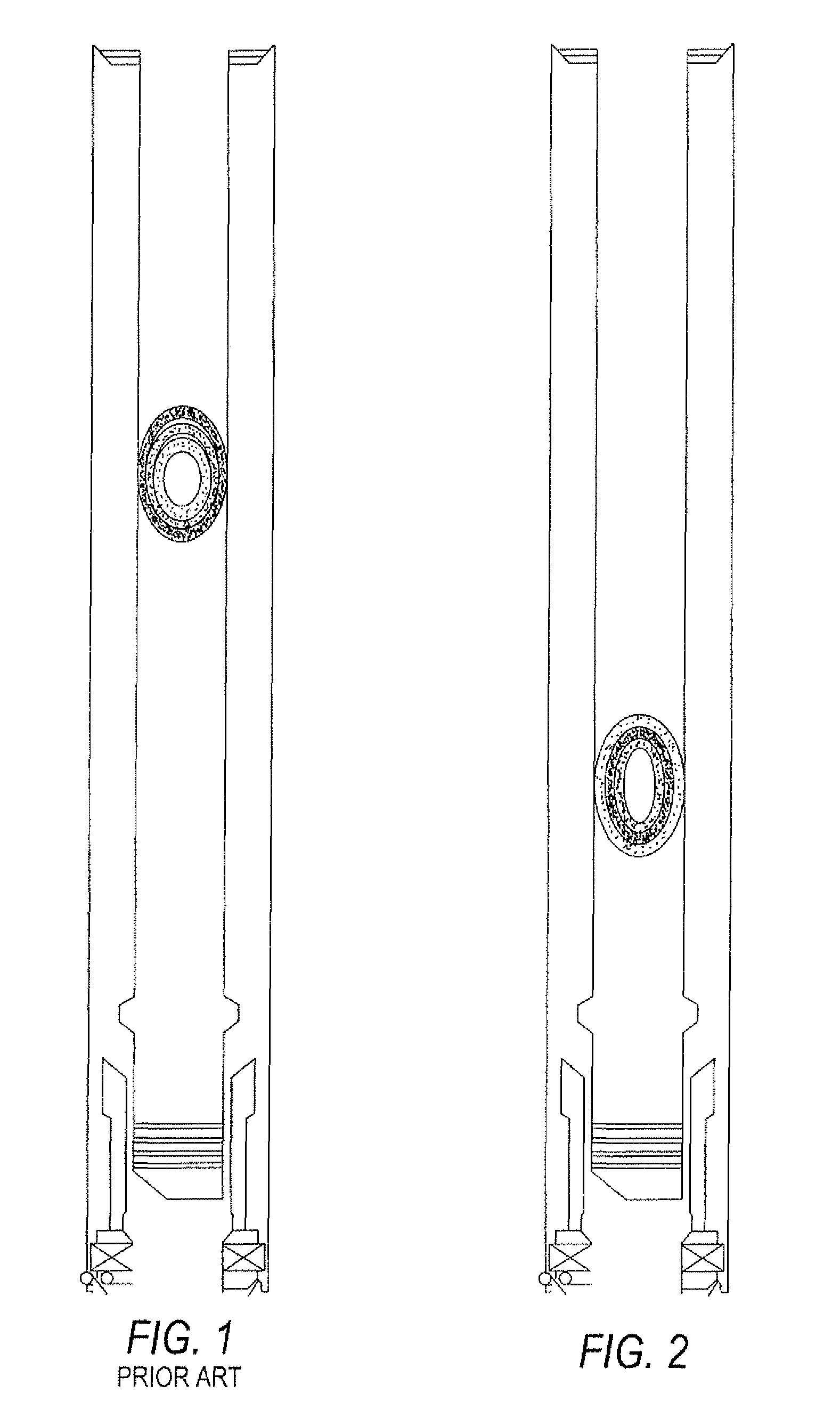

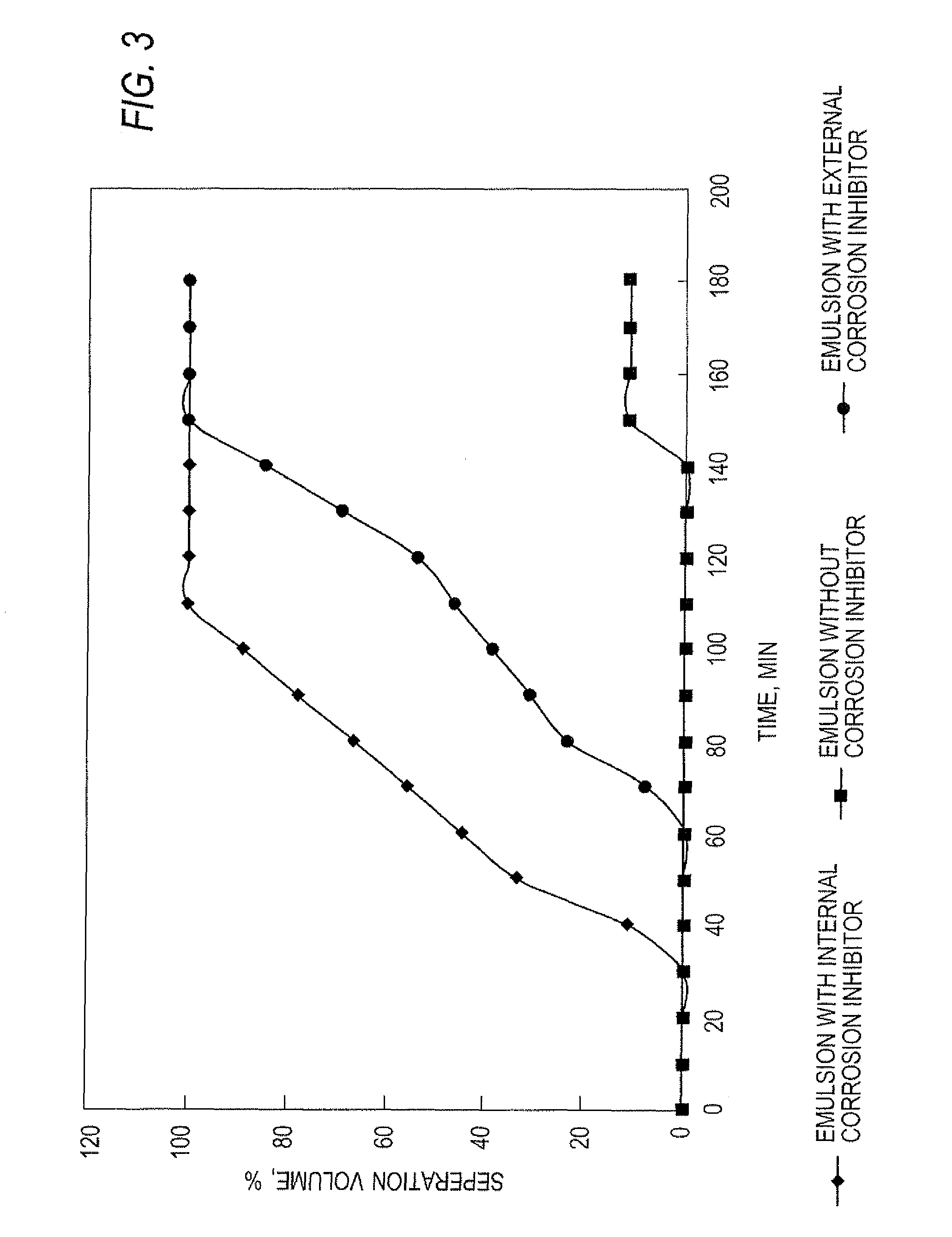

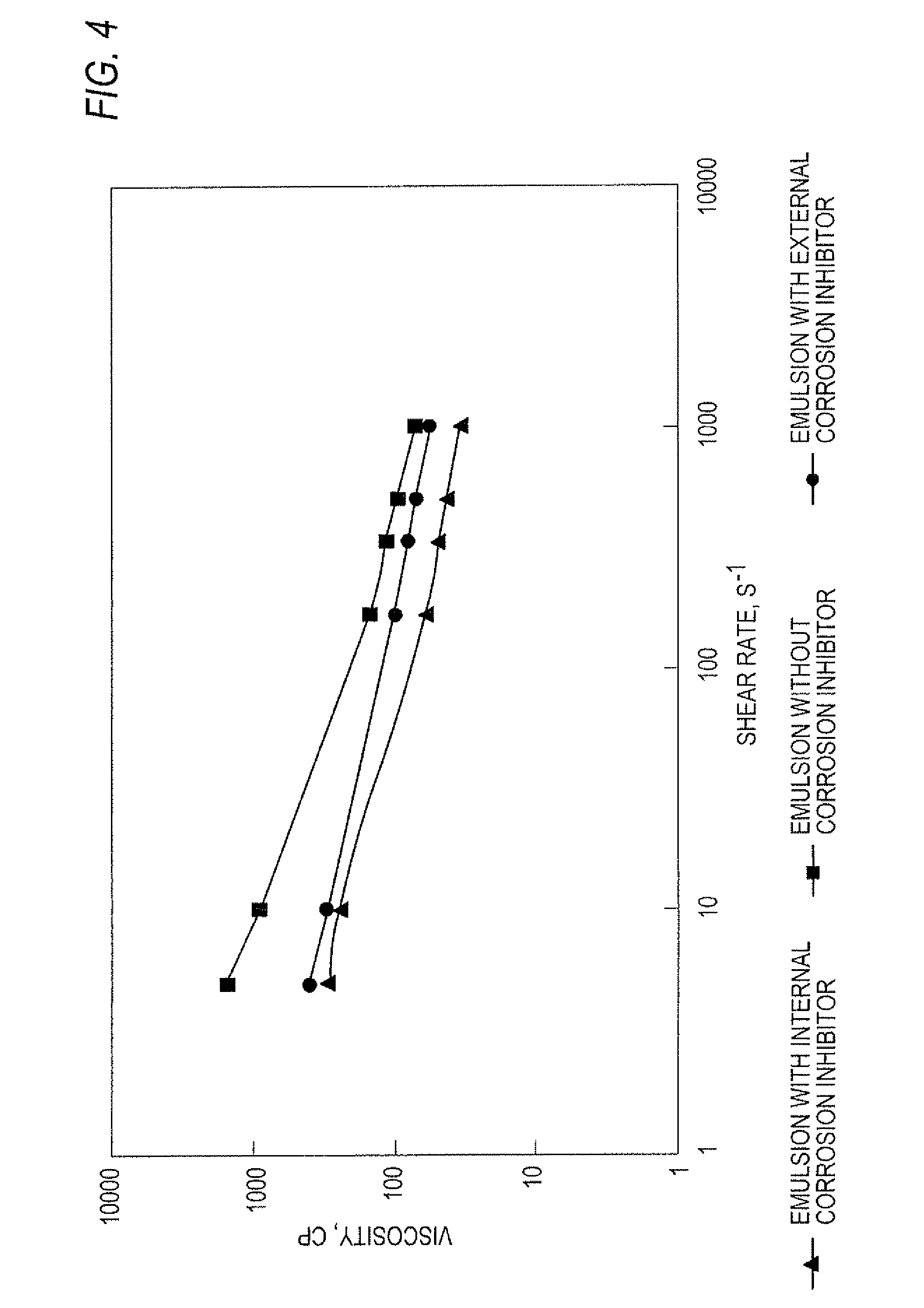

Method of mixing a corrosion inhibitor in an acid-in-oil emulsion

ActiveUS8039422B1Avoid corrosionPromote recoveryOther chemical processesMixing methodsOil emulsionWater in oil emulsion

An acid-in-oil emulsion having a corrosion inhibitor as the external phase has been found to prevent downhole corrosion when acidizing carbonate formations to enhance hydrocarbon recovery.

Owner:SAUDI ARABIAN OIL CO

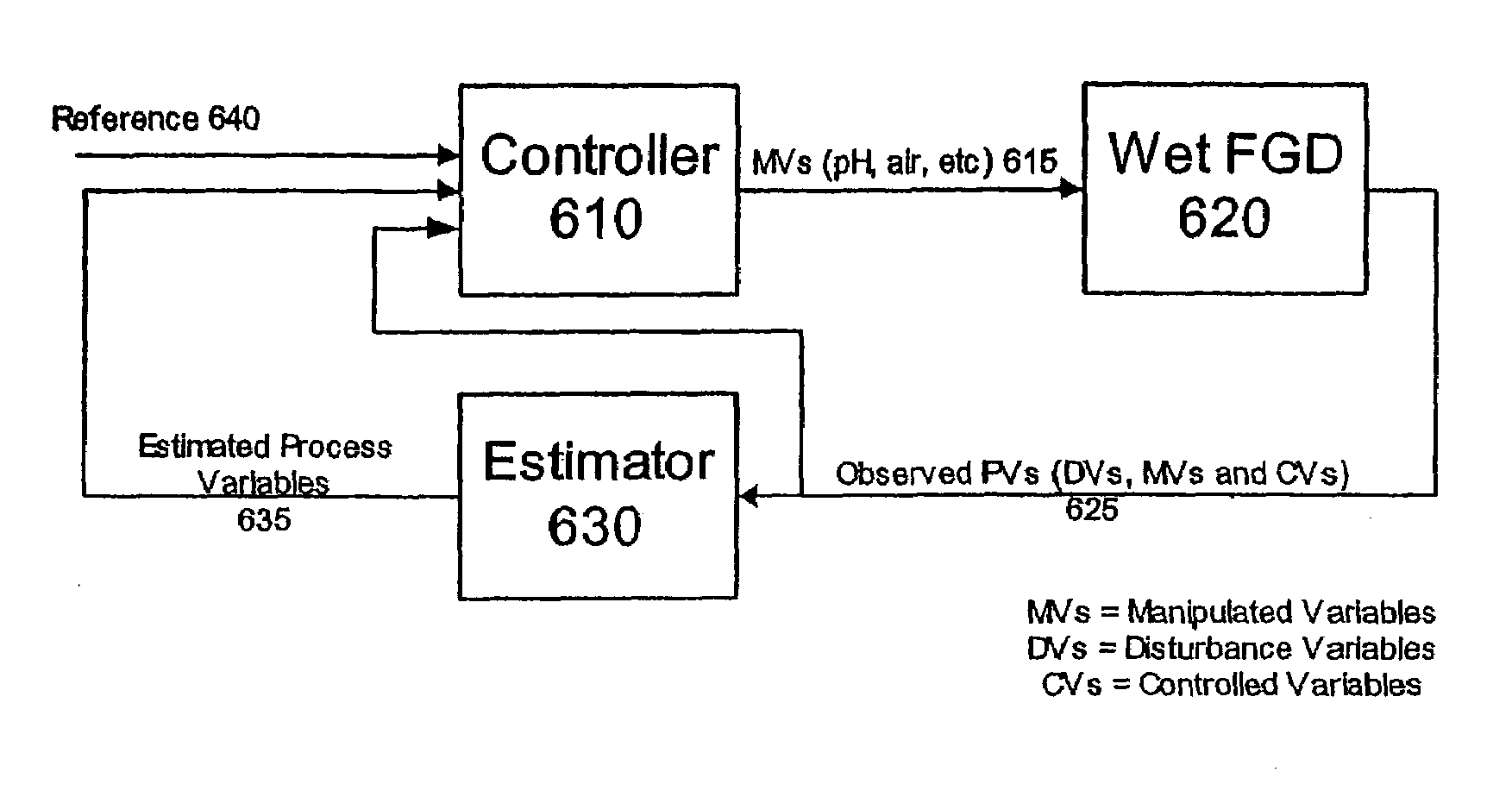

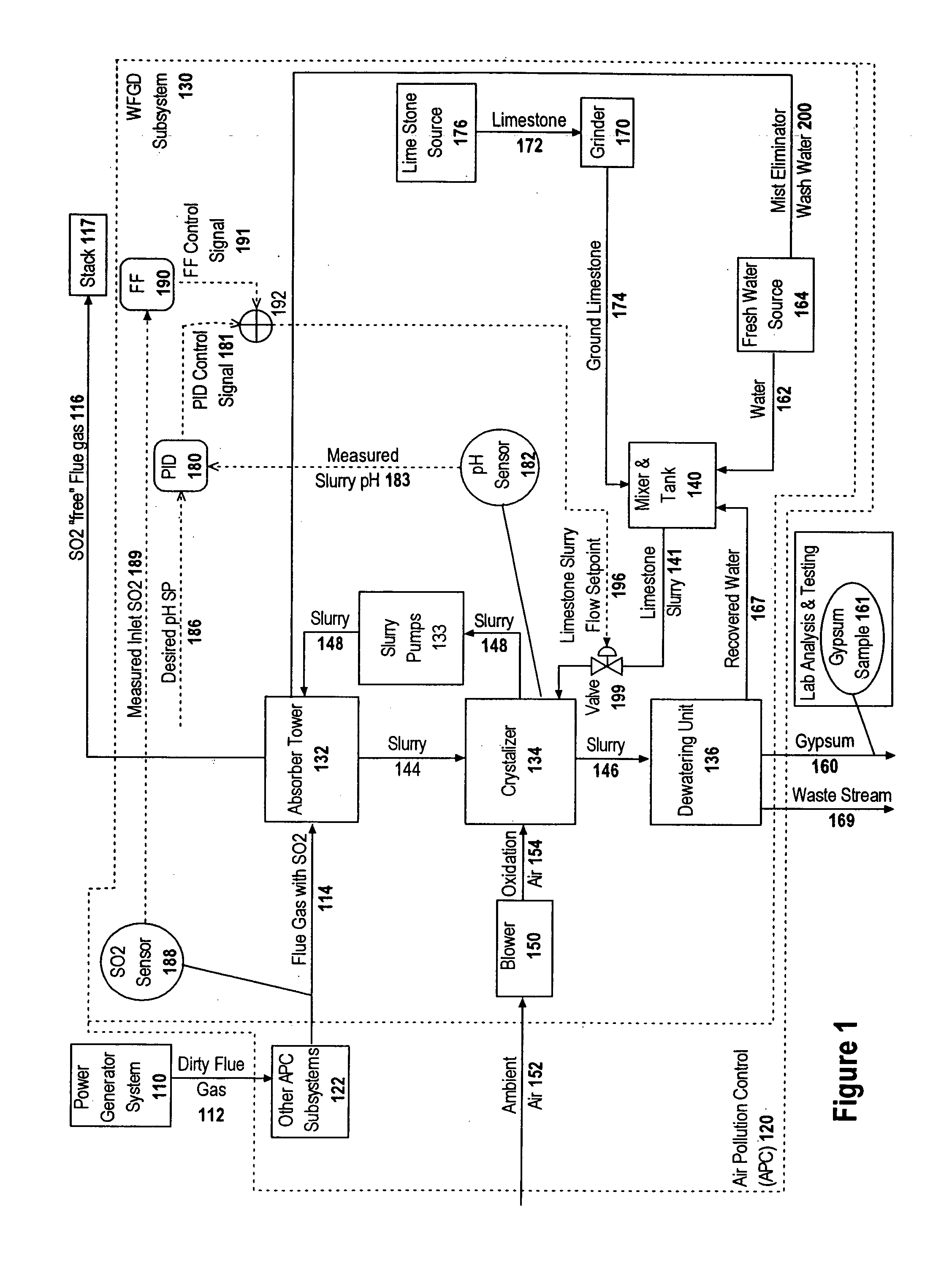

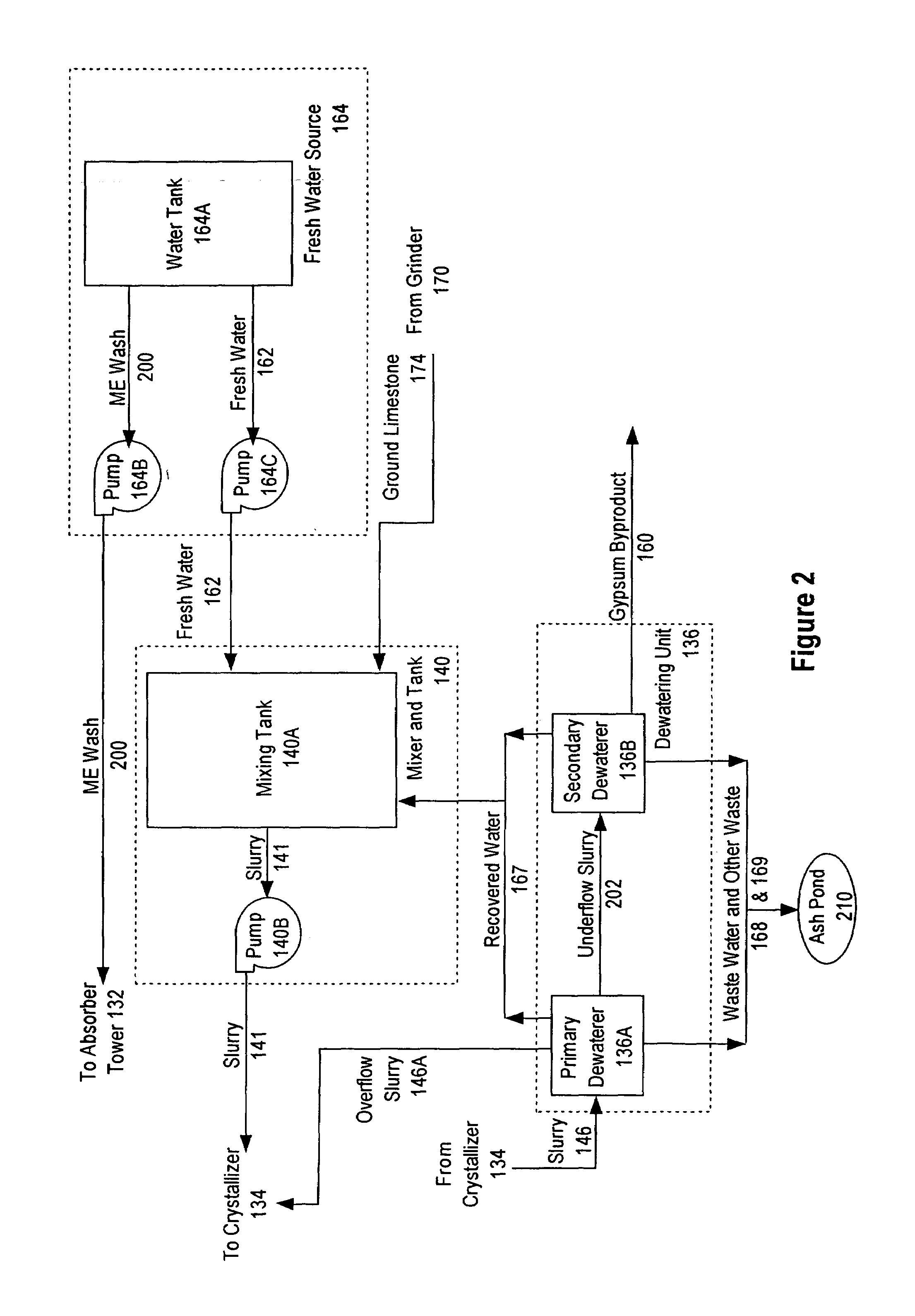

Control of rolling or moving average values of air pollution control emissions to a desired value

ActiveUS7113835B2Easy to planCombination devicesSolid sorbent liquid separationMoving averageEngineering

A controller directs performance of a process having multiple process parameters (MPPs), including a controllable process parameter (CTPP), a targeted process parameter (TPP), a defined target value (DTV) representing a limit on an actual average value (AAV) of the TPP over a defined moving time period of length TPLAAV. A storage device stores historical data representing the AVs of the TPP at various times over a prior time period (PTP) having a length of at least TPLAAV. A processor predicts future average values (FAVs) of the TPP over a future time period (FTP) based on the stored historical data and the current values of the MPPs. The processor also determines a target set point for each CTPP based on the predicted FAVs, the current values of the MPPs and the DTV, and directs control of each CTPP in accordance with the determined target set point for that CTPP.

Owner:GENERAL ELECTRIC TECH GMBH

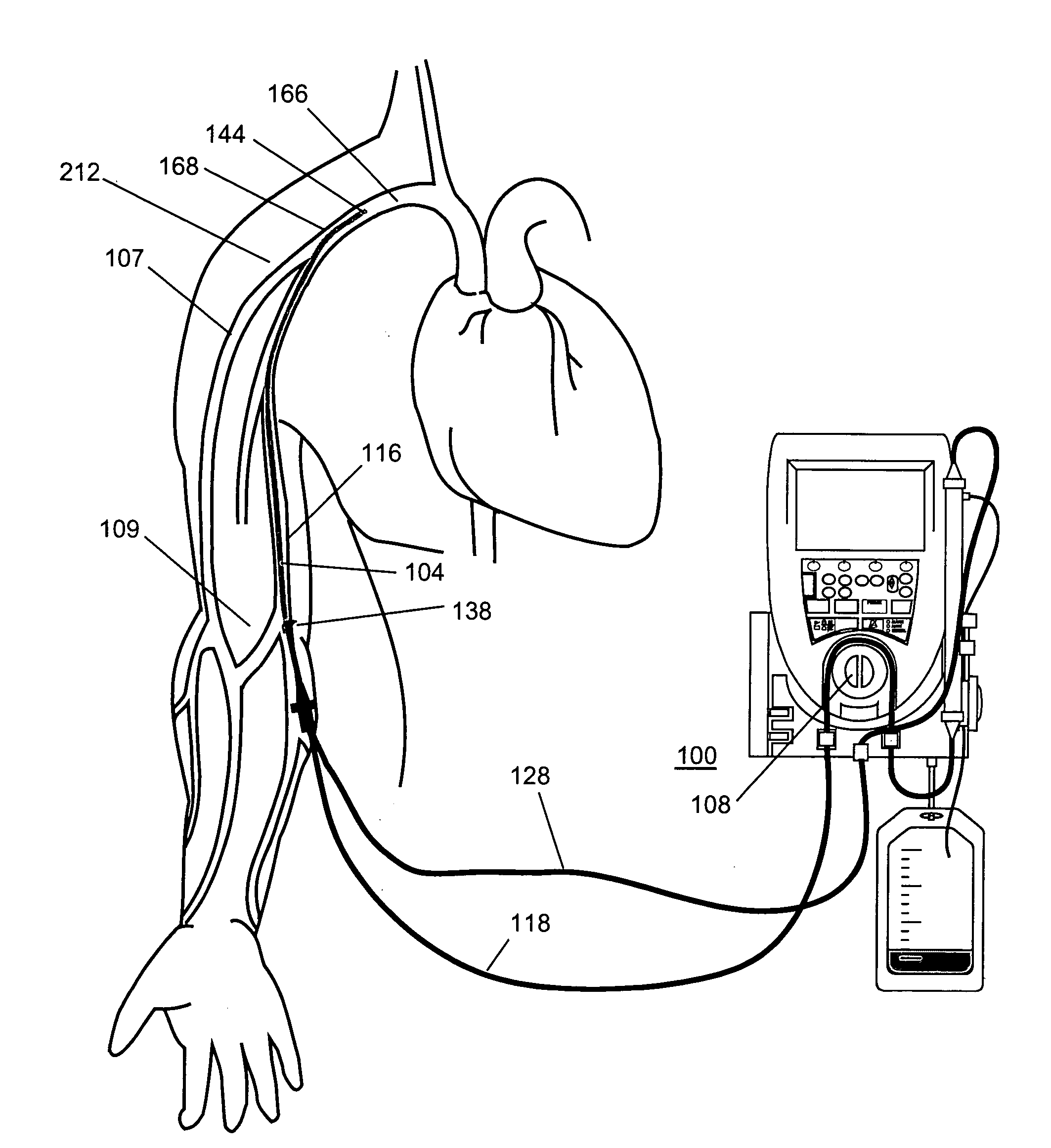

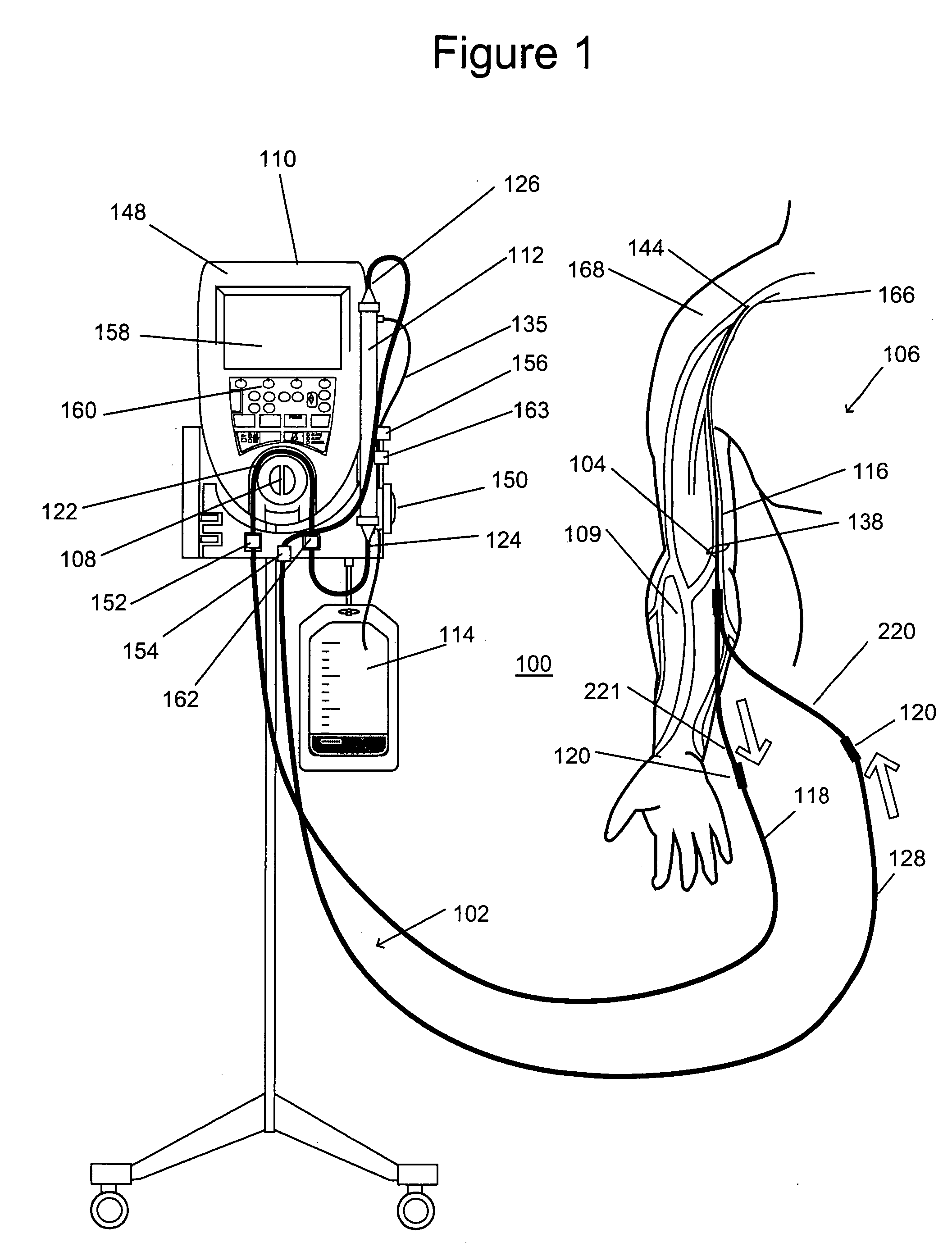

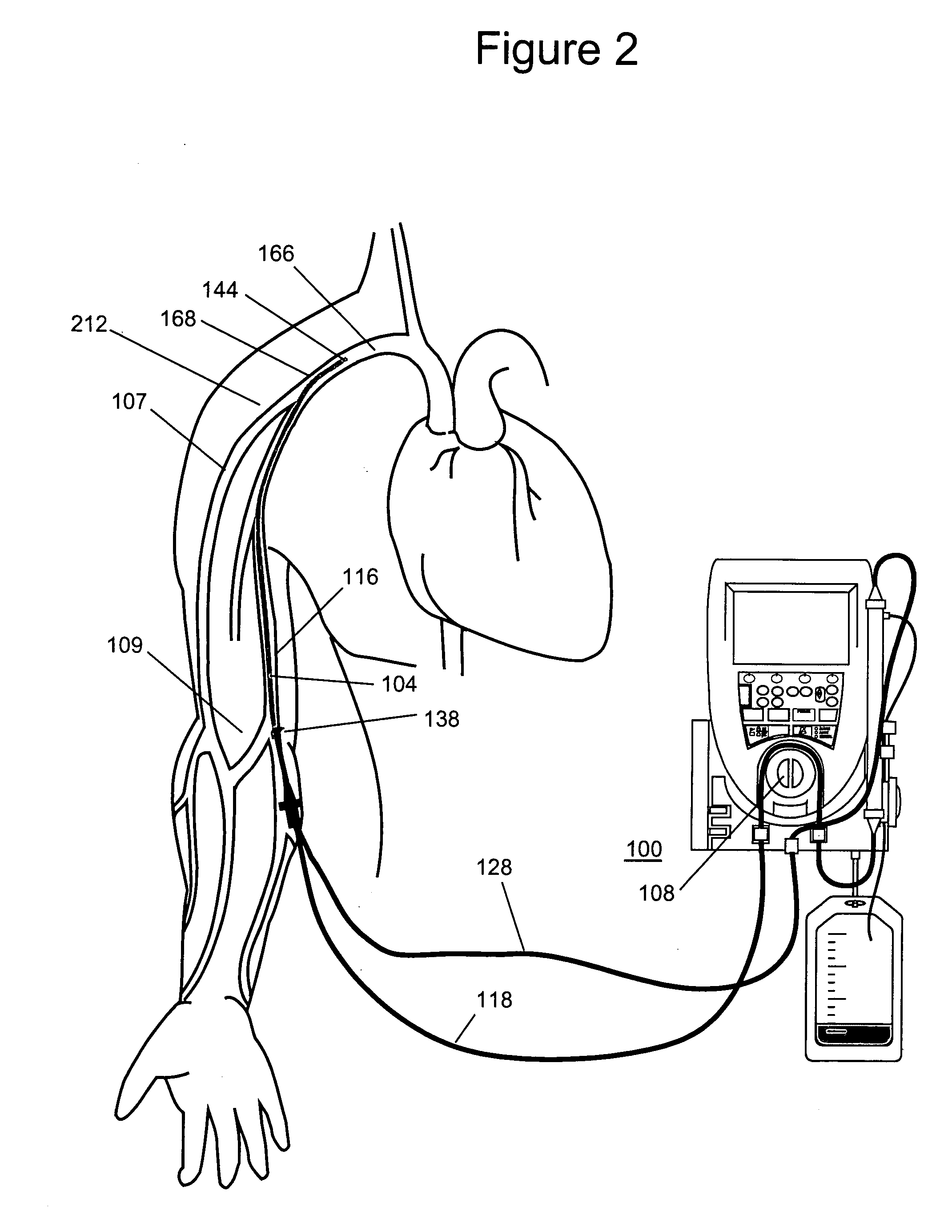

Method and apparatus for ultrafiltration utilizing a peripheral access dual lumen venous cannula

InactiveUS20050119597A1Ease and safetyInadequate blood flowSemi-permeable membranesMulti-lumen catheterUltrafiltrationCongestive heart failure chf

Method and apparatus for the extracorporeal treatment of blood by utilizing a peripherally inserted dual lumen catheter assembly for the continuous removal and return of blood for renal replacement treatment, in particularly, treatment of congestive heart failure and fluid overload by ultrafiltration. A catheter is inserted in a peripheral vein and maneuvered upward through the vascular system to access the reservoir of blood in the large or great veins for continuous blood withdrawal and treatment. Air-tight connectors are incorporated in the catheter assembly to overcome the untoward effects of negative pressure in blood withdrawal.

Owner:GAMBRO LUNDIA AB

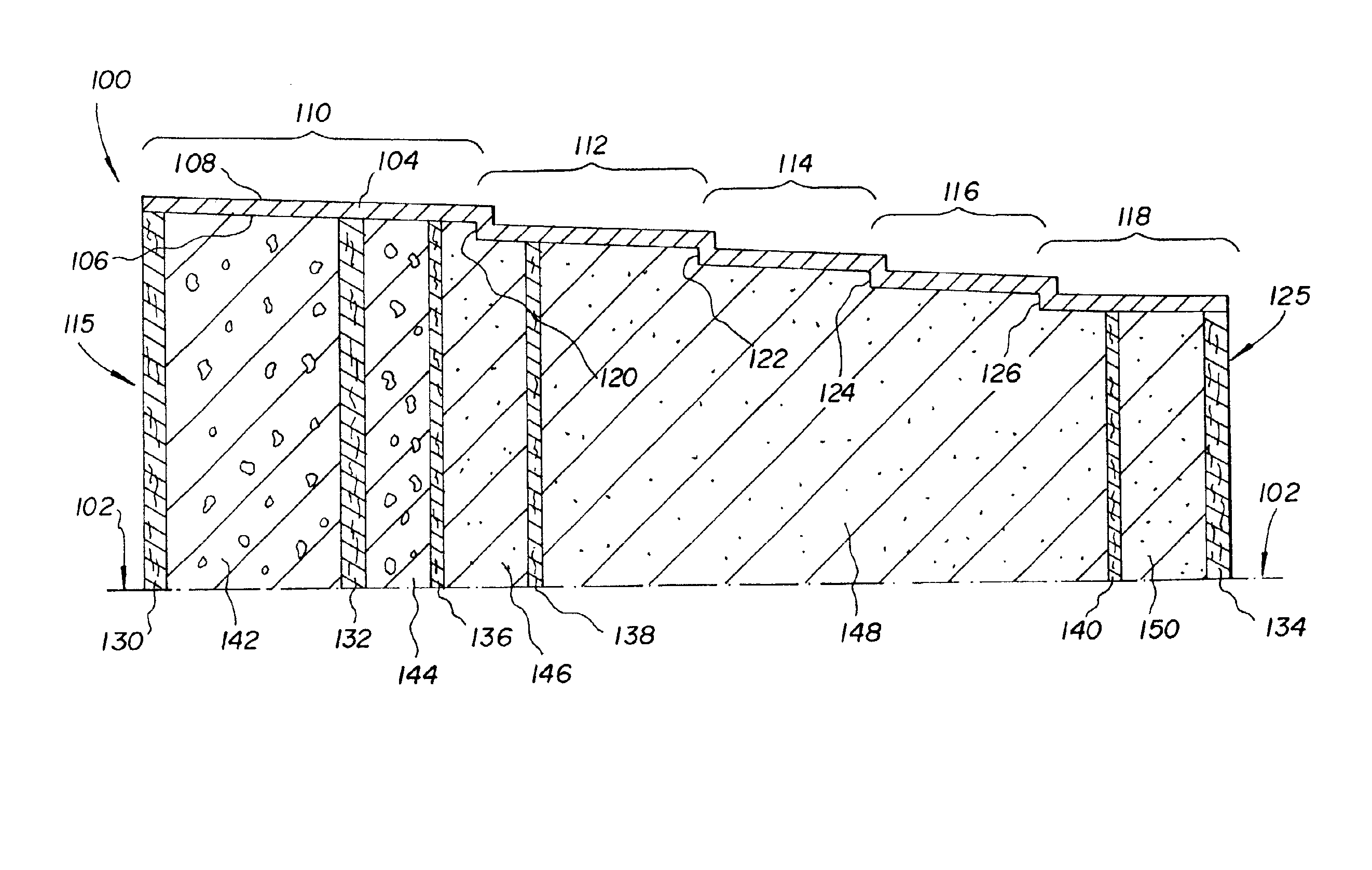

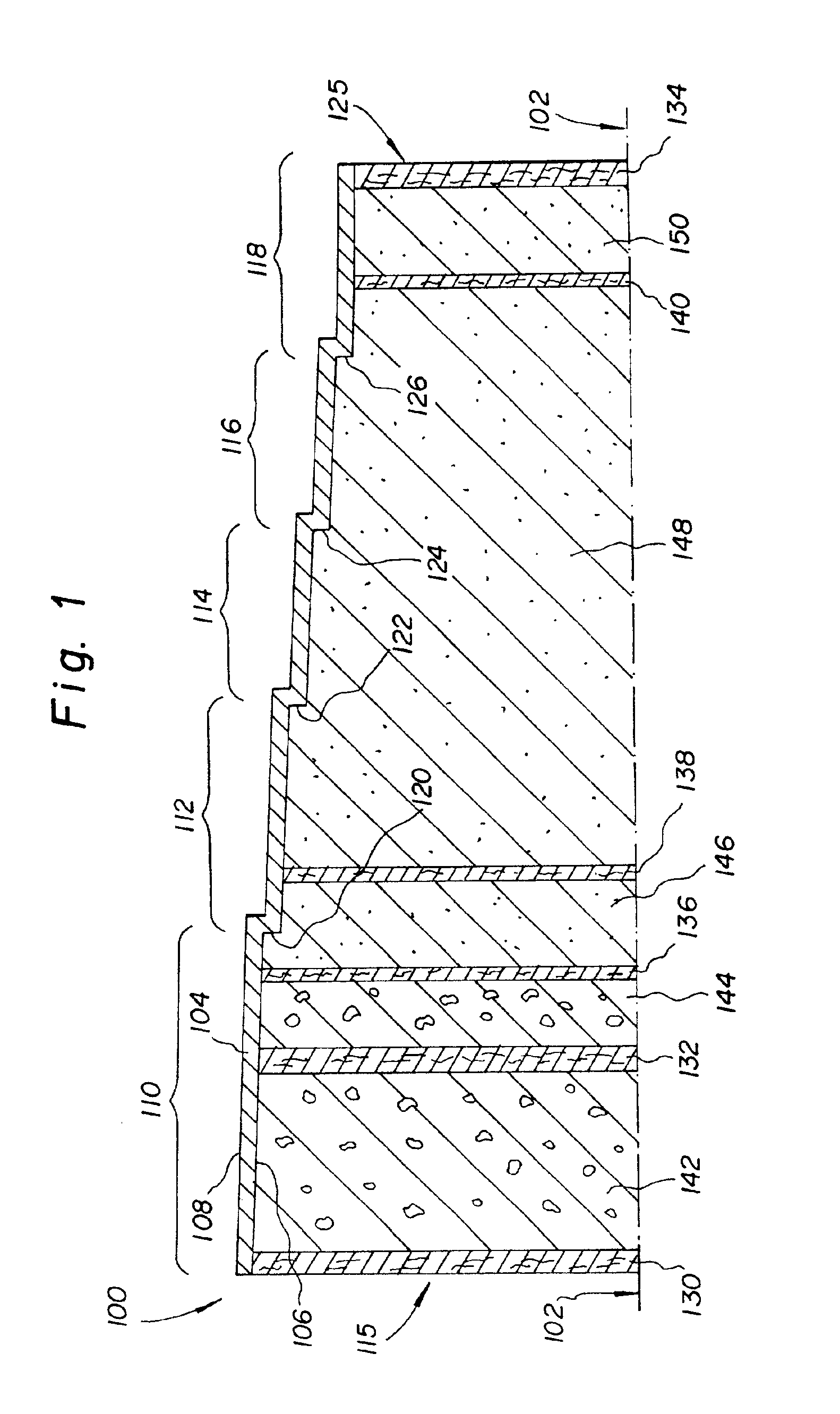

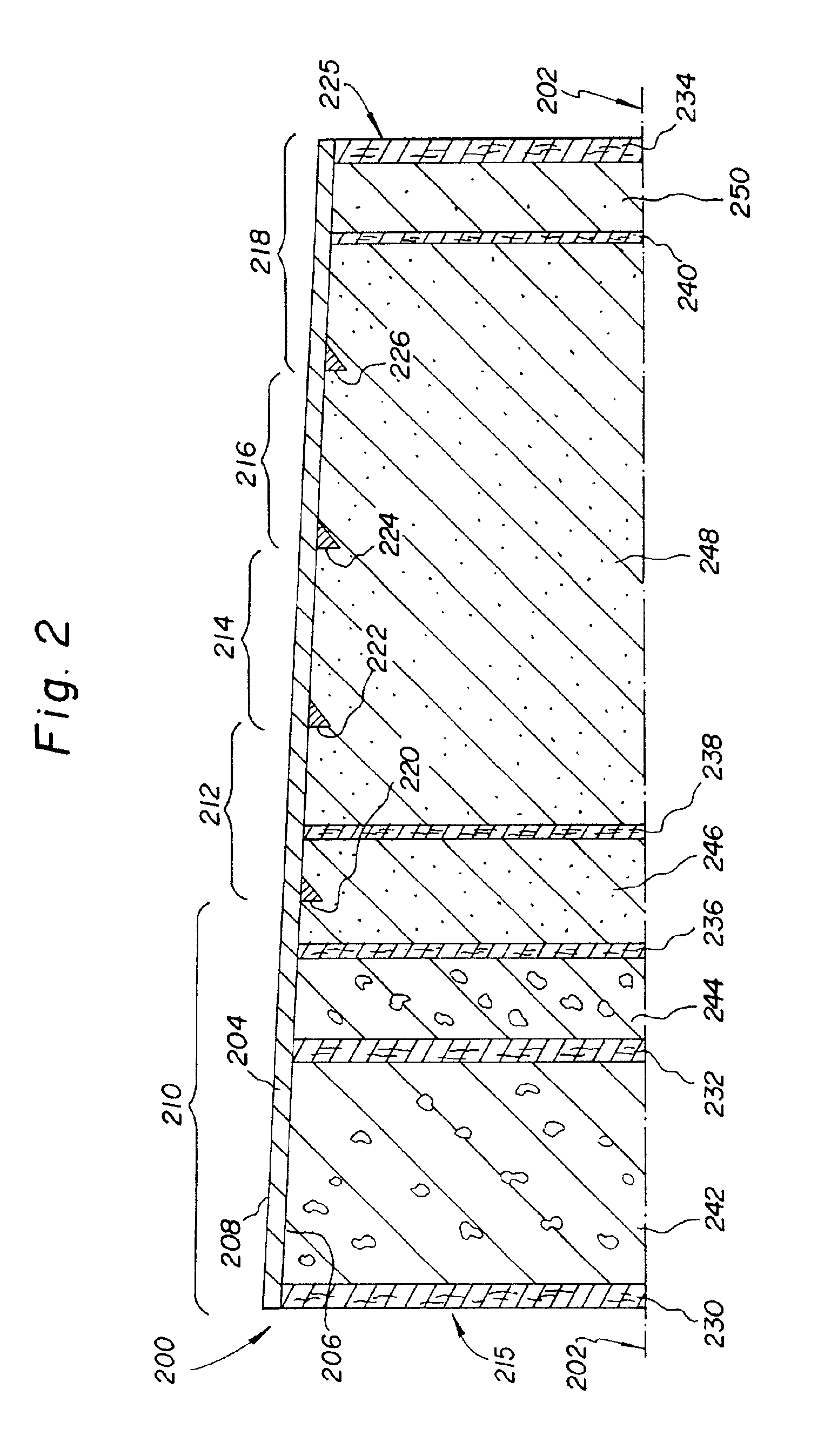

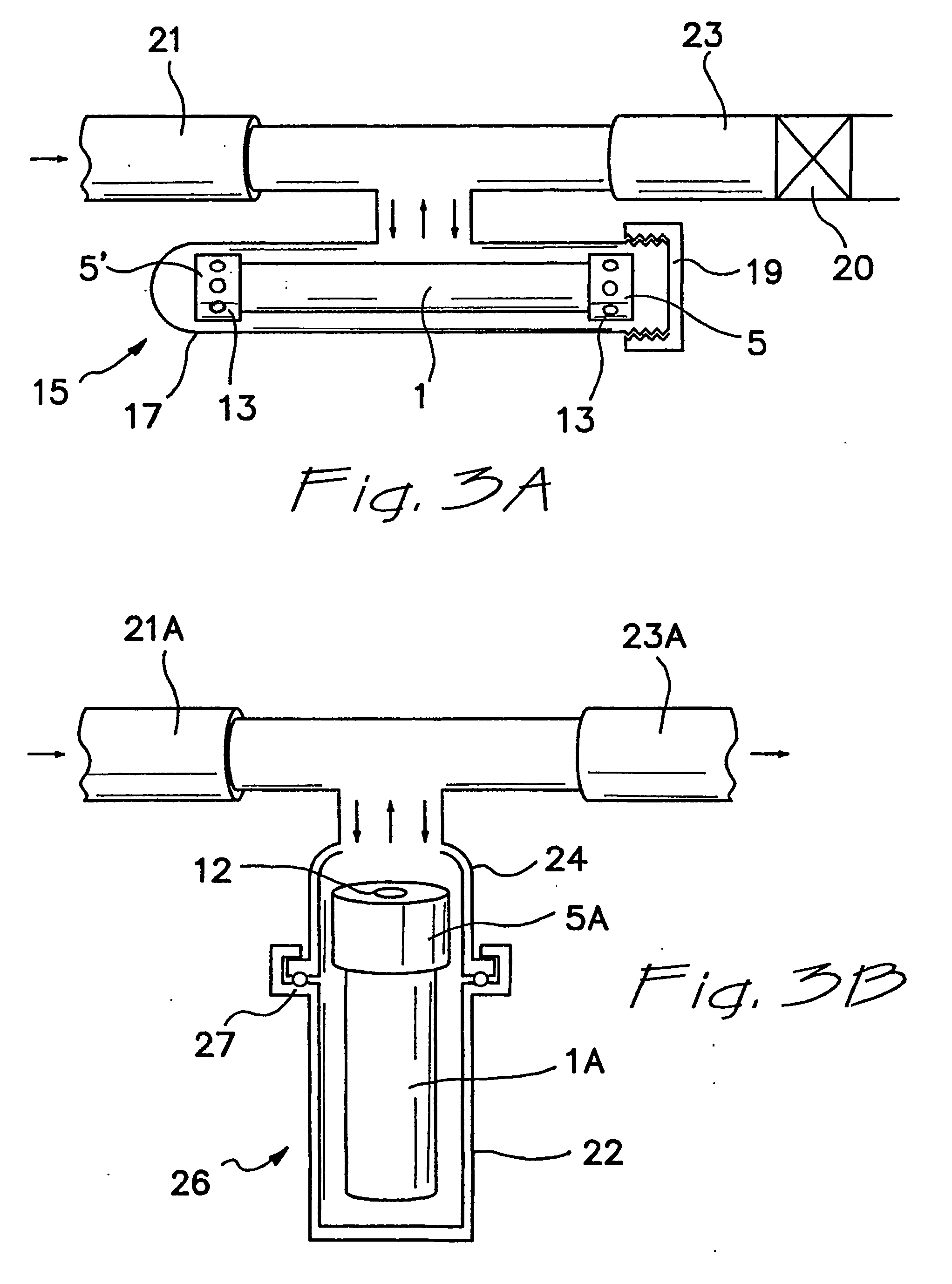

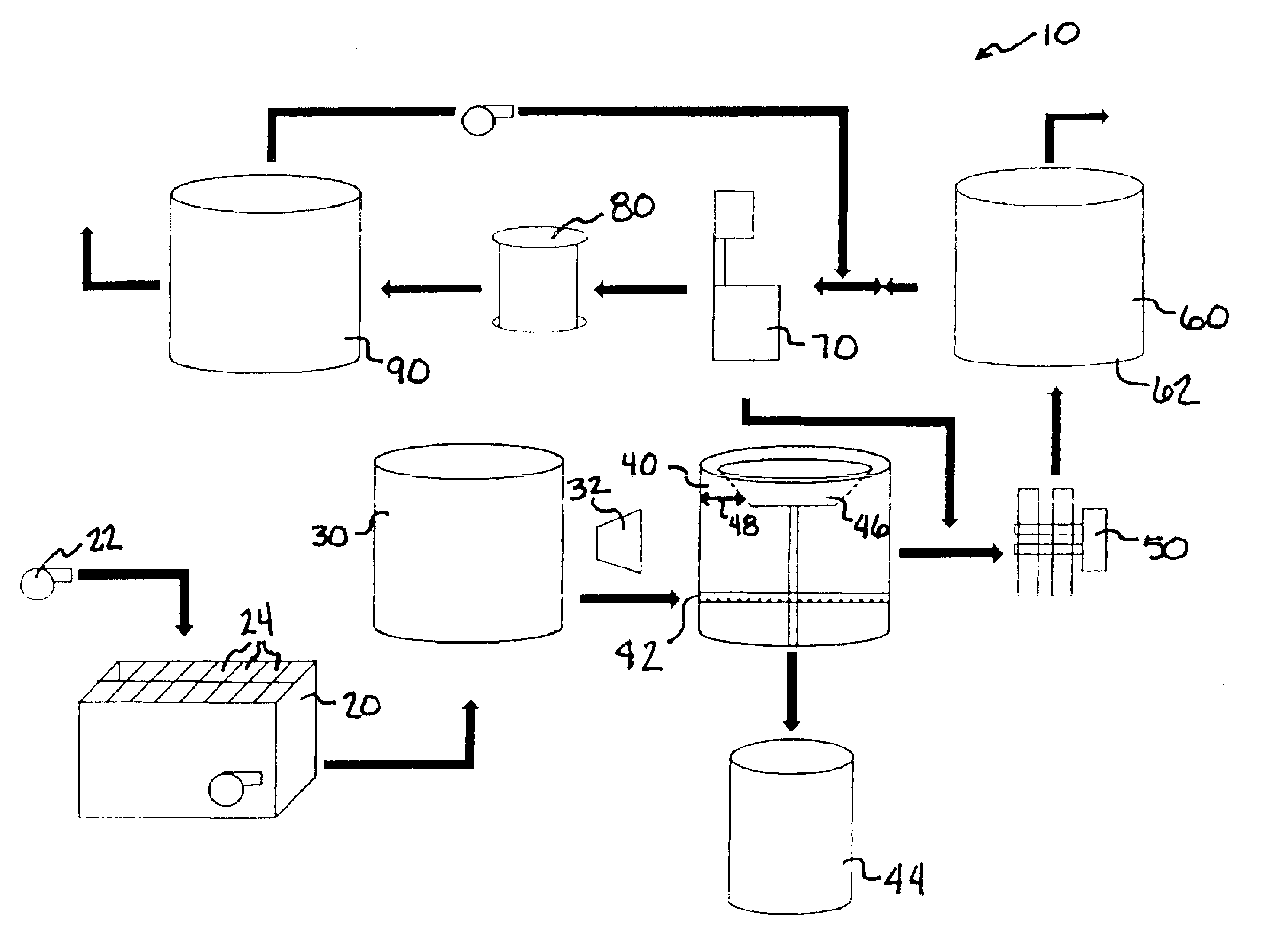

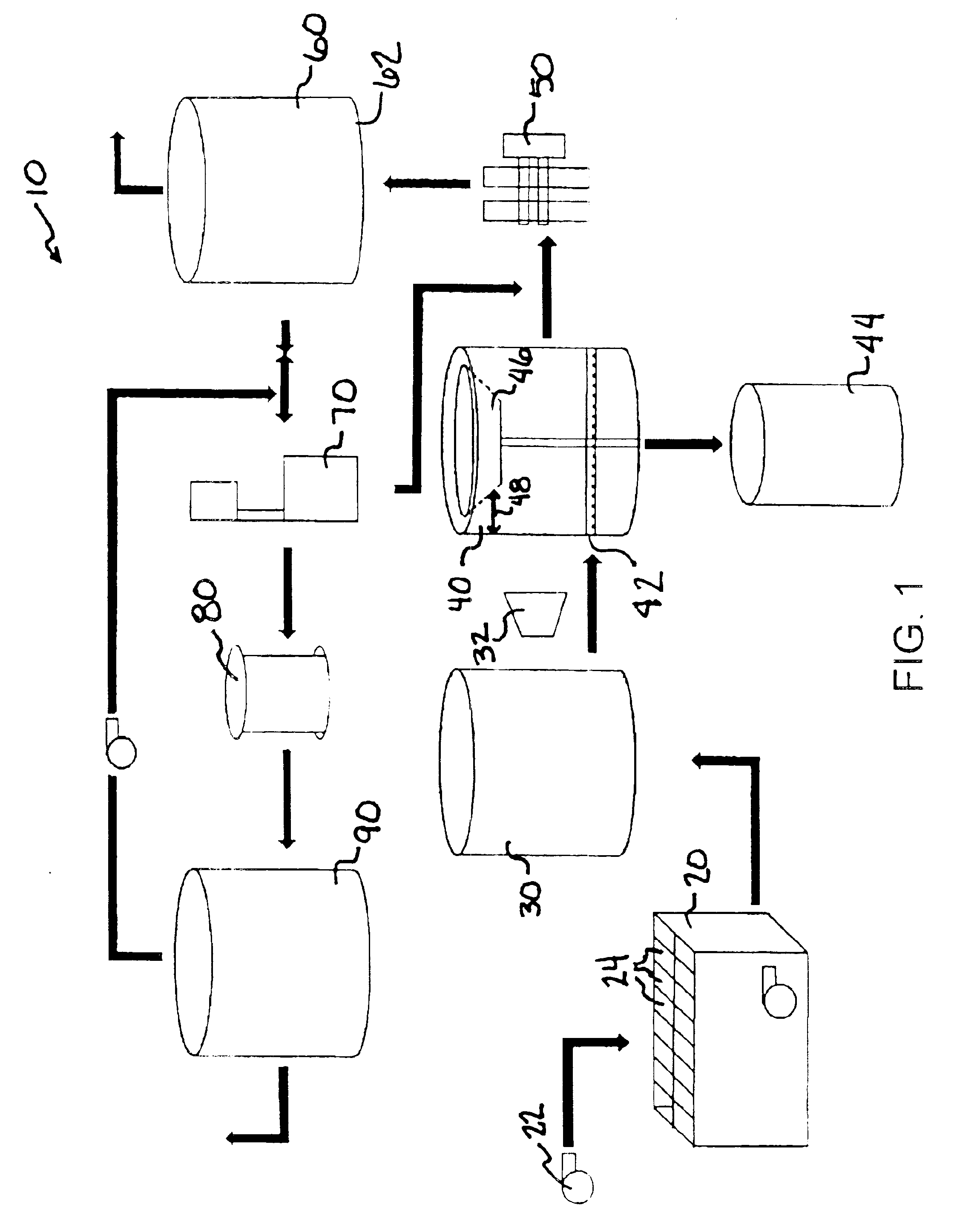

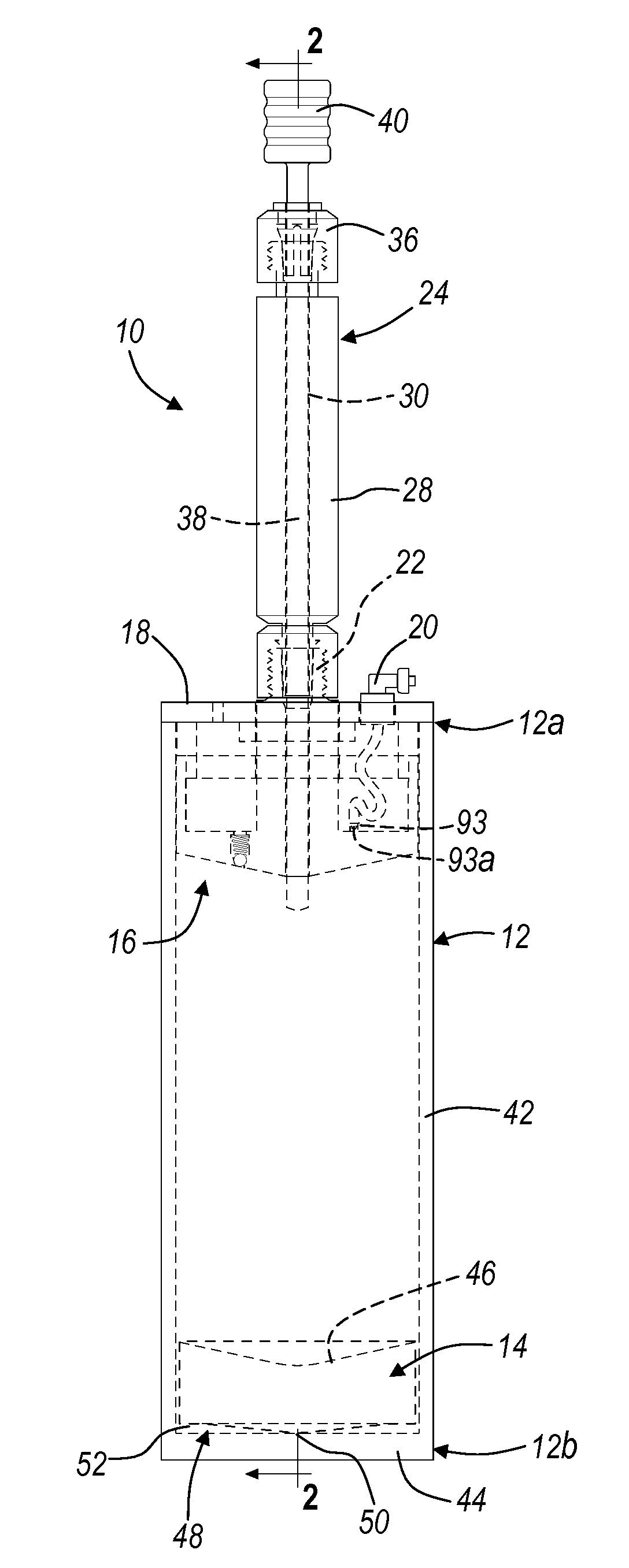

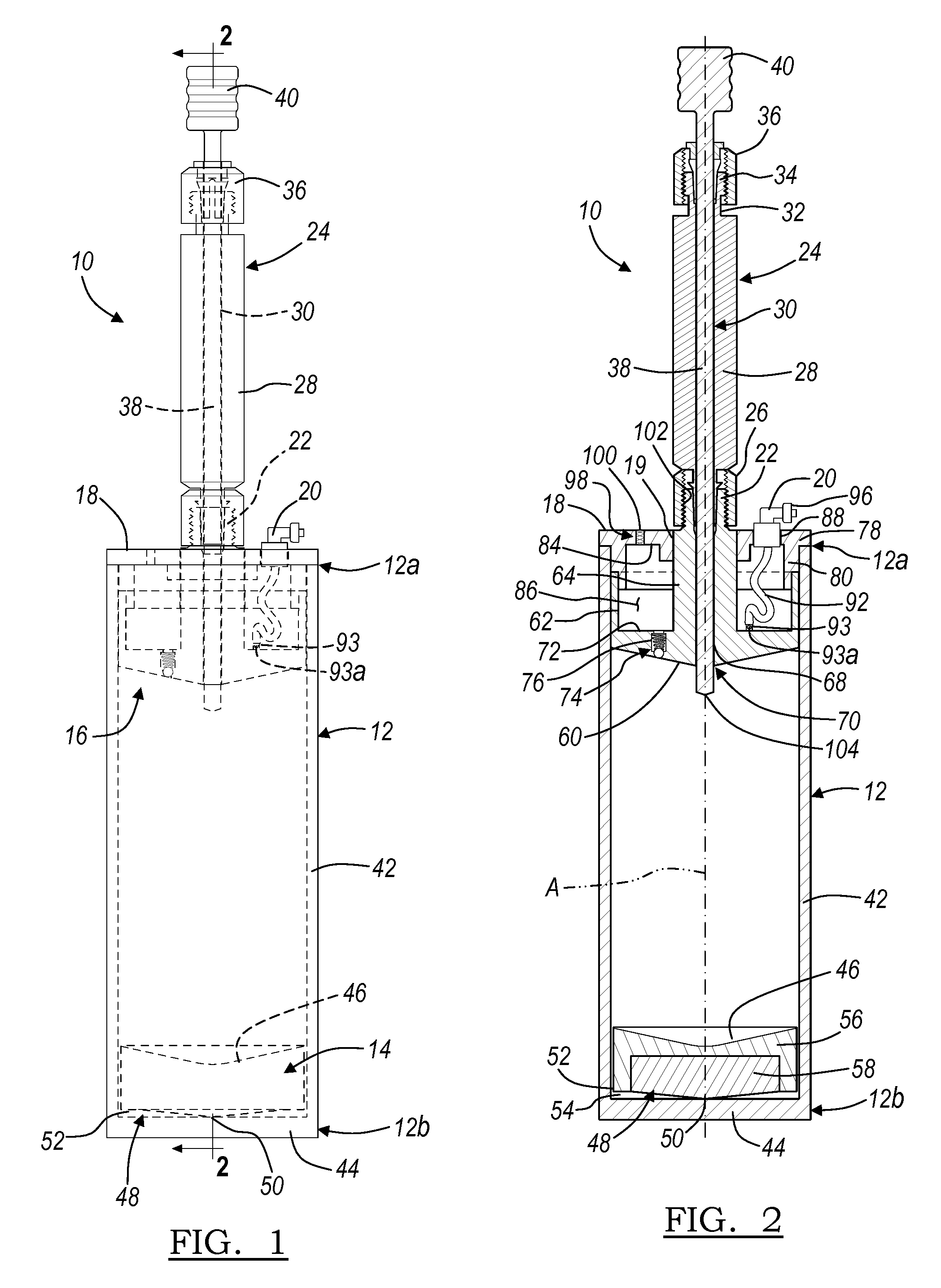

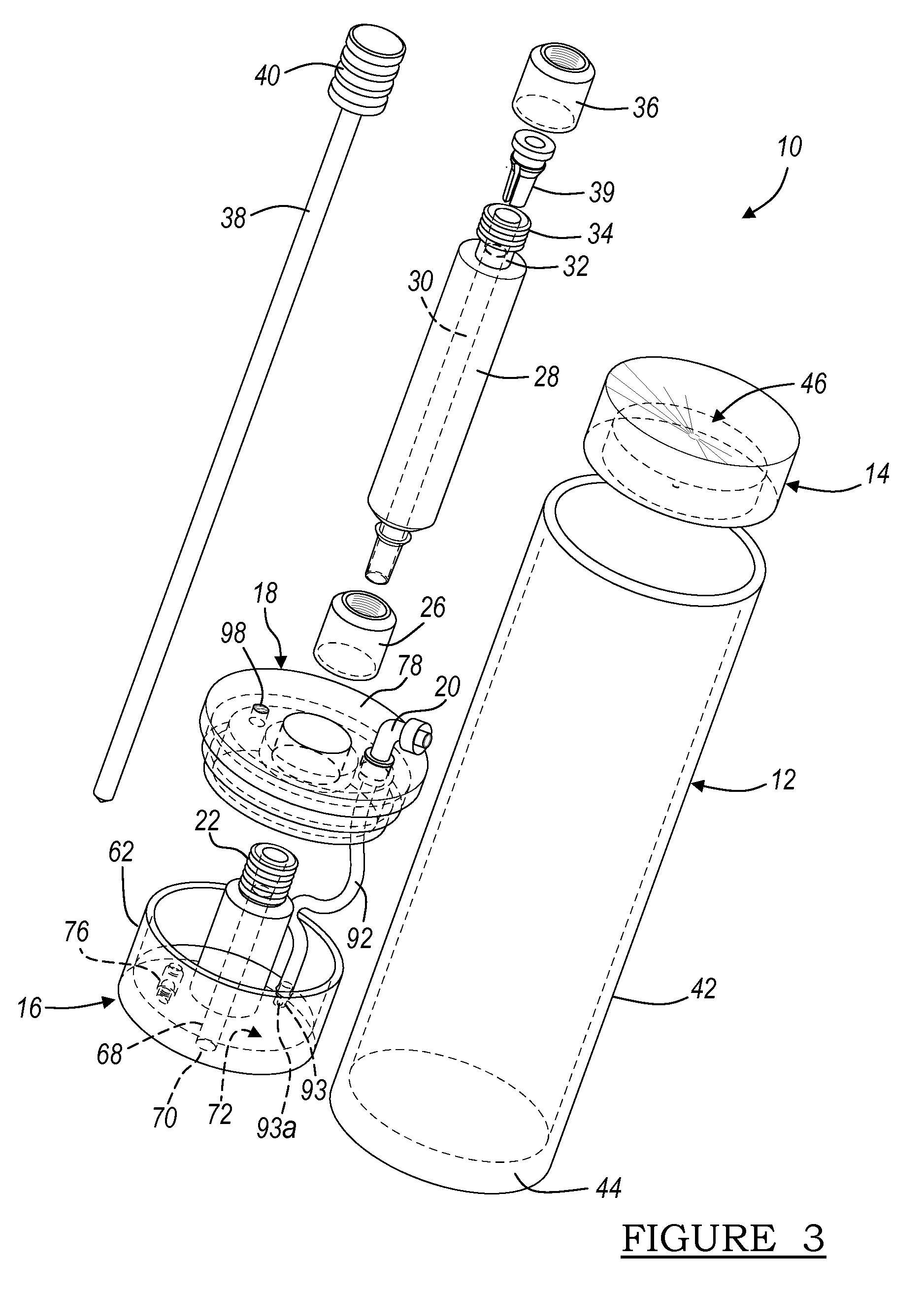

Liquid additive slow-release apparatus driven by a filter pressure gradient

The present invention provides a filter assembly containing a filter element and a container as a depot for a liquid additive. The container can include an inlet and an outlet, which are configured to allow a liquid to flow into the container mix with the contained additive and then flow out into the system. It has been observed that a liquid flowing through a filter assembly exhibits a pressure gradient within the filter. Consequently, the inlets and outlets to the container can be positioned to take advantage of the pressure gradient to enhance the addition of the additive to the liquid in the filter assembly.

Owner:CUMMINS FILTRATION INC

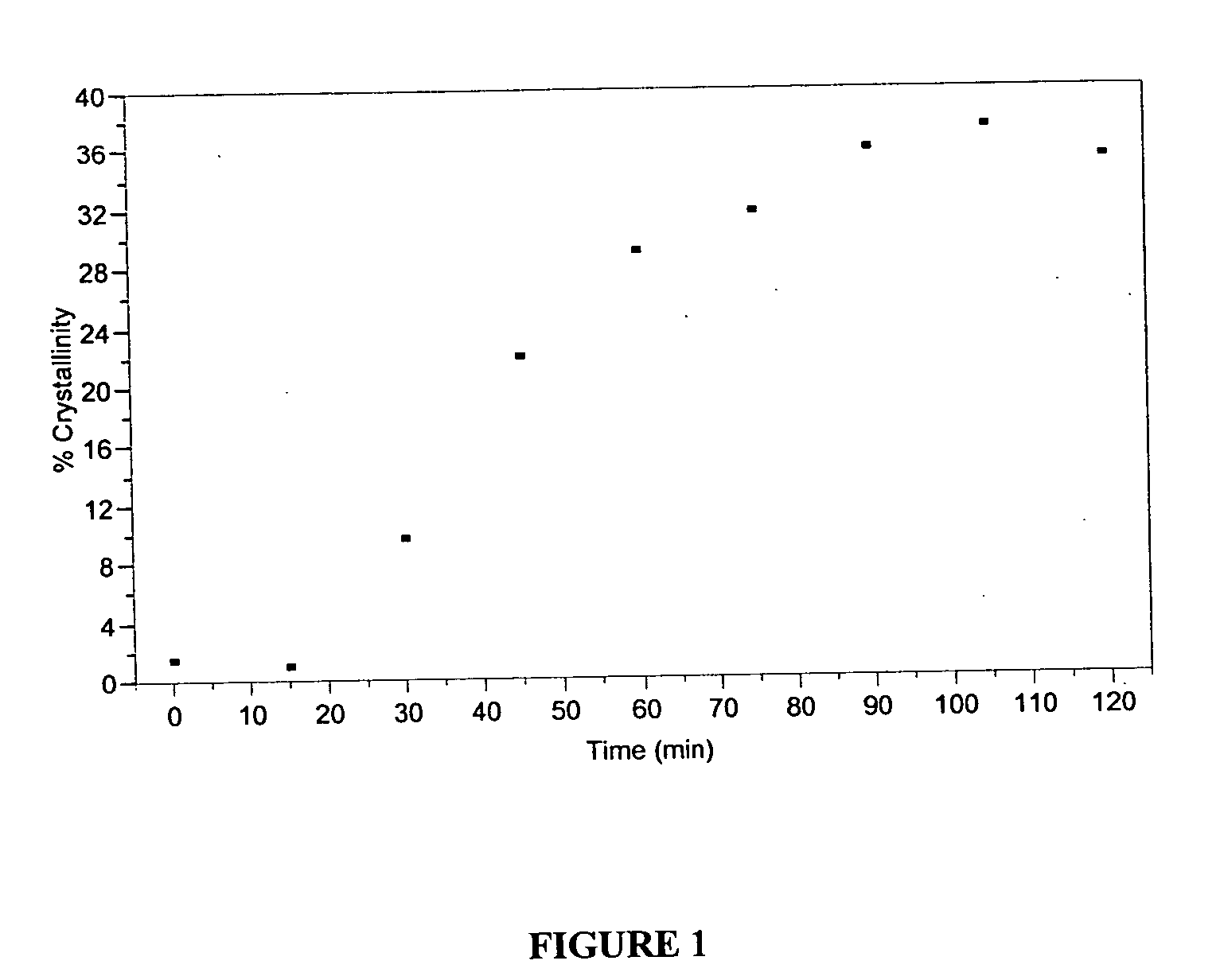

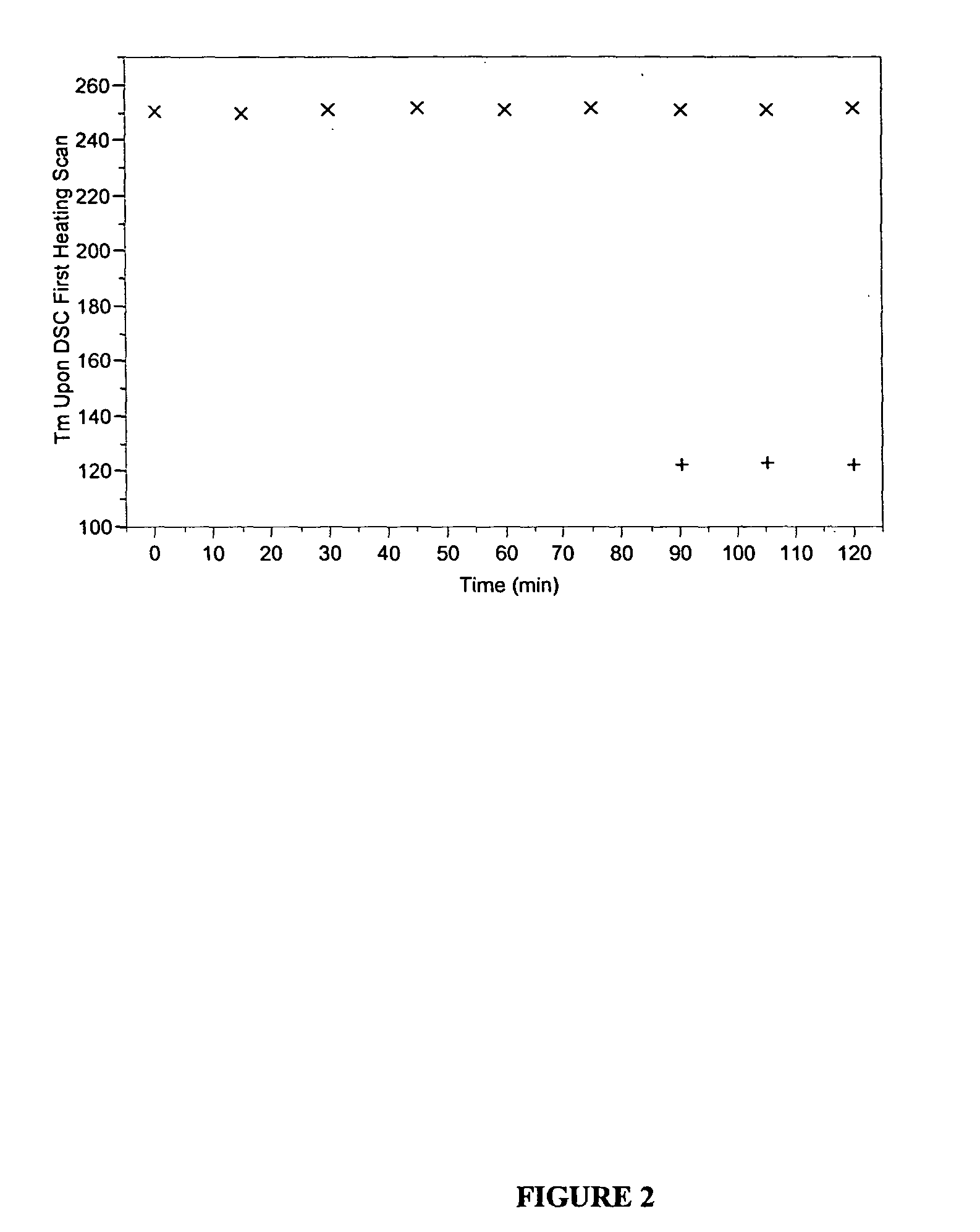

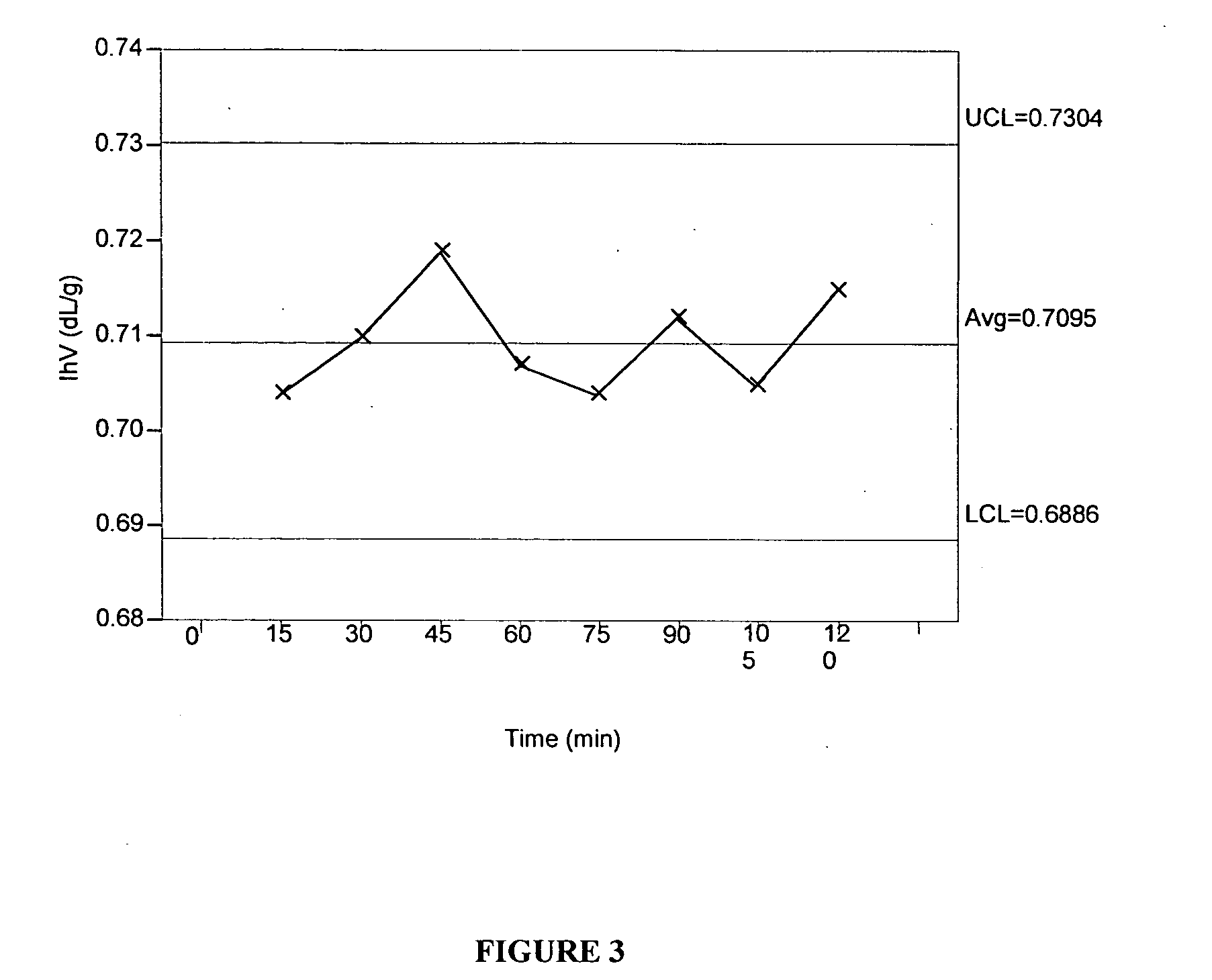

Thermal crystallization of polyester pellets in liquid

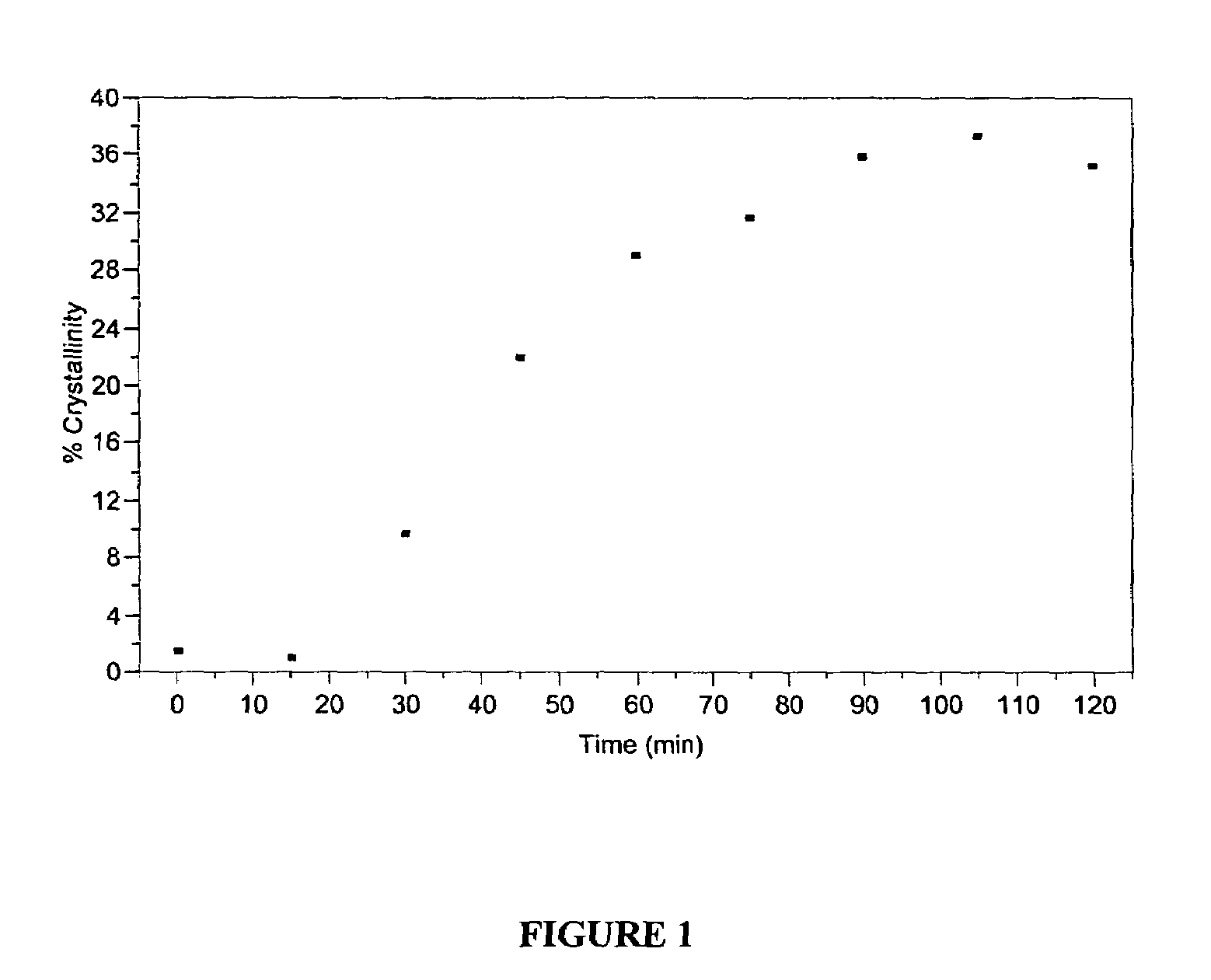

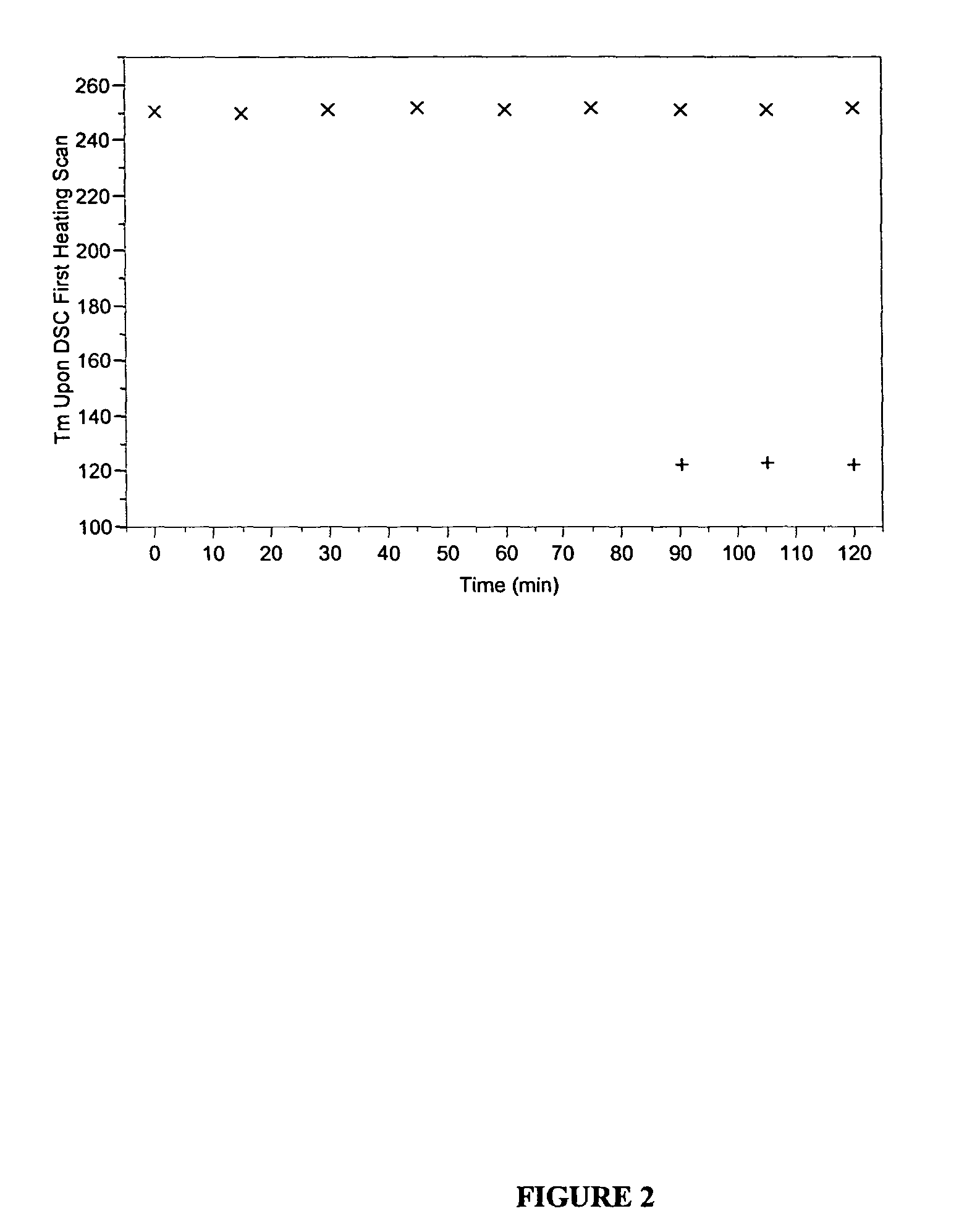

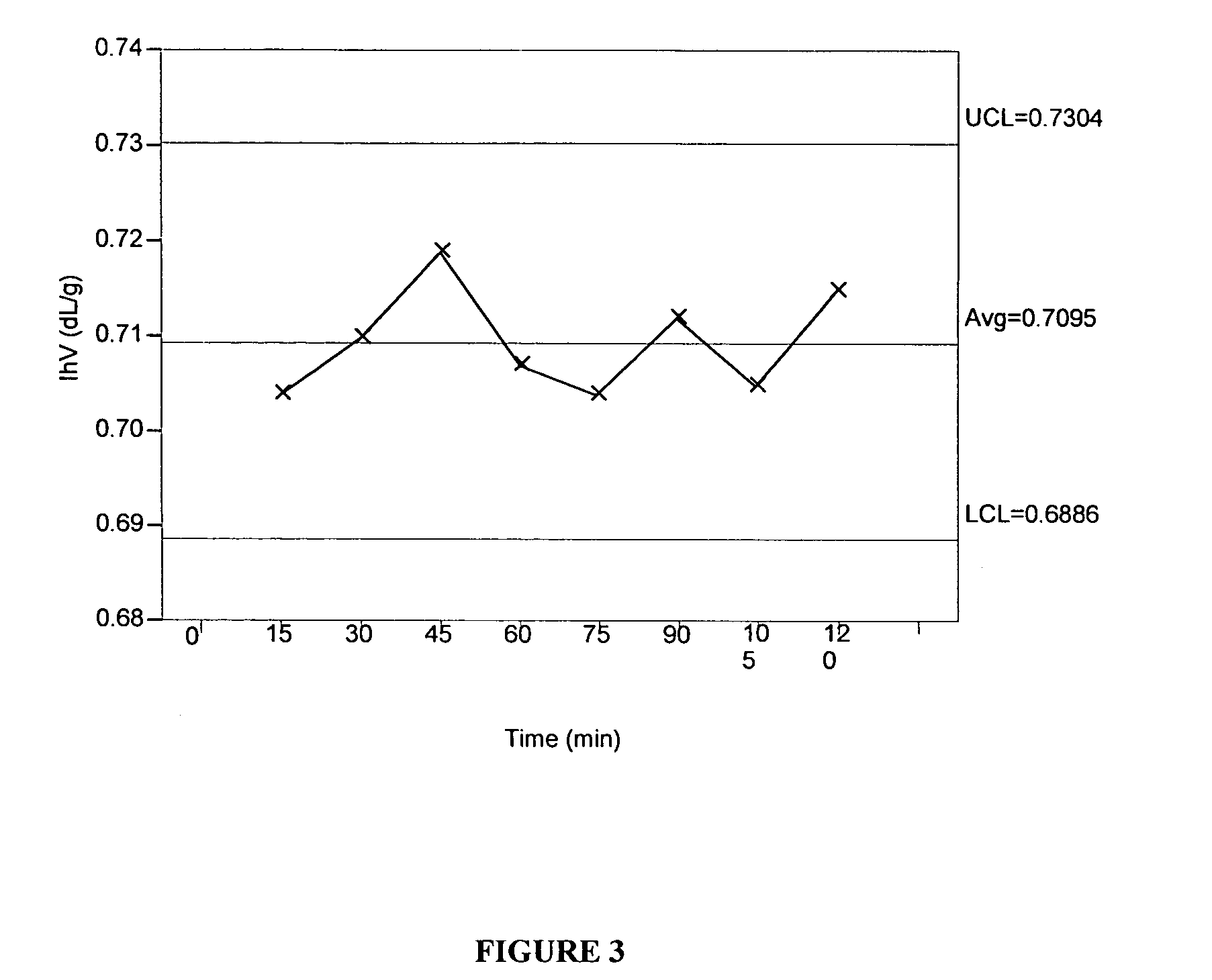

InactiveUS20050065318A1Improve heat transfer rateEnergy efficiencyCrystallization separationSolid sorbent liquid separationPolyesterLiquid medium

A process for thermally crystallizing a polyester polymer by introducing pellets into a liquid medium having a temperature of at least 140° C. within a liquid medium zone and crystallizing the submerged pellets at or above the vapor pressure of the liquid medium without increasing the molecular weight of the pellets, and while the pressure on at least a portion of the pellets is equal to or greater than the vapor pressure of the liquid medium, separating at least a portion of said pellets and at least a portion of the liquid medium from each other. The crystallization is desirably conducted in the liquid medium zone without mechanically induced agitation. Optionally, the pellets are formed by an underfluid pelletizer. There is also provided a process for thermally crystallizing solid pellets in a pipe by directing a flow of solid pellets in a liquid medium through a pipe having an aspect ratio L / D of at least 50:1, wherein the solid pellets are crystallized in the pipe at a liquid medium temperature greater than the Tg of the polyester polymer.

Owner:ALPEK POLYESTER SA DE CV

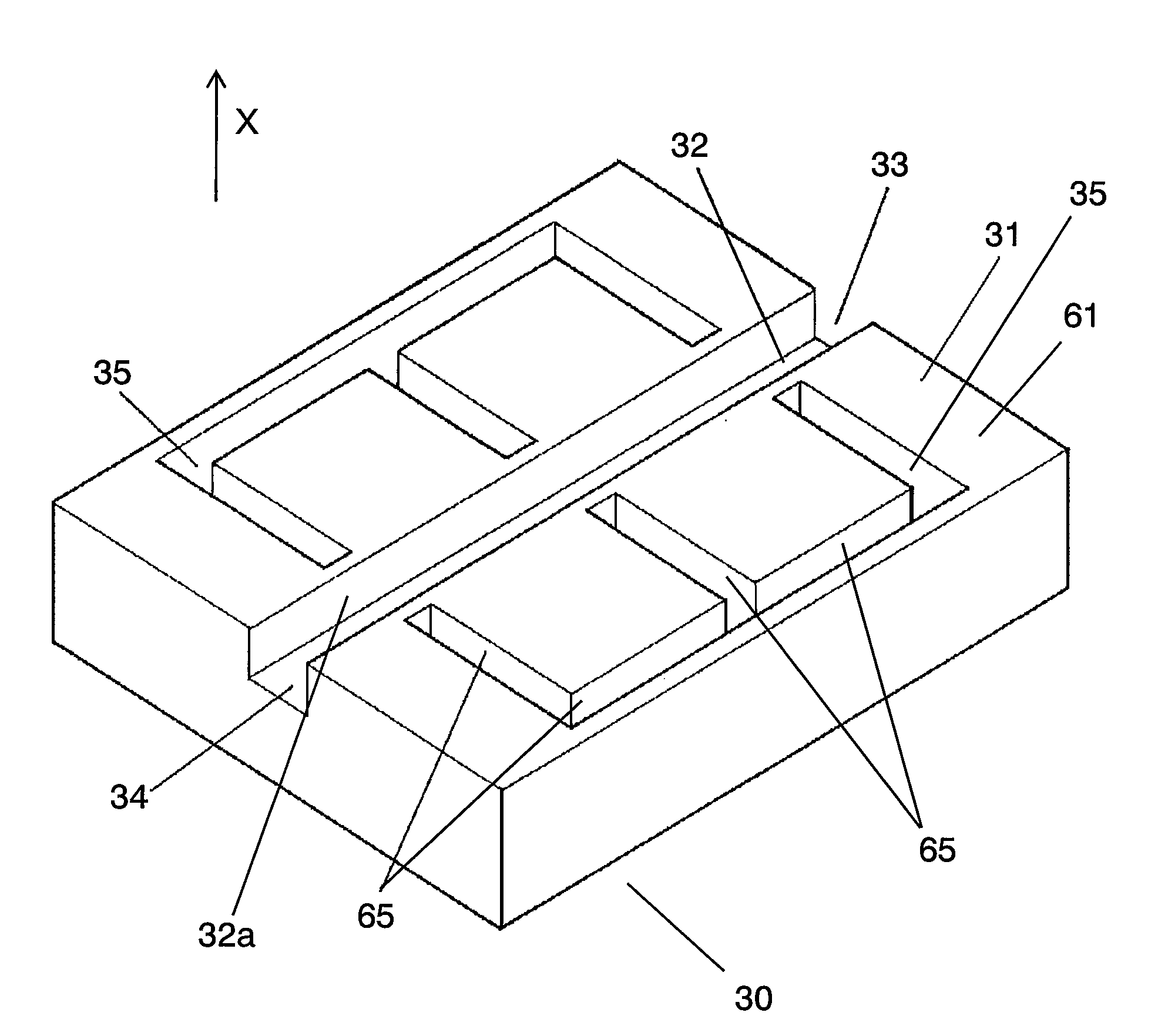

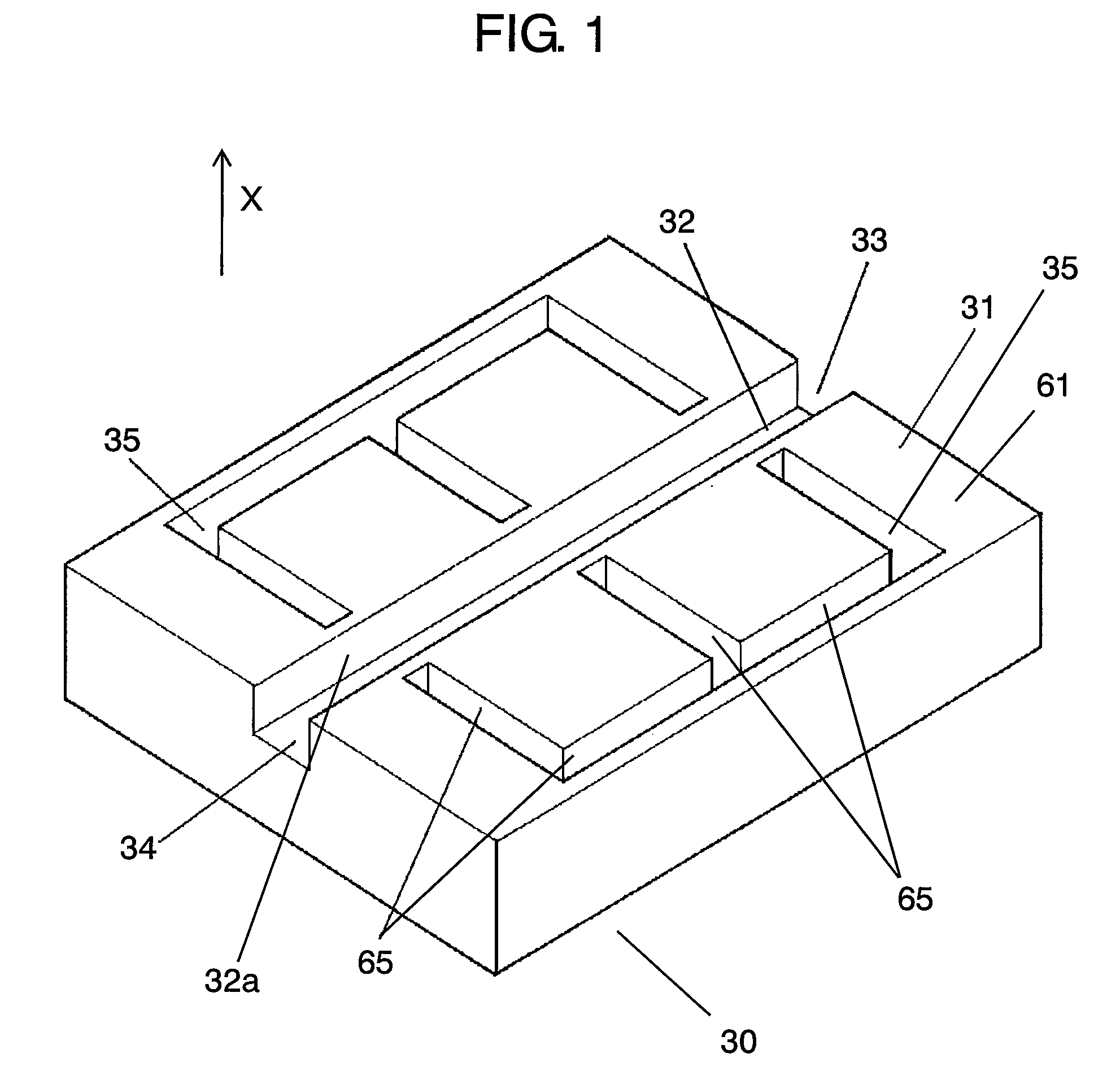

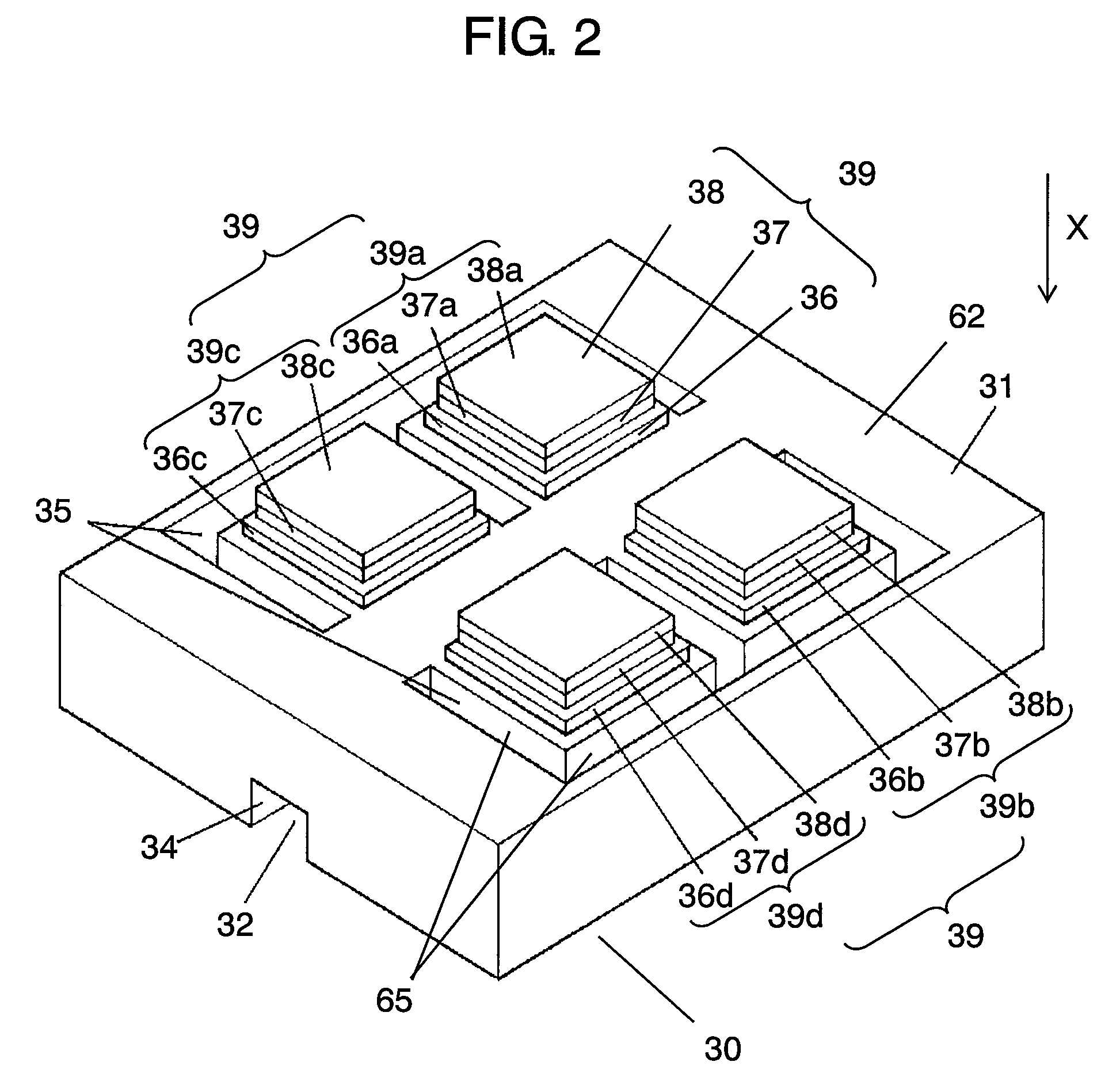

Component separating device and method of separating component

InactiveUS7968049B2Separating respective components highly accuratelyReduce vibration lossWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsSolid componentEngineering

A component separating device includes a substrate, a fluid channel provided at the substrate, an actuator and a groove provided at a surrounding of the actuator, the fluid channel contains a fluid including a liquid component and a solid component, and the actuator generates a standing wave at inside of the fluid channel. By such a constitution, a vibration loss is reduced by reflecting a vibration by the groove to be transmitted to a side of the fluid channel, the standing wave having a strong intensity is generated at inside of the fluid channel, and the small-sized highly accurate component separating device is provided.

Owner:PANASONIC CORP

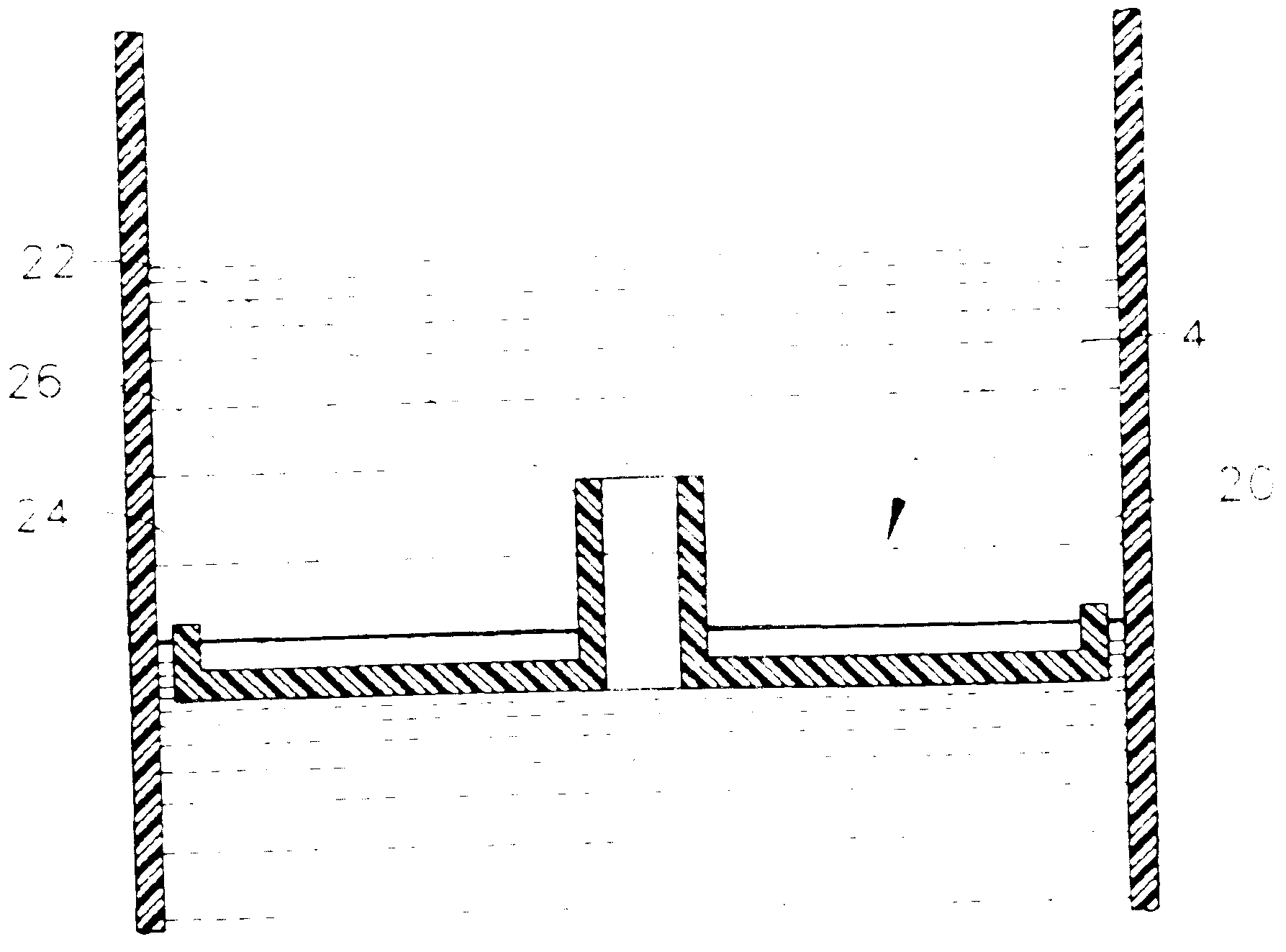

Liquid additive slow-release apparatus driven by a filter pressure gradient

ActiveUS20050167351A1Non-fuel substance addition to fuelSolid sorbent liquid separationEngineeringMechanical engineering

The present invention provides a filter assembly containing a filter element and a container as a depot for a liquid additive. The container can include an inlet and an outlet, which are configured to allow a liquid to flow into the container mix with the contained additive and then flow out into the system. It has been observed that a liquid flowing through a filter assembly exhibits a pressure gradient within the filter. Consequently, the inlets and outlets to the container can be positioned to take advantage of the pressure gradient to enhance the addition of the additive to the liquid in the filter assembly.

Owner:CUMMINS FILTRATION INC

Liquid additive slow-release apparatus driven by a filter pressure gradient

ActiveUS7156991B2Solid sorbent liquid separationCombustion enginesMechanical engineeringFilter element

The present invention provides a filter assembly containing a filter element and a container as a depot for a liquid additive. The container can include an inlet and an outlet, which are configured to allow a liquid to flow into the container mix with the contained additive and then flow out into the system. It has been observed that a liquid flowing through a filter assembly exhibits a pressure gradient within the filter. Consequently, the inlets and outlets to the container can be positioned to take advantage of the pressure gradient to enhance the addition of the additive to the liquid in the filter assembly.

Owner:CUMMINS FILTRATION INC

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

Storage stable autodepositable dispersions of epoxy resins and processes therefor and therewith

InactiveUS6096806AIncreased particle refinementSolvent extractionIon-exchanger regenerationStandard hydrogen electrodePolymer chemistry

PCT No. PCT / US96 / 12540 Sec. 371 Date Feb. 17, 1998 Sec. 102(e) Date Feb. 17, 1998 PCT Filed Aug. 7, 1996 PCT Pub. No. WO97 / 07163 PCT Pub. Date Feb. 27, 1997Epoxy resins, particularly those based on bisphenol A, can constitute the principal film forming polymer component of a storage stable autodepositable composition wherein the particle size distribution of all the film forming polymers in the composition satisfies certain criteria of size distribution, and an accelerator component which is an acid, oxidizing agent or complexing agent is present in amount sufficient to provide an oxidation-reduction potential at least 100 mV more oxidizing than a standard hydrogen electrode. Such dispersions can conveniently be prepared using a two stage process in which a solution of the film forming polymers is emulsified into water to form a preliminary dispersion and this preliminary dispersion is subjected to at least one particle size refinement stage in which the preliminary dispersion is forced through a narrow aperture.

Owner:HENKEL KGAA

Thermal crystallization of polyester pellets in liquid

InactiveUS7329723B2High molecular weightCrystallization separationSolid sorbent liquid separationPolyesterLiquid medium

A process for thermally crystallizing a polyester polymer by introducing pellets into a liquid medium having a temperature of at least 140° C. within a liquid medium zone and crystallizing the submerged pellets at or above the vapor pressure of the liquid medium without increasing the molecular weight of the pellets, and while the pressure on at least a portion of the pellets is equal to or greater than the vapor pressure of the liquid medium, separating at least a portion of said pellets and at least a portion of the liquid medium from each other. The crystallization is desirably conducted in the liquid medium zone without mechanically induced agitation. Optionally, the pellets are formed by an underfluid pelletizer. There is also provided a process for thermally crystallizing solid pellets in a pipe by directing a flow of solid pellets in a liquid medium through a pipe having an aspect ratio L / D of at least 50:1, wherein the solid pellets are crystallized in the pipe at a liquid medium temperature greater than the Tg of the polyester polymer.

Owner:ALPEK POLYESTER SA DE CV

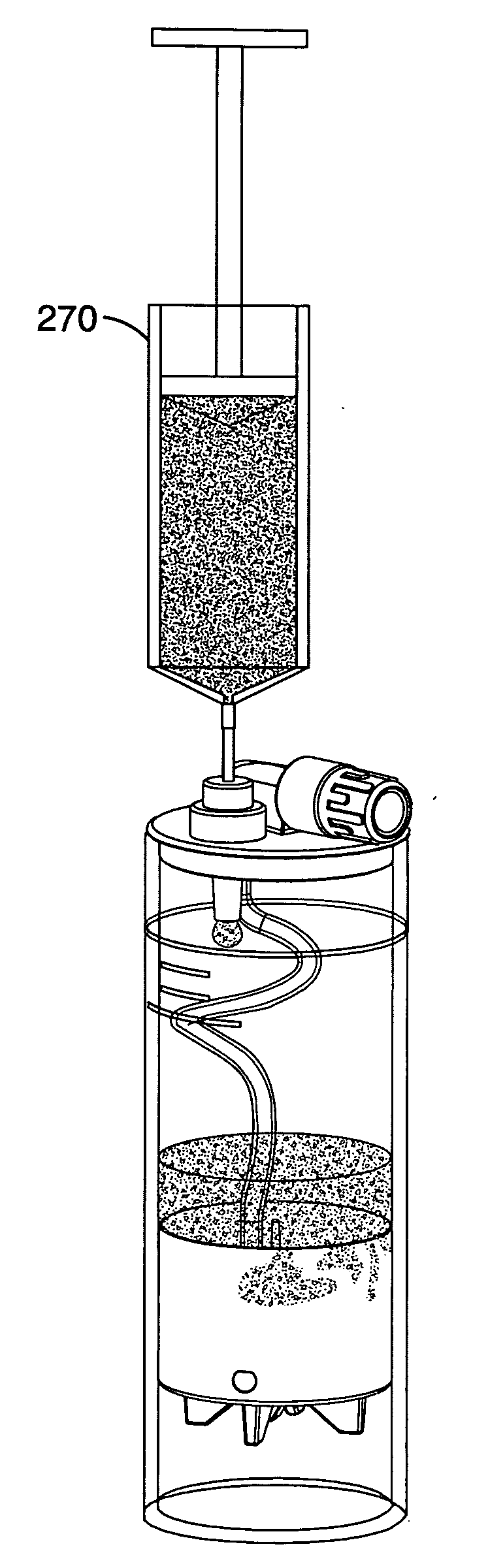

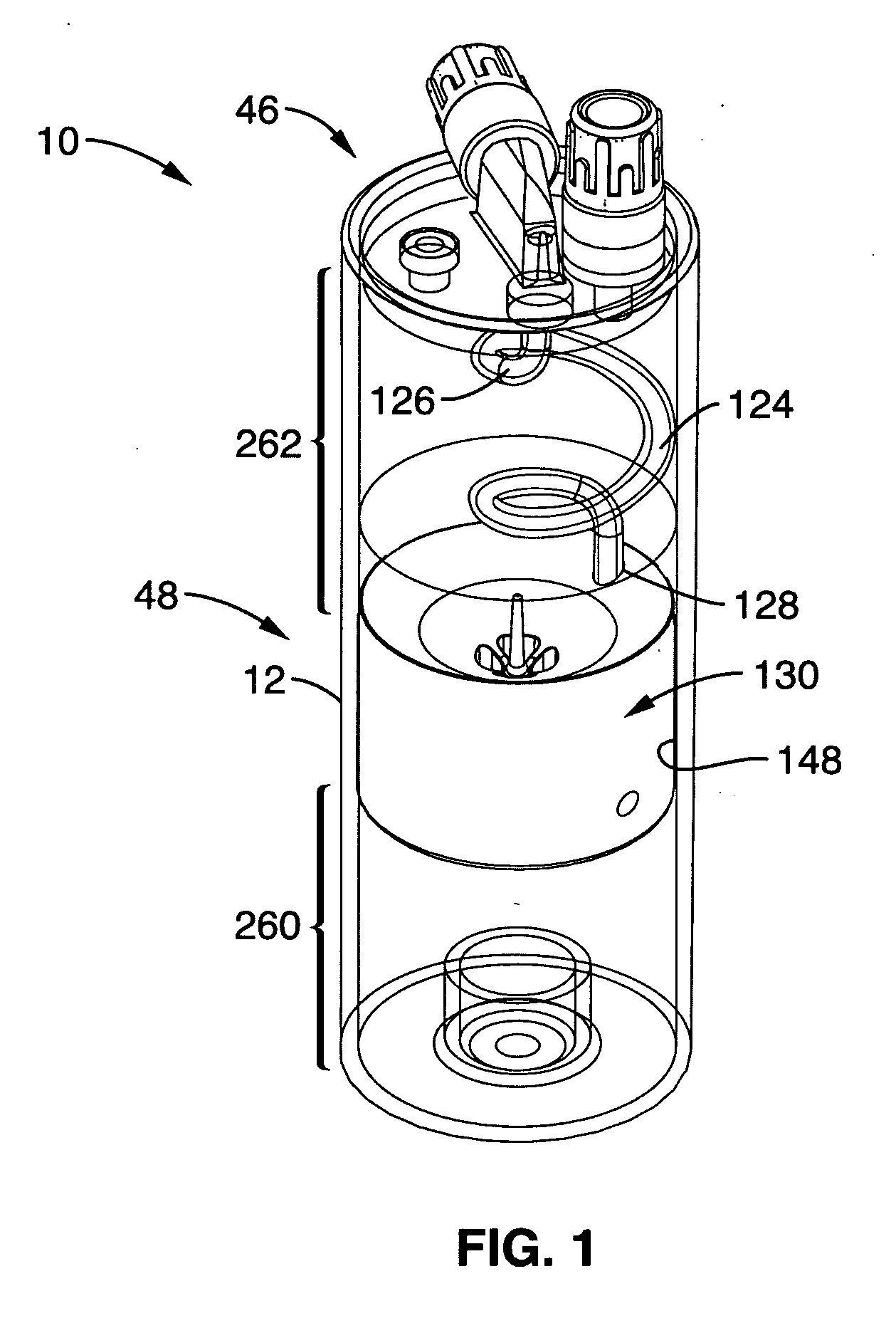

Apparatus And Method For Separating And Concentrating Fluids Containing Multiple Components

An apparatus is disclosed that allows for separating and collecting a fraction of a sample. The apparatus, when used with a centrifuge, allows for the creation of at least three fractions in the apparatus. It also provides for a new method of extracting the buffy coat phase from a whole blood sample. A buoy system that may include a first buoy portion and a second buoy member operably interconnected may be used to form at least three fractions from a sample during a substantially single centrifugation process. Therefore, the separation of various fractions may be substantially quick and efficient.

Owner:BIOMET MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com