Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Improve heat transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal crystallization of a molten polyester polymer in a fluid

InactiveUS7192545B2Reduce molecular weightEnergy efficiencyDrying gas arrangementsCeramic shaping apparatusPolyesterLiquid medium

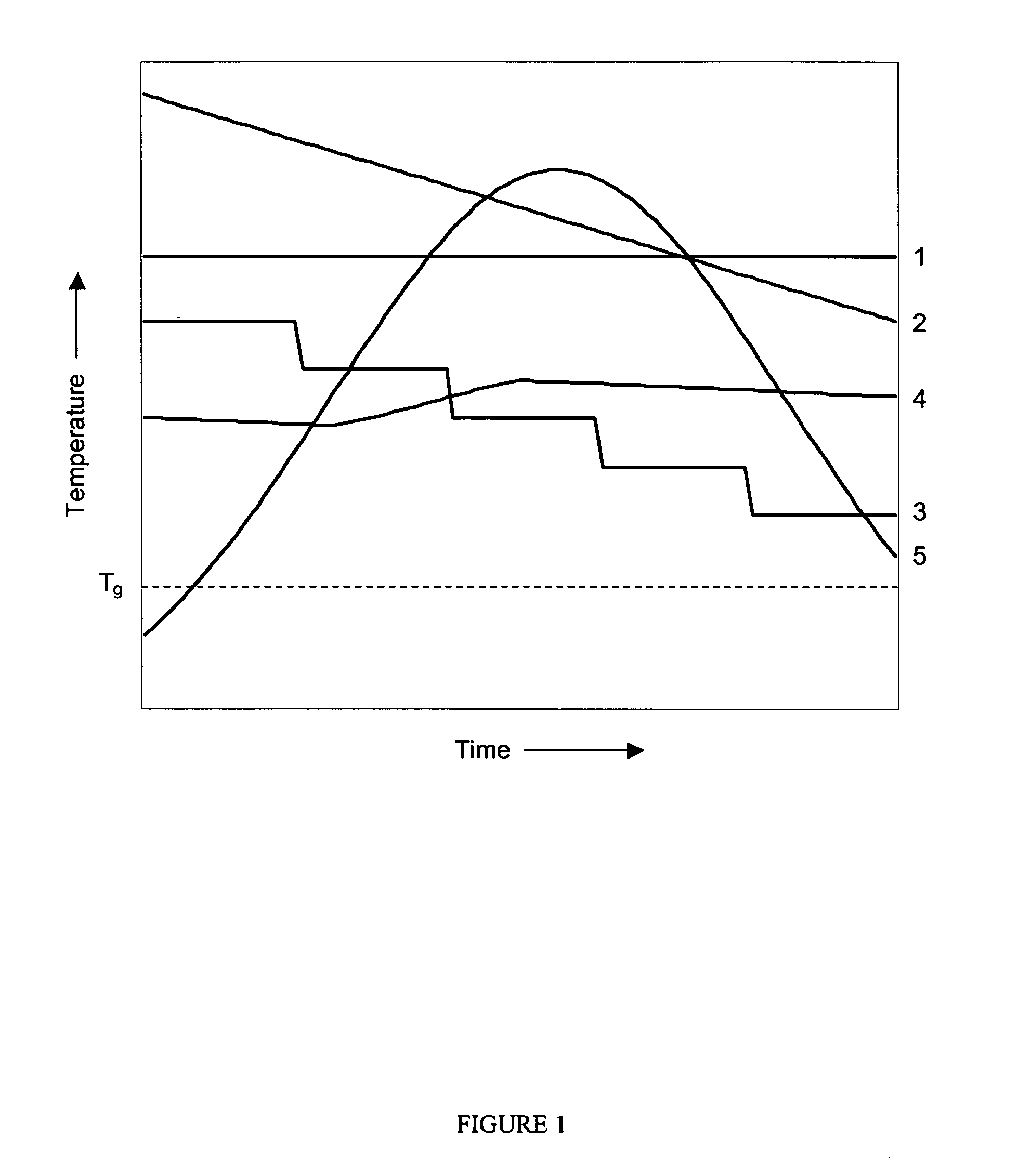

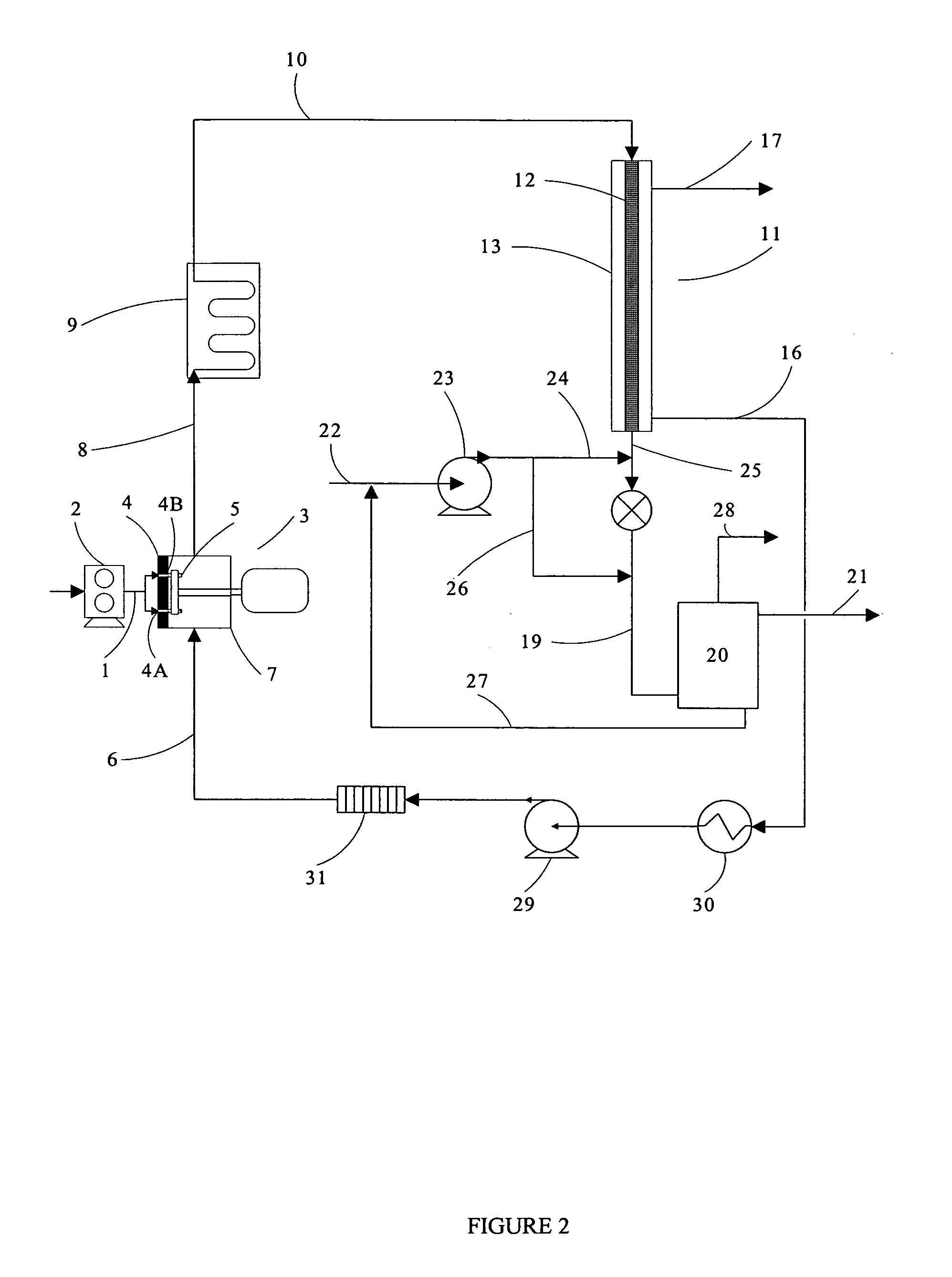

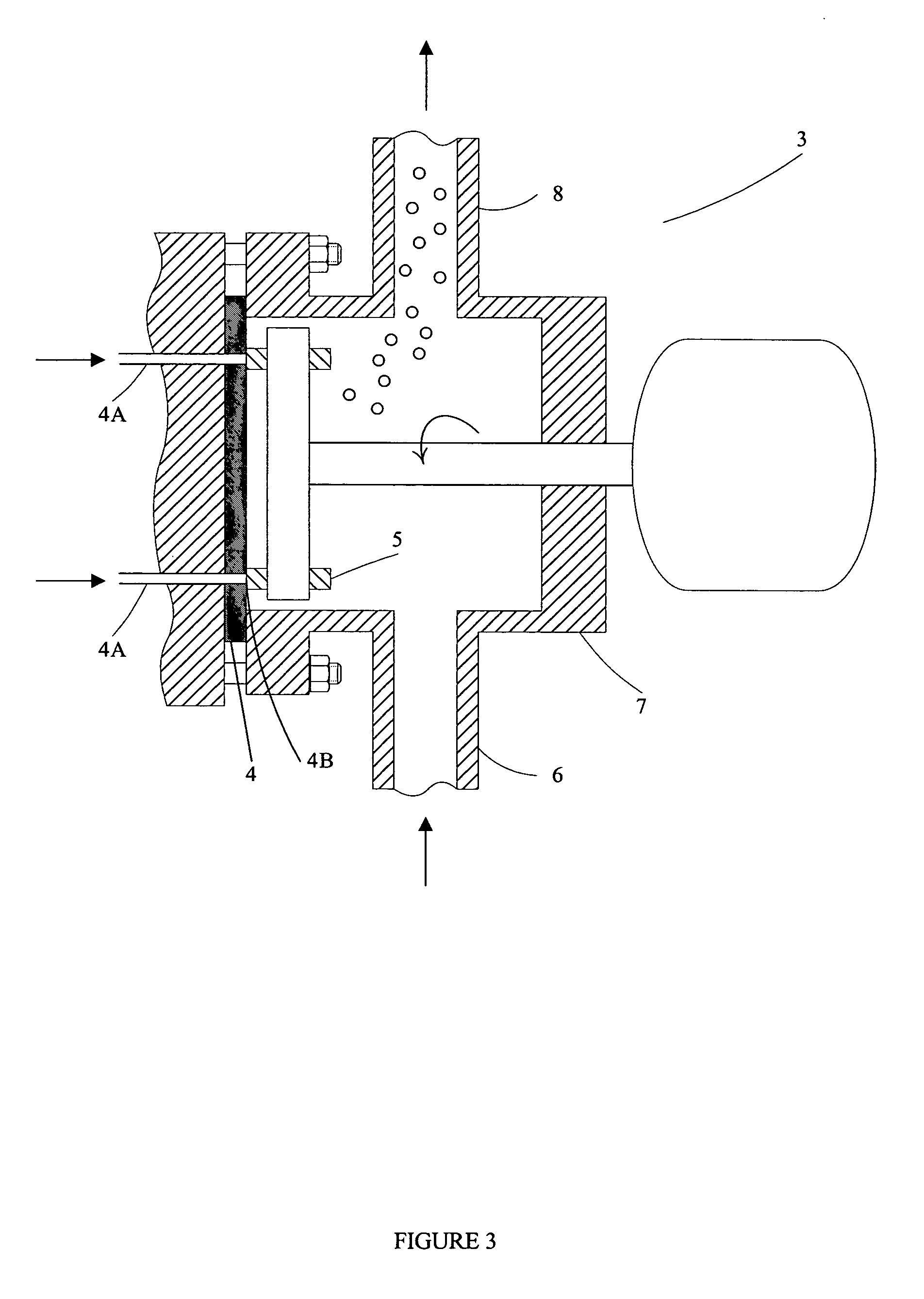

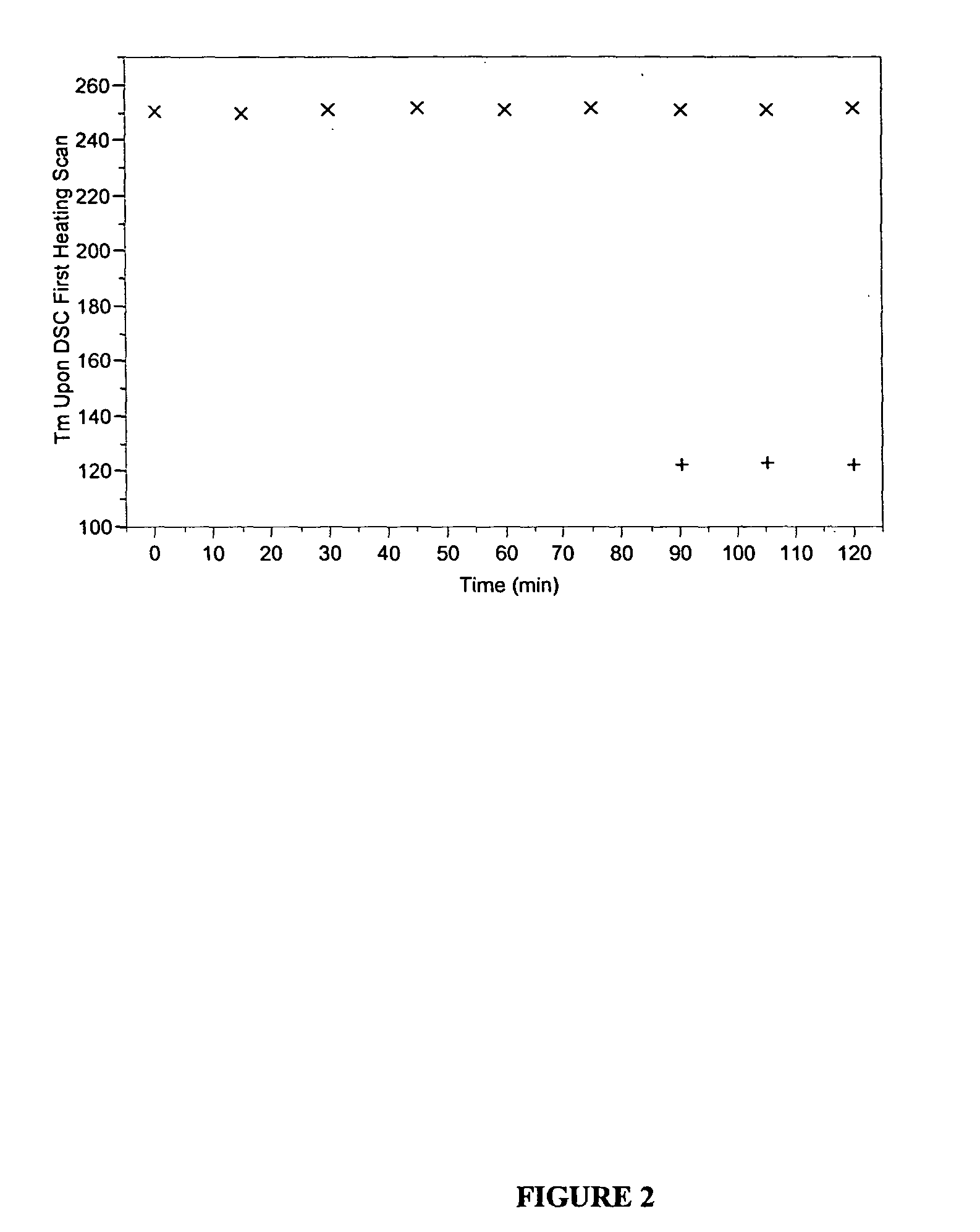

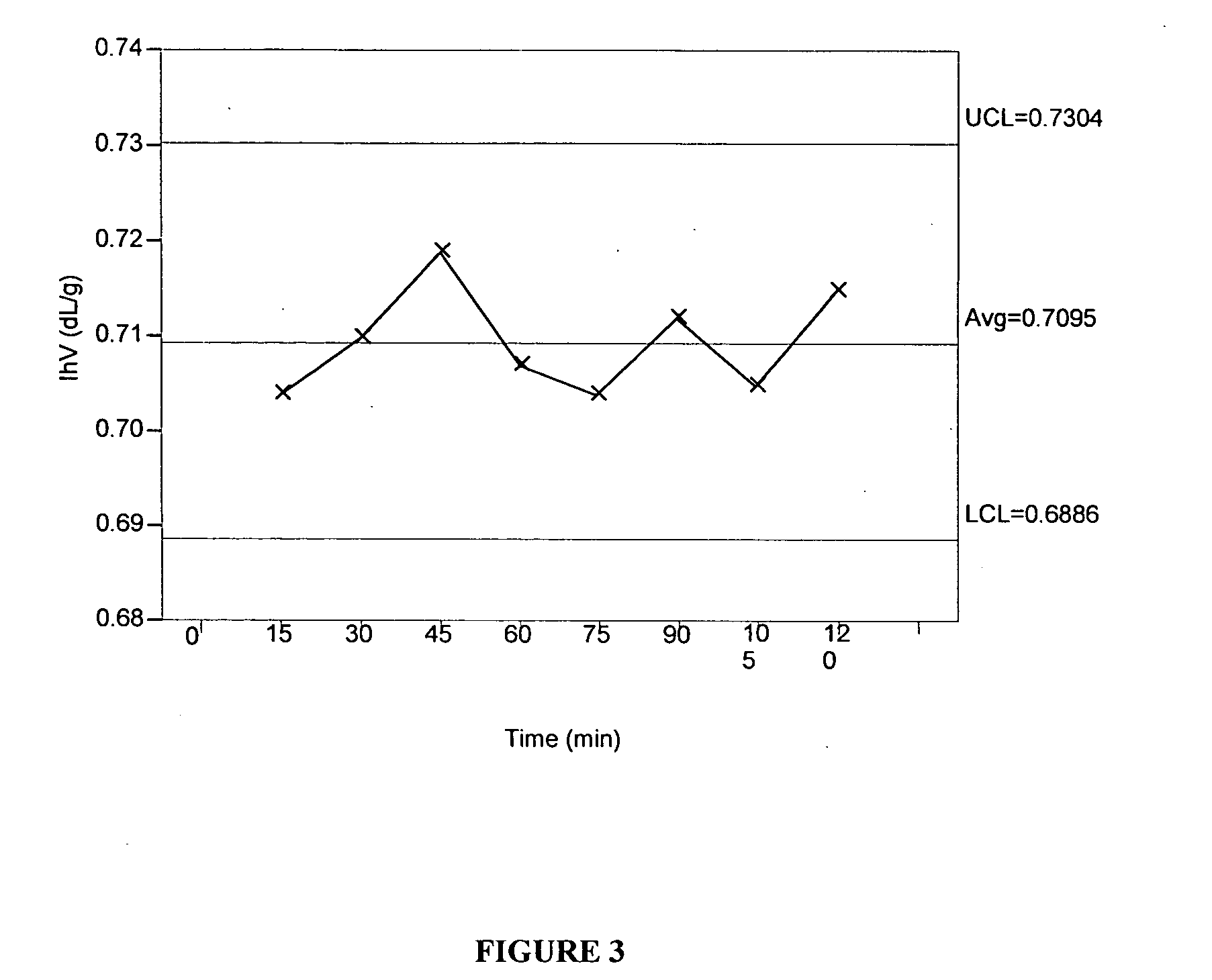

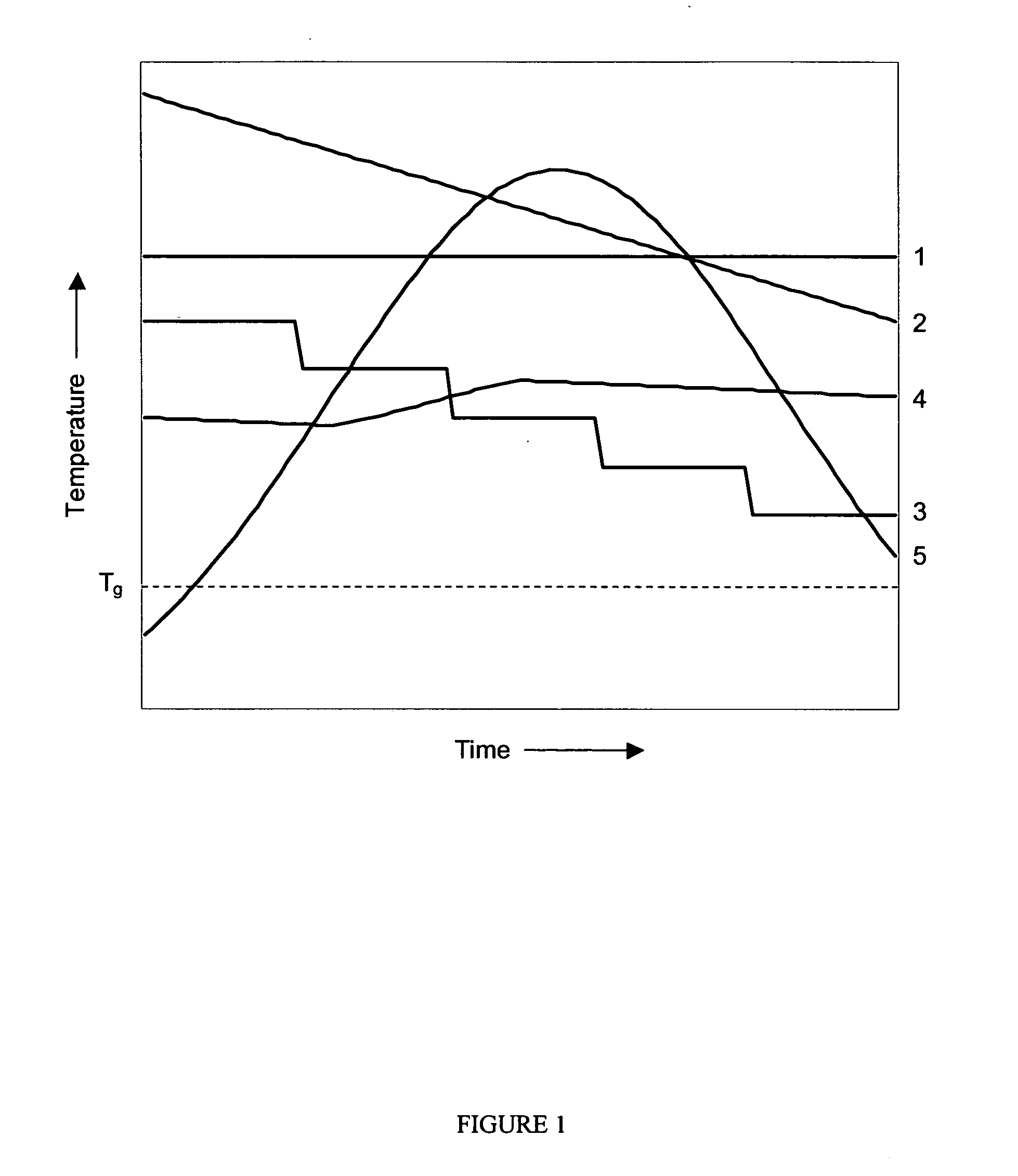

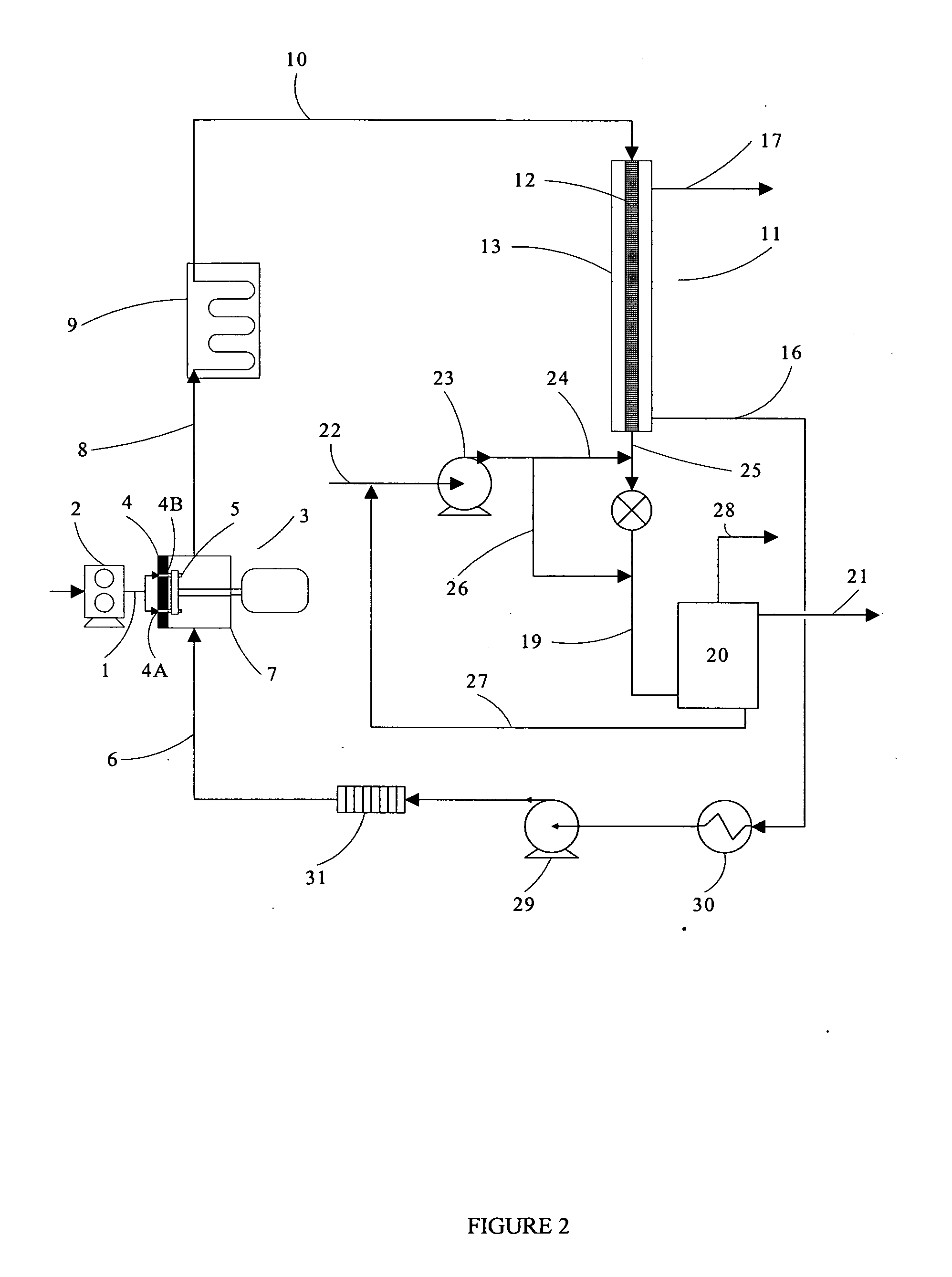

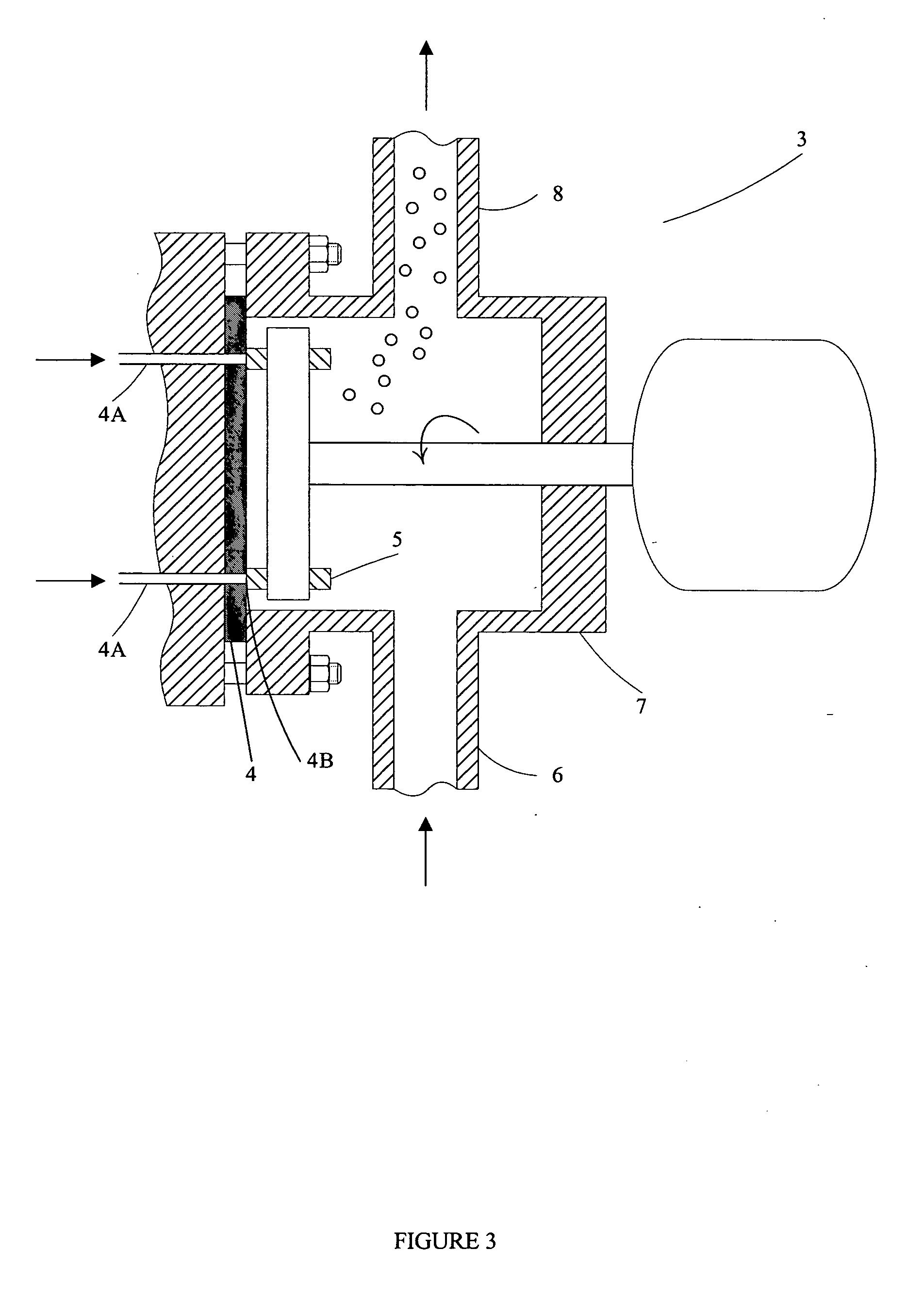

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

Thermal crystallization of polyester pellets in liquid

InactiveUS20050065318A1Improve heat transfer rateEnergy efficiencyCrystallization separationSolid sorbent liquid separationPolyesterLiquid medium

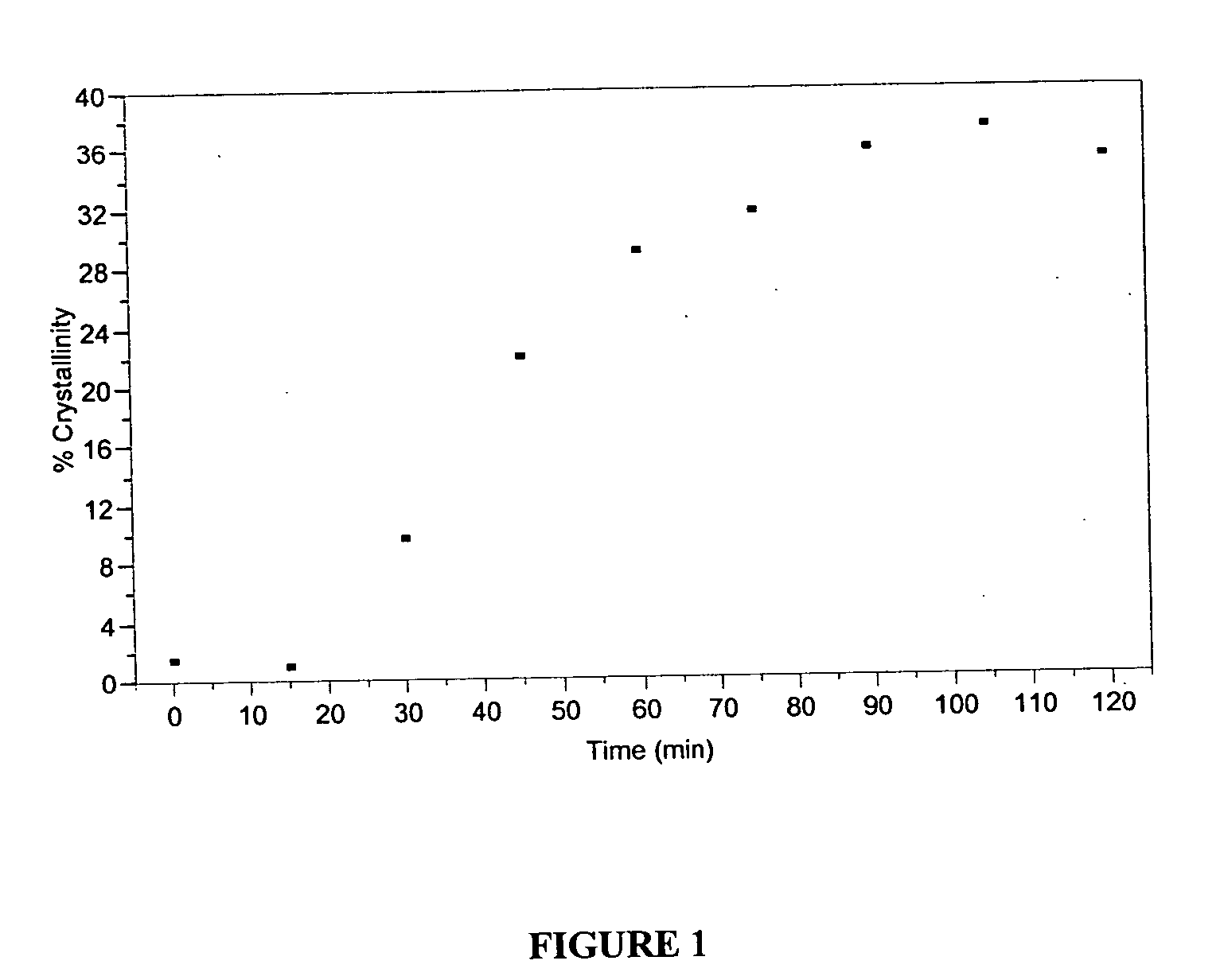

A process for thermally crystallizing a polyester polymer by introducing pellets into a liquid medium having a temperature of at least 140° C. within a liquid medium zone and crystallizing the submerged pellets at or above the vapor pressure of the liquid medium without increasing the molecular weight of the pellets, and while the pressure on at least a portion of the pellets is equal to or greater than the vapor pressure of the liquid medium, separating at least a portion of said pellets and at least a portion of the liquid medium from each other. The crystallization is desirably conducted in the liquid medium zone without mechanically induced agitation. Optionally, the pellets are formed by an underfluid pelletizer. There is also provided a process for thermally crystallizing solid pellets in a pipe by directing a flow of solid pellets in a liquid medium through a pipe having an aspect ratio L / D of at least 50:1, wherein the solid pellets are crystallized in the pipe at a liquid medium temperature greater than the Tg of the polyester polymer.

Owner:ALPEK POLYESTER SA DE CV

Thermal crystallization of a molten polyester polymer in a fluid

ActiveUS20050154183A1Energy efficiencyImprove heat transfer rateDrying gas arrangementsChemical/physical/physico-chemical stationary reactorsThermal crystallizationPolyester

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

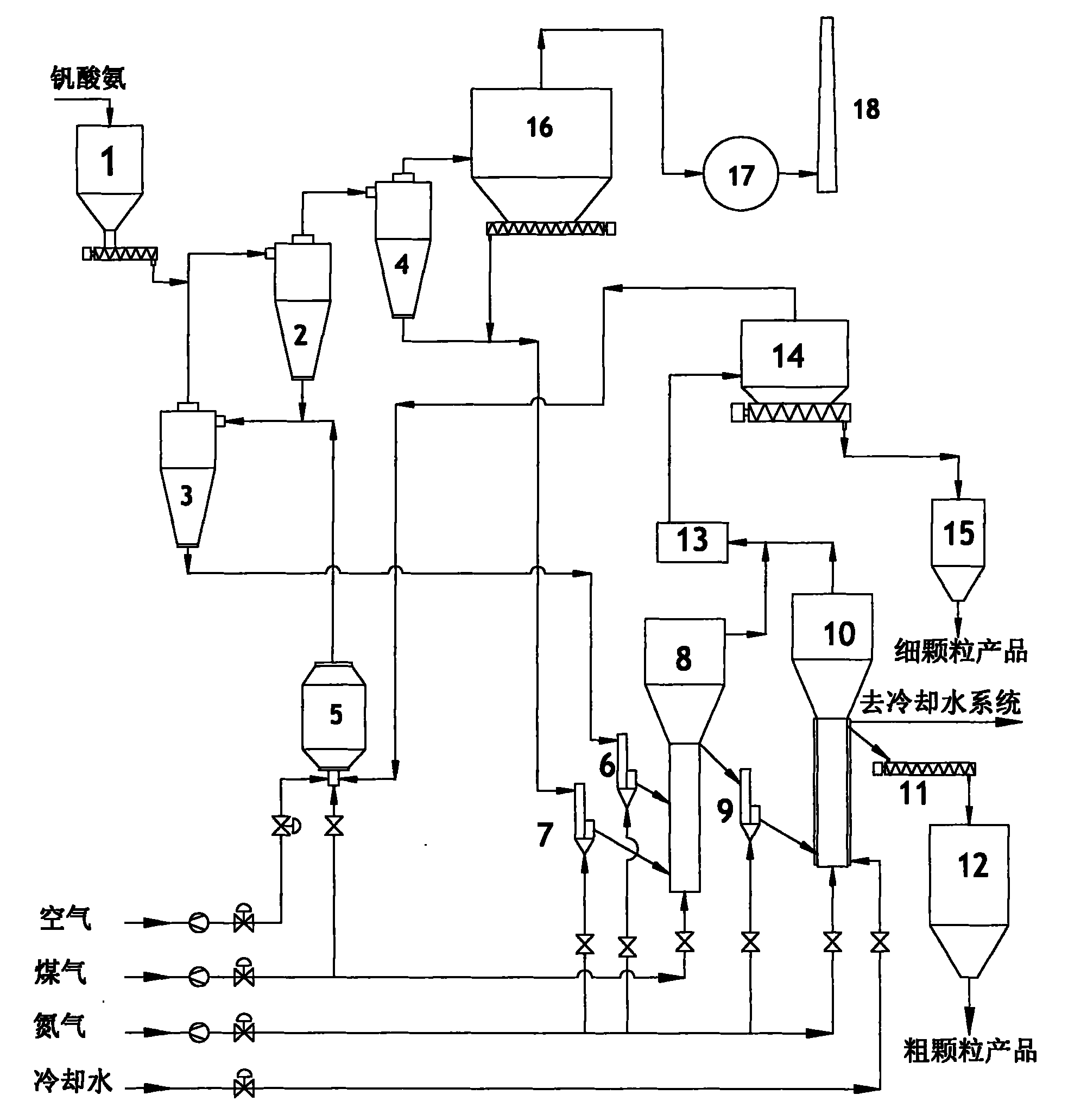

Method for producing vanadium trioxide by adopting fluidized bed reactor

ActiveCN101880059AImprove efficiencySuitable for mass productionVanadium oxidesCombustion chamberFluidized bed

The invention relates to a method for producing vanadium trioxide by adopting a fluidized bed reactor, belonging to the field of the chemical industry and metallurgy. Heat is provided for reaction by a mode of preheating the materials containing vanadium to be 400-550 DEG C, the materials containing vanadium are preheated by adopting a two-stage cyclonic preheater, and high-temperature smoke generated by a combustion chamber provides heat. Gas with heat value of being larger than 1250kcal / Nm<3> is adopted to be reduced for 5-20 minutes at the temperature of 700-850 DEG C, and a vanadium trioxide product with vanadium grade of being more than 66% can be obtained. The method has the advantages of high reduction efficiency, good energy utilization and suitability for large-scale production of vanadium trioxide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

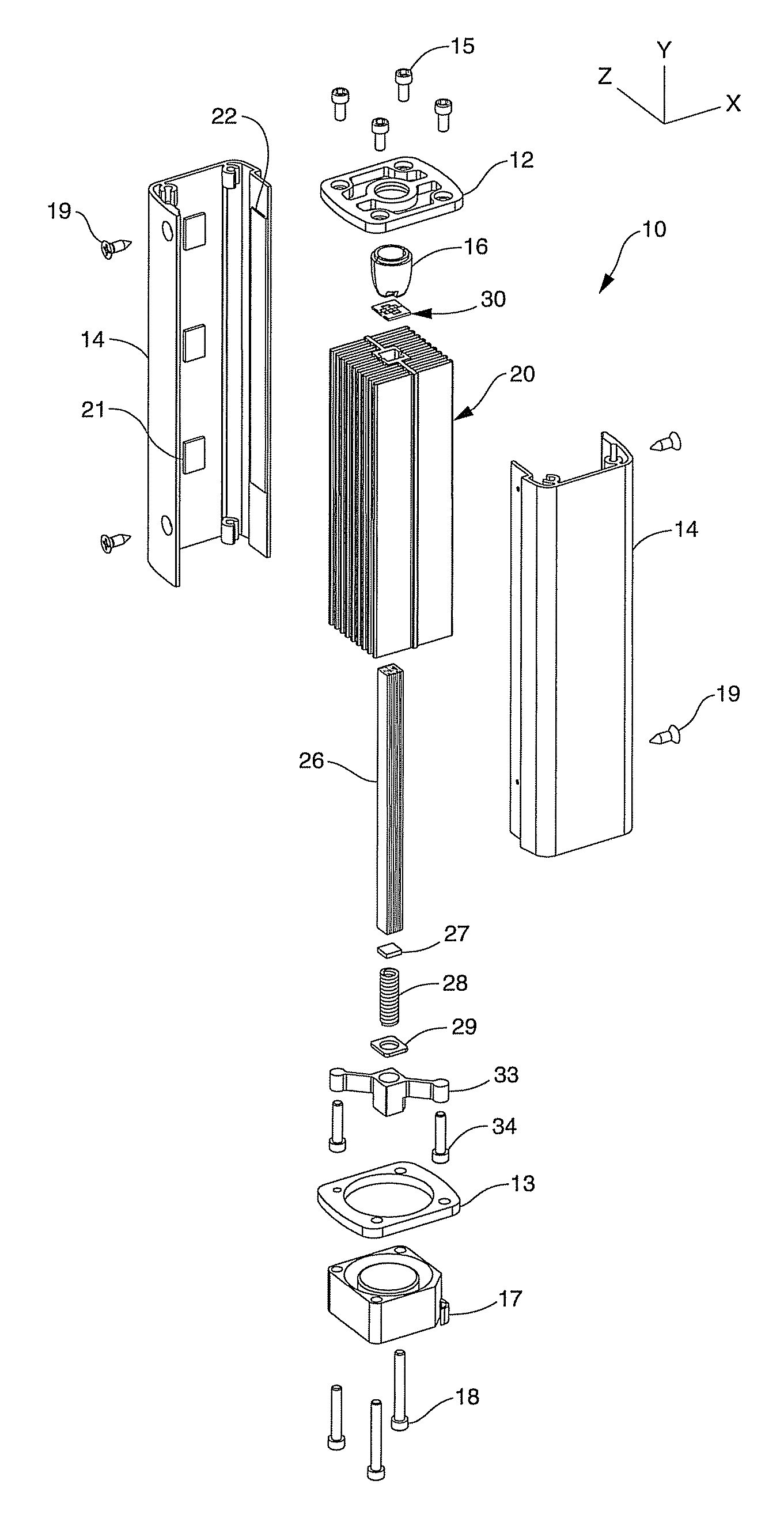

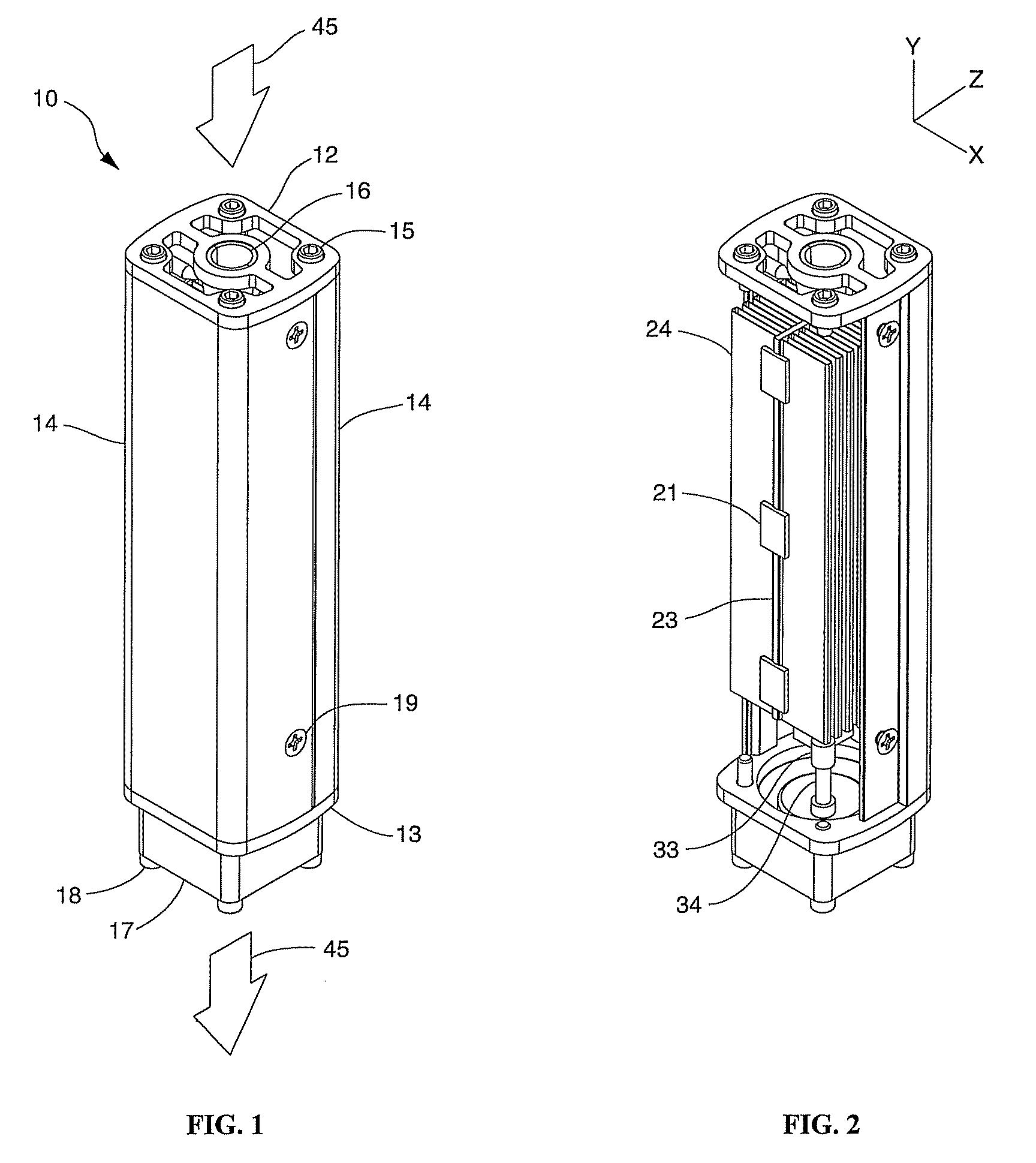

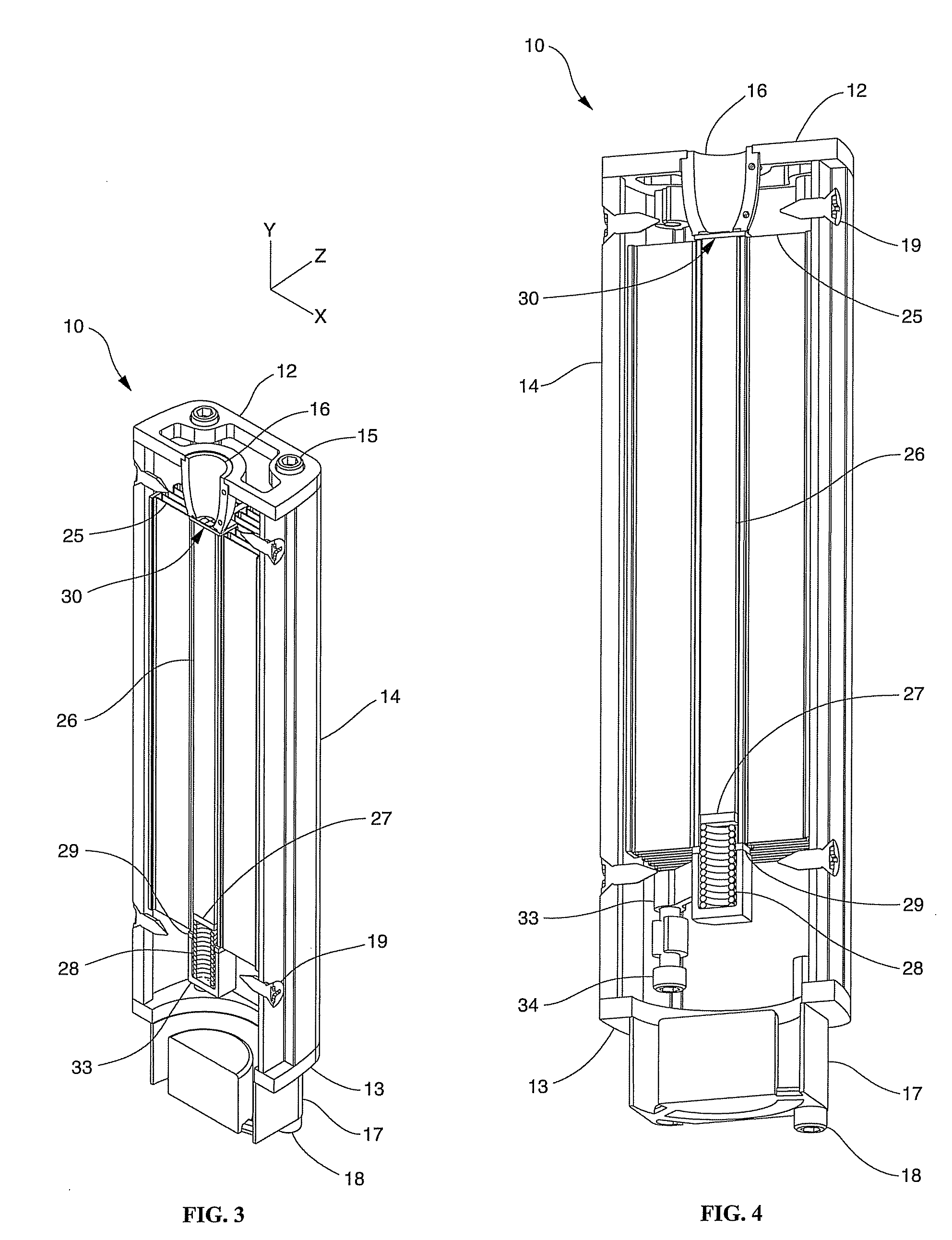

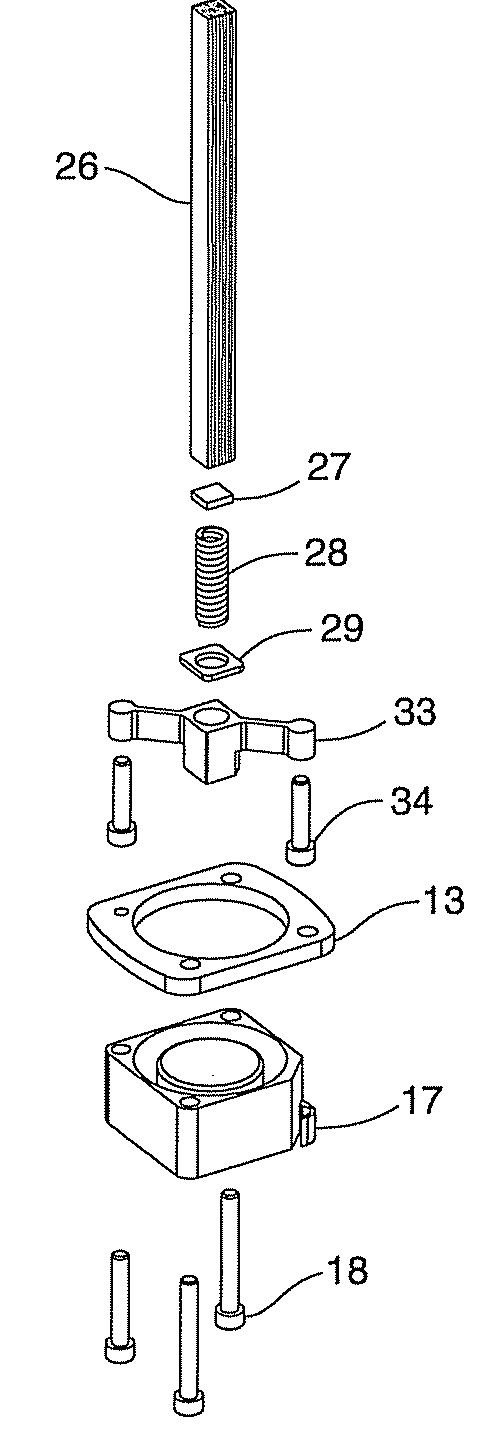

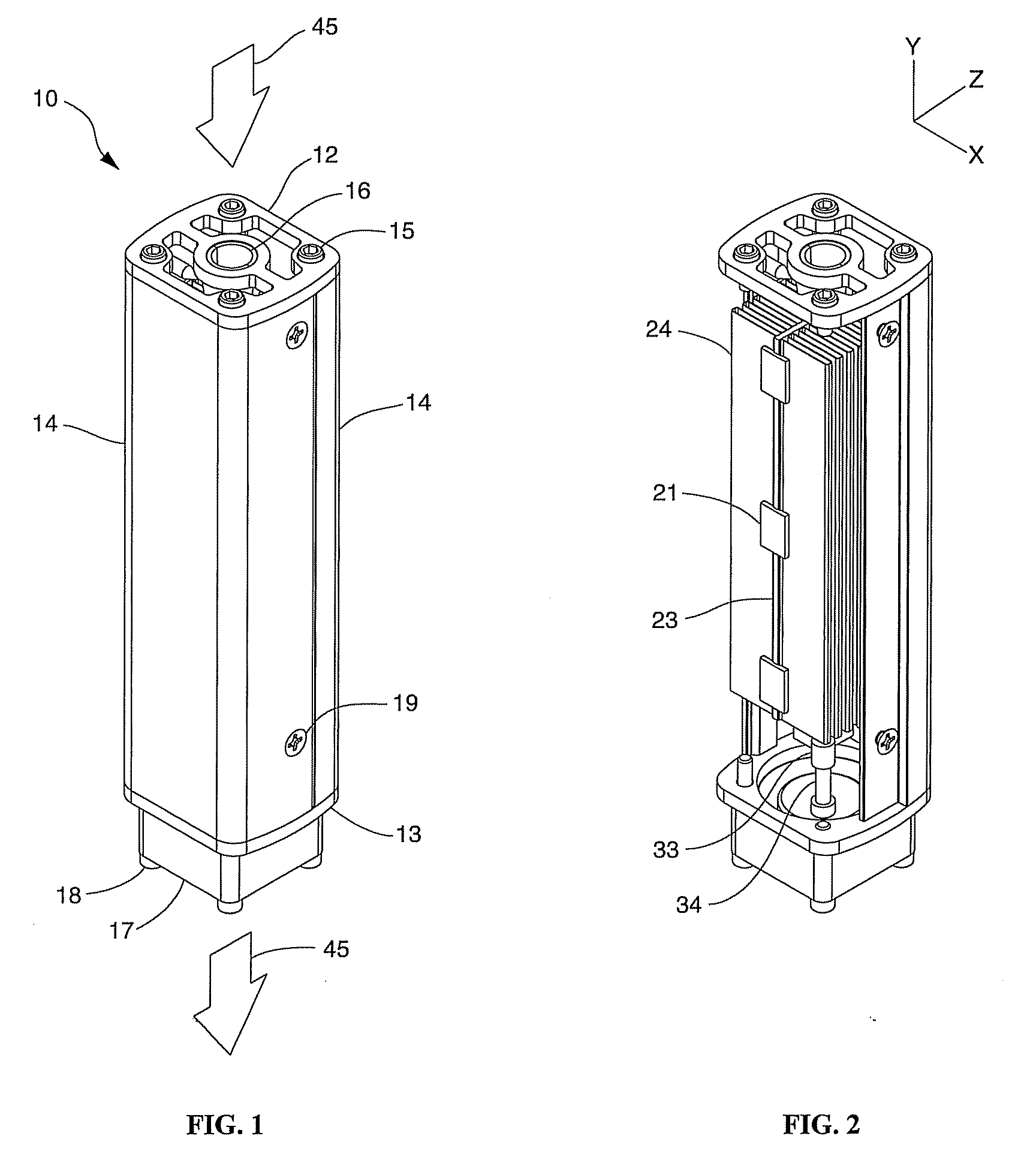

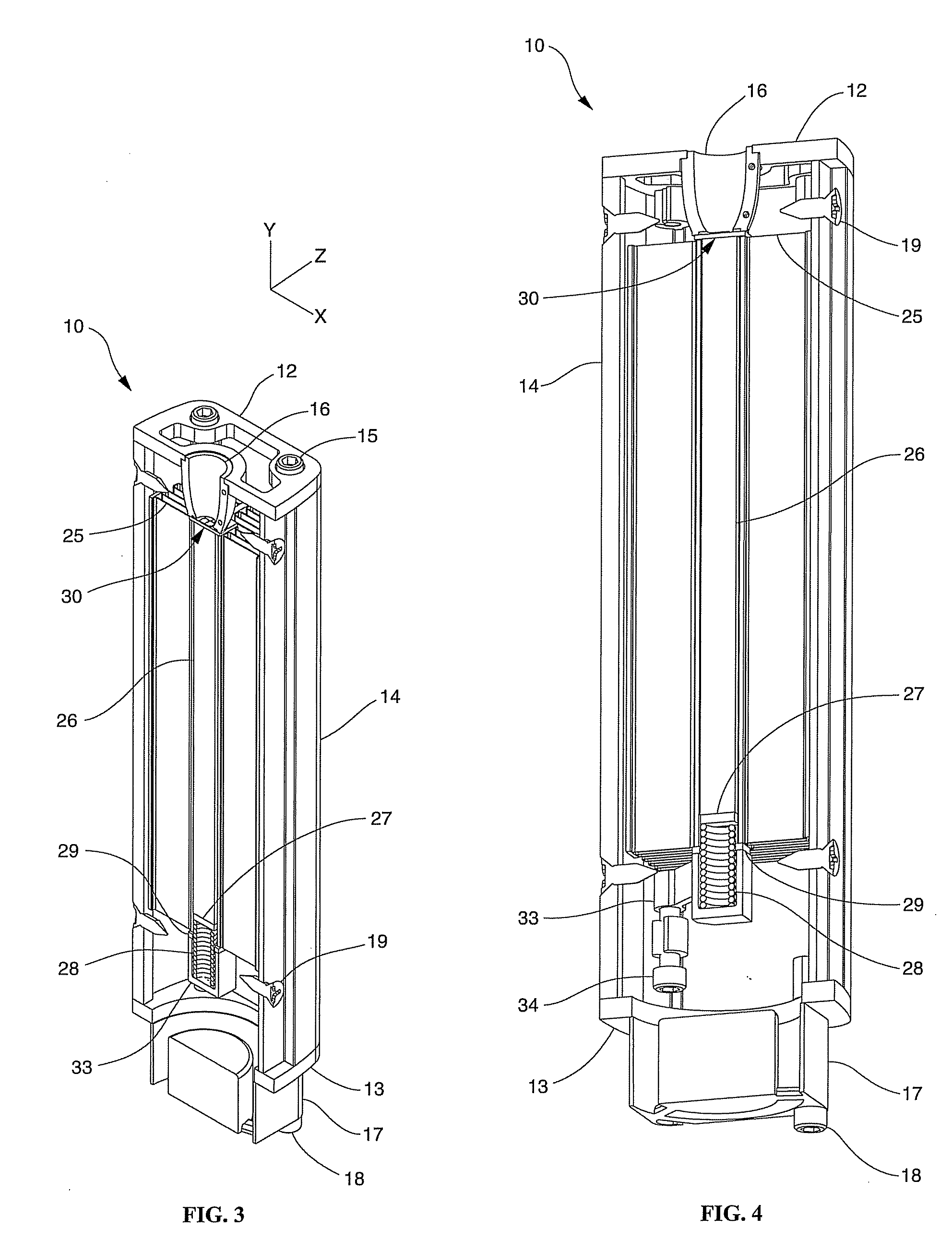

Solid state lighting apparatus utilizing axial thermal dissipation

InactiveUS7740380B2Improve cooling effectHeat dissipationPoint-like light sourceLighting support devicesLight equipmentHighly oriented pyrolytic graphite

A solid state lighting apparatus characterized by its compact, predominately axial form factor, utilizes an axial thermal transfer member constructed of Highly Oriented Pyrolytic Graphite (HOPG) to aid in the dissipation of waste heat generated during its operation. The lighting apparatus is chiefly comprised of a Light Emitting Diode (LED) die array and circuit structure assembly affixed to one end of the axial thermal transfer member and further includes a transversely mounted heat sink structure, running the length of, and being affixed to, opposite sides of the axial member. The axial member serves to distribute waste heat down its length, and simultaneously, into a transverse plane where the waste heat is dissipated into the transversely mounted heat sink structure. A fan may be utilized to evacuate the waste heat out of the lighting apparatus and into the ambient environment.

Owner:THRAILKILL JOHN E

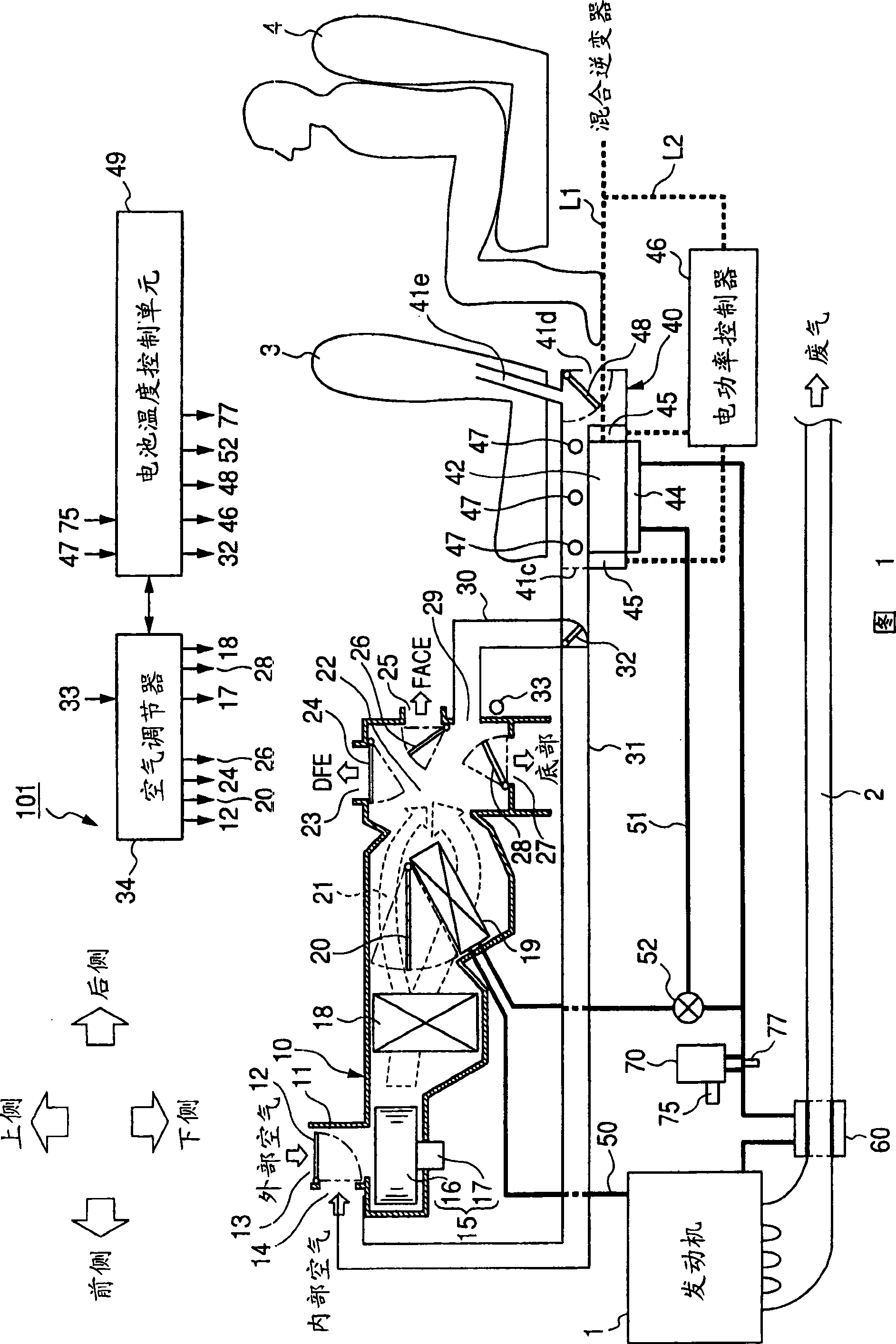

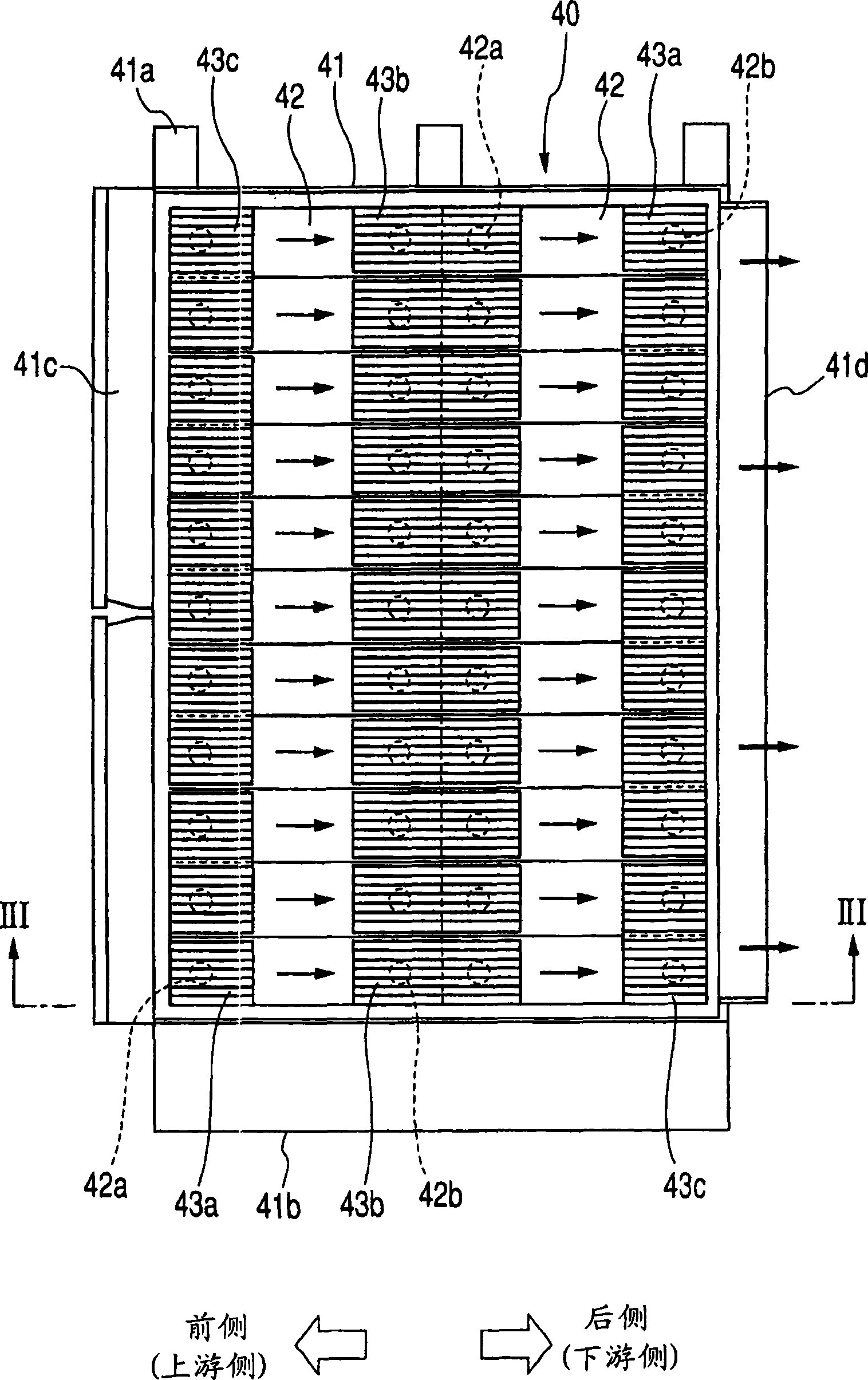

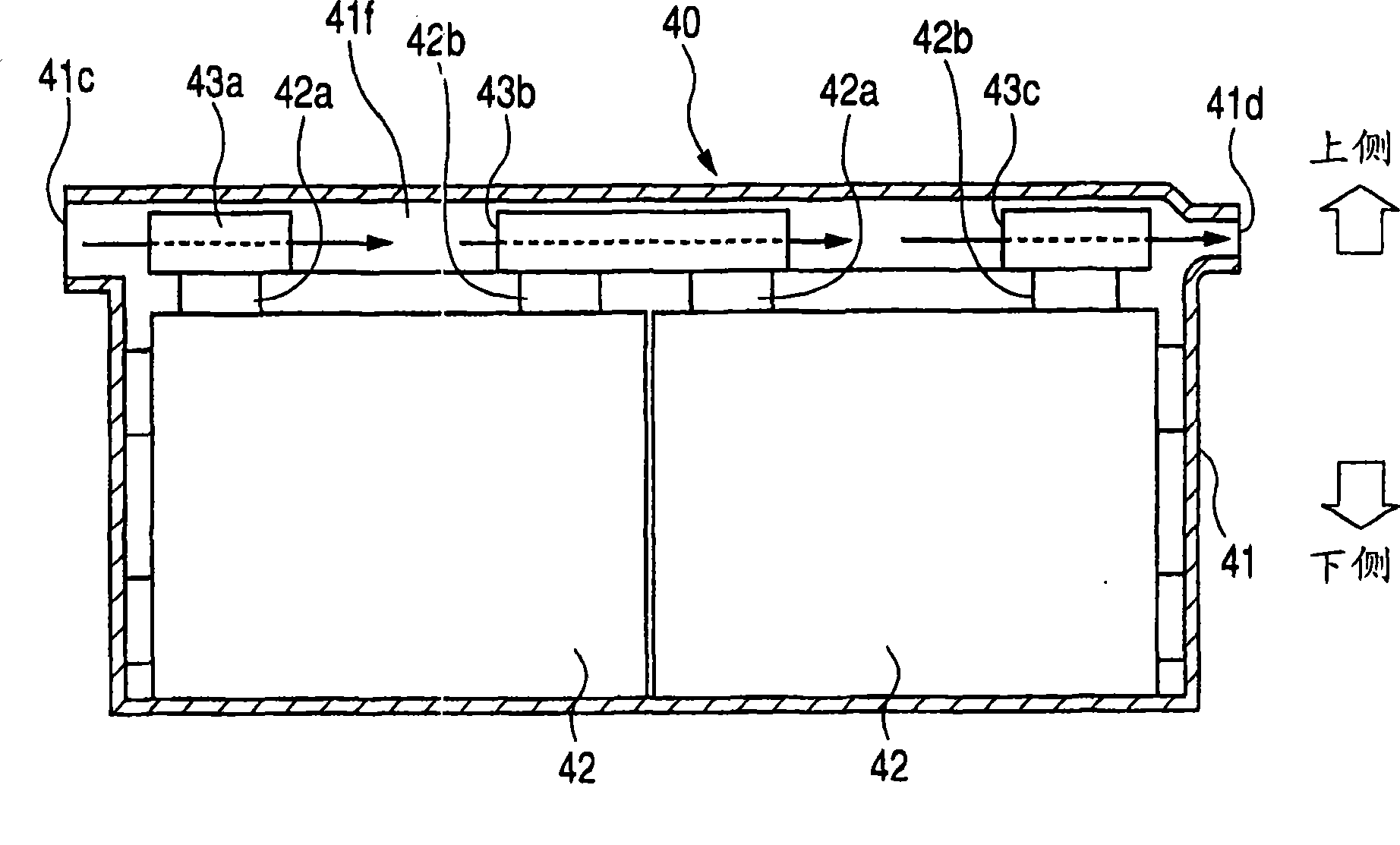

Temperature control device for on-board battery pack

ActiveCN101396953AIncrease temperatureImprove heat transfer rateTemperature control without auxillary powerCell temperature controlTemperature controlIn vehicle

A temperature control device has a heat exchanger recovering heat from exhaust gas of an engine, a water circulating passage in which a cooling water is circulated while receiving the recovered heat, an air conditioning unit heating air with the hot cooling water of the passage to produce a temperature controlled air, an air duct, a water heater attached to the bottom surface of a battery pack, and an electric heater attached side surfaces of the pack. The conditioning unit blows the controlled air against the battery pack through the duct. The water heater receives the hot cooling water of the passage and raises the temperature of the battery pack. The electric heater subsidiarily warms the battery pack with heat generated from electric power of the pack.

Owner:DENSO CORP

Solid state lighting apparatus utilizing axial thermal dissipation

InactiveUS20100103667A1Improve cooling effectHeat dissipationPoint-like light sourceLighting elementsTransverse planeSolid-state

A solid state lighting apparatus characterized by its compact, predominately axial form factor, utilizes an axial thermal transfer member constructed of Highly Oriented Pyrolytic Graphite (HOPG) to aid in the dissipation of waste heat generated during its operation. The lighting apparatus is chiefly comprised of a Light Emitting Diode (LED) die array and circuit structure assembly affixed to one end of the axial thermal transfer member and further includes a transversely mounted heat sink structure, running the length of, and being affixed to, opposite sides of the axial member. The axial member serves to distribute waste heat down its length, and simultaneously, into a transverse plane where the waste heat is dissipated into the transversely mounted heat sink structure. A fan may be utilized to evacuate the waste heat out of the lighting apparatus and into the ambient environment.

Owner:THRAILKILL JOHN E

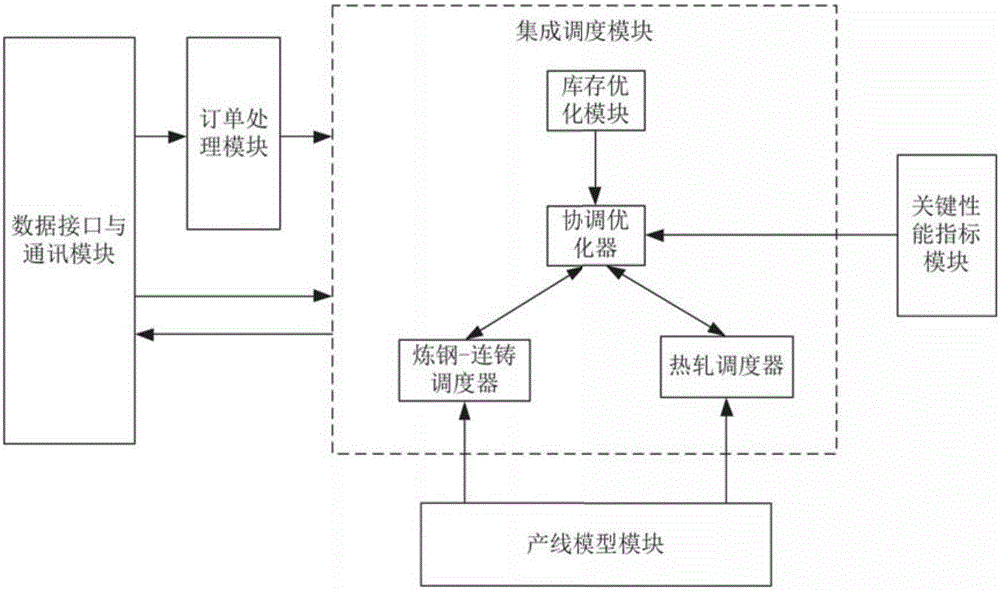

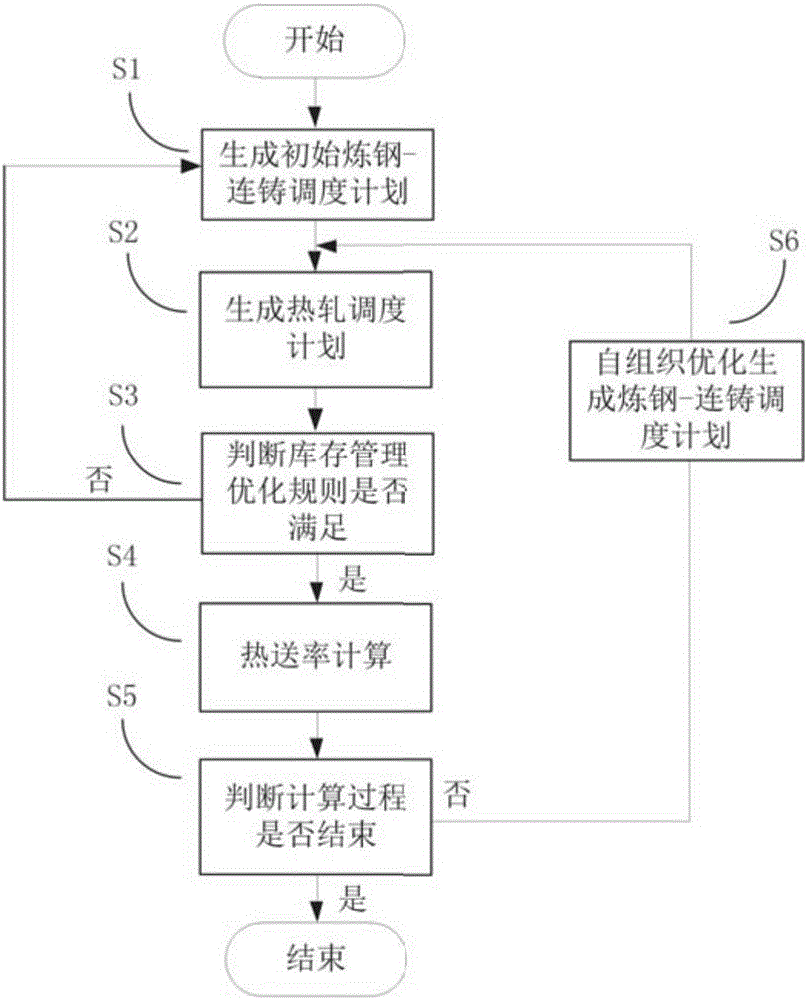

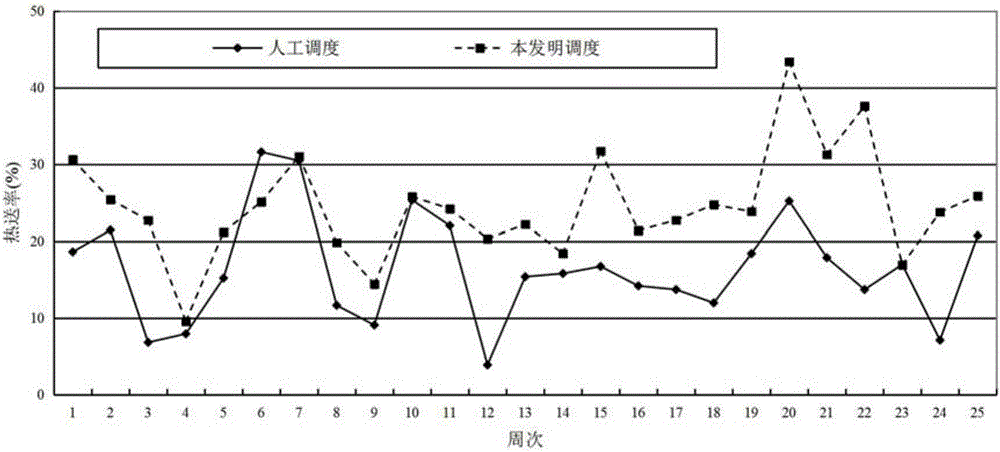

Steelmaking-continuous casting-hot rolling integrated scheduling method and system

ActiveCN106779220AAvoid confictImprove heat transfer rateForecastingResourcesProduction lineHardness

The invention provides a steelmaking-continuous casting-hot rolling integrated scheduling method and system. The method comprises the steps of S1, performing initialization to obtain a steelmaking-continuous casting scheduling plan; S2, obtaining a hot rolling scheduling plan according to the current steelmaking-continuous casting scheduling plan as well as a working order demand, a production line model, a current production rhythm, a rolling unit length constraint, and a rolling unit internal adjacent plate blank width, thickness and hardness jump constraint; S3, determining whether an inventory change situation meets a preset inventory optimization plan or not according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan, and if the preset rule is met, entering the next step, otherwise, adjusting current parameters related to inventory optimization and returning to the step S1; S4, obtaining overall heat supply rate data according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan; S5, judging whether an integrated scheduling stop condition is met or not, and if the stop condition is met, performing the scheduling plan, otherwise, performing the next step; and S6, performing re-optimization to generate the steelmaking-continuous casting scheduling plan, and returning to the step S2.

Owner:ZHEJIANG SUPCON RES

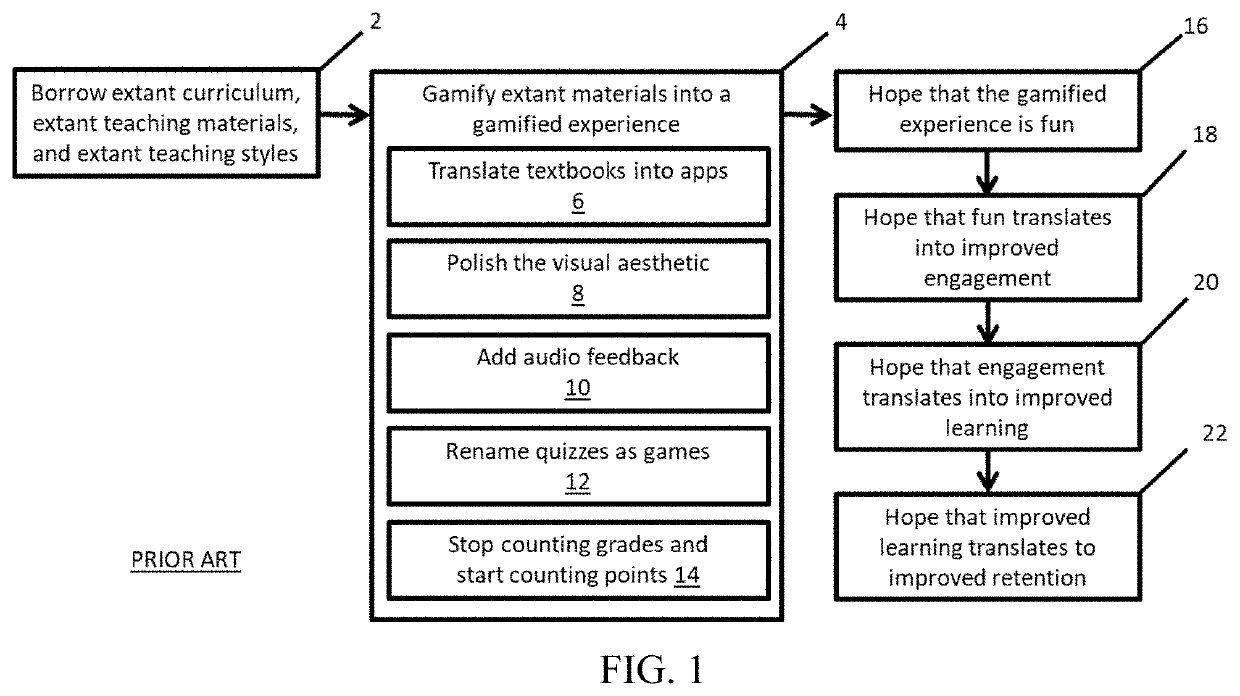

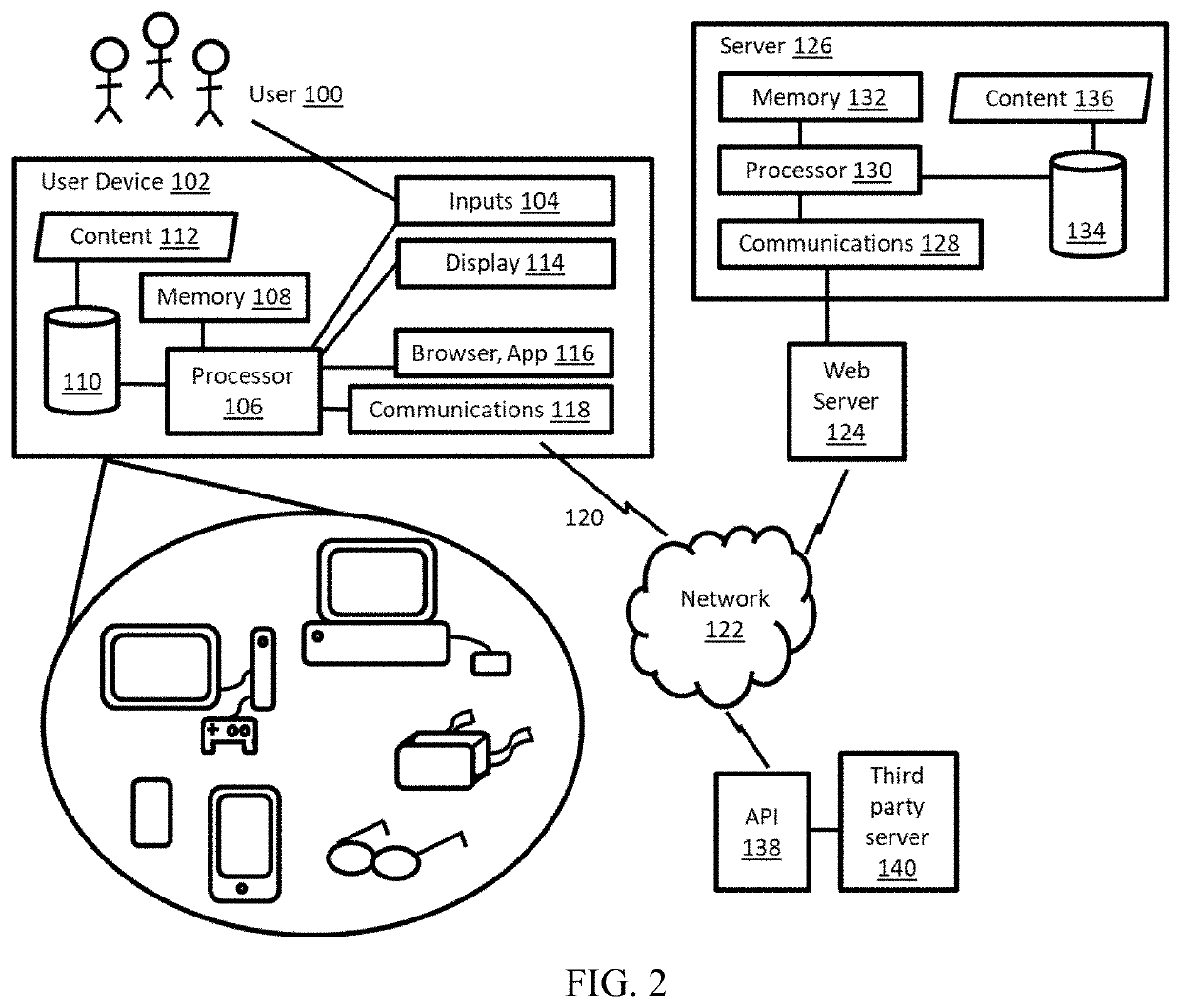

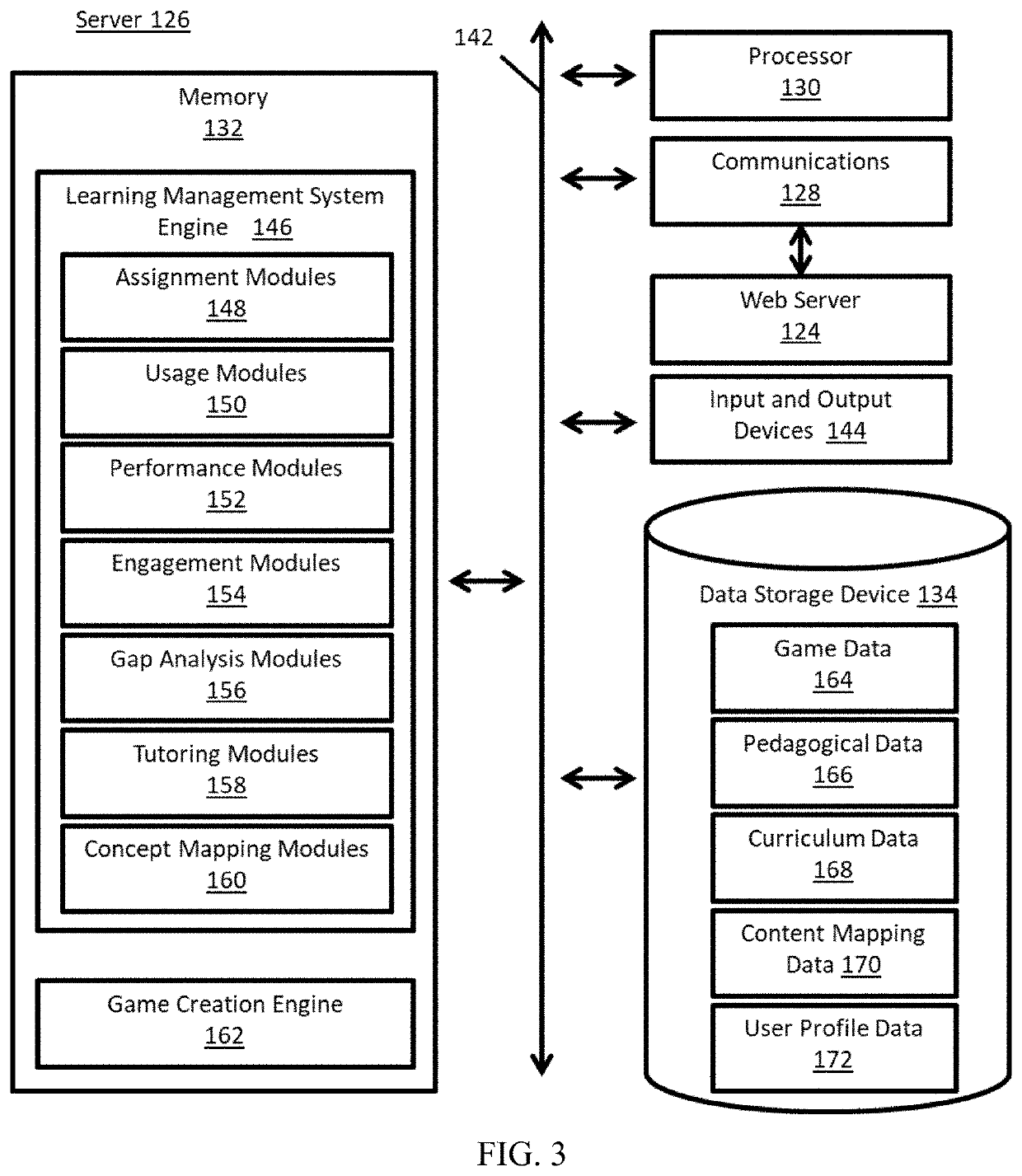

System and method for teaching curriculum as an educational game

ActiveUS20200051460A1User performanceAugments the scientific propertyElectrical appliancesTeaching apparatusEducational gameSystems thinking

An educational game (and learning management system and methods pertaining to the same) can be configured for the effective teaching of advanced educational curriculum, such as STEM subjects for high school and above. The educational game is configured to integrate social context, real scientific principles and strategic tradeoffs within game mechanisms. This covert teaching and testing environment promotes exploration, individualized discovery, repeat engagement, and systems thinking and planning skills. The educational game can be dynamically and procedurally generated.

Owner:PLASMA GAMES LLC

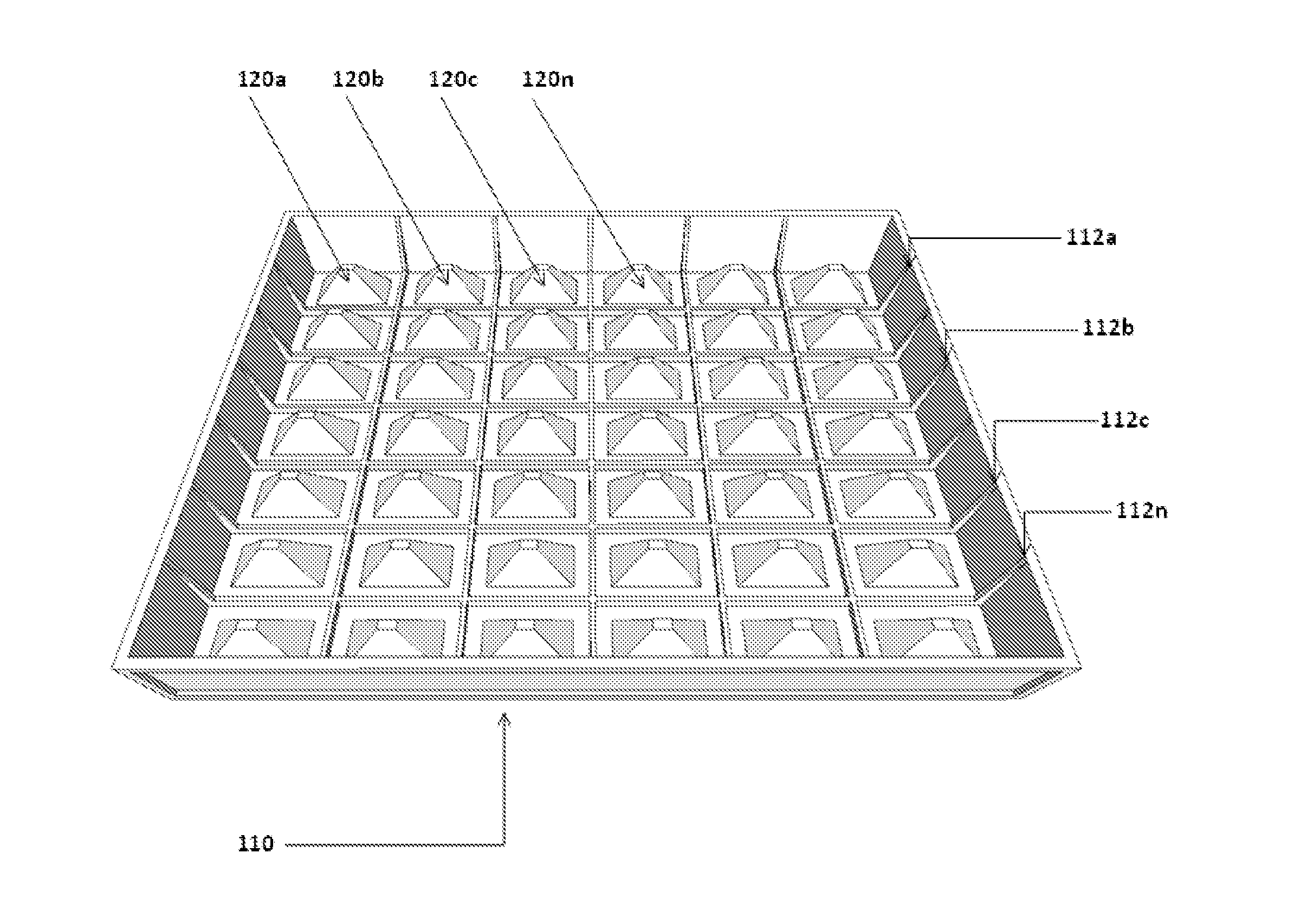

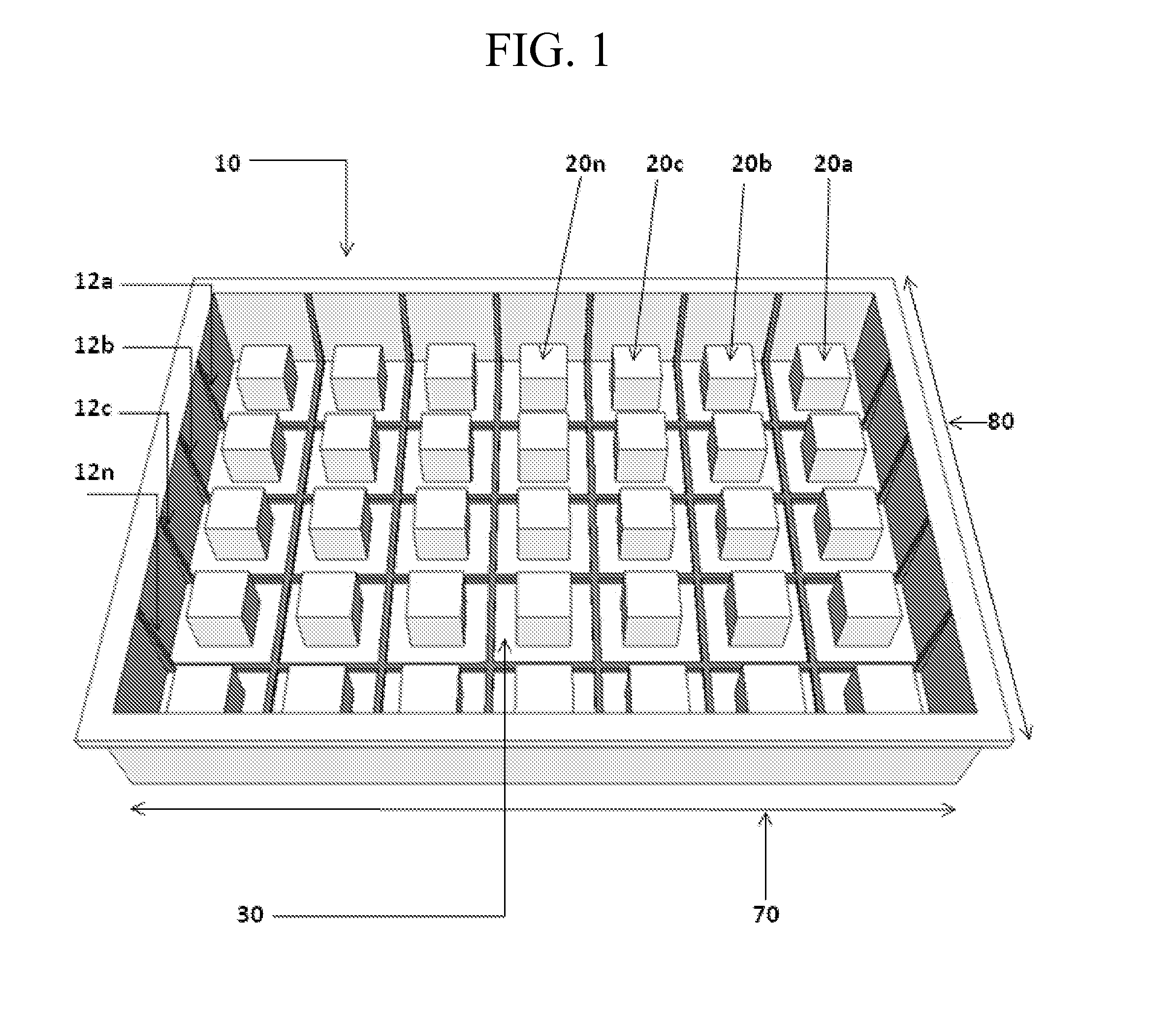

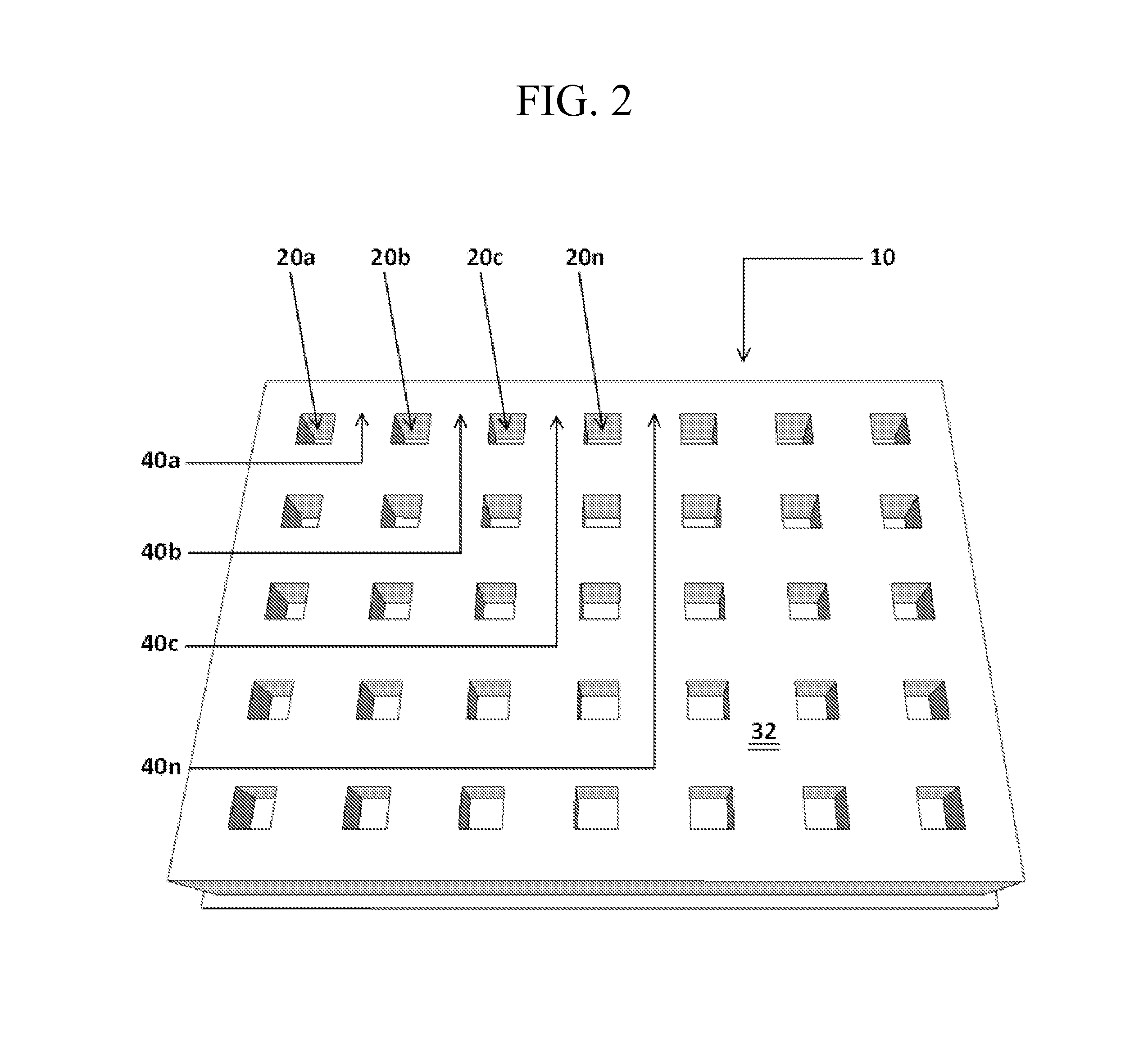

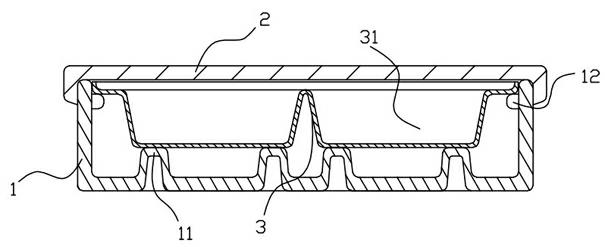

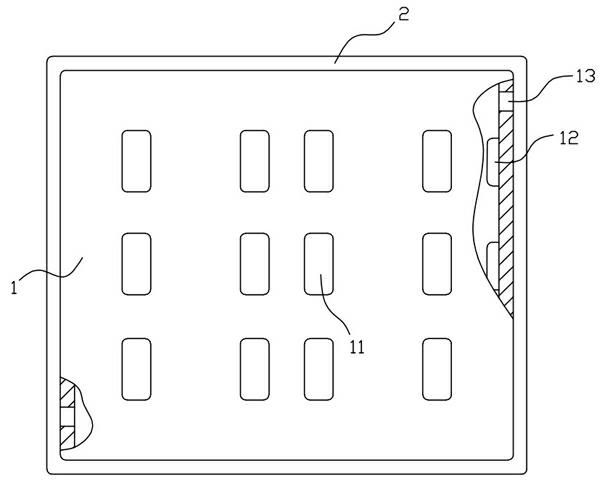

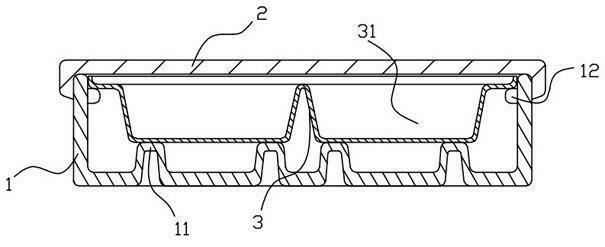

Food pans with thermal conveyance depressions

InactiveUS20130129890A1Excellent mean of portion controlImproves transfer of heating and cooling propertyDough treatmentMilk preservationEngineering

Various types of food preparation pans such as but not limited to food preparation pans used for baking, steaming, chilling, freezing and molding various foods and food combinations intended for consumption are disclosed. The pan includes a plurality of thermal conveyance depressions protruding in a vertically oriented disposition relative to a horizontal inner pan bottom surface; and upwardly projected depressions in an outer pan bottom surface of the thermal conveyance depressions to form hollow depressions spaced in between by bridging portions.

Owner:COX MONTE WILLIAM

Production method of aluminum-aluminum composite inflation type pipeline board

The invention provides a method for manufacturing an Al-Al composite inflation-typed pipeline plate, comprising the steps as follows: a. blanking and punching; b. cleaning and drying; c. printing; d. heating; e. hot rolling; f. cold rolling; g. cleaning; h. annealing; i. inflating; j. marking, shearing and punching; k. welding connecting pipe; l. whole detecting, etc. The composite aluminium pipeline plate processed by the method can increase or reduce the proportion of the internal chamber and the heat exchanging surface in extremely large range, and freely changes the geometrical shape, diameter and volume of the pipeline. The component is completely a whole and has high heat transfer rate and extremely small temperature difference of the medium and the heat exchanging surface. Compared with the traditional heat exchanger, the Al-Al composite inflation-typed pipeline plate has the supreme characteristic that the working pressure endurance value is large and generally keeps at 30kgf / cm<2> for long-term operation. The Al-Al composite inflation-typed pipeline plate has wide application and can be used in internal-heat type or external-heat type and is an extremely good exhaust-reducing and energy-saving product.

Owner:奚啸谷

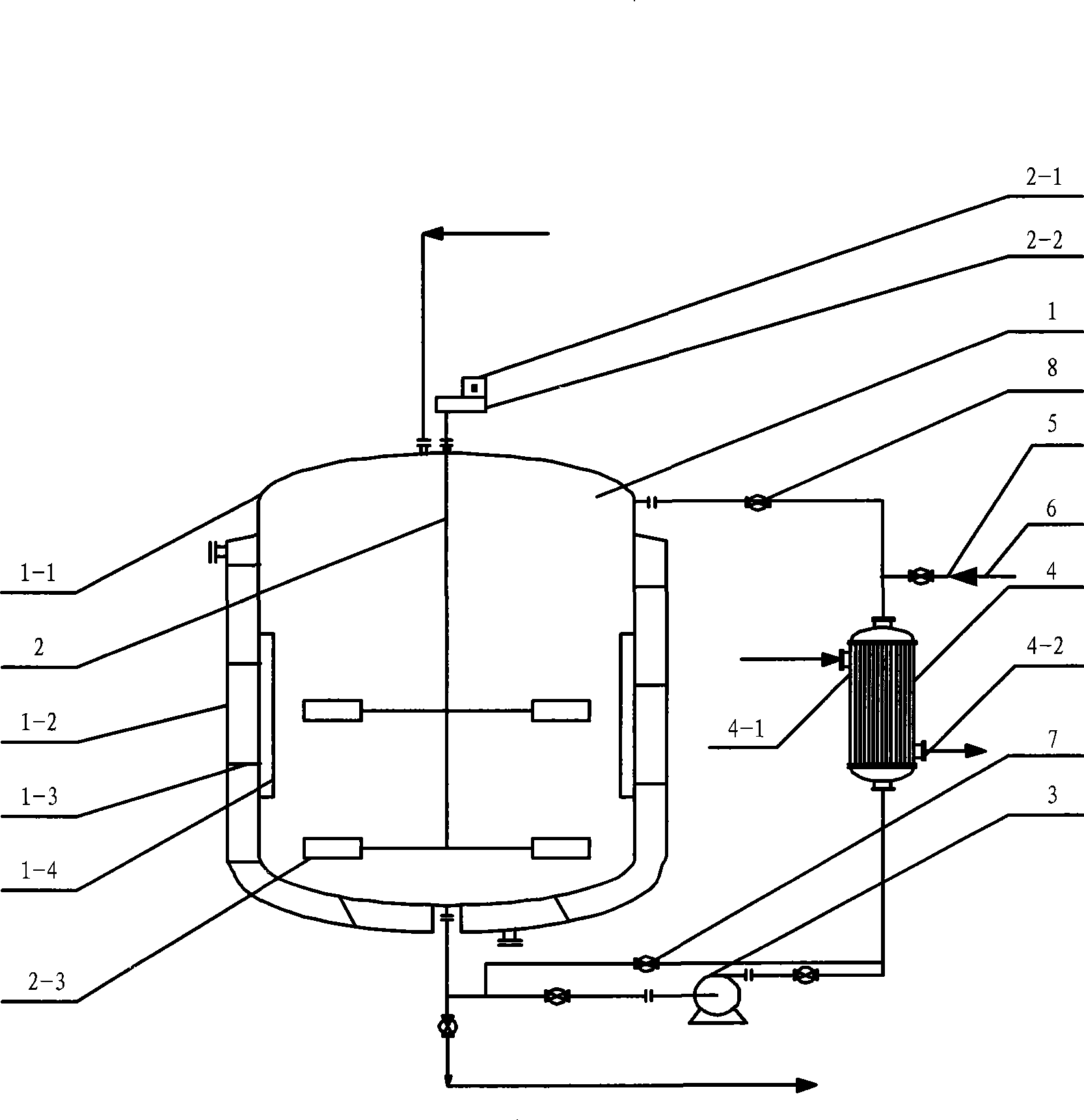

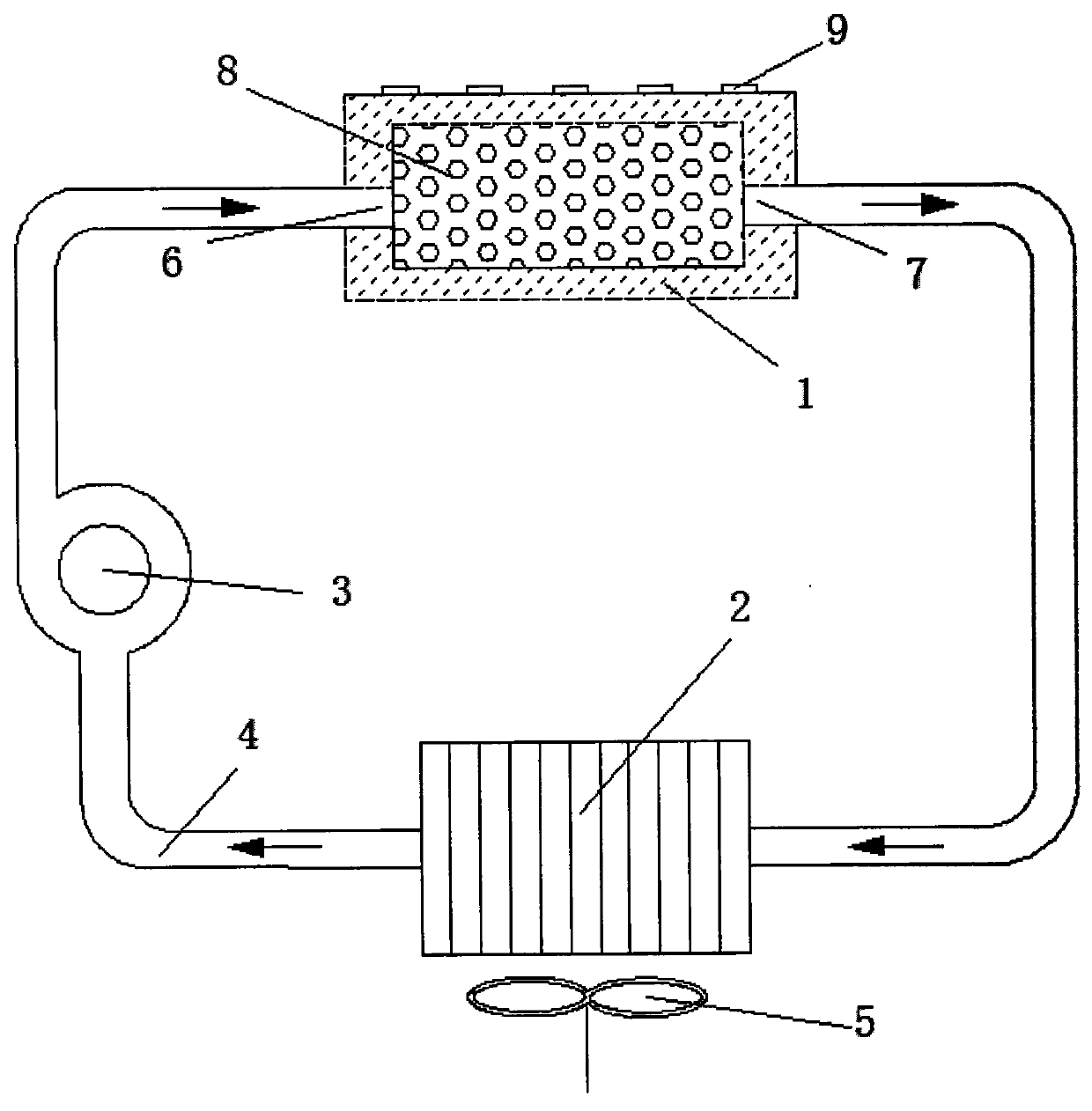

Reaction device with outer circulation device and method for controlling the reaction process

InactiveCN101362070AWide viscosity rangeImprove heat transfer rateChemical/physical/physico-chemical stationary reactorsLiquid-liquid reaction processesOperational costsProcess engineering

The invention discloses a reaction apparatus with external circulation equipment and a method for the reaction apparatus to control reaction process. The reaction apparatus comprises a reaction kettle as well as a fluid conveyer and a heat exchanger. One end of the fluid conveyer is connected to the lower part of the reaction kettle by a pipeline, while the other end is connected with the intake of heat exchanger by the pipeline, and the outlet of the heat exchanger is connected with the upper part of the reaction kettle by the pipeline, thereby constructing an external circulation passage for reactants. Stir and heat exchange are carried out to the reactants by the external circulation passage. The control carried out to the liquid-phase reaction by adopting the reaction apparatus with external circulation equipment and the method for the reaction apparatus to control reaction process is characterized by high heat exchange rate in the reaction process and suitability to a reactant system with a wide viscosity range, meanwhile, the construction cost and operational cost are both relatively low.

Owner:北京德润盛欣科技有限公司

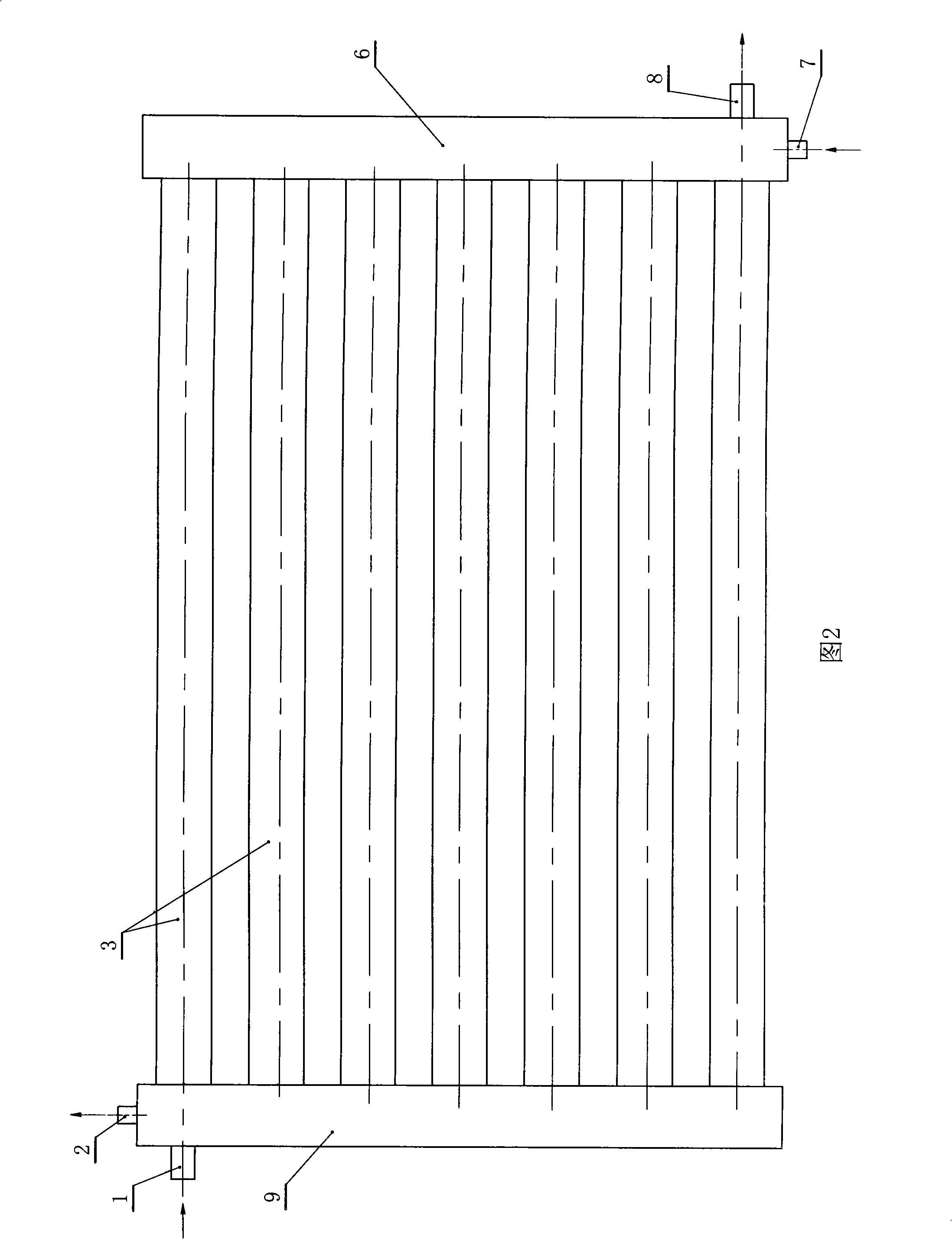

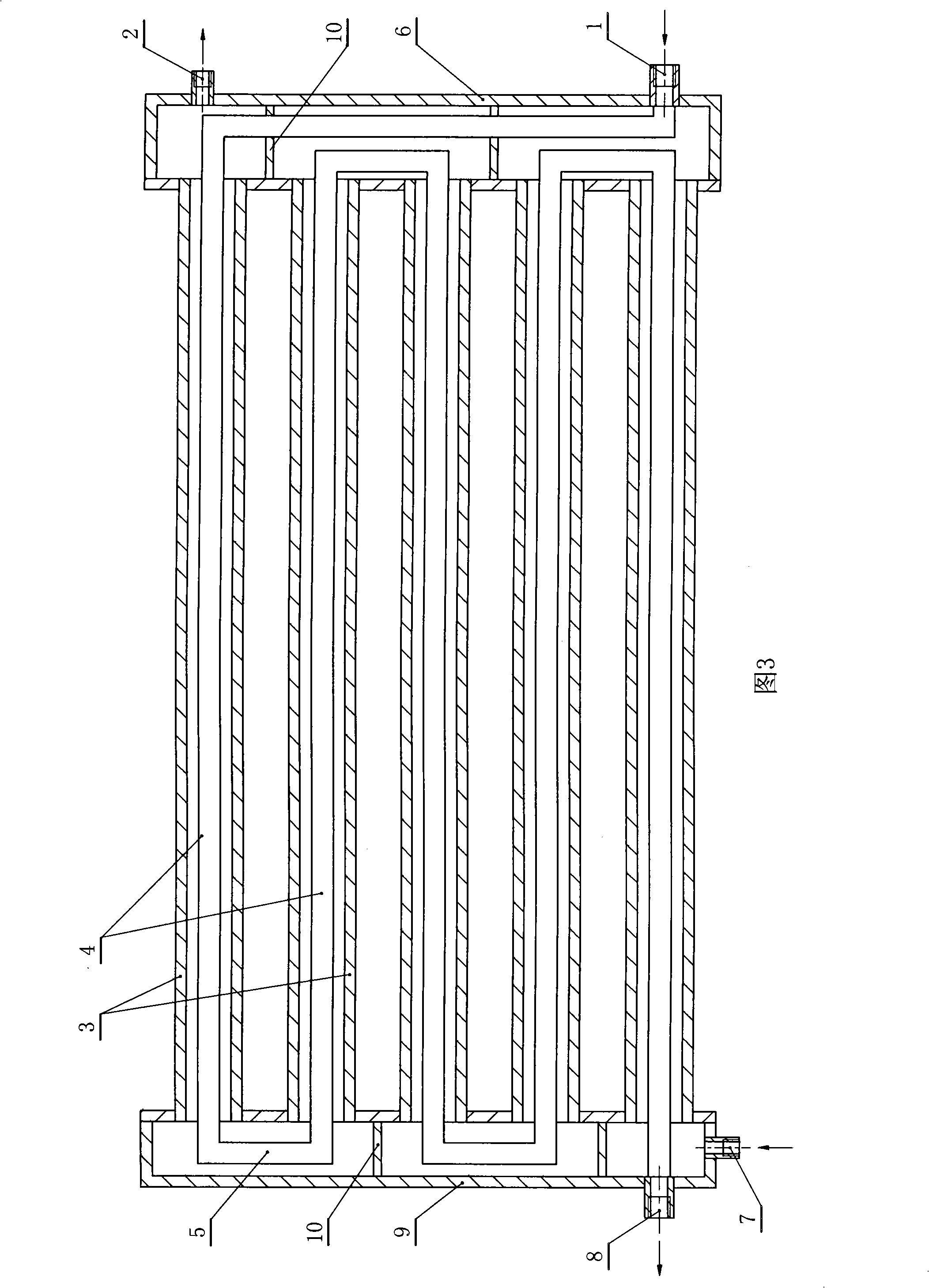

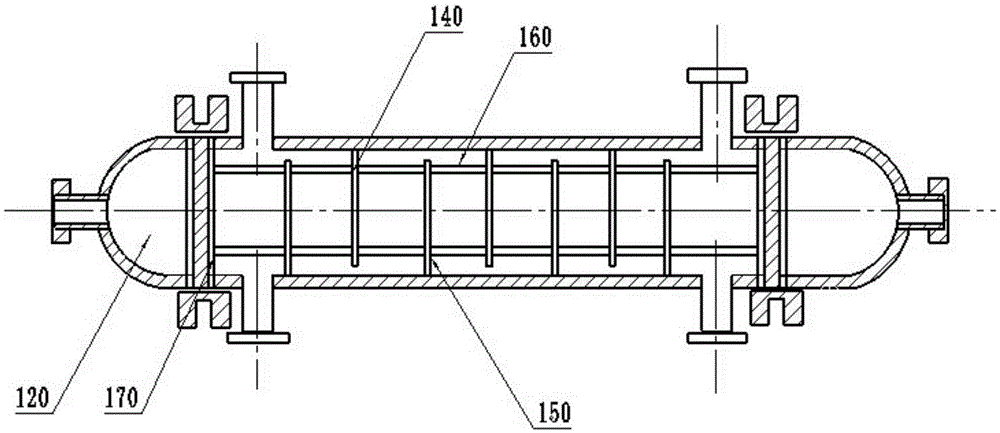

Header shunting heat storage adverse current type heat exchanger

InactiveCN101290196ANot easy to formLarge cavityStationary tubular conduit assembliesCounter flowEngineering

The invention discloses a header tank divided-flow heat-storage counter flow heat exchanger, which comprises a left header tank and a right header tank which are connected with a warm air water inlet, a warm air water outlet, a tap water inlet and a tap water outlet, wherein, a plurality of tap water heat-absorbing pipes are connected with the left and right header tanks; warm air heat supply pipes are connected through tap water heat-absorbing pipes; the warm air heat supply pipes are serially communicated with each other by heat supply communicating pipes; one end of each warm air heat supply pipe is connected with the warm air water inlet, while the other end is connected with the warm air water outlet; and a plurality of water insulation boards is alternatively connected the inside of the left and the right header tanks in order to separate the left and right header tanks to obtain the oriented flow channel. The counter flow heat exchanger of the invention has the advantages that: firstly the heat exchange efficiency is high and the temperature of the outlet water is high; secondly the joints of the heat supply pipes are arranged on the same level of axis line, which is suitably installed in household-measured users of the new heat supply pipe network unit, in particular to the needs of the three northeast provinces; thirdly the users can take a shower in the heat supply region of low temperature, and the heat-absorbing pipes at heat supply region of high temperature is free from scale formation; finally the counter flow heat exchanger is totally made of stainless steel, thereby saving brass pipe, reducing the cost and producing the clean water by exchange.

Owner:张伟

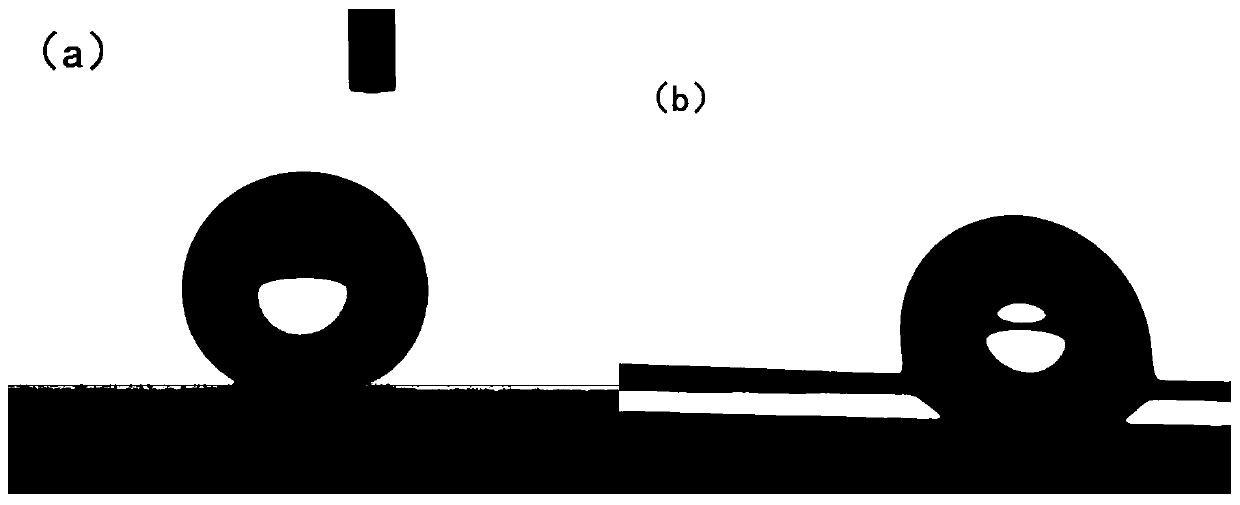

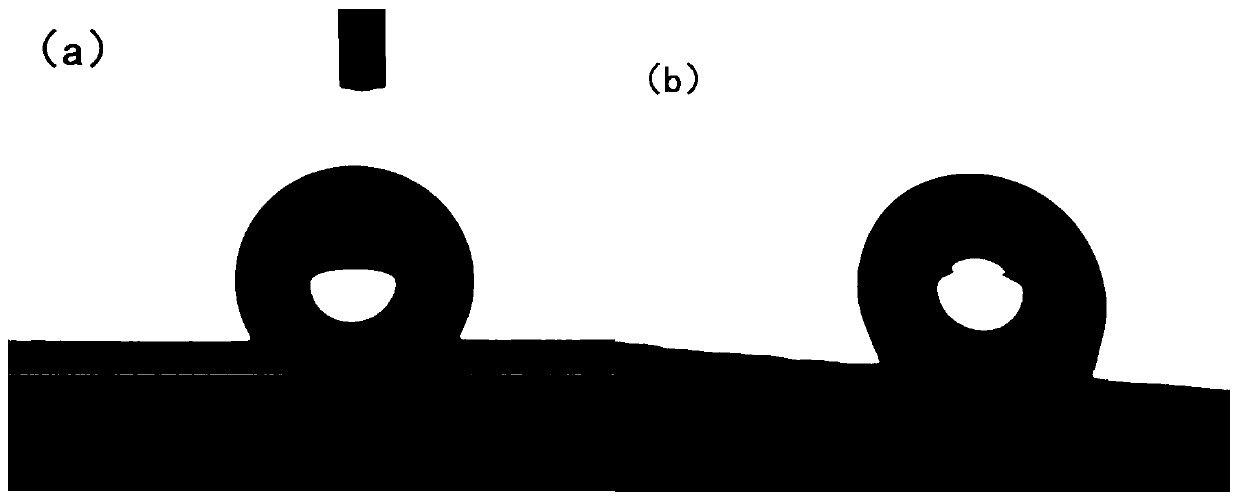

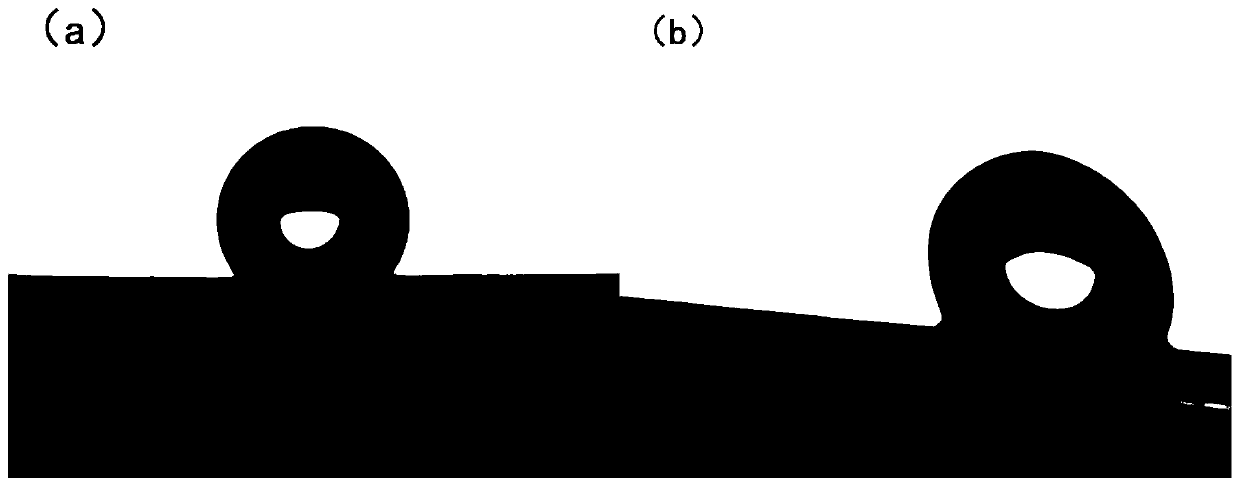

Titanium alloy super hydrophobic-super hydrophilic surface and preparing method and application of titanium alloy super hydrophobic-super hydrophilic surface

InactiveCN109732195AExcellent superhydrophobic propertiesReduce adhesionHeat exchange apparatusLaser beam welding apparatusHigh concentrationCondensation heat transfer

The invention discloses a titanium alloy super hydrophobic-super hydrophilic surface. Multiple sub arrays are distributed on the surface of a titanium alloy. Multiple super hydrophobic areas and multiple super hydrophilic areas in each sub array are arranged alternately in a wedge shape or a triangular shape, and super hydrophilic gathering areas are distributed between the sub arrays. The super hydrophobic surface has the good super hydrophobic performance, drop adhesion is very little, and rolling is extremely easy; drops can be adsorbed by the super hydrophilic areas, the drops at the top ends of the super hydrophilic areas in the wedge shape or the triangular shape can rapidly move towards the bottom of the wedge shape or the triangular shape under the drive of Plath pressure generatedby the wedge shape or the triangular shape, the super hydrophilic areas arranged alternately with the super hydrophilic areas can repel directional transportation of the drops, under the synergisticeffect of the super hydrophobic areas and the super hydrophilic areas, the condensation small drops can be gathered into the hydrophilic gathering area constantly, high-concentration-ratio self-driving water gathering is achieved, disengaging of the drops is accelerated, and therefore the condensation heat transfer efficiency is improved. The invention provides a preparing method and application of the titanium alloy super hydrophobic-super hydrophilic surface.

Owner:HUBEI UNIV OF TECH

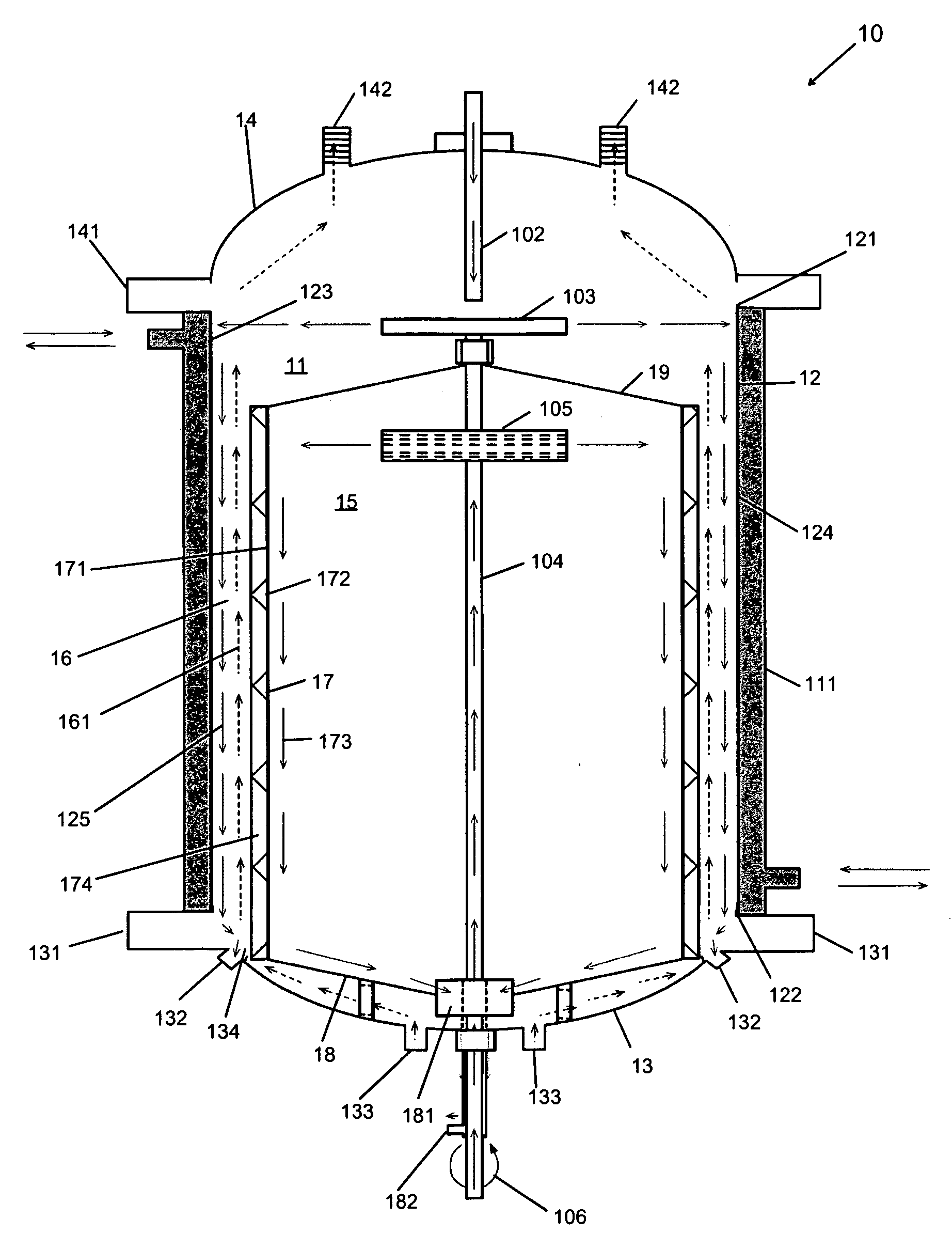

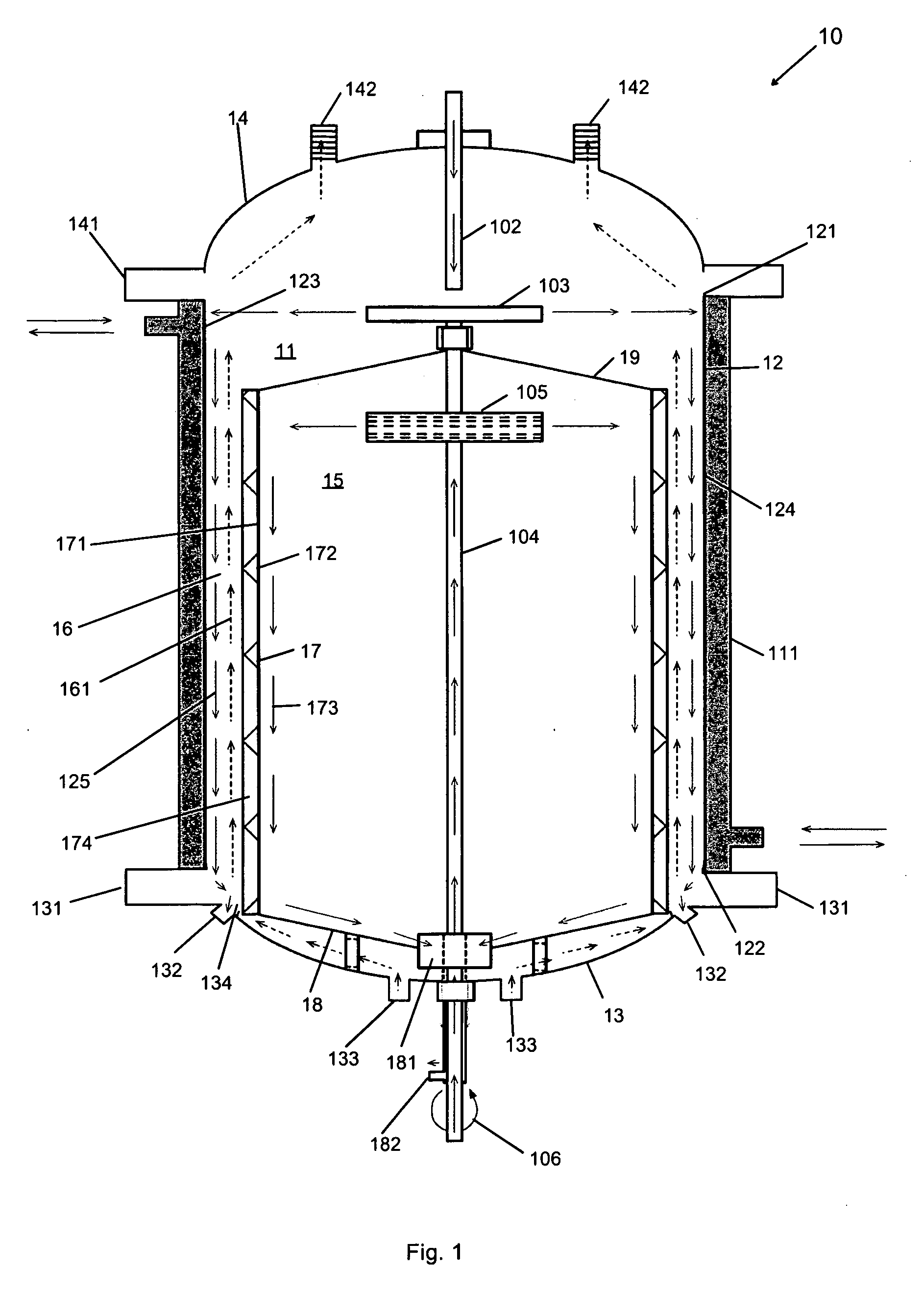

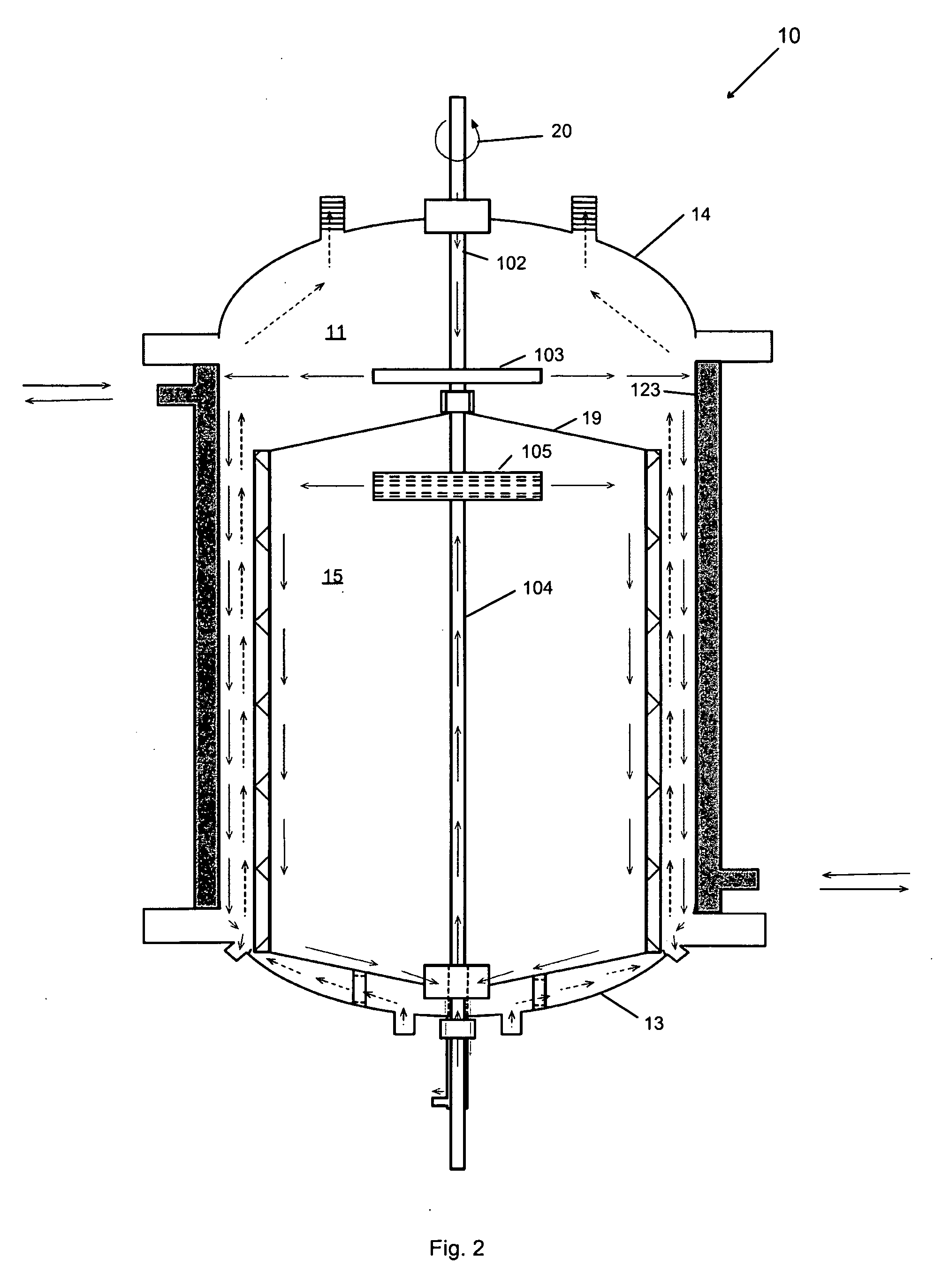

Continuous Processing Reactors and Methods of Using Same

InactiveUS20100288640A1Increased timeHigh thermal transfer rateGeneral water supply conservationSeawater treatmentDesalinationDistillation

A system having a reactor for continuous processing of fluid is provided herein. The reactor, in general, includes an outer vessel to accommodate fluids to be processed or used in connection therewith, an inner vessel situated within the outer vessel to serve as an energy exchange surface, and an annular space defined between the outer and inner vessels and along which processing of the fluids can be implemented. The continuous thin film reactor can be used to perform, for example, distillation and evaporation, fluid-fluid or solid-fluid-fluid reactions, organic reactions, cooling, and desalination.

Owner:R3 FUSION

Inoxidable sludge stripping agent

InactiveCN104108758AGood dispersionImprove permeabilityWater/sewage treatment using germicide/oligodynamic-processMicroorganismSludge

The invention provides an inoxidable sludge stripping agent and a preparation method thereof. The inoxidable sludge stripping agent is composed of an organic inoxidable biocide, a surfactant, a dispersing agent and water, wherein the mass ratio of the organic inoxidable biocide to the surfactant to the dispersing agent to the water is (10-30) to (5-15) to (1-10) to (40-60). The invention also provides the preparation method of the inoxidable sludge stripping agent. The preparation method comprises the steps of sequentially adding the organic inoxidable biocide, the surfactant, the dispersing agent and the water into a reactor with a stirring device according to the mass part, and stirring to dissolve all the components to obtain the inoxidable sludge stripping agent. The inoxidable sludge stripping agent provided by the invention is an efficient liquid agent and can be used when a circulating cooling water system is polluted by sludge. The inoxidable sludge stripping agent provided by the invention has a favorable function for stripping and removing sludge and dead microorganisms attached on the inner walls of equipment and pipelines, can also be used for killing various microorganisms such as bacteria and fungi in a circulating water system and can be widely applied to the field of circulating cooling water treatment.

Owner:WEIHAI XIANGYU TECH

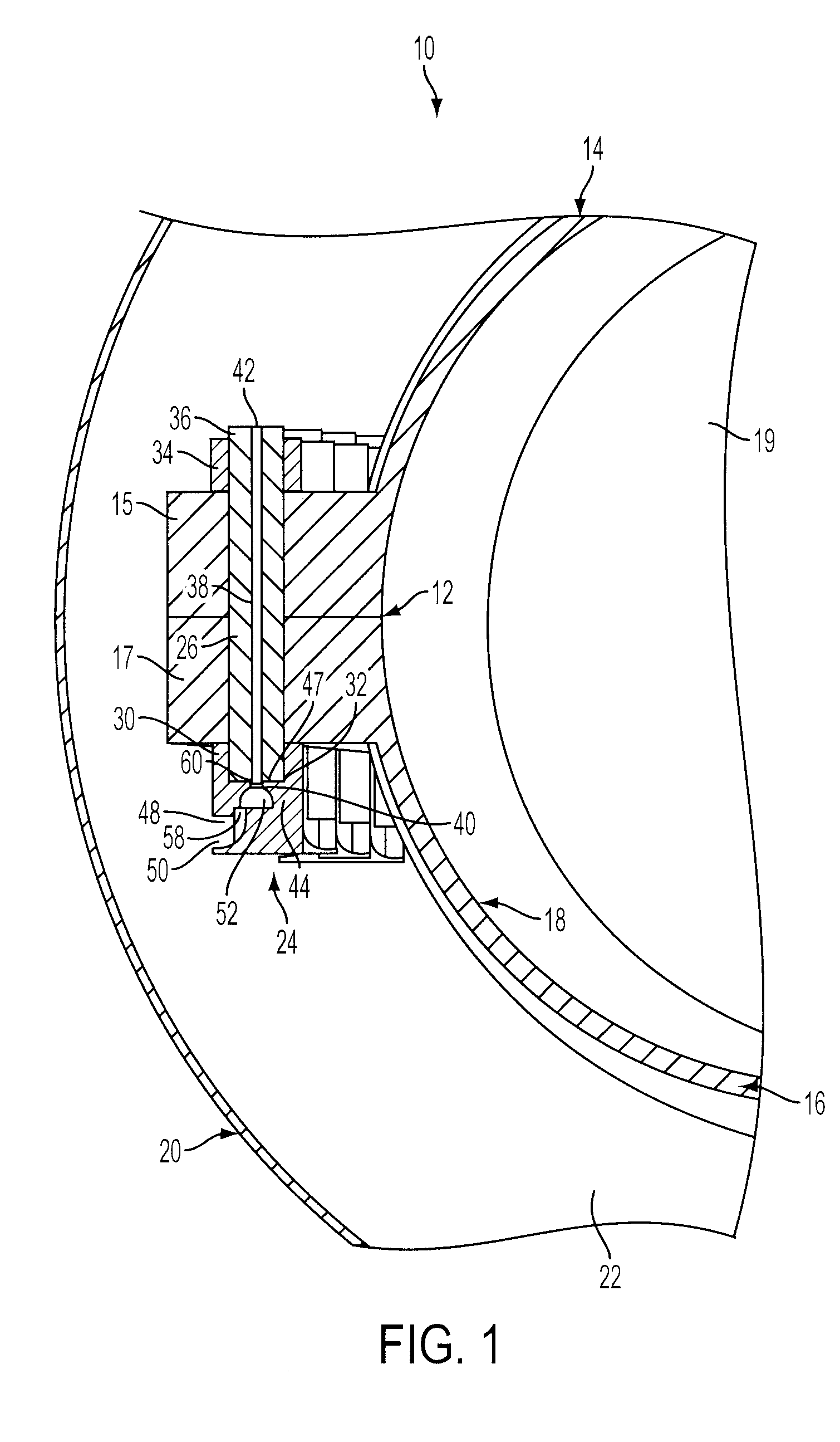

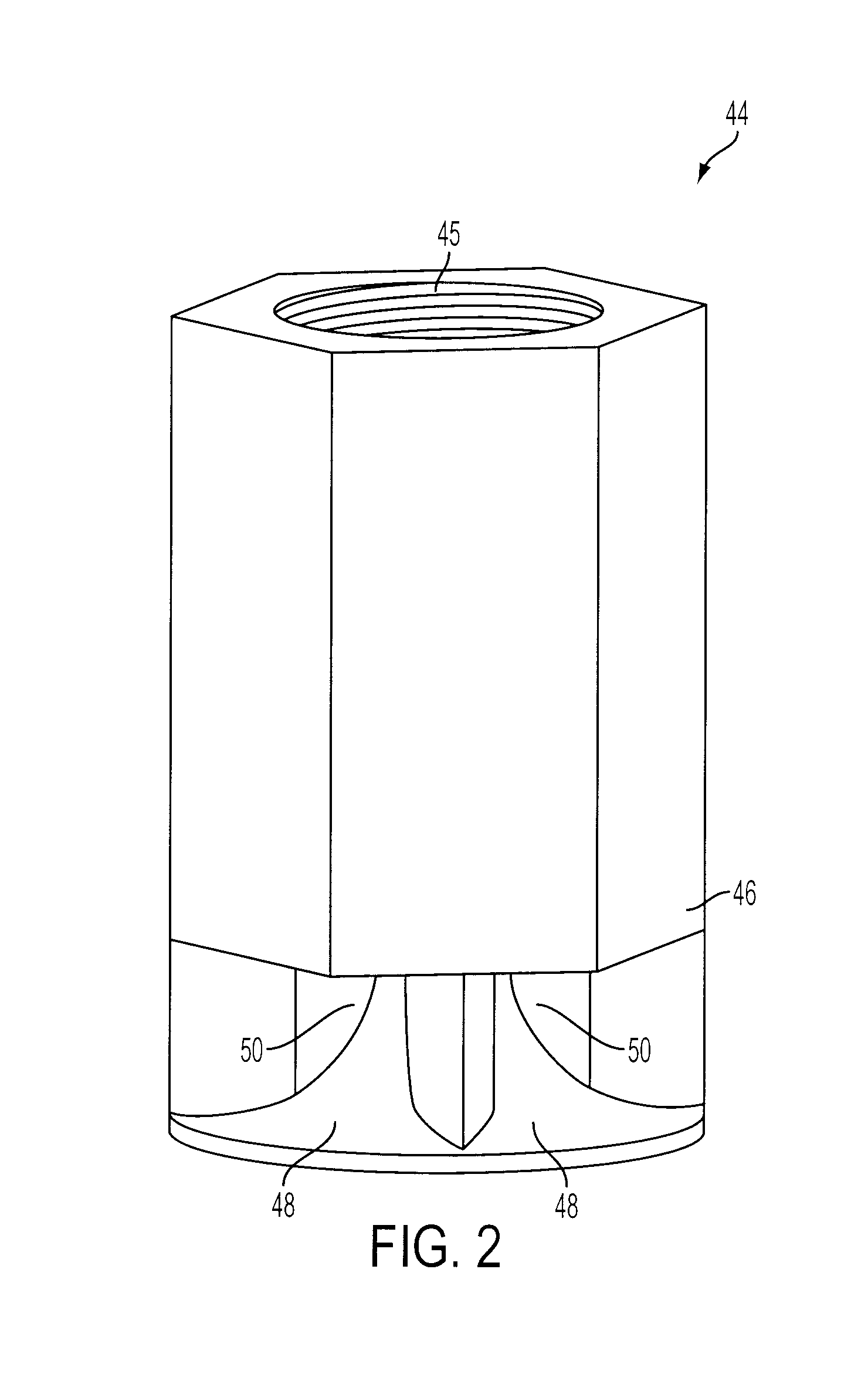

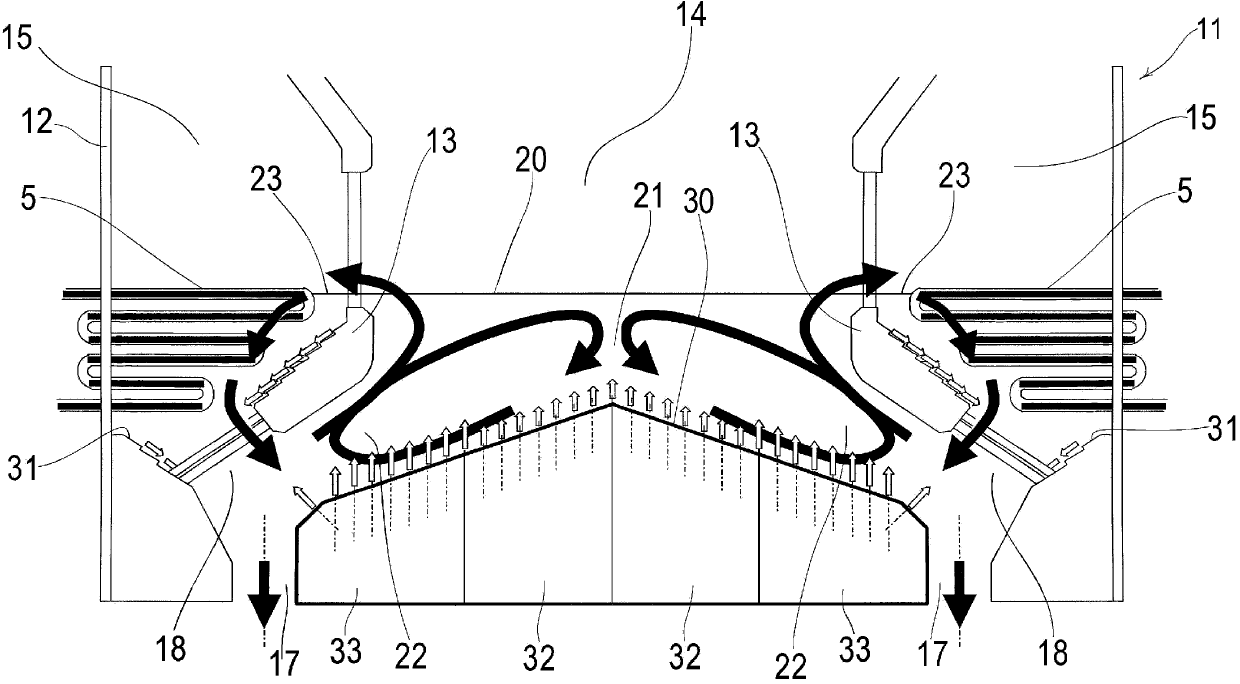

Fastener Assembly with Cyclone Cooling

A fluid cooled fastener assembly for use in a high temperature environment and a method of fluid cooling a fastener assembly are provided. The fastener has a coolant passage extending axially through the fastener and a coolant collector coupled to an end of the fastener. The coolant collector includes a collector opening configured to capture a portion of a cooling fluid flowing past the coolant collector and a contoured passage in communication with the collector opening and the passage in the fastener. The contoured passage is configured to accelerate the cooling fluid captured by the coolant collector and to direct it into the coolant passage in the fastener.

Owner:SIEMENS ENERGY INC

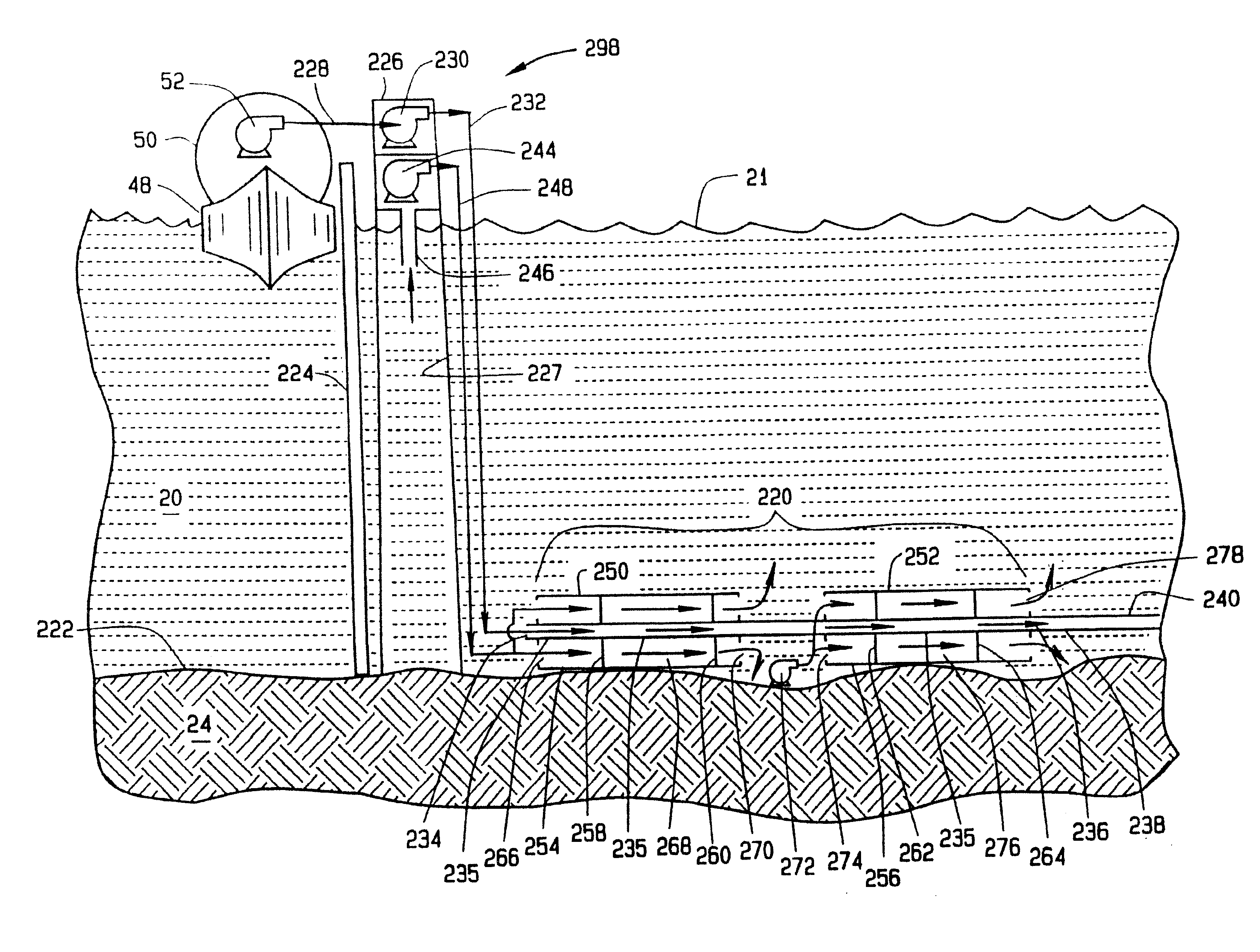

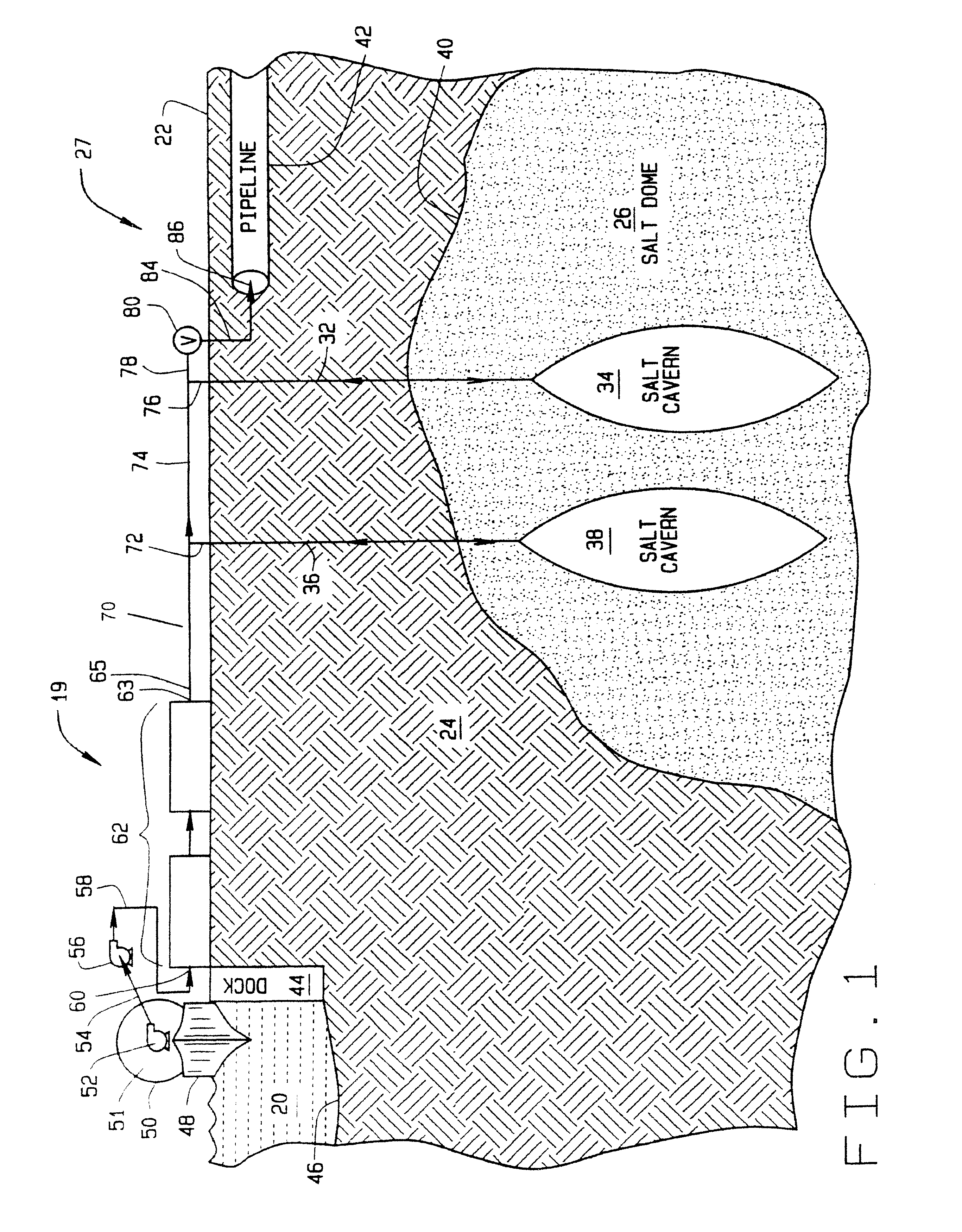

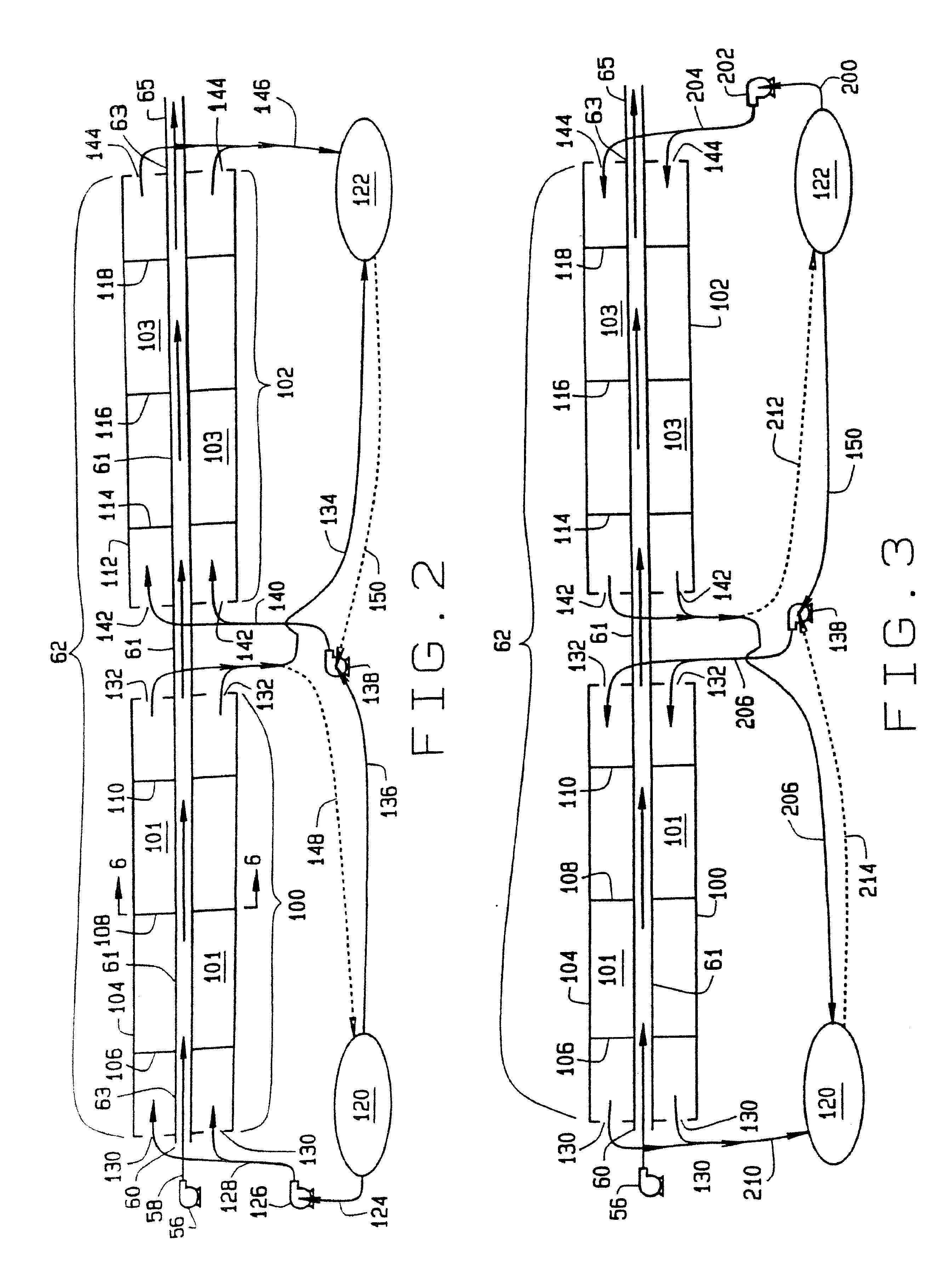

Method and apparatus for warming and storage of cold fluids

InactiveUS20040112067A1Less efficiencyImprove heat transfer rateGas handling applicationsGas handling/storage effectsLiquefied natural gasProcess engineering

Stranded natural gas is sometimes liquefied and sent to other countries that can use the gas in a transport ship. Conventional receiving terminals use large cryogenic storage tanks to hold the liquefied natural gas (LNG) after it has been offloaded from the ship. The present invention eliminates the need for the conventional cryogenic storage tanks and instead uses uncompensated salt caverns to store the product. The present invention can use a special heat exchanger, referred to as a Bishop Process heat exchanger, to warm the LNG prior to storage in the salt caverns or the invention can use conventional vaporizing systems some of which may be reinforced and strengthened to accommodate higher operating pressures. In one embodiment, the LNG is pumped to higher pressures and converted to dense phase natural gas prior to being transferred into the heat exchanger and the uncompensated salt caverns.

Owner:CONVERSION GAS IMPORTS

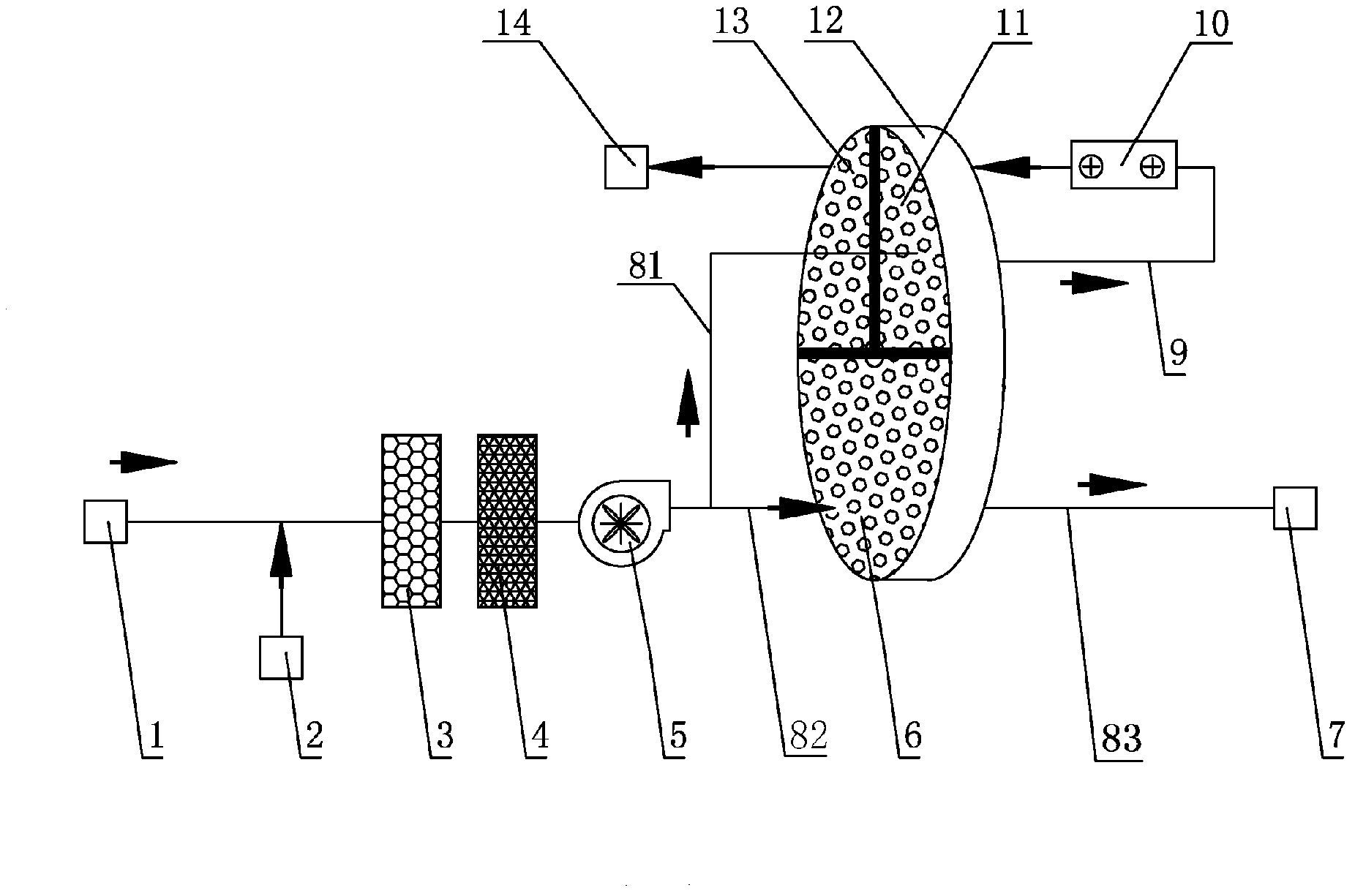

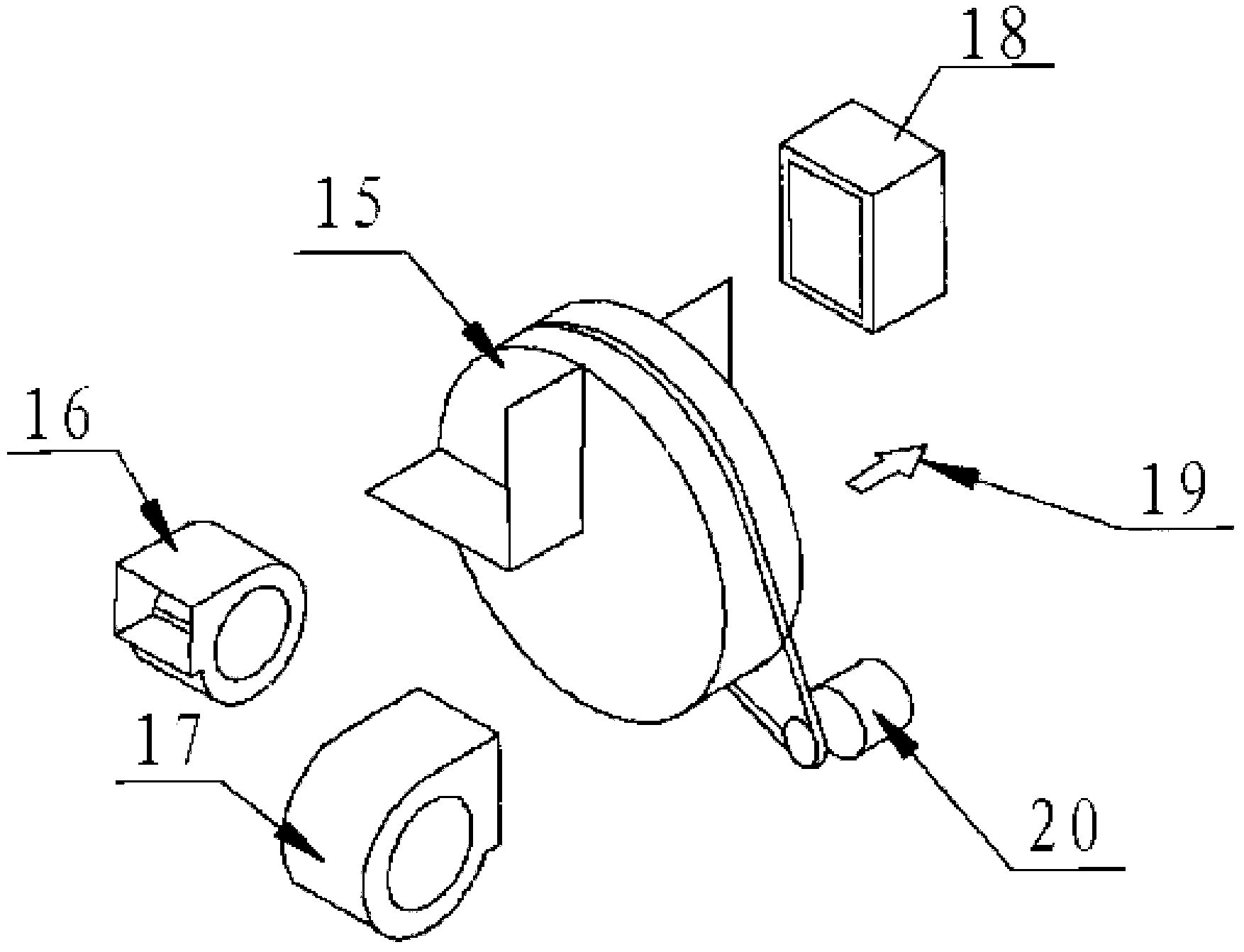

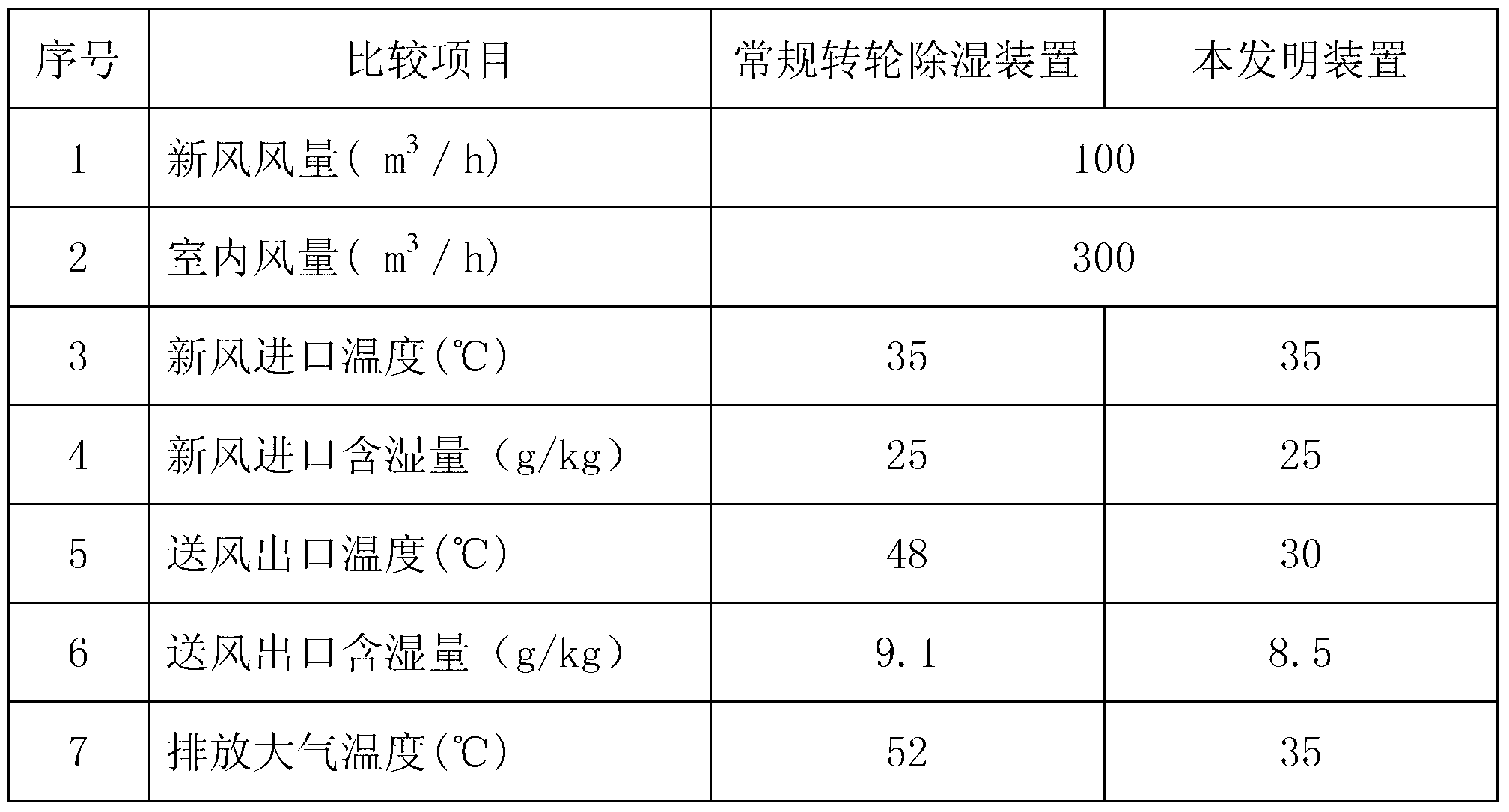

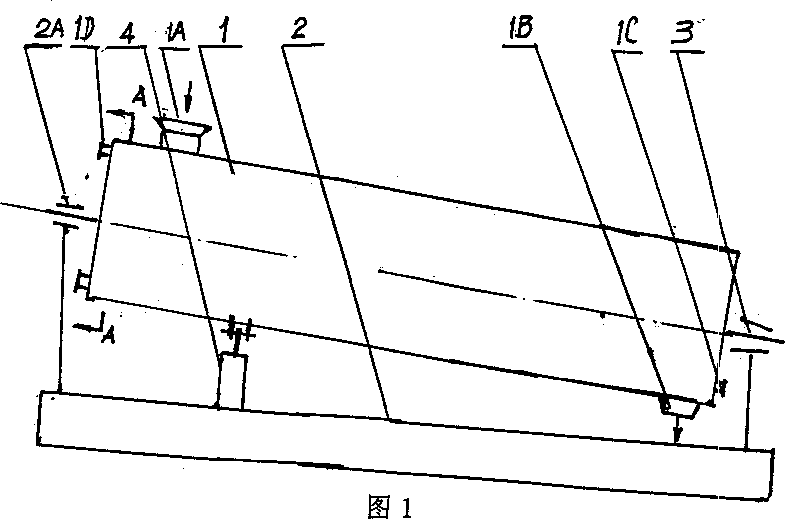

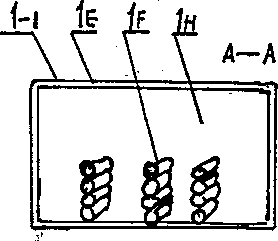

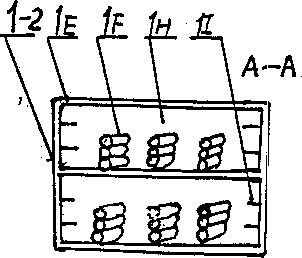

Dehumidification device with rotating wheel

InactiveCN103196188AReduce wasteImprove heat transfer rateEnergy recovery in ventilation and heatingLighting and heating apparatusActivated carbonAir filter

The invention relates to a dehumidification device with a rotating wheel. The dehumidification device comprises a fan, a heater, the rotating wheel, a regeneration air outlet, a regeneration air inlet pipeline and a regeneration air outlet pipeline. A working area of the rotating wheel is divided into three sealed areas including a moisture absorption area, a waste heat recovery area and a regeneration area; a regeneration air course is formed at an air outlet of the fan, sequentially flows through the regeneration air inlet pipeline, the waste heat recovery area, the regeneration air outlet pipeline, the heater and the regeneration area and then is exhausted to the atmosphere via the regeneration air outlet; and a dehumidification air course is further formed at the air outlet of the fan, sequentially flows through a clean air pipeline, the moisture absorption area and a clean and dry air pipeline and then flows into an indoor environment from a clean and dry air outlet. The dehumidification device has the advantages that the dehumidification device is further provided with an activated carbon filter and an air filter, toxic chemical gas such as formaldehyde in air can be adsorbed by the activated carbon filter, fine dust in the air can be filtered, and the quantity of harmful germs can be reduced; and on the basis that the air is dehumidified and dried, aldehyde, the dust and the germs can be removed, and the indoor air can be purified.

Owner:奥波环境新能源(无锡)有限公司

Rocking type slag-cooling machine

The slag-cooling machine adopts stable swing balance shaft structure for supporting the hot slag conveyance heat-absorbing box on the machine frame, and adopts swing driving mechanism to make the boxbody reciprocally-swing in tilet angle of 10-30 deg. devialed from centre to make hot stag come into cooling box implement snakelike downslide and rolling along the heat-absorbing water pipe and heat-absorbing guide plate, so that it can greatly increase contacting area of hot slag and heat-absorbing medium and can make hot slag uniformly contact with cooling wall. Said ivnention is simple in structure, its wear abrasion is less and cost is low.

Owner:李玉清

Method for controlling centrifugal granulation of molten blast furnace slag

InactiveCN101845526AAvoid local overheatingExtended service lifeRecycling and recovery technologiesSlagGenetics algorithms

The invention relates to a method for controlling centrifugal granulation of molten blast furnace slag. The method comprises the following steps of: 1) uniformly arranging a plurality of temperature measuring devices along the direction vertical to a water cooled wall; 2) embedding a genetic algorithm program in a PLC controller, comparing a few temperature measuring points, and optimally judging and predicating a position with a minimum temperature value of the temperature measuring points; and 3) controlling a hydraulic device under a rotor by the PLC controller, and adjusting the height of a rotor to the position with the minimum temperature value. The method for controlling the centrifugal granulation of the molten blast furnace slag has the advantages of being compact and simple in structure and easy in operation, avoiding local overheating of the water cooled wall, prolonging the service life of slag centrifugal granulation devices, improving heat exchange rate and providing convenience for energy source recovery.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

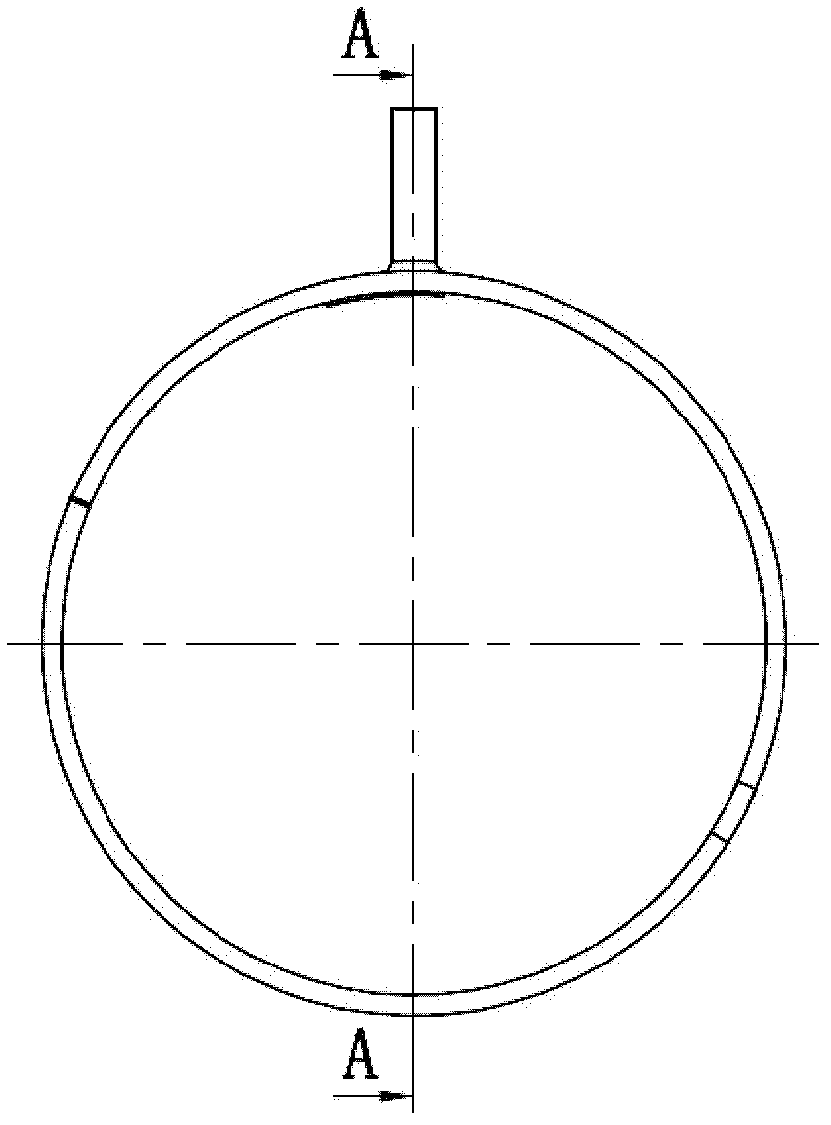

Spiral and axial circulating cooling water channel structure for motor

InactiveCN102624154ACool evenlyUniform temperature differenceCooling/ventillation arrangementWater channelWater flow

Disclosed is a spiral and axial circulating cooling water channel structure for a motor. The cooling water channel structure comprises a stator iron core of the motor, a cooling water channel is arranged in the iron core, the cooling water channel comprises a first spiral channel and a second spiral channel which are adjacent and extend parallelly, the inlet end of the first spiral channel is adjacent to the outlet end of the second spiral channel, and the outlet end of the first spiral channel is adjacent to and communicated with the inlet end of the second spiral channel. The first spiral channel and the second spiral channel are arranged parallelly along the axial direction of the iron core. Cooling water flows from the front end of the stator iron core to the back end of the stator iron core, then flows back to the front end, can evenly cool the iron core, and reduce the temperature difference between the front end and the back end of the stator iron core. The cooling water generates turbulence during backflow, which reduces the thermal resistance, and increases the heat exchange coefficient and the ratio of heat exchange, so that temperature increasing of the motor can be reduced, the power density can be improved; and the sealing can be achieved by using one rubber gasket, and the reliability and the process are remarkably improved.

Owner:华域汽车电动系统有限公司

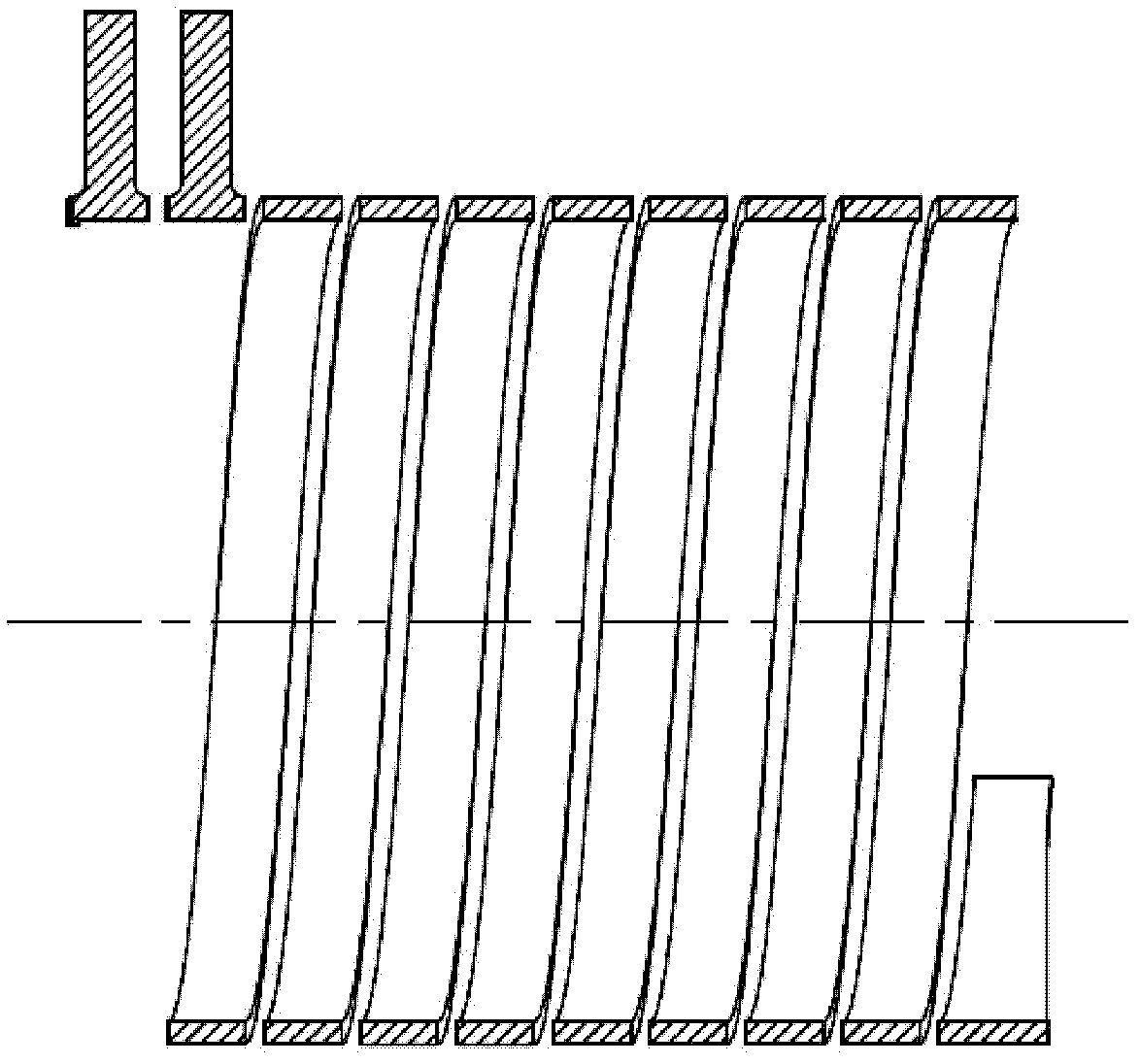

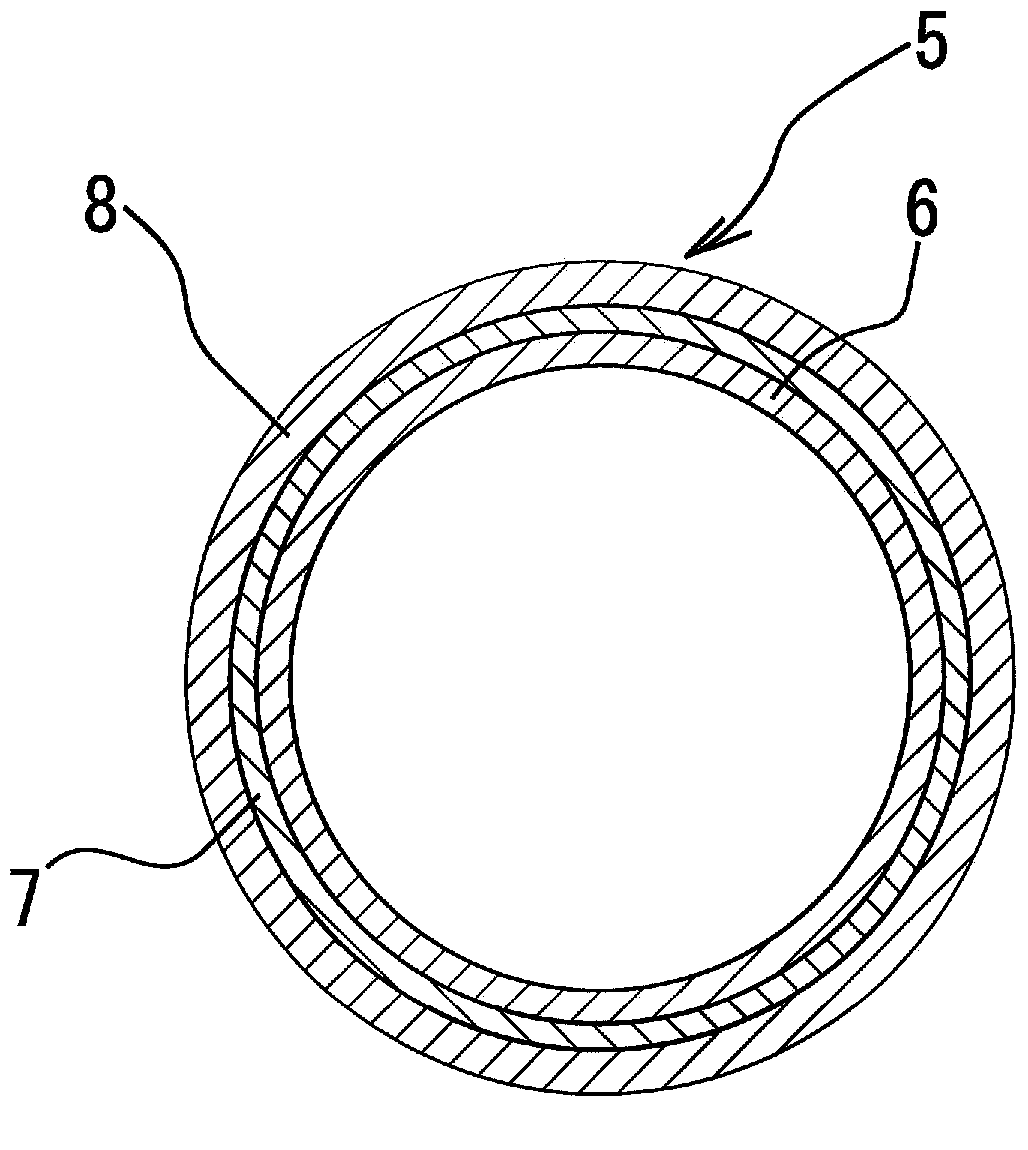

In-bed heat transfer tube for fluidized bed boiler

ActiveCN104136842AIncreased durabilityMolten Salt Corrosion InhibitionFluidized bed combustionBoiler water tubesFluidized bedHeat of combustion

The present invention pertains to an in-bed heat transfer tube installed in the fluidized bed of a fluidized bed boiler that burns fuels such as refuse-derived fuel (RDF) and waste with a high calorific value, including biomass and plastic, and recovers combustion heat. This in-bed heat transfer tube (5) for a fluidized bed boiler is installed in the fluidized bed (3) of the fluidized bed boiler (1), and the in-bed heat transfer tube (5) consists of: a water tube (6) through which a fluid flows; a protector (8) for protecting the water tube (6), said protector (8) being disposed on the outer circumferential side of the water tube (6); and a filler layer (7) disposed between the water tube (6) and the protector (8).

Owner:EBARA ENVIRONMENTAL PLANT

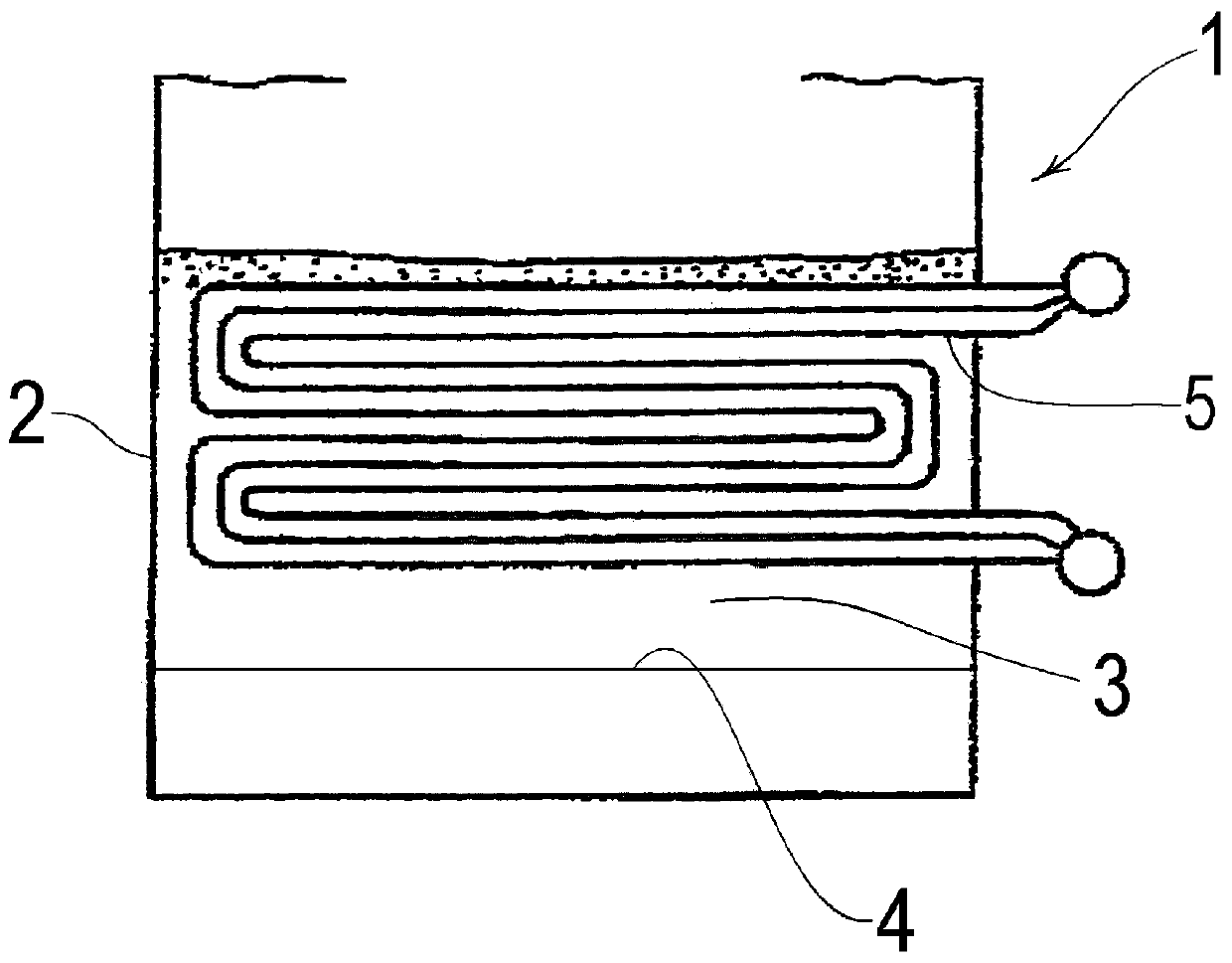

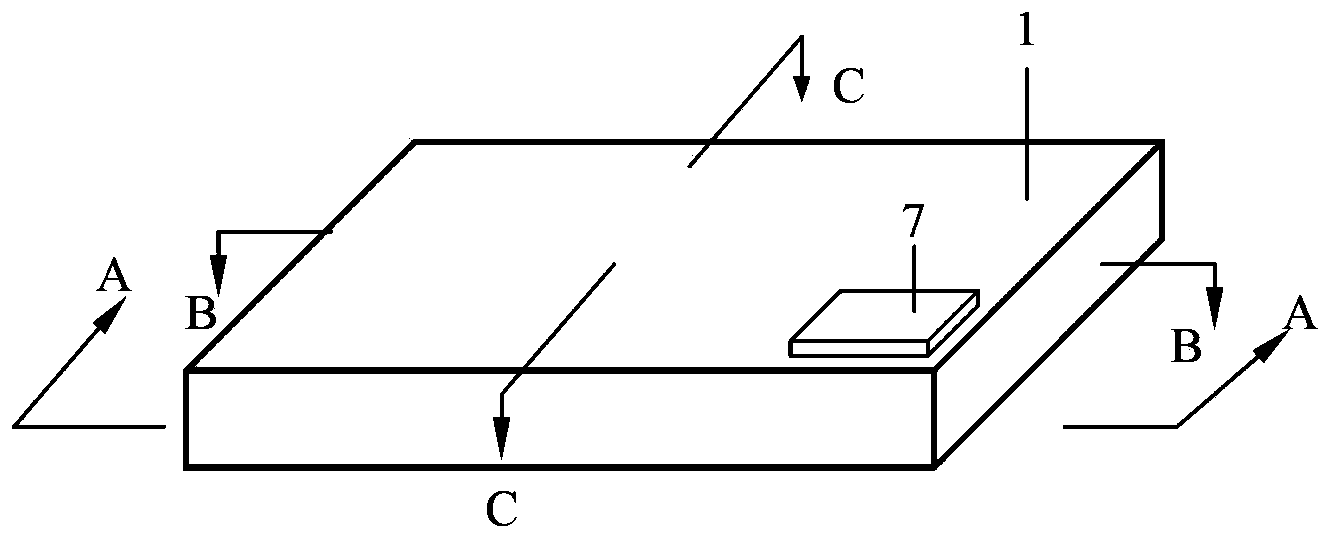

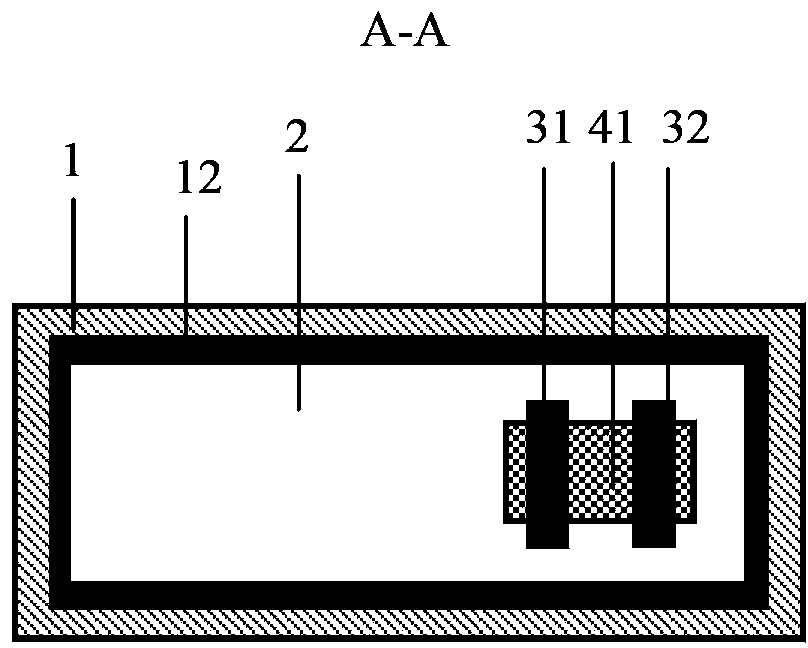

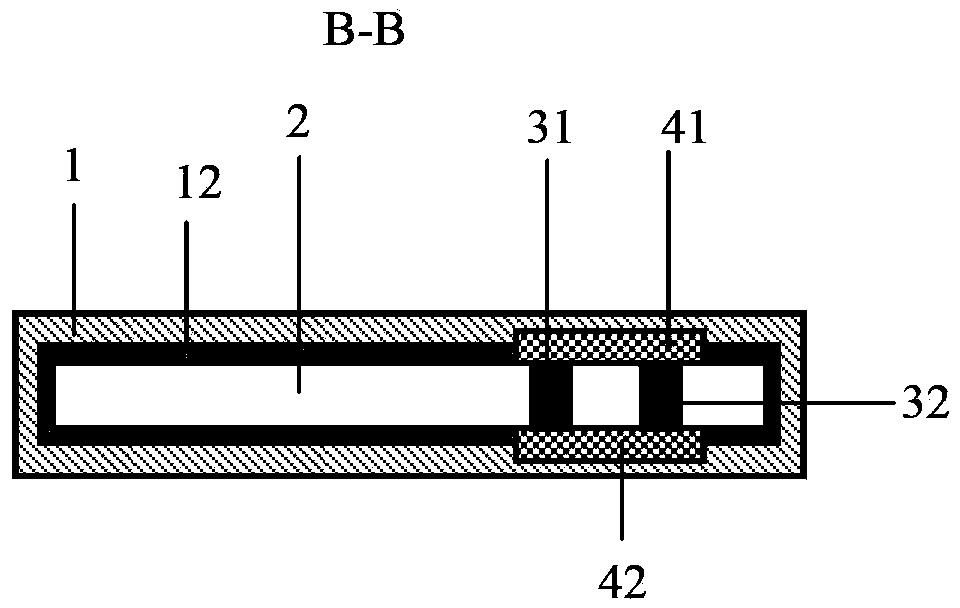

Integrated cavity type conductive fluid heat spreader

ActiveCN104125753AEliminate tightnessPrevent leakageCooling/ventilation/heating modificationsMagnetic polesEngineering

The invention provides an integrated cavity type conductive fluid heat spreader which includes a cavity (1), the heat absorbing end, flow, liquid, fluid pool, driving pump and a heat radiating end together in one room, the internal cavity structure, and the inner surface is an insulating layer (12); runner type electrode for (31, 32), arranged on the cavity surface, which is used as a channel and the direction of fluid flow regulator; a magnet for (41, 42), in the cavity body and the direction of the magnetic poles and the electrode is arranged on the current direction is vertical range setting; conductive fluid (2), the filling in the cavity; power supply chip (7) which is arranged in the cavity, the outer surface of the electrodes used to provide the input current. According to the heat spreader is provided by the invention greatly reduces the production and packaging process, completely avoid the fluid leakage; the compact volume, heat transfer capacity significantly; the cavity electrode on the position can be set flexibly, significantly enhance the electromagnetic driving force, resulting in the enhancement of heat transfer and flow effect is strong; between different parts of the body temperature of the fluid cavity different mixing efficiency is high, the heat transport capability is strong.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

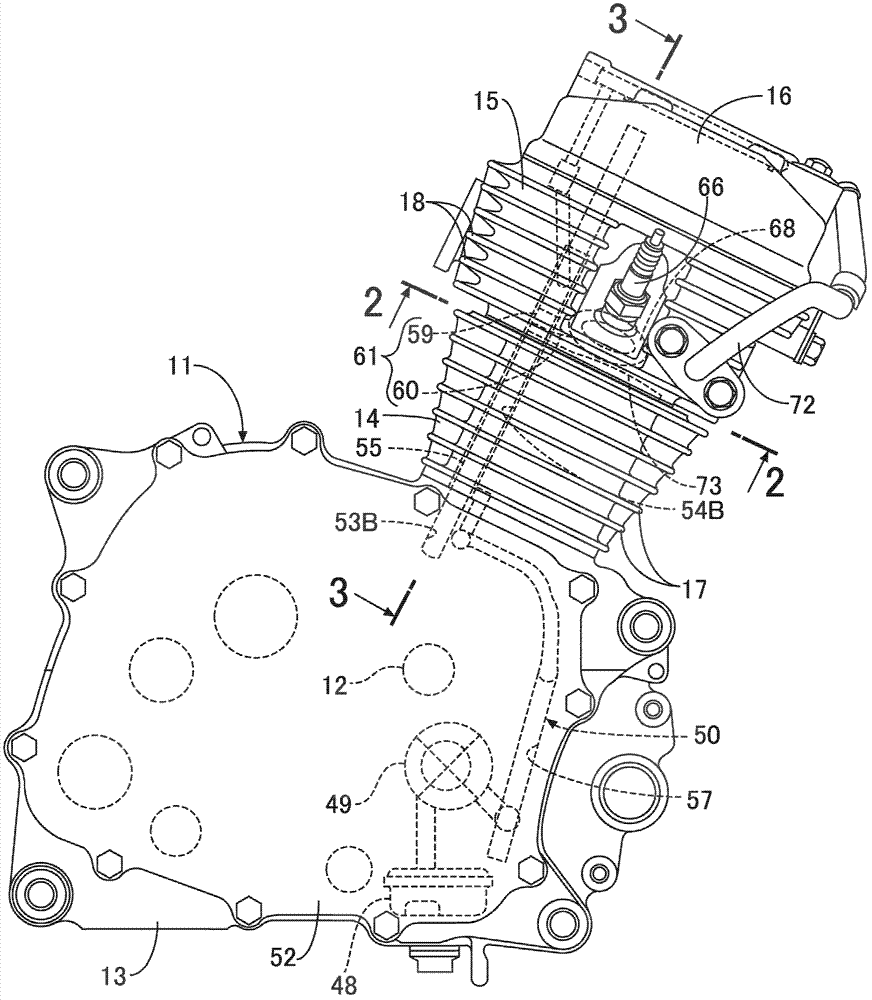

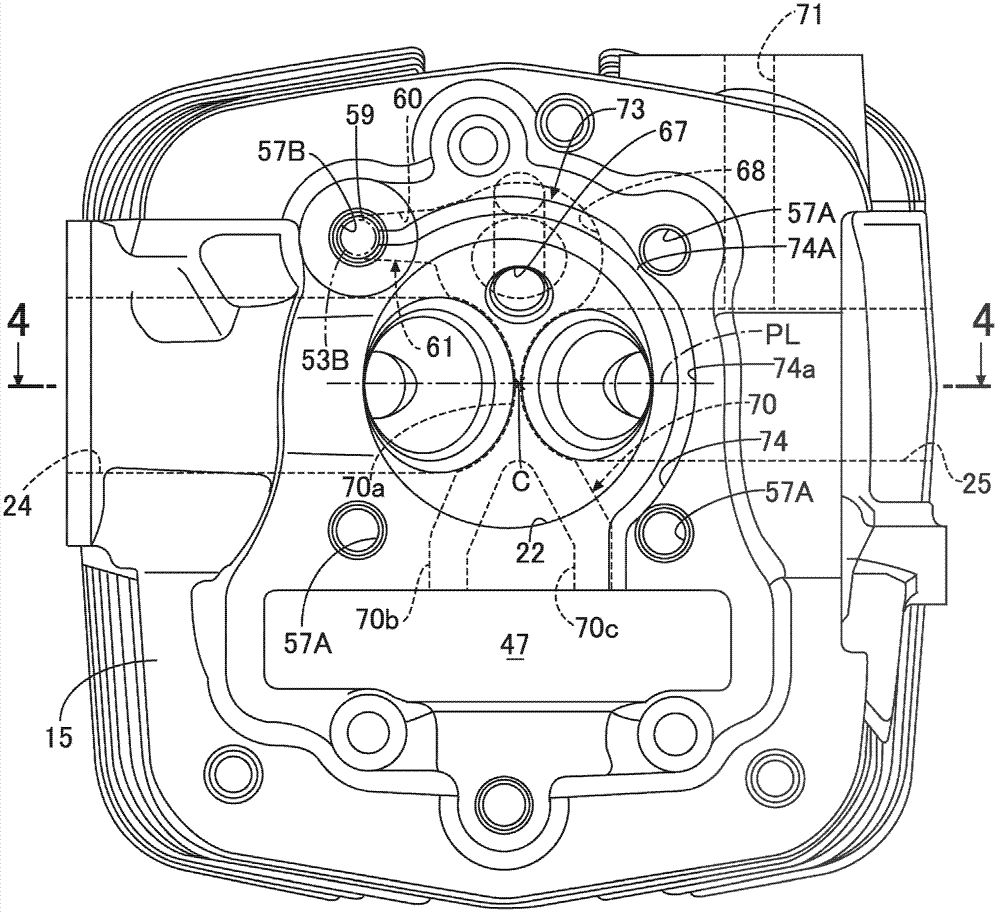

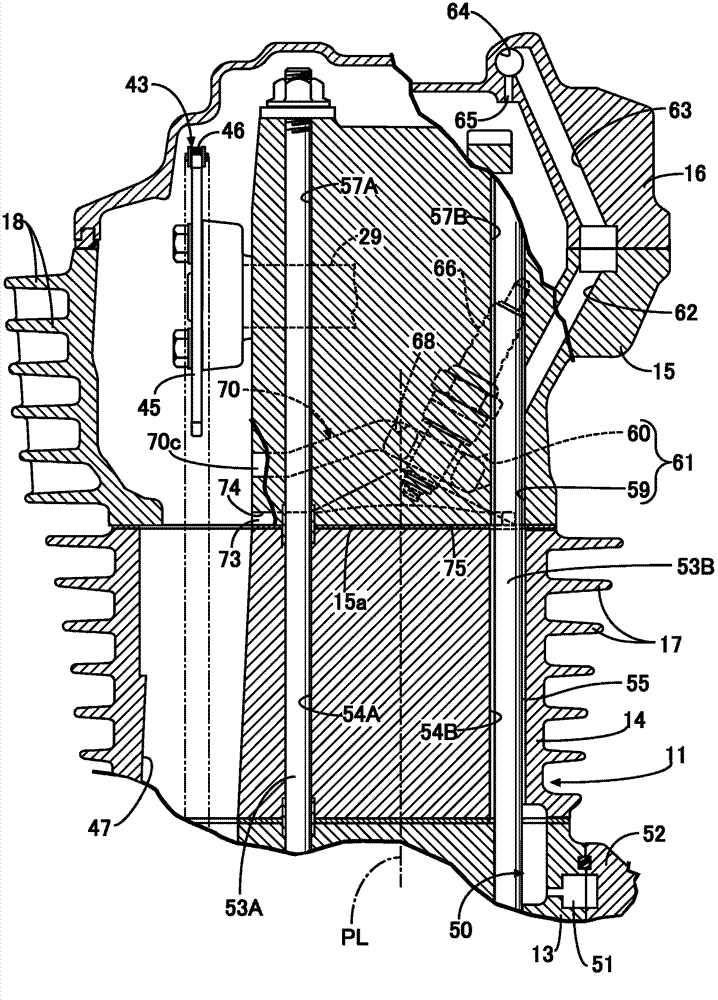

Oil cooling motor

ActiveCN102733922AInhibit heatingImprove coolingLiquid coolingMachines/enginesProjection imageCombustion chamber

The invention provides an oil cooling motor. A motor body is provided with a cooling oil circulation path which can circulate the cooling oil. A cooling oil passage which is a part of the cooling oil circulation path is arranged on a cylinder cover by surrounding a hole of a sparking plug. In the oil cooling motor, the cooling oil which is supplied to the cooling oil passage around the sparking plug is not easy to become hot, so the cooling performance around the hole of the sparking plug is improved. The hole (67) of the sparking plug is arranged on a projection image of the plane projection which is orthogonal to an axial line (C) of a cylinder barrel and on one side of a plane (PL). The plane includes a linear line which connects the centers of opening parts of a gas inlet (24) and a gas outlet (25), and the opening parts are open to a combustion chamber (22). A cooling oil supplying passage (61) is arranged on one side of the plane and is arranged on the cylinder cover (15), and is closer to the gas outlet than the gas inlet. The cooling oil supplying passage forms a part of the cooling oil circulation path and is connected with an upstream end of the cooling oil passage around the sparking plug.

Owner:HONDA MOTOR CO LTD

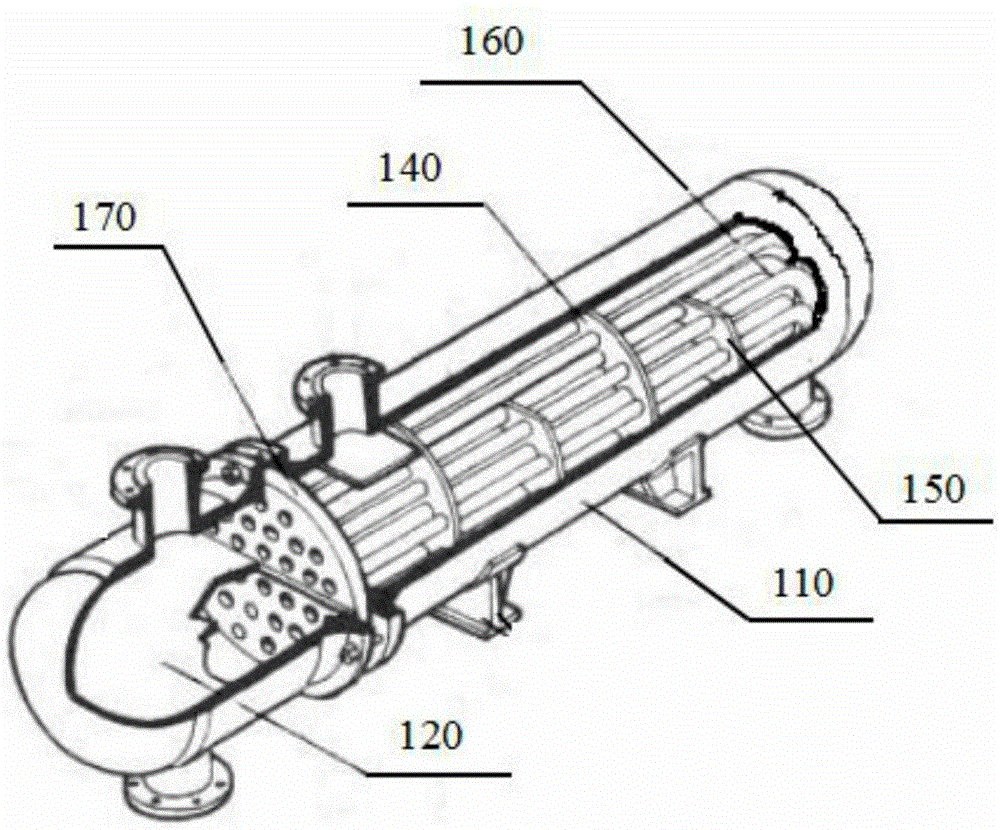

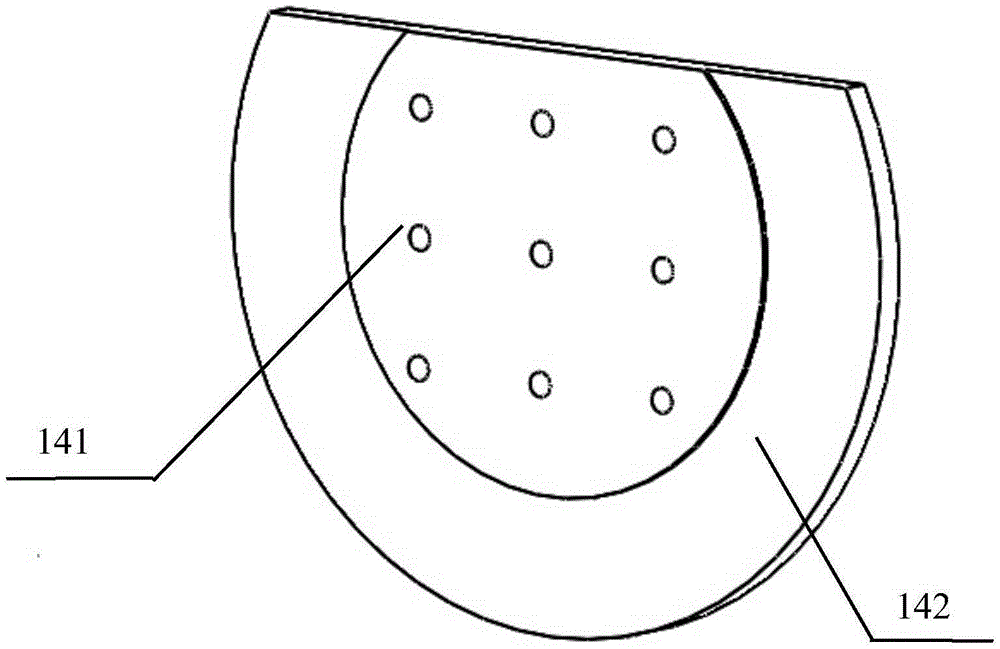

Shape memory alloy baffle heat exchanger and preparation method for baffles

InactiveCN105387738AImprove heat transfer rateSave energyHeat exchanger casingsStationary tubular conduit assembliesShape-memory alloyEngineering

The invention discloses a shape memory alloy baffle heat exchanger. The heat exchanger comprises a barrel body, pipe boxes, baffles and a heat exchange pipe bundle. The pipe boxes are arranged on the two sides or one side of the barrel body. The upper baffles are attached to the top of the barrel body, the lower baffles are attached to the bottom of the barrel body, and the upper baffles and the lower baffles are arranged at intervals. The heat exchange pipe bundle is connected in connecting holes of the baffles in a penetrating mode. In addition, structural parameters and a preparation method for the shape memory alloy in the heat exchanger are provided.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Binary ice transport box for pseudosciaena crocea

InactiveCN102514831APrevent inflowAvoid affecting the quality of frozen storageLiving organism packagingShock-sensitive articlesFrozen storageEngineering

The invention discloses a binary ice transport box for pseudosciaena crocea, which comprises an outer box body and a sealing cover. The outer box body and the sealing cover can be closed together in a covering manner, a supporting convex plate is manufactured on the lower side of the outer box body, a storage box is further disposed in the outer box body, a gap is reserved between a lower edge opening of the storage box and the bottom of the outer box due to the effect of the supporting convex plate, an upper edge opening of the storage box exactly matches with the inner side of an edge opening of the outer box body, and at least two through holes are further manufactured on the outer box body. The supporting convex plate is manufactured on the lower side of the outer box, accordingly, the storage box is arranged aerially, heat exchange liquid can flow between the bottom of the outer box and the storage box, and the purpose of exchanging heat is achieved. In addition, the upper edge opening of the storage box exactly matches with the inner side of the edge opening of the outer box, so that the heat exchange liquid can be prevented from flowing into the storage box to affect frozen storage quality. Furthermore, the through holes are used for filling and draining the heat exchange liquid, and accordingly the purpose of circulatory refrigeration is realized. Besides, the binary ice transport box has the advantages of novel structure, high heat exchange efficiency, fast cooling, easiness in quick packaging, convenience in stacking and simplicity in manufacture.

Owner:浙江海洋学院普陀科学技术学院

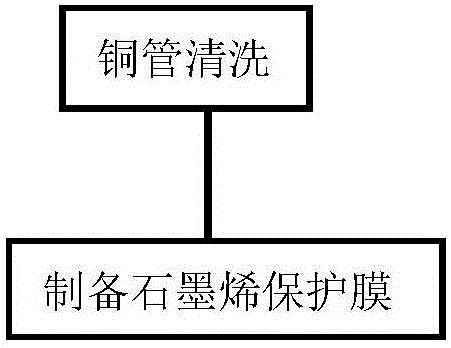

Preparation method of heat exchanger with efficient heat exchange and corrosion resistance and provided with graphene protective membrane

InactiveCN106802106AGuaranteed thermal conductivityEnhanced heat transferSingle layer grapheneChemical industryCvd grapheneBatch production

The invention discloses a preparation method of a heat exchanger with efficient heat exchange and corrosion resistance and provided with a graphene protective membrane. The preparation method is characterized by comprising the following steps: (1) firstly cleaning a copper pipe; (2) growing graphene on the surface of the copper pipe: setting the growth temperature at 800 to 1,200 DEG C, feeding protective gas into a reaction chamber, quickly heating the reaction chamber to the growth temperature of the graphene, then feeding methane gas, keeping feeding the methane gas for 8 to 15 minutes, then quickly cooling the reaction chamber, and cutting the feeding of all types of gas, wherein the growth time of the graphene is equal to the methane feeding time; and (3) controlling the pressure of the reaction chamber at 8 to 15 mbar in a graphene preparation process, thus the high-quality graphene protective membrane is prepared on the surface of the copper pipe, and covers copper to prevent corrosion. The preparation method disclosed by the invention is proper in cost, suitable for large-batch production and relatively high in membrane forming quality.

Owner:GUANGDONG MACRO GAS APPLIANCE

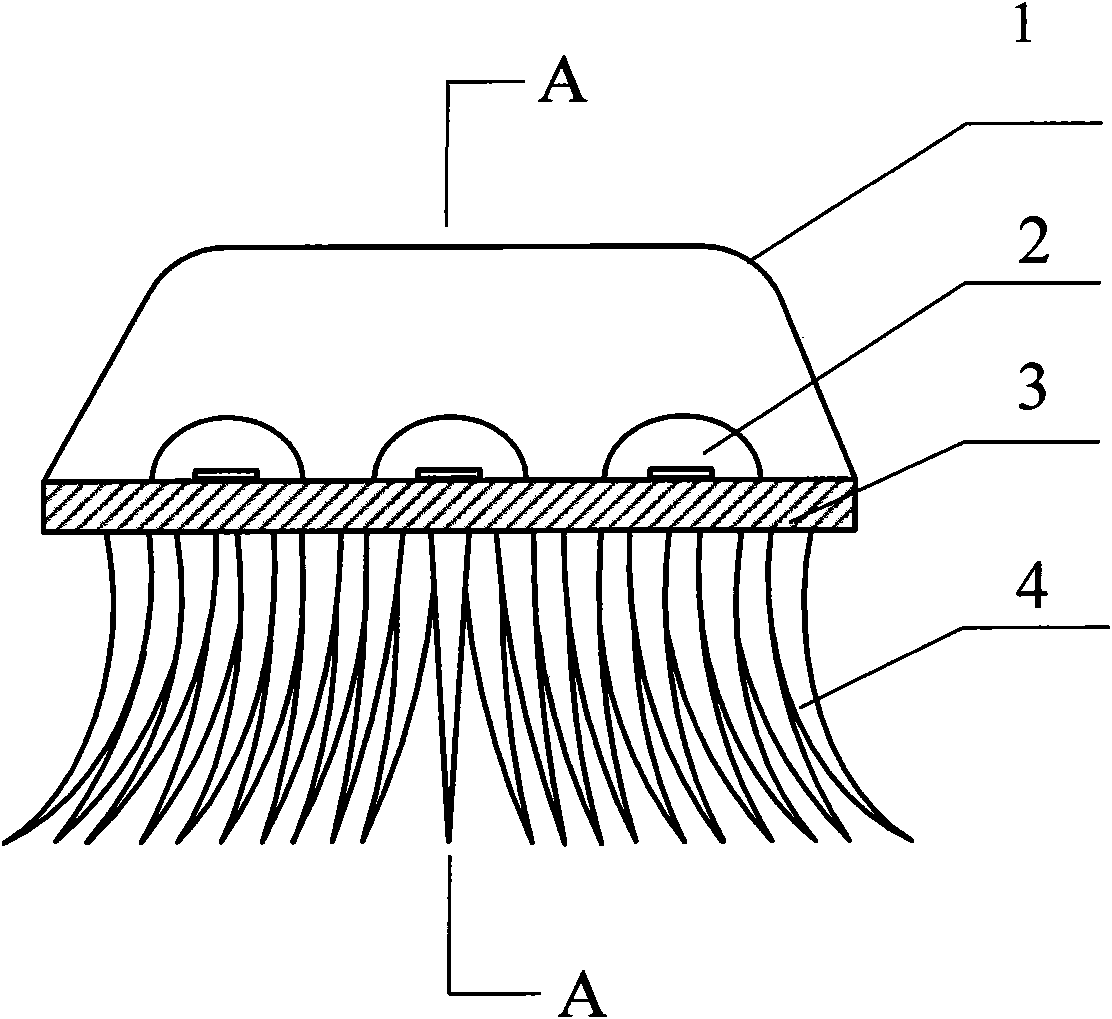

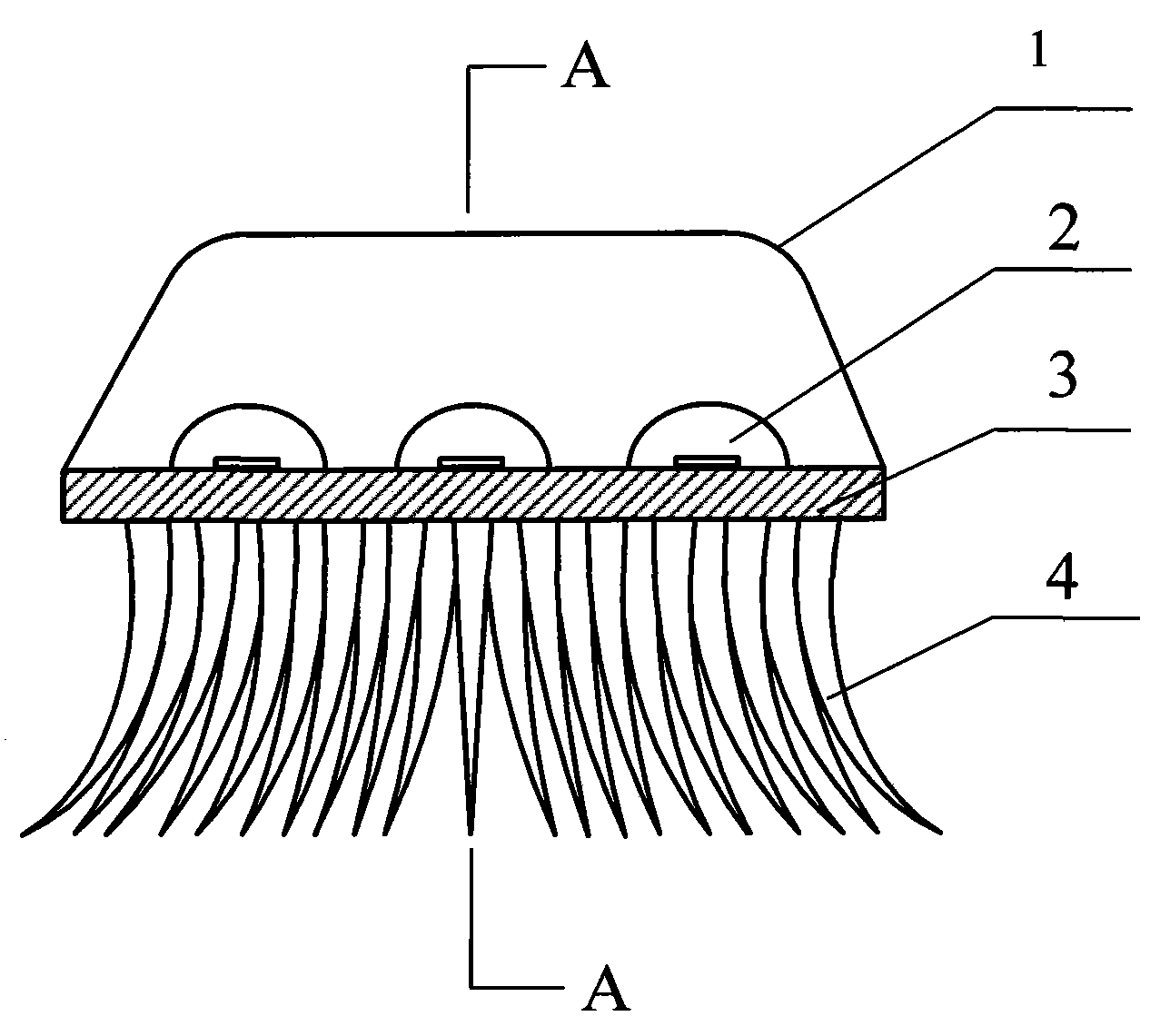

LED automobile lamp

InactiveCN101832502AIncrease transfer speedImprove heat transfer ratePoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

The invention discloses an LED automobile lamp comprising a lamp housing, an LED device and a heat conducting substrate, wherein the LED device and the heat conducting substrate are arranged in the lamp housing. The LED automobile lamp is characterized in that the LED device is mated with one face of the heat conducting substrate, the other face of the heat conducting substrate is provided with a pin fin integrated with the heat conducting substrate, and the pin fin is arranged outside the lamp housing. In the pin fin type LED automobile lamp, heat generated by the LED device is directly transmitted to the outside of the automobile lamp through the heat conducting substrate and is then radiated through heat convection with the air outside the automobile lamp through the bent pin fin. The heat conducting substrate and the pin fin are formed by being cut wholly without thermal contact resistance, therefore, high heat transfer efficiency is achieved; in addition, the bent pin fin effectively expands the heat transfer area and improves the heat radiating performance.

Owner:SOUTHEAST UNIV

Novel high-power LED radiating device

InactiveCN104197292AImprove cooling effectIncrease contact areaPoint-like light sourceLighting heating/cooling arrangementsPorous mediumHigh heat

The invention relates to a novel high-power LED radiating device which comprises a base plate, a finned radiator, a miniature pump, a fan and a liquid delivery tube. An inlet and an outlet which are used for being communicated with the liquid delivery tube are formed in two ends of the base plate, the liquid delivery tube is communicated with the miniature pump and the finned radiator and is filled with cooling liquid, the miniature pump provides power for the cooling liquid to form a circulating circuit, the fan is arranged below the finned radiator, the base plate is filled with porous media, and the finned radiator is free of location limitation and can be placed at a required position according to actual conditions. The novel high-power LED radiating device has the advantages that LED heat can be transferred by the aid of characteristics of large contact area and high heat transfer rate of the porous media, the miniature pump provides the power for the cooling liquid to form the circulating circuit, the flow rate of the liquid can be changed, and accordingly the LED heat can be radiated under the control.

Owner:HEFEI HUICAI ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com